Dyeing technology utilizing spaced dyeing fancy yarn cheese dyeing device

A technology for dyeing equipment and cheese, applied in the field of dyeing technology, can solve the problems of time-consuming, labor-intensive, complicated process, etc., and achieve the effects of short process flow, uniform color and good weaving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

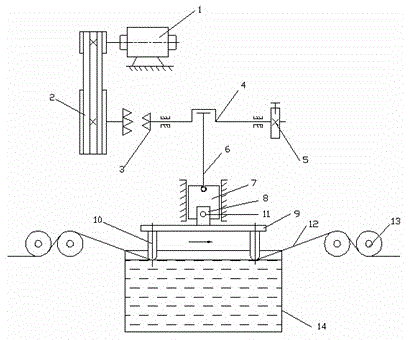

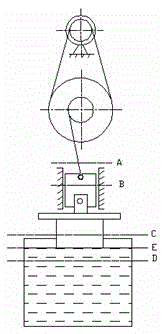

[0032] like Figure 1-2 As shown in the figure, a dyeing equipment for segment dyeing yarn and cheese yarn includes a motor 1, a pulley 2, a clutch 3, a crank 4, a brake 5, a connecting rod 6, a slider 7, a connecting block 8, a connecting plate 9, and a vibration block 10. , horizontal pin 11, roller 13 and sink 14. The two ends of the crank 4 are respectively installed with a clutch 3 and a brake 5. The motor 1 rotates to drive the pulley 2 to rotate. After engaging with the clutch 3, it drives the crank 4 to rotate. The crank 4 is also connected with a connecting rod 6, and the rotation of the crank 4 will drive the connecting rod 6 and the slider 7 fixedly connected with the connecting rod 6 to reciprocate up and down in the guide rail. The slider 7 is fixedly connected with the vibration device, and the slider 7 will drive the vibration device to reciprocate up and down. The vibration device is composed of a connecting block 8, a connecting plate 9 and a vibration block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com