Flexible fiber electrode coated with polyetheretherketone coating layer, preparation and application thereof

A polyether ether ketone and flexible fiber technology, applied in the field of flexible fiber electrodes, can solve the problems of complex preparation process and poor biocompatibility of flexible fiber electrodes, and achieve excellent biocompatibility, good flexibility, materials and preparation costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

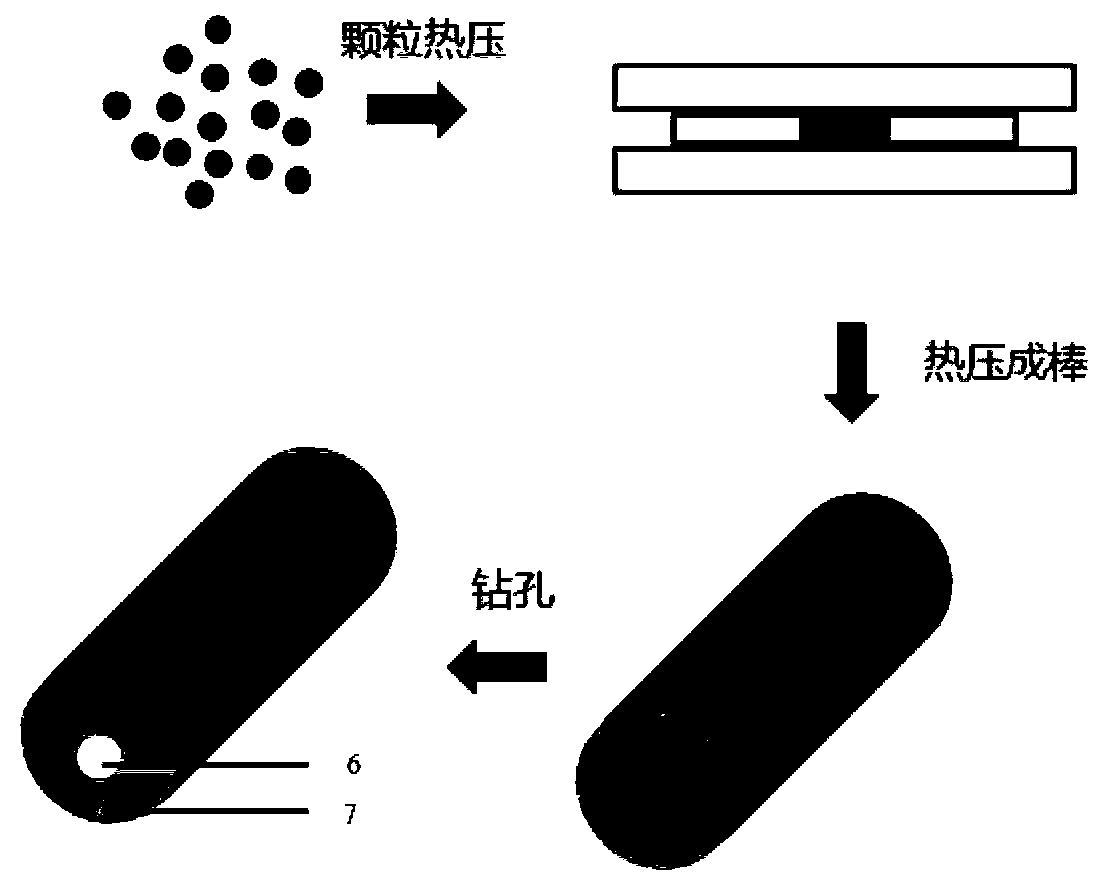

[0033] A method for preparing a flexible fiber electrode coated with polyetheretherketone provided by the invention comprises the following steps:

[0034] (1) Obtaining a polyether ether ketone preform containing through holes;

[0035] (2) Make the flexible filamentary conductive material pass through the through hole of the preform, and adopt the method of thermal softening drawing to implement co-drawing of the preform and the flexible fiber electrode to obtain a flexible filamentary conductive material It is a flexible fiber electrode coated with polyetheretherketone as the core layer.

[0036] In some embodiments, step (1) includes the following sub-steps:

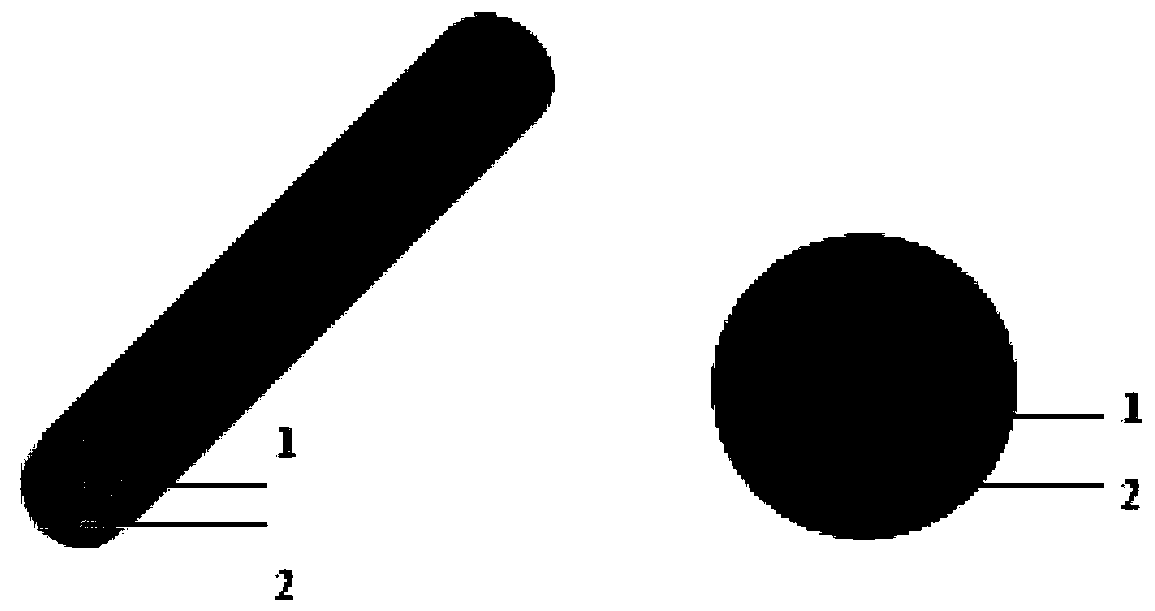

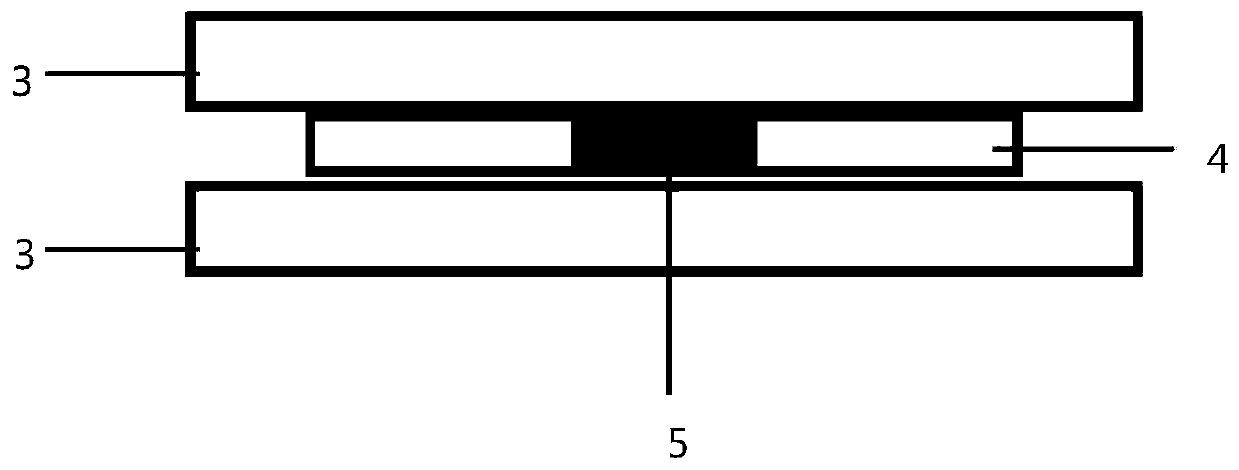

[0037] (2-1) The polyetheretherketone raw material is made into a solid rod structure by hot pressing; here, the polyetheretherketone raw material can be polyether ether ketone particles or polyetheretherketone film.

[0038] (2-2) Piercing the solid rod obtained in the step (1-1) to obtain a polyetheretherketone p...

Embodiment 1

[0057] In this embodiment, a flexible fiber electrode coated with a polyetheretherketone coating with a coaxial structure is provided, which has flexibility, electrical conductivity, and biocompatibility. Wherein, the flexible filamentous conductive material of the flexible fiber electrode coated with polyetheretherketone coating, that is, the electrode material is 304 stainless steel filament, the diameter of which is 50 μm, and the thickness of the cladding is 125 μm.

[0058] This embodiment also provides the method for the above-mentioned flexible fiber electrode coated with polyetheretherketone coating, including: pre-treatment of materials, preparation of prefabricated rods and thermal drawing of fibers.

[0059] The pre-treatment of the material includes the following steps: (1) pass the metal wire through acetone, isopropanone, and deionized water in sequence to remove the stains on its surface, wind the processed metal wire on a coil and store it in a vacuum drying ove...

Embodiment 2

[0065] In this embodiment, a flexible fiber electrode coated with a polyetheretherketone coating with a coaxial structure is provided, which has flexibility, electrical conductivity, and biocompatibility.

[0066] Wherein, the electrode material of the flexible fiber electrode coated with polyetheretherketone coating is 304 stainless steel filament, the diameter of which is 300 μm, and the diameter of the cladding is 1750 μm.

[0067] The embodiment of the present invention also provides the flexible fiber electrode method coated with polyetheretherketone coating, including: pre-treatment of materials, preparation of prefabricated rods and hot drawing of fibers.

[0068] The pre-treatment of the material includes the following steps: (1) Pass the metal wire through acetone, isopropanone, and deionized water in order to remove the stains on its surface, wind the processed metal wire on a coil and store it in a vacuum drying oven to prevent (2) Pretreatment of thermoplastic spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com