Patents

Literature

131 results about "Thermal softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

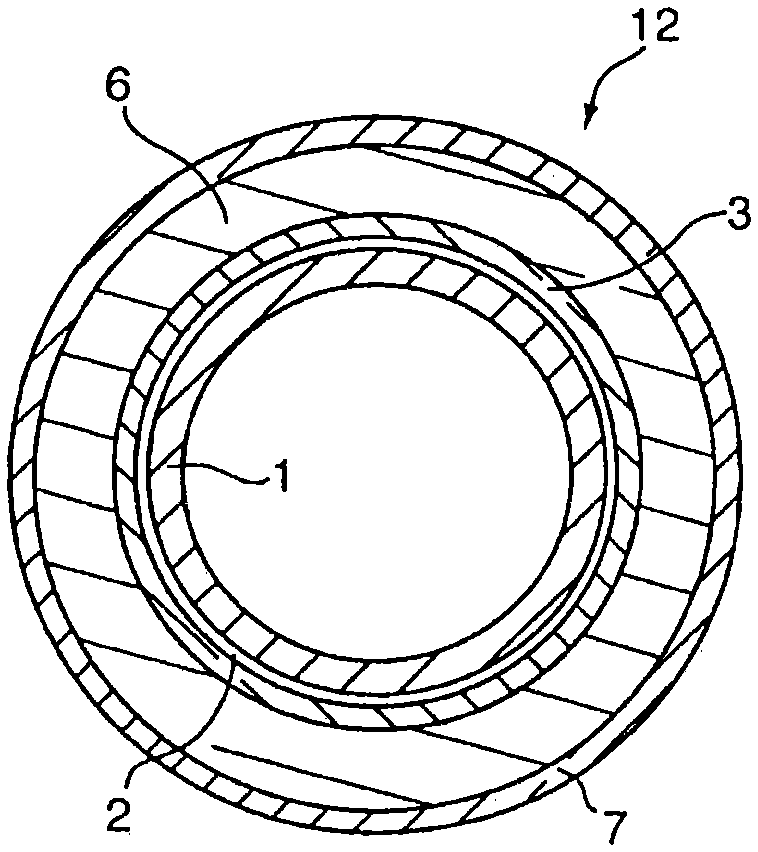

Styrenic insulation for pipe

ActiveUS20090159146A1Improve insulation effectReduce coating thicknessThermal insulationCorrosion preventionThermoplasticCompressive creep

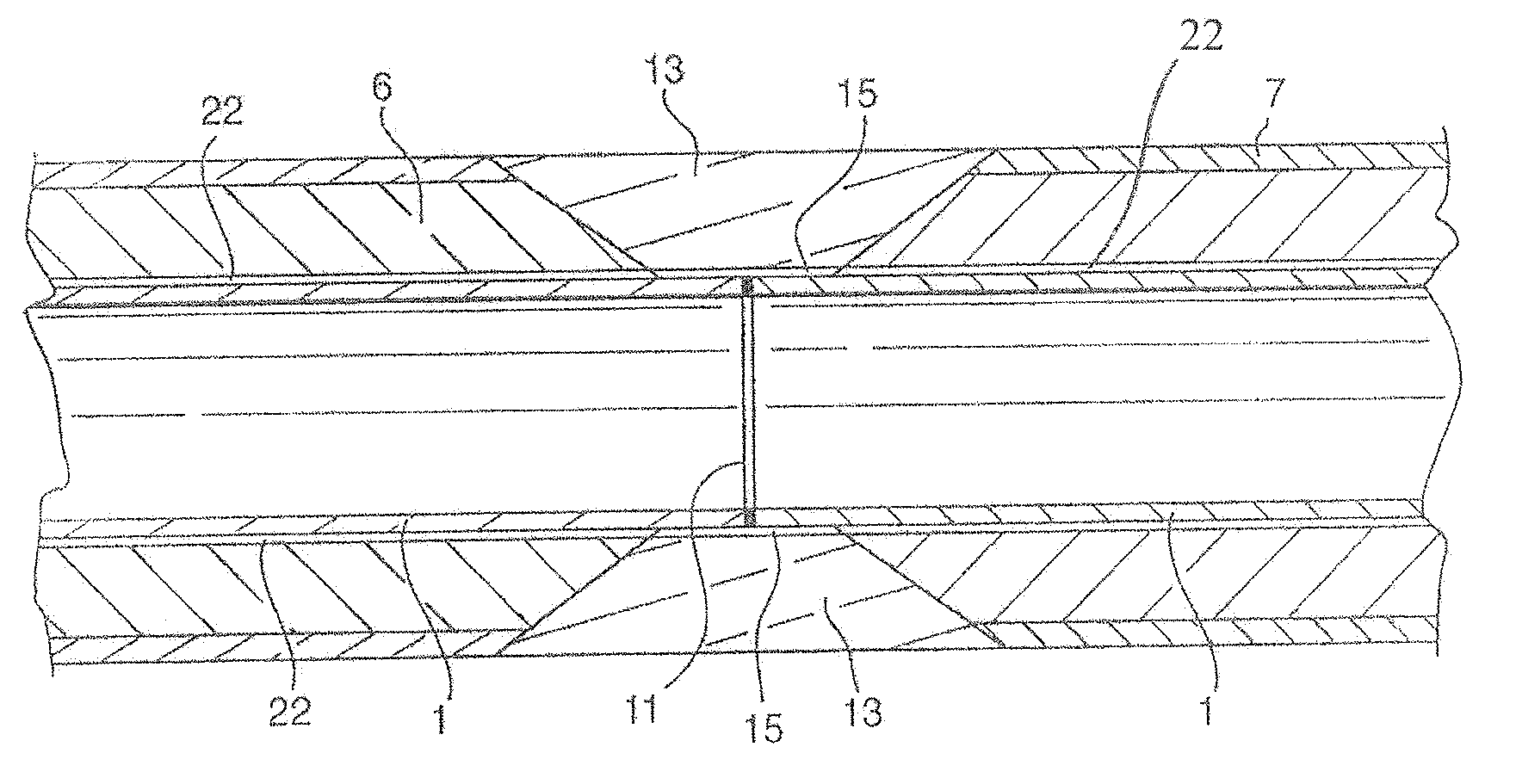

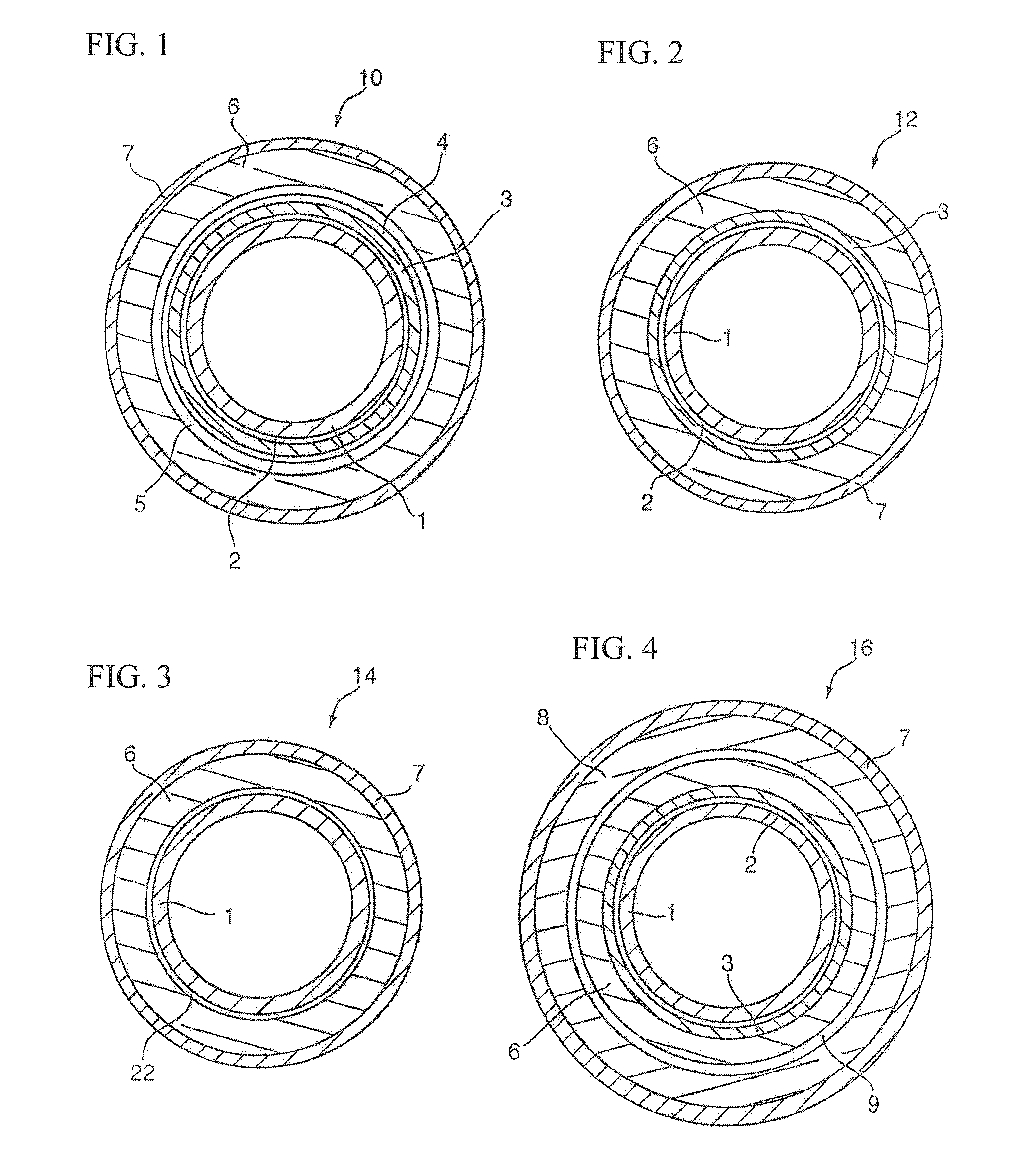

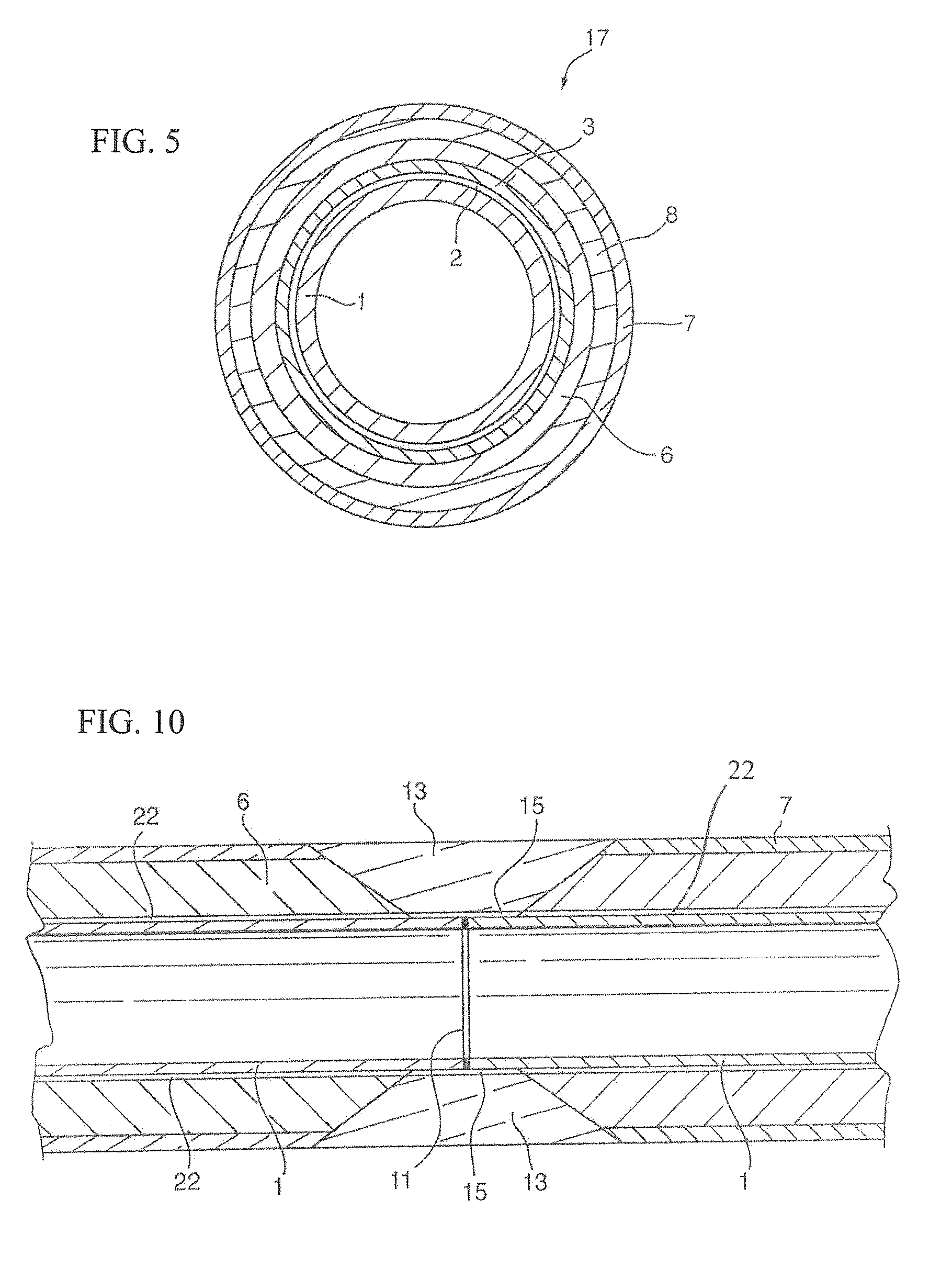

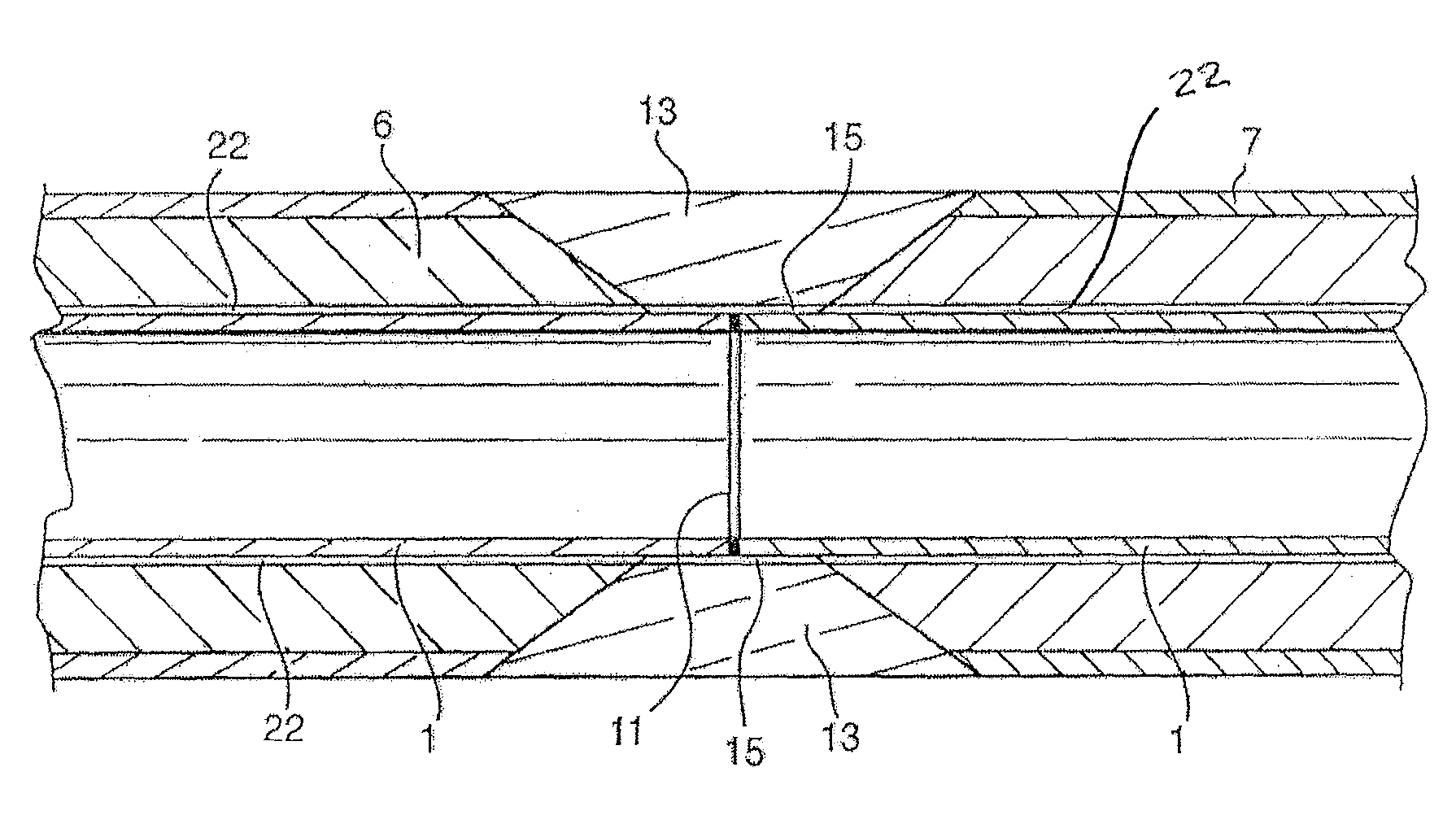

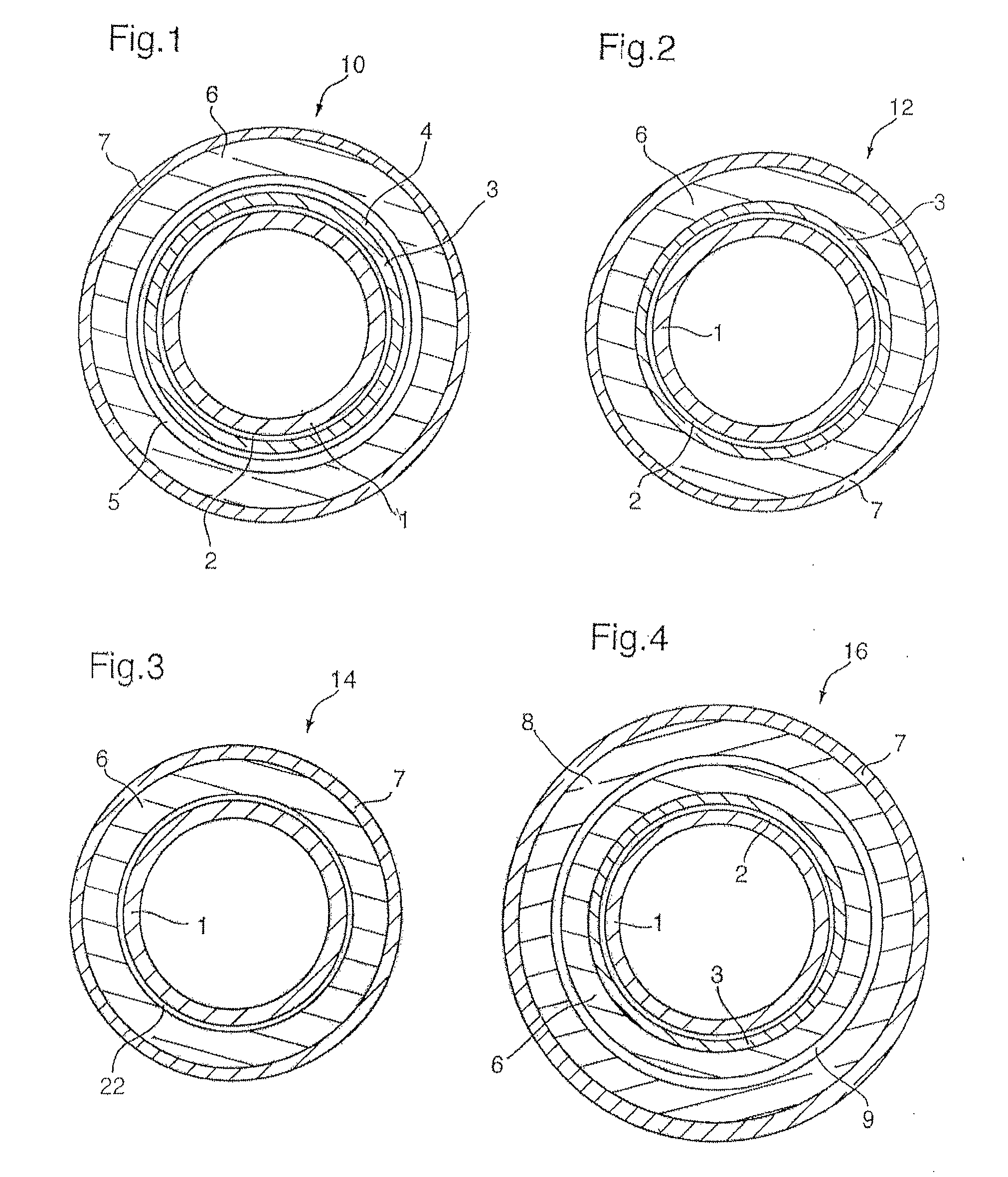

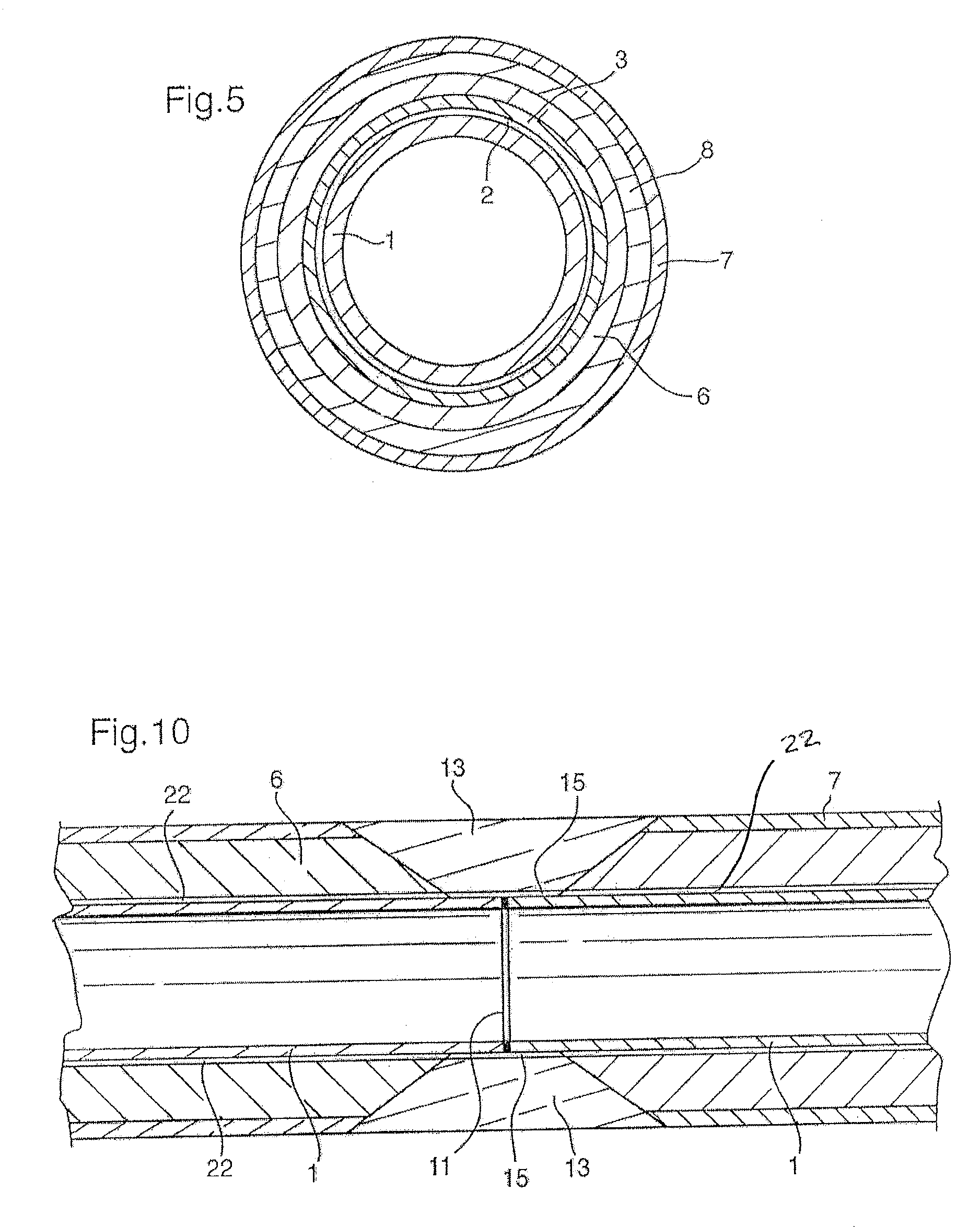

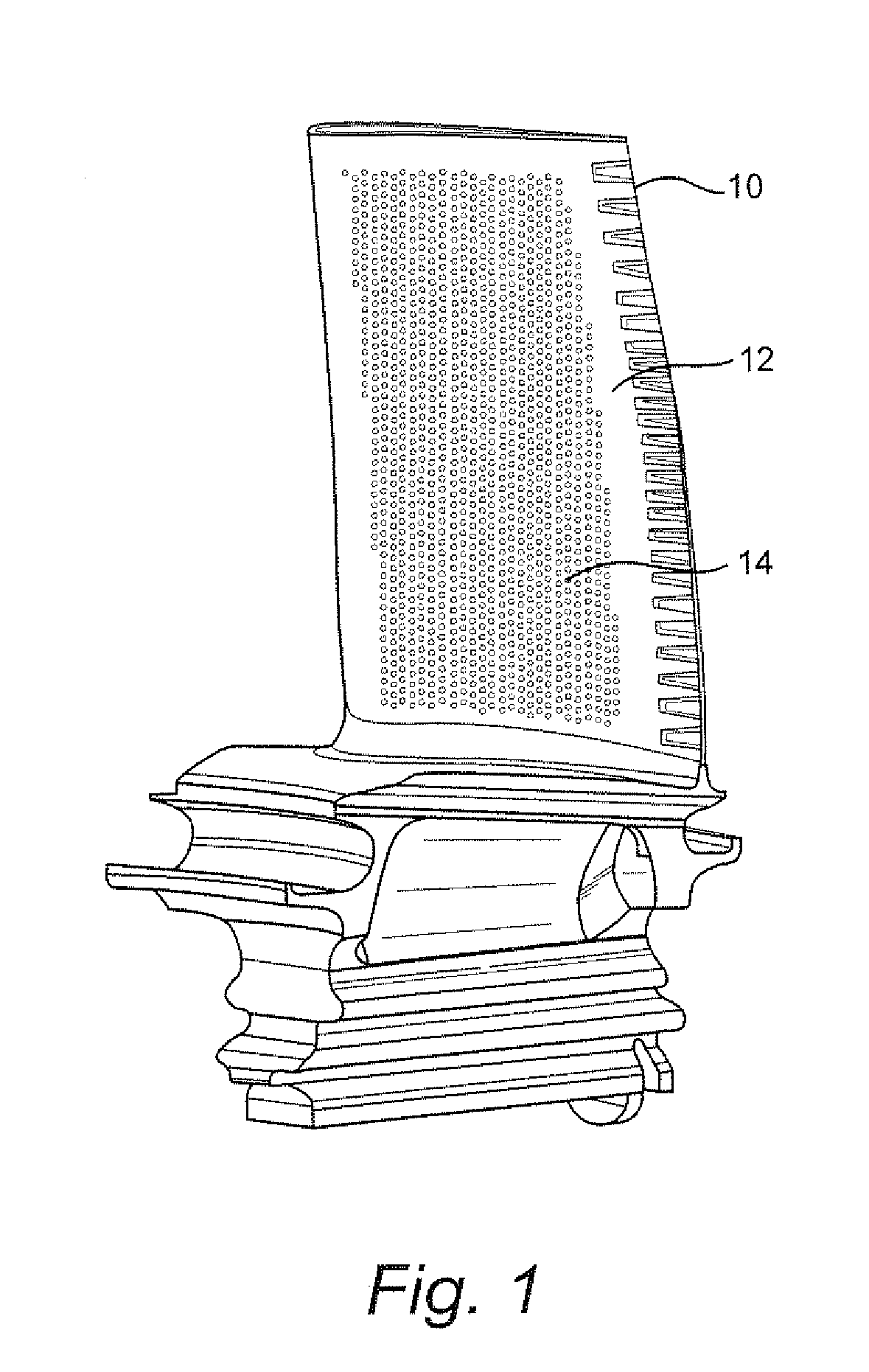

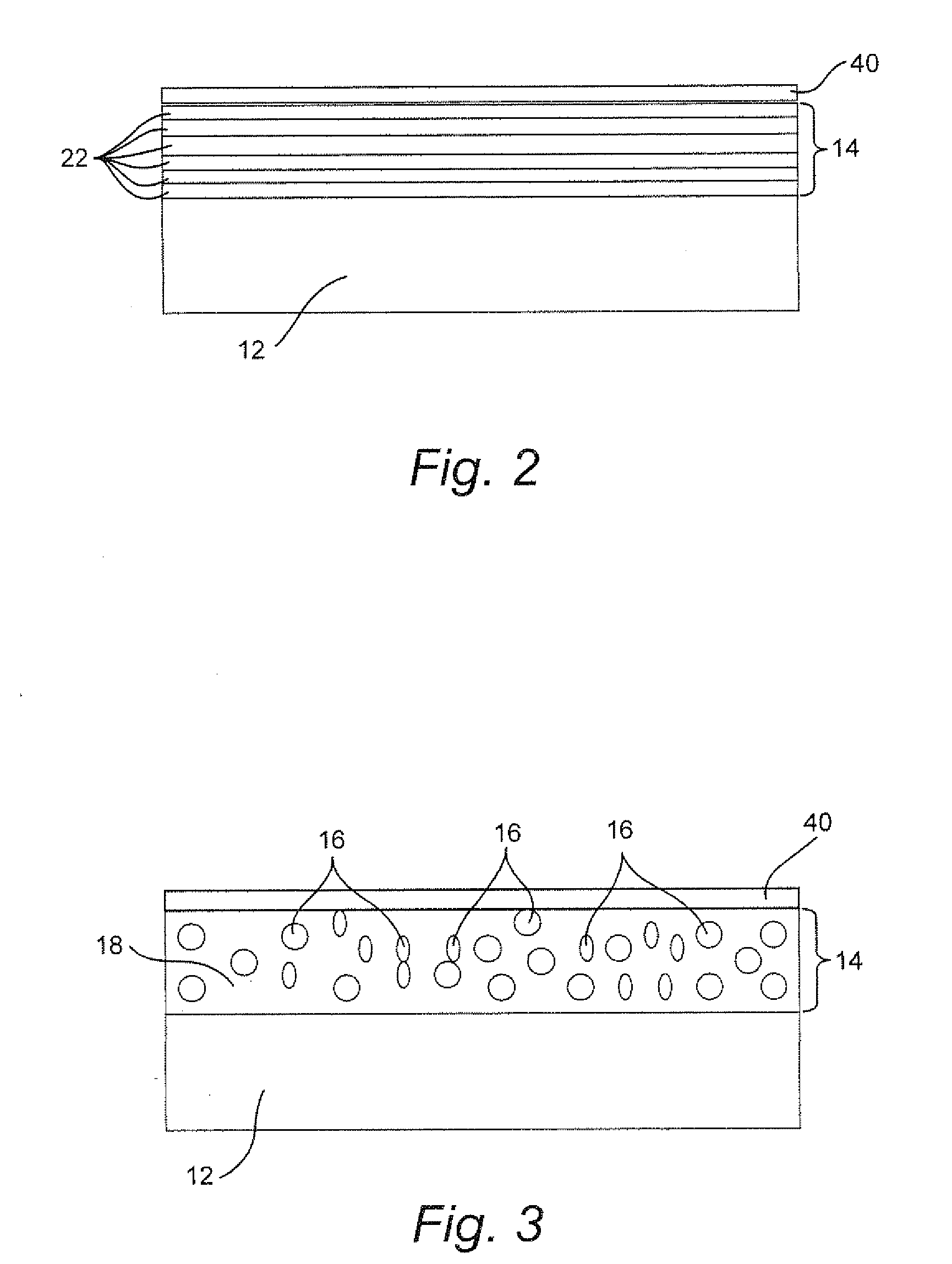

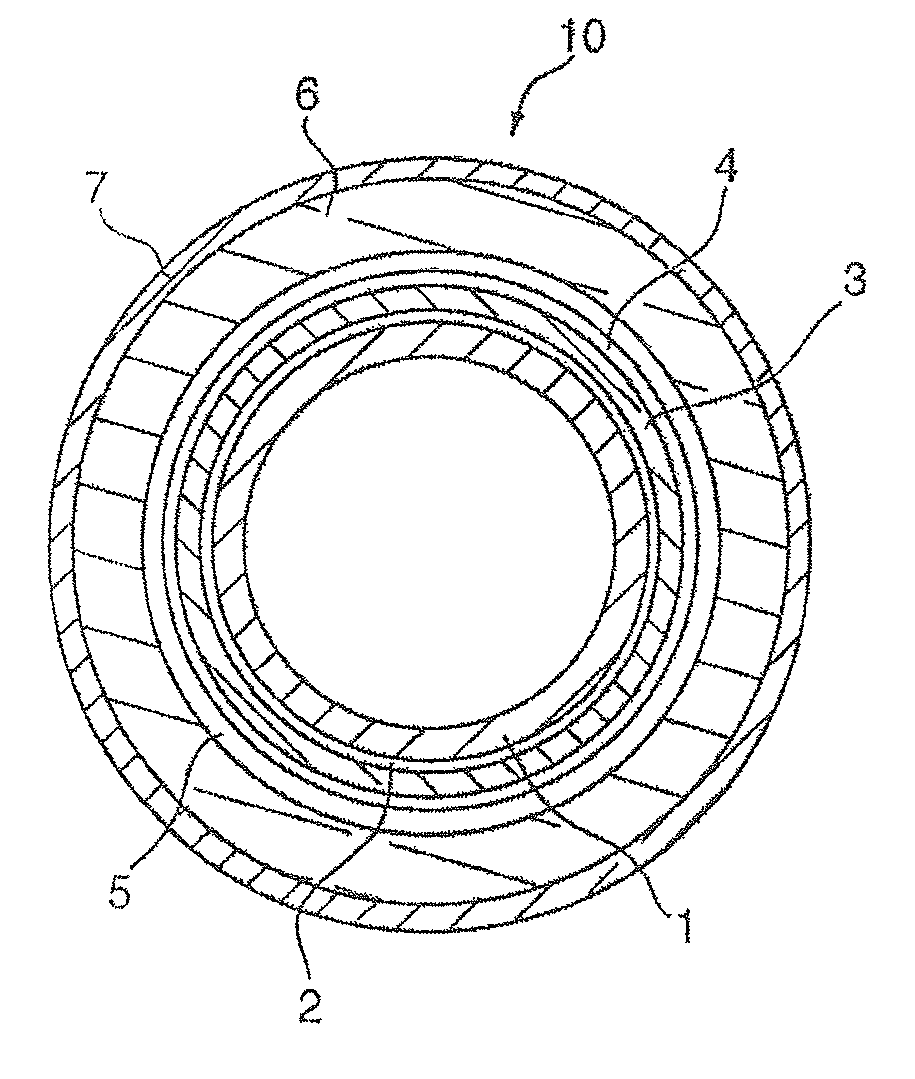

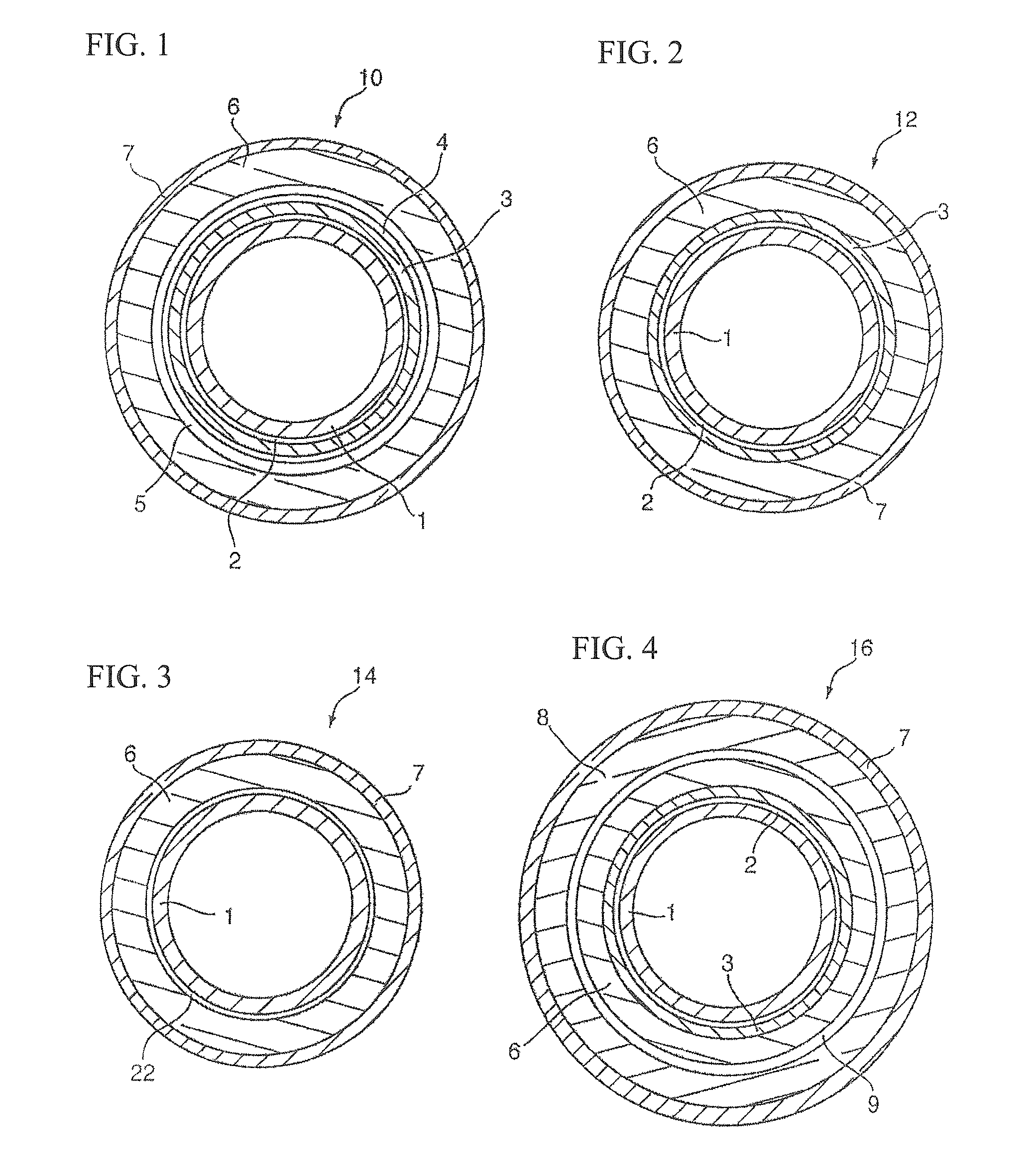

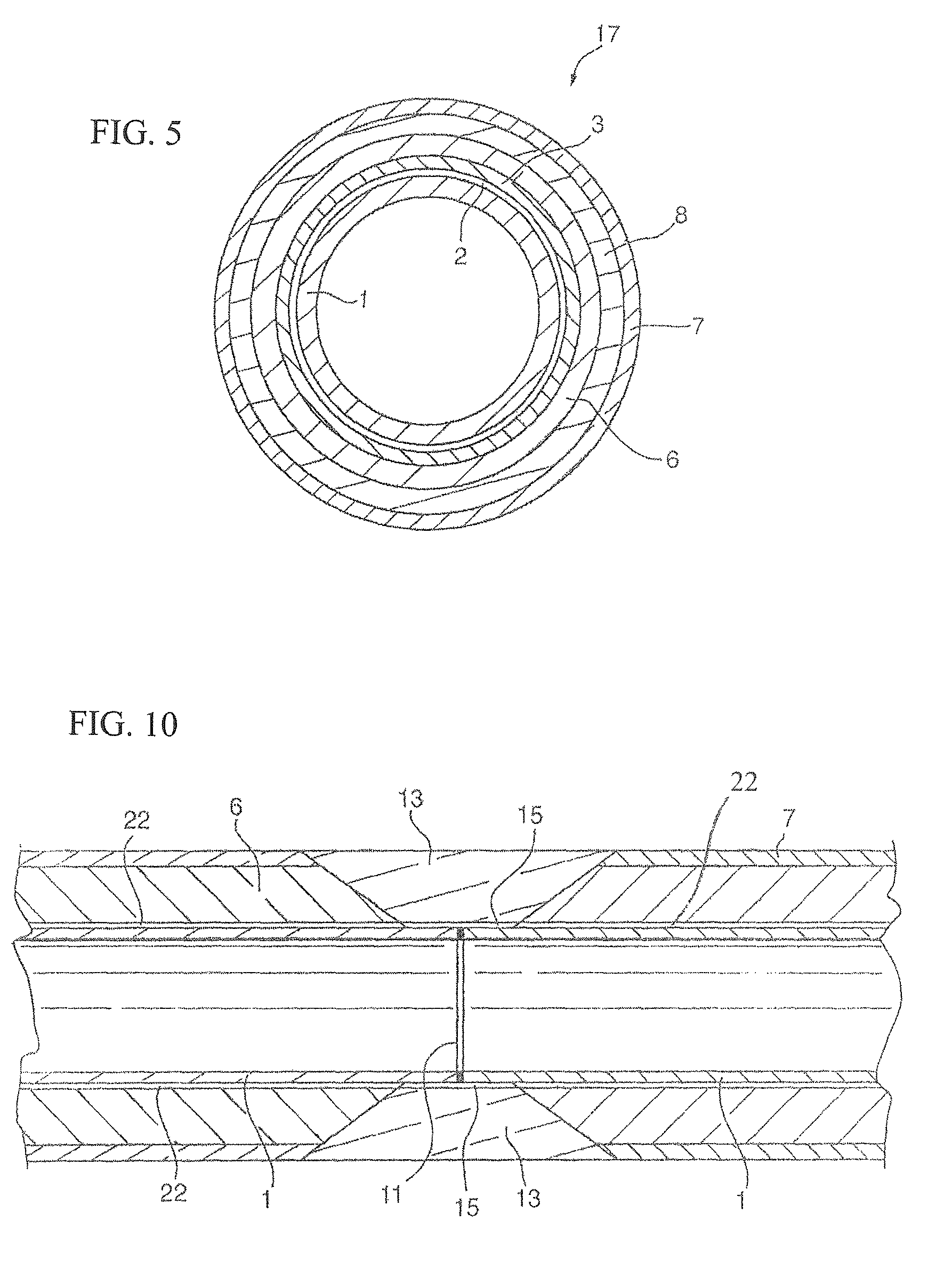

Coatings for protecting and insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of up to 100° C. in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of thermal insulation comprising polystyrene or styrene-based thermoplastic, having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance.

Owner:SHAWCOR LTD

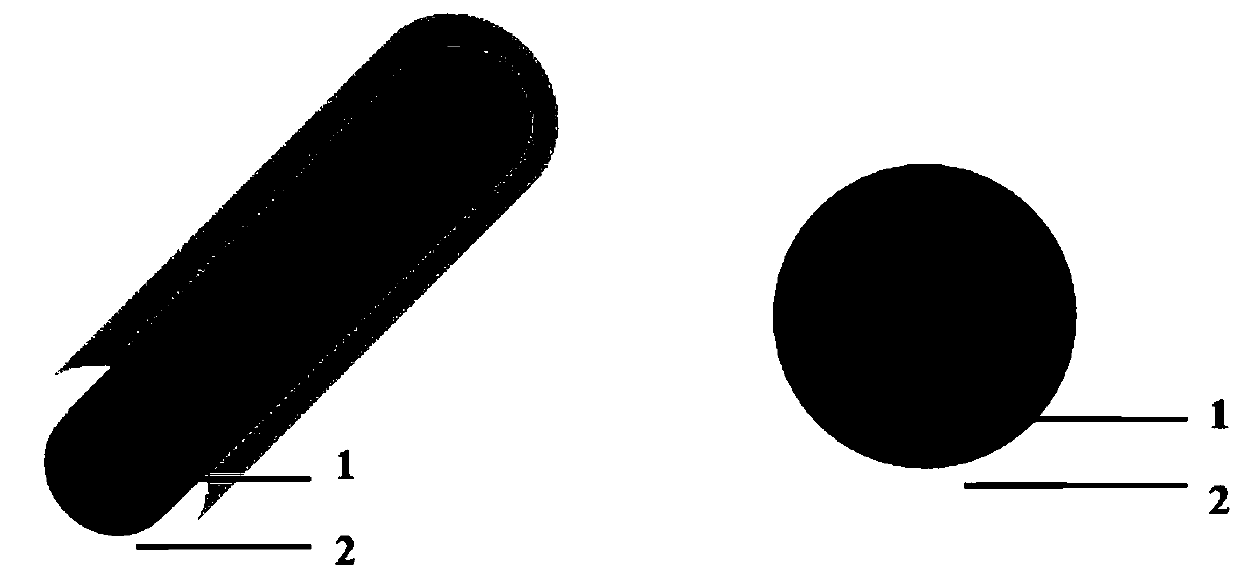

Encapsulated cosmetic composition

The present invention relates to encapsulated cosmetic compositions that are topically applied. The compositions contain at least one frangible capsule that has a seamless shell of a thermo-softening material. The shell is solid at about room temperature and melts upon application to the skin. The shell holds a core cosmetic that is added to a clear gel base. Thus, the color of the capsule is visible and multiple colored capsules can be added to the base for a custom colored composition.

Owner:ELC MANAGEMENT LLC

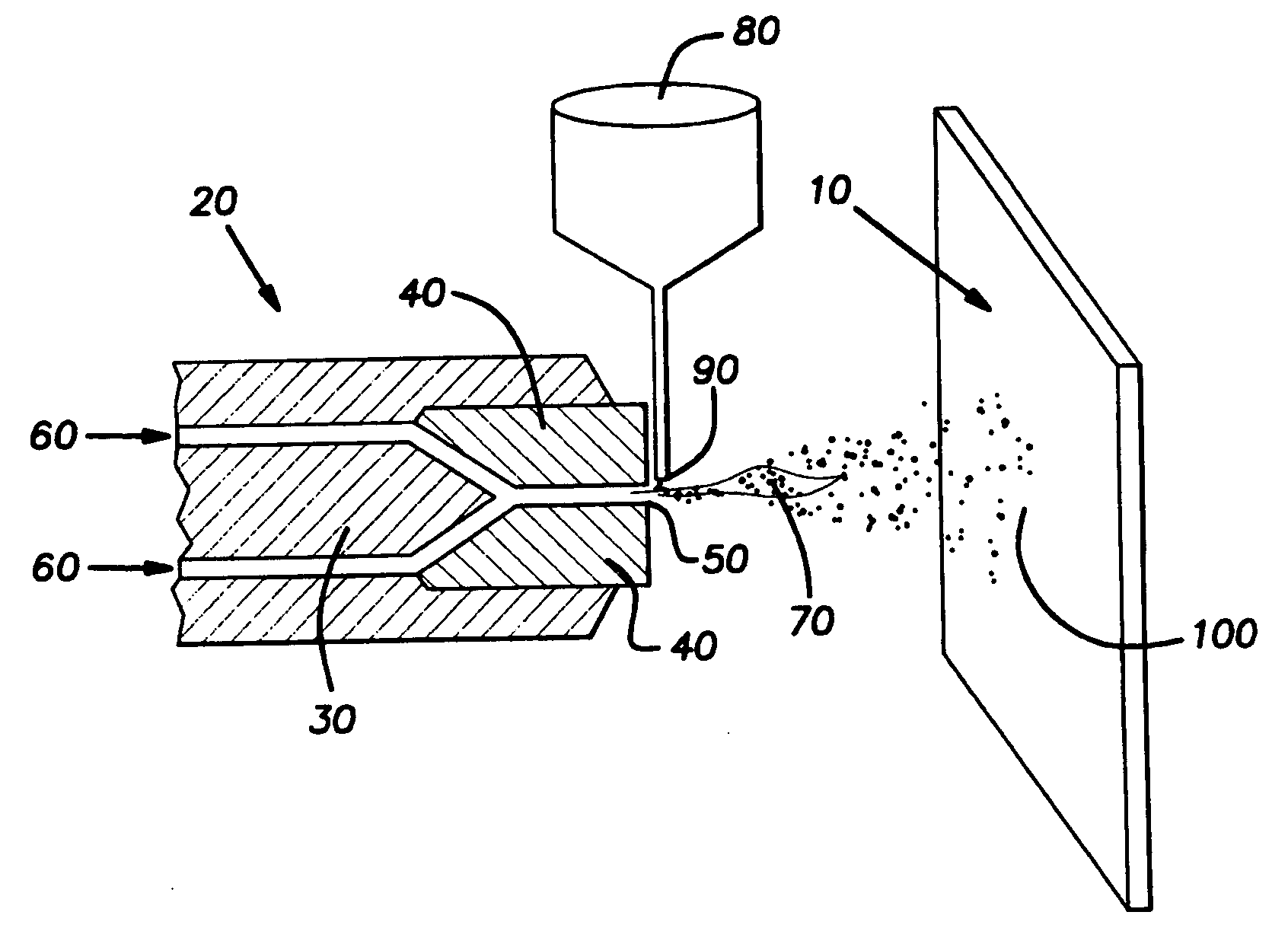

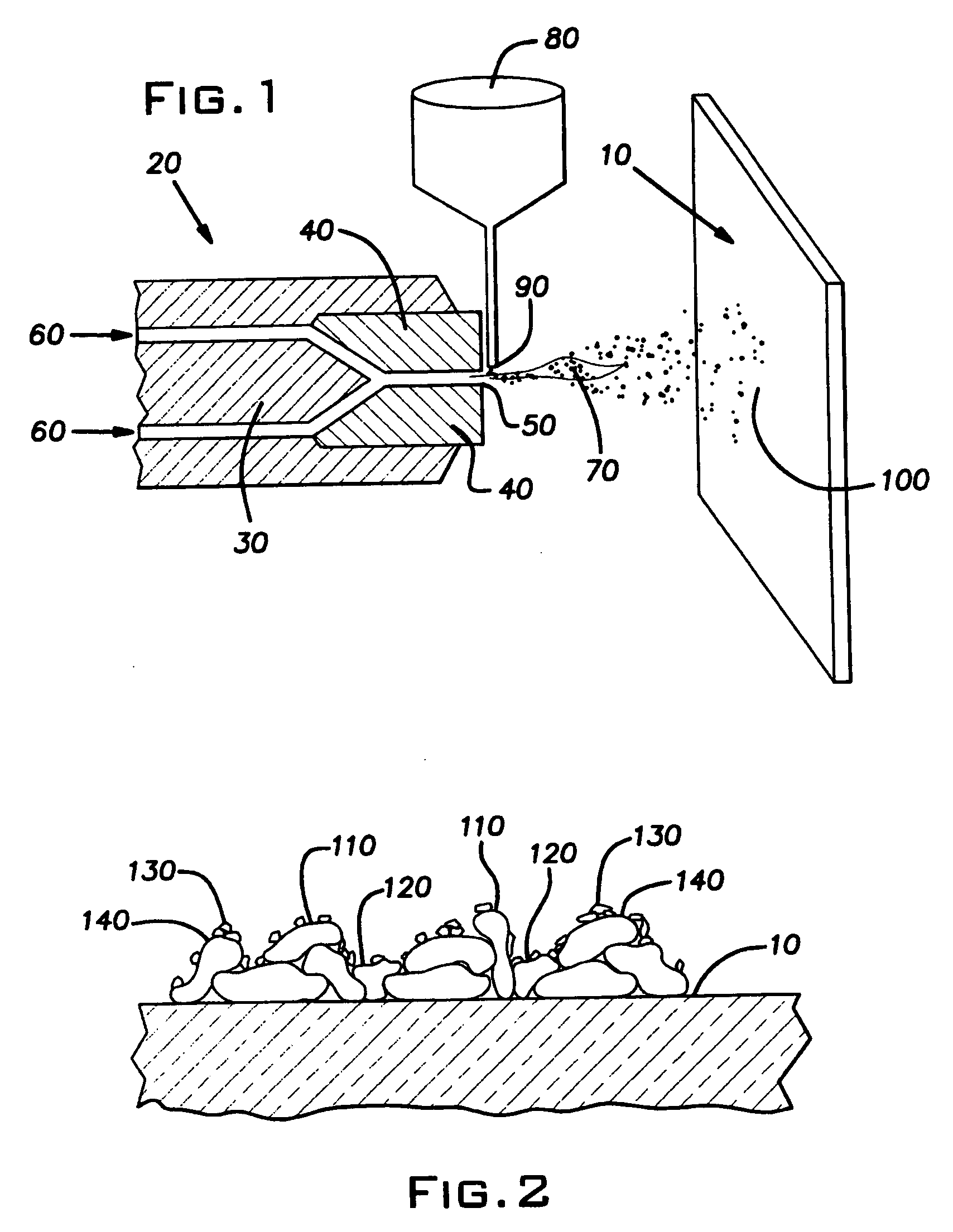

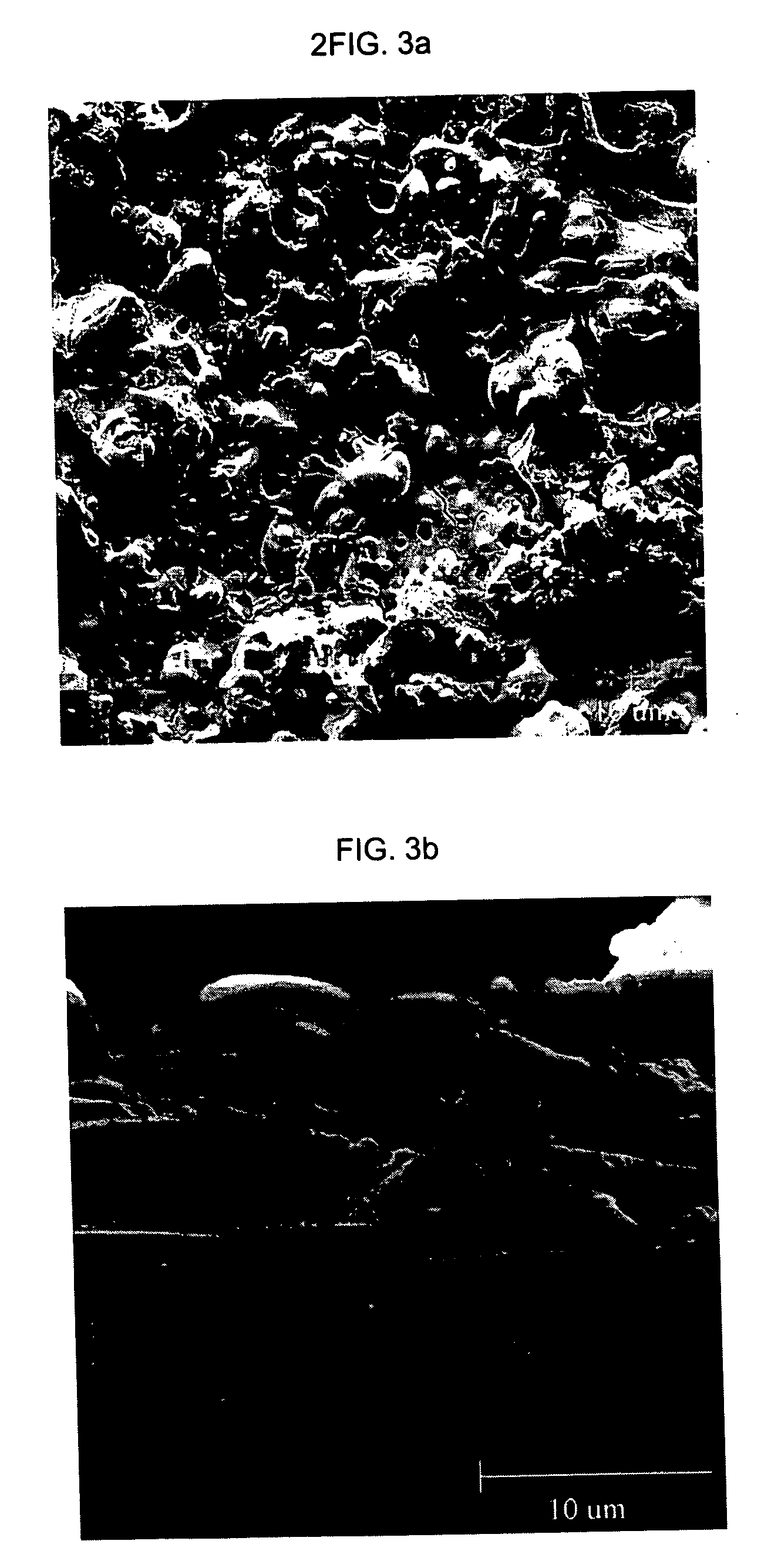

Process for structuring self-cleaning glass surfaces

A plasma spray process for structuring self-cleaning glass surfaces and self-cleaning glass surfaces formed according to the process. Molten or heat softened particles of inorganic material are plasma spray deposited onto the surface of a substrate to create a micro-rough surface. If desired, a hydrophobic top coating layer can optionally be applied to the micro-rough surface. The micro-structured surface formed according to the invention is durable and self-cleaning.

Owner:FERRO CORP

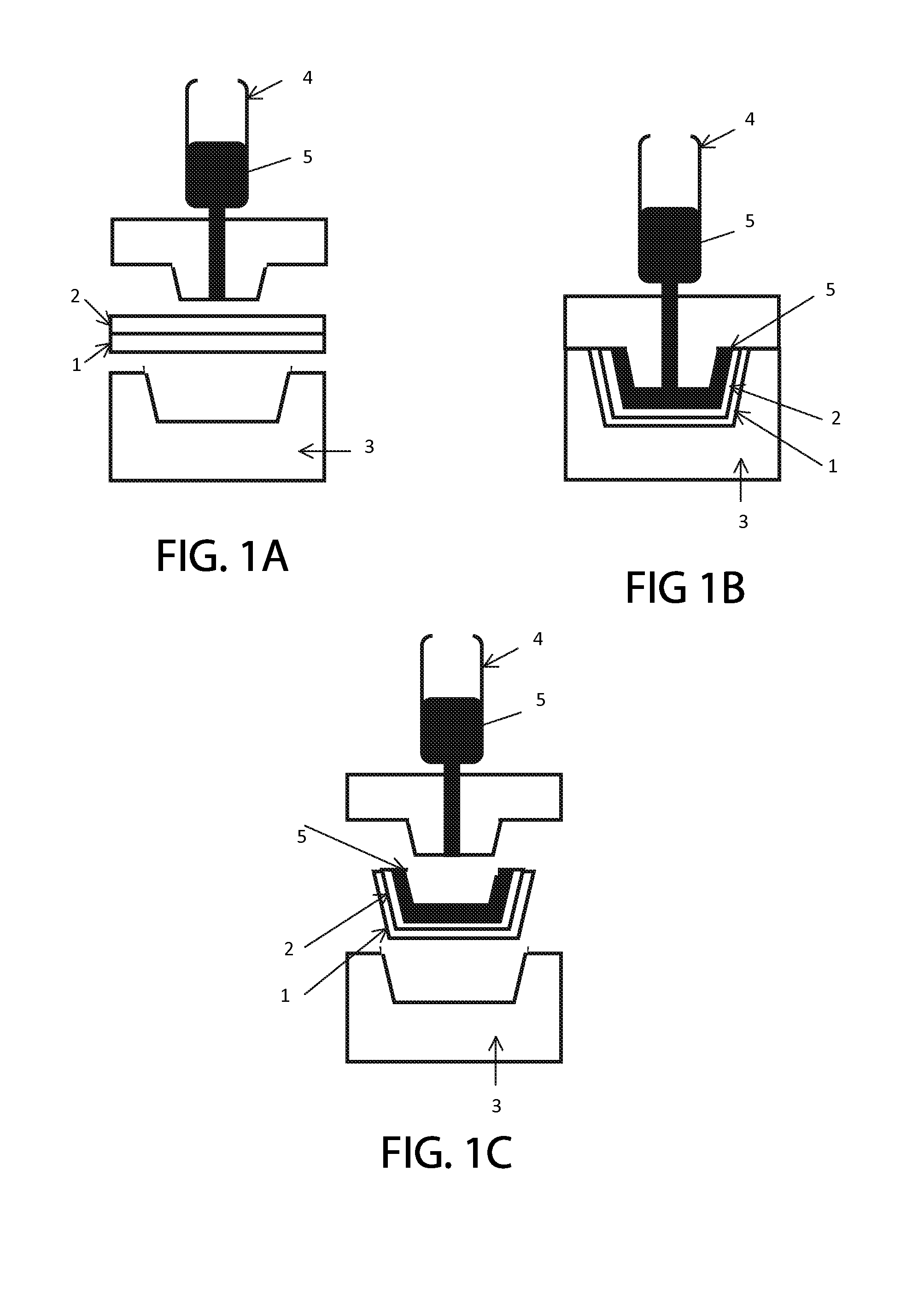

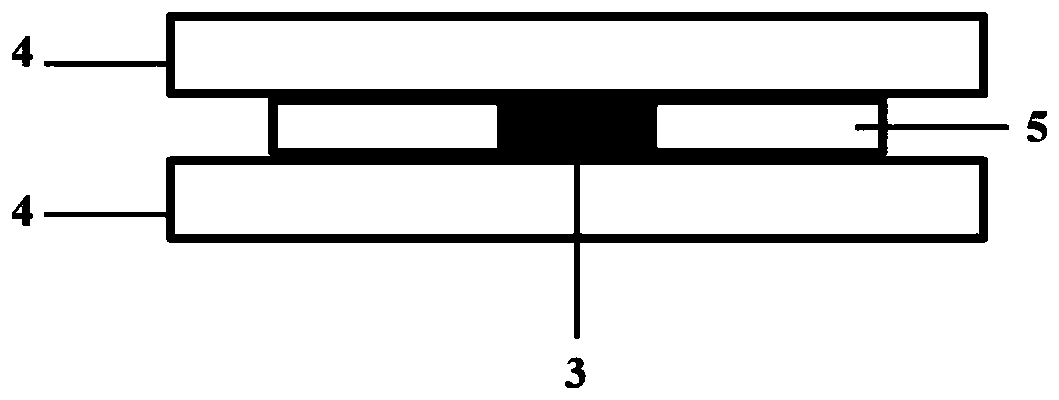

Manufacturing method of front-end component of endoscope

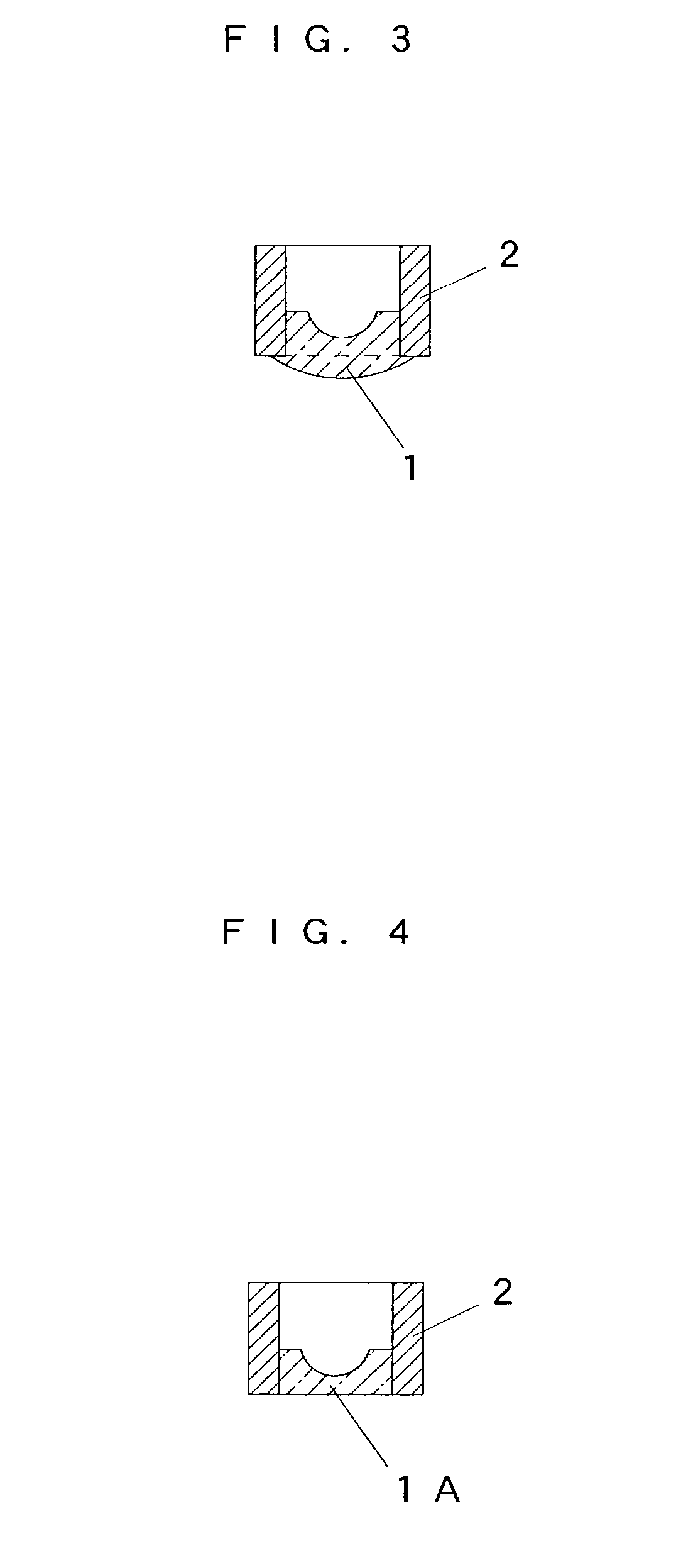

The invention relates to a method of manufacturing a front-end optical component of an endoscope realizing resistance to humidity. In the method of manufacturing a front-end optical component in which a lens is mounted on the front end of a metallic lens-barrel provided on the front end of the inserting portion of an endoscope, the configuration is made such that a lens raw material is placed on the front-end side in the lens-barrel, the lens raw material is press-formed in a heat-softened state with a pair of upper and lower shaping dies, thereby tightly joining the outer edge of the pressed lens raw material to the inner peripheral surface of the lens-barrel.

Owner:FUJI PHOTO OPTICAL CO LTD

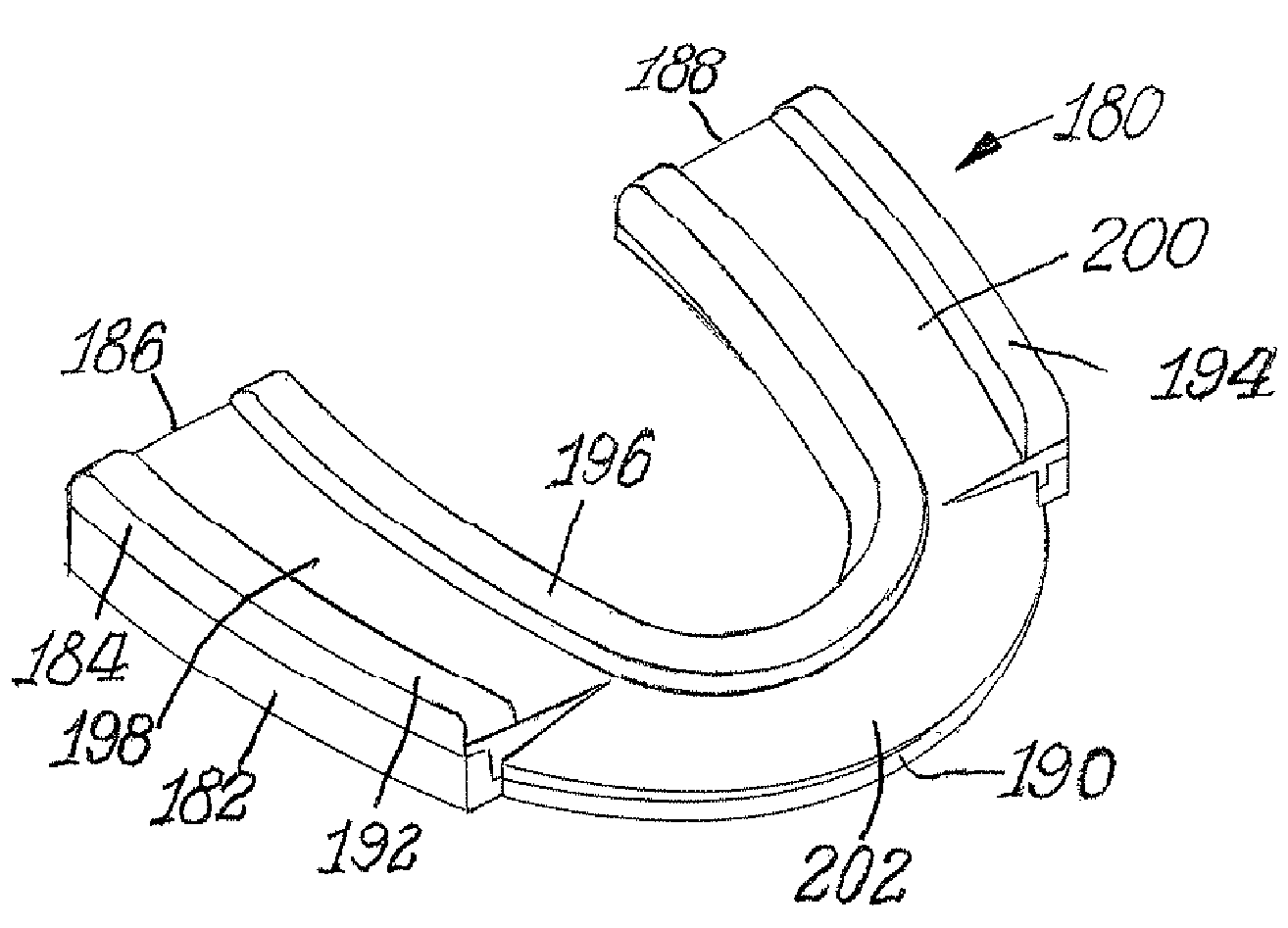

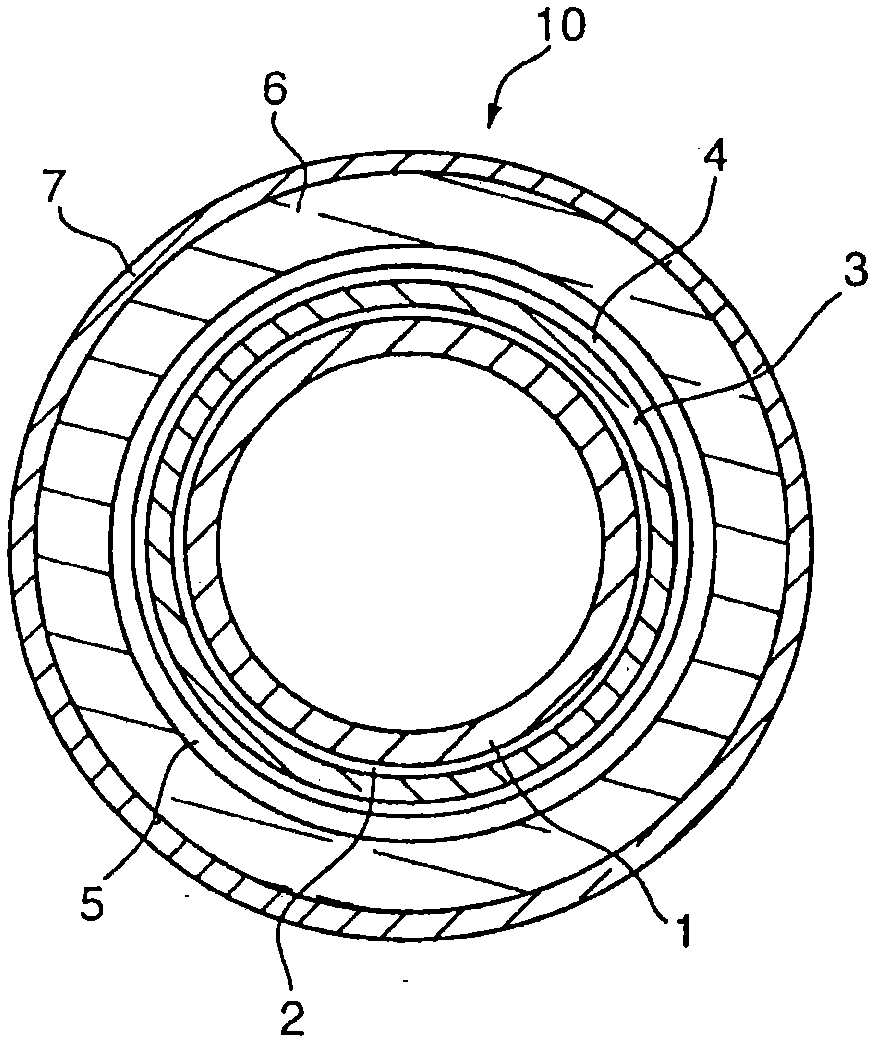

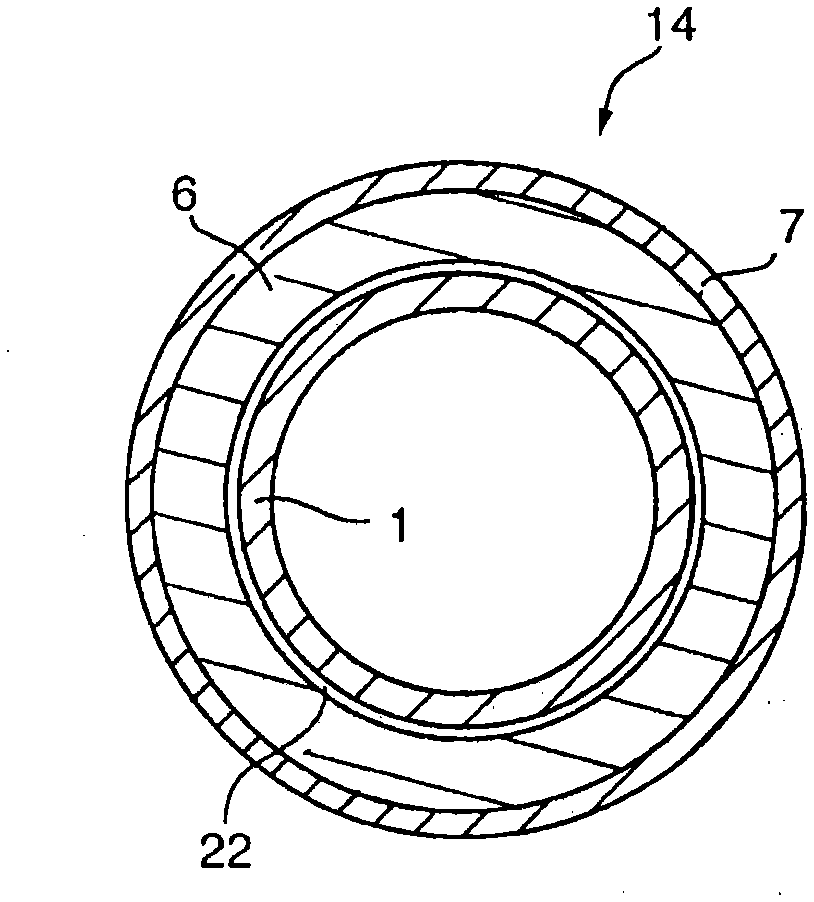

High temperature resistant insulation for pipe

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

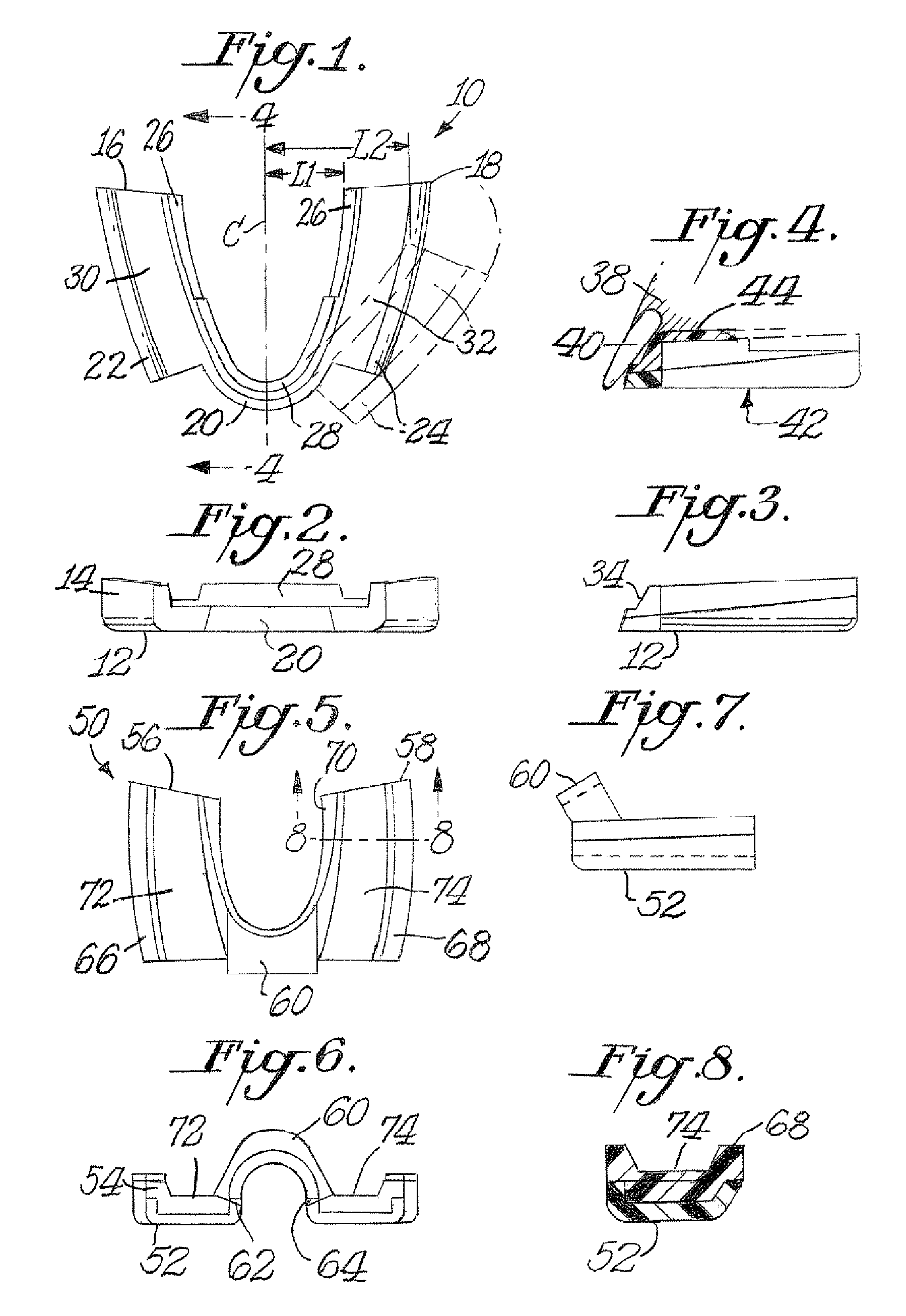

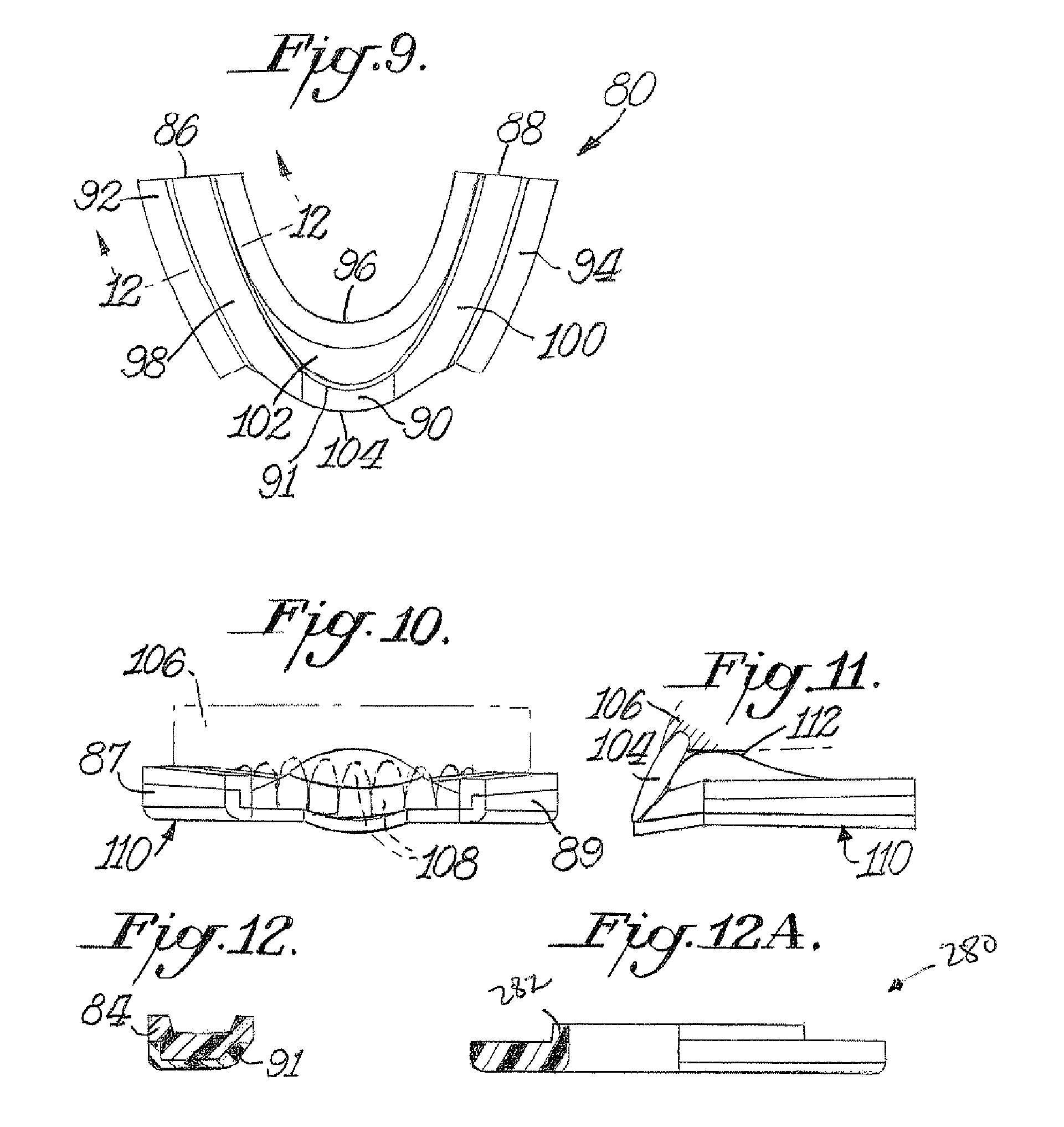

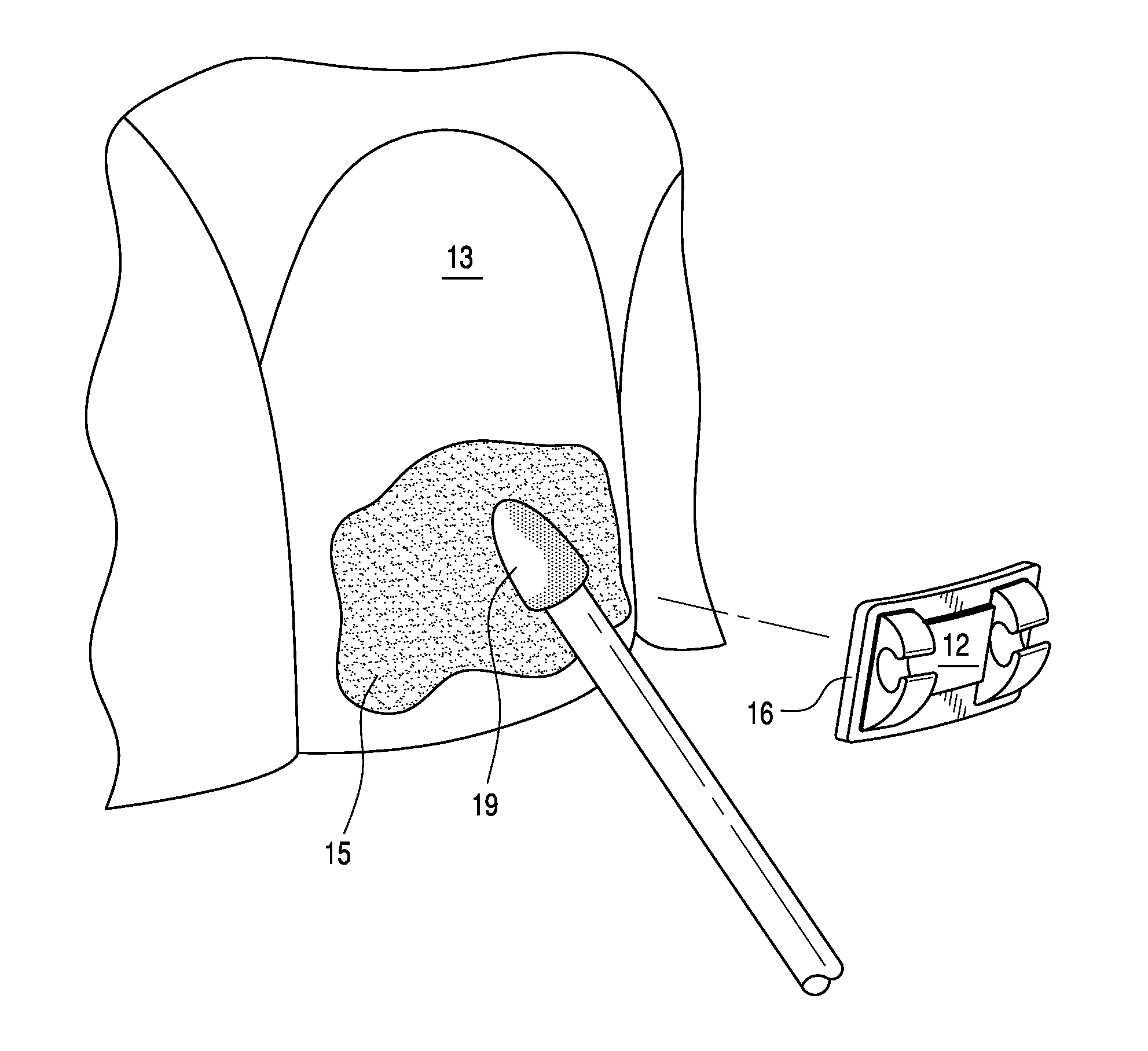

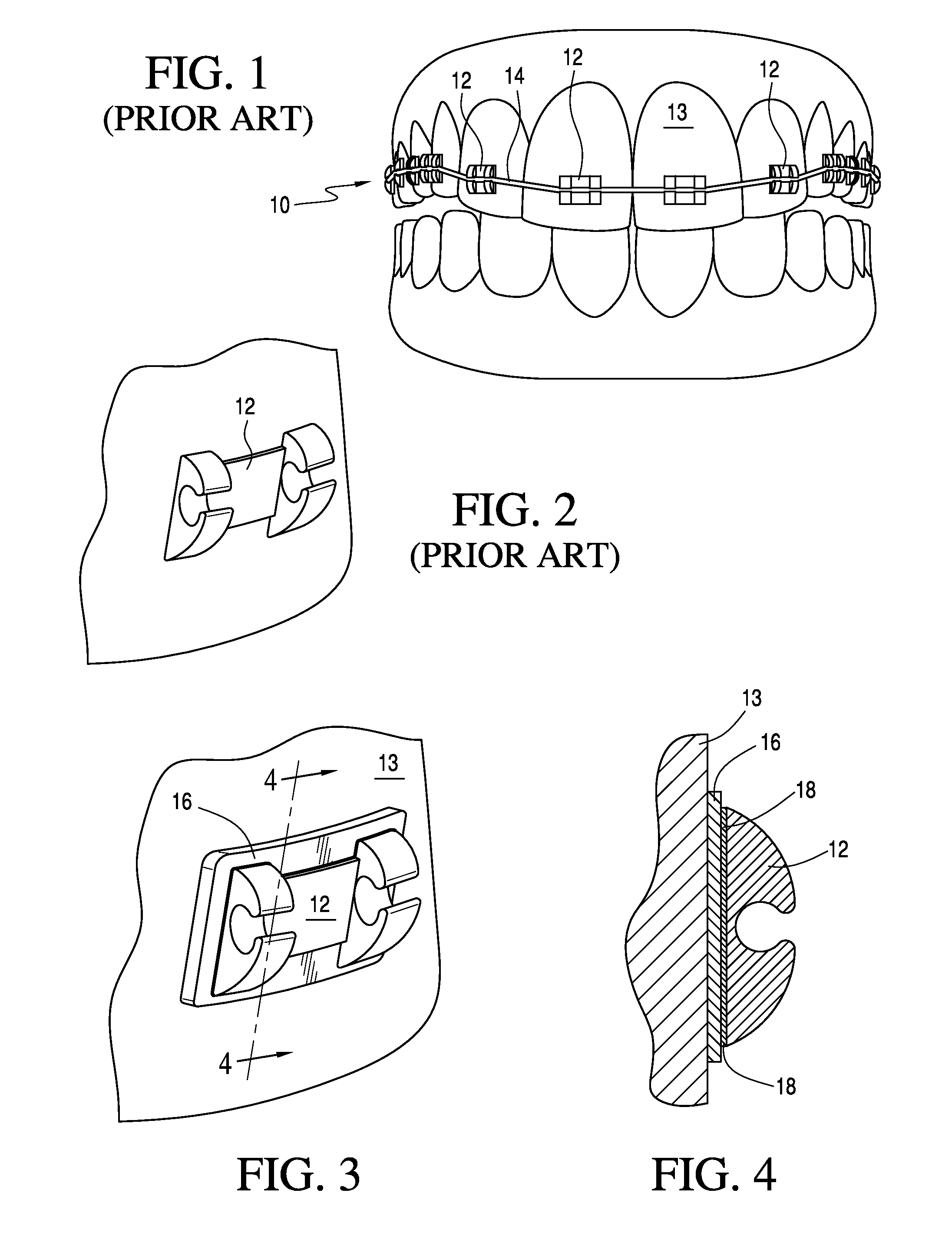

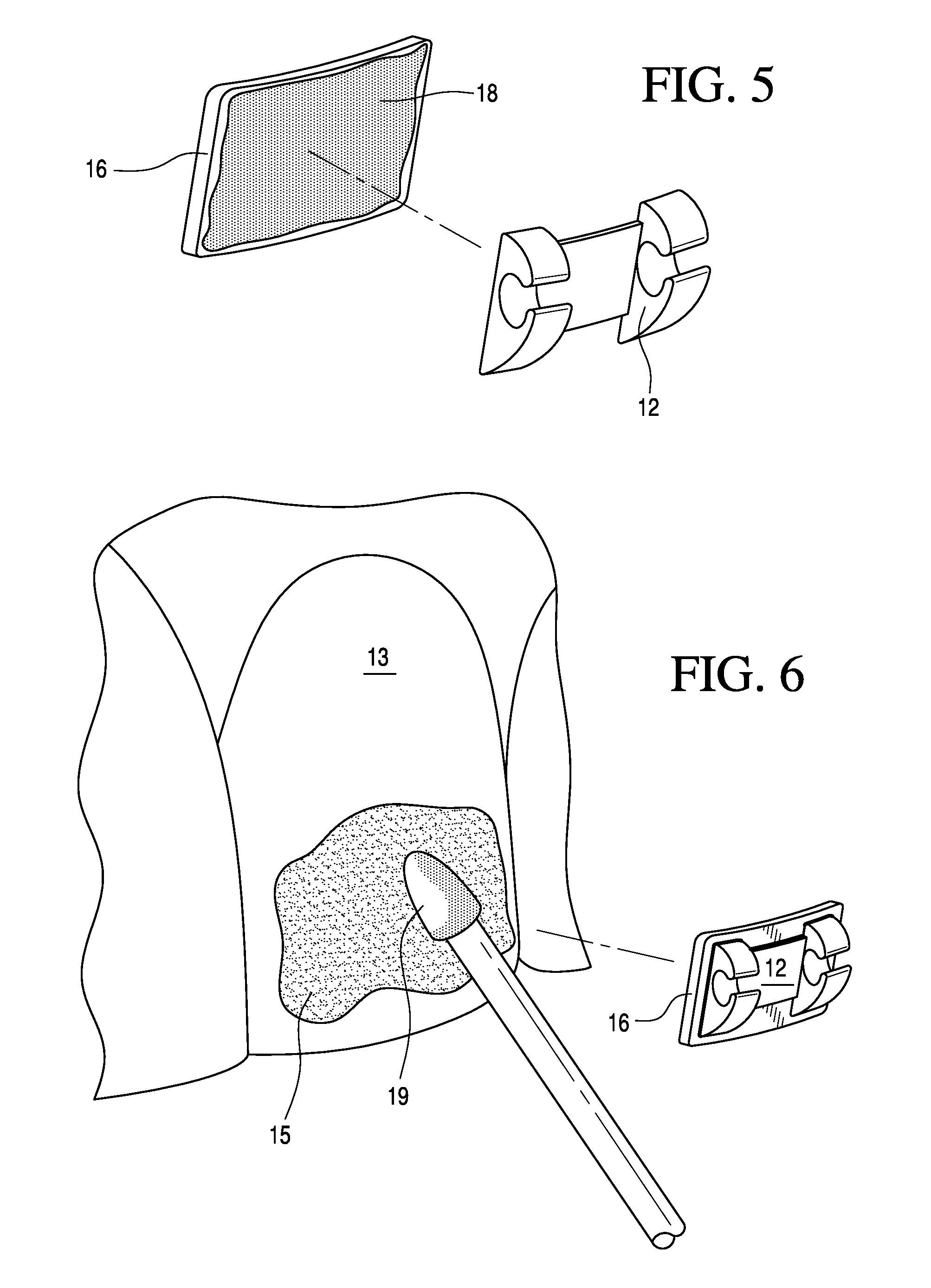

Interocclusal appliance and method

ActiveUS7658193B2Color be alteredHardness be alteredImpression capsOthrodonticsInterocclusal appliancePermlastic

An interocclusal appliance is formed from a single polymer material composition as one unitary piece or from multiple polymer material compositions as a two-piece preform. The two-piece preform includes a base material and an impression material that has a softening point lower than the base material. Teeth are received into the heat-softened impression material, so as to contour the impression material. A portion of the impression material also may contour to a portion of the user's palate. In certain embodiments, substantially no polymeric material contacts the front surfaces of the front teeth, leading to greater comfort and better air flow between front teeth. In still another embodiment, the appliance fits over front teeth only and no polymeric material contacts the maxillary molars.

Owner:HAYLOFT ENTERPRISES INC

Vibration damping novel surface structures and methods of making the same

A gas turbine or turbine component partially or fully coated with a damping surface layer. The damping surface layer may have a thickness between 0.1 and 2000 microns and may be capable of dissipating vibration or modifying a resonance frequency of the gas turbine or turbine component at ambient room temperatures including operational temperatures greater than 500° F., and the damping surface layer comprises at least one of (a) at least two layers comprising a first layer of at least one hard material and a second layer comprising at least one soft material, (b) a composite comprising a nickel alloy with a heat softenable chemistry, (c) a fine-grained nickel-based superalloy, or (d) a porous metallic coating, a porous metallic and ceramic coating, or a ceramic coating.

Owner:GENERAL ELECTRIC CO

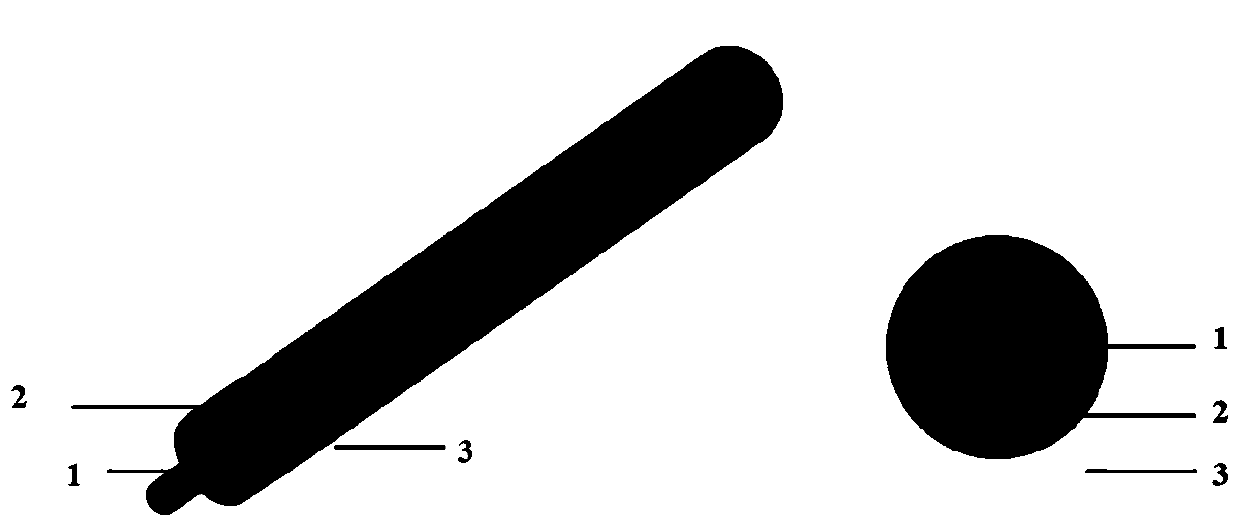

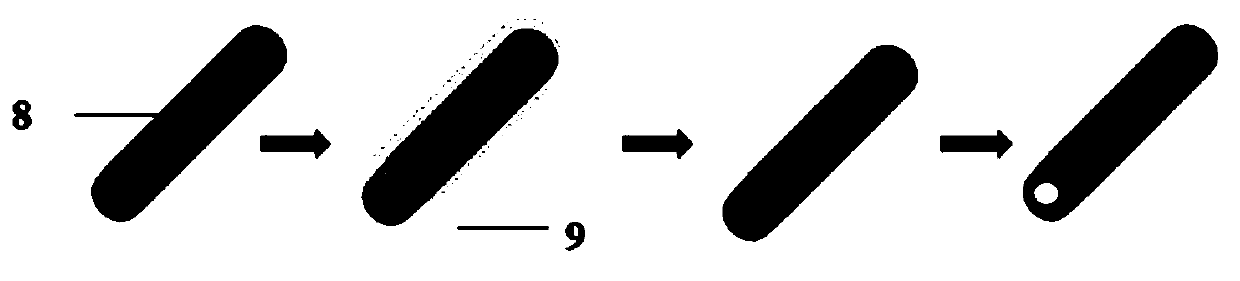

Electrochromic fiber and preparation method and application thereof

ActiveCN110205688AWide range of choicesPerfect structural designFilament/thread formingWoven fabricsFiberColor changes

The invention belongs to the field of functional fibers and particularly relates to an electrochromic fiber and a preparation method and application thereof. The electrochromic fiber comprises a composite material in a three-layer structure which comprises a coating layer, a middle layer and a core layer sequentially from outside to inside, wherein the coating layer is a protective layer, the middle layer is an electrochromic layer, and the core layer is a conductive layer. The conductive layer is made of a conductive layer material with an electrothermal effect; the electrochromic layer is prepared according to a thermal softening wire-drawing method, and a preformed rod of the electrochromic layer comprises a hole structure; the conductive layer material penetrates a hole of the preformed rod, and the conductive layer serving as the core layer is prepared in the electrochromic layer while the electrochromic layer is obtained according to the thermal softening wire-drawing method. Inuse of the electrochromic fiber, the conductive layer material emits heat under an electrified condition, and the electrochromic layer material of the middle layer gives play to a color changing function under the thermal action of the conductive layer.

Owner:武汉新润兴材料科技有限公司

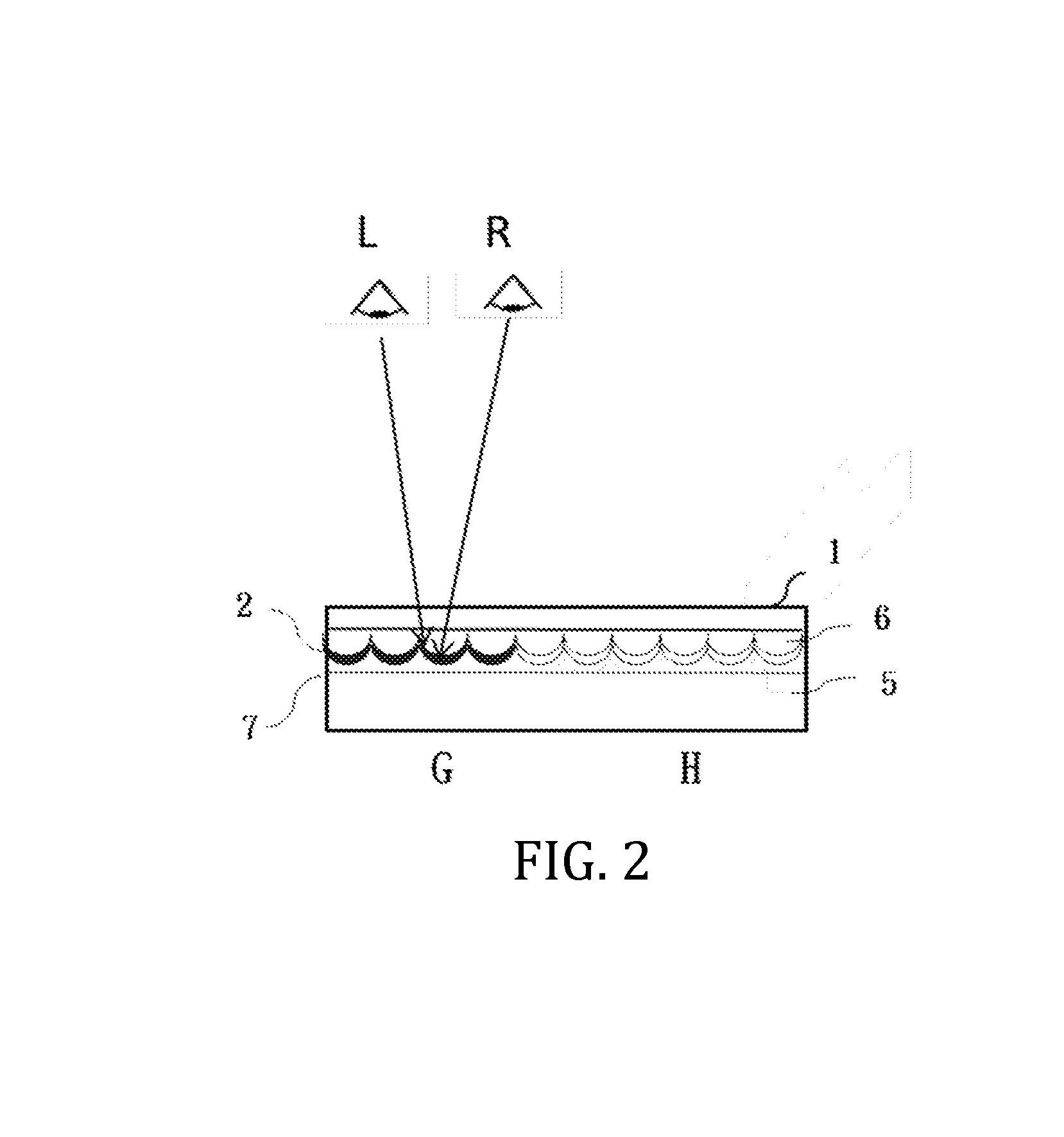

3D Printed Decorative Film And Products Made Thereof

InactiveUS20140205814A1Unique visual effectsDecorative surface effectsDuplicating/marking methodsConvex structureFresnel lens

A 3D printed decorative film includes a transparent substrate with one-sided or two-sided concave or convex structures and a printing layer. The transparent substrate is a thermoplastic film. The heat softening temperature of concave or convex structures is at least 50° C. higher than that of thermoplastic film. An additional reflective layer was applied on top or bottom of printed layer. The reflective layer can be reflective powder, metalized film or high reflective index materials. The concave or convex structure lens is prism, half sphere, half cylindrical, pyramidal, Fresnel lens structures or the combination of above.

Owner:HWANG YU CHEN

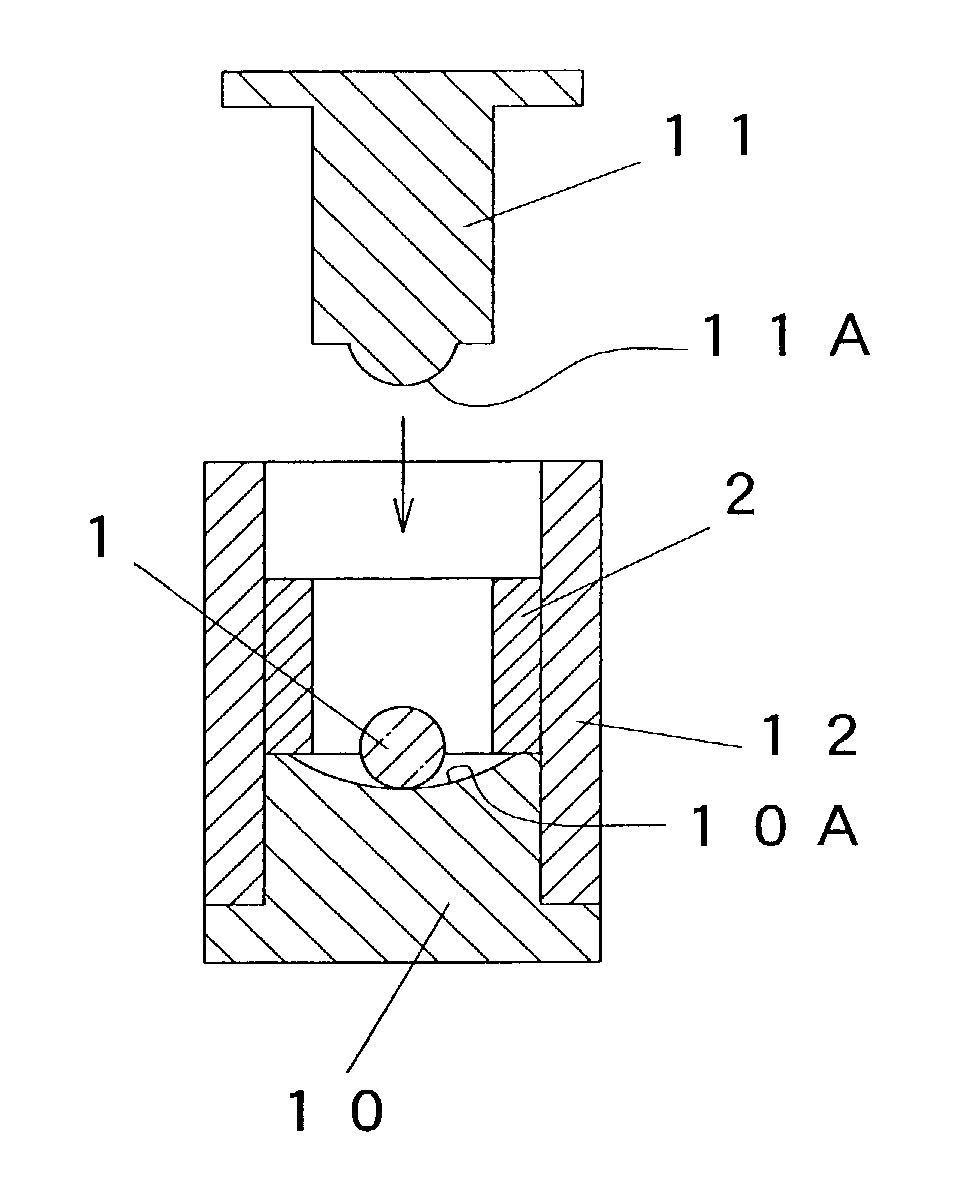

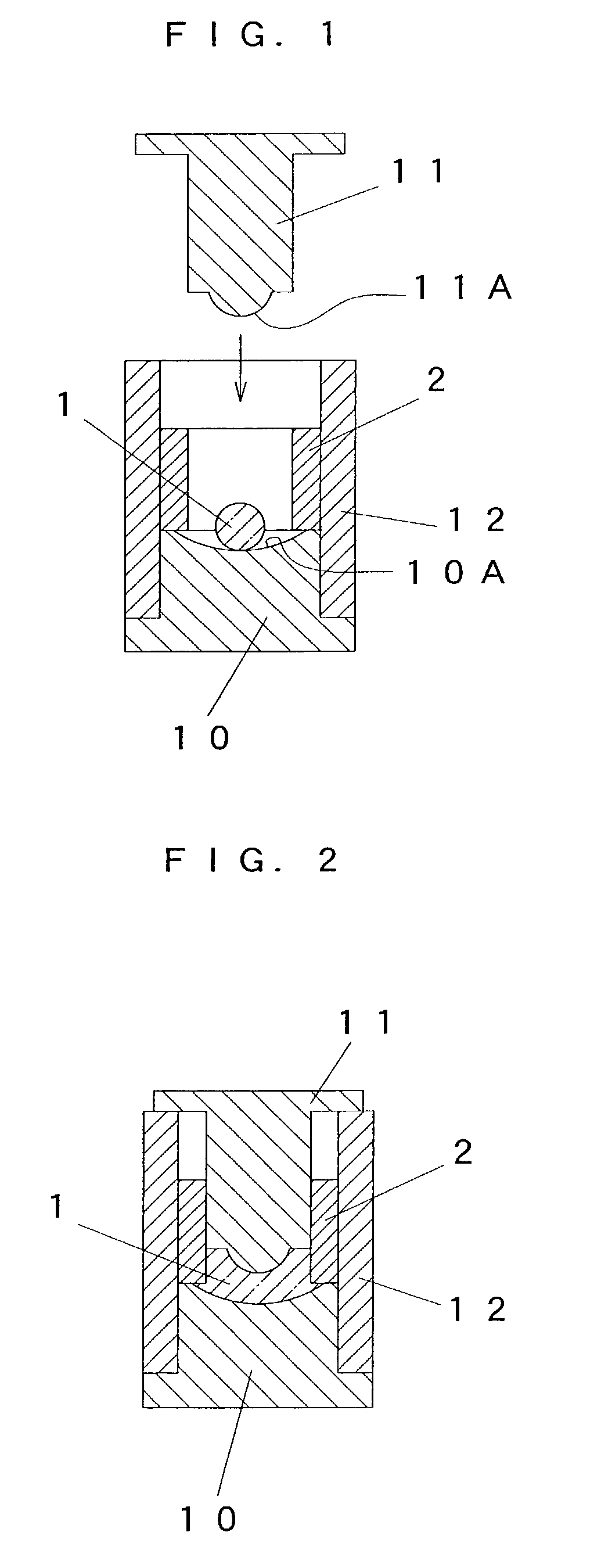

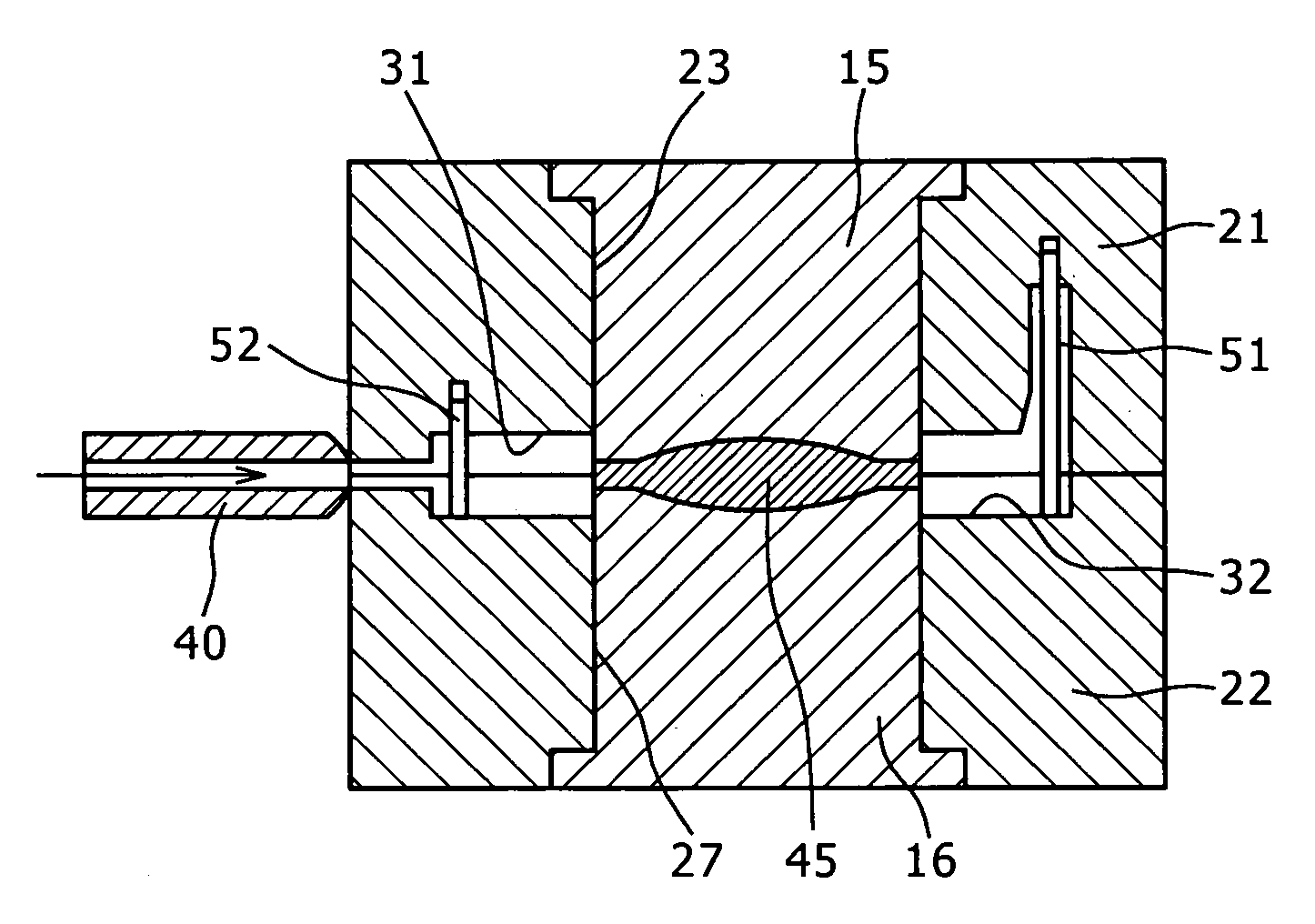

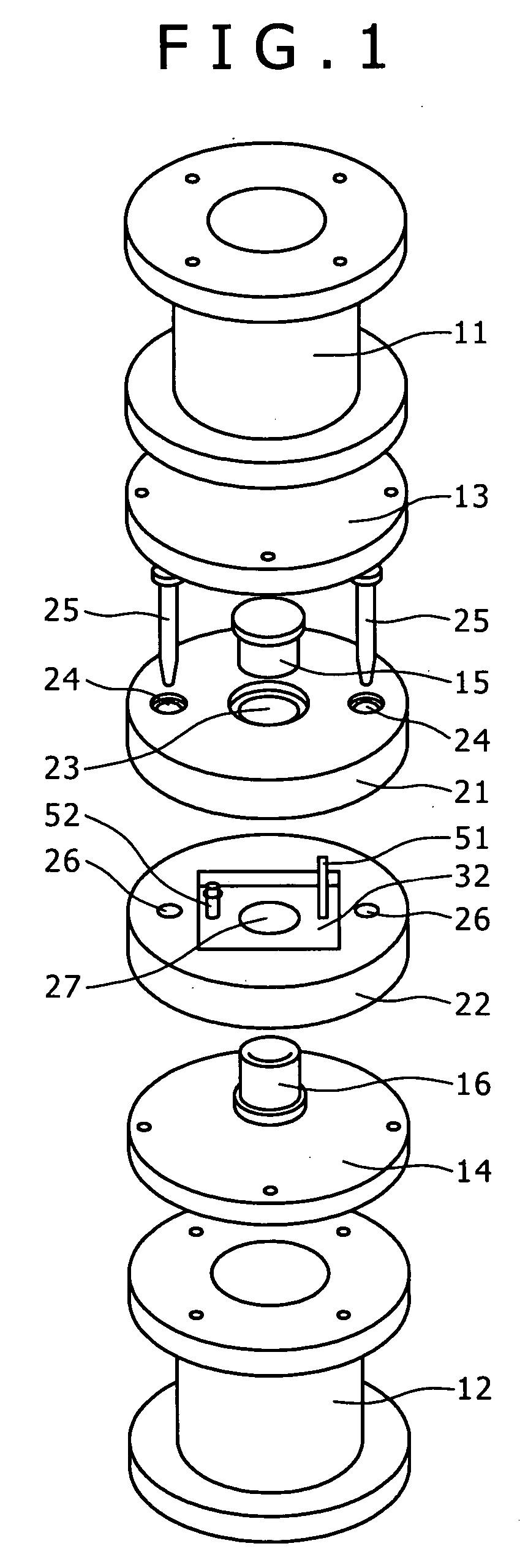

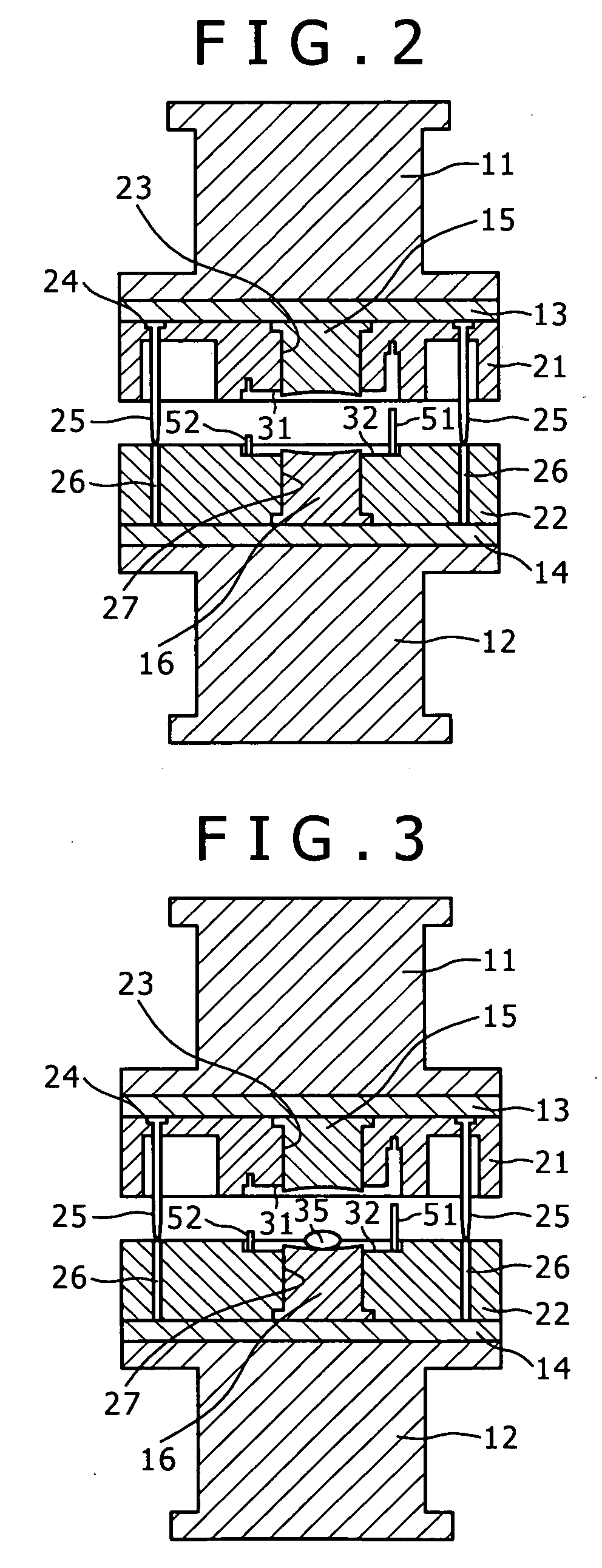

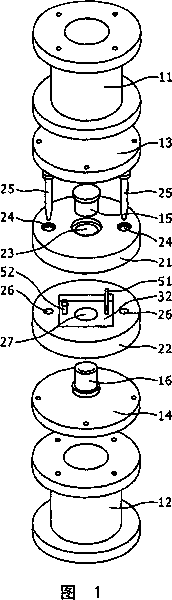

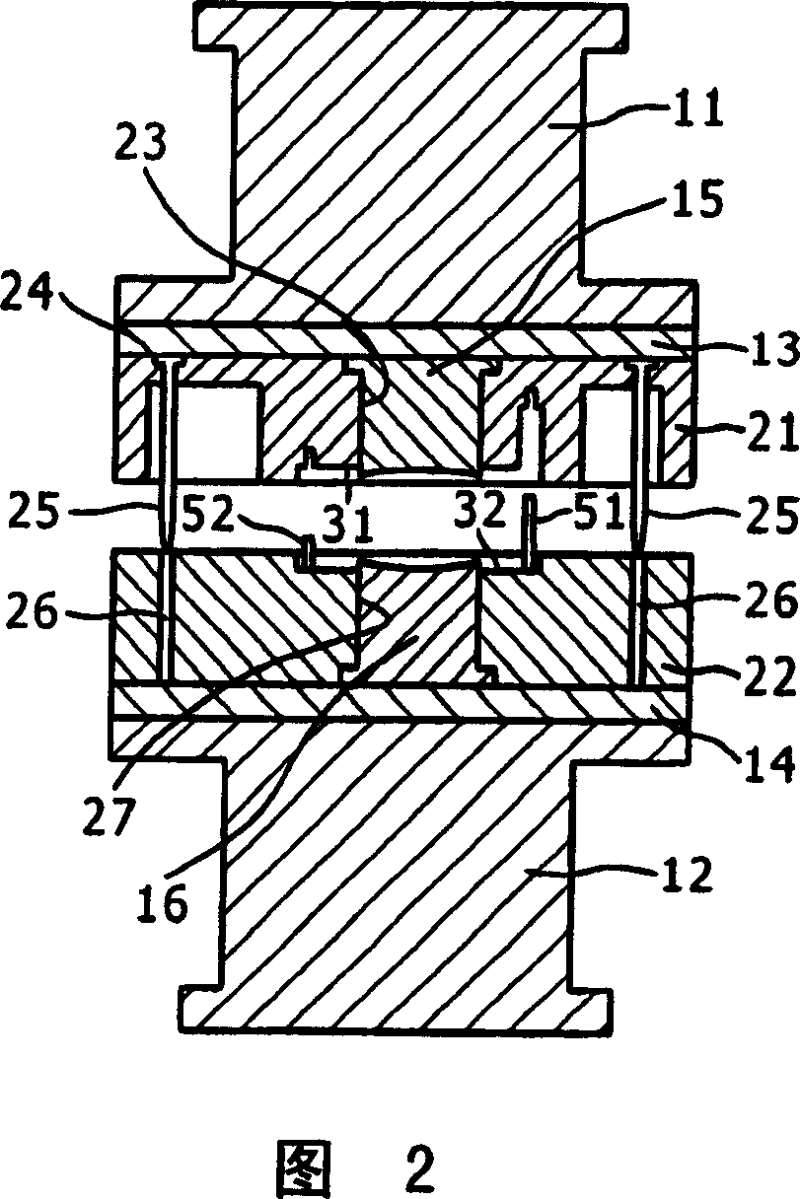

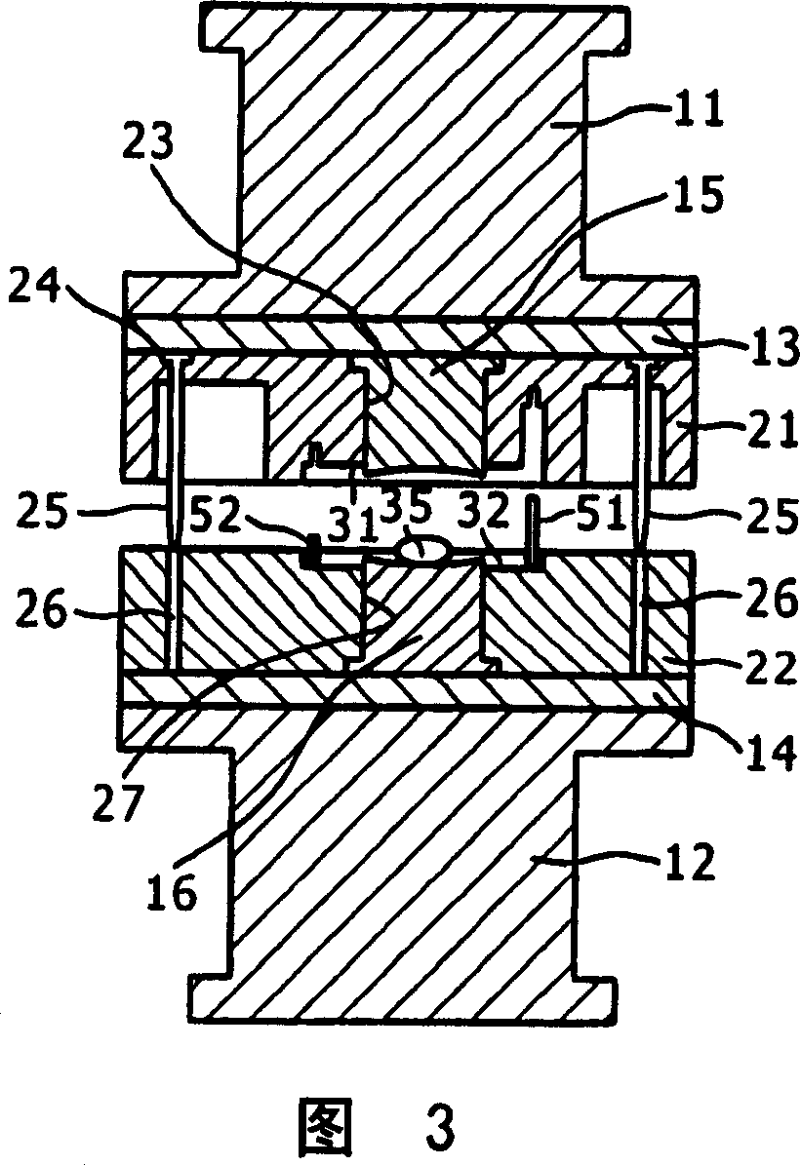

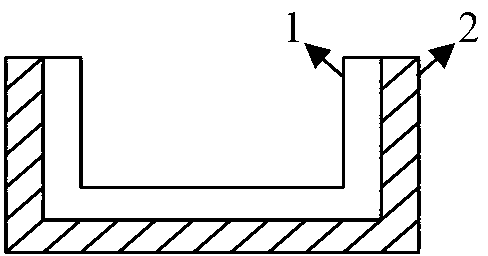

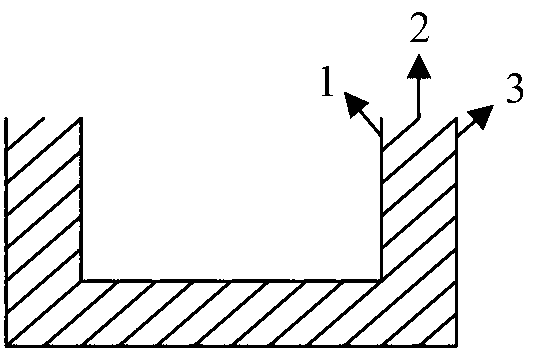

Optical unit manufacturing method, optical unit, and forming apparatus

InactiveUS20060284327A1Reduction in degree of formabilityImprove accuracyFramesOptical articlesEngineeringThermal softening

There is provided an optical unit manufacturing method in which an optical element is obtained by giving compression to an optical material using a mold after thermal softening of the optical material, and uniting of a frame unit with the optical element is required. The optical unit manufacturing method includes a step of forming the frame unit as an integral part of the optical element with reference to a position of the mold while holding the optical element without opening the mold after forming of the optical element.

Owner:SONY CORP

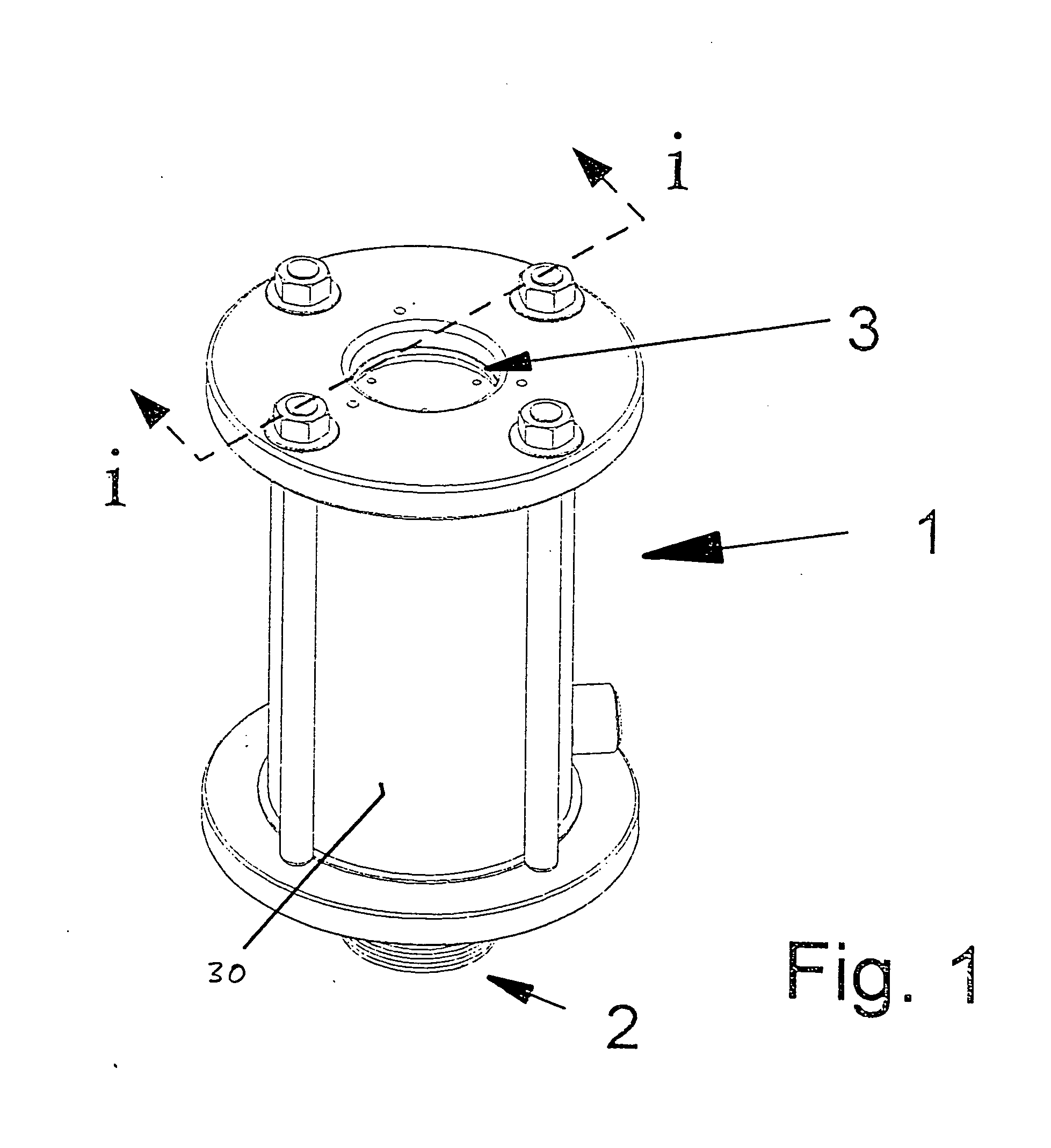

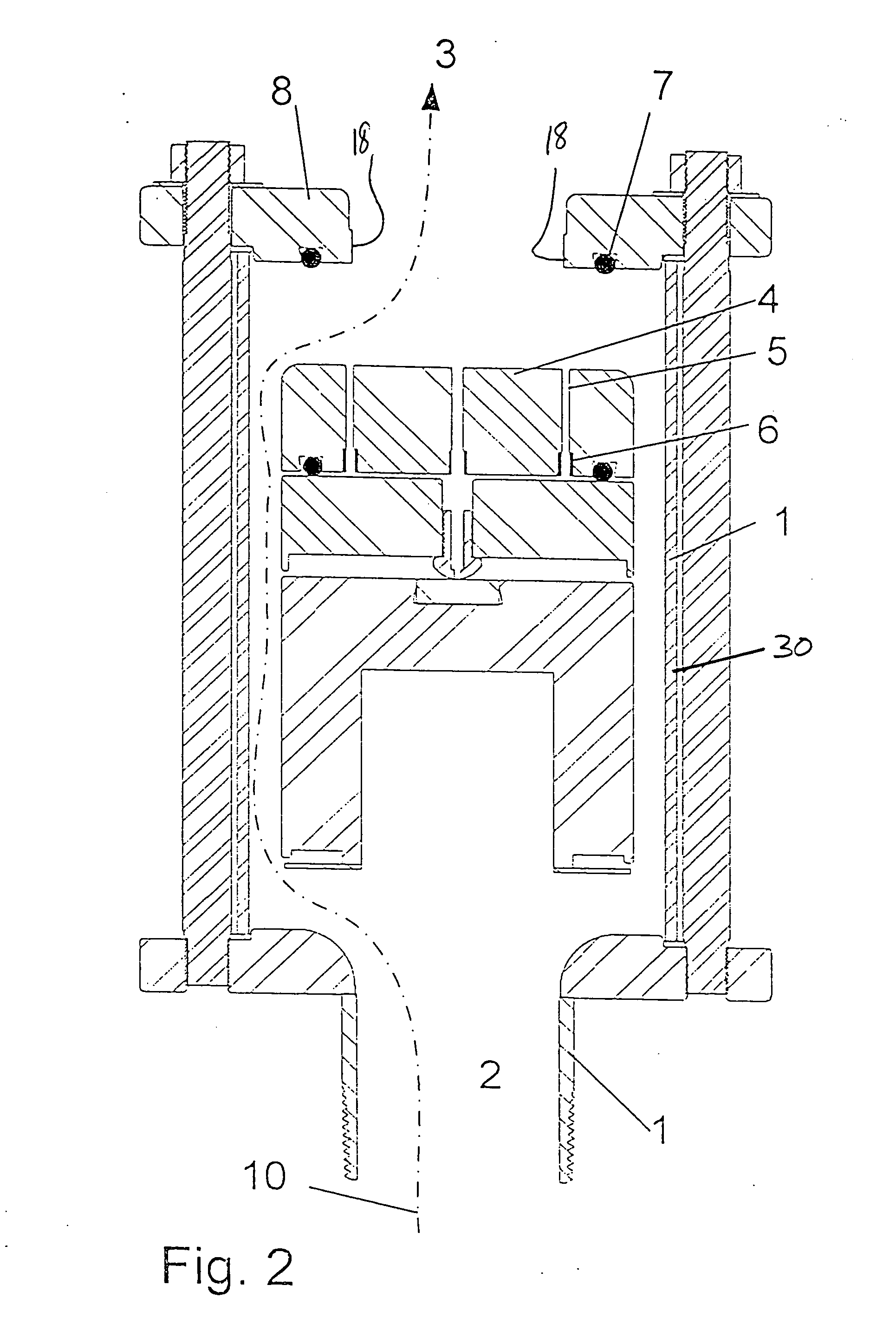

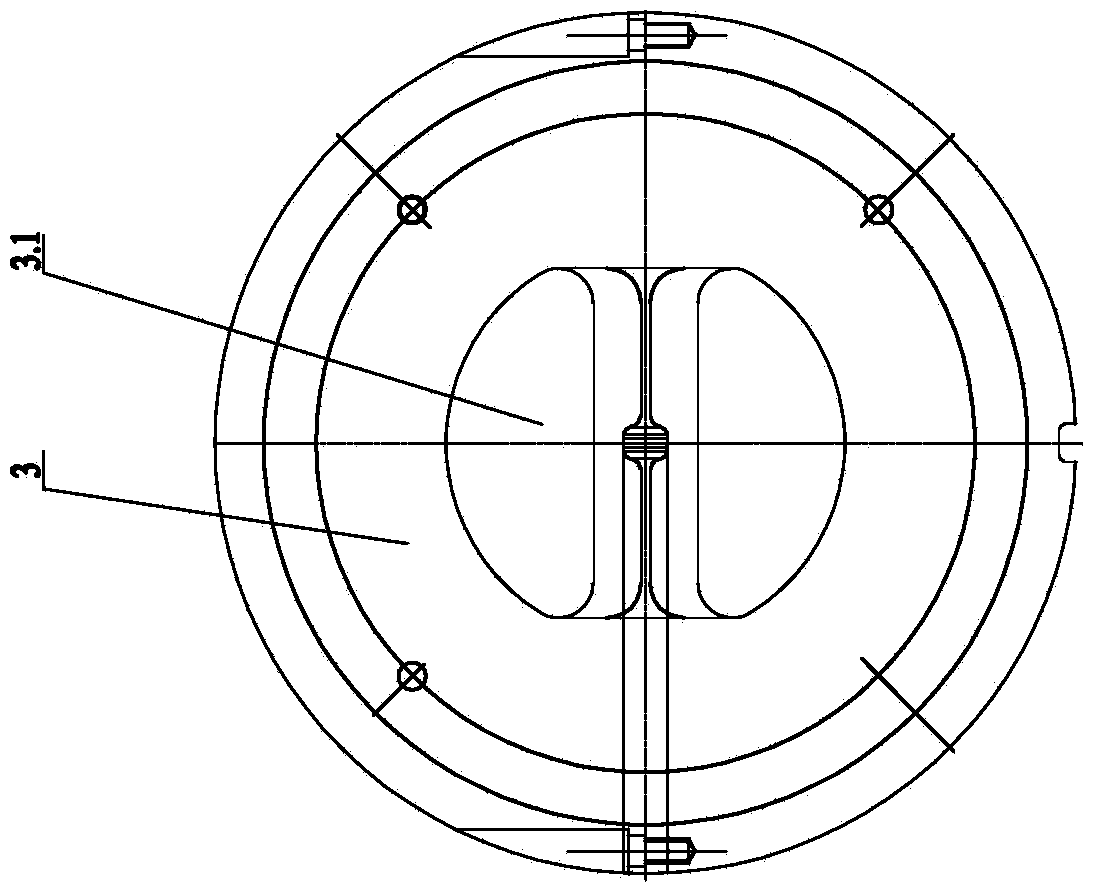

Method and apparatus for venting gas from liquid-conveying conduit

InactiveUS20120037834A1Increased durabilityReduce wear rateSewerage structuresVenting valvesExhaust valveHeat flow

A valve-venting method increases the durability of flow restrictors within gas venting valves used on large diameter water and sewer pipelines such that transient high pressure conditions that can cause rapid adiabatic heating of the discharging gases are prevented from causing flow erosion and debris wear induced by the high velocities and thermal softening of the valve components. The method utilizes wear resistant orifice inserts that are more conductive than the valve component to better distribute the heat, and dynamic surge control geometry to slow the heat flow and provide progressive water-hammering control during high pressure events.

Owner:INT VALVE MFG

Optical unit manufacturing method, optical unit, and forming apparatus

InactiveCN101038348AHigh precisionReduce the difficulty of formabilityFramesOptical articlesEngineeringThermal softening

Owner:SONY CORP

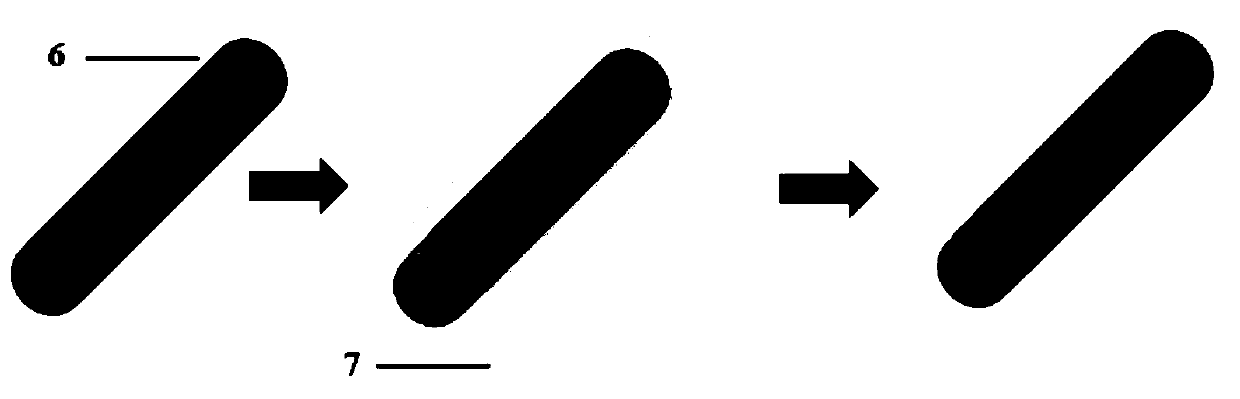

Thermochromic fiber and preparation method and application thereof

InactiveCN110205705AWide range of choicesPerfect structural designConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberPolymer substrate

The invention belongs to the field of functional fiber, and particularly relates to thermochromic fiber and a preparation method and application thereof. The thermochromic fiber is of a core-claddingstructure, a core layer of the core-cladding structure is a thermochromic layer, and the cladding layer is a protection layer and positioned outside the core layer. The thermochromic layer is preparedby adopting a thermal softening drawing method. The preparation method includes: obtaining a prefabricated rod of the thermochromic layer, and performing thermal softening drawing on the prefabricated rod to obtain the thermochromic layer fiber, wherein thermal softening drawing is a thermal softening drawing method adopted in an optical fiber preparation process. Compared with existing thermochromic fiber preparation methods, the drawing process is wide in thermochromic material and polymer base material selection range and diverse in structure design; fiber different in section structure can be designed, distribution of different thermochromic materials in the fiber can be controlled accurately, and the preparation method is high in production efficiency and suitable for large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

Die steel with high heat resistance, high stability and high tenacity and manufacturing technology thereof

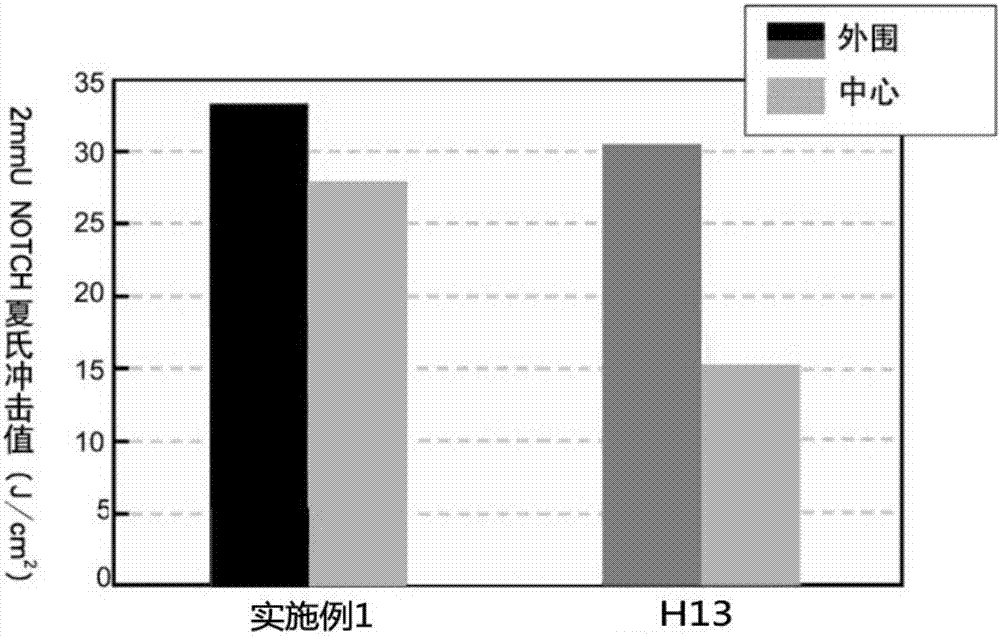

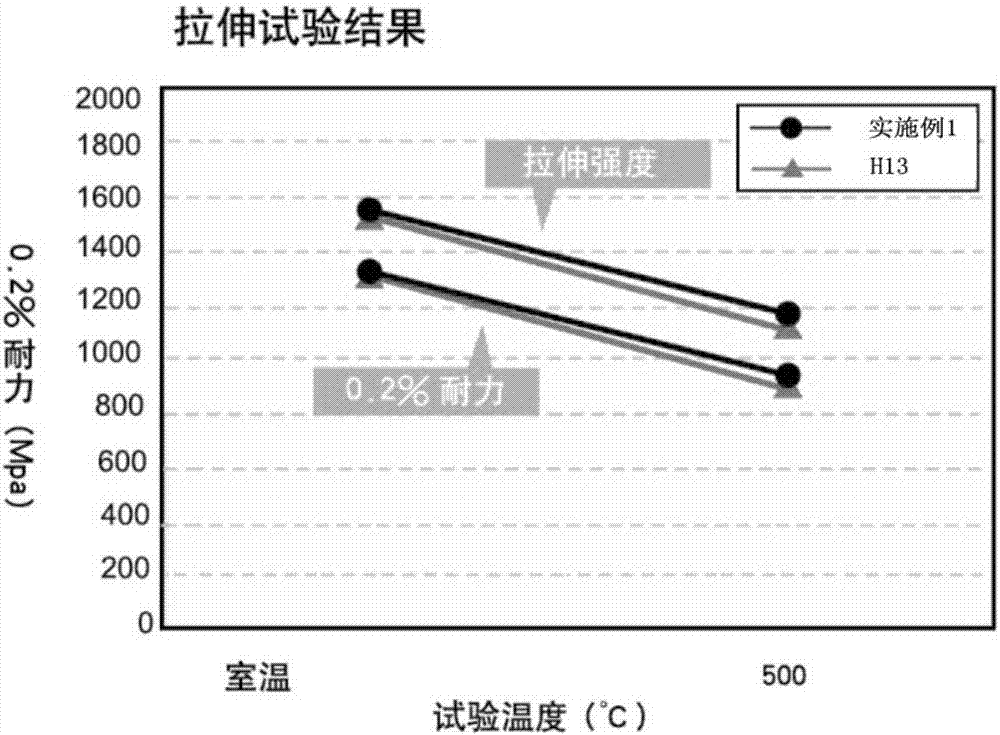

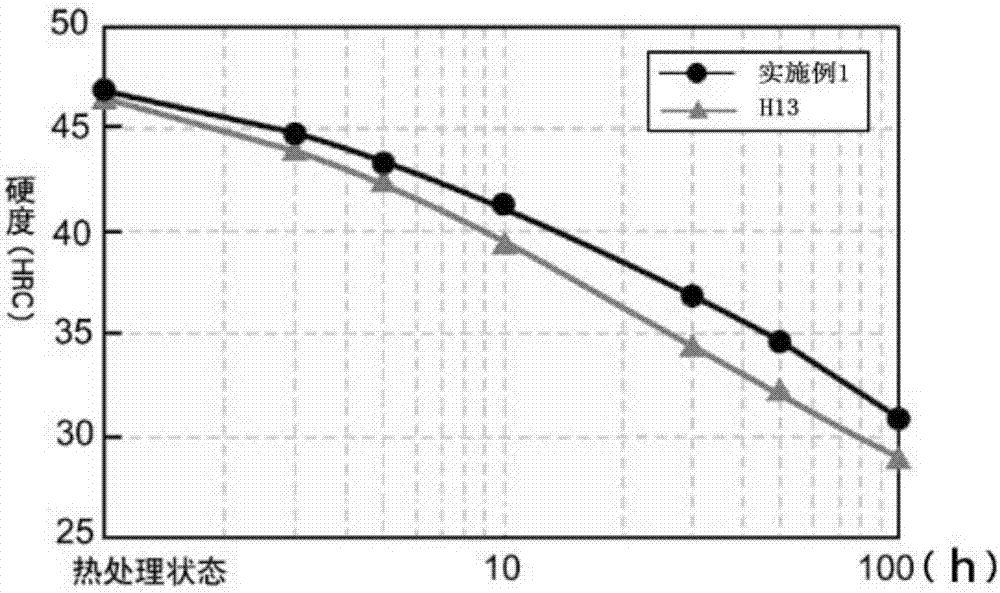

ActiveCN106967930AExcellent central part cracking propertyImprove toughnessHigh resistanceManufacturing technology

The invention relates to die steel with high heat resistance, high stability and high tenacity and a manufacturing technology of the die steel. A base body of the die steel is prepared from 0.37-0.42% of C, 0.40-0.60% of Si, 0.38-0.55% of Mn, 4.50-5.50% of Cr, 0.08-0.20% of Ni, 1.40-1.80% of Mo, 0.40-0.80% of V, 0.01-0.03% of Nb, 0.02-0.05% of Ti, 0.01-0.03% of Os, 0.04-0.06% of La, 0.006-0.012% of Co, 0.005-0.010% of W, 0.06% or smaller of Cu, 0.005% or smaller of S, 0.015% or smaller of P and the balance Fe. The hot work die steel has the excellent center cracking property, is good in heat resistance and softening property, can keep high hardness for a long time, and is good in heat stability and heat conductivity.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

Glass material for mold pressing, method for manufacturing same, and method for manufacturing optical glass element

InactiveUS20100292066A1Stable productionHigh yieldGlass reforming apparatusGlass severing apparatusOptical glassFluorine containing

A glass material for mold pressing, comprised of a core portion comprised of a multicomponent optical glass containing at least one readily reducible component selected from among W, Ti, Bi, and Nb, and a covering portion covering the surface of said core portion, comprised of a multicomponent glass containing none or a lower quantity of said readily reducible component than is contained in said core portion. A glass material for mold pressing comprising a core portion comprised of a fluorine-containing multicomponent optical glass and a covering portion covering the surface of said core portion, comprised of a multicomponent glass containing none or a lower quantity of fluorine than is contained in said core portion. A method for manufacturing an optical glass element comprising heat softening a glass material that has been preformed into a prescribed shape, and conducting press molding with a pressing mold, employing the above glass material of the invention. To provide a stable production of optical elements affording adequate optical performance by using optical glass containing readily reducible components or fluorine and inhibiting undesirable interface reactions during press molding.

Owner:HOYA CORP

Manufacturing method of solid wood furniture bent parts

InactiveCN105599096ASolve the technical problems of large amount of sewage and long softening cycleImprove bending qualityRadiation/waves wood treatmentWood treatment detailsSolid woodProcess engineering

The invention provides a manufacturing method of solid wood furniture bent parts. The method includes the following steps that firstly, material varieties are selected, and raw materials are machined; secondly, microwave heating softening treatment is performed; thirdly, bending and forming are performed; fourthly, drying and shaping are performed; fifthly, cooling is performed. The manufacturing method can replace a common cooking softening technology and a kiln drying shaping technology, production technology time is shortened, and production efficiency is improved; the springback rate of bend wood is reduced through a microwave heating softening method, and the bending quality of manufactured products is improved; no waste liquid is generated in the production process, and environmental friendliness is facilitated in the production process; the production period is short, production cost is low, and economic benefits can be increased easily.

Owner:中山市大涌镇生产力促进中心

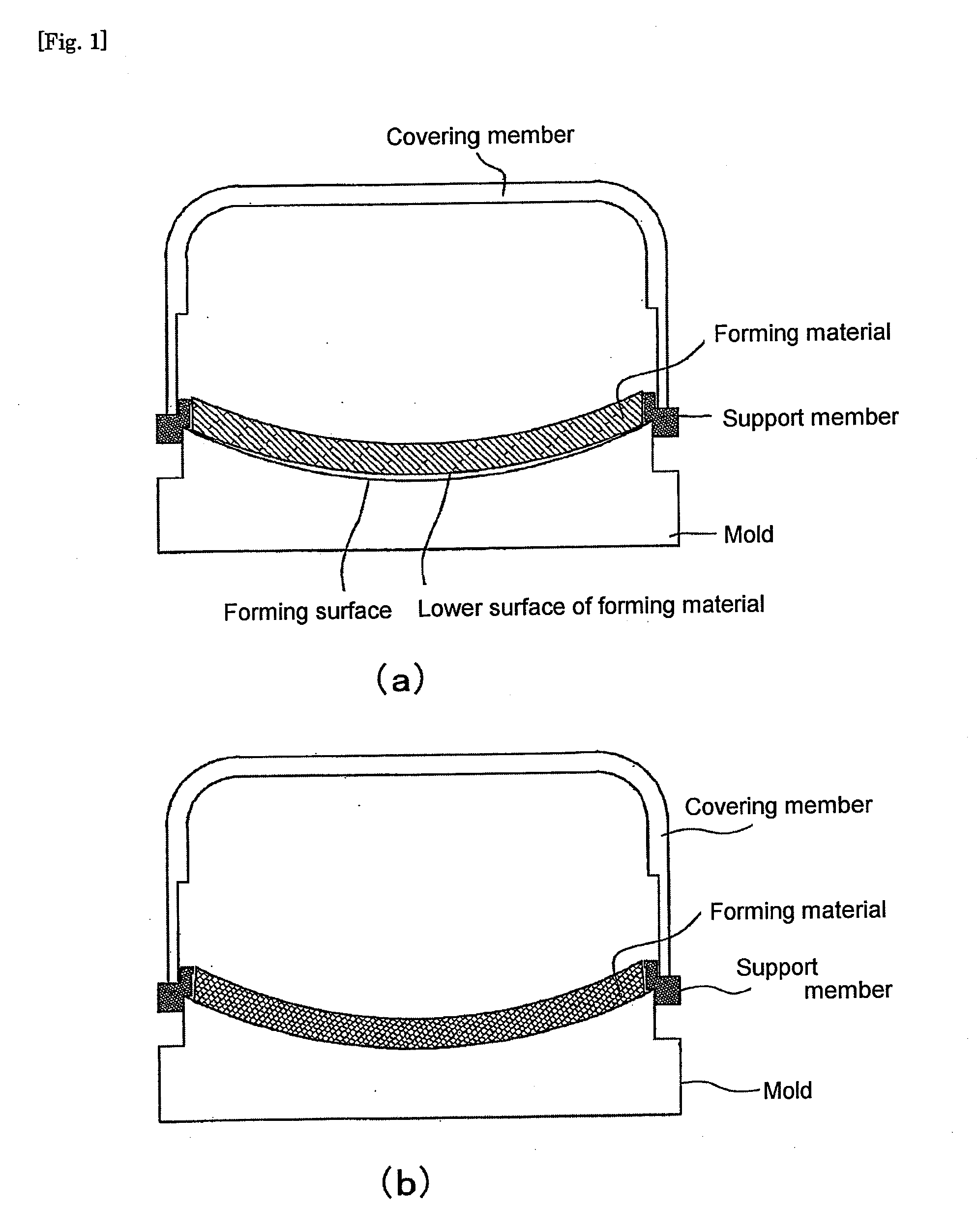

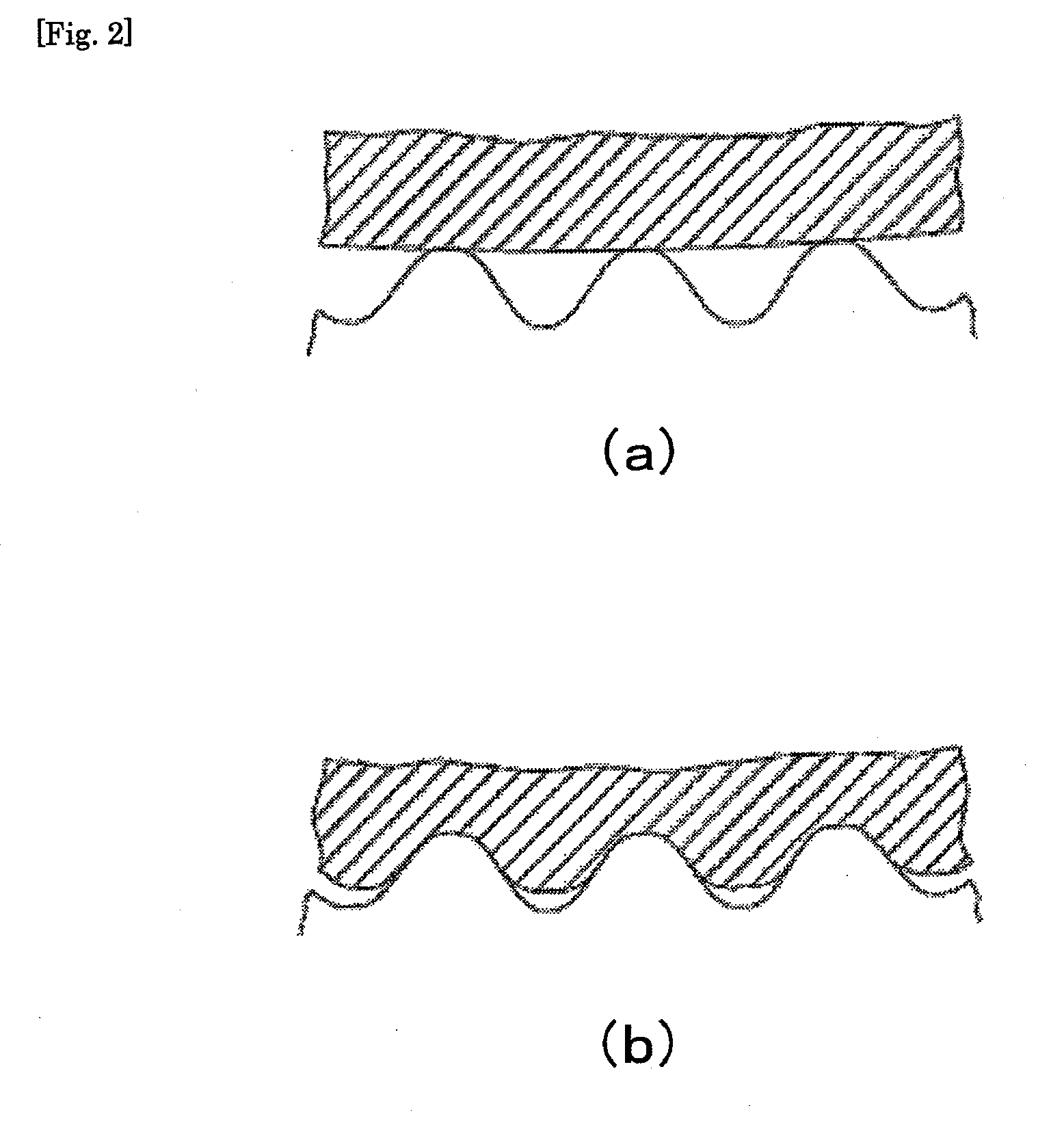

Method of manufacturing formed article, covering member, and forming apparatus comprising the same

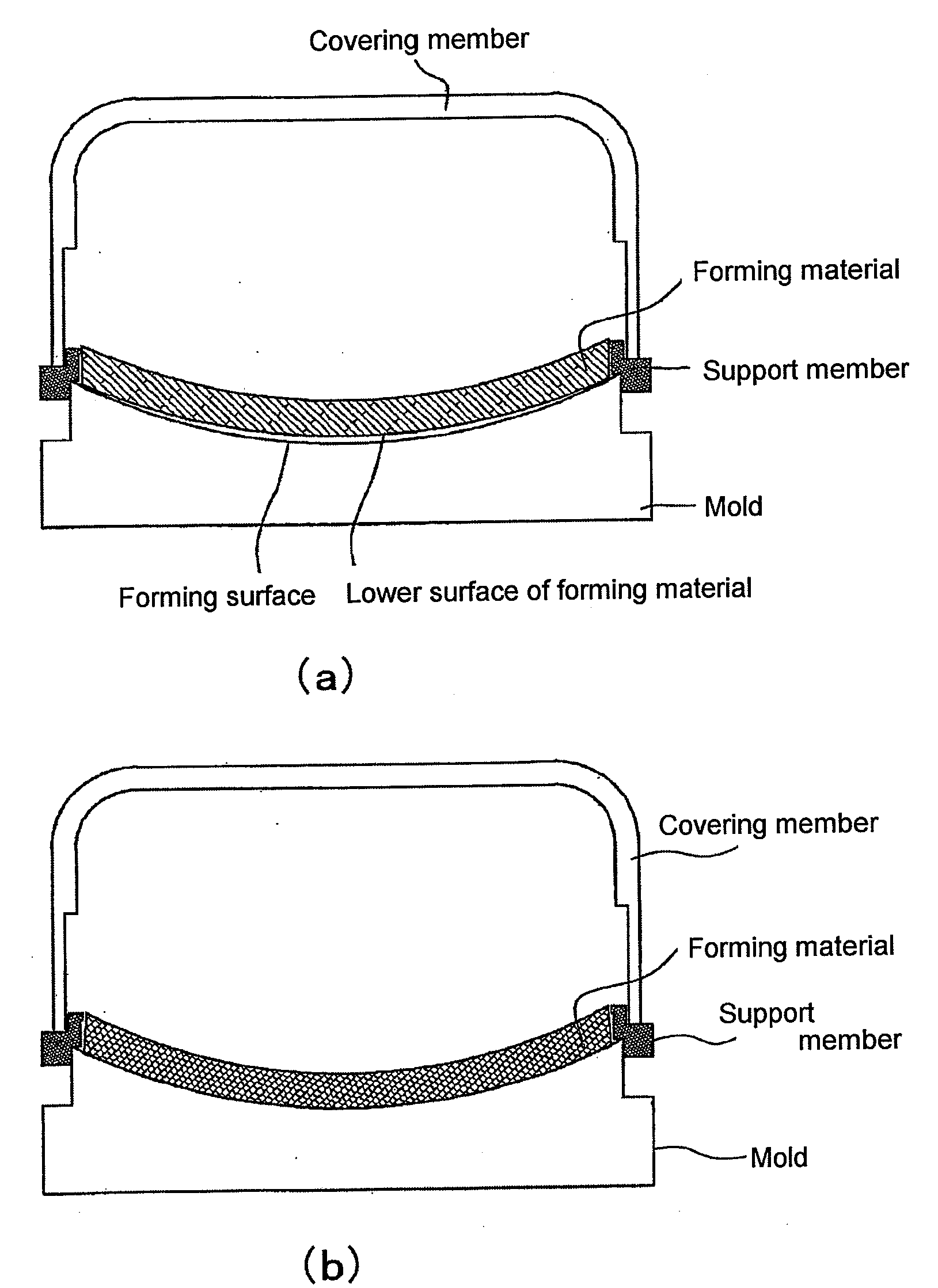

InactiveUS20090289380A1Improve accuracyRemove distortionMelt-holding vesselsOptical articlesForeign matterBiomedical engineering

The present invention relates to a method of manufacturing a formed article forming an upper surface of a forming material comprised of a thermosoftening substance into a desired shape by positioning the forming material on a forming surface of a mold and heating the forming material to a temperature permitting deformation to bring a lower surface of the forming material into tight contact with the forming surface. The forming is conducted while an exposed portion on the forming surface side of the mold upon which the forming material has been positioned is covered with a covering member. The present invention further relates to a covering member and a forming apparatus. According to the present invention, formed articles with a desired shape can be formed with high accuracy by preventing the contamination of upper surface of forming materials by foreign matter during forming.

Owner:HOYA CORP

Composite material of pulp molding product and plastic and preparation method thereof

InactiveCN102991063AReduce dosageImprove barrier propertiesFlexible coversWrappersLiquid productShell molding

The invention discloses a composite material of pulp molding product and plastic and a preparation method thereof, and belongs to the technical field of packaging products. The composite material of pulp molding product and plastic at least comprises a pulp molding layer and a plastic layer which is composited with the pulp molding layer, wherein the plastic layer is used as an inner layer, and the pulp molding layer is used as an outer layer; a plastic thermal forming process is adopted in preparation, wherein on a thermoforming machine, a plastic film or a sheet material is placed on an upper module or a lower module of the thermoforming machine to heat, and the plastic is heated to be softened; then, the lower module or the upper module embedded with the pulp molding product is compressed with the plastic, and the plastic and the pulp molding product are composited together; and finally, the upper and lower modules are cooled so as to form the composite material of the pulp molding product and plastic, and the composite material has the same shape as the pulp molding product. The composite material of pulp molding product and plastic and the preparation method provided by the invention improves the obstruction performance of the pulp molding products, and the leakage of the internally packaged liquid products cannot destroy the external package and cannot pollute the environment.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

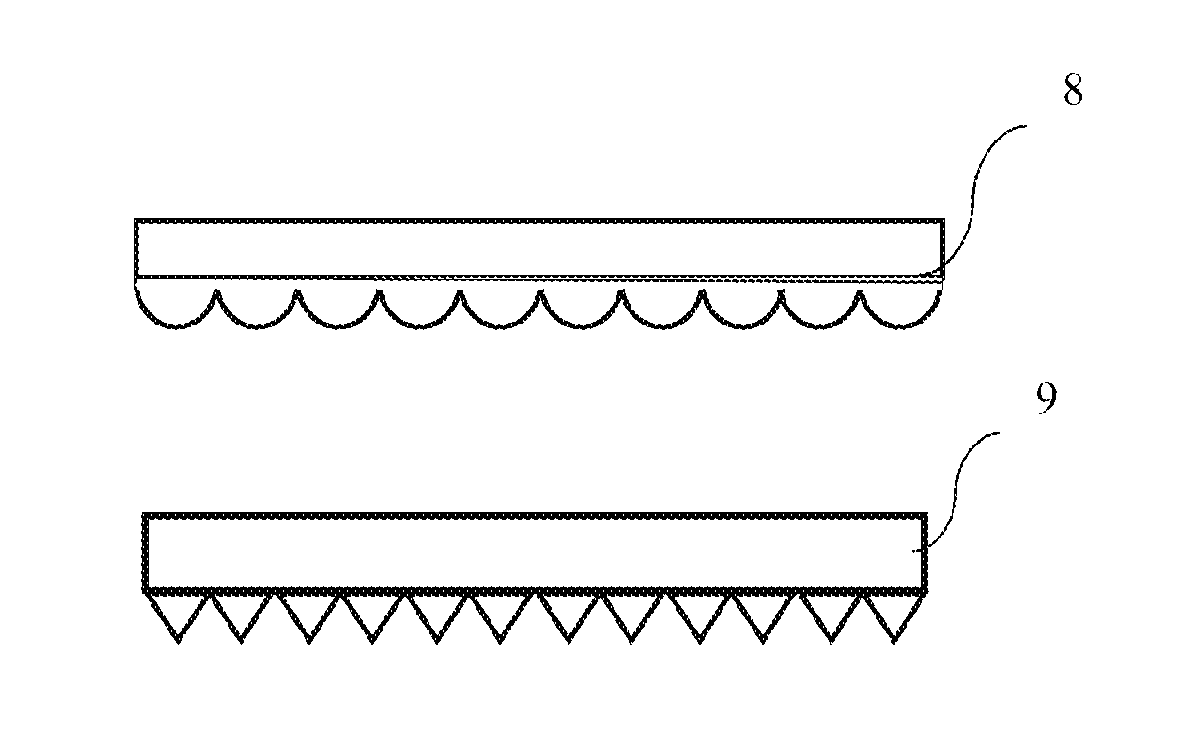

Heat conductive composite sheet and process for producing same

InactiveUS7279224B2Improve thermal conductivityImprove repair effectSemiconductor/solid-state device detailsSynthetic resin layered productsElectronic componentSoftening

A heat conductive composite sheet comprising (a) a heat softening, heat conductive layer containing a silicone resin and a heat conductive filler, and (b) a heat conductive silicone rubber layer containing a heat conductive filler is ideally suited to use as a heat radiating structure provided between a heat generating electronic component and a heat radiating component such as a heat sink or a circuit board, for the purposes of radiating heat away from the heat generating electronic component and thus cooling it. This heat conductive composite sheet not only offers good thermal conductivity, but if an installed heat conductive member formed from this type of heat conductive composite sheet needs to be removed temporarily to enable the electronic component such as a CPU to be repaired or replaced, the electronic component is not removed together with the heat conductive member.

Owner:SHIN ETSU CHEM IND CO LTD

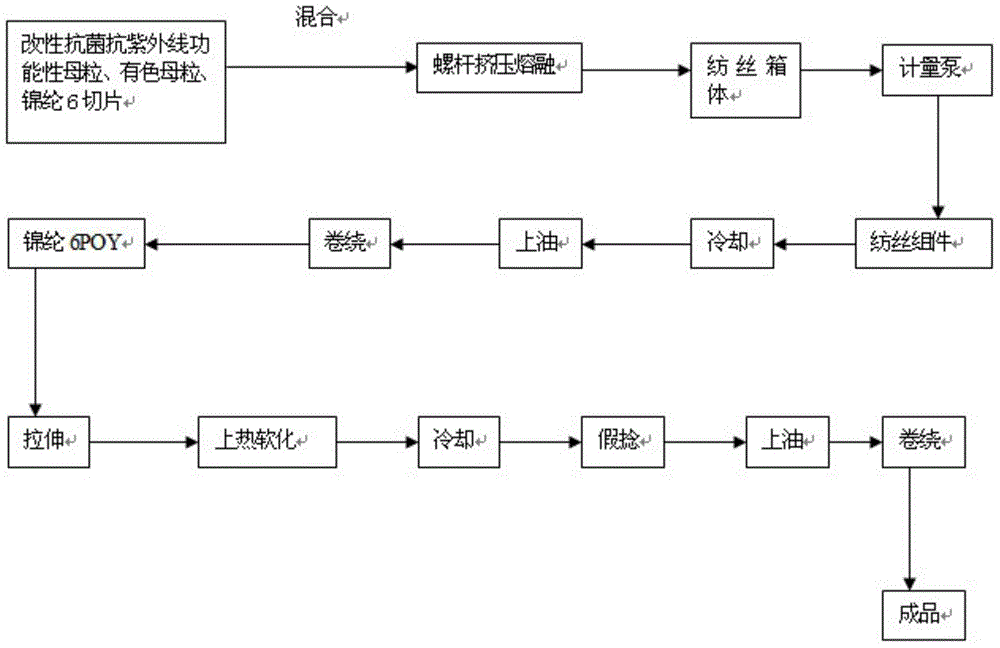

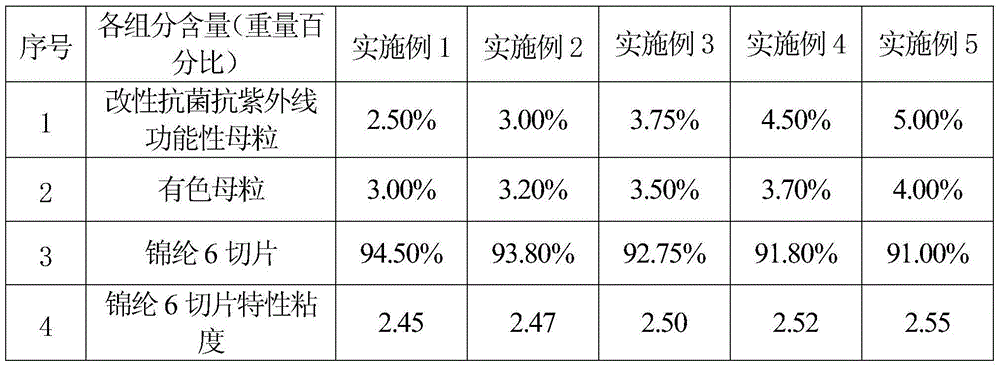

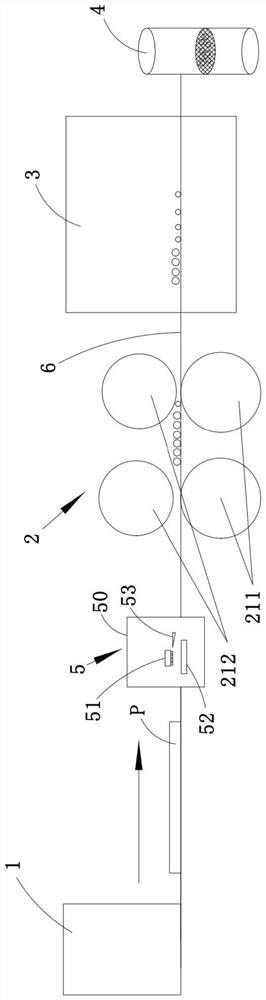

Functional chinlon 6 colored fiber and manufacturing method thereof

InactiveCN104060337AAntibacterial and UV resistantImprove antibacterial propertiesFilament forming substance formingMelt spinning methodsFiberMetering pump

The invention discloses a functional chinlon 6 colored fiber and a manufacturing method thereof. The colored fiber comprises the following materials in percentage by weight: 2.5 to 5 percent of modified antibacterial ultraviolet resistant functional master batch, 3.0 to 4.0 percent of colored master batch and 91 to 94.5 percent of chinlon 6 slices. The invention further discloses a manufacturing method of the functional chinlon 6 colored fiber, which comprises the following steps: a, mixing drying modified antibacterial ultraviolet resistant functional master batch, the colored master batch and chinlon 6 slices and adding the mixture in a screw extrusion machine to melt; b, extrusion spinning the mixed molten material through a metering pump, and then cooling, applying oil on and winding silk bundles for preparing chinlon 5 POY; c, stretching, thermal softening, and then cooling and false twisting the chinlon 6 POY; d, applying oil on and winding the false twisted silk bundles to obtain the finished products. The functional chinlon 6 colored fiber provided by the invention integrates triple functions of coloredness, antibacterial property and ultraviolet resistance, and reduces production processes and sewage discharge.

Owner:ZHEJIANG MESBON CHEM FIBER

Styrenic insulation for pipe

ActiveUS8714206B2Improve insulation effectLow costThermal insulationCorrosion preventionThermoplasticCompressive creep

Owner:SHAWCOR LTD

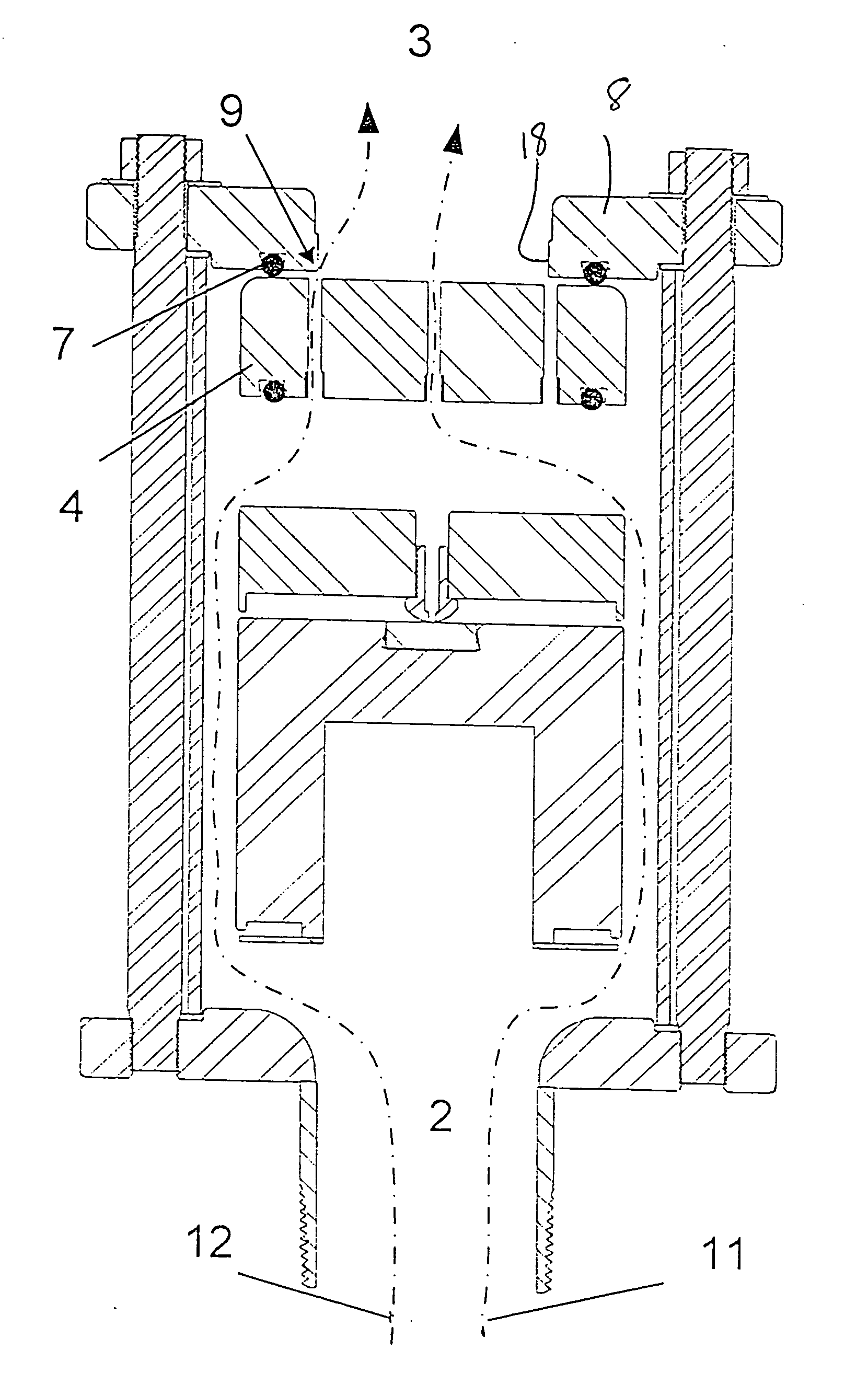

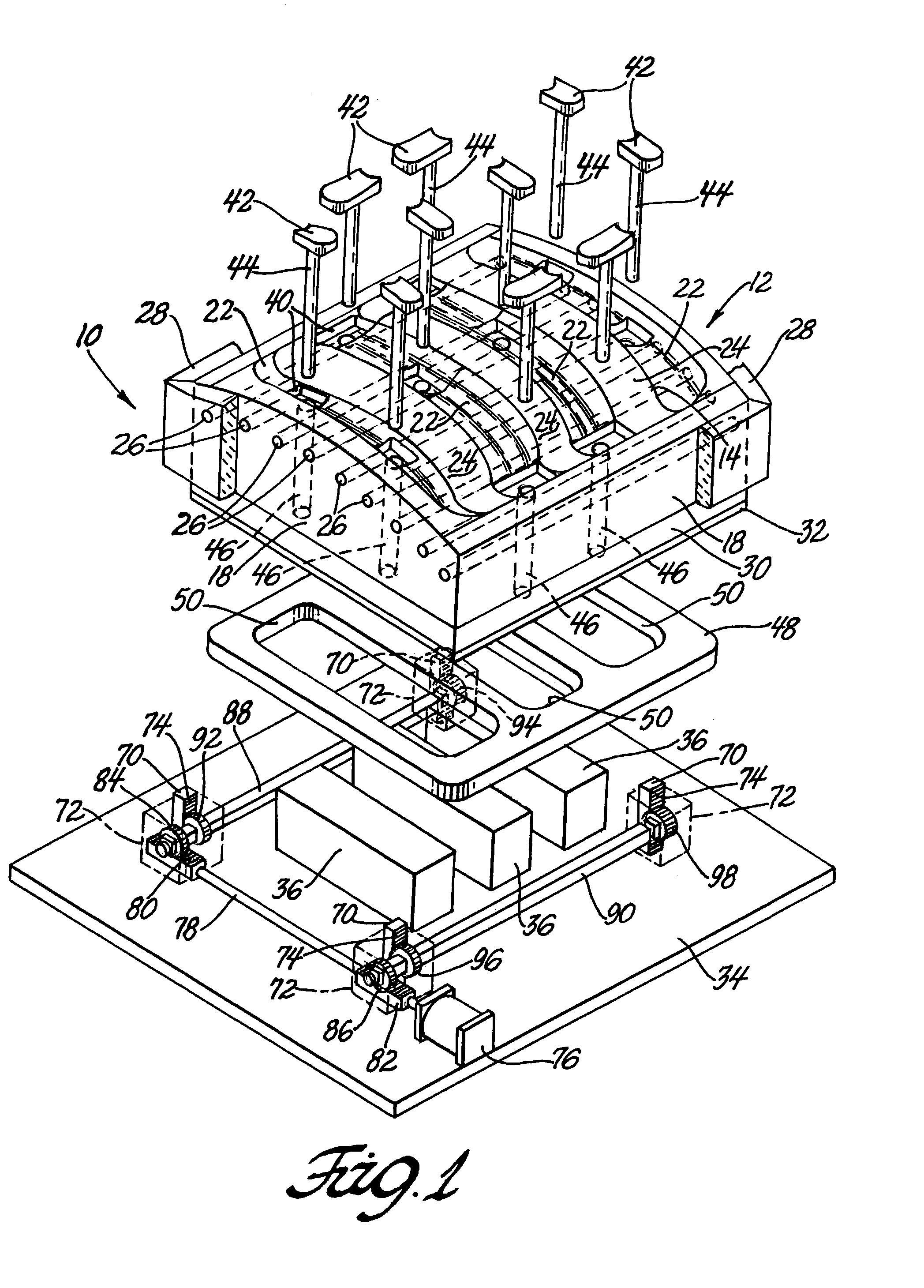

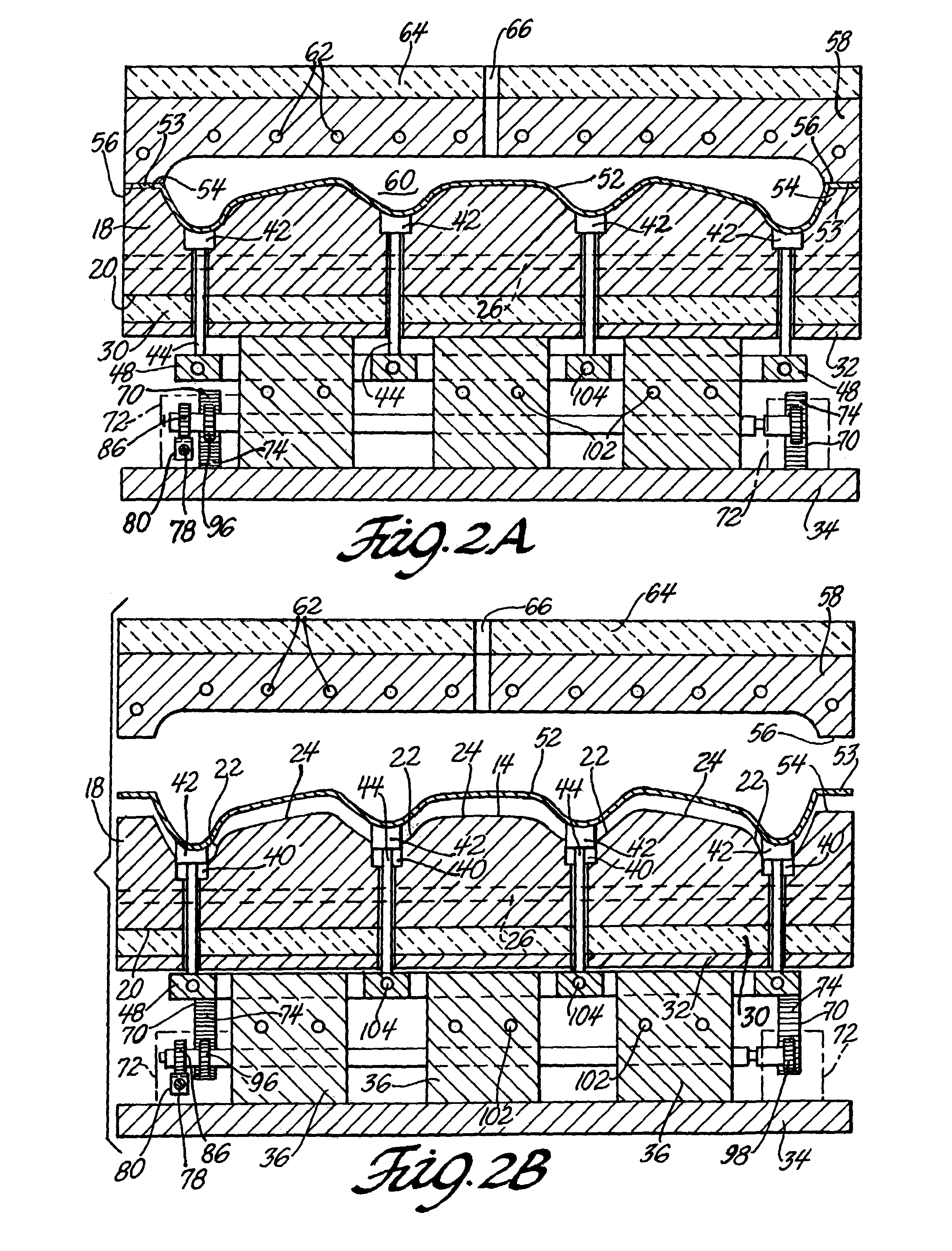

Extraction system for hot formed parts

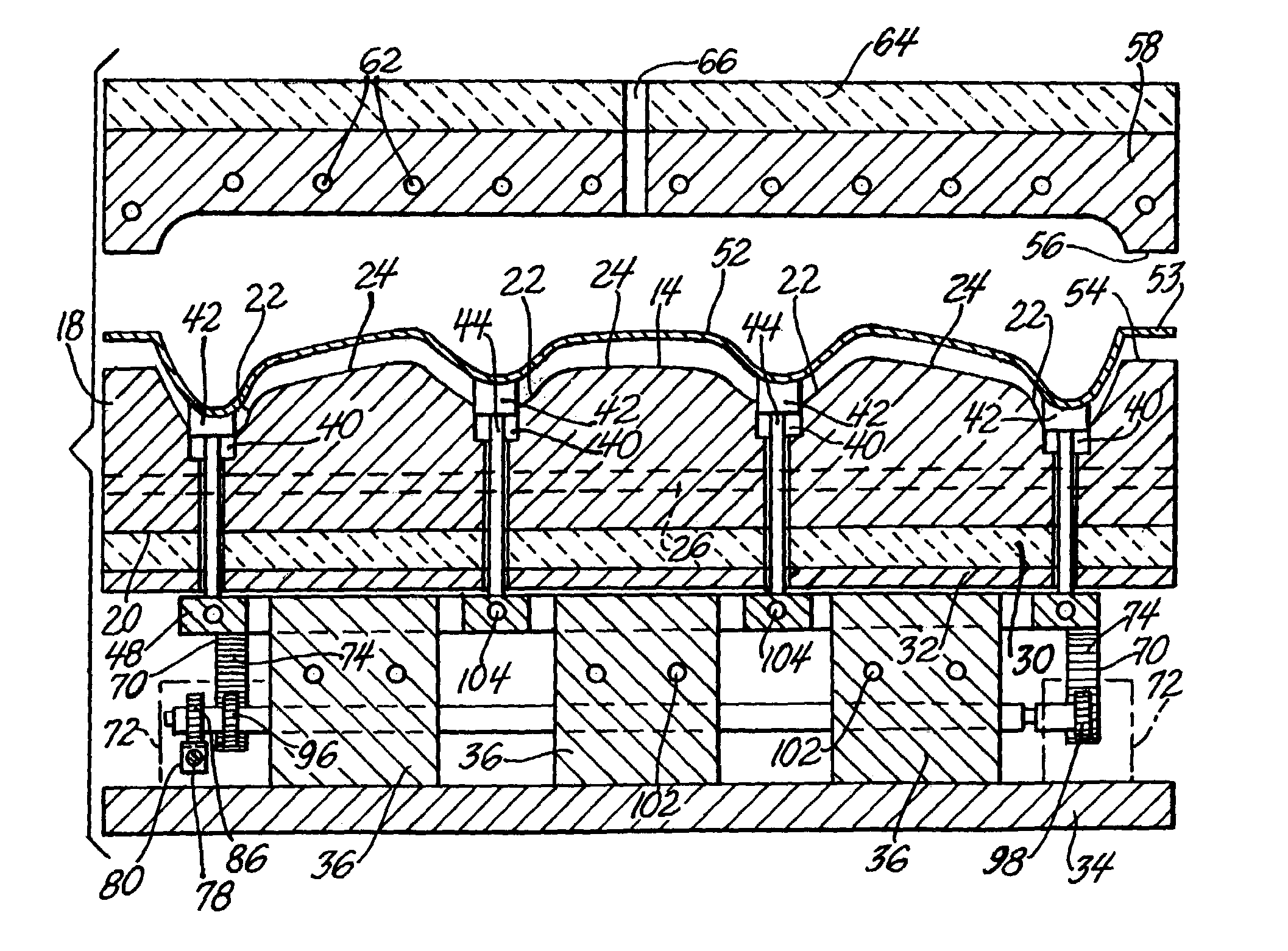

ActiveUS7021099B2Reduce heat lossCareful and uniform and distortion and damage-free separationStripping-off devicesEjection devicesDistortion freeEngineering

The distortion-free removal of a heat softened sheet metal part from a heated forming surface is enabled by the elevation of lift pads in the forming surface. Strategically located and sized pads are recessed in the forming surface of the hot forming tool and the pads are part of the forming surface. At the completion of the stretch forming, or other hot forming, of a sheet metal blank on the forming surface, the pads are lifted in unison, without rotating them, on lift posts by a suitable lift mechanism to carefully and uniformly strip the flexible part from the hot forming surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

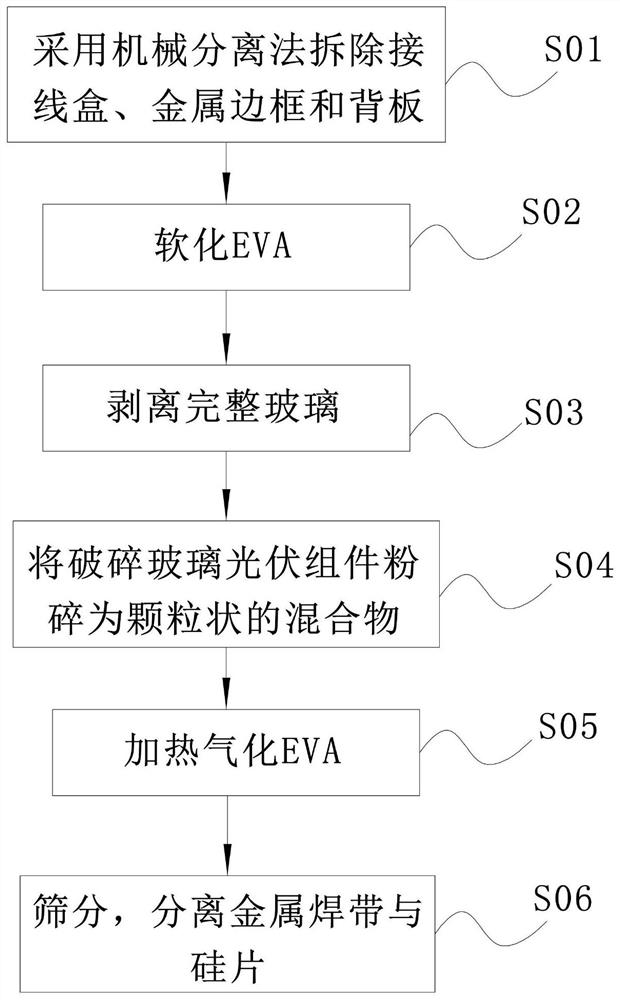

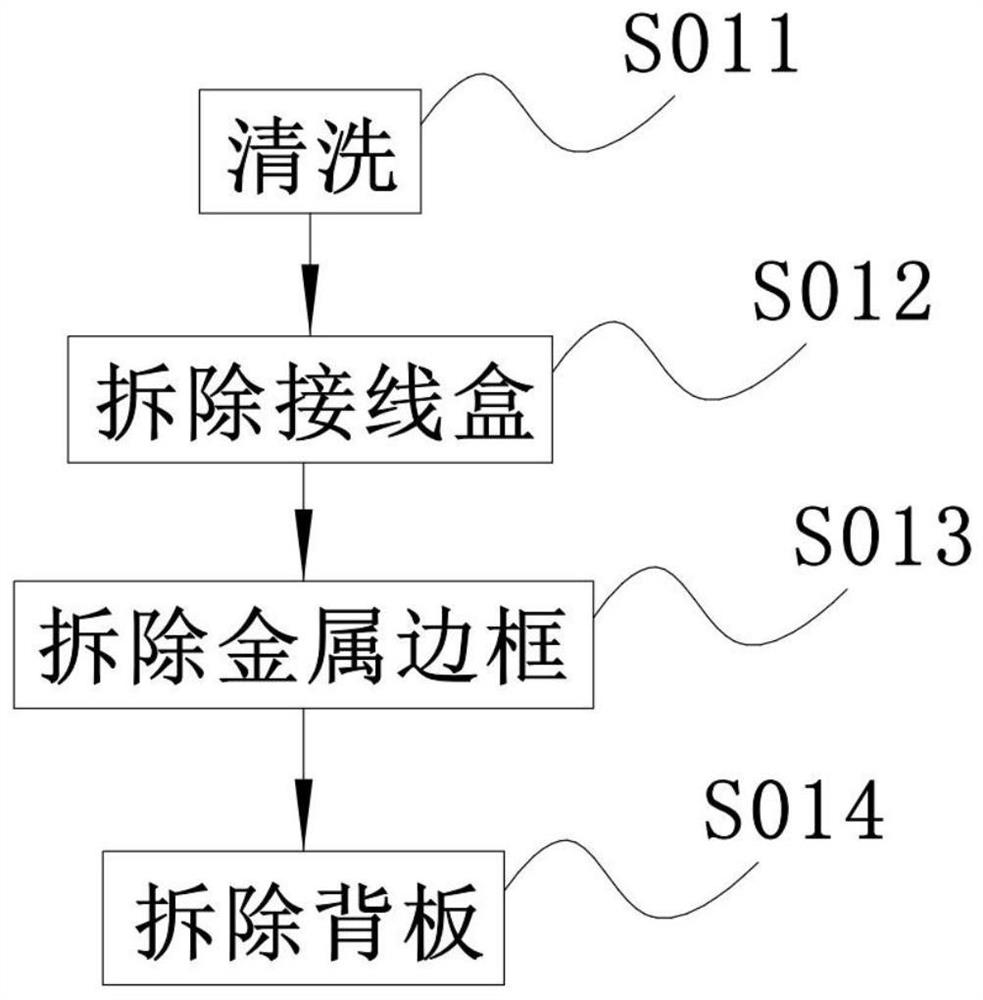

Recovery method and device for complete glass photovoltaic module

PendingCN111790723AEasy to separateSimple processWaste processingGlass recyclingSilicon chipWaste gas

The invention discloses a recovery method and device for a complete glass photovoltaic module. The recovery method comprises the following steps of dismantling a junction box, a metal frame and a backplate by adopting a mechanical separation method; heating to soften the EVA material; stripping the complete glass on the surface of the complete glass photovoltaic module; crushing the photovoltaicmodule from which the complete glass is stripped into a granular mixture; heating the granular mixture, and gasifying the EVA material to enable silicon wafer and metal solder strip to be in a mutually separated state; and screening the silicon wafer and the metal solder strip which are in a separated state, and respectively recovering the silicon wafer and the metal solder strip. The invention further discloses a recovery device of the complete glass photovoltaic module. The complete glass photovoltaic module is recovered in a mechanical and thermal decomposition combined separation mode, full separation of single components in the photovoltaic module is achieved, and due to the fact that glass is stripped in advance, the monomer separation difficulty in the subsequent recovery process isreduced, waste gas affecting the environment cannot be generated, the separation difficulty is reduced, the operation cost is low, and the recovery rate is high.

Owner:QINGHAI HUANGHE HYDROPOWER DEV +3

High teMPERATURE resistant insulating for pipe

The invention provides a polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130 DEG C or higher in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

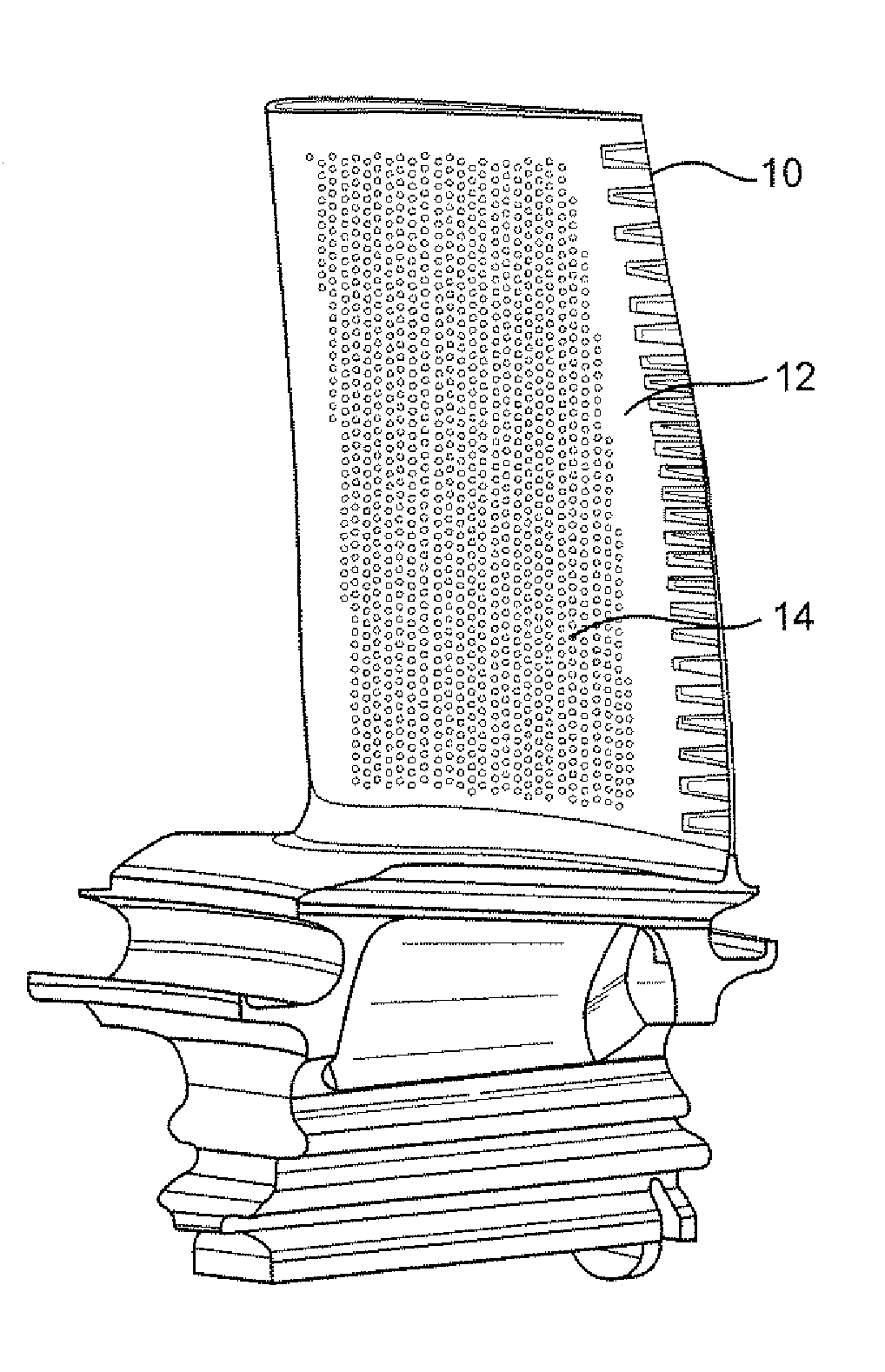

Adjustable orthodontic bracket and method using a microstructured shape memory polymer surface with reversible dry adhesion

An adjustable orthodontic bracket includes a metal base adapted to be rigidly secured directly to a tooth by a relatively thin layer of an orthodontic adhesive. This relatively thin layer of heat softening material fastens an orthodontic bracket directly to a tooth and subsequently heats the orthodontic material with a digital laser that allows the polymer material to reproduce a liquidous surface for adjusting the position of the bracket so that the bracket can be adjusted in all directions around the base member without overlapping the periphery of the base member.

Owner:IZADI MOHAMMAD

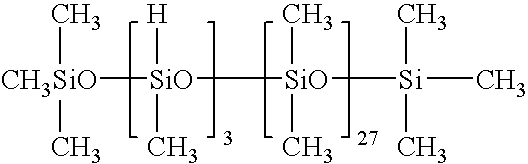

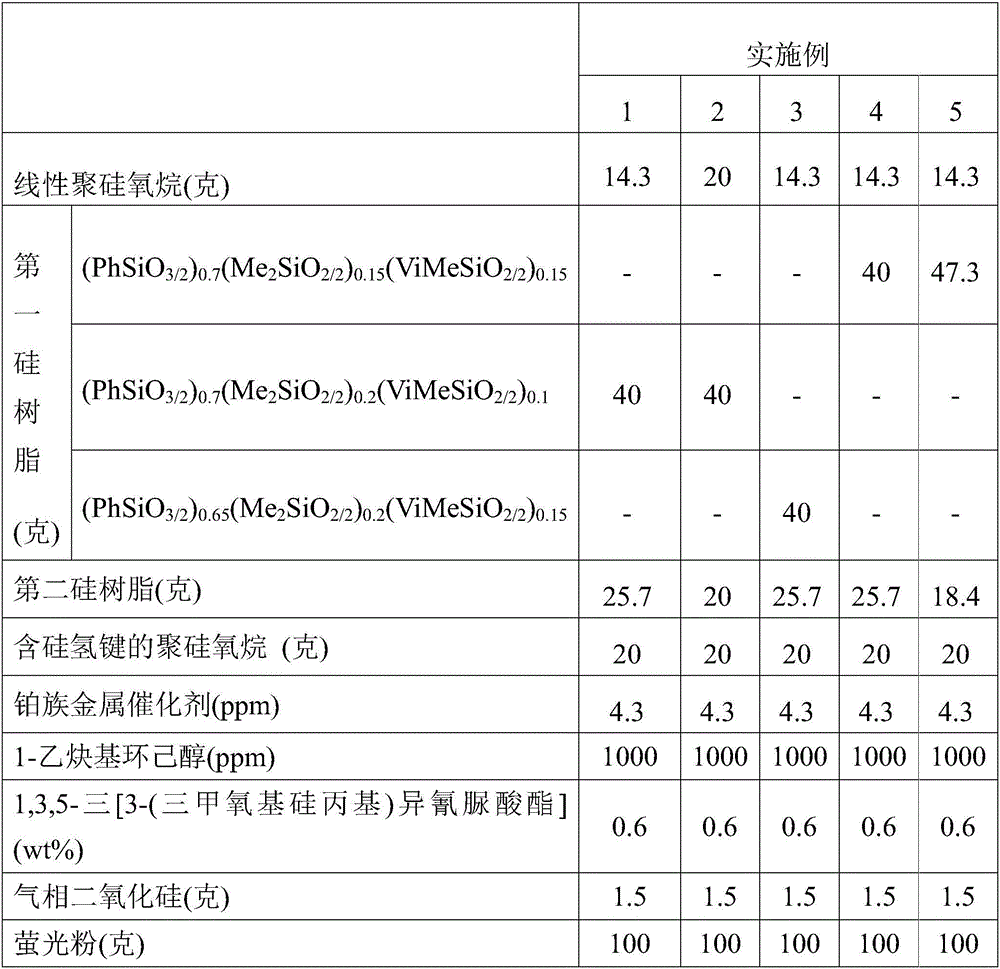

Silicon resin film, solidifiable silicon resin composition, optical semiconductor device and packaging method thereof

InactiveCN106433452AExcellent heat softening propertiesHigh hardnessCoatingsSemiconductor devicesHydrogenDevice material

The invention provides a silicon resin film, a solidifiable silicon resin composition, an optical semiconductor device and a packaging method thereof. The silicon resin film comprises a release base material and a silicon resin coating and is formed by solidifying the release base material with the solidifiable silicon resin composition, wherein the solidifiable silicon resin composition is prepared from, by weight, 10-25 parts of linear polysiloxane, 40-55 parts of first silicon resin, 15-30 parts of second silicon resin, 15-25 parts of polysiloxane containing silicon-hydrogen bonds, a platinum group metal catalyst and fluorescent powder, wherein an averaging unit structural formula for representing the first silicon resin at least has a R1SiO3 / 2 monomer and a R22SiO2 / 2 monomer, and the molar rate of the R1SiO3 / 2 monomer in the averaging unit structural formula is 0.60-0.75. The silicon resin film has the excellent thermal softening characteristic and the good hardness characteristic.

Owner:BENQ MATERIALS +1

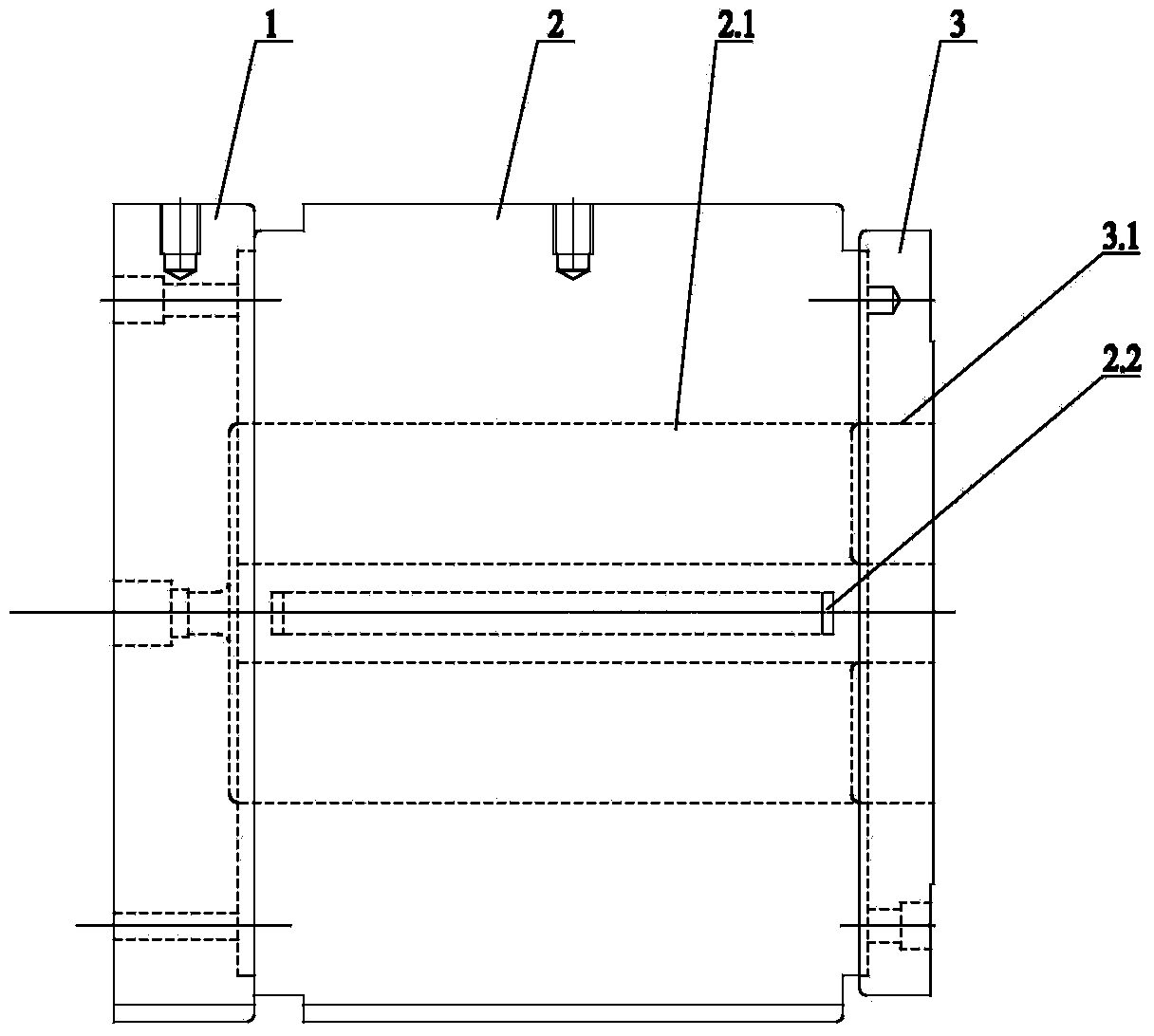

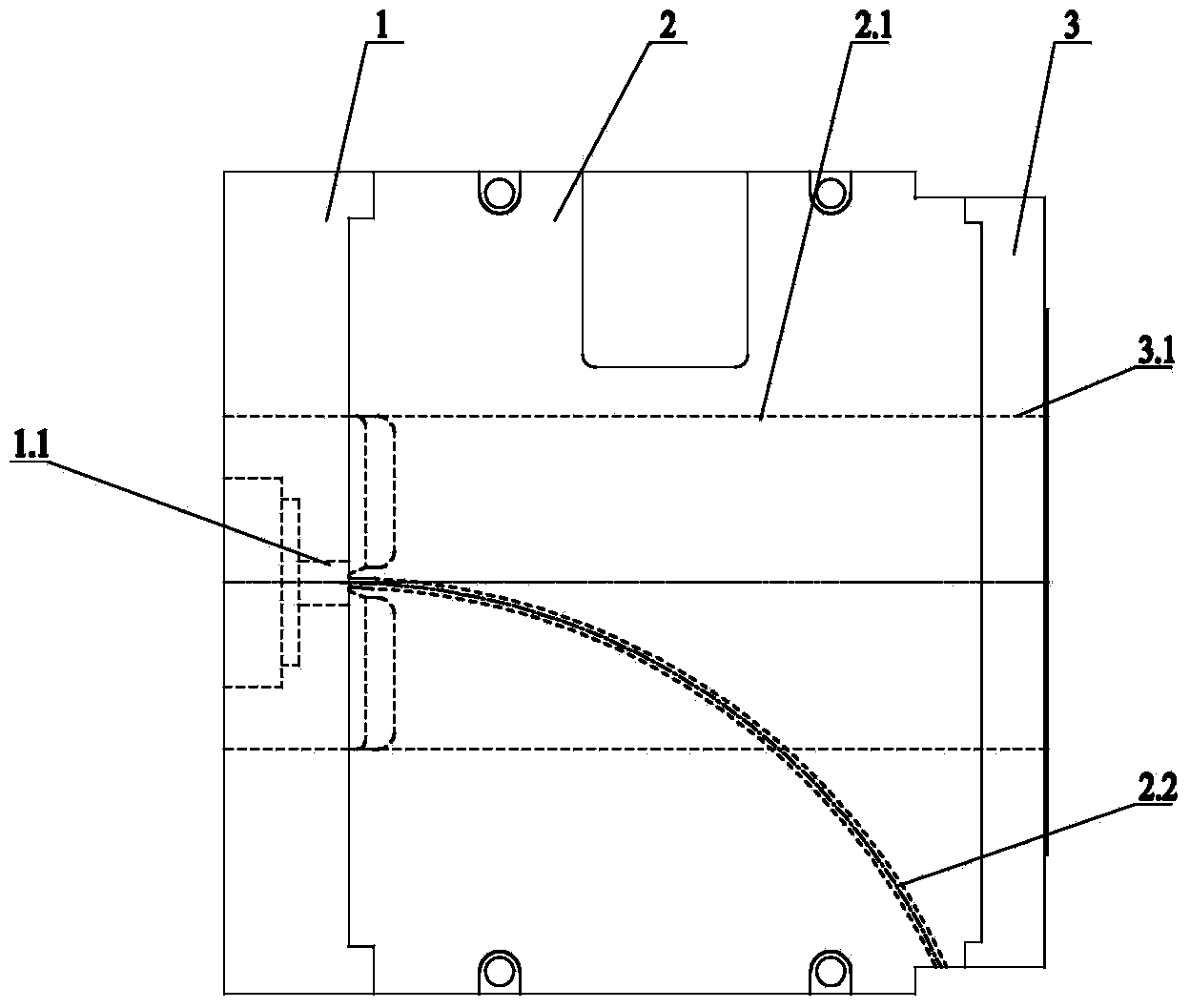

Extrusion equipment and production process of conductive stainless steel plate lateral feeding type composite conductive track

InactiveCN103962405ASimple structureReduce use costExtrusion diesExtrusion mandrelsWear resistantUltimate tensile strength

The invention discloses extrusion equipment and a production process of a conductive stainless steel plate lateral feeding type composite conductive track. The extrusion equipment comprises a forming mold plate, a through mold and a feeding plate mold. A method comprises the following steps: fixing the forming mold plate, the through mold and the feeding plate mold; producing a wear-resistant conductive stainless steel plate according to the regulations, and inserting the wear-resistant conductive stainless steel plate into a feeding channel of the through mold; heating and softening a conductive track base material, sequentially extruding the heated and softened conductive track base material into a base material feeding opening, a base material feeding channel and a conductive track cavity through an oil cylinder, physically combining the conductive track base material and the wear-resistant conductive stainless steel plate at set temperature and under set pressure, and extruding from the conductive track cavity; performing conventional thermal treatment and surface treatment on a crude composite conductive track product to obtain a finished composite conductive track product. The extrusion equipment is simple in structure; the tensile strength and the mechanical strength of the product produced by adopting the method are greatly improved, and the resistance of the conductive track is reduced.

Owner:WUXI BAIHONG TRANSMISSION ELECTRIC

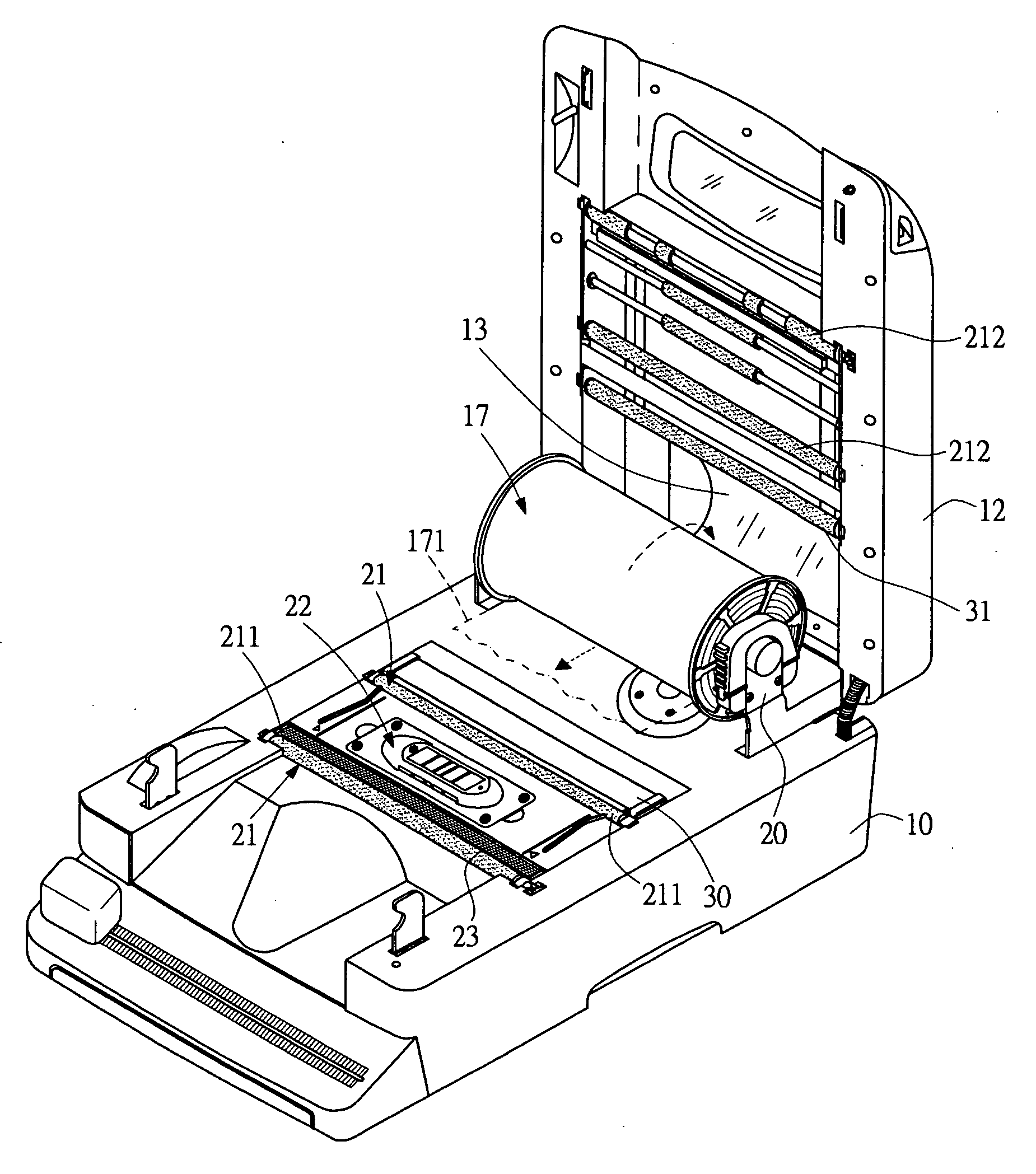

Film-aligning device for air cushion maker

InactiveUS20100012762A1Uneven pulling forcePaper/cardboard articlesFilament handlingPlastic filmPartial heating

A film-aligning device applicable to an air cushion maker implements an eclectic heater to partially heat and soften a plastic film before the plastic film receives an inflating process and a softening process. When the plastic film is tending to proceed slantingly, the heated and soften plastic film performs a plastic deformation to realign the feeding stork of the plastic film.

Owner:CHIANG TUNG LUNG

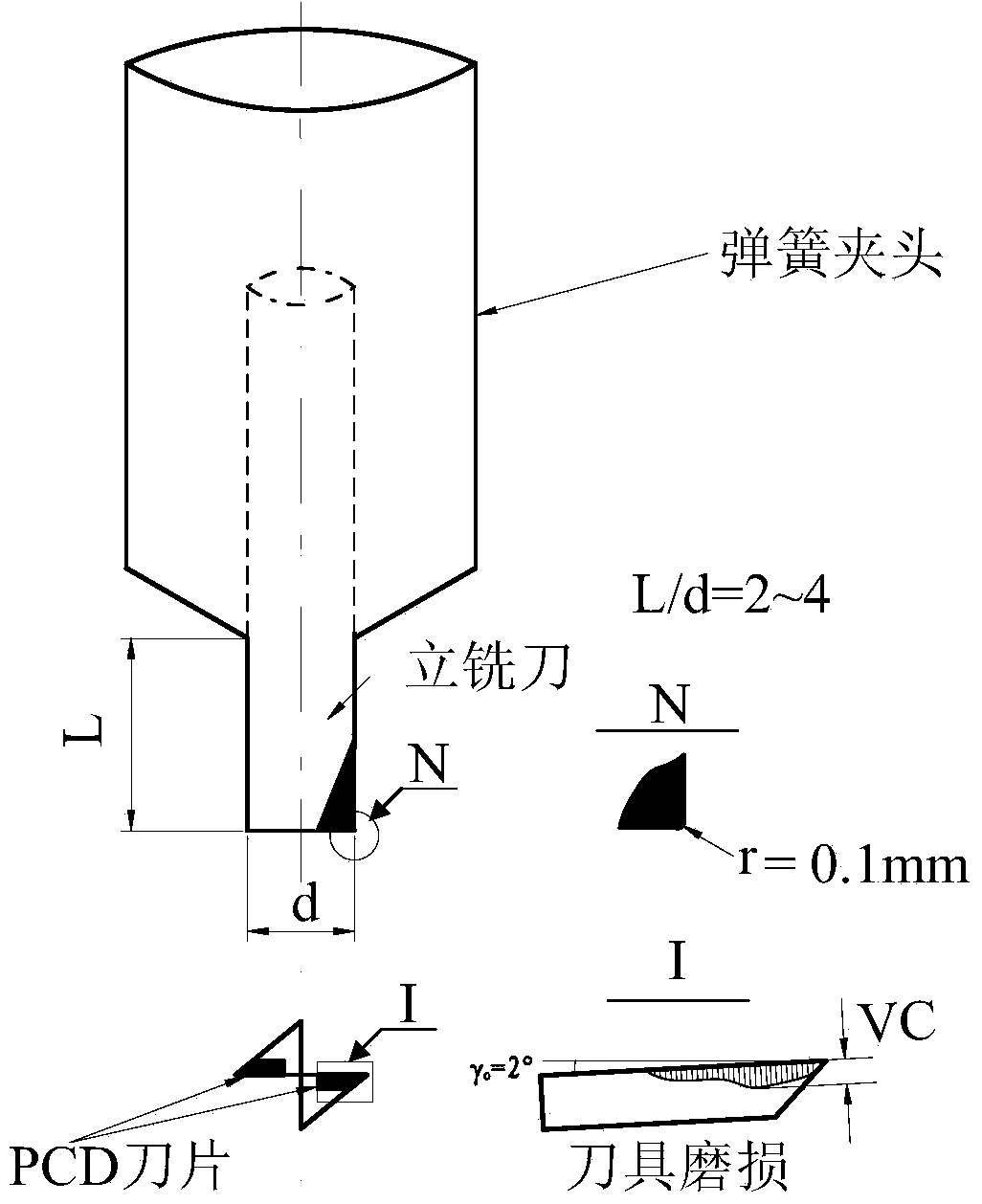

Matrix heat softening effect based high-efficiency high-precision milling technology of composite material

InactiveCN103658785AAchieve high-efficiency and high-precision millingReduce roughnessMilling equipment detailsGranularitySurface roughness

A matrix heat softening effect based milling technology of a high-volume-fraction (above 30%) SiC particle reinforced aluminum matrix composite material part is characterized in that milling process parameters, a PCD cutter granularity, a cutter glazing standard, a coarse / fine finishing cutter overhanging length / diameter, and the geometric dimension and shape of the above cutter are optimized in the invention in order to finally realize the high-efficiency high-precision milling of the material part, so the processed workpiece surface roughness Ra value stably reaches below 0.4mum.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

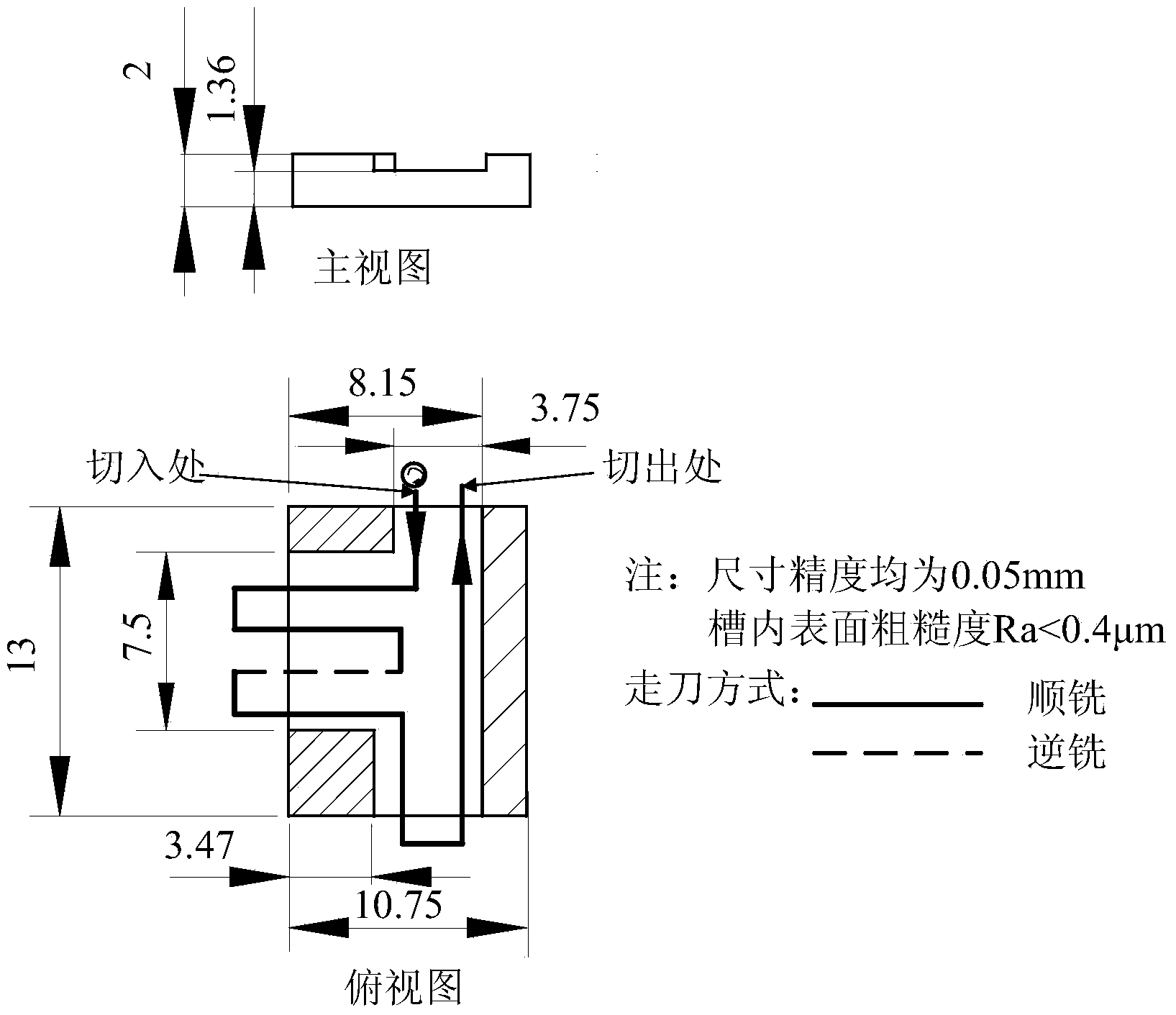

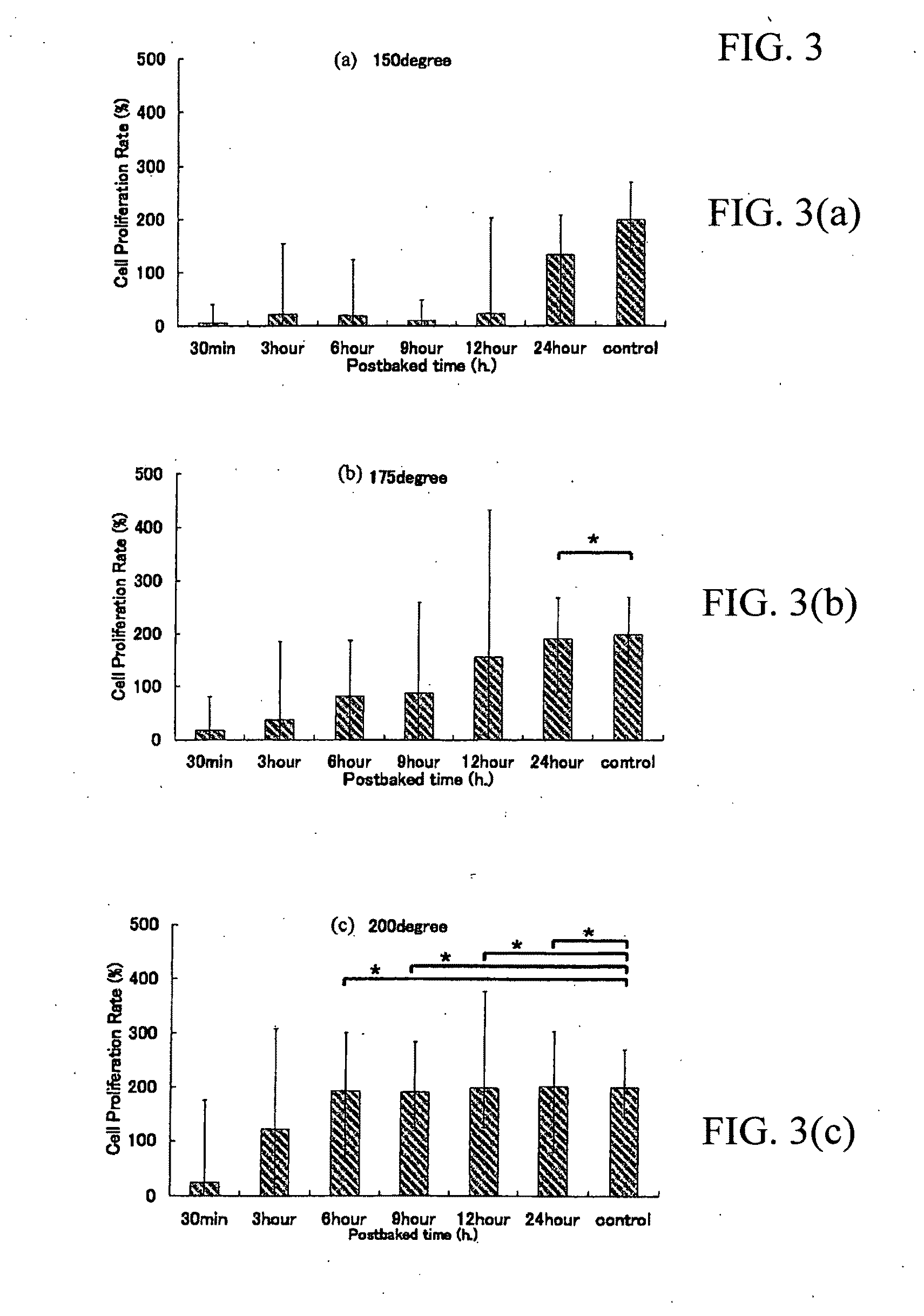

Cytocompatible three-dimensional structures fabricated by microstereolithography

ActiveUS20110268948A1Same levelAdditive manufacturing apparatusSynthetic resin layered productsThree dimensional microstructureStructure of the Earth

Three-dimensional microstereolithographic objects fabricated by microstereolithography are exposed to UV light for one hour to accelerate hardening. The structures are then heated at 175° C. or above for at least 6 hours. The heating temperature may exceed the glass transition temperature, which is the index of thermal softening temperature of materials. The present invention relates to three-dimensional microstructures formed by microstereolithography. Deformation due to a structure's own weight, which generally poses a problem in heat treatment, is reduced with microstructures due to the size effect. As a result, the dimensions of the three-dimensional structure fabricated by the present invention remain almost unchanged before and after the heat treatment.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com