Thermochromic fiber and preparation method and application thereof

A technology of thermochromic and thermochromic materials, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of single structure of thermochromic fibers, limited selection of raw materials, high preparation cost, etc., and achieve structural design Diversification, ensuring cycle stability, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

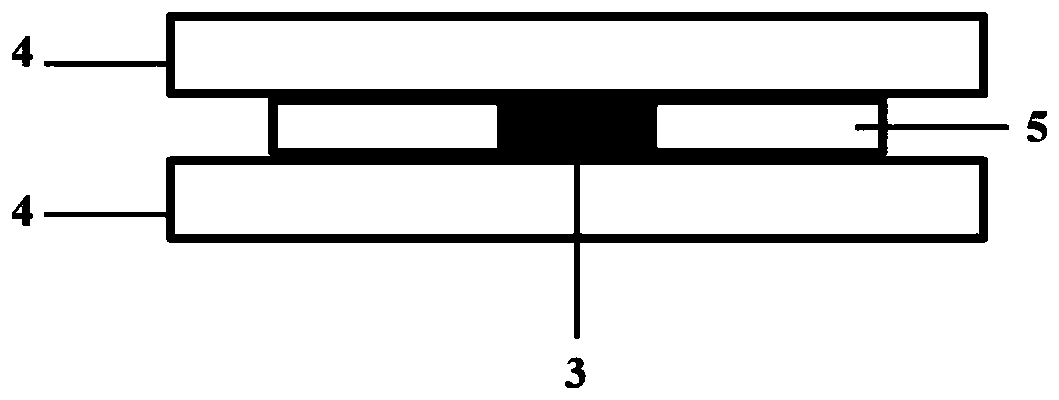

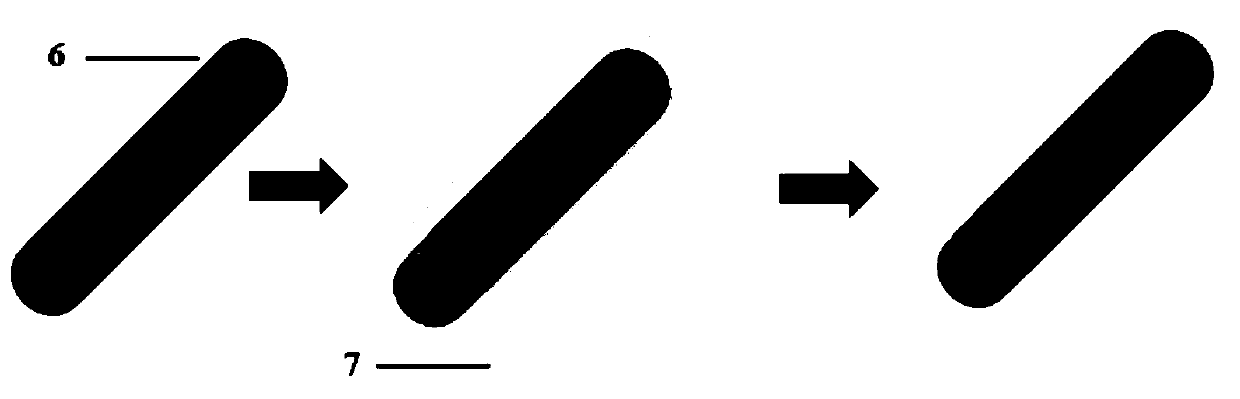

[0047] The invention provides a method for preparing a thermochromic fiber, the thermochromic fiber is a fiber with a core-wrapped structure, the core layer of the core-wrapped structure is a thermochromic layer, the cladding is a protective layer, and the clad The layer is located outside the core layer; the thermochromic layer is prepared by adopting a thermosoftening wire drawing method, specifically: first obtain a preform rod of the thermochromic layer, and then perform thermosoft wire drawing on the preform rod to obtain the Thermochromic layer fibers; the thermosoftening drawing is a thermosoftening drawing method adopted in the optical fiber preparation process. After heating and softening the preform of the thermochromic layer, it is drawn into a fine thermochromic layer fiber whose diameter meets the requirement.

[0048] In some embodiments, the material used in the thermochromic layer includes a polymer-based composite material obtained by doping the first polymer ...

Embodiment 1

[0104] In the embodiment of the present invention, a thermochromic fiber with a sheath-core structure is firstly provided, which has certain stability, rubbing resistance and color fastness to washing, is suitable for wearing, and has a thermochromic temperature of 31°C.

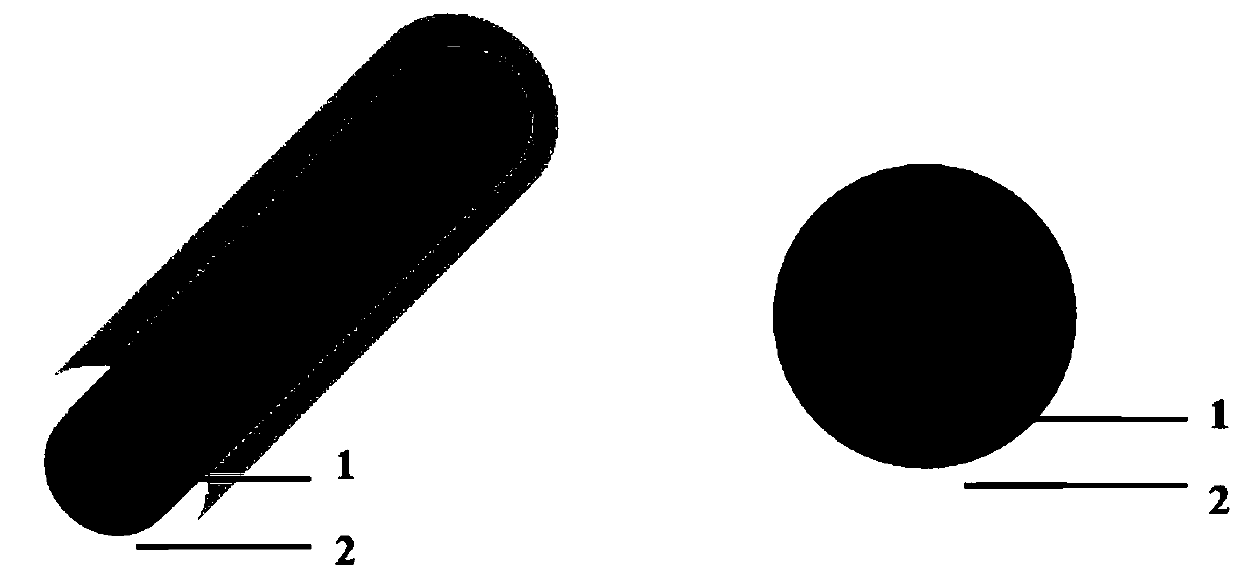

[0105] figure 1 It is a schematic diagram of a thermochromic fiber with a circular cross-section prepared in this embodiment, wherein 1 is the core layer of the thermochromic fiber, and 2 is the cladding layer.

[0106] Wherein, the thermochromic fiber color-changing layer material is a composite material of thermochromic microcapsules and polymethyl methacrylate, the diameter of the color-changing layer is 100 μm, the cladding material is polymethyl methacrylate, and the thickness is 50 μm.

[0107] An embodiment of the present invention provides a thermochromic fiber method including: preparation of a thermochromic composite material, preparation of a preform and thermal drawing of the fiber.

[0108] The...

Embodiment 2

[0116] In the embodiment of the present invention, a thermochromic fiber with a sheath-core structure is firstly provided, which has certain stability, rubbing resistance and color fastness to washing, is suitable for wearing, and has a thermochromic temperature of 31°C.

[0117] Wherein, the thermochromic fiber color-changing layer material is a composite material of thermochromic microcapsules and polymethyl methacrylate, the diameter of the color-changing layer is 1000 μm, the cladding material is polymethyl methacrylate, and the thickness is 50 μm.

[0118] An embodiment of the present invention provides a thermochromic fiber method including: preparation of a thermochromic composite material, preparation of a preform and thermal drawing of the fiber.

[0119] The preparation method of thermochromic material comprises the following steps: (1) take by weighing 100g polymethyl methacrylate, and measure 200ml dimethylacetamide to mix, and place on the magnetic stirrer heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com