Method for preparing fluorescence color adjustable carbon dots

A color and fluorescence technology, applied in fluorescence/phosphorescence, chemical instruments and methods, nano-optics, etc., to achieve the effect of improving quantum efficiency and wide selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

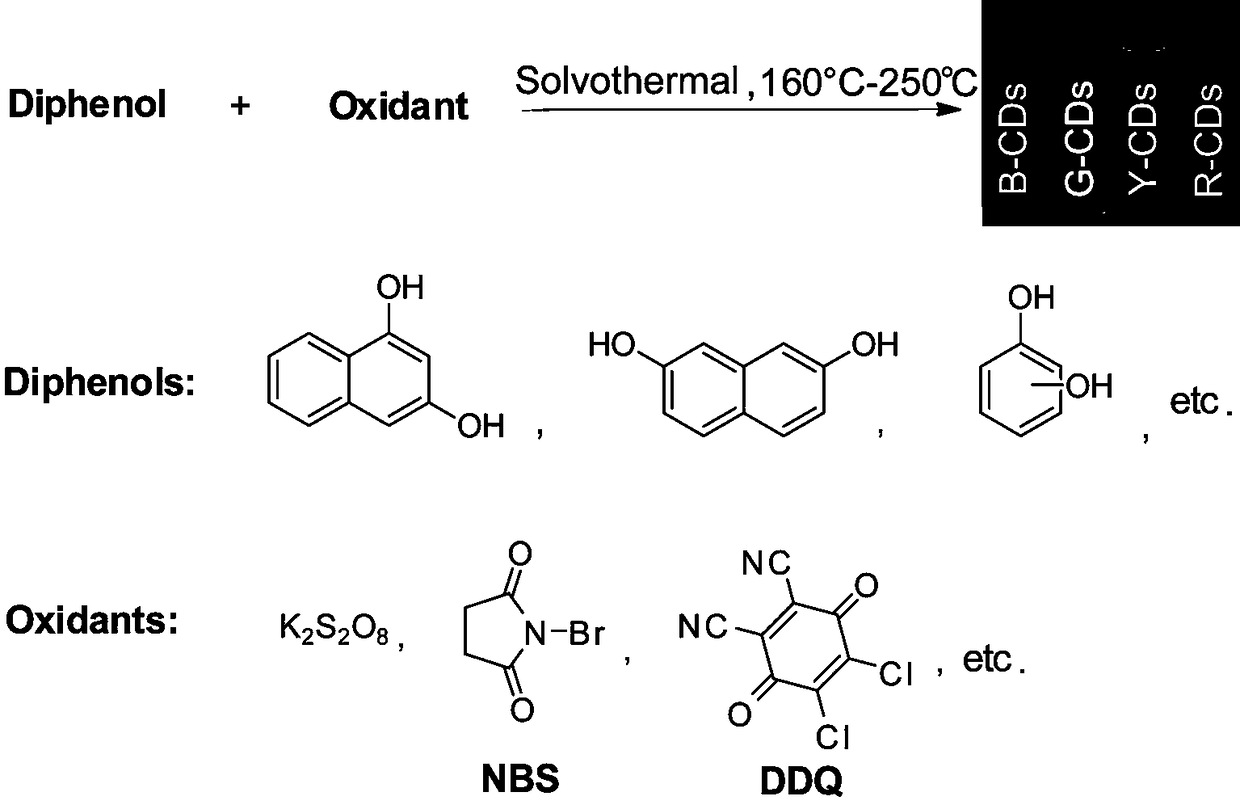

Method used

Image

Examples

Embodiment 1

[0036] Weigh 160 mg of 1,6-dihydroxynaphthalene and 445 mg of N-bromosuccinimide at room temperature, put them into a 250 ml beaker, add 160 ml of ethanol, and sonicate until completely dissolved to obtain a mixture. Transfer the mixed solution to a 250 ml polytetrafluoro autoclave, heat to 160 °C, react for 4 h, cool the autoclave to room temperature naturally, and obtain a mixed solution of carbon dots, pass the mixed solution of carbon dots through a silica gel chromatographic column Separation and purification, the eluent is dichloromethane and methanol, the volume ratio of the two is 30:1. After the solvent is removed by rotary evaporation, the purified carbon dots are obtained, and the purified carbon dots are in the form of powder. The purified carbon dots were dissolved in methanol solvent to make a 0.1 mg / ml solution, and the carbon dot solution was excited with a 365nm excitation light source, and the carbon dot solution appeared orange.

Embodiment 2

[0038] Weigh 160 mg of 1,6-dihydroxynaphthalene and 445 mg of N-bromosuccinimide at room temperature, put them into a 250 ml beaker, add 160 ml of ethanol, and sonicate until completely dissolved to obtain a mixture. Transfer the mixed solution to a 250 ml polytetrafluoro autoclave, heat to 200 °C, react for 4 h, and cool the autoclave to room temperature naturally to obtain a carbon dot mixed solution, pass the carbon dot mixed solution through a silica gel chromatographic column Separation and purification, the eluent is dichloromethane and methanol, the volume ratio of the two is 30:1. After the solvent is removed by rotary evaporation, the purified carbon dots are obtained, and the purified carbon dots are in the form of powder. The purified carbon dots were dissolved in methanol solvent to make a 0.1 mg / ml solution, and the carbon dot solution was excited with a 365nm excitation light source, and the carbon dot solution appeared orange.

Embodiment 3

[0040]Weigh 160 mg of 1,6-dihydroxynaphthalene and 445 mg of N-bromosuccinimide at room temperature, put them into a 250 ml beaker, add 160 ml of ethanol, and sonicate until completely dissolved to obtain a mixture. Transfer the mixed solution to a 250 ml polytetrafluoro autoclave, heat it to 250 °C, react for 4 h, cool the autoclave to room temperature naturally, and obtain a mixed solution of carbon dots, pass the mixed solution of carbon dots through a silica gel chromatographic column Separation and purification, the eluent is dichloromethane and methanol, the volume ratio of the two is 30:1. After the solvent is removed by rotary evaporation, the purified carbon dots are obtained, and the purified carbon dots are in the form of powder. The purified carbon dots were dissolved in methanol solvent to make a 0.1 mg / ml solution, and the carbon dot solution was excited with a 365nm excitation light source, and the carbon dot solution appeared orange.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com