Patents

Literature

291results about How to "Enhanced Amorphous Formation Ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance

ActiveCN102220538ALow cooling rate requirementsEnhanced Amorphous Formation AbilityInorganic material magnetismAlloyGas quenching

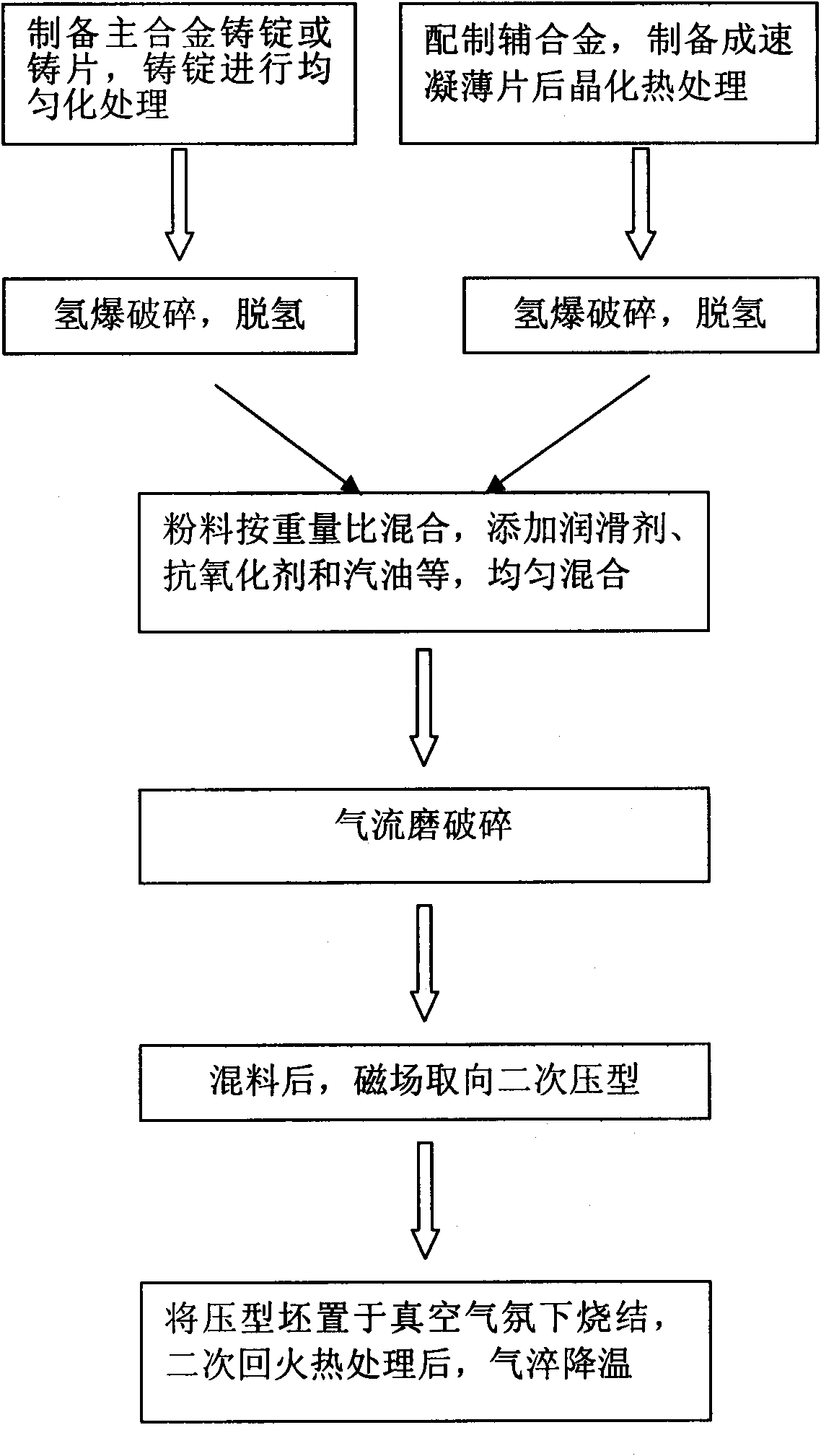

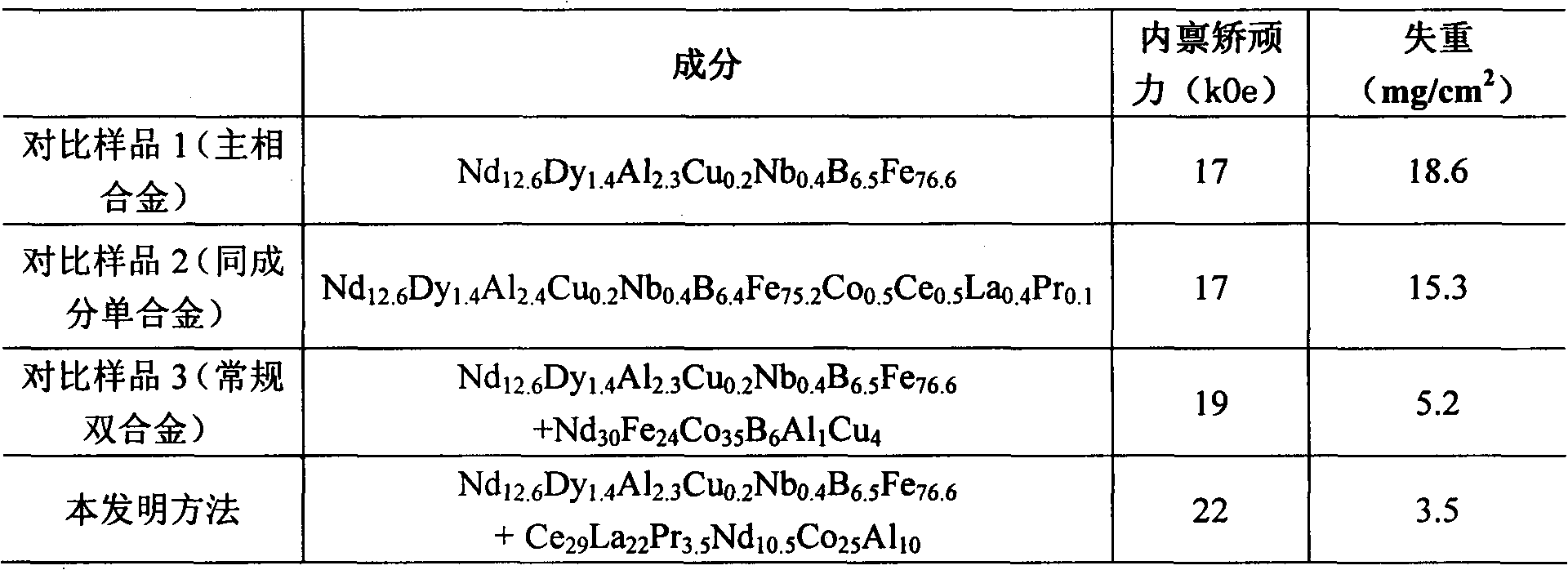

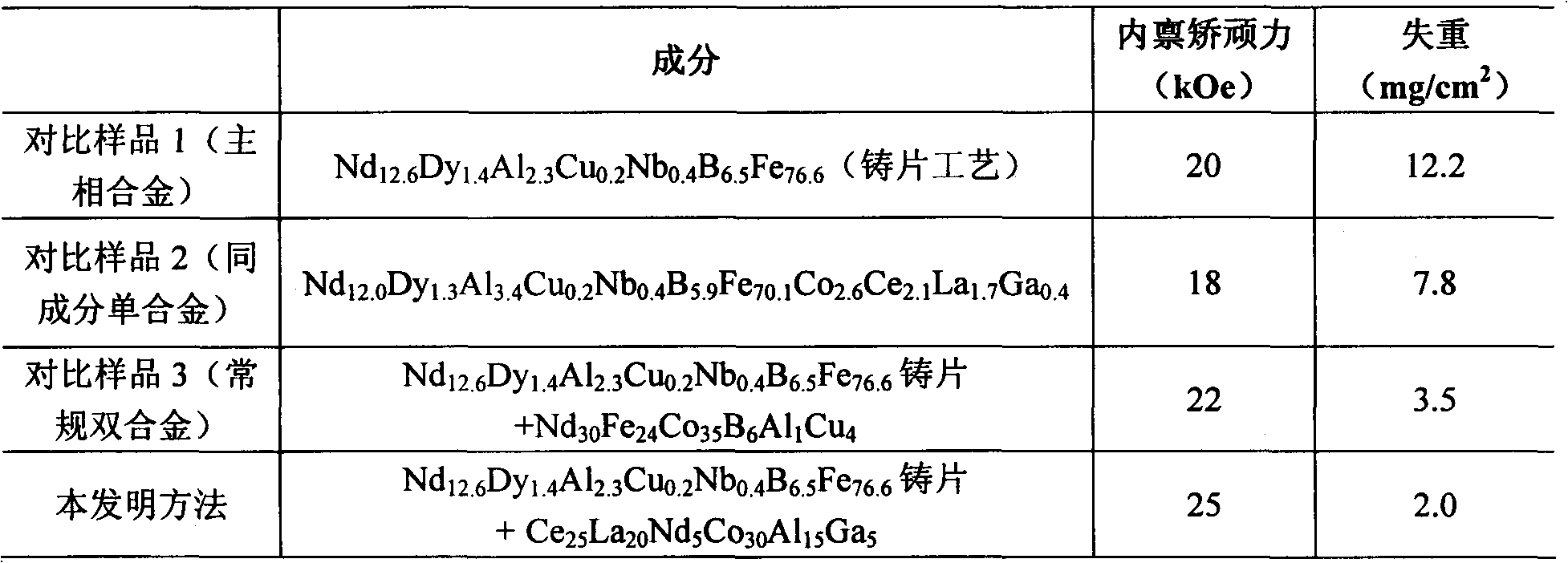

The invention discloses a sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance. On the basis of a double-alloy preparation process, Ce-enriched multicomponent rare-based alloy with high amorphous forming ability is used as an auxiliary alloy, and the decrystallizatoin of crystal boundary phase structure is realized by gas quenching cooling in a sintering tempering process. In the invention, the intrinsic coercivity is obviously improved, the anticorrosive weight loss is greatly reduced, the magnetic performance and anticorrosive performance are high, and the method can be widely used in the field of production of high-performance anticorrosive sintered neodymium-iron-boron material.

Owner:NANJING UNIV OF SCI & TECH +1

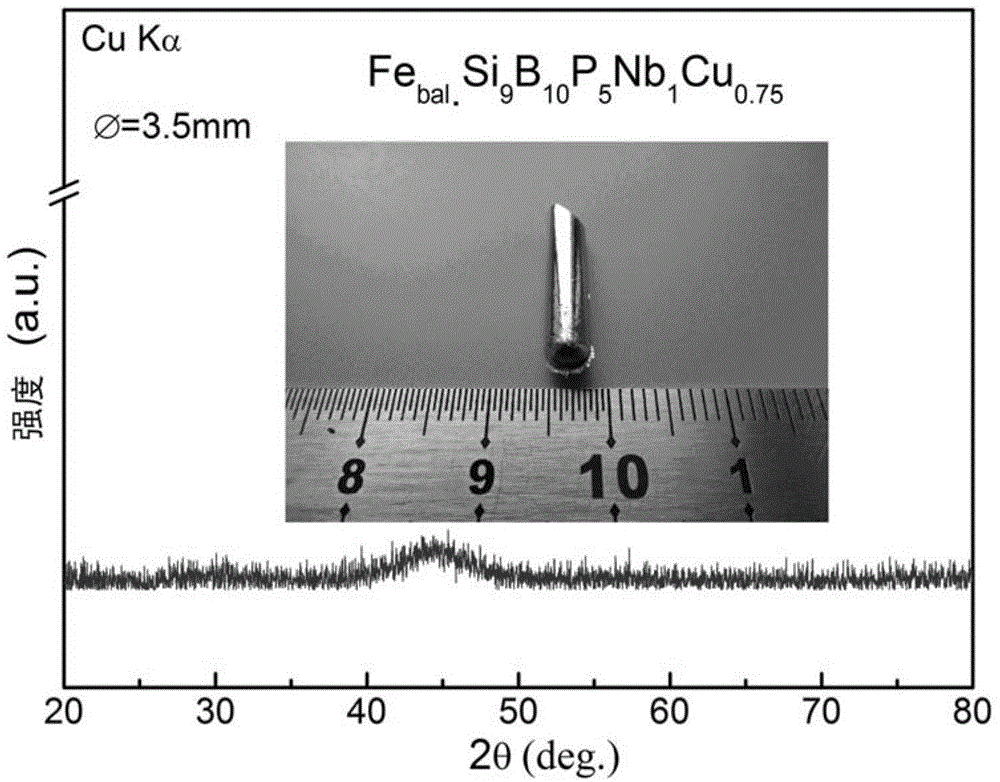

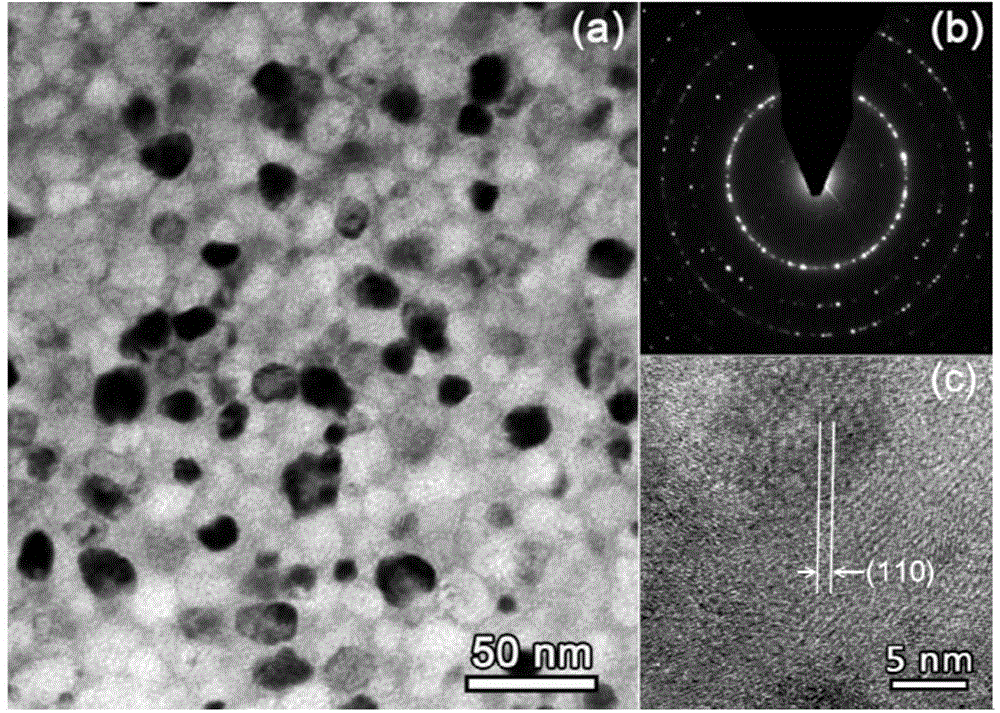

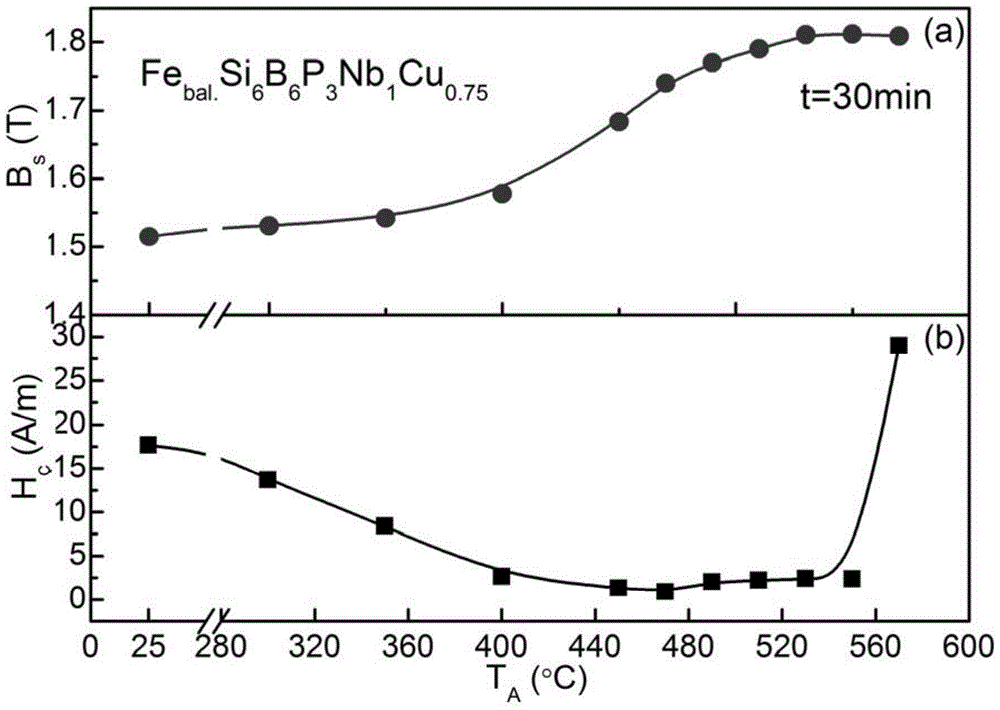

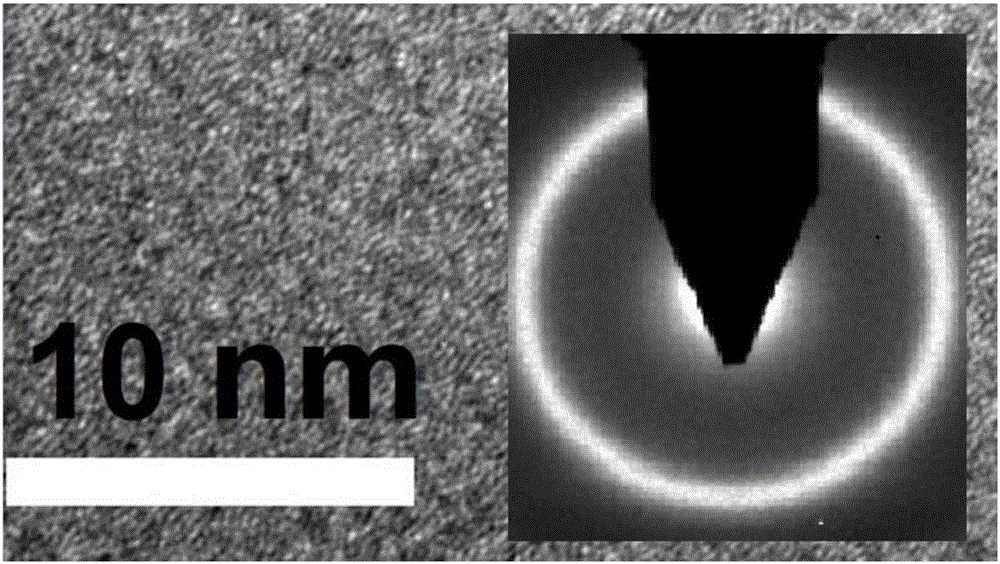

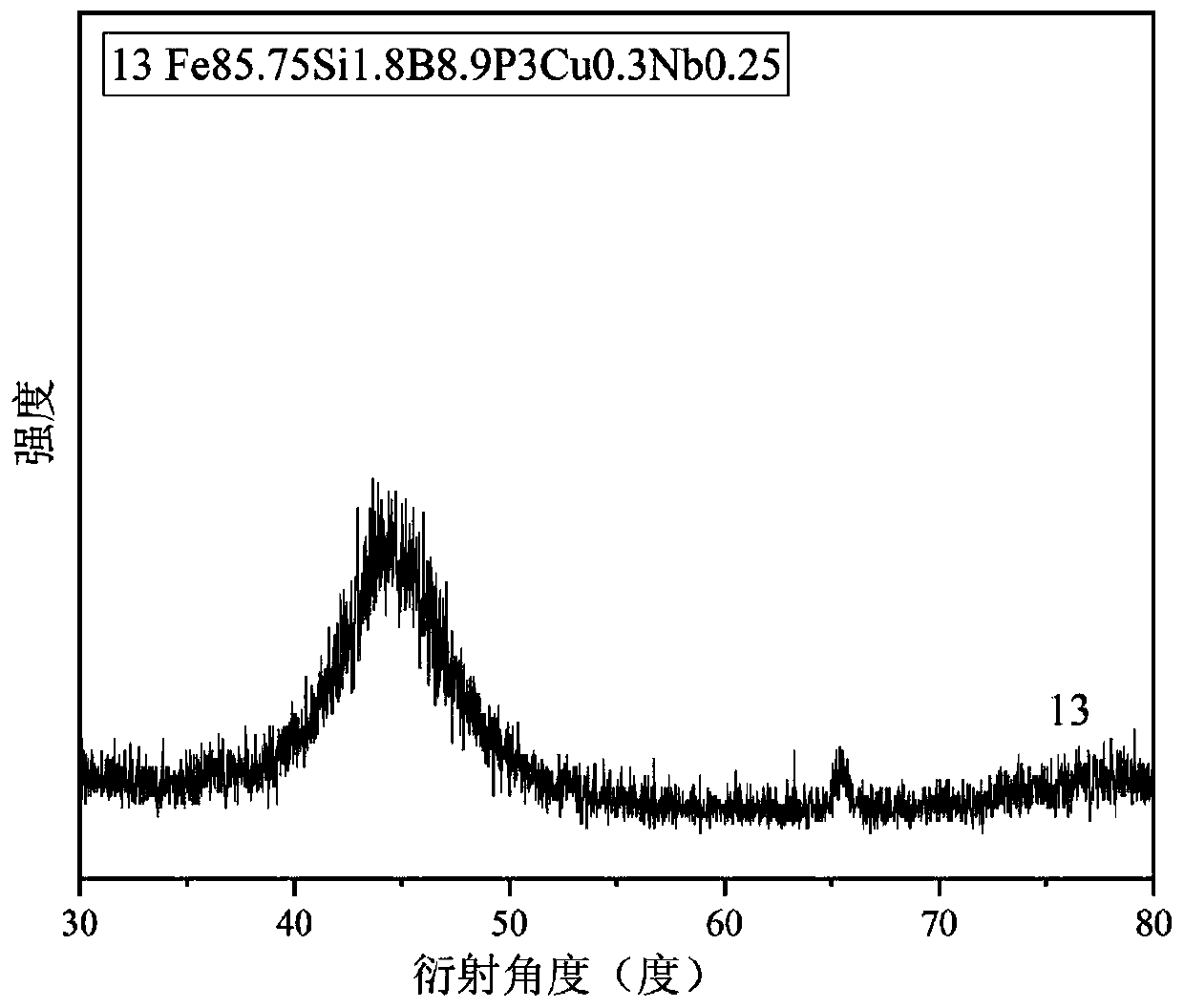

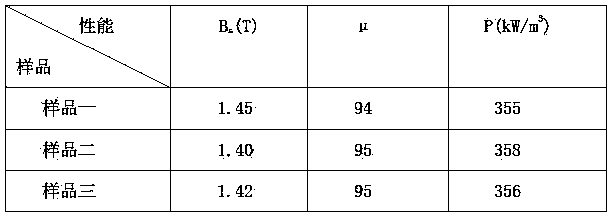

Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

ActiveCN104934179AHigh saturation magnetic inductionLow coercivityMagnetic materialsCopper moldMagnetic alloy

The invention discloses a Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and a preparing method of the Fe-based nanocrystalline soft magnetic alloy. The alloy has an expression of Fe<x>SiBP<c>Nb<d>Cu<e>, wherein in the expression, each of the x, the a, the b, the c, the d and the e shows the atomic percentage content of the corresponding ingredient, and meets the following conditions that the a is greater than or equal to 0.5 but smaller than or equal to 12; the b is greater than or equal to 0.5 but is smaller than or equal to 15; the c is greater than or equal to 0.5 but smaller than or equal to 12; the d is greater than or equal to 0.1 but smaller than or equal to 3; the e is greater than or equal to 0.1 but smaller than or equal to 3; the x is greater than or equal 70 but smaller than or equal to 85; and the sum of the x, the a, the b, the c, the d and the e is 100 percent. The soft magnetic alloy has the advantages that an ordinary copper mold casting method can be used for preparing a Fe-based amorphous alloy with the critical dimension being 3.5mm; after the annealing; the saturation flux density is greater than 1.5T; and the coercive force value is smaller than 1A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Boron-containing titanium-based amorphous solder for braze welding Si3N4 ceramic and preparation method thereof

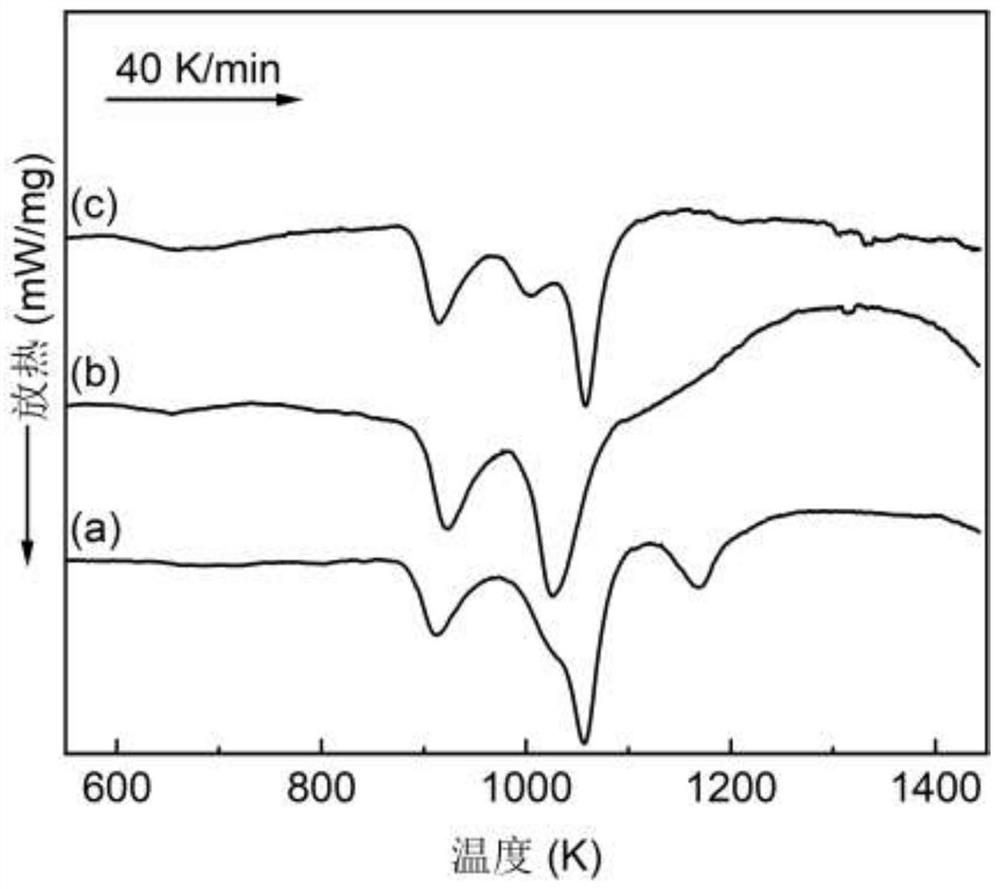

The invention relates to braze welding Si3N4 ceramics containing the boron Ti-based amorphous solder and the preparation method thereof, and belongs to the brazing material in the field of amorphous state and metallurgy. The ingredients of the brazing material consist of the following according to the mass percent: Zr of 12.0-28.0 percent, Ni of 12.0-28.0 percent, Cu of 12.0-28.0 percent, and B of 0.05-0.5 percent, and the remains is Ti. The melting scope of the brazing material ranges 1,150K to 1,250K, and the brazing temperature is from 1,273K to 1,373K. The Ti-Zr-Ni-Cu-B amorphous braze vacuum braze welding Si3N4 ceramics, which is produced by the rapid solidification technology, has superior high-temperature performance to Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder. The tie-in high-temperature bend strength reaches 145MPa under 673K DEG,108MPa under 773K DEG, and still 93MPa under 873K DEG.

Owner:JIANGSU UNIV OF SCI & TECH

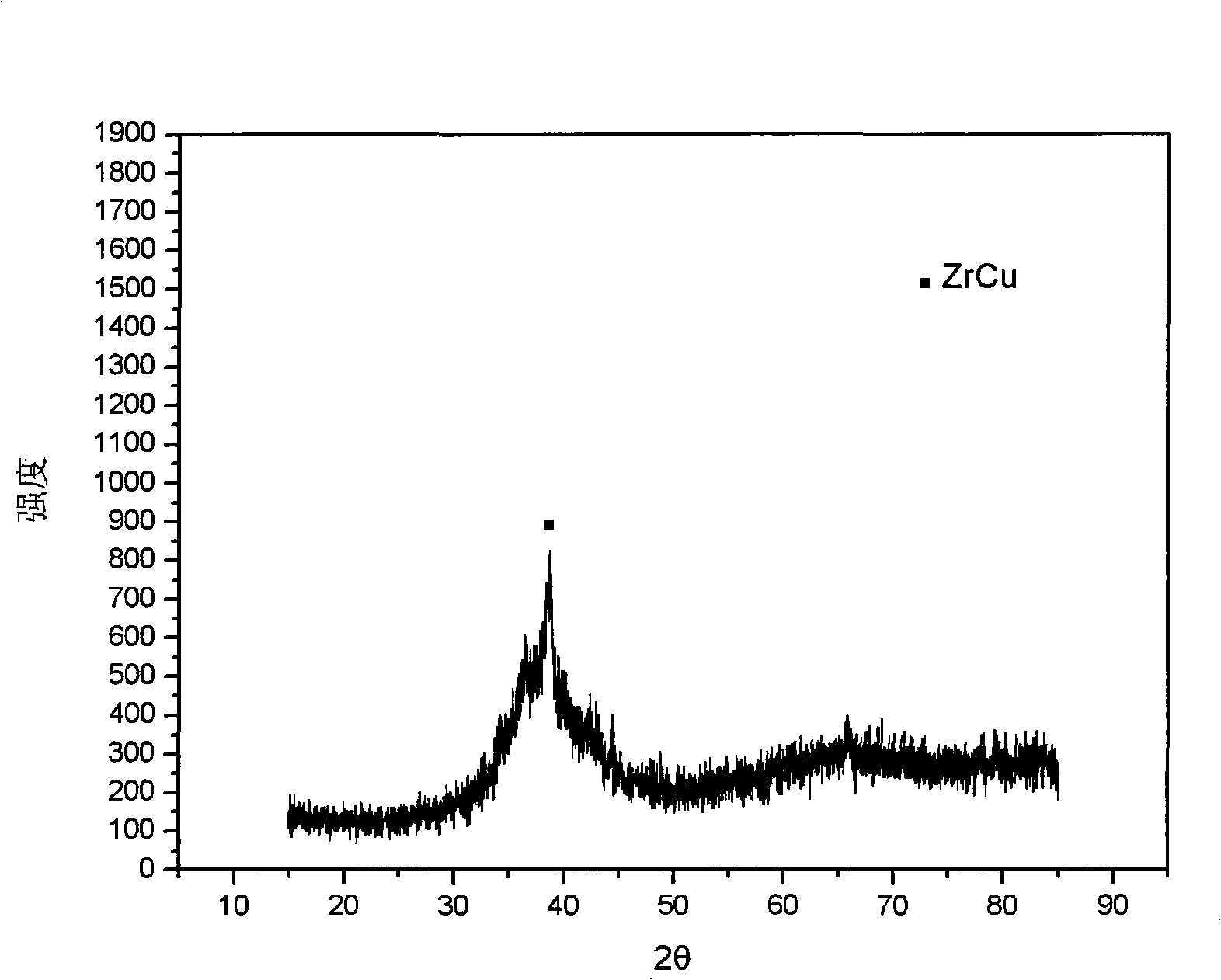

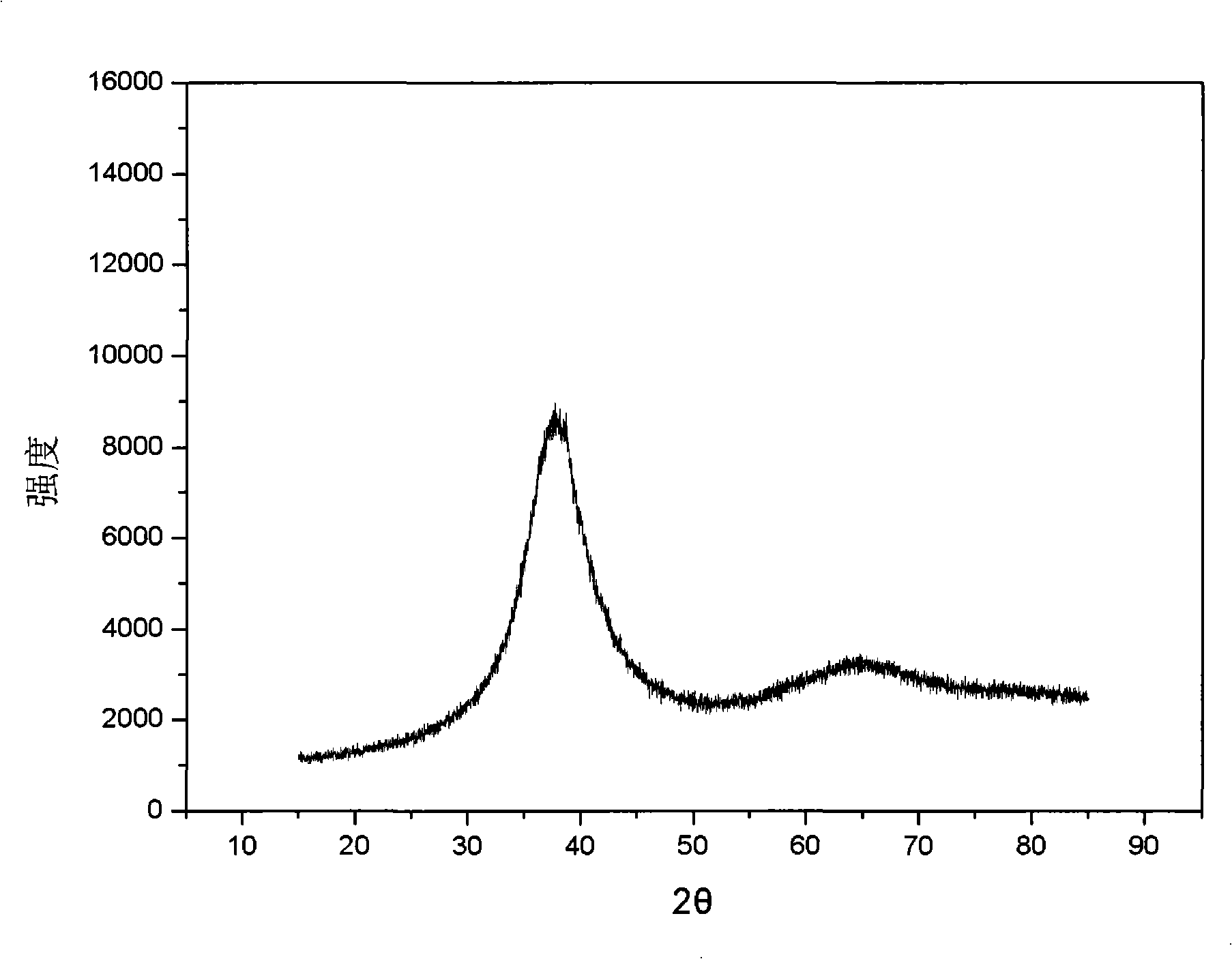

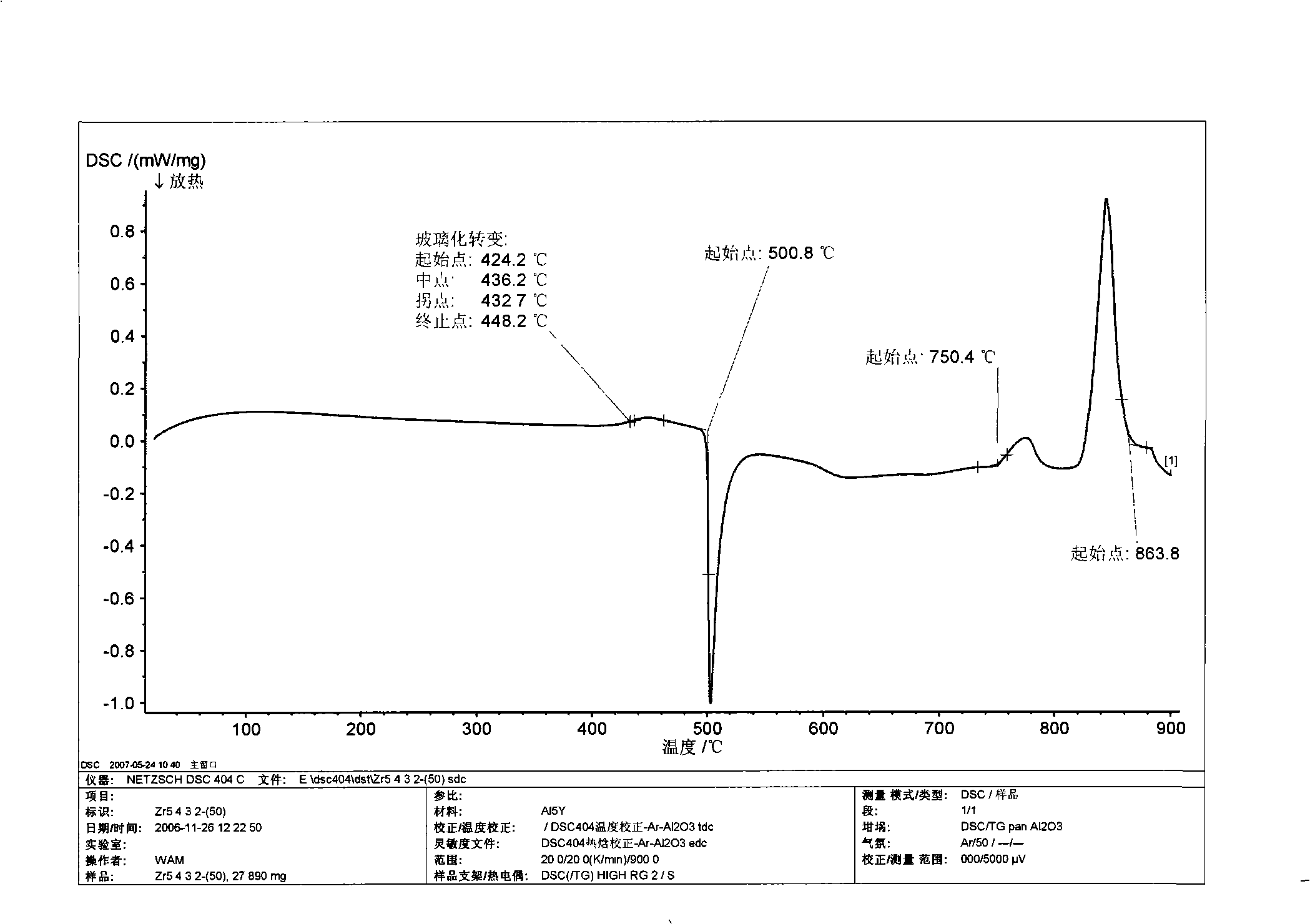

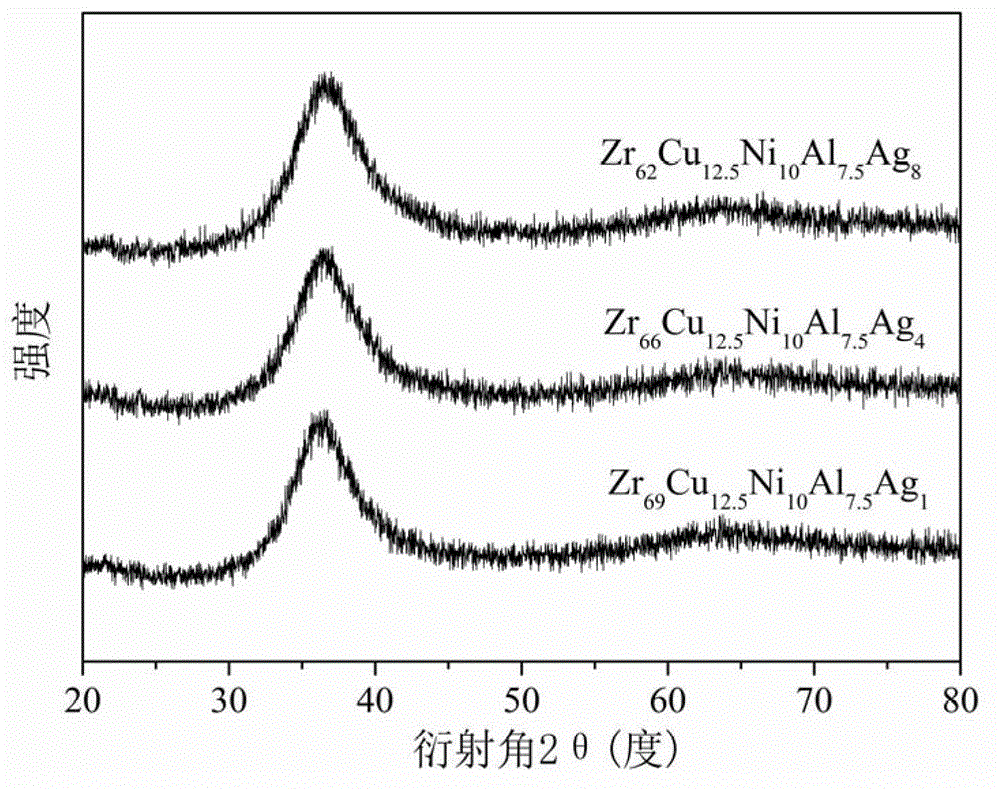

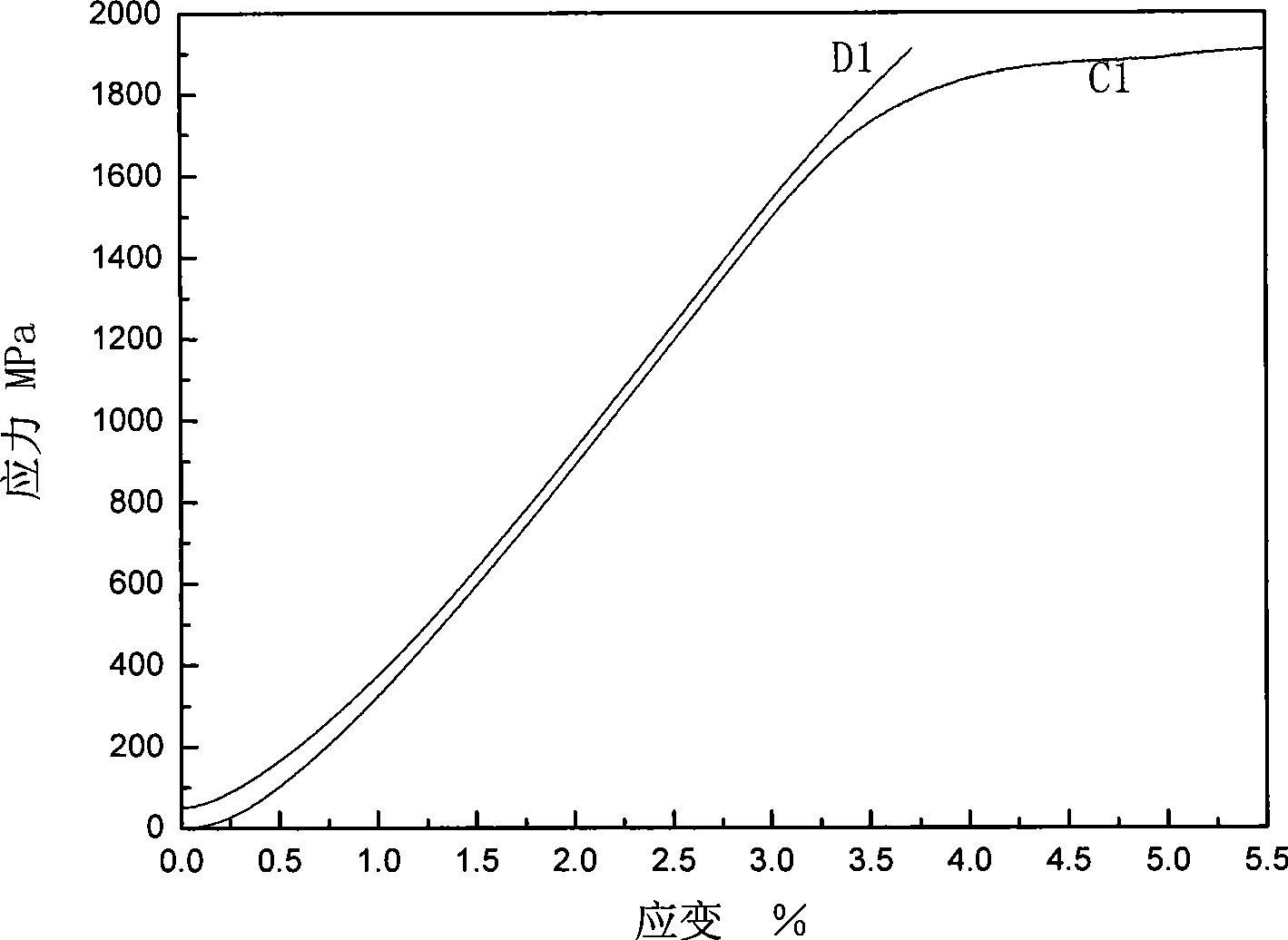

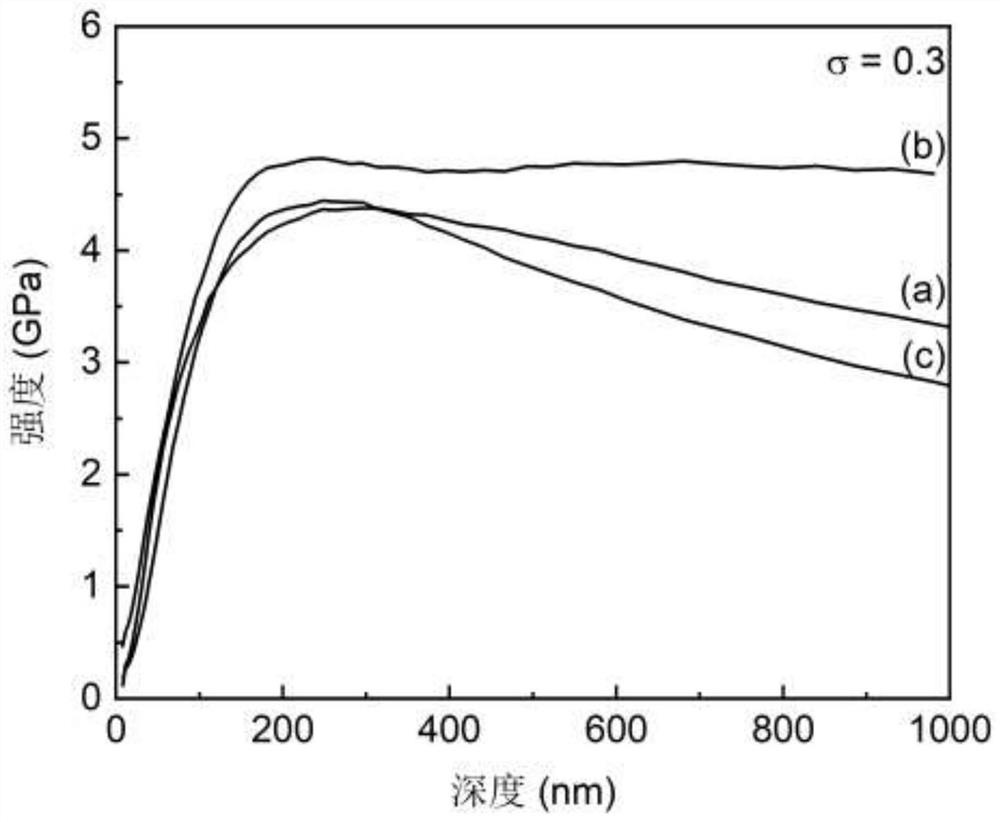

Zr-Cu-Ni-Al-Ag alloy with higher amorphous forming ability and production method thereof

The invention relates to a preparation technology of a block zirconium-base amorphous alloy, in particular to a Zr-Cu-Ni-Al-Ag alloy with higher glass-forming ability and a preparation method thereof, and the characteristic thermodynamics parameter and the mechanical property of the alloy are characterized and tested at the same time. The alloy system is the Zr-Cu-Ni-Al-Ag alloy, which has the component ranges (by atom percentage) that Zr is 41 to 63, Cu is 18 to 46, Al is 4 to 15, Ni is 1.5 to 12.5, and Ag is 1.5 to 26. Based on a Zr-Cu-Ni-Al quaternary alloy, the forming ability of the amorphous alloy is increased through inhibiting the precipitation of a crystalline state phase. The preparation technology adopts an electric arc melting method to prepare a master alloy ingot, then adopts a copper mold casting method to prepare amorphous alloy rods with different diameters, and the alloy in the system can easily prepare amorphous round bars, the diameter of which can reach 2cm. Due to stronger amorphous forming ability and good mechanical property, the alloy has good application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Zirconium-based amorphous alloy

The invention relates to a zirconium-based amorphous alloy. Composition of the zirconium-based amorphous alloy is (Zr, Hf, Nb)aCubNicAldRee, wherein a, b, c, d and e are corresponding contents in atomic percent of each element in the zirconium-based amorphous alloy, a is more than or equal to 45 and less than or equal to 65, b is more than or equal to 15 and less than or equal to 40, c is more than or equal to 0.1 and less than or equal to 15, d is more than or equal to 5 and less than or equal to 15, e is more than or equal to 0.05 and less than or equal to 5, the sum of a, b, c, d and e is less than or equal to 100, Re is one or combination of more than one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu elements, or Re is one or combination of Y with more than one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu elements.

Owner:HUAWEI TECH CO LTD

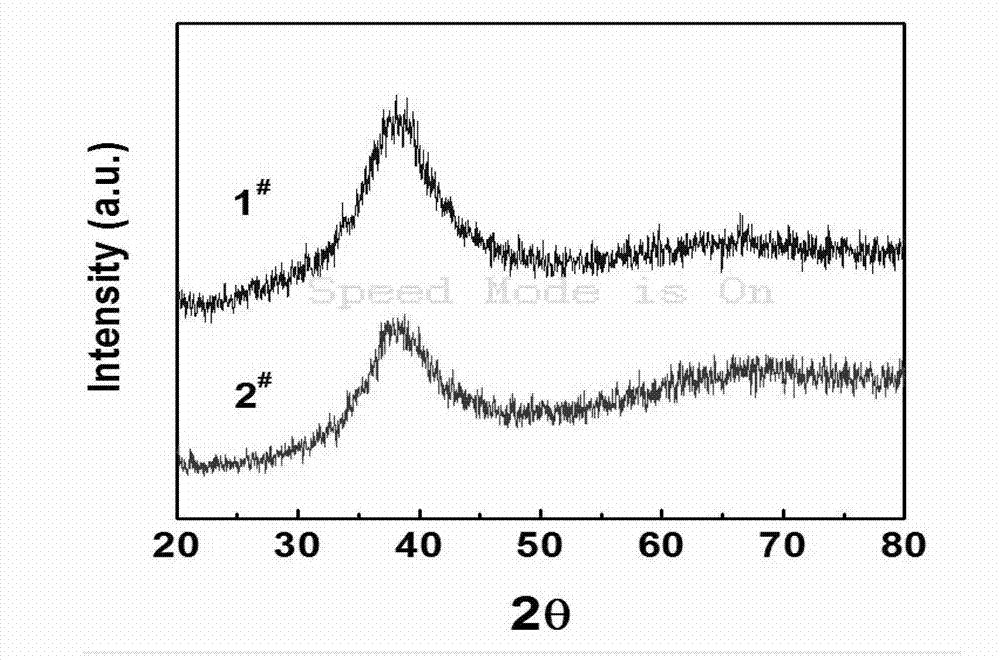

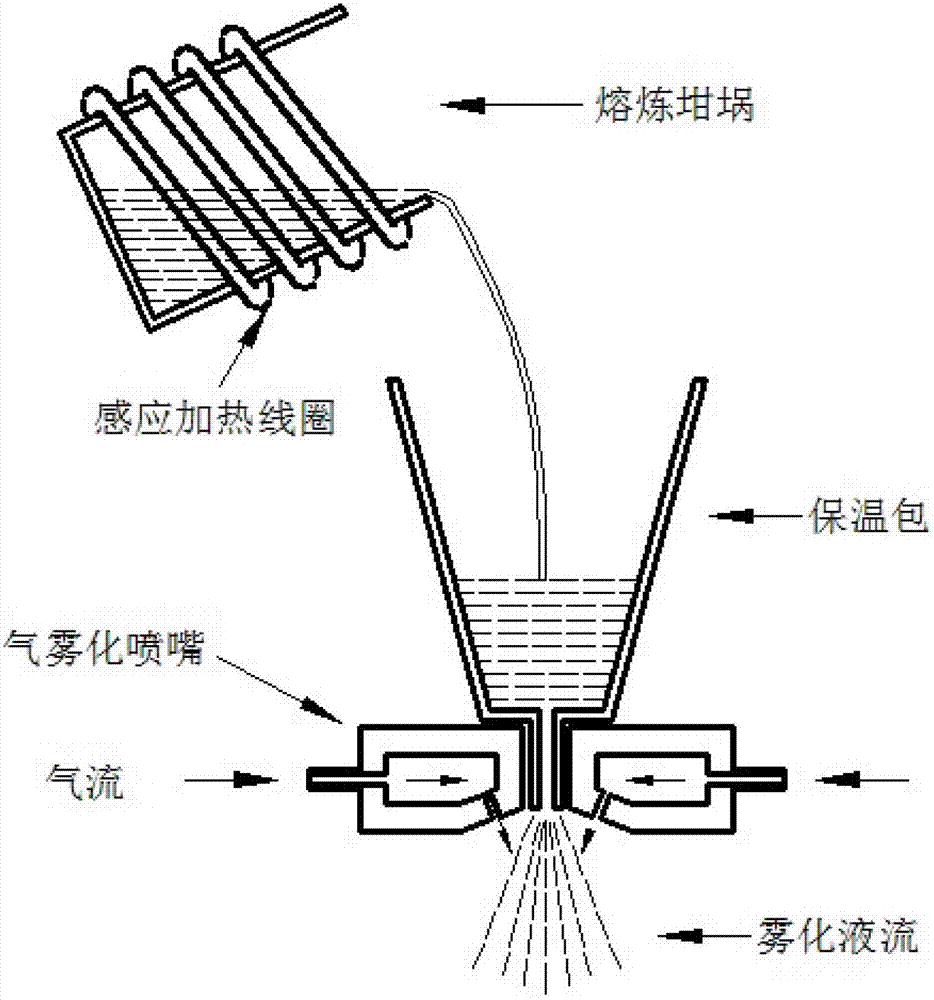

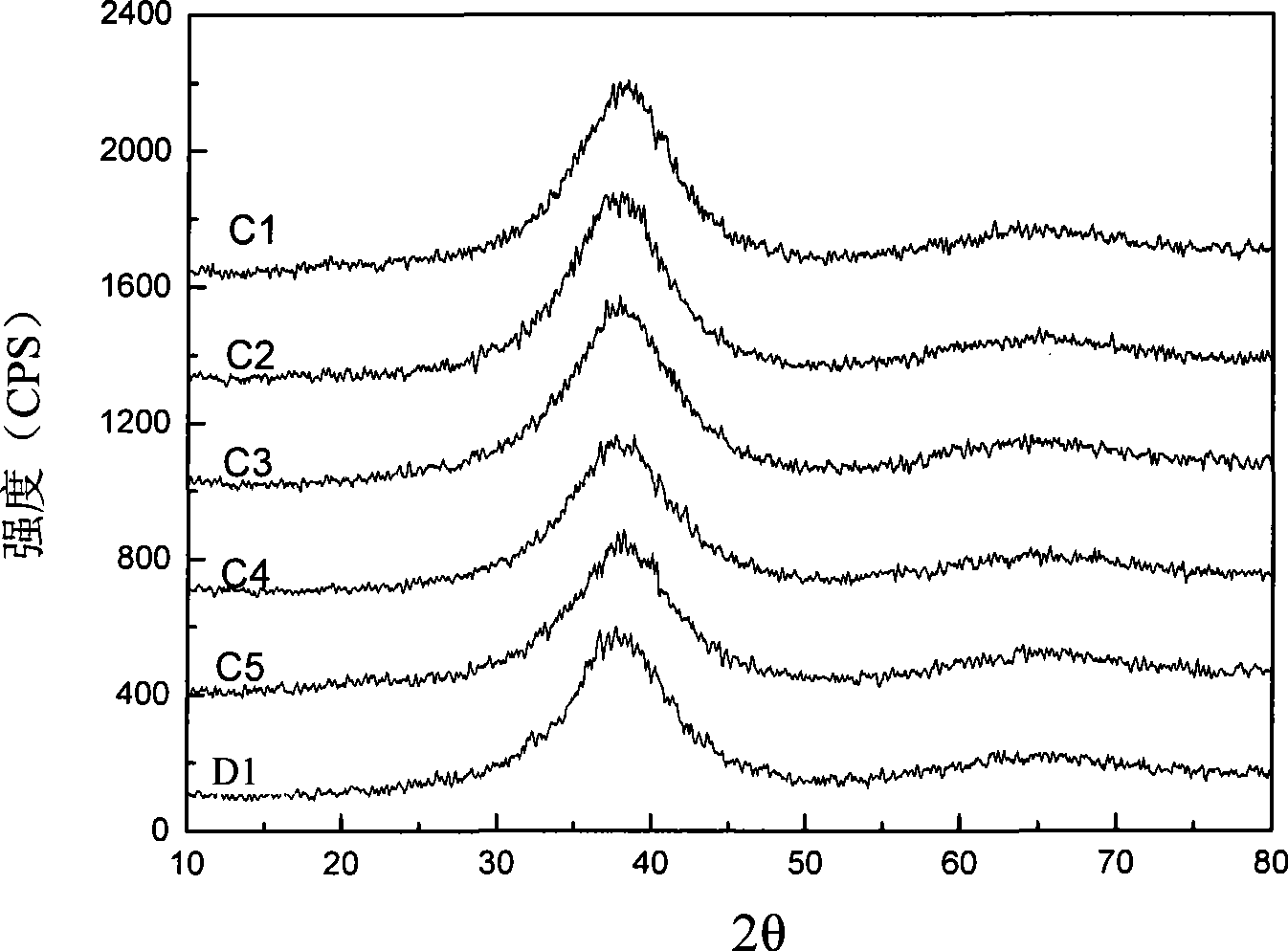

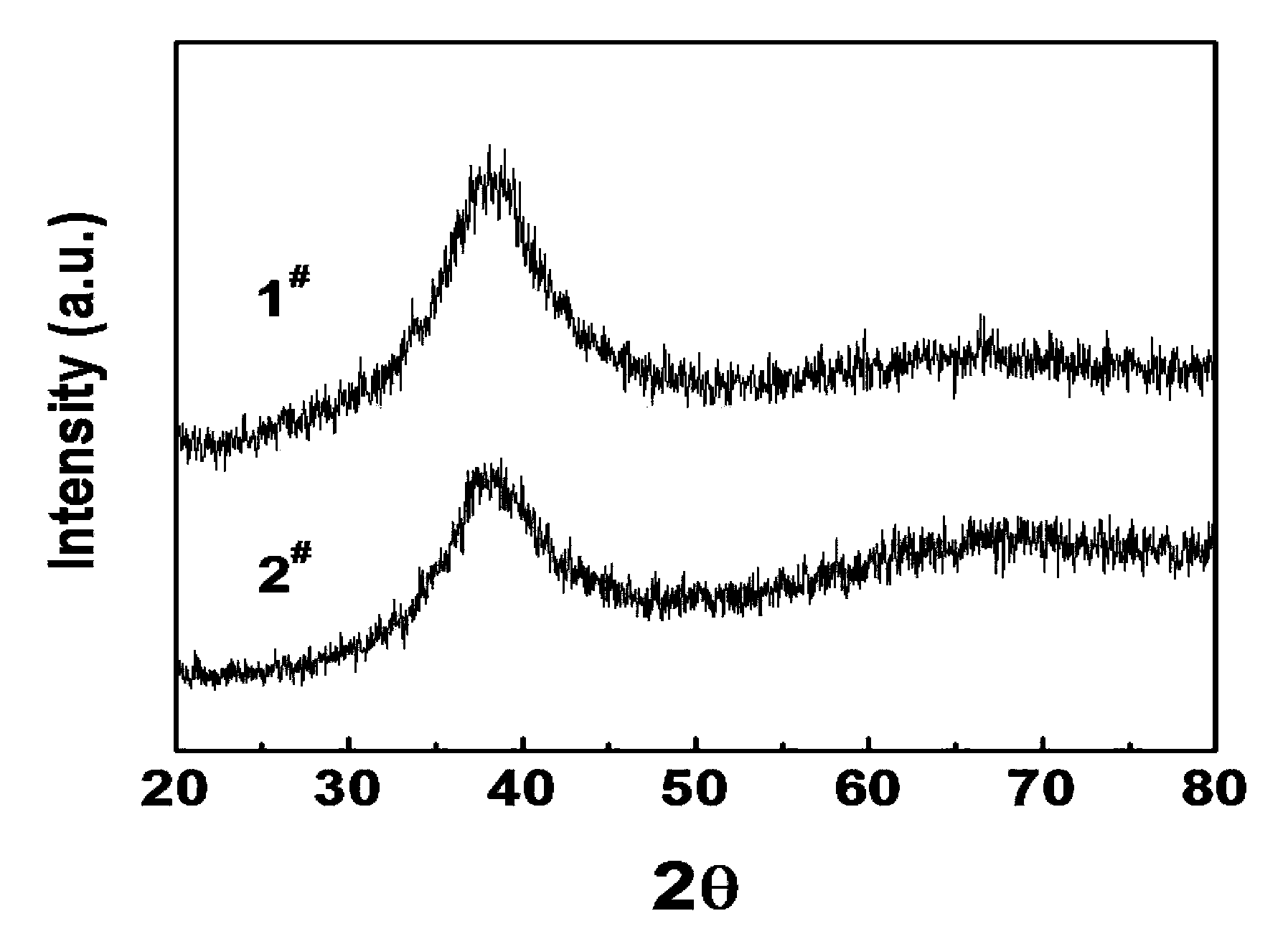

Preparation method for zirconium-based amorphous alloy as well as powder and large-sized block of zirconium-based amorphous alloy

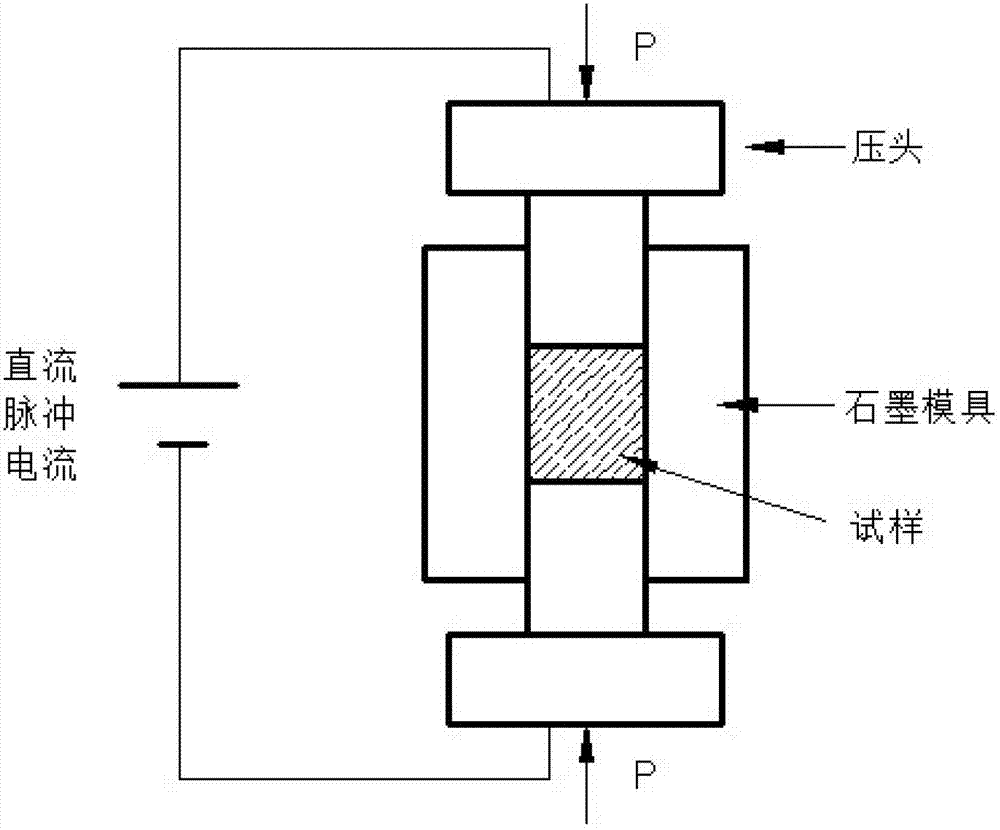

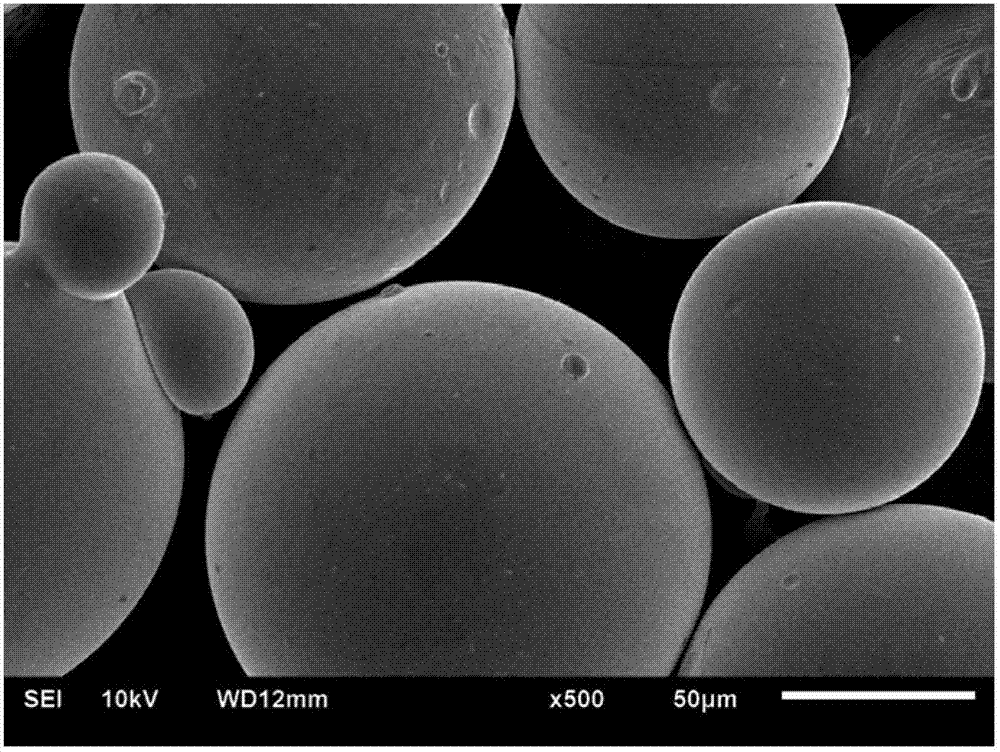

The invention relates to a preparation method for a zirconium-based amorphous alloy as well as powder and a large-sized block of the zirconium-based amorphous alloy, which belongs to the field of amorphous alloys, and is characterized by comprising the component of Zr61(Cu, Ni)27.5Al10Re1.5(at%), wherein Re is Y, La, Ce, Nd, Gd and Er, and adopting a manner of combination of the gas atomization powder milling technology and the spark plasma sintering technology. The preparation method comprises the following steps: preparing raw materials according to components of the amorphous alloy, and placing the raw materials into an induction crucible of gas atomization powder milling equipment; vacuumizing and filling inert gas for shielding; smelting to obtain an alloy solution with uniform components under the action of induction heating; pouring the alloy solution after smelting into an insulation bag at a constant speed slowly, and filling high-pressure inert gas as an atomizing medium at the same time; atomizing the alloy solution flow into small droplets under the impact of high-pressure airflow, and finally cooling to form amorphous alloy powder; collecting and screening the amorphous alloy powder; and under the protection of the inert gas, utilizing the spark plasma sintering technology to perform sintering on the amorphous alloy powder at different temperatures and pressure to obtain an amorphous alloy block.

Owner:UNIV OF SCI & TECH BEIJING

Titanium group high temperature amorphous solder of hard solder Si*N* ceramic and method for producing the same

The invention discloses braze welding Si3N4 porcelain Ti base high temperature non-crystalline brazing filler metal and the preparing method thereof, in particular to Ti-Zr-Ni-Cu high temperature active non-crystalline brazing filler metal and the preparing method thereof, and pertains to the braze welding material of non-crystalline state and metallurgy field. The brazing filler metal has the ingredients and the contents (matching according to the quality percentage) as follows: Ti of 30.0 to 45.0 percent, Zr of 22.0 to 26.0 percent, Ni of 12.0 to 16.0 percent, and Cu of 15.0 to 30.0 percent. The melting temperature range of the brazing filler metal is 1100 to 1170 K; the braze welding temperature is 1223 to 1323 K. Compared with the brazing filler metal prepared by normal melting technique with the same component, the Ti-Zr-Ni-Cu high temperature active non-crystalline brazing filler metal leaf obtained by the rapid solidifying technique has favorable wetting property and tie-in dynam performance; adopting the non-crystalline brazing filler metal to vacuum braze weld Si3N4 porcelain, the tie-in chamber temperature bending intensity is 160 MPa; when the temperature is 673 K, the tie-in high temperature bending intensity is 126 MPa; when the temperature is 773 K, the high temperature bending intensity is 83 MPa.

Owner:JIANGSU UNIV OF SCI & TECH

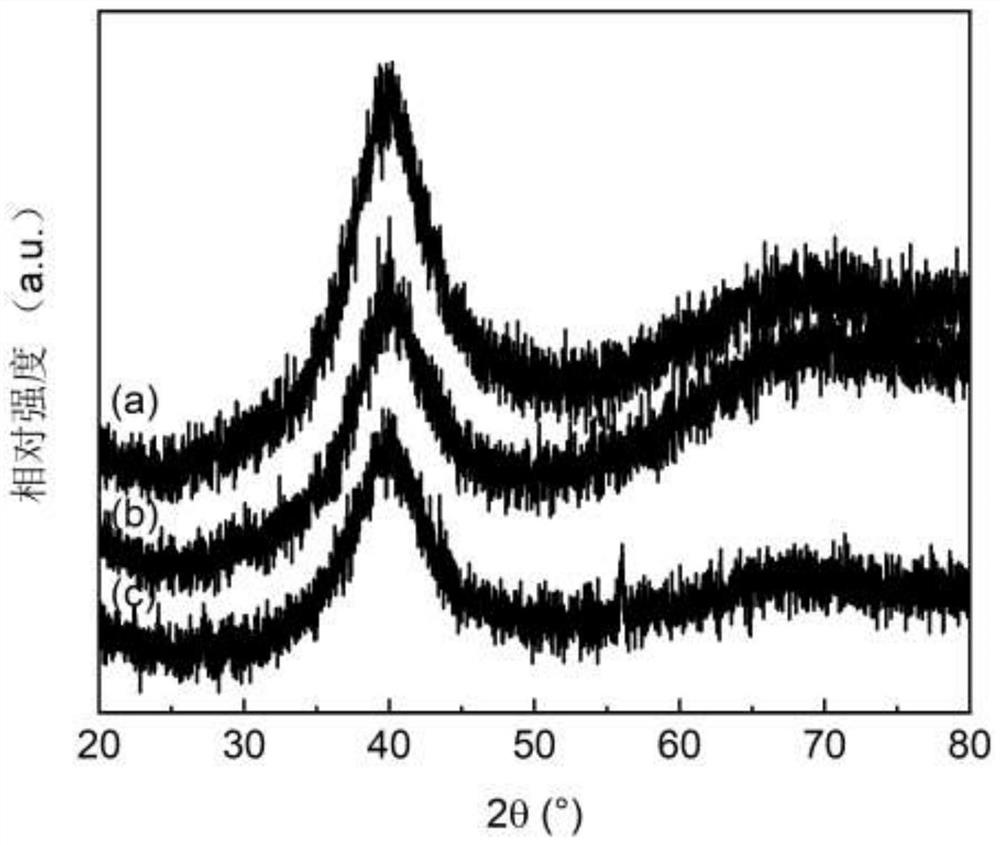

Zr-based amorphous alloy and manufacturing method thereof

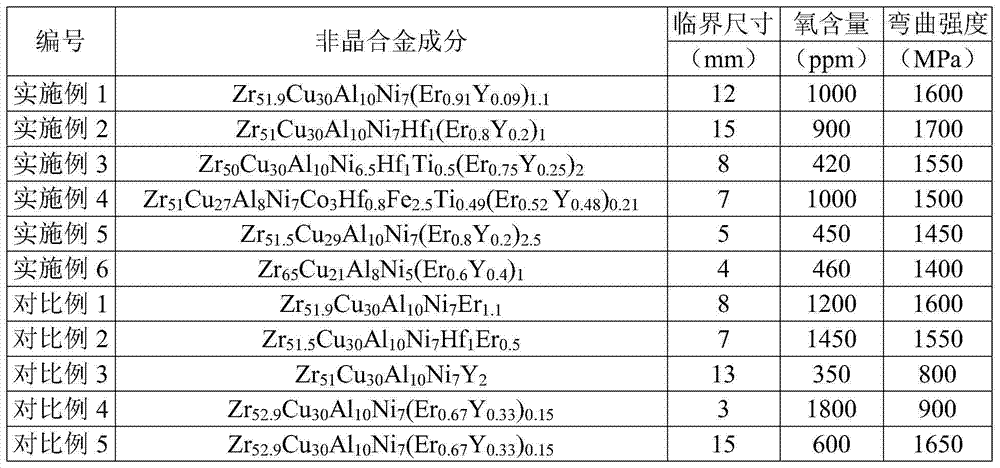

InactiveCN104745973ALittle impact on mechanical propertiesEnhanced Amorphous Formation AbilityAlloyZirconium

A zirconium-based amorphous alloy and a preparation method therefor. The composition of the amorphous alloy is ZraCubAlcMd(Er1-xYx)e, wherein M is at least one selected from Ni, Fe, Co, Mn, Cr, Ti, Hf and Ta, 40≤a≤70, 15≤b≤35, 5≤c≤15, 3≤d≤15, 0.2<e≤2.5, and 0<x<0.5, and the amorphous alloy is obtained by smelting and cooling molding under the protection of an inert gas or a vacuum condition.

Owner:BYD CO LTD

Zirconium-based amorphous alloy and preparation method thereof

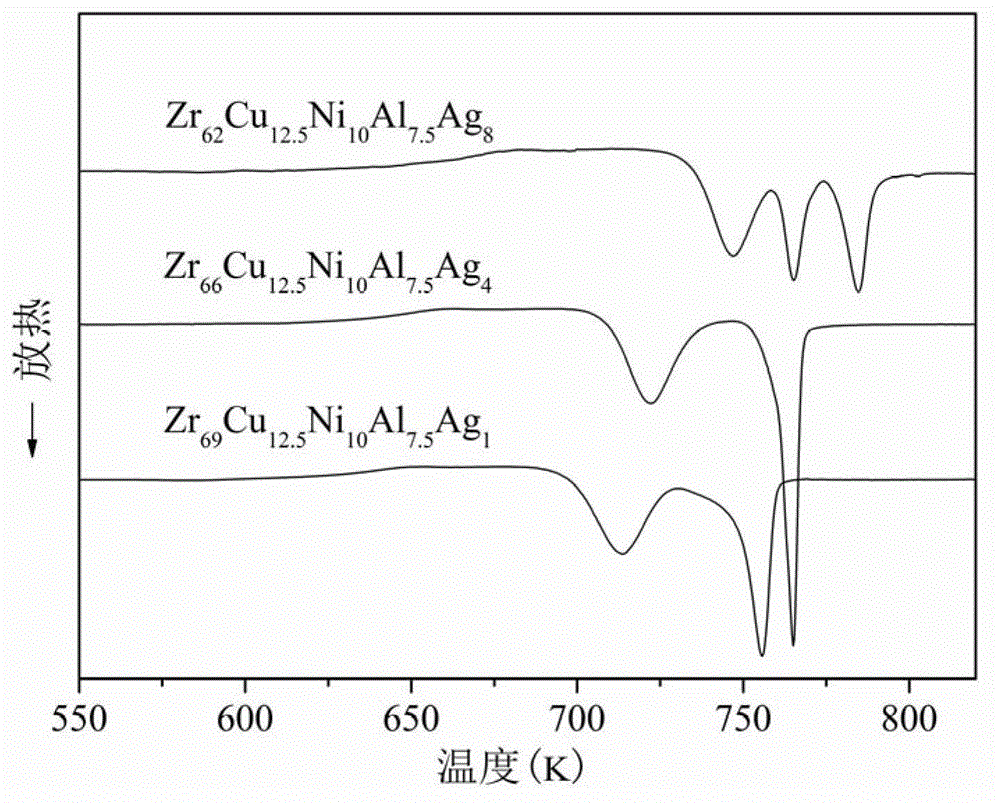

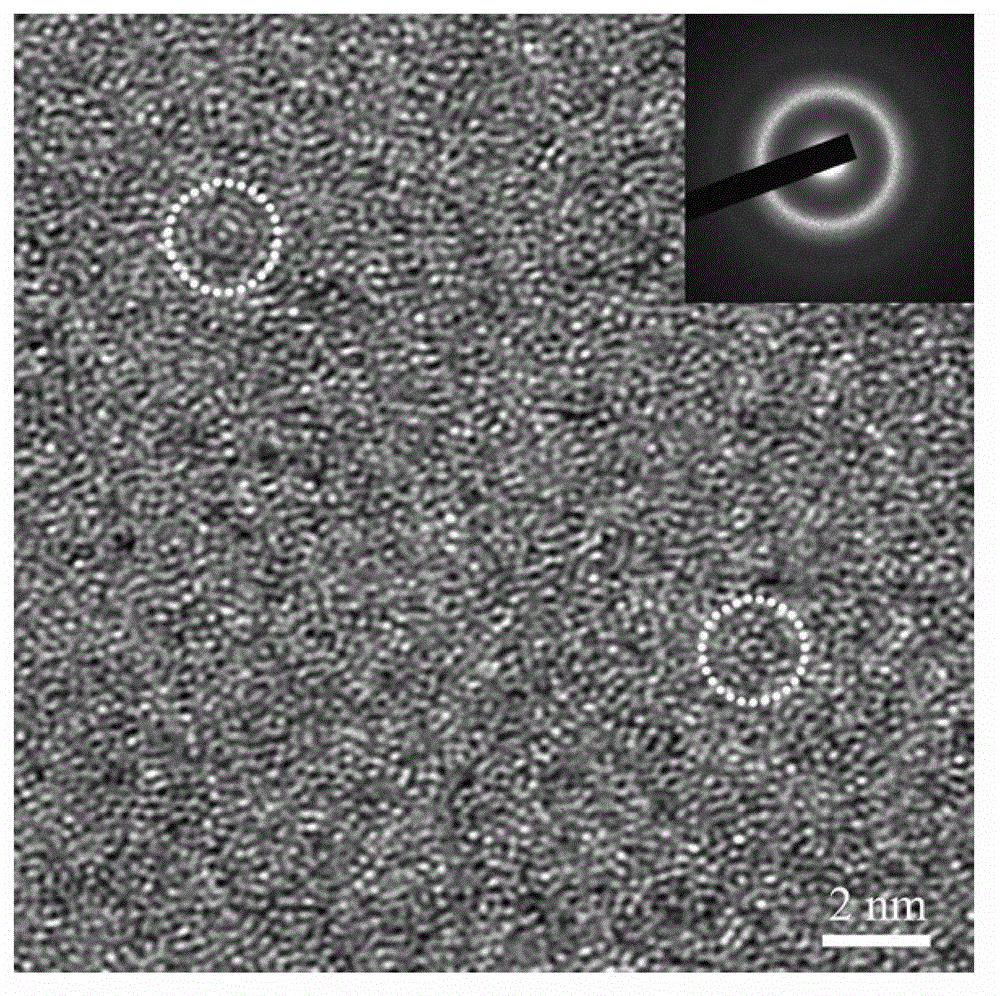

InactiveCN102912261AHigh compressive strengthImprove plastic deformation abilityCopperGlass transition

The invention relates to a zirconium-based amorphous alloy. The zirconium-based amorphous alloy comprises zirconium, copper, nickel, aluminum and sliver; and the zirconium-based amorphous alloy is shown by the following formula: Zr70-xCu12.5Ni10Al7.5Agx, wherein x is more than or equal to 1 and less than or equal to 10. The preparation method comprises the steps of replacing zirconium element by a silver part, and melting by arc under vacuum, and then carrying out suction casting, so as to obtain the zirconium-based amorphous alloy. The zirconium-based amorphous alloy is excellent in plastic deformation capacity and high in strength; the amorphous alloy is high in glass transition temperature and initial crystallizing temperature, and wide in sub-cooled liquid phase area, and has a potential application prospect.

Owner:SHANGHAI JIAO TONG UNIV

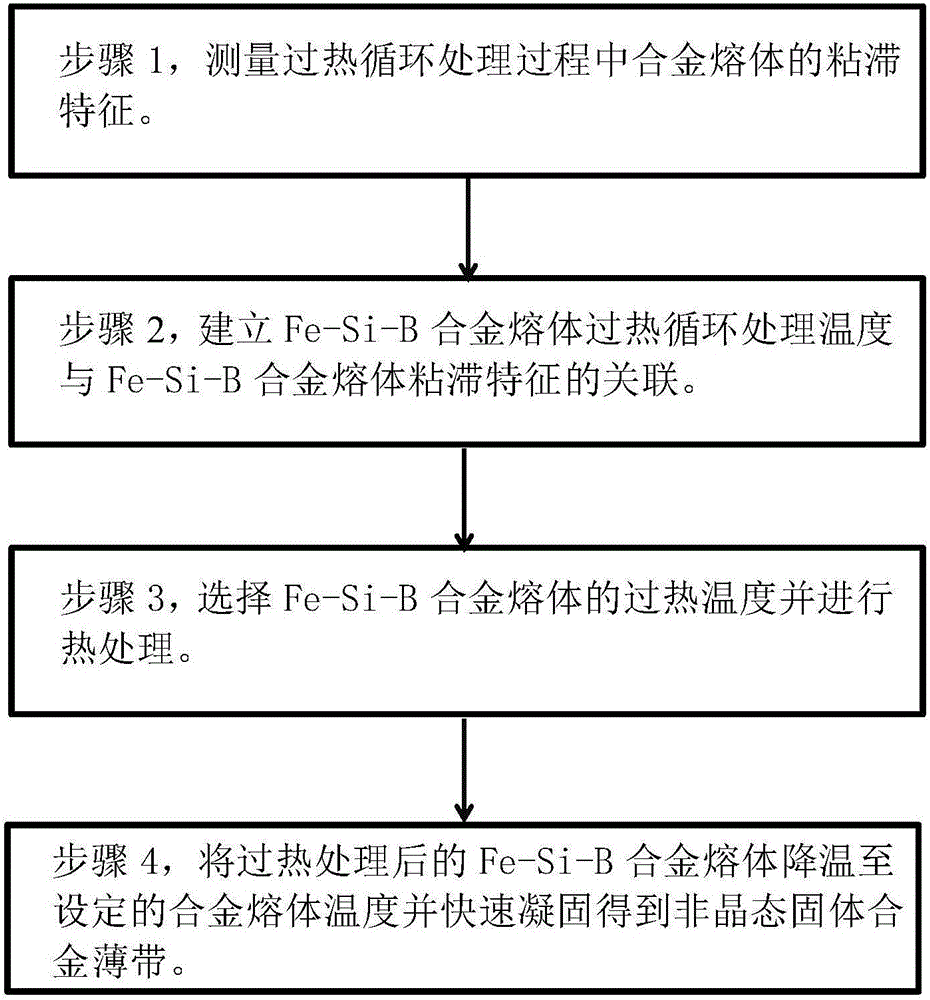

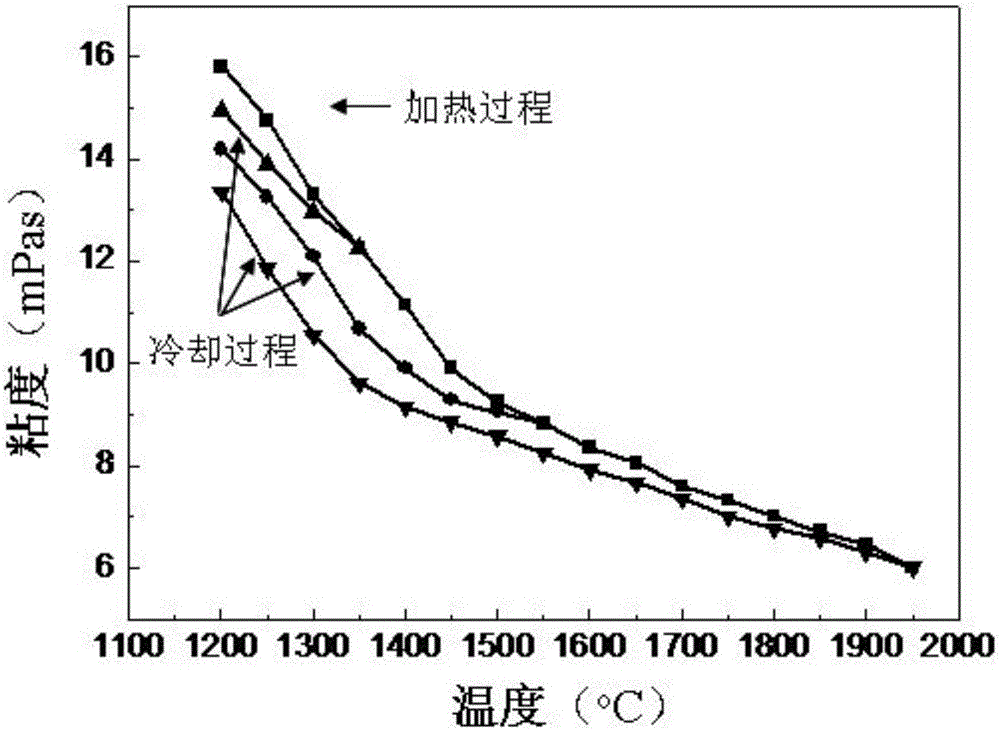

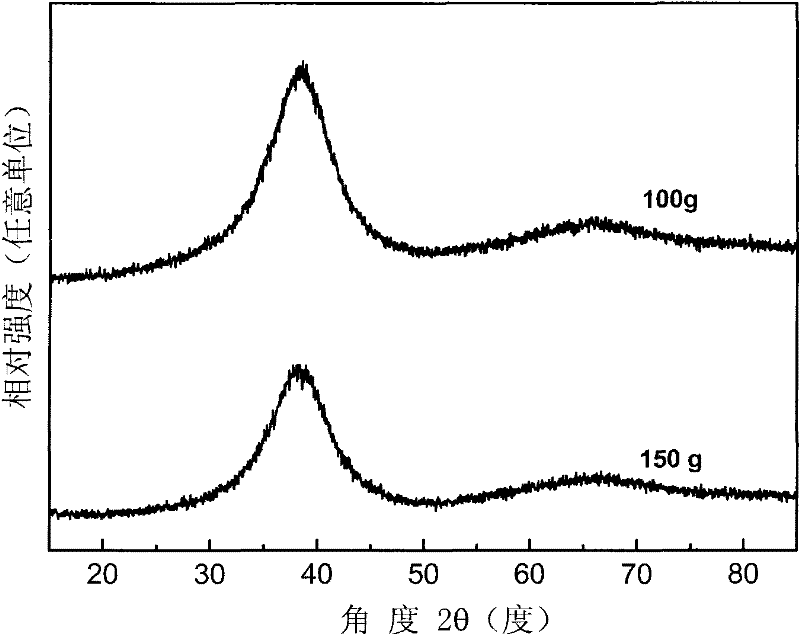

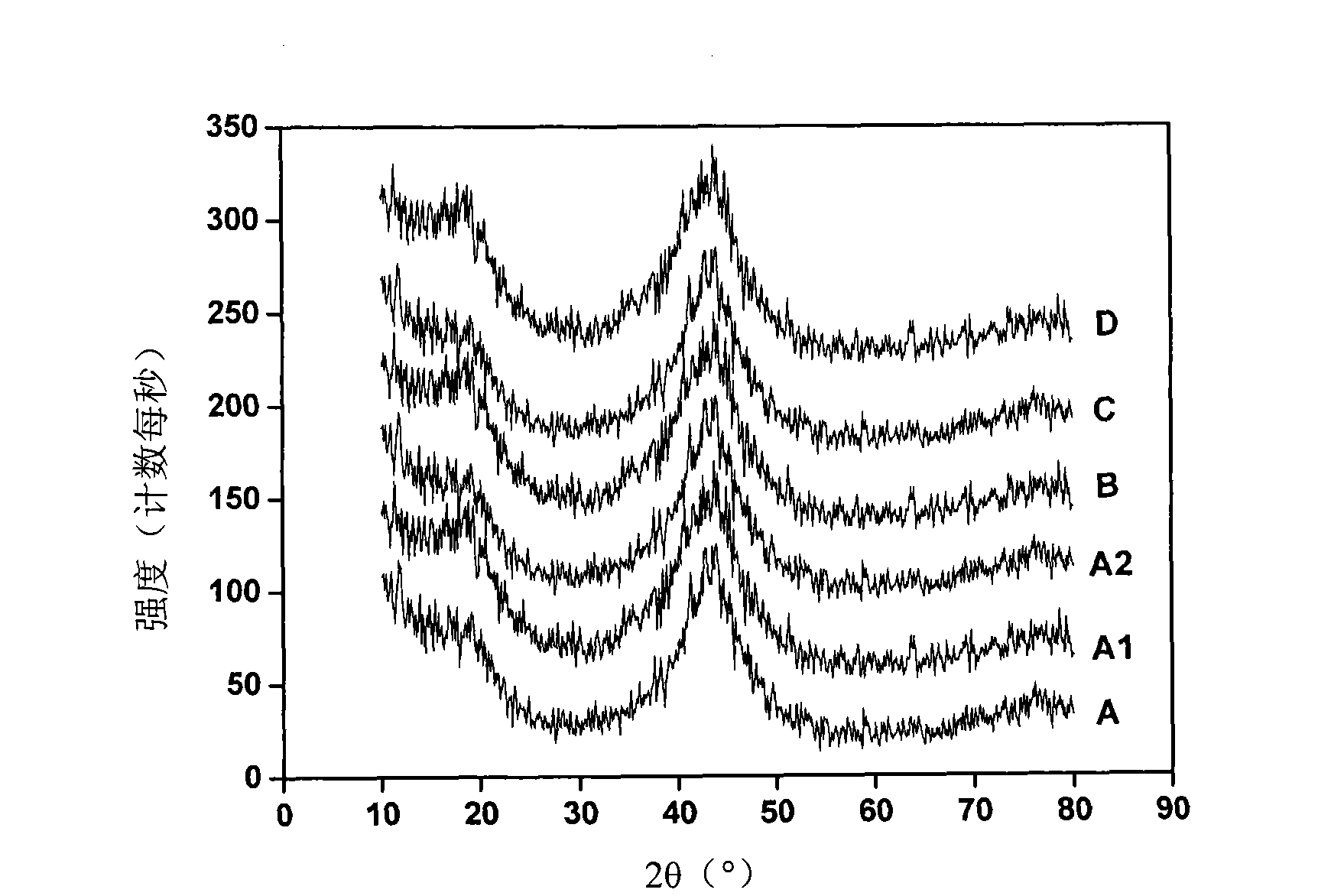

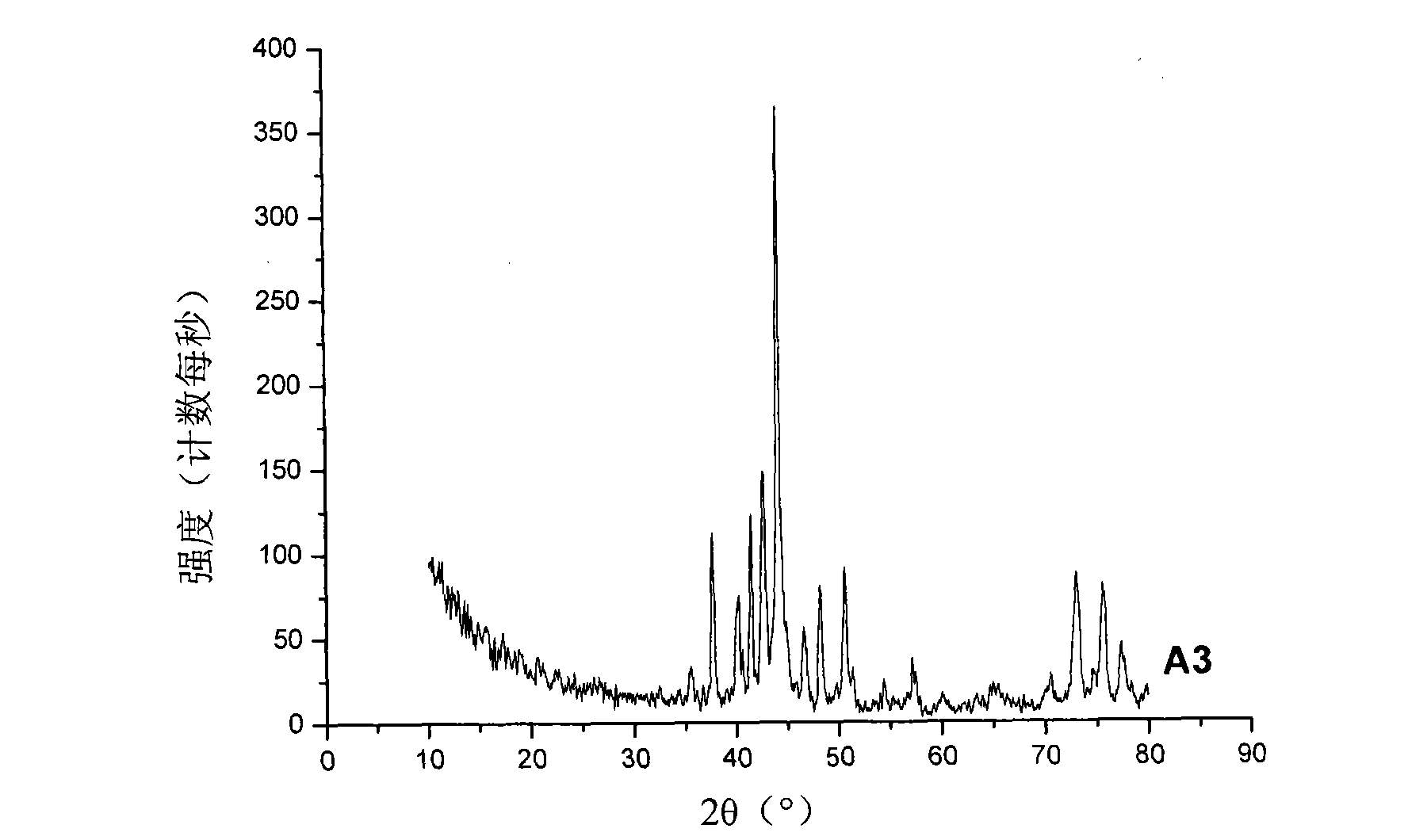

Technique for enhancing amorphous forming ability of alloy melt

The invention relates to a technique for enhancing amorphous forming ability of an alloy melt. The technique is characterized by comprising the following steps: 1. measuring the viscous characteristic of an superheating circulation treatment alloy melt; 2. establishing the relation between the superheating circulation treatment temperature and alloy melt viscous characteristic of the Fe-Si-B alloy melt; 3. selecting the Fe-Si-B alloy melt superheating treatment temperature, and carrying out heat treatment; and 4. cooling the Fe-Si-B alloy melt subjected to superheating treatment to the set melt temperature, and quickly setting to obtain the solid amorphous alloy. The technique can enhance morphous forming ability of lloy melt and lower morphous solid alloy preparation difficulty by utilizing the viscous characteristic of the superheating treatment on the premise of not changing lloy composition and quick setting technological conditions. The technique has dvantages of low implementation cost, high efficiency, high controllability, high repetitiveness, high technical reliability and the like, and can be widely used in the technical field of metal functional material preparation.

Owner:江苏非晶电气有限公司 +2

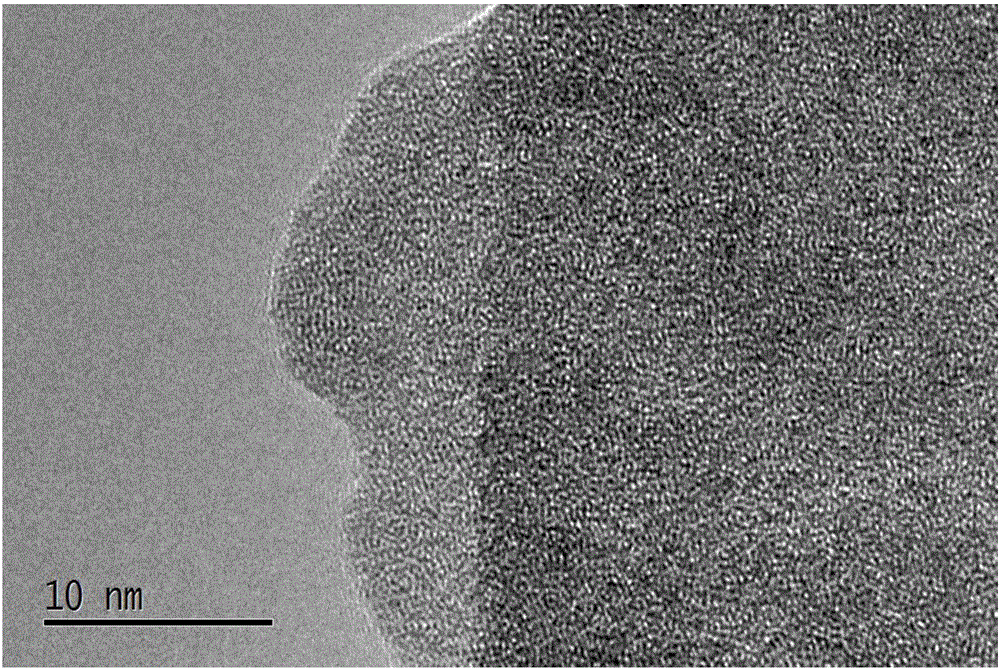

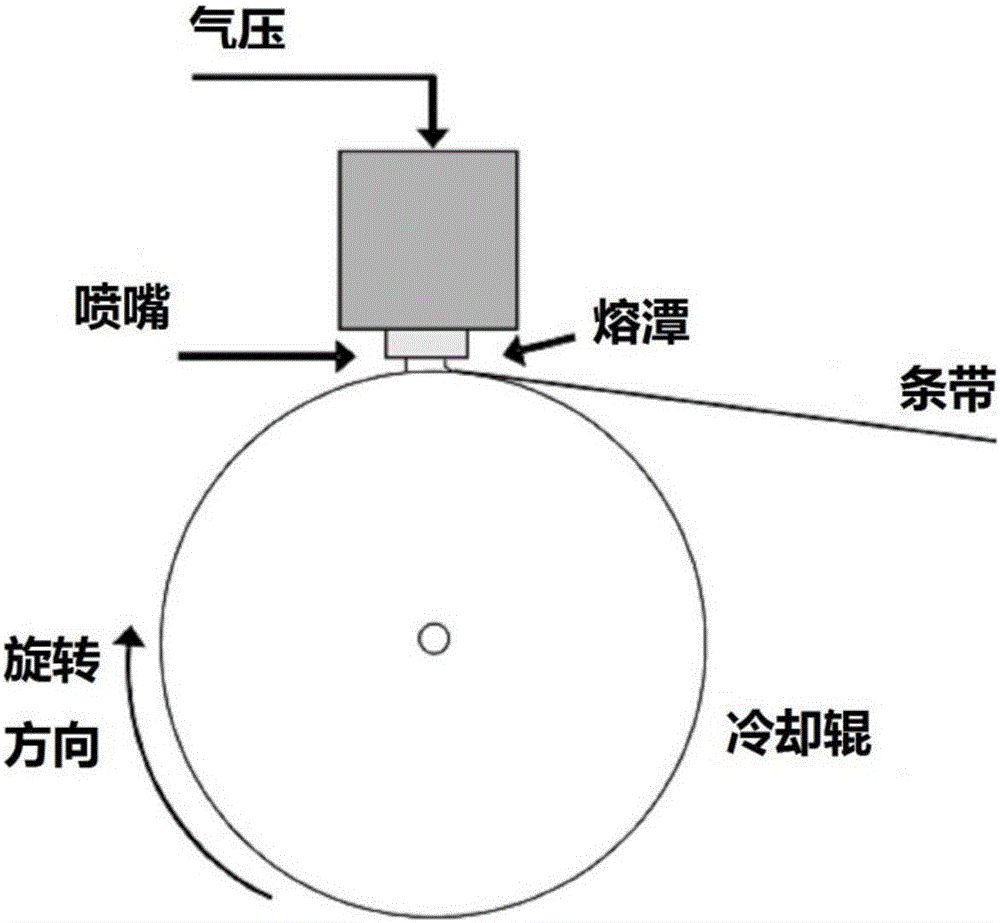

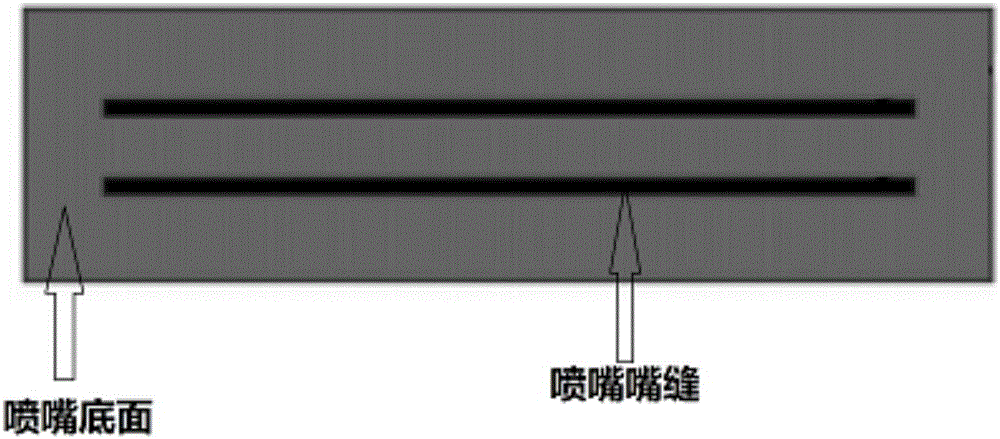

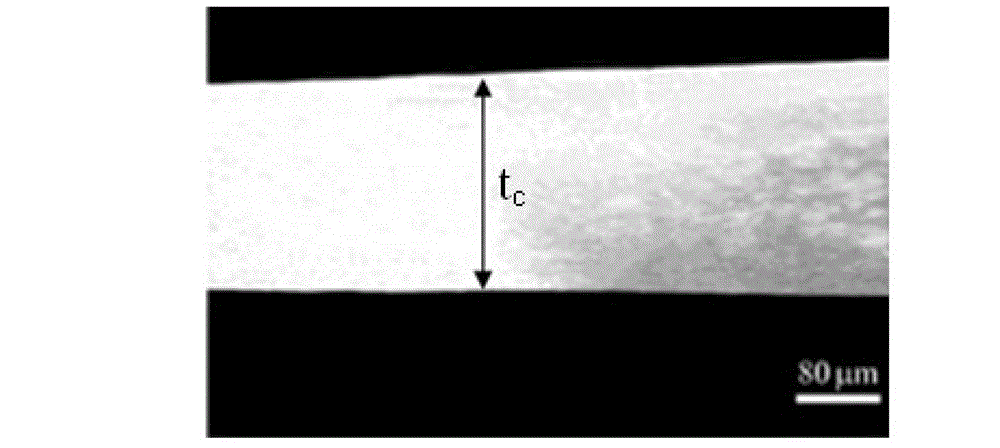

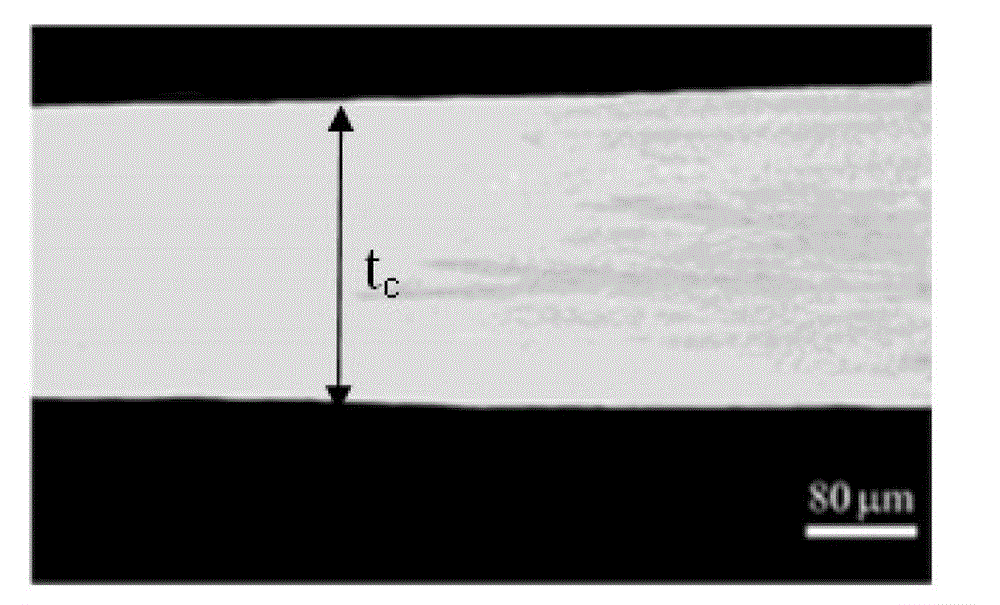

Rare-earth-doped iron-based amorphous thick strip and preparing method thereof

The invention relates to a rare-earth-doped iron-based amorphous thick strip and a preparing method thereof. The component expression of the iron-based amorphous thick strip is FexSiaBbPcYd, wherein x, a, b, c and d are atomic percents of corresponding elements, wherein a is larger than or equal to 0.5 and smaller than or equal to 10, b is larger than or equal to 0.5 and smaller than or equal to 12, c is larger than or equal to 0.5 and smaller than or equal to 8, d is larger than or equal to 0.001 and smaller than or equal to 0.5, and x+a+b+c+d is equal to 100. A plane flow casting method is adopted for manufacturing the strip, during strip manufacturing, a double-line nozzle is adopted, the thickness of the prepared amorphous thick strip ranges from 50 micrometers to 100 micrometers, the lamination coefficient is larger than 0.92, the saturated magnetic induction density is larger than 1.67T. Micro rare earth yttrium is contained in an alloy, the content of impurities of oxygen, sulphur and the like is greatly reduced, and the molten steel mobility is improved; meanwhile the rare earth yttrium improves the amorphous forming capacity of an alloy system, and the amorphous alloy strip with the thickness ranging from 50 micrometers to 100 micrometers can be prepared through the technology method.

Owner:南京腾元软磁有限公司 +3

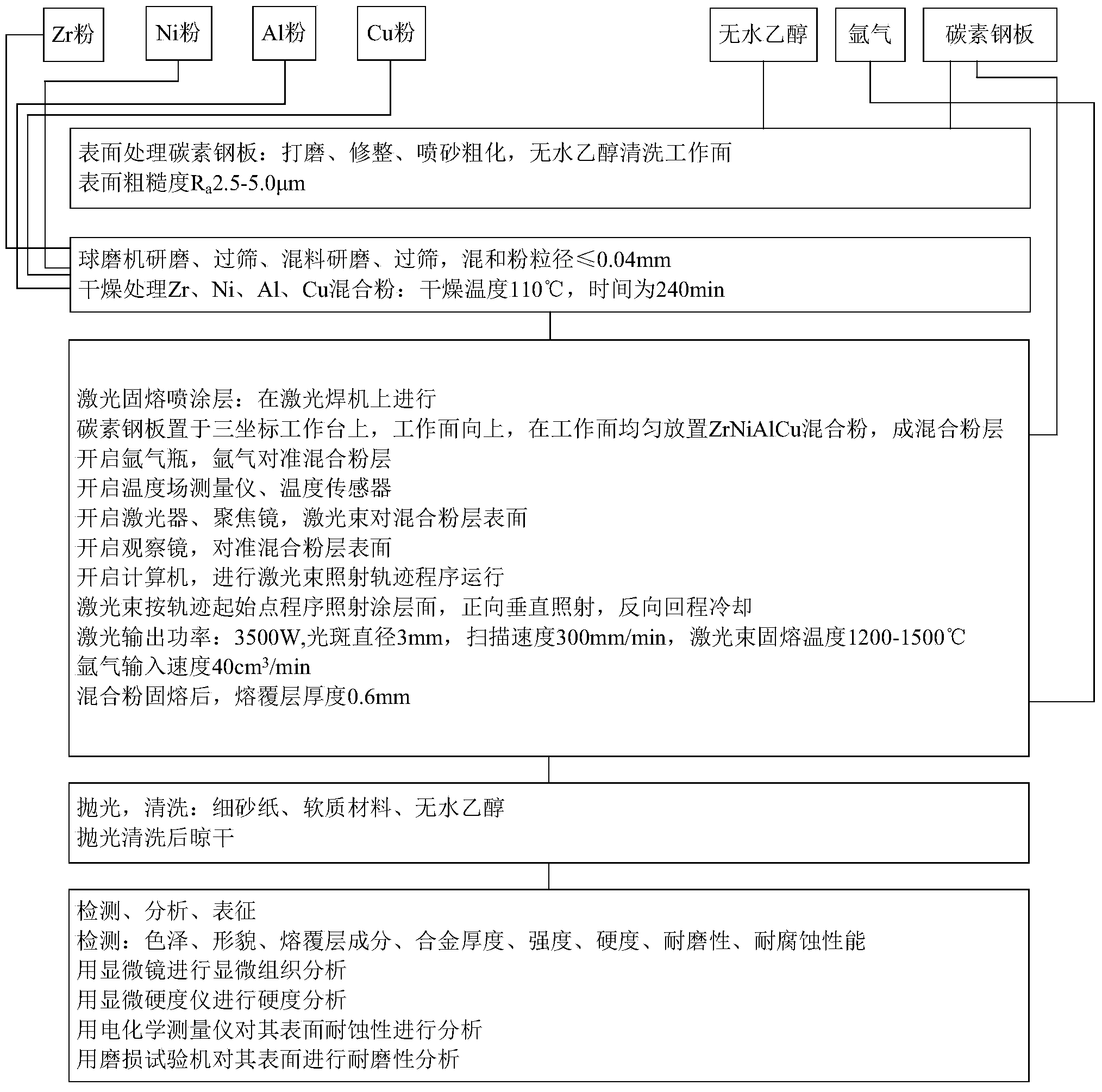

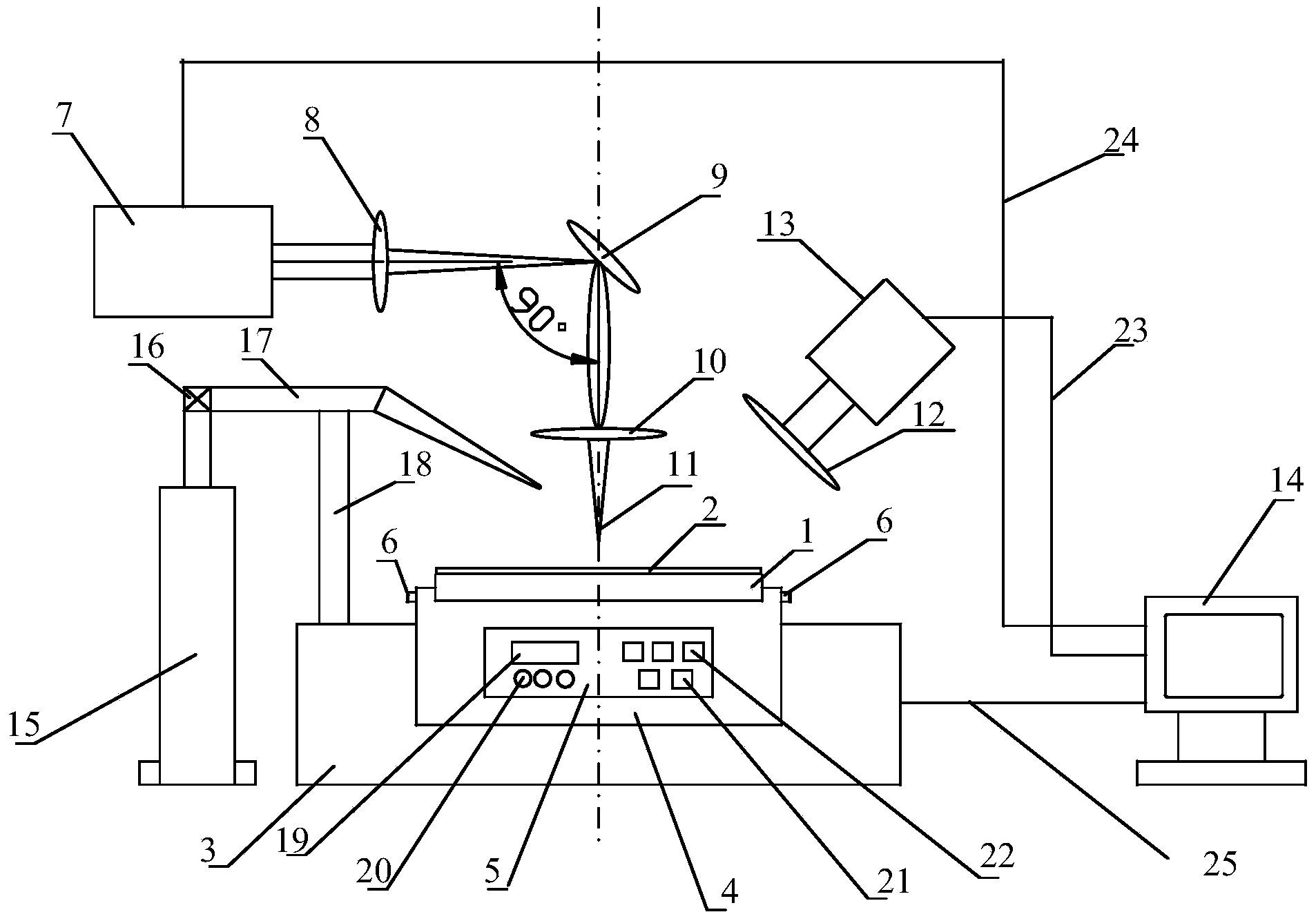

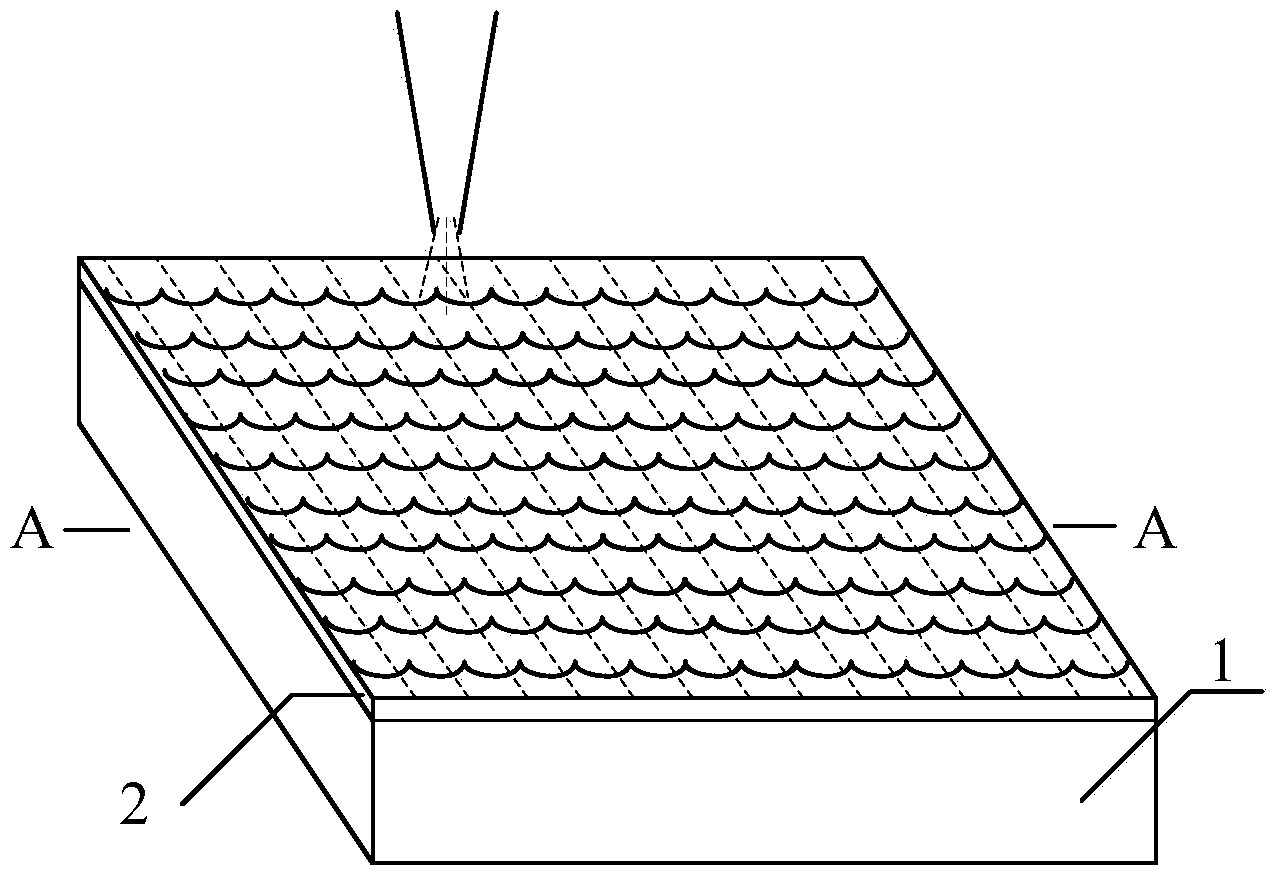

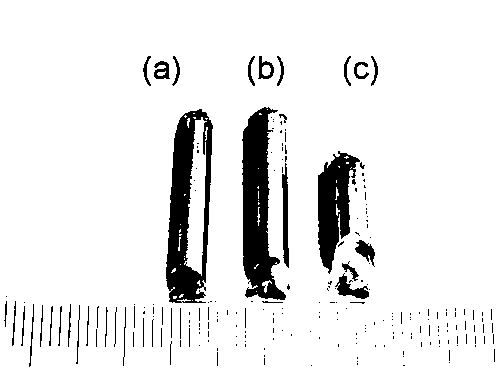

Method adopting laser cladding to form amorphous alloy coating on surface of carbon steel

ActiveCN103668177AEnhanced Amorphous Formation AbilityShort processMetallic material coating processesAlloy coatingLaser beams

The invention relates to a method adopting laser cladding to form an amorphous alloy coating on the surface of carbon steel, and as the laser cladding method is adopted on a laser welder, the carbon steel plate is intensified. The technical scheme comprises the following steps: sand blasting the surface of the carbon steel; preparing mixed powder of zirconium, nickel, aluminum and copper; cladding the surface of the carbon steel by utilizing a laser beam, and enabling the laser beam to perform all-directional irradiation along a locus curve set by a computer program; forming the amorphous alloy coating after amorphous alloy powder is fused and cured on the surface of the carbon steel. By the adoption of the method, the surface hardness, abrasion resistance and corrosion resistance of the carbon steel are greatly improved; compared with the performances before treatment, the surface hardness of the carbon steel is increased by four times, the abrasion resistance is increased by four times, and the corrosion resistance is increased by 1000%; the intensifying method has the advantages of advanced process, detailed and accurate data, short technological process and simplicity in realization, and is safe, stable and reliable; the cladding coating is solid and not easy to drop off; the method is ideal in intensifying the surface of the carbon steel.

Owner:大同市森源激光再制造技术有限公司

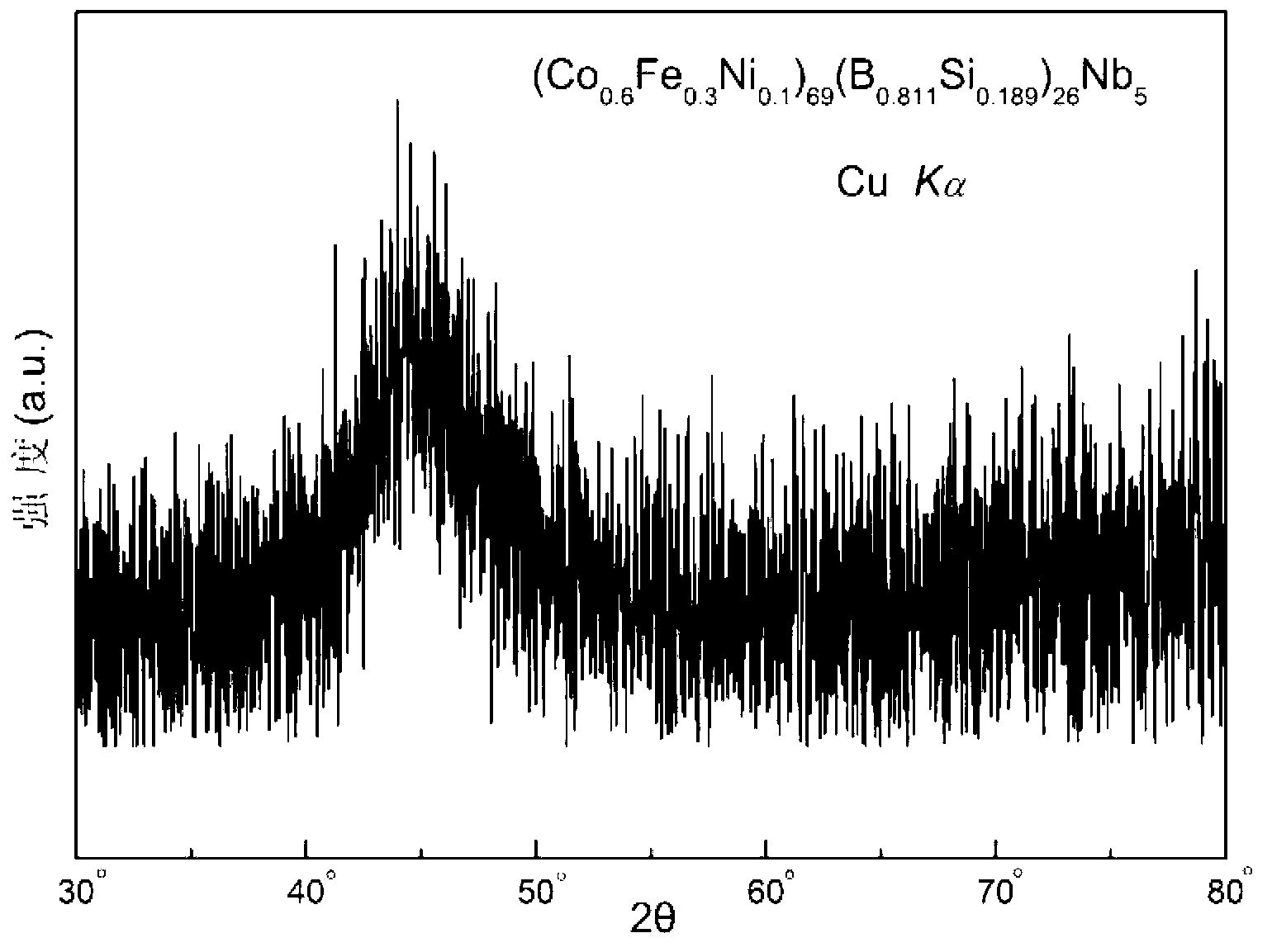

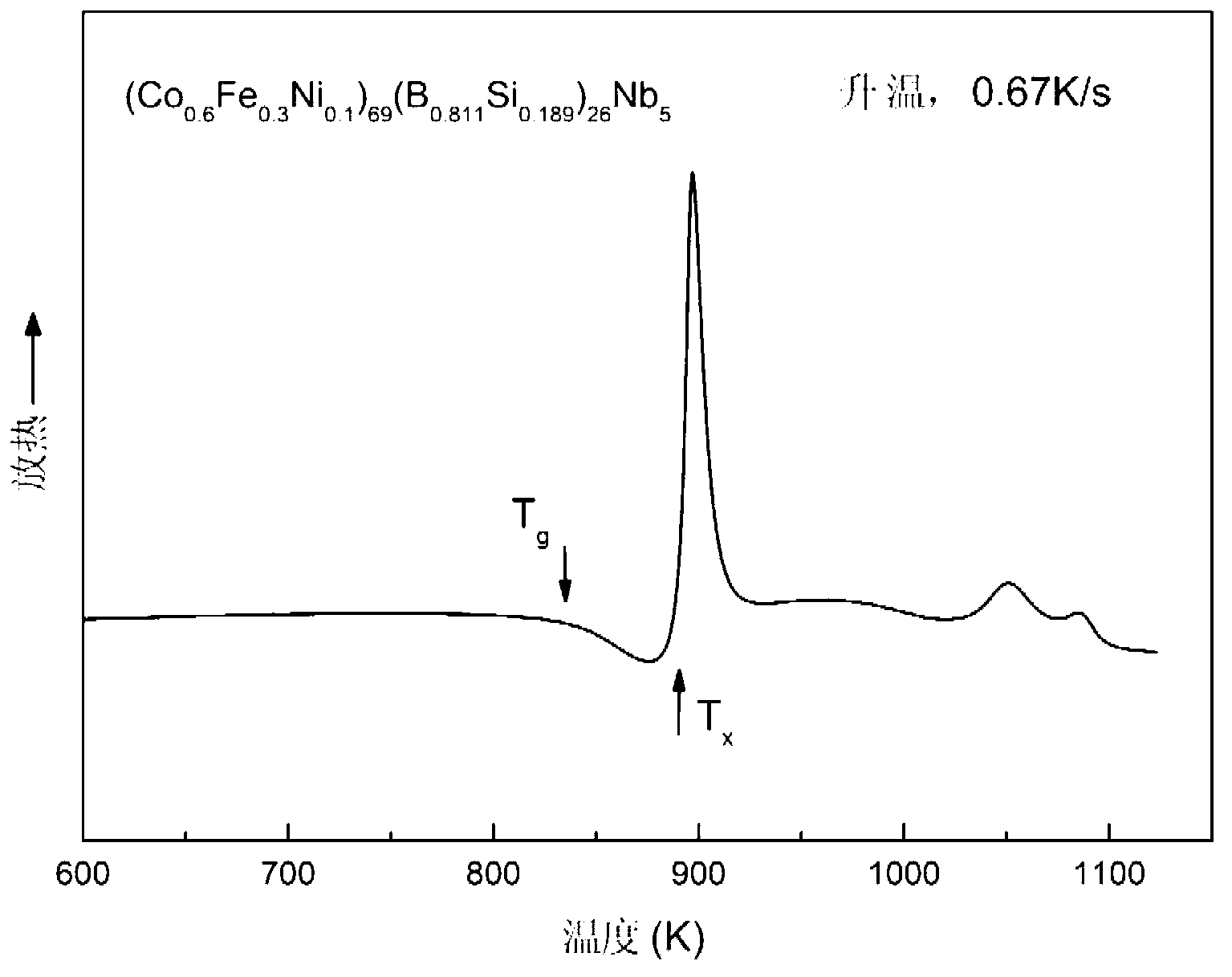

Cobalt-base block amorphous soft magnetic alloy with high amorphous forming ability and preparation method thereof

InactiveCN102915820ARaise the transition temperatureEnhanced Amorphous Formation AbilityMagnetic materialsMechanical properties of carbon nanotubesLiquid phase

The invention provides a cobalt-base block amorphous soft magnetic alloy with high amorphous forming ability and a preparation method thereof. The molecular formula of the amorphous soft magnetic alloy is CoaFebNicBdSieNb5, in which a, b, c, d and e are atomic percents, wherein a is larger than or equal to 25 and smaller than or equal to 60, b is larger than or equal to 10 and smaller than or equal to 28, c is larger than or equal to 2 and smaller than or equal to 10, d is larger than 0, e is larger than 0, d+e is larger than or equal to 14 and smaller than or equal to 39, and a+b+c+d+e+5 is equal to 100. Compared with the prior art, the alloy material has the advantages of high amorphous forming ability, excellent soft magnetic property and mechanical property, the reduced glass transition temperature of the alloy material reaches 0.5-0.7, the coercive force of the alloy material reaches below 1.5A / m, the rupture strength of the alloy material is larger than 4200MPa, and the alloy material can be prepared into amorphous bars with the diameters of 1mm-7mm due to the high amorphous forming ability; therefore, the alloy material can be widely applied in the fields of transformers, magnetic sensors and the like, and has good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

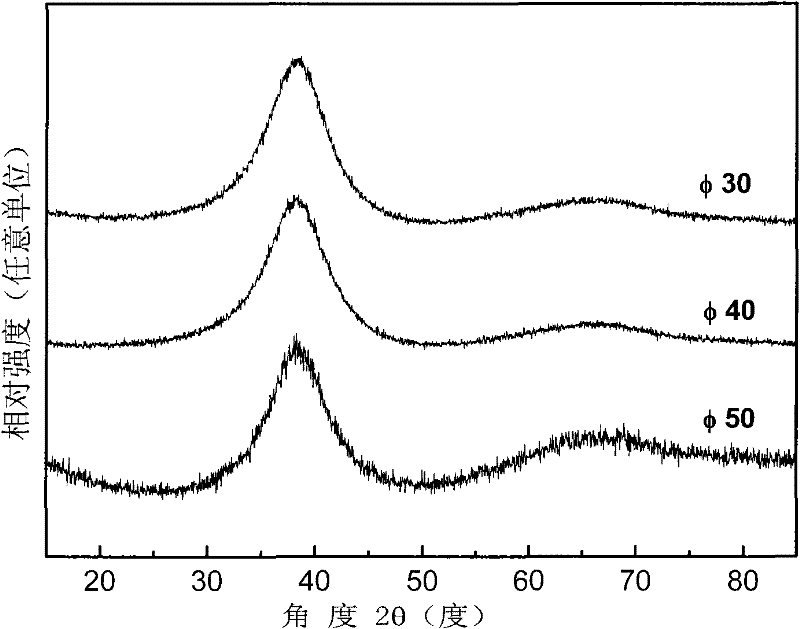

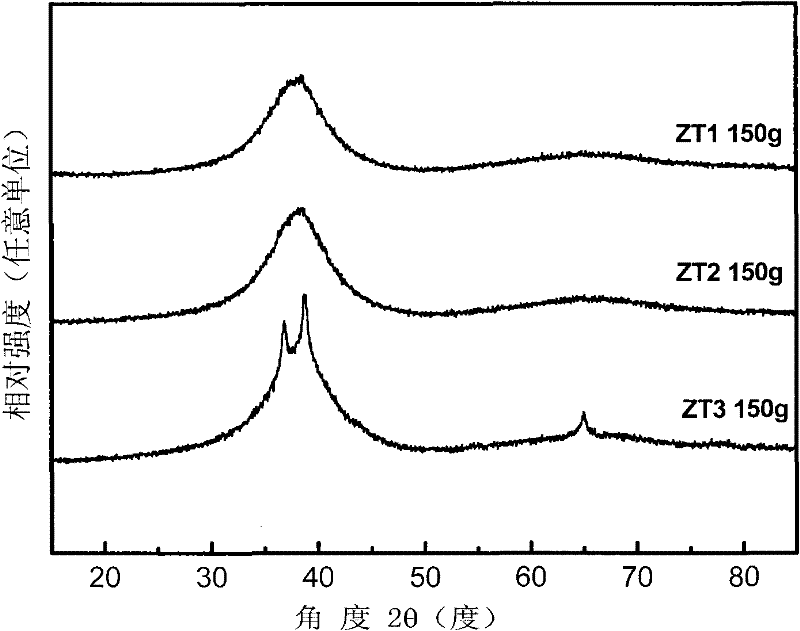

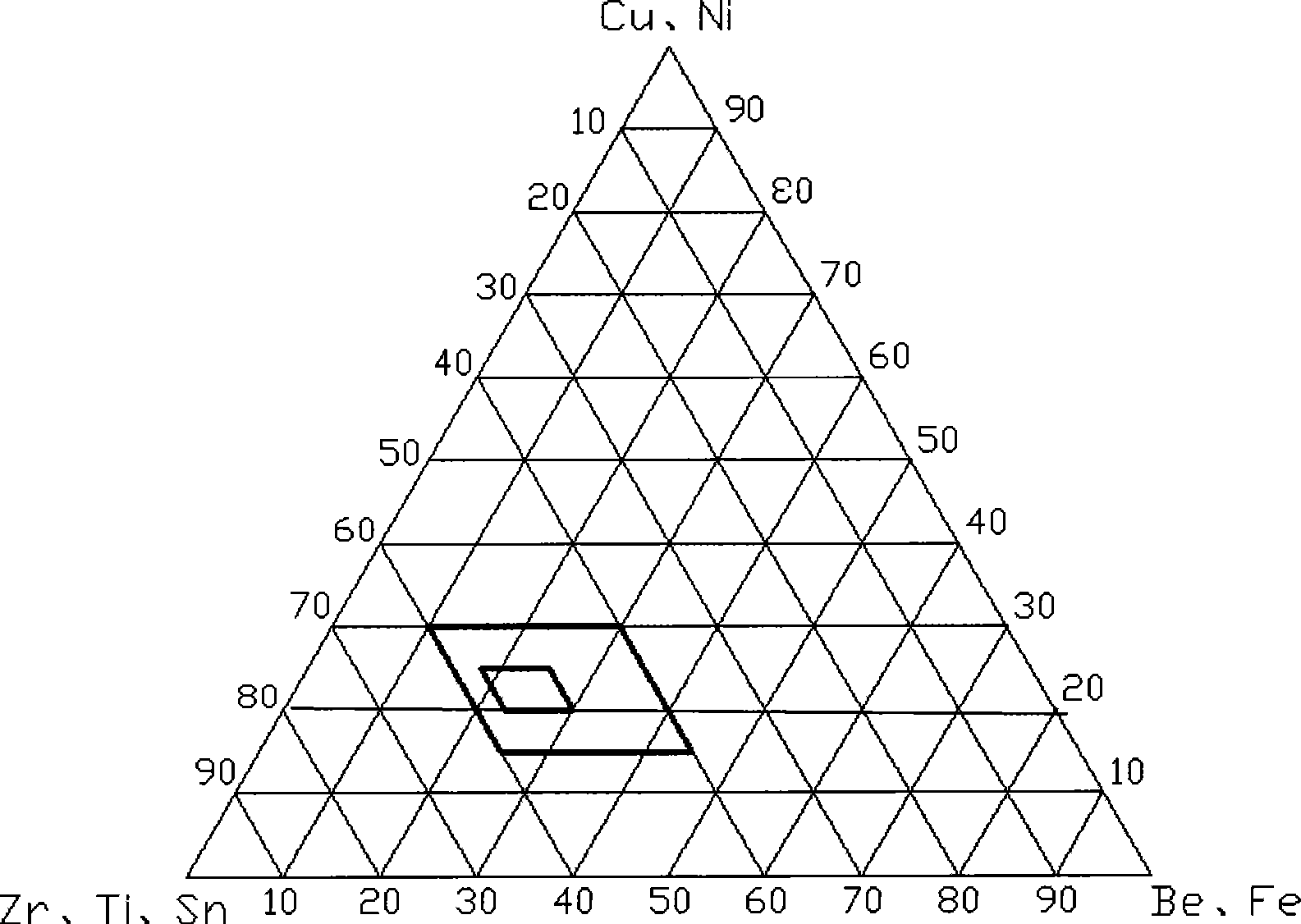

Ti-zr-cu-ni(fe)-be alloy with extremely high amorphous forming ability and preparation method

The invention relates to the field of Ti-based amorphous alloys, in particular to a Ti-Zr-Cu-Ni(Fe)-Be alloy with extremely high glass forming capacity and a preparation method. The alloy system is Ti-Zr-Cu-Ni(Fe)-Be alloy, of which the composition range varies according to the following principle (atomic percent): the proportion mode is [TiaZrb(NixFe1-x)cBed]100-yCuy, wherein a is equal to 31-40percent; b is equal to 23-38 percent, c is equal to 0-9 percent, d is equal to 20-35 percent, x is equal to 0-1 and y is equal to 0-20. In the invention, initial alloy which can be used for developing amorphous alloy with high glass forming capacity is discovered by systematically analyzing a Ti-Zr-Cu-Ni(Fe)-Be alloy solidification structure, and has a typical solidification structure characteristic, namely the initial alloy mainly consists of an amorphous structure and a primary crystalline state structure; and a plurality of types of titanium-based amorphous alloys with extremely high glassforming capacity are successfully obtained by further optimizing the amorphous phase composition in the alloy. The titanium-based amorphous alloy with maximum size of at least more than phi 50mm is obtained by using a water quenching technology. The alloy shows superior mechanical property and has great application prospect.

Owner:辽宁金研液态金属科技有限公司 +1

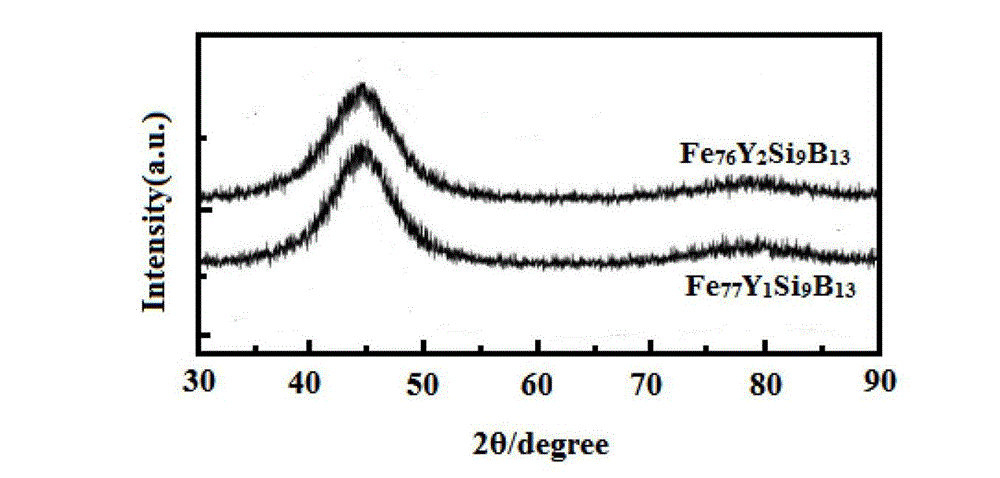

Ferrum-based amorphous soft magnetic material and preparation method thereof

InactiveCN103187136AEnhanced Amorphous Formation AbilityExcellent saturation magnetic inductionMagnetic materialsRare-earth elementDistribution transformer

The invention discloses a ferrum-based amorphous soft magnetic material. The ferrum-based amorphous soft magnetic material is FeaYbSicBd, wherein a, b, c and d are atomic percentage contents of corresponding components respectively; the sum of a, b, c and d is 100; and a is more than or equal to 72, but less than or equal to 78, b is more than or equal to 1, but less than or equal to 5, c is more than or equal to 8, but less than or equal to 10, and d is more than or equal to 11, but less than or equal to 14. The invention further discloses a preparation method of the ferrum-based amorphous soft magnetic material. Compared with amorphous alloy of the conventional Fe-Si-B ternary system, the ferrum-based amorphous soft magnetic material is prepared by adding a rare earth element Y on the basis of Fe-Si-B. The ferrum-based amorphous soft magnetic material has the advantages as follows: the amorphous alloy of the FeaYbSicBd system has a relatively high amorphous formation ability, excellent saturation magnetic induction intensity, low coercivity and high initial permeability, has the maximum supercooled liquid region width of 65K and the maximum saturation magnetic induction intensity of 1.67T, and is an ideal material for an iron core of a novel distribution transformer and other electronic and electrical components.

Owner:SHANGHAI JIAO TONG UNIV

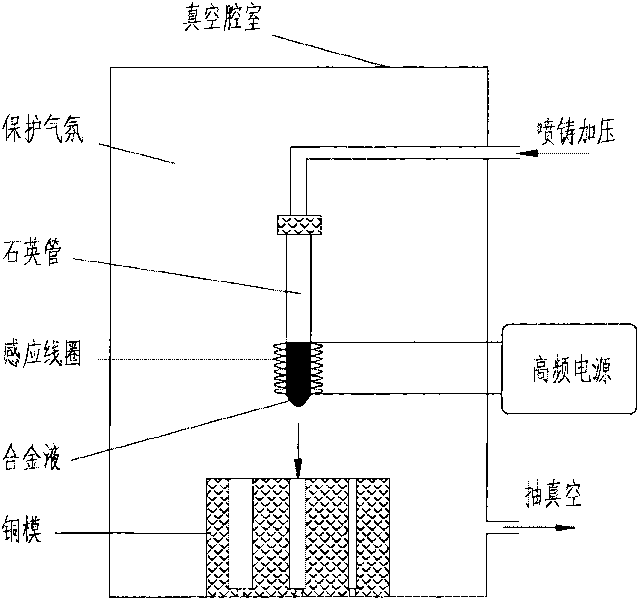

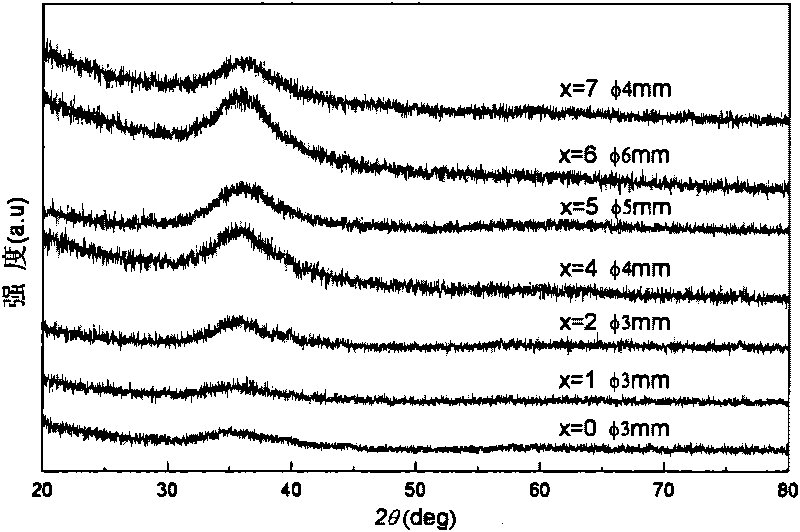

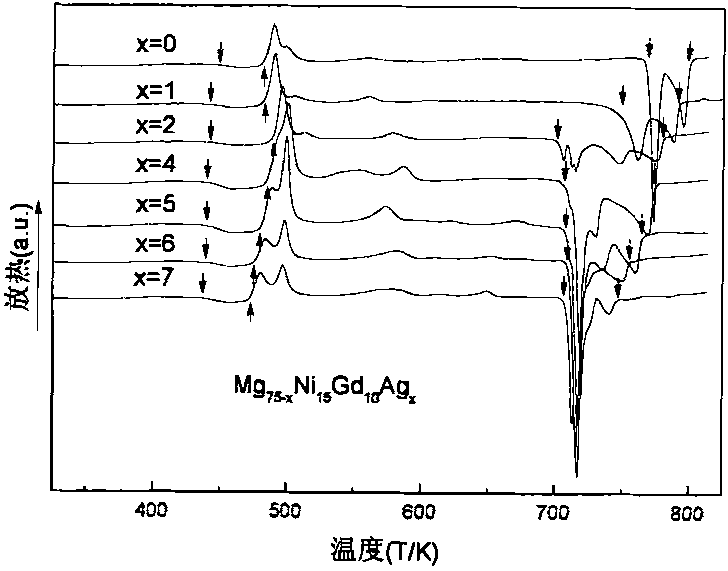

Mg-Ni-Gd-Ag serial block amorphous alloy and preparation method thereof

The invention relates to an Mg-Ni-Gd-Ag serial block amorphous alloy and a preparation method thereof, belonging to the technical field of alloy materials. The alloy uses Mg as a main element, and the formula of the alloy is Mg75-xNi15Gd10Agx(x is not more than 0 and not less than 7), wherein x is the atom percentage of the Ag element, and the purity of all elements is not lower than 99.9 percent. After being weighed according to the atom percentage, the elements of Ni, Gd and Ag are smelted and cooled in an argon atmosphere electric arc furnace; after being broken, the obtained three-element intermediate alloy ingot is smelted in an induction furnace with Mg with corresponding mass; and the product is resmelted and sprayed in a metal cavity to obtain the Mg-based block amorphous alloy Mg75-xNi15Gd10Agx. The Mg-based block amorphous alloy has the advantages of high amorphous formation ability, high Mg content, high strength, good corrosion resistance, and the like. The serial Mg-based block amorphous alloy has wide application prospect in the fields of novel light structure materials, and the like by excellent performance.

Owner:TSINGHUA UNIV

Powder core wire as well as preparation method and application thereof

ActiveCN104032251AEnhanced Amorphous Formation AbilityImprove corrosion resistanceMolten spray coatingVulcanizationSand blasting

The invention discloses a powder core wire as well as a preparation method and application thereof. The powder core wire is prepared by coating a powder core in a stainless steel strip; the powder core is prepared by mixing seven element powder in percentage by weight: 30-50% of Cr, 2-10% of B, 1-5% of Al, 1-5% of Si, 3-15% of Nb, 2-10% of Mo and the rest amount of Fe; the skin of the powder core wire selects the stainless steel strip; the weight ratio of the powder core to the stainless steel strip is (0.43-0.67): 1; when a coating layer is prepared by adopting an electric arc spraying technology, oil and rust on the surface of a matrix are removed firstly; and then, the pretreatment such as sand blasting is performed. The powder core wire can obtain the coating layer with low porosity, high hardness and excellent high-temperature oxidization and sulphuration corrosion resistance, and is suitable for such high-temperature structural members as a boiler pipe, a roller and an engine cylinder body.

Owner:HOHAI UNIV

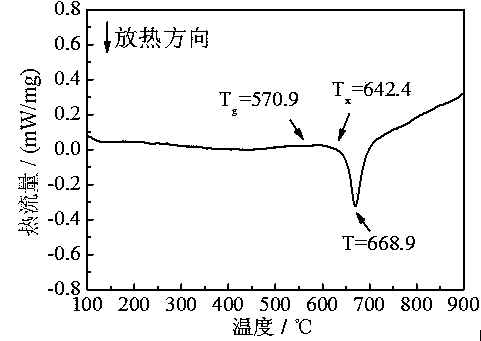

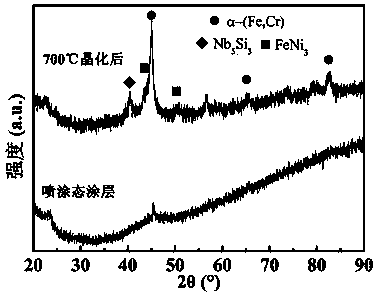

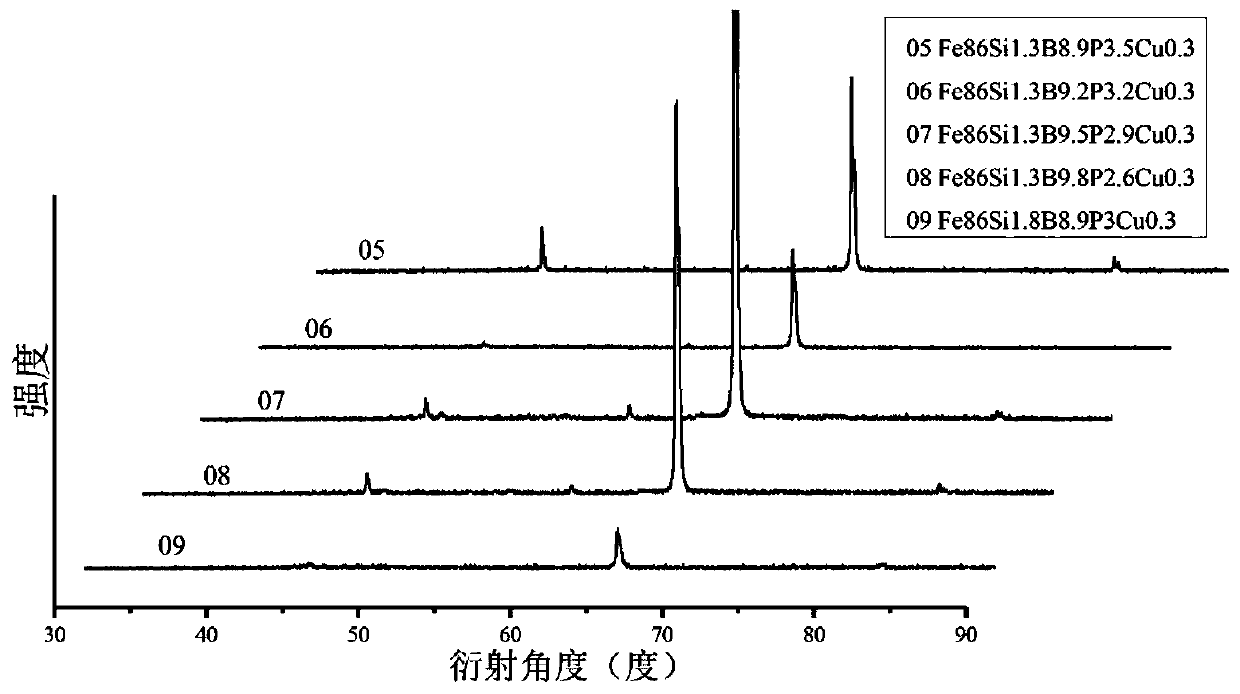

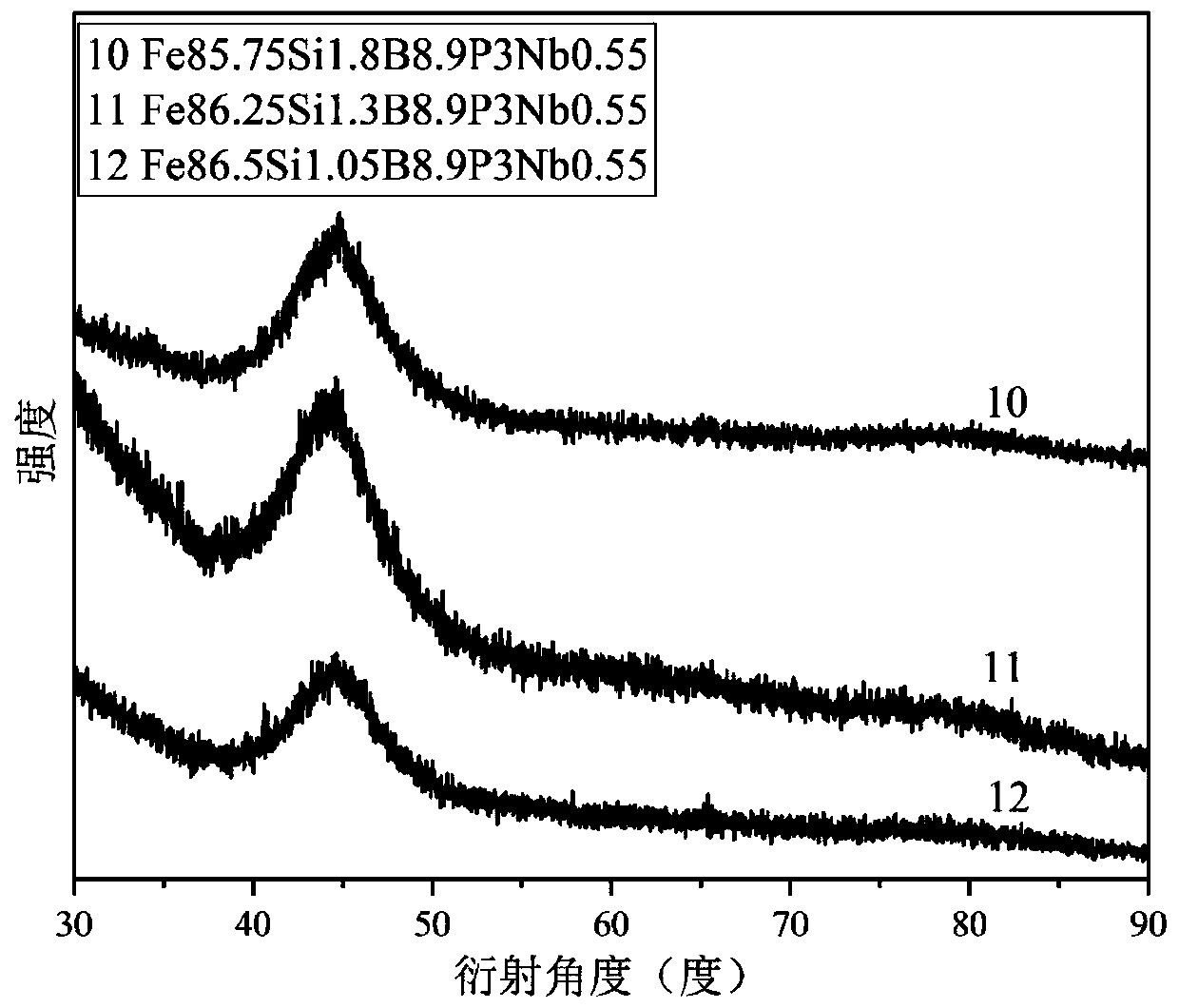

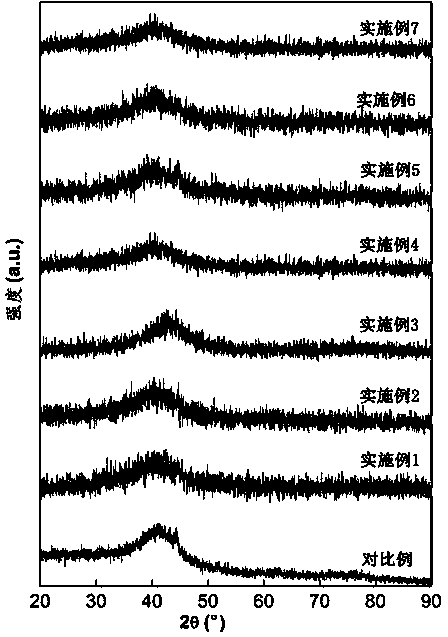

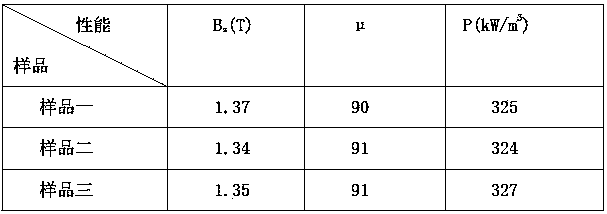

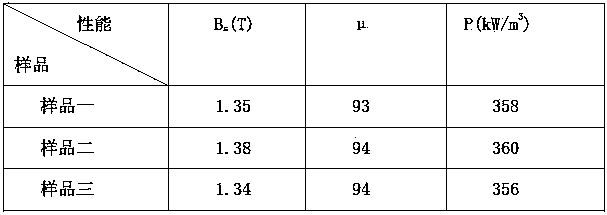

High-iron content Fe-Si-B-P-Cu-Nb amorphous and nanocrystalline soft magnetic alloy and preparation method

ActiveCN110306130AHigh saturation magnetizationEnhanced Amorphous Formation AbilityInductances/transformers/magnets manufactureMagnetic materialsNew energyMagnetization

The invention discloses a high-iron content Fe-Si-B-P-Cu-Nb series amorphous and nanocrystalline alloy and a preparation method. A chemical composition expression of the alloy is FeaSibBcPdCueNbf, where a, b, c, d, e and f correspondingly represent the atomic percentages of various corresponding components of Fe, Si, B, P, Cu and Nb, and the following conditions: 85.5<=a<=86.5, 1<=b<=2, 8<=c<=9.8,2.6<=d<=4, 0<=e<=1, 0<=f<=0.55, and a+b+c+d+e+f=100 are achieved. The alloy is low in cost, a quenched state nanocrystallization soft magnetic thin band and a quenched state amorphous soft magnetic thin band can be prepared through an existing single-roller rotating quenching technology; due to adding of a little amount of the Cu and Nb elements, the amorphous forming capacity, the toughness andthe saturation magnetization strength of the alloy are improved, and the grain size of nanocrystalline is refined. The saturation magnetization strength of the quenched state nanocrystalline thin bandin the alloy reaches 1.82 T. After crystallization annealing of the amorphous thin band, the saturation magnetization strength of the nanocrystalline thin band reaches 1.84 T. The prepared amorphousand nanocrystalline alloy serves as a motor, a mutual inductor and other devices to be applicable to the fields of electric power industry transformer iron cores, inverter welding machines, new energy, wireless charging, digital, automation and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

Nanometer TiF3 catalyzed high-volume hydrogen-storing alloy and preparation method thereof

InactiveCN103667837AReduced thermal stabilityImprove hydrogen desorption capacityCell electrodesRare-earth elementYttrium

The invention discloses nanometer TiF3 catalyzed high-volume hydrogen-storing alloy and a preparation method thereof. The compositions of the alloy are shown as the following: La2-xRExMg17-yNiy+100 wt% Co+z wt% TiF3, wherein 0.2<x<0.5, 1<y<3, 3<z<10, RE is at least one of rare earth elements neodymium, yttrium and samarium. The preparation method comprises: in the protection of inert gas, employing induction heating for melting, injecting fused alloy into a copper mold to obtain cylinder ingots; filling a quartz tube with the ingots, performing induction heating fusion, continuously spraying liquid alloy on the surface of a rotating water-cooling copper roller by a slit nozzle at the bottom of the quartz tube to obtain rapid-quenched alloy; and mixing fragmented alloy powder and cobalt powder, performing ball milling, adding trace TiF3 catalyst and continuing to perform ball milling to obtain the alloy powder. Through composition design and structure adjusting, the thermal stability of alloy hydride is reduced and the hydrogen adsorption / desorption capacity and the dynamic performances of the alloy are improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

High-temperature amorphous solder for soldering Si3N4 ceramics

InactiveCN101823188AGood flexibilityImprove wettabilityWelding/cutting media/materialsSoldering mediaRoom temperatureFlexural strength

The invention discloses high-temperature amorphous solder for soldering Si3N4 ceramics, belonging to the technical field of soldering materials. The high-temperature amorphous solder of the invention for soldering the Si3N4 ceramics comprises the following components by weight percent: 35.0% to 45.0% of Ti, 20% to 30% of Zr, 0.1% to 0.3% of B and Cu in balancing amount, wherein the melting temperature of the solder ranges from 1,100K to 1,200K, and the soldering temperature thereof is 1,223K to 1,373K. The Si3N4 ceramics is prepared by vacuum-soldering the Ti-Zr-Cu-B high-temperature active amorphous solder on the basis of the rapid solidification technology, and the maximal room-temperature strength of the Si3N4 ceramics reaches 245MPa; and the high-temperature performance thereof is much higher than that of the Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder, particularly, the high-temperature bending strength of the ceramic connector is 165.5MPa at the testing temperature of 673K.

Owner:JIANGSU UNIV OF SCI & TECH

High saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and manufacturing method thereof

InactiveCN104036904AHigh saturation magnetic inductionImprove self-fluxingMagnetic materialsCompression moldingElectron

The invention discloses a high saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and a manufacturing method of the composite material. The atomic ratio expression of the alloy composition forming the amorphous soft magnetic composite material is Fe100-a-b-c-dREaMbPcSd, wherein 0<a<=8, 10<=b<=25, 0<c<=10, 0<d<=0.5, RE is one or a mixture selected from Y, La, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu, and M is one or a mixture selected from C, Si and B. The manufacturing method of the iron-based amorphous soft magnetic composite material includes the technical steps of alloy smelting, atomizing and pulverizing, insulating cladding, compression molding and heat treating. The iron-based amorphous soft magnetic composite material prepared through the method is high in saturation magnetic induction intensity and can be applied to electronic devices high in power and frequency.

Owner:ZHEJIANG UNIV

Boracic Cu-P-based amorphous brazing filler metal and method for preparing same

InactiveCN101530952AAvoid difficultiesLower melting temperatureWelding/cutting media/materialsSoldering mediaWettingFiller metal

The invention discloses a boracic Cu-P-based amorphous brazing filler metal and a method for preparing the same, which belong to the technical field of the brazing of amorphous brazing filler metal and copper as well as copper alloy. The amorphous brazing filler metal comprises the following components in percentage by weight: 7.2 percent of P, 14.0 percent of Ni, 5.4 percent of Sn, 0.02 to 0.04 percent of B, 0.2 percent of Si, and the balance of Cu. The amorphous brazing filler metal is prepared by adopting a rapid solidification technique, and the prepared brazing filler metal has a bright and clean surface, two smooth sides and better toughness. The melting temperature of the amorphous brazing filler metal is between 602 and 663 DEG C and the brazing temperature is between 670 and 720 DEG C. The amorphous brazing filler metal is applicable to the brazing of the copper and the copper alloy, and applicable brazing process methods comprise flame brazing, furnace brazing, gas shield brazing, salt bath brazing, and the like. By adopting the amorphous brazing filler metal to perform flame brazing of red copper, the wetting property of the brazing filler metal is obviously better than the brazing filler metal with same components prepared by a conventional melting technique, and the shear strength of a brazed joint is more than 112 MPa.

Owner:JIANGSU UNIV OF SCI & TECH

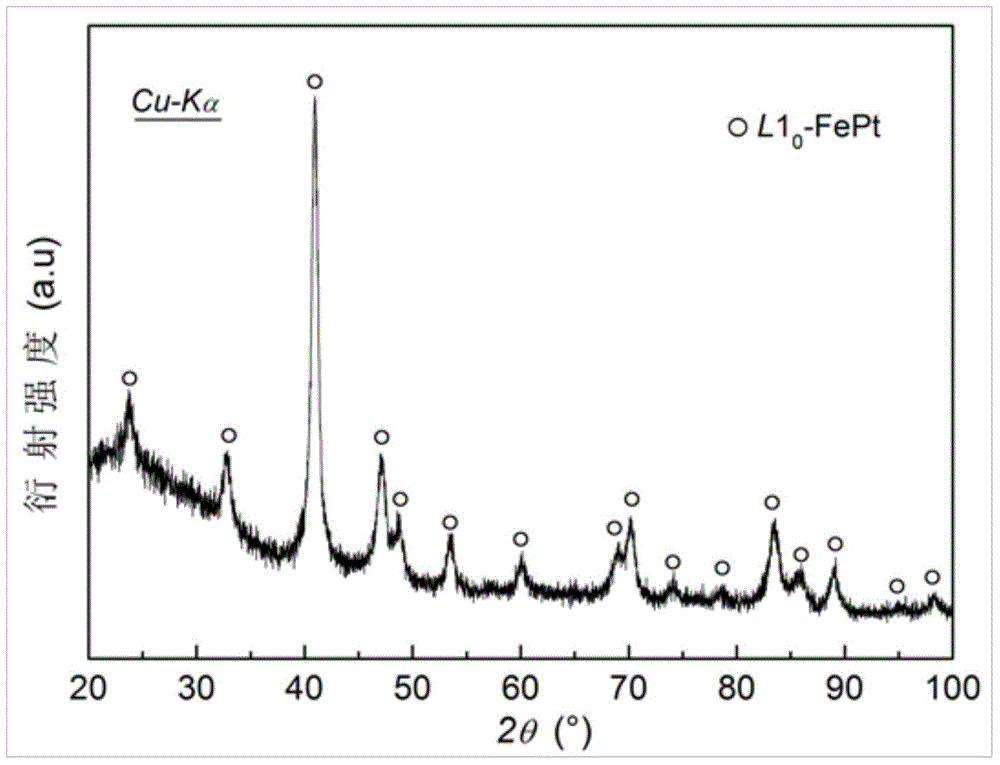

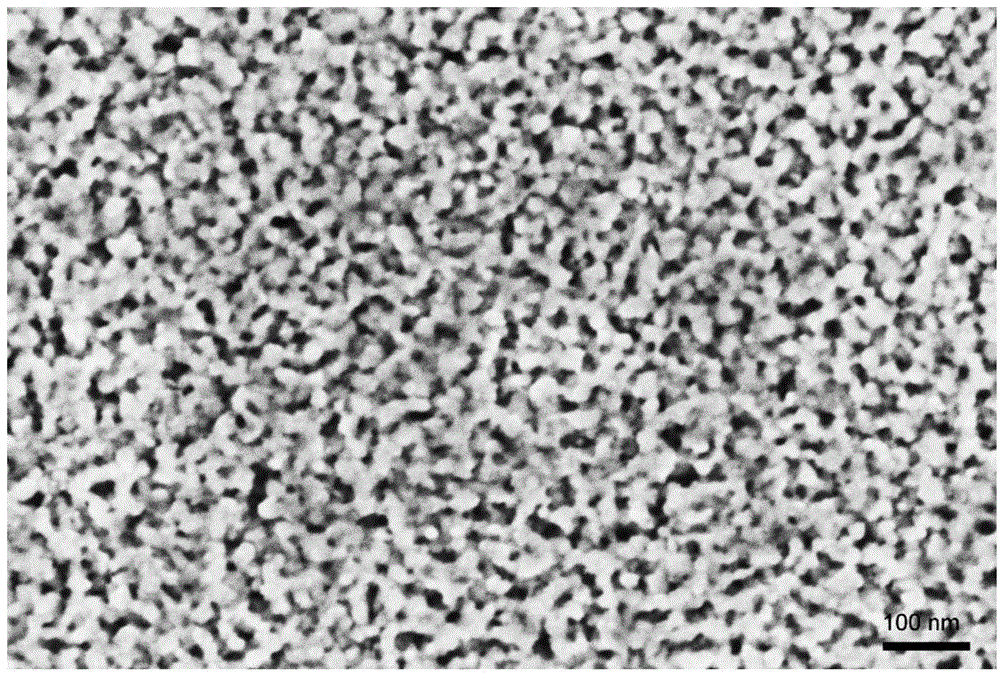

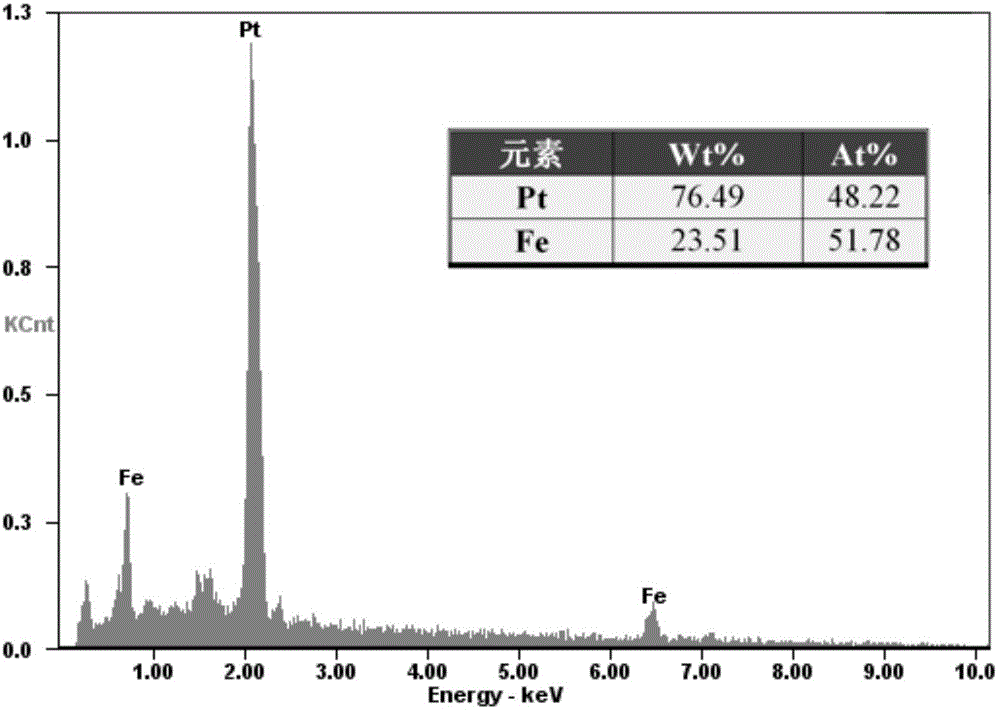

Strong-permanent-magnetic nano-porous Fe-Pt alloy and preparation method thereof

ActiveCN104946921AComplete structureUniform pore sizeMaterial nanotechnologyThin magnetic filmsMagnetic phaseIngot

The invention discloses a strong-permanent-magnetic nano-porous Fe-Pt alloy and a preparation method thereof. The strong-permanent-magnetic nano-porous Fe-Pt alloy has the composition of FewCoxPtyPdz, is composed of an L10-FePt ordered hard magnetic phase, and has a complete doubly-connected nano-porous structure, a pore diameter of 10-50nm and a ligament thickness of 20-80nm; the coercivity, the magnetization intensity and the residual magnetism of the alloy under a 50kOe external magnetic field are 13.4-18.5kOe, 40.4-56.3 and 28.3-37.4emu / g respectively. A master alloy ingot is prepared by electric arc melting or induction melting during preparation; an alloy strip is prepared by single-roll spinning; a nano-complex-phase precursor containing hard-magnetic L10-FePt and soft-magnetic Fe2B is obtained directly or through an annealing treatment; the nano-porous Fe-Pt alloy with a single L10-FePt phase structure is obtained through an electrochemical dealloying process, thus filling up the technical gaps of a permanent-magnetic metal nano-porous material.

Owner:DALIAN UNIV OF TECH

Zirconium based amorphous alloy and manufacture method thereof

Owner:BYD CO LTD

Refractory high-entropy amorphous alloy material, and preparation method and application thereof

The invention discloses a refractory high-entropy amorphous alloy material which comprises more than three refractory metal elements including Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W and Re and one or two non-refractory metal elements including Al, Si, Co, B and Ni, and the refractory high-entropy amorphous alloy material is an amorphous structure. The refractory high-entropy amorphous alloy material has relatively high corrosion resistance and mechanical properties. The invention further discloses a preparation method of the refractory high-entropy amorphous alloy material. The preparation method comprises the following steps: burdening according to the atomic fraction of each element of the refractory high-entropy amorphous alloy material, and uniformly smelting to prepare a master alloy ingot; and melting the mother alloy ingot and then spraying to the surface of a rotating copper roller, and preparing the refractory high-entropy amorphous alloy strip. The method is simple and efficient, and can be applied to large-scale industrial production. The invention further discloses application of the refractory high-entropy amorphous alloy material to pipeline transportation in nuclear reactors, nuclear power and corrosive environments.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Zirconium base amorphous alloy

The invention relates to a zirconium base amorphous alloy, wherein the composition of the zirconium base amorphous alloy is (Zr, Hf, Nb)CuTiAlRe, a, b, c, d and e are the percentage contents of the corresponding atoms in the zirconium base amorphous alloy, a is more than or equal to 40 and is less than or equal to 65, b is more than or equal to 20 and is less than or equal to 50, c is more than or equal to 0.1 and is less than or equal to 10, d is more than or equal to 5 and is less than or equal to 15, e is more than or equal to 0.05 and is less than or equal to 5, (a+b+c+d+e) is less than or equal to 100, Re is a combination comprising one or a plurality of materials selected from elements such as La , Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu, or is a combination comprising Y and one or a plurality of materials selected from elements such as La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu.

Owner:HUAWEI TECH CO LTD

Low-angle-difference nanocrystalline magnetically soft alloy magnetic core for intelligent electric meter and preparation method thereof

ActiveCN105861959AExcellent soft magnetic propertiesImprove thermal stabilityTransformers/inductances magnetic coresMagnetic materialsAlloyInductor

The invention belongs to the field of magnetically soft alloy and particularly discloses a low-angle-difference nanocrystalline magnetically soft alloy magnetic core for an intelligent electric meter and a preparation method thereof. The molecular formula of the magnetic core is shown as follows: Fe100-a-b-c-d-eSiaBbMcCudNbeM'f, wherein a, b, c, d, e and f are atomic percents, 8<=a<=14, 2<=b<=10, 0.8<=c<=3, 1<=d<=4, 0.5<=e<=2, 0.02<=f<=0.5, the balance is Fe and unavoidable impurities, M is Al or Zn, and M' is one or more of Y, Gd, V, Mo, Mn, Ge, Er, Ga and Sn. The magnetic core which is prepared through a resultant magnetic field annealing treatment method and is excellent in soft magnetic property is further provided, and the requirement for high-precision measurement with a low-angle-difference mutual inductor for the intelligent electric meter is met.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

Iron-based amorphous/nanocrystalline thin band with low cost and excellent soft magnetic properties and preparation method thereof

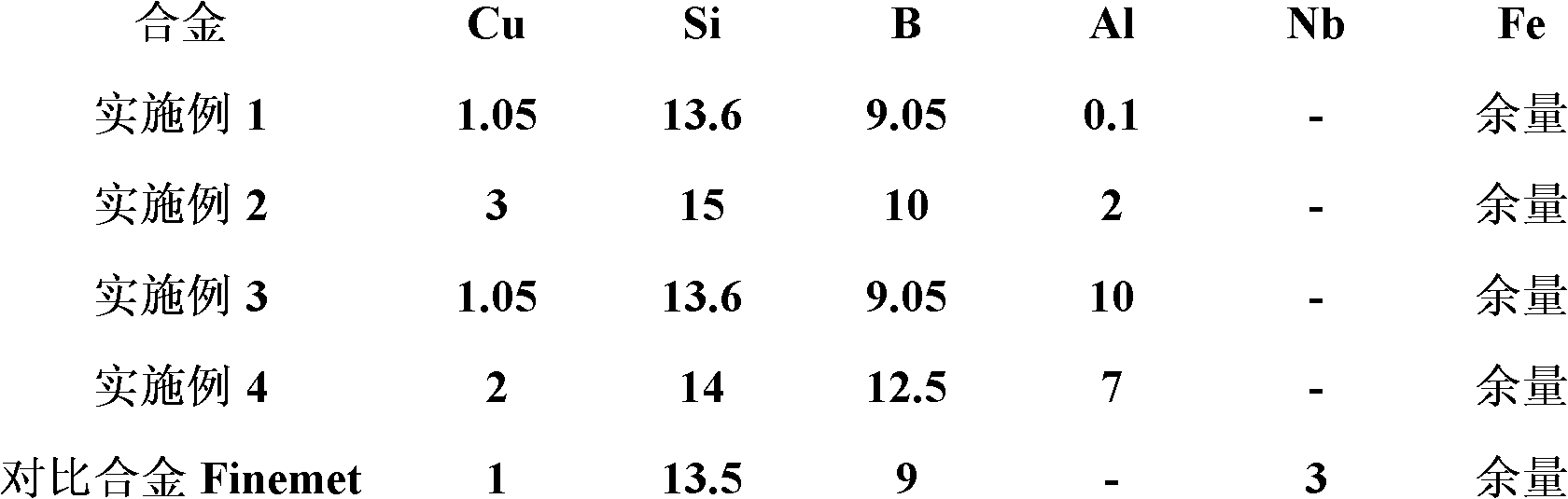

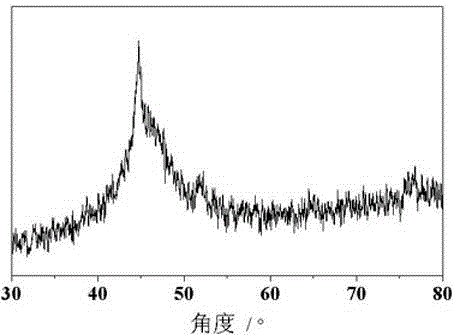

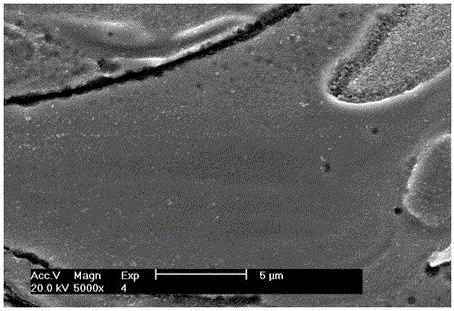

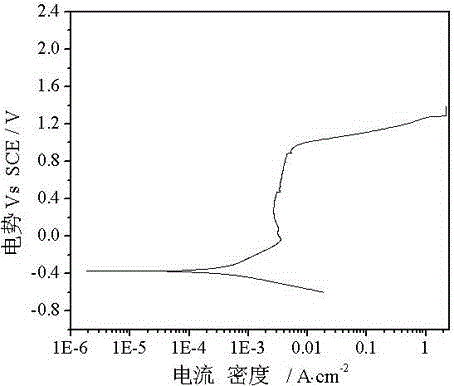

The invention discloses an iron-based amorphous / nanocrystalline thin band with low cost and excellent soft magnetic properties and a preparation method thereof and belongs to the field of soft magnetic alloy in functional materials. The material comprises the following components in percentage by atom: 1.05 to 3 percent of cu, 13.6 to 15 percent of Si, 9.05 to 12.5 percent of B, 0.1 to 10 percent of Al and the balance of Fe. The preparation method comprises the following steps of: mixing materials according to the alloy formula; melting by using a vacuum medium frequency induction melting furnace for multiple times to prepare master alloy; preparing the amorphous thin band in a single-roller quenching device by controlling the speed of a rotary roller; and annealing properly to obtain the final product. The product has excellent soft magnetic properties such as high saturated magnetization intensity, low coercive force and the like. Compared with the traditional iron-based nanocrystalline soft magnetic alloy Finemet, the cheap Al is used for replacing expensive Nb, thus the production cost of the iron-based amorphous / nanocrystalline thin band is greatly lowered. At the same time, the thin band is high in surface finishment, high in toughness, simple in production process and wide in application range.

Owner:CENT SOUTH UNIV

Thermal spraying nickel-based self-fused alloy amorphous coating

InactiveCN104561877AImprove corrosion resistanceEnhanced Amorphous Formation AbilityMolten spray coatingCorrosion resistantTi element

The invention discloses a thermal spraying nickel-based self-fused alloy amorphous coating which is prepared by preparing a nickel-based self-fused alloy into spray powder and spraying on the surface of a workpiece in a thermal spraying manner. The thermal spraying nickel-based self-fused alloy amorphous coating comprises the following elements in percentage by weight: 15-20% of Cr, 3.0-5.0% of B, 3.0-5.0% of Si, 0.5-1.1% of C, 3-5% of Fe and the balance of Ni, totaling 100%. The thermal spraying nickel-based self-fused alloy amorphous coating is good in wearing resistance and corrosion resistance, convenient to prepare, low in production cost and relatively good in application prospect.

Owner:FUZHOU UNIV

Iron-based amorphous alloy and preparation method thereof

ActiveCN101538693AEnhanced Amorphous Formation AbilityReduce production conditionsRare-earth elementVitrification

The invention provides an iron-based amorphous alloy, which comprises components as the following formula: (FexCo1-x)aETMbCcBdREe, wherein a, b, c, d and e are atomic percent; a is more than or equal to 40 and less than or equal to 60, b is more than 0 and less than or equal to 30, c is more than 0 and less than or equal to 20, d is more than 0 and less than or equal to 10, e is more than 0 and less than or equal to 10, and the sum of the a, the b, the c, the d and the e is equal to 100; x is atomic percent, and x is more than or equal to 0.5 and less than 1; ETM is one or more IVB elements, VB elements and VIB elements; and RE is one or more rare-earth elements. The invention also provides a method for preparing the iron-based amorphous alloy. Compared with the prior iron-based amorphous alloy, the iron-based amorphous alloy forming capability is high, and other properties of the amorphous alloy such as melting point, vitrification temperature, hardness and compressive fracture strength are still high.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com