Strong-permanent-magnetic nano-porous Fe-Pt alloy and preparation method thereof

A magnetic nano and nanoporous technology, applied in the direction of magnetic objects, magnetic materials, magnetic films, etc., to achieve the effect of improving the ability of amorphous formation, uniform pore size and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

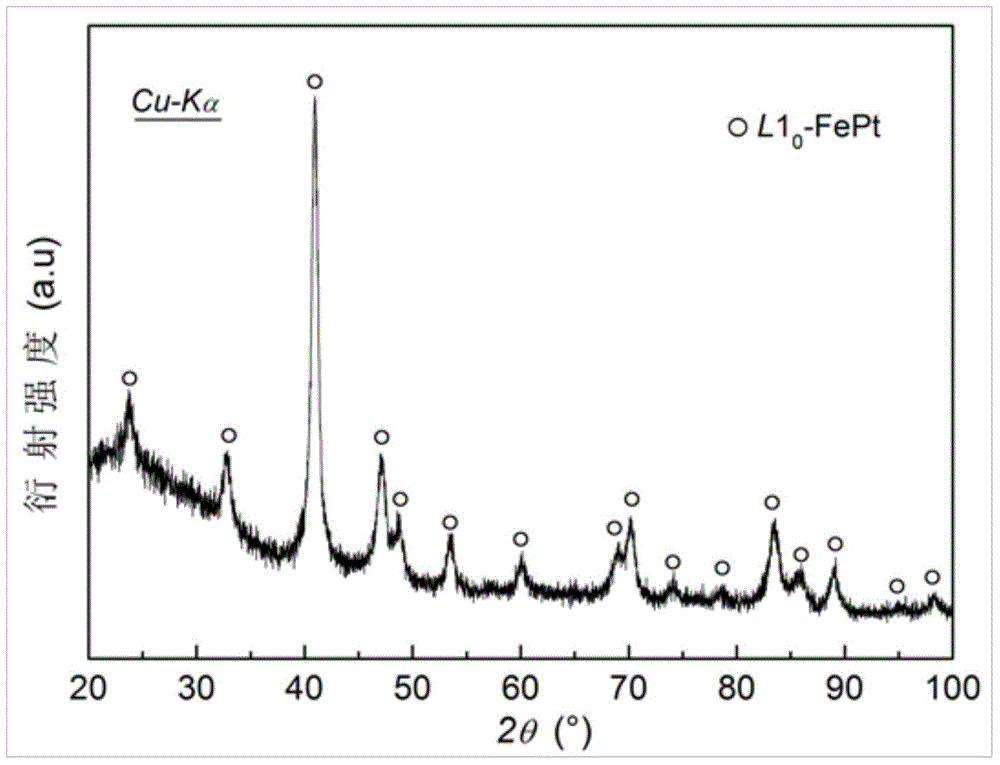

[0032] Embodiment 1: Precursor alloy composition Fe 60 Pt 10 B 30

[0033] Step 1. Ingredients

[0034] Fe, Pt and B raw materials with purity greater than 99wt% are used according to Fe 60 Pt 10 B 30 Nominal ingredients are weighed for batching.

[0035] Step 2: Master alloy ingot melting and quench strip sample preparation

[0036] The weighed metal raw materials were mixed into a water-cooled copper crucible in a non-consumable arc melting furnace, and smelted repeatedly in an Ar gas atmosphere for 4 times to obtain an alloy ingot with uniform composition. The master alloy ingot is crushed and put into a quartz tube with a nozzle diameter of about 0.5mm. The master alloy is heated to a molten state by induction melting in an Ar atmosphere, and then the alloy liquid is sprayed onto the high-speed rotating copper roller by using the pressure difference. , and throw the strip at a speed of about 25-50m / s to obtain a continuous alloy strip with a width of about 2mm and ...

Embodiment 2

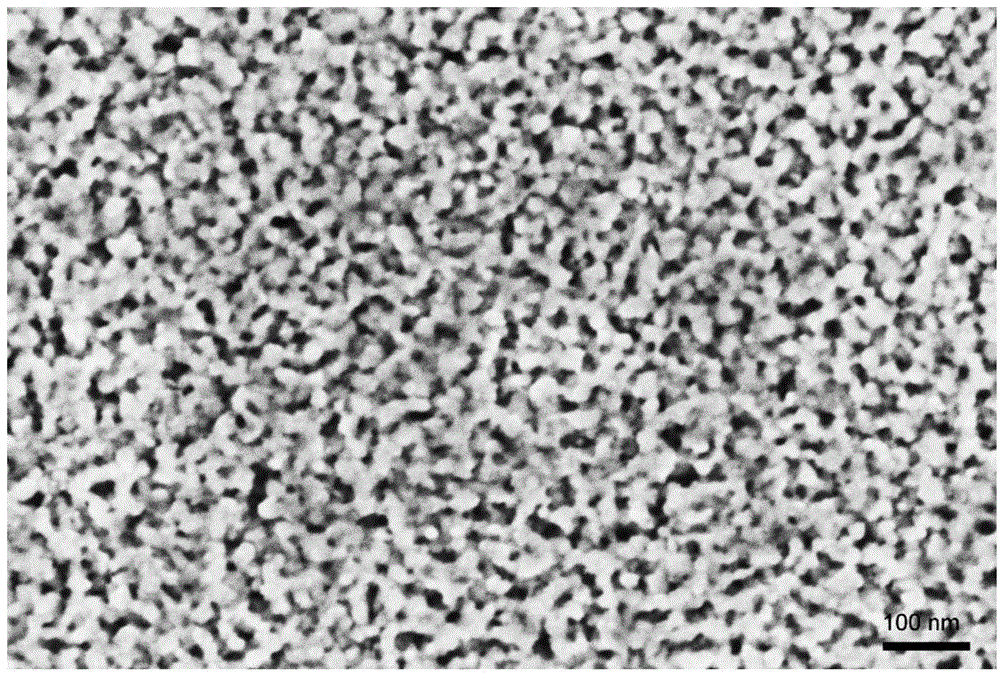

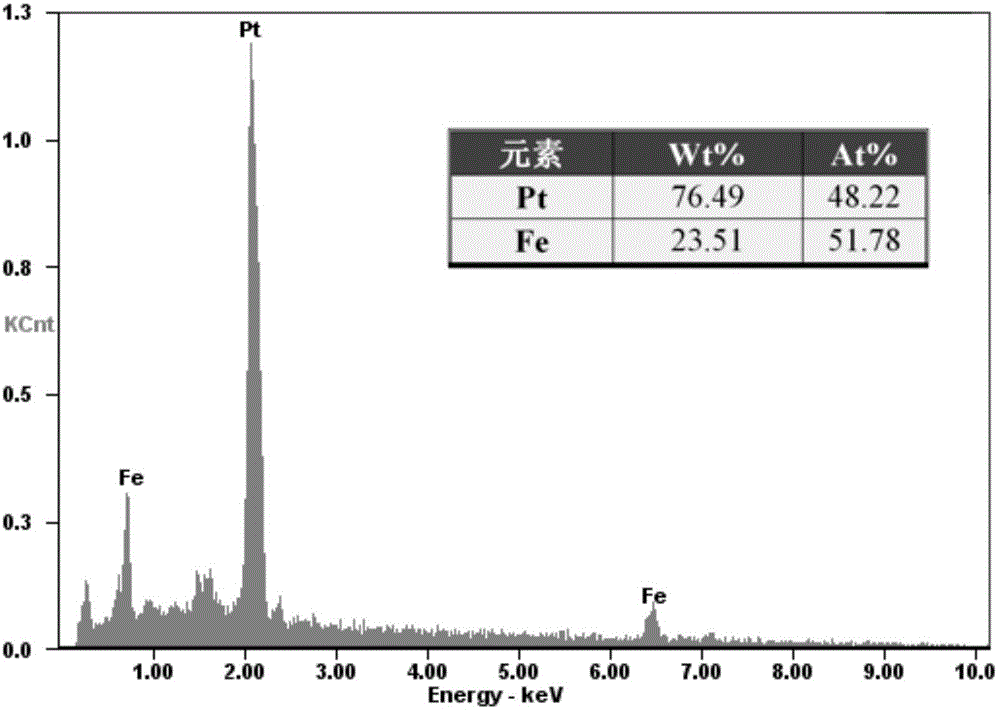

[0045] Example 2: Precursor alloy composition Fe 52 Pt 29 B 19

[0046] The steps of batching, master alloy ingot smelting, quenching strip sample preparation and sample structure detection are the same as Steps 1-3 in Example 1. The results of XRD and HRTEM show that the alloy strips prepared at the speed of 20-37m / s have L1 0 -FePt and Fe 2 The B nanocomposite structure can be dealloyed as a precursor alloy without heat treatment. The steps of electrochemical performance test, dealloying and nanoporous alloy structure, morphology characterization and magnetic property test are the same as Steps 5 and 6 in Example 1. The chemical composition of the finally obtained nanoporous FePt alloy is Fe 50.1 Pt 49.9 , i h c , M 50 and M r They are: 16.2kOe, 51.9emu / g and 36.2emu / g.

[0047] The advantage of this embodiment is that the heat treatment process of the alloy strip can be optionally omitted, the alloy strip can be directly dealloyed, and the process for preparing ...

Embodiment 3

[0048] Embodiment 3: Precursor alloy composition Fe 50 Pt 20 B 30

[0049] The implementation steps are the same as in Example 2, and the alloy strip prepared under the strip speed of 25~35m / s has L1 0 -FePt, Fe 2 B and FeB nanocomposite structure without annealing process. The chemical composition of the finally obtained nanoporous FePt alloy is Fe 47.7 Pt 52.3 , i h c , M 50 and M r They are: 16.6kOe, 47.8emu / g and 32.8emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com