Patents

Literature

196results about How to "Uniform and controllable thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

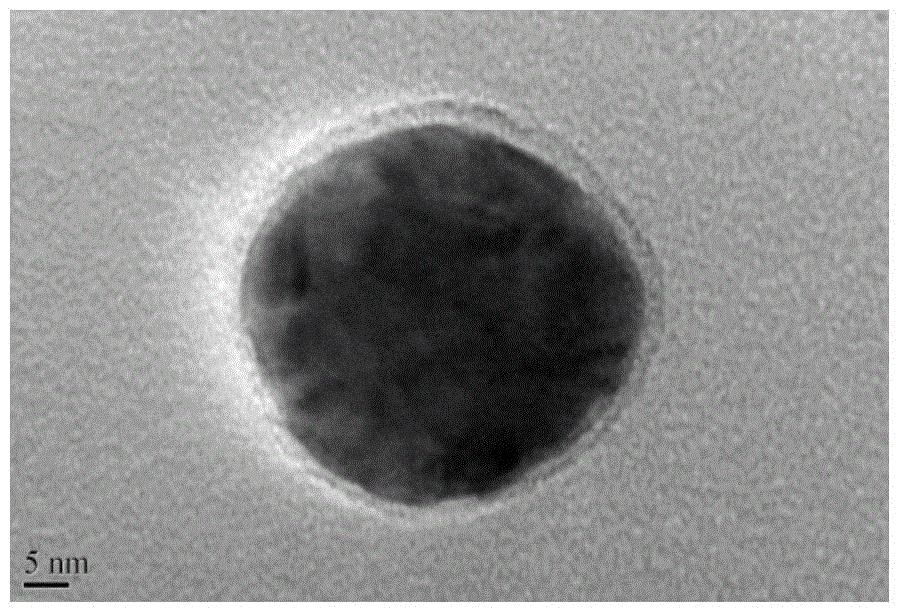

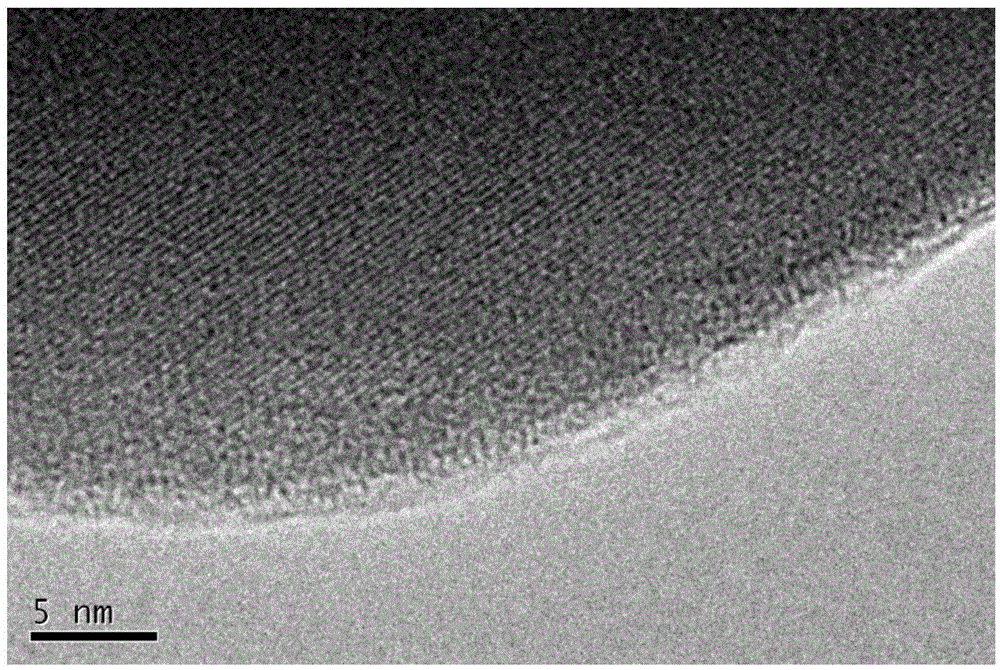

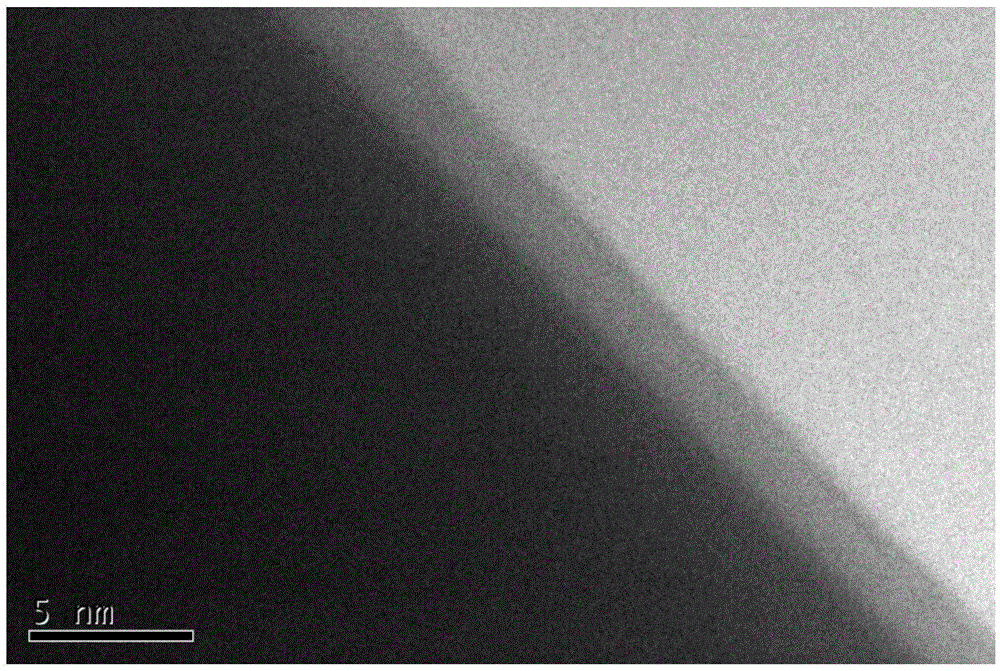

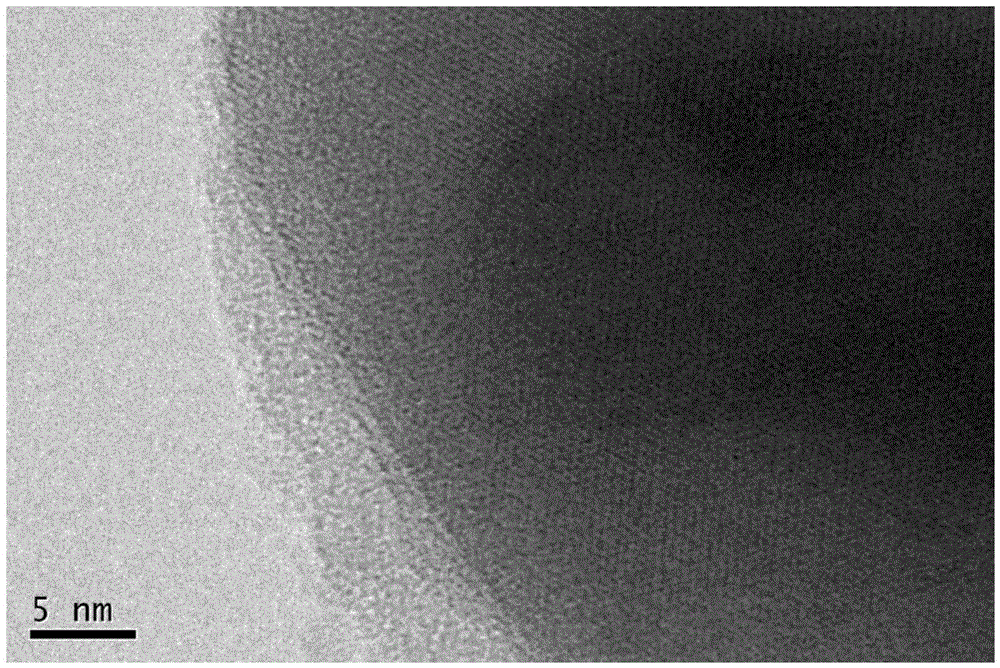

Metal-coated oxide nano core-shell structure catalyst and preparation method thereof

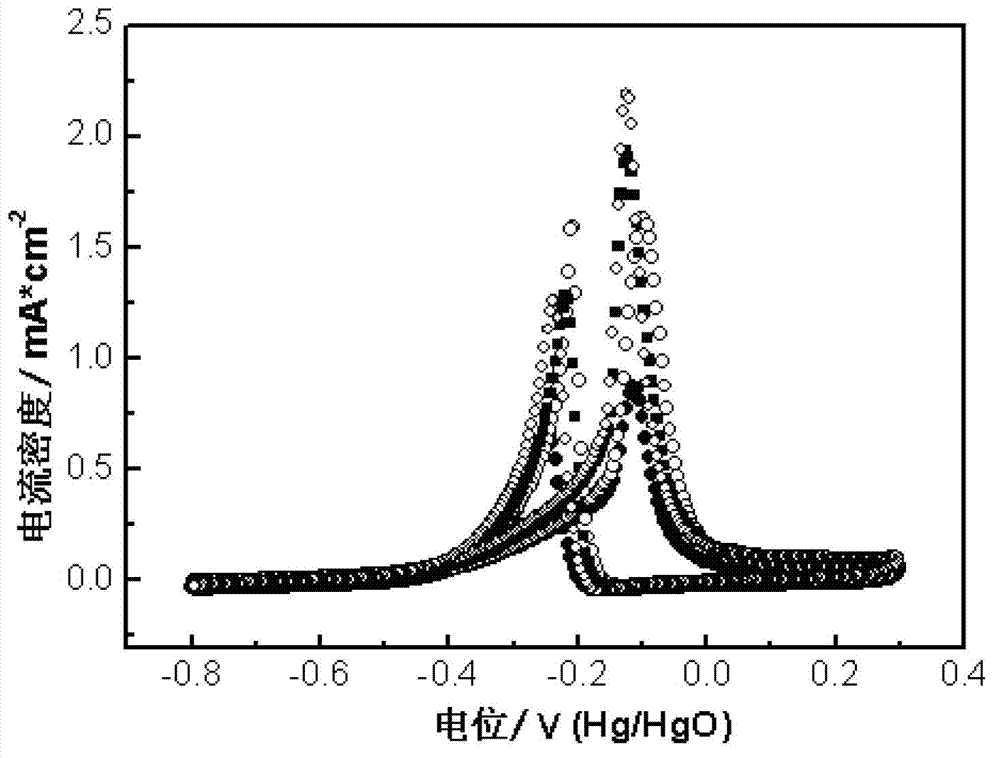

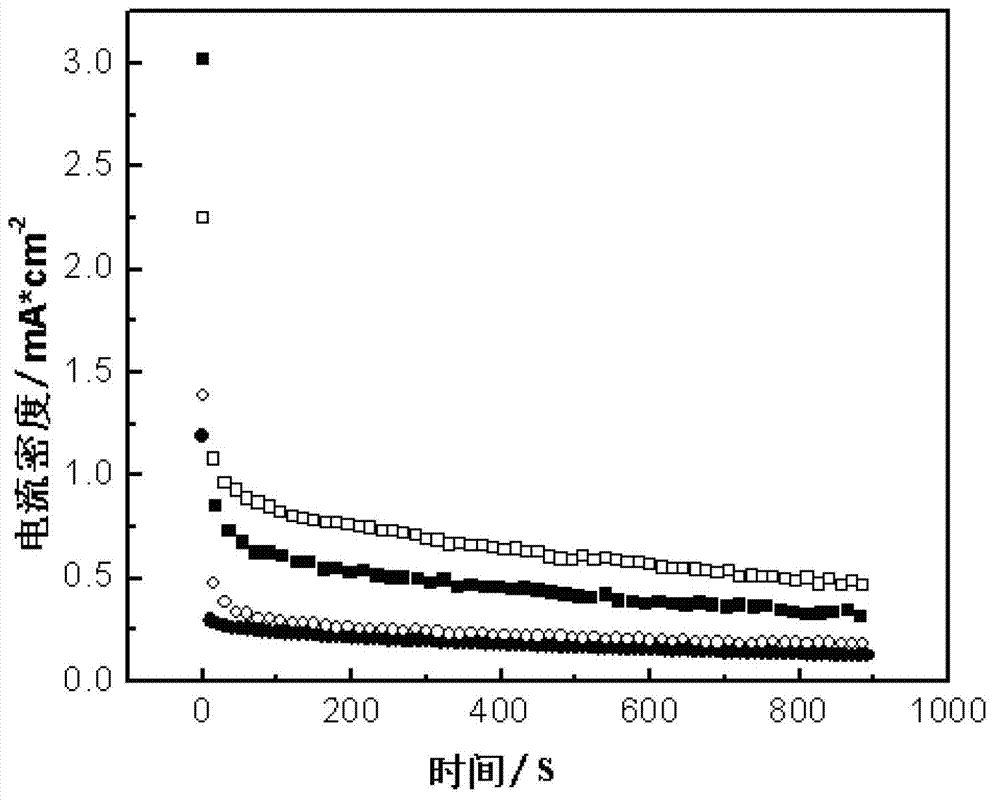

ActiveCN102969514AGood dispersionEasy to controlCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFuel cellsCore shell

The invention relates to a metal-coated oxide nano core-shell structure catalyst and a preparation method thereof, and in particular relates to a nano fuel cell catalyst with a core-shell structure, and a preparation method of the nano fuel cell catalyst. The invention aims at solving the problems that the conventional fuel cell catalyst is not high in catalytic activity and stability as well as low in cost at the same time. According to the metal-coated oxide nano core-shell structure catalyst, metal uniformly covers a shell, and oxide nano-particles are used as an inner core. The preparation method comprises the steps of: 1, preparing uniform, transparent and stable mixed solution; 2, blending and mixing; 3, adding reducing agent into the mixture; 4, adding extraction agent into the mixture; and 5, carrying out centrifugal washing and drying to obtain the metal-coated oxide nano core-shell structure catalyst. The invention is mainly used for preparing the metal-coated oxide nano core-shell structure fuel cell catalyst.

Owner:HARBIN INST OF TECH

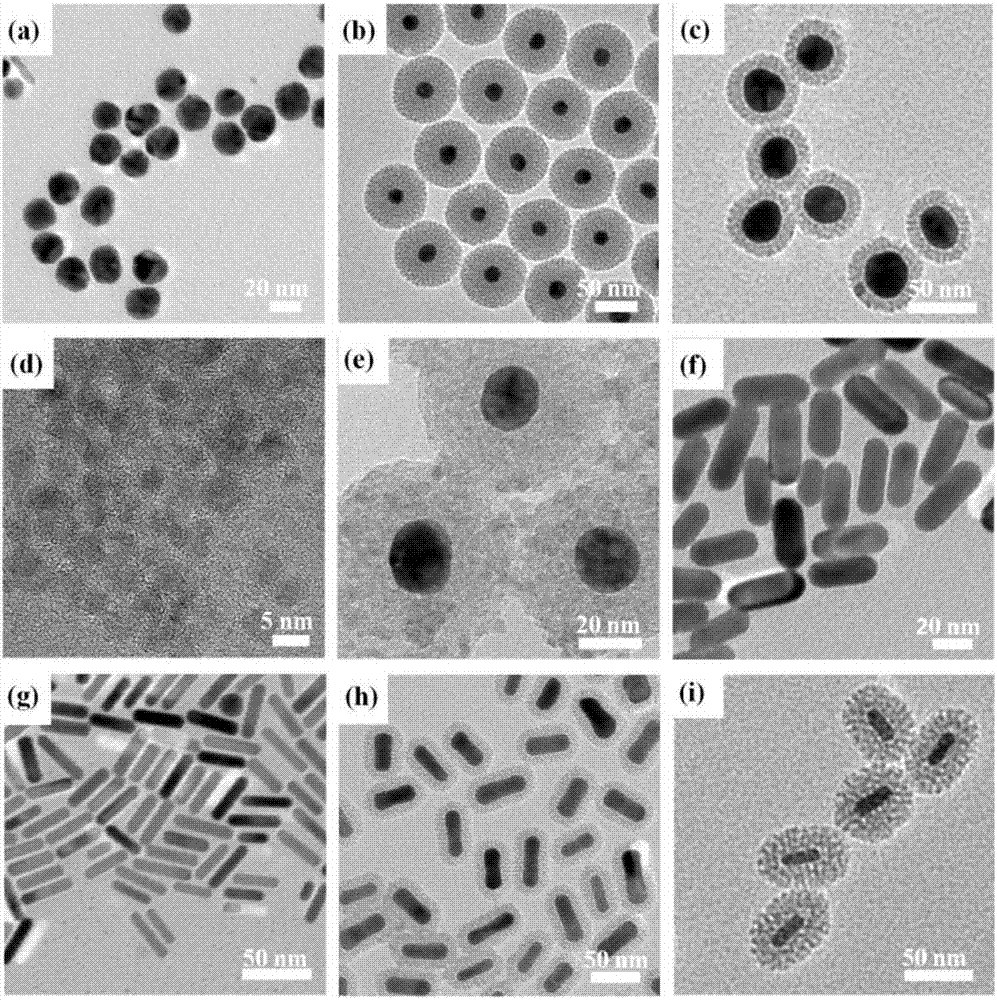

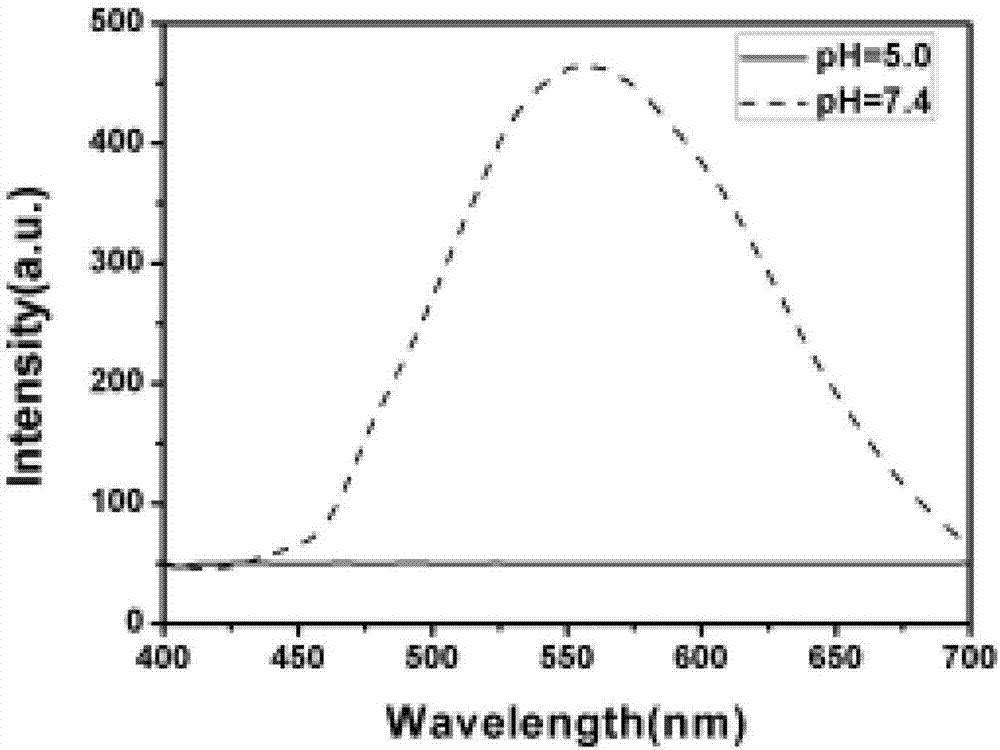

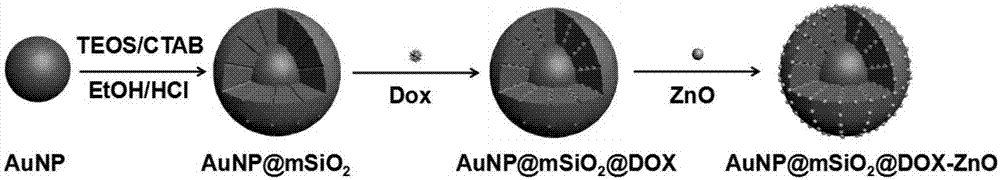

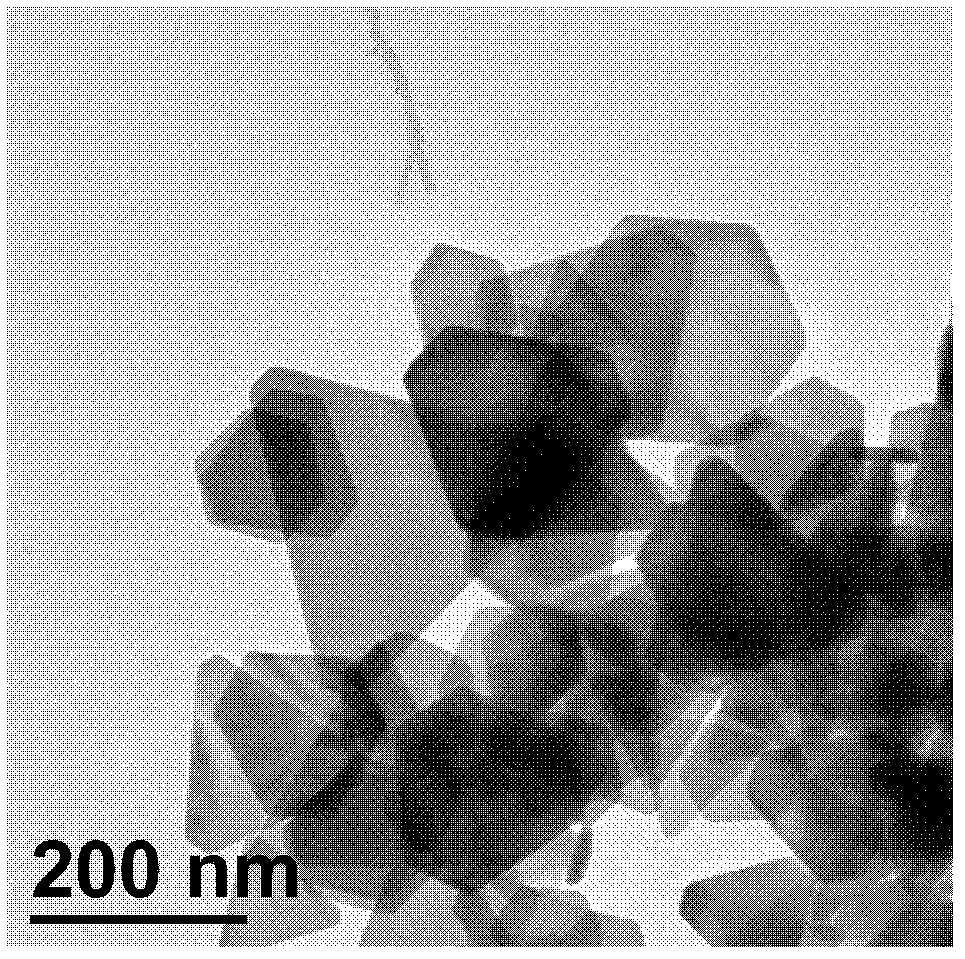

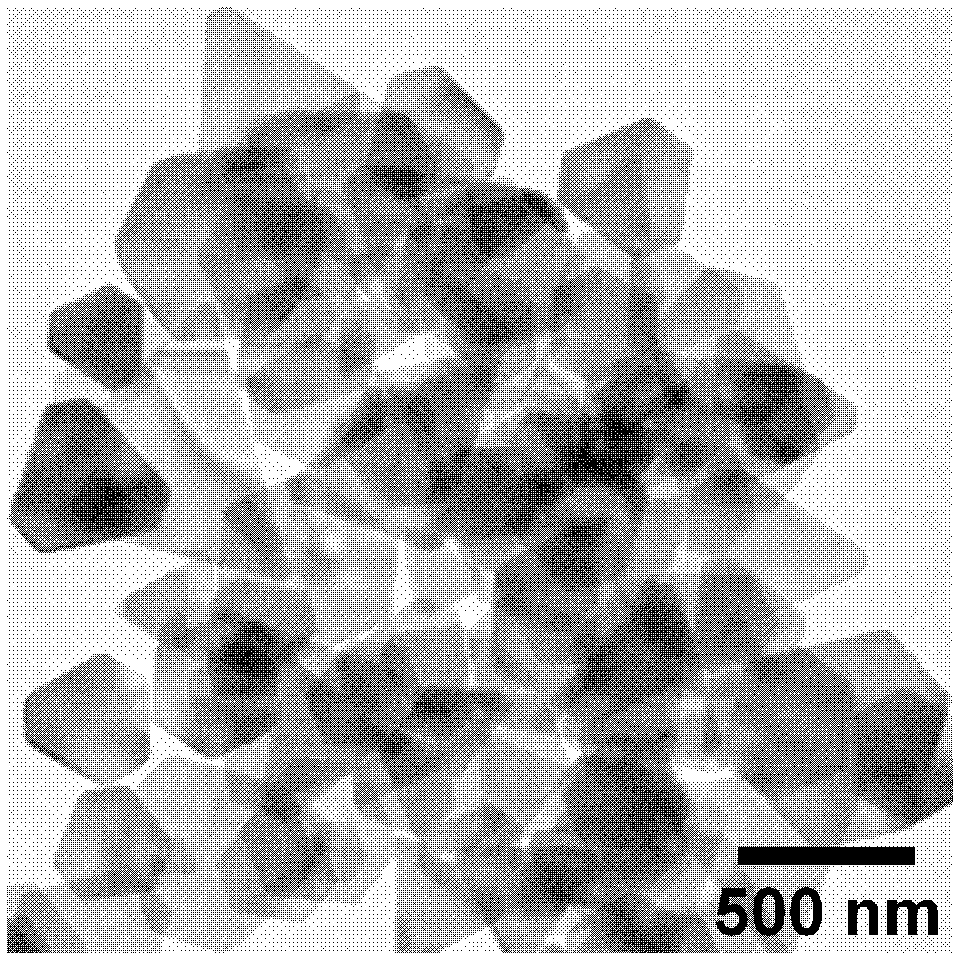

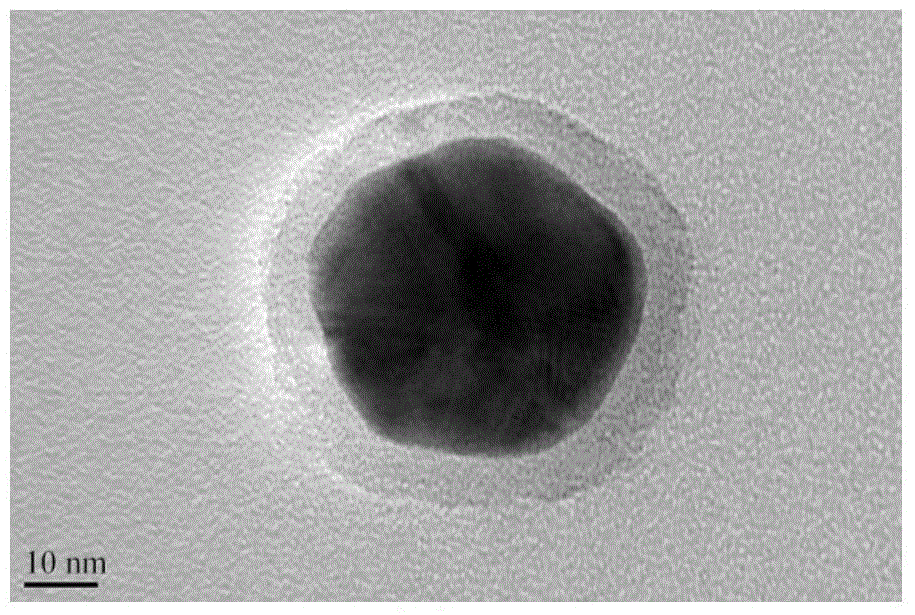

PH-responsive anti-tumor drug carrier material and preparation and application of pH-responsive anti-tumor drug carrier material

ActiveCN107412195AIncrease loadUniform particle sizeOrganic active ingredientsEnergy modified materialsSide effectMesoporous silica

The invention discloses a pH-responsive anti-tumor drug carrier material and a preparation and application of the pH-responsive anti-tumor drug carrier material. The preparation method comprises the following steps that (1) gold nanoparticles wrapped by mesoporous silica are prepared, and the gold nanoparticles comprise gold nanospheres or gold nanorods; (2) gold nanoparticles wrapped by carboxylation mesoporous silica are prepared; (3) water-soluble zinc oxide quantum dots are prepared; and (4) the pH-responsive anti-tumor drug carrier material is prepared. According to the pH-responsive anti-tumor drug carrier material and the preparation and application of the pH-responsive anti-tumor drug carrier material, the whole technological process design of the preparation method, the parameter conditions adopted by the reaction steps and the like are optimized, and the existing problems that drug releasing is uncontrollable, the drug loading capacity is low, and side effects are prone to being caused when the gold nanoparticles wrapped by the mesoporous silica serve as a drug carrier can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

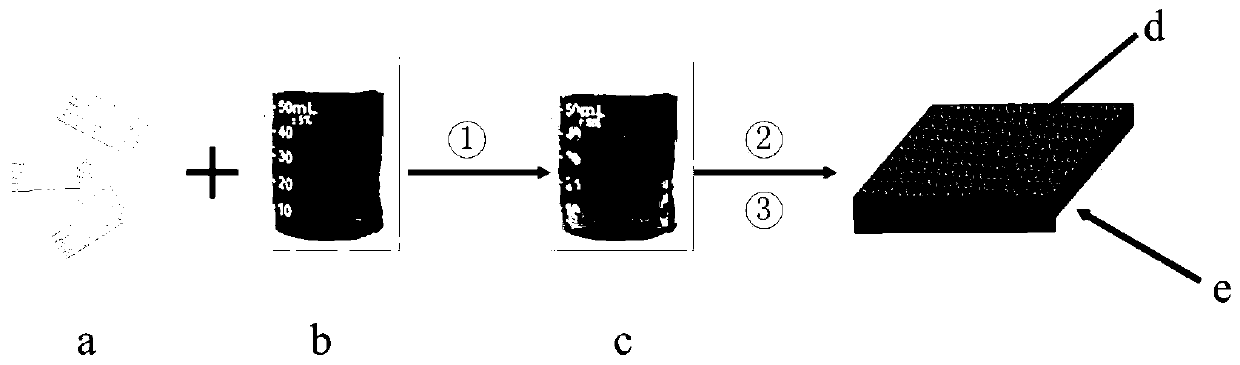

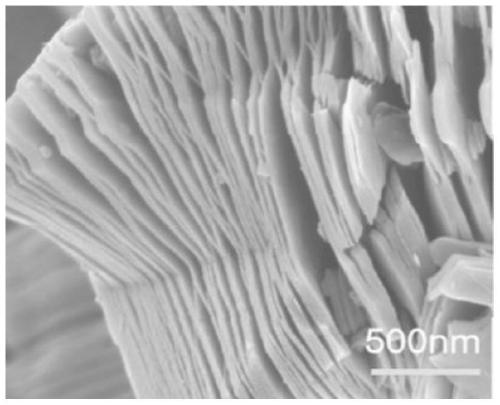

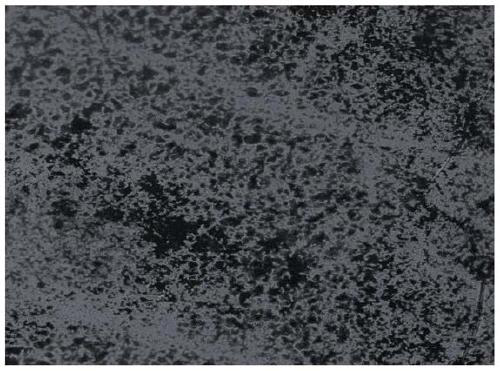

Method for preparing series silver nano-sheets in batch

The invention relates to a method for manufacturing series silver nano-sheets in a batch. The method includes dividing polyhydric alcohol, dimethyl formamide, high-polymer surfactant, metal salt adjuvant containing halogen and metal silver salt into three batches to be treated by the aid of the metal salt adjuvant containing the halogen; then uniformly mixing the materials; and obtaining the series silver nano-sheets by means of heating reaction. The silver nano-sheets are uniform in shape, high in purity, fine in monodispersity and low in cost, a reaction device is simple, large-scale preparation of the silver nano-sheets can be realized, and the method has an industrial prospect.

Owner:苏州冷石纳米材料科技有限公司

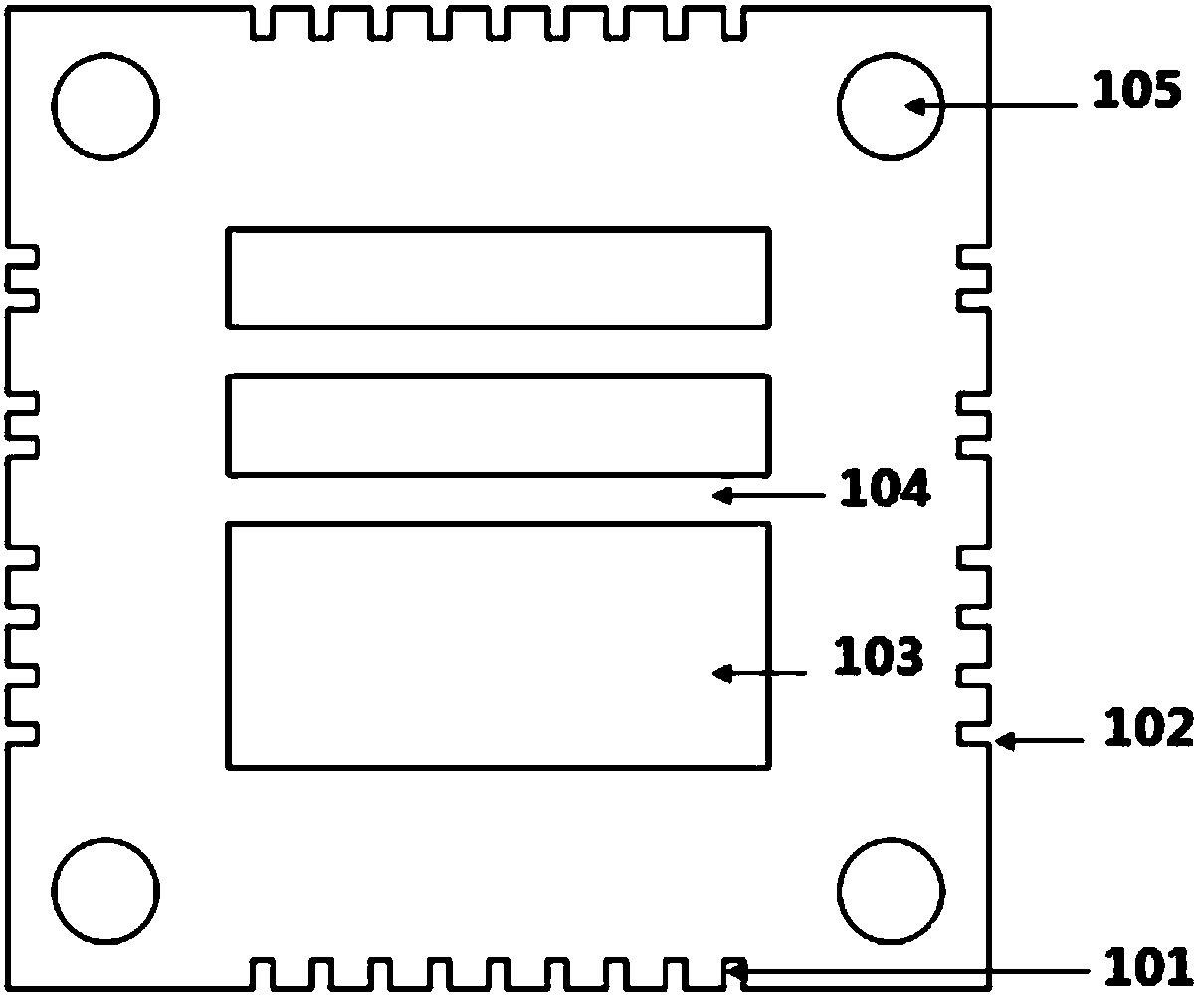

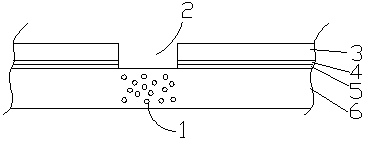

Thin film field effect transistor type gas sensor and preparation method thereof

ActiveCN108447915AEnhanced room temperature gas-sensing effectImprove adsorption capacityTransistorMaterial analysis by electric/magnetic meansBottom gate bottom contactQuantum dot

The invention discloses a thin film field effect transistor type gas sensor and a preparation method thereof. The sensor is a thin film field effect transistor with a bottom gate top contact type structure or a bottom gate bottom contact type structure. A thin film field effect transistor with a bottom grid top contact structure is taken as an example. The transistor comprises a substrate, a gateinsulating layer and a channel active layer from bottom to top. The channel active layer is a quantum dot thin film. A source electrode and a drain electrode are deposited above the substrate. A gateelectrode is further led out of the substrate. The internal composition, the structure, the overall process of the corresponding preparation method and the parameters during all steps of the preparation method of the thin film field effect transistor type gas sensor are improved. The quantum dot thin film serves as a channel active layer and a gas sensitive layer at the same time, and the gas response of multiple parameters is comprehensively regulated by utilizing the grid bias voltage. As a result, the prepared gas sensor is high in sensitivity, low in power consumption and high in selectivity. The effect of detecting low-concentration target gases, such as NO2 and H2S, is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

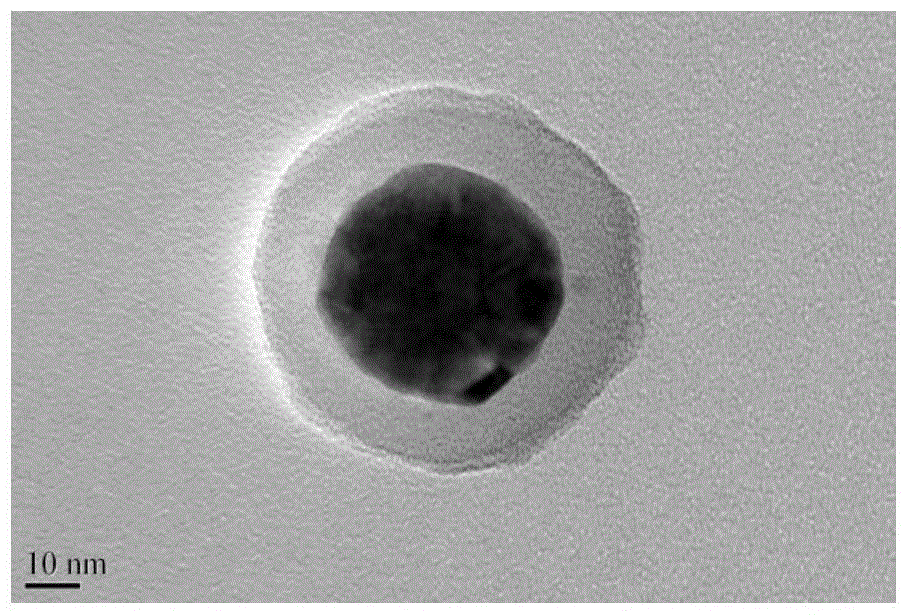

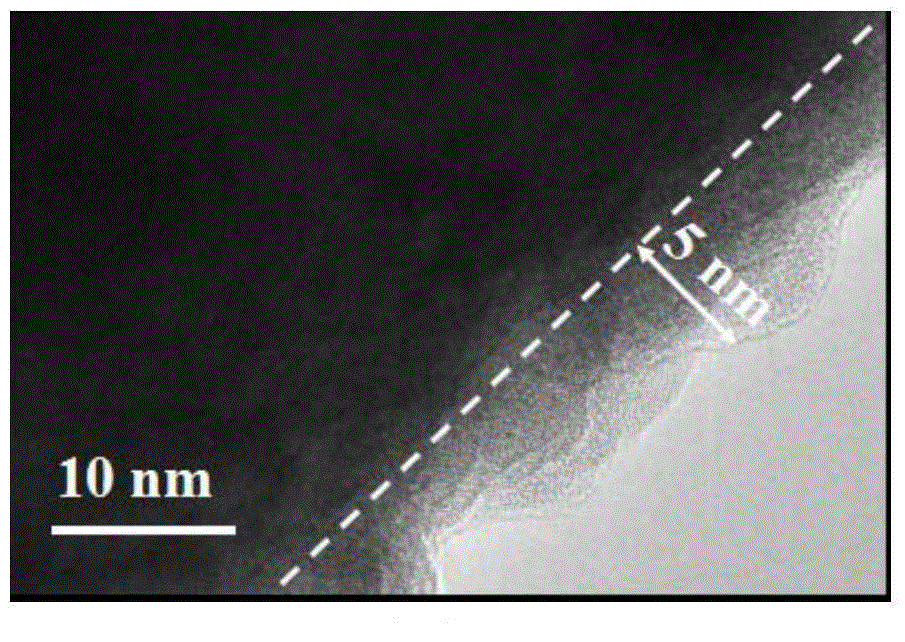

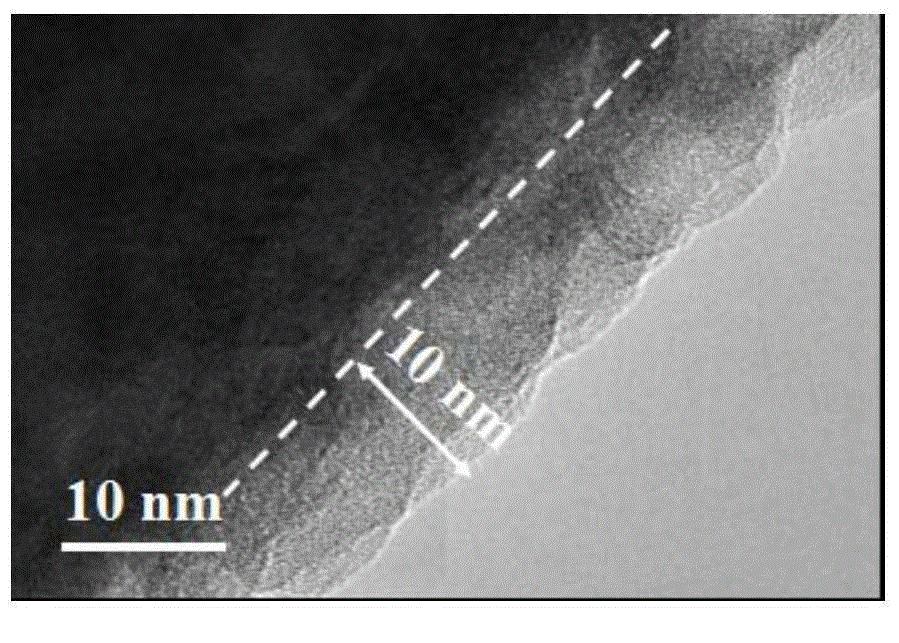

Method for wrapping gold-silver alloy nanometer particles through silicon dioxide

The invention discloses a method for wrapping gold-silver alloy nanometer particles through silicon dioxide. According to the method, isopropyl alcohol serves as a solvent, tetraethyl orthosilicate serves as a silicon source, a stirring reaction is conducted for 1-3 hours at the temperature of 40-60 DEG C by adjusting the proportion of the tetraethyl orthosilicate and the gold-silver alloy nanometer particles, and then the Au-Ag alloy@SiO2 composite nanometer particles wrapped by SiO2 of different thicknesses can be obtained. The method is simple, the reaction condition is gentle, the reaction time is short, no surface active agents need to be added, the prepared Au-Ag alloy@SiO2 composite nanometer particles are high in dispersity and regular in morphology, the thicknesses of silicon dioxide shell layers are uniform and controllable, quite high plasmon resonance peaks are achieved, and adjustable plasmon resonance peaks can be obtained by changing the thicknesses of the silicon dioxide shell layers.

Owner:SHAANXI NORMAL UNIV

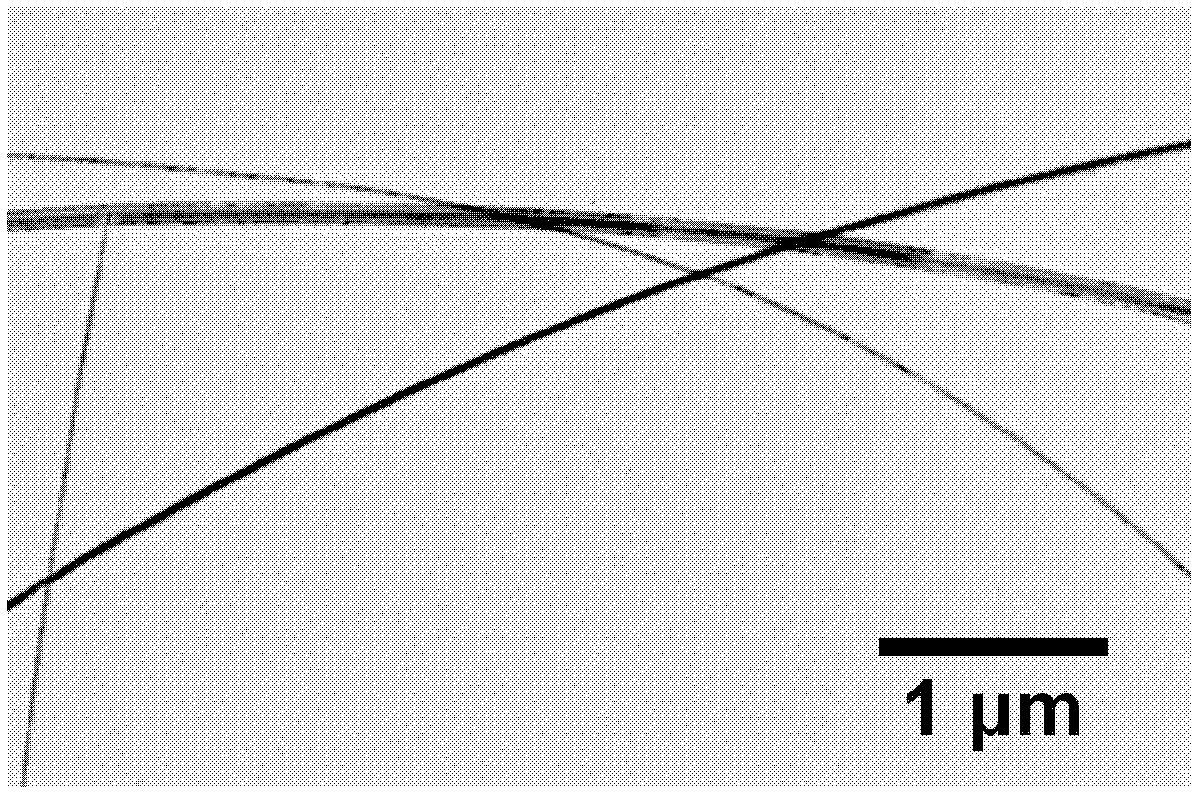

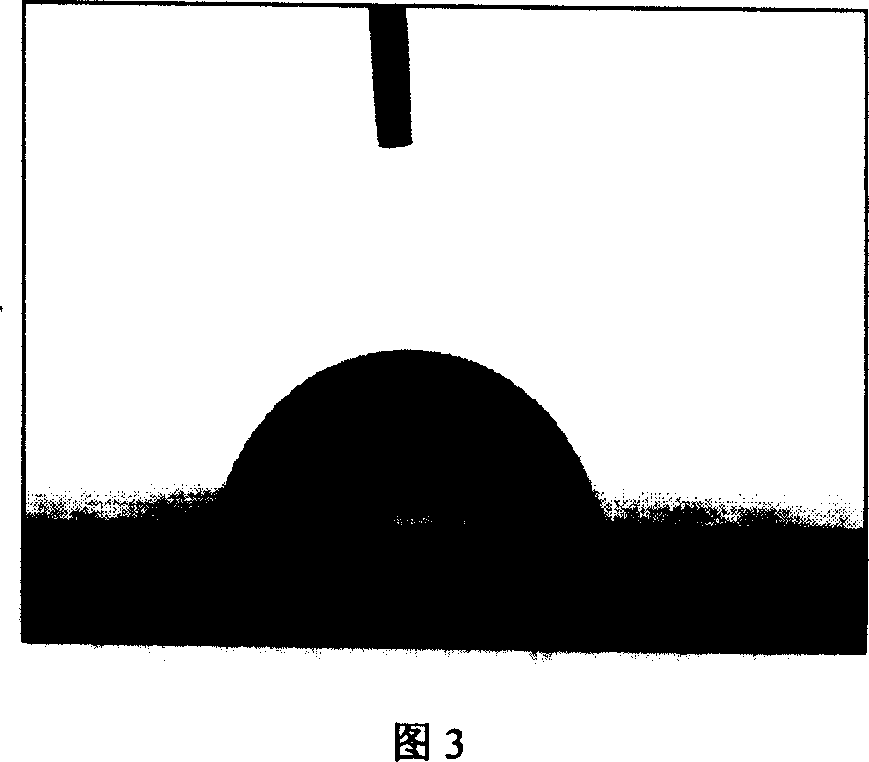

Conductive type polyaniline composite film, prepn. method and use thereof

InactiveCN1831033AImprove self-cleaning abilityNot affectedPlastic/resin/waxes insulatorsOther chemical processesFiberJet aeroplane

The invention relates to the current conducting ployaniline composite membrane having the framework of the lotus leaf genus. It is the cancellated film composed by the nm fibre with microsphere and has the tuber on the surface of the fibre and the microsphere. The producing process of the composite includes the below steps: the eigenstate polyaniline is dissolved into the solvent; the insoluble substance is rejected, the adulterating acid is added; then, the polystyrene is added; the current conducting polyaniline mixed liquor is gained; finally, the petrified urrent conducting ployaniline composite membrance is gained one the receiving system using the electrostatic spinning technique. The composite membrane is indicative of the contact angle of 160 degree and the roll angle of below 5 degree to the pure water, the acid and the alkaline solution in the range of the entirely PH value and express the sky high ability of self purging; at the same time, the conductivity of the conducting macromolecule composite membrane don't change with the acid and alkaline solution. The conducting composite membrane can be used for producing the resisting electromagnetic shielding material, the antistatic stuff, the anticorrosion stuff, the anti fouling stuff of the shipping and the airplane, the latent stuff, the liquid transmission without the loss and the micro-flow stuff.

Owner:INST OF CHEM CHINESE ACAD OF SCI

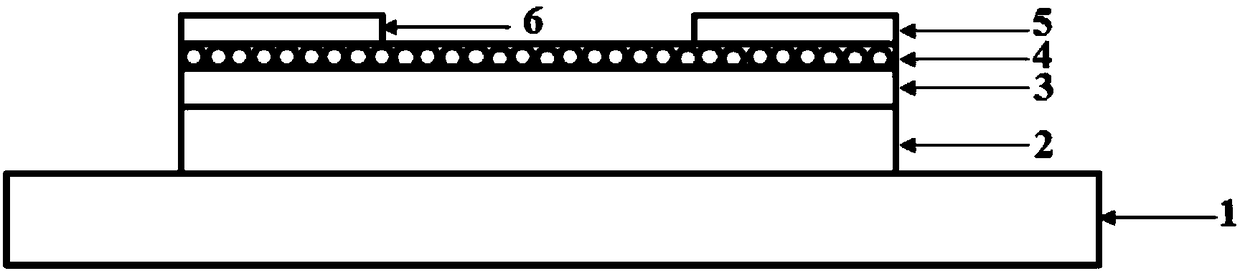

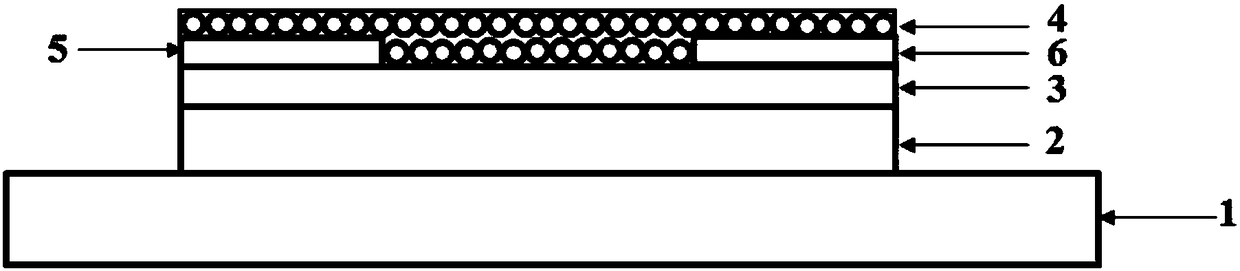

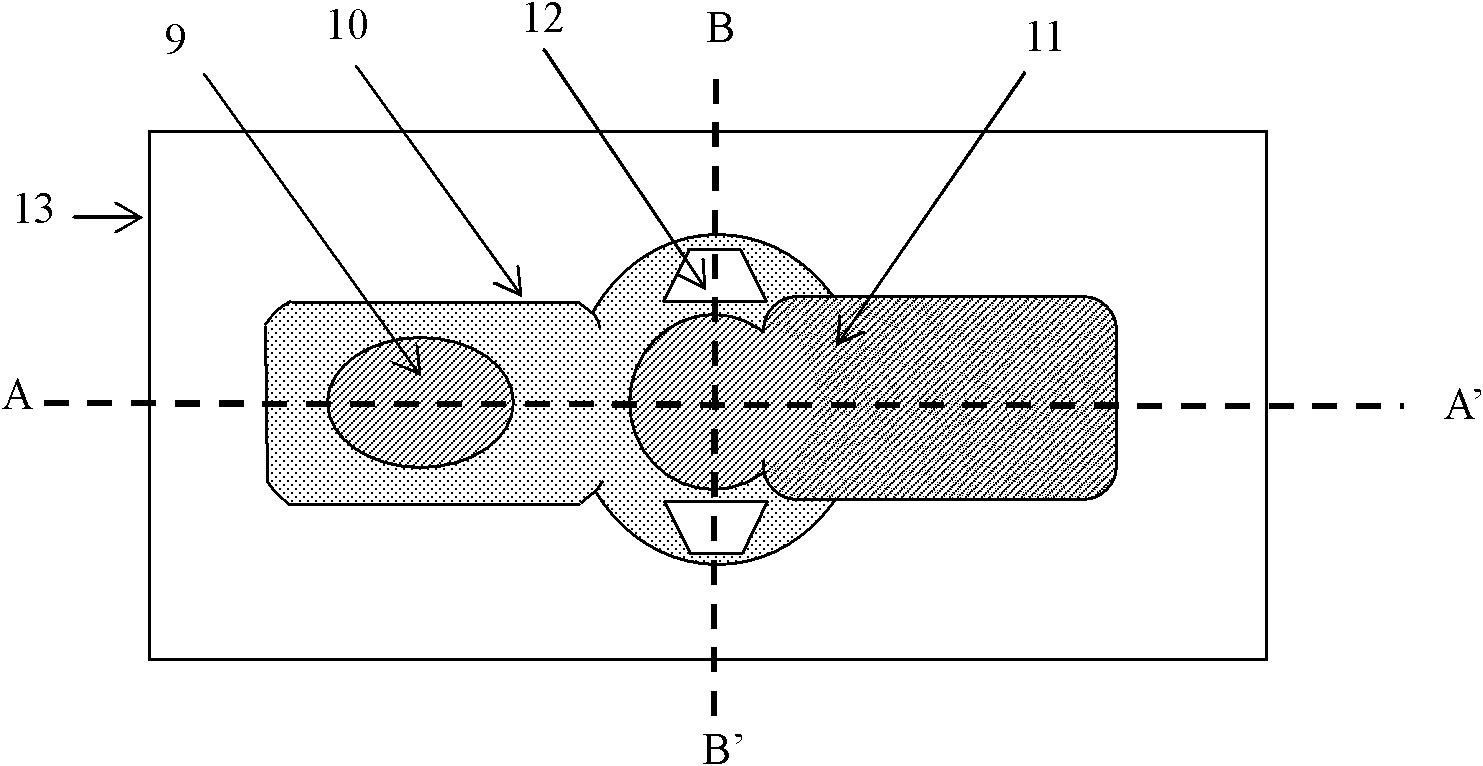

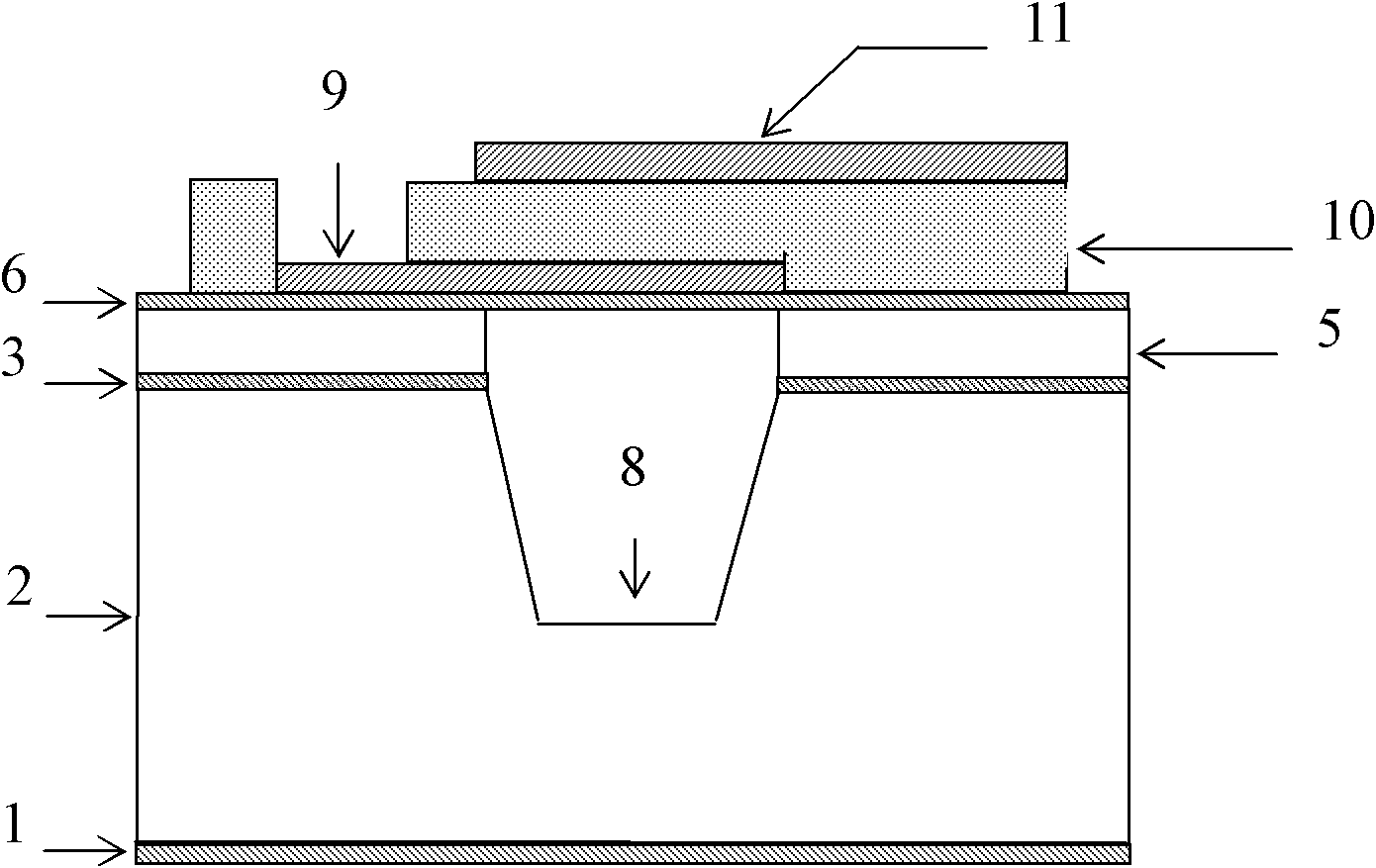

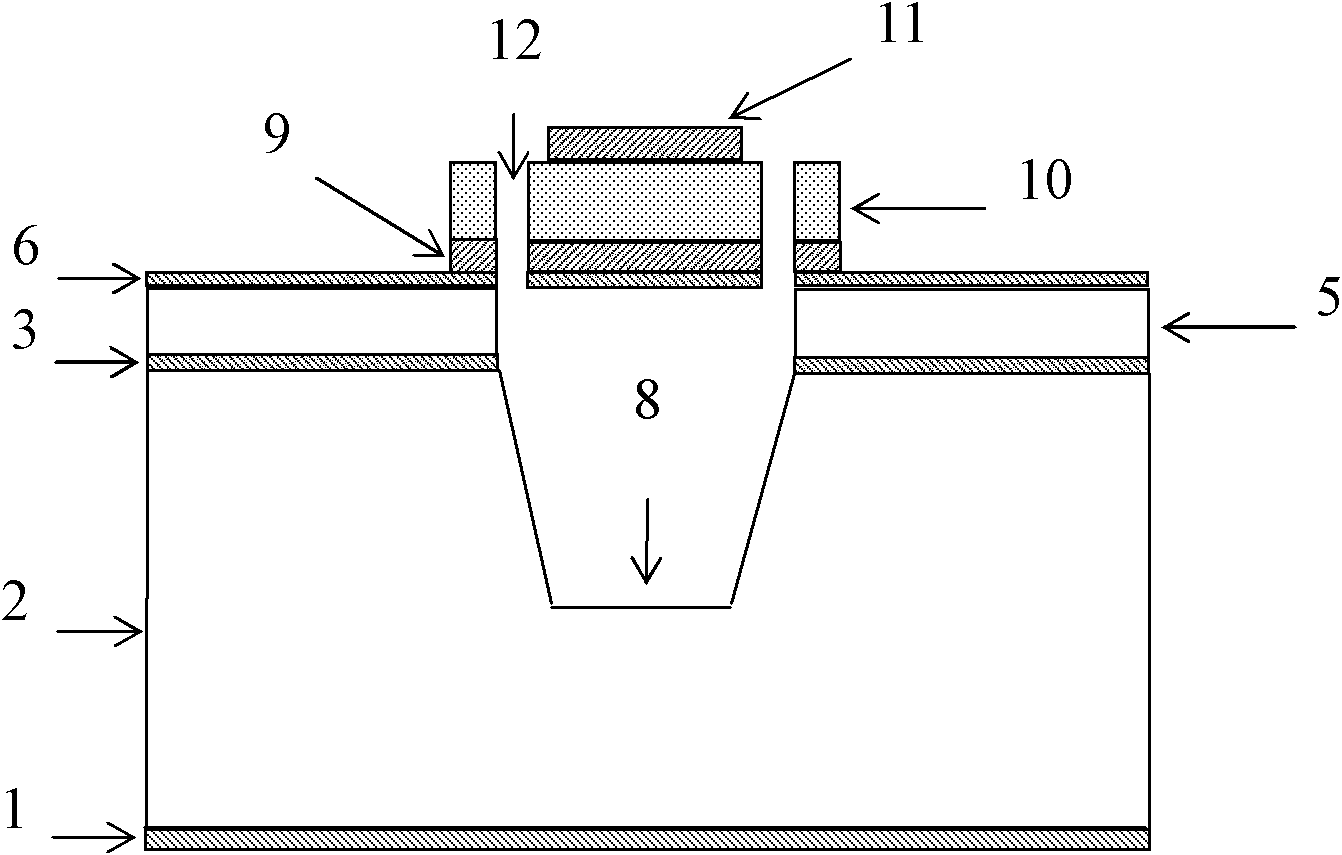

Preset cavity type SOI (silicon on insulator) substrate film bulk acoustic wave filter and manufacturing method thereof

ActiveCN102122939AEasy to integrateSimple processImpedence networksThin-film bulk acoustic resonatorElectricity

The invention discloses a preset cavity type SOI (silicon on insulator) substrate film bulk acoustic wave filter and a manufacturing method thereof, relating to the field of electronic devices. The filter is formed by electrically cascading a plurality of film bulk acoustic wave resonators which are manufactured on a preset cavity type SOI substrate, wherein each resonator comprises a piezoelectric film, a base electrode and a top electrode; a groove is arranged on the upper surface of substrate silicon of the SOI substrate; a sealed cavity is formed by the substrate silicon having the groove and top silicon; the top silicon is transferred from a groove-free SOI substrate by using a bonding technique and has even and controllable thickness; the cascaded mode of the filter includes a balancing bridge type, a stair type and a grid type; the frequency of the filter is adjustable and can be adjusted by controlling the thickness by controlling the etching time of the top silicon above the cavity; the electrodes of the resonators are approximate to oval, which is beneficial to the enhancement of the energy trap action; and a duplexer and a multiplexer can be formed by using the filter. In the invention, the advantages of SOI material are taken, the relative technique of a sacrifice layer is unnecessary, the process is simple, and the filter and the manufacturing method thereof are suitable for batch production.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Synthesis method of silicon dioxide coated lithium-rich manganese-based cathode material

ActiveCN105655566AImprove electrochemical performanceImproved magnification performanceCell electrodesSecondary cellsSynthesis methodsDecomposition

The invention discloses a synthesis method of a silicon dioxide coated lithium-rich manganese-based cathode material, belonging to the technical field of cathode materials of lithium ion batteries. The synthesis method is realized mainly in the following way: the surfaces of the lithium-rich manganese-based cathode material and precursor thereof are coated with silicon dioxide through the hydrolysis of tetraethyl orthosilicate; by controlling the dispersing agent composition and reaction temperature, a uniform and dense coating layer with controllable thickness can be formed on the material surface by the synthesis method; and the uniform and controllable coating layer can effectively separate electrode from electrolyte, the decomposition of electrolyte is inhibited, the HF generated by LiPF6 decomposition is absorbed, and the electrochemical performance and particularly the rate performance, high-temperature performance and safety performance of the lithium-rich manganese-based cathode material are improved. The synthesis method has the advantages of easily available raw materials, simplicity in operation, mild conditions and environment-friendly and recyclable dispersing agents while industrial production is facilitated.

Owner:BEIJING UNIV OF TECH

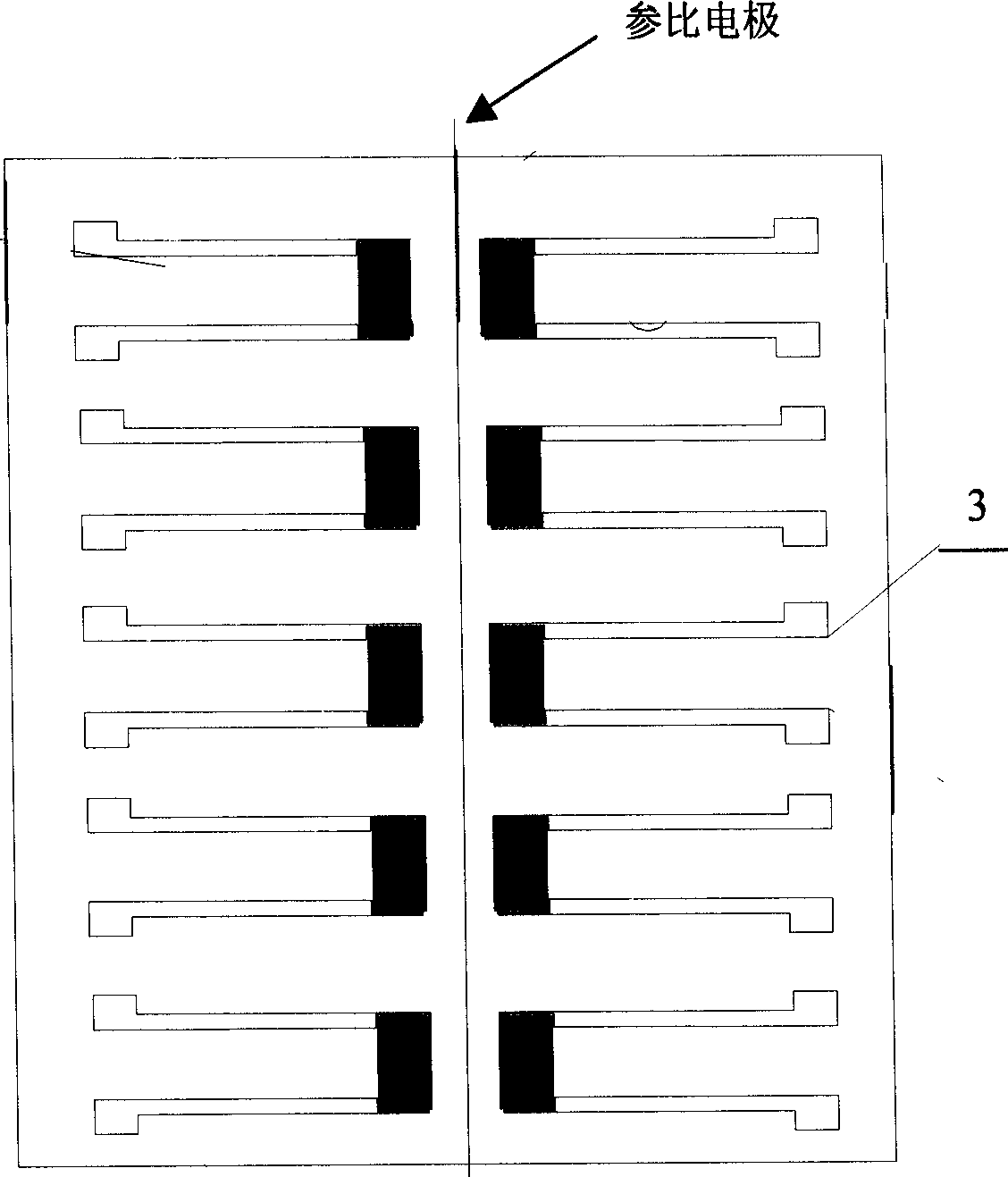

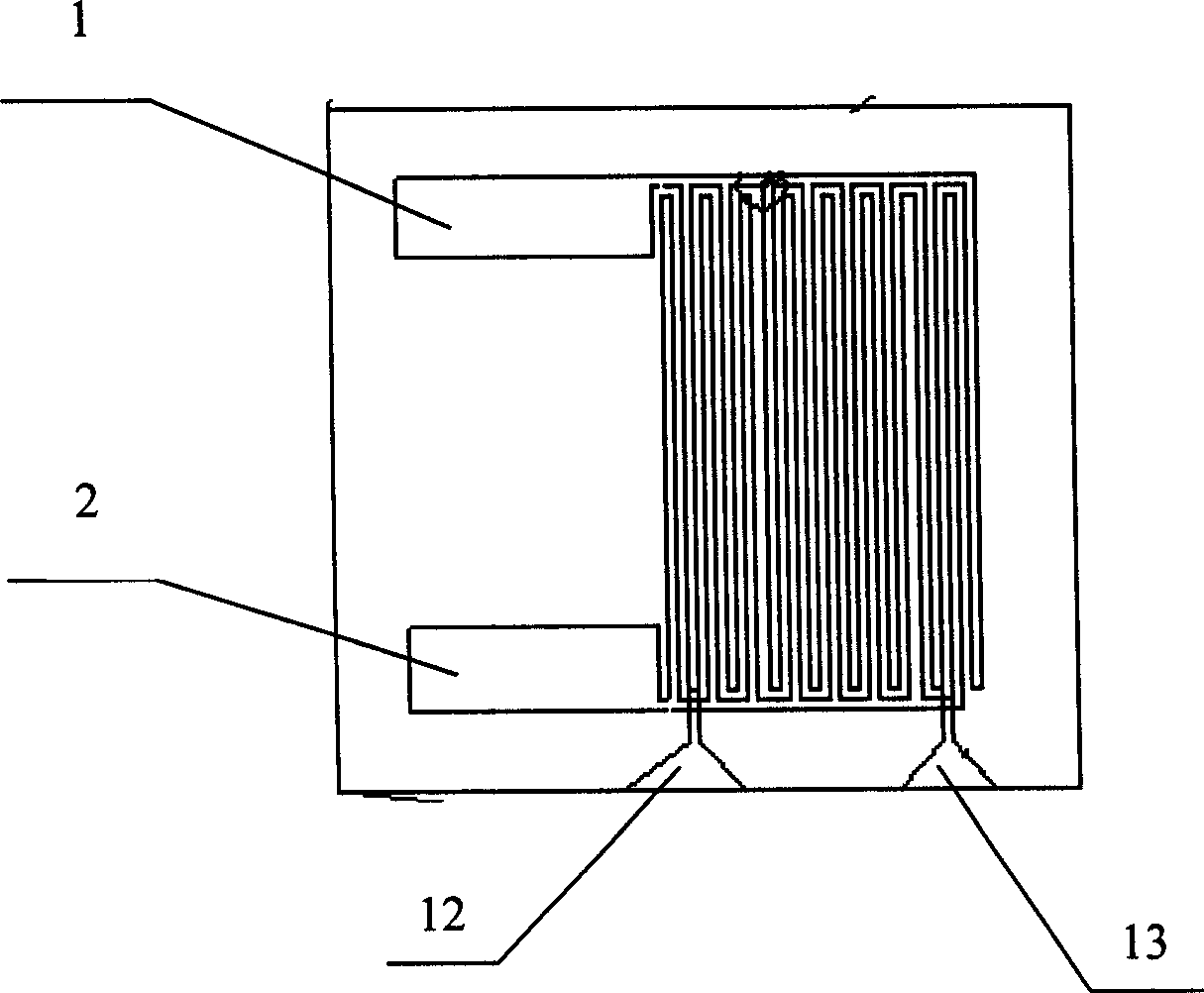

Sensor of chip contaonong microelectrode array

InactiveCN1462878AReduce distanceUniform and controllable thicknessMicrobiological testing/measurementBiological testingMicroelectrodeElectron

A microelectrode array chip sensor on the silicon substrate features that said microelectrode array is composed of interdigital electrodes for smaller gap between positive and negative electrodes andhigher transmission speed of electrons. It is prepared by MEMS technique. Its advantages are simple preparing process and high sensitivity.

Owner:FUDAN UNIV

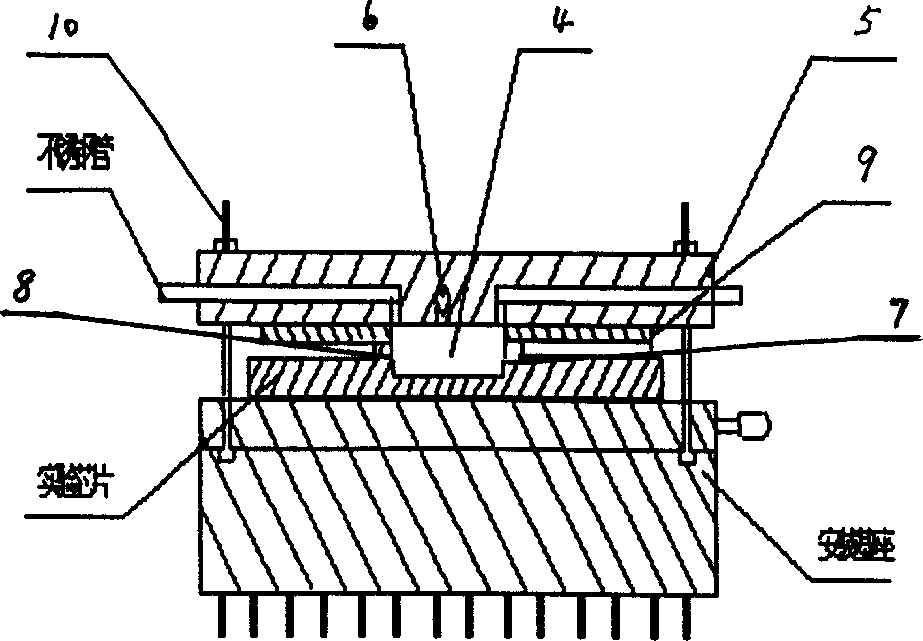

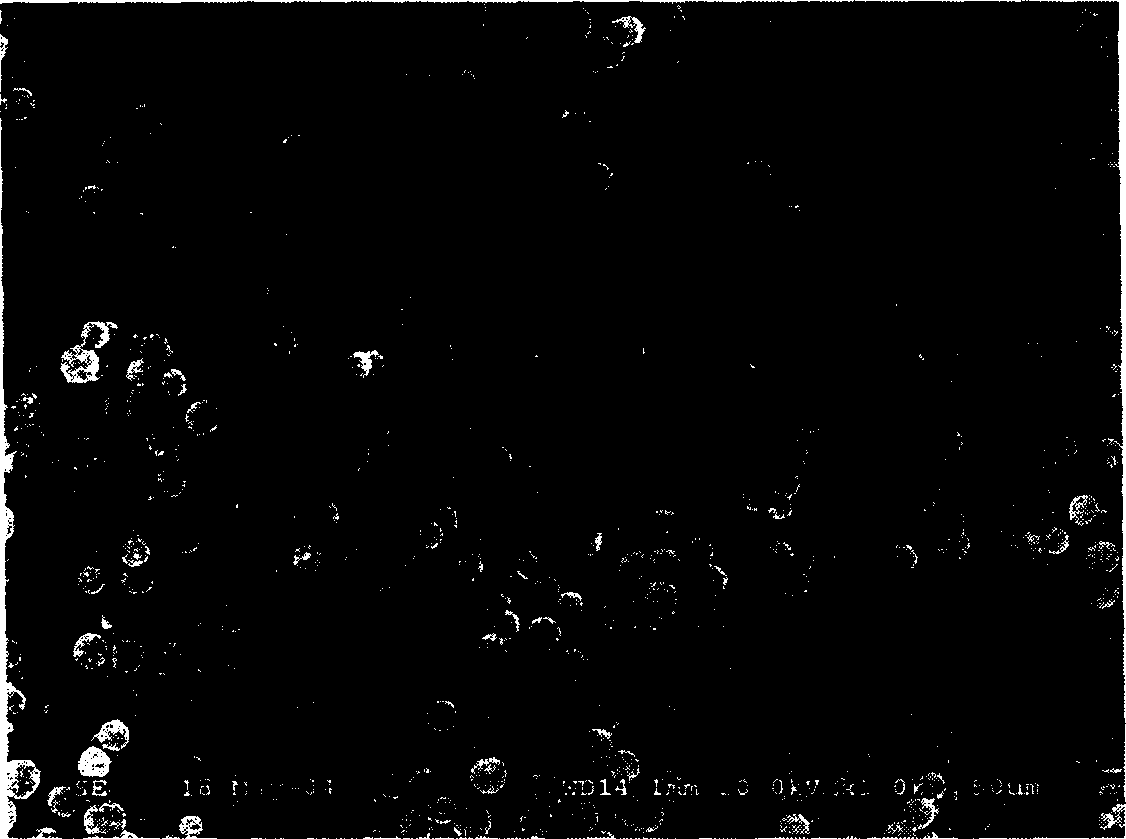

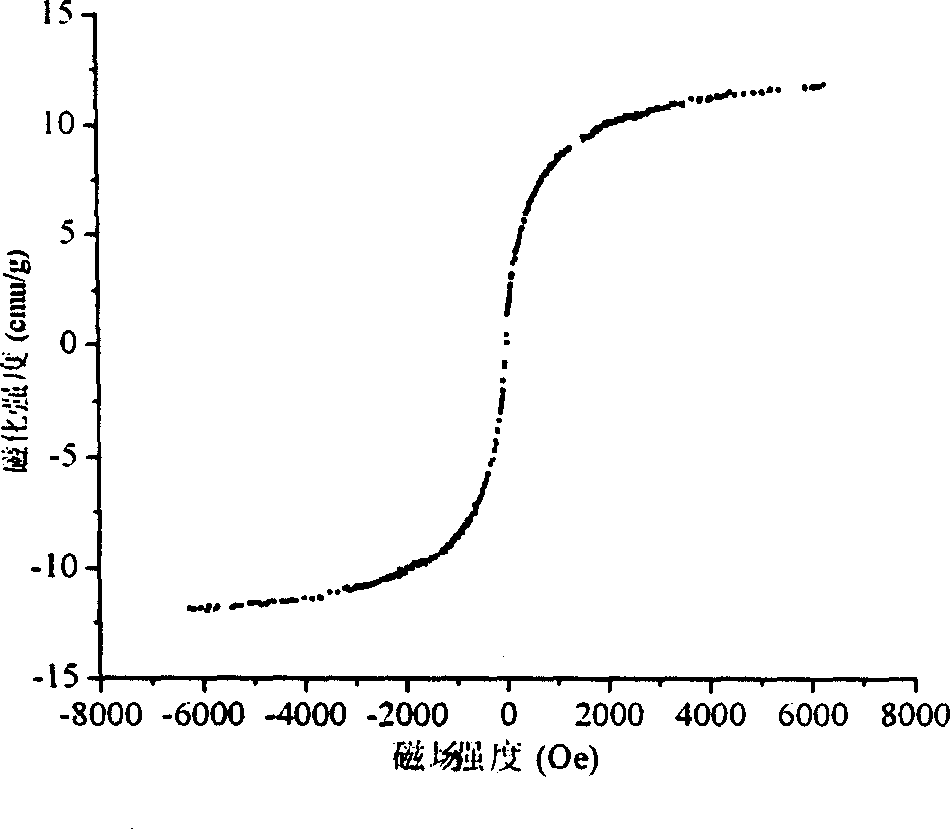

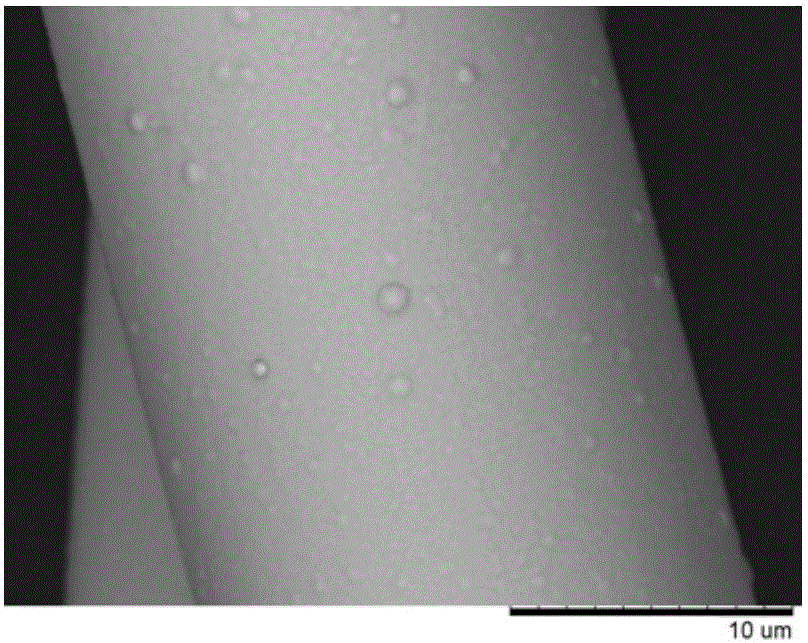

Composite electro and magneto conductive polyaniline microsphere and its prepn

InactiveCN1810861ANot easy to reuniteUniform and controllable film thicknessElectrospinningFunctional composite

The present invention relates to electrically and magnetically conductive polyaniline microsphere of particle size of 2-5 microns and containing polymer in 40-85 wt% and homogeneously distributed nanometer magnetic particle in 8-50 wt%. It is prepared through an electrostatic spinning process. It can form film in various kinds of substrates of different material and in different shapes, and may be used as electrode material, electromagnetic shielding material, antistatic sealing material, etc. It possesses electric conductivity, magnet conductivity and superparamagnetism simultaneously and thus may be dispersed homogeneously without coagulation. The preparation process has wide temperature range, simple and convenient operation and low cost, and is suitable for large scale preparation of various kinds of functional composite polymer microsphere.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Process for preparing TiO2 nanocrystal porous film electrode by low-temp. electrophoresis sedimentation

InactiveCN1905215ASimple and efficient operationEnergy savingFinal product manufactureElectrophoretic coatingsElectrophoretic depositionThin film electrode

The invention belongs to the manufacturing technical field of dye sensibilized TiO2 nanocrystalline porous thin film electrode and photo- catalyzed electrode, especially relating to a method for preparing TiO2 nanocrystalline porous thin film electrode at low temperature by electrophoretic deposition, mixing alcohol solution containing Ti salt or not with TiO2 grains, making TiO2 colloidal solution by supersonic diffusion, depositing TiO2 colloidal solution on clean conducting substrate by electrophoretic deposition to make TiO2 thin film electrode; and preparing TiO2 nanocrystalline porous thin film electrode at low temperature by postprocessing. And the preparing method is easy to operate, saving energy sources, low-cost, fast to form film, and especially applied to low temperature preparation of flexible TiO2 nanocrystalline porous thin film electrode.

Owner:INST OF CHEM CHINESE ACAD OF SCI

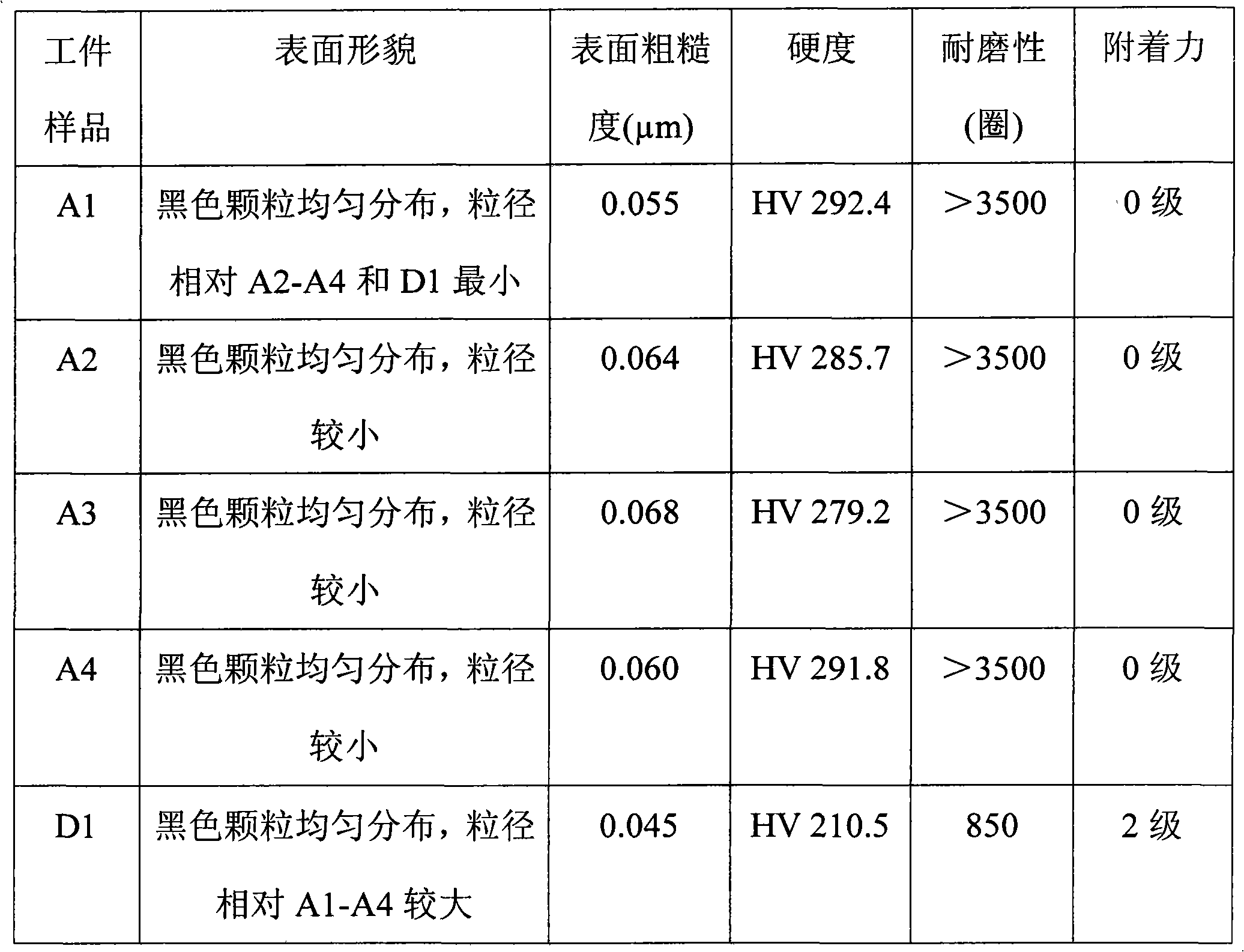

Surface treatment method of metal base materials

InactiveCN101994147AHigh surface hardnessImprove adhesionElectrophoretic coatingsElectrophoretic depositionSmooth surface

The invention provides a surface treatment method of metal base materials, which comprises the following steps of: a. placing the metal base materials into electrophoretic paint, and forming an electrophoretic deposition layer on the surface of the metal base materials through electrophoretic coating, wherein the electrophoretic deposition layer contains at least one kind of materials of MoS2, graphite and WS2; and b. carrying out laser modification on the metal base materials obtained in step a under the protection of inert gas, wherein the laser power is 1.5 to 2.5KW, and the scanning speed is 225 to 1,800mm / min. The invention adopts a mode of combining the electrophoretic coating and the laser modification so that on the premise that the flat and smooth surfaces and low roughness of the metal base materials are ensured, the surface hardness and the wear resistance of the metal base materials and the adhesive force the electrophoretic deposition layer and the metal base materials can be obviously improved at the same time.

Owner:BYD CO LTD

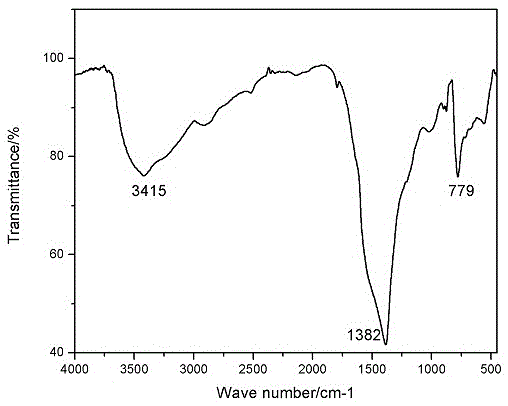

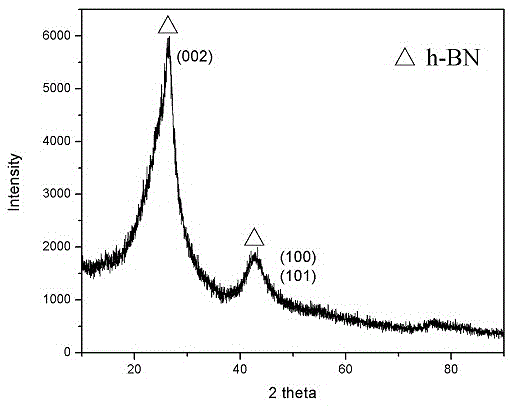

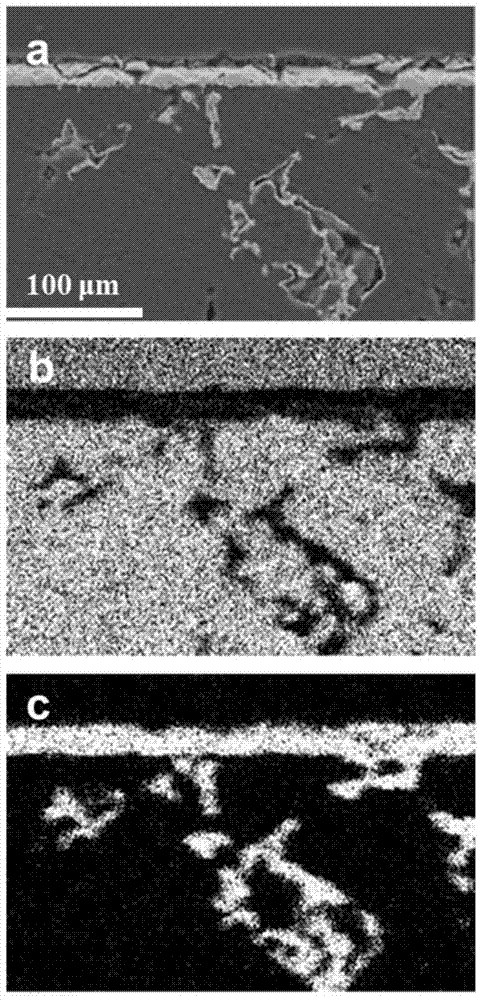

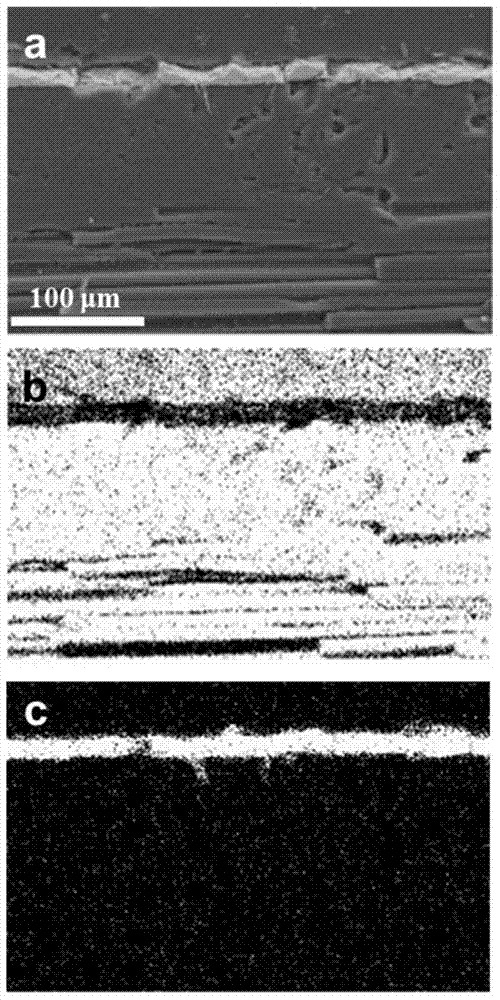

Low-temperature low-pressure preparation method of boron nitride coating

InactiveCN105669253AStrong penetration abilityUniform and controllable thicknessChemical vapor deposition coatingBoron nitrideBoron trichloride

The invention discloses a low-temperature low-pressure preparation method of a boron nitride coating. The method of the invention is used for solving the problem that required preparation temperature is high by a chemical vapor deposition method in the prior art. Boron trichloride (BCl3) and ammonia gas (NH3), which are used as main raw materials, undergo chemical vapor deposition under the condition of low temperature; a sample obtained undergoes high-temperature heat treatment; and through Fourier transformed infrared and X-ray diffraction detection, a boron nitride coating which has stronger infiltration capacity, uniformly and controllable thickness and high degree of crystallization is prepared. The method can be used for preparation of a composite material boron nitride interface and for preparation of a sample surface coating. By the method, deposition temperature of boron nitride chemical vapor deposition is reduced from 1300-1800 DEG C to 300-800 DEG C. The method mainly comprises low-temperature chemical vapor deposition and high-temperature heat treatment.

Owner:SHANGHAI UNIV +1

Metal carbide coating covered carbon-based material and preparation method therefor

The present invention discloses a metal carbide coating covered carbon-based material and a preparation method therefor. The preparation method comprises the following steps: putting the carbon-based material and metallic chromium and / or titanium into chloride and / or fluoride molten salt, carrying out a reaction under anhydrous oxygen-free conditions for 1-100 hours, and obtaining metal carbide coating covered carbon-based material. The metal carbide is chromium carbide and / or titanium carbide. According to the preparation method disclosed by the present invention, molten salt is used as a reaction medium, a metal carbide coating is prepared on the surface of the carbon-base in situ, the method is simple in a process and easy to operate, and has no requirement of a sample shape, and industrial production is facilitated; and the prepared metal carbide coating is uniform in thickness, and combined tightly with a substrate, so that surface hardness, abrasion resistance and high-temperature oxidation resistance of the carbon-based material can be significantly improved, use performance of the carbon-based material is greatly improved, and a practical application scope of the carbon-based material is expanded.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

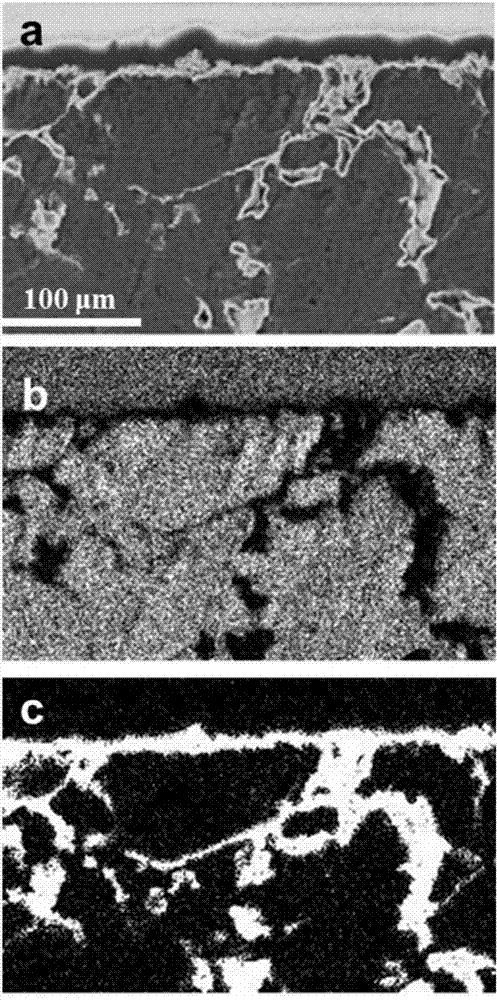

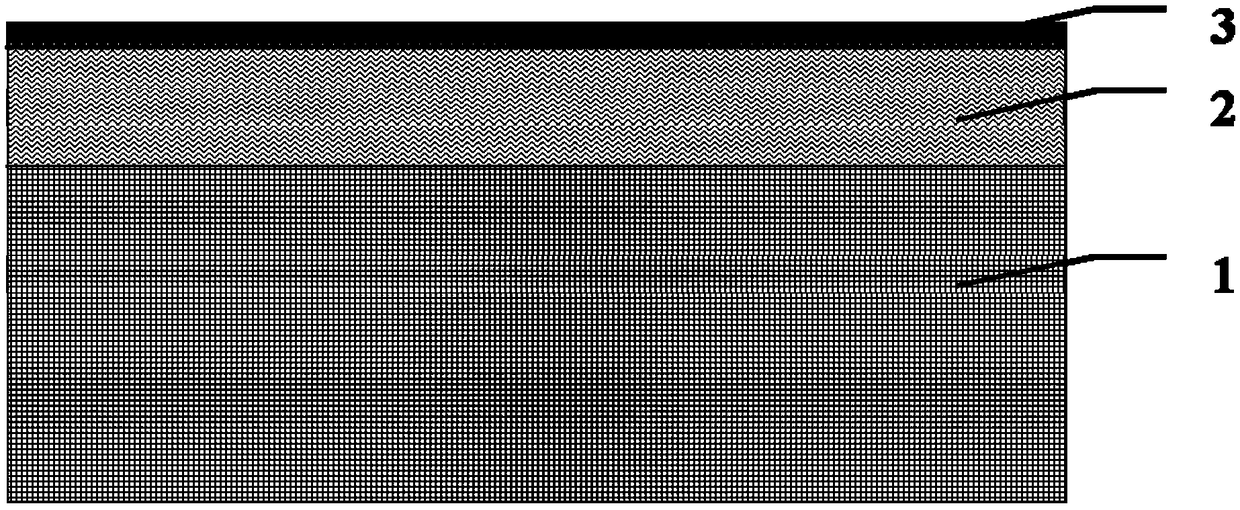

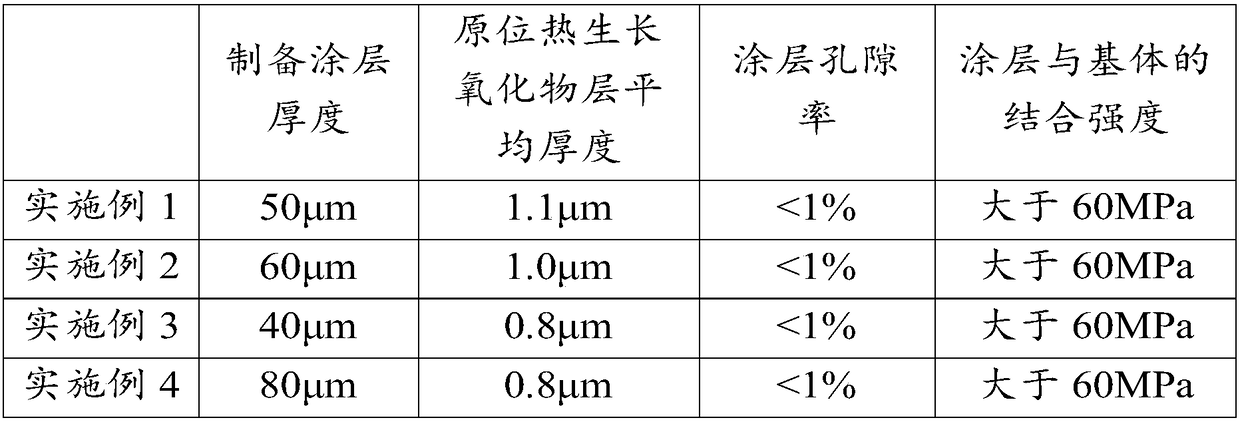

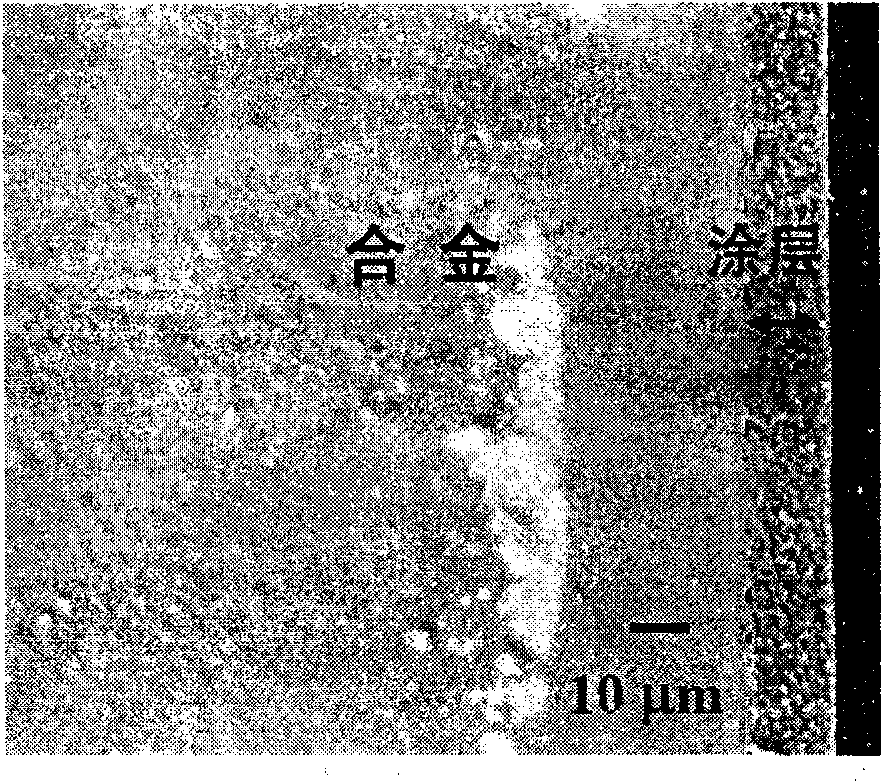

Liquid-state lead bismuth alloy corrosion resisting coating layer and preparation method thereof

ActiveCN108866471ACompact structureUniform and controllable thicknessMolten spray coatingLead bismuthCoated surface

The invention provides a liquid-state lead bismuth alloy corrosion resisting coating layer and a preparation method thereof and relates to the technical field of material surface treatment. The liquid-state lead bismuth alloy corrosion resisting coating layer comprises a matrix, a coating layer body and a thermally-growing oxide layer, wherein the coating layer body is attached to the surface of the matrix, the thermally-growing oxide layer is attached to the surface of the coating layer body, and the coating layer body is prepared from a material of FeCrAlY. The preparation method of the liquid-state lead bismuth alloy corrosion resisting coating layer comprises the steps: preparing the coating layer body on the surface of the pretreated matrix and then directly performing pre-oxidation treatment on the coating layer body. The FeCrAlY coating layer body of the liquid-state lead bismuth alloy corrosion resisting coating layer disclosed by the invention has good combination with the matrix; the liquid-state lead bismuth alloy corrosion resisting coating layer has the advantages of compact structure, even and controllable thickness, low oxygen content and low surface roughness; pre-oxidation is directly performed on the surface of the coating layer body to in situ generate an even, continuous and compact thermally-growing oxide layer, the thermally-growing oxide layer can directly contact a lead bismuth cooling agent for a long time, and liquid-state lead bismuth alloy corrosion resistance of the coating layer body is improved; a preparation process has the advantages of lowcost, high, efficiency, greenness, environmental friendliness and the like.

Owner:GUANGDONG INST OF NEW MATERIALS

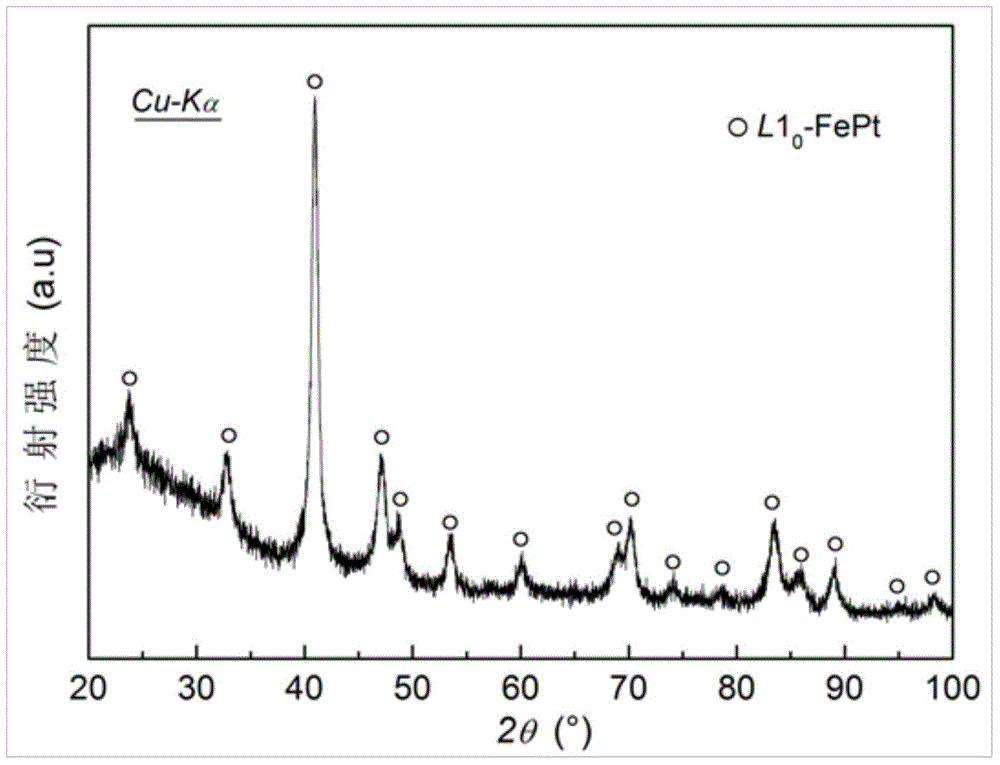

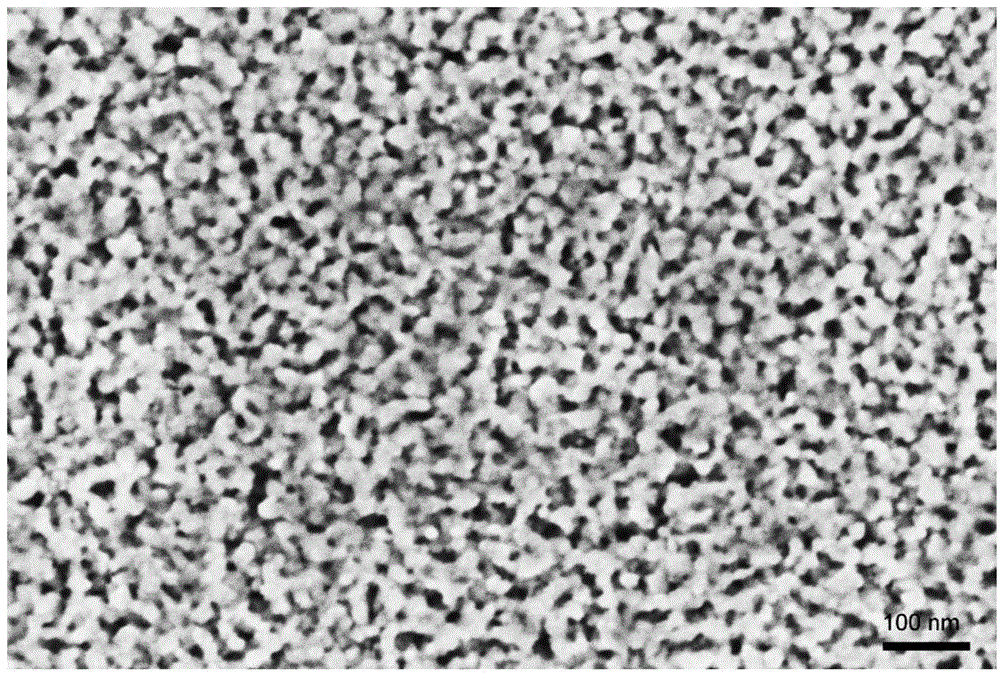

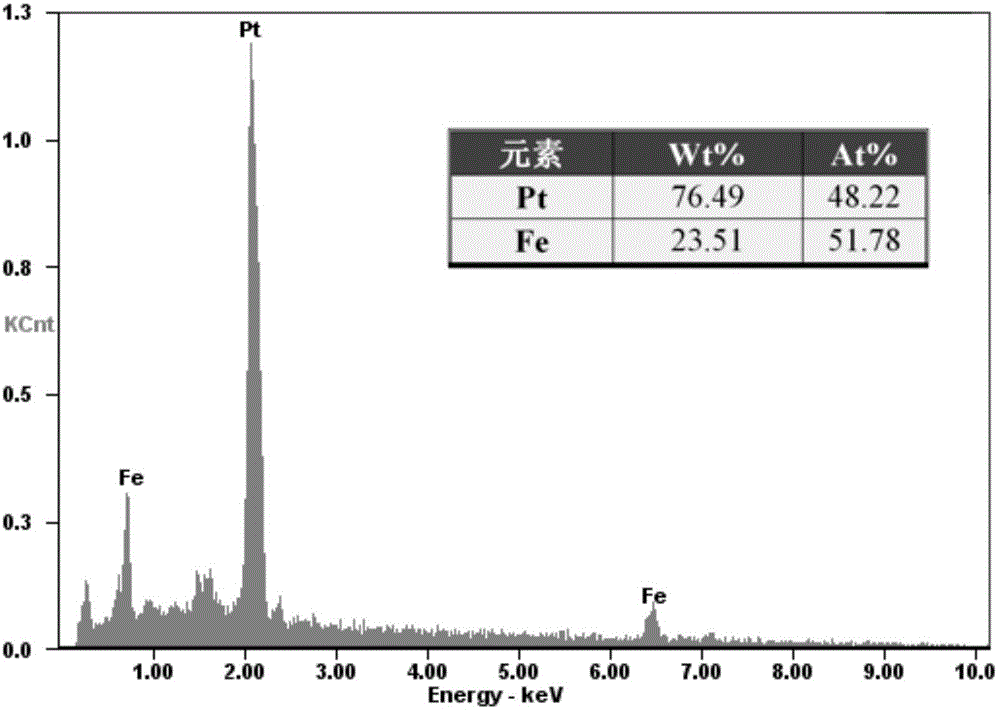

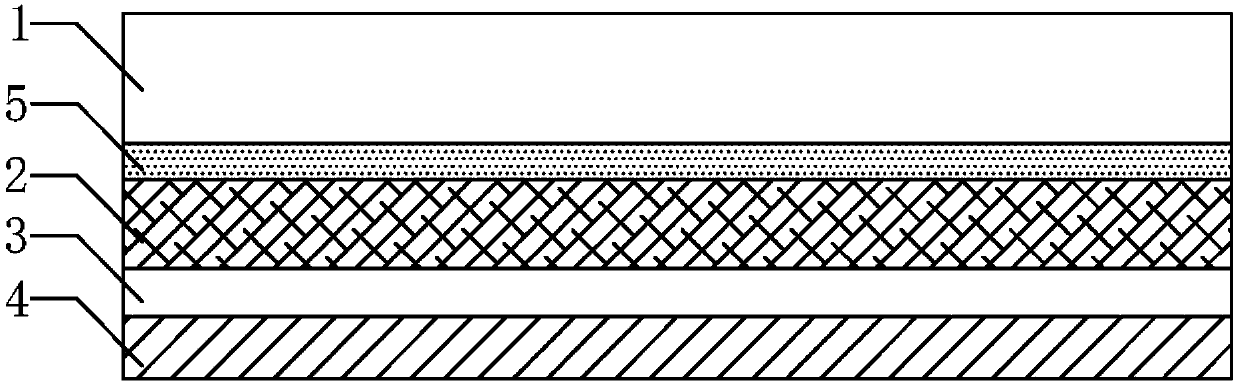

Strong-permanent-magnetic nano-porous Fe-Pt alloy and preparation method thereof

ActiveCN104946921AComplete structureUniform pore sizeMaterial nanotechnologyThin magnetic filmsMagnetic phaseIngot

The invention discloses a strong-permanent-magnetic nano-porous Fe-Pt alloy and a preparation method thereof. The strong-permanent-magnetic nano-porous Fe-Pt alloy has the composition of FewCoxPtyPdz, is composed of an L10-FePt ordered hard magnetic phase, and has a complete doubly-connected nano-porous structure, a pore diameter of 10-50nm and a ligament thickness of 20-80nm; the coercivity, the magnetization intensity and the residual magnetism of the alloy under a 50kOe external magnetic field are 13.4-18.5kOe, 40.4-56.3 and 28.3-37.4emu / g respectively. A master alloy ingot is prepared by electric arc melting or induction melting during preparation; an alloy strip is prepared by single-roll spinning; a nano-complex-phase precursor containing hard-magnetic L10-FePt and soft-magnetic Fe2B is obtained directly or through an annealing treatment; the nano-porous Fe-Pt alloy with a single L10-FePt phase structure is obtained through an electrochemical dealloying process, thus filling up the technical gaps of a permanent-magnetic metal nano-porous material.

Owner:DALIAN UNIV OF TECH

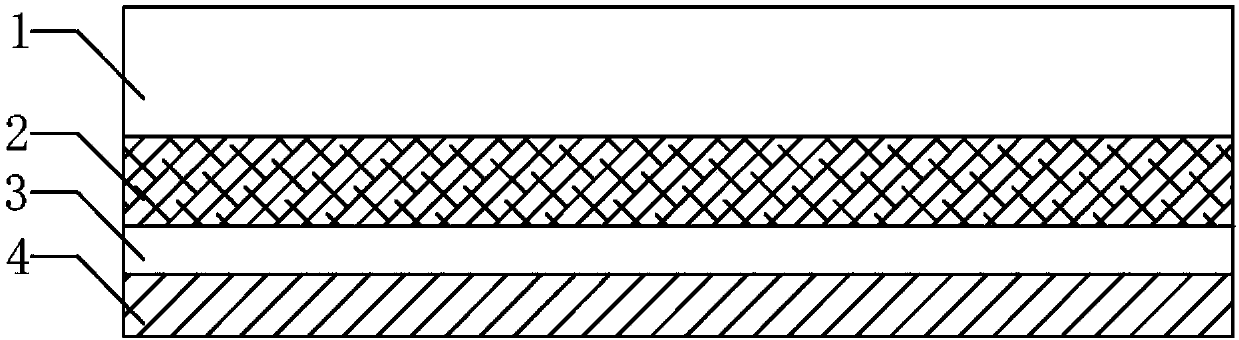

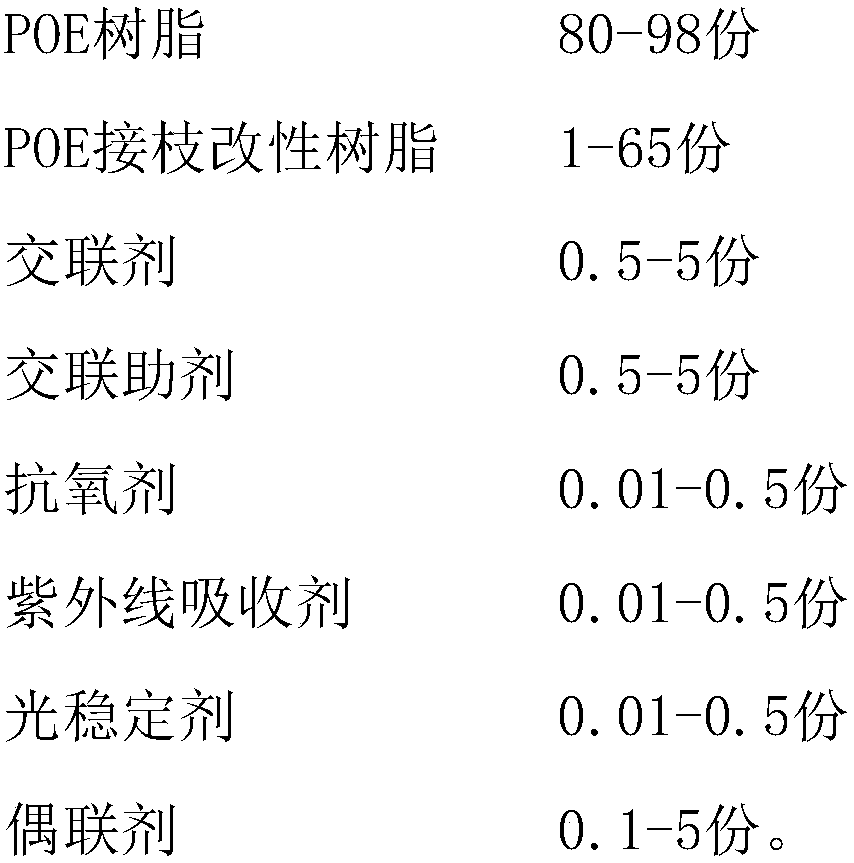

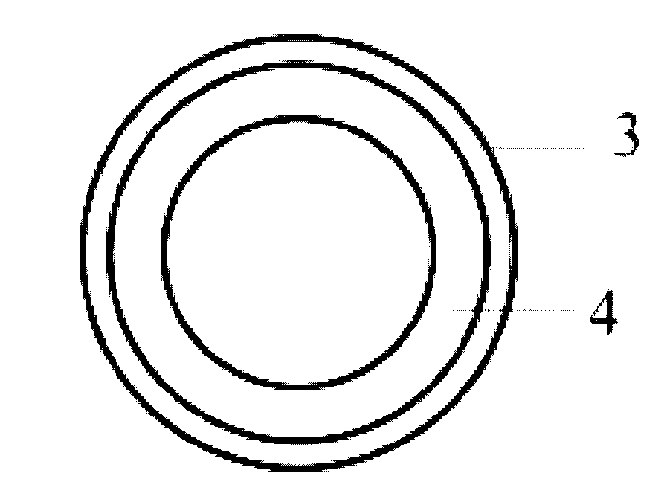

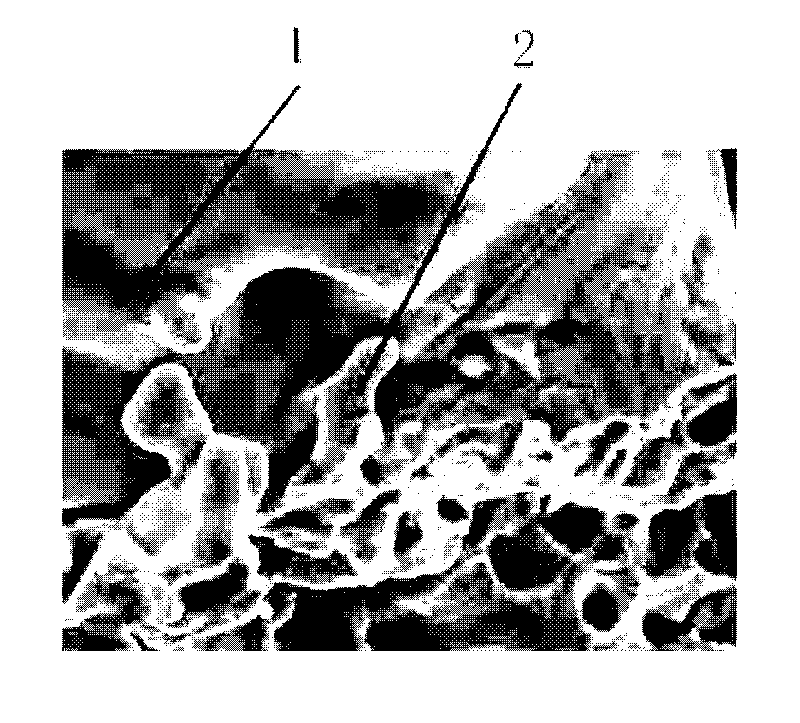

Adhesive film back plate integrated material and preparation process thereof

InactiveCN108034377AGood weather resistanceHigh light transmittanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerThermoplastic

The invention relates to the technical field of adhesive film back plates, in particular to an adhesive film back plate integrated material and a preparation process thereof. The adhesive film back plate integrated material comprises an adhesive film layer, a structure reinforcement layer, a bonding layer and a weather-proof layer which are sequentially connected from inside to outside, a frostedlayer is arranged between the adhesive film layer and the structure reinforcement layer, and the adhesive film layer is prepared from modified thermoplastic POE (polyolefin elastomer). The adhesive film back plate integrated material has performances such as better barrier property, heat resistance, aging resistance, toughness, light transmittance and electrical insulating property, and is strongin layer-to-layer bonding power, not easy to fall off and long in service life. The preparation process is convenient to operate and control, high in production efficiency and low in production cost,the POE adhesive film layer and the frosted layer can be firmly adhered and smoothly curled, the thicknesses of the POE adhesive film layer and the frosted layer can be controlled, the prepared adhesive film back plate integrated material is excellent in performance, the assembly procedure of a component is simplified, and the assembly cost of the component is reduced.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

Fluoride nanometer crystal for wideband optical amplification and preparation method and application of fluoride nanometer crystal

ActiveCN104403671AReduce chance of quenchingUniform and controllable thicknessNanoopticsLuminescent compositionsMulti bandLuminous intensity

The invention relates to a fluoride nanometer crystal for wideband optical amplification and a preparation method and application of the fluoride nanometer crystal in the technical field of materials science. According to the fluoride nanometer crystal for the wideband optical amplification, NaYF4: Yb, Re@NaYF4 or NaGdF4: Yb, Re@NaGdF4 nanometer crystal is in a monodisperse nucleocapsid structure. Laser of 980nm is used for exciting the monodisperse nanocrystal, and multi-band near infrared luminescence is produced; the peak position of a luminous peak is freely mixed with the fluoride nanometer crystals at different wave bands, so that the near infrared luminescence using a rare earth ion as a luminescence center is formed, and the effective bandwidth is enlarged. For the nanometer crystal in the monodisperse nucleocapsid structure with the near infrared luminescence is in a hexagonal phase structure, the luminescence center is free from the influence of high energy groups, the lower conversion luminescence efficiency and the luminous intensity are effectively improved, and the fluoride nanometer crystal is extremely suitable for the wideband optical amplification.

Owner:CHINA JILIANG UNIV

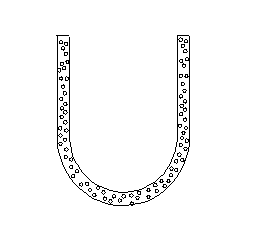

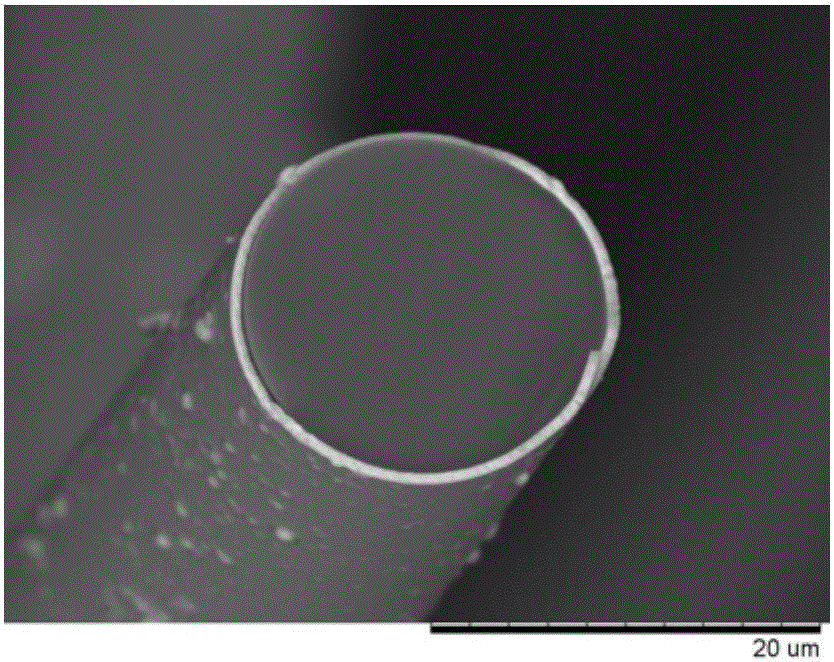

Porous composite filter tube and preparation method thereof

The invention discloses a porous composite filter tube. The filter tube comprises a tube-shaped structural layer with the thickness of 2-10mm, wherein the surface of the structural layer is provided with a functional layer with the thickness of 50-200mu m, the aperture of the structural layer is 20-150mu m, and the aperture ratio of the structural layer to the functional layer is 2.5-5. The invention also discloses a preparation method of the porous composite filter tube and the method comprises the following steps: weighting composite layer powder and carrier to prepare suspension liquid, adopting fluidization technology to distribute air and stir, then adopting heterogeneous atomization technology to ensure that the suspension liquid to perform atomization deposition or be coated on the outer surface of the matrix of porous material, sintering at 600-1400 DEG C under vacuum or hydrogen atmosphere, and keeping temperature for 1-3 hours to prepare the porous composite filter tube. The invention increases the filtration precision and permeation flux of the filtering element, overcomes the defects of ceramic porous materials and metal porous materials prepared by conventional sintering, has high strength and good filterability and breathability, has corrosion resistance, oxidation resistance and high temperature resistant, and is not easy to break.

Owner:WESTERN BAODE TECH CO LTD

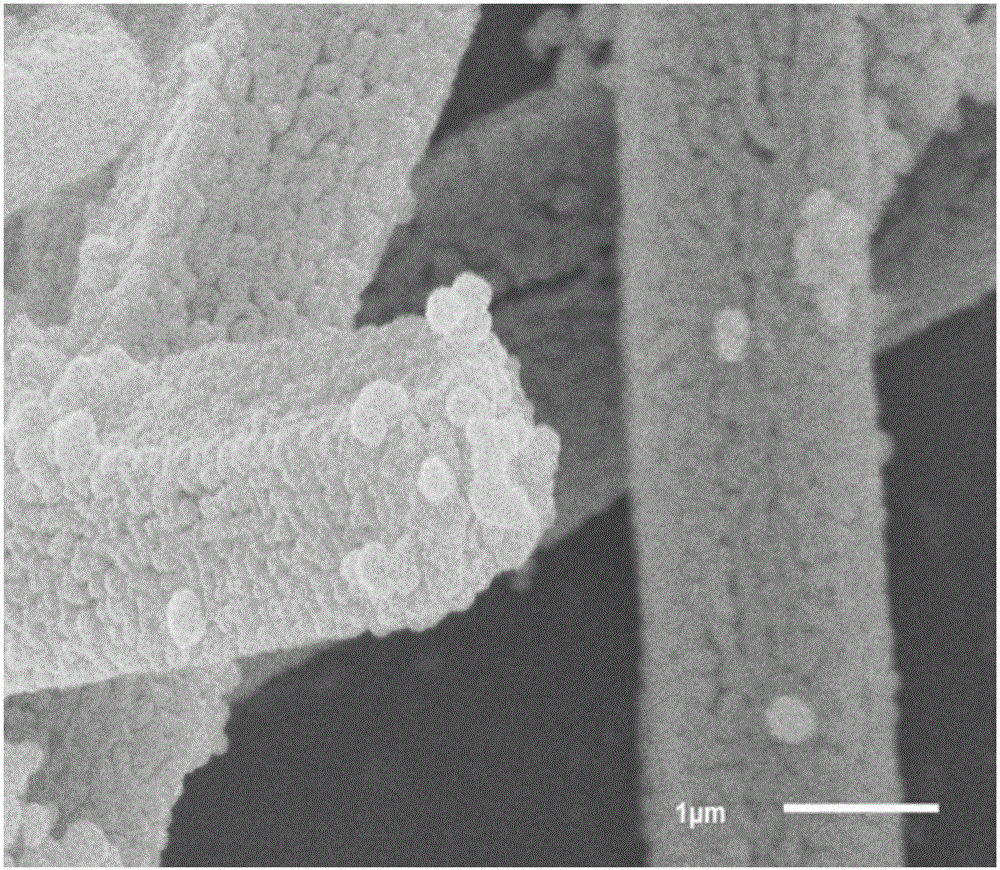

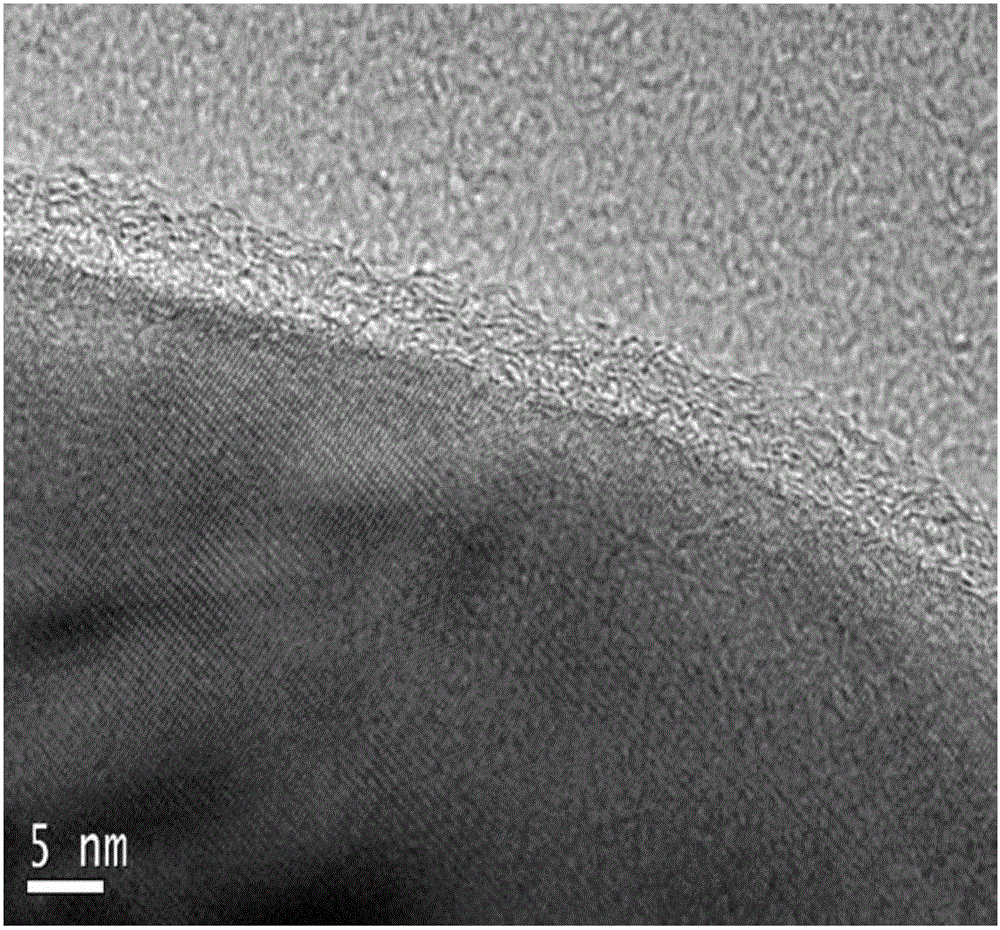

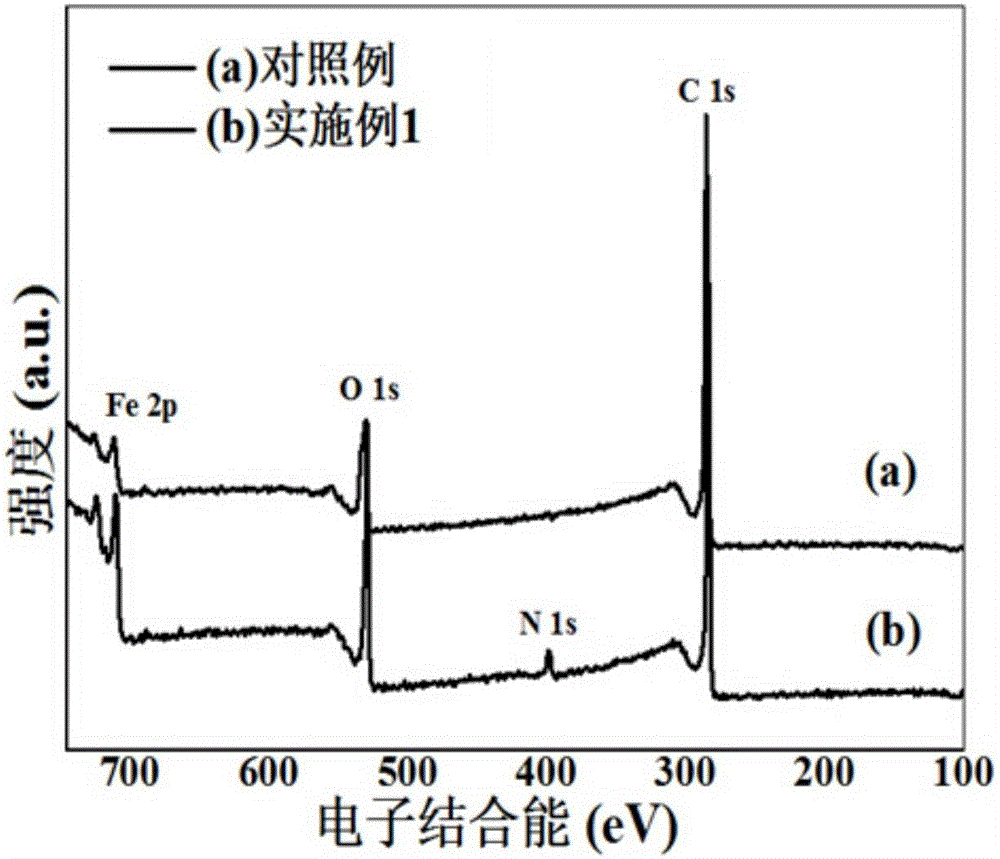

Nitrogen-doped carbon-coated iron oxide negative electrode material for lithium-ion battery and preparation

The invention belongs to the technical field of a negative electrode material for a lithium-ion battery, and discloses a nitrogen-doped carbon-coated iron oxide negative electrode material for the lithium-ion battery and a preparation method of the nitrogen-doped carbon-coated iron oxide negative electrode material. The method comprises the following steps of adding ferrite to a mixed solution of water and ethanol, stirring, dissolving, adding oxalate and stirring to obtain a turbid liquid; heating the turbid liquid to 120-220 DEG C for reaction for 8-15 hours to obtain a ferrous oxalate precursor; heating the ferrous oxalate precursor to 500-600 DEG C and burning the ferrous oxalate precursor for 4-8 hours to obtain an iron oxide; dissolving an emulsifier into water, adding n-butyl methacrylate, acrylonitrile and styrene, heating the solution to 55-65 DEG C, adding an initiator, stirring for 4-10 hours to obtain an emulsion and carrying out demulsification to obtain a polymer; and dispersing the polymer into an organic solvent, adding the iron oxide, stirring for 12-36 hours, separating to obtain a solid, heating the solid to 500-600 DEG C and burning the solid for 2-4 hours to obtain the nitrogen-doped carbon-coated iron oxide negative electrode material with excellent cycle performance and rate capability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

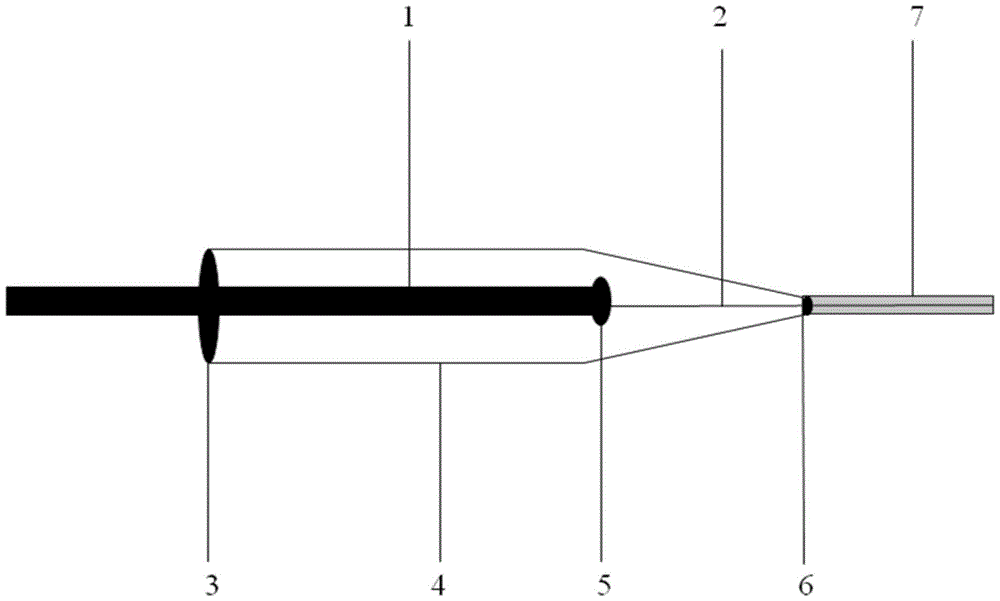

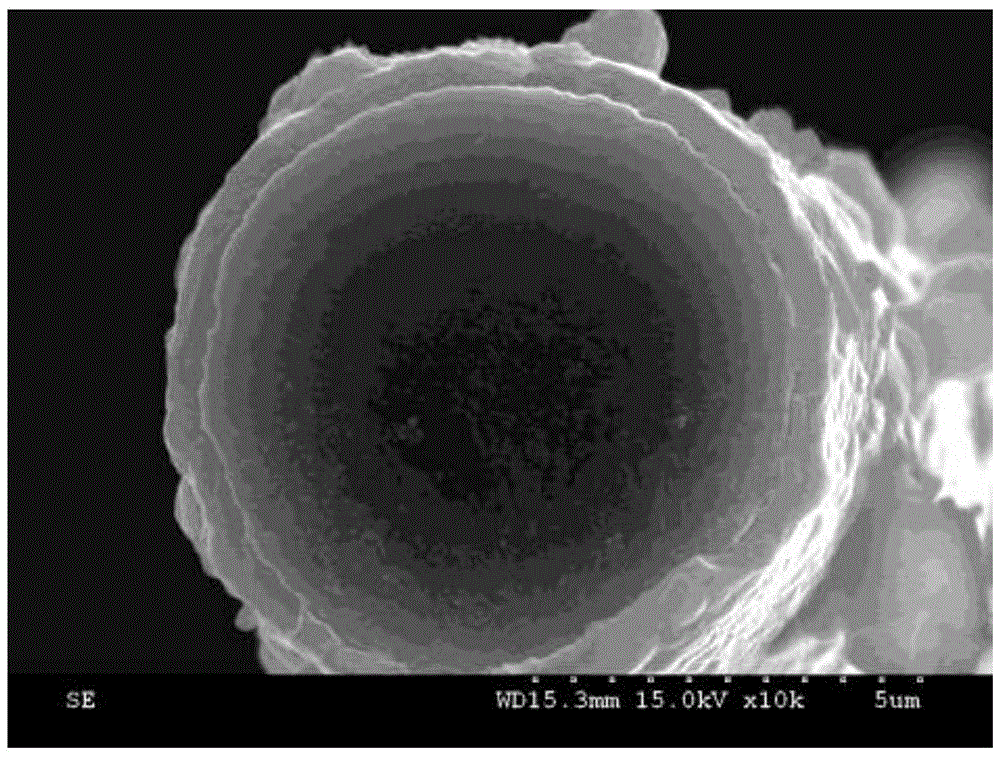

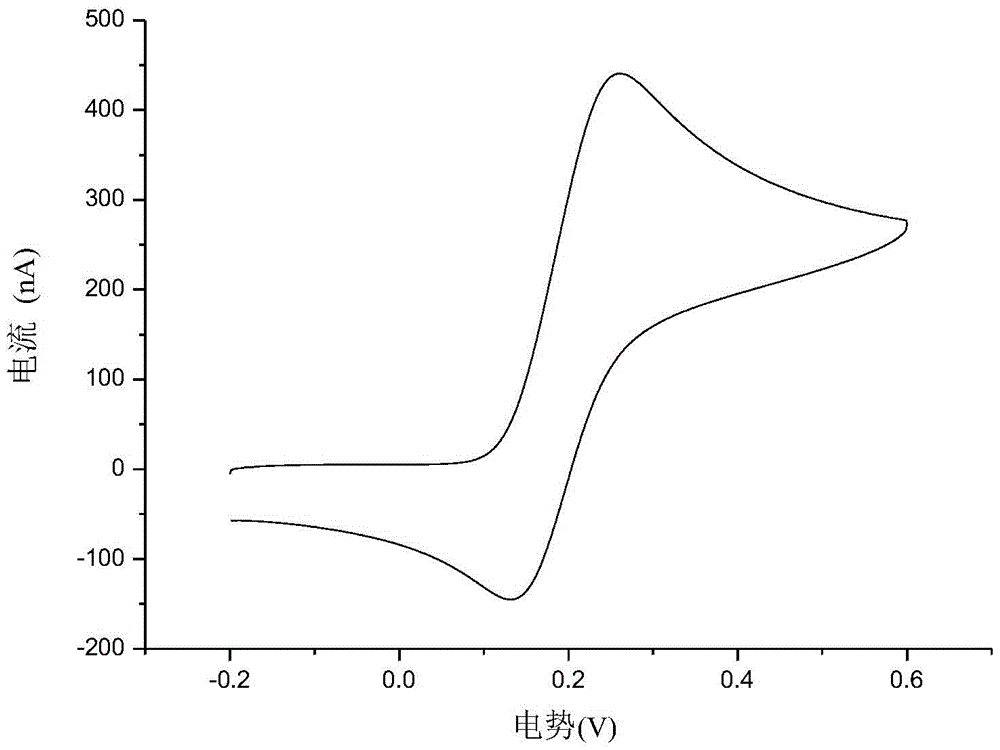

Preparation method and application of dual-purpose probe integrating solid-phase micro-extraction fibers and electrochemical detection working electrodes

ActiveCN105699452AExcellent electrochemical performanceGood environmental stabilityPreparing sample for investigationMaterial electrochemical variablesSolventCvd graphene

The invention relates to a preparation method and an application of a dual-purpose probe integrating solid-phase micro-extraction fibers and electrochemical detection working electrodes, and belongs to the field of analysis chemicals. The preparation method comprises the following steps of firstly, adhering carbon fibers and a copper conducting wire by silver conductive adhesive, inserting into a capillary tube of which one end is drawn into a tip end, sealing the two ends of the capillary tube by epoxy resin adhesive, enabling the carbon fiber to expose with 1-20mm out of the glass capillary tube, and polymerizing a polypyrrole-graphene quantum dot copolymerizing coating to the surface of carbon fiber by an electrochemical polymerizing method, so as to obtain the dual-purpose probe integrating the solid-phase micro-extraction fibers and the electrochemical detection working electrodes. The preparation method has the advantages that by integrating the solid-phase micro-extraction fibers and the electrochemical detection working electrodes, the direct online detection is realized without solvent dissolving after extraction, and a series of problems of sample thinning, sample state change and the like in the solvent dissolving after the traditional solid-phase micro-extraction are improved; the preparation method is simple, the environment-friendly effect is realized, the detection sensitivity is high, and the application prospect in the fields of biological analysis, environment analysis and the like is broad.

Owner:BEIJING UNIV OF TECH

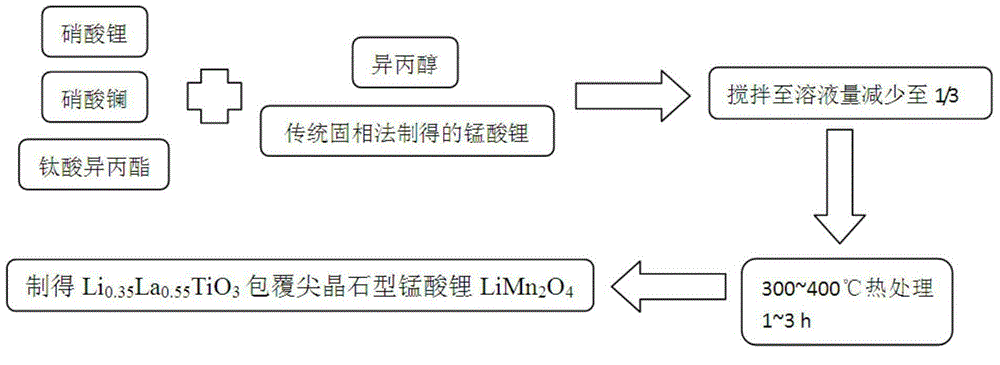

Method for synthesizing lithium ion battery positive electrode material

InactiveCN105206821AUniform and controllable thicknessReduce exposureMaterial nanotechnologyCell electrodesLanthanum nitrateLithium electrode

The invention discloses a method for synthesizing a lithium ion battery positive electrode material. The method comprises the following steps: dissolving lithium nitrate, lanthanum nitrate and titanium tetraisopropanolate in isopropyl alcohol to prepare an isopropyl alcohol solution; adding spinel-type lithium manganate into the isopropyl alcohol solution for stirring, and carrying out 1-3 hours' heat treatment at 300-400 DEG C to prepare Li0.35La0.55TiO3 coated spinel-type lithium manganate. According to the technical scheme, the method has the advantages that nanocrystallization of a coating layer can be effectively realized, and the coating thickness is uniform and controllable; through the coating layer with a nano-sized surface, the contact between LiMn2O4 and an electrolyte can be effectively reduced, side reactions triggered in a charge-discharge process of a lithium ion battery can be reduced, the stability of the lithium ion battery can be improved, and the high-temperature cycle life of the lithium ion battery can be prolonged.

Owner:SHANGHAI ELECTRICGROUP CORP +1

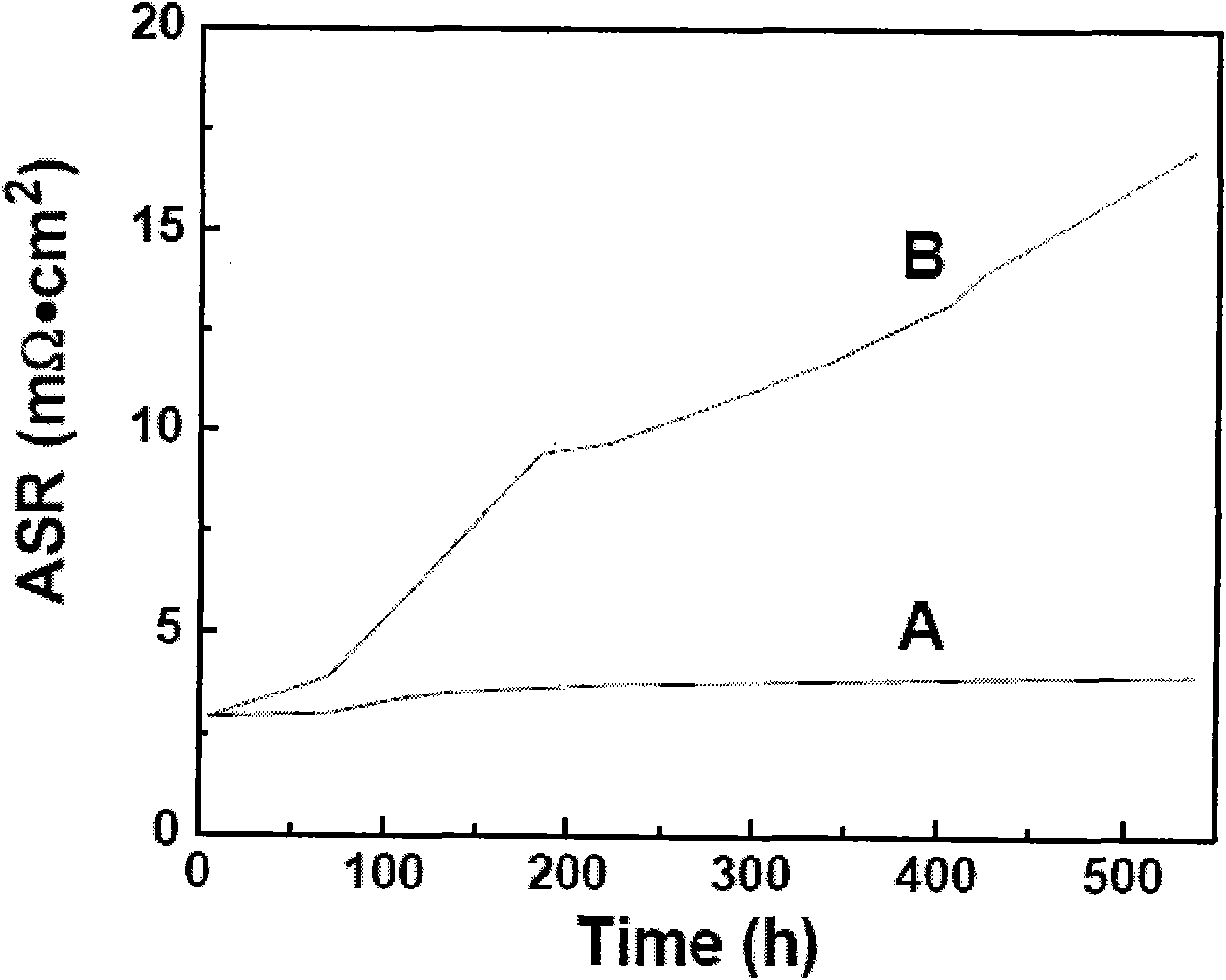

Alloy high temperature oxidation resisting nanostructure conductive coating prepared with spinel powder reduction method

InactiveCN101671829AImprove sinterabilityUniform and controllable thicknessConductive layers on insulating-supportsCable/conductor manufactureAlloy coatingNanostructure

The invention provides a preparing method of an alloy high temperature oxidation resisting nanostructure conductive coating, i.e. a spinel powder reduction coating method. On one hand, coating powdermaterial with favorable sintering performance is obtained by the regulation and control of the preparing process of coating powder material and effective reductive treatment; on the other hand, a nanometer microstructure film is prepared on the alloy surface by adopting silk screen assisted improved sizing agent coating technology. The film has controllable and even thickness and superior performance, and coating is tightly combined with the alloy; the coating alloy has lower area specific resistance (ASR) and higher long-time running stability under high temperature oxidation environment. Thespinel powder reduction coating method originated by the invention has simple film manufacturing method, low cost and strong repetitiveness, can be applied to coating preparation of alloy with different shapes or sizes, has superiority especially when preparing the large-area alloy coating in practical application, can greatly lower the preparing cost of the alloy coating and has strong applicability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

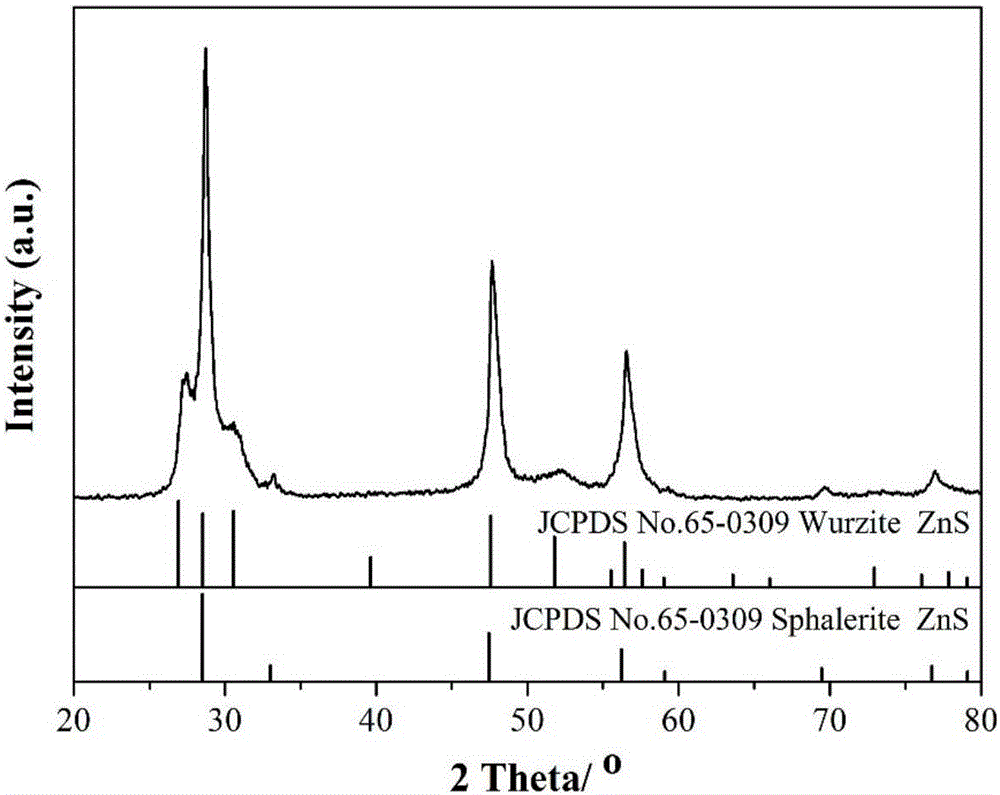

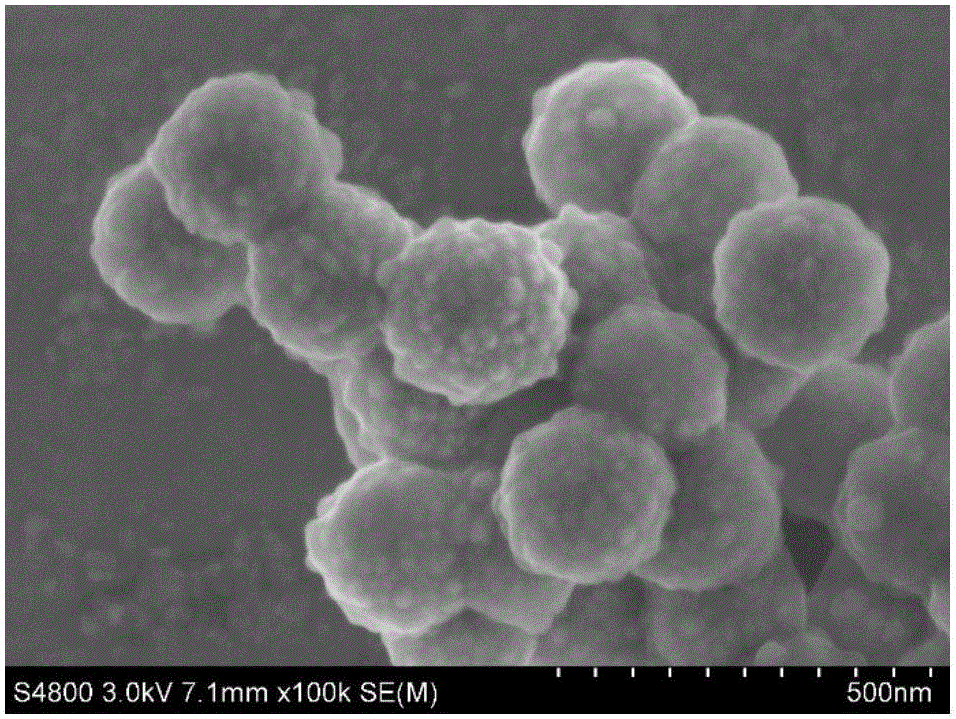

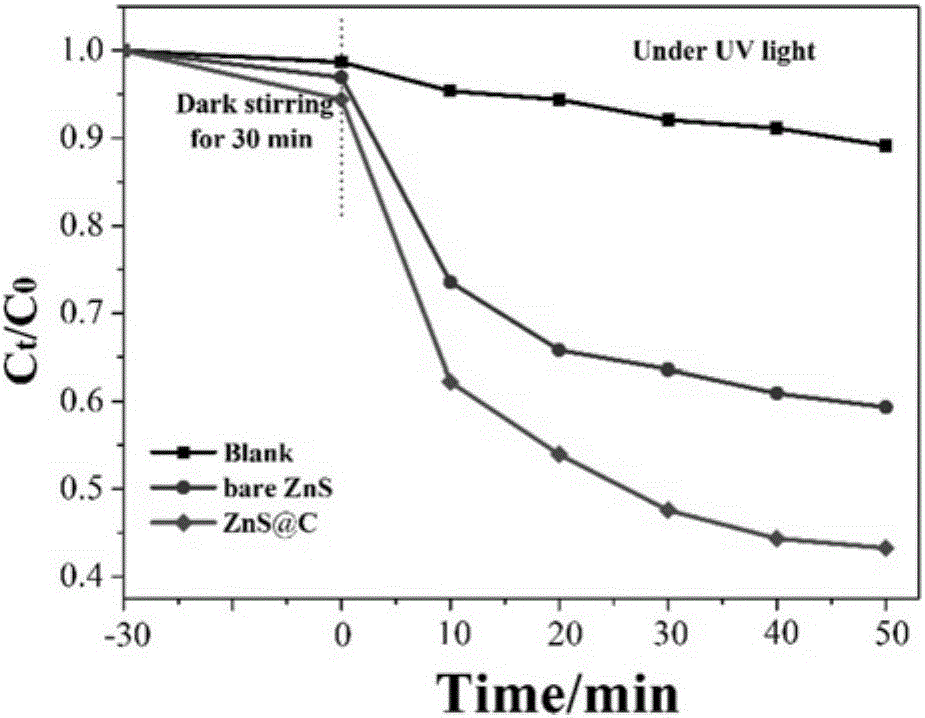

Method for preparing carbon-coated zinc sulfide microspheres through microwave hydrothermal method

InactiveCN106179407AUniform and controllable thicknessHigh purityCatalyst activation/preparationMicrowaveMicrosphere

The invention discloses a method for preparing carbon-coated zinc sulfide microspheres through a microwave hydrothermal method. The method includes following steps: 1), dissolving analytically-pure Zn(NO3)2.6H2O and a sulfur source in deionized water to obtain a precursor solution; 2), adding a carbon source into the precursor solution during magnetic stirring; 3), sufficiently stirring, putting reaction precursor liquid in a polytetrafluoroethylene liner, sealing a hydrothermal reaction kettle, placing the hydrothermal reaction kettle into a microwave hydrothermal reactor for reaction, and naturally cooling to room temperature after reaction finishes; 4), washing a product, and vacuum drying to obtain the carbon-coated zinc sulfide microspheres. The method is short in reaction time, simple, efficient, low in cost and high in feasibility, thereby being highly economical and practical and having great industrialization prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Flexible packaging film capable of being composited by microwaves, automatic exhaust packaging film for microwave ovens, and packaging bag

InactiveCN102991072AIncrease productivityUniform and controllable thicknessFlexible coversWrappersPolypropylenePolyamide

The invention relates to the technical field of flexible packaging, and particularly relates to a packaging film which can be applied to the heating of food in microwave ovens, and a packaging bag prepared from the packaging film. A flexible packaging film capable of being composited by microwaves is composited by multiple layers of films, the innermost layer is a polyethylene film or a casting polypropylene film, and the other layers of films are any one or more of a biaxially oriented polyester film, a biaxially oriented polypropylene film and a biaxially oriented polyamide film; and the polyethylene film is composed of low-density polyethylene, linear low-density polyethylene, metallocene polyethylene and inorganic filler, the casting polypropylene film is composed of homo-polypropylene, co-polypropylene and inorganic filler, and the inorganic filler is at least one of titanium dioxide, calcium carbonate and silica with a particle size of 30-700 nanometers. According to the invention, as the film at the innermost layer contains a certain amount of inorganic filler, a certain number of micropores can be drilled by using laser, and in the process of microwave heating, the gaps between micropores are widened, so that an effect of automatic exhaust is achieved.

Owner:惠州宝柏包装有限公司

Method for nickel electroplating on surfaces of Sic fibers

The invention discloses a method for nickel electroplating on the surfaces of Sic fibers and relates to surface treatment of the Sic fibers. Continuous Sic fibers are cut, continuous Sic fibers with certain lengths are obtained and subjected to heat treatment and degumming, and degummed Sic fibers are obtained; the degummed Sic fibers are placed in a NaOH solution to be boiled, and after rinsing, degreased Sic fibers are obtained; the degreased Sic fibers are put in a nitric acid aqueous solution to be soaked and subjected to acid corrosion, so that the surfaces of the Sic fibers are roughened to improve the surface energy of the Sic fibers, the binding force between a plating layer and the fibers is strengthened, the Sic fibers are taken out from the nitric acid aqueous solution and rinsed, and surface-roughened Sic fibers are obtained; the surface-roughened Sic fibers are dried, and pretreated and dried Sic fibers are obtained; and an electroplating solution is prepared, the obtained pretreated and dried Sic fibers serving as a cathode and a metal nickel plate serving as a anode are placed in the electroplating solution, a layer of bright and compact nickel metal coating is formed on the surfaces of the pretreated and dried Sic fibers, and nickel electroplating on the surfaces of the Sic fibers is achieved.

Owner:XIAMEN UNIV

Method for bonding preparation of Ge-on-insulator (GOI) through Ge film

ActiveCN104867814ASolve the problem of surface micro voidsReduced fragilitySemiconductor/solid-state device manufacturingSurface energyEngineering

The invention discloses a method for bonding preparation of Ge-on-insulator (GOI) through a Ge film, and relates to GOI. The method comprises the following steps: performing ion implantation on a Ge sheet to form a defect plane; binding PDMS with the processed Ge sheet by use of light cured glue; applying a cutting force parallel to a peeling plane on a processed flexible support substrate, and tearing a surface Ge film from a body Ge substrate along the defect plane to obtain a flexible Ge film; then obtaining the Ge film through polishing, then cleaning the Ge film and an SiO2 / Si wafer, performing bumping with the surface of the wafer by use of plasma, and at the same time, performing activation processing on the surface; attaching the processed Ge film to the SiO2 / Si wafer; fully discharging air of an interface by use of a rolling method; and performing pre-bonding on a sample after processing, afterwards, peeling the flexible susbtrate from a GOI structure, and performing annealing so as to enhance bonding surface energy and improve the bonding intensity.

Owner:XIAMEN UNIV

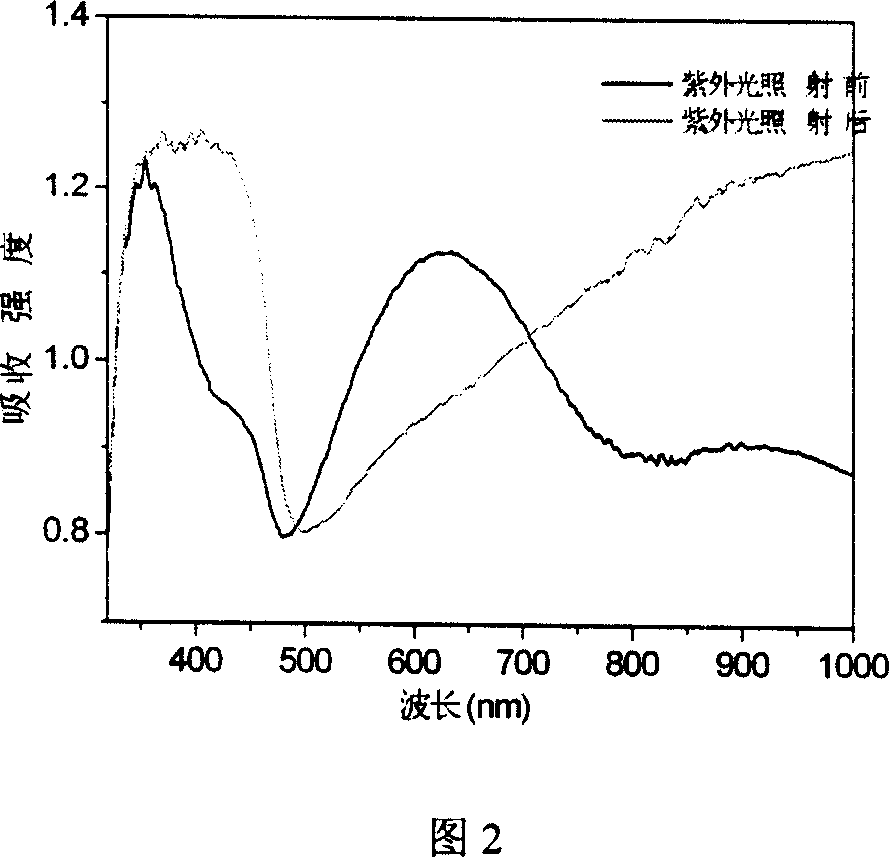

High obstructive polyaniline composite film and its preparation method and use

The present invention is one kind of composite polyaniline film with high obstruction. The composite polyaniline film comprising polyaniline and copolyvinylidene chloride microsphere in 100-1000 nm diameter is prepared through mixing intrinsic polyaniline solution and copolyvinylidene chloride solution, spraying the mixture solution with an electric sprayer to some accepting device to obtain the intrinsic composite polyaniline film through volatilizing solvent, and irradiating under 45 W ultraviolet lamp for 1-30 min. The said process can form the film in adjustable thickness and conductivity on substrate of different materials and in different shapes. The composite polyaniline film has electromagnetic shield property, antistatic property, waterproofing, acid and alkali resistance, high gas obstruction, etc, and may be applied widely.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Flexible polyimide-based composite dielectric film material and preparation method and application thereof

ActiveCN110330646ASmall coefficient of thermal expansionHigh electromagnetic absorption efficiencyDielectricReflection loss

The invention belongs to the field of dielectric materials and discloses a flexible polyimide-based composite dielectric film material and a preparation method thereof. The flexible polyimide-based composite dielectric film material is prepared by stirring MXene and polyamic acid formed by dianhydride and diamine at room temperature to obtain a mixed solution of MXene / PAA, coating a base materialwith the mixed solution of MXene / PAA, and amidating at 150-550 DEG C, wherein the MXene is Mn+1Xn, X is selected from C or N, M is selected from Sc, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo AND Mn transition metal elements. The preparation method of the flexible polyimide-based composite dielectric material is simple, the thickness is uniform and controllable, and the dielectric property is good; and as a supercapacitor device or an electromagnetic wave absorbing material, the flexible polyimide-based composite dielectric material has the characteristics of higher electromagnetic absorption efficiency, good cycle stability, small maximum reflection loss, wide absorption frequency range and the like.

Owner:GUANGDONG UNIV OF TECH +1

B and Gd-containing overall composite combustible toxic fuel and preparation method

ActiveCN102129889AAvoid demandLow costNuclear energy generationVacuum evaporation coatingNegative temperatureNuclear power

The invention belongs to a combustible toxic fuel, in particular to a B and Gd-containing overall composite combustible toxic fuel and a preparation method. The fuel aims to control excess reactivity and meets the requirements of long-period reactivity control and moderator negative temperature coefficient control on the composite combustible toxic fuel. The composite combustible toxic fuel consists of a ZrB2 coating and a UO2-Gd2O3, wherein the UO2-Gd2O3 comprises 2 to 12 mass percent of Gd2O3; and the linear density of concentrated <10>B is 0.1 to 1.0 mg / cm. By using the overall composite combustible toxic fuel, the requirements of the long-period reactivity control and the moderator negative temperature coefficient control on the composite combustible toxic fuel can be met; moreover, the cost of the composite combustible toxic fuel is lower than that of an Er-containing combustible toxic fuel. Simultaneously the service life of a reactor core is prolonged, the refueling period is prolonged and the nuclear power operation cost is reduced, so that the refueling period of a light-water reactor nuclear power station fuel can reach 24 to 48 months.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com