Metal-coated oxide nano core-shell structure catalyst and preparation method thereof

A technology of structural catalysts and nano-core shells, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low catalyst cost and achieve good dispersion , avoid metal organic compounds, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

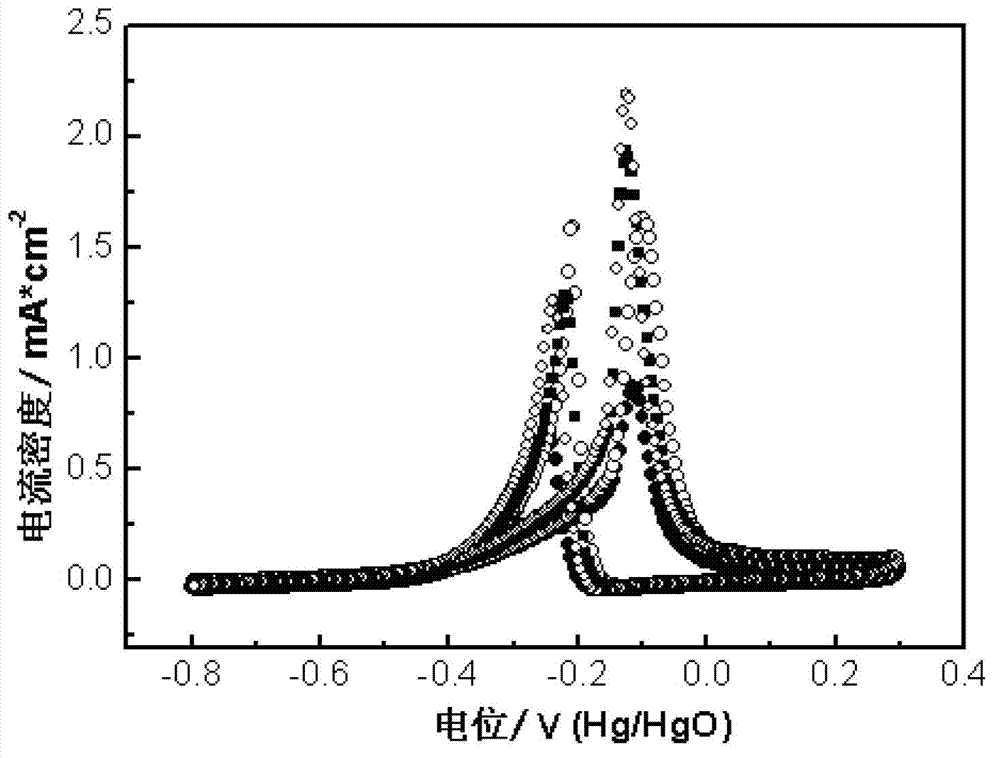

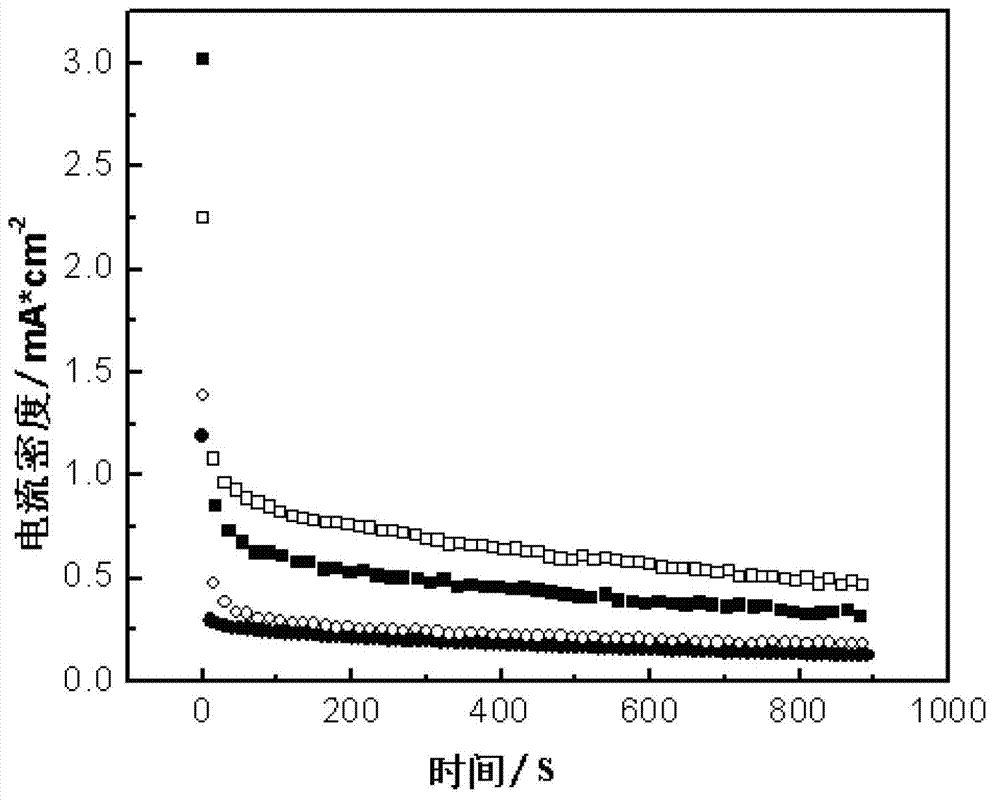

[0010] Specific Embodiment 1: In this embodiment, a metal-coated oxide nano-core-shell catalyst is a nano-core-shell catalyst whose shell is uniformly coated with metal and whose core is oxide nanoparticles. The shell is uniformly coated with a metal thickness is 1nm-20nm, and the particle size of the oxide nanoparticles is 1nm-200nm.

[0011] The metal-coated oxide nano-core-shell structure catalyst described in this embodiment has a unique oxide core, and its oxide core can change the electronic structure and geometric structure of the outer metal, thereby effectively improving the catalytic activity and stability of the noble metal catalyst. Compared with the commercial carbon-supported palladium (Pd / C) catalyst, the catalytic activity is 1.5~3 times of the commercial carbon-supported palladium (Pd / C) catalyst.

[0012] The core of the metal-coated oxide nano-core-shell structure catalyst described in this embodiment is oxide nanoparticles, and compared with the metal-coate...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the oxide nanoparticles are Al 2 o 3 , Ga 2 o 3 , SiO 2 、GeO 2 、TiO 2 , ZrO 2 , V 2 o 5 、Cr 2 o 3 , MnO 2 , Fe 2 o 3 , Fe 3 o 4 、Co 2 o 3 , NiO, CuO, ZnO, Nb 2 o 5 、MoO 3 , RuO 2 、In 2 o 3 , SnO 2 , Sb 2 o 3 , Sb 2 o 5 , Tl 2 o 3 , PbO, Bi 2 o 3 , La 2 o 3 、 Ta 2 o 5 、WO 2 、WO 3 、 Bi 2 o 3 and CeO 2 One of them, or a mixture of two or more of them, or a solid solution of oxides prepared by two or more of them. Others are the same as the first embodiment.

[0015] The oxide solid solution described in this embodiment is prepared according to the following steps: ① First, two or more oxides are dissolved in acid in any proportion, and the mixed solution is obtained after stirring evenly; ② Add Distilled water and polyvinylpyrrolidone (PVP), and use acid to adjust the pH value to 4~6 to obtain the bottom liquid, ③Then add the mixed solut...

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and one of the specific embodiments one or two is: the metal is Pt, Pd, Ru, Os, Rh, Ir, Ag, Au, Re, Cr, Fe, Mn, One or more of Co, Ni, Cu, Zn, In, Sn, and Sb. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com