Patents

Literature

318 results about "Carbide coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated tool of cemented carbide

InactiveUS6187421B1Improve propertiesImprove tool lifePigmenting treatmentOther chemical processesCoated membraneCarbide coating

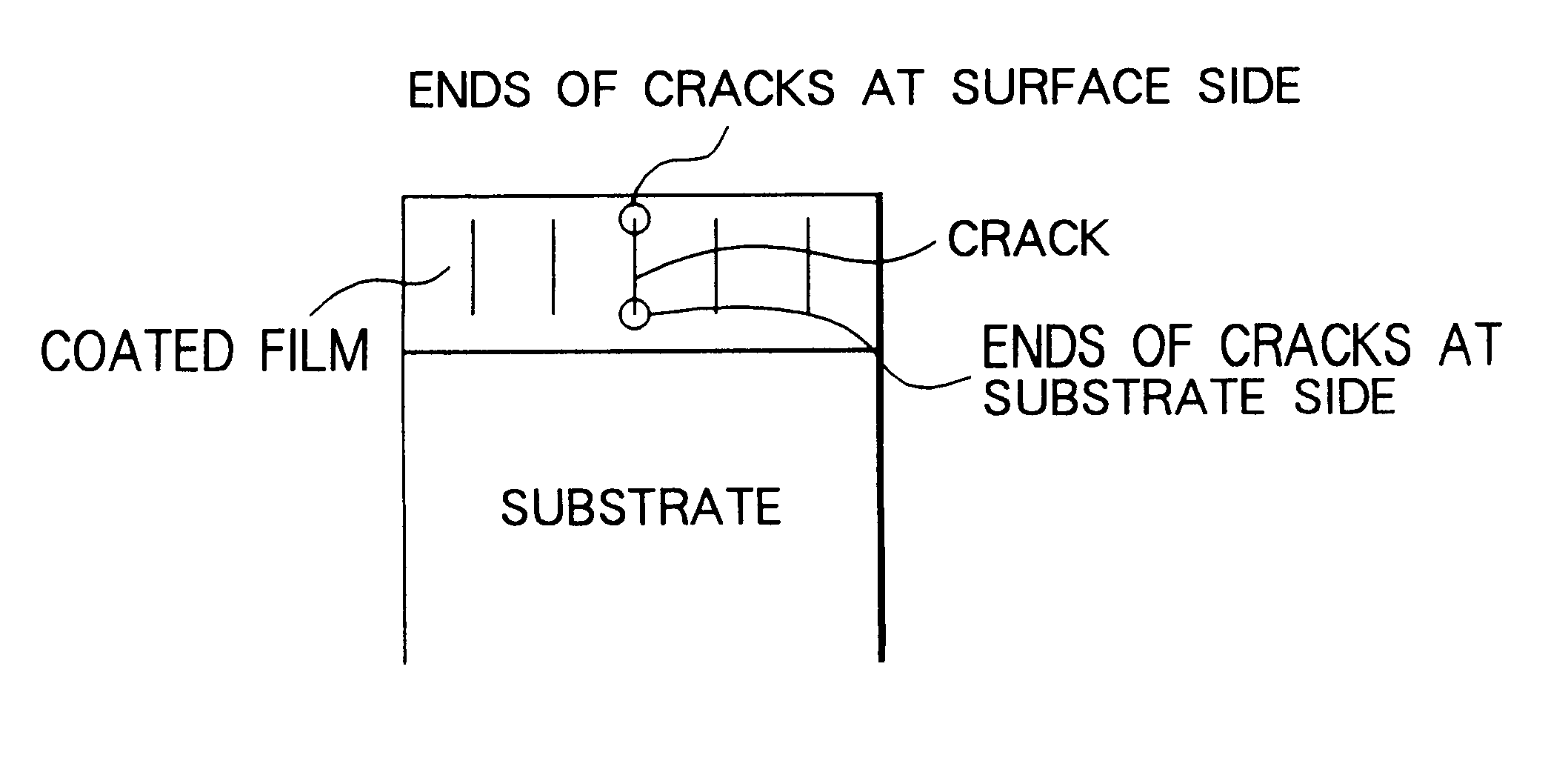

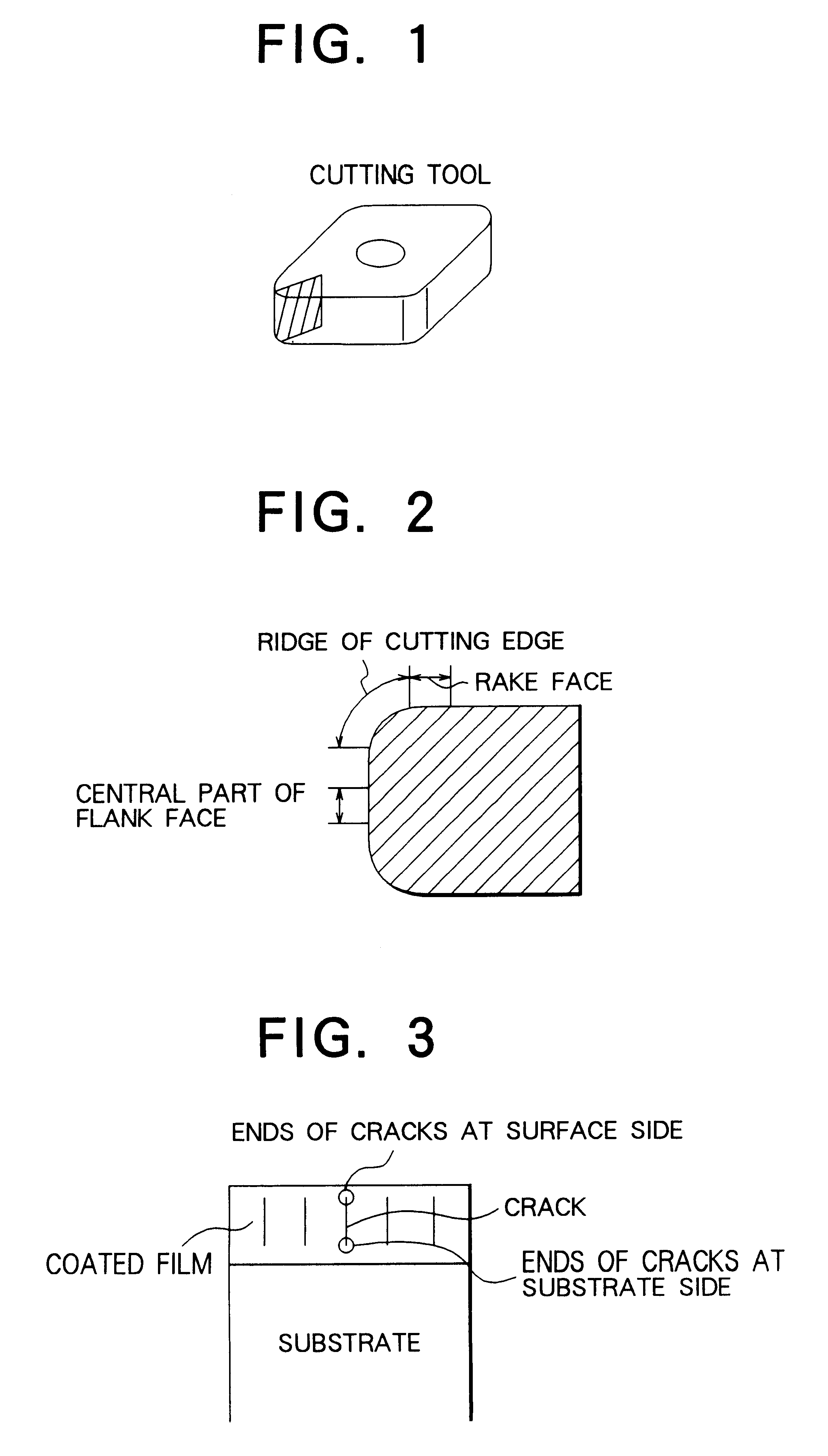

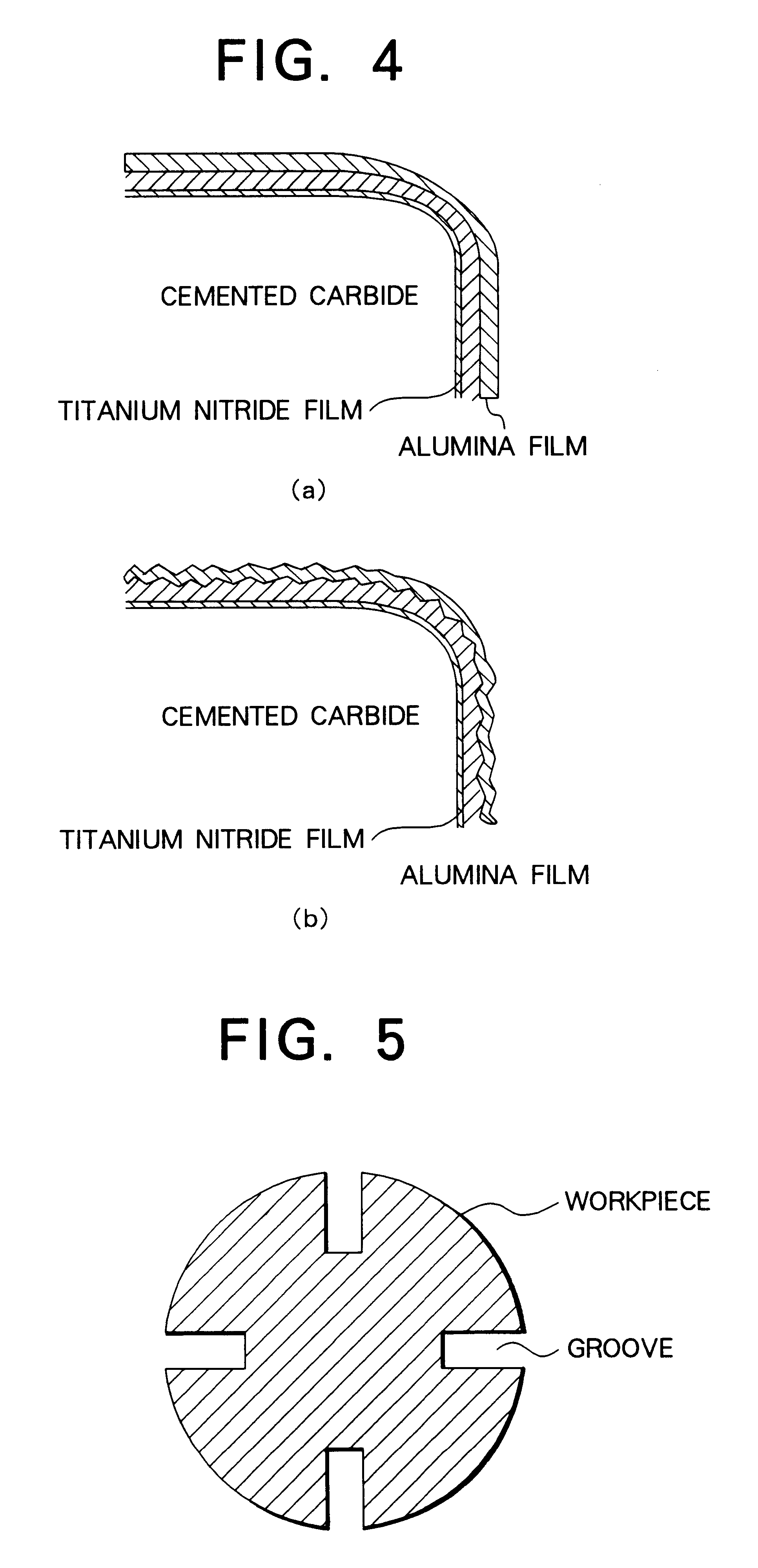

The principal object of the present invention is to provide a coated cemented carbide tool whose both properties of breakage resistance and wear resistance are improved and whose life is lengthened.The present invention has been made to achieve this object and is related with a coated cemented carbide cutting tool comprising a substrate consisting of a matrix of WC and a binder phase of an iron group metal and a plurality of coated layers provided on a surface of the substrate, in which (a) an innermost layer, adjacent to the substrate, of the coated layers consists essentially of titanium nitride having a thickness of 0.1 to 3 mum, (b) on a mirror-polished cross-sectional microstructure of the said tool, an average crack interval in the coated film on a ridge of a cutting edge and / or rake face is smaller than an average crack interval in the coated layer on a flank face, (c) at least 50% of the cracks in the coated film on the said ridge of the cutting edge and / or rake face have ends of the cracks in the said innermost titanium nitride layer, in a layer above the titanium nitride layer or in an interface between these layers and (d) an average crack length in the coated film on the said ridge of the cutting edge and / or rake face is shorter than an average film thickness on the flank face.According to the present invention, quantitatively specifying the crack intervals and positions of the ends of the cracks in the coated layer results in excellent breakage resistance as well as wear resistance.

Owner:SUMITOMO ELECTRIC IND LTD

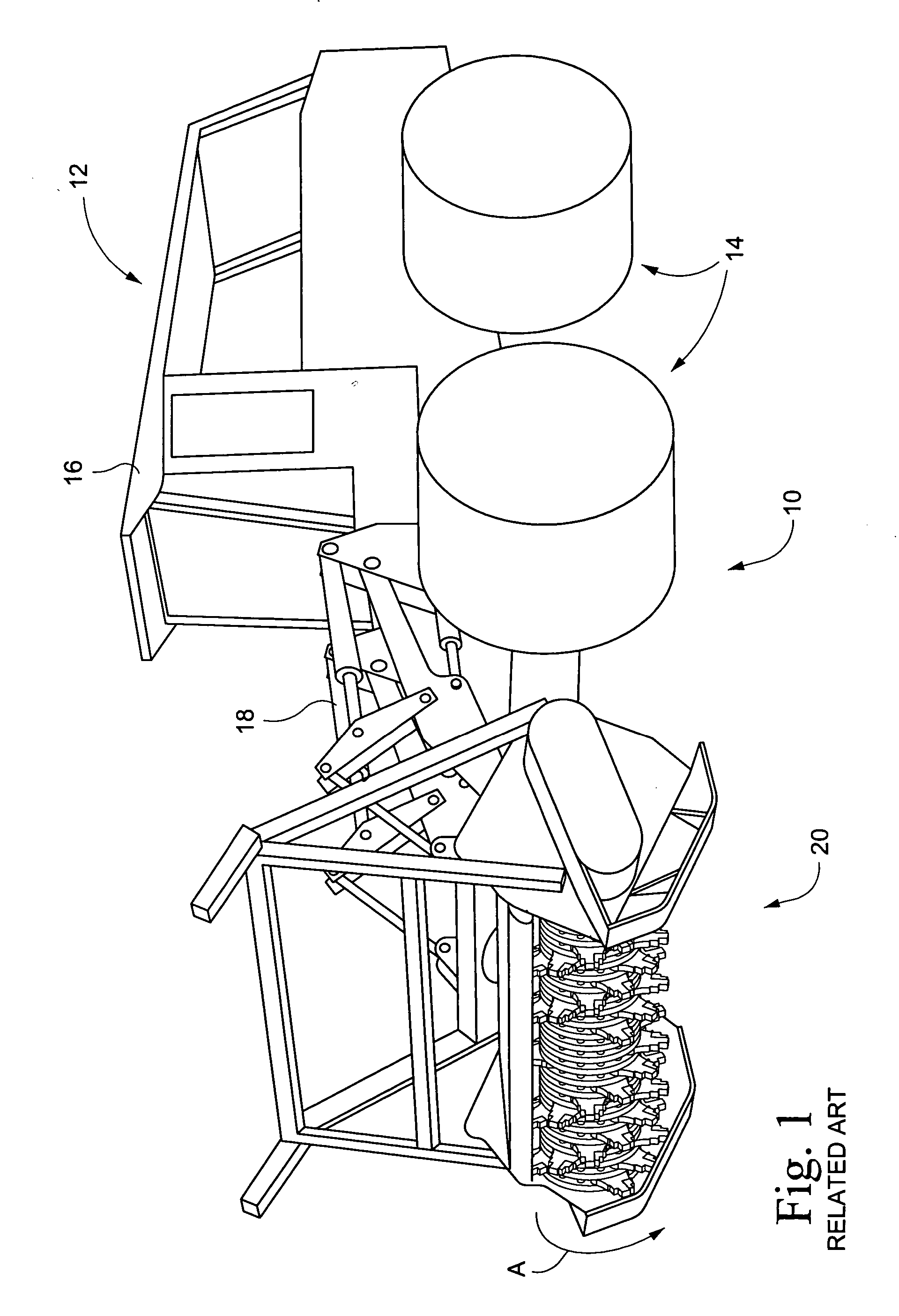

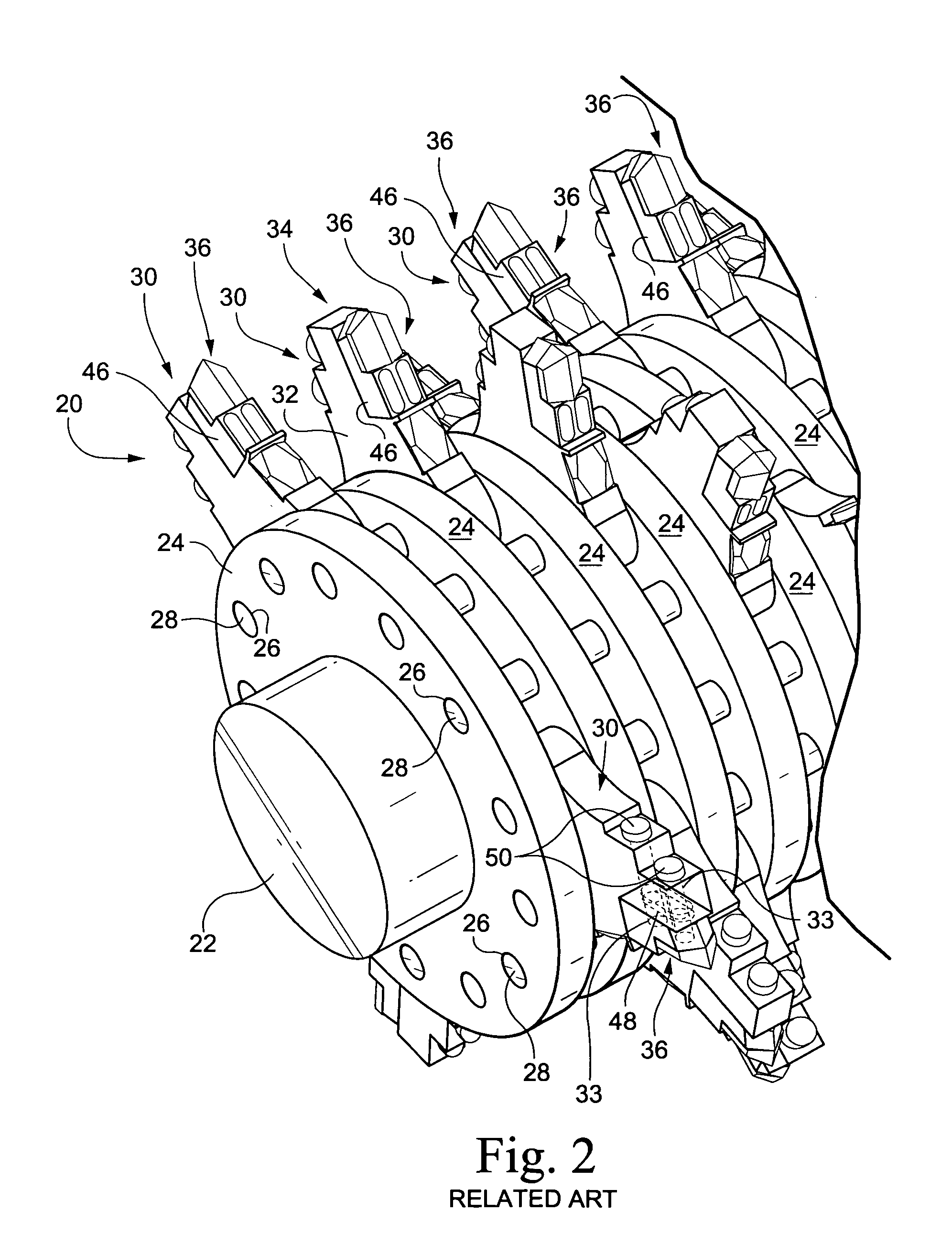

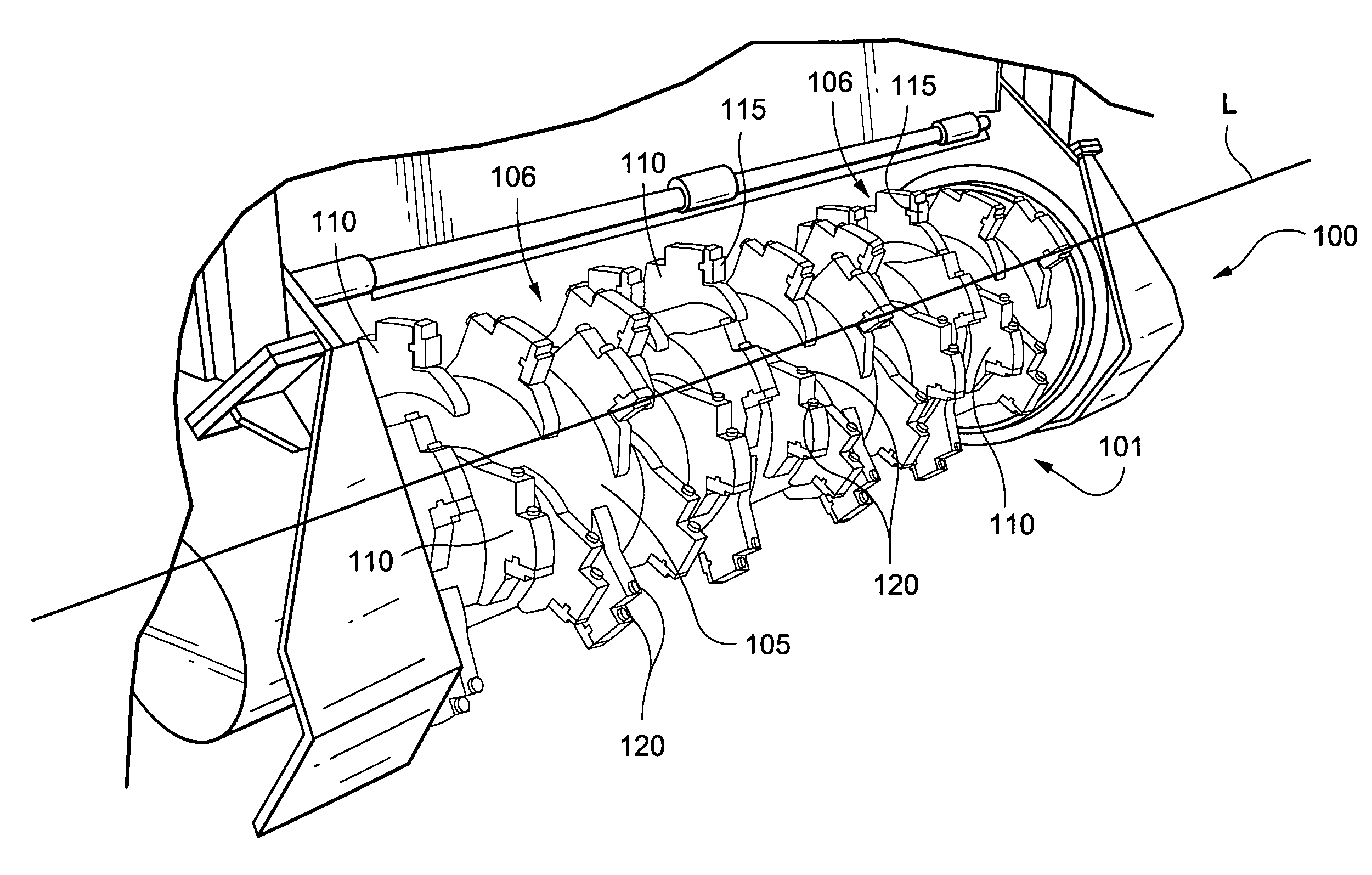

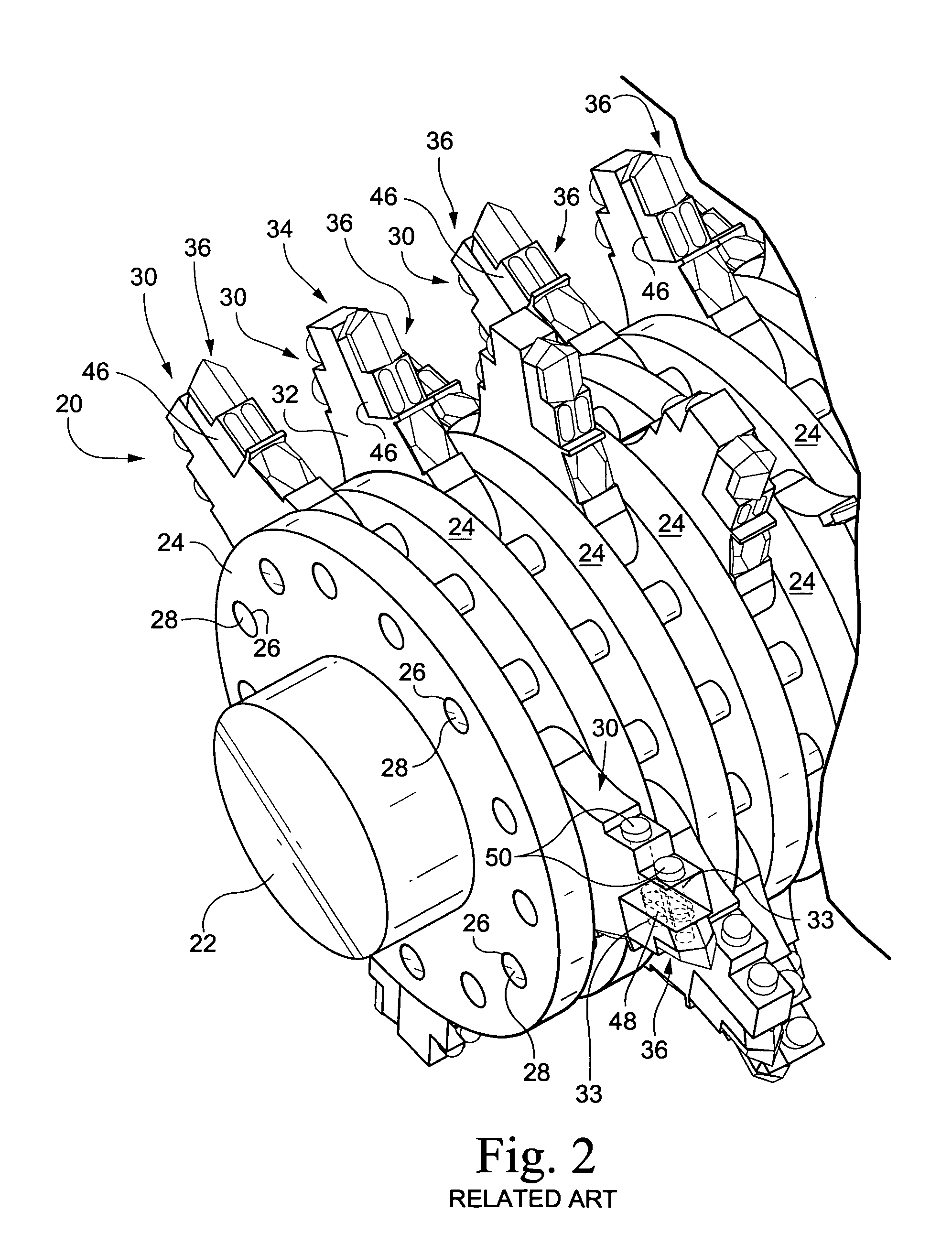

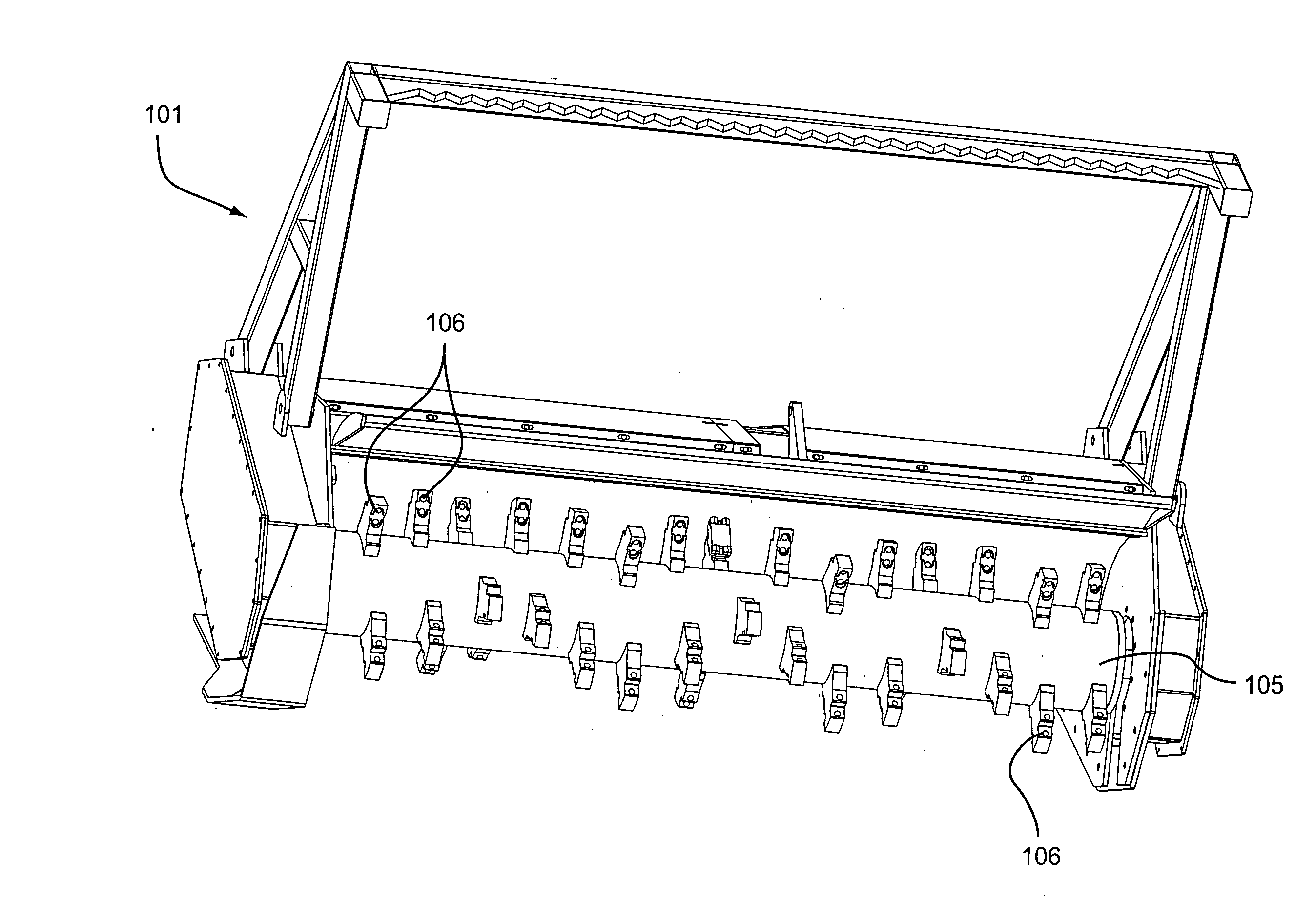

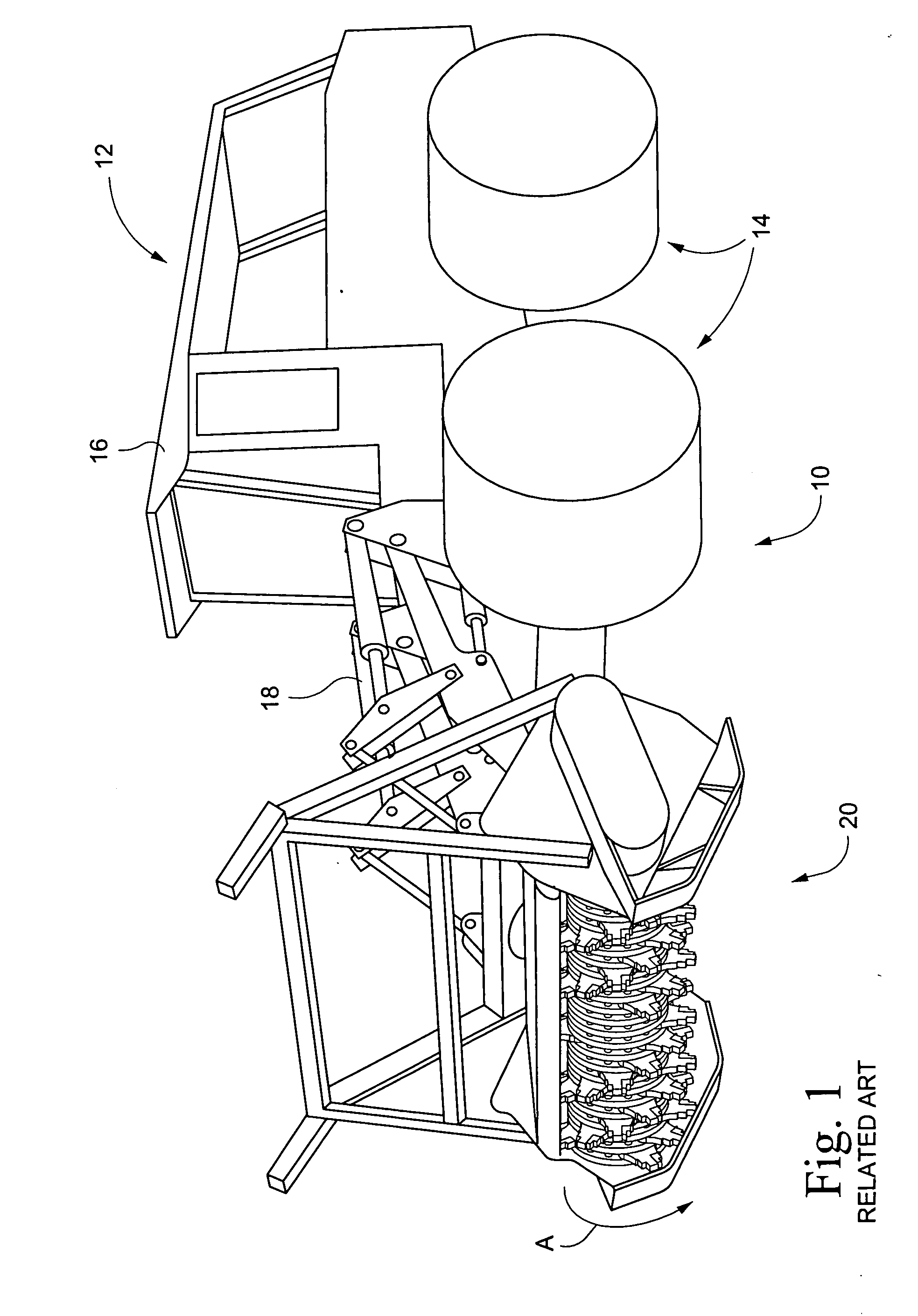

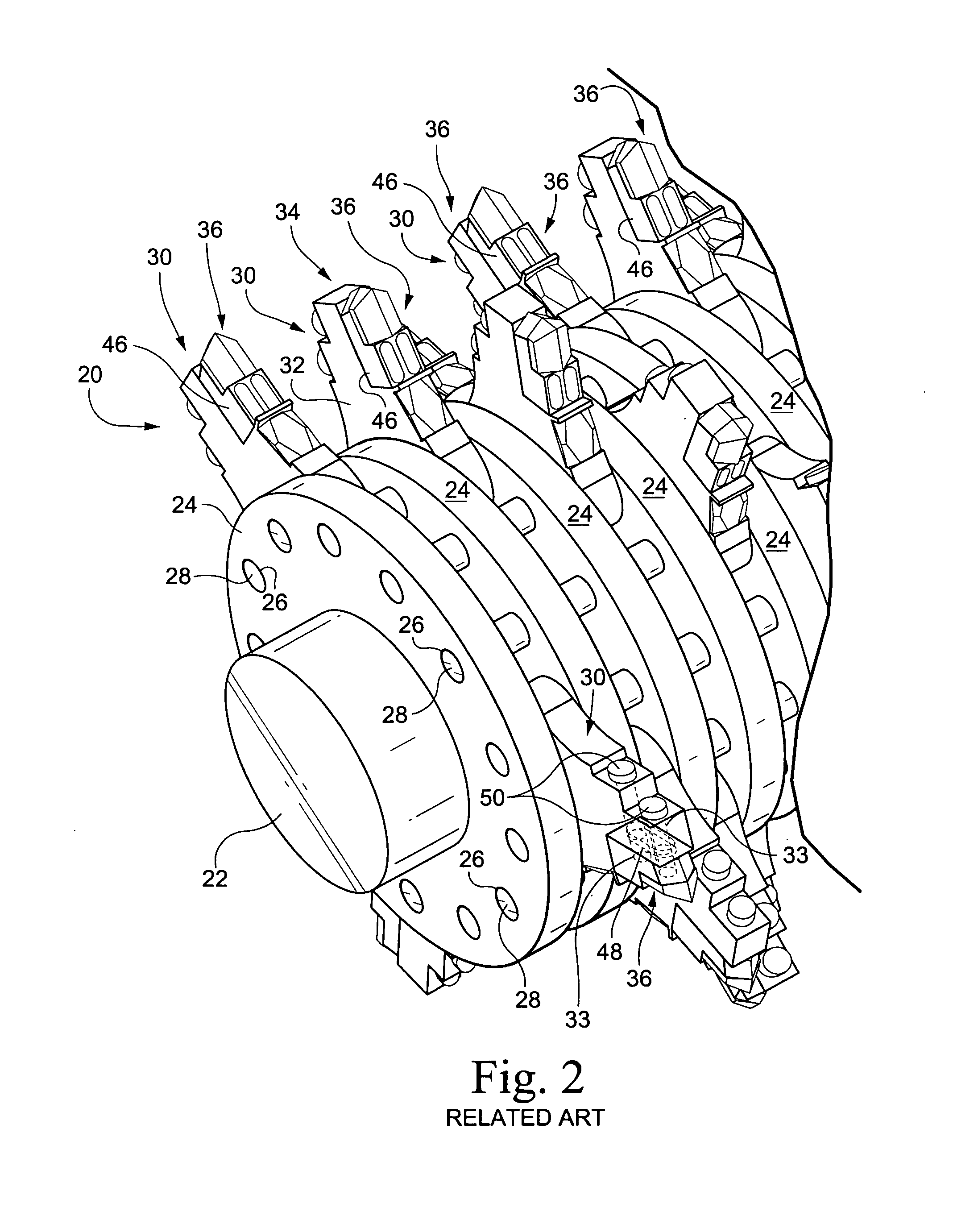

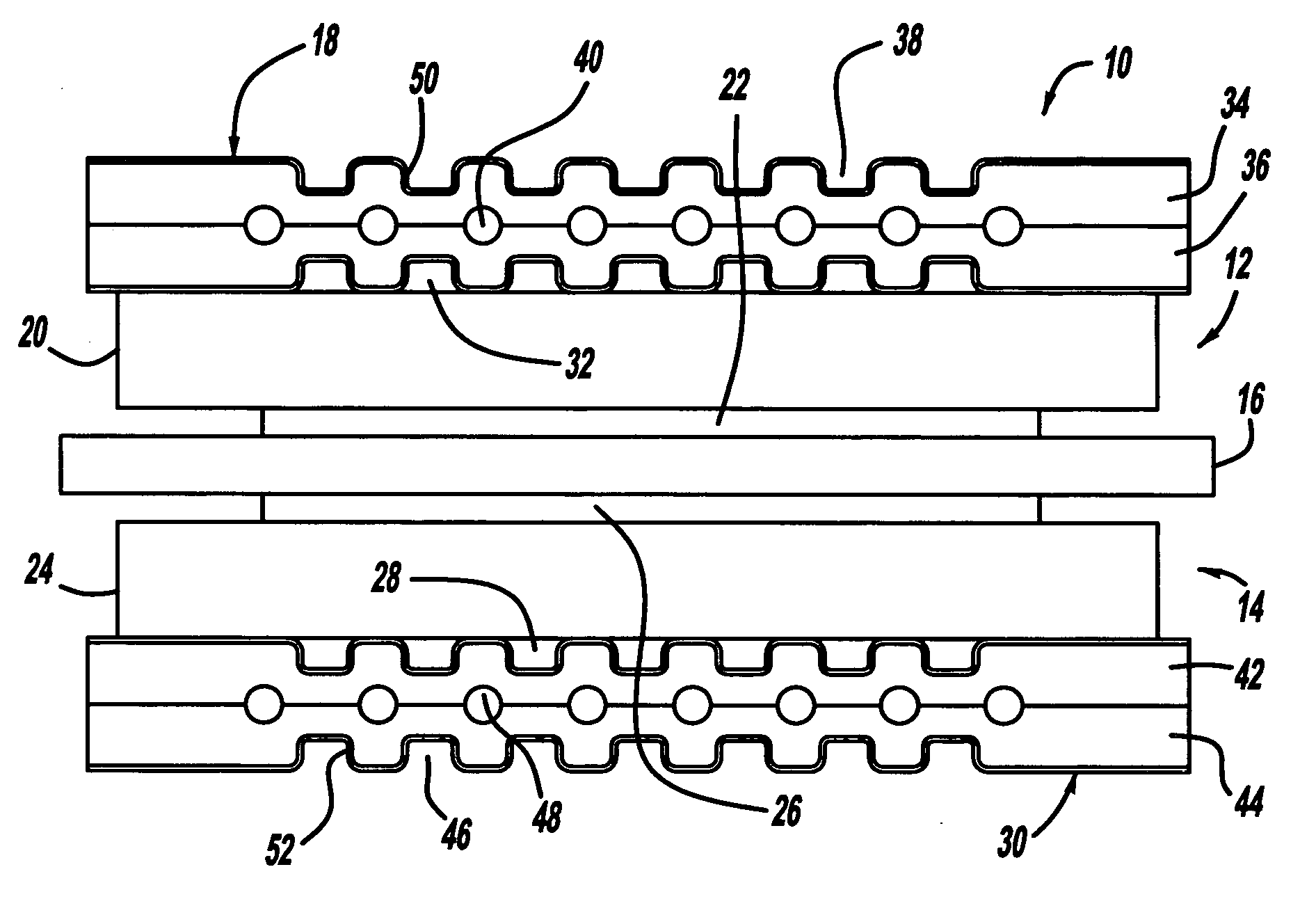

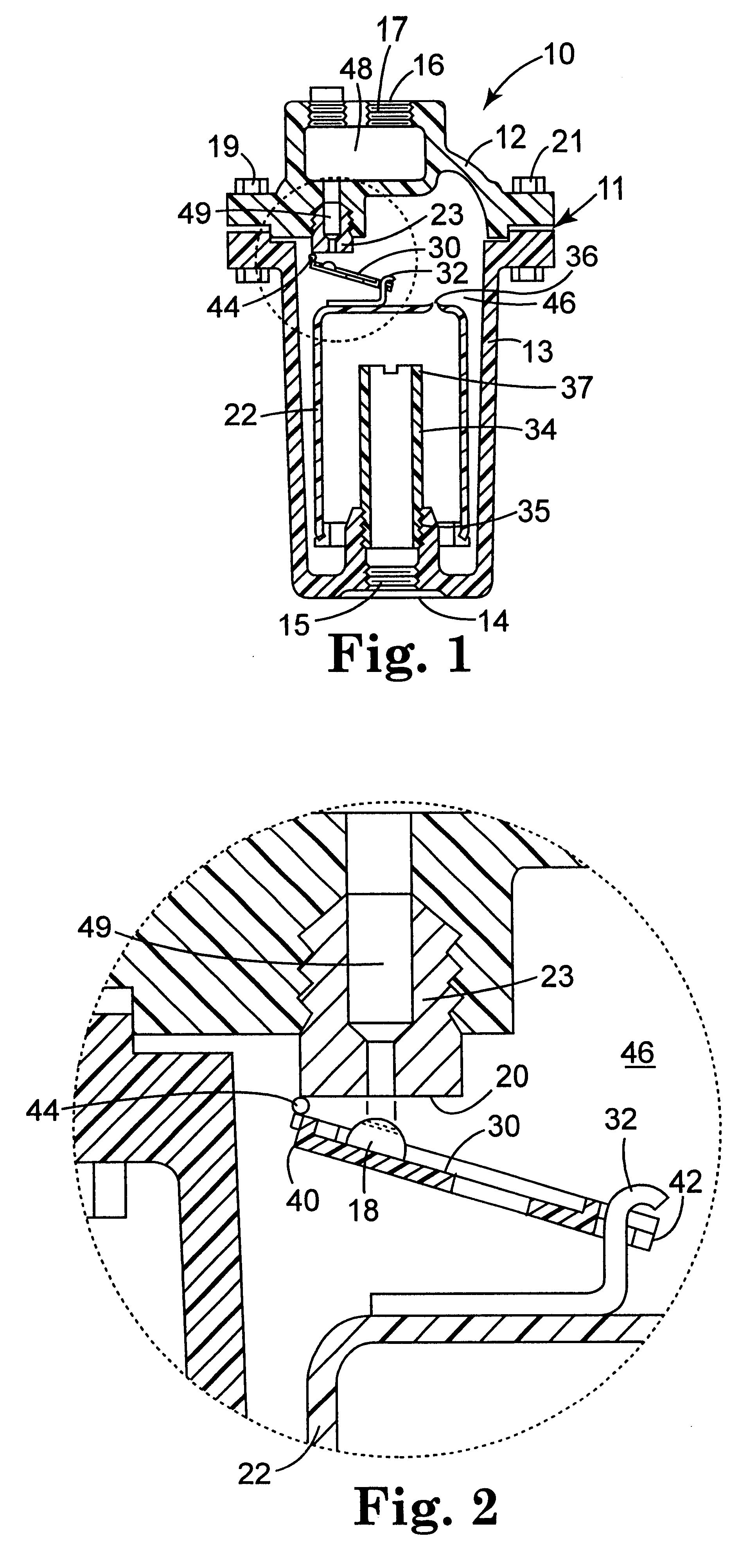

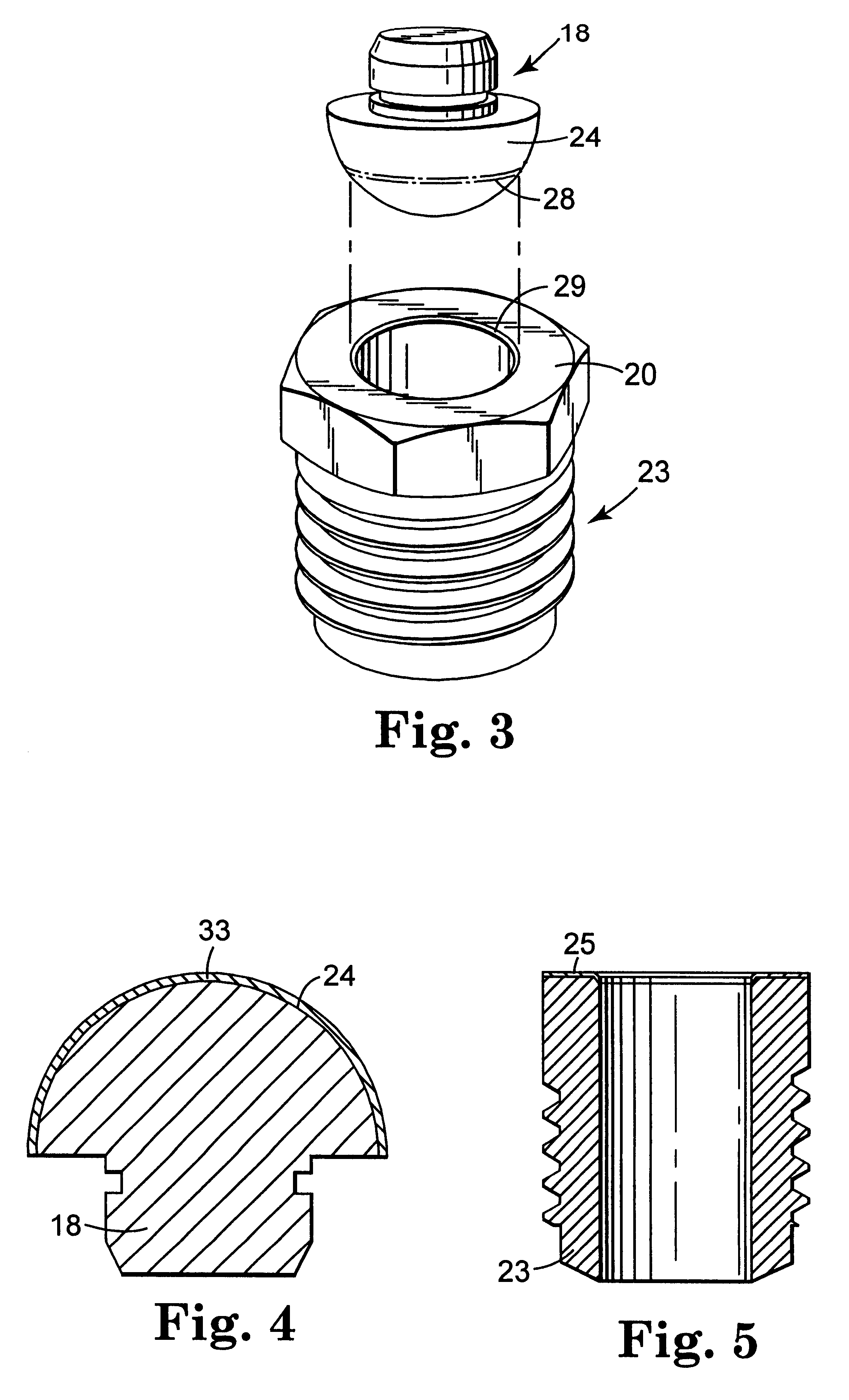

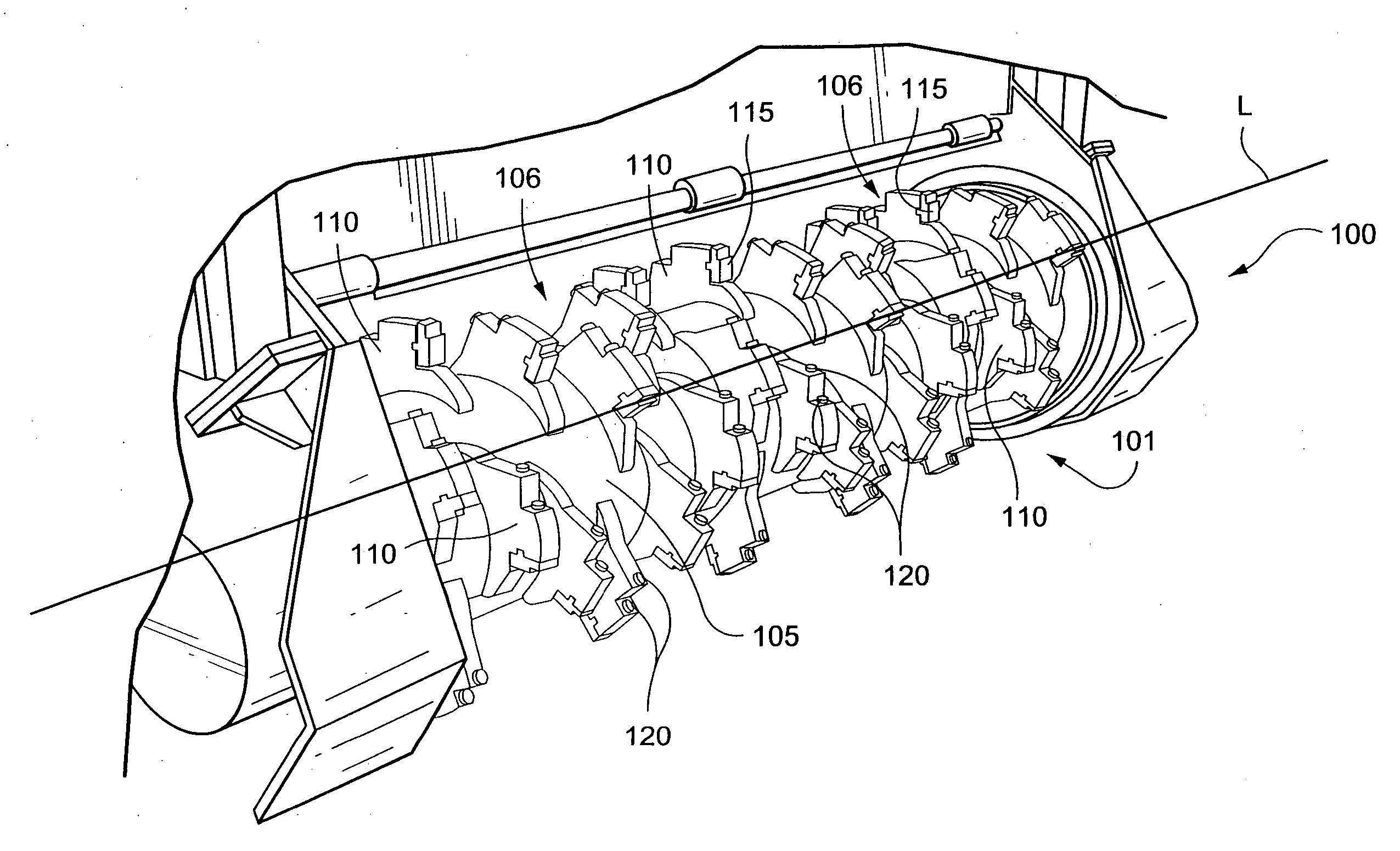

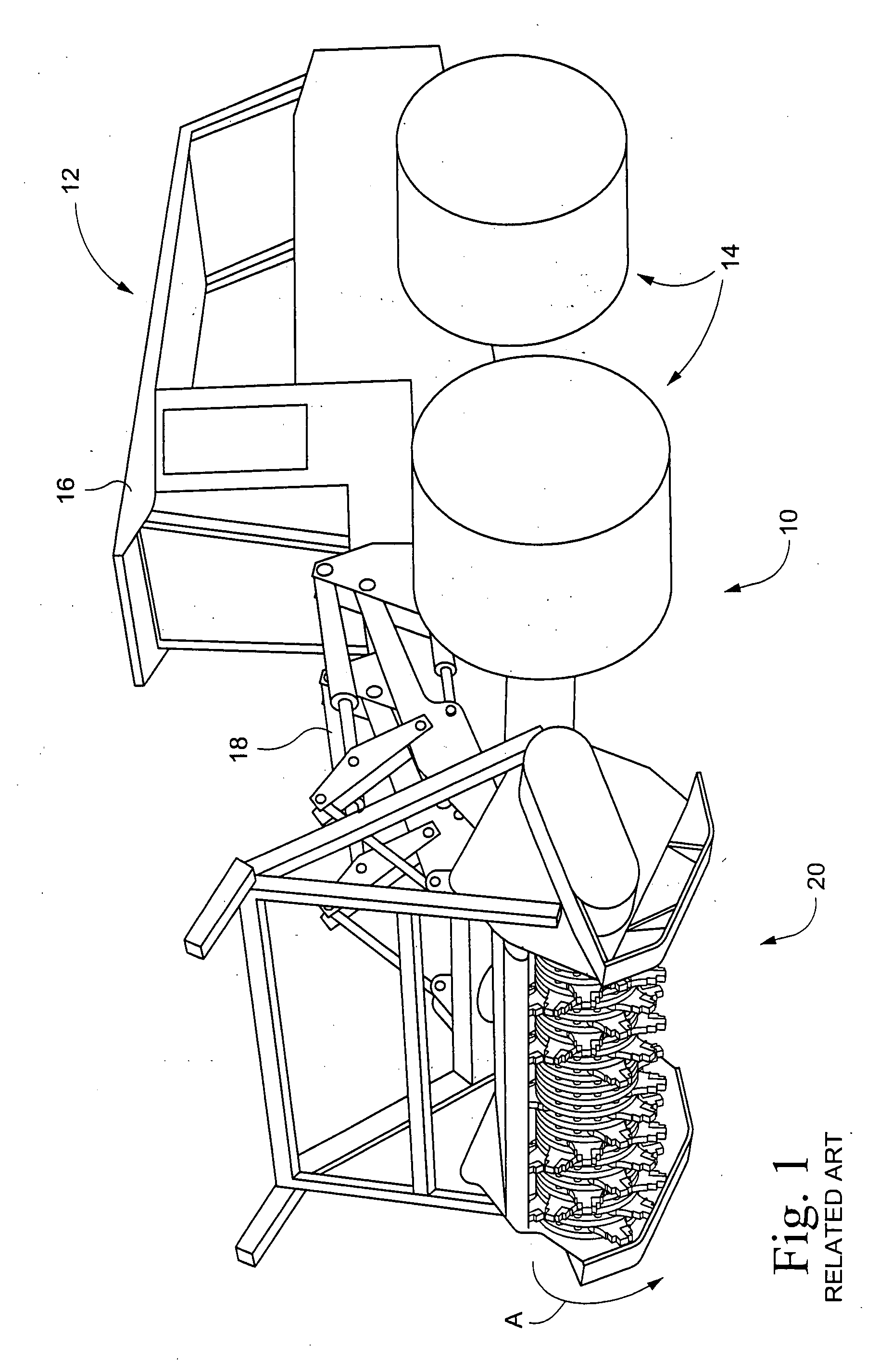

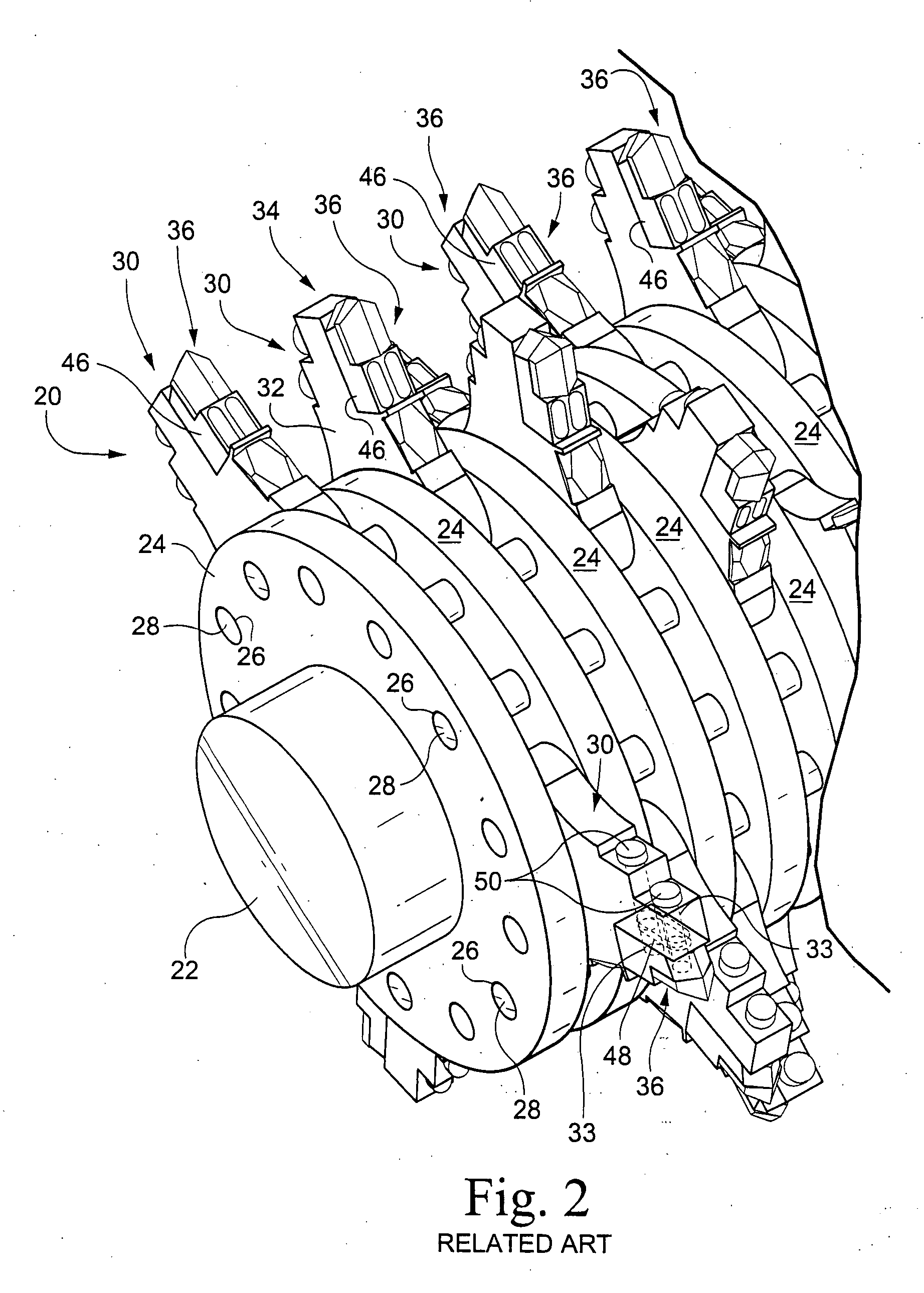

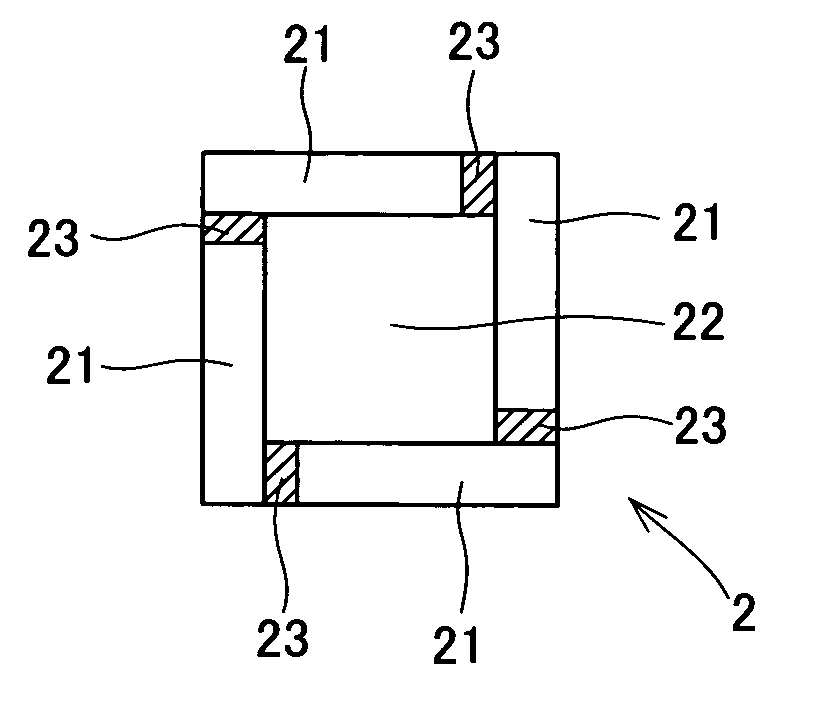

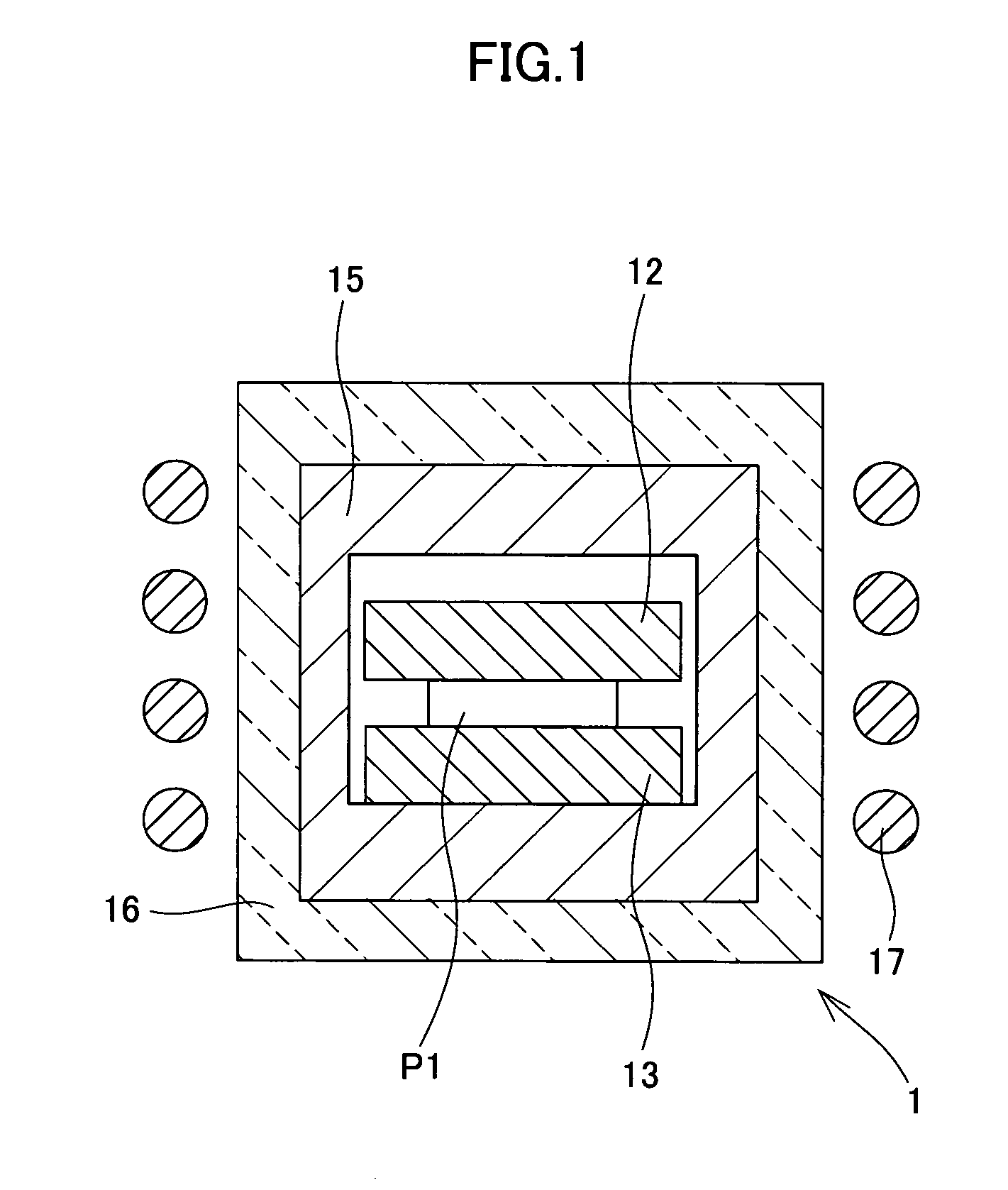

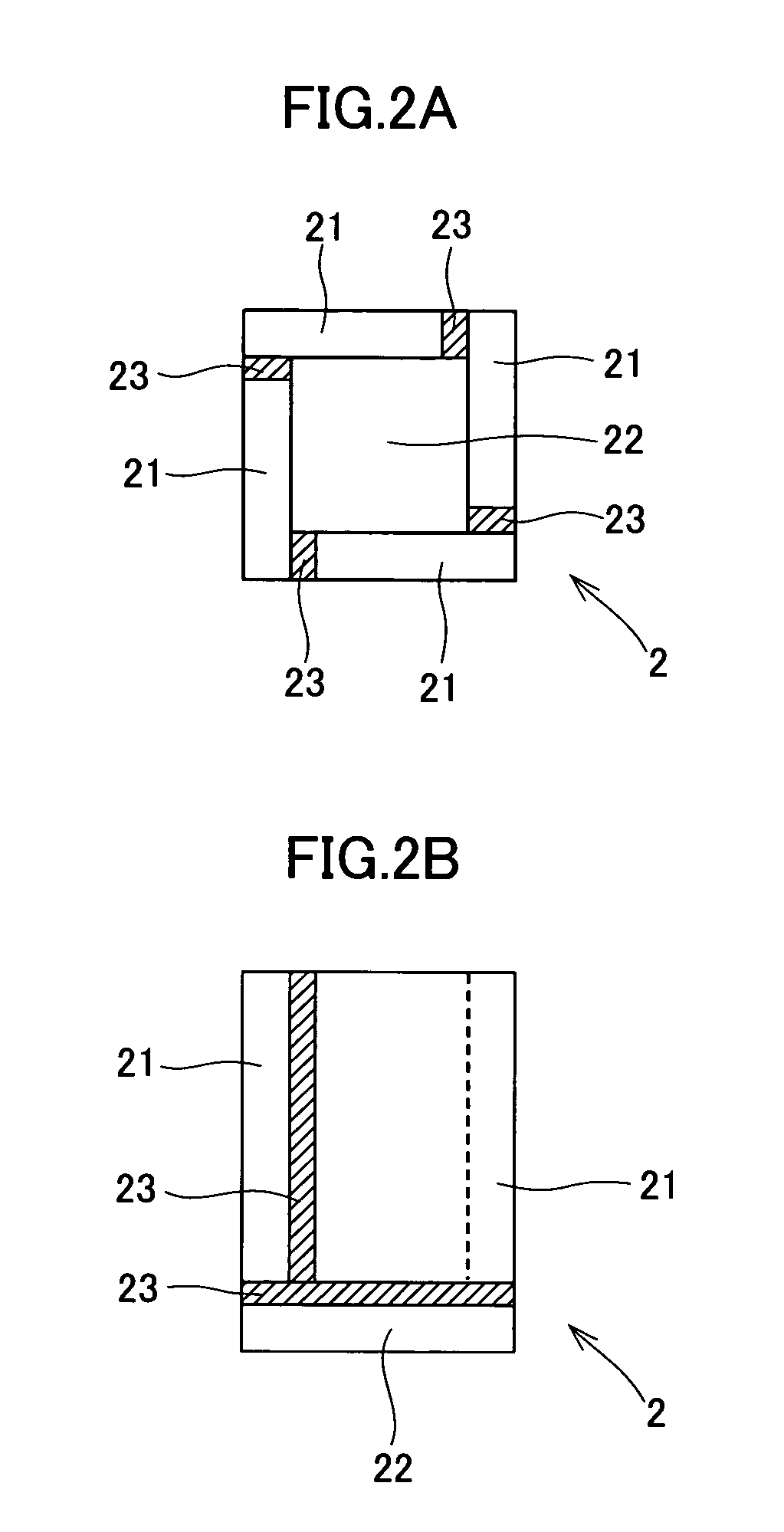

Mulcher with improved tooth design

ActiveUS20050098331A1Improve efficiencyIncrease laborMechanical machines/dredgersPlant waste comminutingCarbide coatingEngineering

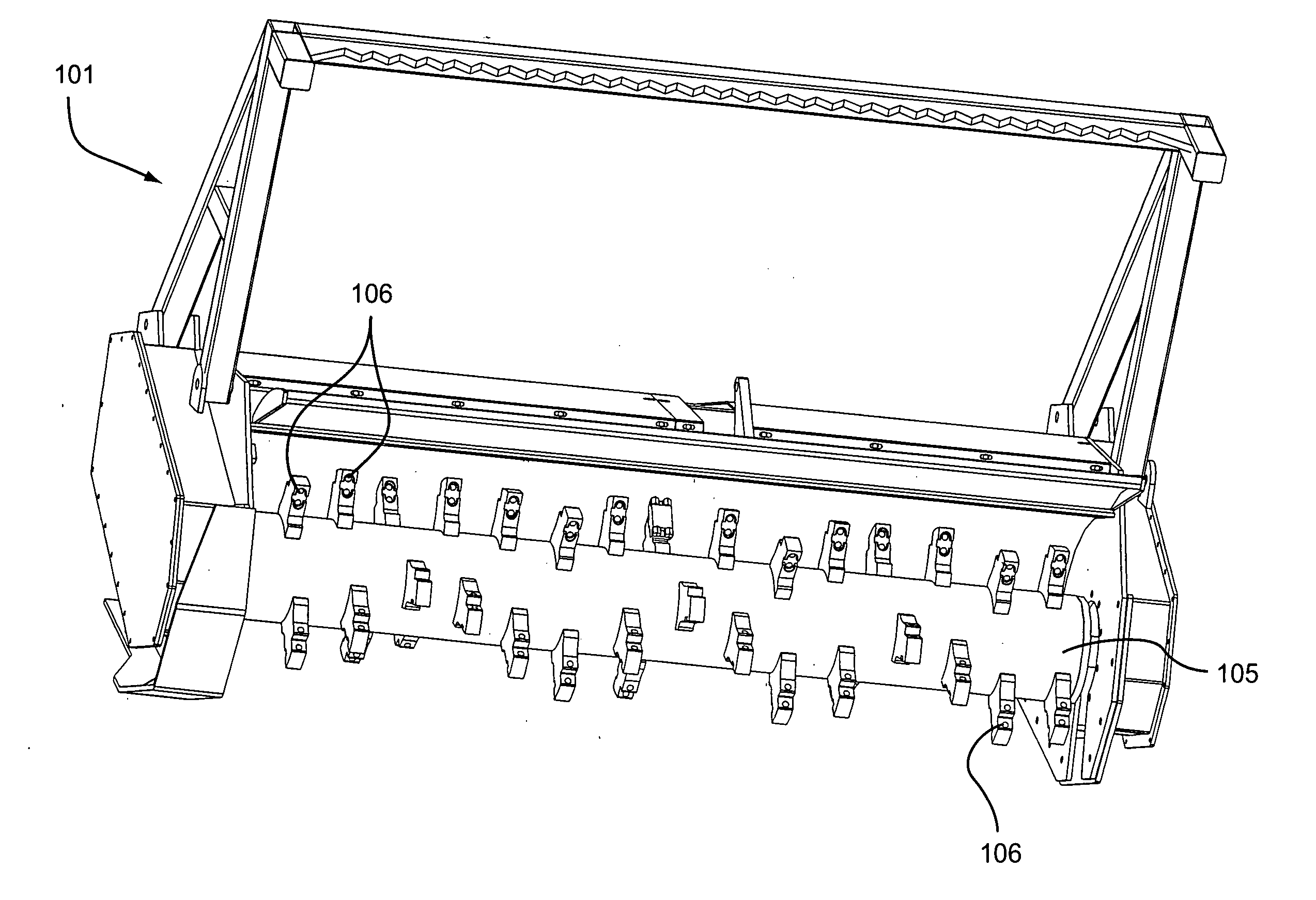

A mulcher apparatus includes a tractor and a mulcher unit provided to the tractor. The mulcher unit includes a tooth assembly with a holder and a cutter element with a cooperating notch portion and cross bar arrangement. The notch portion can be retrofit to existing holder arrangements. The cutter element may include various features, to enhance cutting efficiency. For example, the cutter elements may include a double-ended structure, angle tab portions at each corner portion, carbide coatings, a pair of tip portions at each end with a space therebetween, and / or a generally H-shaped configuration.

Owner:PALADIN BRANDS GROUP

Mulcher with improved tooth design

ActiveUS7222808B2Improve efficiencyIncrease laborMechanical machines/dredgersPlant waste comminutingCarbide coatingEngineering

A mulcher apparatus includes a tractor and a mulcher unit provided to the tractor. The mulcher unit includes a tooth assembly with a holder and a cutter element with a cooperating notch portion and cross bar arrangement. The notch portion can be retrofit to existing holder arrangements. The cutter element may include various features, to enhance cutting efficiency. For example, the cutter elements may include a double-ended structure, angle tab portions at each corner portion, carbide coatings, a pair of tip portions at each end with a space therebetween, and / or a generally H-shaped configuration.

Owner:PALADIN BRANDS GROUP INC

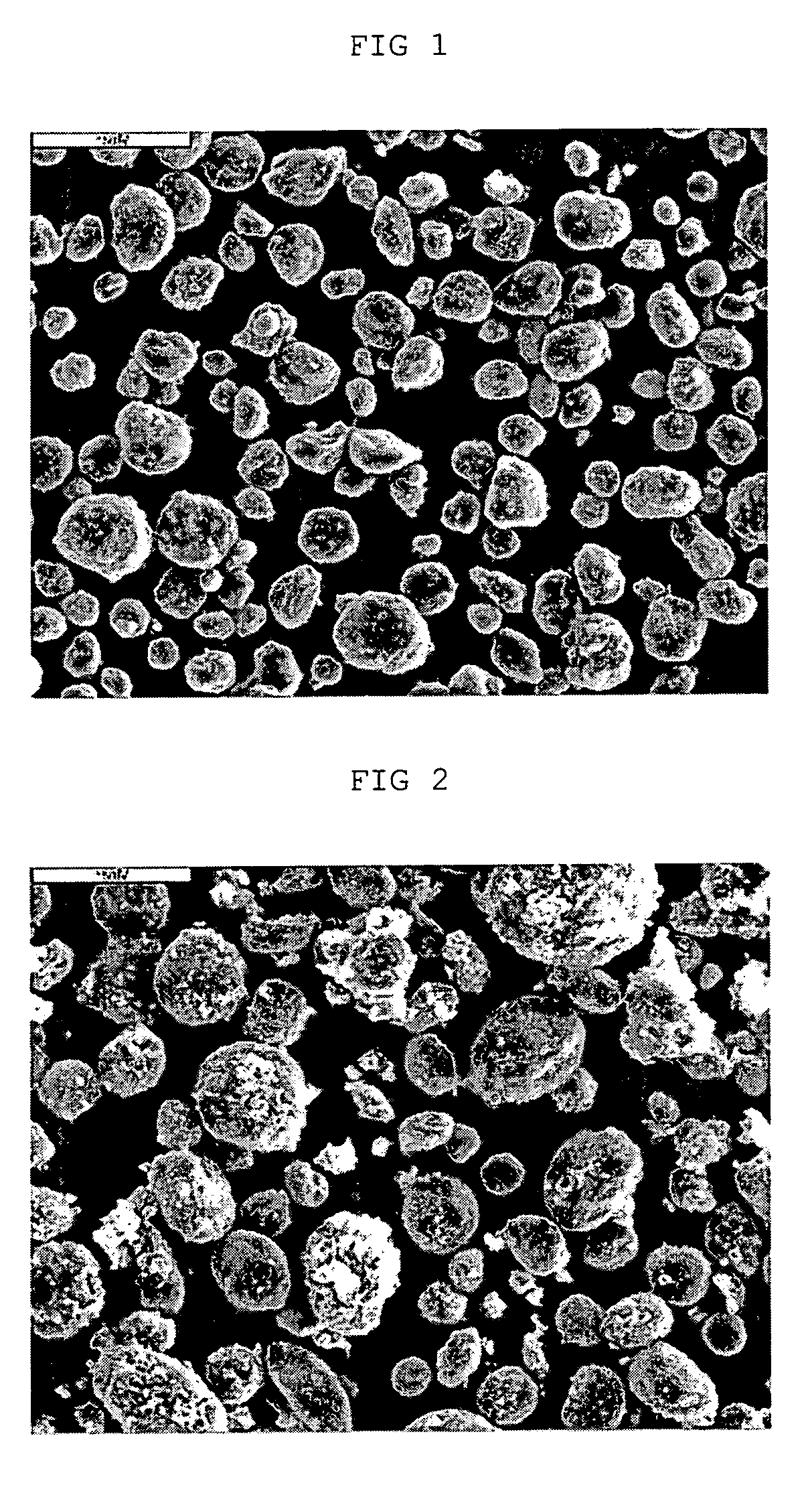

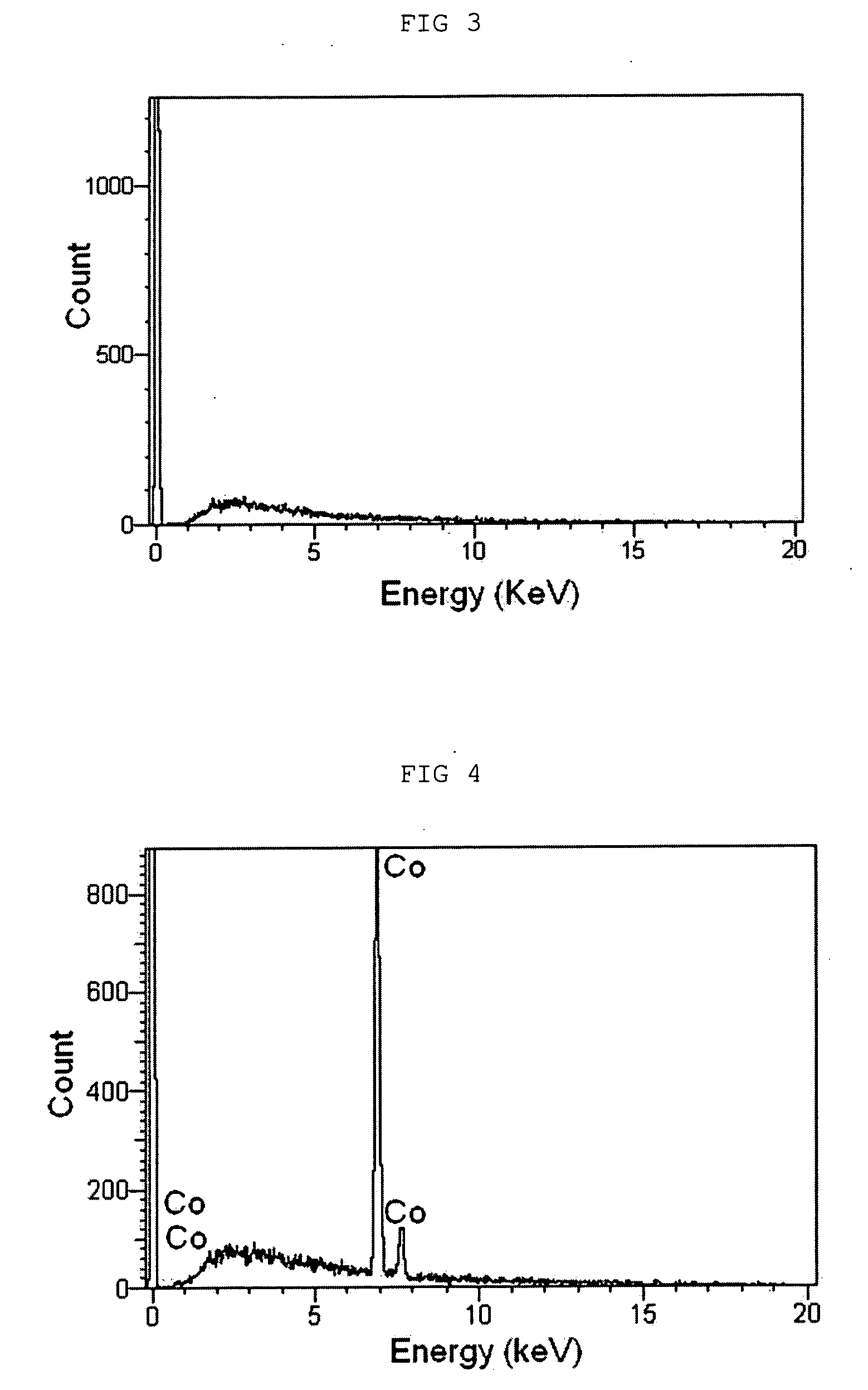

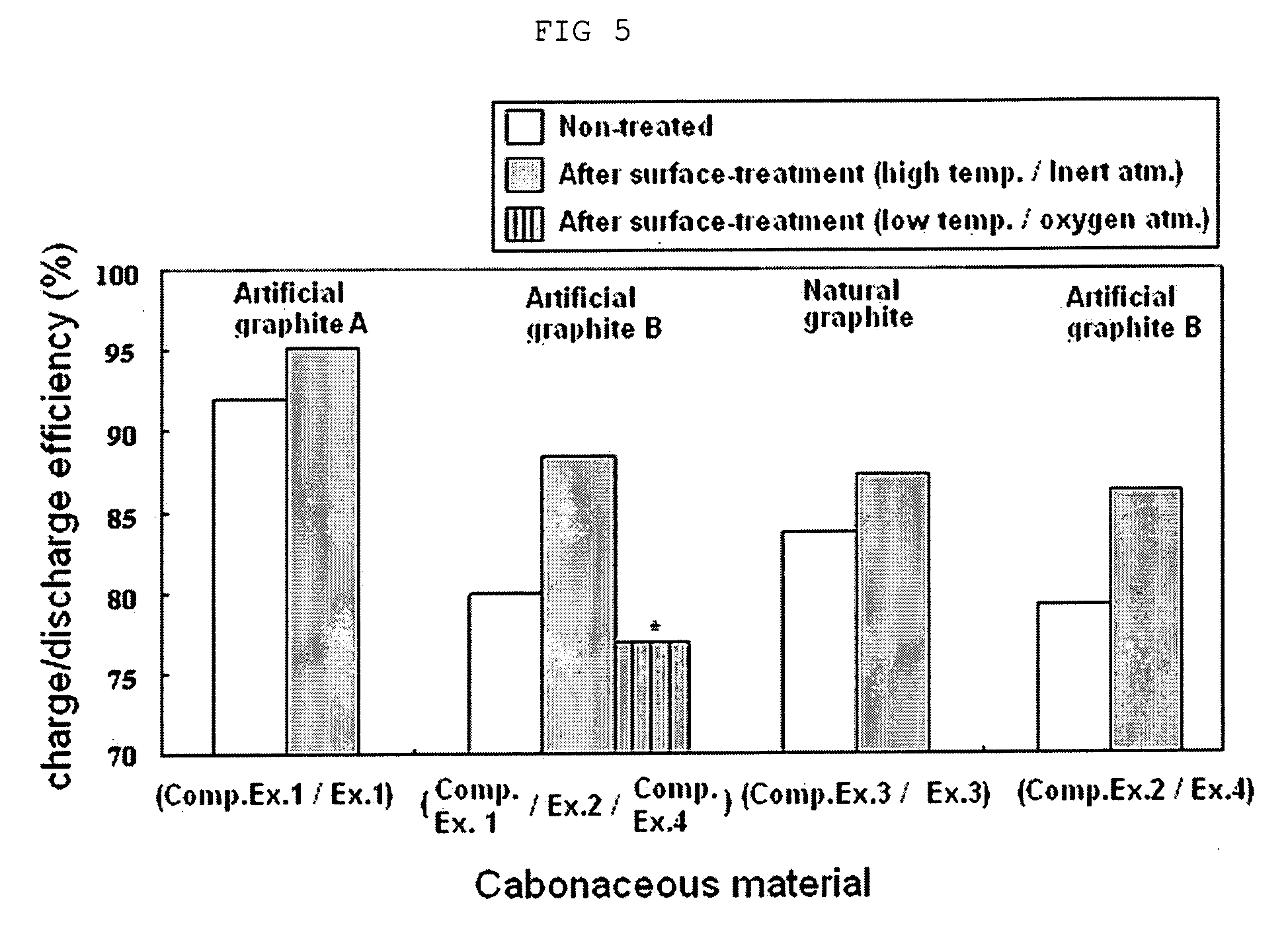

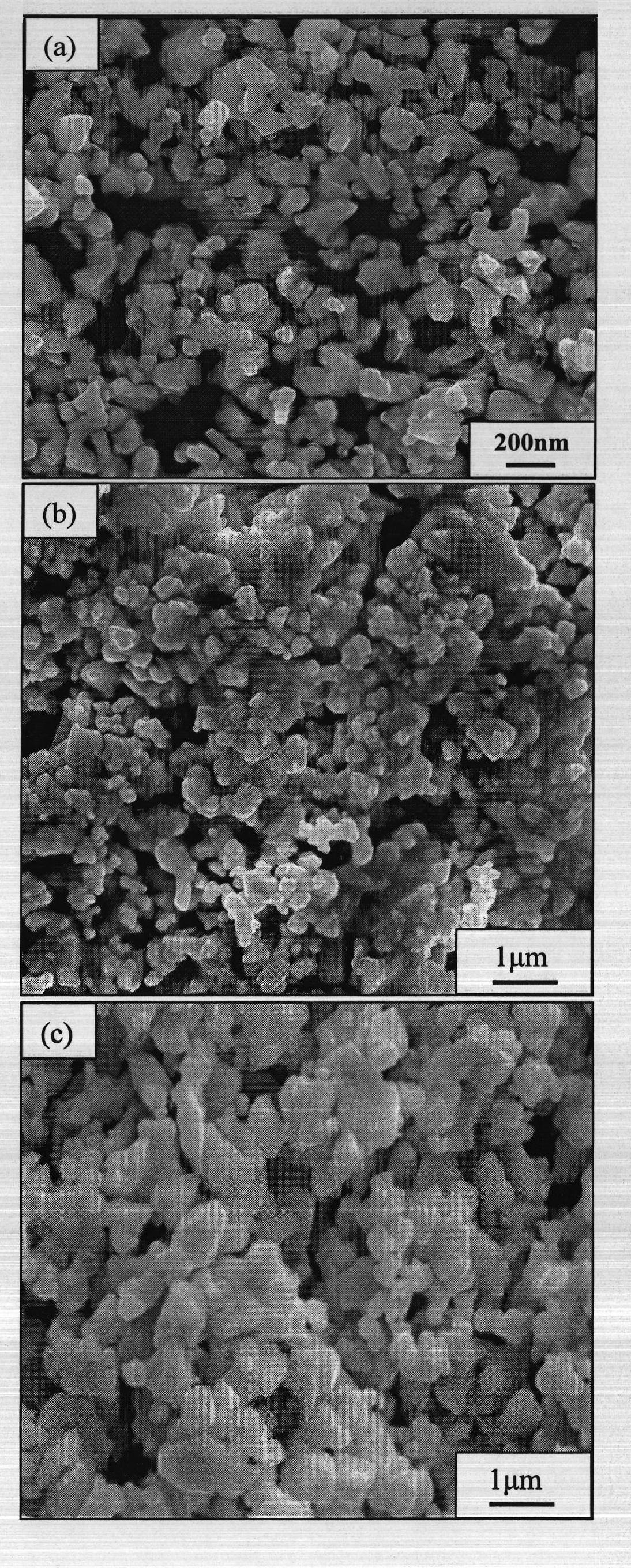

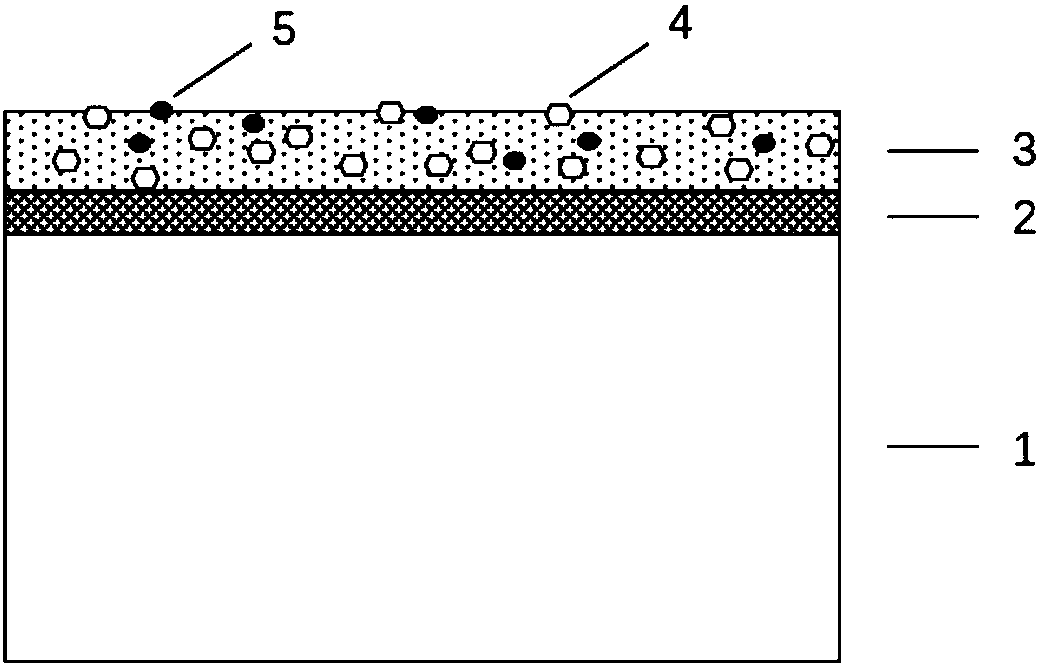

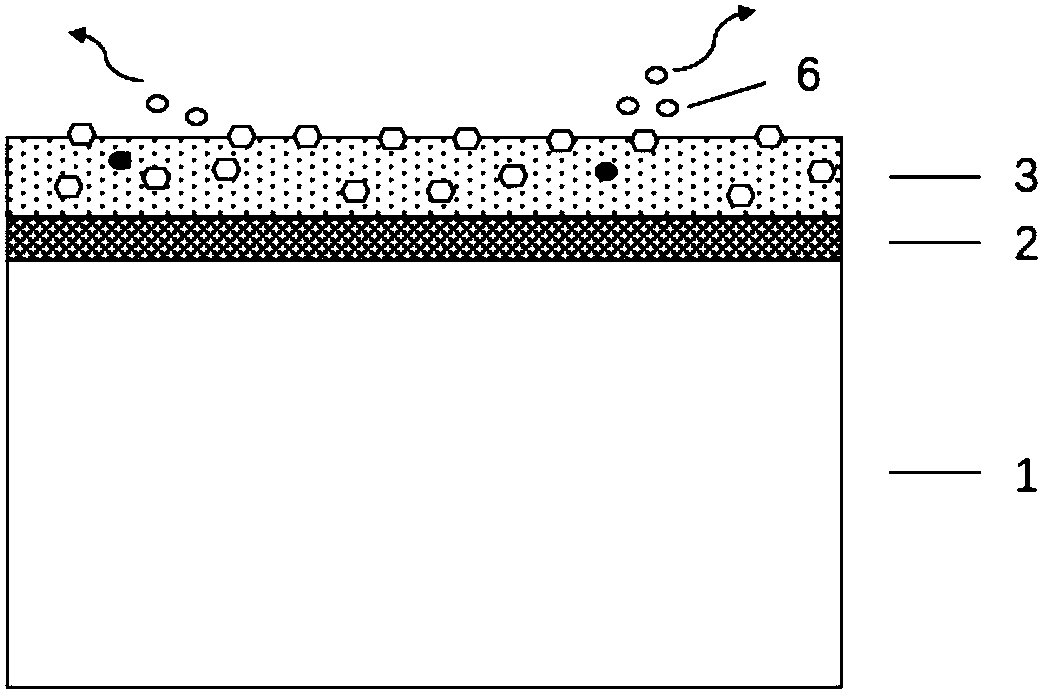

Anode active material with improved electrochemical properties and electrochemical device comprising the same

ActiveUS20050287440A1Minimizing irreversible capacityMinimized reactivityElectrode thermal treatmentFinal product manufactureLithiumCarbide coating

Disclosed is an anode active material, comprising: (a) a carbonaceous material; and (b) a carbide coating layer partially or totally formed on a surface of the carbonaceous material, the carbide coating layer comprising at least one element selected from the group consisting of metals and metalloids. An anode obtained by using the anode active material and an electrochemical device comprising the anode are also disclosed. The carbonaceous material comprises a coating layer of metal- / metalloid-carbide obtained by treating it at high temperature under inert atmosphere, wherein the coating layer has increased interfacial boding force to the carbonaceous material and thus shows minimized reactivity to lithium. The carbonaceous material as anode active material can minimize the irreversible anode capacity needed for the formation of an SEI film during the first charge / discharge cycle, thereby providing high capacity, high efficiency and significantly improved anode qualities.

Owner:LG ENERGY SOLUTION LTD

Mulcher apparatus and cutter element and/or tooth assembly therefor

InactiveUS20080283257A1Improve efficiencyIncrease laborSoil-working equipmentsTilling equipmentsCarbide coatingEngineering

A mulcher apparatus includes a tractor and a mulcher unit provided to the tractor. The mulcher unit includes a tooth assembly with a holder and a cutter element with a cooperating notch portion and cross bar arrangement. The notch portion can be retrofit to existing holder arrangements. The cutter element may include various features, to enhance cutting efficiency. For example, the cutter elements may include a double-ended structure, a relatively wide serrated cutting edge at one or both ends, carbide coatings, layers or inserts, etc.

Owner:ATTACHMENT TECH

DLC (diamond-like carbon) hard coating on copper based material for bearings

Owner:OERLIKON TRADING AG TRUEBBACH

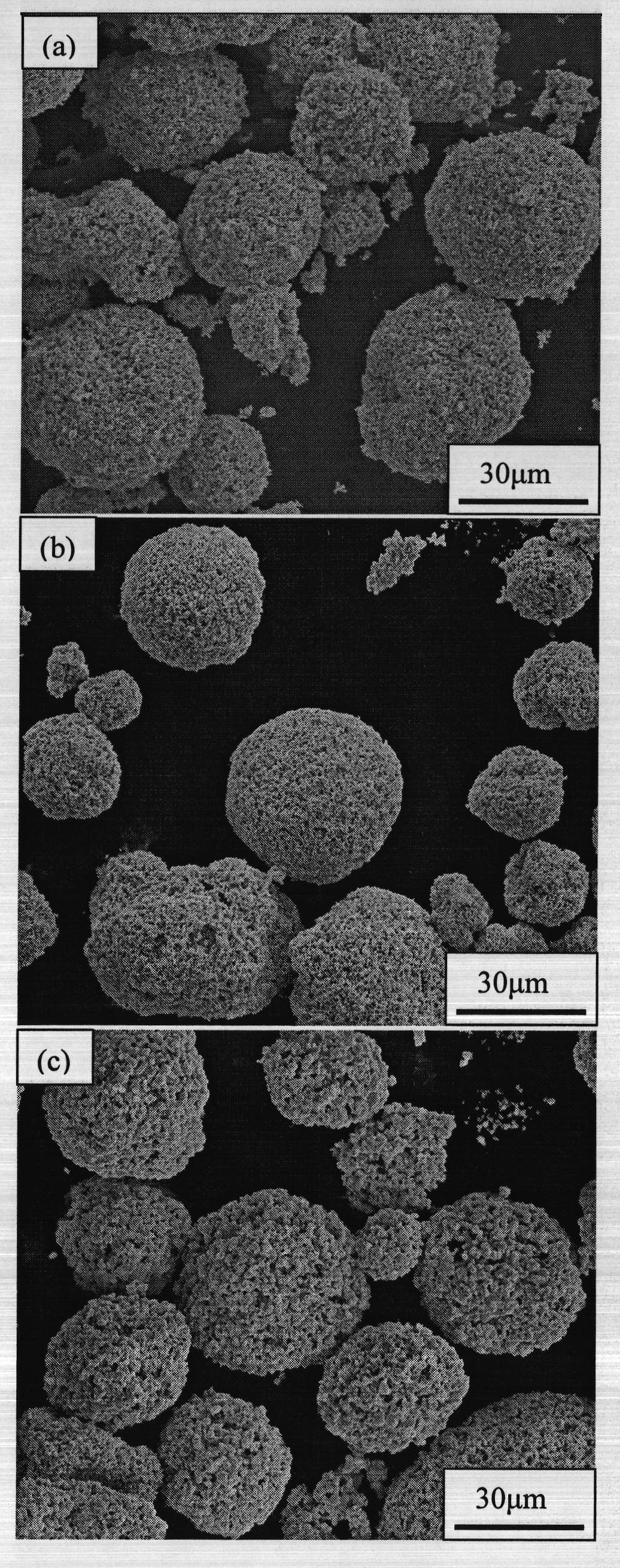

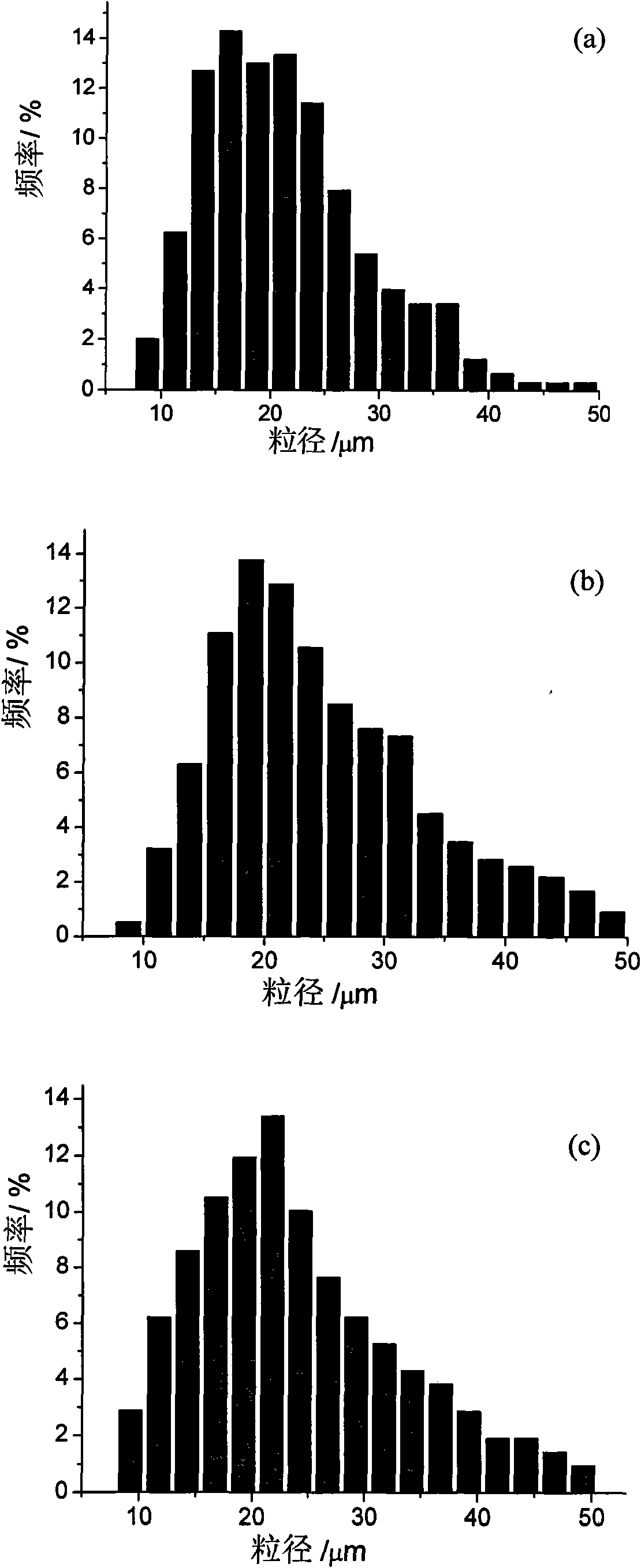

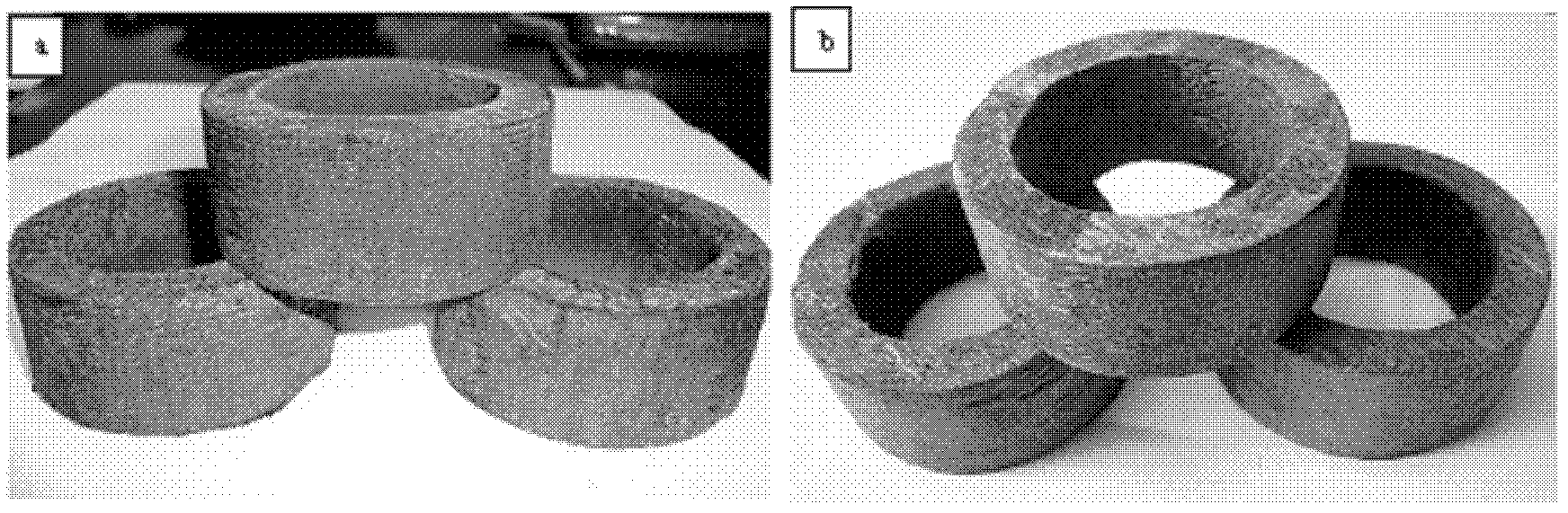

Method for agglomerating and granulizing superfine nano WC-Co composite powder

ActiveCN101884892AReduce contentIncrease contentGranulation by liquid drop formationThermal sprayingCarbide coating

The invention discloses a method for agglomerating and granulizing superfine nano WC-Co composite powder, which belongs to the technical field of metal ceramic coatings and comprises the following steps of: mixing the superfine nano WC-Co composite powder with polyvinyl alcohol, polyethylene glycol and deionized water according to a certain ratio to prepare a slurry; atomizing and granulizing the slurry of the WC-Co composite powder with centrifugal atomizing drying equipment, wherein the inlet temperature of the dryer is 140-200 DEG C and the rotation frequency of an atomizing tray is 200-300Hz; and performing heat treatment on the atomized and dried powder with a vacuum heat treating furnace, wherein the temperature of heat treatment is 950-1,200 DEG C, the time for heat preservation is 1-2 hours and argon is maintained in the furnace. By the method, agglomerated granules of which the average particle diameter and the granulometric distribution meet the requests of the thermal spraying technique can be obtained. The sphericility of the agglomerated granules is good, so the agglomerated granules can be used for preparing hard alloy coating with a superfine nano structure and good combination property.

Owner:BEIJING UNIV OF TECH

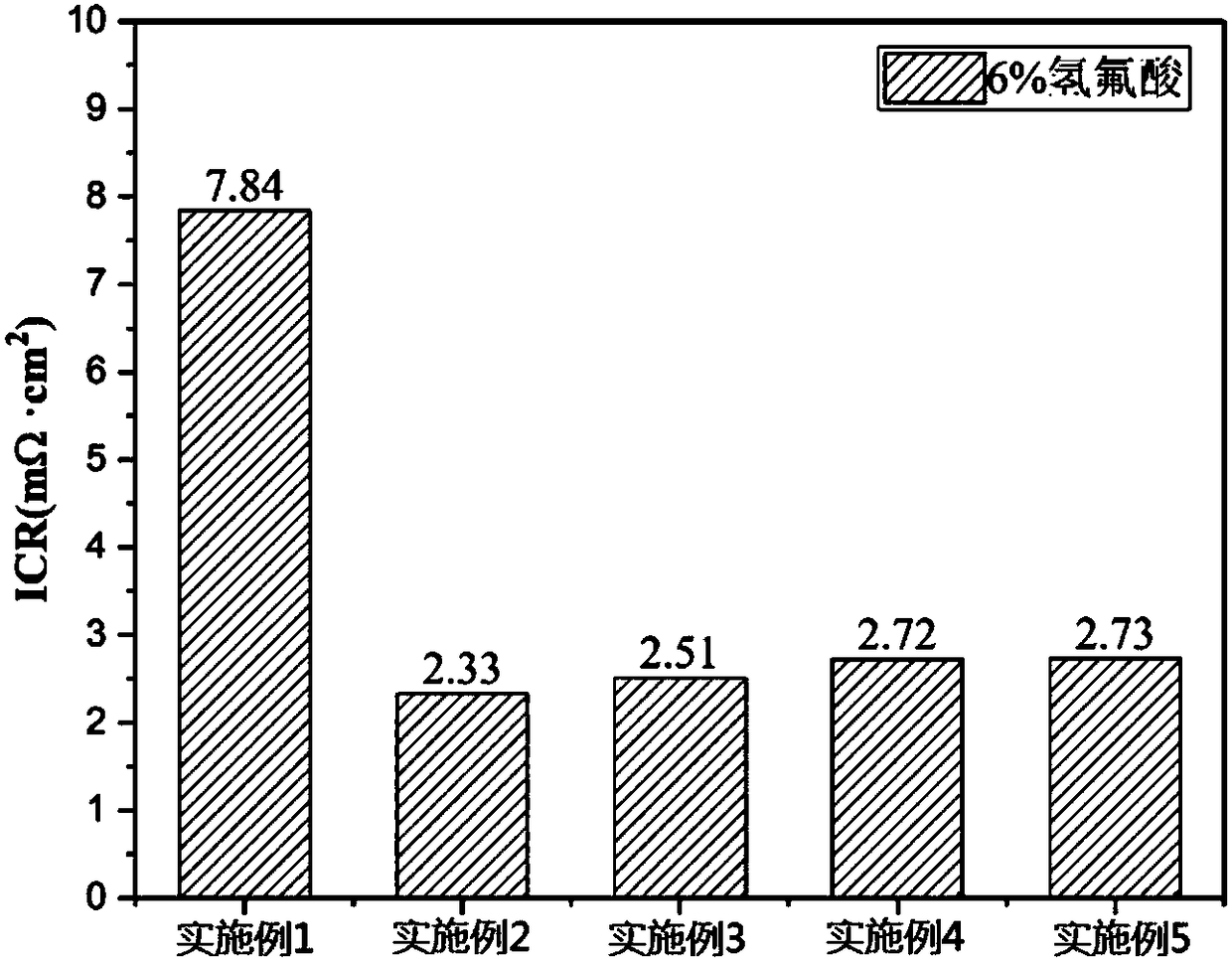

Method for improving conductivity and corrosion resistance of fuel cell bipolar plate carbide coating layer

InactiveCN108574107AImprove surface roughnessAccelerated corrosionCollectors/separatorsCarbide coatingFuel cells

The invention relates to a method for improving the conductivity and corrosion resistance of a fuel cell bipolar plate carbide coating layer. The method includes: sequentially depositing a metal transition layer and a metal carbide coating layer on the surface of a metal bipolar plate, etching the coated bipolar plate to change the surface structure and composition of the carbide coating layer, and cleaning and drying to obtain the carbide coating layer with improved corrosion resistance and conductivity. Compared with the prior art, the method has the advantages that the etching technology isused to optimize the performance of the coating layer of the coated metal bipolar plate, coupling influence caused by parameter regulation during coating layer preparation is avoided, and accordinglythe method is applicable to the further improvement of the performance of the fuel cell bipolar plate carbide coating layer so as to allow the coating layer to meet the working requirements of fuel cells.

Owner:SHANGHAI JIAO TONG UNIV

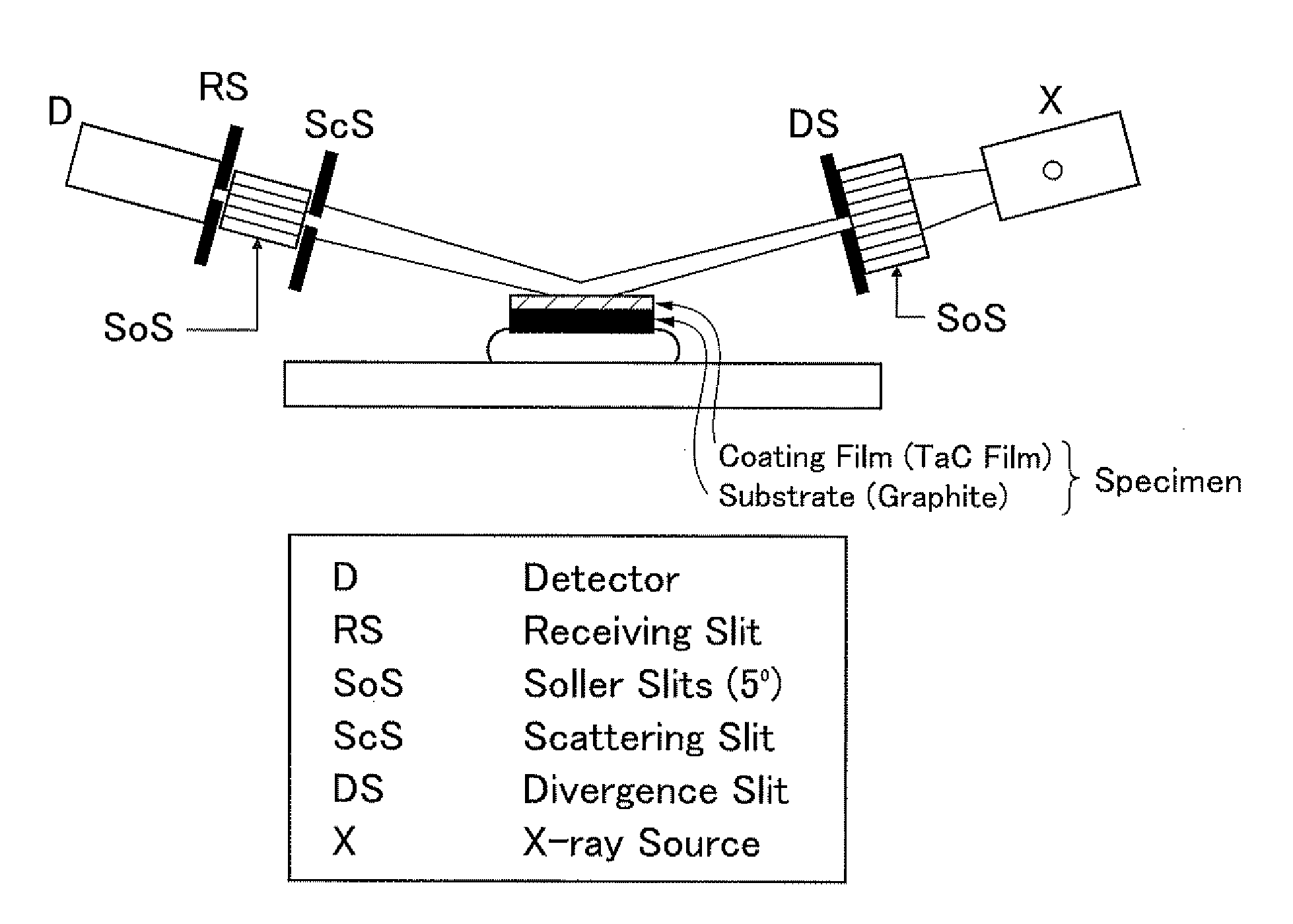

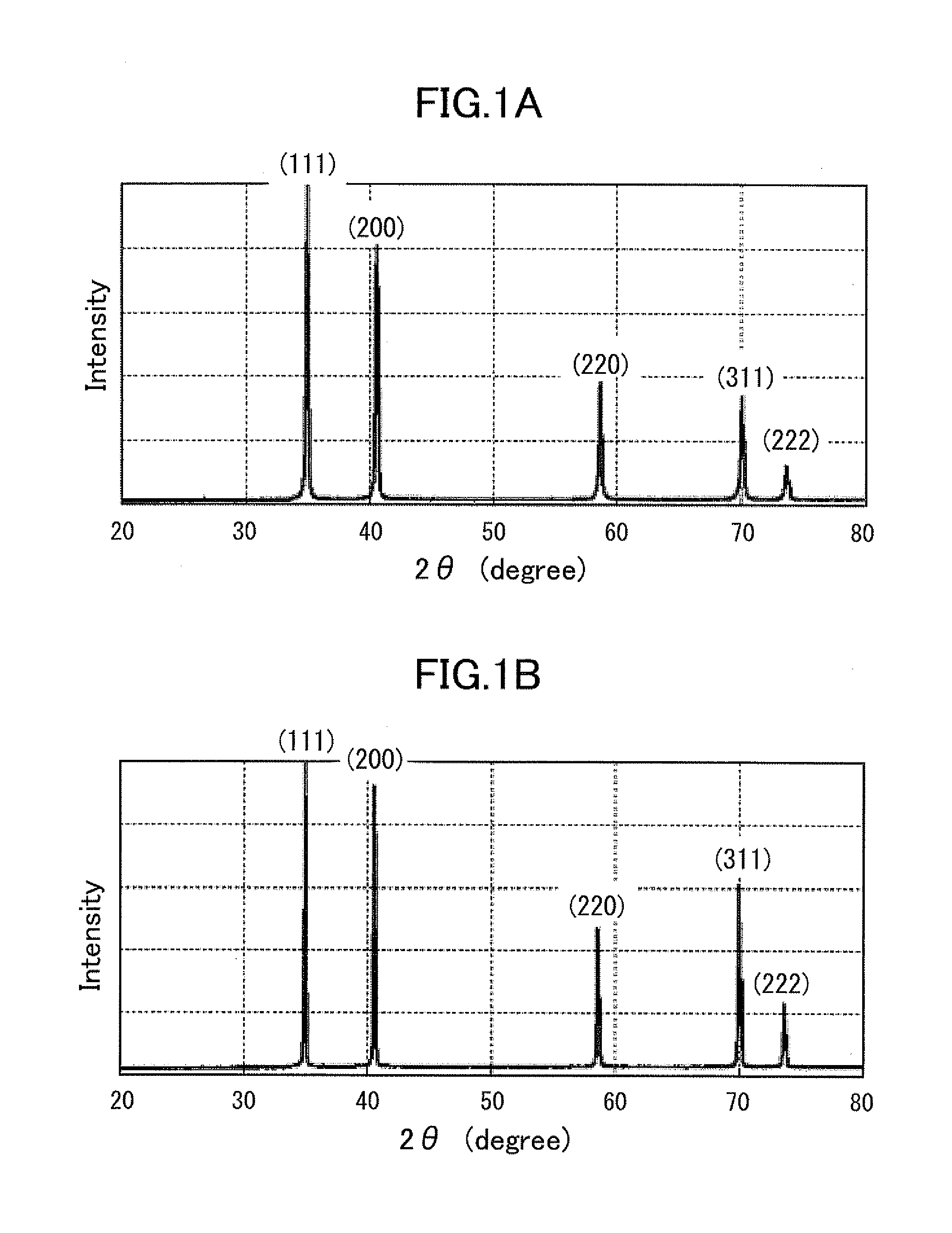

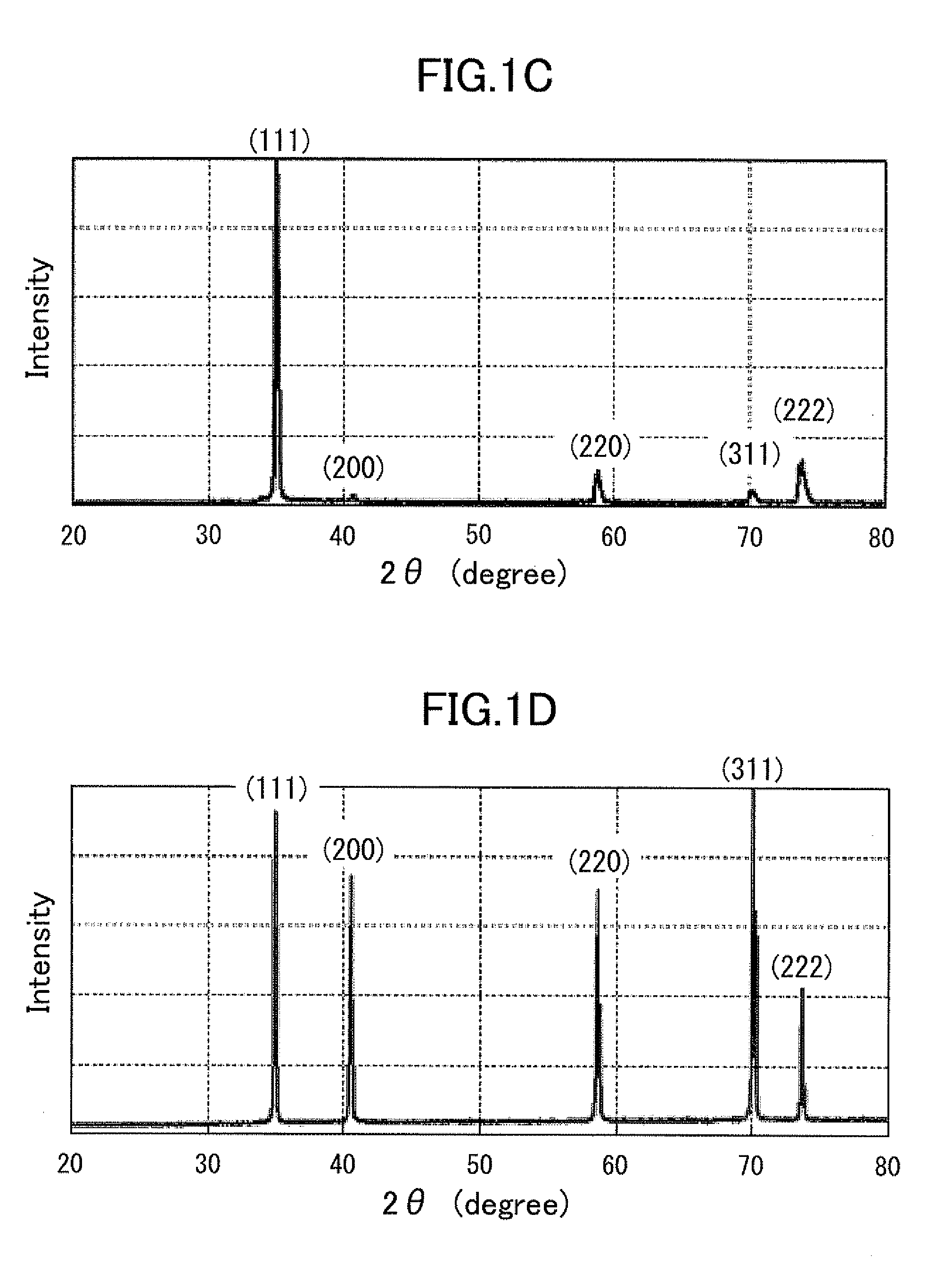

High heat-resistant member, method for producing the same, graphite crucible and method for producing single crystal ingot

ActiveUS20130061800A1Improve heat resistanceIncreased durabilityAfter-treatment apparatusPolycrystalline material growthCarbide coatingX-ray

A high heat-resistant member includes a graphite substrate including isotropic graphite and a carbide coating film including a carbide, such as tantalum carbide, and covering a surface of the graphite substrate, the carbide coating film having a randomly oriented isotropic grain structure in which crystallites having a size indexed by a full width at half maximum of a diffraction peak of an X-ray diffraction spectrum of not more than 0.2° from (111) planes are accumulated at substantially random. The orientation of the carbide coating film is determined by whether degree of orientation (F) in any Miller plane calculated based on an XRD spectrum using the Lotgering method is within a range from −0.2 to 0.2.

Owner:TOYOTA CENT RES & DEV LAB INC

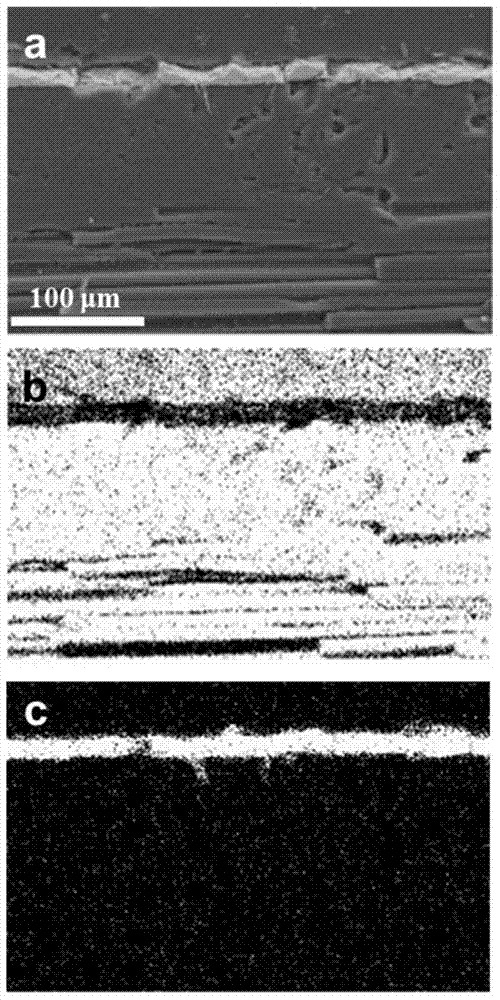

Metallic bipolar plates with high electrochemical stability and improved water management

InactiveUS20070117003A1More hydrophilicStable environmentFuel cells groupingFuel cell auxillariesChromium carbideEtching

A flow field plate or bipolar plate for a fuel cell that includes a carbide coating that makes the bipolar plate conductive, hydrophilic and stable in the fuel cell environment. Suitable carbides include, but are not limited to, chromium carbide, titanium carbide, tantalum carbide, niobium carbide and zirconium carbide. The carbide coating is then polished or textured by a suitable process, such as laser or chemical etching, to provide a surface morphology that makes the coating more hydrophilic, and further reduces the contact resistance on its surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

Steam valve

InactiveUS6302136B1Easy to useExtended service lifeOperating means/releasing devices for valvesSteam trapsCarbide coatingNitride

Owner:3M INNOVATIVE PROPERTIES CO

Fe/Ni-based carbide alloy coating cutter material for cutting rolled steel and preparation thereof

InactiveCN101301686AAvoid gatheringReduce intensityTurning toolsChemical vapor deposition coatingCarbide coatingAlloy substrate

The invention relates to a blade used for cutting processing of steels and a preparation method thereof. The blade comprises a hard alloy substrate which takes Fe and Ni as binding phase and a wearable coating. The binding phase in the hard alloy substrate occupies the proportion of 6 to 10 percent, wherein, the proportion of Fe to Ni is 3 : 1; the hard alloy substrate is all carbonyl powder; the coating is prepared by adopting a chemical vapour deposition technique; from a layer adjacent to the substrate to the most external layer, the coating materials sequentially comprises TiN (0.5-1 Mu meters), Ti(C, N) (5-8 Mu meters), Al2O3 (3-5Mu meters) and TiN (1-2Mu meters). After being coated, the blade coating and the substrate have high binding strength, good wearability, can be used for the rough turning processing of the carbon structural steels and alloy steels, and have an equivalent service life with P30 alloy.

Owner:SICHUAN UNIV

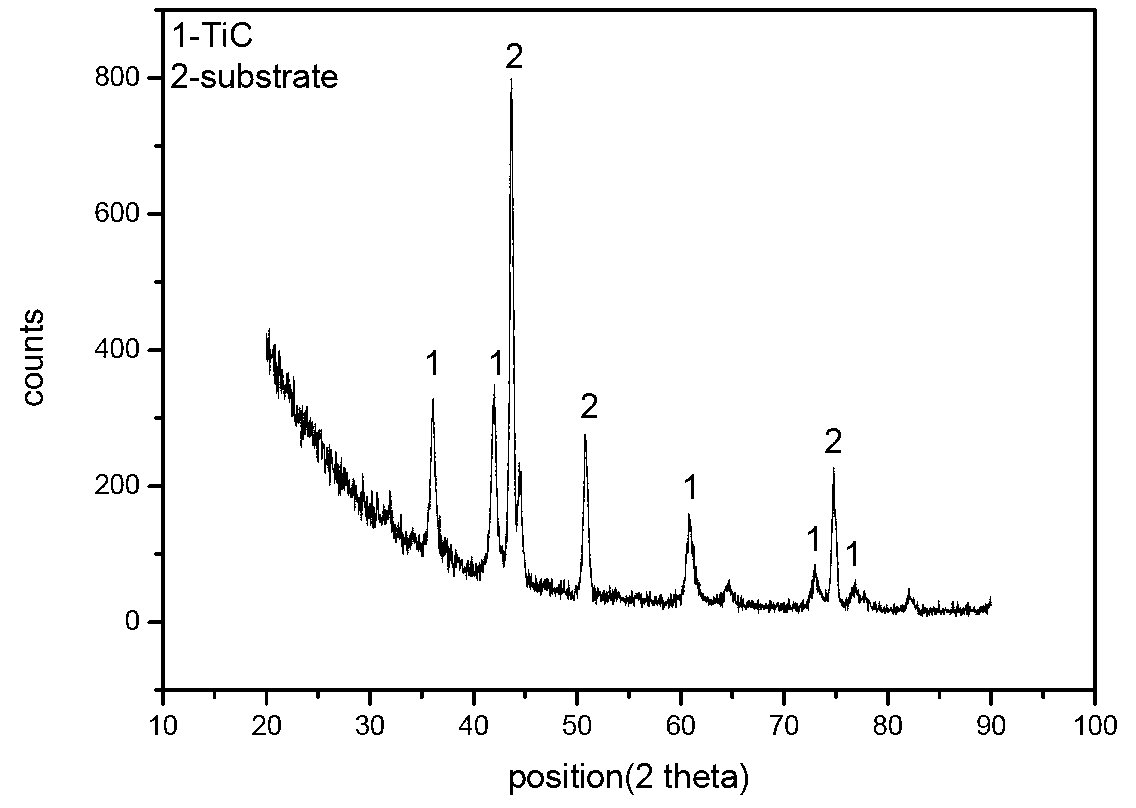

Method for preparing titanium carbide coating through pulse electrodeposition

ActiveCN103014793AImprove performanceReduce the binding forceElectrolytic coatingsCarbide coatingHazardous substance

The invention discloses a method for preparing a titanium carbide coating through pulse electrodeposition. The method comprises the following steps: through taking a substrate as a cathode, taking graphite as an anode and a carbon source and taking nickel as a reference electrode, melting a titanium source into a salt mixture; reacting for 0.5-2h under the protection of inert gas, at a temperature of 800-950 DEG C and under a pulse voltage of 2.5-3V, thus forming a titanium carbide coating on the substrate. According to the invention, deposition is performed by using a molten salt electro-deposition method without use of large equipment and precious materials, therefore, the method is low in cost and simple in operation; and in the reaction process, no harmful gas is required, and no harmful substance is produced, therefore, the method is environment-friendly; and a titanium carbide coating prepared by using the method disclosed by the invention is dense and good in performances.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Preparation method for metal carbide coating

InactiveCN103820761APrecise content controlExtended service lifeVacuum evaporation coatingSputtering coatingCarbide coatingGraphite

The invention discloses a preparation method for a metal carbide coating. The metal carbide coating is prepared by adopting a multi-target magnetron sputtering equipment, taking pure metals (titanium, chromium and the like) and graphite as target materials, and performing the processes of vacuumizing, introducing argon, coating and the like. The preparation method for the metal carbide coating disclosed by the invention has the characteristics that the process is simple and stable, the coating components are controlled accurately, the processes are few, and the industrial production is easy to realize. The prepared metal carbide coating has the performance of high hardness, low friction coefficient and the like, and is suitable for performing deposition on the surfaces of a high-speed operating tool, a precise tool, a mold and the like; a workpiece can be endowed with high performance; the service life of a product can be prolonged.

Owner:西安金唐材料应用科技有限公司

Use of pad printing in the manufacture of capacitors

ActiveUS20050041374A1Increase productionImprove adhesionRotary intaglio printing pressHybrid capacitor electrodesPad printingCarbide coating

Deposition of a metal-containing reagent solution or suspension onto a conductive substrate by various pad-printing techniques is described. This results in a pseudocapacitive oxide coating, nitride coating, carbon nitride coating, or carbide coating having an acceptable surface area for incorporation into an electrolytic capacitor, such a s one have a tantalum anode.

Owner:WILSON GREATBATCH LTD

Method for preparing WC cemented carbide anti-wear layer on petroleum drilling tool stabilizer through laser cladding

InactiveCN103194748AImprove surface wear resistanceGood toughness transitionMetallic material coating processesCarbide coatingMetallurgy

The invention relates to a method for preparing a WC cemented carbide anti-wear layer on a petroleum drilling tool stabilizer through laser cladding. The method is characterized in that a high-power laser is utilized to clad a good-toughness priming transition layer forming a metallurgic combination with a matrix on a shell surface through rapid laser scanning, and spherical WC and Ni-Cr-B-Si mixed alloy powder having good wear and corrosion resistances is prepared on the priming alloy surface through laser cladding. The method which allows the WC cemented carbide coat forming the metallurgic combination with the matrix to be prepared substantially improves the wear, corrosion and hot tearing resistances of the surface of the matrix; and the above laser cladding technology has the characteristics of no pollution to the environment, no radiation, low noise, high productivity, low energy consumption, small cladding layer working allowance, high yield, low comprehensive cost and the like.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

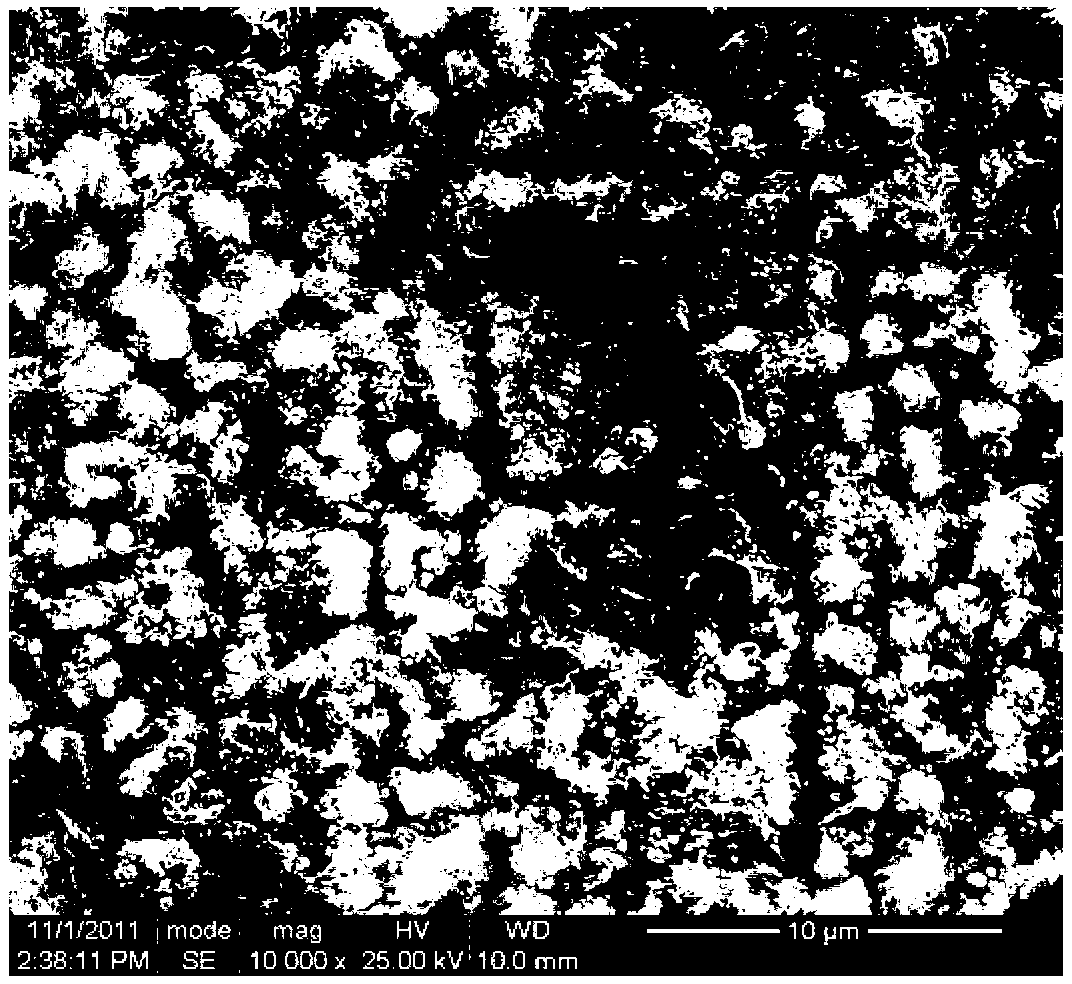

Direct laser synthesis and making process of hard alloy coating

InactiveCN1417380AReduce manufacturing costSolve the problem of stomataMetallic material coating processesLaser beam welding apparatusMicro structureMelting tank

The present invention relates to a direct laser synthesis and making process of hard alloy coating, and belongs to the field of hard alloy making and applying technology. By means of the hard alloy forming material system and high-energy laser to produce special physical and chemical metallurgical and fast solidification characteristic, hard alloy coating is formed directly through reaction in melting bath. The hard coating is dense, gas hole free and without crack and other faults, combines metallurgically with the base material, has the components, micro structure and performance of the hard alloy and any required shape. The coating may be formed in the surface of various engineering metal parts, and may be used widely in hard alloy cutter, mold antiwear part, etc.

Owner:TSINGHUA UNIV +1

Method of pad printing in the manufacture of capacitors

InactiveUS20060154416A1Increase productionImprove adhesionElectrode thermal treatmentHybrid capacitor electrodesPad printingCarbide coating

Deposition of a metal-containing reagent solution or suspension or a carbon nanotube-containing suspension onto a conductive substrate by various pad-printing techniques is described. In the case of a metal-containing solution or suspension, a pseudocapacitive oxide coating, nitride coating, carbon nitride coating, carbide coating, or carbon nanotube coating results. In any event, the active coating has acceptable surface area for incorporation into an electrolytic capacitor, such as one having a tantalum anode.

Owner:WILSON GREATBATCH LTD

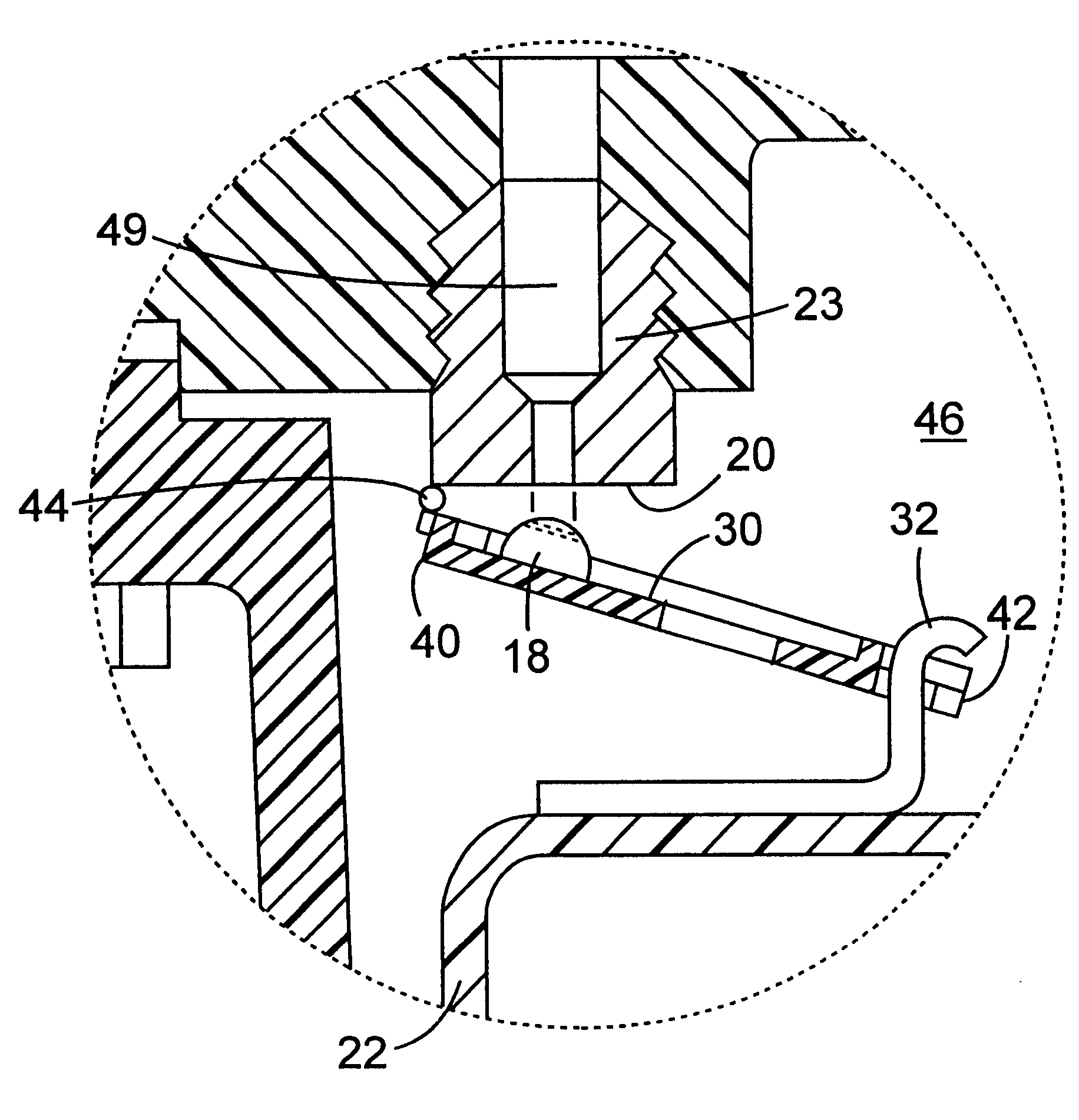

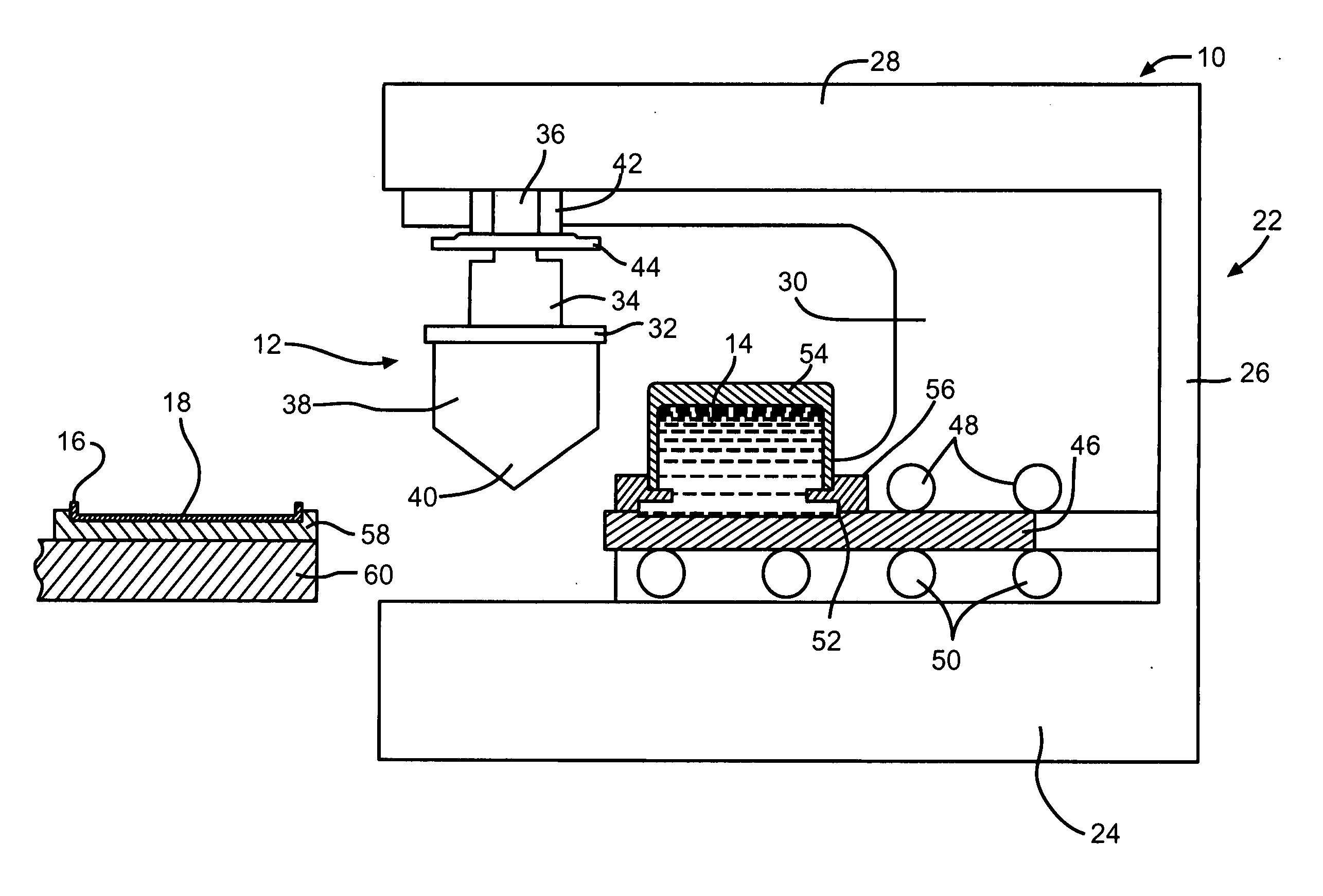

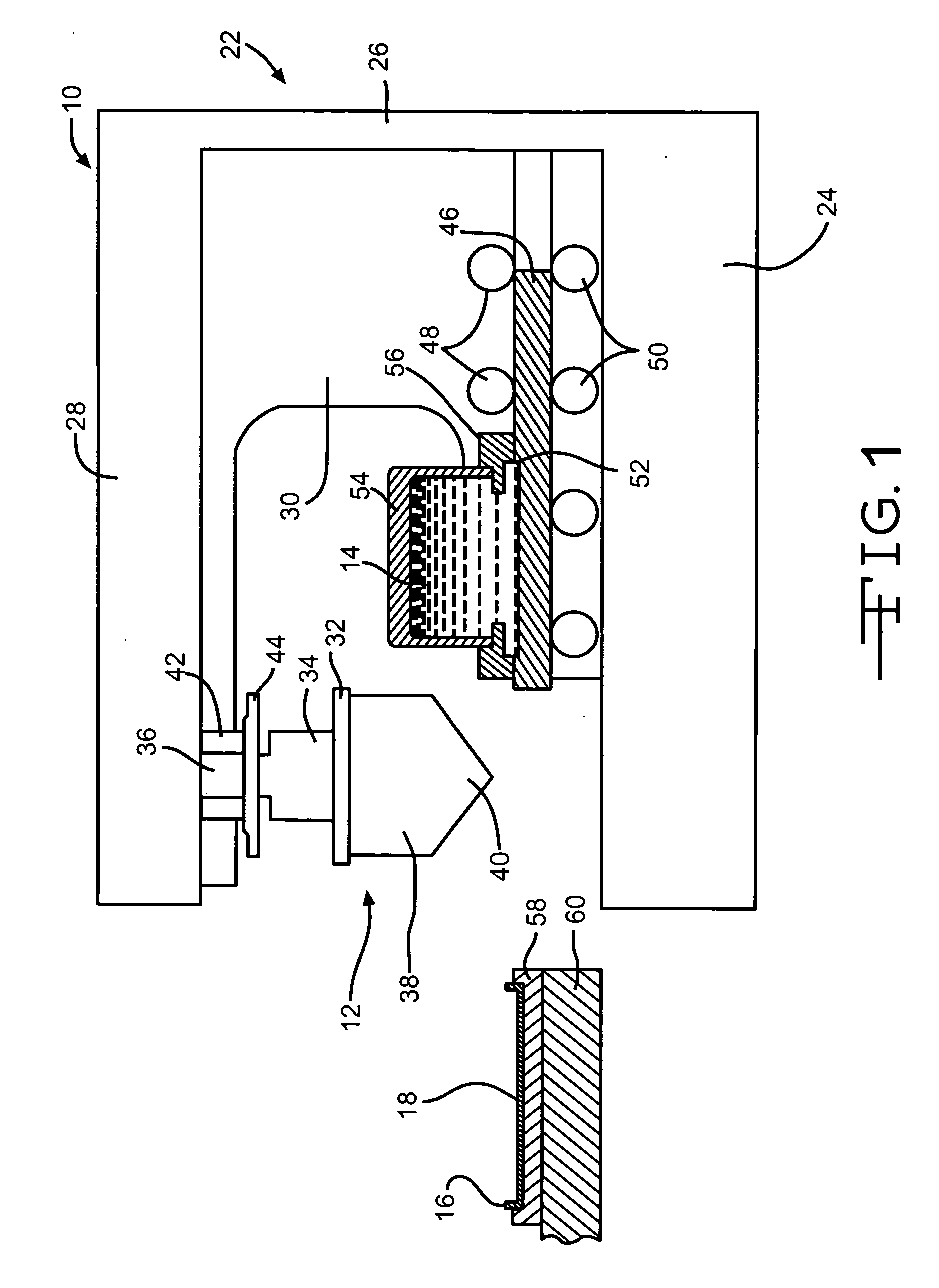

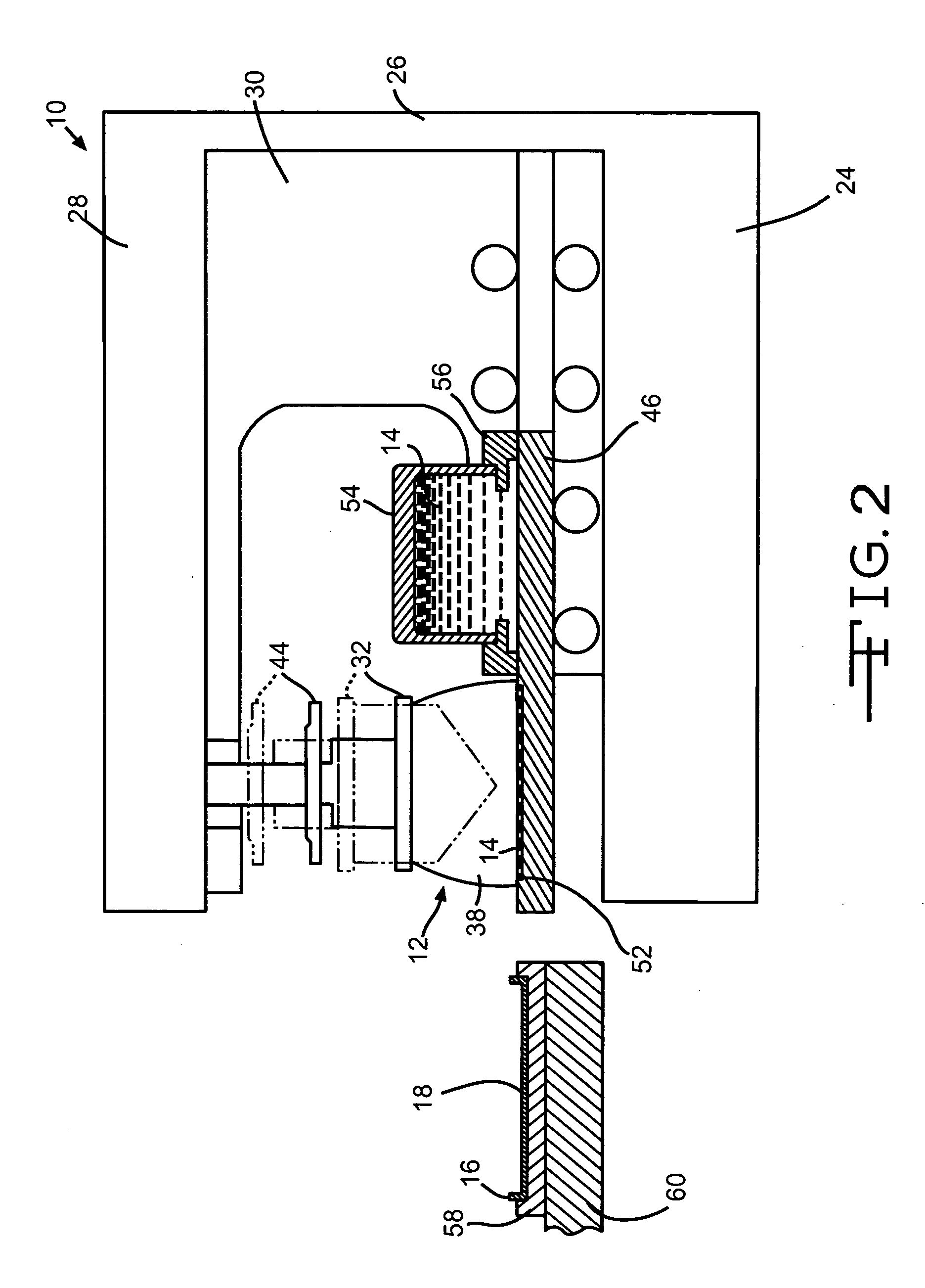

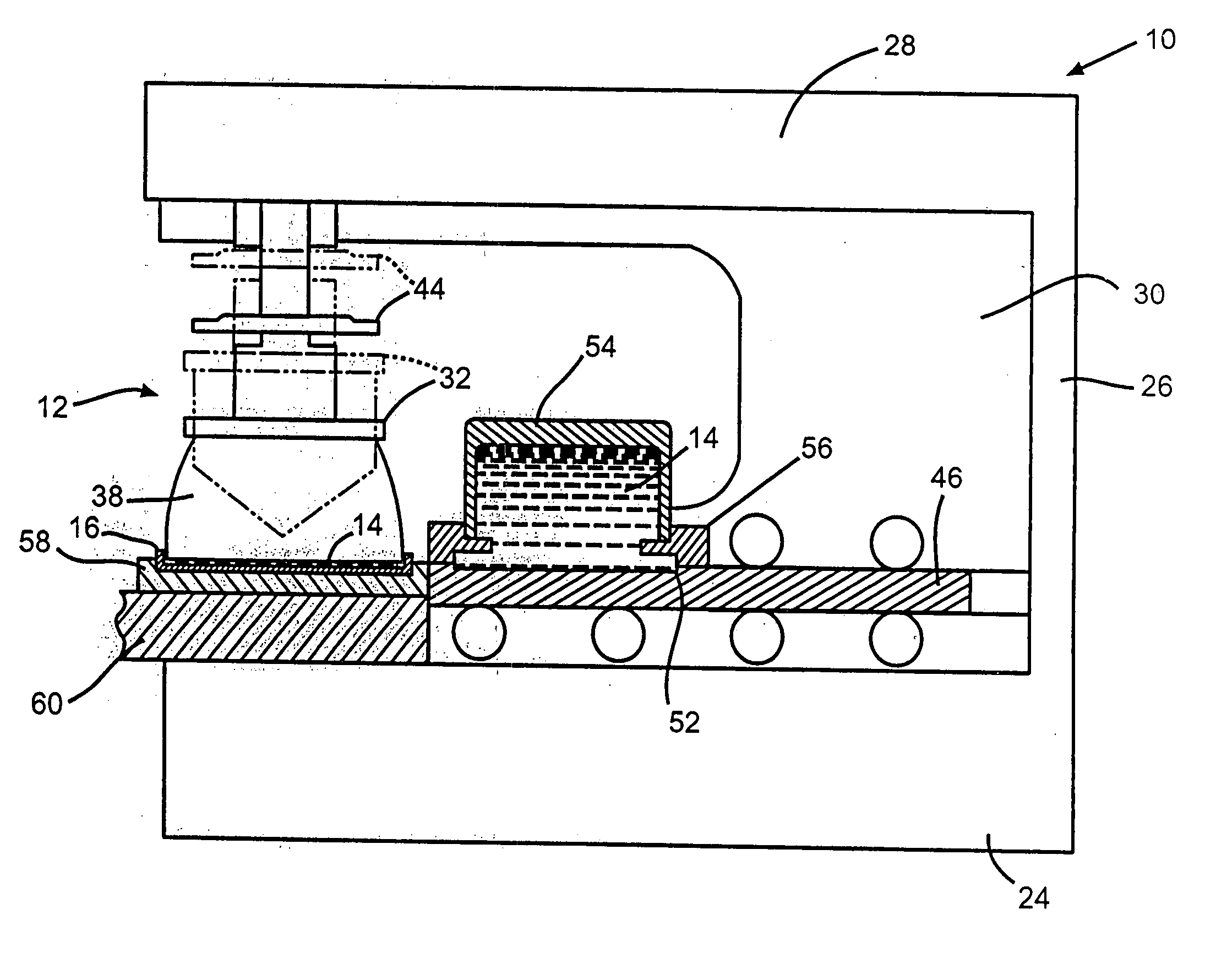

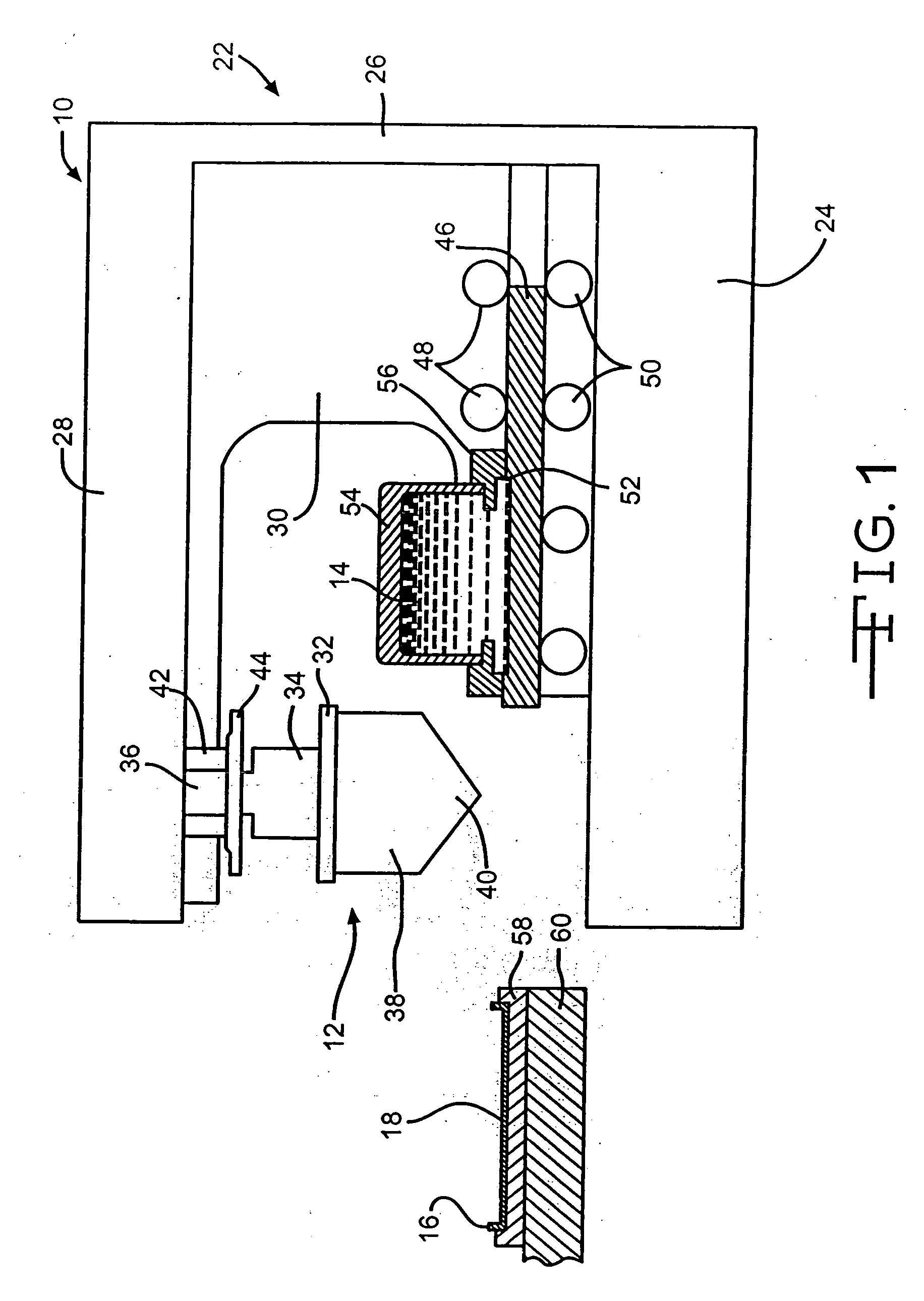

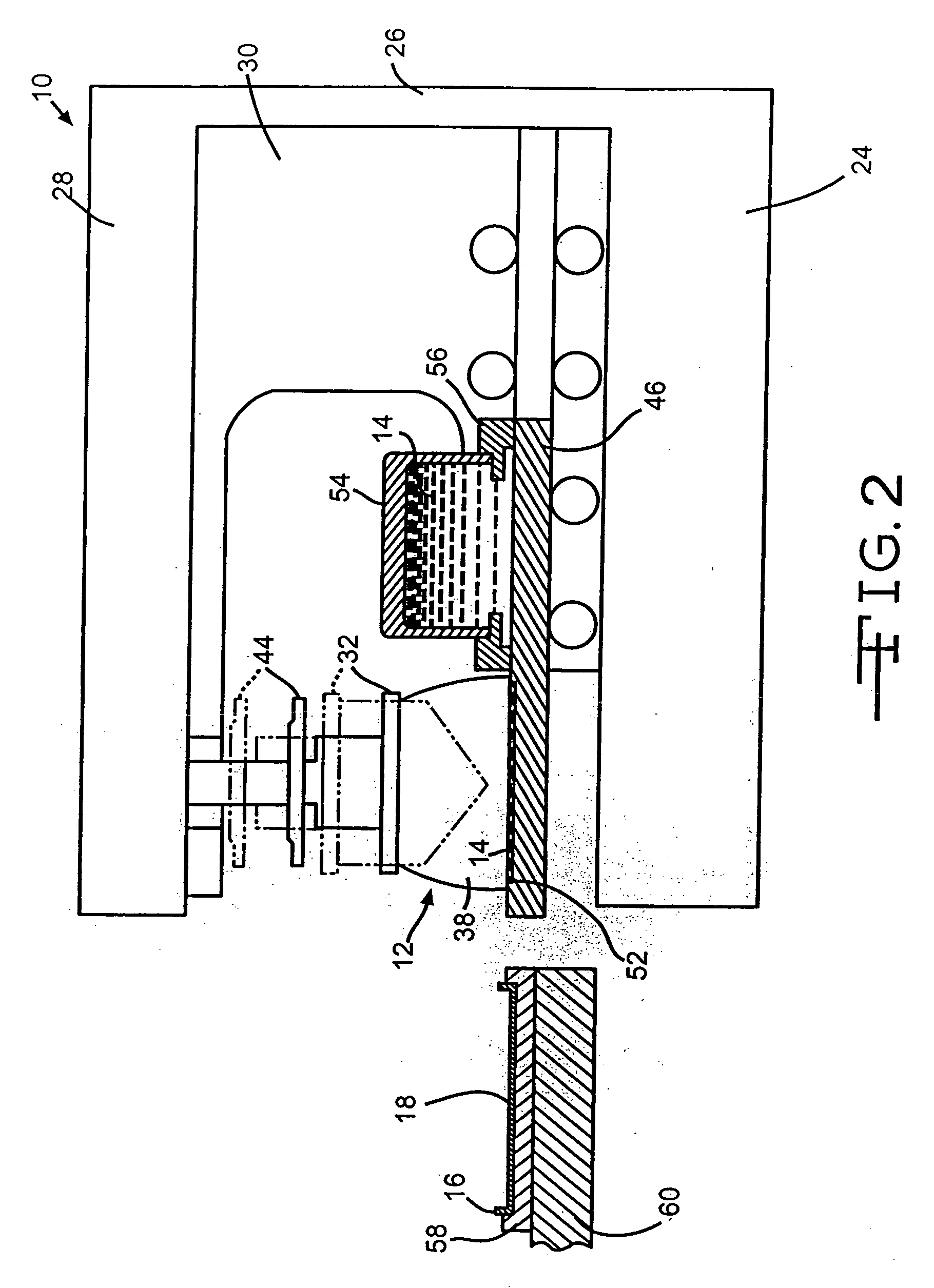

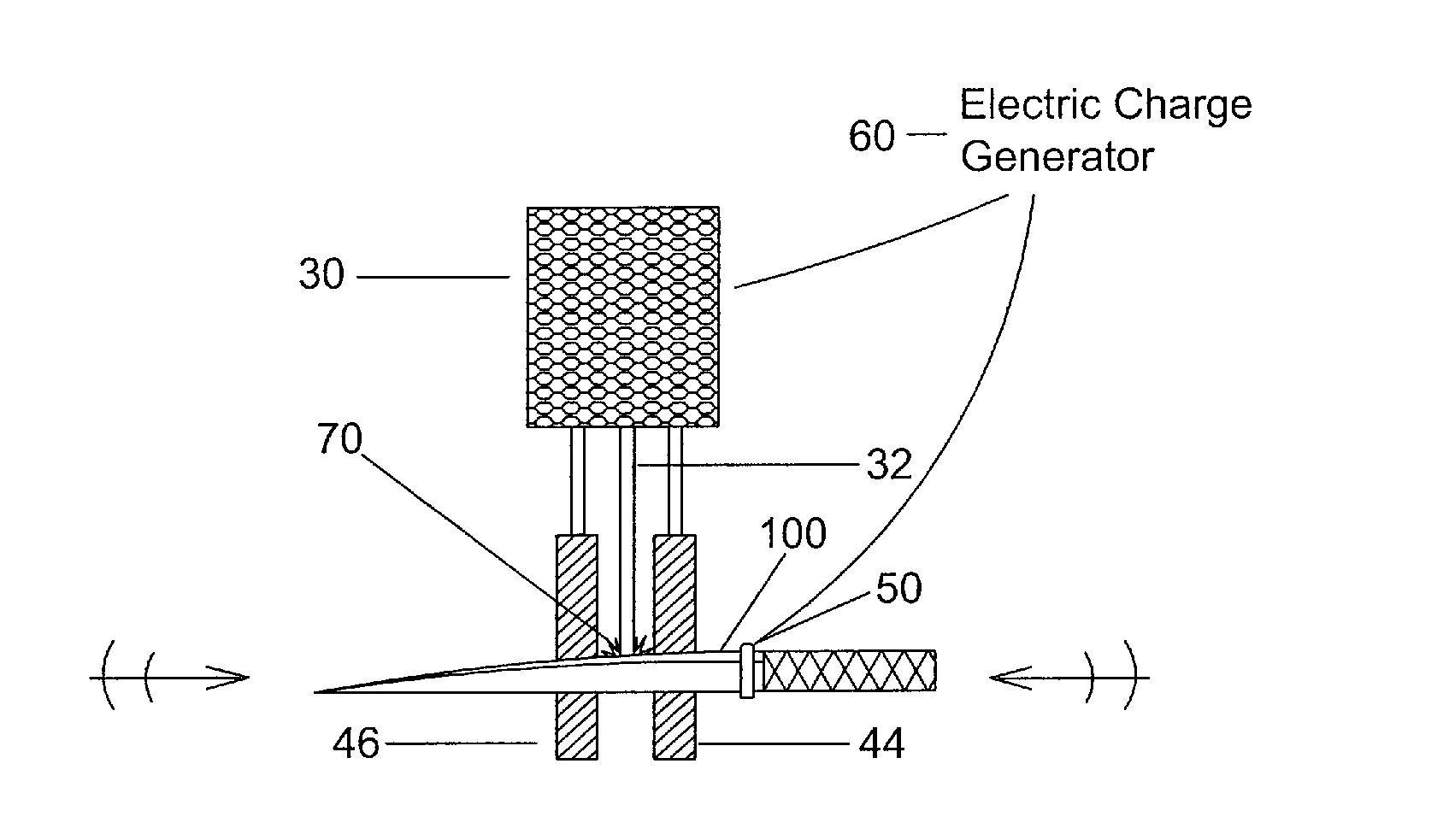

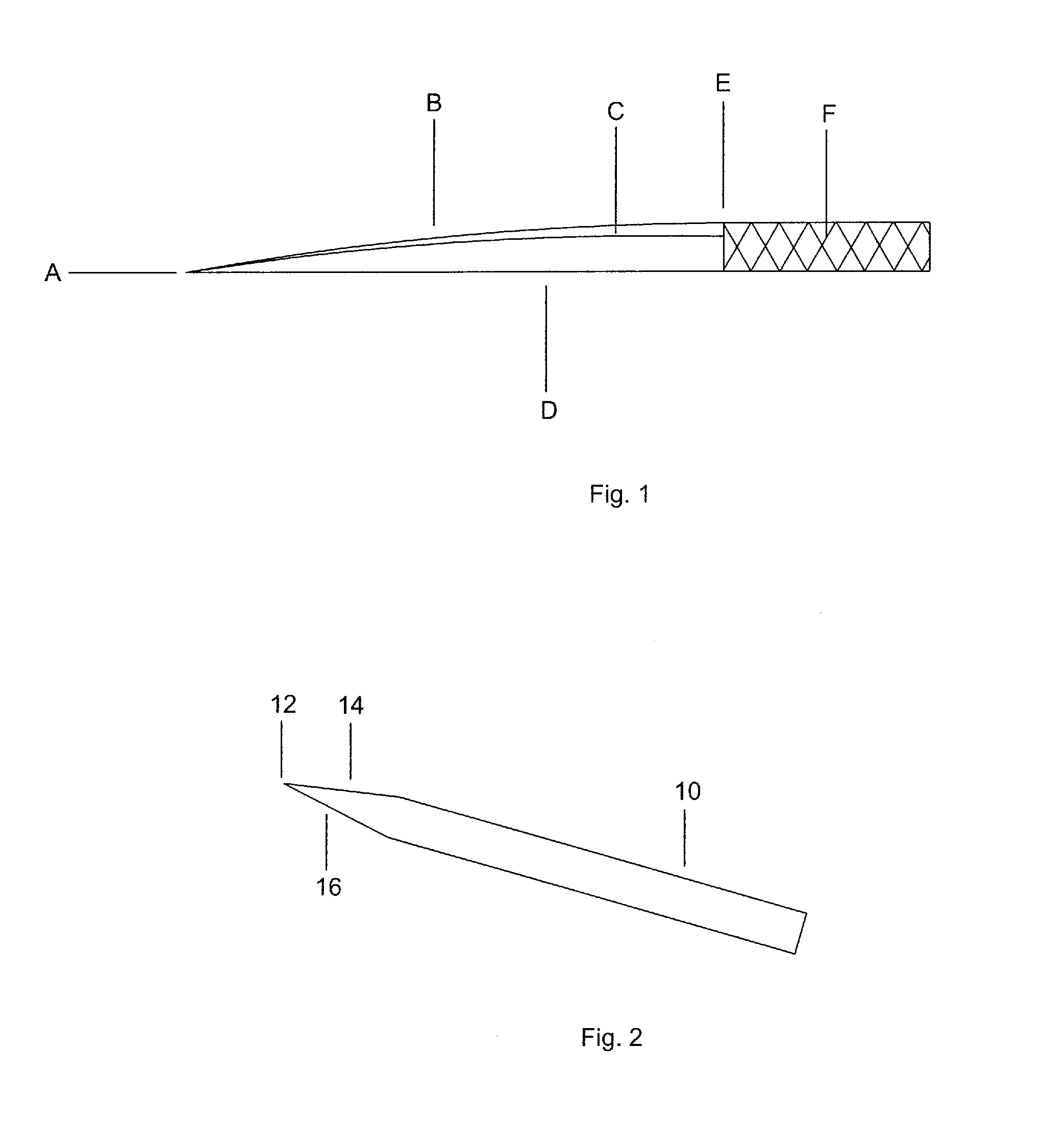

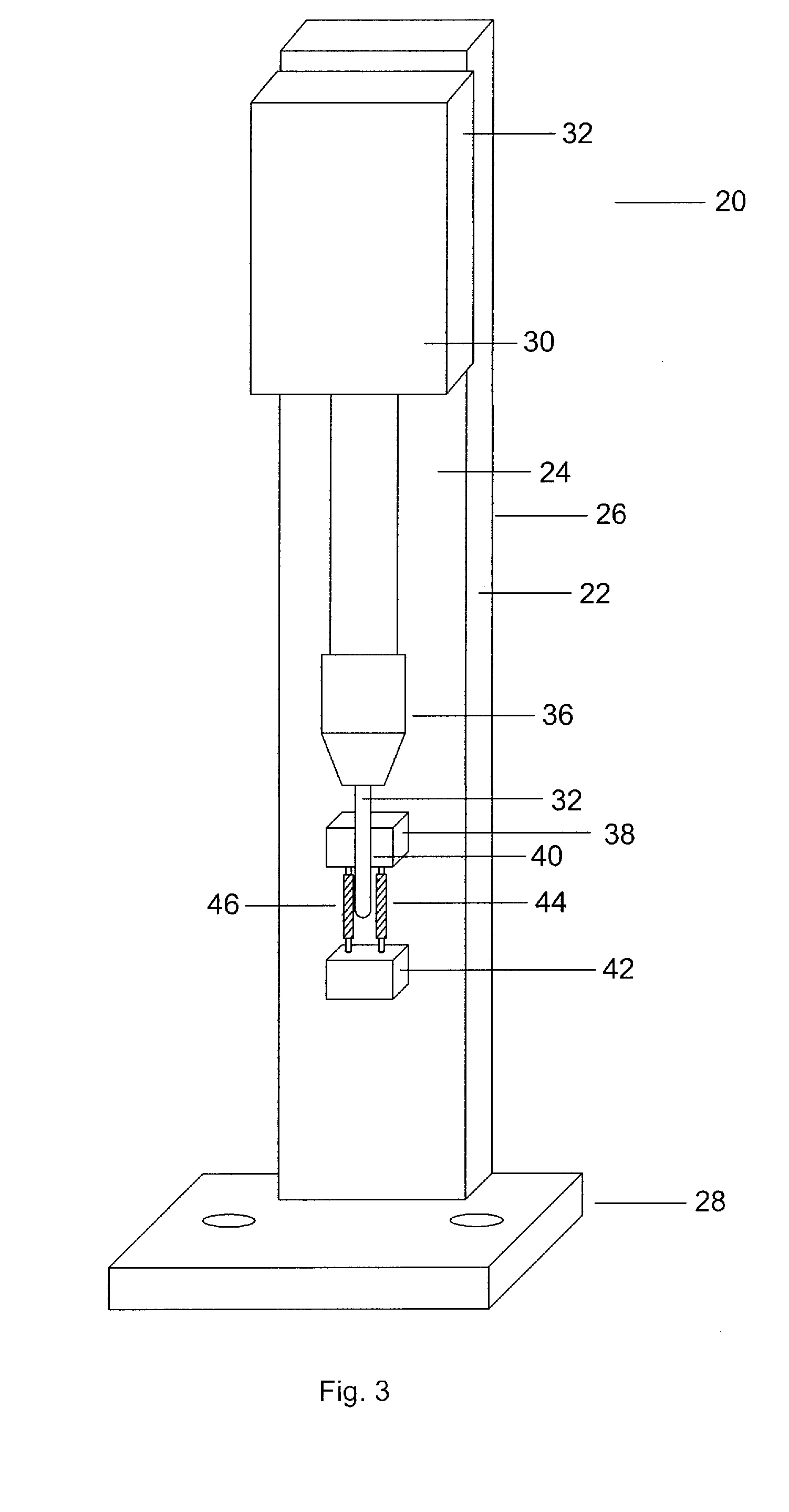

Apparatus and method of electronically impregnating a wear-resistant cutting edge

ActiveUS20110078909A1Improve cutting effectQuick wearElectrode vibration holdersOther manufacturing equipments/toolsCarbide coatingWear resistant

An apparatus and method for treating a cutting edge with a carbide coating to form a high endurance cutting edge that is self sharpening. The cutting edge has one side of its bevel treated with an electronically impregnated coating to create a wear resistant surface employing Tungsten, Titanium or Vanadium Carbide. The coating providing an abrasion resistant cutting edge and creates a differential hardness on the total cutting edge thereby extending its cutting ability through a wear-resistant surface on its treated face and a faster wear on the untreated surface causing the cutting edge to be self sharpening.

Owner:LAMBERT GEORGE H

Mulcher with improved tooth design

ActiveUS20070181725A1Improve efficiencyIncrease laborMechanical machines/dredgersPlant waste comminutingCarbide coatingTractor

A mulcher apparatus includes a tractor and a mulcher unit provided to the tractor. The mulcher unit includes a tooth assembly with a holder and a cutter element with a cooperating notch portion and cross bar arrangement. The notch portion can be retrofit to existing holder arrangements. The cutter element may include various features, to enhance cutting efficiency. For example, the cutter elements may include a double-ended structure, angle tab portions at each corner portion, carbide coatings, a pair of tip portions at each end with a space therebetween, and / or a generally H-shaped configuration.

Owner:PALADIN BRANDS GROUP INC

Method for prolonging service life of piercing plug for seamless steel tubes

ActiveCN102534604AImprove wear resistanceImprove antioxidant capacityMetallic material coating processesChromium carbideCarbide coating

The invention relates to the technical field of seamless steel tube production, in particular to a method for prolonging the service life of a piercing plug for seamless steel tubes. Applying a high-energy micro-arc alloying into the technique for preparing coating on the surface of the piercing plug, the method comprises: firstly, preparing a metal yttrium modified chrome carbide electrode by a hot pressing sintering process; secondly, depositing a chrome carbide coating on the piercing plug by using high-energy micro-arc alloying equipment, controlling the argon flow and the output voltage, frequency, power and deposition time of the equipment in a coating preparation process, and thus, preparing the high-performance coating on the surface of the piercing plug and prolonging the service life of the piercing plug.

Owner:南通东湖国际商务服务有限公司

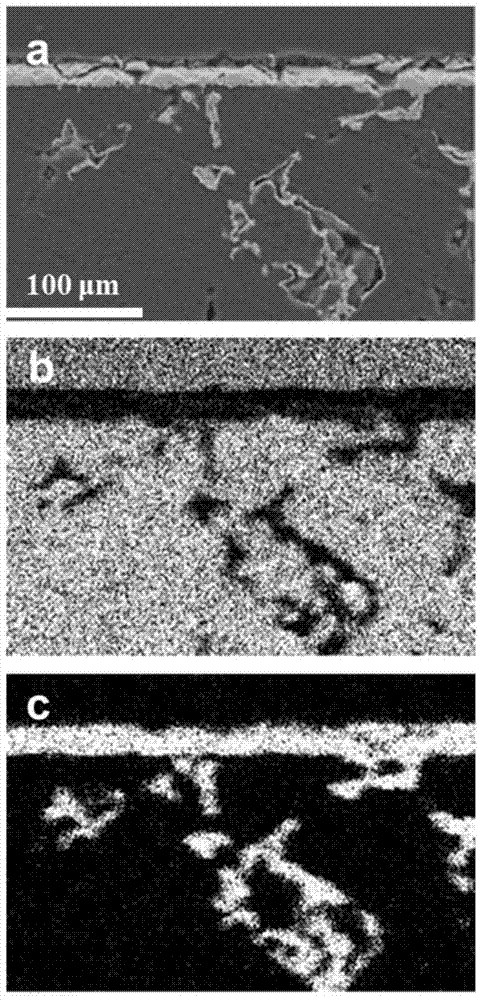

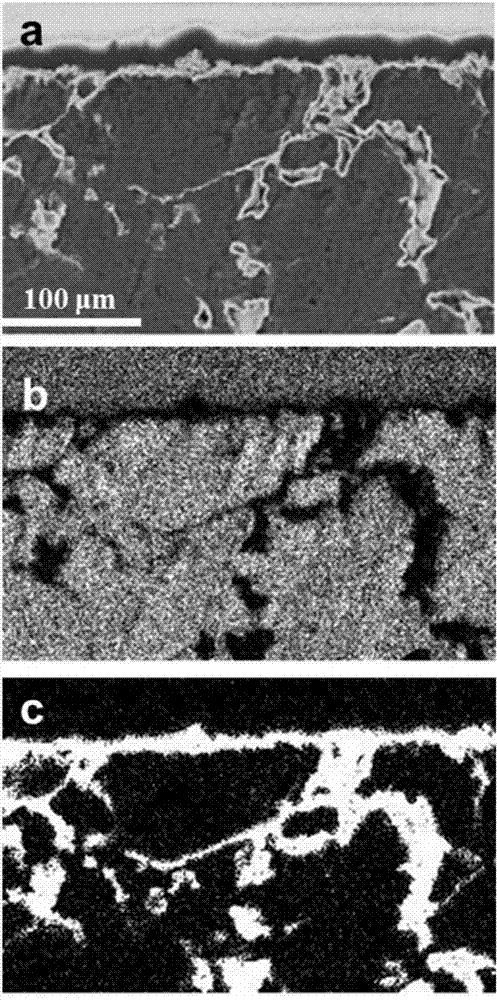

Metal carbide coating covered carbon-based material and preparation method therefor

The present invention discloses a metal carbide coating covered carbon-based material and a preparation method therefor. The preparation method comprises the following steps: putting the carbon-based material and metallic chromium and / or titanium into chloride and / or fluoride molten salt, carrying out a reaction under anhydrous oxygen-free conditions for 1-100 hours, and obtaining metal carbide coating covered carbon-based material. The metal carbide is chromium carbide and / or titanium carbide. According to the preparation method disclosed by the present invention, molten salt is used as a reaction medium, a metal carbide coating is prepared on the surface of the carbon-base in situ, the method is simple in a process and easy to operate, and has no requirement of a sample shape, and industrial production is facilitated; and the prepared metal carbide coating is uniform in thickness, and combined tightly with a substrate, so that surface hardness, abrasion resistance and high-temperature oxidation resistance of the carbon-based material can be significantly improved, use performance of the carbon-based material is greatly improved, and a practical application scope of the carbon-based material is expanded.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

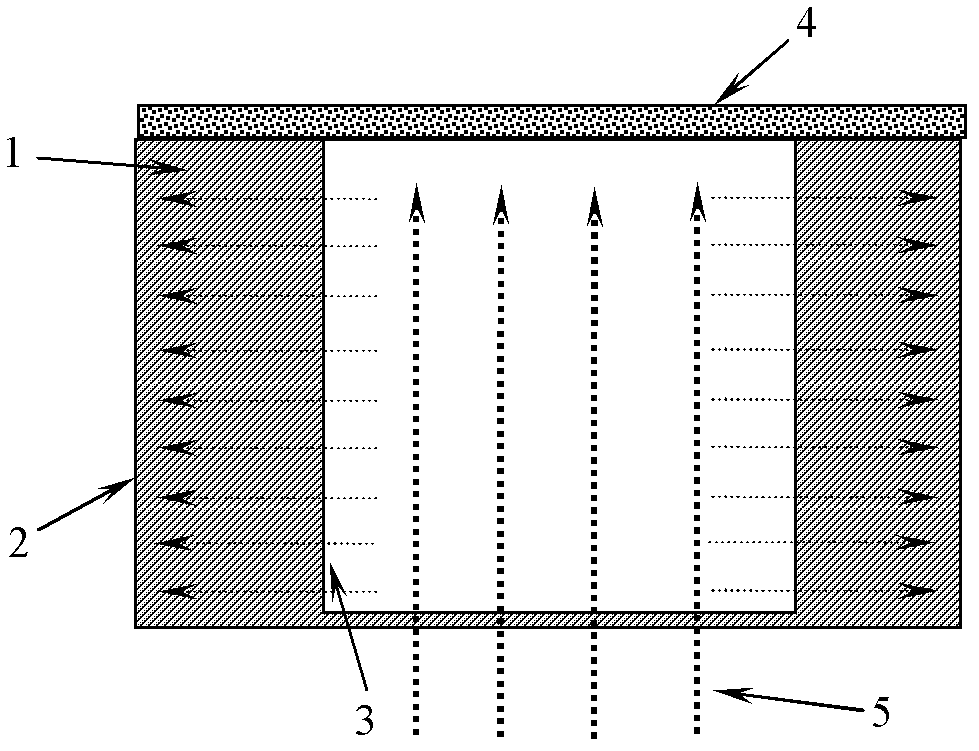

Method for preparing double-gradient carbide modified C/C composite material

The invention discloses a method for preparing a double-gradient carbide modified C / C composite material. A double-element matrix of carbon and carbide is deposited on the surface of carbon fibers in a carbon fiber preformed body by using a chemical vapor infiltration / deposition process; in the prepared composite material, the density of the carbide is in high-low gradient distribution from the inside diameter surface to the outside diameter surface, and the density of the carbon is in low-high gradient distribution from the inside diameter surface to the outside diameter surface, and thus acarbon-ceramic macro gradient is formed; on the surface of the carbon fibers in the composite material, the whole carbon coating is transited to a carbon-carbide co-deposition coating, finally the whole carbide coating is in gradient distribution, and thus a carbon-ceramic micro gradient is formed; and the double-gradient carbide modified C / C composite material is obtained. The material prepared by the method has the characteristics of excellent high-temperature resistance, abrasion resistance, scouring resistance, oxidation resistance, ablation resistance and thermal shock performance. The method is simple, convenient to operate and low in preparation cost; the prepared C / C composite material has excellent ablation resistance and thermal shock performance; and the method is suitable for industrialized production.

Owner:CENT SOUTH UNIV

Method for improving bonding strength of interface between hard coating and substrate

InactiveCN102517539ALow temperature annealing effect is goodMolten spray coatingVacuum evaporation coatingCarbide coatingUltimate tensile strength

The invention discloses a method for improving the bonding strength of an interface between a hard coating and a substrate. The method is implemented by treating the hard coating / substrate compound system at the low temperature or ultralow temperature of between 50 DEG C and 273 DEG C below zero for 5-48 hours. The hard coating comprises nitride coatings such as TiN, CrN, TiAlN, TiSiN, CrAlTiN, BN and the like, C coatings such as diamond, diamond-like carbon and the like, and carbide coatings such as TiC, WC and the like. Due to the adoption of the method, the bonding strength of the interface between the coating and the substrate can be raised by 10-50 percent, and deterioration of the performance of the substrate or coating can be avoided by adopting of the conventional high-temperature annealing method; and meanwhile, low-temperature or ultralow-temperature treatment cost is low, and the method is suitable for various coatings / substrate compound systems.

Owner:SOUTHWEST UNIVERSITY

High temperature-resistant article, method for producing the same, and high temperature-resistant adhesive

ActiveUS20100239885A1Low costPolycrystalline material growthPretreated surfacesCarbide coatingAdhesive

A method for producing a high temperature-resistant article comprises an assembling step of foaming an assembly of a first substrate and a second substrate with an adhesive layer interposed therebetween and comprising paste of powder of at least one carbide of niobium carbide, hafnium carbide, tantalum carbide and tungsten carbide; and a bonding step of heating the assembly to bond the first substrate and the second substrate by sintering, thereby obtaining a high temperature-resistant article comprising the assembly after sintering. Moreover, a method for producing a high temperature-resistant article comprises a coating step of coating a slurry comprising powder of at least one carbide of niobium carbide, hafnium carbide, tantalum carbide and tungsten carbide on a surface of a high temperature-resistant substrate; a drying step of drying the substrate after the coating step; and a film-forming step of heating the substrate after the drying step to form a carbide coating film on the surface of the substrate by sintering, thereby obtaining a high temperature-resistant article having the carbide coating film. A high temperature-resistant article of a complicated shape can be easily produced at low costs by these methods.

Owner:TOYOTA CENT RES & DEV LAB INC

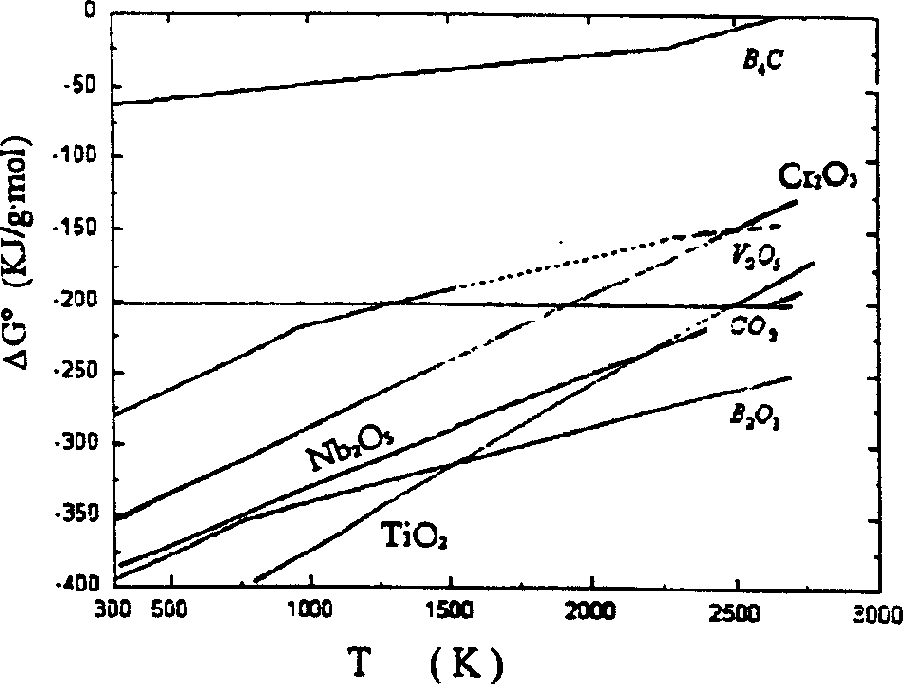

Process for producing metal carbonide hard face coating and application thereof

InactiveCN1609272AIncreased continuous working lifeImprove anti-wear performanceMetallic material coating processesCarbide coatingNiobium

The present invention relates to one kind of metal carbide coating and its making process and application, and belongs to the field of the surface chemical and heat treating technology for iron and steel material. Inside molten borax salt bath, B4C powder is used to reduce flue ash from ferroalloy works, so that the iron and steel mother material heated inside the molten borax salt bath has hard metal carbide coating formed on its surface. The coating has firm binding with the mother material, thickness of 15-25 microns, hardness of HV 1600-3200 and the advantages of high wear resistance, high corrosion resistance, etc. The hard metal carbide coating of the present invention is especially suitable for workpiece or member with high requirement in wear resistance and corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

Hard, ductile coating system

InactiveUS7211338B2Improve deposition efficiencyLiquid surface applicatorsEngine manufactureCarbide coatingSurface layer

Owner:HONEYWELL INT INC

Insertion piece with hard metal coating

ActiveCN1517450AImprove toughnessImprove enduranceCutting insertsWorkpiecesCarbide coatingHard metal

The present invention relates to a cutting tool insert particularly for turning of steel comprising a cemented carbide body, a coating with a post treatment with a first, innermost layer system of one or several layers of TiCxNyOz with x+y+z<=1 with a total thickness of 0.7-4.5 mum a second multilayer system consisting of a totally 5-31 alternating Al2O3 and TiCxNyOz (x+y+z<=1), preferably kappa-Al2O3 and TiN, the Al2O3-layers having an individual layer thickness of <0.5 mum and the TiCxNyOz-layers 0.01-0.2 mum with a total thickness of the multilayer of 1.0-4.0 mum. The multilayer is exposed along the edge line and into the rake and flank face, at least 0.02 mm, from the edge line on the rake face, preferably the contact length of the chip at most 0.9 mm, and 0.02-0.20 mm on the flank face.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Precision piece part watch surface chromium base alloy carbides cladding process method

ActiveCN101182644AHigh hardnessImprove wear resistanceSolid state diffusion coatingCarbide coatingHardness

The invention discloses a treatment method of a chromium base alloy carbide coating on a precise part surface, and is applicable for the surface treatment of medium-low carbon alloy steel parts and car-poor surfaced carbon steel parts. First, the carbon addition treatment is conducted on a carbon steel part, which is just mechanically processed, and then the chromizing treatment is conducted on a carbon-rich surfaced carbon steel part. The chromizing time is short, but the efficiency is high. A chromium base alloy carbide coating on the part surface is provided with the strong adhesive force and is evenly distributed. Moreover, no unfavorable effect is caused to carbon steel texture. The surface of the treated part is provided with the high hardness, the high abrasion resistance, the high corrosion resistance, and the high high-temperature resistance.

Owner:QINGDAO CHOHO IND CO LTD

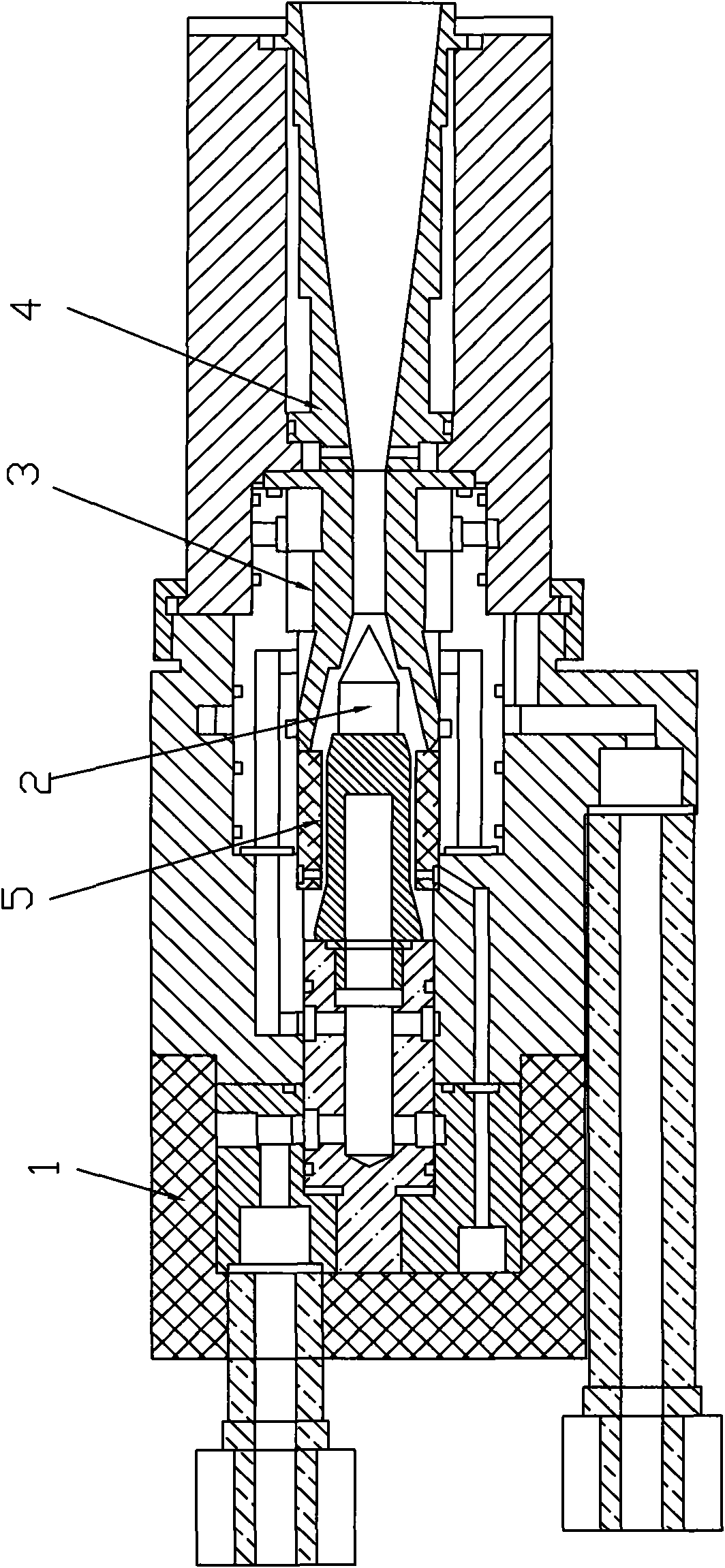

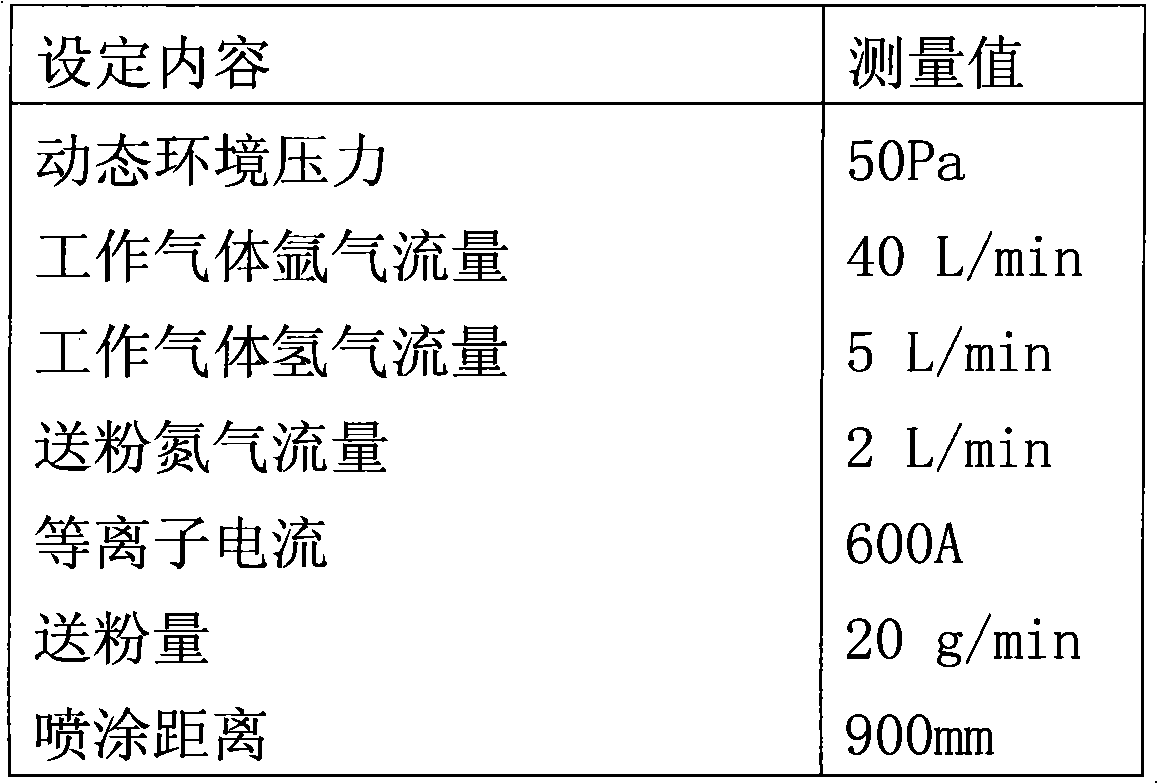

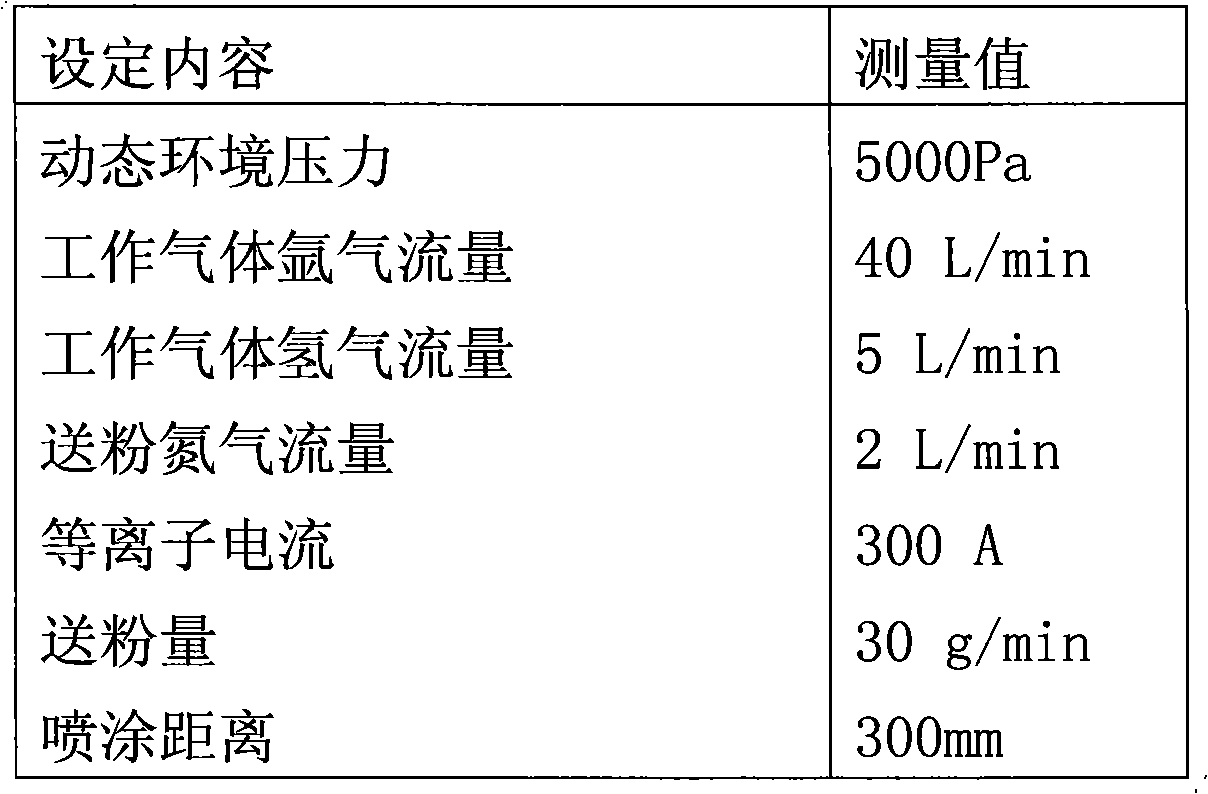

Plasma spray gun used for low-pressure plasma spraying

InactiveCN101954324AExtend your lifeLiquid spraying plantsMolten spray coatingCarbide coatingSpray nozzle

The invention discloses a plasma spray gun used for low-pressure plasma spraying, and belongs to spray equipment used for preparing metal and metal oxide or metal carbide coatings. The spray gun comprises a gun body, a cathode, an anode and a spray nozzle, wherein a club-shaped cathode with a conical head is arranged in the gun body; an external water-cooling cylindrical anode and an internal compressed spray nozzle which is connected with the cathode closely are arranged in front of the cathode along the axial direction; and a spray powder material is fed into the inlet of the spray nozzle, is heated and accelerated in the spray nozzle, is heated in plasma in a low-pressure environment after being sprayed out from the spray nozzle, and flies to the surface of a spraying workpiece. The positive electrode of a direct current power supply is connected with the anode while the negative electrode is connected with the cathode. The device of the invention has high powder heating capacity and is suitable for performing plasma spray in low-pressure or ultra-low-pressure environment.

Owner:DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com