Method for improving conductivity and corrosion resistance of fuel cell bipolar plate carbide coating layer

A fuel cell and carbide technology, used in fuel cell parts, fuel cells, electrochemical generators, etc., can solve the problem of increasing the cost of coating preparation, complex process, corrosion resistance and electrical conductivity of metal carbide coatings performance improvement and other issues to achieve the effect of reducing execution complexity, increasing surface roughness, and improving corrosion resistance and electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

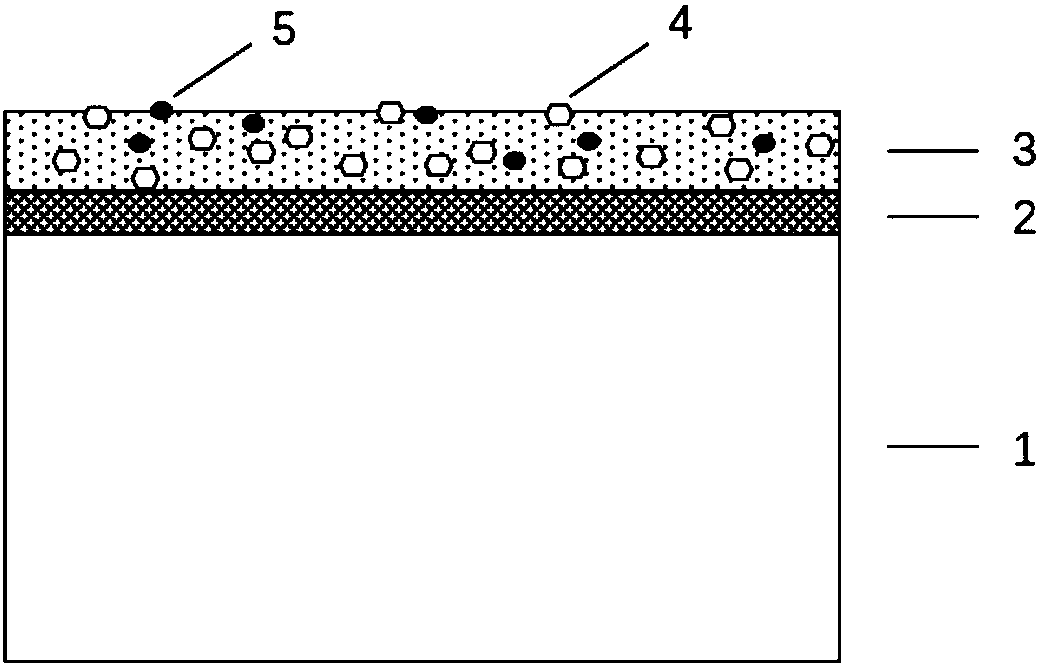

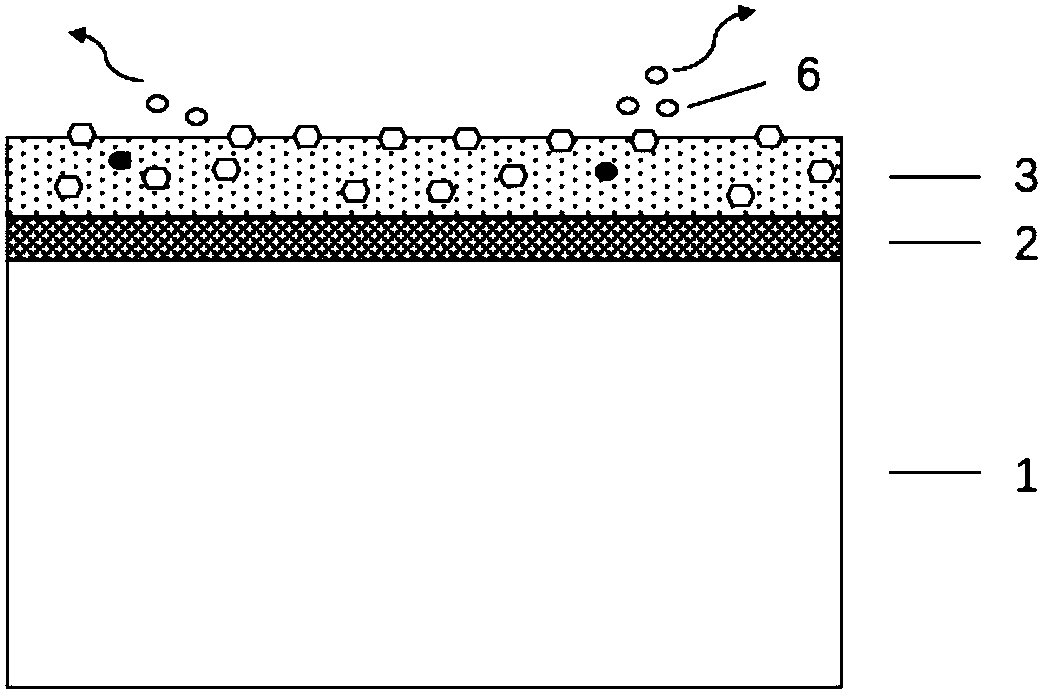

Method used

Image

Examples

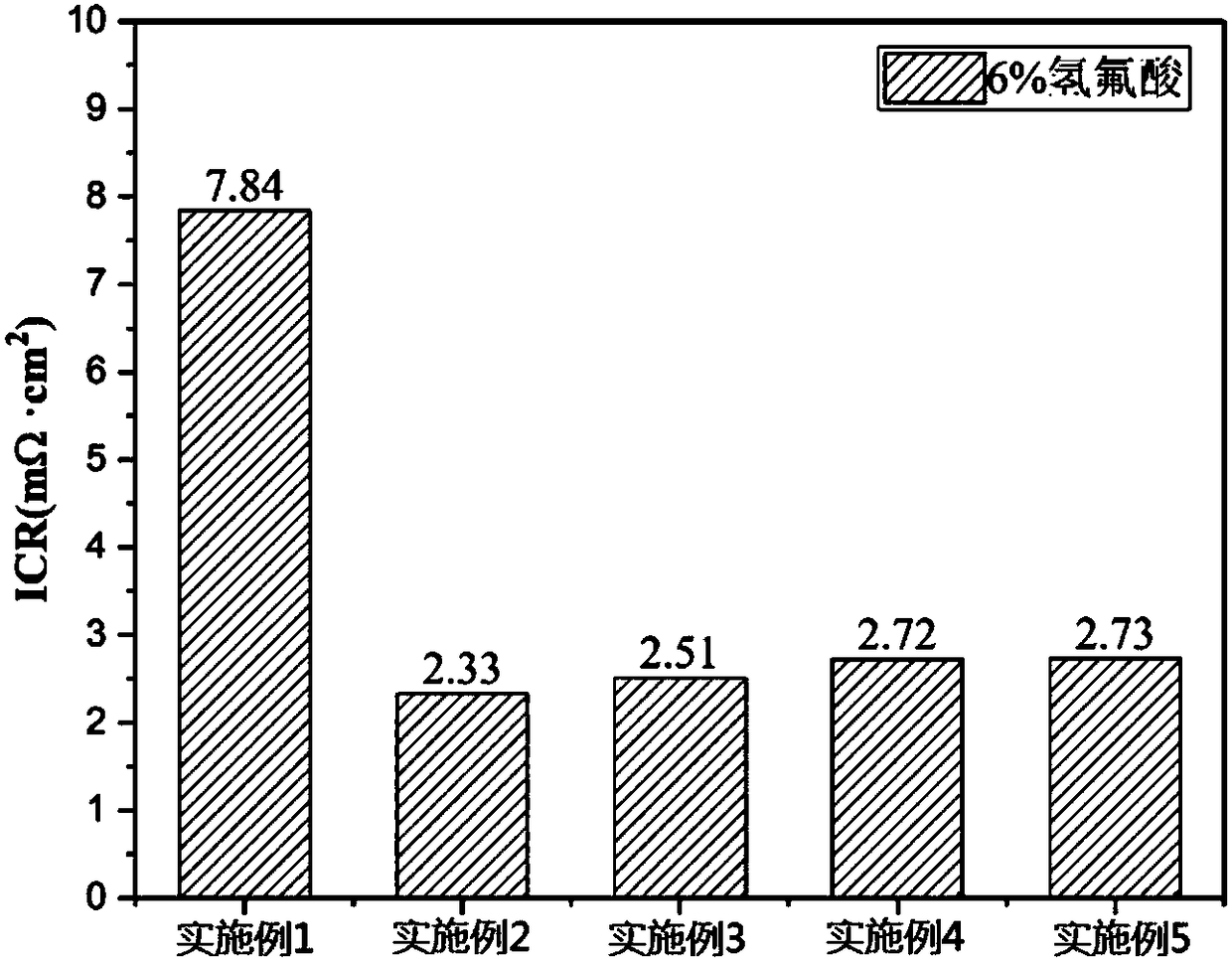

Embodiment 1

[0028] The stainless steel bipolar plate is used as the substrate, and the titanium carbide coating is prepared on its surface. The process is as follows:

[0029]1) Plate pretreatment: use deionized water, acetone, and absolute ethanol in sequence to ultrasonically clean the surface of the stainless steel bipolar plate and dry it;

[0030] 2) Hang the pretreated stainless steel bipolar plate on the planetary turret platform in the unbalanced magnetron sputtering ion plating furnace cavity, keep the turret speed at 4r / min, and evacuate to the background vacuum of 3*10 -5 After Torr, fill with argon and keep the working pressure at 4*10 -4 Torr, apply a bias voltage of -500V to the stainless steel substrate, so that the ions continue to bombard the surface of the substrate, clear the passivation layer on the surface, and the cleaning time is 30 minutes;

[0031] 3) Introduce 20 sccm of argon as a protective gas, and 20 sccm of reaction gas acetylene for 30 minutes, keep the su...

Embodiment 2

[0035] The stainless steel bipolar plate is used as the substrate, and the titanium carbide coating is prepared on the surface, and the corrosion resistance and conductivity of the titanium carbide coating are improved by wet etching. The process is as follows:

[0036] 1) Plate pretreatment: use deionized water, acetone, and absolute ethanol in sequence to ultrasonically clean the surface of the stainless steel bipolar plate and dry it;

[0037] 2) Suspend the pretreated stainless steel bipolar plate on the planetary turret platform in the unbalanced magnetron sputtering ion plating furnace cavity, vacuumize to the background vacuum, fill it with argon, and apply bias on the stainless steel substrate. pressure, so that the ions continue to bombard the surface of the substrate, and the cleaning time is 30 minutes;

[0038] 3) Pass the working gas and the reaction gas into the vacuum container at the same time, and deposit the titanium carbide coating on the surface of the stai...

Embodiment 3

[0042] The stainless steel bipolar plate is used as the substrate, and the titanium carbide coating is prepared on the surface, and the corrosion resistance and conductivity of the titanium carbide coating are improved by wet etching. The process is as follows:

[0043] 1) Plate pretreatment: use deionized water, acetone, and absolute ethanol in sequence to ultrasonically clean the surface of the stainless steel bipolar plate and dry it;

[0044] 2) Suspend the pretreated stainless steel bipolar plate on the planetary turret platform in the unbalanced magnetron sputtering ion plating furnace cavity, vacuumize to the background vacuum, fill it with argon, and apply bias on the stainless steel substrate. pressure, so that the ions continue to bombard the surface of the substrate, and the cleaning time is 30 minutes;

[0045] 3) Pass the working gas and the reaction gas into the vacuum container at the same time, and deposit the titanium carbide coating on the surface of the stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Contact resistance | aaaaa | aaaaa |

| Contact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com