Method for preparing titanium carbide coating through pulse electrodeposition

A technology of pulse electrodeposition and titanium carbide, applied in the direction of coating, electrolytic coating, etc., can solve the problems of reducing adhesion and achieve the effect of dense coating, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for preparing the titanium carbide coating by pulse electrodeposition in this embodiment is as follows:

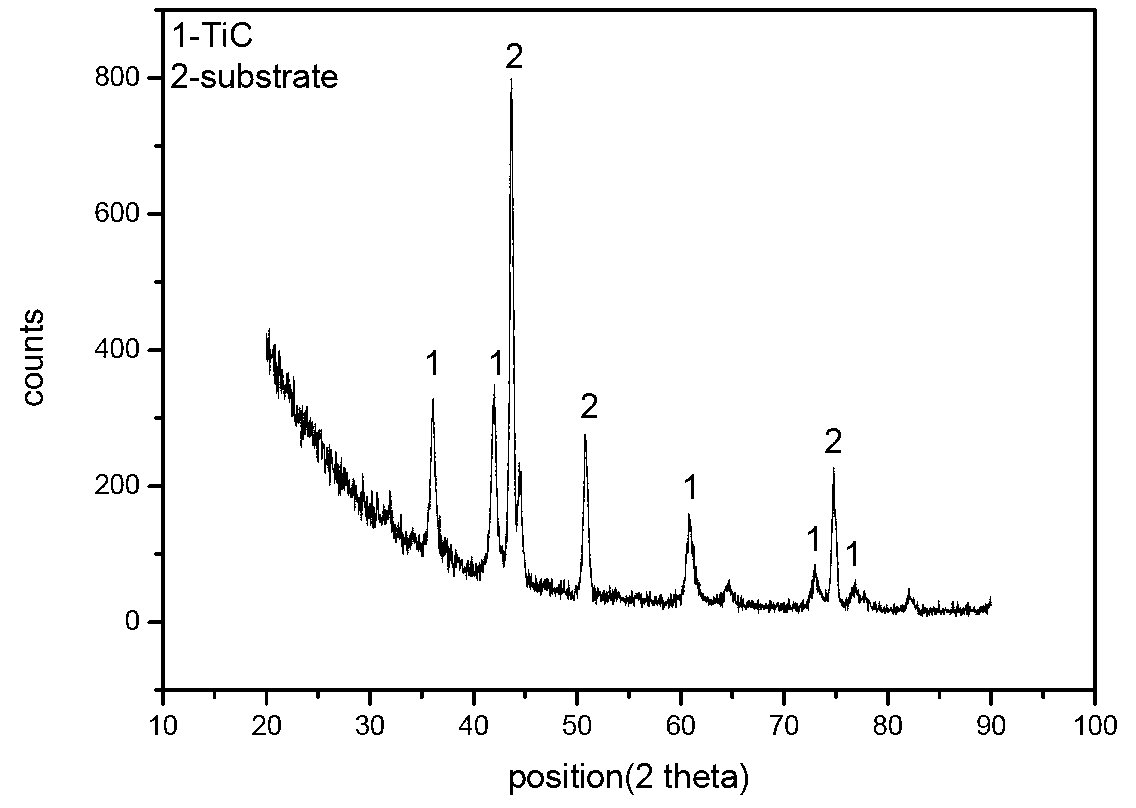

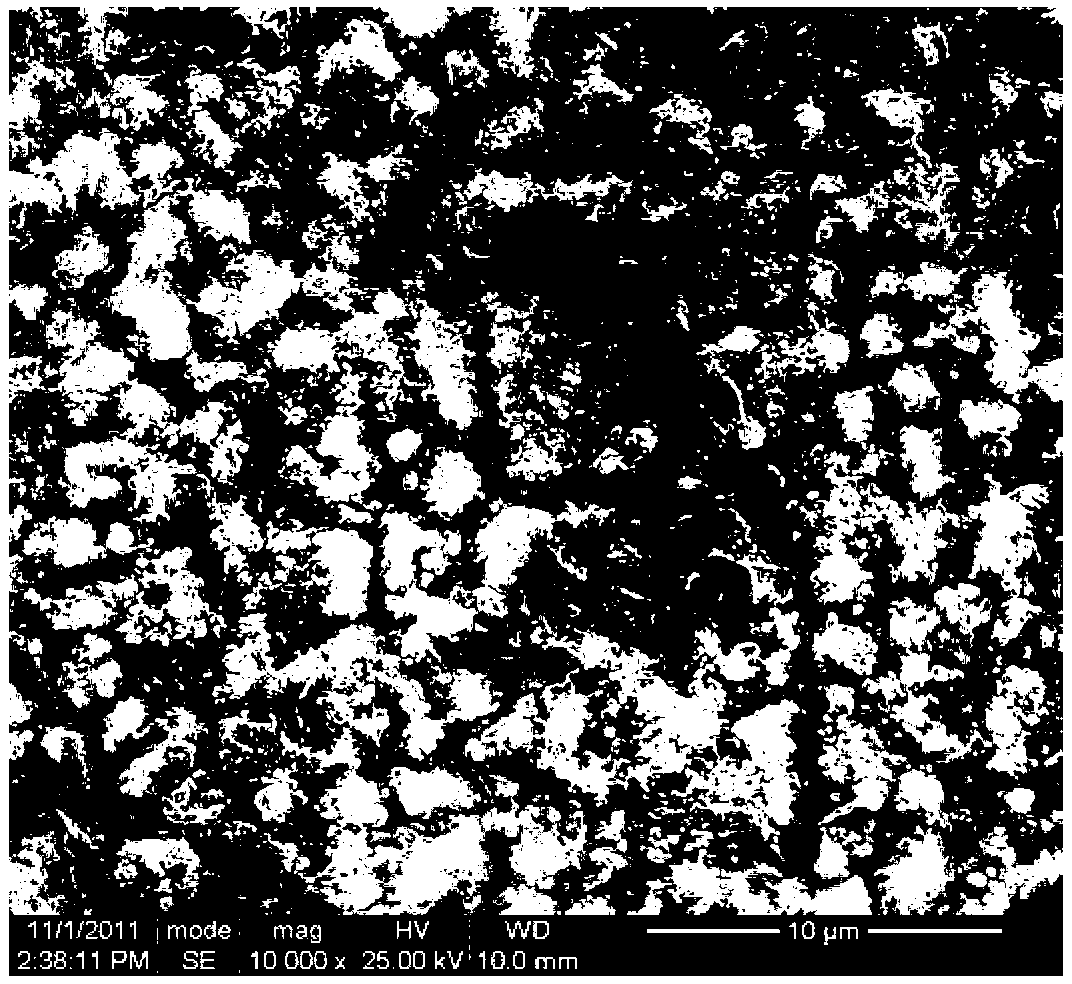

[0027] The 304 stainless steel plate is cut into sheet samples by wire cutting, and is ground, cleaned and dried. Spot welding Fe-Cr wire to one end of the sample as the electrode lead. Electrodeposition adopts a three-electrode system, that is, the stainless steel plate sample is used as the cathode, the graphite electrode is used as the auxiliary electrode and carbon source (anode), and the nickel electrode is used as the reference electrode. . Take K 2 TiF 6 As the titanium source, the ternary eutectic (mixed salt) 40.25mol%NaCl-50.5mol%KCl--9.25mol%NaF salt is used as the active material K 2 TiF 6 Solvent, K 2 TiF 6 The content in the solvent is 7wt%. Put the mixed salt and titanium source prepared above into an alumina crucible, and raise the temperature to 900°C under the protection of argon gas. PAR2273 electrochemical workstation was used for const...

Embodiment 2

[0033] The method for preparing the titanium carbide coating by pulse electrodeposition in this embodiment is as follows:

[0034] The 304 stainless steel plate is cut into sheet samples by wire cutting, and is ground, cleaned and dried. Spot-welded Fe-Cr wire to one end of the sample as the electrode lead. Electrodeposition adopts a three-electrode system, that is, the stainless steel plate sample is used as the cathode, graphite is used as the auxiliary electrode and carbon source (anode), and the nickel electrode is used as the reference electrode. Take K 2 TiF 6 As the titanium source, the ternary eutectic (mixed salt) 40.25mol%NaCl-50.5mol%KCl--9.25mol%NaF salt is used as the active material K 2 TiF 6 Solvent, K 2 TiF 6 The content after the solvent is 5wt%. Put the mixed salt and titanium source prepared above into an alumina crucible, and raise the temperature to 850°C under the protection of argon gas. PAR2273 electrochemical workstation was used for constant potential p...

Embodiment 3

[0037] The method for preparing the titanium carbide coating by pulse electrodeposition in this embodiment is as follows:

[0038] The 304 stainless steel plate is cut into sheet samples by wire cutting, and is ground, cleaned and dried. Spot-welded Fe-Cr wire to one end of the sample as the electrode lead. Electrodeposition adopts a three-electrode system, that is, the stainless steel plate sample is the cathode, graphite is the auxiliary electrode and carbon source (anode), and the nickel electrode is the reference electrode. Take K 2 TiF 6 As the titanium source, the ternary eutectic (mixed salt) 40.25mol%NaCl-50.5mol%KCl--9.25mol%NaF salt is used as the active material K 2 TiF 6 Solvent, K 2 TiF 6 The content in the solvent is 10wt%. Put the mixed salt and titanium source prepared above into an alumina crucible, and the temperature is raised to 950°C under the protection of argon gas. PAR2273 electrochemical workstation was used for constant potential pulse deposition. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com