Plasma spray gun used for low-pressure plasma spraying

A plasma spray gun, low-pressure plasma technology, applied in plasma, liquid spraying equipment, coating, etc., can solve the problems of high powder deposition efficiency, coating quality problems, difficult to spray low thermal conductivity materials, etc., to achieve low plasma current, The effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

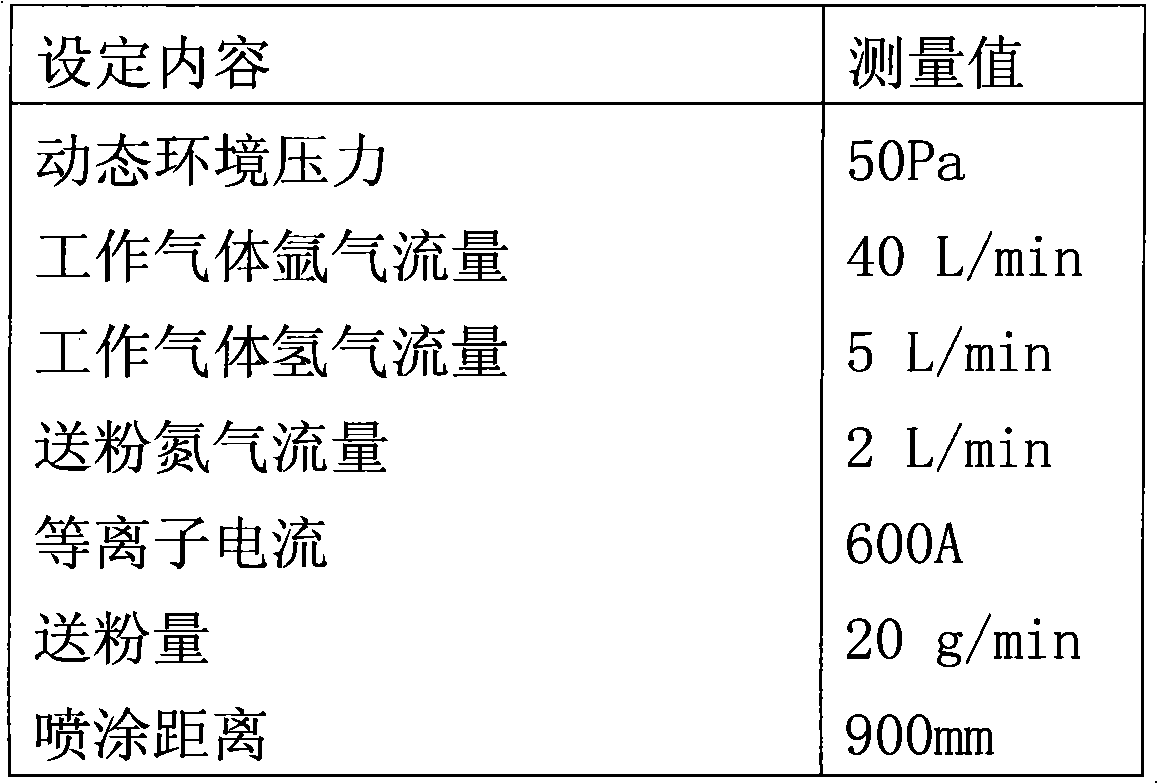

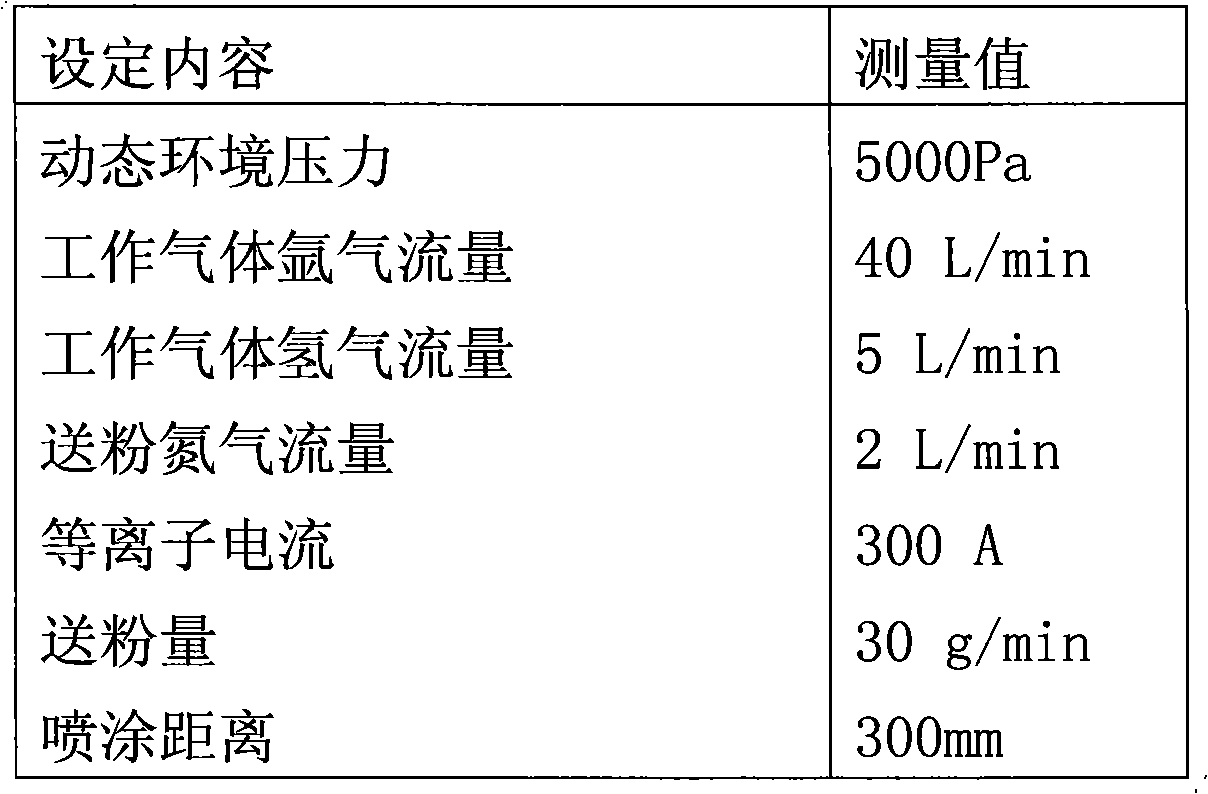

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the examples.

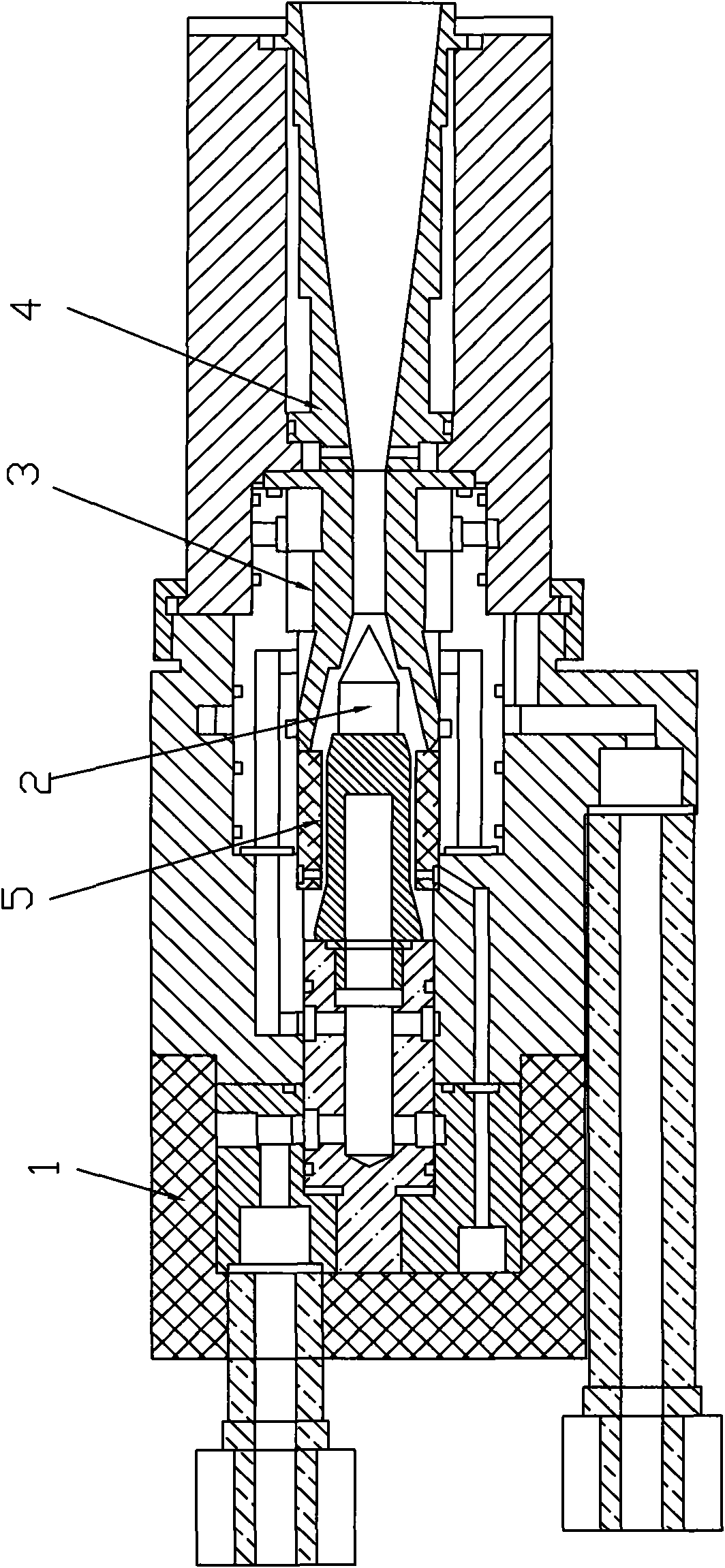

[0014] A kind of plasma spray gun for low-pressure plasma spraying of the present embodiment comprises gun body 1, cathode 2, anode 3 and nozzle 4, and the positive pole of DC power supply is connected on the anode 3, and the negative pole of DC power supply is then connected on the cathode 2, described gun The body 1 is provided with a rod-shaped cathode 2 with a conical head, and the front of the cathode is provided with a cylindrical anode 3 along the axial direction. The inlet of the anode 3 is provided with a gas uniform distribution ring 5, and the outlet of the anode 3 is provided with an internal compression nozzle 4, spraying material powder The powder feeding port is inside the nozzle outlet, and the high-temperature plasma jet heats and melts the powder and sprays it out from the nozzle 4.

[0015] The inlet of the nozzle 4 is closely connected with the outlet of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com