Patents

Literature

1316results about How to "Improve endurance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

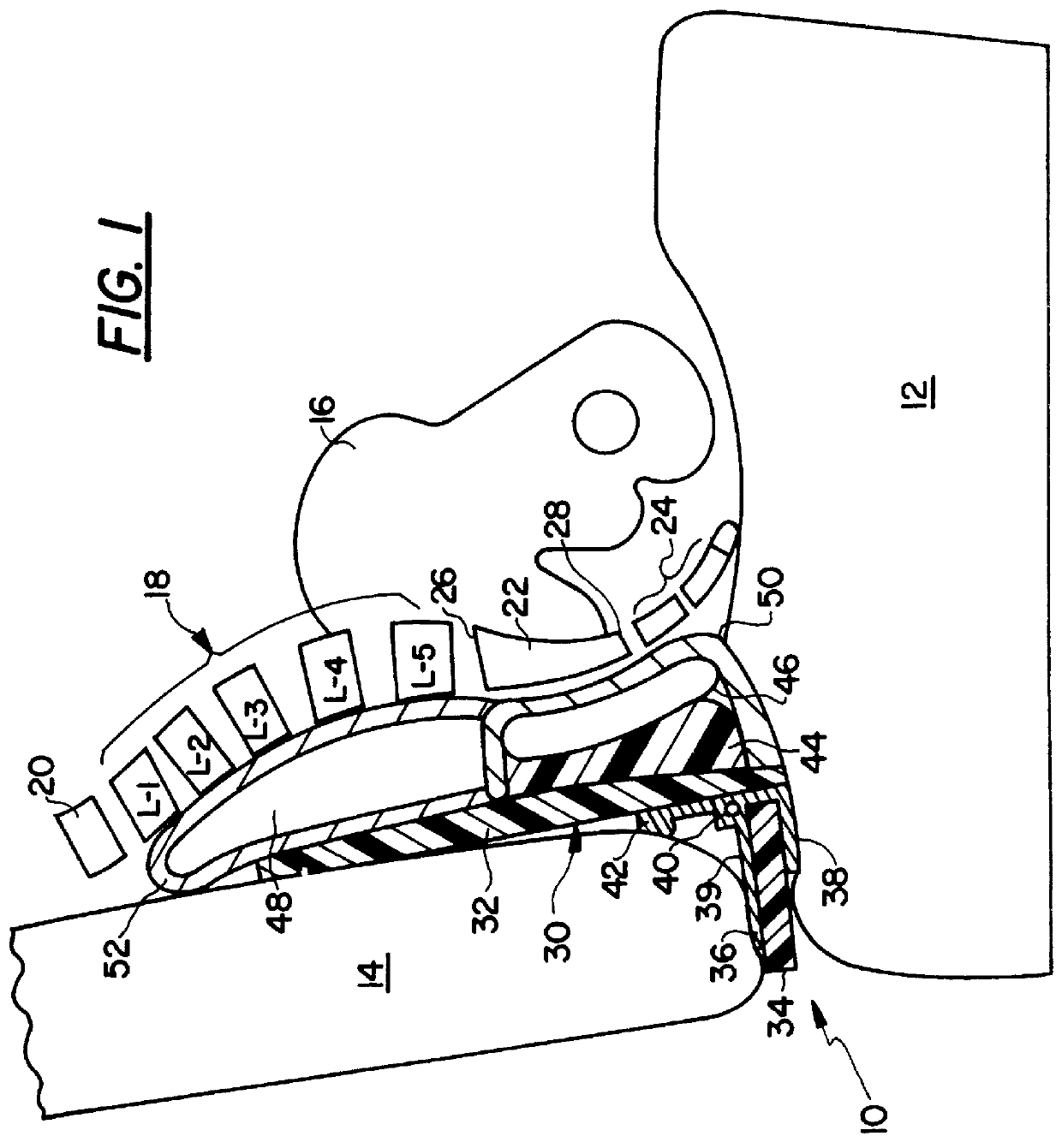

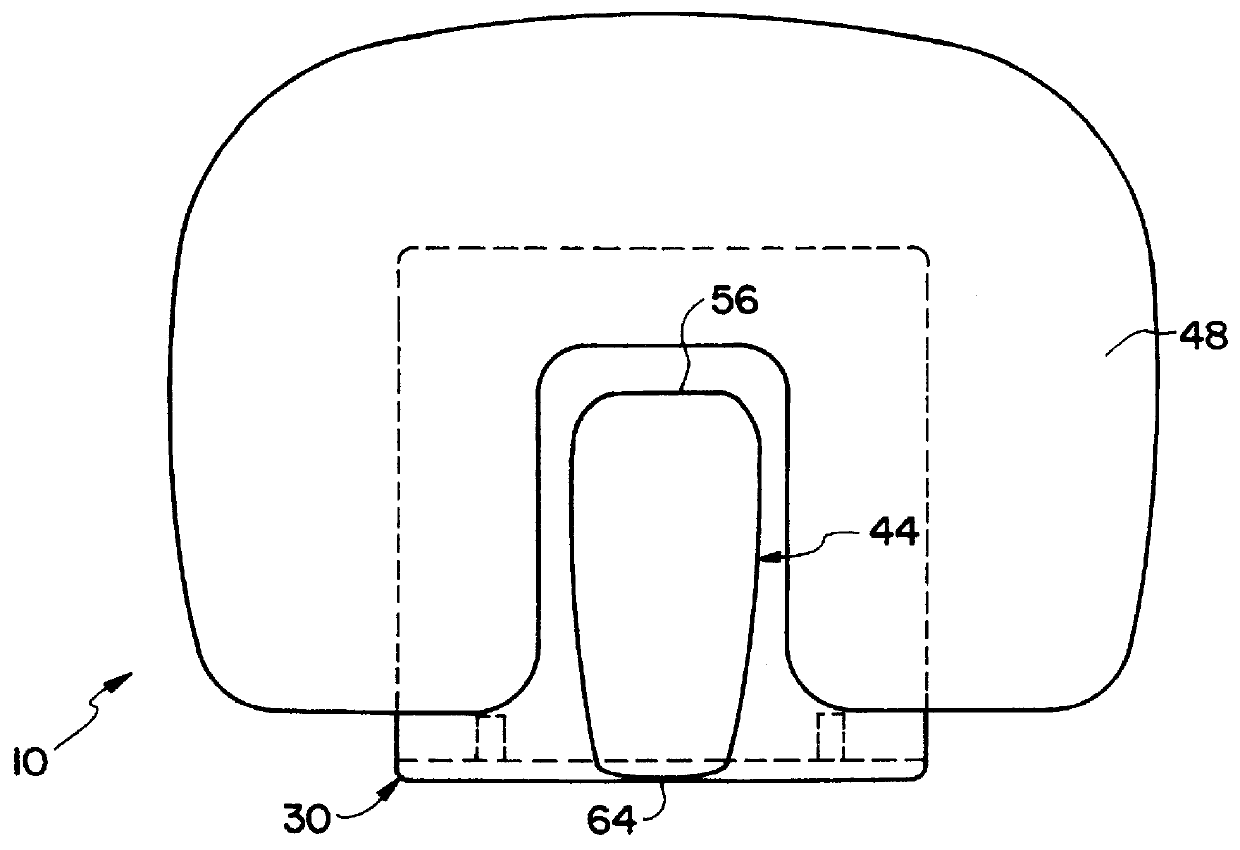

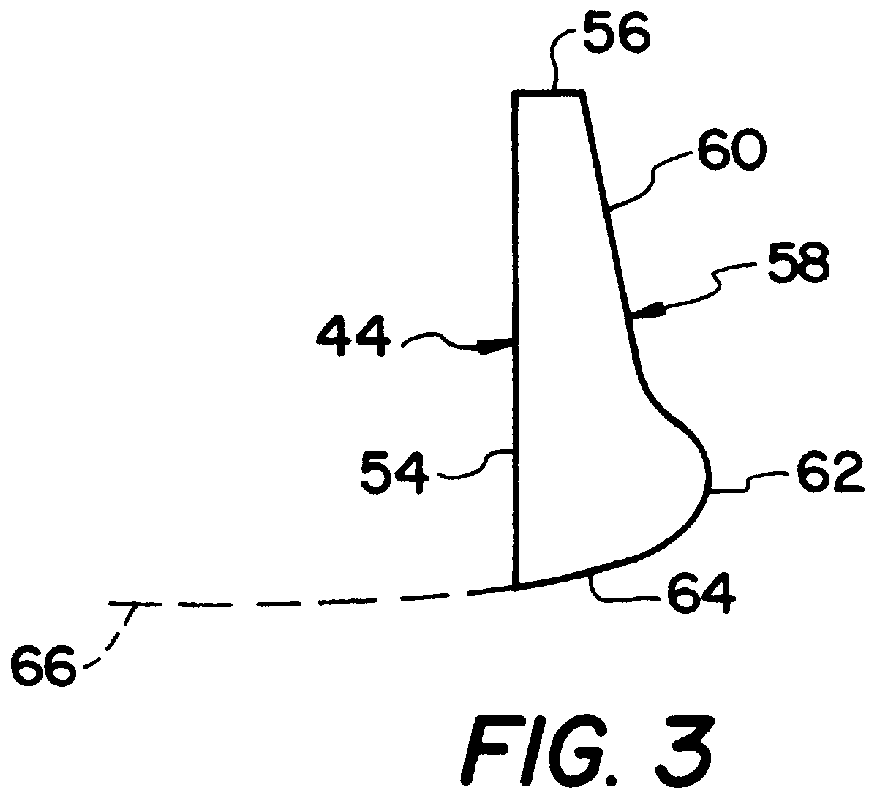

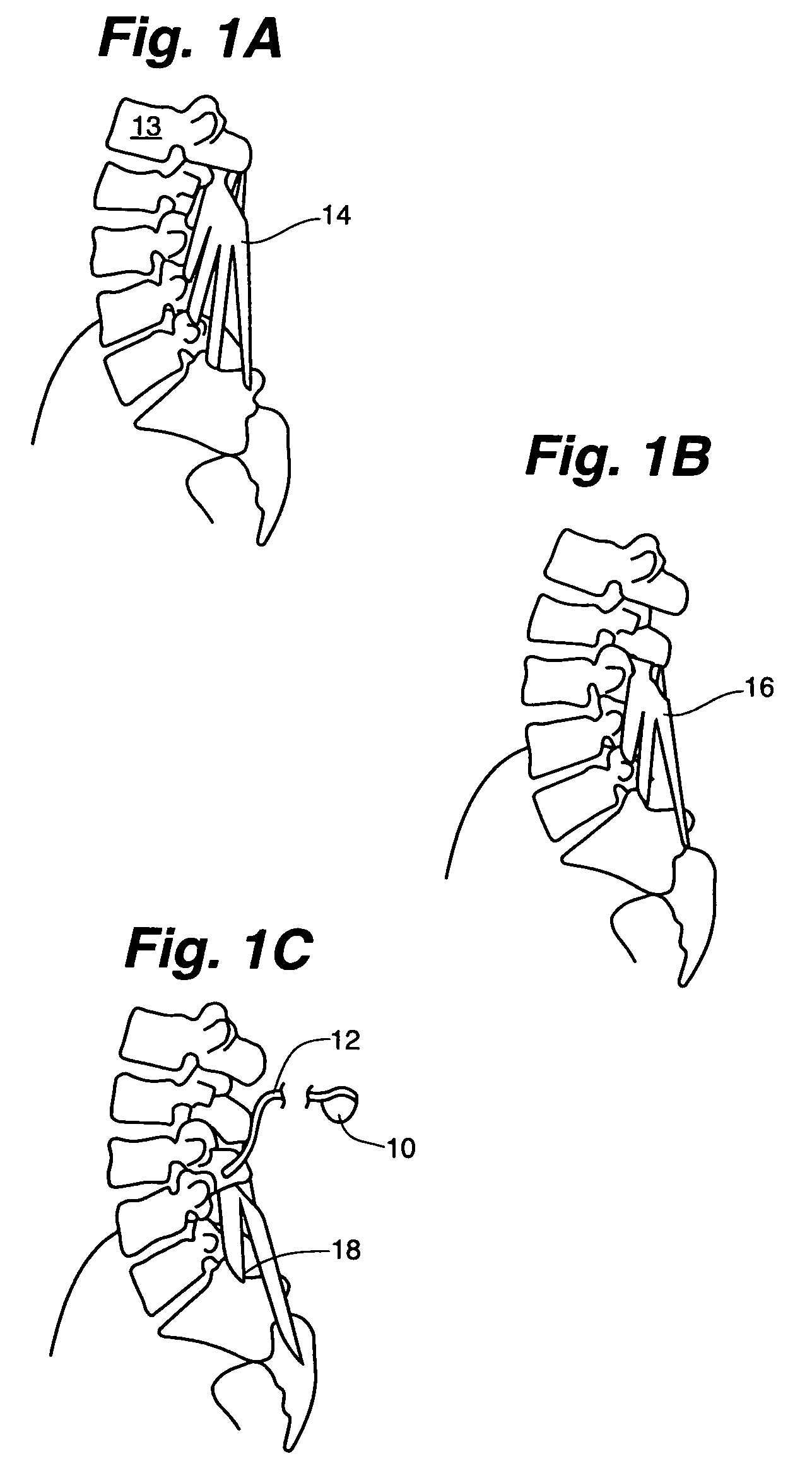

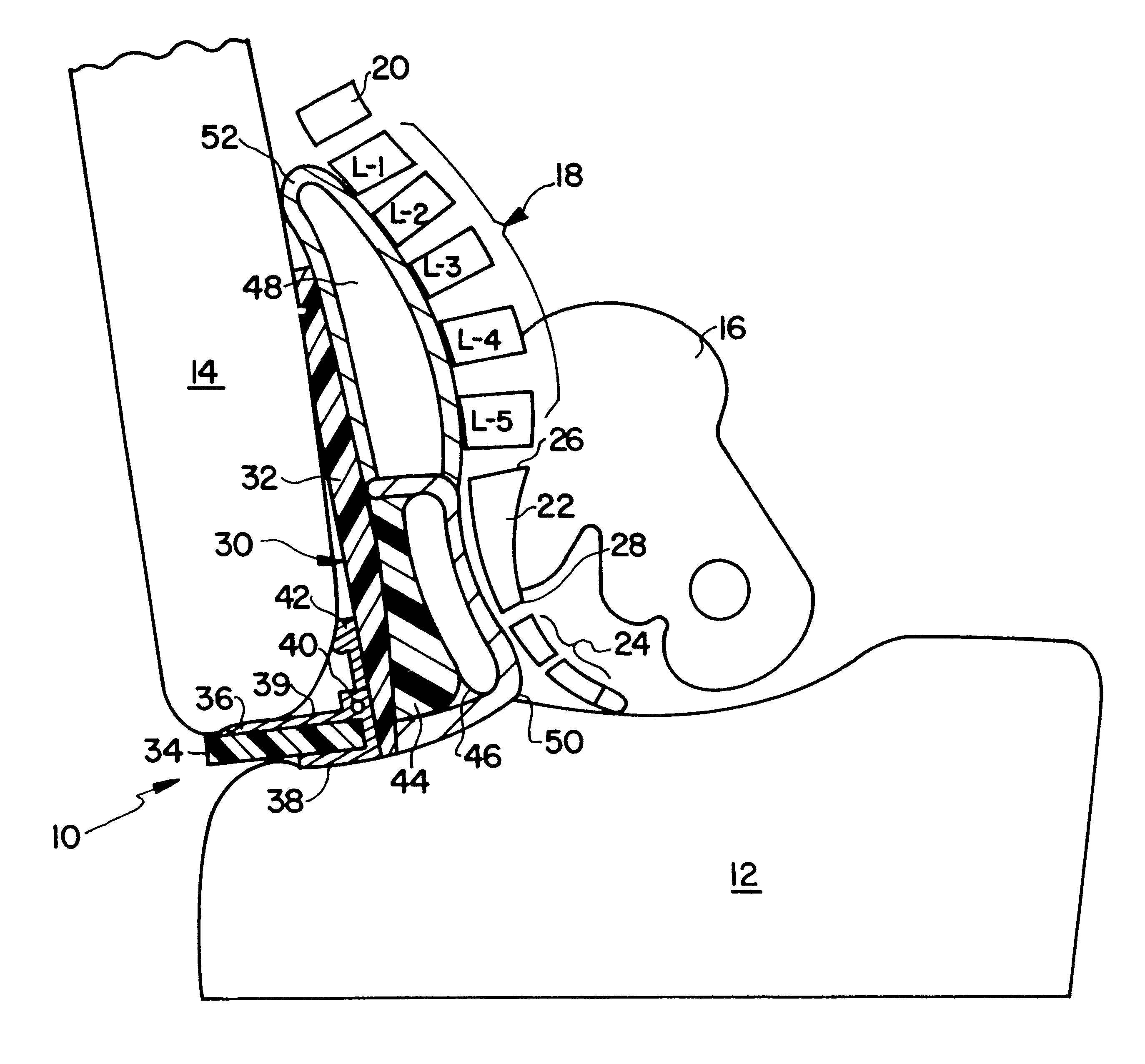

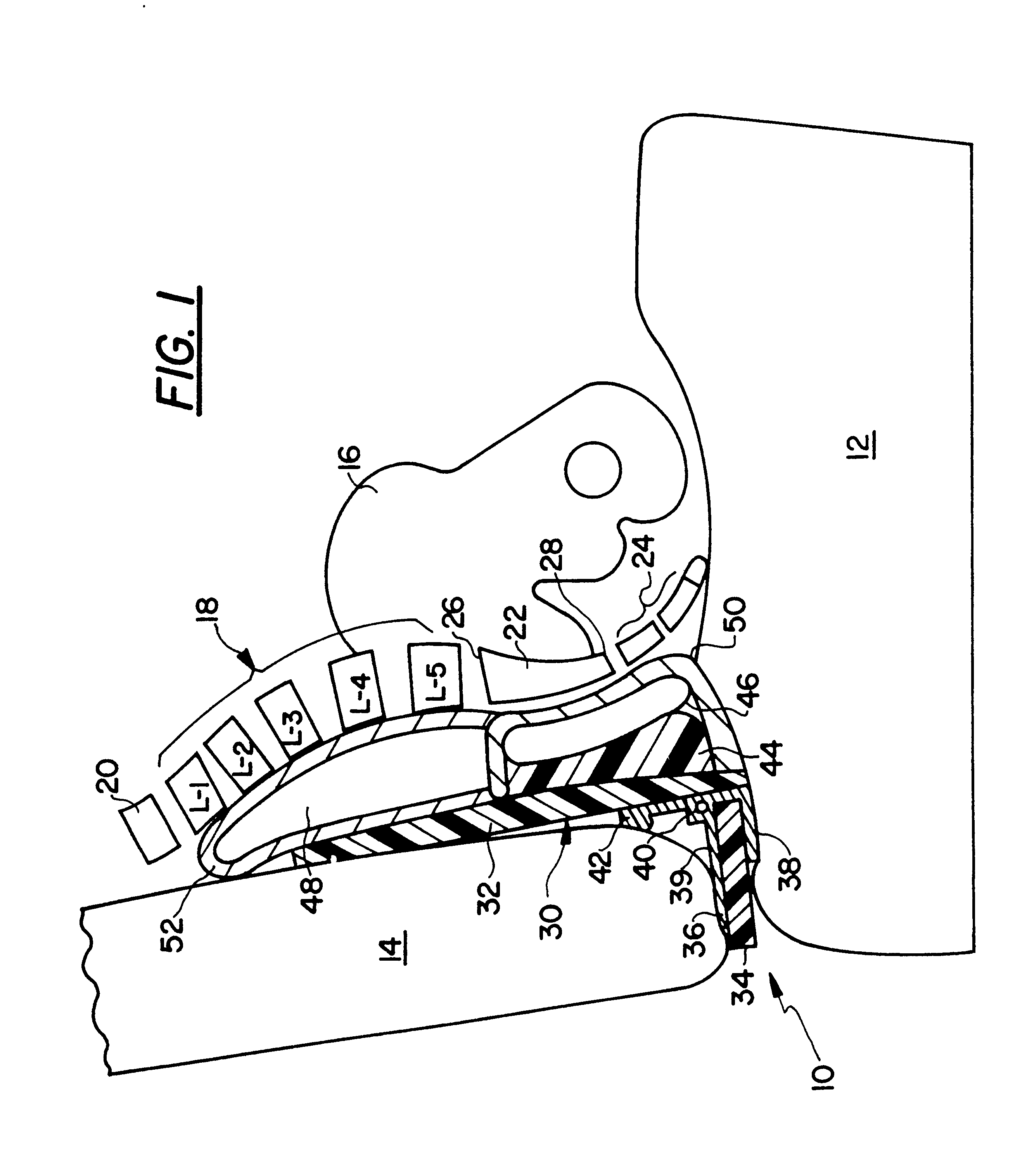

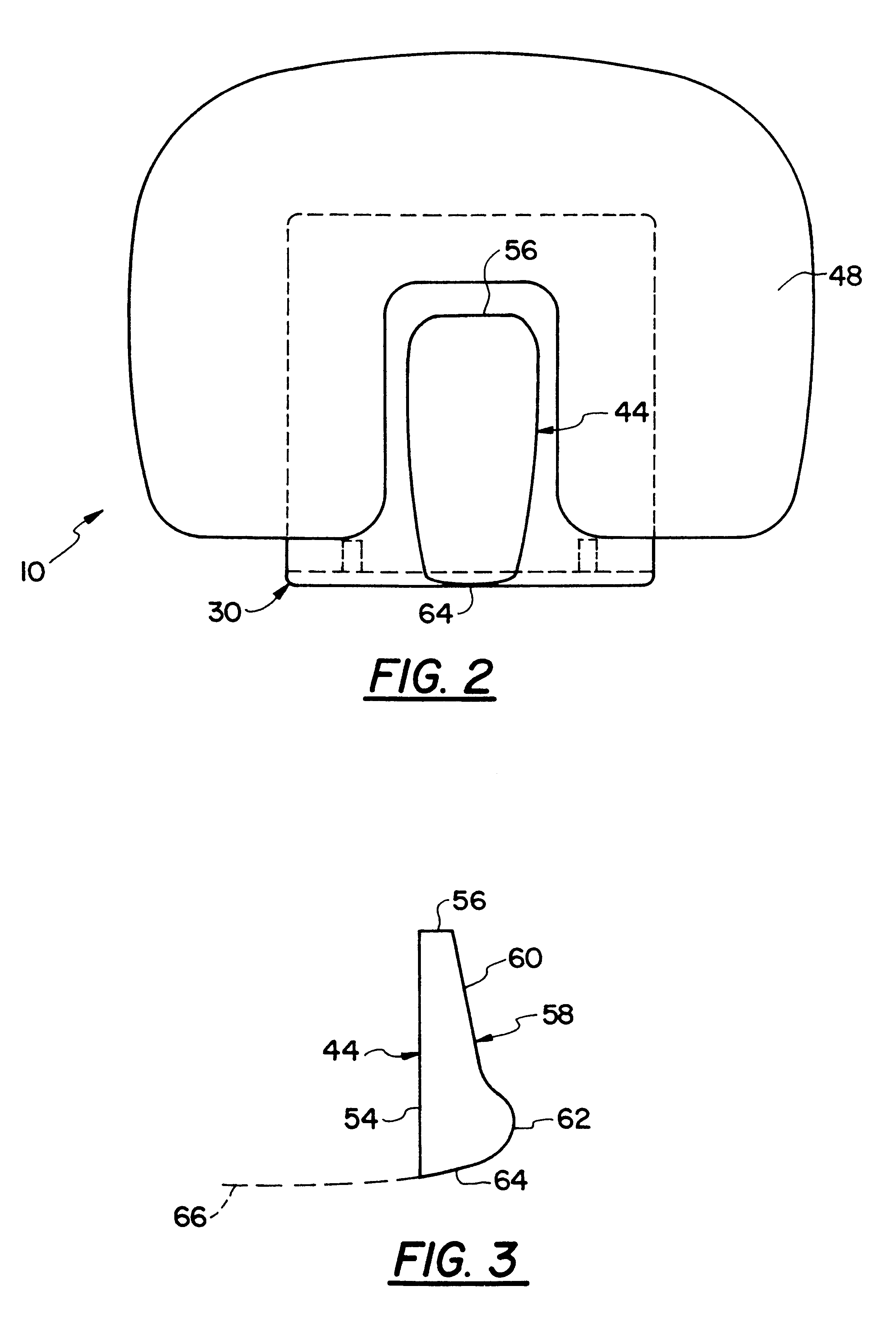

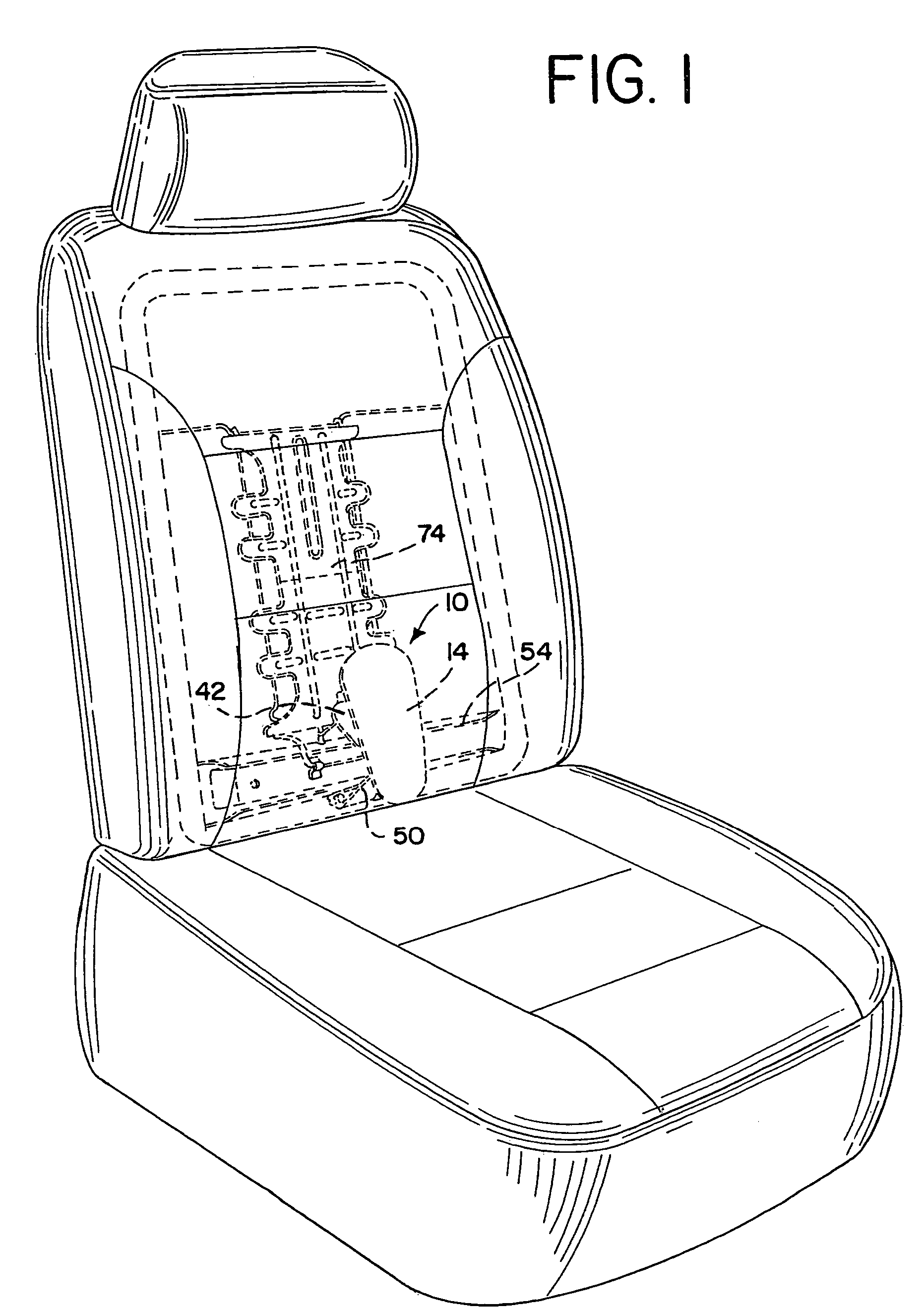

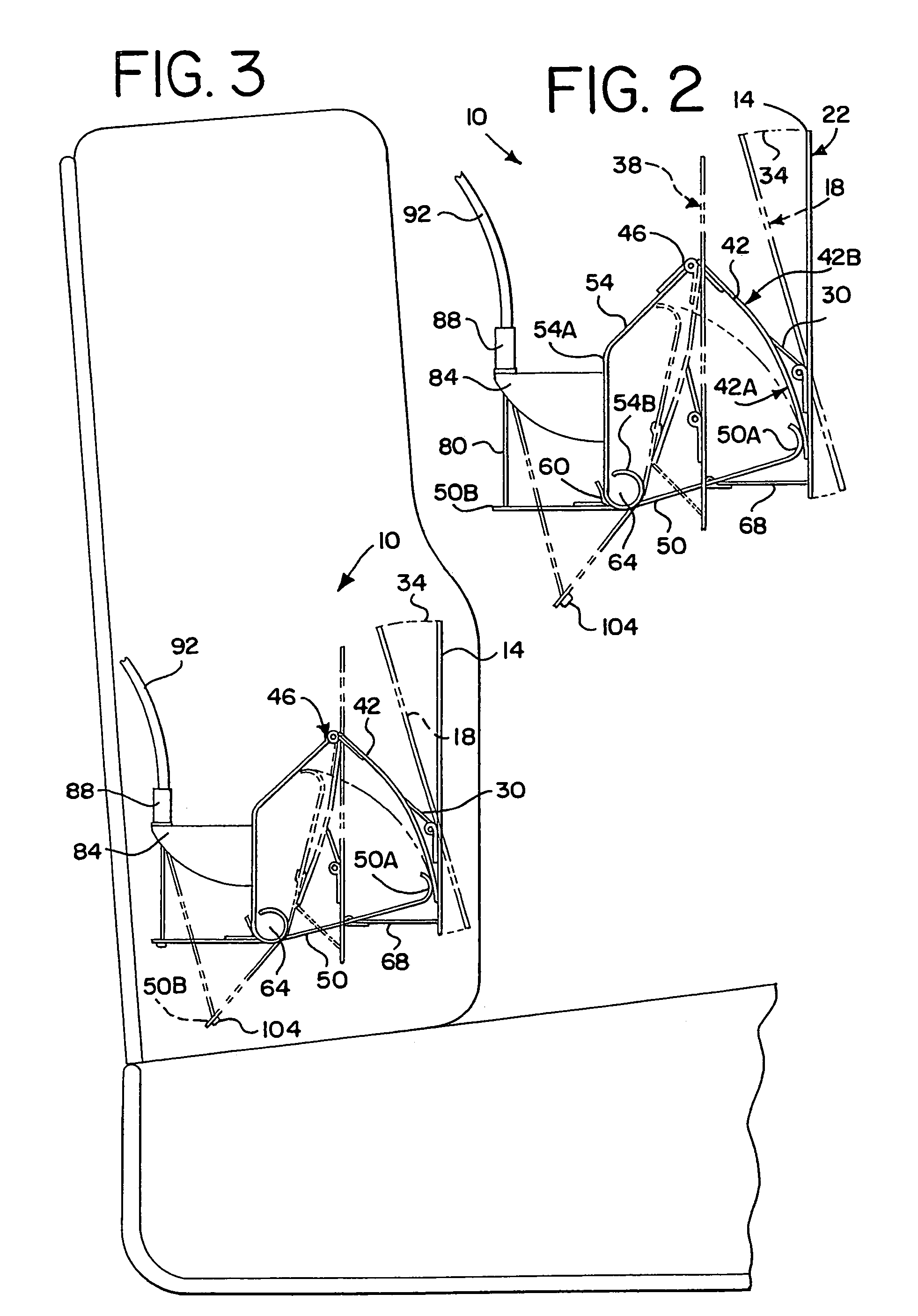

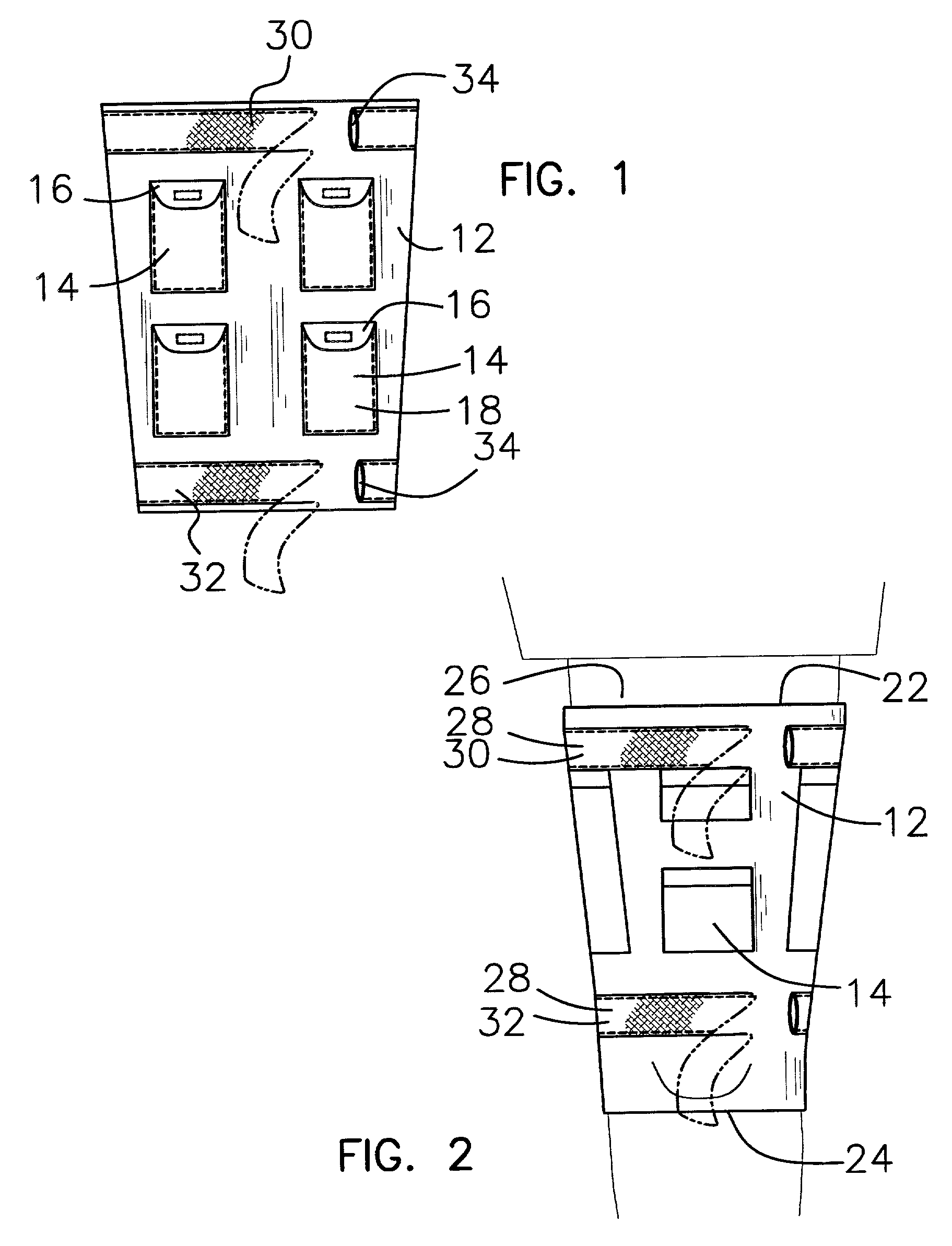

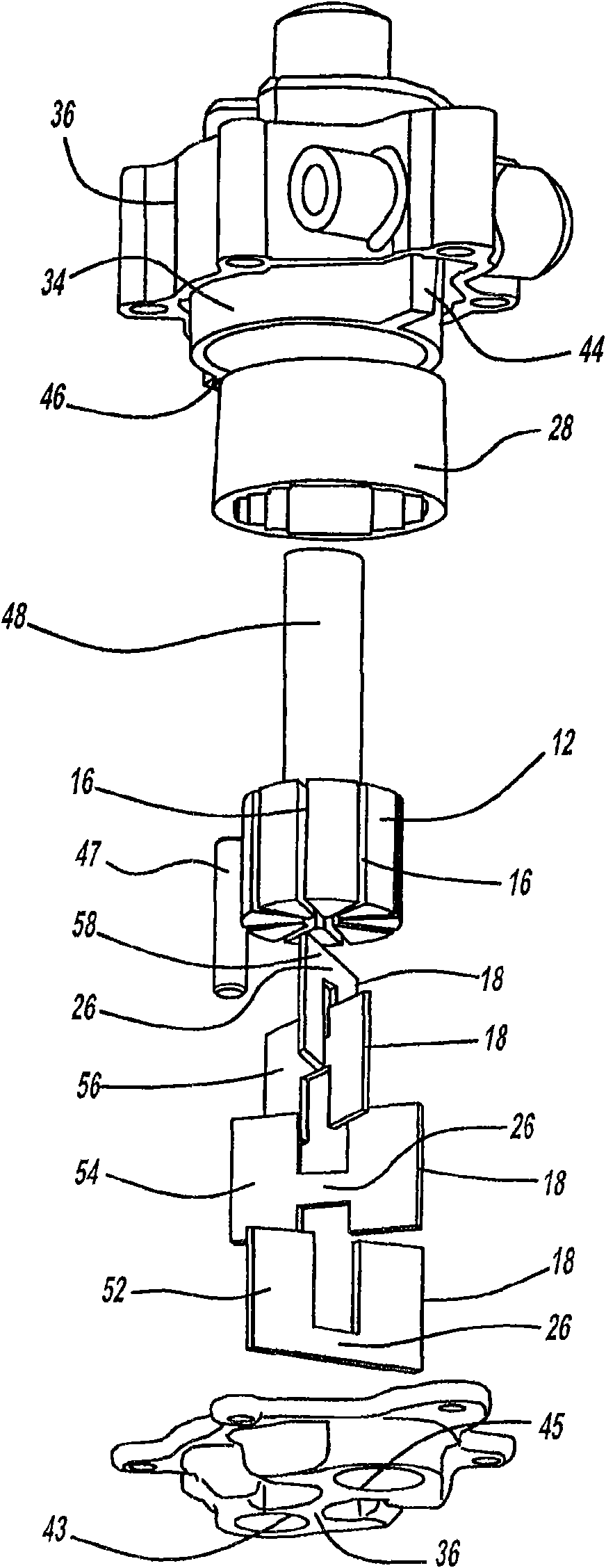

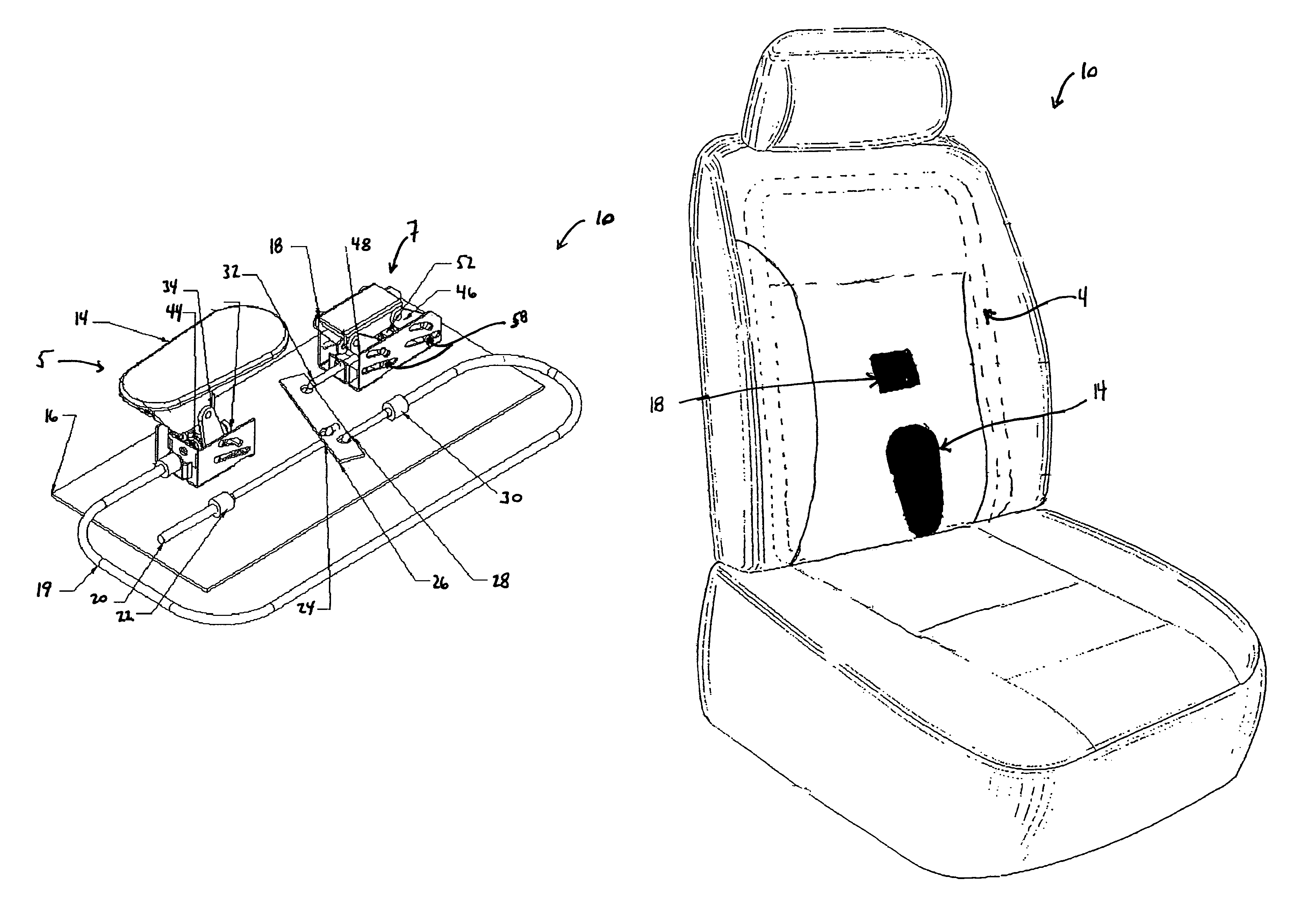

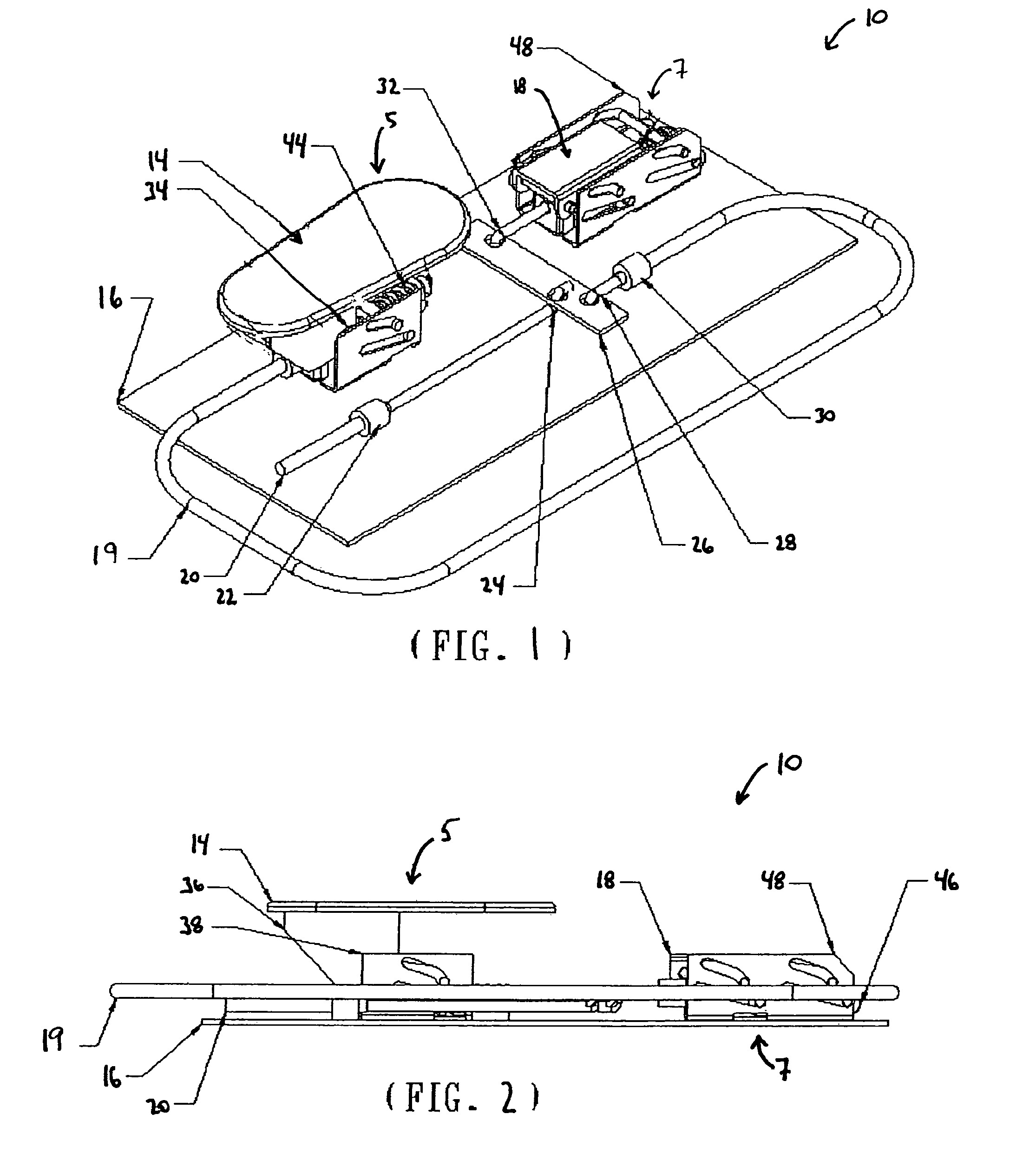

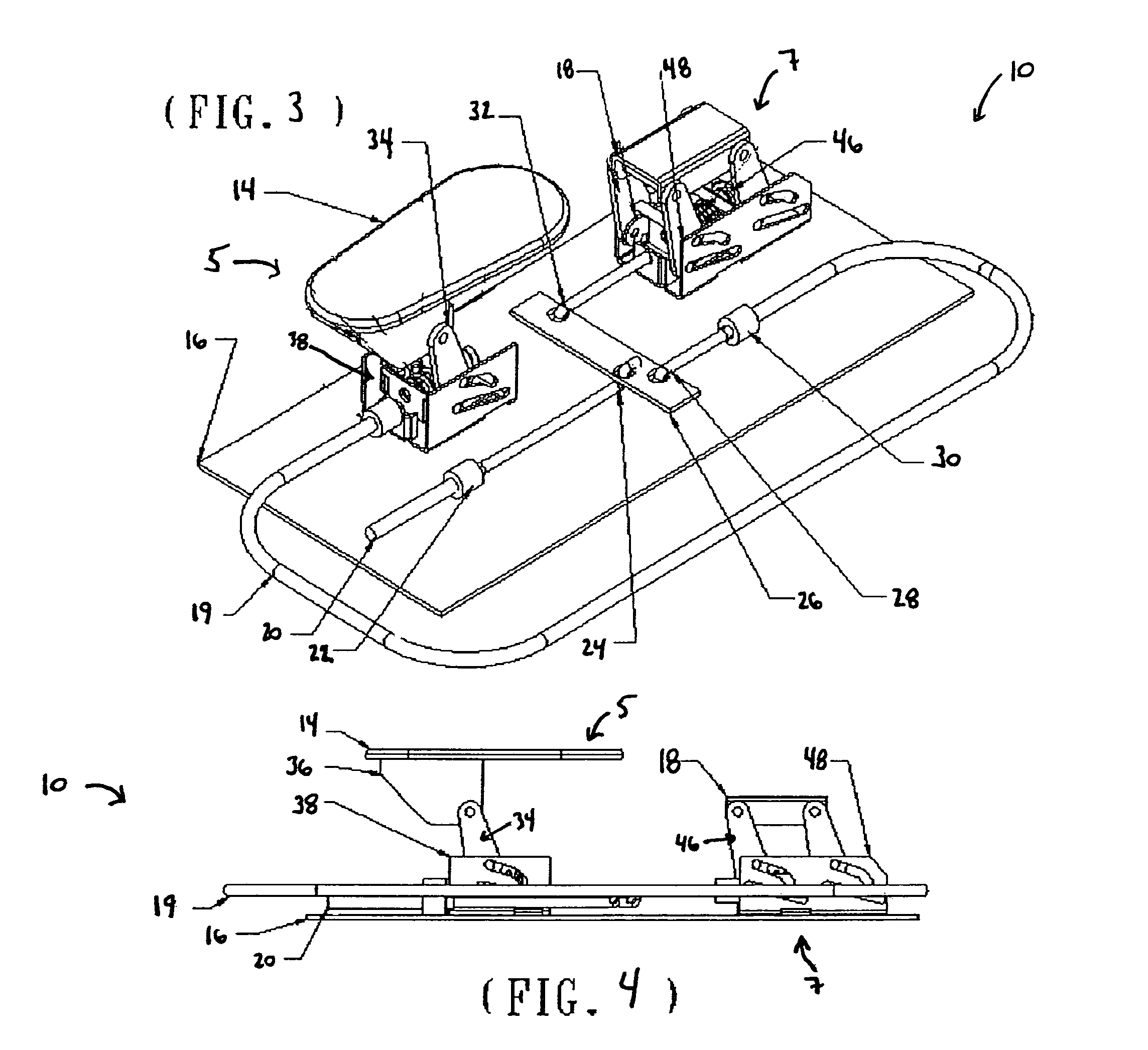

Spinal support system for seating

InactiveUS6125851AStress minimizationImprove comfortOperating chairsRestraining devicesSupporting systemSacrum

A spinal support device for applying a directed and concentrated force on the sacrum to position the sacrum and pelvis to thereby establish a desired spinal posture when in a seated position. The device provides isolatable force on the sacrum from the sacral base line downwardly to a bottom seat surface and for a width across an individual's back approximately equal to twice the dimension of the posterior portion of the individual's sacrum.

Owner:WALKER BROCK M +1

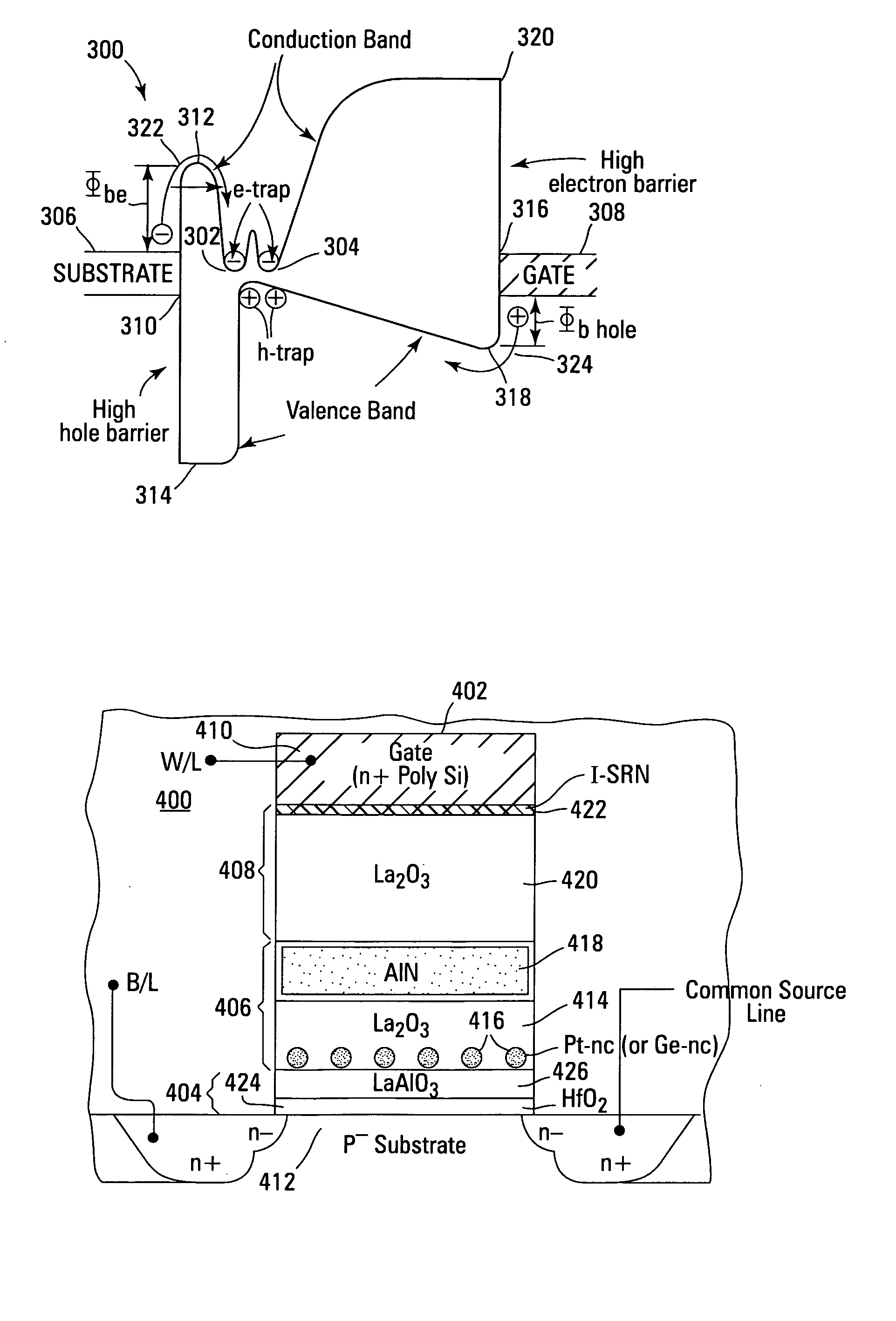

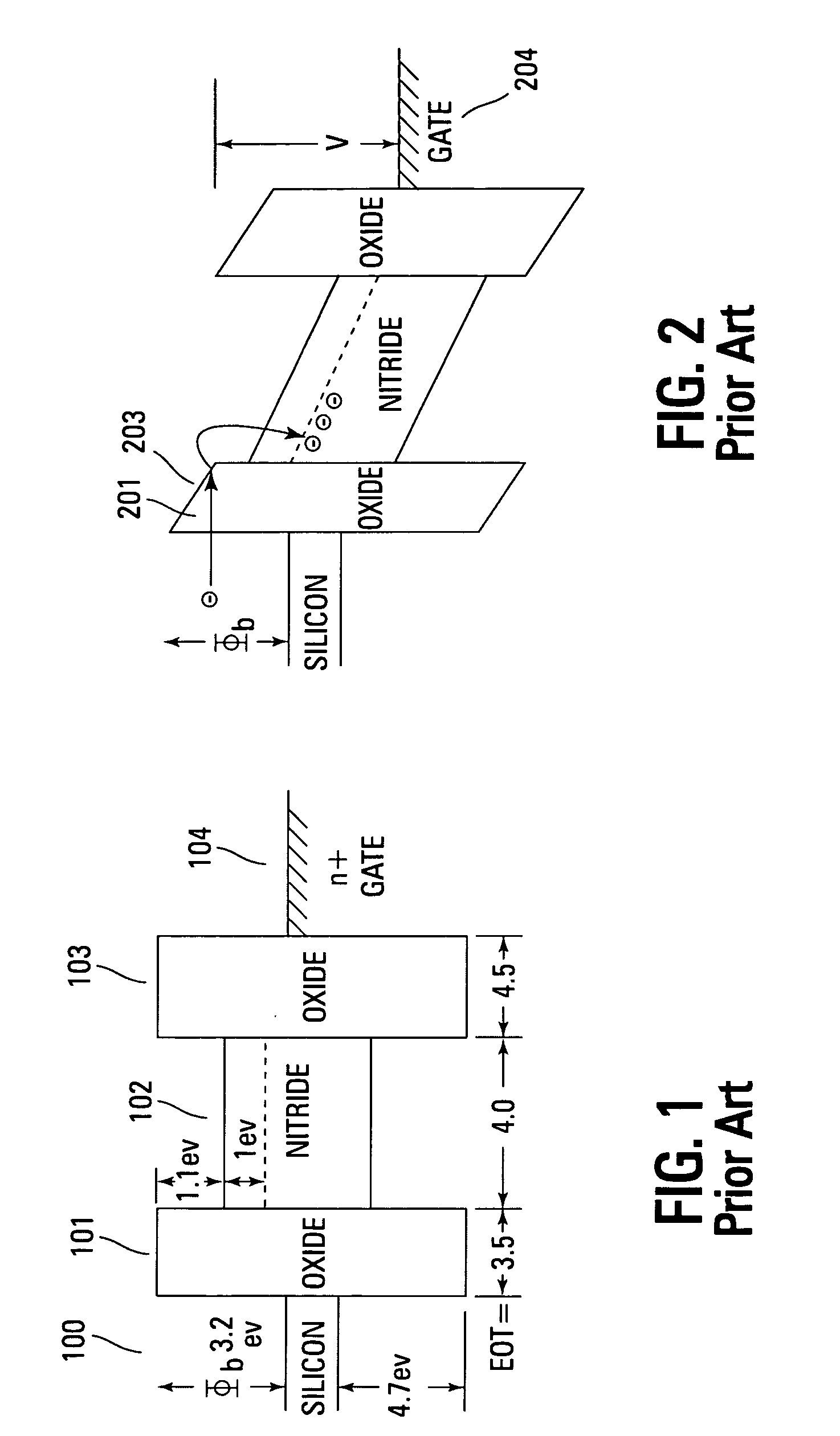

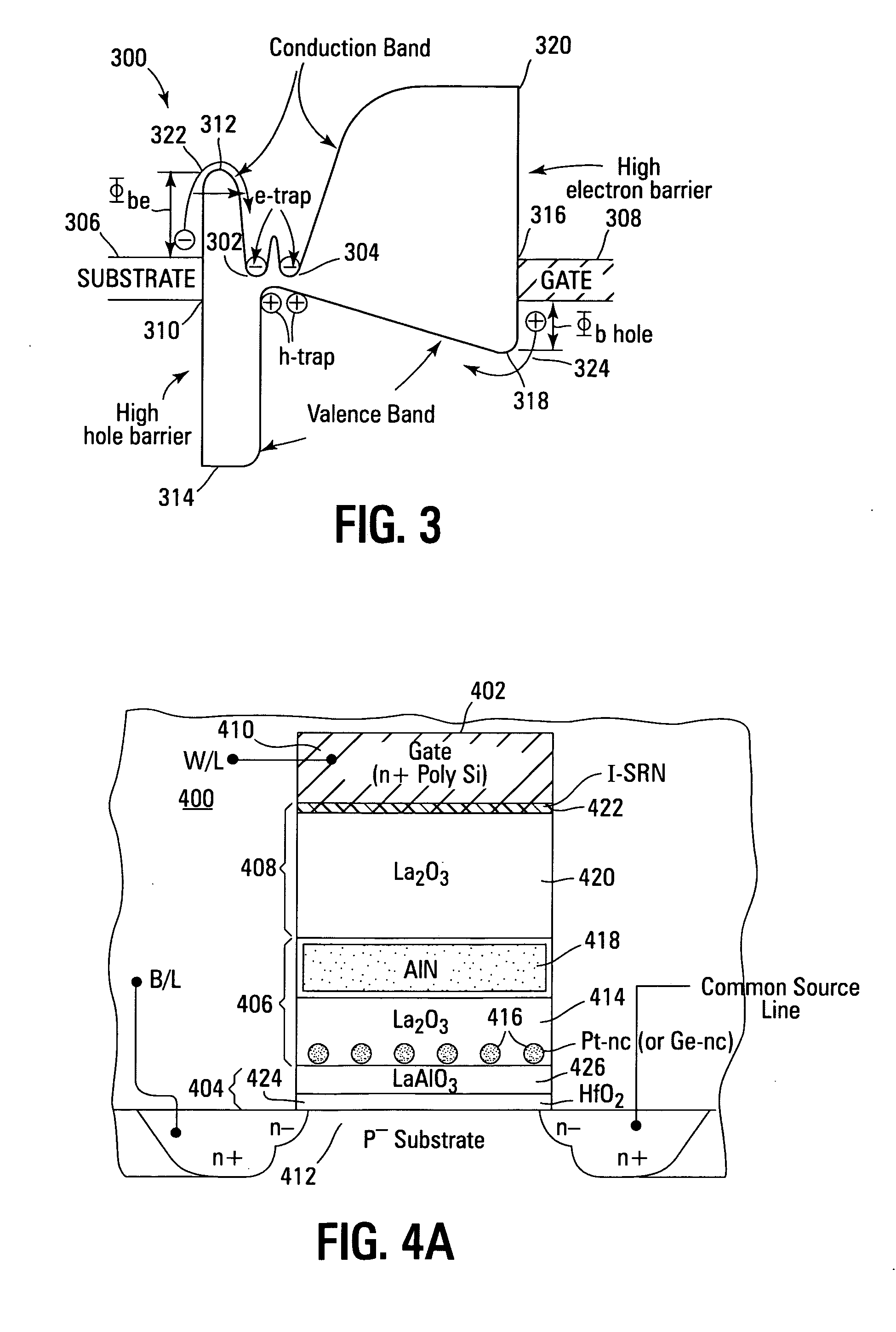

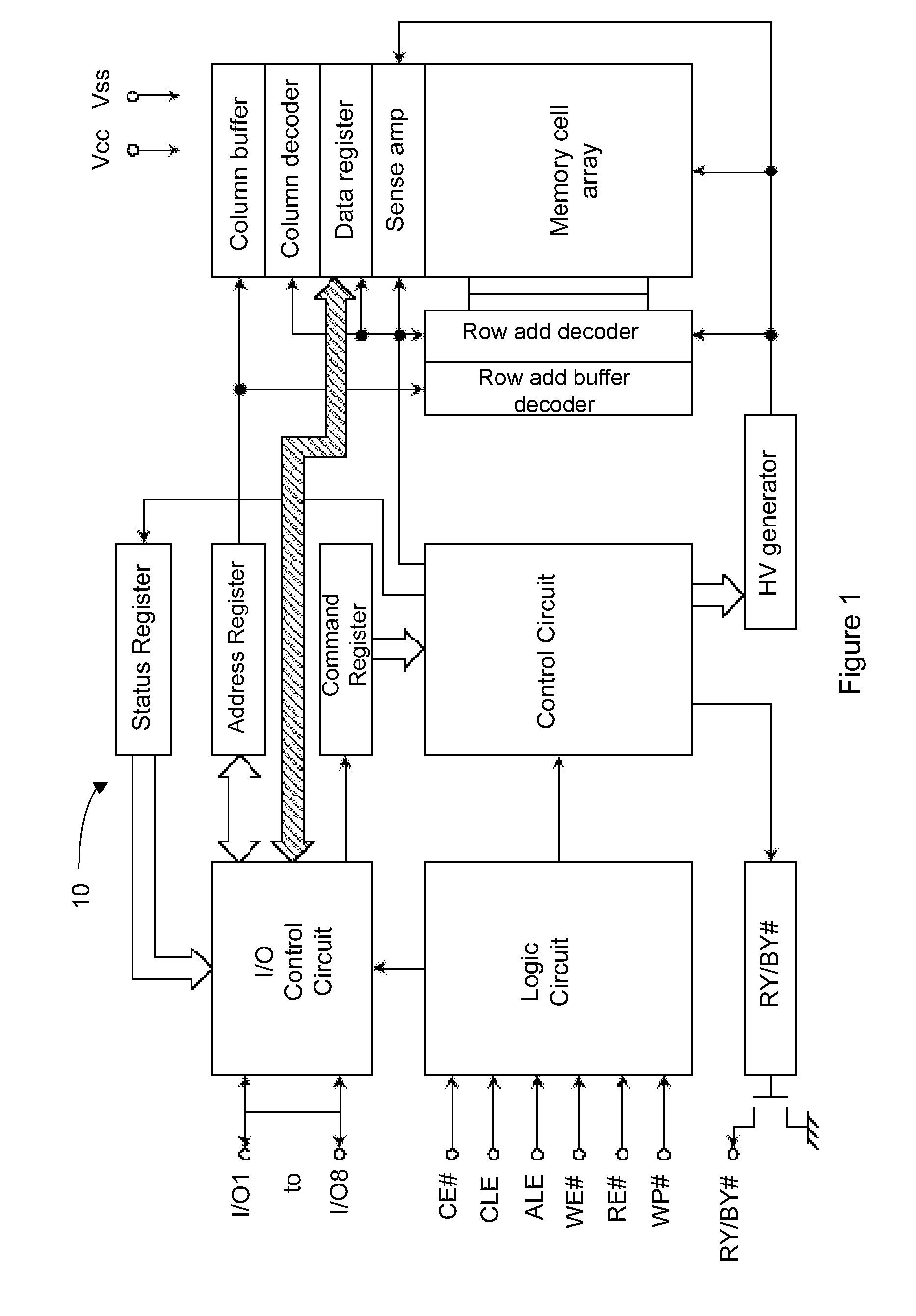

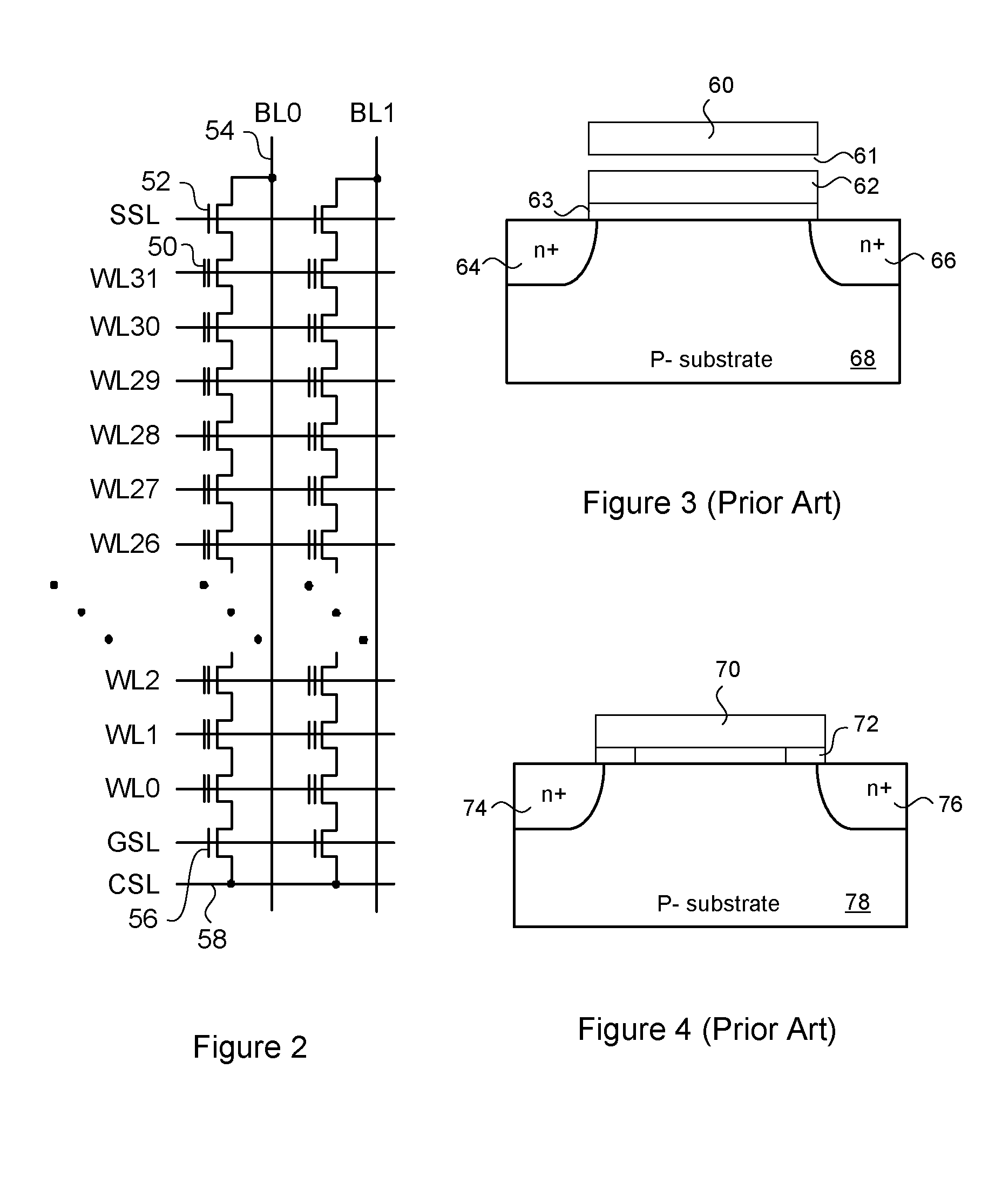

High performance multi-level non-volatile memory

ActiveUS20070045711A1Increased device feature scalingEfficient erasureTransistorSemiconductor/solid-state device manufacturingCharge retentionNon symmetric

Non-volatile memory devices and arrays are described that utilize band engineered gate-stacks and multiple charge trapping layers allowing a multiple trapping site gate-insulator stack memory cell that utilizes a band engineered direct tunneling or crested barrier tunnel layer and charge blocking layer for high speed programming / erasure. Charge retention is enhanced by utilization of nano-crystals and / or bulk trapping materials in a composite non-conductive trapping layer and a high K dielectric insulating layers. The band-gap engineered gate-stack with asymmetric direct tunneling or crested barrier tunnel layers of the non-volatile memory cells of embodiments of the present invention allow for low voltage high speed tunneling programming and erase with electrons and holes, while maintaining high charge blocking barriers and deep carrier trapping sites for good charge retention. Memory cell embodiments of the present invention allow multiple levels of bit storage in a memory cell through multiple charge centroids and / or multiple threshold voltage levels.

Owner:MICRON TECH INC

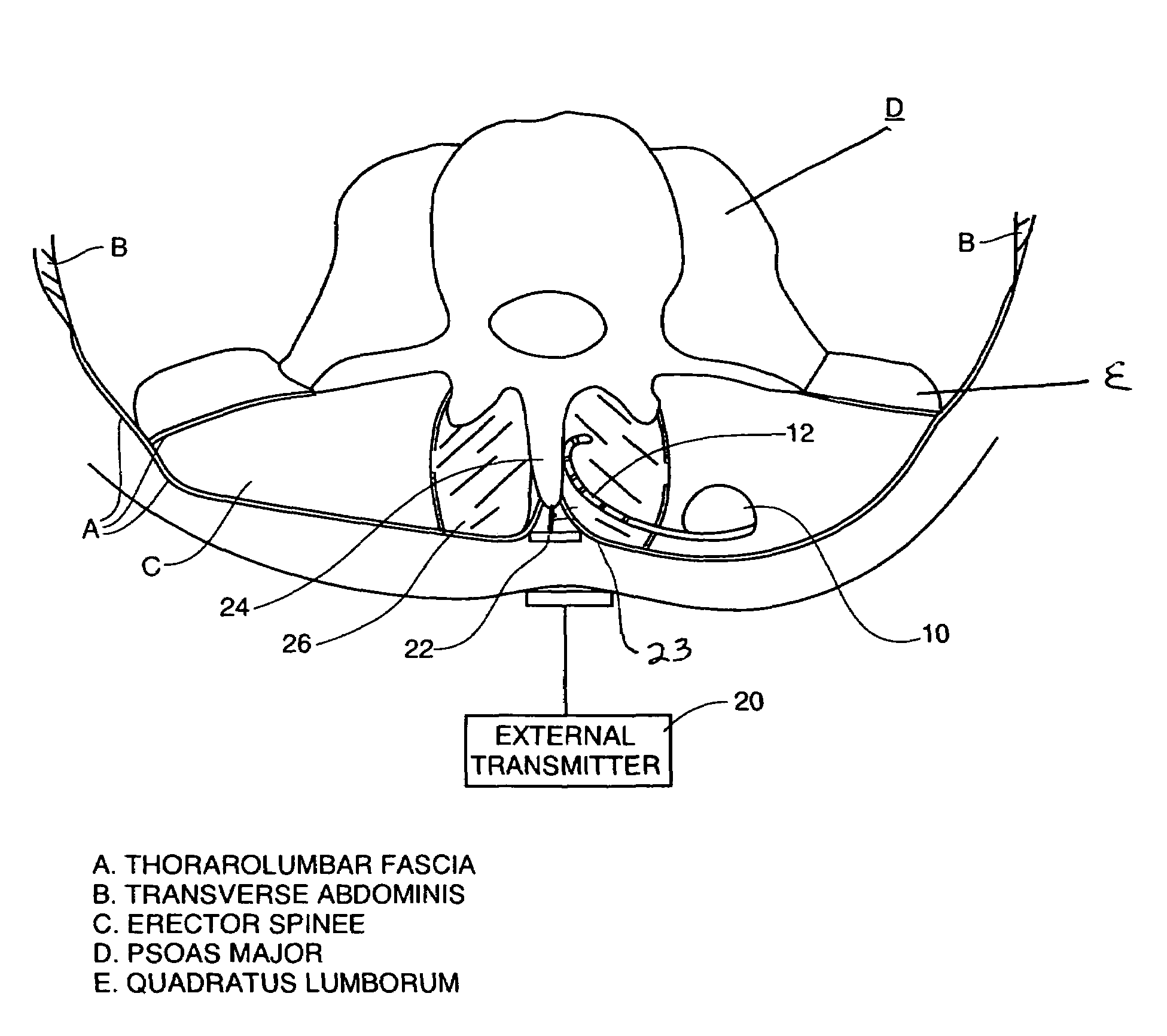

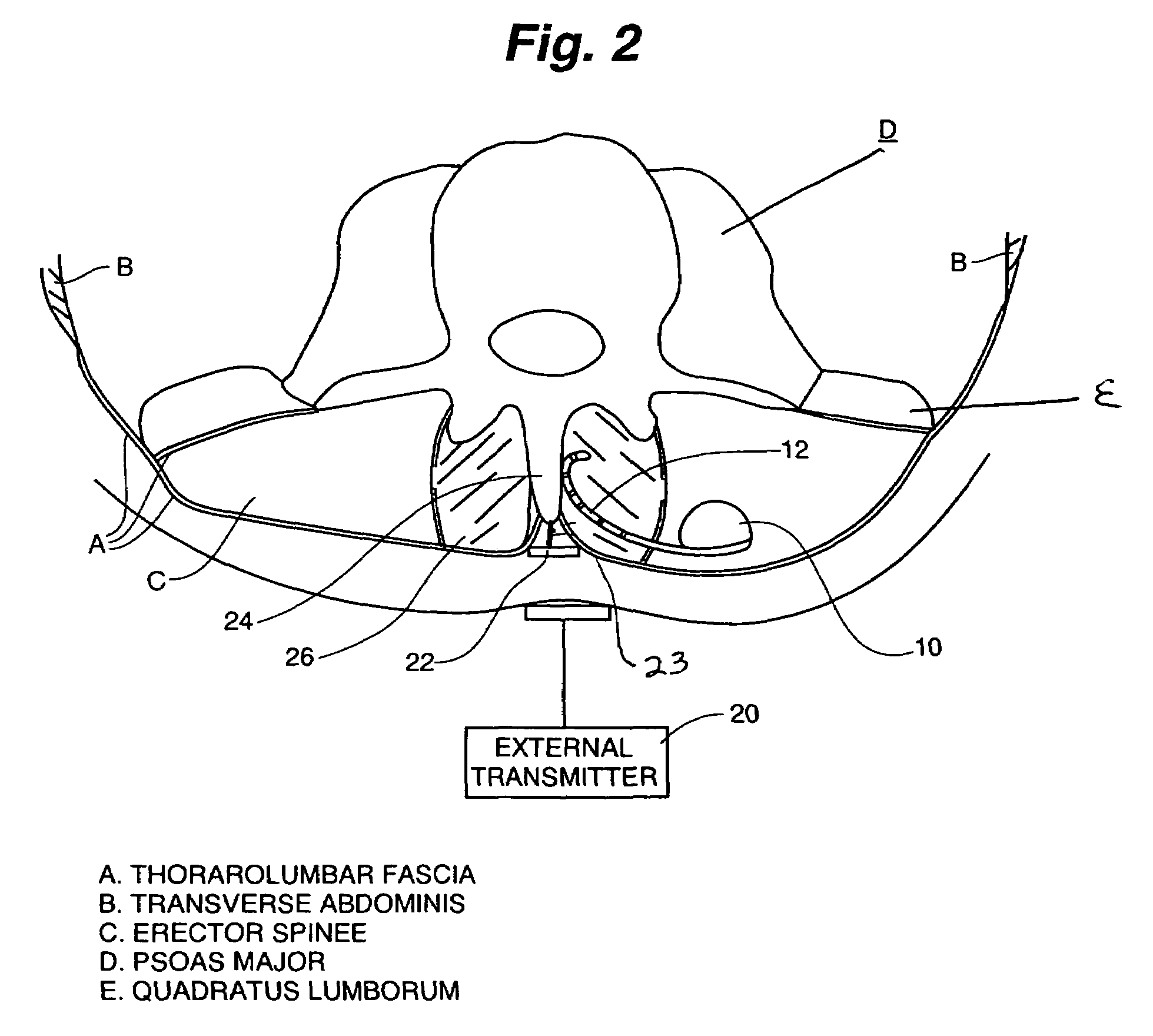

Muscle stimulator

ActiveUS8428728B2Reduce severityExcellent toneSpinal electrodesMagnetotherapy using coils/electromagnetsNerve fiber bundleMuscle stimulator

An implantable medical device for treating the back of a patient. Stimulation energy is delivered to muscles or joint capsules or ligaments or nerve fibers to improve the heath of the back.

Owner:MAINSTAY MEDICAL

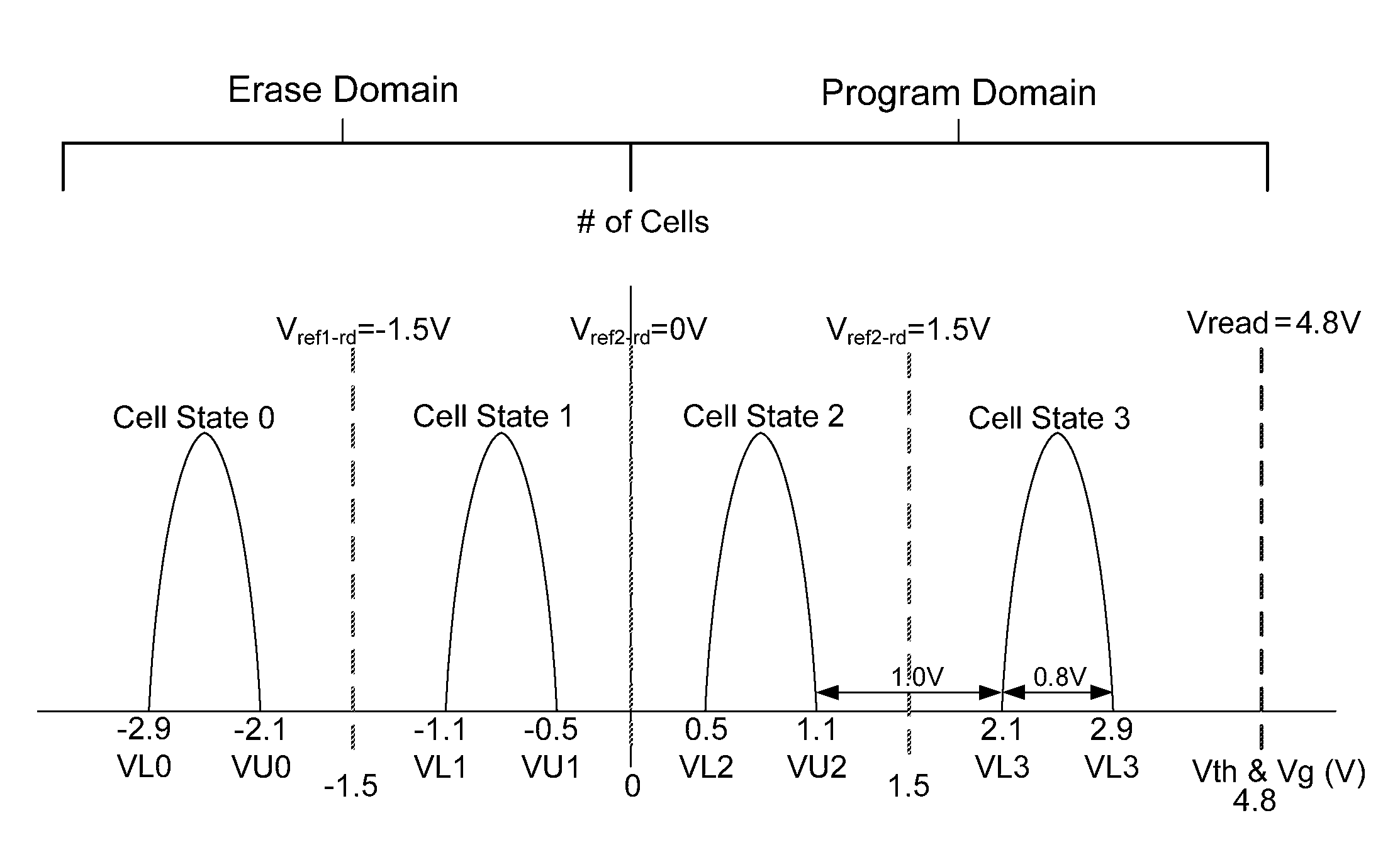

Flash multi-level threshold distribution scheme

ActiveUS20080062760A1Improve enduranceImprove staminaRead-only memoriesDigital storageEngineeringHemt circuits

A threshold voltage distribution scheme for multi-level Flash cells where an erase threshold voltage and at least one programmed threshold voltage lie in an erase voltage domain. Having at least one programmed threshold voltage in the erase voltage domain reduces the Vread voltage level to minimize read disturb effects, while extending the life span of the multi-level Flash cells as the threshold voltage distance between programmed states is maximized. The erase voltage domain can be less than 0V while a program voltage domain is greater than 0V. Accordingly, circuits for program verifying and reading multi-level Flash cells having a programmed threshold voltage in the erase voltage domain and the program voltage domain use negative and positive high voltages.

Owner:CONVERSANT INTPROP MANAGEMENT INC

Spinal support system for seating

InactiveUS6532962B1Stress minimizationImprove comfortOperating chairsRestraining devicesSupporting systemSacrum

A spinal support device for applying a directed and concentrated force on the sacrum to position the sacrum and pelvis to thereby establish a desired spinal posture when in a seated position. The device provides isolatable force on the sacrum from the sacral base line downwardly to a bottom seat surface and for a width across an individual's back approximately equal to twice the dimension of the posterior portion of the individual's sacrum.

Owner:WALKER BROCK M +1

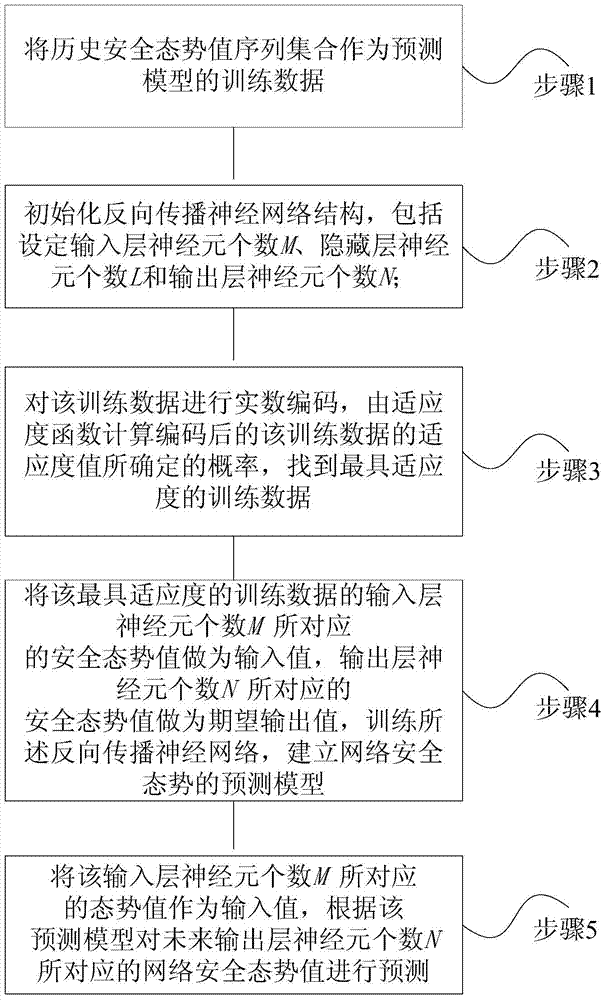

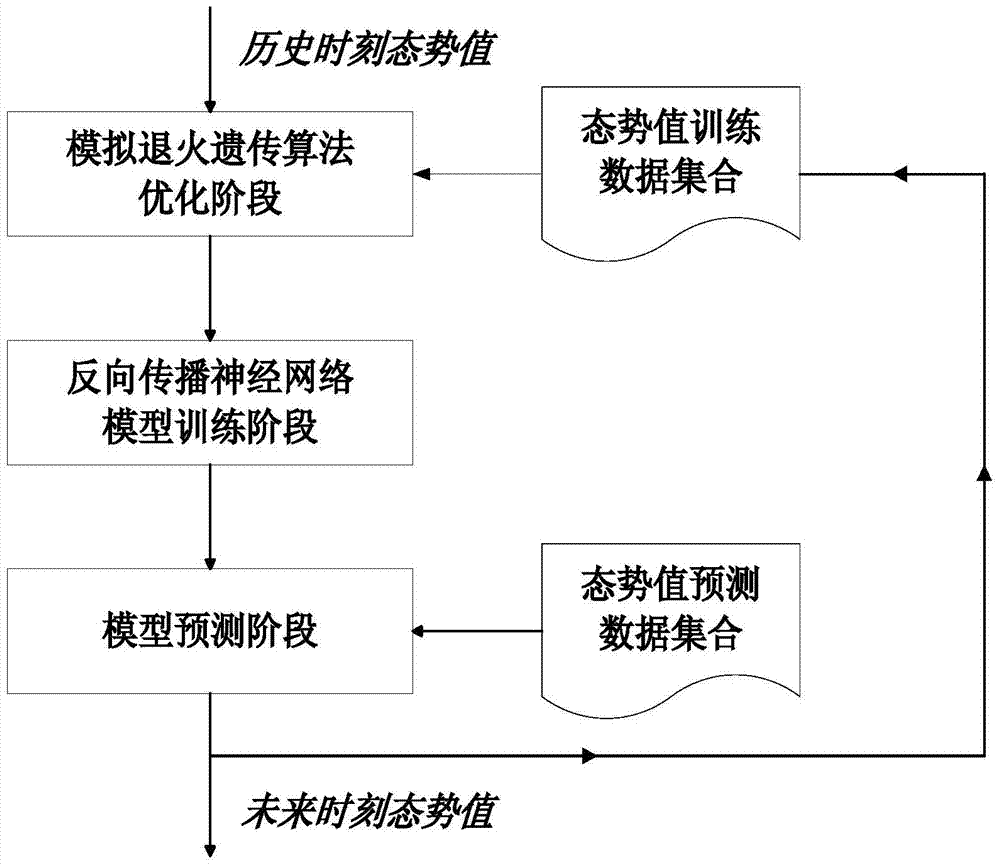

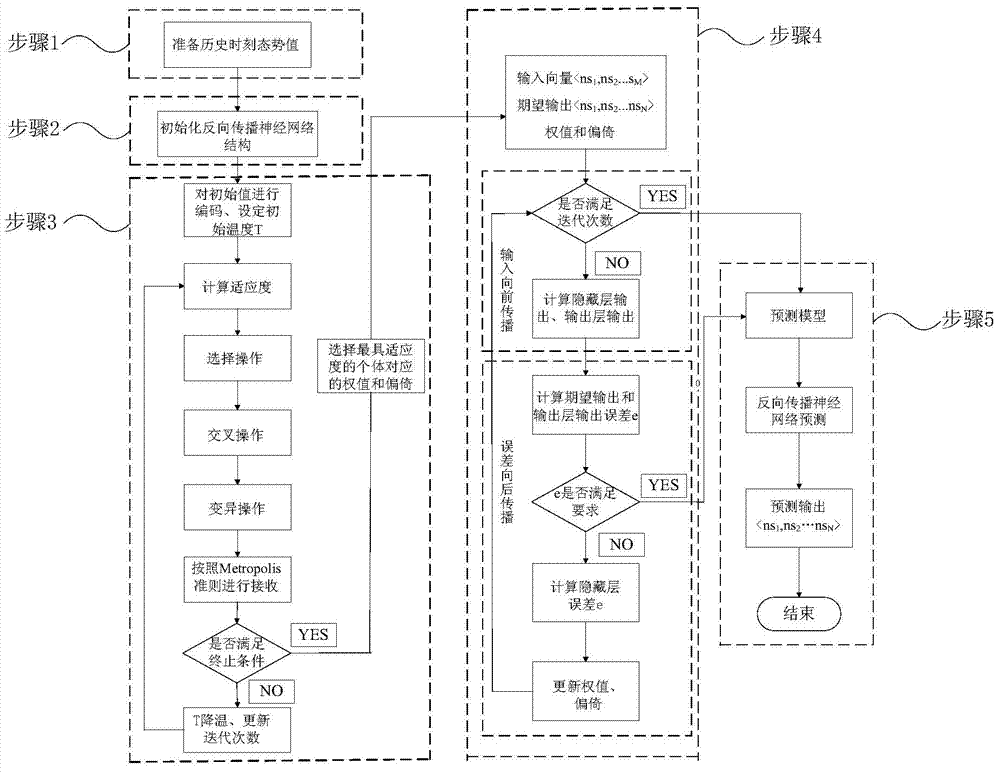

Network security situation forecasting method and system

ActiveCN103581188AFast convergenceReduce time errorGenetic modelsBiological neural network modelsMachine learningPrediction methods

The invention relates to a network security situation forecasting method and system. The network security situation forecasting method comprises the steps that an obtained network security situation value sequence set serves as training data; a back propagation neural network structure is initialized, and the initialization operation comprises the step of setting the number M of nerve cells of an input layer and the number N of nerve cells of an output layer; real number encoding is carried out on the training data and the training data with the maximum fitness are found; a security situation value corresponding to the number M of the nerve cells of the input layer in the training data with the maximum fitness serves as an input value, a security situation value corresponding to the number N of the nerve cells of the output layer serve as a desired output value, the back propagation neural network is trained, and a forecasting model of the network security situation is established; the security situation value corresponding to the number M of the nerve cells of the input layer serves as the input value, and the security situation value corresponding to the number N of the nerve cells of the output layer is forecast according to the forecasting model. The network security situation forecasting method can improve the convergence rate of network security situation forecasting, shorten training time and reduce forecasting errors.

Owner:SHANGHAI YINGLIAN SOMATOSENSORY INTELLIGENT TECH CO LTD

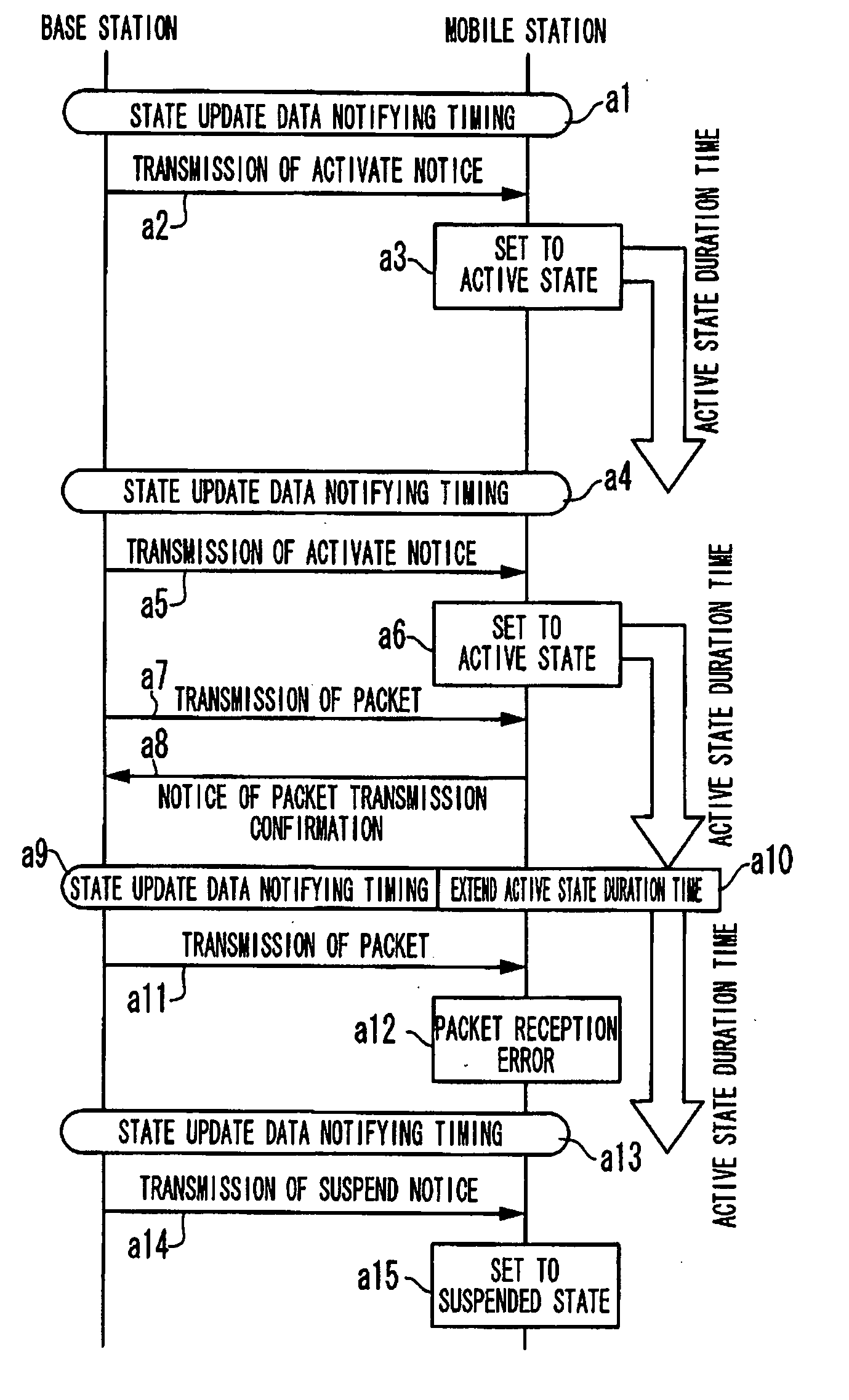

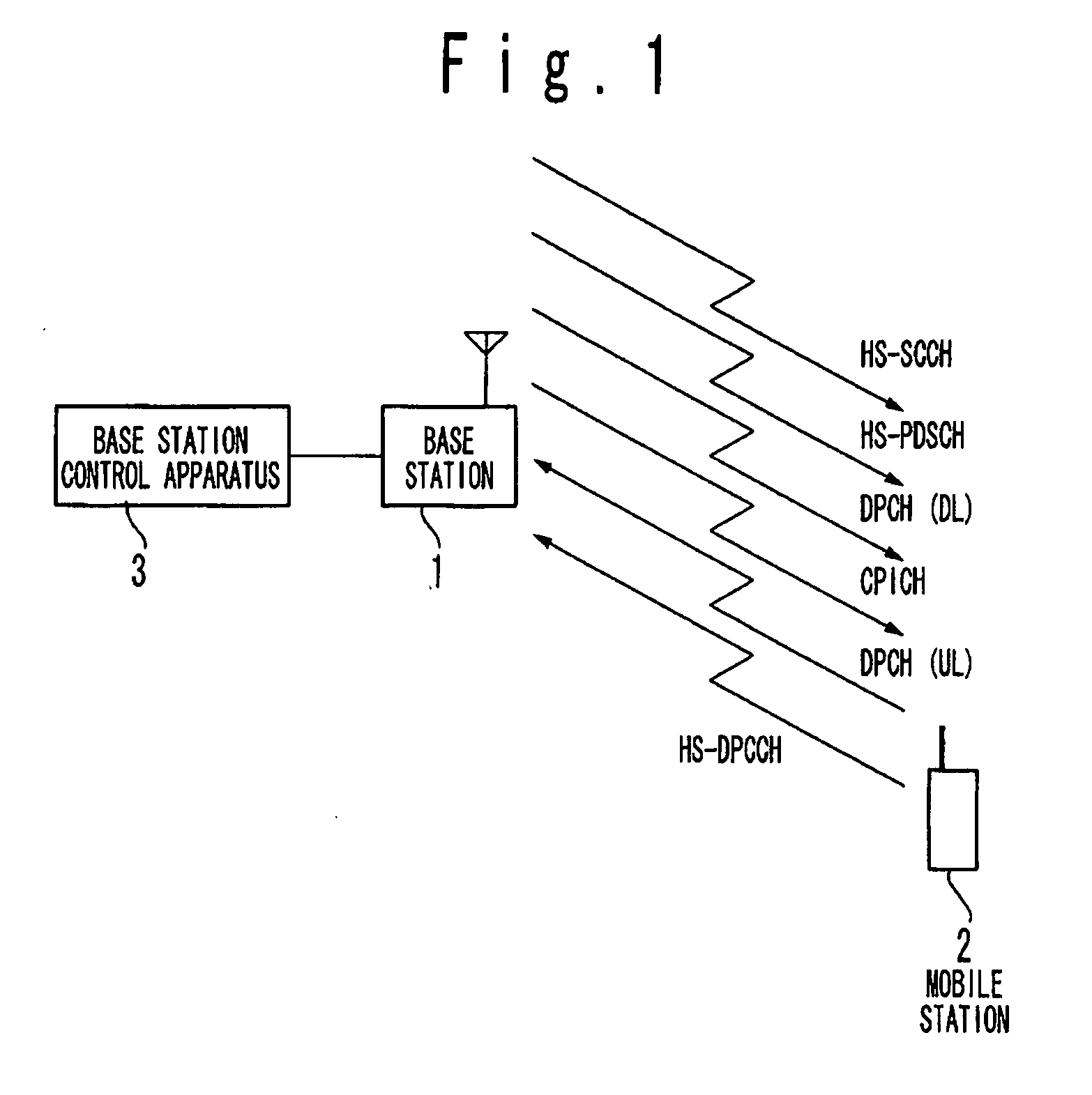

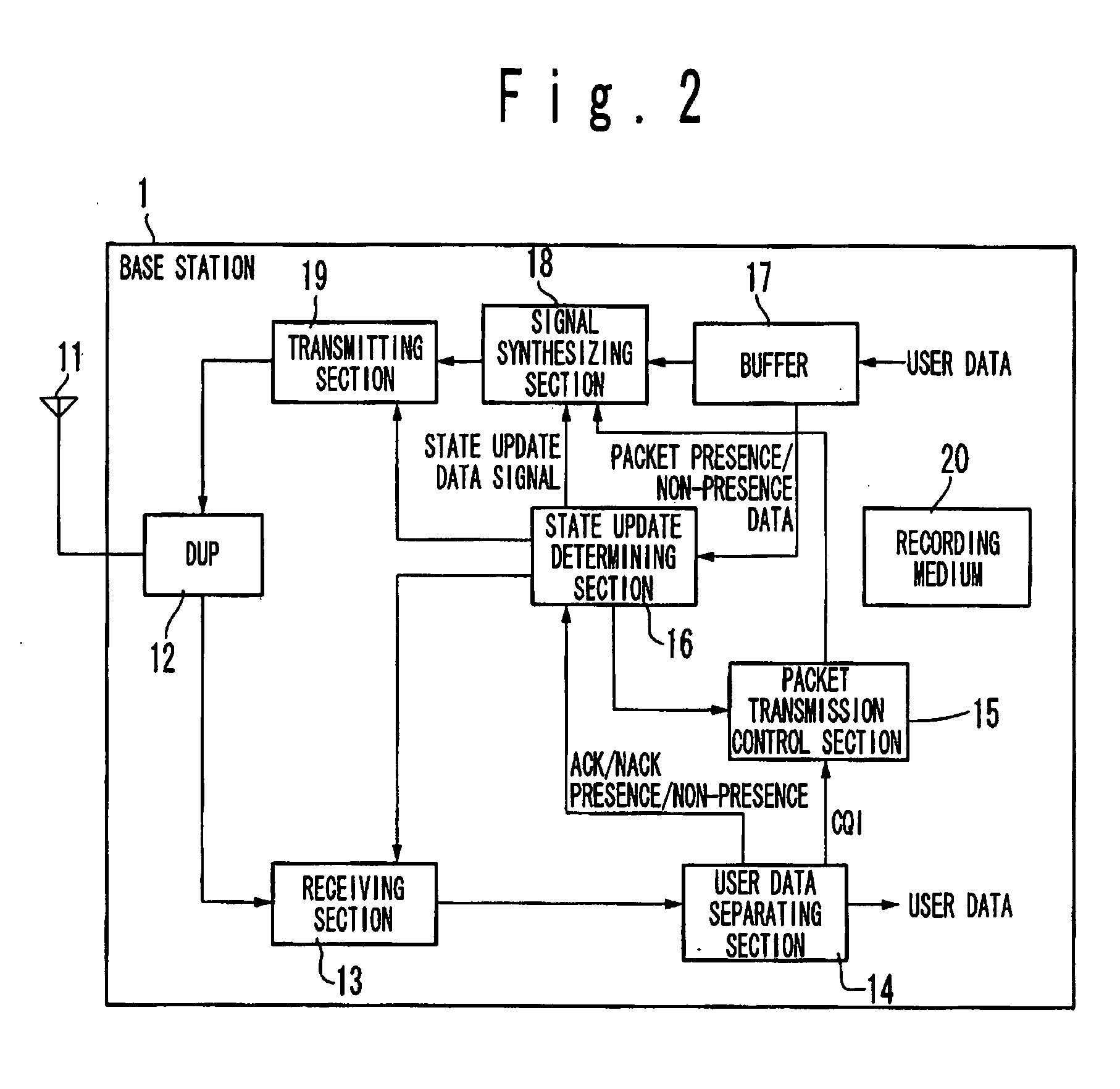

System and method for mobile communication

InactiveUS20060159061A1Reduce power consumptionReduce switchingPower managementNetwork traffic/resource managementTime domainMobile station

A mobile communication system according to the present invention is provided with a base station and a mobile station that communicates with the base station. In a communication protocol between the base station and the mobile station, a plurality of state update frames are defined in a time domain. The base station is configured to transmit a state update data to instruct that the mobile station is set to either an active state or a suspended state, in each of the plurality of the state update frames. At the same time, the base station is configured to transmit a packet only to the mobile station that has been set to the active state by the state update data. The base station in advance notifies the mobile station of packet transmission by transmitting a control data including a data necessary to receive the packet, earlier than the packet transmission by a predetermined time difference. The mobile station is set to either the active state or the suspended state in response to the state update data. At the same time, the mobile station is configured to receive the control data and the packet when being set to the active state, and is configured not to receive the control data and the packet when being set to the suspended state.

Owner:NEC CORP

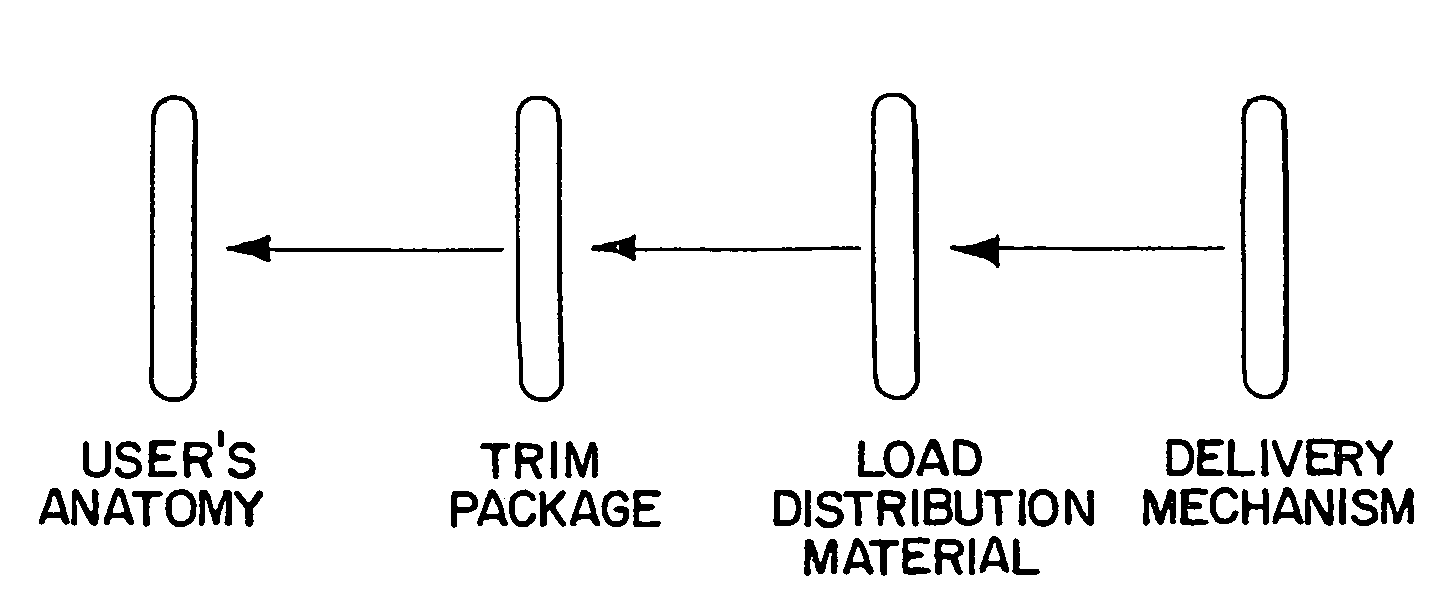

Seat with adjustable support system

ActiveUS7429080B2Improve comfortImprove enduranceBack restsStoolsSupporting systemAnatomical structures

Owner:MILLERKNOLL INC

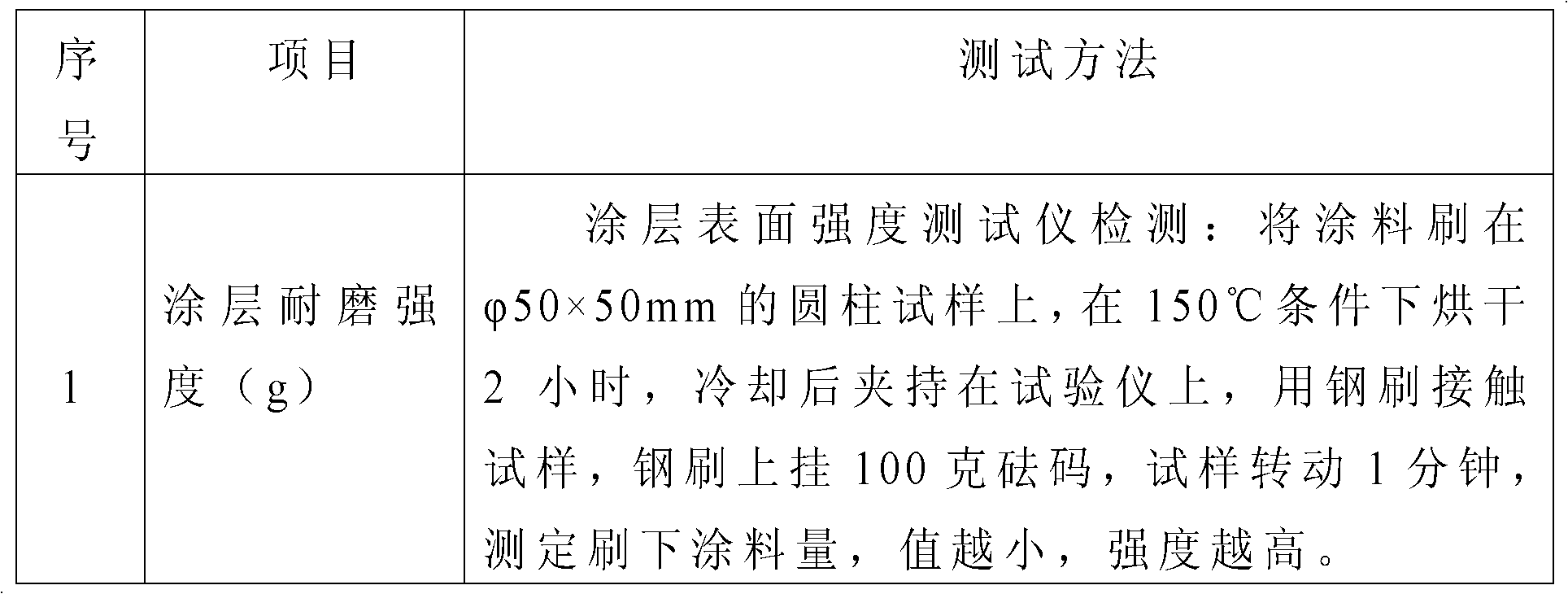

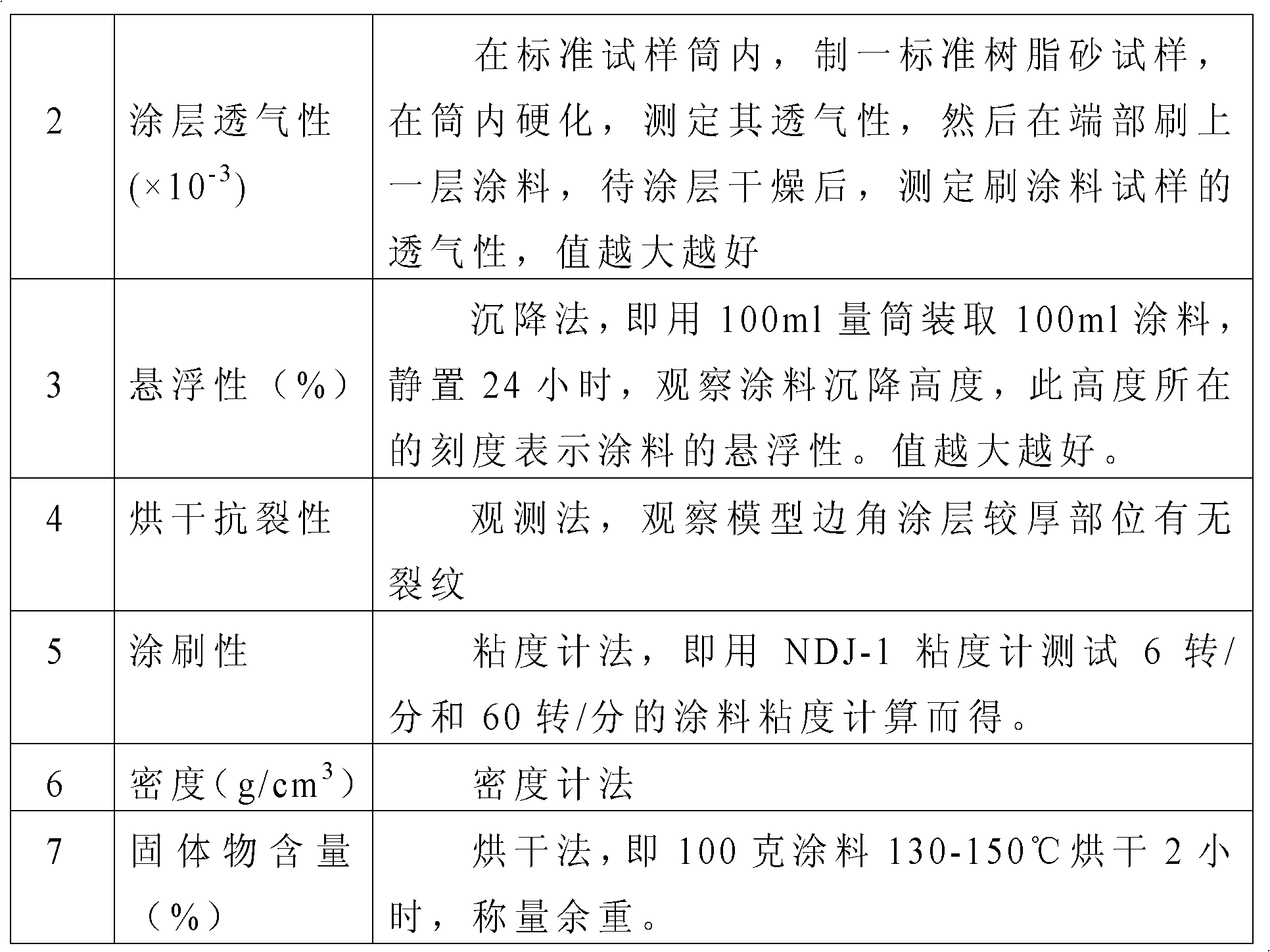

Solid pattern casting special paint and preparation method thereof

InactiveCN102049464AHigh strengthImprove integrityFoundry mouldsFoundry coresGraphiteSuspending Agents

The invention discloses a solid pattern casting special paint and a preparation method thereof. The mass percentages of various constituents in the paint are: 30-40% of bauxite chamotte, 20-30% of flaky graphite powder, 6.3-8.5% of bonder, 1-2% of iron oxide red powder, 4-6% of suspending agent, 0.8-1.5% of water reducing agent and 20-30% of water. The preparation method comprises the steps: mixing the various components of the solid pattern casting special paint according to the mass percentages and loading the constituents into a ball mill; adding 50-80 ceramic balls with a diameter of 30-50 mm into the ball mill; and mixing and stirring the materials evenly to obtain the paint. Practices show that the paint has strong abrasion performance, high adhesiveness, good air permeability and fast-dry performance both in low and high temperature environments; the paint can satisfy the production requirement of large casting production; the preparation method disclosed by the invention is simple; and the cost is low.

Owner:DONGFENG MOTOR CO LTD

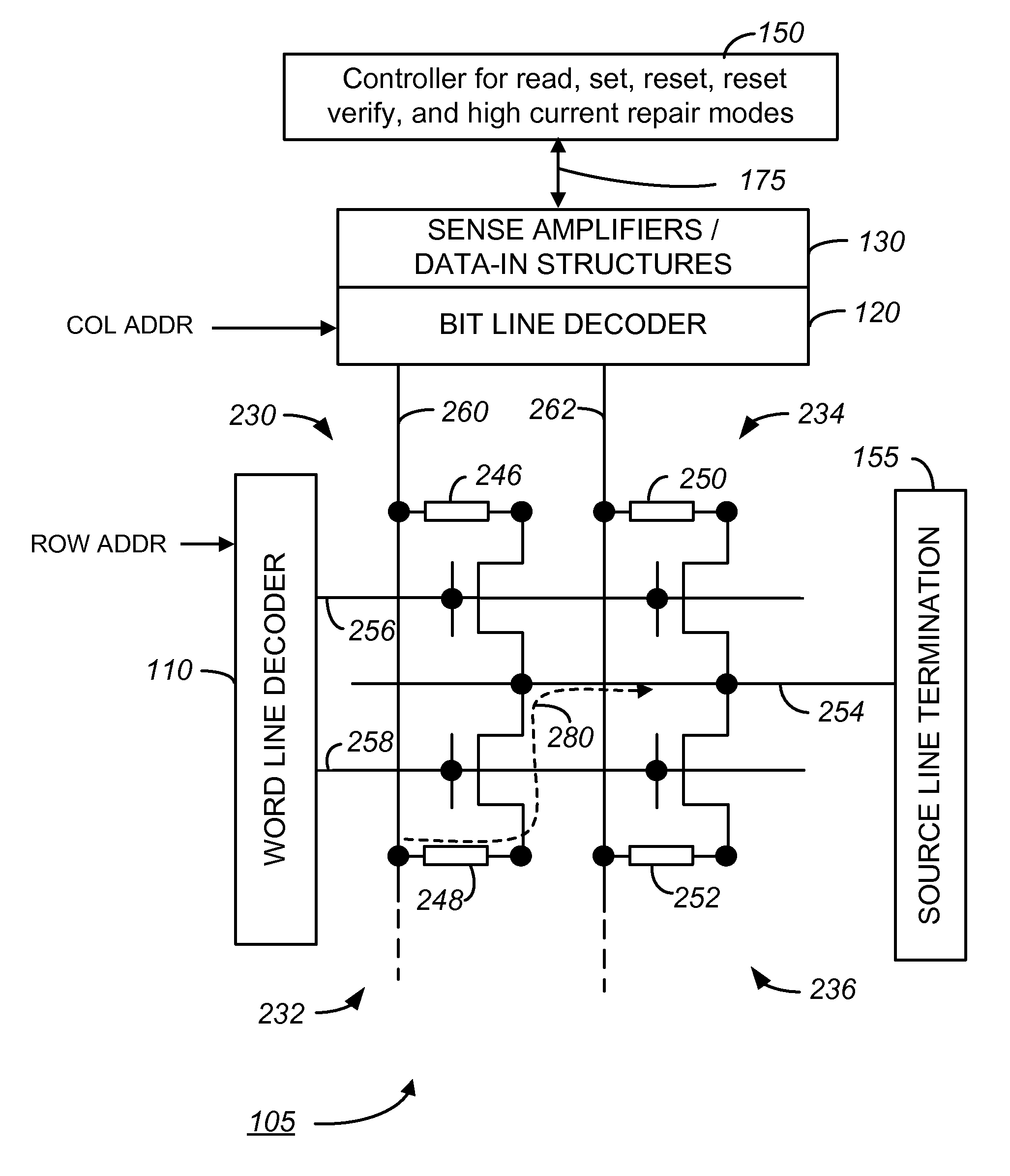

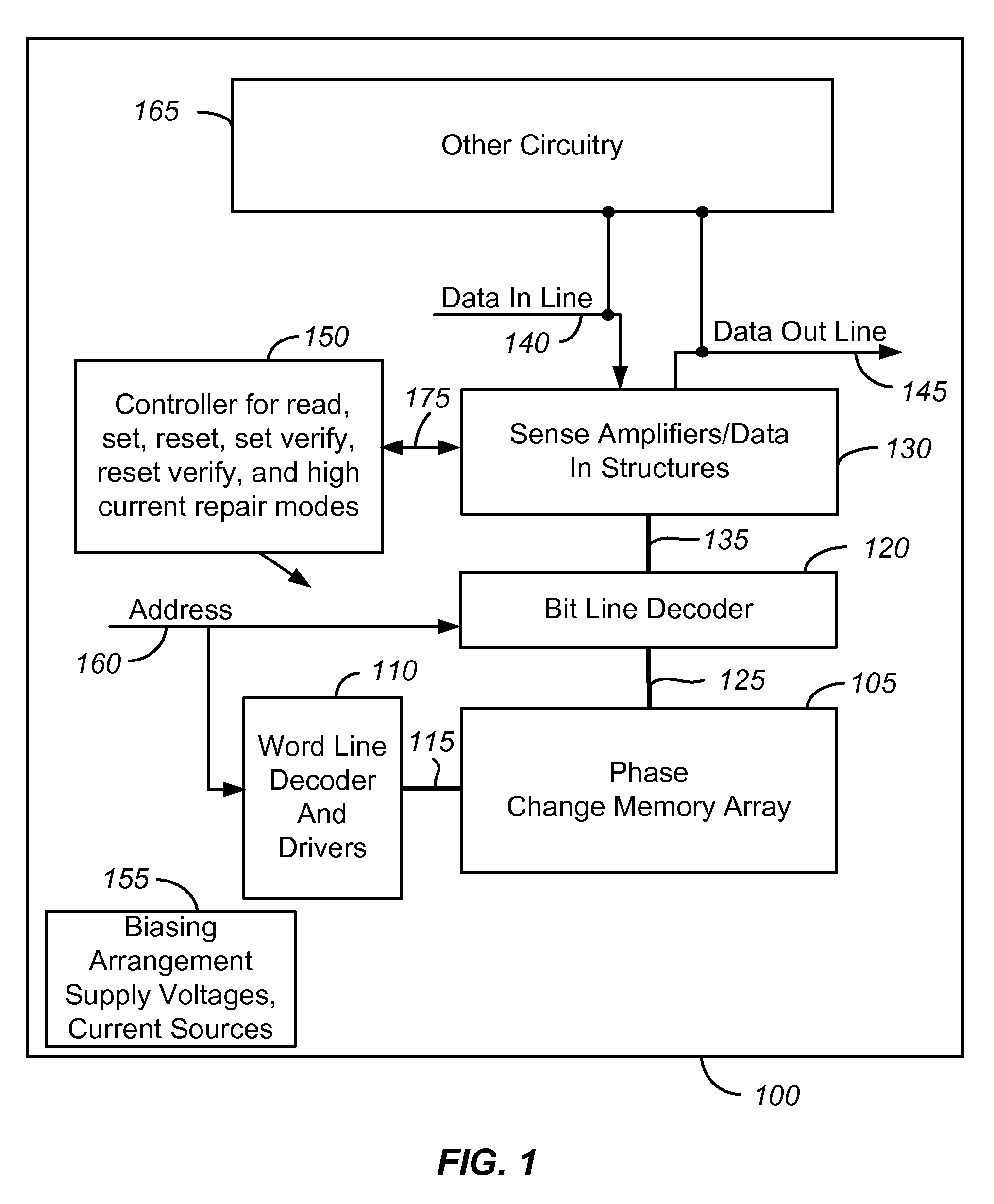

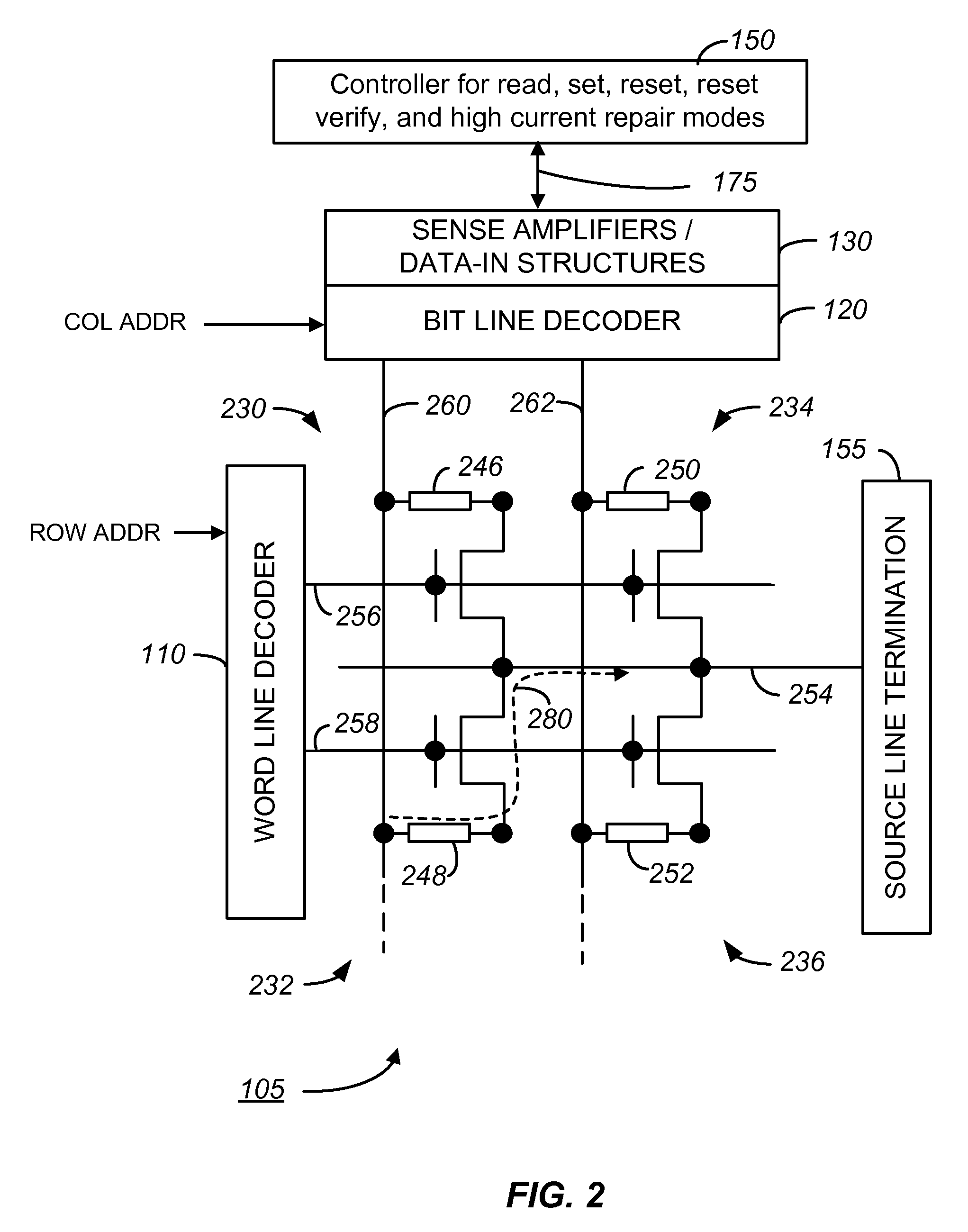

High-endurance phase change memory devices and methods for operating the same

ActiveUS20120327708A1Improve enduranceImprove reliabilityDigital storagePhase-change materialPhase-change memory

Phase change based memory devices and methods for operating such devices described herein overcome the set or reset failure mode and result in improved endurance, reliability and data storage performance. A high current repair operation is carried out in response to a set or reset failure of a phase change memory cell. The higher current repair operation can provide a sufficient amount of energy to reverse compositional changes in the phase change material which can occur after repeated set and reset operations. By reversing these compositional changes, the techniques described herein can recover a memory cell which experienced a set or reset failure, thereby extending the endurance of the memory cell. In doing so, phase change based memory devices and methods for operating such devices are provided which have high cycle endurance.

Owner:IBM CORP +1

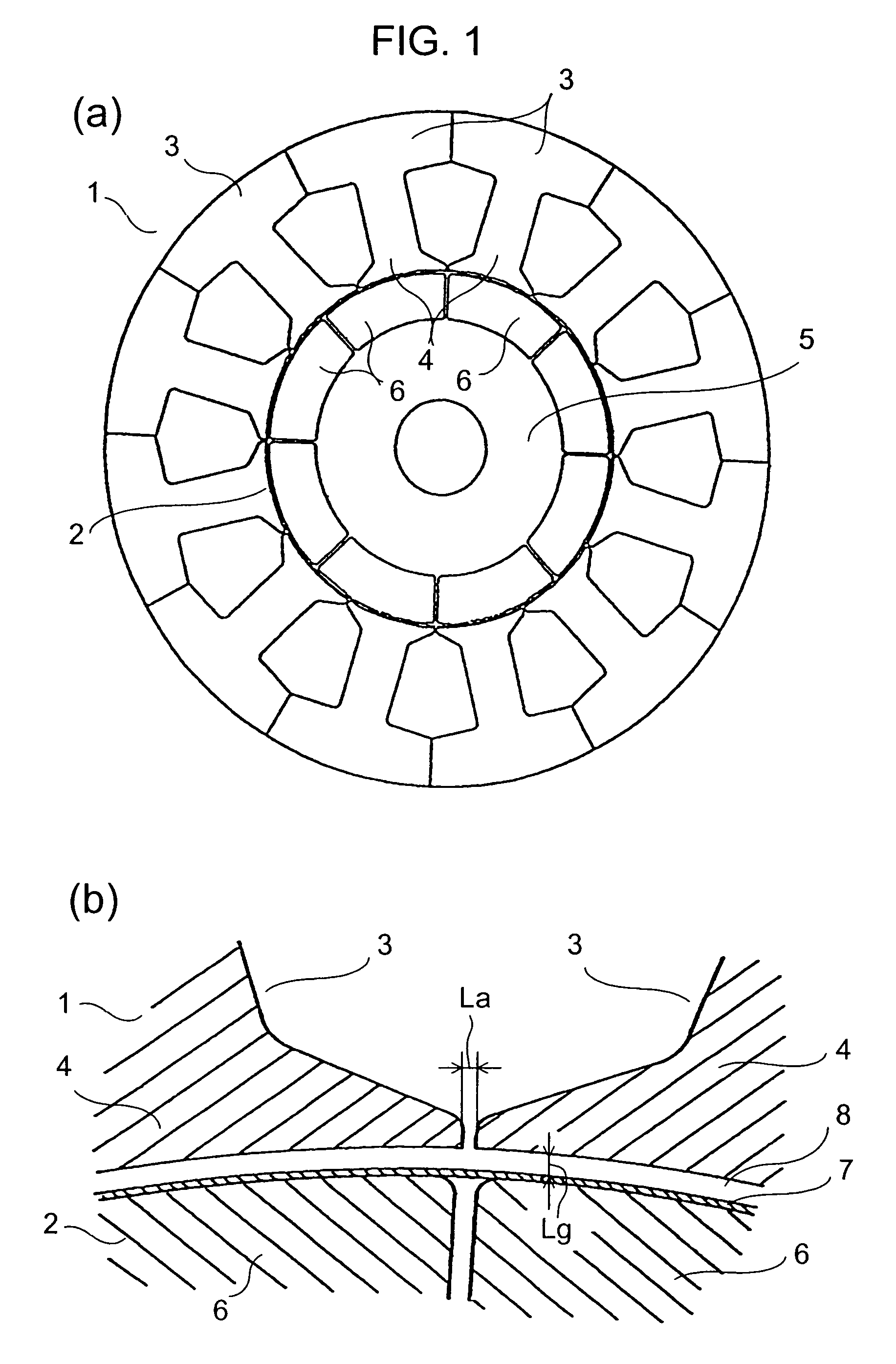

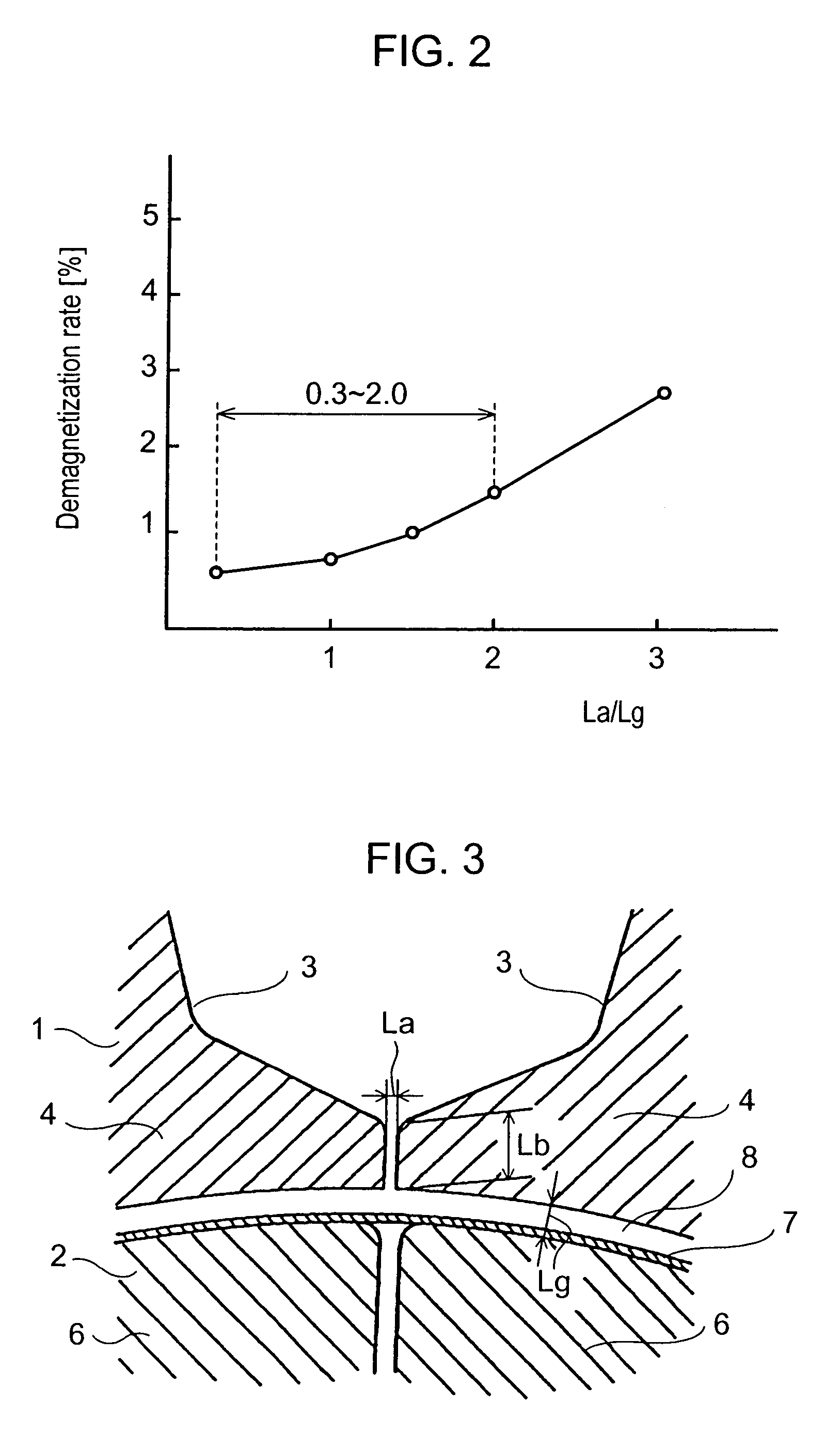

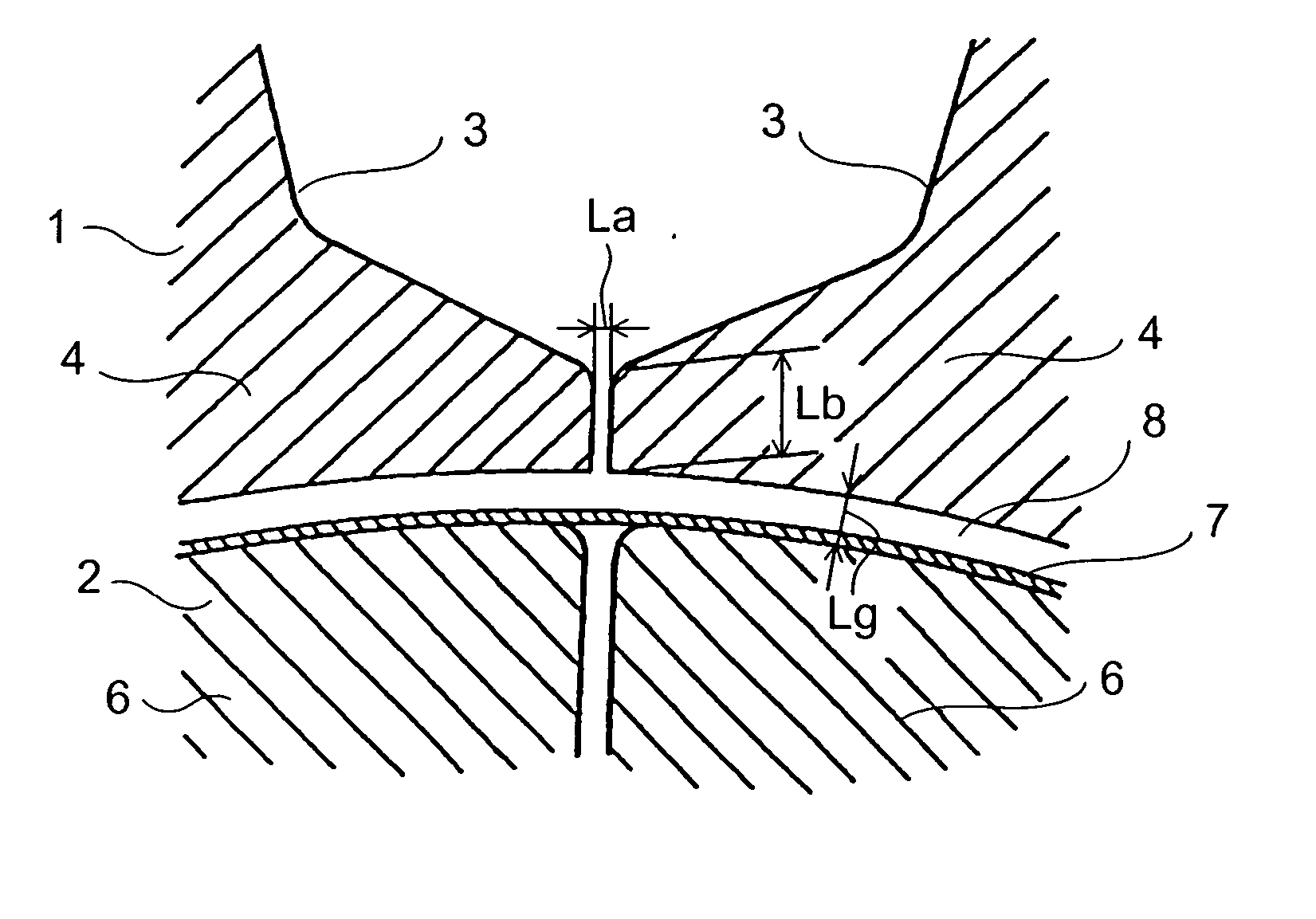

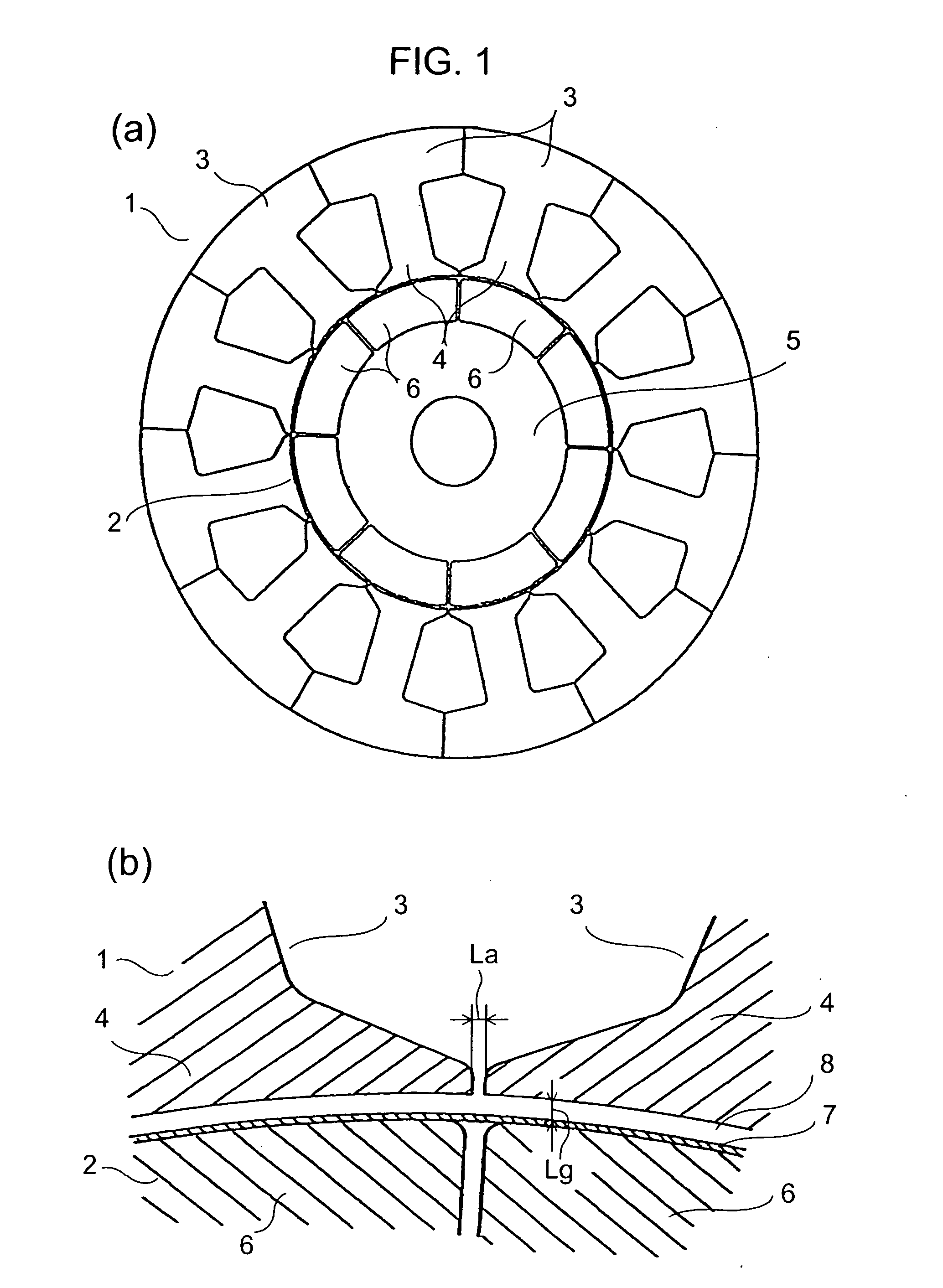

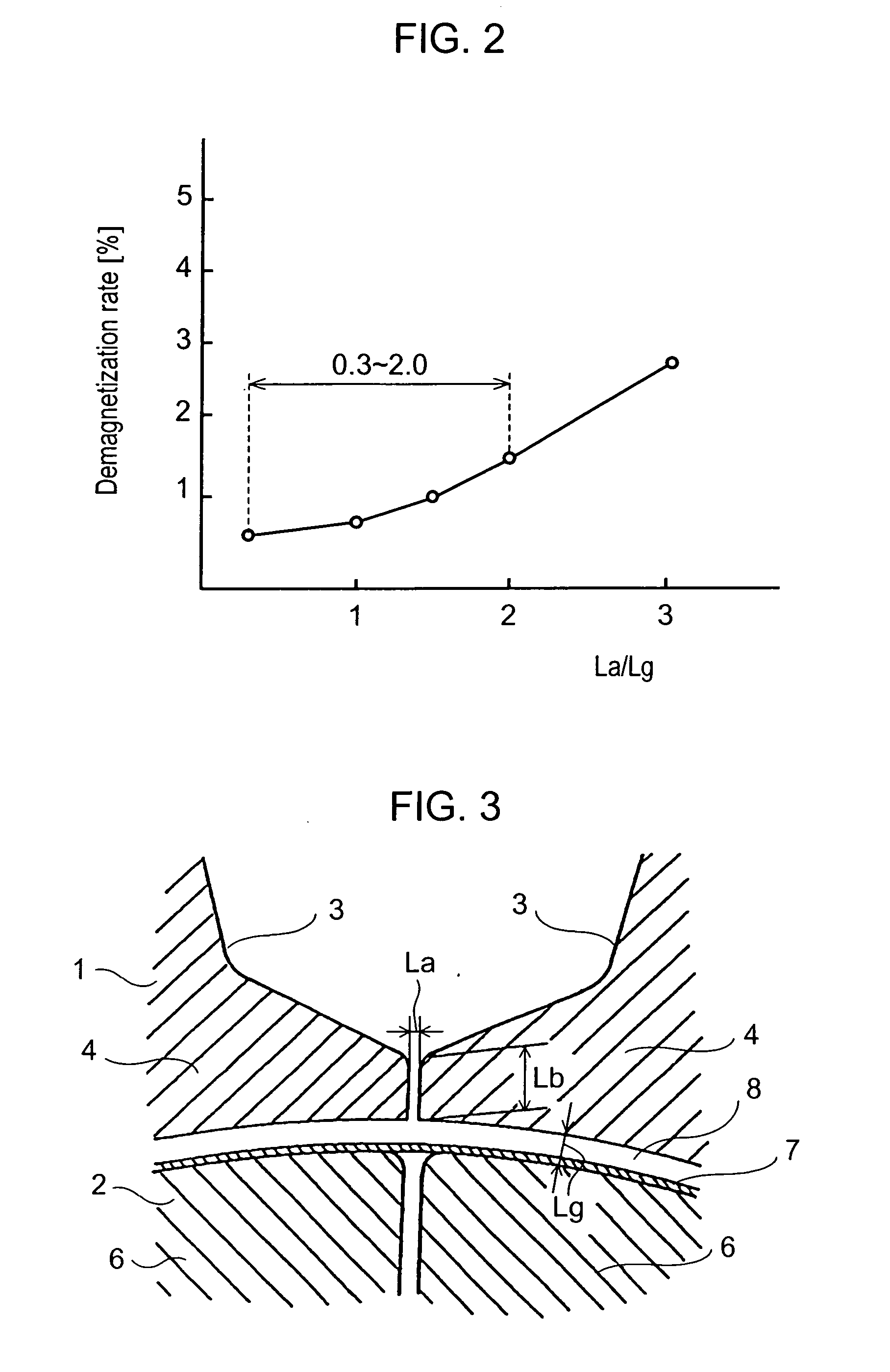

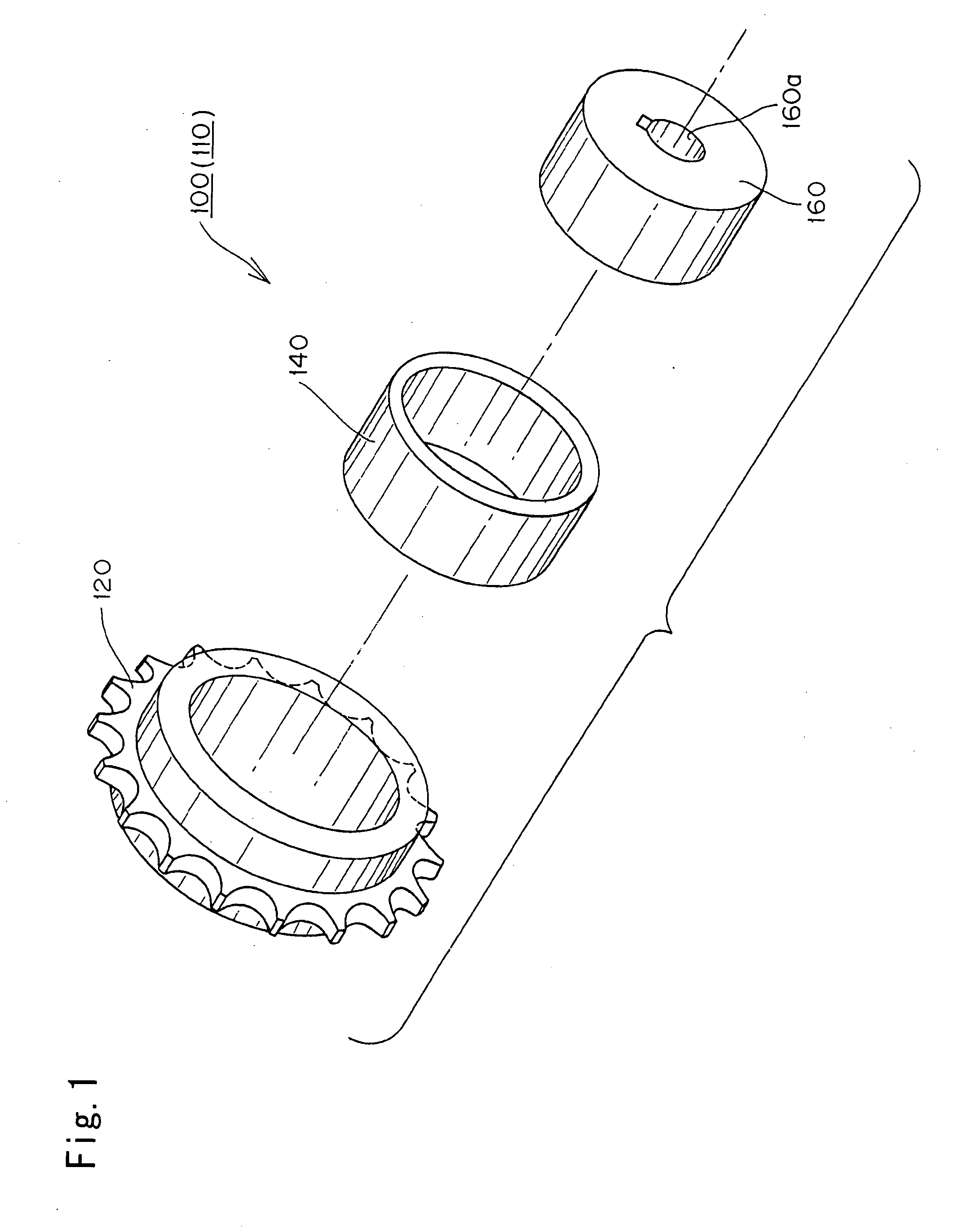

Permanent magnet synchronous motor

InactiveUS6940205B1Reduce outputGreater withstanding force against demagnetizationMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorConductor Coil

The present invention provides a permanent-magnet-synchronous-motor having a stator with concentrating windings with the following structure so that permanent magnet (6) is hard to subjected to demagnetization magnetic field: 0.3 Lg<La≦2.0 Lg, where La is a clearance between teeth of stator (1), and Lg is an air-gap between stator (1) and rotor (2), and yet outer walls of both ends of the permanent magnet (6) disposed within rotor (2) in a rim direction are tapered toward inside from a rotor rim in a radial direction and thus form recessed section on the outer walls of the magnets. As a result, withstanding force against demagnetization is expected to increase.

Owner:PANASONIC CORP

Antirust emulsion of self-crosslinked interpenetrating net polymer and its production

InactiveCN101029115AImprove stabilityExcellent calcium ion stabilityAnti-corrosive paintsCross-linkEpoxy

A self-cross-linked interpenetrating network polymer antirust emulsion and its production are disclosed. The emulsion consists of epoxy resin 2-50 proportion, unsaturated hydrocarbon monomer mixture 20-80 proportion, olefine hydroxyl-acid 0.5-8 proportion, functional organic silane 0.5-25 proportion, functional organic fluoride monomer 0.5-20 proportion, cross-linking agent 0.1-1.2 proportion, neutralizing agent 0.5-1.5 proportion, emulsifying agent 1-8 proportion, chain transfer agent 0.05-0.6 proportion, pH regulator 0.2-0.6 proportion, initiating agent 0.3-0.8 proportion, softened water 90-150 proportion and cross-linking curing agent 0.2-5 proportion. The process is carried out by dosing in the first, second and third reactors, mixing in the third reactor and discharging to obtain final product. It has excellent weather and water resistances, better anti-corrosive performance and storage stability.

Owner:HARBIN INST OF TECH

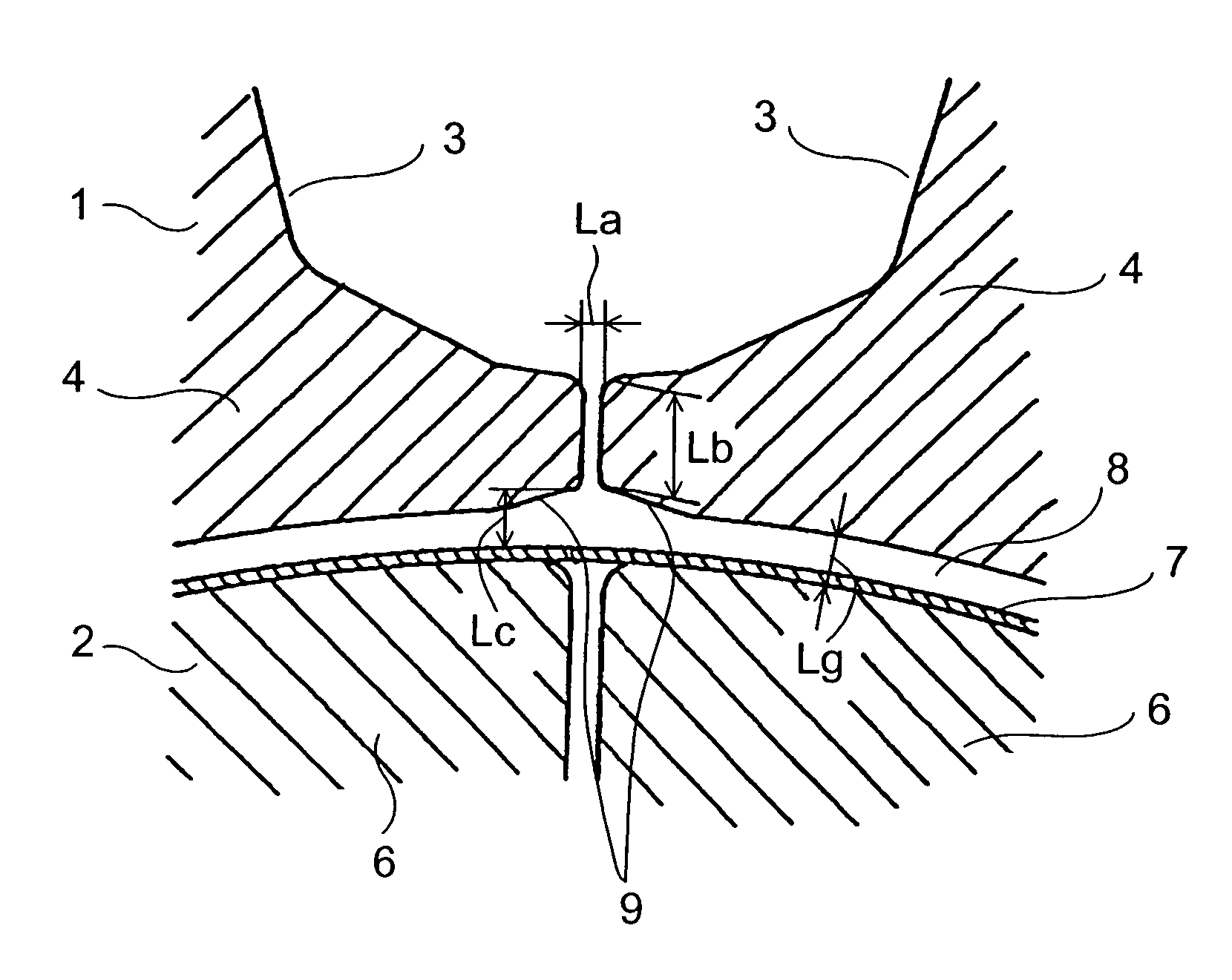

Permanent magnet synchronous motor

InactiveUS20050225194A1Reduce outputGreater withstanding force against demagnetizationMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorConductor Coil

The present invention provides a permanent-magnet-synchronous-motor having a stator with concentrated windings with the following structure so that permanent magnet (6) is hard to subjected to demagnetization magnetic field: 0.3 Lg<La≦2.0 Lg, where La is a clearance between teeth of stator (1), and Lg is an air-gap between stator (1) and rotor (2). Outer walls of both ends of the permanent magnet (6) disposed within rotor (2) in a rim direction may be tapered toward inside from a rotor rim in a radial direction and to form a recessed section on the outer walls of the magnets. As a result, withstanding force against demagnetization is expected to increase.

Owner:PANASONIC CORP

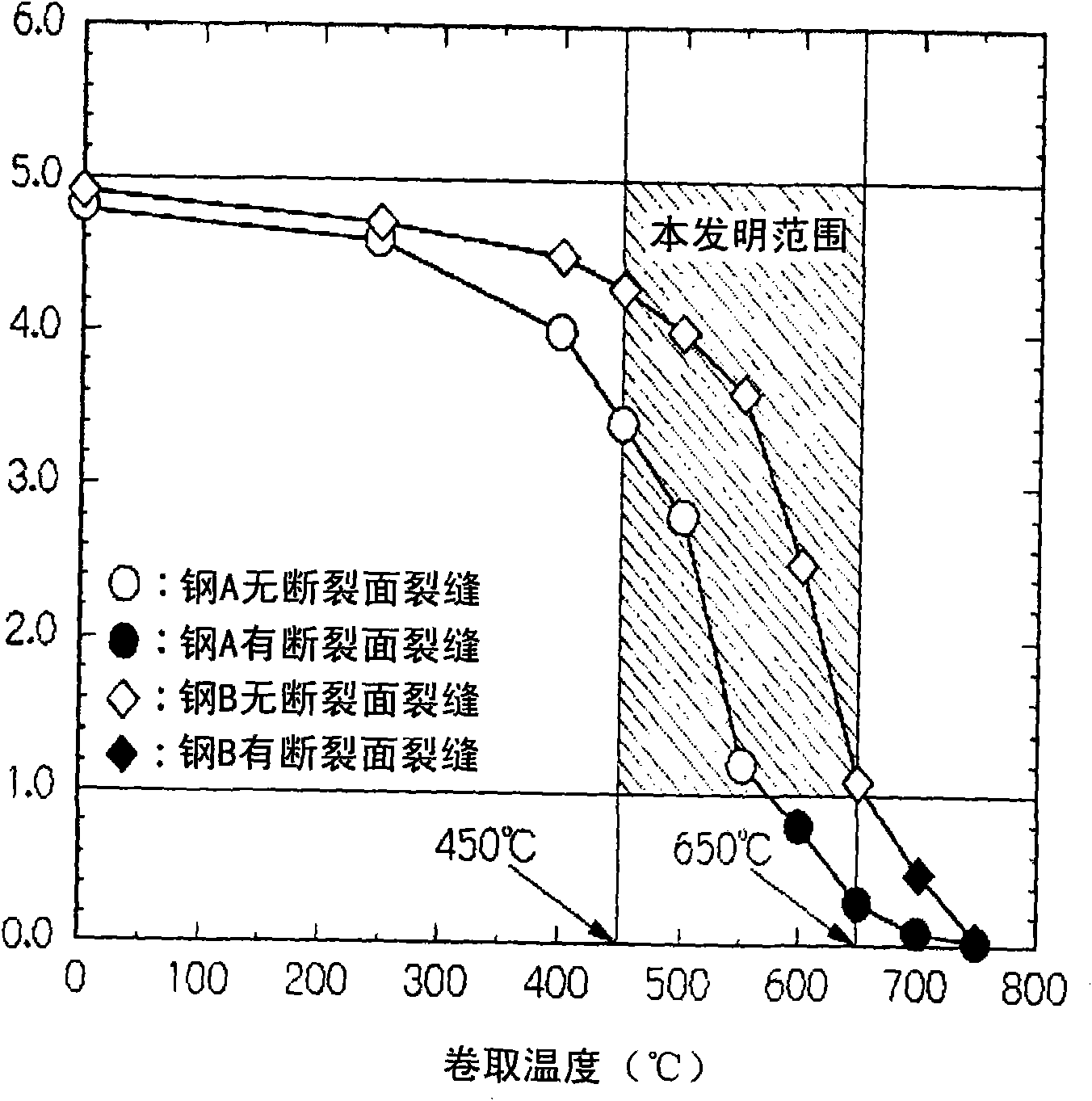

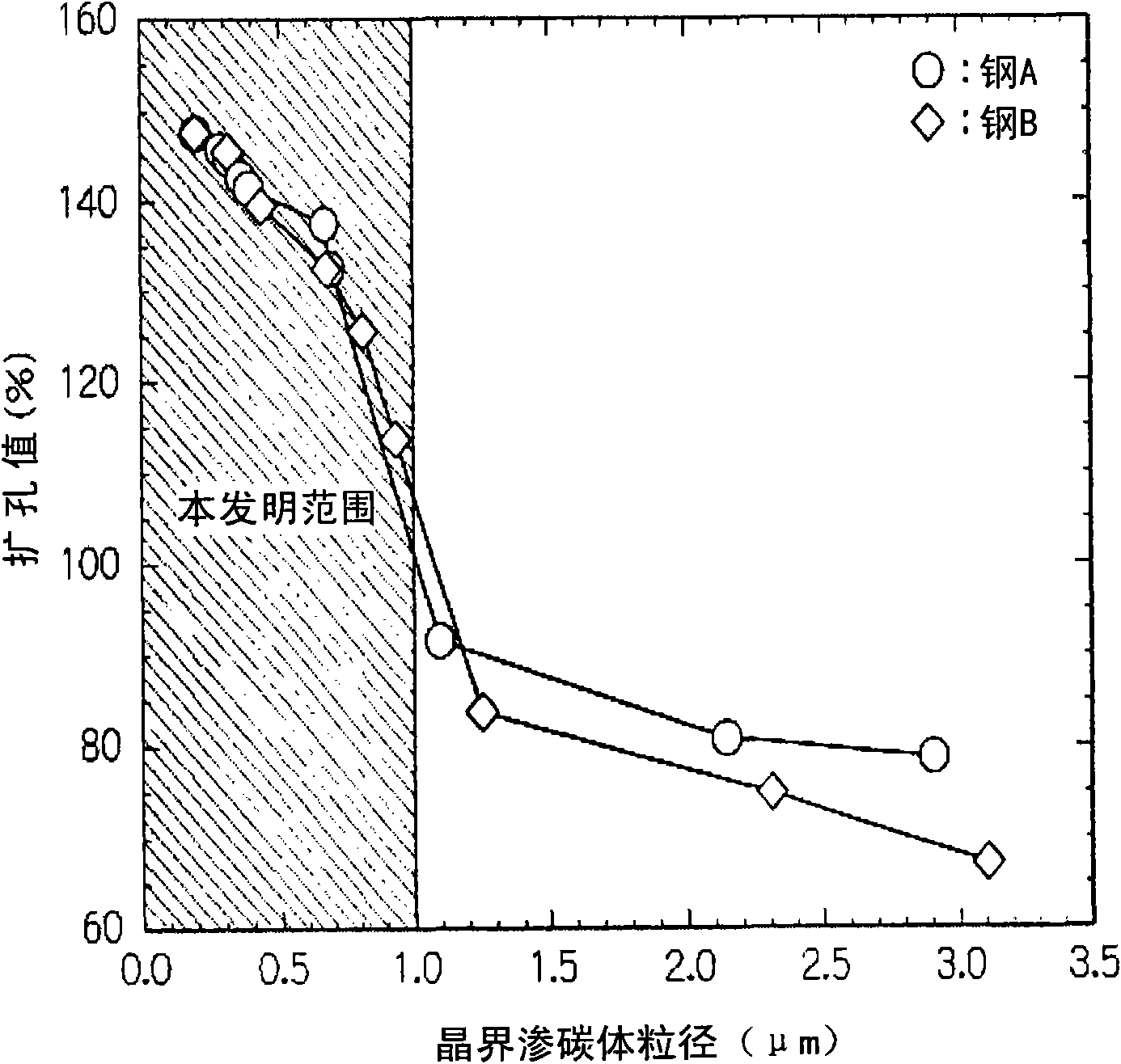

High-strength hot rolled steel sheet being free from peeling and excelling in surface and burring properties and process for manufacturing the same

InactiveCN101646794AImprove surface propertiesImprove enduranceHot-dipping/immersion processesFurnace typesGrain boundaryHot rolled

A hot rolled steel sheet comprised of, by mass, 0.01 to 0.1% C, 0.01 to 0.1% Si, 0.1 to 3% Mn, 0.1% or less P, 0.03% or less S, 0.001 to 1% Al, 0.01% or less N, 0.005 to 0.08% Nb, 0.001 to 0.2% Ti andthe balance Fe and unavoidable impurities, satisfying the formula ¢Nb! x ¢C!=4.34 x 10<-3>, wherein the density of solid solution C grain boundary quantity is in the range of 1 to 4.5 grain boundaries / nm<2>, and wherein the diameter of cementite grains precipitated on the grain boundaries within the steel sheet is 1 ¢mu!m or less. This hot rolled steel sheet is manufactured according to the following process. A steel piece with the above composition of the hot rolled steel sheet is heated at temperature SRTmin ( DEG C) to 1170 DEG C and subjected to rough rolling in the condition of 1080 DEGto 1150 DEG C finalization temperature. Thereafter, finishing rolling is started at 1000 DEG to below 1080 DEG C within 30 to 150 sec and terminated at temperature ranging from the Ar3 transformation point temperature to 950 DEG C so that the draft upon final pass is in the range of 3 to 15%. The resultant steel sheet is subjected to cooling from the start to the temperature range of 450 DEG to550 DEG C at a cooling rate of over 15 DEG C / sec and wound up.

Owner:NIPPON STEEL CORP

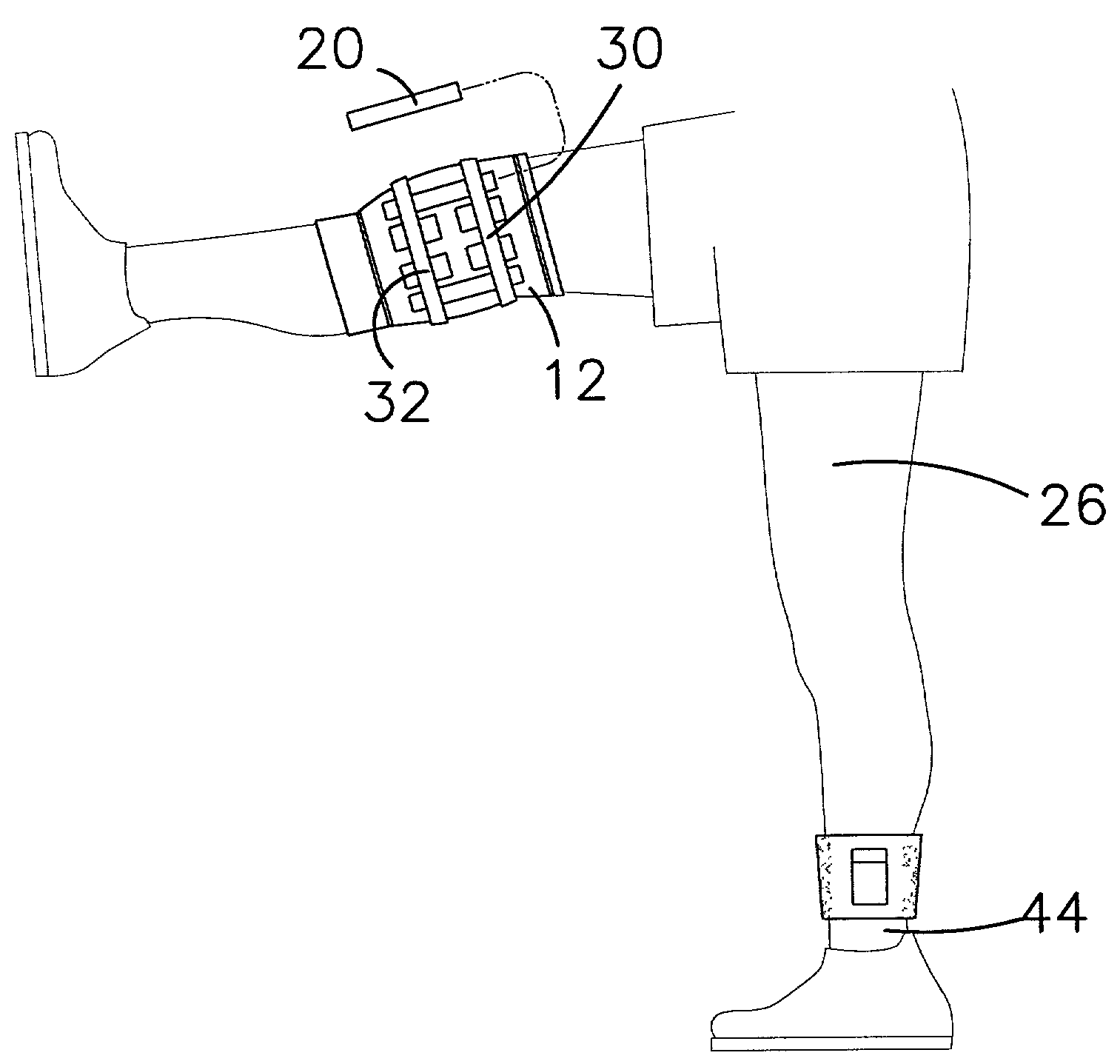

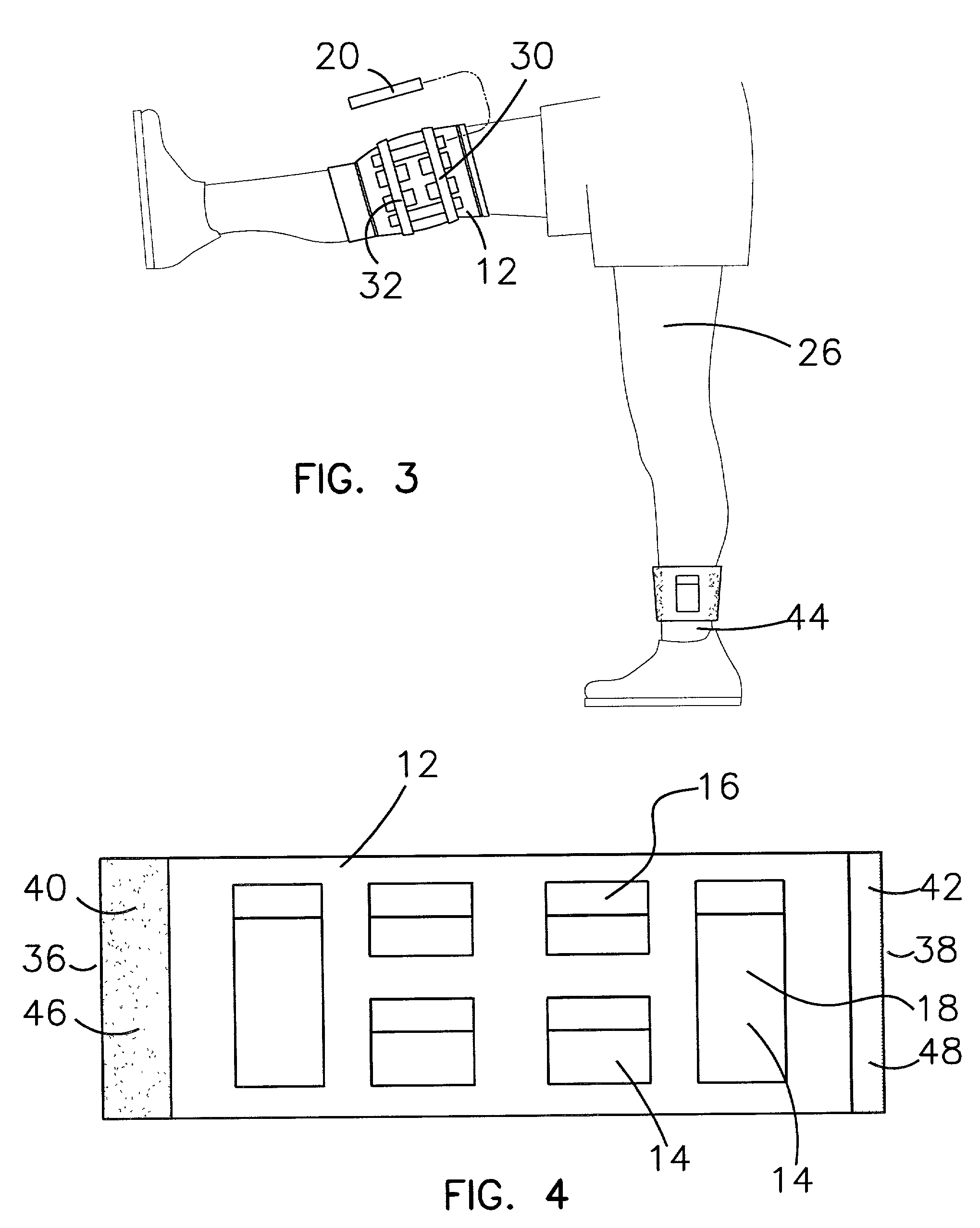

Exercise system

An exercise system for allowing a user to increase endurance, power, speed, quickness, and overall body conditioning. The exercise system includes a body member that is adapted to snuggly fit around a portion of a user. A plurality of pockets is coupled to the body member. Each of the pockets has a flap that is secured to a front panel of each the pockets such that the flap is for closing each of the respective pockets. A plurality of weight members each are selectively insertable into each of the pockets such that the weight members are adapted to change the weight resistance against the muscles of the user when the body member is fitted around a portion of a user.

Owner:KINESIFIT

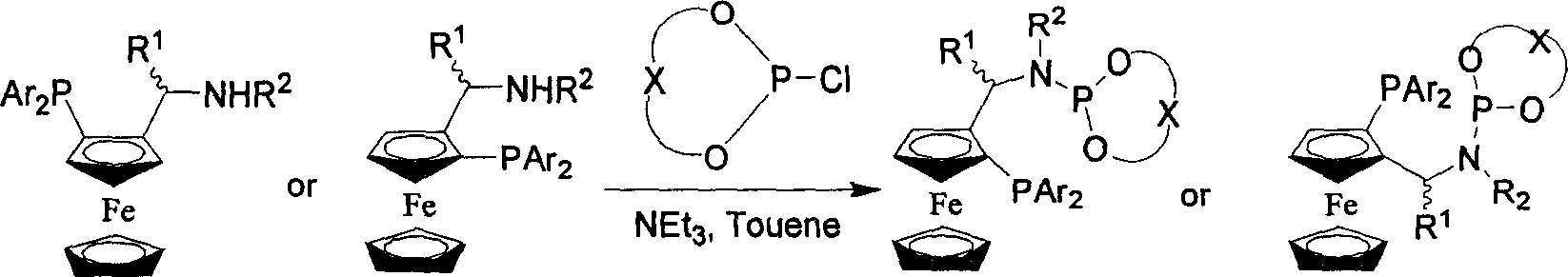

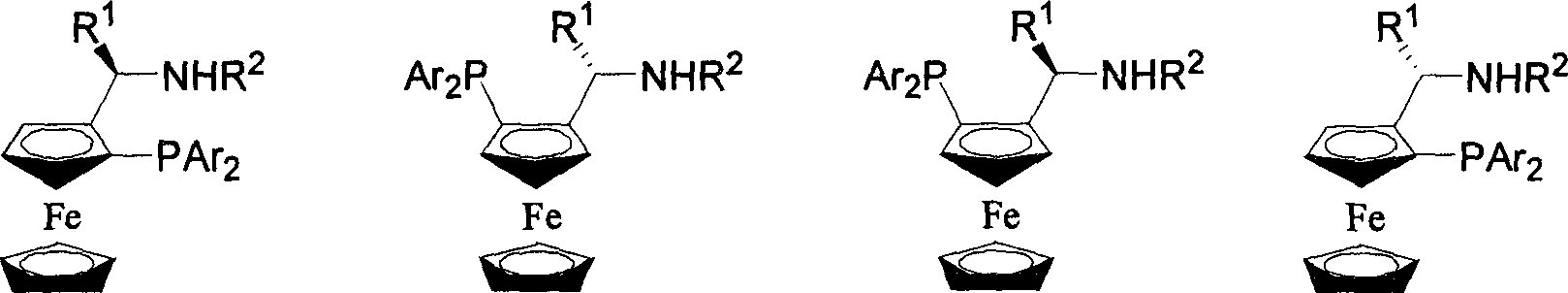

Catalyst using phosphine-phosphoramidite ester as ligand, its preparation method and application

InactiveCN1768944AThe synthetic route is simpleHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsIridiumPt element

The invention relates to a catalyst which uses the phosphor-phosphamide as ligand, which is the phosphor-phosphamide ligand metallic complex of chiral ferrocenyl bone, wherein, the metal is rhodium, ruthenium, iridium, platinum or palladium; and the mol rate between the ligand and the metal precursor is 1.1:1-2.2:1. The ligand is compounded from chiral ferrocenyl to intermediate compound via several reaction steps, to be processed condensation with phosphite ester chloridate to attain the phosphor-phosphamide ligand with different chiral centers. Said ligand has new structure, stable property, simple compounding method, and wider application to the catalyst, which has higher catalysis activity (TON reaches 10000) and higher spatial selectivity (ee reaches more than 99%) in catalyzing asymmetry hydrogenization of itaconic acid, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

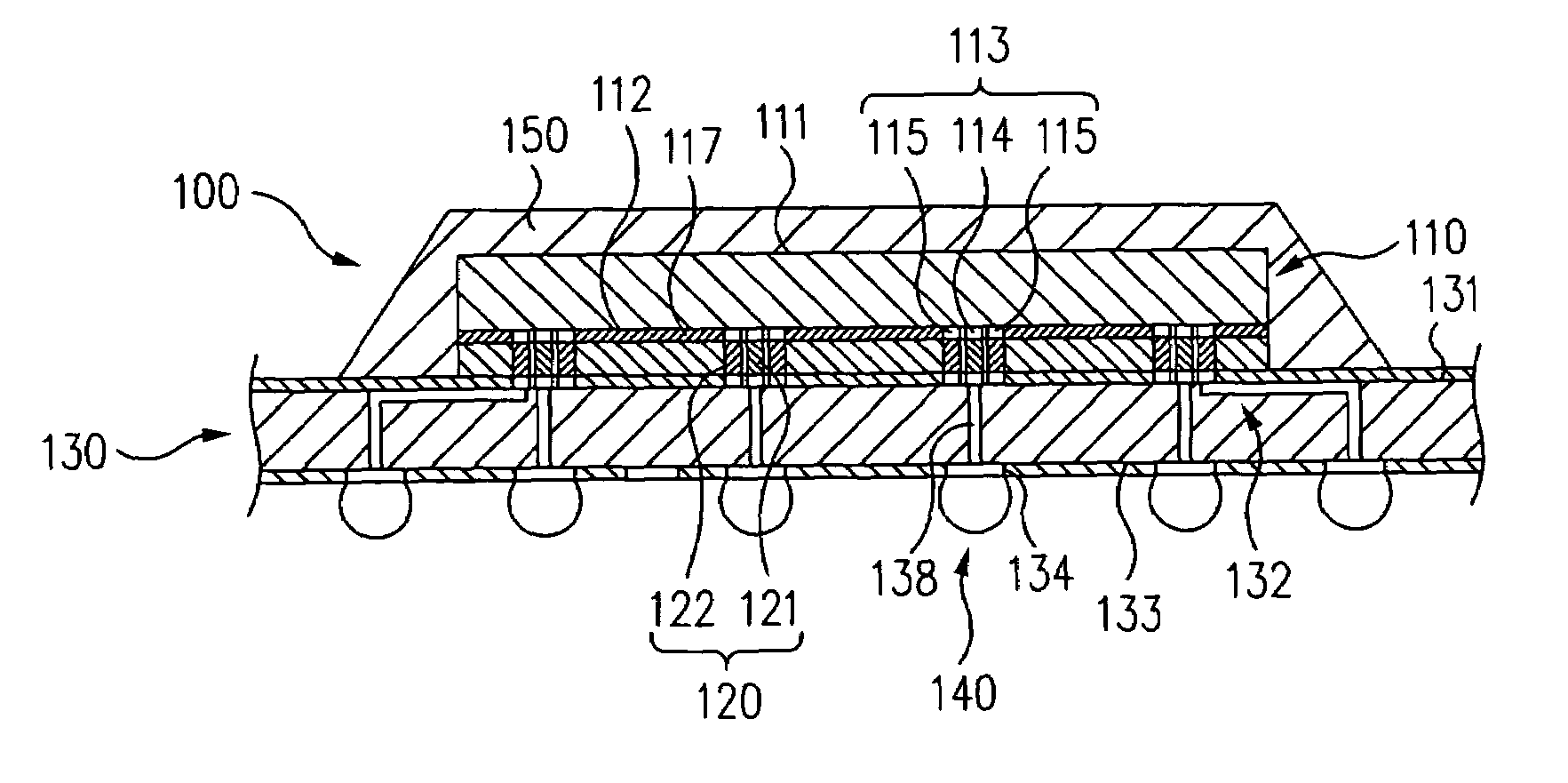

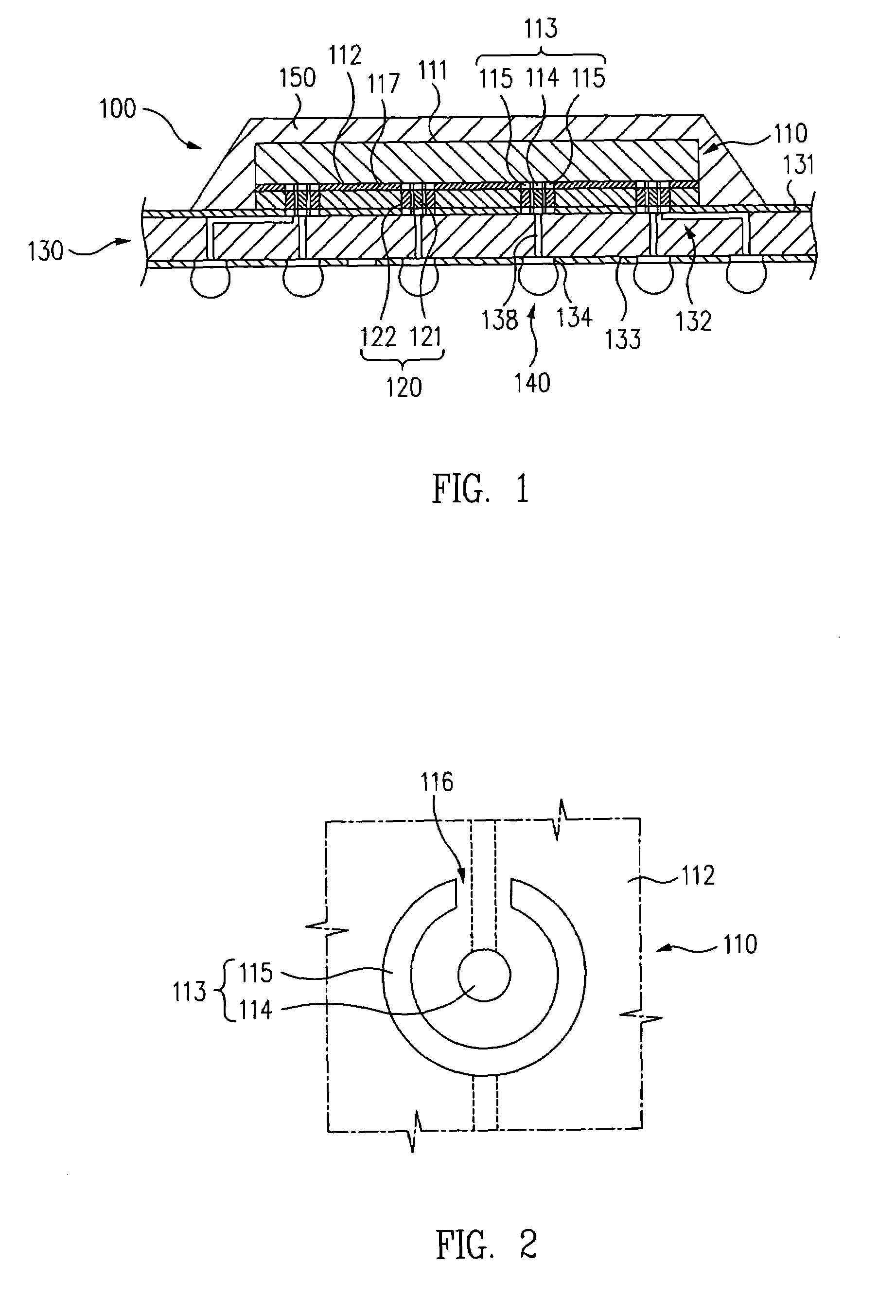

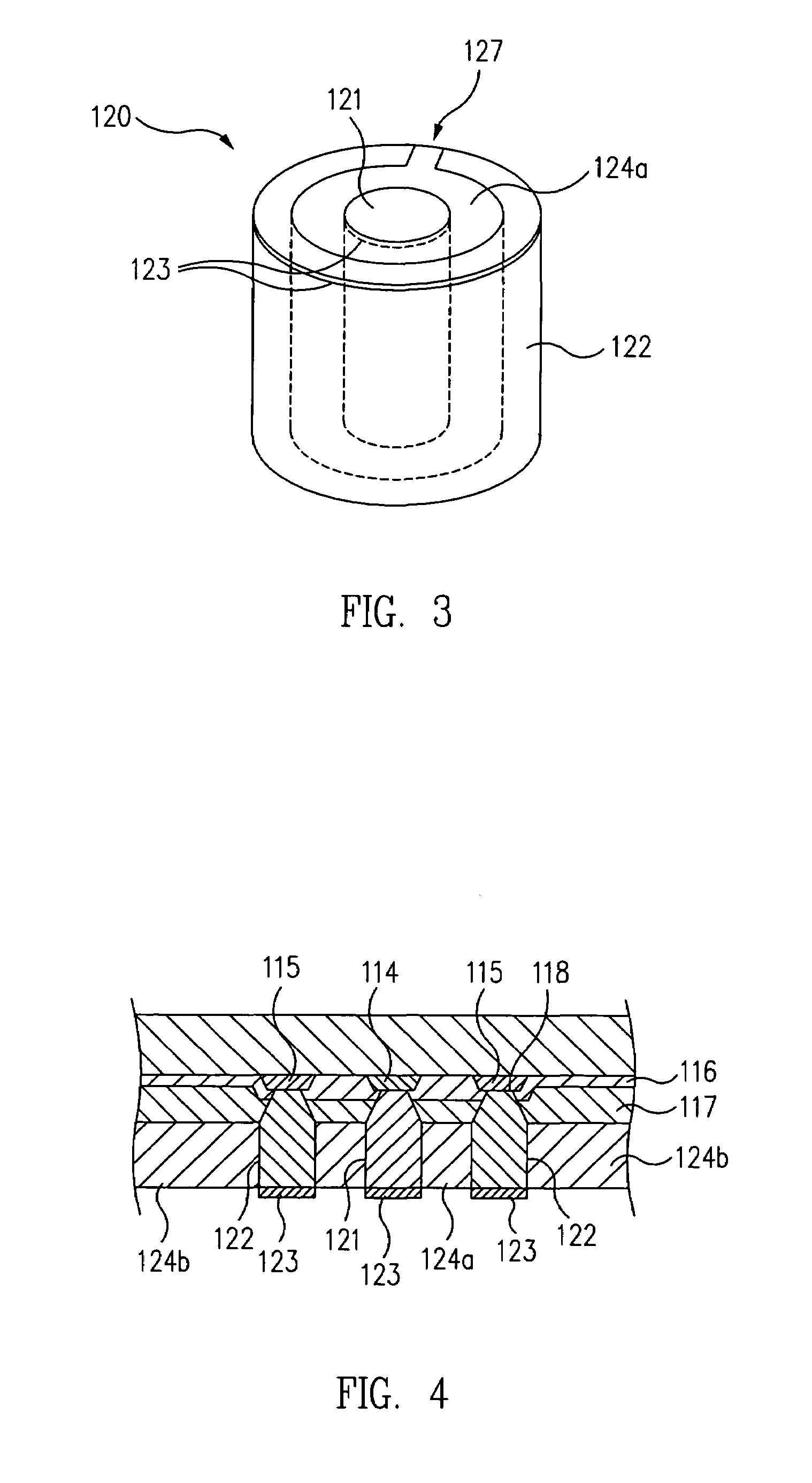

Semiconductor package and method for manufacturing the same

ActiveUS7045893B1Improve enduranceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrically conductiveEngineering

A semiconductor package, and a method for fabricating the semiconductor package, includes a semiconductor die having a plurality of bond pads including a first bond pad positioned at a center of the bond pad and formed at a first surface of the semiconductor die and a second bond pad spaced from the first bond pad by a predetermined distance while surrounding the first bond pad. The semiconductor package includes first and second posts formed on the bond pads of the semiconductor die and a substrate formed with electrically conductive patterns corresponding to the bond pads of the semiconductor die and bonded to the post.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

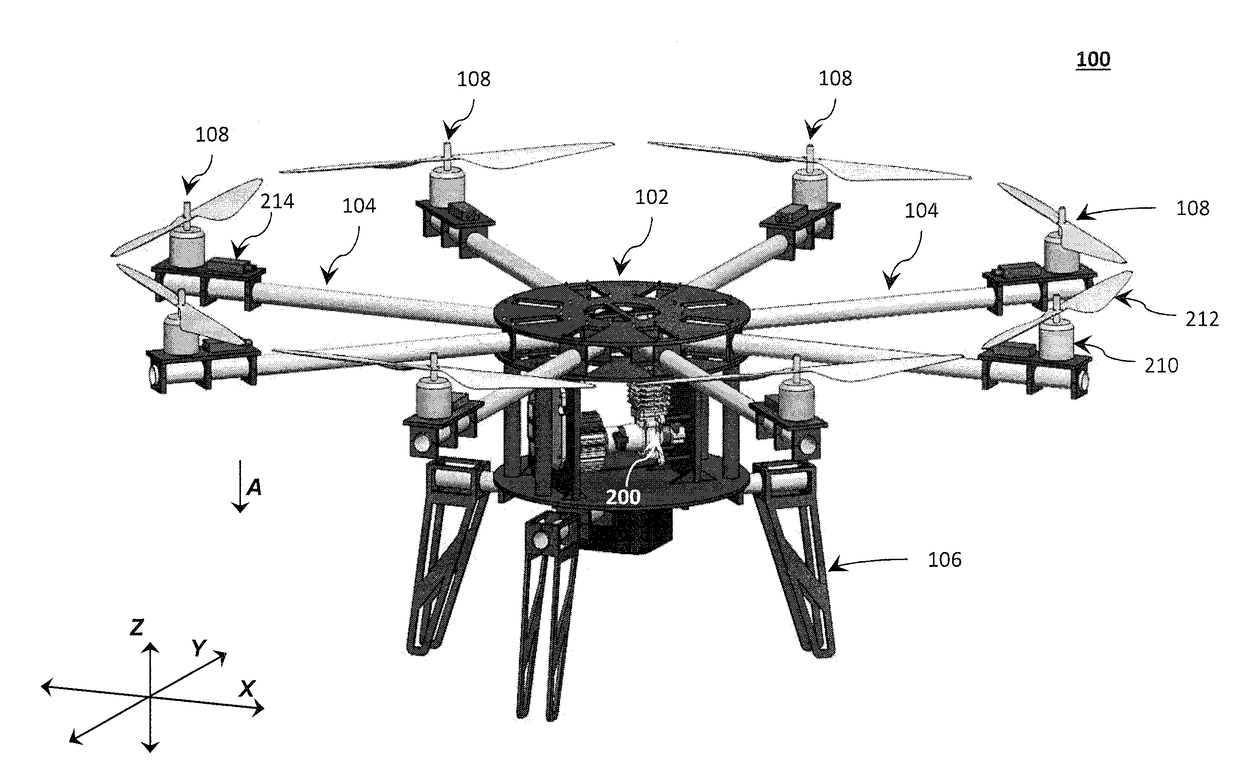

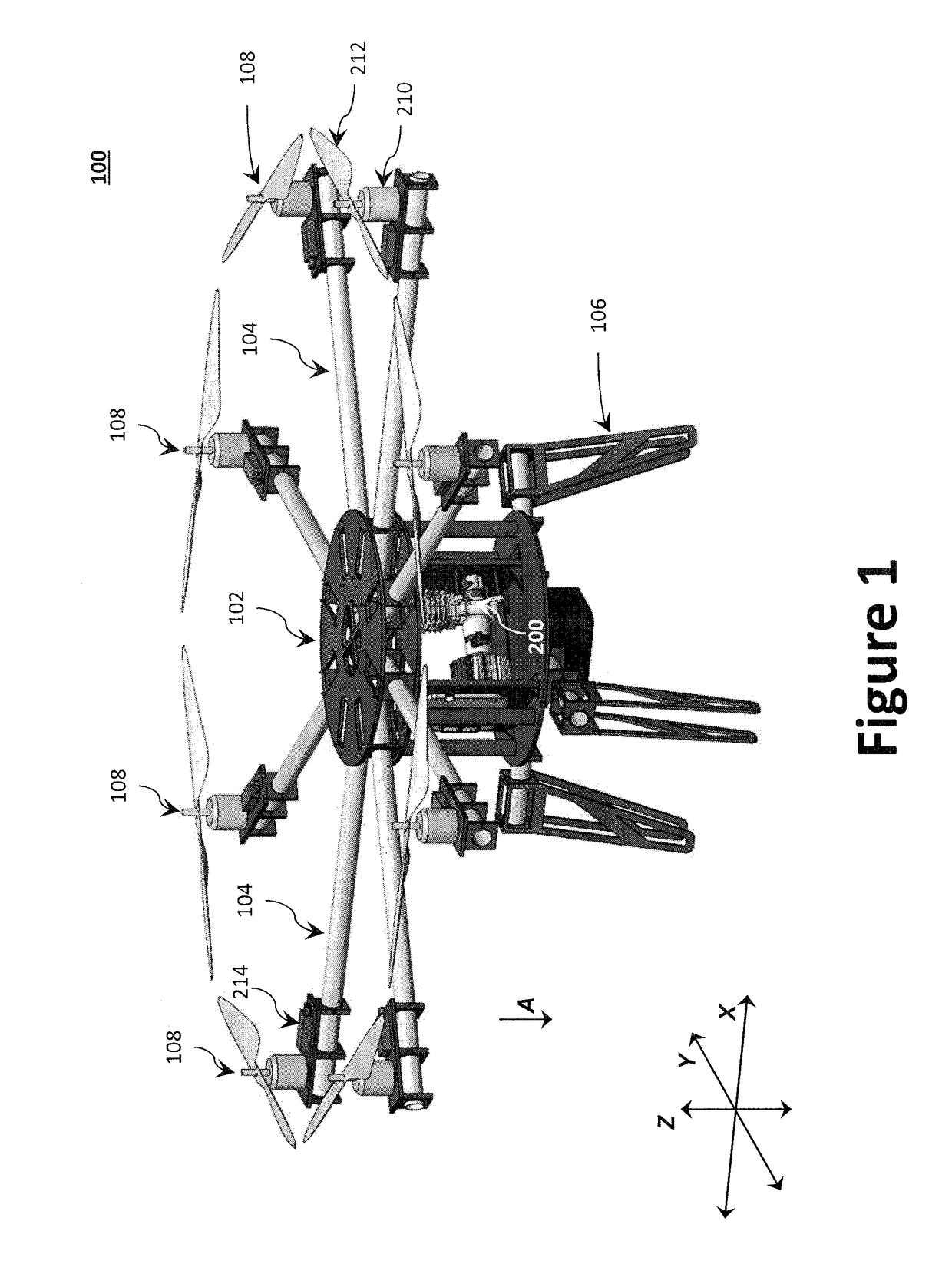

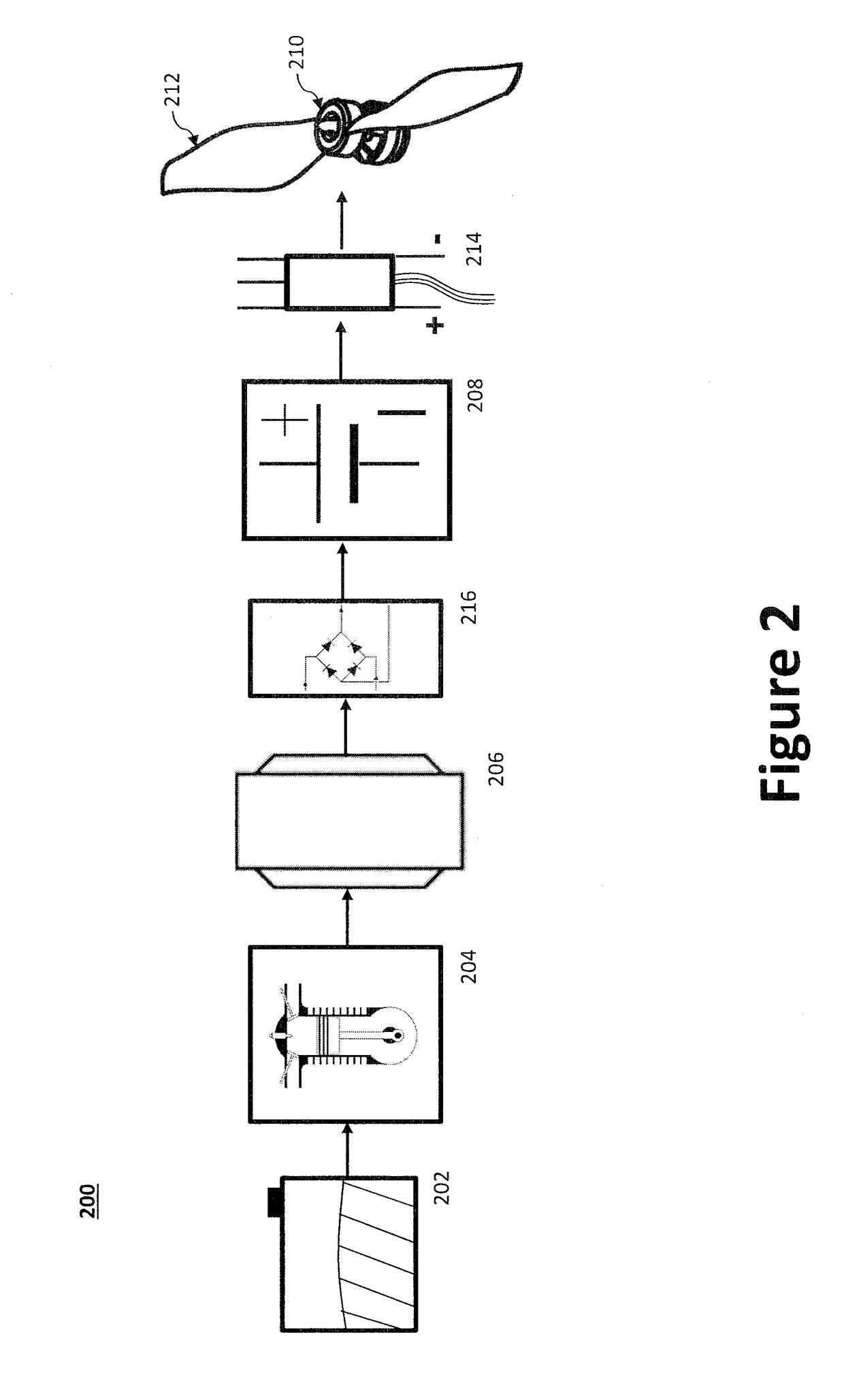

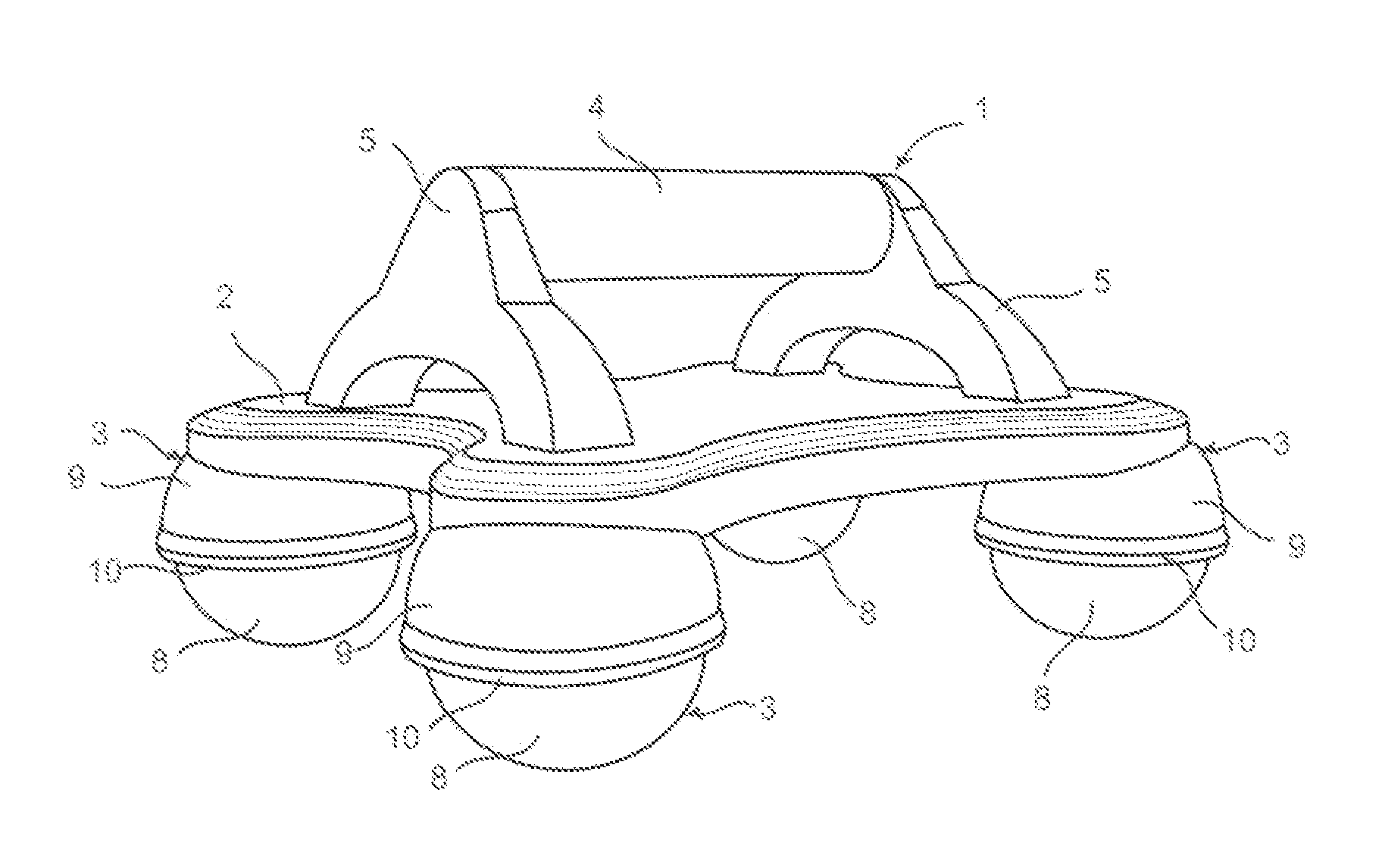

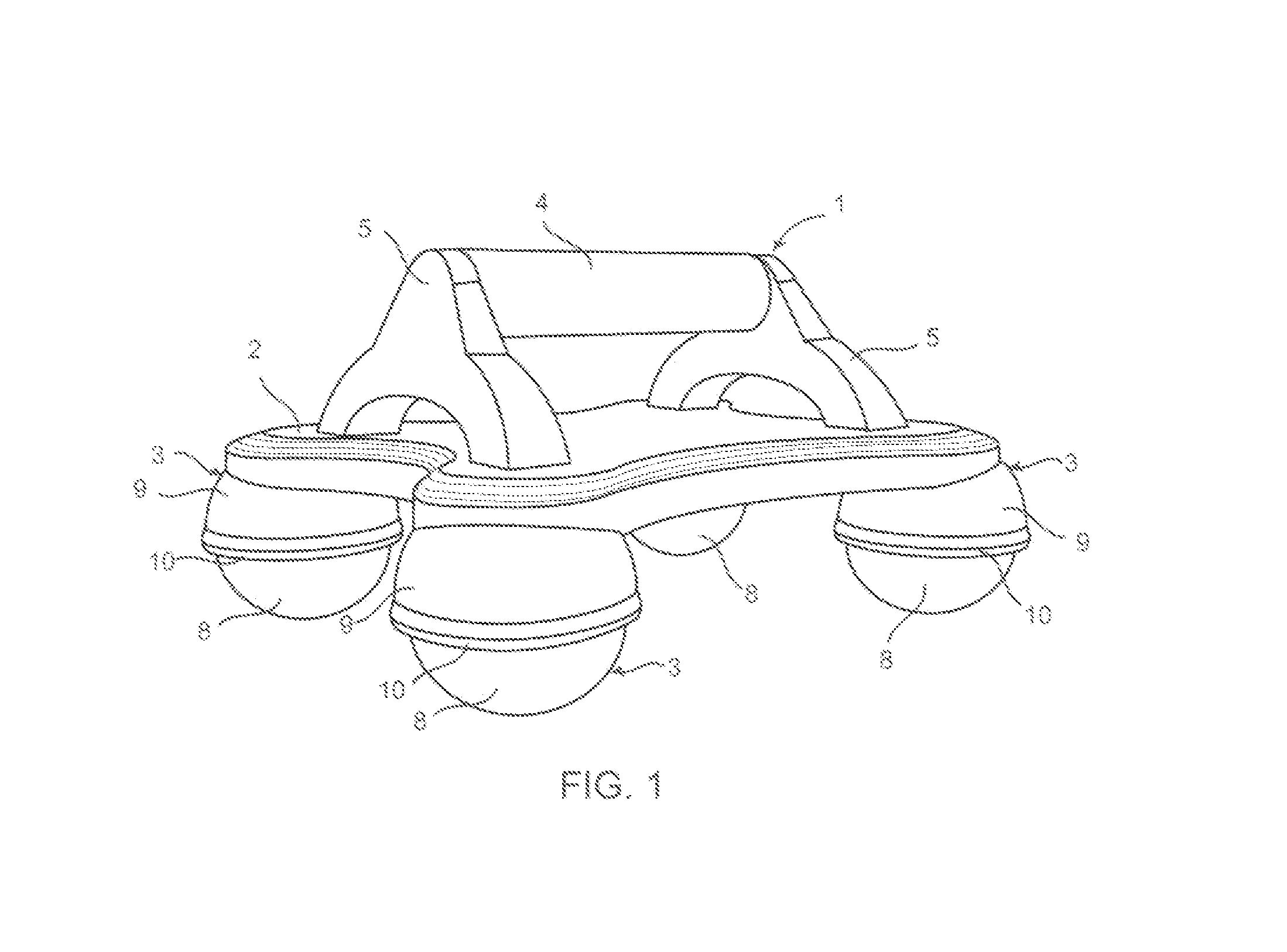

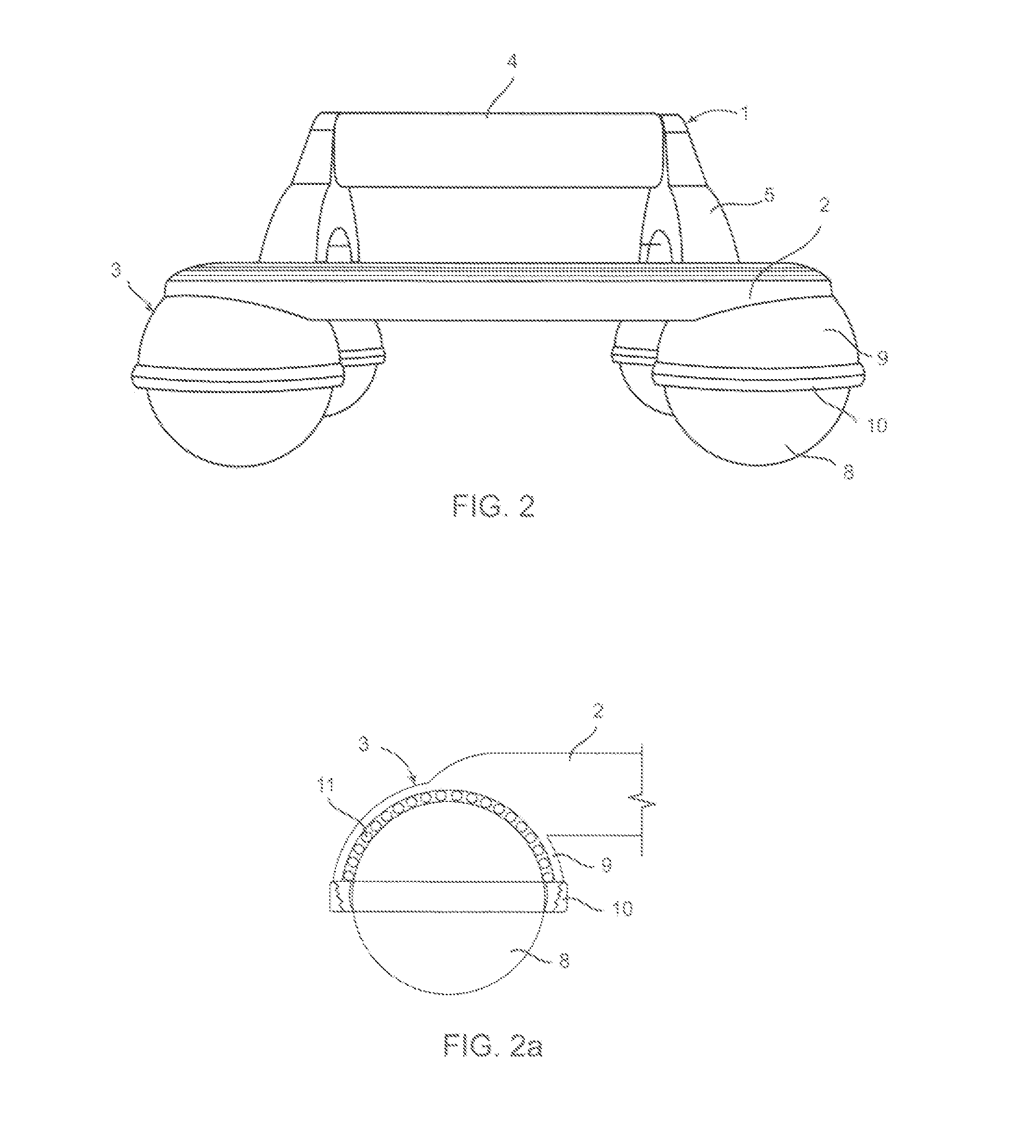

Vertical Lift by Series Hybrid-Propulsion

ActiveUS20180194484A1Increase rangeImprove enduranceHybrid vehiclesInternal combustion piston enginesPropellerCombustion chamber

A hybrid-electric aerial vehicle is disclosed comprising: an airframe; a plurality of longitudinal booms extending radially from the airframe; a passively charged internal combustion engine operatively coupled with a fuel tank, a generator operatively coupled with the passively charged internal combustion engine; a battery bank operatively coupled with the generator; and a plurality of motors. The passively charged internal combustion engine has an intake engine valve, an exhaust engine valve, and a combustion chamber, wherein the intake engine valve is delayed to provide an expansion ratio in the combustion chamber that is greater than a compression ratio in the combustion chamber. Each of said plurality of motors may be positioned at a distal end of one of said plurality of longitudinal booms and be operatively coupled with a propeller, wherein the plurality of motors is electrically coupled with the battery bank and the generator.

Owner:AURORA FLIGHT SCI CORP

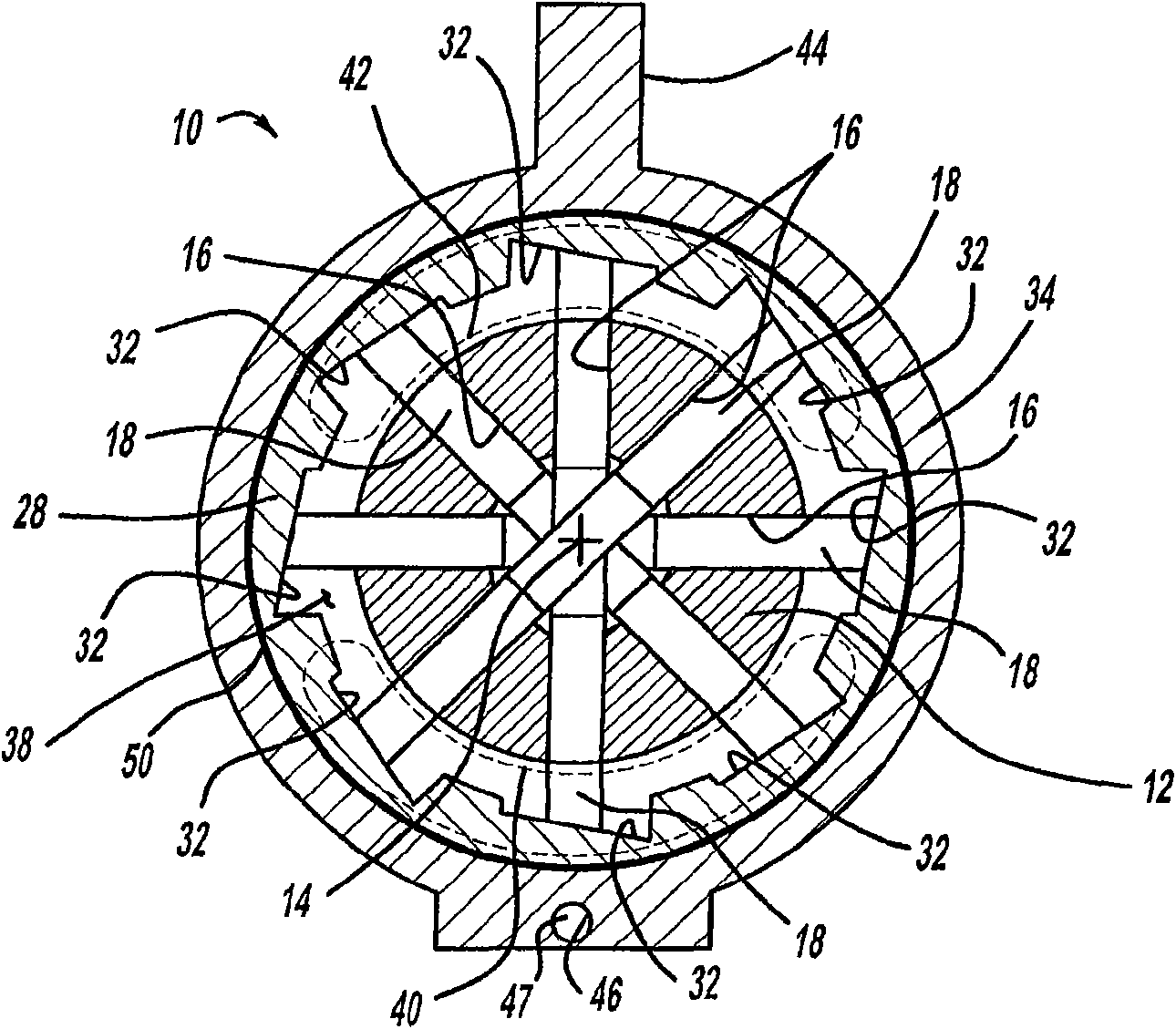

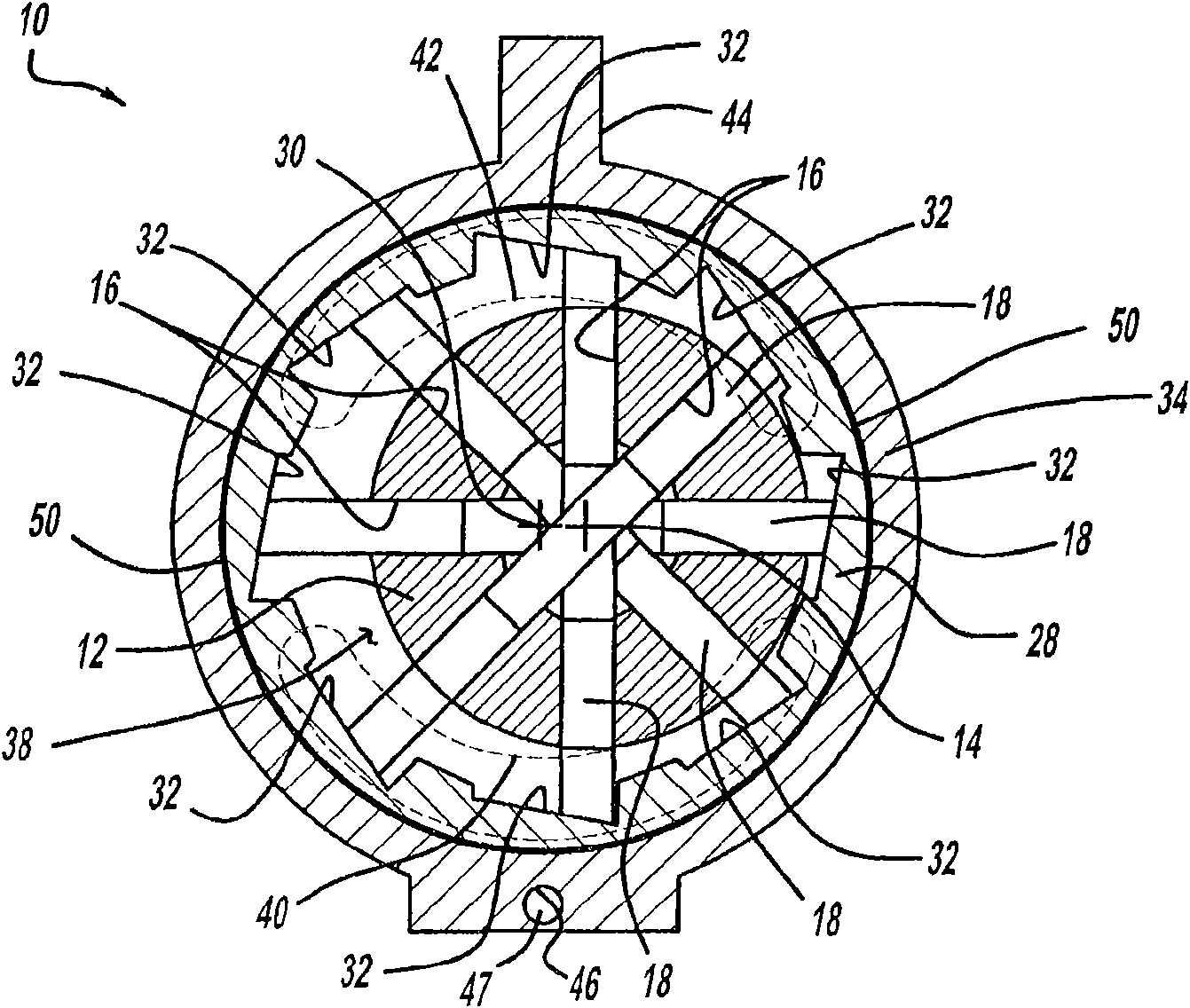

Variable displacement dual vane pump

InactiveCN101605995AGuaranteed to workImprove volumetric efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringVariable displacement pump

The present invention is a variable displacement pump having an inner rotor rotatable about a first axis and having at least two slots. The pump also has at least two vanes, each located in a distinct one of the at least two slots. The pump also has an outer rotor rotatable about a second axis, operably associated with the inner rotor, the outer rotor having two or more recesses, each configured to receive one of the vanes. The pump also includes an expandable chamber formed by the outer rotor and the inner rotor, an eccentric ring surrounding the outer rotor, and a housing. The eccentric ring is located within the housing for adjusting the relative relationship between the first axis and the second axis in order to vary the displacement of the pump.

Owner:SLW AUTOMOTIVE

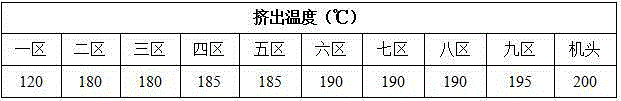

High-flame-retardant polypropylene material and preparation method thereof

InactiveCN105385028AGood flame retardant performanceGood self-extinguishingPolypropyleneBrominated flame retardant

The invention discloses a high-flame-retardant polypropylene material and a preparation method thereof. The material is composed of the following raw materials in parts by mass: 60-75 parts of homo-polypropylene aggregates, 5-15 parts of homo-polypropylene powder, 10-20 parts of a brominated flame retardant, 3-8 parts of an antimony flame retardant, 1-3 parts of a flame retardant synergist, 0-10 parts of a cooling master batch, 0-3 parts of a flexibilizer, 0-1 part of a lubricant, 0-1 part of an ultraviolet light absorber, and 0-1 part of an antioxidant. The preparation method of the material comprises the following steps: 1) uniformly mixing all materials in certain proportion; and 2) adding the obtained mixture into a twin-screw extruder, carrying out high-temperature mixing and shearing, and after the obtained object is subjected to water cooling, sequentially carrying out bracing and grain-sized dicing, so that the high-flame-retardant polypropylene material is obtained. The high-flame-retardant polypropylene material disclosed by the invention is excellent in flame resistance, good in self-extinguishment, excellent in aging resistance, good in insulating property and heat resistance, not easy to deform by heating, excellent in processing fluidity, and easy to shape.

Owner:GUANGDONG JUSHI CHEM CO LTD

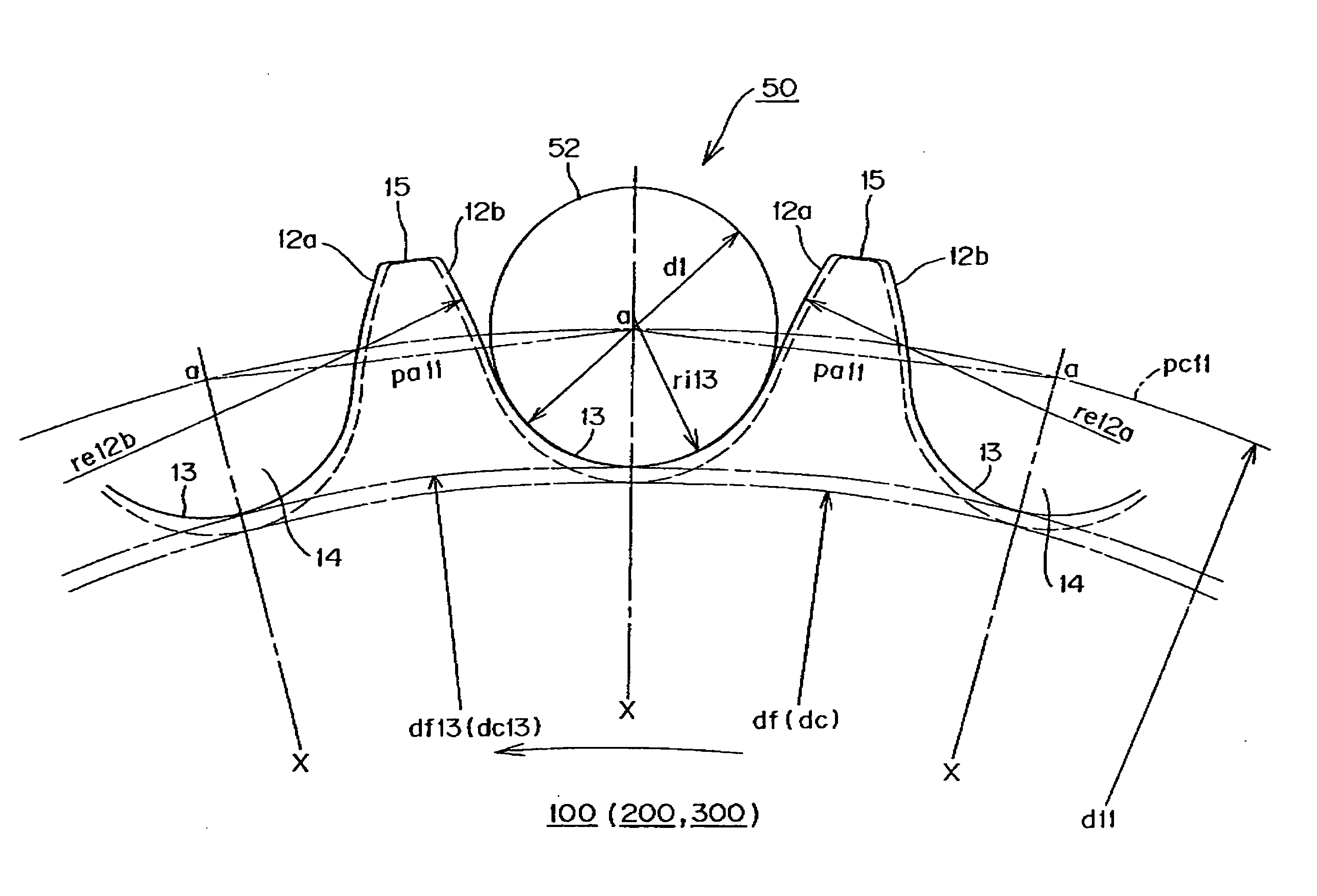

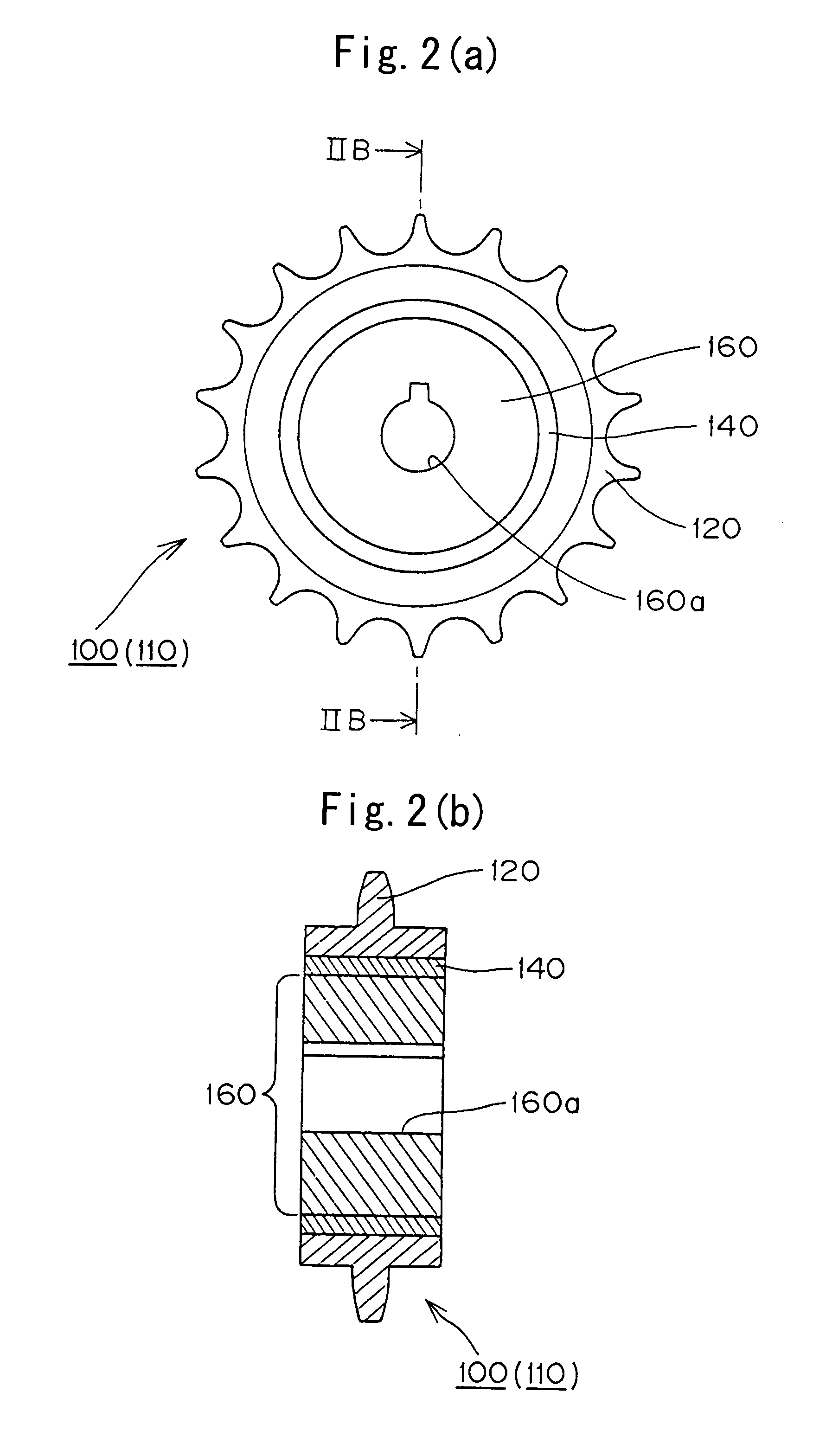

Chain transmission device

In a chain transmission, a sprocket having an elastic ring sandwiched between a central hub and an annular toothed outer member, the tooth form is such that the root diameter, that is, the diameter of the tooth gap bottom circle, is greater than the root diameter in a sprocket having a standard ISO tooth form.

Owner:TSUBAKIMOTO CHAIN CO

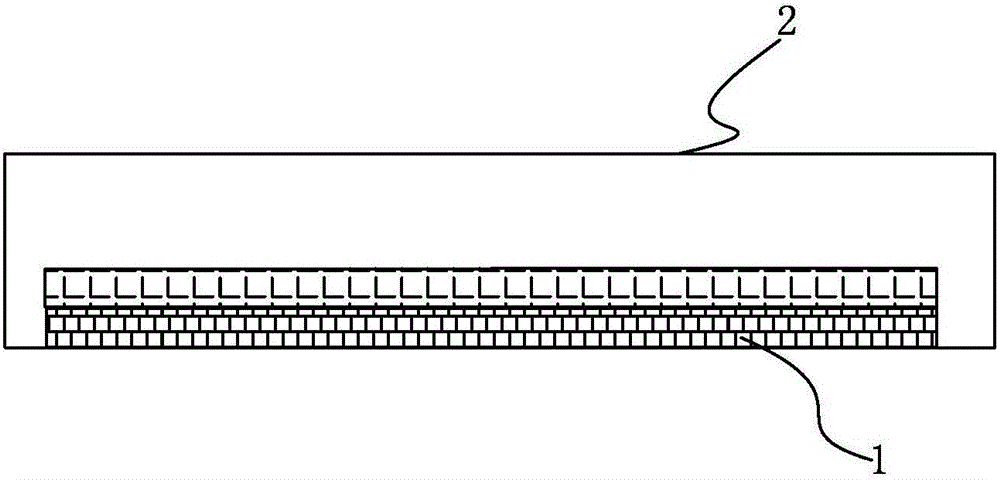

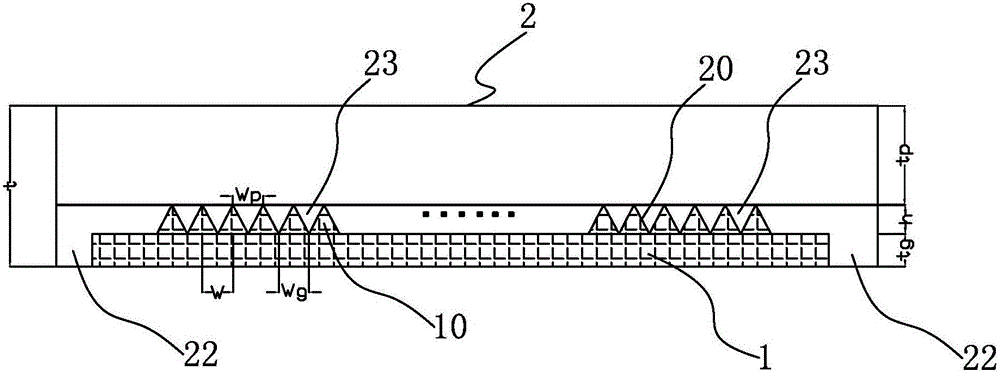

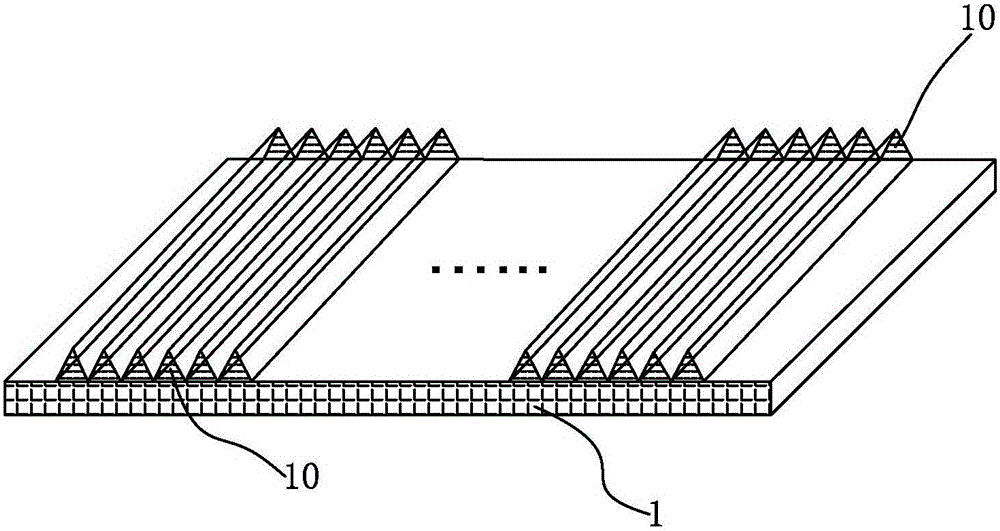

Flexible display substrate thin film and manufacturing method therefor, and display apparatus

ActiveCN105679774AExcellent gas barrier performanceImprove impact resistanceSynthetic resin layered productsSolid-state devicesThermal impactMechanical impact

The invention discloses a flexible display substrate thin film and a manufacturing method therefor, and a display apparatus. The flexible display substrate thin film comprises a glass thin film and a plastic thin film for coating the glass thin film, wherein multiple convex parts are arranged on the upper surface of the glass thin film; multiple concave parts for accommodating the convex parts are arranged on the lower surface of the plastic thin film; and the multiple convex parts are arranged transversely, vertically or in an array manner on the glass thin film. The flexible display substrate thin film has simple manufacturing process and excellent gas barrier property; for avoiding glass thin film fracture or cracks caused by mechanical impact or thermal impact, the weight of the flexible display substrate thin film can be lowered, and the buffering shock absorption function of the plastic thin film can be utilized, so that the anti-fall-off performance and impact-resistance of the flexible display substrate thin film are greatly improved.

Owner:DALIAN DKE LCD CO LTD

Rope for an elevator, elevator and method

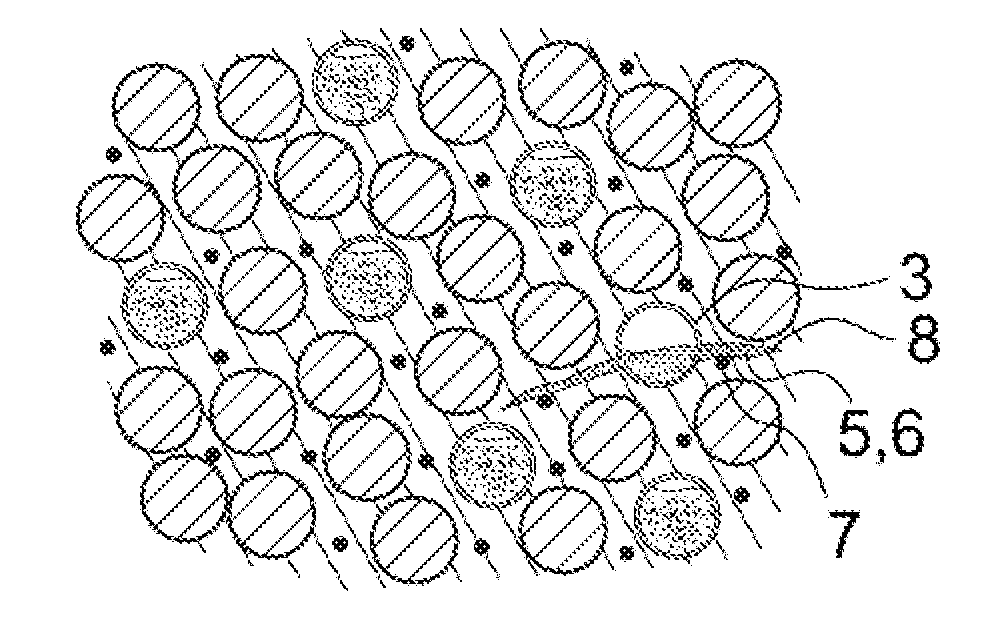

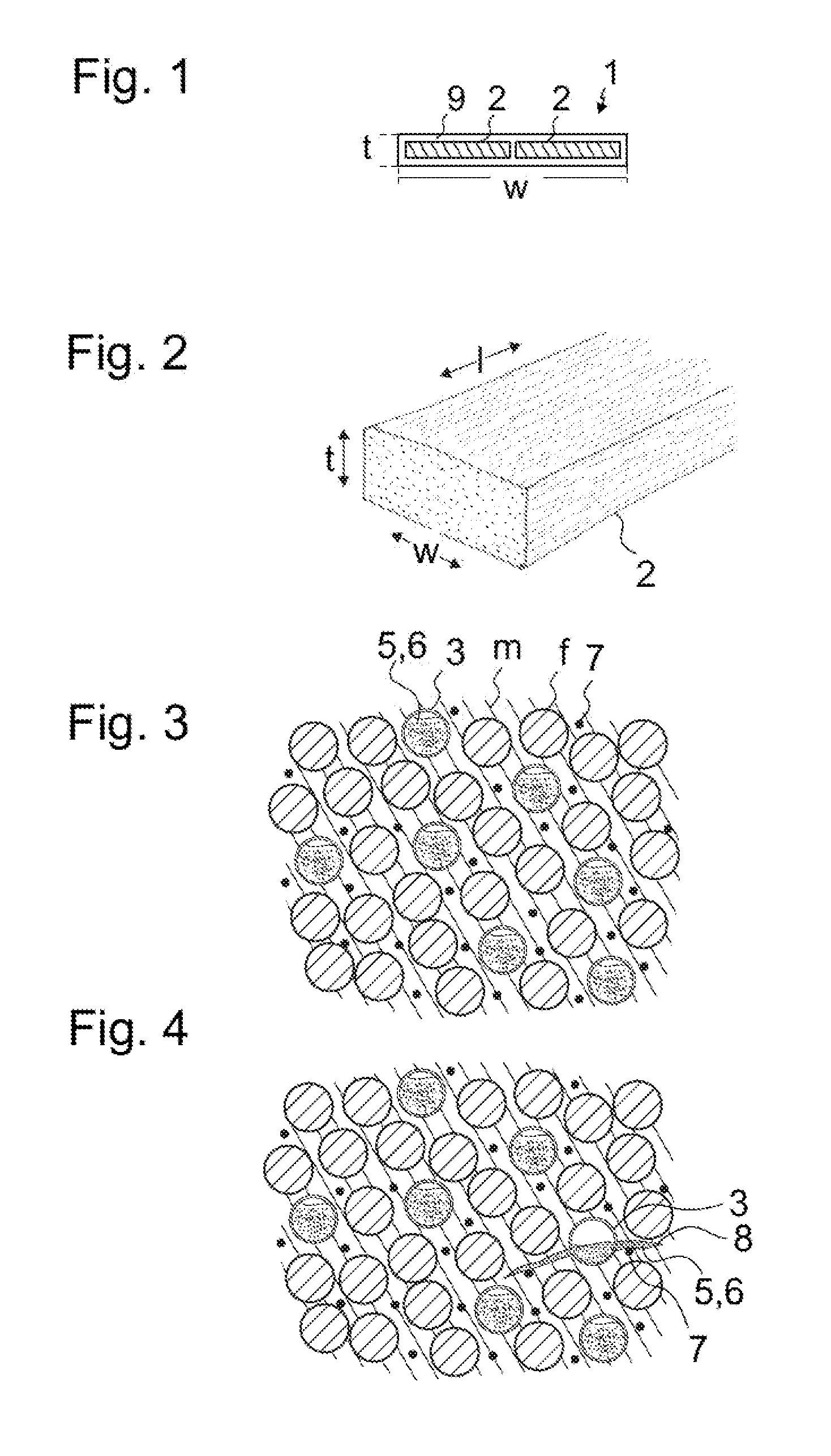

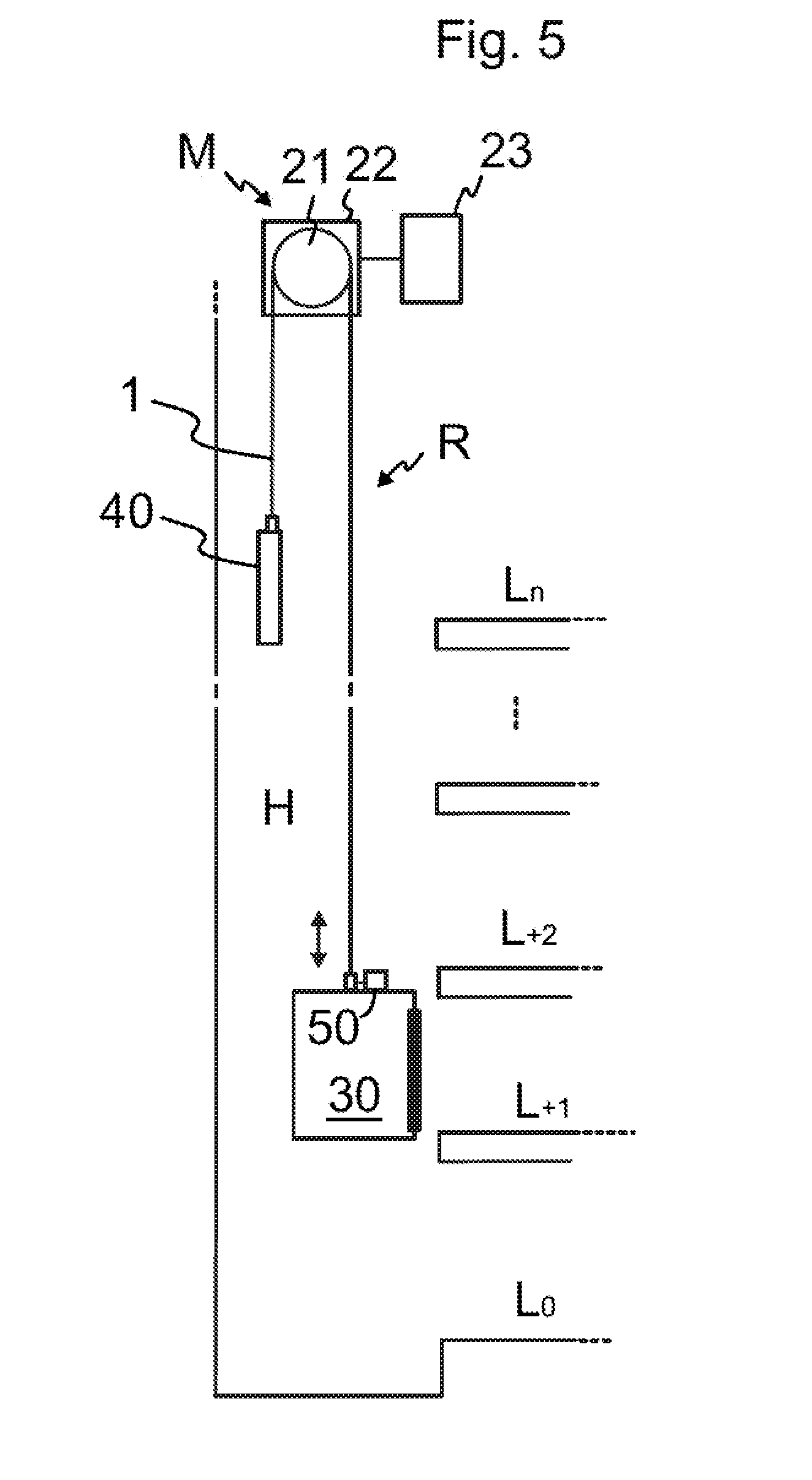

ActiveUS20150191332A1Transportation safetyImprove staminaControlSynthetic resin layered productsFiberBiomedical engineering

A rope for a hoisting device, in particular for an elevator, includes at least one continuous load bearing member extending in longitudinal direction of the rope throughout the length of the rope, the load bearing member being made of composite material including reinforcing fibers embedded in polymer matrix. The composite material includes capsules embedded in the polymer matrix, the capsules storing monomer substance in fluid form. An elevator includes a rope of the aforementioned kind and a method for condition monitoring of a rope of an elevator.

Owner:KONE CORP

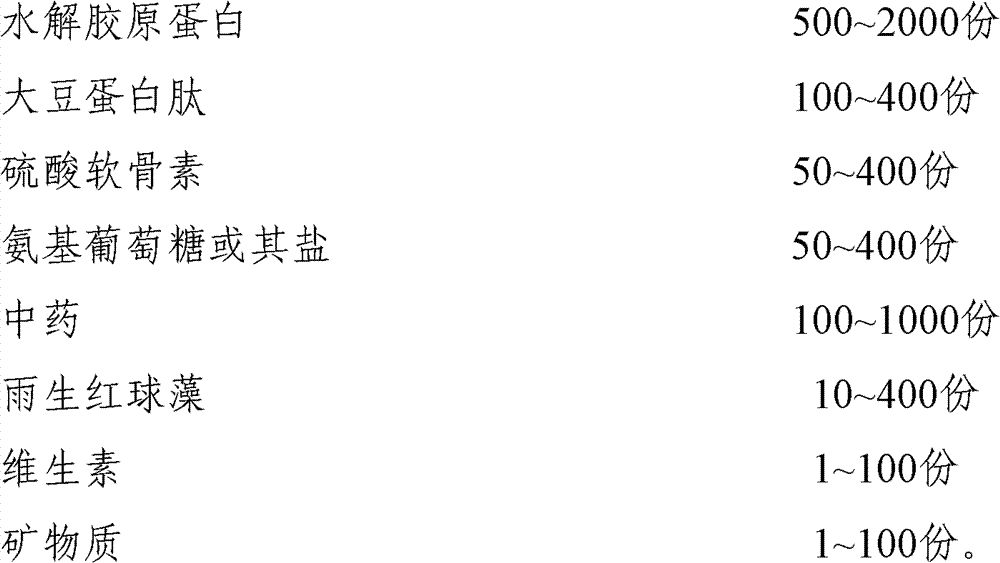

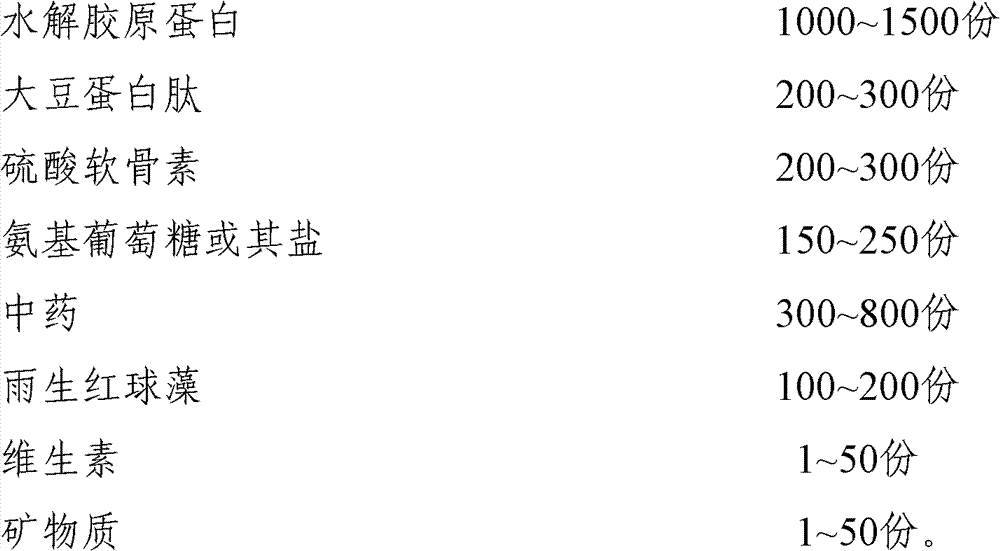

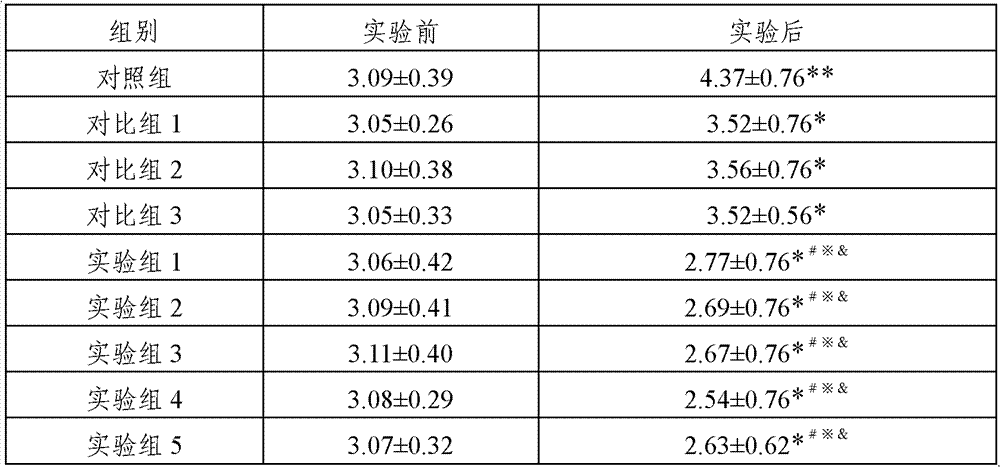

Composition for reducing sport injury and promoting sport injury repair

ActiveCN103082276AReduce and promote recovery from sports injuriesGood effectHydroxy compound active ingredientsPeptide/protein ingredientsTraditional Chinese medicineChondroitin sulphate

The present invention relates to a composition for reducing sport injury and promoting sport injury repair. The composition comprises the following raw materials and auxiliary materials, by weight, 500-2000 parts of hydrolyzed collagen protein, 100-400 parts of soybean protein peptide, 50-400 parts of chondroitin sulphate, 50-400 parts of glucosamine or a salt thereof, 100-1000 parts of a traditional Chinese medicine, 10-400 parts of haematococcus pluvialis, 1-100 parts of vitamin, and 1-100 parts of a mineral. The composition provides good effects for sport injury reduction and sport injury repair promotion.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

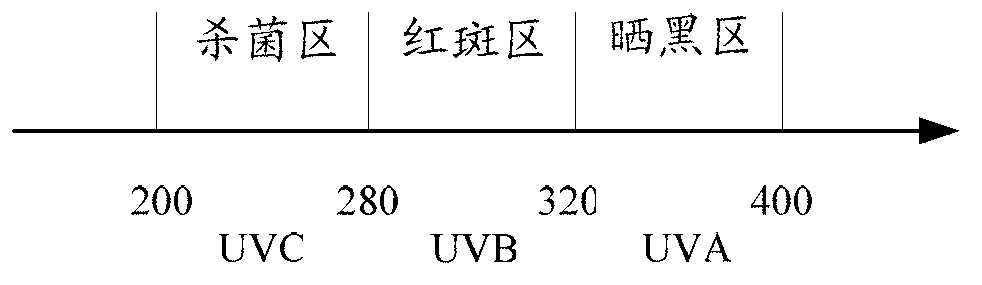

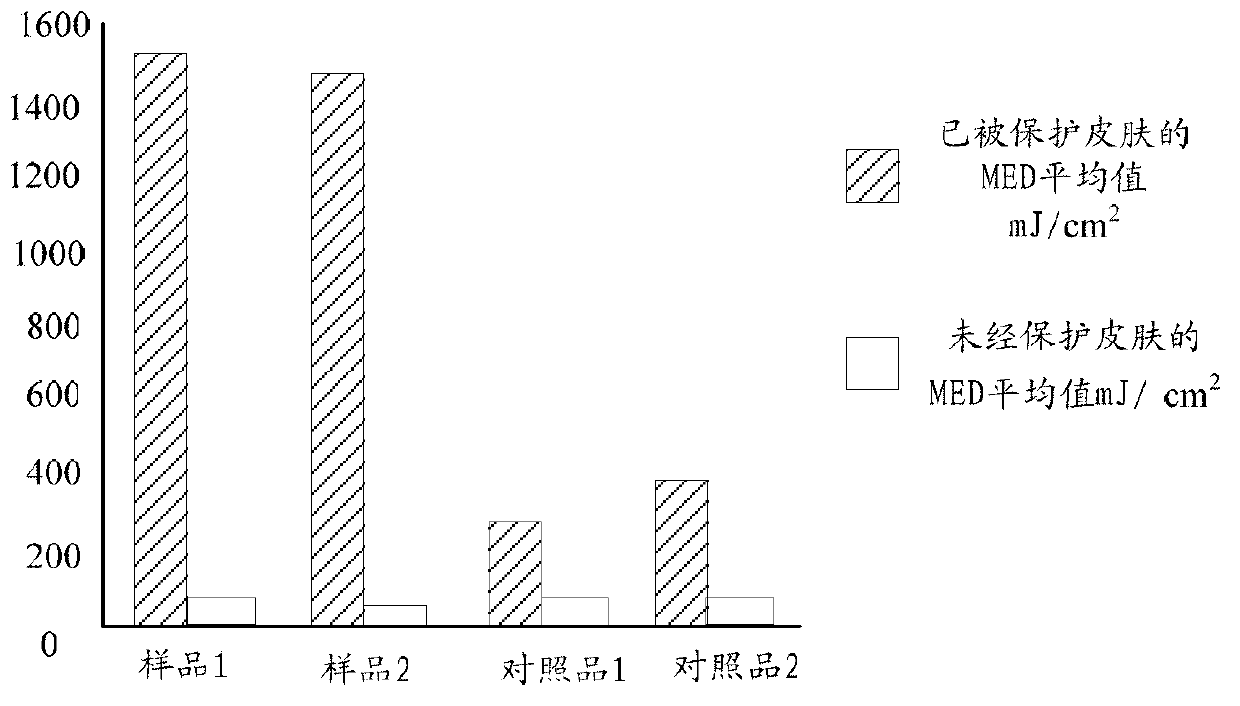

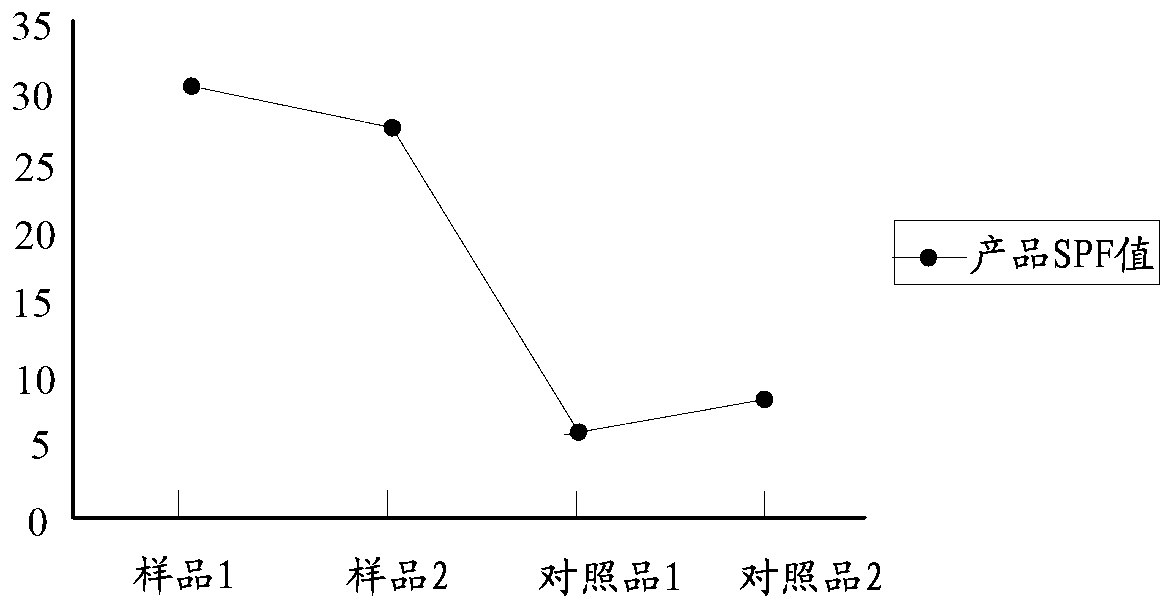

Natural plant sun-screening agent as well as preparation method and application of natural plant sun-screening agent

ActiveCN103006519ASimple processReduce manufacturing costCosmetic preparationsToilet preparationsVitamin E AcetateSunscreen agents

The invention discloses a natural plant sun-screening agent as well as a preparation method and application of the natural plant sun-screening agent. The natural plant sun-screening agent comprises mulberrin, isononyl isononanoate and vitamin E acetate, wherein the weight ratio of mulberrin to isononyl isononanoate to vitamin E acetate is 1:1:1-1:3:3. According to the natural plant sun-screening agent, the mulberrin, the isononyl isononanoate and the vitamin E acetate are compounded to form a stable mulberrin-containing sun-screening agent. The natural plant sun-screening agent and the traditional organic sun-screening agent and an inorganic sun-screening agent have a synergistic interaction function, and therefore, a sun care preparation added with the sun-screening agent is mild in skin and high in safety, and is greatly improved in SPF (Sun Protection Factor) value. The preparation method of the sun-screening agent is simple in process and low in production cost.

Owner:广州市新东方生物科技有限公司

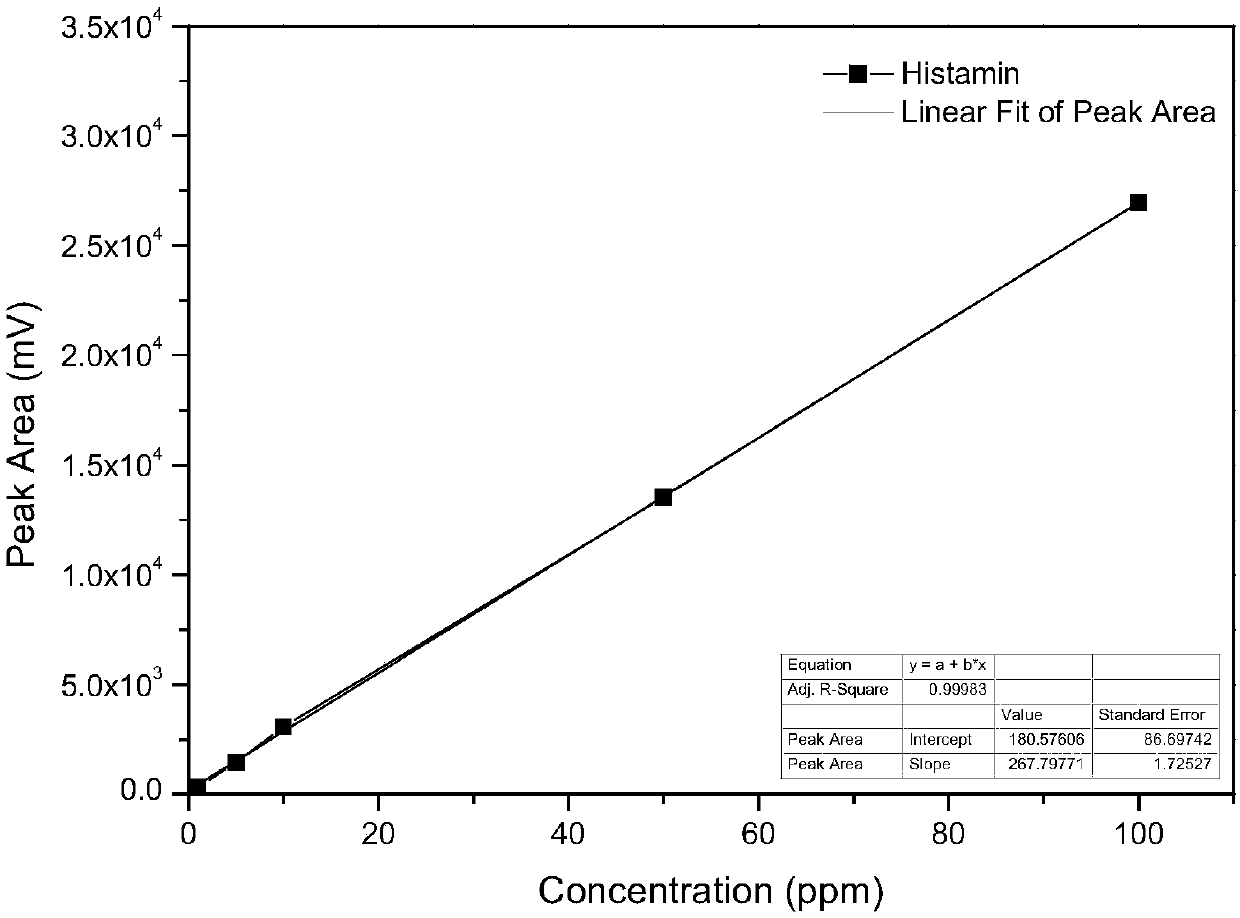

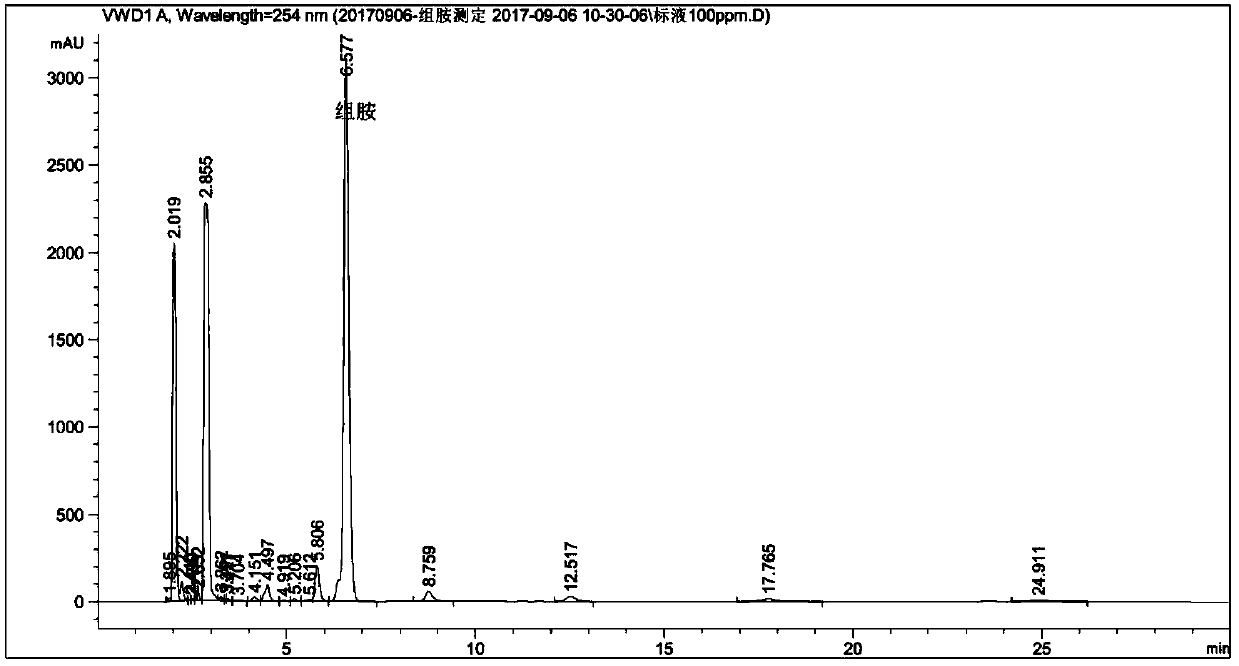

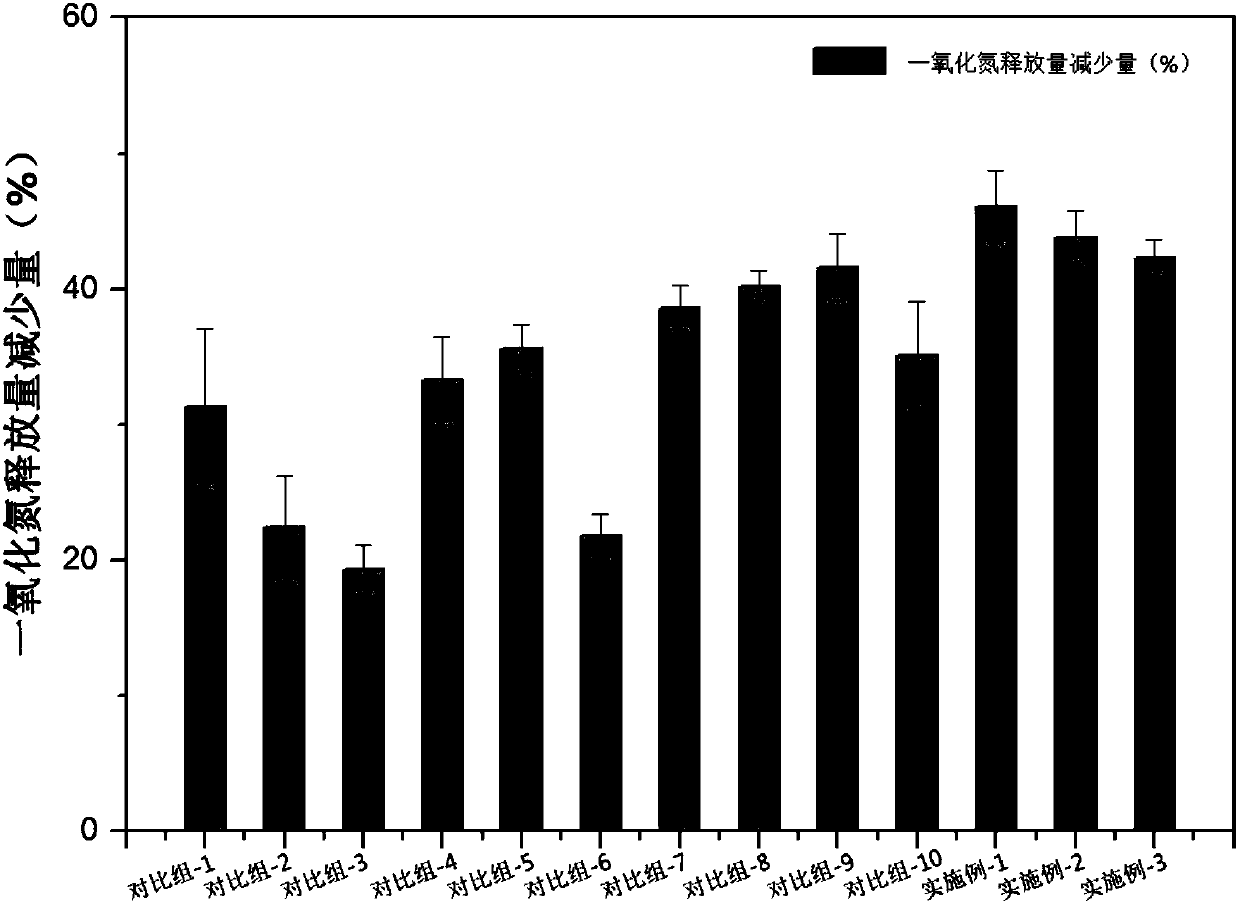

Anti-allergic composition for relieving as well as application thereof

ActiveCN107714531AEnhanced Tolerance ThresholdReduce trafficCosmetic preparationsToilet preparationsAdemetionineNitric oxide

The invention relates to an anti-allergic composition for relieving as well as an application thereof. The anti-allergic composition for relieving comprises the following components: a first anti-allergic composition, a second anti-allergic composition, an anti-allergic peptide composition, Crambe abyssinica seed oil, bisabolol, and a Cardiospermum halicacabum extract product; the active componentof the first anti-allergic composition comprises 4-tert-butylcyclohexanol and 2-(3-(4-hydroxyphenyl)propanamido)benzoic acid; the active components of the second anti-allergic composition comprise anextract product of Stephania tetrandra, potassium lactate, phenoxyethanol, and dipotassium glycyrrhizinate; the active components of the anti-allergic composition comprise palmitoyl tripeptide-8 andacetyl tetrapeptide-15. The anti-allergic composition for relieving is evaluated by a macrophage nitric oxide inflammation releasing model, inhibition rate of nitric oxide releasing reaches 46.07%, and inhibition rate of histamine reaches 61.59%.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

Seat with adjustable support system

InactiveUS7537286B2Improve comfortImprove enduranceBack restsOperating chairsAnatomical structuresSupporting system

A sacral support assembly for use with a seat is provided. The seat includes a seat frame. An adjustable sacral support assembly is connected to the seat frame. The sacral support assembly includes a sacral support member adapted to support the sacrum of a seated user even when an obstruction is located between the user and the sacral support assembly. A method is also provided for delivering primary support to a user's sacrum and sacral-pelvic anatomy and secondary support to the remaining regions of the spine and / or adjacent anatomy to reduce fatigue, increase comfort, structural balance, stability, and posture control for a user, and a system for adjusting and controlling the load distribution from the sacral anatomy to the spine and other anatomical structures adjacent to a user's sacrum, for example, the pelvis, lumbar, thoracic and cervical regions.

Owner:TRAC TEC

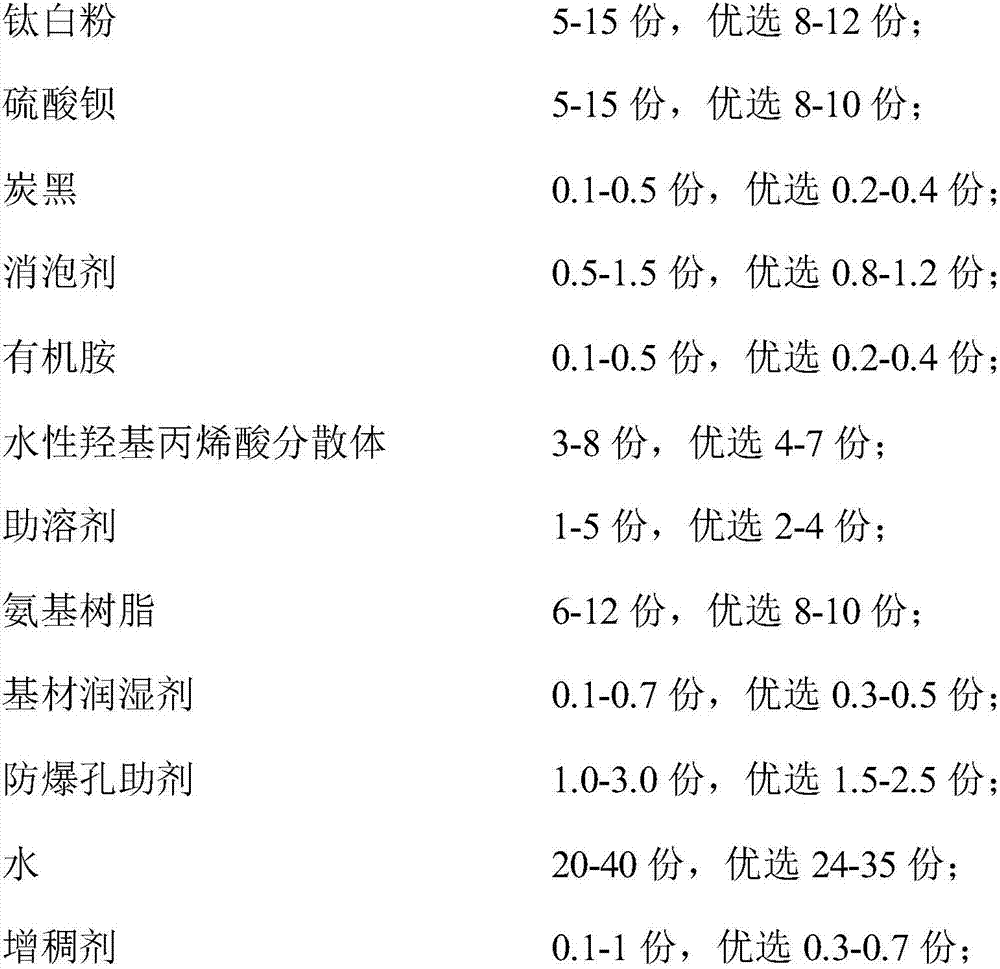

A waterborne automobile coating composition and a preparing method and applications thereof

InactiveCN107099238AImprove stone impact resistanceIncreased chemical resistancePolyurea/polyurethane coatingsPolyesterCooking & baking

A waterborne automobile coating composition is provided. The composition is prepared from, by weight, 20-60 parts of a waterborne polyurethane dispersoid, 1.0-3.5 parts of a dispersing agent, 5-15 parts of titanium dioxide, 5-15 parts of precipitated barium sulfate, 0.1-0.5 part of carbon black, 0.5-1.5 parts of a defoamer, 3-8 parts of a waterborne hydroxy acrylic acid dispersoid, 0.1-0.5 part of an organic amine, 6-12 parts of amino resin, 0.1-1 part of a substrate wetting agent, 1-3 parts of an explosion-proof auxiliary agent, 1-5 parts of a cosolvent, 20-40 parts of deionized water and 0.1-1 part of a thickening agent. The waterborne polyurethane dispersoid is a compound of a polycarbonate-type waterborne polyurethane dispersoid having hydroxy groups and a polyester-type waterborne polyurethane dispersoid preferably. The coating composition has excellent resistance to rock crash, and can meet requirements on an automobile coating process including three times of coating and one time of baking, namely a 3C1B process, in the field of environment protection.

Owner:WANHUA CHEM GRP CO LTD

Rolling, multi-directional fitness device

InactiveUS20140018217A1Muscle strengtheningImprove enduranceFrictional force resistorsMovement coordination devicesRange of motionMuscle mass

A multi-directional rolling fitness device is disclosed. The device can be used individually or as a pair with either the hands or the feet. The device comprises a handle assembly, which can also comprise a stirrup for the foot, a base unit and a plurality of ball-transfer units. By using a single or pair of these devices, a person can use their body weight to engage in a nearly unlimited number of upper and lower body exercises. The device's ball transfer contact points allow the unit to move in any direction across the floor during exercise repetitions, engaging complex muscle groups, increasing range of motion, and aiding in the development of muscle mass, strength and endurance.

Owner:BROWN LUKE F

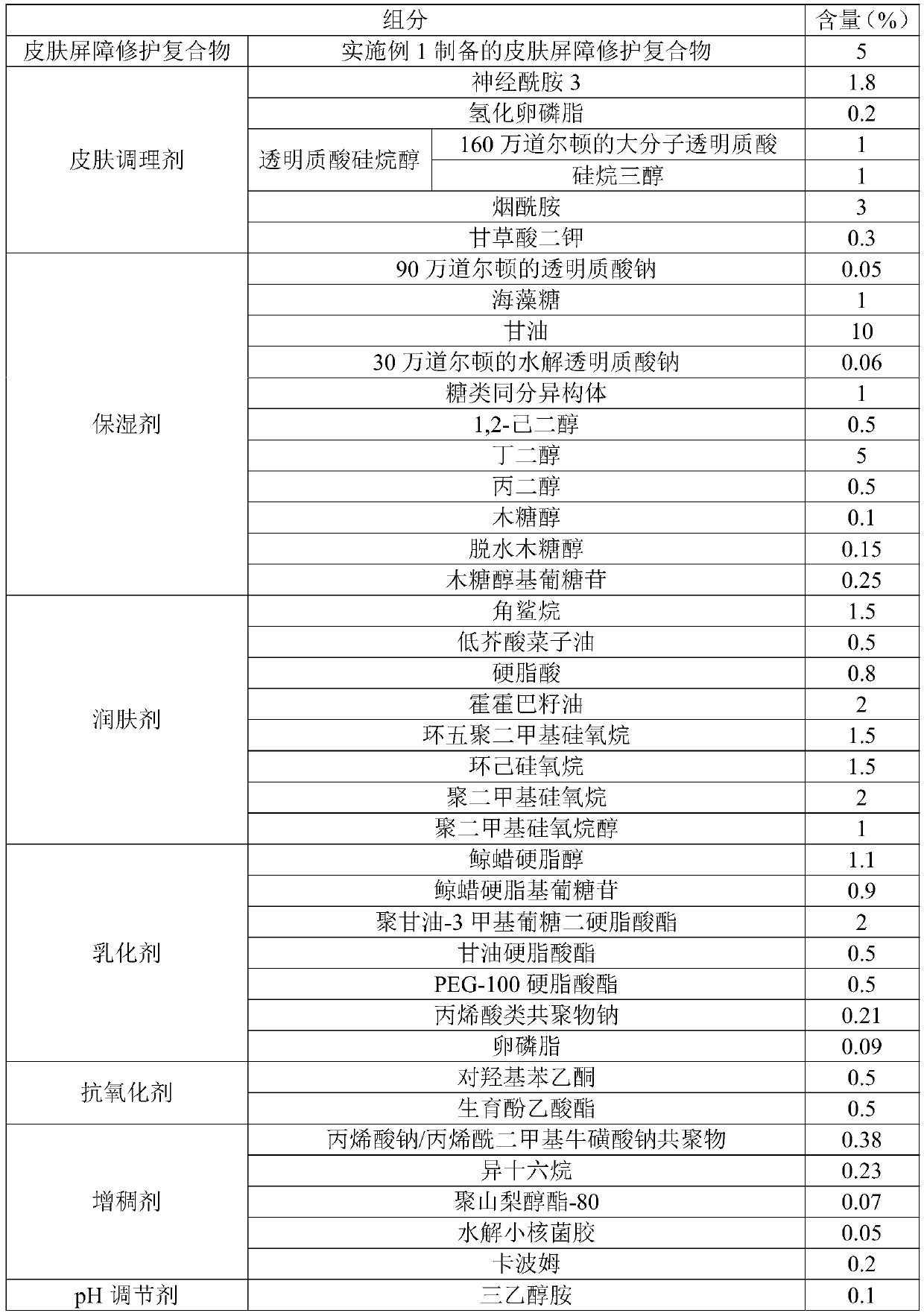

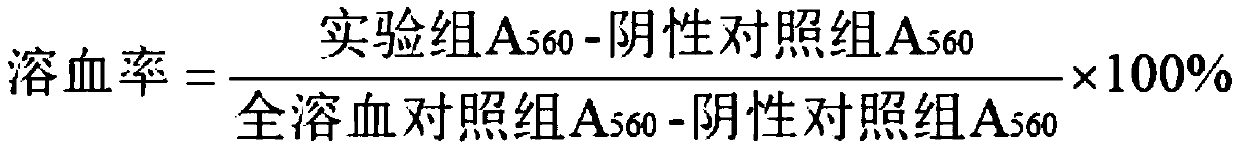

Skin barrier repairing complex, facial cream and preparation method therefor

ActiveCN111407719AImprove water retentionRepair cuticle barrierCosmetic preparationsToilet preparationsGlycyrrhiza inflata root extractPhotoaging

The invention provides a skin barrier repairing complex, facial cream and a preparation method therefor. The skin barrier repairing complex comprises a composition for repairing skin barrier, hydroxylasiaticoside, deacidified carnosine, a glycyrrhiza inflata root extract, a radix scutellariae extract and a hamamelis extract, wherein the composition for repairing skin barrier comprises sea fennelcallus culture filtrate, Ectoin and a hydrolyzed red alga extract. The skin barrier repairing complex can achieve triple effects of simultaneously repairing cutin barrier, repairing immunologic barrier and strengthening microbiologic barrier; and the facial cream prepared from the skin barrier repairing complex is obvious in repairing effect and can be used for effectively improving hydrature of skin, increasing the content of hyaluronic acid in the skin, improving photoaging, helping cell saccharification reversing and reducing fine grain area.

Owner:广州一一生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com