High-flame-retardant polypropylene material and preparation method thereof

A polypropylene material and high flame-retardant technology, which is applied in the field of high flame-retardant polypropylene material and its preparation, can solve the problems of great influence on the mechanical properties of materials, poor resistance to precipitation of flame retardants, and reduced heat resistance, etc., to achieve Improve fluidity and flame retardant performance, good flame retardant effect, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the high flame-retardant polypropylene material corresponding to above-mentioned formula or preferred formula, comprises the following steps:

[0067] 1) Prepare homopolypropylene powder, brominated flame retardant, antimony flame retardant, flame retardant synergist, cooling masterbatch, toughening agent, lubricant, ultraviolet absorber and antioxidant according to the ratio Then add to the horizontal mixing tank, pre-mix at 50-60°C for 20-50 minutes, fully pre-mix evenly, and then divide and pack according to actual production needs;

[0068] 2) Put the homopolymer polypropylene pellets and the pre-mixed uniform material in step 1) into the high-speed mixing tank, and stir for 1-2 minutes;

[0069] 3) Put the material into a twin-screw extruder, carry out high-temperature mixing and shearing, and then draw strands and pelletize after water cooling to obtain a high flame-retardant polypropylene material.

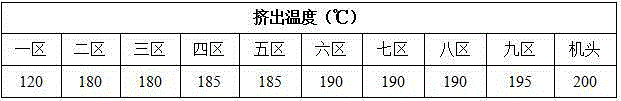

[0070] Preferably, the screw diamete...

Embodiment 1

[0083] A high flame-retardant polypropylene material, which is composed of the following raw materials measured in parts by weight: homopolypropylene pellets: 63 parts; homopolypropylene powder: 15 parts; brominated flame retardant tetrabromobisphenol A : 13 parts; antimony-based flame retardant antimony trioxide: 3 parts; flame retardant synergist magnesium hydroxide: 1 part; cooling masterbatch LV-20: 3 parts; toughening agent styrene-butadiene thermoplastic elastomer Body: 1 part; lubricant stearic acid: 0.5 part; ultraviolet absorber UV-234: 0.2 part; antioxidant 2,6-tertiary butyl-4-methylphenol: 0.3 part. The performance test results of the high flame-retardant polypropylene material are shown in Table 2.

Embodiment 2

[0085] A high flame-retardant polypropylene material, which is composed of the following raw materials measured in parts by weight: homopolypropylene pellets: 64 parts; homopolypropylene powder: 9 parts; brominated flame retardant decabromodiphenylethylene Alkane: 15 parts; antimony-based flame retardant antimony pentoxide: 6 parts; flame retardant synergist magnesium aluminum hydrotalcite: 2 parts; cooling masterbatch LV-20: 1 part; toughening agent methyl methacrylate- Butadiene-styrene terpolymer: 1 part; lubricant ethylene bisstearamide: 1 part; ultraviolet absorber UV-328: 0.5 part; antioxidant bis(3,5-tertiary butyl- 4-hydroxyphenyl)sulfide: 0.5 parts. The performance test results of the high flame-retardant polypropylene material are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Screw diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com