Patents

Literature

118results about How to "Good self-extinguishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retarding polymer foam material and preparation method thereof

ActiveCN102127269AIncrease the amount addedAddition changeLaminationLamination apparatusPolymer sciencePolystyrene

The invention discloses a flame-retarding polymer foam material which is characterized by comprising polymer foam plastic, wherein the surface of the polymer foam plastic is provided with an organic flame retardant layer; and the organic flame retardant layer is formed by attaching a molten organic flame retardant to the surface of the polymer foam plastic through a spraying, coating or soaking way. The invention also discloses a preparation method of the flame-retarding polymer foam material. In the invention, a flame-retarding variety which is effective to the polymer foam plastic, in particular to extrusion foamed polystyrene foam plastic, is selected from numerous flame retardants, and the polymer foam product with excellent flame-retarding property is prepared by adopting a simple and feasible method. Through the invention, an effective method for increasing the addition amount of the flame retardant is obtained on the premise of not influencing the foaming property of the foam products and not reducing the strength and the insulation and thermal preservation property of foams, and different flame-retarding requirements can be met by flexibly changing the attaching amount of the flame retardant.

Owner:连云港传奇阻燃科技有限公司

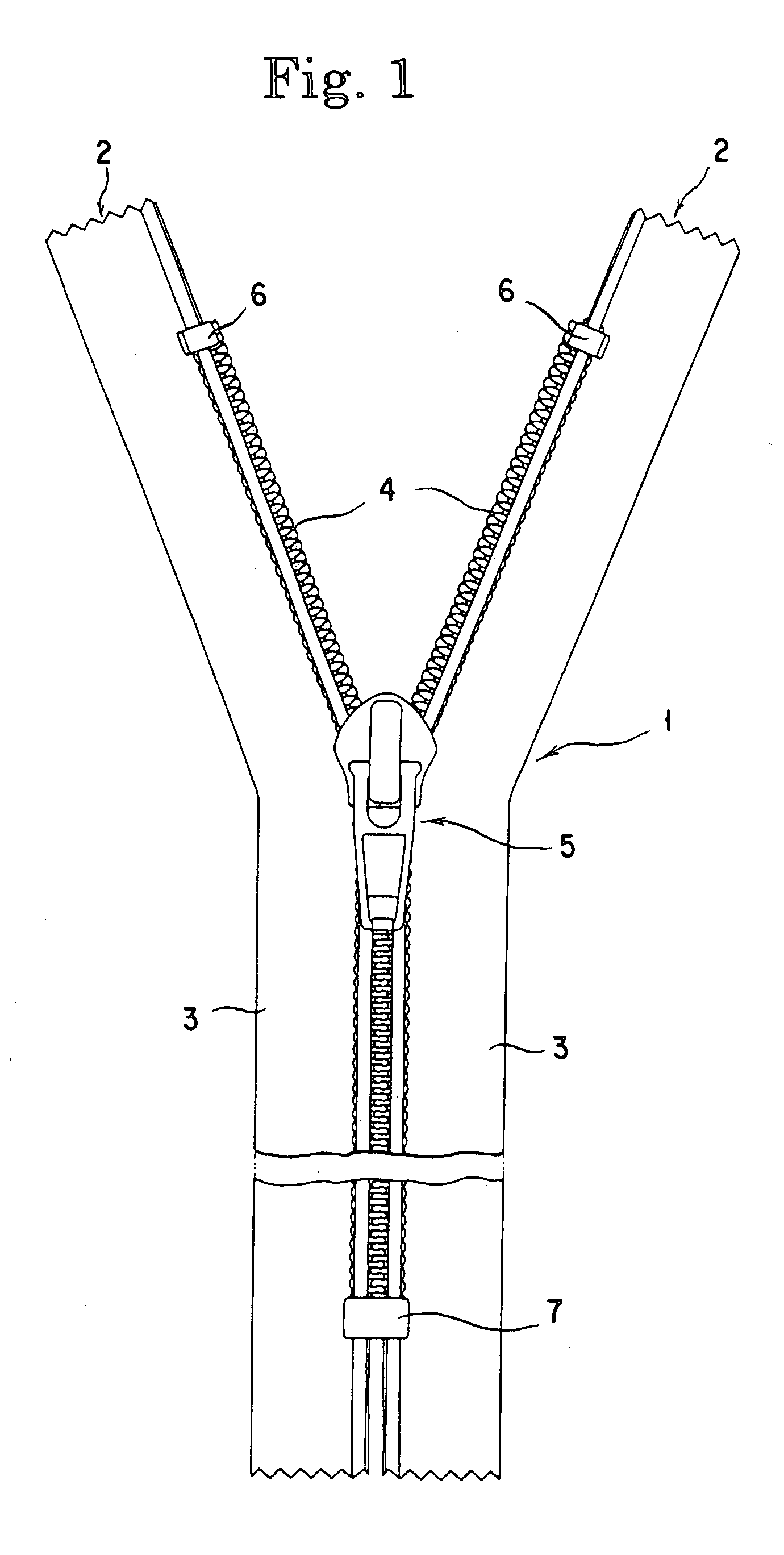

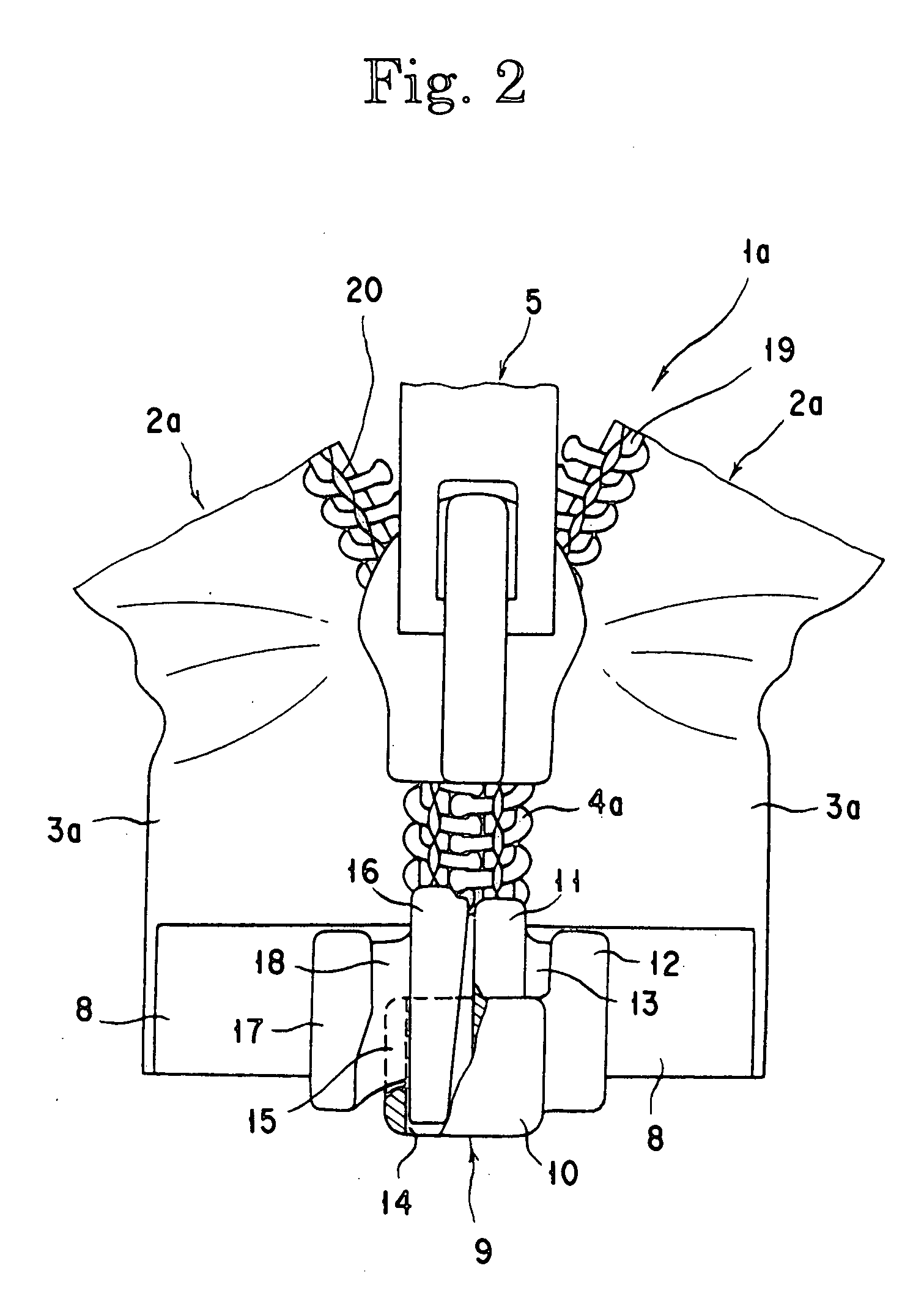

Flame-retardant molded article and fabric product

InactiveUS20060008664A1Prevent the spread of flamesSufficient flame-retardant propertySlide fastenersSynthetic resin layered productsFastenerFire retardant

A flame-retardant fastening product (a molded article and a fabric product) which is made of a flame retardancy-imparting material or contains or / and is coated with the flame retardancy-imparting material, wherein the flame retardancy-imparting material comprises 100 parts by weight of a synthetic resin and 1 to 400 parts by weight of a flame-retardant containing an inorganic flame-retardant which exhibits such a volume change as expansion and / or foaming at the time of combustion, more preferably at least one member selected from the group consisting of hydrated metallic compounds and thermally expansible graphite, the flame-retardant being dispersed in the synthetic resin. Such flame-retardant products are useful as various molded articles and fabric products, such as surface fasteners, slide fasteners, and resin buttons.

Owner:YKK CORP

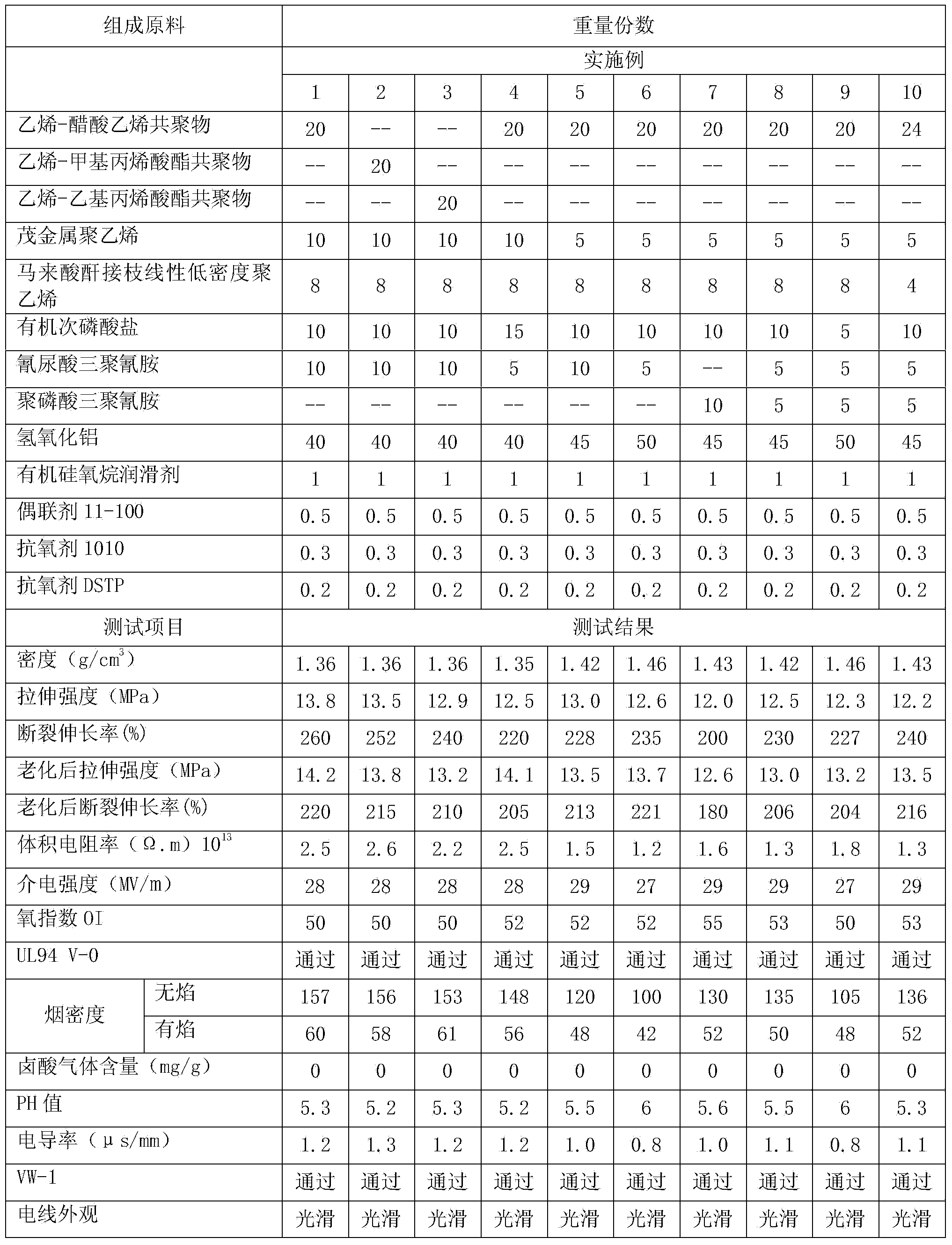

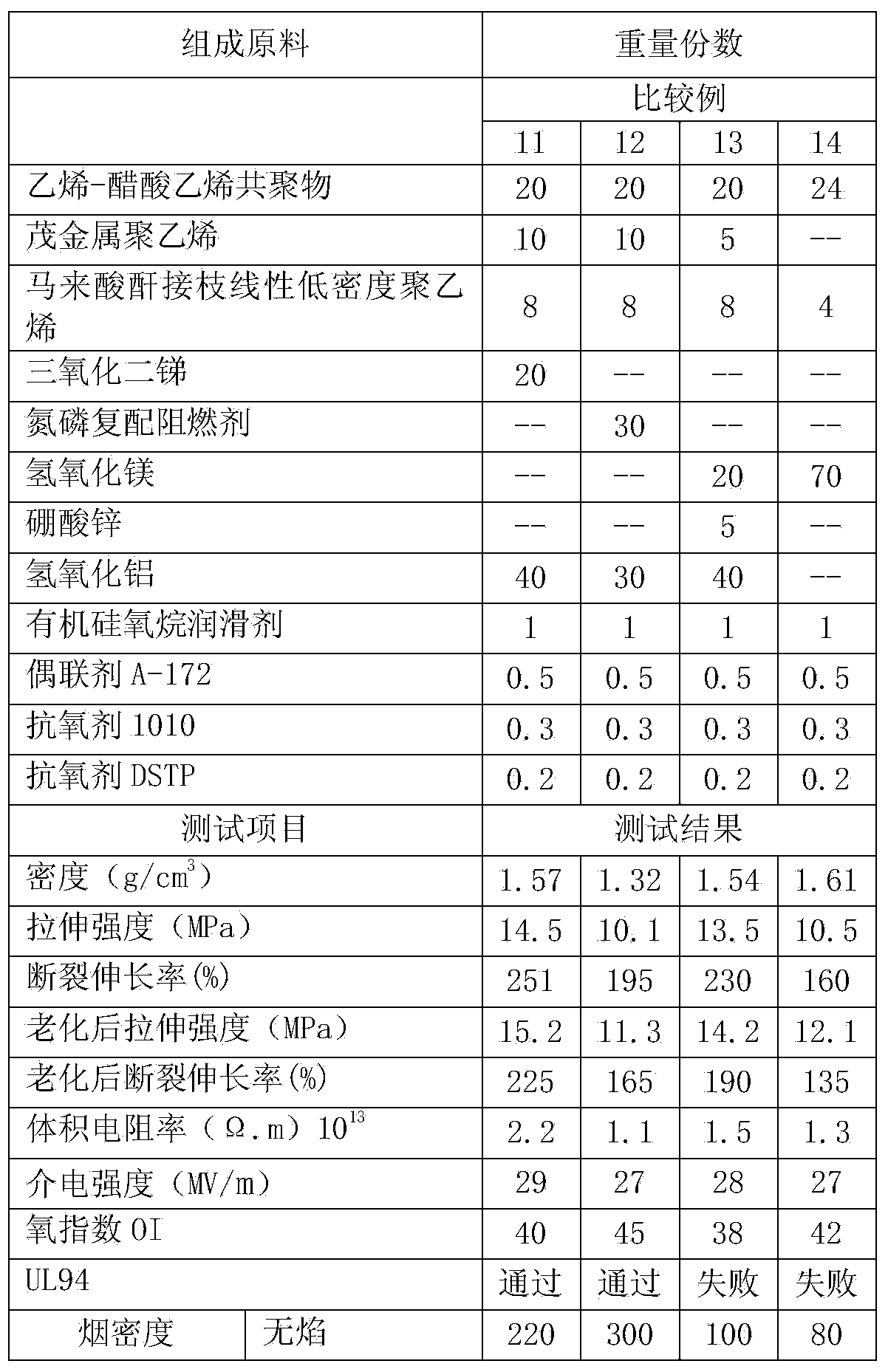

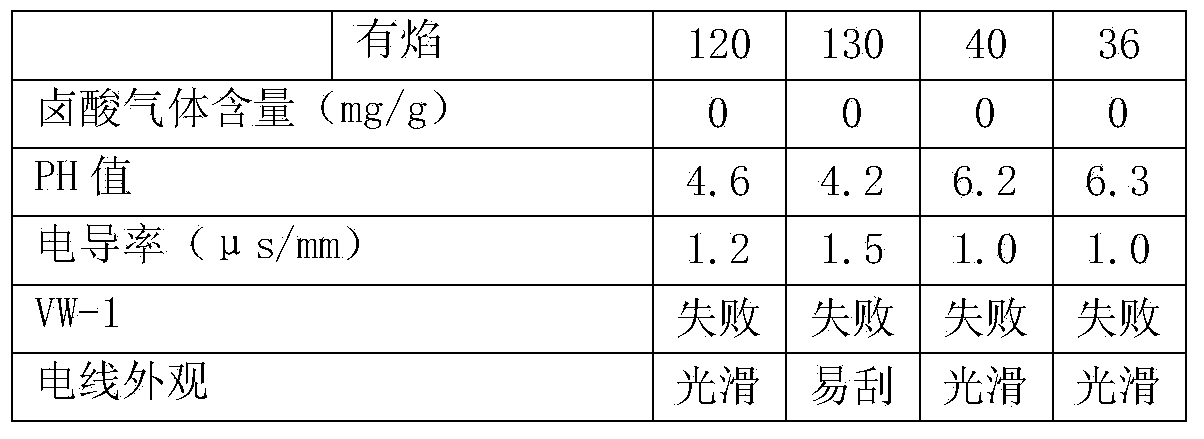

High-flame-retardant and halogen-free polyolefin cable material and preparation method thereof

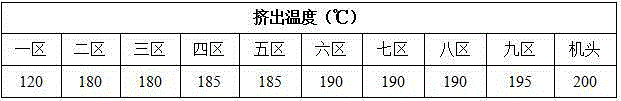

The invention discloses a high-flame-retardant and halogen-free polyolefin cable material and a preparation method thereof. The high-flame-retardant and halogen-free polyolefin cable material comprises the following components in parts by weight: 20-70 parts of ethylene copolymer, 5-30 parts of polyethylene, 10-60 parts of metal hydroxide, 3-20 parts of organic phosphate flame retardant, 3-30 parts of melamine compound, 4-10 parts of compatilizer and 2-5 of other additives. The preparation method comprises the following steps of: (1) firstly putting granular materials into a high-speed mixing machine, adding liquid additive after stirring for 30 seconds at low speed, mixing for 3 minutes at high speed, then stopping, adding the granular materials, mixing for 3 minutes at high speed, then stopping and obtaining premixed materials; and (2) adding the premixed materials into a mixer for mixing for 15 minutes, then mixing by double screws with same directions, finally extruding by single screw, carrying out air cooling, hot cutting and granulation, wherein the extruding temperature is set between 90-130 DEG C.

Owner:GUANGDONG JUSHI CHEM CO LTD

Structural glue containing nano material

InactiveCN1417282AImprove flexibilityStrong interface bindingEpoxy resin adhesivesNano sio2Pliability

The structural adhesive containing nano material includes two components, the component A consists of epoxy resin, liquid polysulfide rubber, stuffing and nano SiO2, and the component B consists of modified curing agent, promoter, plasticizier, fine silica powder, fine titania powder, aluminum powder and coupling agent, with the ratio between component A and component B being 0.5-1.5 to 0.5-1.5. The liquid polysulfide rubber can increase the flexibility of the adhesive and the nano material can increase the contact area between the adhesive and adhered body and binding force, improve mechanical performance. The structural adhesive is dense, waterproof, flexible, antiaging, and has high adhering strength, shearing strength, high stability, etc.

Owner:湖南省宏尚土木工程技术有限公司 +1

High-flame-retardant polypropylene material and preparation method thereof

InactiveCN105385028AGood flame retardant performanceGood self-extinguishingPolypropyleneBrominated flame retardant

The invention discloses a high-flame-retardant polypropylene material and a preparation method thereof. The material is composed of the following raw materials in parts by mass: 60-75 parts of homo-polypropylene aggregates, 5-15 parts of homo-polypropylene powder, 10-20 parts of a brominated flame retardant, 3-8 parts of an antimony flame retardant, 1-3 parts of a flame retardant synergist, 0-10 parts of a cooling master batch, 0-3 parts of a flexibilizer, 0-1 part of a lubricant, 0-1 part of an ultraviolet light absorber, and 0-1 part of an antioxidant. The preparation method of the material comprises the following steps: 1) uniformly mixing all materials in certain proportion; and 2) adding the obtained mixture into a twin-screw extruder, carrying out high-temperature mixing and shearing, and after the obtained object is subjected to water cooling, sequentially carrying out bracing and grain-sized dicing, so that the high-flame-retardant polypropylene material is obtained. The high-flame-retardant polypropylene material disclosed by the invention is excellent in flame resistance, good in self-extinguishment, excellent in aging resistance, good in insulating property and heat resistance, not easy to deform by heating, excellent in processing fluidity, and easy to shape.

Owner:GUANGDONG JUSHI CHEM CO LTD

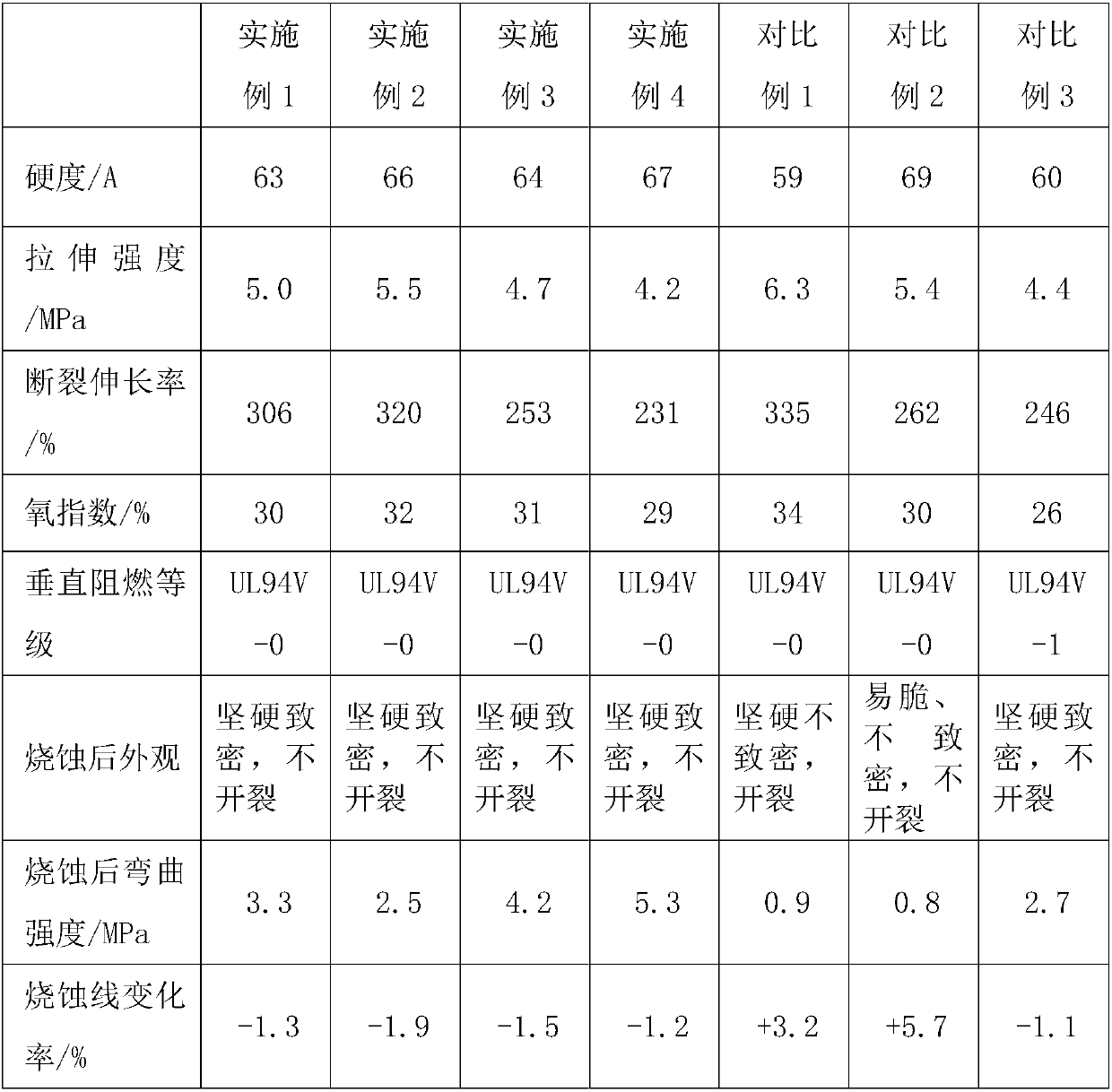

Ceramic flame-retardant and fireproof silicone rubber and preparation method thereof

The invention discloses ceramic flame-retardant and fireproof silicone rubber and a preparation method thereof. The silicone rubber contains the following components in parts by weight: 100 parts of raw silicone rubber, 10-50 parts of white carbon black, 10-100 parts of aluminum hydroxide, 10-50 parts of low-melting-point glass powder, 10-100 parts of sericite powder, 1-20 parts of hydroxyl silicone oil, 1-20 parts of hexamethyl disilazane, 0.1-3 parts of a platinum compound and 0.1-5 parts of a vulcanizing agent. The silicone rubber is good in flame retardance, excellent in mechanical property, safe and environmentally friendly, has good mechanical strength and insulating property after being ablated, is capable of preventing burnt objects from being damaged and keeping a circuit completefor a long time and can play a good fireproof role.

Owner:GUANGDONG POLYSIL TECH CO LTD

Resist composition excellent in flame resistance

InactiveUS6528552B1Improve flame retardant performanceGood self-extinguishingLactams stabilisationSemiconductor/solid-state device detailsResistStannate

A resist composition for permanent protective coating of a printed wiring board, which resist composition is excellent in flame resistance and is obtained by incorporating as essential components a flame retardant containing 100 to 140 parts by weight of (a) aluminum hydroxide, 0.1 to 15 parts by weight of (b) a molybdenum compound and 0.1 to 10 parts by weight of (c) a zinc stannate type compound into 100 parts by weight of a resin.

Owner:MITSUBISHI GAS CHEM CO INC

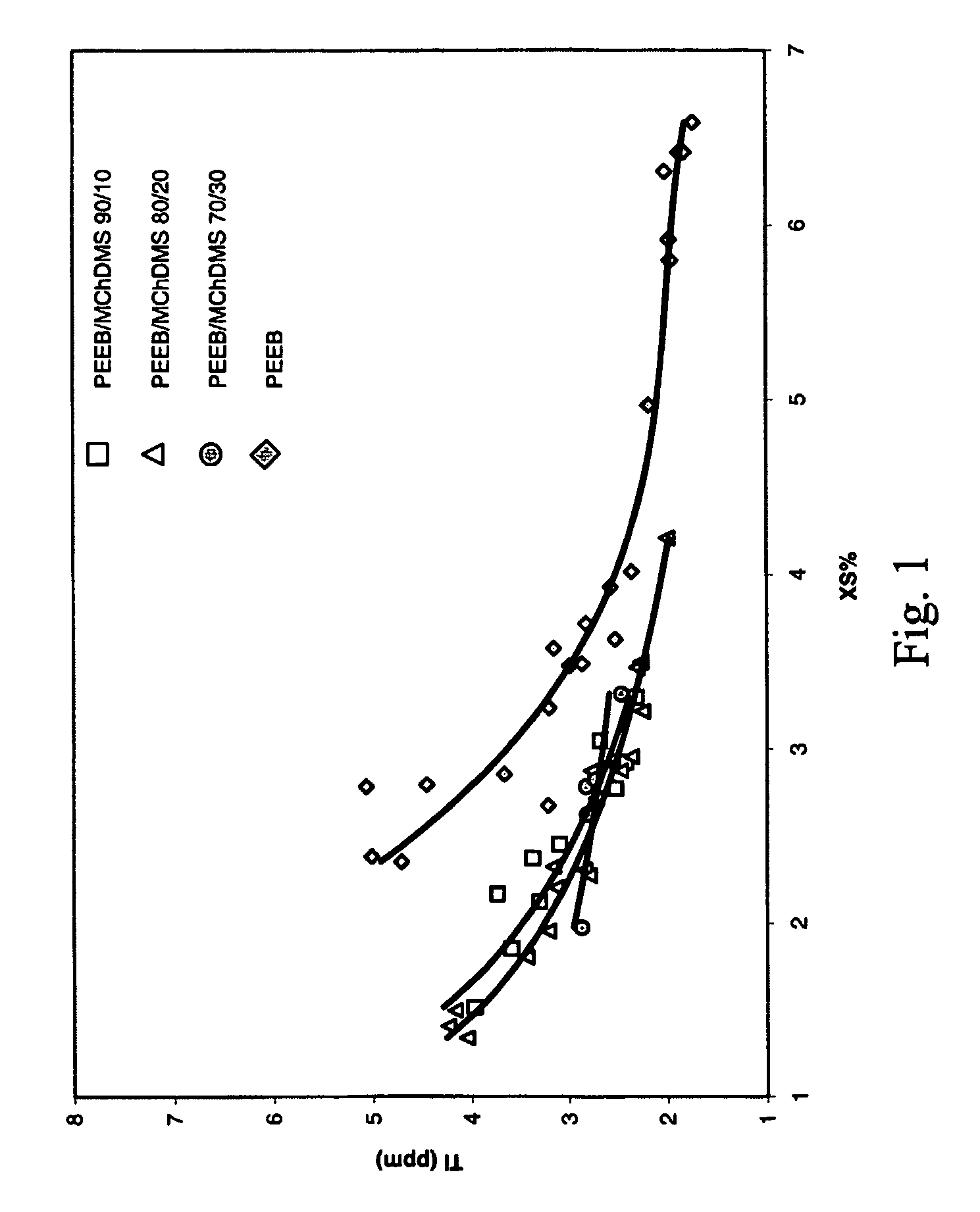

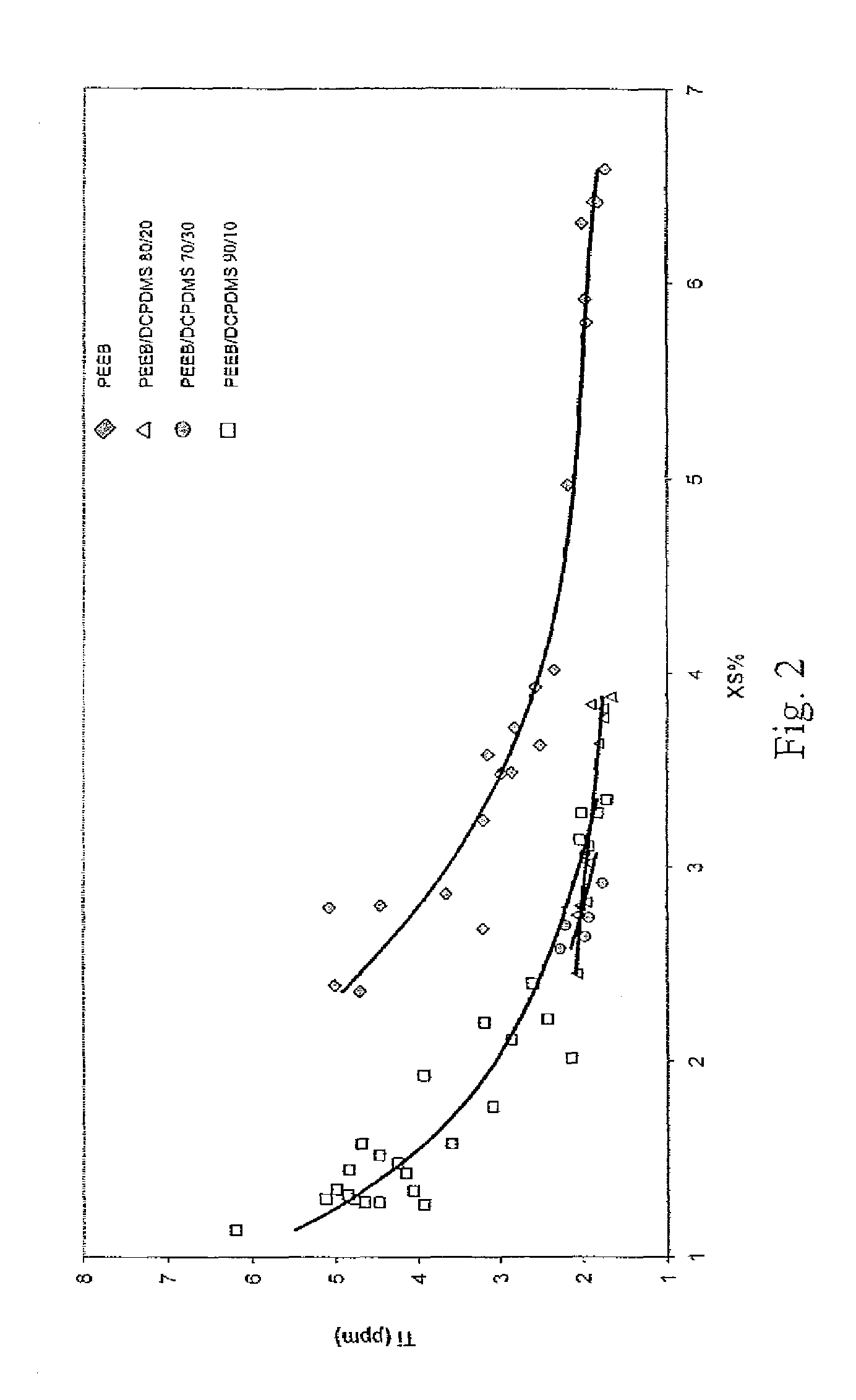

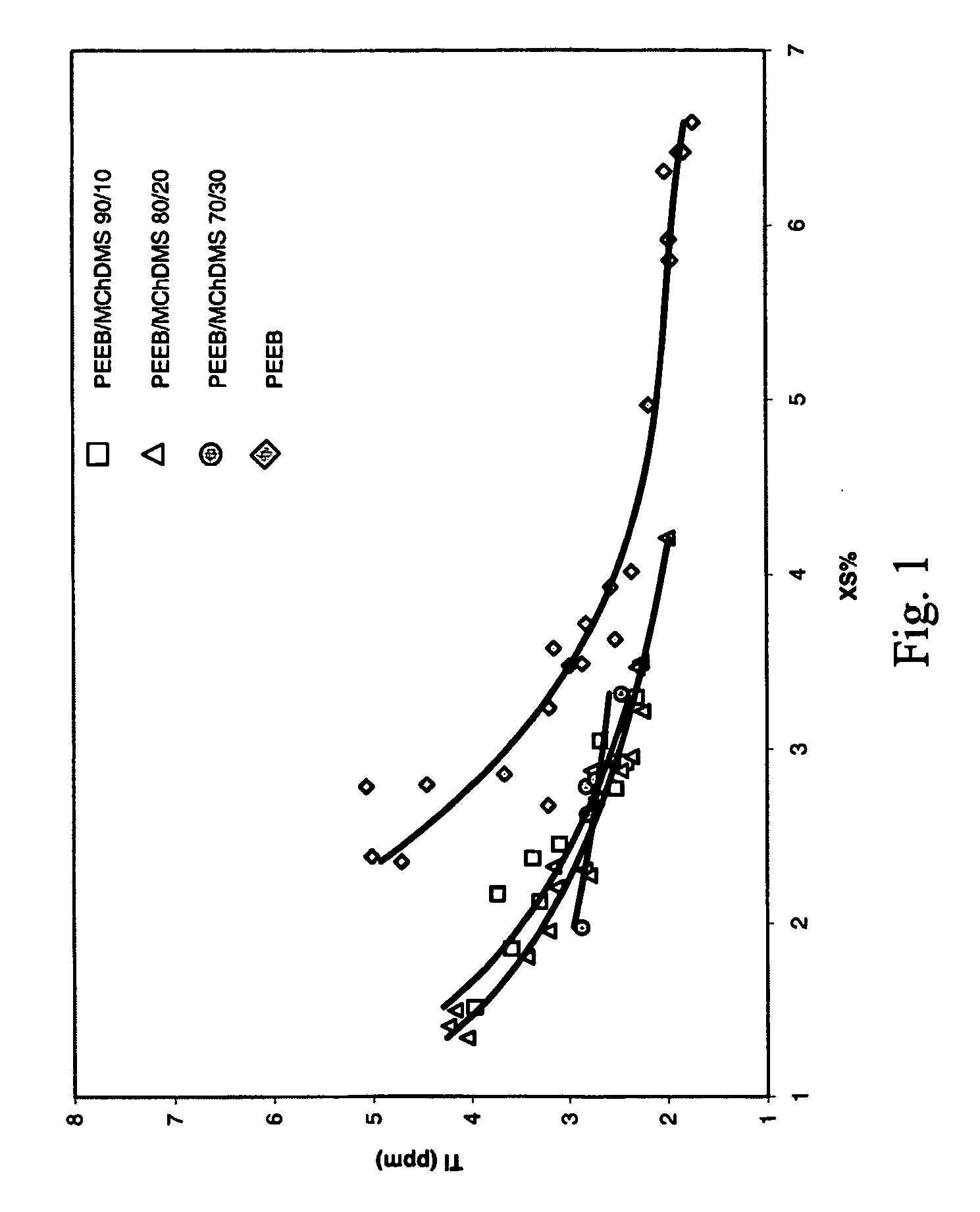

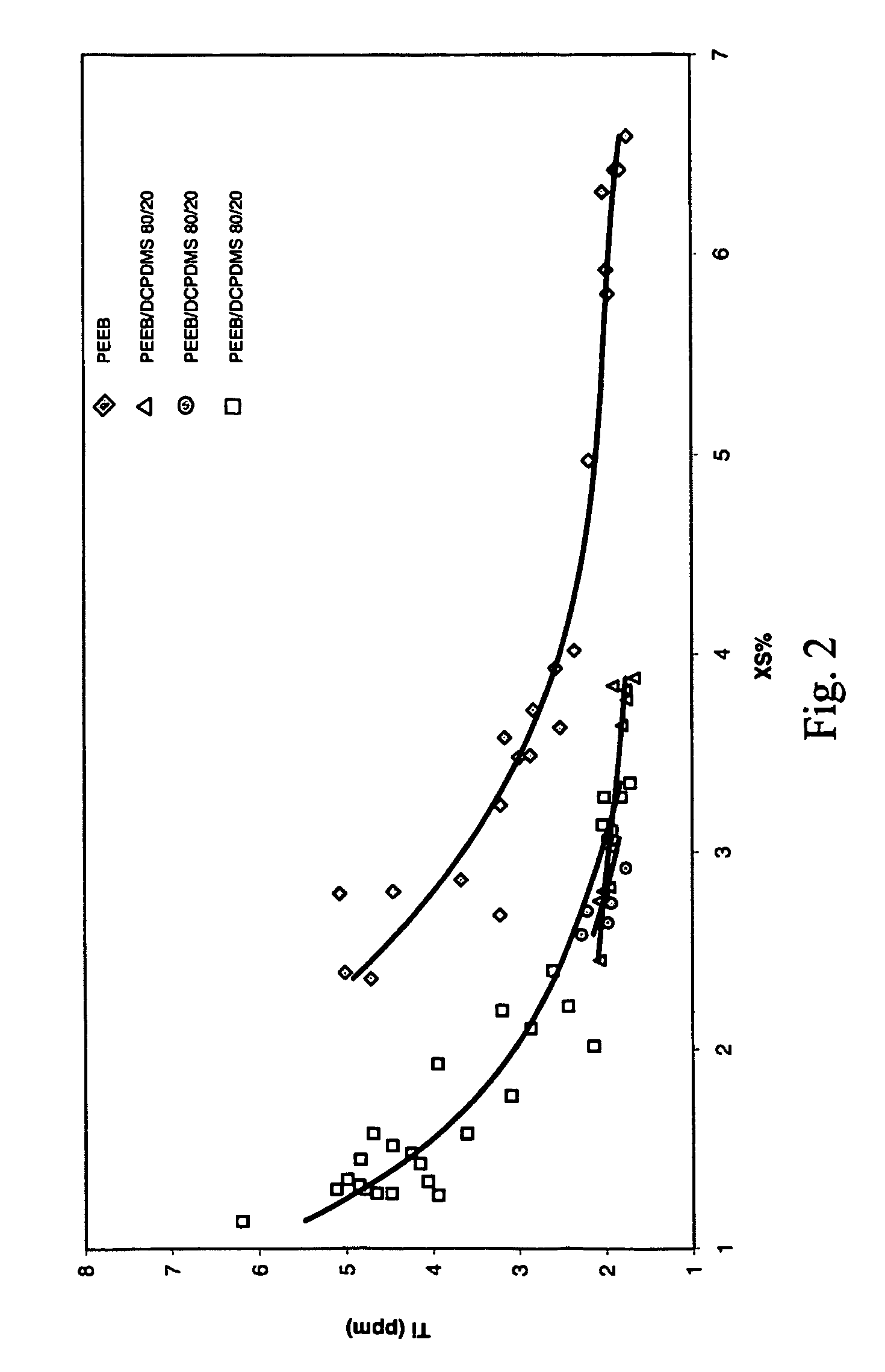

Self-extinguishing catalyst composition with monocarboxylic acid ester internal door and propylene polymerization process

InactiveUS7420021B2Good self-extinguishingNarrow molecular weight distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSilane compoundsElectron donor

A catalyst composition for the polymerization of propylene comprising one or more Ziegler-Natta procatalyst compositions comprising one or more transition metal compounds and one or more monoesters of aromatic carboxylic acid internal electron donors; one or more aluminum containing cocatalysts; and a mixture of two or more different selectivity control agents, said SCA mixture comprising from 98.0 to 99.9 mol percent of one or more esters of one or more aromatic monocarboxylic acids or substituted derivatives thereof, and from 2.0 to 0.1 mol percent of one or more alkoxysilane compounds.

Owner:WR GRACE & CO CONN

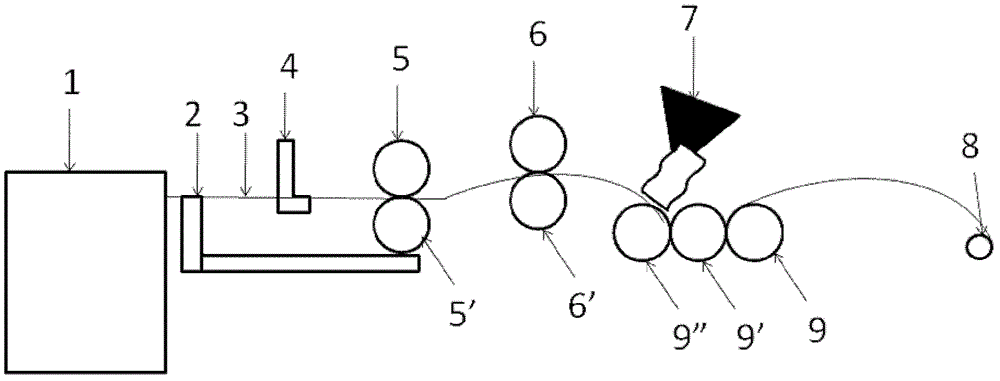

Biodegradable composite prepreg cloth, and preparation method and device for the same

ActiveCN103061162AGood self-extinguishingGenerates less gasPhysical treatmentNatural fiberBiodegradable composites

The invention relates to a biodegradable composite prepreg cloth, and a preparation method and a device for the same. The composite prepreg cloth comprises a modified polylactic acid (PLA) resin accounting for 40-70 wt% of the composite prepreg and natural fiber. The preparation method comprises the following steps: conducting a continuous drying treatment on natural fiber; immersing the fiber with molten modified PLA; coating the modified PLA on the surface of the natural fiber; and rolling, cooling and winding to obtain the prepreg cloth. The device comprises an untwisting machine, an arrangement warping device, a direction control device, a friction roll, a tenslator, a film extruder, a gum dipping cooling device, and a winding device. Compared with the prior art, the invention has the advantages of large fiber draw ratio, obvious PLA enhancement effect, small wear of the extruder screw, simple process, energy saving and environment-friendliness.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

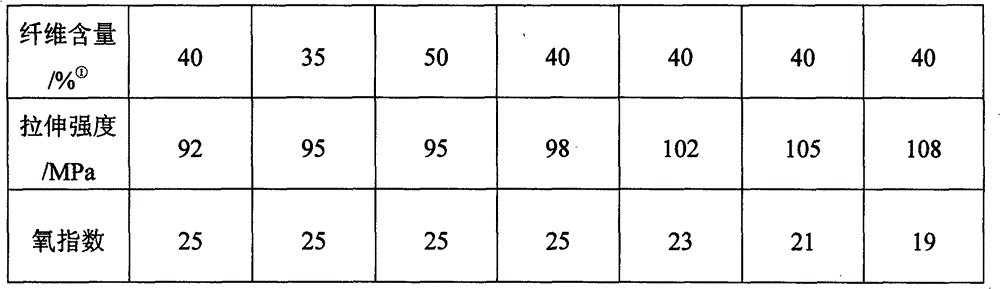

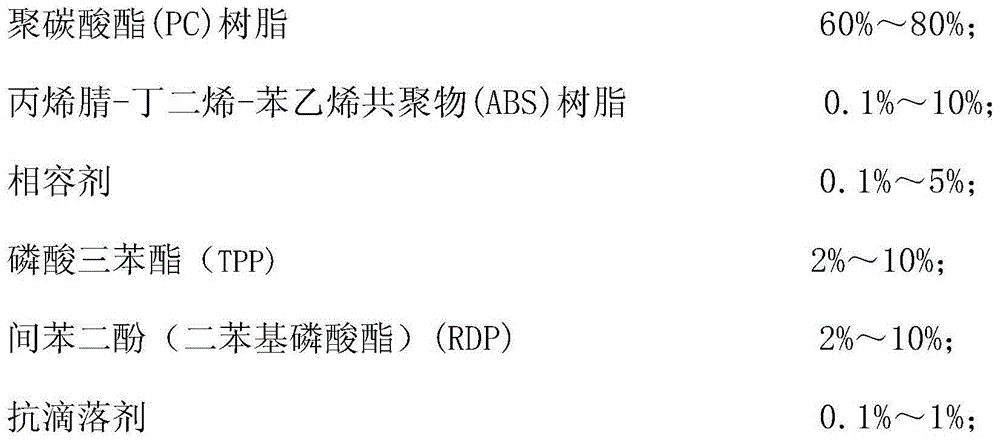

High weather resistant, halogen-free and flame retardant PC/ABS alloy material special for outdoor telecommunication box and preparation method thereof

The invention discloses a high weather resistant, halogen-free and flame retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material special for an outdoor telecommunication box and a preparation method thereof. The PC / ABS alloy material is prepared from the following raw materials by weight percentage: 60%-80% of polycarbonate resin; 0.1%-10% of acrylonitrile-butadiene-styrene resin; 0.1%-5% of a compatibilizer; 2%-10% of triphenyl phosphate; 2%-10% of resorcinol (diphenyl phosphate); 0.1%-1% of an anti-dripping agent; 0.1%-2% of a light stabilizer; and 0.1%-2% of assistants. According to the invention, the PC and ABS resin with good weather resistance are adopted as the matrix, and through synergy of the compatilizer, the halogen-free flame retardants and the light stabilizer, the halogen-free and flame retardant PC / ABS alloy material with high heat resistance and high performance can be obtained, and can be widely used in the communications industry, the automobile industry, building materials, decoration materials, cables and the electrical industry. The preparation method of the alloy material adopts existing equipment, is simple to operate, and is suitable for industrialized production.

Owner:SHANGHAI AUSELL CHEM TECH

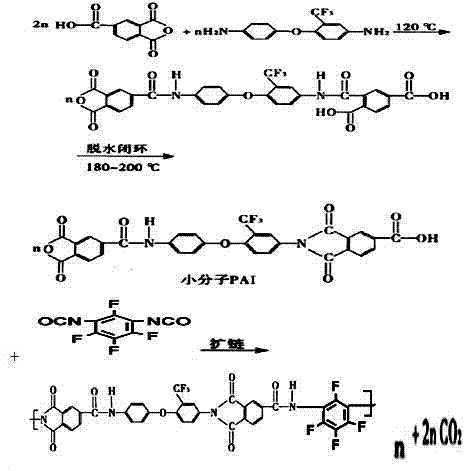

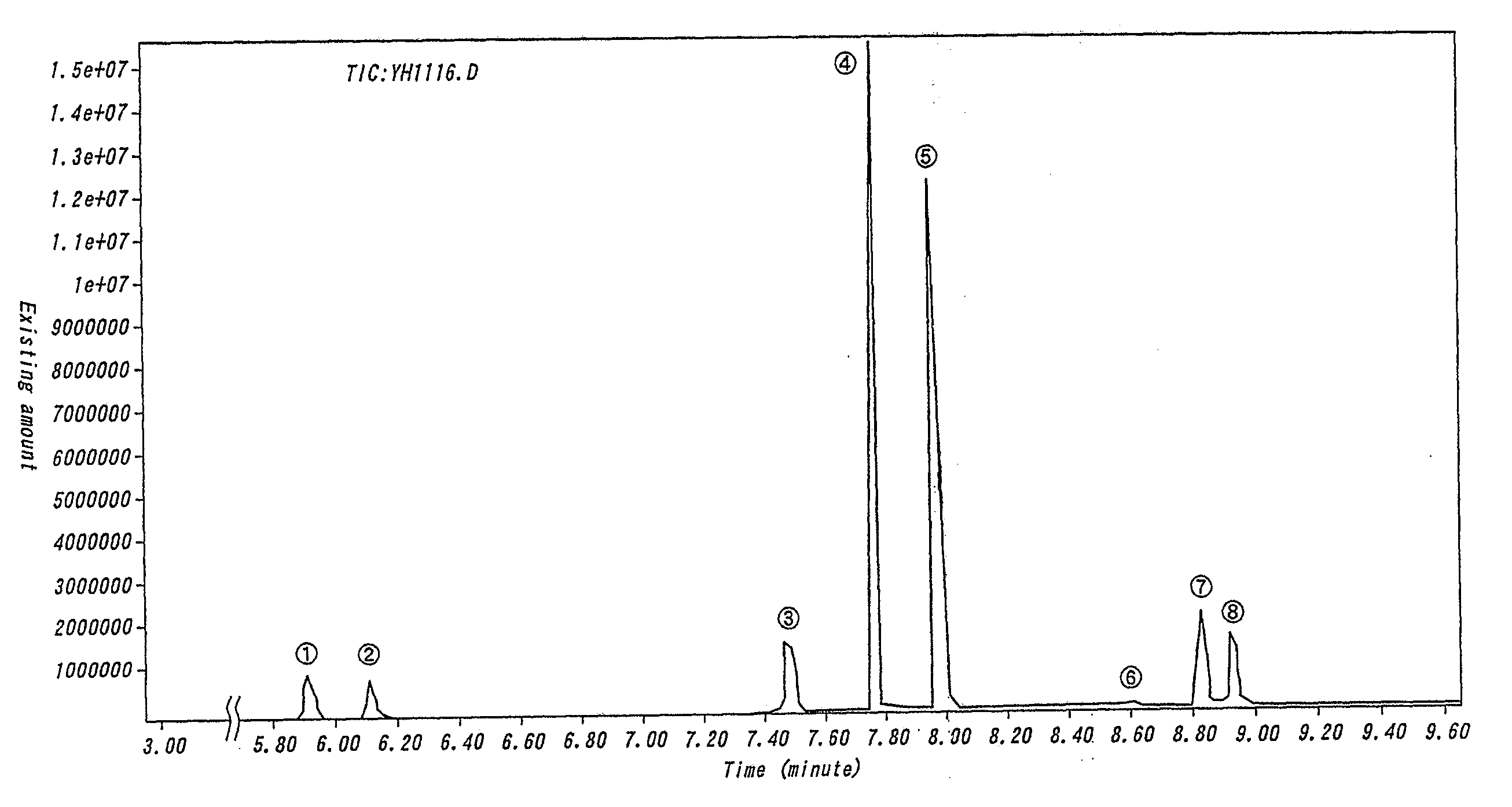

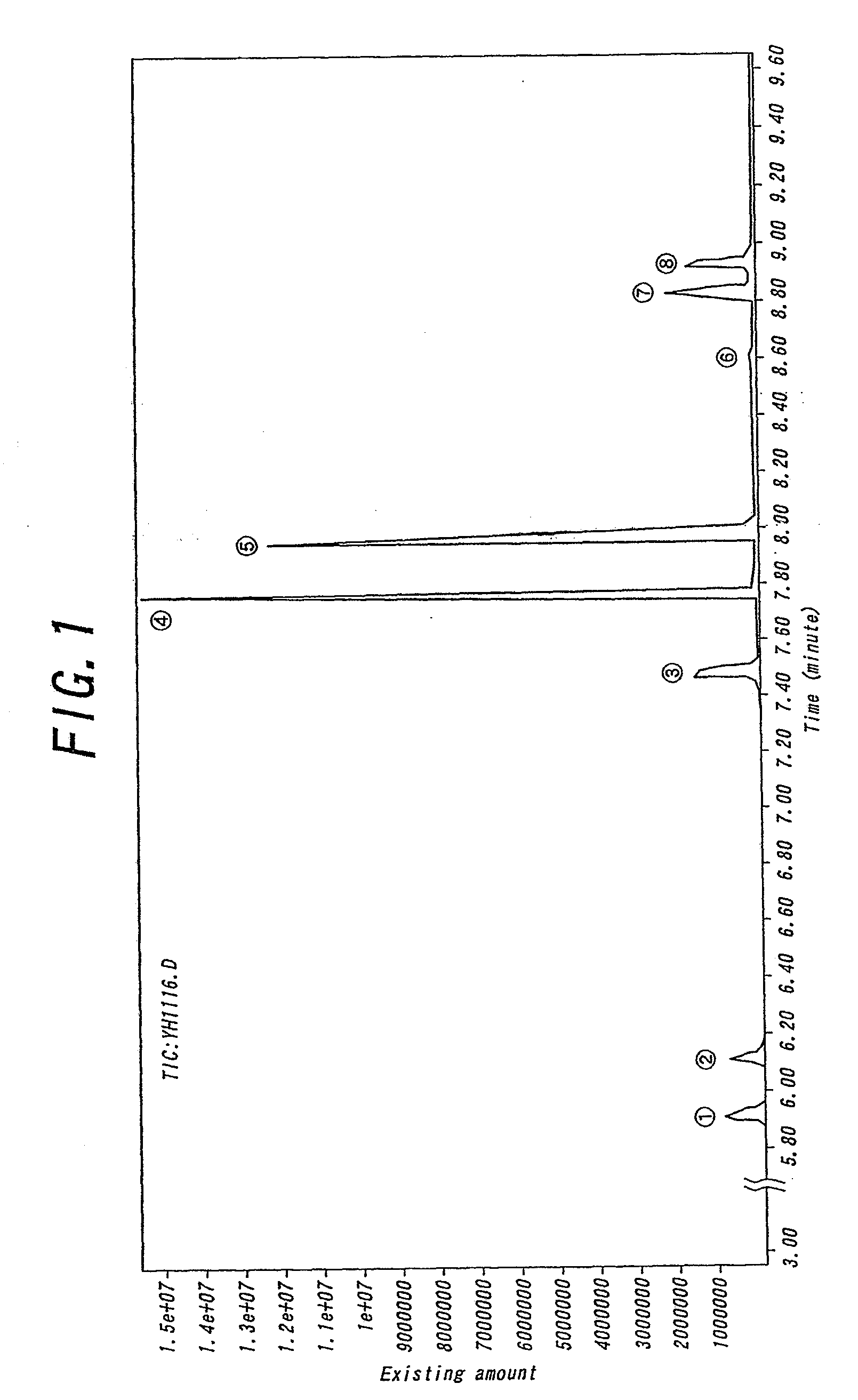

Conductive silver adhesive for high-power LED (light-emitting diode) and preparation method and curing and using method thereof

InactiveCN102786901AHigh tensile strengthImprove heat resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesPolyamideElectrically conductive

The invention discloses a conductive silver adhesive for a high-power LED (light-emitting diode). The conductive silver adhesive comprises the following components in parts by weight: 18 to 25 parts of base resin and curing agent, 0.5 to 2 parts of coupling agent, 65 to 80 parts of conducting particles and 1 to 10 parts of carbon fiber, wherein the proportion of the base resin and the curing agent is determined according to the stoichiometric ratio of reaction functional groups, i.e. 1:1; and the base resin is a mixture consisting of 40 to 80 percent of epoxy resin and 20 to 50 percent of fluorine-containing fusible and soluble polyamide-imide resin. The conductive silver adhesive has very high tensile strength, heat resistance and flame resistance and can work in a working environment with high temperature and high pressure, and the service life of electronic appliances can be obviously prolonged. Therefore, the conductive silver adhesive has very good application prospect.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

Non-aqueous electrolyte cell, electrode stabilizing agent, phosphazene derivative and method of producing the same

InactiveUS20090253035A1High densityHigh outputSolid electrolyte cellsLi-accumulatorsCombustionStructure function

A non-aqueous electrolyte cell comprises a positive electrode, a negative electrode and a non-aqueous electrolyte containing a support salt. The non-aqueous electrolyte further comprises a phosphazene derivative. The phosphazene derivative having a specified structure functions as an electrode stabilizing agent or a non-combustion agent.

Owner:BRIDGESTONE CORP

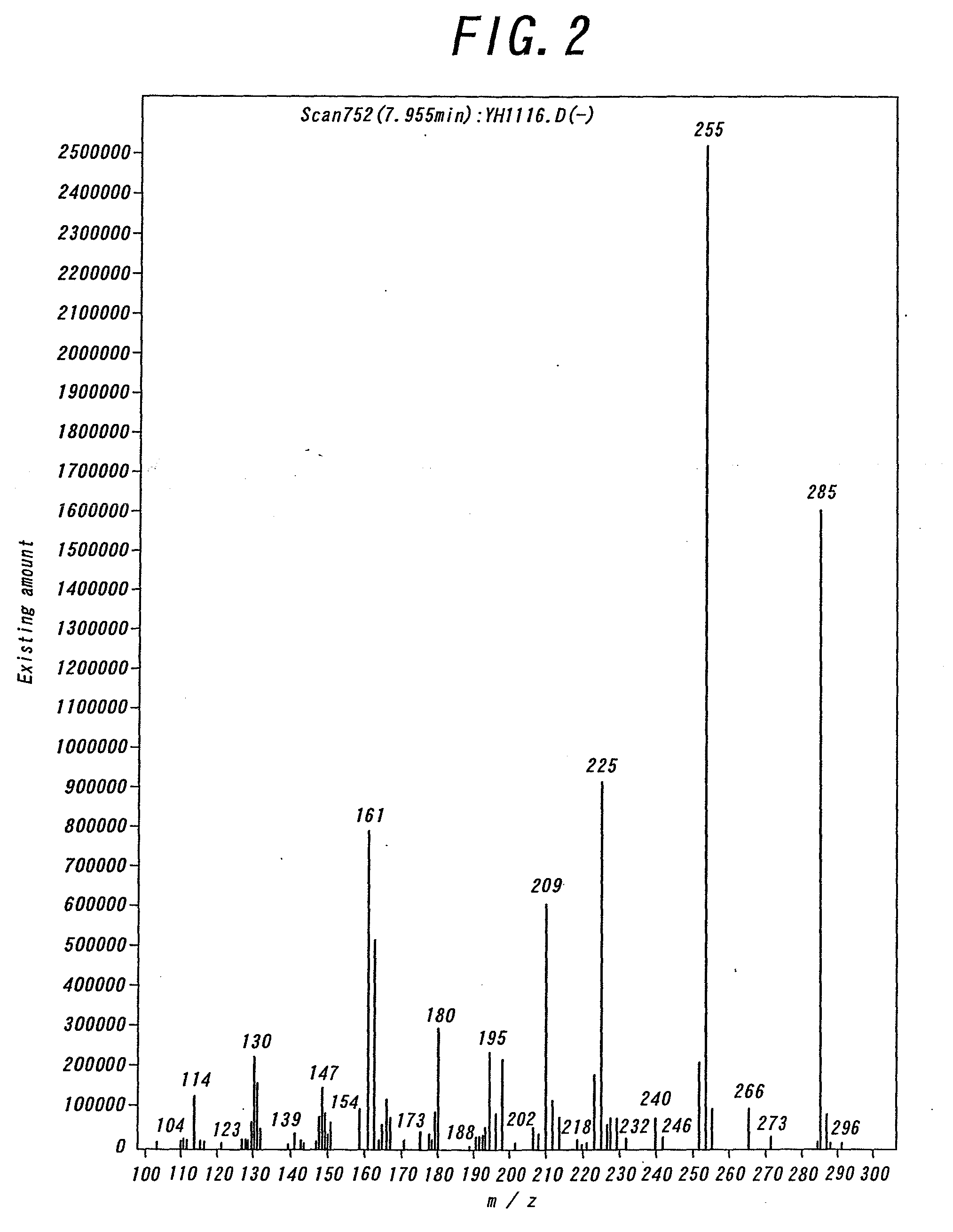

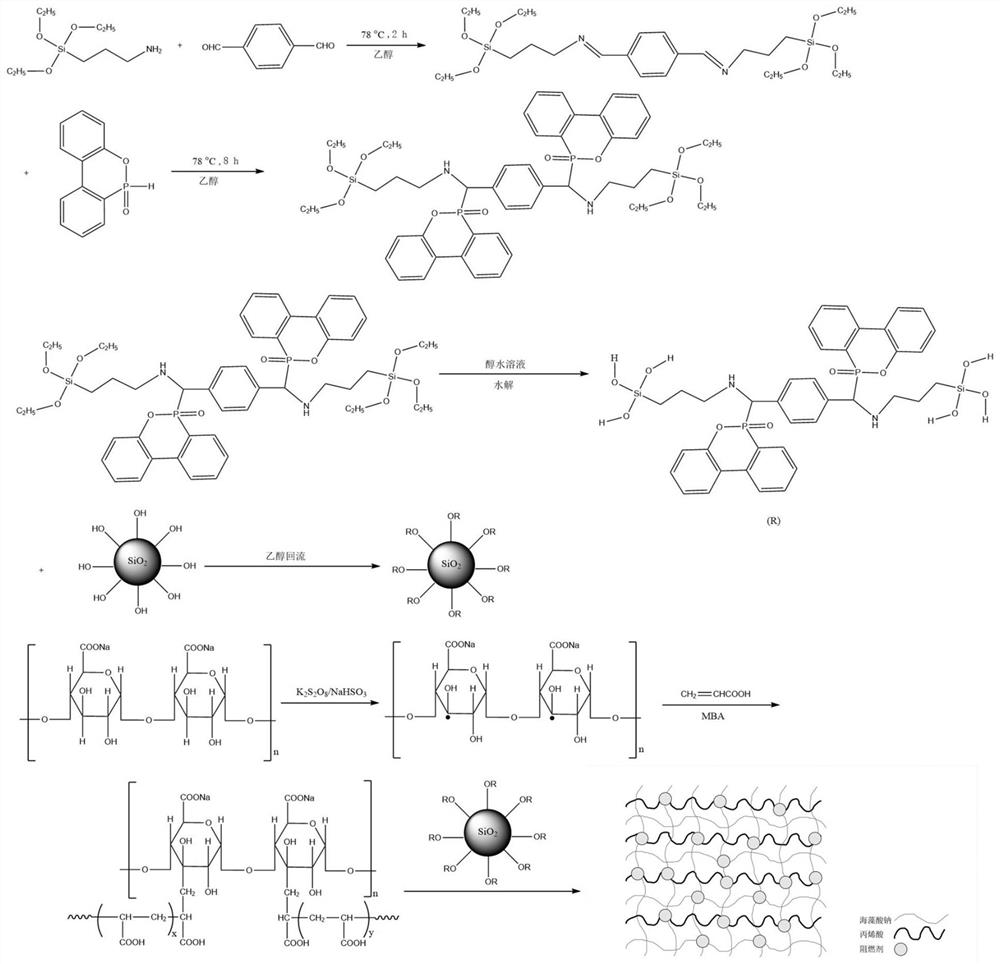

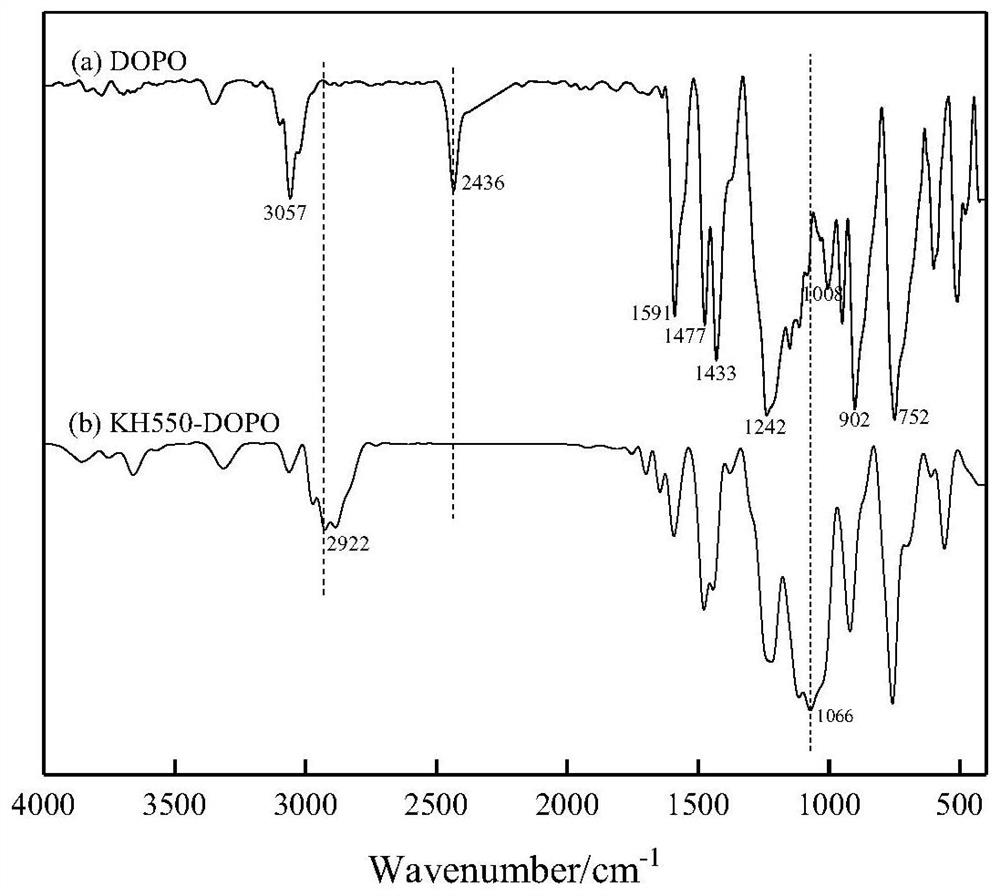

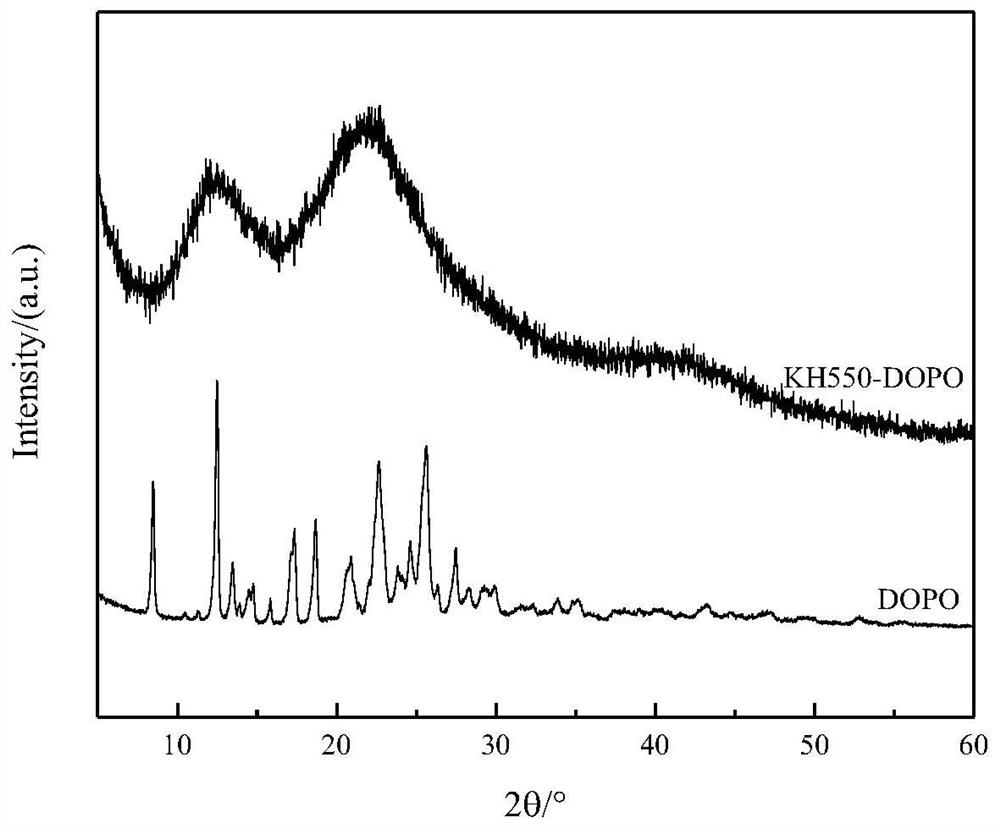

Nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant and preparation method thereof

ActiveCN111849270AAvoid breakingNot easy to driftFireproof paintsOther chemical processesSilanesActive agent

The invention belongs to the field of coal flame-retardant dust suppressants. The invention specifically discloses a nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant and apreparation method thereof. The nitrogen-phosphorus-silicon synergistic coal flame-retardant dust suppressant comprise the following components: 0.08 to 0.12 part of a phosphorus-based flame retardant, 0.10 to 0.14 part of a nitrogen-containing silane coupling agent, 0.01 to 0.05 part of an aldehyde compound, 100.0 to 200.0 parts of a solvent, 0.18 to 0.36 part of a silicon flame retardant, 0.1-0.4 part of a pH regulator, 83.0 to 125.0 parts of deionized water, 57.0 to 95.0 parts of alcohol, 1.0 to 2.0 parts of a natural polymer, 10.0 to 20.0 parts of a monomer, 4.0 to 8.0 parts of a pH buffer agent, 0.1 to 0.4 part of an initiator, 0.02 to 0.08 part of a cross-linking agent, 0.2 to 0.4 part of a surfactant and 0.2 to 1.0 part of a plasticizer. The preparation method comprises the following steps: grafting a nitrogen-containing silane coupling agent onto phosphorus flame retardant molecules by using an aldehyde compound, then hydrolyzing the silicon-based flame retardant, carrying outdehydration reaction between hydroxyl groups on the hydrolyzed silicon-based flame retardant and surface hydroxyl groups on the silicon-based flame retardant to obtain a nitrogen-phosphorus-silicon synergistic flame retardant, and finally organically combining the nitrogen-phosphorus-silicon synergistic flame retardant with dust suppression components such as a natural polymer, a monomer, glycerol and a surfactant in the same system through a polymer free radical polymerization reaction, so that the flame retardant has flame retardance and dust suppression properties.

Owner:SHAANXI UNIV OF SCI & TECH

Catalyst composition with monocarboxylic acid ester internal donor and propylene polymerization process

InactiveUS7393806B2Sacrificing control over reaction conditionsRaise the reaction temperatureOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorHeteroatom

A catalyst composition for the polymerization of propylene comprising one or more Ziegler-Natta procatalyst compositions comprising one or more transition metal compounds and one or more monoesters of aromatic carboxylic acid internal electron donors; one or more aluminum containing cocatalyst; and a mixture of two or more different selectivity control agents, said SCA mixture comprising from 70 to 98 mol percent of one or more esters of one or more aromatic monocarboxylic acids or substituted derivatives thereof, and from 30 to 2 mol percent of one or more alkoxysilane compounds containing one or more 5- or 6-membered cyclic groups optionally containing one or more Group 14, 15 or 16 heteroatoms.

Owner:WR GRACE & CO CONN

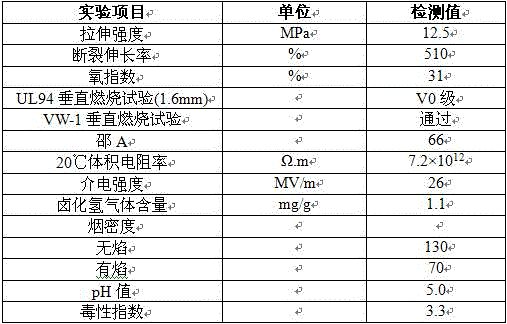

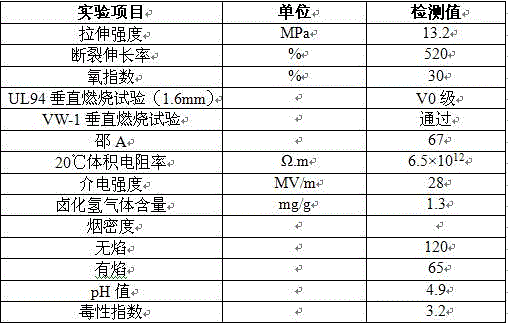

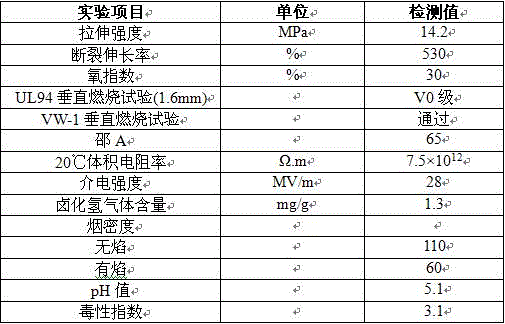

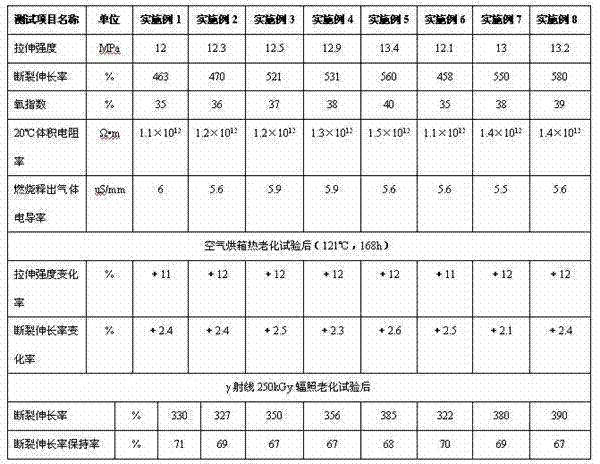

Ethylene propylene diene terpolymer low-smoke zero-halogen flame retardant soft rubber

The invention provides ethylene propylene diene terpolymer low-smoke zero-halogen flame retardant soft rubber which is prepared from the following raw materials in parts by weight: 100 parts of ethylene propylene diene terpolymer, 80-100 parts of inorganic flame retardant, 20-30 parts of phosphorus nitrogen flame retardant and 15-25 parts of synergistic flame retardant. According to the invention, the flame retardant property and the mechanical property of the whole formula are comprehensively considered; the tensile strength is above 12MPa; the elongation at break is above 500%; the Shore A hardness is less than 70; LOI is more than or equal to 30%; and the rubber can meet the requirement of UL94-V0 level vertical combustion test. The ethylene propylene diene terpolymer low-smoke zero-halogen flame retardant soft rubber has excellent overall performance and can be widely applied to the flame retardant places, such as, cable insulators, jackets and sealing rings.

Owner:南京璟仕汇新材料科技有限公司

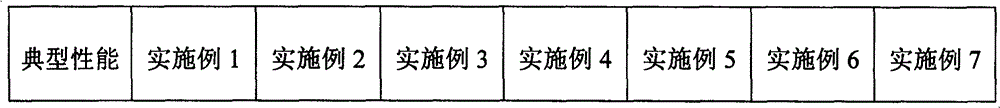

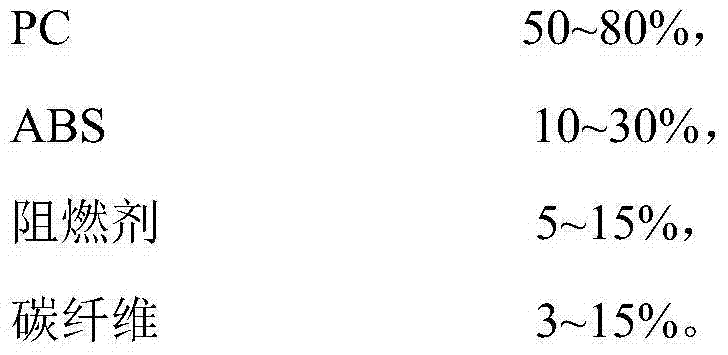

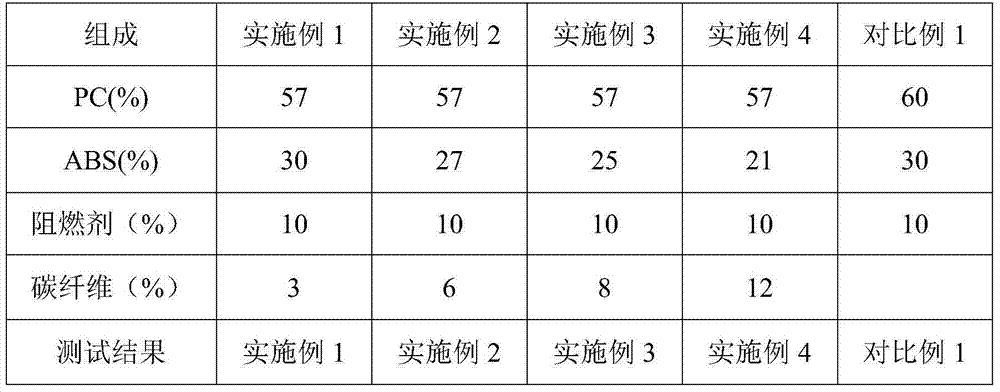

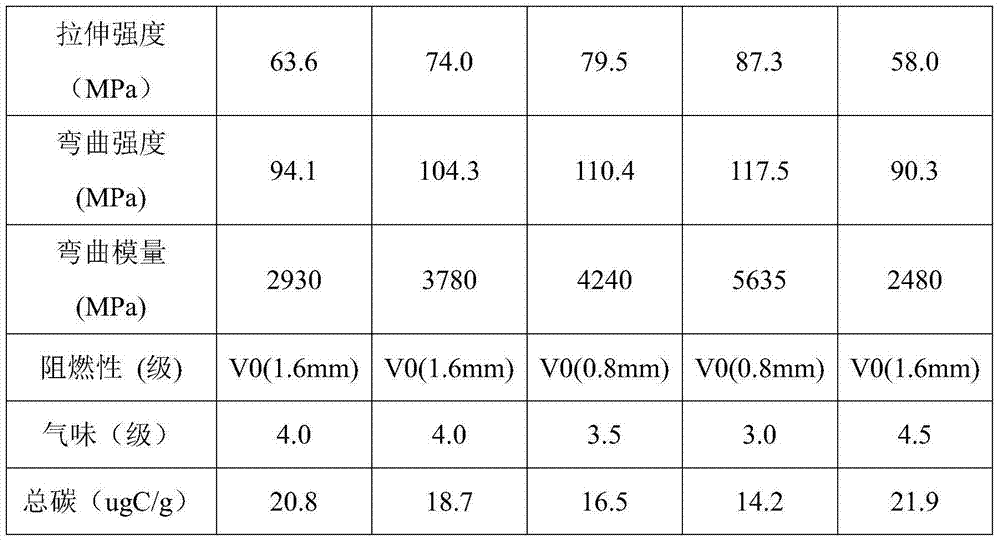

Highly environmental-friendly flame retardant reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) blending material and preparation method thereof

The invention discloses a highly environmental-friendly flame retardant reinforced PC / ABS blending material and a preparation method thereof. The flame retardant reinforced PC / ABS blending material comprises the following raw materials in percentage by weight: 50-80% of PC, 10-30% of ABS, 5-15% of flame retardant and 3-15% of carbon fiber. The carbon fiber is subjected to surface activating treatment. The flame retardant reinforced PC / ABS blending material obtained through the technical scheme of the invention has the many advantages, such as high strength, high flame retardance and high environmental-friendly property. By addition of the carbon fiber subjected to surface activation, stretching and bending performance of the blending material can be enhanced, and various organic volatile matter constituents in the PC / ABS can be adsorbed effectively by lots of micropores on the surface of the carbon fiber, so that multiple environmental indexes, such as material odor and TVOC (Total Volatile Organic Compounds), are improved, more importantly, the promotion of environmental performance is not at the cost of sacrificing the flame retardance of material, on the contrary, the flame retardance of the blending material is also promoted, the combustion time of the blending material away from the fire becomes shorter, and the self-extinguish ability of the blending material becomes better.

Owner:SHANGHAI PRET COMPOSITES +2

Irradiation crosslinked LSOH (low smoke halogen-free) high-flame-retardant polyolefin cable material and preparation method thereof

InactiveCN103450552AImprove thermal stabilityWide range of processing conditionsPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethylenePolymer science

The invention relates to an irradiation crosslinked LSOH (low smoke halogen-free) high-flame-retardant polyolefin cable material and a preparation method thereof. The preparation method is characterized in that the irradiation crosslinked LSOH high-flame-retardant polyolefin cable material is prepared from linear low-density polyethylene resin, an ethylene-vinyl acetate copolymer, an ethylene-ethyl acrylate copolymer, aluminum hydroxide, magnesium hydroxide, 3.5 hydrated zinc borate, a high-viscosity organic silicon mixture, magnesium stearate, a phosphorus-containing halogen-free flame retardant, polyethylene wax, an antioxidant, a crosslinking agent, and the like through the steps of mixing the raw materials by using a closed mixing machine and then carrying out extrusion by using a six-temperature-period twin-screw extruder. An electric wire and a cable prepared by taking the irradiation crosslinked LSOH high-flame-retardant polyolefin cable material as an insulating layer not only have the advantages of good flame retardance, high light transmittance, good electrical insulation, good water resistance and the like, but also have the characteristics of high-temperature resistance level (can be used for a long time in a 105 DEG C environment), good mechanical and physical properties of insulating layers, and the like. The irradiation crosslinked LSOH high-flame-retardant polyolefin cable material can be used as a raw material of LSOH high-flame-retardant insulating layers of electric wires.

Owner:WUXI JAKE PLASTIC

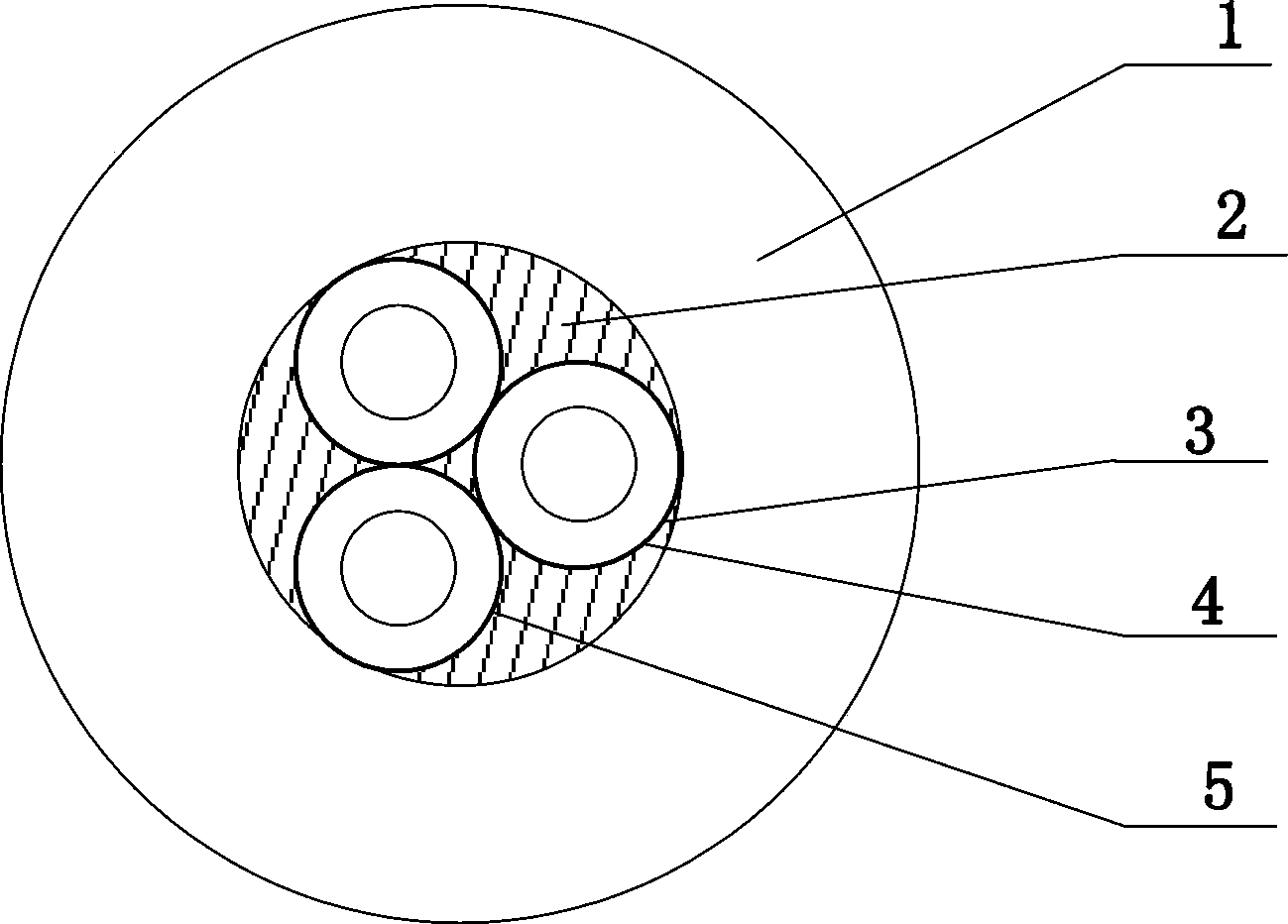

High-flame-resistance filler and preparation method thereof as well as mining high-flame resistance flexible cable made from high-flame-resistance filler

ActiveCN103756225AGuaranteed uptimeImprove stabilityInsulated cablesInsulated conductorsAdhesive cementSilicon oxide

The invention provides high-flame-resistance filler comprising superfine talcum powder, light calcium carbonate, acrylate rubber, dioctyl sebacate, adhesive, barium stearate, nanoscale calcium oxide and silicon dioxide. The invention further provides a mining high-flame-resistance flexible cable comprising a cable core formed by a plurality of insulating wire cores, wherein the cable core is wrapped with an outer sheath layer; the insulating wire cores are coated with cured fire retardant coatings layers; a high-flame resistance filler layer is filled between the insulating wire cores and the outer sheath layer. By means of the high-flame-resistance filler and the mining high-flame-resistance flexible cable made from the high-flame-resistance filler, provided by the invention, the defects of poor flame resistance and poor self-extinguishing performance of existing flexible cables can be solved; the provided flexible cable has the advantages of excellent physical performance, mechanical performance, temperature resistance and flame resistance and good self-extinguishing performance.

Owner:宜昌华润红旗电缆有限公司

Flame-retardant polyethylene fabric with ultrahigh molecular weight and preparation method thereof

ActiveCN106087445AImprove flame retardant performanceGood self-extinguishingTextiles and paperPolyvinylidene fluorideFire retardant

The invention provides a flame-retardant polyethylene fabric with ultrahigh molecular weight and a preparation method thereof. The method comprises the following steps: firstly, carrying out a two-leaching and two-mangling process on a polyethylene fabric with ultrahigh molecular weight in a fire retardant solution for a polymer, which has the mass percent of 20%-30%, wherein the mangle expression is 70%; drying at 60 DEG C for 15min and drying the fabric; carrying out single-face or double-face coating on the surface of the fabric by utilizing a polyvinylidene fluoride solution with the mass percent of 10%-20%, and controlling the thickness of the coating to be 0.5mm-2mm; and drying the coating fabric at a drying temperature of 60 DEG C-85 DEG C to prepare the flame-retardant polyethylene fabric with the ultrahigh molecular weight. The oxygen index of the flame-retardant polyethylene fabric with the ultrahigh molecular weight is more than 27; the flame-retardant polyethylene fabric can be rapidly self-extinguished when leaving away from fire; meanwhile, the flame-retardant polyethylene fabric has flame-retardant, high-strength and non-ventilation performances; and the process method is simple, and industrial implementation is easy to realize. The fabric can be used for high-strength, flame-retardant and non-ventilation conditions in the fields of military affairs or terrorism prevention and the like.

Owner:河北新大东纺织有限公司

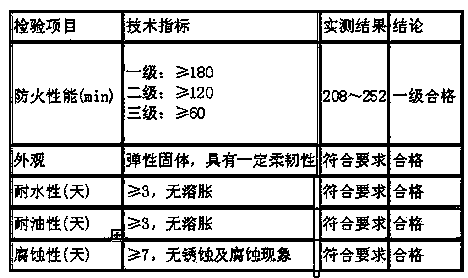

Grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for nuclear power plant and preparation method thereof

ActiveCN103087395AEnvironmental protection is goodReduce pollutionPlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention relates to a grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for a nuclear power plant and a preparation method thereof, belonging to the field of new chemical materials. The cable material comprises raw materials including base resin EVA (ethylene-vinyl acetate copolymer), flame retardants A and B, a flame retardant synergist, basic antioxidants 1010 and 168, a radiation-resistant auxiliary agent 4,4'-thiobis(6-tertiary-butyl-3-methylphenol) and a processing agent; and the preparation method comprises the process steps of material weighing, pretreatment, mixing, extrusion granulation, drying and the like. The cable material is a red-phosphorus-free halogen-free environment-friendly flame-retardant material, phenoxy polyphosphazene is used as a main flame retardant in a flame-retardant system of the cable material, an inorganic flame retardant is auxiliary, the flame-retardant system accounts for a small weight percentage of the material, and the cable material is high in flame-retardant efficiency and excellent in mechanical properties, processability and radiation resistance, so that the cable material is a novel environment-friendly flame-retardant material which has excellent comprehensive properties and is suitable for a nuclear power plant environment.

Owner:SICHUAN INST OF ATOMIC ENERGY +1

Flame-retarding non-halogen silicon core pipe as special material and its preparing process

InactiveCN1369518AReduce smokeReduce toxic gasInsulated cablesInsulated conductorsToxic gasProcedure Agents

A non-halogen fire-retarding material for the conduit of electric wire, electric cable or optical cable is prepared from HCPE resin (51-73 wt%), non-haloen composite fire retardant (25-45%), assistant (1-5%) and stabilizer (0.1-2%) through mixing, dual-screw extruding out and granulating. Its advantages are high fire-retarding effect and not releasing a lot of toxic gas.

Owner:SINOPEC YANGZI PETROCHEM

Catalyst composition with mixed sca and propylene polymerization process

A catalyst composition for the polymerization of propylene comprising one or more Ziegler-Natta procatalyst compositions comprising one or more transition metal compounds and one or more esters of aromatic carboxylic acid internal electron donors; one or more aluminum containing cocatalysts; and a mixture of two or more different selectivity control agents, said SCA mixture comprising one or more esters of one or more aromatic monocarboxylic acids or substituted derivatives thereof and the reaction product or mixture formed by contacting one or more alkoxysilane compounds with an organoaluminum compound.

Owner:CHEN LINFENG

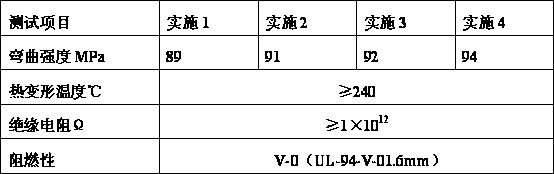

Halogen-free flame retardant phenolic epoxy glass reinforced plastic molding material

The invention provides a halogen-free flame retardant phenolic epoxy glass reinforced plastic molding material, belonging to the technical field of polymer materials. The molding material comprises the following raw materials in parts by weight: 50-54 parts of phenolic epoxy resins, 10-15 parts of melamine resins, 4-8 parts of curing agent, 0.8-1.5 parts of curing accelerator, 6-9 parts of phosphate ester, 3-4 parts of phosphate, 1.3-2.2 parts of release agent, 44-48 parts of mineral filler, 1.1-1.5 parts of reinforcing agent and 25-28 parts of reinforced fibers. The molding material has the beneficial effects that the molding material has the characteristics of good heat resistance, excellent self-extinguishing effect, good strength and convenience in molding; and through tests, the bending strength is 88MPa, the heat deformation temperature is 240 DEG C and the flame retardance reaches grade V-0 (UL-94-V-0 1.6mm).

Owner:CHANGSHU CHIKUSHI MACHINERY

Catalyst composition with monocarboxylic acid ester internal donor and propylene polymerization process

InactiveUS20070066771A1Decrease productivityHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMetalloleElectron donor

A catalyst composition for the polymerization of propylene comprising one or more Ziegler-Natta procatalyst compositions comprising one or more transition metal compounds and one or more monoesters of aromatic carboxylic acid internal electron donors; one or more aluminum containing cocatalyst; and a mixture of two or more different selectivity control agents, said SCA mixture comprising from 70 to 98 mol percent of one or more esters of one or more aromatic monocarboxylic acids or substituted derivatives thereof, and from 30 to 2 mol percent of one or more alkoxysilane compounds containing one or more 5- or 6-membered cyclic groups optionally containing one or more Group 14, 15 or 16 heteroatoms.

Owner:WR GRACE & CO CONN

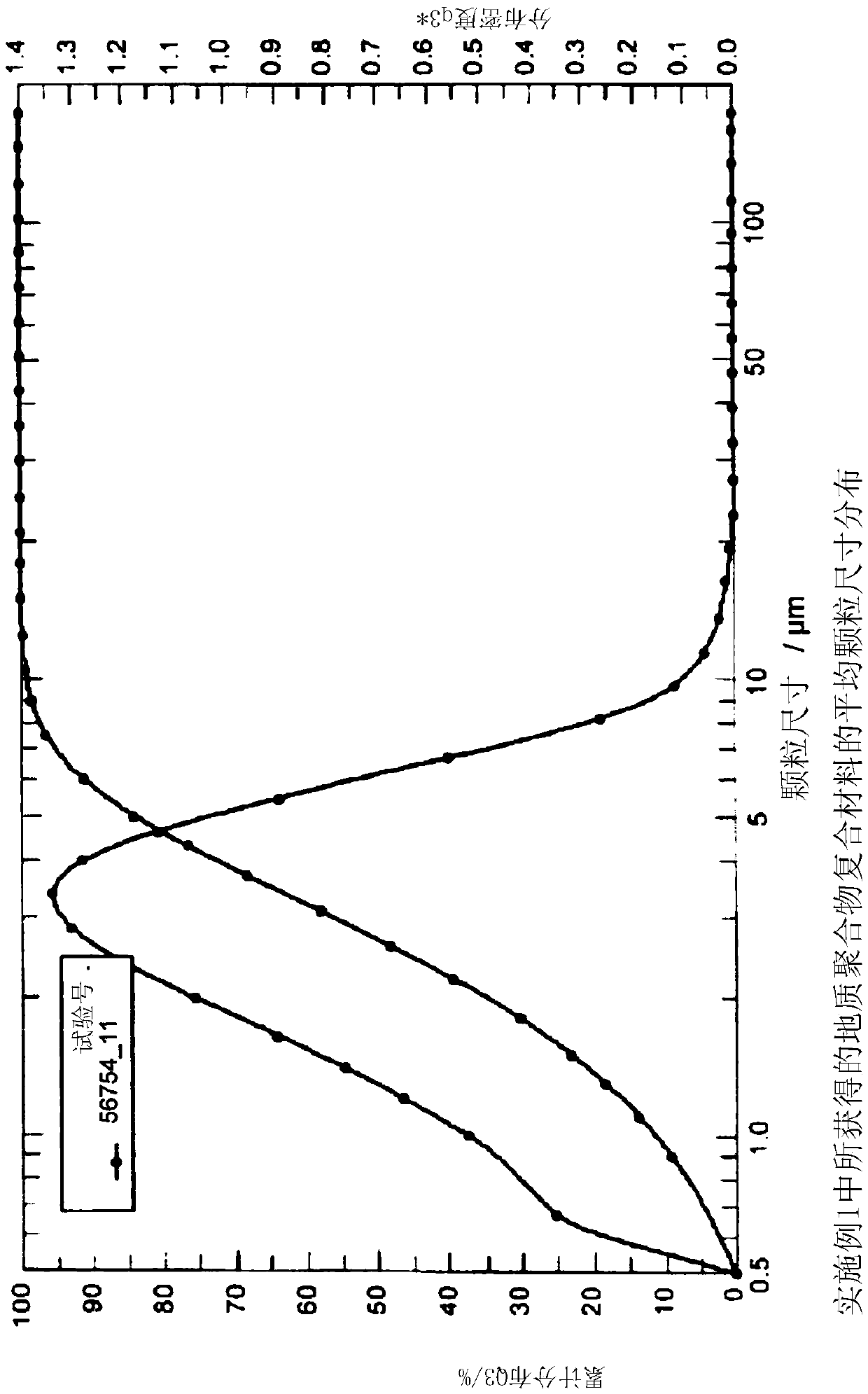

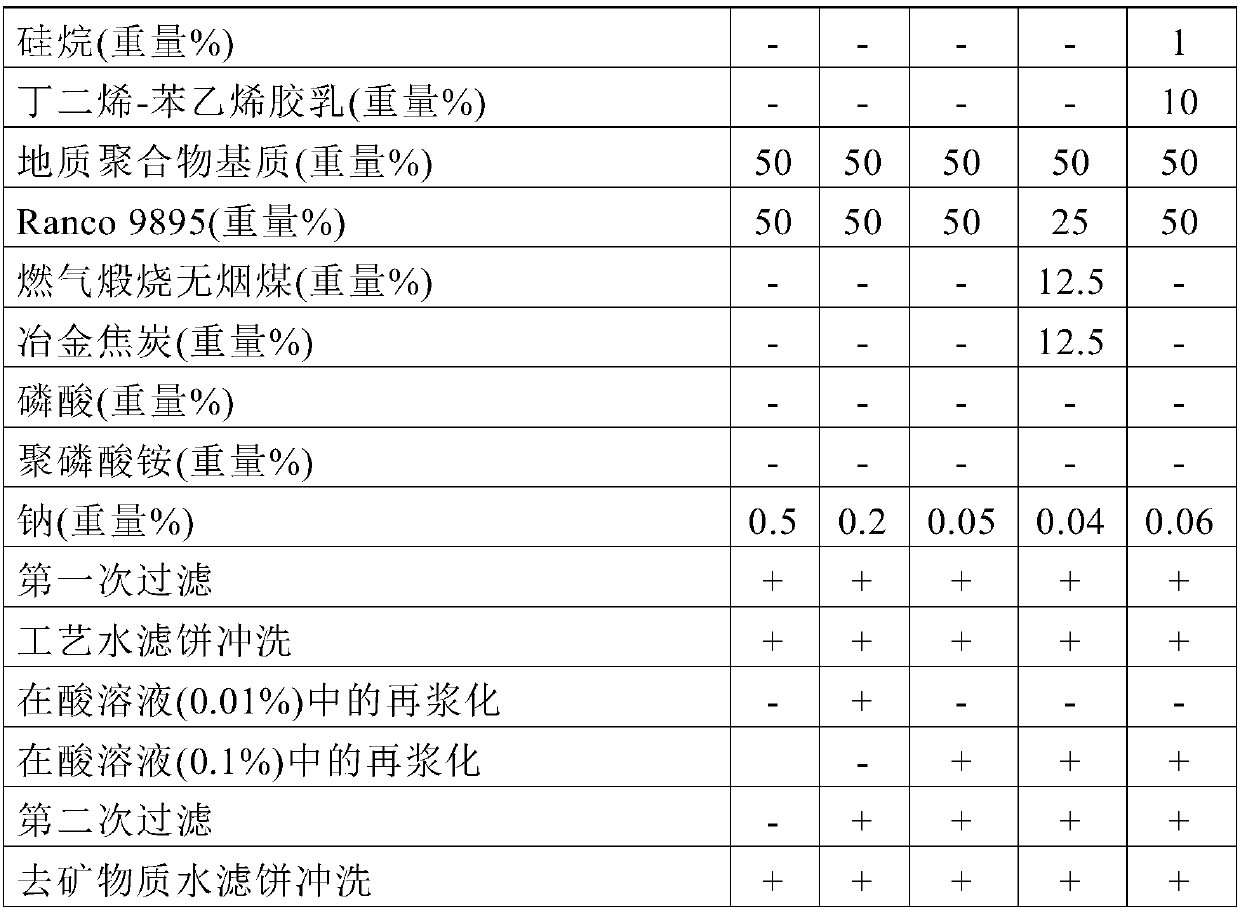

Modified geopolymer and modified geopolymer composite and process for the production thereof

PendingCN109641798AImprove convenienceGood adhesionSolid waste managementCement productionPolymer scienceGeopolymer

The invention relates to a modified geopolymer and a modified geopolymer composite comprising additive. The additive is preferably an athermanous additive. The modification is with one or more water-soluble compounds, the water-soluble compound is preferably selected from phosphorus compounds, nitrogen compounds, copper compounds, silver compounds, zinc compounds, tin compounds and magnesium compounds. Also, it relates to compositions which contain the modified geopolymer or modified geopolymer composite. The compositions preferably comprise vinyl aromatic polymer and are in the form of a foam.

Owner:SYNTHOS

Novel preparation method of ceramized organic silicon resin

The invention provides a novel preparation method of ceramized organic silicon resin. The novel preparation method comprises the following steps: (1) preparing solvent-free vinyl MDTQ silicon resin; (2) preparing base rubber; (3) adding 1 to 5 weight parts of hydrogen-containing silicone oil with 0.2 to 1 percent of hydrogen and 0.1 to 0.5 weight part of an inhibitor into 100 weight parts of the base rubber, kneading the materials in a kneading machine for 1 to 2 hours, then carrying out grinding on a three-roller machine for 2 to 3 times, and carrying out discharging and packaging, thereby obtaining a component A; (4) adding 0.04 to 1 weight part of a platinum complex catalyst into 100 weight parts of the base rubber, kneading the materials in the kneading machine for 1 to 2 hours, then carrying out grinding on the three-roller machine for 2 to 3 times, and carrying out discharging and packaging, thereby obtaining a component B. The organic silicon resin prepared through the preparation method disclosed by the invention is high in adhesion force to a base material, and is difficult to deform or strip during twisting or stretching; furthermore, the ceramized organic silicon resin can be subjected to scrape coating without being diluted through methylbenzene or xylene, and is high in flame retardancy and self-extinguishing performance.

Owner:襄阳玖润氟硅材料有限公司

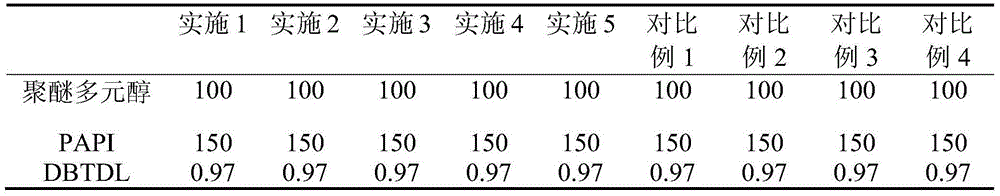

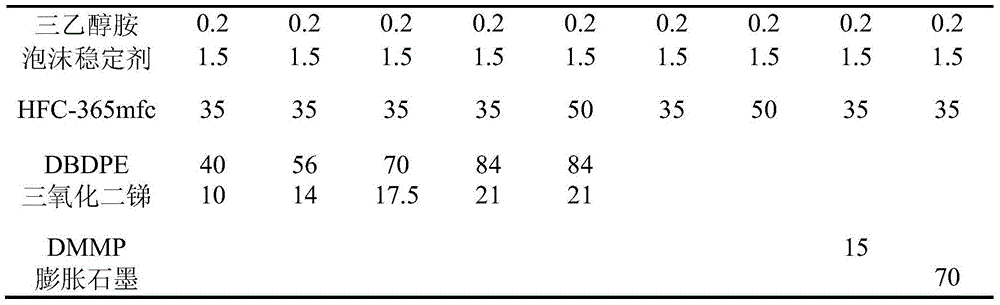

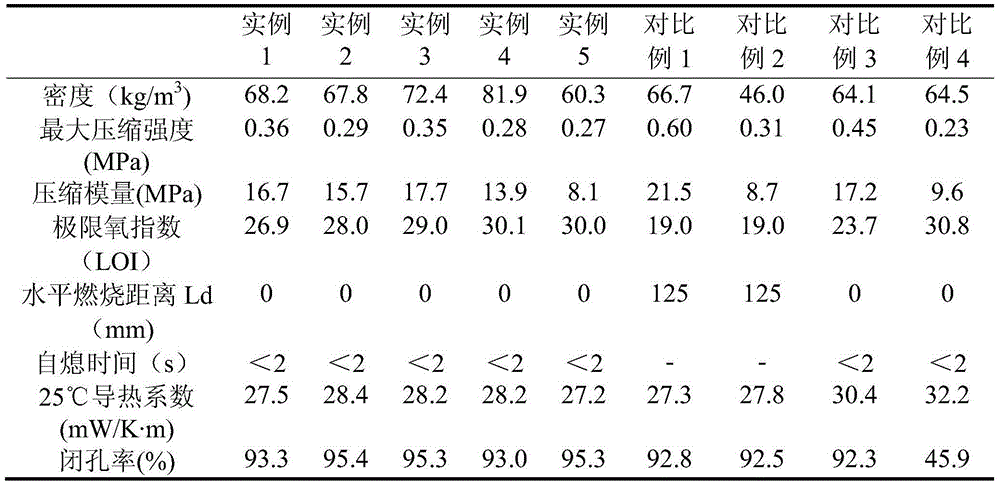

Flame-retardant hard polyurethane thermal-insulation foam material and preparation method thereof

ActiveCN104829812AGood flame retardant performanceGood self-extinguishingIsocyanateThermal insulation

Owner:SHANGHAI JIAO TONG UNIV

Non-aqueous electrolyte cell, electrolyte stabilizing agent, and phosphazene derivative and method for preparation thereof

ActiveUS7560595B2High densityHigh outputNitrogen-metal/silicon/boron binary compoundsOrganic electrolyte cellsCombustionStructure function

A non-aqueous electrolyte cell comprises a positive electrode, a negative electrode and a non-aqueous electrolyte containing a support salt. The non-aqueous electrolyte further comprises a phosphazene derivative. The phosphazene derivative having a specified structure functions as an electrode stabilizing agent or a non-combustion agent.

Owner:BRIDGESTONE CORP

Self-extiguishing catalyst compostion with monocarboxylic acid ester internal donor and propylene polymerization process

InactiveUS20070032376A1Good self-extinguishingNarrow molecular weight distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorCarboxylic acid

A catalyst composition for the polymerization of propylene comprising one or more Ziegler-Natta procatalyst compositions comprising one or more transition metal compounds and one or more monoesters of aromatic carboxylic acid internal electron donors; one or more aluminum containing cocatalysts; and a mixture of two or more different selectivity control agents, said SCA mixture comprising from 98.0 to 99.9 mol percent of one or more esters of one or more aromatic monocarboxylic acids or substituted derivatives thereof, and from 2.0 to 0.1 mol percent of one or more alkoxysilane compounds.

Owner:WR GRACE & CO CONN

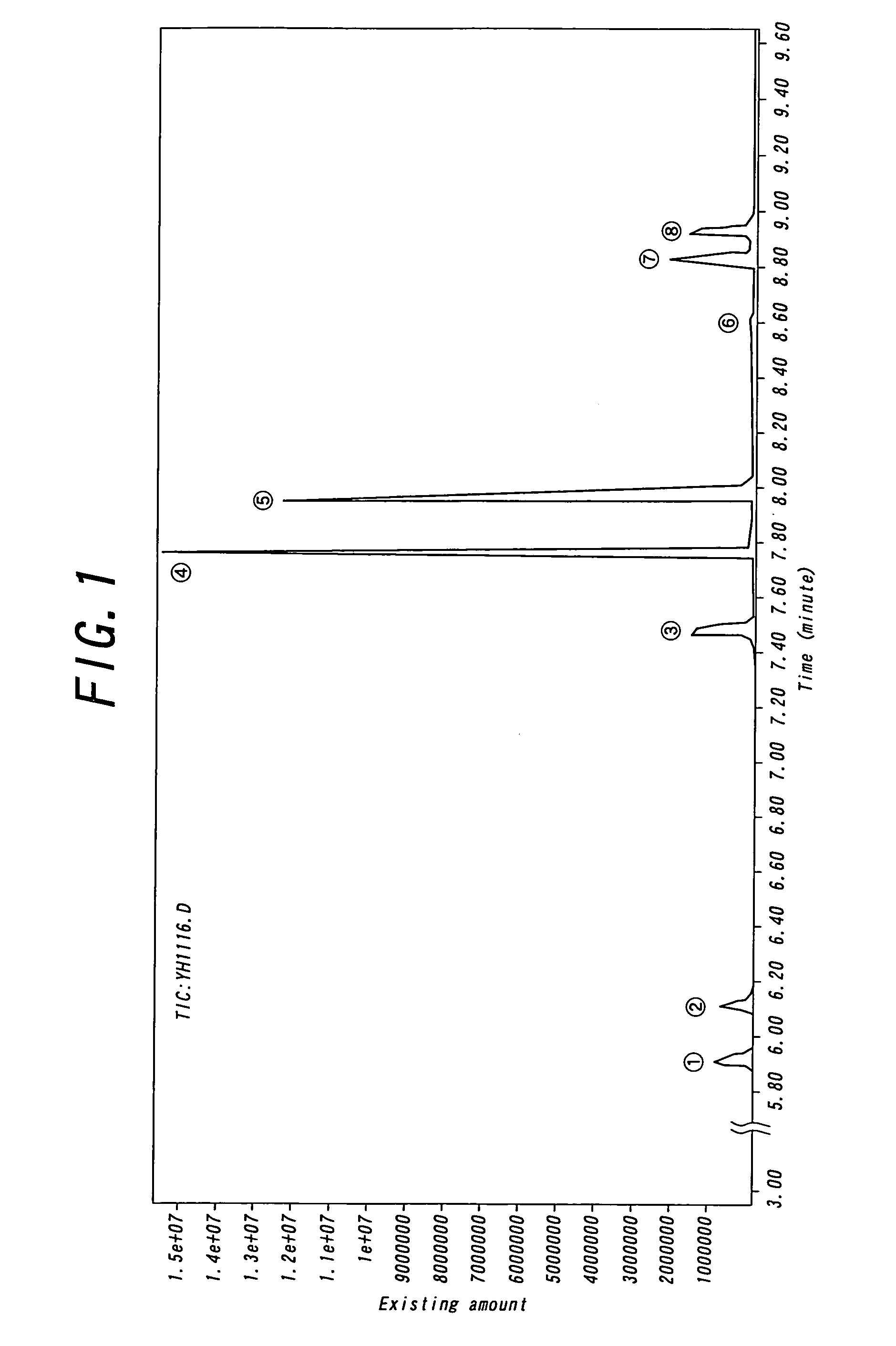

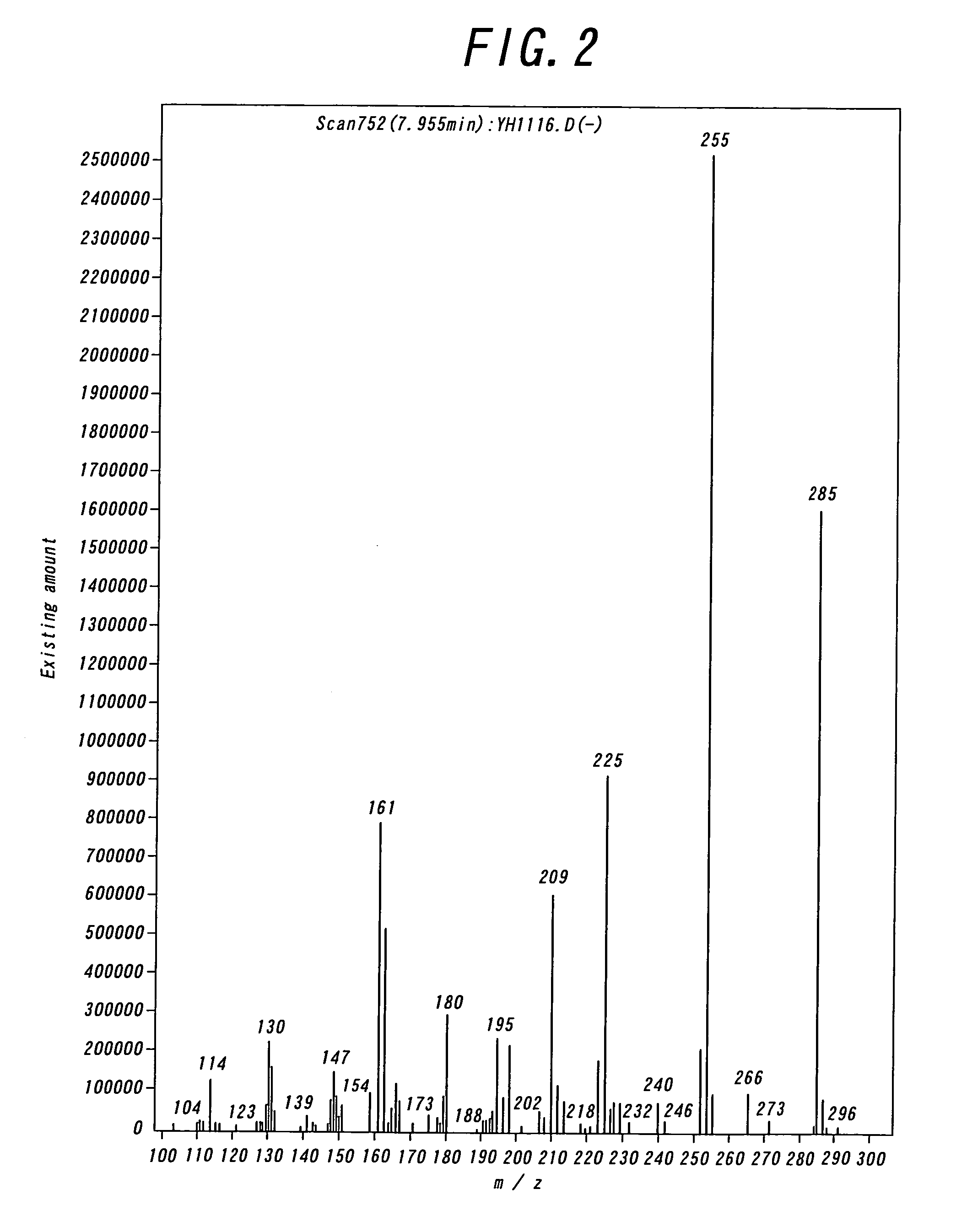

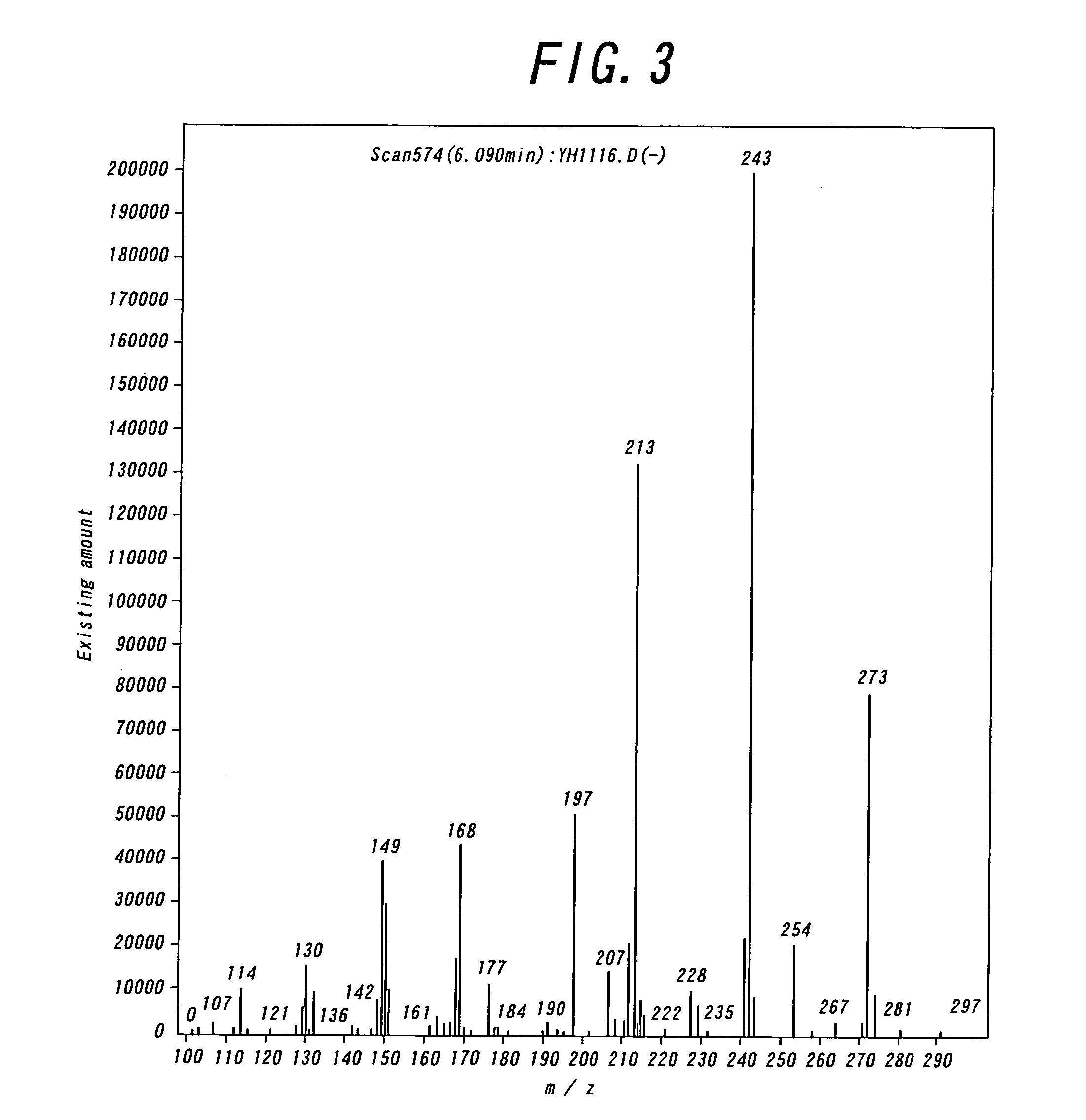

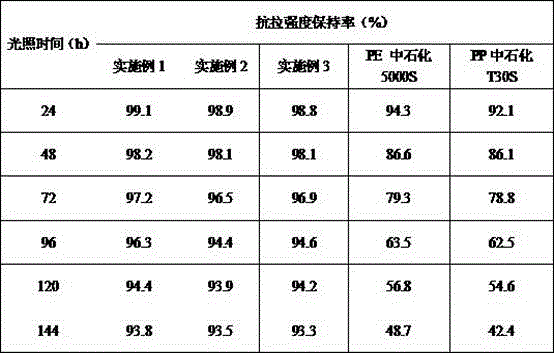

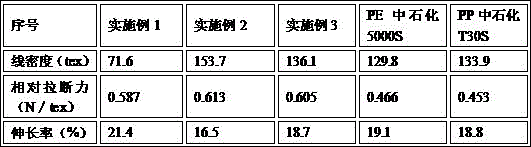

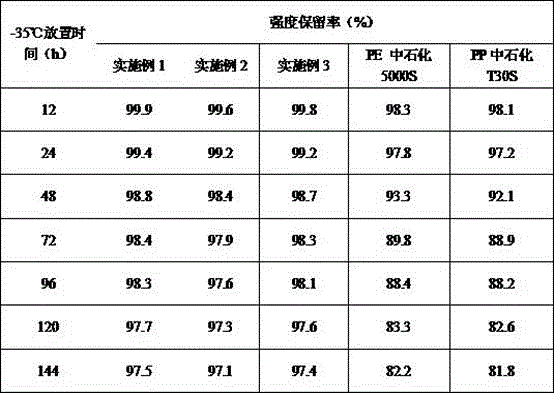

Method of producing flat fibers for plastic woven bags and flexible freight containers by using waste PET (polyethylene terephthalate) bottles

InactiveCN105538640ANo pollution in the processGood self-extinguishingPlastic recyclingArtificial filament heat treatmentPolyesterFiber

The invention relates to a method of producing flat fibers for plastic woven bags and flexible freight containers by using waste PET (polyethylene terephthalate) bottles. The method is characterized by comprising the following steps of: mixing the waste PET bottles which are dried or crystalized in advance with a compatibilizer, an antioxidant, a tackifier, a filling agent, a color masterbatch, a lanthanide series metallic compound and additives, then adding the mixture to an extruder, carrying out extrusion, filtering and measurement in sequence, carrying out tape casting by using a die head, and cooling on a cooling roller to obtain films. The relative pulling strength (N / tex) of the flat fibers is greater than or equal to 0.58; the elongation rate (%) of the flat fibers is 16.5-21.4; the oxygen index of the flat fibers is above 26; the linear density (tex) of the flat fibers reaches 71.6-153.7; the tensile strength retention rate of the flat fibers is 93.3%-93.8% when the flat fibers are placed for 144 hours; the strength retention rate of the flat fibers is 97.1%-97.5% when the flat fibers are placed for 144 hours at the temperature of minus 35 DEG C; when being placed for 2 hours at the temperature of 140 DEG C, the shrinkage rate of the 10 cm flat fiber is 0; and the ink layer combination firmness of the flat fibers is 92%-99%.

Owner:QINGDAO UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com