Halogen-free flame retardant phenolic epoxy glass reinforced plastic molding material

A phenolic epoxy and molding material technology, applied in the field of polymer materials, can solve the problems of easy combustion and insufficient safety, and achieve the effects of convenient molding, excellent self-extinguishing effect and good heat resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

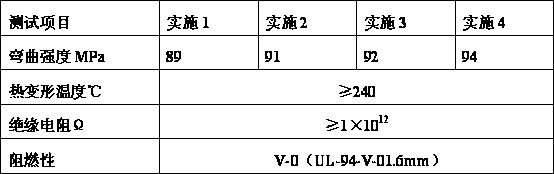

Examples

Embodiment 1

[0026] 50 parts of novolac bisphenol A epoxy resin;

[0027] The condensation polymer of melamine and formaldehyde is 15 parts of melamine resin;

[0028] 6 parts of hexamethylenetetramine;

[0029] 1.5 parts of zinc oxide;

[0030] 7 parts of bisphenol A tetraphenyl diphosphate;

[0031] 3 parts of melamine polyphosphate;

[0032] 1.3 parts of calcium stearate;

[0033] 46 parts of mica;

[0034] 1.5 parts of vinyltrimethoxysilane;

[0035] 28 parts of alkali-free glass fiber with a length of 3mm.

Embodiment 2

[0037] 54 parts of novolac bisphenol A epoxy resins;

[0038] The condensation polymer of melamine and formaldehyde is 10 parts of melamine resin;

[0039] 4 parts of hexamethylenetetramine;

[0040] 0.8 parts of zinc oxide;

[0041] 6 parts of bisphenol A tetraphenyl diphosphate;

[0042] 3.3 parts of melamine polyphosphate;

[0043] 1.5 parts of calcium stearate;

[0044] 44 parts of mica;

[0045] 1.1 parts of vinyltrimethoxysilane;

[0046] 25 parts of alkali-free glass fiber with a length of 3mm.

Embodiment 3

[0048] Novolac bisphenol A epoxy resin 51 parts;

[0049] The condensation polymer of melamine and formaldehyde is 12 parts of melamine resin;

[0050] 8 parts of hexamethylenetetramine;

[0052] 9 parts of bisphenol A tetraphenyl diphosphate;

[0053] 3.6 parts of melamine polyphosphate;

[0054] 1.8 parts of calcium stearate;

[0055] 45 parts of mica;

[0056] 1.2 parts of vinyltrimethoxysilane;

[0057] 26 parts of alkali-free glass fiber with a length of 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com