Patents

Literature

1212 results about "Plastic molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The injection molding process uses a specialized tool, called the plastic injection mold or die, to produce the plastic parts for many different industries. Injection molds are usually made from metal alloys, like steel and aluminum.

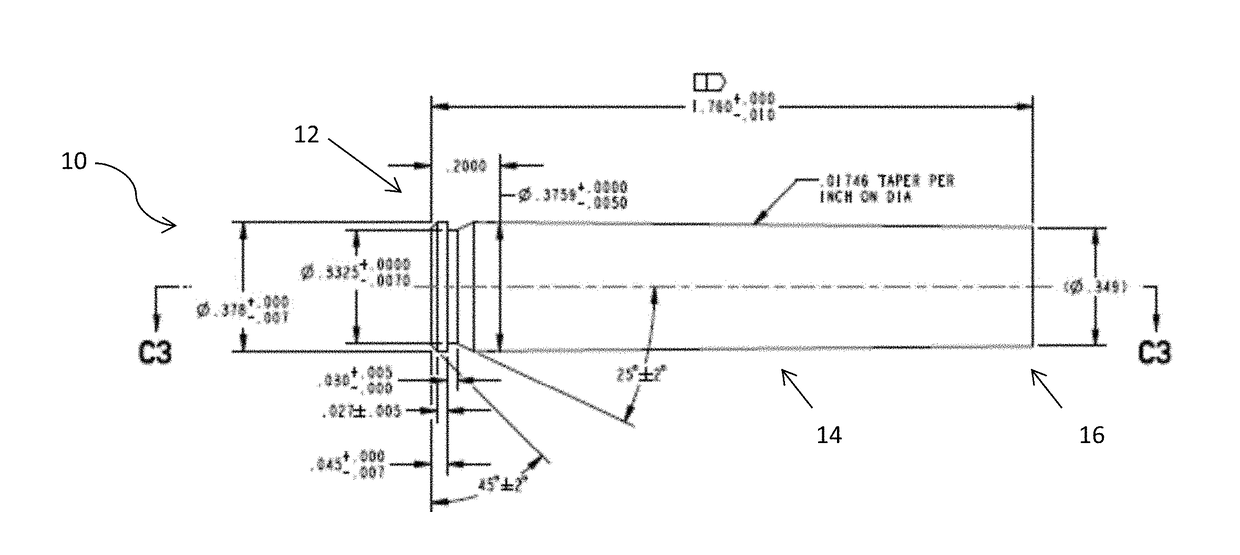

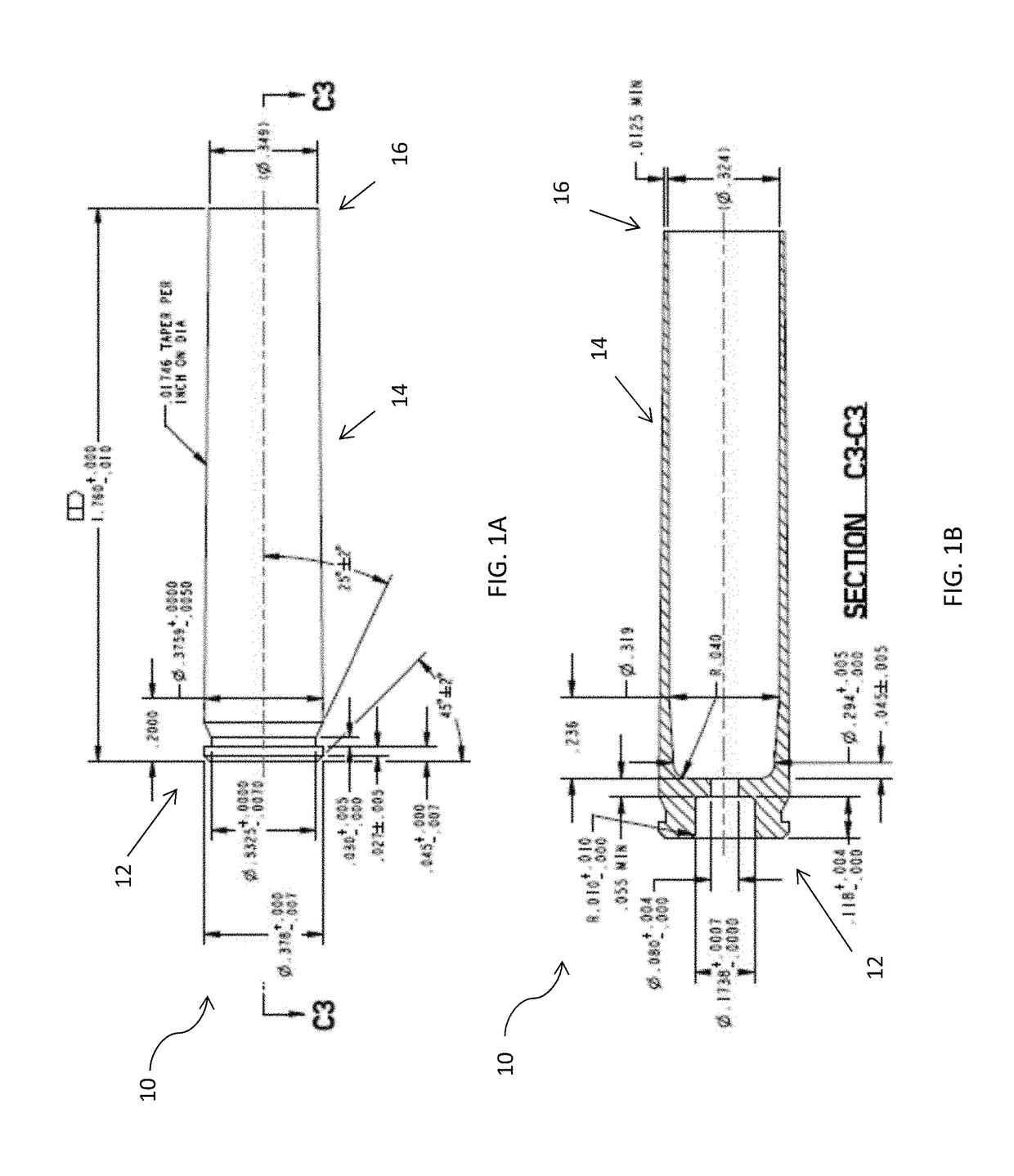

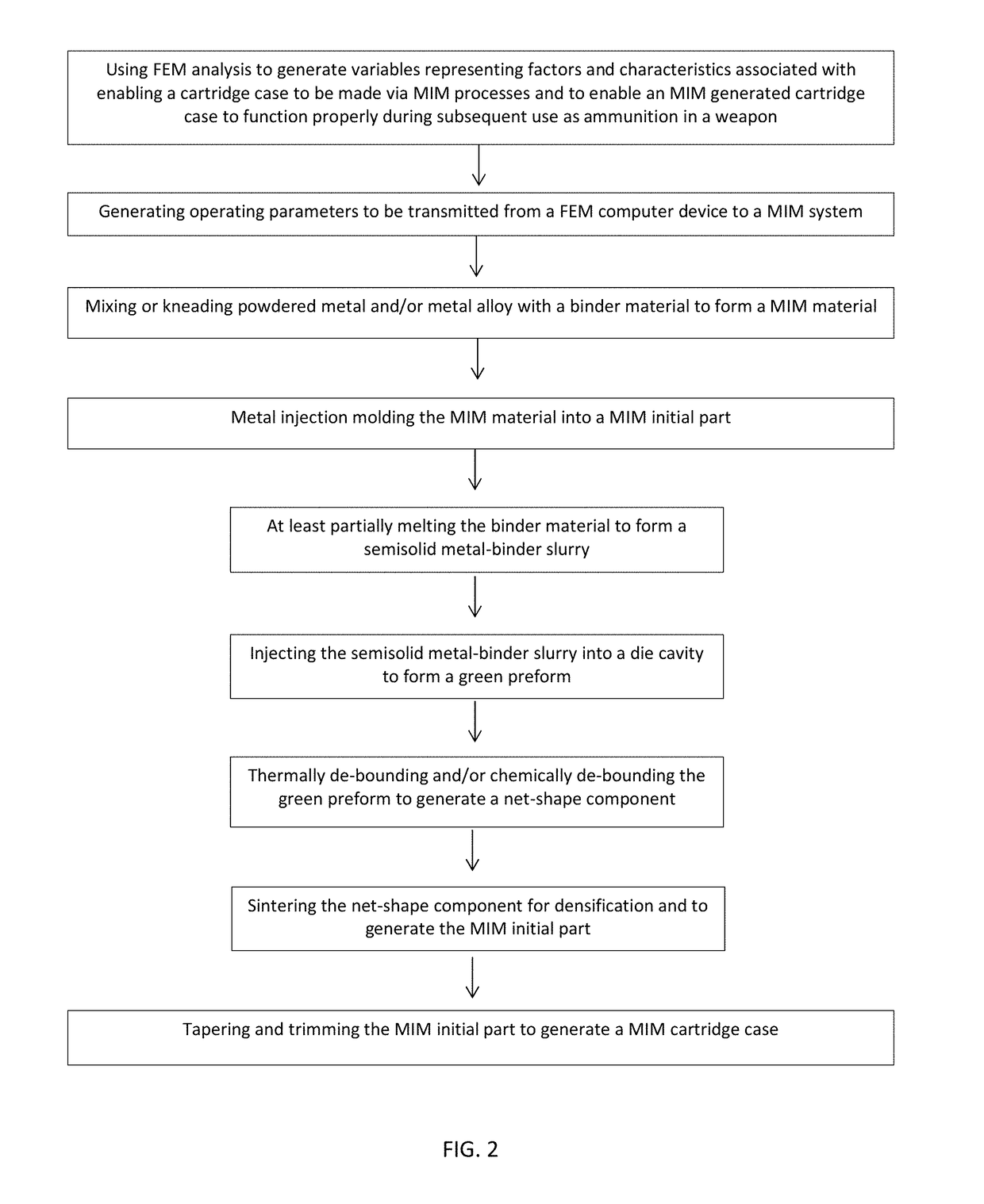

Metal Injection Molded Cased Telescoped Ammunition

ActiveUS20180066925A1Promote generationLight weightTransportation and packagingMetal-working apparatusMetal alloySlug

Disclosed is a cartridge case for various caliber ammunition that can consist essentially of a powdered metal and / or powdered metal alloy(s) that is formed into the cartridge case through an injection mold processing. Also disclosed is a method for forming a cartridge case, which may include use of Metal Injection Molding (“MIM”) processes to produce the cartridge case which retains a primer, propellant, and / or a bullet. Also disclosed are embodiments related to a case telescoped cartridge that may include a cap and a body. The body can consist essentially of or consists entirely of a powdered metal and / or powdered metal alloy(s) that has been formed through MIM. The cap can comprise plastic that has been formed through plastic molding or comprise powdered metal and / or powdered metal alloy(s) that has been formed through MIM.

Owner:CONCURRENT TECH

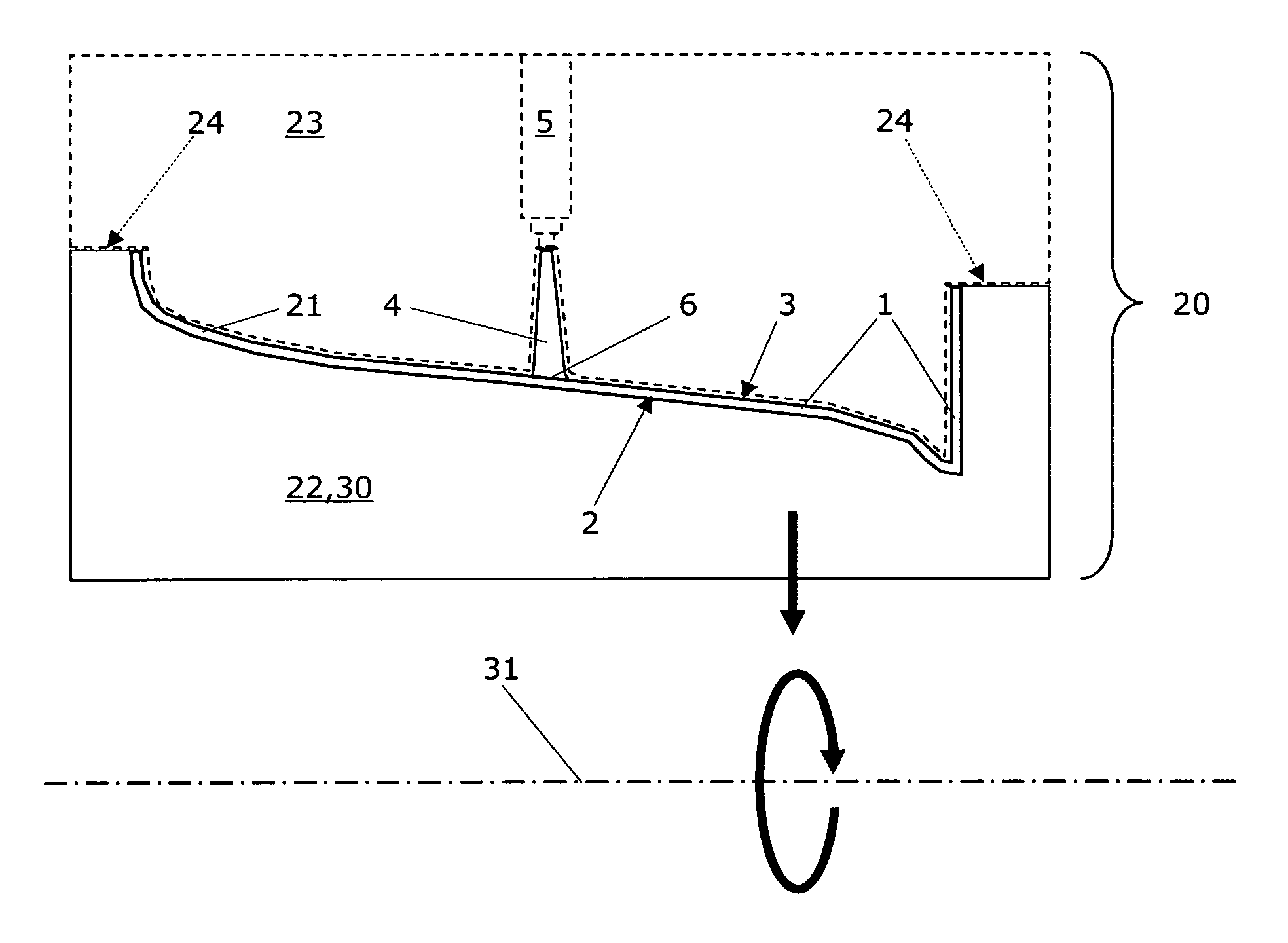

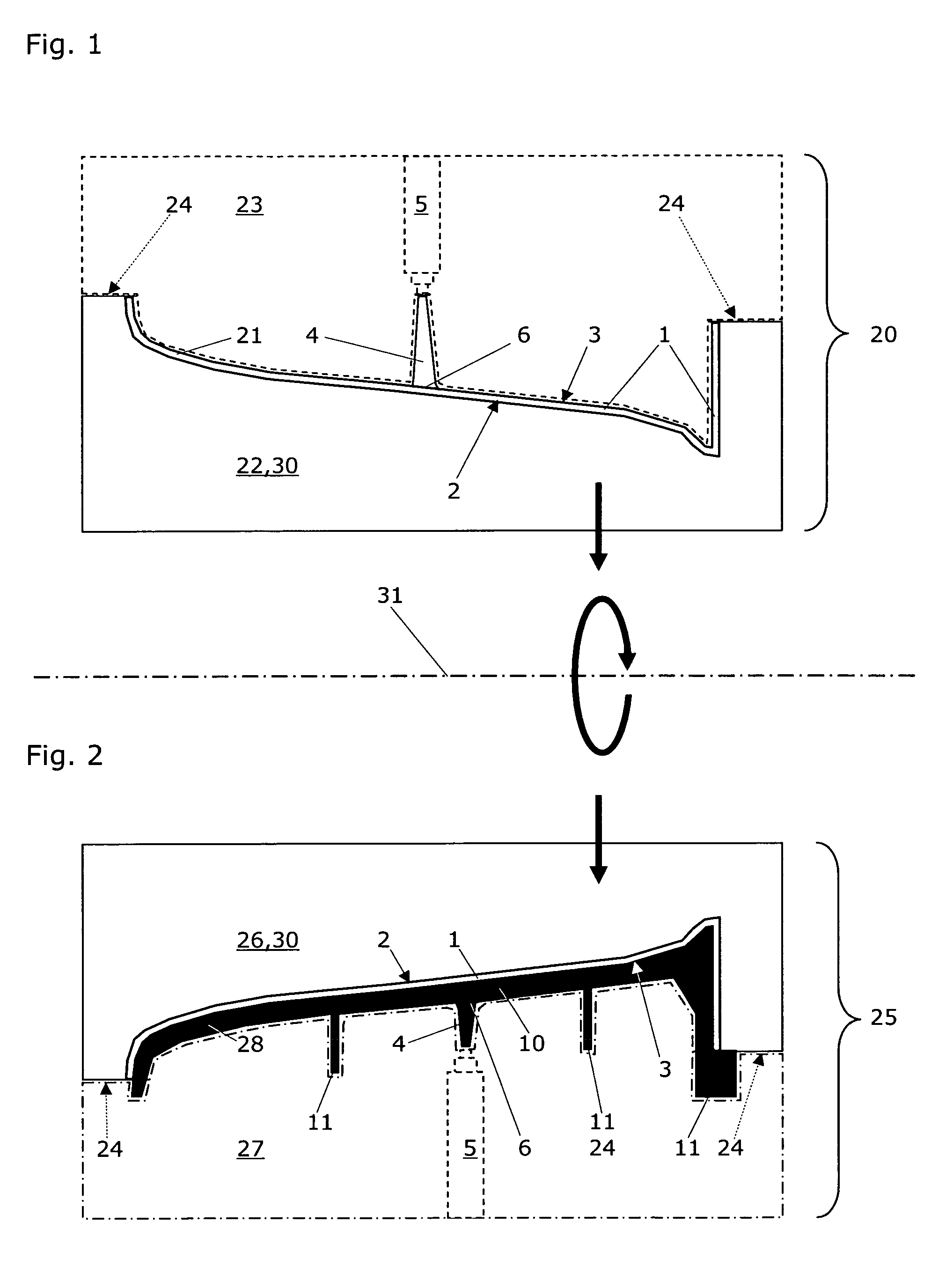

Injection molding method for manufacturing plastic parts

InactiveUS20060068206A1Quality improvementImprove replicationMouldsLayered productsInjection pointSingle injection

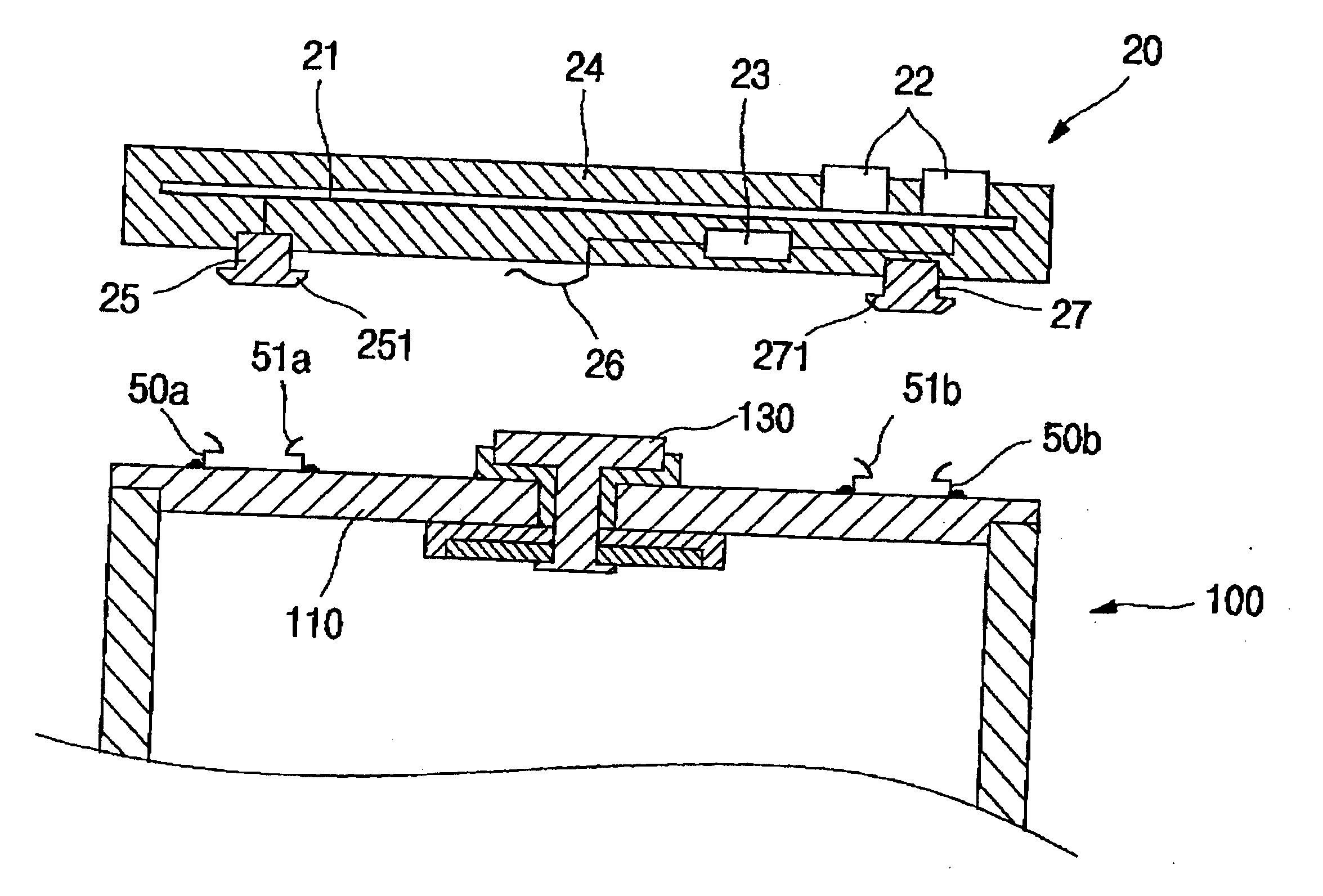

Disclosed is an injection molding method for manufacturing plastic parts from thermoplastically processible plastic molding materials with at least one exposed part (1) and at least one functional part (10), whereby the plastic molding material for the exposed part (1) comprises a transparent or translucent matrix with added effect pigments, and whereby the functional parts (10) can exhibit different physical and / or chemical plastic properties to the exposed parts (1). The injection molding method comprises the following steps: a) injection molding and solidification of the plastic molding material of the at least one exposed part (1) with an exposed surface (2) and a core surface (3) facing away from the latter in a first mold (20) with a first cavity (21); b) opening of the first mold (20) along a parting line or plane (24); c) closing of a second mold (25) with the at least one exposed part (1) in a second cavity (28); d) injection molding and solidification of the plastic molding material of the functional part (10) on the core surface (3) of the at least one exposed part (1); and e) opening of the second mold (25) and removal of the part. The injection molding method according to the invention is characterized in that for each exposed part (1)—to prevent irregularities such as flow marks and / or knit lines—a single injection nozzle (5) positioned to optimize the flow or at least two injection nozzles in a cascaded injection molding method are used, and that the plastic molding material for the exposed part (1) comprises at least one transparent polymer. The corresponding plastic parts manufactured by injection molding exhibit an exposed surface (2) and a core surface (3) facing away from the latter with at least one injection point (6), whereby the functional part (10) of the plastic part is injection molded onto the core surface (3) of the previously solidified exposed part (1).

Owner:EMS CHEM AG

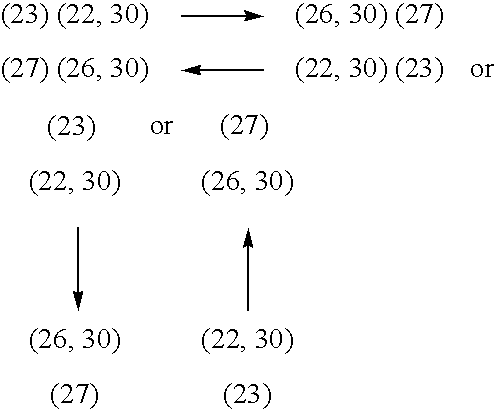

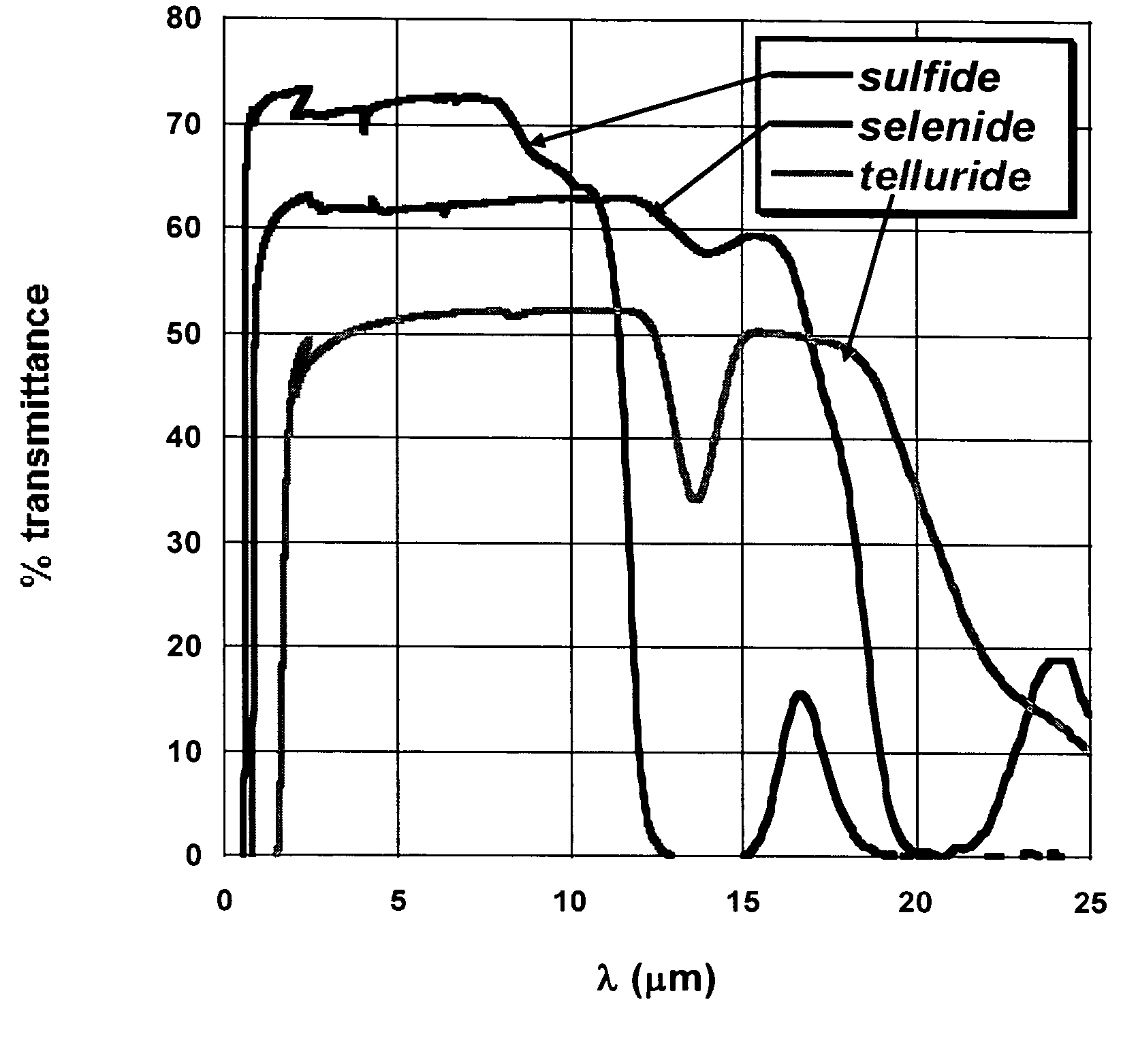

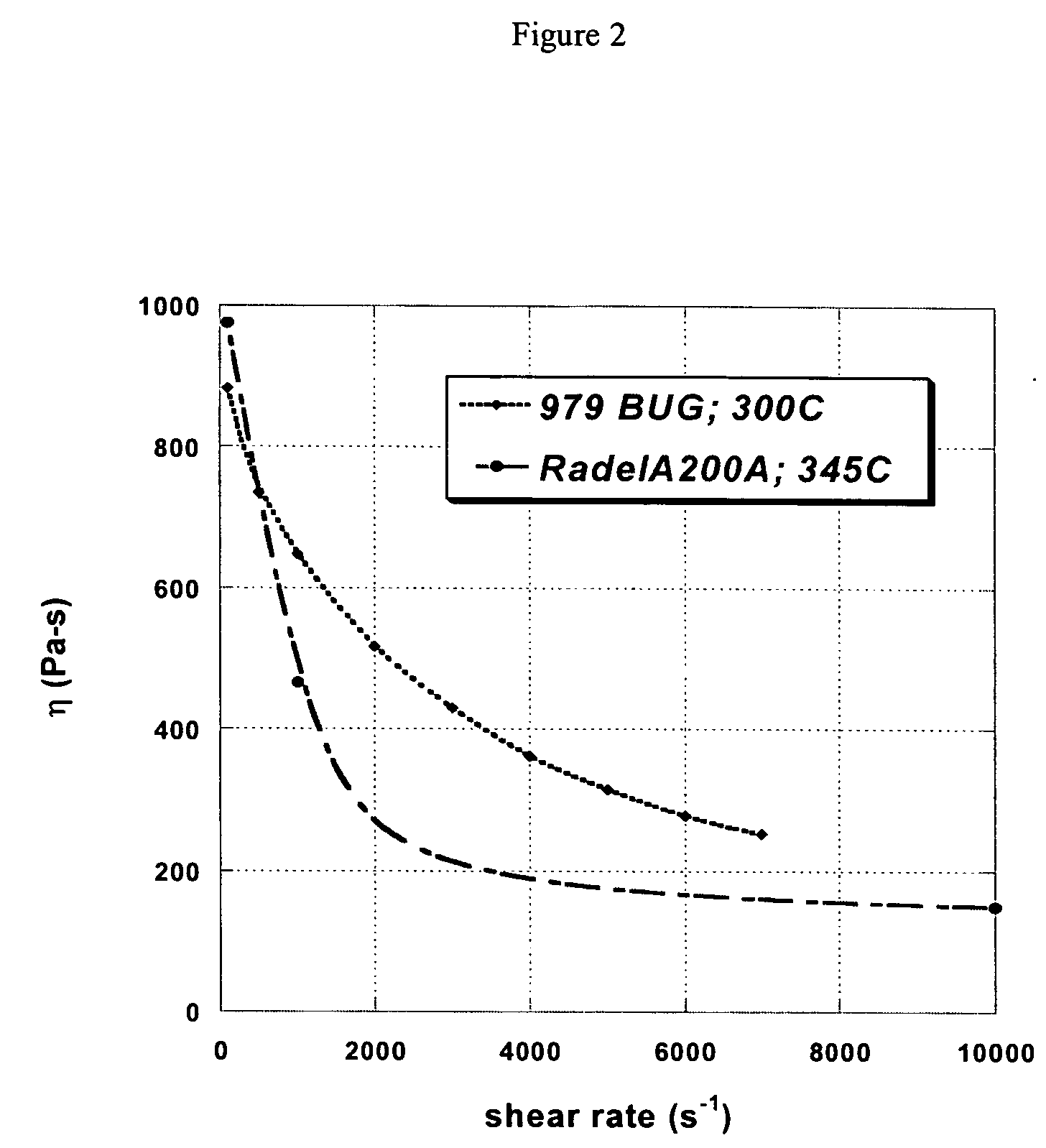

Chalcogenide glass for low viscosity extrusion and injection molding

ActiveUS20060233512A1Low cost manufacturingGlass making apparatusCladded optical fibreSulfurChalcogenide glass

Owner:CORNING INC

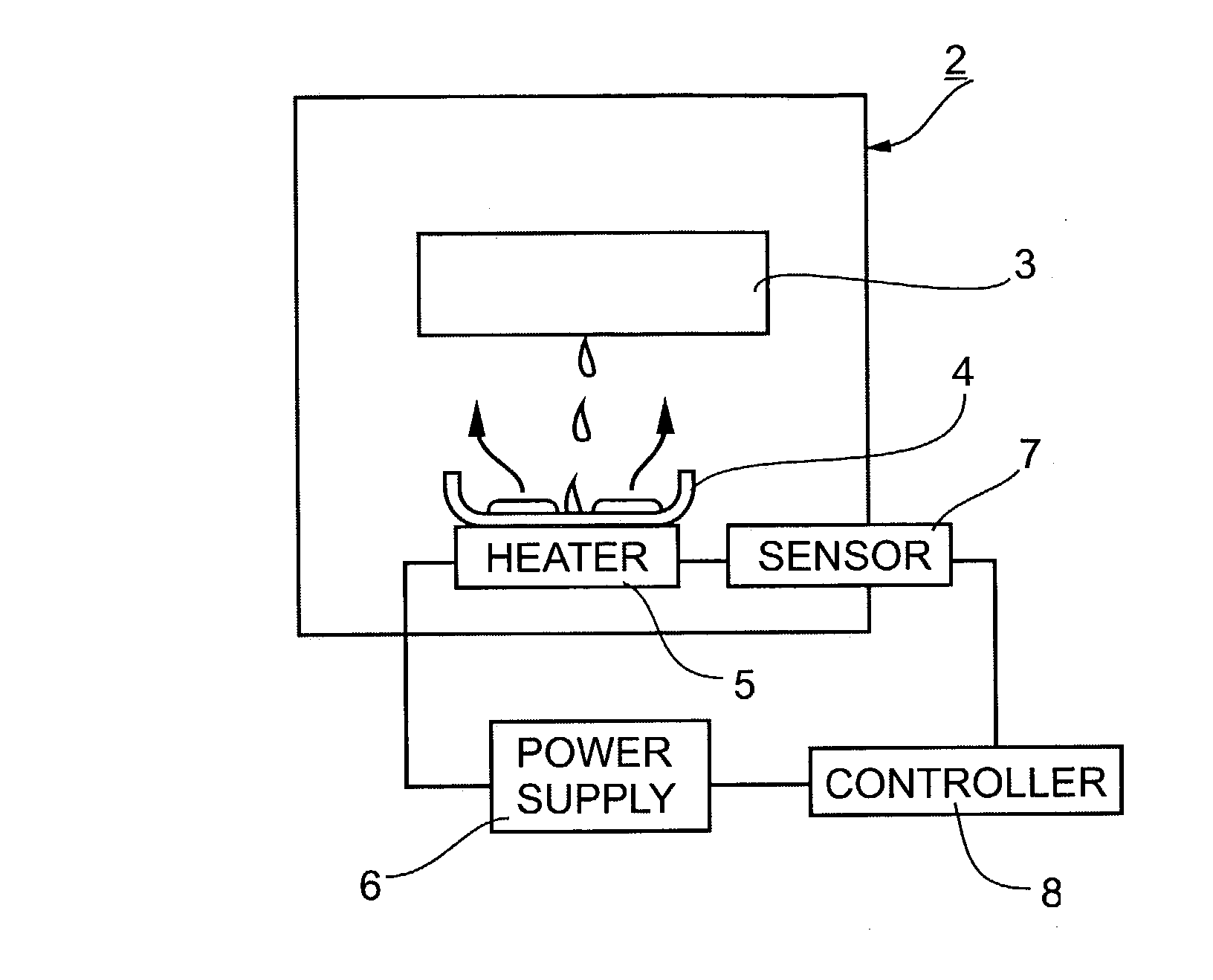

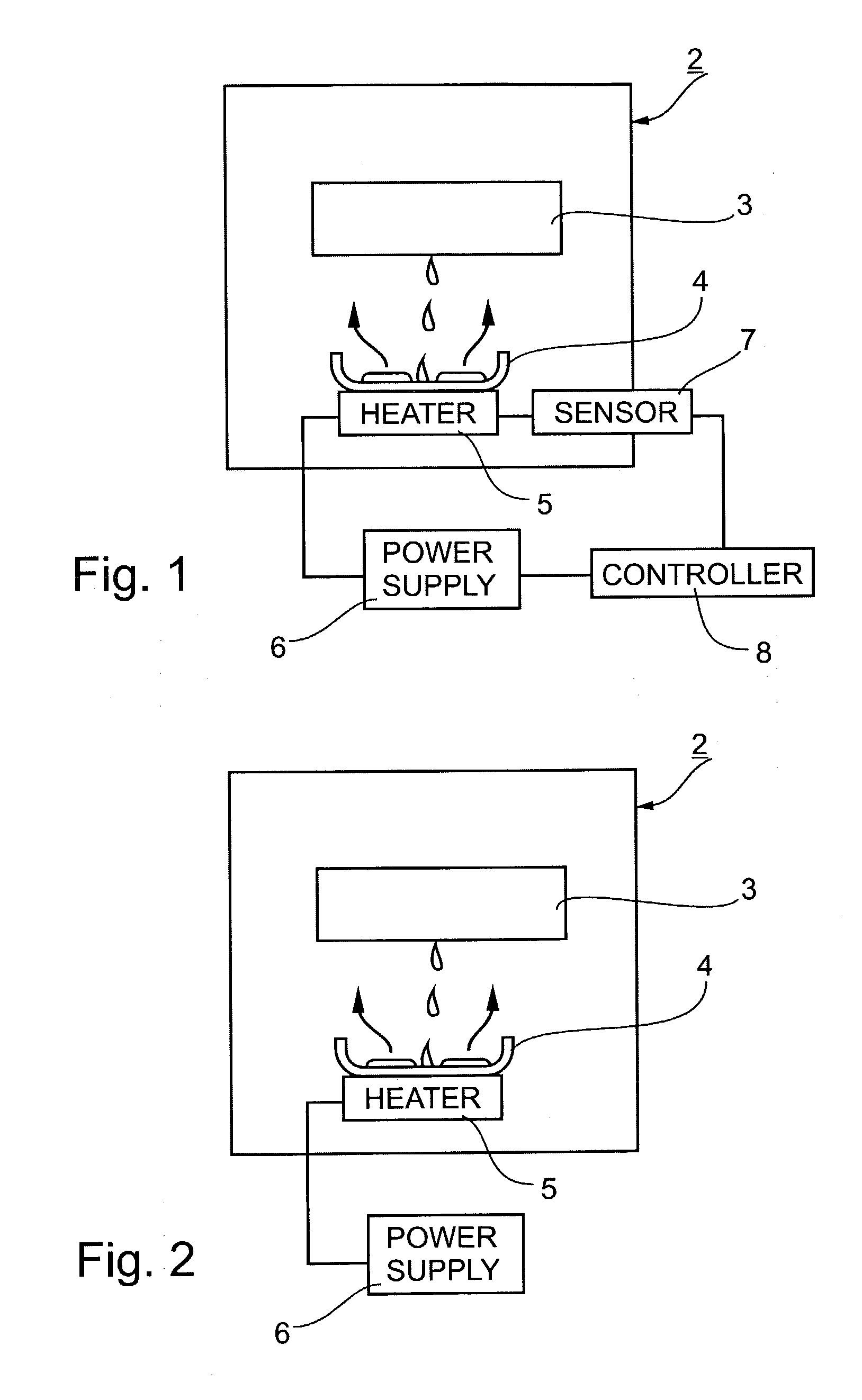

Liquid heating method and apparatus particularly useful for vaporizing a liquid condensate from cooling devices

InactiveUS20030206730A1Minimize power consumptionRule out the possibilitySpace heating and ventilationSteam cooking vesselsElectrical resistance and conductanceBoiling point

A method and heating device for heating a liquid, particularly useful for removing liquid condensate from cooling devices, by wetting a heating plate with the liquid and controlling the electrical power supply to maintain the heating plate at a the predetermined temperature above the boiling point of the liquid, such that when the heating plate is not wetted by the liquid, the electrical power supply to the heating plate is automatically maintained at a relatively low value, but as soon as the heating plate is wetted by the liquid, the electrical power supplied to the heating plate is automatically increased until the liquid is completely evaporated. The heating plate is heated by one or more PTC thermistors in which the electrical resistance increases with temperature to automatically maintain the predetermined temperature. Besides evaporating liquid condensate, the heating device is described for use in many other applications including steam generation, space heating and plastic molding.

Owner:A T C T ADVANCED THERMAL CHIP TECH

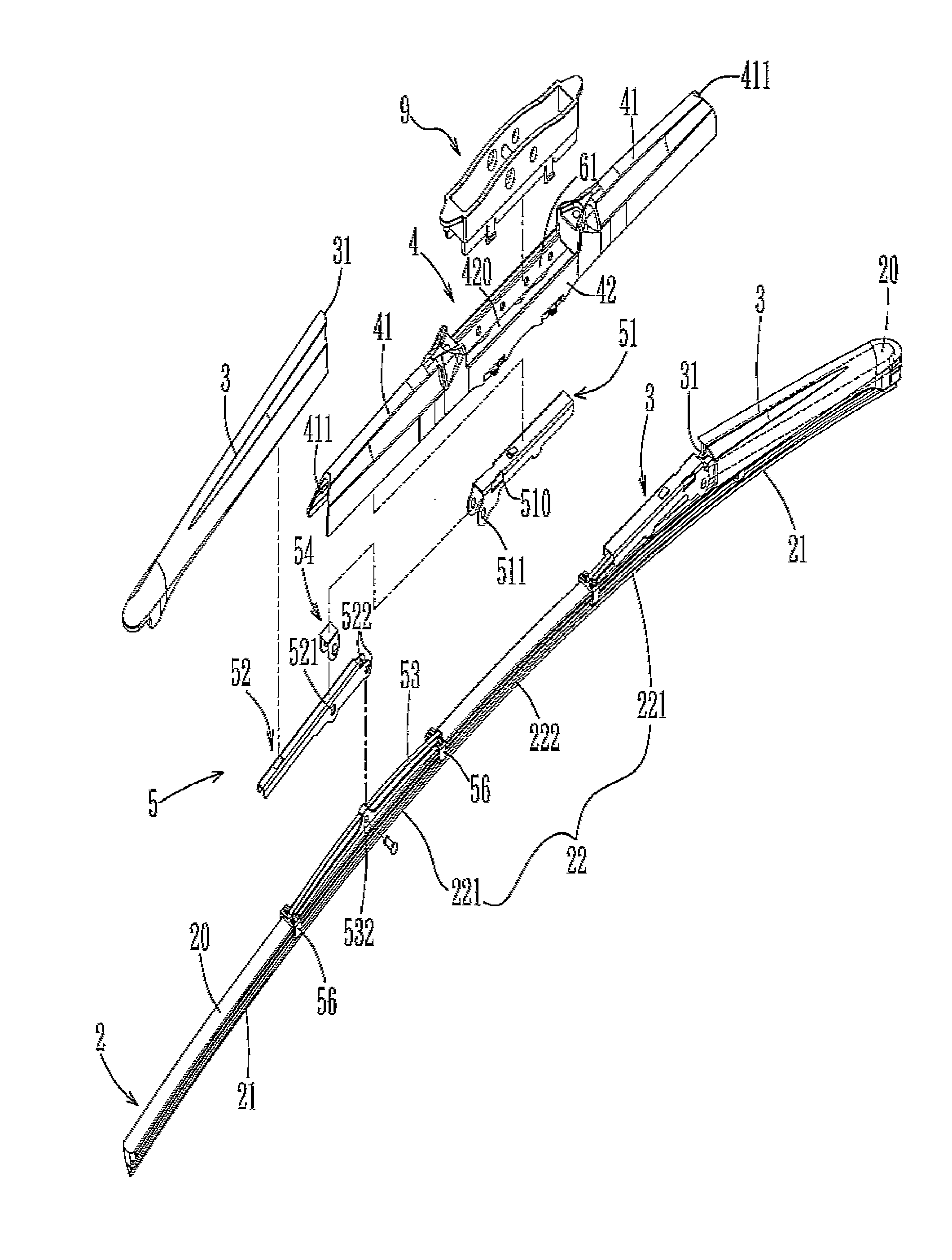

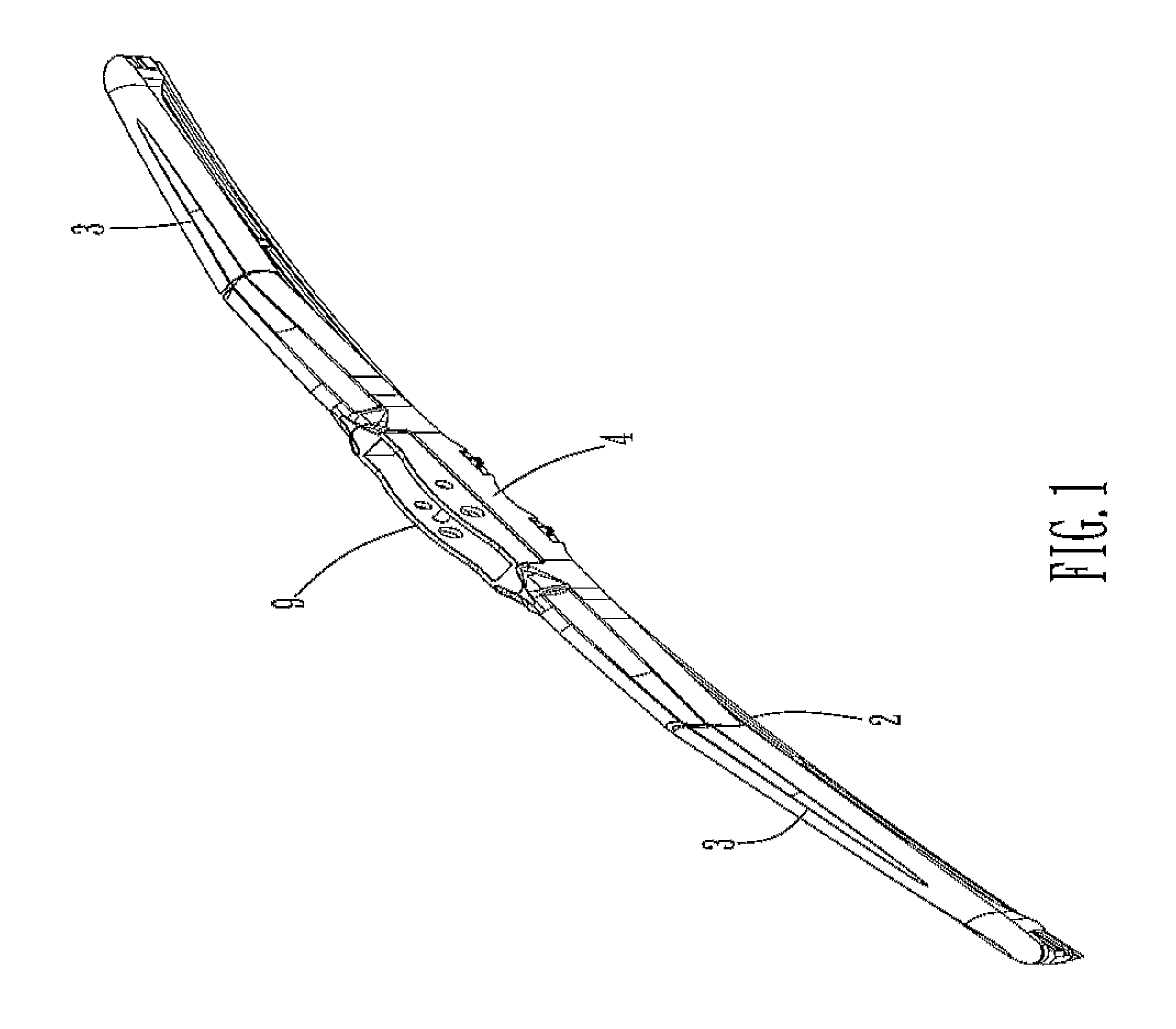

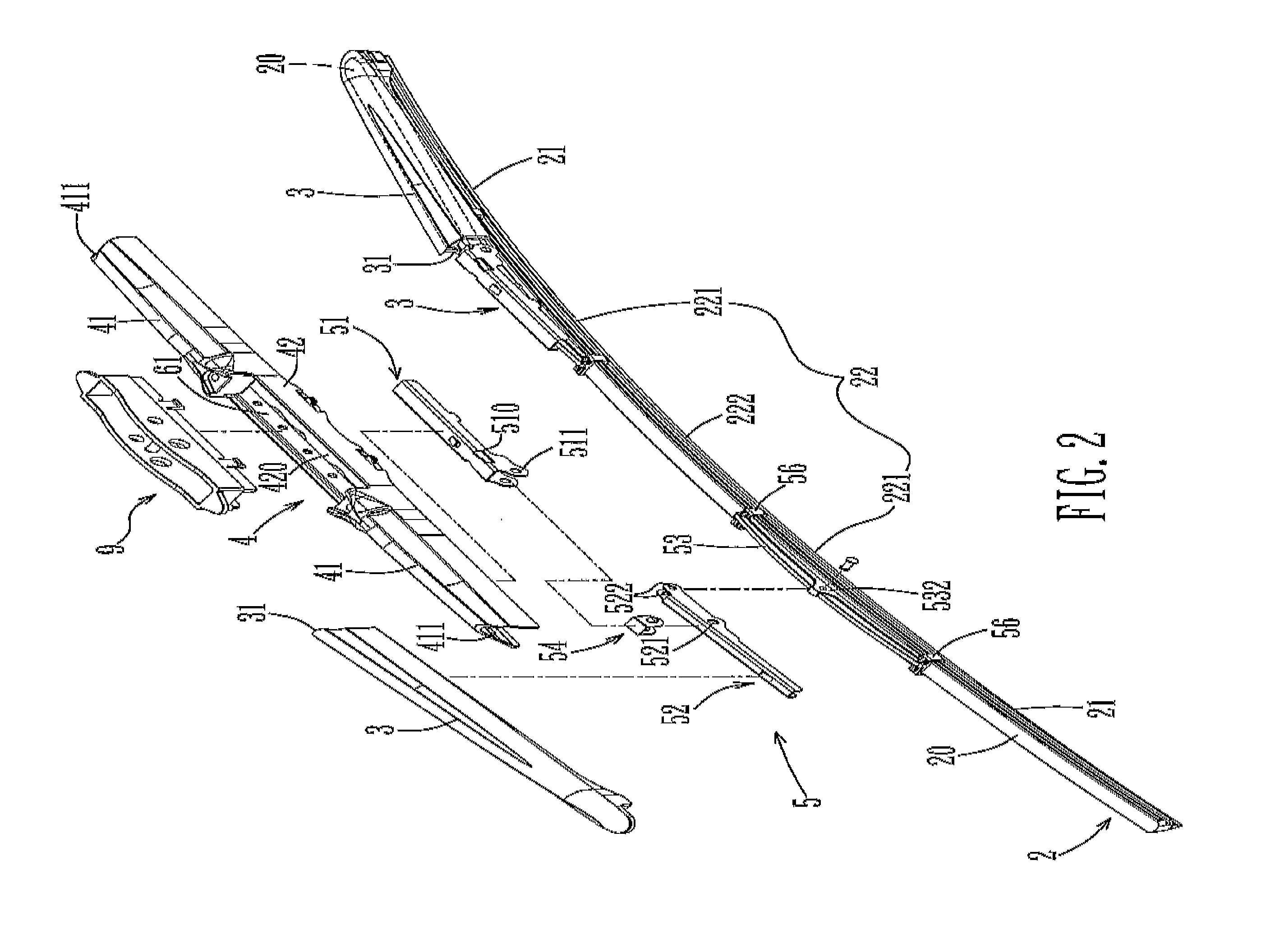

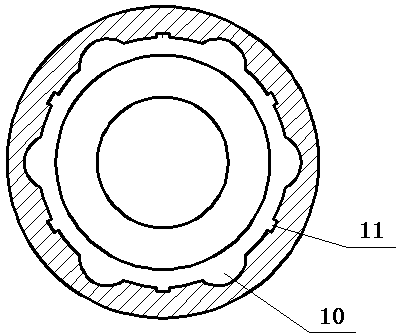

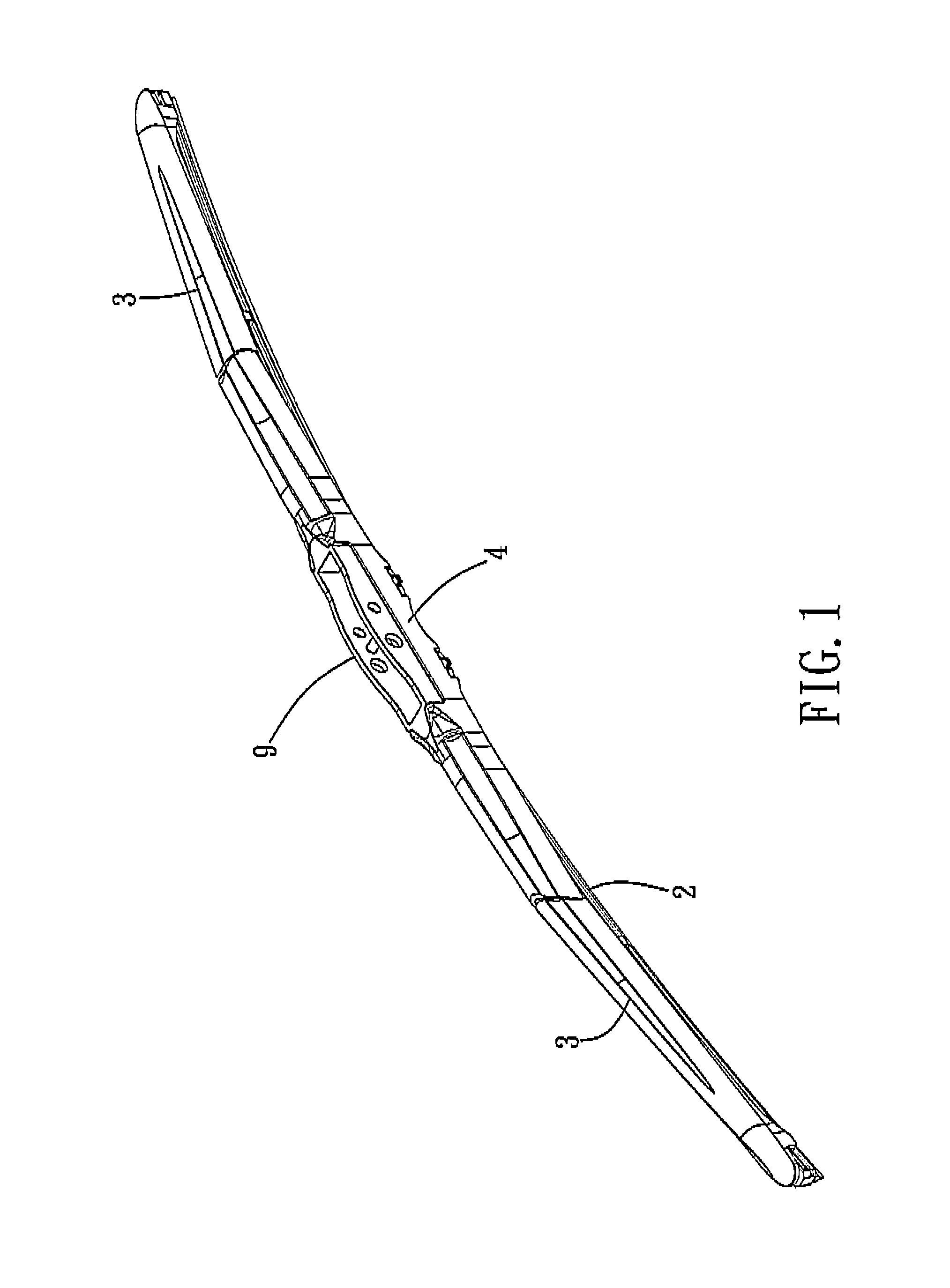

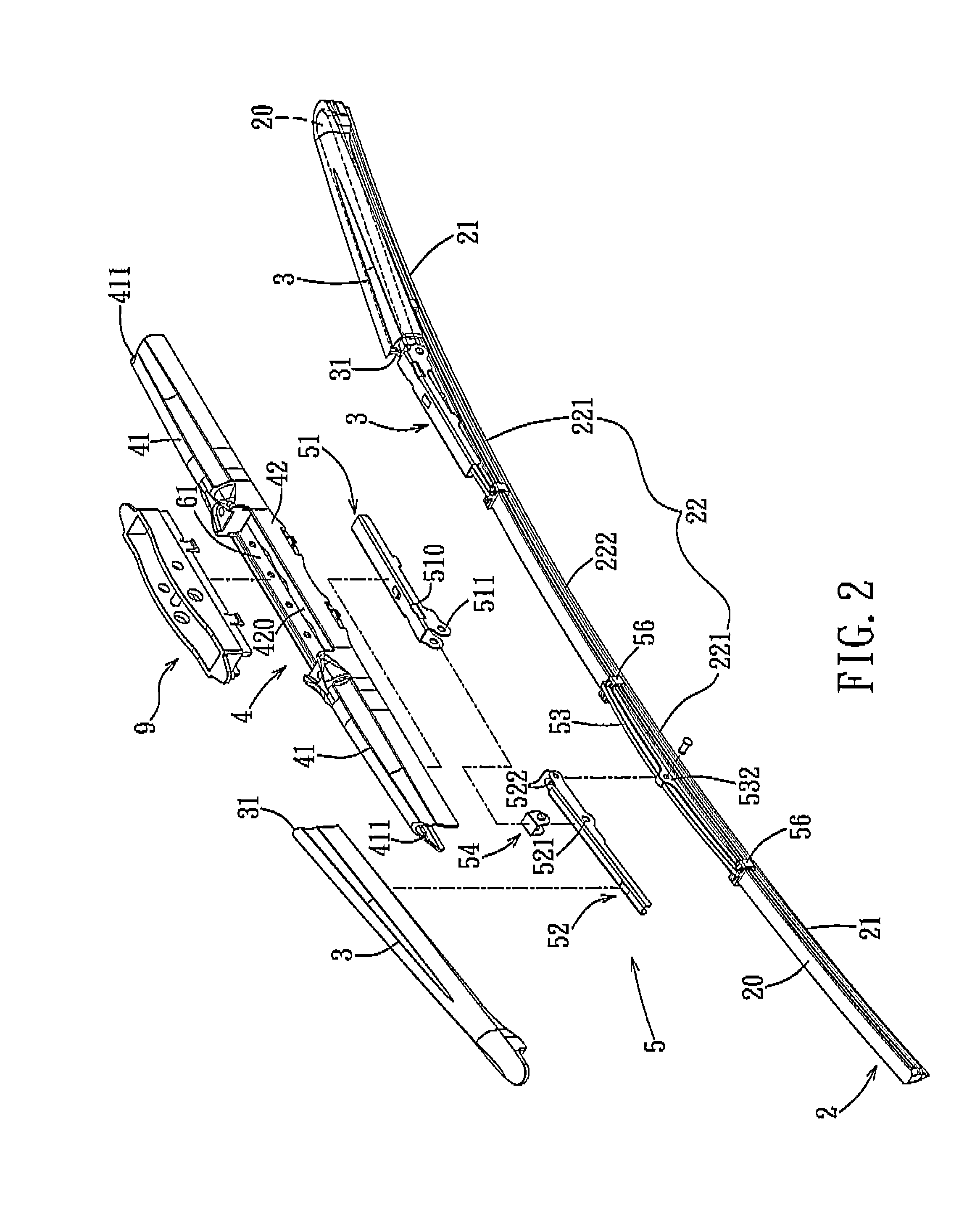

Windshield wiper blade assembly

InactiveUS20120180245A1Overcomes drawbackWindow cleanersVehicle cleaningPlastic materialsPlastic molding

A windshield wiper blade assembly comprises: an elastic wiper blade; first and second housings secured to and covering a top end of the wiper blade and made from a plastic material; and a middle housing disposed between the first and second housings and having two end segments and a middle segment extending between the end segments. The end segments of the middle housing cover and are secured to the top end of the wiper blade at the end sections of the middle portion, respectively, and have ends in contact with ends of the first and second housings, respectively. The middle segment defines a frame space for extension of a connecting piece therein and includes a skeleton and a plastic molding layer molded over the skeleton.

Owner:DONGGUAN HONGYI WIPER

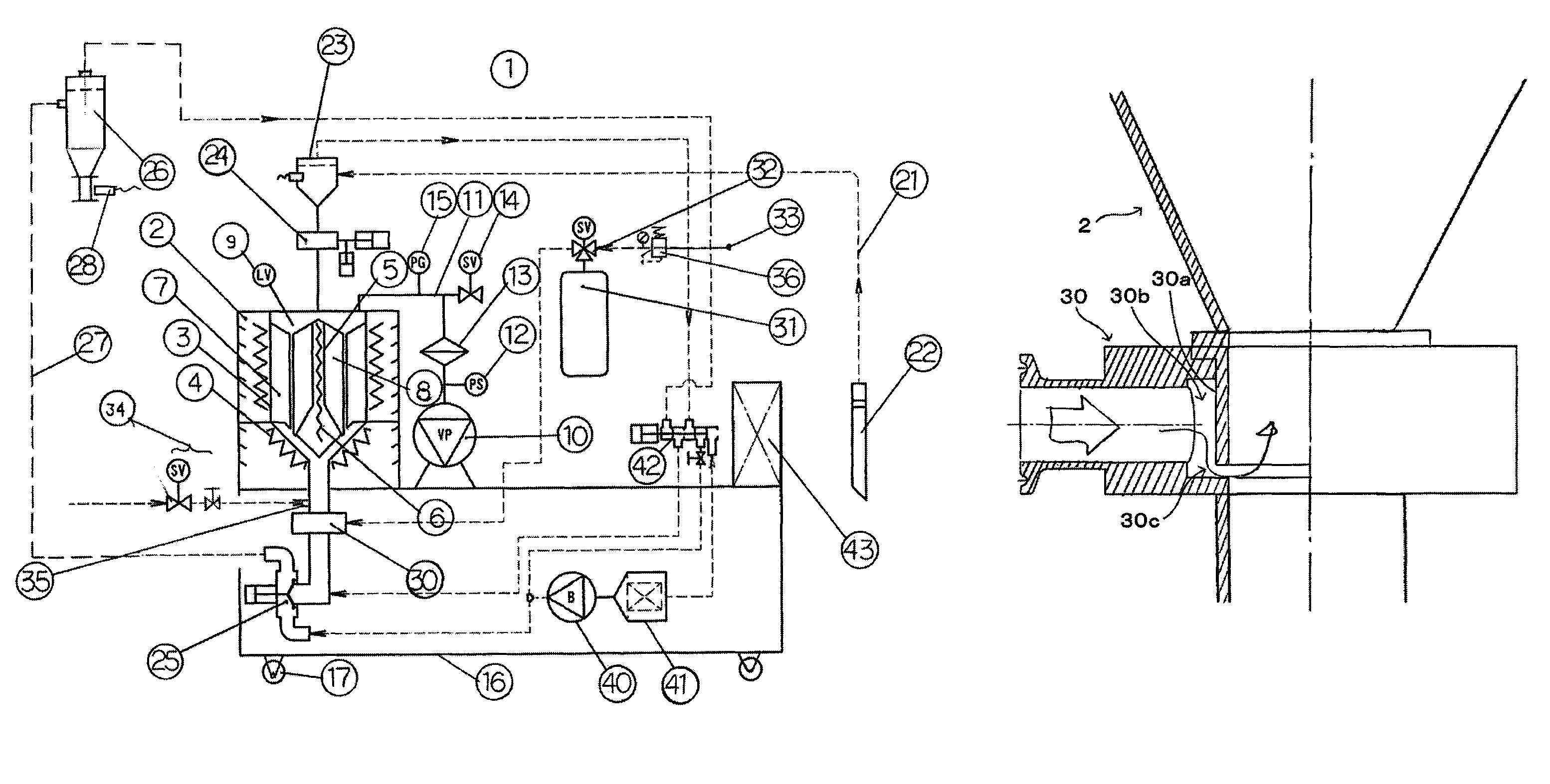

Drying apparatus under reduced pressure for plastic molding material

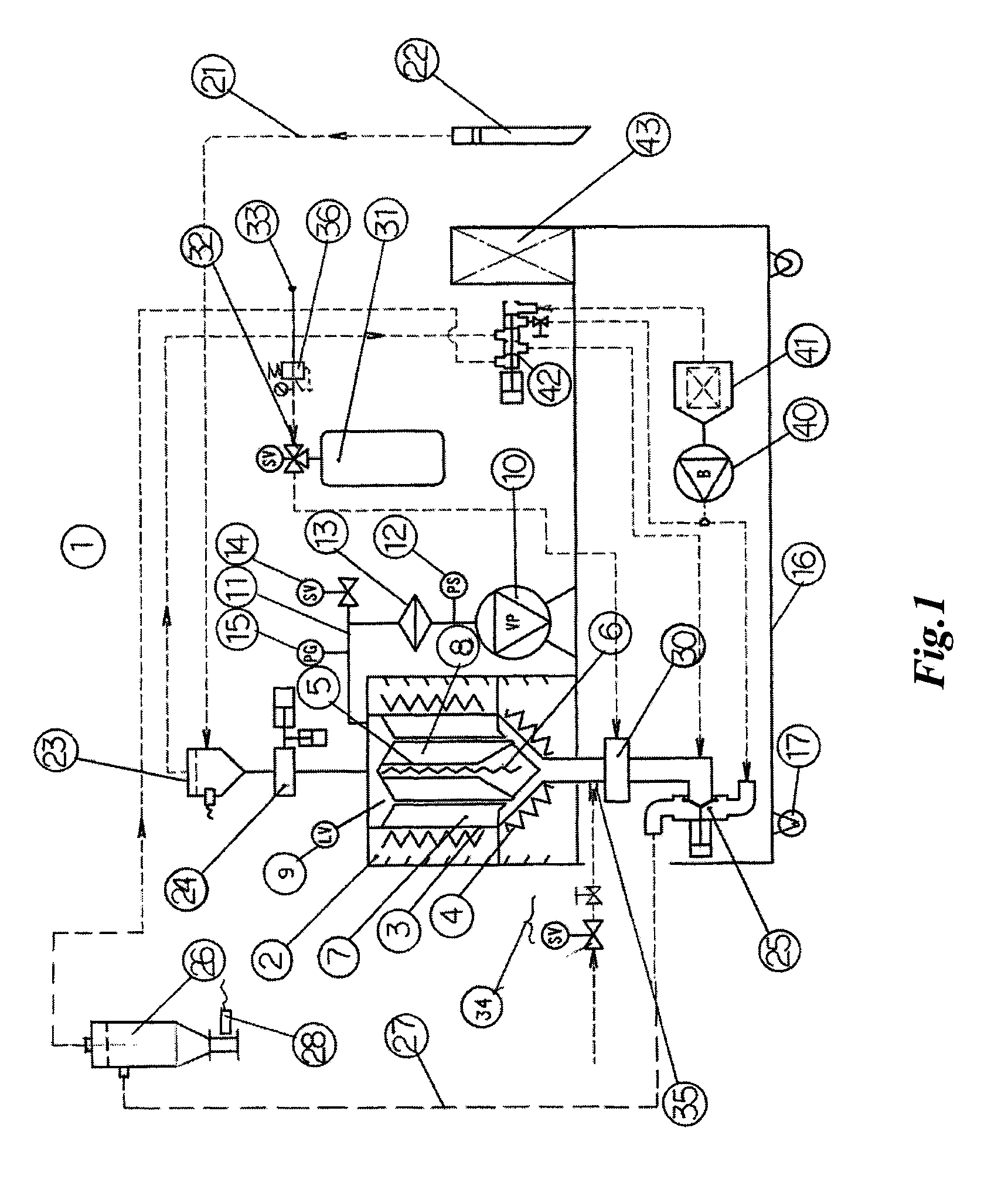

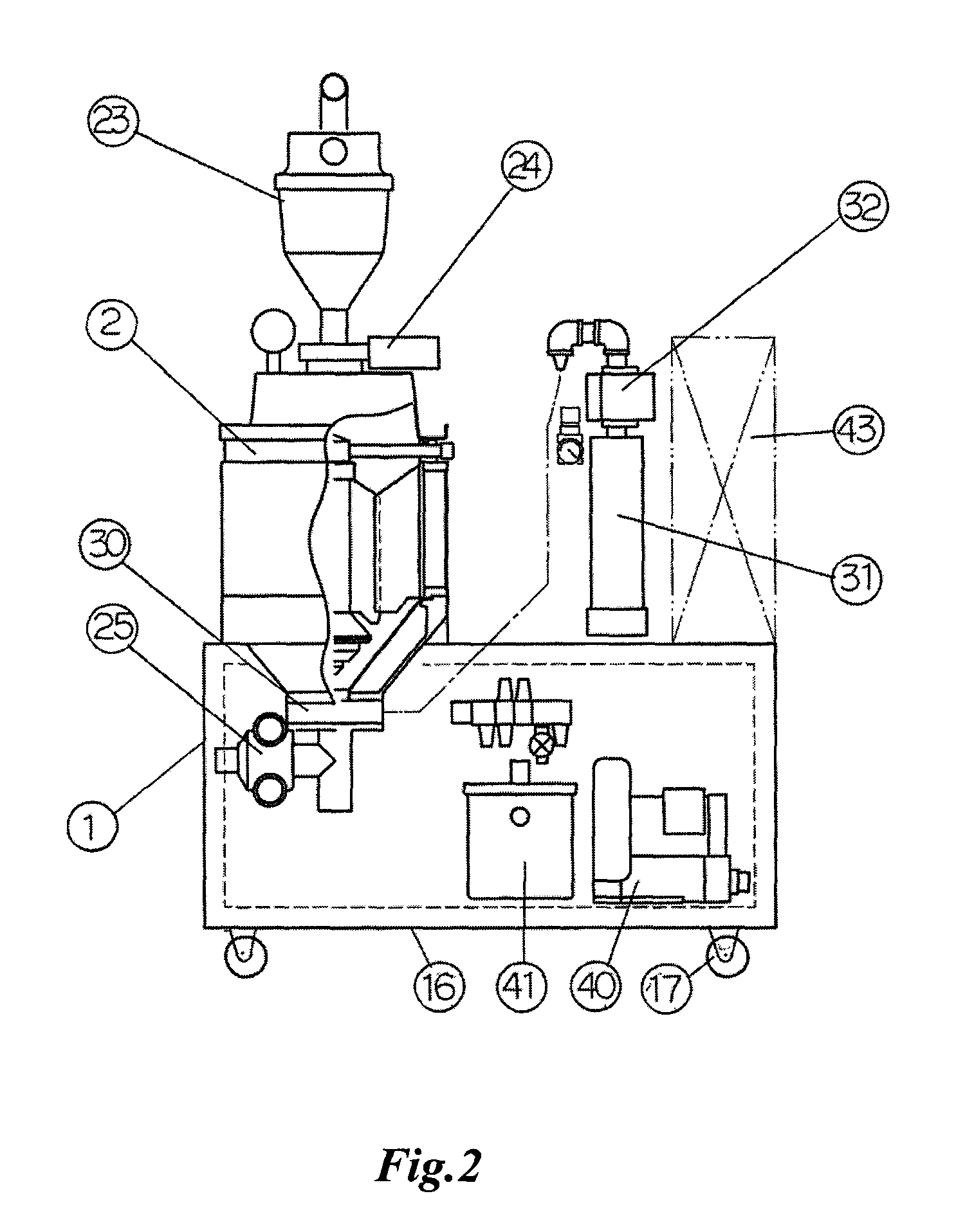

InactiveUS8776390B2Preventing short-pass phenomenonAvoid stickingDrying solid materials without heatLayered productsPlastic materialsEngineering

A drying apparatus under reduced pressure for a plastic molding material. The apparatus comprises a drying hopper provided with an airtight material charge valve capable of containing gas therein at its upper portion and a material discharge valve at its lower portion, and connected to a vacuum pump via vacuum piping, a heating means of thermal conduction type provided in the drying hopper, and a plastic material adherence preventing means in which a gas charge port connected to a gas tank storing gas via a gas changeover valve is provided between the material discharge valve and the drying hopper and stored gas is fed into the drying hopper by opening the gas changeover valve after predetermined time, thereby preventing adherence of plastic molding material.

Owner:MATSUI MFG

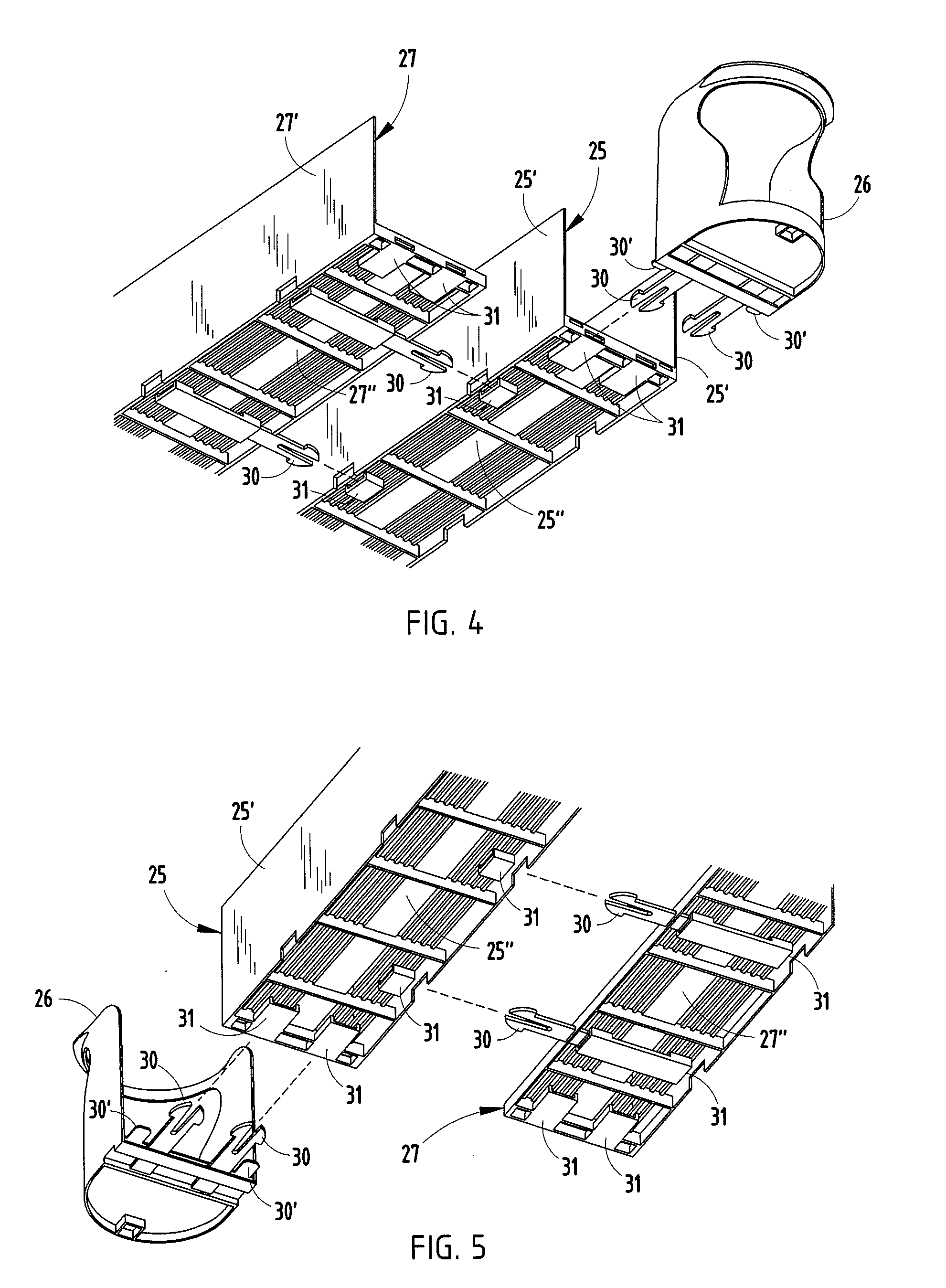

Display channel apparatus

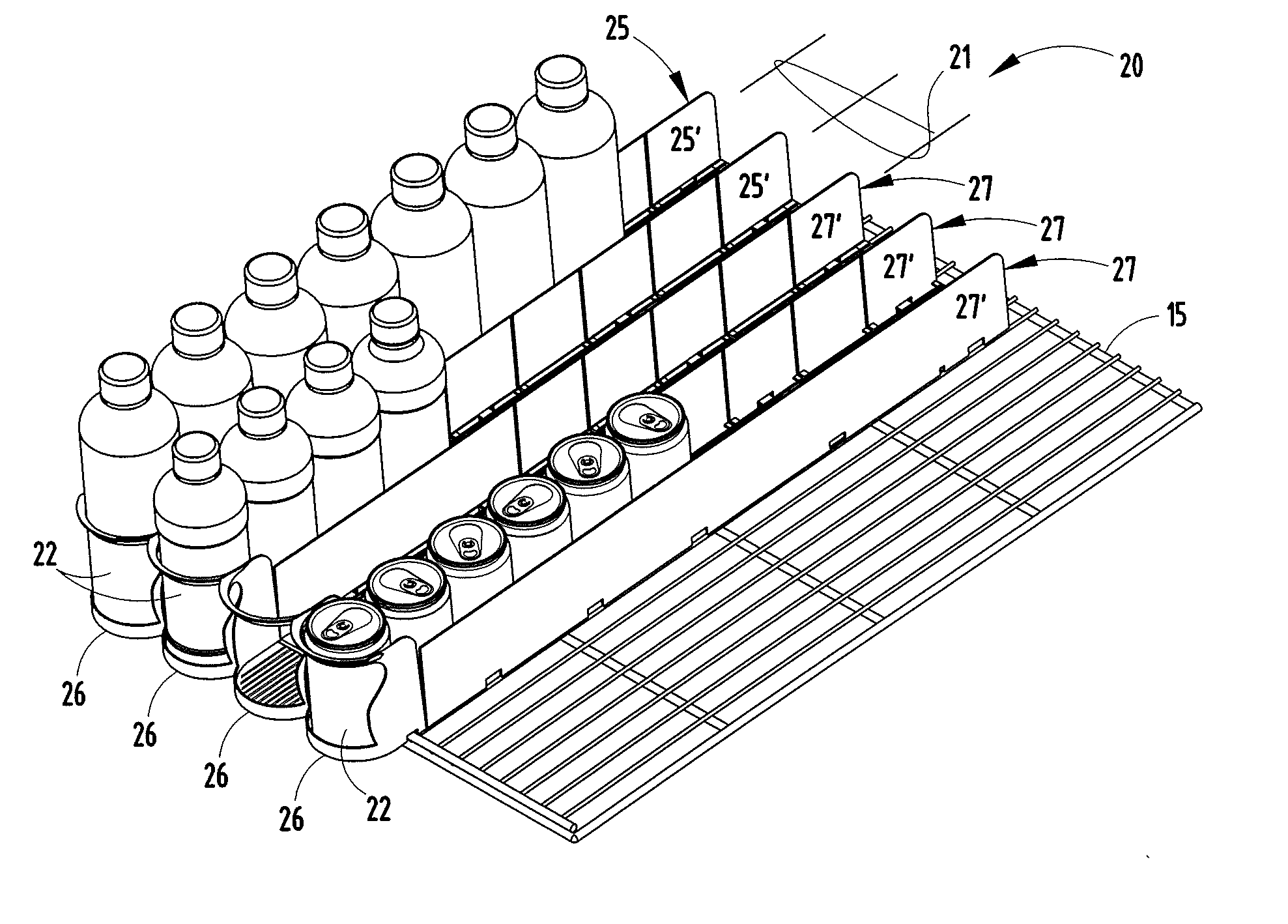

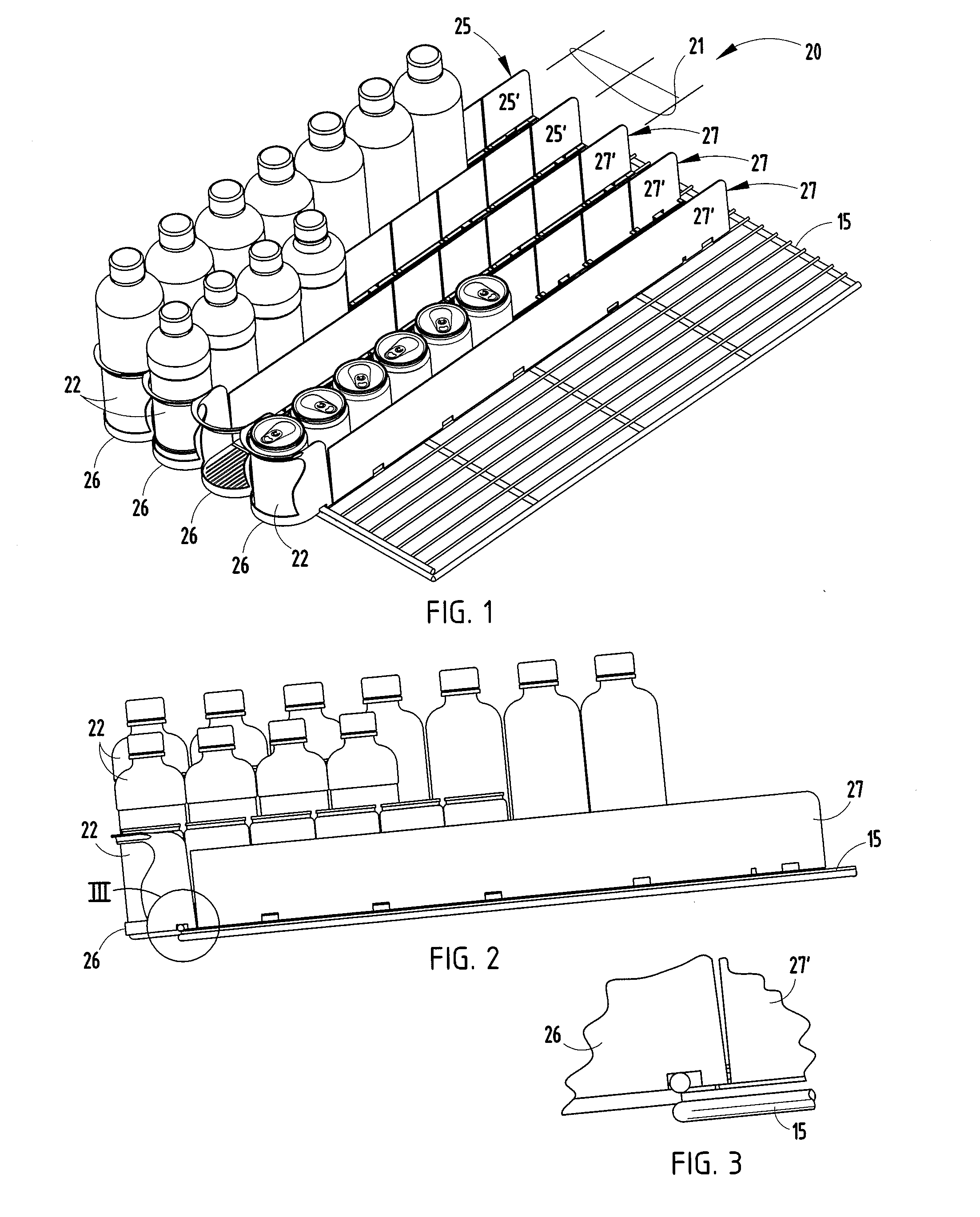

InactiveUS20110094980A1Flexibility at assemblyLow costRacksMetal working apparatusMating connectionInterconnection

A display channel apparatus for displaying containers comprises a starter channel, a plurality of extender channels, fronts and rears. These components include a plurality of horizontally-engaging mating connectors that are preferably integrally formed, and formed without slides or pulls in the plastic molding dies, and further that have sufficient length and stiffness to provide a stable assembly after interconnection. They also facilitate quick assembly by sliding engagement on a table top. In one form, the components are laterally compressible / extendable to a selected width for receiving a particular sized product, and clips or connectors are adapted to fix the selected width. The individual components and the assembled components mate together for densely-stacked compact arrangements for storage (unassembled or assembled) and / or shipping. Also, the components can be selectively assembled to meet individual needs and preferences, as well as broken down for reuse, refurbishing, and / or recycling.

Owner:SEABROOK PLASTICS

Plastic component having visible part and light source

ActiveUS20070091614A1Impair impressionImpair qualityNon-electric lightingPoint-like light sourceFiberIn vehicle

The present invention relates to a plastic component having a visible part that is made in one single layer from a plastic molding compound and that comprises a transparent or translucent matrix, and having a light source that comprises one or more lamp elements, situated under the surface of the visible part. The visible part is implemented as essentially opaque in relation to daylight and transparent or translucent in relation to the light emitted by the lamp elements. The visible part also contains admixed effect pigments and defines a surface appearance image which, when the light source is inactive, essentially corresponds to the surface appearance image of the remaining wall of an object in which the plastic component is installed and which, when the light source is active, is essentially determined by the light source activity. The plastic component according to the invention is characterized in that the lamp elements are selected from a group which comprises light-emitting diodes, organic light-emitting diodes, and fiber-optic light systems, the lamp elements at least partially being embedded in the plastic molding compound of the visible part. The manifold uses of this plastic component comprise installation in vehicles, paneling elements, and furniture, as well as in housings of greatly varying devices.

Owner:EMS CHEM AG

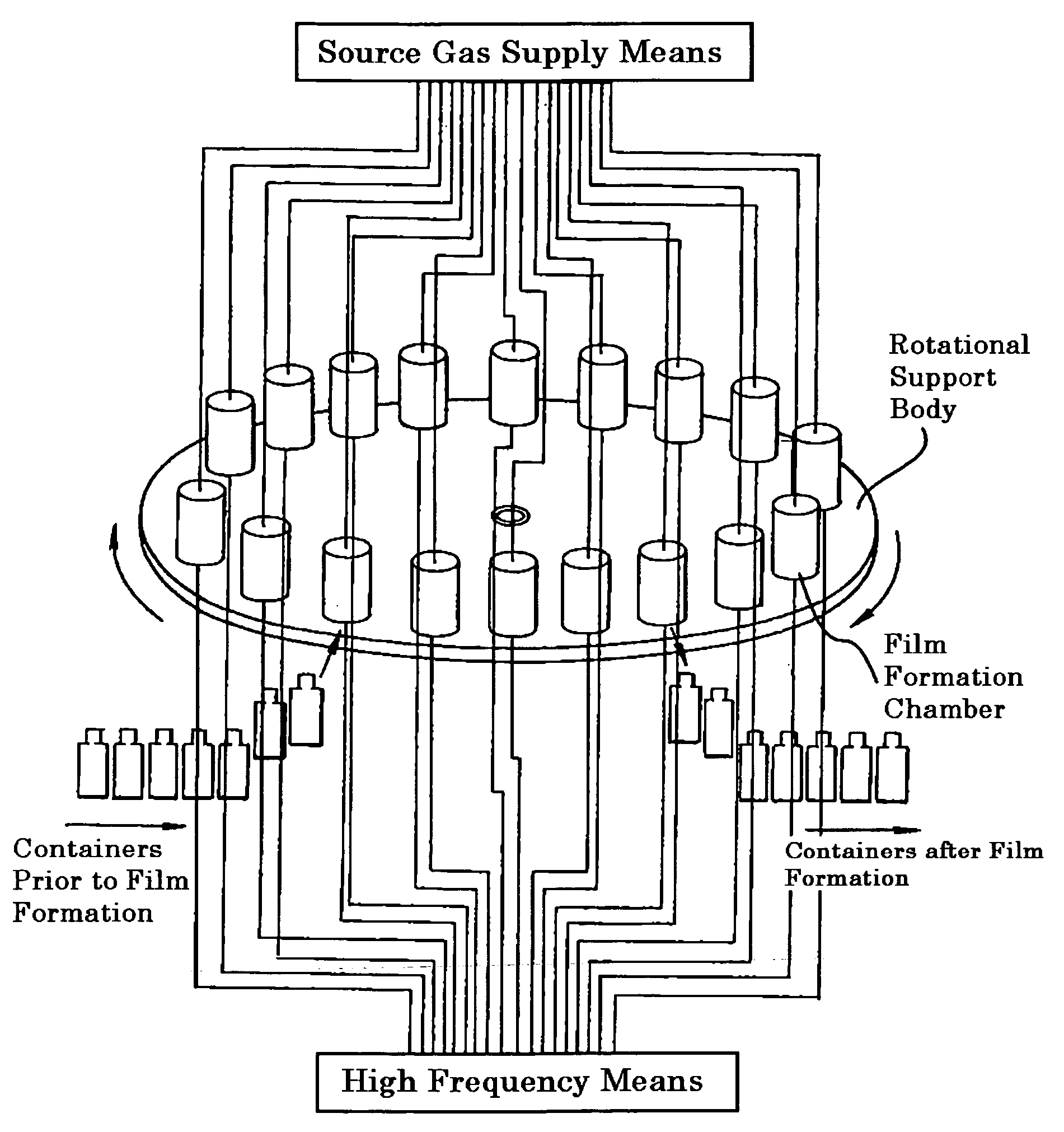

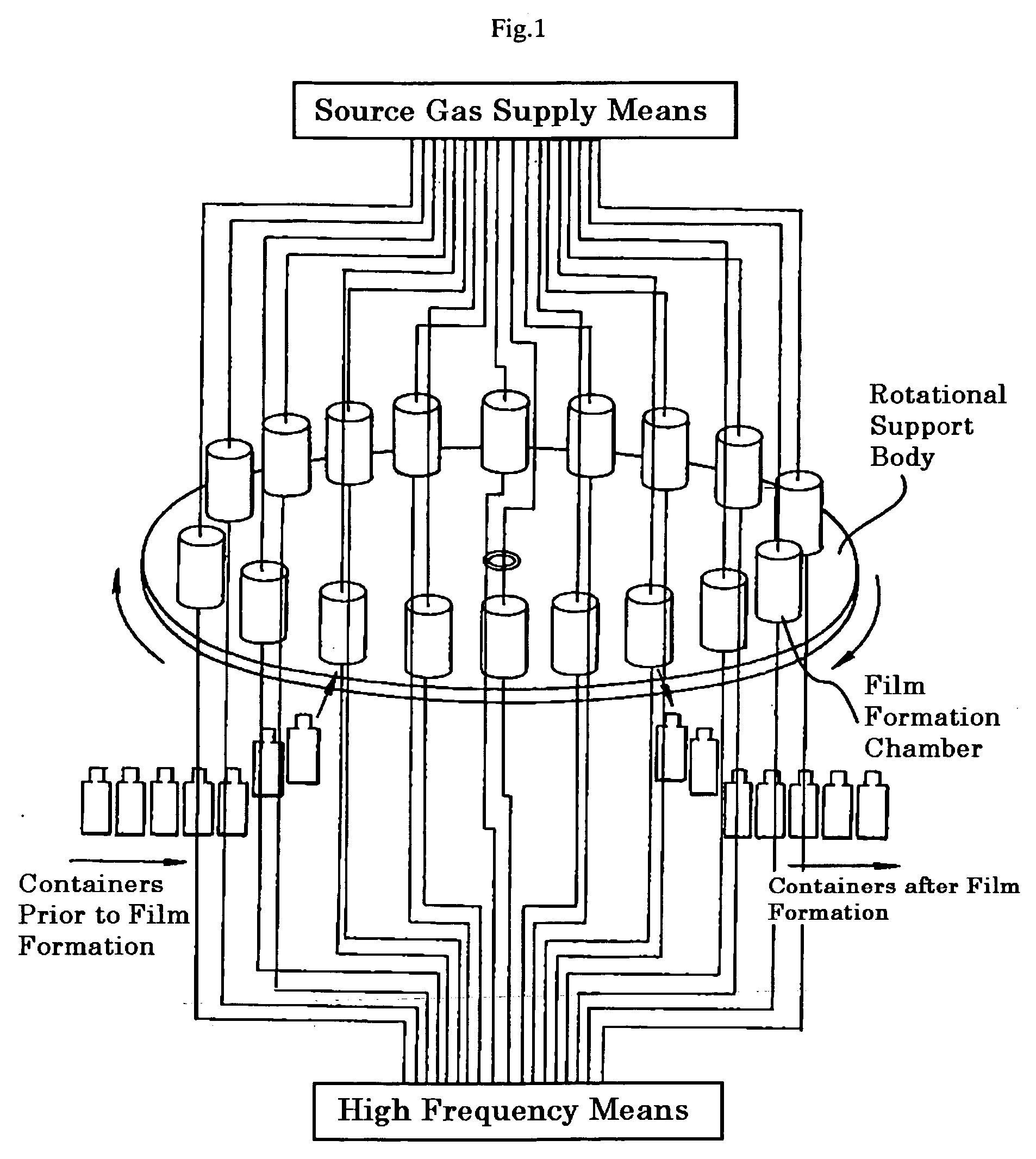

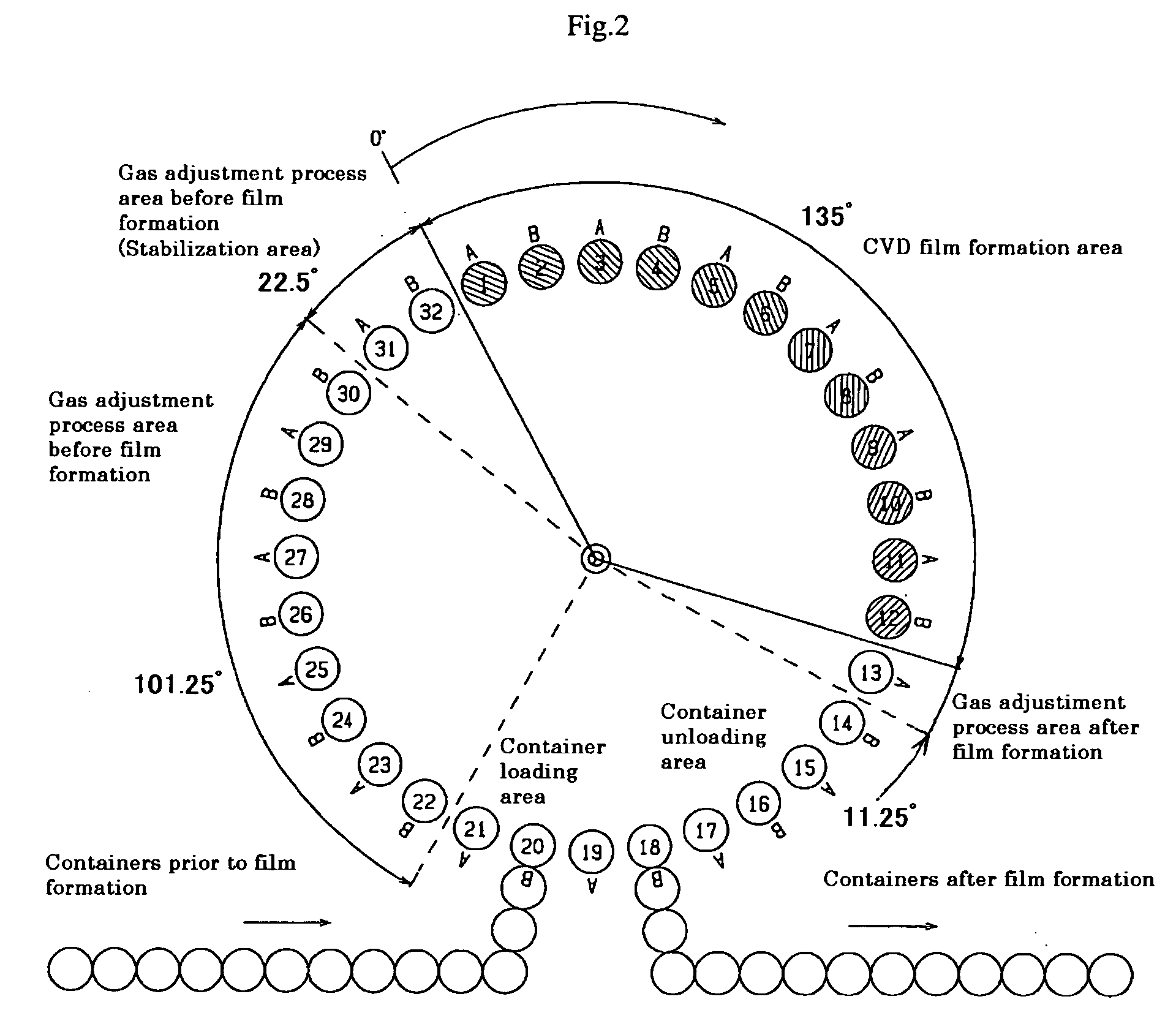

Method of measuring gas barrier property of plastic molding

InactiveUS20060169026A1Improve accuracyReduced measurement timeDetection of fluid at leakage pointMaterial analysis by electric/magnetic meansEngineeringPlastic film

Object of present invention to overcome a problem of a dispersion of an evaluation of gas barrier property depending on absorbed moisture of plastic, and carry out measurements in which a measurement value response is good and accuracy is good, wherein from the beginning of a container the gas barrier property of a plastic molded body does not depend on the amount of moisture absorbed thereof. A method of measuring the gas barrier property of the plastic molded body such as a plastic container, a plastic sheet or a plastic film or the like which uses a gas analyzer to measure the amount of permeation of a measurement object gas permeating through the plastic molded body, comprising: a heat drying process which heats and dries said plastic molded body in a temperature range which does not cause deformation or heat deterioration.

Owner:YOUTEC CO LTD +2

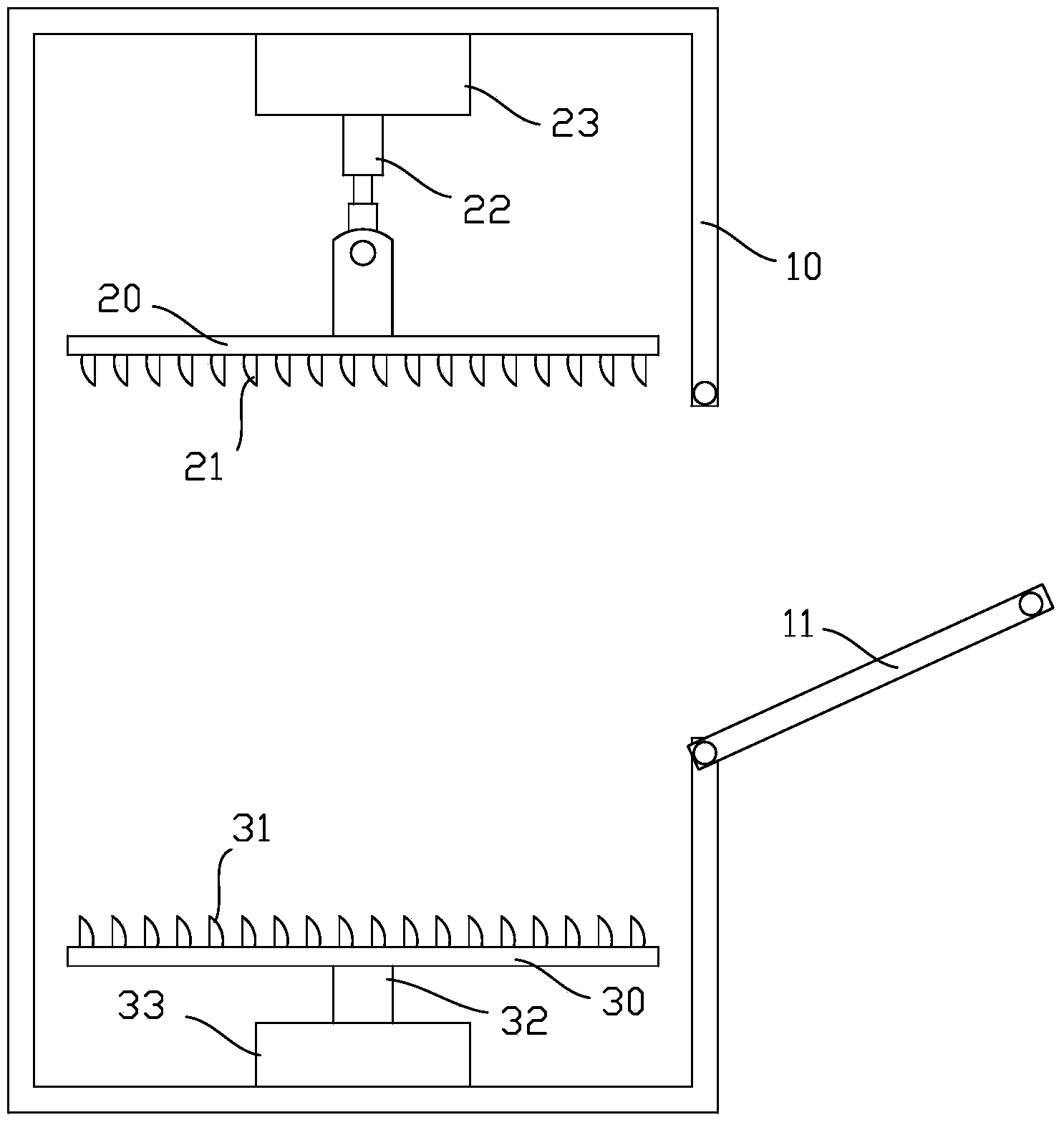

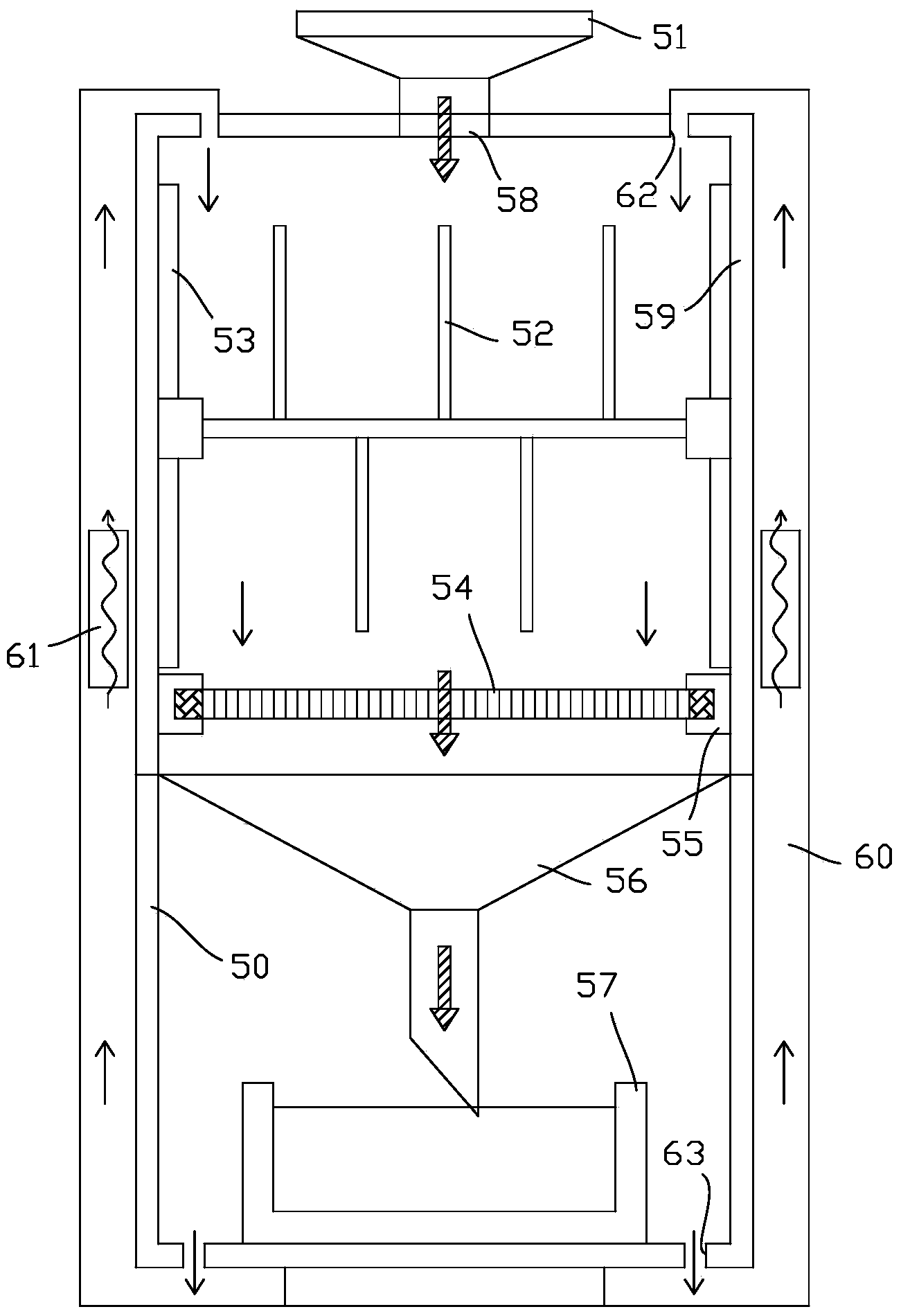

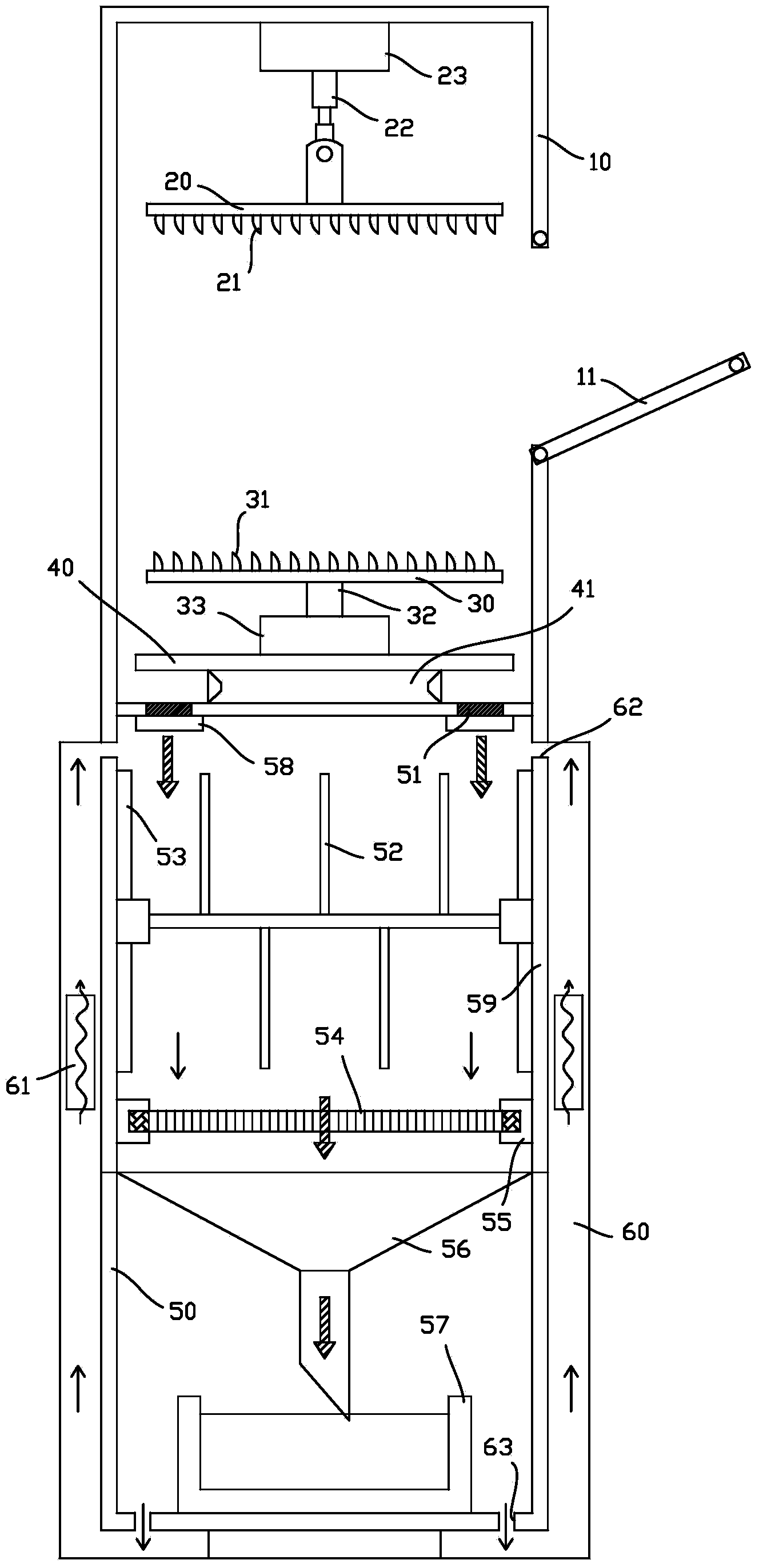

Waste and old mixed plastic recovery and separation device and method

ActiveCN103934923AEffective classificationRealize resource utilizationPlastic recyclingMechanical material recoveryPlastic forming machineMolten state

The invention discloses a waste and old mixed plastic recovery and separation device and method, and belongs to the field of resource recycling of waste and old mixed plastic. The waste and old mixed plastic recovery and separation device comprises a crushing device and a melting, sorting and recovering device, wherein a material feeding mechanism, a crushing mechanism and a material discharging mechanism are arranged in a crushing box body of the crushing device; a heating device, a screening mechanism and a plastic molding mechanism are arranged in a melting box body of the melting, sorting and recovering device; the heating mechanism is used for heating crushed granular materials to a molten state in a staged way; the screening mechanism is used for separating the materials in the molten state and un-melted granular materials; the plastic molding mechanism is placed on the bottom of the melting box body and recycling the separated materials in the molten state. The recovery and separation device can effectively classify the waste and old plastic generated in daily life and industrial production; different plastics are separated and are made into a single plastic which is relatively pure, so that the resource utilization of the waste and old plastic is realized; the post-processing process is omitted; energy resources are saved; the operation is simple; the automation degree is high; the sorting degree is high; the sorting range is wide.

Owner:ANHUI UNIV OF SCI & TECH

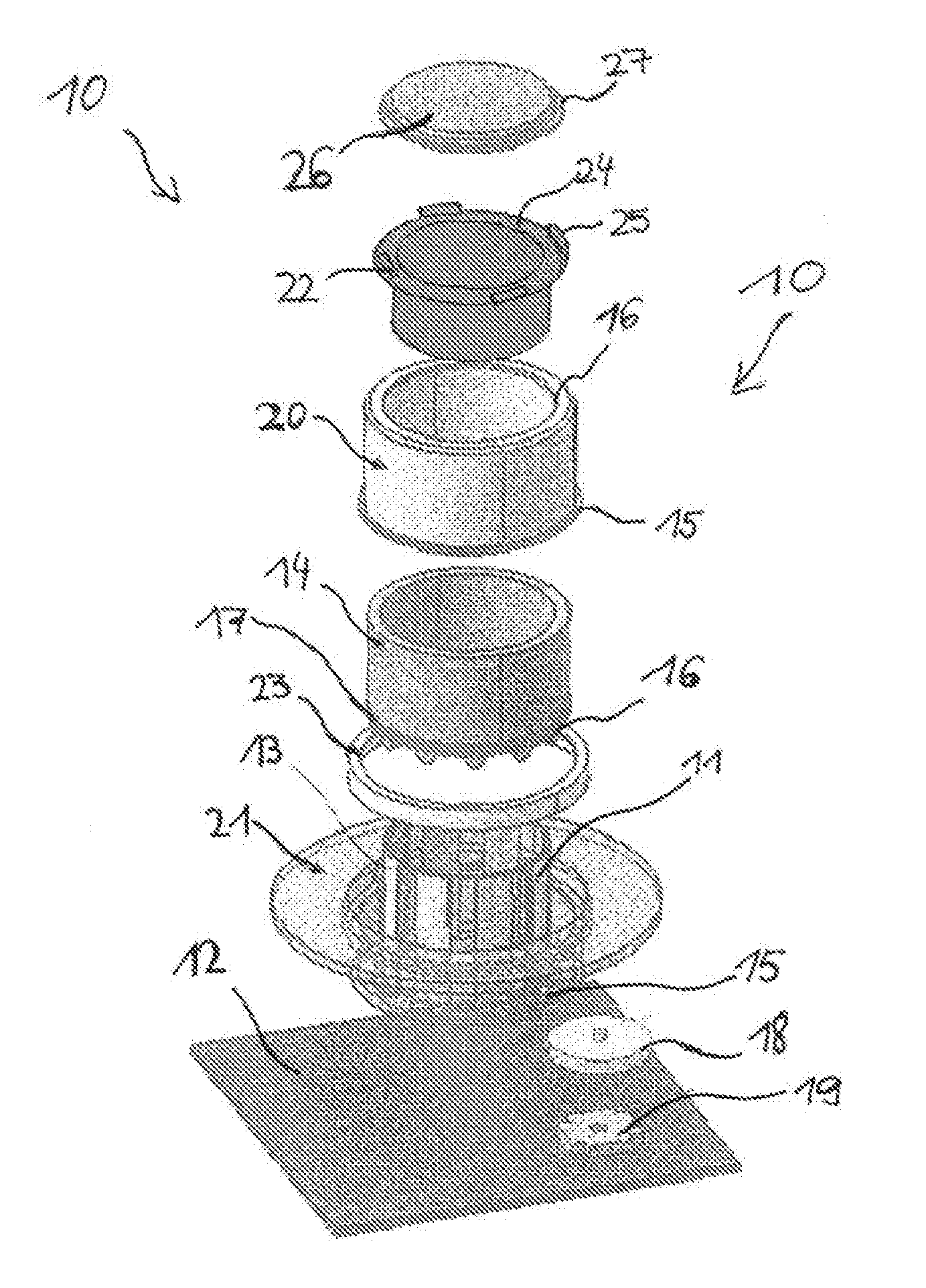

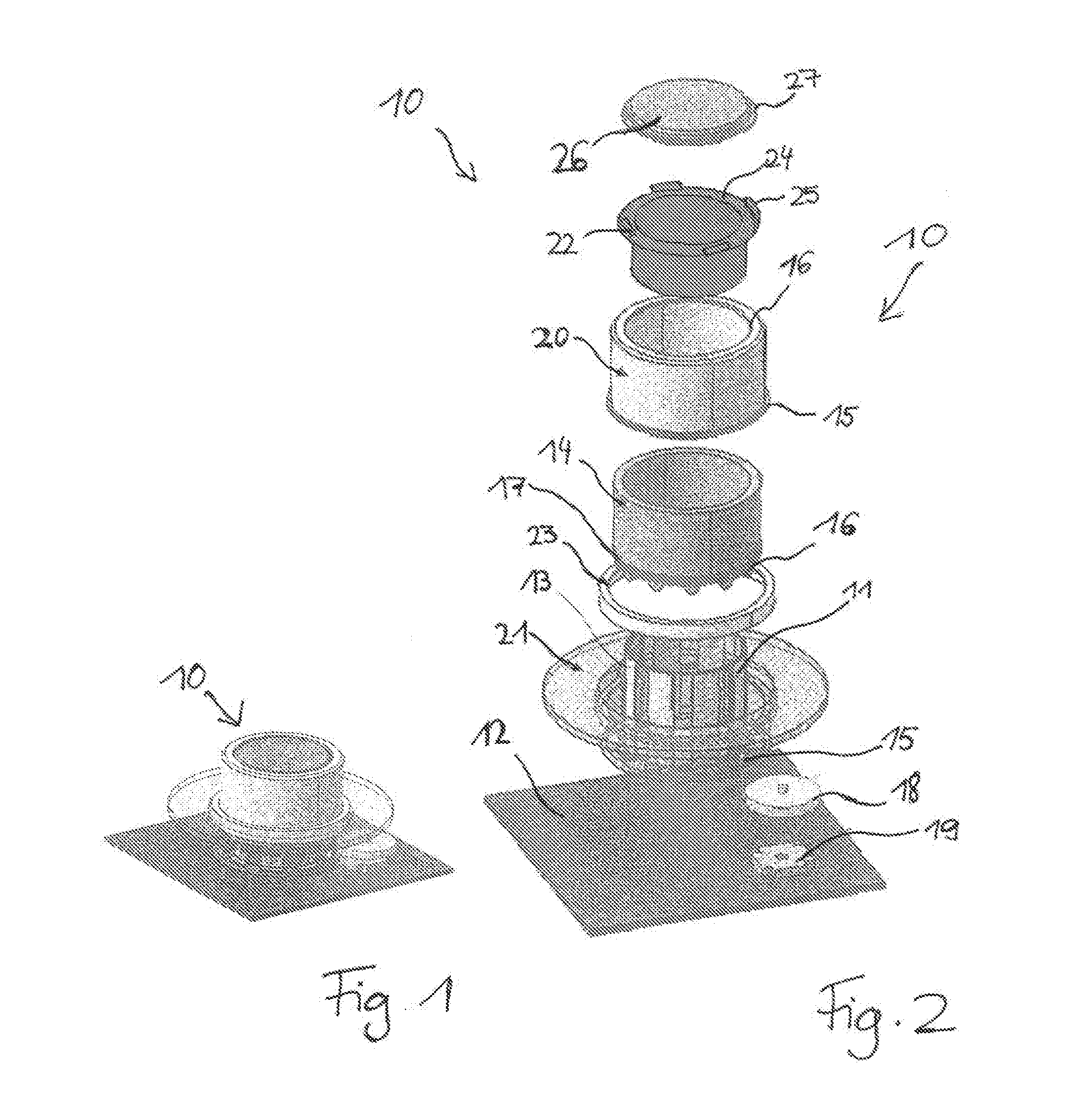

Secondary battery

InactiveUS20050153195A1Stable and simple mannerFormed stably and easilyPrinted circuit assemblingFinal product manufactureCouplingPlastic molding

A secondary battery including a bare cell and a safety device coupled to the bare cell, wherein the secondary battery has a battery component part having a safety device such as a protective circuit board mounted in a plastic molding or an assembled casing. An exterior surface of the bare cell and an exterior surface of the battery component part has a coupling portion for coupling the exterior surface of the bare cell to the exterior surface of the battery component part. Additionally, the exterior surface of the bare cell and the exterior surface of the battery component part further includes a supplementary element for supplementing the coupling between both coupling portions.

Owner:SAMSUNG SDI CO LTD

Capacitive sensing node integration to a surface of a mechanical part

ActiveUS20150241195A1Easy to carryHaptic feedback can be providedResistance/reactance/impedenceMouldsCapacitancePlastic materials

A motion detecting device has a stationary plastic sensor carrier. The stationary plastic sensor carrier has two sensor carrier sections and an insulation section. The carrier section has a first plastic material and the insulation section has a second plastic material. The insulation section extends between two adjacent sensor carrier sections. The sensor carrier sections and the at least one insulation section are integrally formed by a plastic molding process. Plated metal sensing surfaces are provided on the surfaces of the sensor carrier sections. Surface electrode contacts connect the plated metal sensing surface electrodes with a PCB and define at least one capacitive area between at the plated metal sensing surface electrodes. A plastic knob element is movably arranged on the plastic sensor carrier, such that the insulating plastic separator sections and the plated metal sensing surface electrodes are at least partly covered by the knob element.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Colorful ceramic and preparation method thereof

The invention provides colored ceramics and a preparation method thereof. Ceramic mud for the colored ceramics at least comprises the following compositions in weight percentage: 20 to 35 percent of kaoline, 60 to 70 percent of at least two of pottery stones, lithium pottery stones, feldspar and quartz, 0.2 to 6 percent of coloring matter, and 1 to 5 percent of nanometer quartz. The method for preparing the colored ceramics comprises the following: a step of pulp injection molding, in which part of colored mud cake or colored mud strip is mixed with liquefacient with 0.3 to 0.8 percent of total amount for pulping, and the mud which is screened from a screen of between 80 and 120 meshes is injected into a mold to produce a hollow or solid briquette; and a step of glazing and maturing, in which the briquette which is manufactured by pulp injection molding or plastic molding is cemented and dried according to creativities, and are directly applied with clear glaze, and the glazed briquette body is placed in an oxydizing flame roller kiln or an electrical kiln for 1 to 4 hours at a temperature of between 1,150 and 1,200 DEG C for maturing. The method can not only reduce clinkering cost, but also improve the moisture retention, bonding performance and corrosion resistance of strong ceramic mud, and further show energy conservation and environmental protection.

Owner:JINGDEZHEN HAHANI CERAMIC CULTURE DEV

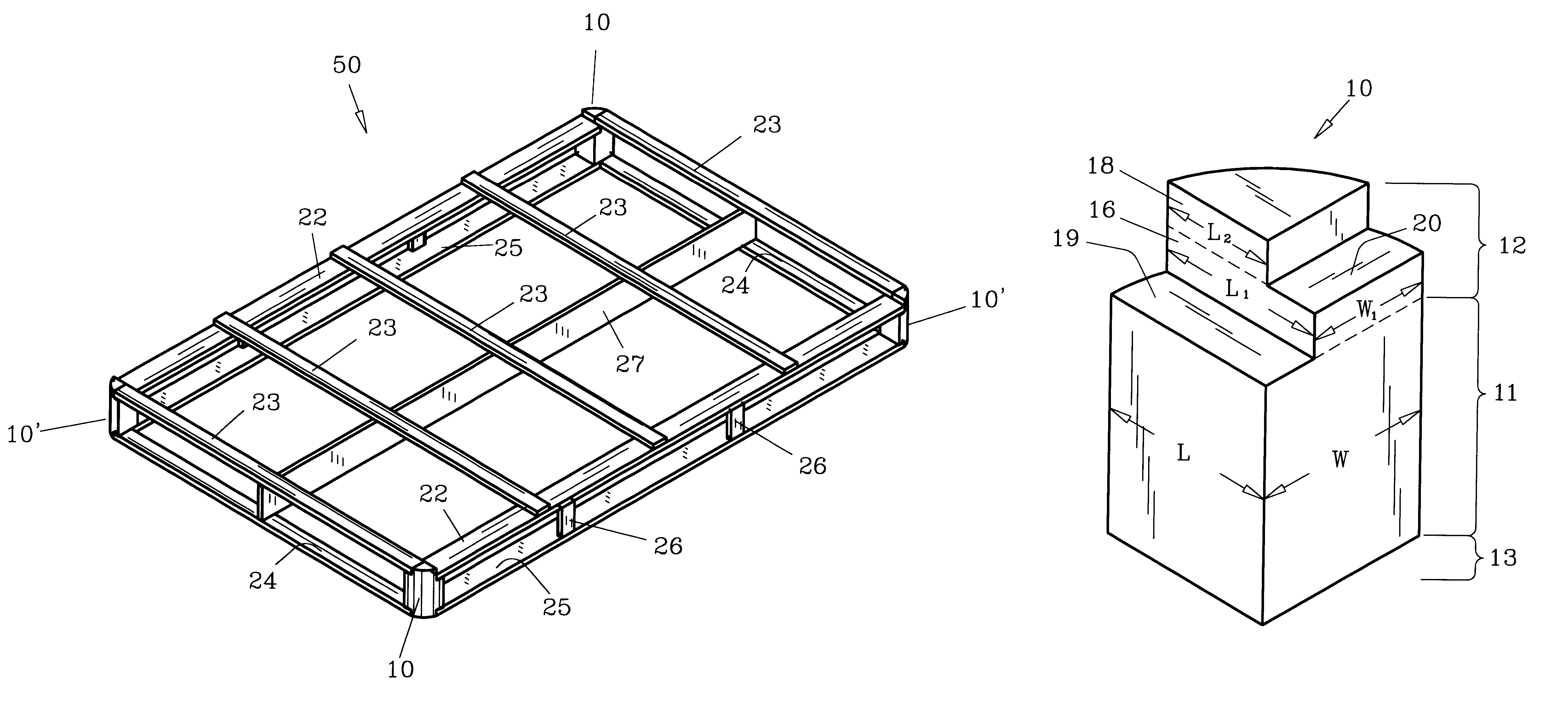

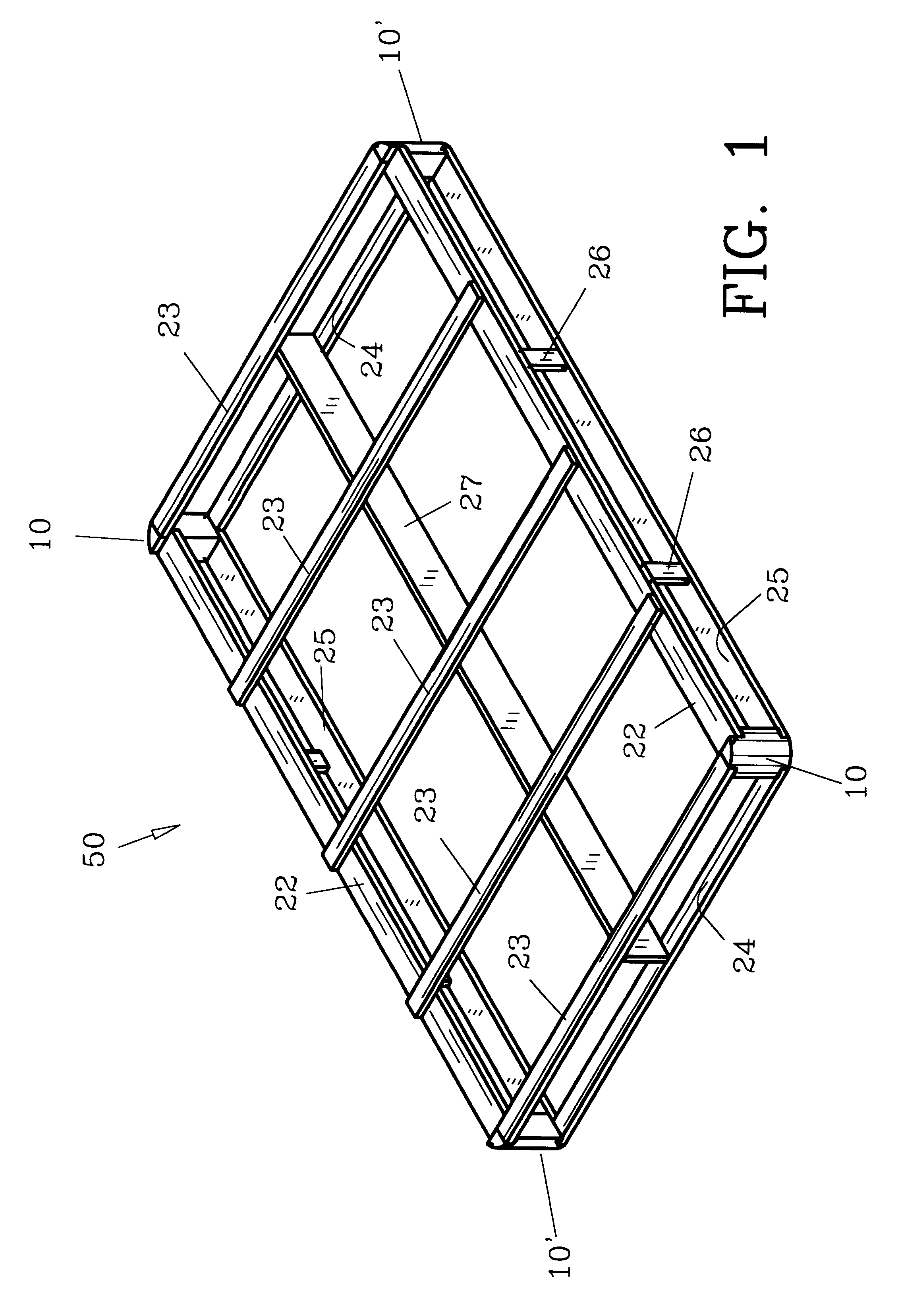

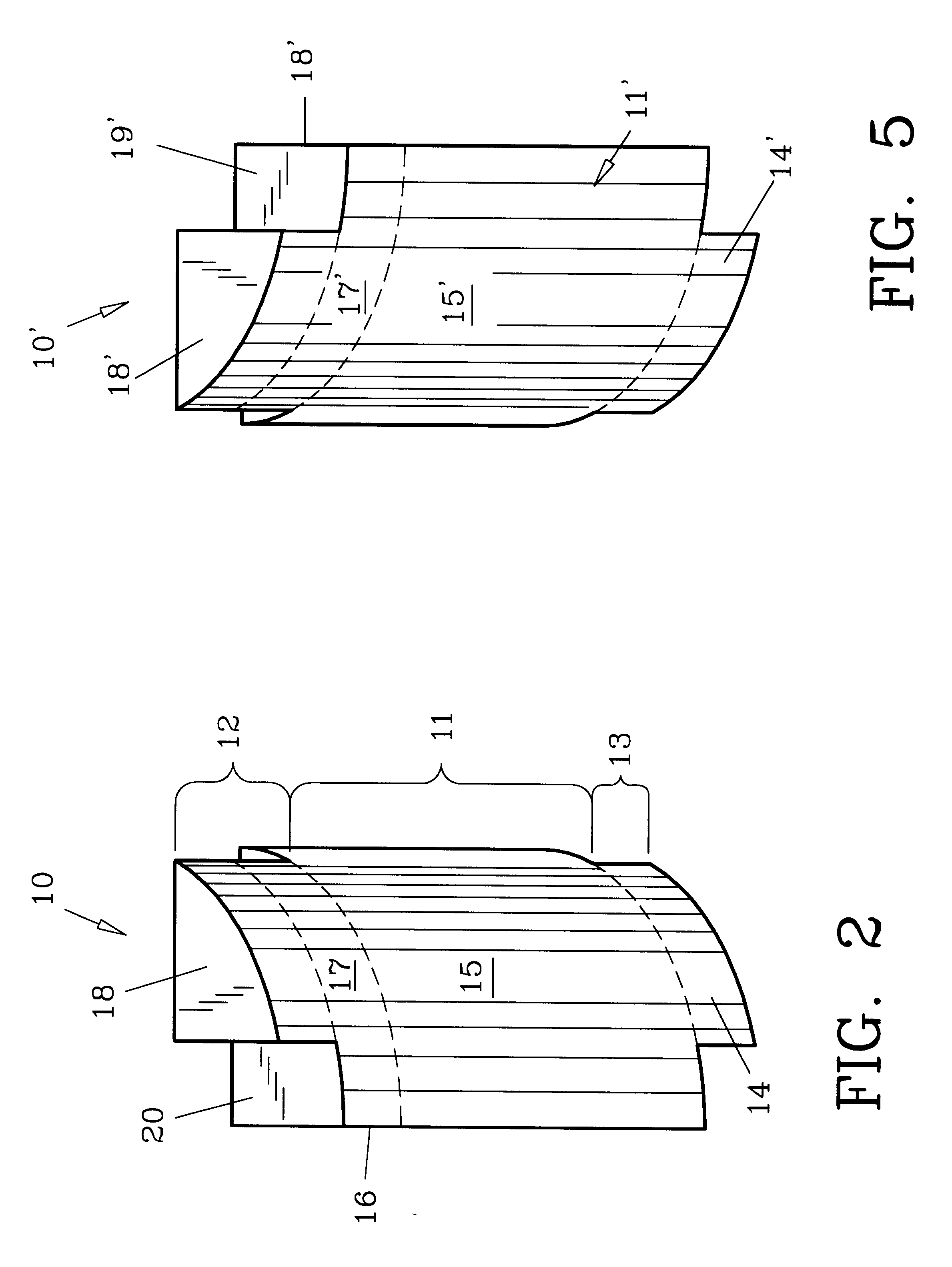

Corner connectors and methods

Preformed corner connectors for mattress supports and box spring bases are provided to simplify and reduce the costs of constructing the same. The corner connectors are preferably unitarily formed by plastic molding or other suitable processes. The method of using the corner connectors includes preforming the same and attaching frame members with conventional fasteners for box spring bases and mattress supports as required.

Owner:MCCALL & BROOKS

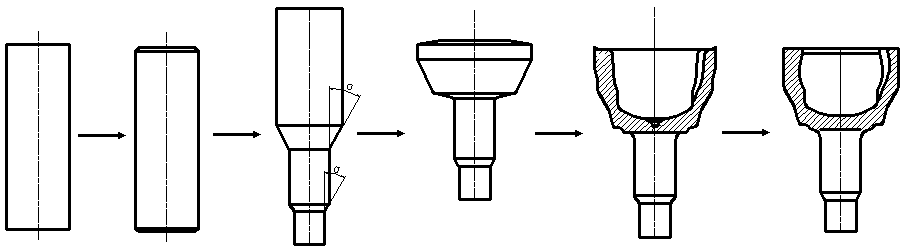

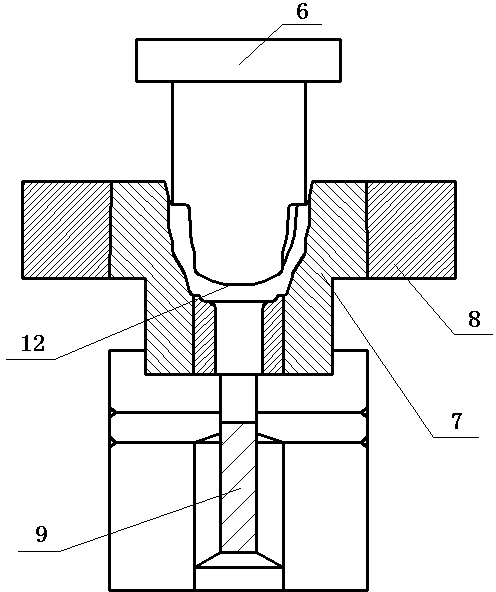

Precision-forging plastic molding technology of bell shell of ball-cage type universal joint

InactiveCN102861861AReduce workloadImprove product qualityRailway componentsForging/hammering/pressing machinesSand blastingUniversal joint

The invention discloses a precision-forging plastic molding technology of a bell shell of a ball-cage type universal joint, comprising steps of warm-forging plastic molding and cold-forging plastic molding. The warm-forging plastic molding technology comprises the following steps: a. blanking; b. manufacturing a blank; c. coating; d. heating; e. directly extruding; f. upsetting; g. extruding reversely; h. normalizing, shaping, sand blasting, parkerising, and treating the surface by a manner of saponification; and adopting the forging plastic molding technology of combining the warm-forging plastic molding technology with the cold-forging plastic molding technology, firstly upsetting to obtain the pre-molding blanking material, secondly, extruding reversely in the chamber of the molding mold to form a ball channel and finally forming the inner spherical surface by using the cold-forging plastic molding technology. The product quality is steady, the production efficiency is improved, the production period is short, the method for adopting the machine tool after the hot-forging is replaced, the workload of the machine tool process is reduced, the precision requirements are met, the manufacturing cost and the period are reduced, and the development trend of the manufacturing field in the world is met.

Owner:张太良

Windshield wiper blade assembly

A windshield wiper blade assembly comprises: an elastic wiper blade; first and second housings secured to and covering a top end of the wiper blade and made from a plastic material; and a middle housing disposed between the first and second housings and having two end segments and a middle segment extending between the end segments. The end segments of the middle housing cover and are secured to the top end of the wiper blade at the end sections of the middle portion, respectively, and have ends in contact with ends of the first and second housings, respectively. The middle segment defines a frame space for extension of a connecting piece therein and includes a skeleton and a plastic molding layer molded over the skeleton.

Owner:DONGGUAN HONGYI WIPER

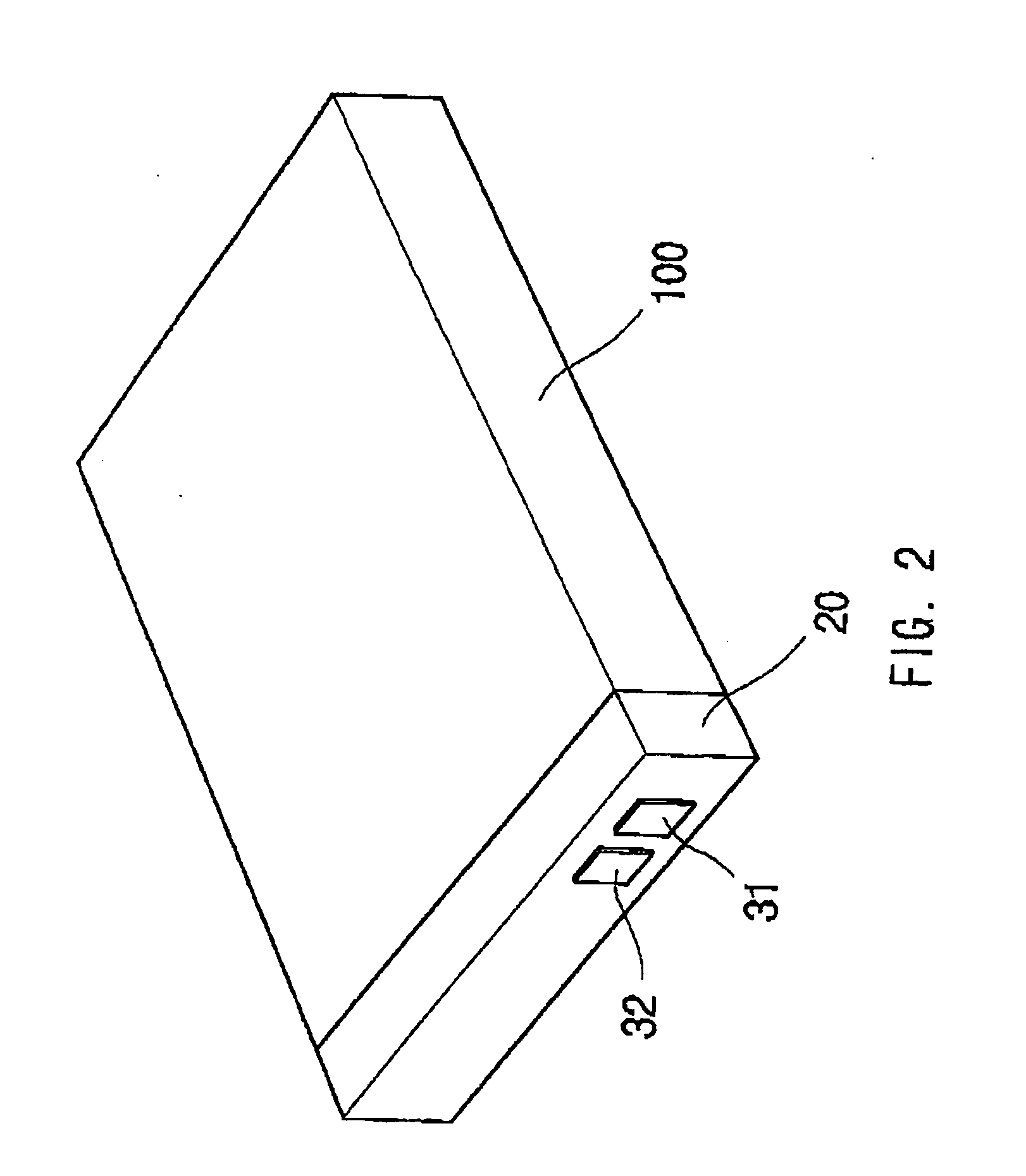

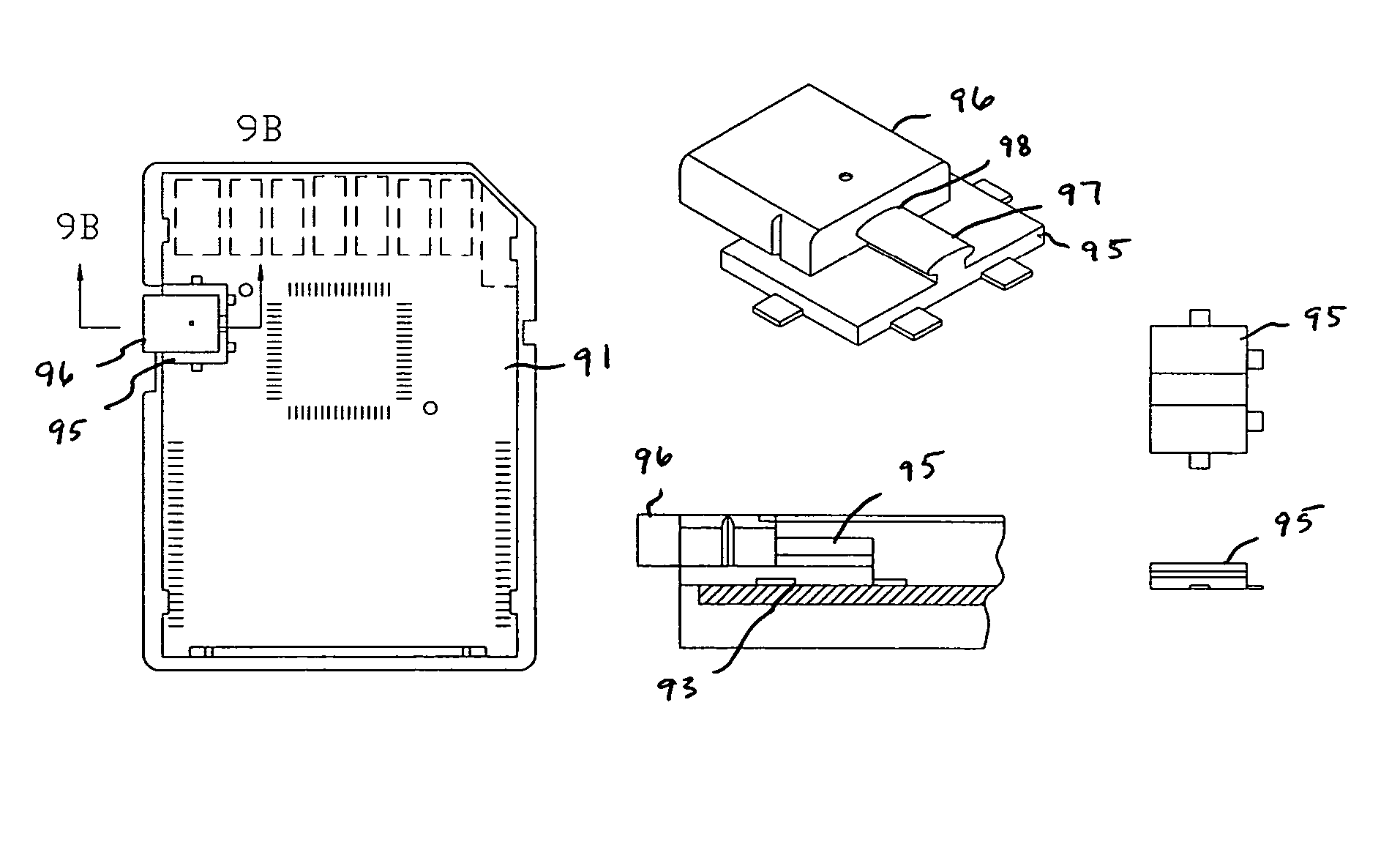

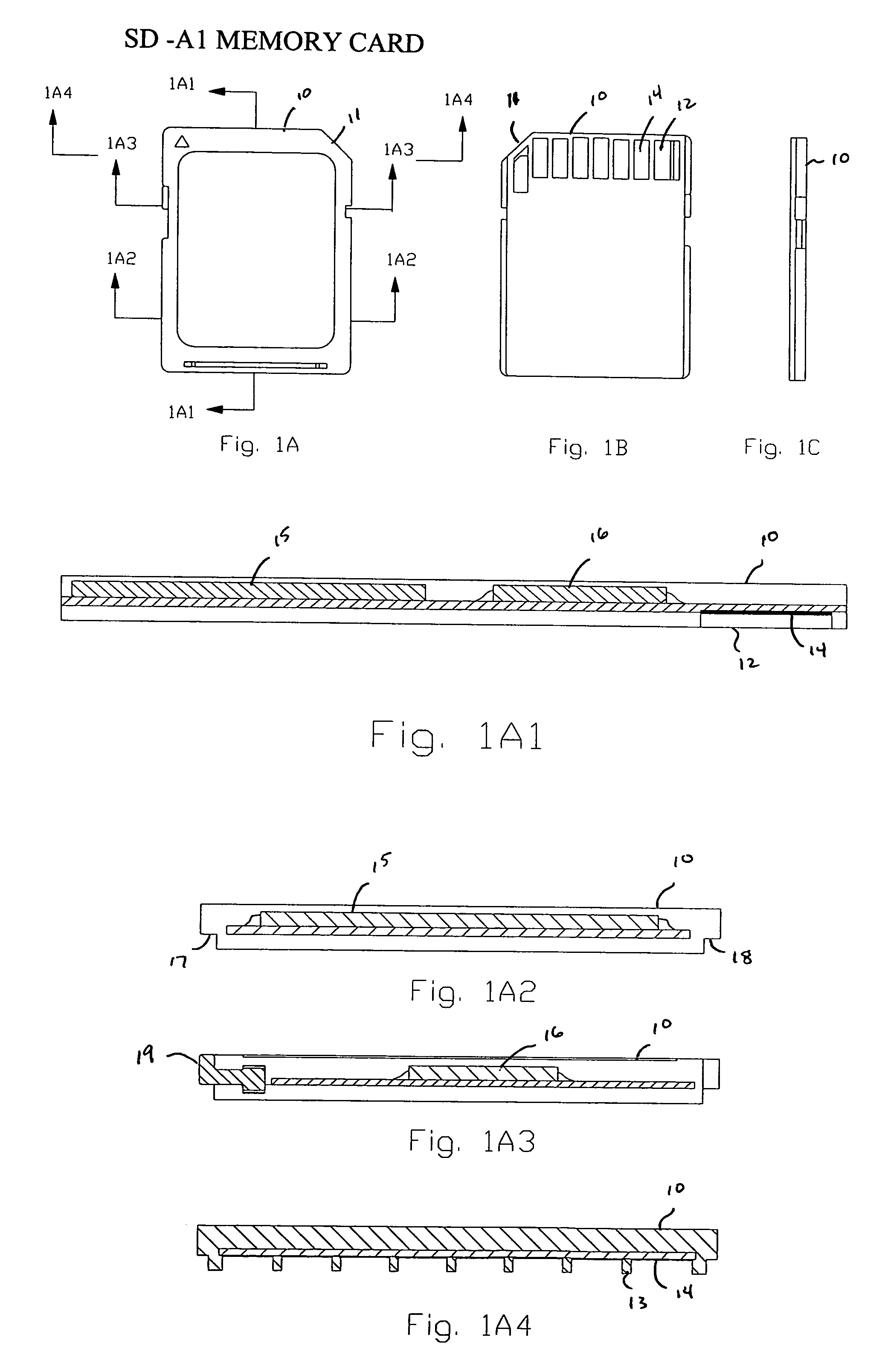

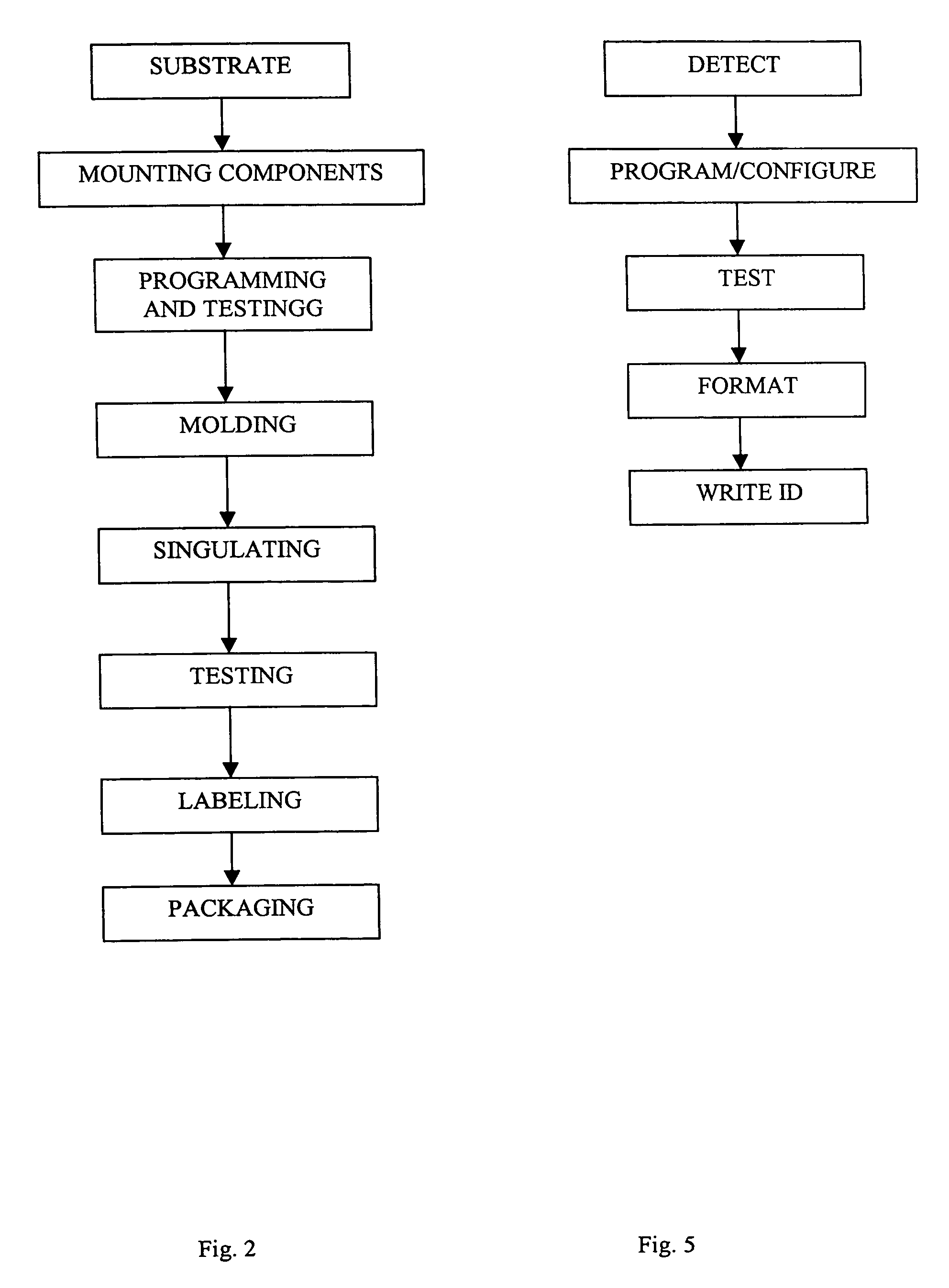

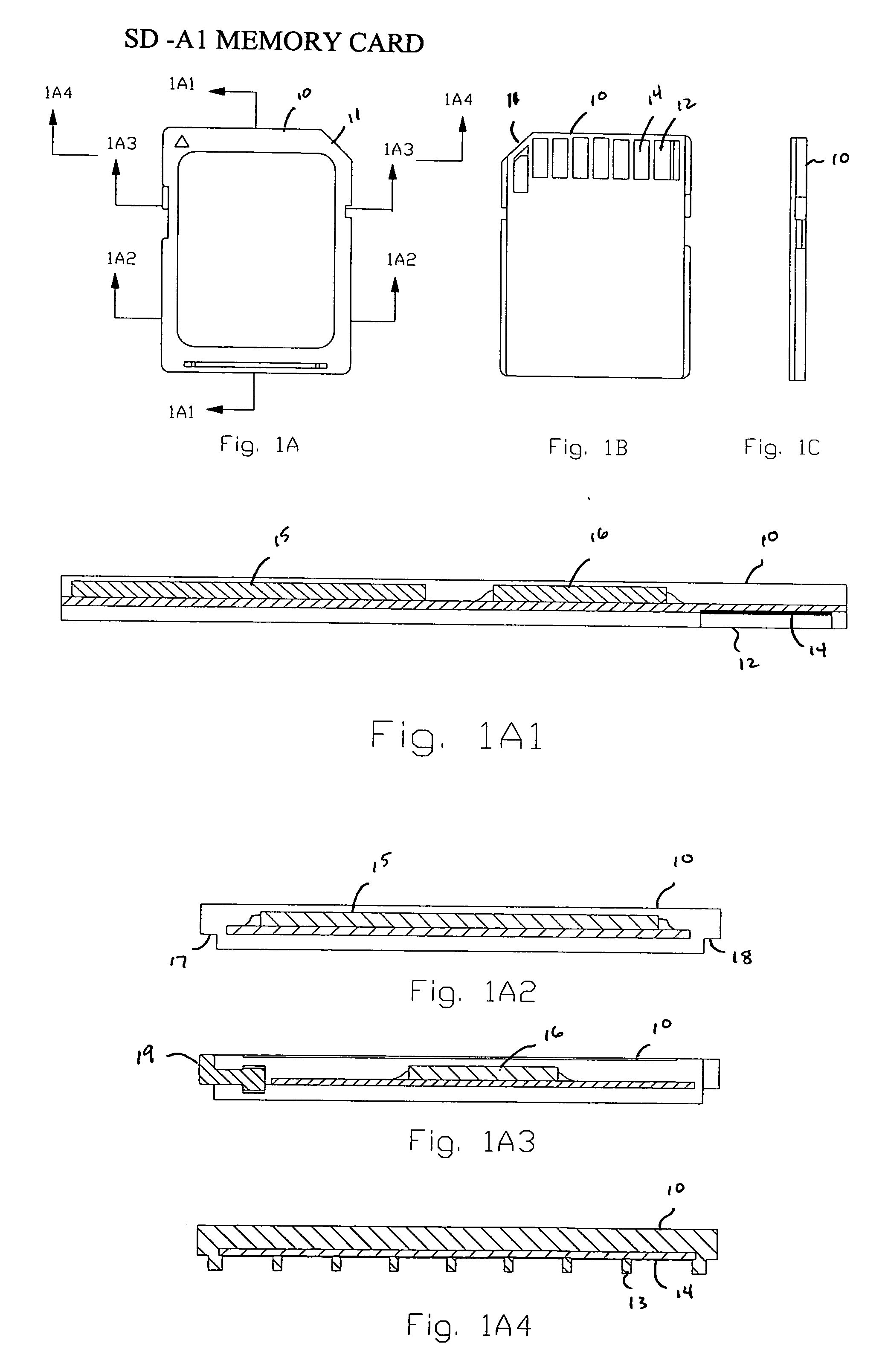

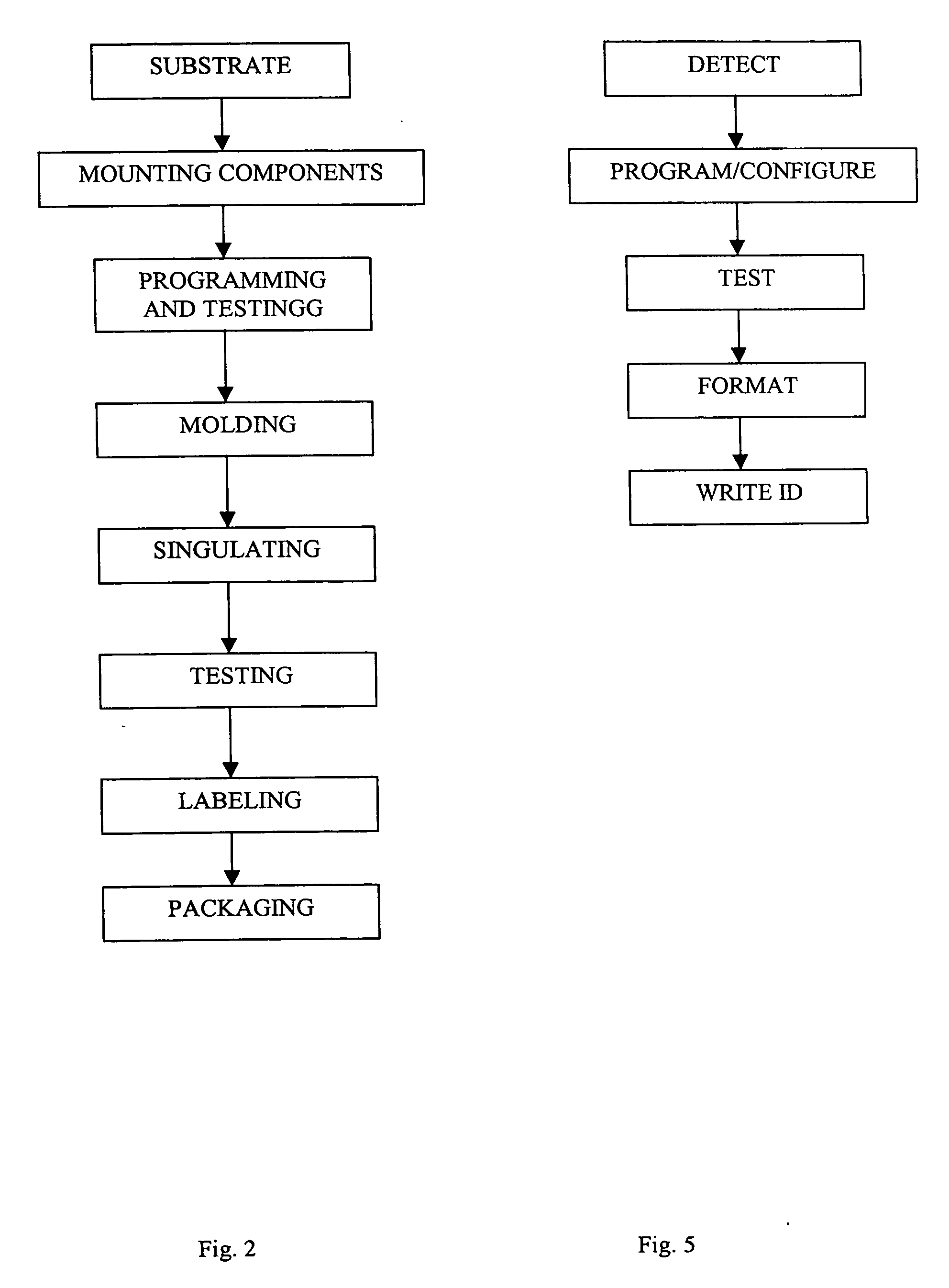

Removable flash integrated memory module card and method of manufacture

InactiveUS7264992B2Increased card capacity and functionalityPromote resultsSemiconductor/solid-state device detailsPrinted circuit aspectsContact padEngineering

A removable Flash integrated memory module card has a plastic shell and an integral Flash memory module. On the backside of the card, there are exposed contact pads. When the card is inserted into a card-hosting device, the card can communicate with the device through the exposed pads. The manufacturing method includes manufacturing of the memory module and utilizing plastic molding techniques for making the card outer body. The method involves preparing the substrate, mounting the components, testing the module, preparing the molding device, and molding the card body.

Owner:SUPER TALENT ELECTRONICS

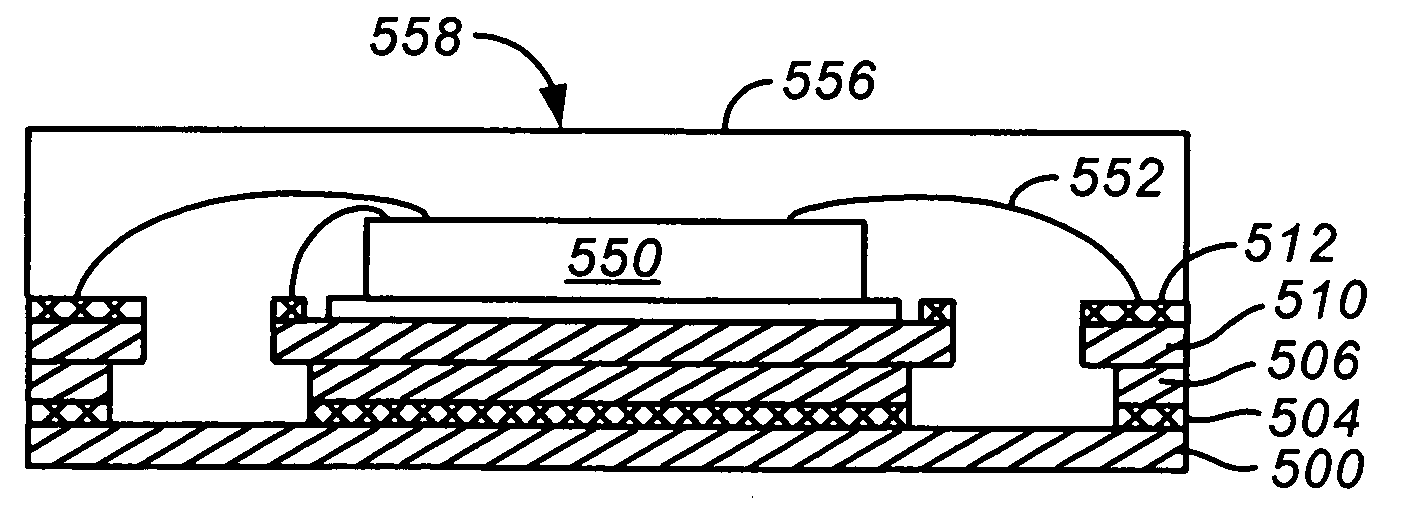

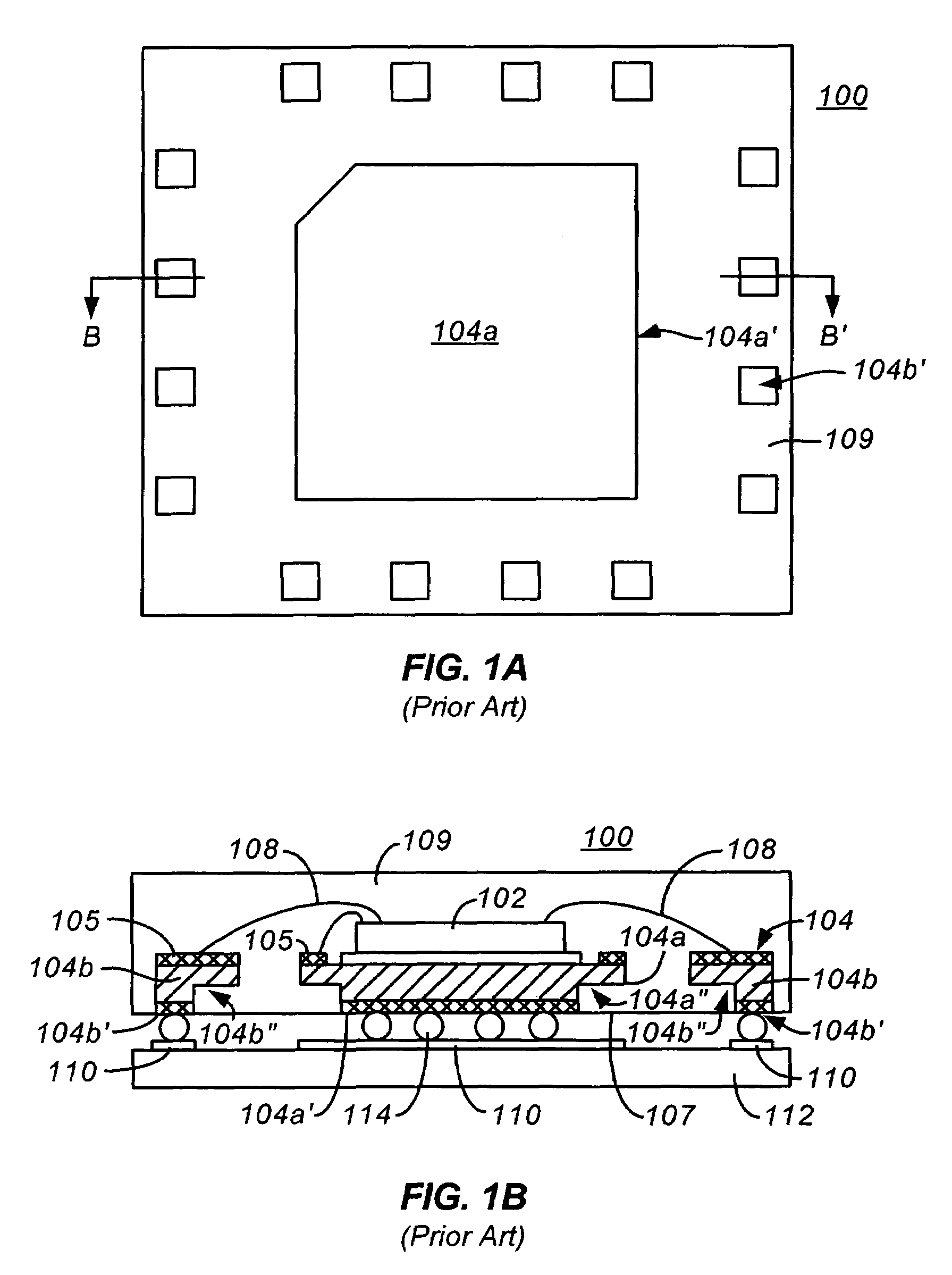

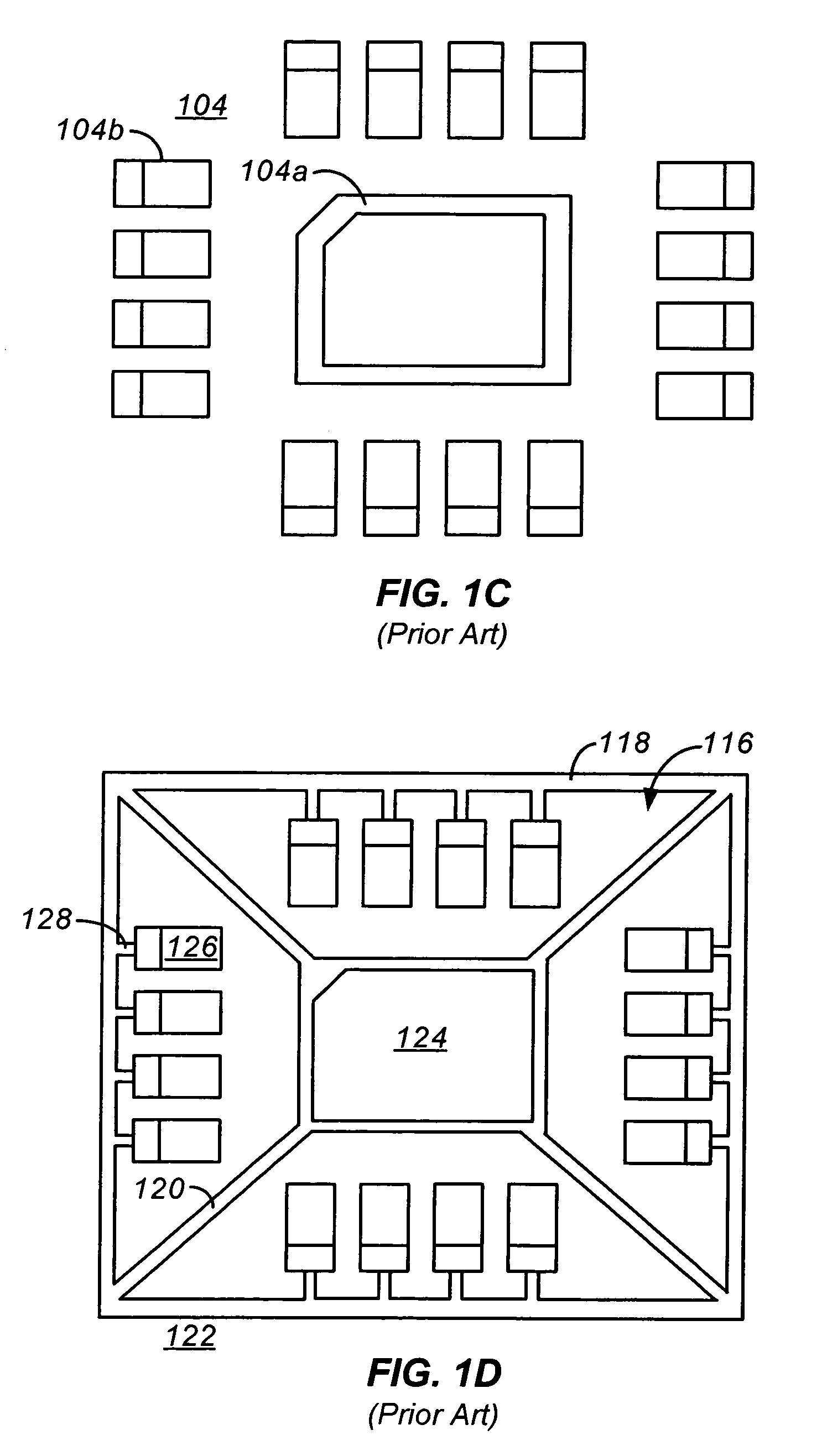

Semiconductor device package diepad having features formed by electroplating

ActiveUS7122406B1Level attitudeEvenly distributedSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSolder ball

Embodiments in accordance with the present invention relate to the fabrication of packages for semiconductor devices, and in particular to the use of electroplating techniques to form features on the surface of a metal lead frame. In accordance with one embodiment, electroplating is used to fabricate non-integral pin portions shaped to remain securely encapsulated within the plastic molding of the package. In accordance with another embodiment, electroplating may be used to fabricate protrusions on the underside of the lead frame for elevating the package above the PC board, thereby preserving the rounded shape of solder balls used to secure the diepad to the PC board. In accordance with yet another embodiment, electroplating may be used to fabricate raised patterns on the upper surface of the diepad for ensuring uniform spreading of adhesive used to secure the die to the diepad, thereby ensuring level attitude of the die within the package.

Owner:GEM SERVICES

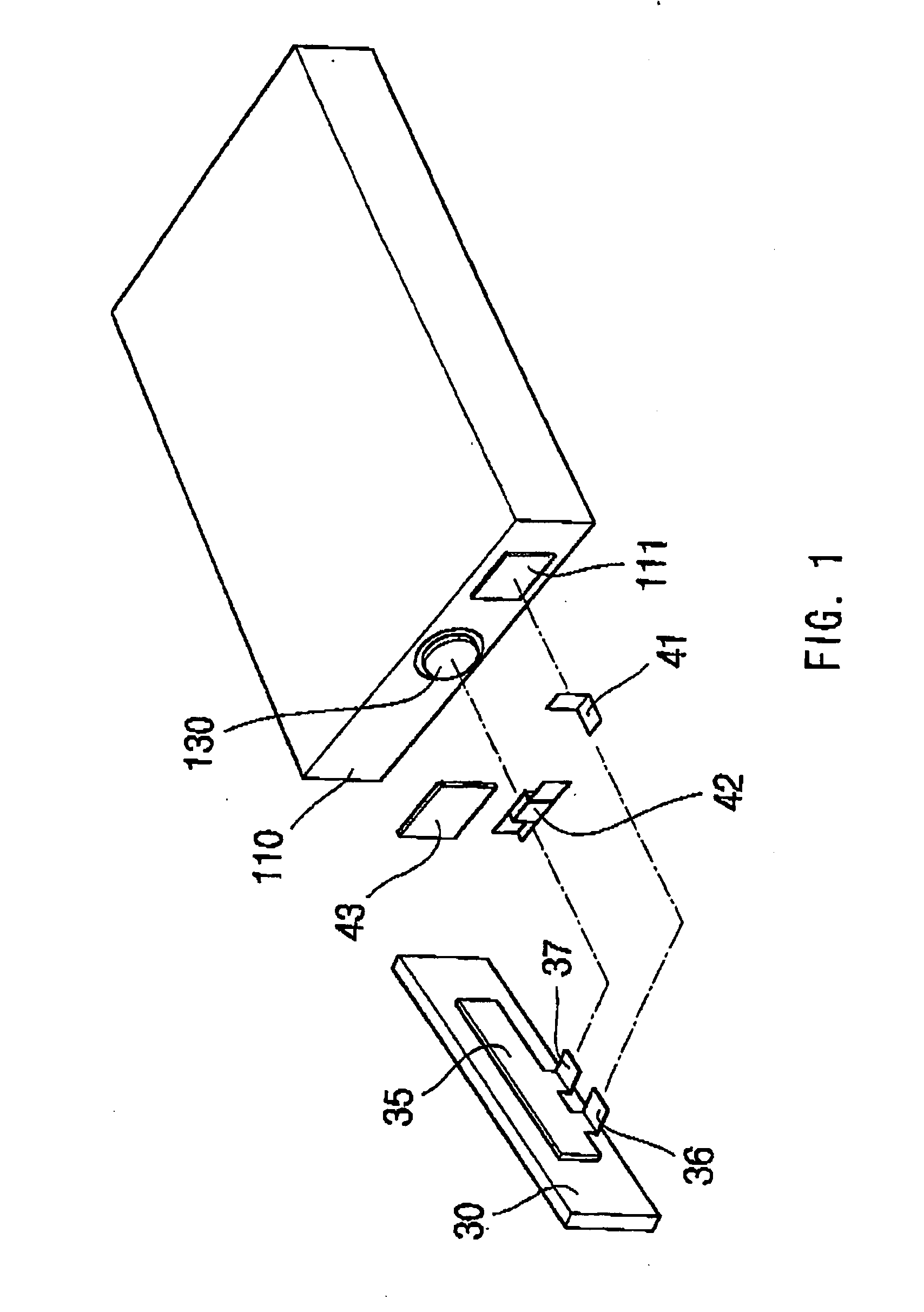

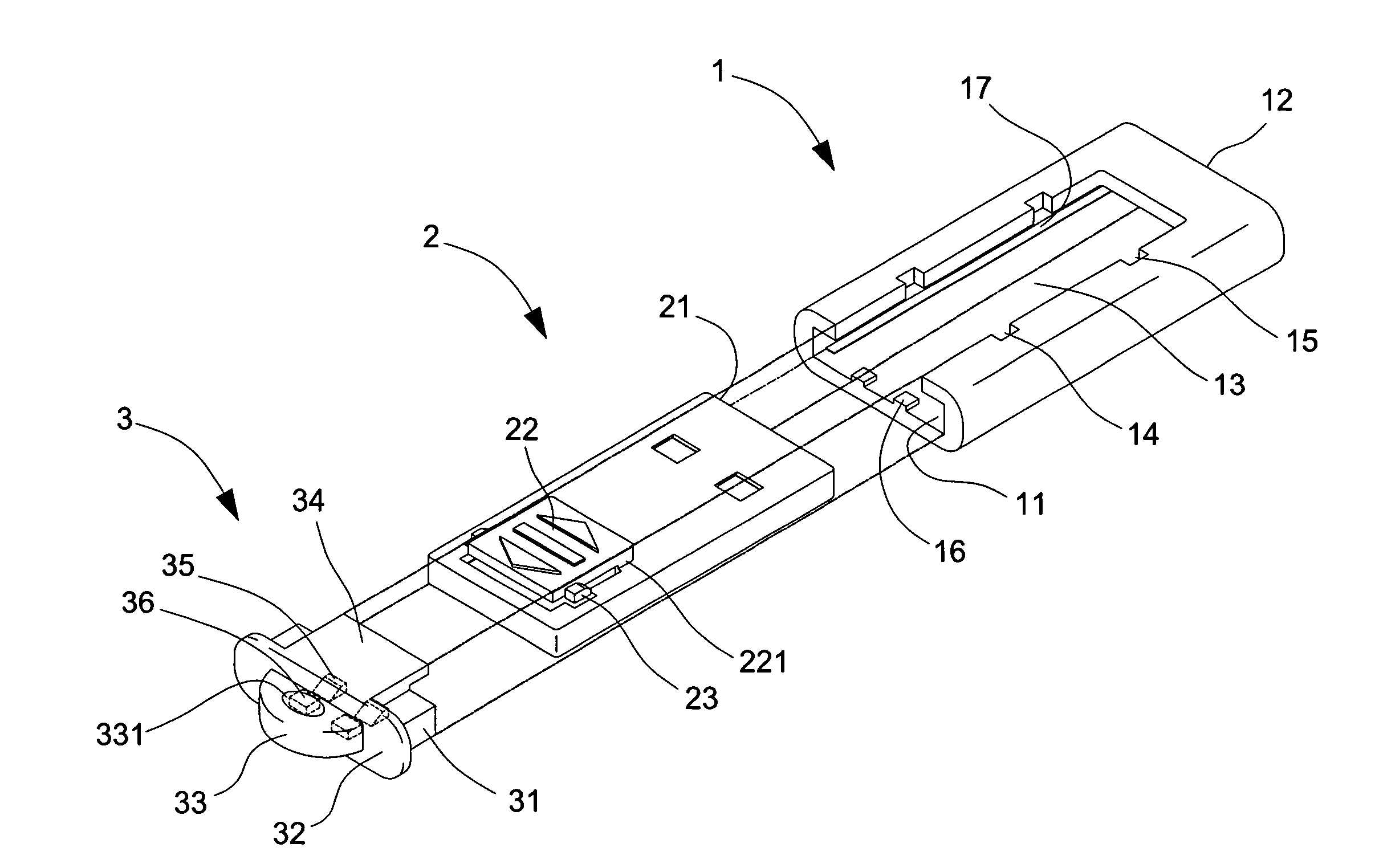

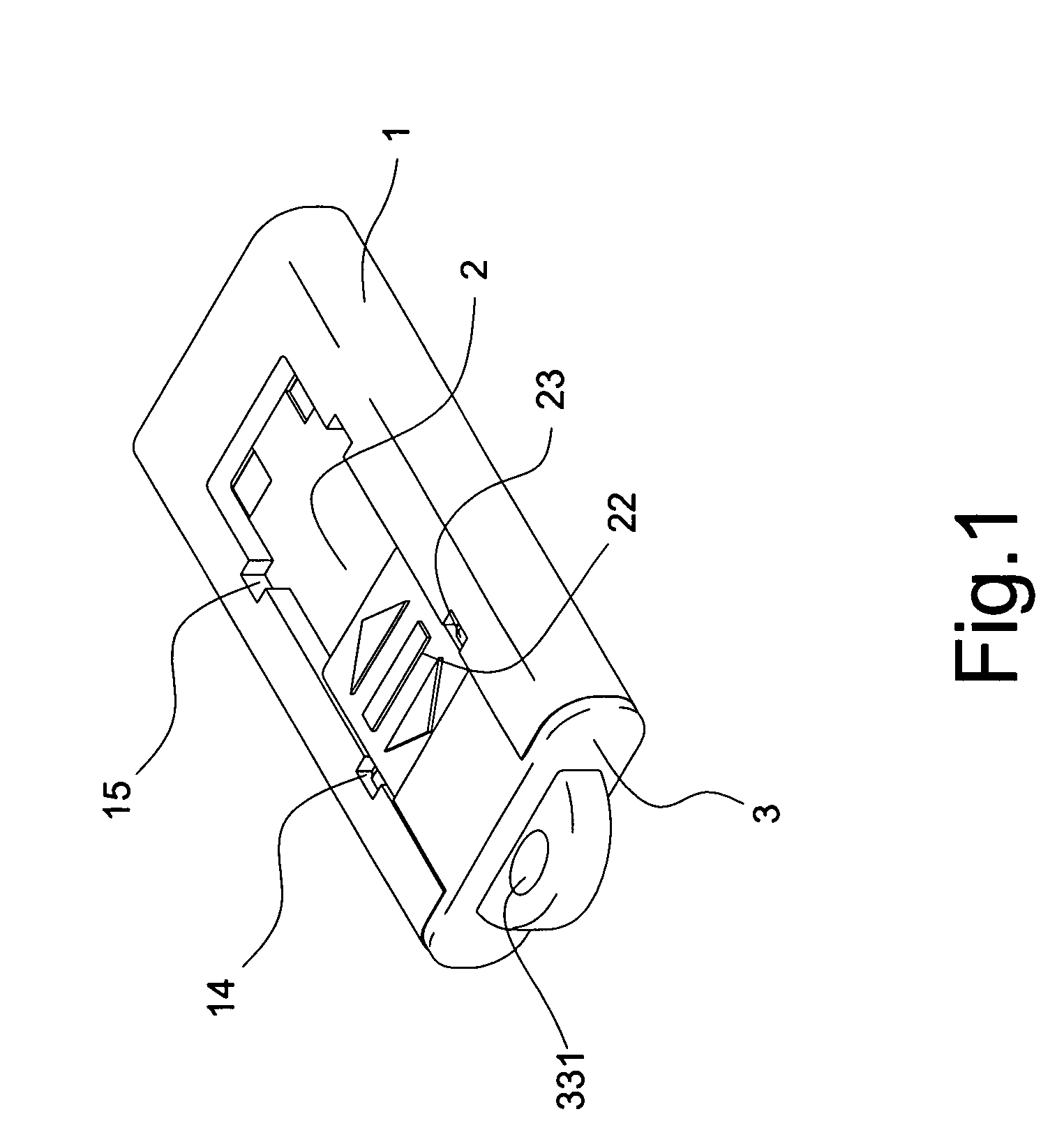

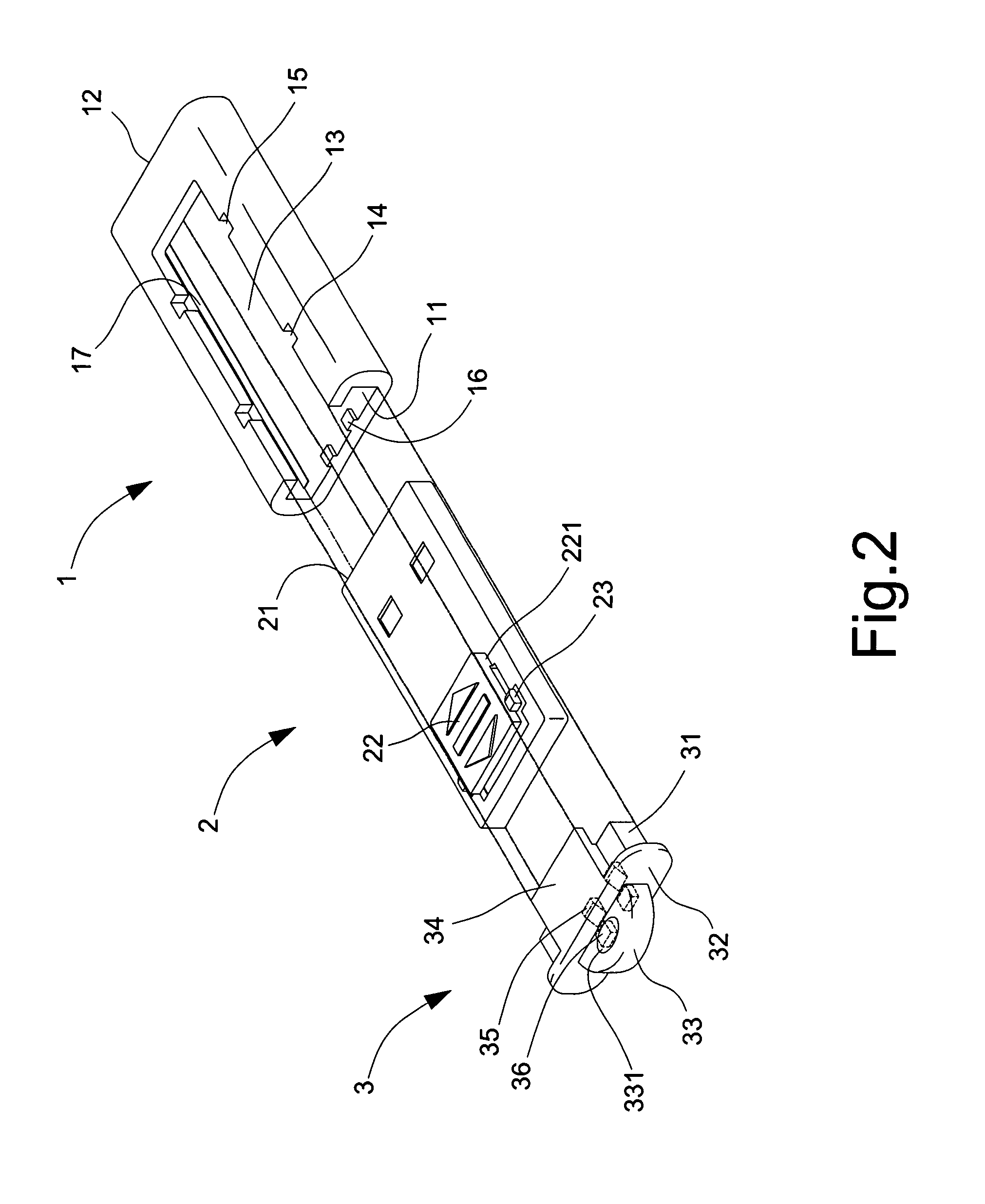

Extension structure for plastic molding portable memory product

InactiveUS7558069B2Simple manufacturing processReduce defective rateLive contact access preventionComponent plug-in assemblagesMechanical engineeringPlastic molding

An extension structure for a plastic molding portable memory product includes an outer casing unit, an inner sliding unit, and a closing unit. The inner sliding unit is positioned inside the outer casing unit, and can be extended by sliding, whereas the closing unit is combined with the outer casing unit to ensure the inner sliding unit will not slip out. The outer casing unit is produced using one body formation method that is free from the traditional method of combining two pieces of structures through high frequency wave compression work sequence to effectively increase product yield, reduce cost and improve the cosmetics.

Owner:HAHNTEK TECH CORP

Highly-conductive polyphenylene sulfide composite material and method for making same

InactiveCN101161726AImprove conductivityEvenly dispersedNon-conductive material with dispersed conductive materialFiberSurface resistivity

The invention discloses a high electric conduction polyphenylene sulfide (PPS) composite material and the preparation method thereof. The percentage by weight of the compositions of the high electric conduction polyphenylene sulfide composite material is as follows: 40 to 70 percent of polyphenylene sulfide, 5 to 30 percent of conducting fiber, 5 to 30 percent of conducting powder, and other auxiliary agents from 0 to 5 percent. The conducting fiber and conducting powder in the conducing plastics provided by the invention disperse evenly with a plurality of lapping joints and high electric conductivity, thereby remarkably improving electric conductivity. The surface resistivity and volume resistivity of the material respectively reach 0.3-11.0 ohm and 0.07-8.5 ohm*cm, thereby meeting the requirements of plastic shaping techniques such as repeated injection molding, plastic extruding or die stamping. The processing art of the material is simple and can control the conducting fiber and conducting carbon black to evenly disperse in plastic particles, thereby enabling the PPS composite material to have high electric conductivity and meeting the requirements of industrial big production.

Owner:SHENZHEN KEJU NEW MATERIAL

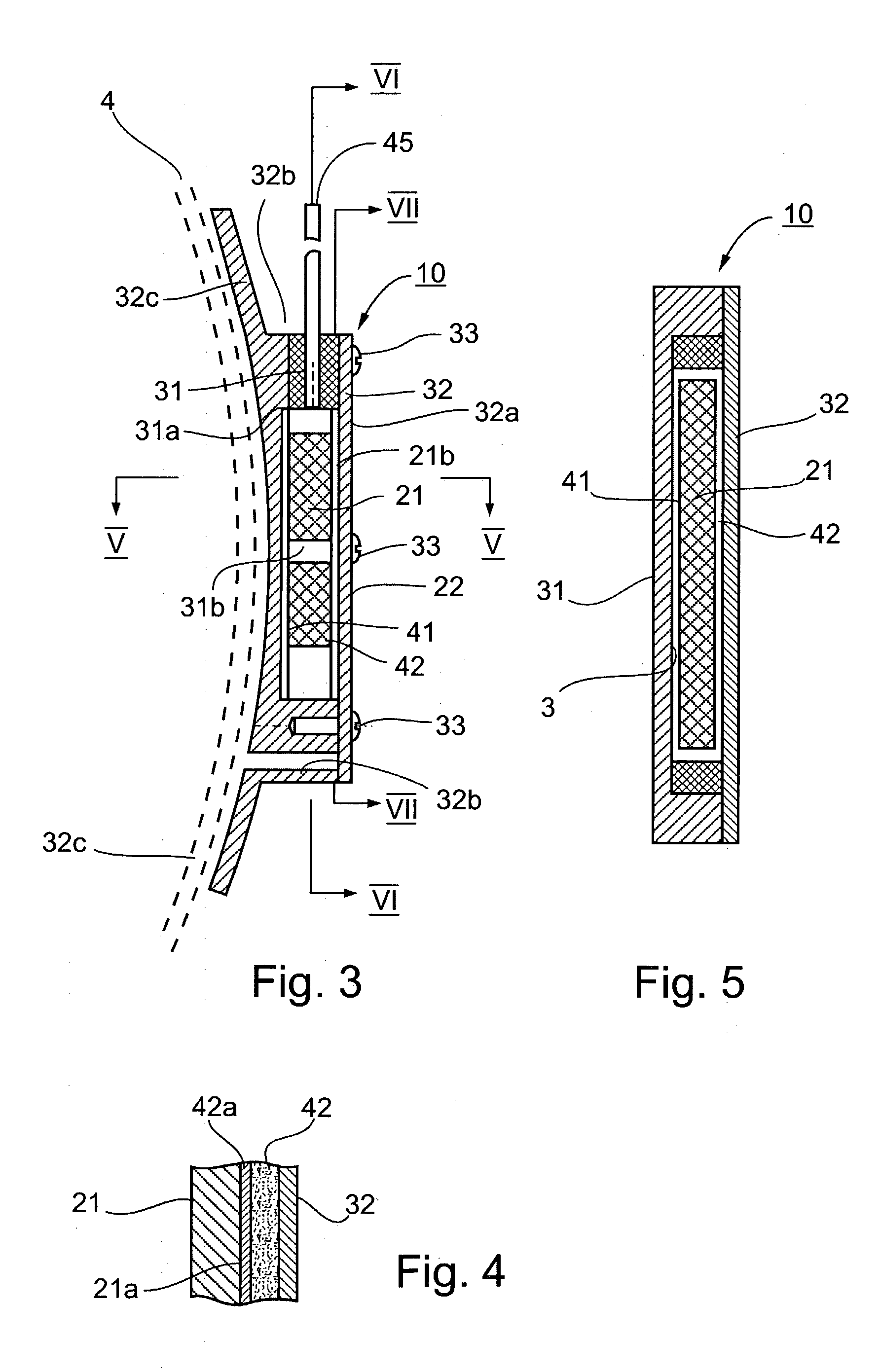

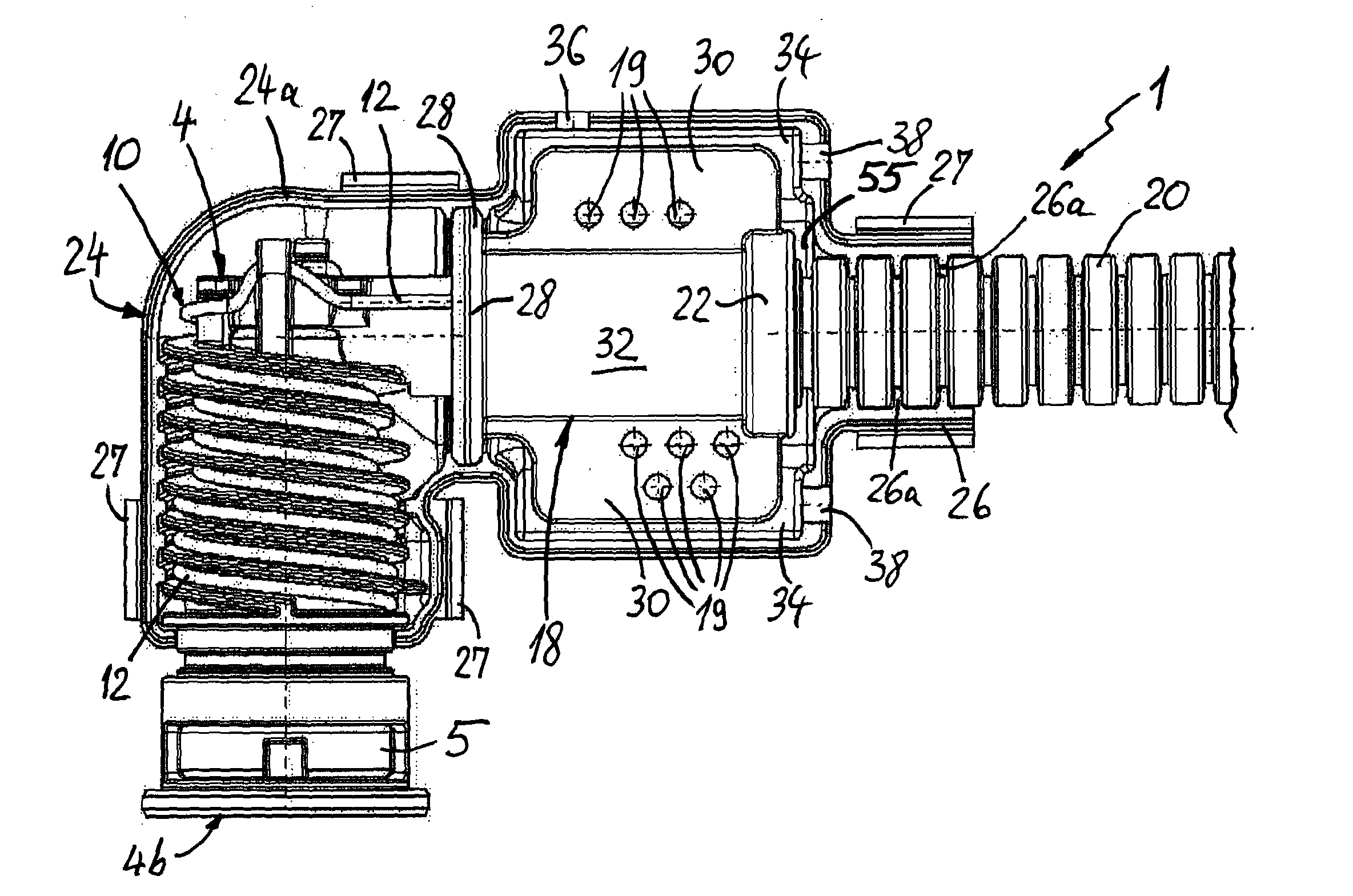

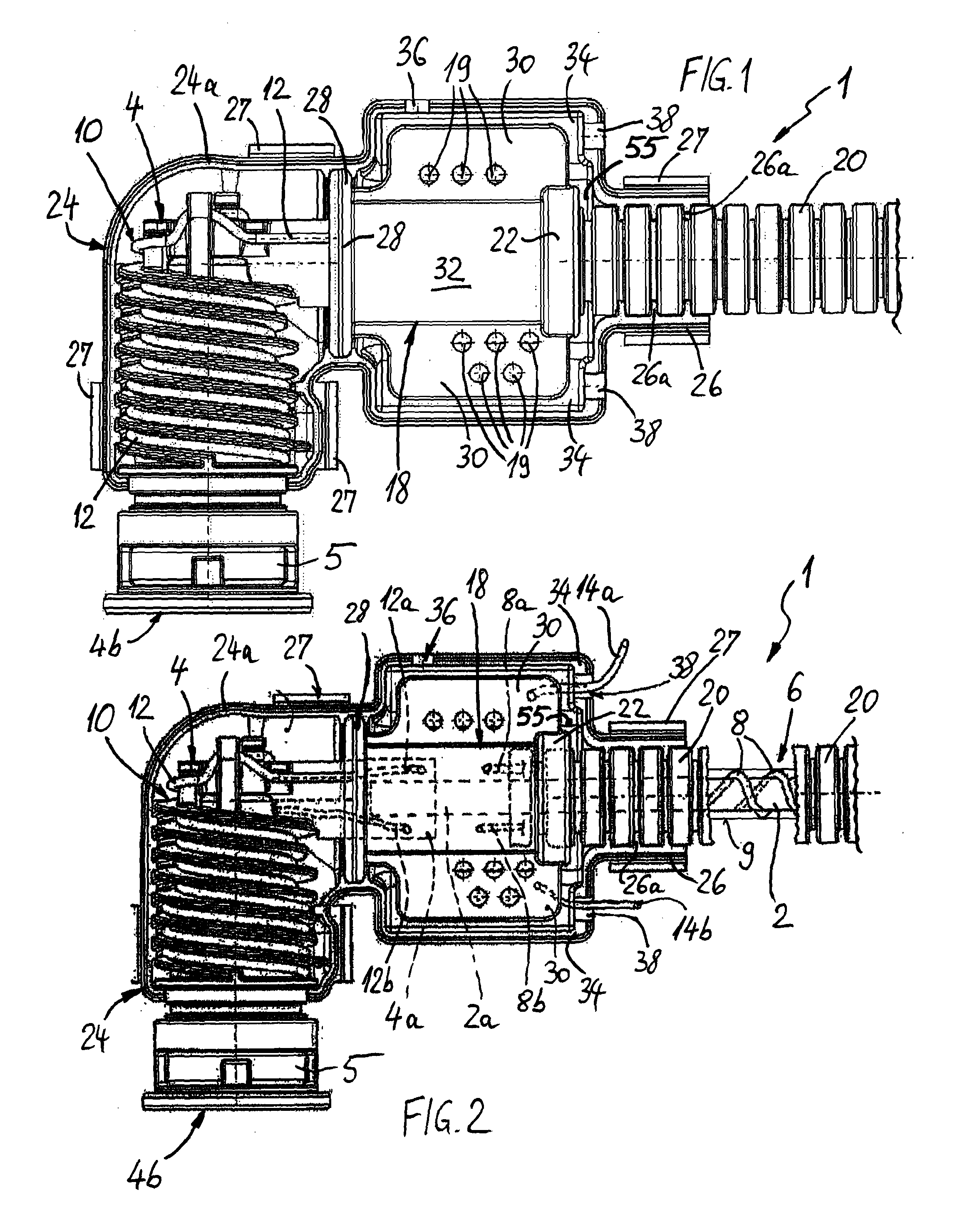

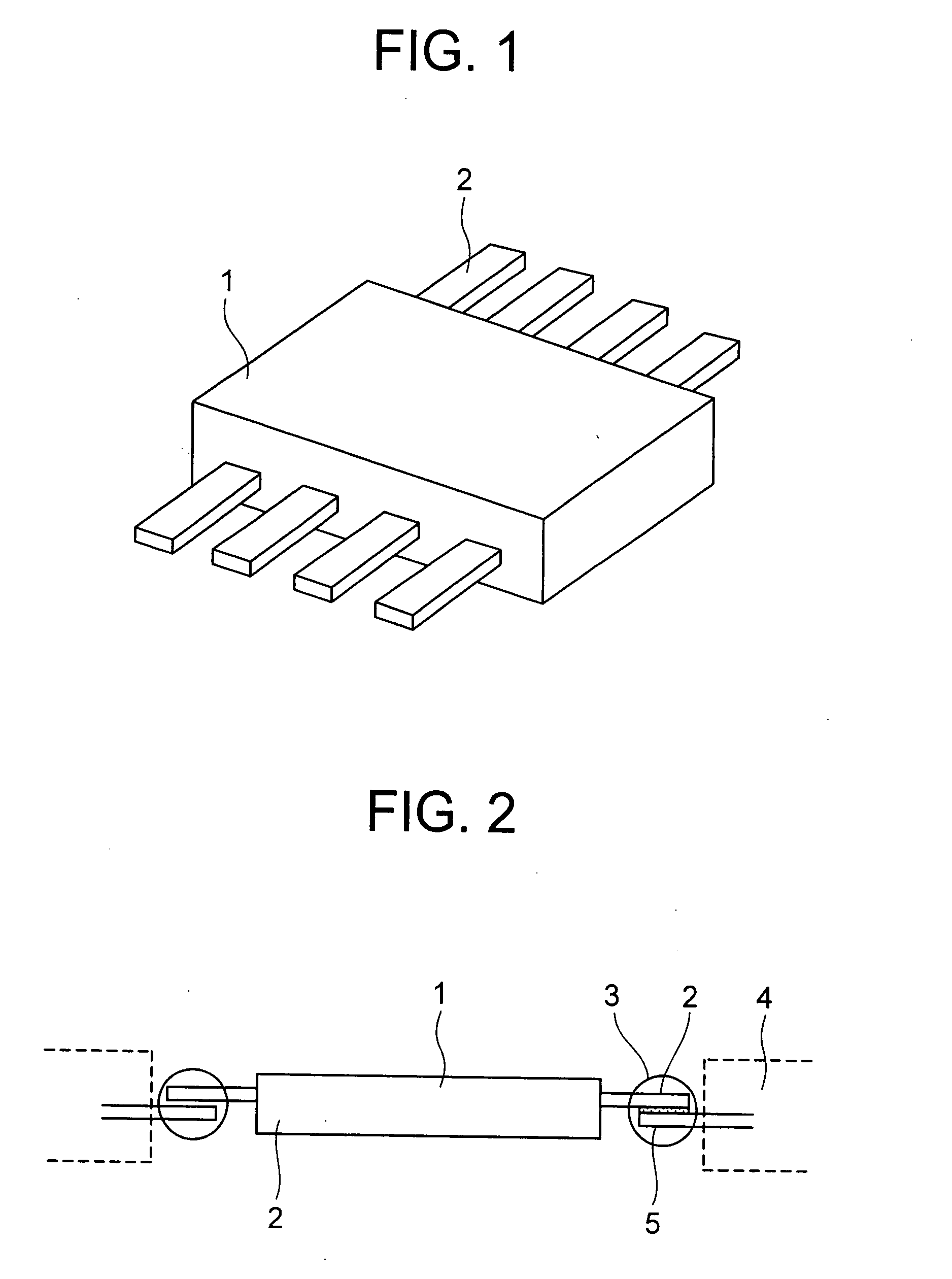

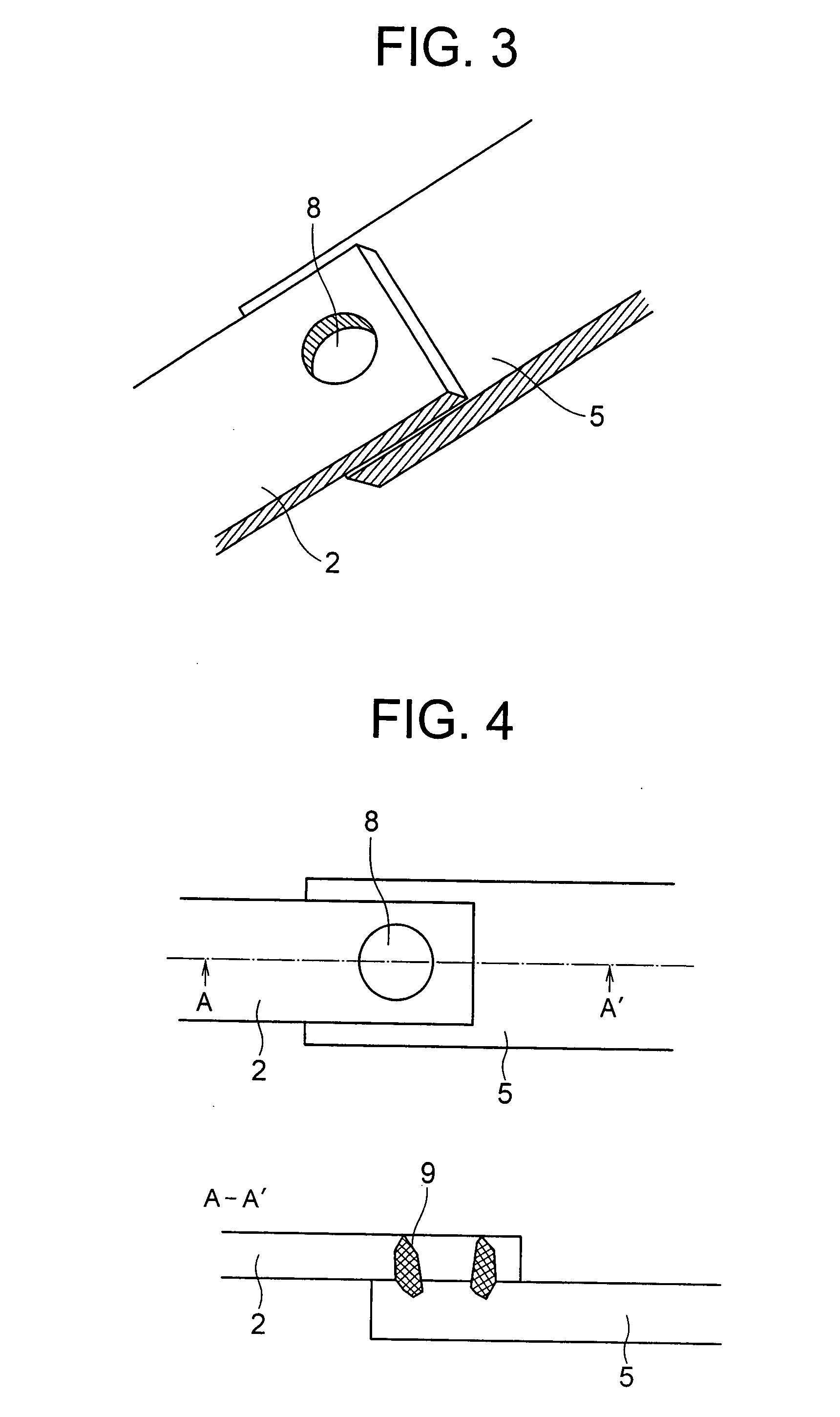

Heatable Media Line

InactiveUS20100263740A1Prevent freezingHigh degreeValve members for heating/coolingExhaust apparatusLine tubingPlastic molding

The present invention relates to an electrically heatable media line (1), comprising a fluid line (2) and at least one fluid connector (4) connected to a line end (2a). The fluid line (2) and the fluid connector (4) respectively have electric heating means (6, 10), wherein the fluid line (2) and / or the fluid connector (4) including electric connections (16) of the heating means (6, 10) are / is enclosed by a plastic molding compound.

Owner:VOSS AUTOMOTIVE

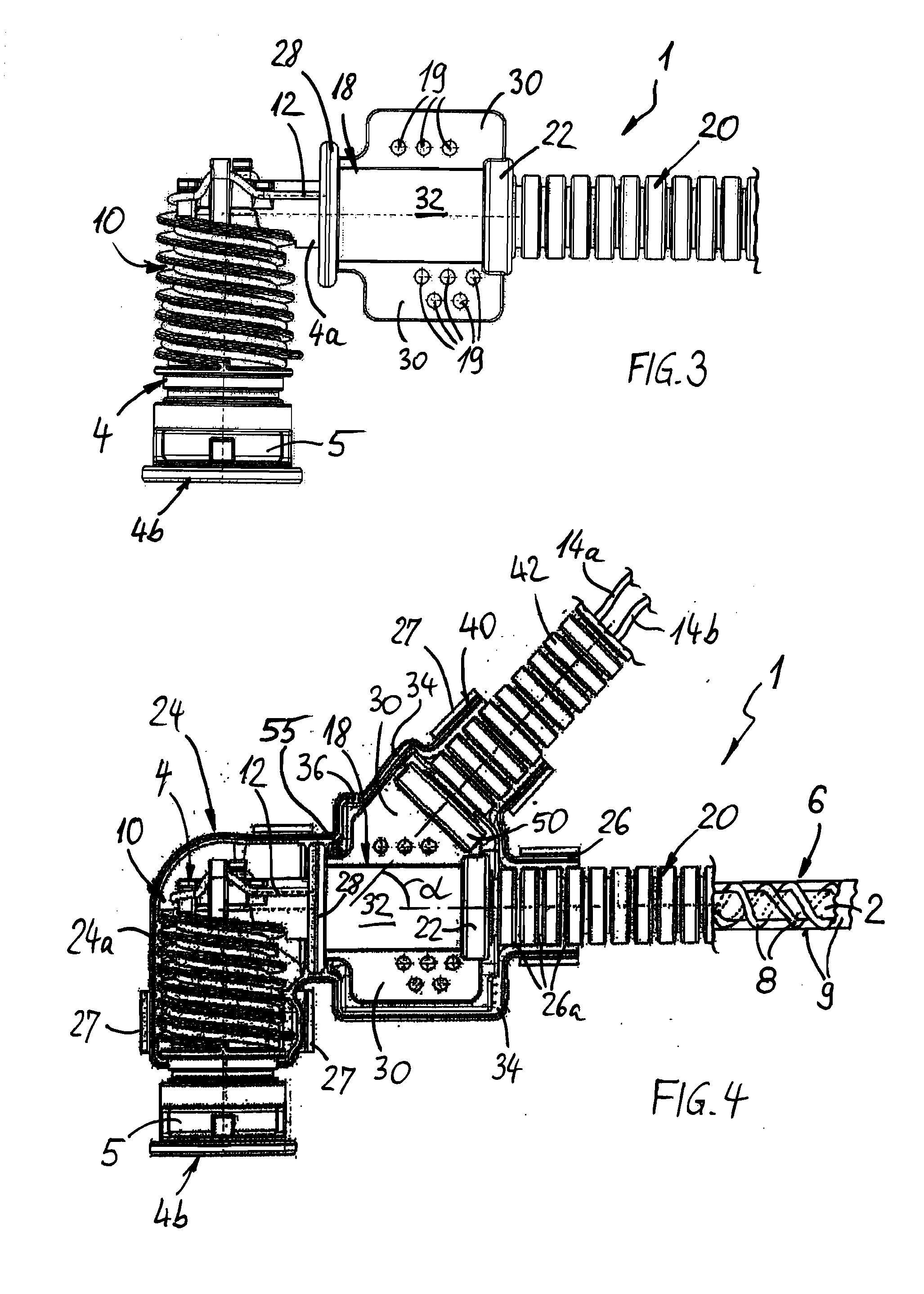

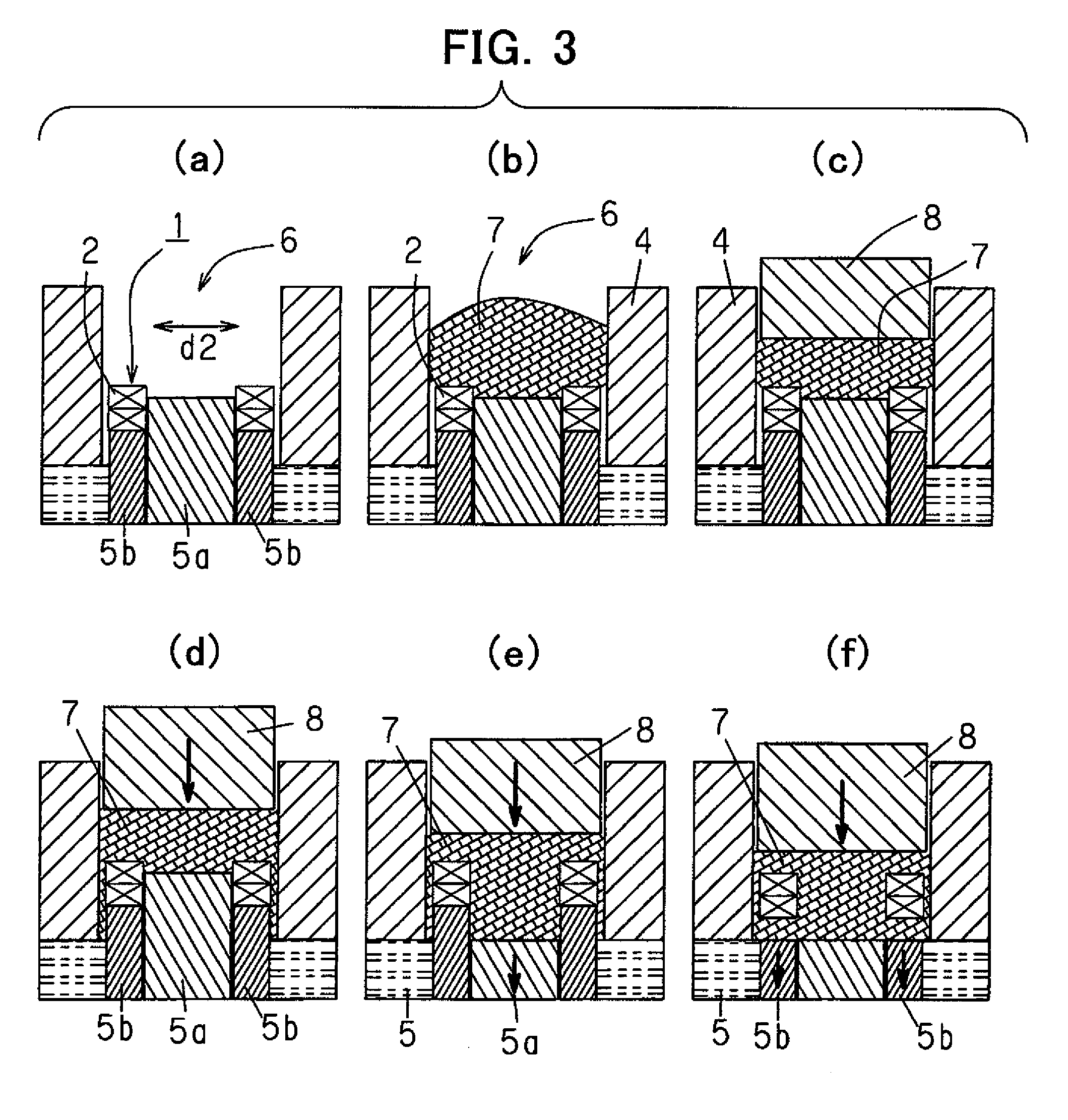

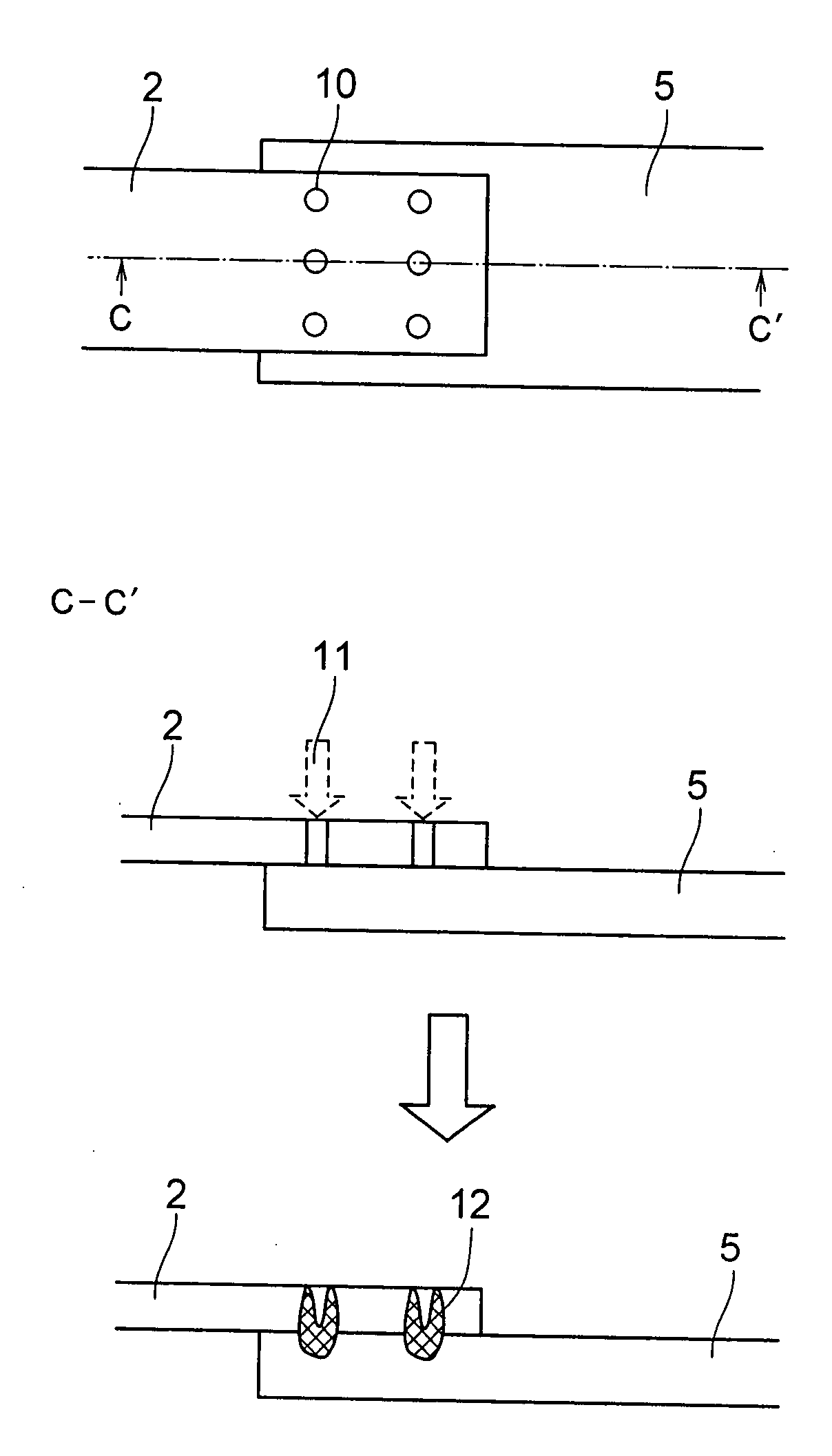

Production Method for Molded Coil

InactiveUS20090250836A1High positioning accuracyEasy to produceTransformers/inductances detailsEncapsulation/impregnationEngineeringPlastic molding

Disclosed is a method oft by using a plastic molding process, encapsulating an air-core coil with a moldable magnetic resin material prepared by kneading a mixture of a magnetic powder and a resin. The method comprises the steps of (a) preparing a molding die assembly which includes a plurality of dies adapted to define a cavity therewithin, and a positioning pin adapted to be movable in a vertical or horizontal direction within the cavity, (b) arranging the air-core coil at a given position within the cavity by the positioning pin, (c) charging the moldable magnetic resin material into the cavity and moving the positioning pin to a given retracted position in a course of the charging.

Owner:TOKO KABUSHIKI KAISHA

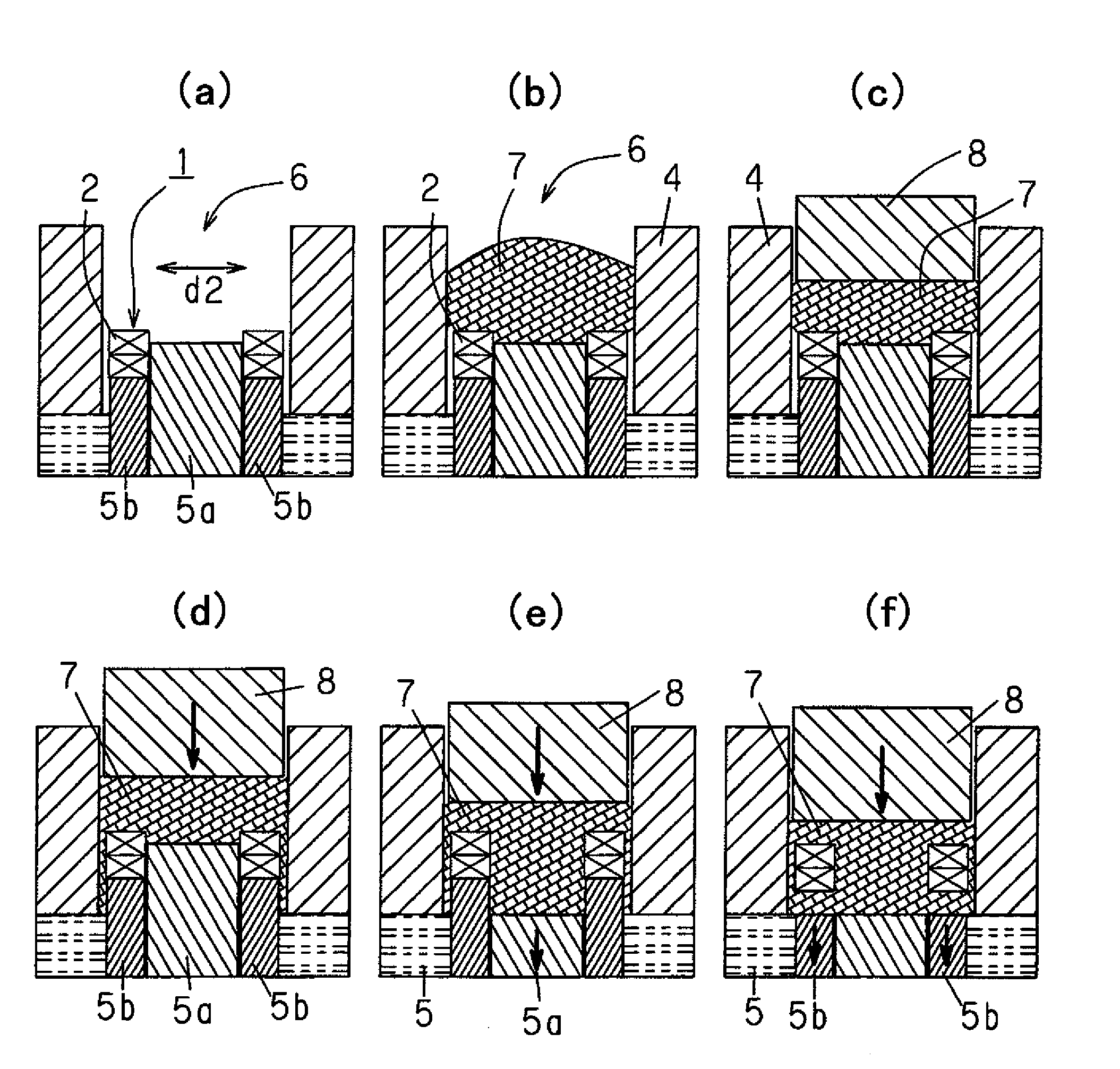

Method of laser welding, manufacturing method of control unit, and car electronic control unit

InactiveUS20070199926A1Improve welding qualityLow costLine/current collector detailsPrinted circuit aspectsEngineeringLaser beams

The invention stabilizes a quality of a laser welding in a terminal in which an outer appearance characteristic is not stabilized, and achieves an improvement of a positioning characteristic at a time of executing the laser welding without generating a cost increase. A hole is formed in a terminal of an integrated circuit sealed by a plastic molding. At a time of welding, a welding operation position is positioned by recognizing the hole in accordance with an image recognition, and a laser welding is executed by irradiating a laser beam to a portion of a terminal and a bus bar positioned near an edge portion of the hole. The hole is preferably formed in a circular shape or a similar shape thereto.

Owner:HITACHI LTD

Steel for a plastic molding die

To provide a steel for plastic molding die which possesses enough hardness, wear resistance and corrosion resistance, and is excellent in high-precision processability and mirror polishing properties. The steel for a plastic molding die contains not more than 0.80 wt% C, not less than 0.01 wt% and less than 1.40 wt% Si, not less than 0.05 wt% and not more than 2.0 wt% Mn, not less than 0.005 wt% and not more than 1.00 wt% Ni, not less than 13.0 wt% and not more than 20.0 wt% Cr, not less than 0.20 wt% and not more than 4.0 wt% Mo + 1 / 2 W, not less than 0.01 wt% and not more than 1.00 wt% V, not less than 0.36 wt% and not more than 0.80 wt% N, not more than 0.02 wt% O, not more than 0.80 wt% A1, and the remainder substantially including Fe and unavoidable impurities.

Owner:DAIDO STEEL CO LTD

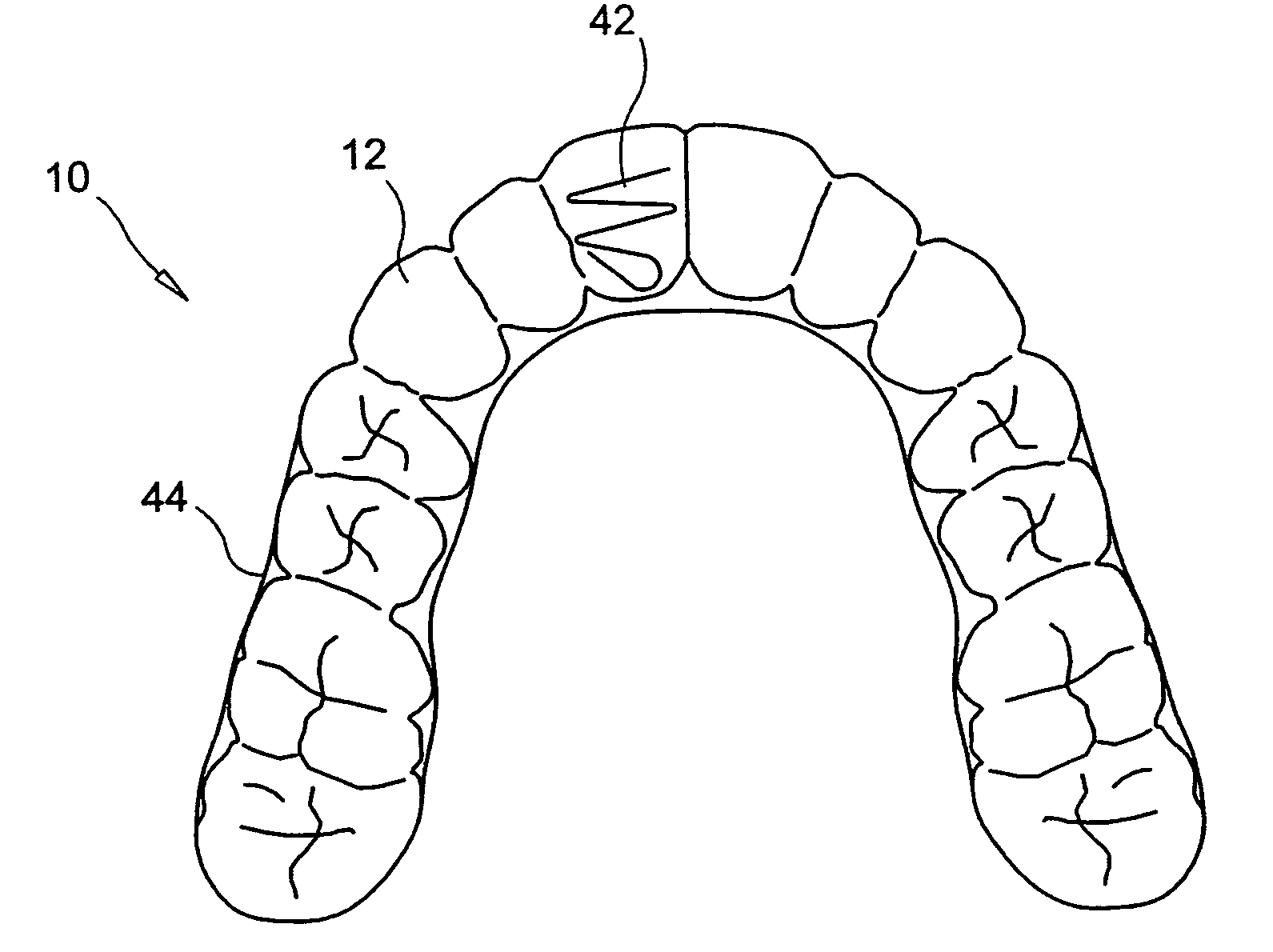

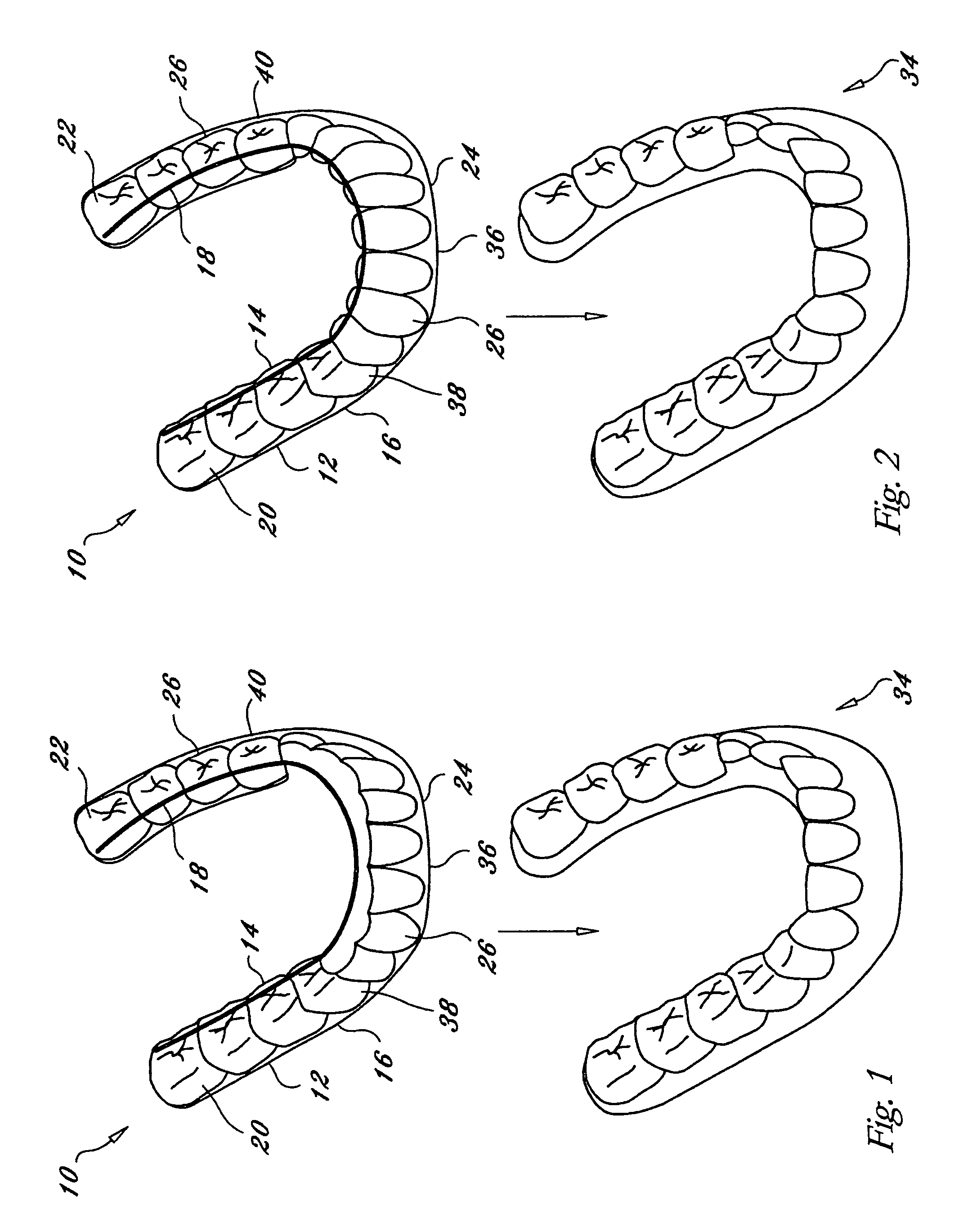

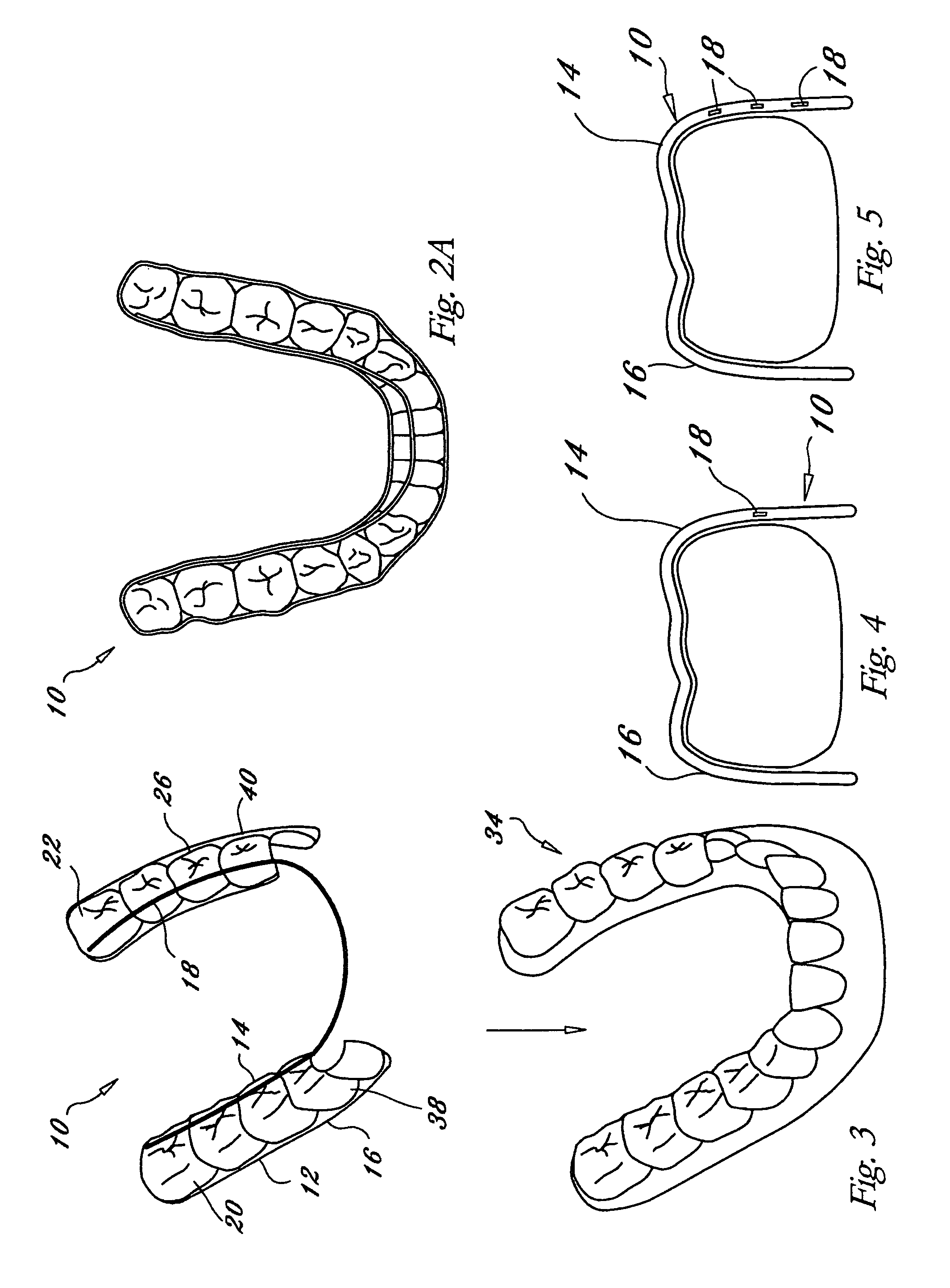

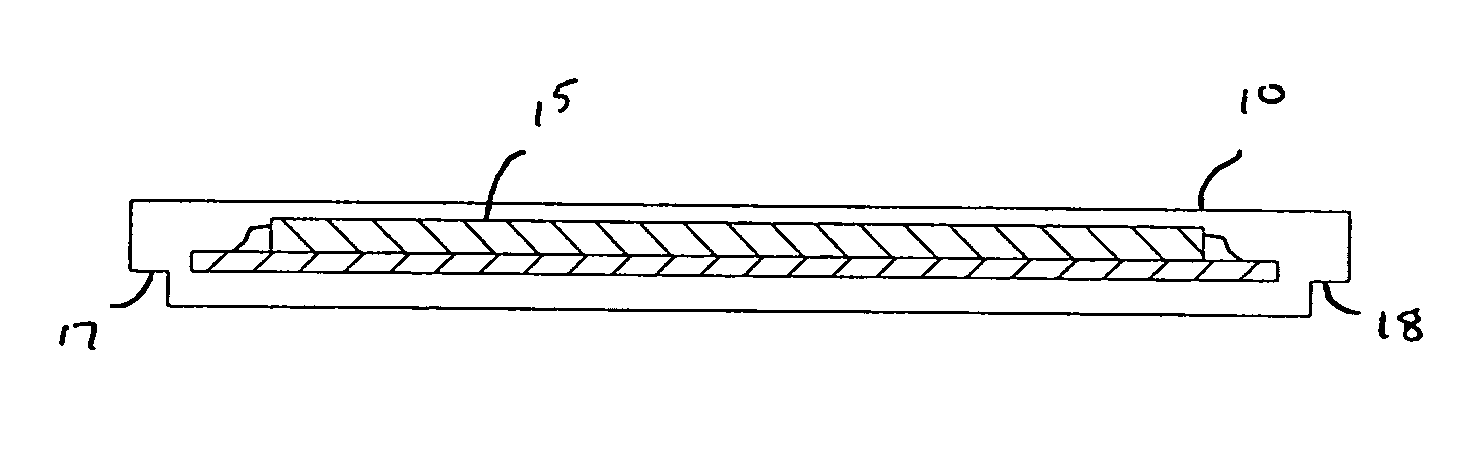

Orthodontic appliance with embedded wire for moving teeth and method

InactiveUS7416407B2Easy to manufactureMore forceful and less obtrusive movementOthrodonticsDental toolsPlastic forming machineWire rod

A generally horseshoe shaped clear flexible resilient plastic wire-imbedded orthodontic appliance is made with a plastic portion with contours on the lingual side and on the labial side, wherein the contours snugly cover the patient's teeth so that the appliance remains in place. One or more flexible wires are imbedded within the lingual side of the plastic portion from the left molar area to the right molar area of the plastic portion, whereby the wires apply force on the lingual side of the patient's bite. The appliance is formed by obtaining a plaster cast of the patient's teeth and gums, removing plaster teeth from the plaster cast of the gums, reattaching the plaster teeth to the plaster cast of the gums to form a cast of proper bite alignment, attaching one or more wires to the labial surface of the aligned plaster teeth so the wires become imbedded within thermosetting plastic placed over the cast, putting the cast in a thermosetting plastic molding machine, inserting thermosetting plastic in the machine, and heating the thermosetting plastic around the cast of the proper bite alignment, so the wires are imbedded within the formed appliance after the thermosetting plastic cools. A series of appliances may be used to shift a patient's bite to proper bite orientation.

Owner:CRONAUER EDWARD A

Formable composite films of plastic and composite elements of plastic coated with soft touch coating, and the production thereof

InactiveUS20060078745A1Synthetic resin layered productsPolyurea/polyurethane coatingsComposite filmComposite element

The present invention relates to composite plastic moldings containing A) a thermoplastically formable, heat-resistant composite film having A1) a carrier film of a thermoplastic resin and A2) a layer of a heat-resistant soft touch coating on one side of the carrier film (A1) and B) a thermoplastic layer on the side of the carrier film (A1) facing away from the soft touch coating, wherein the soft touch coating (A2) is obtained from a composition containing i) polyurethanes and / or polyurethane-ureas which are free from hydroxyl and / or amine groups, ii) ionically modified polyurethanes and / or polyurethane-ureas which contain hydroxyl and / or amine groups, iii) at least one crosslinking agent, iv) optionally film-forming resins other than A1) or A2), and v) optionally additives. The present invention also relates to a process for the production of these composite moldings and their use in telecommunications equipment and in vehicle, ship and aircraft construction.

Owner:BAYER MATERIALSCIENCE AG

Removable flash integrated memory module card and method of manufacture

InactiveUS20060030080A1Flexible in manufacturingFlexible in usageSemiconductor/solid-state device detailsPrinted circuit aspectsContact padEngineering

A removable Flash integrated memory module card has a plastic shell and an integral Flash memory module. On the backside of the card, there are exposed contact pads. When the card is inserted into a card-hosting device, the card can communicate with the device through the exposed pads. The manufacturing method includes manufacturing of the memory module and utilizing plastic molding techniques for making the card outer body. The method involves preparing the substrate, mounting the components, testing the module, preparing the molding device, and molding the card body.

Owner:SUPER TALENT ELECTRONICS

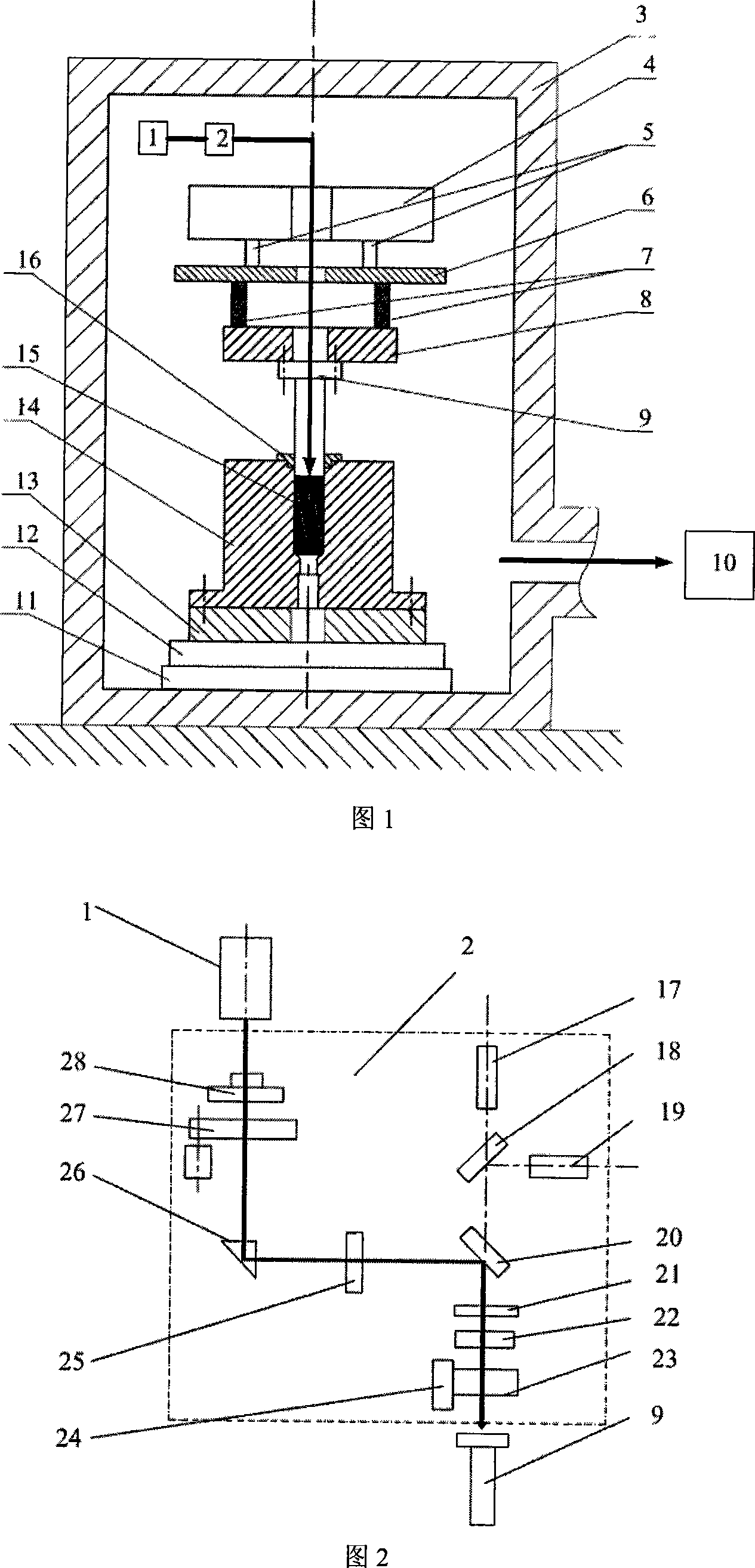

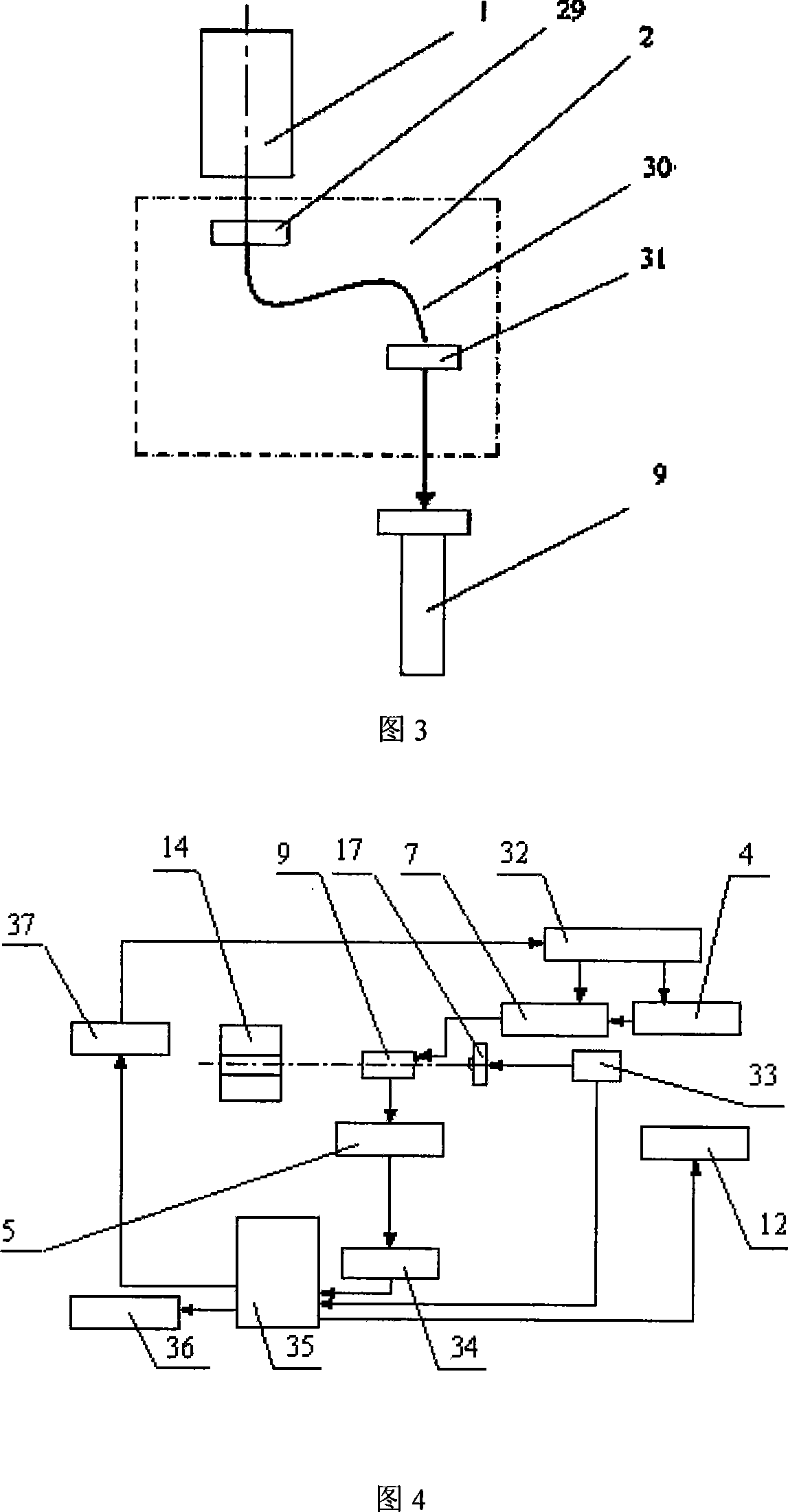

Micro-plastic molding method and apparatus for micro-device

InactiveCN101130196AAccurate temperatureReduce deformation resistanceShaping toolsExtrusion diesControl systemLaser heating

The invention discloses a microplastic shaping method and device of microelement in the microplastic piece preparing and shaping technical domain, which comprises the following parts: laser heating system, microshaping system, loading system, control system and assembling platform, wherein the flat-top laser beam emitted by laser is loaded on the surface of microelement surface through transmittable terrace die, which utilizes laser to do non-contact heating of working piece and heat conductivity; the heat work piece material is below recrystallizing temperature for shaping temperature scale; the terrace die does feeding movement towards female die through microdriving system; the loading system combines the microdriving system to realize loading action for microblank to finish microplastic shaping. The invention reduces the deformation resistance of material at non-contact heating on the upper surface of working piece through laser, which increases the evenness of material fluidity for batching manufacturing of microelement to realize automation manufacturing easily.

Owner:JIANGSU UNIV

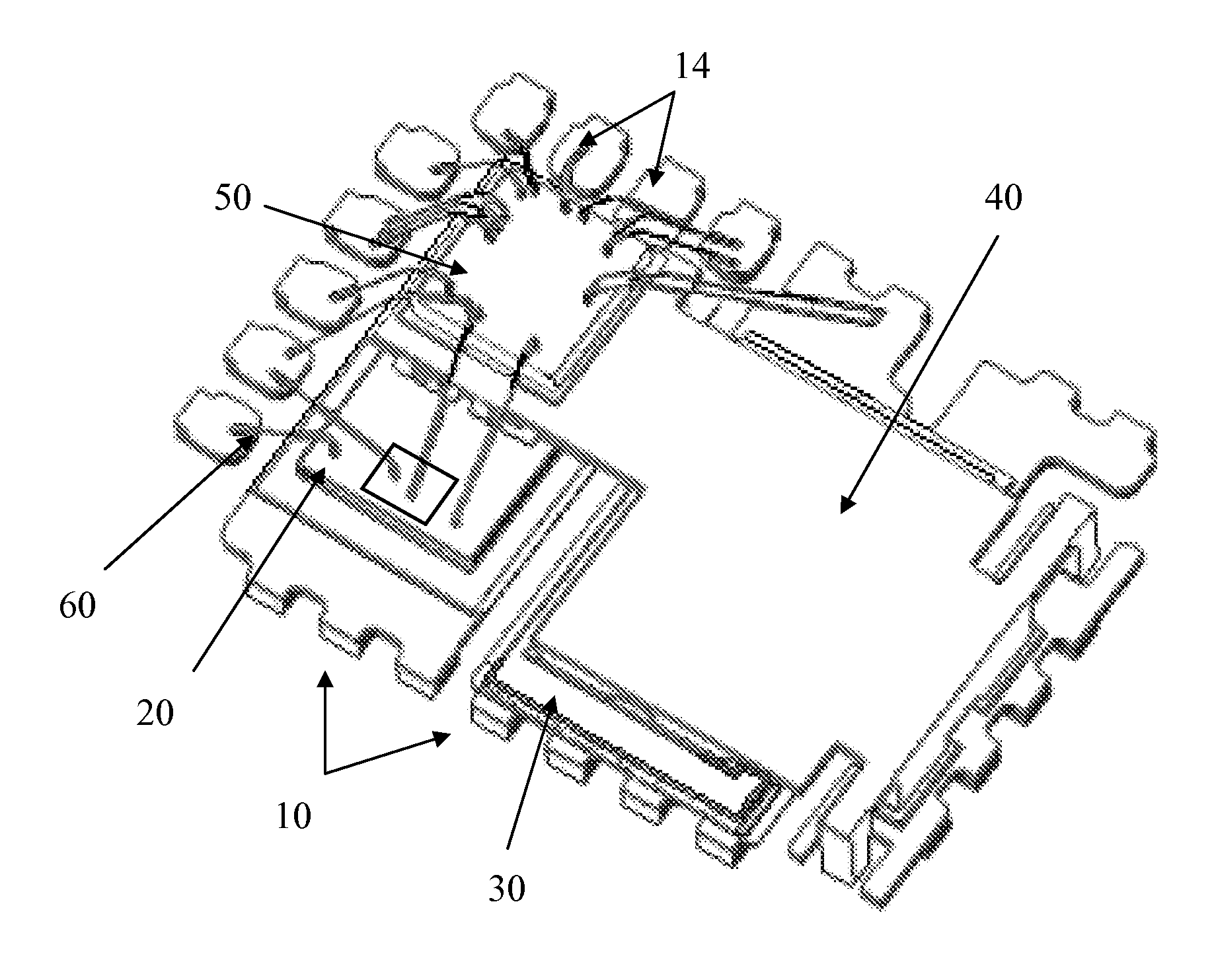

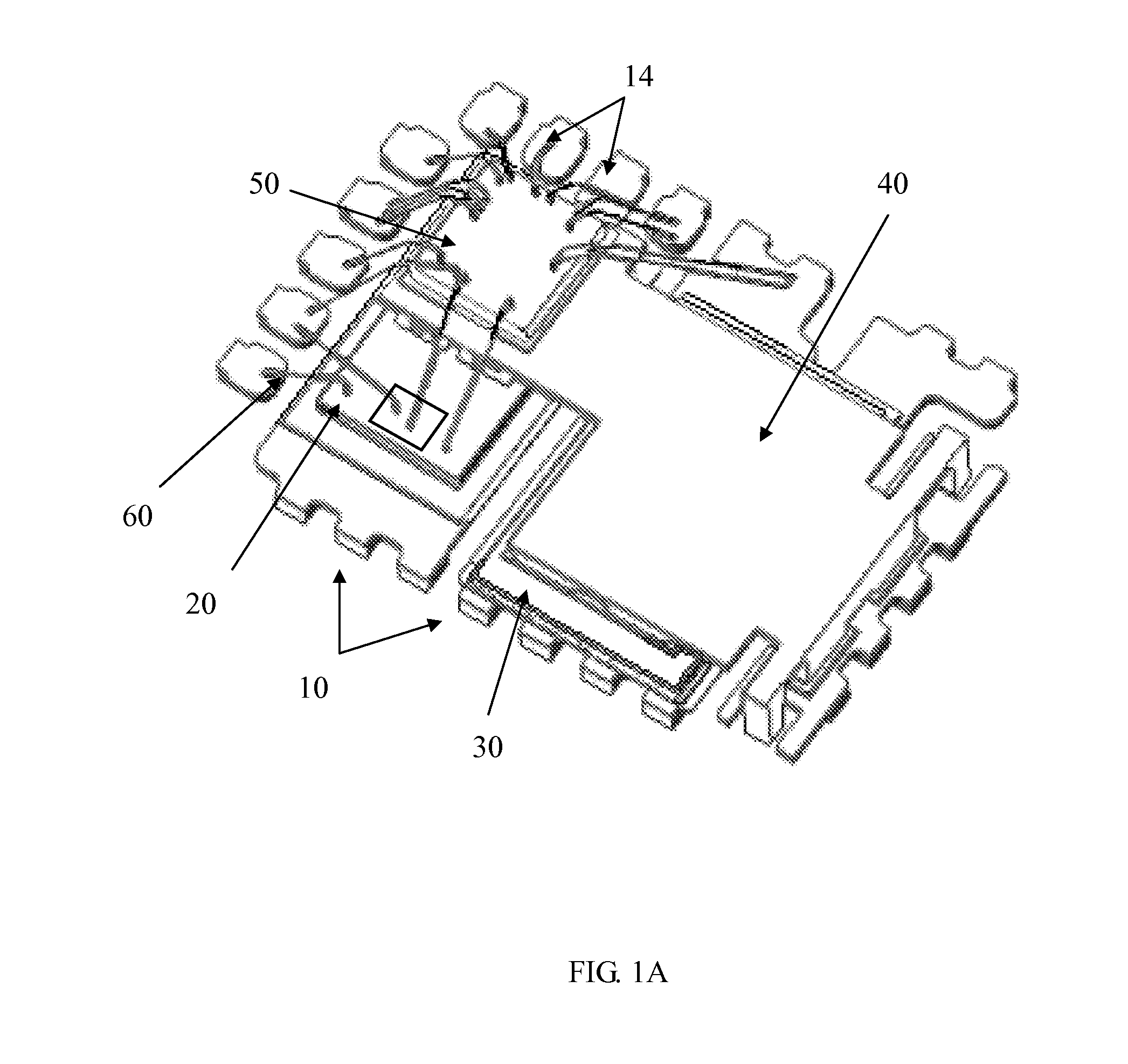

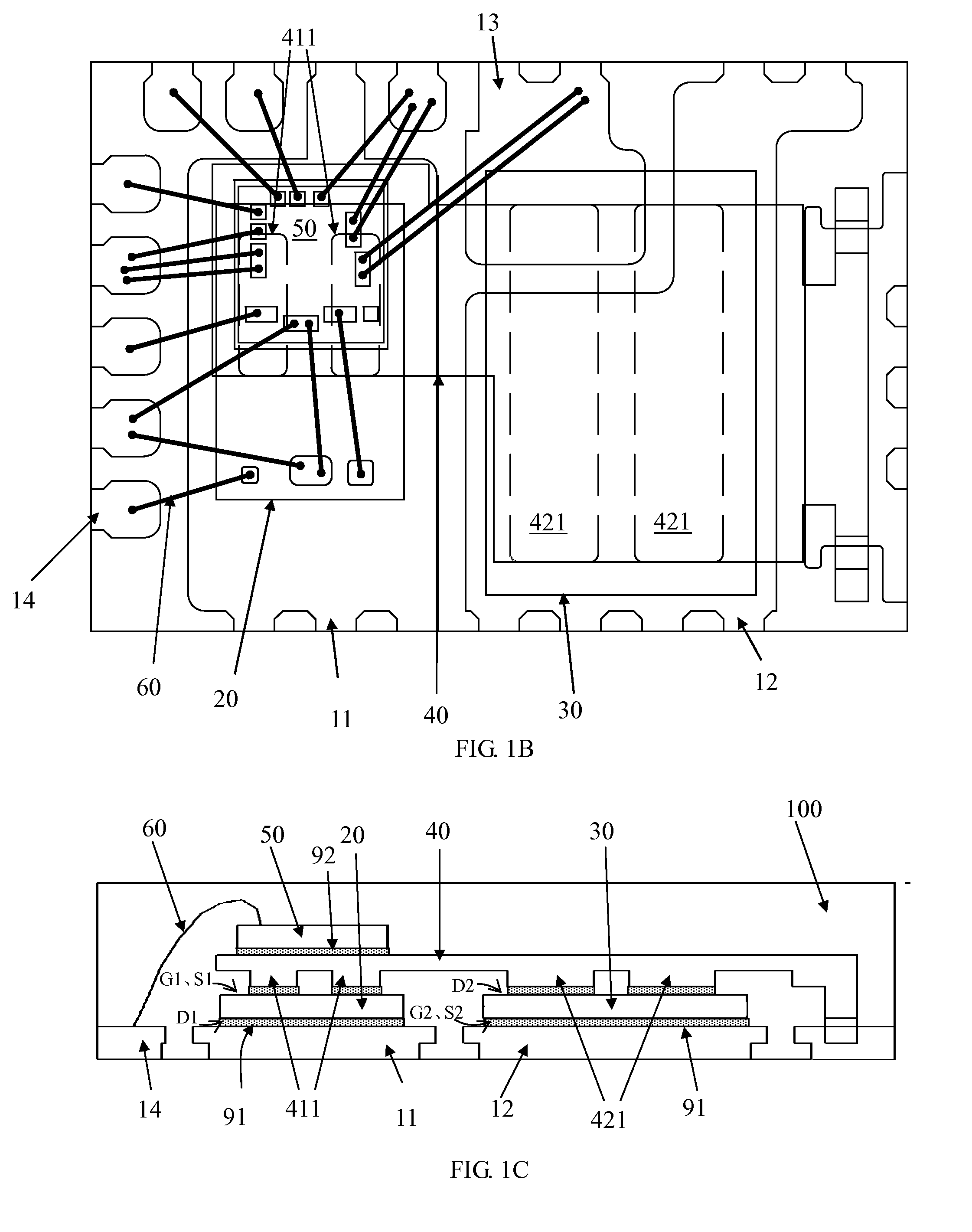

Stacked multi - chip packaging structure and manufacturing method thereof

ActiveUS20150035129A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipEngineering

A stacked multi-chip packaging structure comprises a lead frame, a first semiconductor chip mounted on the lead frame, a second semiconductor chip flipped-chip mounted on the lead frame, a metal clip mounted on top of the first and second semiconductor chips and a third semiconductor chip stacked on the meal clip; bonding wires electrically connecting electrodes on the third semiconductor chip to the first and second semiconductor chips and the pins of the lead frame; plastic molding encapsulating the lead frame, the chips and the metal clip.

Owner:ALPHA & OMEGA SEMICON INC

Thermal conductive plastic and method for manufacturing mobile telephone shell by utilizing thermal conductive plastic

The invention discloses a thermal conductive plastic and a method for manufacturing a mobile telephone shell by utilizing the thermal conductive plastic. The thermal conductive plastic comprises the following materials in percentage by weight: 30%-70% of high polymer base material, 20%-60% of thermal conductive filler, 5%-15% of fire retardant and less than 10% of coupling agent; the high polymer base material, the thermal conductive filler and the like are mixed, extruded, pelletized and dried; and the obtained thermal conductive plastic particles are used for injection molding to obtain the thermal conductive plastic mobile telephone shell. According to the method for manufacturing mobile telephone shell by utilizing the thermal conductive plastic disclosed by the invention, special filler is added to the high polymer material, so that the weight of the manufactured mobile telephone shell is smaller than the weight of the aluminum material with the same size by 40%-50%; and the manufactured mobile telephone shell is quick and uniform in heat dissipation, so that the local deformation of the components, caused by high temperature, is reduced. Meanwhile, the thermal conductive plastic disclosed by the invention is convenient to mould and process without being secondarily processed, so that the product design freedom is high; besides, the problem that the existing mobile telephone shell processing material can not has the heat dissipation, insulating property and processing strength at the same time is well solved.

Owner:SHENZHEN FRD SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com