Thermal conductive plastic and method for manufacturing mobile telephone shell by utilizing thermal conductive plastic

A technology for thermally conductive plastics and mobile phone casings, applied in the field of materials, can solve the problems that the processing mobile phone casing materials cannot meet the processing requirements, etc., and achieve the effects of avoiding burning spots, fast and uniform heat dissipation, and convenient molding and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The processing technology of preparing mobile phone shell with PA6 as the base material:

[0027] PA6 35%-50%;

[0028] Alumina (Al 2 o 3 ) 15%~25%, graphite 15%~20%;

[0029] Flame retardant 5%-15%;

[0030] The amount of coupling agent A-151 is 2% of alumina.

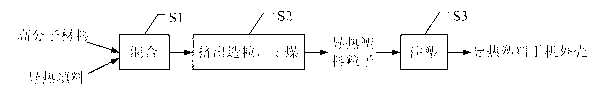

[0031] The method for preparing a mobile phone casing by using the heat-conducting plastic includes steps: S1, mixing PA6, a flame retardant, a coupling agent A-151 and a heat-conducting filler Al 2 o 3 Mix with graphite for 10 minutes with a high mixer. S2. Extrude, granulate and dry the mixed materials to obtain heat-conducting plastic particles. Extrusion process parameters: extrusion temperature 220-270°C, main feeding frequency 8, main side feeding frequency 10.5 main engine speed 30, main engine current 28.7-29.3. Drying: drying in a forced air constant temperature drying oven at 100°C for 10 hours. S3. Using heat-conducting plastic particles for injection molding to obtain a heat-conducting plas...

Embodiment 2

[0034] Processing technology for preparing mobile phone shell with PPS as base material

[0035] PPS 30%-50%

[0036] Magnesium oxide (MgO) 30%-50%, graphite 5%~10%;

[0037] Flame retardant 5%-15%;

[0038] The dosage of coupling agent KH-560 is 0.5% of magnesium oxide.

[0039] The method for preparing a mobile phone shell using the heat-conducting plastic includes the steps: S1, mixing PPS, flame retardant, coupling agent KH-560, heat-conducting filler MgO, and graphite with a high-speed mixer for 10 minutes. S2. Extrude, granulate and dry the mixed material to obtain heat-conducting plastic particles. Process parameters: extrusion temperature is 290-330°C, main feeding frequency is 8, main side feeding frequency is 10.5, host speed is 30, Host current 28.5-29.1; Drying: Dry in a blast constant temperature drying oven at 150°C for 10 hours. S3. Using heat-conducting plastic particles for injection molding to obtain a heat-conducting plastic mobile phone case. Injection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com