Chalcogenide glass for low viscosity extrusion and injection molding

a technology of chalcogenide glass and low viscosity, applied in the field of optical components, can solve the problems of large-scale manufacturing, unsuitable methods, and high cost of methods, and the vast majority of conventional machining processes for manufacturing optical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0040] By way of illustration not to be construed as limiting the invention, the chalcogenide glass 979 BUG was prepared and extruded in the following manner which is representative of the process of the invention. The equipment used in the following process is all commercially available.

[0041] A mixture, in atomic percent, of 1.6% Ge, 28.4% As and 70% Se was mixed together in an amount sufficient to prepare a 500 gram glass boule and placed in a quartz ampoule that was evacuated (to 10−3 mm Hg or less) and sealed. The ampoule was heated to a temperature of approximately 800° C. for a time in the range of 30-36 hours, slow cooled to 500° C., and then rapidly cooled (quenched) by immersing the ampoule in a 4000 ml beaker of room temperature water until the chalcogenide glass delaminated from the ampoule wall. At this point the ampoule was placed in an annealing furnace at an approximate temperature of 125° C. and held at this temperature for 0.25 to 2 hours. The furnace power was th...

example 2

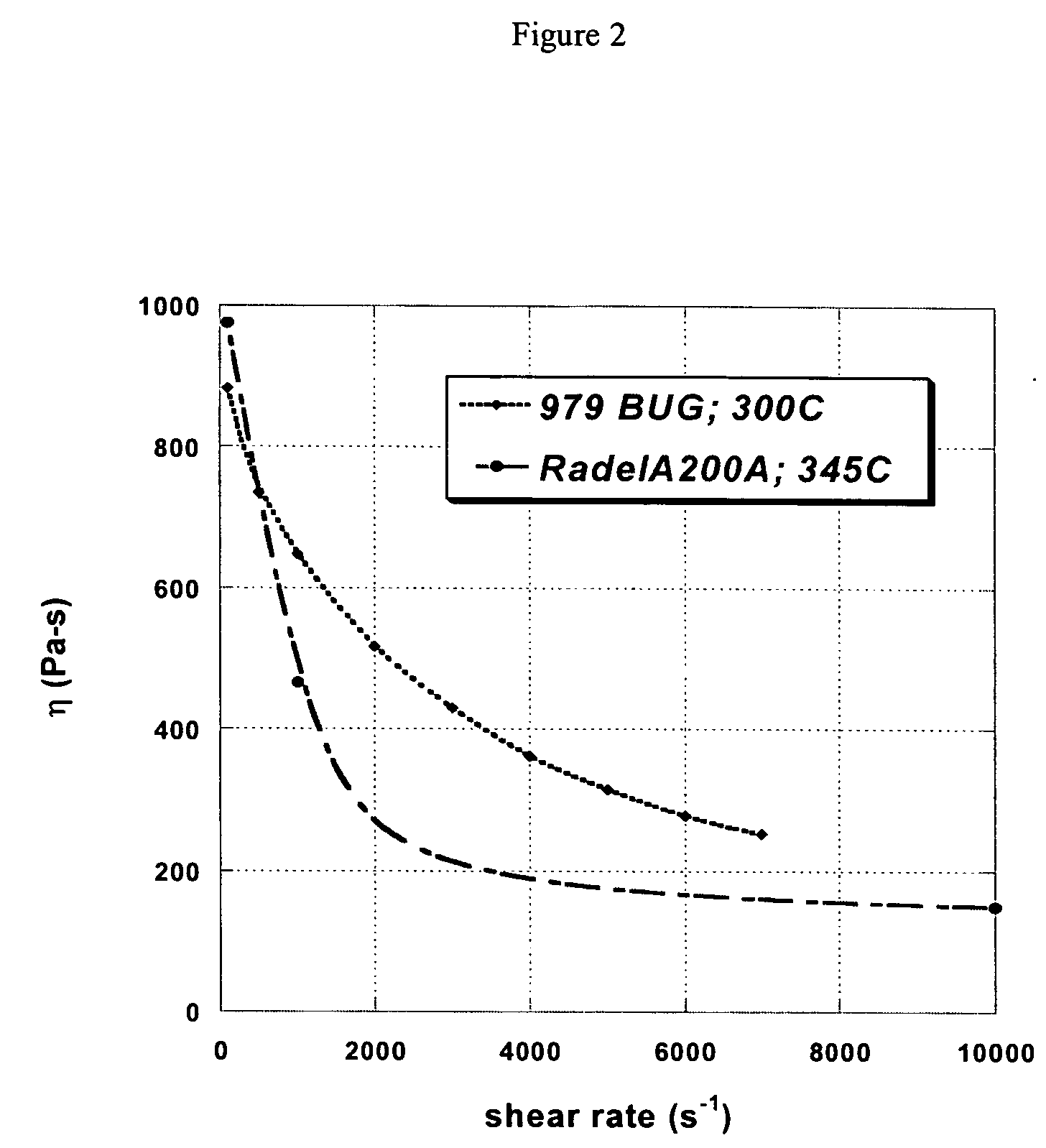

[0047] A two-cavity, double convex lens (25 mm diameter by 8 mm thick) mold was used to injection mold the 979BUG glass composition on an Arburg 370 CS 600-100 molding machine (Arburg, Inc., Newington, Conn.), which had a 30 mm diameter injection unit with a 2:1 compression-ratio screw. A thin layer of boron nitride, from water slurry, was applied to all surfaces of the screw, nozzle, sprue bushing, runner, gates and cavity to prevent adhesion of the glass. Crushed glass was sieved to a particle size range of approximately 0.5-2.0 mm, and placed in a standard hopper for flood feeding. Parts were molded at the following process conditions given in Table 2.

TABLE 2PositionTemp., ° C.:Other ConditionsFeed Throat52Clamp Force400kNZone 1293Shot Size15.00ccmZone 2299Switchover Point7.9ccmZone 3305Injection Speed20ccm / sec.Zone 4305Switchover Pressure670barNozzle295Hold Pressure900barMold235Hold Time5.0sec.Circumfer. Screw Speed4.0m / min.Back Pressure30barCooling Time45sec.Total Machine Tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com