Precision-forging plastic molding technology of bell shell of ball-cage type universal joint

A ball cage type universal joint and plastic forming technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of high investment in machine tools, low labor production efficiency, and waste of metal materials. Achieve the effect of meeting precision requirements, stable product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

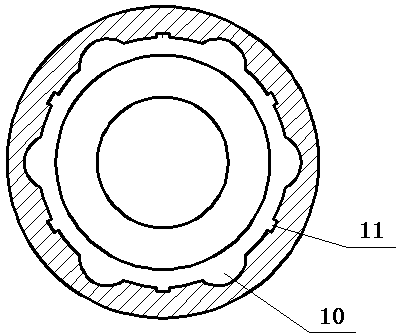

[0019] Example: see attached figure 1 And attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 And attached Figure 6 , the precision forging of the ball cage type universal joint bell-shaped shell according to the present invention includes a housing 1 and a handle 2 provided at the lower end of the housing, the upper end of the housing 1 is set as a middle hole, and the middle hole It is composed of six evenly distributed ball channels 3 and the connecting portion 4 between the ball channels, and the connecting portion 4 between the ball channels is provided with a process storage tank 5 .

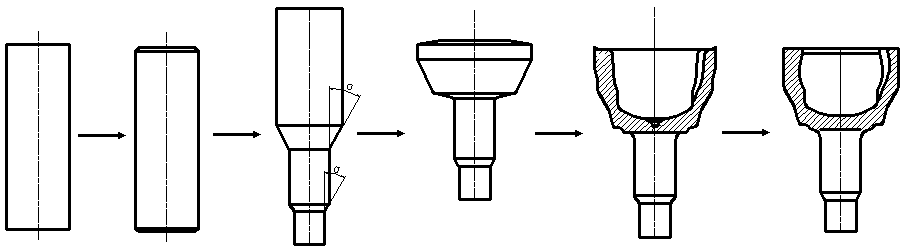

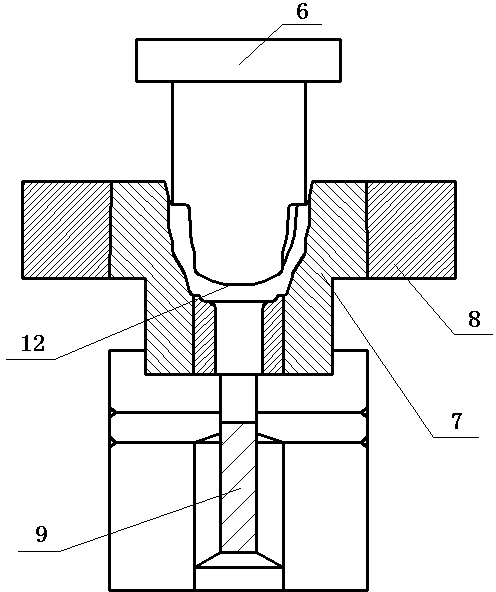

[0020] See attached image 3, the precision forging plastic forming process of the ball cage type universal joint bell-shaped shell of the present invention includes warm forging and cold forging plastic forming, and the described warm forging plastic forming includes the following steps: a, cutting material: circular saw intercepts metal bar ; b. Billet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com