Patents

Literature

154 results about "Plastic forming machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plastic forming machine, or plastic molding machine, is developed on the basis of rubber machinery and metal die-casting machine. Since the polymer injection molding process and molding equipment in the 1870s, as an industry, plastic forming machines were rapidly developed until the 1930s, with the gradual commercialization of plastic molding equipment, injection molding and extrusion molding became the most common industrialized processing methods. Blow molding is the third-largest plastic molding method after the injection molding and extrusion blow molding method, it is also the fastest development of plastic molding method.

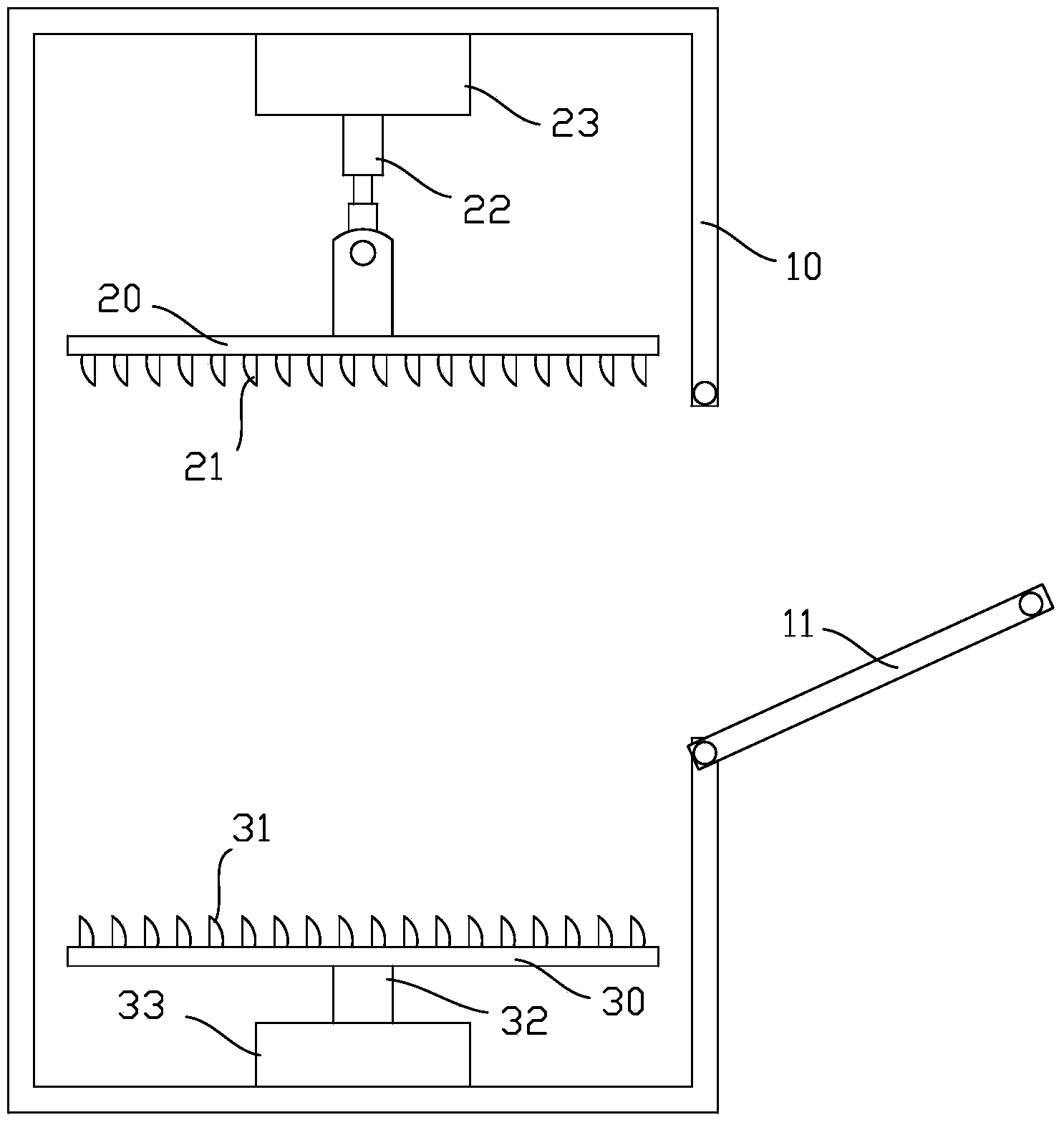

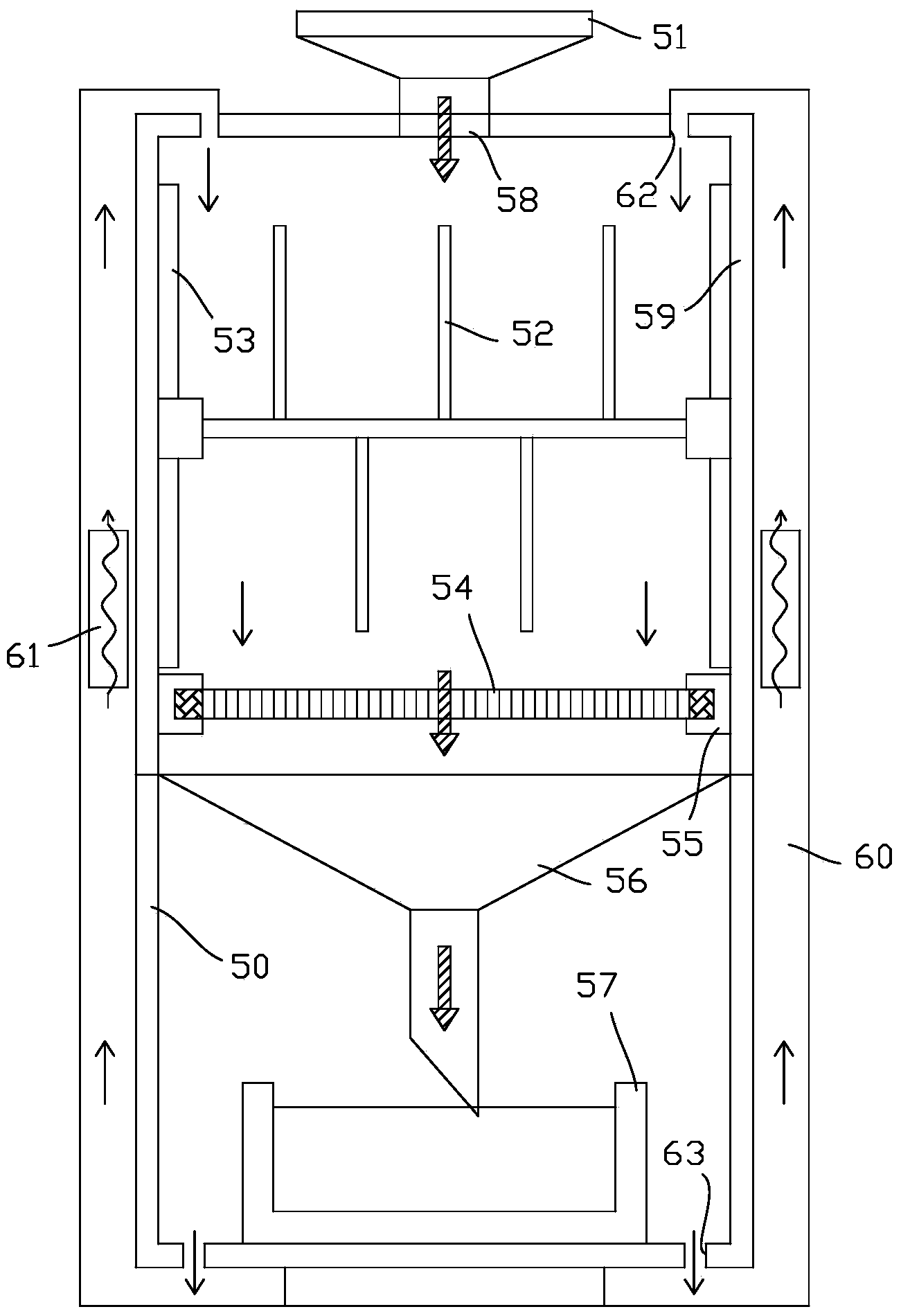

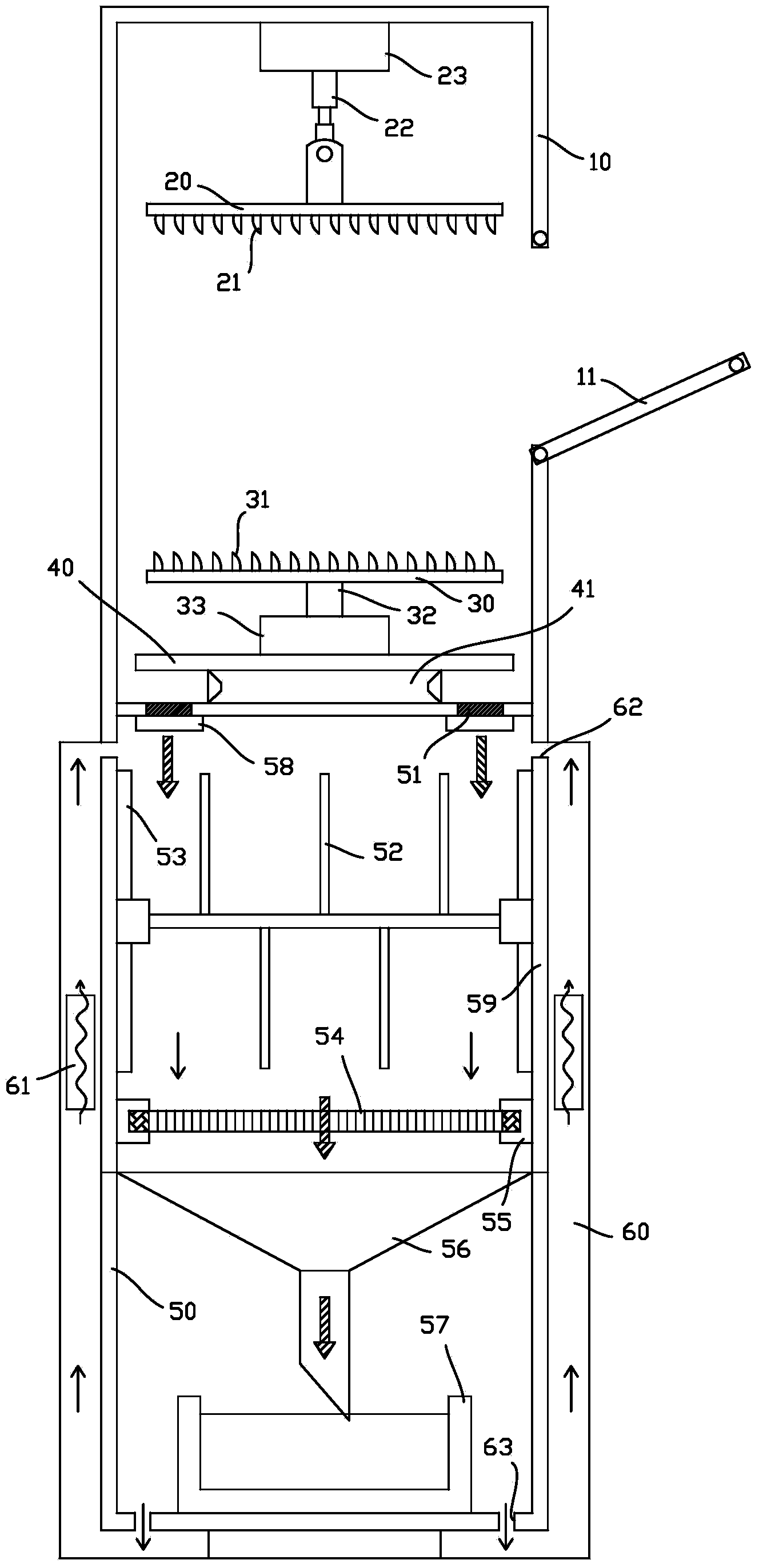

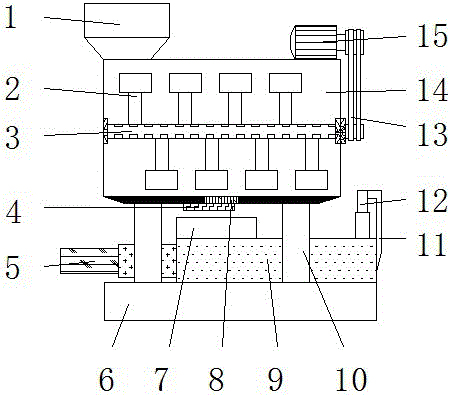

Waste and old mixed plastic recovery and separation device and method

ActiveCN103934923AEffective classificationRealize resource utilizationPlastic recyclingMechanical material recoveryPlastic forming machineMolten state

The invention discloses a waste and old mixed plastic recovery and separation device and method, and belongs to the field of resource recycling of waste and old mixed plastic. The waste and old mixed plastic recovery and separation device comprises a crushing device and a melting, sorting and recovering device, wherein a material feeding mechanism, a crushing mechanism and a material discharging mechanism are arranged in a crushing box body of the crushing device; a heating device, a screening mechanism and a plastic molding mechanism are arranged in a melting box body of the melting, sorting and recovering device; the heating mechanism is used for heating crushed granular materials to a molten state in a staged way; the screening mechanism is used for separating the materials in the molten state and un-melted granular materials; the plastic molding mechanism is placed on the bottom of the melting box body and recycling the separated materials in the molten state. The recovery and separation device can effectively classify the waste and old plastic generated in daily life and industrial production; different plastics are separated and are made into a single plastic which is relatively pure, so that the resource utilization of the waste and old plastic is realized; the post-processing process is omitted; energy resources are saved; the operation is simple; the automation degree is high; the sorting degree is high; the sorting range is wide.

Owner:ANHUI UNIV OF SCI & TECH

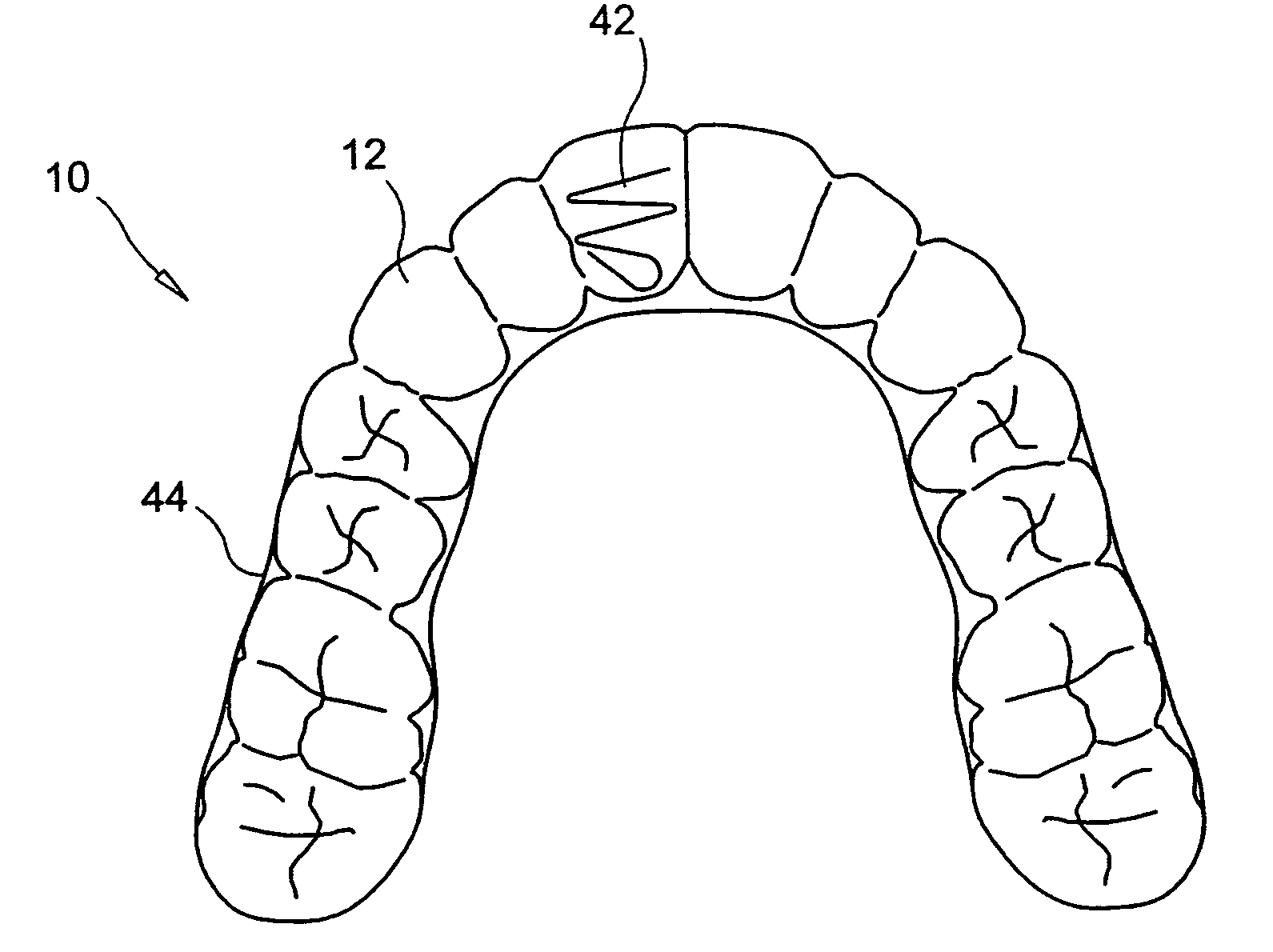

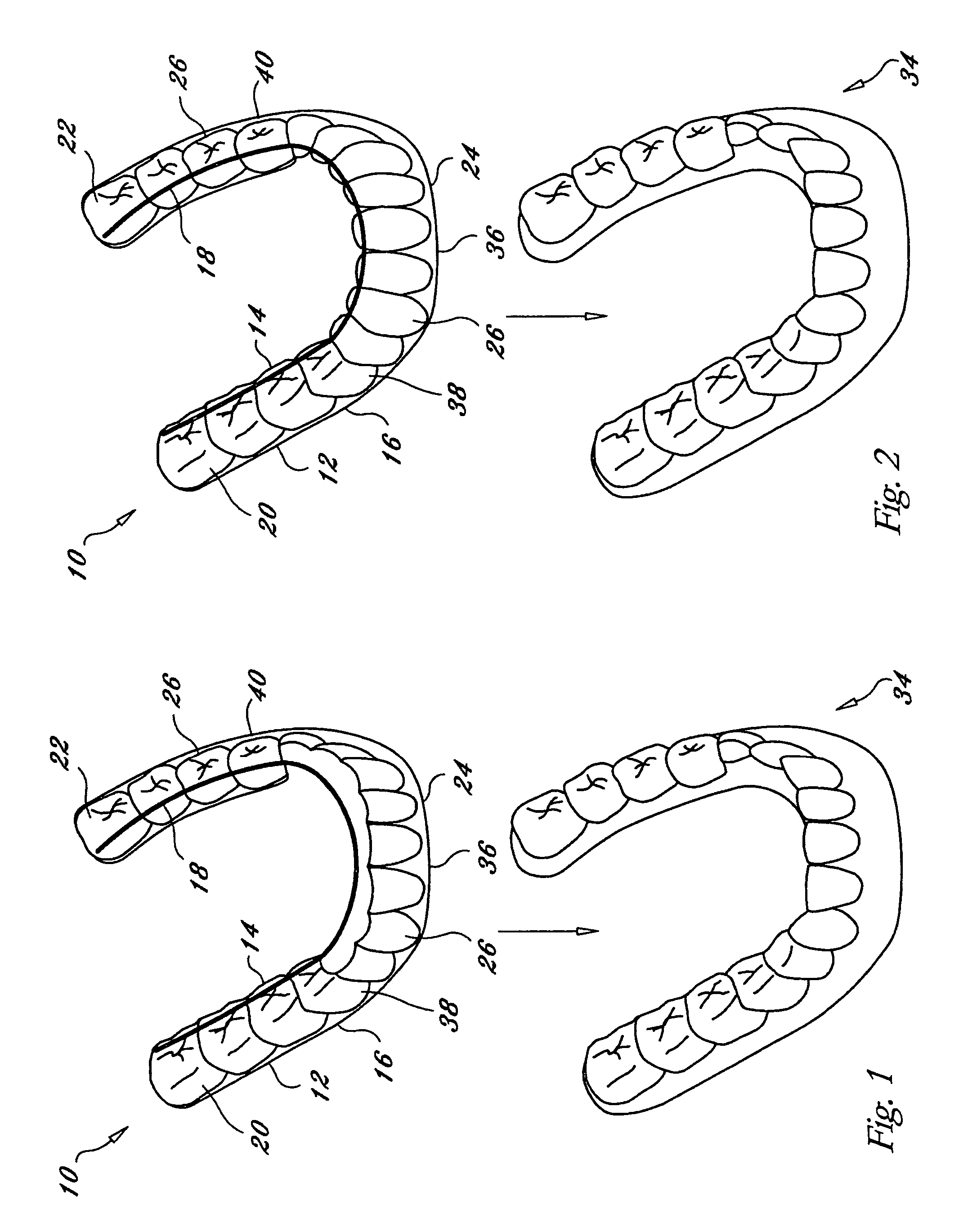

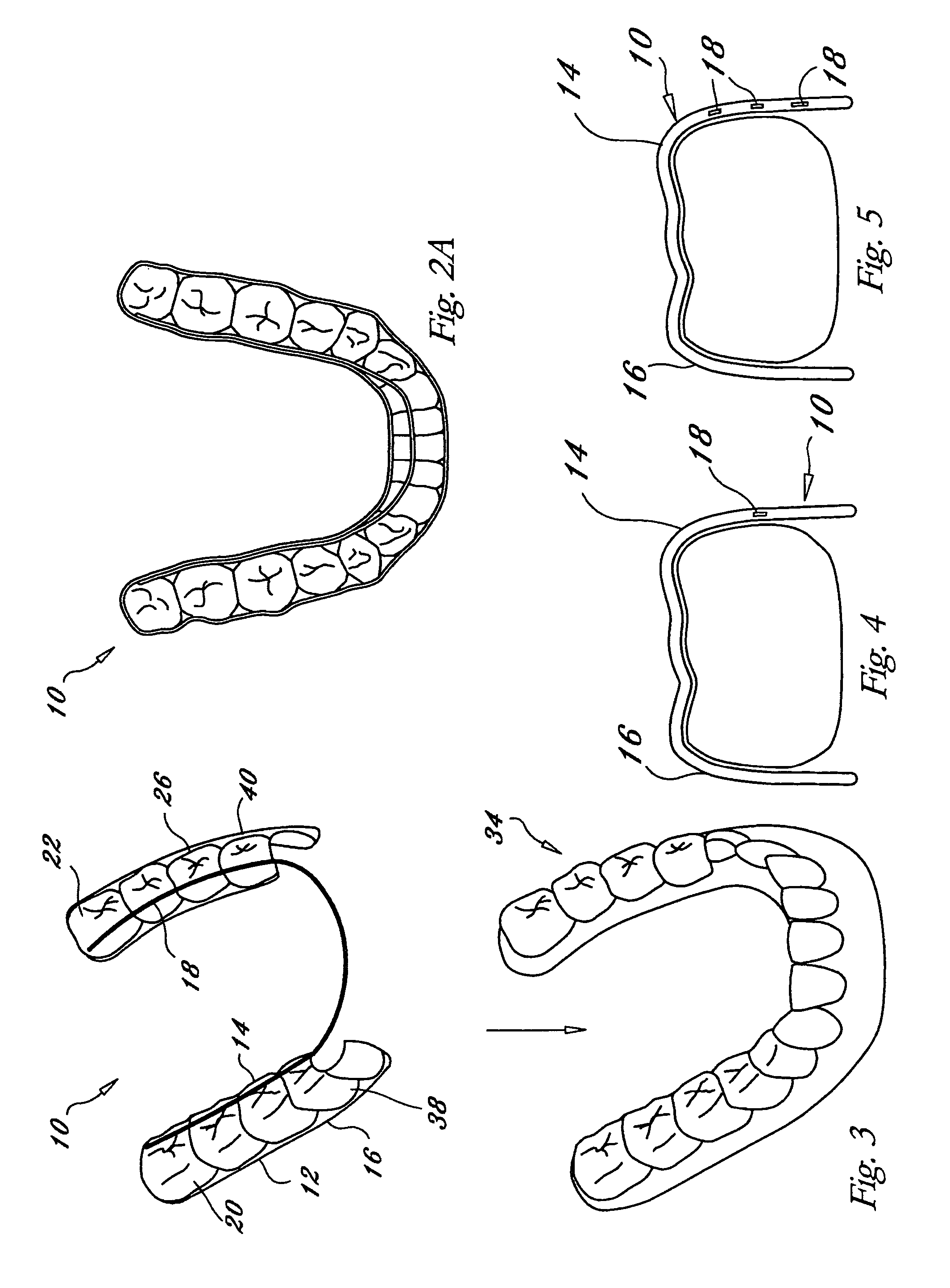

Orthodontic appliance with embedded wire for moving teeth and method

InactiveUS7416407B2Easy to manufactureMore forceful and less obtrusive movementOthrodonticsDental toolsPlastic forming machineWire rod

A generally horseshoe shaped clear flexible resilient plastic wire-imbedded orthodontic appliance is made with a plastic portion with contours on the lingual side and on the labial side, wherein the contours snugly cover the patient's teeth so that the appliance remains in place. One or more flexible wires are imbedded within the lingual side of the plastic portion from the left molar area to the right molar area of the plastic portion, whereby the wires apply force on the lingual side of the patient's bite. The appliance is formed by obtaining a plaster cast of the patient's teeth and gums, removing plaster teeth from the plaster cast of the gums, reattaching the plaster teeth to the plaster cast of the gums to form a cast of proper bite alignment, attaching one or more wires to the labial surface of the aligned plaster teeth so the wires become imbedded within thermosetting plastic placed over the cast, putting the cast in a thermosetting plastic molding machine, inserting thermosetting plastic in the machine, and heating the thermosetting plastic around the cast of the proper bite alignment, so the wires are imbedded within the formed appliance after the thermosetting plastic cools. A series of appliances may be used to shift a patient's bite to proper bite orientation.

Owner:CRONAUER EDWARD A

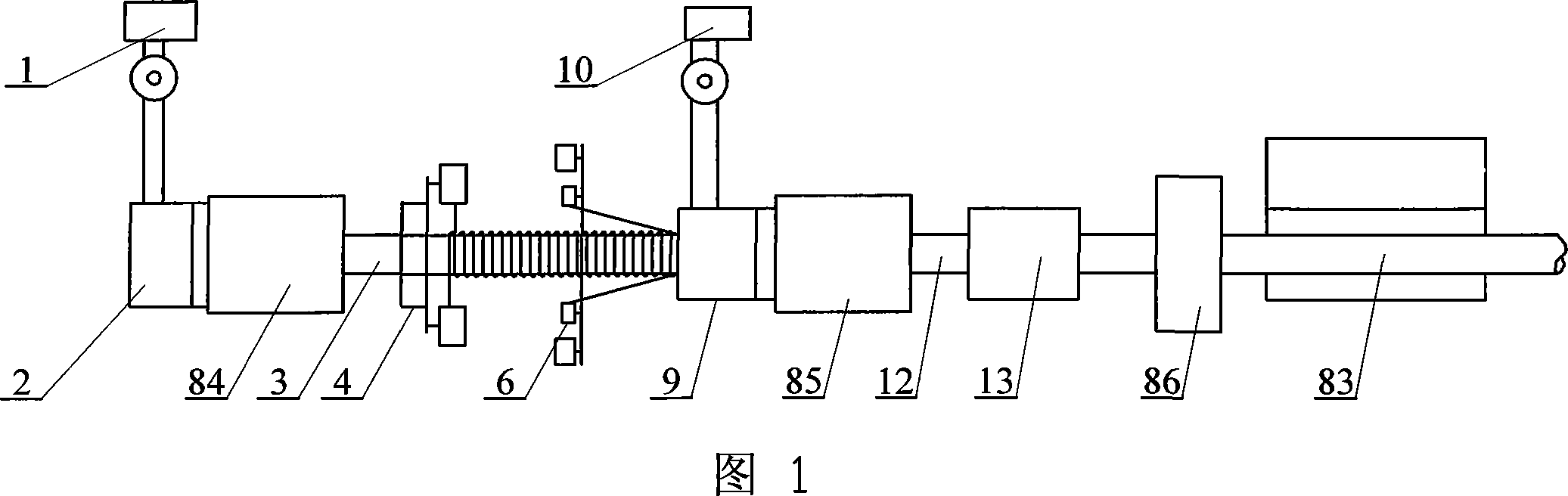

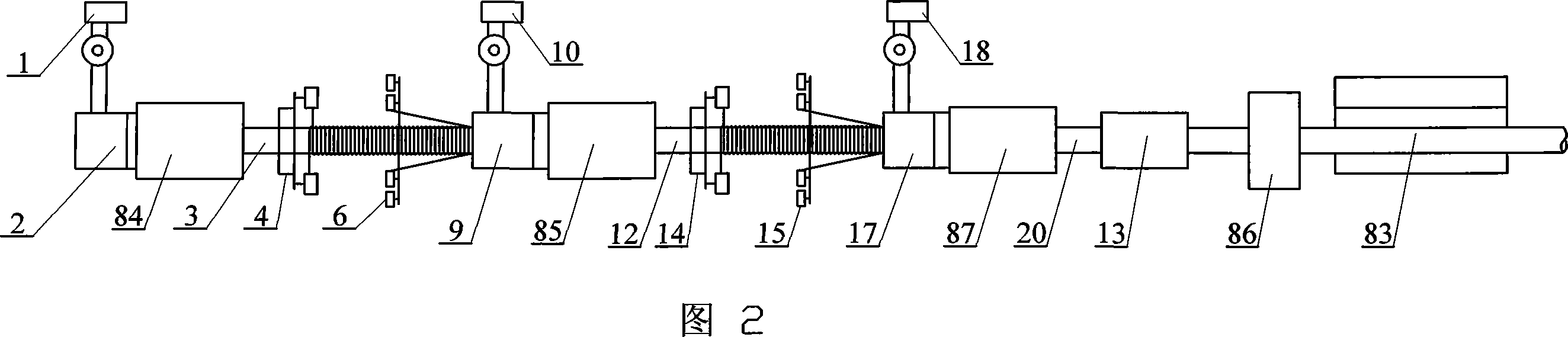

Method for producing steel mesh reinforced plastic composite pipes and its self-contained equipment

InactiveCN101077613AFast shapingEasy to shapeTubular articlesPlastic forming machineProcess configuration

The present invention is process and apparatus for producing steel net reinforced plastic composite pipe as one kind of steel structure reinforced plastic composite pipe. The process includes: extruding hot molten plastic into the inner plastic forming machine and cooling to obtain the inner plastic pipe blank layer, winding steel wire and arranging longitudinal wire onto the inner plastic pipe blank layer to form steel net, setting inside the first plastic pipe forming machine and extruding hot molten plastic into the first plastic pipe forming machine to form the composite plastic blank comprising one inner plastic pipe blank layer, one steel net layer and one outer plastic coating layer, and cutting to obtain the steel net reinforced plastic composite pipe. The equipment includes also one cooling water tank.

Owner:李富春

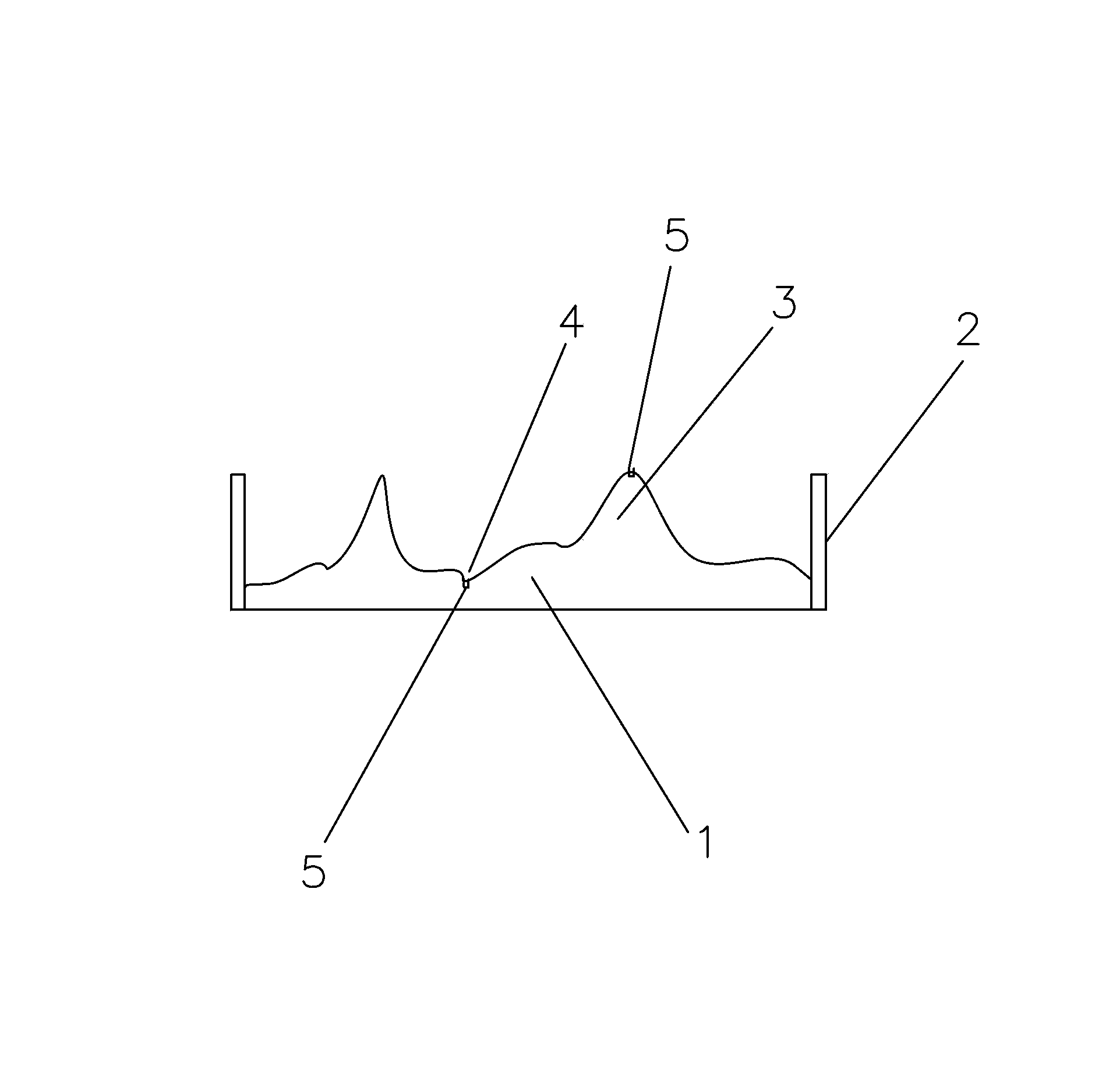

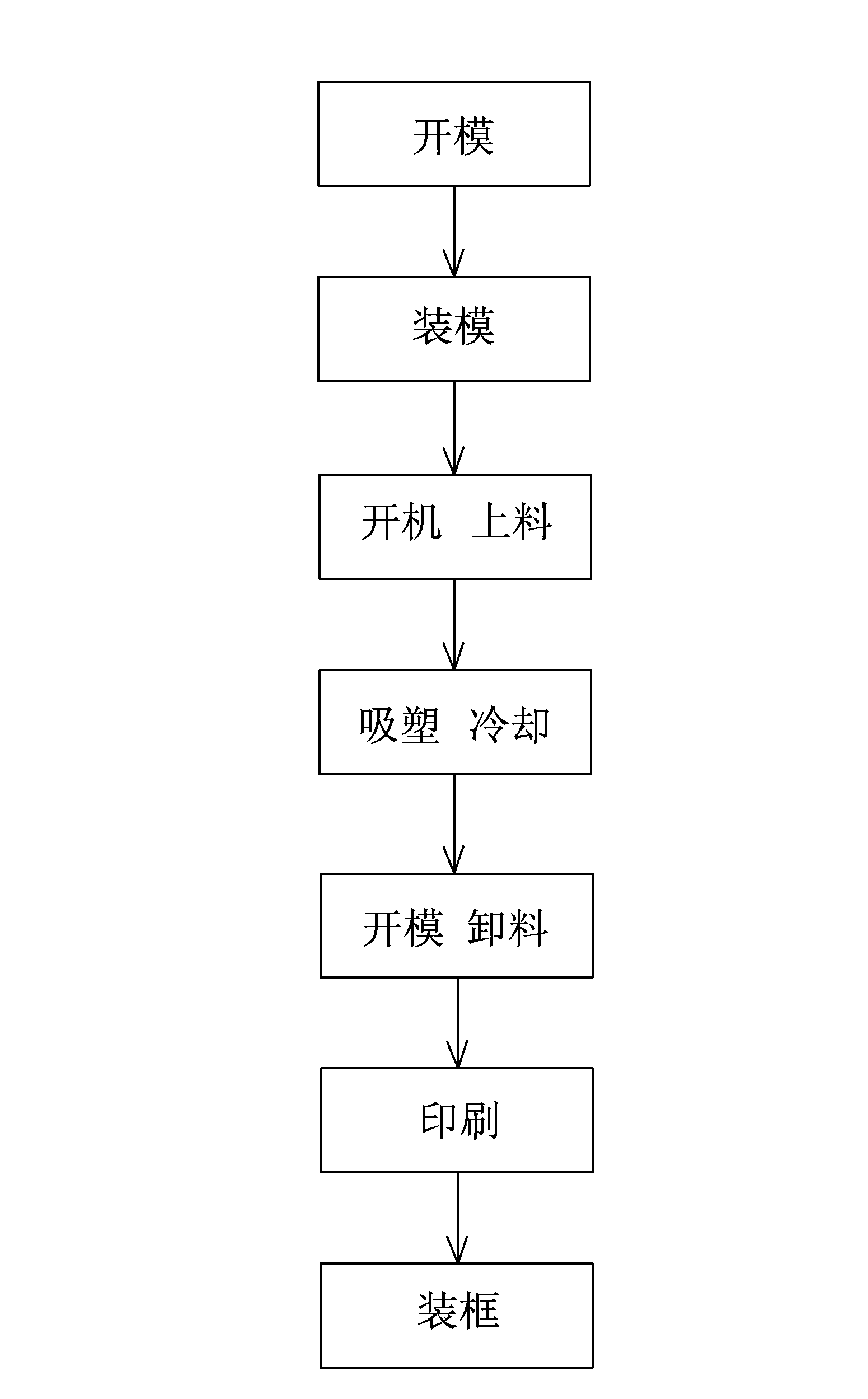

Three-dimensional topographic map model and forming process thereof

InactiveCN103390368AStable structureExtended service lifeEducational modelsPlastic forming machineTopographic map

The invention discloses a three-dimensional topographic map model which comprises a three-dimensional topographic map model body and a framework. The three-dimensional topographic map model body is made of plastic materials and formed in an integrated mode, and different colors are printed on the surface of the three-dimensional topographic map model body to distinguish different altitudes. The framework is of a rectangular structure, and the three-dimensional topographic map model body is arranged in the framework. Due to the facts that the three-dimensional topographic map model body is made of the plastic materials and formed in the integrated mode and the different colors are printed on the surface of the three-dimensional topographic map model body to distinguish the different altitudes, the three-dimensional topographic map model is firm and durable, and attractive in appearance. According to the forming process of the three-dimensional topographic map model, mould opening is carried out according to the shape of the three-dimensional topographic map model, the three-dimensional topographic map model is plastic molded in an integrated mode through a mould of a plastic forming machine instead of a manual splicing method, therefore, firmness of the three-dimensional topographic map model is improved, meanwhile, production efficiency is improved, and manufacturing cost is saved.

Owner:苏州育龙科教设备有限公司

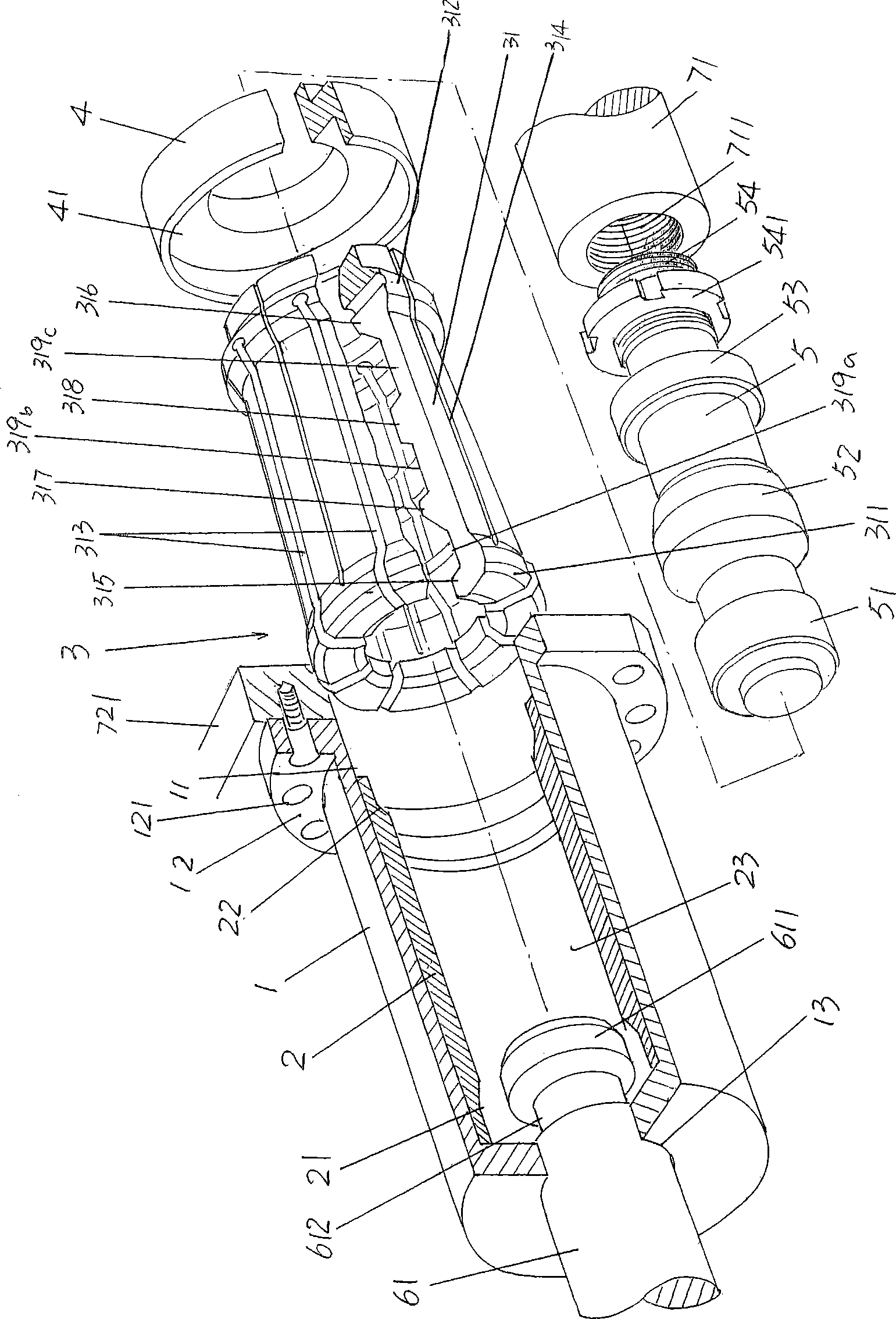

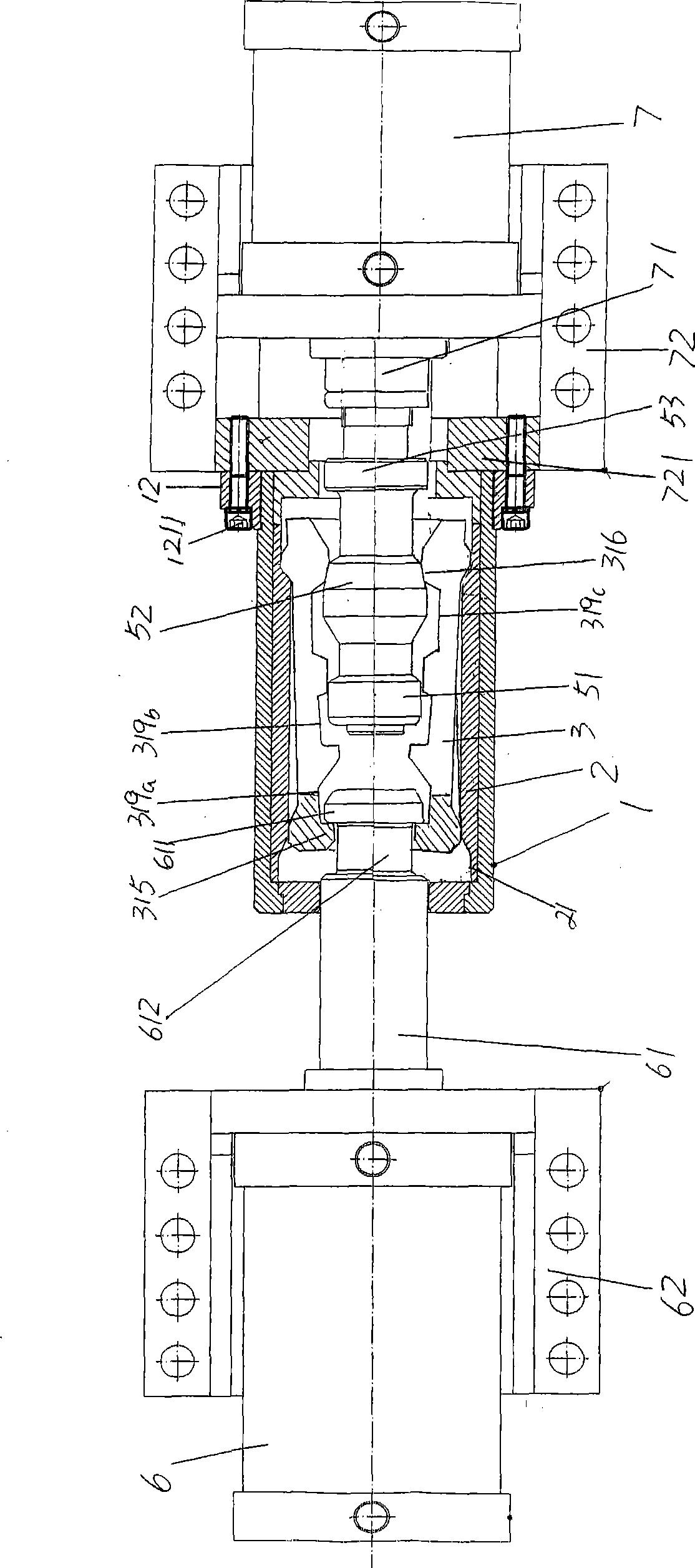

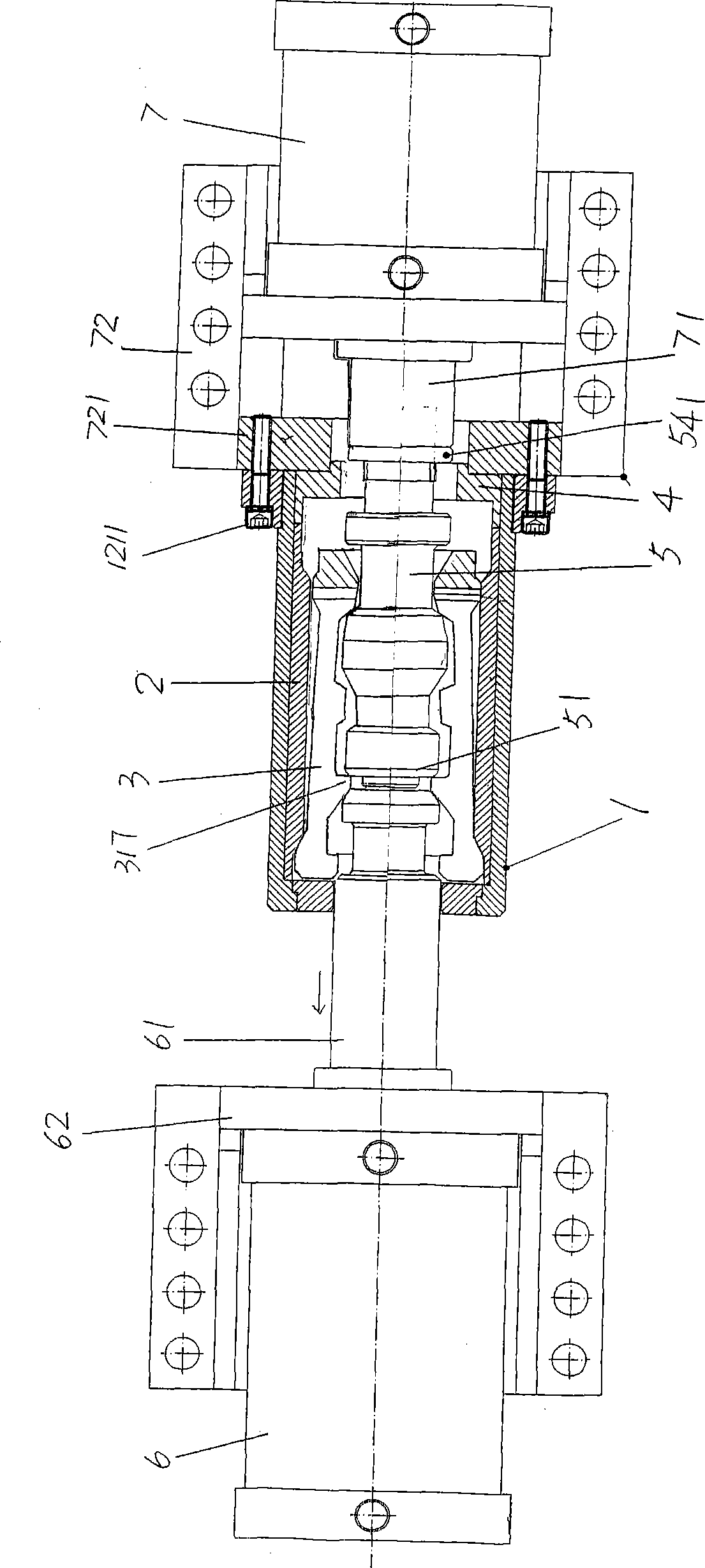

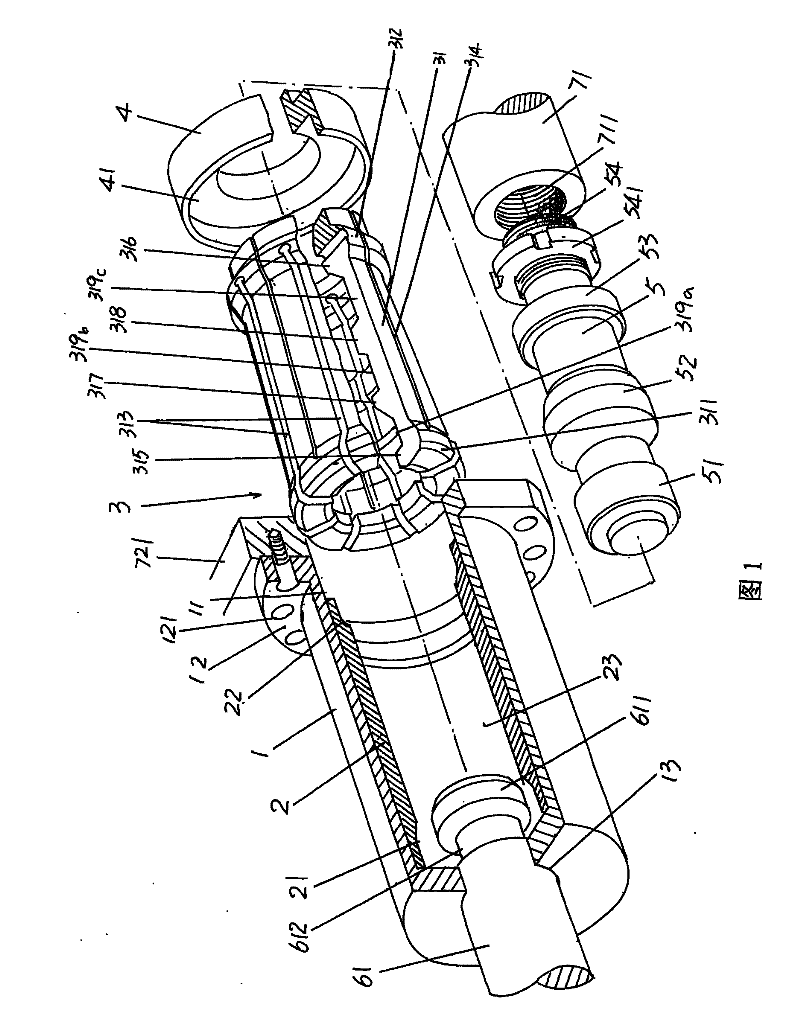

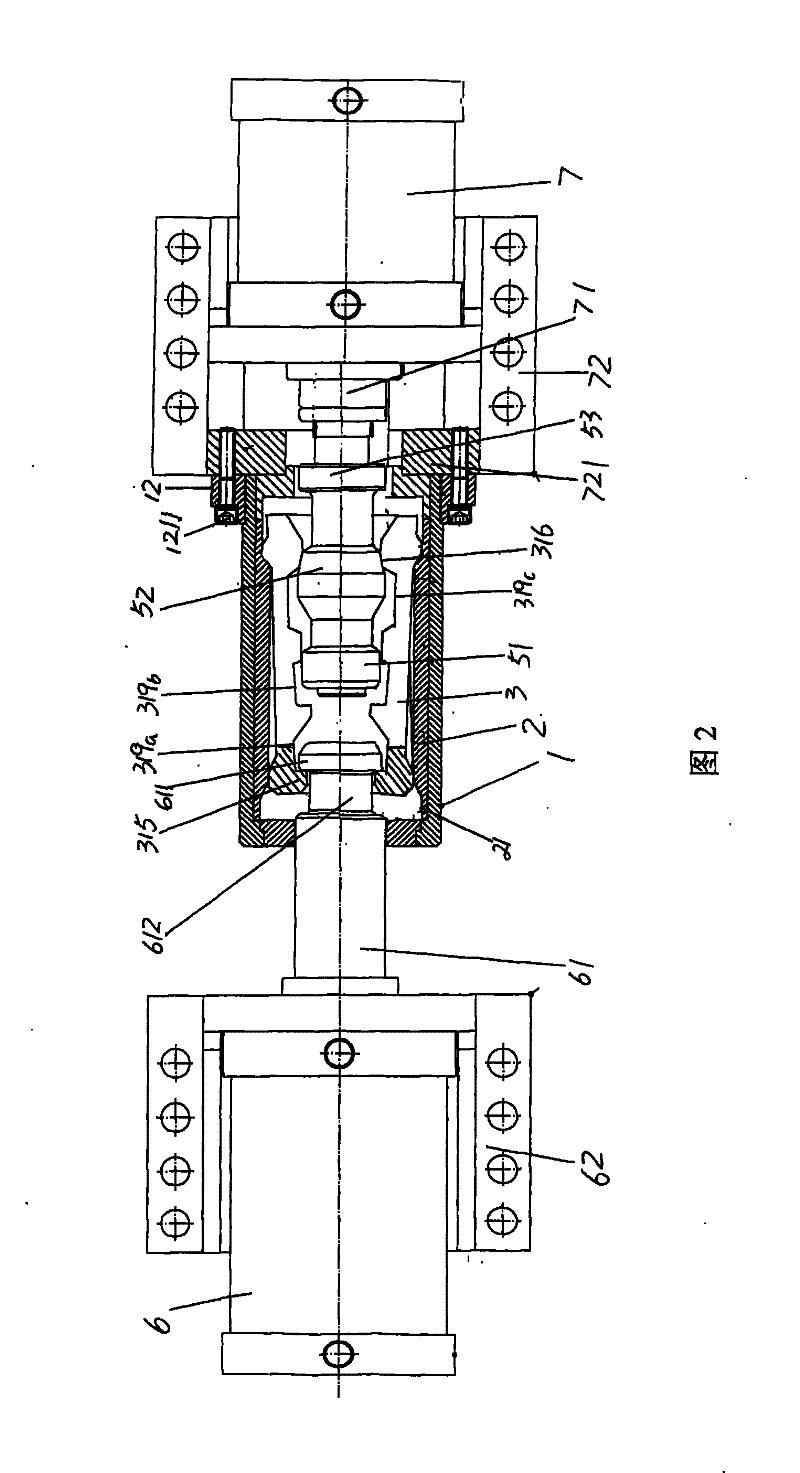

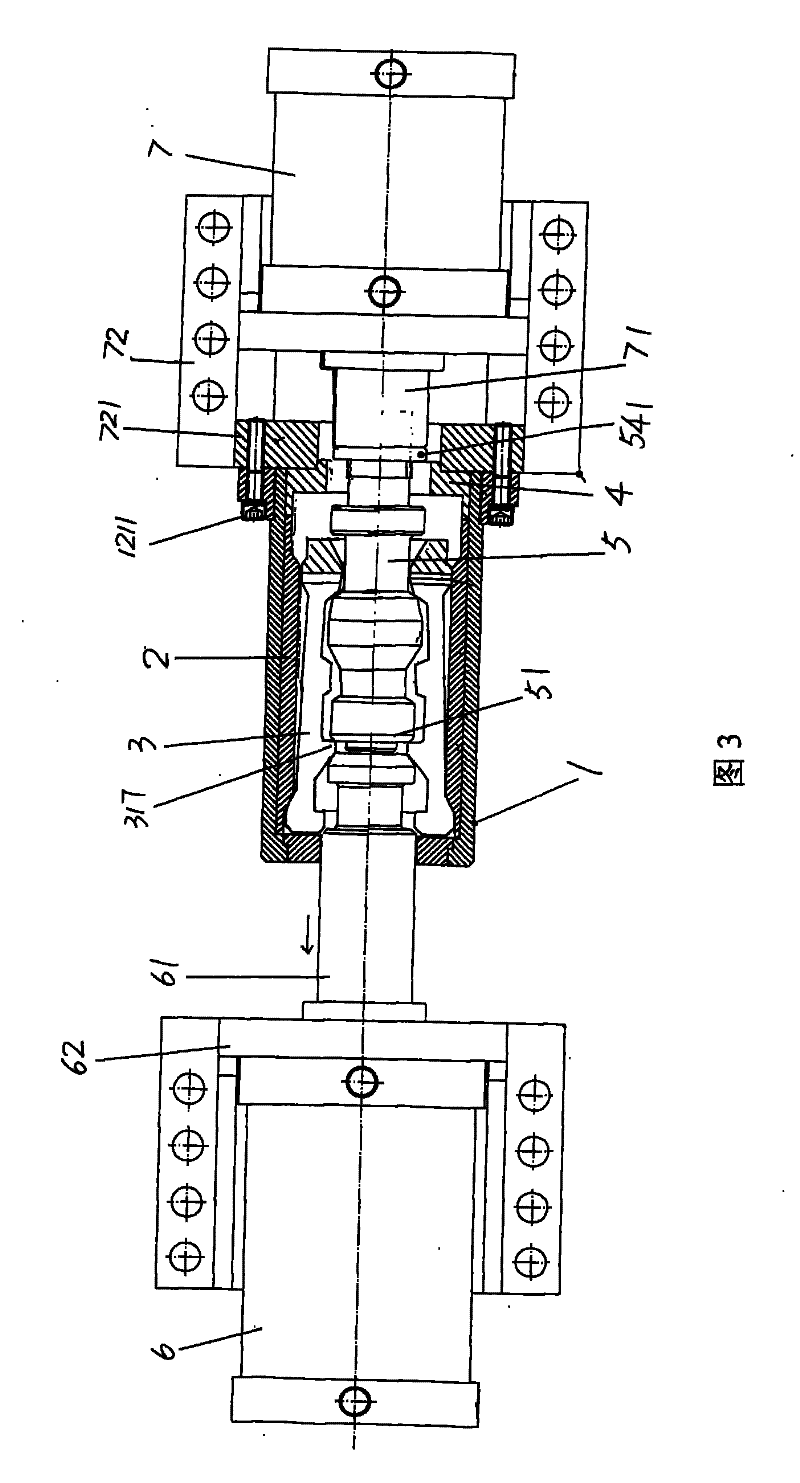

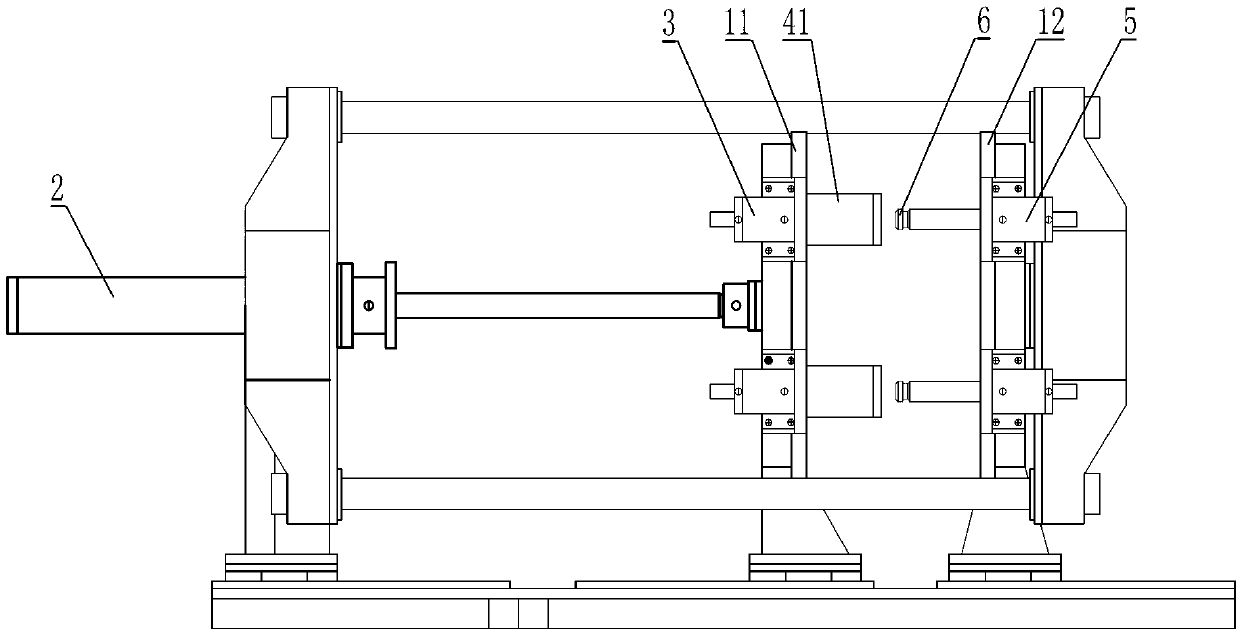

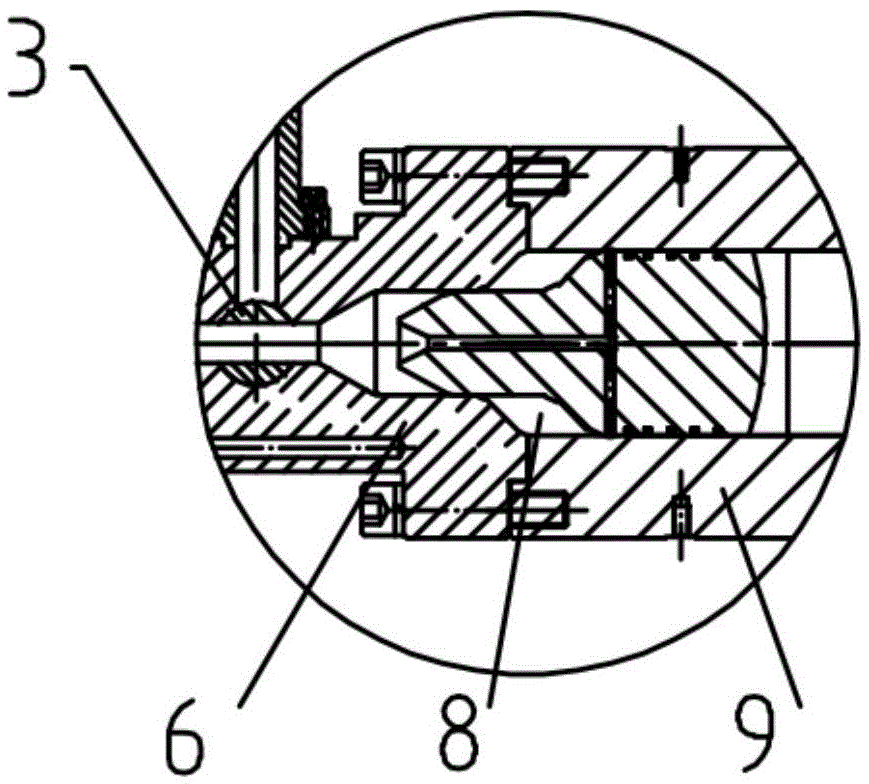

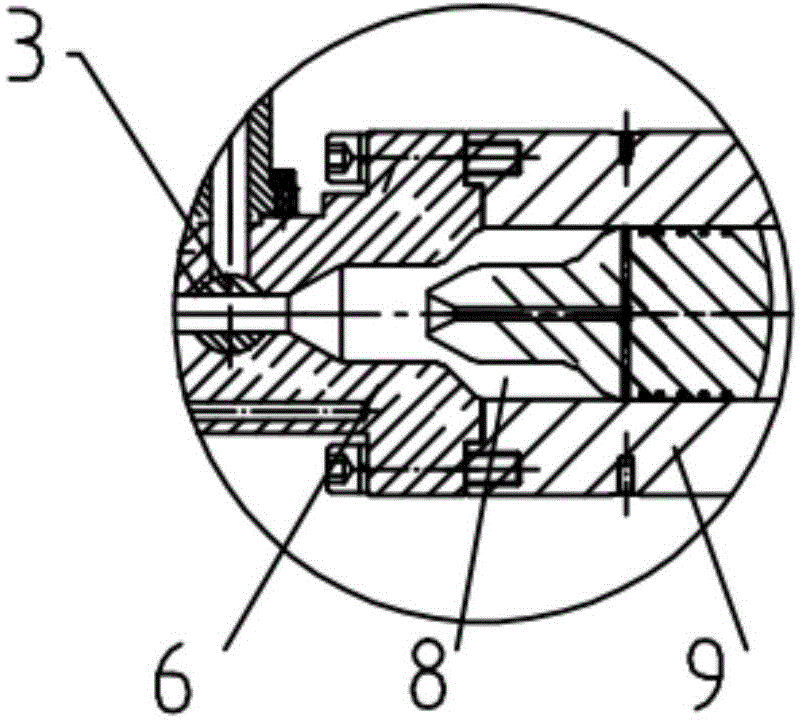

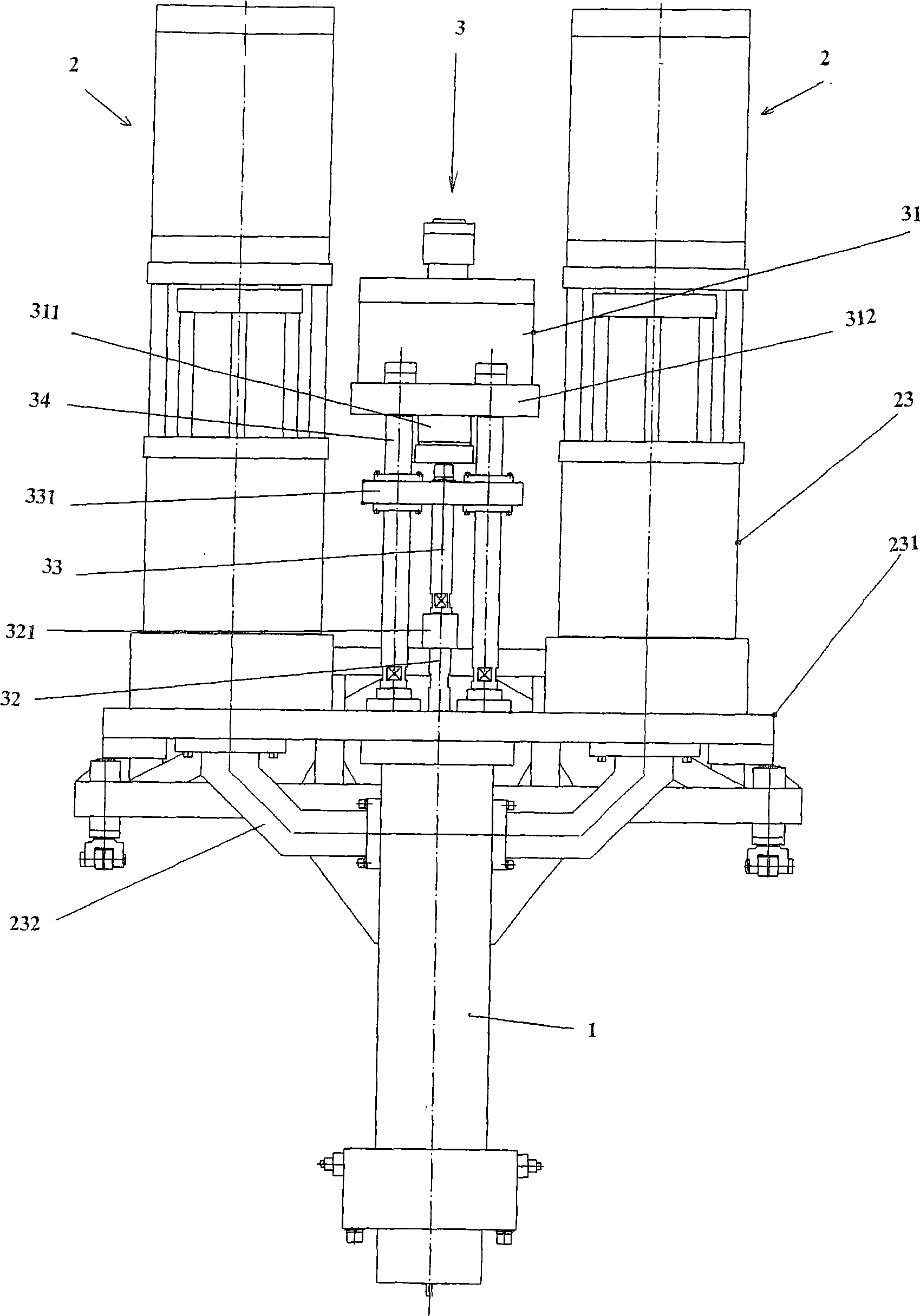

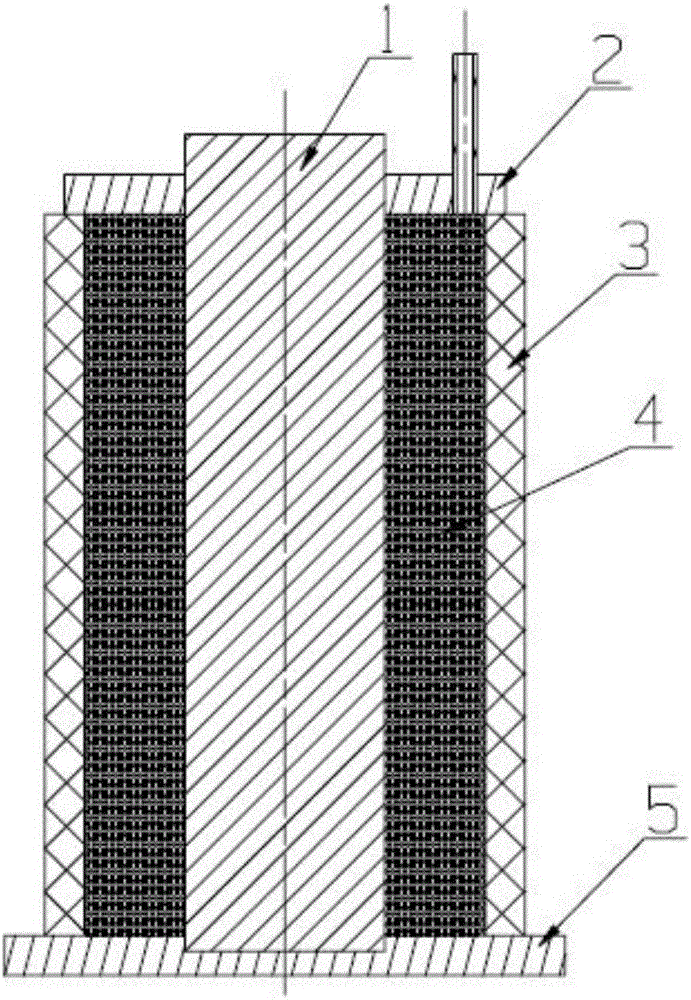

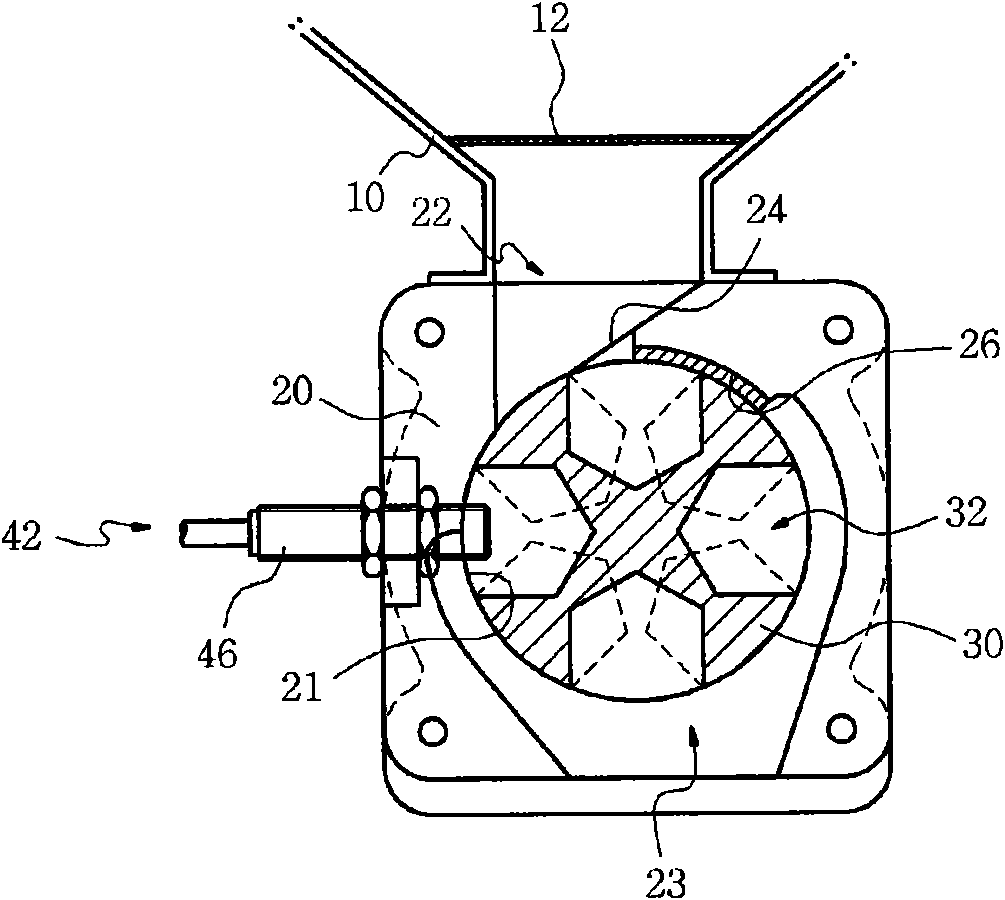

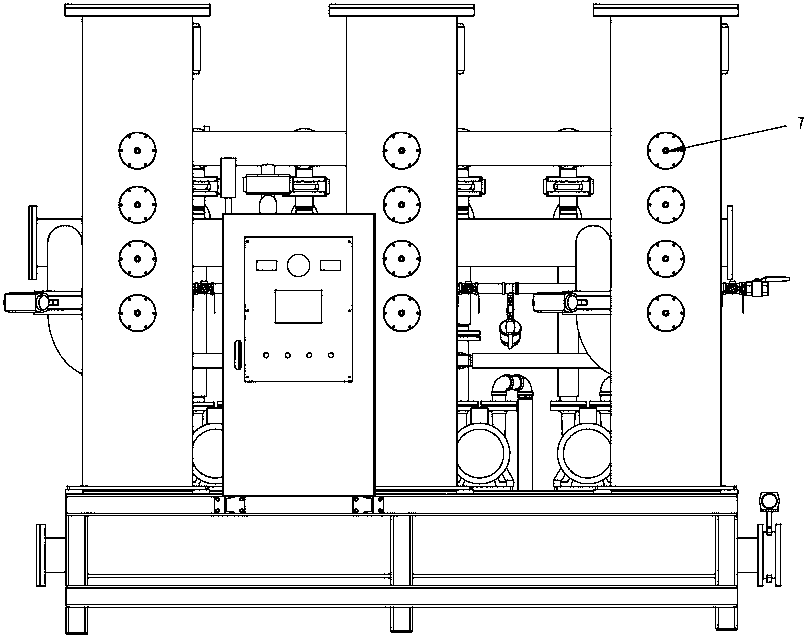

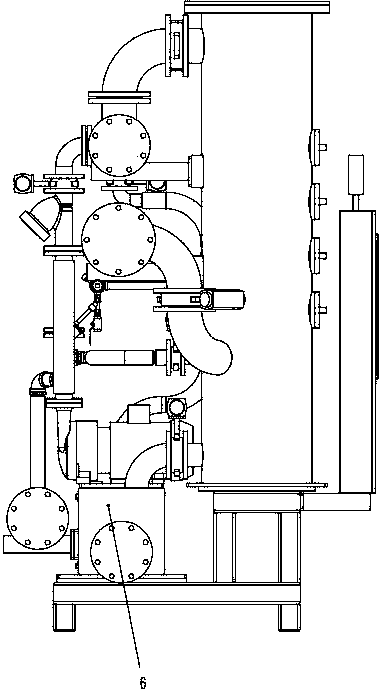

Matched mould locking mechanism of hollow plastic forming machine

ActiveCN101502999AImprove reliabilityReduce the numberHollow articlesPlastic forming machineLocking mechanism

A die assembly locking mechanism of a hollow plastic molding machine belongs to the technical field of hollow plastic product molding machine and comprises a fixed sleeve, a lock sliding bush, an expansion sleeve, a pressing sleeve and an interlocking bar. The locking sliding bush is fixedly installed inside the fixed sleeve, and a first lock lug boss chamber is formed at one end of the lock sliding bush, and a second lock lug boss chamber is formed at the other end; the expansion sleeve is held inside the expansion sleeve chamber of the lock sliding bush, and the expansion sleeve is formed by a group of lock catches with same structure for enclosing a barrel body together; a first lock lug boss is formed at one end of each lock catch, and a second lock lug boss is formed at the other end of each lock catch; the pressing sleeve is installed inside a pressing sleeve chamber at one end of the fixed sleeve. The interlocking bar is held inside the expansion sleeve and is matched with the lock matches. The invention has the advantages of convenient process, installation and maintenance, and the material can be saved; the reliability of die assembly locking is high; and the expansion sleeve moves stably in the lock sliding bush, and cannot be degenerated as time goes on.

Owner:SUZHOU TONGDA MACHINERY

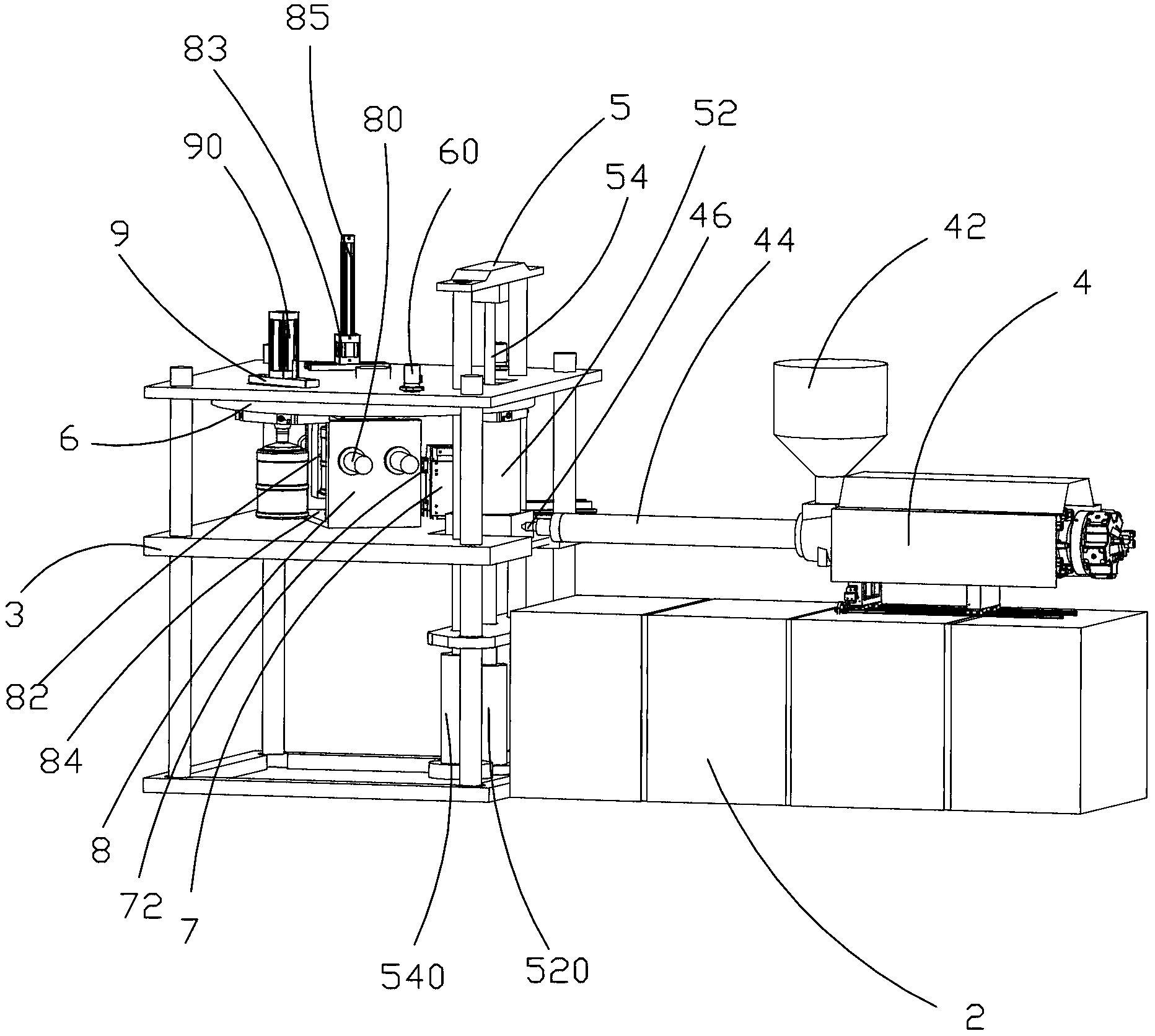

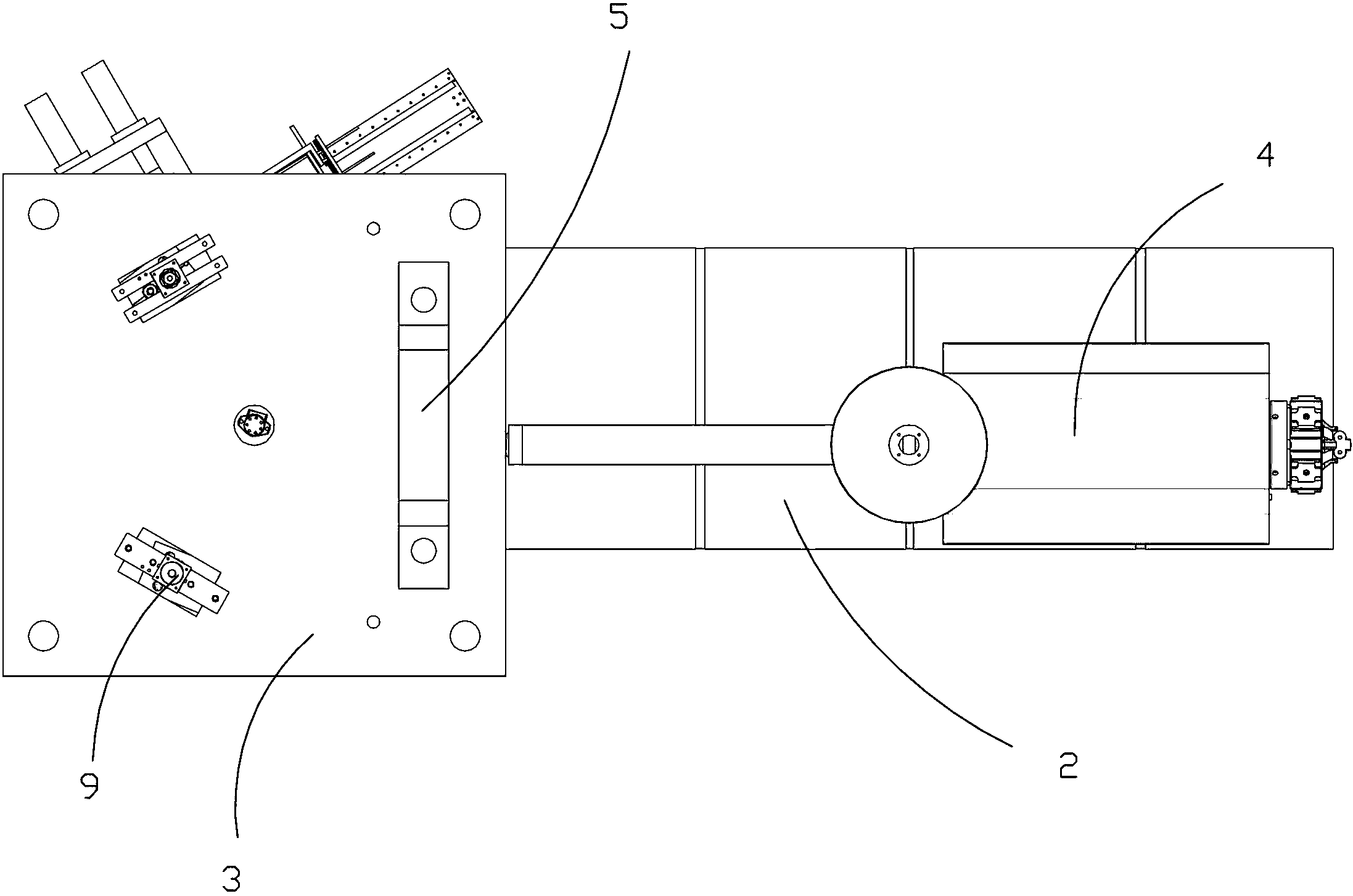

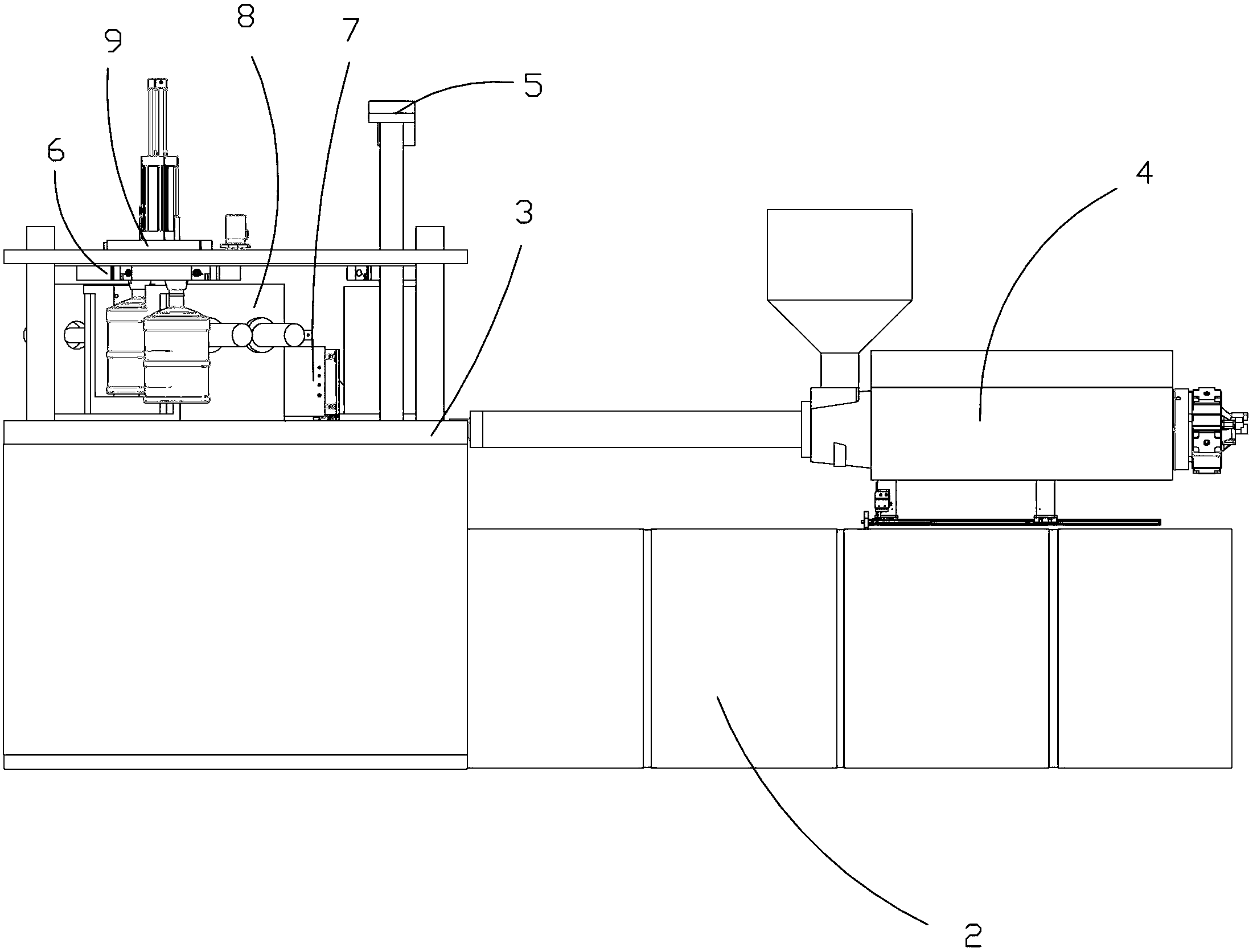

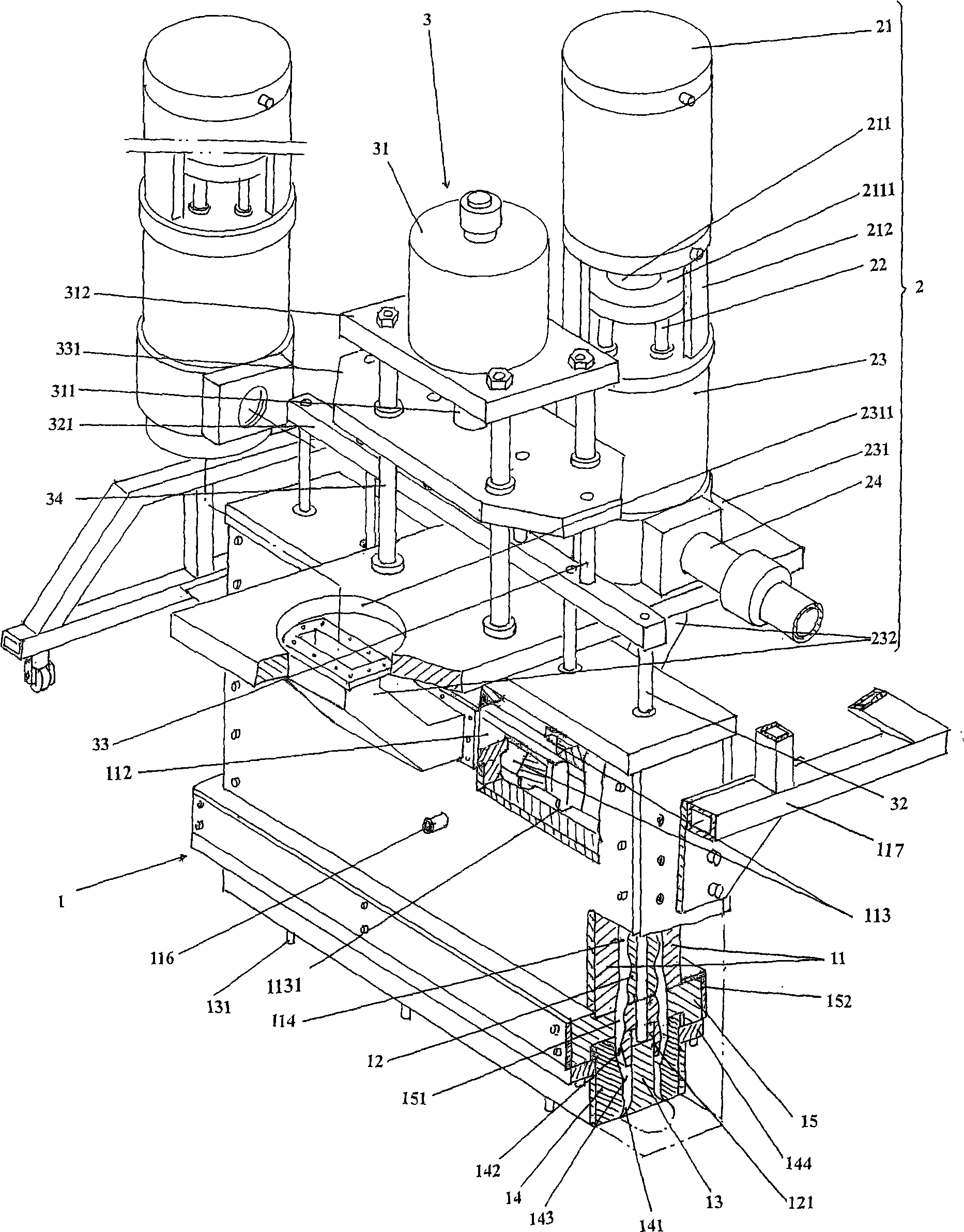

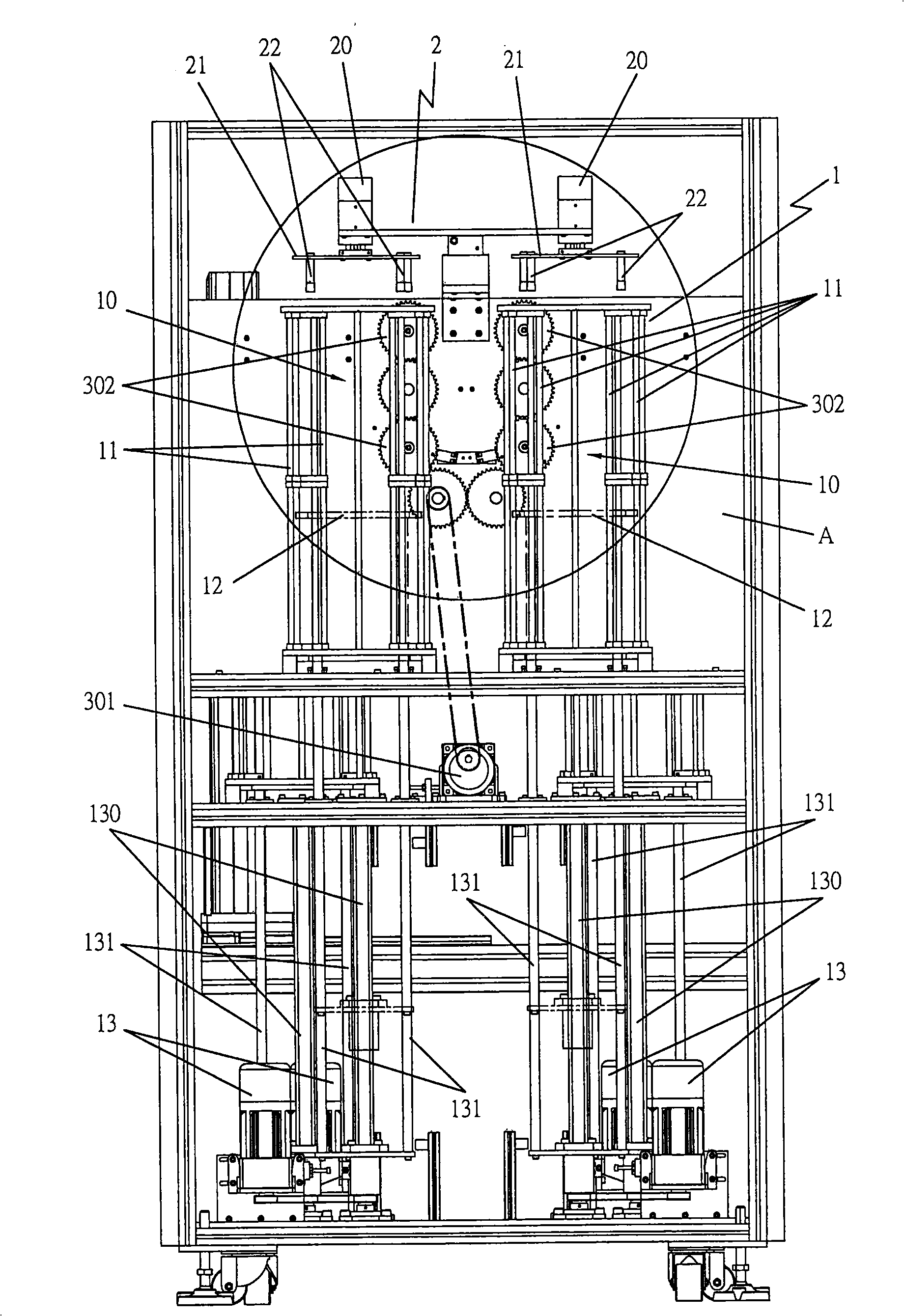

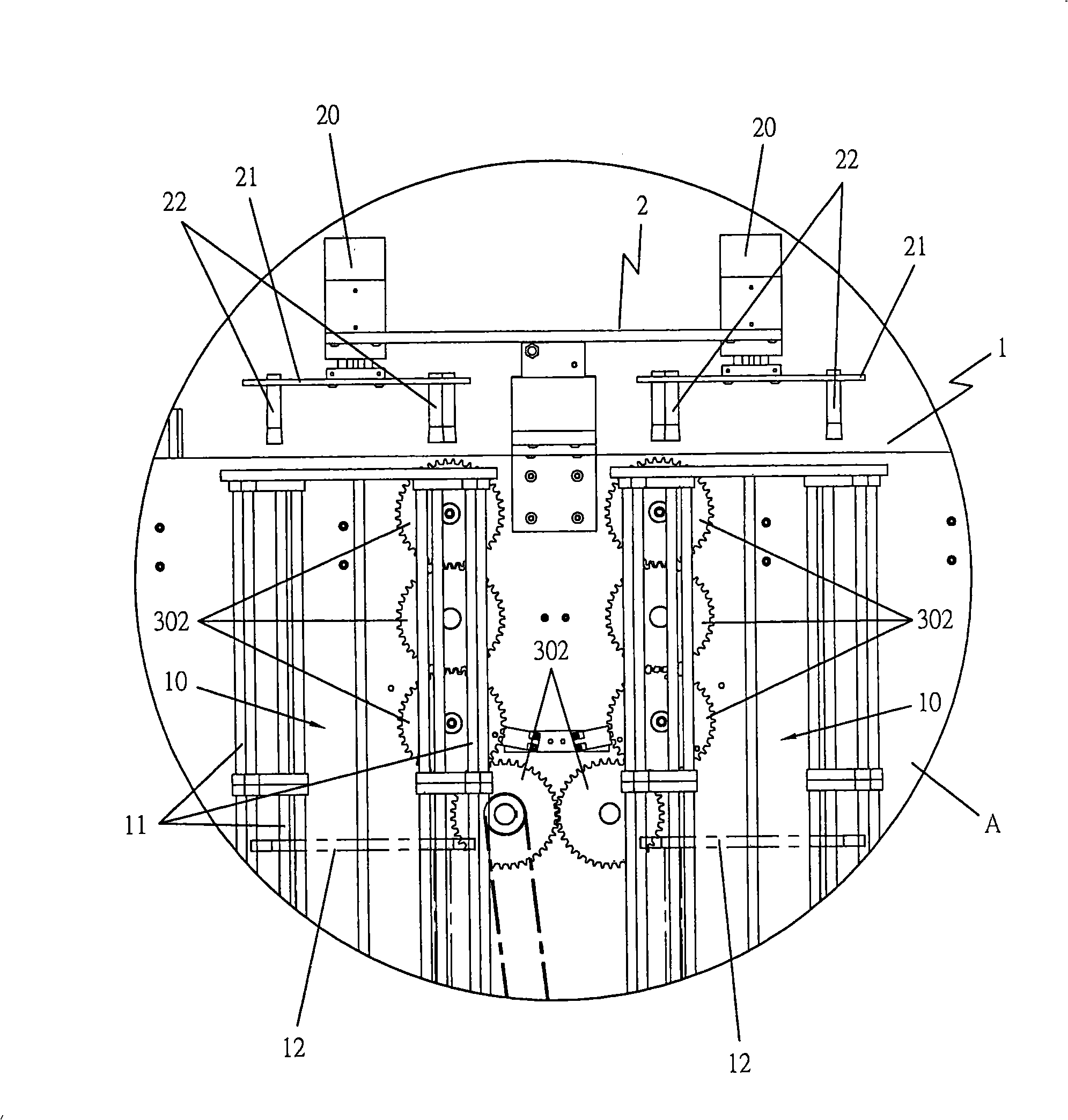

One-step three-station injecting, drawing and blowing plastic molding machine

InactiveCN102837417ARealize circular productionImprove efficiencyPlastic forming machineBlow molding

The invention provides a one-step three-station injecting, drawing and blowing plastic molding machine which comprises a mounting base, a fixing frame, an injection device, an injection bottle blank component, a rotating template assembly, a pre-blowing mould component, a drawing blowing component and a product de-molding component, wherein the fixing frame is arranged on one side of the mounting base; the injection device is arranged on the mounting base; the injection bottle blank component is fixed on the fixing frame; the rotating template assembly is fixed on the fixing frame; the pre-blowing mould component is fixed on the mounting base; the drawing blowing component is fixed on the fixing frame; the product de-molding component is fixed on the fixing frame; the injection bottle blank component is injected and molded into a semi-finished product bottle blank in an injection bottle blank mould; an injection mould core lifting cylinder is used for driving the semi-finished product bottle blank to ascend; an injection bottle blank mould lifting cylinder is used for driving the semi-finished product bottle blank to descend; and then a rotary power motor is used for driving the rotating template assembly to rotate, thereby driving the semi-finished product bottle blank to enter into a drawing blowing molding mould; and an end product is drawn, blown and molded after the temperature is adjusted by a temperature adjusting cylinder, or the pre-blowing mould component is used for adjusting the temperature and drawing, thereby obtaining a semi-finished product bottle after pre-blowing, and then the drawing blowing molding mould is used for blowing and molding, thereby forming the end product.

Owner:SHENZHEN DONGCHUAN HUATE TECH CO LTD

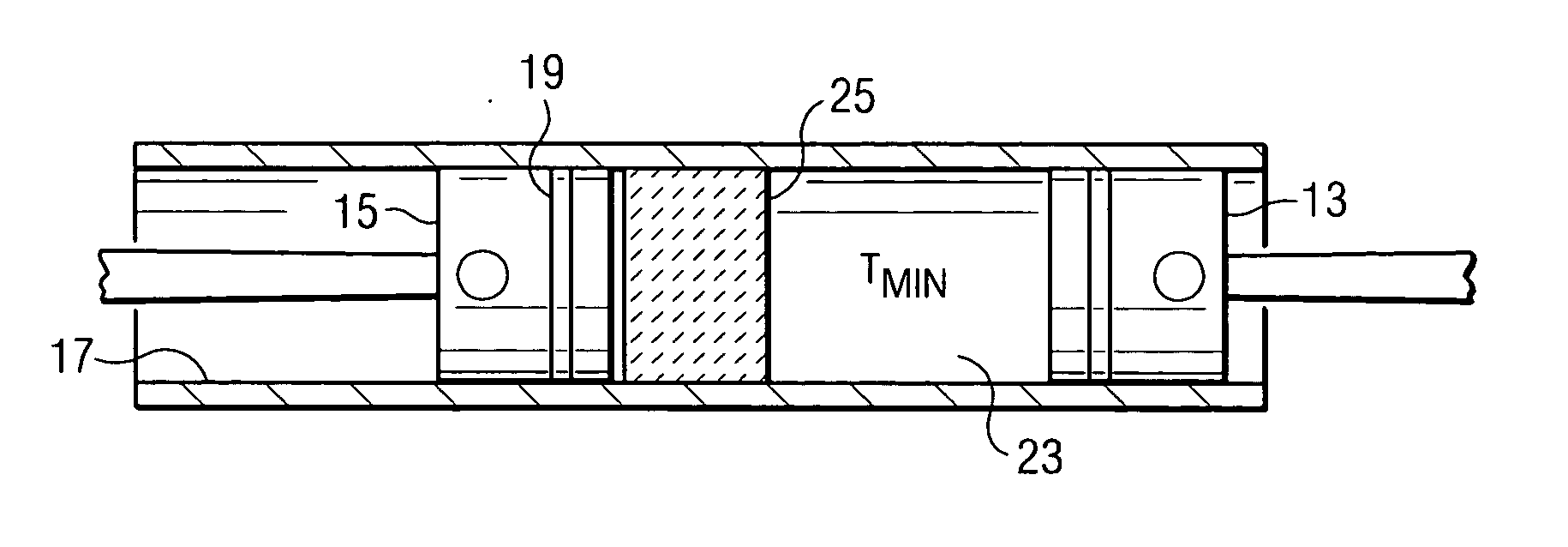

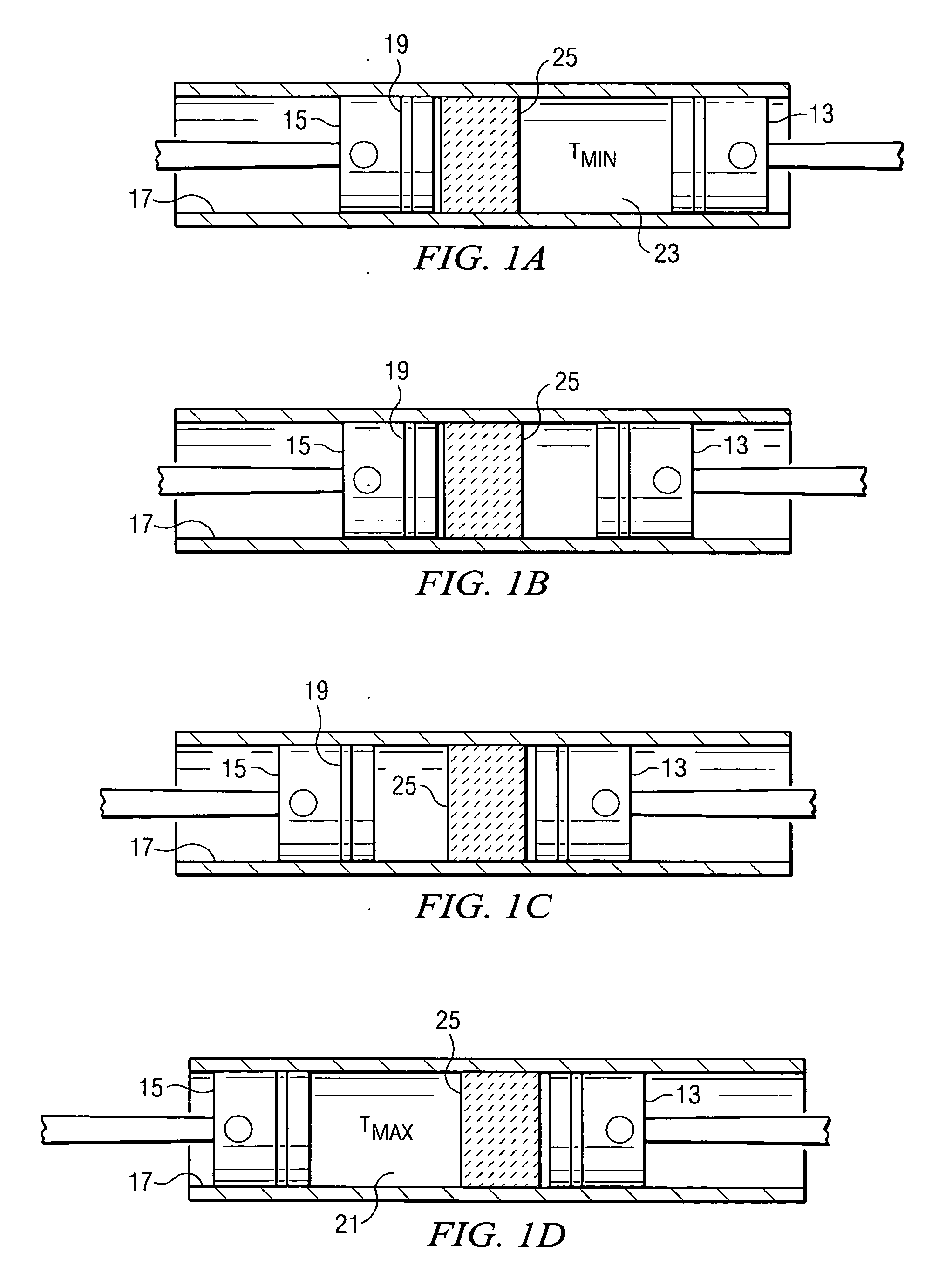

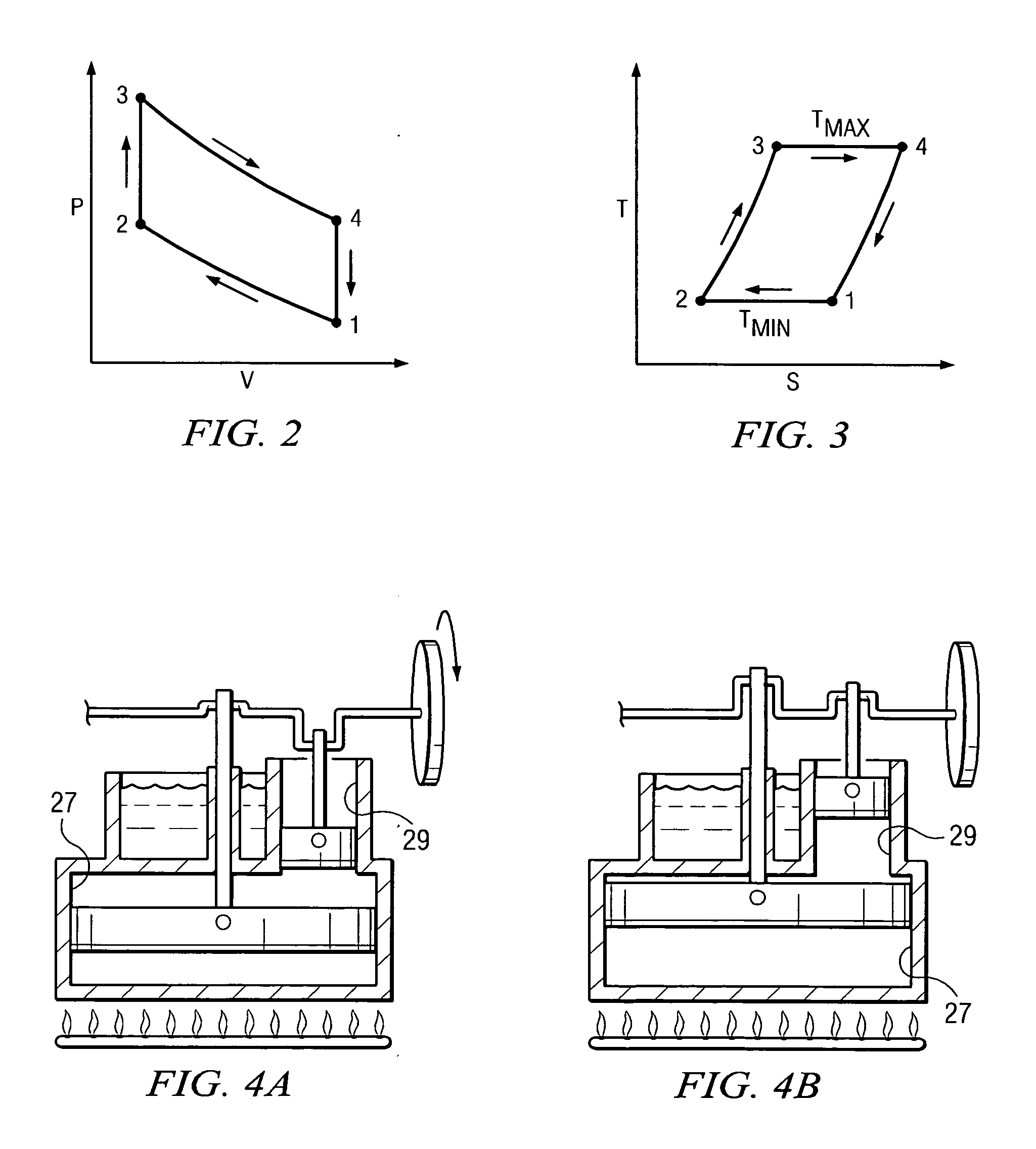

Energy recovery system for rubber and plastic molding machines

InactiveUS20060288699A1Domestic articlesClosed-cycle gas positive displacement engine plantCompression moldingPlastic forming machine

An energy recovery system for a compression or injection molding operation is shown. A Stirling engine cycle is used to recover heat. The Stirling engine is driven by waste heat from the mold members or other associated parts of the injection or compression molding apparatus.

Owner:CORBETT BRADFORD G JR

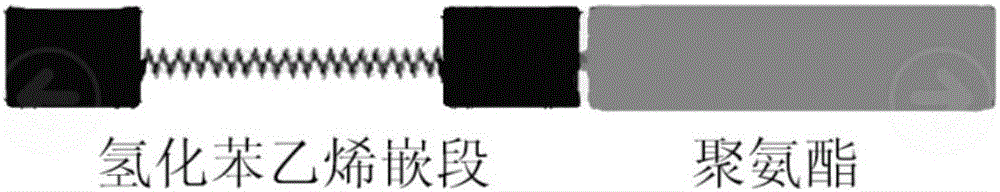

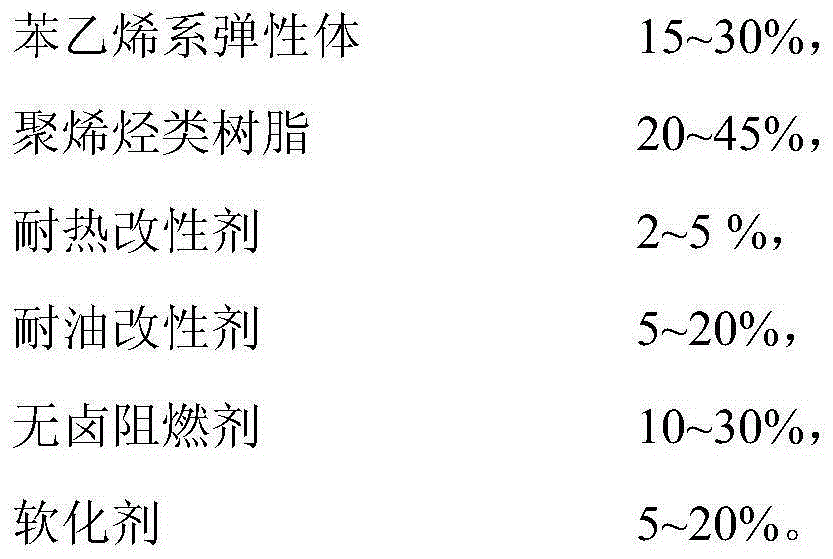

Thermoplastic elastomer used for electric car charging pile cable and preparing method of thermoplastic elastomer

The invention discloses a thermoplastic elastomer used for an electric car charging pile cable and a preparing method of the thermoplastic elastomer. The thermoplastic elastomer is prepared from, by weight, 15-30% of styrene elastomer, 20-45% of polyolefin resin, 2-5% of heat-resisting modifier, 5-20% of oil-resisting modifier, 10-30% of halogen-free flame retardant and 5-20% of softener. The thermoplastic elastomer used for the electric car charging pile cable has high elasticity and strength as well as excellent flame retardancy, and ageing resistance, water resistance, heat resistance, tear resistance and oil resistance are improved substantially. According to the thermoplastic elastomer used for the electric car charging pile cable, the preparation method is simple, high in yield and capable of effectively saving energy, and the thermoplastic elastomer can be machined through a common thermoplastic plastic forming machine, is particularly suitable for producing various electric car charging pile cables with the production hardness of 65-85, suitable for other application fields with high requirements for tear resistance and oil resistance and wide in application range and has high economic and social benefits.

Owner:宁波聚泰新材料科技有限公司

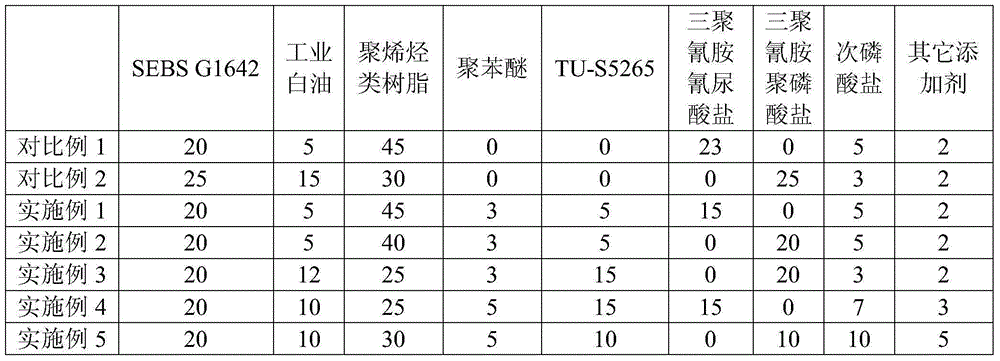

Novel spinning machine

The invention discloses a novel spinning machine, and relates to a plastic forming machine. The novel spinning machine comprises a control cabinet, a working table, a circuit box and a spinning mechanism, wherein the control cabinet is fixedly connected to the upper lateral portion of the working table, and a reinforcing rib is arranged between the control cabinet and the working table. The spinning mechanism comprises a motor, a lower clamp, a spinning head, an upper clamp and a servo motor, wherein the motor is installed on the working table, the lower clamp is installed on the motor, the spinning head is arranged opposite to the motor, the upper clamp is installed on the spinning head, and the servo motor is used for driving the spinning head. A spinning guiding mechanism composed of a sliding block and guiding columns is arranged on the spinning head, wherein the guiding columns are fixedly connected to the working table, and the sliding block is installed on the spinning head and in sliding connection with the guiding columns. The novel spinning machine is stable in operation, low in noise and vibration and convenient to operate, a machined product is good in surface quality, smooth in appearance, high in accuracy and stable in mechanical performance, and the novel spinning machine is convenient to use and practical.

Owner:CHENGDU GRASP MOBILE INFORMATION TECH

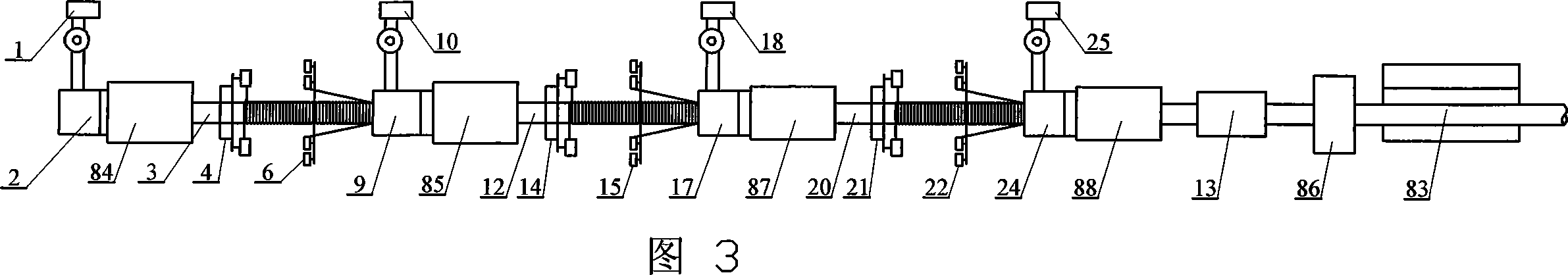

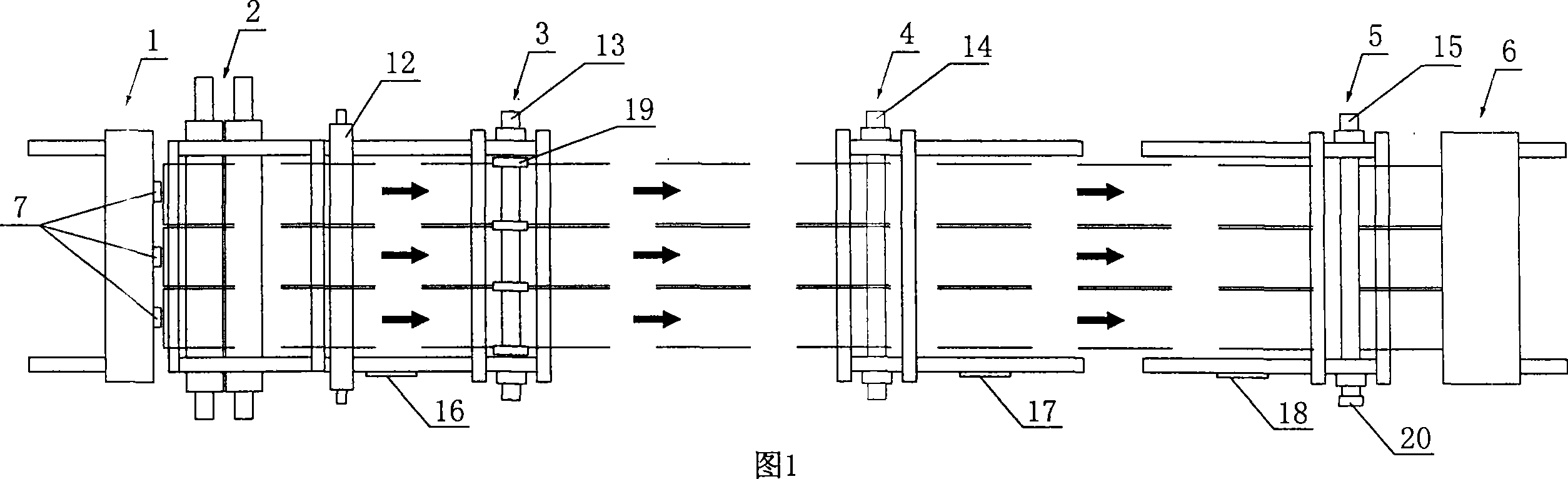

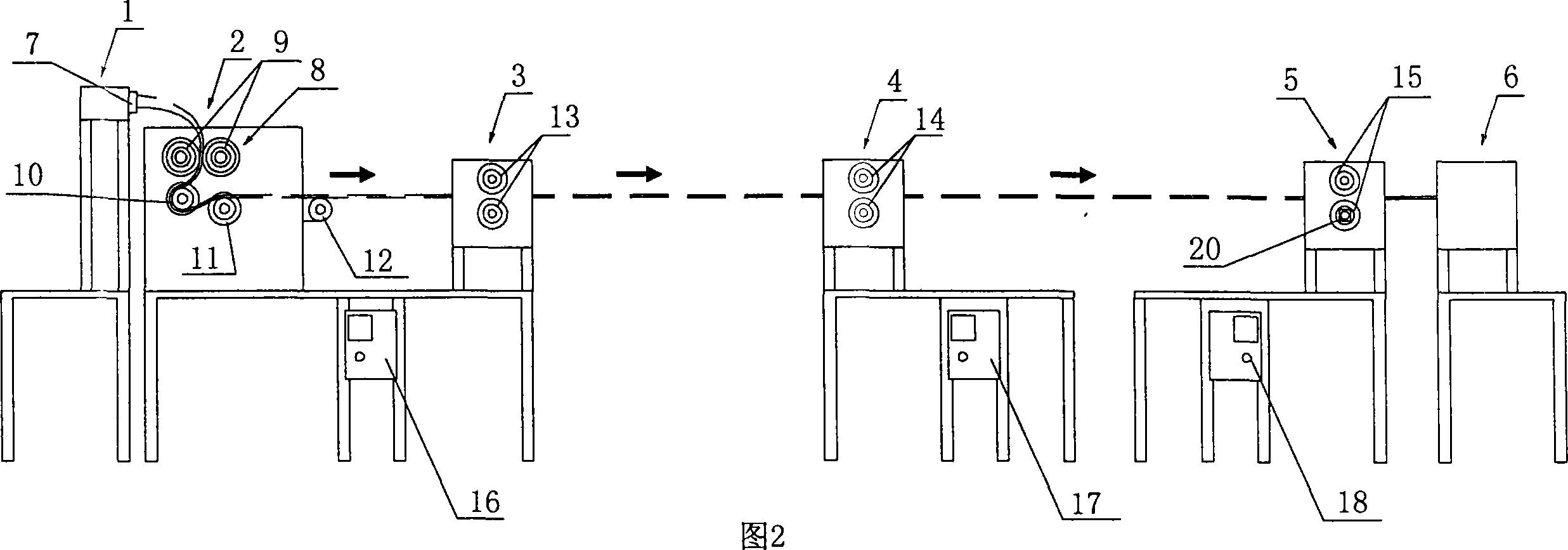

Rolling plastic forming machine

InactiveCN101058222AAchieve uninterrupted productionIncrease productivityPlastic forming machineMolding machine

The invention relates to a rolling style plastic molding machine. It has plastic distributor, mold forming set, several assistant delivery sets and cut off sets from left to the right. There are mold forming roller set installed on the mold molding set that is set at the plastic distributor's outlet, assist delivery set installed at the rear of the mold forming machine, each assistant delivery set installed with assistant drive rolling set, each assistant delivery set having corresponding speed tuning machine, knife frame installed on the first assistant delivery set, edge cutting knife on the knife frame, time sensor on the last assistant delivery machine set, cutting off machine set at the rear of the last assistant delivery machine. It can extend the length of the plastic forming limitlessly, without restraint for the plastic material and its flow feature, realizing continuous production, being able to roll several plastic parts with high production efficiency and fine quality.

Owner:何志炜

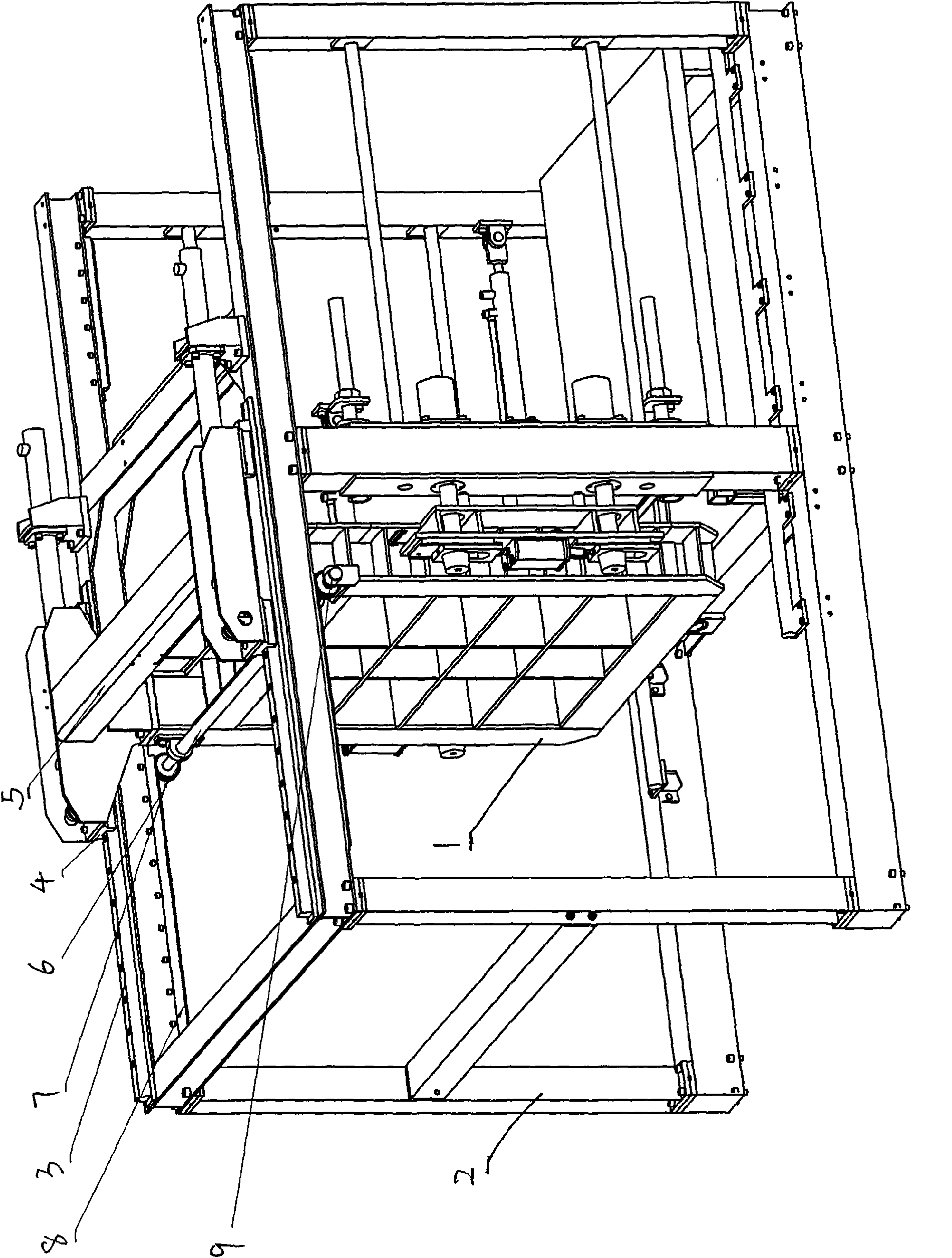

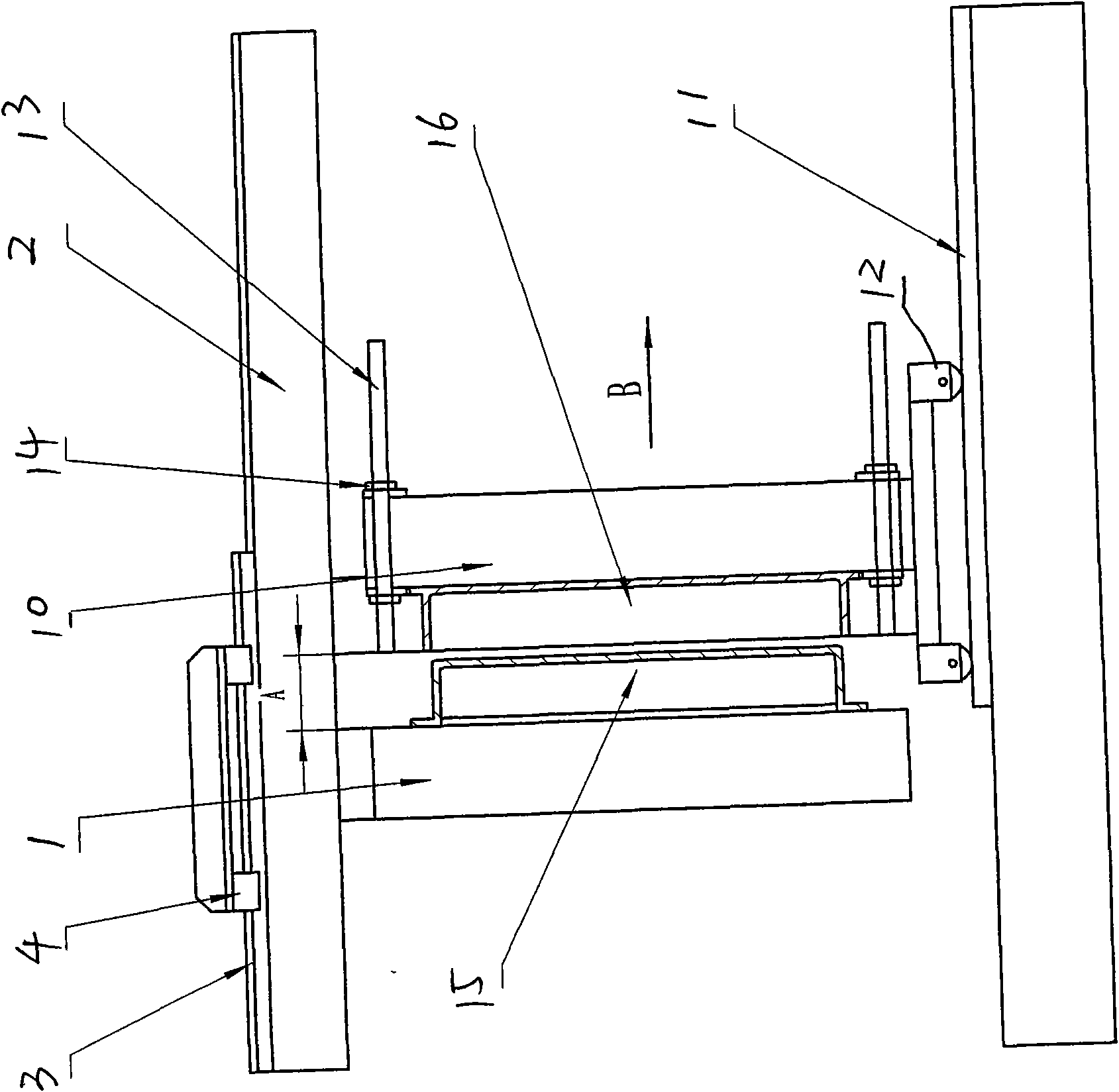

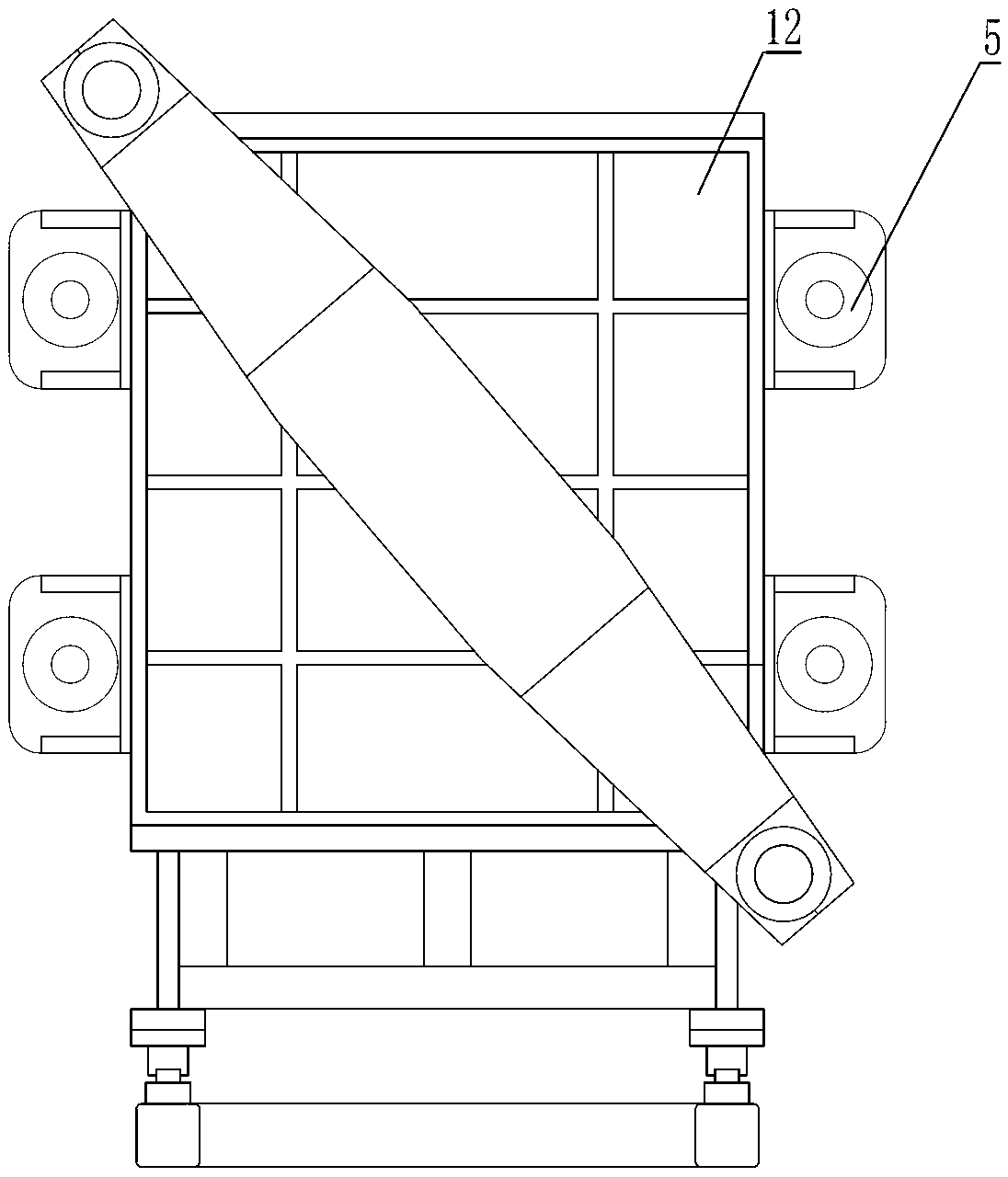

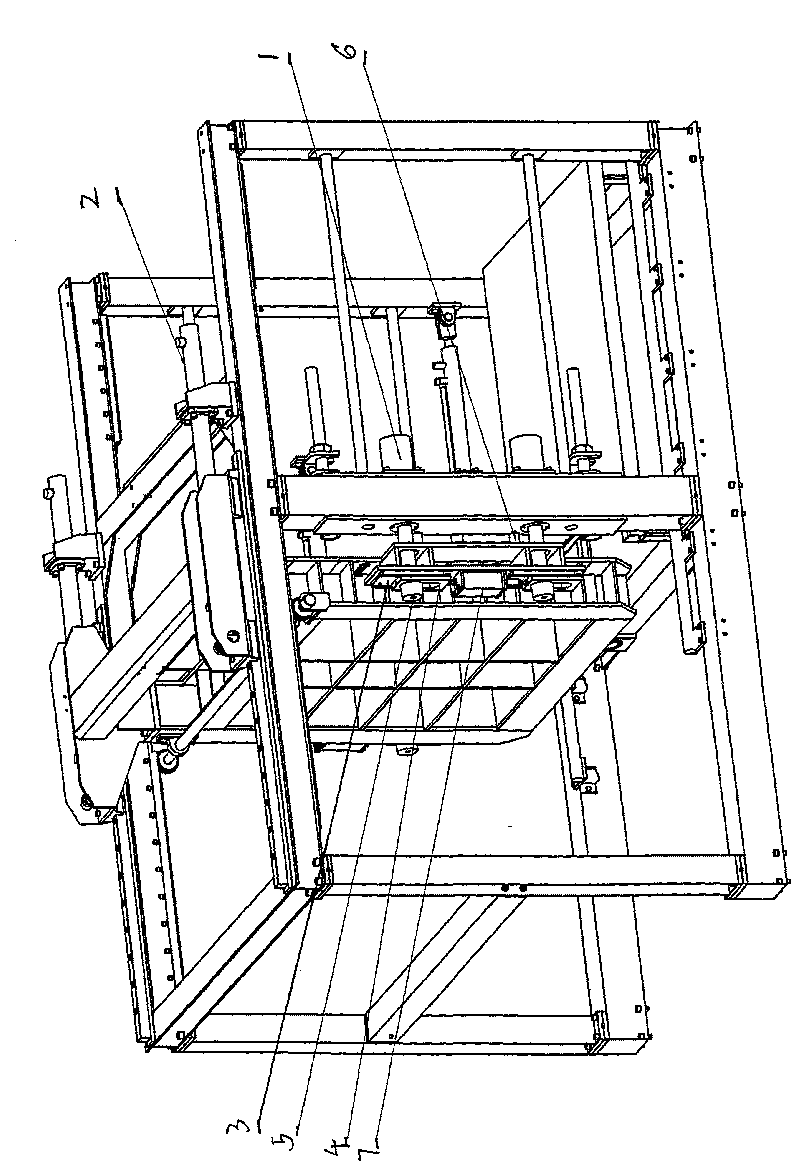

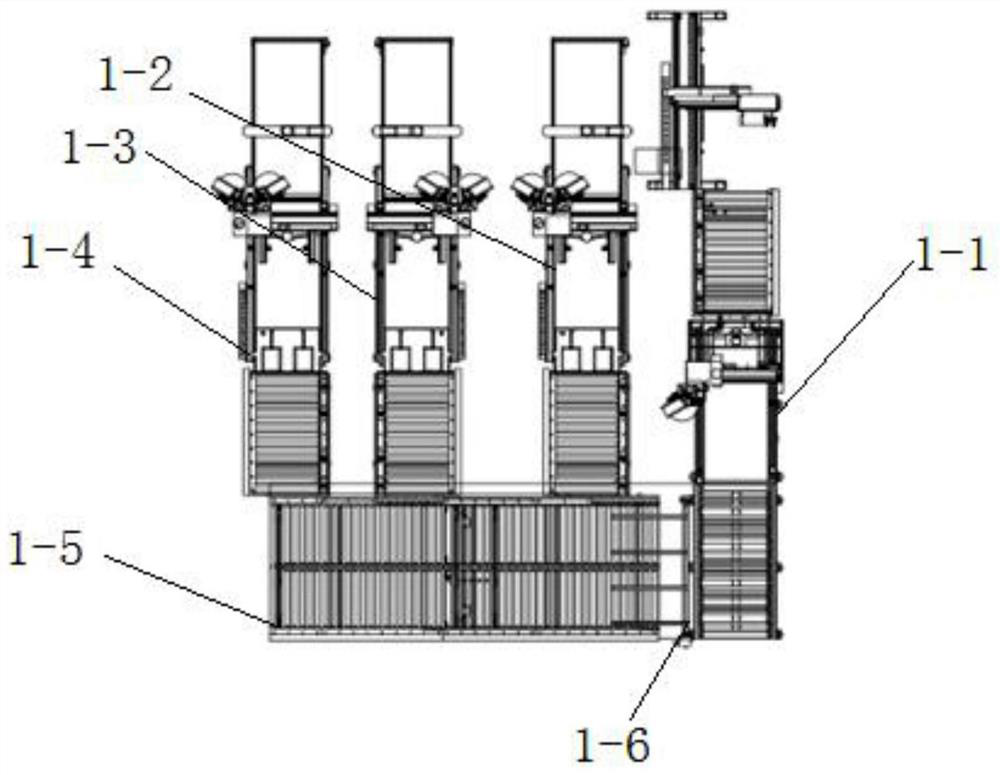

Full automatic foam plastic forming machine of two opposite-clamping type templates

The invention provides a full automatic foam plastic forming machine of two opposite-clamping type templates and relates to a full automatic foam plastic forming machine, in particular to an opposite template structure of the full automatic foam plastic forming machine. The full automatic foam plastic forming machine comprises a machine frame, a heating steam pipeline, a driving oil cylinder, a mould moving frame, a mould fixing frame, a mould exchange frame and a control system. The full automatic foam plastic forming machine has the main technical characteristic that the mould moving frame and the mould fixing frame of the forming machine are both in an opposite-clamping type, a mould moving plate is hung on the top of the machine frame and moves along a line track, and a mould fixing plate is supported on a support guide rail at the lower part of the machine frame. The invention adopts an opposite-clamping type double-displacement template system and enables parting planes to be fixed on the same position, the opposite parting planes of the mould frame are arranged along with the increase of the height of a product, and a mould moves backwards at a corresponding distance along with the mould frame, therefore, the immutability of the parting planes is ensured, the running distance of the templates is greatly shortened, and one third of the travel route is reduced.

Owner:HANGZHOU FANGYUAN PLASTICS MASCH CO LTD

Matched mould locking mechanism of hollow plastic forming machine

ActiveCN101502999BImprove reliabilityReduce the numberHollow articlesPlastic forming machineMolding machine

A die assembly locking mechanism of a hollow plastic molding machine belongs to the technical field of hollow plastic product molding machine and comprises a fixed sleeve, a lock sliding bush, an expansion sleeve, a pressing sleeve and an interlocking bar. The locking sliding bush is fixedly installed inside the fixed sleeve, and a first lock lug boss chamber is formed at one end of the lock sliding bush, and a second lock lug boss chamber is formed at the other end; the expansion sleeve is held inside the expansion sleeve chamber of the lock sliding bush, and the expansion sleeve is formed by a group of lock catches with same structure for enclosing a barrel body together; a first lock lug boss is formed at one end of each lock catch, and a second lock lug boss is formed at the other endof each lock catch; the pressing sleeve is installed inside a pressing sleeve chamber at one end of the fixed sleeve. The interlocking bar is held inside the expansion sleeve and is matched with the lock matches. The invention has the advantages of convenient process, installation and maintenance, and the material can be saved; the reliability of die assembly locking is high; and the expansion sleeve moves stably in the lock sliding bush, and cannot be degenerated as time goes on.

Owner:SUZHOU TONGDA MACHINERY

Method for producing vacuum by utilizing waste steam of expansion plastic forming machine

The invention provides a method for attaining vacuum by waste steam of plastic molding presser, which imports exhaust tube of waste steam of expanded plastic molding presser into vacuum chamber. The top of vacuum chamber has a cooling-water injection pipe and a vacuum meter, while its top part or side edge has a vacuum pipe and the bottom part has a water exhaust tube. The vacuum pipe of vacuum chamber is connection to the expanded plastic molding presser. The steam is imported into expanded plastic molding presser, and the exhaust steam is imported into vacuum chamber, then injecting cooling-water to the vacuum chamber to reduce the volume of its waster, to attain the vacuum inside the vacuum chamber. The water of expanded plastic product in the mould can be sucked into vacuum chamber via vacuum pipe. With said invention, the water steam of expanded plastic molding presser can be used secondary, while it can produce vacuum replacing the vacuum pump to save the power.

Owner:梁志强

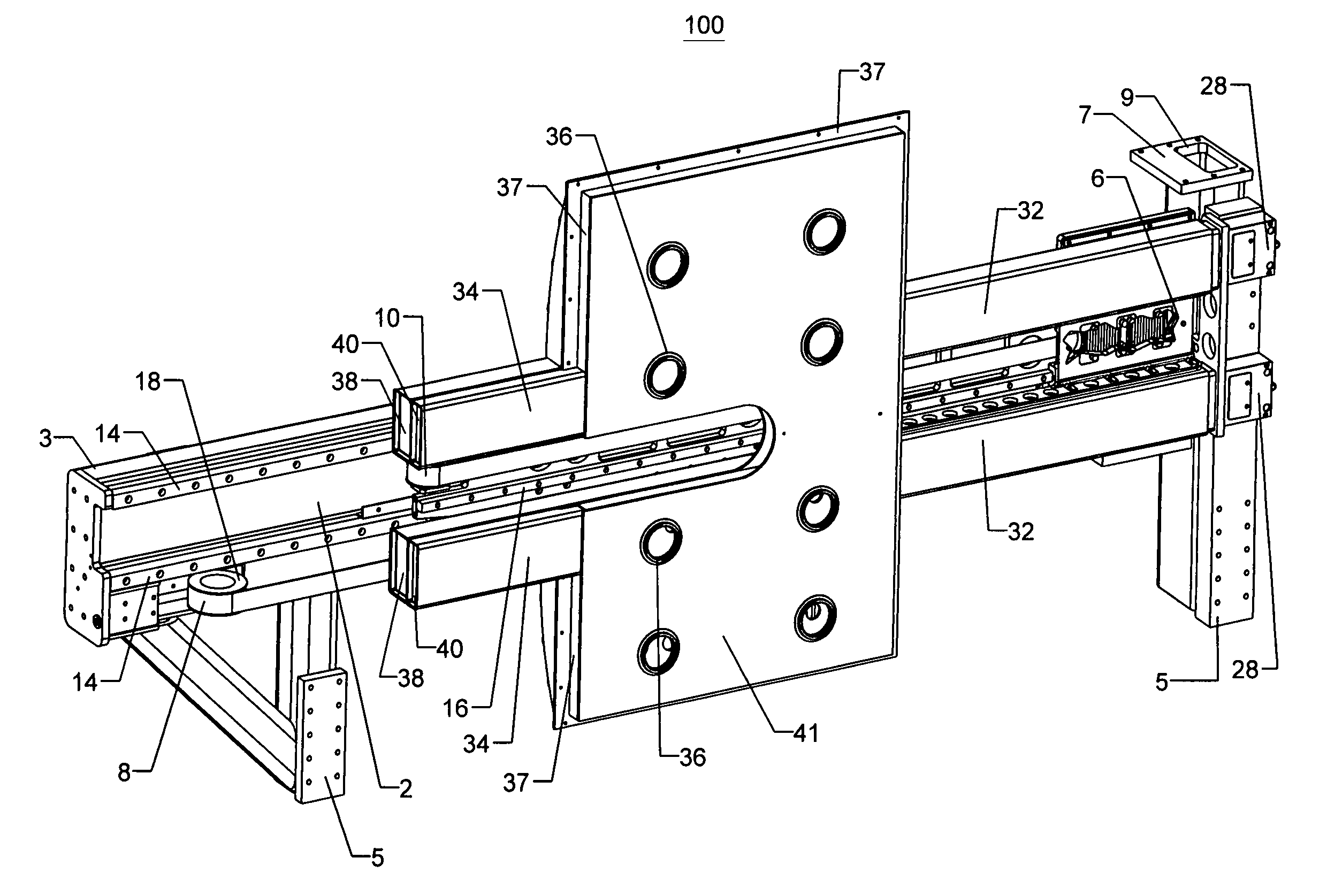

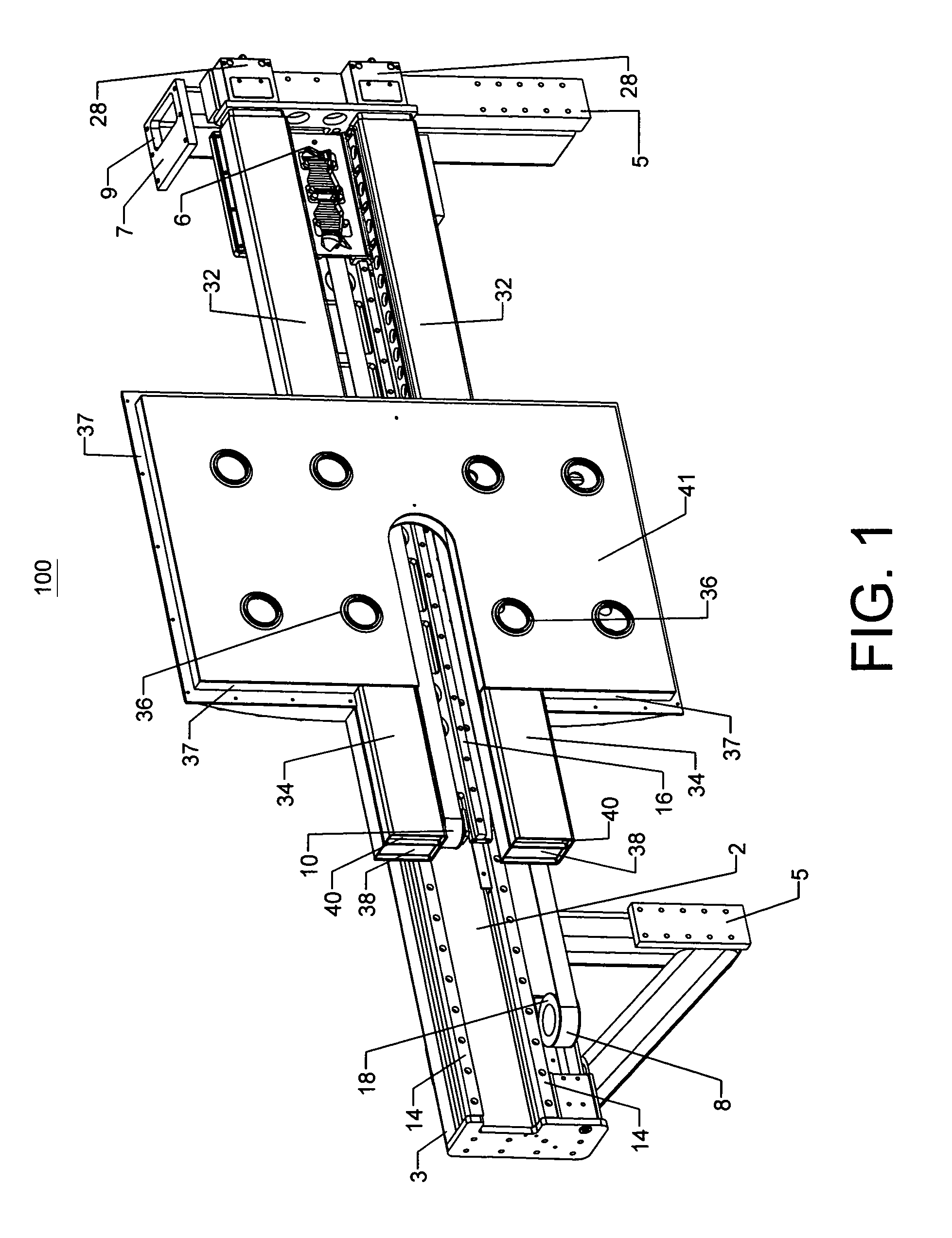

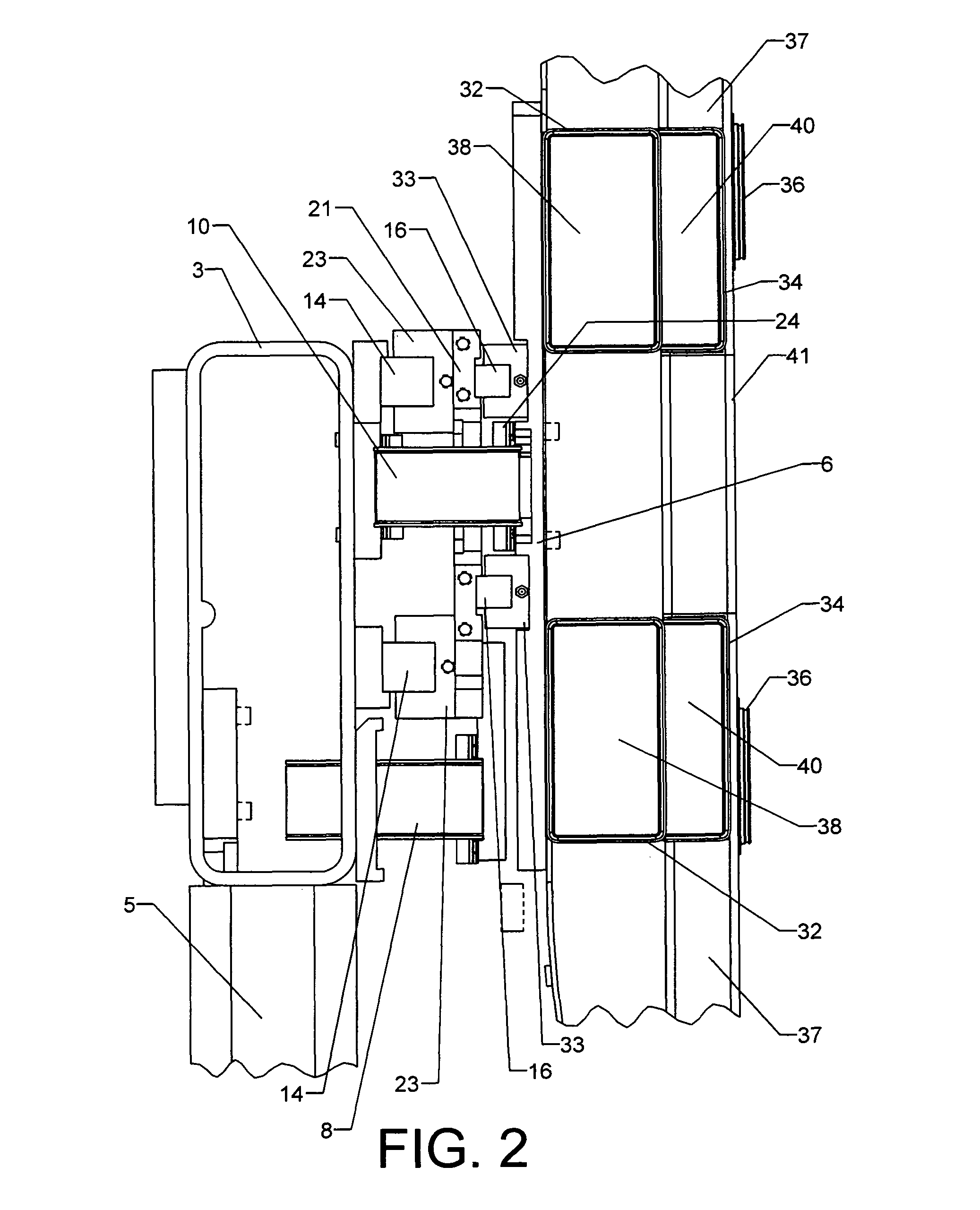

Telescoping article retrieval system with plenum assembly attached to slave belt

InactiveUS9126764B1Long cycle timeShorten cycle timeConveyorsSupporting framesLinear motionPlastic forming machine

A telescoping article retrieval system for rapidly removing articles from a plastic molding machine or other manufacturing process in a way that significantly reduces the cycle time, while consistently maintaining vacuum control of the articles being handled. Two light weight double telescoping tubes are driven by a dual carriage assembly in which power is conveyed to one carriage by means of a servo, belt drive or other mechanism, allowing it to extend and retract. A second belt drive encompasses a first carriage and ties a second carriage to a fixed main beam such that linear movement of the first carriage of the dual carriage assembly a certain distance causes linear movement of the second carriage of the dual carriage assembly and also causes linear movement of the double telescoping tubes a distance equal to twice the distance that the first carriage has moved.

Owner:CBW AUTOMATION

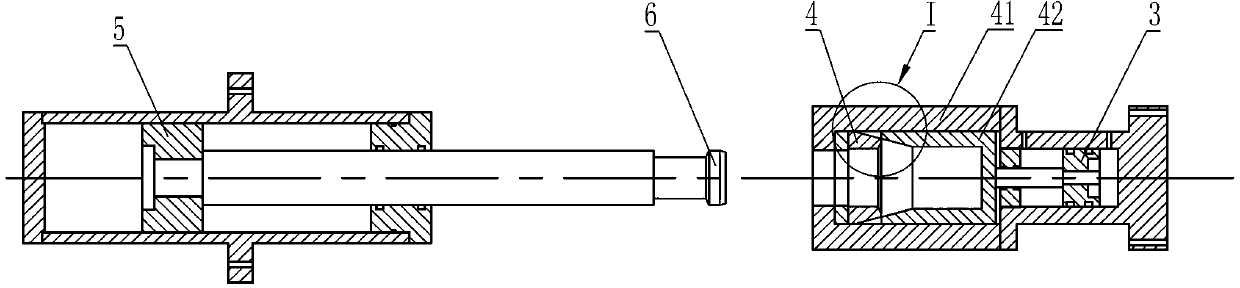

Mould closing device for plastic forming machine

The invention discloses a mould closing device for a plastic forming machine. The mould closing device comprises a first mould plate and a second mould plate which are arranged on a rack, wherein the first mould plate is connected with a mould closing oil cylinder, at least one pair of clamping sleeve drive oil cylinders are arranged at two sides of the first mould plate, each clamping sleeve drive oil cylinder is connected with a clamping sleeve connecting device, clamping head drive oil cylinders in one-to-one correspondence with the clamping sleeve drive oil cylinders are arranged on the second mould plate, and clamping head connecting devices matched with the clamping sleeve connecting devices are arranged on the clamping head drive oil cylinders. In a mould closing process, under the action of the clamping sleeve drive oil cylinders and the clamping head drive oil cylinders, the clamping sleeve connecting devices and the clamping head connecting devices are matched and connected to provide a uniform and stable mould locking pressure for mould closing, and the mould closing oil cylinder can provide no mould closing force or a little mould locking force, so that product quality can be ensured while the load of the mould closing oil cylinder is reduced. The mould closing oil cylinder with small diameter can be adopted, and thus the mould closing speed and the production efficiency are improved.

Owner:WEIFANG HUAYU PLASTIC MACHINERY

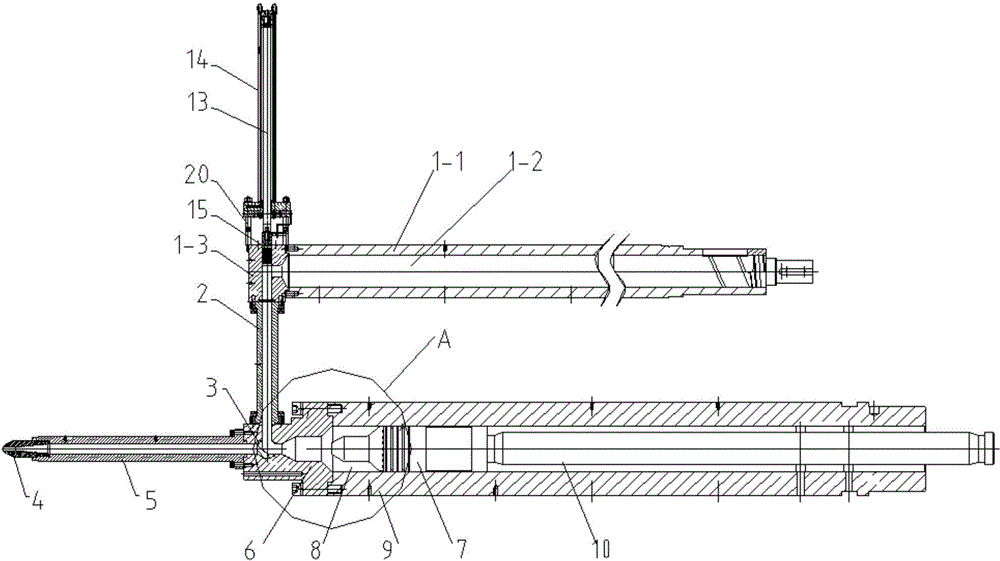

Plastic extrusion injection molding machine with injection connecting rod defective material cleaning function

The invention relates to a plastic molding machine, and particularly relates to a plastic extrusion injection molding machine with an injection connecting rod defective material cleaning function. The plastic extrusion injection molding machine with the injection connecting rod defective material cleaning function comprises an injection component and a plasticizing component which are connected by an injection connecting rod; the plasticizing component comprises a plasticizing screw rod, a pre-plasticizing front charging barrel and a plasticizing charging barrel; a cleaning component is fixed above the pre-plasticizing front charging barrel, and comprises a cleaning oil cylinder and a cleaning plunger; the cleaning oil cylinder is internally provided with a piston rod; the cleaning plunger is installed at one end of the piston rod, and the other end of the piston rod is sleeved by a seal ring so that a piston head is formed at the end part of the piston rod; the piston rod drives the cleaning plunger to move in a reciprocating mode along the inner cavity of the pre-plasticizing front charging barrel and the inner cavity of the injection connecting rod. In order to remove defective materials out of the injection connecting rod, the invention designs a special cleaning oil cylinder and the cleaning plunger with a cleaning groove in the head part.

Owner:TEDERIC MACHINERY

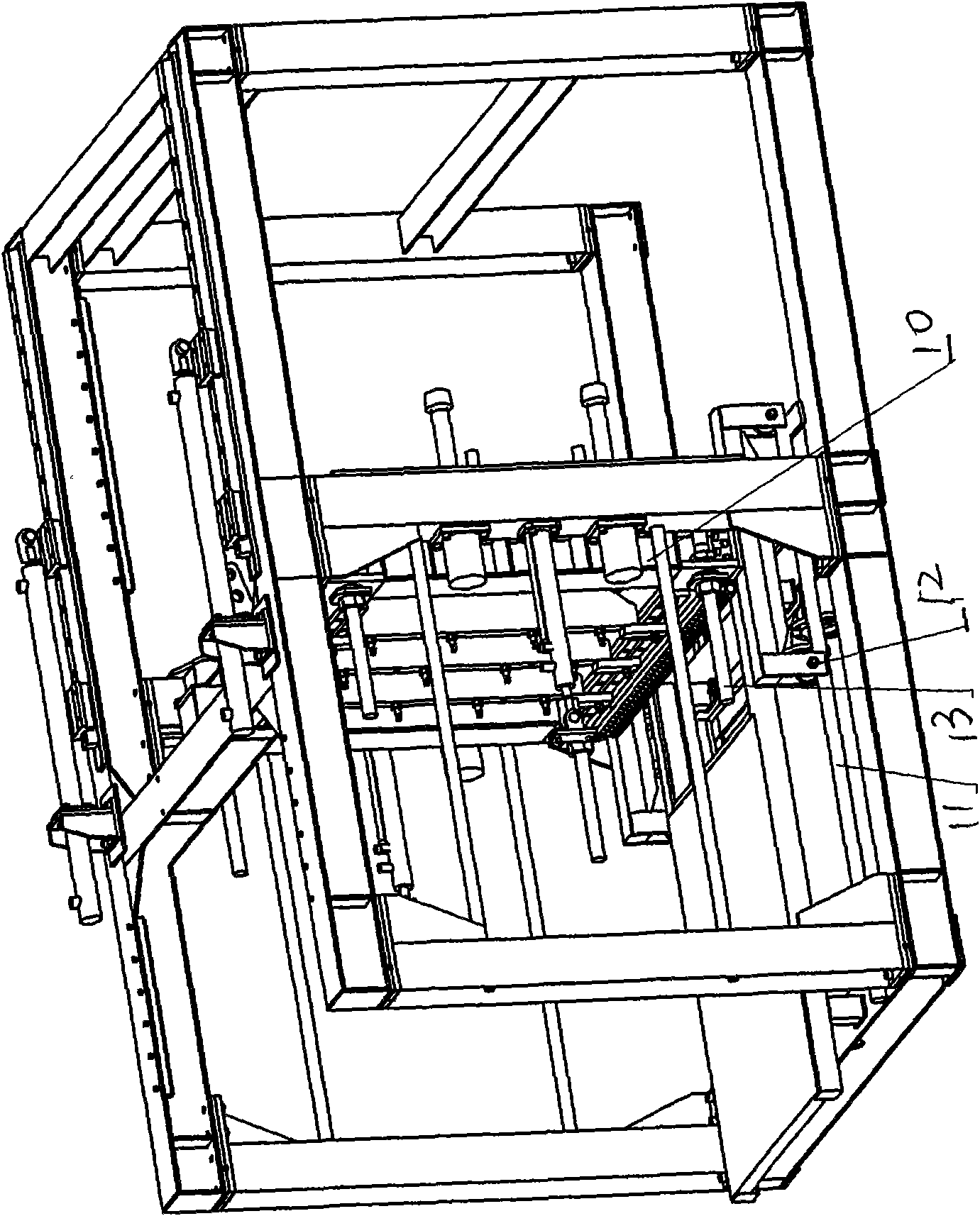

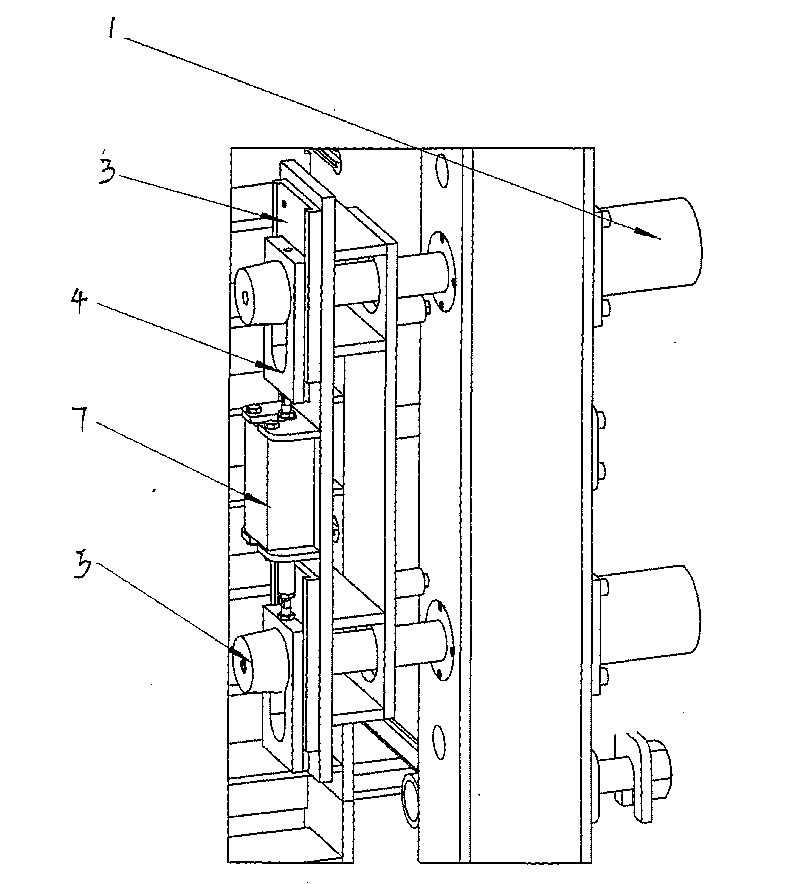

Locking mechanism of clamp type double-template full-automatic foamed plastic forming machine

The invention provides a micromovement oil cylinder locking mechanism of a clamp type double-template full-automatic foamed plastic forming machine, relates to a full-automatic foamed plastic forming machine, in particular to a locking mechanism of the clamp type double-template full-automatic foamed plastic forming machine; the locking mechanism is driven by a locking oil cylinder, the locking mechanism comprises a locking plugboard base, a locking plugboard is fixed on the locking plugboard base, a locking head is arranged on the locking plugboard which is connected with a plugboard air cylinder, and the plugboard air cylinder controls the locking plugboards at two sides at the same time; in the invention, a driving oil cylinder and the locking oil cylinder are separated out to realize the position of a parting line of a mold to be fixed, and the location is convenient for adjustment when mold setting is carried out. The stroke of the micromovement oil cylinder of the mechanism is no more than 50mm; furthermore, multi-point locking technology is adopted, mold locking force is increased by 20 percent compared with the traditional machine type, and the sealing performance of the parting line of the mold is greatly increased.

Owner:HANGZHOU FANGYUAN PLASTICS MASCH CO LTD

High-strength magnesium-lithium alloy and preparation method of cryogenic strengthening treatment of high-strength magnesium-lithium alloy

The invention provides a high-strength magnesium-lithium alloy and a preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy, and belongs to the technicalfield of high-strength alloys and preparation thereof. The high-strength magnesium-lithium alloy comprises Li, Y, Zn, unavoidable impurity elements and Mg. The atomic ratio of Y and Zn is higher than1.32. The preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy comprises the steps of smelting and casting, homogenization heat treatment, 77 K cryogenic treatment, plastic forming machining and the like. According to the high-strength magnesium-lithium alloy and the preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy, the Y and Zn elements are dissolved into a magnesium-lithium alloy matrix by simultaneously adding the Y and Zn elements, twin crystal refined grains are obtained in an alpha-Mg phase through homogenization heat treatment, cryogenic treatment, plastic forming machining, self-generating in a beta-Li phase is conducted to obtain an X-Mg12YZn phase of a layered LPSO structure, the effect of strengthening the beta-Li phase is achieved, and therefore the alloy is strengthened.

Owner:铜川华铸精密科技有限公司

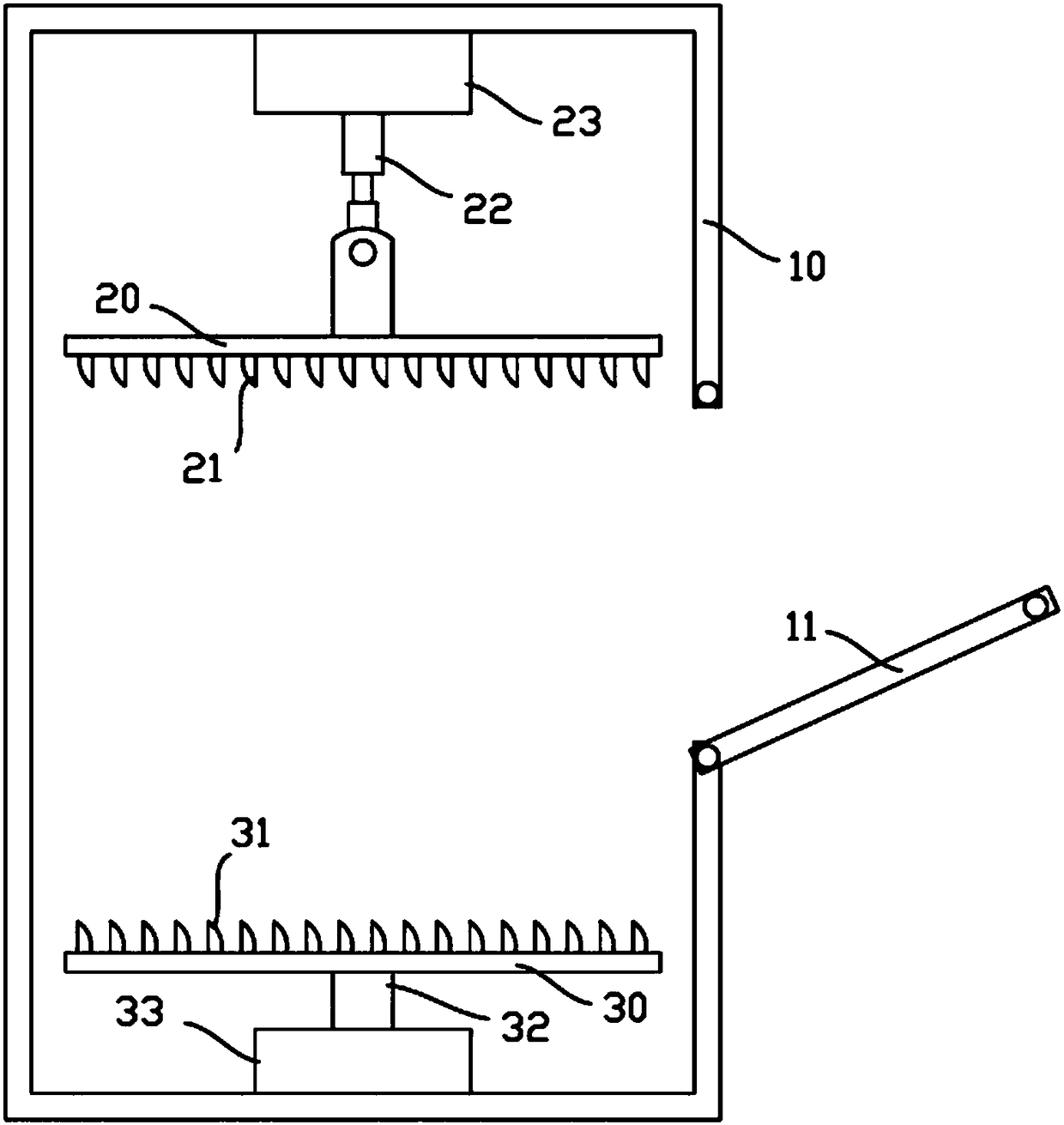

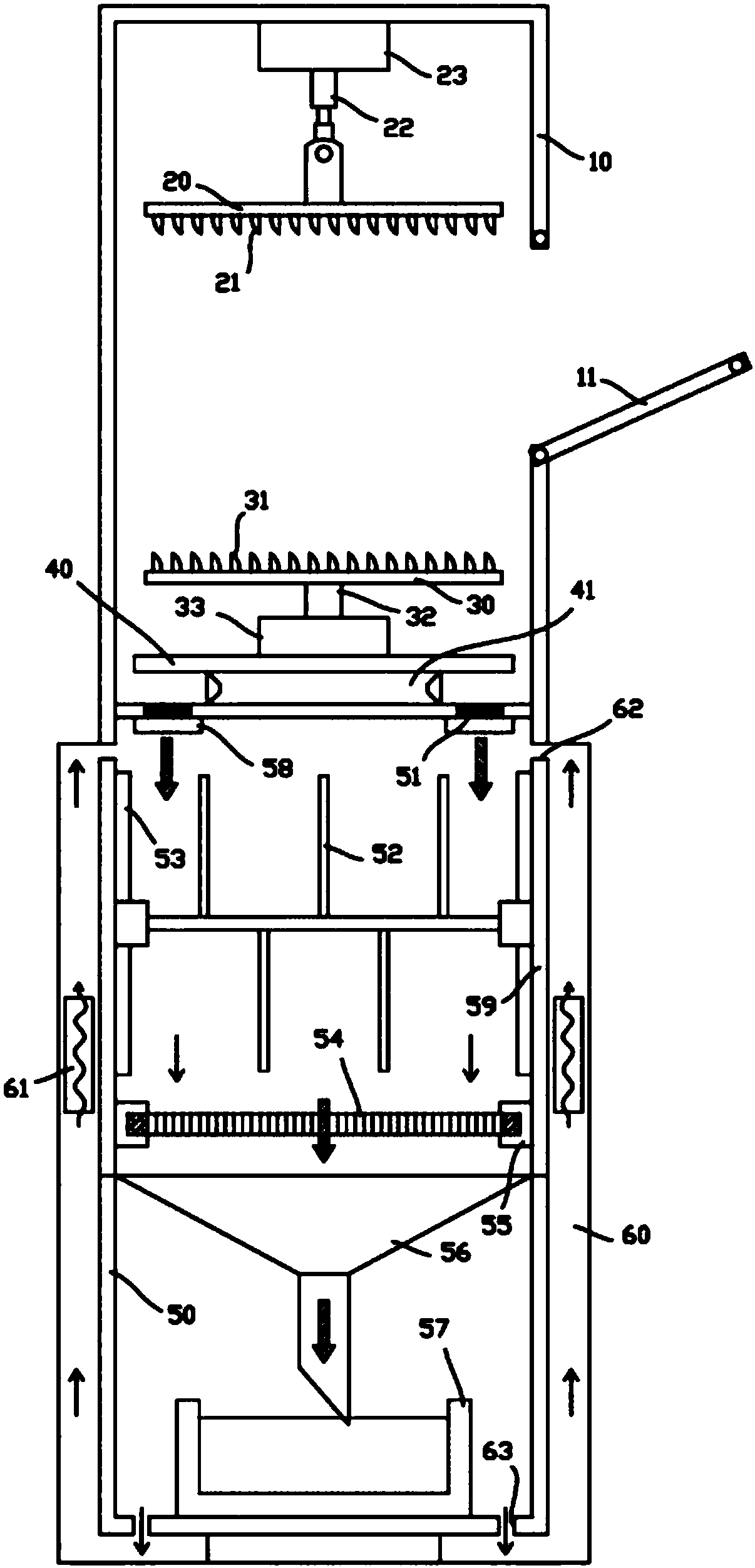

Waste mixed plastic recovery and separation device and method

InactiveCN108162241AEffective classificationRealize resource utilizationPlastic forming machineMolten state

The invention discloses a waste mixed plastic recovery and separation device and method, and belongs to the field of waste mixed plastic resourceful reutilization. The device comprises a crushing device and a melting, sorting and recovery device; a feeding mechanism, a crushing mechanism and a discharge mechanism are arranged in a crushing box body of the crushing device; and a heating mechanism for heating granular materials to a molten state after crushing in a phase manner, a screening mechanism for separating the molten materials from non-molten granular materials and a plastic molding mechanism positioned at the bottom of a melting box body and recycling the molten materials after separation are arranged in the melting box body of the melting, sorting and recovery device. The recoveryand separation device can effectively classify waste mixed plastic generated in daily life and industrial production, separates different plastic to prepare relatively pure single plastic to realizeresourceful utilization, saves later machining process, saves the energy, and is simple in operation, high in the automation degree, high in sorting degree and wide in sorting range.

Owner:宁波江北文增新材料科技有限公司

Water adsorbing agent for plastic formation and production thereof

A water adsorbent for plastic forming machining and its production are disclosed. The water adsorbent consists of super-fine inorganic oxide 100 proportions, disperser 1-4 proportions, grafting modifier 0.5-3 proportions, carrier resin 20-50 proportions, lubricating plasticizer, and stabilizer 0.5-4 proportions. The production is carried out by mixed reacting, plastifying pressing and forming. Its advantages include good water absorbability product quality, simple process, and different formulas for different carriers.

Owner:陈明忠

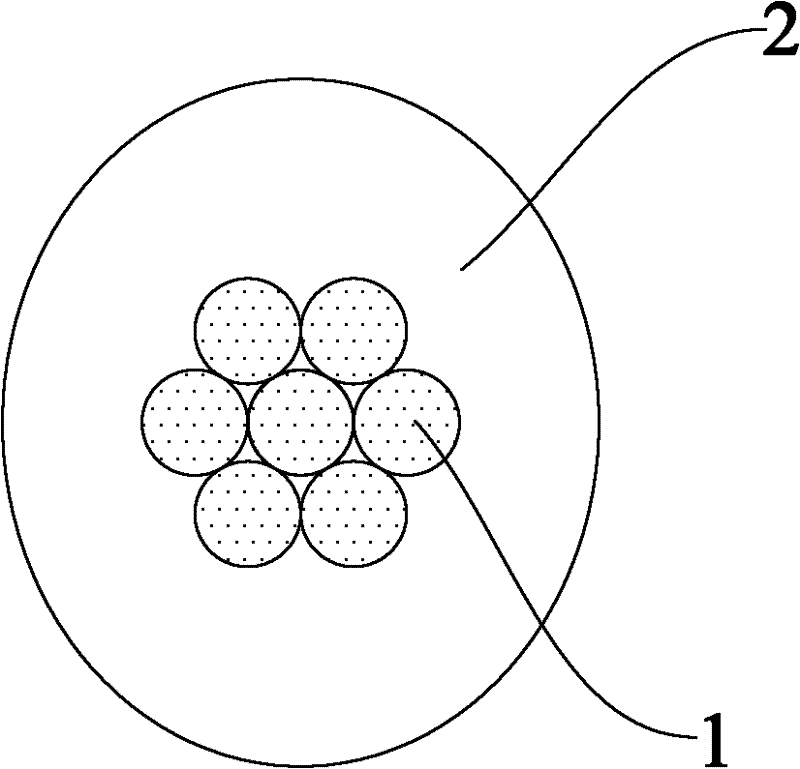

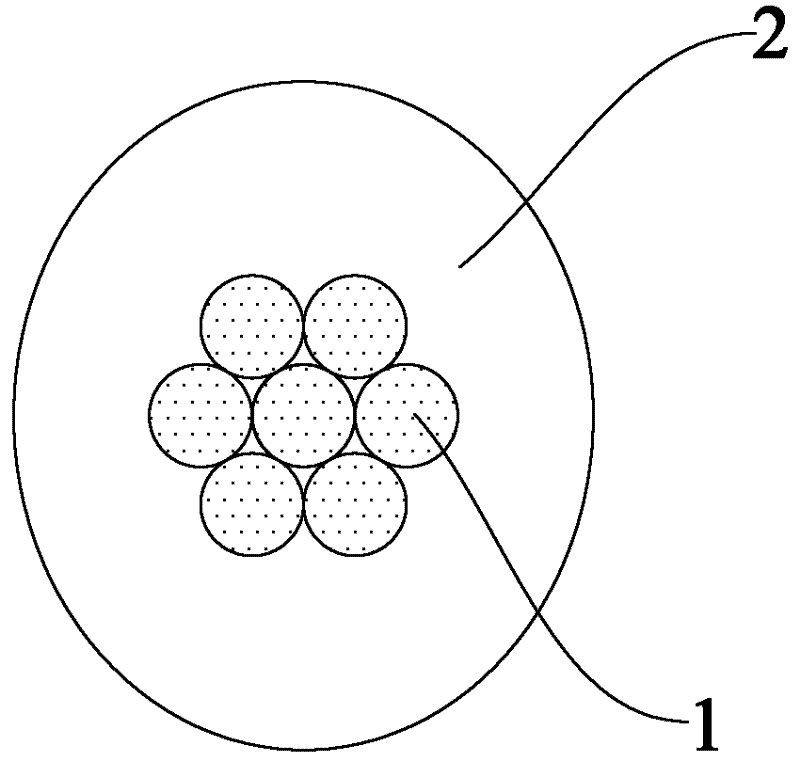

Yarn

The invention provides a yarn, comprising an inner core and a coating coated on the surface of the inner core, wherein the inner core is a fibre multifilament; the coating is plastic formed from a thermoplastic elastomer (TPE) as a main material. The yarn provided by the invention has the coating advantage of the plastic material, and is more environment-friendly; the used TPE can be processed by a general thermoplastic plastic forming machine without special processing equipment, and is easy to reclaim, so that the production efficiency is higher and the cost is lower; and the yarn formed from the TPE and various fibre inner cores is widely applied in a plurality of products, such as furniture fabric, table mats, bags and the like.

Owner:昆山维信纺织工业有限公司

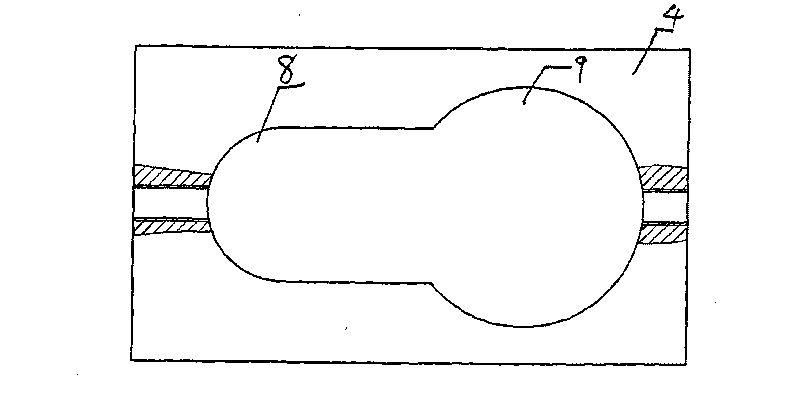

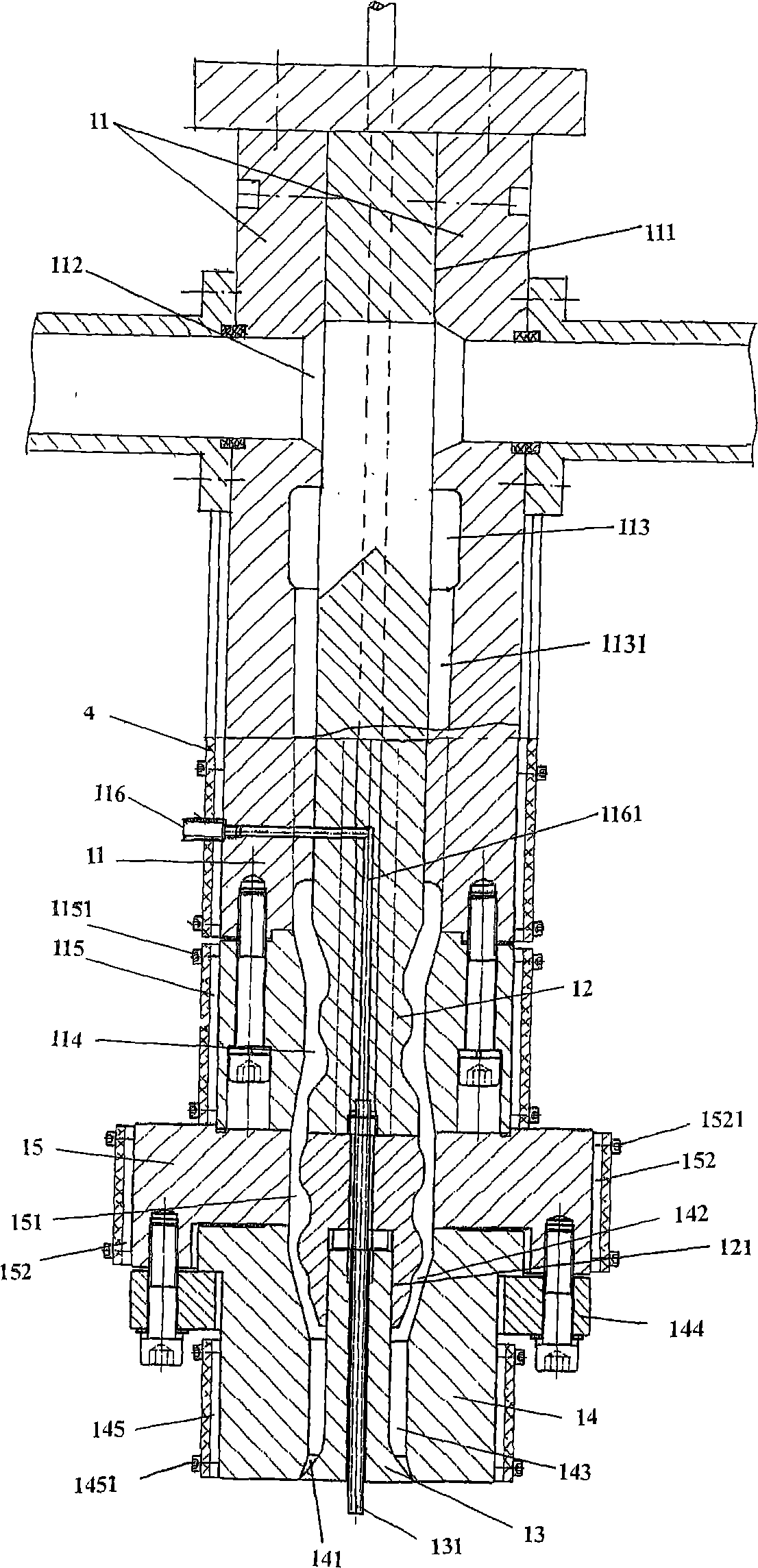

Flat parsion shaping mechanism of plastic hollow shaping device

ActiveCN101508170AShorten the mold opening and closing strokeReduce volumeFlat articlesHollow articlesPlastic forming machineMolding machine

The invention relates to a parison molding mechanism of a plastic hollow molding machine, which belongs to the technical field of hollow plastic molding machines. The mechanism comprises a molding machine head, material storage devices for feeding molten plastic into the molding machine head and extruding the molten plastic outside the molding machine head to form a parison, and a parison wall thickness control device for controlling the thickness of the wall of the parison, wherein the molding machine head has a flat and rectangular structure; the pair of material storage devices is correspondingly arranged on the upper part of the molding machine head and is connected and communicated with the molding machine head; and the parison wall thickness control device is arranged on the upper part of the molding machine head, positioned between the pair of material storage device and linked with the molding machine head. The mechanism has the advantages of forming flat parisons, reducing mold opening and closing travels of a molding mechanism of the plastic hollow molding machine, providing a technical guarantee of improved processing efficiency and energy conservation, ensuring the uniform wall thickness of finally molded hollow plastic products, and saving space.

Owner:SUZHOU TONGDA MACHINERY

Method for preparing food-grade disposable product

The invention relates to a method for preparing a food-grade disposable product. The method comprises the following steps of (1) pulp preparation, wherein native wood pulp of bleached sulfate needle wood and broadleaf wood is taken as a raw material, the concentration of the pulp is 5%, the pulping degree of the pulp is controlled to be larger than or equal to 25 degrees at steradian through pulping, nanocellulose of which the mass ratio is 0.1-5% is added to serve as a reinforcing agent and a binder, a certain amount of a water-repellent agent and oil-repellent agent are added, and the mass concentration of the pulp is controlled to be 1-10% to form the stable and uniformly dispersed pulp; (2) adsorption and forming, wherein the pulp is processed into pulp-molding plastic by a pulp-molding plastic forming machine through vacuum forming and hot press curing; (3) drying and sizing, wherein the pulp-molding plastic is heated, dried, sized, cut, trimmed and surface-finished to form the food-grade disposable product. The method for preparing the food-grade disposable product has the advantages that when straws, stirrers, spoons and other disposable products are in use, the wet strength, permeability, water resistance and other indexes completely meet the requirements, and the food-grade disposable product is non-toxic and harmless, can be naturally degraded, and is green and environmentally friendly.

Owner:ZHEJIANG JINCHANG SPECIALTY PAPER CO LTD

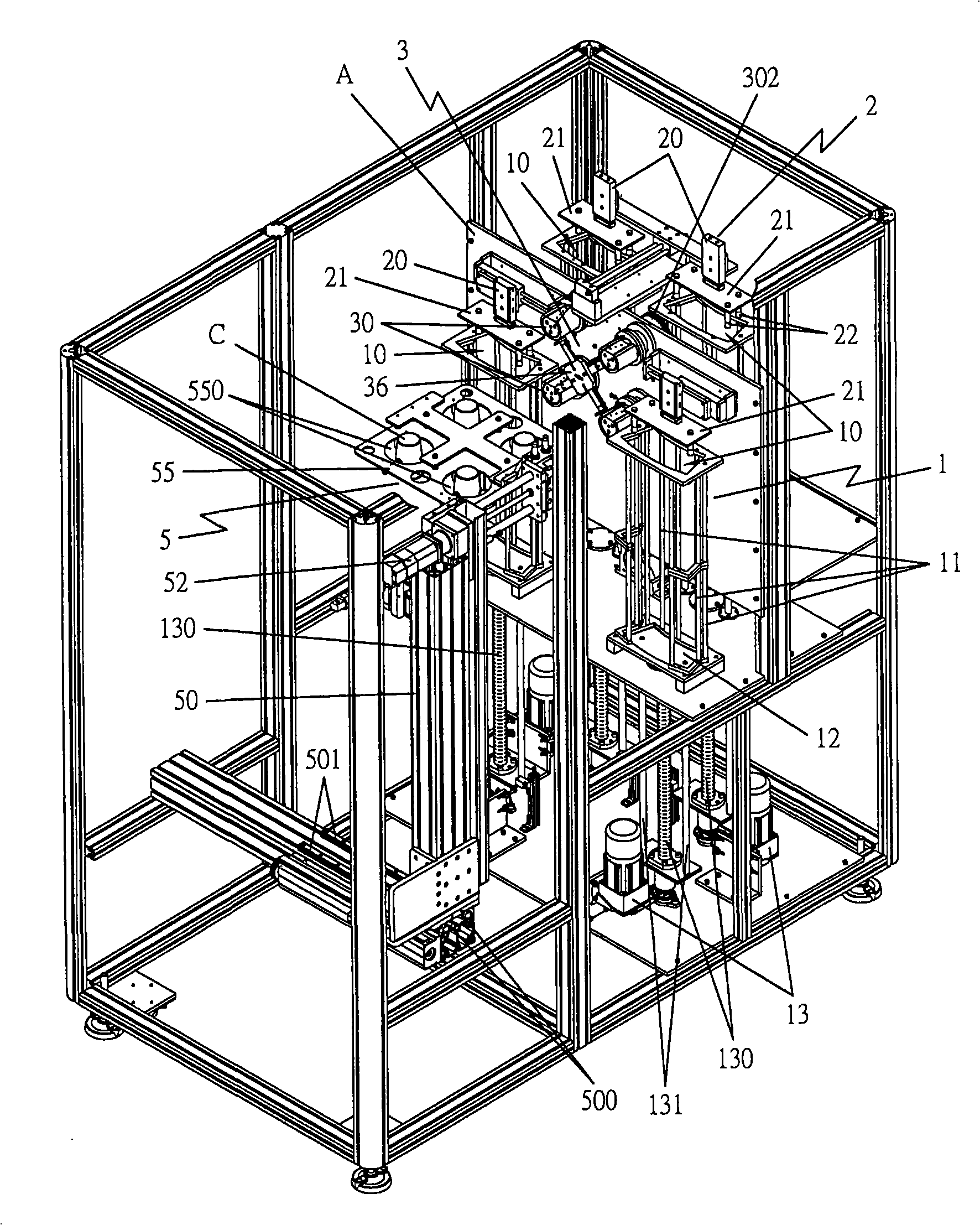

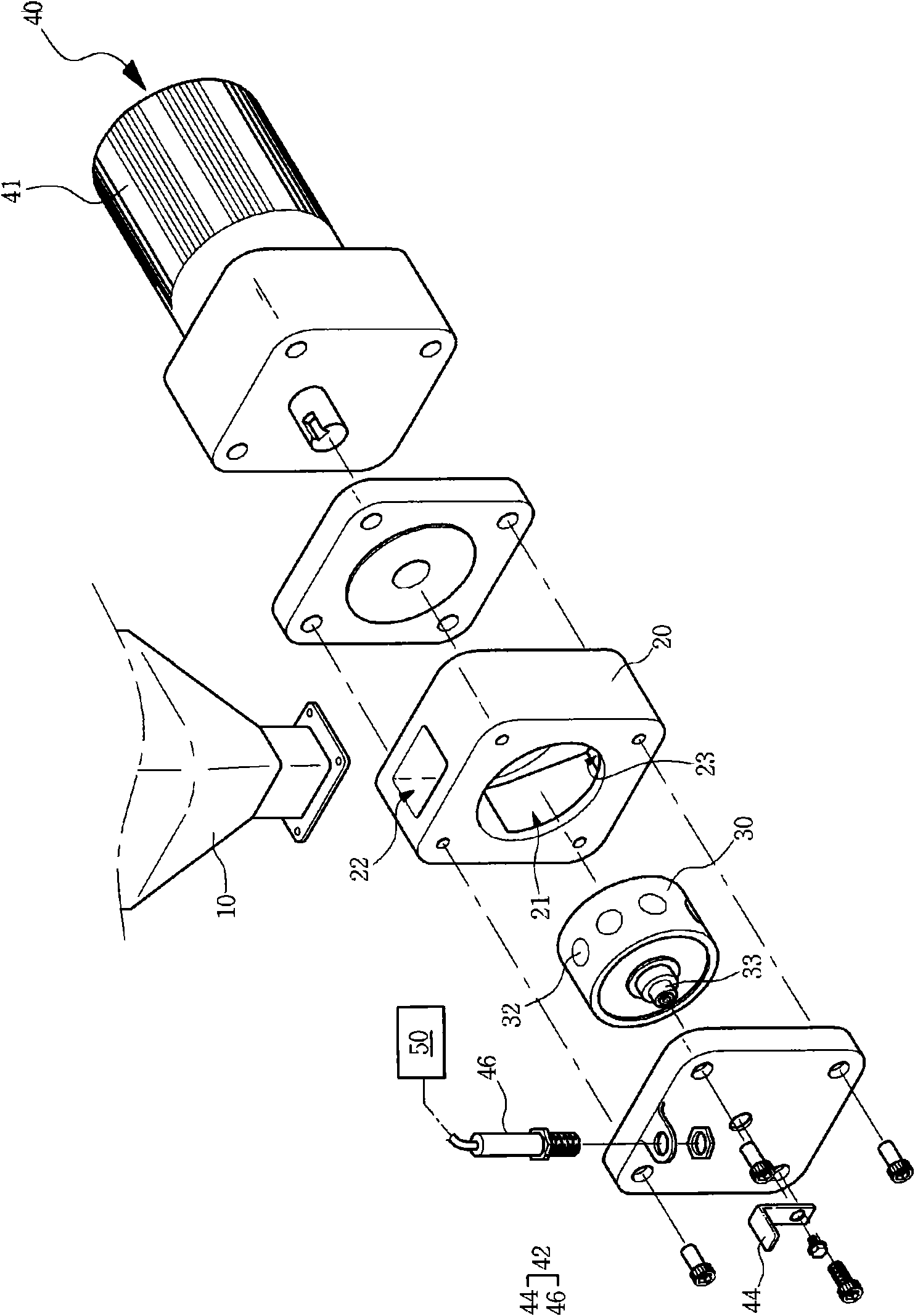

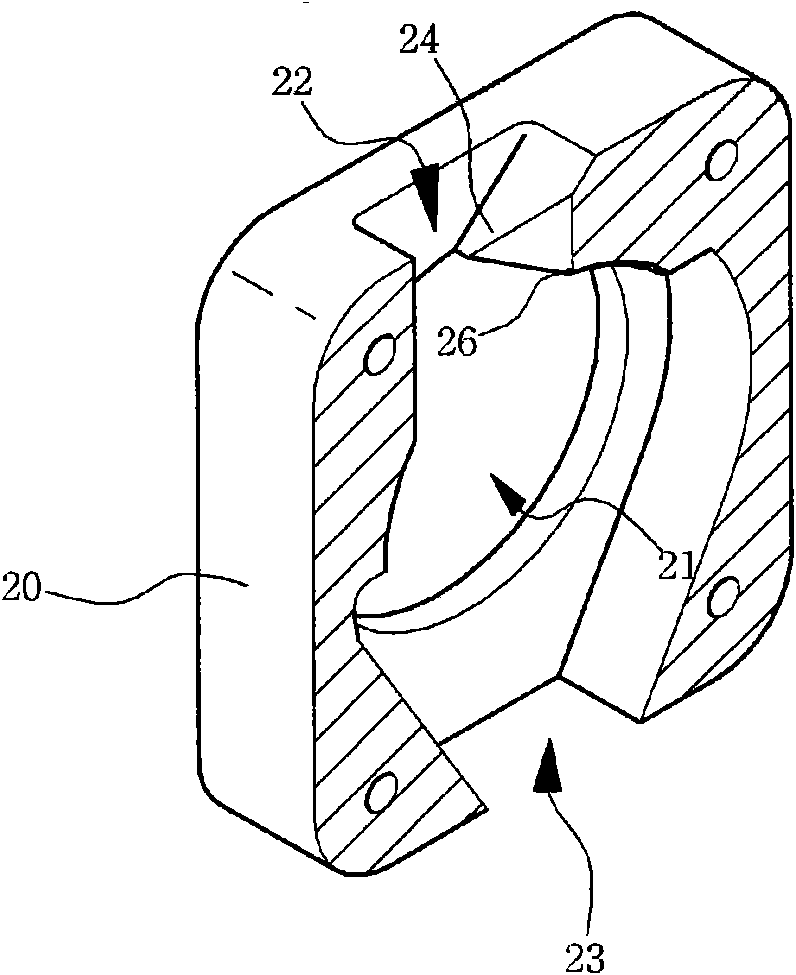

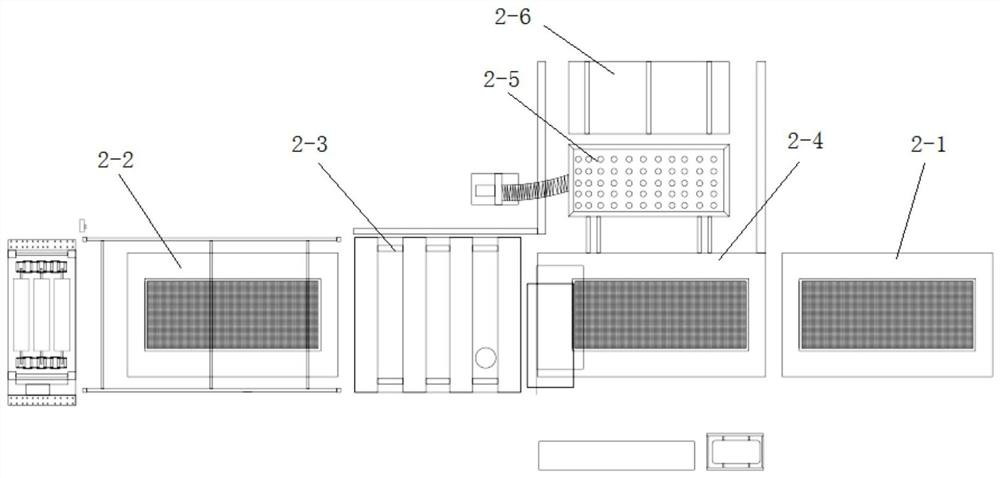

In-mold label multifunctional conveying system

InactiveCN101337406APrecise suctionPrecise windingStacking articlesPlastic forming machineEngineering

The invention relates to a multi-functional in-mould label conveying system, which comprises a volume label positioning device, a volume label sucking device, a rolling bar, a detecting component, a manipulator and a stacking device. The volume label positioning device is provided with a volume label tank to contain a large quantity of volume labels; a power component is arranged under the volume label tank to drive a pushing plate and push the volume labels upward; the volume label sucking device is arranged on the front side of the machine support, and is also provided with a power component to drive a moving part; the moving part is provided with a sucking component, which can be used for sucking the volume labels from the volume label positioning device to a rolling device; the rolling device is provided with the rolling bar; the rolling bar is provided with a C-shaped rolling tank, and can adsorb the volume labels first; after the rolling bar starts rotating, the C-shaped rolling tank is utilized to roll the volume labels into appropriate shape smoothly; the rolling device is provided with the detecting component to control the rotating radian and distance of the rolling bar of the rolling device; the manipulator is used for clamping rolled volume labels and is positioned into the cavity of the forming die of a plastic forming machine; plastic end products are taken out from the forming die of the plastic forming machine; the stacking device receives the plastic end products from the manipulator and conveys the end products to a packing place after the end products are stacked on a conveying belt.

Owner:黄胜昌 +1

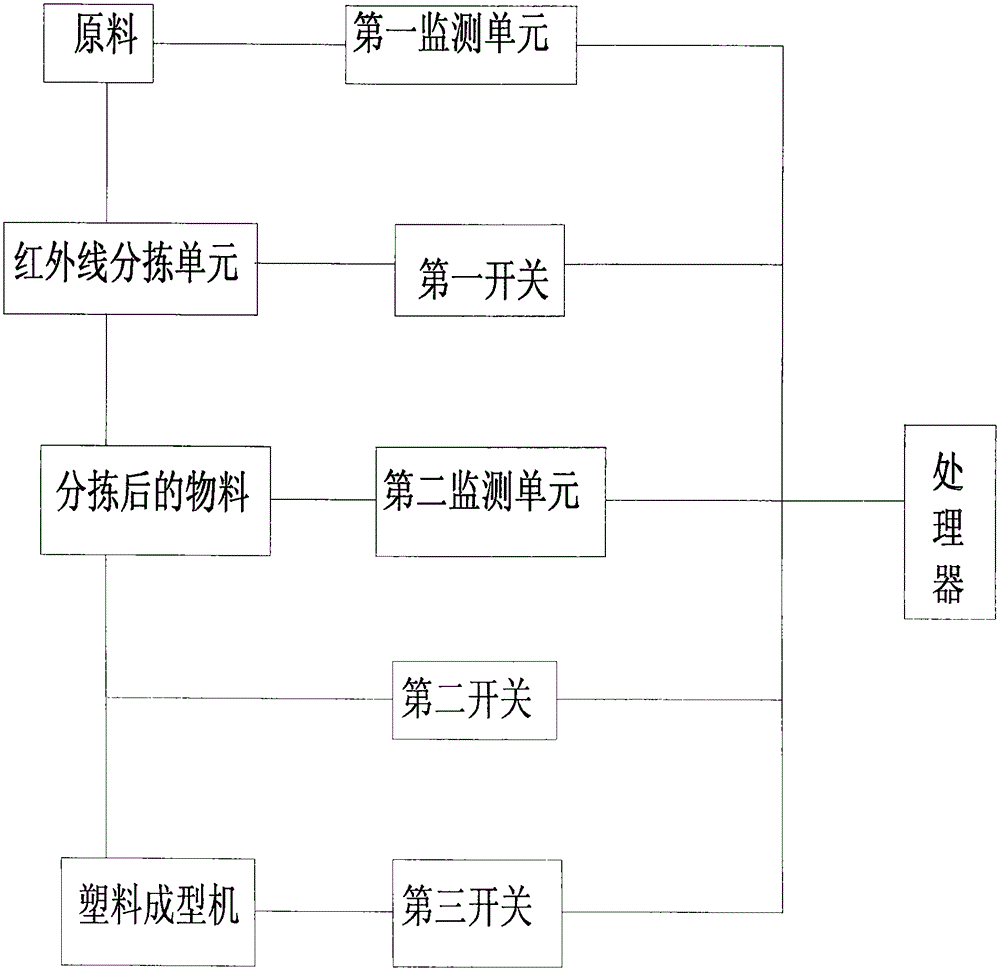

Plastic molding machine with automatic sorting and molding functions

InactiveCN105414055AShorten the timeSave productivityPlastic recyclingSortingPlastic forming machineMolding machine

The invention relates to a plastic molding machine with automatic sorting and molding functions. The plastic molding machine comprises an infrared sorting unit and a plastic molding machine body, wherein the infrared sorting unit comprises a feeding mechanism, a sorting mechanism, a collecting mechanism and a control unit. The control unit comprises a treater, a first monitoring unit for monitoring whether the infrared sorting unit finishes the raw material sorting operation or not, a second monitoring unit for monitoring a sorted material, a first switch for controlling the starting / stopping of the infrared sorting unit, a second switch for opening / closing an opening of the collecting mechanism and a third switch for controlling the starting / stopping of the plastic molding machine; the first monitoring unit is arranged at the tail end of the feeding mechanism of the infrared sorting unit; and the second monitoring unit is arranged on the collecting mechanism. Due to the arrangement of the control unit, the sorted material is automatically treated in time, so that the production cost is reduced.

Owner:XIAOGAN TIANCHUANG INFORMATION TECH CO LTD

Manufacturing method for plastic molding machine cylinder

ActiveCN106735228AImprove mechanical propertiesImprove wear resistancePlastic forming machineMechanical components

The invention provides a manufacturing method for a plastic molding machine cylinder. A layer of metal-base carbon tungsten alloy with the thickness ranging from 1 mm to 10 mm is evenly distributed on the inner wall of a steel pipe through a hot isostatic pressure sintering method, and a steel pipe base material and the carbon tungsten alloy are metallurgical bonding. By means of the hot isostatic pressure sintering machine cylinder manufacturing process method, the design idea that a mechanical part is made of two kinds of materials is achieved, the steel-base machine cylinder has excellent comprehensive mechanical performance, and the metal-base tungsten carbide surface layer has especially excellent abrasion resistant and corrosion resistant performance which is a characteristic cannot be achieved by any single material.

Owner:KUNSHAN SERGEANT EQUIP IND

Rotor-type raw material supplier

The present invention relates to a raw material feeder which measures and supplies fixed quantities of raw materials to various types of plastic molding machines, such as injectors and extruders. The present invention provides a smooth supply of raw material because a cutting knife with a V-shaped groove is placed in the rotor with a measuring cup, and a raw material transfer groove is formed in a portion where material accumulates so that the material on top of the measuring cup is cut and the rest is discharged through an outlet, thereby minimizing load and preventing transfer failure.

Owner:金泉坤

Plastic molding machine

InactiveCN106393465AImprove molding qualityEasy cutting workCoatingsPlastic forming machineMolding machine

The invention discloses a plastic molding machine. The plastic molding machine comprises a supporting base, a molding bin and a stirring bin. Supporting legs are arranged on the upper surface of the supporting base. The stirring bin is arranged at the upper ends of the outer surfaces of the supporting legs. A first feeding inlet is formed in the left end of the top of the outer surface of the stirring bin. A motor is arranged at the right end of the top of the outer surface of the stirring bin and is in transmission connection with a rotary shaft through a belt. Stirring blades are arranged on the outer surface of the rotary shaft. A discharging outlet is formed in the middle end of the bottom of the outer surface of the stirring bin. An electromagnetic valve is arranged at the bottom of the outer surface of the discharging outlet. A second feeding inlet is formed in the position, corresponding to the electromagnetic valve, of the bottom of the outer surface of the discharging outlet and formed in the left end of the top of the outer surface of the molding bin. A first lifting hydraulic rod is arranged at the middle end of the left side of the outer surface of the molding bin. The plastic molding machine is provided with the stirring blades, materials can be stirred before entering the molding bin, the material mixedness is improved, and the plate molding quality is improved.

Owner:蓝灿玉

Production method of woodcarving inlaid door panels subjected to film pressing

PendingCN112025903AReduce idle wait timeShorten the timeDecorative surface effectsWood working apparatusPlastic forming machineNumerical control

The invention discloses a production method of woodcarving inlaid door panels subjected to film pressing. The production method of the woodcarving inlaid door panels subjected to film pressing comprises the following steps: (1) carving door panel substrates by means of a numerical control carving machine provided with a rear surface carving machine station and at least two front surface carving machine stations, making the door panel substrates sequentially enter the rear surface carving machine station to complete rear surface carving, then turning over the door panel substrates to front surfaces by an overturning part, conveying the door panel substrates to one spare front surface carving machine station through a conveyor belt for front surface pattern carving at the same time, keepingthe rear surface carving time of the door panel substrates short, and carving corresponding inlaid core panels; (2) conducting surface polishing on the carved door panel substrates and inlaid core panels; (3) conducting glue-spraying and airing on the door panel substrates and the inlaid core panels which are subjected to surface polishing; (4) conducting PVC high-temperature coating on the aireddoor panel substrates and inlaid core panels by means of a plastic forming machine; and (5) bonding the inlaid core panels and inlaid grooves of the door panel substrates by means of glue, and conducting pressing and fixing. The production method of the woodcarving inlaid door panels subjected to film pressing is simple in process, the production efficiency of the door panels can be improved, andthe production cost is reduced.

Owner:上海速居科技集团有限公司

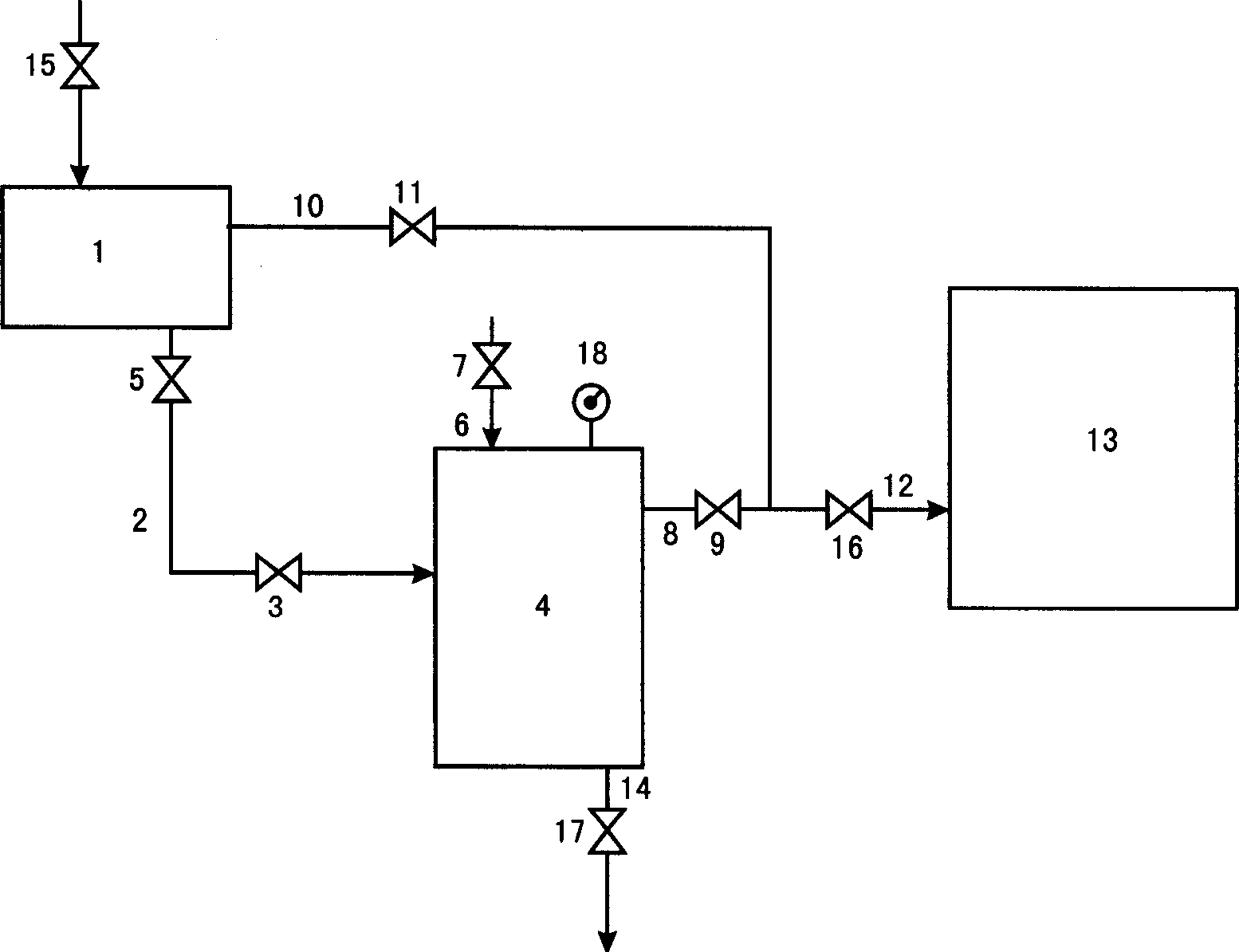

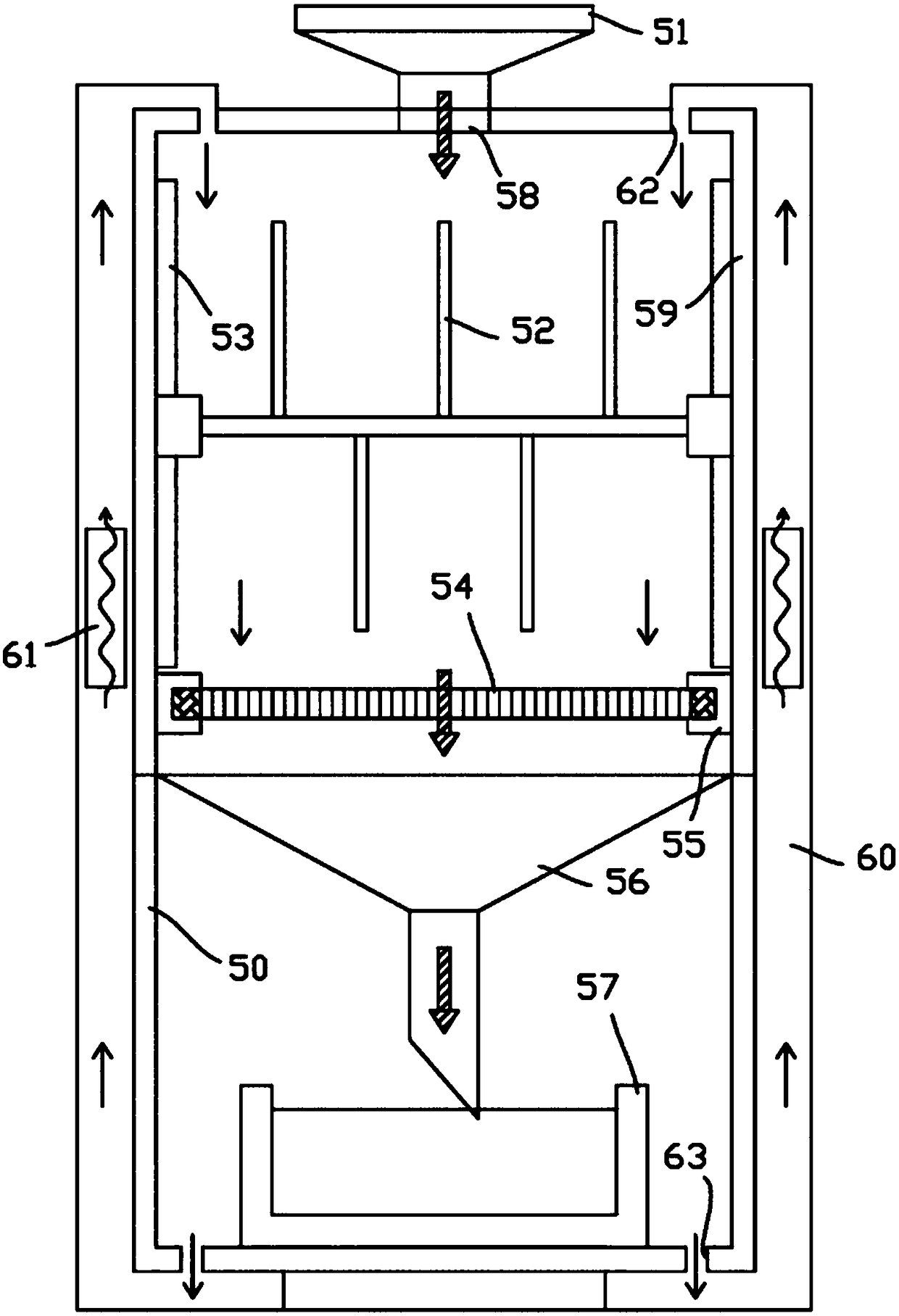

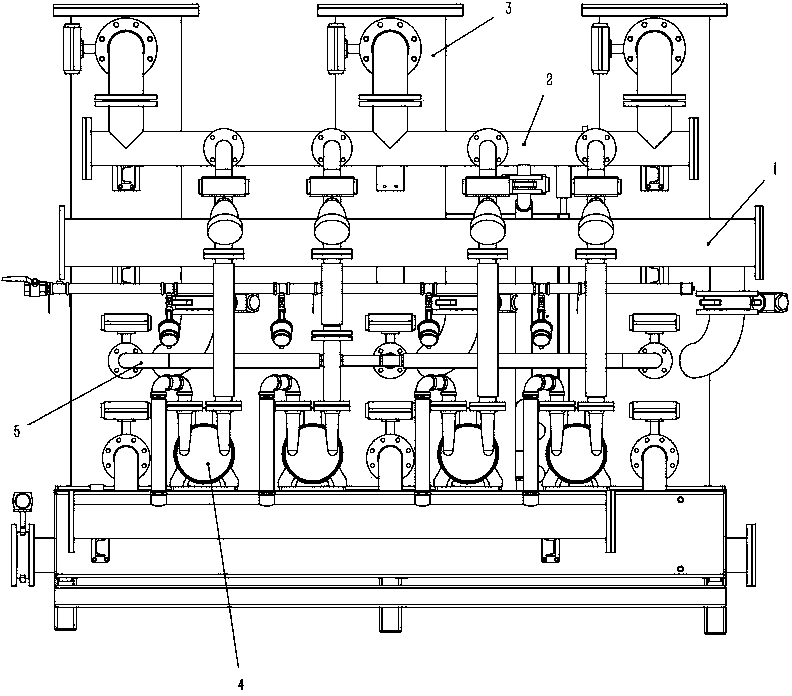

Central vacuum system of foam-plastic forming machine

The invention discloses a central vacuum system of a foam-plastic forming machine. The central vacuum system is characterized in that a rack is provided with three condensing barrels (3), a water discharging box (6) and a plurality of vacuum pumps (4); a gas inlet pipeline (1) is communicated with the condensing barrels (3); the upper parts of the condensing barrels (3) are communicated with a distribution pipeline (2) by upper valves; the lower parts of the condensing barrels (3) are communicated with the water discharging box (6) by lower valves; the middle parts of the condensing barrels (3) are communicated with auxiliary vacuum pipelines (5) by auxiliary vacuum valves; the vacuum pumps (4) are communicated with a distribution pipeline (2) and the water discharging box (6); the condensing barrels (3) are provided with a plurality of sprayers (7); and all the parts form the central vacuum system. The central vacuum system disclosed by the invention has the advantages that the relatively independent condensing barrels are adopted, independent pre-vacuumizing can be adopted for vacuumizing, and no pressure drop of the whole pipeline can be maintained in working, so that the qualification rate of a product is guaranteed.

Owner:郁震宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com