Patents

Literature

47results about How to "Achieve uninterrupted production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

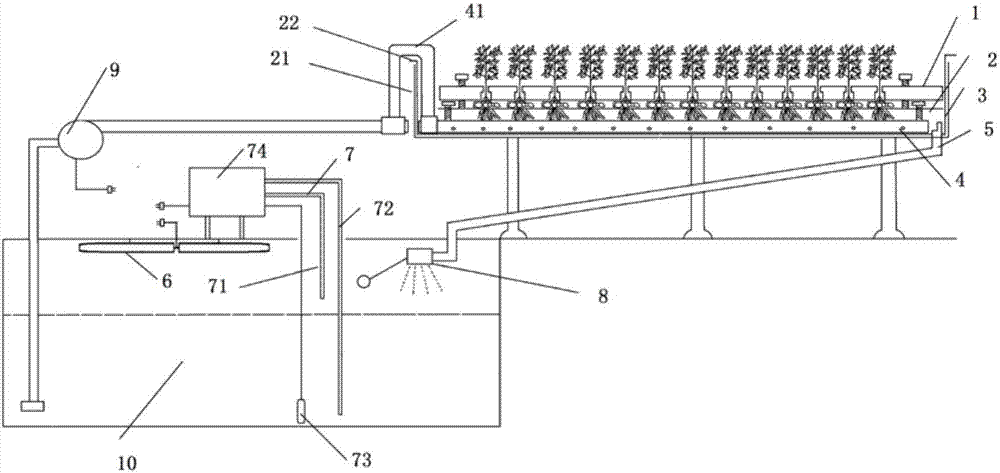

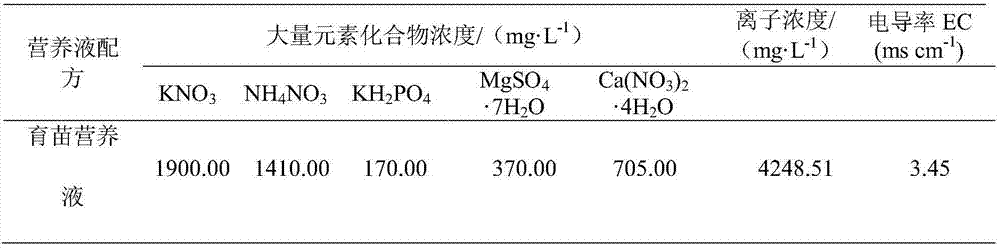

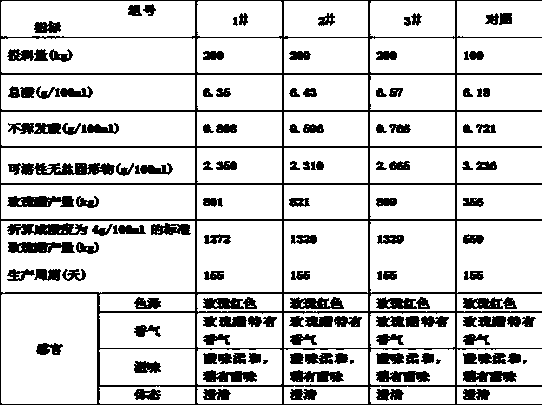

Integrated high propagation method of water planting of virus-free potato seeds and seedlings

InactiveCN107347608APromote circulationReduce holdupAgriculture gas emission reductionCultivating equipmentsNutrient solutionPlant propagation

The invention relates to an integrated high propagation method of water planting of virus-free potato seeds and seedlings. The method comprises the steps that a multiplication technology of the water-planting virus-free seedlings and a water planting production technology of the seedlings and the seeds are integrated, and the concentration of nutrient solution components, the light quality of a supplementary light source, hormone components, seedling cutting times and the like are optimized at the same time. According to the method, the stability and security are high, operation and daily management are simple and convenient, the maintenance and production costs are low, the sound seedling index of water-planting potato plants are significantly improved, the yield and quality of the seedlings and mini-potato are improved, the plant propagation coefficient is enlarged, the production cycle of the mini-potato is shortened, and the method is of great importance in breeding of the potato seeds and seedlings.

Owner:SOUTHWEST UNIVERSITY

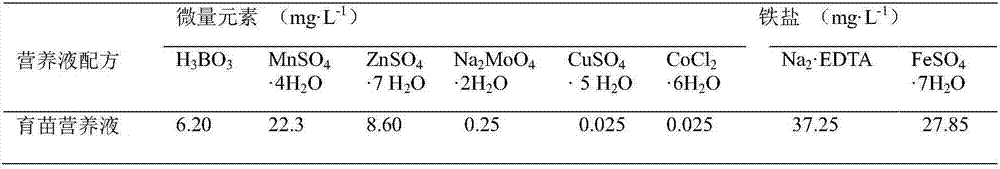

Faceplate assembly line

PendingCN108890291AIncrease productivityGuarantee product qualityAssembly machinesMetal working apparatusGrippersPrinted circuit board

Owner:山东红宝自动化有限公司

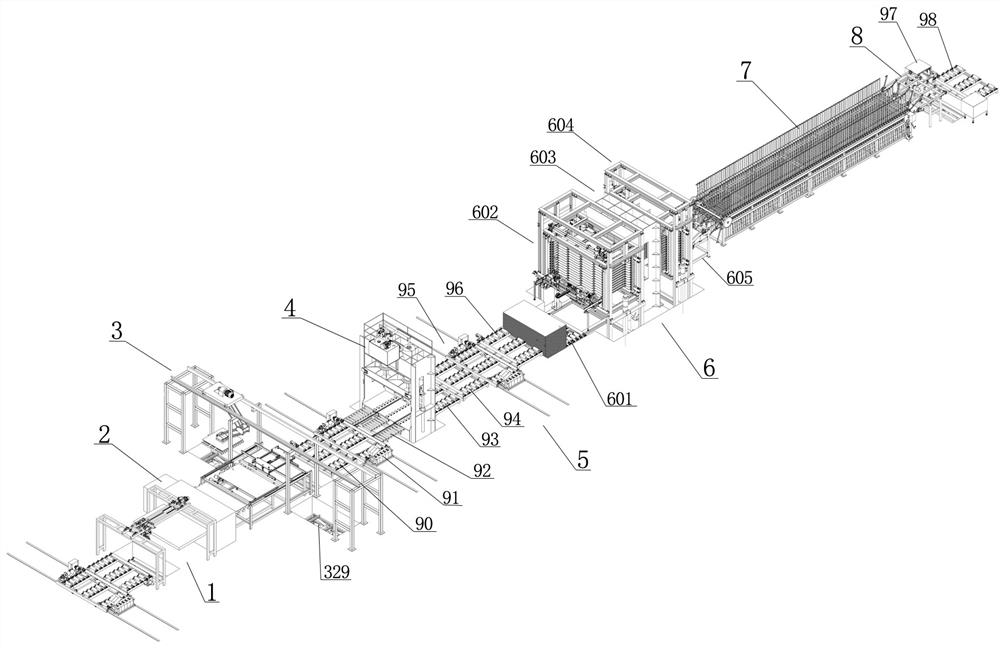

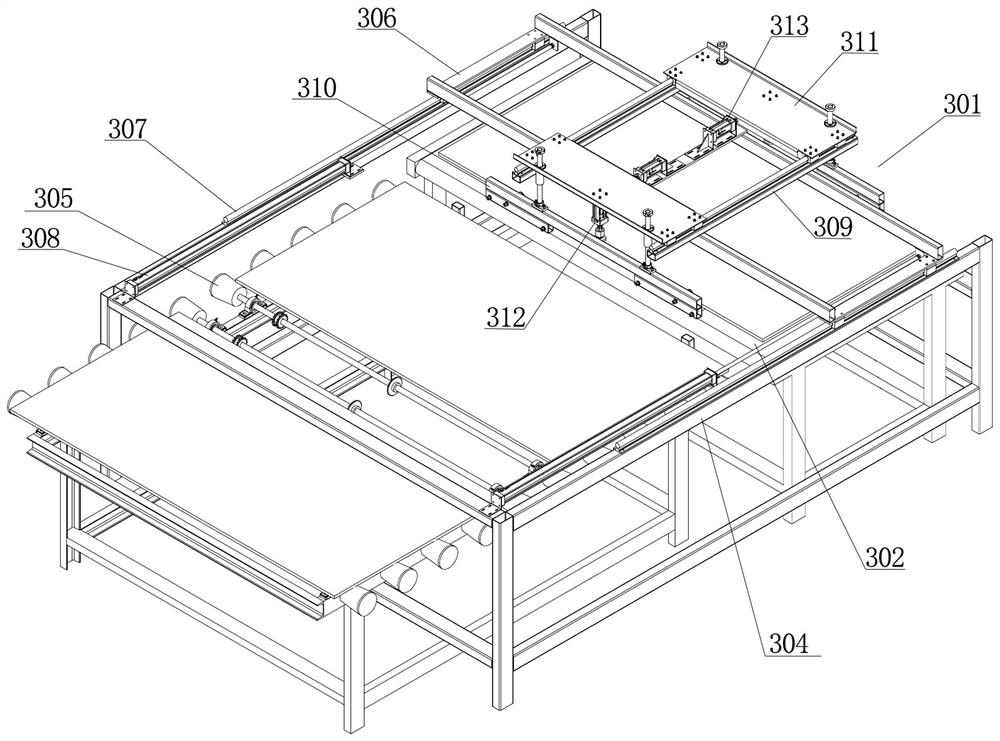

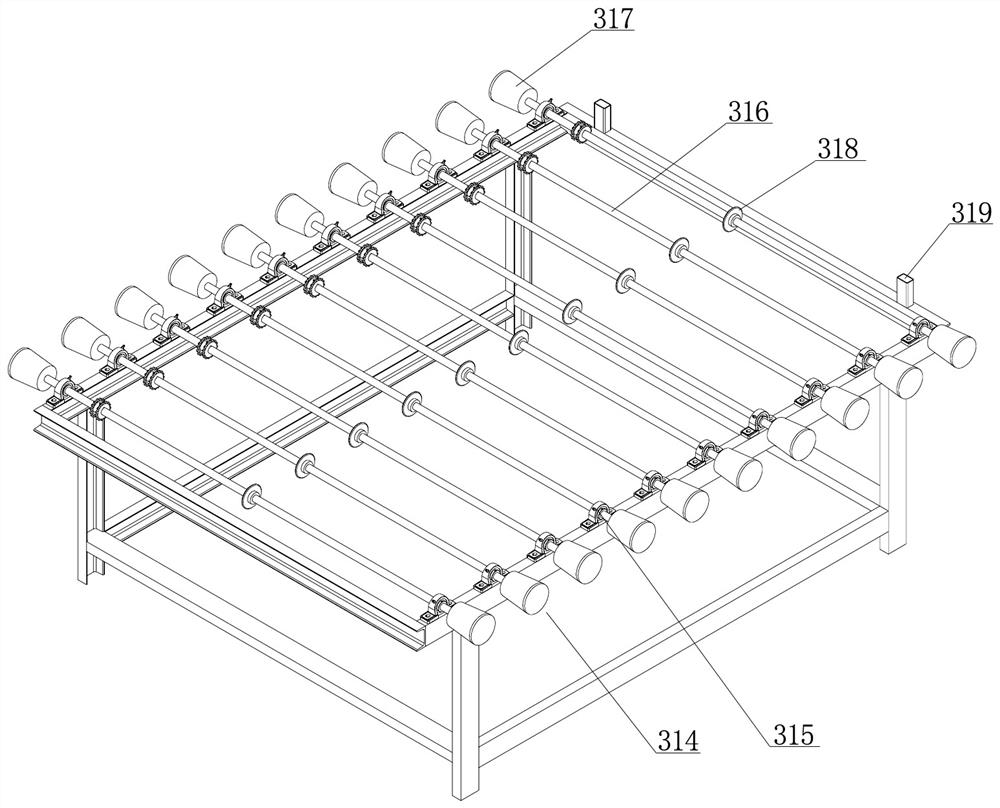

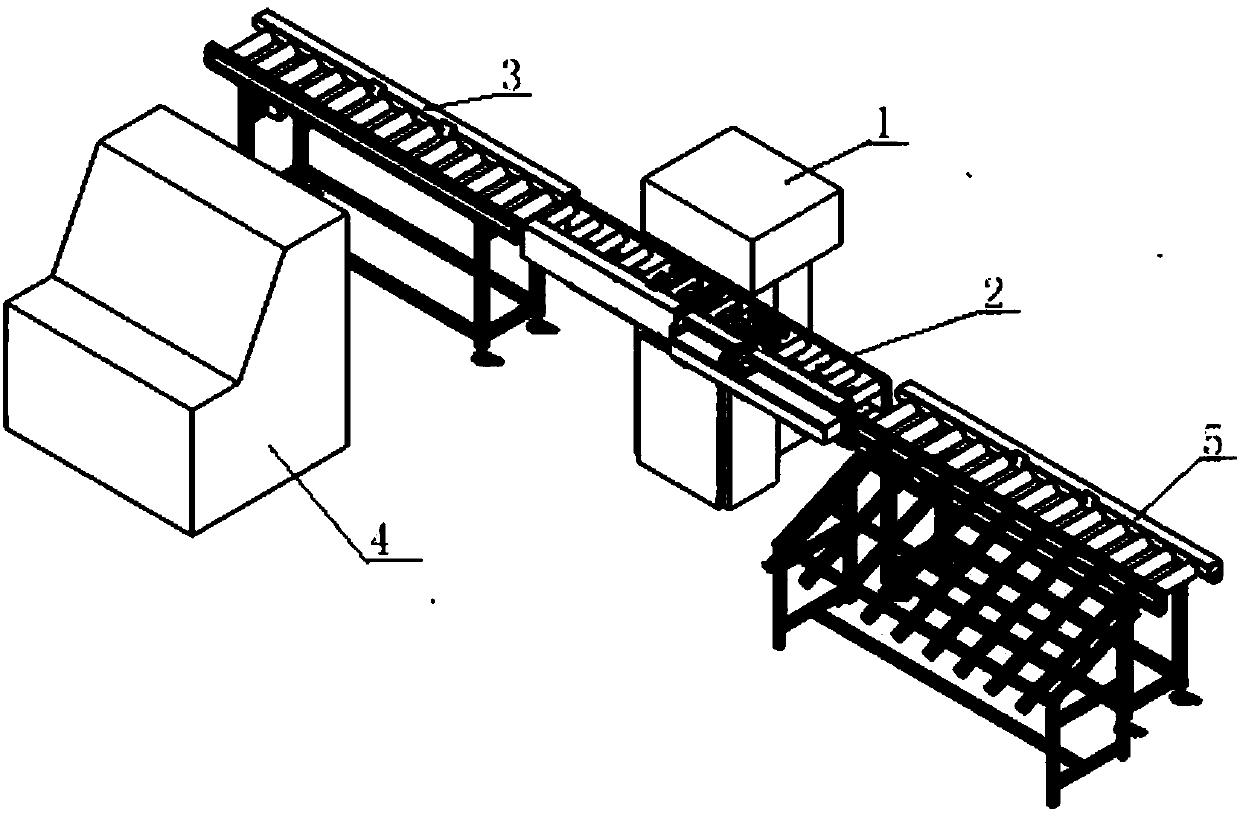

Rapid board veneering production line

PendingCN112776101ASmooth and efficient veneerPrecise veneerOther plywood/veneer working apparatusPlywood pressesProduction lineControl system

The invention discloses a rapid board veneering production line. The rapid board veneering production line comprises a veneering production line body; the veneering production line body mainly comprises a plywood feeding device, a glue coating machine, a veneer material feeding device, a cold pressing main machine, a discharged plate conveying device, a hot pressing device, a cold plate conveyor, a discharging plate conveying machine and a control system which are sequentially arranged, wherein the control system is used for controlling the working states of all the assemblies; the plywood feeding device is used for feeding conveyed and stacked plywood and conveying the plywood to the glue coating machine, the glue coating machine conducts gluing on the plywood, and the veneer material feeding device is used for attaching veneer materials to the upper outer surface and the lower outer surface of the plywood and conveying the plywood subjected to veneering to the cold pressing main machine for cold pressing; and the discharged plate conveying device is used for conveying the plywood subjected to veneering and cold pressing to the hot pressing device, the hot pressing device is used for carrying out hot pressing forming on the plywood subjected to veneering and cold pressing, and the cold plate conveyor is connected with a discharging port of the hot pressing device and cools the plywood subjected to hot pressing forming.

Owner:JIAXING QUNLUN MACHINERY

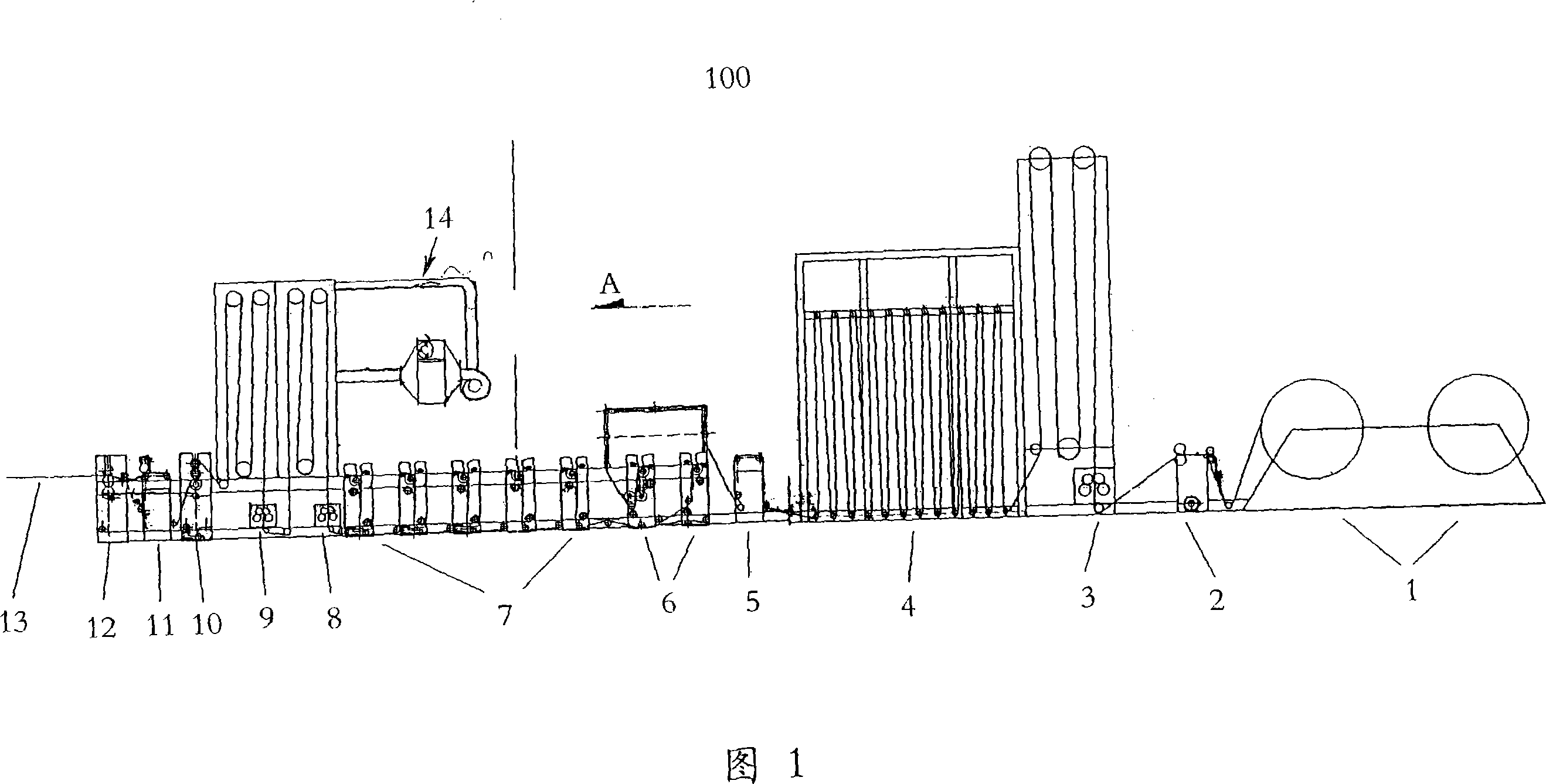

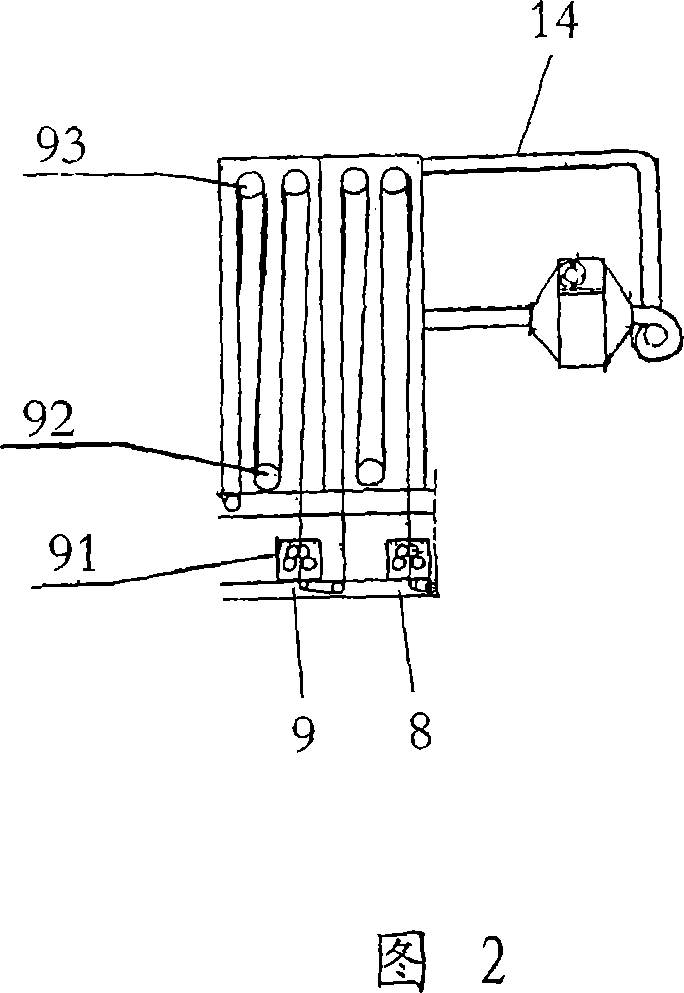

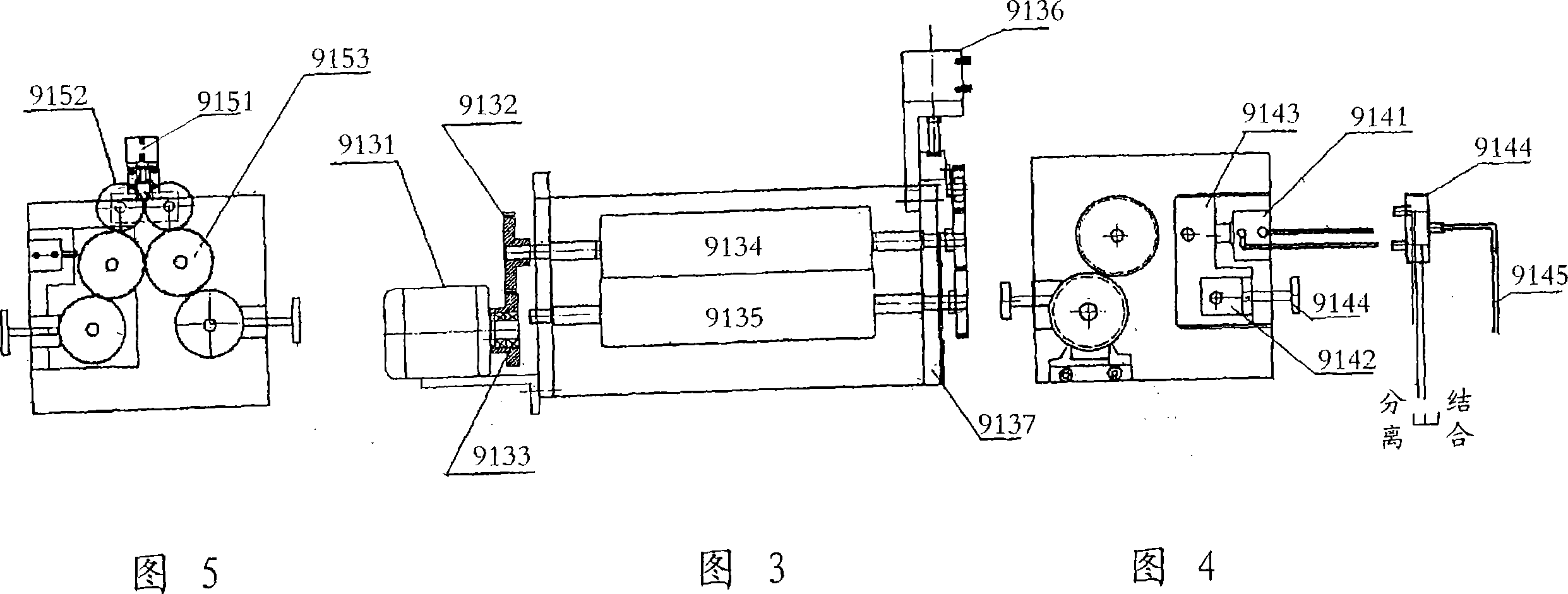

Vertical type reeled paper glazing device and the printing system thereof

ActiveCN101032881AFully automatedImprove printing qualityOffice printingPrinting press partsGear driveRolling paper

The vertical coil paper glazing machine includes one glazing head, a coil paper conveying and supporting roller and a stoving unit. The glazing head includes a frequency variable speed regulating motor with synchronous rotation with the printing unit during glazing operation and slowed rotation in no glazing operation, one driving gear driven with the motor, one glazing roller and one slurry roller driven with the driving gear, and one roller clutch driving unit. The present invention also discloses one kind of printing system with the vertical coil paper glazing machine. The present invention has raised printing quality, lowered production cost and other advantages.

Owner:浙江武义华东实业有限公司

Method for producing vanadium-nitrogen alloy

The invention relates to a production method for vanadium-nitrogen alloy, which comprises following steps: evenly mixing oxide of powder vanadium or ammonium metavanadate, carbon powder and binder, continuously adding into an external-heating rotary kiln in nitrogen atmosphere after briquetting and forming, and presintering to below 1000 DEG C under the protection of nitrogen; collecting the presintered block product which is cooled to ambient temperature under the protection of nitrogen at a discharge opening, pushing into an improved soft magnetic nitrogen atmosphere furnace kiln, heating to 1000 to 1500 DEG C for carbonization and nitridation reaction, and vanadium-nitrogen alloy product is obtained after discharge. The composition of the vanadium-nitrogen alloy: V is 78 to 83%, N is 16 to 21%, C is 6% max, and silicon, phosphorus and aluminum are less than 0.10%; the apparent density is greater than 3.5g / cm<3>. The production method for vanadium-nitrogen alloy has the advantages of adopting rotary kiln for precalcination, removing harmful impurities and corrosive elements, reducing stacking volume, greatly improving productivity of carbonization and nitridation working procedures, and greatly prolonging service life of nitriding furnace kiln.

Owner:刘先松 +1

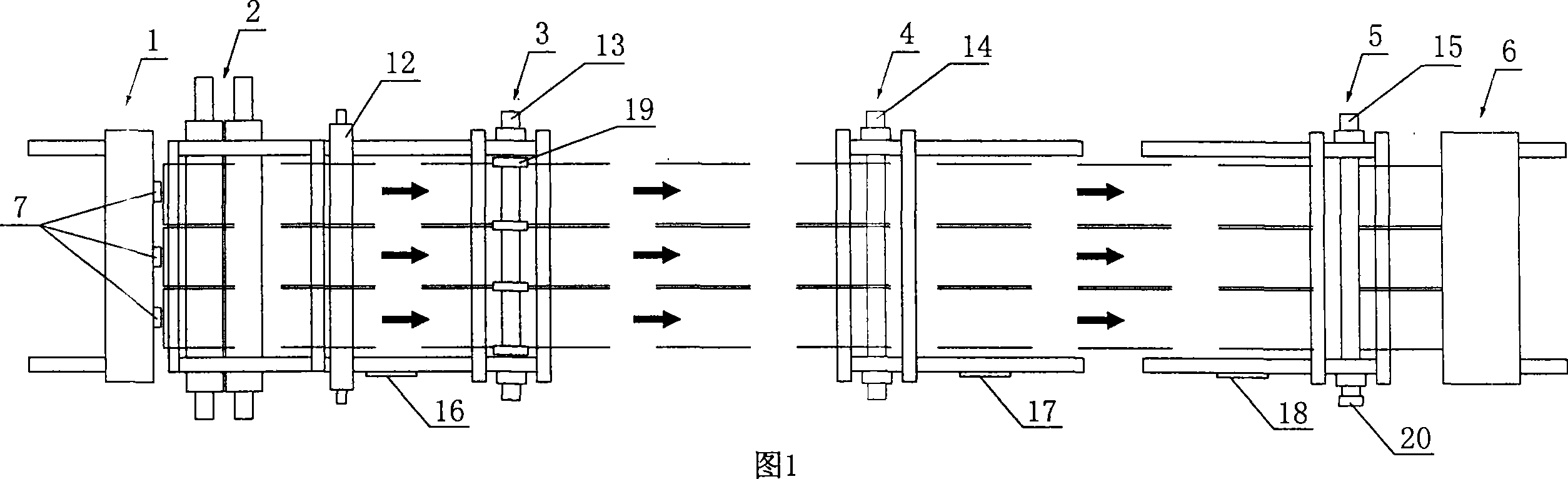

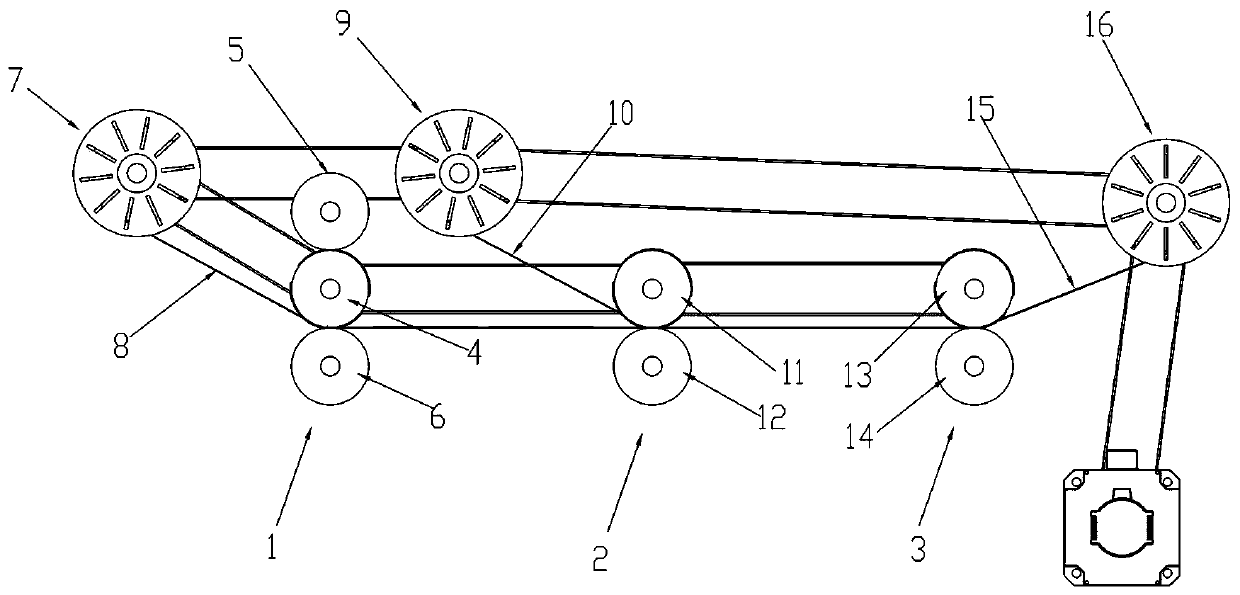

Rolling plastic forming machine

InactiveCN101058222AAchieve uninterrupted productionIncrease productivityPlastic forming machineMolding machine

The invention relates to a rolling style plastic molding machine. It has plastic distributor, mold forming set, several assistant delivery sets and cut off sets from left to the right. There are mold forming roller set installed on the mold molding set that is set at the plastic distributor's outlet, assist delivery set installed at the rear of the mold forming machine, each assistant delivery set installed with assistant drive rolling set, each assistant delivery set having corresponding speed tuning machine, knife frame installed on the first assistant delivery set, edge cutting knife on the knife frame, time sensor on the last assistant delivery machine set, cutting off machine set at the rear of the last assistant delivery machine. It can extend the length of the plastic forming limitlessly, without restraint for the plastic material and its flow feature, realizing continuous production, being able to roll several plastic parts with high production efficiency and fine quality.

Owner:何志炜

Single-bucket serial-bucket charging method applied to bell-free blast furnaces

InactiveCN101709340AReduce the shutdown rateGuarantee normal production and operationBlast furnace detailsEngineeringBlast furnace

The invention discloses a single-bucket serial-bucket charging method applied to bell-free blast furnaces. The method comprises: taking a material-receiving hopper and one failure-free charging bucket as an upper charging bucket and a lower charging bucket connected in series; adding a car of material to the upper charging bucket first in a charging process and discharging the material through the lower charging bucket; putting the material in the upper charging bucket into the lower charging bucket and putting a car of material into the lower charging bucket at a normal charging speed through a hoist skip car at the same time; putting two cars of material in the lower charging bucket into a blast furnace under the control of a blast furnace control computer so as to finish the process of charging the blast furnace; and repeating the steps. Therefore, when a certain charging-bucket equipment system breaks down, a single normal charging bucket can still be utilized to continue production so as to prevent the blast furnace from damping down, ensure that the blast furnace can continue to produce and meet requirements for charging capacity and charging speed.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

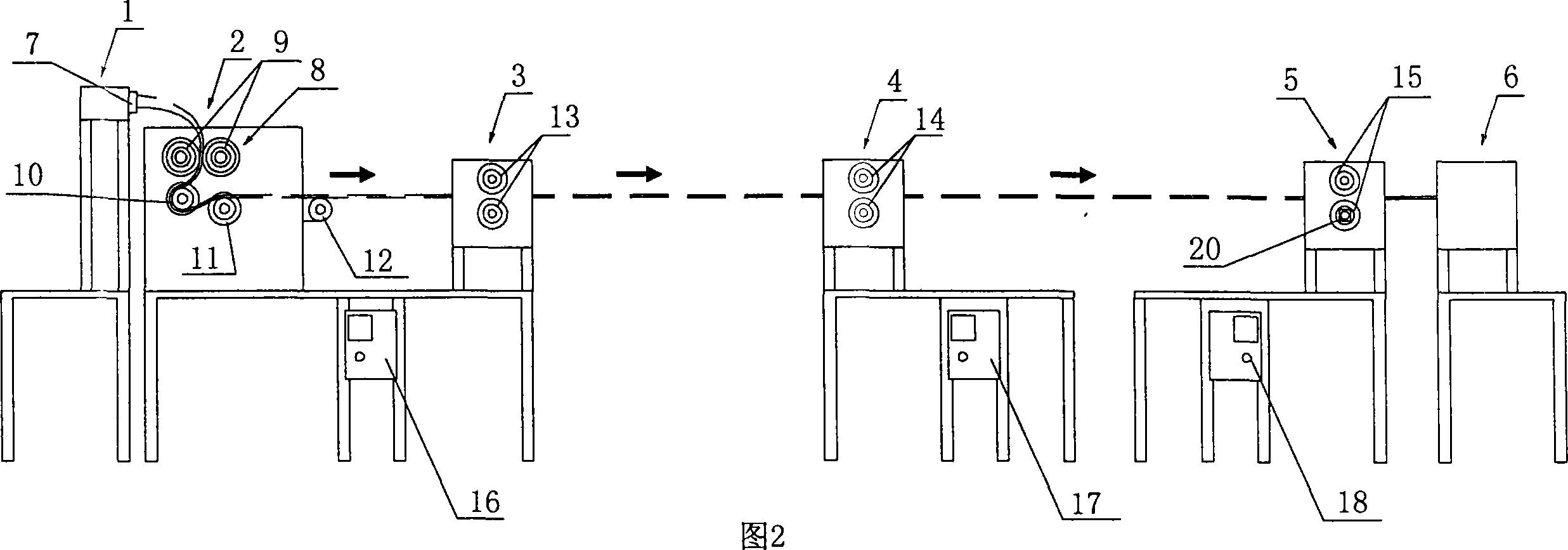

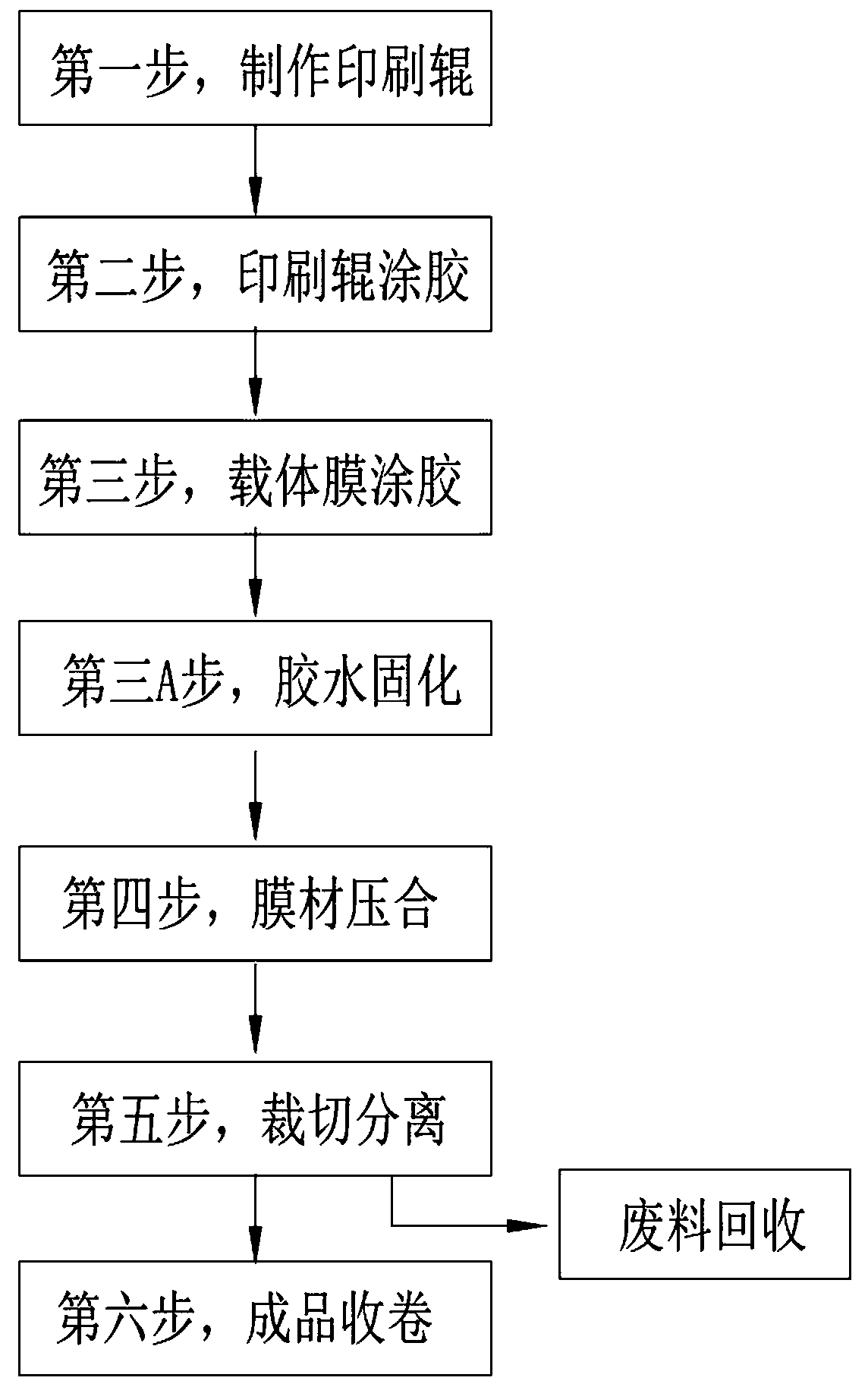

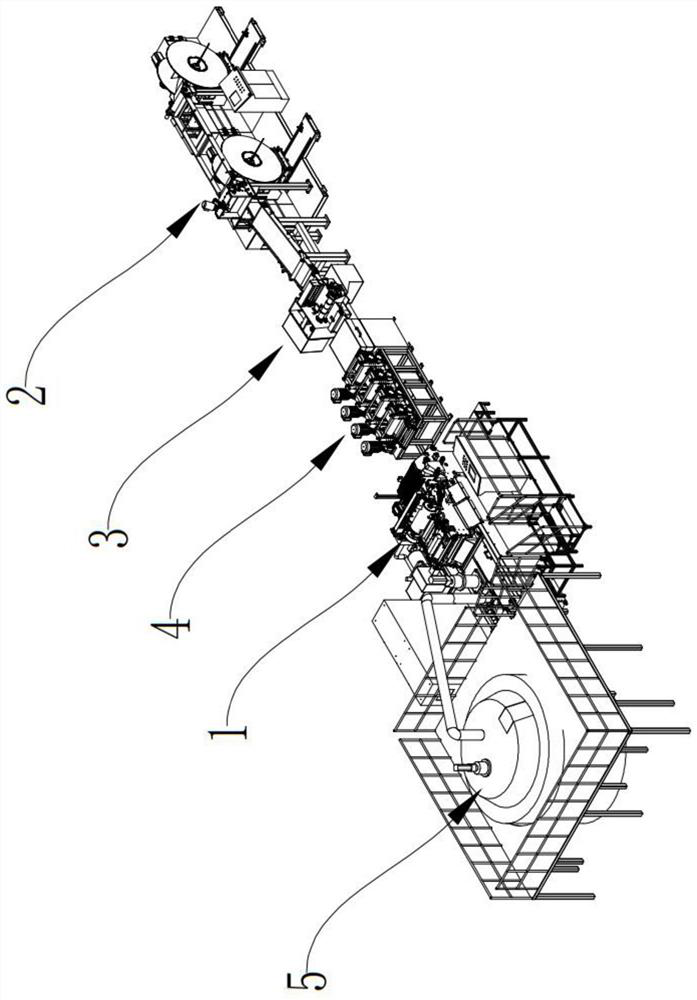

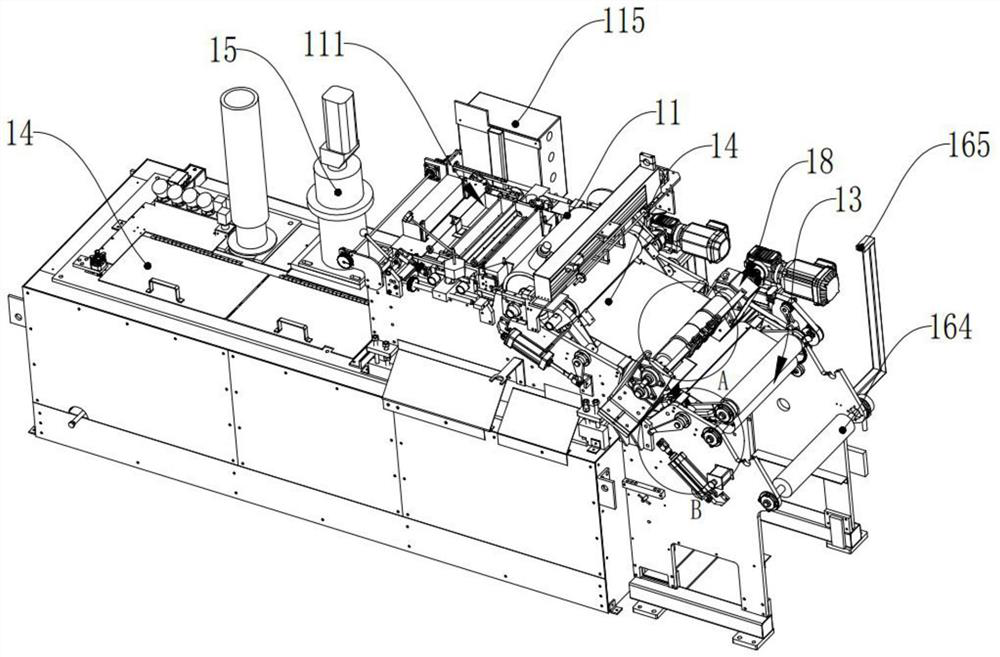

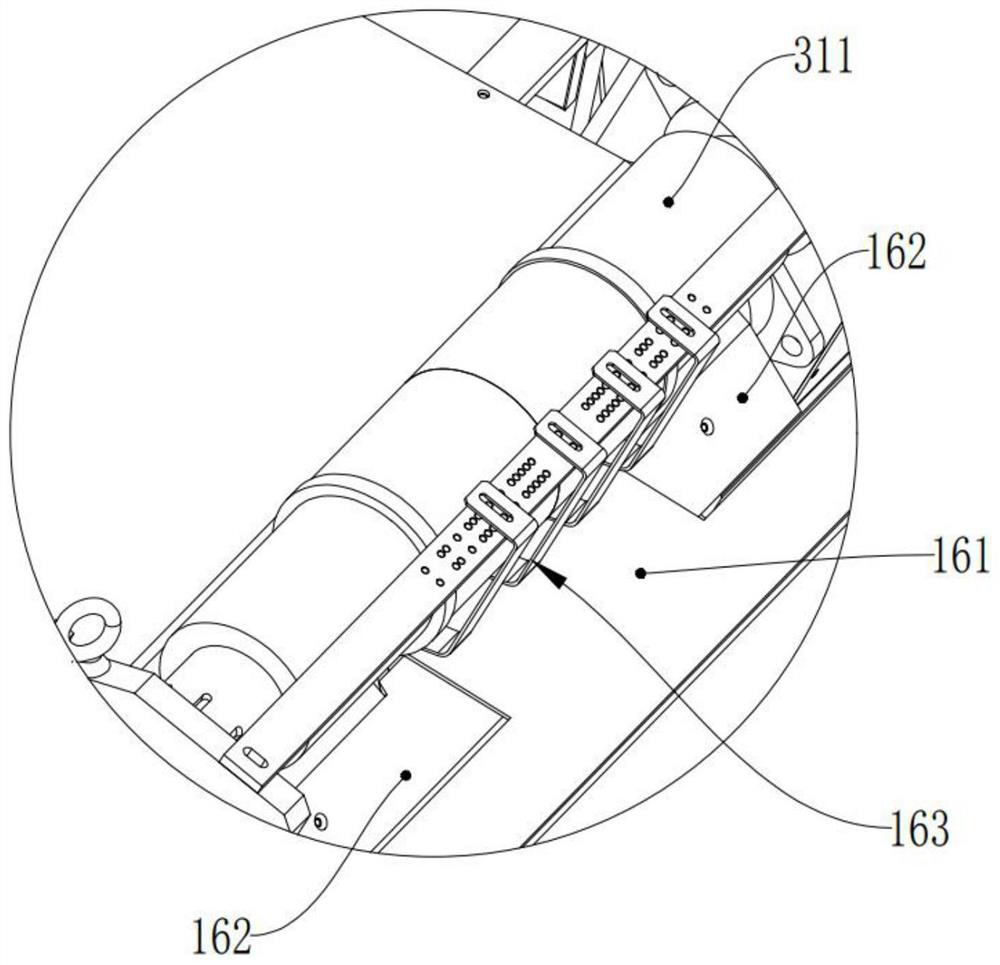

Technology for continuously producing RFID tag antenna in rolling manner

PendingCN110288073AAchieve uninterrupted productionReduce production processLamination ancillary operationsLaminationTag antennaEtching

The invention relates to technology for continuously producing an RFID tag antenna in a rolling mode, and belongs to the technical field of non-contact automatic identification. The process comprises the following steps of: step 1, manufacturing a printing roller, step 2, gluing by a printing roller; step 3, gluing a carrier film; step 4, laminating the membrane material; step 5, die cutting separation; and step 6, performing finished product rolling. The whole body is produced in a continuous rolling manner; uninterrupted production can be realized. In the production process, a gluing station, a pressing station and a die cutting station are sequentially arranged. Automatic roll feeding and automatic rolling are matched.T he gluing station, the pressing station and the die cutting station are all directly produced in a rolling mode. After the RFID tag antenna is subjected to rolling cutting by the die-cutting roller, the antenna material tightly attached to the carrier film is the produced RFID tag antenna, uninterrupted production can be integrally achieved, the production efficiency is high, the width of each station can be adjusted according to the production scale, and compared with a production mode of a traditional etching method, automatic mechanical production does not generate any pollution.

Owner:郑致远 +1

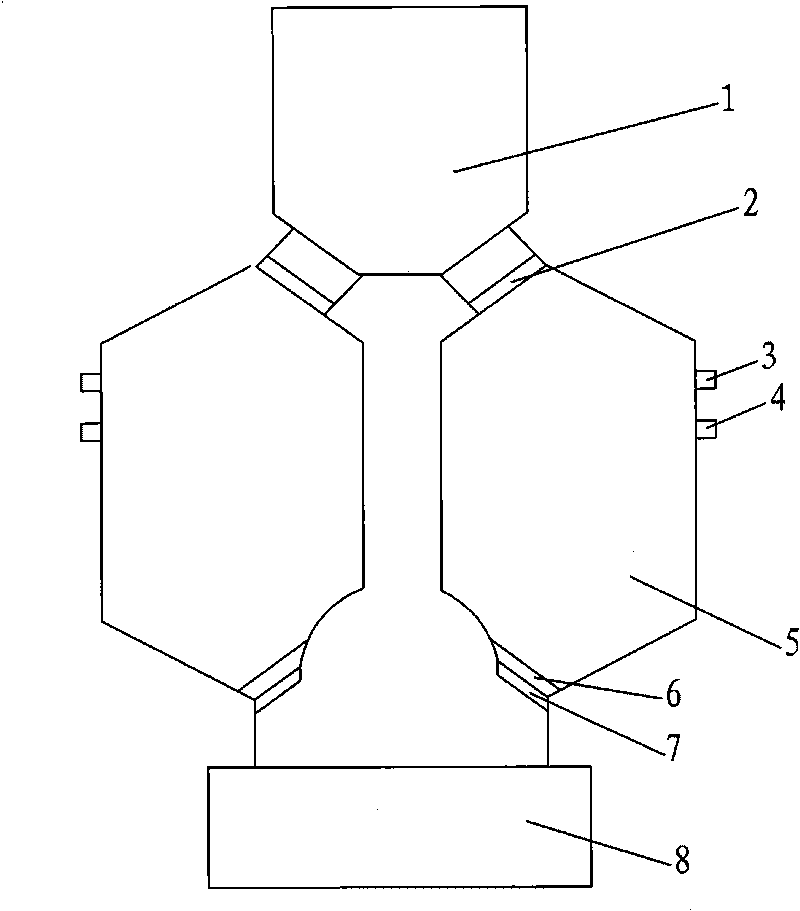

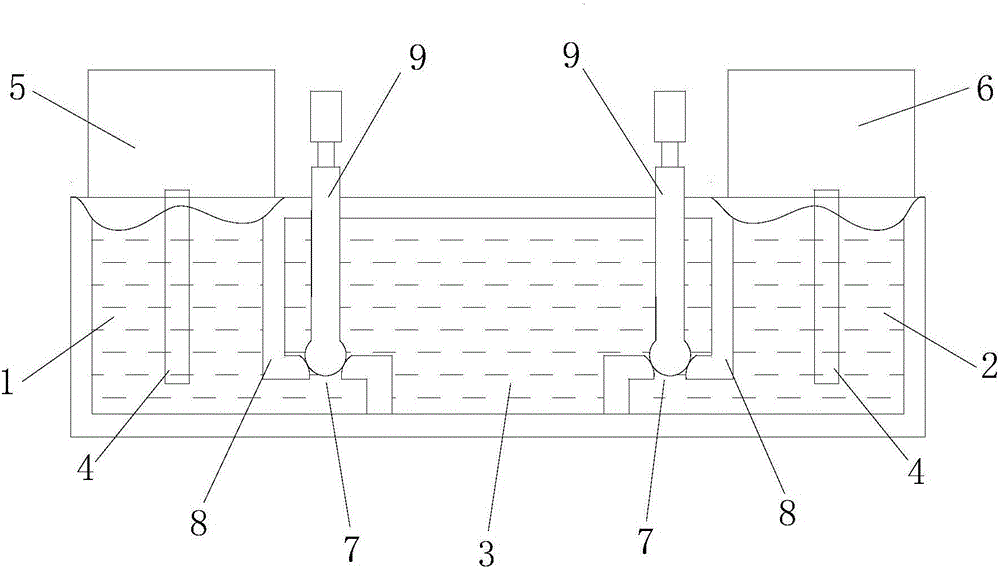

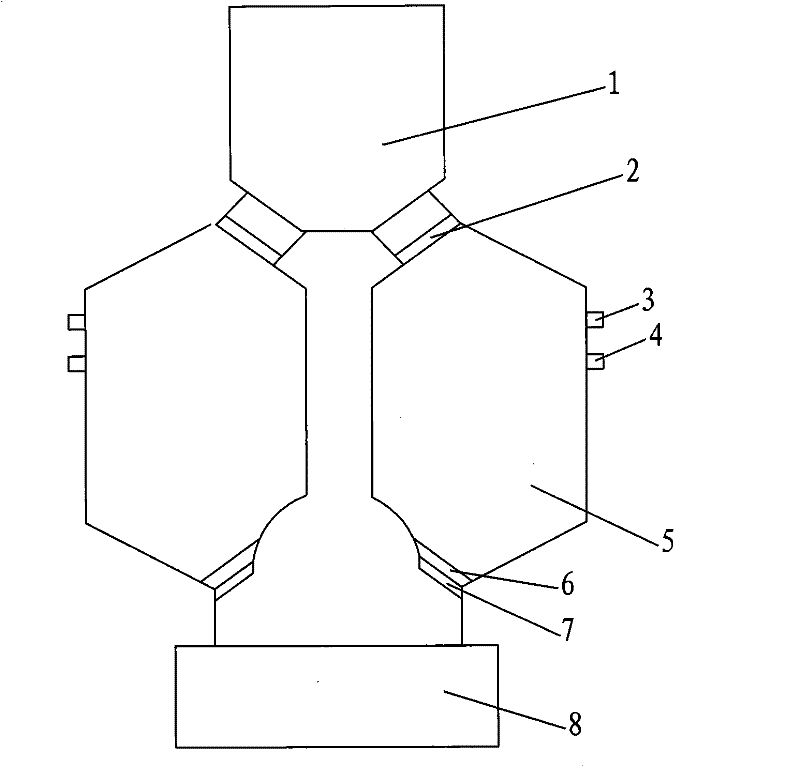

Automobile hub pouring system and pouring method

The invention discloses an automobile hub pouring system and a pouring method and relates to the technical field of hub casting. The automobile hub pouring system comprises a first mold cavity, a second mold cavity and a public mold cavity located between the first mold cavity and the second mold cavity. The first mold cavity communicates with a first mold above the first mold cavity through a liquid lifting pipe. The second mold cavity communicates with a second mold above the second mold cavity through a liquid lifting pipe. The public mold cavity communicates with the first mold cavity and the second mold cavity through liquid supplementing ports. The upper portion of the public mold cavity is provided with a feeding inlet, and a heater and a temperature detector are arranged in the public mold cavity. The invention further discloses the pouring method for the automobile hub pouring system. The pouring method comprises the steps of feeding, liquid supplementing, liquid lifting, molding filling pressurizing, pressure maintaining and pressure relief demolding. According to the automobile hub pouring system and the pouring method, melting liquid is supplemented into the first mold cavity and the second mold cavity by arranging the public mold cavity, the generating probability of oxide is greatly reduced, the influence of the liquid supplementation process on a hub is eliminated, uninterrupted production of hub casting is effectively achieved, and the production efficiency is improved.

Owner:昆山六丰机械工业有限公司

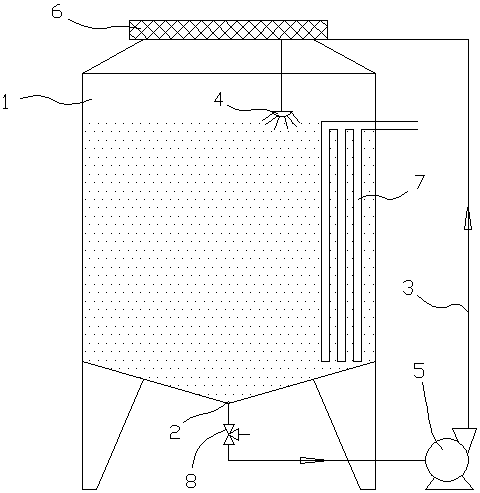

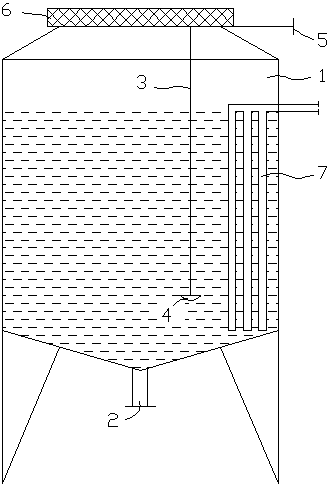

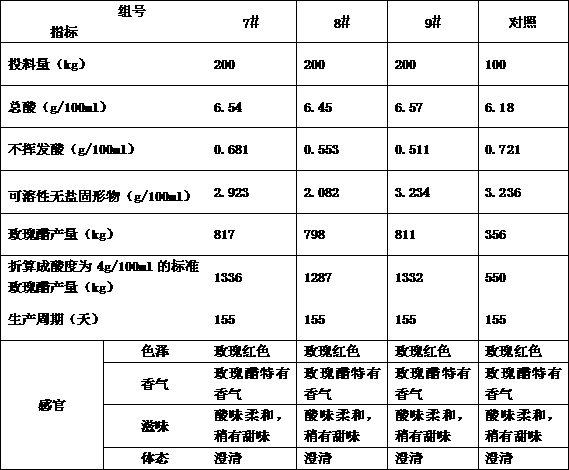

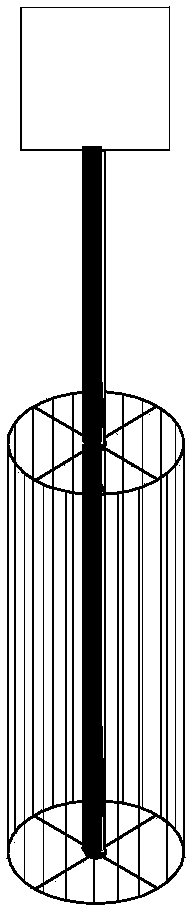

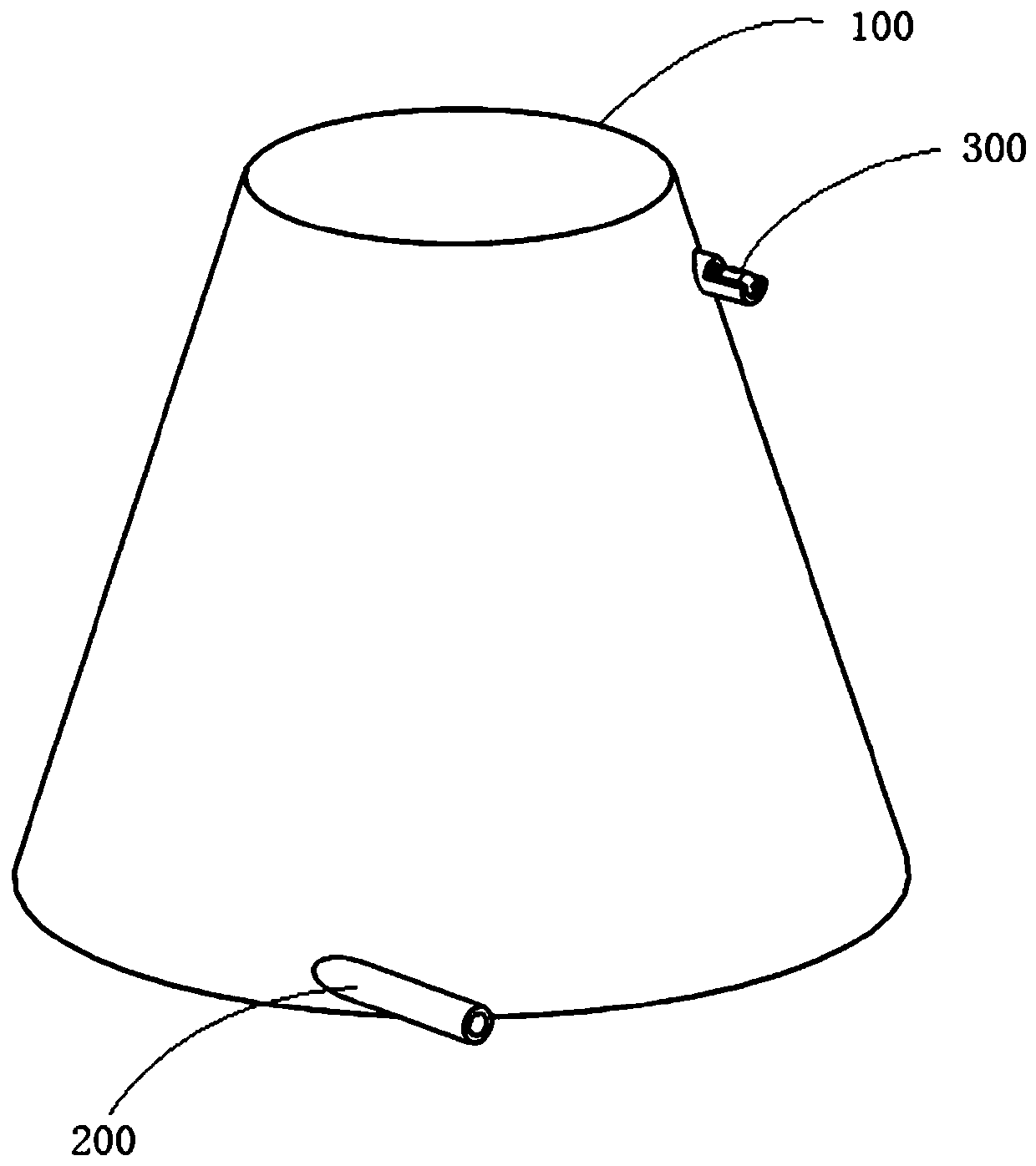

Method for producing rose vinegar by pump reflux method

ActiveCN107904133AReduce labor intensityHigh degree of mechanizationVinegar preparationRefluxBiochemical engineering

The invention discloses a method for producing rose vinegar by a pump reflux method. The method comprises the following steps: rinsing rice; steaming rice; cooling cooked rice; putting the cooked ricein a tank and erecting a nest; floating; adding water; fermenting; aging; squeezing; and sterilizing. The tank is cylindrical, the upper end of the tank is open while the lower end of the tank is provided with a cone-shaped or arc-shaped bottom; a mash discharge hole is formed in the lowest part of the cone-shaped or arc-shaped bottom of the tank; the mash discharge hole is connected to a refluxspray hole in the upper end hole of the tank through a pipeline; a liquid pump is arranged on the pipeline; and a grass cover is arranged on the upper end hole. The fermenting step comprises the following steps: (1) medium frequency large reflux fermentation control in early stage; (2) high frequency medium reflux fermentation control in middle stage; and (3) low frequency small reflux fermentation control in later stage. According to the method for producing rose vinegar by the pump reflux method disclosed by the invention, the production scale of the rose vinegar can be expanded, the yield of the rose vinegar is increased, the quality of the rose vinegar is stabilized and improved, and the labor intensity is alleviated.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

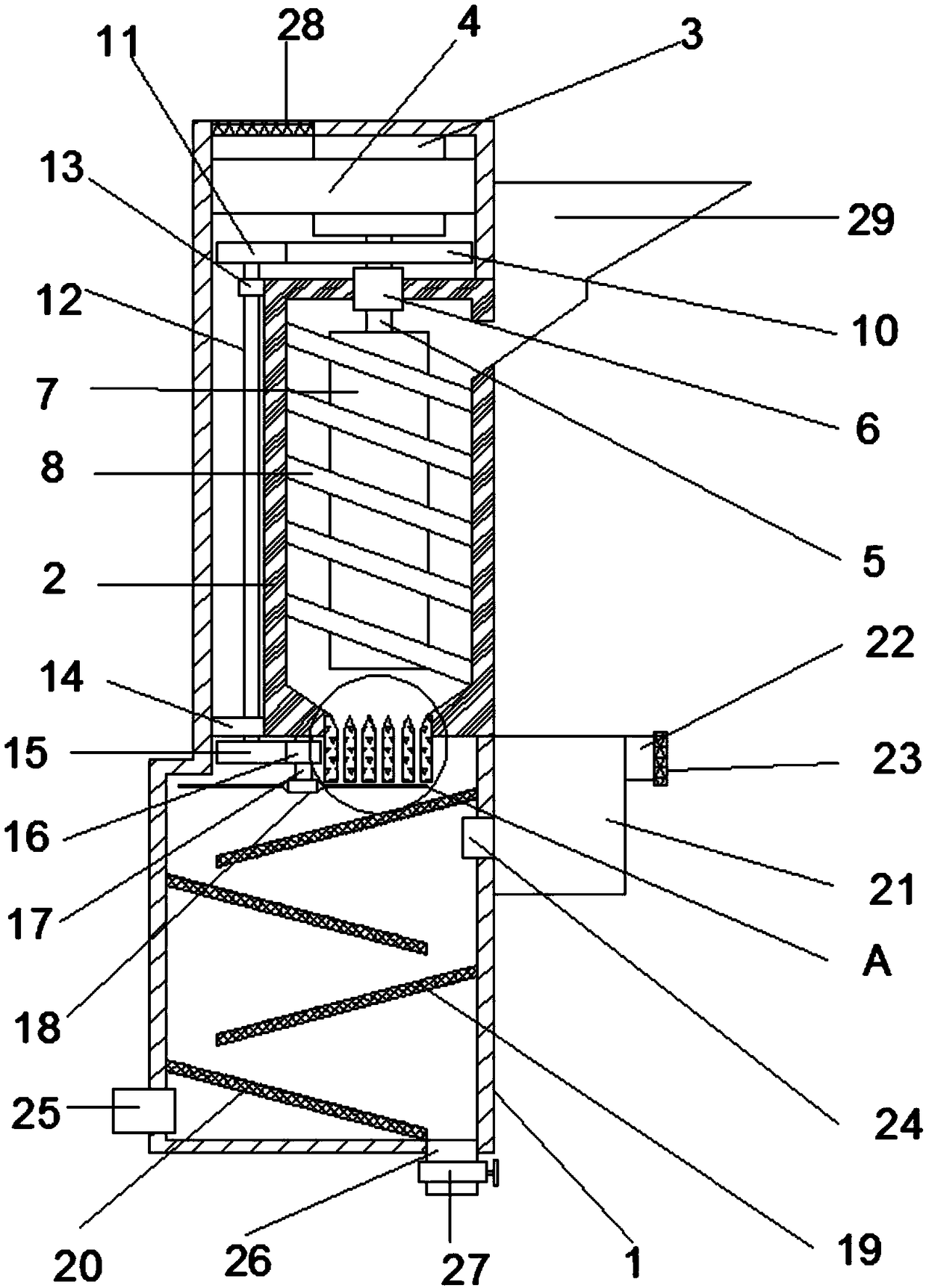

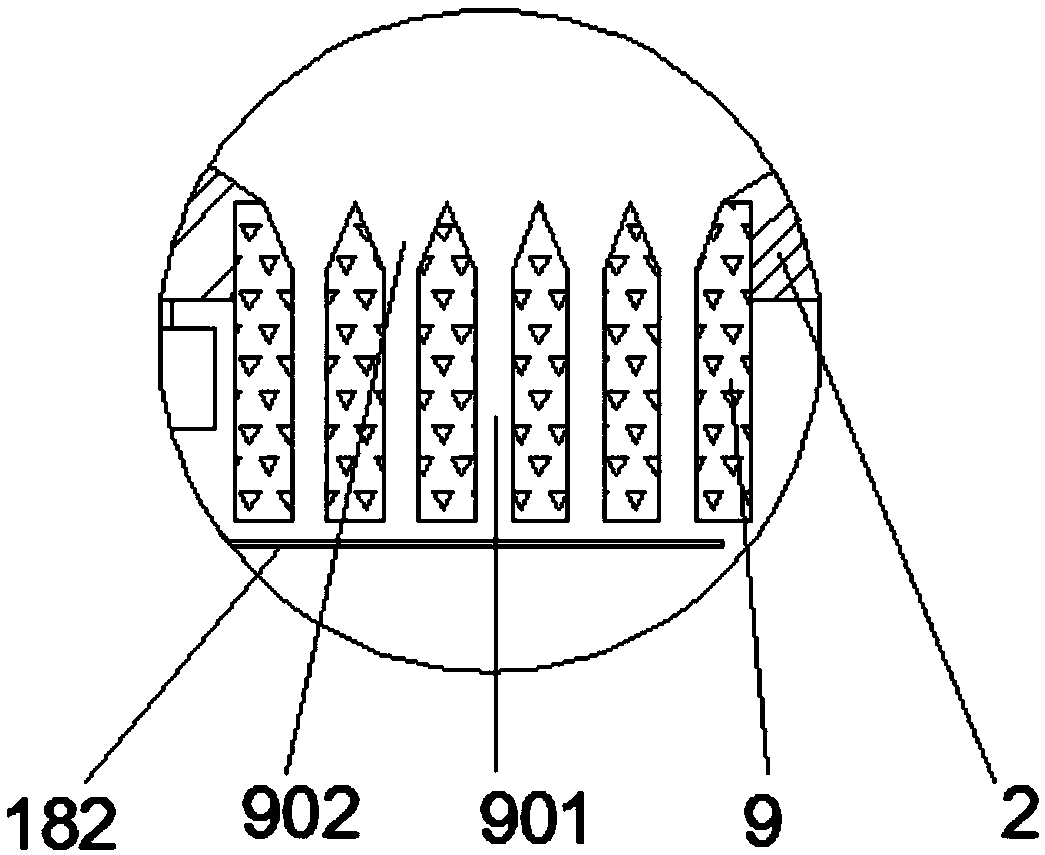

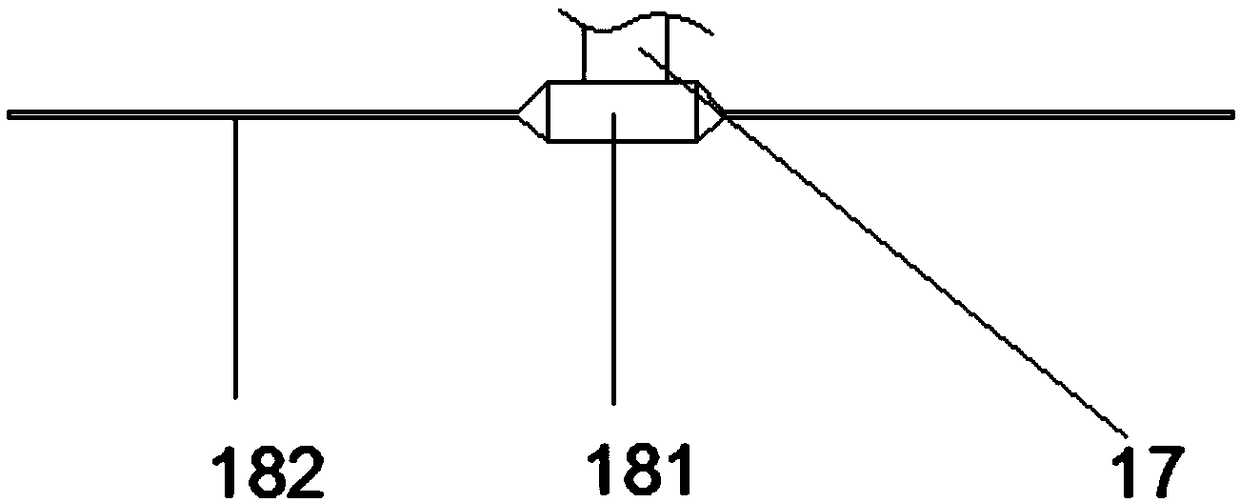

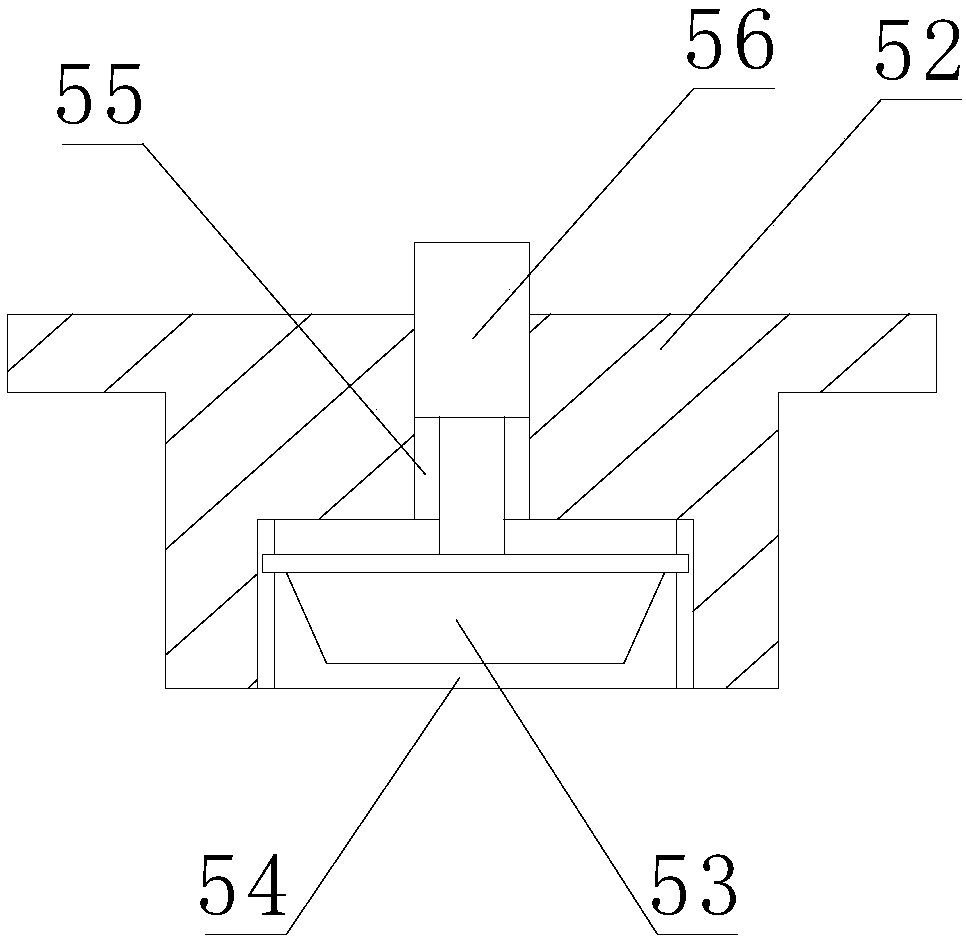

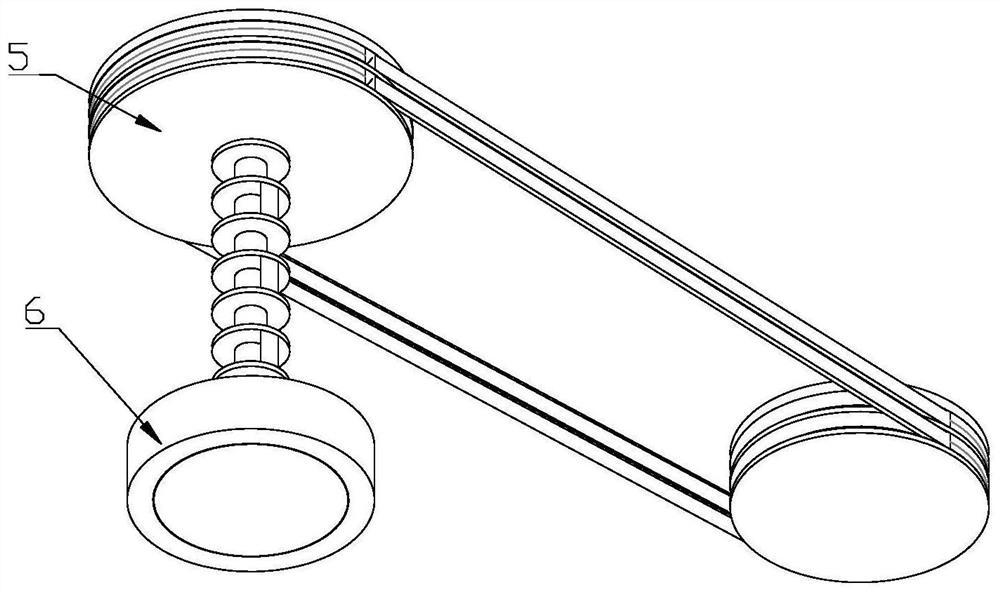

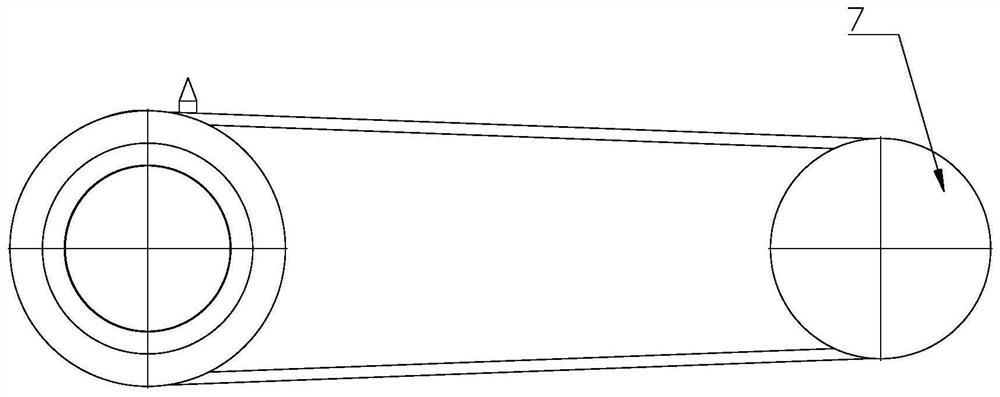

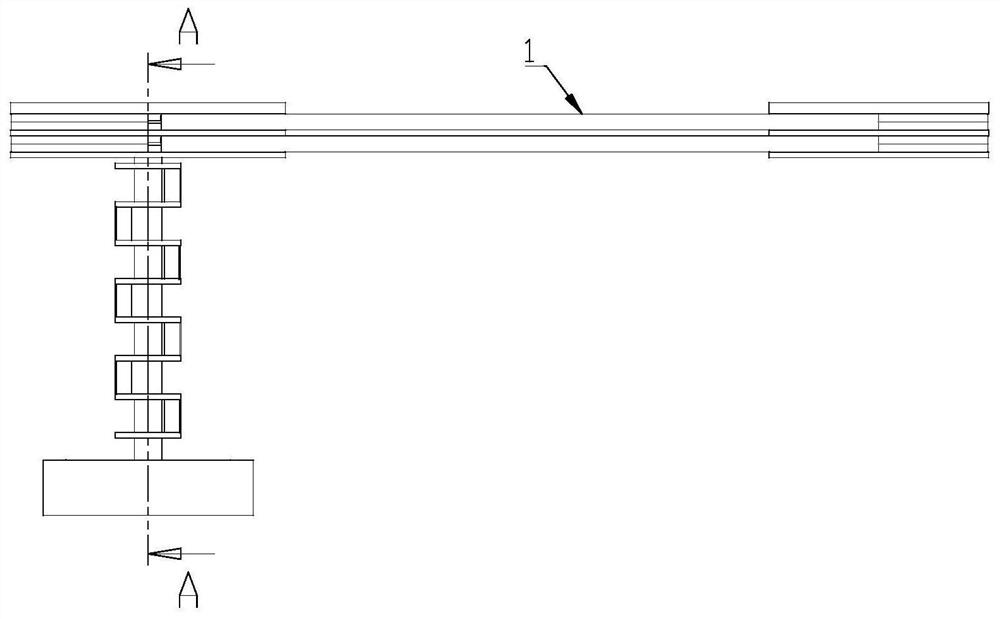

Feed granulation device

InactiveCN109007926AAchieve uninterrupted productionIncrease productivityFeeding-stuffEngineeringMechanical engineering

The present invention discloses a feed granulation device. The feed granulation device comprises an outer shell, a pressurized box, a motor, molding parts and a hot air fan; the upper part inside theouter shell is provided with the pressurized box; the right side of the top end inside the outer shell is provided with the motor; besides, the motor is fixedly connected with the inner side wall of the outer shell via a first fixing frame; a first rotating shaft is arranged at the lower end of the motor; the lower end of the motor passes through the top end of the pressurized box and is connectedwith a rotating wheel column; and the outside of the rotating wheel column is provided with a compression spiral disk. The motor is started to drive the first rotating shaft to rotate; the first rotating shaft drives the rotating wheel column to rotate; the rotating wheel column is then drives the compression spiral disk to rotate, thereby pressing a feed mixture downward, generating high-strength pressure and thereby realizing the extruding of the feed into tight strips; and the first rotating shaft then drives a rotating blade assembly to rotate at a high speed through various gears, thereby cutting the strips into the granular feed, realizing the uninterrupted production of the granular feed and improving the production efficiency of the feed granulation device.

Owner:WANGJIANG YUANYUAN AGRI CO LTD

Honey impurity removing device and method

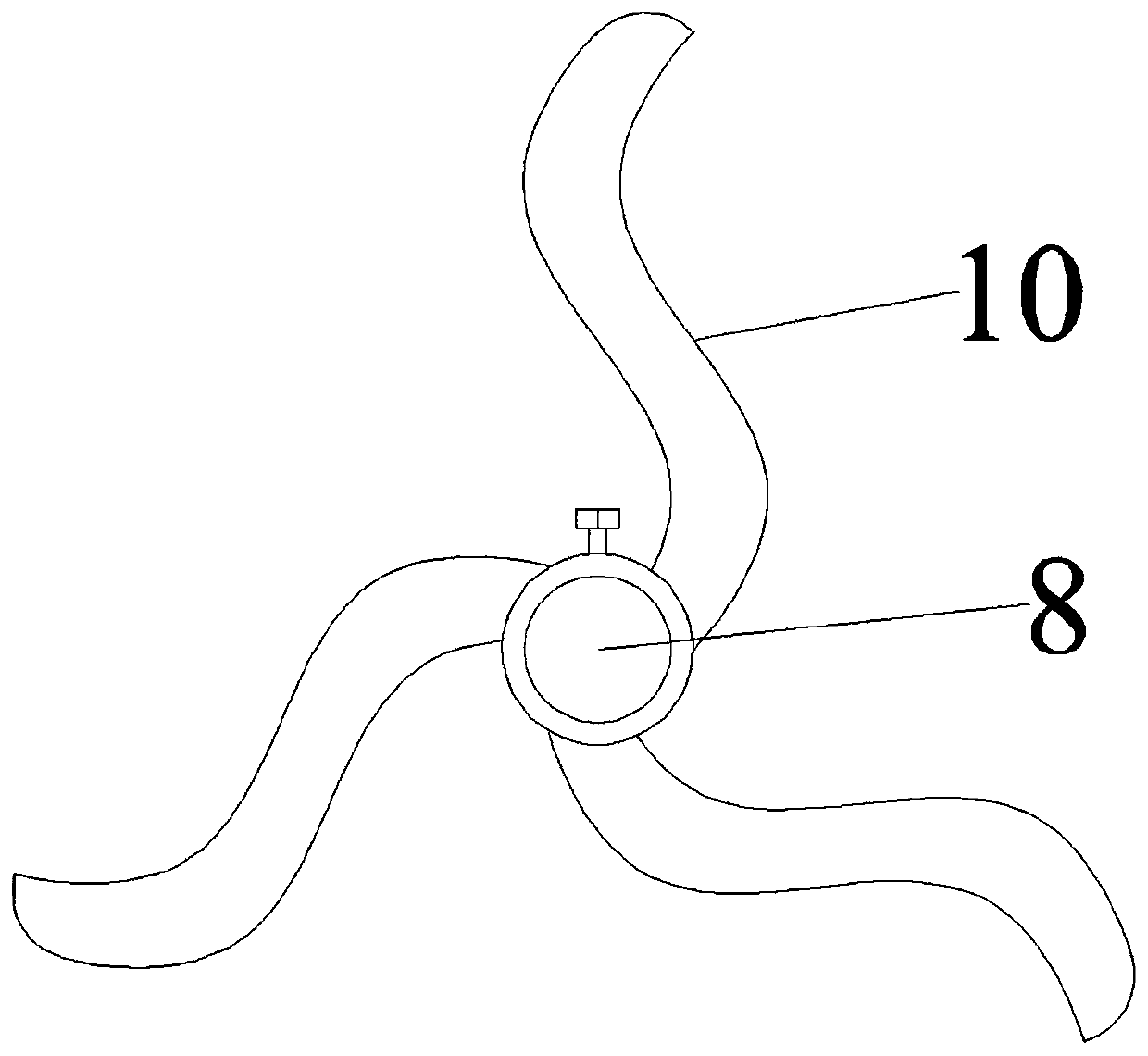

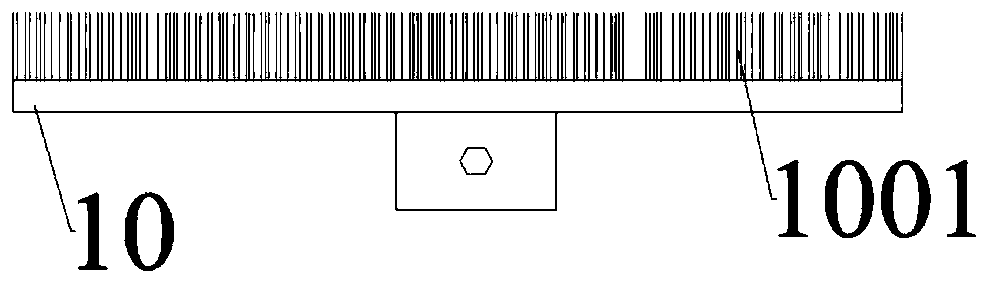

ActiveCN109701307AImprove the efficiency of impurity removalImprove stabilityClimate change adaptationStationary filtering element filtersBiochemical engineeringPropeller

The invention discloses a honey impurity removing device, comprising: a honey impurity removing device, which is characterized in that: a box body is provided with a feeding port at the top, a filtering port is arranged on the side wall of the box body, and a filter screen is arranged at the filtering port; a main shaft is arranged inside that box body, one end of the main shaft is provided with aimpurity scraping plate, the impurity scraping plate is in contact with the surface of the filter screen, and a propeller is arranged on the main shaft, and the acting force generated by the rotationof the propeller faces the filter screen. The invention also discloses a honey impurity removing method. The invention can automatically remove and convey the impurities on the filter screen, save time and labor, realize the continuous impurity removal operation, and improve the efficiency, stability and product quality of the impurity removal of honey.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

Method for producing rose vinegar by adopting pneumatic stirring way

ActiveCN107937236AStable qualityHigh product yieldVinegar preparationIntermediate stageMedium frequency

The invention discloses a method for producing rose vinegar by adopting a pneumatic stirring way. The method comprises the steps of carrying out immersion cleaning on rice, steaming the cleaned rice,cooling the cooked rice, building a nest, flooding, adding water, fermenting, aging, squeezing and sterilizing; a tank is in a cylinder shape, an opening is formed in the upper end of the tank, and the diameter-height ratio D / H of the cylinder part of the tank is equal to 1 to (0.8-1); one end of a compressed air pipeline is connected with an air inlet, and the other end of the compressed air pipeline is connected with an air nozzle arranged at the lower part of mash in the tank; a grass cover is arranged at the opening formed in the upper end of the tank; step of fermenting comprises the following process: (1) medium-frequency and large-pneumatic stirring intensity fermentation control in the early stage; (2) high-frequency and medium-pneumatic stirring intensity fermentation control in the middle stage; (3) low-frequency and small-pneumatic stirring intensity fermentation control in the late stage. The method for producing the rose vinegar by adopting the pneumatic stirring way can enlarge the production scale, increase the yield, improve and stabilize the quality of the rose vinegar and lighten the labor intensity.

Owner:绍兴至味食品有限公司

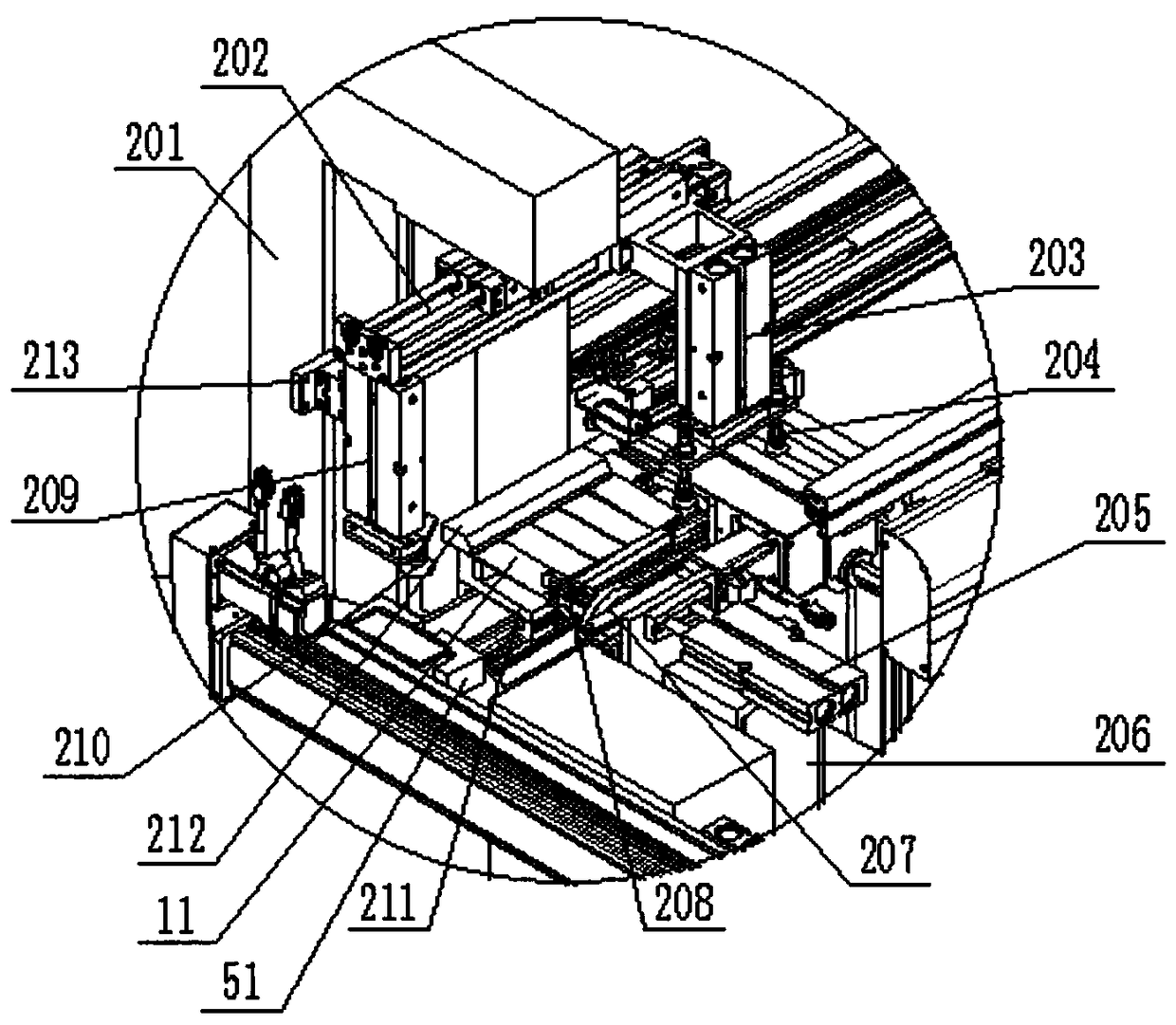

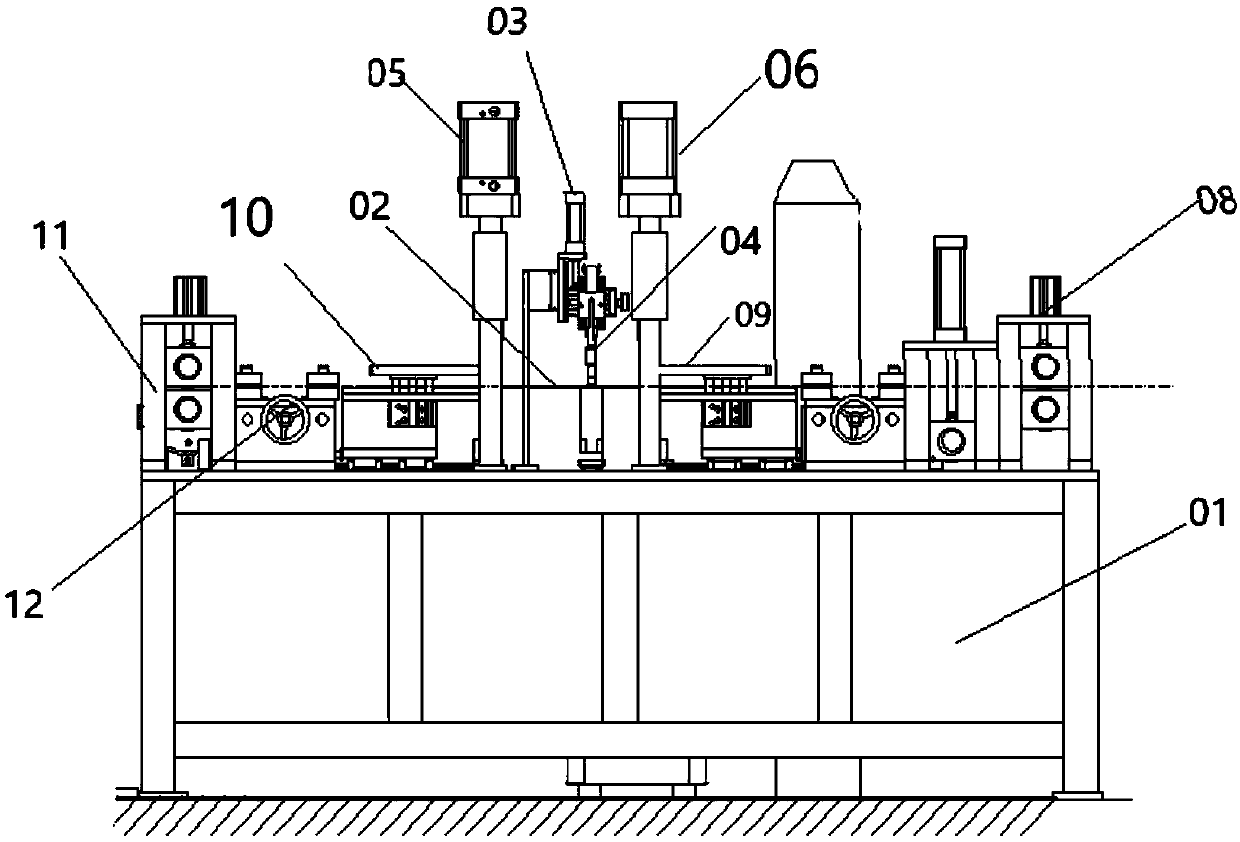

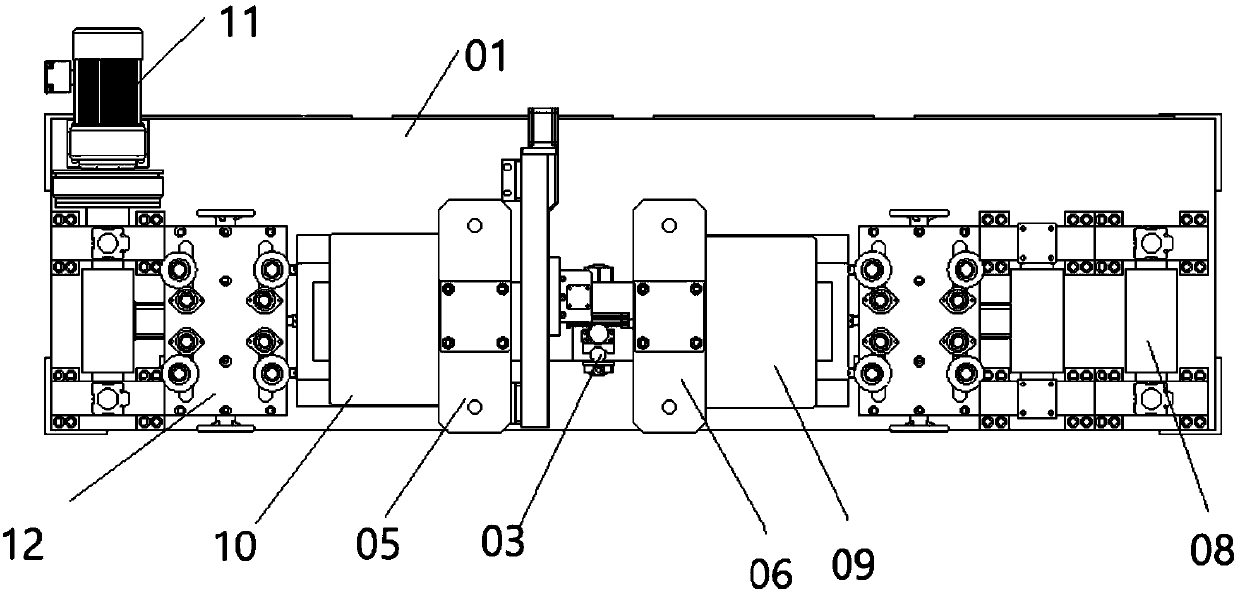

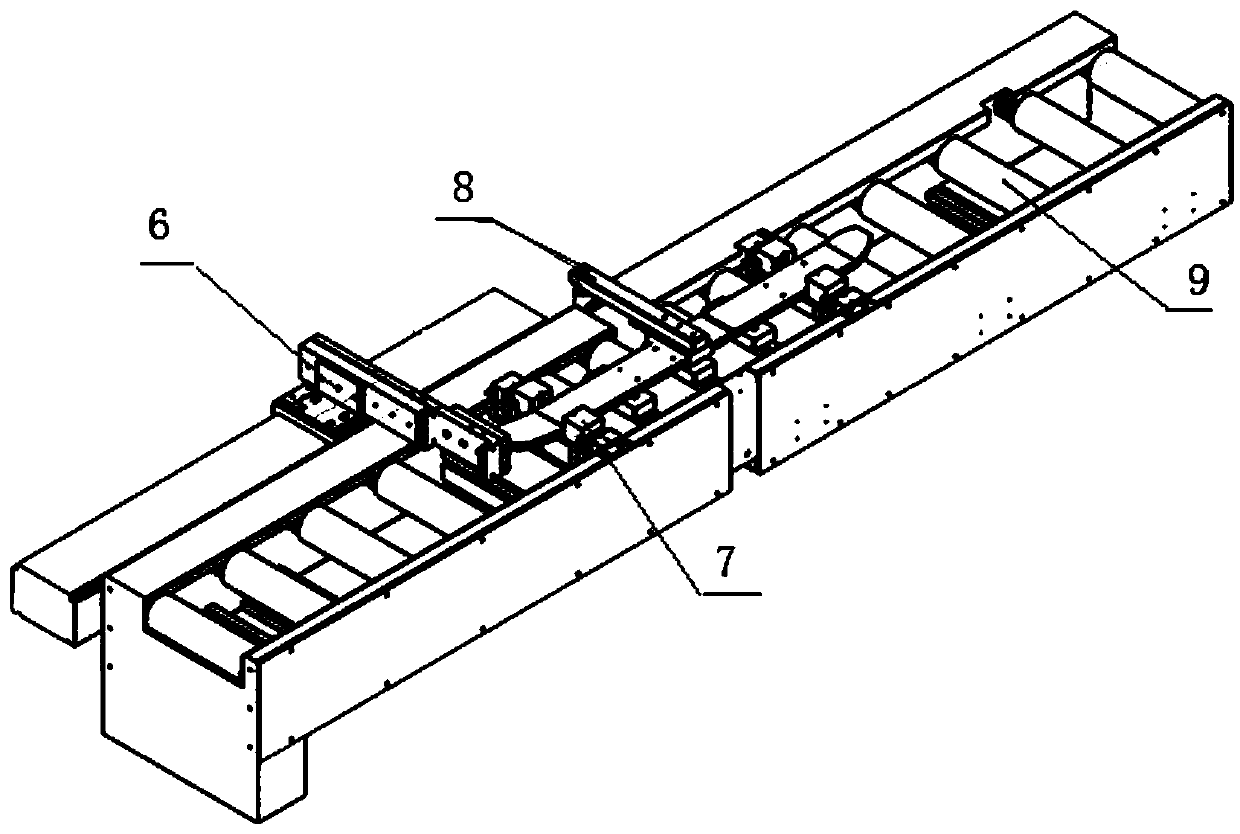

Automatic welding device

InactiveCN111085758AChange the status quo of putting steel beltMeet production requirementsOther manufacturing equipments/toolsWelding accessoriesControl systemEngineering

The invention discloses an automatic welding device which comprises a machine tool base (01), a welding operation table (02), a welding gun walking device (03), a welding gun (04), a first shear mechanism (05), a second shear mechanism (06) and a control system. The machine tool base (01) is divided into a feeding area located on one side of the welding operation table (02) and a pushing area located on the other side of the welding operation table (02). A locating and welding clamp groove communicating with the feeding area and the pushing area is arranged on the welding operation table (02).A pressing rolling shaft (08) away from the welding operation table (02), a pressing pushing mechanism (09) close to the welding operation table (02) and a material tail detection switch in inductionconnection with the pressing rolling shaft (08) and the pressing pushing mechanism (09) are arranged in the pushing area of the machine tool base (01). A conveying rolling shaft (11) and a material head detection switch in induction connection with the conveying rolling shaft (11) are arranged in the feeding area of the machine tool base (01).

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

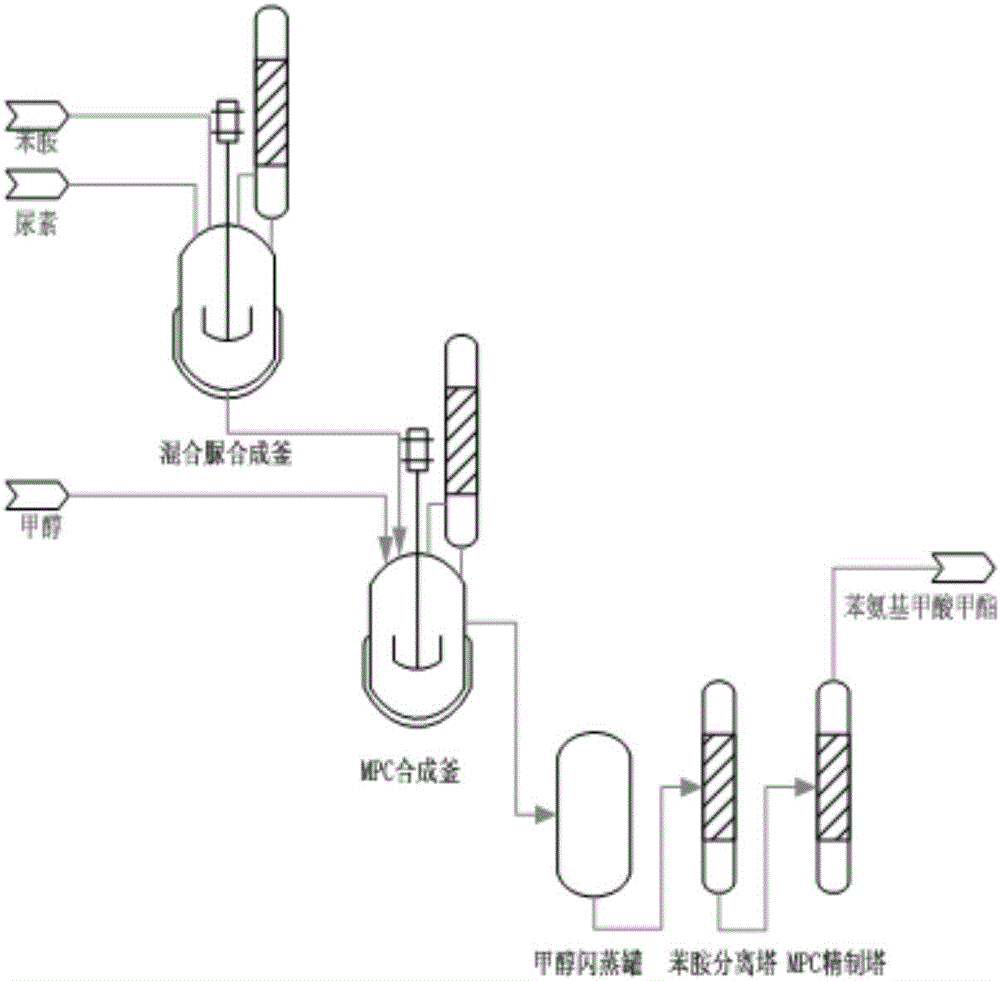

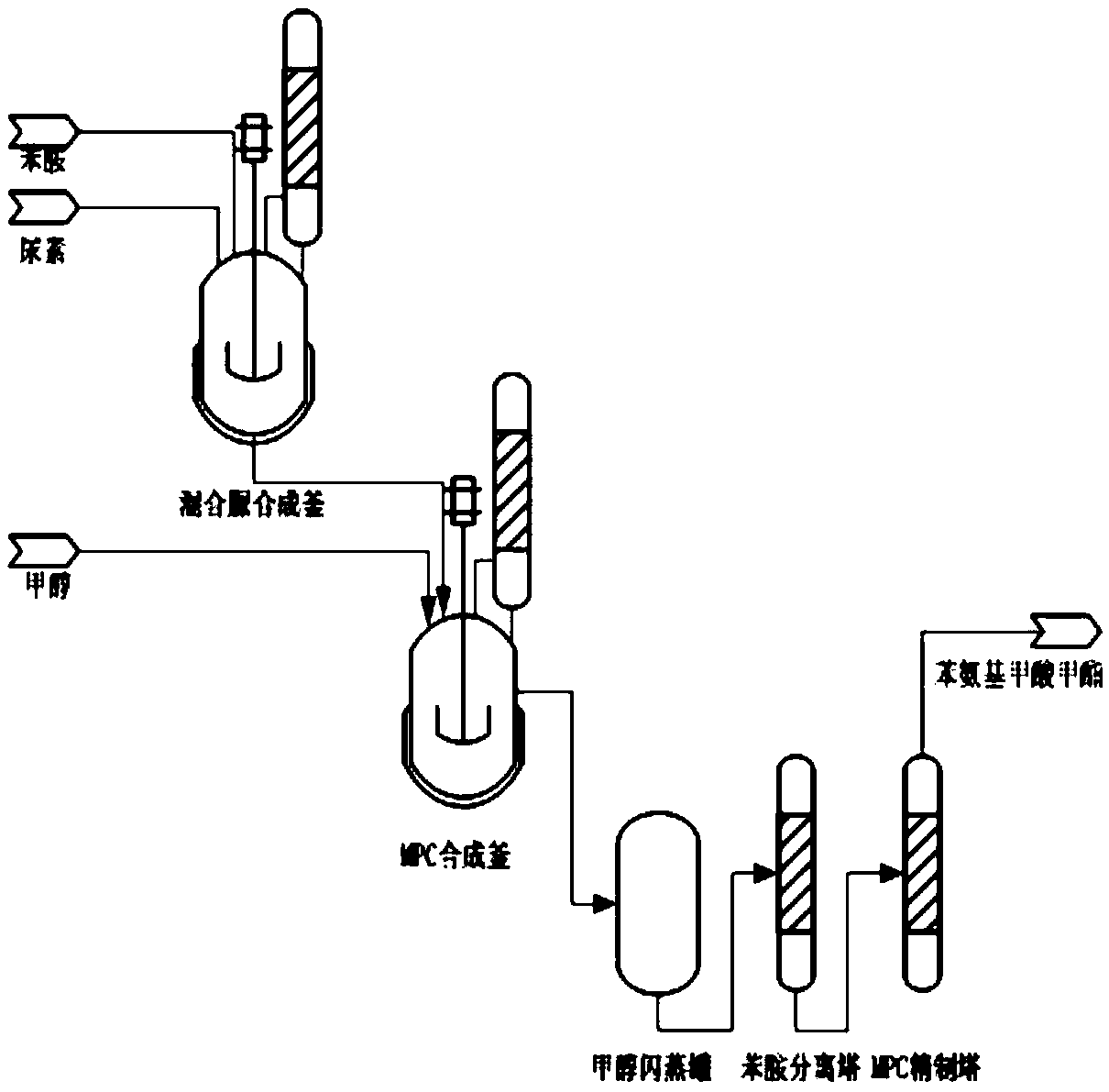

Method for directly synthesizing phenyl carbamate with aniline and urea

ActiveCN106810466AHigh yieldReduce the impact of subsequent reactionsCarbamic acid derivatives preparationOrganic compound preparationAlcoholOrganic solvent

The invention provides a method for directly synthesizing phenyl carbamate with aniline and urea. The method includes: 1), mixing a product generated from reaction of the urea and the aniline with methyl alcohol to form a reaction mixture; 2), mixing the reaction mixture with an organic solvent to form a reaction system; 3), under protection of inert gases, controlling pressure to be MPa, heating the reaction system to be 120-210DEG C and sustaining for 10-300 minutes to obtain a crude product of the phenyl carbamate; 4), performing separation on the crude product of the phenyl carbamate to obtain the phenyl carbamate. With the method, synthesizing process can be performed continuously, uninterrupted production is realized, and industrialized promotion is facilitated.

Owner:陕西煤业化工技术开发中心有限责任公司

Automatic steel strip machining method

InactiveCN111085818AComply with processing requirementsReduce in quantityProduction lineMolding machine

The invention discloses an automatic steel strip machining method. The method comprises the steps that (1), a forming machine machines the nth coil of steel strip, a material tail detection switch detects the material tail of the nth coil of steel strip, the forming machine stops, wherein n is larger than or equal to 1; (2), the steel strip is stopped at the material tail cutting point position ofthe nth coil of steel strip, and a shearing mechanism is started to cut off the material tail of the nth coil of steel strip; (3), the (n+1)th coil of steel strip is conveyed to the material head cutting point position, and the shearing mechanism is started to cut off the material head of the (n+1)th coil of steel strip; (4), the cutting surface of the nth coil of steel strip and the cutting surface of the (n+1)th coil of steel strip are spliced and aligned; (5), a welding machine is started to weld a joint formed by the cutting surface of the nth coil of steel strip and the cutting surface of the (n+1)th coil of steel strip so as to weld the nth coil of steel strip and the (n+1)th coil of steel strip into a whole; and (6), the forming machine is started again, and the nth coil of steel strip moves forwards in the production line direction to drive the (n+1)th coil of steel strip to enter the forming machine to be machined.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

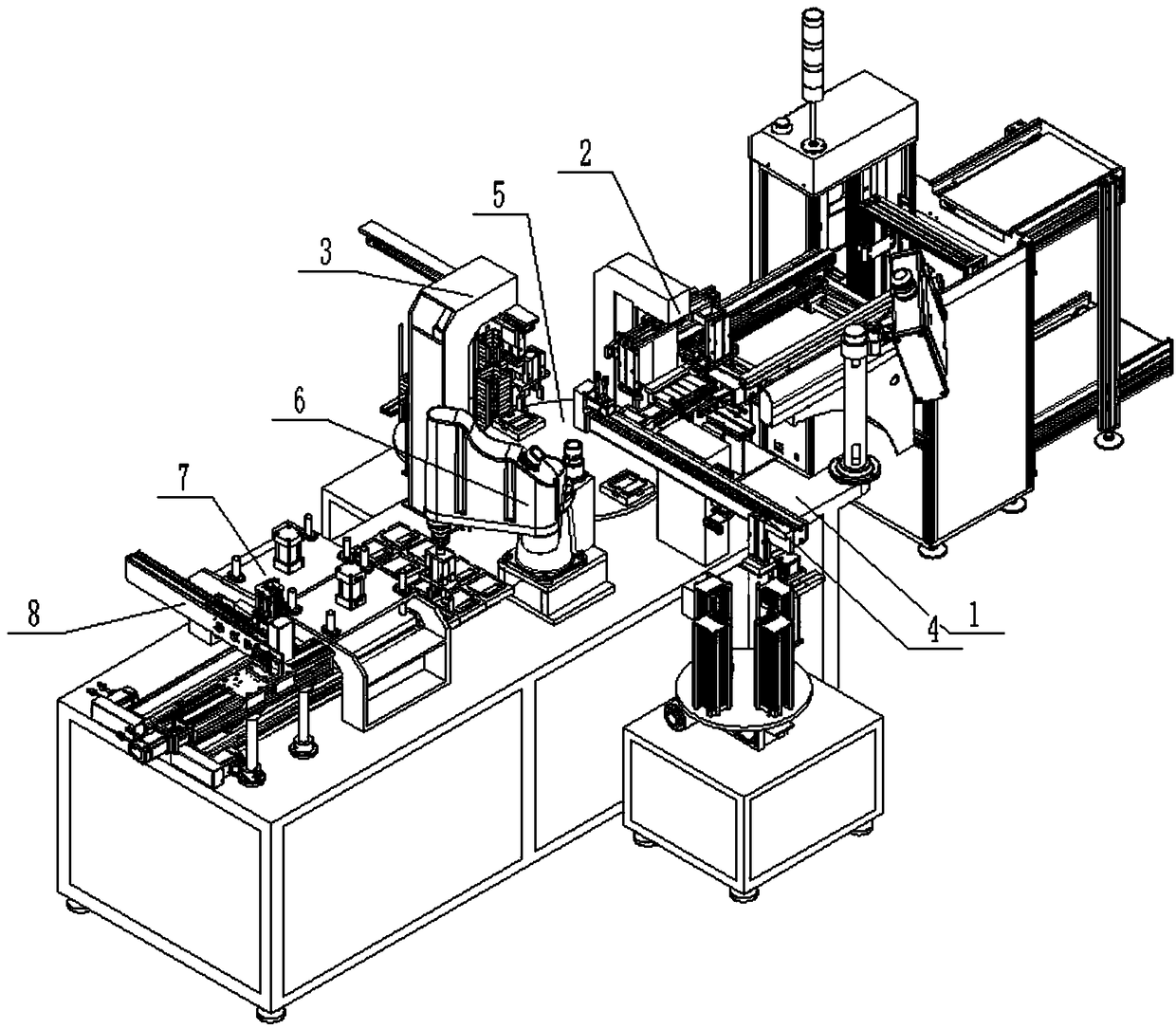

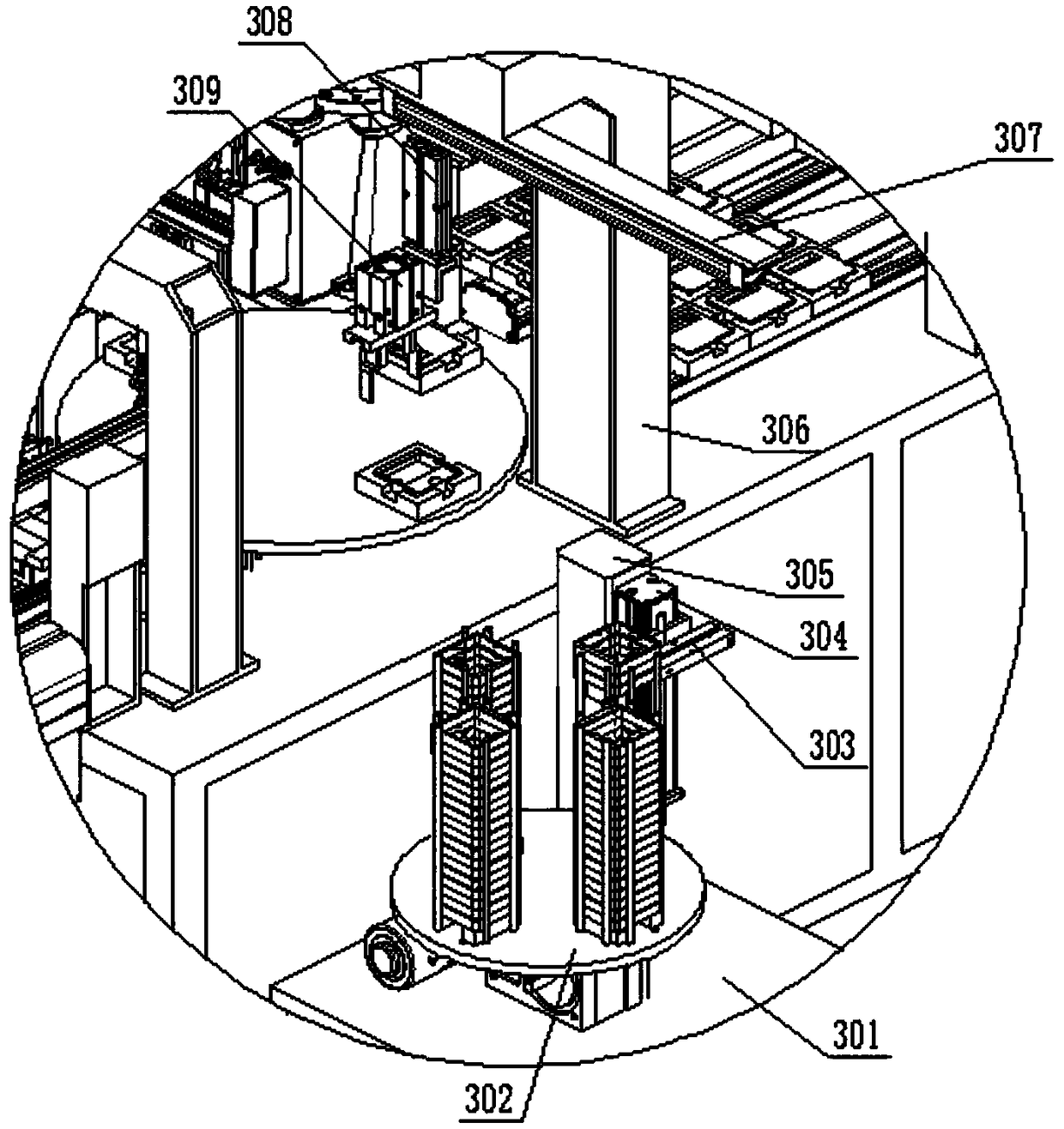

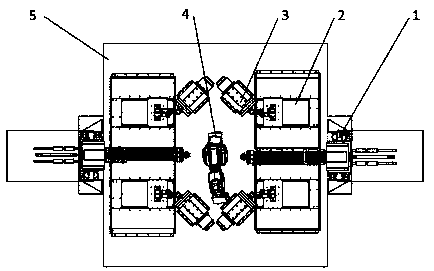

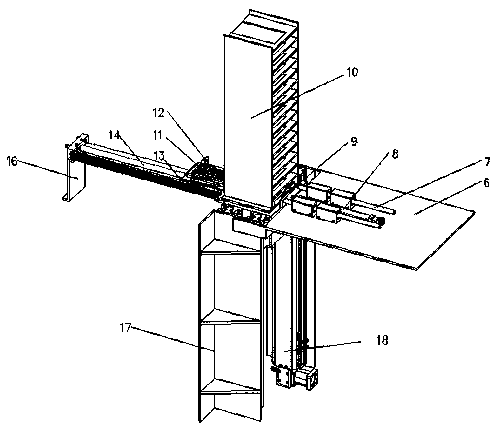

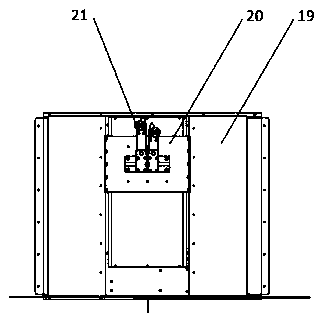

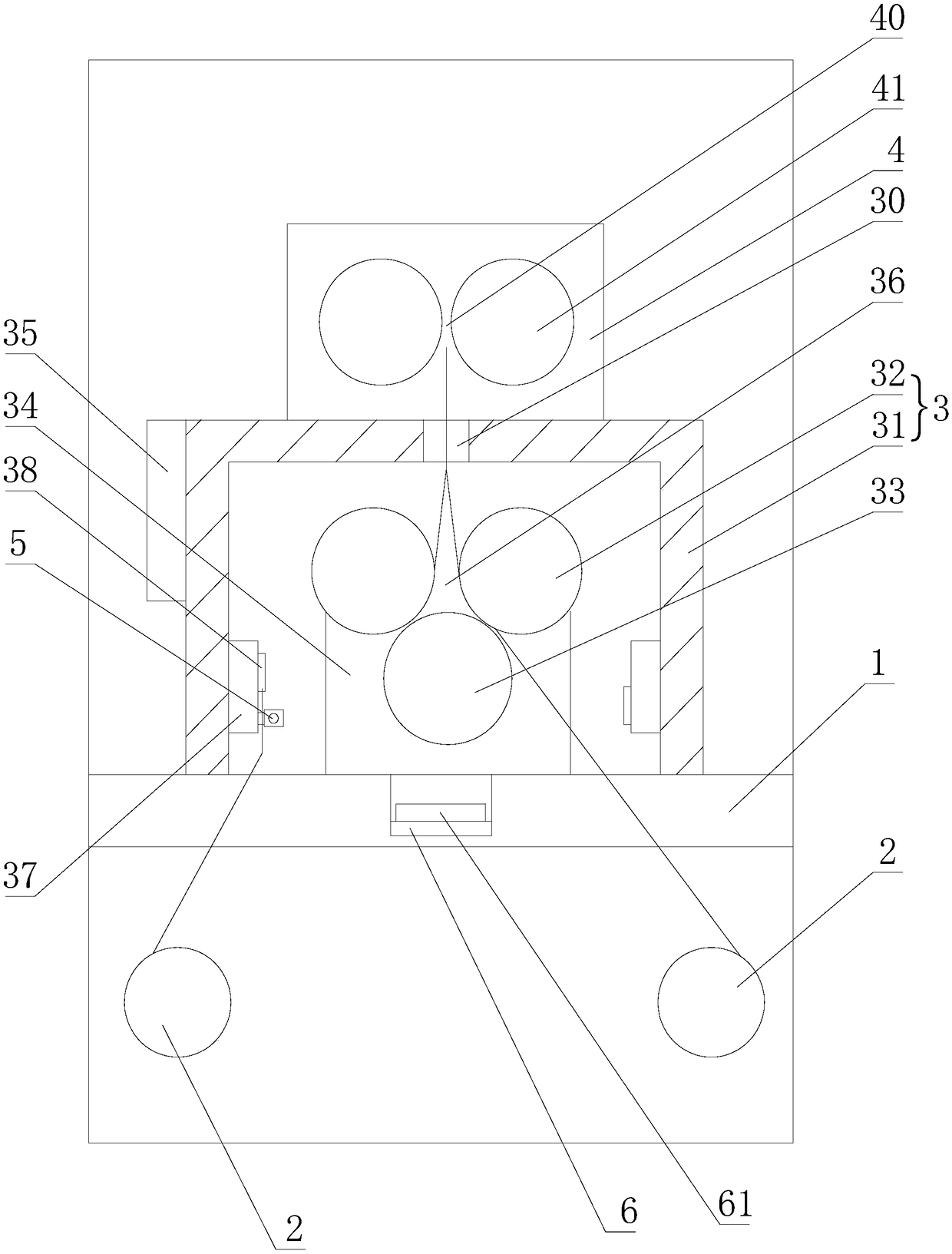

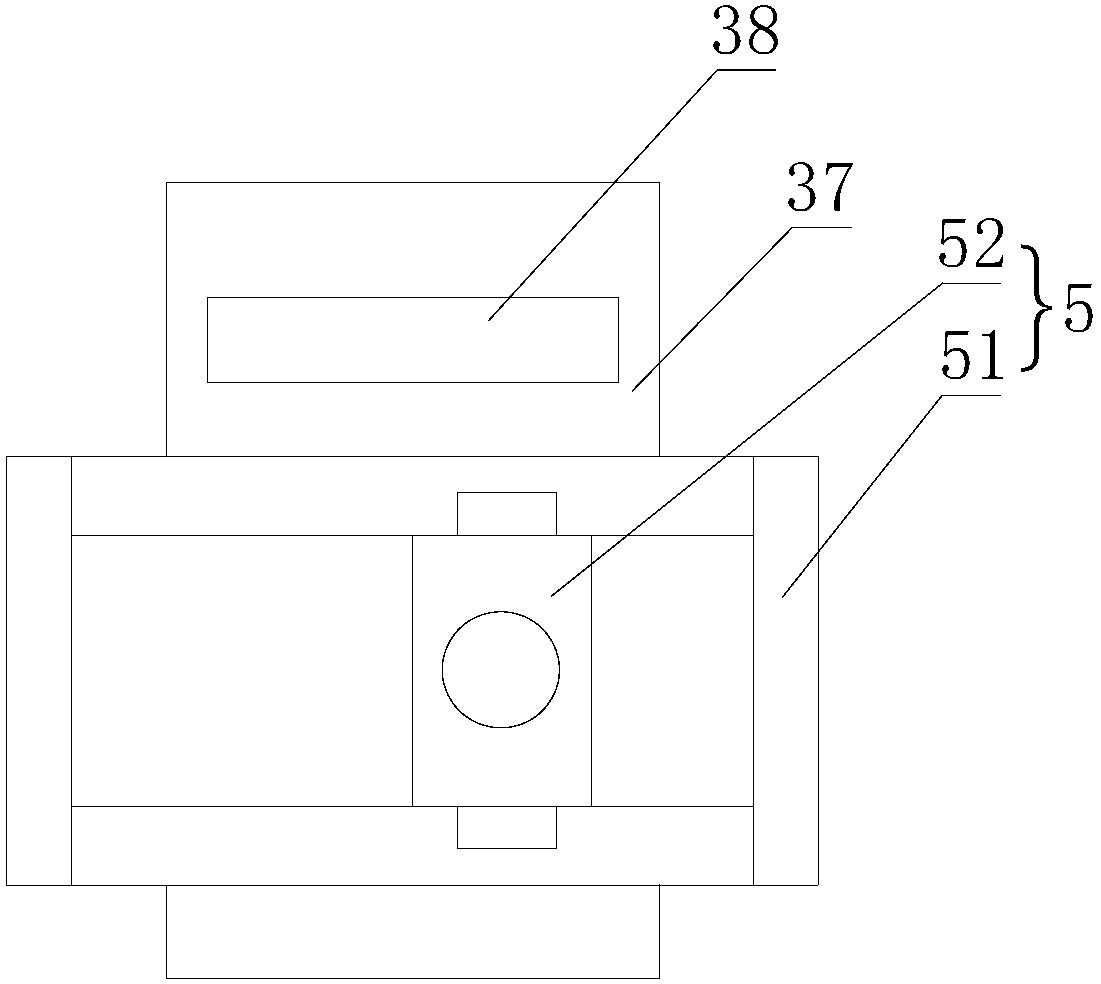

Full-automatic feeding and discharging machining workstation for ultra-precision cone body

InactiveCN109623468AAchieve uninterrupted productionImprove work efficiencyMetal working apparatusEngineeringWorkstation

The invention relates to a feeding and discharging machining workstation for an ultra-precision part, in particular to a full-automatic feeding and discharging machining workstation for an ultra-precision cone body. According to the technical scheme, the full-automatic feeding and discharging machining workstation for the ultra-precision cone body comprises two sets of automatic feeding tray systems which are symmetrically arranged on a machine table assembly, ultra-precision tool holder systems which are respectively arranged on both sides of the feeding tray systems, an ultra-precision spindle matched with the ultra-precision tool holder systems, and a robot handling system which is arranged in the middle of the machine table assembly. The full-automatic feeding and discharging machiningworkstation for the ultra-precision cone body has the advantages that ultra-precision production and automation are combined, manual labor can be replaced, uninterrupted production is realized, workefficiency is improved advantageously, at the same time, a discrete machine tool is changed into the workstation, and the overall equipment cost is saved.

Owner:姜堰经济开发区科创中心

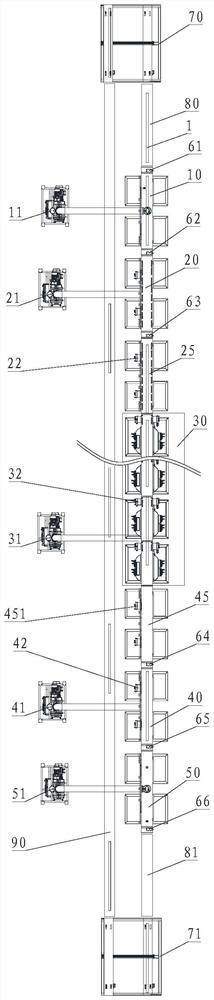

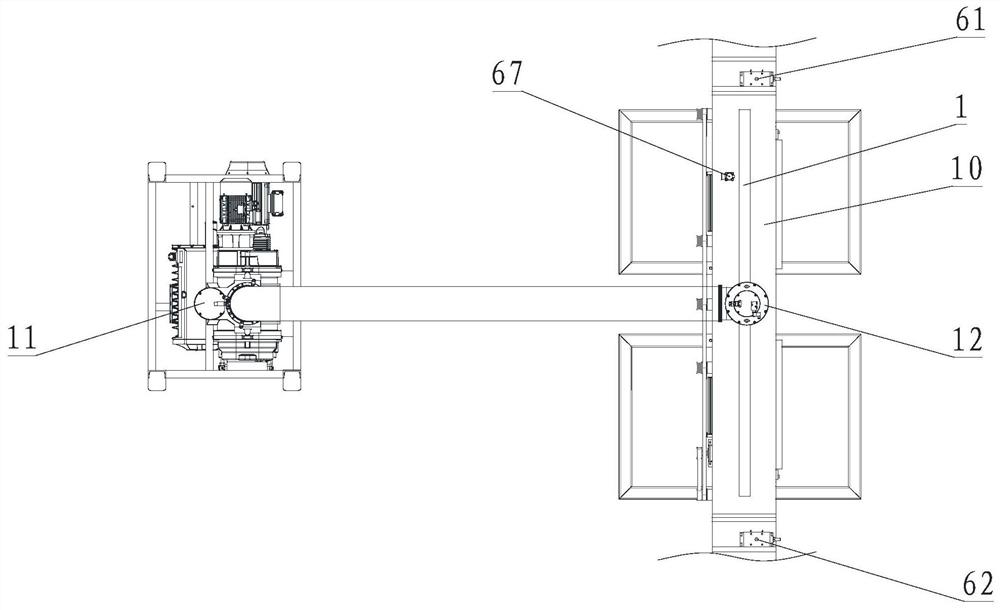

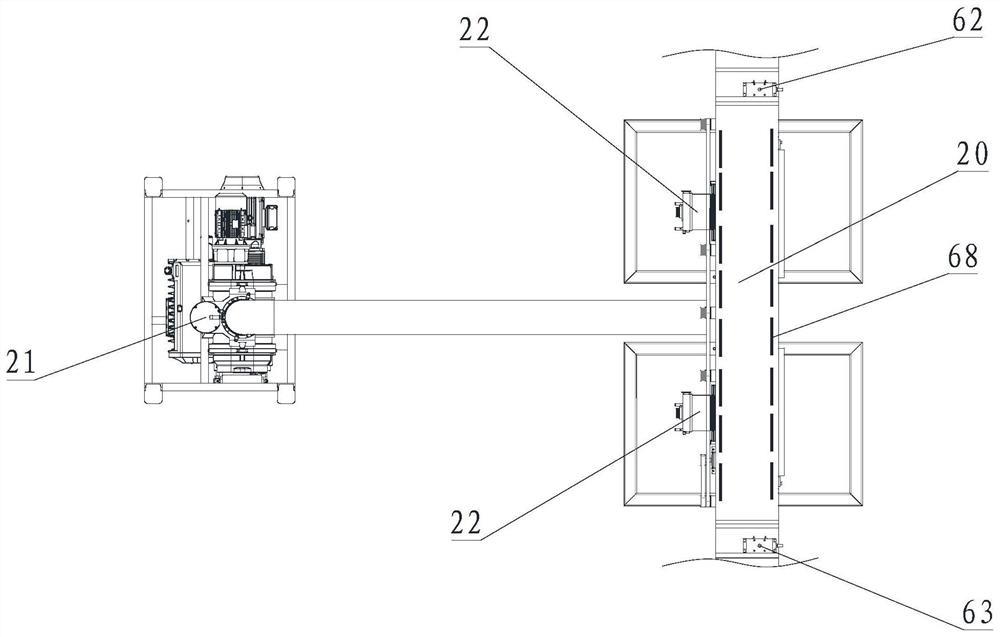

PVD continuous coating equipment and coating method

PendingCN112626485AShorten pump/deflate timeIncrease production capacityVacuum evaporation coatingSputtering coatingManufacturing engineeringPhysical vapor deposition

The invention provides PVD (physical vapor deposition) continuous coating equipment and a coating method. The PVD continuous coating equipment comprises a loading cavity, a first transition cavity, a coating cavity group, a second transition cavity, an unloading cavity and a conveying assembly, wherein vacuum isolation valves are arranged at an inlet of the loading cavity, a position between the loading cavity and the first transition cavity, a position between the first transition cavity and the coating cavity group, and a position between the coating cavity group and the second transition cavity, a position between the second transition cavity and the unloading cavity and an outlet of the unloading cavity, each cavity is provided with a corresponding vacuum pump set, and the loading cavity and the unloading cavity are each provided with an air escape valve. The PVD continuous coating equipment has the beneficial effects that the coating equipment with a multi-stage vacuum cavity structure is provided, so that the air exhaust / deflation time can be greatly shortened; a product continuously enters from one end of the equipment and is continuously output from the other end of the equipment, so that uninterrupted production is achieved, the capacity is high, and the product process consistency is good; and a manipulator is adopted for loading and unloading the product, so that the labor cost is saved, and the economic benefit of a factory is effectively improved.

Owner:广东谛思纳为新材料科技有限公司

Human-machine interconnect type intelligently-controlled mass drill equipment

PendingCN107775036AContinuous uninterrupted productionImprove accuracyAutomatic control devicesFeeding apparatusProgrammable logic controllerMan machine

The invention relates to human-machine interconnect type intelligently-controlled mass drill equipment. The human-machine interconnect type intelligently-controlled mass drill equipment comprises an upper computer PC and a material delivery rail, wherein the material delivery rail extends in the longitudinal direction and comprises a material charging section, a processing section and a material discharging section; two-dimensional code scanning equipment is arranged at one side of the material charging section; a material positioning and clamping mechanism and a mass drill mechanism are arranged at the processing section, and are connected with a PLC (programmable logic controller); the two-dimensional code scanning equipment and the PLC are respectively in signal connection with the upper computer PC. The human-machine interconnect type intelligently-controlled mass drill equipment has the advantages that the continuous production on multiple sizes of products is realized; the seamless connection between a database and the product production is realized; the frequent adjusting of processing equipment is not needed, the procedures are simple, the labor intensity of a worker is low, the requirement on the operation level of the worker is low, and the working efficiency is greatly improved.

Owner:威海英诺威智能装备股份有限公司

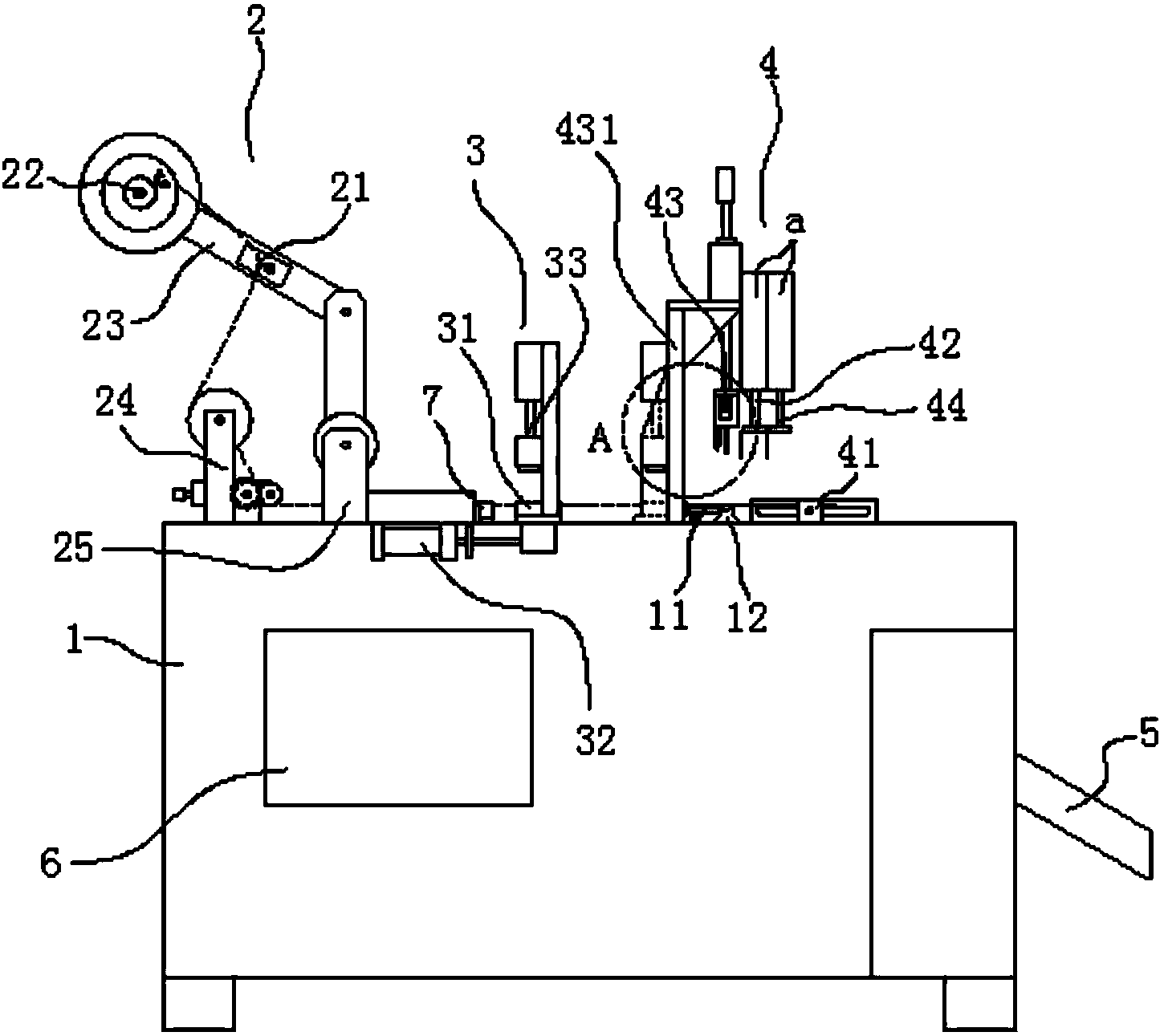

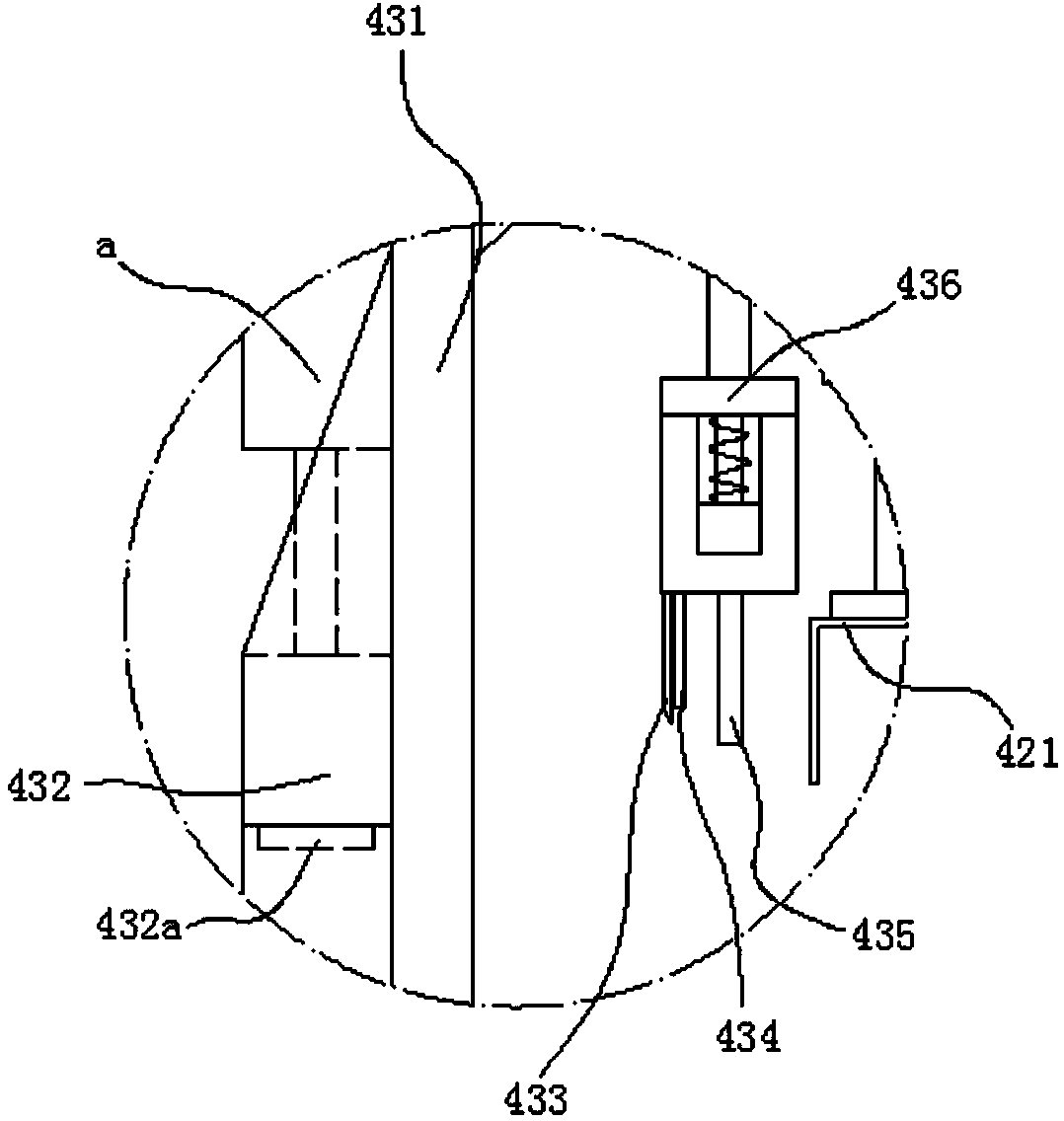

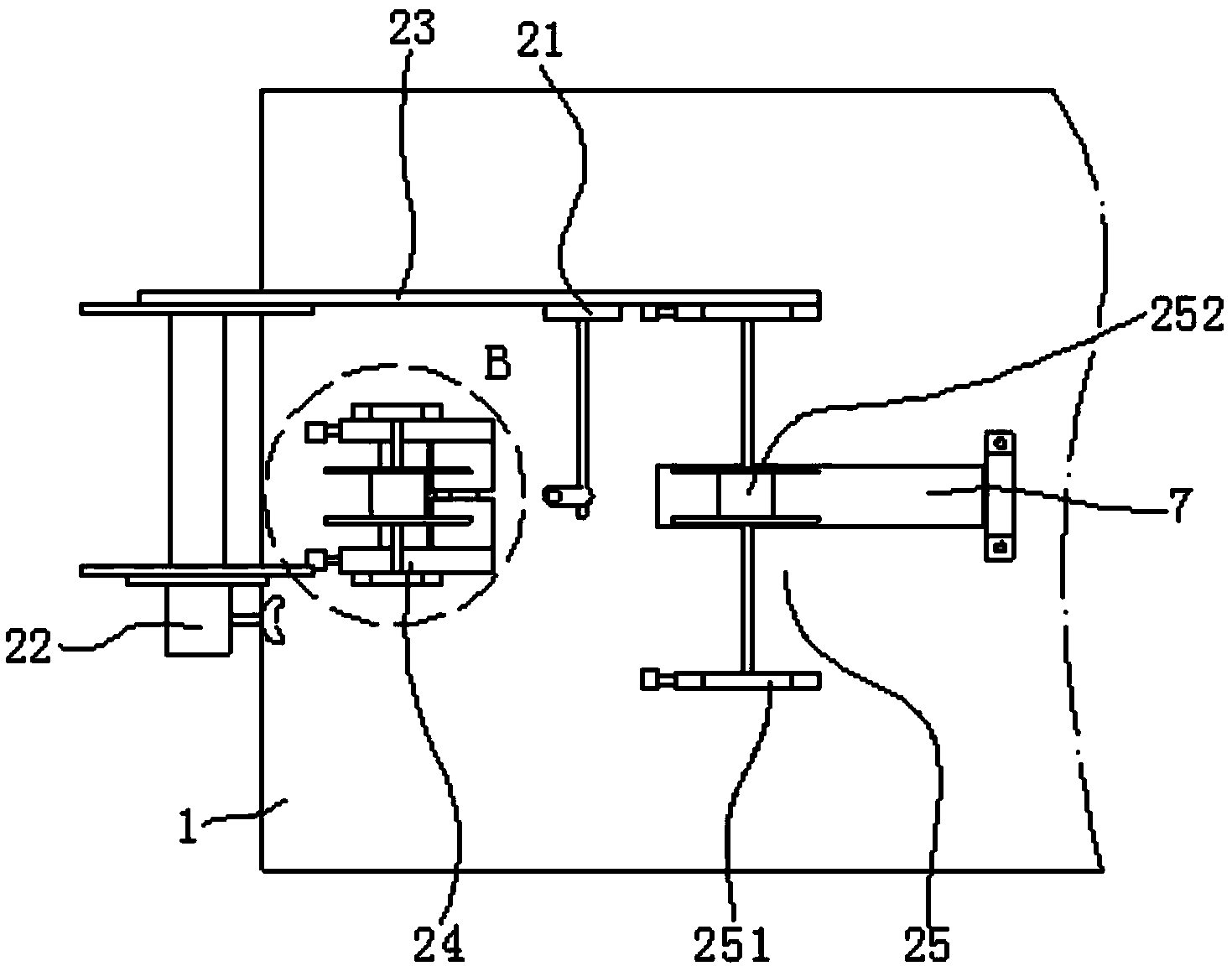

Fully-automatic rope head welding device

The invention relates to the technical field of production of injection molding accessories and discloses a fully-automatic rope head welding device. The fully-automatic rope head welding device comprises a bed body, wherein a micro-control center is arranged in the bed body; a charging shaping mechanism, a delivery mechanism, a welding forming mechanism and an accommodating part are mounted on the bed body sequentially from left to right; a knotting brake part is arranged in the charging shaping mechanism; a starving brake part is arranged between the charging shaping mechanism and the delivery mechanism; the welding forming mechanism consists of a clamping and coiling part, a pre-bending part, a welding cutting part and a pressing part; the clamping and coiling part is mounted on one side of the accommodating part; the pre-bending part is arranged above the material feeding direction; the welding cutting part is arranged on one side of the pre-bending part; the pressing part is arranged between the clamping and coiling part and the accommodating part; the delivery mechanism, the welding forming mechanism and the micro-control center are electrically connected. The fully-automatic rope head welding device realizes fixed-speed, fixed-length and fixed-yield production and has high production efficiency; the products have high standard precision, high safety performance and high yield, energy is saved, the efficiency is high, manpower and material resources are saved, microcomputer fully-automatic control is realized, and continuous production of the products is realized.

Owner:陈保鹏

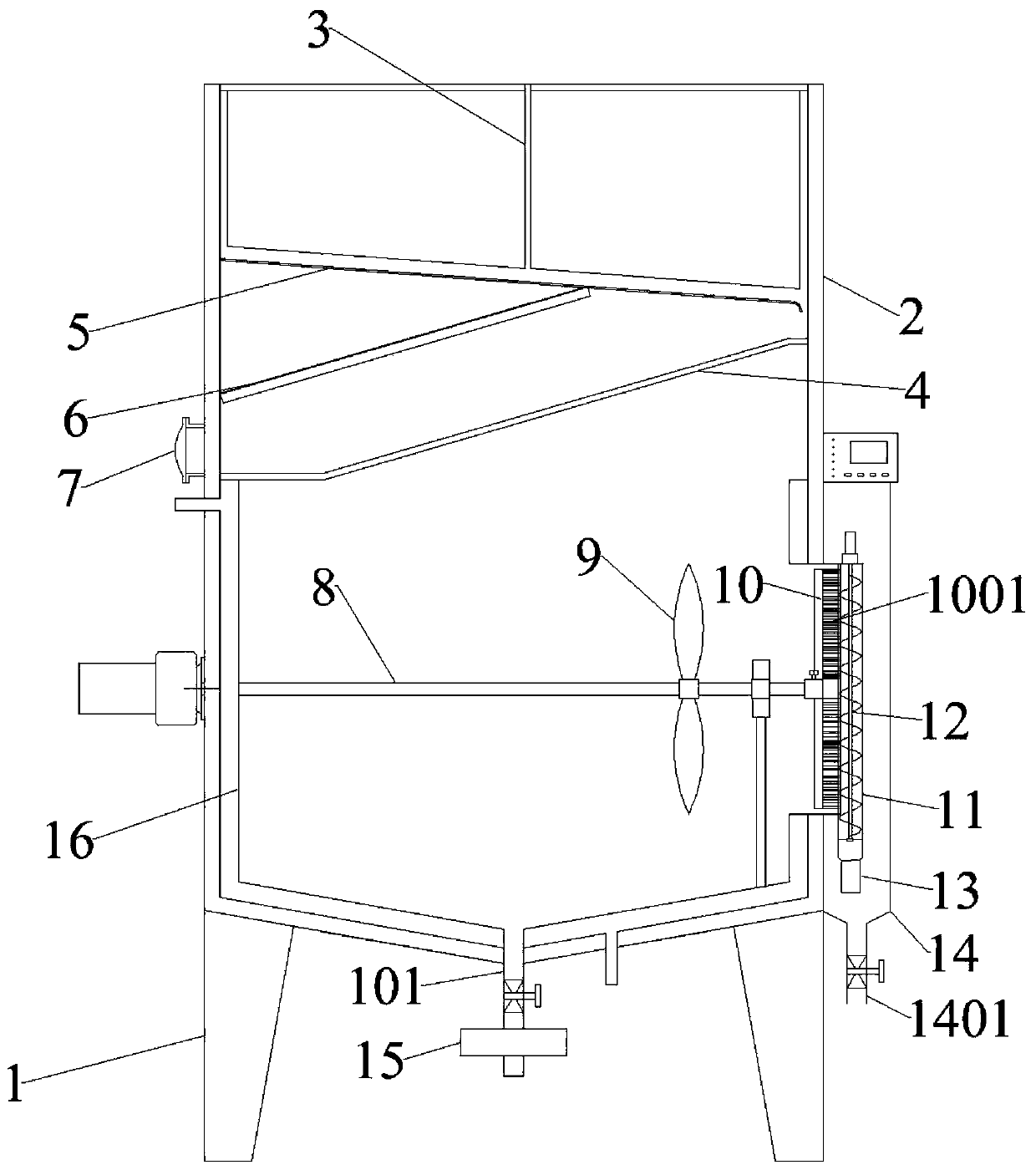

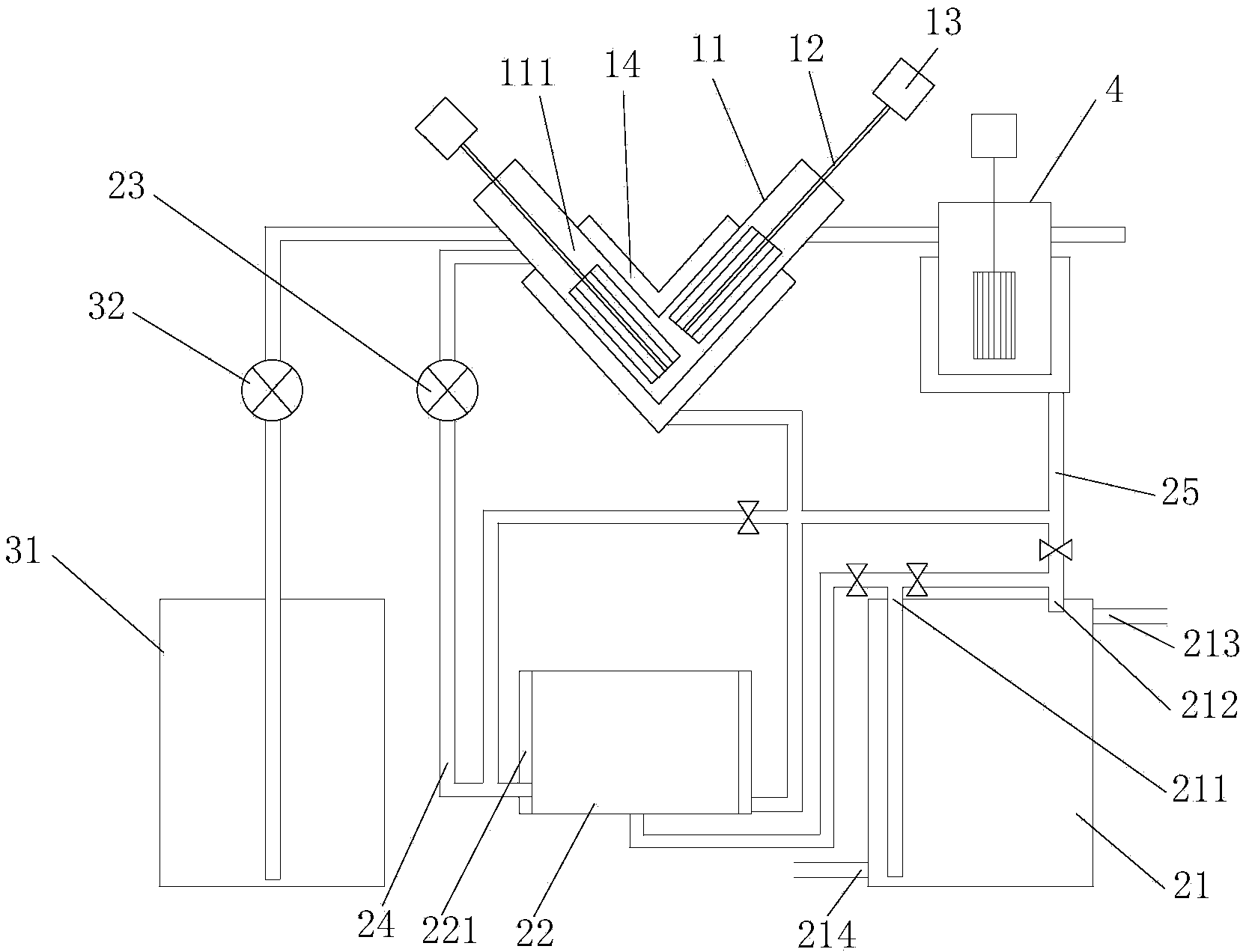

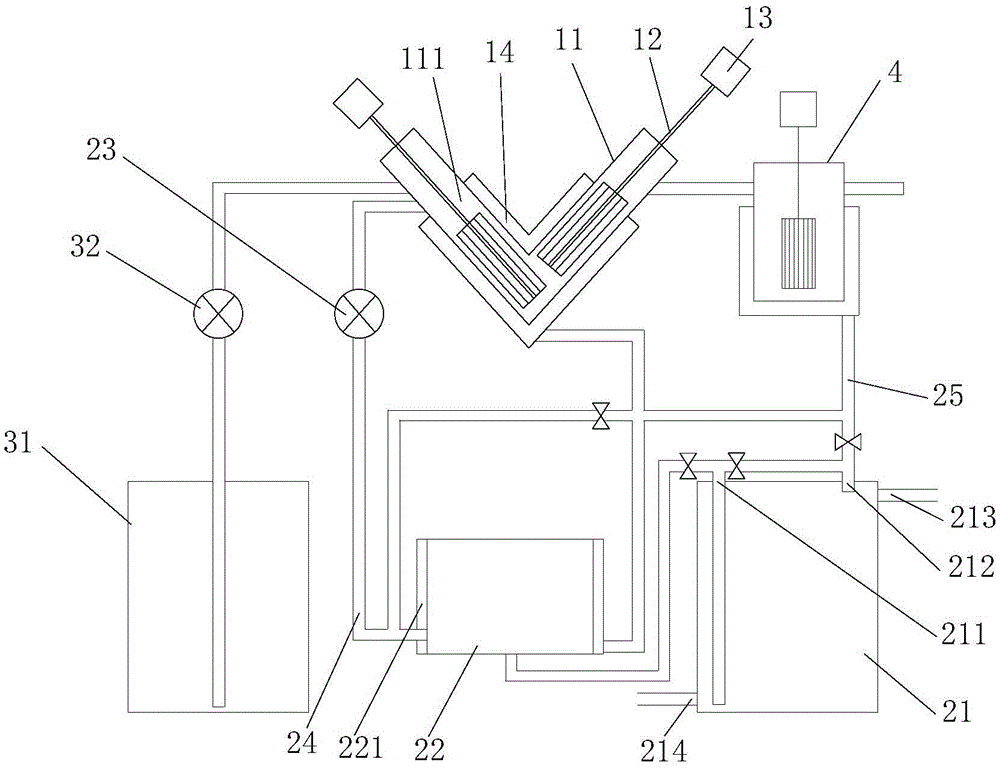

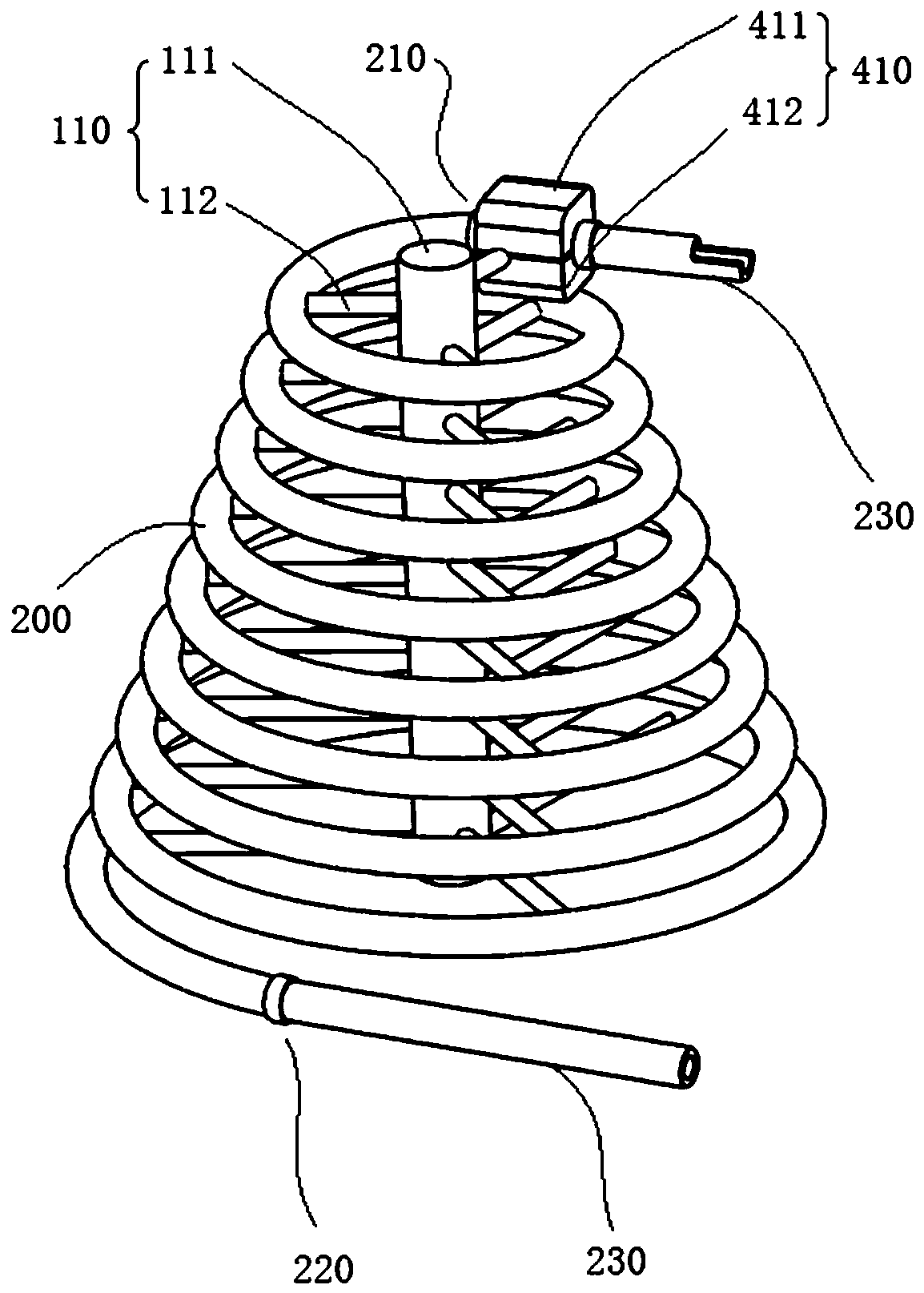

Microsphere emulsifying equipment

ActiveCN104258750ARealize automatic quantitative timing feedingSmall distributionMixing methodsRotary stirring mixersMicrosphereOil phase

The invention provides microsphere emulsifying equipment. The microsphere emulsifying equipment comprises an emulsifying system, a water phase delivery system and an oil phase delivery system, wherein the emulsifying system comprises a V-shaped emulsifying barrel with a jacket, stirrers and a motor; the stirrers are arranged in two emulsifying cavities of the V-shaped emulsifying barrel with the jacket and are connected with the motor, one emulsifying cavity is provided with a water phase inlet and an oil phase inlet, and the other emulsifying cavity is provided with a discharge hole; the water phase delivery system and the oil phase delivery system are communicated with the water phase inlet and the oil phase inlet of the V-shaped emulsifying barrel respectively, and water phase and oil phase are conveyed into the V-shaped emulsifying barrel in a certain ratio of the water phase and the oil phase; furthermore, another stirring machine is additionally arranged behind the emulsifying system for third-level emulsification, and therefore, the emulsifying efficiency is greatly improved and the distribution range of the particle sizes is reduced; the emulsifying system adopting the V-shaped emulsifying barrel can realize stream type continuous mechanical agitation and emulsification and can realize the goal that high capacity is achieved by small equipment, and the emulsifying equipment is particularly suitable for agarose microsphere emulsification.

Owner:WUHAN GEOCHROM BIOTECH CO LTD

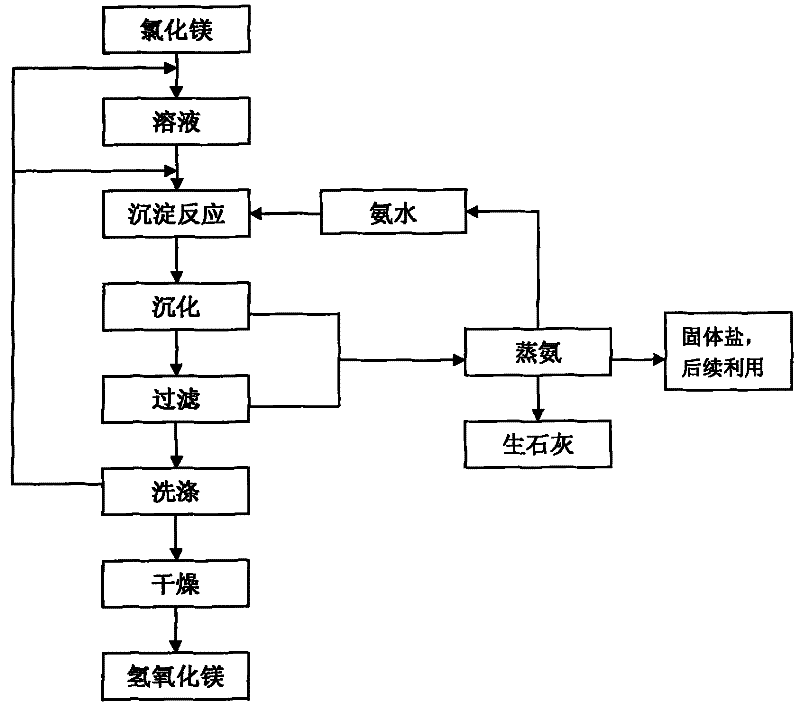

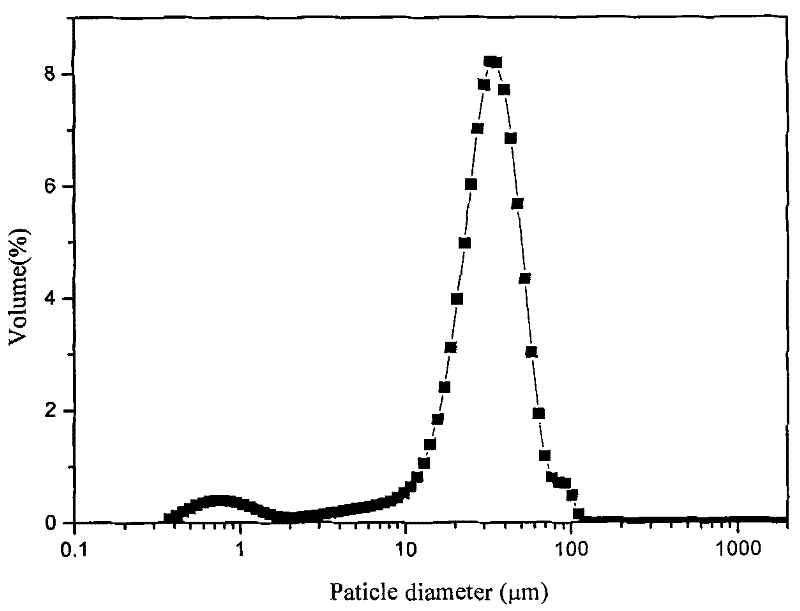

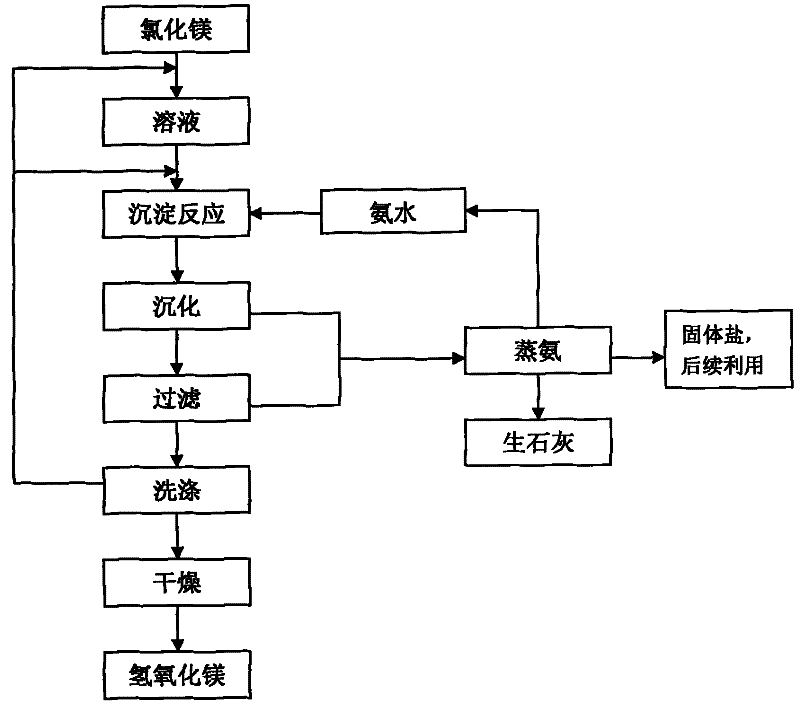

Method for preparing large-grain magnesium hydroxide by taking highly acid ammonium salt as crystal control agent

Owner:ZHEJIANG HAIHONG HLDG

Microsphere emulsification equipment

ActiveCN104258750BRealize automatic quantitative timing feedingSmall distributionRotary stirring mixersMixing methodsMicrosphereOil phase

The invention provides microsphere emulsifying equipment. The microsphere emulsifying equipment comprises an emulsifying system, a water phase delivery system and an oil phase delivery system, wherein the emulsifying system comprises a V-shaped emulsifying barrel with a jacket, stirrers and a motor; the stirrers are arranged in two emulsifying cavities of the V-shaped emulsifying barrel with the jacket and are connected with the motor, one emulsifying cavity is provided with a water phase inlet and an oil phase inlet, and the other emulsifying cavity is provided with a discharge hole; the water phase delivery system and the oil phase delivery system are communicated with the water phase inlet and the oil phase inlet of the V-shaped emulsifying barrel respectively, and water phase and oil phase are conveyed into the V-shaped emulsifying barrel in a certain ratio of the water phase and the oil phase; furthermore, another stirring machine is additionally arranged behind the emulsifying system for third-level emulsification, and therefore, the emulsifying efficiency is greatly improved and the distribution range of the particle sizes is reduced; the emulsifying system adopting the V-shaped emulsifying barrel can realize stream type continuous mechanical agitation and emulsification and can realize the goal that high capacity is achieved by small equipment, and the emulsifying equipment is particularly suitable for agarose microsphere emulsification.

Owner:WUHAN GEOCHROM BIOTECH CO LTD

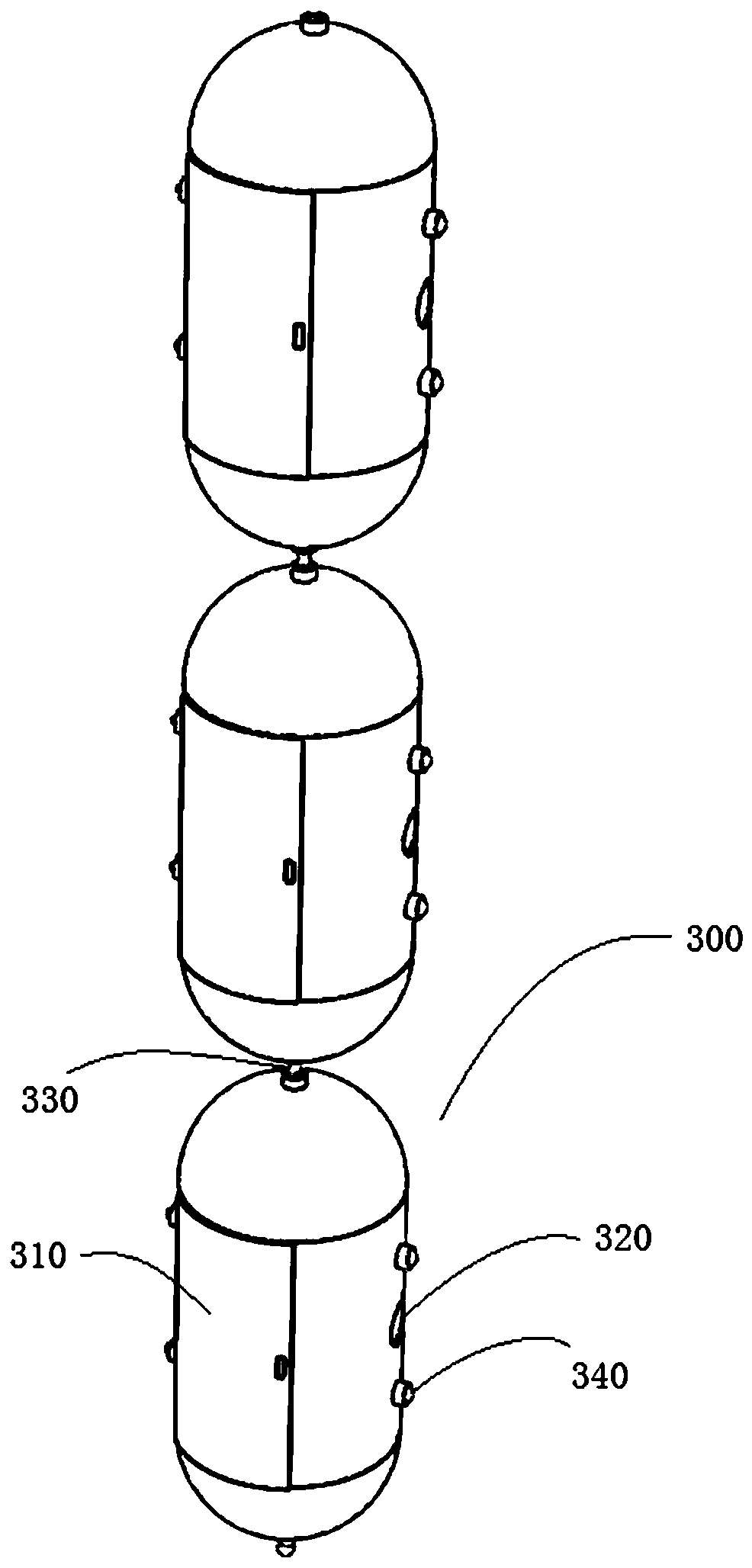

Aluminum alloy heat treatment furnace

InactiveCN111534678AReduce aging processing timeImprove performanceFurnace typesQuenching agentsHeat treatingAluminium alloy

The invention discloses an aluminum alloy heat treatment furnace. The aluminum alloy heat treatment furnace comprises a furnace body, capsule cabin body for placing aluminum alloy materials, a spiralchannel formed in the furnace body and a processing device group; the spiral channel comprises an inlet formed in the top end, and an outlet formed in the bottom end, and a guide rail is arranged in the spiral channel in the bending length direction; a cabin door for the aluminum alloy materials in and out, and at least one processing port communicating with the processing device group are arranged on the side edge of the capsule cabin body, sealing covers are arranged on the processing ports, a guide block is arranged on the side edge of the capsule cabin body, and the guide block can be slidably connected with the guide rail; and the processing device group comprises a quick cooling device and a heating device, the quick cooling device is arranged close to the inlet, the quick cooling device can communicate with the processing port, and the heating device is arranged in the axial direction of the spiral channel. According to the aluminum alloy heat treatment furnace, a continuous heat treatment device suitable for industrial application is provided for heat treatment of the aluminum alloy materials, the aging processing time of the aluminum alloy materials is shortened, the performance of the aluminum alloy materials is improved, moreover, continuous production is achieved, and the production cost is lowered.

Owner:惠民县久盛铝业有限公司

A kind of method of directly synthesizing methyl phenylcarbamate by aniline and urea

ActiveCN106810466BHigh yieldReduce the impact of subsequent reactionsCarbamic acid derivatives preparationOrganic compound preparationCarbamateOrganic solvent

Owner:陕西煤业化工技术开发中心有限责任公司

Single-bucket serial-bucket charging method applied to bell-free blast furnaces

InactiveCN101709340BReduce the shutdown rateGuarantee normal production and operationBlast furnace detailsBlast furnaceElectrical and Electronics engineering

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

A non-stop paper feeding device

ActiveCN106743827BAchieve uninterrupted productionIncrease productivityArticle feedersElectric machineEngineering

The invention relates to a non-stop paper feeding device. The non-stop paper feeding device comprises a machine frame and discharge shafts, wherein the machine frame is also provided a feed guiding device; the feed guiding device comprises a frame and feed rolls; a driving roll is arranged on the frame; a driving motor is connected to the driving roll; a fixed plate is arranged in the frame; adhesive layers for sticking paper are arranged on the fixed plate; and a cutting assembly is arranged on the frame. The non-stop paper feeding device has the advantages that the driving roll is controlled by the driving motor to rotate; the feed rolls are driven by the driving roll to rotate; the discharge shafts are driven by the feed rolls to rotate to realize paper feeding operation; the two discharge shafts are controlled to rotate through the switch of rotating directions of the driving motor; and compared with a conventional paper feeding device, the non-stop paper feeding device has the advantage that non-stop production can be realized, so that the production efficiency is improved. The paper is fixed on the fixed plate through the adhesive layers, and then the paper is cut by the cutting assembly, so that extra or irregular regions on the paper can be rapidly removed; and through the arrangement of the adhesive layers, the cutting efficiency can be improved, and the cutting assembly can be prevented from being damaged.

Owner:ZHEJIANG MOZHIHUA PRINTING

Cod skin frozen block crushing and melting device and crushing and melting method

PendingCN112841289AAchieve uninterrupted productionQuick thawMeat/fish preservation by freezing/coolingGrain treatmentsMechanical engineeringRaw material

The invention relates to a cod skin frozen block crushing and melting device and crushing and melting method. The crushing and melting device comprises a cutting table and a lead screw cutting device, cutting discs with the thickness being 10 mm are welded to a rotating shaft of a lead screw cutting rod of the lead screw cutting device at a certain interval, an iron block is welded between every two adjacent cutting discs, the two adjacent iron blocks are arranged on the two sides of the rotating shaft respectively, and the cutting disc and the iron blocks are combined to quickly unfreeze the frozen cod skin blocks through mechanical cutting, vibration and extrusion. Moreover, the process does not need to consume water, the cod skin blocks can be continuously crushed, the production land is reduced, and the continuous production of the cod skin is realized. The phenomenon of production halt caused by the fact that the raw materials are not unfrozen is avoided, the production time can be greatly shortened, and the water consumption is reduced.

Owner:QINGDAO LANGYATAI GRP

Lead alloy cast plate production system

ActiveCN113285075AFully automatedAchieve uninterrupted productionElectrode carriers/collectorsWinding machineCasting mold

The invention discloses a lead alloy cast plate production system, and belongs to the field of lead alloy plate production. The system comprises a lead liquid smelting furnace, a plate casting device, a rolling and air-drying device, a trimming and shearing device and a winding device which are arranged in sequence; the plate casting device comprises a plate casting mold, a plate casting roller and a pressing roller, the lead liquid smelting furnace conveys lead liquid to the plate casting mold, and the plate casting roller drives the lead liquid on the plate casting mold to be uniformly distributed on the surface of the plate casting roller when rotating, so that the lead liquid is solidified on the plate casting roller to form a lead belt; the rolling and air-drying device is used for rolling and air-drying the cured and formed lead belt; the trimming and shearing device is used for trimming the rolled and air-dried lead belt; and the winding device comprises a winding machine; the winding machine is used for winding the lead alloy plate strip. By means of the lead alloy cast plate production system, full automation of the lead alloy plate strip casting process is achieved, shutdown is not needed in the roll changing process, uninterrupted production of the lead alloy plate strip is achieved, the production efficiency is high, and the cast lead alloy plate strip meets the requirement.

Owner:广州市通上德智能装备有限公司

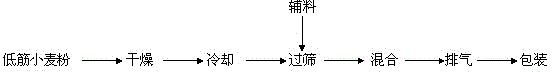

Cheese cake flour containing wheat dietary fibers and production method

The invention discloses a home cheese cake flour containing wheat dietary fibers and a production method thereof. The cheese cake flour is made of a premixed flour A and a premixed flour B, especially the premixed flour A is added with wheat dietary fiber powders. The materials of the premixed flour A and the premixed flour B are scientifically proportioned, and the premixed flour A and the premixed flour B are whipped by an egg separation method, and cheese cakes whose dietary fiber content is 50-100% higher than that of a conventional product are conveniently and rapidly made at home. The cakes are delicious and supplement dietary fibers which are lacking in daily life, and increase nutritive values. The processing method for the cheese cake flour is formed by drying, cooling, sieving, mixing, venting, and packaging procedures, and continuous production of drying and ingredient mixing is realized, shelf life of the cake flour is improved, and breakage rate caused by product extrusion in a transportation process is reduced.

Owner:江苏江南上一道科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com