Rolling plastic forming machine

A molding machine and plastic technology, applied in the field of plastic molding, can solve the problems of high power requirements, increased costs, and low production efficiency of extrusion machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

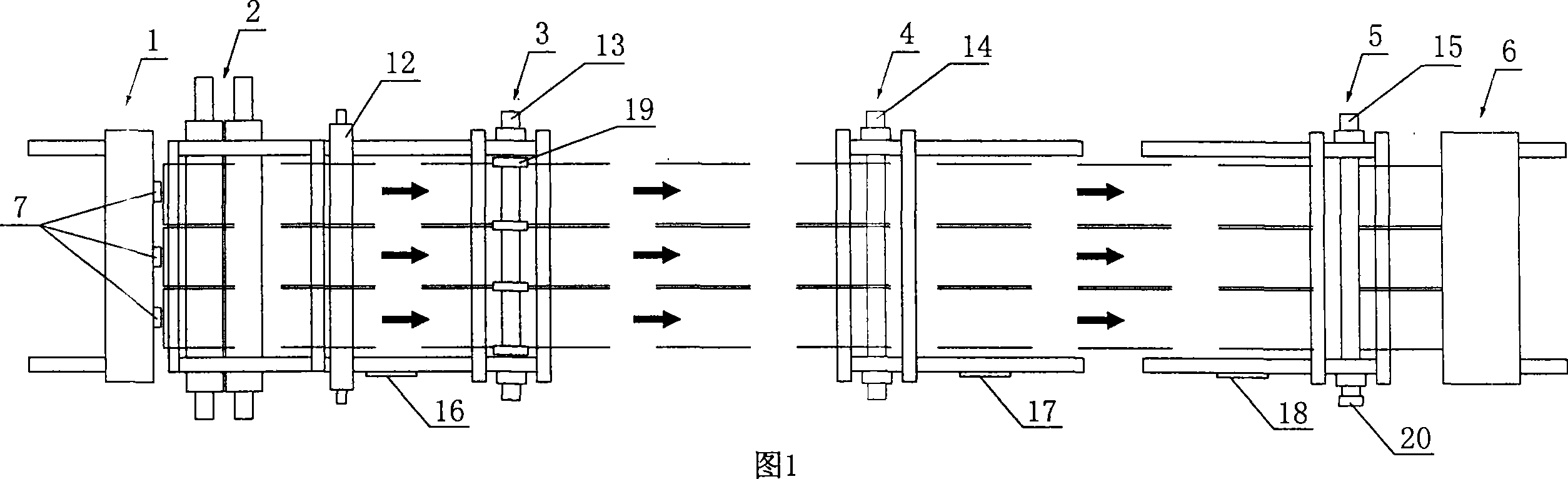

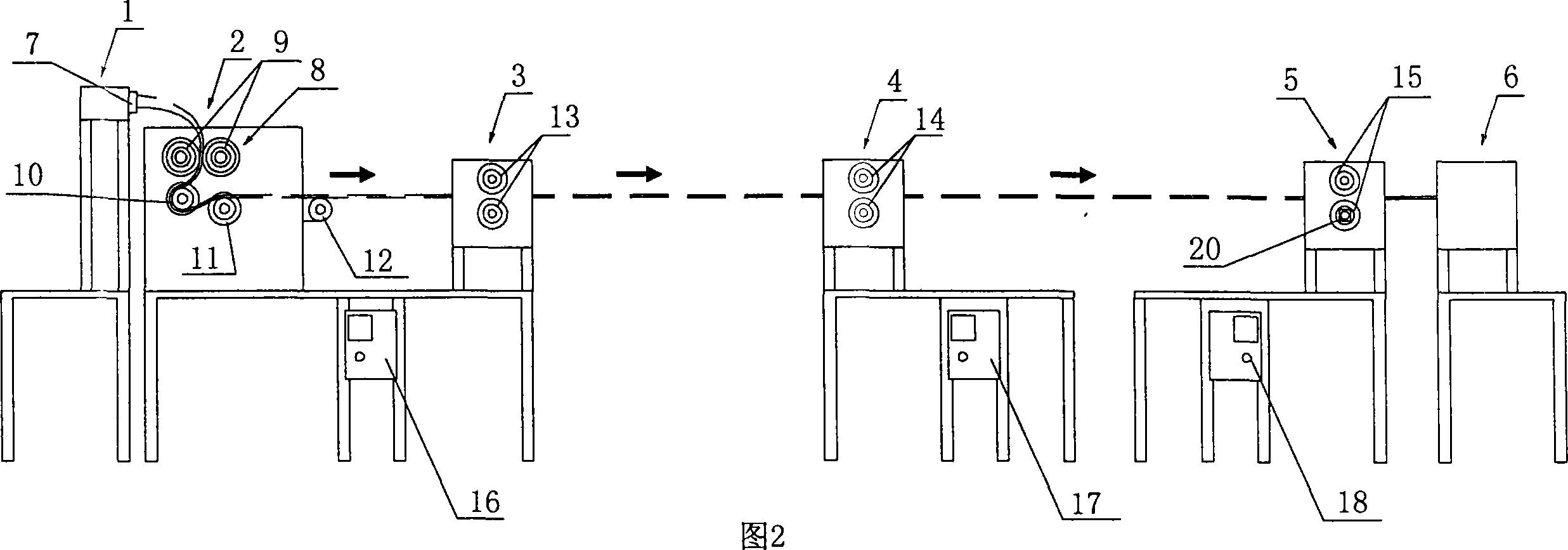

[0010] Now set forth the present invention in detail in conjunction with accompanying drawing:

[0011] As shown in accompanying drawings 1 to 2, the rolling plastic molding machine of this embodiment can realize the simultaneous production of three plastic strips, and it is provided with a plastic distributor 1, a mold forming unit 2, and three auxiliary Transfer units 3, 4, 5 and cut-off unit 6. The plastic distributor 1 is divided into three discharge ports 7, and the mold forming roller group 8 is installed on the mold forming unit 2, and the mold forming roller group 8 is arranged at the discharge place of the plastic distributor 1, and the mold forming roller group 8 is a pair of horizontally opposite mold rollers 9, a guide roller 10 is arranged below the mold roller 9, and support rollers 11, 12 are arranged at the rear end of the guide roller 10. Auxiliary conveying units 3, 4, 5 are arranged at the rear end of mold forming unit 2, each auxiliary conveying unit is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com