A non-stop paper feeding device

A paper feeding and guiding device technology, applied in the directions of object supply, transportation and packaging, pile separation, etc., can solve the problem of low paper feeding efficiency, and achieve the effect of improving efficiency, ensuring flatness and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

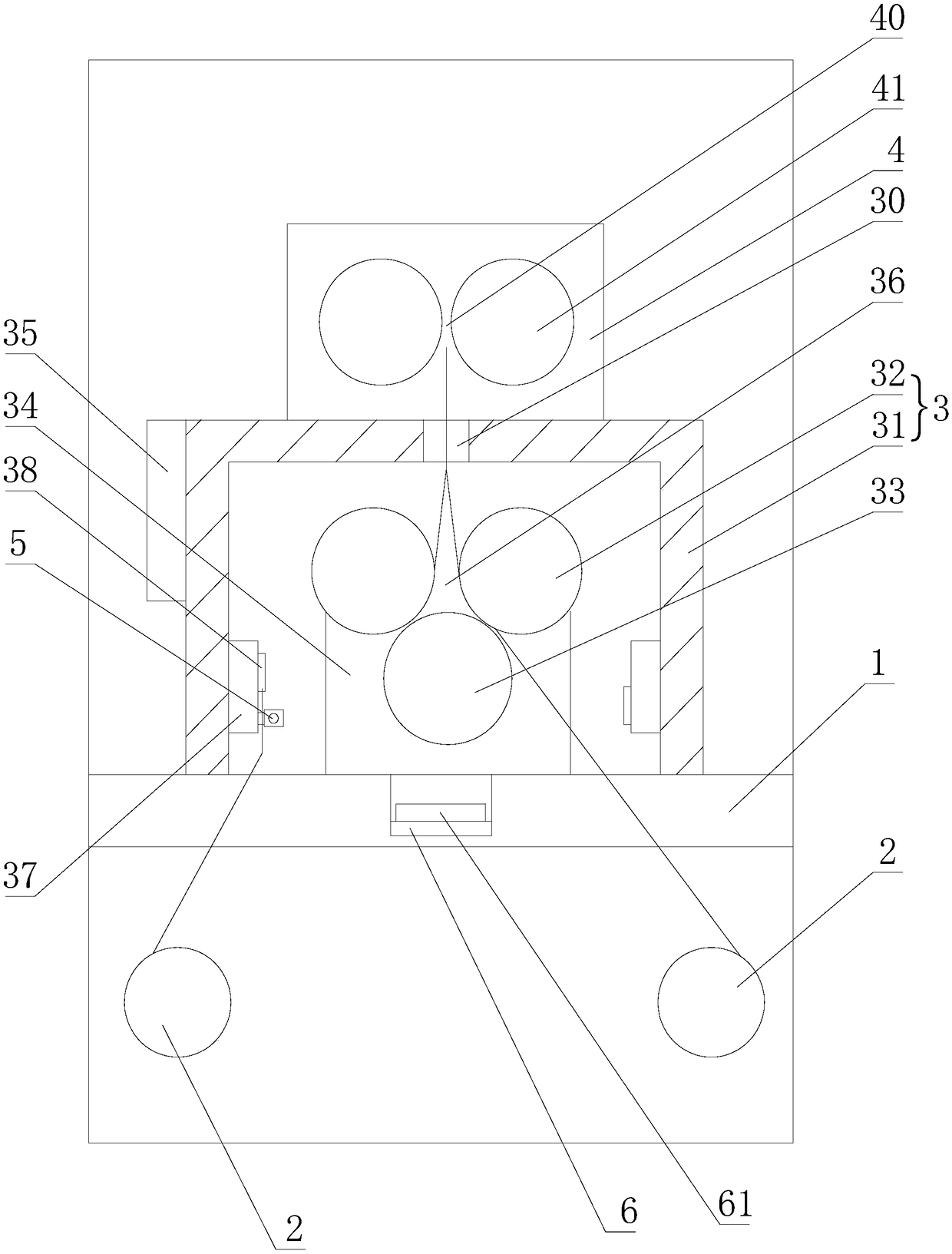

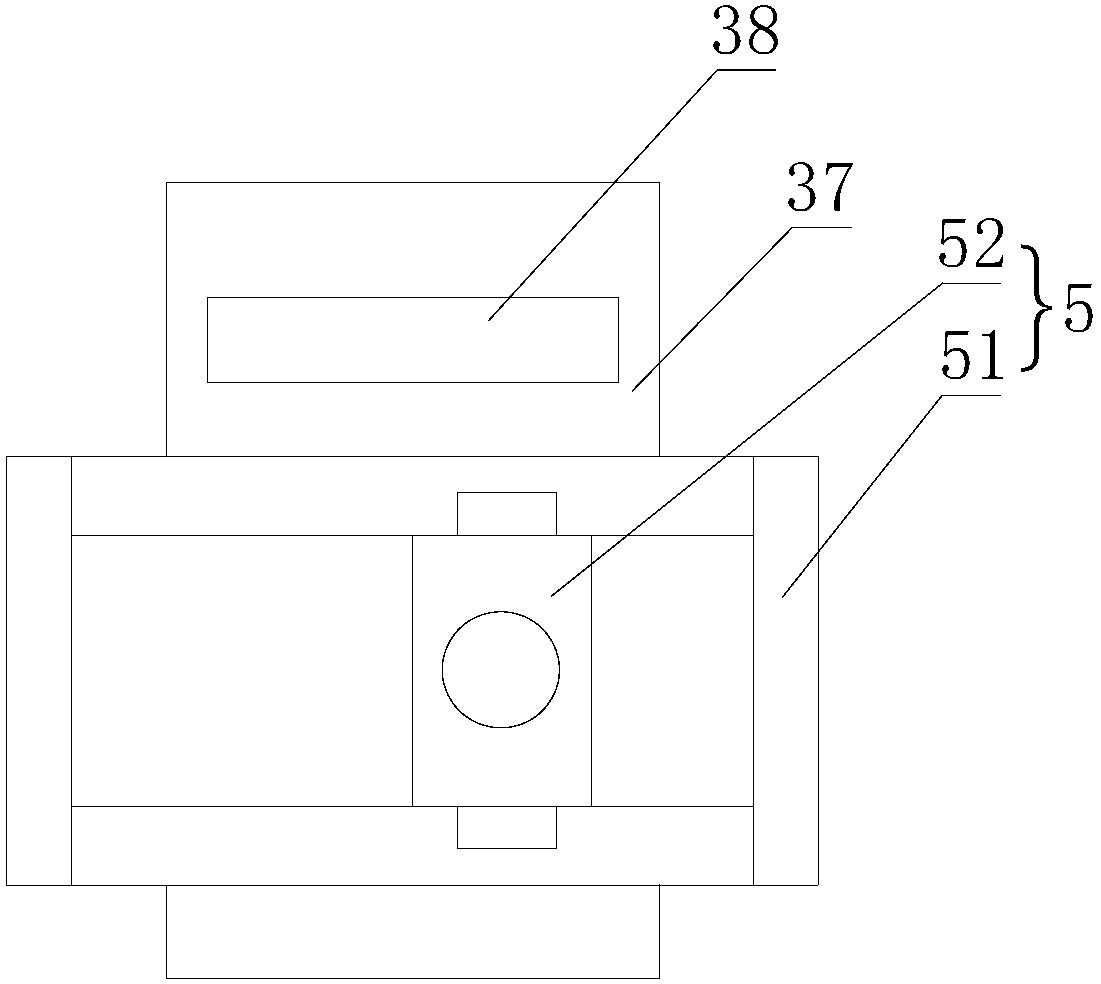

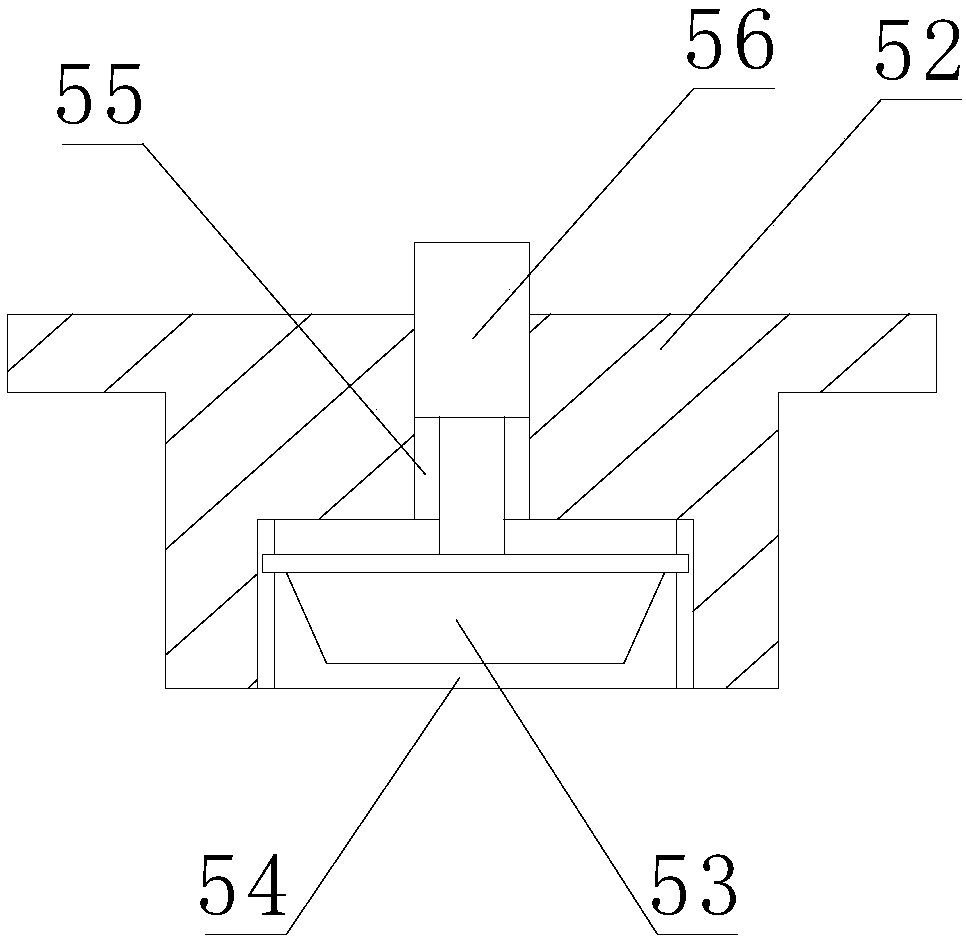

[0020] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a non-stop paper feeding device includes a frame 1 and two discharge shafts 2 arranged on the frame 1, and the rotation directions of the two discharge shafts 2 are set oppositely, and the frame 1 is also provided with a feeding Material guiding device 3, feeding guiding device 3 is arranged in the middle of two discharge shafts 2, and feeding guiding device 3 comprises frame 31 and two feed rollers 32 that are arranged in frame 31, and frame 31 is provided with driving feed roller. The driving roller 33 that the material roller 32 rotates, the driving roller 33 is connected with a driving motor 34, the driving motor 34 is connected with a PLC controller 35 that controls the forward rotation and reverse rotation of the driving motor 34, and the frame 31 is provided with a paper discharge mechanism. The discharge hole 30, the frame 31 is provided with a fixed plate 37, the fixed plate 37 is provided with an ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com