Patents

Literature

70results about How to "Guarantee normal production and operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler coke eliminating agent

InactiveCN1487262AReduce dosageEasy to useTreatment using complexing/solubilising chemicalsFlush cleaningMagnesium nitrateCopper nitrate

The present invention relates to the technology of cleaning the inner wall of boiler with chemical solution. The chemical solution consists of potassium nitrate, copper nitrate, magnesium nitrate, aluminum nitrate and boric acid; and it may be jetted via the observation hole to the flame area of operating boiler or sprayed to the surface of formed coke of idle boiler.

Owner:戴琦

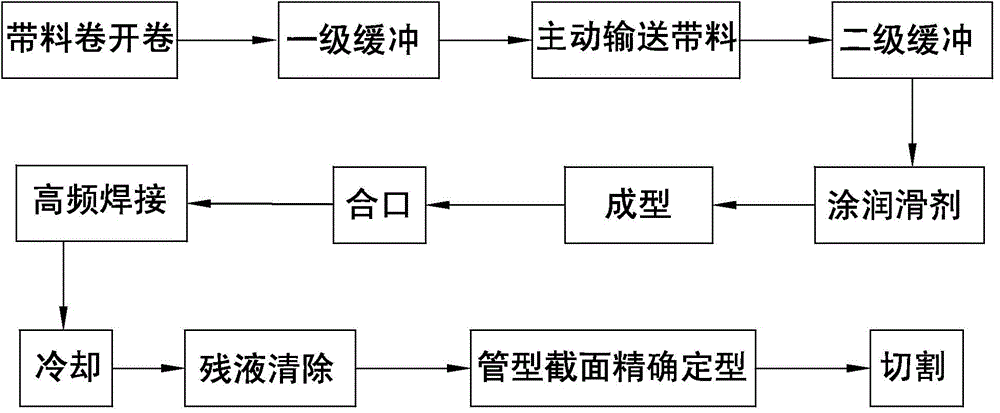

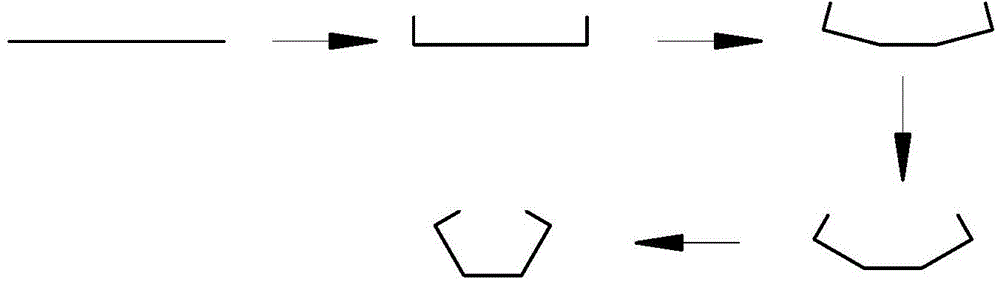

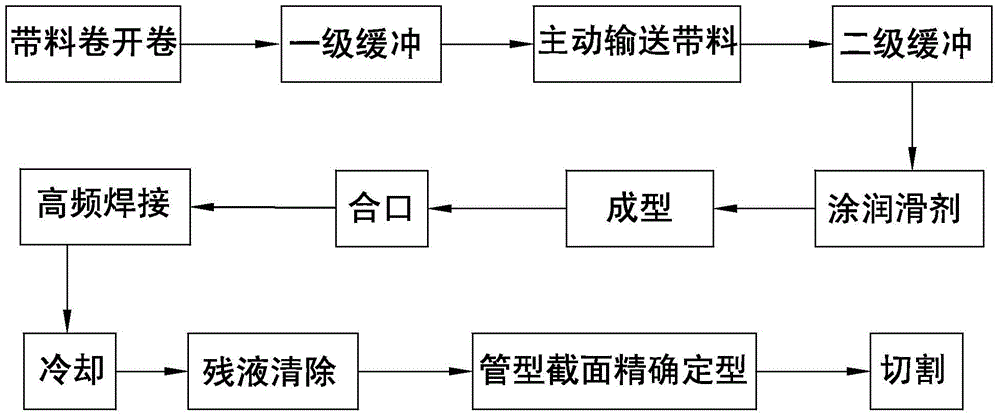

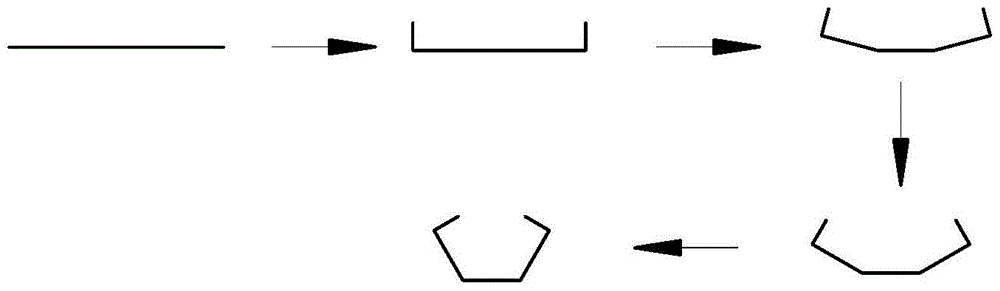

Machining method for thin-wall squared tube

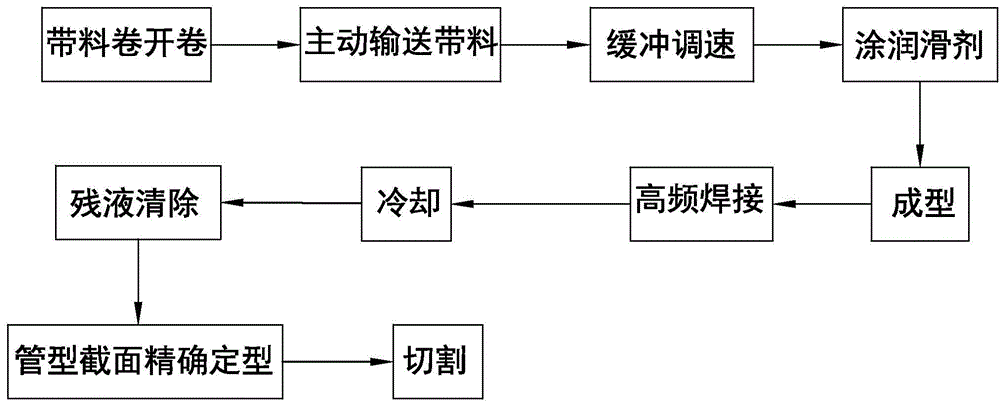

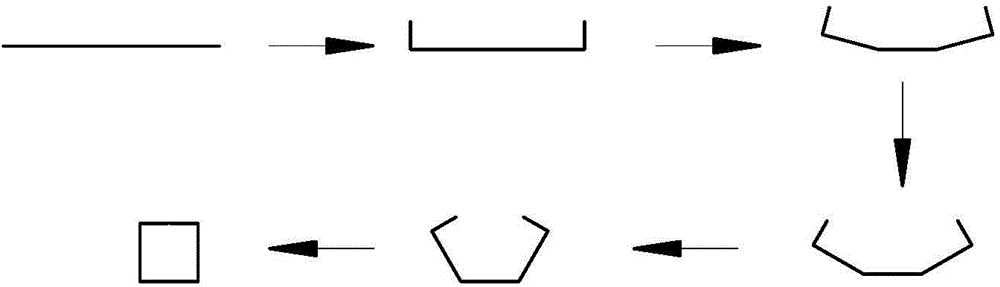

The invention discloses a machining method for a thin-wall squared tube and belongs to the technical field of square tube forming processes. The machining method for the thin-wall squared tube mainly includes the following steps that 1 a strip roll is decoiled, wherein the strip roll is unfolded and a strip is discharged; 2 the strip is conveyed actively, wherein the strip is discharged downstream under the action of traction force; 3 buffering speed governing is conducted, wherein the strip is discharged at a constant speed without the action of tensile force, and the active conveying frequency of the strip is controlled; 4 lubricant coating is conducted, wherein the two surfaces of the strip are coated with lubricants; 5 forming is conducted, wherein the strip is gradually bent in a cold mode, so that the strip forms a tube blank with a weld joint and a square section, and the weld joint is located on the upper surface of the tube blank; 6 high-frequency welding is conducted; 7 cooling is conducted; 8 residual liquor is cleaned away; 9 the tube section is accurately shaped; 10 cutting is conducted. The machining method solves the technical problems that existing thin-wall squared tubes are poor in forming quality and low in production efficiency, and the machining method is widely applied to manufacturing thin-wall squared tubes.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

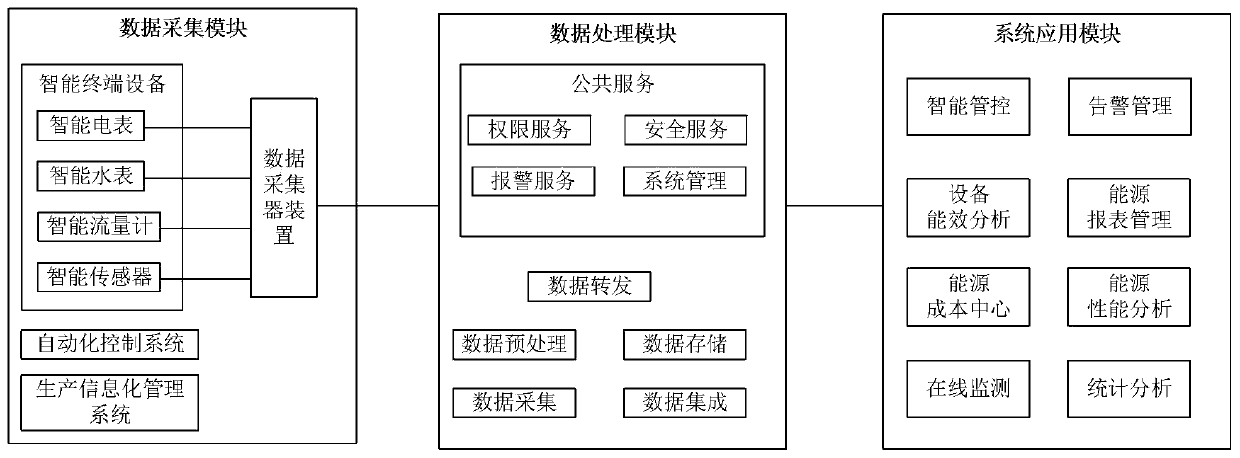

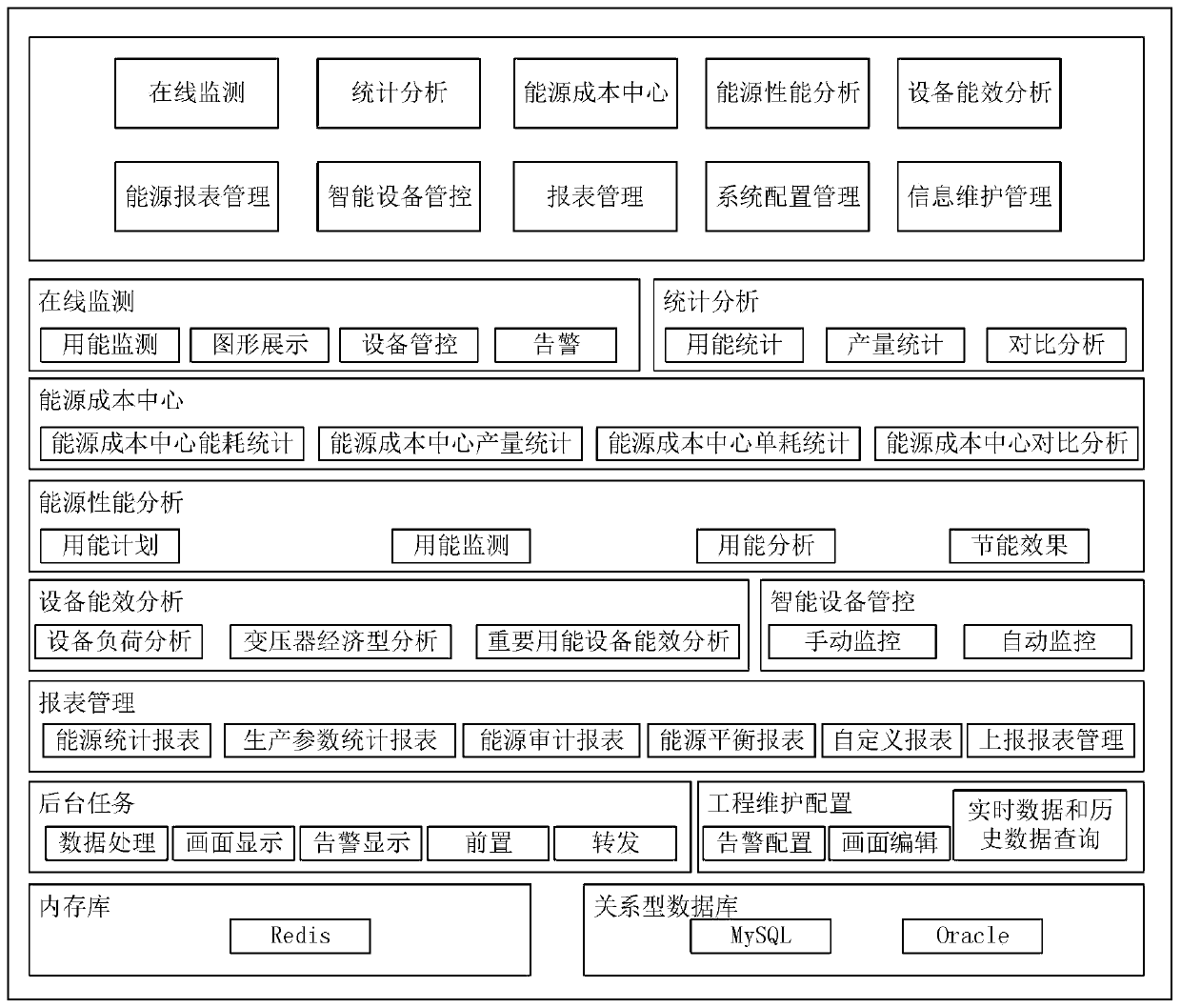

Enterprise comprehensive energy management and control system and method

InactiveCN111367241AGuarantee normal production and operationEnergy industryTotal factory controlStatistical analysisData acquisition

The invention relates to an enterprise comprehensive energy management and control system. The system comprises a data acquisition module, a data processing module and a system application module, andis characterized in that a data acquisition device is connected with intelligent terminal equipment to acquire real-time energy data, the data acquisition module is connected with the data processingmodule after acquiring the energy data, the production data and the yield data, and is used for processing, storing and forwarding the data, the system application module acquires the data processedby the data processing module and are used for performing on-line monitoring, statistical analysis, energy cost analysis, energy performance analysis, equipment energy efficiency analysis, energy report management, intelligent equipment management and control and alarm management of energy of an industrial enterprise. The system is advantaged in that through real-time monitoring comprehensive energy information management, energy consumption monitoring and management analysis of enterprise comprehensive energy consumption are realized, energy consumption is reduced, and the overall effect andefficiency of energy-saving work are improved.

Owner:HEFEI POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER

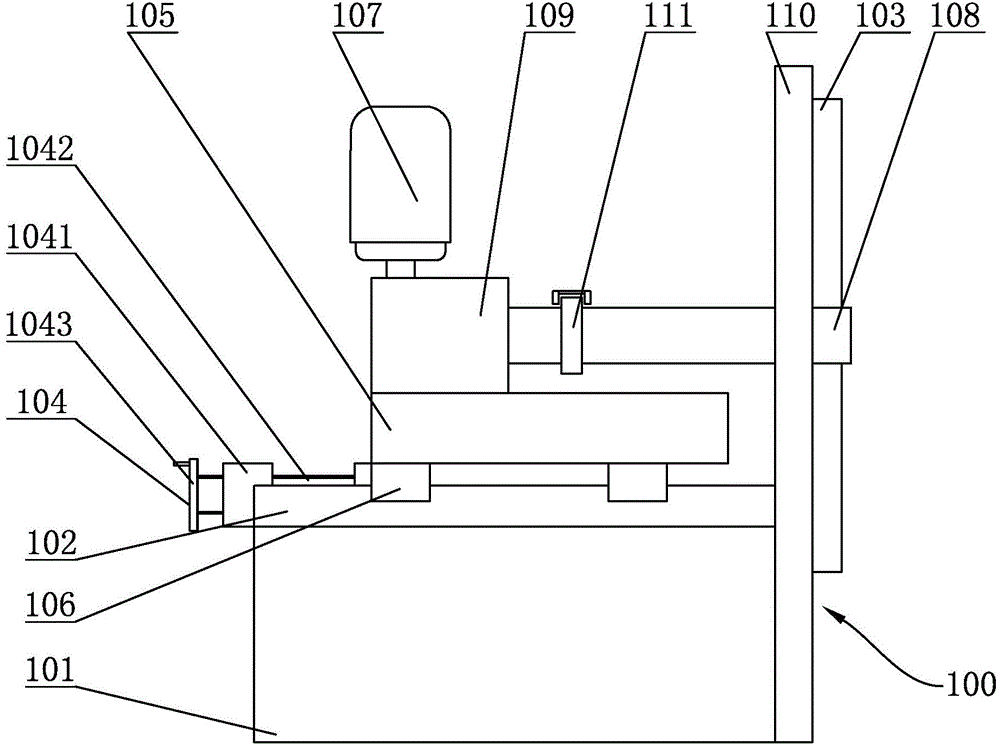

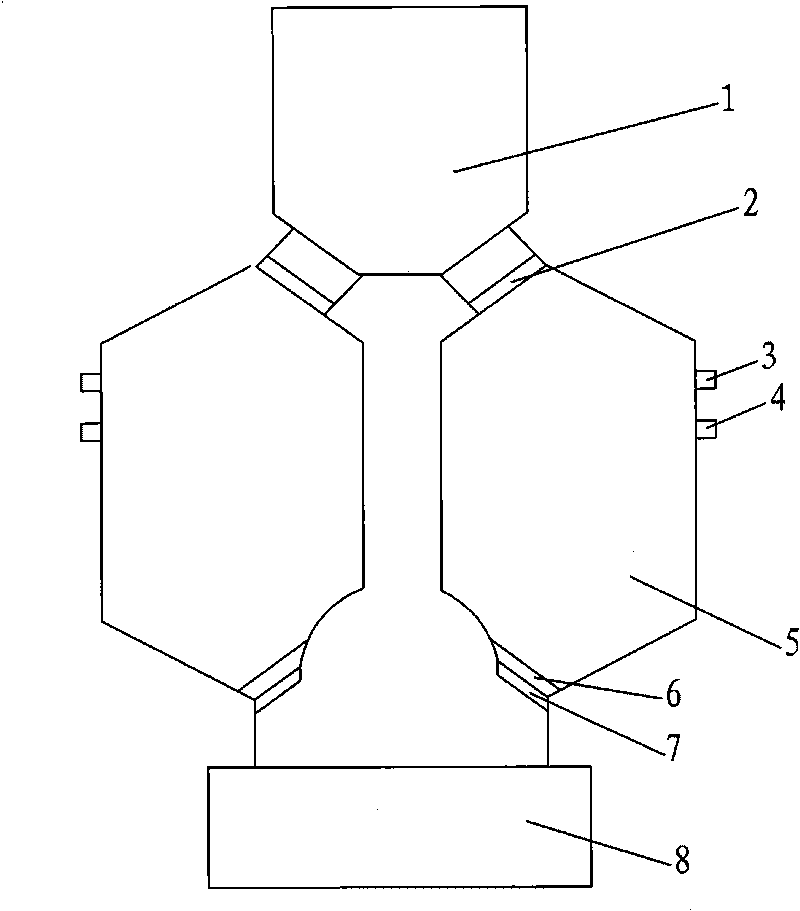

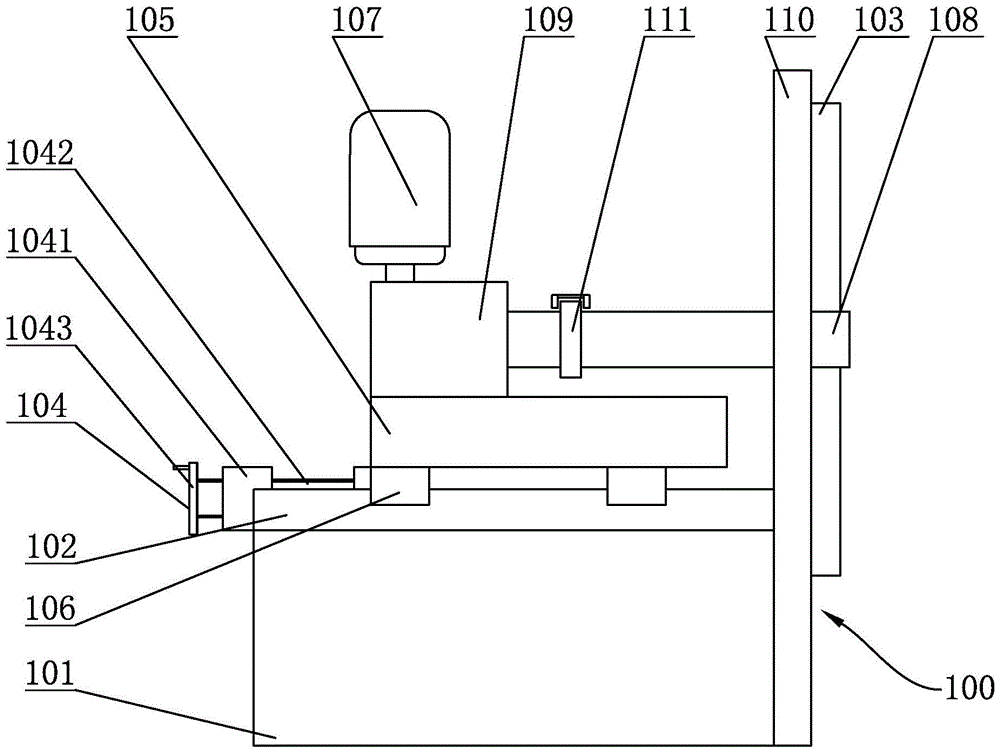

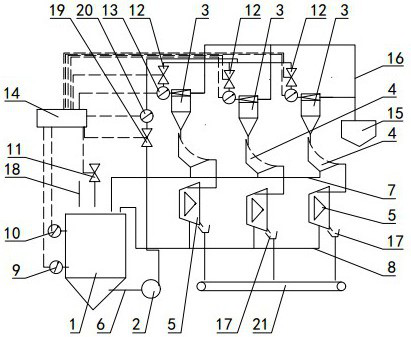

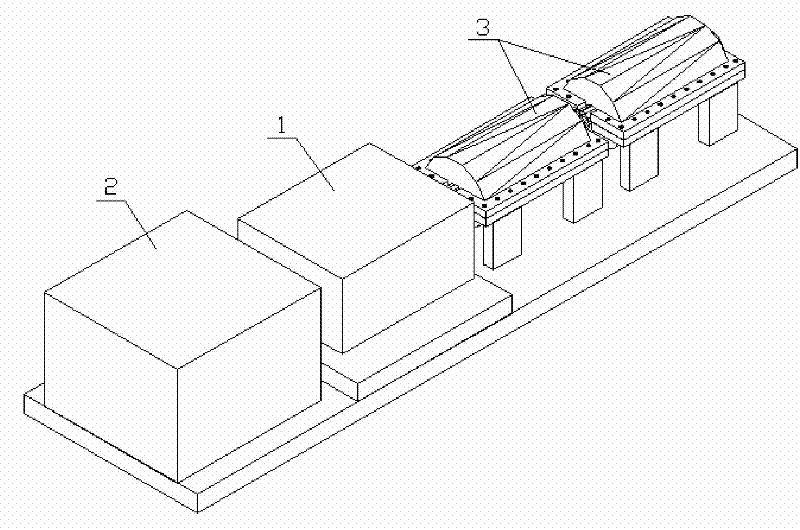

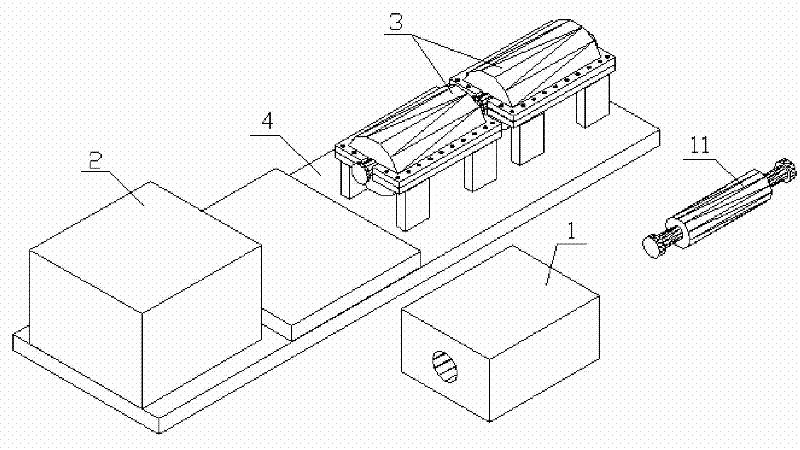

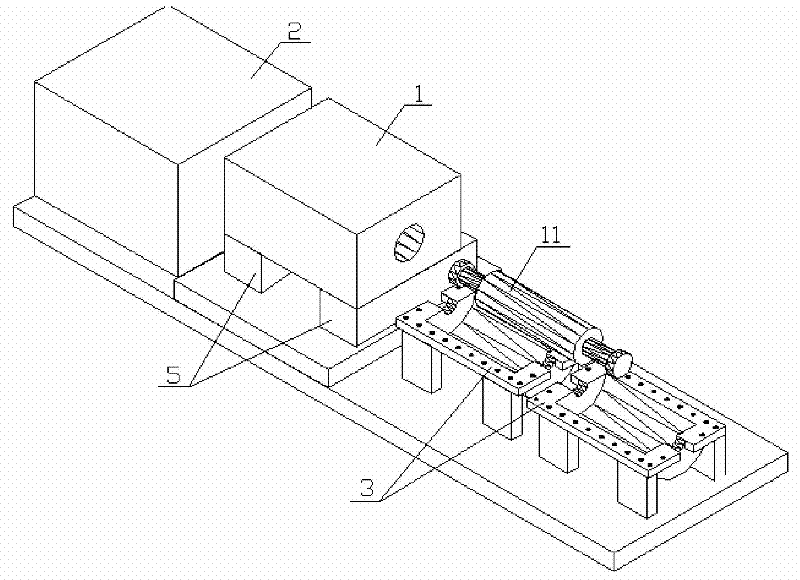

Machining device of square tubes made of thin-wall strips

InactiveCN104625753AEasy to weldEasy to weld and formOther manufacturing equipments/toolsEngineeringLubricant

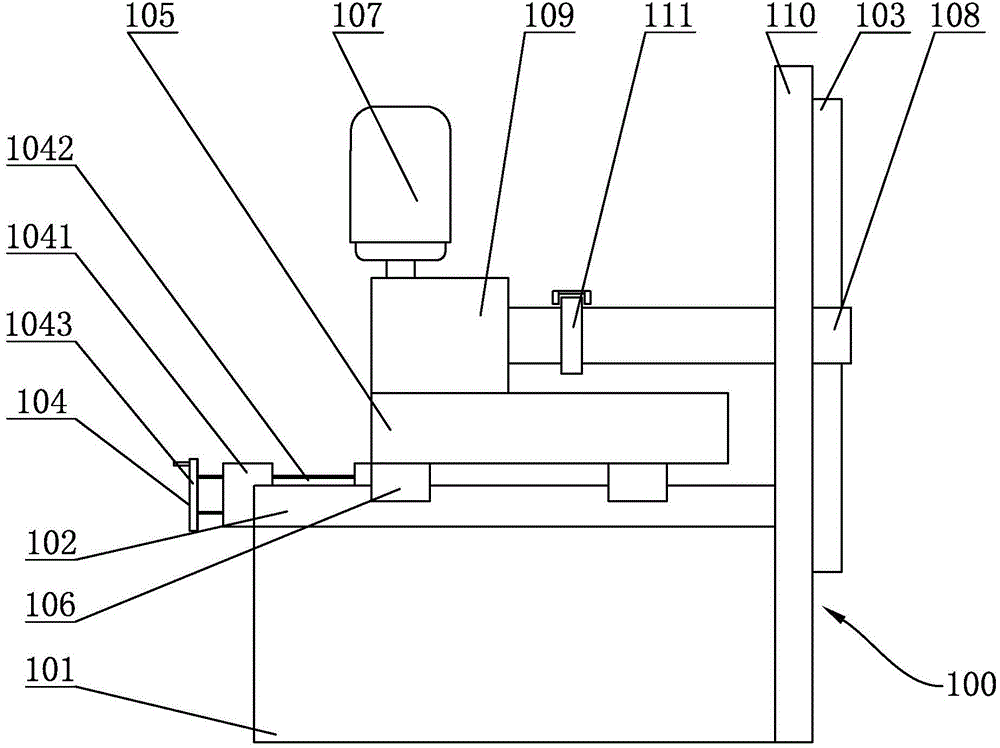

The invention discloses a machining device of square tubes made of thin-wall strips and belongs to the technical field of square tube forming equipment. According to the strip conveying direction, the machining device mainly comprises a strip decoiling device, a primary buffering device, an active strip conveying device, a secondary buffering device, a strip surface lubricant coating device, a forming device, a tube blank shaping device, a high-frequency welding device, a post-welding cooling device, a surface residual liquid removing device, a square tube shaping device and a cutting device which are arranged in sequence. The machining device solves the technical problems that existing thin-wall square tubes are poor in forming quality and low in production efficiency, and the machining device is widely applied to manufacturing the thin-wall square tubes.

Owner:佛山市九钢制管有限公司

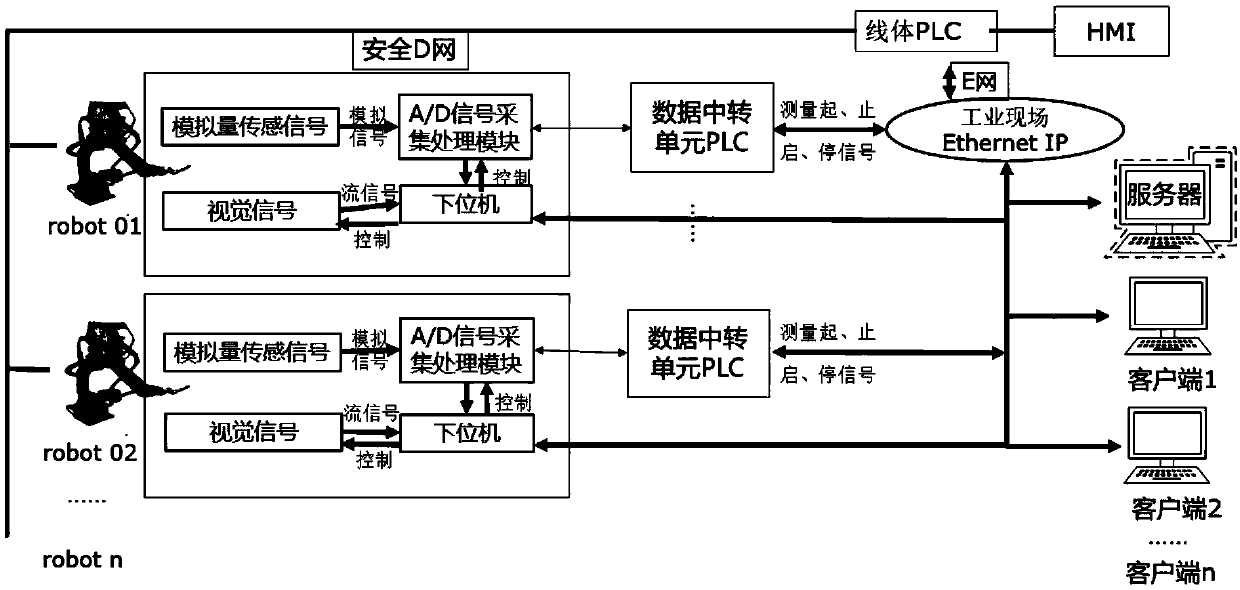

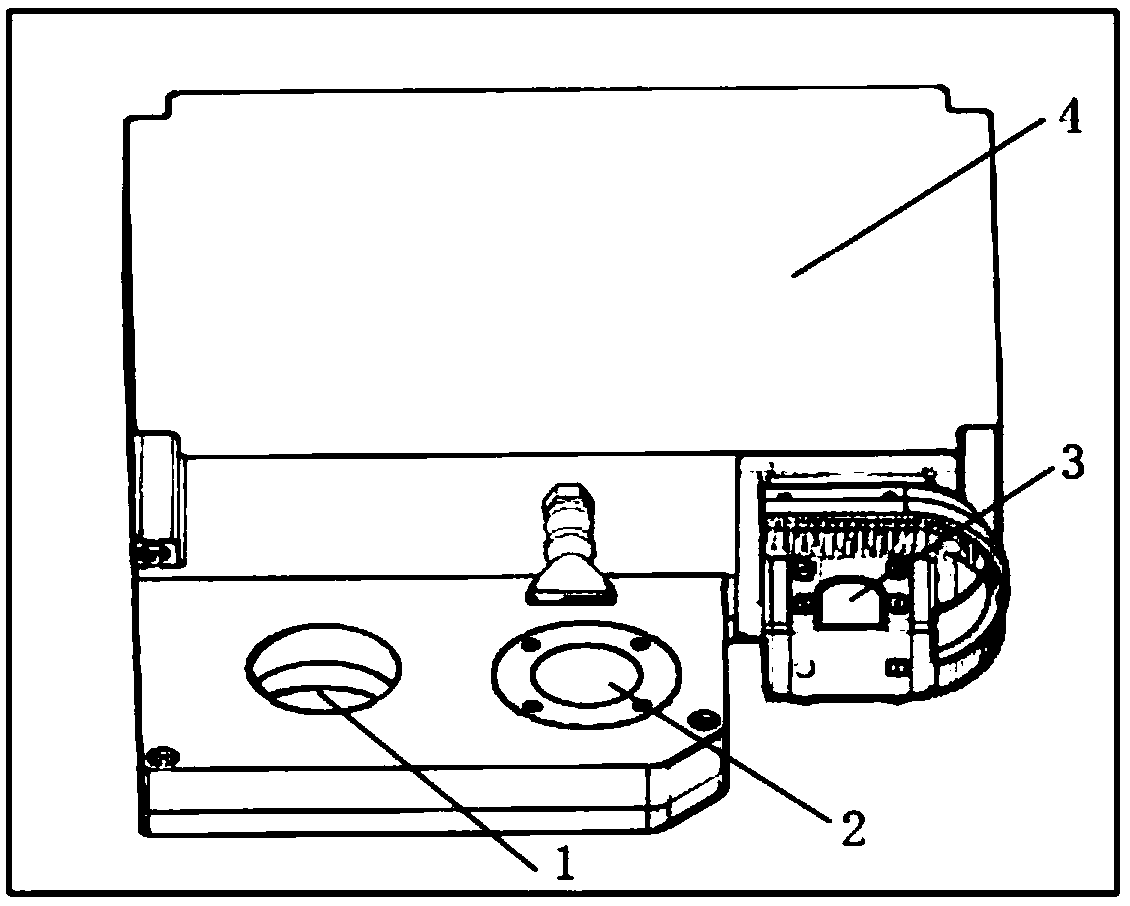

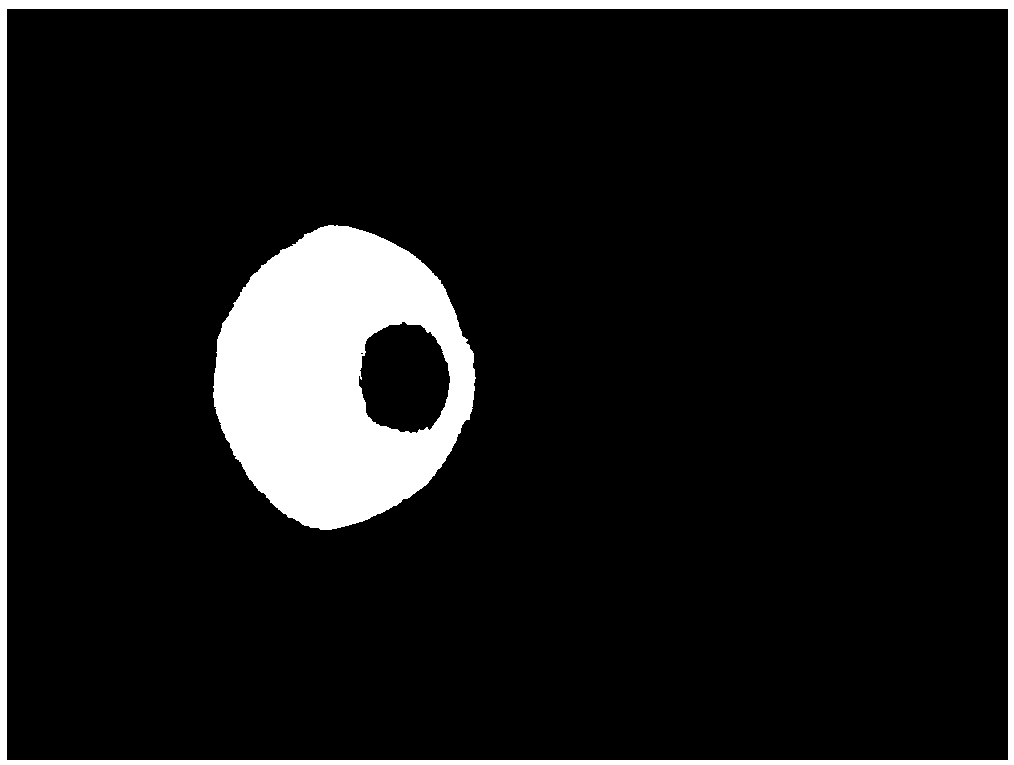

Feedforward type electric resistance welding quality monitoring system and method

ActiveCN109664009AEasy to installLow costWelding monitoring devicesElectrical resistance and conductanceEngineering

The invention discloses a feedforward type electric resistance welding quality monitoring system and method. The system includes a server and a sensor group fixedly arranged in a working area and non-working area of an electric resistance welding gun, the sensor group is in signal connection with the server, and the sensor group includes an analog quantity sensing signal detection window, an A / D signal acquisition processing circuit, a visual signal detection window and lower computer. The method comprises the following steps that (1) the electric resistance welding gun to be detected is controlled to be periodically in the sensing signal detection window and the visual signal detection window; (2) analog quantity signals detected by the analog sensing signal detection window are collected; (3) end face pictures of upper and lower electrode caps are collected; and (4), whether the analog quantity signals are within a normal range is judged, and whether the upper and lower electrode caps are centered and the grinding states of the electrode caps are judged according to the upper and lower electrode cap pictures. Early warning can be carried out, maintenance and repair are pulled, and therefore generation and overflow of defective solder joints are reduced or even avoided.

Owner:武汉百舸自动化工程有限责任公司

Single-bucket serial-bucket charging method applied to bell-free blast furnaces

InactiveCN101709340AReduce the shutdown rateGuarantee normal production and operationBlast furnace detailsEngineeringBlast furnace

The invention discloses a single-bucket serial-bucket charging method applied to bell-free blast furnaces. The method comprises: taking a material-receiving hopper and one failure-free charging bucket as an upper charging bucket and a lower charging bucket connected in series; adding a car of material to the upper charging bucket first in a charging process and discharging the material through the lower charging bucket; putting the material in the upper charging bucket into the lower charging bucket and putting a car of material into the lower charging bucket at a normal charging speed through a hoist skip car at the same time; putting two cars of material in the lower charging bucket into a blast furnace under the control of a blast furnace control computer so as to finish the process of charging the blast furnace; and repeating the steps. Therefore, when a certain charging-bucket equipment system breaks down, a single normal charging bucket can still be utilized to continue production so as to prevent the blast furnace from damping down, ensure that the blast furnace can continue to produce and meet requirements for charging capacity and charging speed.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Process technology for guaranteeing continuous production of industrial microwave facilities

InactiveCN102012154AExtended service lifeControl moisture contentDrying solid materials with heatHearth type furnacesThermal energyMicrowave

The invention discloses a process technology for guaranteeing continuous production of industrial microwave facilities. In the invention, microwave is adopted to penetrate into the interior of a material so that the exterior and the interior of the material generate heat energy at the same time, the phenomenon of dry exterior and wet interior doest not exist, and the water ratio of the material is controlled by controlling the radiation time of the material by the microwave; double-sided cooling is carried out on a multiple tube microwave generating source, thus improving the service life of the microwave generating source; and at the same time, a distributing device and a dustproof airtight device are respectively arranged on a feeding funnel and a hopper, thus preventing the leakage and dust raising of the material during the transporting process, improving the material transporting efficiency, and reducing environmental pollution and harm to the health of workers.

Owner:HENAN BODA MICROWAVE EQUIP

Ash-coke-removal fire-aid anti-corrosion additive for use on fire-side of boiler

The invention is a boiler flame-side dust-cleaning, coke-cleaning, combustion-supporting, corrosion-resistant four-effect additive, belonging to the additive field, and it is a water solution prepared of the following matters: KNO3 5-8wt%, KNO2 2-5wt%, Mg(NO3)2.6H2O 12-15wt%, Cu(NO3)2.3H2O 1.5-2.2wt%, Al(NO3)3.9H2O 2.5-4wt%, H3BO3 0.2-1.3wt% and the rest water. And its advantage is solving the problems of large dosage of coke-cleaning agent, hard to put in, environmental pollution, single effect, etc.

Owner:UNIV OF SCI & TECH BEIJING

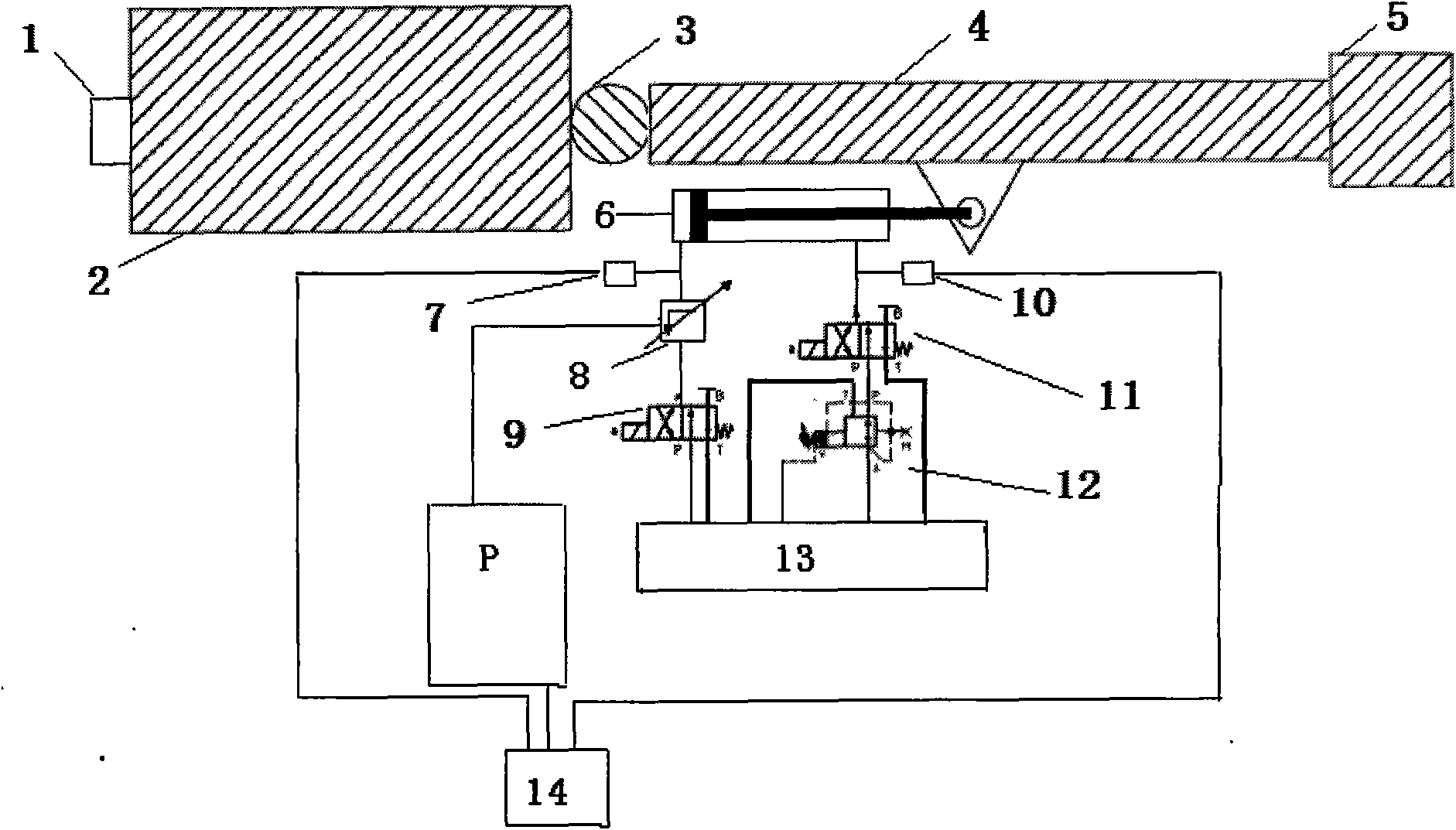

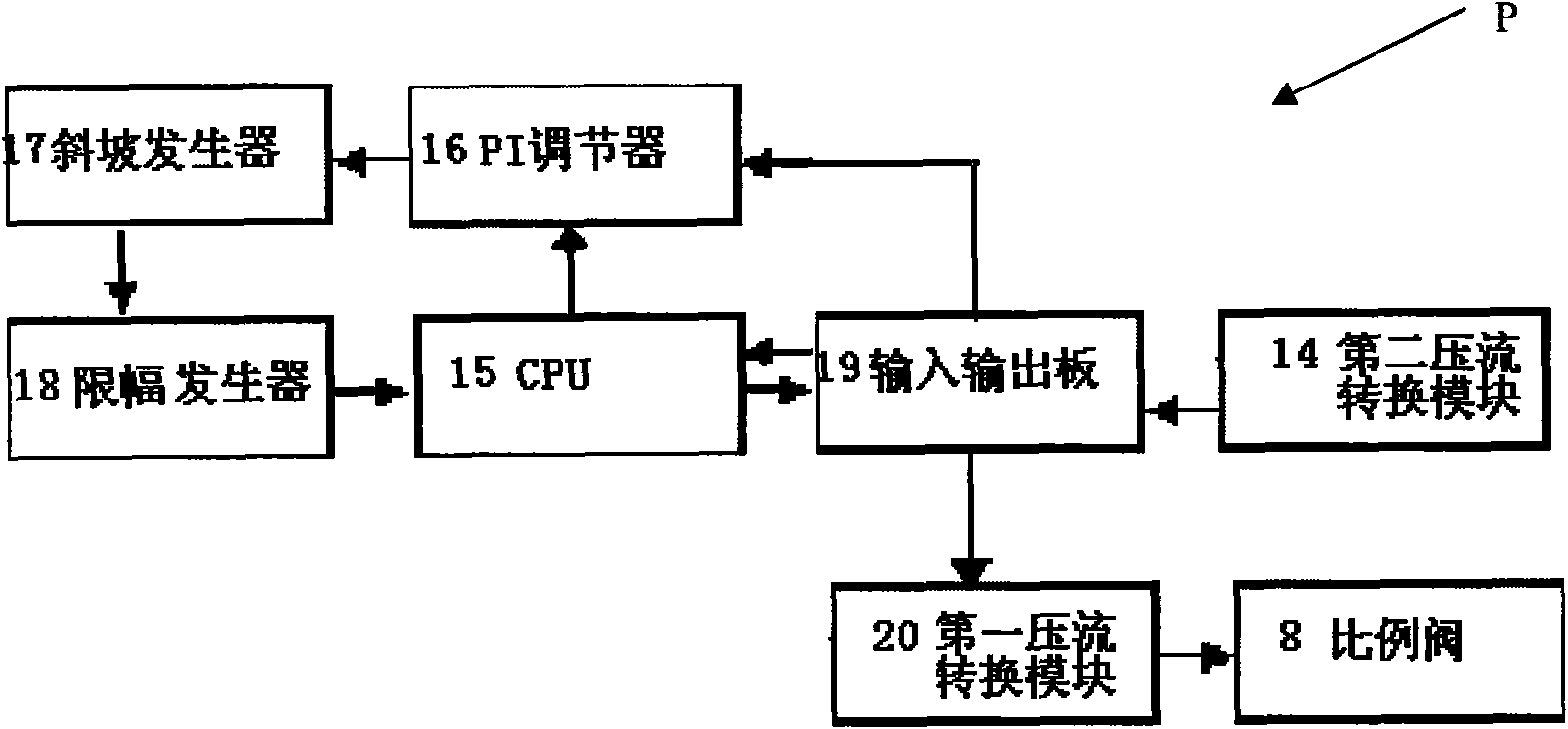

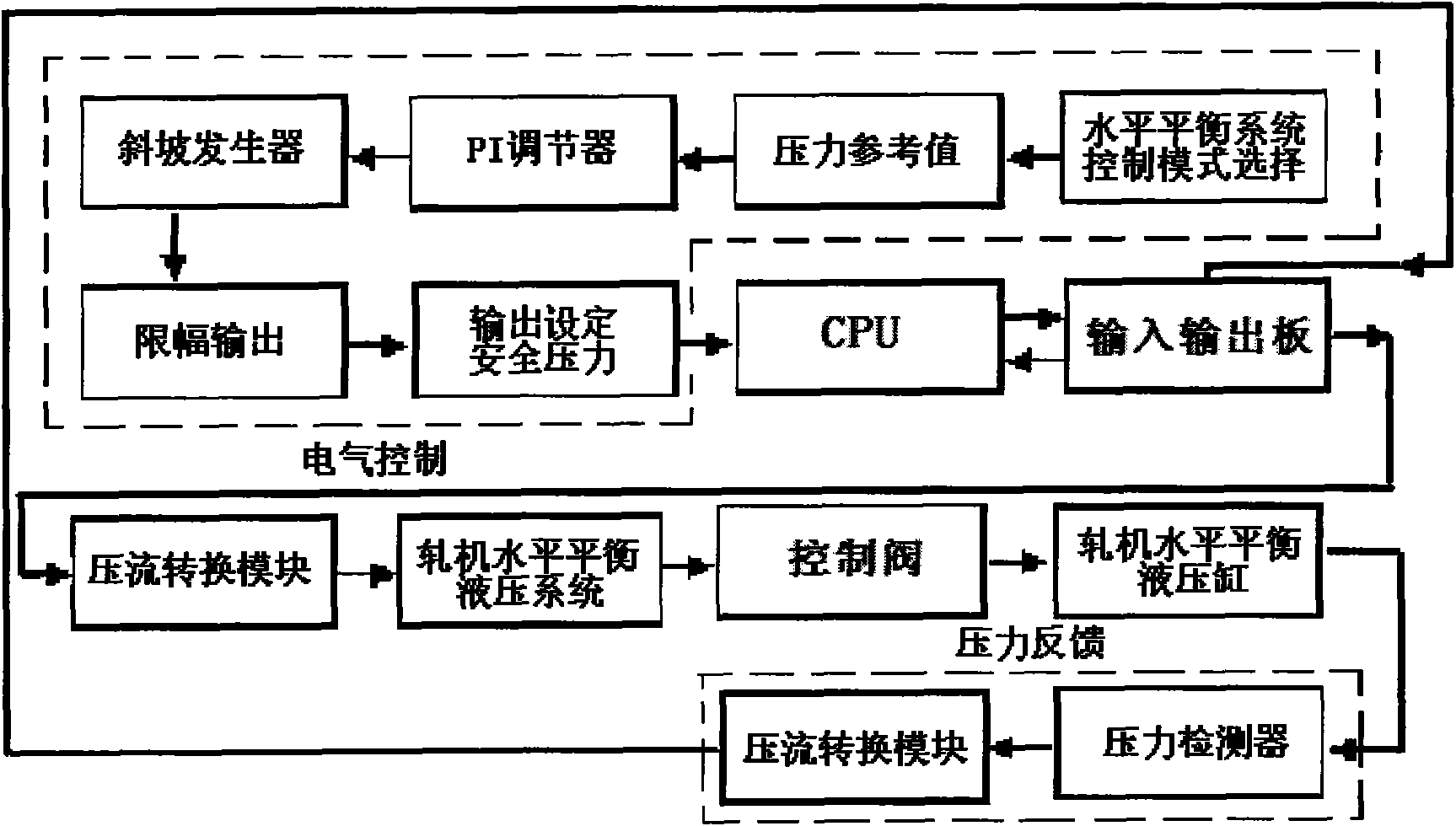

Device and method for controlling safe pressure of horizontal balance system of rolling mill

ActiveCN101992217AAchieve safe pressure protectionAvoid equipment damage accidentsRolling equipment maintainenceRoll mill control devicesInput/outputData lines

The invention discloses a device for controlling the safe pressure of a horizontal balance system of a rolling mill. The device comprises an electric control system and a hydraulic execution system connected with the electric control system through a data line, the electric control system comprises a CPU (Central Processing Unit), a PI (Proportional Integral) regulator, a amplitude-limiting generator, an input / output board and a pressure flow conversion module, can calculate corresponding pressure values according to different cascading modes of the rolling mill and then limit the amplitude so as to output minimum balance force. Accordingly, the invention also discloses a method for controlling the safe pressure of the horizontal balance system of the rolling mill. The method is simple and convenient to operate and can ensure the long-term safe and stable operation of the system.

Owner:BAOSHAN IRON & STEEL CO LTD

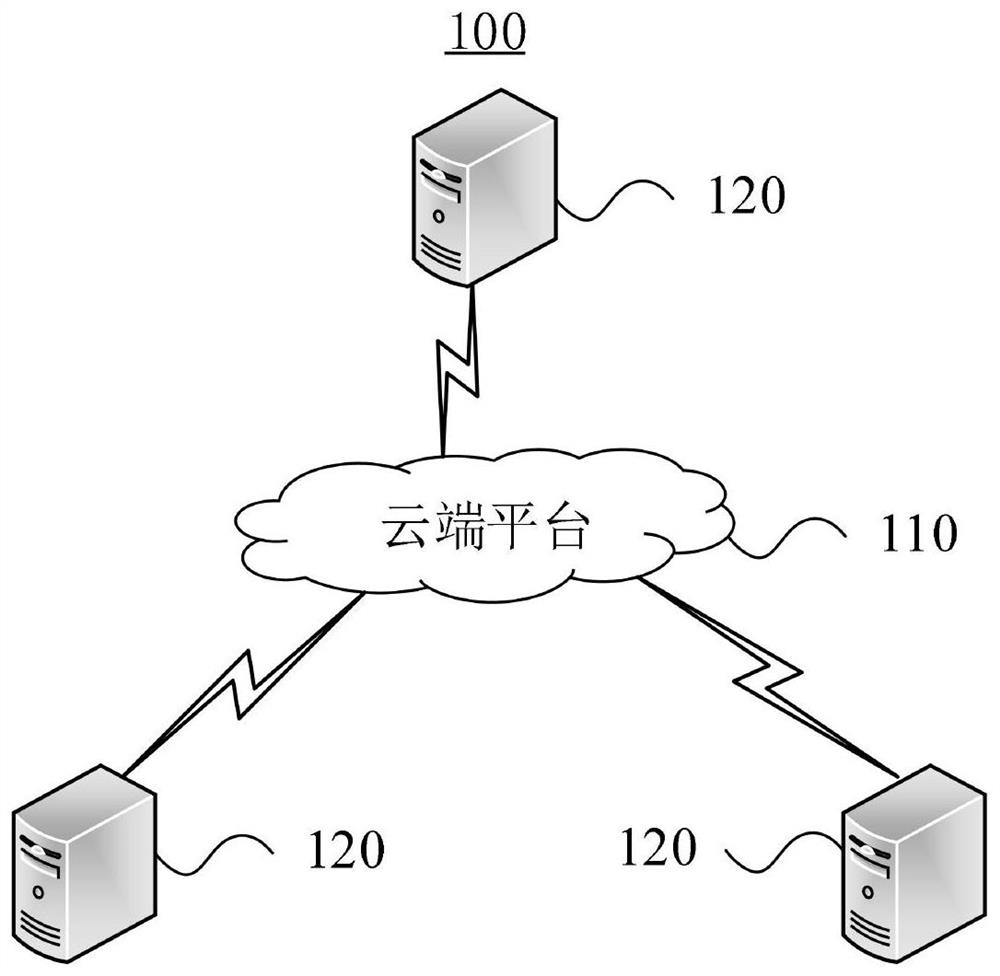

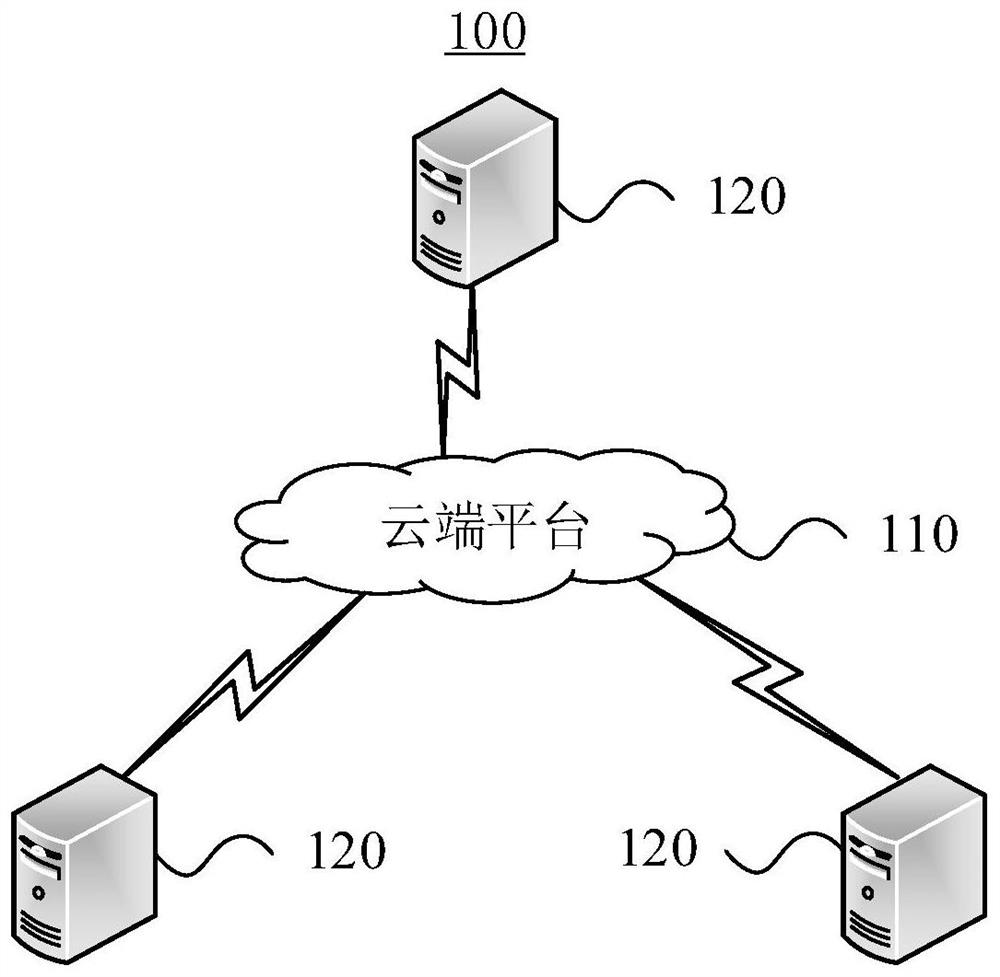

Service data processing method based on cloud network fusion and artificial intelligence, and cloud platform

ActiveCN111984383AAvoid OverloadingLower latencyProgram initiation/switchingPathPingResource information

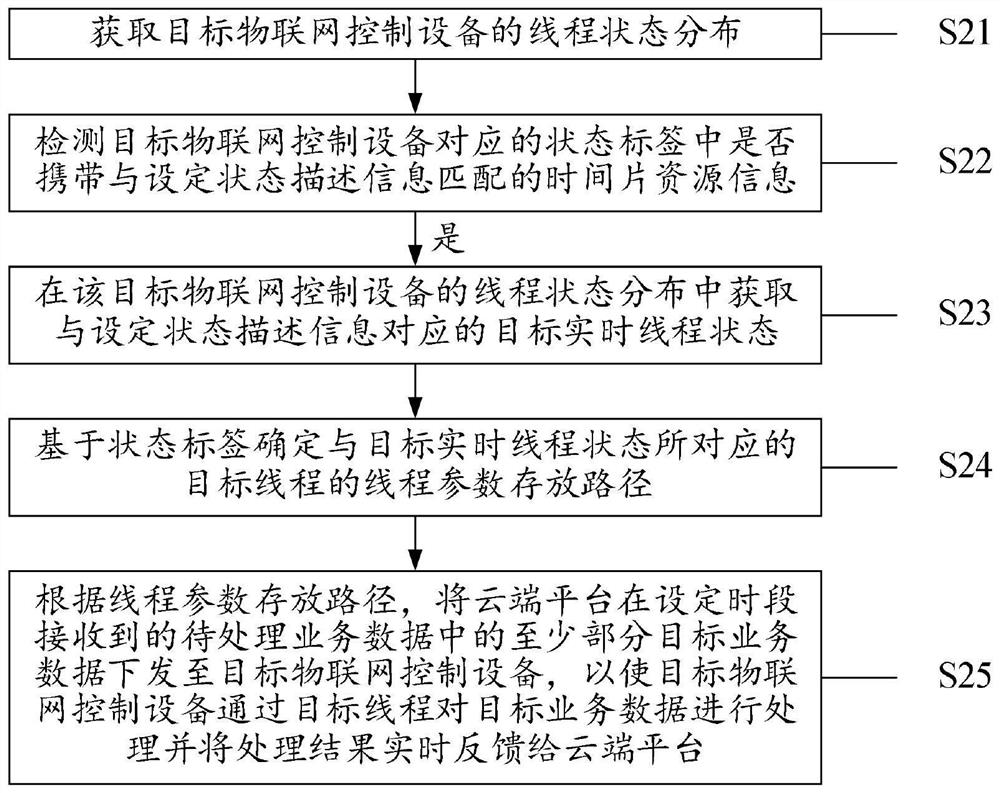

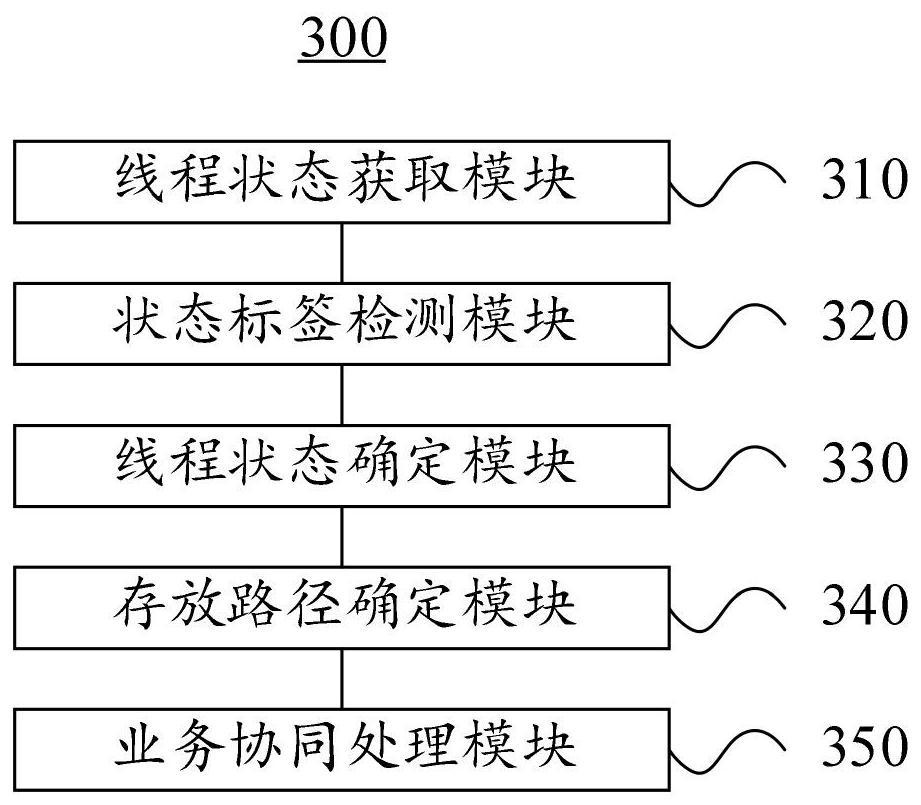

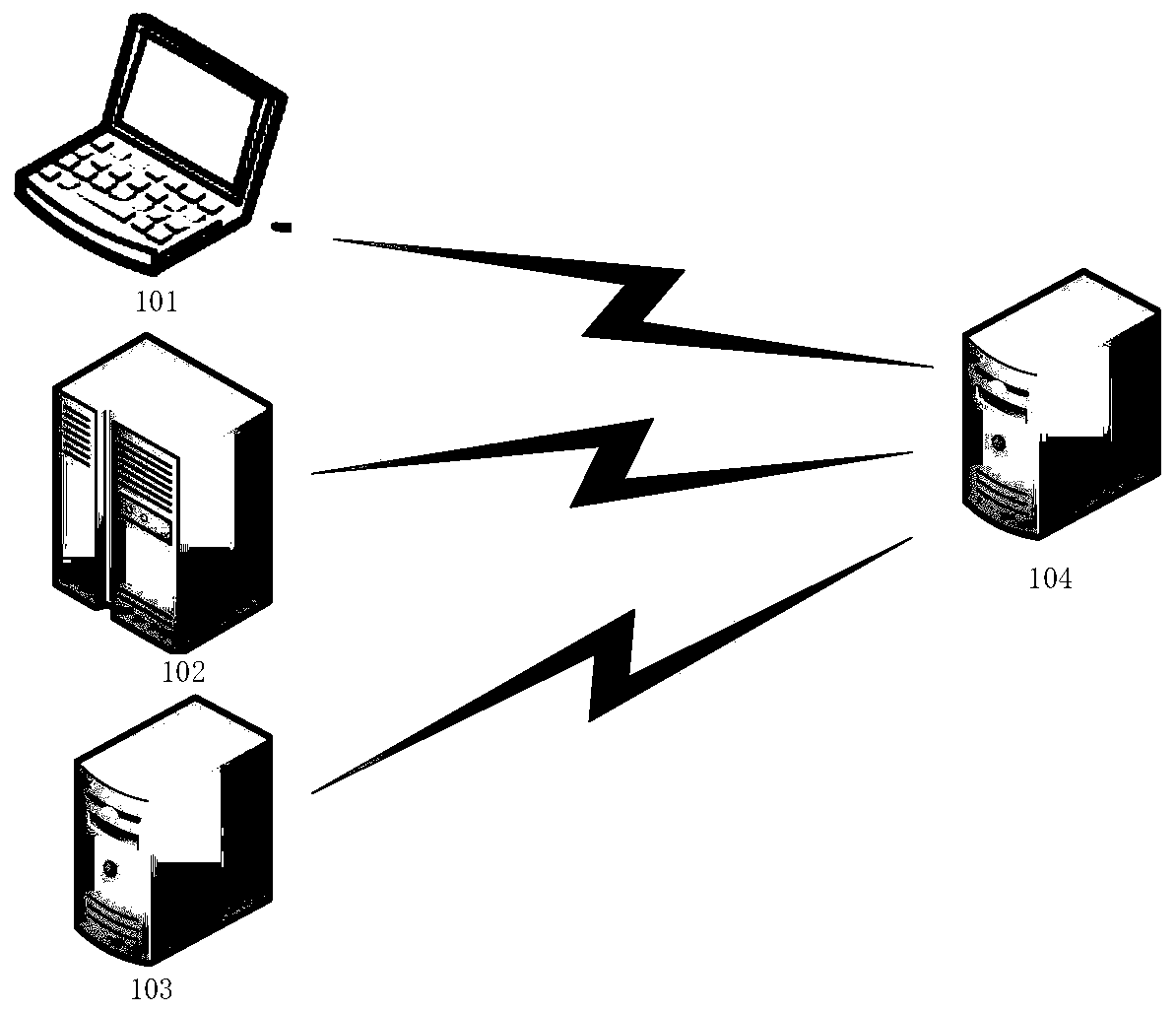

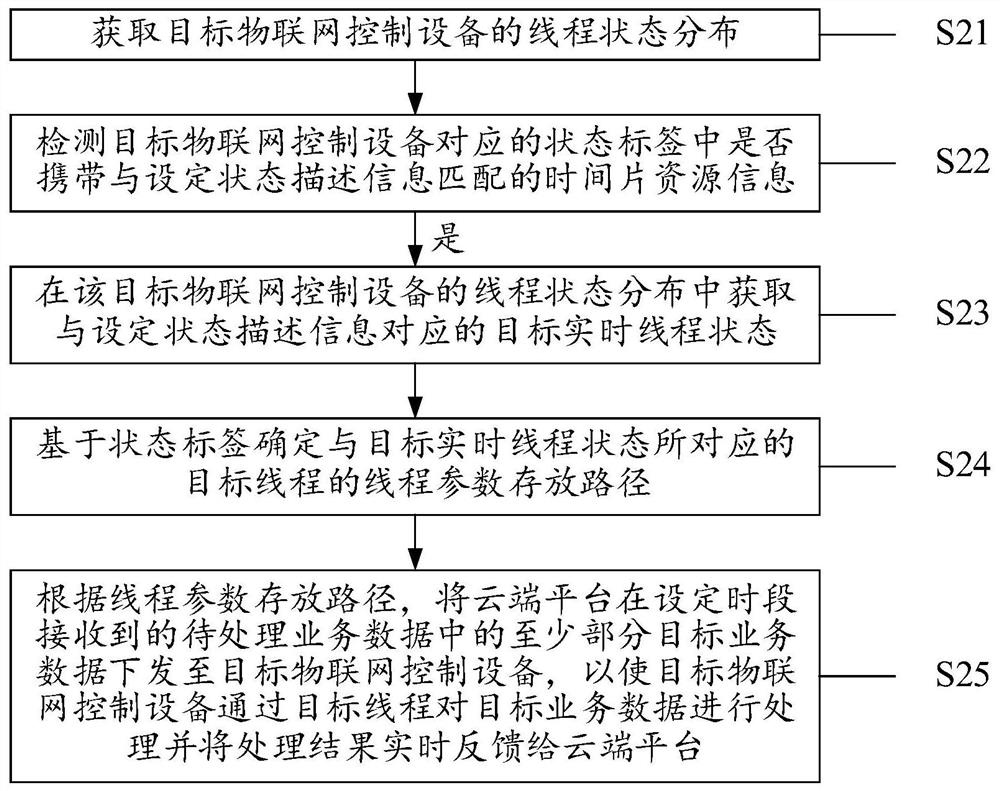

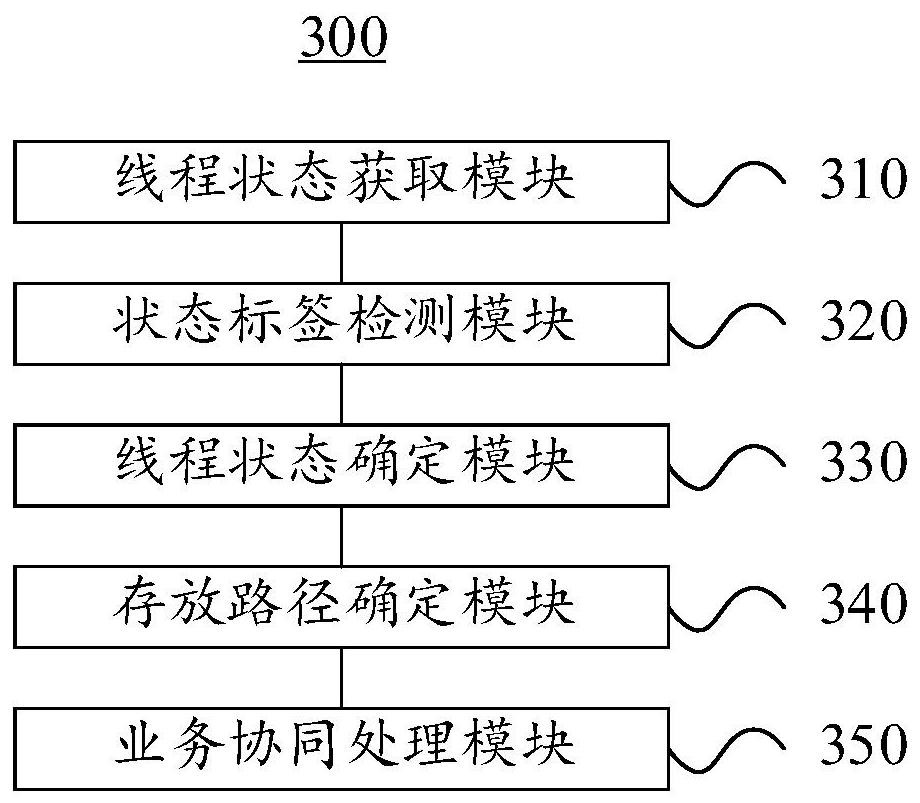

The invention provides a service data processing method based on cloud network fusion and artificial intelligence, and a cloud platform. The method comprises the following steps: firstly, obtaining thread state distribution of target Internet of Things control equipment; secondly, acquiring a target real-time thread state corresponding to the preset state description information from thread statedistribution of the target Internet of Things control equipment when detecting that a state label corresponding to the target Internet of Things control equipment carries time slice resource information; then determining a thread parameter storage path of a target thread corresponding to the target real-time thread state based on the state label after detecting that the authorization authentication check code exists in the service co-processing protocol at present; and finally issuing at least part of target service data to target Internet of Things control equipment according to the thread parameter storage path. Thus, the target Internet of Things control equipment can perform cooperative processing on the target service data through the target thread, cooperation between the cloud platform and part of the Internet of Things control devices is realized, and overload of the cloud platform is avoided.

Owner:上海悟景信息科技有限公司

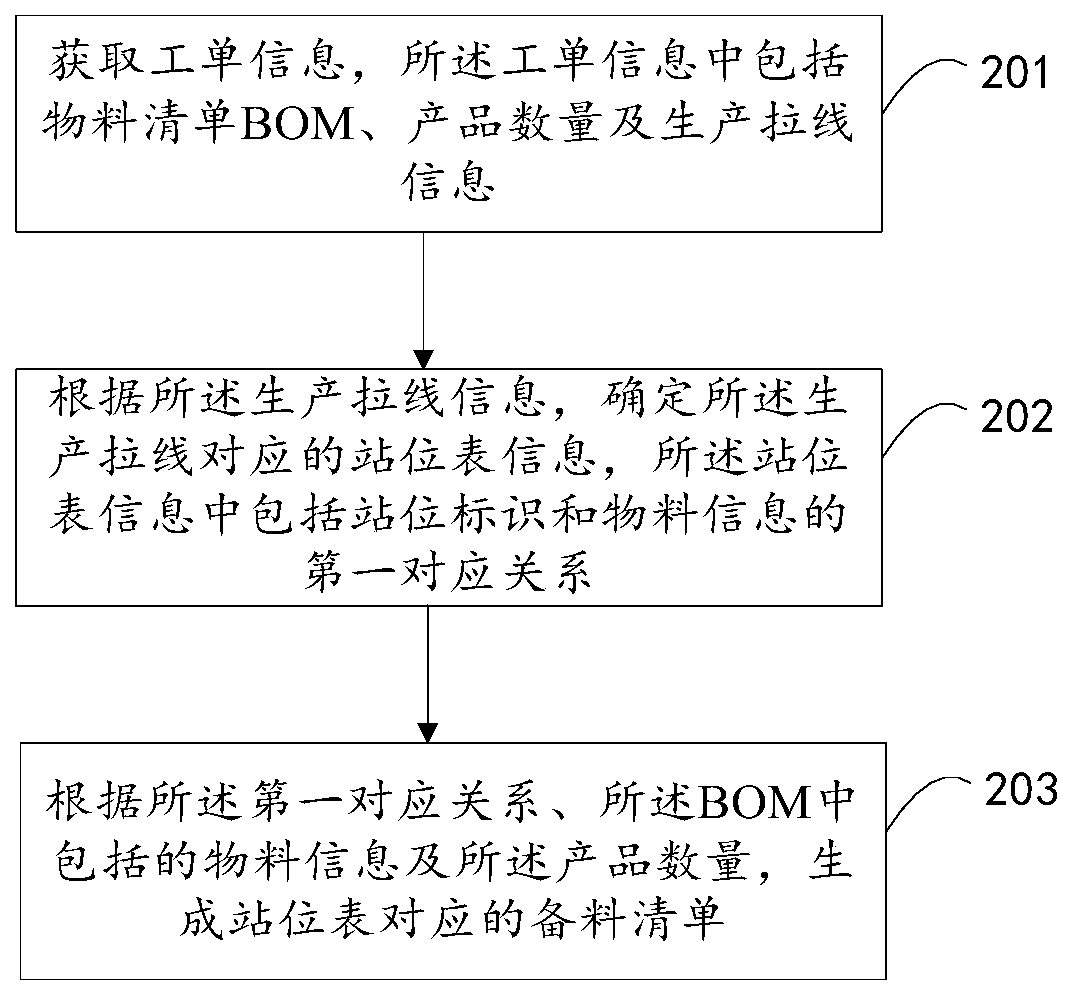

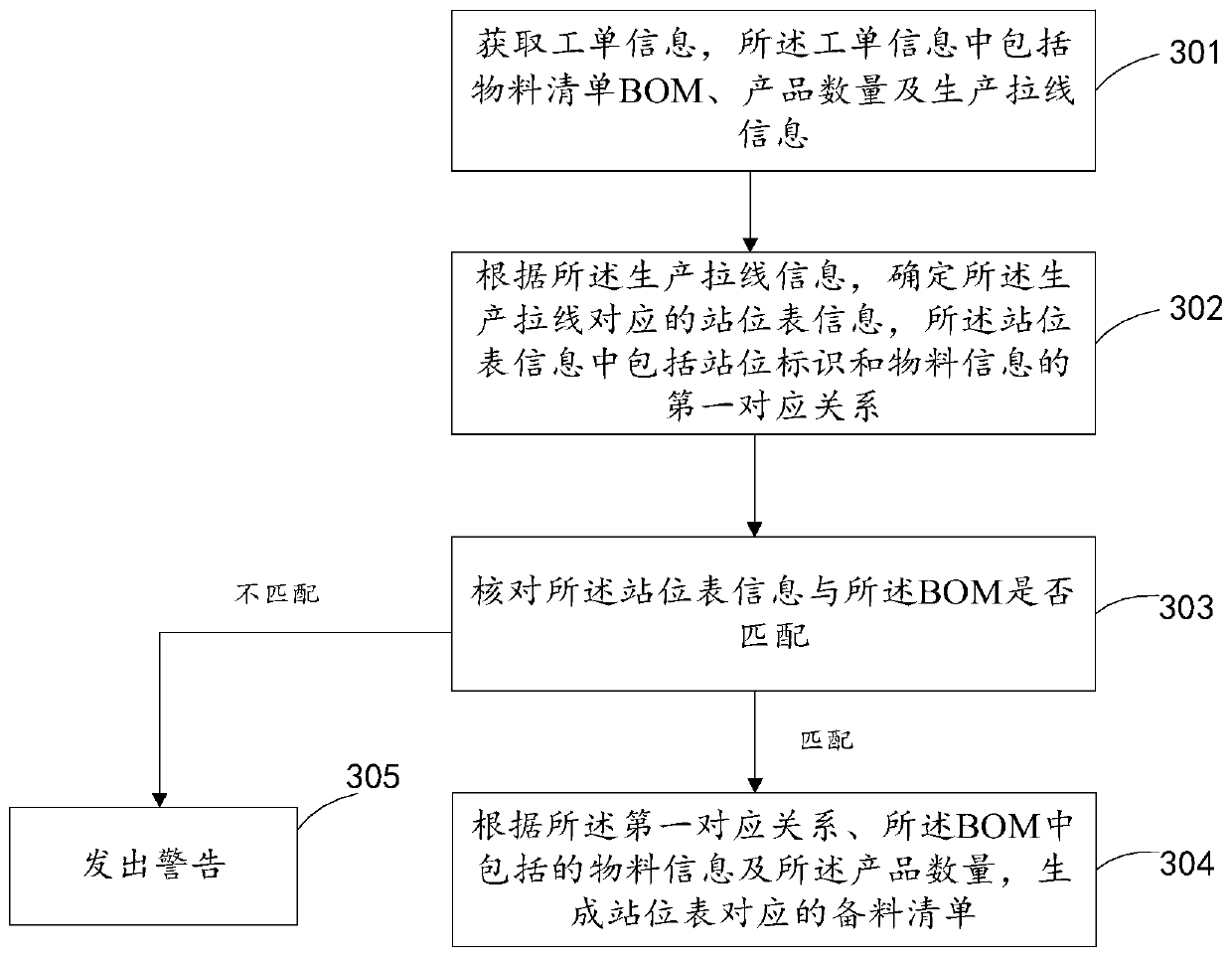

Method and device for generating stock list and electronic equipment

ActiveCN110490523AGuarantee normal production and operationImprove efficiencyLogisticsManufacturing computing systemsProduction lineBill of materials

The invention provides a stock list generation method and device and electronic equipment, and the method comprises the steps: obtaining work order information which comprises a BOM (bill of materials), the number of products, and production line drawing information; according to the production stay wire information, determining station table information corresponding to the production stay wire,wherein the station table information comprises a first corresponding relation between station identifiers and material information; and generating a stock list corresponding to the station table according to the first corresponding relationship, the material information included in the BOM and the product number. Compared with the mode of manually generating the stock list, the s method and device not only improve the efficiency, but also reduce the probability of misoperation, and ensure the normal production and operation of enterprises.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

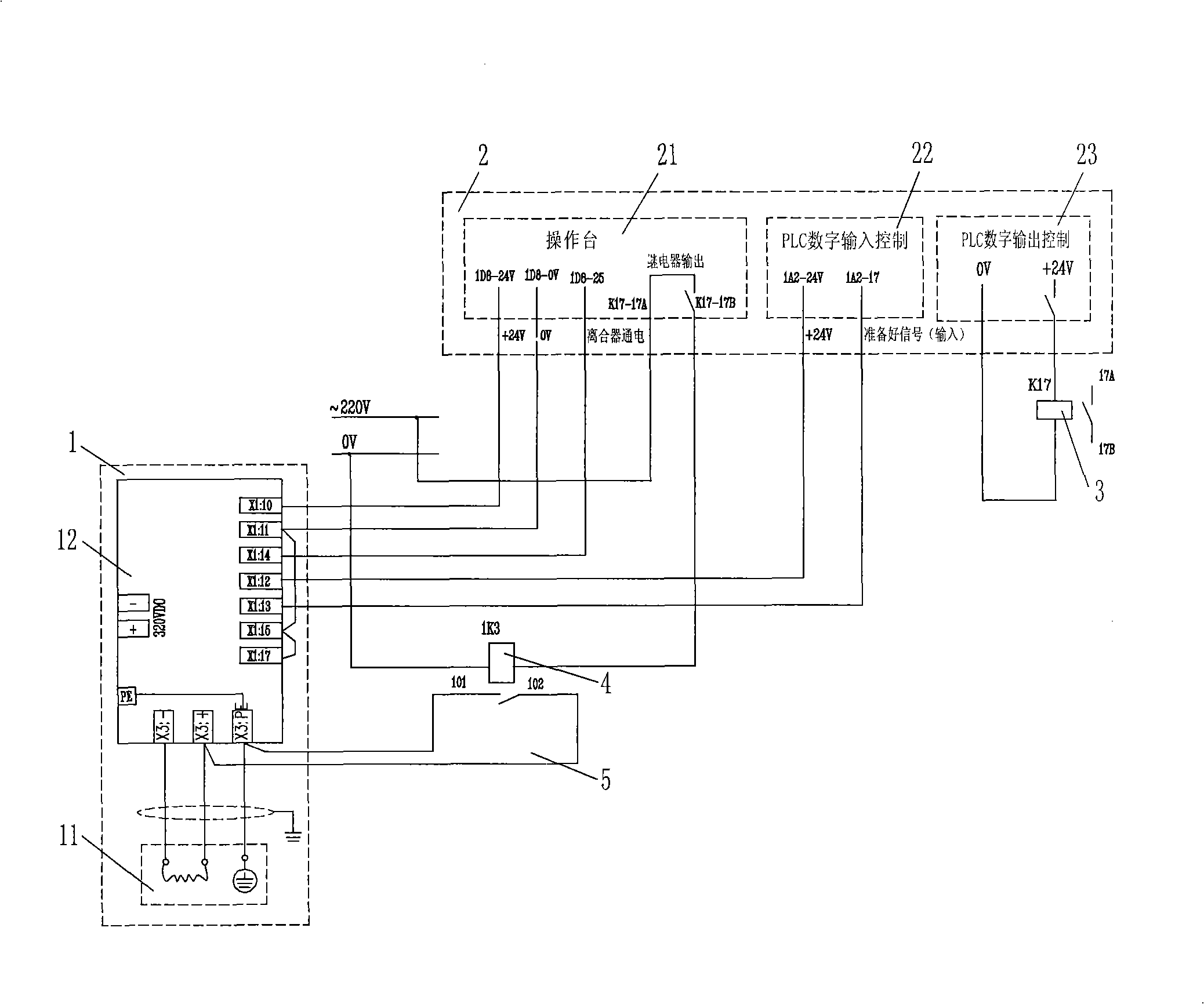

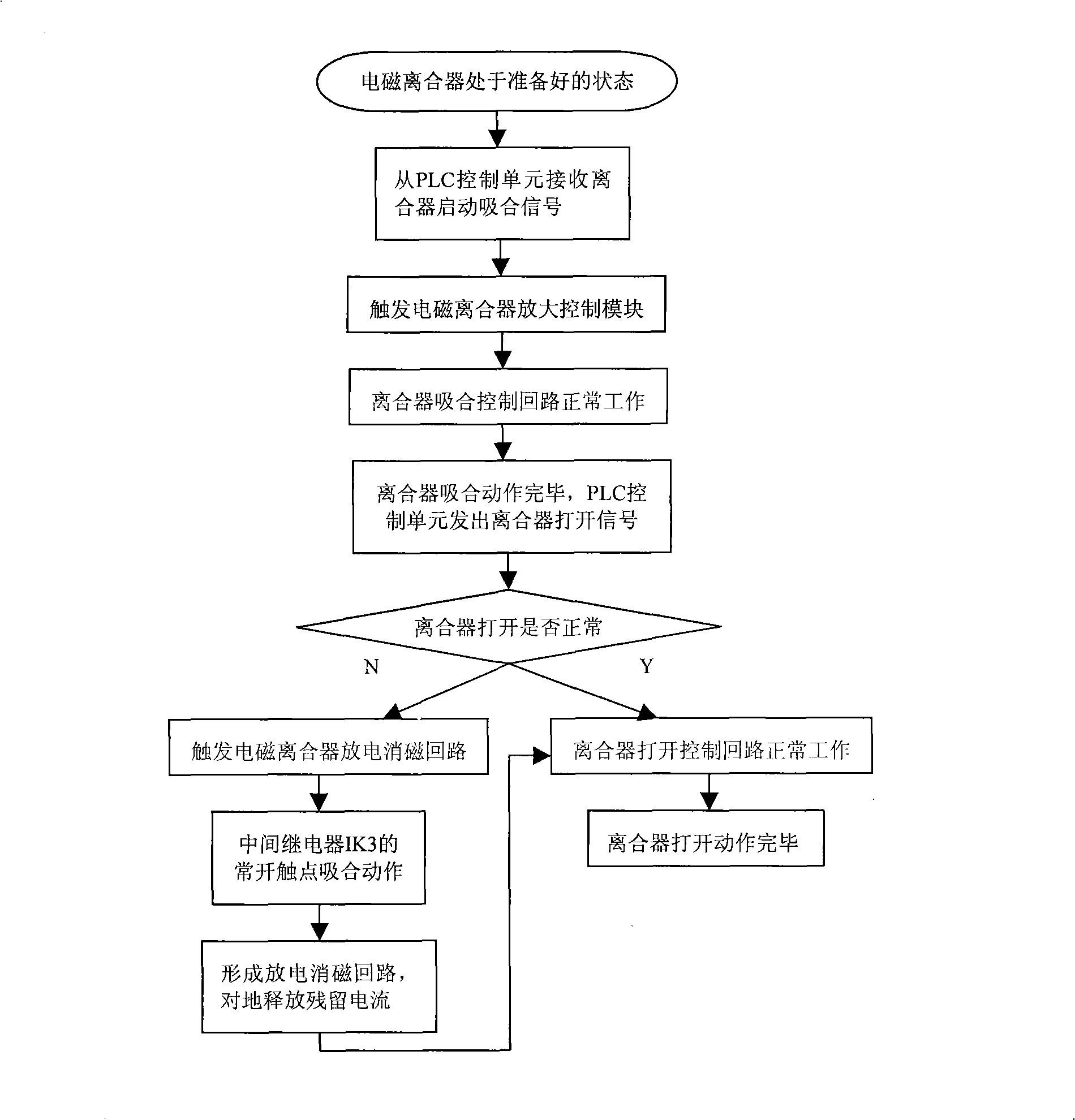

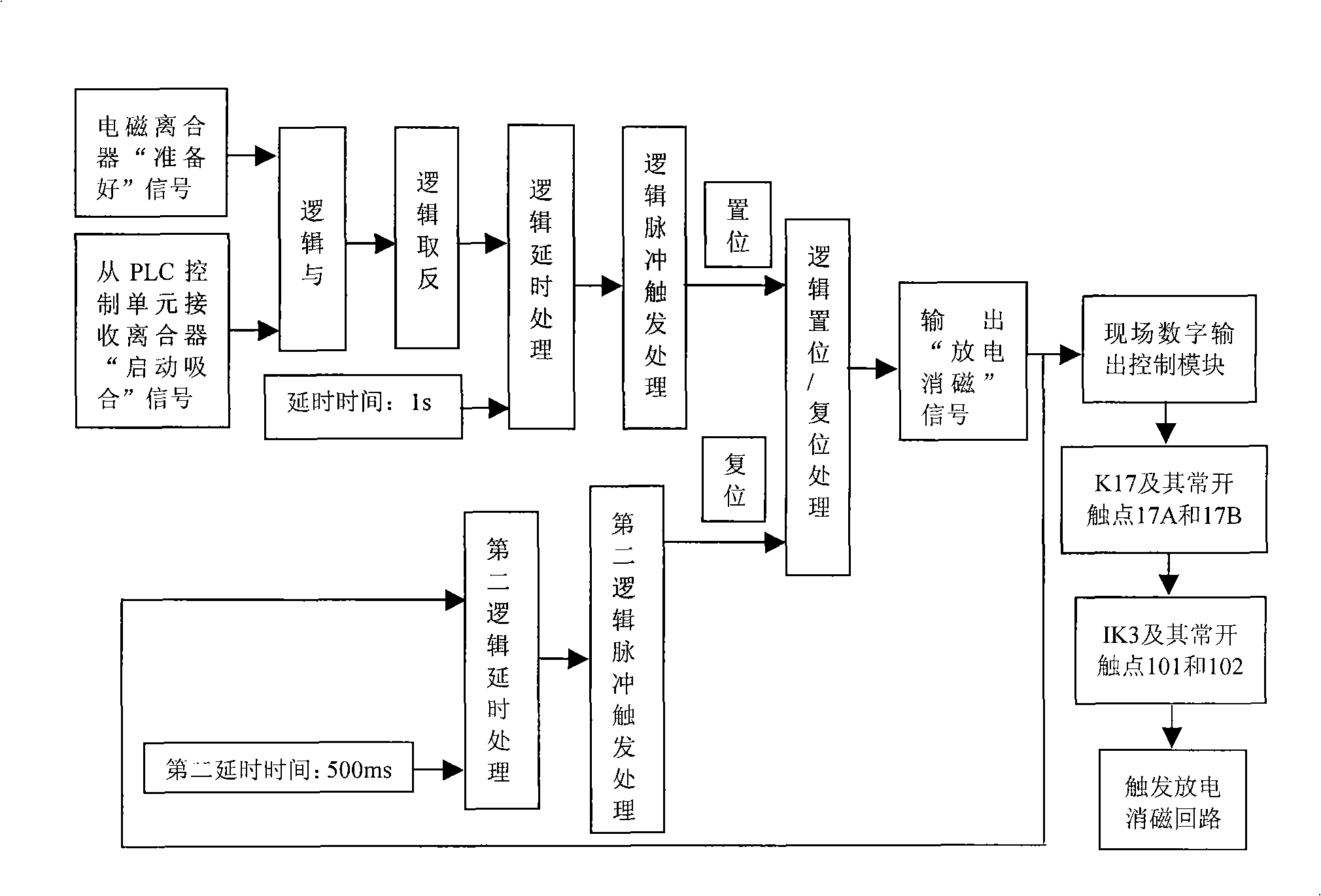

Apparatus and method for discharging and degaussing of electromagnetic clutch

ActiveCN101354065AReduce short circuitAvoid abnormal damageMagnetic bodiesMagnetically actuated clutchesElectromagnetic clutchEngineering

The invention discloses a discharging and degaussing device for an electromagnetic clutch and a method thereof. The discharging and degaussing device comprises the electromagnetic clutch and a control unit thereof, a PLC control unit which is connected with the electromagnetic clutch and the control unit of the electromagnetic clutch. The invention is characterized in that: the discharging and degaussing device also comprises an intermediate relay and a degaussing intermediate relay; wherein, the intermediate relay is connected to the digital output control end of the PLC control unit; the auxiliary normal open contact of the intermediate relay is connected to a main circuit of the degaussing intermediate relay; one of the auxiliary normal open contacts of the degaussing intermediate relay is connected with a grounding wire and the other is connected with the coil of the electromagnetic clutch; a discharging and degaussing circuit of the electromagnetic clutch is formed by the connection of the two auxiliary normal open contacts of the degaussing relay with the coil of the electromagnetic clutch and the grounding wire. The device of the invention can discharge and degauss the coil of the clutch, thus reducing the short circuit of the coil and preventing the electromagnetic clutch from abnormal damage.

Owner:BAOSHAN IRON & STEEL CO LTD

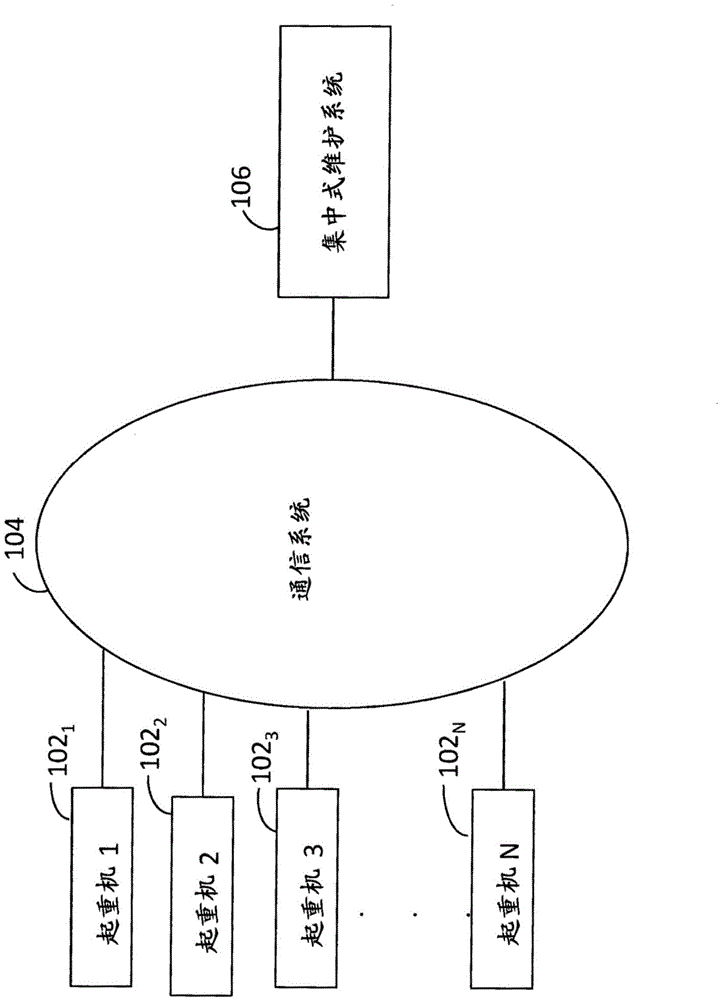

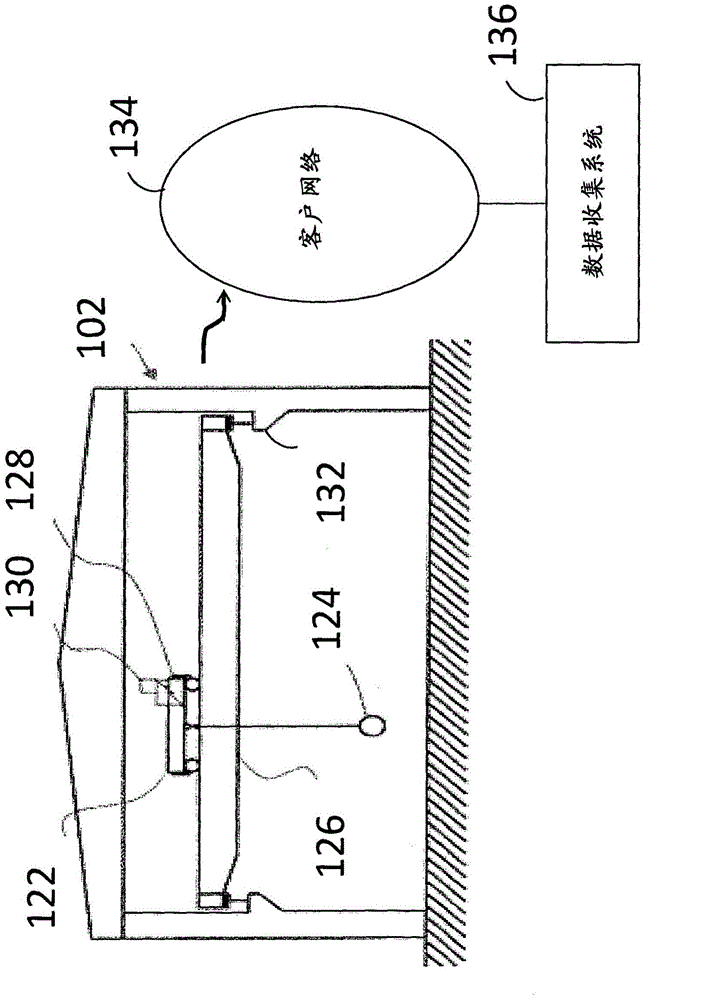

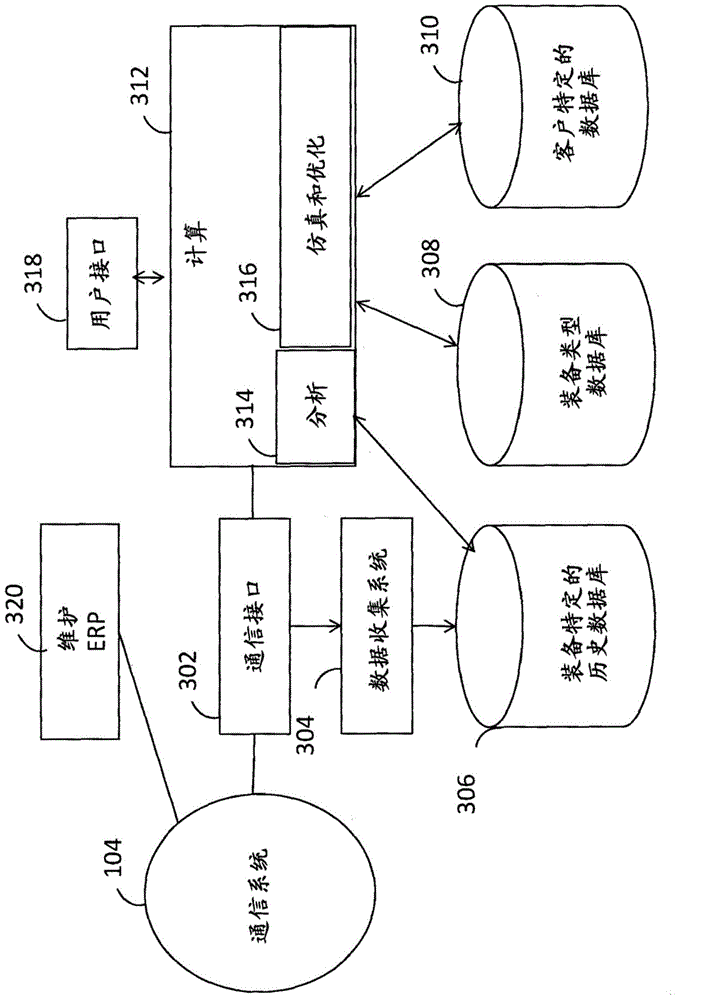

Predictive maintenance method and system

ActiveCN104620268AHigh transparencyAvoid unexpected breakdownsTesting/monitoring control systemsTechnology managementDiagnostic dataPredictive maintenance

The invention relates to a predictive maintenance of hoisting equipment (102), particularly cranes. A maintenance centre (106) automatically collects diagnostic data relating to least one component of the remote hoisting equipment and optionally sensor data relating the operational environment of the remote hoisting equipment (102). The maintenance centre (106) has an access to configuration data of the remote hoisting equipment and the reliability data on the at least one component of the remote hoisting equipment (102). The maintenance centre (106) is then able to generate a maintenance plan optimizing the cost of maintenance and reliability of the hoisting equipment over a life cycle of the hoisting equipment.

Owner:KONECRANES GLOBAL

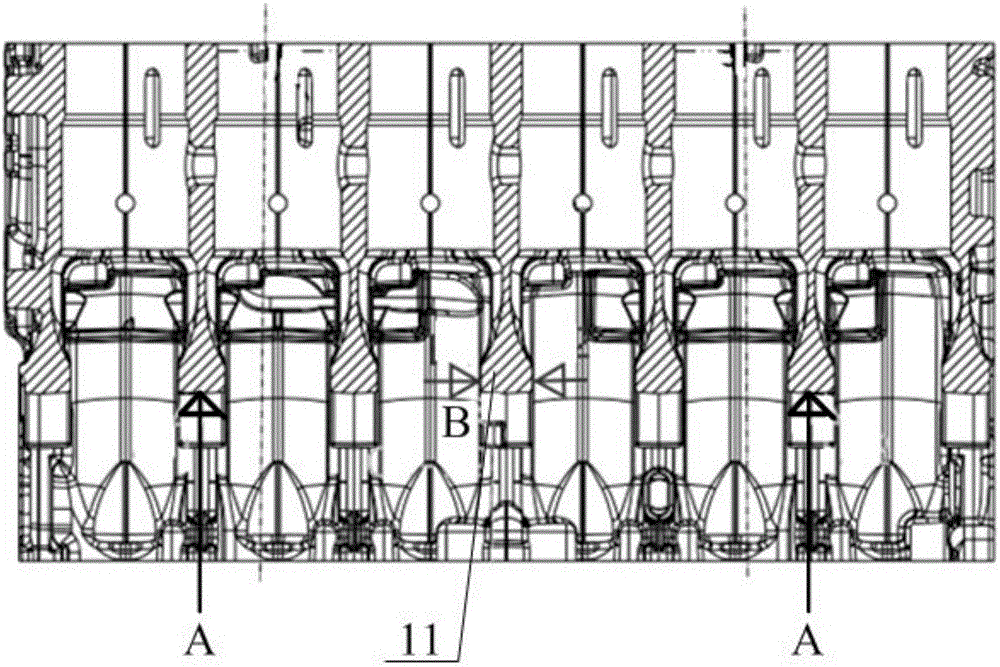

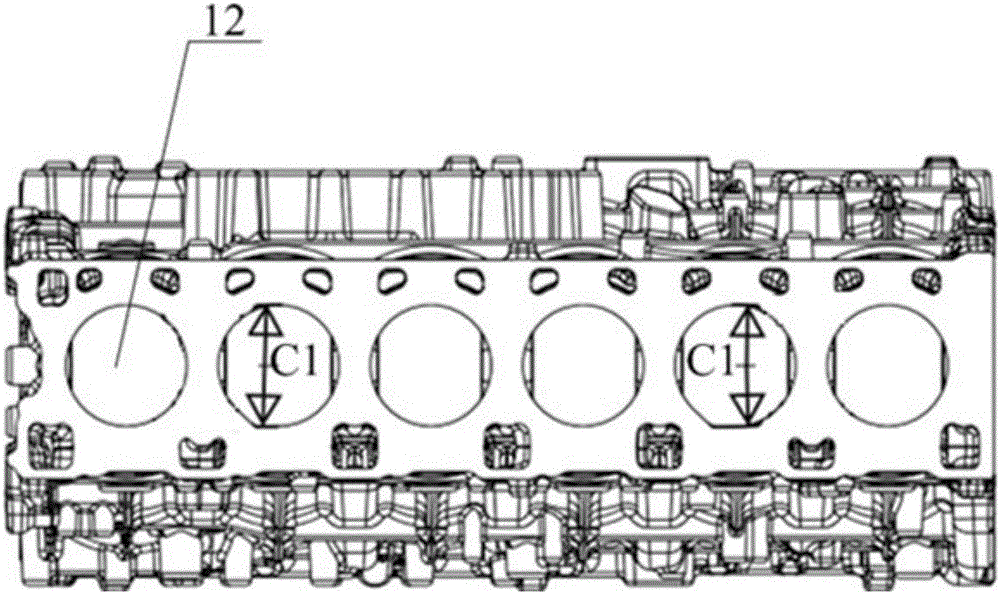

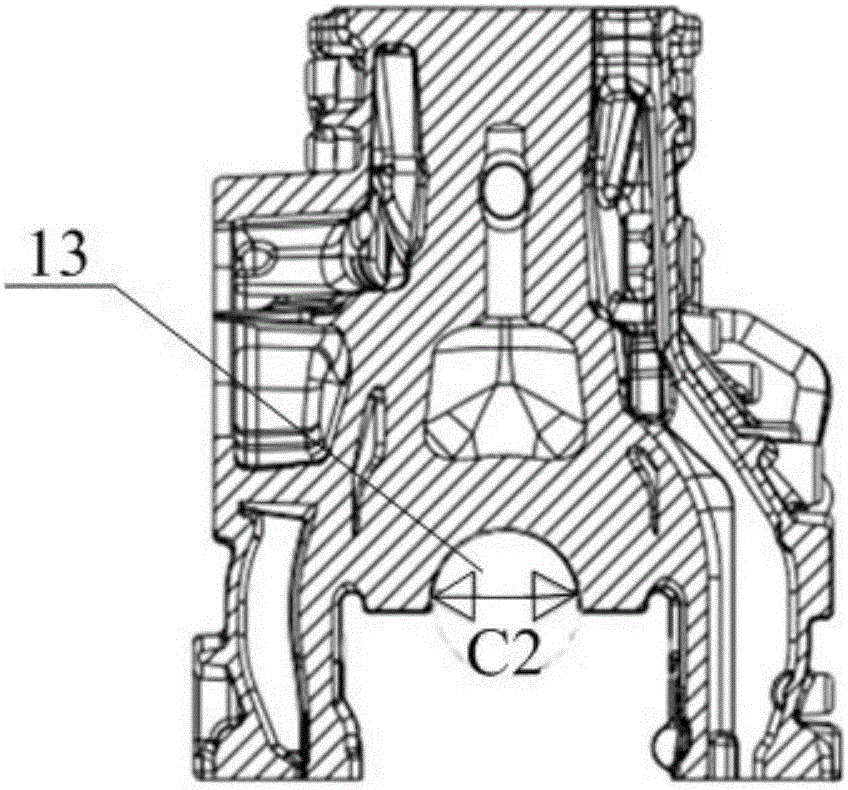

Automatic centering hydraulic fixture

InactiveCN105773248ARealize three-dimensional positioningSolve the problem of uneven distribution of machining allowancePositioning apparatusMetal-working holdersProduction lineEngineering

The invention discloses an automatic centering hydraulic fixture. The automatic centering hydraulic fixture comprises a fixture body, a stand column mounted on the fixture body for penetrating through a cylinder hole of a cylinder blank, height positioning parts mounted on the two sides of the fixture body and used for supporting the cylinder blank, a left-right centering positioning part mounted at the middle part of the fixture body and used for positioning in the thickness direction of a main bearing base of the cylinder blank, and a first front-back centering positioning part mounted on the stand column and used for positioning in the front-back diameter direction of the cylinder hole. The automatic centering hydraulic fixture, provided by the invention, respectively positions the height direction, the left-right direction and the front-back direction of the cylinder blank, realizes three-dimensional positioning of the cylinder blank, provides excellent positioning foundation for subsequent further clamping and machining procedures, can effectively solve the problem of nonuniform machining allowance distribution of the cylinder blank, guarantees high-efficiency and high-quality positioning and clamping of the cylinder blank, and guarantees normal production of a quick production line.

Owner:ANHUI HUALING AUTOMOBILE

A processing device for preparing square tubes with thin-walled belt materials

InactiveCN104625753BEasy to weldEasy to weld and formOther manufacturing equipments/toolsEngineeringLubricant

The invention discloses a machining device of square tubes made of thin-wall strips and belongs to the technical field of square tube forming equipment. According to the strip conveying direction, the machining device mainly comprises a strip decoiling device, a primary buffering device, an active strip conveying device, a secondary buffering device, a strip surface lubricant coating device, a forming device, a tube blank shaping device, a high-frequency welding device, a post-welding cooling device, a surface residual liquid removing device, a square tube shaping device and a cutting device which are arranged in sequence. The machining device solves the technical problems that existing thin-wall square tubes are poor in forming quality and low in production efficiency, and the machining device is widely applied to manufacturing the thin-wall square tubes.

Owner:佛山市九钢制管有限公司

Detection method of photovoltaic power station equipment health index

ActiveCN109085437ALow failure rateReduce power lossElectrical testingHealth indexPhotovoltaic power station

The invention discloses a detection method of a photovoltaic power station equipment health index. The mainly solved technical problem is the problem of how to detect the photovoltaic power station equipment health index in the prior art. The health index detection on strings and the health index detection on modules can be performed through the detection method of the photovoltaic power station equipment health index; the detection method comprises the following steps: performing health index detection on the strings: step (1) selecting 60 strings mutually connected in parallel, and performing current sampling by serving as a sampling point at a current combining box in each string, and transmitting the sampled current to a CPU through four current combining collector so as to perform operation, wherein the problem is well solved, and the detection method can be used for the detection of the photovoltaic power station equipment health index.

Owner:苏州协鑫新能源运营科技有限公司

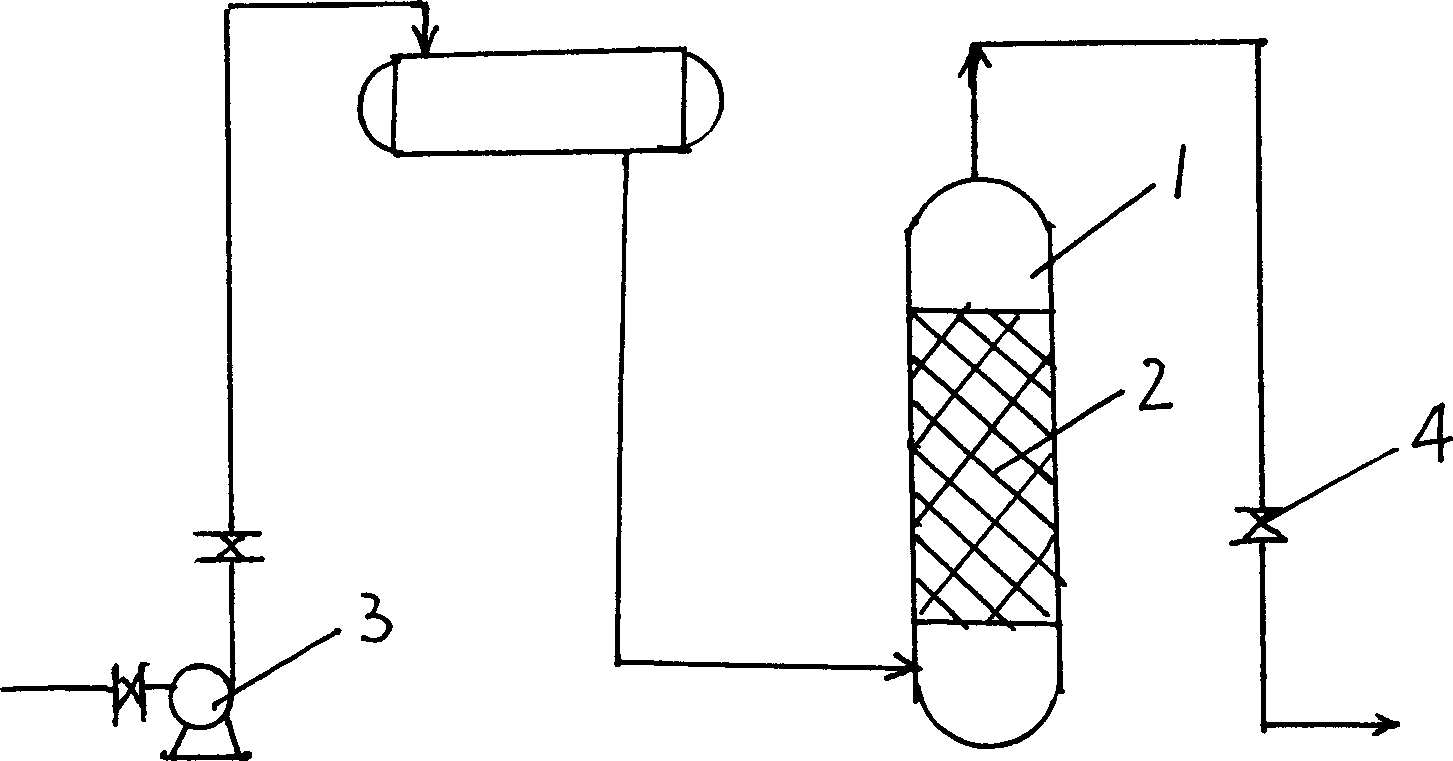

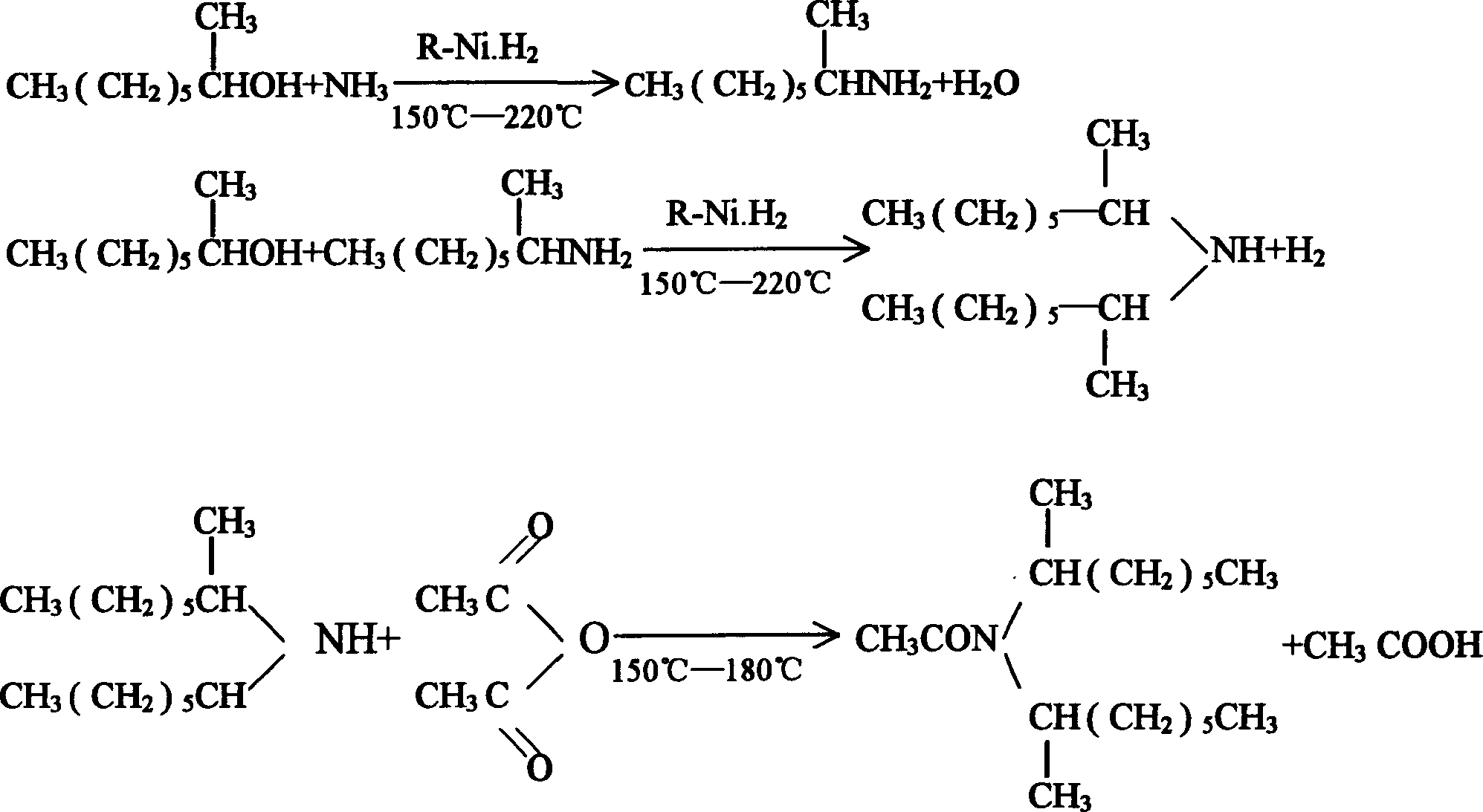

Methyl heptol desulfurizing process

InactiveCN1810748AAvoid poisoningReduce manufacturing costHydroxy compound separation/purificationRoom temperatureSulfide

The present invention relates to chemical technology, and is especially methyl heptol desulfurizing process. At normal temperature and normal pressure, methyl heptol is countercurrent input into a desulfurizing tower filled with SN-3 type active carbon to eliminate sulfide and to reach the sulfide content below 2 ppm. The process can provide the subsequent step with high purity material to reduce catalyst poisoning, raise product yield and raise production efficiency.

Owner:邵阳市化工研究所

Service data processing method combining cloud network fusion and artificial intelligence, and cloud platform

InactiveCN112764900AAvoid OverloadingLower latencyProgram initiation/switchingPathPingResource information

According to the service data processing method combining cloud network fusion and artificial intelligence and the cloud platform provided by the invention, the method includes: firstly, acquiring the thread state distribution of the target Internet of Things control equipment; secondly, acquiring a target real-time thread state corresponding to the set state description information in the thread state distribution of the target Internet of Things control equipment when it is detected that the state label corresponding to the target Internet of Things control equipment carries the time slice resource information; determining a thread parameter storage path of a target thread corresponding to the target real-time thread state based on the state label after it is detected that the service co-processing protocol currently has an authorization authentication check code; and finally, issuing at least part of the target service data to the target Internet of Things control equipment according to the thread parameter storage path. Thus, the target Internet of Things control equipment can perform cooperative processing on the target service data through the target thread, cooperation between the cloud platform and part of the Internet of Things control equipment is realized, and overload of the cloud platform is avoided.

Owner:薛东

Rapid re-blowing method for vanadium bearing titanomagnetite blast furnace smelting

ActiveCN108546791AIncrease contact areaIncrease wind speedBlast furnace detailsFurnace temperatureAlkalinity

The invention discloses a rapid re-blowing method for vanadium bearing titanomagnetite blast furnace smelting, and belongs to the technical field of vanadium bearing titanomagnetite blast furnace smelting. A reasonable charging system, a reasonable blowing system, a reasonable slagging system and a reasonable thermal system are adopted to achieve re-blowing. The charging system is characterized byadopting 2-3-ring distribution to achieve charging and ensuring that an angle difference between the outer ring of the above ore and outer coke is controlled at 1-3 DEG and an angle difference between the inner ring of the ore and inner coke is controlled at 5-6 DEG; the blowing system is characterized by adjusting the sizes of 2-8 air ports having an angle of 90 DEG with an iron notch in order to reduce the blowing area by 5-25%; the slagging system is characterized by reducing the binary alkalinity of slag by 0.01-1.05; and the thermal system is characterized by controlling the furnace temperature to ensure that the total content of Si and Ti in molten iron is 0.30-0.60 mass%. The method improves the contact area of a raw material and air, the wind speed and the fluidity of a mixture, so the recovery of a blast furnace to a state before damping down is greatly accelerated.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

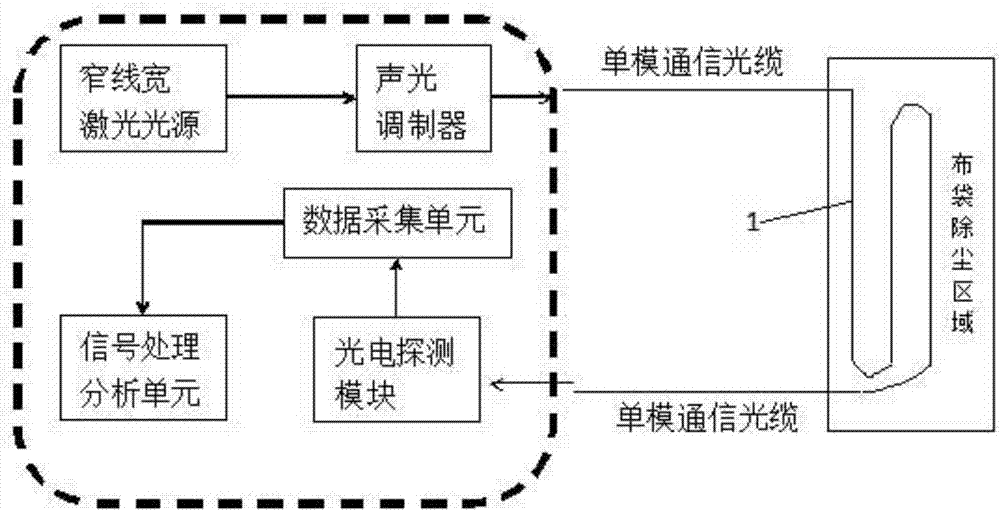

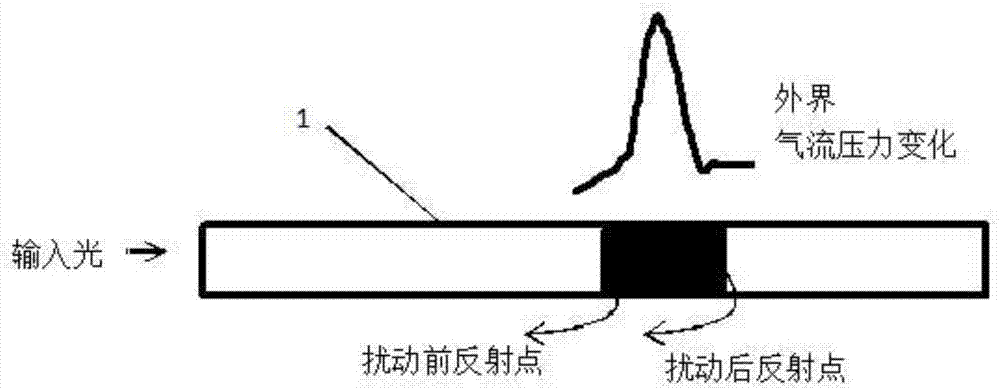

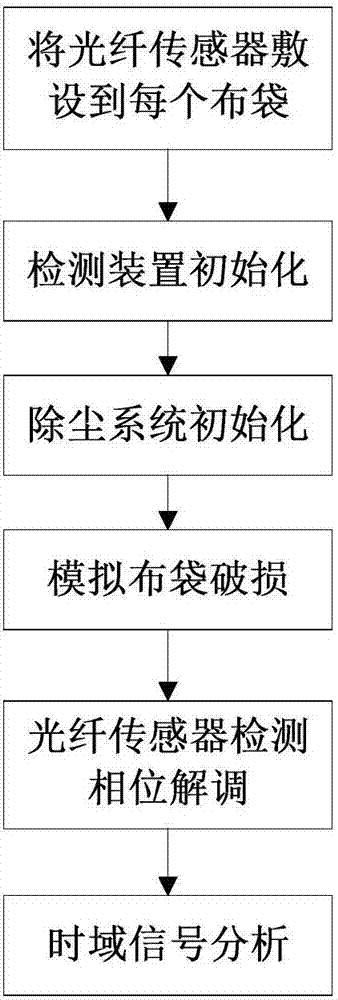

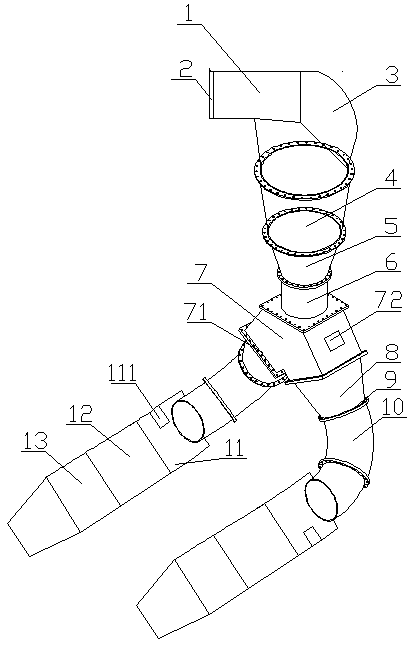

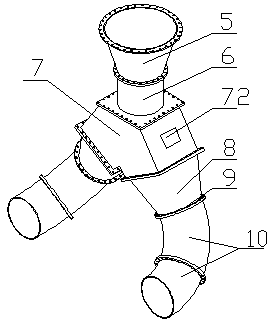

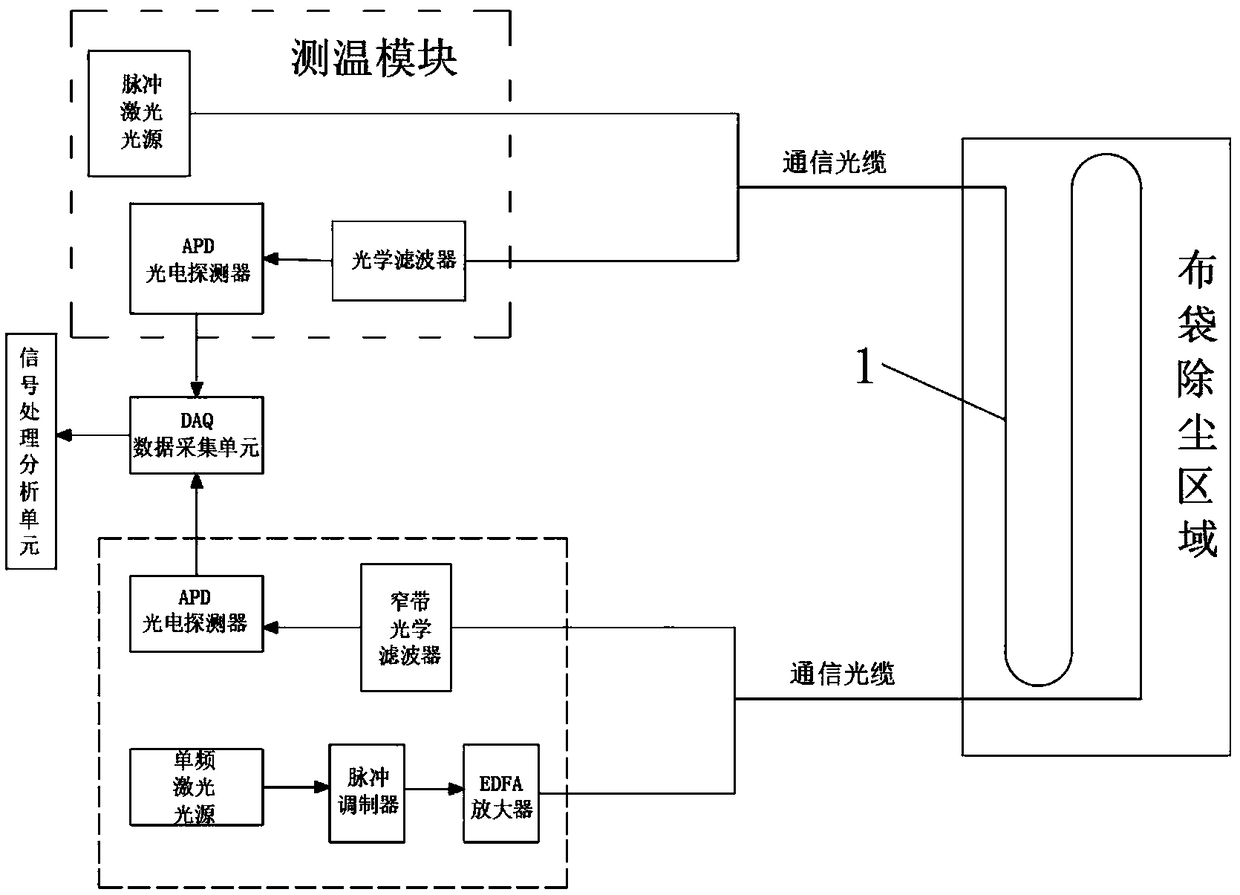

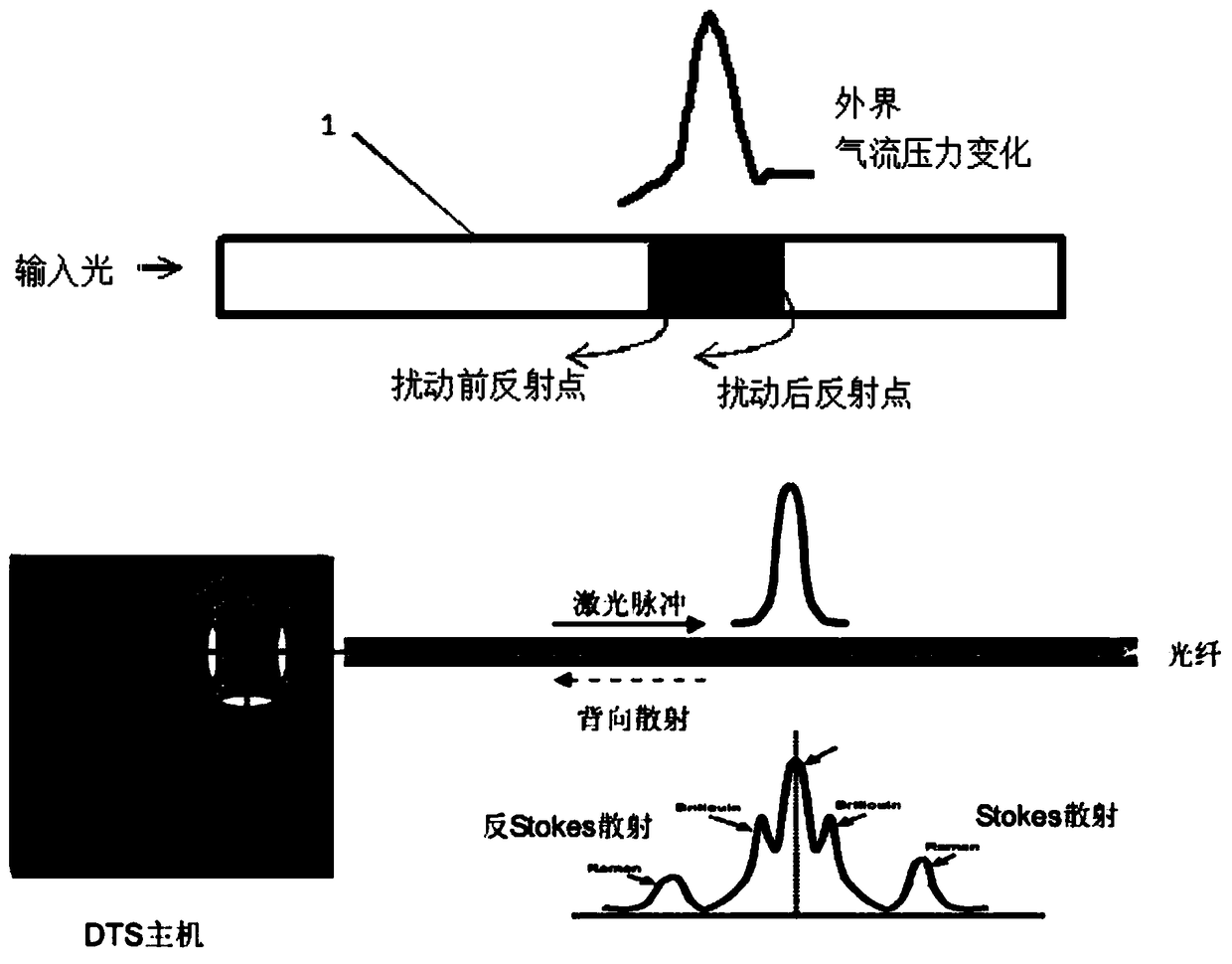

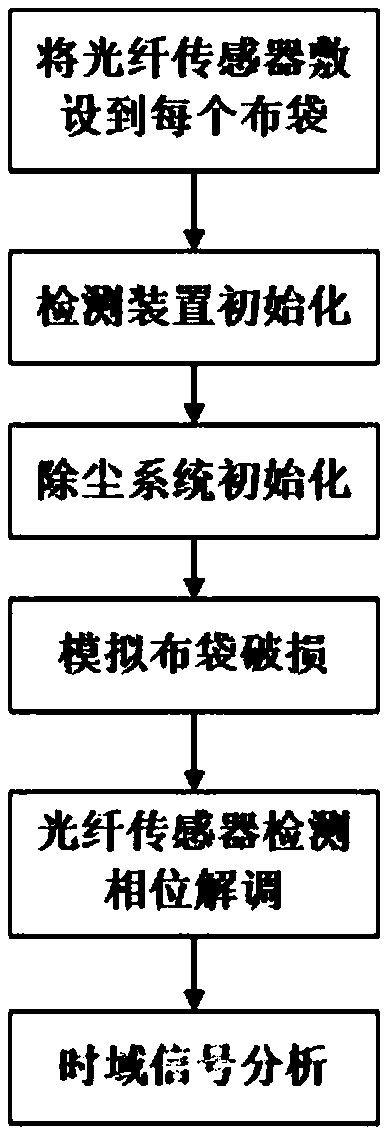

Baghouse system intelligent bag leakage positioning and detecting device and method

ActiveCN107024327ARealize online blockingGuarantee normal production and operationFluid-tightness measurement using lightContinuous lightLight energy

A baghouse system intelligent bag leakage positioning and detecting device of the present invention comprises a narrow linewidth laser light source for providing the coherent light energy for an optical fiber sensor; an acoustic optical modulator used for converting the continuous light into the pulse light of a certain pulse width and a repetition frequency; the optical fiber sensor used for detecting the airflow change caused by the bag breakage; a photoelectric detection module for converting the light energy into a voltage signal to output; a data acquisition unit for carrying out the analog-digital conversion on the collected voltage signal; a signal processing and analyzing unit for demodulating a bag breakage airflow signal, extracting the pressure change information of the airflow, and determining whether a baghouse system operates normally. The present invention also discloses a positioning and detecting method of the baghouse system intelligent bag leakage positioning and detecting device. The positioning and detecting device and the positioning and detecting method of the present invention integrate the sensing and transmission functions as one via an optical fiber, detect and transmit the bag breakage airflow pressure change signal, and are suitable for being applied to a space limited complicated industrial site.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Anti-blocking system based on computer analog simulation

PendingCN110705121AImprove delivery efficiencyImprove running stabilityLarge containersDesign optimisation/simulationClassical mechanicsEngineering

The invention belongs to the technical field of bulk material conveying systems, and particularly relates to an anti-blocking system based on computer analog simulation, which comprises a roller protective cover and a connecting head protective cover, the head shield is connected with the transition hopper; the lower end of the transition hopper is connected with a funnel which is connected with astraight cylinder connecting pipe; the bottom of the straight cylinder connecting pipe is connected with a three-way distributor, the three-way distributor is of a polygonal structure, and two crossed square discharging openings are formed in the bottom end of the three-way distributor; the discharge port is connected with a small funnel, and the small funnel is connected with a universal flangeand used for adjusting the blanking direction and the material flow track; the lower end of the universal flange is connected with a curve blanking pipe, and the bottom of the curve blanking pipe is connected with a sealed flow guide box. The anti-blocking system is designed by adopting a computer simulation technology and combining a discrete technology (DEM) principle, and the curve blanking pipe system has the characteristics of effectively preventing material blockage, inhibiting dust, being low in production and maintenance cost, reducing noise, being high in automation degree and the like.

Owner:湖南西拓新材料科技有限公司

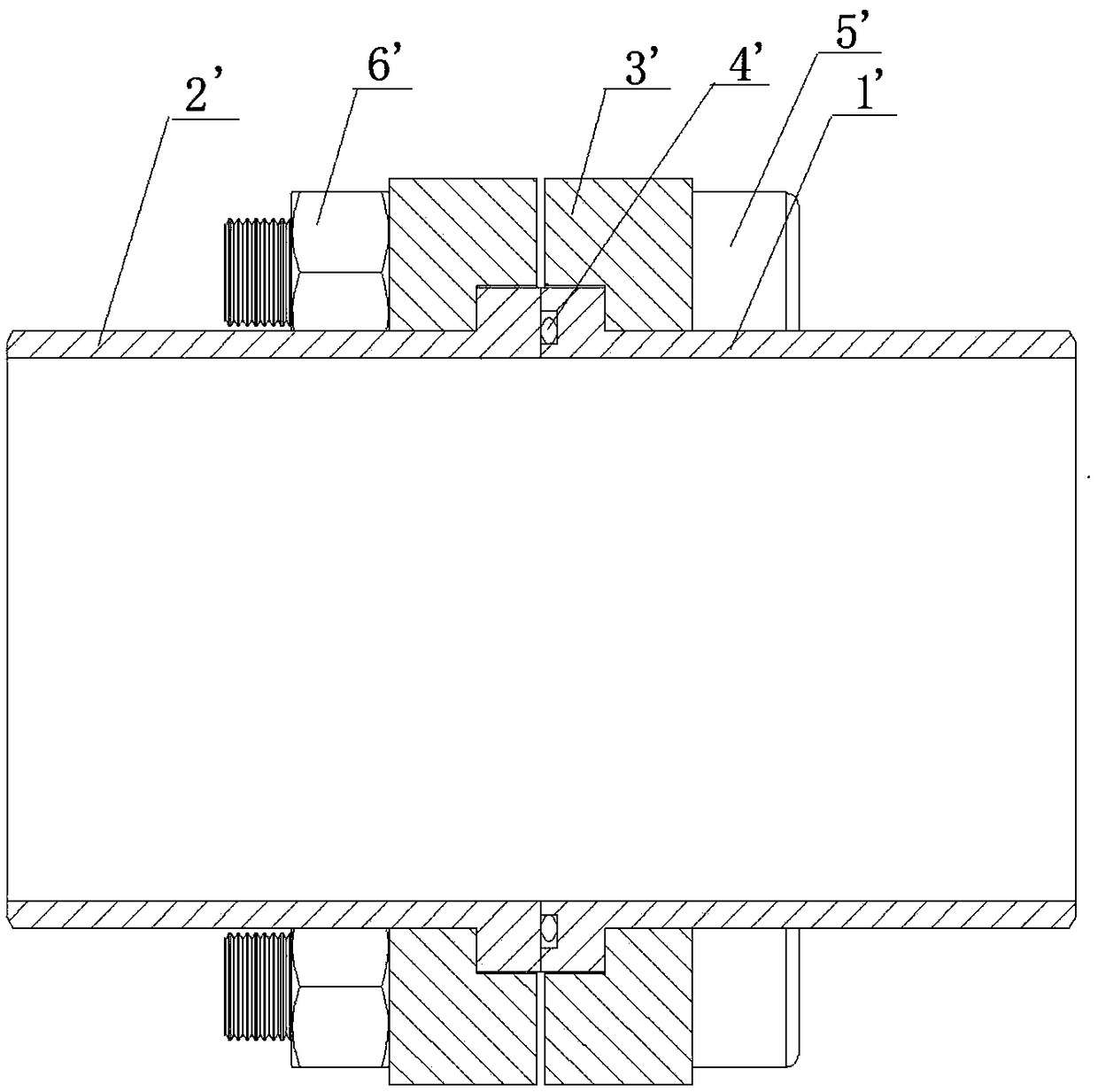

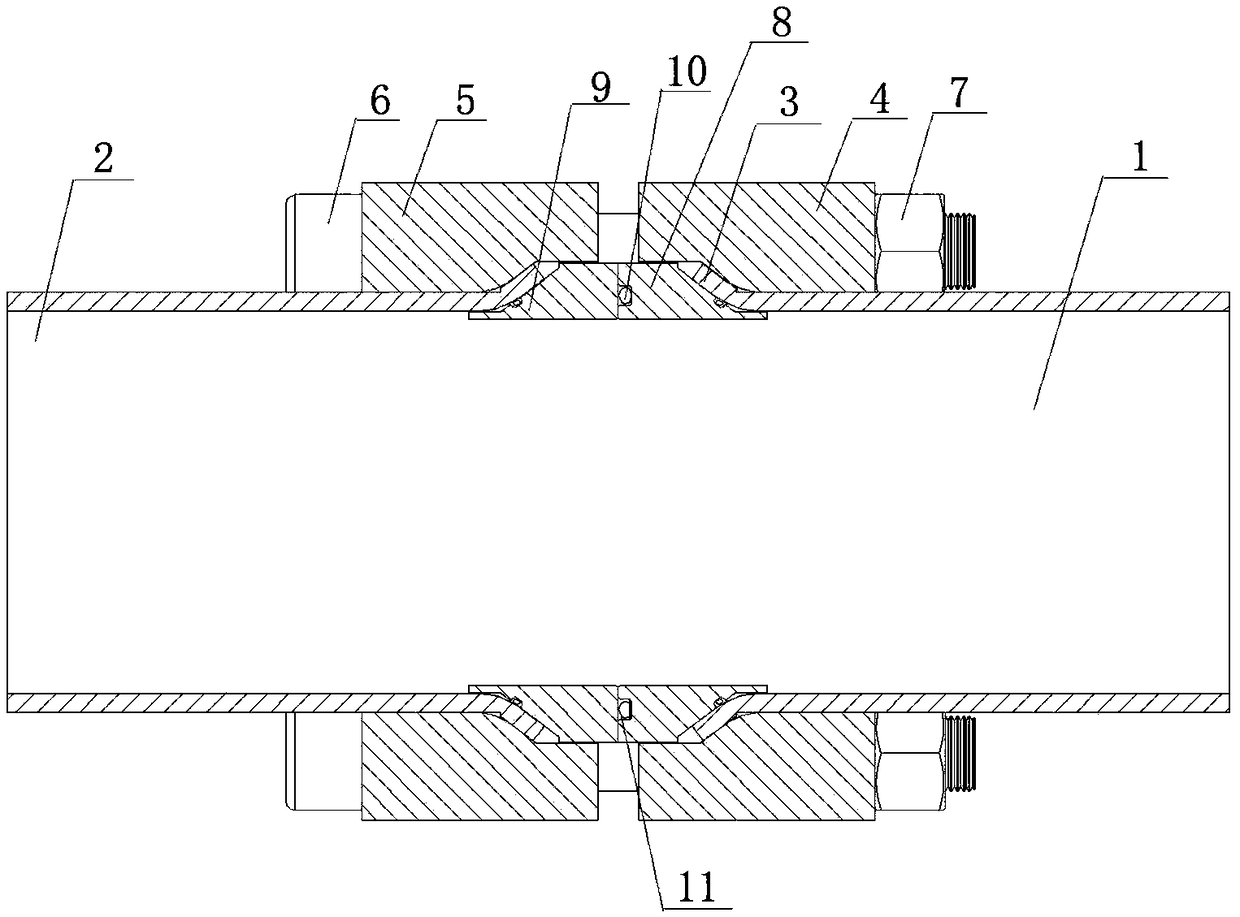

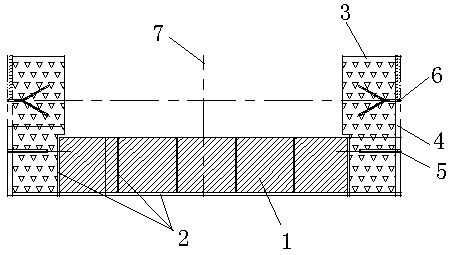

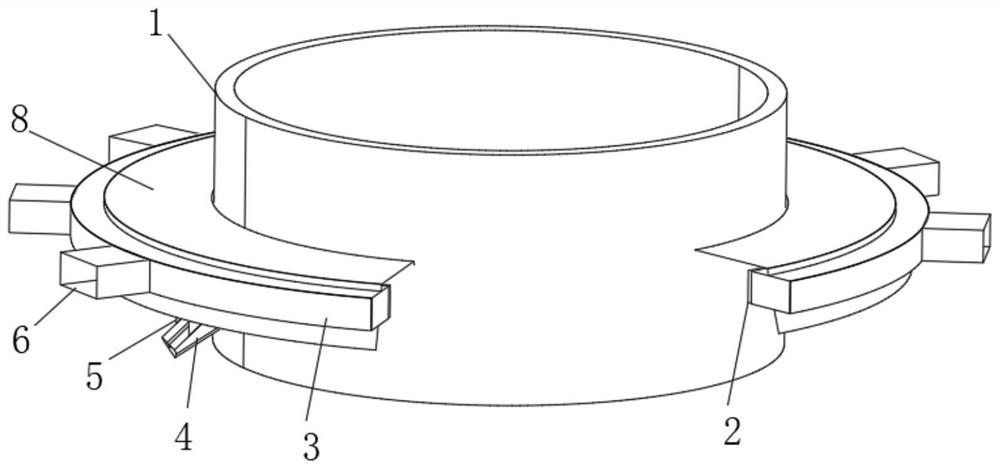

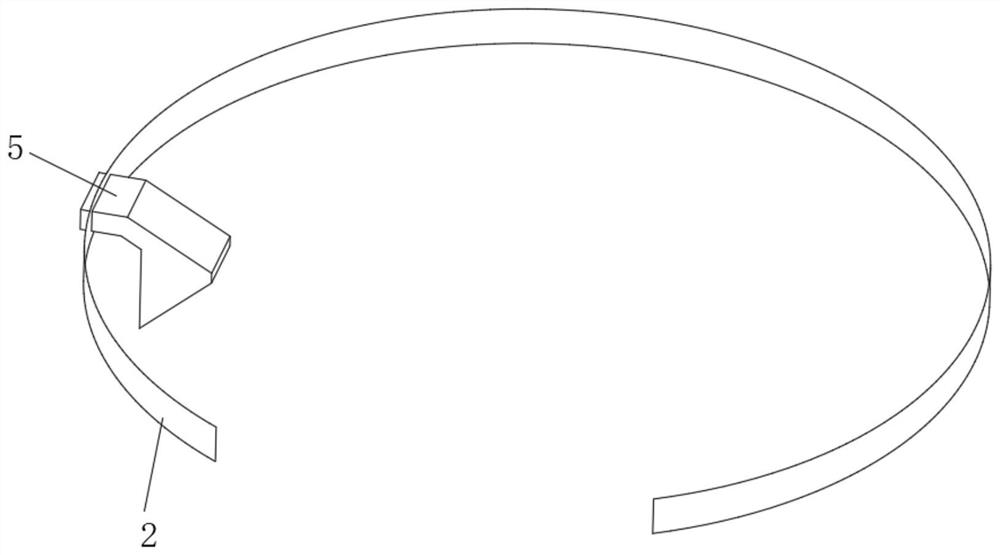

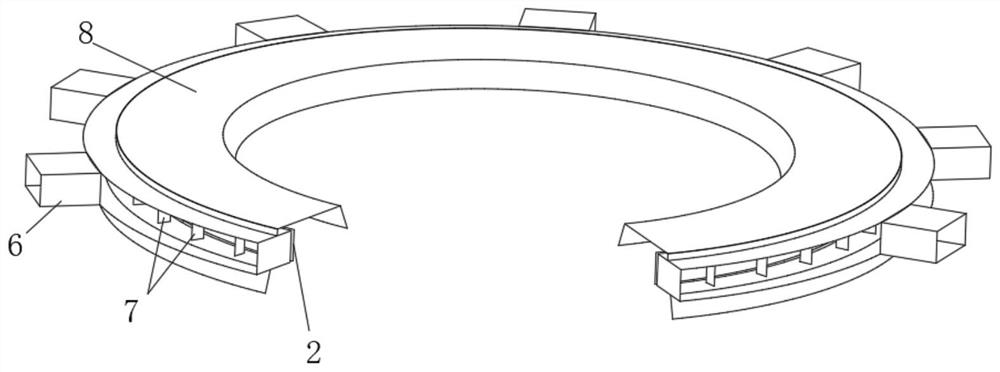

Flared flange pipe connecting system

The invention discloses a flared flange pipe connecting system. The flared flange pipe connecting system comprises two or more branch pipes. A conical flared opening is outwards formed in the end of each branch pipe. Every two adjacent branch pipes are connected through a connecting mechanism. Each connecting mechanism comprises a first flange, a second flange, a first seal conical body and a second seal conical body. The first seal conical bodies and the second seal conical bodies each comprise a conical section and a cylindrical section. The first flanges and the second flanges are arrangedon the different branch pipes. Each first flange is connected with the corresponding second flange through bolts and nuts. According to the flared flange pipe connecting system, spinning flaring is conducted on the end of each pipe through a flaring machine, so that the conical flared openings are formed; and by means of close matching of the first flanges, the second flanges, the first seal conical bodies, the second seal conical bodies, bolts and nuts, a safe and zero-leakage pipe system can be formed.

Owner:弗通流体科技(上海)有限公司

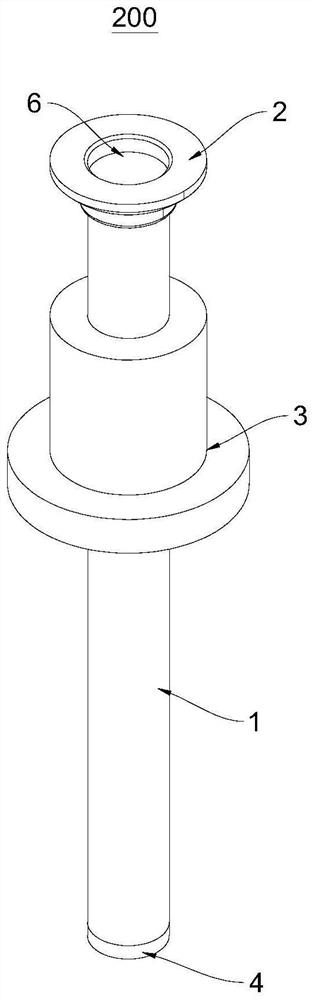

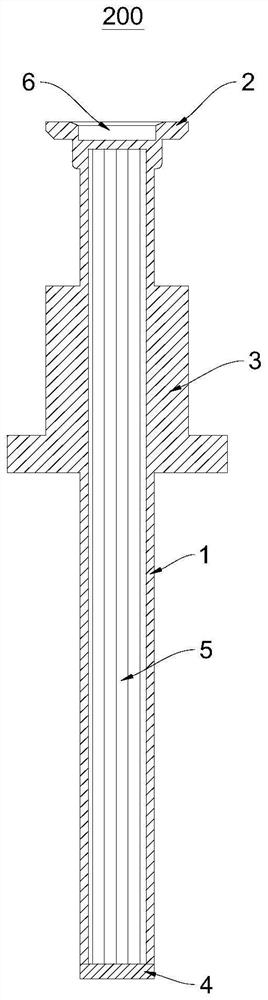

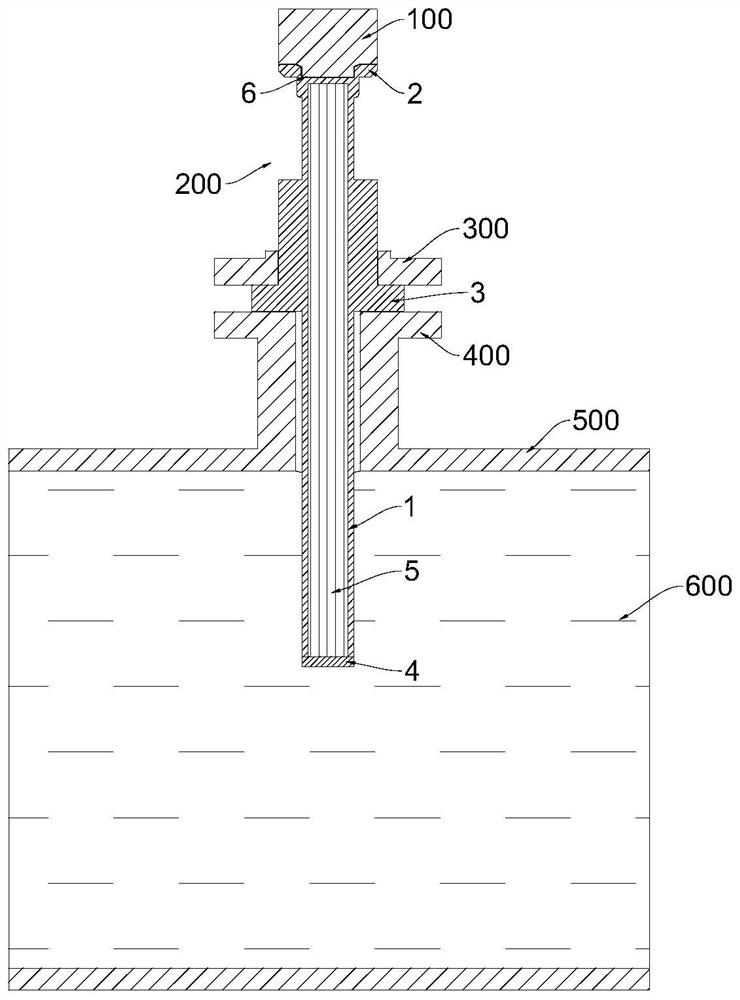

Sound wave communication rod with heat insulation and sound conduction functions and flow measuring device

PendingCN114554317AGood heat insulationImprove corrosion resistanceTelemetry/telecontrol selection arrangementsNon-electrical signal transmission systemsTransducerEngineering

The invention relates to the technical field of fluid flow measurement, in particular to a heat-insulating sound-conducting sound wave communication rod and a flow measurement device. The sound wave communication rod comprises a protective shell, a mounting clamp, a connecting part and a coupling protective sheet, a heat-insulating sound-conducting material is packaged in an inner cavity of the protective shell, the mounting clamp is arranged at the top end of the protective shell and used for being connected with an ultrasonic transducer, and the connecting part is arranged outside the protective shell and used for being connected with a measuring pipeline; the coupling protection piece is arranged at the bottom end of the protection shell to package the protection shell, and the bottom end of the sound wave communication rod extends into the measurement pipeline to make contact with fluid to be measured so as to conduct sound waves during use. The flow measuring device comprises an ultrasonic transducer, a sound wave communication rod and a locking device. The ultrasonic flowmeter can accurately measure the flow of high-temperature and low-temperature fluid in a pipeline, is good in heat insulation and sound conduction effect and convenient to operate, and can effectively solve the technical problem that an existing ultrasonic flowmeter cannot directly make contact with the high-temperature and low-temperature fluid and cannot measure the flow.

Owner:美卓伦仪表中国有限公司

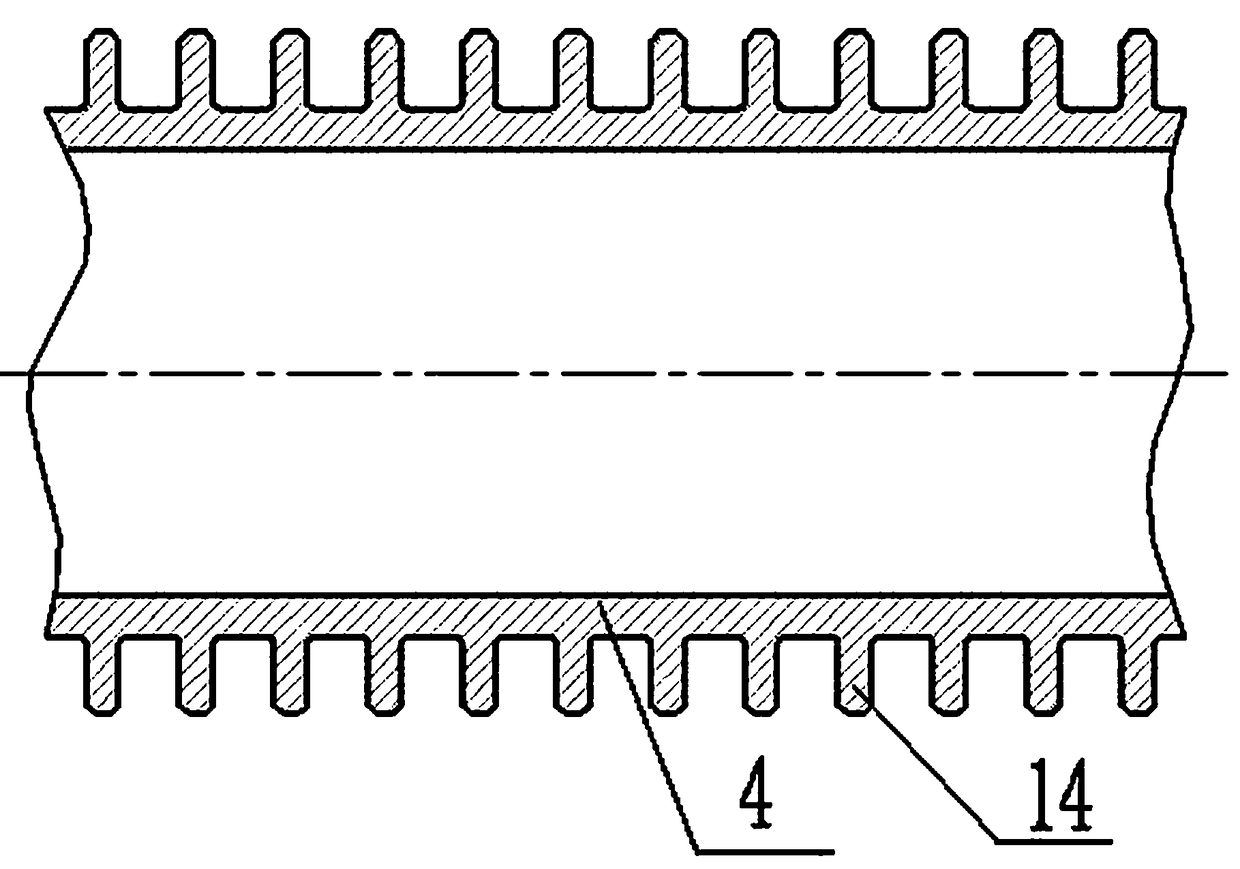

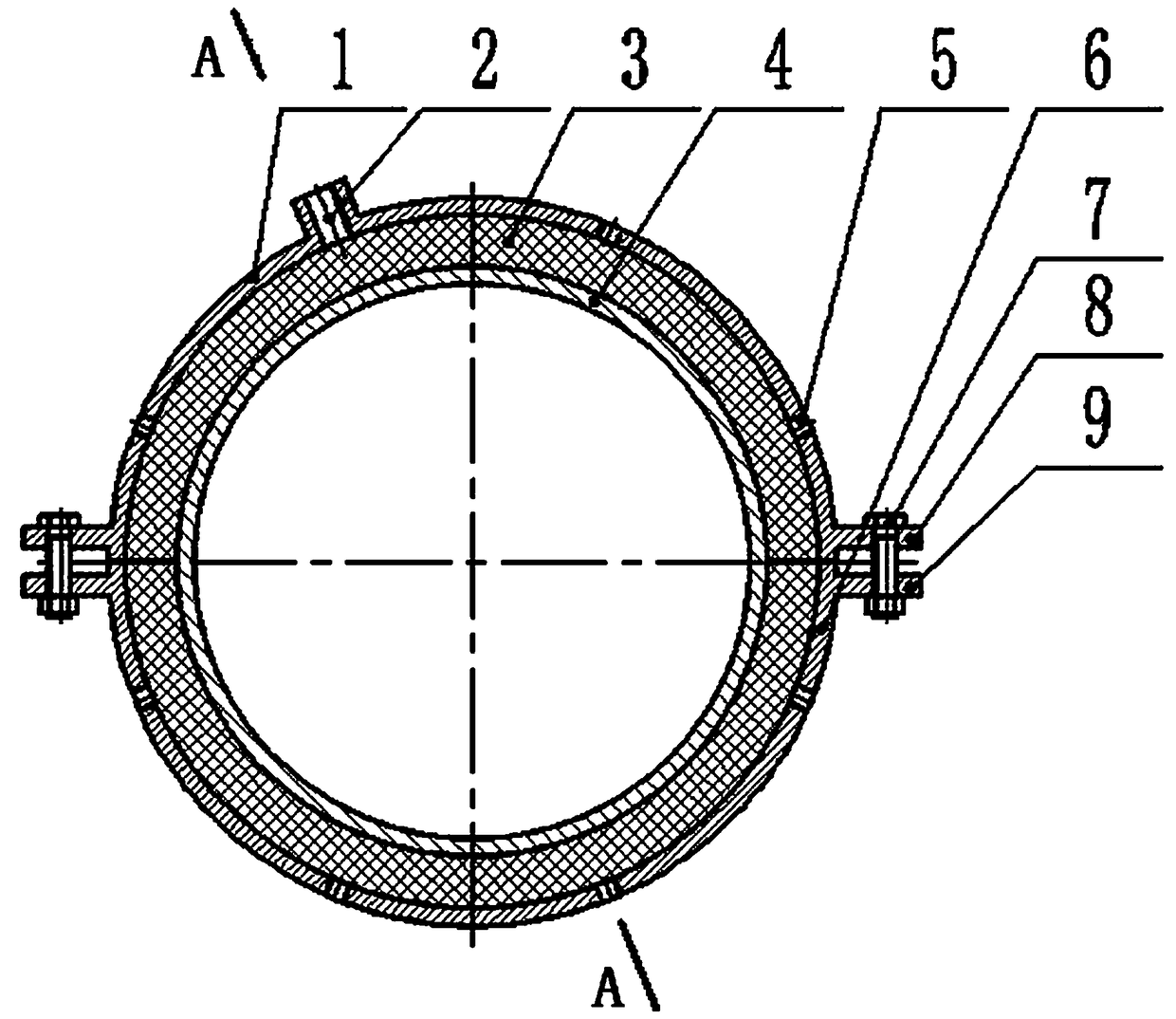

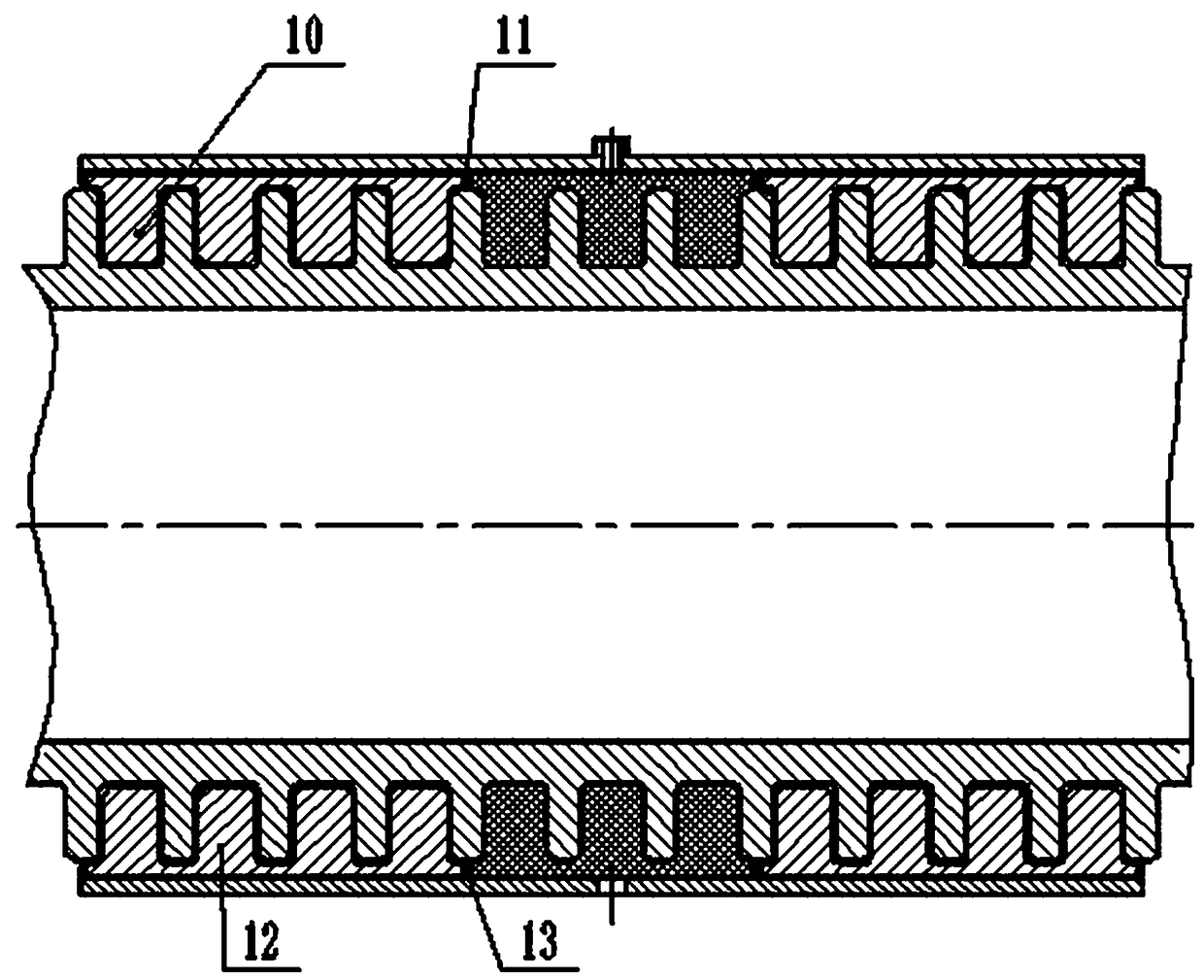

Multi-strengthened steel-plastic composite pipe emergency maintenance device and method

ActiveCN109163167ARealize plugging repairRealize online emergency repairPipe elementsEngineeringFastener

The invention discloses a multi-strengthened steel-plastic composite pipe emergency maintenance device and method, and belongs to the technical field of pipeline repairing. The multi-strengthened steel-plastic composite pipe emergency maintenance device comprises an upper shell, a lower shell and fasteners connected with the upper shell and the lower shell, and the upper shell and the lower shellwrap a leakage point on the outer wall of a pipeline through the fasteners; a pouring opening is formed in the middle of the upper shell or the lower shell and corresponds to the leakage point on theouter wall of the pipeline, the middle of the upper shell and the middle of the lower shell are provided with grooves for containing a plugging agent, and the pouring opening is arranged at the grooves; and the bottom of the lower shell is provided with gas vents, and gas can be exhausted conveniently when the plugging agent is poured. The leaked position of the outer all of the pipeline is wrapped with the upper shell and the lower shell at first, the plugging agent is poured into the grooves in the middles of the upper shell and the lower shell through the pouring opening by a plugging machine, and plugging maintenance of the pipeline is achieved. Through the multi-strengthened steel-plastic composite pipe emergency maintenance device and method, on-line emergency maintenance can be conducted on the leakage point of the pipeline, normal operation of production is ensured, and the production efficiency is improved.

Owner:HUACHUANG TIANYUAN IND DEVING

Building method for abrasive bricks at end part of unloading chute of rotary hearth furnace

ActiveCN109405555AGuarantee normal production and operationImprove stabilityLinings repairBrickMetallurgy

The invention discloses a building method for abrasive bricks at the end part of an unloading chute of a rotary hearth furnace. According to the method, casting strips are reserved on the two sides ofa steel structured shell at the end part of the unloading chute; an abrasive brick building position is positioned between the reserved casting strips; wear resisting steel plates are welded on the two sides of the shell; tie pieces are welded on the inner sides of the wear resisting steel plates, and are connected with a steel plate at the bottom of the shell; anchoring nails are welded to gapsof the tie pieces in a crossed manner; in the abrasive brick building position, wear resisting stoppers are welded between adjacent abrasive bricks along the axis of the shell and welded at the positions, at the abrasive brick end faces, of the steel plate at the bottom of the shell, and the abrasive bricks are built; abrasive castable is cast in the reserved casting strips for compaction; and during casting, combined parts of the abrasive bricks and the reserved casting strips form slopes for supporting the abrasive bricks slightly projected. According to the method, the end part of the unloading chute is built as an organic whole, so that both wear and scouring are resisted, excellent heat stability is achieved, meanwhile, the overall stability of the structure is improved, the service life is prolonged, and the production operation of the rotary hearth furnace is guaranteed.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Hydraulic classification recovery method for coal slime

PendingCN113000195AGrading is accurateImprove recycling effectWet separationThermodynamicsPressure stabilization

Disclosed is a hydraulic classification recovery method for coal slime, which belongs to the technical field of coal slime recovery equipment. The method is characterized by including the following steps: step 1) feeding coal slime water into a coal slime barrel (1) by a coal slime water feeding pipe (18); step 2) feeding the coal slime water in the coal slime barrel (1) into a hydraulic cyclone (3) through a coal slime pump (2) so as to grade, and meanwhile, enabling, by a control cabinet (14), the pressure of the coal slime water entering the hydraulic cyclone (3) to be stable through an electric valve and a pressure transmitter which are arranged between the coal slime pump (2) and the hydraulic cyclone (3); and step 3) enabling the coal slime delivered by the hydraulic cyclone (3) to enter a recovery device to perform classification recovery again, and returning the classified water to the coal slime barrel (1) to complete coal slime classification. According to the hydraulic classification recovery method for coal slime, the pressure of the coal slime entering the hydraulic cyclone is kept stable, fine control is completed, coal slime classification is accurate, and the problem of pipeline blockage caused by improper coal slime classification is avoided.

Owner:陕西博选科技有限公司

Tapping and smoke exhausting system of rotary submerged arc furnace

PendingCN114812207ASolve the problem of iron and smoke exhaustPrevent splashCharge composition/stateCharge manipulationThermodynamicsExhaust fumes

The invention belongs to the technical field of submerged arc furnace smoke exhaust equipment, and particularly discloses a rotary type submerged arc furnace tapping smoke exhaust system. The system comprises a chute exhaust fume collecting hood, an annular flow baffle, an annular flue and a plurality of exhaust fume hoods, the chute exhaust fume collecting hood comprises an exhaust fume collecting port and an exhaust fume outlet, the exhaust fume collecting port is fixedly connected above an iron outlet of the submerged arc furnace, and the exhaust fume outlet is fixedly connected with an annular flow baffle; the annular flow baffle surrounds the periphery of the submerged arc furnace and rotates along with the submerged arc furnace together with the chute exhaust fume collecting hood; an annular flue is fixedly arranged on the periphery of the annular flow baffle, a plurality of smoke exhaust hoods are fixedly arranged on the outer side wall of the annular flue at intervals, and the smoke exhaust hoods communicate with smoke exhaust branch pipes of the dust removal system. Smoke collected by the chute smoke collecting hood penetrates through the annular flow baffle to enter the annular flue, and finally enters the smoke exhaust branch pipes through the smoke exhaust hood at the corresponding position to reach a dust removal system. The problems of tapping and smoke exhaust of the rotary submerged arc furnace can be solved, the smoke collection effect of the tap hole is improved, and the power loss of the smoke exhaust fan is reduced.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司 +1

Drawing method of gas turbine generator rotor in overhauling operation

InactiveCN102651588AOvercoming Drawbacks of Extraction JobsGuarantee normal production and operationManufacturing dynamo-electric machinesGas compressorEngineering

The invention discloses a drawing method of a gas turbine generator rotor in overhauling operation. According to the method, when a gas compressor is dismounted for overhauling, all components of the gas compressor are dismounted and hung out, pipelines connected with a generator and electric connecting wires are fully broken off at the connecting end, and the dismounting is not needed; the bottom of the generator is provided with a plurality of hydraulic jacks for integrally lifting the generator until the outer diameter of a generator rotor exceeds the center height of the gas compressor; the bottom of the lifted generator is padded and provided with a pad block for bearing the generator weight, so that the generator is stably seated on the pad block; and then, a standard process is adopted for drawing the generator rotor in the gas compressor direction, and a crane trolley in the production field is used for hanging and separating the rotor. The method has the advantages that the defects of the drawing operation of the traditional generator rotor are overcome, the time and the labor are saved in the drawing operation of the generator rotor, the overhauling operation period is reduced, the overhauling efficiency is improved, and the normal production operation of a unit is ensured.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

Broken bag locating-detecting device and method for distributed optical fiber bag type dust collector

InactiveCN108982516ALower final operating costsHave final operating costsThermometers using physical/chemical changesOptically investigating flaws/contaminationContinuous lightLight energy

The invention relates to a broken bag locating-detecting device and method for a distributed optical fiber bag type dust collector. The broken bag locating-detecting device comprises a single-frequency laser light source and a pulse modulator, wherein the single-frequency laser light source is used for supplying coherent light energy to optical fiber sensors; the pulse modulator is used for converting continuous light output by the single-frequency laser light source into pulsed light of a certain pulse width and repeated frequency; the optical fiber sensors are vertically suspended in each bag in a helical manner; the bottoms of the optical fiber sensors are tied into knots; background noise in a non-running state is measured and recorded. The invention further discloses a broken bag locating-detecting method for the distributed optical fiber bag type dust collector. Two fiber cores of a communication cable integrate sensing and transmission, so that the detection of cable micro-vibration by air current through coherent Rayleigh noise is realized after the bag is broke. Meanwhile, detection of abnormal leakage temperature is realized in combination with a Raman thermometry principle, and signal transmission is realized by adopting the cable. The broken bag locating-detecting device and method are suitable for being applied to industrial fields with limited space and severe environment.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Boiler coke eliminating agent

InactiveCN1206508CNo corrosionNo explosion hazardTreatment using complexing/solubilising chemicalsFlush cleaningPotassium nitrateChemical solution

A boiler decoking agent belongs to the technical field of cleaning boiler inner walls with chemical solutions. It solves the problems of the existing powdery decoking agents such as large dosage, laborious putting in, polluting the environment, and incomplete decoking. It consists of an aqueous solution of potassium nitrate, copper nitrate, magnesium nitrate, aluminum nitrate, and boric acid. It can be sprayed into the flame area from the observation hole during the operation of the boiler, and it can also be sprayed on the coking surface when the furnace is shut down.

Owner:戴琦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com