Apparatus and method for discharging and degaussing of electromagnetic clutch

An electromagnetic clutch and degaussing device technology, applied in the direction of magnetic drive clutches, clutches, non-mechanical drive clutches, etc., can solve the problems of mechanical failure, coil burnout, coil heat and moisture, etc., to avoid abnormal damage and reduce accidents rate, to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

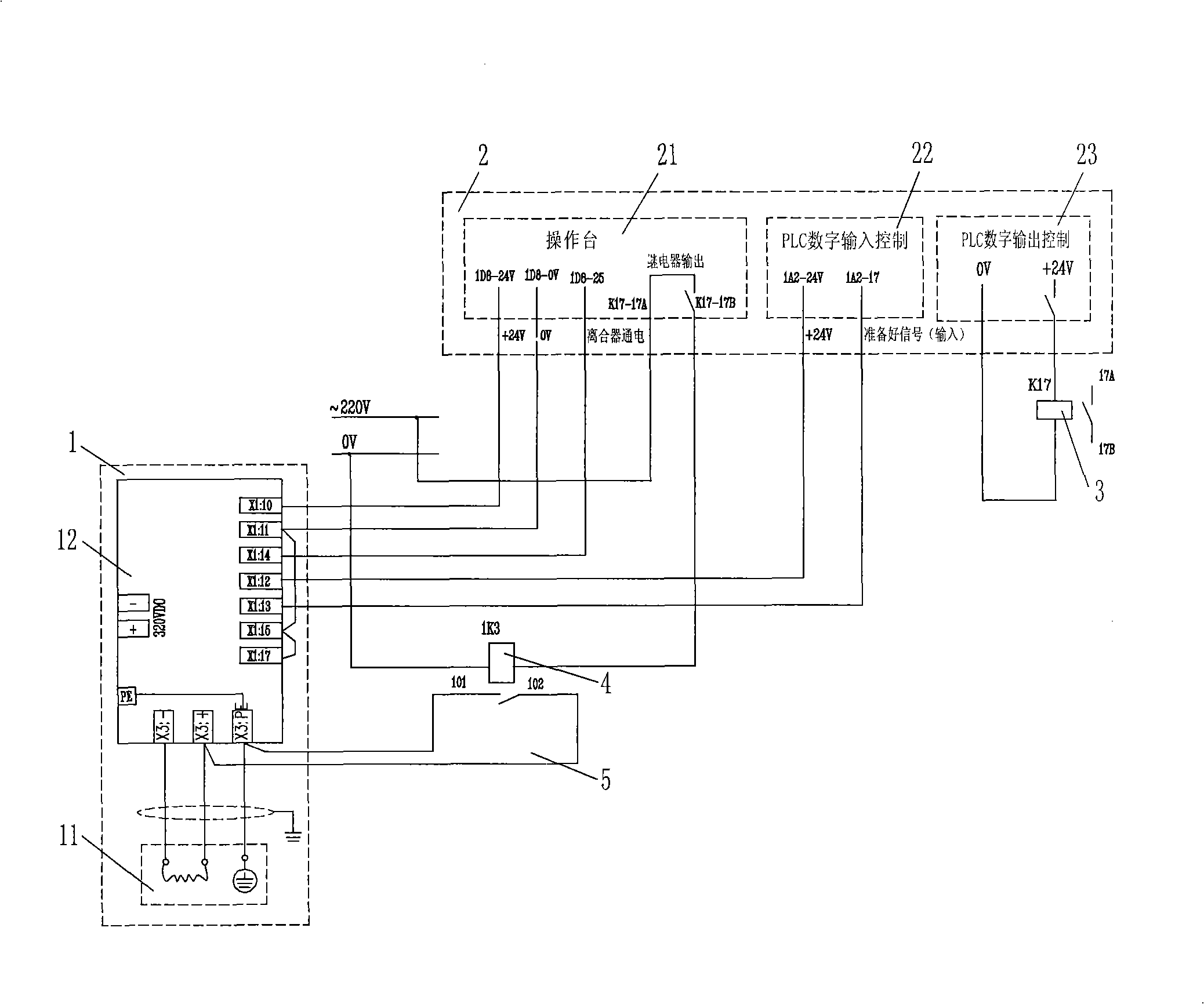

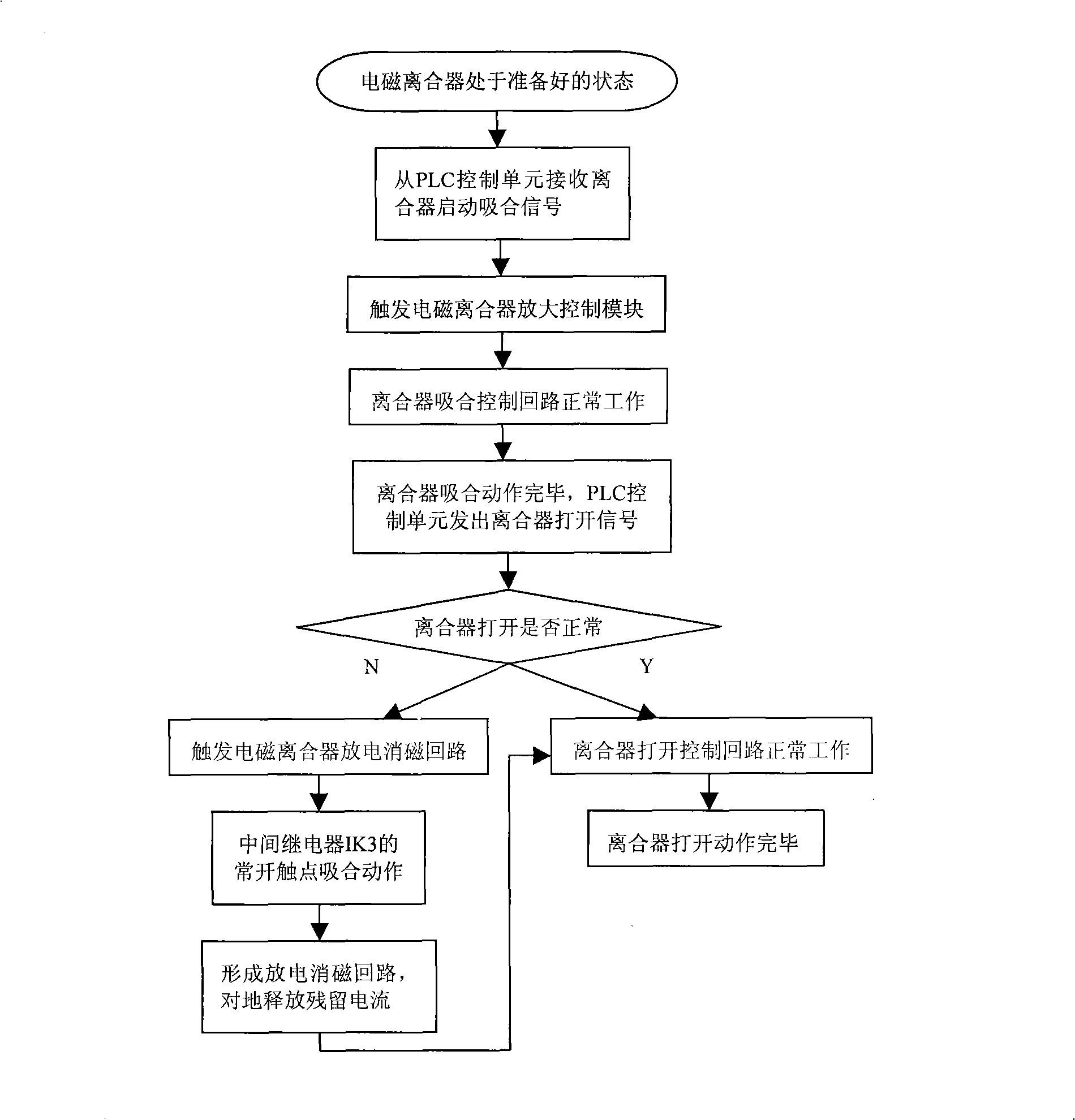

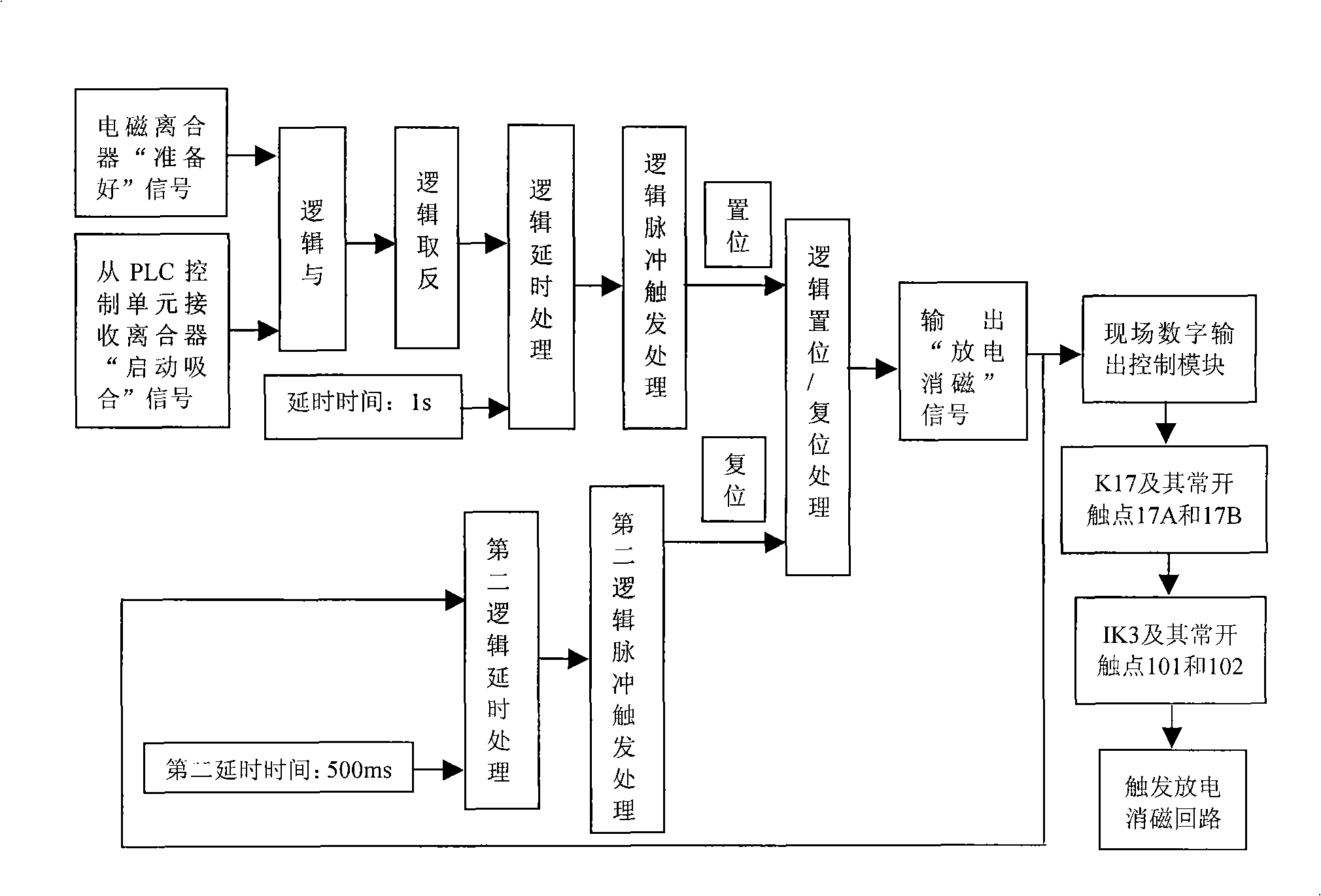

[0021] see figure 1 , an electromagnetic clutch discharge degaussing device, comprising an electromagnetic clutch and its control unit 1, a PLC control unit 2, and a discharge degaussing unit. The electromagnetic clutch and its control unit 1 include an electromagnetic clutch body 11, an electromagnetic clutch amplification control module 12, a rectifier transformer, a low-voltage circuit breaker, and a corresponding working power supply; the PLC control unit 2 includes an operating console 21, a PLC digital input control 22, and a PLC digital output control 23. The discharge degaussing unit includes the intermediate relay 3 and its auxiliary normally open contacts 17A and 17B, the degaussing intermediate relay 4 and its auxiliary normally open contacts 101 and 104. The PLC control unit 2 is connected with the electromagnetic clutch and its co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com