Patents

Literature

70results about How to "Avoid abnormal damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

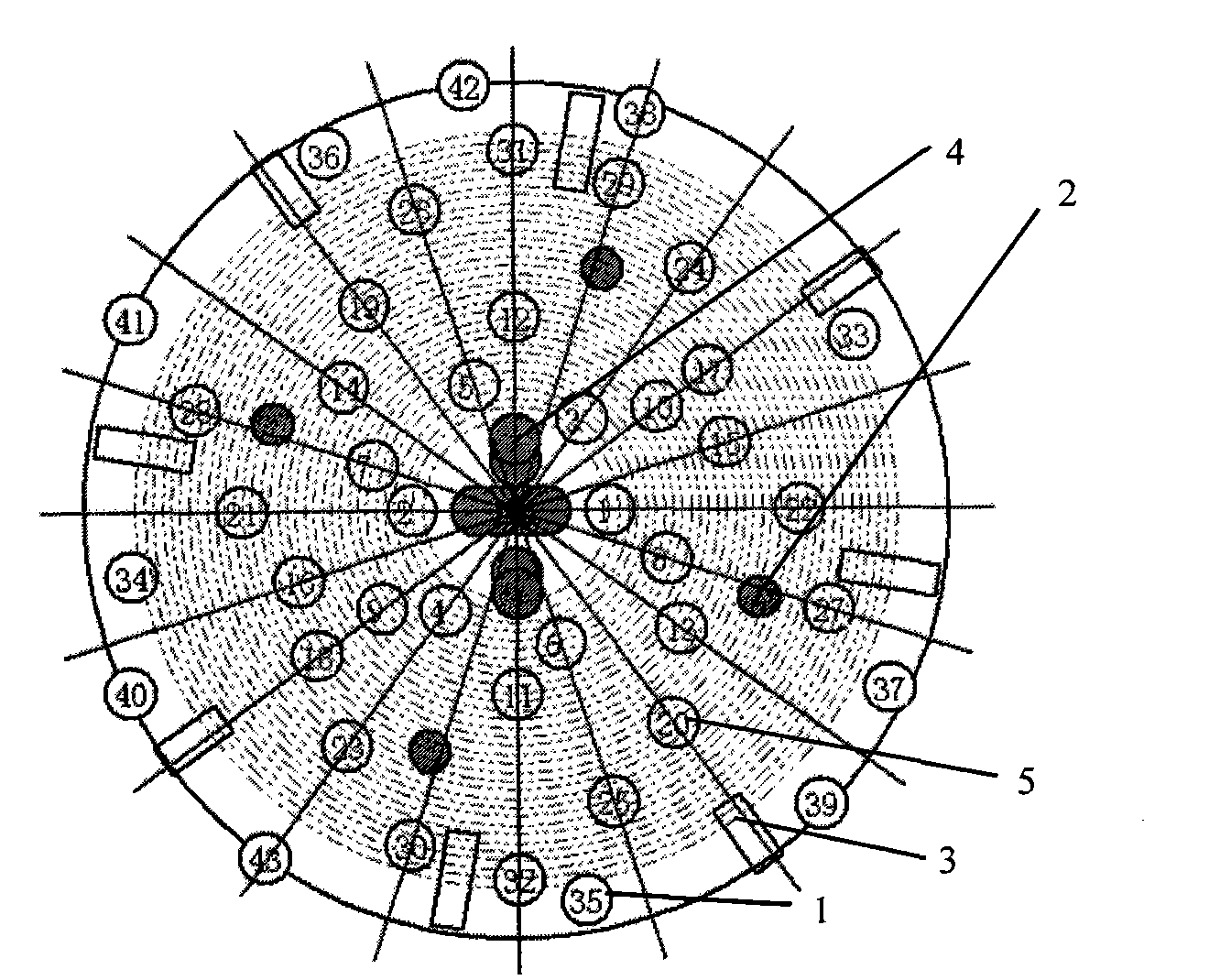

All-section rock tunneling machine cutter layout design optimization method

InactiveCN101086208AShorten the development cycleReduce vibrationTunnelsDesign cycleGenetic algorithm

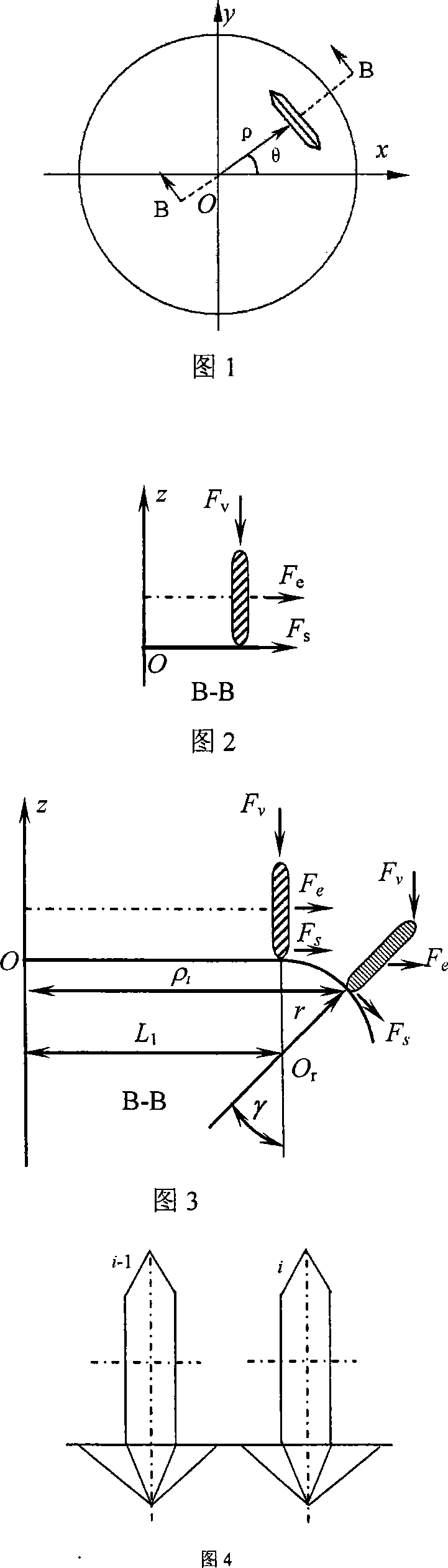

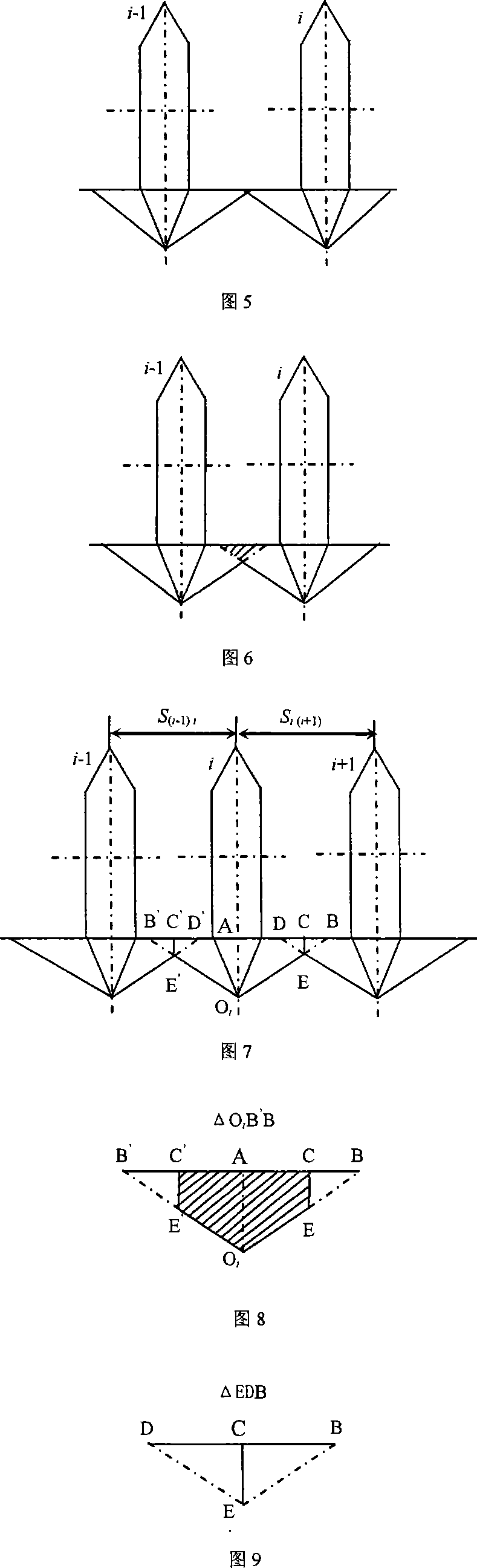

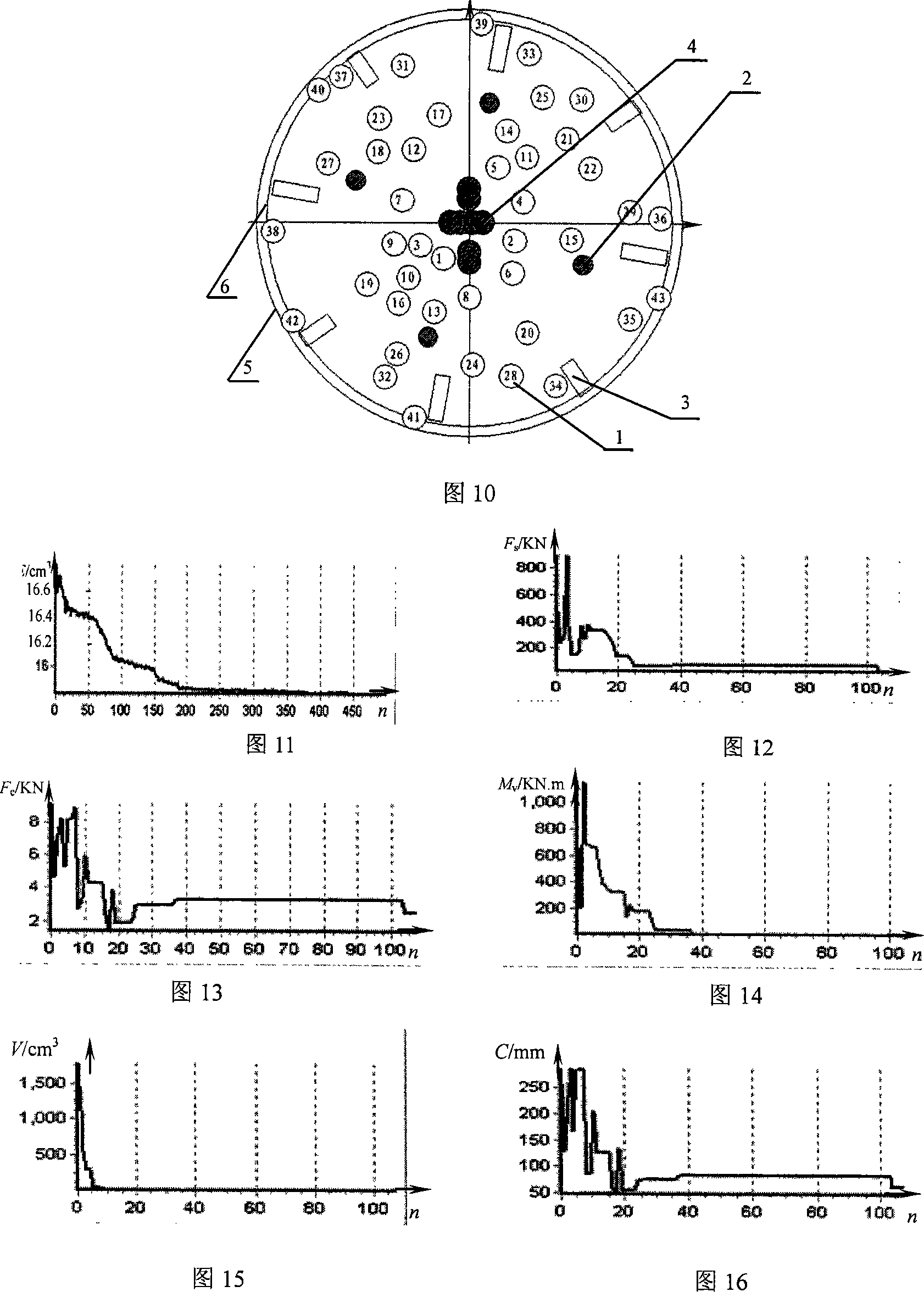

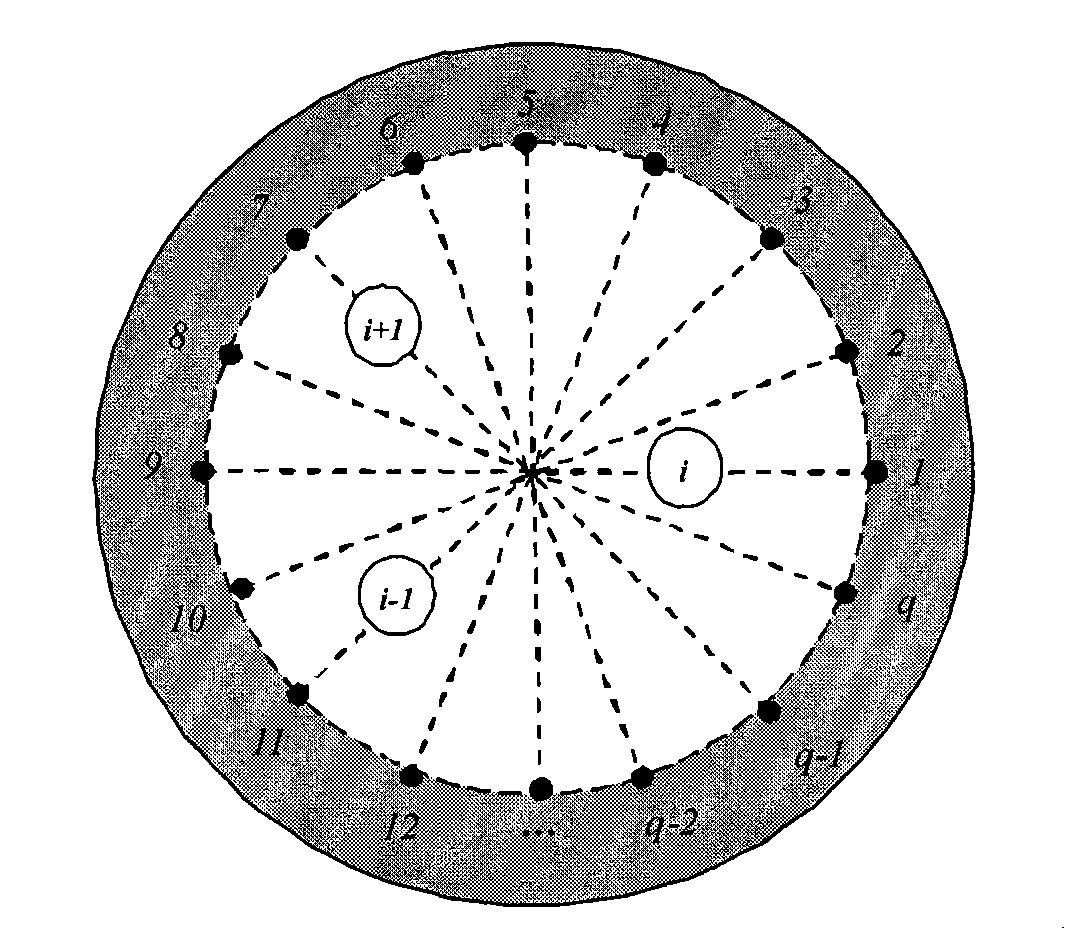

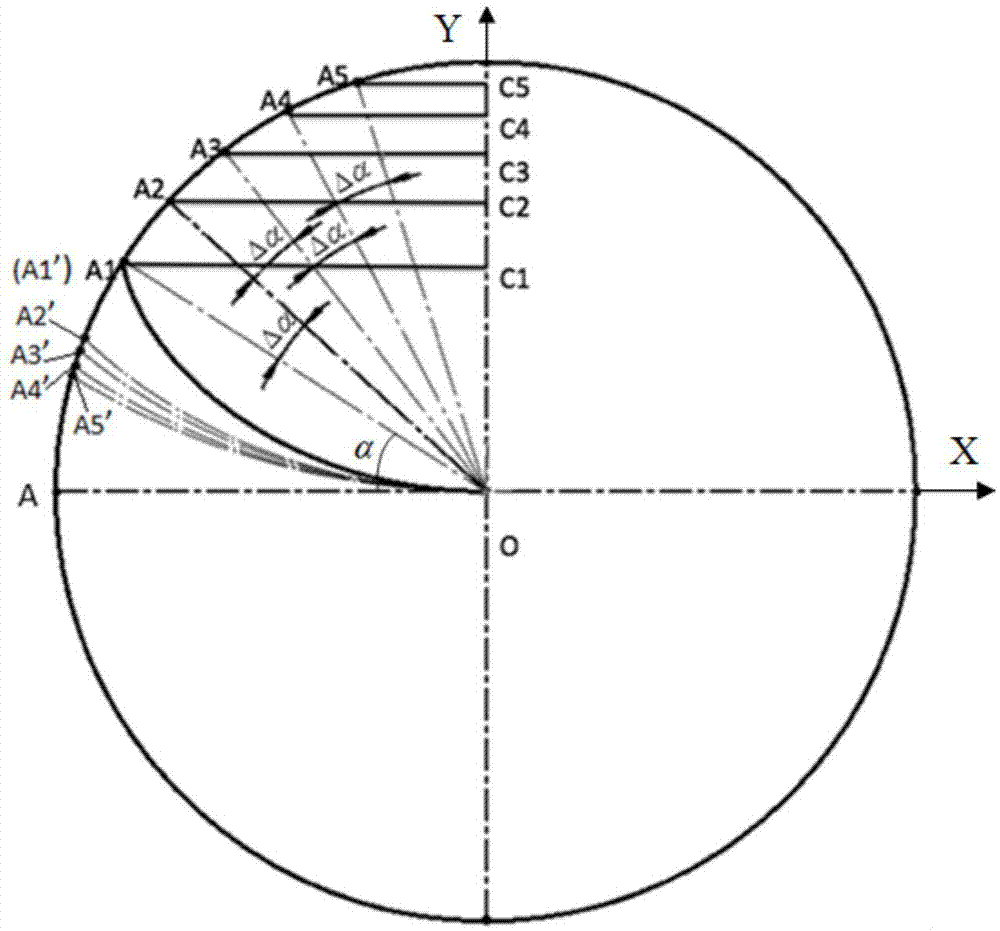

The invention relates to a disk cutter layout design optimization method of development machine, concerning not micro and multi-modal disk cutter layout design optimization problems, especially applicable to full-face rock tunnel boring machine tool optimized layout design. A full-face rock tunnel boring machine knife tool layout design method, first determine disc hob position on the knife set and knife set overall technical performance parameters, in accordance with the actual knife tool layout technical requirements of the full-face rock tunnel boring machine, establishment of the binding properties of complex nonlinear multi-objective optimization model for knife tool layout; layout tool to establish grading optimization design model of knife tool layout polar pathway and angle calculation; putting the knife tool polar pathway and disc cutter knife polar angle as a design variable, adoption the genetic algorithm. The invention fast and effective in the determination of the knife tool optimized layout on the knife disc, made the knife disc having a small outside force and outside torque, thereby prolonging knife disc, knife tool and knife disc axletree life of the development machine, shorten the design cycle and improve design efficiency .

Owner:XCMG KAIGONG HEAVY IND NANJING

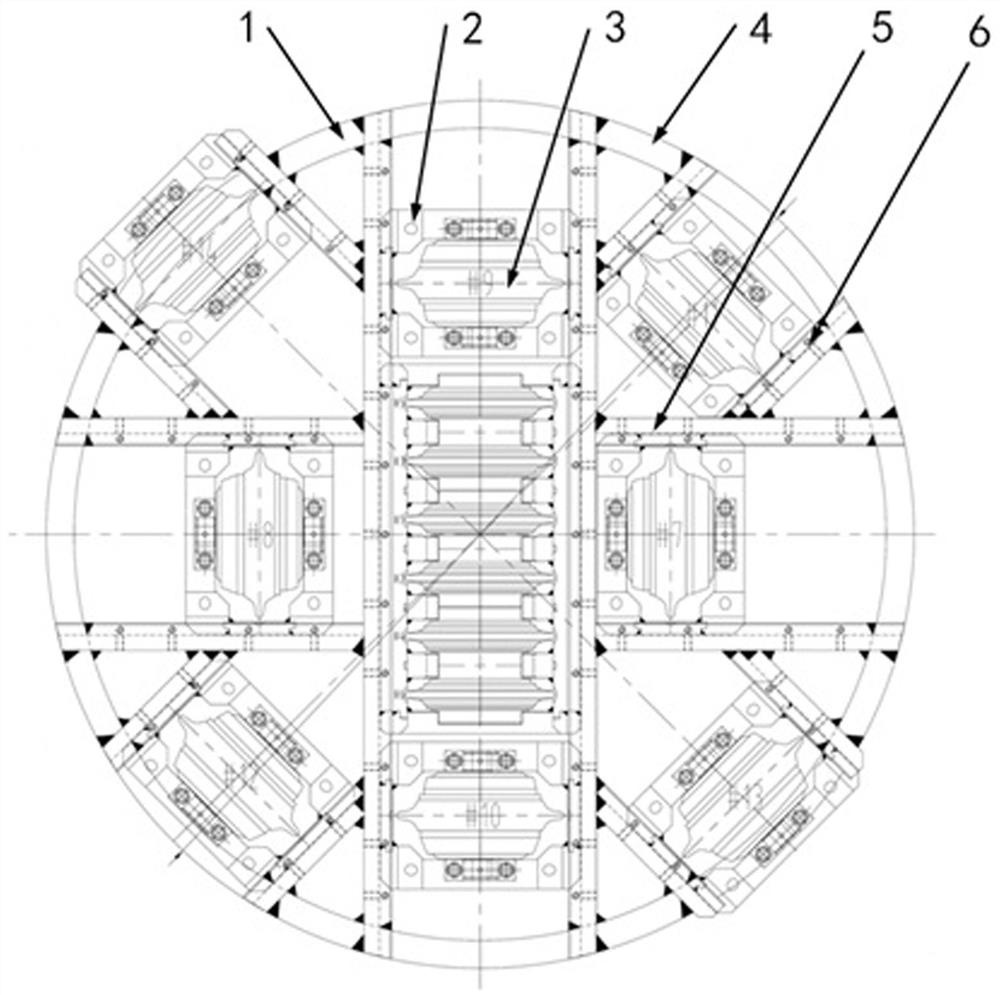

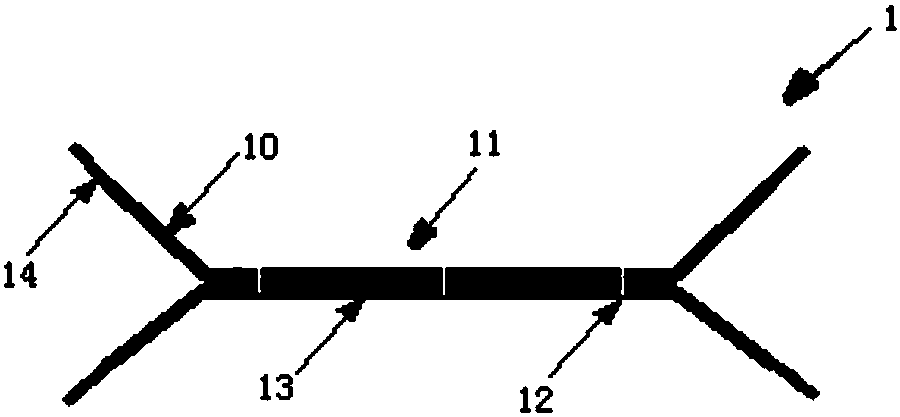

Rice character type structure arrangement method of hobs of full section rock digging machine

InactiveCN101672184ASmall external forceImprove tunneling efficiencyTunnelsCompressive strengthUltimate tensile strength

The invention discloses a rice character type structure arrangement method of hobs of a full section rock digging machine, belonging to the design field of a cutter disk of the full section rock digging machine. Geologic parameters and digging parameters are confirmed according to a geologic report of tunnel engineering, wherein the parameters comprise rock unconfined shear strength, rock uniaxial compressive strength Sigma, rock brazilian tensile strength Sigma Tau, rock stability, digging speed and cutter disk rotate speed. An automatic solve model of the arrangement problem of the hobs on the cutter disk is built, so as to confirm the arrangement position of the positive hobs and the edge hobs with the rice character type arrangement method and a synergetic evolution method. When the hobs are arranged on the faceplate type cutter disk, the technical performance index needs to be met comprises side force to the cutter disk, the overturning moment, interfere area, and the quantity and the mass center of non-order cock fragmentation of the adjoining hobs. The method can fast and effectively confirm the arrangement position of the cutter on the cutter disk, prolong the service lifeof the cutter disk of the digging machine, the cutter and the large bearing of the cutter disk, reduce the shake and the noise of the digging machine, and improve the digging efficiency of the cutterdisk.

Owner:XCMG KAIGONG HEAVY IND NANJING

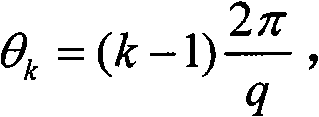

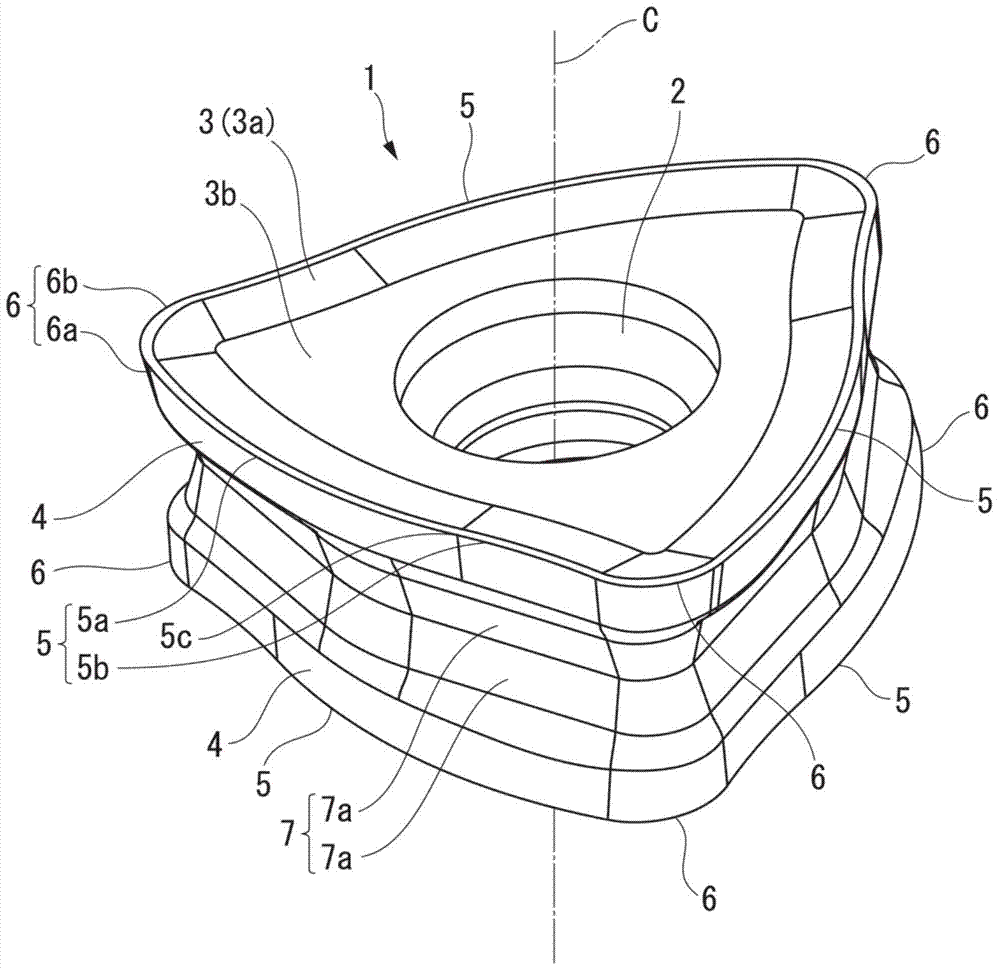

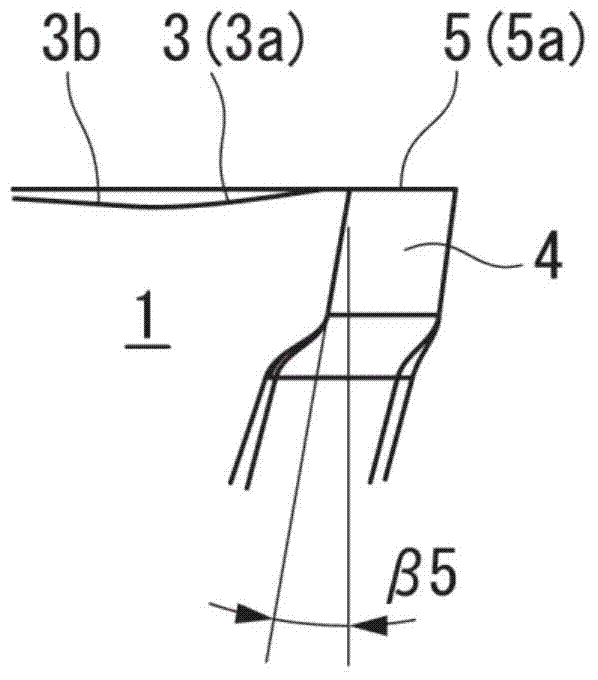

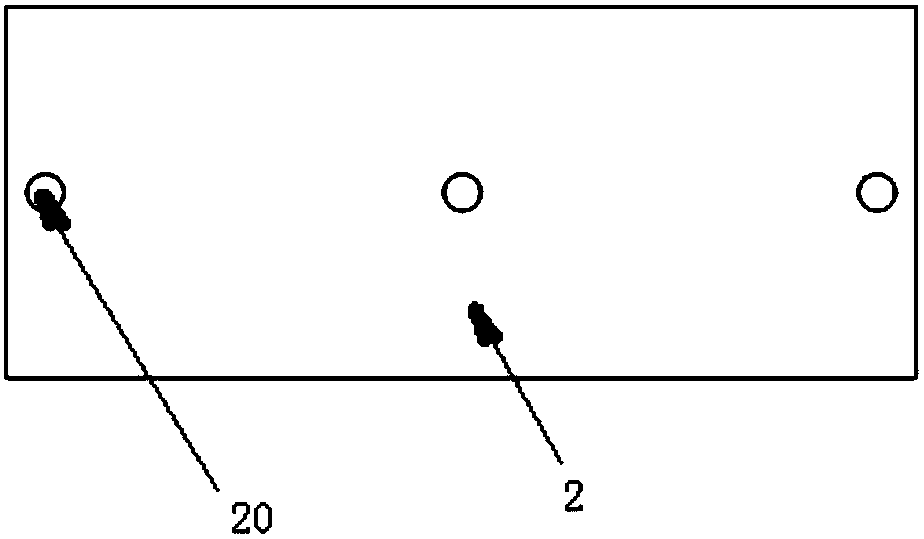

Cutting insert and interchangeable cutting edge-type cutting tool

ActiveCN103945968AAvoid abnormal damageIncrease feed rateTransportation and packagingMilling cuttersCurve shapeEdge type

In the present invention, a cutting insert is provided with an insert body (1) having a polygonal plate shape. A rake face (3) is formed on the polygonal surface of the insert body (1) and flank faces (4) disposed at the periphery of the polygonal surface are formed on the lateral face of the insert body (1). At the intersecting ridge line between the rake face (3) and the flank faces (4), a main cutting blade (5) is formed at the side ridge of the polygonal surface. From among the corners of the polygonal surface, the main cutting blade (5) crosses and extends between two corners adjacent in the circumferential direction of the polygonal surface. Seen from the direction opposing the rake face (3), one edge (5a) of the main cutting blade (5) stretches to one of the two corners and has a protruding curved shape, and the other edge (5b) of the main cutting blade (5) stretches to the other of the two corners and has a recessed curved shape.

Owner:MITSUBISHI MATERIALS CORP

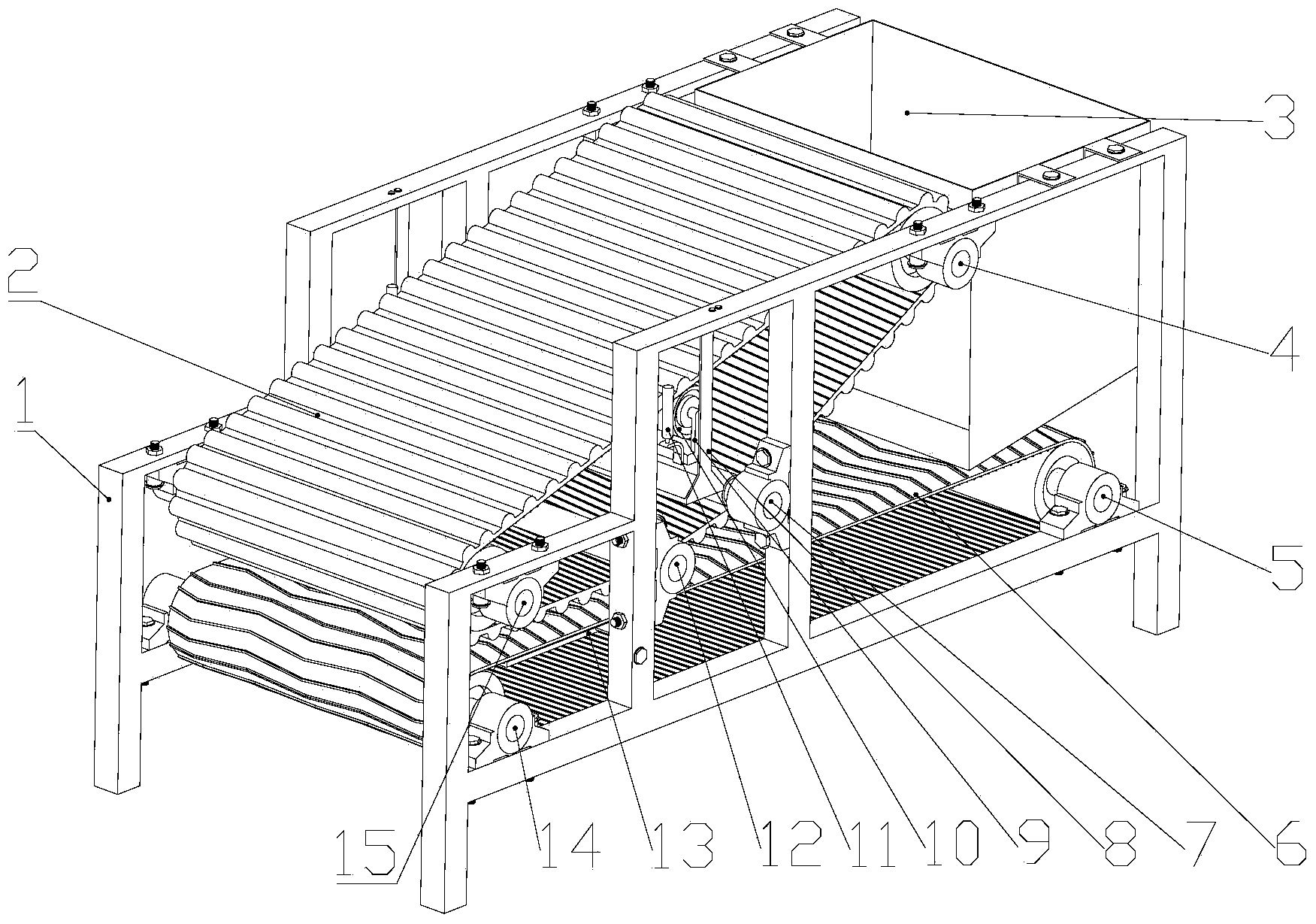

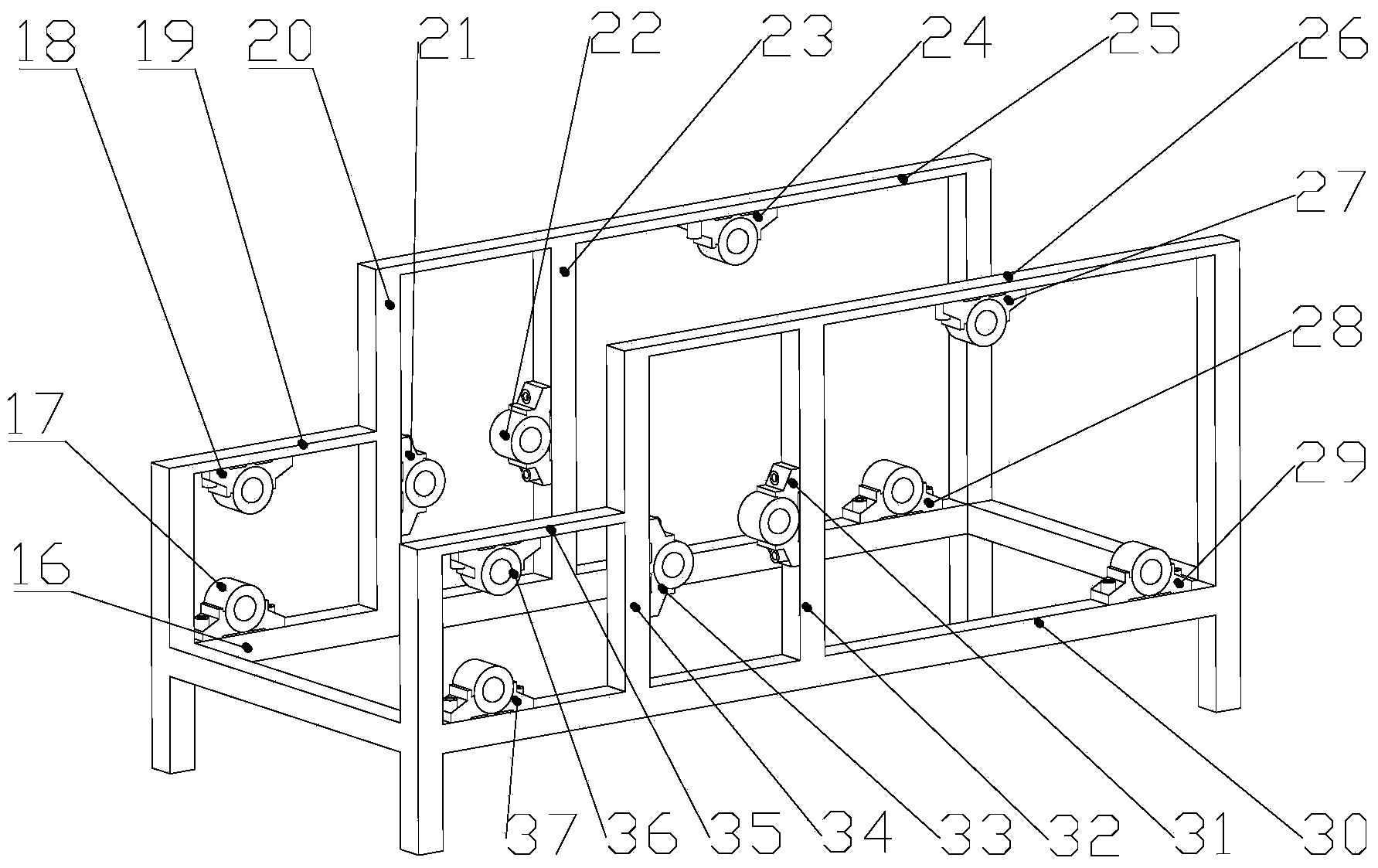

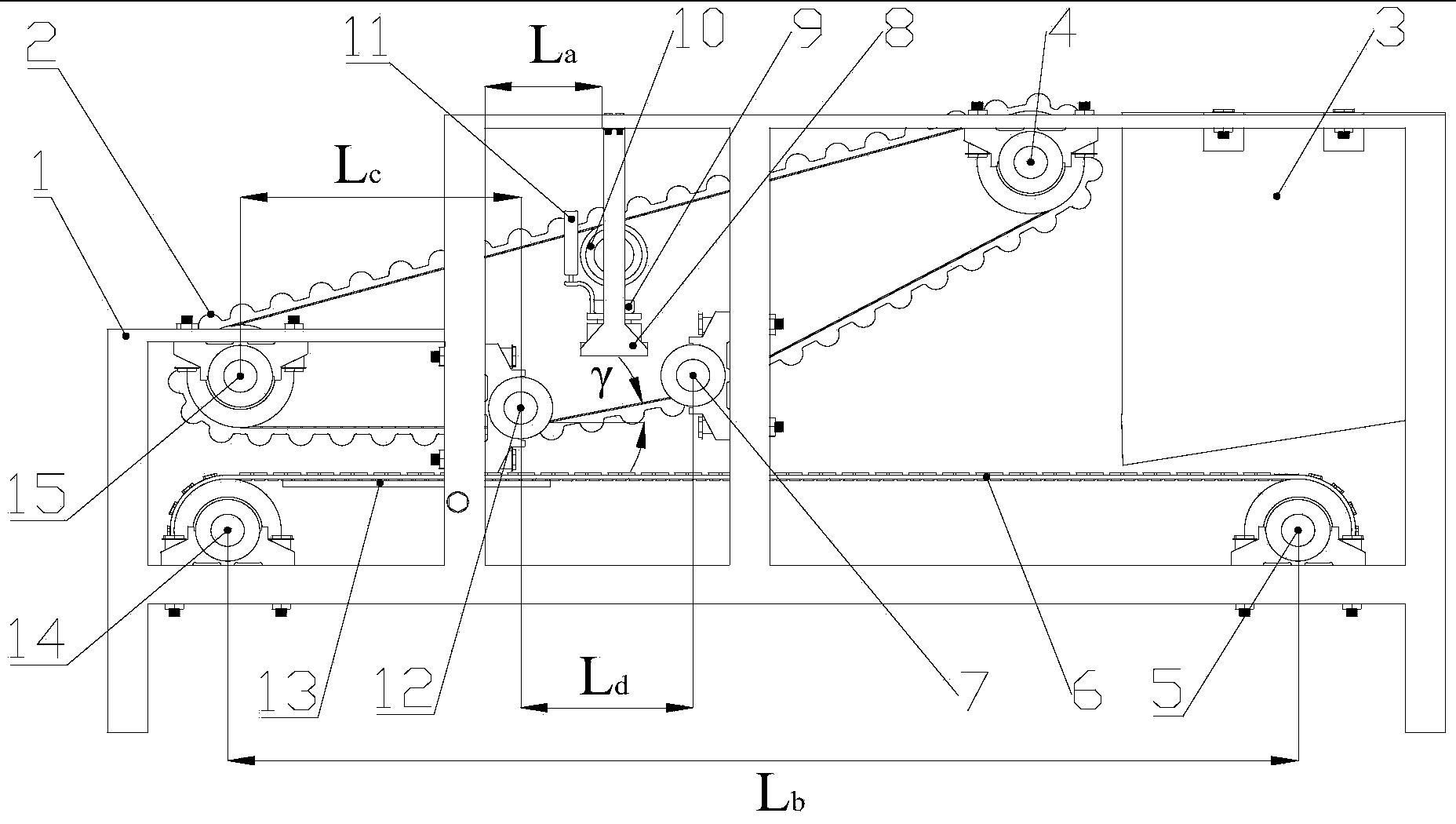

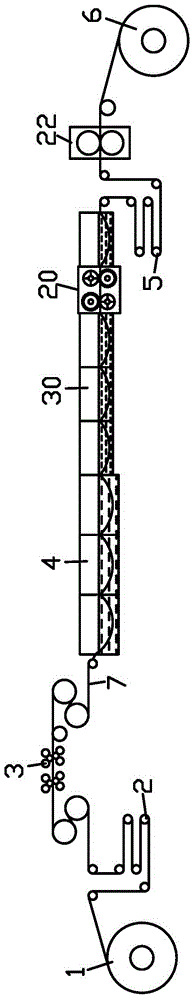

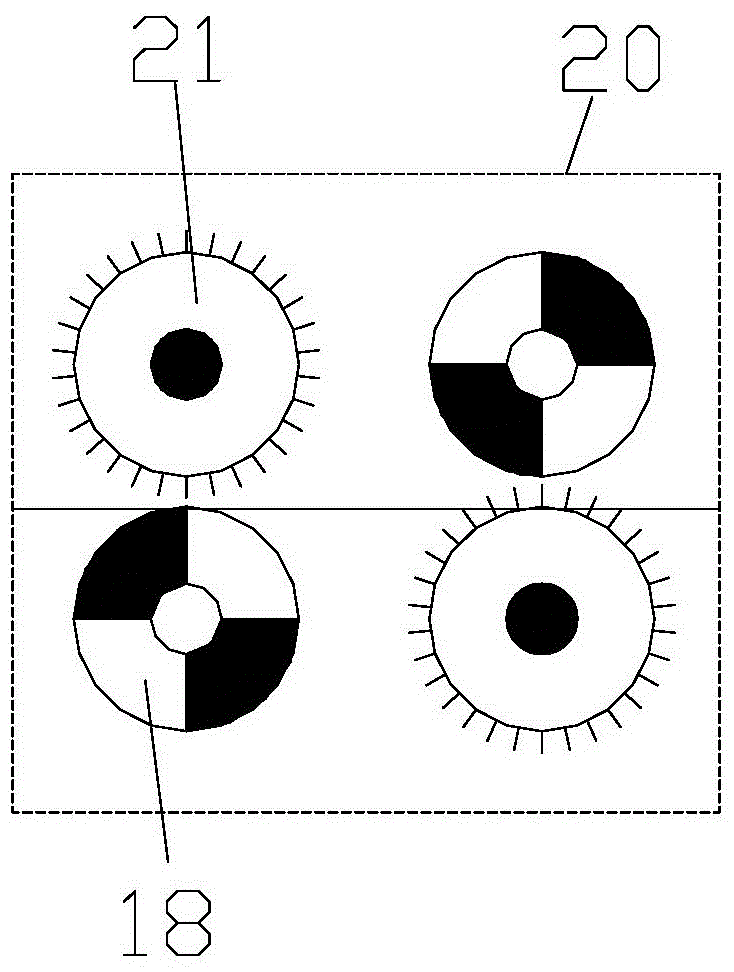

Forming belt automatic skew detection shearing extrusion and flexible shell smashing device for walnut

ActiveCN104207303AReduce breakage rateGuaranteed safety rulesHuskingHullingMechanical engineeringSerration

The invention relates to a forming belt automatic skew detection shearing extrusion and flexible shell smashing device for a walnut, which is characterized in that the walnut is subjected to the action of a periodic concentrated force, so that the shell smashing uniformity of the walnut is realized, the shell smashing efficiency is improved, and the integrity of a walnut kernel is ensured. The forming belt automatic skew detection shearing extrusion and flexible shell smashing device for the walnut comprises supports; a feeding hopper is arranged on the supports; a conveyer is arranged at the outlet of the feeding hopper; the conveyer is provided with a serration belt for conveying the walnut to the other ends of the supports; an extrusion device arranged above the conveyer and used for performing extrusion on the conveyed material is also arranged on the supports; a synchronous belt is adopted by the extrusion device; flexible shell smashing is performed on the walnut by utilizing pressure between the synchronous belt and the serration belt; an automatic skew detection device for the synchronous belt is also arranged on the supports; the automatic skew detection device comprises a bottom end rail connected with the supports; the bottom end rail is provided with a top end rail through a rotation device; the top end rail is provided with a self-aligning carrier roller so as to bear the synchronous belt; the lower end rail is provided with a limiting device for limiting the rotation angle of the top end rail; the top end rail is provided with a synchronous belt limiting device.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

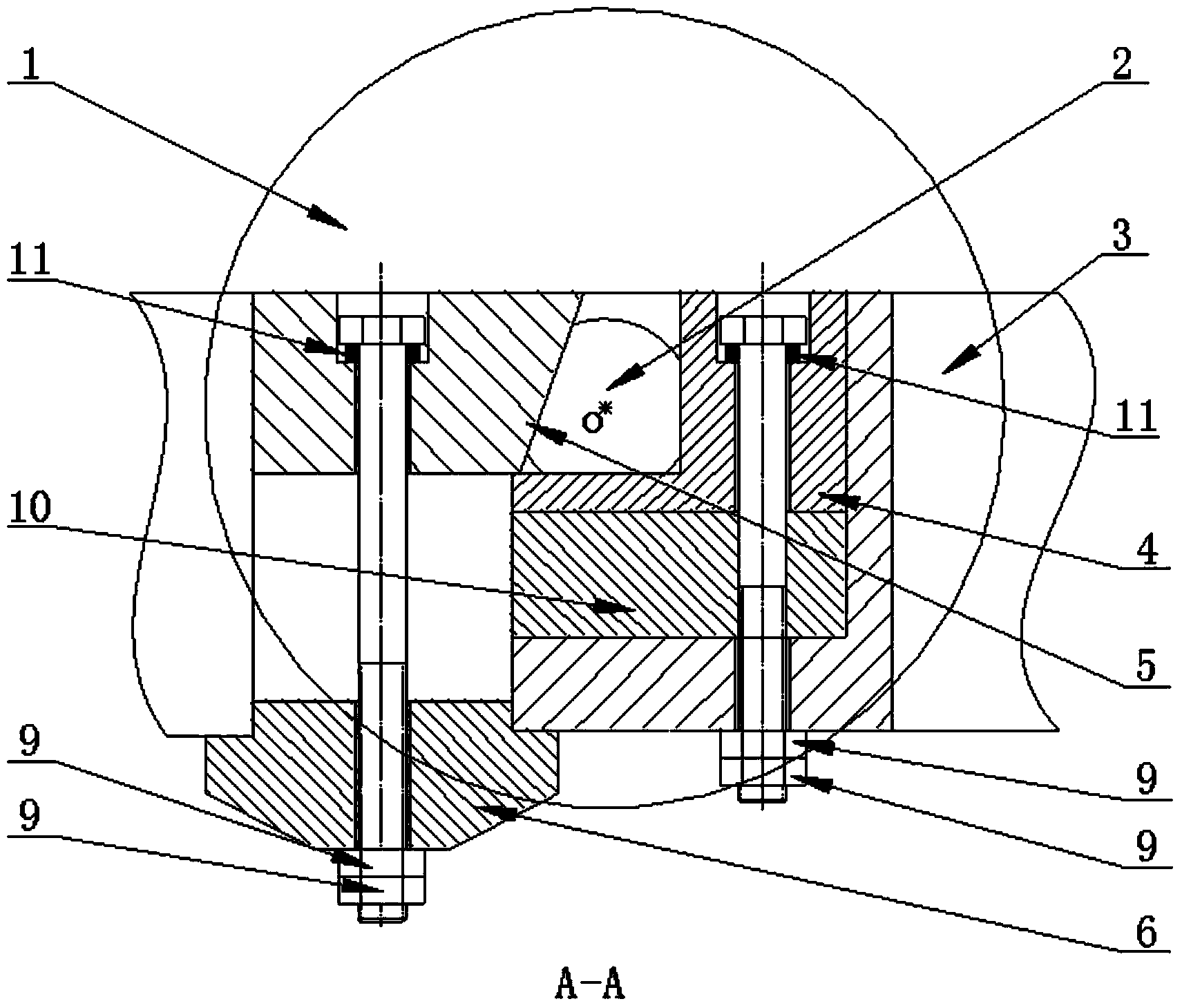

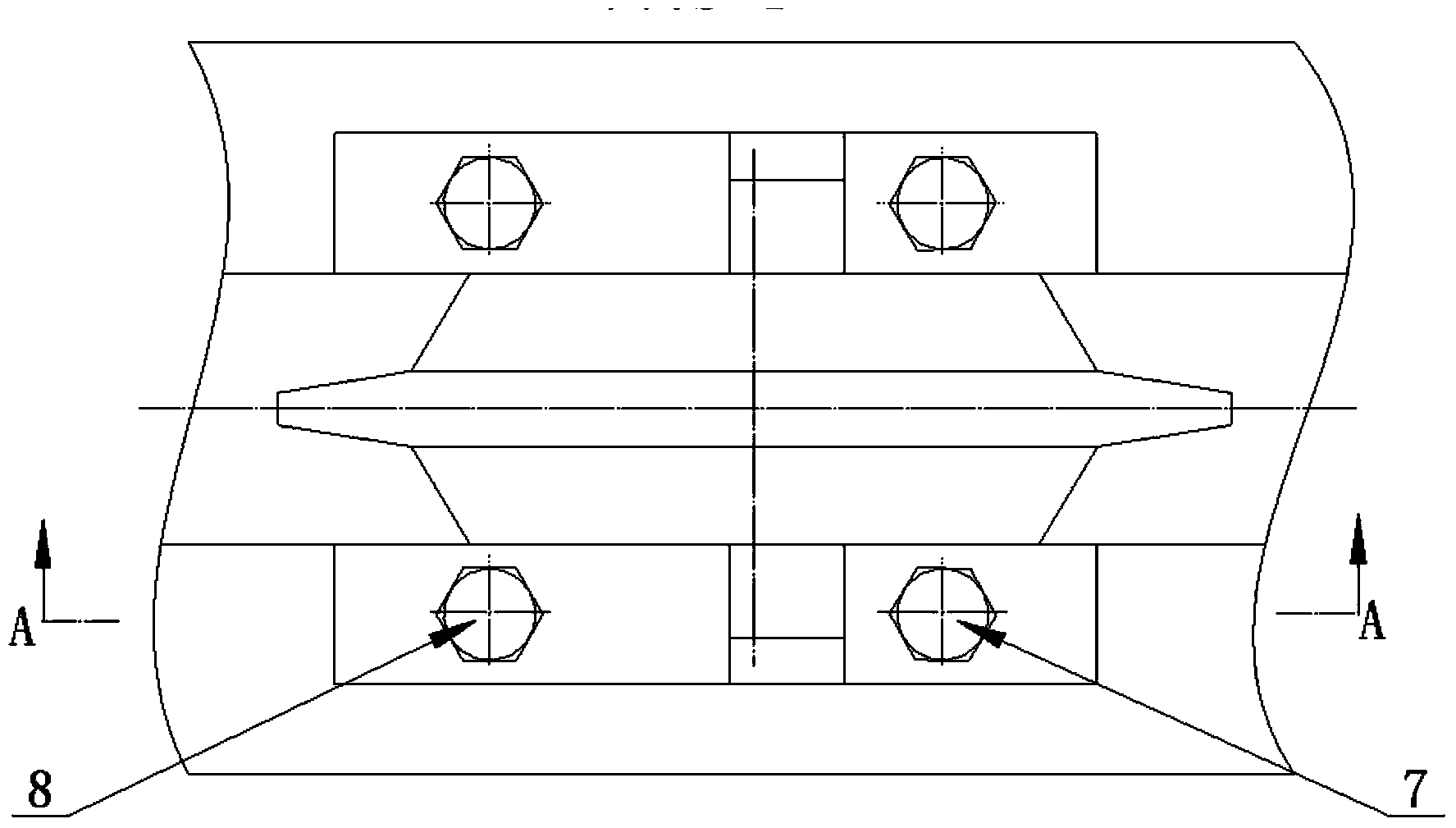

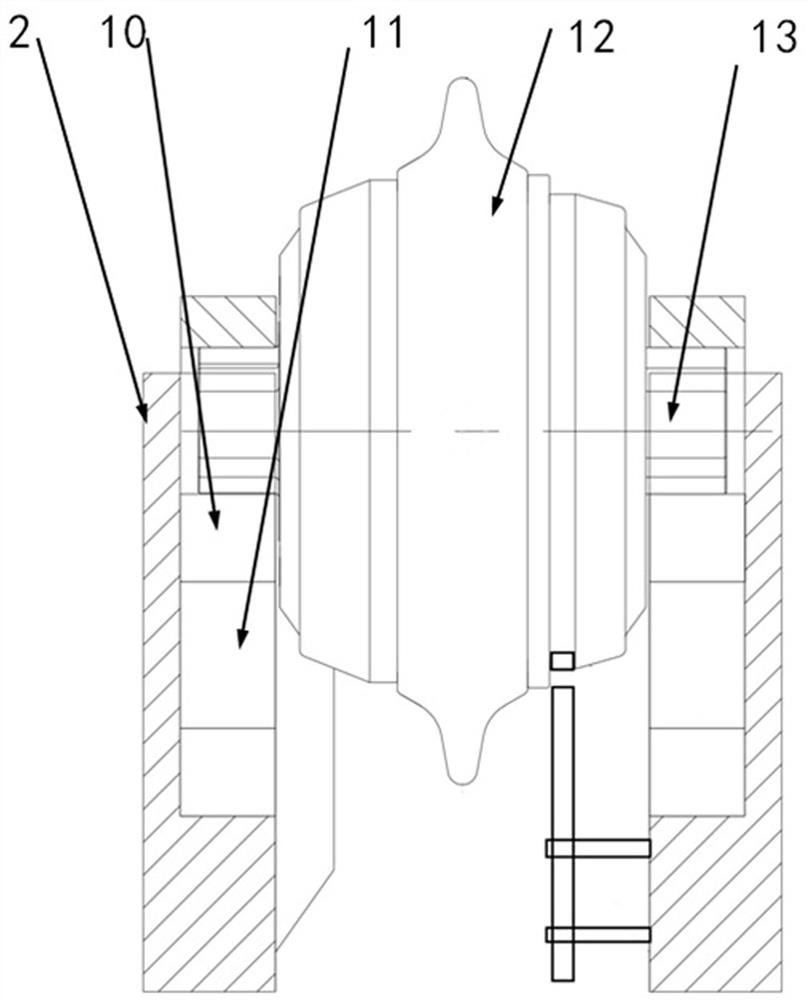

Hob height adjustment methods based on gaskets and positioning blocks

InactiveCN103643962APrevent looseningPrevent institutional failureTunnelsWork performanceEngineering

The invention provides hob height adjustment methods based on gaskets and positioning blocks, belongs to the field of a cutter and cutter head structure design of a shield tunneling machine, and particularly relates to two hob height adjustable methods for a combined type cutter. The methods adopt two cutter head structure forms for adjusting the gaskets and the positioning blocks; the cutter head structure form based on the gaskets realizes hob height adjustment by adding the gaskets with different thickness into the cutter head structure; and the cutter head structure form based on the positioning blocks realizes the hob height adjustment by changing the positioning blocks with different sizes. Through hob height adjustment, working performance of a hob and a scraper can be greatly improved, simultaneously, and by virtue of a reasonable height difference, the reduction of the cutter life caused by abnormal damage to the cutter can be prevented; and if the uniaxial compressive strength change of racks at a drivage road section is larger, the drivage efficiency of the cutter head of the shield tunneling machine can be substantially improved by means of the reasonable height difference between the hob and the scraper, and accordingly, certain economic benefits are achieved.

Owner:DALIAN UNIV OF TECH

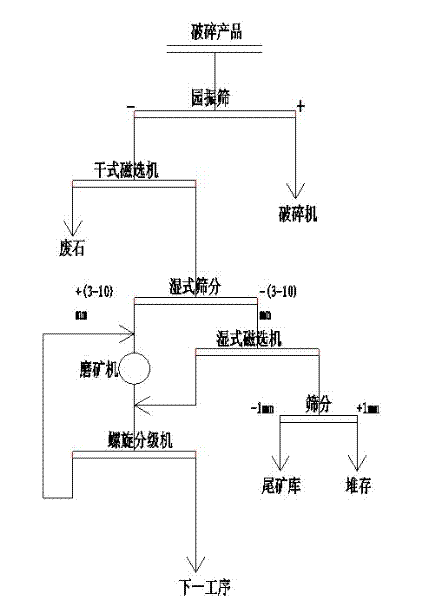

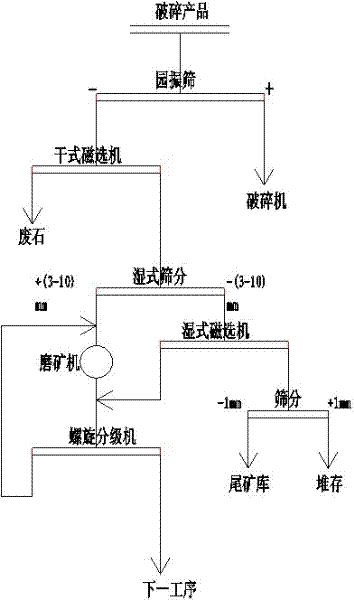

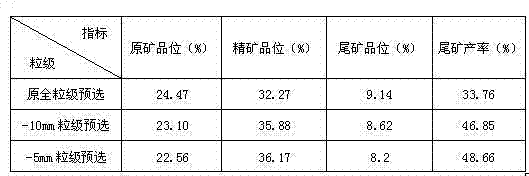

Preliminary separation process for ferromagnetic ore separation

The invention discloses a preliminary separation process for ferromagnetic ore selection, which comprises the following steps of: (1) screening crushed raw ore, returning the oversize product to a crushing machine and crushing, directly performing dry magnetic separation on the undersize product to magnetically separate dry magnetic separation concentrates and dry magnetic separation tailings, and taking the dry magnetic separation tailings as waste ore; (2) performing wet screening on the dry magnetic separation concentrates by using a 3-10 mm screen, performing wet magnetic separation on the undersize product to magnetically separate wet magnetic separation concentrates and wet magnetic separation tailings, grinding the oversize product in a grinding machine, and grading the grinding products; (3) directly grading the wet magnetic separation concentrates, and taking the wet magnetic separation tailings as final tailings; and (4) returning coarse products obtained through grading to the grinding machine and grinding again, forming the closed grinding-grading cycle, and leading overflow products obtained by grading to the next procedure of the ore separation process. The preliminary separation process provided by the invention has the advantages of reasonability of allocation, smoothness of flow, stability of operation, capability of realizing full and reasonable tailing casting and increased productivity and metal recovery rate of the preliminary separation procedure.

Owner:HEBEI IRON & STEEL GRP MINING +1

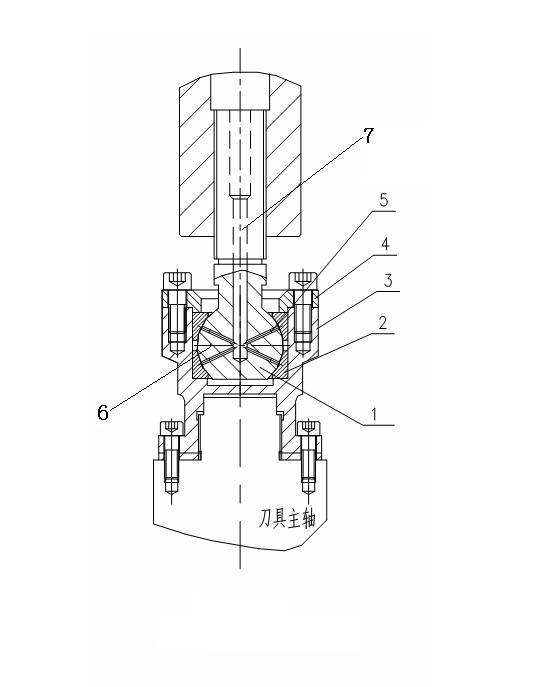

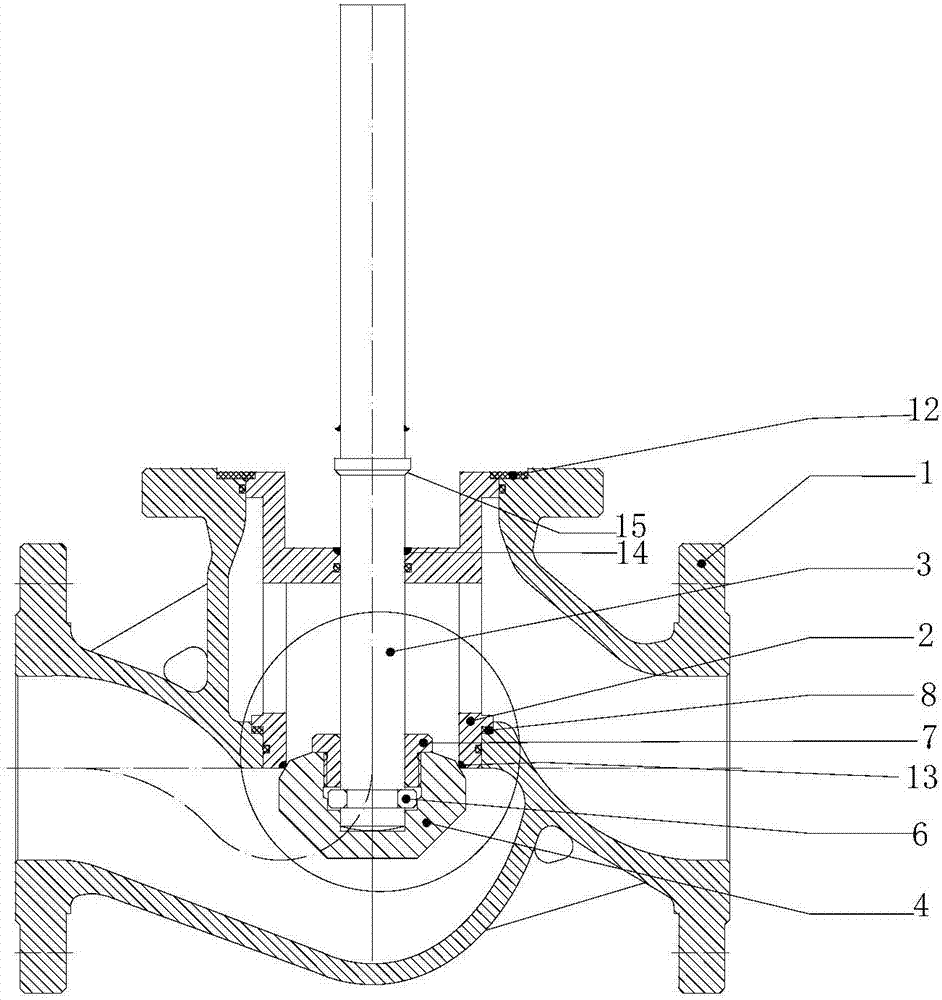

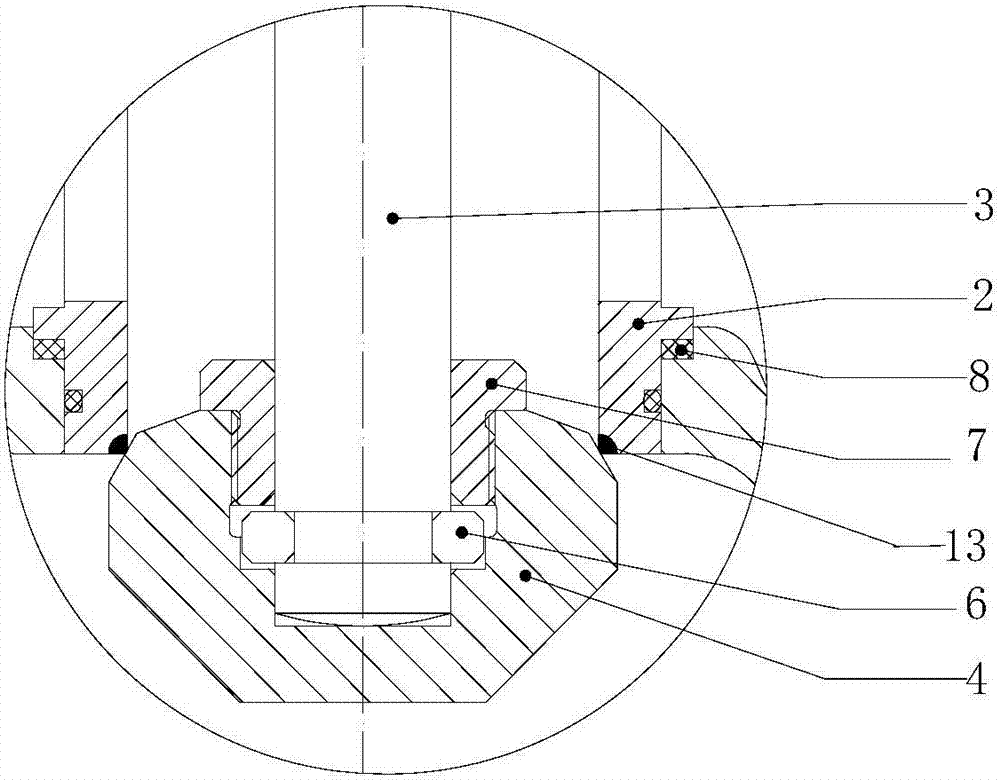

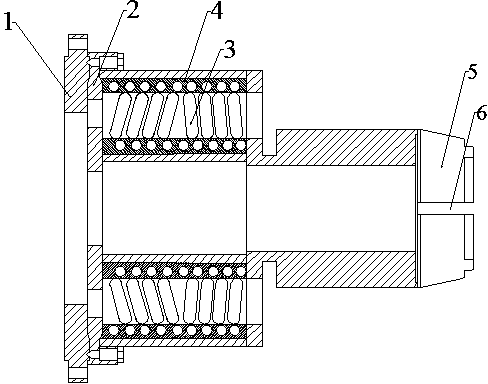

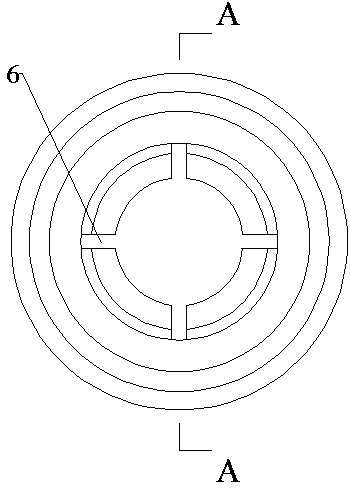

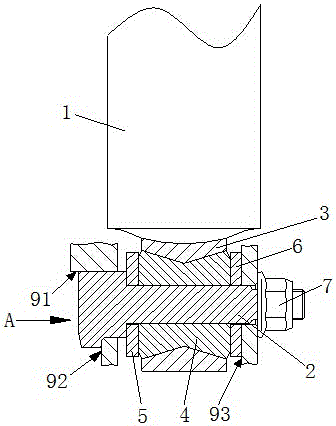

Dynamic and static pressure ball socket bearing structure for high speed gear shaper

ActiveCN102221039AImprove mean time between failuresImprove the lubrication effectPivotal connectionsGear-cutting machinesEngineeringAxial force

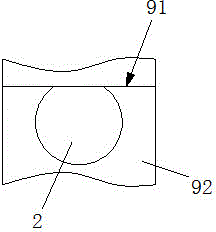

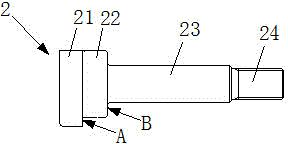

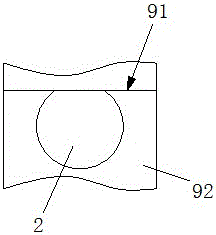

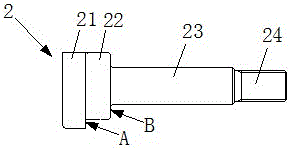

The invention relates to a dynamic and static pressure ball socket bearing structure for a high speed gear shaper. The structure comprises a ball rod (1), a ball socket (2) and a shell (3), wherein the lower end of the shell (3) is connected with a cutter spindle; a ball main body (6) at the lower end of the ball rod (1) is positioned in the ball socket (2); the ball socket (2) is arranged in an installation seat of the shell (3) and is positioned and subjected to gap adjustment along the axial direction of the ball rod (1) through a pressing ring (4); and the upper end of the ball rod (1) stretches out of the pressing ring (4) and is connected with a crank. The structure is characterized in that: an oil injection hole (7) is formed in the center of the ball rod (1) and reaches the ball center of the ball main body (6); the ball main body (6) is provided with a throttler (5) along the radial direction; and the oil inlet end of the throttler (5) is communicated with the oil injection hole (7) which reaches the ball center, and the oil outlet end of the throttler (5) is communicated with an annular shallow cavity on the surface of the ball main body (6), so that the shallow cavity generates dynamic pressure bearing force and static pressure bearing force due to a step effect to bear upper and lower axial forces from a gear shaping spindle when the ball main body (6) moves. The structure is simple and has a good lubricating effect and long service life.

Owner:南京二机齿轮机床有限公司

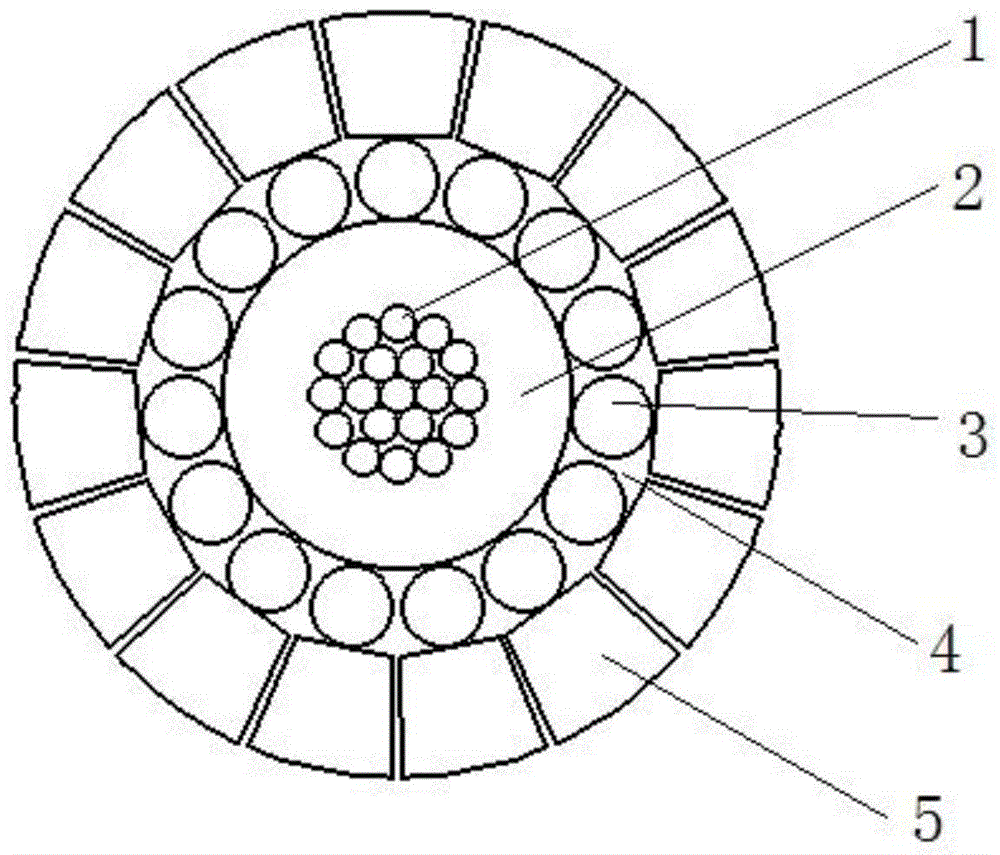

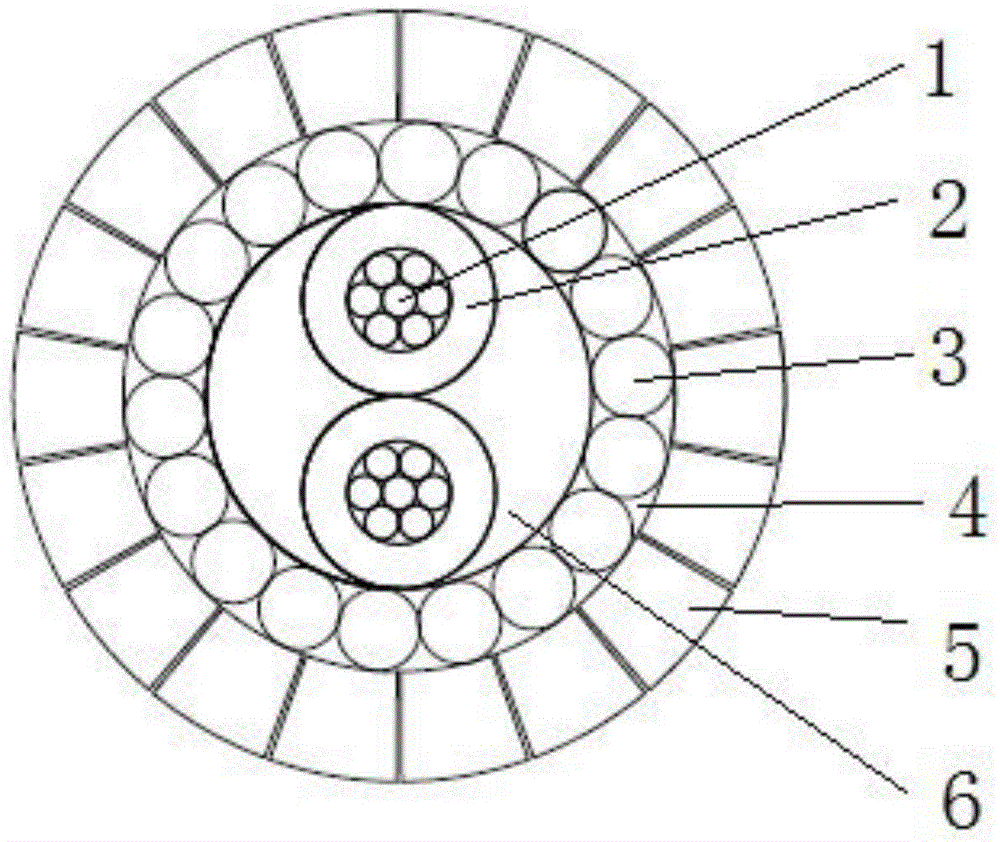

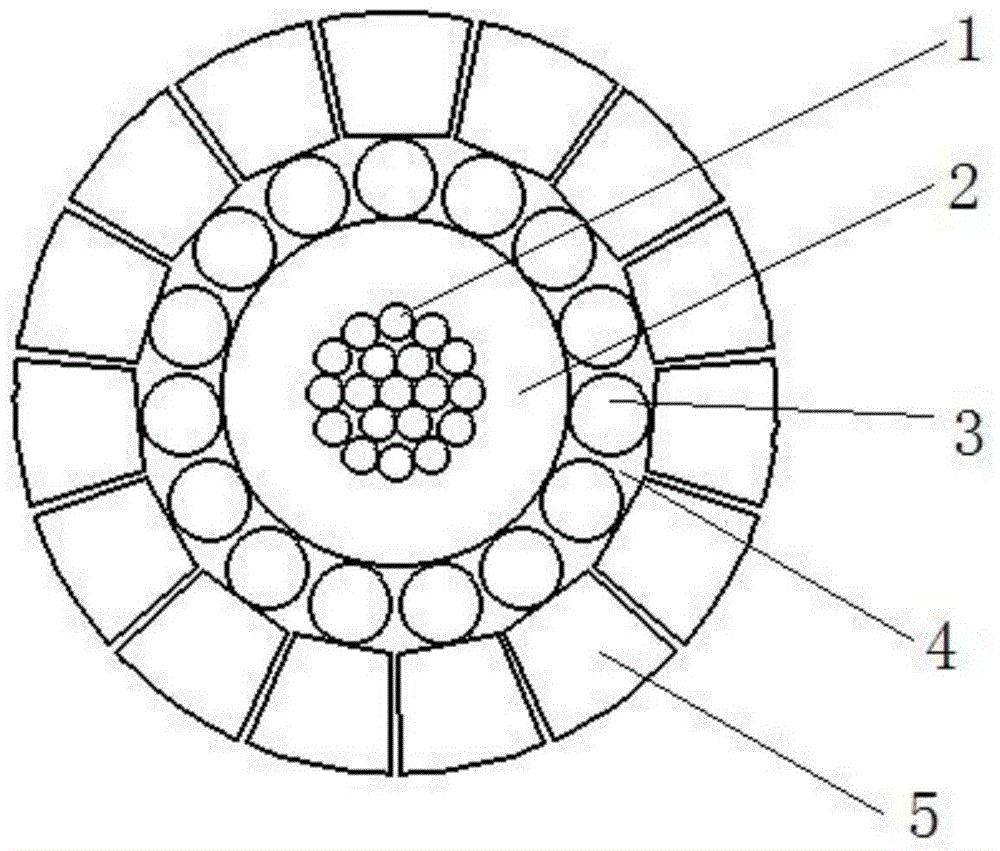

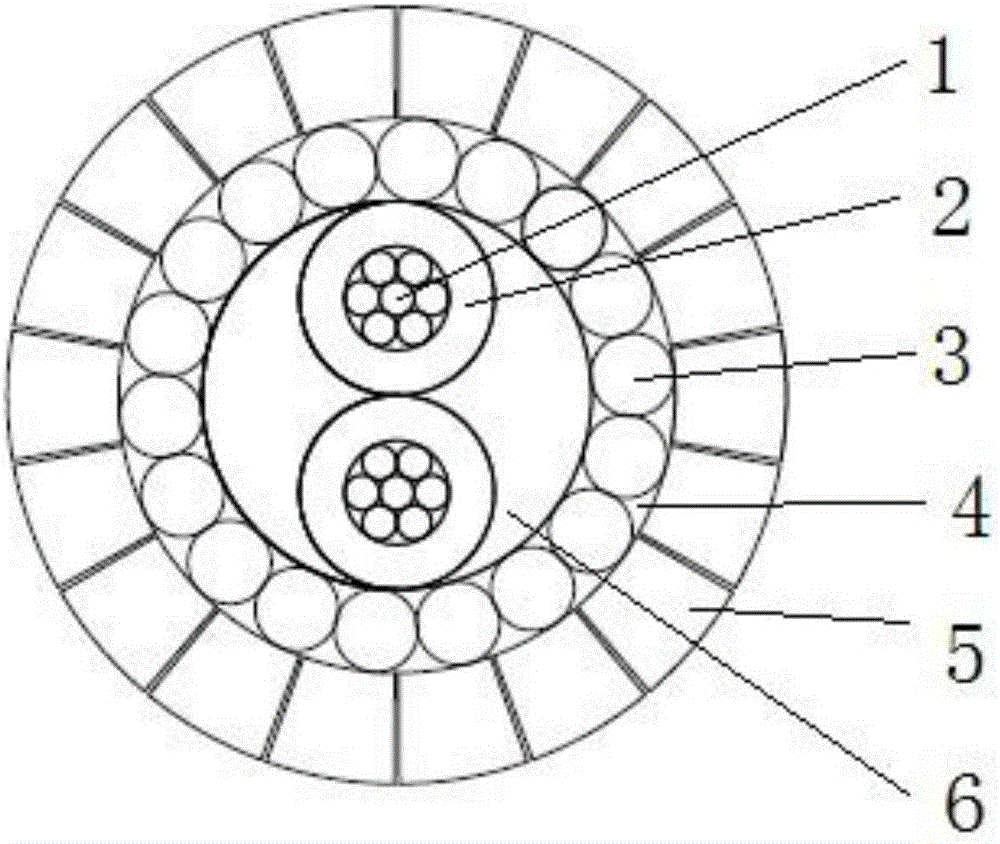

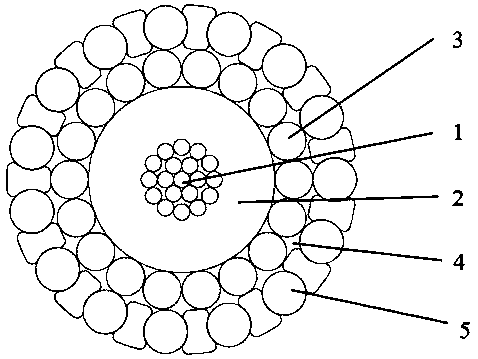

Anti-overflow sealed bearing loading and detecting cable

ActiveCN104681166AIncrease friction areaImprove wear resistanceInsulated cablesInsulated conductorsCopperSealant

The invention relates to an anti-overflow sealed bearing loading and detecting cable which comprises a copper stranded wire, wherein the outer layer of the copper stranded wire is annularly sleeved by an insulating layer, the insulating layer is annularly sleeved by an inner armor layer, and the inner armor layer is annularly sleeved by an outer armor layer; the inner armor layer is composed of steel wires with a circular section and sealant layers, and the outer part of the insulating layer is annularly sleeved by a plurality of circular steel wires; gaps between the adjacent circular steel wires are filled with the sealant layers, and the sealant layers and the circular steel wires constitute the sealed structure with the circular section together; the outer armor layer is formed by annularly sleeving the steel wires with a fan-shaped section, and the outer armor layer also forms a sealed structure with a circular section after a plurality of fan-shaped steel wires are annularly sleeved. The cable provided by the invention has the novel inner and outer armor layer structures, so that the bearing capacity of the cable is improved, while the sealing performance and the reliability of the cable are improved.

Owner:山东希尔电缆有限公司

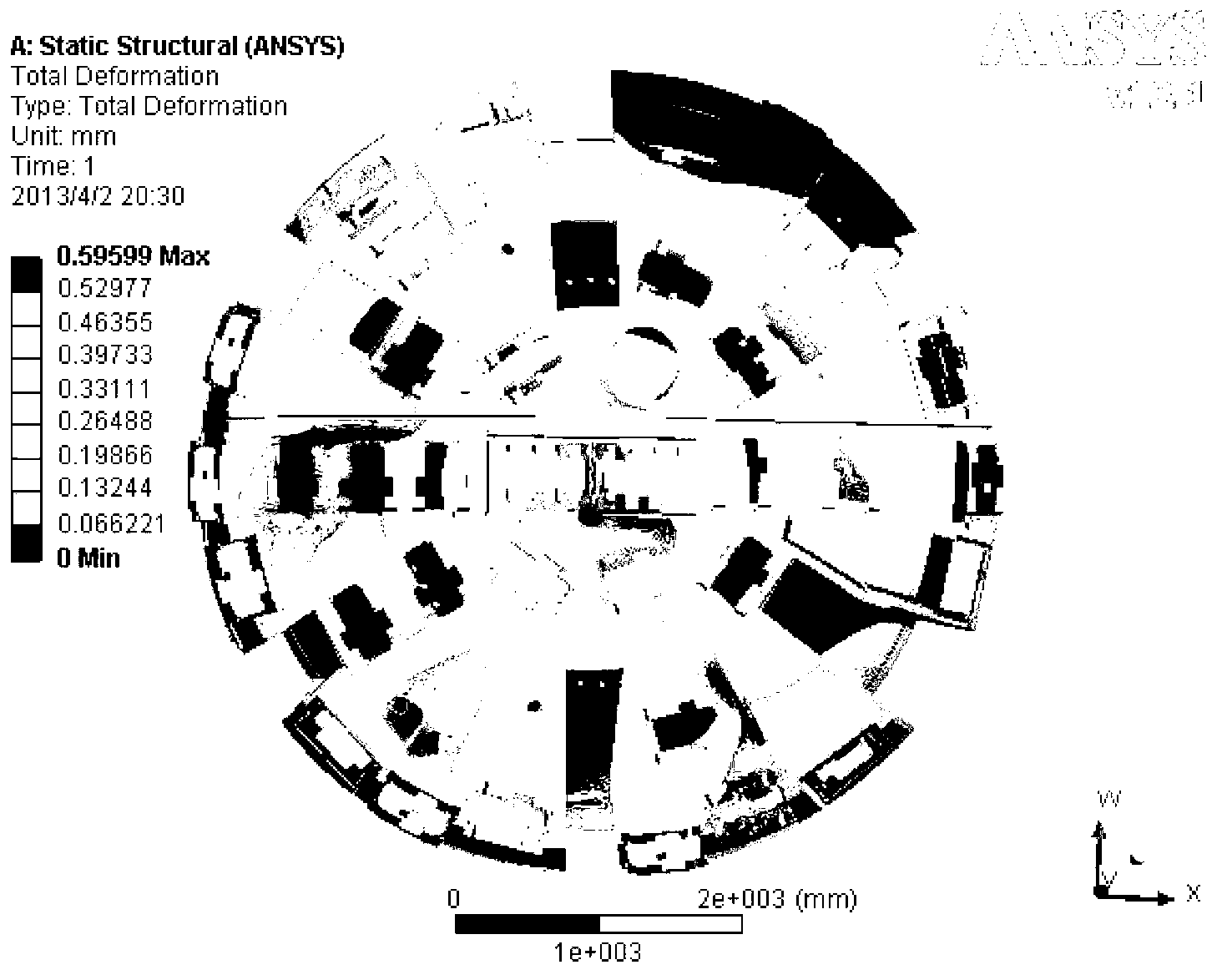

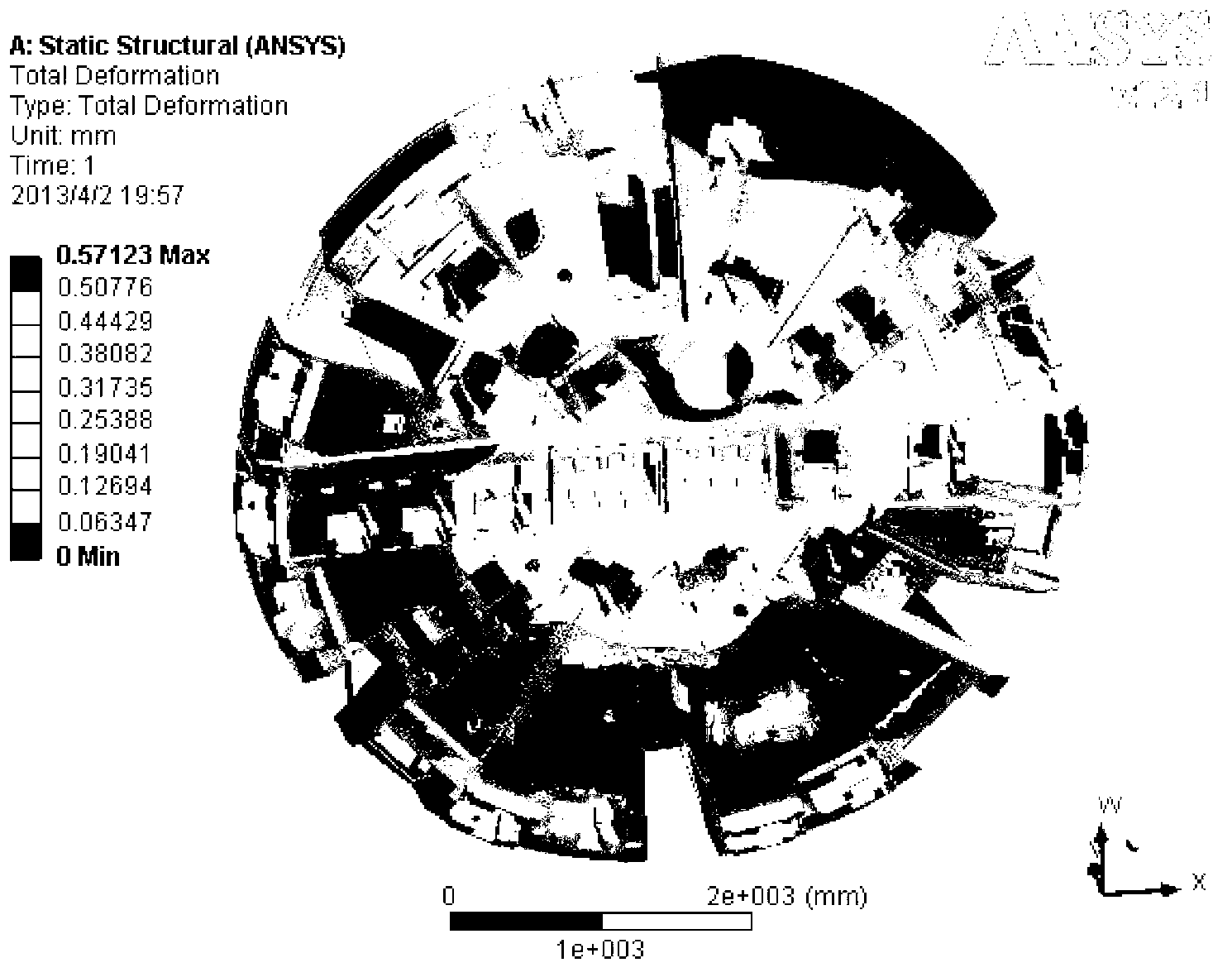

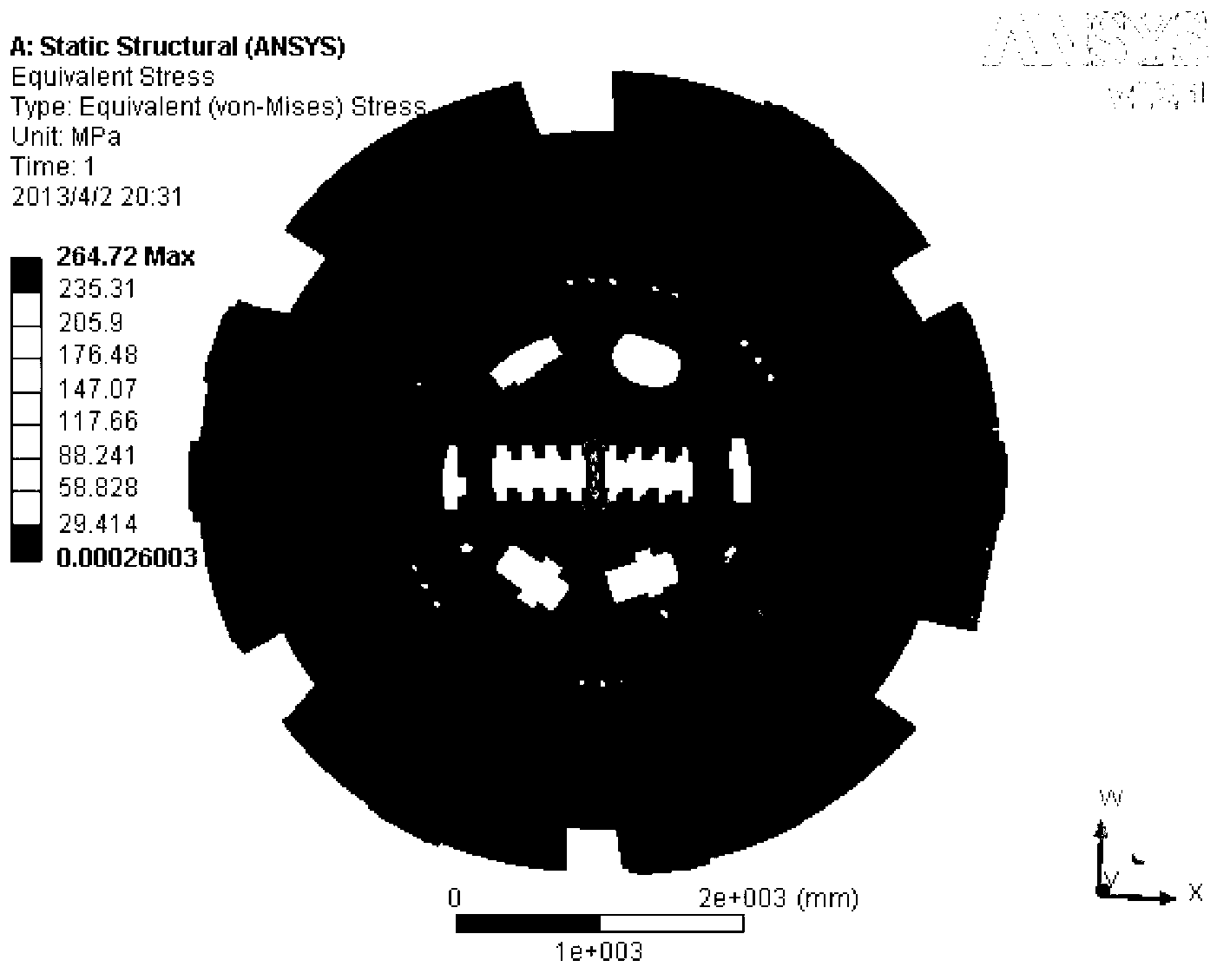

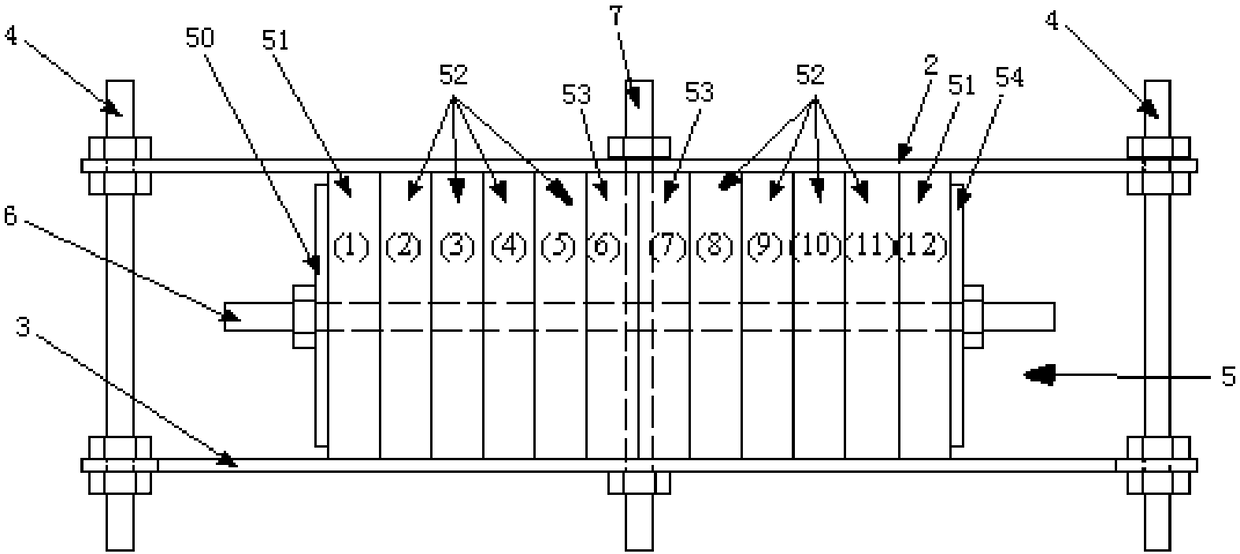

Design method for support ribs of ballast slipping plate of cutter head of full face rock tunnel boring machine

The invention belongs to the field of design methods for a cutter head structure of a tunneling machine and particularly relates to a design method for support ribs of a ballast slipping plate of a cutter head of a full face rock tunnel boring machine. The design method takes the overall technical performance requirement of the cutter head, the construction requirement, and the requirement of the cutter head for quickly discharging ballast into consideration while ensuring maximal strength and rigidity of the cutter head. According to the design method, four L-shaped support ribs from first to fourth are welded at the part of the ballast slipping plate on the rear panel of the cutter head, and each L-shaped support rib has an L-shaped cross section and comprises an arc part and a straight plate part. Due to the adoption of the design method, given that the rock ballast can be smoothly discharged under given conditions, the cutter head is improved in strength, rigidity and stability, so that the cutter head of the tunneling machine has prolonged tunneling service life, the tunneling machine vibration is alleviated, the noise is reduced, and the engineering economic loss in is also reduced.

Owner:DALIAN UNIV OF TECH

Secondary mould returning method of magnesium carbon brick and alumina-magnesite carbon brick used for steel ladle

ActiveCN101985223AEliminate the problem of spallationImprove densification performanceCeramic shaping apparatusTotal countBrick

The invention discloses a secondary mould returning method of magnesium carbon brick and alumina-magnesite carbon brick used for steel ladle. The method includes the following steps: firstly, mixed magnesium carbon brick or alumina-magnesite carbon brick pug used for steel ladle is weighed as required; secondly, the mixed magnesium carbon brick or alumina-magnesite carbon brick pug used for steel ladle is poured into a moulding mould, and primary moulding is carried out; the primary moulding adopts the method of first light hind heavy, step-by-step pressurization and exhaust by hanging and beating, and the thickness of moulded green brick is 0.6-1.6mm higher than design thickness; thirdly, green bricks after primary moulding are piled up, and standing is carried out for 30-60min for natural exhausting; fourthly, the green bricks obtained by the step three are placed into the mould according to mould stripping direction, secondary beating is carried out, the count of the secondary beating is half of the total count regulated by design, and beating pressure is 215-340MPa; fifthly, the green bricks obtained by the step four are subject to sampling inspection, drying, sorting and packaging. The invention has the advantage that lamination crack of magnesium carbon brick and alumina-magnesite carbon brick used for steel ladle is effectively avoided.

Owner:ZHENGZHOU ZHENDONG TECH

Detachable anchorage device with prestressed carbon fiber plate

ActiveCN107503527AWide range of prestressed design valuesLow costBuilding repairsBuilding material handlingFiberCarbon fibers

The invention discloses a detachable anchorage device with a prestressed carbon fiber plate. The detachable anchorage device comprises detachable anchorage device bodies, slide rails, tension supports, anchor plates and a carbon fiber plate. The slide rails are mounted at the bottom of the detachable anchorage device, and the detachable anchorage device bodies are mounted on the upper portions of the slide rails; another portion of the detachable anchorage device is sequentially provided with the tension supports, the anchor plates and the carbon fiber plate from top to bottom; each detachable anchorage device body comprises an ejector head, a gland, a wedge, a base and a pin, one end of each ejector head is connected with a side surface of the corresponding gland, and the other end of each ejector head is connected to a side surface of the corresponding tension support; the wedges are mounted on the bases. The carbon fiber plate is adhered with a concrete base plane by epoxy adhesive, and the epoxy adhesive is made of soft metal materials with the thicknesses ranging from 1 mm to 3 mm. Inclination angles of the detachable anchorage device which is a wedge-shaped anchorage device range from 2 degrees to 5 degrees. Compared with fixed anchorage devices, the detachable anchorage device has the advantages that the detachable anchorage device is low in cost and high in universality; soft metal plates for adhering the carbon fiber plate can be aluminum plates, copper plates and aluminum alloy plates, and accordingly stress can be relieved in prestress applying procedures.

Owner:CARBON COMPOSITESTIANJIN CO LTD

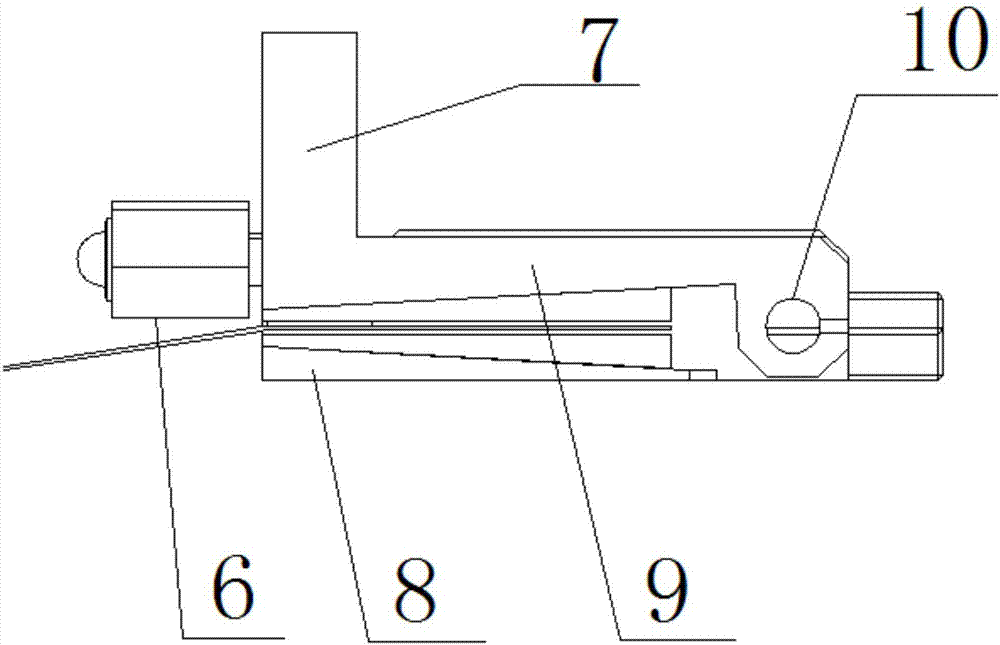

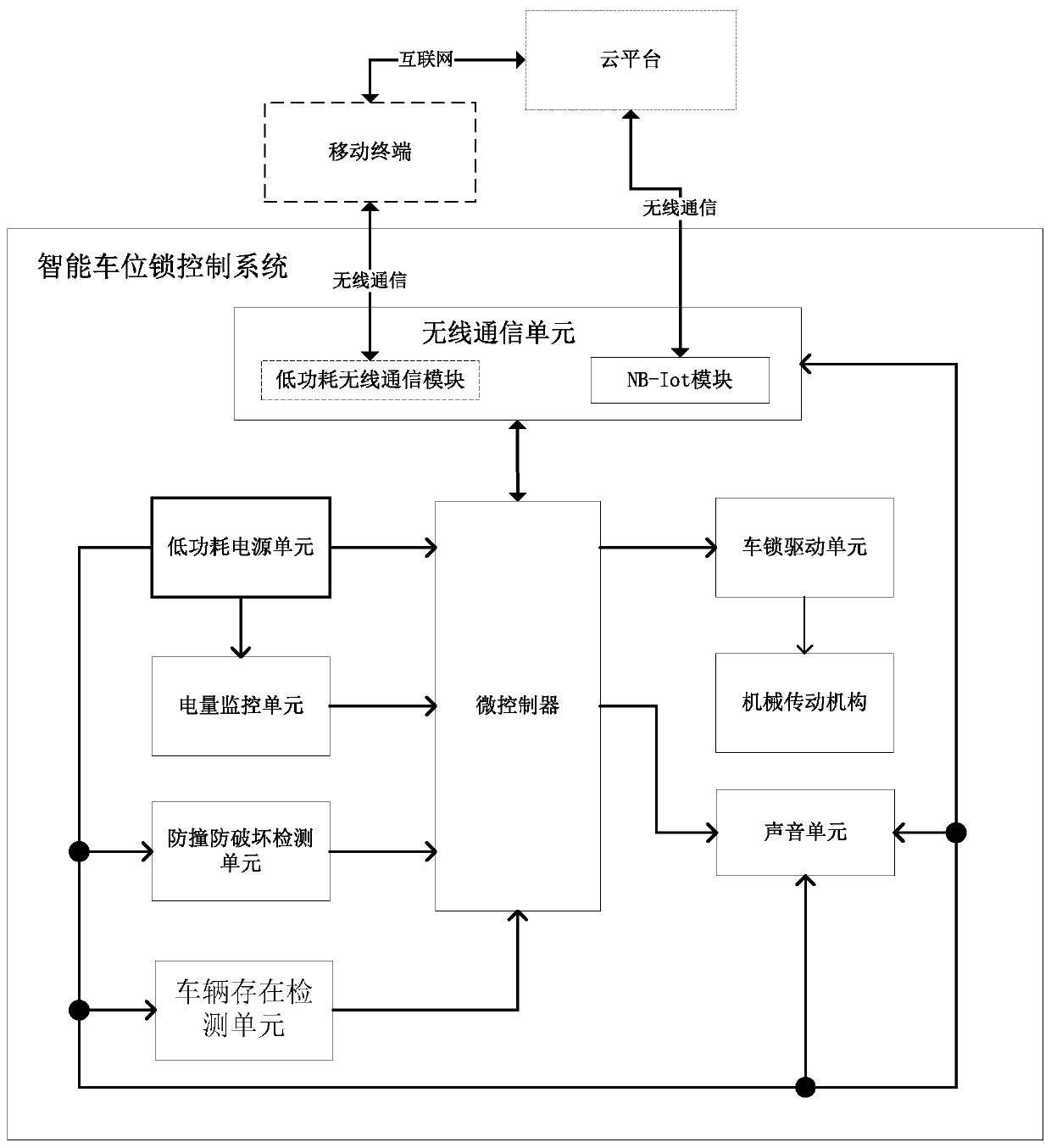

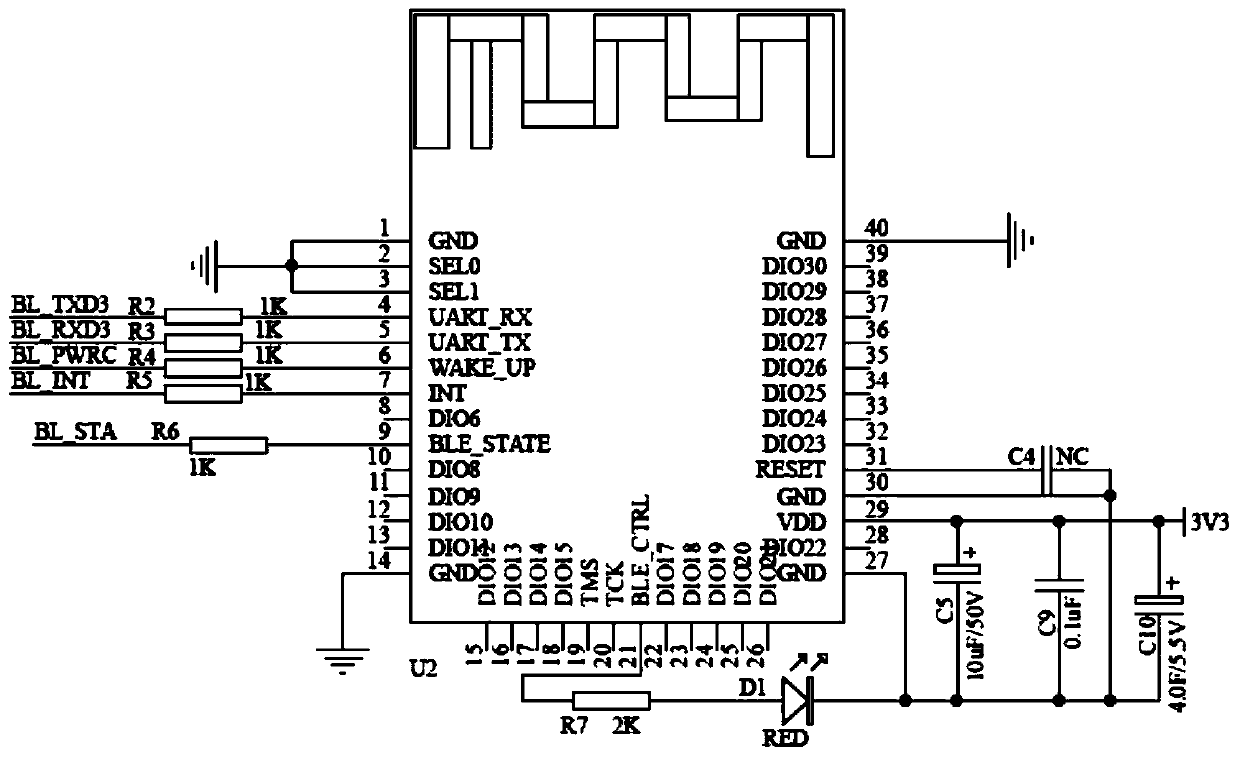

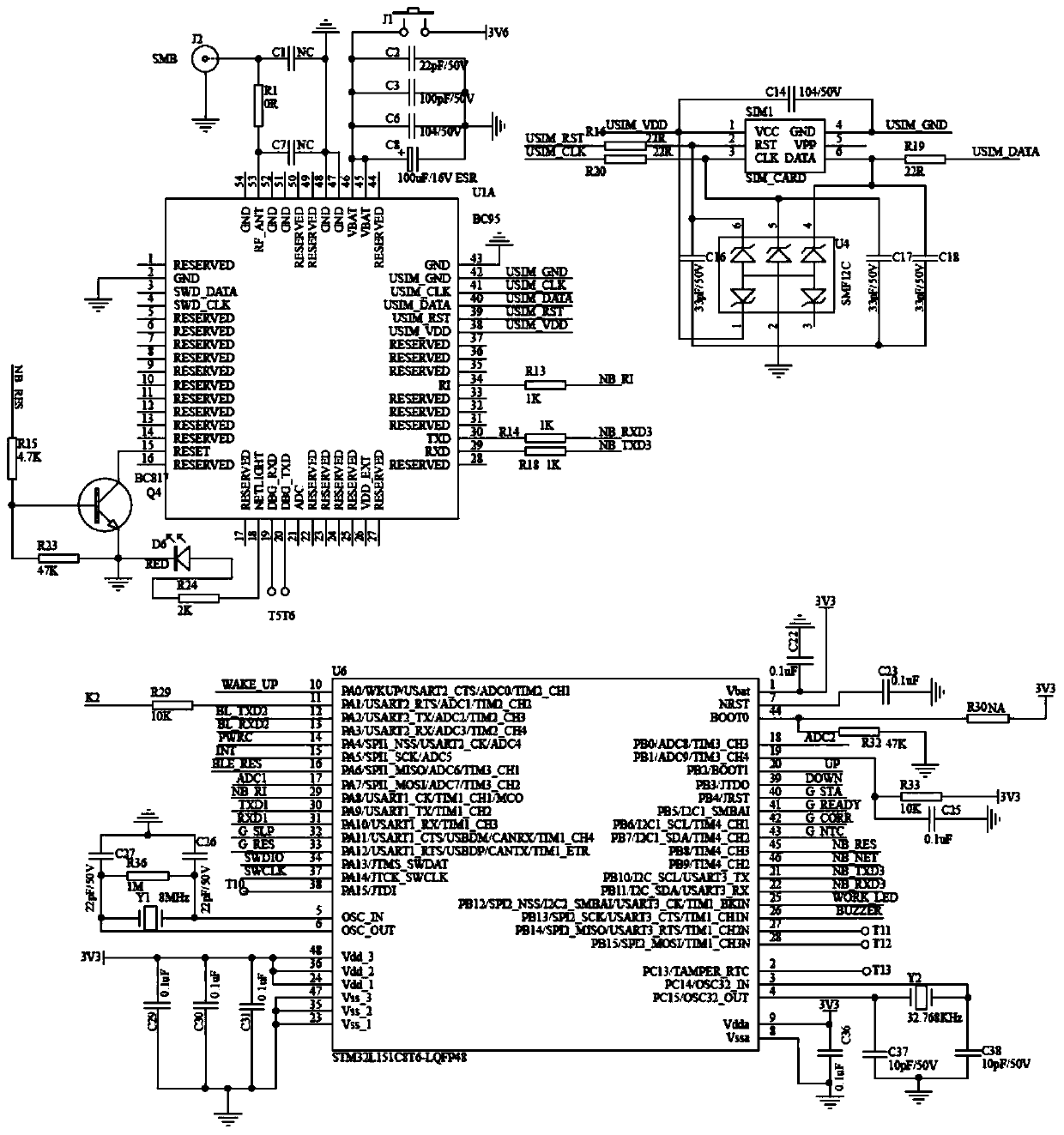

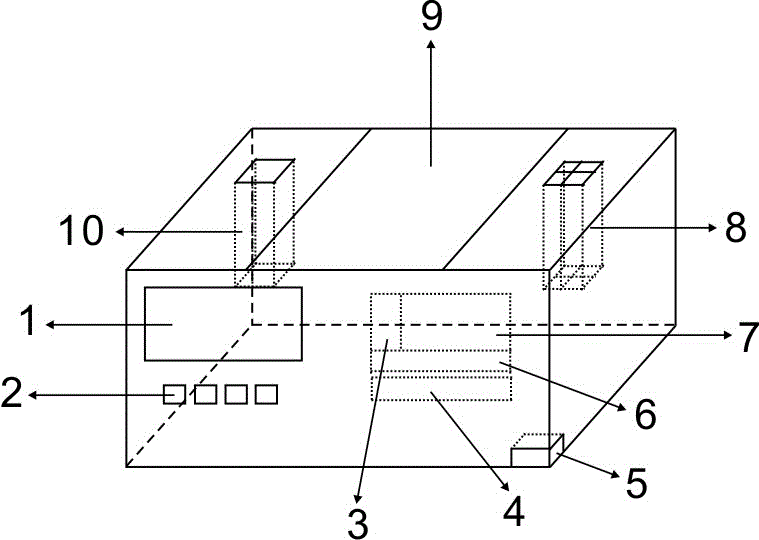

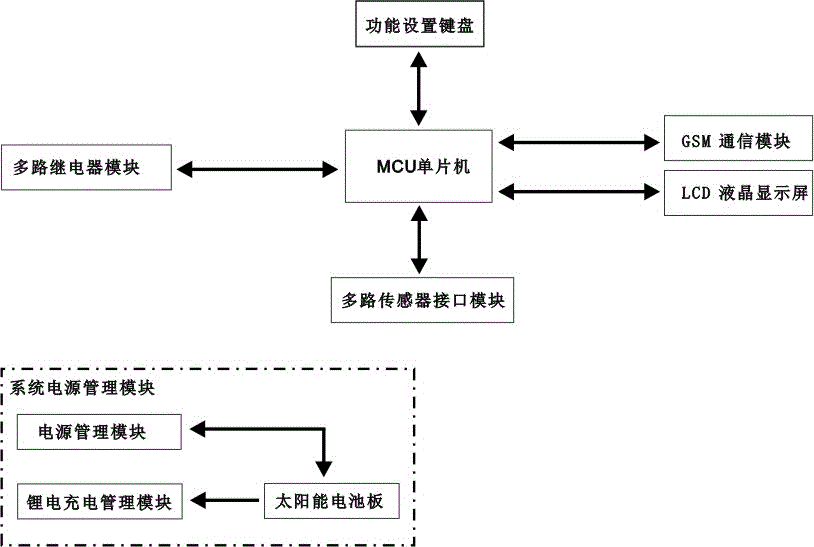

Intelligent parking lock control system

InactiveCN110924330ASolve the management problem of time-staggered sharingReduce charging frequencyTraffic restrictionsParkingsMicrocontrollerCommunication unit

The invention discloses an intelligent parking spot lock control system which comprises a microcontroller. The microcontroller is connected with a power supply unit, an anti-collision detection unit,a vehicle existence detection unit, a vehicle lock driving unit, a sound unit and a wireless communication unit; the wireless communication unit communicates with a mobile terminal and a cloud platform; the mobile terminal communicates with the cloud platform; the vehicle existence detection unit detects whether a vehicle is parked above the parking space lock or not, and when it is detected thatthe parked vehicle leaves, the microcontroller controls the parking space lock driving unit to be automatically locked. According to the invention, the accident that the parking space lock or the vehicle is abnormally damaged due to wrong detection is solved. The problem of high power consumption of communication between the parking space lock and a cloud platform and controlled locking and unlocking is solved, the microprocessor in the wireless communication unit is used for replacing a microcontroller, the cost of the parking space lock is reduced, and guarantee is provided for relieving urban parking space resource shortage and achieving parking space staggered sharing.

Owner:HUNAN SCIENTOP AUTOMATIC EQUIP SHARES +1

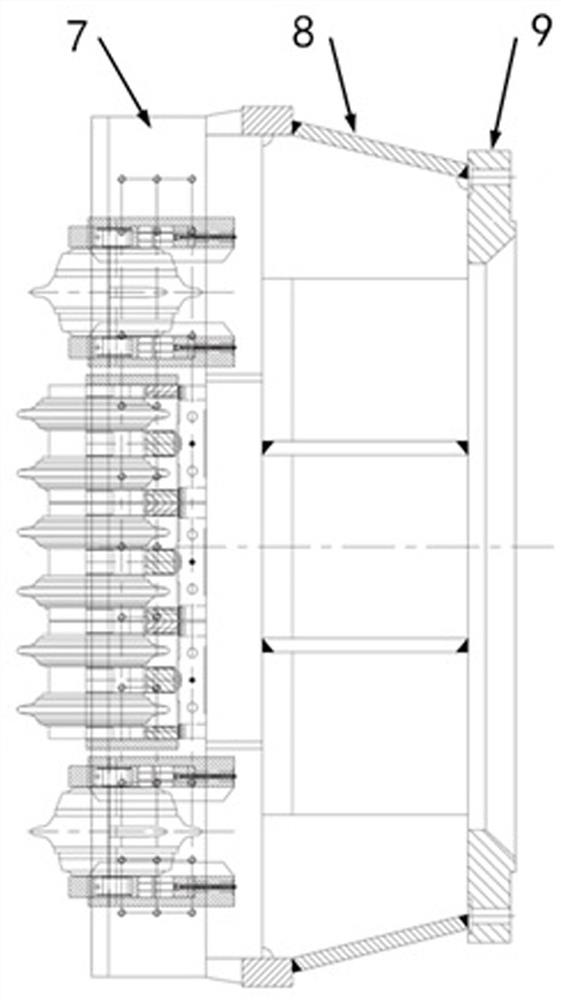

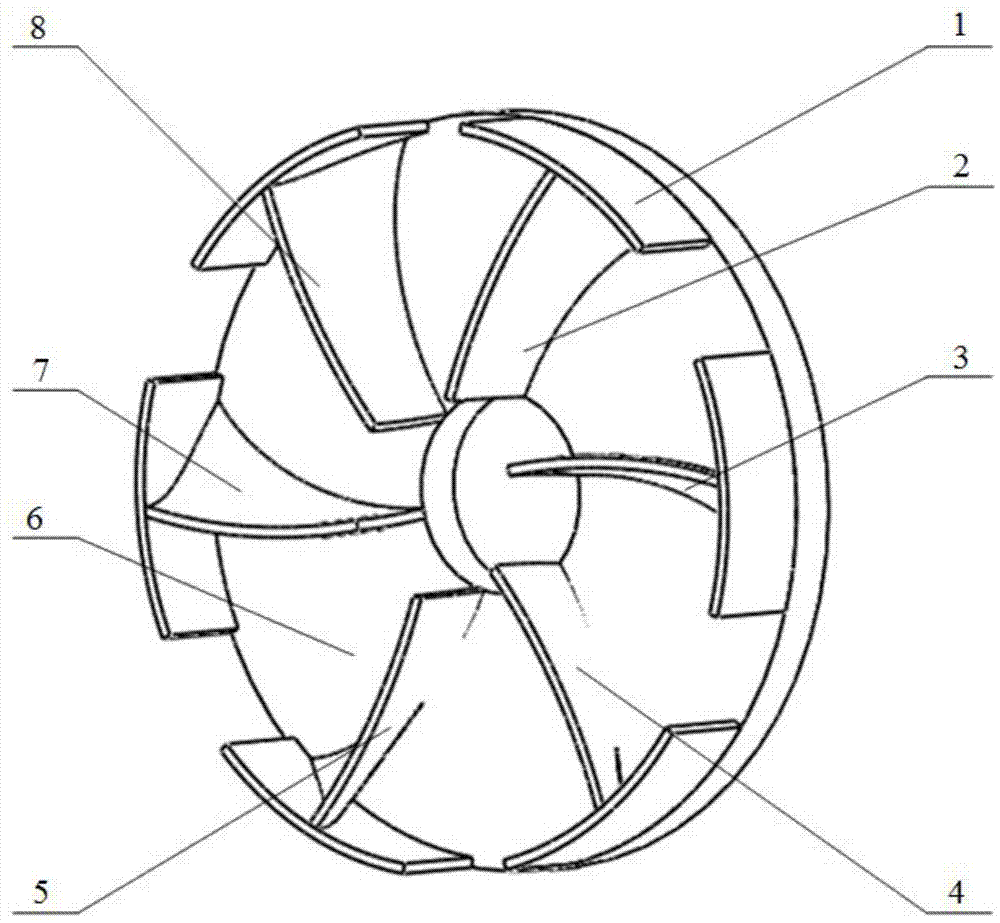

Full-face tunnel boring machine multifunctional cutterhead suitable for complex stratums

ActiveCN112145194AImprove rock breaking abilityReduce consumptionMining devicesTunnelsTunnel boring machineScrew thread

The invention discloses a full-face tunnel boring machine multifunctional cutterhead suitable for complex stratums. The full-face tunnel boring machine multifunctional cutterhead comprises a cutterhead body, a plurality of cutter holders movably mounted on the cutterhead body, and cutters mounted on the cutter holders, wherein the cutterhead body comprises a flange, a cutterhead panel, and a connecting rib plate welded between the periphery of the flange and the cutterhead panel, and the connecting rib plate comprises a ring beam welded to the outer ring of the connecting rib plate and a star-shaped cutter beam welded on the ring beam. Sliding grooves are formed in the cutter beam in the radial direction, the two side walls of the cutter holders are arranged in the sliding grooves in eachdirection of the cutter beam in a sliding fit mode, threaded holes are evenly distributed in the cutter beam, and after the cutters are adjusted in place, the cutter holders are matched with the threaded holes through first screws to be arranged on the cutter beam so that the cutter installation distance can be adjusted, and the cutterhead adapts to full-section tunneling of the complex stratums.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +2

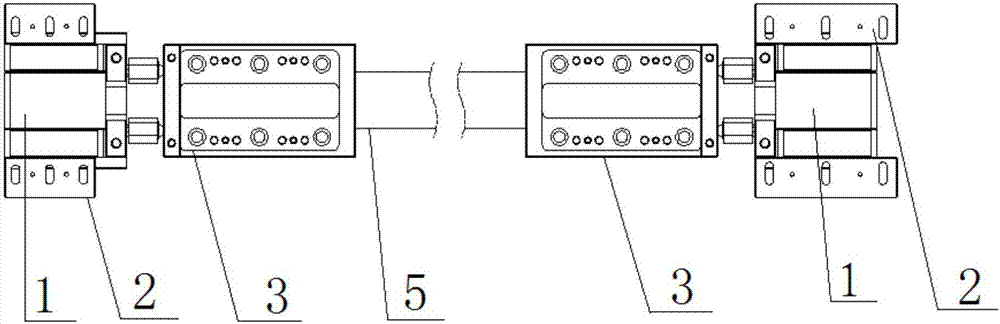

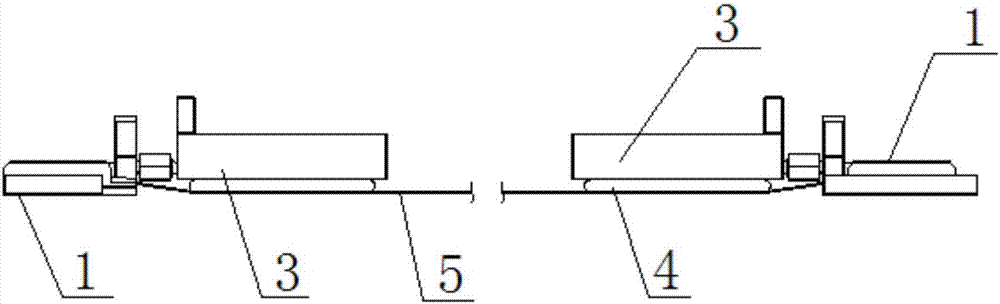

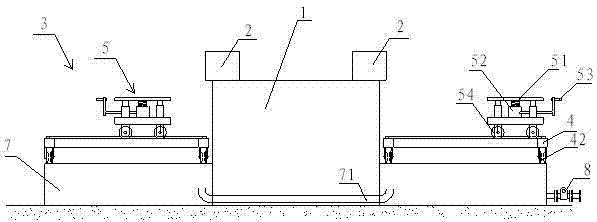

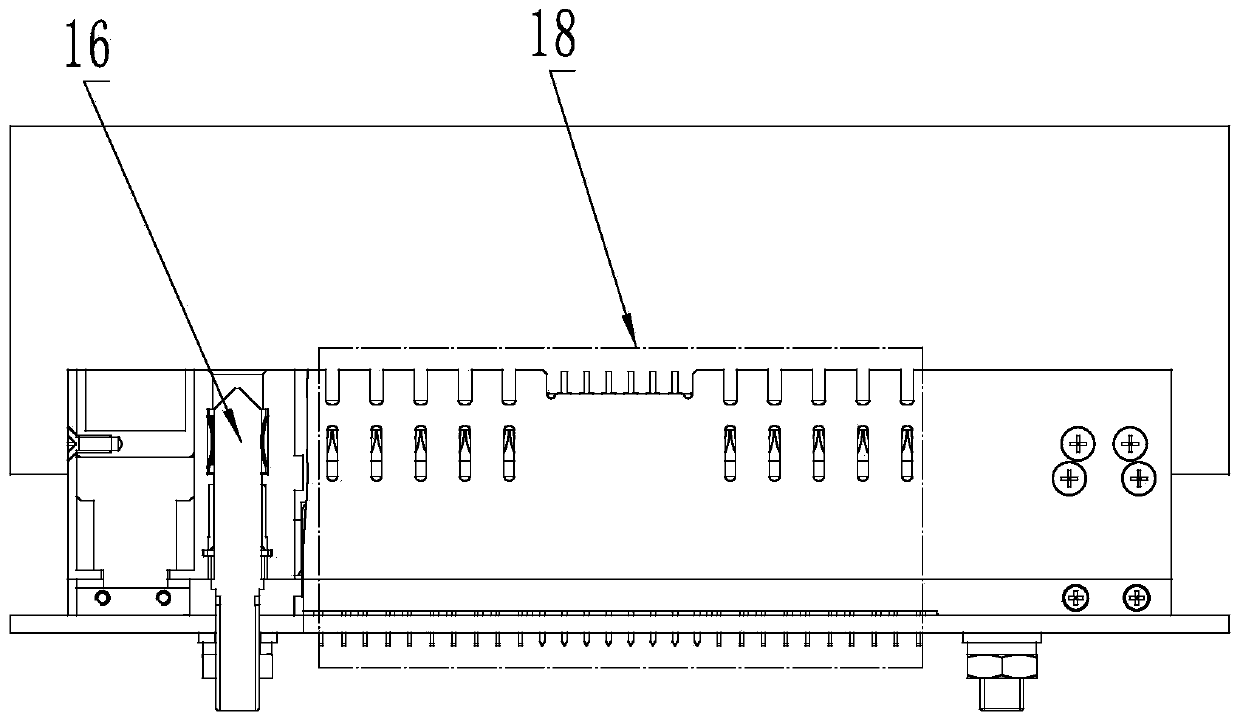

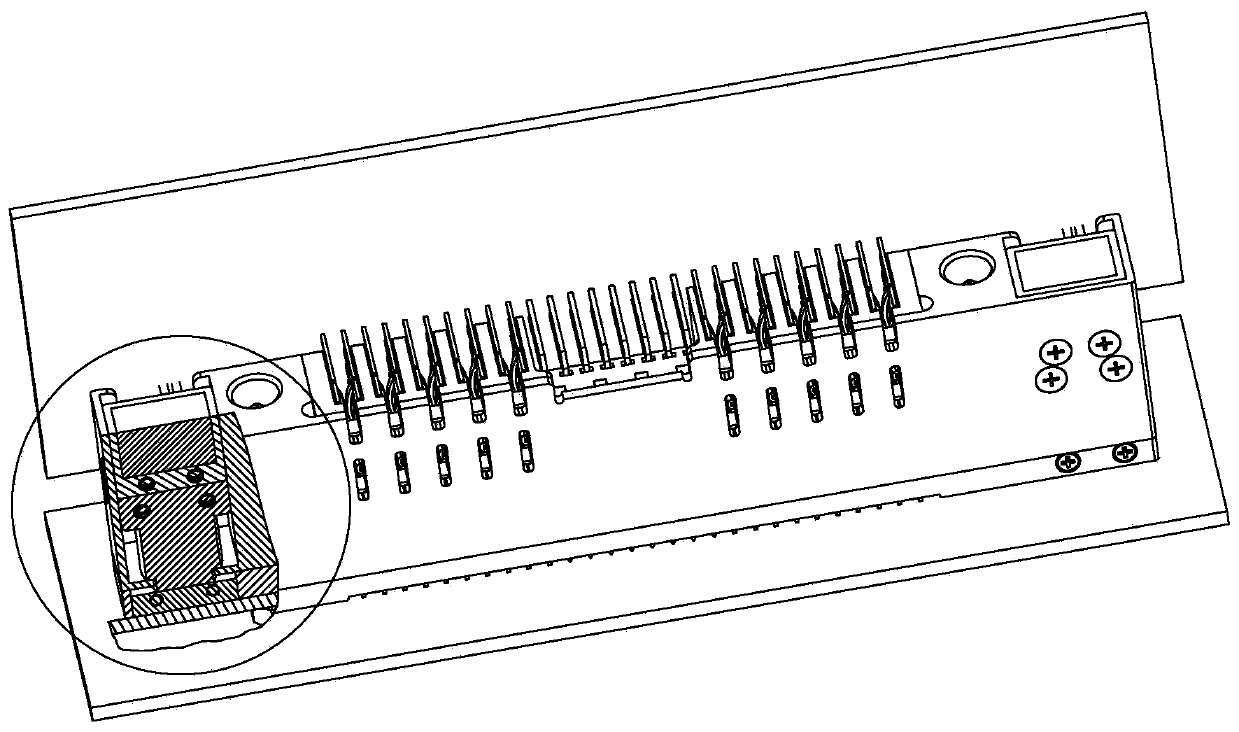

Disassembly and assembly equipment for bearing box of working roll of aluminum foil mill

InactiveCN102921737AAvoid damagePrecise positioningMetal rolling stand detailsMetal rolling arrangementsEngineeringAluminum foil

The invention provides disassembly and assembly equipment for a bearing box of a working roll of an aluminum foil mill and can solve the problems in the prior art that abnormal damage is liable to be caused in disassembly and assembly of the bearing box and the disassembly and assembly efficiency is low. The technical scheme is that the disassembly and assembly equipment comprises a roll bed, U-shaped racks, worktables and operating devices, wherein the U-shaped racks are arranged on two side of the top surface of the roll bed and used for holding the working roll; the worktables are arranged on two sides of the bed body of the roll bed and used for bearing the operating devices; the operating devices comprise transversally moving carts arranged on the table boards of the worktables; and travelling cars capable of performing lifting motion and lengthwise motion are arranged on the transversally moving carts. The disassembly and assembly equipment provided by the invention has the advantages that the positioning is accurate, the abnormal damage of the bearing box is avoided, the cost is greatly reduced, the disassembly and assembly time is shortened, the disassembly and assembly efficiency is improved, and the production requirement is met.

Owner:QINGDAO RUNFENG ALUMINUM FOIL

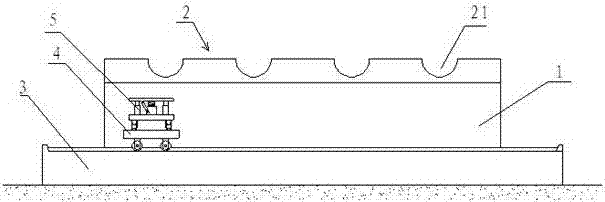

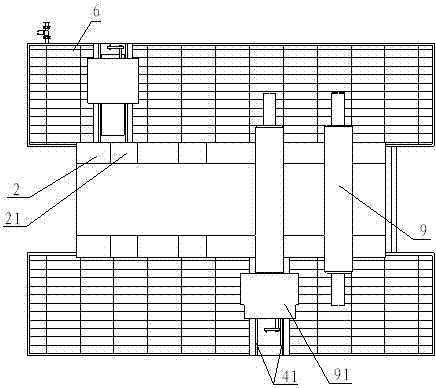

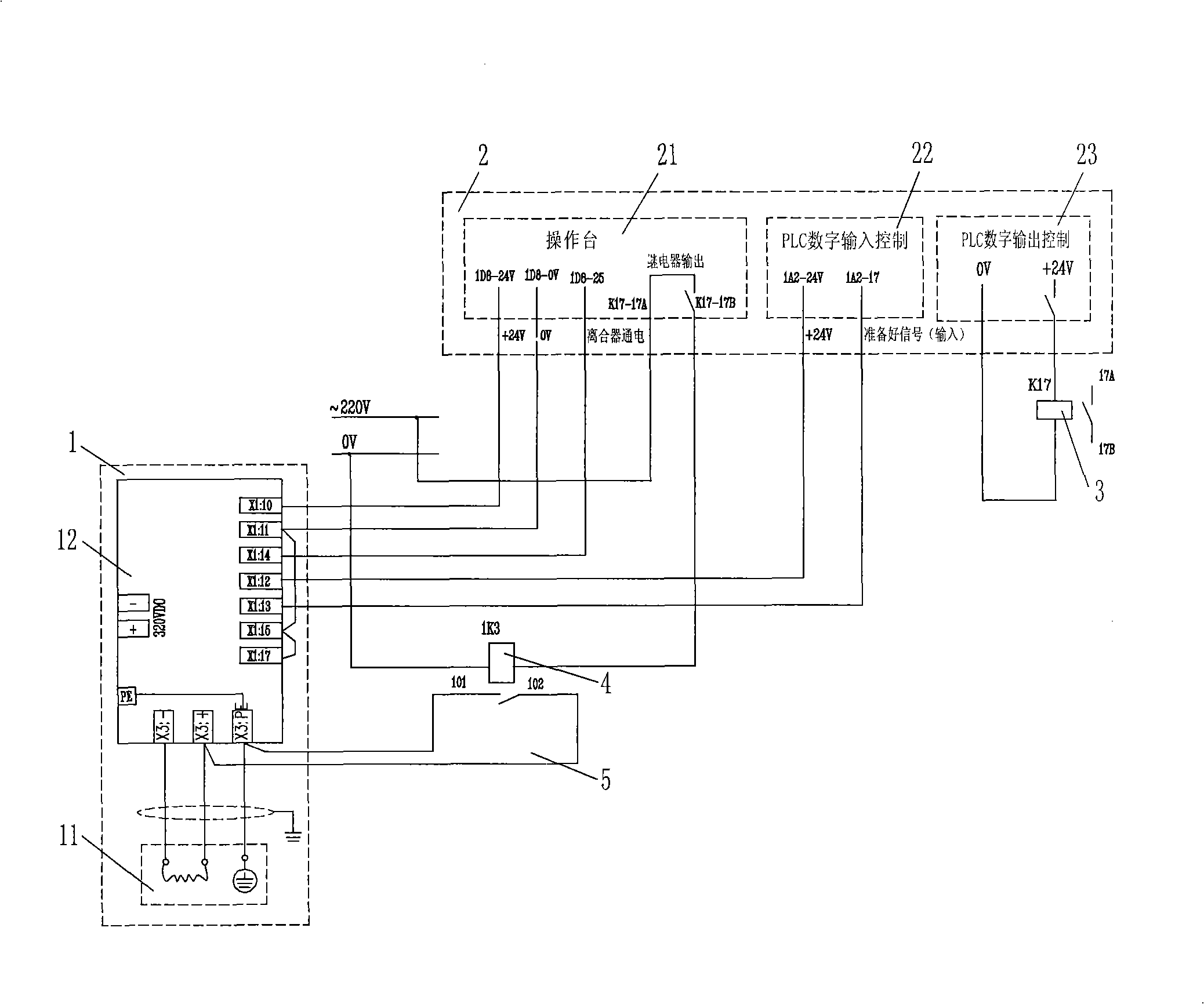

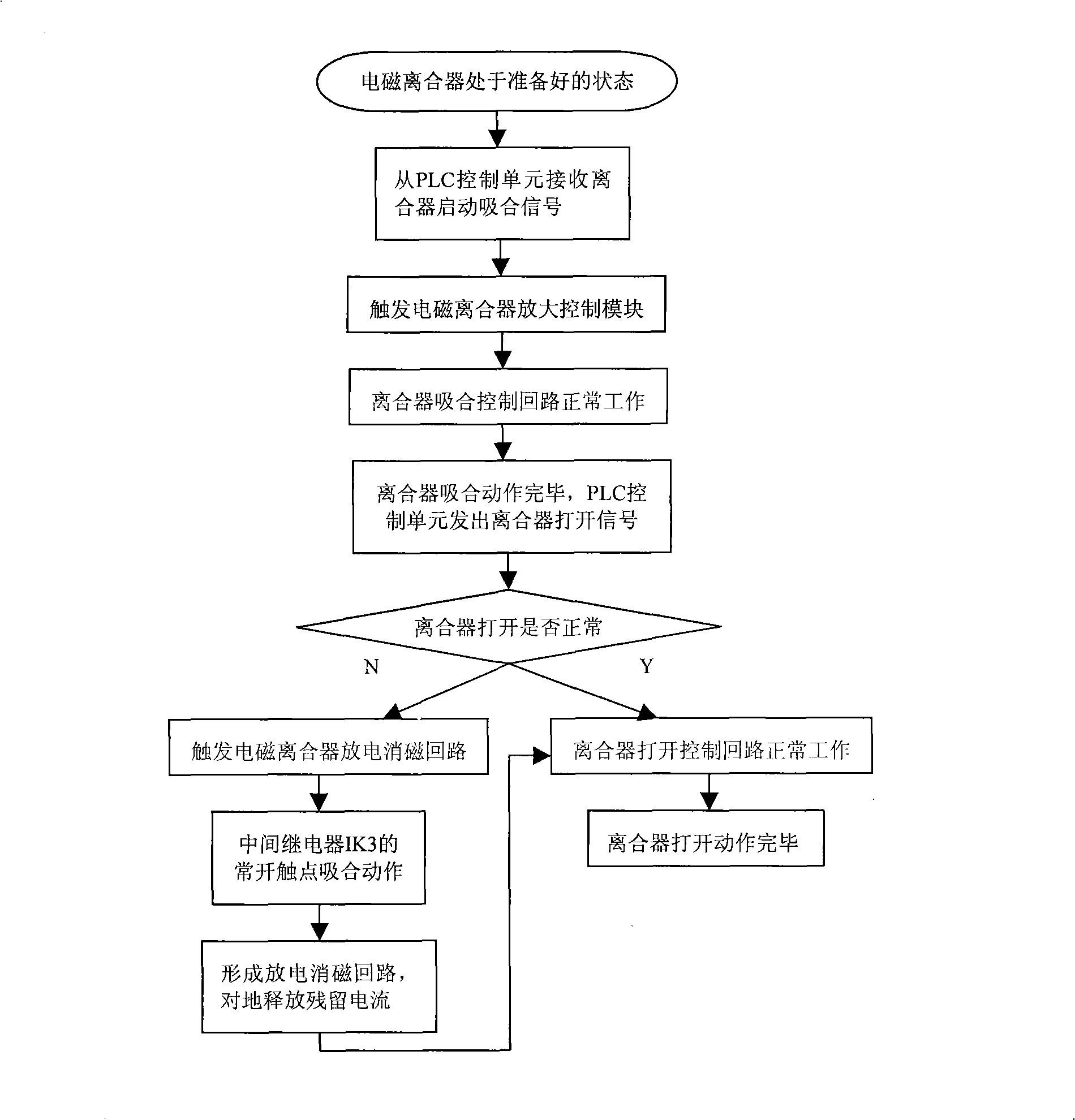

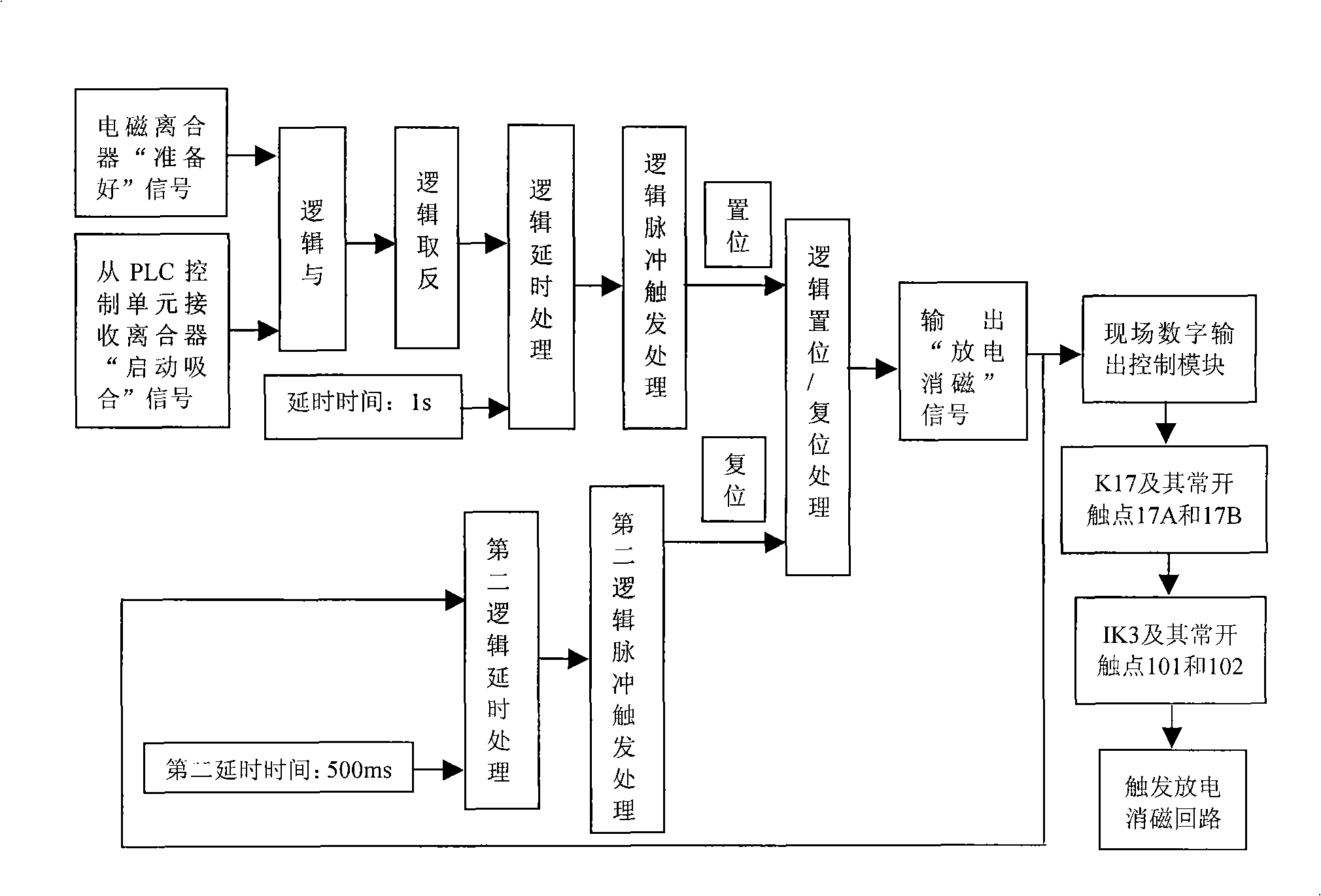

Apparatus and method for discharging and degaussing of electromagnetic clutch

ActiveCN101354065AReduce short circuitAvoid abnormal damageMagnetic bodiesMagnetically actuated clutchesElectromagnetic clutchEngineering

The invention discloses a discharging and degaussing device for an electromagnetic clutch and a method thereof. The discharging and degaussing device comprises the electromagnetic clutch and a control unit thereof, a PLC control unit which is connected with the electromagnetic clutch and the control unit of the electromagnetic clutch. The invention is characterized in that: the discharging and degaussing device also comprises an intermediate relay and a degaussing intermediate relay; wherein, the intermediate relay is connected to the digital output control end of the PLC control unit; the auxiliary normal open contact of the intermediate relay is connected to a main circuit of the degaussing intermediate relay; one of the auxiliary normal open contacts of the degaussing intermediate relay is connected with a grounding wire and the other is connected with the coil of the electromagnetic clutch; a discharging and degaussing circuit of the electromagnetic clutch is formed by the connection of the two auxiliary normal open contacts of the degaussing relay with the coil of the electromagnetic clutch and the grounding wire. The device of the invention can discharge and degauss the coil of the clutch, thus reducing the short circuit of the coil and preventing the electromagnetic clutch from abnormal damage.

Owner:BAOSHAN IRON & STEEL CO LTD

An anti-overflow sealed load-bearing detection cable

ActiveCN104681166BIncrease friction areaImprove wear resistanceInsulated cablesInsulated conductorsEngineeringCopper

The invention relates to an anti-overflow sealed bearing loading and detecting cable which comprises a copper stranded wire, wherein the outer layer of the copper stranded wire is annularly sleeved by an insulating layer, the insulating layer is annularly sleeved by an inner armor layer, and the inner armor layer is annularly sleeved by an outer armor layer; the inner armor layer is composed of steel wires with a circular section and sealant layers, and the outer part of the insulating layer is annularly sleeved by a plurality of circular steel wires; gaps between the adjacent circular steel wires are filled with the sealant layers, and the sealant layers and the circular steel wires constitute the sealed structure with the circular section together; the outer armor layer is formed by annularly sleeving the steel wires with a fan-shaped section, and the outer armor layer also forms a sealed structure with a circular section after a plurality of fan-shaped steel wires are annularly sleeved. The cable provided by the invention has the novel inner and outer armor layer structures, so that the bearing capacity of the cable is improved, while the sealing performance and the reliability of the cable are improved.

Owner:山东希尔电缆有限公司

Intelligent active type anti-thunder switch device based on environment parameter analyzing

InactiveCN103986234AAvoid abnormal damageLow costPower network operation systems integrationCircuit arrangementsSolar cellLithium-ion battery

The invention discloses an intelligent active type anti-thunder switch device based on environment parameter analyzing. The device comprises an MCU single chip microcomputer, a multi-path environment parameter sensor module, a GSM communication module, a set key, a multi-path relay module, a liquid crystal displayer (LCD), a solar cell panel, a lithium ion battery, a power supply management module and the like. After the device is started, a microprocessor carries out continuous sampling on the multi-path environment parameter sensor module according to preset sampling rate, various environment parameter sampling results are subjected to intelligent analyzing, whether a thunderstrike danger response mode is started is judged, and the response mode can be divided into a high level and a low level, namely, a thunderstrike early-warning short message is sent to an appointed mobile phone terminal, or electric connection of various peripherals and the device is cut off automatically. Abnormal damage of equipment in operation caused by thunderstrike can be effectively avoided, the device is especially suitable for electric equipment in outer fields or unattended zones, cost is low, and reliability is high.

Owner:CHENGDU MICRO ENVIRON ENVIRONMENTAL MONITORING EQUIP

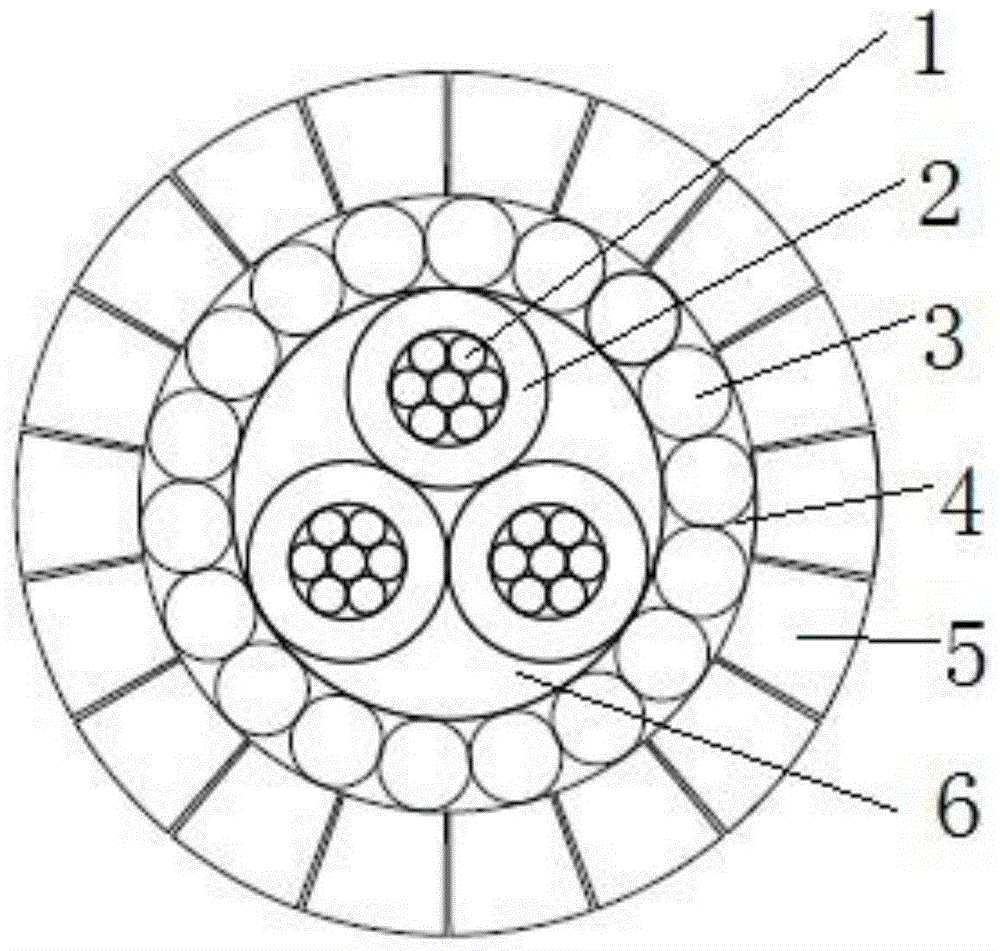

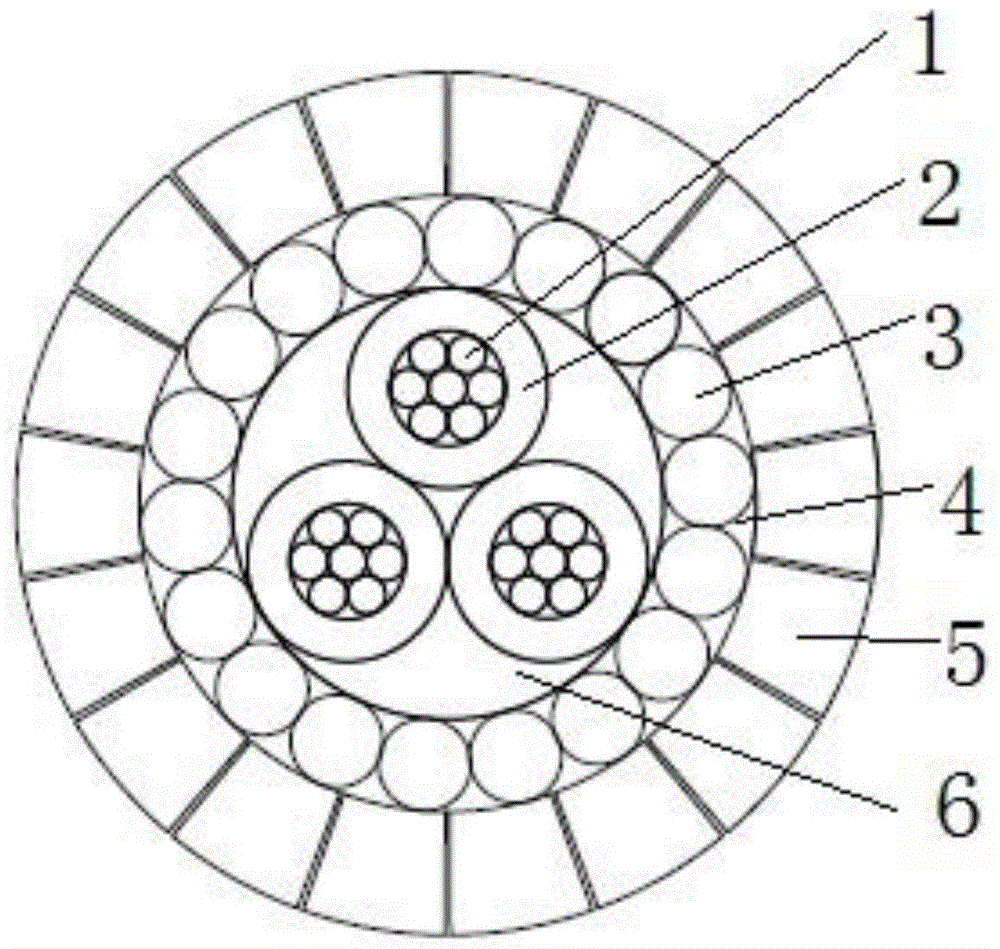

WMF series sealed load-bearing detecting cable

PendingCN109585077AReduce gapIncrease friction areaInsulated cablesCommunication cablesCable designEngineering

The invention relates to a WMF series sealed load-bearing detecting cable. The WMF series sealed load-bearing detecting cable comprises a copper stranded wire, the outer layer ring of the copper stranded wire is coated with an insulation layer, the outer ring of the insulation layer is sleeved with an inner armor layer, and the outer ring of the inner armor layer is sleeved with an outer armor layer; the inner armor layer is commonly formed by round steel wires and a sealant layer, the round steel wires sleeve the outer portion of the insulation layer, gaps between the adjacent round steel wires are filled with the sealant layer, the sealant layer and the round steel wires commonly form a sealed structure having a circular cross section; the outer armor layer is formed by sleeving steel wires having round and dumbbell-shaped cross sections, and after the steel wires having round and dumbbell-shaped cross sections are sleeved, the outer armor layer forms a sealed structure having a circular cross section. The cable designs novel inner and outer armor layer structures to improve the sealing and the reliability of the cable while improve the cable bearing.

Owner:山东希尔电缆有限公司

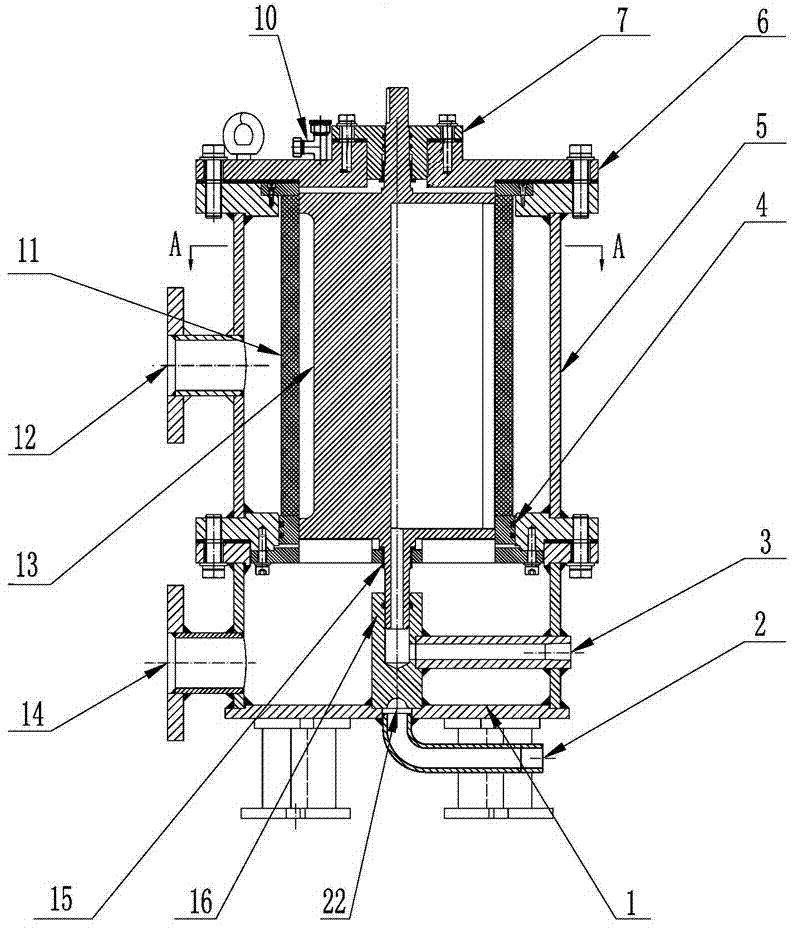

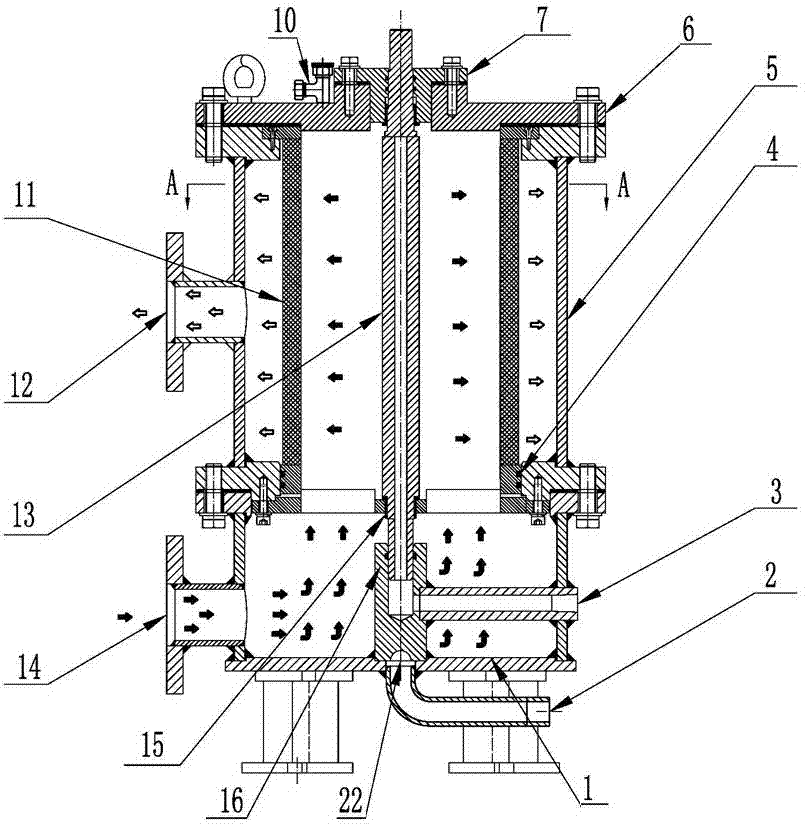

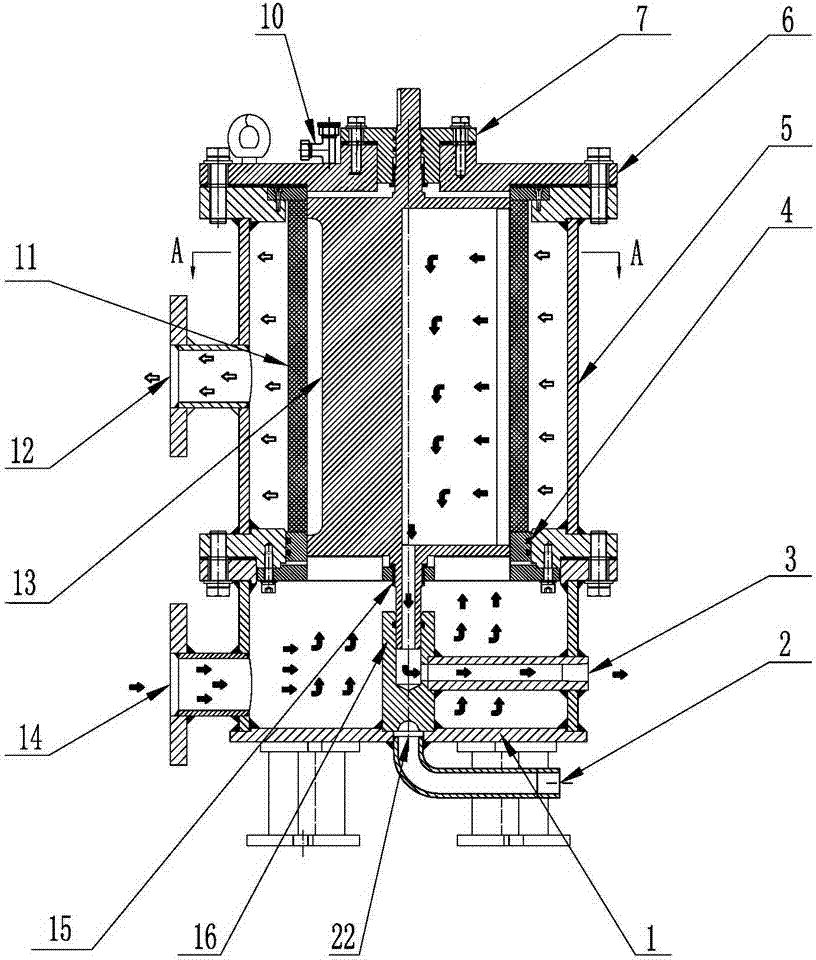

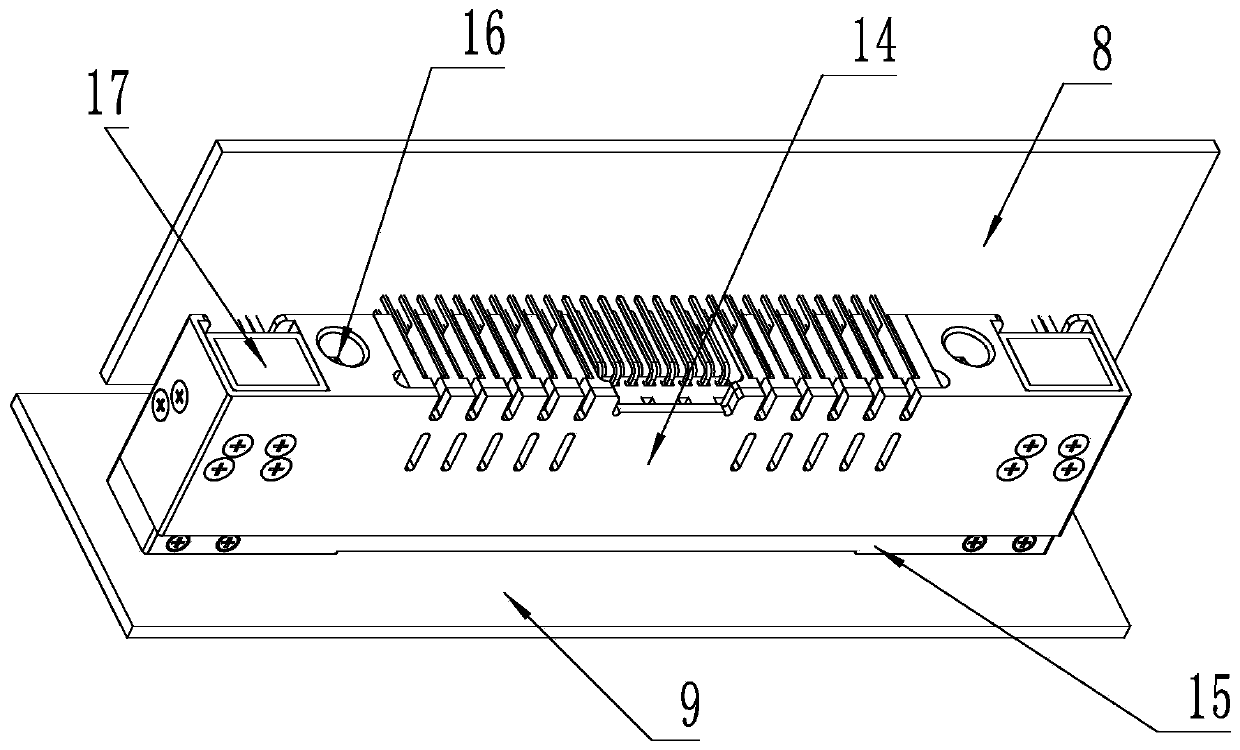

Full-automatic backwash filter

ActiveCN103527371AEasy and precise controlImprove cleaning effectMachines/enginesLiquid fuel feedersEngineeringNozzle

The invention relates to a full-automatic backwash filter. The full-automatic backwash filter comprises a tubular barrel and a lower barrel, wherein a tubular filter element is arranged in the barrel, and a cleaning rotating shaft is arranged in the filter element; the filter element is composed of a tubular inner mesh plate, a tubular outer mesh plate and a foldable filter screen; a left scraping plate and a right scraping plate are symmetrically arranged on the cleaning rotating shaft, wherein the left scraping plate is provided with a cleaning groove, the cleaning groove stretches deep into the left scraping plate in the radial direction of the cleaning rotating shaft to form a flow passage, and the cleaning groove is communicated with a tubular shaft at the lower end of the cleaning rotating shaft; an opening of the cleaning groove makes contact with the inner mesh plate of the filter element. According to the full-automatic backwash filter, the structural design of the fixed filter element and the cleaning rotating shaft is adopted, the running torque of the cleaning rotating shaft is quite small, the opening of the cleaning groove in the left scraping plate is an inverted horn-shaped opening, a divergent nozzle design in fluid dynamics is adopted, differential pressure inside and outside the filter element is fully utilized, so that the flow velocity of cleaning fluid is increased, and the cleaning effect is improved effectively; the service life of the filter element can be effectively prolonged, and the maintenance cost of the filter in a later period is lowered substantially.

Owner:安庆泰邦船舶科技有限公司

A method for producing low board surface residue by substituting heat for cold products

The invention relates to a production method of a hot-rolled product with low plate surface residue. The production method comprises the steps of uncoiling by an uncoiling machine; crushing and peeling off oxides on the surface of a strip steel by a withdrawal and straightening machine; carrying out acid pickling and rinsing on the strip steel; carrying out mechanical surface residue cleaning on the acid pickled and rinsed strip steel by a mechanical plate surface residue cleaning device; performing surface roughness homogenizing and finishing treatment to the treated strip steel in a finishing machine; and coiling the treated strip steel by a coiling machine to obtain a finished product. With the adoption of the technical scheme, the production method has the beneficial effects that: firstly, the mechanical surface residue cleaning process is additionally adopted in a rinsing section of the traditional acid-pickling temper mill unit, the plate surface chloride ion residue is reduced and the product corrosion resistance is improved; secondly, the temperature of a rinsing tank does not need to be increased gradually, the technology purpose of reducing the chloride ion residue on the surface of the strip steel can be achieved, and the production consumption is low; thirdly, the temperature of the strip steel entering the temper mill is reduced favorably, and the final strip shape and the strip quality are good.

Owner:WISDRI ENG & RES INC LTD

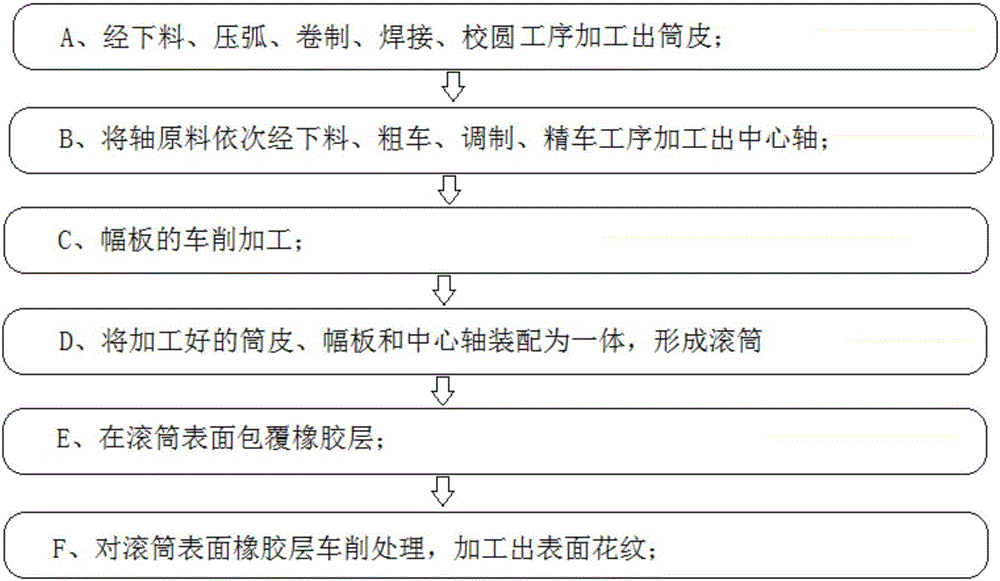

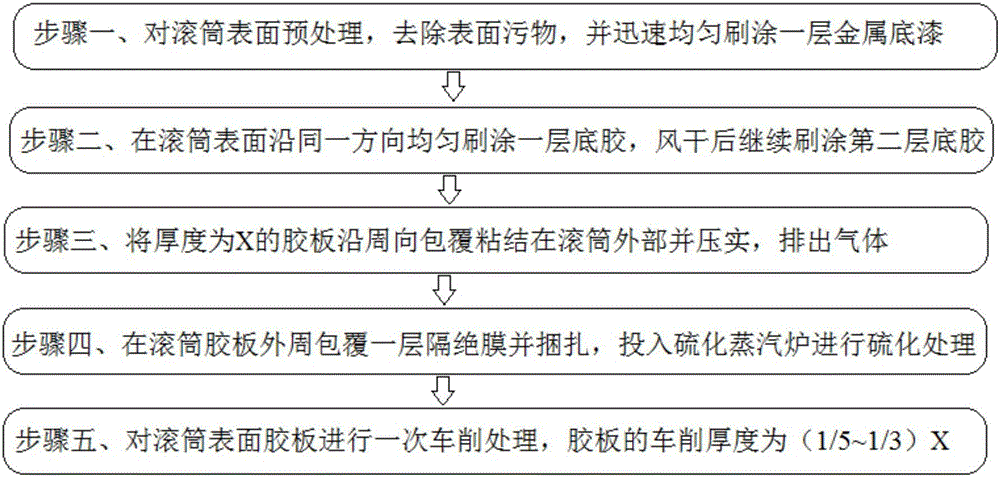

Machining method for transmission drum of belt conveyor

The invention discloses a machining method for a transmission drum of a belt conveyor, and belongs to the field of conveyors. The machining method disclosed by the invention comprises the following steps: A. production for a drum shell: machining a raw material of the drum shell into the drum shell through the working procedures of blanking, arc pressing, rolling, welding and roundness correction sequentially; B. production for a central shaft: machining a raw material of the shaft into the central shaft through the working procedures of blanking, rough turning, quenching and tempering, and finish turning sequentially; C. turning machining for a centre plate; D. assembly: assembling the machined drum shell, centre plate and central shaft into one piece to form the drum; E. coating the surface of the drum with a rubber layer; and F. carrying out turning treatment on the rubber layer on the surface of the drum, and machining surface patterns. The machining method disclosed by the invention contributes to improving the use performance of the transmission drum, avoiding abnormal damage of the drum in use, and guaranteeing the efficient running of a conveying system.

Owner:ANHUI TAIFU HEAVY IND MFG CO LTD

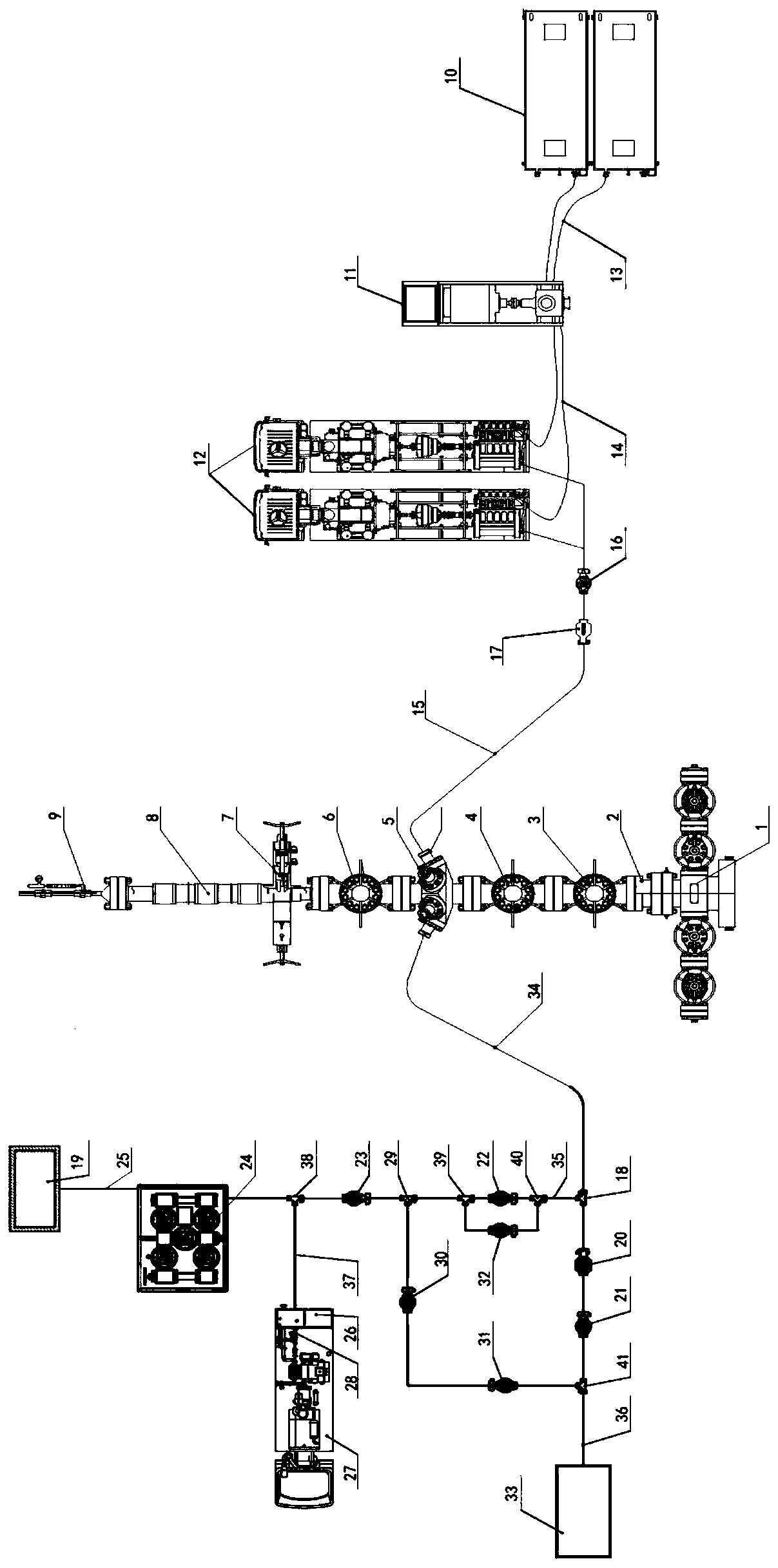

Shale gas horizontal well high pressure bridge plug pumping device

PendingCN110219610AAvoid abnormal damageAchieve independent controlFluid removalSealing/packingShale gasWellhead

The invention relates to a shale gas horizontal well high pressure bridge plug pumping device, including a well barrel, a well opening mechanism, a well opening bridge plug packaging mechanism, a bridge plug pumping mechanism, and a fracturing fluid pumping mechanism. The well opening mechanism and the well opening bridge plug packaging mechanism are correspondingly connected to both ends of the well barrel, and the bridge plug pumping mechanism and the fracturing fluid pumping mechanism are connected with the well barrel in a pipeline mode. Due to the fact that the bridge plug pumping mechanism and the fracturing fluid pumping mechanism of the shale gas horizontal well high pressure bridge plug pumping device are separately arranged, independent control over the bridge plug pumping mechanism and the fracturing fluid pumping mechanism can be realized without interference, and the bridge plug pumping mechanism can be maintained during operation of the shale gas horizontal well high pressure bridge plug pumping device; and a pressure relief assembly can ensure normal starting of the well opening mechanism, etc., abnormal damage of the shale gas horizontal well high pressure bridge plug pumping device is avoided, and working reliability of the well opening mechanism, etc., can be further ensured.

Owner:CHINA PETROCHEMICAL CORP +3

Wireless intelligent locking electric connector

InactiveCN110544851AAvoid abnormal damageAuthorize to unlock and lockCoupling device detailsElectricityControl power

The invention relates to a wireless intelligent locking electric connector, and the connector comprises two plugging ends, and further comprises one or more wireless intelligent control locking modules and a far-end wireless instruction transmitting module; the wireless intelligent control locking module comprises a wireless receiving control module and an electromagnet which are arranged at a plug end, and the wireless receiving control module inputs a power supply through the functional module printed board and controls power supply of the electromagnet; the wireless intelligent control locking module further comprises an adsorption fixing end which is arranged at the other plug end and attached to the electromagnet when the two plug ends are plugged in place. And the wireless instruction transmitting module transmits an unlocking signal to the wireless receiving control module. According to the invention, through the wireless intelligent control locking module, the automatic electromagnetic locking between the plug and the socket of the electrified electric connector is achieved, and the continuous locking can be carried out under the condition that the system is electrified. According to the invention, the damage to a functional board card and a connector and even abnormal damage such as burnout of the whole system caused by live-line misplug and unplugging can be effectively avoided.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

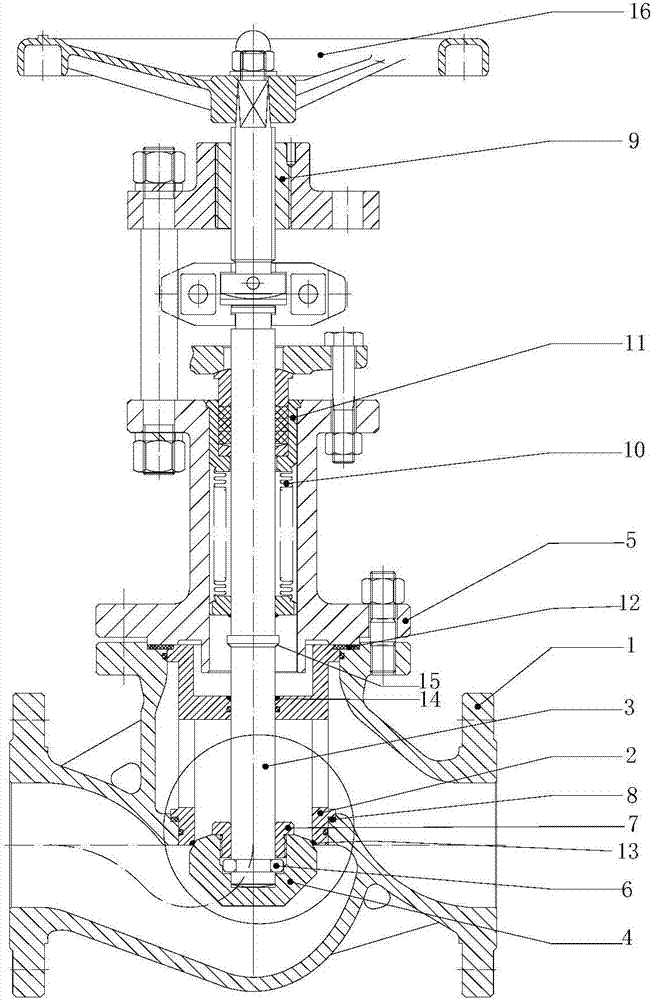

Block valve capable of being opened and closed reversely

The invention provides a block valve capable of being opened and closed reversely. The block valve capable of being opened and closed reversely comprises a valve body, a valve seat, a valve rod and a valve clack. Through holes are formed in the middle of the valve seat and in the middle of the valve body. The valve rod is arranged in the through holes of the valve body and the valve seat and can move up and down. The valve seat is arranged on the valve body. The maximum width of the valve clack is larger than the diameter of the through hole in the valve seat, and the valve clack is located below the valve seat. A blind hole is formed in the middle of the valve clack and used for being connected with the valve rod. The block valve capable of being opened and closed reversely is novel in structure and can be opened and closed easily; a sealing surface is arranged on the valve seat, the valve seat can be dismounted and replaced, and online maintenance can be achieved; a seal is additionally arranged, so that a medium is prevented from entering a cavity of a corrugated pipe when the valve is opened; the sealing surface of the valve is a linear sealing surface and faces downwards, so that abnormal damage, caused by accumulation of particles in the medium, to the sealing surface is avoided, and the service life of the valve is effectively prolonged; and the frequency of halts for replacement is reduced, the labor intensity of operators on a field is relieved, and harm, caused by external leakage of the valve, to the environment and human bodies is eliminated.

Owner:四川固特阀门制造有限公司

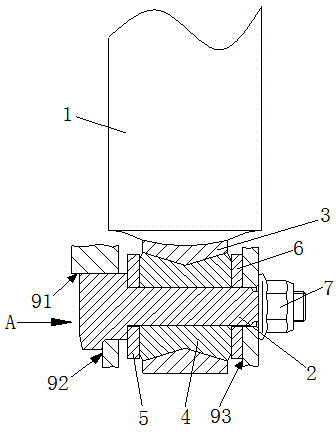

Novel elastic coupler

InactiveCN103727146AAchieving Elastic ConnectionsAutomatically compensates for positional offsetsYielding couplingCouplingEngineering

The invention discloses a novel elastic coupler. Spiral elastic bodies and fixed connection mechanisms are evenly arranged in the circumferential direction of a drive hub body; the spiral elastic bodies are of a spiral structure formed by winding multiple strands of stainless steel stranded wires in a symmetrical mode at equal pitches; the fixed connection mechanisms are single stainless steel wires and wind the spiral elastic bodies; a flange plate and an anti-torsion base plate are arranged at the end of the drive hub body; the anti-torsion base plate is fixed between the flange plate and the drive hub body; through holes are formed in the middle of the flange plate and the middle of the anti-torsion base plate; the axes of the flange plate and the anti-torsion base plate coincide with the axis of the drive hub body; the diameter of the through hole in the middle of the anti-torsion base plate is smaller than that of the through hole of the flange plate and the middle of the drive hub body; a conical circular truncated cone is arranged at the end of a driven hub body; a circular hole is formed in the middle of the conical circular truncated cone; a cross through groove is formed in the circumferential wall of the conical circular truncated cone. The novel elastic coupler can automatically compensate for the position offset of a shaft system under the installation and operation conditions, can improve the stability of system operation, and is easy to assemble and convenient to operate.

Owner:芜湖欣荣管业科技有限公司

Shock absorber installation structure

ActiveCN104626910AEasy to install and fastenImprove assembly efficiencyResilient suspensionsAxial displacementVehicle frame

The invention relates to a shock absorber installation structure. The shock absorber installation structure comprises a shock absorber, a shock absorber installation shaft and a frame, wherein the shock absorber installation shaft is matched with the shock absorber, and the frame is used for fixing the shock absorber installation shaft. The shock absorber installation shaft is a stepped shaft and comprises a first diameter part, a second diameter part, a third diameter part and a fourth diameter part, wherein the diameters of the first diameter part, the second diameter part, the third diameter part and the fourth diameter part gradually decrease. A threaded section is arranged on the fourth diameter part and matched with a self-locking nut. The shock absorber installation shaft and the frame are connected and fixed by locking the self-locking nut. According to the technical scheme, by limiting the radial displacement and the radial rotation of the shock absorber installation shaft, the abnormal damage to installation rubber pads is avoided, the deformation of the first installation pad and the second installation pad in the disassembly and assembly process is avoided, the risk that a shock absorber installation support cracks is lowered, and the assembly efficiency of a shock absorber is improved.

Owner:ANHUI ANKAI AUTOMOBILE

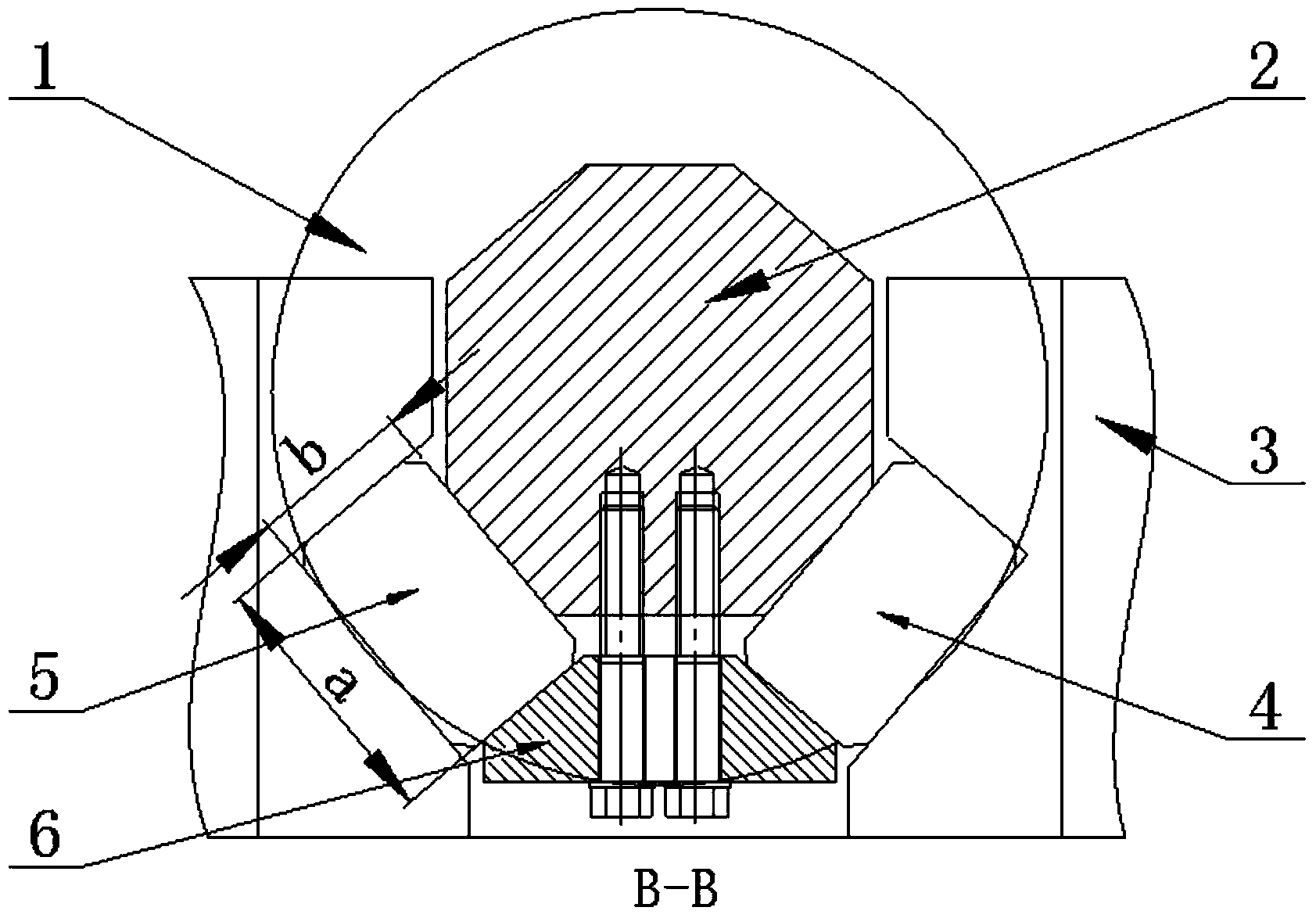

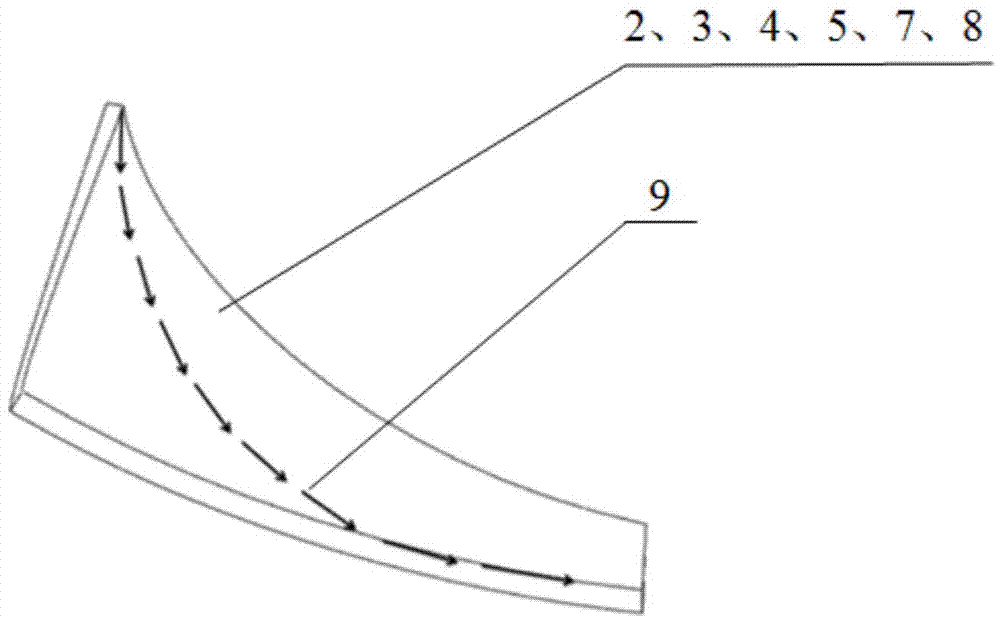

Design method for dreg slide plate curved surface of heading machine cutter head

InactiveCN103758528ASmooth slidingThe decline process is orderlyTunnelsDischarge efficiencySteep descent

The invention relates to a design method for dreg slide plate curved surfaces of a heading machine cutter head, and belongs to the field of design methods for heading machine cutter head structures. In the surface design method, technical performance requirements for the overall heading machine cutter head, construction requirements and requirements for smooth dreg removal of the cutter head are taken into consideration, the dreg discharging track on conventional dreg slide plates is changed, and shapes of dreg slide plate curved surfaces of the cutter head are constructed according to the steepest descent curve. The design method includes respectively designing a first, a second, a third, a fourth, a fifth and a sixth dreg slide plate curved surfaces of the cutter head, and uniformly welding the designed dreg slide plate curved surfaces to a back panel of the cutter head and supporting plates on the periphery of the cutter head. In application of the cutter head dreg slide plate curved surfaces designed by the method, dregs slide smoothly and sequentially, the cutter head dreg discharging efficiency is increased, vibration and noises of the heading machine are reduced effectively by means of changing the dreg discharging track, and research cycle of the heading machine is shortened; therefore, heading service life of the heading machine cutter head is prolonged and economic loss caused in engineering is reduced.

Owner:DALIAN UNIV OF TECH

Test fixture for model bar for studying vibration aging of reactor turn-to-turn insulation

The invention discloses a testing clamp for a model winding bar used for studying reactor turn-to-turn insulation vibrating and aging. The testing clamp comprises an upper pressing plate, a lower pressing plate fixed to a vibrating testing table and connected with the upper pressing plate through a first connecting piece, and a model winding bar clamp plate module arranged between the upper pressing plate and the lower pressing plate. A model winding bar clamp plate comprises a left pressing plate, a first clamp plate, a second clamp plate, a third clamp plate and a right pressing plate, wherein a groove matched with model winding bars in appearance is formed in one face of the first clamp plate, grooves matched with the model winding bars in appearance are formed in the both sides of the second clamp plate, a groove matched with the model winding bars in appearance is formed in one face of the third clamp plate, and a semi-circular groove is formed in the other face of the third clamp plate. The left pressing plate, the first clamp plate, the second clamp plate, the third clamp plate and the right pressing plate are fixedly connected through a second connecting piece so that the model winding bar can be clamped by the two adjacent clamp plates. Vibrating and aging of the multiple model winding bars are tested, the insulating and aging situation can be learned, testing time is saved, and reliability of test data is improved.

Owner:HARBIN UNIV OF SCI & TECH

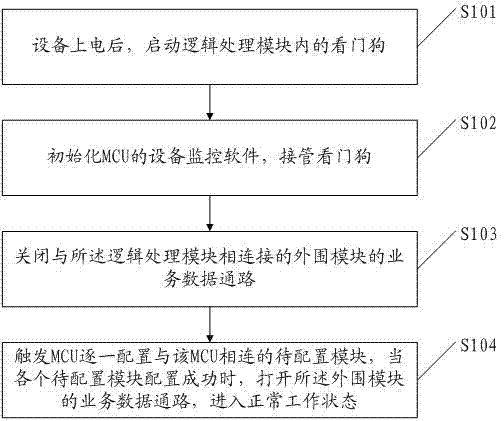

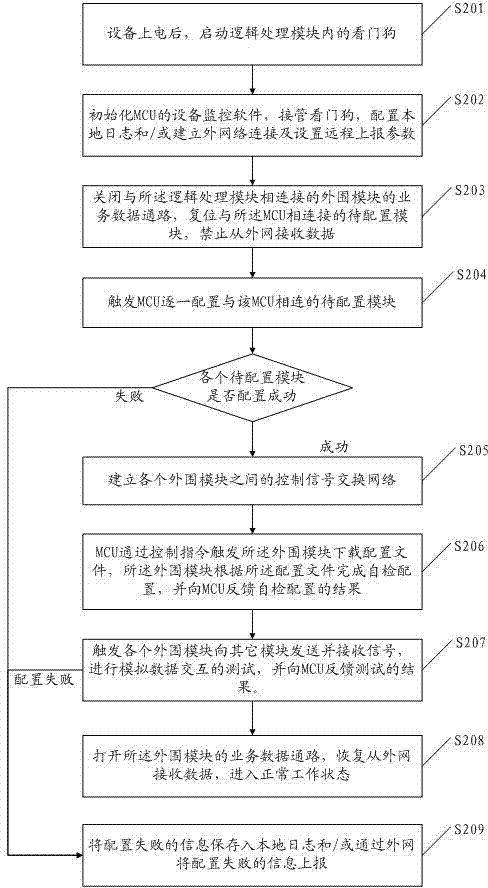

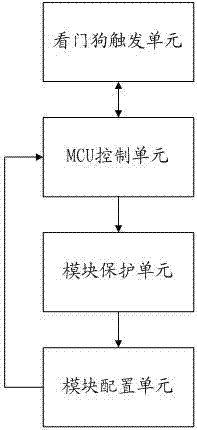

Equipment power-on detection method and device with protection function

ActiveCN102646065BPerformance in timeAvoid abnormal damageDetecting faulty computer hardwareElectricityComputer module

The invention discloses an equipment power-on detection method and device with a protection function. The method comprises the following steps: after equipment is power-on, starting a watchdog in a logic processing module; initializing equipment monitoring software of an MCU (micro control unit) to take over the watchdog; closing a service data path of a peripheral module connected with the logic processing module; and triggering the MCU to configure modules which are to be configured and connected with the MCU one by one, and when each module to be configured is configured successfully, opening the service data path of the peripheral module to enter into a normal operating state. By using the method and device disclosed by the invention, through hardware resources of equipment, and with the aid of a power-on flow of the equipment, a self-testing method with a protection function is embedded for protection to prevent abnormal damages after the specific modules are power-on and before the specific modules run normally, thereby effectively prolonging the normal operating time of the equipment.

Owner:COMBA TELECOM SYST CHINA LTD

Shock absorber installation structure

ActiveCN104626910BEasy to install and fastenImprove assembly efficiencyResilient suspensionsEngineeringSelf locking

The invention relates to a shock absorber installation structure. The shock absorber installation structure comprises a shock absorber, a shock absorber installation shaft and a frame, wherein the shock absorber installation shaft is matched with the shock absorber, and the frame is used for fixing the shock absorber installation shaft. The shock absorber installation shaft is a stepped shaft and comprises a first diameter part, a second diameter part, a third diameter part and a fourth diameter part, wherein the diameters of the first diameter part, the second diameter part, the third diameter part and the fourth diameter part gradually decrease. A threaded section is arranged on the fourth diameter part and matched with a self-locking nut. The shock absorber installation shaft and the frame are connected and fixed by locking the self-locking nut. According to the technical scheme, by limiting the radial displacement and the radial rotation of the shock absorber installation shaft, the abnormal damage to installation rubber pads is avoided, the deformation of the first installation pad and the second installation pad in the disassembly and assembly process is avoided, the risk that a shock absorber installation support cracks is lowered, and the assembly efficiency of a shock absorber is improved.

Owner:ANHUI ANKAI AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com