Rice character type structure arrangement method of hobs of full section rock digging machine

A technology of structural layout and rice-shaped, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the research on the automatic design method of the unseen tool rice-shaped layout, does not consider various technical requirements for hob layout, and does not give Problems such as the automatic design method of the position of the hob

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

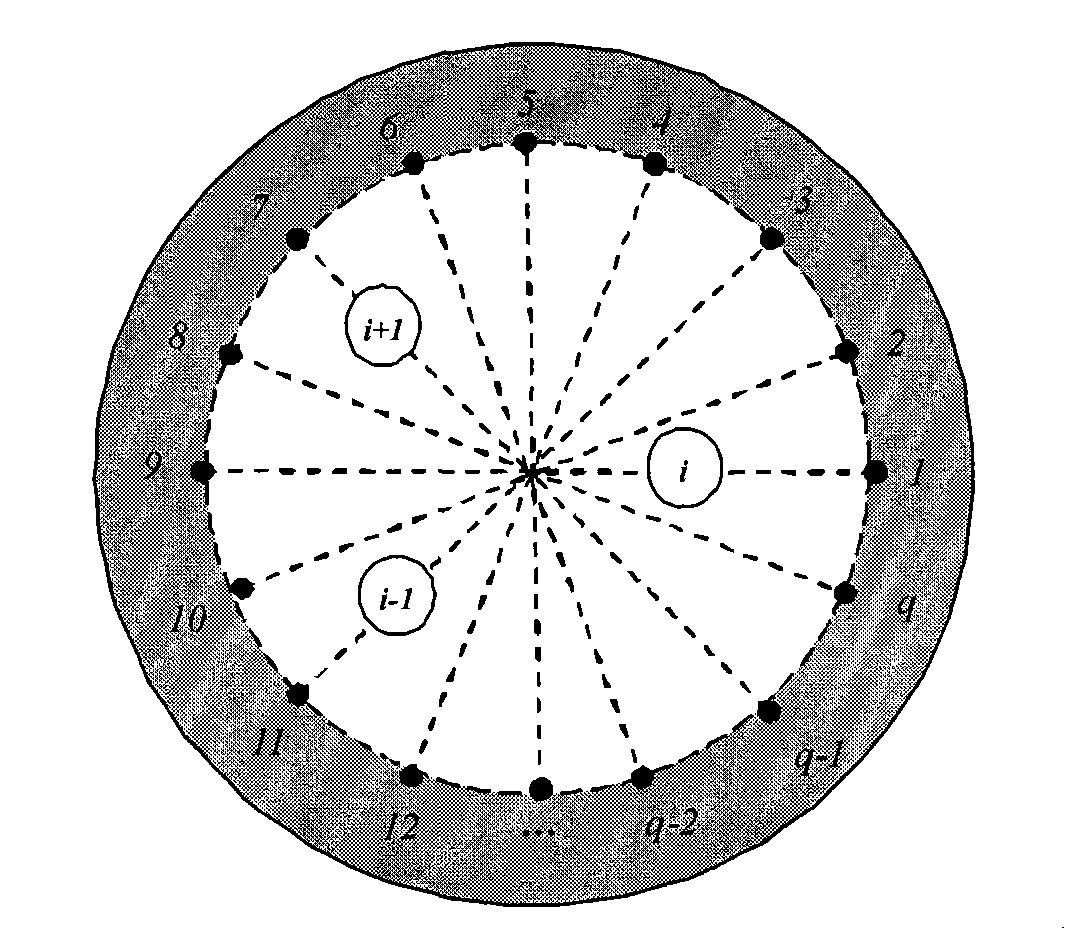

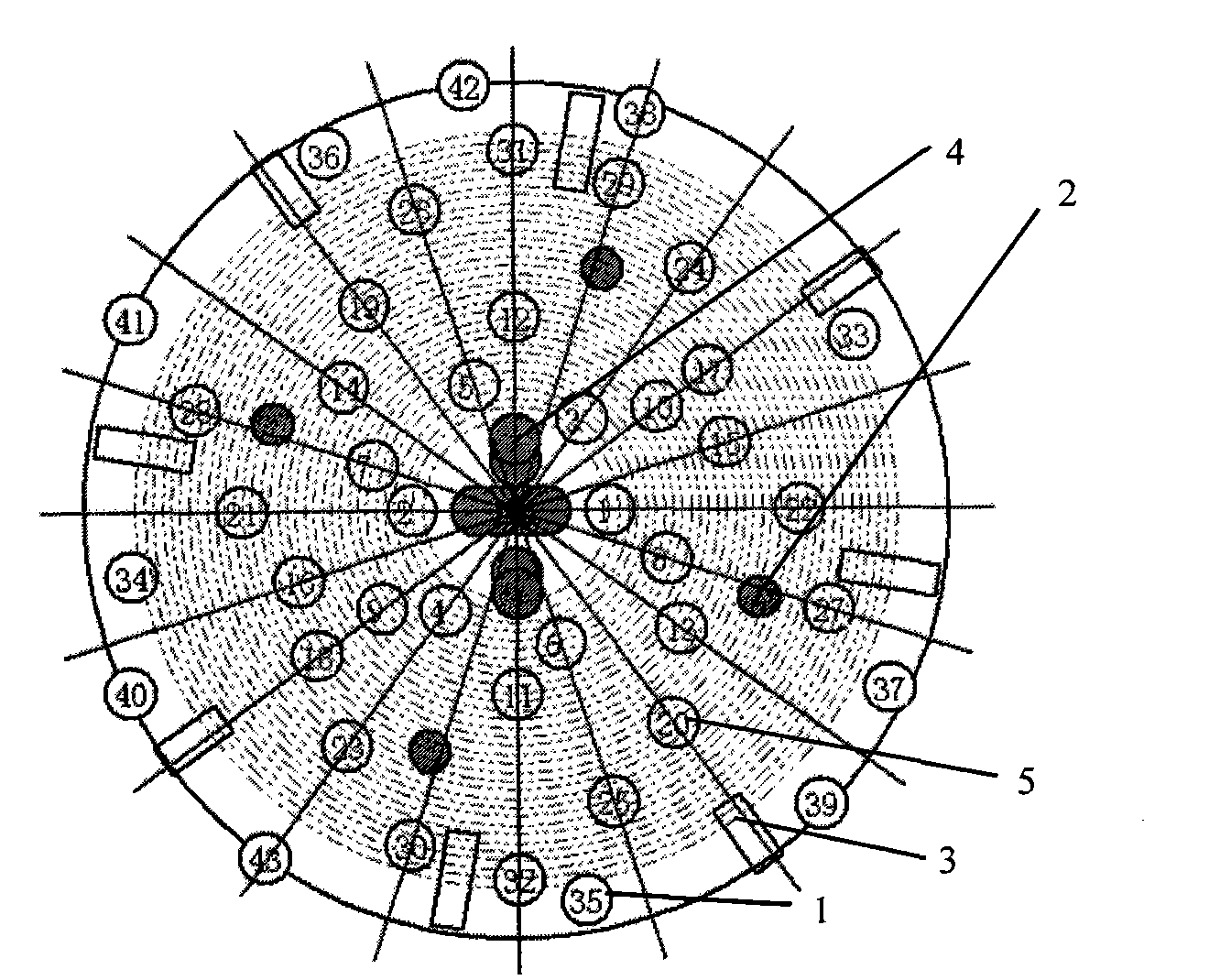

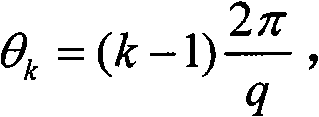

[0033] The implementation of the present invention is described in detail in conjunction with the accompanying drawings and the technical scheme. The present invention takes a water diversion tunnel project as an example to design the hob arrangement on the cutter head of the shield machine. 51 hobs are arranged on the panel cutter head. The known conditions are as follows : ①Geological parameters: The rocks in the geological section are mainly mixed granite (mixgranite), the rock unconfined shear strength τ=5~8(MPa), the rock uniaxial compressive strength σ=50~80(MPa),② The basic parameters of the cutterhead of the roadheader: the radius of the cutterhead R=4.015m, the speed of the cutterhead ω=6(r / min)=0.6283rad / s, the mass of each disc-shaped hob M=200kg, and the diameter D= 19 inches = 483mm, depth of cut h = 10mm, tool edge angle α = 2.09434rad. center knife n 1 = 8, side knife n 2 =10, positive knife n 3 =33, the technical requirements for the overall cutterhead layou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com