Forming belt automatic skew detection shearing extrusion and flexible shell smashing device for walnut

An automatic deviation correction and shell breaking device technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of automatic crushing, non-pollution walnuts, etc., and achieve the goal of breaking shells, reducing manpower consumption, and improving integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

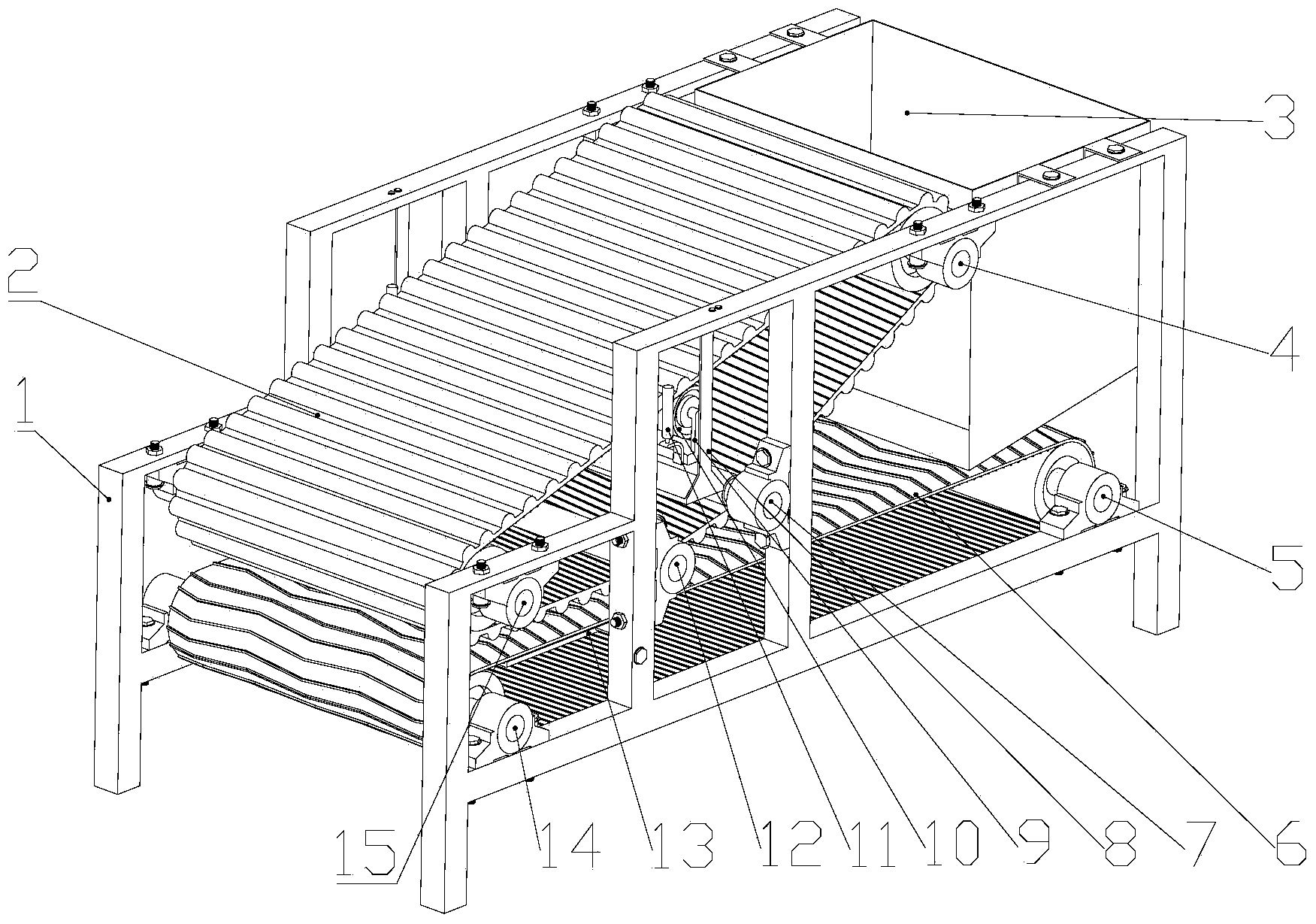

[0058] Such as figure 1 As shown, the feeding hopper 3 is fixed on the support 1 by bolts.

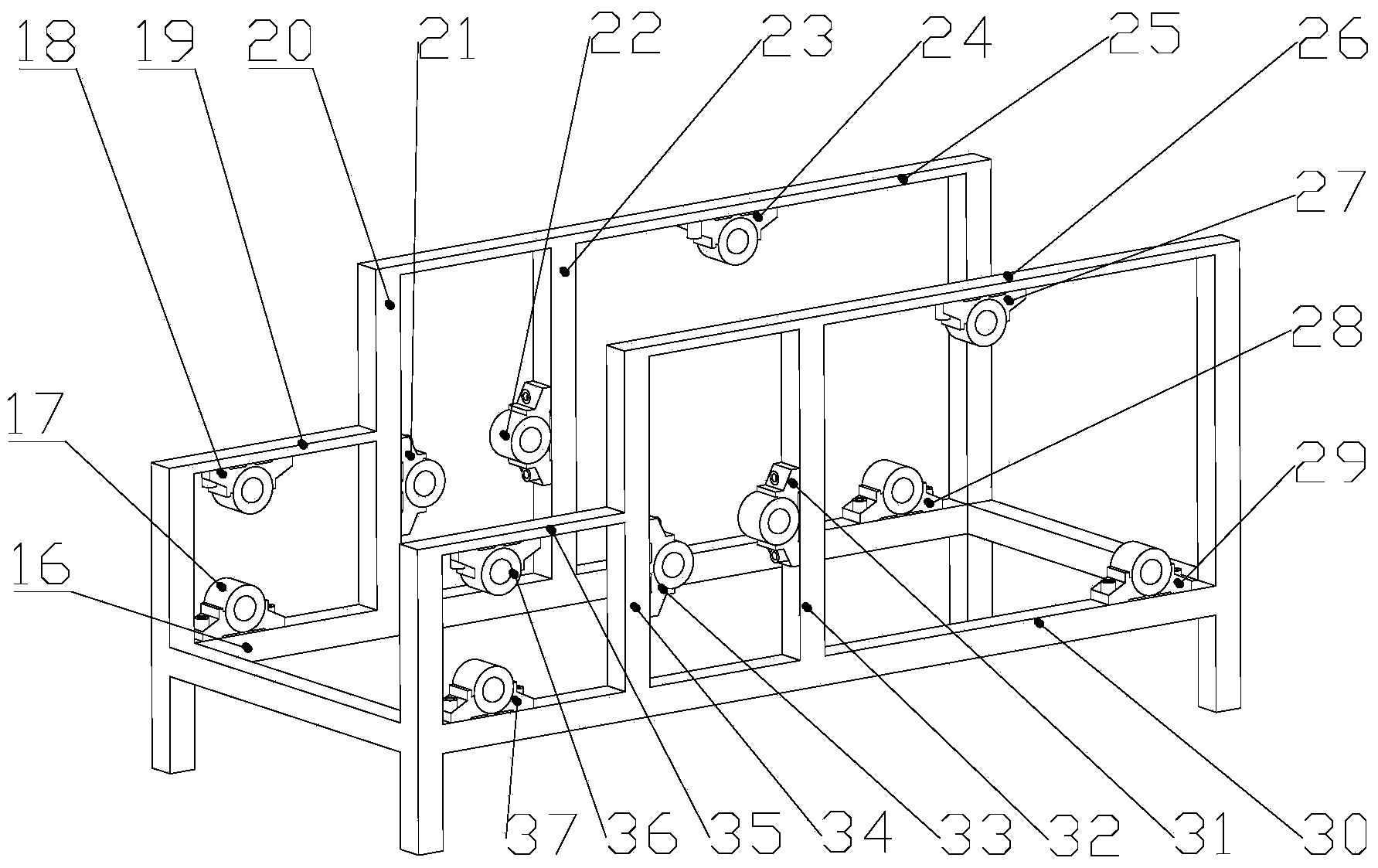

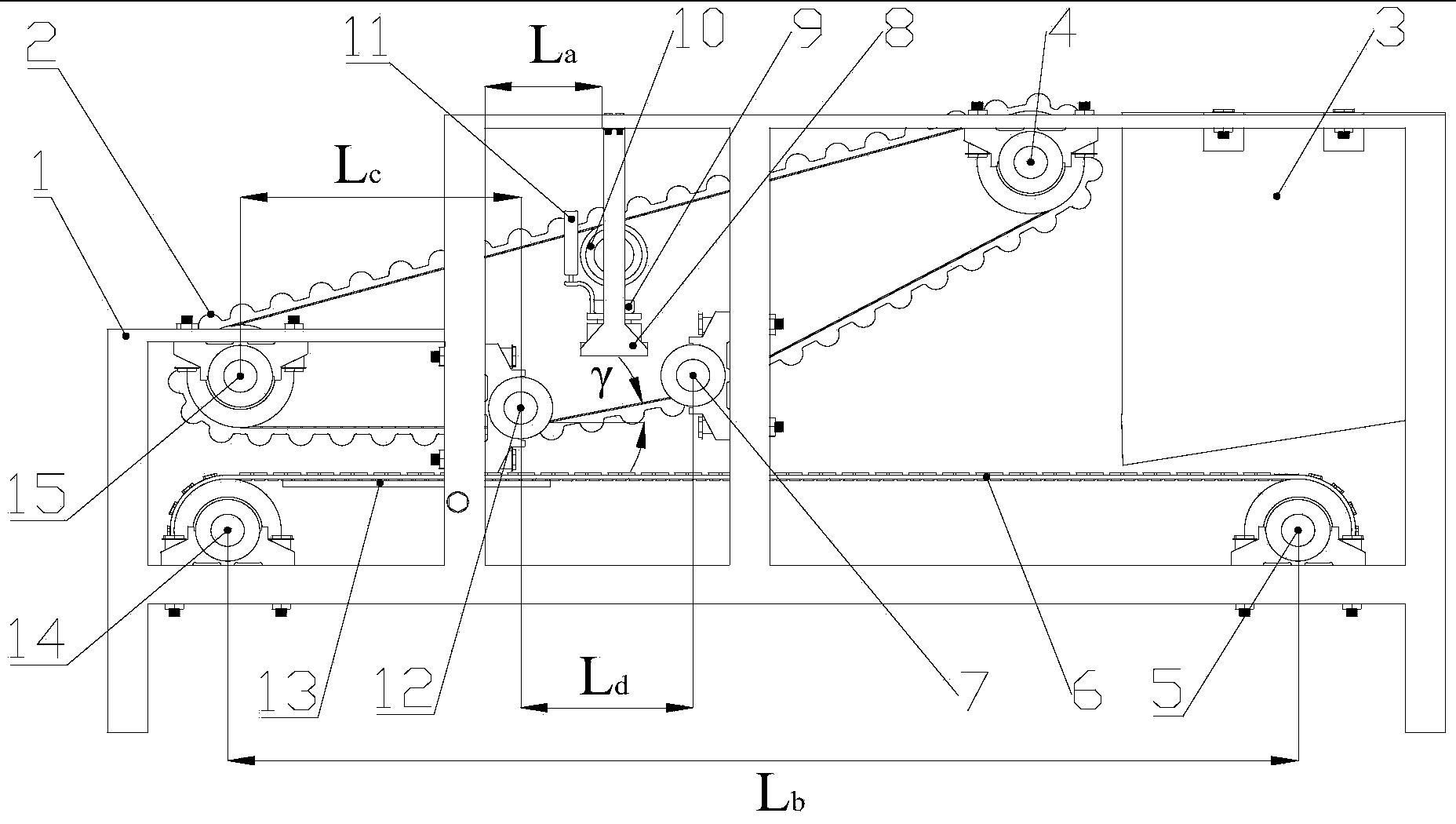

[0059] Such as figure 1 , figure 2 , image 3 As shown, the two ends of the idler roller I4 are respectively assembled in the bearing seat VI27 and the bearing seat V24, and the bearing seat VI27 and the bearing seat V24 are respectively fixed on the third-stage support crossbar II26 and the third-stage support crossbar I25 by bolts. The two ends of idler roller Ⅺ15 are respectively assembled in bearing housing Ⅺ36 and bearing housing Ⅱ18, and bearing housing Ⅺ36 and bearing housing Ⅱ18 are respectively fixed on the secondary support cross bar Ⅱ35 and the secondary support cross bar Ⅰ19 by bolts. Both ends of the tension roller 7 are respectively assembled in the bearing seat IX31 and the bearing seat IV22, and the bearing seat IX31 and the bearing seat IV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Tooth height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com