Patents

Literature

695results about How to "Improve broken rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

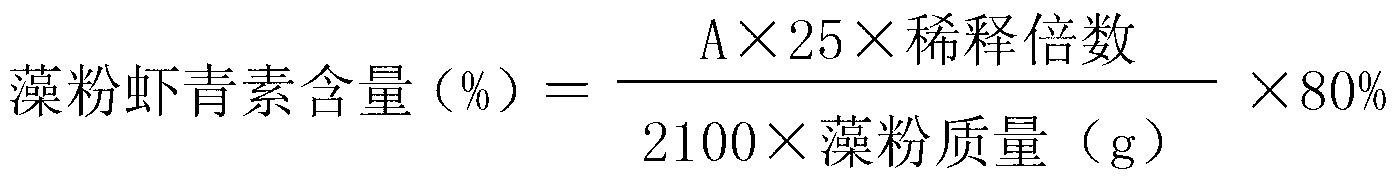

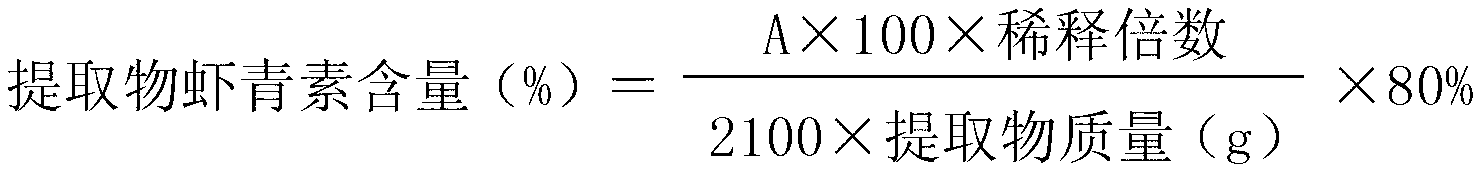

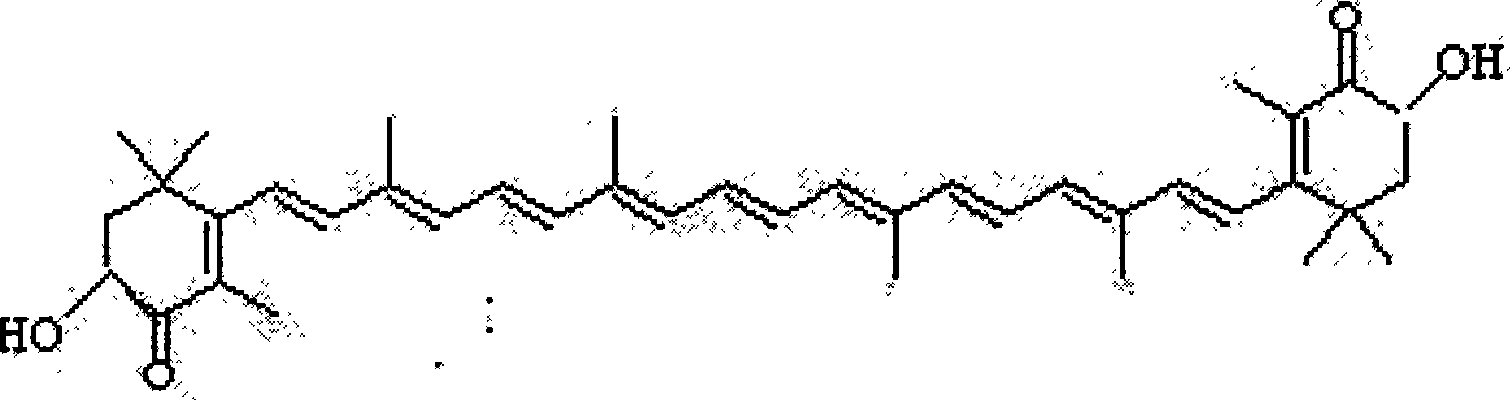

Novel high-efficiency extraction process for astaxanthin in Haematococcus pluvialis

ActiveCN103232375AMeet raw material requirementsSimple extraction methodOrganic chemistryOrganic solventBetaxanthins

The invention discloses a process for extraction of astaxanthin in Haematococcus pluvialis. According to the process, wall-broken Haematococcus pluvialis is obtained by using an acid method, and then an astaxanthin extract is obtained through ethanol dehydration and organic solvent extraction. The wall breaking and extraction process provided by the invention has the advantages of easiness, high efficiency, convenient operation, low energy consumption and controllable quality, and the wall breaking rate and the extraction ratio of Haematococcus pluvialis can reach more than 95%. The astaxanthin extract prepared by using the process is a dark red oily viscous substance and can meet requirements for raw materials needed in production of health food, cosmetics and medicines.

Owner:INNOBIO CORP LTD

Supercritical carbonic anhydride wall-breaking method for melissa powder

ActiveCN101268815ARemove the effect of active ingredientsImprove permeabilityFood shapingFood preparationExhaust valveAdditive ingredient

The invention discloses a method using supercritical carbon dioxide to perform bee pollen broken-face. Bee pollen is put in an extraction plant of supercritical carbon dioxide, to react for a certain time in supercritical carbon dioxide liquid at the proper pressure and temperature, a vent valve is opened to rapidly empty carbon dioxide, so that a pollen cell expands acutely due to larger pressure difference of the inside and the outside, thereby cracking. The method has the advantages that the operation is simple and convenient, the cost is low, the whole process is performed below 50 DEG C, the broken-face time does not exceed 30 minutes, the influence of the product by thermotropy is reduced, so that the active ingredient is preserved completely, at the same time, bacillus can be killed, the unification of the broken-face and the sterilization processes is realized, the broken-face ratio of the pollen cell is high, but the percentage of damage is low, and the inclusion still exists in a cracked pollen wall under the dry condition, thereby favoring the preservation of the nutritious content.

Owner:陕西康泰莱生物医药工程有限公司

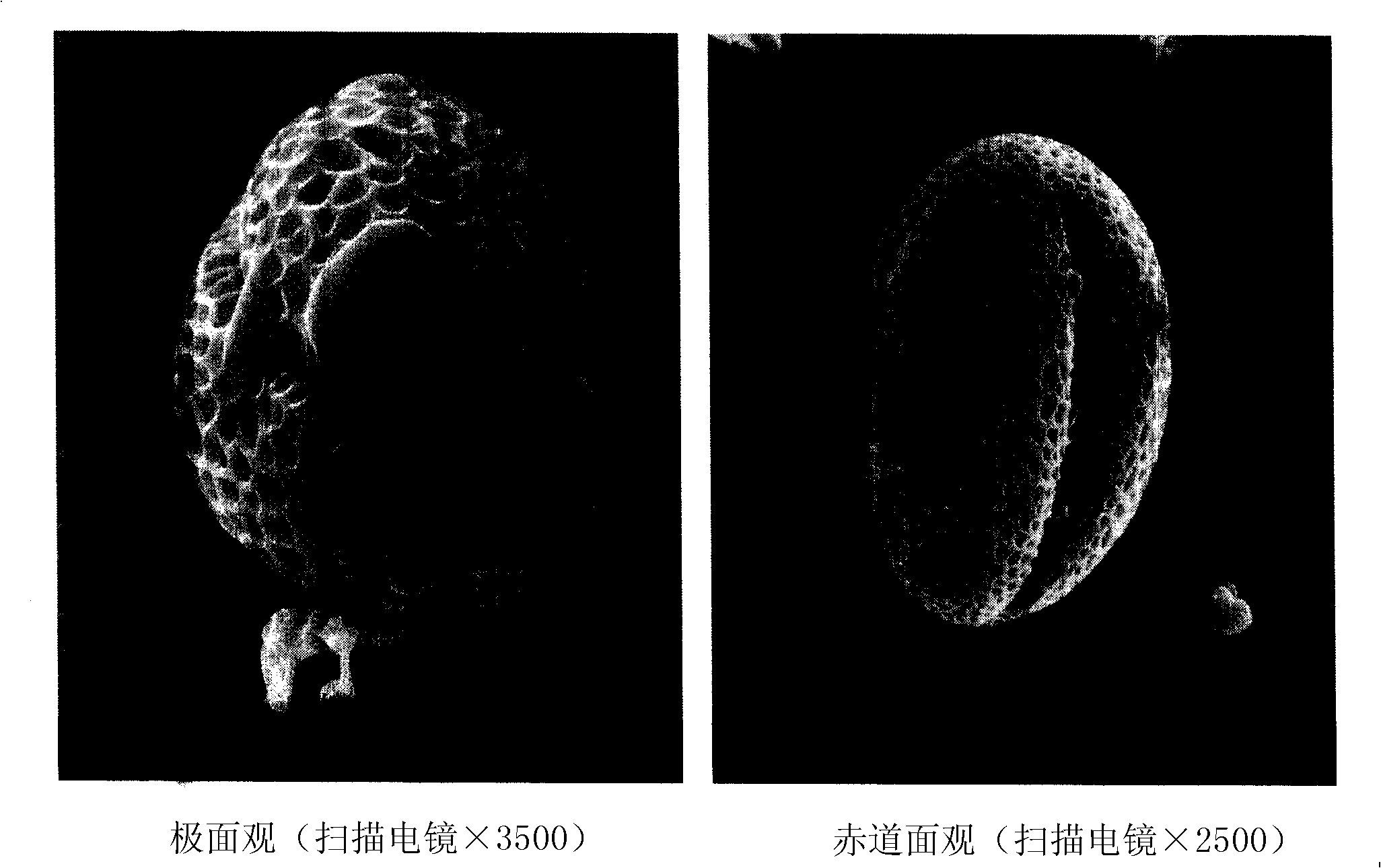

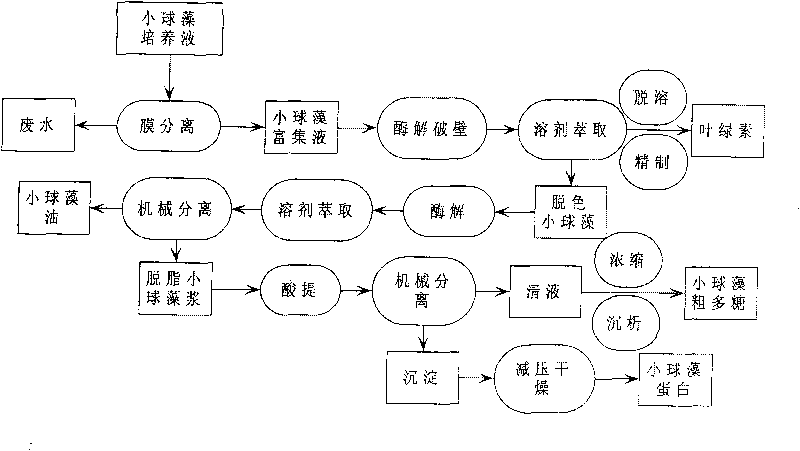

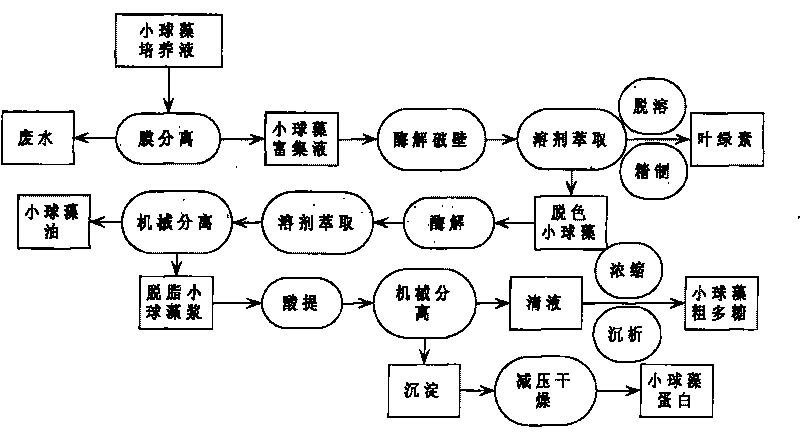

Method for continuously extracting functional components of chlorella vulgaris

InactiveCN101736045AEasy to keep activeReliable operationPeptide preparation methodsNatural dyesSolventChemistry

The invention relates to a method for continuously extracting functional components of chlorella vulgaris, which comprises the steps of enriching the chlorella vulgaris through the membrane separation technology, obtaining concentrated slurry of the chlorella vulgaris, adding a proper enzyme in a liquid phase system for wall-breaking, and using a solvent for extracting chlorophyll from chlorella vulgaris solution after wall-breaking, thereby being capable of obtaining a functional pigment product and reducing the color value of follow-up products; and firstly carrying out enzymatic hydrolysis on a water phase of the chlorella vulgaris after decoloring, then using the solvent for extracting functional grease, extracting active polysaccharides from the obtained degreased chlorella vulgaris by using the acid method, and then drying the other parts for obtaining crude proteins of the chlorella vulgaris. The main products comprise the chlorophyll, the active polysaccharides of the chlorella vulgaris, the functional grease of the chlorella vulgaris, the proteins of the chlorella vulgaris and the like, and the method optimizes the process on the basis of ensuring the activity of the functional components of the chlorella vulgaris, thereby obtaining high yield and reducing production cost.

Owner:BOHAI UNIV

Pre-sulfurizing process of hydrogenating catalyst

InactiveCN1417299AReduce breakage rateImprove broken rateHydrocarbon oils refiningSulfurRoom temperature

The pre-sulfurizing process of hydrogenating catalyst includes impregnating the hydrogenating catalyst in solution containing sulfurized olefin at room temp-220 deg.c for 0.5-5 hr, and heating catalyst in inert atmosphere. The solution containing sulfurizing olefin is in the temperature of room temperature to 220 deg.c and has dissolved S element, total S content of 4-40 wt% and the weight ratio between S in element state and S in sulfurized olefin of 0.5-7. The sulfurized hydrogenating catalyst contains S in 1-7.5 w. The pre-sulfurizing process of hydrogenating catalyst can lower its breaking rate greatly and raise the S retention degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

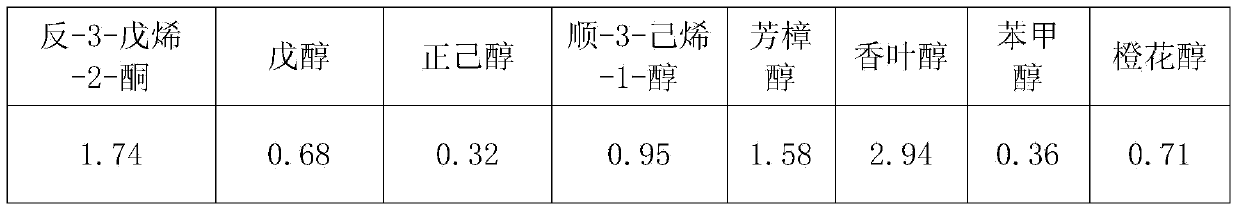

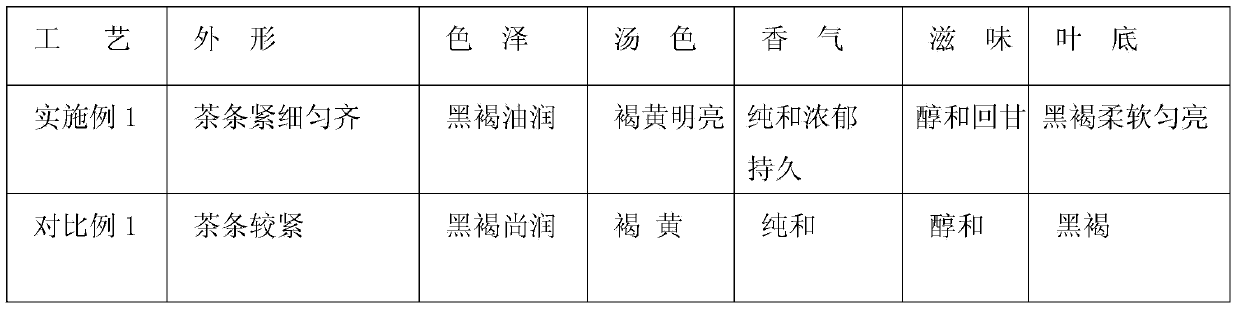

Processing method of flower fragrance type kung fu black tea

InactiveCN106070796AHigh organic contentShort organic contentPre-extraction tea treatmentClimate change adaptationShootBlack tea

The invention discloses a processing method of flower fragrance type kung fu black tea. The method comprises the steps of fresh leaf picking, sun drying, fine manipulation of green tea leaves, quick-freezing withering, unfreezing, rolling, fermentation, first firing, full firing, fragrance increasing, vacuum packaging and the like. The technology is improved for solving the problems that when Lingyun white tea variety black tea is processed, taste is light in freshness and sweetness, fragrance is light and style and variety are monotonous. The processing method comprises the specific steps that tea shoots with two leaves and a bud or with three leaves and a bud of Lingyun white tea trees are picked as raw materials, and technological parameters of sunlight withering, fine manipulation of green tea leaves, freezing withering, rolling, fermentation, full-fire drying, drying and fragrance increasing are enhanced so as to improve a traditional processing method, so that the product has the quality style characteristics that strips are compact and uniform, color and luster are black and smooth, the soup color is orange red and bright, the fragrance is rich and lasting, the taste is mellow and refreshing and leave bottoms are red, bright and uniform, and the black tea has obvious nectar fragrance besides sweet fragrance, and meets requirements of different consumers.

Owner:广西隆林三冲茶业有限公司

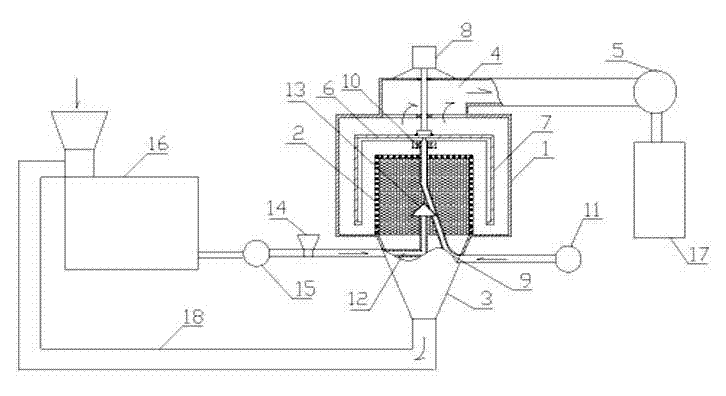

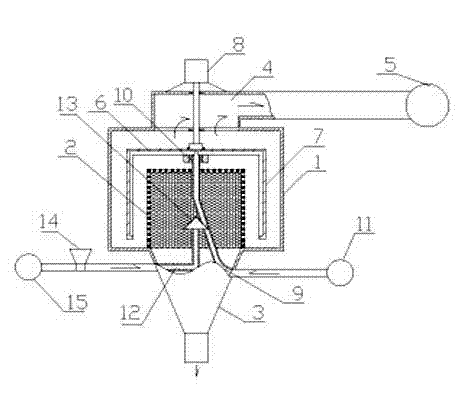

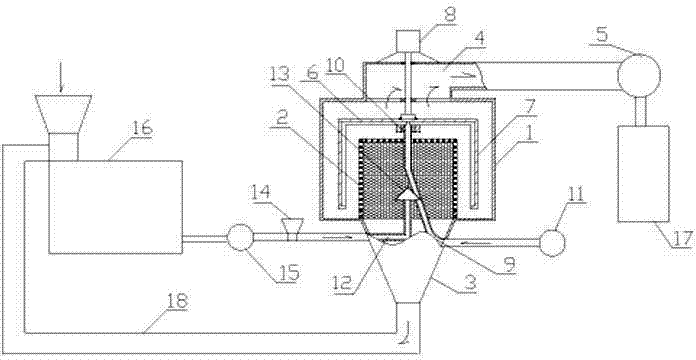

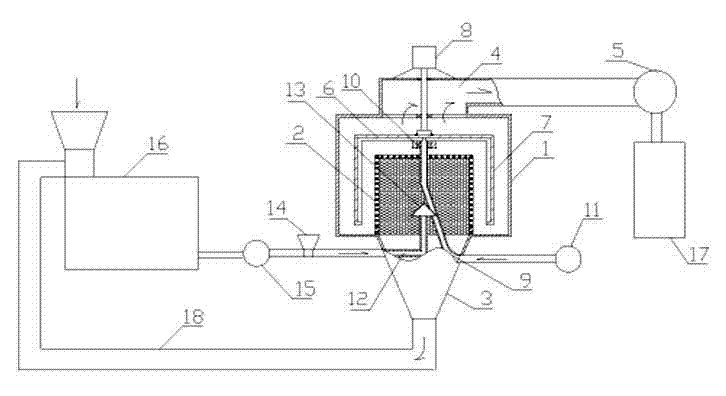

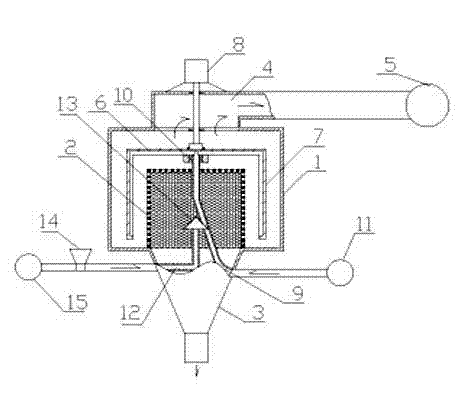

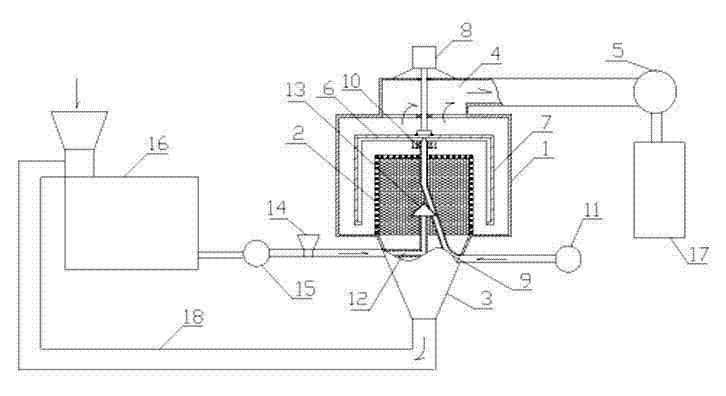

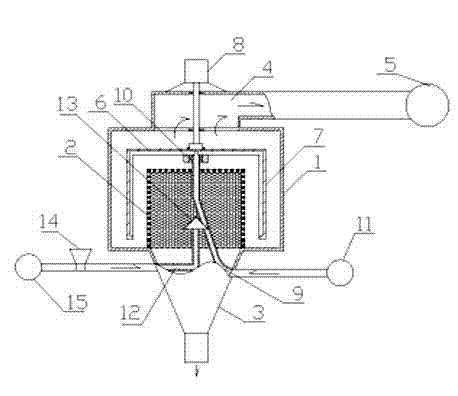

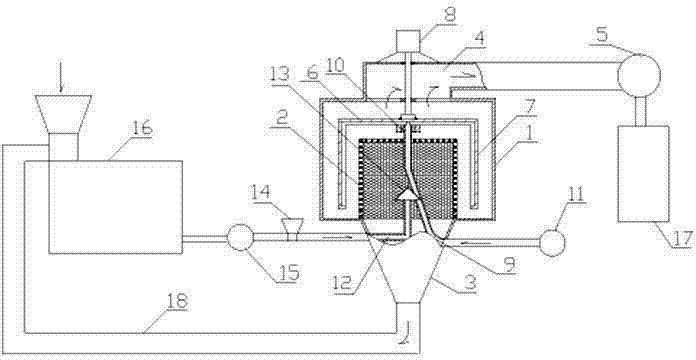

Normal-temperature preparation method for ultrafine coccidia powder and special bilateral airflow sieving machine thereof

ActiveCN102512514AImprove smellGreat tastePowder deliveryGas current separationChinese cinnamonEngineering

The invention discloses a normal-temperature preparation method for ultrafine coccidia powder. The method comprises the following steps of: selecting decoction pieces of sweet wormwood, hairyvein agrimony, tuber fleeceflower root, Chinese pulsatilla root and cinnamon according to parts by weight, drying and smashing to obtain coarse powder of which the granularity is 80 meshes; putting the obtained coarse powder into a rod mill for smashing, feeding into the special bilateral airflow sieving machine through wind for sieving with a 500-mesh sieve, sieving to obtain power of which the particle diameter is less than or equal to 25 micrometers, conveying the powder which is obtained by sieving into a cyclone aggregator through airflow generated by a draught fan for collecting to obtain finished ultrafine coccidia powder; and collecting powder which is not sieved with the 500-mesh sieve with a funnel, and conveying to the rod mill through a pipeline for smashing circularly once again. The method has the advantages that: the entire preparation process is performed at the normal temperature without low temperature or special additional conditions; the particle diameter of a prepared finished medicament is less than or equal to 25 micrometers, and the cell-wall breaking rate and the biological availability are greatly increased; and due to the adoption of the bilateral airflow sievingmachine, the preparation process of the ultrafine coccidia powder is simplified, and the aim of controlling the quality standard of Chinese medicinal powder is fulfilled.

Owner:河南省康星常笑动物药业有限公司

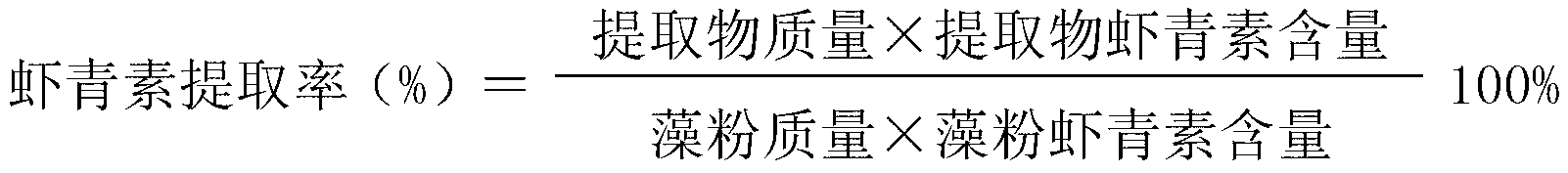

Astaxanthin extraction method

InactiveCN101381337AReduce lossAvoid high temperature oxidation lossOrganic chemistryLoss rateAstaxanthin

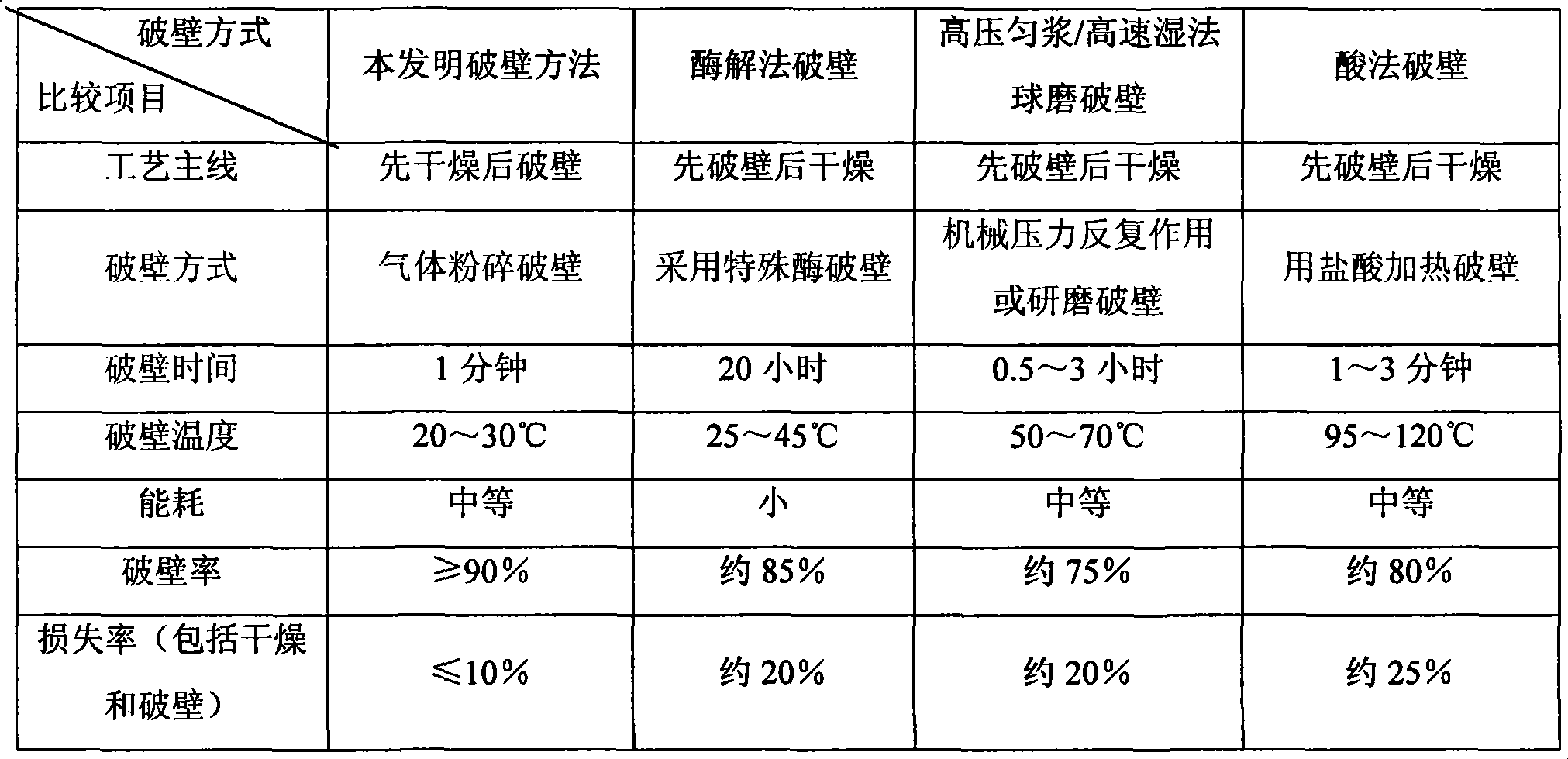

The invention discloses a method for extracting astaxanthin, which is finished by taking a rhodotorula or microalgae feed liquid containing the astaxanthin as a raw material, and performing separation, drying, crushing wall-breaking processes to the feed liquid. The method comprises the following concrete steps: the raw material is separated first to produce a mashed material with the water content less than or equal to 90 percent; the mashed material is dried to produce feed powder with the water content of between 5 and 10 percent; then an airflow crushing method is adopted to crush the feed powder to particles with diameters less than or equal to 10mu m. In the method, the drying is performed first and then the wall-breaking is performed, so the loss of the astaxanthin is reduced; the airflow crushing method is adopted, and has high wall-breaking rate and short wall-breaking time (only 1 minute or so), the temperature is between 20 and 30 DEG C during the wall-breaking process, and avoids the loss of the astaxanthin due to high-temperature oxidation; and the loss rate of the astaxanthin is less than or equal to 10 percent, and the wall-breaking rate is more than or equal to 90 percent.

Owner:陈锦猜

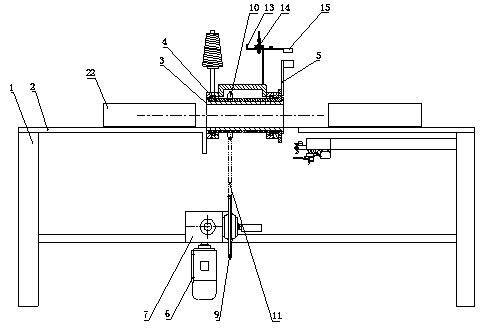

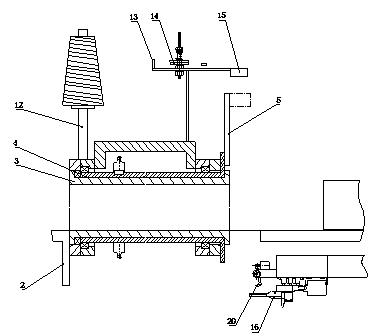

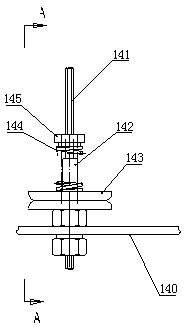

Walnut processing technology and whole set of processing equipment

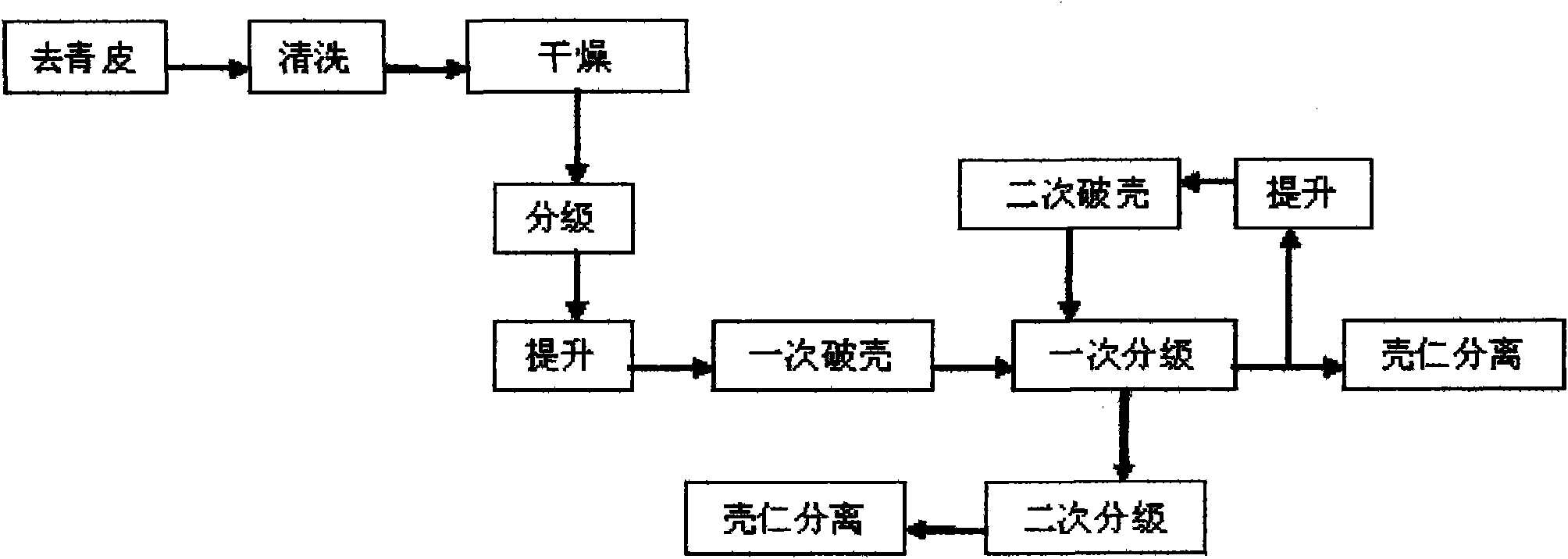

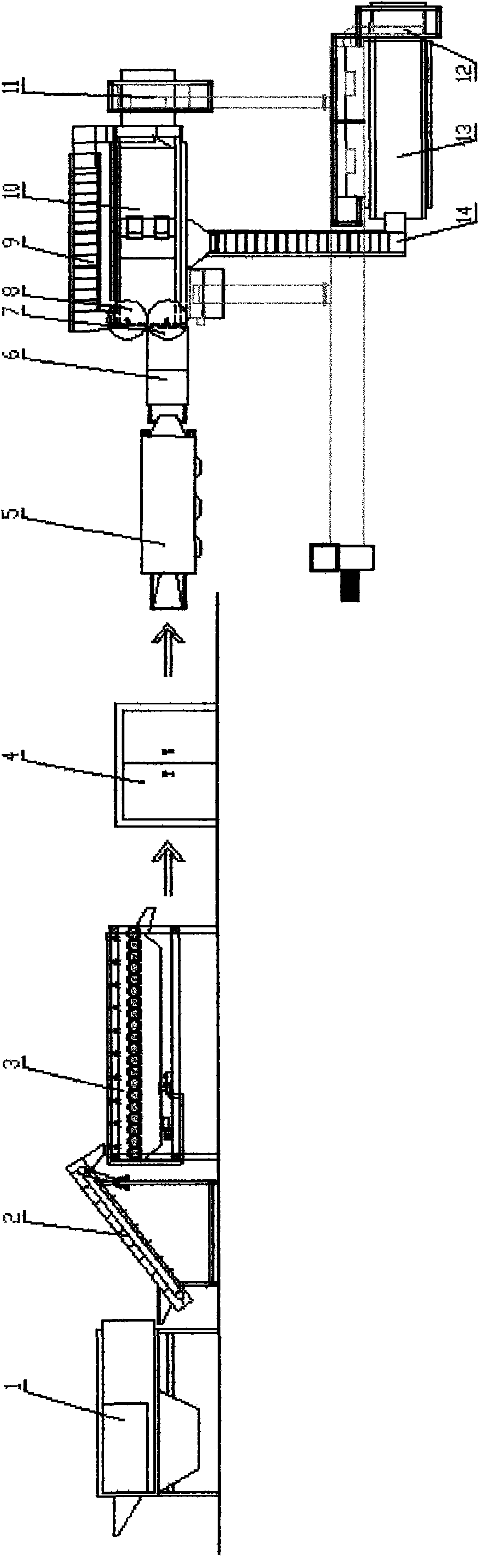

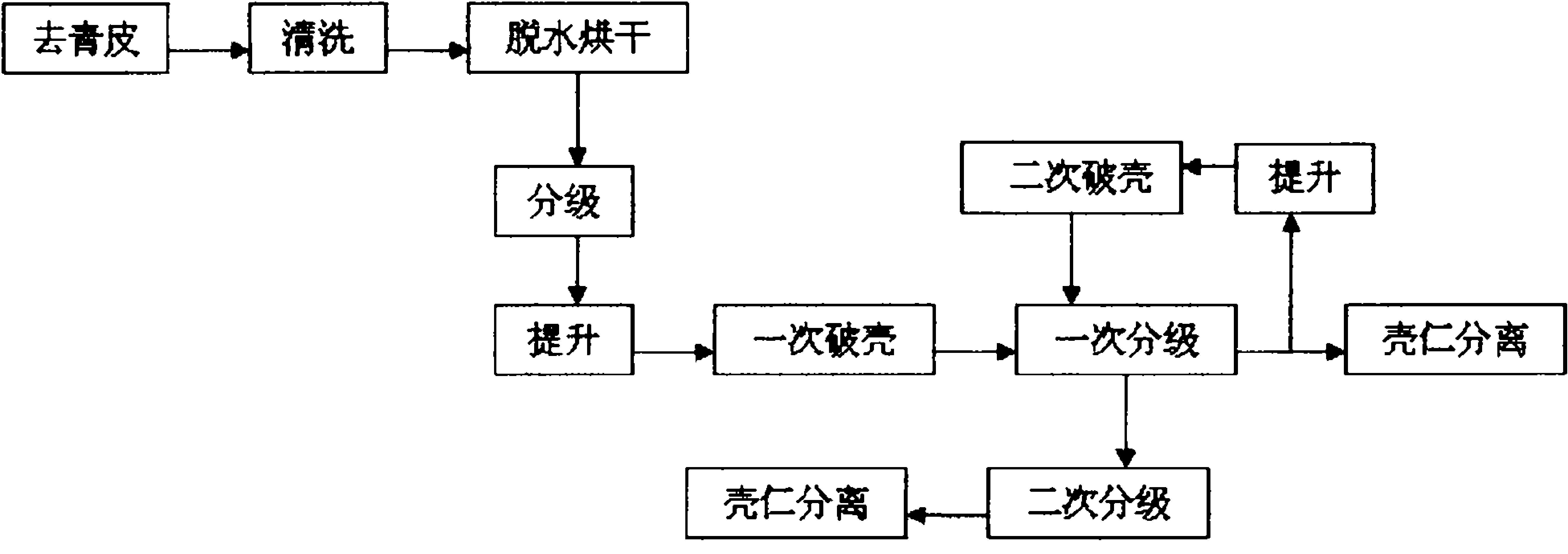

The invention discloses a dried fruit processing method and a whole set of processing equipment and aims to provide a walnut processing technology and a whole set of processing equipment. The walnut processing technology comprises the working procedures of scrapping off the outer layer of a walnut, cleaning, drying, grading, primary crushing, primary grading of a walnut kernel, secondary crushing, secondary grading of a walnut kernel, shell and kernel separating, and the like. The whole set of processing equipment comprises a walnut outer layer scrapping-off machine, a multifunctional high-efficient cleaning machine, drying equipment, a grader, a vertical elevator, a primary crusher, a secondary crusher, a primary walnut kernel grader, a secondary walnut kernel grader, a scrapping plate elevator I, a scrapping plate elevator II, a shell and kernel separator and the like. The technology and the whole set of processing equipment are mainly used for scrapping off the outer layer of the picked walnut with the outer layer, cleaning and drying, and then grading, crushing the walnut, grading the crushed walnut kernel and separating the shell and the kernel, and the like, and finally obtaining walnut kernels and walnut shells in different sizes, thereby solving the technology bottleneck of walnut deep processing. The invention also fundamentally solves the problems of low production efficiency by manual crushing and kernel separation, large labor strength, high cost, kernel high breakage rate during crushing, poor sanitary condition, mixing of kernels, shells and seeds after crushing, long time consumption and high loss of manually separating kernels and shells, and the like.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

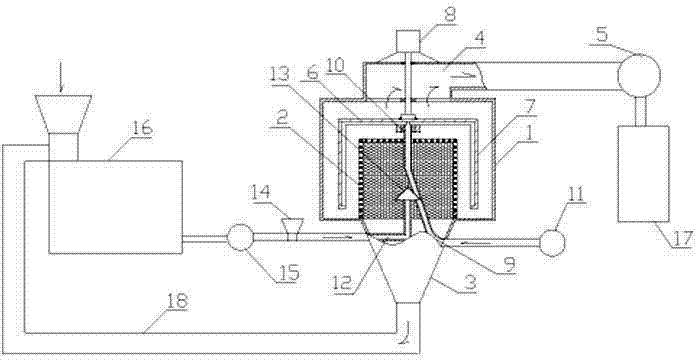

Submicron powder bazheng powder normal temperature preparation method and special bidirectional airflow sieving machine thereof

ActiveCN102512545AImprove smellGreat tastePowder deliveryGas current separationPolygonum aviculareMetallurgy

The invention discloses a submicron powder bazheng powder normal temperature preparation method, which comprises choosing technical materials of akebiaquinata, dianthus superbus, polygonum aviculare, liquorice, fried jasmine, rheum officinale, juncos communis medicinal slices, soapstone and plantain seed raw materials in proportion; drying and smashing to obtain coarse powder; extracting plantainseed oil in the plantain seed coarse powder to be reserved; evenly mixing the rest of coarse powder and the plantain seed dregs in a rod mill to be smashed to be sent into a special bidirectional airflow sieving machine for 500 sieves to obtain powder materials with the grain diameter equal to or smaller than 25 micrometers; achieving bazheng powder submicron powder by collecting powder materialsconveyed to a cyclone material collector by air airflow generated by an air induced fan; collecting the powder material not sieved for 500 sieves to be conveyed into the rod mill through a pipeline to be smashed repeatedly; and evenly mixing the collected bazheng powder submicron powder and the plantain seed oil to obtain submicron powder bazheng powder end products. The submicron powder bazheng powder normal temperature preparation method has the advantages of performing the whole process at the normal temperature. The special bidirectional airflow sieving machine simplifies preparation process of the submicron powder bazheng powder.

Owner:HENAN KANGXING PHARMA

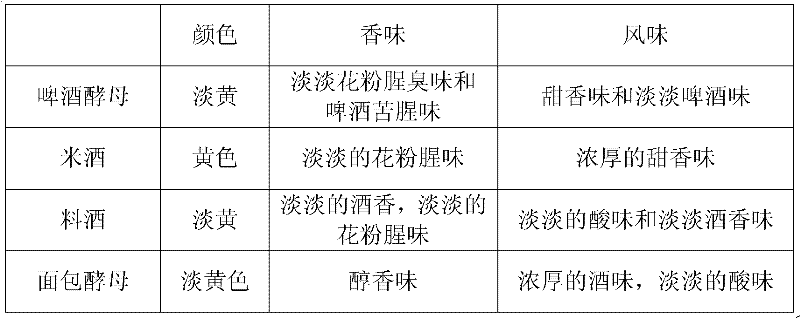

Bee pollen cell-wall breaking method, bee pollen oral solution and its preparation method

Belonging to the food field, the invention relates to a bee pollen cell-wall breaking method, a bee pollen oral solution and its preparation method. Technically, the invention aims to provide a bee pollen cell-wall breaking method and an oral solution prepared with the wall-broken bee pollen. The bee pollen cell-wall breaking method of the invention comprises the step of: adding yeast into the bee pollen for fermentation so as to make the cell-wall of the bee pollen broken. The bee pollen oral solution of the invention is prepared by the wall-broken bee pollen obtained by the above method as an active component together with bromatologically acceptable accessories. The preparation method of the bee pollen oral solution consists of the steps of: breaking bee pollen cell-wall with the above bee pollen cell-wall breaking method, then adding a sweetener of 40-60 wt% of the bee pollen, an acidity regulator of 0.8-1.6 wt% of the bee pollen, as well as water of 4-10 times the weight of the bee pollen, mixing them uniformly, conducting heating and keeping boiling for 5-40min, then carrying out filtration, thus obtaining the filtrate, i.e. the bee pollen oral solution.

Owner:XIHUA UNIV

Ultralow temperature wall-breaking method of ganoderma lucidum spore powder

The invention discloses an ultralow temperature wall-breaking method of ganoderma lucidum spore powder. The method comprises the following steps: sieving ganoderma lucidum spore powder with a 300-mesh sieve to remove the impurities; washing the sieved ganoderma lucidum spore powder with water; soaking the ganoderma lucidum spore powder in a wall-breaking enzyme solution for 8 to 10 hours; placing the ganoderma lucidum spore powder in a space with a temperature of -15 to 0 DEG C for 12 hours, then carrying out vacuum drying; storing the ganoderma lucidum spore powder, which has been freeze-dried, in a refrigeration house with a temperature of 0 to 5 DEG C; carrying out mechanical wall breaking on the ganoderma lucidum spore powder in a space with a temperature of -15 to 0 DEG C; detecting the wall breaking rate of ganoderma lucidum spore powder, wherein when the wall breaking rate is not less than 95% and the fineness is in a range of 300 to 1800 meshes, the ganoderma lucidum spore powder is qualified; and finally carrying out vacuum packaging on the qualified ganoderma lucidum spore powder. The whole processing is carried out at a low temperature, so the effective components of ganoderma lucidum spore powder cannot be destroyed, at the same time, the wall breaking rate of spores is improved, the effective components in spores can be fully released, and thus the nutrition value of ganoderma lucidum spore products is increased.

Owner:无锡飞凤生物科技有限公司

Fermenting and wall-breaking process for rape pollen

The fermenting and wall-breaking process of rape pollen includes the following steps: preparing culture medium; disinfection and inoculation; preparing yeast; preparing enzyme solution through soaking the yeast in hot water, extruding and collecting the fermented liquid as the enzyme solution;enzyme solution fermentation; vacuum stoving rape pollen, crushing and sieving to obtain pollen particle;spraying anhydrous ethanol to sterilize and vacuum stoving; mixing pollen particle and enzyme solution; and culturing the mixture at 37 deg.c to obtain wall-breaking pollen. The said process has high wall-breaking rate, less damage to nutritive components, and improved pollen desensitization, debitterizing and deastruingent effects.

Owner:ZHEJIANG UNIV

Automatic knotting and wire breaking device for producing sausages

ActiveCN103719224AFully automatedReduce labor intensitySausage skin tying apparatusControl systemRotary encoder

The invention relates to an automatic knotting and wire breaking device for producing sausages. The innovation points are that a sausage guiding sleeve, a wire supplying assembly and a length fixing transmission mechanism are mounted on a working platen; a pneumatic wire clamping assembly and a wire breaking assembly are arranged below the working platen; a shaft sleeve of a wire winding assembly is sleeved with the sausage guiding sleeve, and is driven to rotate through a wire winding driving mechanism; a winder is mounted in the shaft sleeve and at one end near the discharging side. The automatic knotting and wire breaking device has the advantages that the wire winding assembly works together with the pneumatic wire clamping assembly and the wire breaking assembly to bundle the sausages, during the bundling process, the coordination of a control system with rotary encoders and a material sensor is utilized to perform cooperation control, so that actions of bundling and wire breaking are enabled to be performed smoothly without mutual noninterference, manual bundling and wire breaking are not needed, the labor intensity of the operating personnel is reduced, the qualified rate of the bundling and wire breaking is high, the coordination of the length fixing transmission mechanism with the material sensor, the rotary encoders and the like is utilized to convey the sausages in rated length, the distance of each section of bundling wire is ensured to be consistent, and the product specification is enabled to meet the requirement.

Owner:JIANGSU CHANGSHOU GRP CO LTD

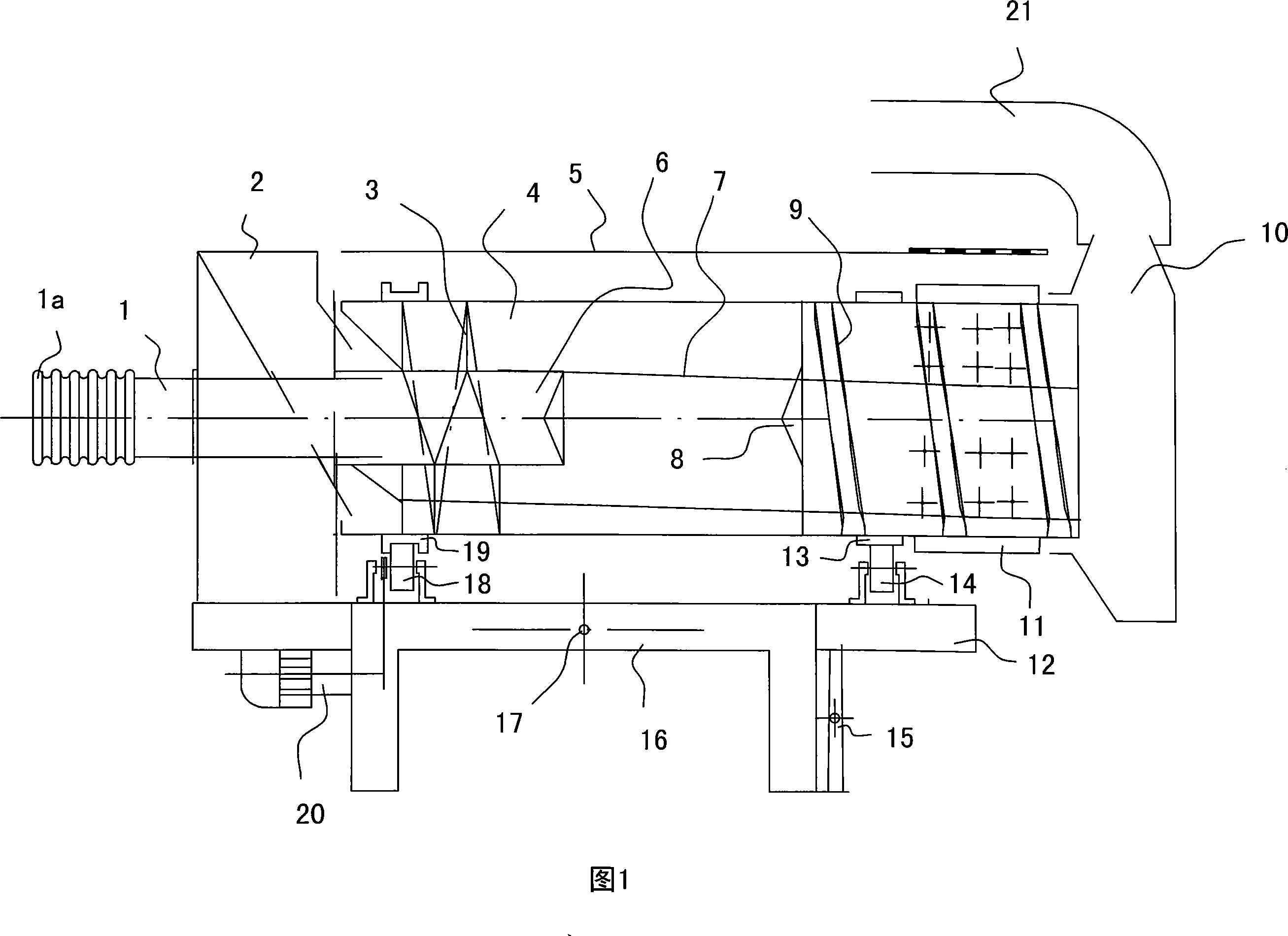

Tea hot air water-removing machine

ActiveCN101238838AIncrease profitImprove thermal efficiencyPre-extraction tea treatmentEngineeringThermal efficiency

The invention provides a tea hot-air green removing machine, including drum and tea inlet bucket, the machine rack is placed on a stand which can adjust the horizontal angle of the machine rack. The inner cavity of the drum is divided into three functional areas of leaf pushing section, green removing section and desiccation section, the leaf pushing section is provided with guide-leaf plate and helix guide-leaf plate, and longitudinal central wind pipe. Part of the rampart of the central wind pipe and the closed surface are provided with small intensive hole; the green removing section is equipped with guide-leaf gluten, the centre shaft passage is equipped with wind cap; the desiccation section is equipped with guide-leaf gluten and many groups of spiral laminas, the drum wall on the tea inlet end is equipped with intensive air holes; interval dynamic-static connected wind wheel cover is equipped along radial direction on the tea outlet end, the upper part of the wind wheel cover is adapted to one end of return vent pipe, the other end of the return vent pipe is adapted to the inlet opening of the heat source device. The machine uses hot air to do the jobs of green removing and parching, the product has the merits of high thermal efficiency, sturdy leaves, good desiccation effect, and the green removing time of tea in the drum can be effectively controlled according to the tea producing methods.

Owner:浙江上洋机械股份有限公司

Normal-temperature preparation method for ultrafine powder hawthorn and special bilateral airflow sieving machine thereof

ActiveCN102512520AImprove broken rateImprove bioavailabilityAntibacterial agentsPowder deliveryGranularityMetallurgy

The invention discloses a normal-temperature preparation method for ultrafine powder hawthorn. The method comprises the following steps of: cleaning hawthorn, and drying till the water content is less than or equal to 10 percent; smashing the hawthorn at the normal temperature to obtain coarse powder of which the granularity is 60-80 meshes; putting the coarse powder into a rod mill for smashing,conveying into the special bilateral airflow sieving machine through wind for sieving with a 500-mesh sieve, sieving to obtain powder of which the particle diameter is less than or equal to 25 micrometers, and conveying to a cyclone aggregator through airflow generated by a draught fan for collecting to obtain finished ultrafine powder coccidia powder; and collecting powder which is not sieved with the 500-mesh sieve with a funnel, and conveying to the rod mill through a pipeline for smashing circularly once again. The method has the advantages that: the entire preparation process is performed at the normal temperature without low temperature or special additional conditions; the particle diameter of prepared finished hawthorn micro powder is less than or equal to 25 micrometers, the cell-wall breaking rate and biological availability are greatly increased, and the pharmacological action of a medicament is enhanced; and due to the adoption of the bilateral airflow sieving machine, thepreparation process of ultrafine powder hawthorn is simplified, and the aim of controlling the quality standard of Chinese medicinal powder is fulfilled.

Owner:河南省康星生物科技有限公司 +1

Making method of radix-codonopsis broken-wall decoction piece

InactiveCN107019718AGood particle shapeModerate tightnessUnknown materialsPlant ingredientsPulverizerNutritional composition

The invention discloses a making method of a radix-codonopsis broken-wall decoction piece. The making method comprises the following contents of first soaking a radix-codonopsis medicinal material in a soaking solution, then oven-drying a radix-codonopsis decoction piece, and then crushing the radix-codonopsis decoction piece through a crusher with a 100-mesh sieve, so as to subsequently make medicinal-material coarse powder of 80 to 120 meshes; afterwards, subjecting the medicinal-material coarse powder to microwave oven-drying in sequence, grinding the medicinal-material coarse powder into ultrafine powder, afterwards, further carrying out granulation through an ethanol-water wetting method, carrying out extrusion molding at a certain rotational speed, and carrying out drying, thereby making the radix-codonopsis broken-wall decoction piece. The radix-codonopsis broken-wall decoction piece provided by the invention is first soaked by adopting the soaking solution; the nutritive value of radix codonopsis is improved; the primary processing is carried out; afterwards, the granulation is further carried out through the ethanol-water wetting method; the grain of the made radix-codonopsis broken-wall decoction piece is better in grain type; the tightness is moderate; the stability is high; the disintegration is good; meanwhile, in comparation with a conventional ultramicro wall breakage crushing method, the making method is used for greatly improving the wall breakage rate of the radix codonopsis; a nutrient substance is maximally maintained; the beneficial effects that the wall breakage rate is high and a nutritional ingredient is stored completely are achieved.

Owner:天马(安徽)国药科技股份有限公司

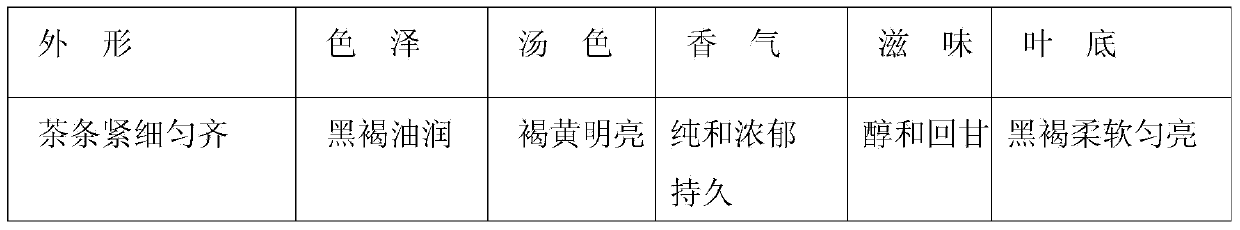

Preparation method of highly fragrant black tea

The invention belongs to the field of preparation of tea, and in particular relates to a preparation method of highly fragrant black tea. The preparation method disclosed by the invention comprises the following steps: (1), picking fresh tea leaves, namely using one bud with two leaves, one bud with three leaves and a pair of leaves of same tenderness as the raw tea leaves; (2), spreading, namely spreading the fresh tea leaves in a ventilated, cleaned and dry tedding room, so that the water content of the fresh tea leaves is controlled within 60-68%; (3), carrying out fixation, namely carrying out fixation by using a roller type continuous fixation machine with the rotation speed of 25-35 rpm, controlling the water content of the tea leaves subjected to fixation within 55-63%, and, after taking out, conveying the tea leaves onto a spreading frame through a conveying vibration tank to be blown and cooled; and (4), rolling preliminarily, namely rolling by using a tea roller with the rotation speed of 30-36 rpm for 7-12 min, so that buds and leaves form strips preliminarily, etc. The black tea prepared by using the preparation method disclosed by the invention is tight, thin and uniform in shape, black brown and oleosus in colour and lustre, pure, full-bodied and everlasting in fragrance, pure, mild and sweet after taste, auburnish yellow and bright in tea colour, and black brown, soft, uniform and bright in soaked tea dregs.

Owner:成都市碧涛茶业有限公司

Bee pollen sugar-free active instant granule

InactiveCN101502307AImprove broken rateHigh content of active ingredientsFood preparationNutritive valuesAdditive ingredient

The invention provides a preparation method and product of instant particles of bee pollen active ingredient and products thereof. The wall of bee pollen is broken using a composite enzymolysis wall-breaking method and the wall-broken bee pollen and the common excipients are processed into the instant particles. The bee pollen is subjected to enzymolysis by the plant composite hydrolase, it is a newest technological process, with marked features such as simpleness, mild condition, easy operation, short time-consumption of reaction process, high wall breaking rate, compared with the other technological process. After the bee pollen is subjected to enzymolysis, the content of the main active ingredient is markedly increased and the sensitizer is subjected to enzymolysis, therefore the nutritive value of the product is greatly increased and the food safety of the bee pollen product is increased and the product quality is increased.

Owner:BIOCHEM ENG COLLEGE OF BEIJING UNION UNIV

Method for preparing capsules of wall broken spore powder of ganoderma lucidum

The present invention relates to a preparation method of ganoderma sporoderm-broken spore powder capsule. Said preparation method includes the following steps: (1), cleaning ganoderma sporobasidium, drying, pulverizing and screening to obtain ganoderma sporoderm-broken spore micropowder whose grain size is 200-300 meshes, sealing and storing for stand-by; (2), adding the above-mentioned ganoderma sporoderm-broken spore micropowder into a microwave counter-current extraction device, adding pure water and making microwave counter-current extraction, filtering extract, removing residue, concentrating and drying filtrate so as to obtain ganoderma sporoderm-broken spore power extract; and (3), according to the contents quality composition of ganoderma sporoderm-broken spore powder capsule uniformly mixing 60-80 portions of ganoderma sporoderm-broken spore micropowder obtained in step 1 and 20-40 portions of ganoderma sporoderm-broken spore powder extract obtained in step 2, then preparing the described ganoderma sporoderm-broken spore powder capsule.

Owner:JINHUA SHOUXIANGU PHAMACEUTICAL CO LTD +1

Method for preparing beta-carotene

InactiveCN104557648AHigh extraction ratePrevent oxidationOrganic chemistryMicroorganism based processesOrganic solventBeta-Carotene

The invention discloses a method for preparing beta-carotene. The method comprises the following steps: inoculating a microbial strain for fermentation; adding bio-enzyme for breaking walls 1 to 24 hours before the fermentation is ended; performing solid and liquid separation on a fermentation solution to obtain a wet cell; mixing the wet cell with an organic solvent, and circularly shearing and crushing; performing solid and liquid separation on the mixed solution to obtain an extraction solution; adsorbing the beta-carotene in the extraction solution by using macro-porous adsorption resin; desorbing the macro-porous adsorption resin by using the organic solvent after the adsorption is ended to obtain a desorption solution containing the beta-carotene; removing the solvent from the desorption solution and drying in vacuum to obtain a beta-carotene crystal. According to the method disclosed by the invention, the wet cell is high in wall breaking rate by combination of bio-enzyme wall breaking and mechanical wall breaking; therefore, the extraction rate of the beta-carotene is high; the strain needs not to be dried during extraction, so oxidation of the beta-carotene is avoided. On the other hand, in the method, the macro-porous adsorption resin is used for separating and purifying the beta-carotene, so the process is simple; the mixed oil generated after the beta-carotene is extracted can be recycled as an extraction solvent, so the cost can be lowered, energy consumption can be reduced and environmental protection can be facilitated.

Owner:CABIO BIOTECH WUHAN CO LTD

Process combination for preparing bletilla polysaccharide

ActiveCN101906169AReduces problems such as color deepeningSolve the problem of cold meltingDigestive systemUltrafiltrationBletilla striataSolvent

The invention mainly relates to a low-temperature preparation method for bletilla polysaccharide, in particular to a process combination for preparing high-purity bletilla polysaccharide at a low temperature by adopting a core process of homogenization-based extraction and ceramic membrane micro-filtration concentration and using water as a solvent.

Owner:广州泽力医药科技有限公司

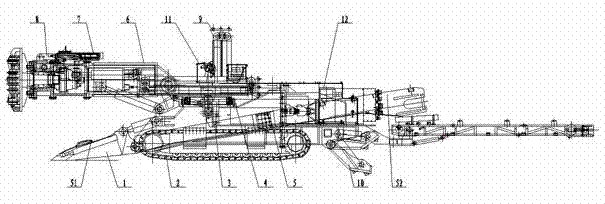

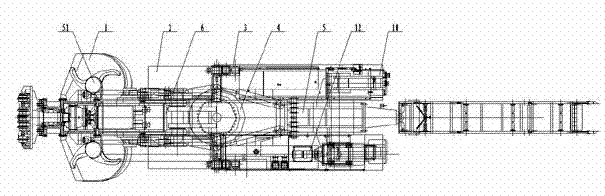

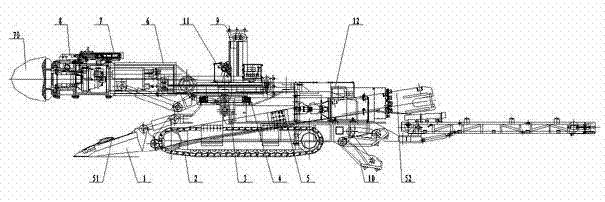

Comprehensive mechanical stone drift digging anchor machine

InactiveCN102808617ASignificant technological progressProminenceDriving meansCutting machinesControl systemElectrical control

The invention discloses a comprehensive mechanical stone drift digging anchor machine, which aims at solving the problems that in the traditional comprehensive mechanical stone drift digging anchor machine, the cutting ability is lower, the installation position of a top anchor rod anchor rope drilling machine is inappropriate, the whole stability of a device during the running is worse, and the like. The comprehensive mechanical stone drift digging anchor machine comprises a shovel board part, a crawler belt running part, a rack, a rotating part, a belt transporting part, a telescopic cutting part, a hydraulic drilling machine device, an advance supporting device, a top board supporting device, a bottom board supporting device, a hydraulic control system and an electrical control system, and is characterized in that the hydraulic drilling machine device is fixedly arranged at two side surfaces of a telescopic height adjusting rack of the telescopic cutting part, each side of the hydraulic drilling machine device comprises a group of top anchor rod anchor rope drilling machines, the top board supporting device is positioned at the middle part of a machine body, and the bottom board supporting device is positioned at the tail part of the machine body. By using a cutting device driven by a permanent magnet motor or a conventional cutting head, the cutting ability, the working efficiency and the whole stability of the device can be further increased.

Owner:马晓山

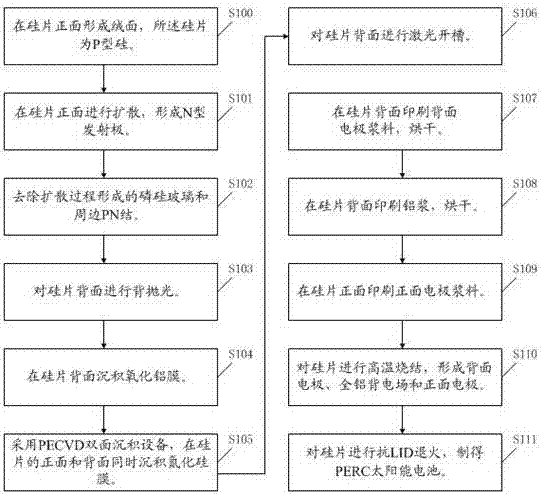

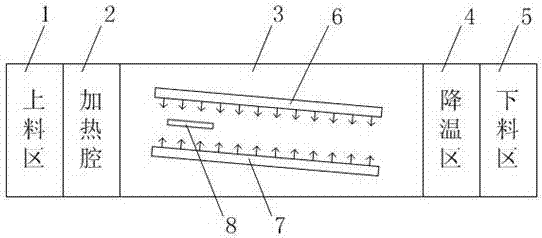

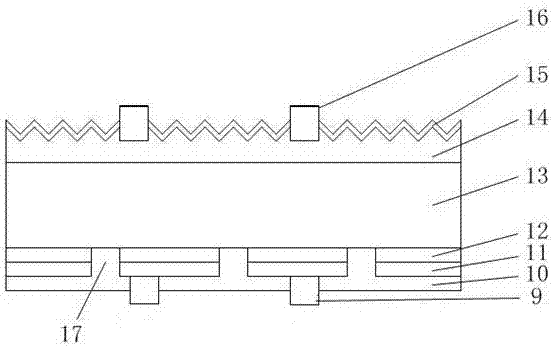

P-type PERC solar energy cell preparation method, cell, assembly and system

InactiveCN107068790AImprove conversion efficiencyImprove broken rateFinal product manufacturePhotovoltaic energy generationSlurryOptoelectronics

The invention discloses a P-type PERC solar energy cell preparation method. The P-type PERC solar energy cell preparation method comprises steps that (1), a suede-like surface is formed at a front surface of a silicon chip; (2), diffusion is carried out at the front surface of the silicon chip, and an N-type emitter electrode is formed; (3), phosphorosilicate glass and peripheral PN junctions are removed; (4), an alumina film is deposited at a back surface of the silicon chip; (5), PECVD double-surface deposition equipment is employed, and silicon nitride films are deposited at the front surface and the back surface of the silicon chip; (6), laser grooving at the back surface of the silicon chip is carried out; (7), back surface electrode slurry is printed at the back surface of the silicon chip and is then dried; (8), aluminum slurry is printed at the back surface of the silicon chip and is then dried; (9), front surface electrode slurry is printed at the front surface of the silicon chip; (10); high temperature sintering is carried out for the silicon chip, and a back surface electrode, a full aluminum back electric field and a front surface electrode are formed; and (11), anti-LID annealing for the silicon chip is carried out, and the P-type PERC solar energy cell is acquired. The invention further discloses the P-type PERC solar energy cell, an assembly and a system. The method is advantaged in that production efficiency can be improved, and scratch of the silicon chip is reduced.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

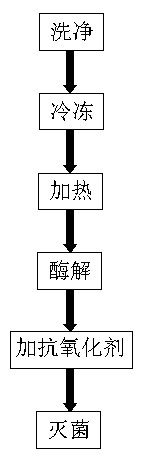

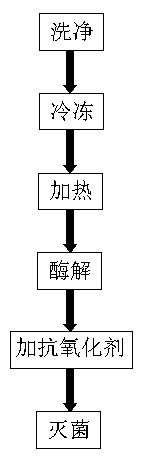

Effective antioxidation method for ganoderma lucidum spore powder

InactiveCN102600213APrevent oxidationReduce oxidationMetabolism disorderPharmaceutical non-active ingredientsBiotechnologySpore

The invention provides a biological sporoderm-breaking technology and an effective antioxidation method for ganoderma lucidum spore powder. Firstly, full mature ganoderma lucidum spores are screened and put into water to be cleaned, then the ganoderma lucidum spores are heated after being frozen, spore enzymolysis and sporoderm breaking are carried out with one of expansin, cellulose, lysozyme, helicase and the like or the mixture of a plurality of enzymes for 3-24 hours at the temperature of 37-45 DEG C, pH (Potential Of Hydrogen) is regulated to 5.5-6.8 by citric acid, and then a vitamin C is used as an antioxidant of the ganoderma lucidum spore powder. Finally, 1% of sweetener-stevioside is used for removing bitter, and treatment with an instantaneous ultra-high temperature sterilization machine and bagging are carried out. The method disclosed by the invention has a good sterilization effect and high sporoderm breaking efficiency, is low in cost, does not break protoplasm of the ganoderma lucidum spore powder and keeps the original characteristics of the ganoderma lucidum powder.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Throwing type fire extinguisher and manufacturing method thereof

ActiveCN103341244AAppropriate size for impact resistanceHas a cooling effectFire rescueFire extinguisherPolyvinyl chlorideFire extinguisher

The invention discloses a throwing type fire extinguisher and a manufacturing method thereof. The throwing type fire extinguisher comprises a fire extinguishing agent and a fire extinguisher bottle for storing the fire extinguishing agent. The throwing type fire extinguisher is characterized in that the fire extinguishing agent comprises the following components: a fluorinated surfactant, potassium carbonate, ammonium sulfate, urea, ammonium polyphosphate, an anionic surfactant, lauryl sodium sulfate and water; the fire extinguisher is a polyvinyl-chloride-resin bottle with self extinguishment. The throwing type fire extinguisher disclosed by the invention has the advantages that due to ingenious utilization of self extinguishment, flame resistance and cold resistance of polyvinyl chloride, normal use can be achieved at the temperature of minus 30 DEG C; the size of impact resistance is proper, breaking can not be finished by hands, the breaking rate is high in throwing, and broken scraps are not splashed and do not hurt persons.

Owner:QINGDAO LONGCHI FIRE EQUIP

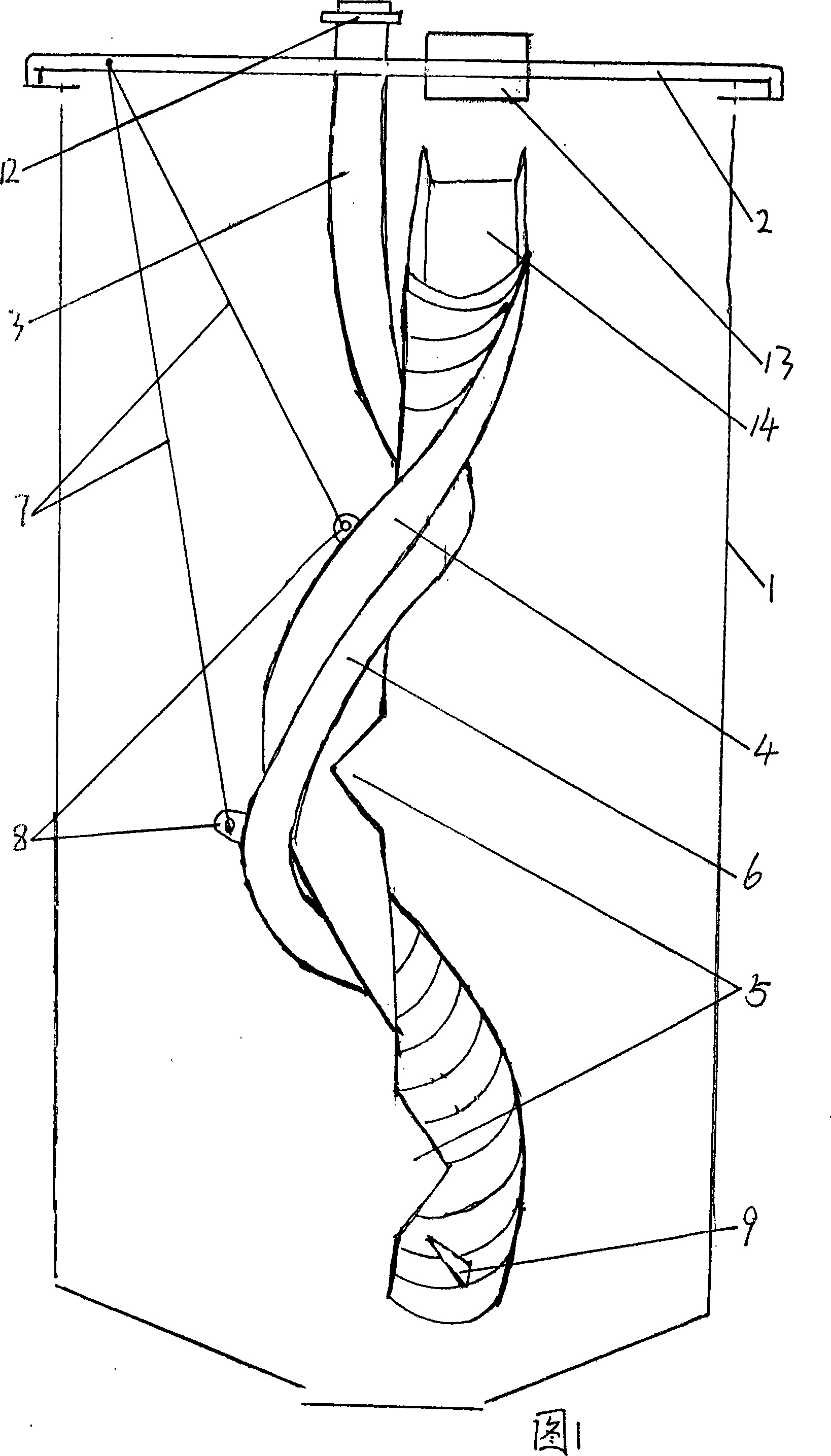

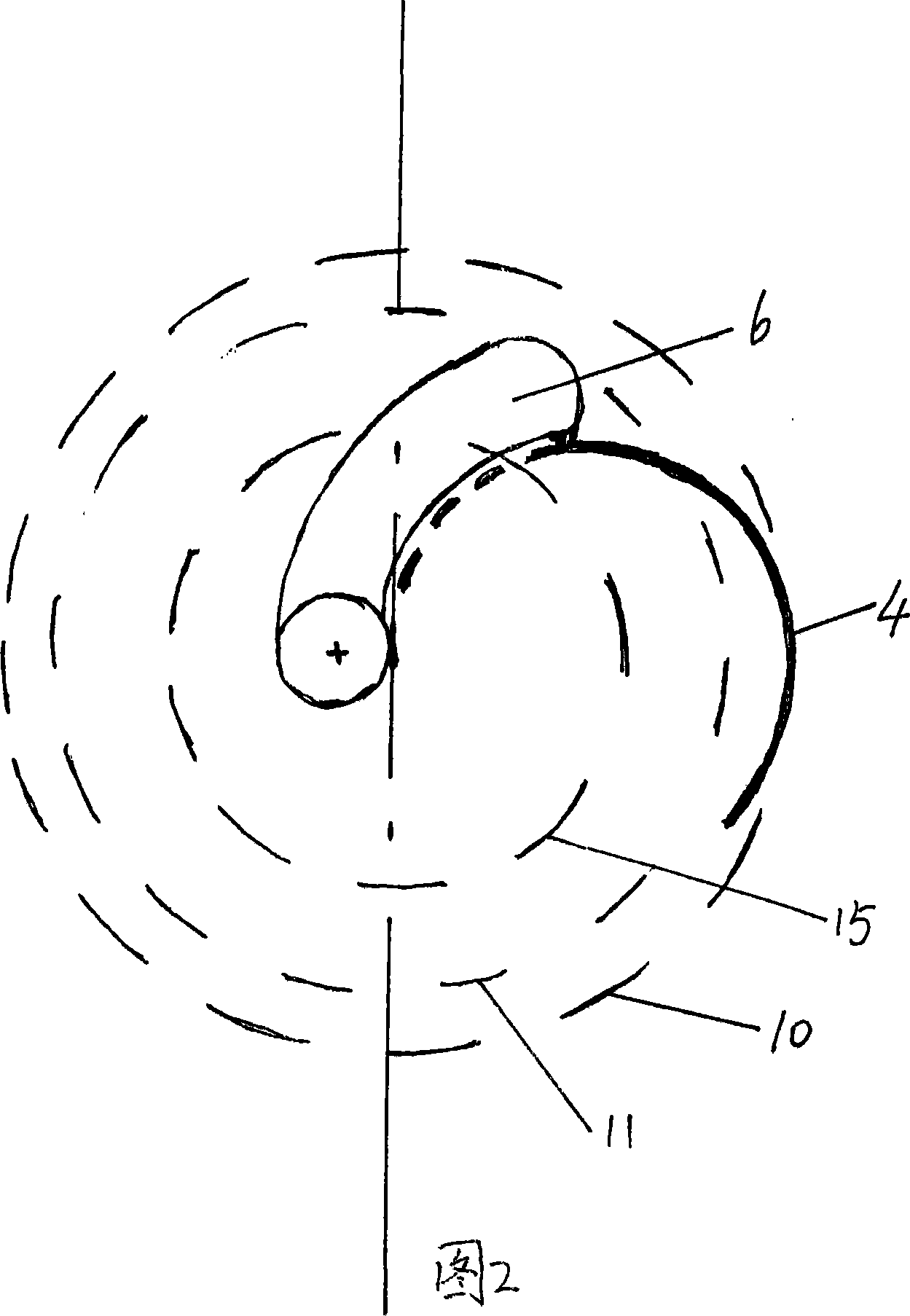

Vertical coal bunker breakage-proof delamination cushioning device

ActiveCN101214872AAvoid accumulationImprove broken rateLarge containersLoading/unloadingCushioningAbove ground

The invention relates to an auxiliary delivery device for an anthracite coal mining and storing bin, in particular to a vertical coal bin tatter prevention hierarchical buffer device which is applied to both underground and above ground. The invention solves the problems of the present coal bin tatter prevention delivery device during the transportation of spiral gradient that the coal is easy to slid out of a chute and fall into the bottom of the bin directly to cause the block charcoal crushing, the spiral chute is uneasy to be reinforced in the limited space of the coal bin and bear the large pressure in the coal bin, and etc. The vertical coal bin tatter prevention hierarchical buffer device includes a fixing stent which is reinforced above the coal bin and a spiral chute. The top end of the spiral chute is fixedly connected with the fixing stent through a fixing axis. The internal bending part of the spiral chute is equipped with a plurality of coal gaps. The outer lateral of the spiral chute is equipped with a plurality of connection earrings which are fixedly connected with and fixing stents through fixing rods. The invention is provided with reasonable structure and is applied to the warehousing storage and transportation of mine block coal. The invention greatly lowers the coal crushing rate and is applied to the anthracite coal mines with high requirement for the block coal rate.

Owner:刘振东

Method for preparing nano-level notoginseng root powder

InactiveCN102085224AImprove broken rateReduce lossesPowder deliveryAntipyreticMetallurgyAdditive ingredient

The invention relates to a method preparing nano-level notoginseng root powder, and belongs to the field of processing materials. The method comprises the followings steps of: performing crushing, impurity removal, air drying and grinding of notoginseng root by ultramicro crushing technology to obtain notoginseng root powder, adding water into the notoginseng root powder while stirring at a high speed to obtain suspension, screening the suspension by a 1,000-mesh steel screen, and collecting and performing low-temperature drying to obtain the finished product. The method for preparing the nano-level notoginseng root powder has the advantages that: the operating method is simple, the broken wall rate of notoginseng root cells is over 90 percent, the effective ingredients are easily dissolved into water, and bioavailability and absorptivity are high.

Owner:周亚强

Animal plant and microbial cell wall lytic enzyme reactive liquid and its application

InactiveCN1740327APromote degradationImproved quality of bioactive substancesEnzymesFermentationAdditive ingredientCell wall

A kind of animals and plants and microbial cell wall dissolving enzymes reaction solutionú¼which belongs to enzyme dissolving technique of cell engineering. The character is: the reaction solution includes cell wall dissolving enzymes, protoplasm solution, enzymes promoter, inorganic salt, mineral water and other ingredients. The cell wall dissolving enzyme reaction solution isní»t poisonous and has good biological degradation ability. As a result of fermenting of animals and plants and microorganism, the molecular structure of the product has changed completely. The mass of biological active substance such as small cell protein, free amino acid, linolenic acid and polypeptide increase a lot. Also, these substances can be absorbed easily by human.

Fermentation preparation technology of granular threonine

InactiveCN108658798AImprove broken rateImprove filtration efficiencyOrganic compound preparationAmino-carboxyl compound preparationSolubilityFluidized bed drying

The invention belongs to the technical field of threonine production, and belongs to a fermentation preparation technology of granular threonine. The technology comprises the followings steps: firstlycentrifuging threonine fermentation liquor by a disc centrifuge, collecting supernate, performing filtering through a ceramic membrane, concentrating filtrate, adjusting pH with sulfuric acid, heating the filtrate to 75 DEG C, performing separation by a horizontal spiral centrifuge, removing precipitate, and collecting supernate; performing filtering through an ultrafiltration membrane, collecting filtrate, crystallizing the filtrate through an intermittent single-effect concentrating crystallizing pan, centrifuging and collecting crystals, then drying the crystals at the temperature of 120 DEG C, compressing the crystals into flake crystals, putting the flake crystals into a granulation tower, performing drying by a fluidized bed, performing crushing and granulation, sieving, collectinggranules with target grain sizes, and performing packaging, so as to obtain the granular threonine. The technology has the advantages that threonine is prepared into granules, the flowability can be improved, the threonine is convenient to store and transport, the solubility is convenient to control, and the quality and the additional value of threonine are improved.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Processing technique for wall-breaking ganoderma lucidum spore powder

InactiveCN108888638AEfficient removalReduce the difficulty of dissolutionPlant ingredientsSporeAdditive ingredient

The invention provides a processing technique for wall-breaking ganoderma lucidum spore powder and relates to the technical field of bio-pharmaceuticals. The extraction method comprises the steps of pretreatment, ultrasonic treatment, enzyme treatment, freezing, wall breaking and sterilization. According to the method, under a synergistic effect of ultrasonic wave, freezing, enzyme treatment and wall breaking, the impurities in the ganoderma lucidum spore powder are effectively removed through deionized water washing, coarse crushing, ultrasonic treatment and enzyme treatment; dissolving difficulty is effectively reduced due to the addition of a wall-dissolving enzyme; the super-freezing and airflow wall-breaking double technique is adopted for breaking the wall of the ganoderma lucidum spore powder; the technological operation is simple; the preparation cost is low; the problems that the wall breaking of the present ganoderma lucidum spore powder is incomplete, the nutritional ingredients of the ganoderma lucidum spore powder are incompletely maintained and the nutritional ingredients are damaged can be effectively solved.

Owner:GUANGXI XIUMEI ZHUANGXIANG ENERGY ENVIRONMENTAL PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com