Patents

Literature

240results about How to "Has a cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

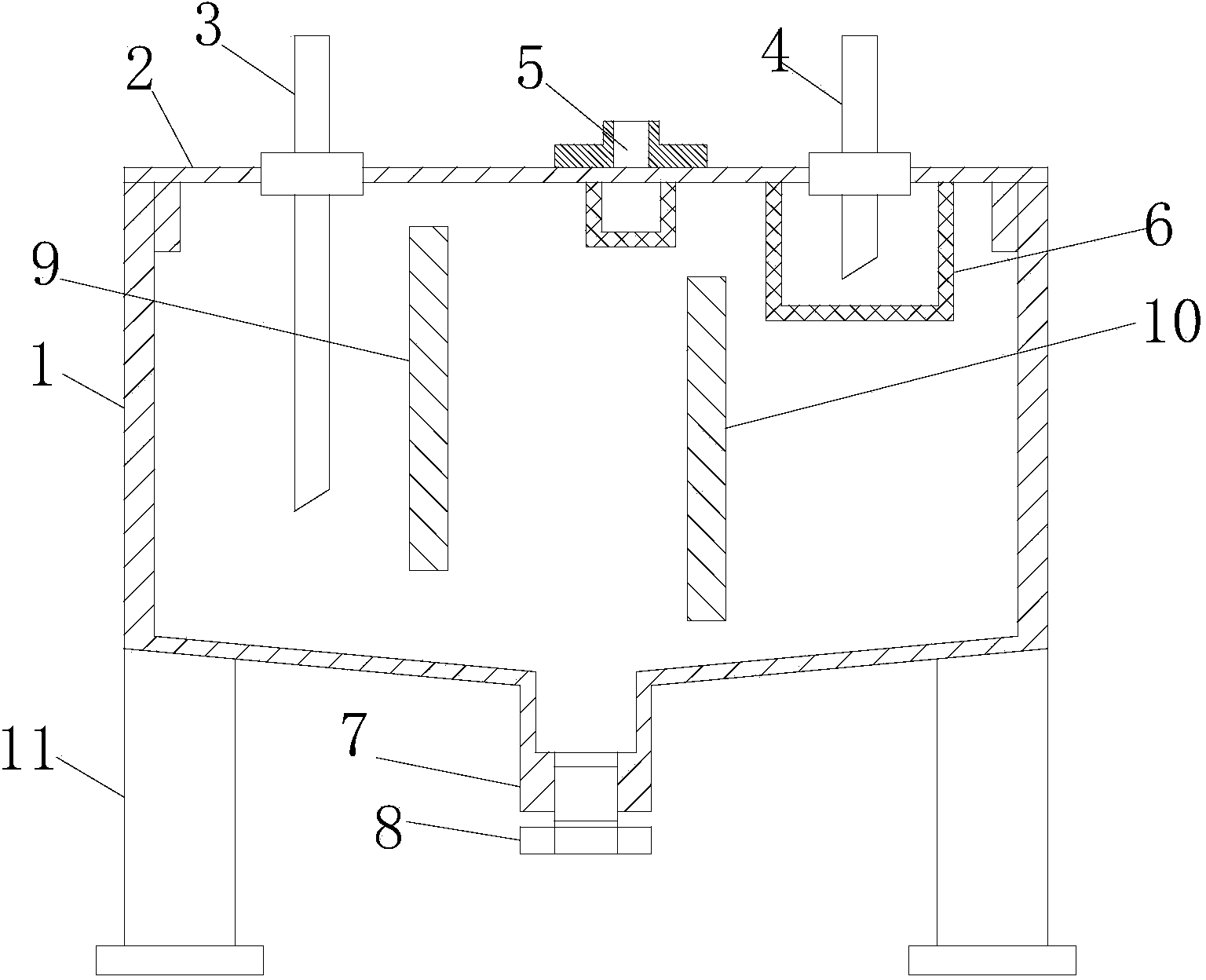

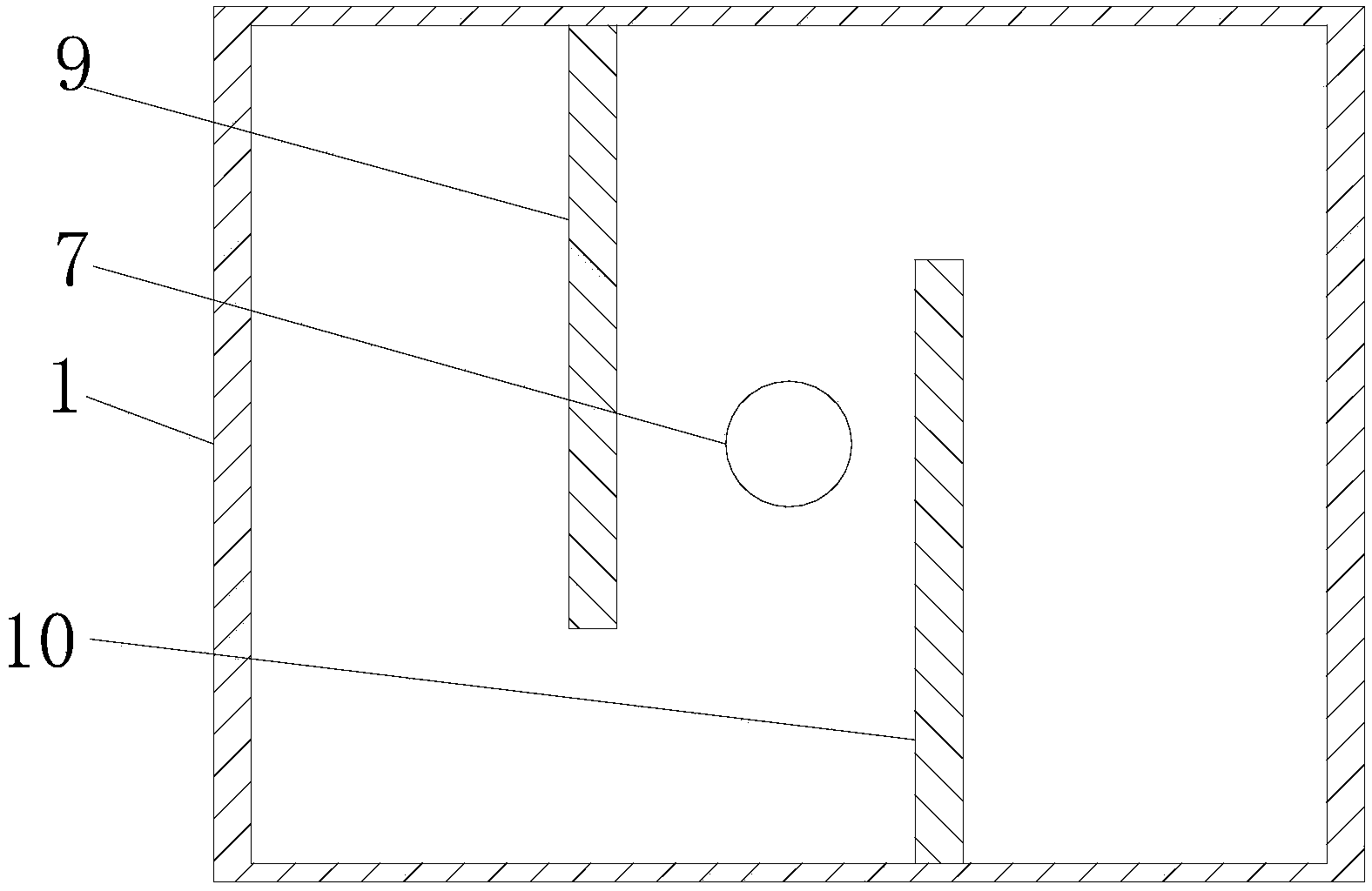

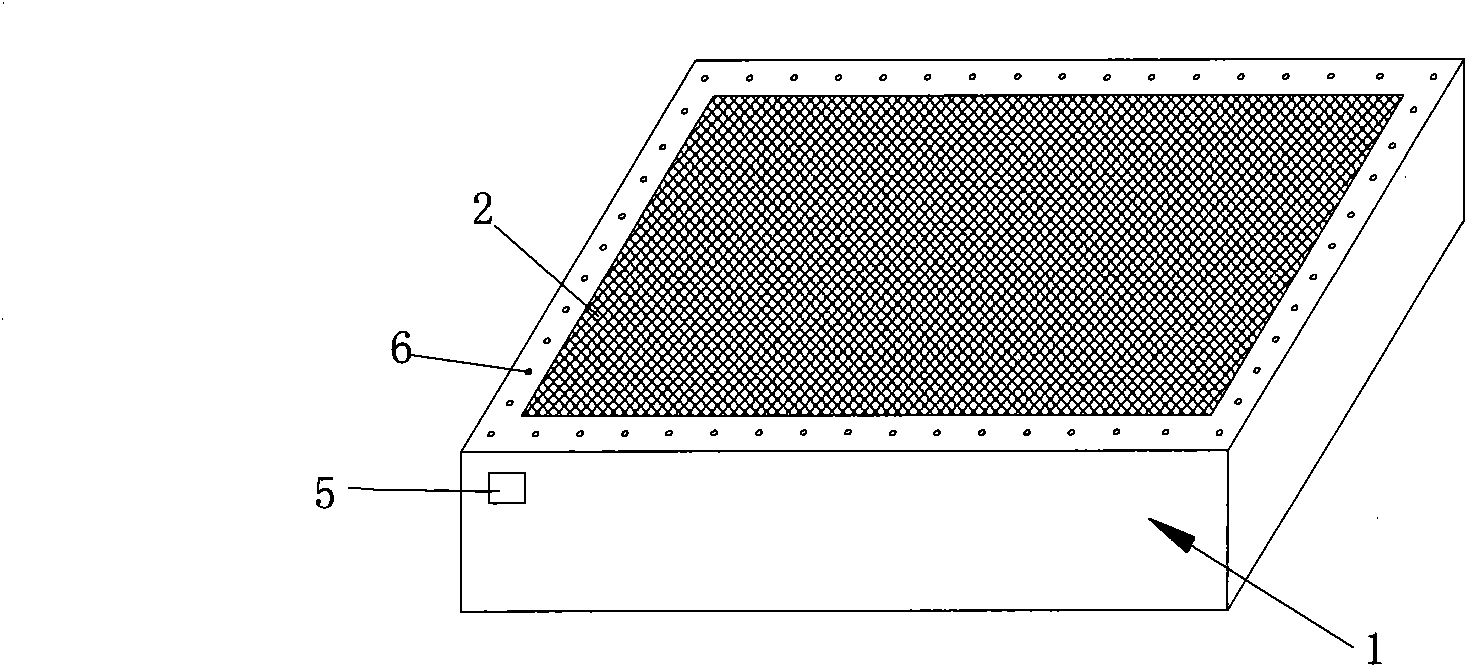

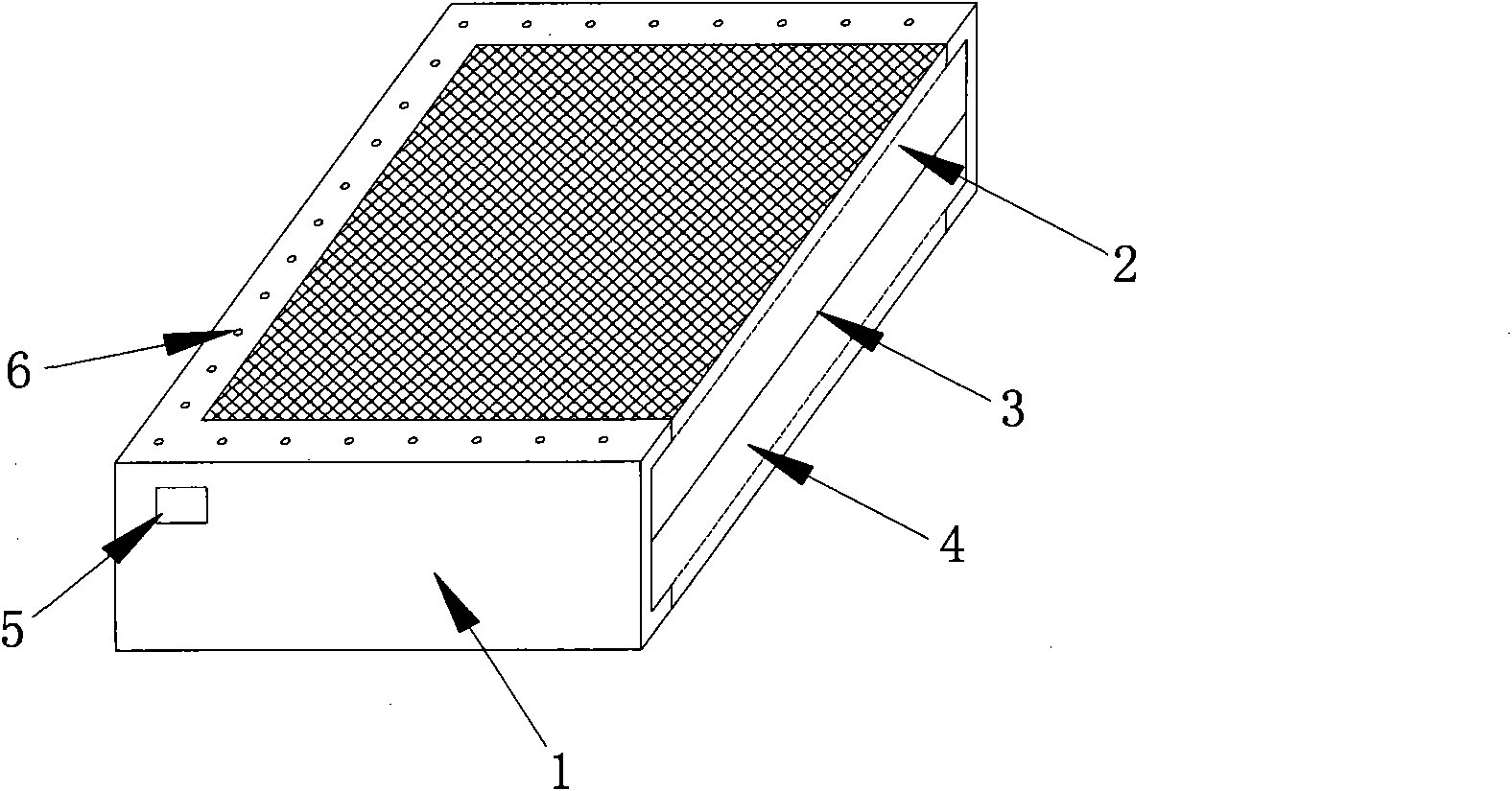

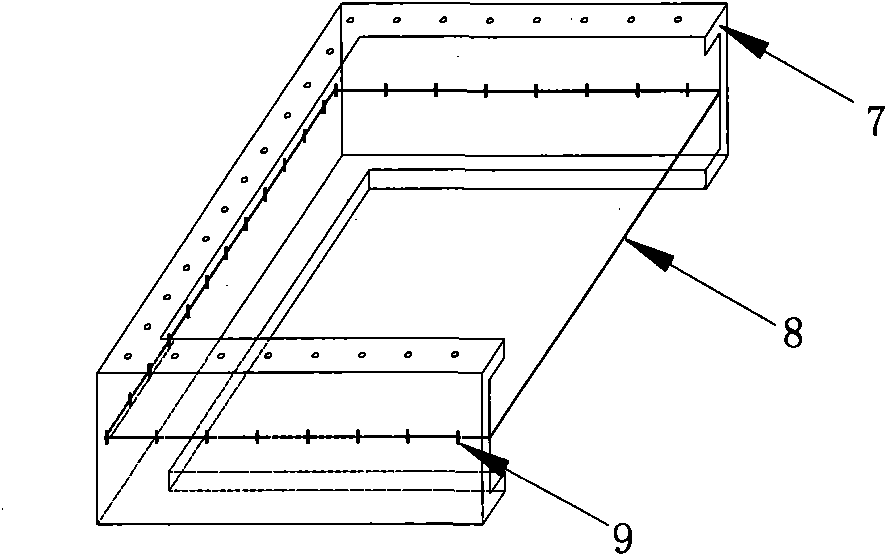

Hydraulic oil tank

InactiveCN104373394AAvoid cloggingAvoid purityPump assembliesFluid-pressure actuator componentsFuel tankFilter effect

The invention relates to a hydraulic oil tank. The hydraulic oil tank comprises an oil tank body. A cover plate is arranged on the oil tank body. An oil suction pipe, an oil return pipe and an oil filling pipe are arranged on the cover plate, a filter screen is arranged on the inner wall of the cover plate, and the opening, located inside the oil tank body, of the oil return pipe is formed in the filter screen. A precipitation tank is arranged at the bottom of the oil tank body, the upper end face of the precipitation tank is lower than the bottom surface of the oil tank body, and a closing plug is arranged on the lower end face of the precipitation tank. A first partition plate and a second partition plate are arranged in the oil tank body and fixed to the inner wall of the oil tank body. The hydraulic oil tank has the advantages of being good in filtering effect, capable of effectively discharging impurities in hydraulic oil and preventing the impurities from flowing in the hydraulic oil and the like.

Owner:CHANGZHOU WEIMATAI PRECISION TOOLS

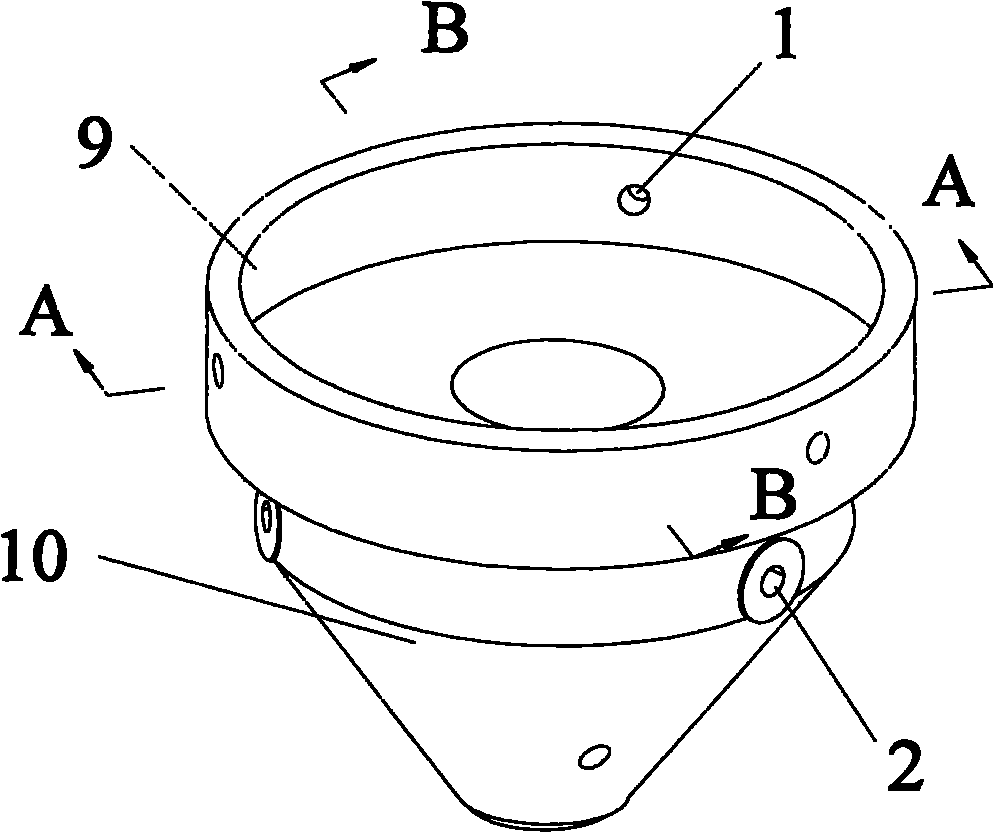

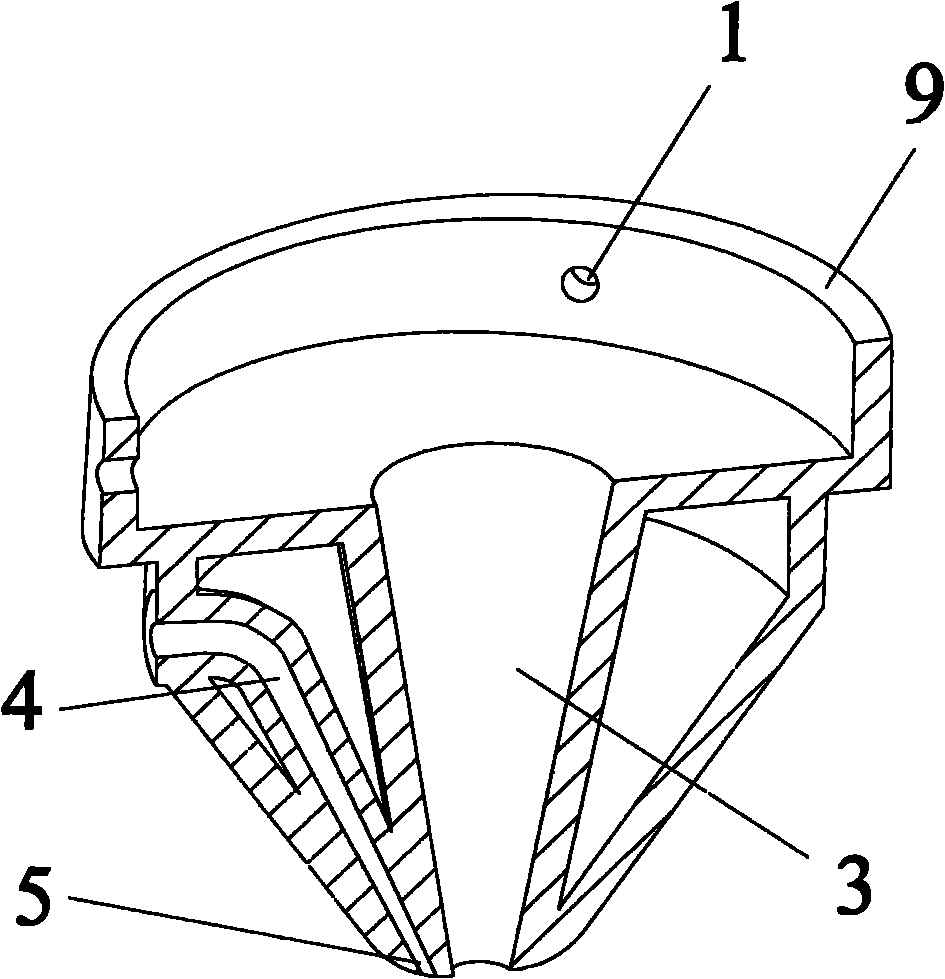

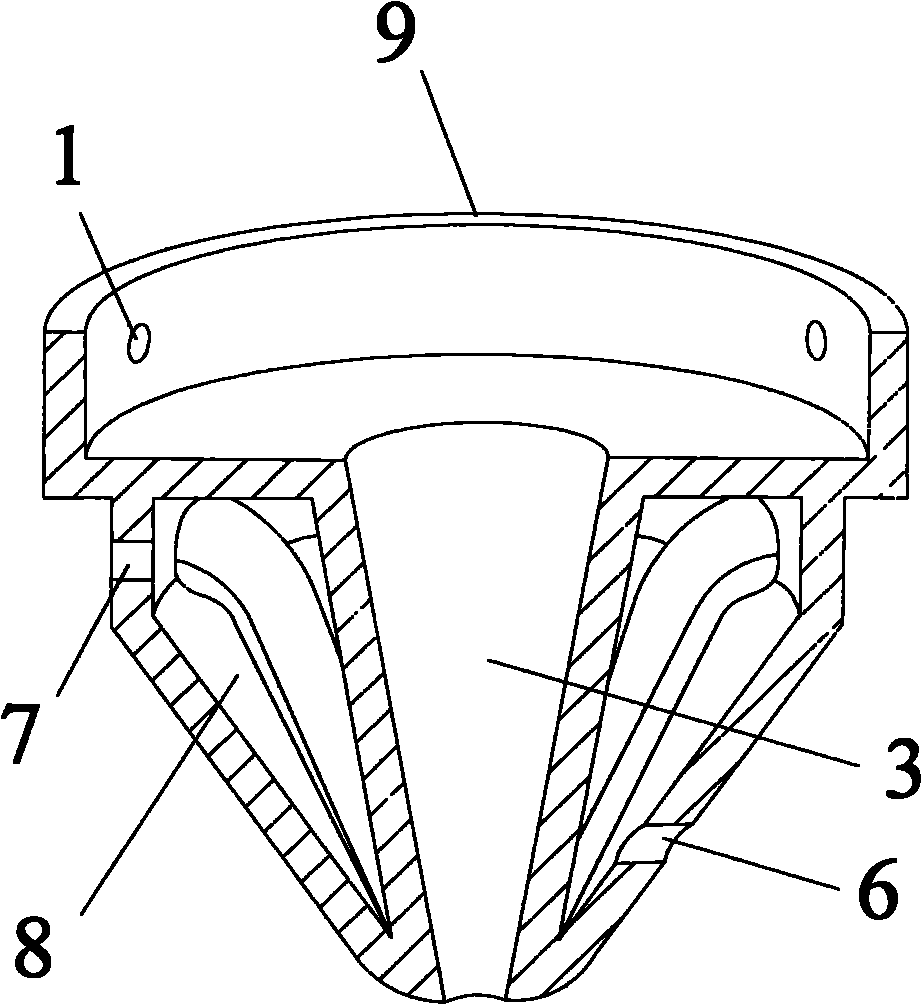

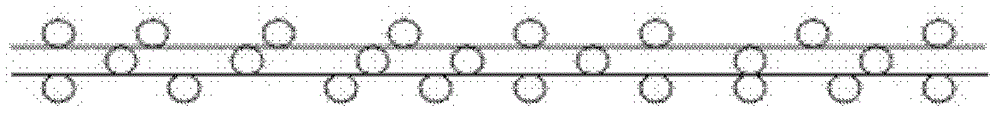

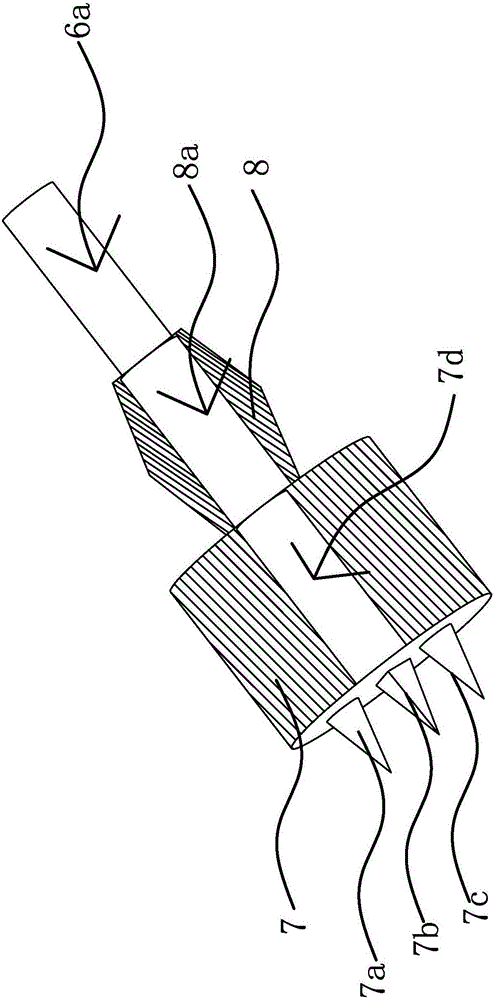

Laser cladding nozzle convenient for cooling and manufacturing method thereof

InactiveCN101942659AImprove cooling effectGood powder delivery effectMetallic material coating processesLaser beam welding apparatusAfter treatmentCooling effect

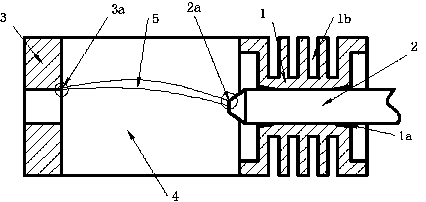

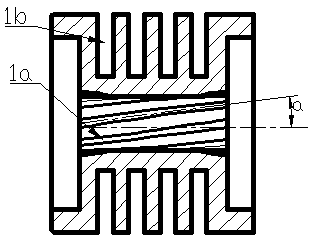

The invention discloses a laser cladding nozzle convenient for cooling, comprising a nozzle wick and a connector which is connected above the nozzle wick and is externally connected with a laser system, wherein the nozzle wick is provided with a light beam channel, cooling cavities and a plurality of powder feeding channels; the cooling cavities are formed by the periphery of the light beam channel and the periphery of each powder feeding channel; the outer side wall of the upper end of the nozzle wick is provided with powder inlets communicated with the powder feeding channels and a water outlet communicated with the cooling cavities respectively; the lower end of the nozzle wick is provided with powder outlets communicated with the powder feeding channels and a water inlet communicated with the cooling cavities; and the water inlet and the water outlet are respectively connected with a cooling system externally. The invention also discloses a manufacturing method of the nozzle, comprising the steps of model drawing, slicing treating, rapid forming, after-treatment, etc. The nozzle has simple structure, high cooling effect and better powder feeding quality and is directly manufactured by the rapid forming method, thus design of the nozzle is free from limitation of the traditional processing methods and the structure of the nozzle is further diversified.

Owner:SOUTH CHINA UNIV OF TECH

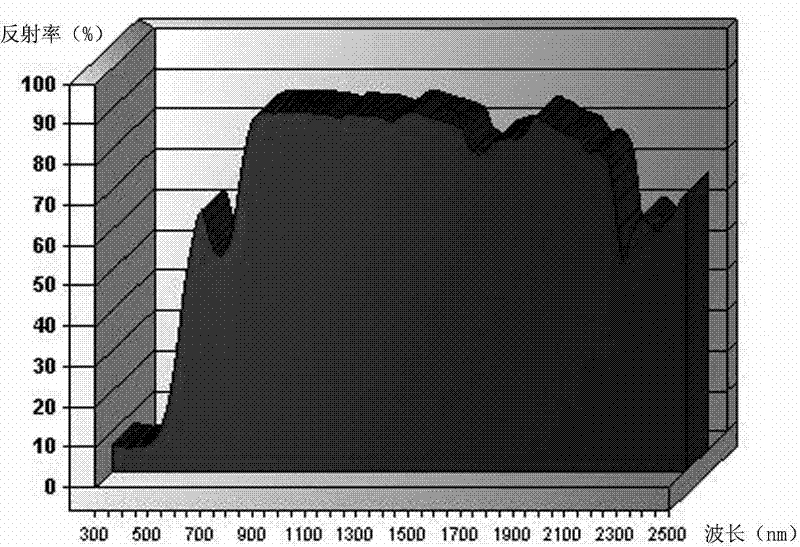

Polyolefin color masterbatch having infrared reflection effect and preparation method thereof

ActiveCN102367316AGood camouflage effectWith reflective infrared camouflage functionInfraredMasterbatch

The invention provides a polyolefin color masterbatch having an infrared reflection effect. The polyolefin color masterbatch comprises, by weight, 40 to 85% of a carrier resin, 5 to 35% of an infrared reflection pigment, 0 to 15% of color blending pigments, 2 to 15% of a dispersant and 5 to 10% of an anti-aging agent. The color masterbatch has the function of infrared camouflage and the effect oflowering down temperature.

Owner:NINGBO COLOR MASTER BATCH

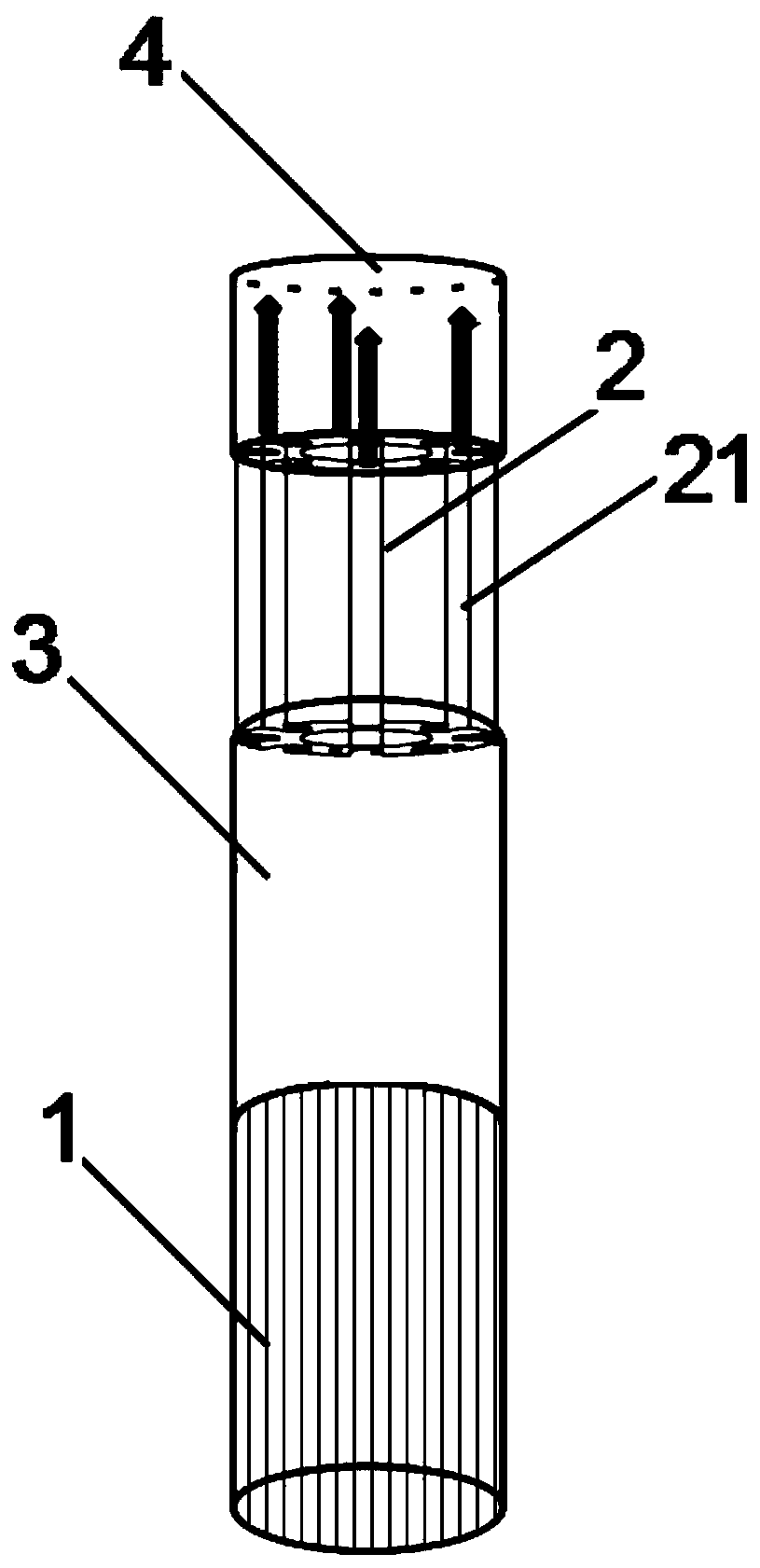

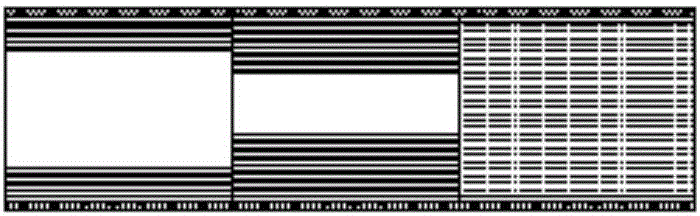

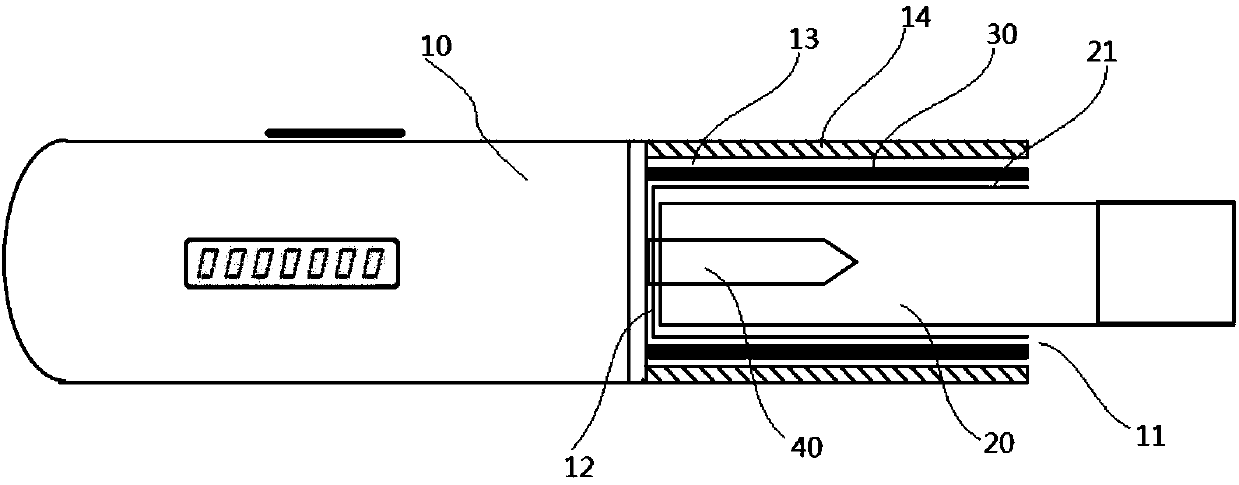

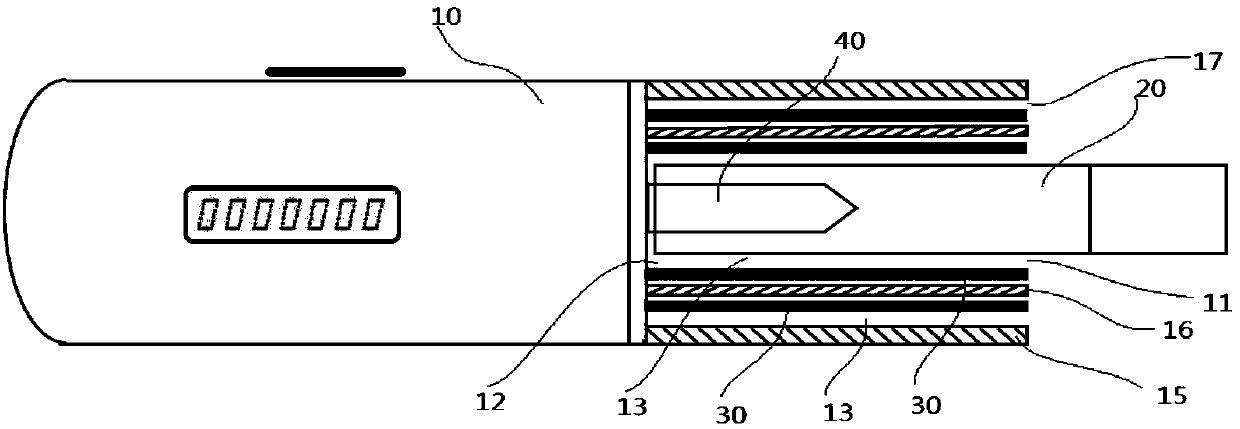

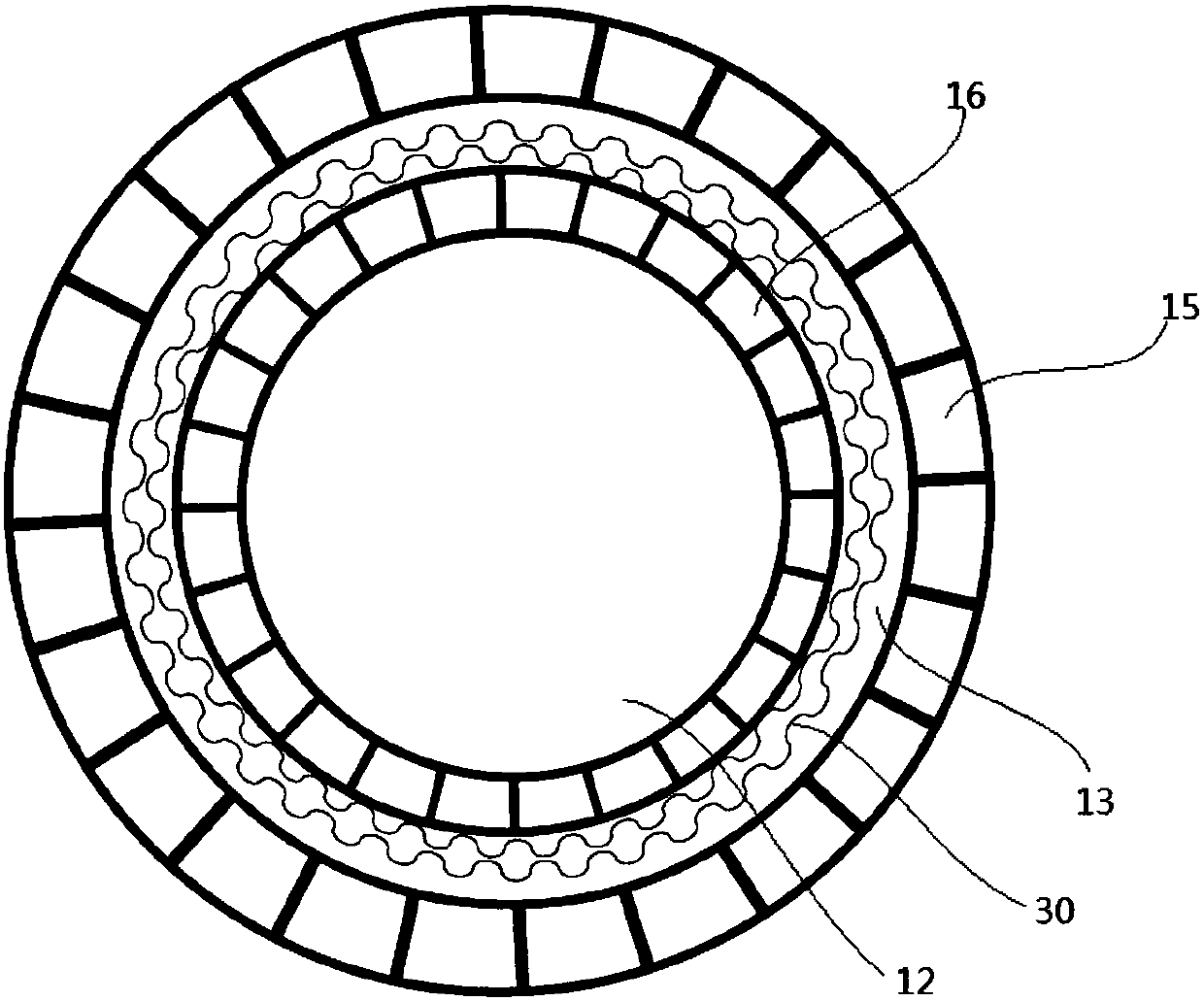

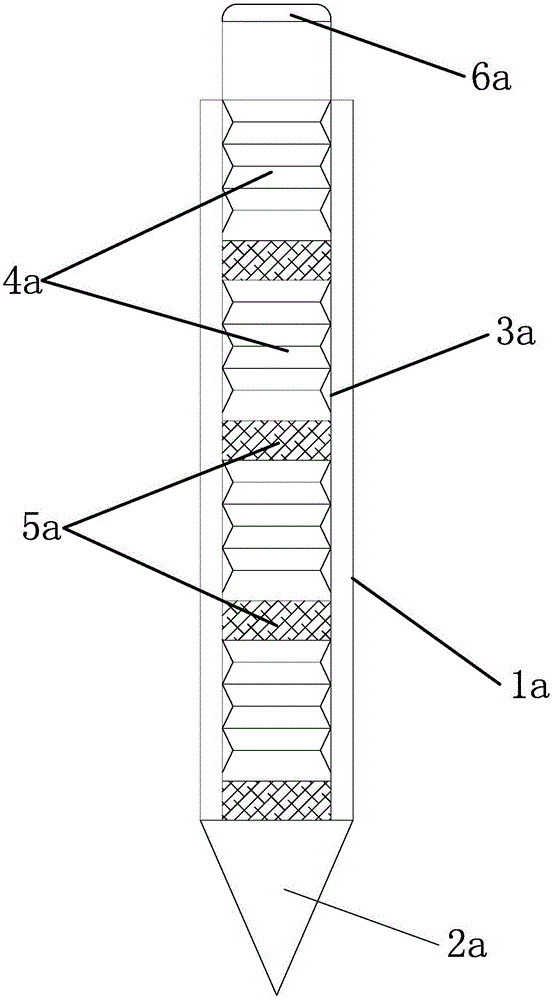

Bar-shaped cigarette and preparation method thereof

PendingCN110150736AReduce the temperatureIncrease contact areaCigar manufactureTobacco devicesWater basedEngineering

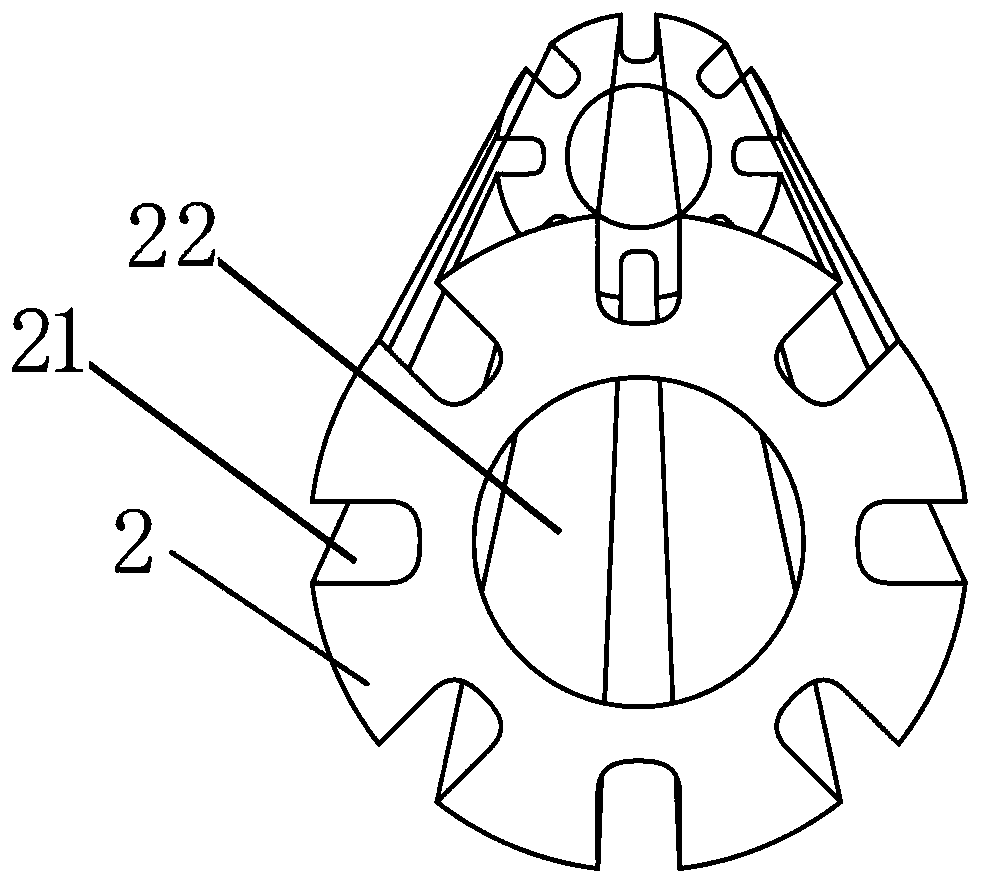

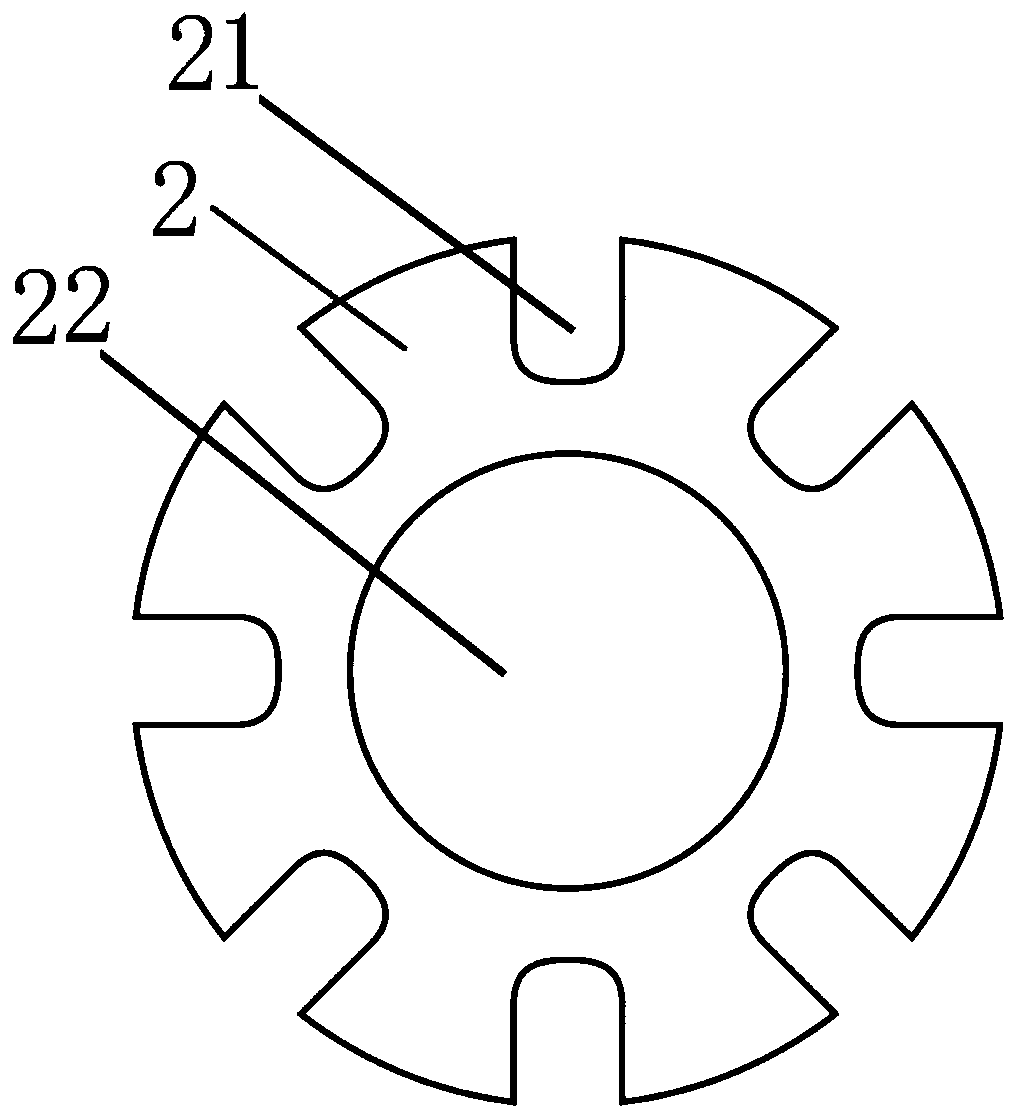

The invention discloses a bar-shaped cigarette. The bar-shaped cigarette sequentially comprises a cigarette core material section (1), a cooling section (2) and a filter tip section (4), wherein the cooling section (2) is of a cylindrical bar-shaped structure, grooves (21) extending in the axial direction are formed in the outer wall of the cooling section (2), and openings of the grooves (21) face away from the axial center of the cooling section (2). The invention further discloses a preparation method of the bar-shaped cigarette. The cooling section (2) of the bar-shaped cigarette can effectively reduce the temperature of smoke gas and can further increase the amount of smoke to a certain extent at the same time; the used base materials and liquid additives can be quickly decomposed inthe nature without the risk of environmental pollution; and the loss in the manufacturing process is low, the preparation method is simple, and the manufacturing cost is reduced by more than 30%. In addition, the cooling section (2) can further be used in traditional cigarette filter tips to realize the addition of water-based essence and flavor filter tips.

Owner:CHINA TOBACCO YUNNAN IND

Throwing type fire extinguisher and manufacturing method thereof

ActiveCN103341244AAppropriate size for impact resistanceHas a cooling effectFire rescueFire extinguisherPolyvinyl chlorideFire extinguisher

The invention discloses a throwing type fire extinguisher and a manufacturing method thereof. The throwing type fire extinguisher comprises a fire extinguishing agent and a fire extinguisher bottle for storing the fire extinguishing agent. The throwing type fire extinguisher is characterized in that the fire extinguishing agent comprises the following components: a fluorinated surfactant, potassium carbonate, ammonium sulfate, urea, ammonium polyphosphate, an anionic surfactant, lauryl sodium sulfate and water; the fire extinguisher is a polyvinyl-chloride-resin bottle with self extinguishment. The throwing type fire extinguisher disclosed by the invention has the advantages that due to ingenious utilization of self extinguishment, flame resistance and cold resistance of polyvinyl chloride, normal use can be achieved at the temperature of minus 30 DEG C; the size of impact resistance is proper, breaking can not be finished by hands, the breaking rate is high in throwing, and broken scraps are not splashed and do not hurt persons.

Owner:QINGDAO LONGCHI FIRE EQUIP

Cathode structure of novel laminar plasma generator

InactiveCN103596350AExtended service lifeHigh temperature resistancePlasma techniquePlasma generatorEngineering

A cathode structure of a novel laminar plasma generator mainly comprises a cathode cover and a cathode body. The cathode cover is made of red copper materials, and therefore the influence of an electromagnetic field on a cathode arc root can be reduced, and the stability of an electric arc can be improved. Meanwhile, an air inlet formed in the inner wall of the cathode cover can provide tangential velocity component for work gas entering an arc column area, the axis of the air inlet and the bus of an inner hole of the cathode cover form a certain angle, and therefore an anode arc root is made to rotate on an anode, and the service life of the anode is prolonged. The cathode body can be made of wolfram with a high melting point or graphite to reduce the loss of the cathode body. The cathode structure is mainly applied to the laminar plasma generator, the electric arc can be stabilized, the service life of the cathode body and the anode can be prolonged, and therefore the usability of the laminar plasma generator is improved.

Owner:SICHUAN UNIV

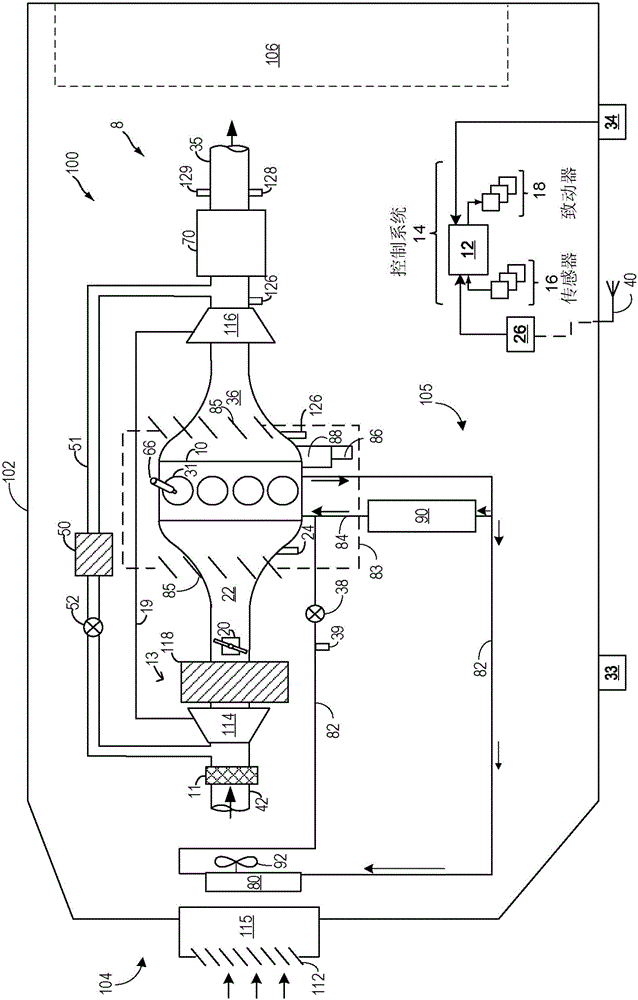

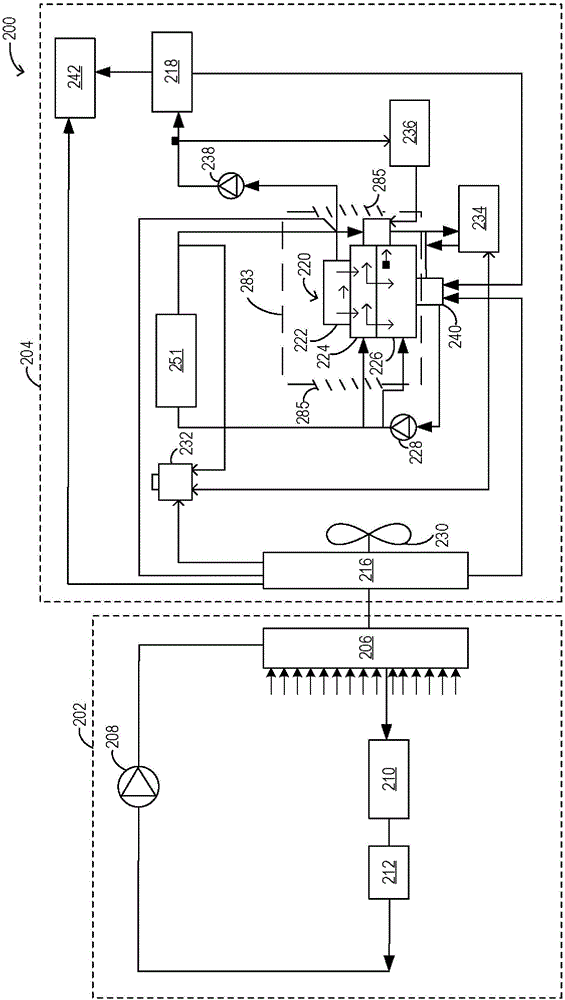

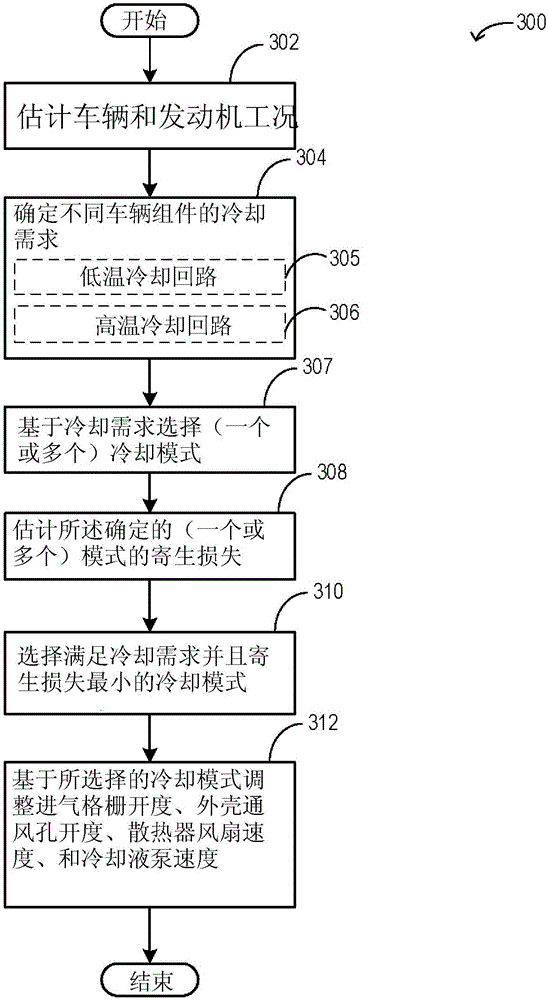

Methods and systems for a vehicle cooling system

ActiveCN107521330AReduce aerodynamic dragImprove efficiencyLiquid coolingCoolant flow controlDrivetrainCooling fluid

Methods and systems are provided for estimating a cooling demand of a vehicle powertrain component and selecting a mode of operation of a vehicle cooling system based on the estimated cooling demands of the vehicle powertrain component and the energy usage of the cooling system components. Based on the selected operating mode, each of a radiator fan speed, a coolant system pump output, a vehicle grille shutter opening, and an opening of vents coupled to a powertrain component insulating enclosure may be concurrently adjusted to minimize the cooling parasitic losses while satisfying the cooling requirements of the vehicle.

Owner:FORD GLOBAL TECH LLC

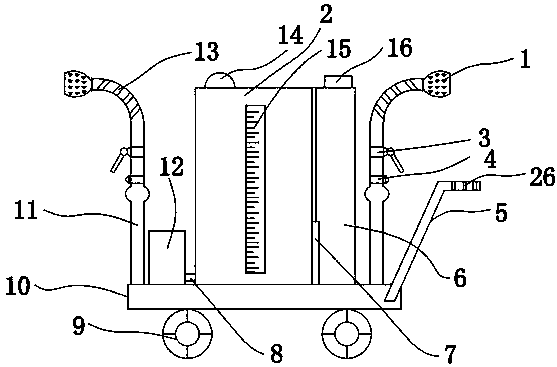

Spray header of garden spraying device

InactiveCN108207564ABig impactStir wellRotary stirring mixersTransportation and packagingSprayerWater filter

The invention discloses a spray header of a garden spraying device, and belongs to the technical field of spraying devices. The device comprises a bottom plate, wherein the lower portion of the bottomplate is fixedly connected to universal wheels, a water filtering cavity is arranged above the bottom plate, the surface of the water filtering cavity is provided with a scale display column, the upper portion of the water filtering cavity is provided with a medicine inlet and a water inlet, the left and right sides of the water filtering cavity are provided with spraying devices, each spraying device comprises a water outlet pipe, the upper end of each water outlet pipe is connected to a corrugated pipe, the water outlet end of each corrugated pipe is connected to a sprayer, each water outlet pipe and corrugated pipe are respectively connected with a control valve, and an adjusting hoop is arranged under each control valve. The spray header of a garden spraying device has the advantagesthat the spraying efficiency is high, the spraying angle can be vertically rotatably adjusted during the spraying process, the working water jet capacity can be controlled, the sprayed moisture can beatomized, dehydration of roots or death of plants do not occur, the device moves conveniently, and the operation is simple.

Owner:兰溪富晟食品科技有限公司

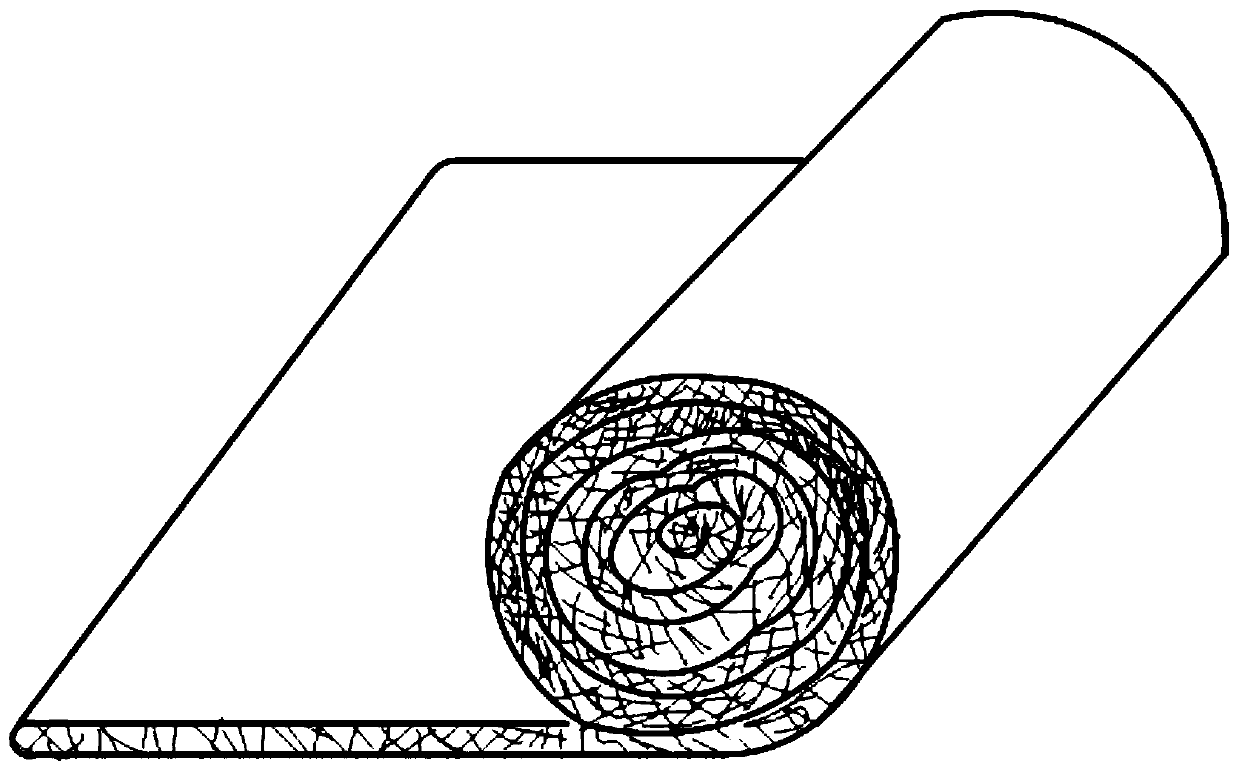

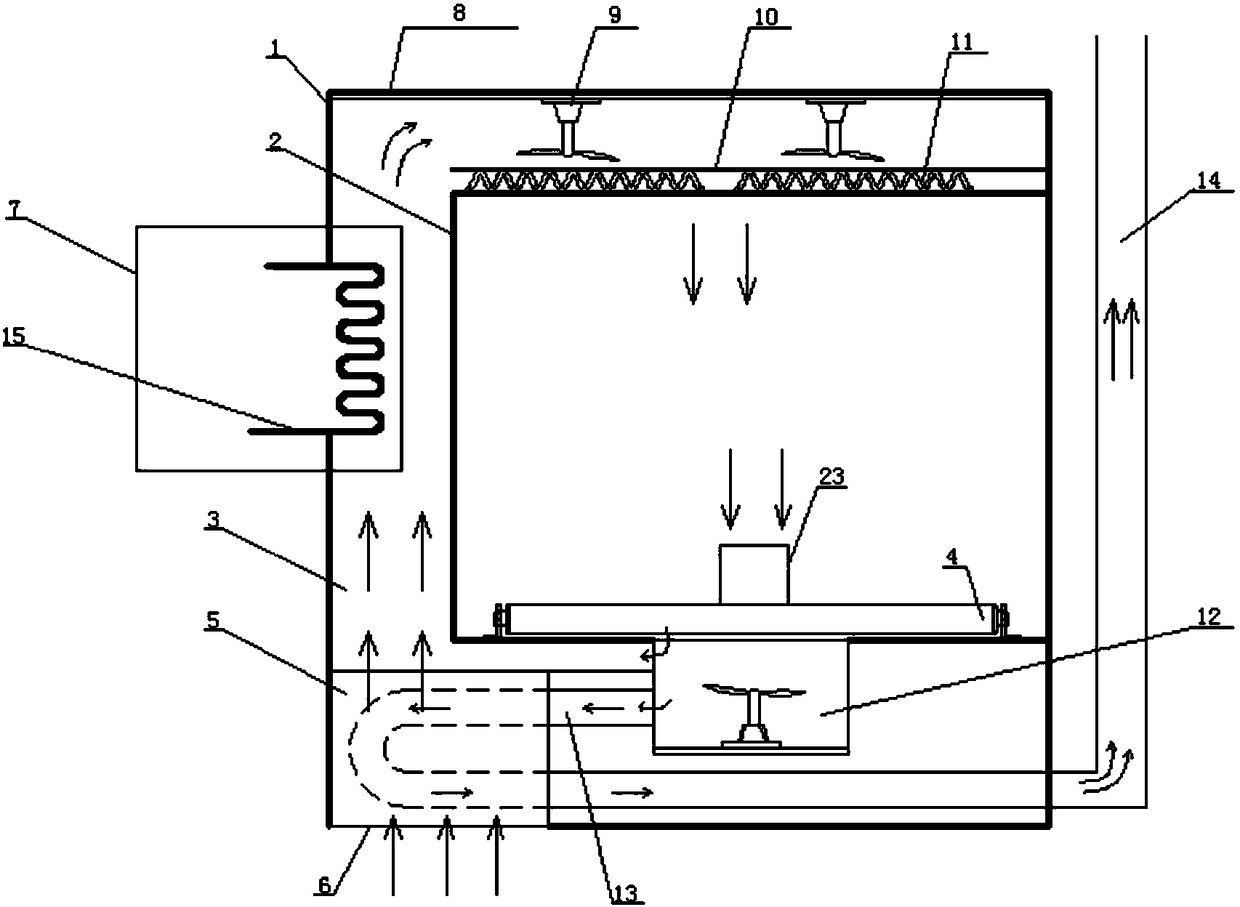

Warp-knitted spacing fabric dual-purpose cushion used both in winter and summer and producing method thereof

ActiveCN101961181AHas a cooling effectHas a heating effectStuffed mattressesSpring mattressesDual purposeEngineering

The invention relates to a warp-knitted spacing fabric dual-purpose cushion used both in winter and summer and a producing method thereof. The cushion has two faces respectively used in winter and summer and is provided with an independent support frame, and by the invention, the problems of deformation and the like during the processes of use, transportation, storage and the like of soft cushion type products can be effectively solved. The dual-purpose cushion is provided with a thermal cycle heating layer, a cool layer and the support frame, wherein the thermal cycle heating layer is provided with a heating system and a warp-knitted spacing fabric layer, and the heating system is arranged in the warp-knitted spacing fabric layer; the support frame is arranged around the thermal cycle heating layer and the cool layer. The processing method comprises the following steps of: manufacturing the support frame, the thermal cycle heating layer and the cool layer in sequence; placing the thermal cycle heating layer and the cool layer into the warp-knitted spacing fabric reinforced composite support frame, assembling with a warp-knitted spacing fabric reinforced composite plane three-dimensional forming component, fixing the support frame together with the thermal cycle heating layer and the cool layer, and combining to obtain the warp-knitted spacing fabric dual-purpose cushion used both in winter and summer.

Owner:福建福联精编有限公司

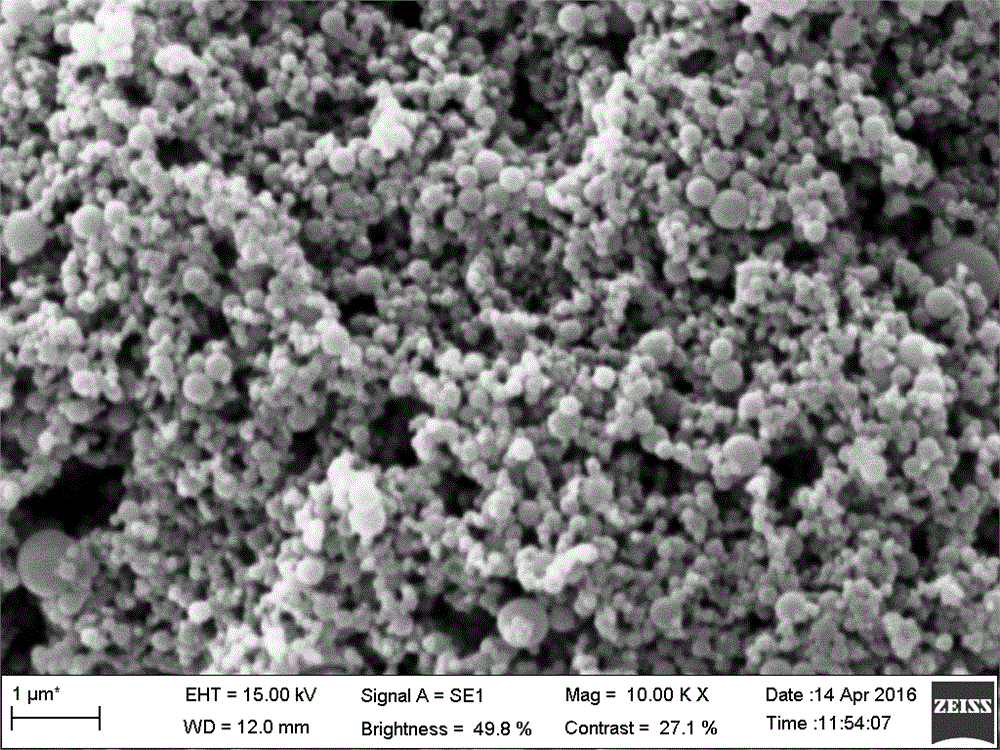

Ultraviolet resistant cold-feeling finishing fabric and processing method, and application of silica coated dodecanol microcapsule to fabric

InactiveCN102720054AUV resistantHas a cooling effectVegetal fibresPolyurethane adhesivePolymer science

The invention discloses an ultraviolet resistant cold-feeling finishing fabric and a processing method thereof, and application of a silica coated dodecanol microcapsule to ultraviolet resistant cold-feeling finishing fabric. The fabric is characterized in that the inner surface and outer surface of the fabric and the interior of the fabric are distributed with silica coated dodecanol microcapsules. The processing method of the fabric comprises the step that the silica coated dodecanol microcapsules are finished to the fabric by using a padding method. The microcapsule particles have size distribution of 0.2-6 mum; in the padding process, rolling waste rate is 80-90%; a capsule dosage is 40-60g / L; drying conditions include a temperature at 80-100 DEG C and a time of 3-5 min; and baking conditions include a temperature at 140-160 DEG C and a time of 1-2 min. A polyurethane adhesive can be used together with the microcapsules. The fabric has ultraviolet resistant and cold-feeling effects.

Owner:SHANGHAI JIALE

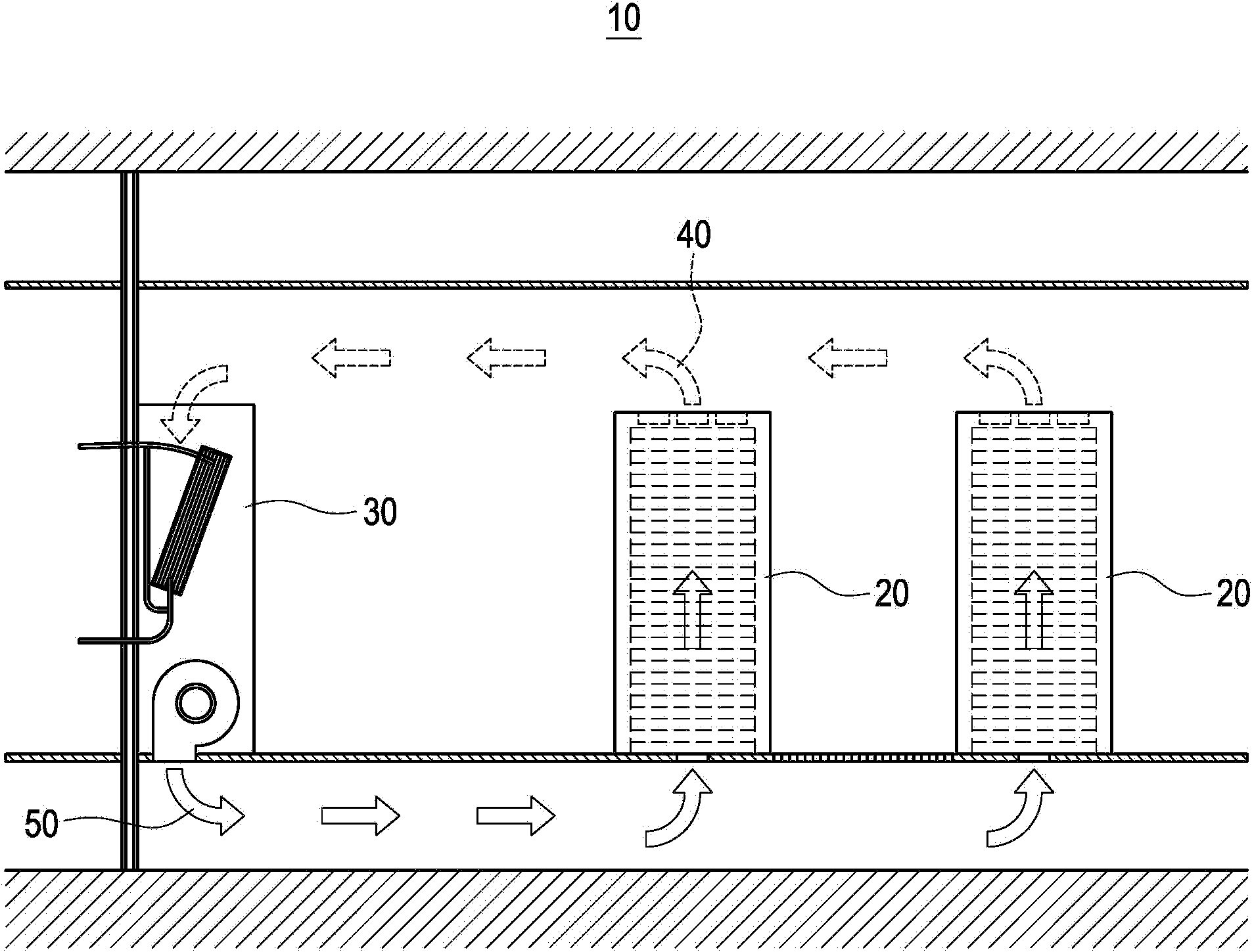

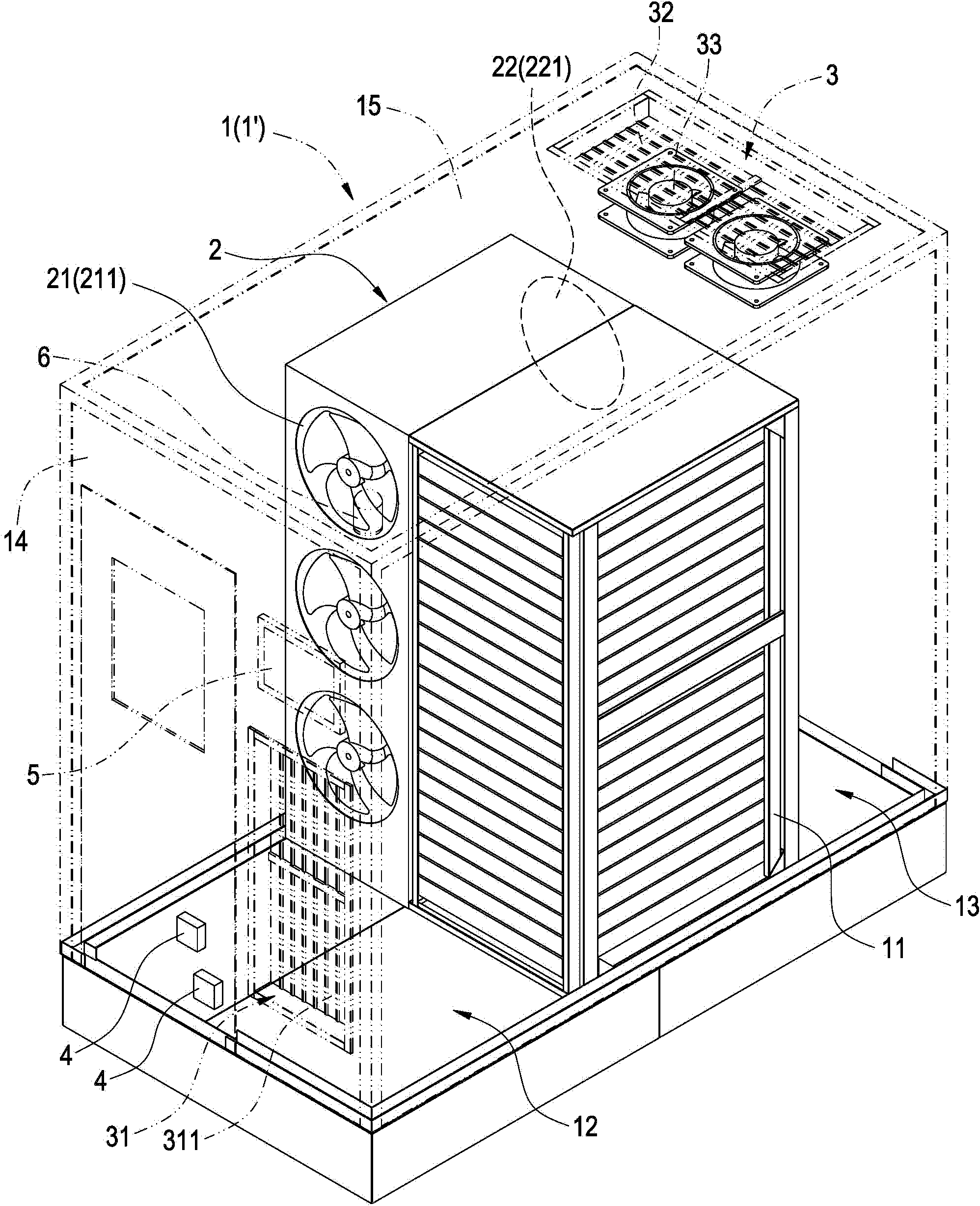

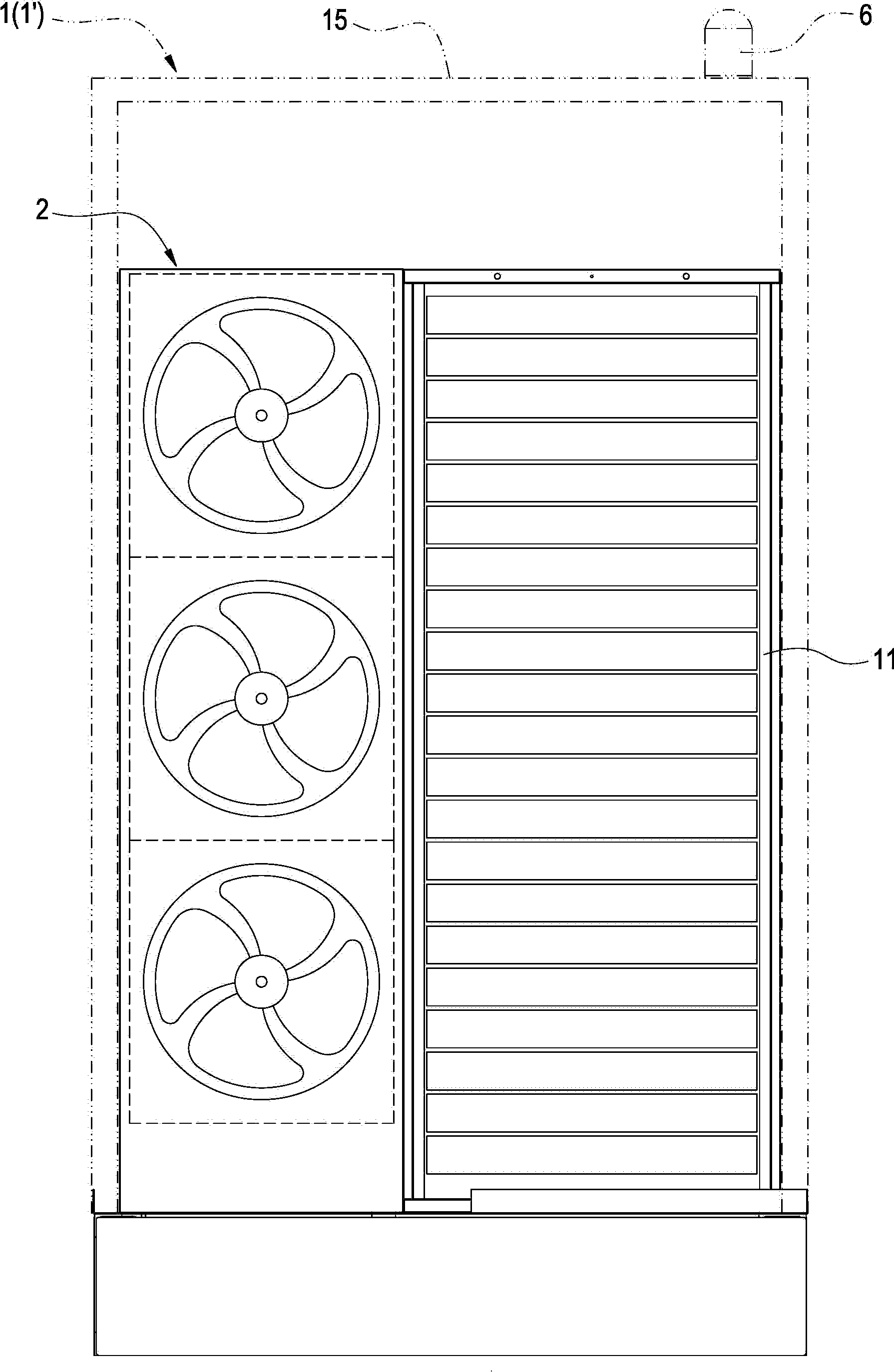

Equipment cabinet system and exhaust equipment thereof

ActiveCN103220895AImprove energy efficiencyEven heat dissipationCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersEngineeringHeat sink

The invention provides an equipment cabinet system and exhaust equipment thereof. The equipment cabinet system comprises a closed equipment cabinet, a rack and a heat sink. The rack is arranged inside the closed equipment cabinet. The heat sink is contained in the closed equipment cabinet, the heat sink and the rack are adjacent and parallel, and the heat sink and the rack altogether enable inner space of the closed equipment cabinet to be divided into a cold blast channel and a hot blast channel. The heat sink is provided with an air outlet and an air inlet, the air outlet is arranged corresponding to the cold blast channel, and the air inlet is arranged corresponding to the hot blast channel. Therefore, the heat sink and the rack are adjacent and parallel and altogether enable the inner space of the closed equipment cabinet to be divided into the cold blast channel and the hot blast channel, so that servers which are arranged inside the rack in a stacked mode can all be evenly cooled, and thus the equipment cabinet system has good energy service efficiency.

Owner:DELTA ELECTRONICS INC

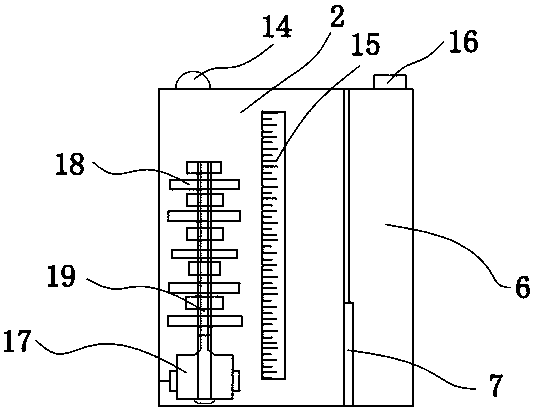

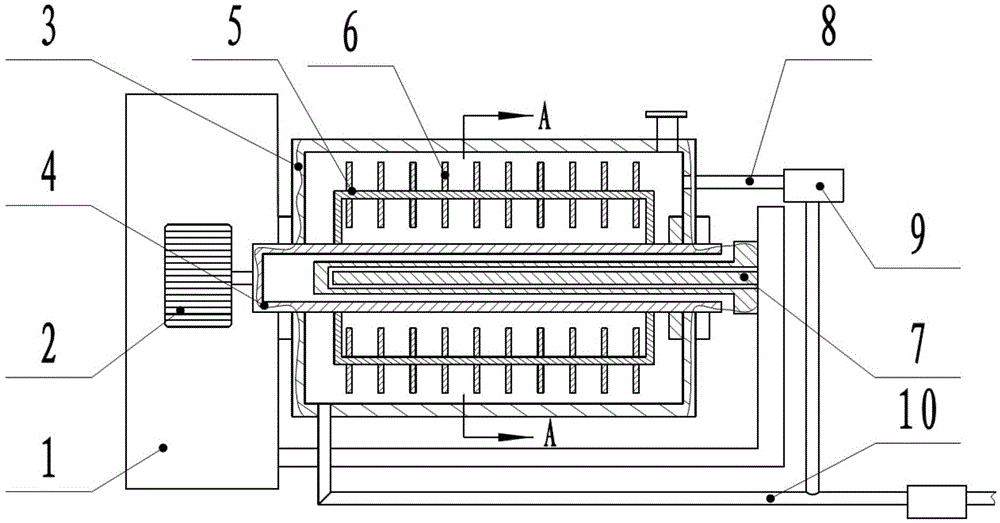

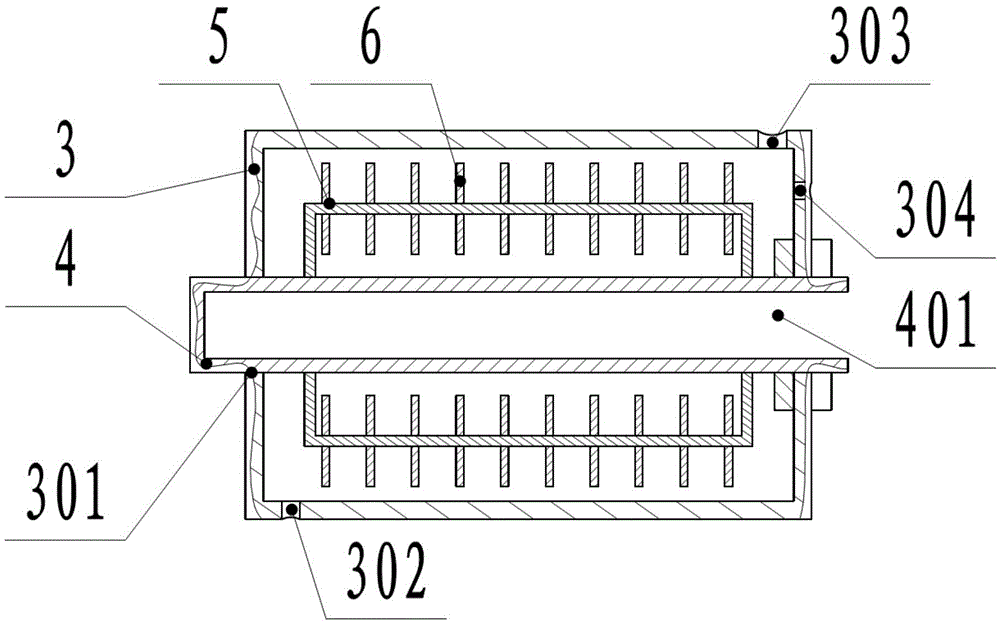

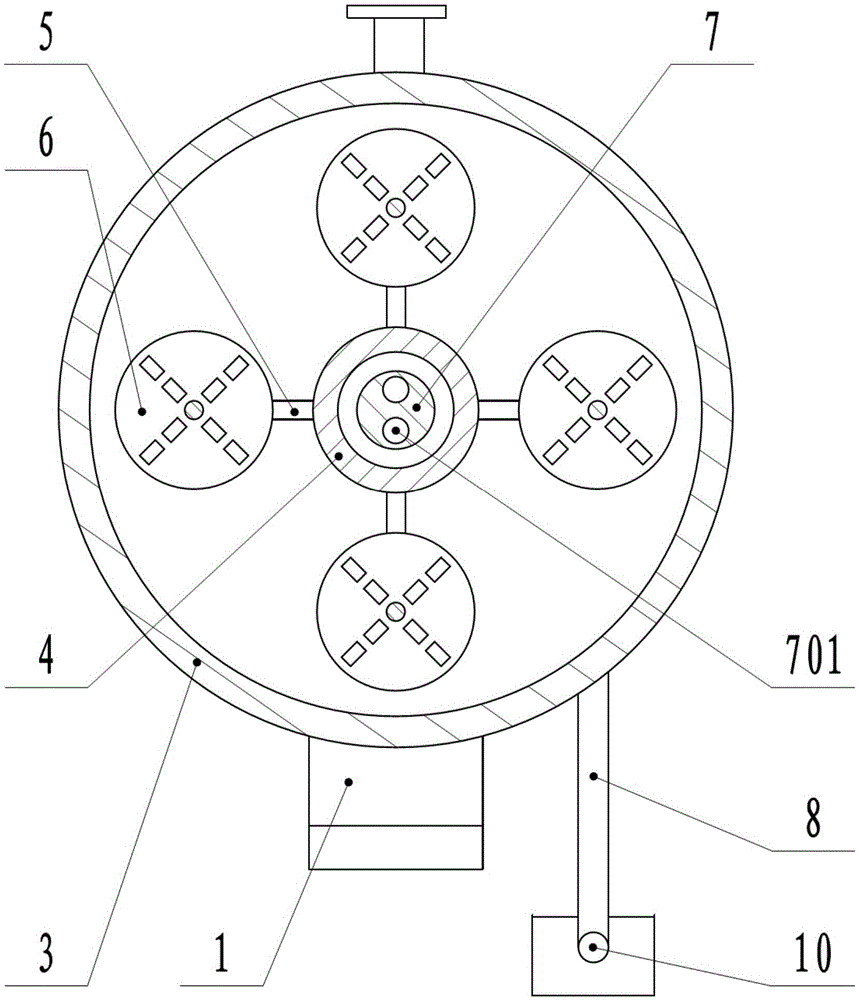

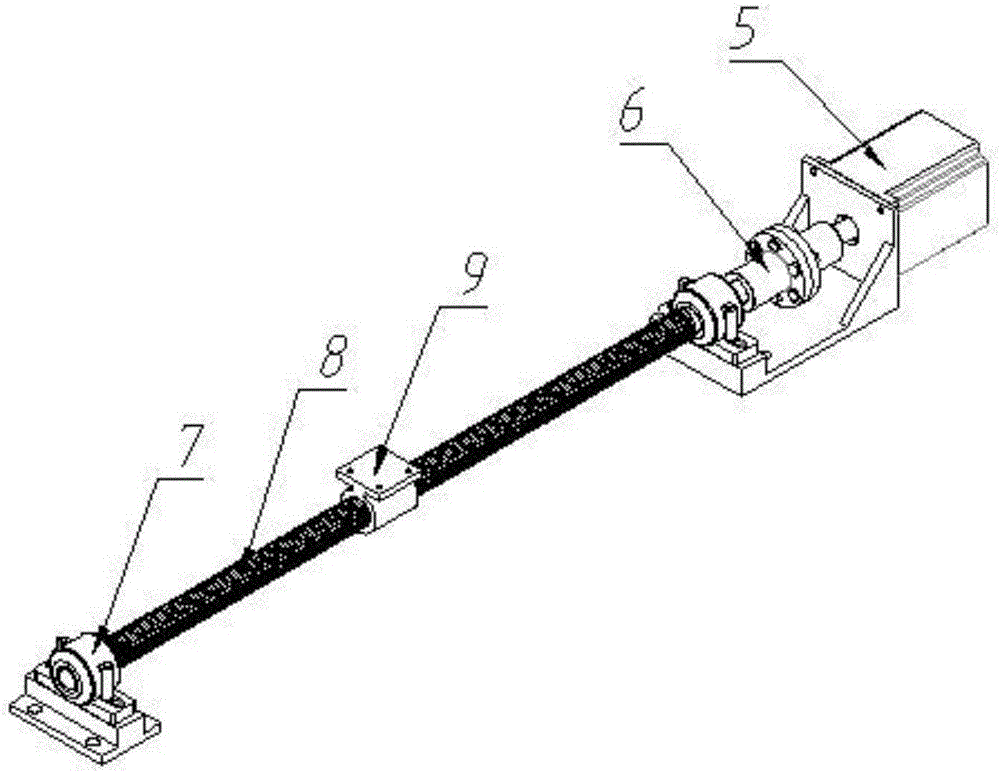

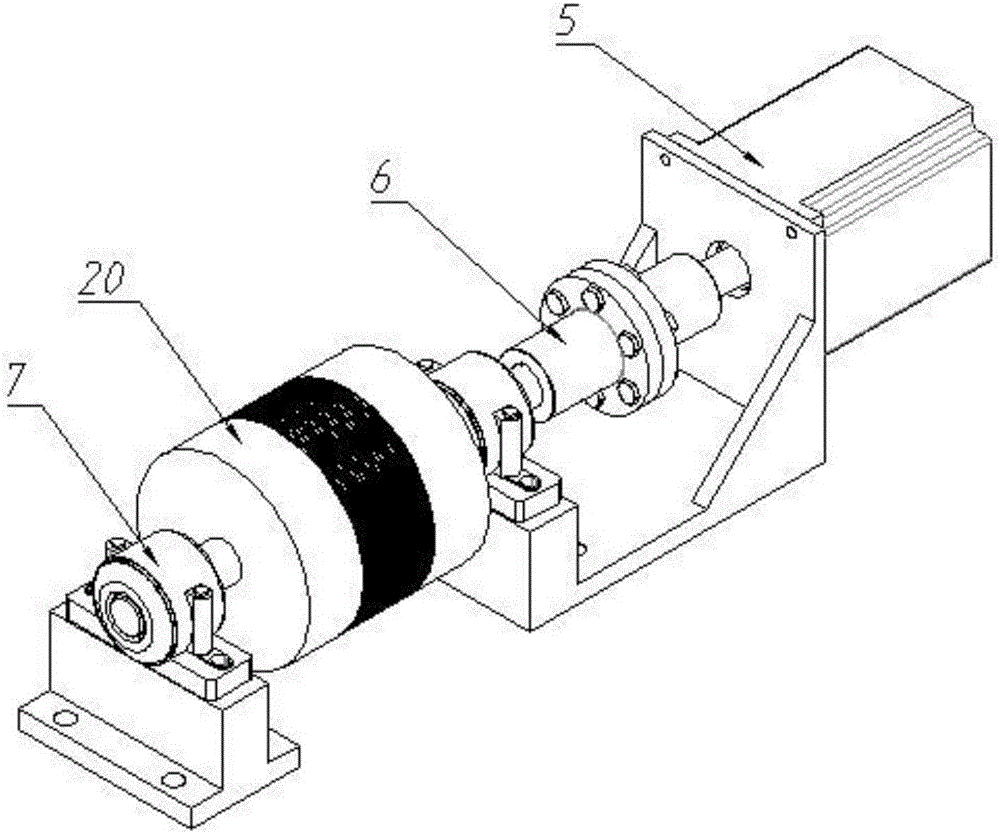

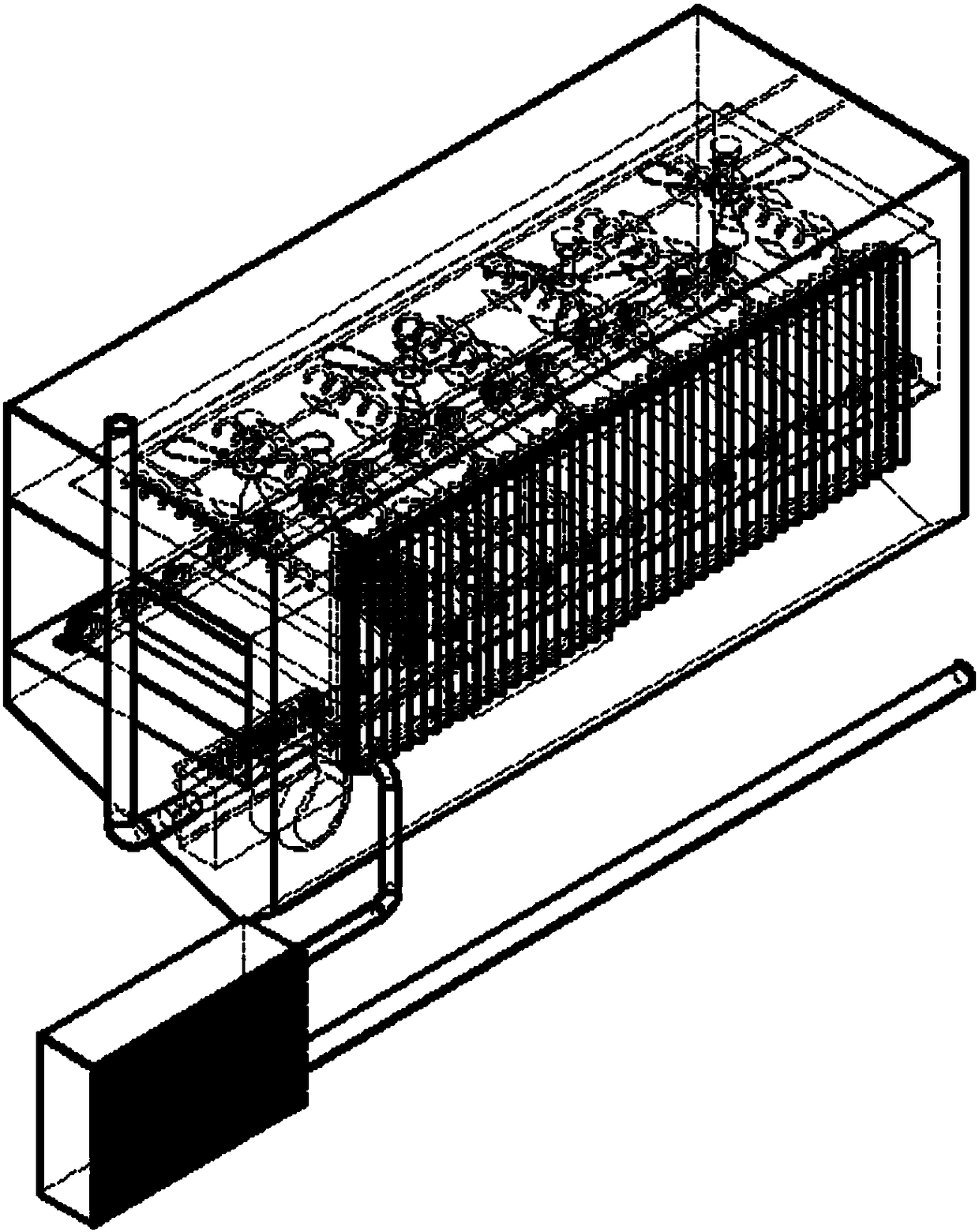

Sand mill

The invention provides a sand mill. The sand mill comprises a rack, a motor, a grinding cylinder, a main shaft, multiple dispersion disc supports, multiple dispersion discs, a cooling core and a return pipe. The motor is fixedly connected to the rack. The grinding cylinder is arranged on the right side of the motor and fixedly connected with the rack. The center of the grinding cylinder is provided with a through hole, the left side of the bottom of the grinding cylinder is provided with a feeding opening, the right side of the top of the grinding cylinder is provided with a discharging opening, and the upper portion of the right side of the grinding cylinder is provided with an overflow opening. One end of the main shaft is fixedly connected with the motor, the other end of the main shaft is provided with a blind hole, and the main shaft is connected with the grinding cylinder. The dispersion disc supports are evenly and fixedly connected to the periphery of the main shaft. The dispersion discs are arranged on each dispersion disc support in parallel. The cooling core is arranged in the blind hole and fixedly connected with the rack. One end of the return pipe is connected with the overflow opening, and the other end of the return pipe is connected with the feeding opening. By the adoption of the technical scheme, pigment near the main shaft is good in fluidity, the pigment flows through the overflow opening and flows in or out of the grinding cylinder circularly to be fully ground in the flowing process, the pigment is fully dispersed and evenly mixed, and the dispersion efficiency is improved.

Owner:TIANJIN CITY JIUYUE TECH

Additive for preventing and treating urinary stone and hematuresis of fattening sheep

InactiveCN102845608AInhibition formationEffective stone removalAnimal feeding stuffUrinary disorderBiotechnologyRhizome

The invention discloses an additive for preventing and treating urinary stone and hematuresis of a fattening sheep. The additive is prepared from 1.5 to 20 parts by mass of Japanese climbing fern spore, 2.2 to 30 parts by mass of christina loosestrife, 1.0 to 10 parts by mass of small centipeda herb, 1.2 to 15 parts by mass of spicate clerodendranthus herb, 0.7 to 10 parts by mass of chicken's gizzard-membrane, 0.7 to 10 parts by mass of plantain, 2.2 to 30 parts by mass of corn stigma, 0.5 to 10 parts of mirabilite, 1.1 to 20 parts by mass of lotus rhizome node, 1.1 to 12 parts by mass of unprocessed rehmannia root, 0.5 to 10 parts by mass of VE, 1.0 to 12 parts by mass of VA, 0.7 to 10 parts by mass of VD and 0 to 22 parts by mass of zeolite powder. A preparation method of the additive comprises the following steps of crushing the Chinese herbal medicines, uniformly mixing the crushed Chinese herbal medicines, VE, VA, and VD, mixing the mixture, and uniformly mixing. The additive isused for preventing and treating urinary stone and hematuresis caused by high-concentration feed fattening, can avoid stone precursor formation, can effectively decompose and discharge stones, and has effects of cooling blood, effectively preventing and treating hematuresis, improving body immunity and oxidation resistance, effectively preventing and treating urinary stone of a fattening sheep, reducing an economic loss of a farmer and guaranteeing safe production and low carbon production of mutton.

Owner:SHANXI AGRI UNIV

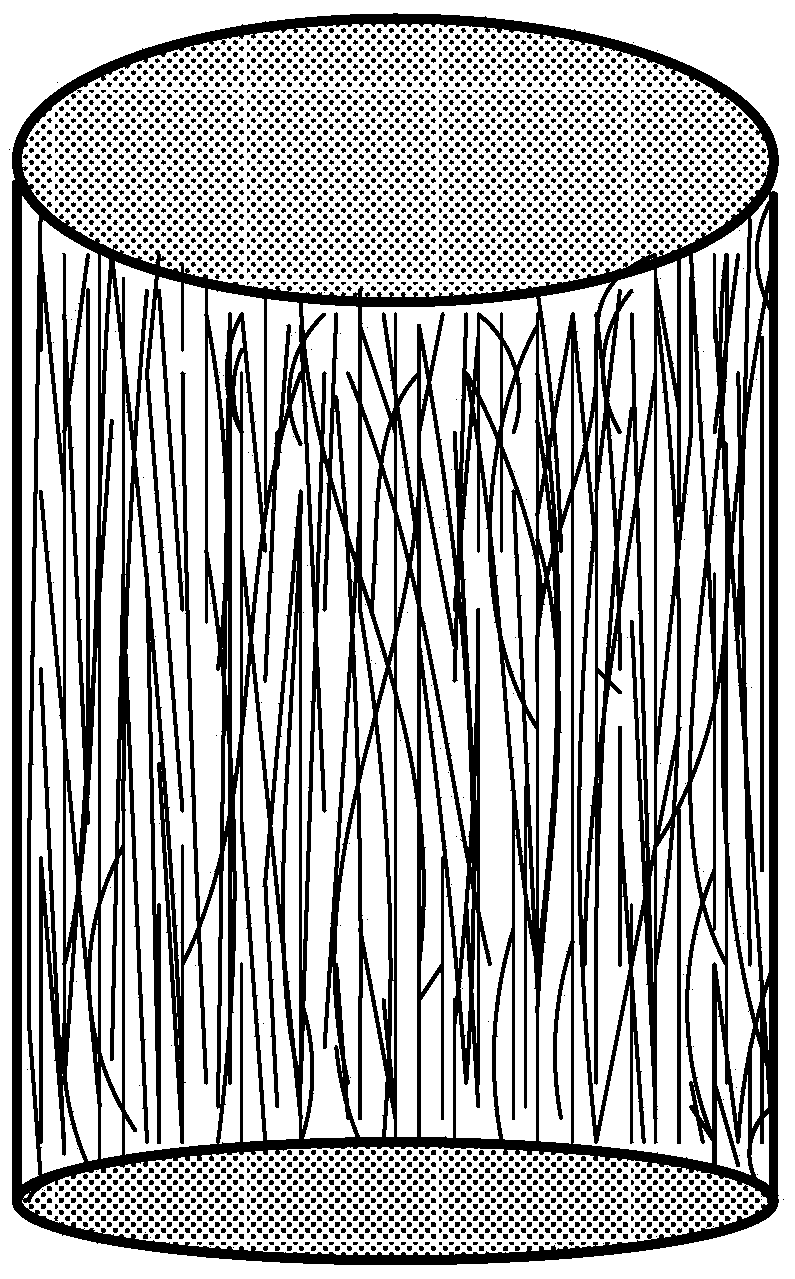

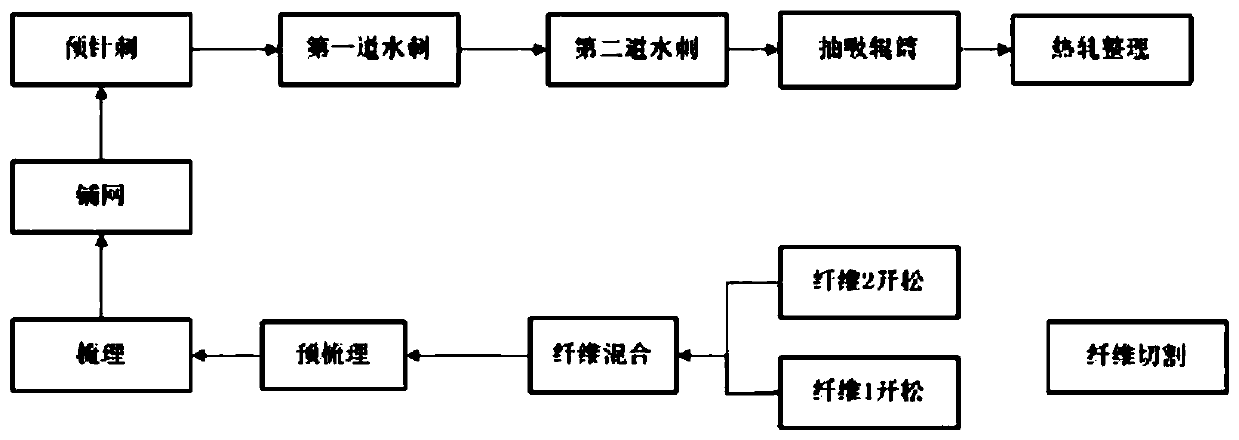

Composite acetate fiber non-woven material applicable to cigarette filters and preparation method and application of composite acetate fiber non-woven material

PendingCN110616505AHigh tensile strengthStrong heat conduction and heat absorption capacityCarbon fibresTobacco smoke filtersAbsorption effectPolylactic acid

The invention relates to a composite acetate fiber non-woven material applicable to cigarette filters and a preparation method of the composite acetate fiber non-woven material. The composite acetatefiber non-woven material is prepared by mixing acetate fiber and other fibers, wherein the other fibers is one, two or three of polylactic acid fibers, metal fibers and carbon fibers. The composite acetate fiber non-woven material comprises 5-99wt% of cellulose acetate fibers and 1-95wt% of non-acetate-fiber material. The preparation method includes: opening the cellulose acetate fibers, mixing with the non-acetate-fiber material, carding, lapping, and performing spunlace to obtain the acetate fiber non-woven material. The acetate fiber non-woven material has a certain heat absorption effect and certain filtering performance and can lower smoke temperature and filter harmful components in smoke. After fiber mixing, the tensile strength of the non-woven material is enhanced, and the strength requirement of the cigarette filters produced by the non-woven material can be satisfied. The composite acetate fiber non-woven material can be used to produce incombustible cigarette filters.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

Method for synthesizing aluminium oxide powder by using combustion method

ActiveCN106629799AMany breakthrough processesBreakout cycleAluminium oxide/hydroxide preparationChemical synthesisOxygen delivery

The invention relates to a method for synthesizing aluminium oxide powder by using a combustion method, and belongs to the technical field of chemical synthesis of powder materials. The method comprises the following steps: (1) ignition: continuously or intermittently igniting in a reaction device; (2) oxygen delivery: feeding oxygen into the reaction device; (3) aluminum powder conveying: conveying aluminum powder with the grain size less than or equal to 100 mu m into the reaction device through gas; (4) combustion: igniting the aluminum powder so that the aluminum powder is combusted in oxygen; and (5) cooling: cooling combustion products and collecting the combustion products to obtain the aluminium oxide powder. The problem that preparation of aluminium oxide powder by an existing aqueous solution method has lots of procedures, and is long in production period and large in water consumption is solved. Water is not used in the method, and the aluminium oxide powder which has the size of nanoscale or above and has the various purities of 2N-6N is obtained at one step by using aluminum as a raw material; and the product is high in purity, low in sodium content, uniform in particle size, good in dispersibility and good in spheroidization. A synthetic process is short in technological process, the equipment is simple, the cost is low, energy consumption is low, synthesis efficiency is high, pollution does not exist, and waste gas, waste water and solid wastes do not exist.

Owner:新疆三锐佰德新材料有限公司

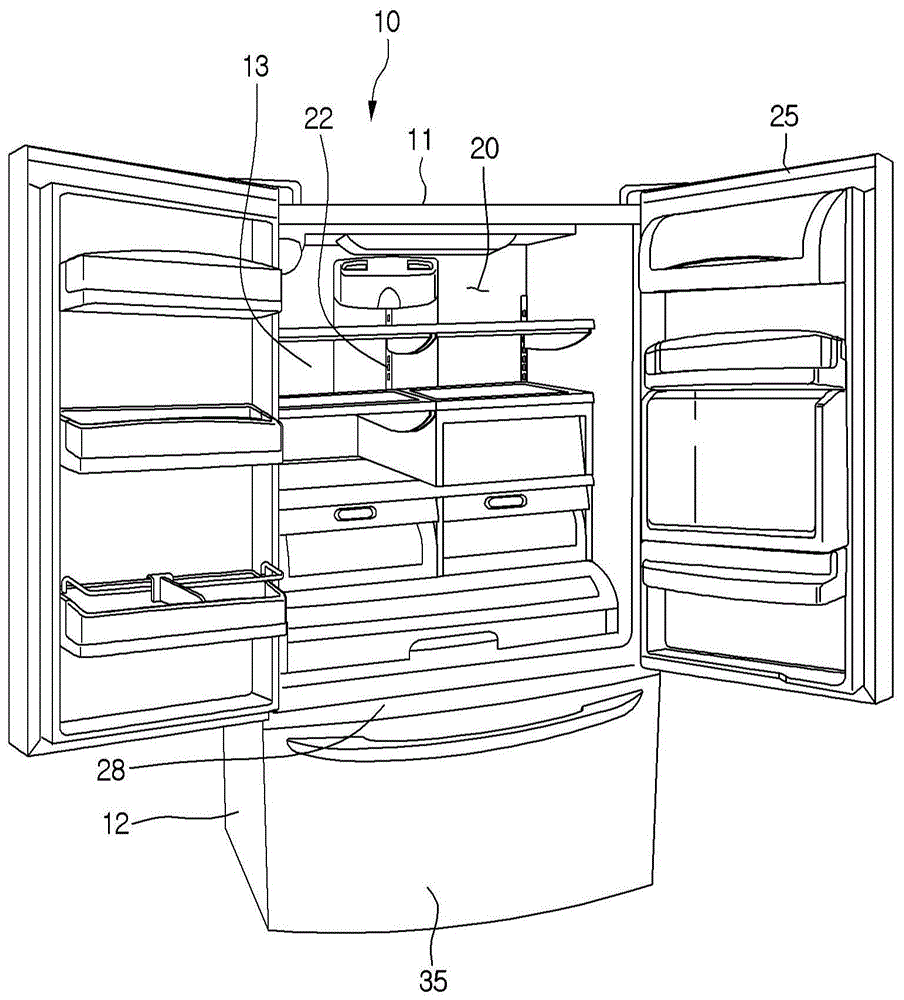

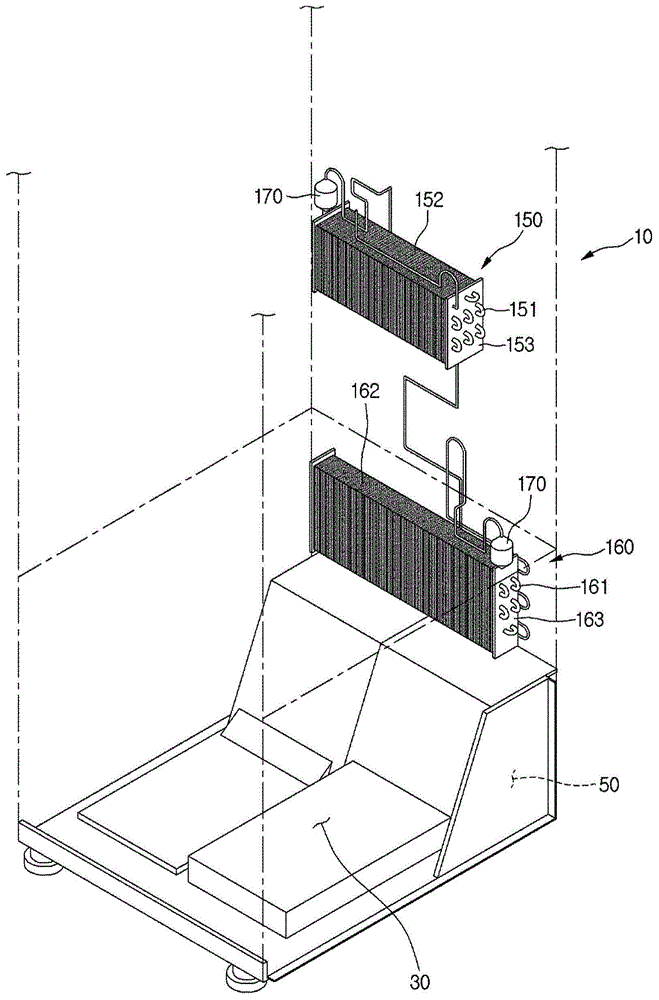

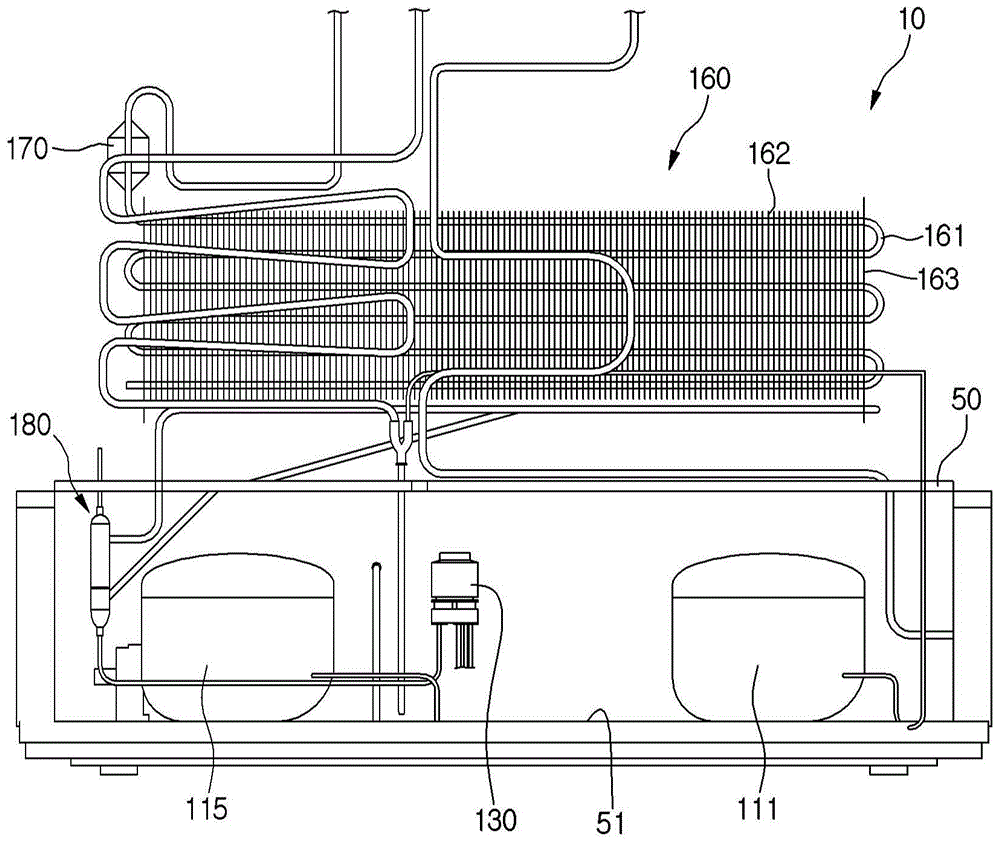

Refrigerator and control method

ActiveCN104613696AEffective simultaneous coolingMinimize temperature deviationCompression machines with non-reversible cycleDomestic refrigeratorsEngineeringRefrigerant

Provided is a refrigerator (10) and a method for controlling the same. The refrigerator (10) includes a compressor (111, 115) compressing a refrigerant, a condenser (120) condensing the refrigerant compressed in the compressor (111, 115), a refrigerant tube (100) guiding the refrigerant condensed in the condenser (120), a flow adjustment part (130) coupled to the refrigerant tube (100) to divide the refrigerant into a plurality of refrigerant passages (101, 103, 105), a plurality of expansion devices (141, 143, 145) respectivley disposed in the plurality of refrigerant passages (101, 103, 105) to decompress the refrigerant condensed in the condenser (120), a plurality of evaporators (150, 160) evaporating the refrigerant decompressed in the plurality of expansion devices (141, 143, 145), and a supercooling heat exchanger (500) disposed at an outlet-side of the condenser (120) to supercool the refrigerant. The refrigerant supercooled in the supercooling heat exchanger (500) is introduced into the flow adjustment part (130).

Owner:LG ELECTRONICS INC

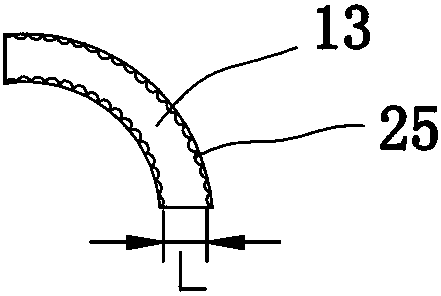

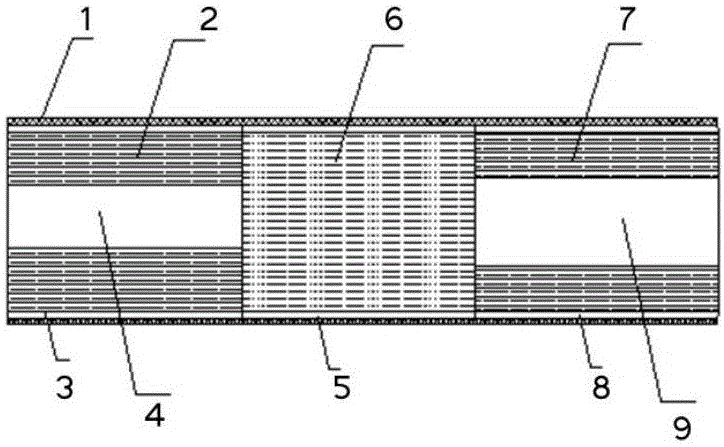

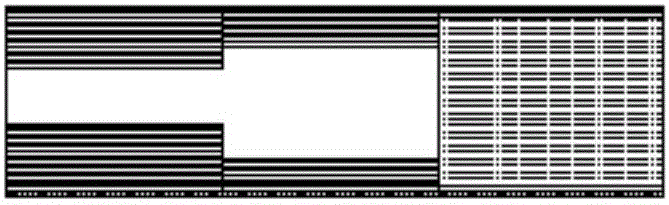

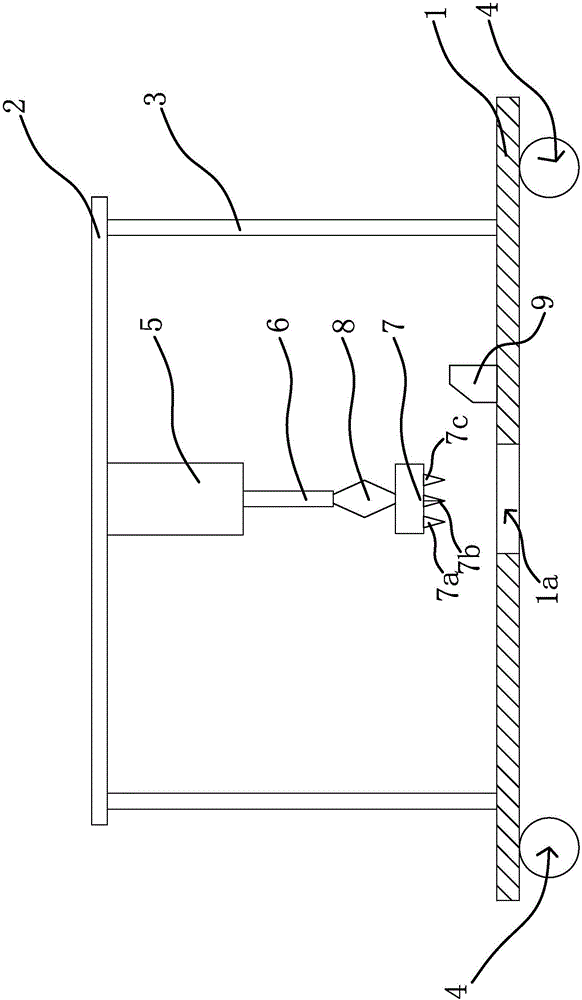

Composite filter tip and application of composite filter tip in heating and incombustible cigarette

InactiveCN105996119AReduce flue gas temperatureImprove pumping sensationCigar manufactureTobacco smoke filtersComposite filterEngineering

The invention belongs to the technical field of cigarettes and particularly relates to a composite filter tip. The composite filter tip comprises a tobacco rod (6), a first hollow filter (2) and a second hollow filter (7), wherein the tobacco rod (6) is formed by wrapping a tobacco material with first tipping paper (5); the first hollow filter (2) is formed by wrapping a polymer fiber material with third tipping paper (3) and is provided with a first hollow cavity (4); the second hollow filter (7) is formed by wrapping a polymer fiber material with fourth tipping paper (8) and is provided with a second hollow cavity (9); the tobacco rod (6), the first hollow filter (2) and the second hollow filter (7) are connected and are wrapped with second tipping paper (1), and the composite filter tip is obtained. The invention further discloses an application of the composite filter tip in reducing the content of aldehyde substances in smoke of the heating and incombustible cigarette.

Owner:CHINA TOBACCO YUNNAN IND

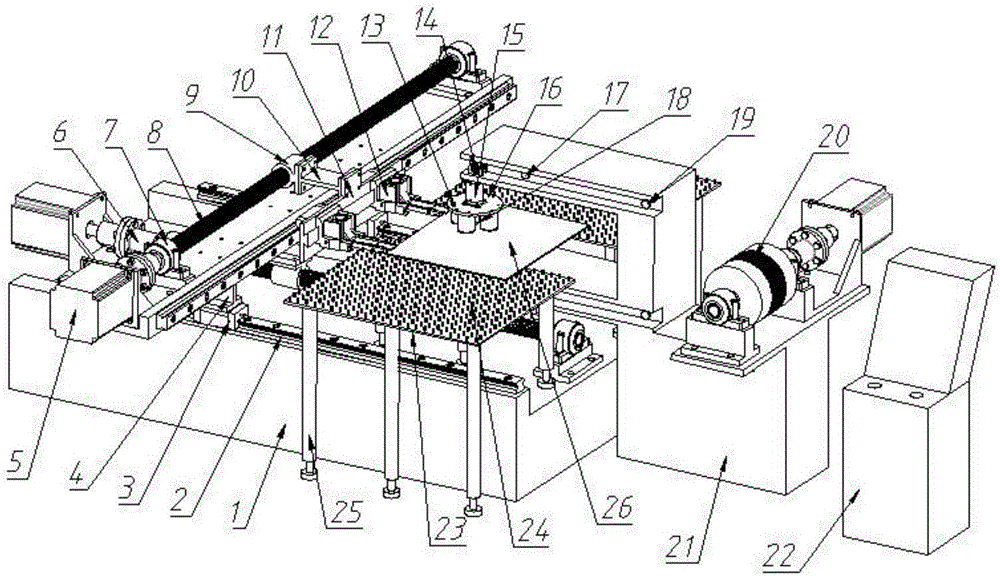

Composite plate emery wire cutting machine

ActiveCN106217659AReduce horizontalReduce longitudinal vibrationWorking accessoriesStone-like material working toolsControl systemWire cutting

The invention provides a composite plate emery wire cutting machine. The composite plate emery wire cutting machine comprises a coordinate table, a wire conveying mechanism, a fixed holding device, a floating pressing vibration damper, a vacuum pump powder suction system and a digital program control system. According to the working process of the cutting machine, a to-be-cut nonmetallic plate is clamped through clamps on the coordinate table, a steel ball on the fixed holding device holds the nonmetallic plate, and a steel ball on the floating pressing vibration damper presses the nonmetallic plate so as to reduce vibration and frictional resistance of the nonmetallic plate during cutting; an emery wire deviation-proof device reduces transverse and longitudinal vibration during emery wire cutting; the wire conveying mechanism makes an emery wire move, the digital program control system operates a program to control the coordinate table to drive the clamp X and the clamp Y clamping a workpiece to move, and then the cutting shape of the machined workpiece is controlled; and nonmetallic powder generated during cutting is sucked and cleared away by the vacuum pump powder suction system always operating during machining.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

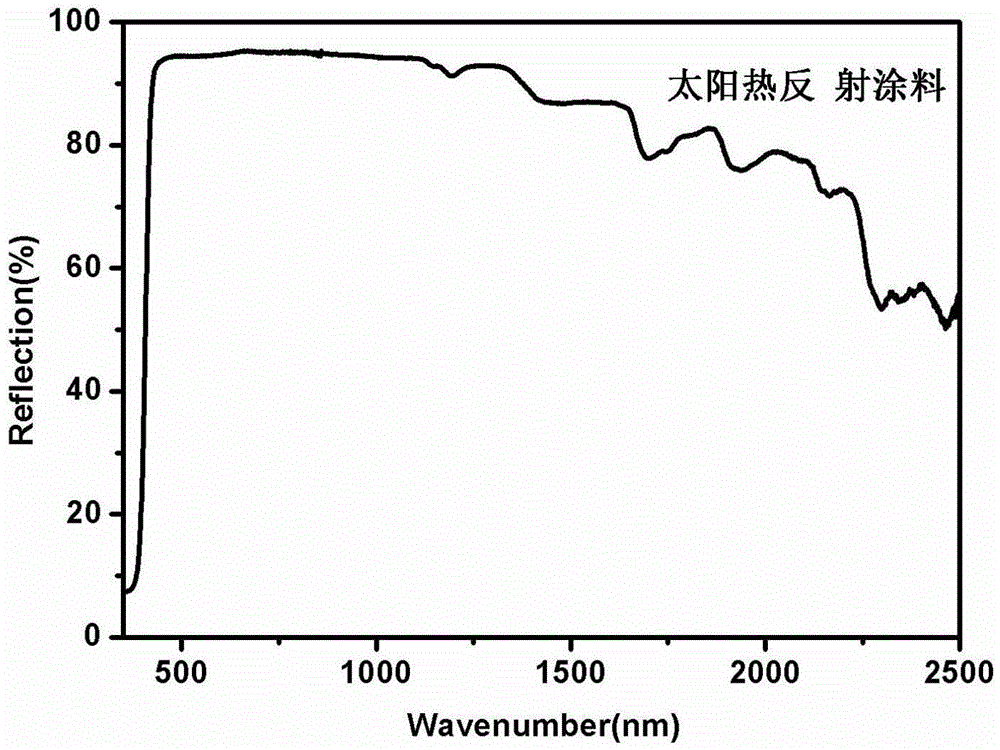

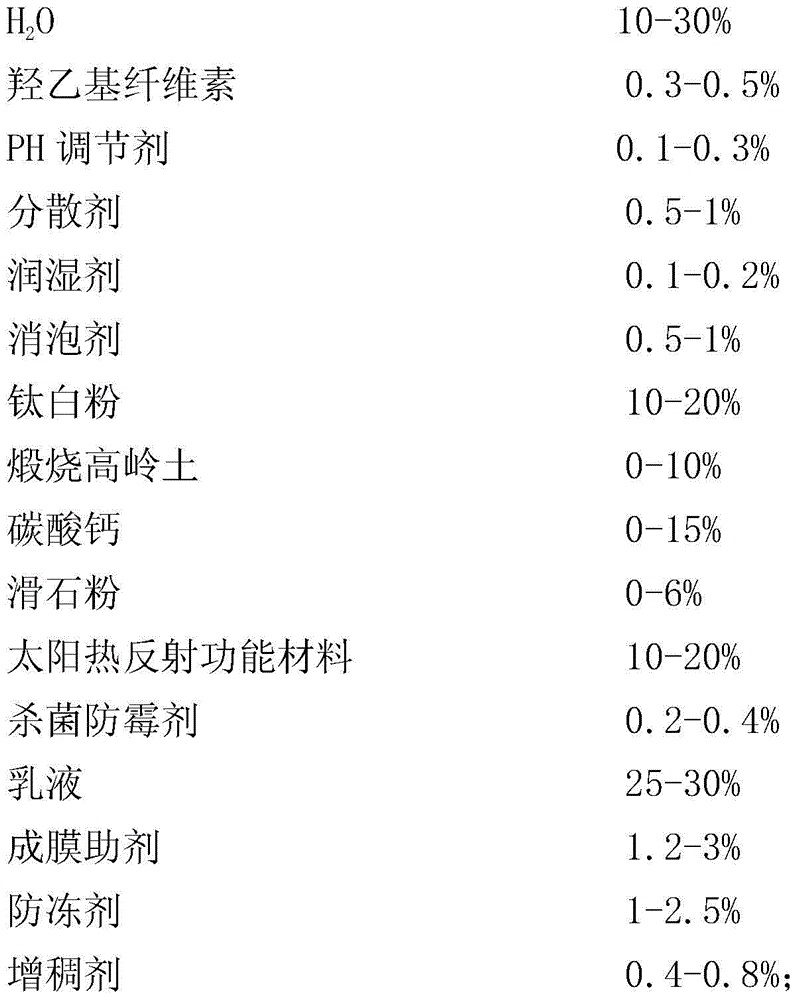

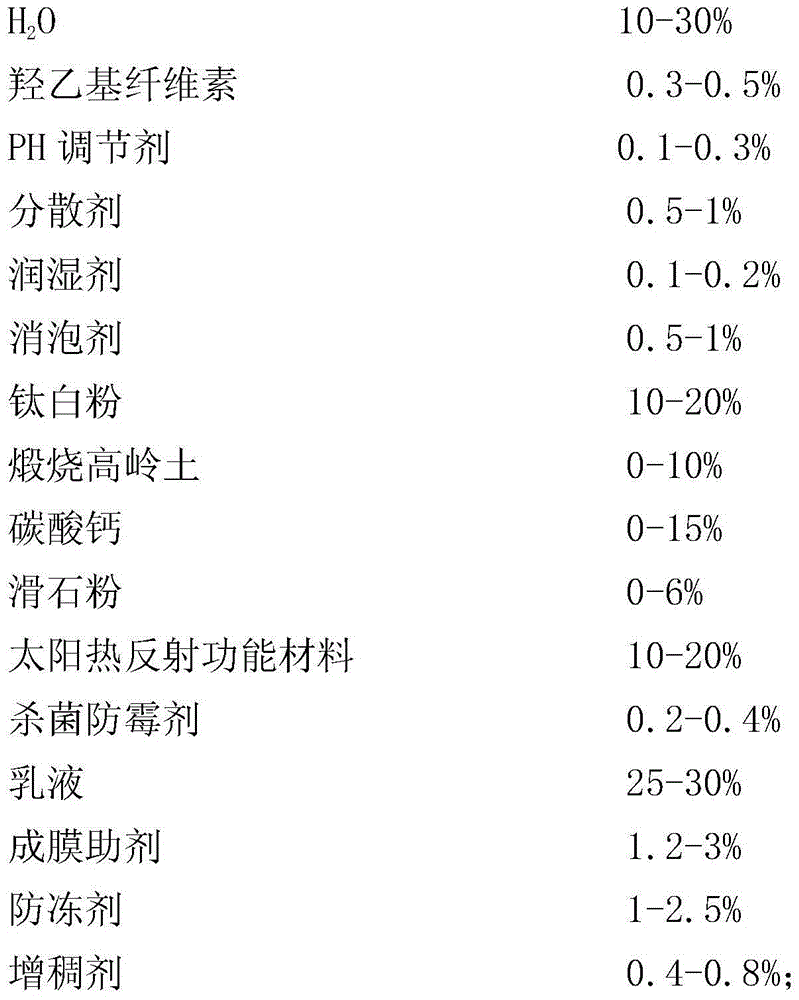

Exterior wall coating with solar heat reflecting function and preparation method of exterior wall coating

InactiveCN104151965AWith solar heat reflective functionGood solar heat reflection functionReflecting/signal paintsEmulsionPreservative

The invention relates to an exterior wall coating with a solar heat reflecting function and a preparation method of the exterior wall coating. The exterior wall coating with the solar heat reflecting function is prepared from the following components: water, an emulsion, a self-made solar heat reflecting powder, titanium dioxide, calcined kaolin, calcium carbonate, talcum powder, a wetting agent, a dispersing agent, a defoaming agent, an antibacterial preservative, a coalescing agent, an antifreezing agent and a thickening agent. The exterior wall coating with the solar heat reflecting function is relatively high in total solar energy reflectivity, capable of playing a favorable heat insulation effect after being thinly coated and also capable of avoiding the condition that a film is crude and nonresistant to dirt.

Owner:SKSHU PAINT

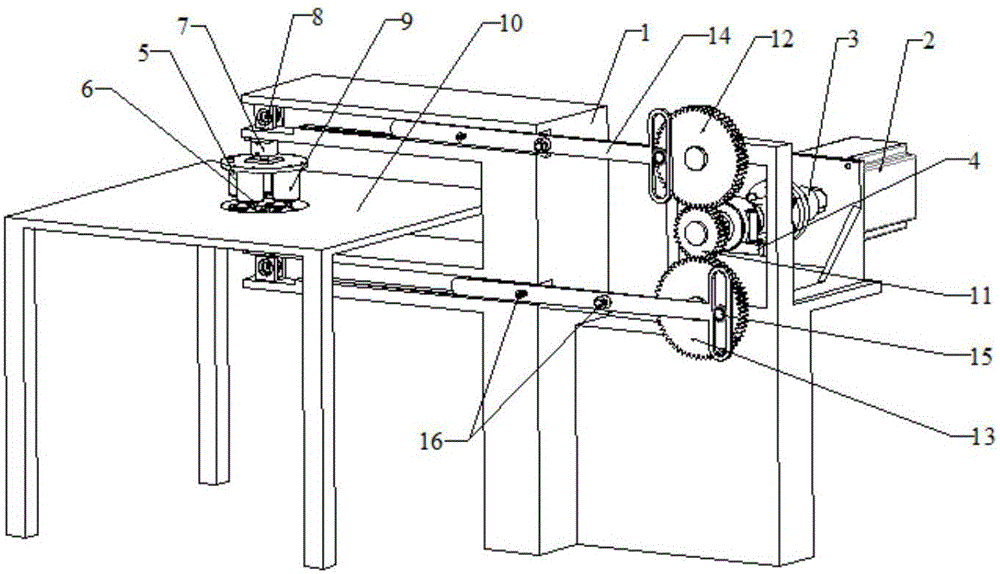

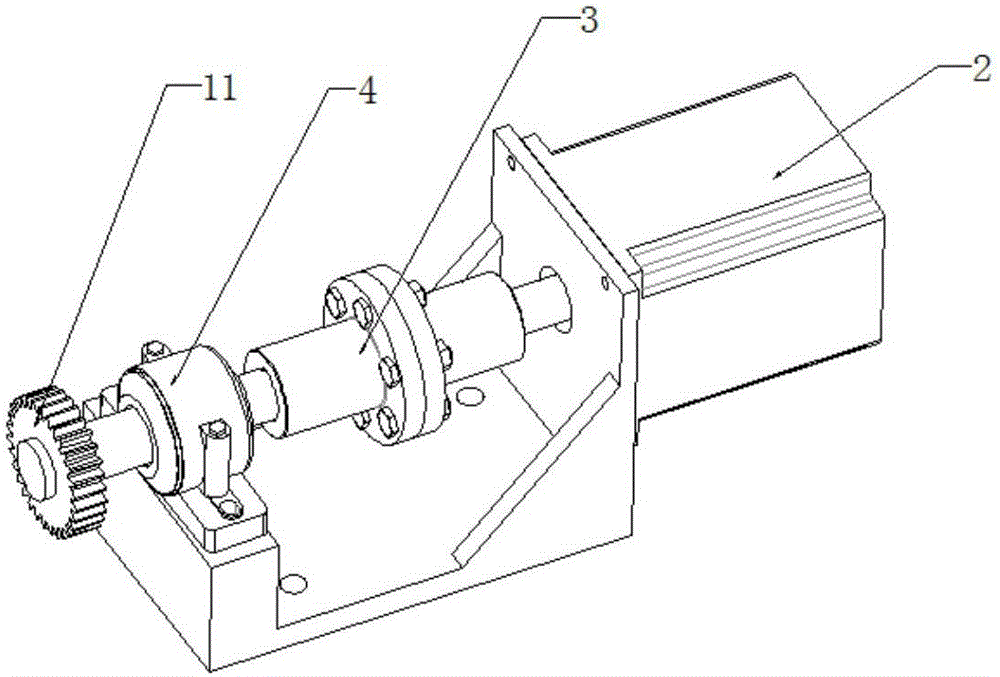

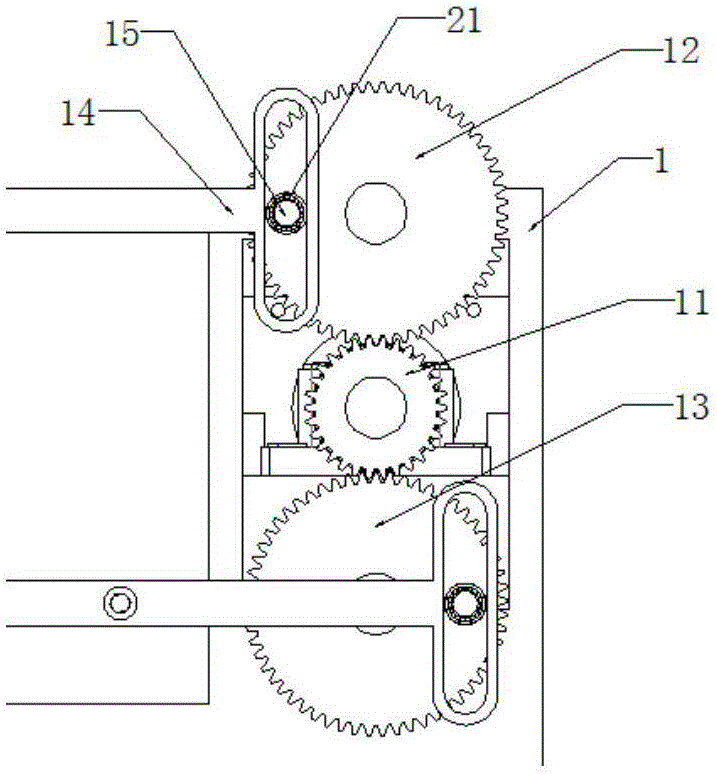

Manual emery wire cutting machine

PendingCN107520892AImprove working environmentConstant lengthMetal working apparatusWire cuttingGear transmission

The invention provides a manual emery wire cutting machine. The manual emery wire cutting machine comprises a machine body, a gear transmission device, a crank slide block guide rod mechanism, wire winding and unwinding devices, a fixed supporting and float pressing device, a wire carrying mechanism and a fixed worktable. The whole working process is as follows: a motor drives a driving gear to rotate to enable two working gears, engaged with the driving gear up and down and with the same geometric sizes, to rotate; crank shafts with a phase difference of 180 degrees and the same eccentric distance are respectively mounted on the working gears; through connection of rolling bearings and slide block guide rods, the rotating motion of the working gears is converted to the linear reciprocating motion of the upper and lower slide block guide rods; meanwhile, the slide block guide rods are provided with the wire winding and unwinding devices for fixing, replacing and changing working sections of emery wires; and nonmetal plates are pressed by the float pressing and fixed supporting device, so that the instant advancing motion distance and speed of the emery wires mounted on the upper and lower slide block guide rods are equal to the instant retreating motion distance and speed, and the reciprocating cutting of nonmetal workpieces is finished.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Smoking set

InactiveCN109645568AReduce the speed at which heat is dissipatedSave heating energyTobacco pipesTobacco devicesTransverse planeEngineering

The invention provides a smoking set, which comprises an elongated shell, a power source, an opening, a cavity and an airflow passage. The power source is arranged in the shell, the end of the shell is provided with the opening, the cavity extends along the shell from the opening longitudinally and used for cigarette storage, and the airflow passage extends longitudinally along a gap between a cigarette and the shell and internally provided with a blocking layer for weakening transverse air flowing. By arrangement of the blocking layer for weakening transverse air flowing in the airflow passage, outward heat diffusion is blocked while a tube wall cooling function is achieved; the blocking layer is intrinsically made from a heat insulation material, the speed of heat diffusion from the storage cavity to the tube wall is sharply decreased while air is partitioned into multiple parts; due to a large contact area between the blocking layer and the flowing airflow, intrinsic heat of the blocking layer and heat of the outer wall of the shell are effectively taken away by air flowing in smoking, so that cooling of the tube wall of the shell is realized.

Owner:SHENZHEN RUXIANGJU TECHCAL DEV LTD +1

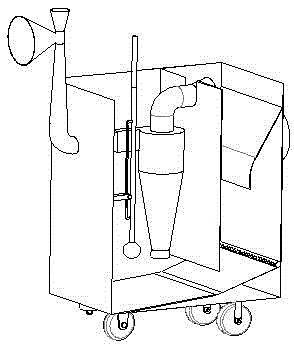

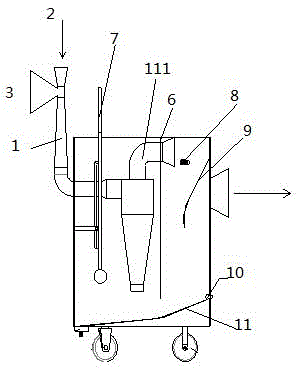

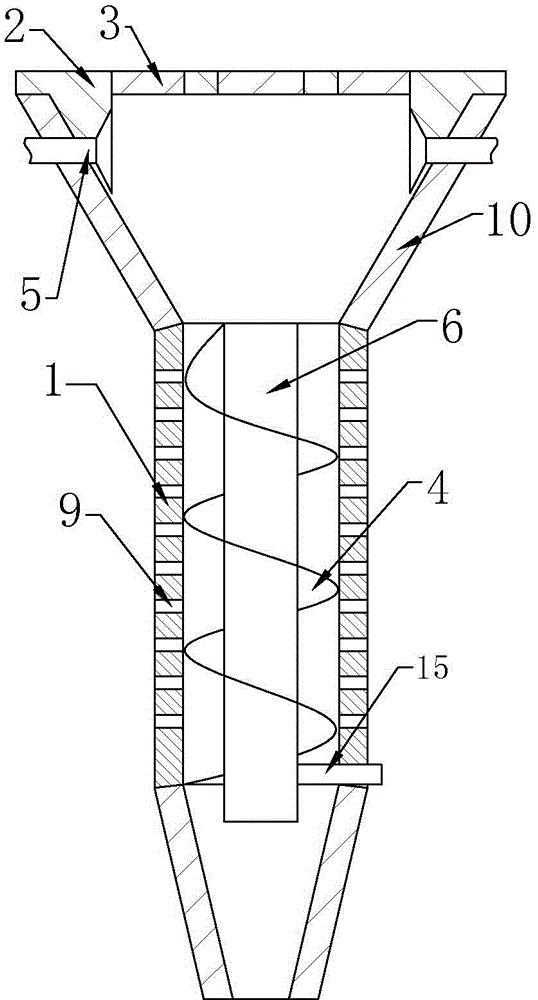

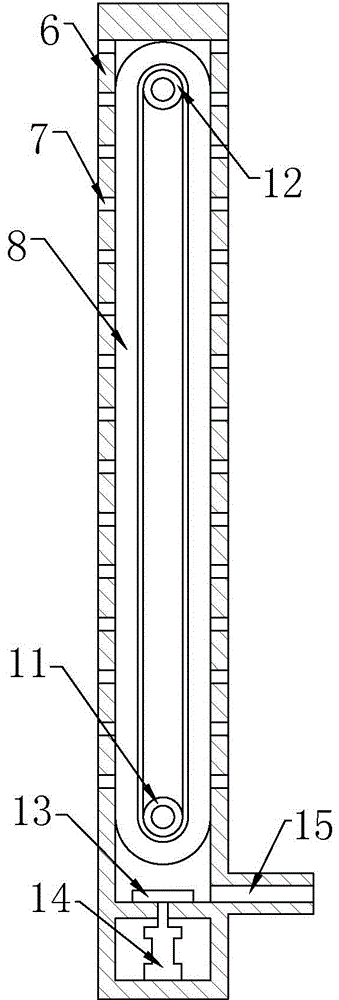

Dry-wet-combining multi-stage dust removing device for mine

InactiveCN105484788AAvoid explosionStructural parameter optimizationDust removalFire preventionWorking environmentRespirable dust

The invention relates to a dry-wet-combining multi-stage dust removing device for a mine. The dry-wet-combining multi-stage dust removing device comprises a Venturi-tube dust capturing mechanism arranged on the outer side of a dust removing device box, a cyclone-dust-remover first-stage dry dust removing mechanism arranged in the dust removing device box and a water-spray-dust-removing second-stage wet dust removing mechanism arranged in the dust removing device box. As traditional draught fan dust sucking is replaced with Venturi tube dust sucking, a better safety effect and a better energy saving effect are achieved, and the dry-wet-combining multi-stage dust removing device can adapt to more working environments; as a cyclone dust remover serves as a mine-dust first-stage processing module, most of respirable dust can be removed, workloads of spray dust removing are reduced, and a large number of water resources are saved; as spray dust removing is used as second-stage dust removing, the dust removing effect is improved, and meanwhile the cooling effect is achieved. The dry-wet-combining multi-stage dust removing device is simple in structure, convenient to use, low in production cost, good in dust removing effect and good in large-scale popularization performance accordingly.

Owner:NANHUA UNIV

Rice dust removing device and rice dust removing process

ActiveCN106076928AGuaranteed dust removal performanceGuaranteed air intake efficiencyDirt cleaningCleaning using liquidsSpiral bladeEngineering

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

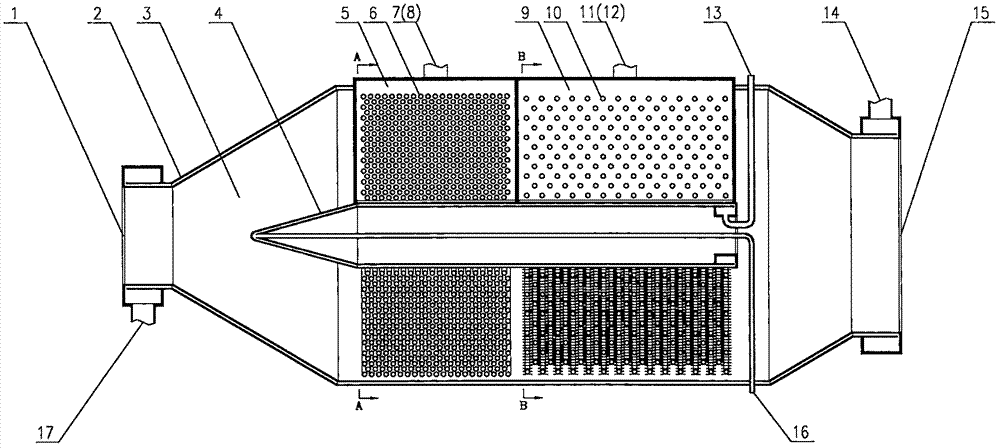

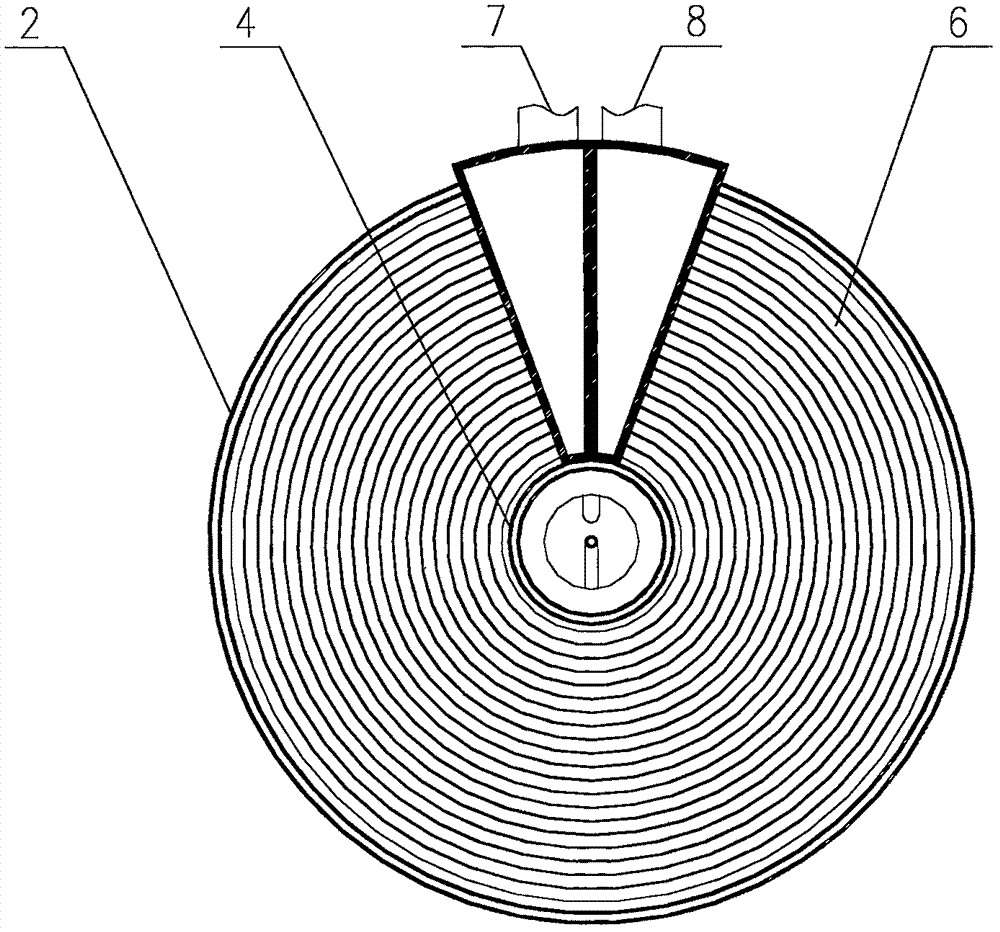

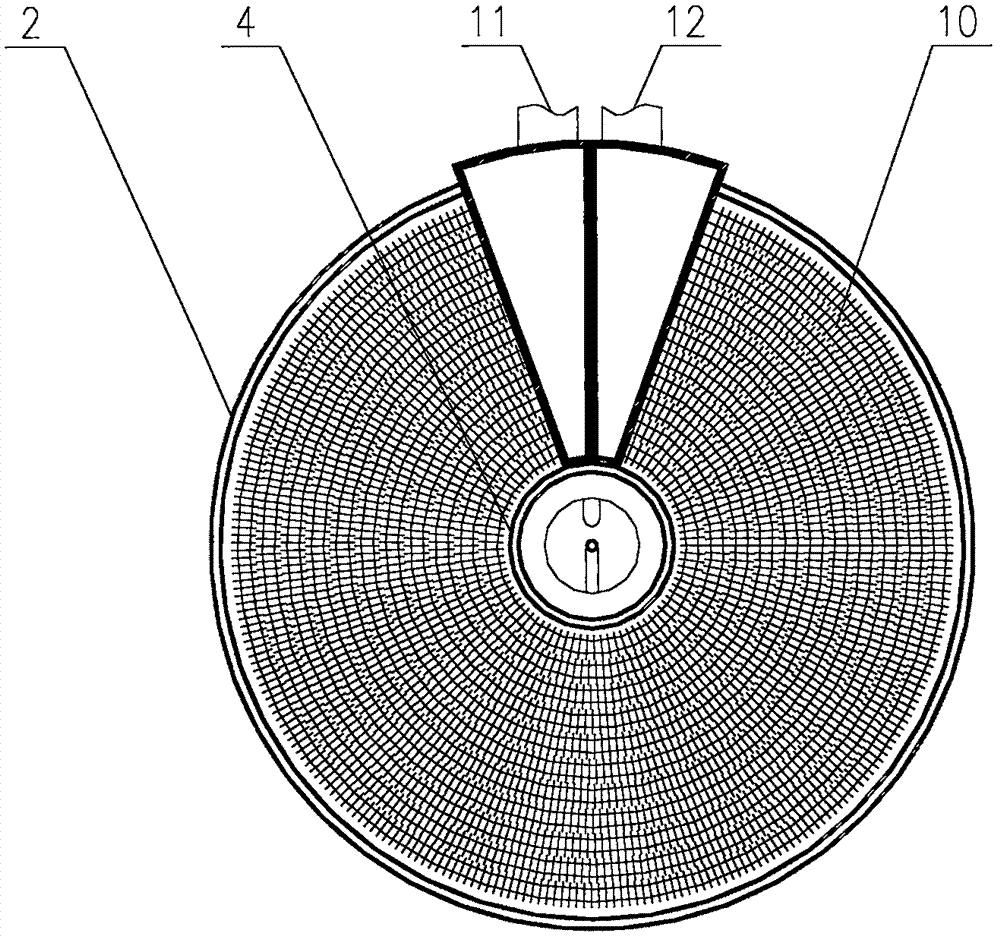

Cooler

InactiveCN107966048AHas a cooling effectEvenly distributedStationary tubular conduit assembliesLight pipeEngineering

The invention discloses a cooler. The cooler is composed of an incoming flow inlet (1), a shell (2), an expansion segment (3), a flow guide cone (4), a light pipe cooling segment (5), a cooling lightpipe (6), a cooling light pipe cooling water inlet (7), a cooling light pipe cooling water outlet (8), a fin pipe cooling segment (9), a cooling fin pipe (10), a cooling fin pipe cooling water inlet (11), a cooling fin pipe cooling water outlet (12), a flow guide cone cooling water outlet (13), a shell cooling water outlet (14), an incoming flow outlet (15), a flow guide cone cooling water inlet (16), and a shell cooling water inlet (17). The cooler is used for cooling high-temperature incoming flow gas.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

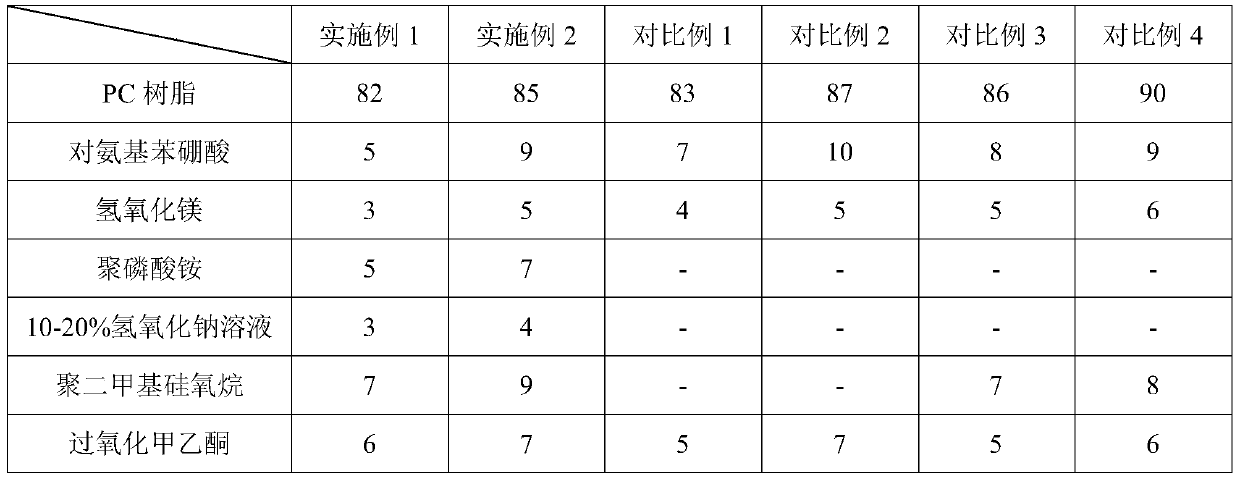

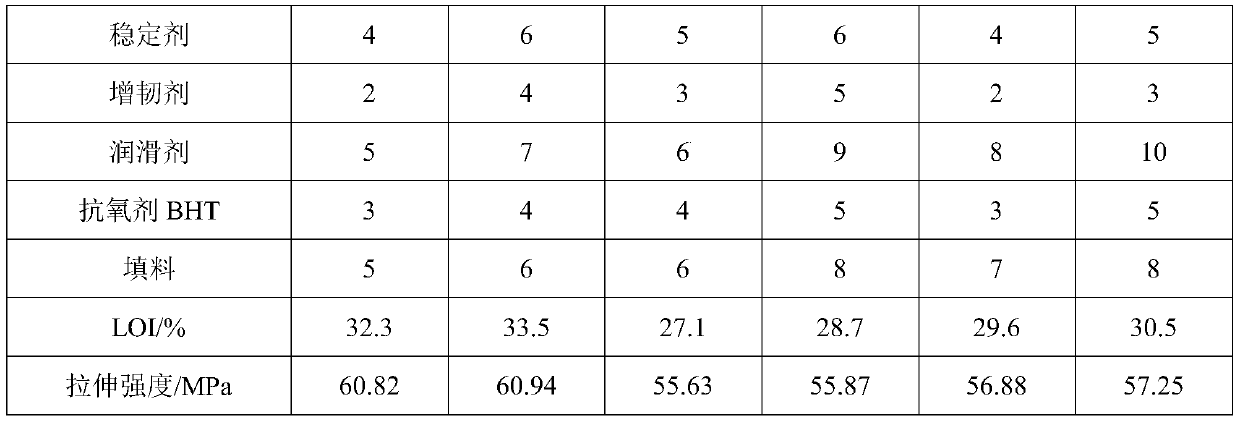

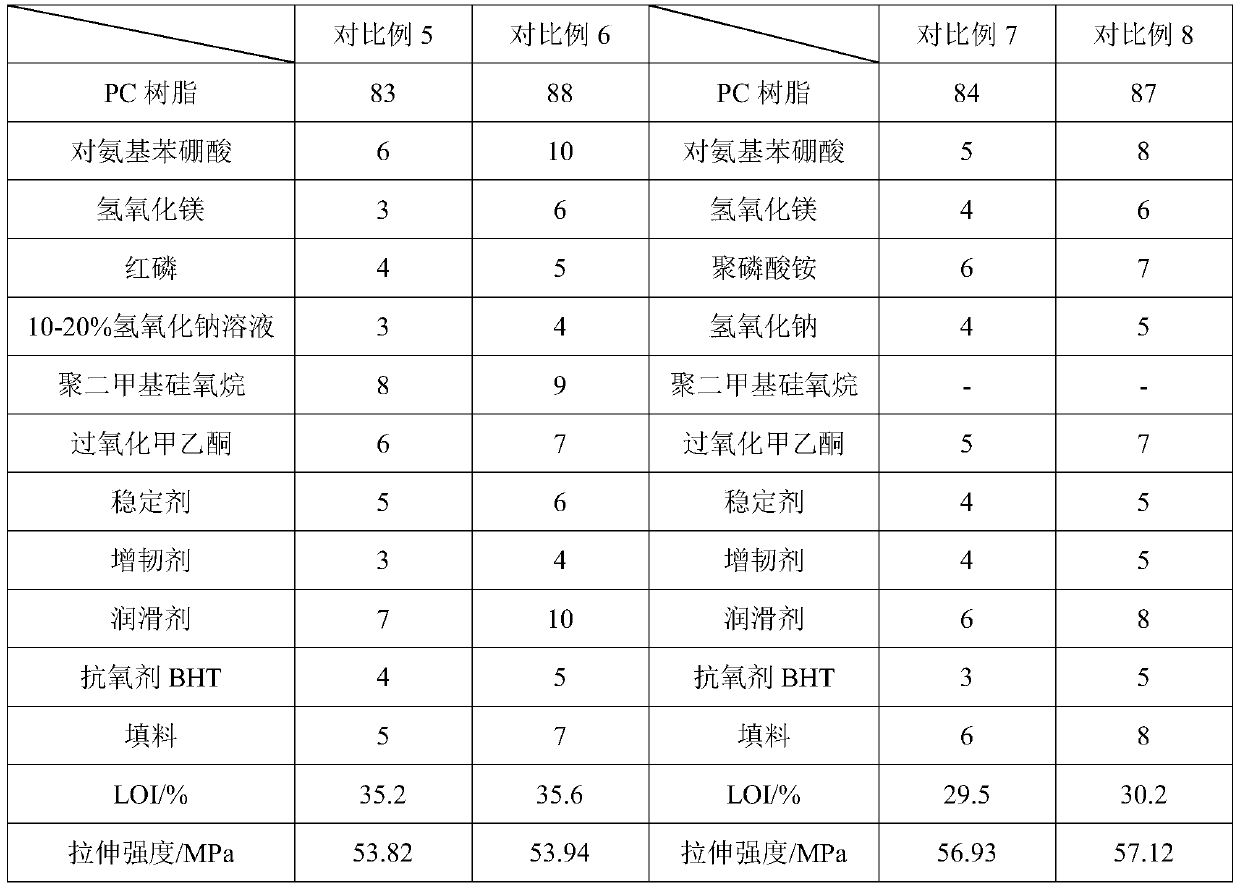

Modified engineering plastic and preparation method thereof

The invention relates to the technical field of engineering plastics, and discloses modified engineering plastic and a preparation method thereof. The engineering plastic comprises the following components: in parts by weight, 80-90 parts of PC resin, 4-6 parts of a stabilizer, 2-5 parts of a toughening agent, 5-10 parts of a lubricant and 3-5 parts of an antioxidant BHT, and a halogen-free flameretardant is also included, and comprises 7-10 parts of p-aminophenyl boronic acid and 3-6 parts of magnesium hydroxide. The modified engineering plastic has the following advantages that a synergistic flame retardant effect is achieved by magnesium hydroxide and p-aminophenyl boronic acid, on the one hand, the amount of magnesium hydroxide can be reduced, and on the other hand, a double-layer flame retardant structure is formed through a magnesium oxide protective film and a B-O-C carbon layer, so that a better flame retardant effect is achieved.

Owner:WENZHOU CITY FANHUA ENG PLASTIC

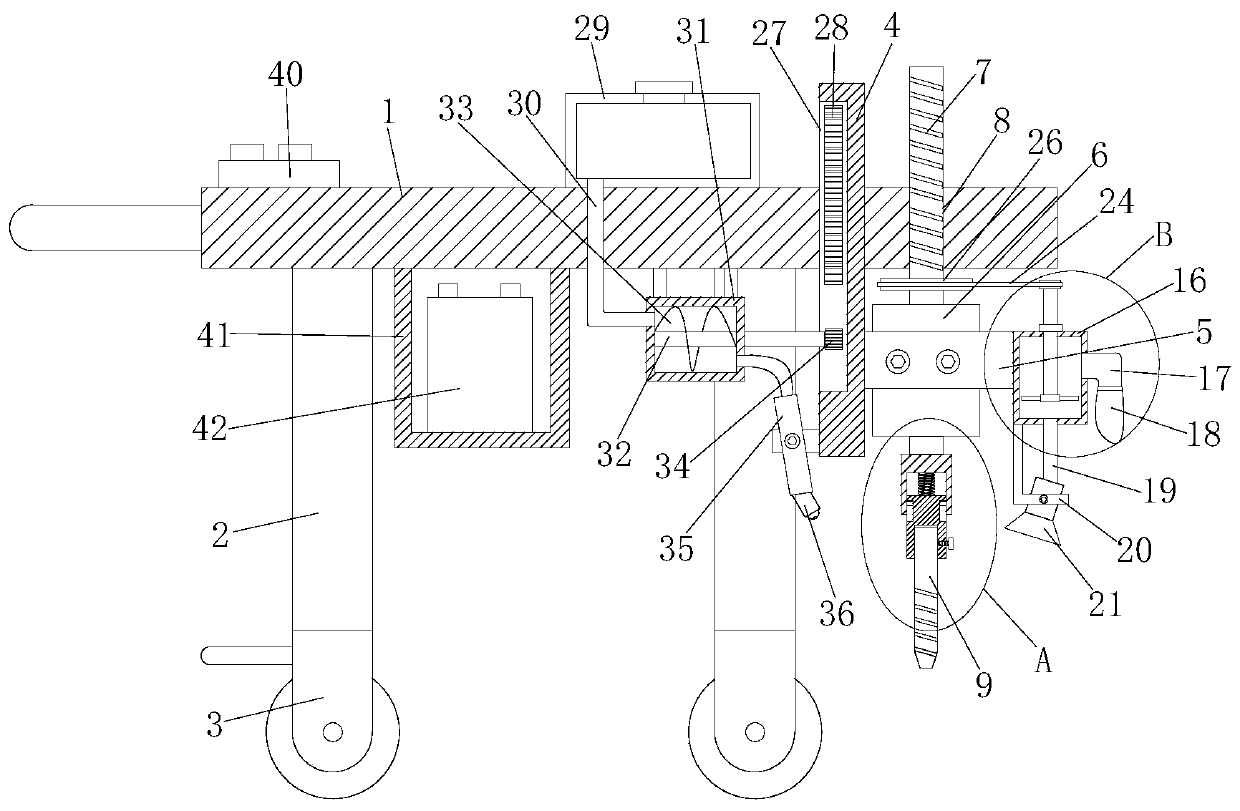

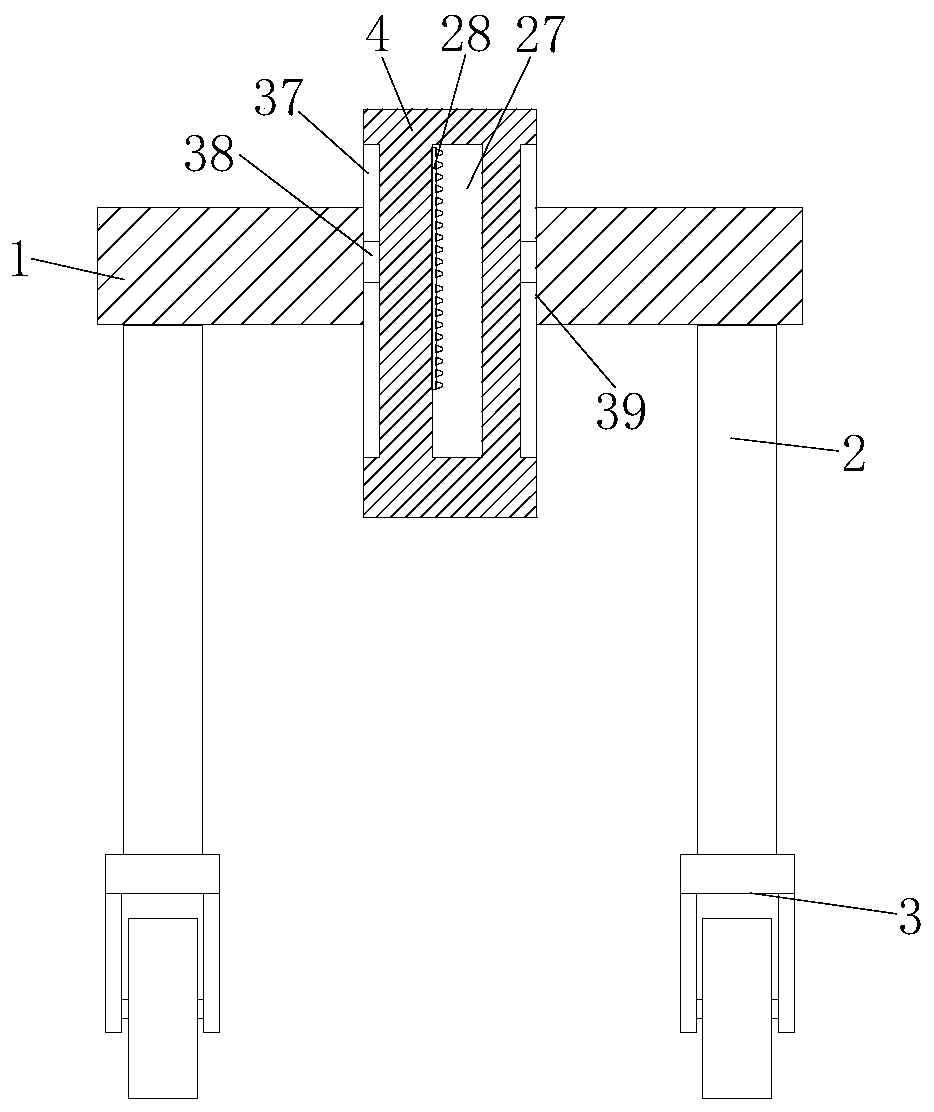

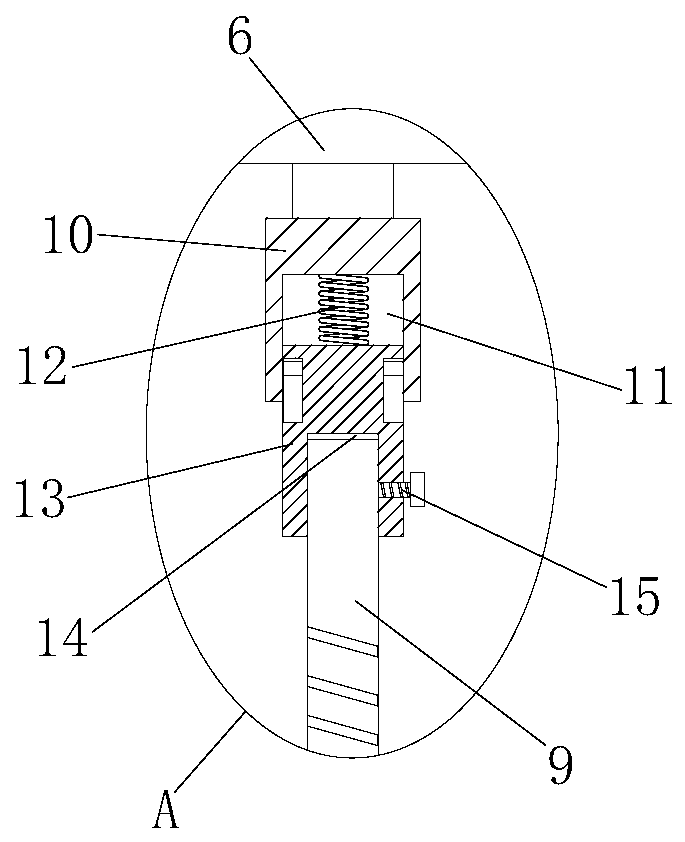

Multifunctional geological survey drilling device

ActiveCN106285468AEasy to carryEasy to findDrill bitsBorehole/well accessoriesGeological surveyHydrology

The invention provides a geological survey drilling device and belongs to the technical field of geological survey. The problem that an existing geological survey drilling device is simplex in function is solved. The geological survey drilling device comprises a base. A traveling mechanism is arranged on the lower portion of the base. A workbench is arranged on the upper portion of the base. The workbench is fixed to the base through a connecting support. A drilling machine is fixed to the lower portion of the workbench. The drilling machine is a hydraulic drilling machine. The drilling machine is detachably connected with a drill bit. A working hole used for allowing the drill bit to penetrate through is formed in the base. The drill bit comprises a connecting part used for being connected with the drilling machine, and a working part used for drilling. A storage groove is formed in the base. A geological survey hammer is arranged in the storage groove. A deposit groove is formed in the base. A soil sampler is arranged in the deposit groove. The geological survey drilling device has the advantage of various functions.

Owner:核工业湖州勘测规划设计研究院股份有限公司

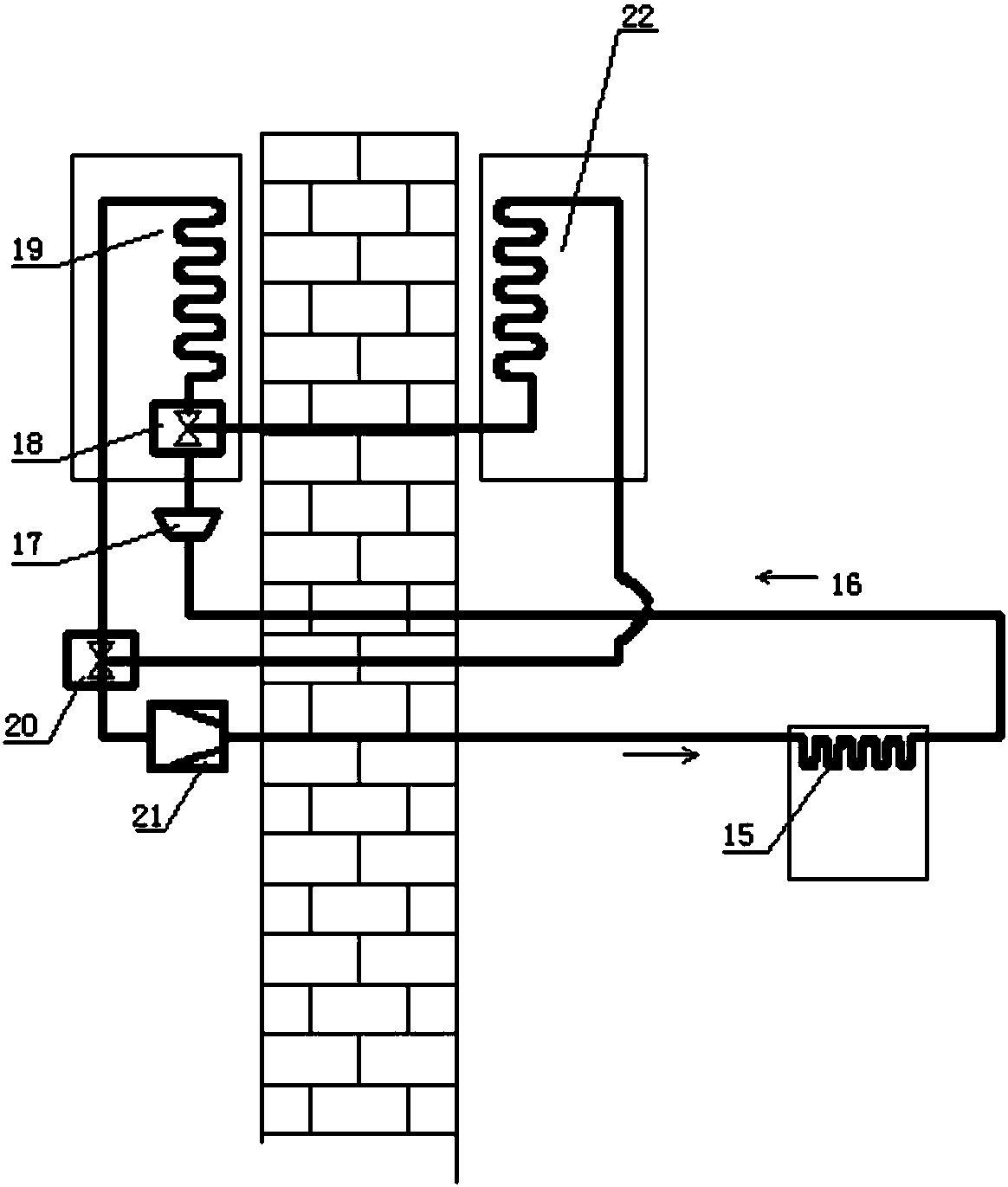

Energy-saving tunnel drying oven

ActiveCN108131930AHeating evenlyFully heatedDrying gas arrangementsDrying chambers/containersWorking environmentEngineering

The invention relates to an energy-saving tunnel drying oven. The energy-saving tunnel drying oven comprises an outer shell, an inner shell, an air channel, a conveyor belt, a heat exchanger, an air inlet, a heat pump system, fans, heating devices, an air flow distributor, an air exhaust pipe and the like. Outside air enters the air channel through the air inlet, the air is preheated by the heat exchanger, heated by the heat pump system and subjected to auxiliary constant temperature keeping by the heating devices, and the air heats and dries heated objects on the conveyor belt; and through distributing of the air flow distributor, the part of hot air is subjected to heat exchanging by the heat exchanger and then exhausted through the air exhaust pipe, and the other part of hot air is mixed with new air preheated by the heat exchanger, heated by the heat pump system and heated by the heating devices, then heats and dries the heated objects, and is distributed by the air flow distributor, in this way, heat energy in the air is circularly utilized, the energy is saved, and the heating efficiency is improved. When the working environment temperature is high, the heat pump system can further be used for cooling the working environment while being used for heating the air.

Owner:GUANGZHOU HENGXINCHUANGZHAN TECH CO LTD

Punching equipment for bridge construction site

InactiveCN111425135AEasy to installEasy to disassembleEarth drilling toolsDrilling rodsPunchingArchitectural engineering

The invention belongs to the technical field of bridge construction, and particularly relates to punching equipment for a bridge construction site. The punching equipment is put forward to solve the problems that existing punching equipment for bridge construction is inconvenient to use, the time and labor are wasted, the working efficiency is low, a drill rod cannot be cooled, the service life ofthe drill rod is affected, and job schedule is influenced. The punching equipment comprises a top plate, wherein four supporting legs are fixedly installed at the bottom of the top plate, universal wheels are arranged at the bottoms of the four supporting legs, a perpendicular plate is vertically and slidably installed on the top plate, a motor installing plate is fixedly installed at one side ofthe perpendicular plate, a double-end motor is arranged on the motor installing plate, a lifting screw rod is fixedly installed on an output shaft of the double-end motor, a lifting screw hole is formed in the top plate, and the lifting screw rod is in threaded connection with the lifting screw hole. The punching equipment is convenient to operate, manual punching is avoided, the labor is saved,and the working efficiency is improved; and meanwhile, the punching equipment has the effects of collecting dust and cooling the drill rod, so that the situation that the temperature rise of the drillrod influences the service life of the drill rod is avoided.

Owner:罗峰

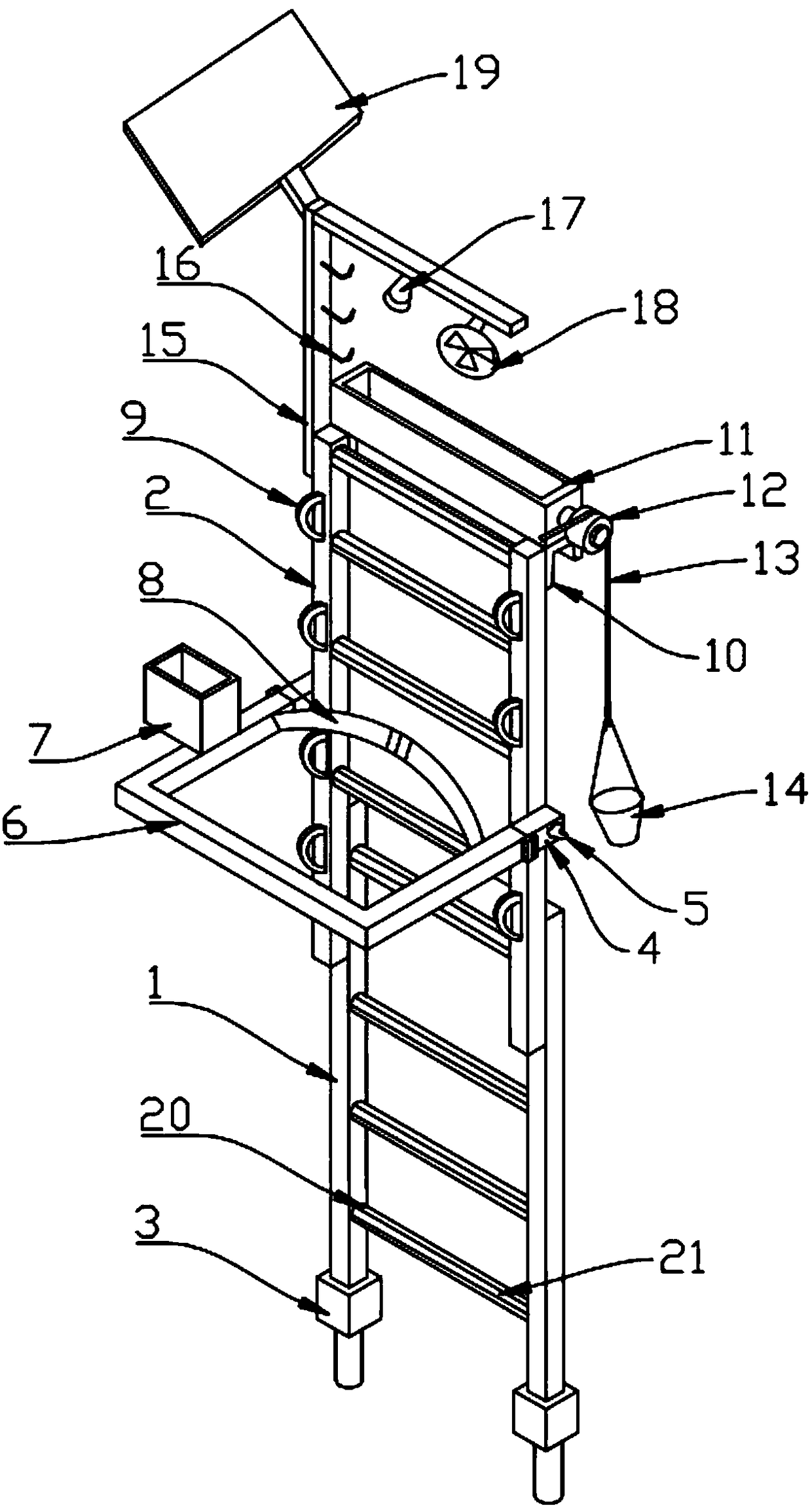

Safe climbing ladder

The invention relates to the technical field of ladders, in particular to a safe climbing ladder. The safe climbing ladder comprises a first-section ladder body, and a second-section ladder body is arranged on the first-section ladder body. The lower end of the first-section ladder body is provided with a telescopic rod capable of adjusting balance, and a butterfly nut having the fastening effectis arranged on a sliding block. A safe support is arranged on the sliding block, and an object containing box and a locking belt are arranged on the safe support. Handles for facilitating grabbing andsupporting of a worker are arranged on the second-section ladder body, and grapnels having the effect of fixing the climbing ladder are arranged at the upper end of the second-section ladder body. Atool cabinet is arranged on the grapnels, and a fixed pulley is arranged on the tool cabinet. A pull rope is arranged on the fixed pulley, and a barrel connected through a lifting hook is arranged onthe pull rope. A support is arranged at the upper end of the second-section ladder body, and rubber strips having the anti-skidding effect are arranged on pedals. The safe climbing ladder is high in working efficiency, safe and capable of facilitating taking and storing of tools.

Owner:徐州孝科编织有限公司

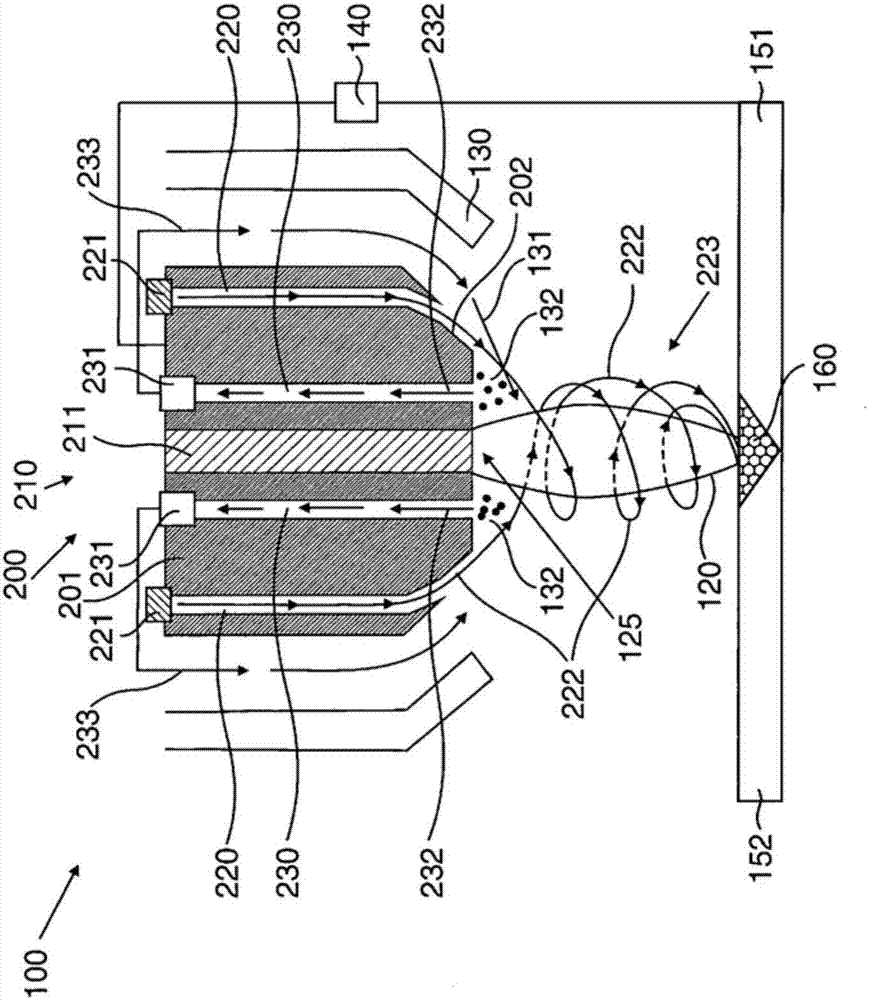

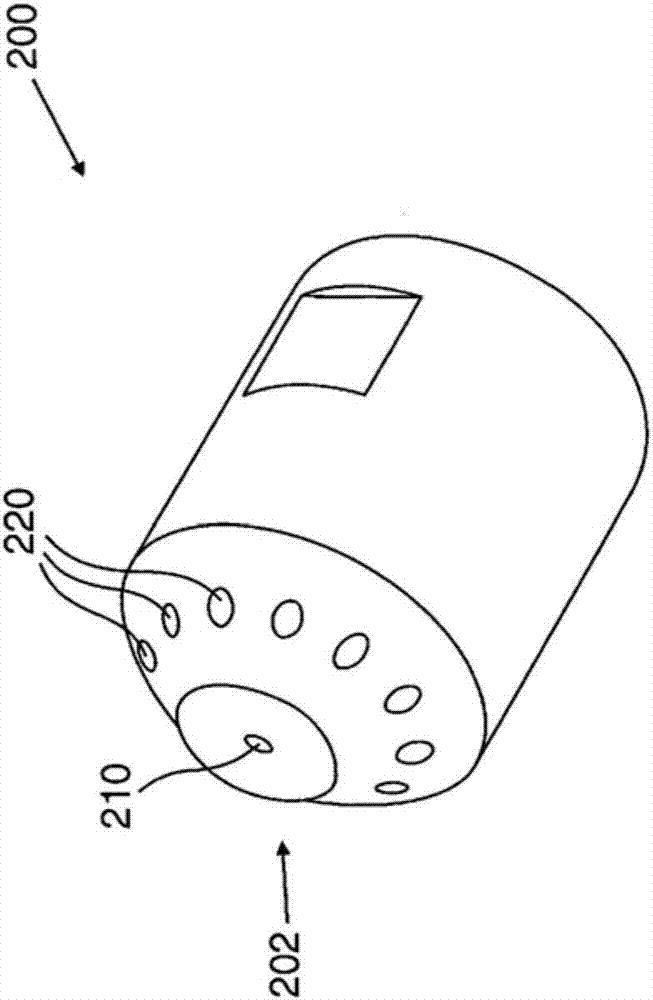

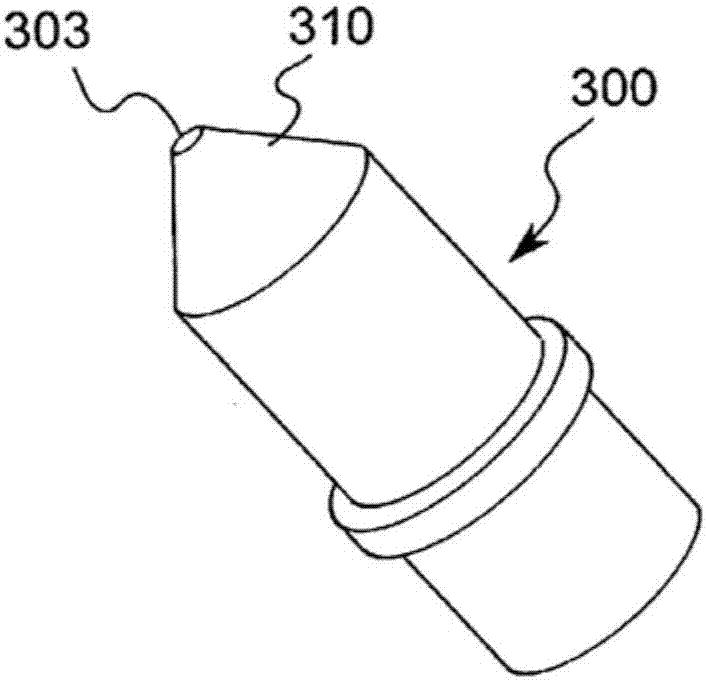

Electrode for a welding torch for tungsten gas-shielded welding and welding torch having such an electrode

ActiveCN107000103AReduce energy densityLarge capacityWelding/cutting media/materialsWelding electrode featuresWelding torchElectrode material

The present invention relates to an electrode (200) for a welding torch (100) for tungsten gas-shielded welding, in particular for tungsten inert gas welding or for plasma welding, wherein the electrode (200) comprises at least one insert (210) composed of a material (211) different from the electrode material (201), wherein the insert (210) at least partially forms an arc-side surface (202) of the electrode, the electrode (200) has, on the arc-side surface thereof, a plurality of focusing-gas bores (220) for supplying a focusing gas (222) for focusing an arc (120), and the electrode (200) has at least one axially extending gas removal bore (230) for removing a gas (132) from the arc-side surface (202) of the electrode (200) through the axially extending gas removal bore (230).

Owner:LINDE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com