Bar-shaped cigarette and preparation method thereof

A technology for rods and cigarettes, applied in the field of heat-not-burn tobacco, can solve the problems of increasing suction resistance, difficulty in manufacturing a filter section, affecting the support performance of a cooling section for cigarettes, etc., so as to increase the amount of smoke and reduce the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example is the preparation of sample 1 of a heat-not-burn cigarette.

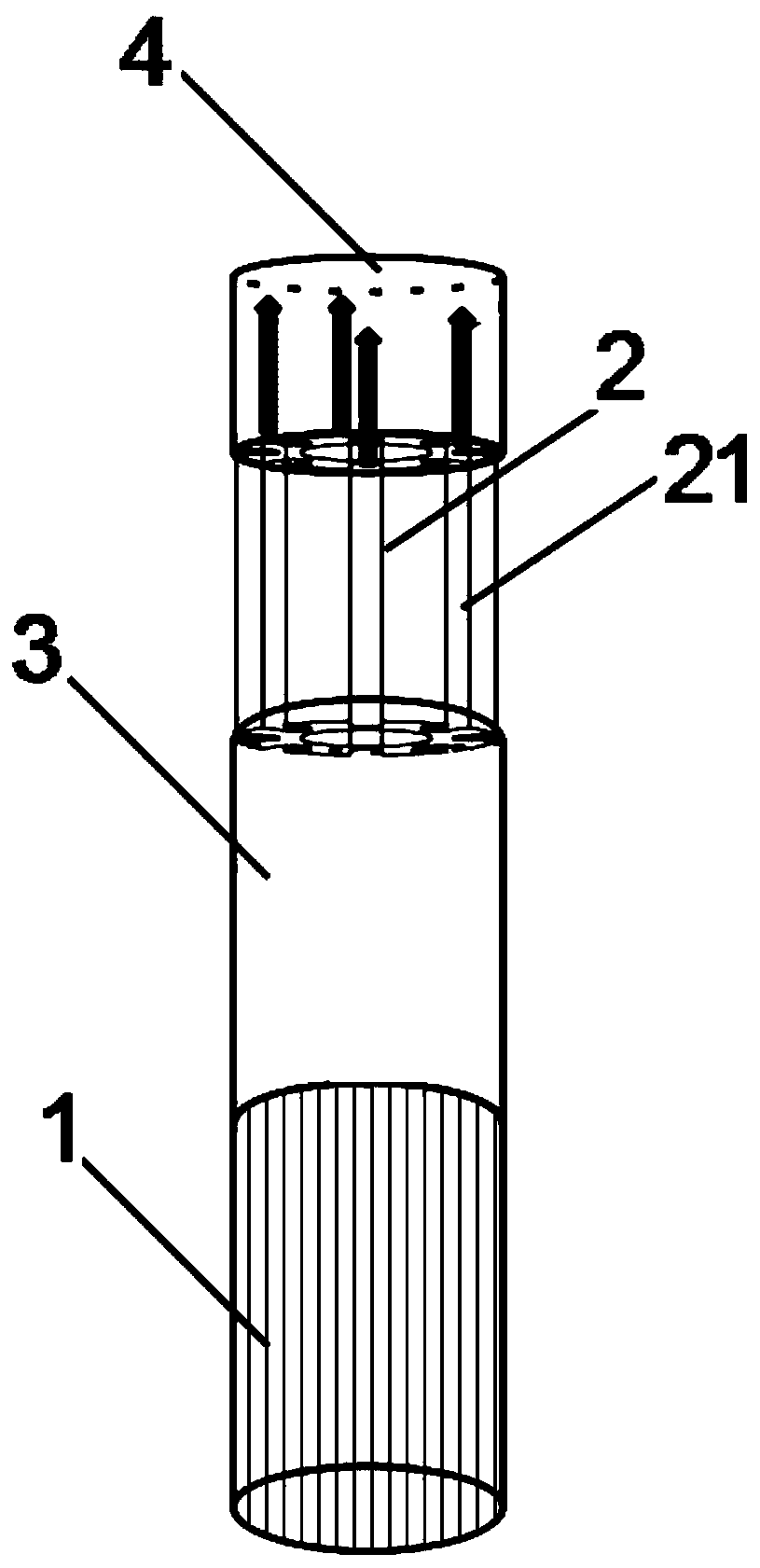

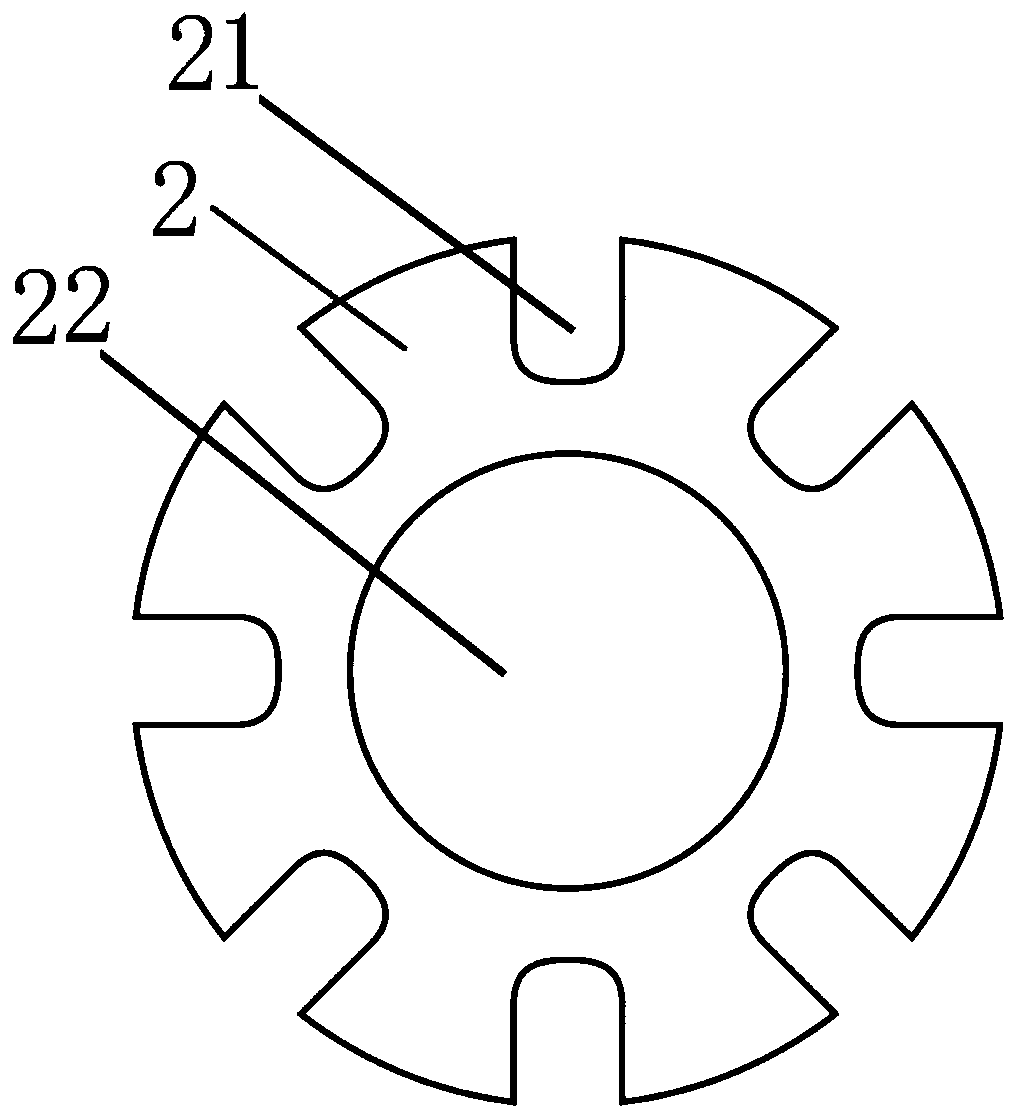

[0040] The cigarette sample 1 sequentially includes a smoking core section 1, a support section 3, a cooling section 2 and a filter section 4, and the cooling section 2 is a cylindrical rod-shaped structure with an axially extending groove 21 on its outer wall , the opening of the groove 21 faces away from the axial center of the cooling section 2 .

[0041] The grooves 21 axially extend the entire length of the cooling section 2; the number of the grooves 21 is two.

[0042] The cross section of the groove 21 is "U" shape.

[0043] The depth of the groove 21 is 0.5mm.

[0044]The preparation method of the cigarette sample 1 described in this embodiment, wherein the preparation method of the cooling section 2 comprises the following steps:

[0045] (1) breaking the base material of the cooling section into powder to obtain the base material of the cooling section in powder form;

[0046] (2)...

Embodiment 2

[0052] This example is the preparation of sample 2 of a heat-not-burn cigarette.

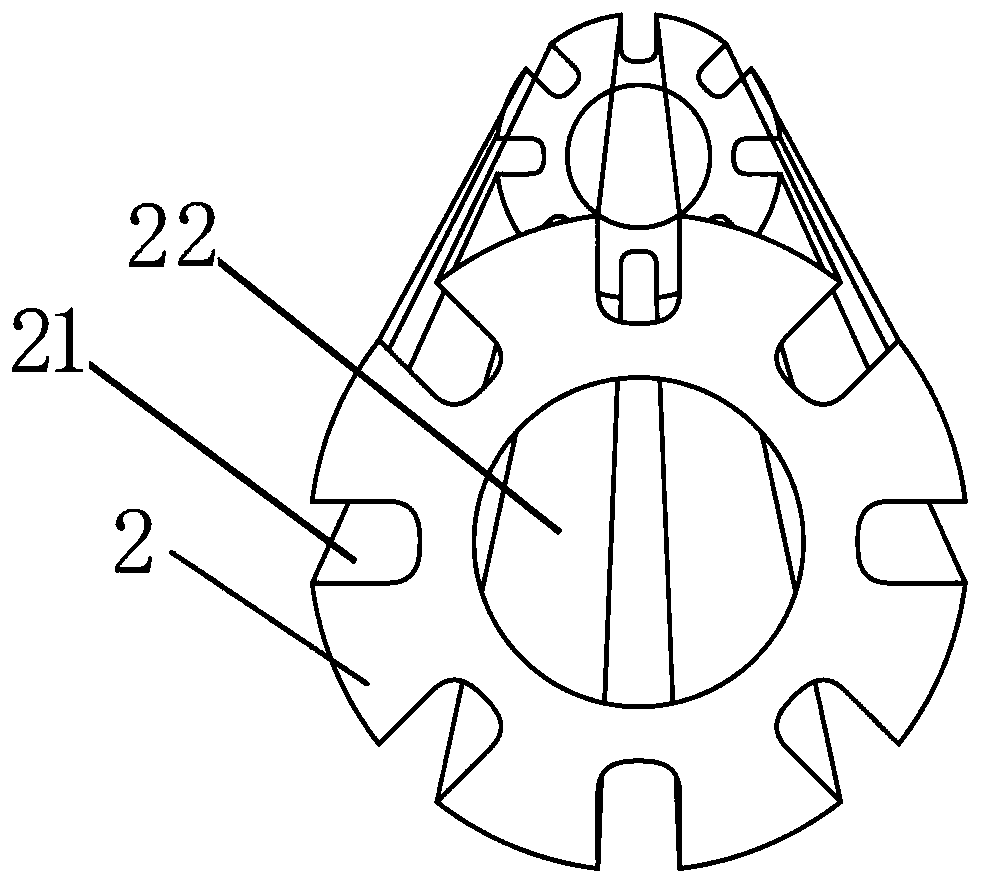

[0053] The cigarette sample 2 sequentially includes a smoking core section 1, a support section 3, a cooling section 2 and a filter section 4. The cooling section 2 is a cylindrical rod-shaped structure with an axially extending groove 21 on its outer wall , the opening of the groove 21 faces away from the axial center of the cooling section 2 .

[0054] The cooling section 2 further includes a cavity 22 extending axially along the cooling section 2 and passing through the cooling section, the number of the cavity 22 is one; the cross section of the cavity 22 is circular.

[0055] The grooves 21 axially extend the entire length of the cooling section 2; the number of the grooves 21 is eight.

[0056] The cross section of the groove 21 is "U" shape.

[0057] The depth of the groove 21 is 0.5 mm.

[0058] The volume of the cavity 22 is 1 / 2 of the total volume of the cooling section 2 .

[0059...

Embodiment 3

[0067] This example is the preparation of sample 3 of a heat-not-burn cigarette.

[0068] The cigarette sample 3 sequentially includes a smoking core section 1, a support section 3, a cooling section 2 and a filter section 4. The cooling section 2 is a cylindrical rod-shaped structure with an axially extending groove 21 on its outer wall , the opening of the groove 21 faces away from the axial center of the cooling section 2 .

[0069] The cooling section 2 further includes a cavity 22 extending axially along the cooling section 2 and passing through the cooling section, the number of the cavity 22 is one; the cross section of the cavity 22 is elliptical.

[0070] The grooves 21 axially extend the entire length of the cooling section 2; the number of the grooves 21 is 12.

[0071] The cross section of the groove 21 is "U" shape.

[0072] The depth of the groove 21 is 3mm.

[0073] The volume of the cavity 22 is 3 / 4 of the total volume of the cooling section 2 .

[0074] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com