Patents

Literature

543 results about "Burn cigarette" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic cigarette

InactiveUS20150296888A1Few or no effectsRealistic effectElectrical apparatusTobacco pipesComputer moduleBurn cigarette

An electronic cigarette comprising a power supply (30) and a light source (40) used for emulating a burning cigarette, also comprising a control module (50) connected to the power supply (30) and to the light source (40). The light source (40) comprises multiple light-emitting units. The control module (50) controls, on the basis of a user operation, the light source (40) to emit a light emulating the burning cigarette. By employing the technical means whereby the control module (50) arranged at the power supply (30) and at the light source (40) comprising the multiple light-emitting units controls, on the basis of the user operation, the light source (40) to emit the light emulating the burning cigarette, the electronic cigarette is capable of implementing emulation under user control scenarios of various burning cigarettes, thus achieving the technical effect of improved vividness whereby the light emitted by the electronic cigarette is of increased likeness to actual smoking.

Owner:KIMREE HI TECH

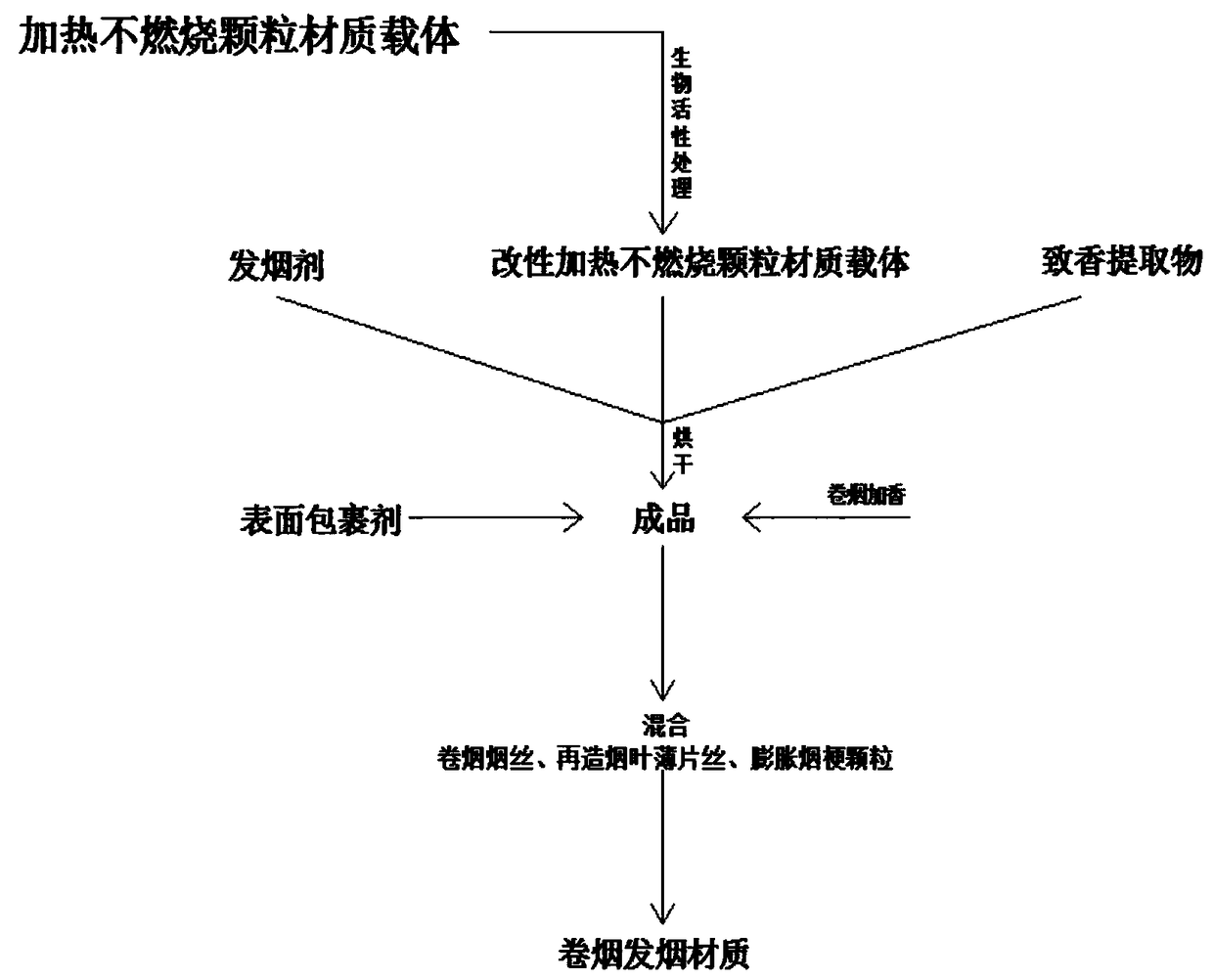

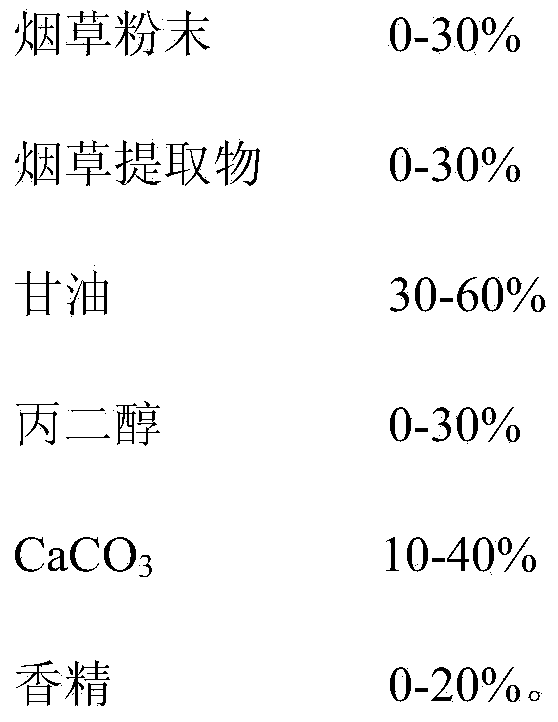

Heating-non-burning cigarette fuming granular material and preparation method thereof

The invention discloses a heating-non-burning cigarette fuming granular material and a preparation method thereof. The granular material includes a heating-non-burning granular material carrier, fuming agents, a surface coating agent and a perfuming extract. The heating-non-burning granular material carrier includes juncus roemerianus, gramineous plant granules, radix puerariae, eupatorium adenophorum, tobacco powder, tobacco stem powder, hydroxypropyl methyl cellulose, beta cyclodextrin, gelatin, sodium alginate, diatom ooze, chitosan, methylcellulose, lignin and other natural plant granules.The preparation method of the granular material includes the following step of preparing the heating-non-burning granular material carrier at first, wherein the carrier is preferably selected from domestic high-quality granules or natural mineral compound granules and powder thereof for pelleting or compounding. The fuming granules are integrally loaded according to volume and then sealed, finished products of a fuming unit are mixed with the fuming agents of perfuming groups different in taste, and the problems that cigarette containers in the heating-non-burning field are monotonous in typeand processing technologies are cumbersome are solved.

Owner:YUNNAN XIKE TECH CO LTD

Resistance wire heating device for non-burning cigarettes

The invention relates to a resistance wire heating device for non-burning cigarettes. The device comprises an outer shell, an insulation jacket and a heater, a cigarette inlet allowing tobacco products to be inserted in is formed at the front end of the outer shell, the rear end of the outer shell is connected with an air inlet, the heater is arranged in the outer shell, and the insulation jacket is arranged between the heater and the outer shell. A resistance wire heating element is adopted as the heater and comprises a resistance wire and a ceramic heat-conducting sleeve, the resistance wire is arranged on the outer surface of the ceramic heat-conducting sleeve, a heating chamber for accommodating the tobacco products is arranged in the middle of the ceramic heat-conducting sleeve, the front end of the heating chamber is communicated with the cigarette inlet, and the rear end of the same is communicated with the air inlet. The resistance wire heating device has the advantages of high heat efficiency, constant-temperature heating, high temperature control precision, good stability and long service life.

Owner:CHINA TOBACCO ZHEJIANG IND

Treatment of mainstream smoke constituents by use of oxygen storage and donor metal oxide oxidation catalyst

InactiveUS20050121045A1Reduction of sidestream smokeReducing toxic constituents in the mainstream smokeNon-fibrous pulp additionTobacco treatmentParticulatesBurn cigarette

The use of a treatment composition for a cigarette to reduce at least one constituent of mainstream smoke from a burning cigarette, the treatment composition comprising, in combination, an oxygen storage and donor metal oxide oxidation catalyst and an essentially non-combustible finely divided porous particulate adjunct.

Owner:ROTHMANS BENSON & HEDGES INC CA

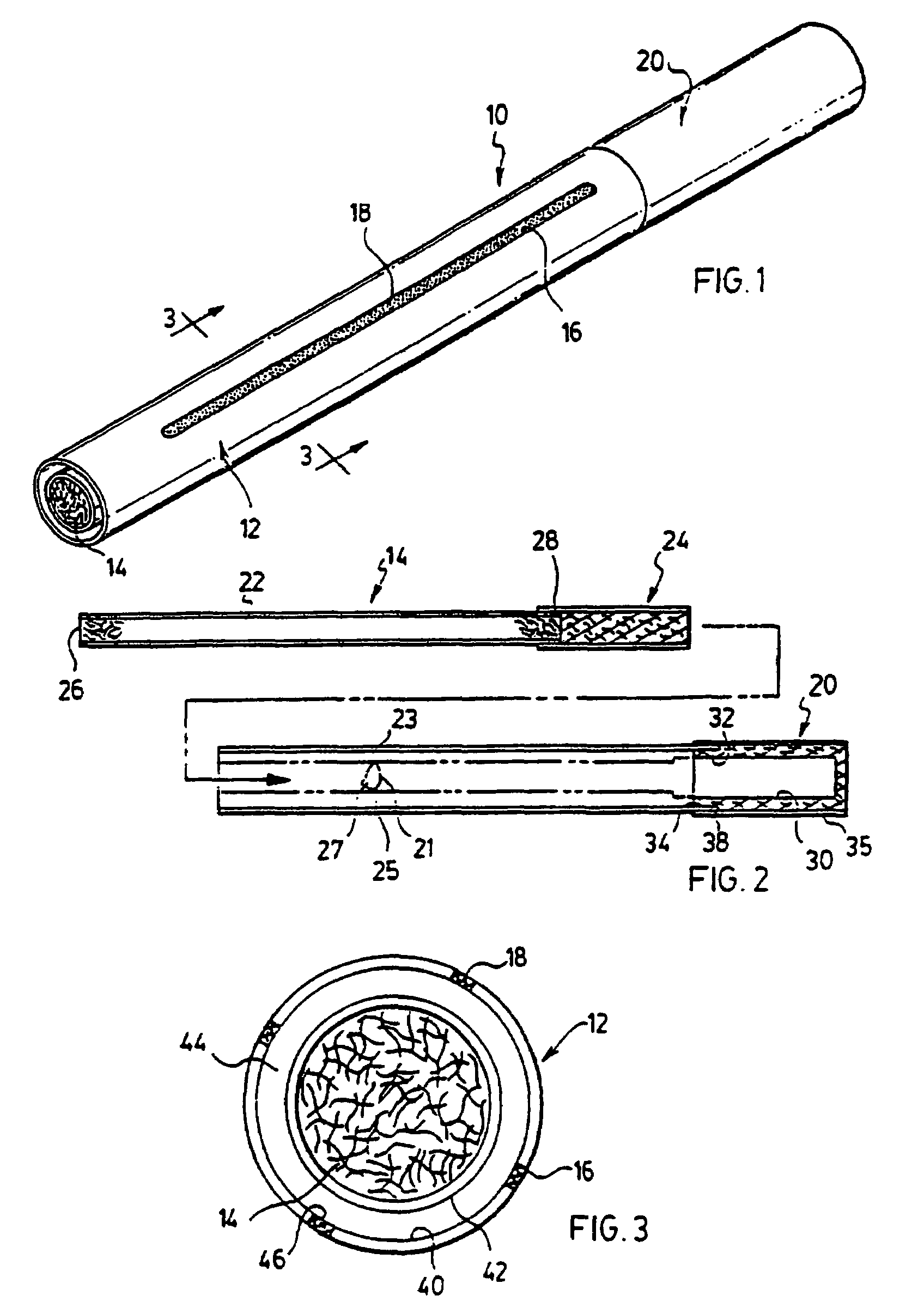

Tubular cigarette device comprising cerium oxide

InactiveUS7624739B2Reduce the probability of burningMinimizing cigarette sidestream smokeTobacco treatmentCigar manufactureBurn cigaretteEffective length

A device for minimizing cigarette sidestream smoke and reducing free-burn rate of a burning cigarette is disclosed. The device comprises a non-combustible tubular element encasing an effective length of a tobacco charge of a cigarette located in the tubular element. The tubular element minimizes sidestream smoke emission from a burning tobacco charge and reduces free-burn rate of such burning tobacco charge to increase the number of puffs from the burning tobacco charge.

Owner:ROTHMANS

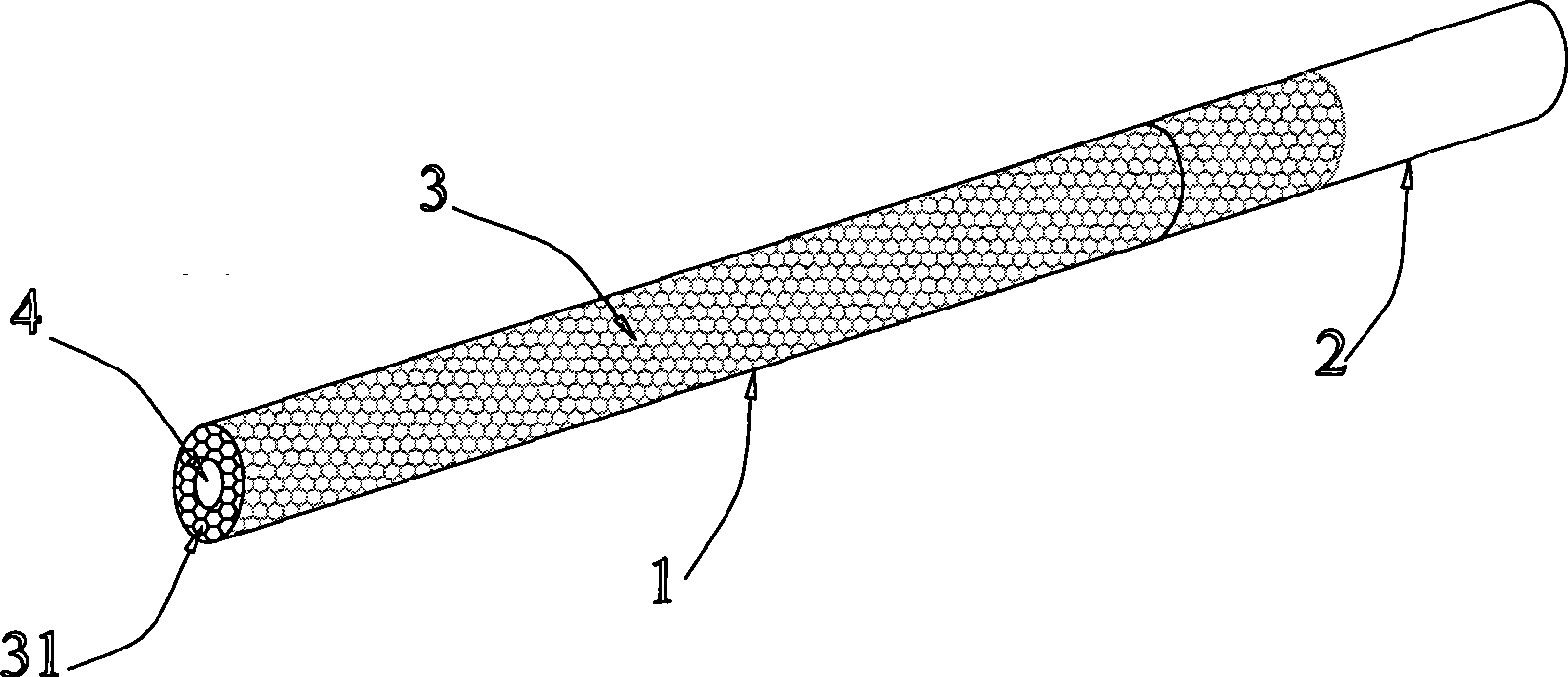

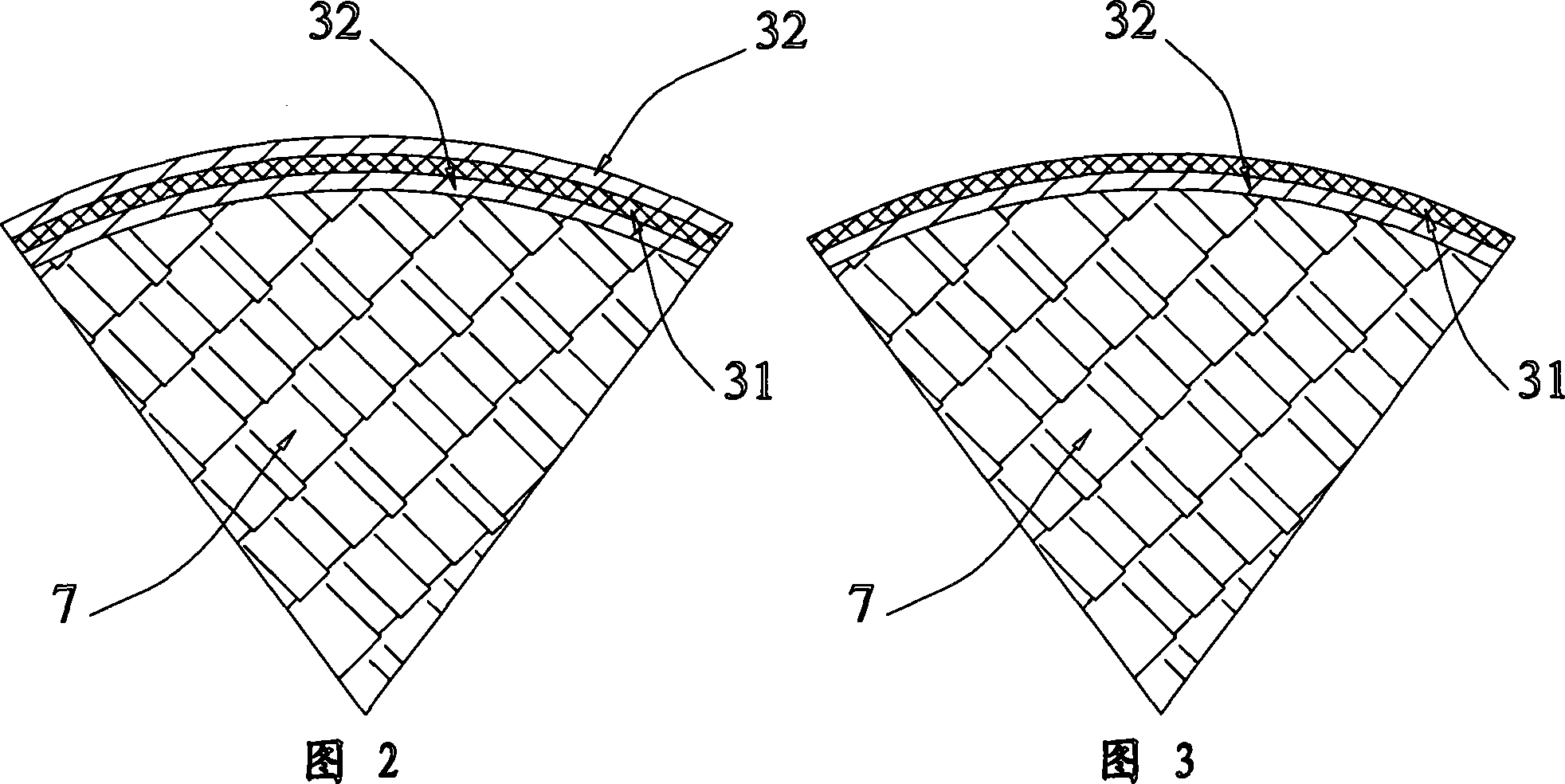

Safety cigarette

The invention relates to the cigarette field. Technical problem to be solved is to overcome the defect of the existing cigarettes. The invention provides safety cigarettes that have high safety and greatly lower fire hazard initiation rate. The structure of the cigarette is that a rigid fire-retardant layer is embedded into the rice paper of the cigarette, and the fire-retardant layer is reticular. After the cigarette is ignited, tobacco shred burns inside the fire-retardant layer, and the reticular structure ensures unobstructed burning. Due to the rigid structure of the fire-retardant layer, the cigarette still keeps the reticular tube-shaped structure while burning. The tube-shaped fire-retardant layer separates the burning surface form the external, ensure that the burning front is not connected with the external, therefore, though the burning cigarette is discarded, the possibility that the burning surface is connected with the external is small, and a fire is difficult to be caused, thus greatly improving the safety of the cigarette.

Owner:CHINA TOBACCO GUANGDONG IND

Method for preparing heat-not-burn tobacco bases containing active carbon

ActiveCN105747264AReduce the impactIncrease loadTobacco preparationTobacco treatmentActivated carbonFlavor

The invention discloses a method for preparing heat-not-burn tobacco bases containing active carbon.The method comprises the following steps that active carbon is weighed and mixed with water, defibering and pulping are conducted, and active carbon pulp is obtained; tobacco raw materials are weighed, soaked, filtered and pulped so that tobacco pulp can be obtained; by weight, 50-80 parts of tobacco pulp, 8-25 parts of wood pulp, 10-30 parts of active carbon pulp and 4-8 parts of adhesive are weighed and evenly mixed; the mixture is formed and dried so that the tobacco bases are obtained; by weight, 1-40 parts of tobacco essential oil, 2-20 parts of tobacco flavor material and 40-80 parts of atomization agent are weighed and evenly mixed so that coating liquid can be obtained; the coating liquid is sprayed to the tobacco bases, standing is conducted for 40-48 h under the constant-temperature and constant-humidity conditions, and finally the heat-not-burn tobacco bases containing active carbon are obtained.Cigarettes prepared from the tobacco bases are put in a smoking set to be used, good satisfaction can be brought to consumers, the amount of smoke is large, the fragrance concentration is high, and the quality of heat-not-burn cigarettes is improved better.

Owner:CHINA TOBACCO GUIZHOU IND

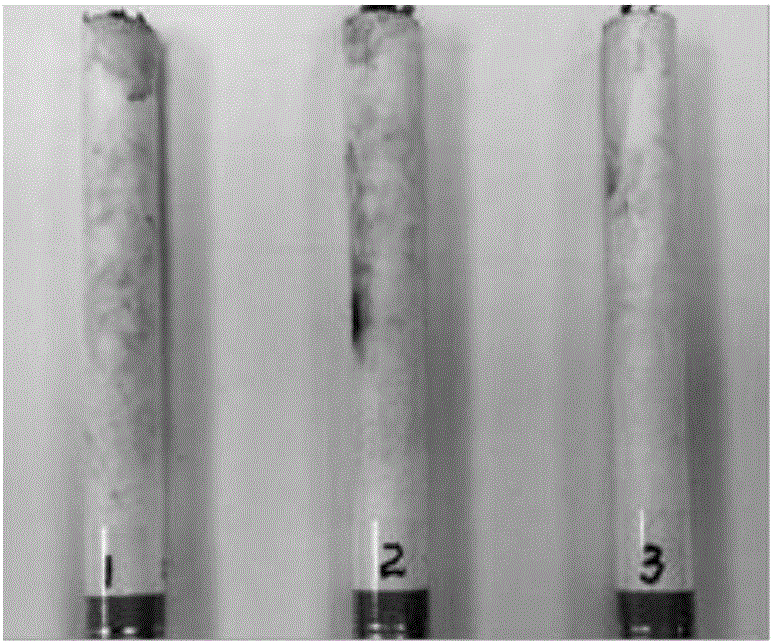

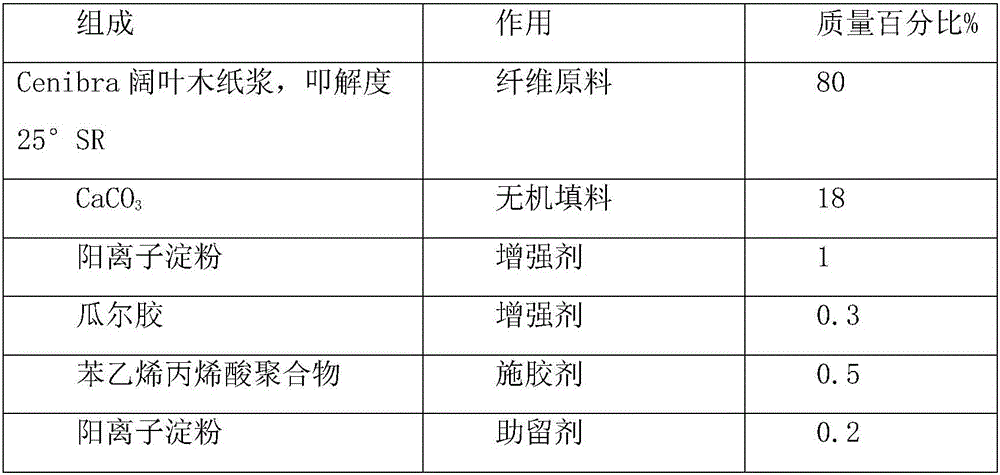

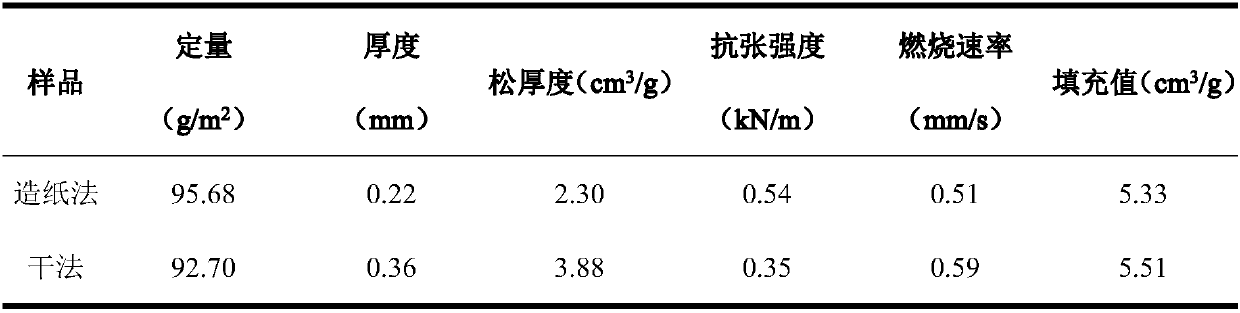

Heating non-combustible cigarette paper and preparation method thereof

ActiveCN106368069ANo tar spotsDoes not start carbonationInorganic fibres/flakesSpecial paperFiberBurn cigarette

The invention discloses heating non-combustible cigarette paper and a preparation method thereof. The preparation method of the heating non-burning cigarette paper comprises the following steps: 1) pulping the plant fiber with the length of 0.5 to 4mm, or adding the appropriate proportion of inorganic fiber; 2) adding the inorganic filler in the process of dilution of the pulp, wherein the addition ratio of the inorganic filler is 5 to 50% of the mass of the pulp; 3) sizing the paper to improve water and oil resistance, and cigarette paper is quantified at 50 to 120 g / m<2>. Compared with the existing heated non-combustible cigarette paper that is heated at 350 DEG C, the non-combustible cigarette paper of the present invention has very few yellow stitches, and no tar spots and carbonization, while the entire surface of the existing non-combustible cigarette paper turns yellow, with large tar penetrating and carbonized. In addition, the non-combustible cigarette paper of the present invention is rarely present broken in actual production, and there is almost no deformation and wrinkling after being sucked as the heated cigarette paper.

Owner:中烟摩迪(江门)纸业有限公司

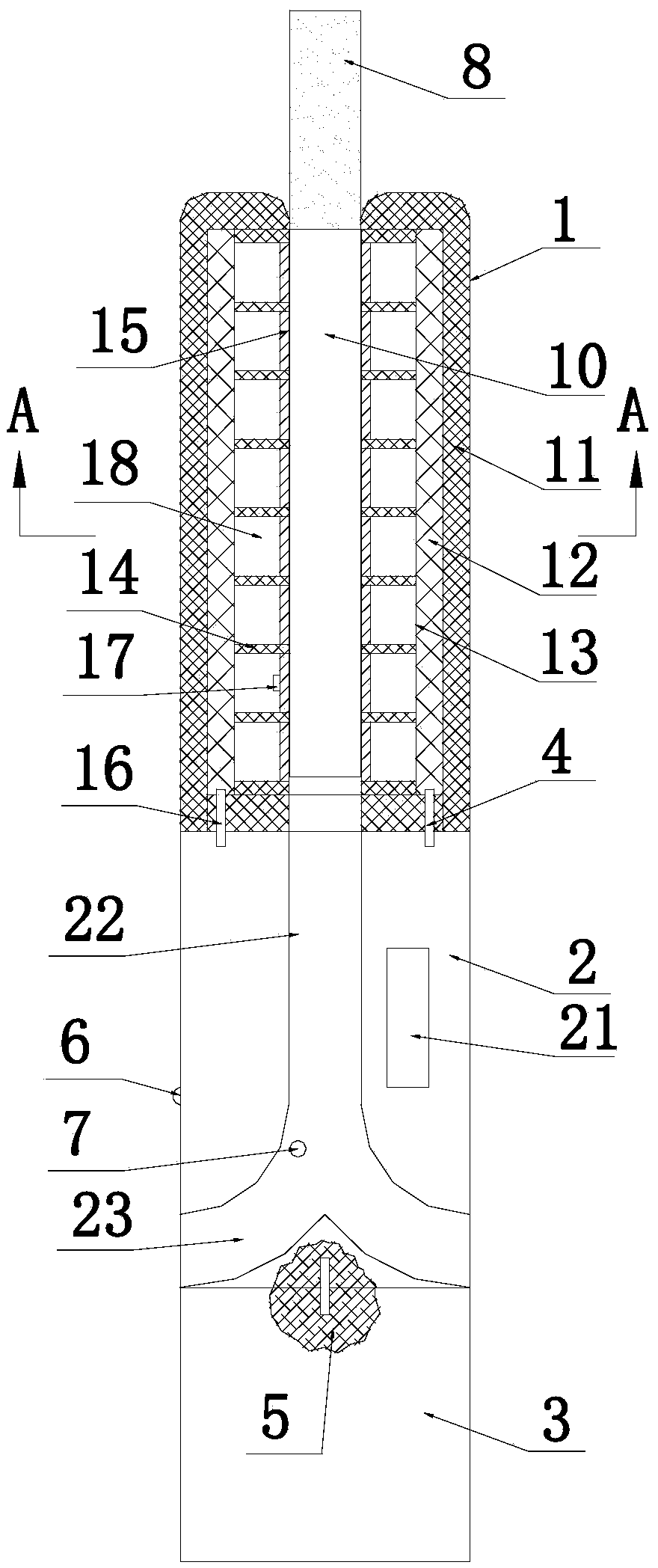

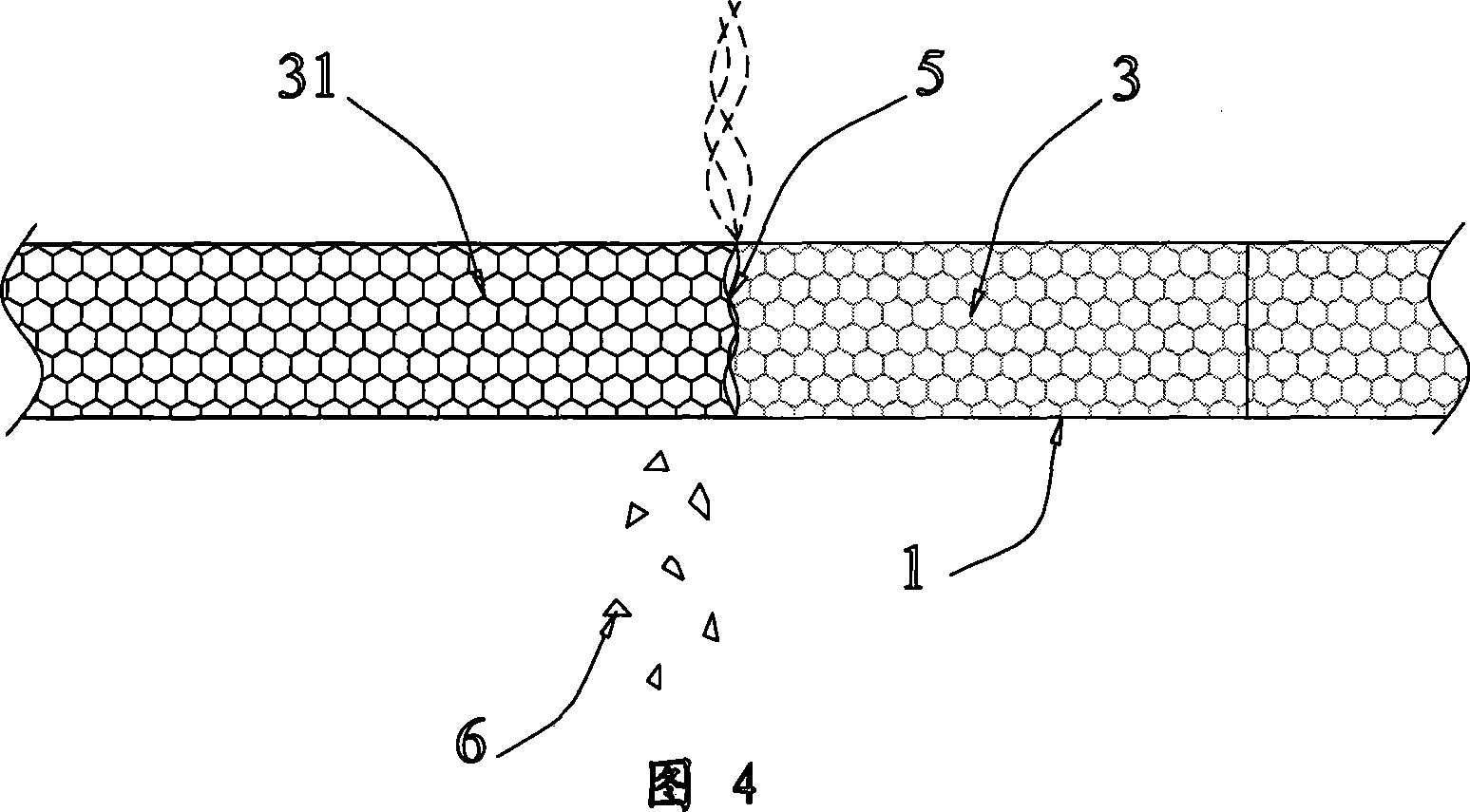

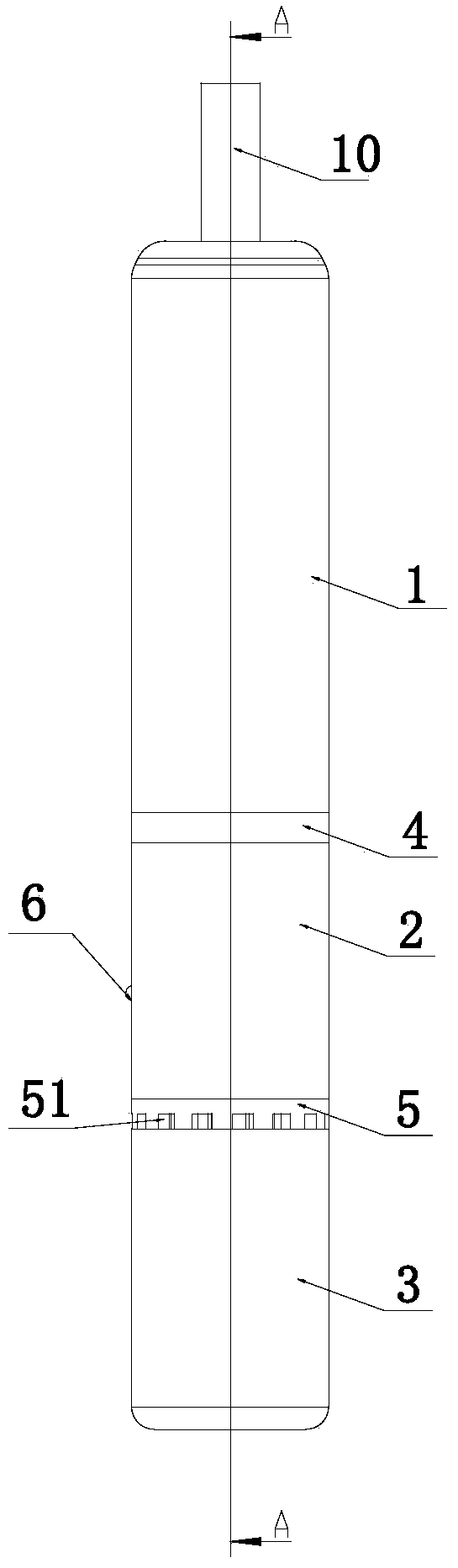

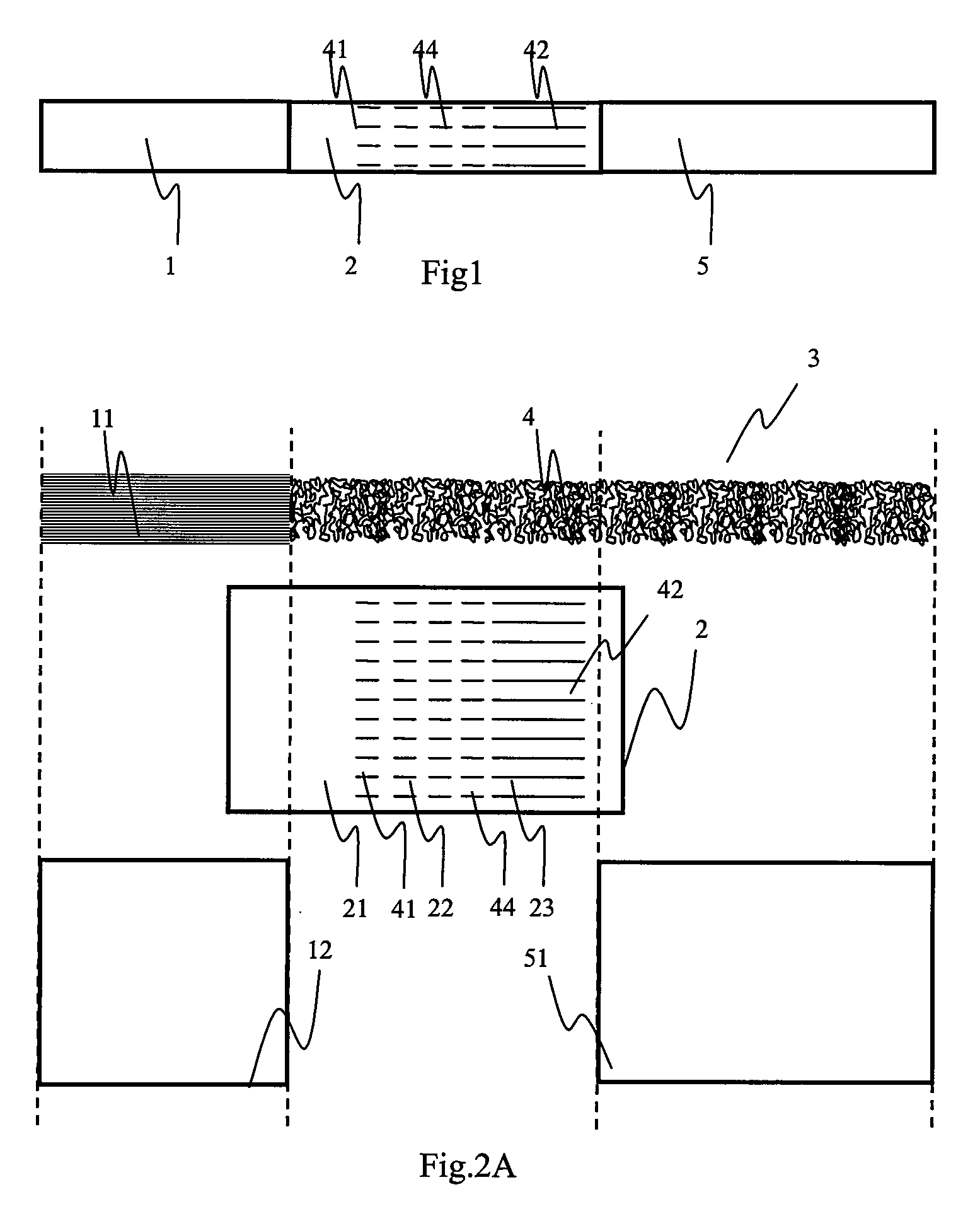

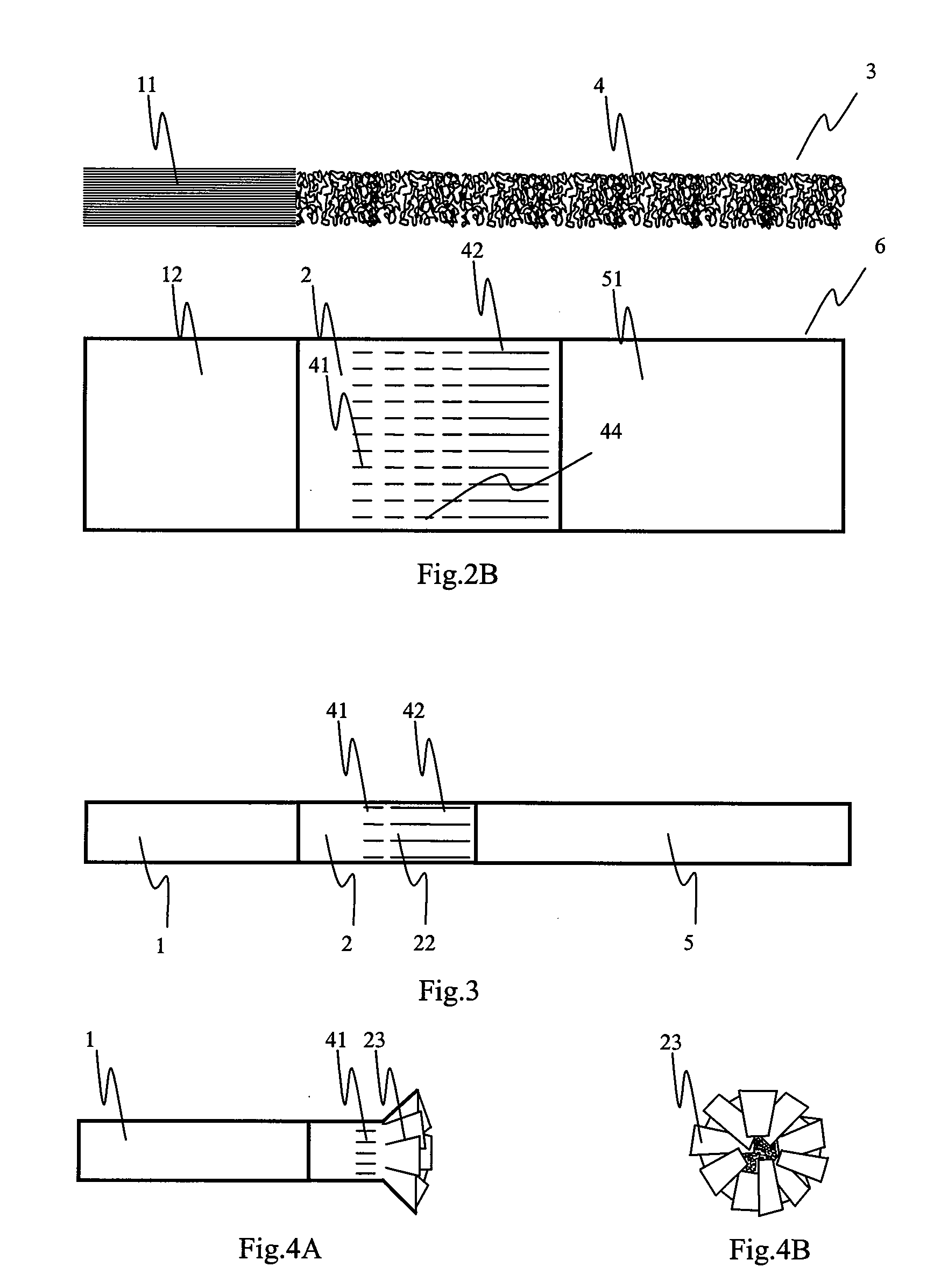

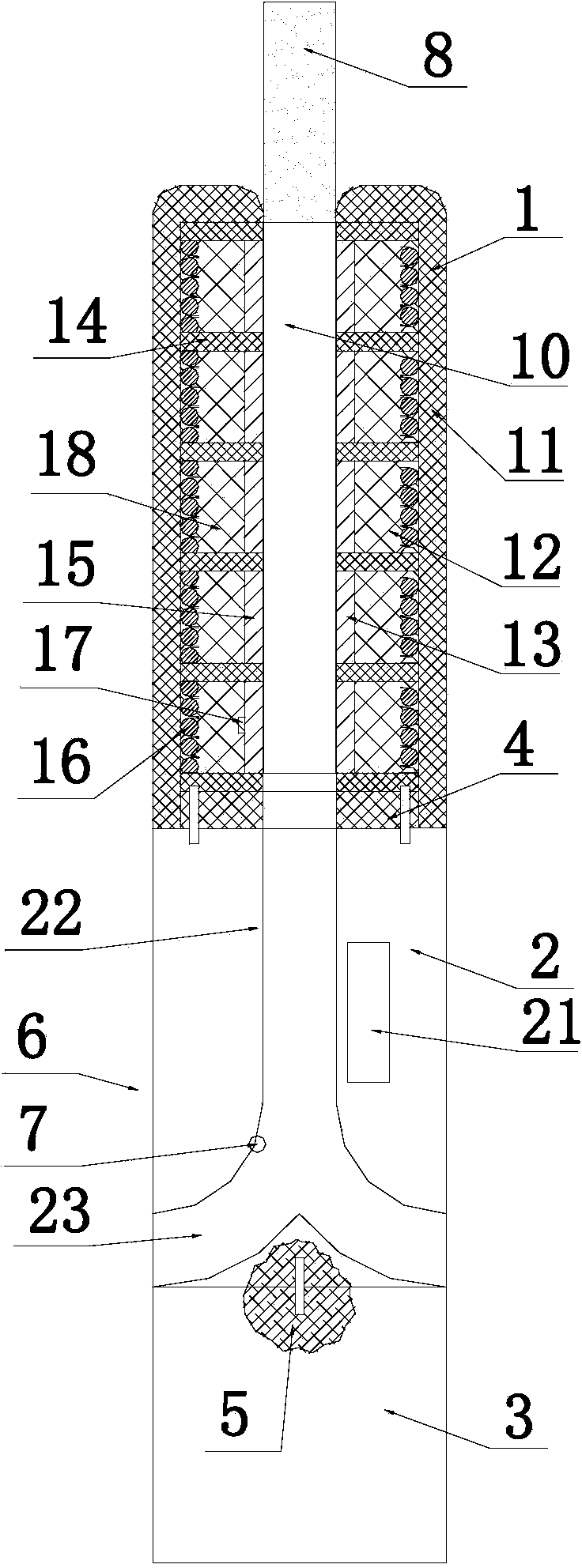

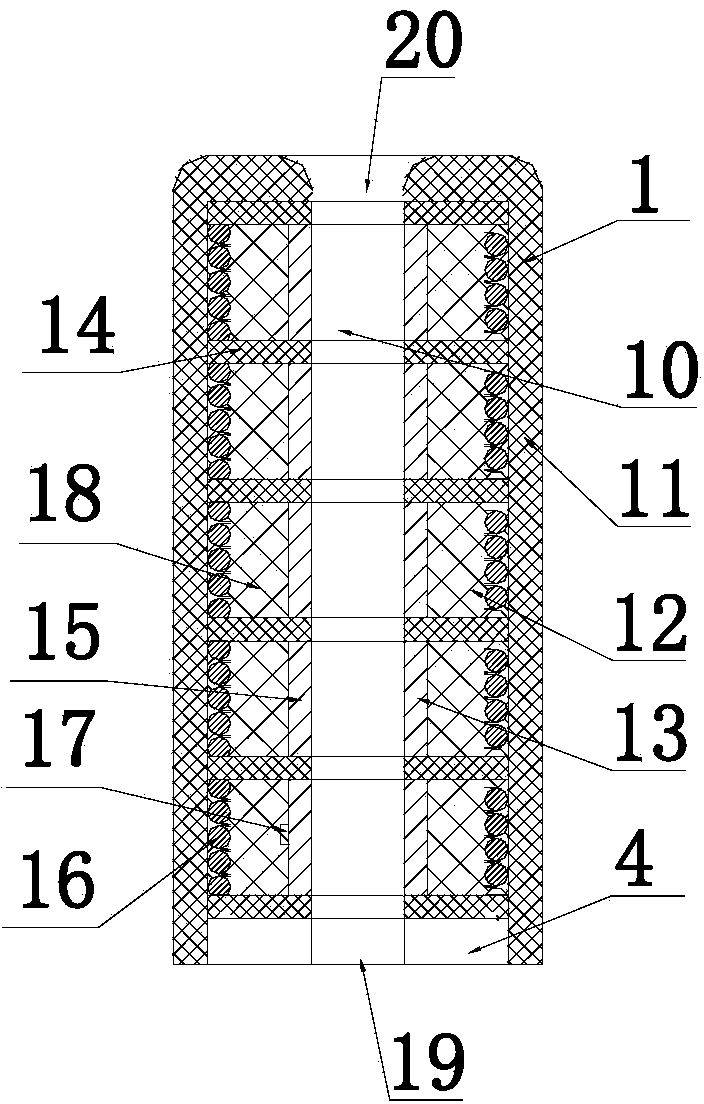

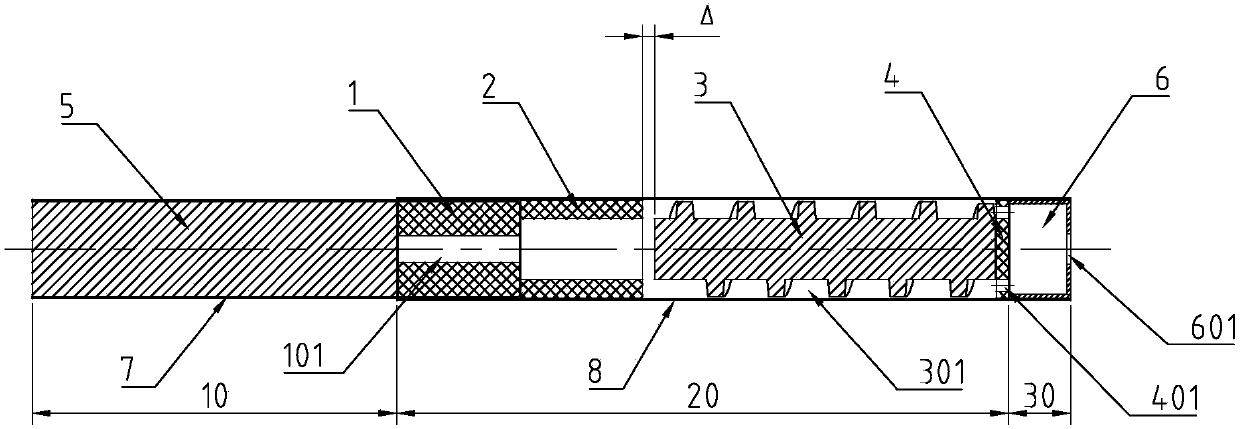

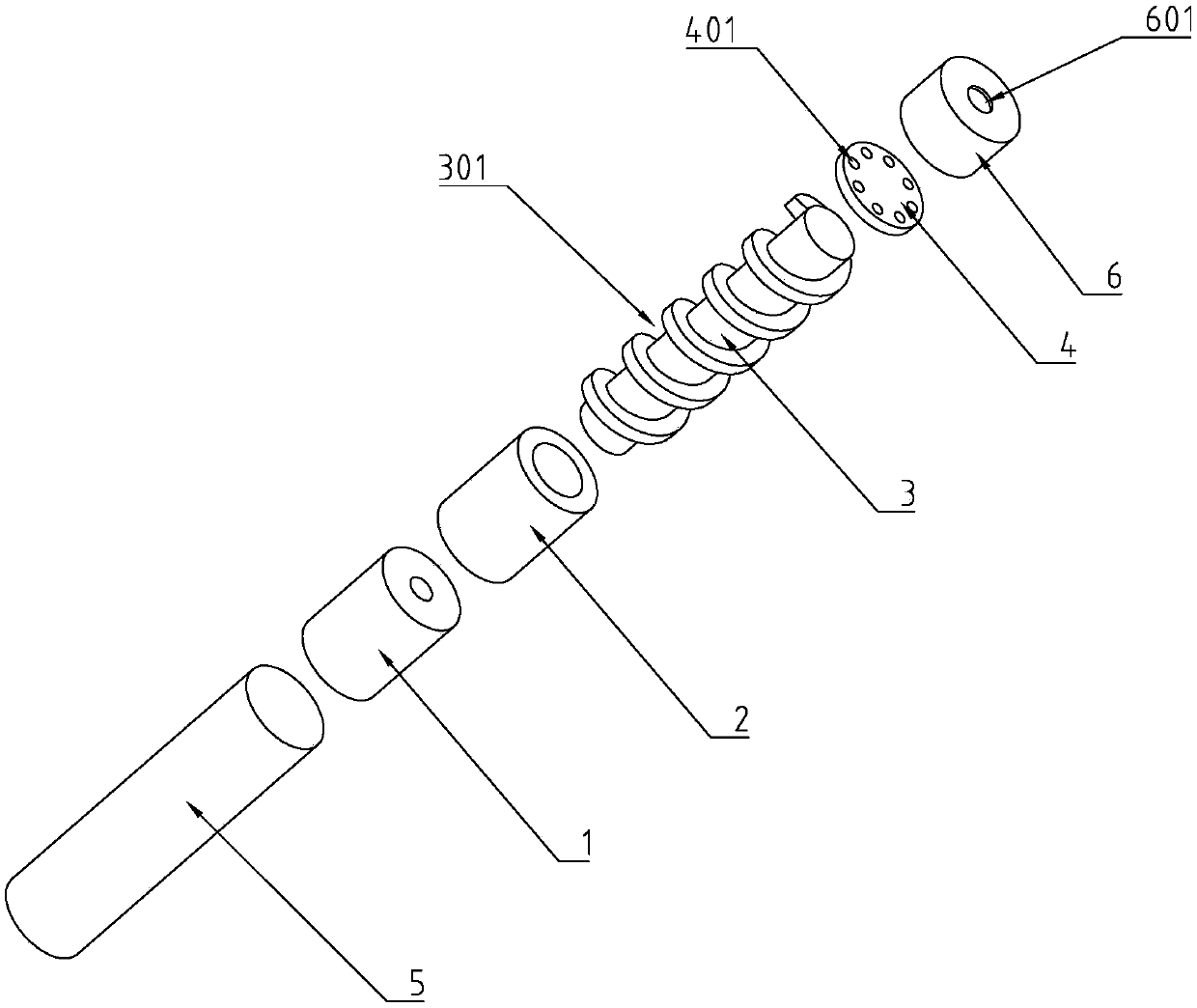

Sectional heating control device for non-burning cigarettes

InactiveCN103720057AEnsure characteristic feelingHarm reductionTobacco devicesControl systemBurn cigarette

The invention relates to a sectional heating control device for non-burning cigarettes. The sectional heating control device comprises a sectional heater and a control system, the sectional heater comprises multiple hollow heating elements, an insulating and heat insulating washer is arranged between every two adjacent hollow heating elements, the hollow heating elements and the insulating and heat insulating washers form a tubular whole, the tubular whole is hollow to from a heating chamber for accommodating tobacco products, one end of the heating chamber is a cigarette inlet, and the other end of the heating chamber is communicated with outside air through an air flow passage. The control system comprises a controller and a power supply, the power supply is connected with the controller which comprises a CPU (central processing unit) and power regulators, the CPU is connected with the power regulators which are connected to the hollow heating elements respectively, and the CPU controls the hollow heating units to heat in axial sequence. Through an electric heating mode, aroma components in the cigarettes can be removed by destructive distillation, and harm of the cigarettes to human bodies is reduced.

Owner:CHINA TOBACCO ZHEJIANG IND

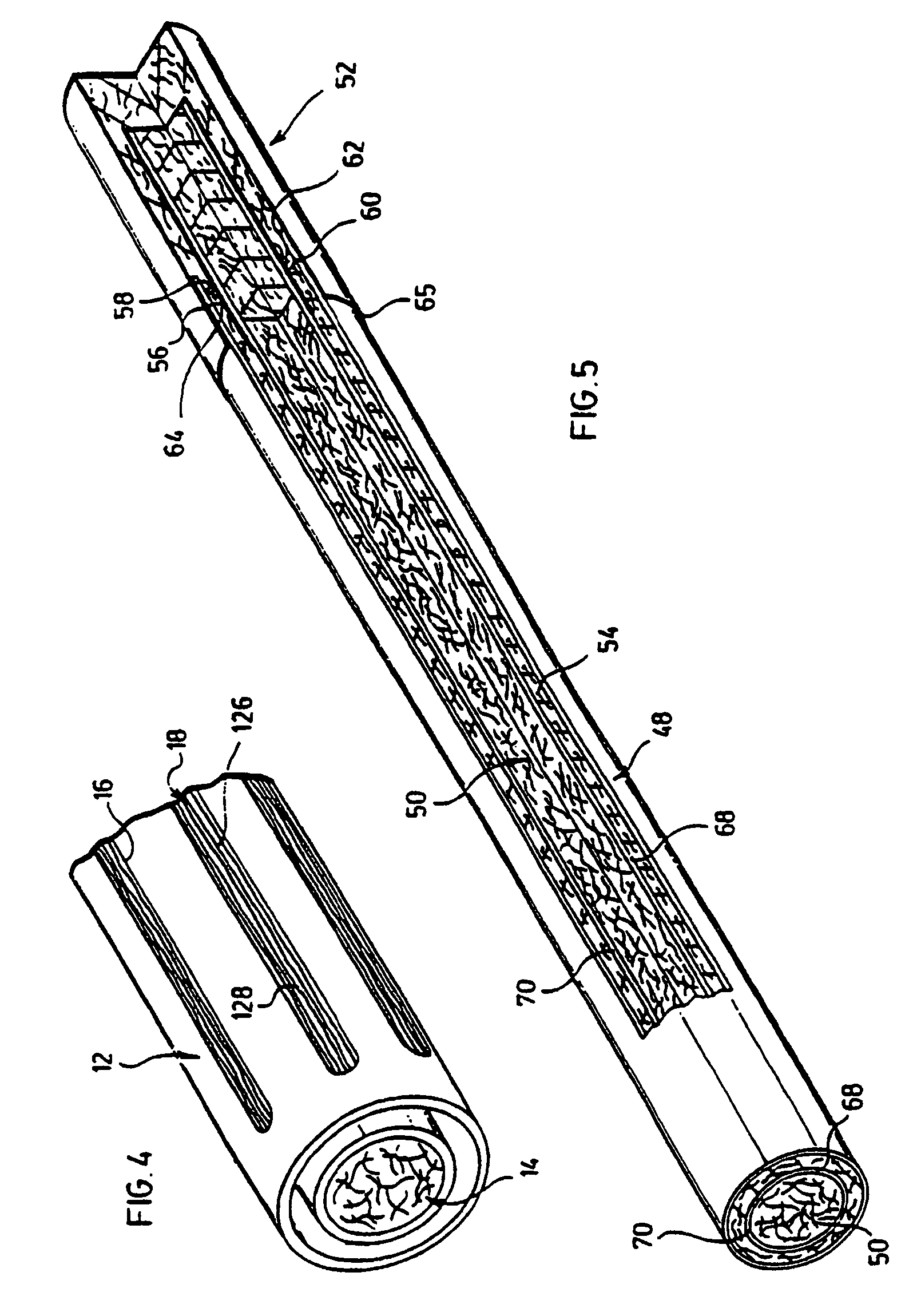

Flame-retardant and Fireproof Cigarette

InactiveUS20090320865A1Reduce morbidityEffectively isolate open fire of a burning cigaretteNon-fibrous pulp additionNatural cellulose pulp/paperBurn cigaretteEngineering

A flame-retardant and fireproof cigarette which aims to contain the combustion process to the cigarette. The flame-retardant and fireproof cigarette has a filter that is aligned with a tobacco body. A flame-retardant and fireproof covering is positioned over at least a portion of the tobacco body and isolates the open fire associated with the consumption of the tobacco during the course of smoking or burning the cigarettes. Such a cigarette reduces the risk of undesired, inadvertent, and latent ignition of adjacent materials.

Owner:NING TIAN

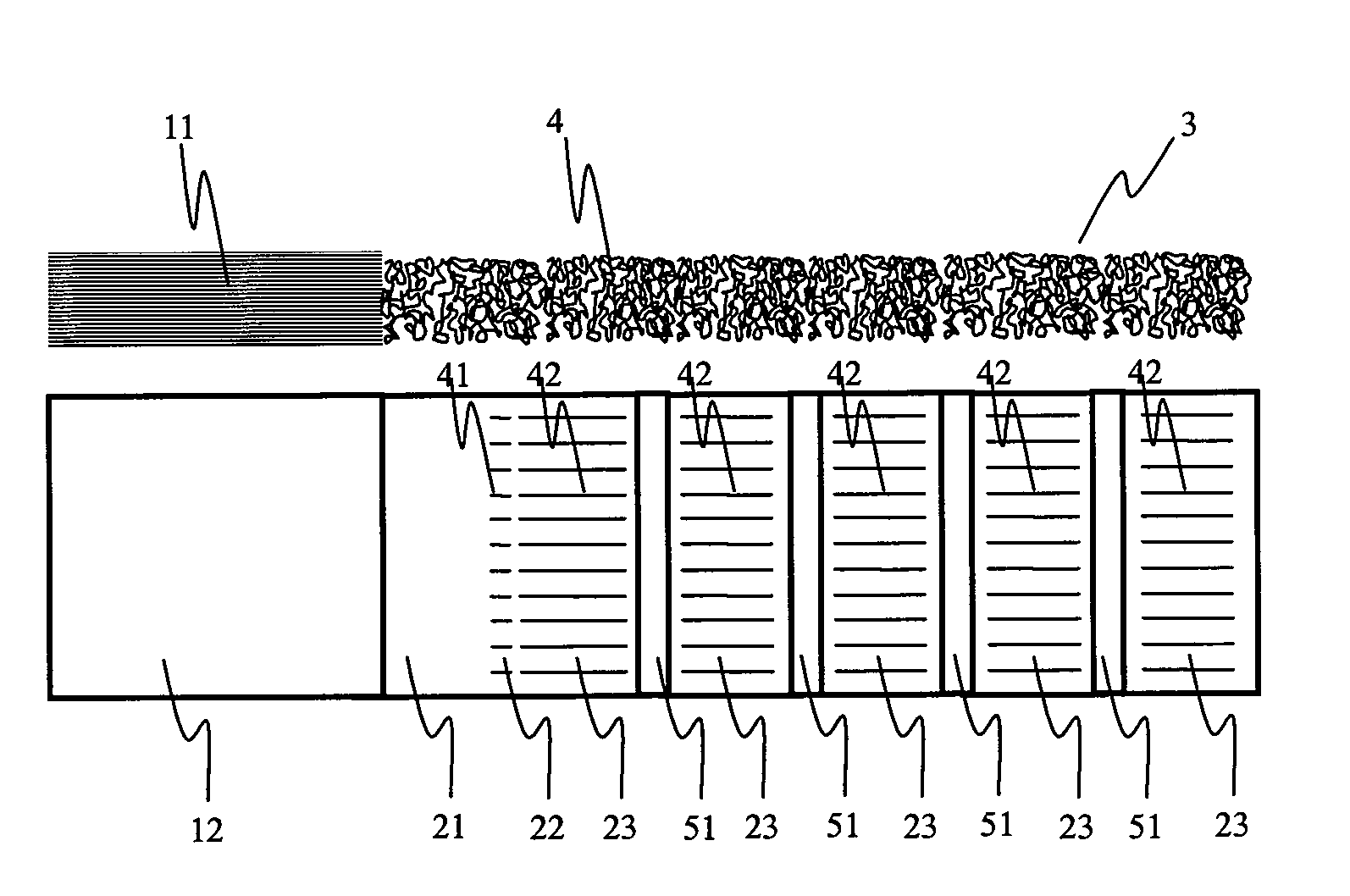

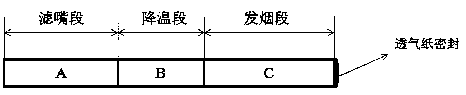

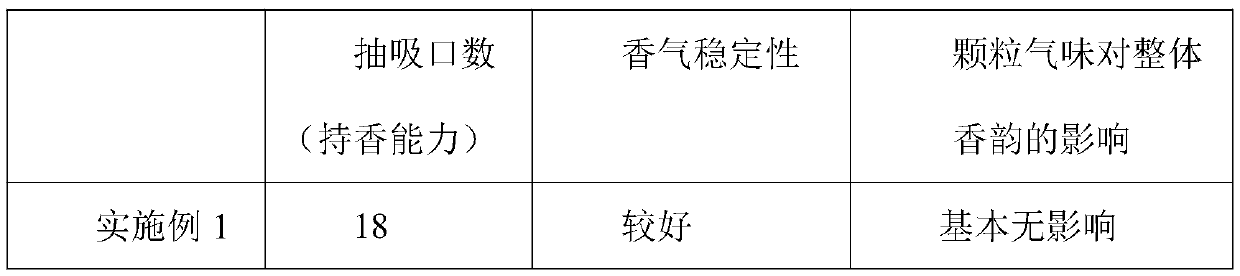

Preparation method of smoking section of granular heat-not-burn cigarette

ActiveCN110876487AHigh adsorption propertiesGood scent release effectTobacco preparationCigar manufactureBurn cigarettePorous particle

The invention discloses a preparation method of a fuming section of a granular heat-not-burn cigarette. The cigarette comprises a filter tip section, a cooling section and a fuming section; the fumingsection is of a closed structure sealed by breathable paper, the length of the fuming section ranges from 15 mm to 20 mm, aroma-attached particles are arranged in the fuming section, and aroma-attached particles prepared by adopting natural animals and plants such as turf, cuttlebone, coconut shells and washed tobacco stems as raw materials are arranged in the fuming section. The closed heating non-combustion cigarette smoke generation section is adopted, due to the fact that the adsorption characteristic of the porous particles is obviously higher than that of the tobacco sheets, the smoke generation agent carrying capacity of the particle type smoke generation section can be 2-3 times that of the sheet type smoke generation section, the fragrance slow release effect is better, moistureabsorption is not likely to happen, and the stability is better.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

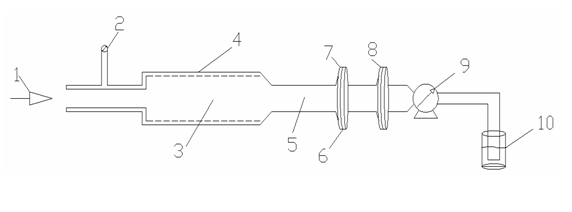

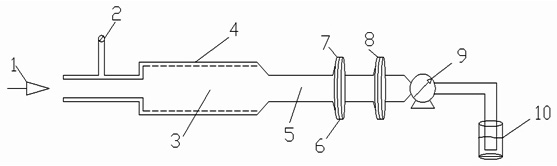

Method and device for simulating process of burning cigarette to generate smoke

InactiveCN102680302AFast Pyrolysis ResearchEasy to operateChemical analysis using combustionPreparing sample for investigationBurn cigaretteProcess engineering

The invention relates to a method and a device for simulating the process of burning a cigarette to generate smoke. The device consists of a heating device, two groups of catchers, a suction pump and a tail gas catching device, wherein the tail part of the heating device is connected with the two groups of catchers which are connected in series; the catchers are connected with the suction pump; the suction pump is connected with the tail gas catching device; the other end of the heating device is connected with a gas source and a gas flow meter; and Cambridge filters are arranged in the two catchers. The method comprises the following steps of: putting a certain amount of prepared sample into the heating device, introducing gas, limiting atmospheric pressure at the gas flow meter to 90-100kPa, and adjusting the inlet amount and discharge amount of the gas to achieve balance by using the suction pump, wherein gas flow is 900 to 1,050mL / min; and performing infrared heating to burn the sample by using the heating device, raising the temperature from 400 to 800 DEG C for 50 seconds, reducing the temperature from 800 to 400 DEG C for 1 minute, heating until the tobacco shred sample is burnt out, and detecting and evaluating gas caught by the gas catching device to obtain the content of a target substance generated in the process of burning the sample.

Owner:YUNNAN RES INST OF TOBACCO SCI

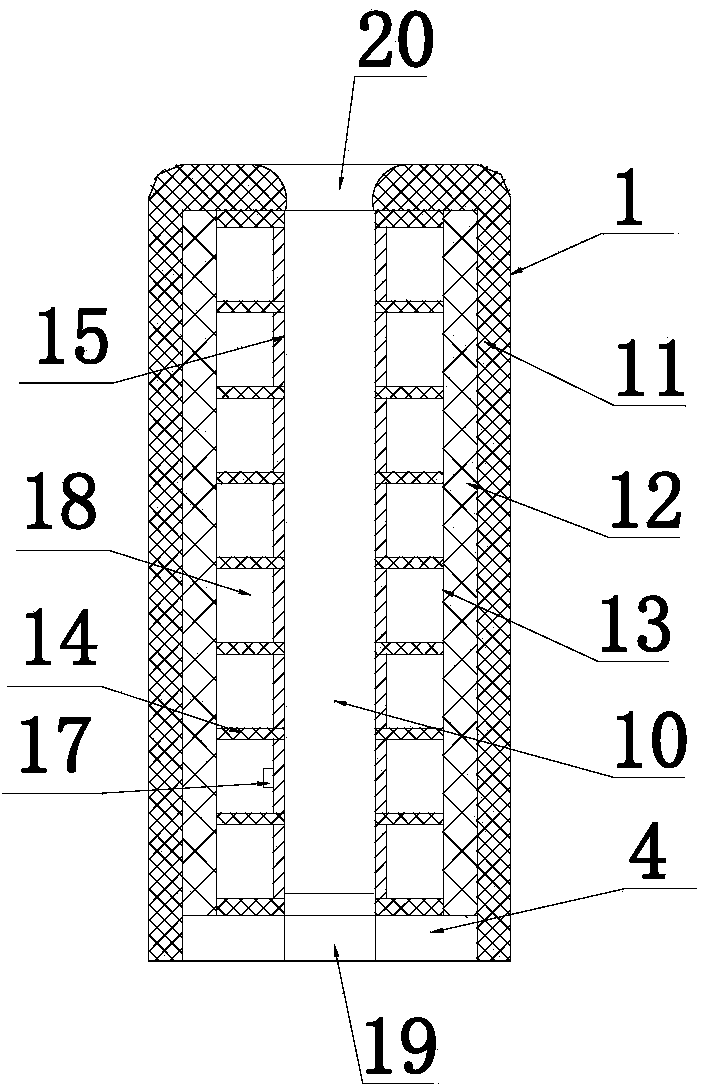

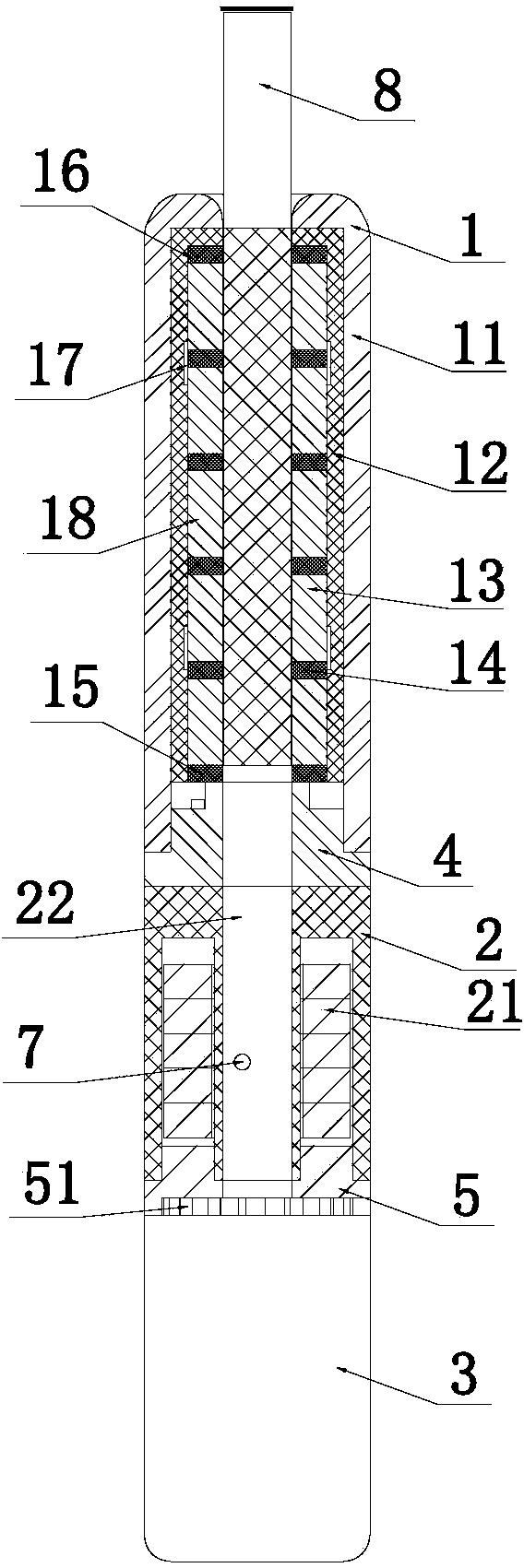

Electromagnetic wave heating device for non-burning cigarettes

The invention relates to an electromagnetic wave heating device for non-burning cigarettes. The device comprises an outer shell, a heat insulation sleeve and a heater. A cigarette inlet allowing tobacco products to be inserted in is formed at the front end of the outer shell, an air inlet is formed at the rear end of the outer shell connectively, the heater is arranged in the outer shell, an electromagnetic wave heating element is adopted as the heater and comprises a coil and an inner heating sleeve, the coil and the inner heating sleeve are matched to realize heating, the heat insulation sleeve is arranged between the coil and the inner heating sleeve, insulation washers are arranged at two ends of the electromagnetic wave heating element respectively, the inner heating sleeve is hollow to form a heating cavity for accommodating the tobacco products, the front end of the heating cavity is communicated with the cigarette inlet, and the rear end of the heating cavity is communicated with the air inlet. By the device, aroma components in the cigarettes can be removed by destructive distillation through an electromagnetic wave heating mode in stead of directly burning the cigarettes, harm of the cigarettes to human bodies is reduced, and a consumer is ensured to obtain a tobacco feature feeling.

Owner:CHINA TOBACCO ZHEJIANG IND

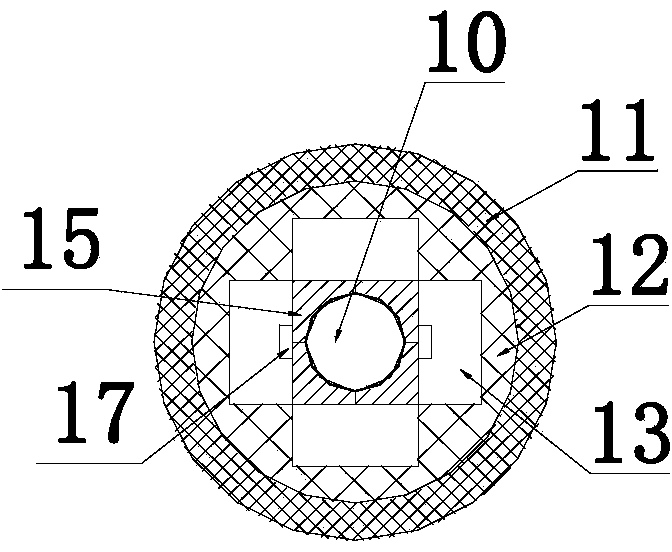

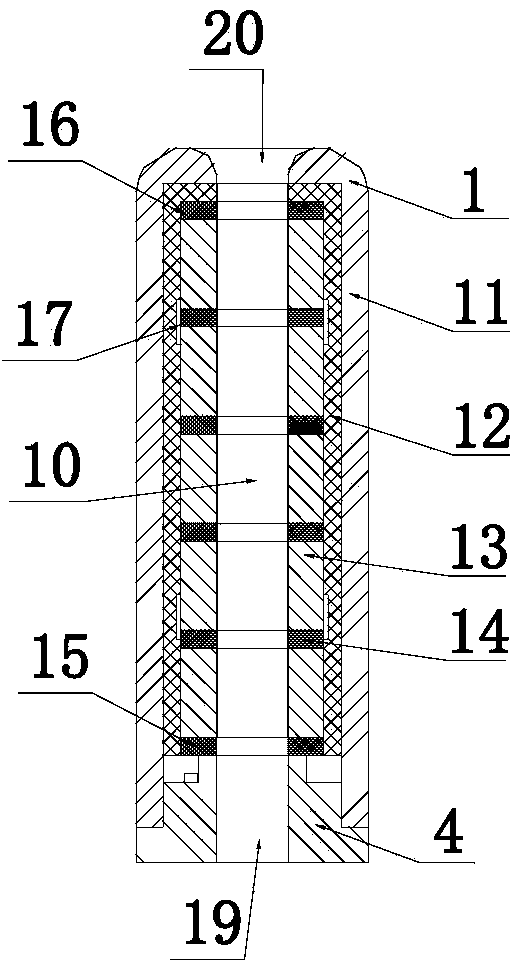

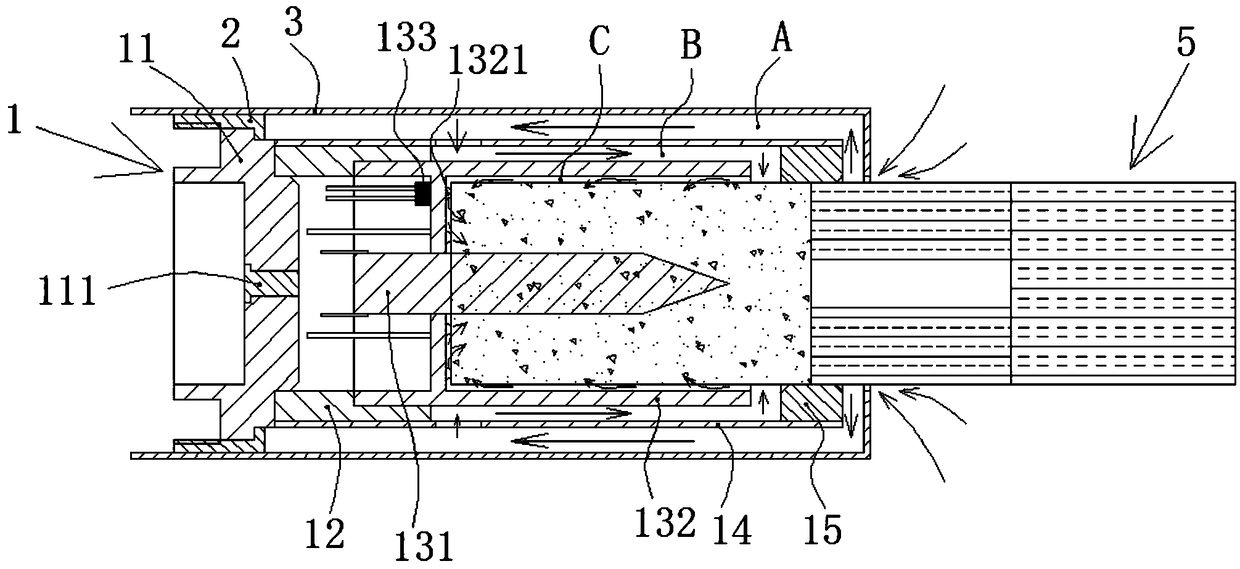

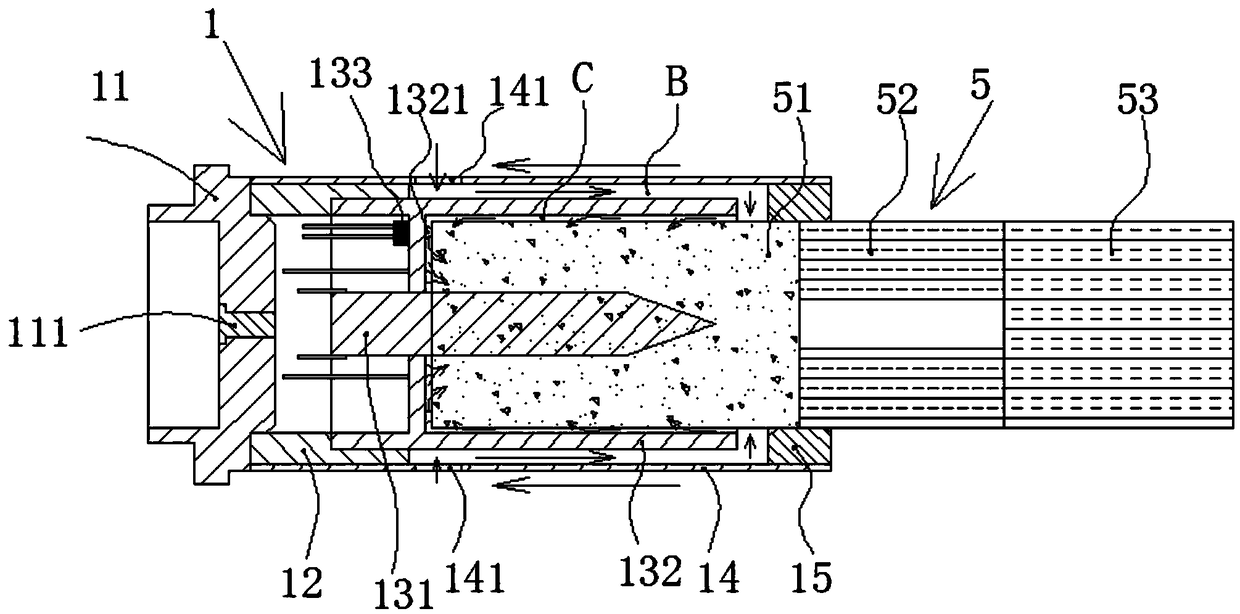

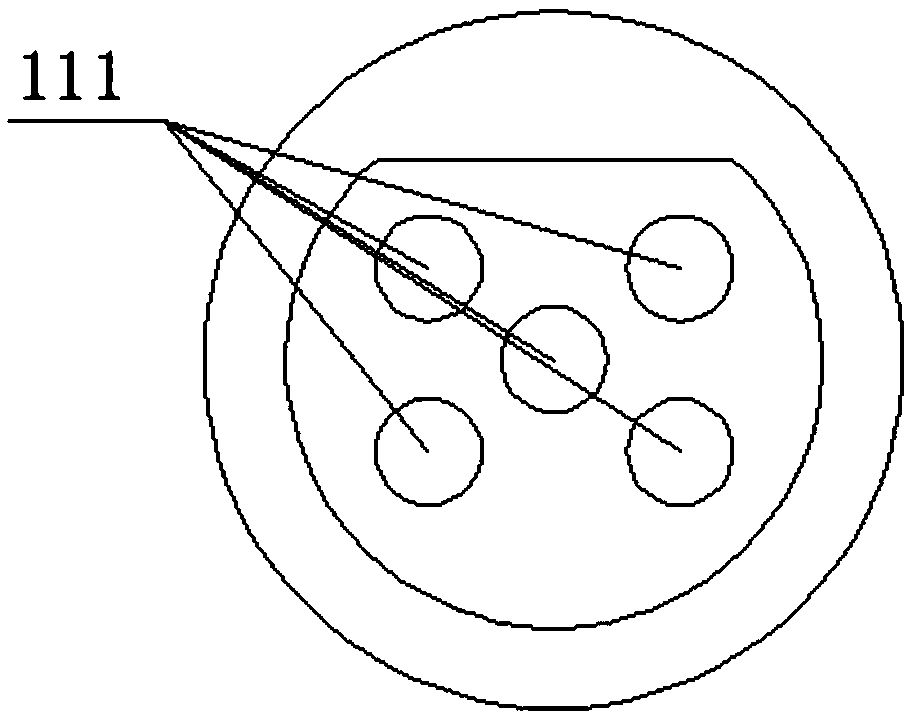

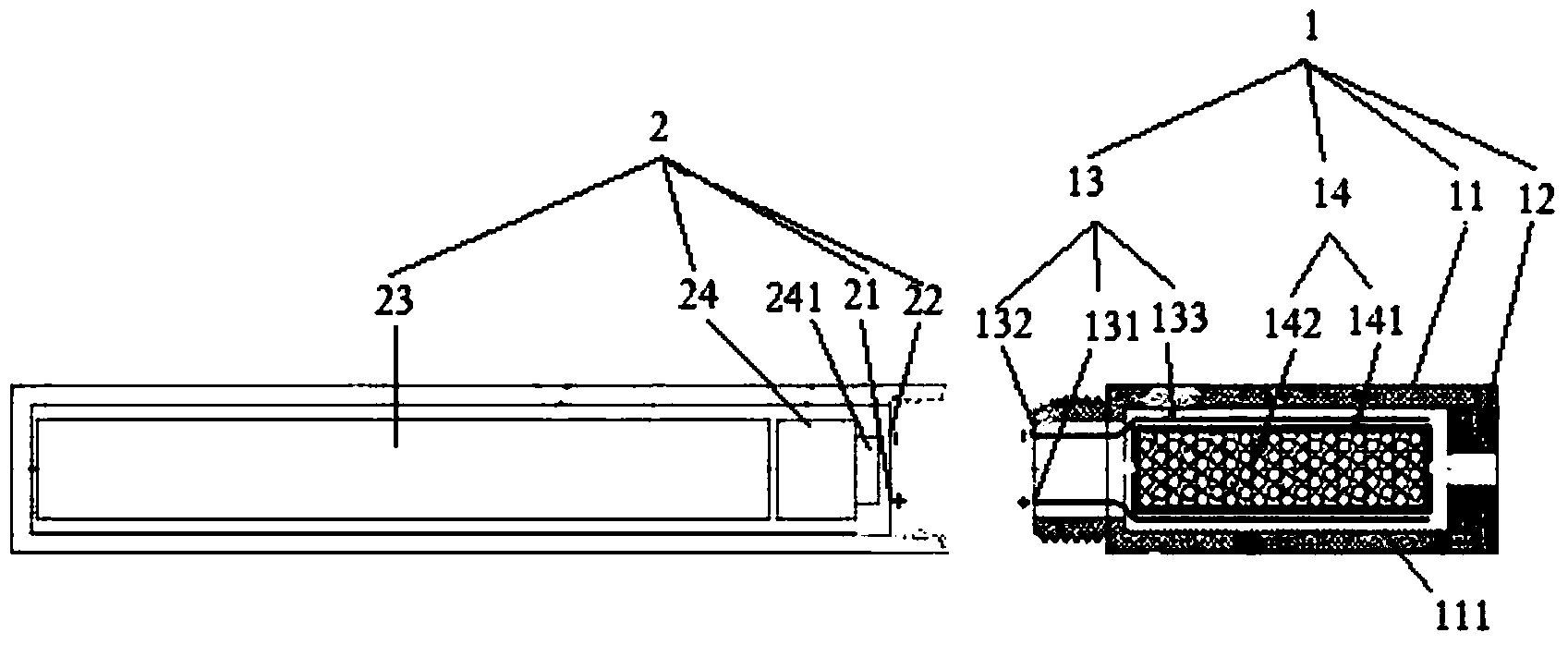

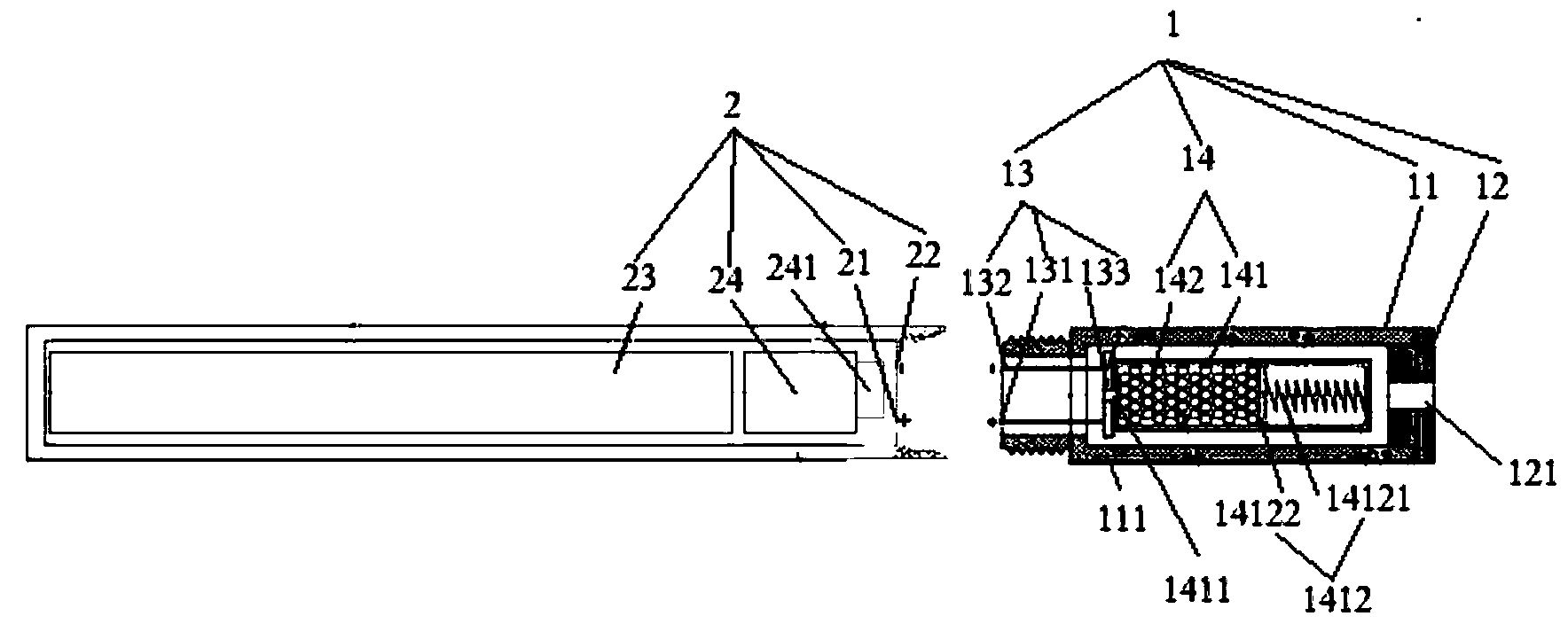

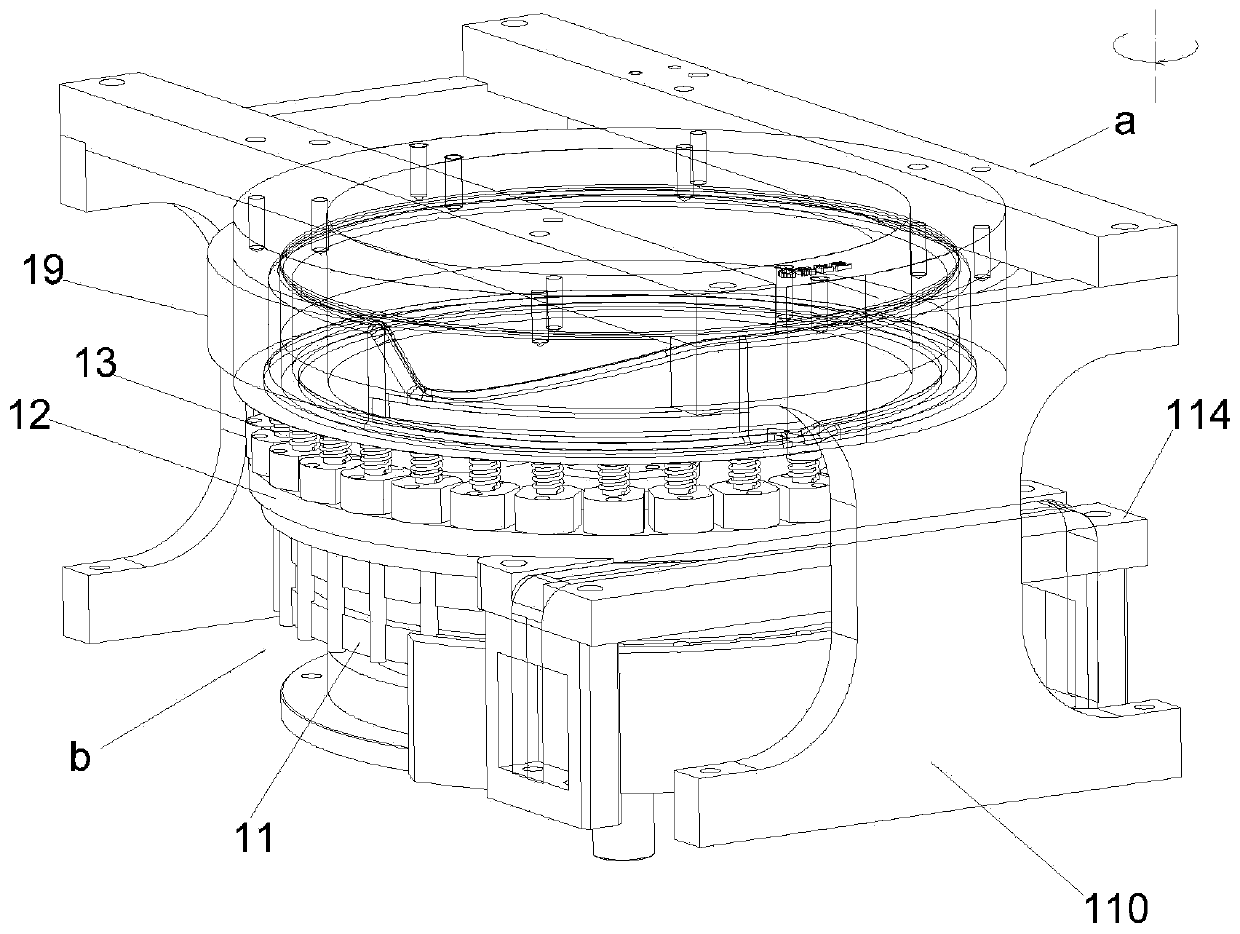

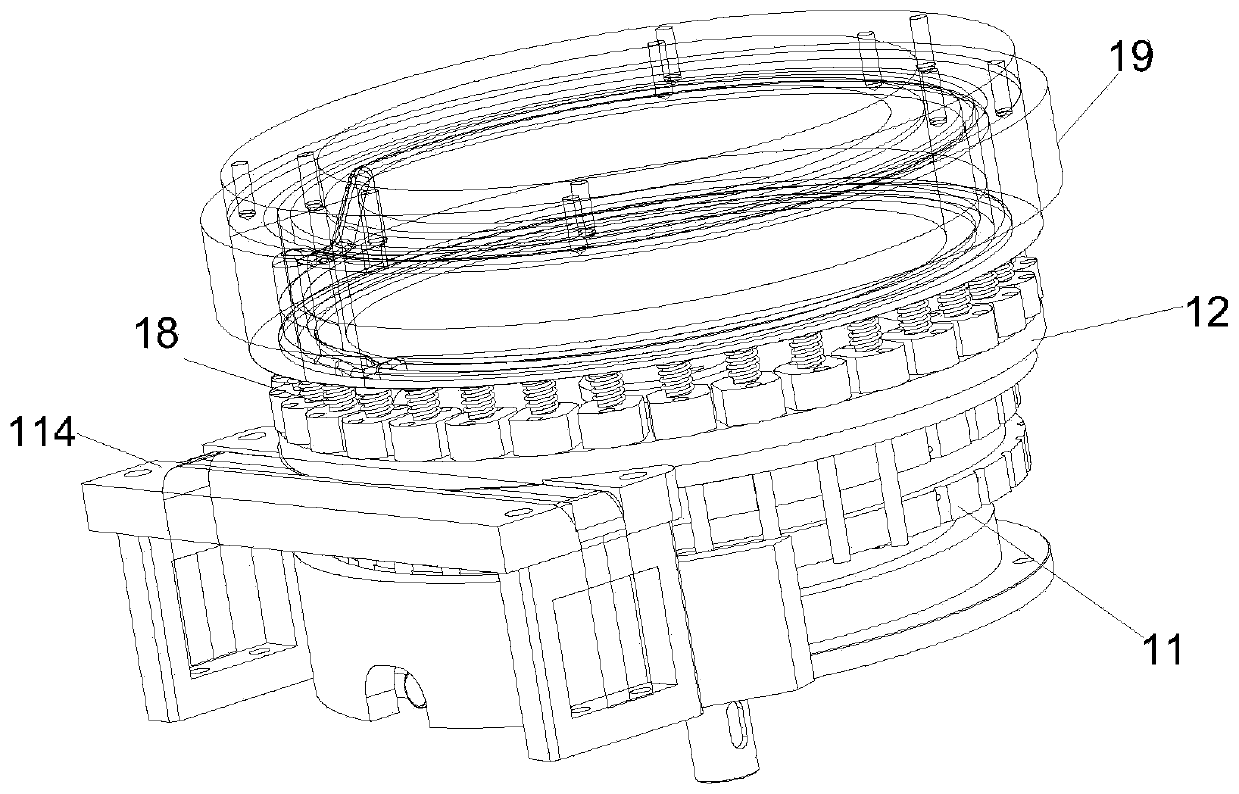

Smart three-dimensional soaking device of heat-not-burn cigarette, kit and heating method thereof

PendingCN109315838AAchieve convection heatingHarm reductionCigar manufactureElectric heatingTwo temperatureProcess engineering

The invention discloses a smart three-dimensional soaking device of a heat-not-burn cigarette, a kit and a heating method thereof. The smart three-dimensional soaking device comprises a heating assembly (1) and an exterior cigarette set shell (3); a first heating cavity (A) is formed in the portion between the cigarette set shell (3) and the heating assembly (1); a second heating cavity (B) is formed in the portion between a heating assembly shell and a combined heater (13) in the heating assembly shell; an inner cavity of a heating cylinder (132) in the combined heater (13) is a third heatingcavity (C); a heating stick (131) with a tip is arranged in the heating cylinder (132); air flow communication is achieved among the three heating cavities; the heating cylinder and the heating stickare both provided with heating circuits, the heating assembly is connected with a control circuit which comprises two temperature control loops, the heating cylinder and the heating stick are regarded as heating objects respectively for independent regulation and control, and heat energy is intelligently distributed. A three-dimensional soaking technology provides all-directional combined even heating of the circumferential surface and the core part for the heat-not-burn cigarette, so that the taste of the cigarette is close to that of a traditional cigarette, and harm is also reduced.

Owner:POWERTHINK (BEIJING) TECH CO LTD

Heat non-burning cigarette body and manufacturing method thereof

InactiveCN109938398AIncrease heat transfer and smoke effectImprove the smoke effectTobacco treatmentBiochemical engineeringProduction effect

The invention relates to a heat non-burning cigarette body and a manufacturing method thereof, and belongs to the field of heat non-burning cigarettes. The heat non-burning cigarette body comprises anauxiliary unit and a smoke production unit, wherein the auxiliary unit comprises a filter section, a cooling section and a hollow section; one end of the hollow section is connected with the smoke production unit, and the other end of the hollow section is connected with the cooling section; the cooling section is connected with the filter section; the smoke production unit is of a compact hollowtubular structure; the inner diameter of the hollow is 1 to 8 mm; the outer diameter of the column is 5 to 10 mm; the length is 10 to 60 mm. According to the heat non-burning cigarette body and the manufacturing method thereof, a paste smoke production material is made into the compact hollow tubular structure to further enhance the heat transfer and smoke production effect of the smoke production material and increase the suction number and the smoke concentration; furthermore, compared with a smoke production unit such as cut tobaccos and a sheet, the smoke production unit of the heat non-burning cigarette body cannot be covered by cigarette paper, so that a layer of cigarette paper is reduced, and the heat transfer effect between a heating tube and a smoke production material can be further enhanced.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

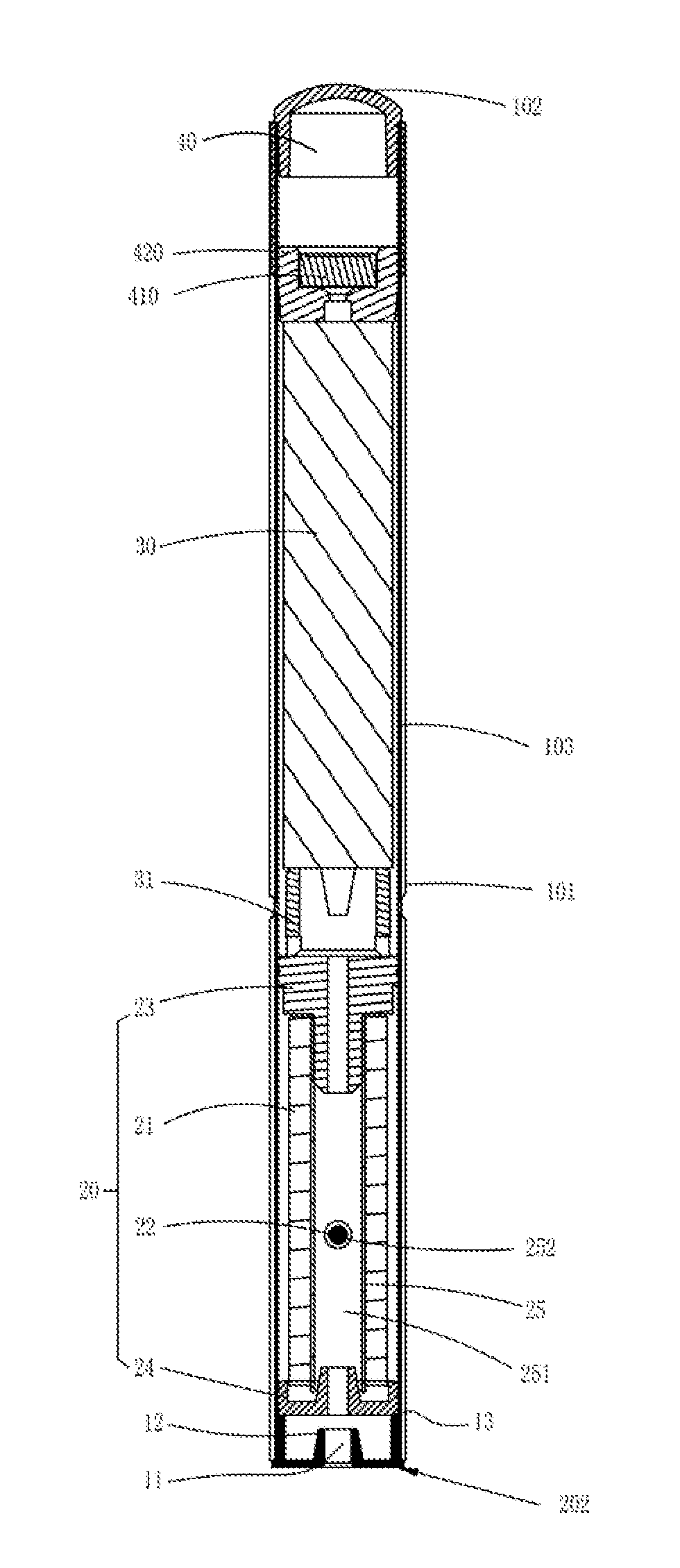

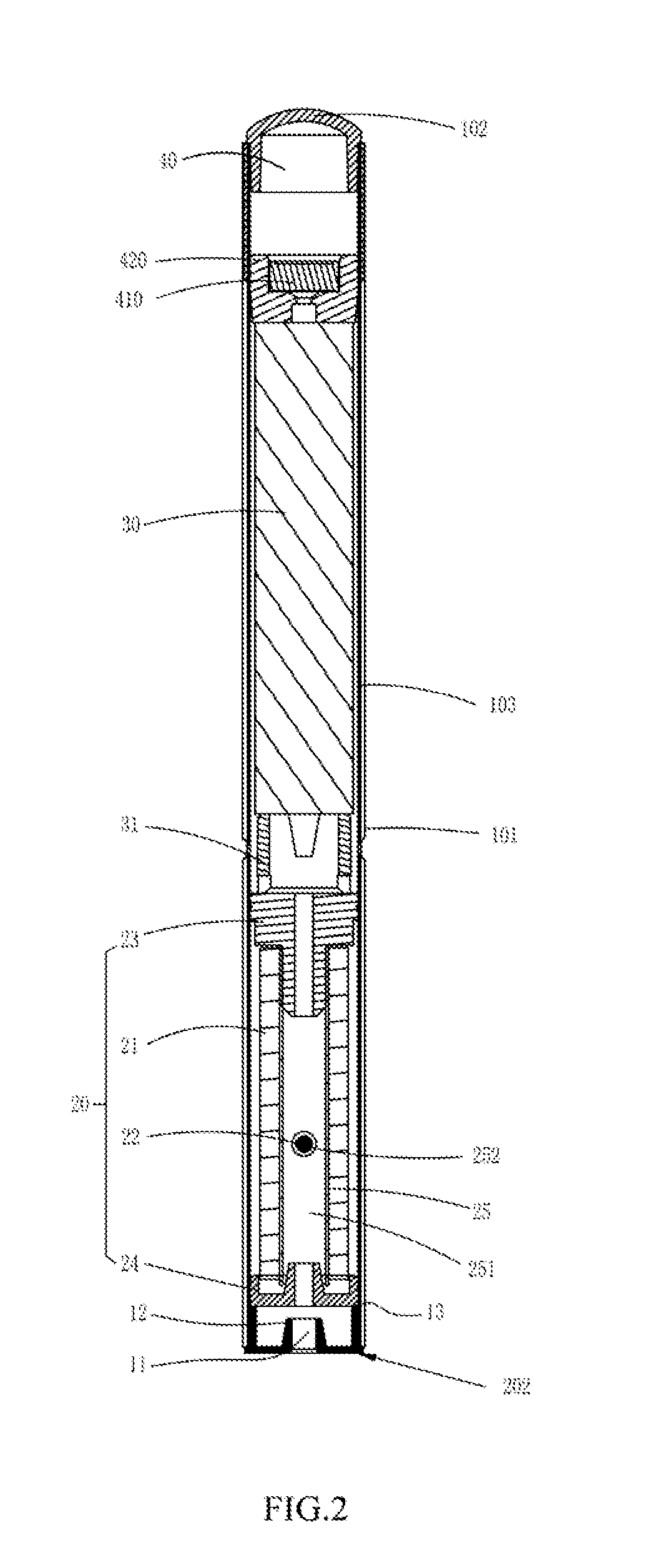

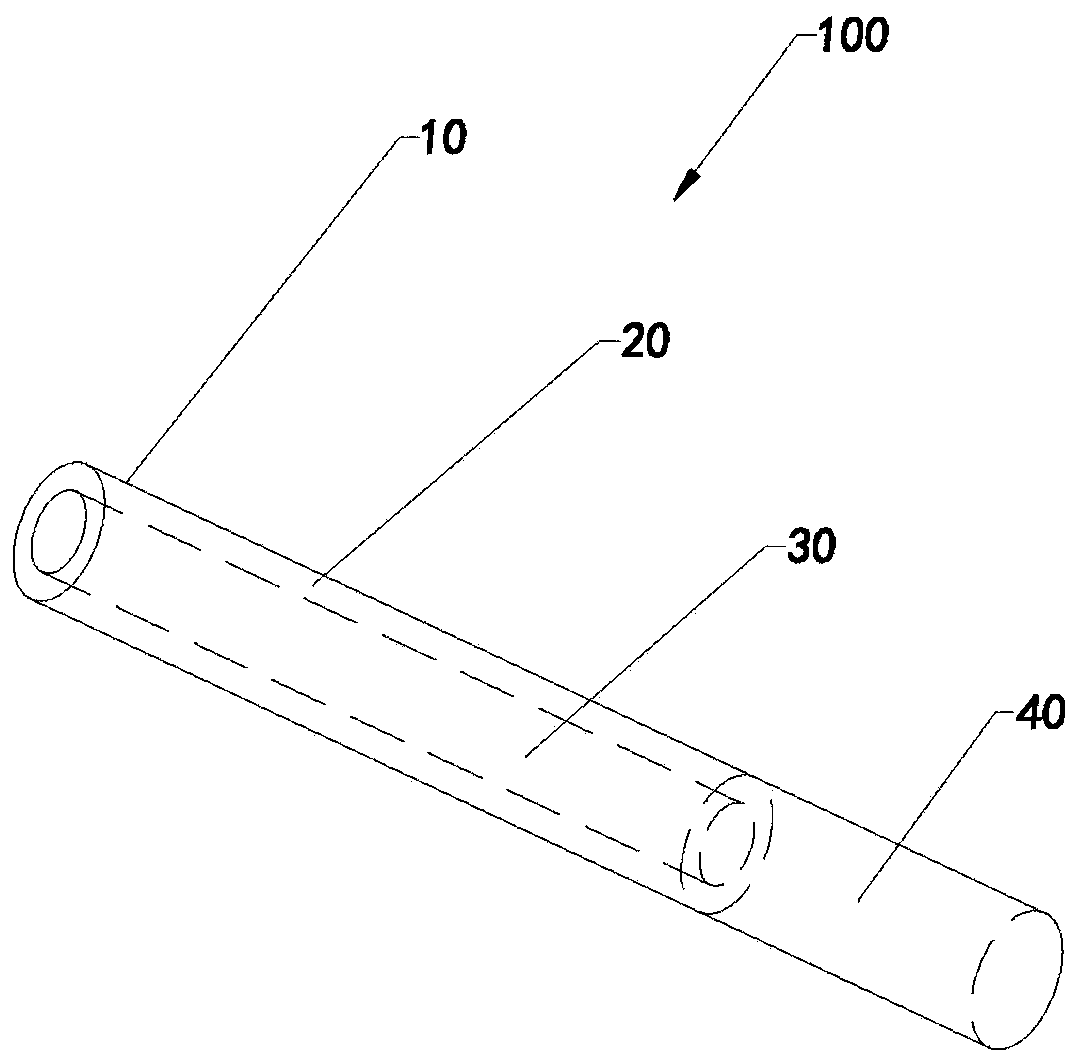

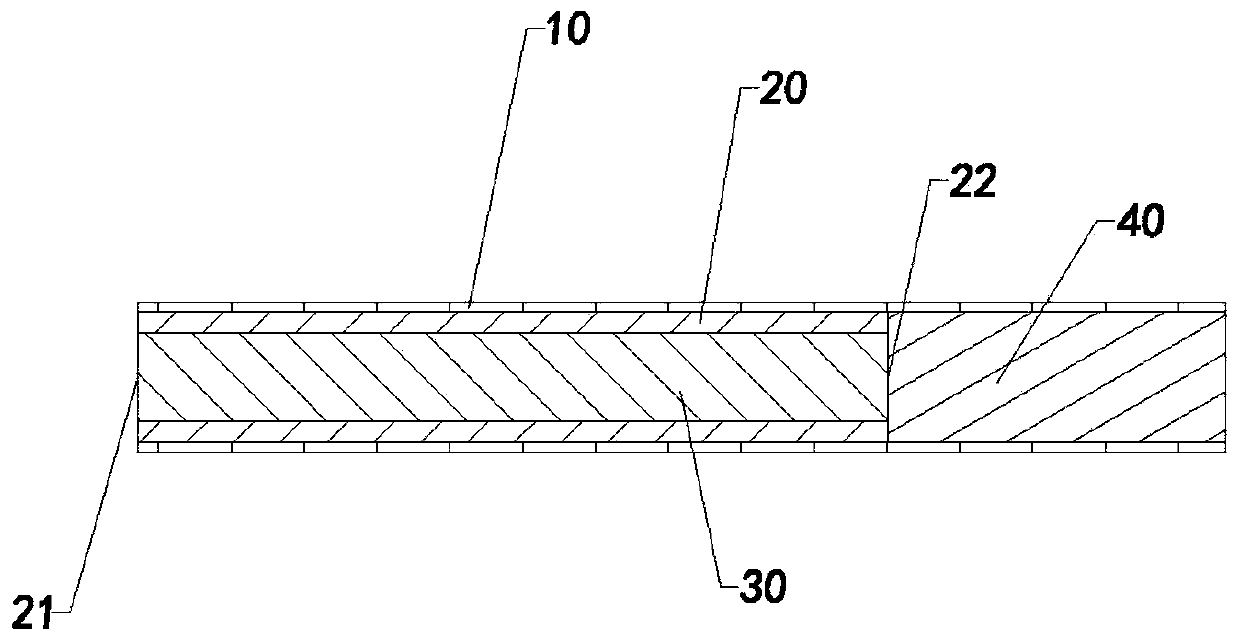

Non-burning cigarette

ActiveCN104013109AControl the burning rateWill not polluteTobacco devicesBurn cigaretteElectronic cigarette

The invention discloses a non-burning cigarette. The non-burning cigarette is of a cylindrical shape and comprises a filter tip assembly and an electronic cigarette rod assembled to one end of the filter tip assembly. The filter tip assembly comprises a filter tip shell, a filter tip cover mounted at one end of the filter tip shell, a heating assembly embedded in the other end of the filter tip shell and a smoke discharging assembly which is fixed into the filter tip shell and makes contact with the heating assembly. The heating assembly comprises a heating assembly positive electrode, a heating assembly negative electrode, a heating component electrically connected with the heating assembly positive electrode and the heating assembly negative electrode and the like. The non-burning cigarette causes small damage to human bodies and low pollution to the environment, solves the key problem that existing cigarette substitute products have liquid leakage, a short guarantee period, uncontrollable temperature and the like, and further improves the using safety.

Owner:SHANGHAI TOBACCO GRP CO LTD

Tobacco essence, extraction method and application thereof

The invention discloses a tobacco essence, an extraction method and application thereof. The extraction method comprises following steps of: (1) carrying out heating and pyrolysis operation on tobaccos within the temperature range for heating and pyrolysis of 150 to 1000 DEG C; (2) absorbing heating and pyrolytic products by utilization of a solvent and condensing absorption liquid in order to obtain tobacco essence.The tobacco essence, the extraction method and application thereof have following beneficial effects: a mode of carbonization and pyrolysis is utilized for processing tobacco so that conventional cigarettes undergo complicated reactions including dissociation and maillard during a burning process; cigarette smoke can be restored to the maximum degree by acquired tobacco in order to compensate for defects that novel tobacco products including electronic cigarettes and non-burning cigarettes during heating have insufficient flavors and obscure styles; and without affecting sensory quality of cigarettes, effects of reducing cigarette smoke and avoiding pollution of second hand smoking to the environment are achieved.

Owner:CHINA TOBACCO ZHEJIANG IND

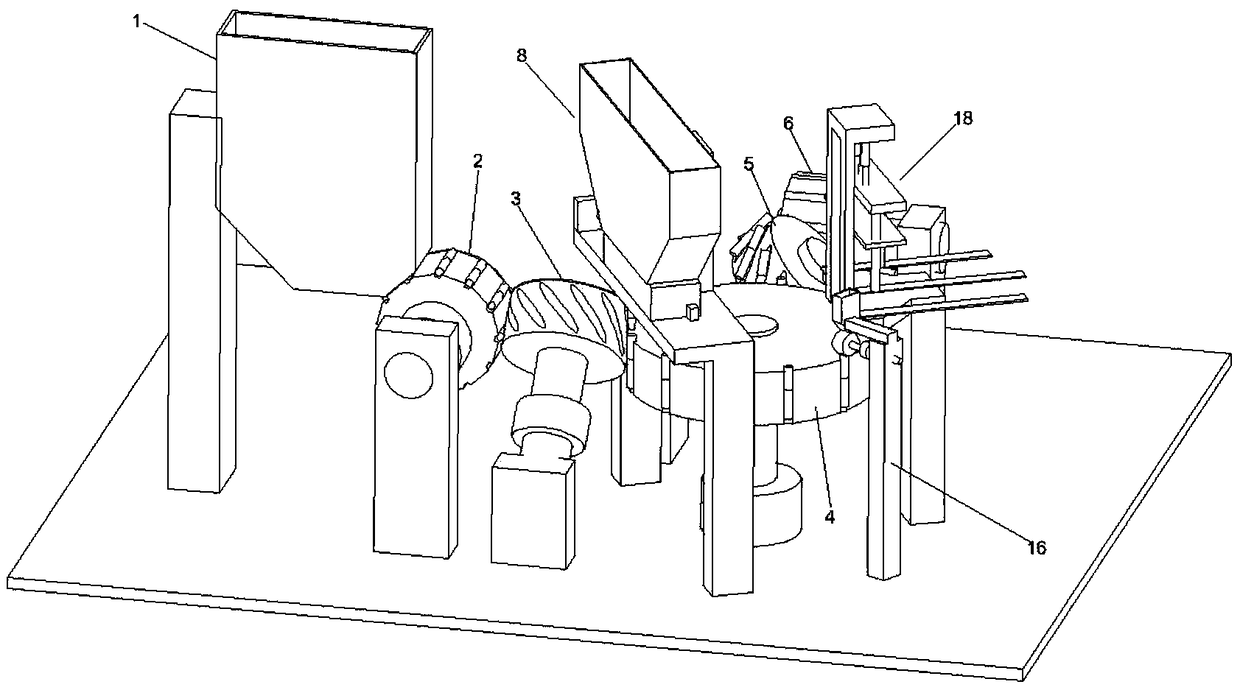

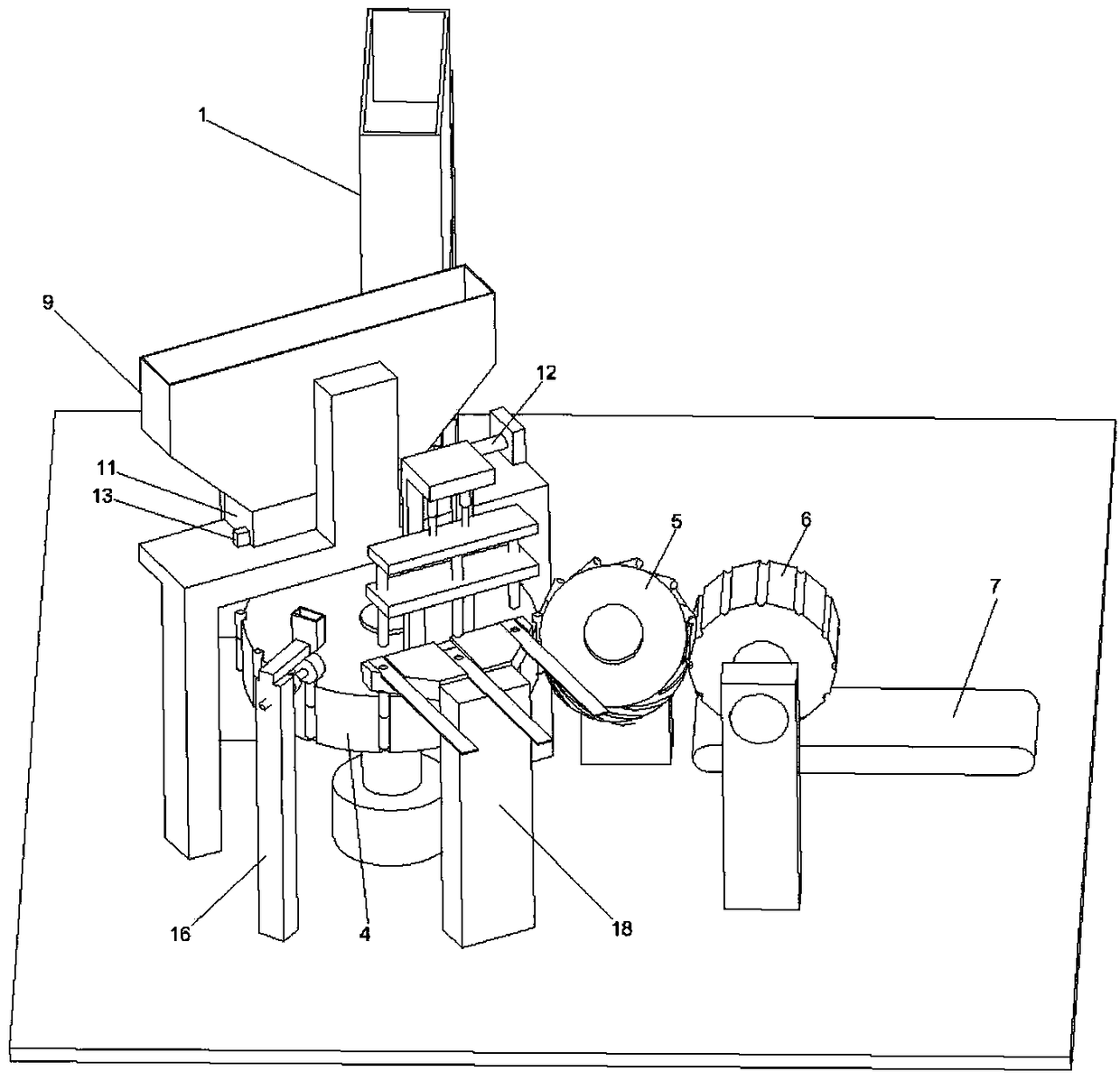

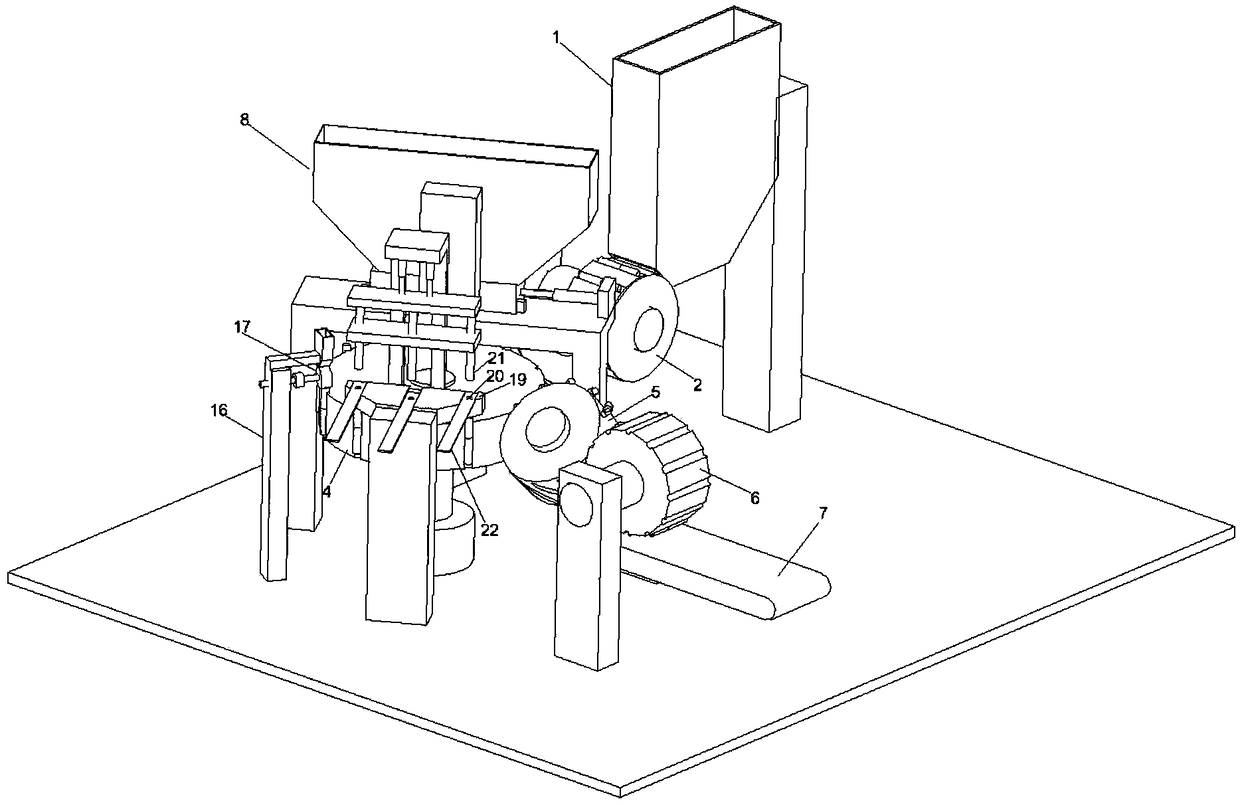

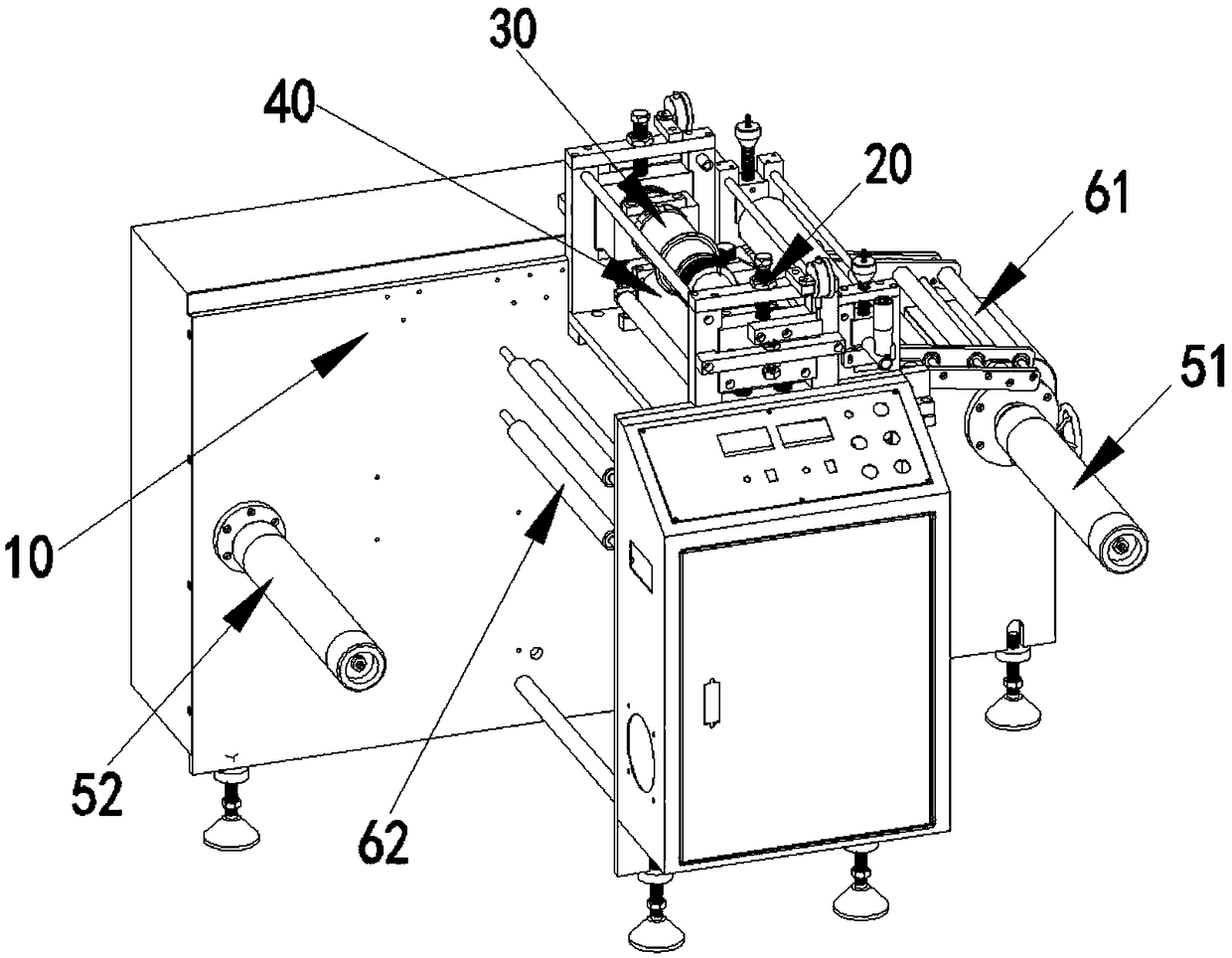

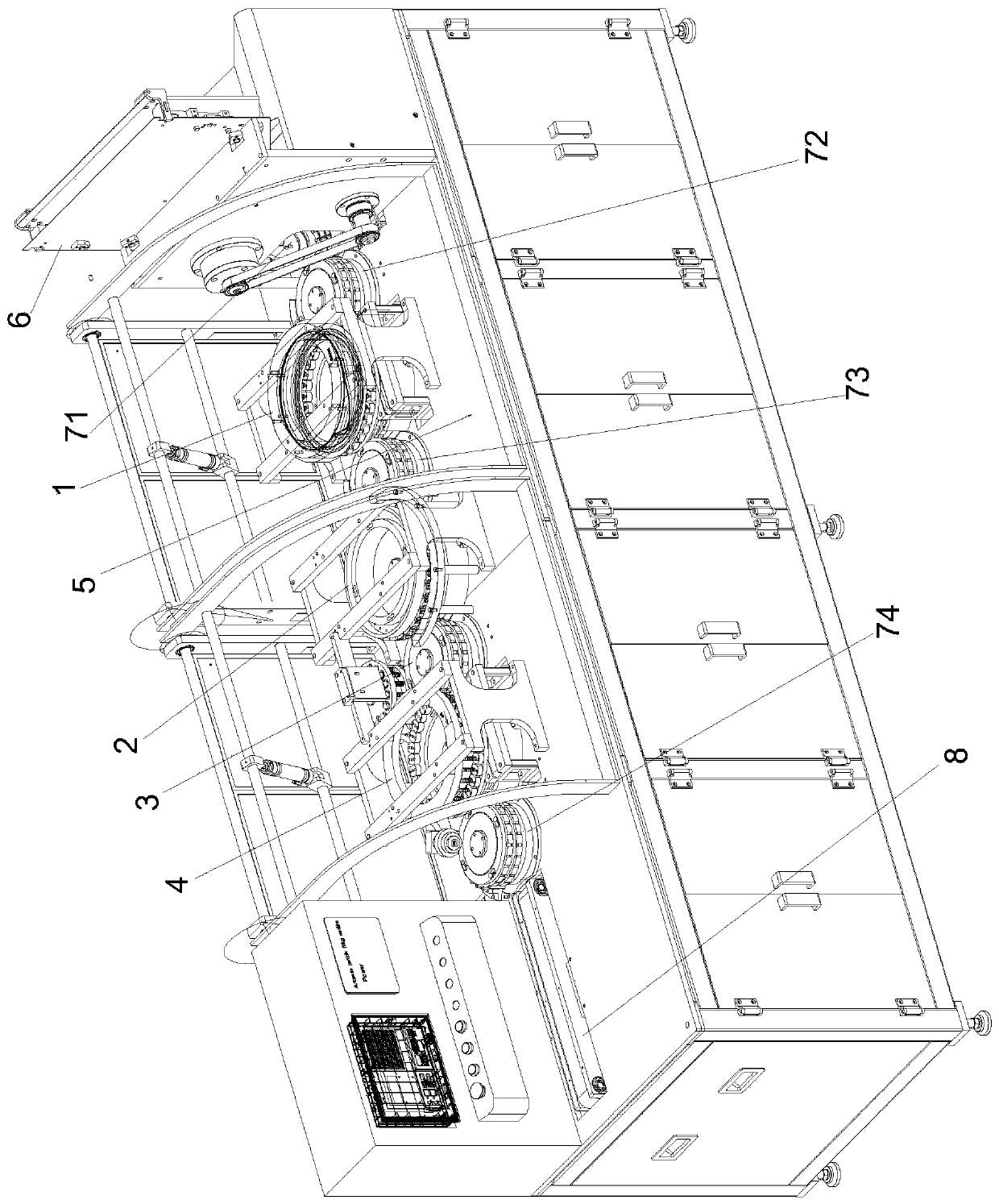

Granular cigarette filling and sealing machine

PendingCN108903065ARealize automatic pottingIncrease productivityTobacco devicesSocial benefitsBurn cigarette

The invention provides a granular cigarette filling and sealing machine. A first stage drum wheel, a first attitude changing drum wheel and a second stage drum wheel are sequentially engaged to form afirst cigarette transport mechanism and a cigarette empty tube storage hopper is used as the input hopper of the first stage drum wheel; a filling device, a dispensing device and a blocking device are arranged on the outer side of the secondary drum wheel, and are arranged at intervals along the rotation direction, and sequentially fill, glue and block the cigarette empty tube on the secondary drum wheel; the secondary drum wheel, the second attitude changing drum wheel and the third-stage drum wheel are sequentially engaged, and the discharging belt is disposed directly below a third-stage drum wheel to constitute a second cigarette transport mechanism to transfer and deliver finished cigarettes to downstream processes. The granular cigarette filling and sealing machine of the inventionrealizes automatic filling of the granular type heating non-burning cigarette tobacco particles, and can be specifically designed as a step mode or a continuous production mode according to actual production requirements. The device greatly improves production efficiency and has great economic and social benefits.

Owner:CHINA TOBACCO ANHUI IND CO LTD

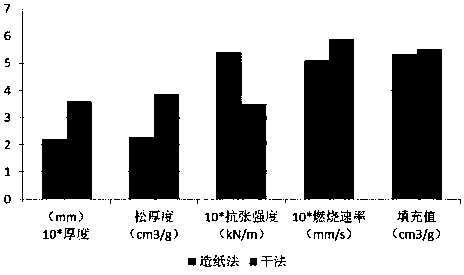

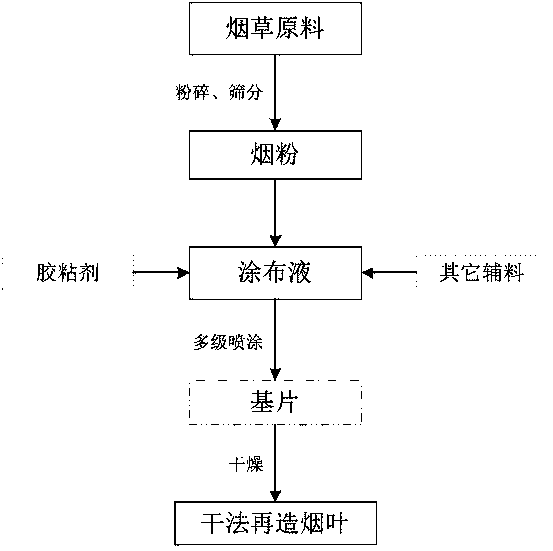

Tobacco composite suitable for being added to dry-method recycled tobacco coating liquid and application of composite for preparing heating non-burning cigarettes

InactiveCN108030142ABest raw material combinationEfficient heatingTobacco treatmentPowder mixtureBurn cigarette

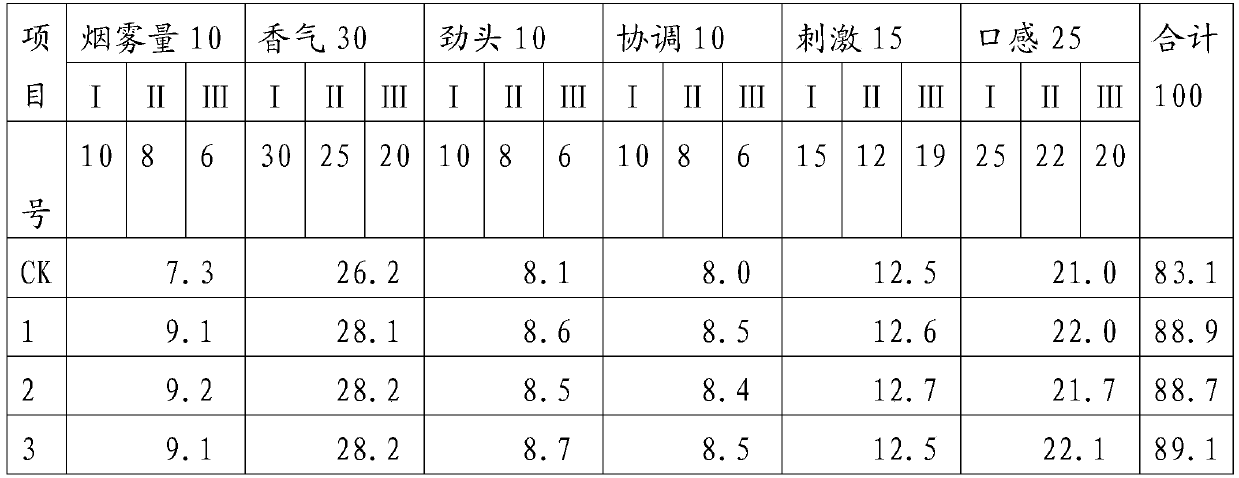

The invention discloses a tobacco composite suitable for being added to dry-method recycled tobacco coating liquid and application of the composite for preparing heating non-burning cigarettes. The tobacco composite is prepared from, by mass, 5 parts of Kunming powder SM1, 2 parts of Dali pieces SP3, 5 parts of Qujing pieces SP1, 25 parts of Yuxi powder SM1, 15 parts of Changde pieces and 30 partsof Dali pieces SP1 which are matched and smashed. The raw materials of the tobacco composite are smashed to obtain a tobacco powder mixture, the tobacco powder mixture is added to the coating liquid,the recycled tobacco is prepared and obtained through a common dry method and applied to a core material for preparing the heating non-burning cigarettes, and the cigarettes are good in physical performance and meet the processing requirement of forming equipment and the adding requirement of a high-content smoking agent; the sensory quality reaches the quality standard of the heating non-burningcigarettes, the fragrance quality is good, the smoke concentration is high, the texture is fine and smooth, less impurity gas and simulation exist, the residual taste is clean, and the coordination is good.

Owner:CHINA TOBACCO GUANGDONG IND +1

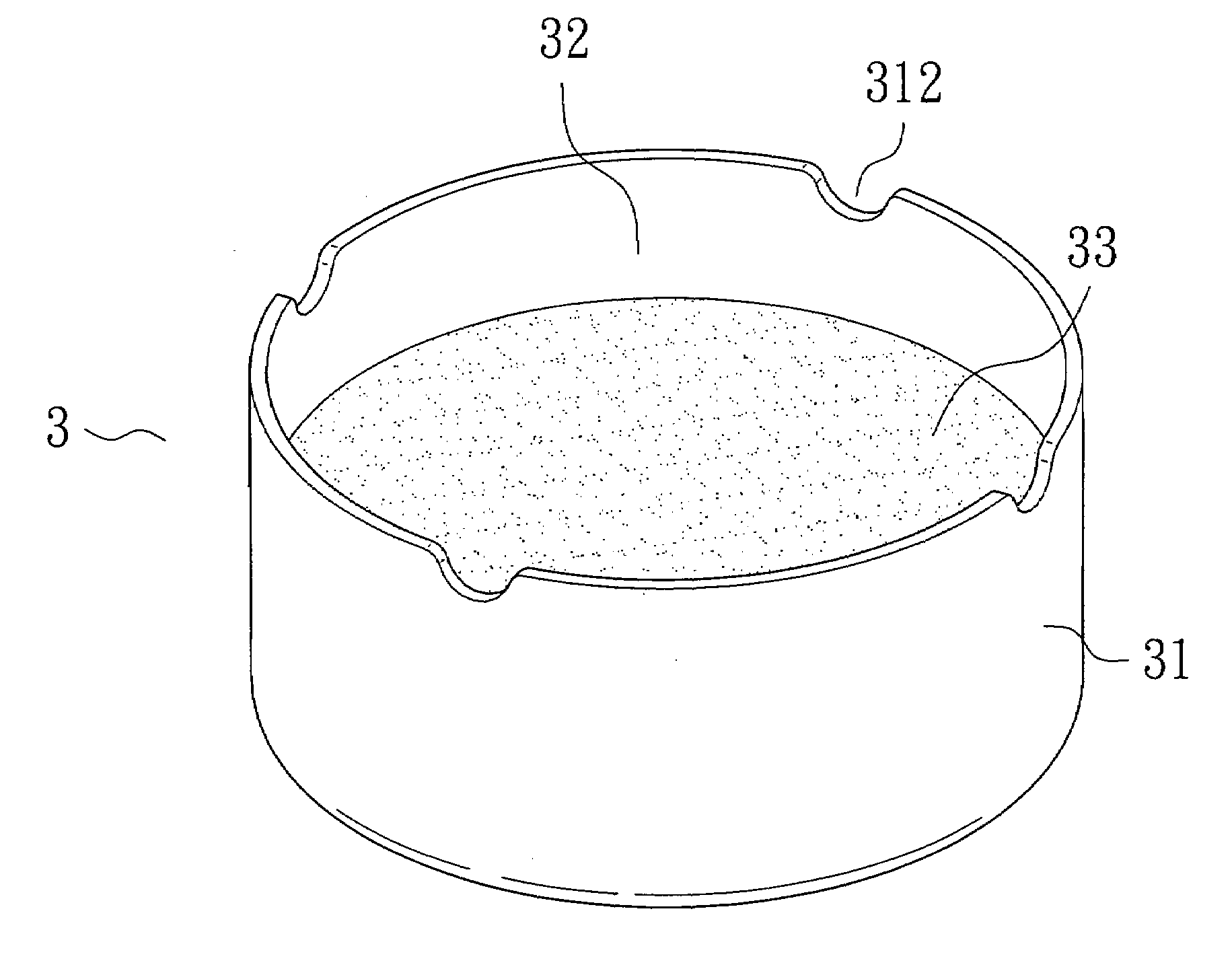

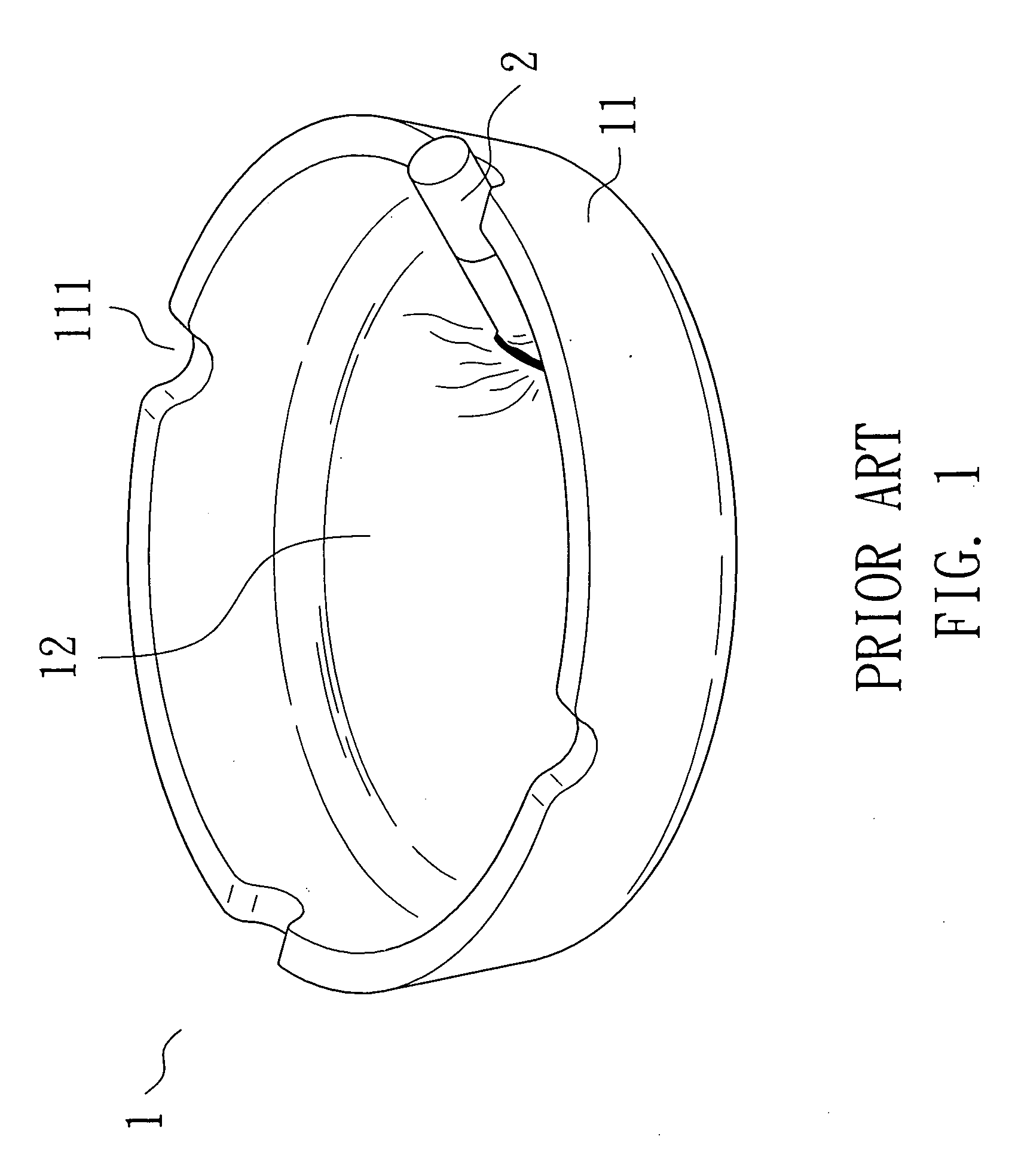

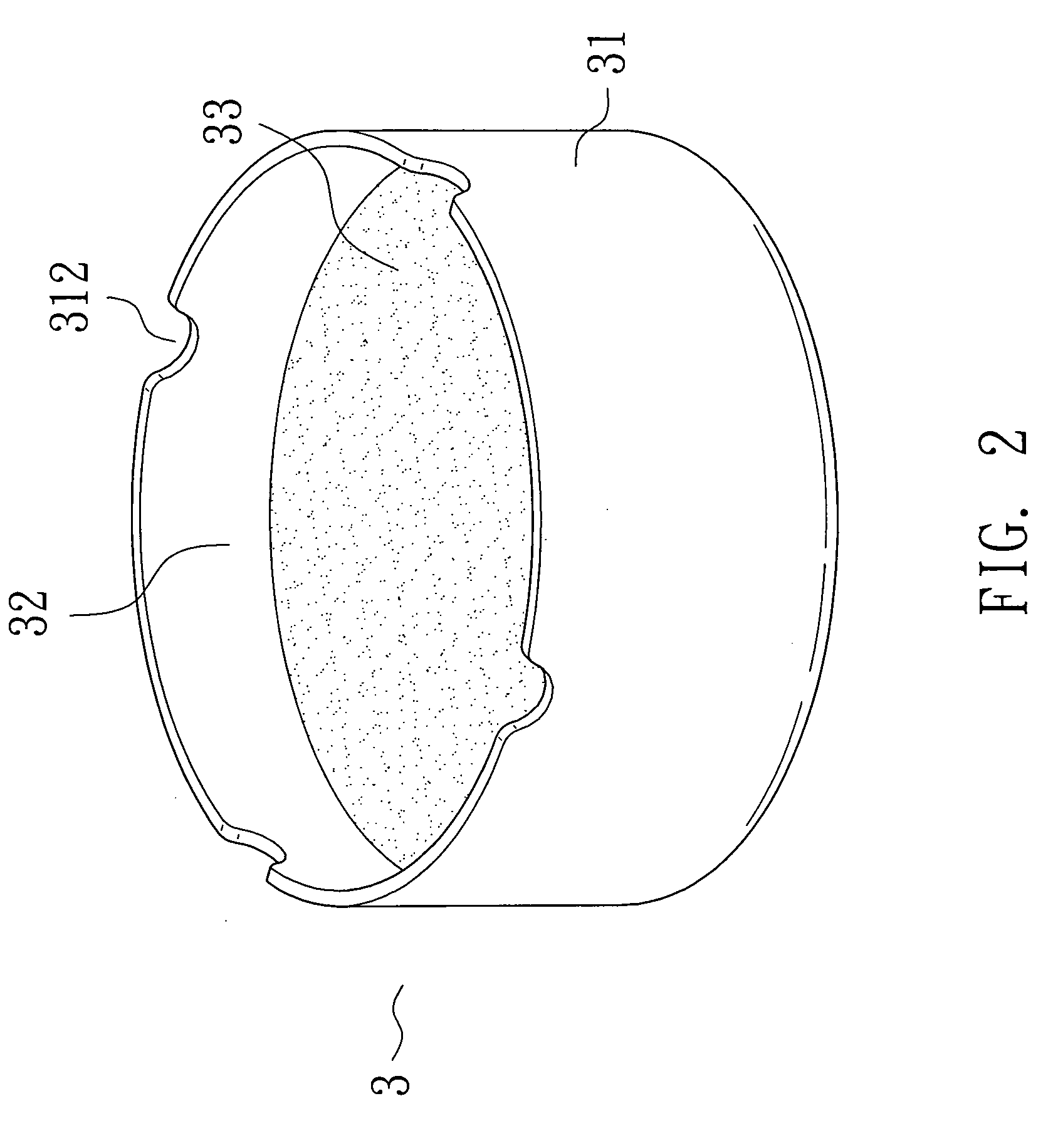

Ashtray

An ashtray includes a peripheral wall and a bottom wall together defining a compartment. A sealing plate having a melting point below 200° C. is mounted to an inner periphery of the peripheral wall and separates the compartment into an open space and a sealed space. A burning cigarette can burn through the sealing plate such that a burning end of the cigarette can enter the sealed space that lacks oxygen. Thus, the cigarette can be put out immediately to avoid injury to the human body.

Owner:WU HSIHNG LAN

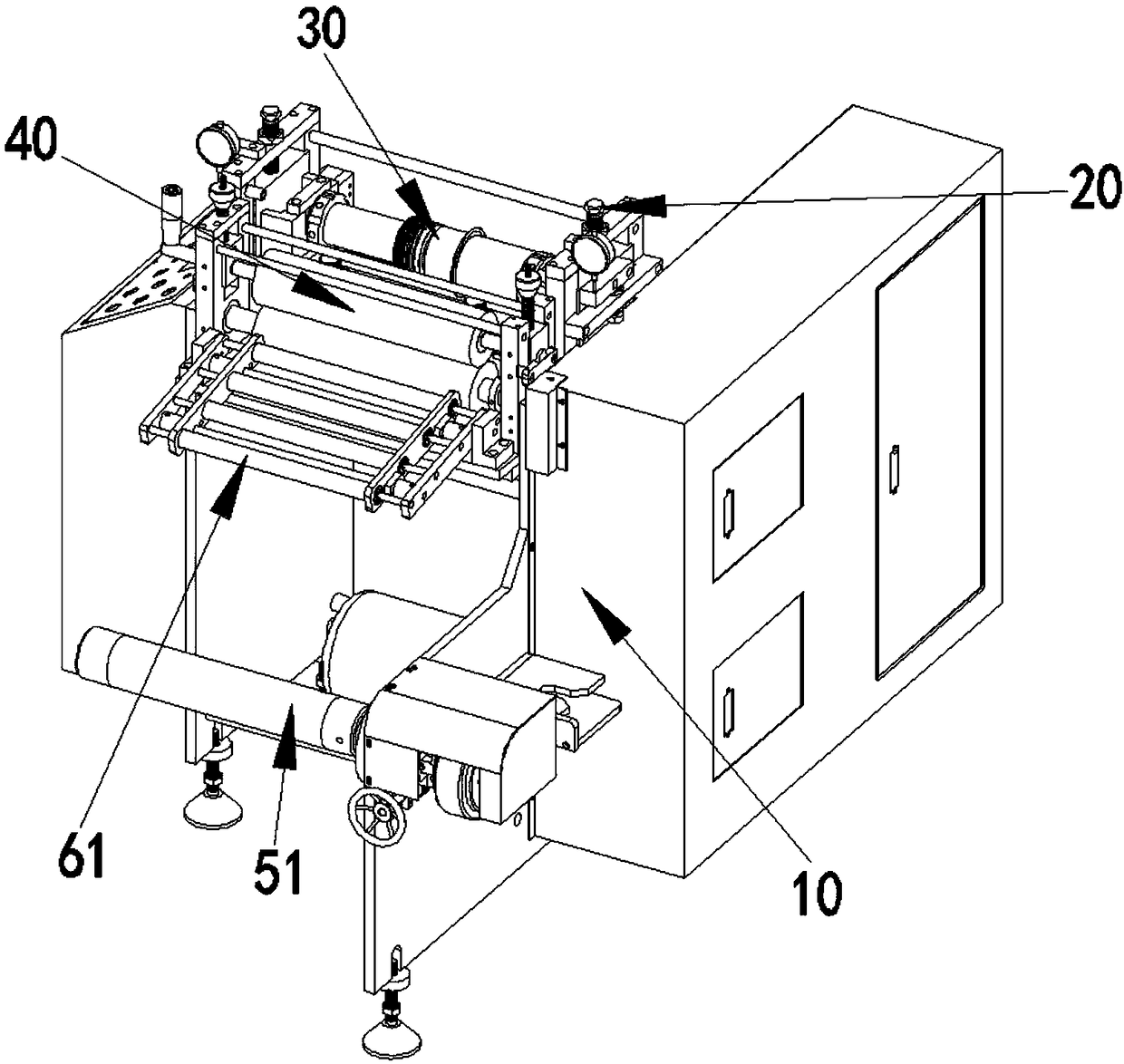

Shredding device and process for heated non-burning reconstituted tobacco

The invention discloses a shredding device and a shredding process for heated non-burning reconstituted tobacco. The shredding device for the heated non-burning reconstituted tobacco comprises a frame, lifting mechanisms, a slitting assembly and bottom rollers which are mounted on the frame, wherein the slitting assembly is used for matching with the bottom rollers to shred the heated non-combustion reconstituted tobacco; the lifting mechanisms are used for controlling the lifting of the slitting assembly and / or the bottom rollers, and further controlling the radial clearance between the slitting group and the bottom rollers. The shredding device for the heated non-burning reconstituted tobacco is simple in structure, convenient to operate, good in shredding effect and wide in applicationrange. The shredding process for the heated non-burning reconstituted tobacco is realized by adopting the shredding device, the operation is convenient, the shredded tobacco can be used for the production of the heated non-burning cigarette with an ordered / disordered array, and the process has better processing adaptability and industrial applicability.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

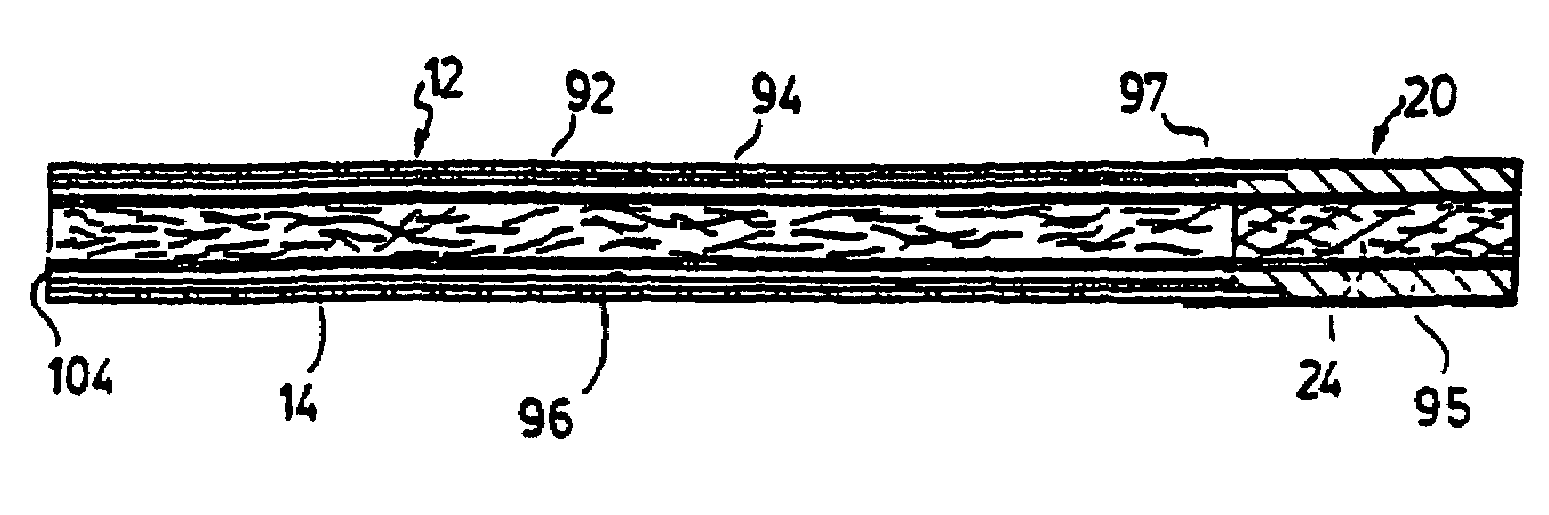

Aerosol cooling composite material as well as preparation method and use thereof

ActiveCN107458055ANot volatileReduce the temperatureNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesiveWater vapor

The invention relates to an aerosol cooling composite material as well as a preparation method and use thereof. The preparation method of the aerosol cooling composite material comprises the steps of preparing a polylactic acid film, preparing complex adhesive, compounding aluminum foil with the polylactic acid film, and the like. The polylactic acid film adopted by the method is a biodegradable film, and the complex adhesive provided by the invention is prepared by taking biological materials as main raw materials, so that the prepared aerosol cooling composite material does not volatilize any harmful substance. Furthermore, an aerosol cooling component prepared from the aerosol cooling composite material can effectively reduce cigarette aerosol temperature and water vapor content when a heated non-burning cigarette product is sucked, thus improving the whole sucking quality of the cigarette.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

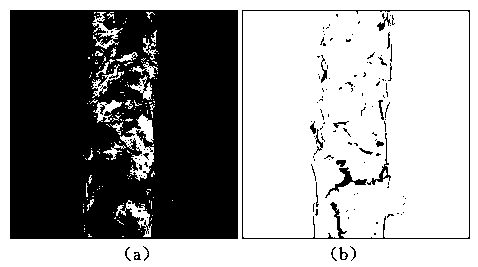

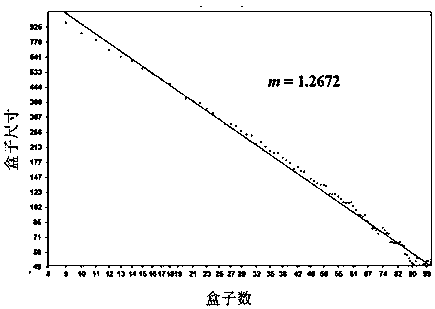

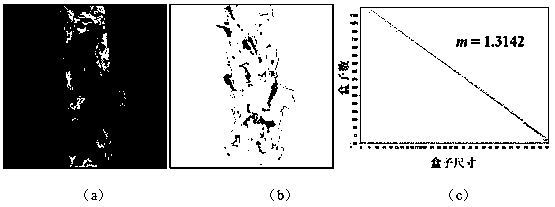

Fractal dimension based quantitative characterization method of cigarette ash column crack distribution characteristics

ActiveCN108896551AImprove developmentImprove qualityOptically investigating flaws/contaminationCombustionBurn cigarette

The invention provides a fractal dimension based quantitative characterization method of cigarette ash column crack distribution characteristics. The method is used for solving the problem of quantitative evaluation of crack morphology of a cigarette ash column. The method includes the following steps: firstly, obtaining an ash column image of a cigarette under static combustion or simulated smoking conditions; secondly, selecting an analysis area by using image processing software (Image J), binarizing the analysis area, and extracting a ash column crack distribution image; and finally, calculating the fractal dimensions of the ash column crack distribution by using a box dimension calculation method. Based on the fractal characteristics of the crack distribution and taking the randomnessof the formation and the complexity of the morphology of cigarette combustion ash column cracks into consideration, the method expresses the rich information contained in the crack distribution stateby the fractal dimensions, can quantitatively evaluate the property of ash integration of burning cigarettes, and can provide method support for cigarette product development and quality improvement.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Improved particle continuous filling equipment

PendingCN110419768AGuaranteed uptimeEfficiencyCigarette manufactureTobacco devicesPunchingBurn cigarette

The invention provides improved particle continuous filling equipment, wherein in a priming section, a priming drum is utilized to drive cigarette blank pipes and an edge layer at the top end to synchronously rotate, a compound cam and compound punching needles above are matched, and by up-and-down movement of the compound punching needles, priming on the cigarette blank pipes is implemented; in afilling section, a filling drum is utilized to drive a feeding disk at the top end to rotate, a filling cam is matched with a plurality of moving pistons on the feeding disk, opening / closing of eachfilling through hole on a ring-shaped groove of the feeding disk is implemented, and filling is carried out in a filling working region where a separator is positioned; in a gluing section, glue dispensing rods and the cigarette pipes can be in contact at a meshing point under the press-against action of a gluing cam, a gluing wheel in a glue pool glues the glue dispensing rod; and in a sealing section, rotation of a sealing drum is utilized to drive sealing punching needles to be matched with a sealing cam above so as to implement up-and-down movement of the sealing punching needles and complete sealing on the glued cigarette pipes. According to the invention, higher efficient and high quality preparation of a particle heating non-burning cigarette product can be implemented, and cost isreduced.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Method for preparing a suction material for heating non-burning cigarette by dry granulation

The invention discloses a method for preparing a suction material for heating non-burning cigarette by dry granulation. The method comprises the following steps S1, an ultrafine tobacco powder is prepared by pulverizing the tobacco raw material with an ultra-micro pulverizing device; S2, a solid base material is obtained by mixing the ultrafine tobacco powder prepared in S1 step with excipient well. S3, atomized liquid is obtained by mixing an adhesive, a smoke agent and tobacco flavors, and the density of the atomized liquid is adjusted by using distilled water; S4, the solid base material prepared in the S2 step and the atomized liquid prepared in the S3 step are added into the granulator of the dry granulator for granulating. After granulation, the granules are dried to remove moistureand sieved to obtain different particle sizes of granular suction material for heating non-burning cigarette. The method provides a new suction experience for consumers and further enhances the suction safety of heating non-burning tobacco products.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

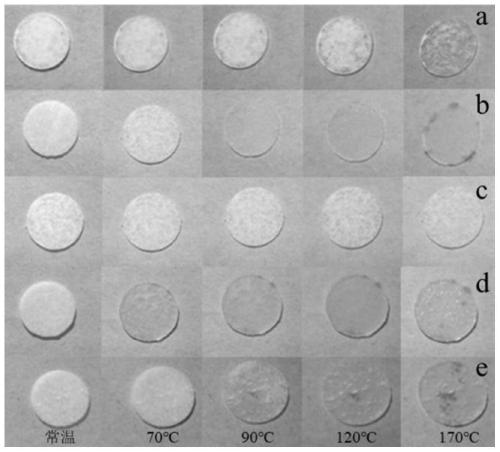

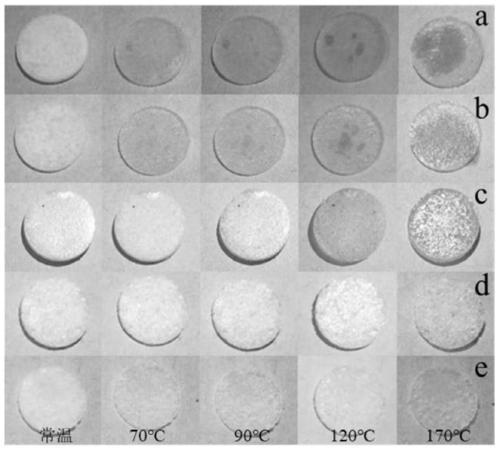

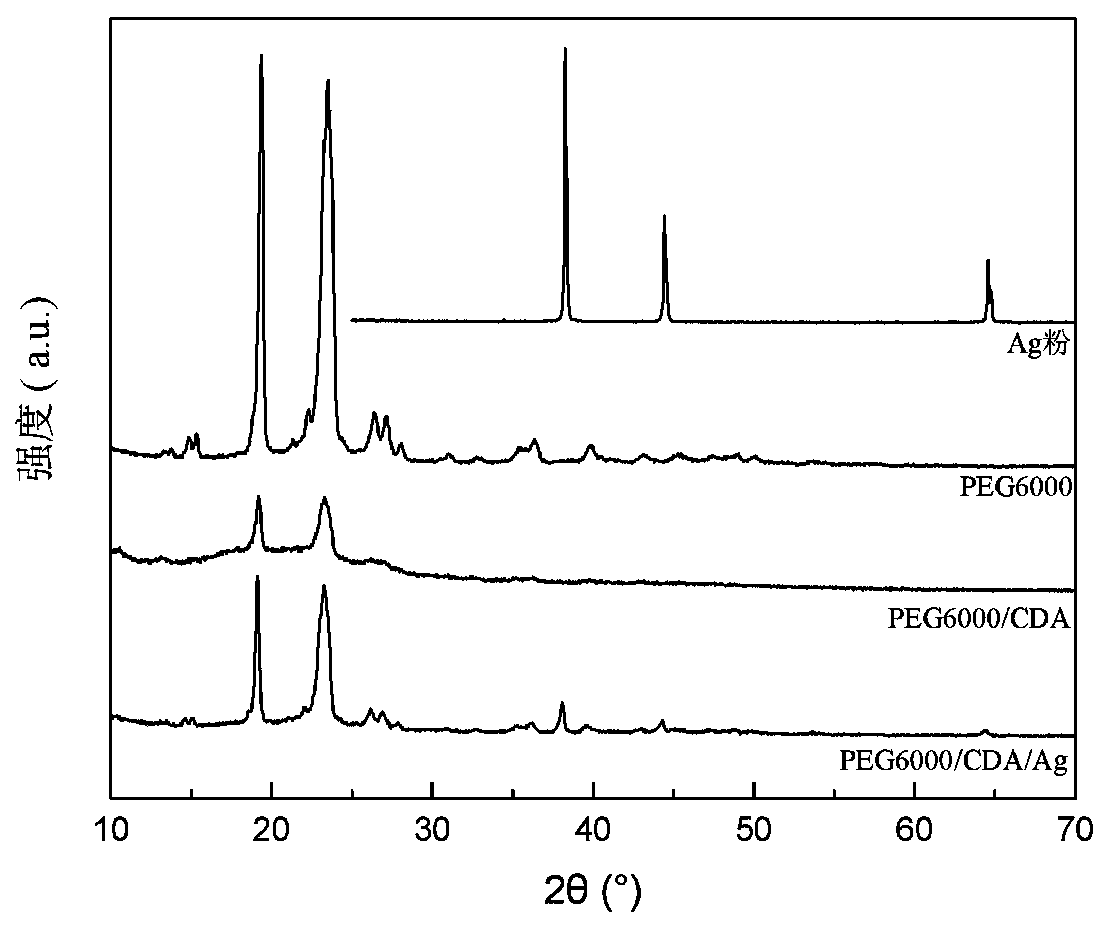

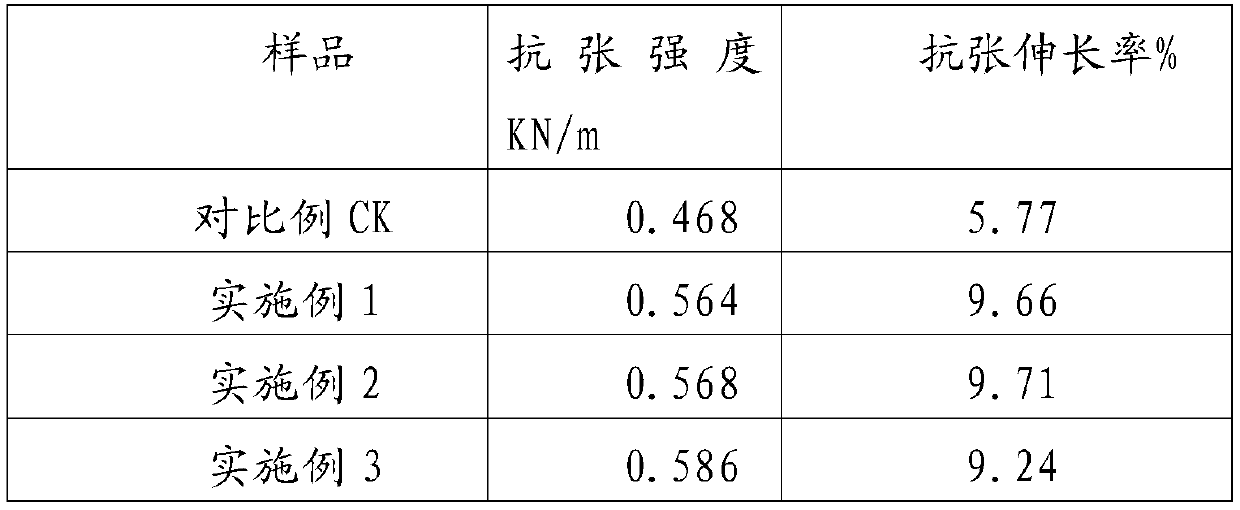

Cellulose diacetate composite shape-stabilized phase-change material, and preparation method and application thereof

InactiveCN111218099ARealize the function of heat absorption and energy storageHigh thermal conductivityTobacco smoke filtersHeat-exchange elementsCellulose diacetateCellulose acetate

The invention discloses a cellulose diacetate composite shape-stabilized phase-change material for reducing the smoke temperature of a heat-not-burn cigarette, and a preparation method and an application thereof. The cellulose diacetate composite shape-stabilized phase-change material is prepared from, by mass, 10-50% of cellulose diacetate, 50-90% of a phase-change material and 1-5% of a heat conduction material through a solvent blending method. The cellulose diacetate composite shape-stabilized phase-change material has a rigid net structure and high-melting-point cellulose diacetate, so that the cellulose diacetate composite shape-stabilized phase-change material has excellent thermal stability and solid-solid phase change characteristics; phase transformation from a PEG branched chaincrystalline state to an amorphous state enables the material to achieve the functions of heat absorption and energy storage; and by adding the heat-conducting metal powder, the heat-conducting property of the material is improved, and the effect of rapid cooling is achieved. The smoking resistance of the cellulose diacetate composite shape-stabilized phase-change material is similar to that of iQOS raw tobacco, the temperatures of first to fourth puffs of smoke can be remarkably reduced, and the temperature of the first puff of smoke can be reduced to 36 DEG C at most.

Owner:NANTONG UNIVERSITY

Heat-not-burn cigarette sheet prepared by fermentation

PendingCN111588068AEvenly suspendedIncrease load capacityTobacco preparationBiotechnologyBurn cigarette

The invention relates to a heat-not-burn cigarette sheet prepared by fermentation. The heat-not-burn cigarette sheet is prepared by the steps: sterilizing a tobacco fermentation culture medium and then inoculating with a strain; carrying out dynamic fermentation for 4-7 d; after fermentation, carrying out rotary evaporation and concentration to enable the water content to be 30-50%; adding 20-40%by weight of a smoke agent, 1-5% by weight of a spice and 0-40% by weight of tobacco powder into slurry, and uniformly mixing to obtain slurry; and spreading the slurry on a lining net, uniformly rolling, and drying until the water content is 6-10%. According to the technical scheme, the tobacco powder is directly and dynamically fermented to generate filamentous bacterial cellulose by controllingthe rotating speed and the fermentation period; the bacterial cellulose is nano cellulose to change the rheological property of the slurry; uniform suspension of the tobacco powder is promoted, and the sheet strength is enhanced to ensure processing adaptability; meanwhile, fibers have high load capacity, can retain more atomizing agents and also have tobacco aroma, various aroma components suchas neophytadiene and furfural in fermented feed liquid are increased, and more aroma components are reserved through low-temperature concentration before rolling, so that the purpose of improving thesensory quality of the sheet is achieved.

Owner:CHINA TOBACCO HENAN IND

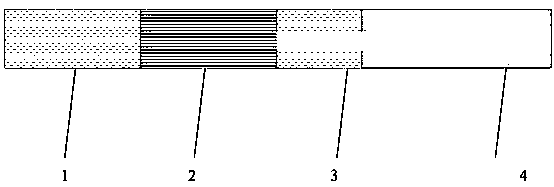

Heat-not-burn cigarette

The invention discloses a heat-not-burn cigarette. The heat-not-burn cigarette comprises a fixing part, a heat-not-burn cigarette main body, a tobacco sheet section and a material rolling part, wherein the firmware is provided with a butt joint end; wherein the heat-not-burn cigarette body is installed on the fixing part, the tobacco sheet section is installed at the butt joint end of the fixing part, the fixing part, the heat-not-burn cigarette body and the tobacco sheet section are wrapped on the material rolling part, and the material rolling part is made of breathable sheet materials.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

Cigarette incombustible under heating

PendingCN107802036AIncreased flow distanceAdequate heat dissipationTobacco devicesFiltrationFlue gas

The invention discloses a cigarette incombustible under heating. The cigarette incombustible under heating comprises a cigarette holder section, a filtration section, a tobacco material section and outer wrapping paper, wherein the filtration section comprises a spiral rod, and the periphery of the spiral rod comprises a spiral smoke channel. The spiral smoke channel of the spiral rod greatly increases a smoke flowing distance to make smoke heat from the cigarette holder section of the cigarette dissipated fully, and the taste experience of smoking can be improved.

Owner:SHENZHEN YUKAN TECH CO LTD

Preparation method for peripherally heated non-burning cigarette shreds

ActiveCN109820233AEasy to integrateFully absorbedTobacco preparationTobacco treatmentFlavorRoom temperature

The invention discloses a preparation method for peripherally heated non-burning cigarette shreds. The method comprises the following steps that 1, the moisture content of reconstituted tobacco is increased; 2, spices and a smoke generating agent are added into the reconstituted tobacco, and the moisture content of the reconstituted tobacco is increased, wherein the spices and the smoke generatingagent account for 5-30% of the weight of the tobacco; 3, the reconstituted tobacco in step 2 is cut into tobacco shreds; 4, the moisture content of the tobacco shreds is decreased at the low temperature; 5, the temperature of the tobacco shreds is lowered to the room temperature with low-humidity and dried air, and the moisture content is decreased to 9-14 wt%; 6, the spices and the smoke generating agent are added into the tobacco shreds for uniform mixing to obtain the heated non-burning cigarette shreds, wherein the addition quantity of the spices and smoke generating agent accounts for 0.5-7% of the weight of the tobacco shreds, and step 4 can be omitted. According to the method, the original flavor in the tobacco is not destroyed, the spices and the smoke generating agent which are added into the tobacco shreds are maintained to the maximum limit, the taste of smoke is improved, and the smoke amount is increased.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com