Shredding device and process for heated non-burning reconstituted tobacco

A heat-not-burn and reconstituted tobacco leaf technology, applied in the fields of tobacco, tobacco preparation, application, etc., to achieve good processing adaptability and industrial applicability, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

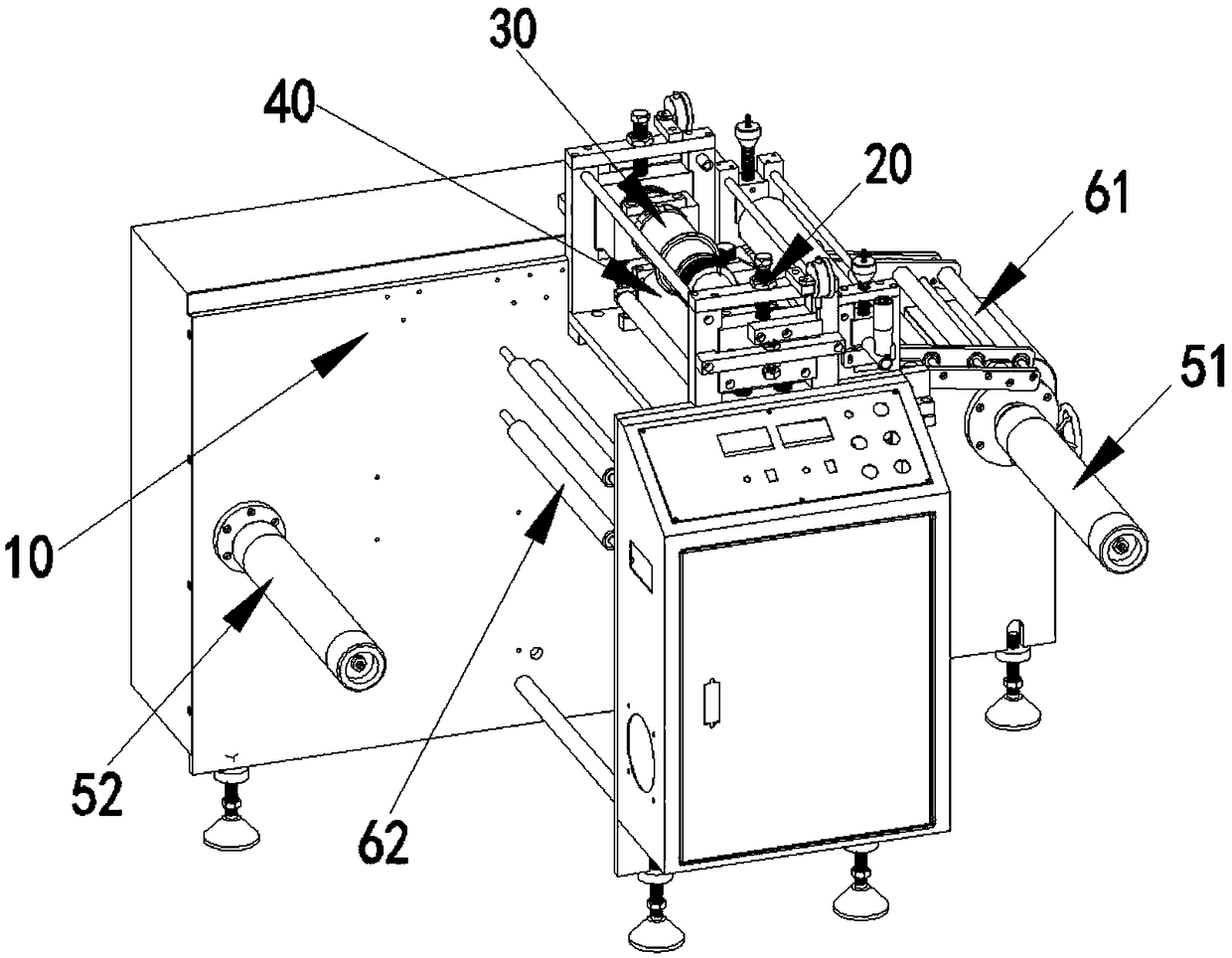

[0053] A shredding device for heat-not-burn reconstituted tobacco leaves, comprising: a frame 10, a lifting mechanism 20 installed on the frame 10, a cutting assembly 30 and a bottom roller 40;

[0054] The cutting assembly 30 is used to cooperate with the bottom roller 40 to shred the heat-not-burn reconstituted tobacco; the lifting mechanism 20 is used to control the cutting assembly 30 and / or the bottom roller 40 Lifting, and then controlling the radial gap between the slitting group and the bottom roller 40 .

[0055] The HNB reconstituted tobacco shredding device further includes: a tobacco leaf fixing shaft 51 for fixing the HNB reconstituted tobacco roll and capable of rotating, a shredded tobacco winding shaft 52 for winding the shredded tobacco and capable of rotating, a sheathing A rewinding cylinder (not shown) on the shredded tobacco rewinding shaft 52 and capable of rotating with the shredded tobacco rewinding shaft 52; the tobacco leaf fixing shaft 51 and the shr...

Embodiment 2

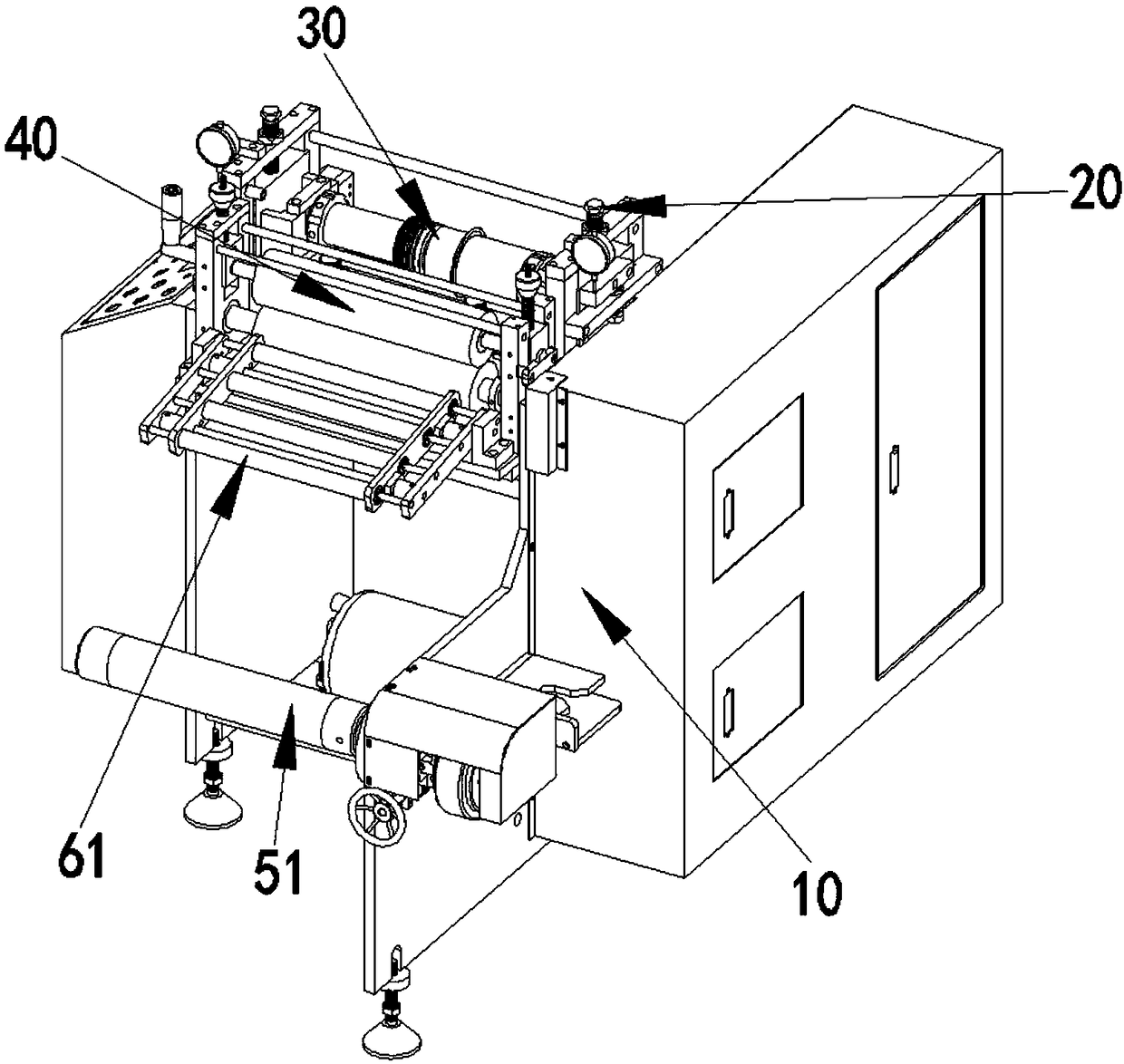

[0070] A shredding device for heat-not-burn reconstituted tobacco leaves, comprising: a frame 10, a lifting mechanism 20 installed on the frame 10, a cutting assembly 30 and a bottom roller 40;

[0071] The cutting assembly 30 is used to cooperate with the bottom roller 40 to shred the heat-not-burn reconstituted tobacco; the lifting mechanism 20 is used to control the cutting assembly 30 and / or the bottom roller 40 Lifting, and then controlling the radial gap between the slitting group and the bottom roller 40 .

[0072] The slitting assembly 30 is a slitting roller, and the slitting roller is a cylindrical roller, and the surface of the cylindrical roller is provided with several annular grooves arranged at intervals along the radial direction.

[0073] Optionally, the length of the slitting roller is 230mm, and the width of the annular groove is 1.2mm.

[0074] The heat-not-burn reconstituted tobacco leaves have an average thickness of 0.2 mm, a length of 2.0 m, and a widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com