Patents

Literature

876 results about "Radial clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The radial clearance is the total clearance between the raceway and the rolling elements - measured normal to the bearing axis. The clearance changes with the expansion or contraction of the bearing rings.

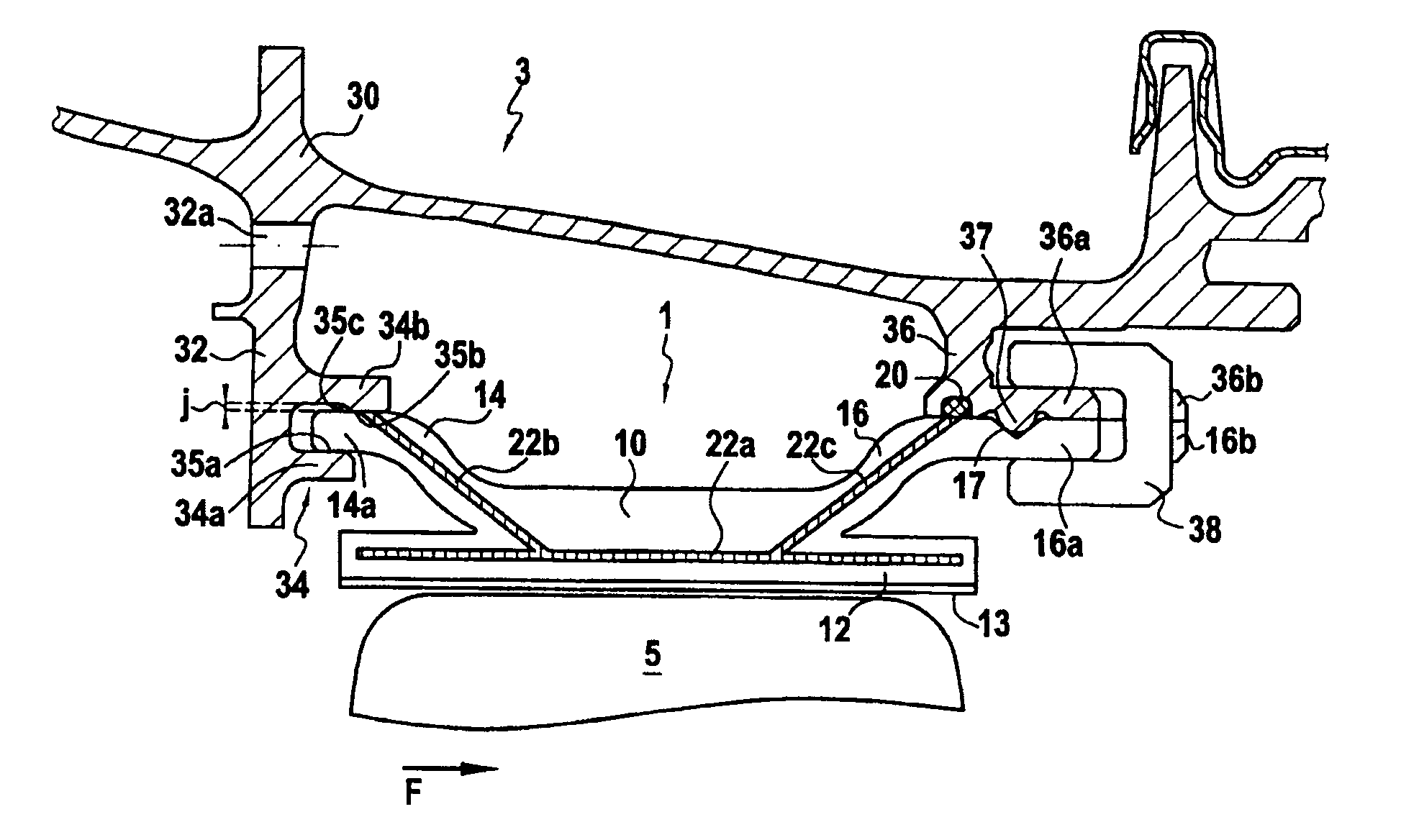

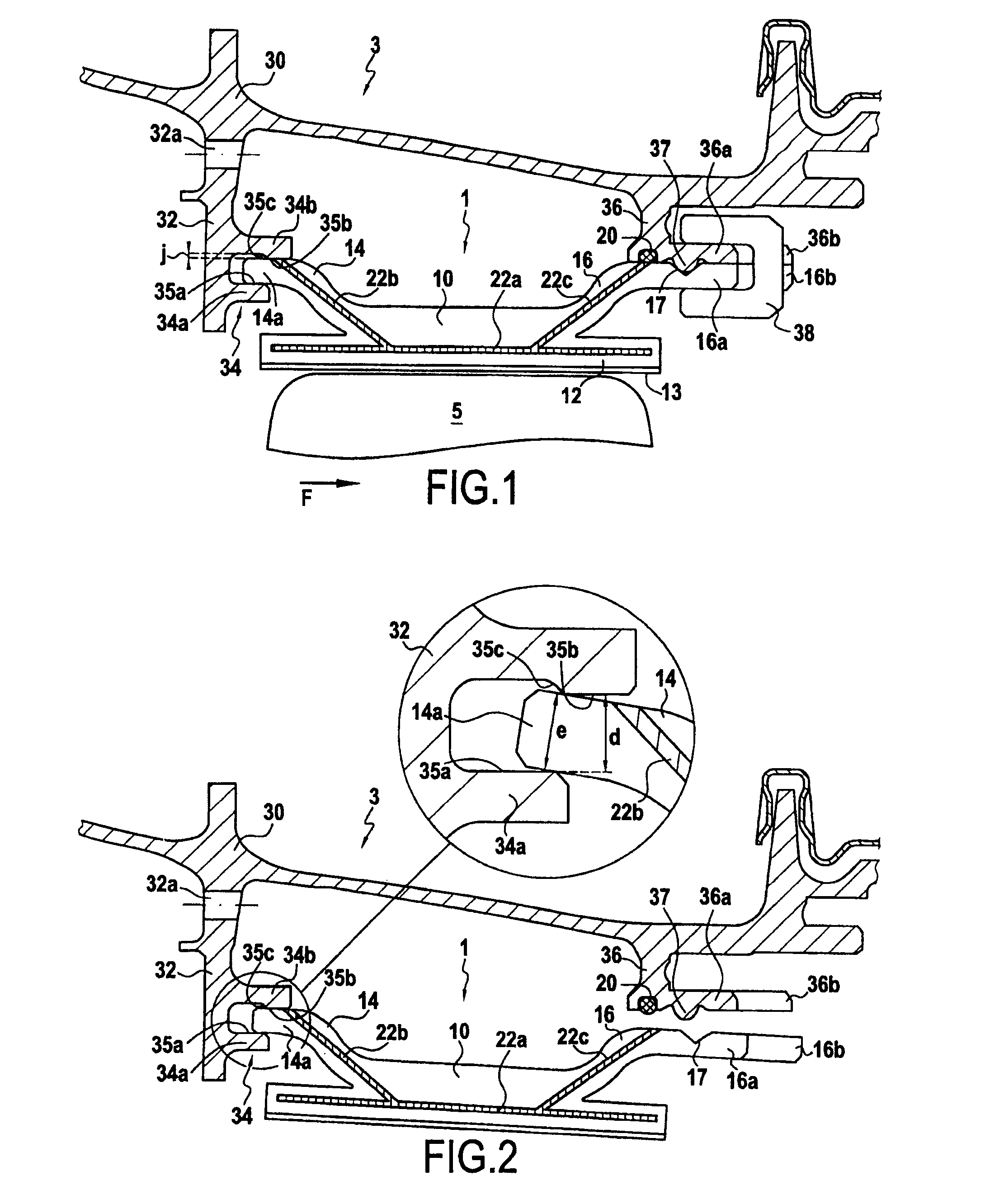

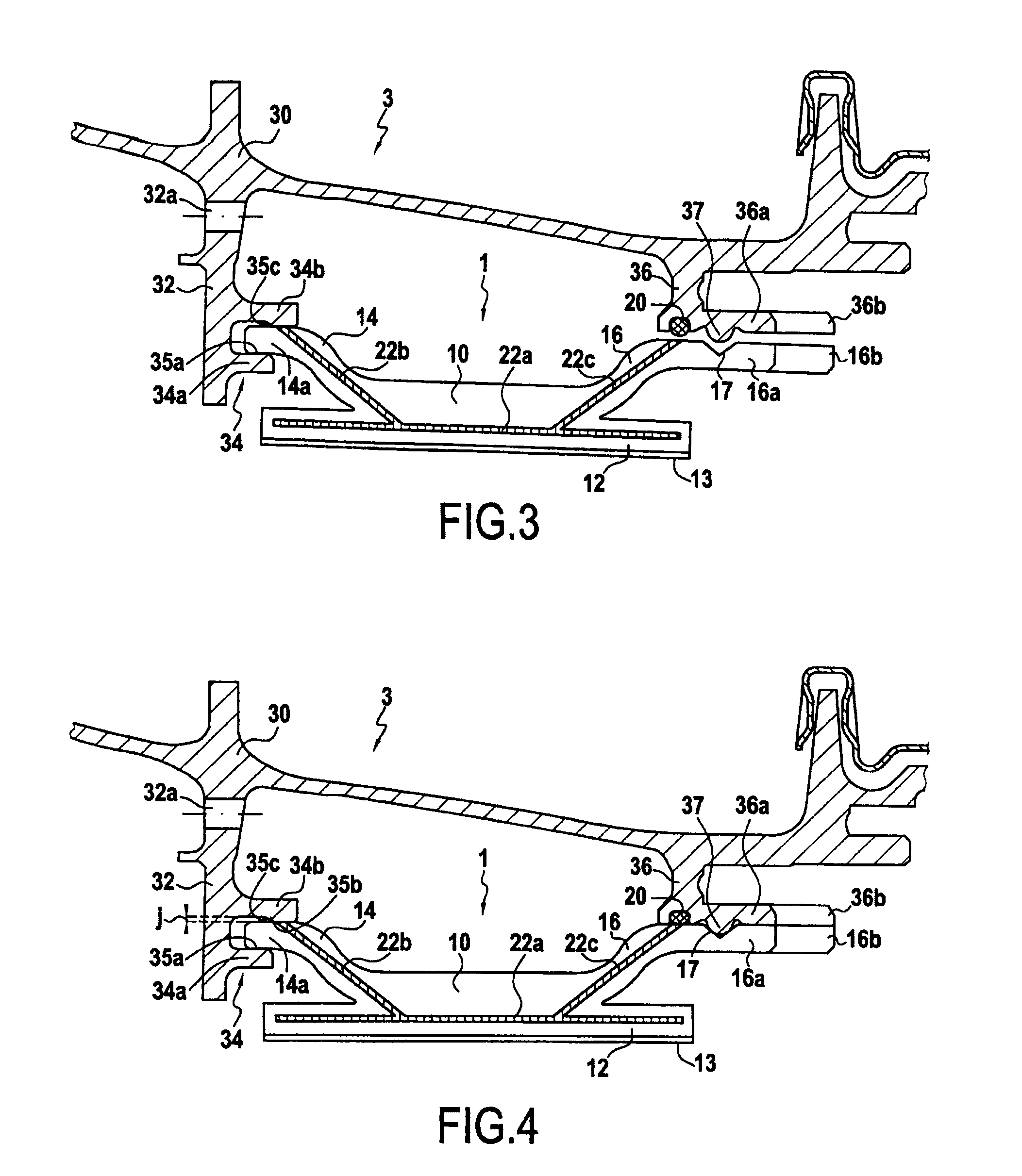

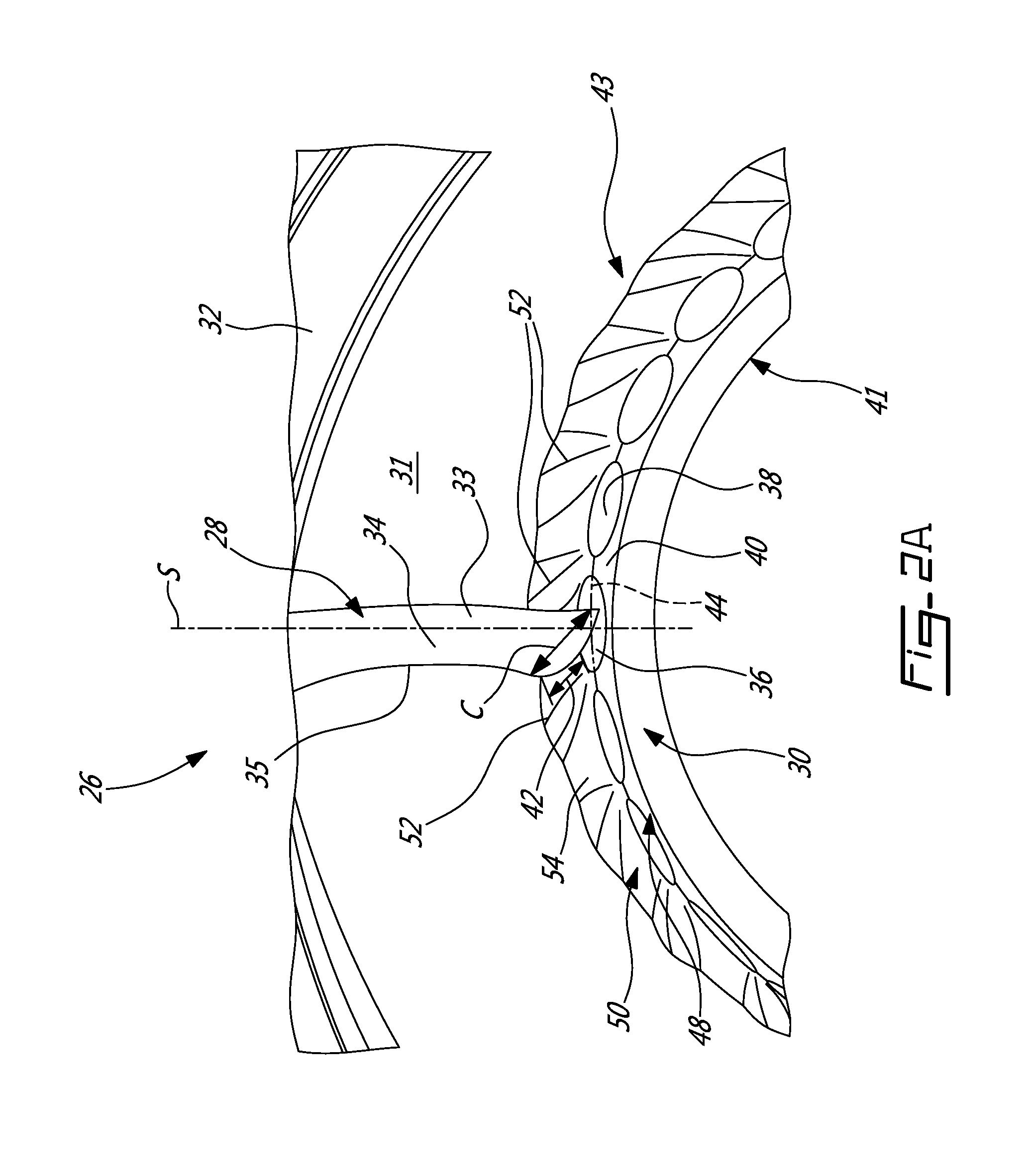

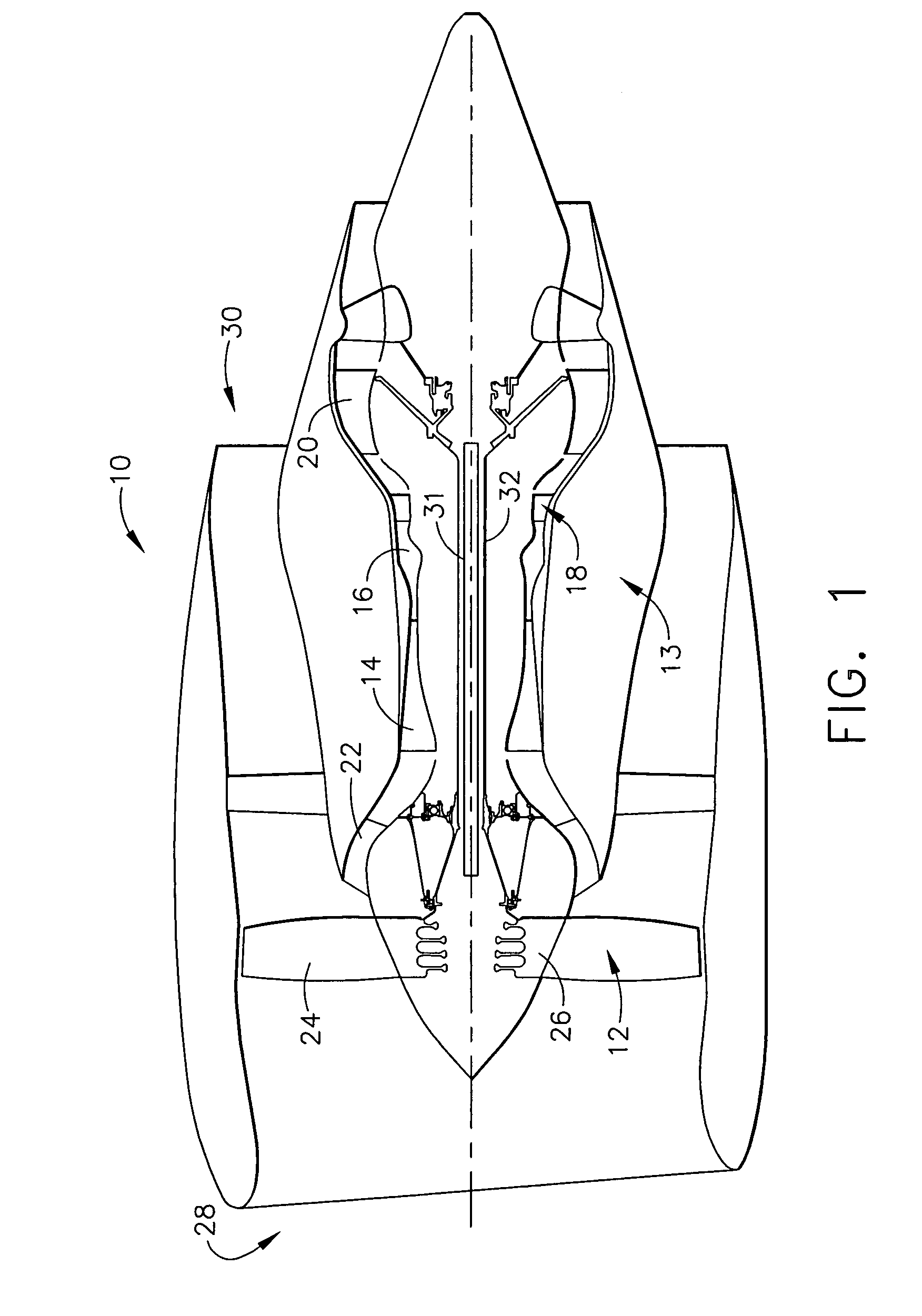

Turbine ring assembly

A turbine ring assembly includes a ring support structure and a plurality of ring sectors, each including a single piece of ceramic matrix composite material. Each ring sector includes a first portion forming an annular base with an inside face defining an inside face of the turbine ring and an outside face from which there extends two tab-forming portions including ends that are engaged in housings in the ring support structure. The ring sectors present a section that is substantially π-shaped and the ends of the tabs are held without radial clearance by the ring support structure. The tabs can have a free length in meridian section that is not less than three times their mean width.

Owner:GERAKL

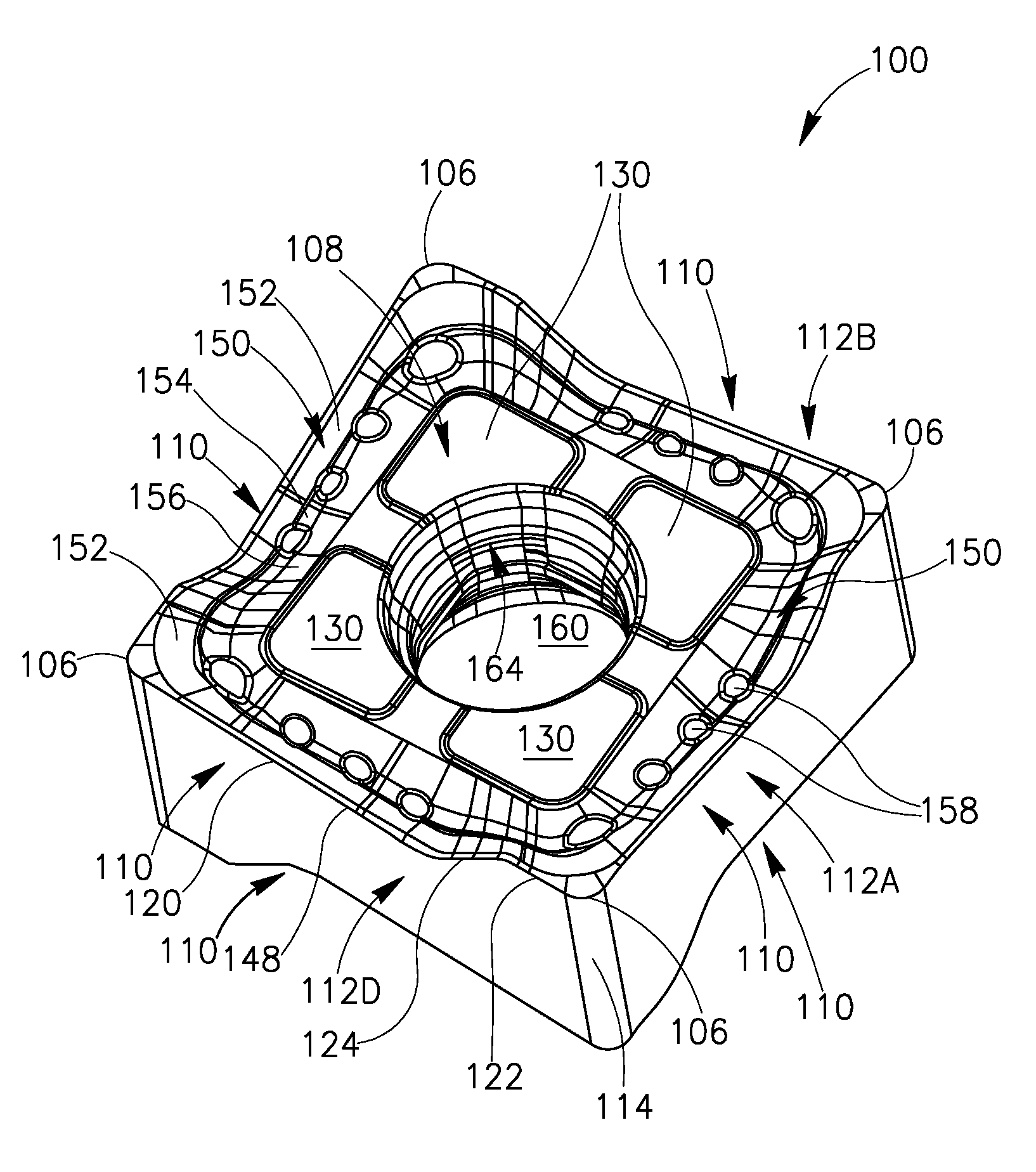

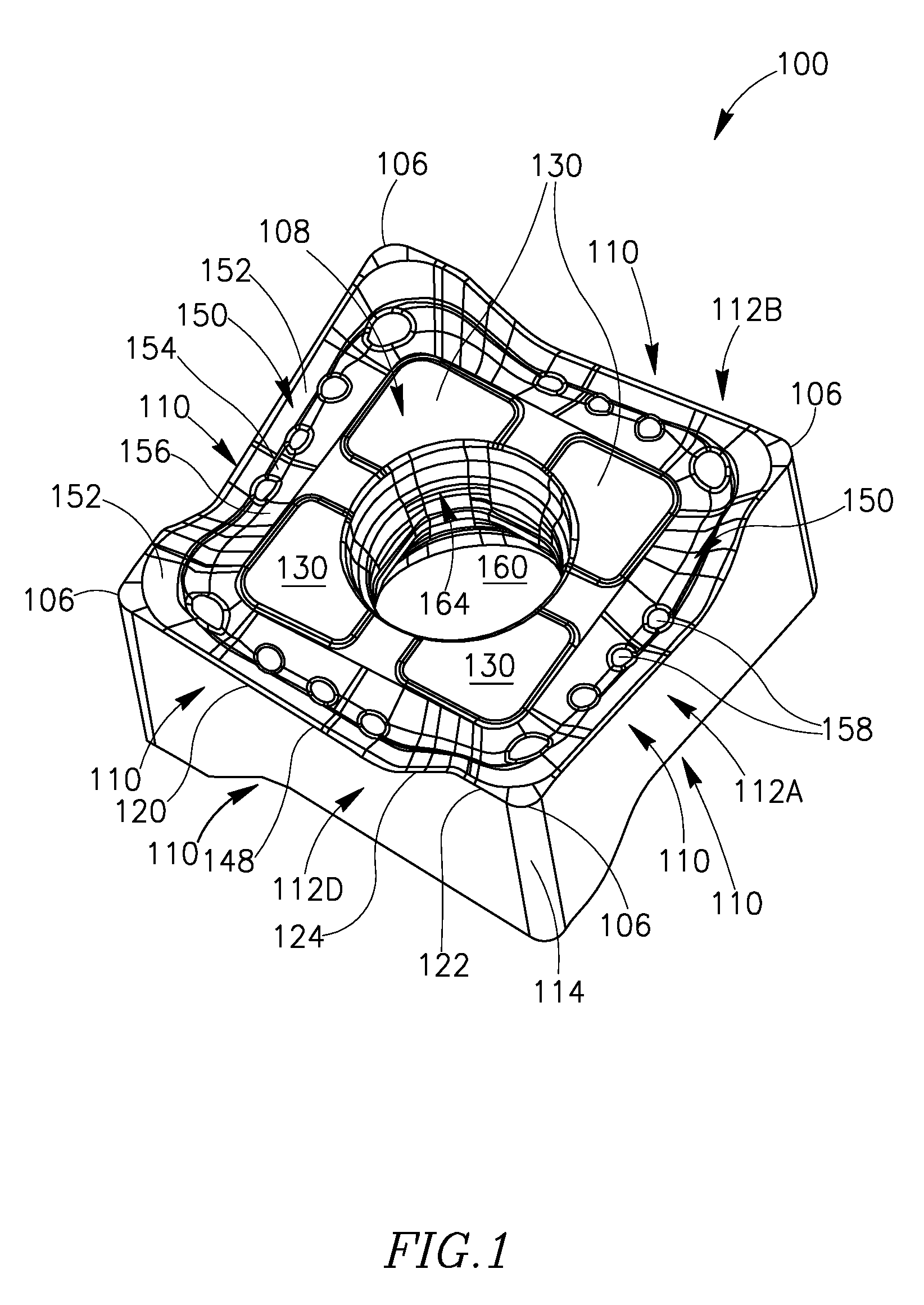

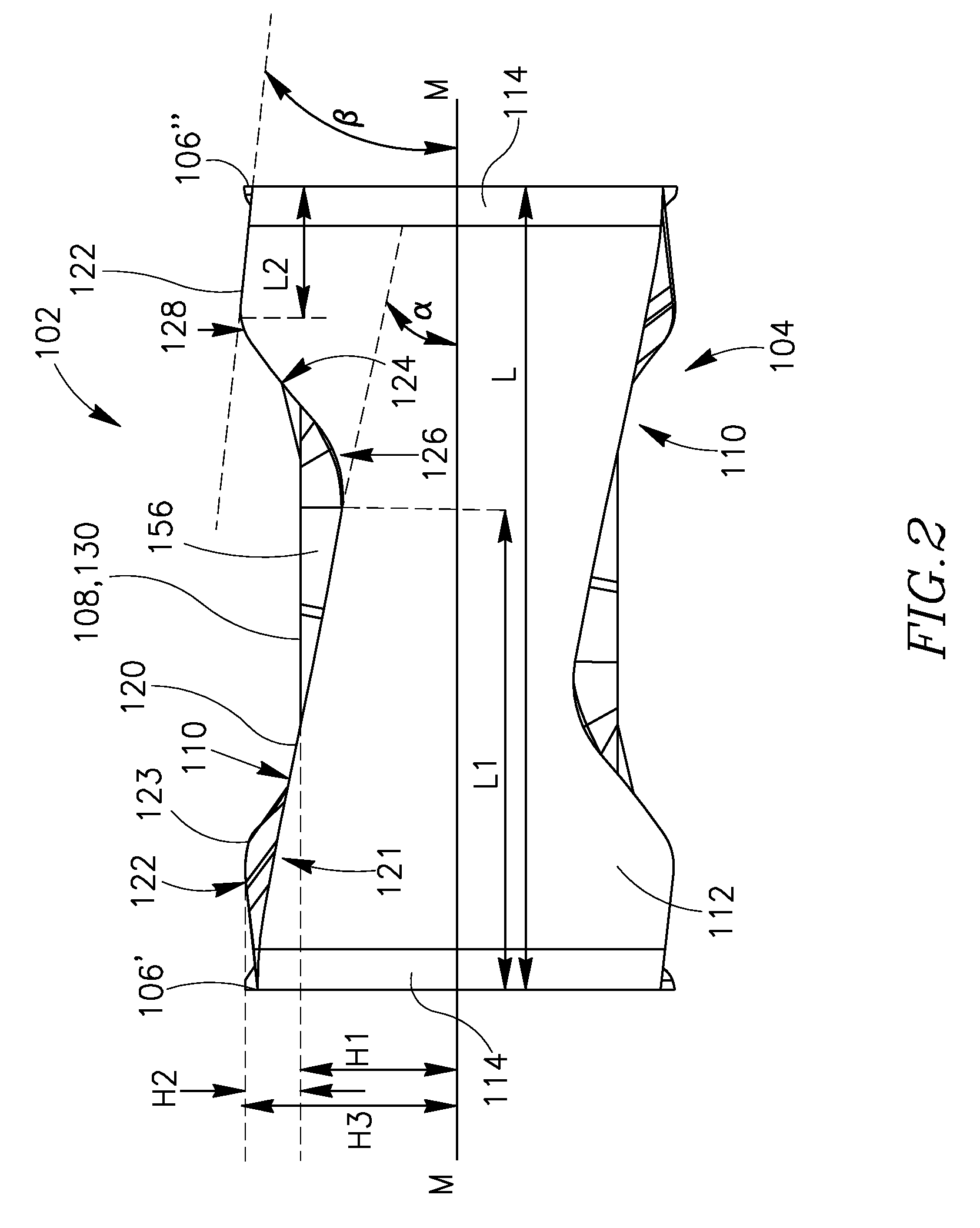

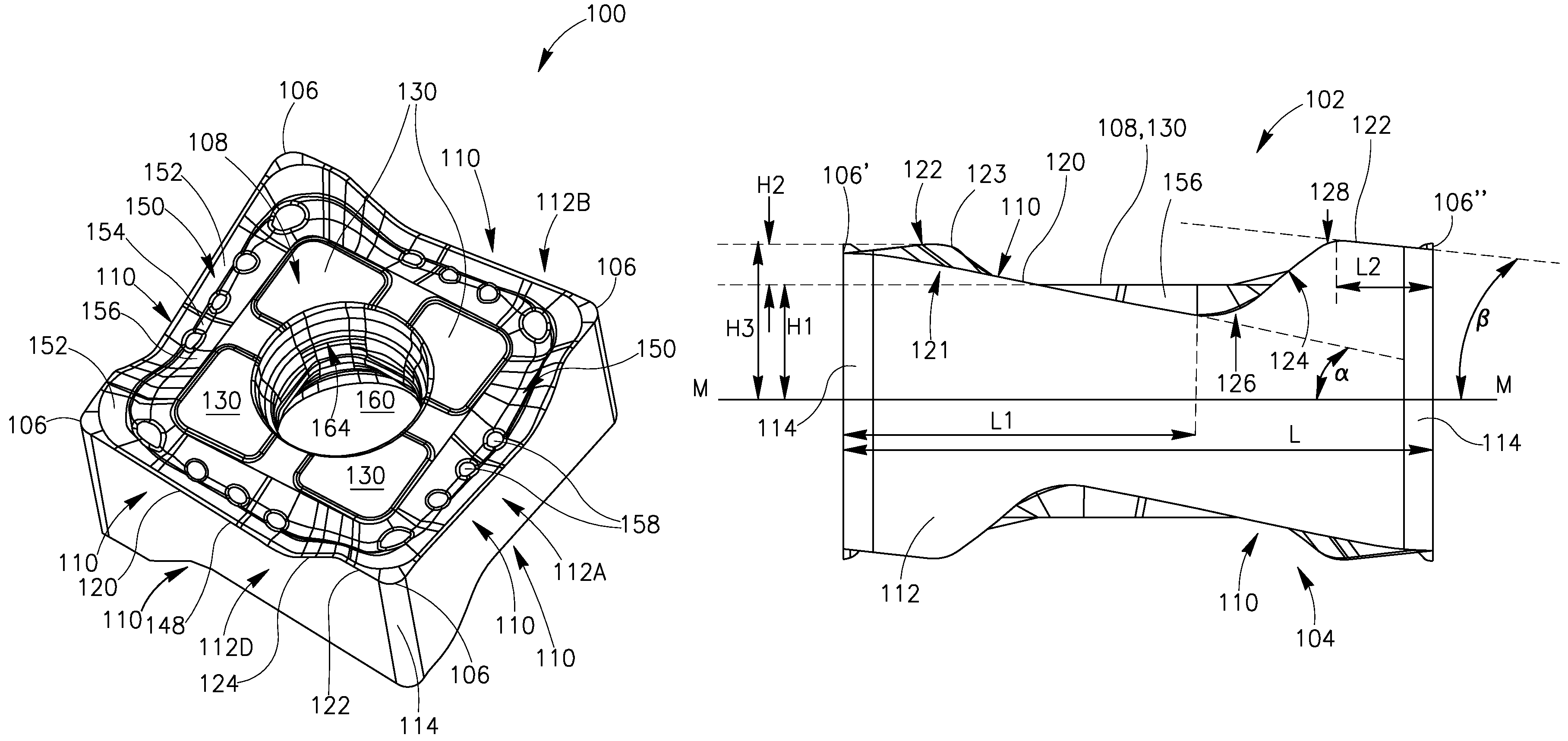

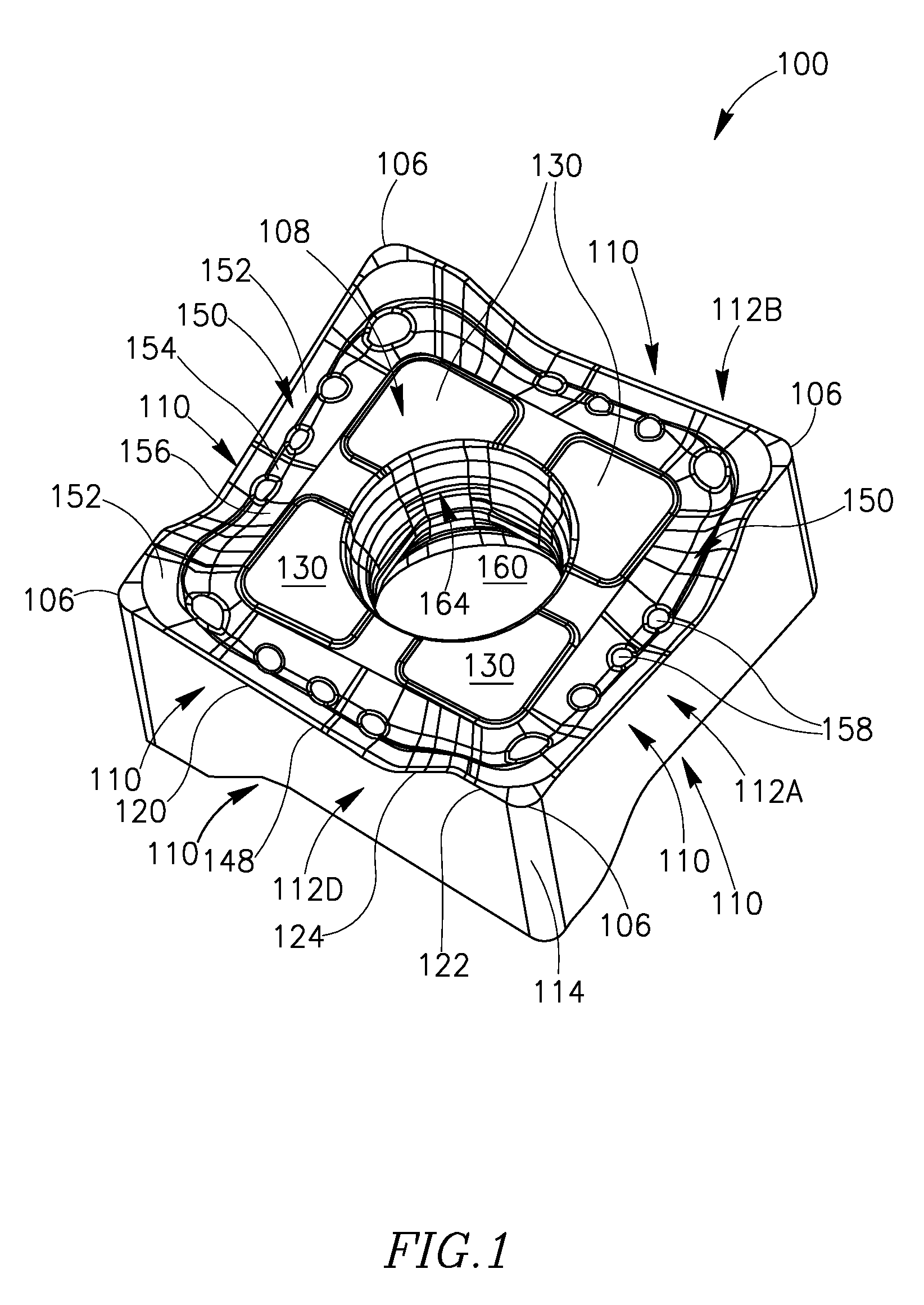

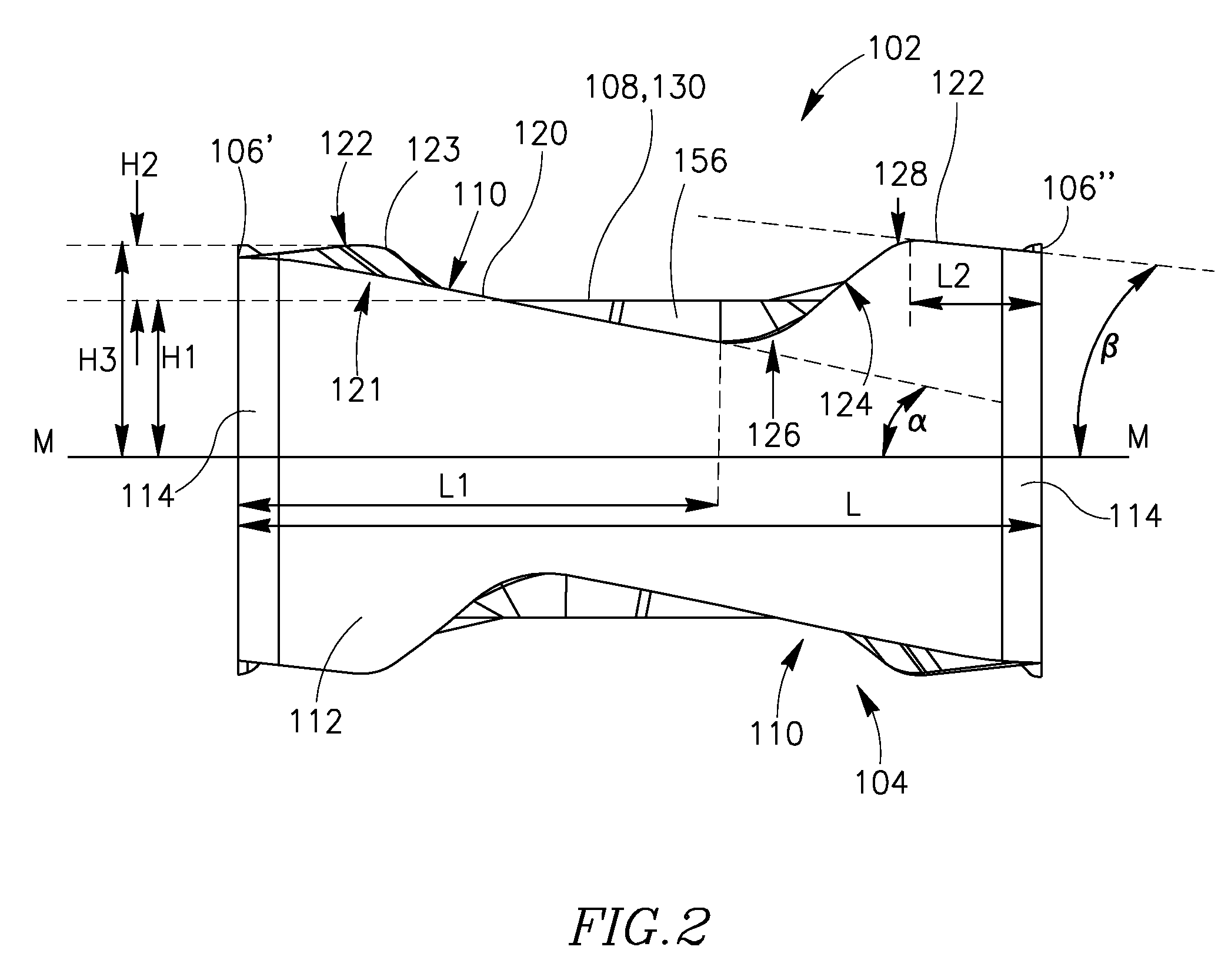

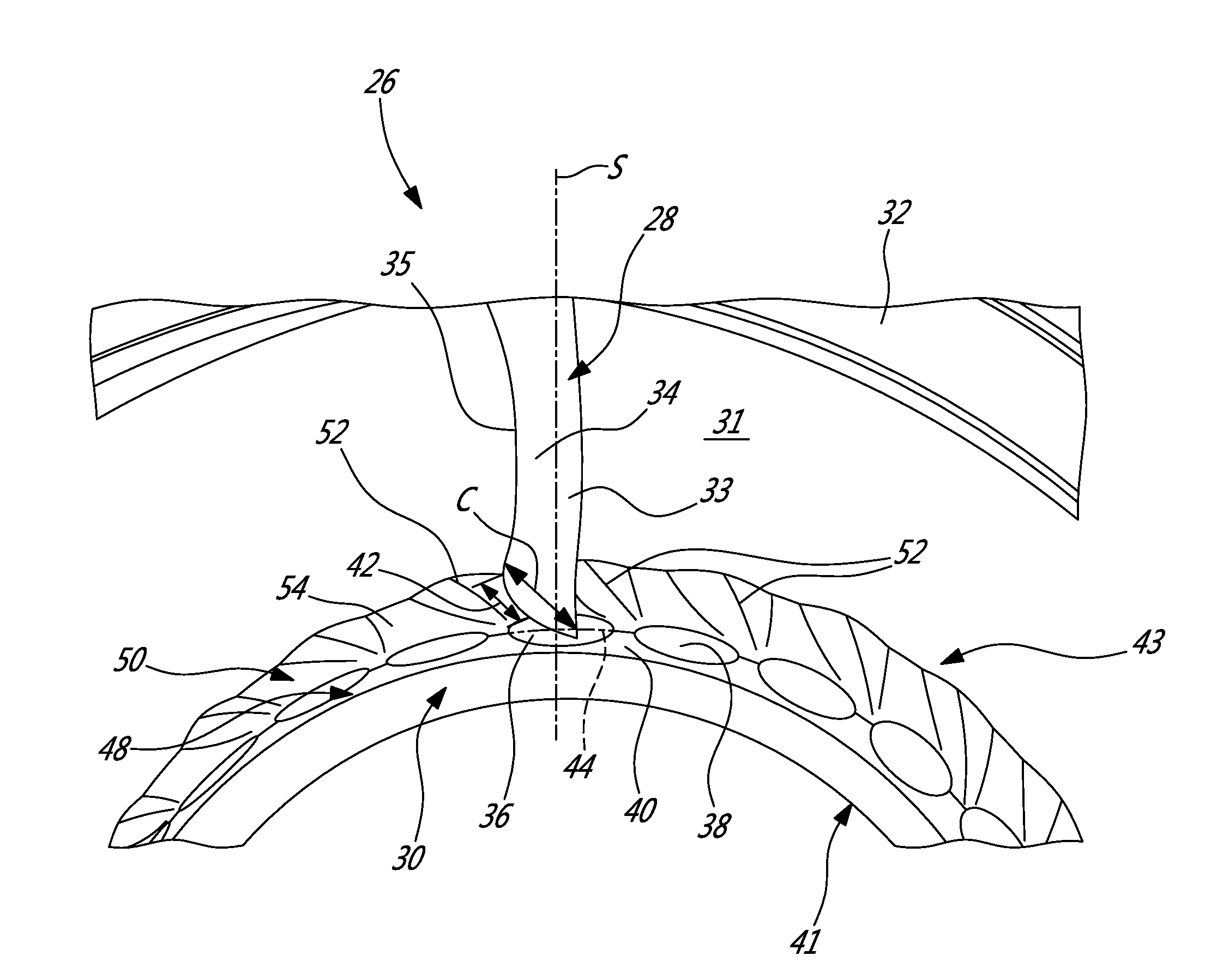

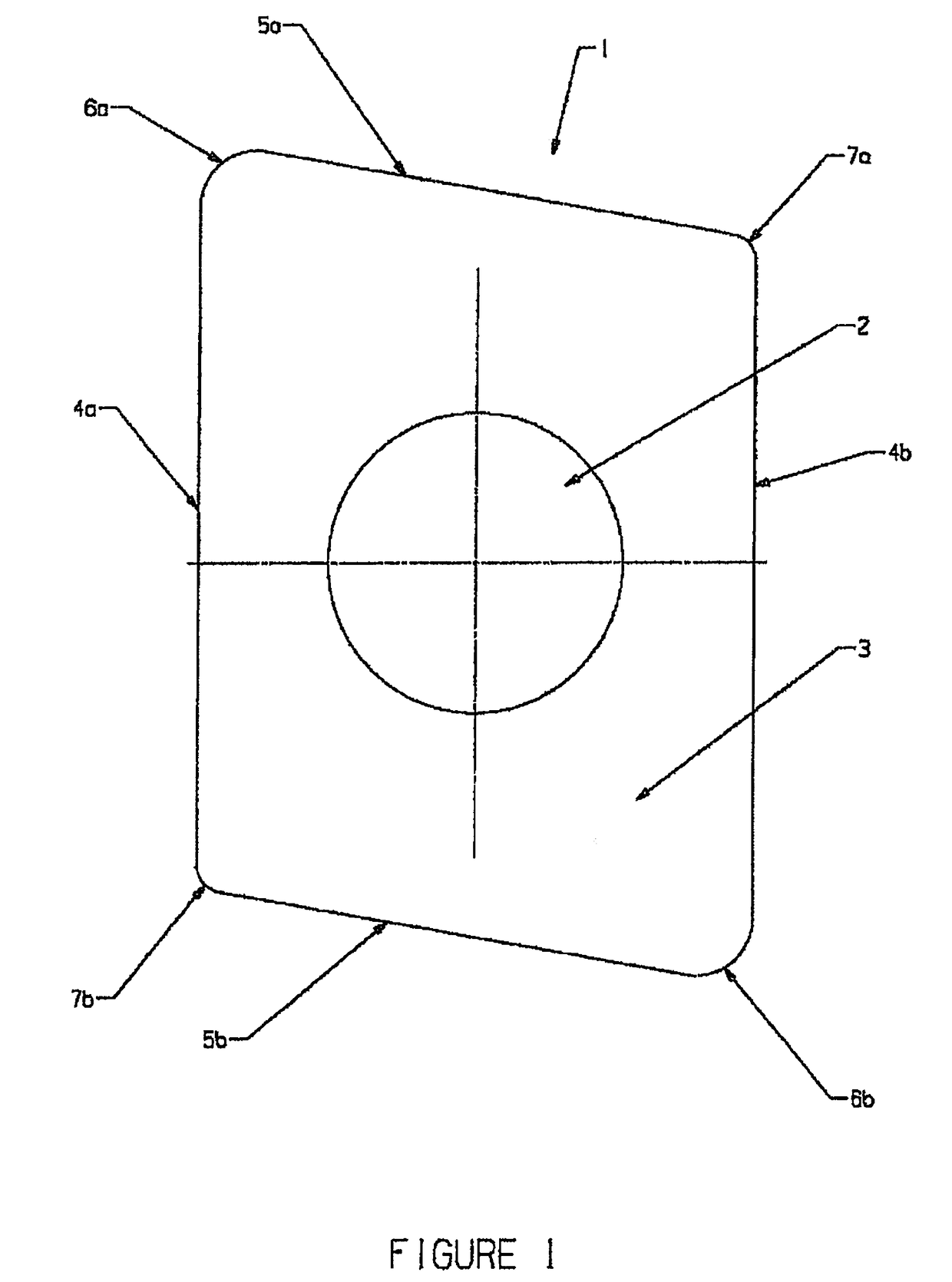

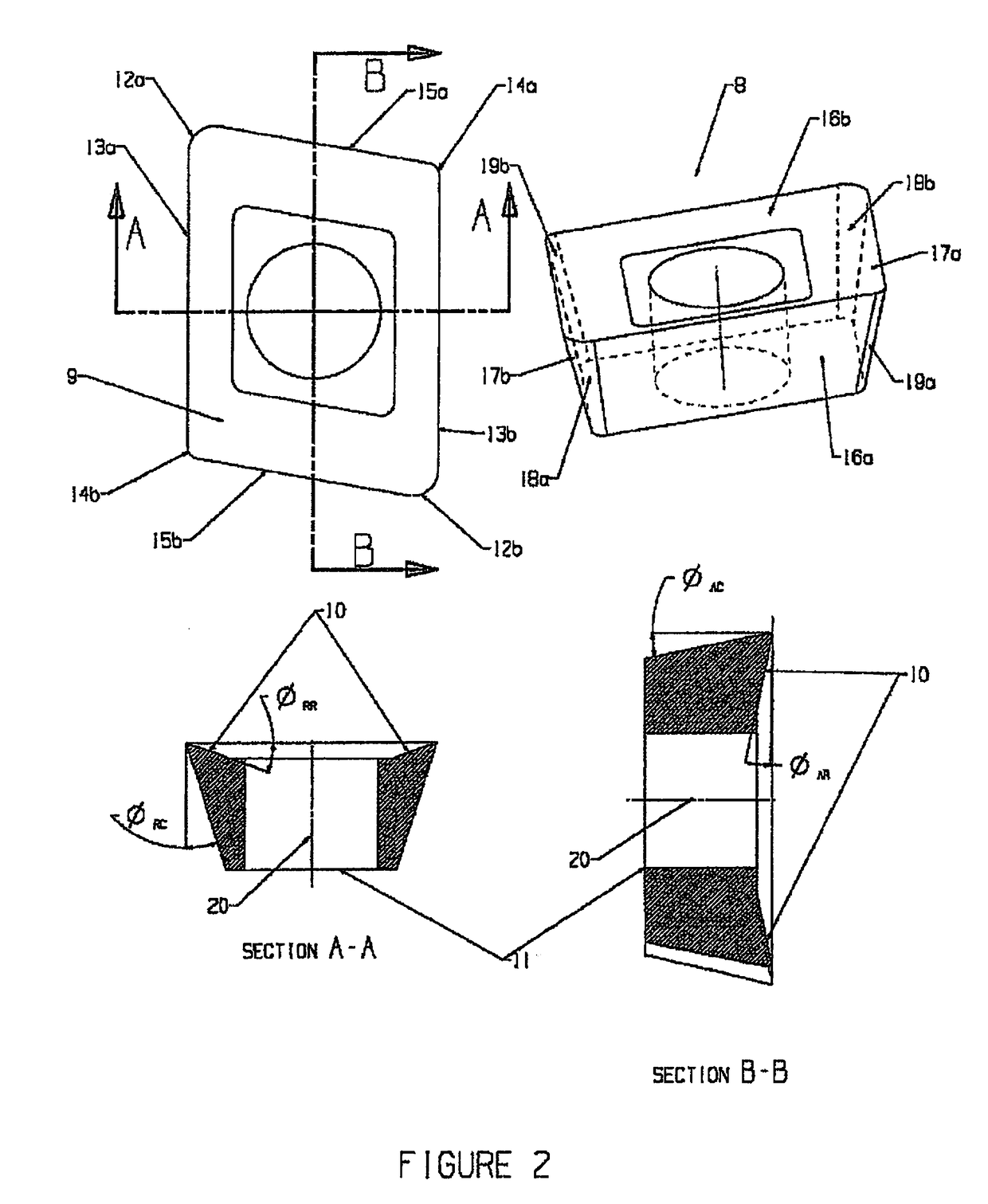

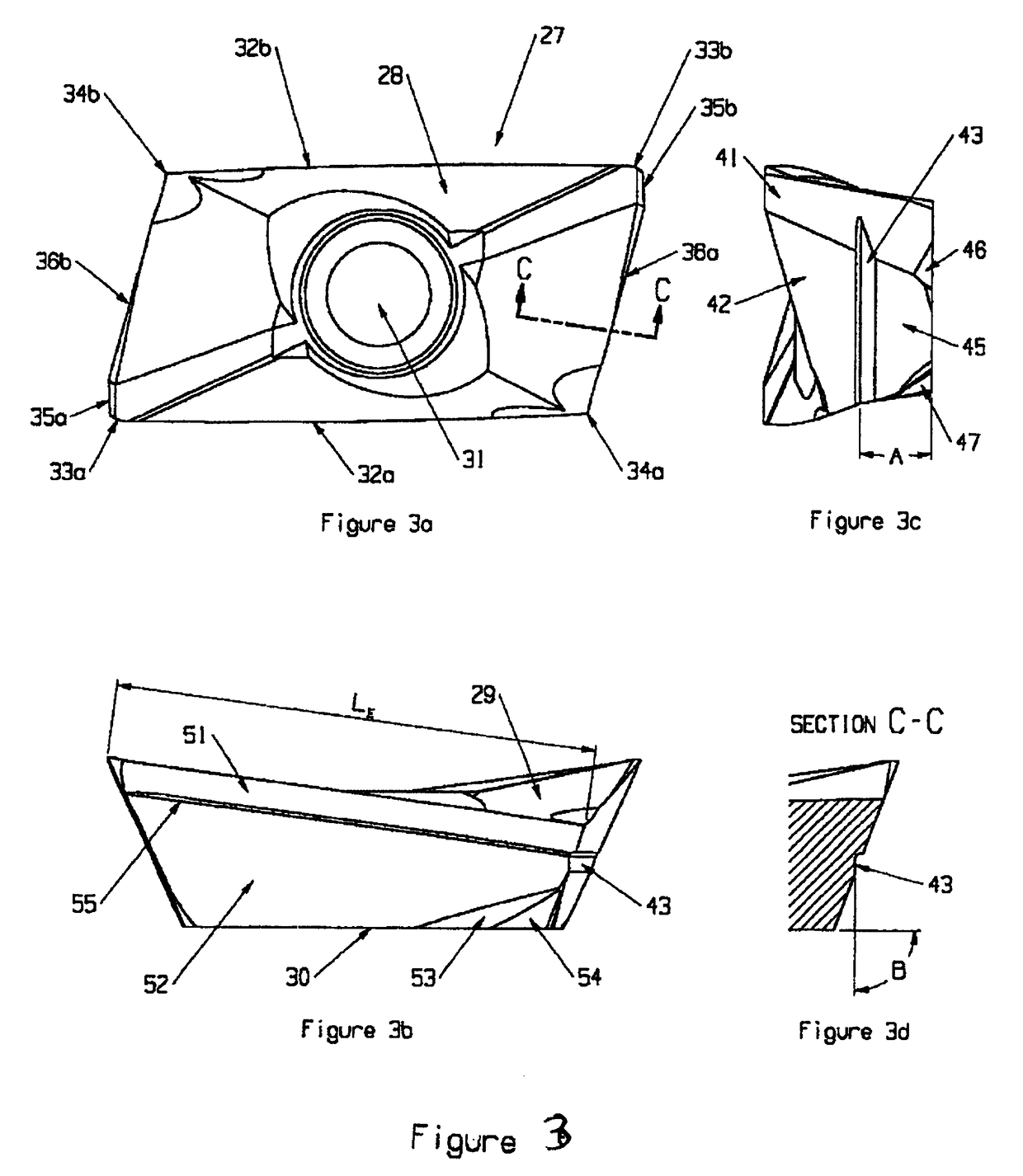

Cutting Insert for a Milling Cutter

ActiveUS20080232912A1Clearance can be providedMilling cuttersShaping cuttersMilling cutterEngineering

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

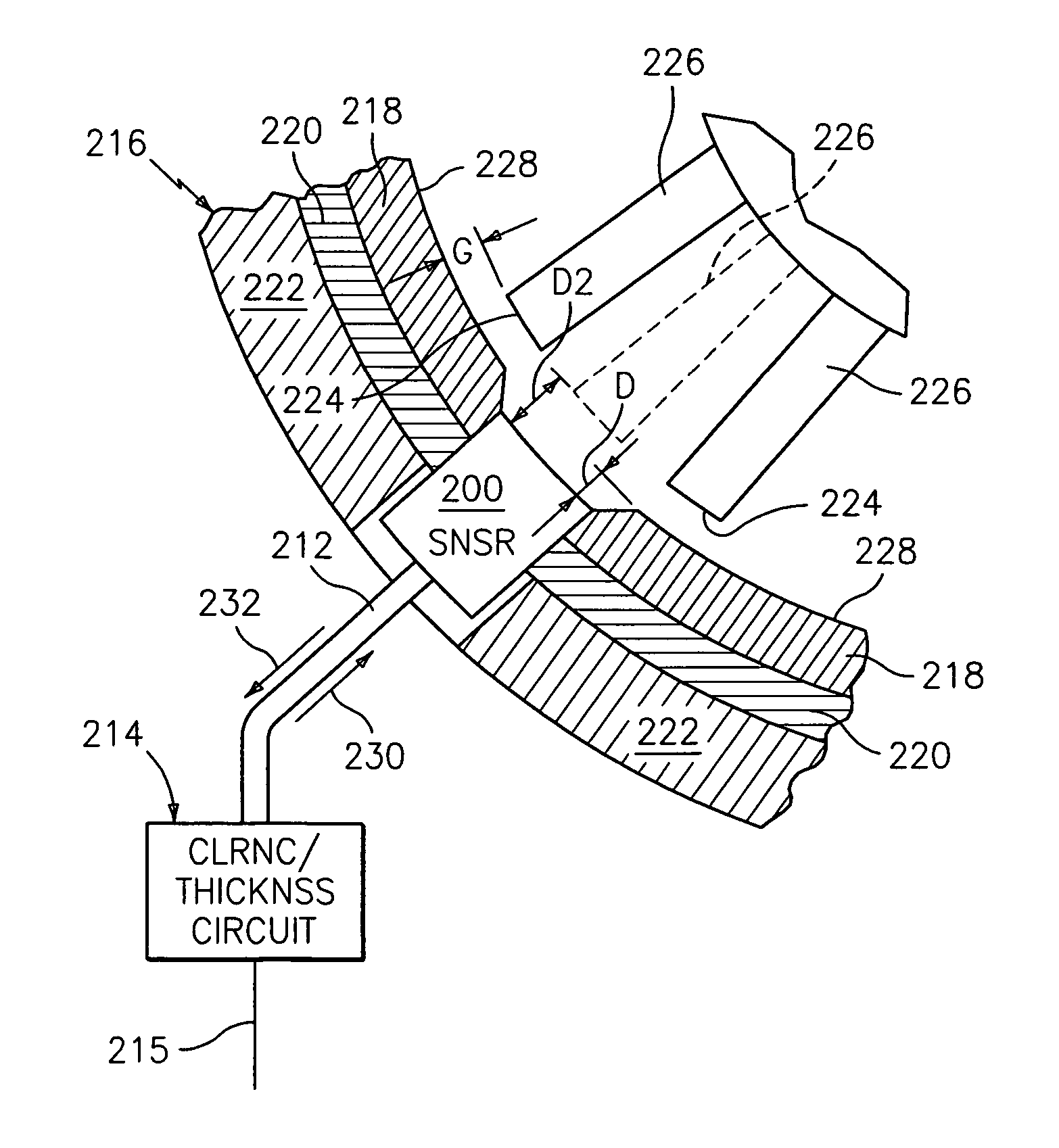

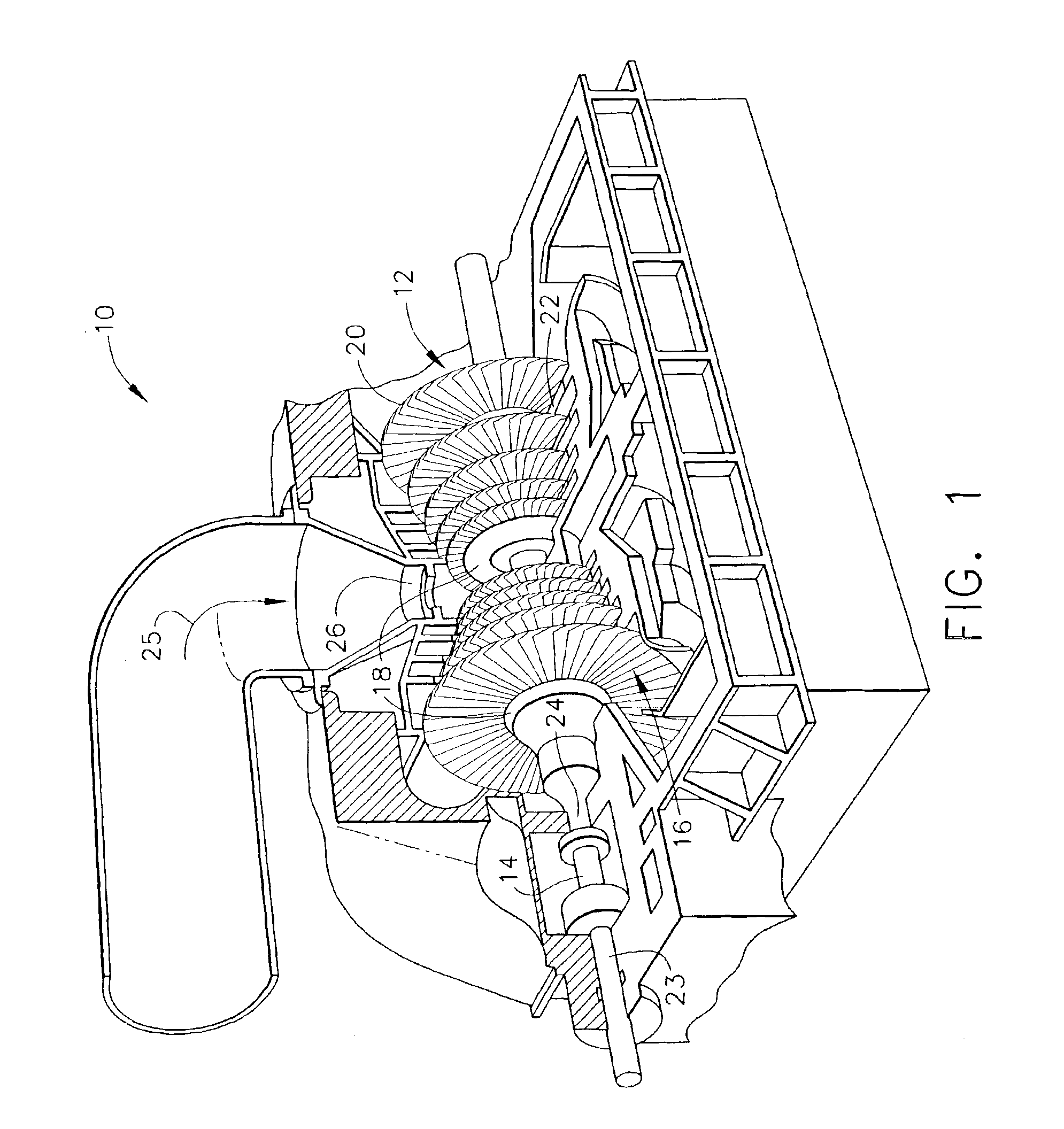

Non-contact measuring method for leaf apex radial clearance of engine rotor

InactiveCN102175135AImprove assembly qualityReduce disassemblyEngine testingUsing electrical meansCapacitanceFailure rate

The invention relates to a non-contact measuring method for a leaf apex radial clearance of an engine rotor, and the method comprises the following steps: 1) assembling a measuring system, calibrating a sensor and determining the relation between the radial clearance and voltage of a leaf apex; 2) preparing before measuring; and 3) measuring the leaf apex radial clearance of the engine rotor. In the measuring method provided by the invention, a measurement technique based on a capacitance method is adopted; the measuring course and the assembling are synchronously carried out; the once cartridge disassembly and assembly is reduced; the measuring time is shortened; the production efficiency is improved; and the measuring accuracy is improved, thereby improving the assembly quality of an engine and reducing the failure rate of the engine. The non-contact measuring method provided by the invention is mainly used for measuring the leaf apex radial clearance of the rotors of parts such as an engine, a high-pressure compressor, a low-pressure compressor, a high-pressure turbine, a low-pressure turbine and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Cutting insert for a milling cutter

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

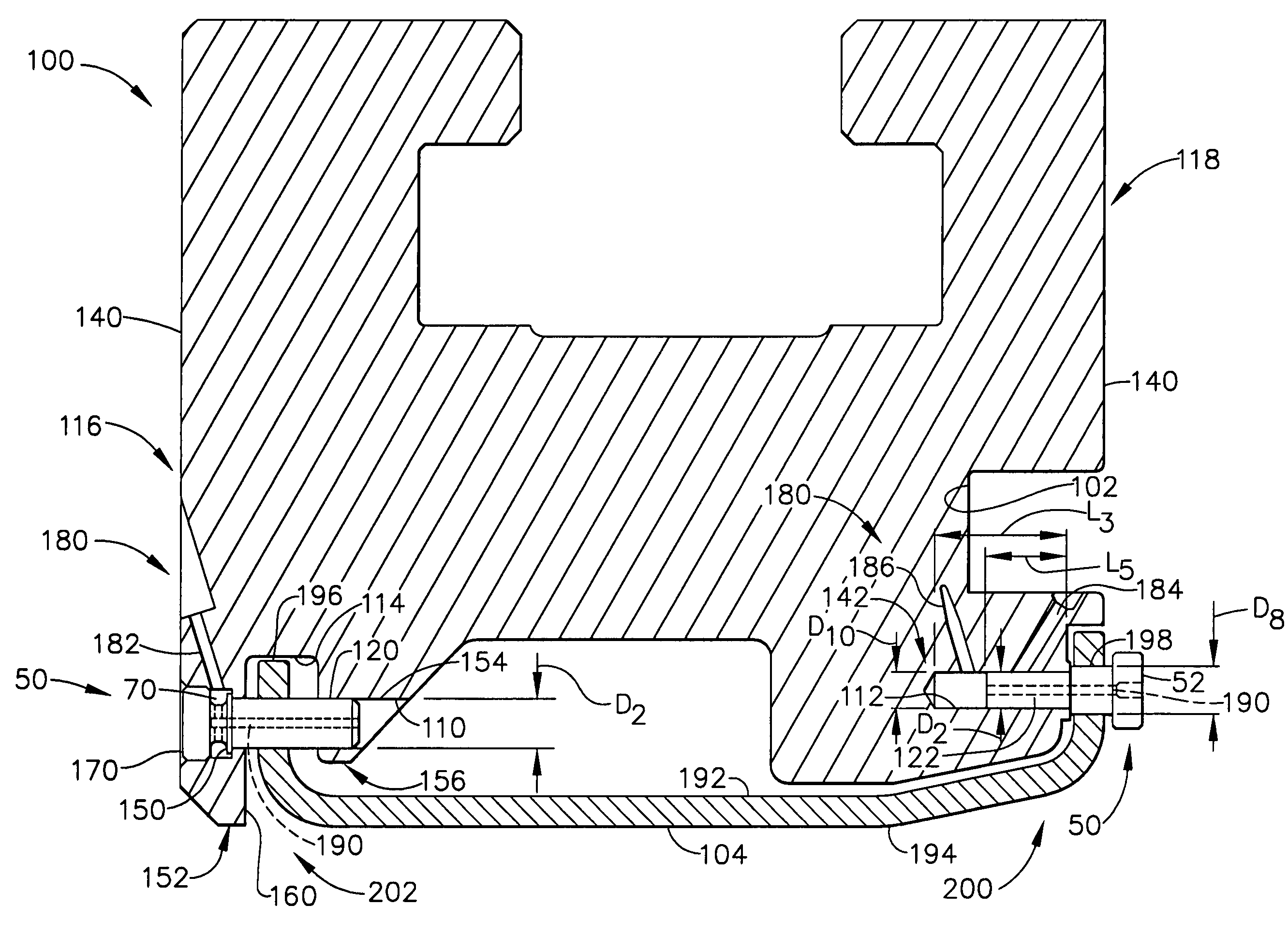

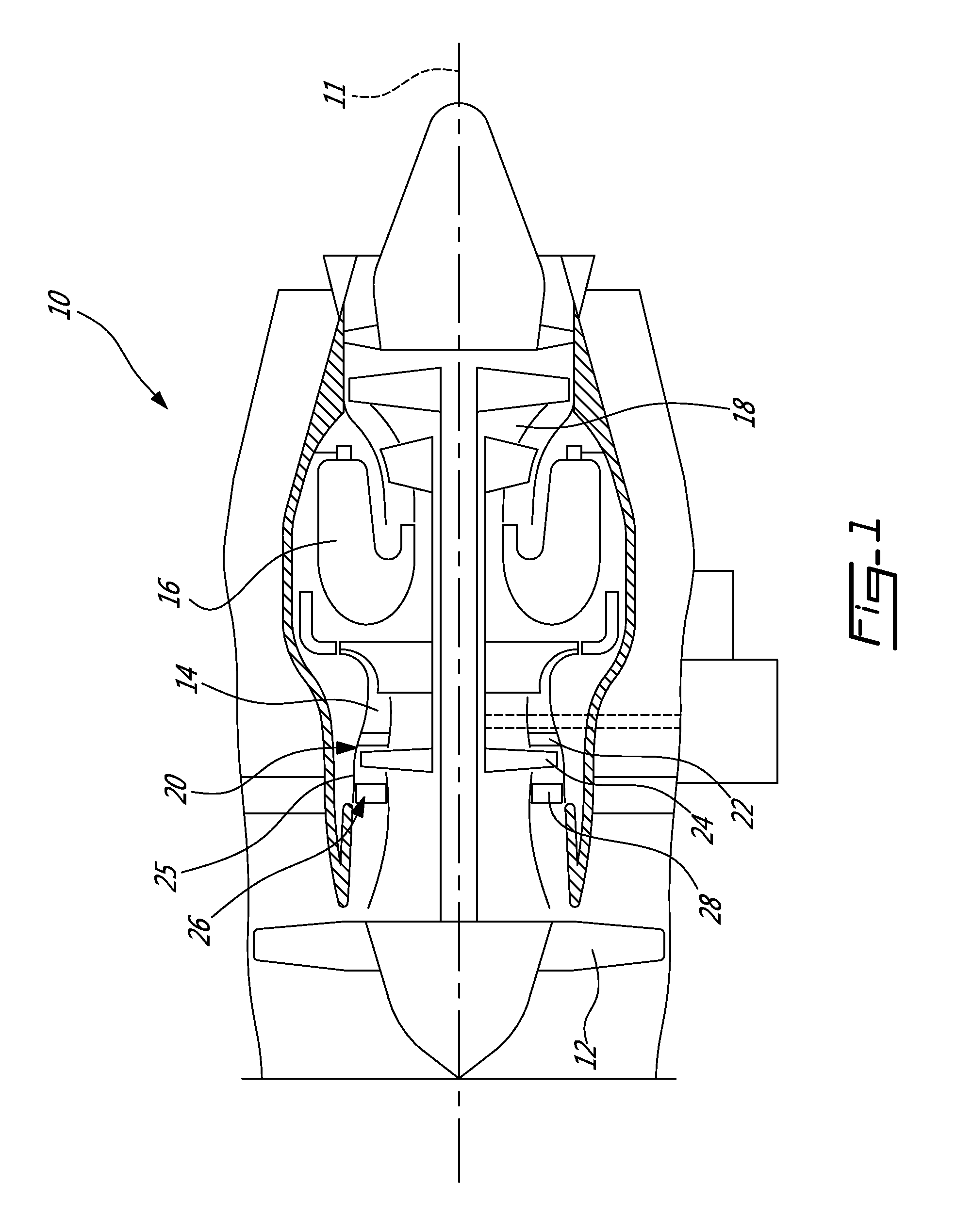

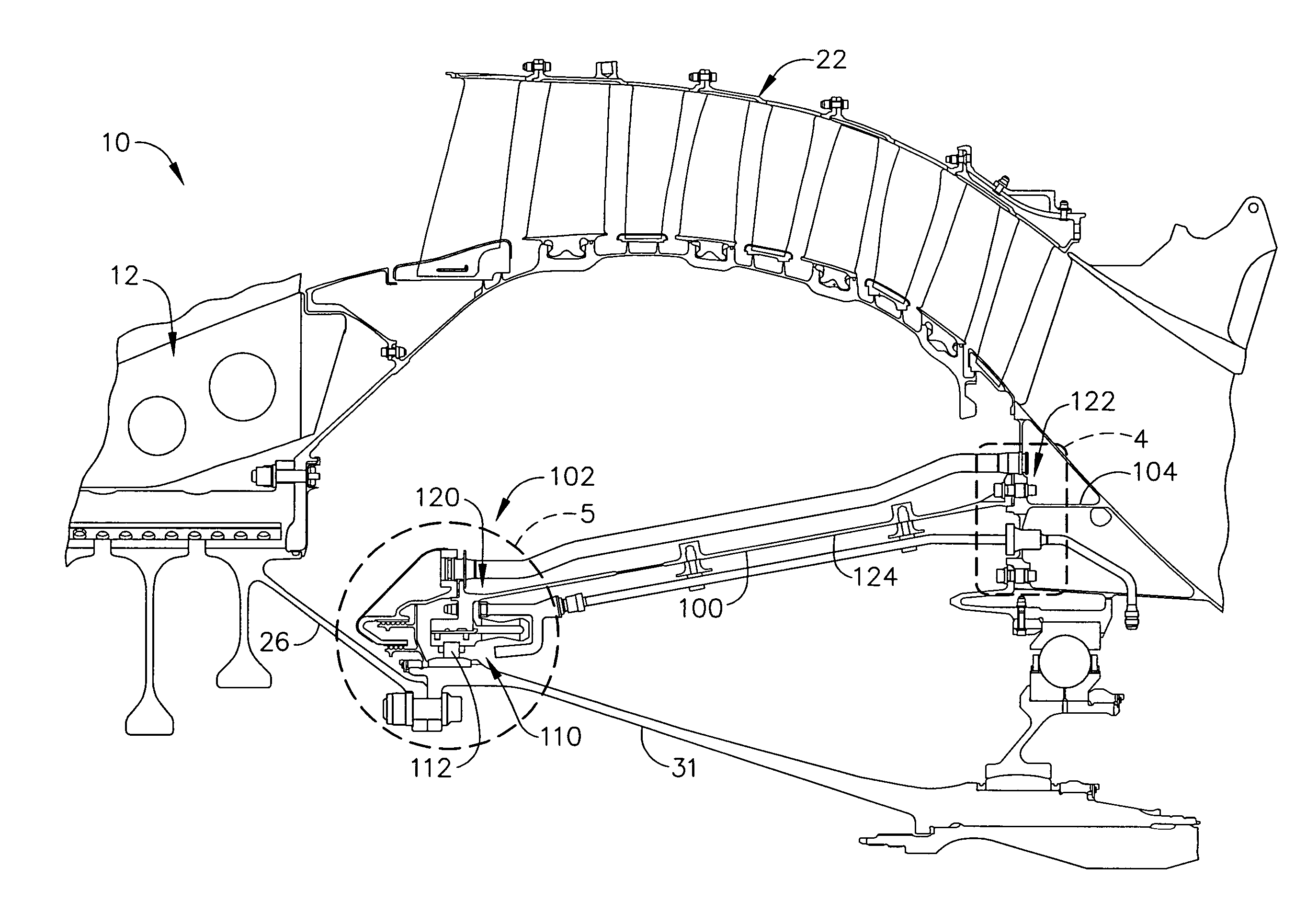

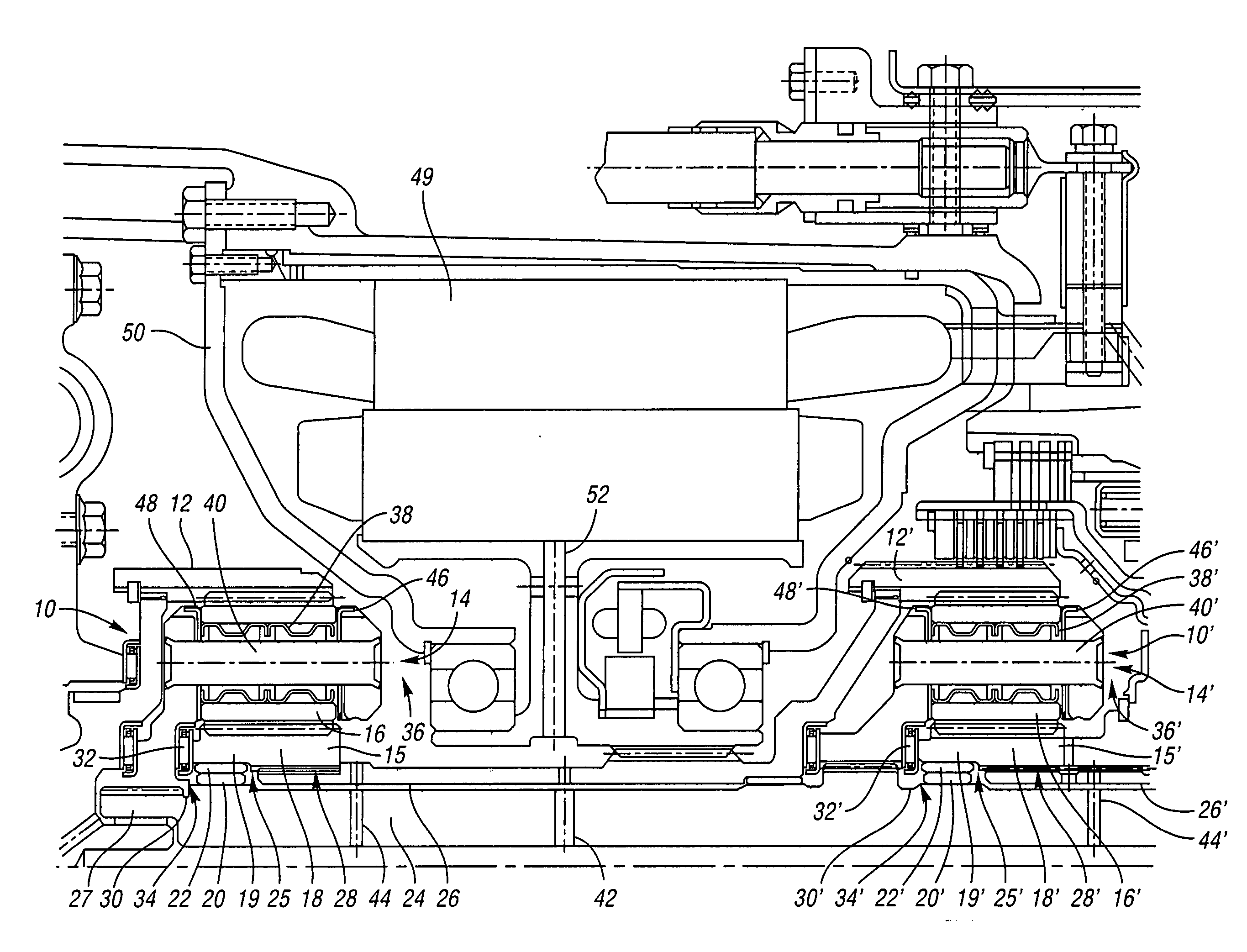

Methods and apparatus for coupling ceramic matrix composite turbine components

A method facilitates assembling a stator assembly for a turbine engine. The method comprises positioning a shroud fabricated from a ceramic matrix composite material adjacent a metallic stator block, and coupling the shroud to the stator block using a coupling arrangement such that a predetermined radial clearance is defined between the shroud and a rotor assembly coupled radially inward thereof.

Owner:GENERAL ELECTRIC CO

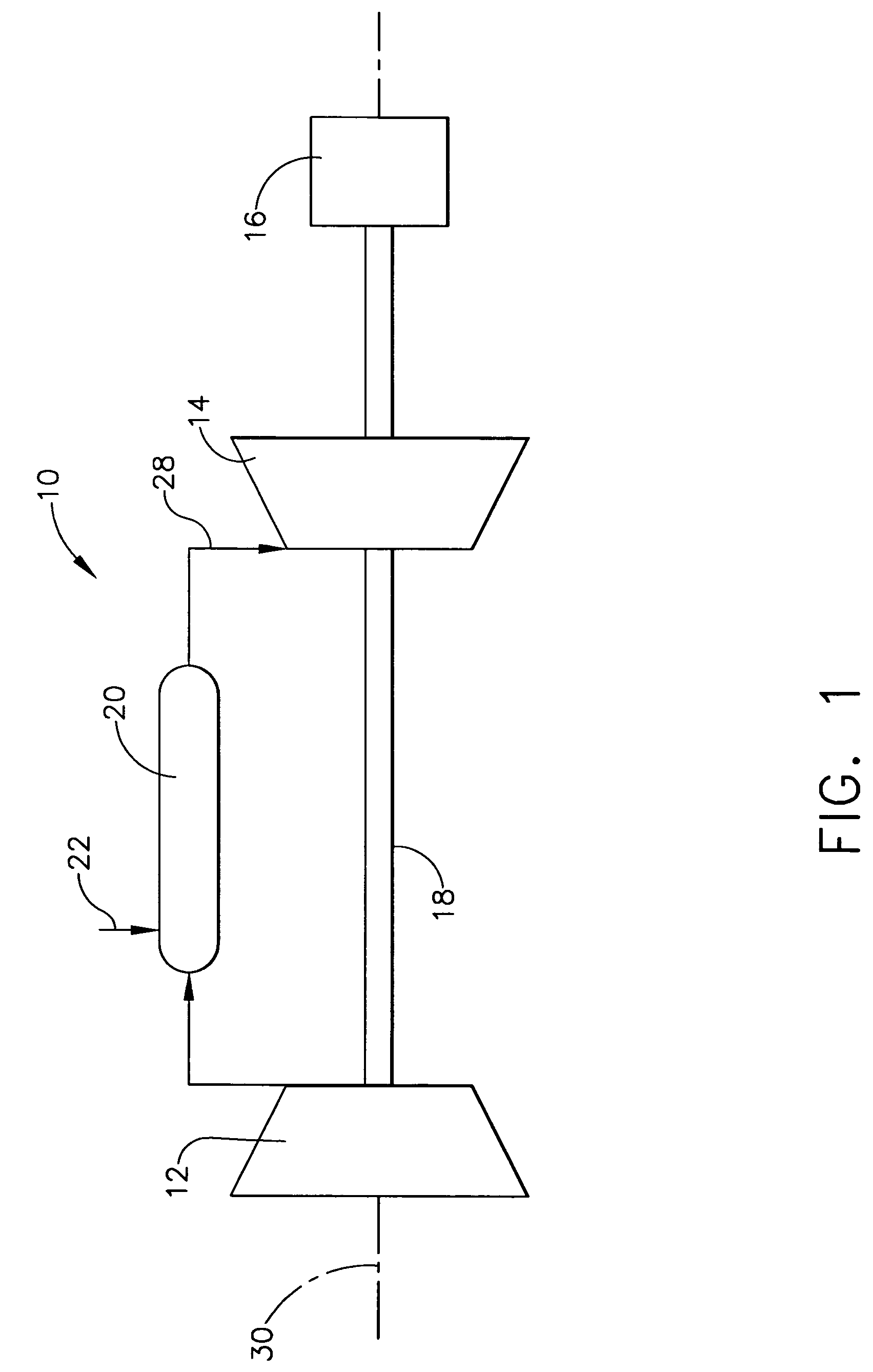

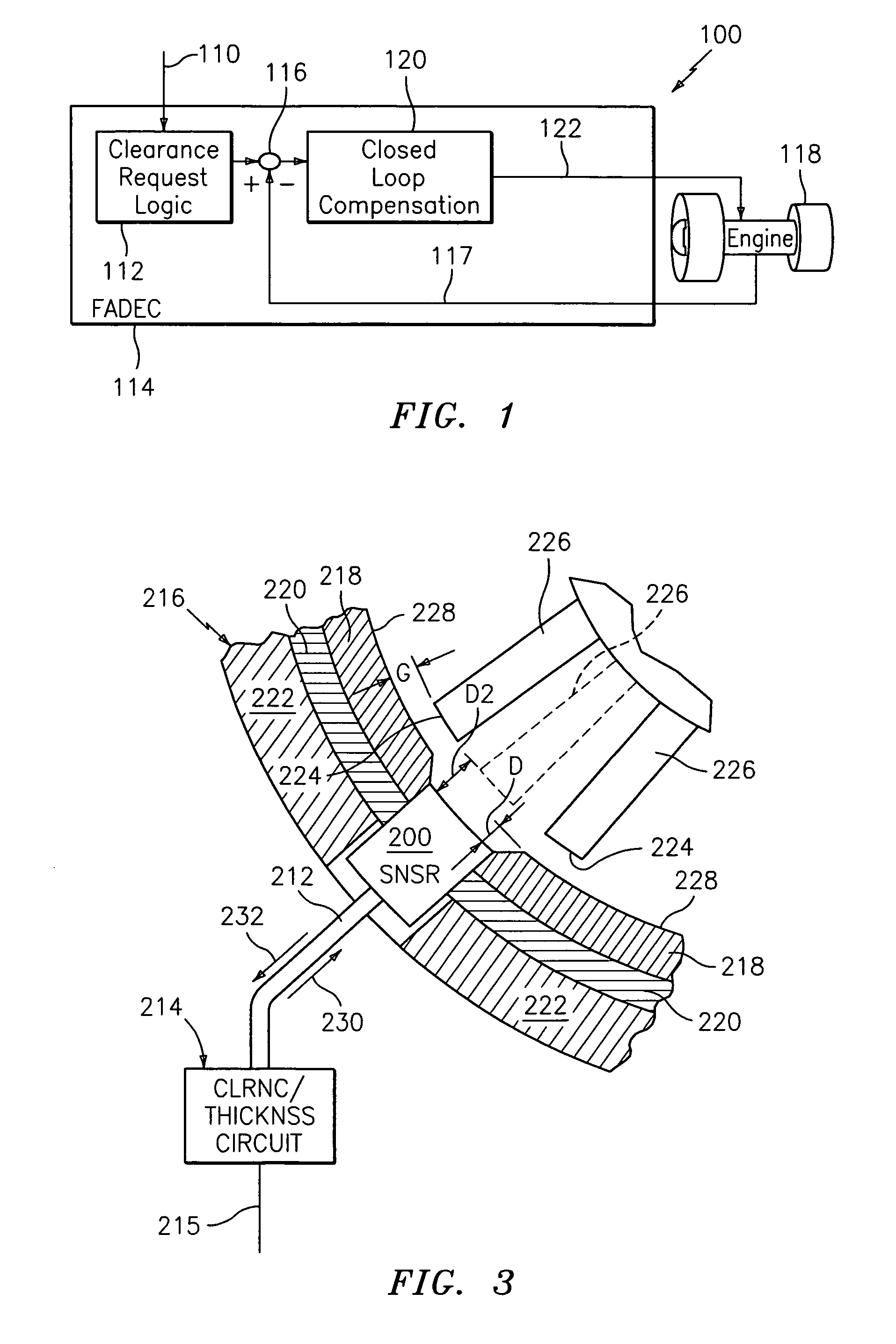

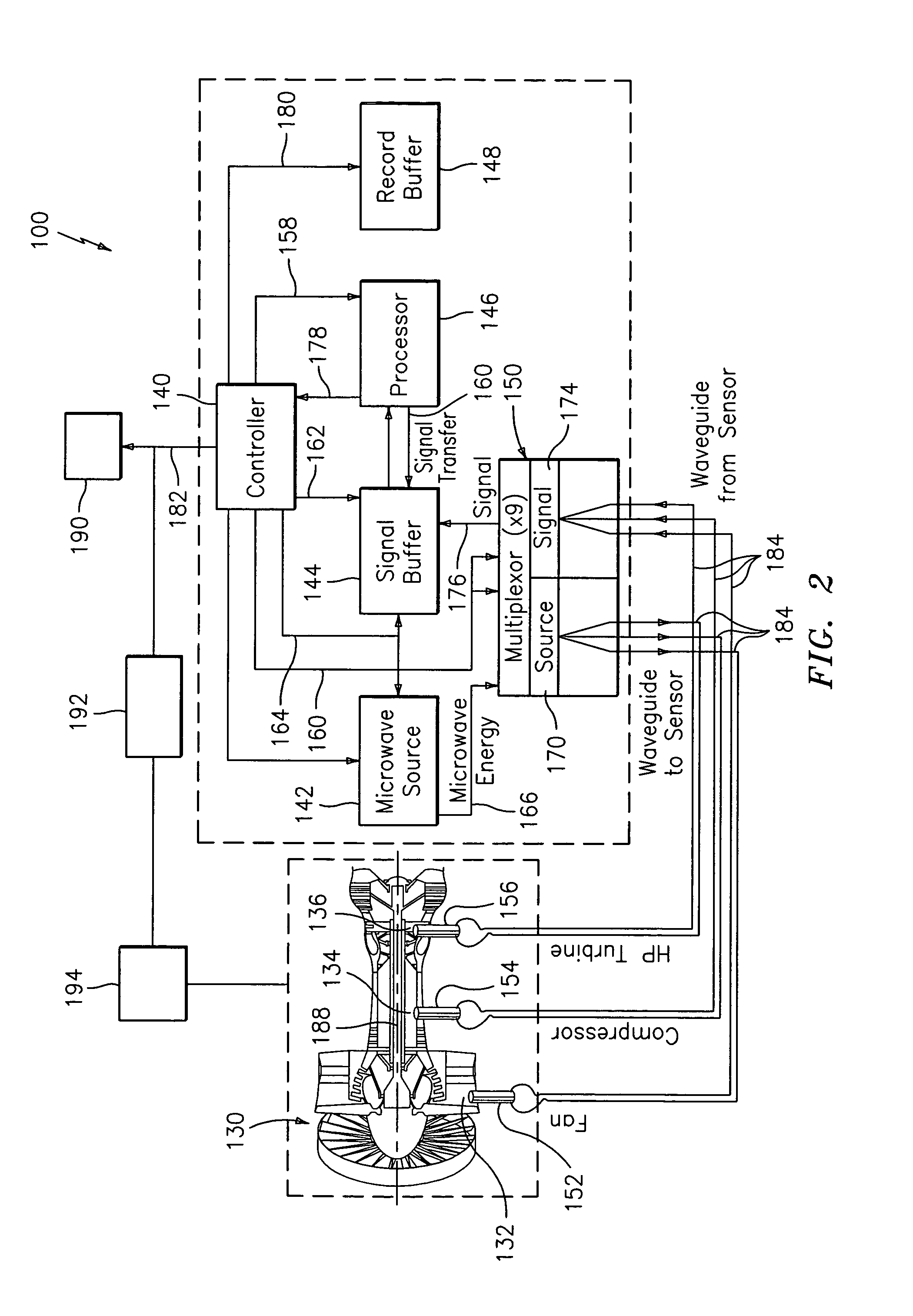

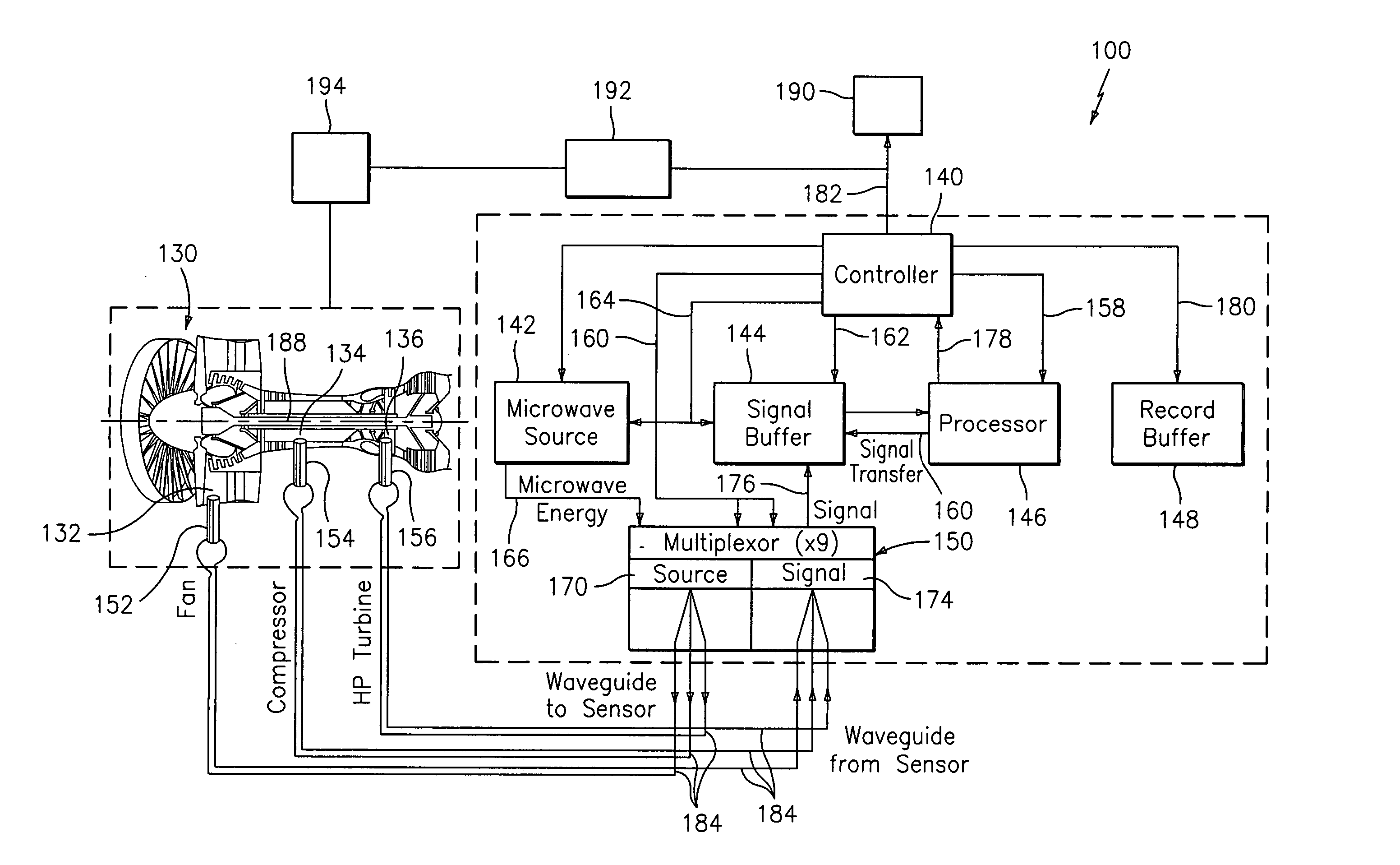

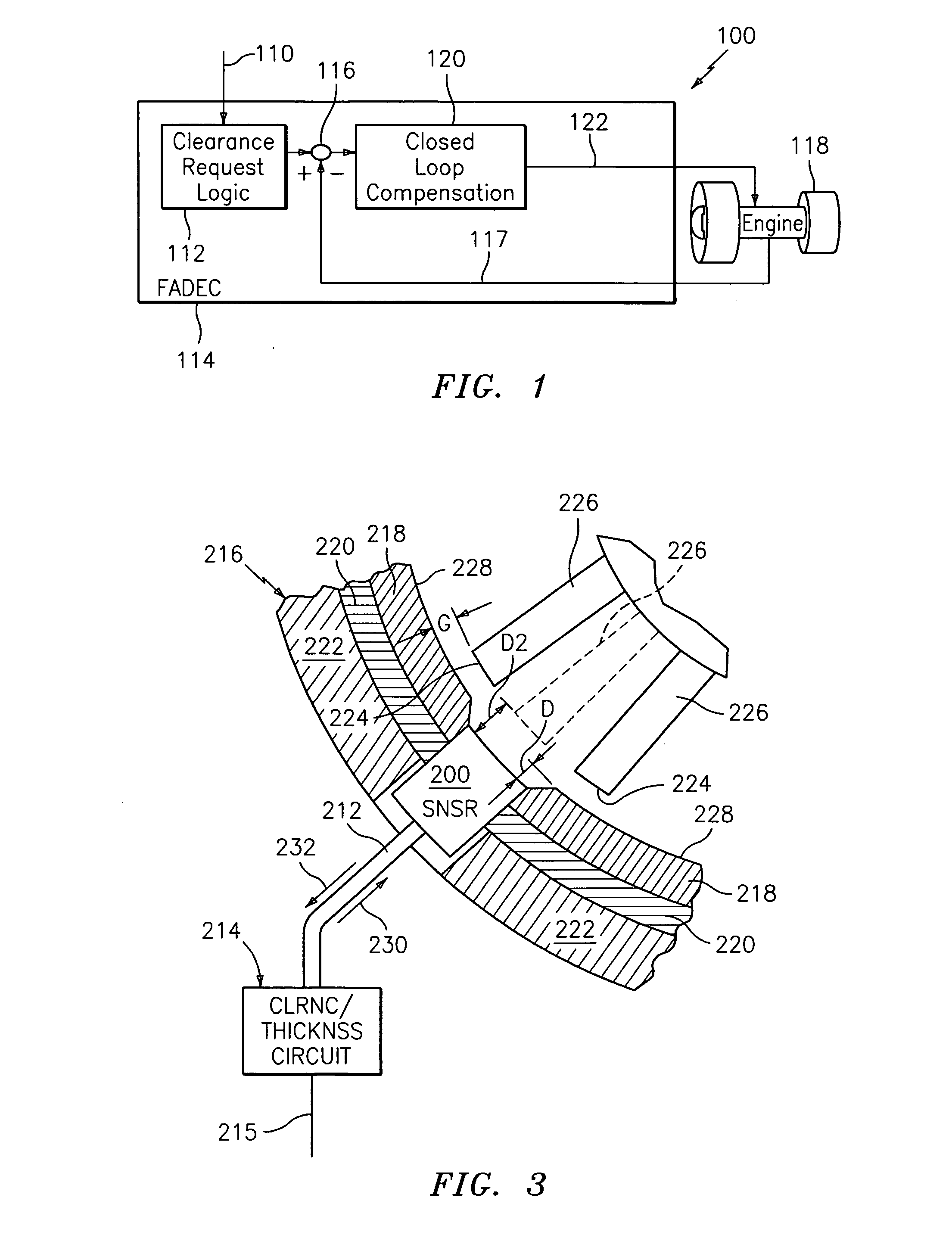

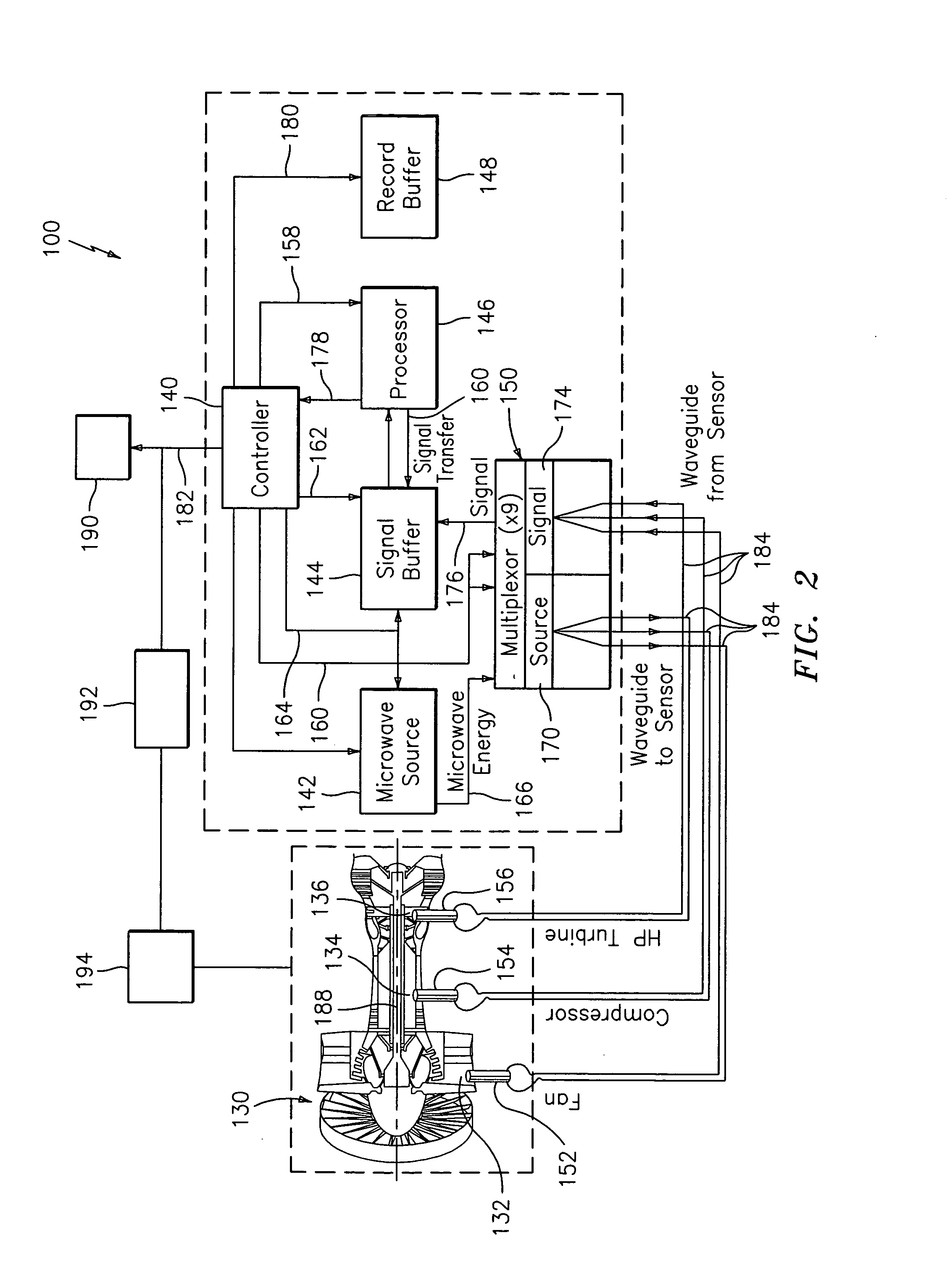

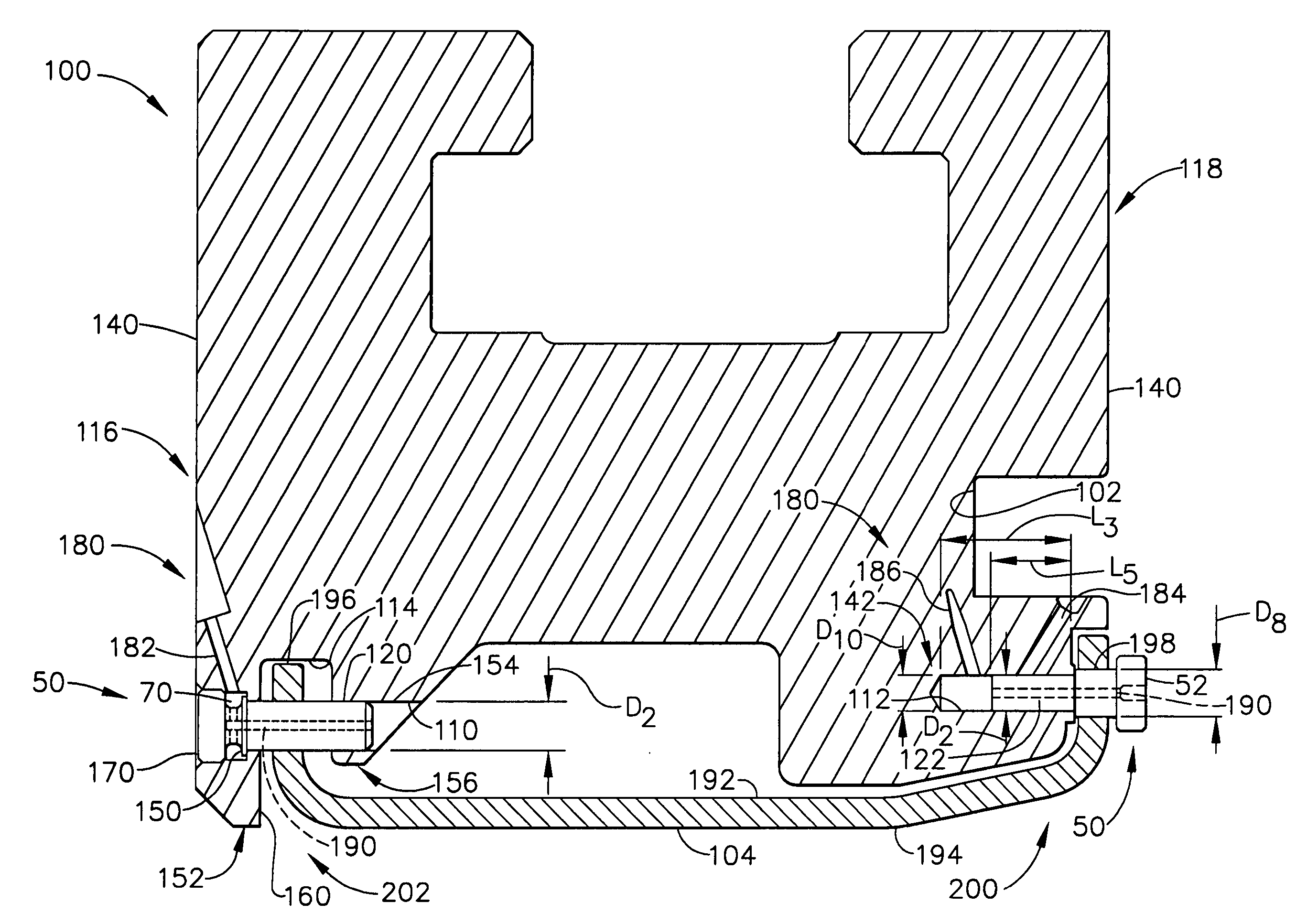

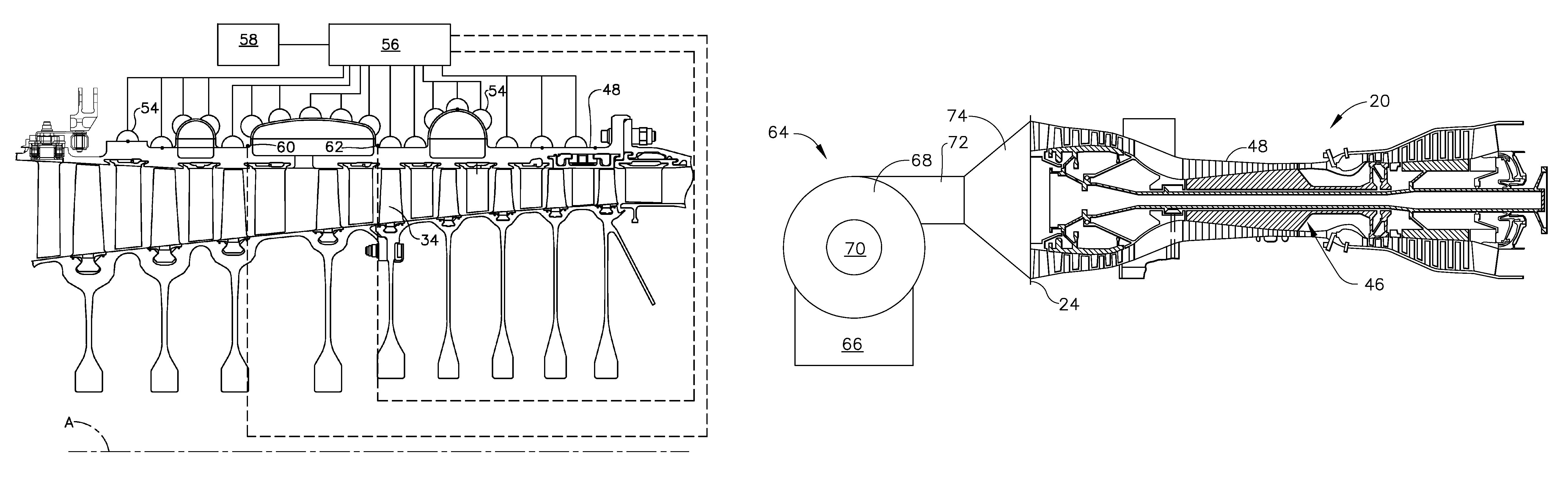

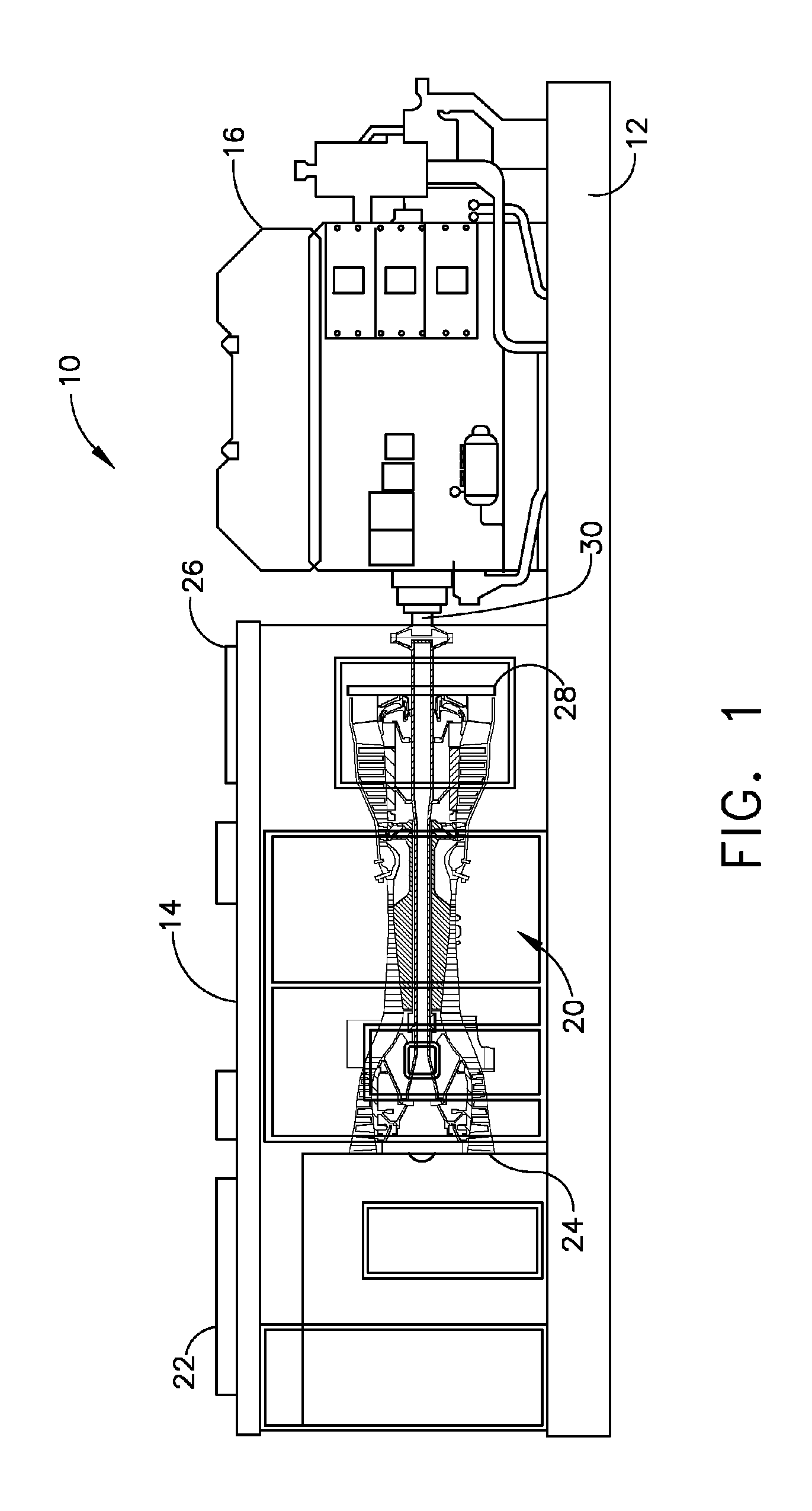

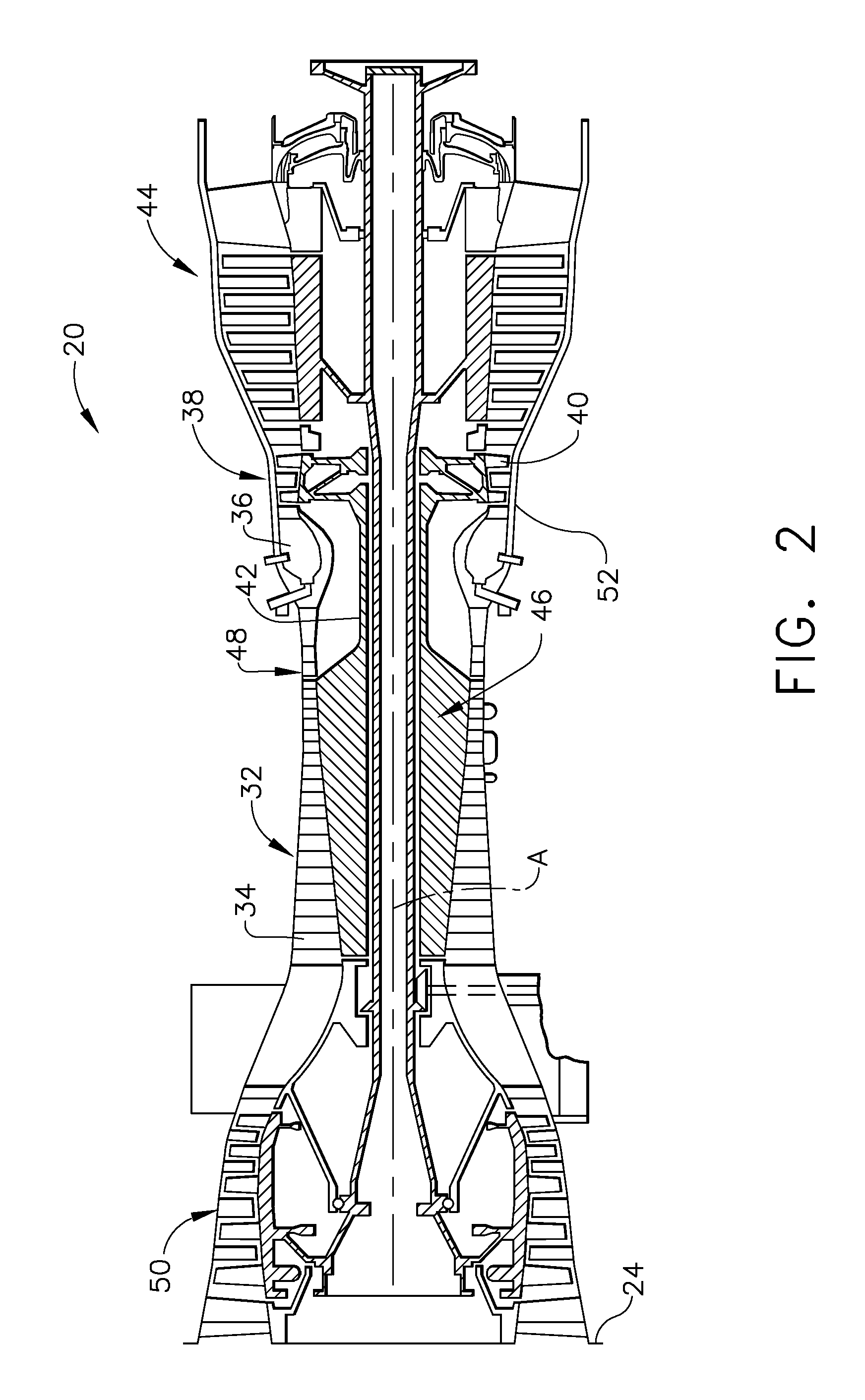

Systems and methods for monitoring thermal growth and controlling clearances, and maintaining health of turbo machinery applications

A system and method for determining thermal growth of motor or engine parts to thereupon control the clearance of motor or engine fan blades is disclosed herein. In addition, a system and method for monitoring the health of a turbine engine, its components and sub-components is also described herein. The system(s) and method(s) described herein permit continuous monitoring during the life of the engine for radial clearances and blade and rotor vibration problems, which will assist in correcting and retaining performance for a longer on-wing time in operation. In addition, inconsistent engine-to-engine performance variations due to component tolerances, engine operation characteristics, and operation during extremes in ambient temperatures can be eliminated or significantly minimized when employing the system(s) and method(s) described herein.

Owner:RAYTHEON TECH CORP

Methods and apparatus for coupling ceramic matrix composite turbine components

A method facilitates assembling a stator assembly for a turbine engine. The method comprises positioning a shroud fabricated from a ceramic matrix composite material adjacent a metallic stator block, and coupling the shroud to the stator block using a coupling arrangement such that a predetermined radial clearance is defined between the shroud and a rotor assembly coupled radially inward thereof.

Owner:GENERAL ELECTRIC CO

Gas turbine engine lockout reduction

ActiveUS8776530B2Shorten the overall cycleShorten the timeLeakage preventionGas turbine plantsCombustorTurbine

A method is provided of reducing lockout time of a gas turbine engine which includes: an inlet, a compressor, a combustor, a turbine, and an exhaust duct, where the compressor and the turbine are carried on a turbomachinery rotor and each include an array of blades mounted for rotation inside a casing of the engine. The method includes: operating the engine at a first power output; shutting down operation of the engine without substantially reducing the power output beforehand, wherein thermomechanical changes occur in the engine subsequent to shutdown that tend to reduce a radial clearance between at least one of the blades and the casing; and subsequent to shutting down the engine, (1) heating the casing and / or (2) pumping an airflow of ambient air into the inlet and through the casing, past the rotor, and out the exhaust duct, so as to reverse at least partially the thermomechanical changes.

Owner:GENERAL ELECTRIC CO

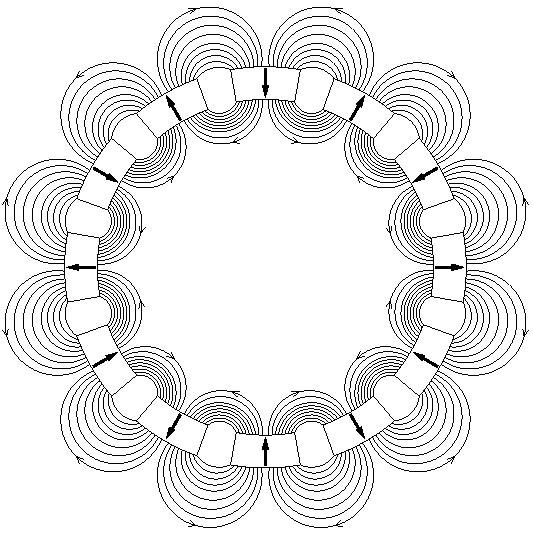

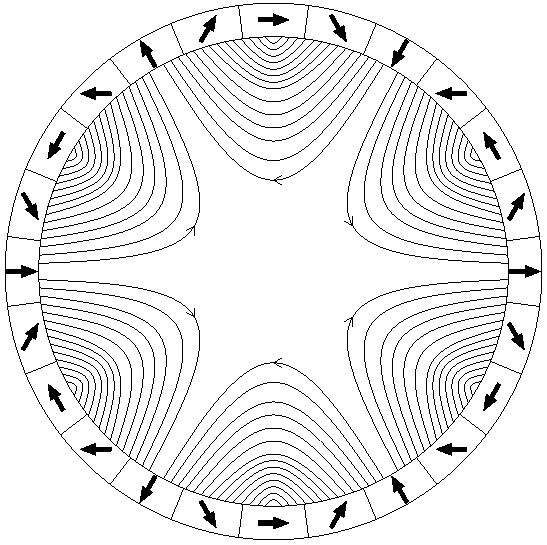

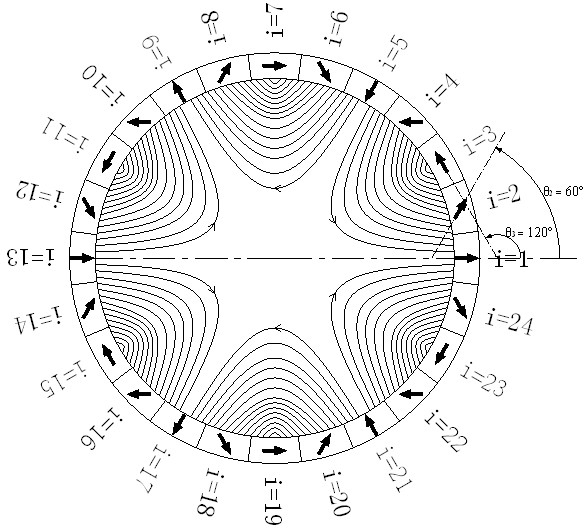

Permanent-magnet eddy current retarder based on Halbach array

InactiveCN102497085AImprove utilization efficiencyIncrease the magnetic field strength of the working air gapPermanent-magnet clutches/brakesOptical axisCoupling

Rotors are installed on a transmission shaft; the transmission shaft is installed in a central hole of a fixing plate; two ends of a bidirectional screw shaft are installed inside holes above the central hole of the fixing plate; two ends of each of three linear optical shafts are fixed into holes in front of, behind and below the central hole of the fixing plate; each of the two rotors consists of a Halbach-array permanent-magnet ring and a retaining rack; an outer cylindrical surface of the permanent-magnet ring is fixed inside a center hole of the retaining rack; a radial clearance is formed between an inner cylindrical surface of the permanent-magnet ring and an outer cylindrical surface of each rotor; four installing holes are uniformly distributed on the retaining rack; an upper installing hole is matched with the bidirectional screw shaft through a screw nut; the other three installing holes are matched with the linear optical shafts through linear bearings; and a servo motor is connected whit the bidirectional screw shaft through a shaft coupler. In the radial-array permanent-magnet eddy current retarder, the utilization ratio of a magnet is high, the brake moment is large, the response is quick, the heat dissipating conditions are good and the stepless regulation of the brake moment is realized.

Owner:ZHEJIANG UNIV

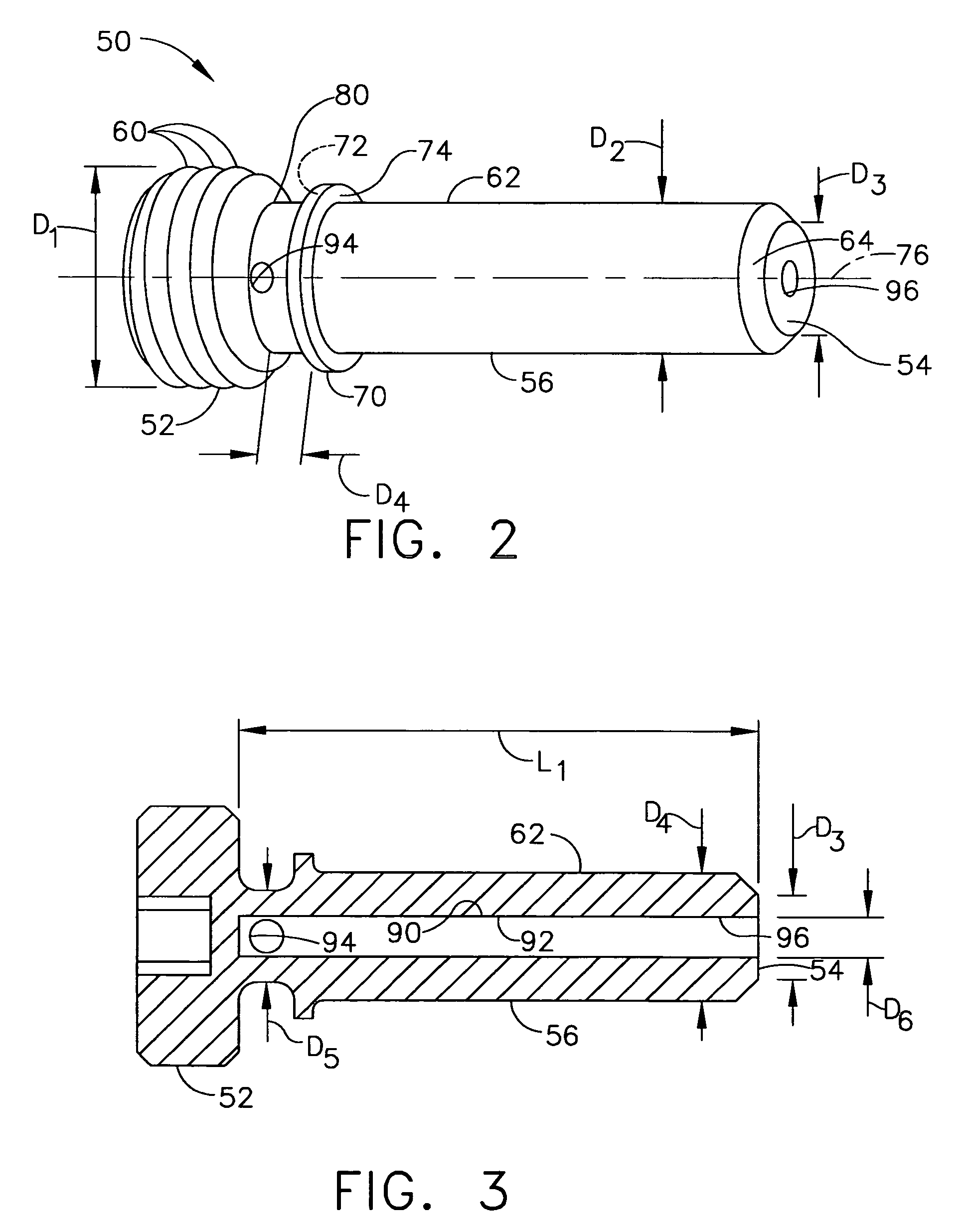

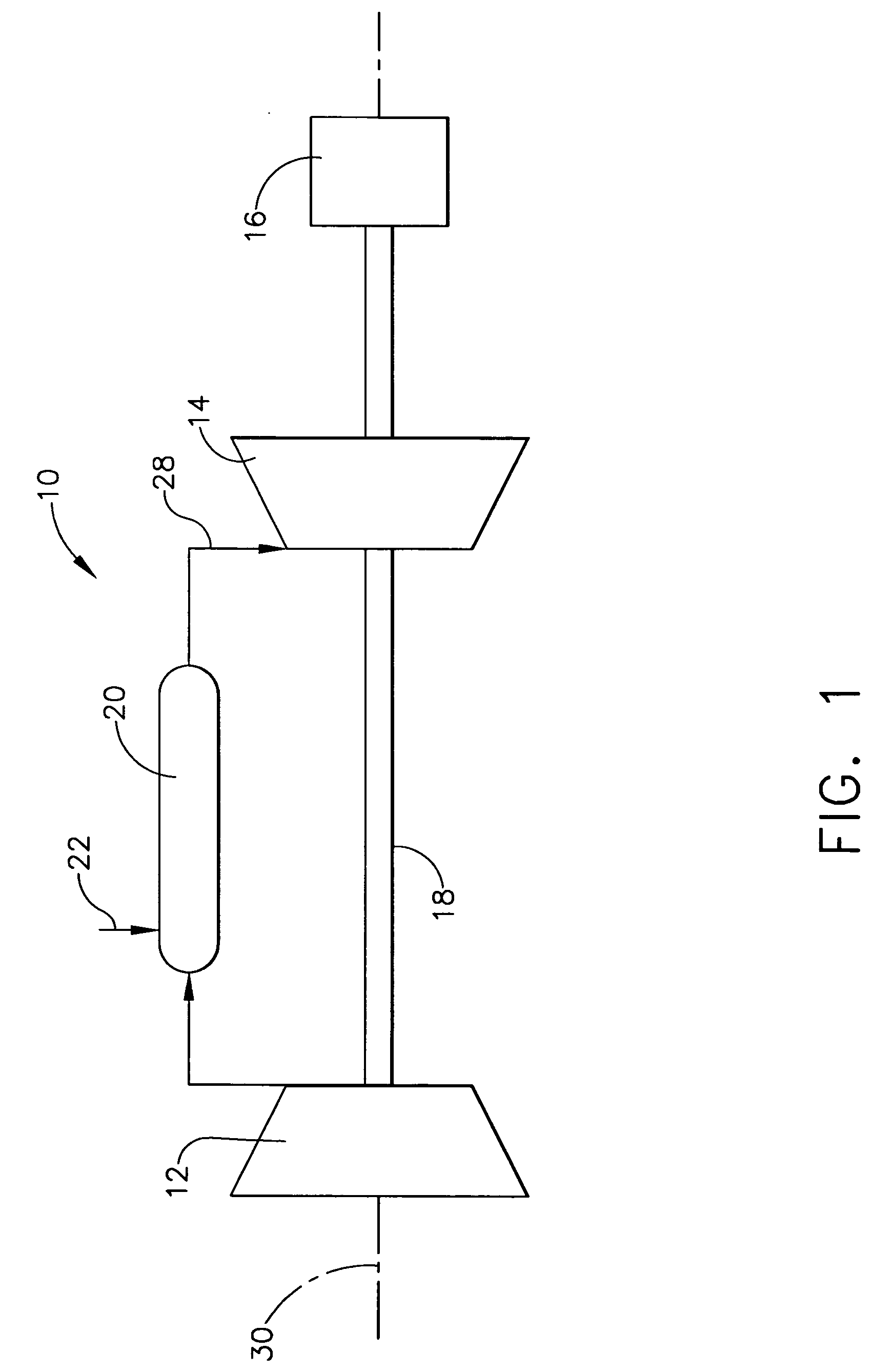

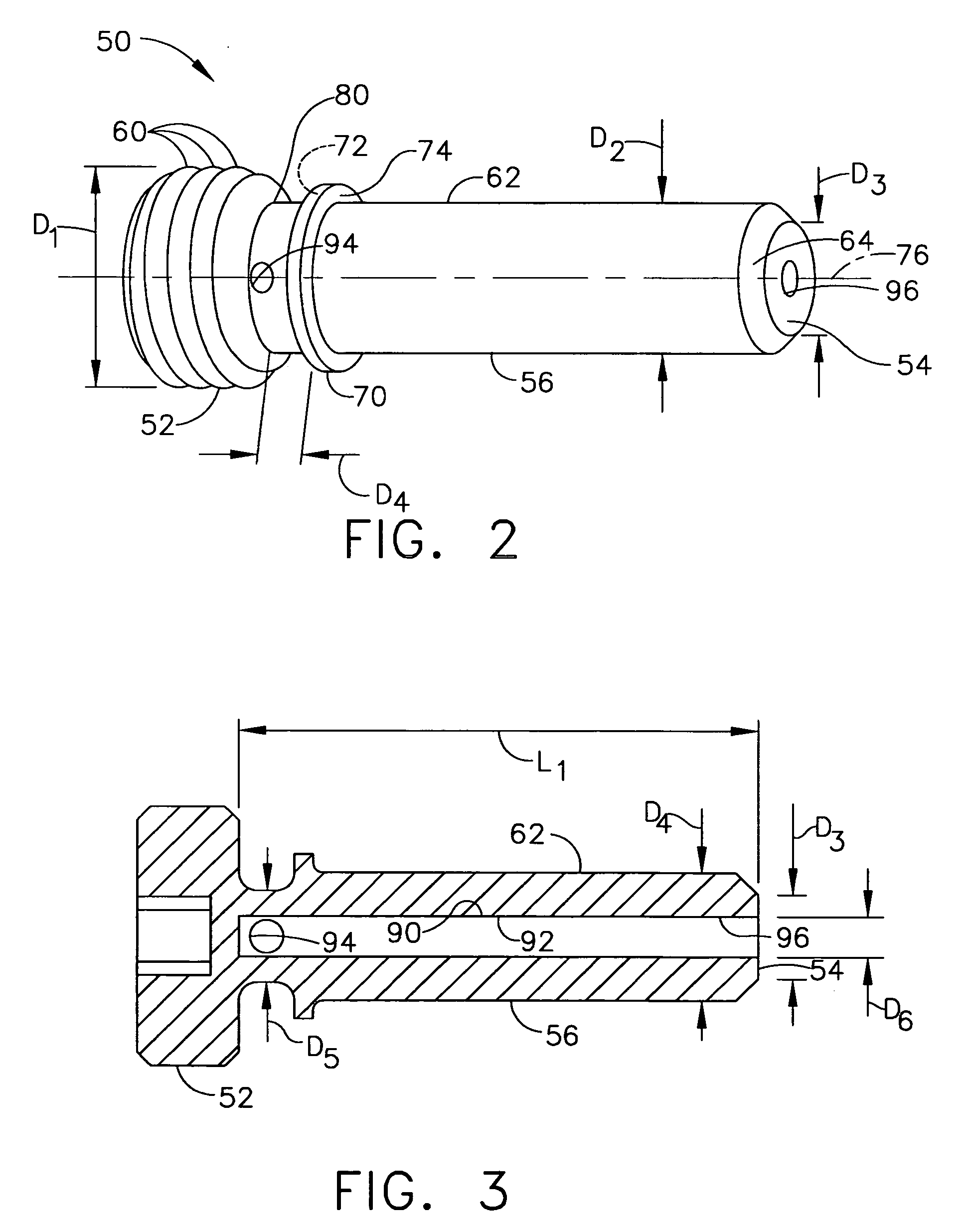

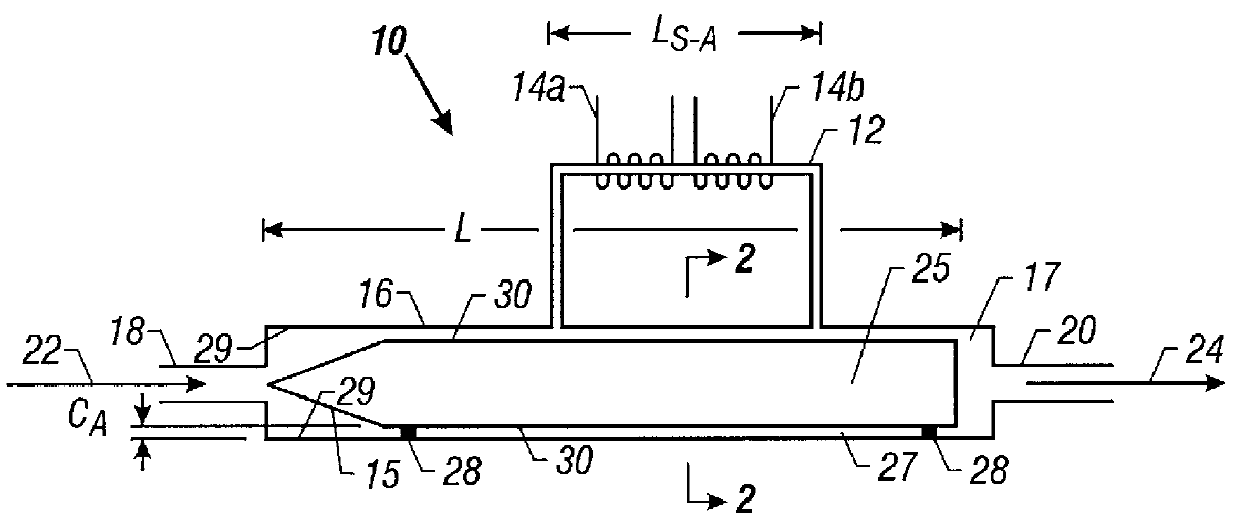

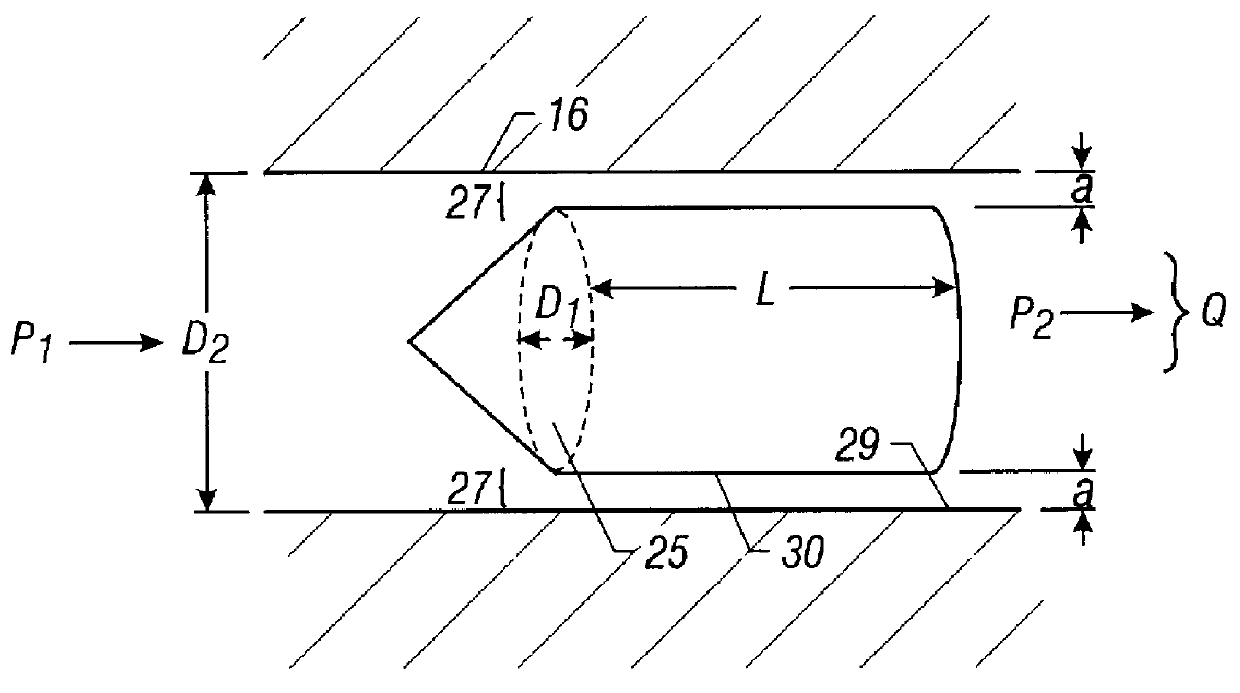

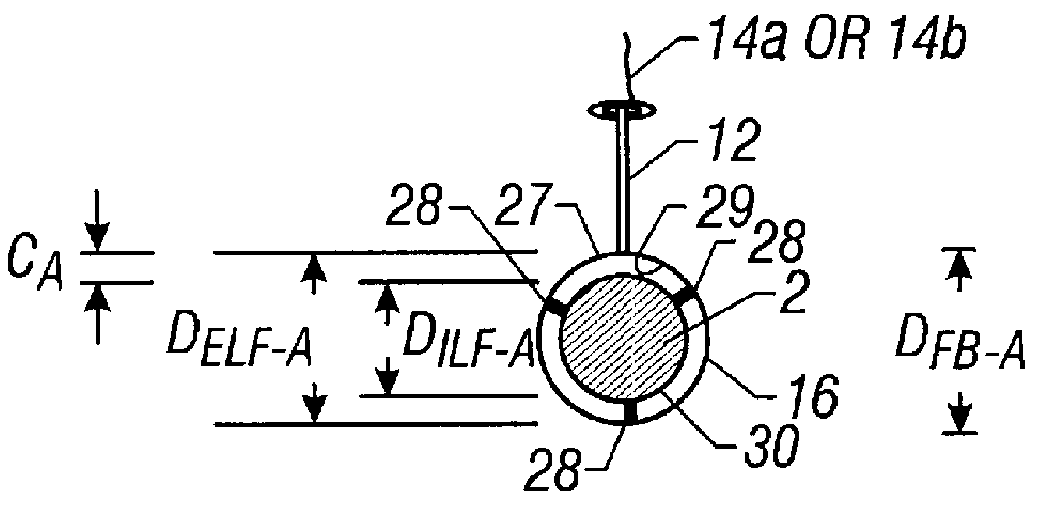

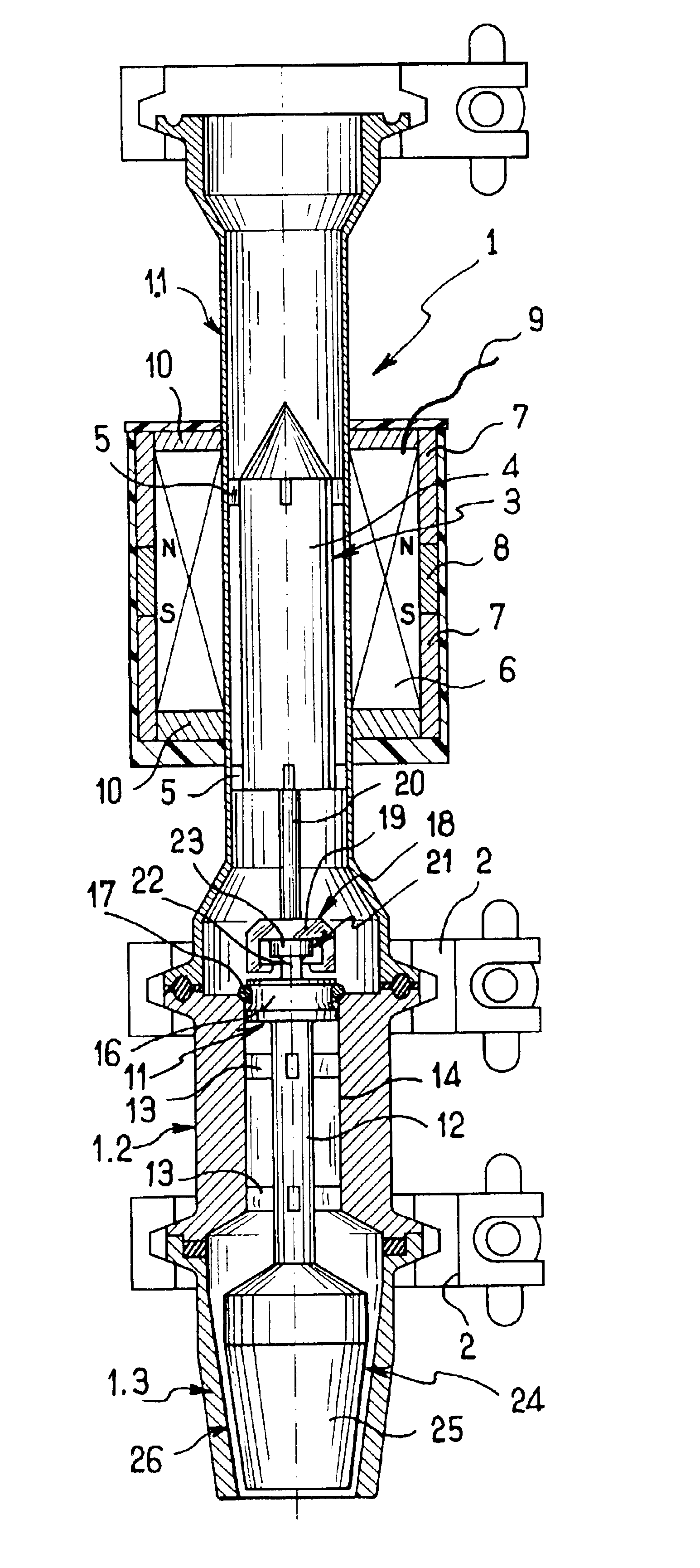

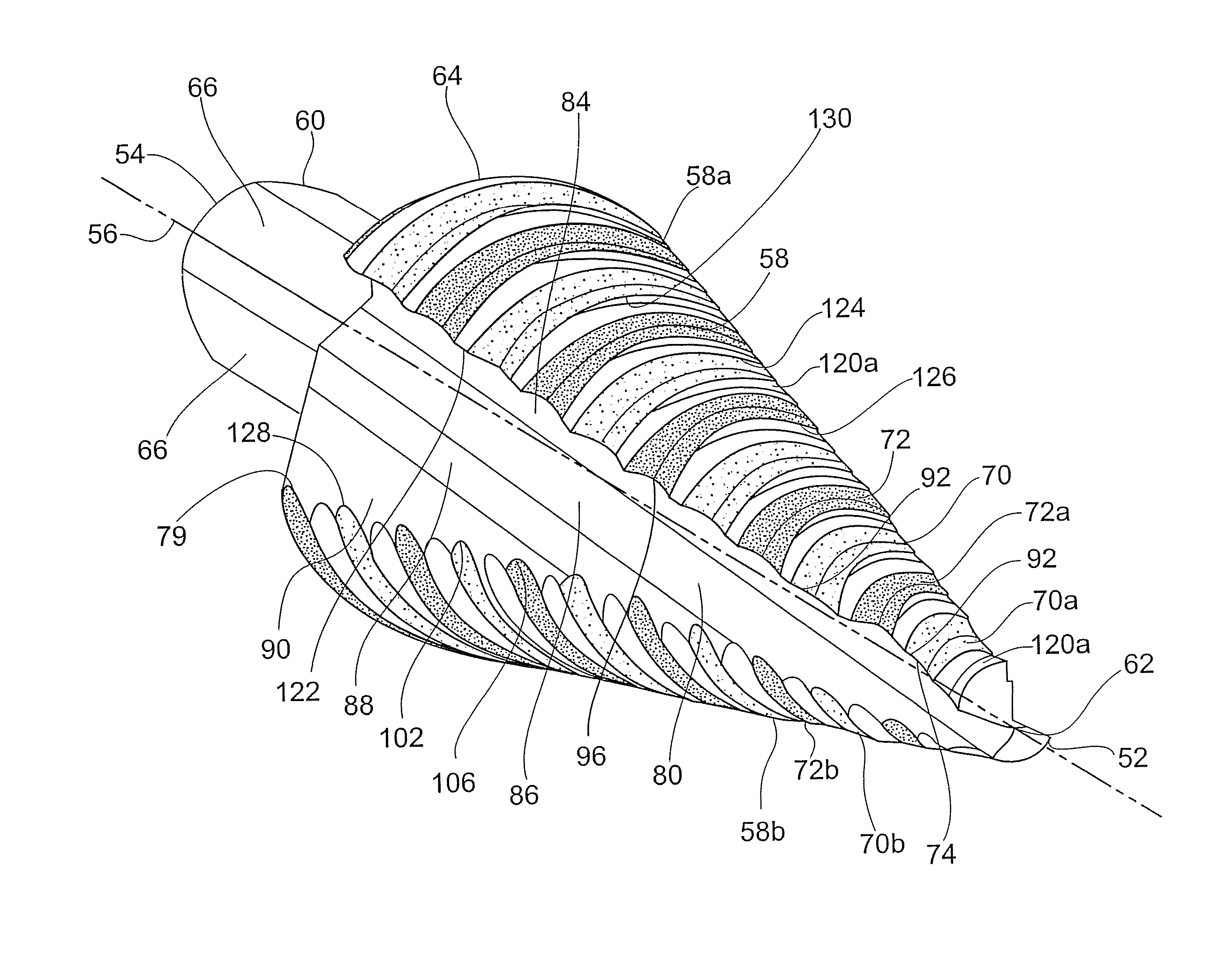

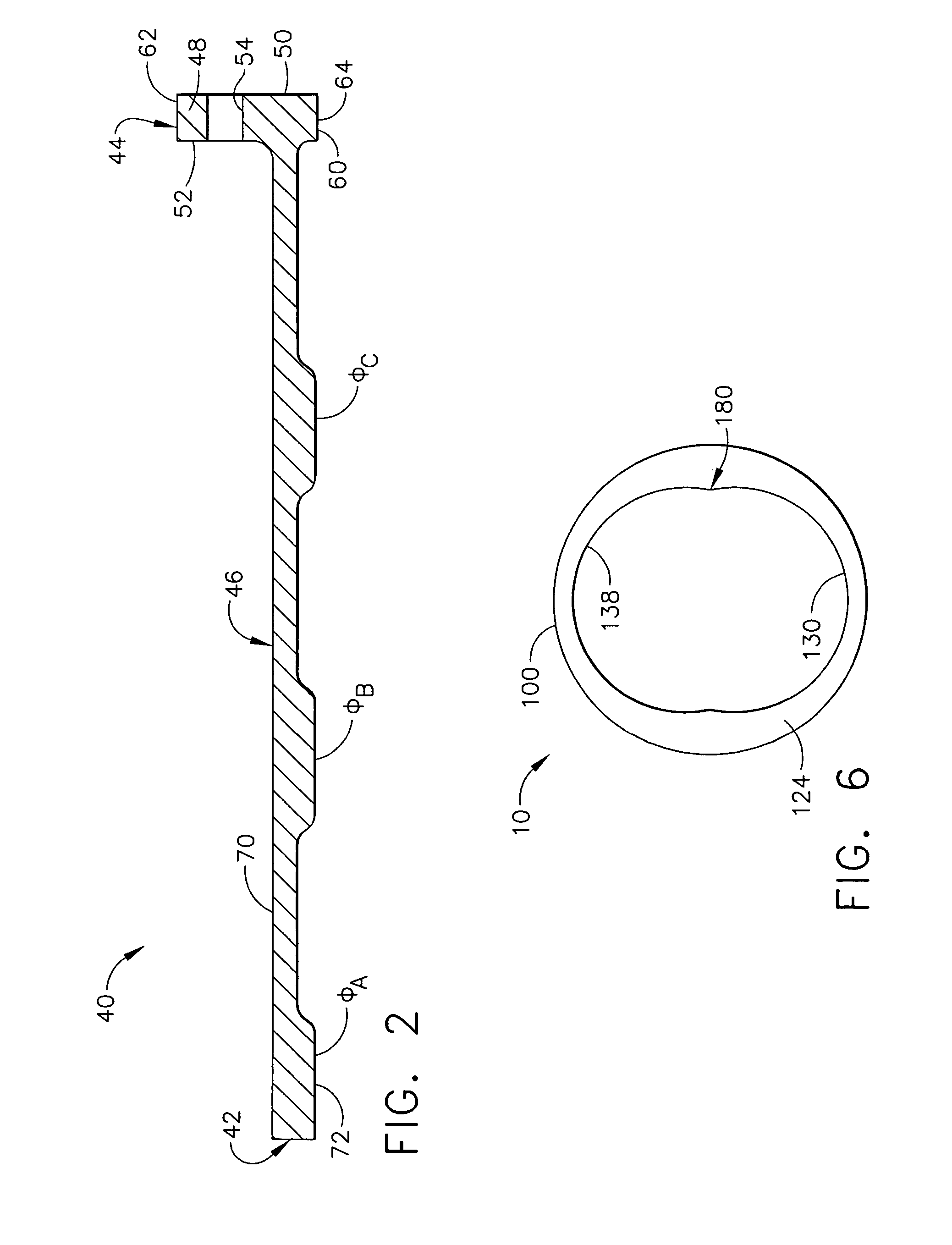

Precision laminar flow element for use in thermal mass flow sensors and flow controllers

InactiveUS6119730ASlide in outSimplifying cleaning and calibrationVolume flow proportion measurementFluid dynamicsEngineeringRadial clearance

A laminar flow element for use in thermal mass flow sensors and flow controllers is designed to provide a high degree of precision. The precision laminar flow element includes a laminar flow element having a generally pointed entry end for maintaining a pure laminar flow path around the laminar flow element. The generally pointed entry end serves to direct an incoming gas flow stream equally about an outer surface of the laminar flow element. In this way, the laminar flow path is uniform so as to maintain a desired flow accuracy. The laminar flow element provides a plurality of standoff pins protruding from the outer surface of the laminar flow element to maintain a substantially equal radial clearance around the outer surface. By maintaining a substantially equal radial clearance from one laminar flow element to another, the laminar flow element is highly interchangeable. The laminar flow element may also provide a plurality of slots formed in the laminar flow element to accept a relatively high incoming gas flow stream. The precision laminar flow element preserves a linear flow ratio for low and high flow rates. The laminar flow element may be incorporated into a thermal mass flow sensor or flow controller such that the laminar flow element is substantially concentric with a borehole of a flow block. Various laminar flow elements with different annular clearances may be inserted in the same borehole of the flow block to provide a variety of flow rate ranges.

Owner:MCMILLAN LLP

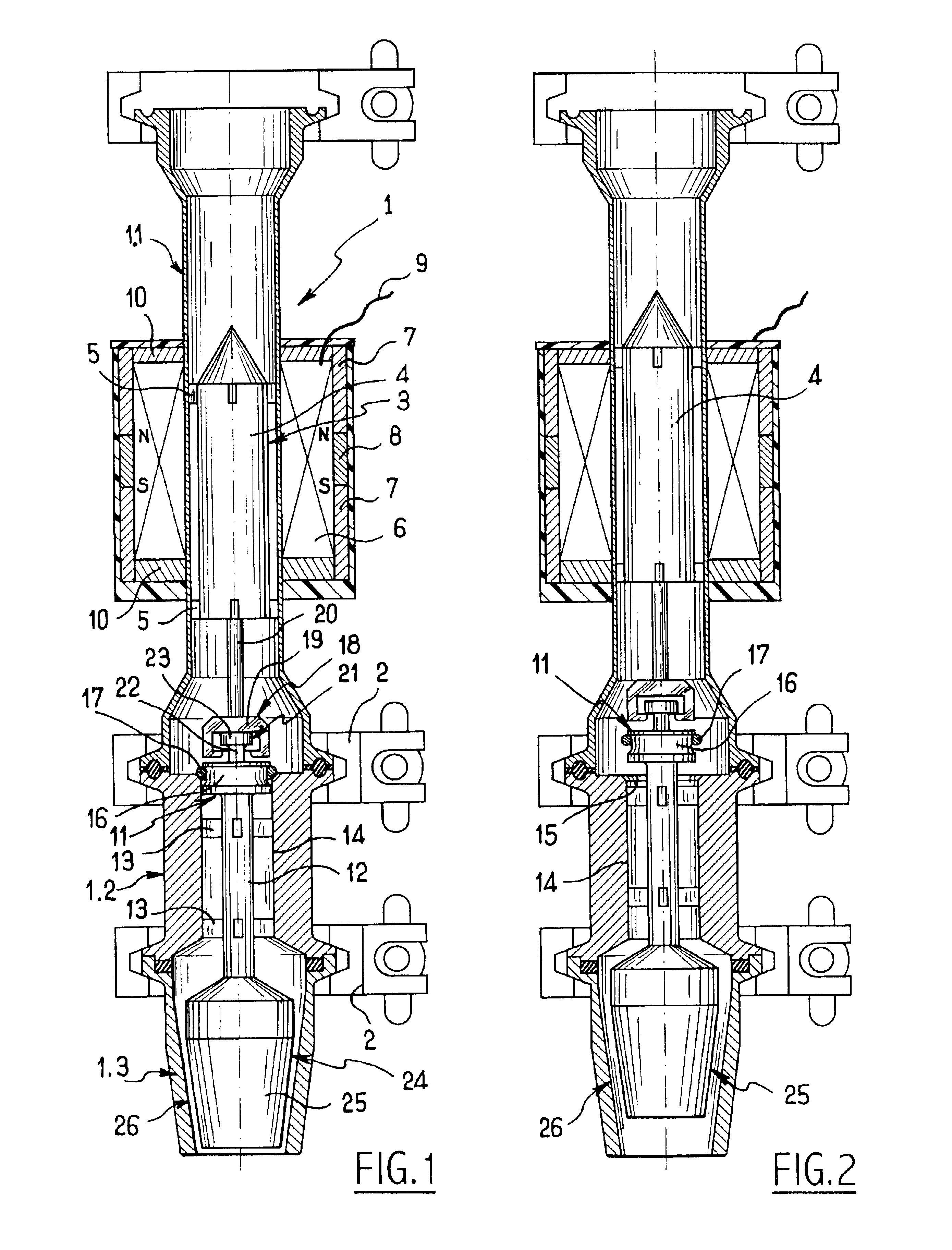

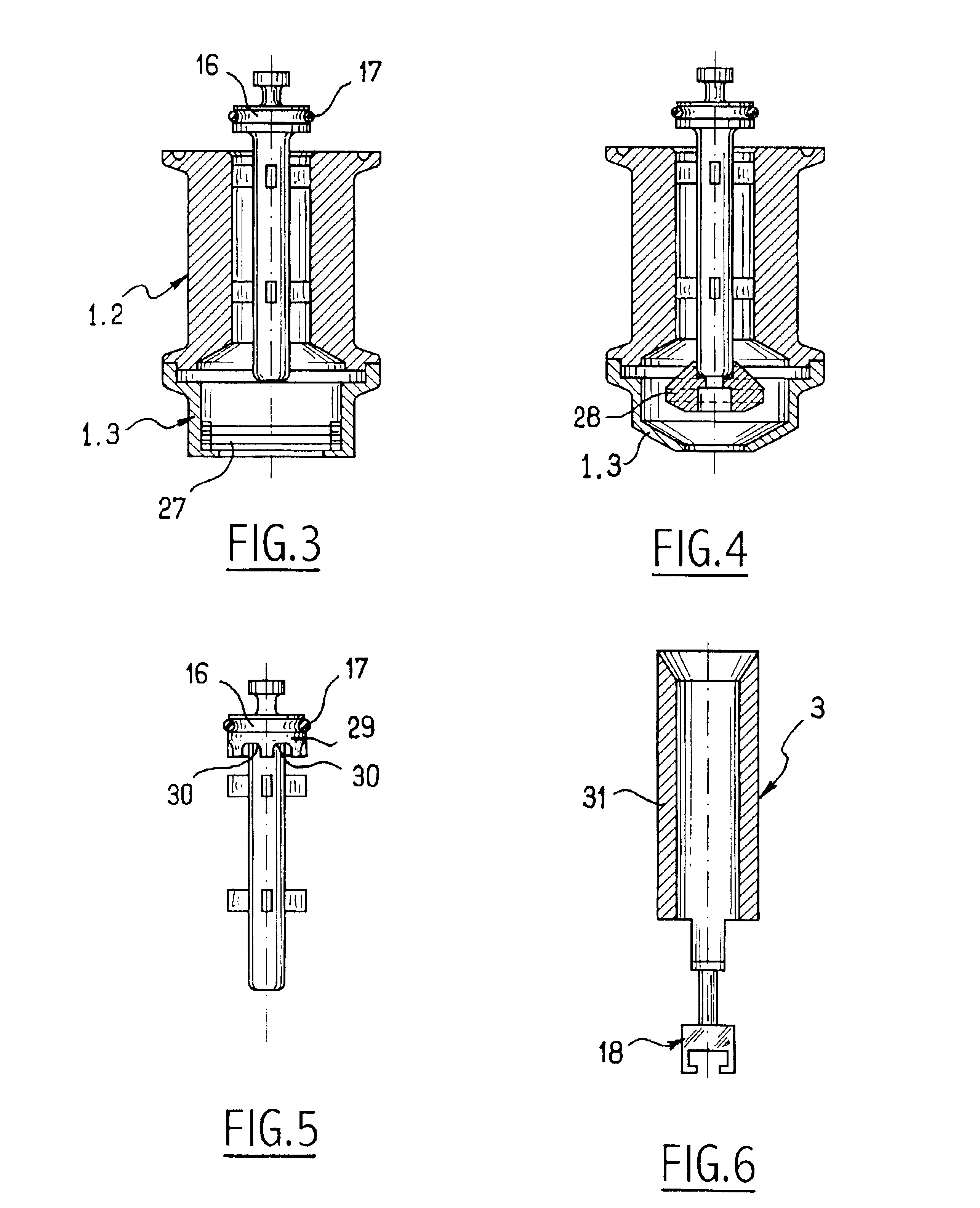

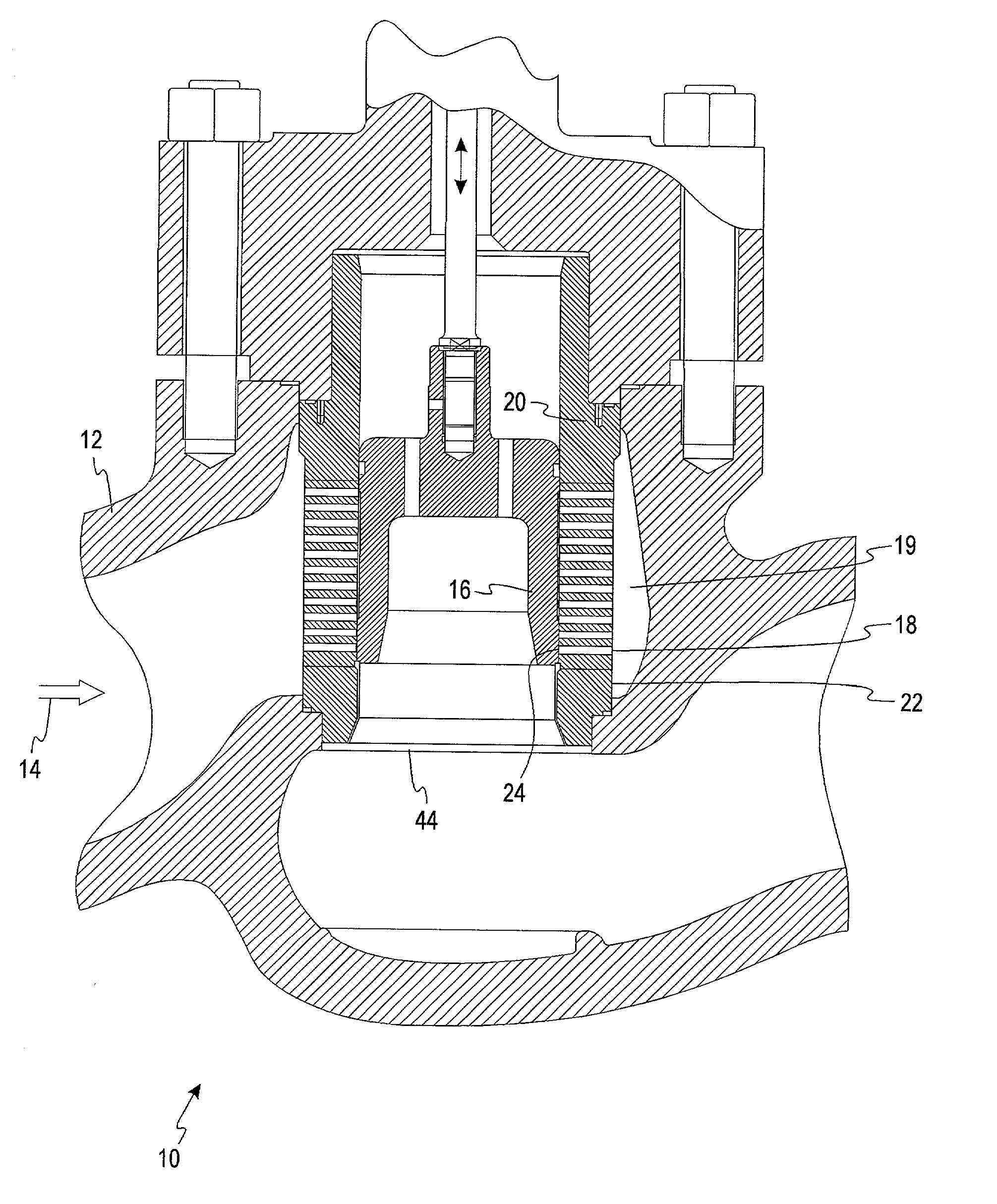

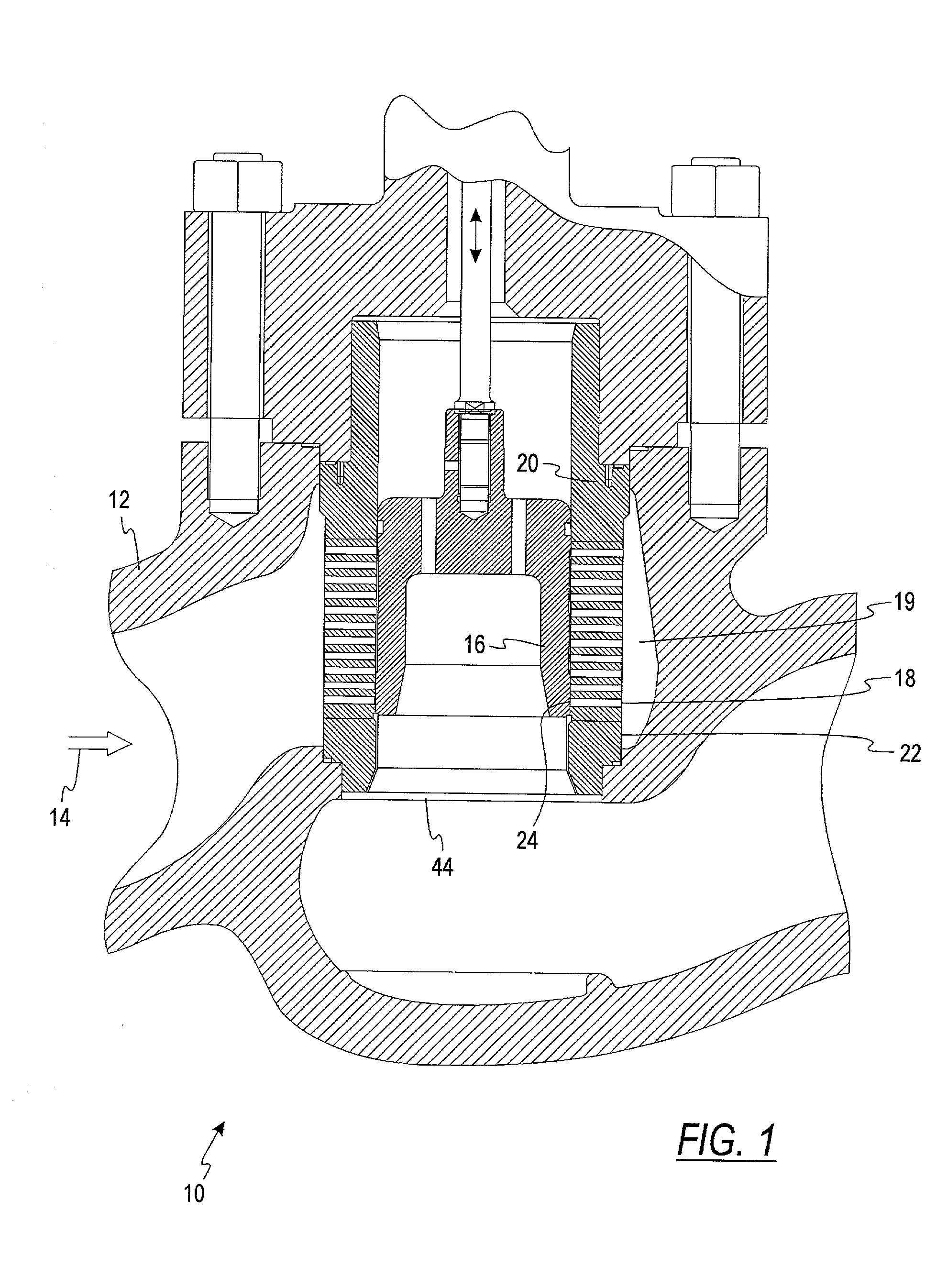

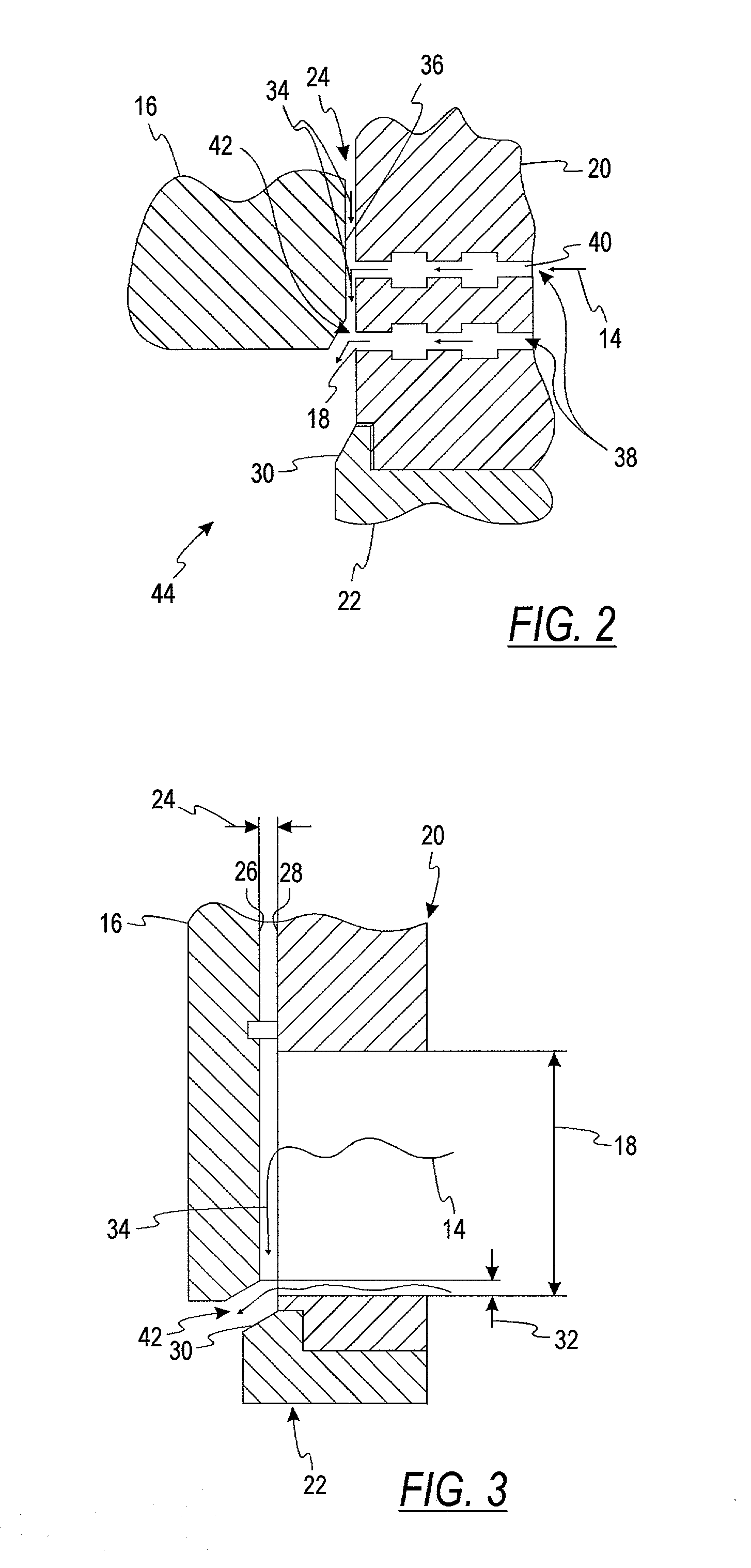

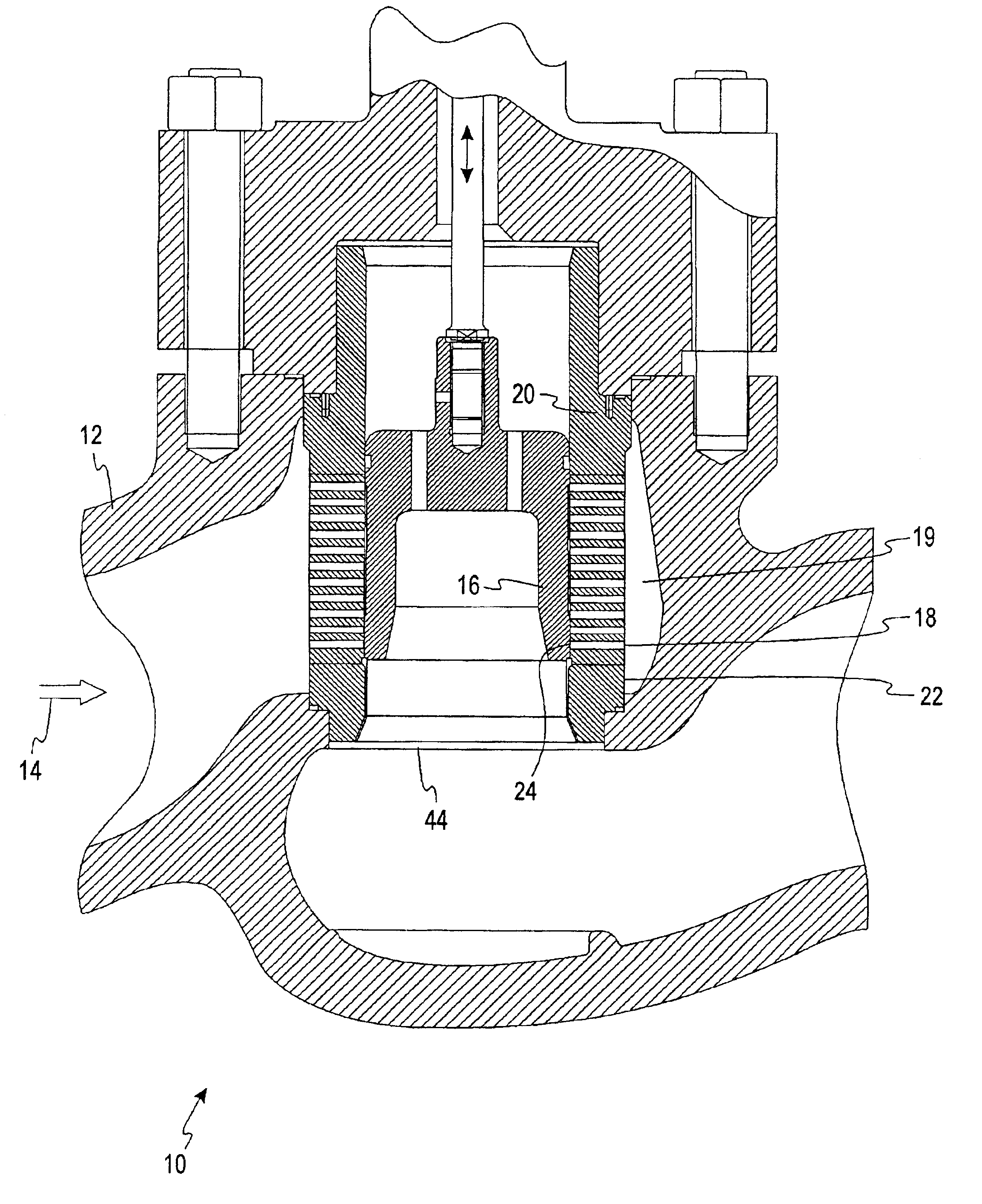

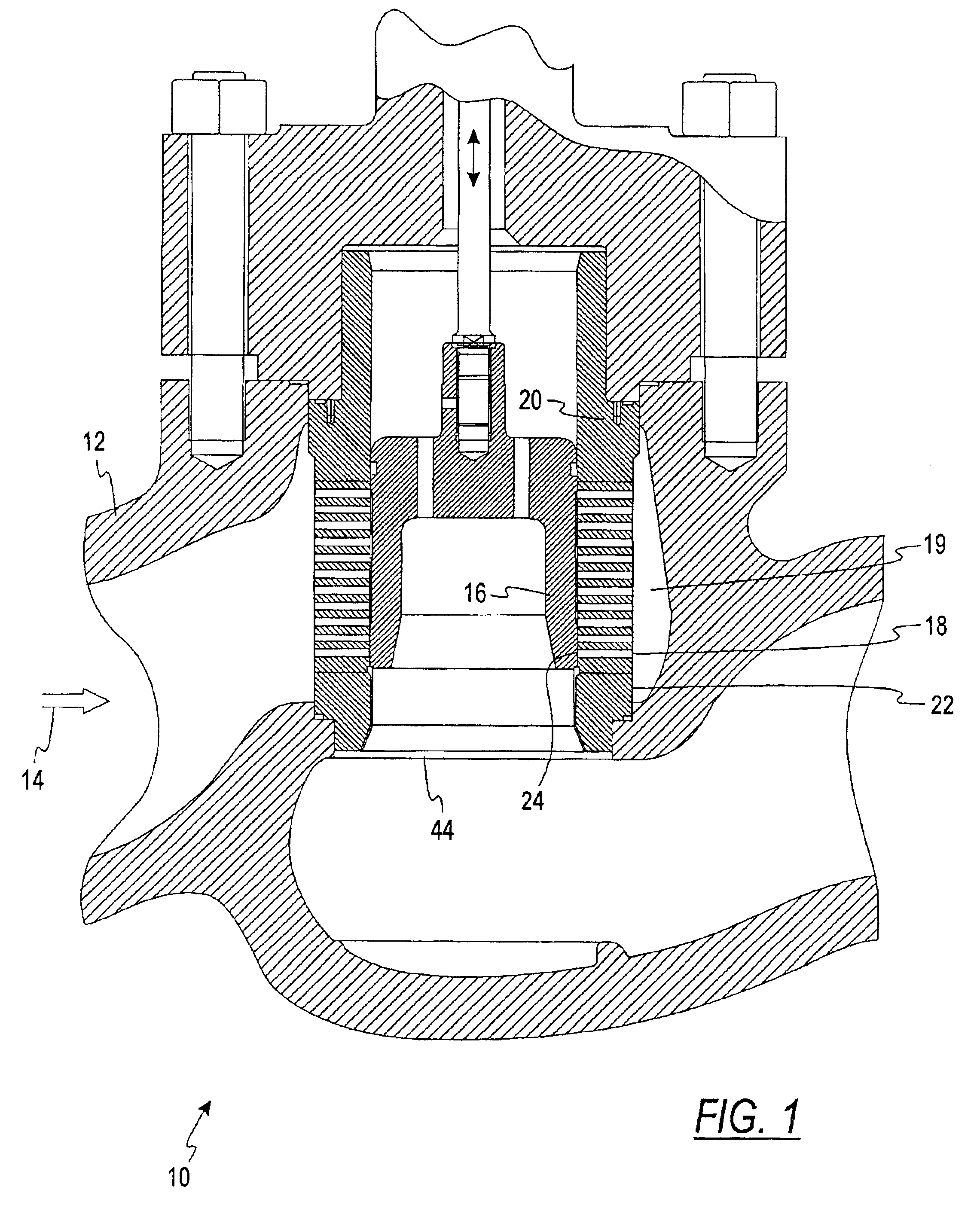

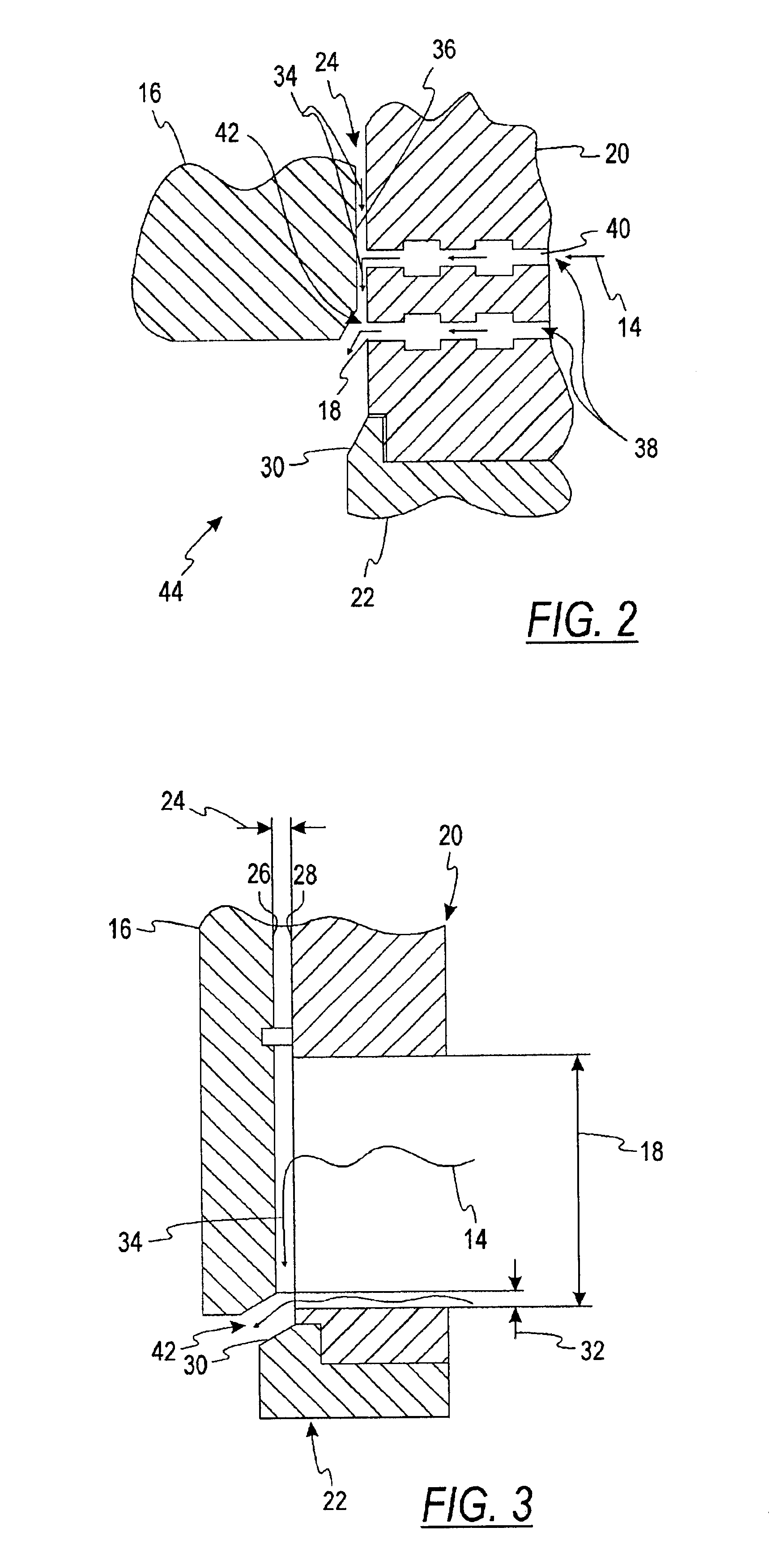

Electromagnetically-controlled filler spout

InactiveUS6810931B2Easy to adaptSufficient clearanceLiquid fillingOperating means/releasing devices for valvesCouplingActuator

The filler spout comprises a tubular body having mounted therein a valve member and a magnetic actuator element connected to the valve member via a coupling member comprising two elements that are coupled to each other via a coupling that includes radial clearance.

Owner:SERAC GROUP

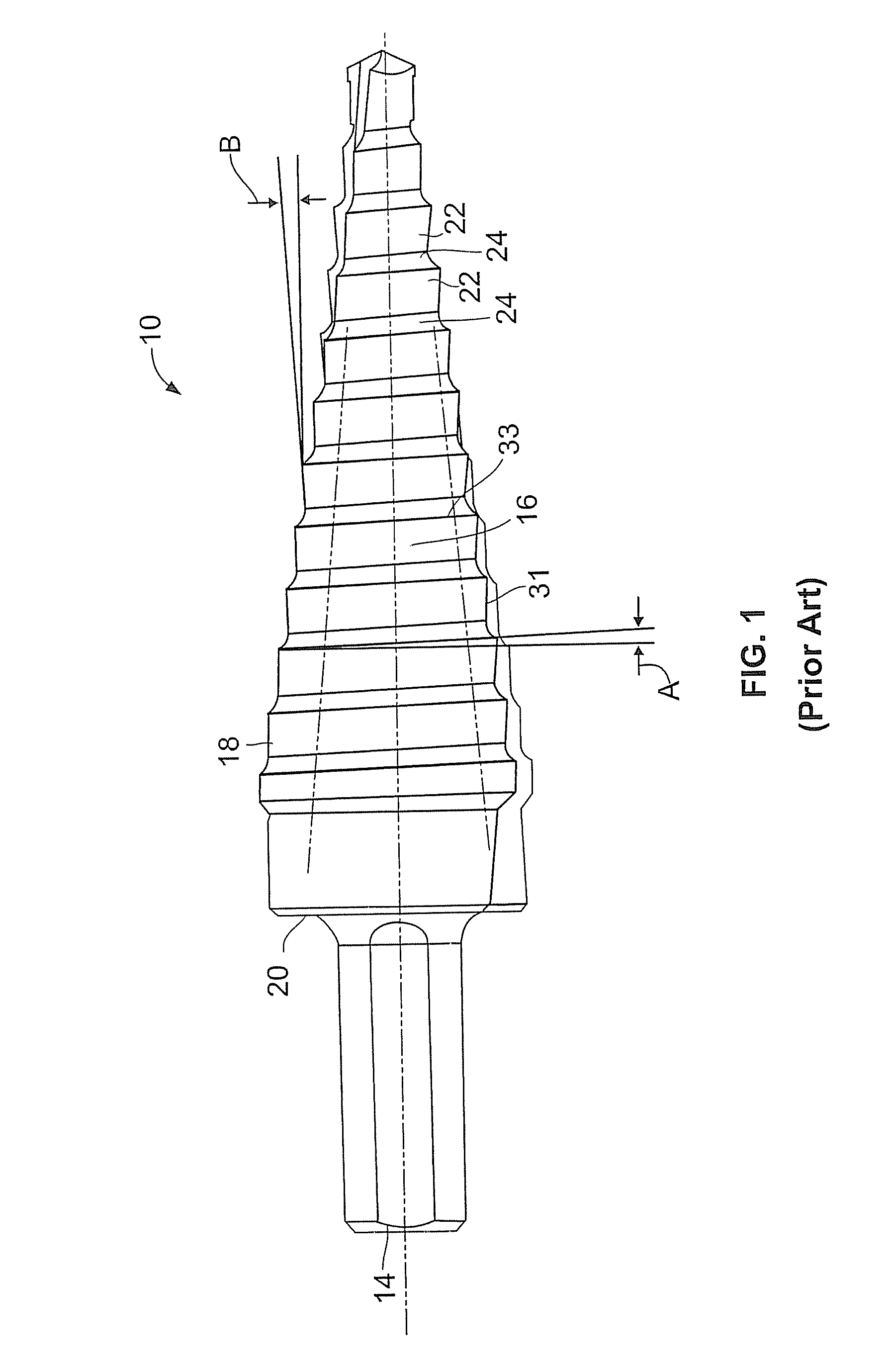

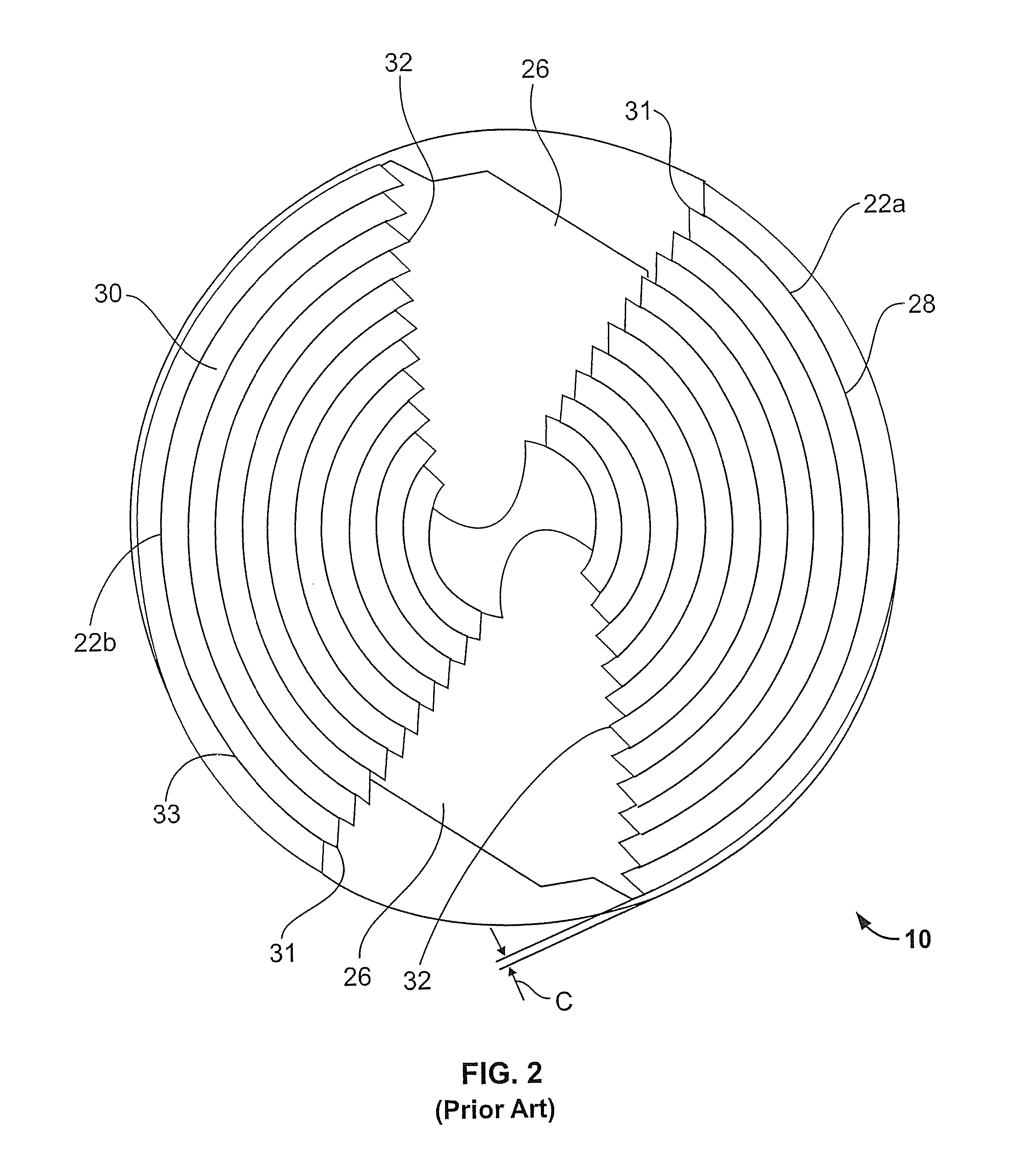

Spiral drill bit and method of forming same

ActiveUS20080166195A1Minimizes amount of grindingShorten the timeWood turning toolsMetal-working drilling toolsFluteEngineering

A spiral drill bit for forming holes of a variety of sizes has a main body which provides first and second helical grooves. First and second flutes extend along the length of the main body to provide first and second helical groove segments. Cutting segments are provided between the helical groove segments. The method for forming the spiral drill bit includes turning the helical groove segments onto a round stock. An axial clearance and an initial diametral clearance are provided upon turning the helical grooves. A grinding process is used to form a radial clearance and a final diametral clearance. The reduction to the amount of grinding required to form the spiral drill bit results in a reduction to the cost of production and a reduction in the time necessary to produce the spiral drill bit.

Owner:GREENLEE TEXTRON

Compressor variable vane assembly

A variable vane assembly for a gas turbine engine compressor and method of manufacturing same is described. A plurality of projections the inner and / or outer shroud which protruded into the annular gas path such as to ensure that a radial clearance gap, defined between the projections and a vane airfoil overhang portion, remains substantially constant throughout a substantial portion of the vane pivot arc of the variable vane. The method includes forming one cavities within the shroud, the cavities isolated from the annular gas path and disposed radially beneath at least each of the projections, and providing one or more structural reinforcing elements within the cavities.

Owner:PRATT & WHITNEY CANADA CORP

Cutting insert, tool holder, and related method

A generally parallelogram-shaped cutting insert includes a top face; first and second main radial clearance faces, each intersecting the top face; first and second minor axial clearance faces each intersecting the top face and connecting the first and second main radial clearance faces; and a main cutting edge at the intersection of the top face and the first main radial clearance face. According to one non-limiting embodiment, the main cutting edge comprises a variable radial rake angle including a portion having a positive radial rake angle and a portion having a negative radial rake angle.

Owner:KENNAMETAL INC

Methods for optimizing turbine engine shell radial clearances

A method facilitates the assembly of a stator assembly for a turbine engine. The method includes providing a cantilevered shell including a first end and a second end, and coupling a second member within the turbine engine. The method also includes coupling the shell to a frame such that the shell extends circumferentially around at least a portion of the second member such that a non-uniform circumferential radial gap is defined radially between the second member and the shell using methods other than directing machining of an inner surface of the shell, and wherein the non-uniform circumferential radial clearance gap becomes substantially uniform during operation of the engine.

Owner:GENERAL ELECTRIC CO

High rangeability control valve

InactiveUS20030226600A1Reduce gapReduces and eliminates cavitation erosion damageValve members for absorbing fluid energySlide valveVapor bubbleEngineering

A guided control valve comprising a vapor recovery area that encourages collapse of vapor bubbles. In a cage-guided valve, a seal comprising inner and outer members reduces flow through a radial clearance between a plug and a cage. The vapor recovery area is positioned below the seal and above a seat interacting with the plug. The vapor recovery area encourages collapse of vapor bubbles to reduce damage to the valve trim.

Owner:DRESSER LLC

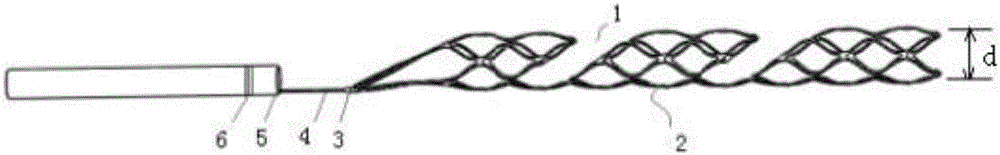

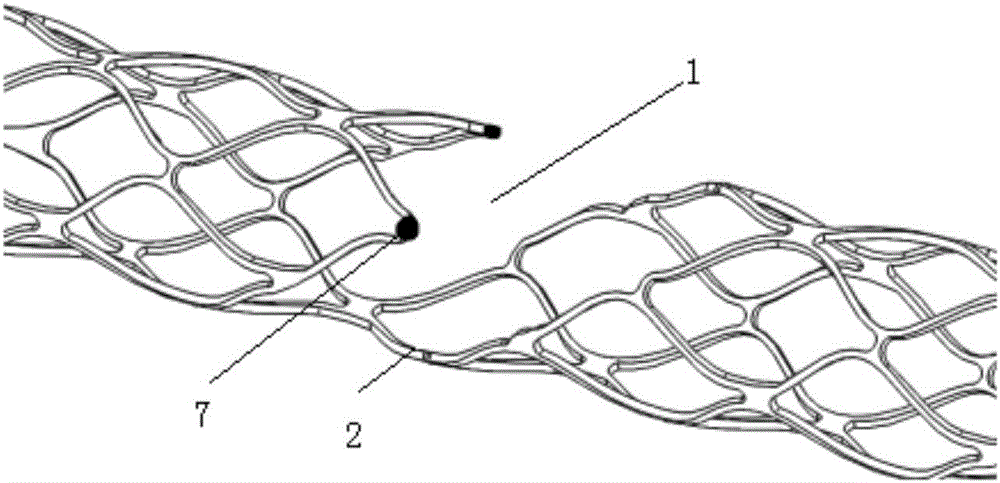

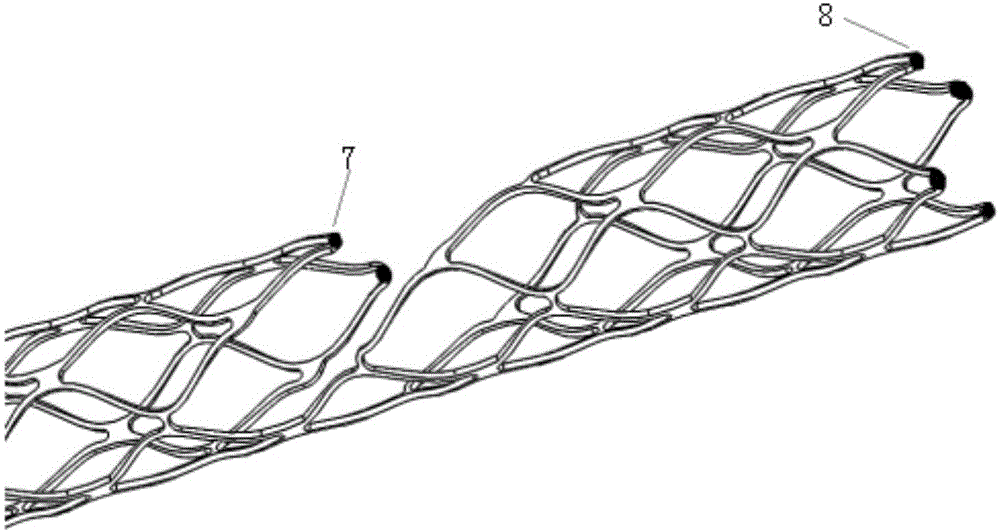

Sectional thrombus extraction device and thrombus extraction method making use of thrombus extraction device

PendingCN106580397AIntegrity guaranteedLow extrusion stiffnessSurgeryDistal embolizationInsertion stent

The invention relates to the technical field of medical apparatuses, in particular to a sectional thrombus extraction device and a thrombus extraction method making use of the thrombus extraction device. The sectional thrombus extraction device comprises a vascular thrombus extraction stent and a conveying system which is connected to one end of the vascular thrombus extraction stent, wherein the vascular thrombus extraction stent is of an auto-expansion meshed pipe structure which is formed by mutually connecting a plurality of unit grids; radial clearances are formed in the meshed pipe structure; by virtue of the radial clearances, the meshed pipe structure is divided into a plurality of sectional structures which are sequentially connected, so that the circumstance that a thrombus is divided by excessive meshes is avoided, and subsequently, the relative integrity of the thrombus is maintained, the risk of distal embolization in the case that the thrombus breaks off is reduced and rapid and reliable thrombus extraction is achieved; due to the design of the sectional structure, the softness and conveying performance of the thrombus extraction stent are enhanced, and the thrombus extraction stent can be conveyed to a blood vessel which is relatively thin in distal end; and the sectional meshed stent structure is low in metal coverage rate and relatively low in injury on endangium in a thrombus extraction process, and related complications caused by mechanical thrombus extraction are reduced.

Owner:北京久事神康医疗科技有限公司

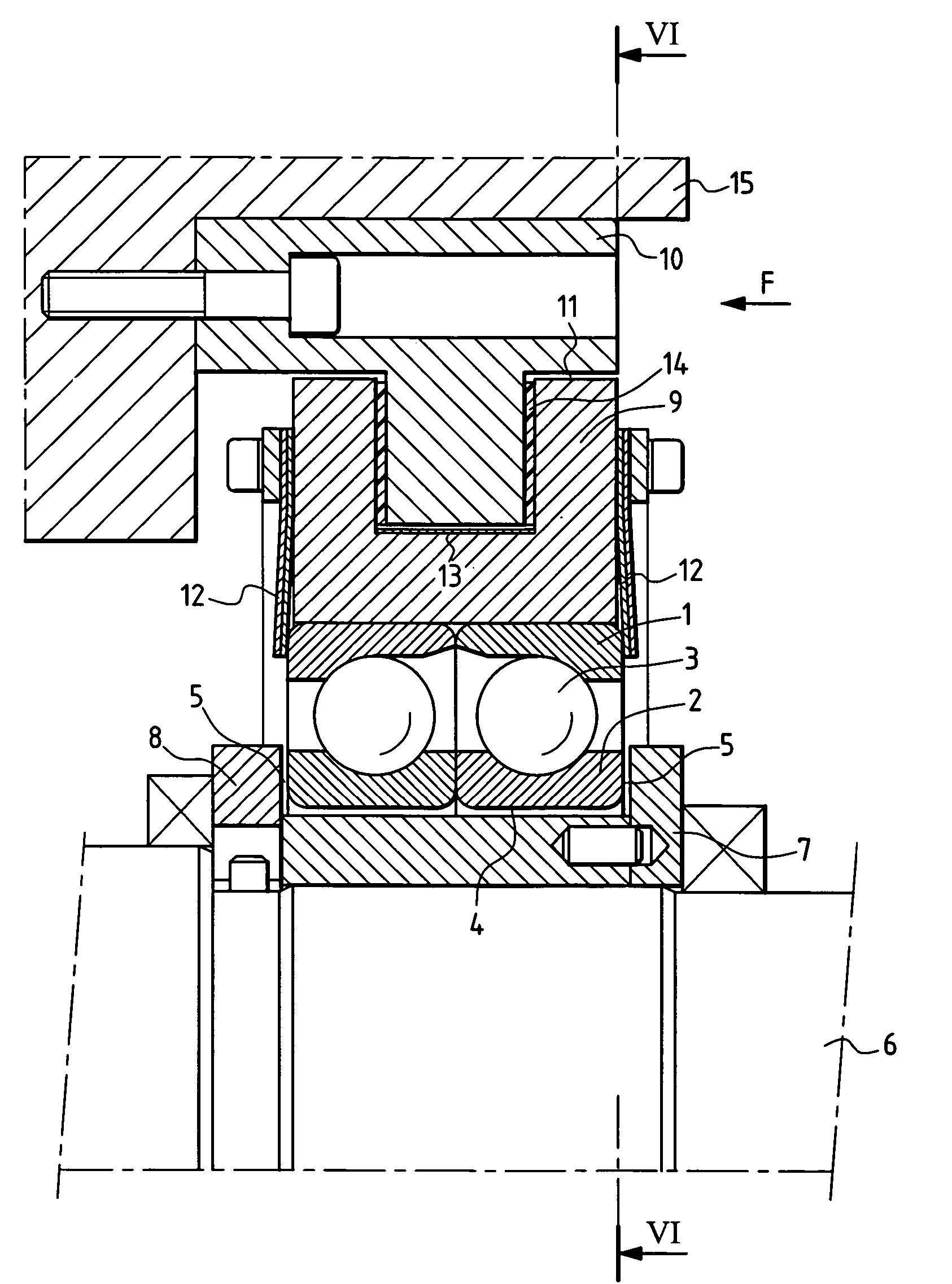

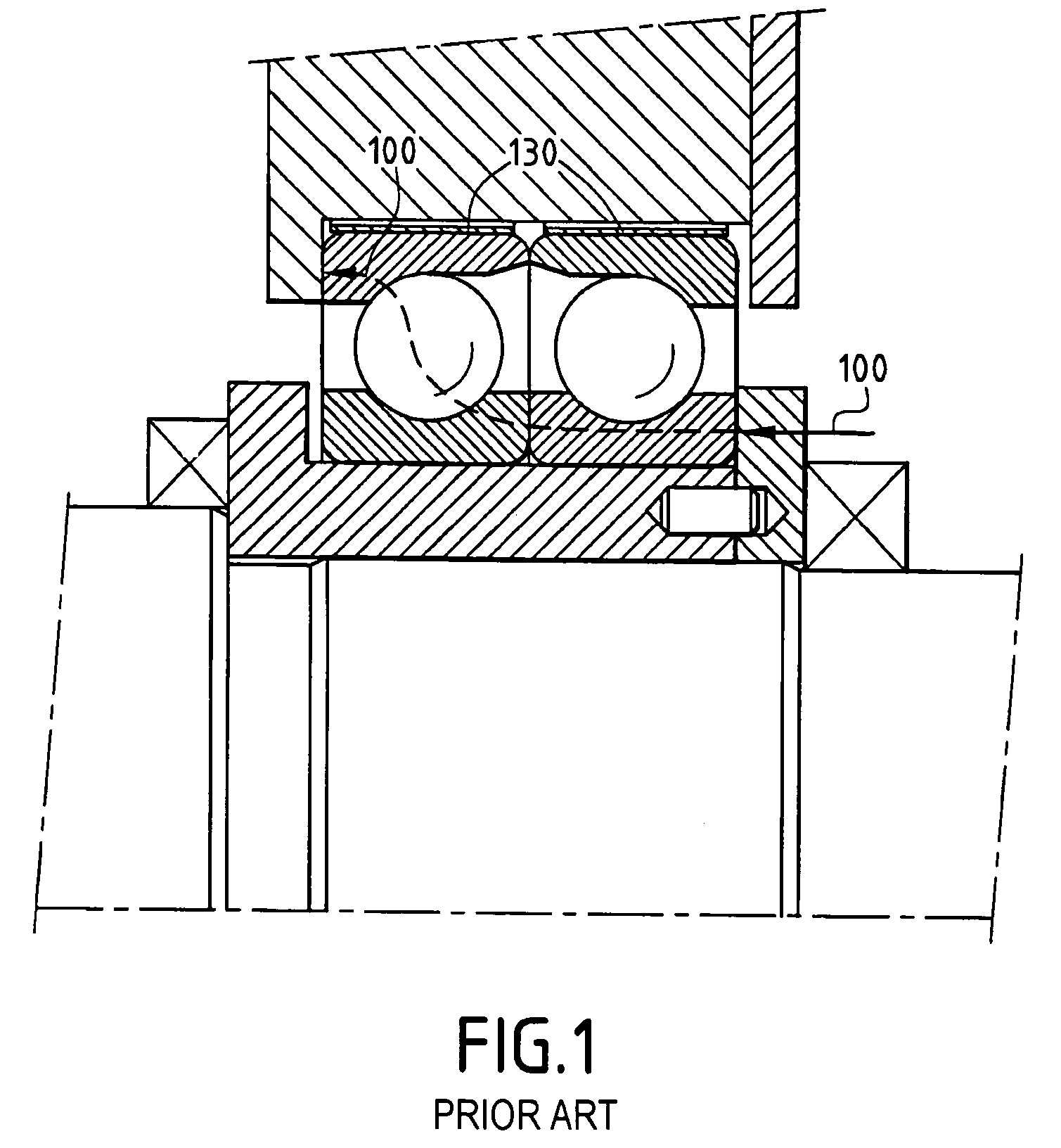

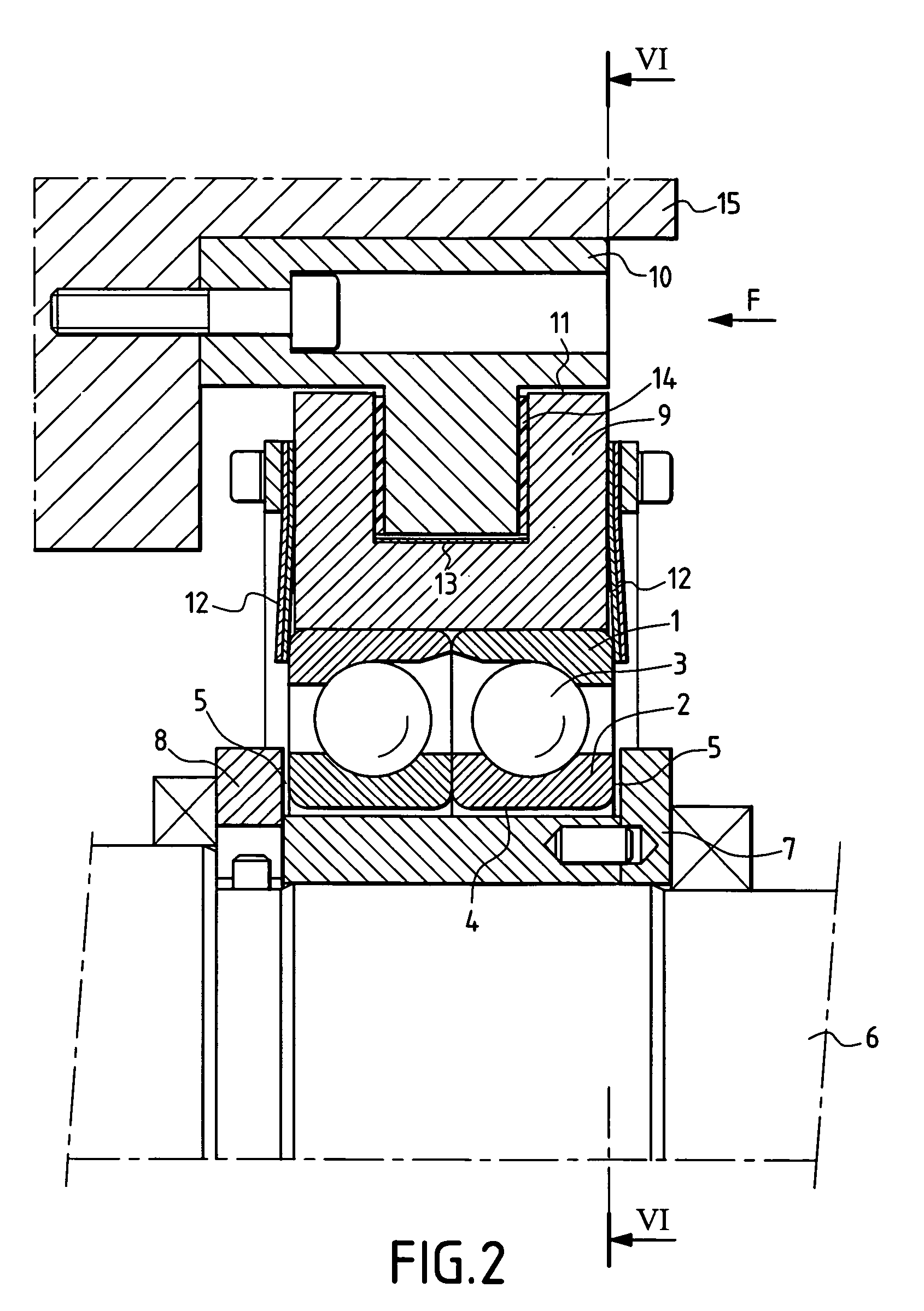

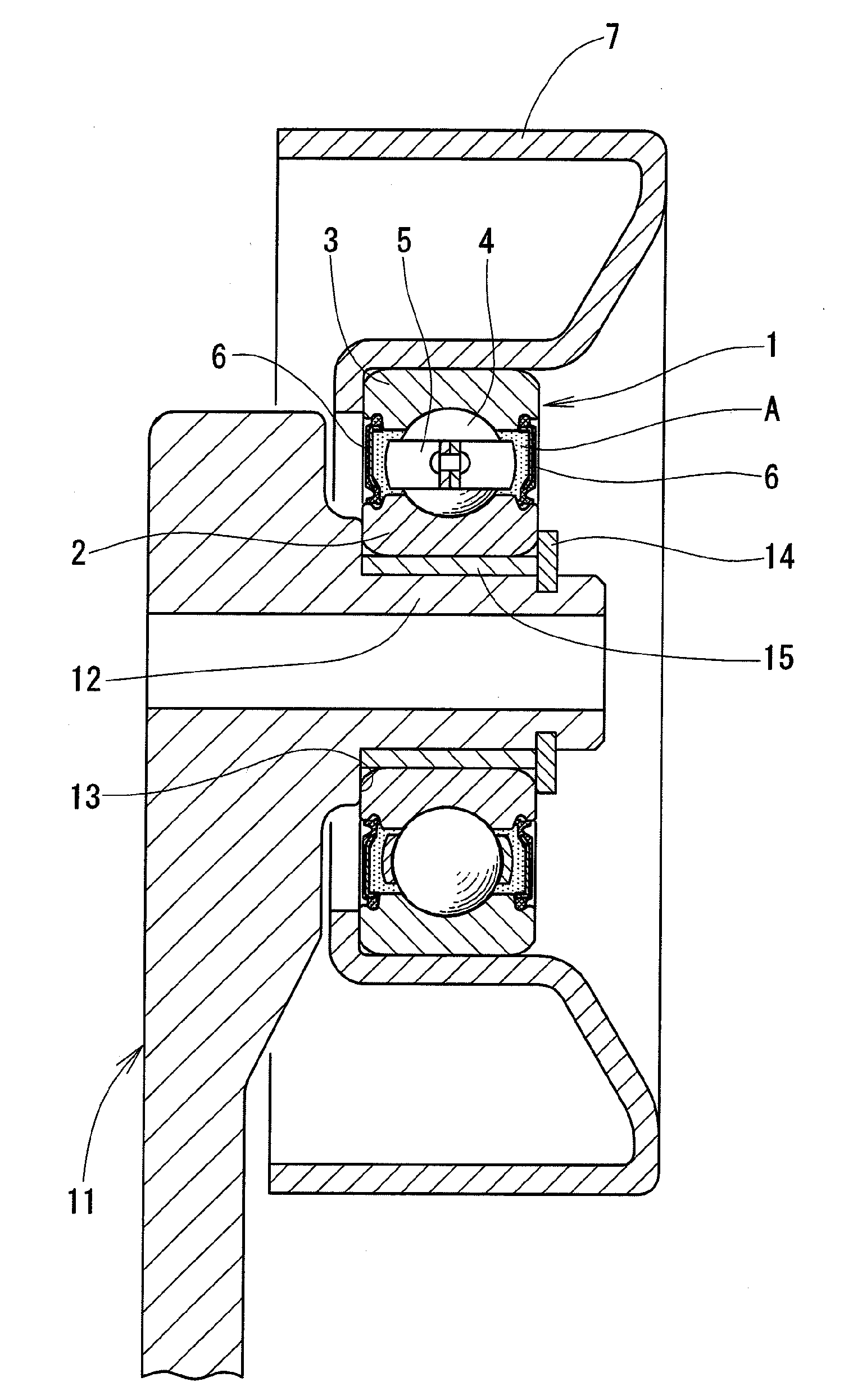

Axial load-insensitive emergency bearing

ActiveUS7217039B2High degree of operating safetyHigh of wearBearing assemblyNon-rotating vibration suppressionMagnetic bearingEngineering

The emergency bearing for a rotary machine having magnetic bearings comprises an emergency landing device including an intermediate element (9) having a large contact area with a stator element (10), the intermediate element (9) being interposed between a bearing member (1, 2, 3) and the stator element (10) fixed to the stator (15) with radial clearance (11, 13) relative to said stator element (10). A damper element (13) acting in the radial direction is interposed between the intermediate element (9) and the stator element (10), and a contact element (14) having very low friction is implemented between the intermediate element (9) and the stator element (10) to reduce friction during rotary movements between these two elements.

Owner:SKF MAGNETIC MECHATRONICS

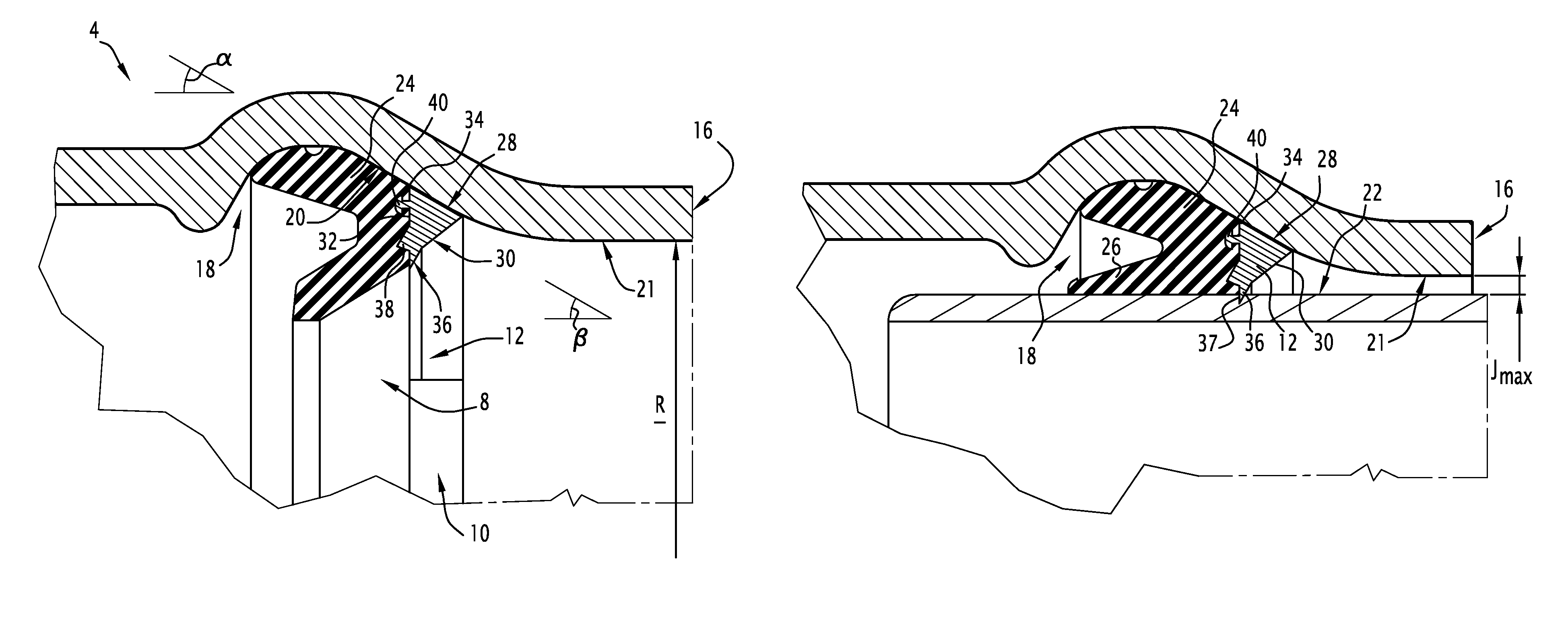

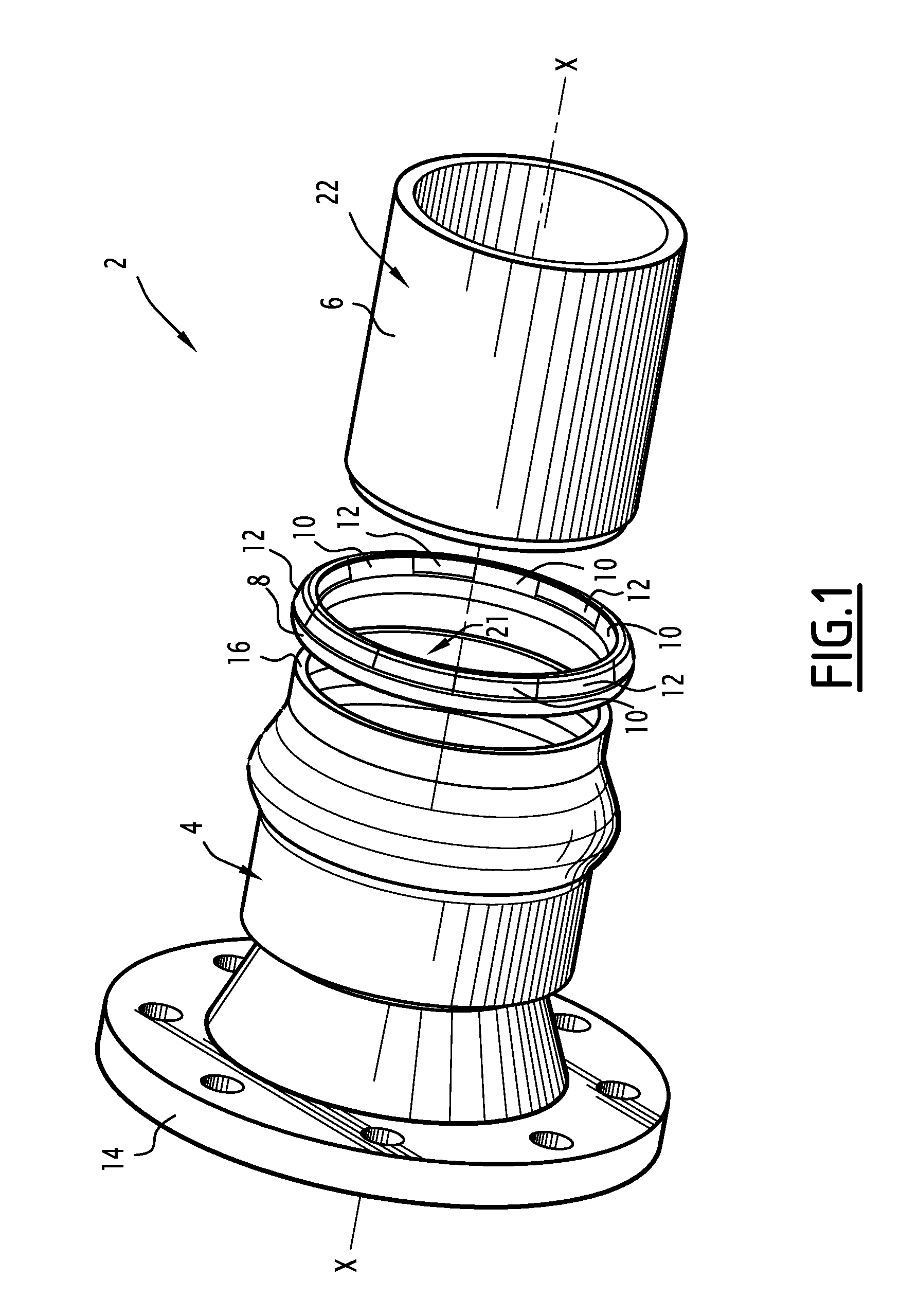

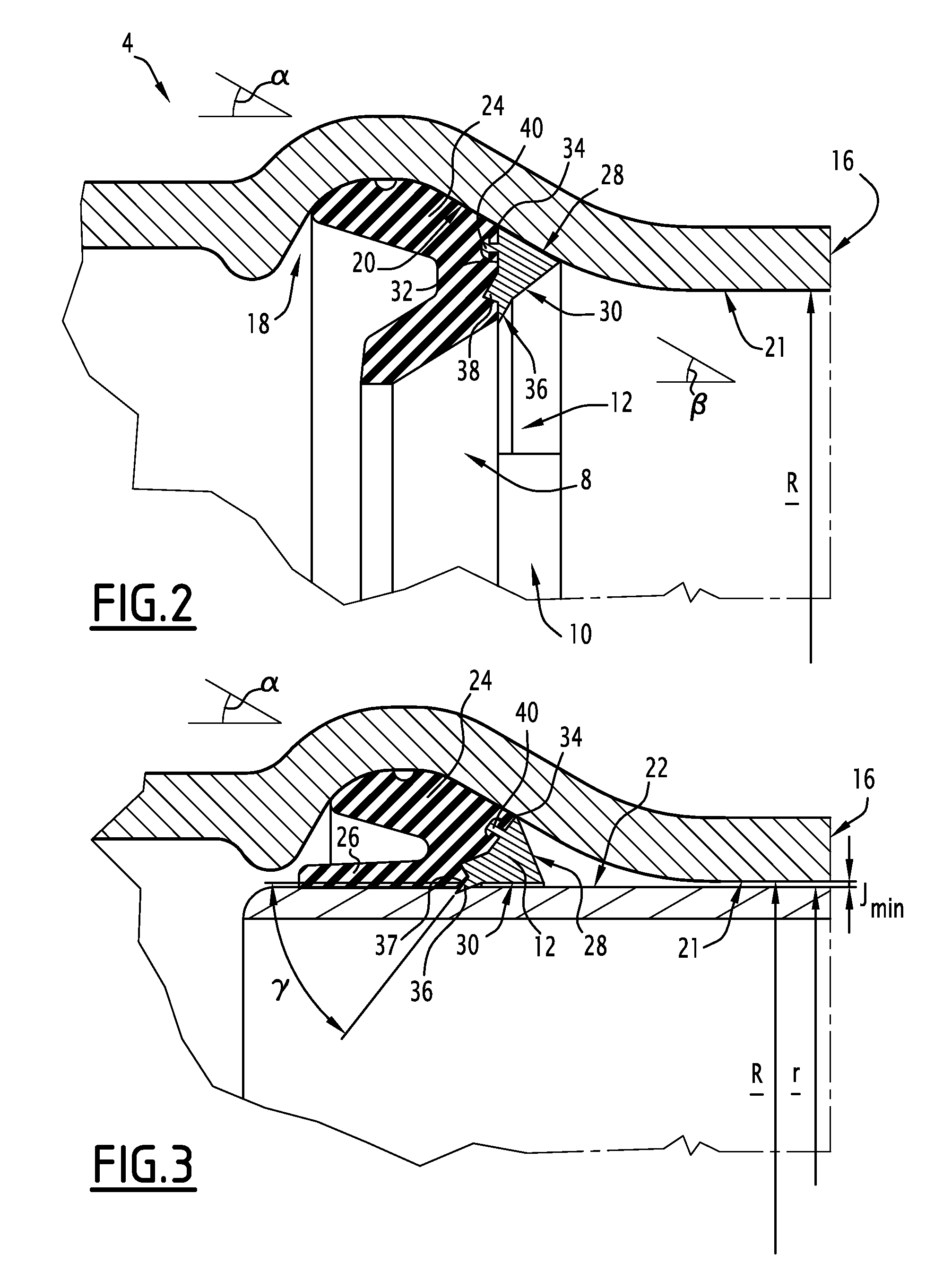

Tubular joint

ActiveUS8096585B2Little strengthEffective lockingSleeve/socket jointsFluid pressure sealed jointsEngineeringFlying buttress

This tubular joint includes a bell end (4) which is equipped with an internal groove (18) and in which is inserted a spigot end (6), a seal (8) and a locking element (12). The groove forms a groove wall (20). The spigot end (6) and the bell end (4) define a radial clearance (J). The locking element (12) includes a fixing tooth (36) and a contact face (28) for application against the wall (20) when the clearance (J) is within a first range of clearances. When the clearance is within a second range of clearances, the locking element (12) forms a rocking point (34) for rocking round the groove wall (20) and the fixing tooth (36) bites into the external surface (22) by a flying buttress effect of the locking element (12).

Owner:SAINT GOBAIN PAM SA

High rangeability control valve

InactiveUS6807985B2Reduces and eliminates cavitation erosion damageExpand the adjustment rangeValve members for absorbing fluid energyMultiple way valvesVapor bubbleControl valves

A guided control valve comprising a vapor recovery area that encourages collapse of vapor bubbles. In a cage-guided valve, a seal comprising inner and outer members reduces flow through a radial clearance between a plug and a cage. The vapor recovery area is positioned below the seal and above a seat interacting with the plug. The vapor recovery area encourages collapse of vapor bubbles to reduce damage to the valve trim.

Owner:DRESSER LLC

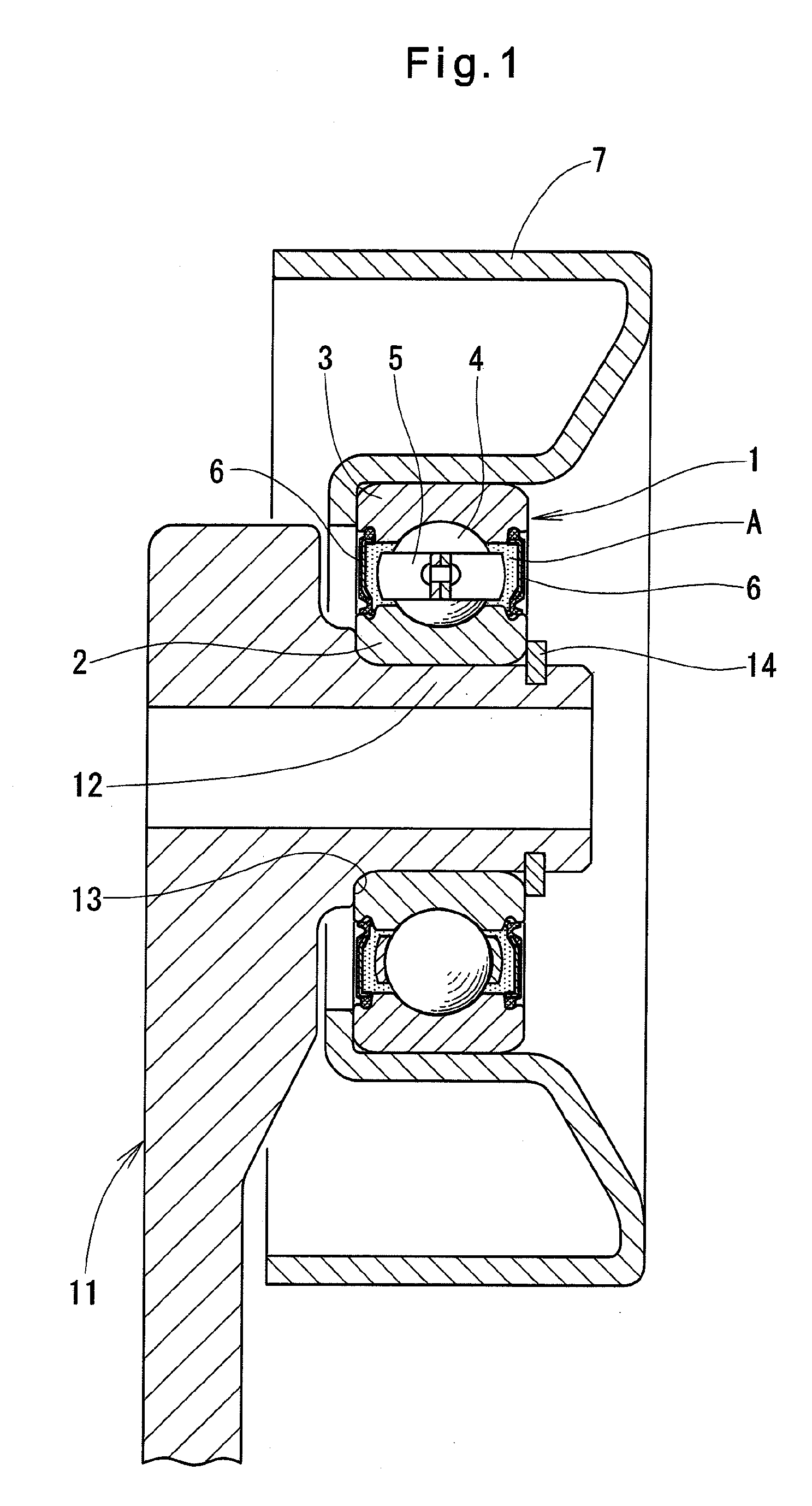

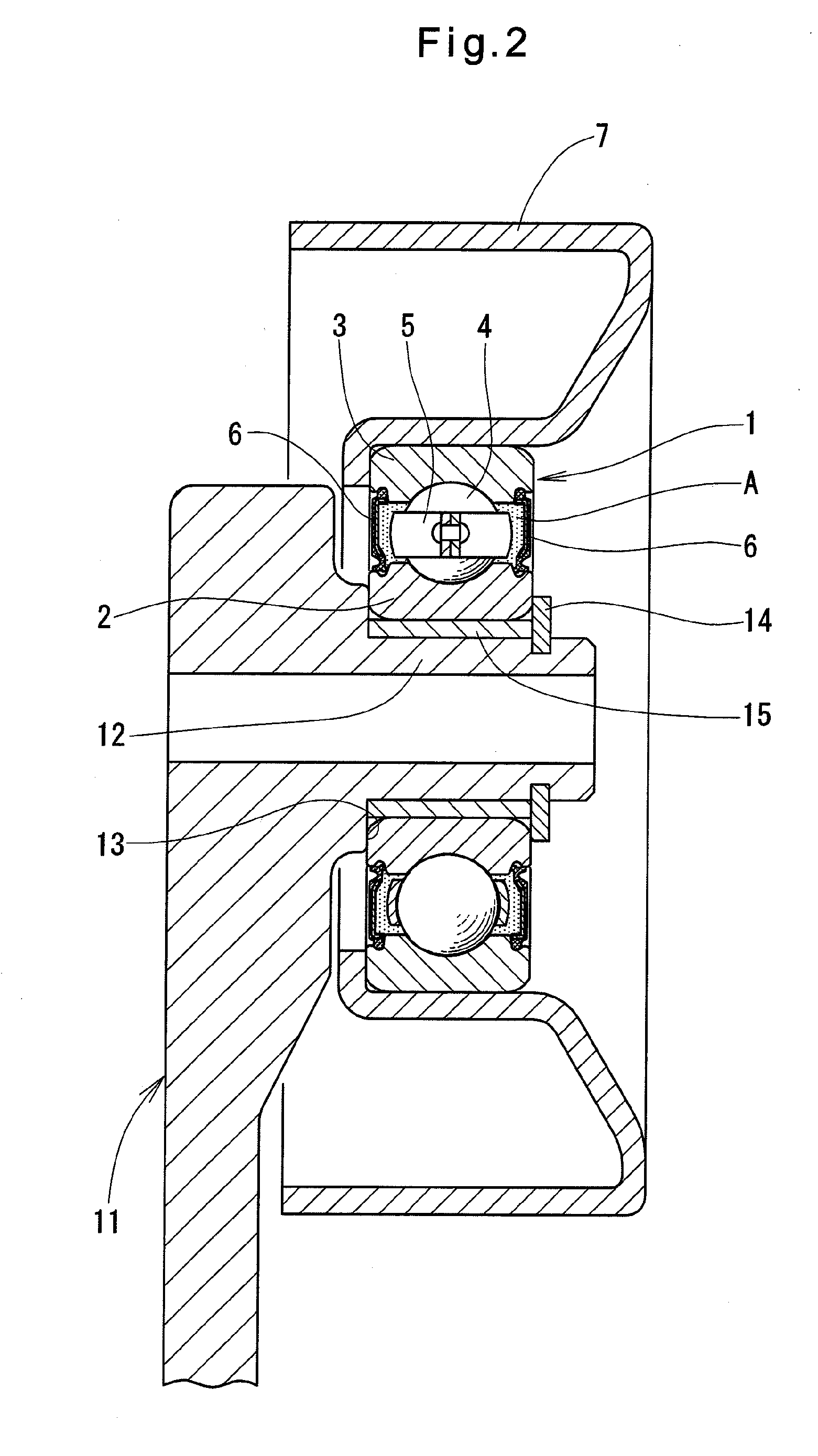

Pulley fixing structure

InactiveUS20090298630A1Reduce in quantityReduce radial clearanceGearingBall bearingsInterference fitBall bearing

A pulley fixing structure includes a pulley with a ball bearing, and a bracket having a shaft portion on which the inner race of the bearing is pressed with an interference fit. The thermal expansion of the radially outer portion of the shaft portion of the bracket is larger than that of the radially inner portion of the inner race of the bearing. The interference thus decreases at a low temperature. Reduction of the radial clearance of the bearing 1 by pressing is thus compensated, and cold weather noise can be prevented while reducing the number of required parts and making the assembly process simple.

Owner:NTN CORP

Seal radiofrequency coaxial connector with self locking mechanism

InactiveCN101005180ARealize the sealing functionQuick plugCoupling device detailsTwo-part coupling devicesLocking mechanismSelf locking

Six slots along axial line are made on head of plug body. The head portion is an arc shaped male tab. Claws are located outside the body case, and outer sheath is located outside the claws. Nut is screwed on postmedian portion of the body case. Three claws with barbs are placed between inner male tab of the body case and the nut in order to restrict axial drunkenness of claws. Radial clearance is kept between the outer sheath and the claws. There are five straight holes with different diameters and two cone shaped bores inside head of socket shell. The holes are matched to diameters of plug. The cone-shaped bores are guide holes. Outline of insulator is in step shape, where small end is extended out of the straight hole, and large end is stopped by the inner hole of shell. Full escaping lock connection between socket and plug is adopted in the invention so as to guarantee quick plugging in or out, and provide firm bond between socket and plug under execrable mechanical condition.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

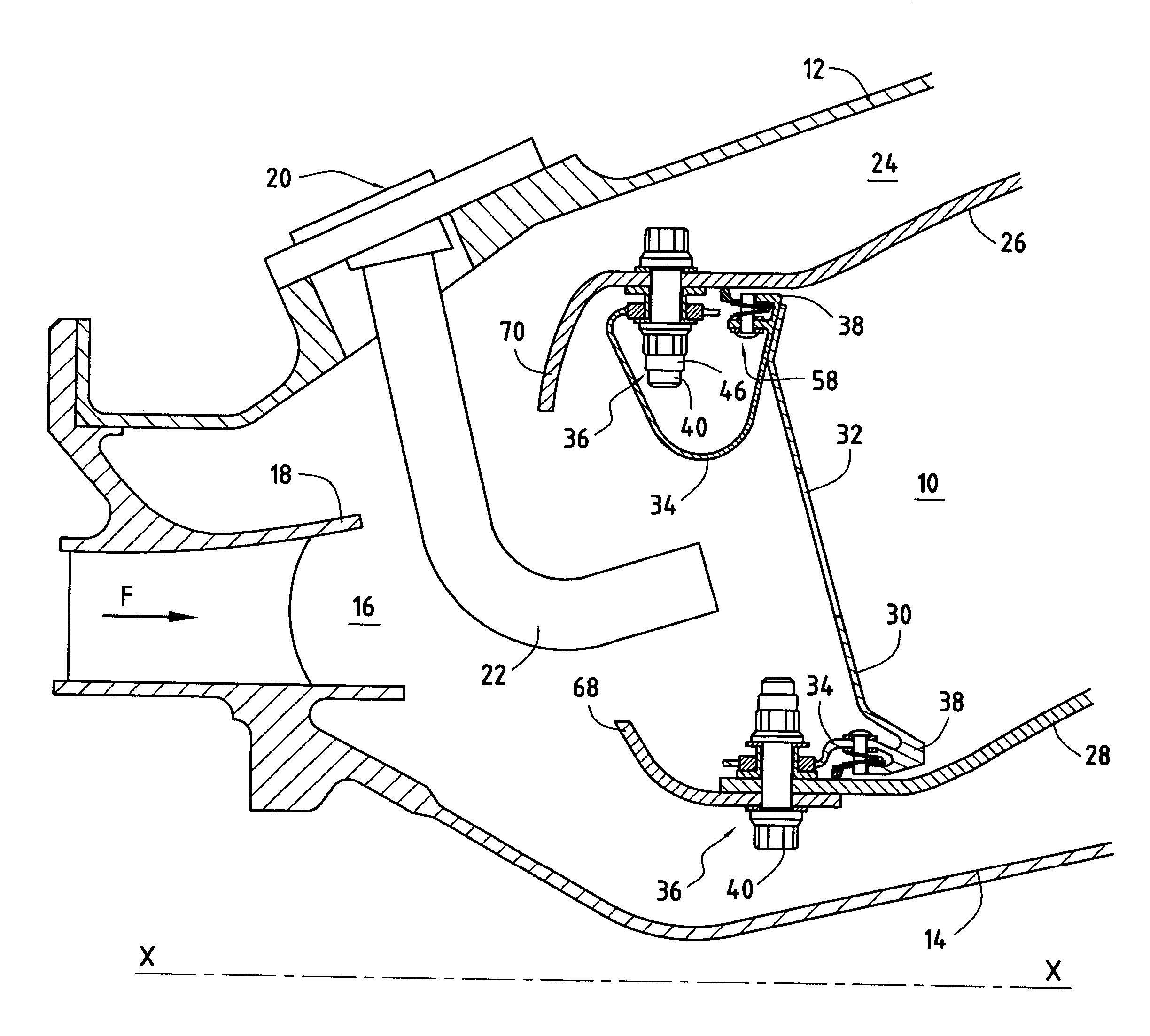

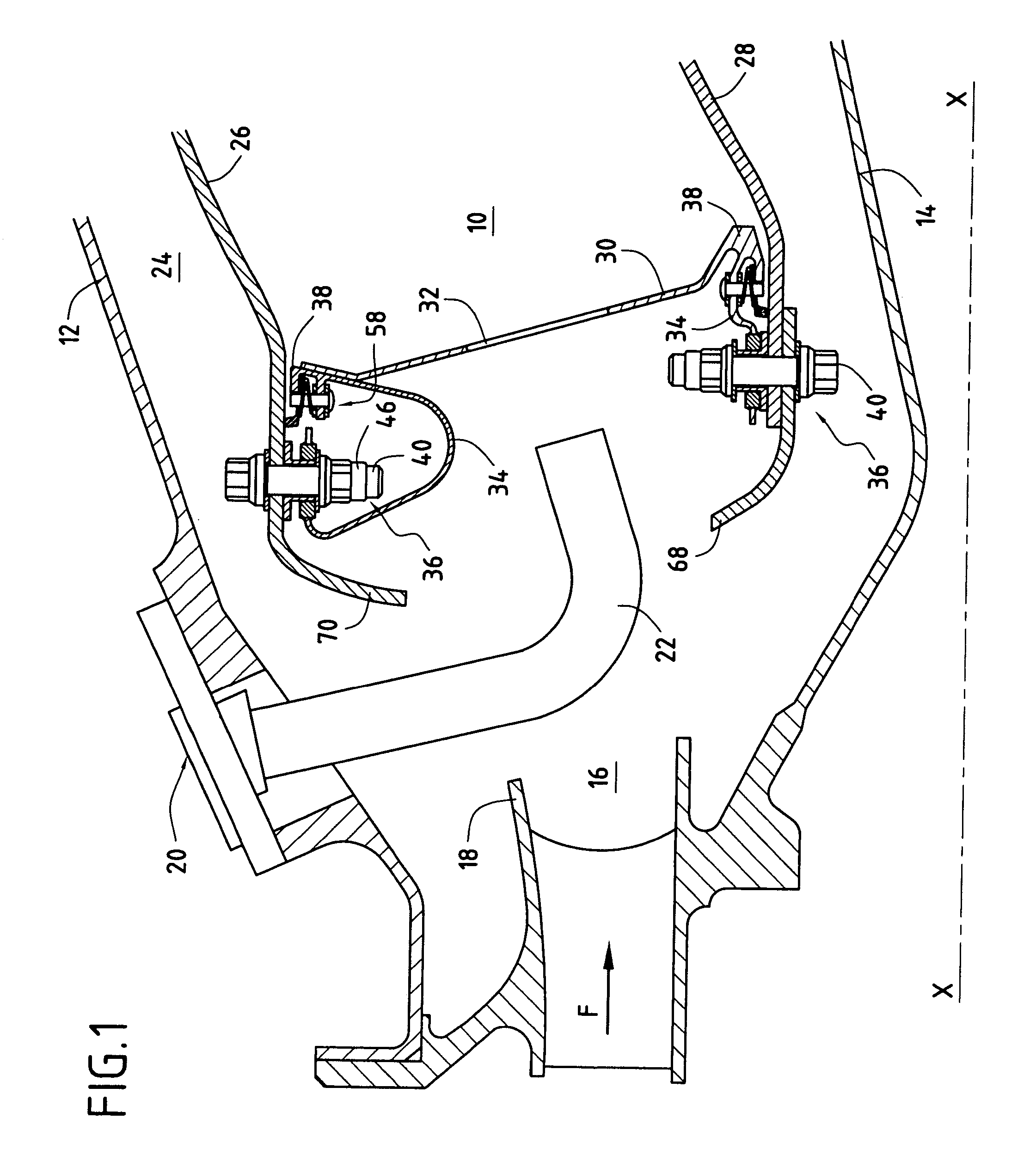

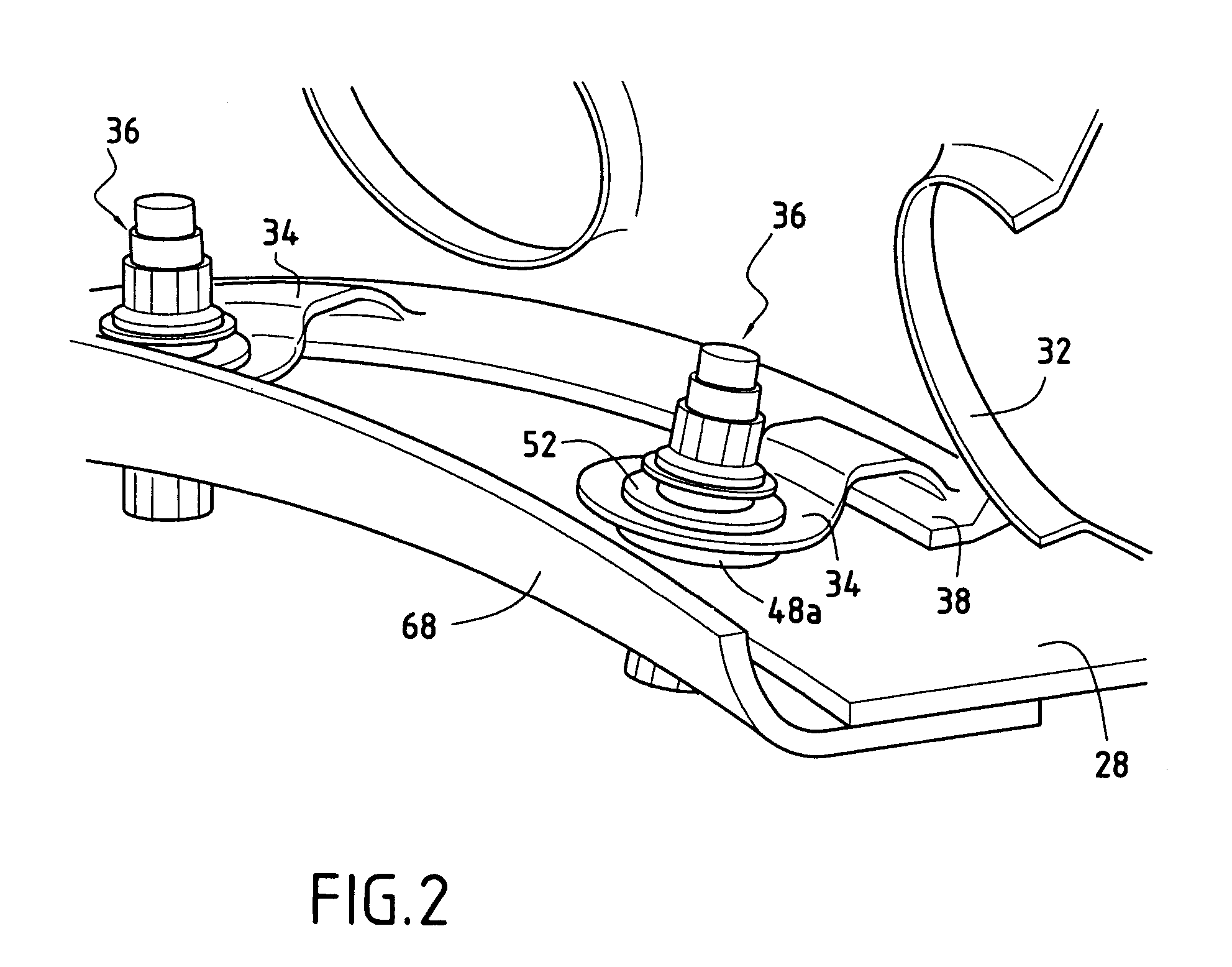

Assembling an annular combustion chamber of a turbomachine

ActiveUS7849696B2Effective dampingMitigate such drawbackContinuous combustion chamberCombustion enginesCombustion chamberThermal expansion

An annular combustion chamber comprising axial walls interconnected by a chamber end wall having a coefficient of thermal expansion that is different from that of the axial walls, the chamber end wall being provided with a plurality of inner and outer fastener tabs secured by fastener systems to the end portions of the axial walls. Each fastener system comprises a bolt, a nut tightened onto one of the ends of the bolt, and a slideway bushing disposed around the bolt between the nut and the end portion of the corresponding axial wall, a determined amount of radial clearance being provided between the nut and the end portion of the axial wall so as to enable the chamber end wall to expand radially freely in operation relative to the axial walls.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

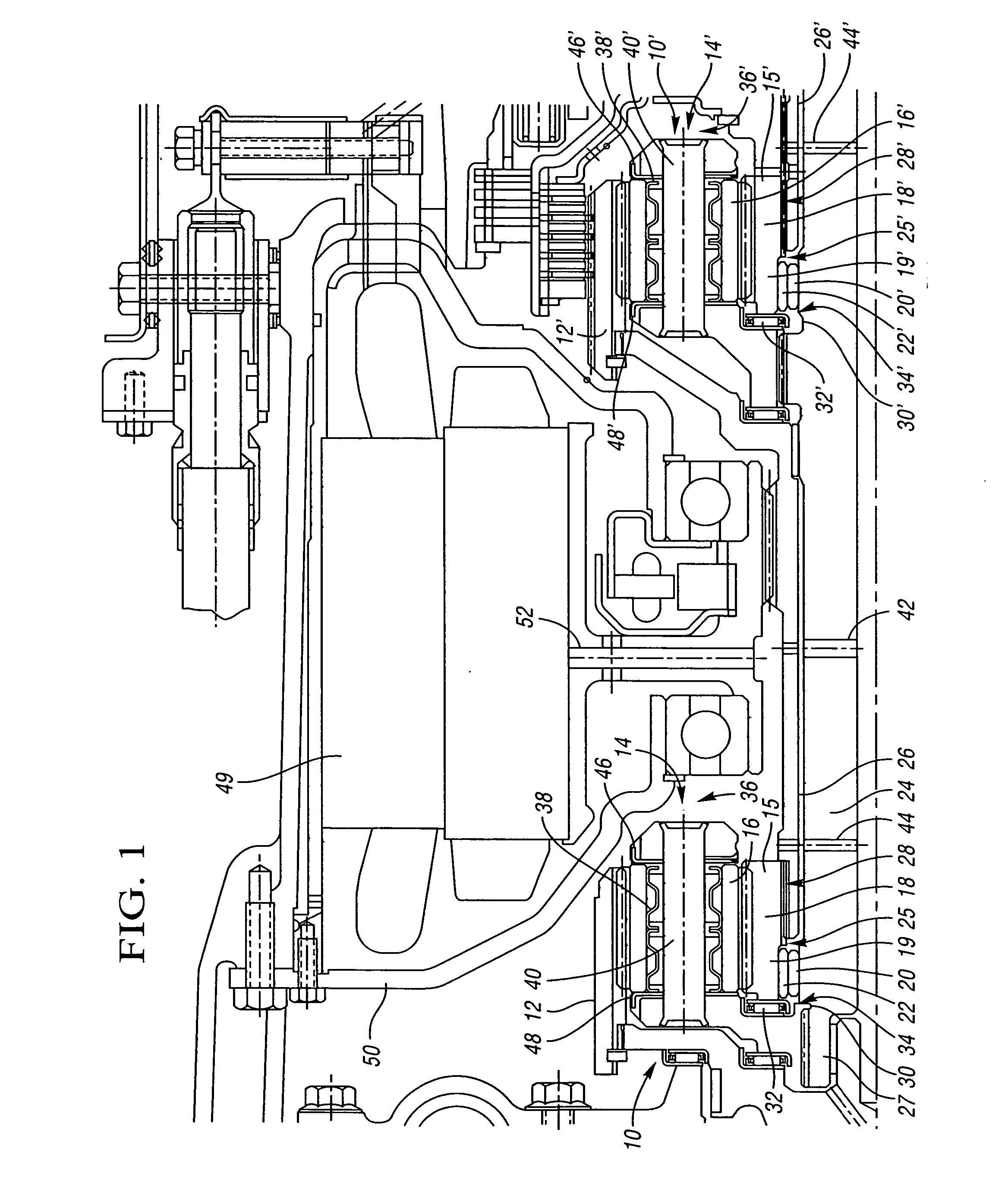

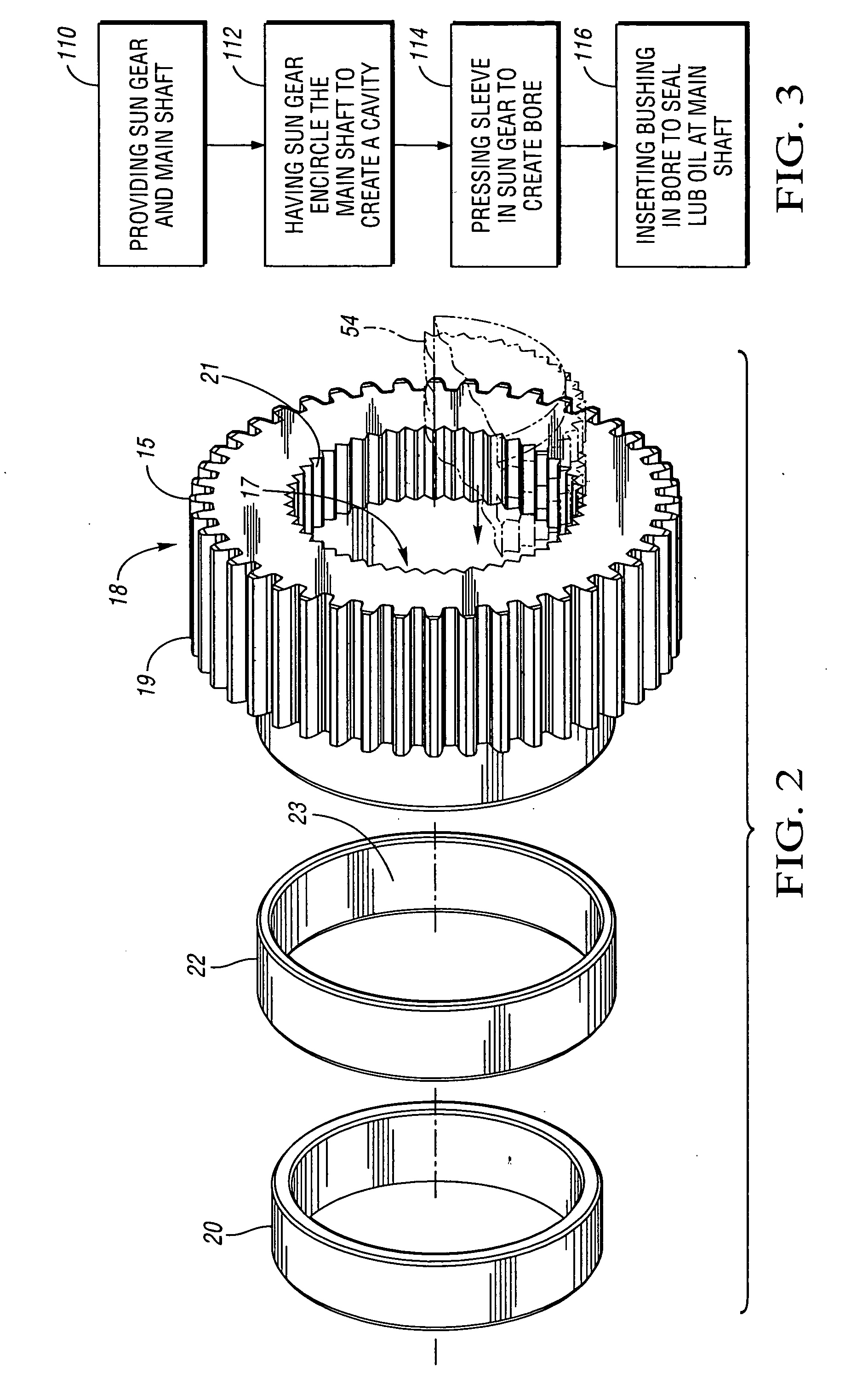

Sun gear bushing and sleeve and method for sealing in a hybrid electromechanical automatic transmission

InactiveUS20050209038A1Easy to assembleEfficient and cost-effective processHybrid vehiclesGear lubrication/coolingAutomatic transmissionGear wheel

The present invention details a sleeve and bushing of an electromechanical automatic planetary transmission. The sleeve and bushing operate to confine the desired flow of transmission lubricant through the components of the planetary gear arrangement. Additionally, the sleeve and bushing assist in maintaining a sufficient pressure level in the cavity of the planetary carrier to enable the lubricant to reach the bearings of the pinion gear. Moreover, the radius or size of the bushing / sleeve arrangement can be adjusted to occupy the radial clearance or cavity between the sun gear and main shaft for an automatic transmission with axially separable splined sun gear and sun gear shaft.

Owner:GM GLOBAL TECH OPERATIONS LLC

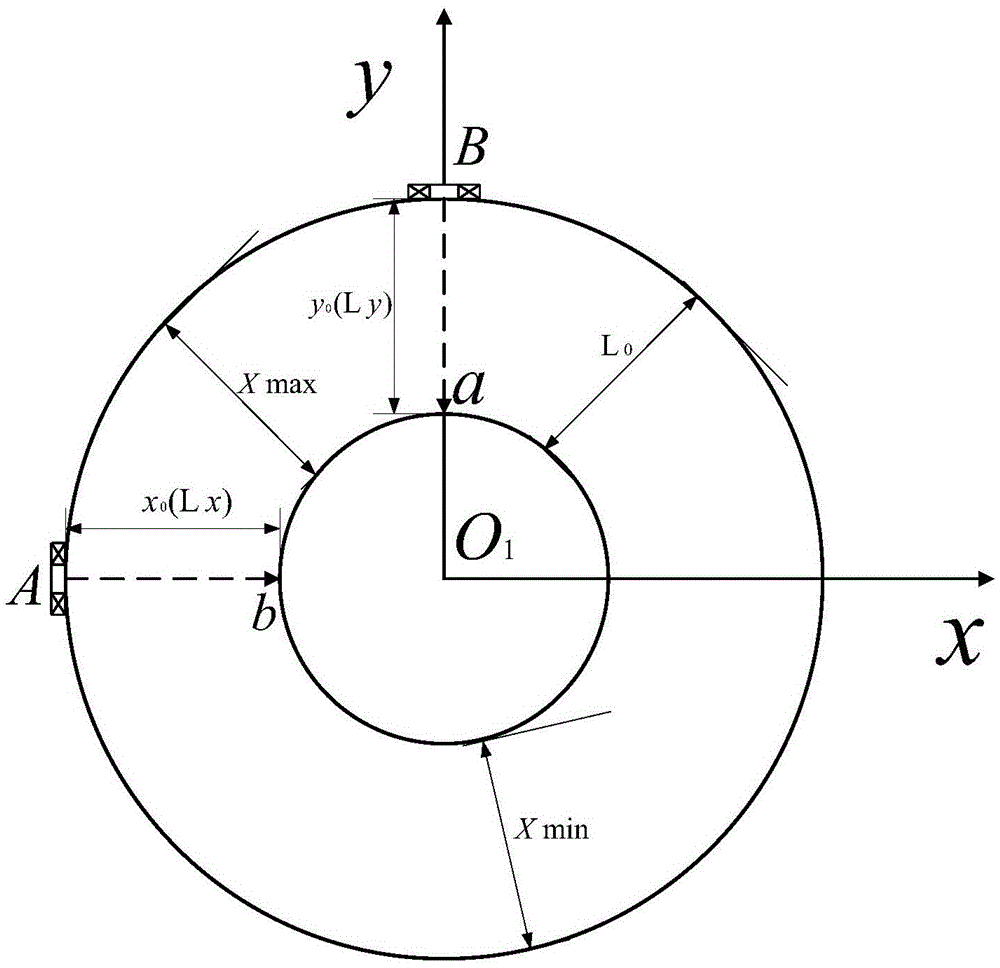

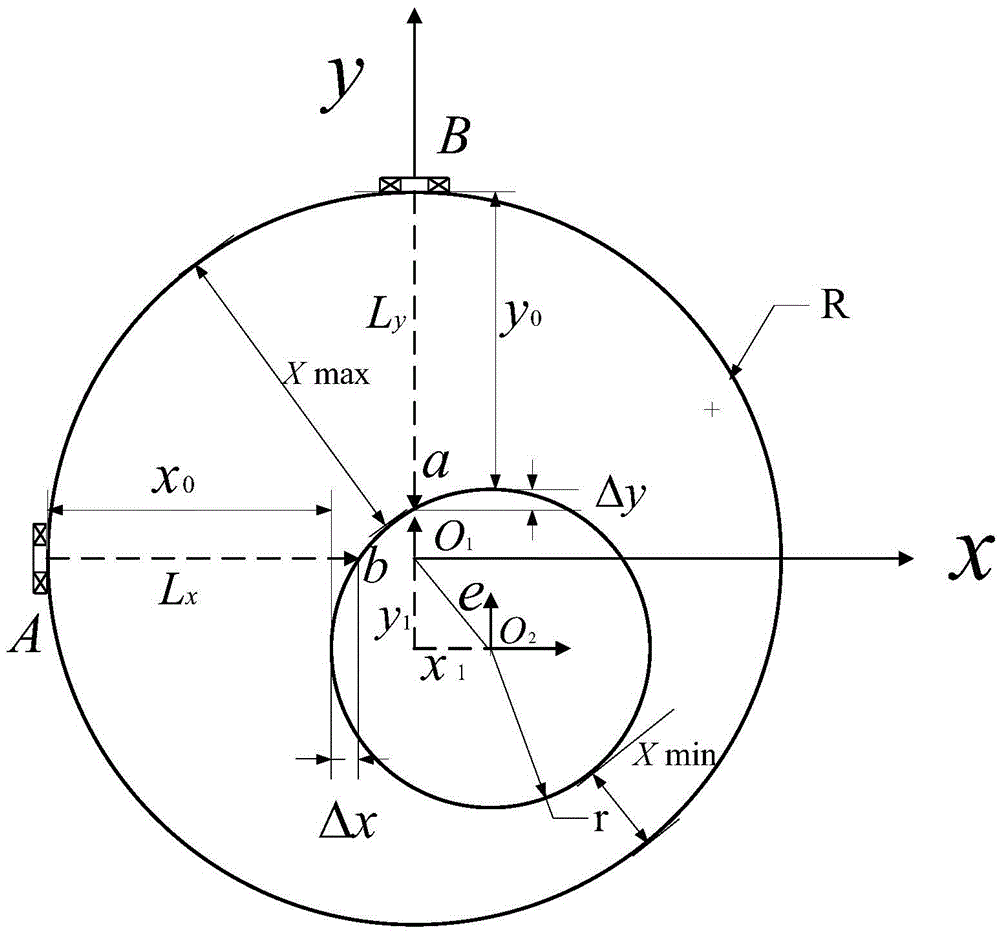

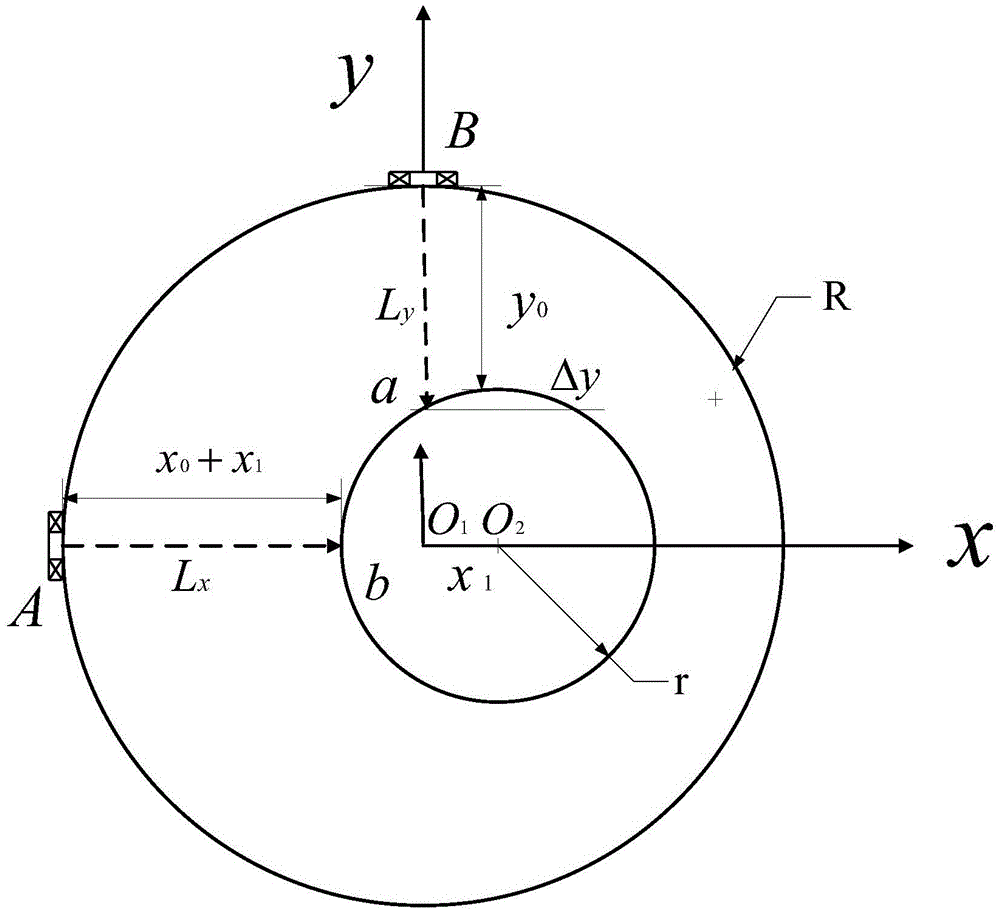

Real-time dynamic measurement method for measuring radial clearance between steam turbine rotor and stator

ActiveCN105526878ARealize non-contact measurementFast and accurate real-time dynamic online monitoringUsing optical meansObservational errorEngineering

The invention provides a real-time dynamic measurement method for measuring radial clearance between a steam turbine rotor and a stator. The method is characterized in that the method comprises the steps of determining distance measurement devices for radial clearance, determining radial clearance between the rotor and the stator, determining the radial clearance between the rotor and the stator, determining the distance from an emitter to the surface of the rotor, calculating vertical offset amount of the rotor when the center of the rotor shifts, calculating horizontal offset amount of the rotor when the center of the rotor shifts, calculating the rotor offset amount at any position and calculating the radial clearance between the steam turbine rotor and the stator. The method can carry out dynamic measurement on the rotor labyrinth clearance and blade top labyrinth clearance of a running steam turbine accurately and quickly, thereby solving the problem that the measuring error of the radial clearance between the steam turbine rotor and the stator is large and the radial clearance cannot be measured online dynamically and accurately, ensuring safe and economical operation of the machine set and saving halt overhaul time.

Owner:NORTHEAST DIANLI UNIVERSITY

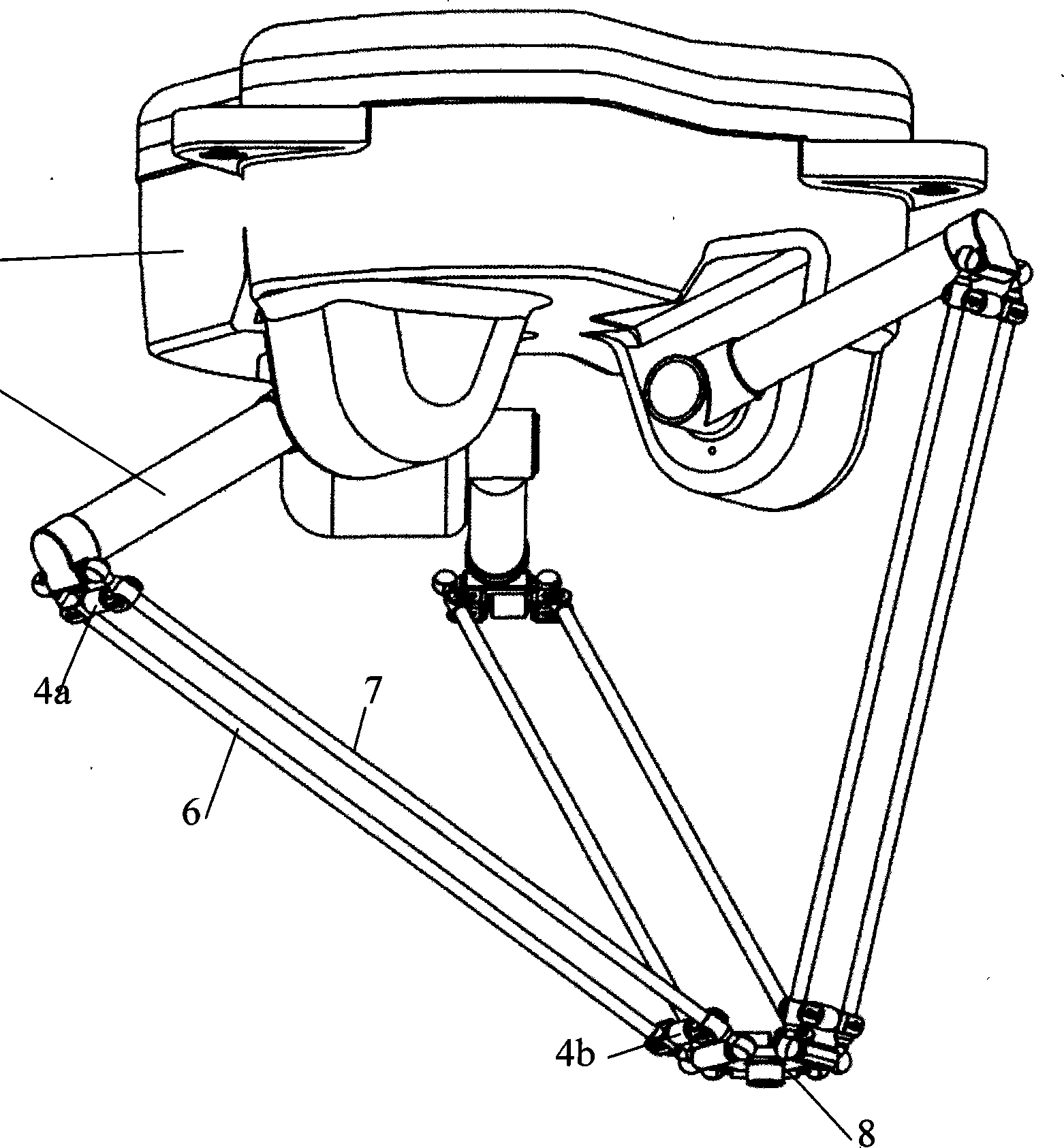

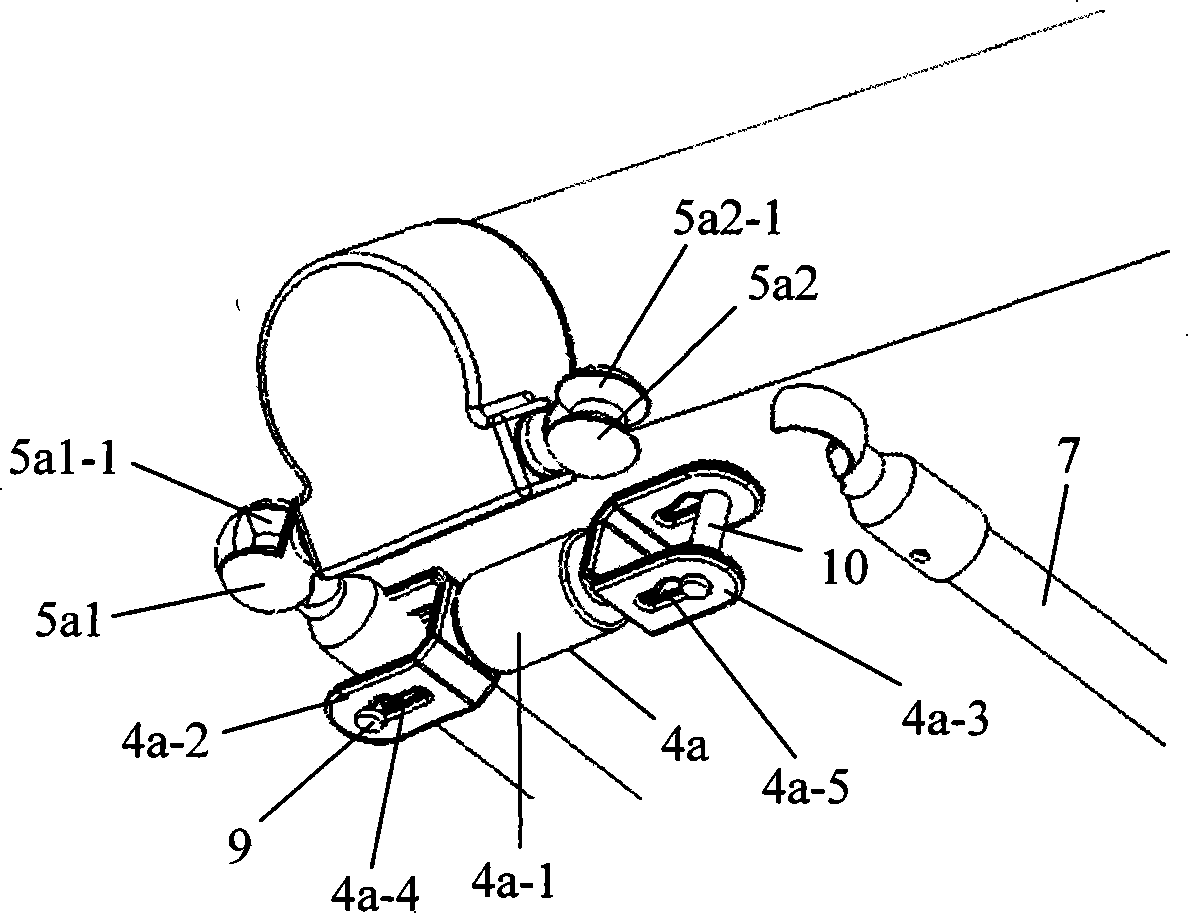

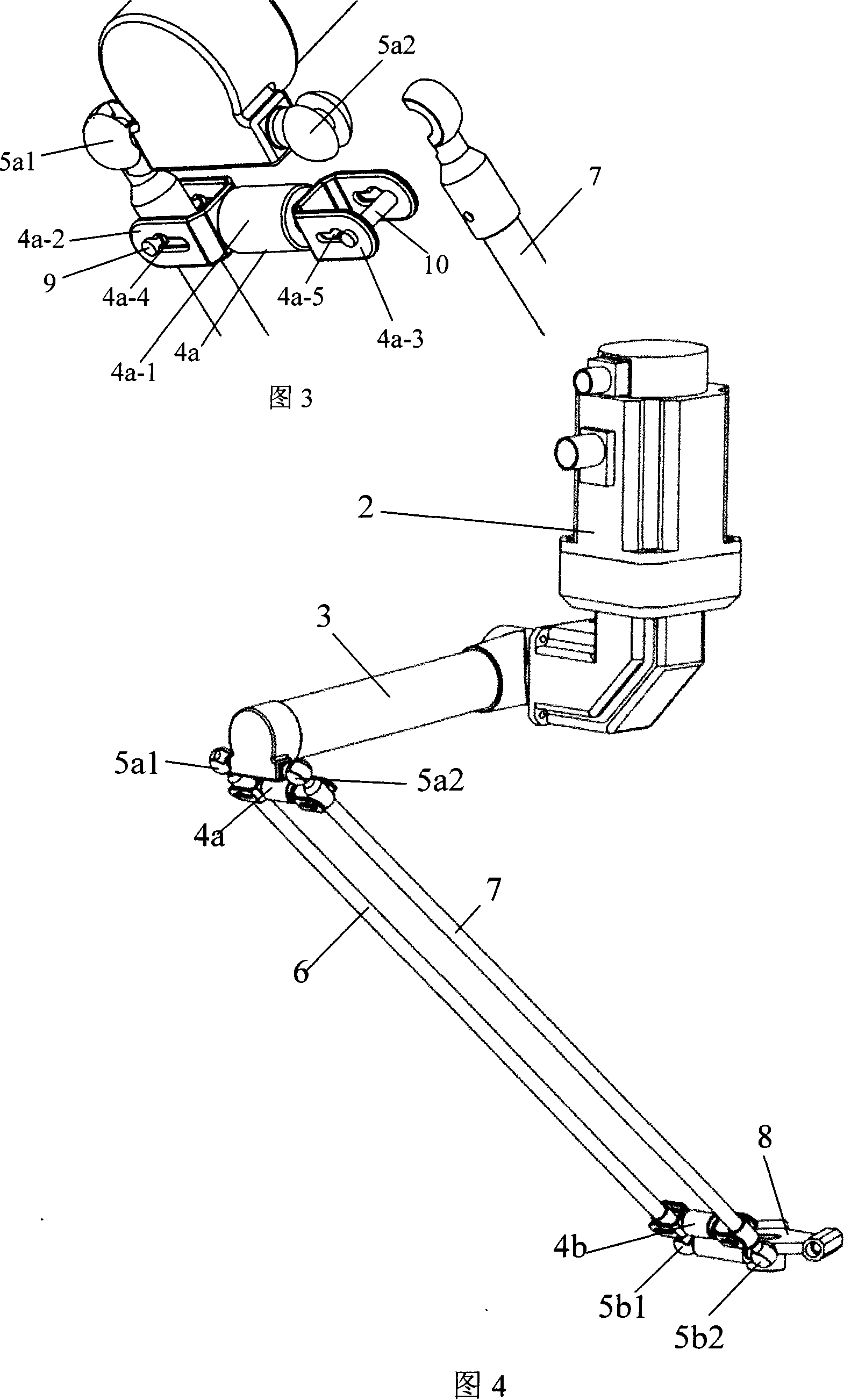

Space three-translational freedom degree parallel connection mechanism with far-rack double lever

InactiveCN101249652AEasy to eliminate gapsAutomatic clearance compensationProgramme-controlled manipulatorParallel kinematicsWorkspace

The invention discloses a space tripod-based parallel kinematic mechanism with remote double bars. Both ends of a first side bar and a second side bar are respectively provided with staining machines, one end of which is rotationally connected with the first side bar and the other is rotationally connected with the second side bar; inner grooves are respectively arranged at the front end and the back end of the first side bar and the second side bar; the junctions of both sides of the ends of the near side bar and the far side bar are respectively rotationally connected with shafts 1, the ends of which are respectively connected with outer grooves which combine and are connected with the front ends of the first side bar and the second side bar; the moving platform and the shaft 1 are correspondingly rotationally connected with shafts 2, the ends of which are respectively provided with outer grooves which combine and are connected with the back ends of the first side bar and the second side bar. With the adoption of open two-degree-of-freedom rotary pair, the mechanism realizes all the functions of the traditional hook joint. However, compared with the traditional hook joint, the mechanism is easier to eliminate the radial clearance and the axial clearance, thus being conducive to enlarging the workspace of the mechanism.

Owner:TIANJIN UNIV

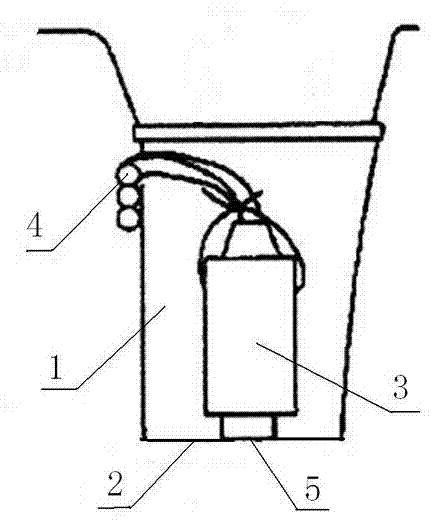

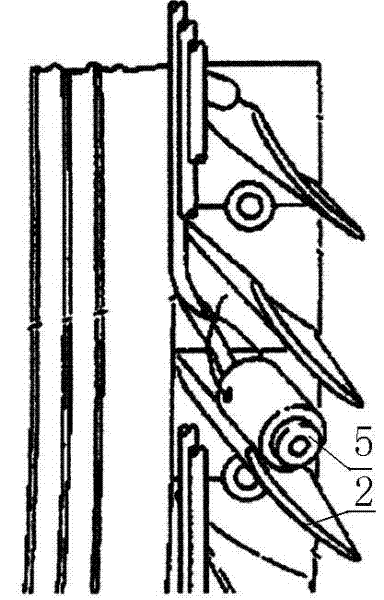

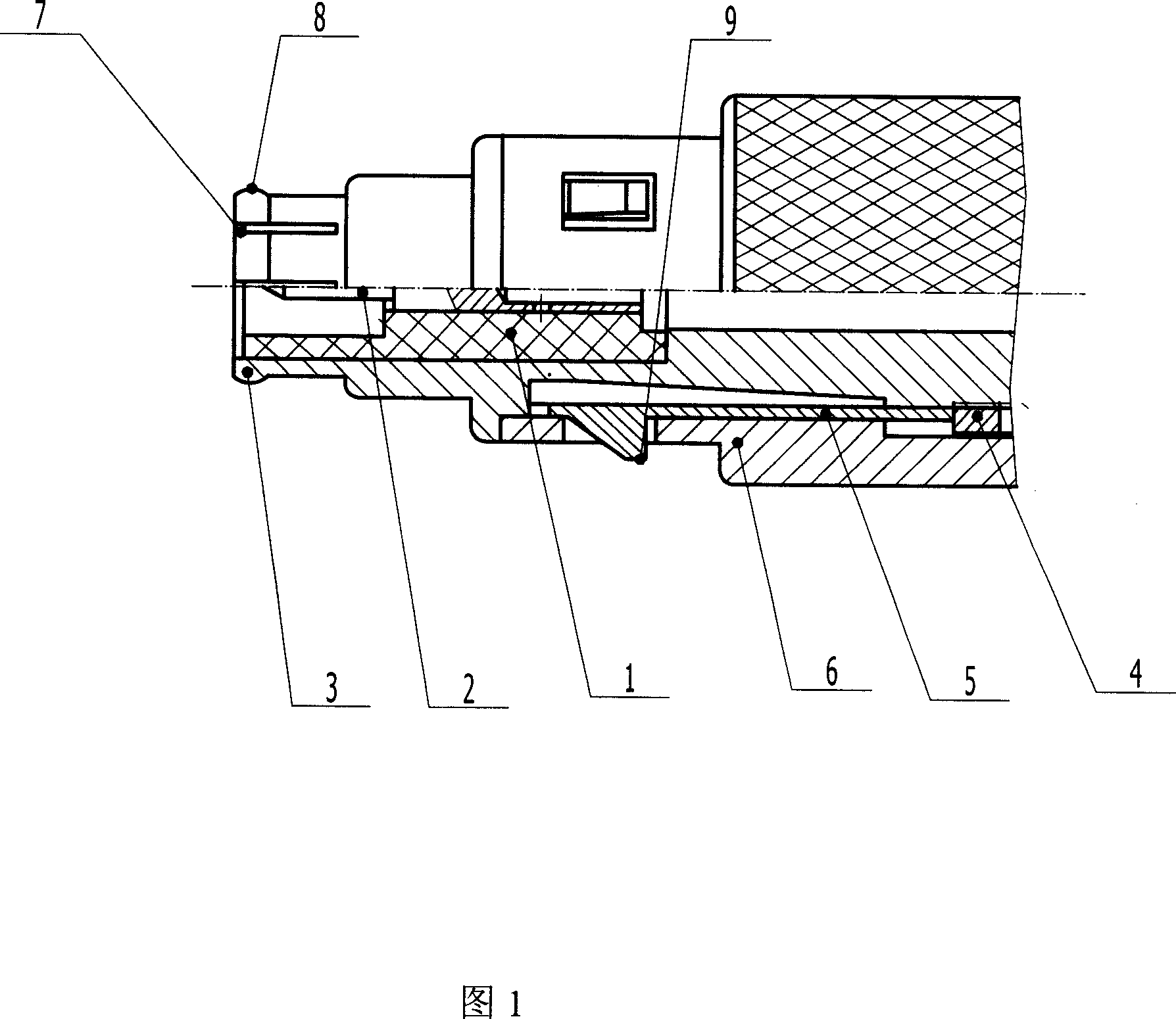

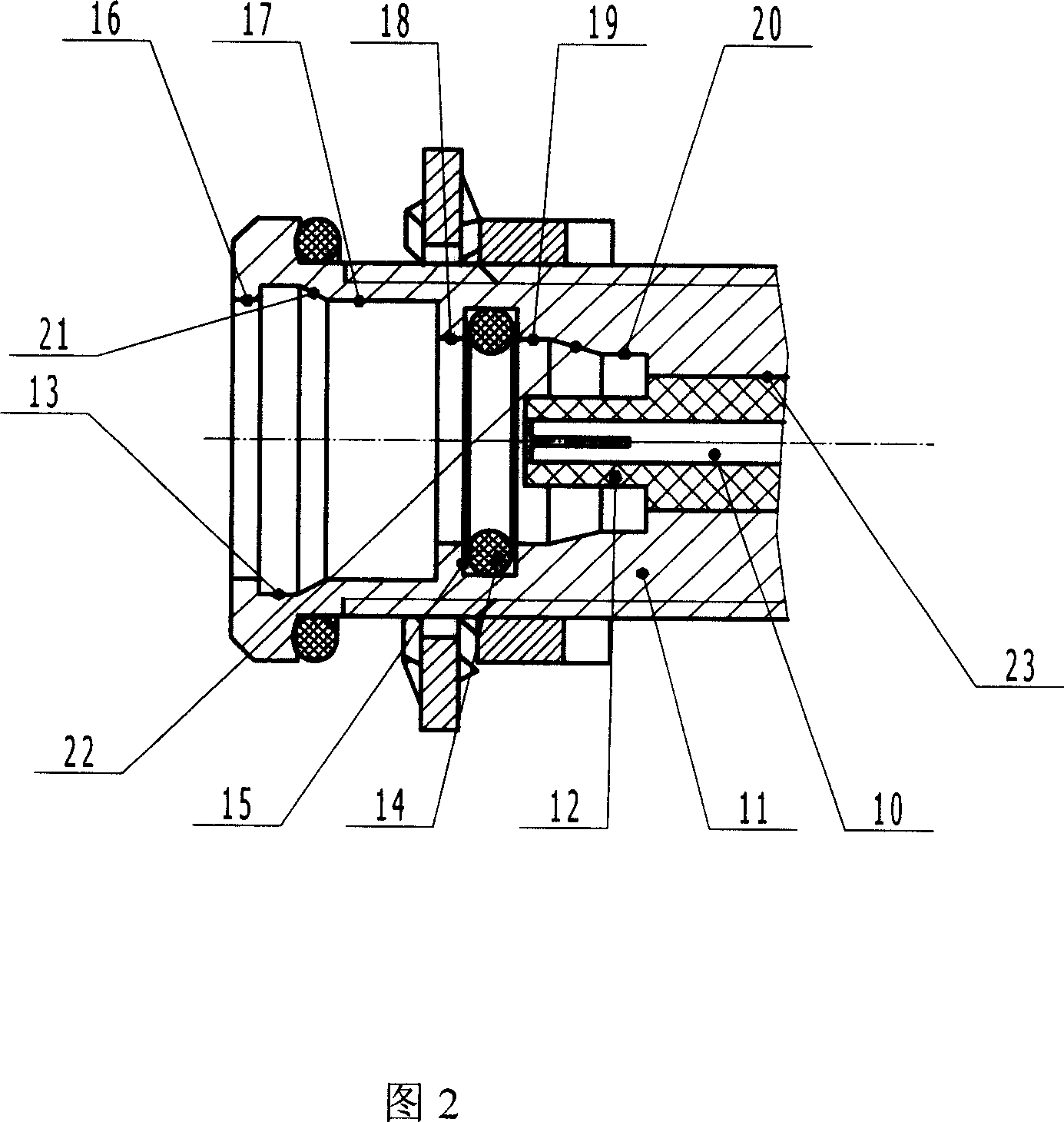

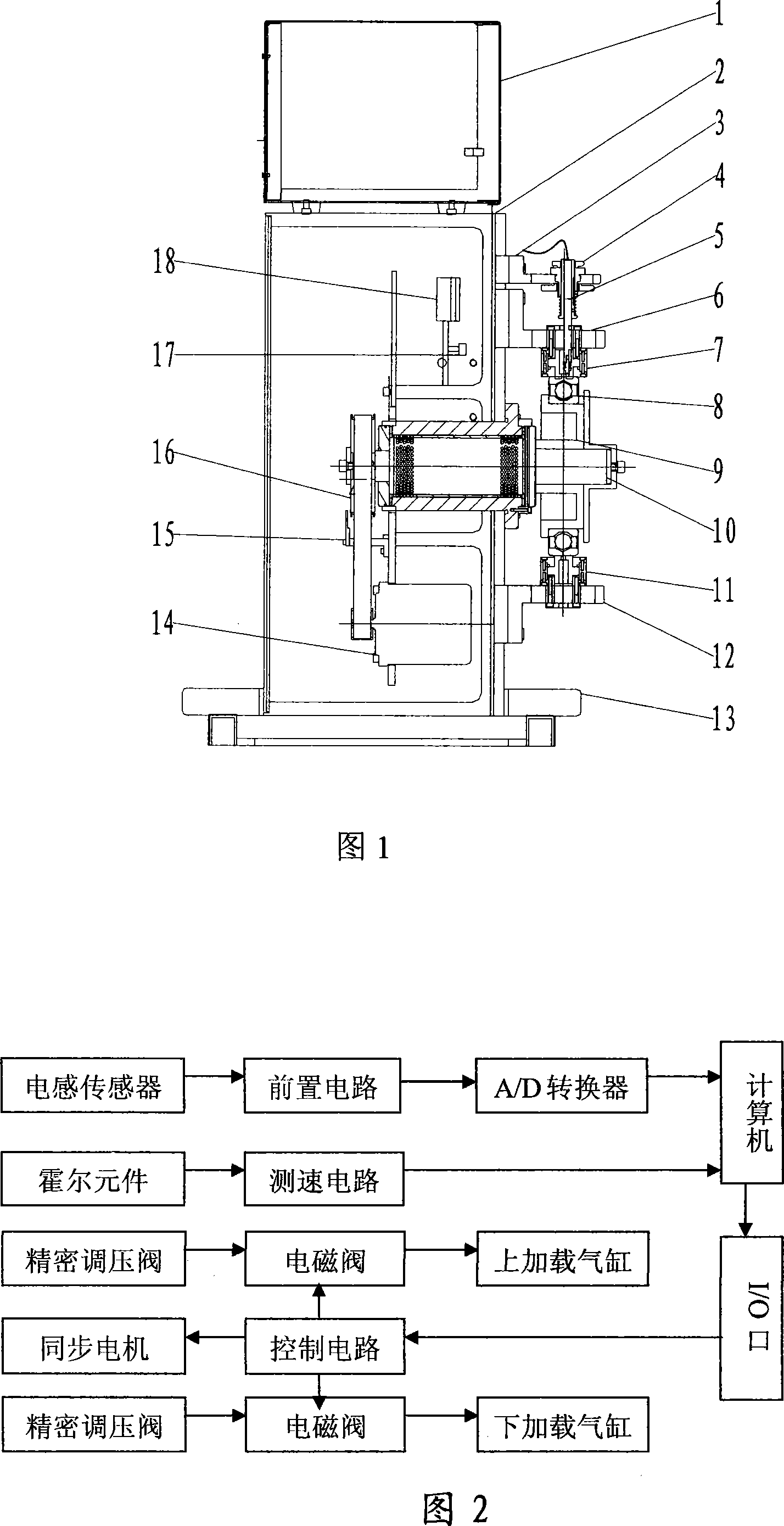

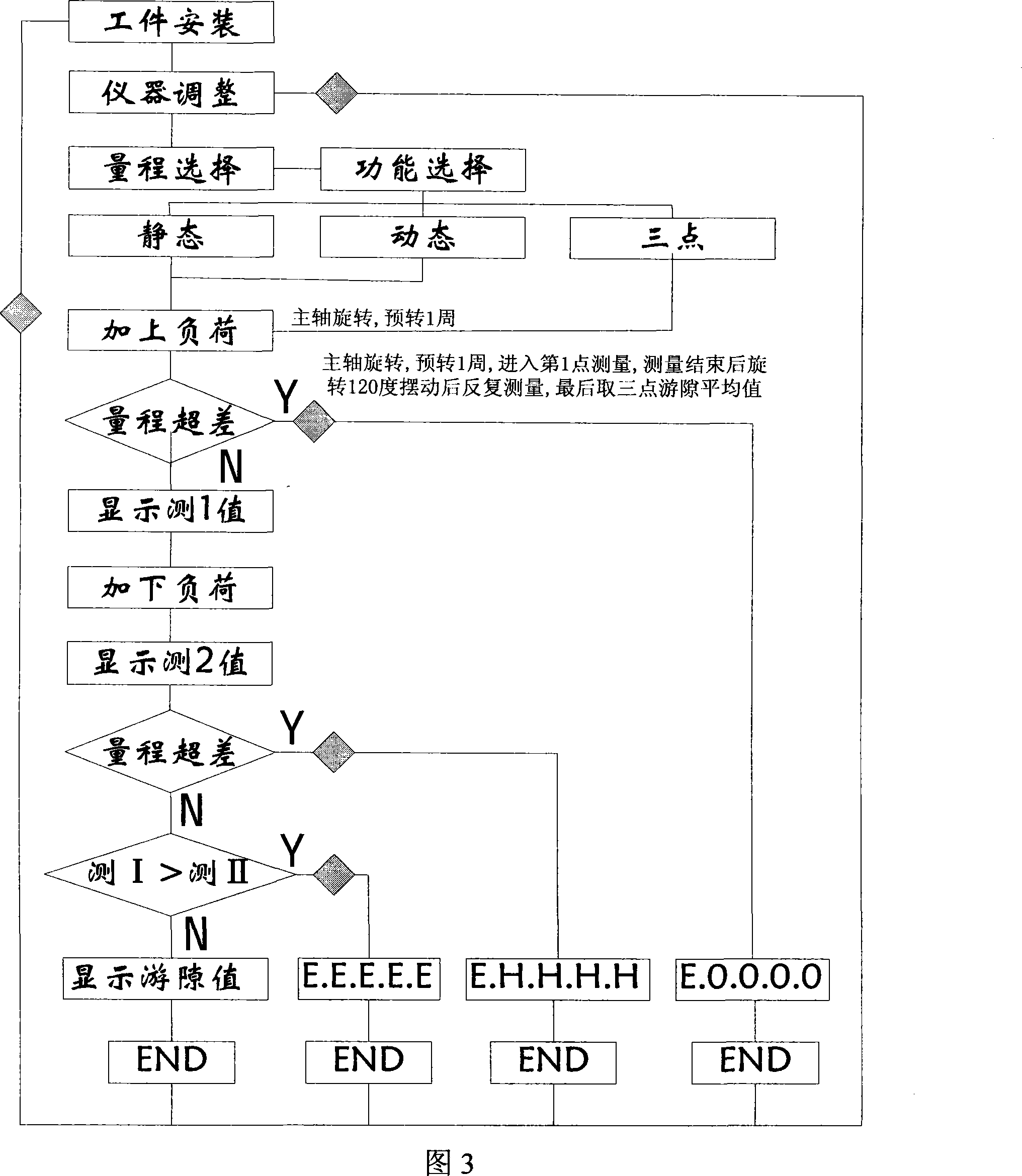

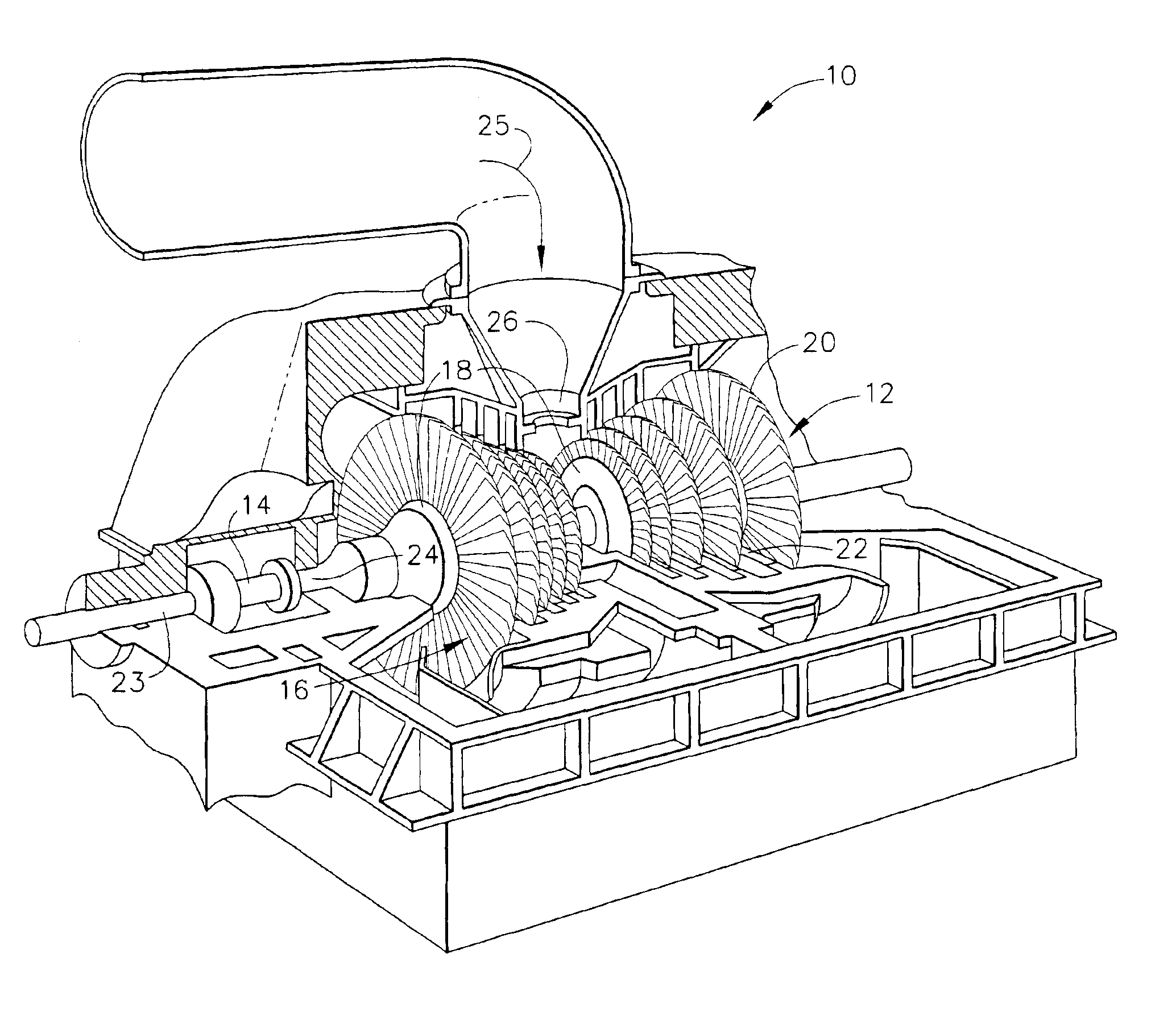

Large-sized precision bearing radial play multifunctional automatic measurement method and measuring apparatus

InactiveCN101216283AImprove accuracyImprove reliabilityMachine bearings testingUsing electrical meansAnalysis dataSynchronous motor

A multifunctional automatic measurement method for radial clearance of large-scaled precision bearing adopts static measurement, dynamic measurement and three-point measurement and is capable of automatically loading and automatically measuring. The three measurement manners can be implemented on one measuring apparatus at the same time. The measuring apparatus mainly comprises an electrical system (1), a measurement pedestal (2), a sensor support (3), a sensor adjusting nut (4), an inductive sensor (5), an upper cylinder support (6), an upper loading cylinder (7), a measurement shaft centre (9), a measurement main shaft (10), a lower loading cylinder (11), a lower cylinder support (12), a measurement support (13), a synchronous motor (14), a Hall element (15), a belt wheel and cog belt (16), a precise pressure regulating valve (17), and a precise pressure gauge (18). The measuring apparatus can provide reliable detection and analysis data for high-precise measurement of radial clearance of large-scaled precision bearings (8).

Owner:LUOYANG BEARING RES INST CO LTD

Guide bushing

The invention relates to a guide bushing between two components axially movable relative to each other, especially for guiding a piston rod subjected to longitudinal and transverse forces in the region of a piston rod seal of a hydropneumatic vibration damper. The guide bushing encompasses the piston rod, is held axially in a piston rod guide and is made of a material having good gliding characteristics. The guide bushing is arranged in the piston rod guide with a radial clearance having a gap with a changeable width when the piston rod is subjected to transverse forces created between the receptacle diameter of the piston rod guide and the outer diameter of the guide bushing.

Owner:ZF FRIEDRICHSHAFEN AG

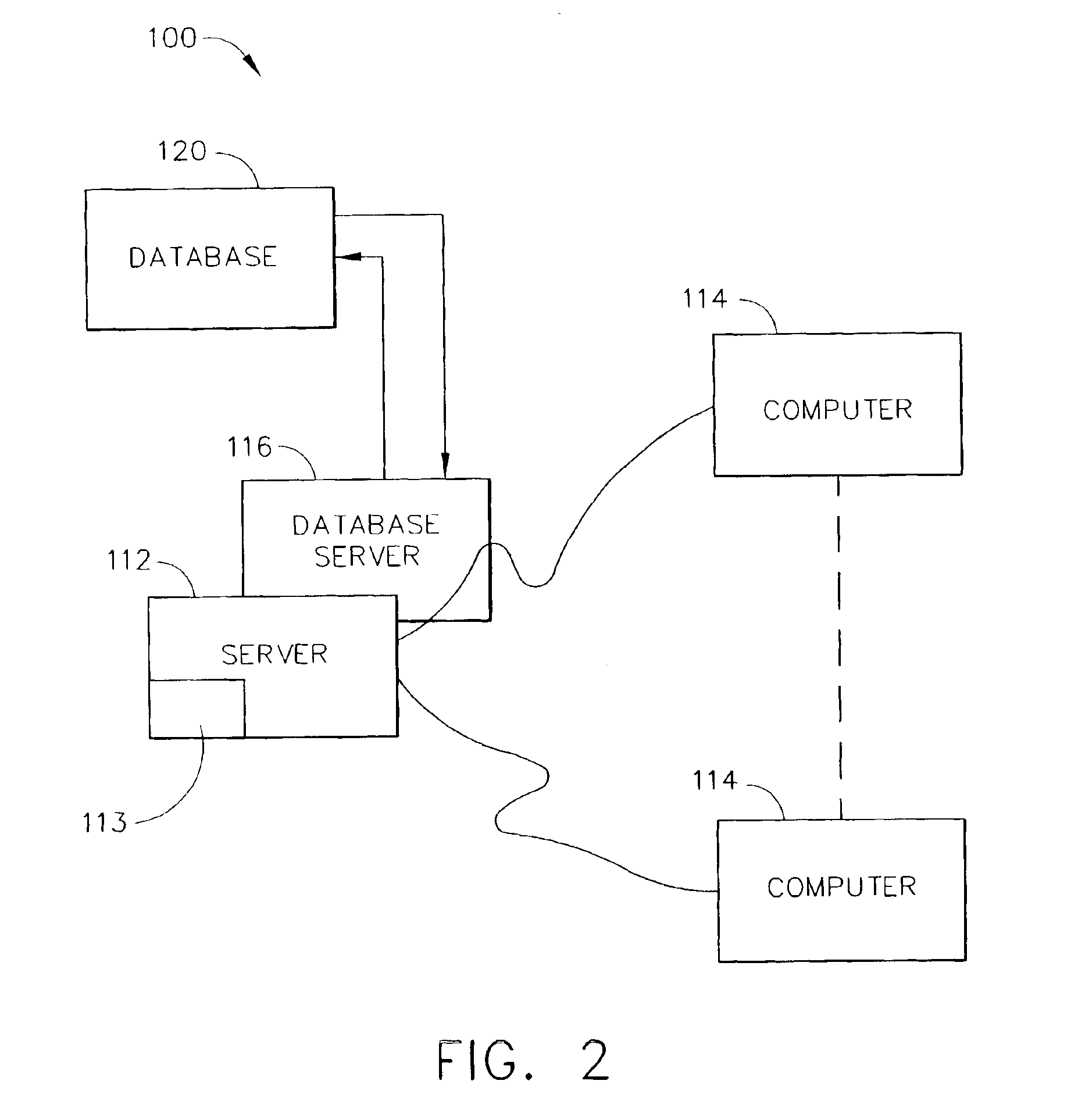

Methods and systems for calculating steam turbine radial clearance

A method and a system for determining radial clearances in a rotating machine are provided. The rotating machine includes at least one shell, at least one rotor, and at least one stationary component. The method includes creating a finite element model for at least one component within the rotating machine, creating a cycle deck data file for the rotating machine, determining an initial clearance versus time, and determining an initial clearance versus location. The system includes a client system including a browser, a centralized database for storing machine information, and a server system configured to be coupled to the client system and the database wherein the server system is further configured to receive machine information from the client system, store finite element model information in the centralized database, track machine information, update the centralized database periodically with newly received machine information to maintain machine information, and provide machine information in response to an inquiry.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com