Patents

Literature

205 results about "Thermal growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

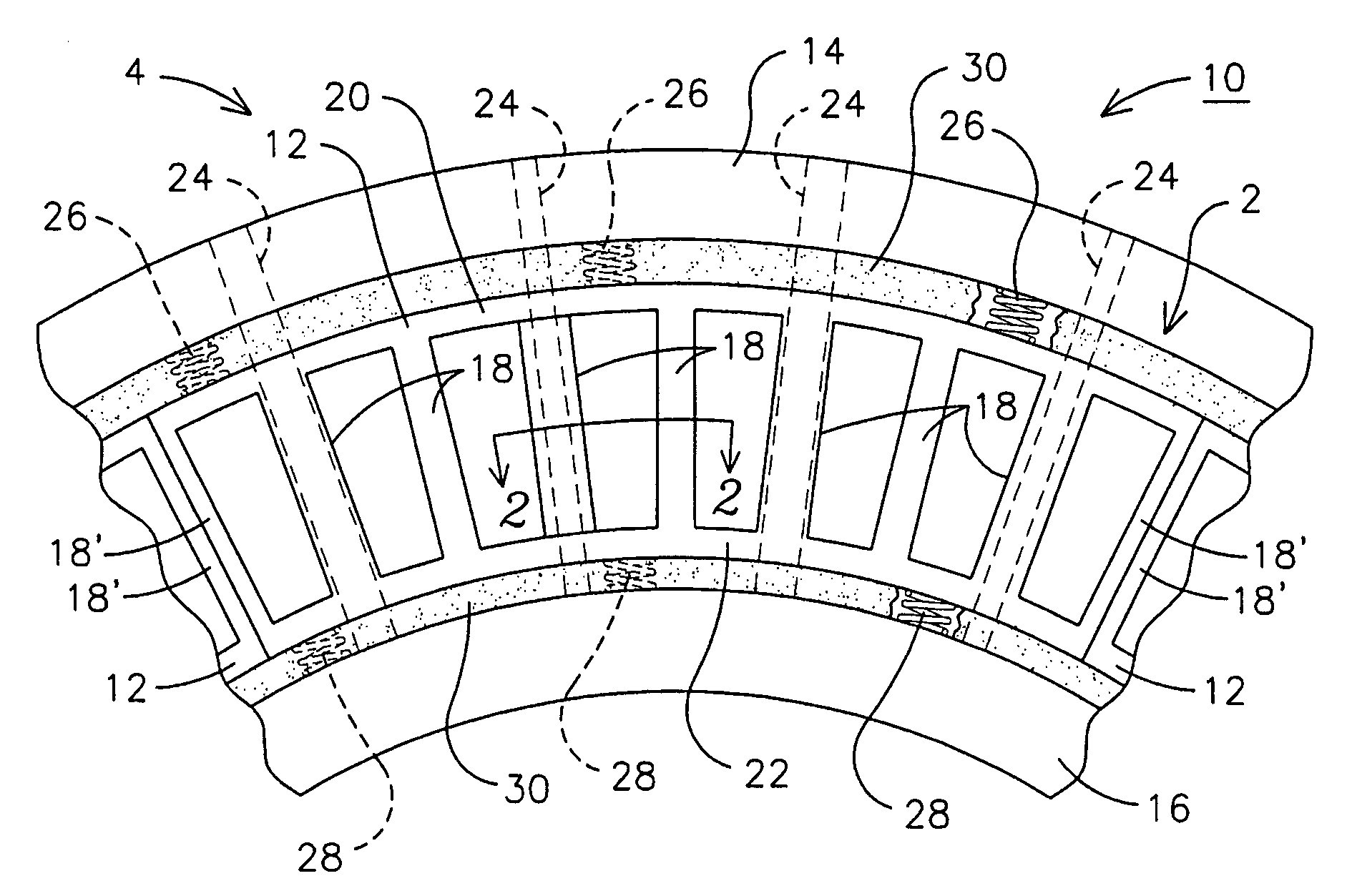

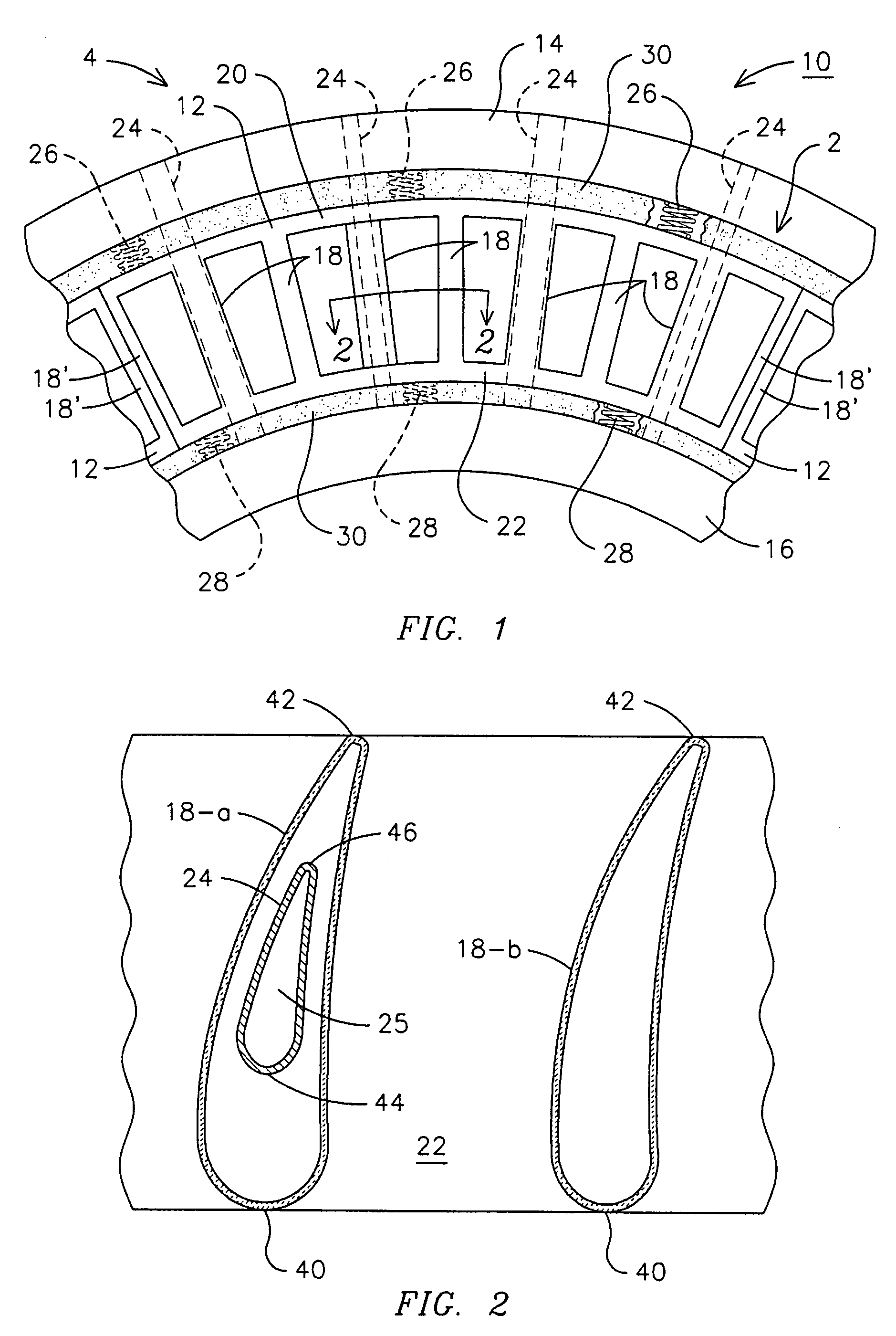

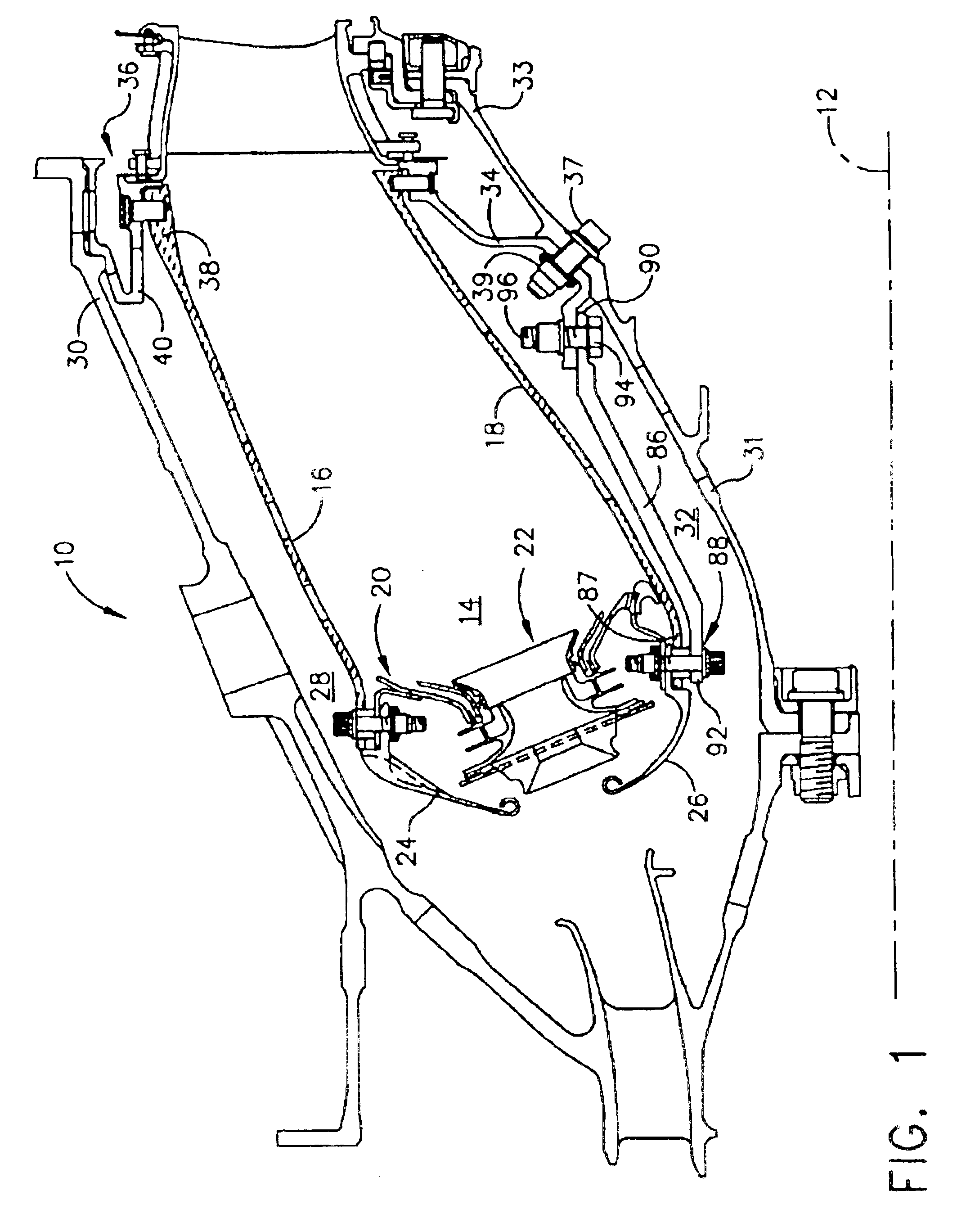

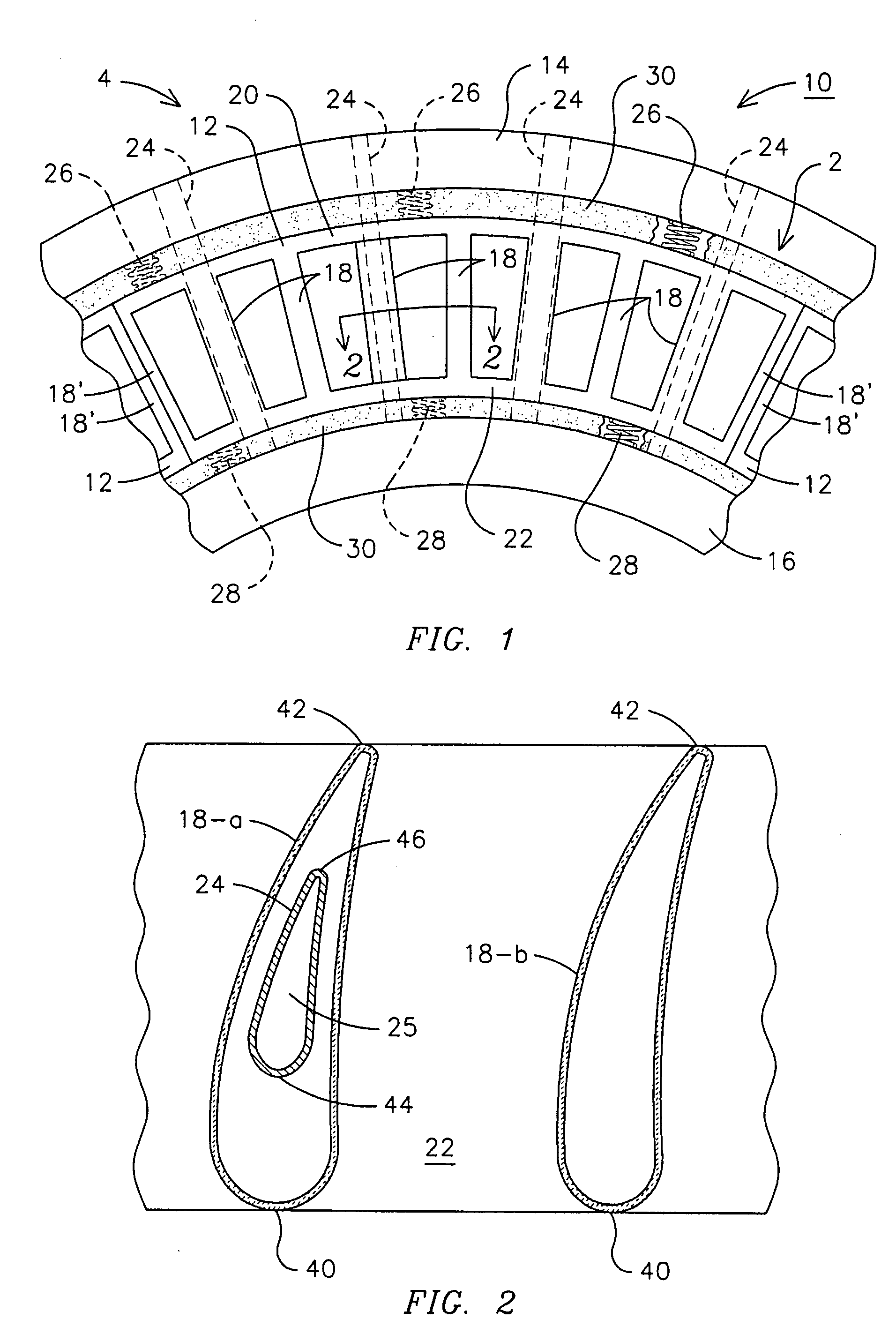

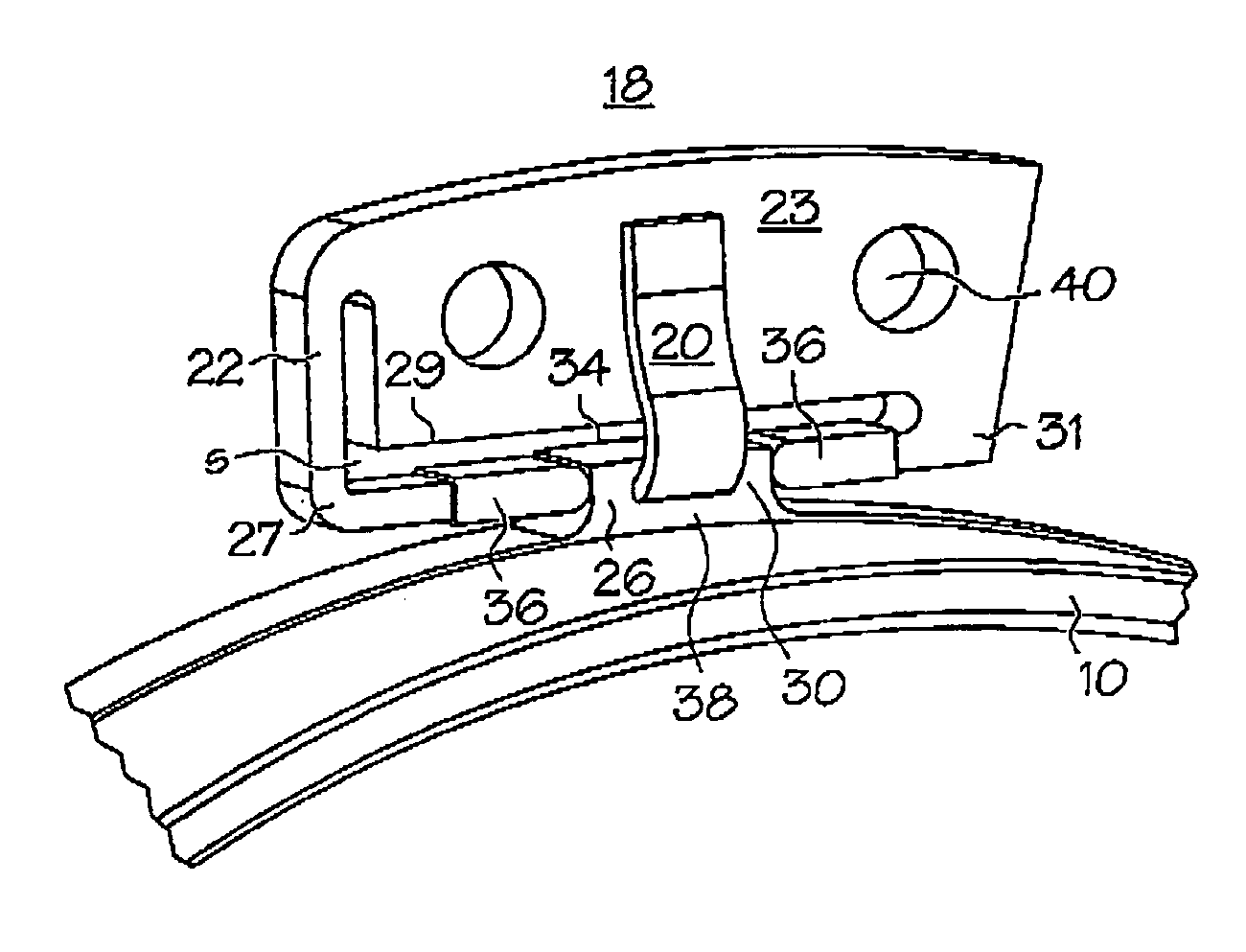

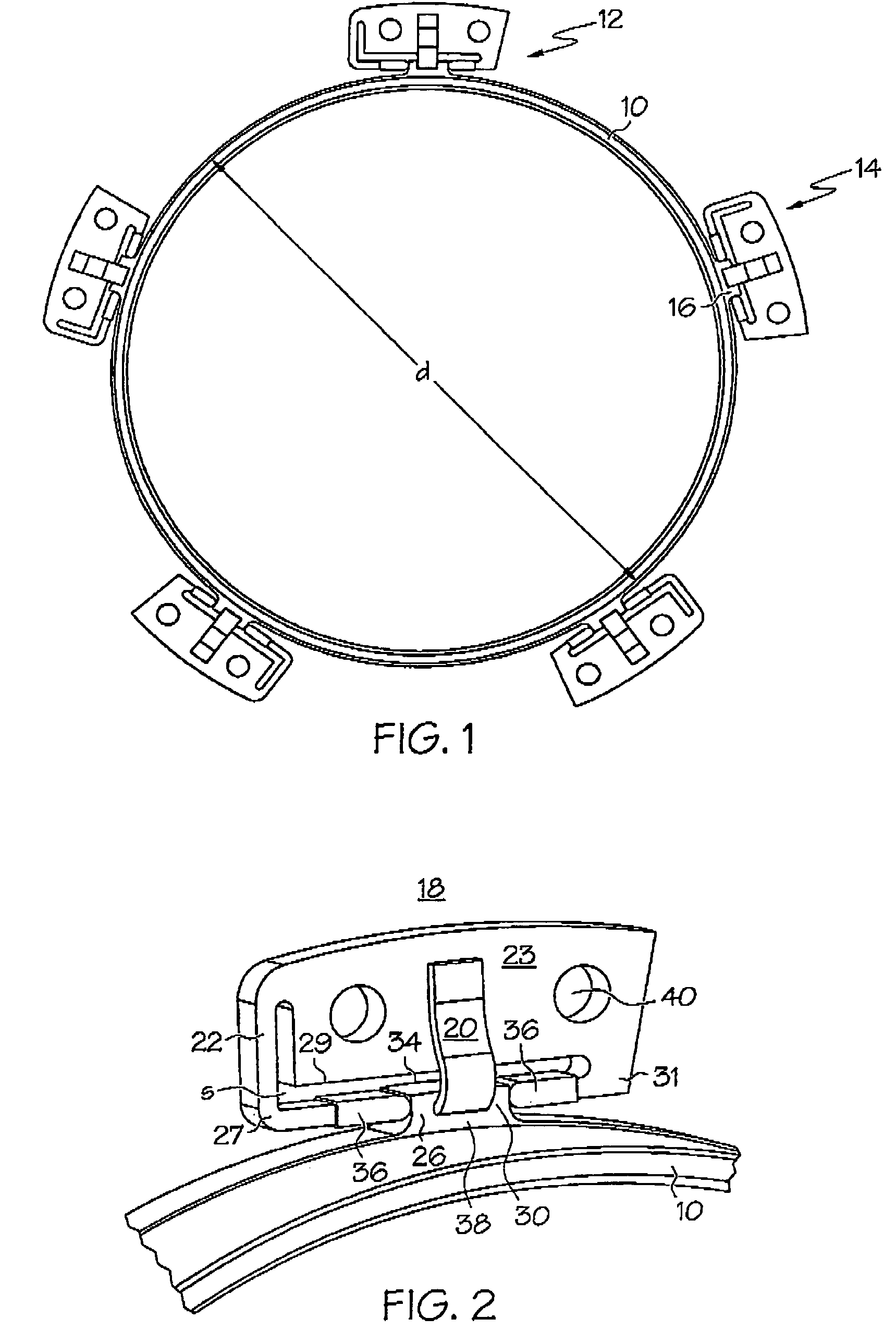

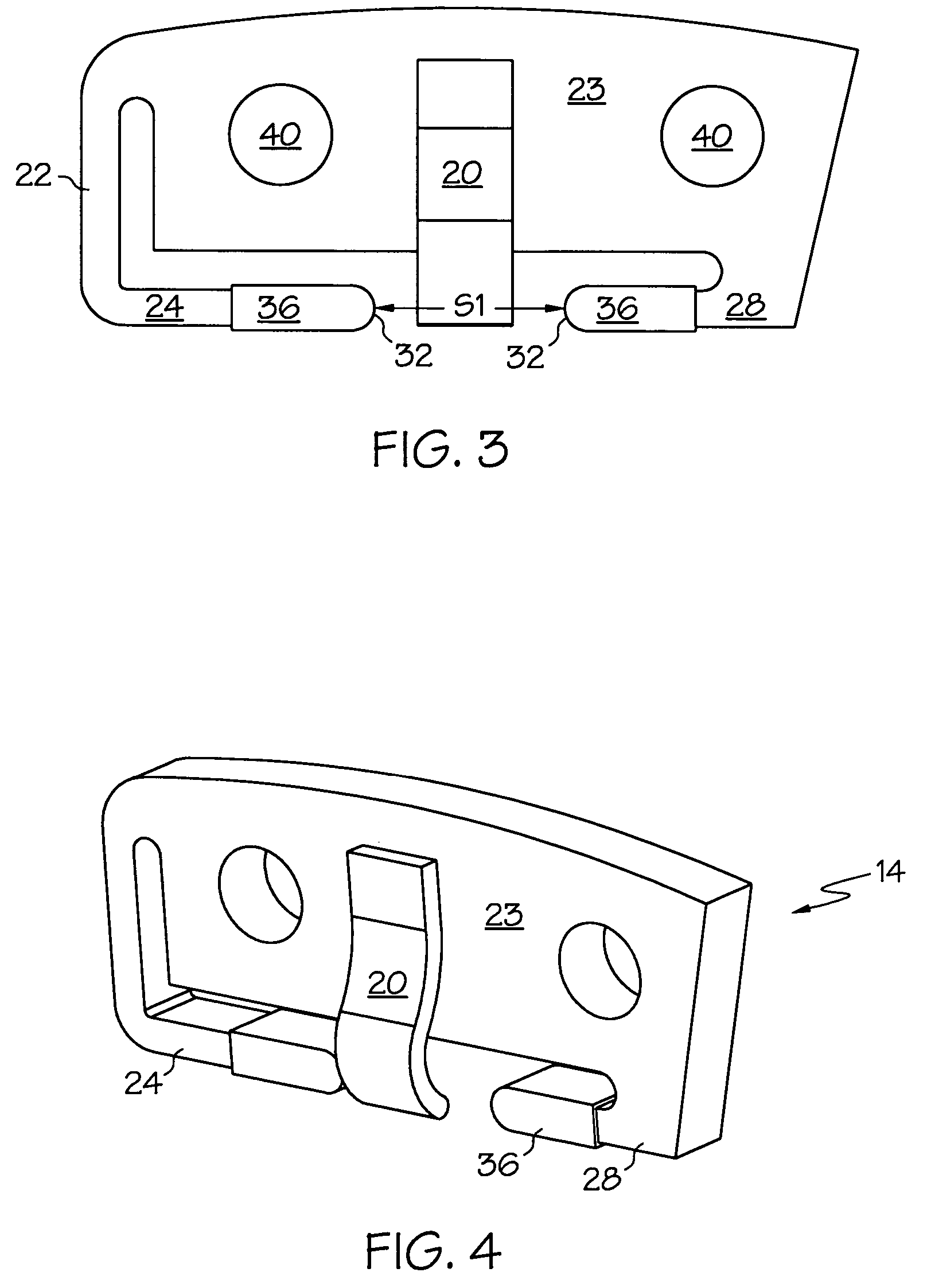

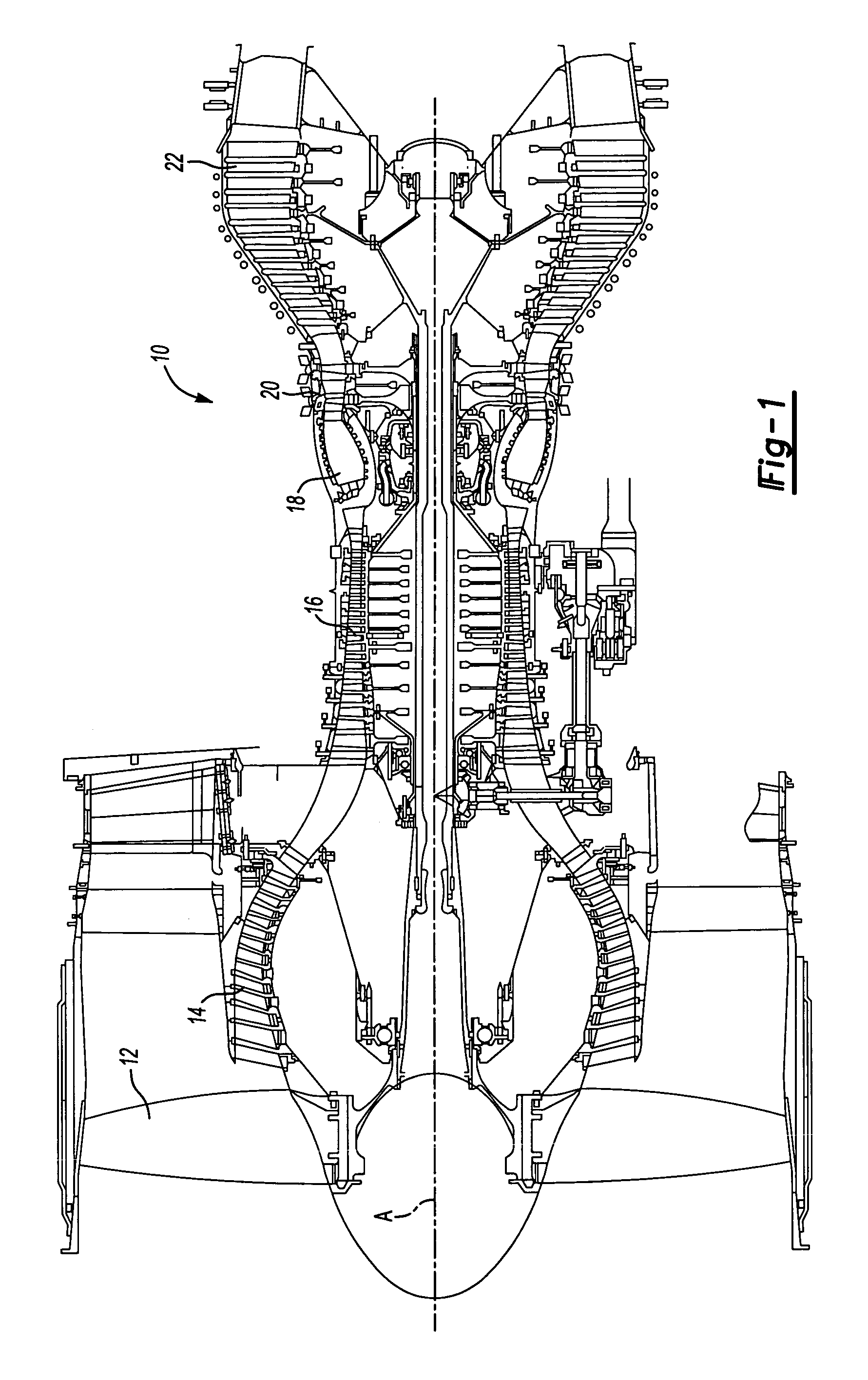

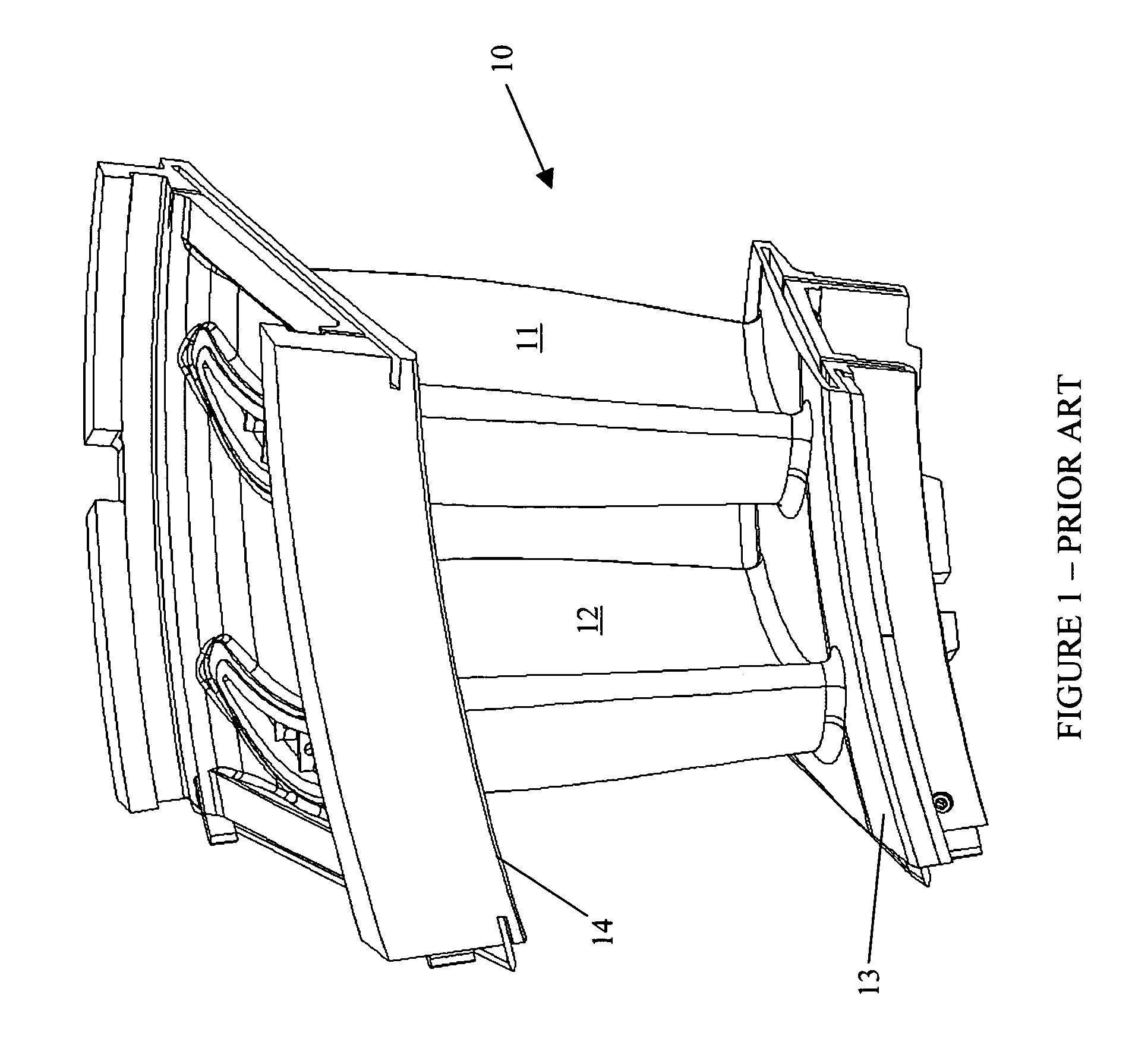

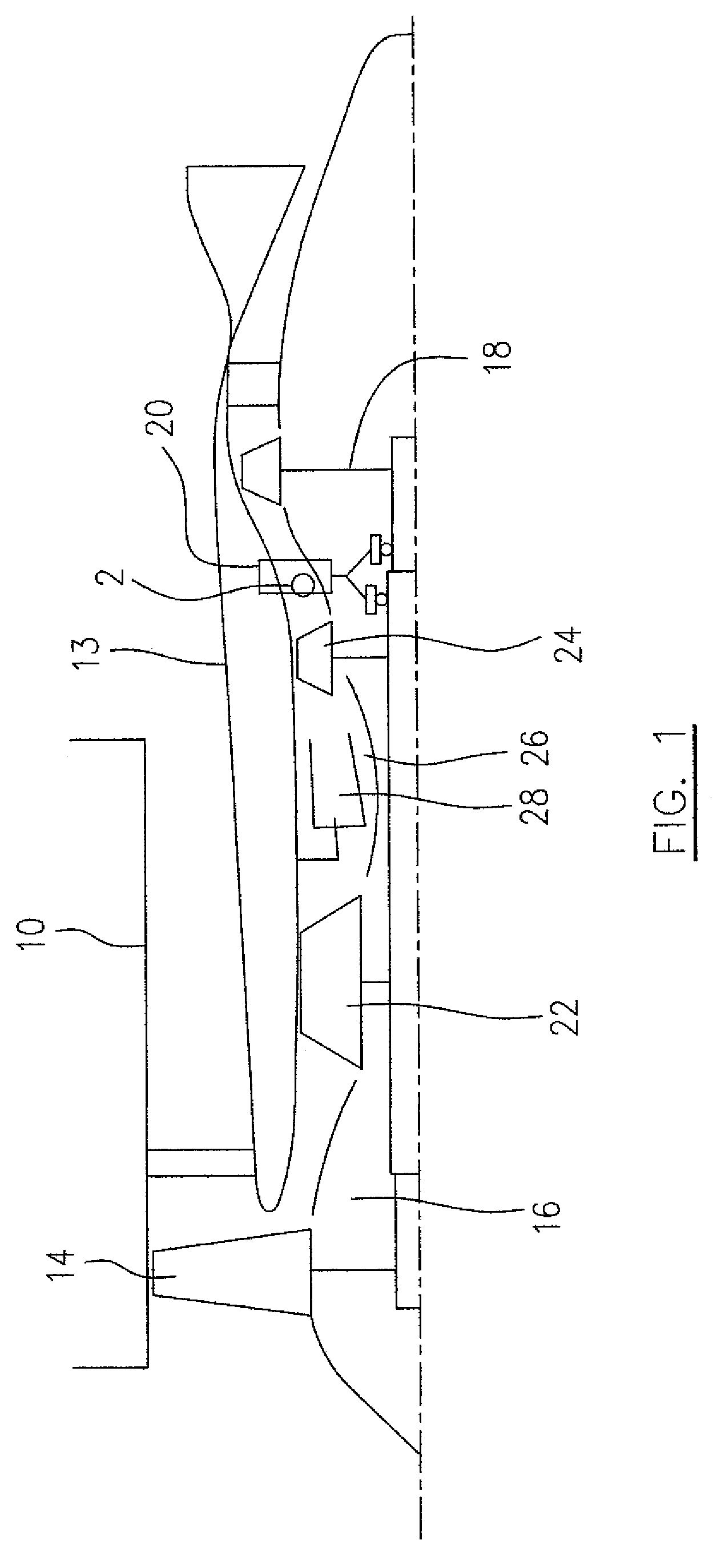

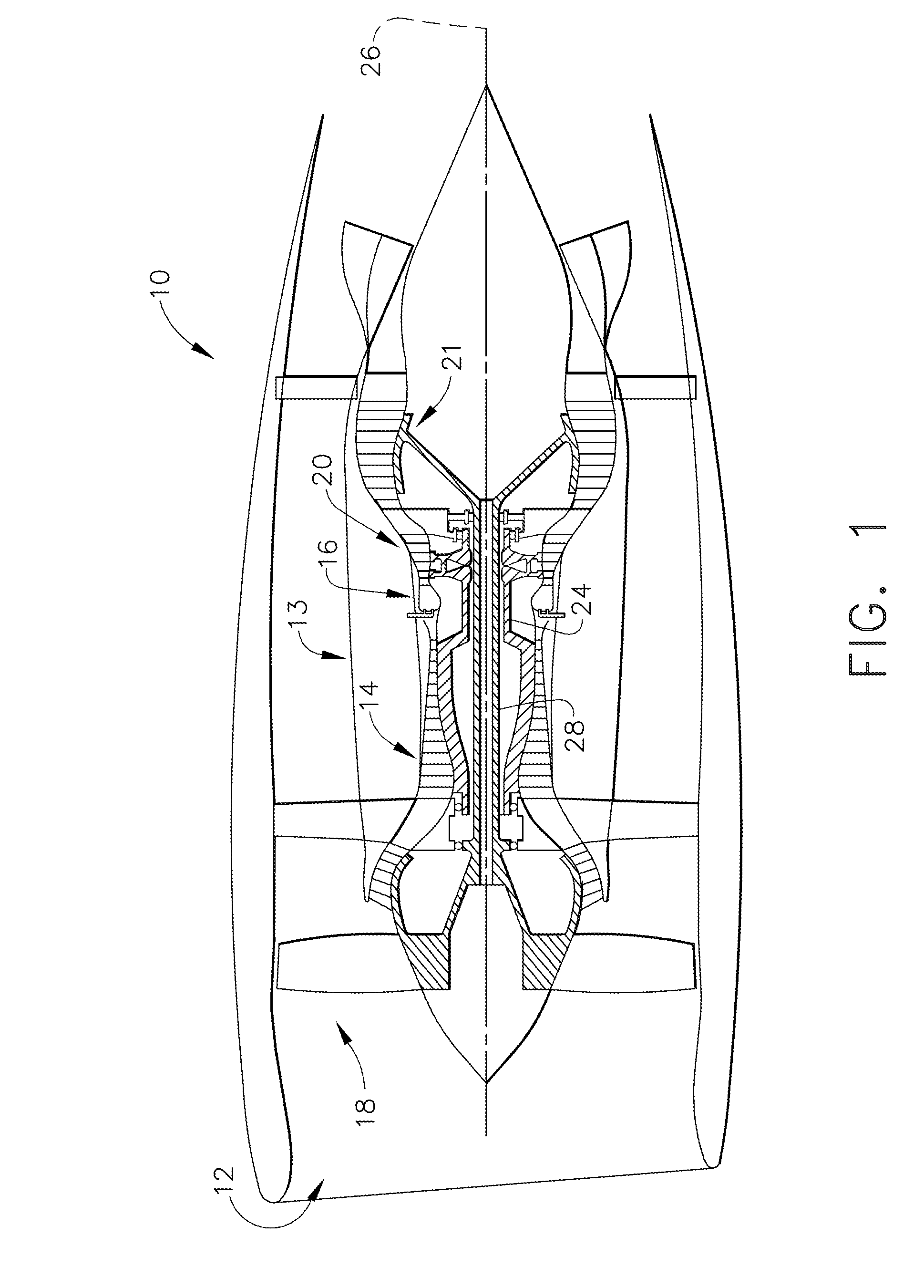

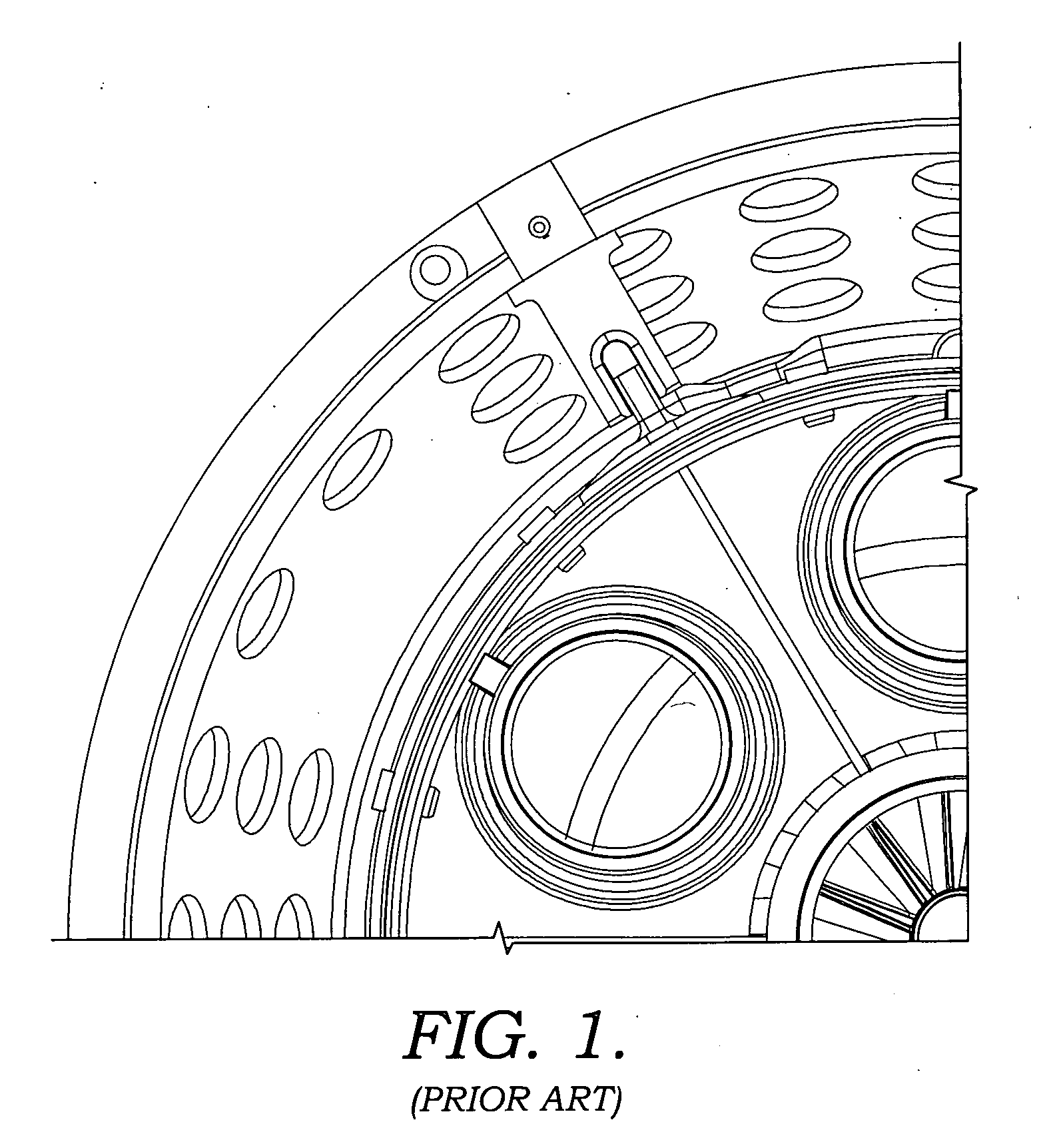

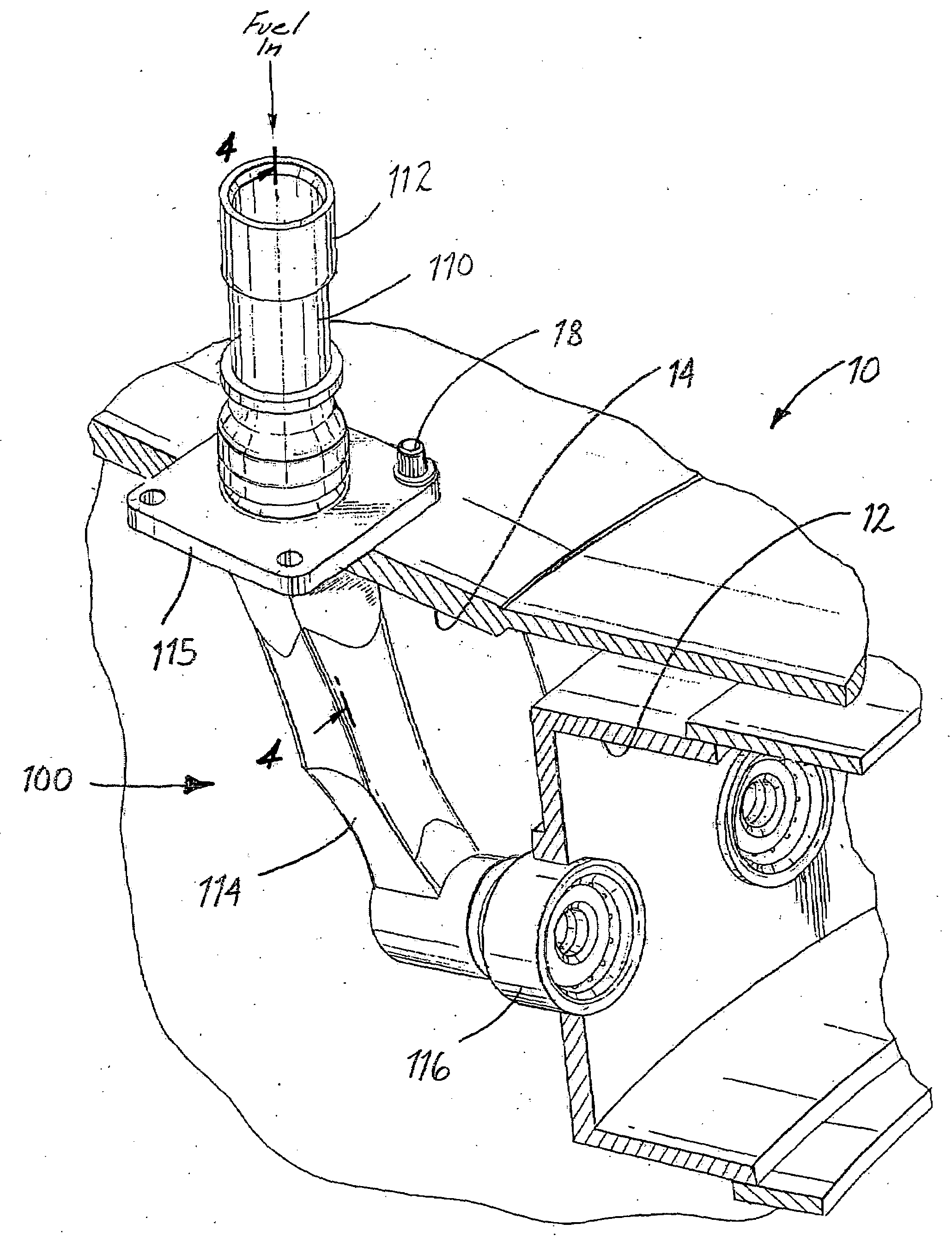

Multivane segment mounting arrangement for a gas turbine

A mounting arrangement (10) for a multivane segment (12) of ceramic matrix composite (CMC) composition positioned between outer and inner metallic rings (14, 16). Selected ones of the vanes (18a) of the multivane segment surround internal struts (24) joining the outer and inner rings. Spring members (26, 28) accommodate differential thermal growth between the multivane segment and the outer and inner rings, and a compliant material (30) seals against gas leakage around the segments.

Owner:SIEMENS ENERGY INC

Mounting assembly for the aft end of a ceramic matrix composite liner in a gas turbine engine combustor

InactiveUS6895761B2Reduction factorPrevent circular motionContinuous combustion chamberEngine manufactureCombustorEngineering

A mounting assembly for an aft end of a liner of a gas turbine engine combustor including a support member, wherein a longitudinal centerline axis extends through the gas turbine engine. The mounting assembly includes a pin member extending through each one of a plurality of circumferentially spaced openings in a portion of the support member for the combustor and into a plurality of partial openings formed in the aft end of the liner, with each pin member including a head portion at one end thereof, and a device positioned within each opening in the support member so as to retain the pin members therein. The pin members and the support member are able to slide radially and / or axially with respect to the liner aft end as the support member experiences thermal growth greater than the liner.

Owner:GENERAL ELECTRIC CO

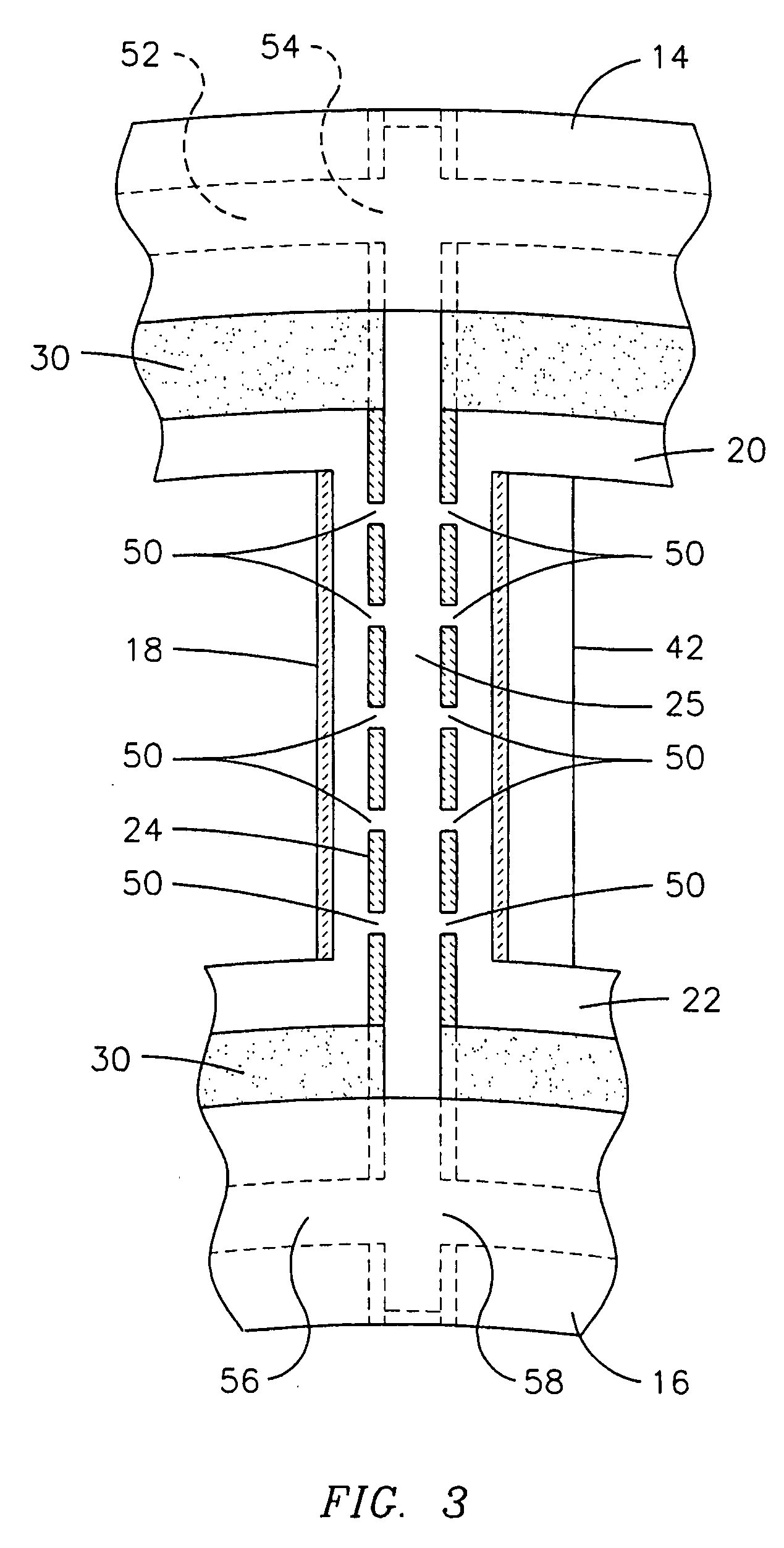

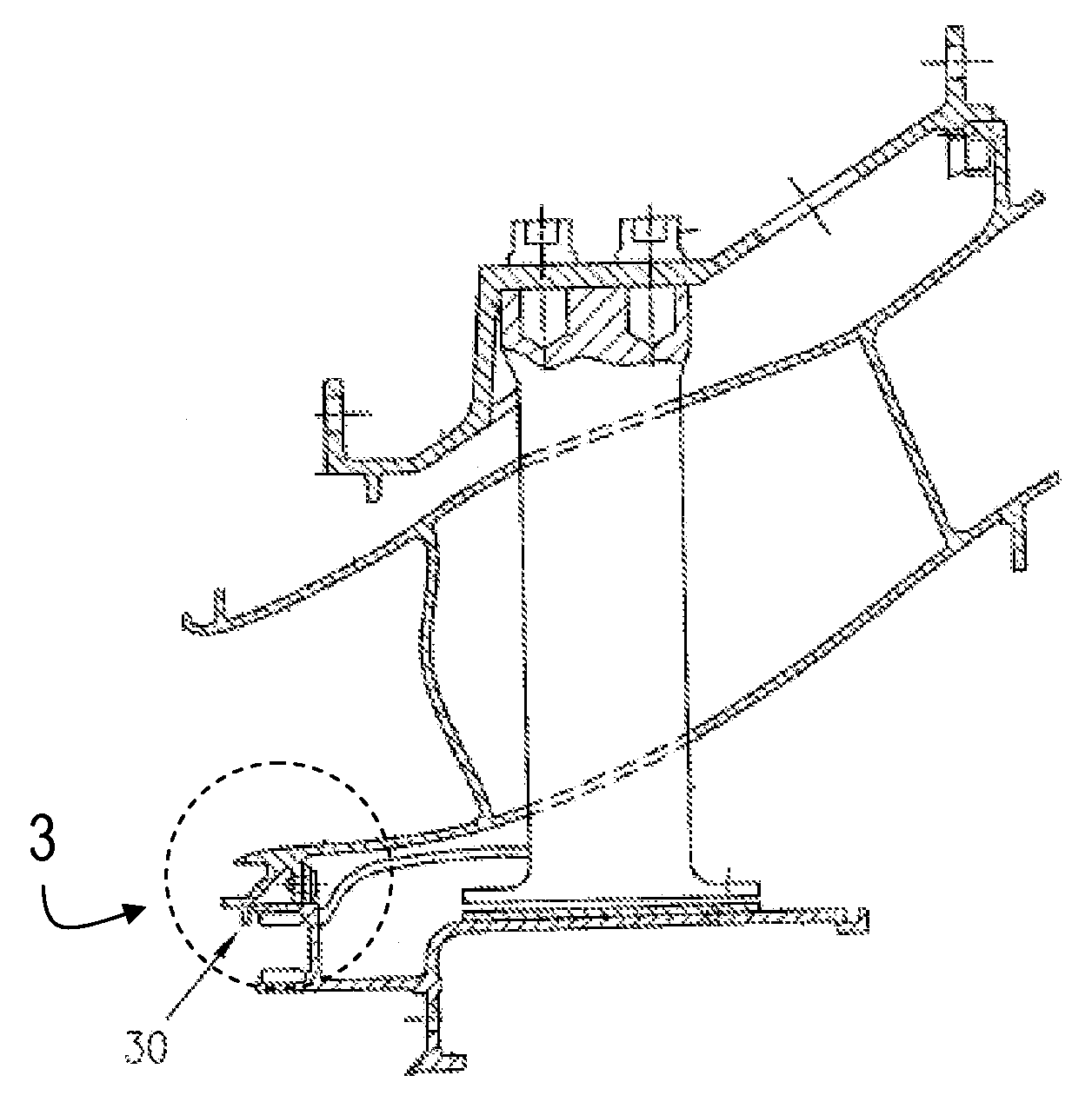

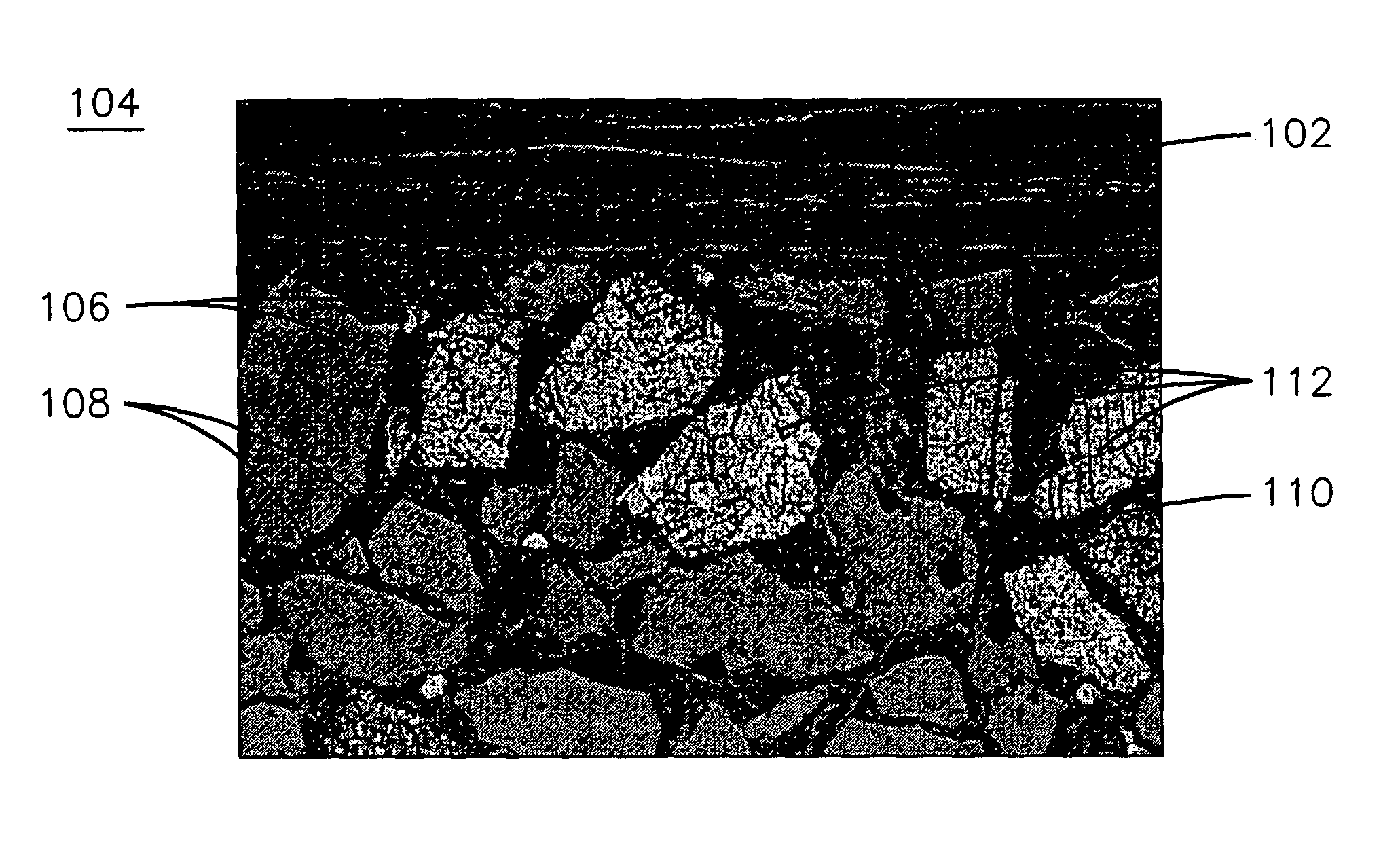

Multivane segment mounting arrangement for a gas turbine

A mounting arrangement (10) for a multivane segment (12) of ceramic matrix composite (CMC) composition positioned between outer and inner metallic rings (14, 16). Selected ones of the vanes (18a) of the multivane segment surround internal struts (24) joining the outer and inner rings. Spring members (26, 28) accommodate differential thermal growth between the multivane segment and the outer and inner rings, and a compliant material (30) seals against gas leakage around the segments.

Owner:SIEMENS ENERGY INC

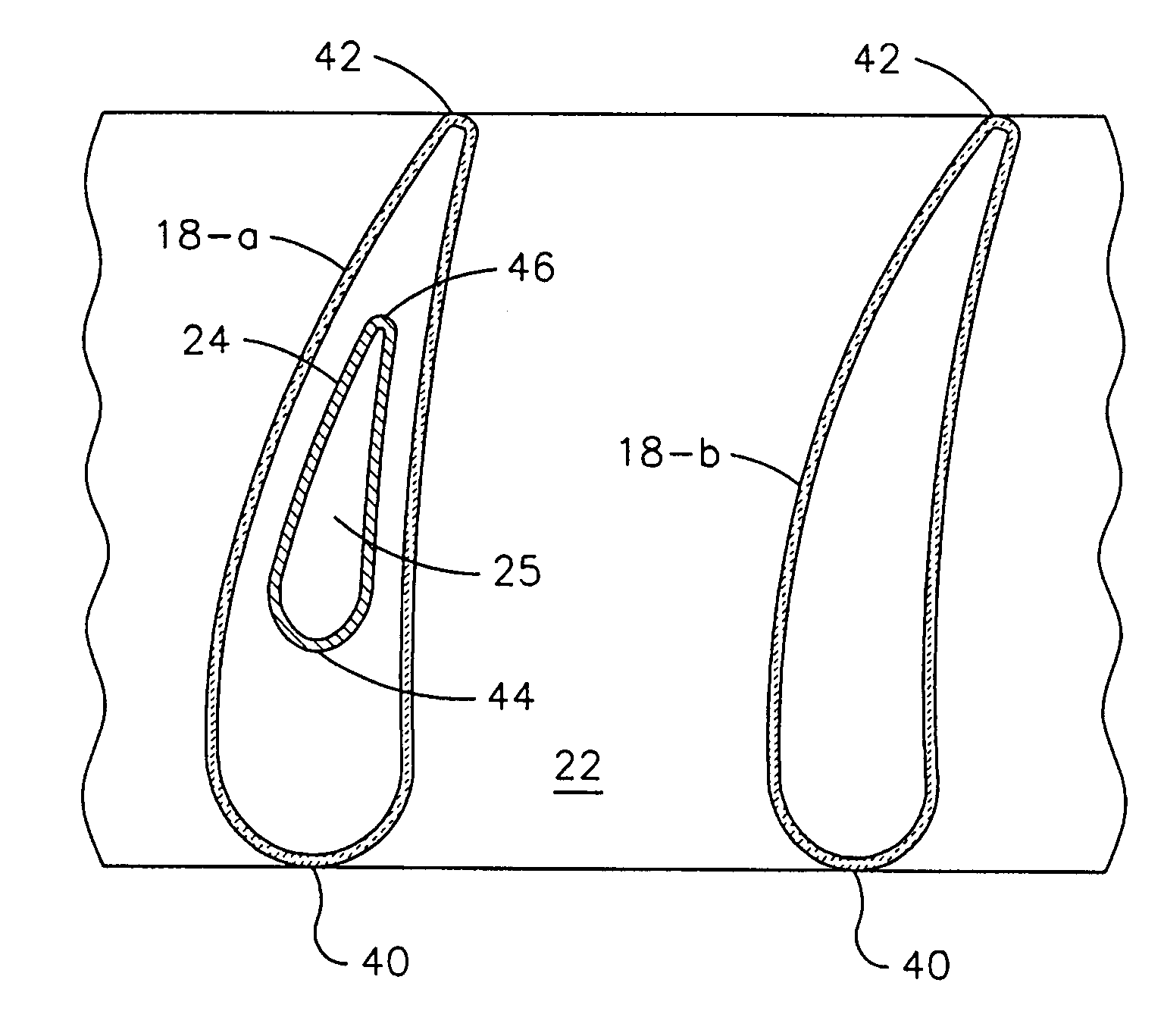

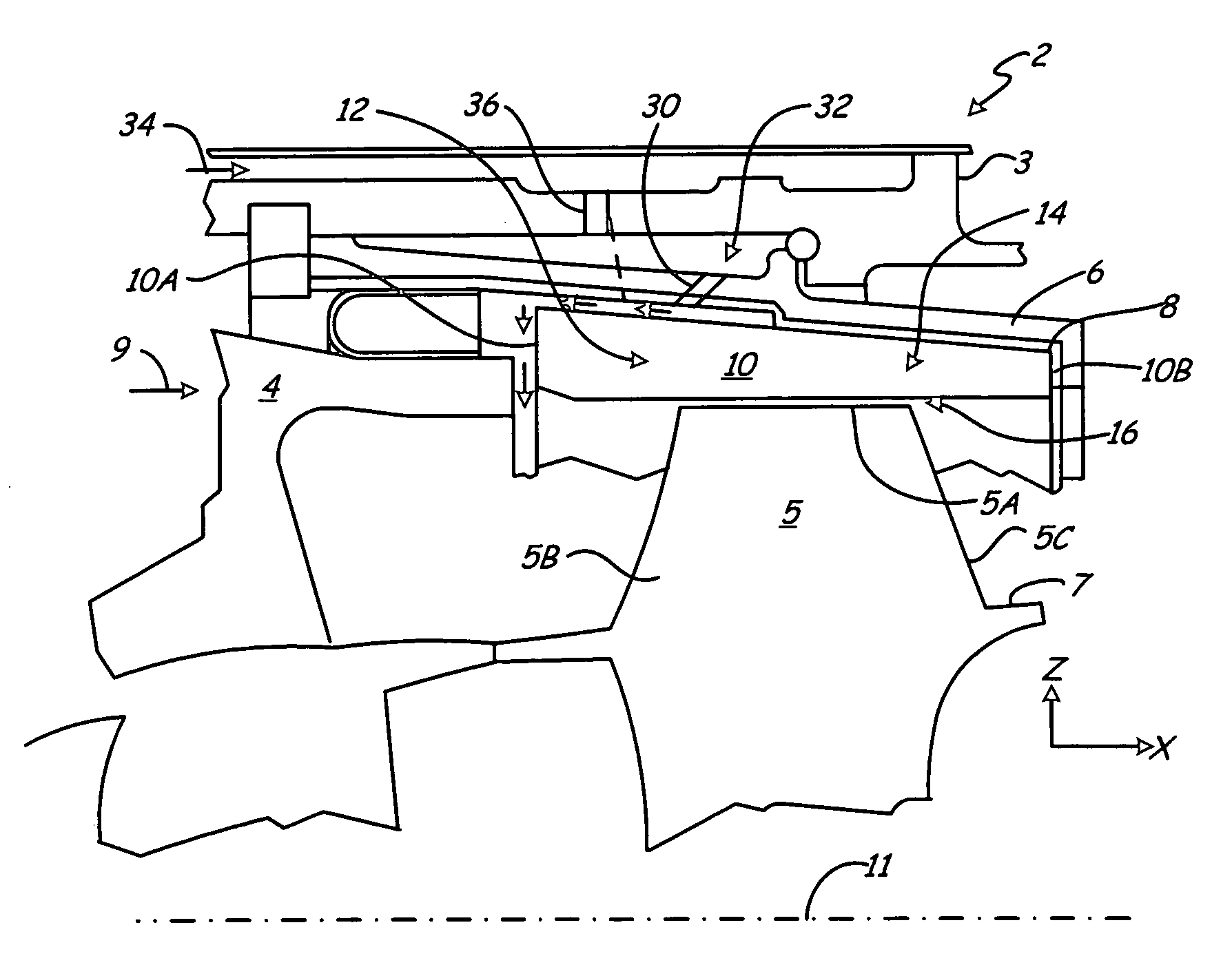

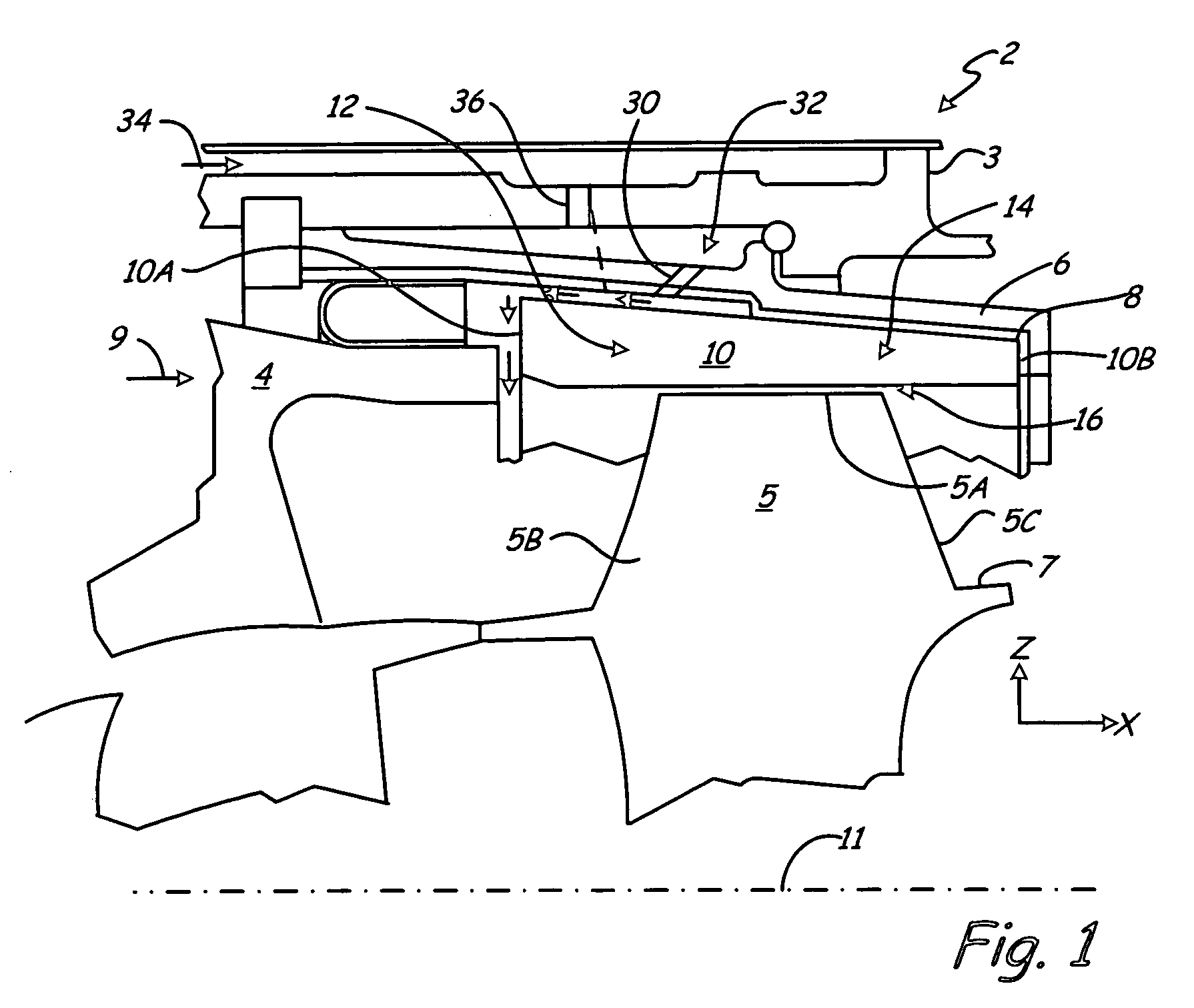

Mounting assembly for the forward end of a ceramic matrix composite liner in a gas turbine engine combustor

InactiveUS6904757B2Low thermal expansionContinuous combustion chamberGas turbine plantsCombustorEngineering

A mounting assembly for a forward end of a liner in a combustor of a gas turbine engine including a dome and a cowl, wherein a longitudinal centerline axis extends through the gas turbine engine. The mounting assembly includes a pin member extending through each one of a plurality of circumferentially spaced openings formed in the forward end of the liner, an aft portion of the cowl, and a portion of the dome, with each pin member including a head portion at one end thereof. A nut is adjustably connected to an end of each pin member opposite the head portion. A bushing is located on each pin member at a position intermediate the head portion and the nut, wherein the openings in the liner forward end are sized to fit around the bushings. In this way, the cowl aft portion and the dome portion are fixedly connected together between the bushing and the nut so that the bushings are able to slide radially through the openings in the liner forward end as the cowl and the dome experience thermal growth greater than the liner.

Owner:GENERAL ELECTRIC CO

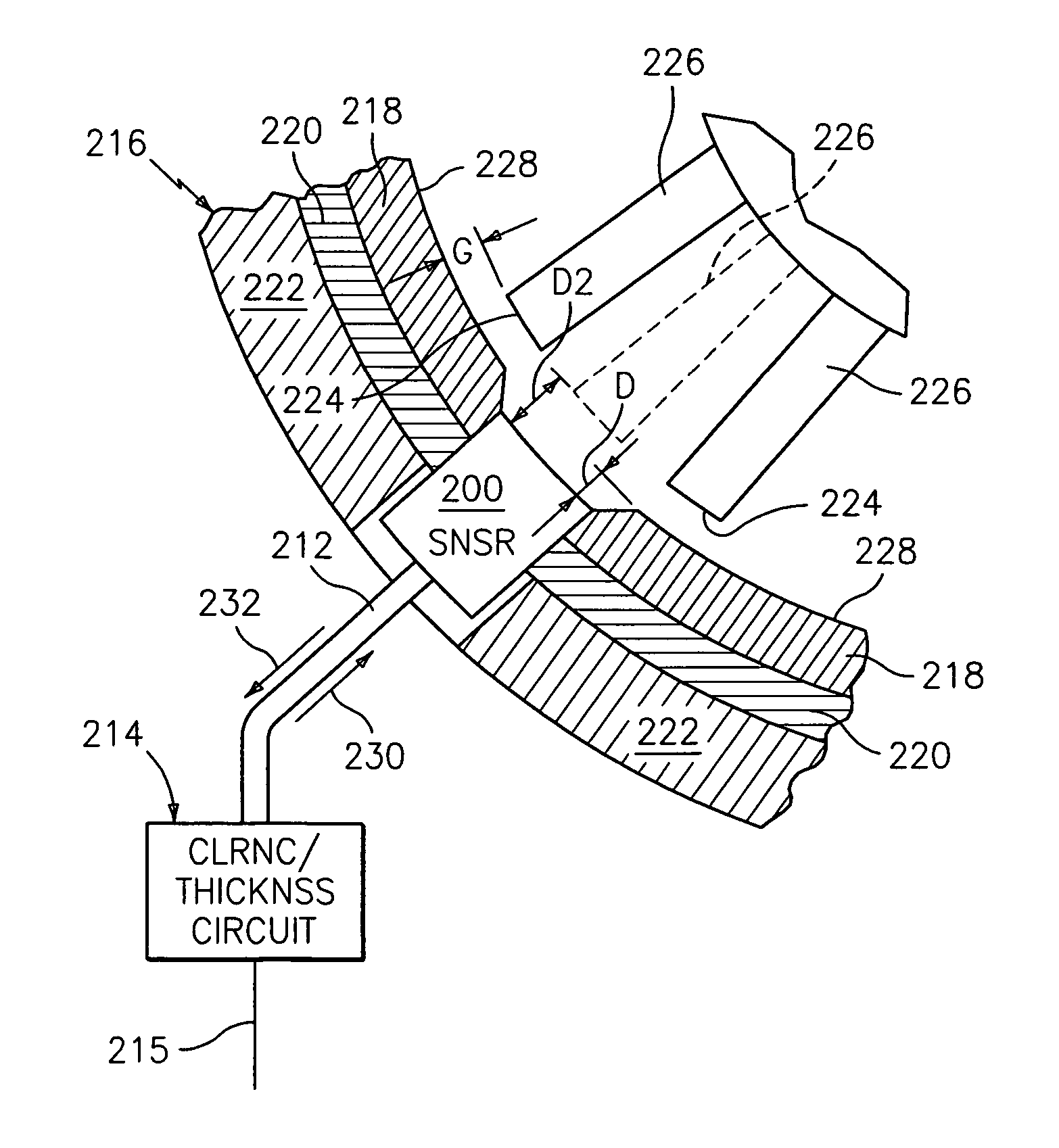

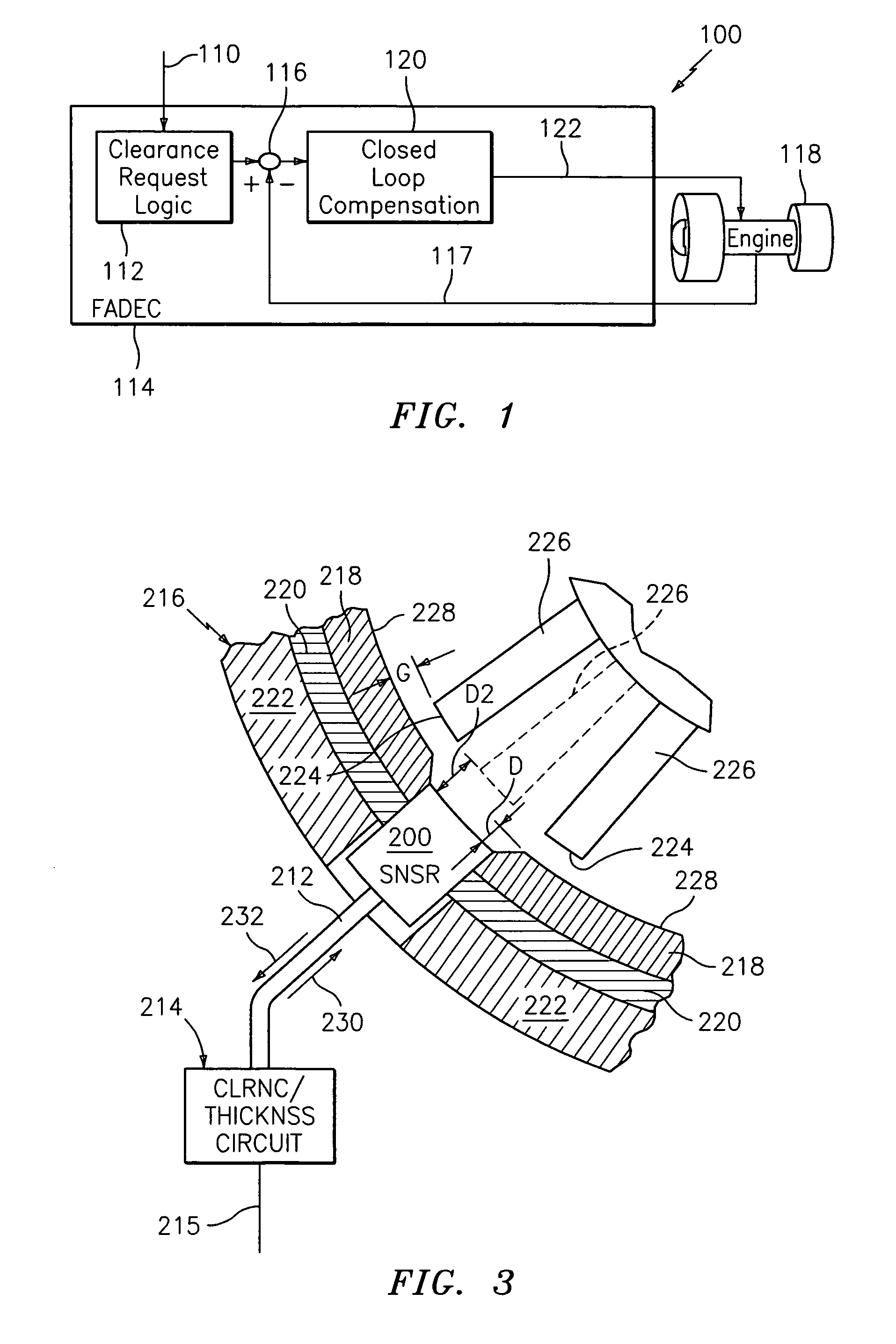

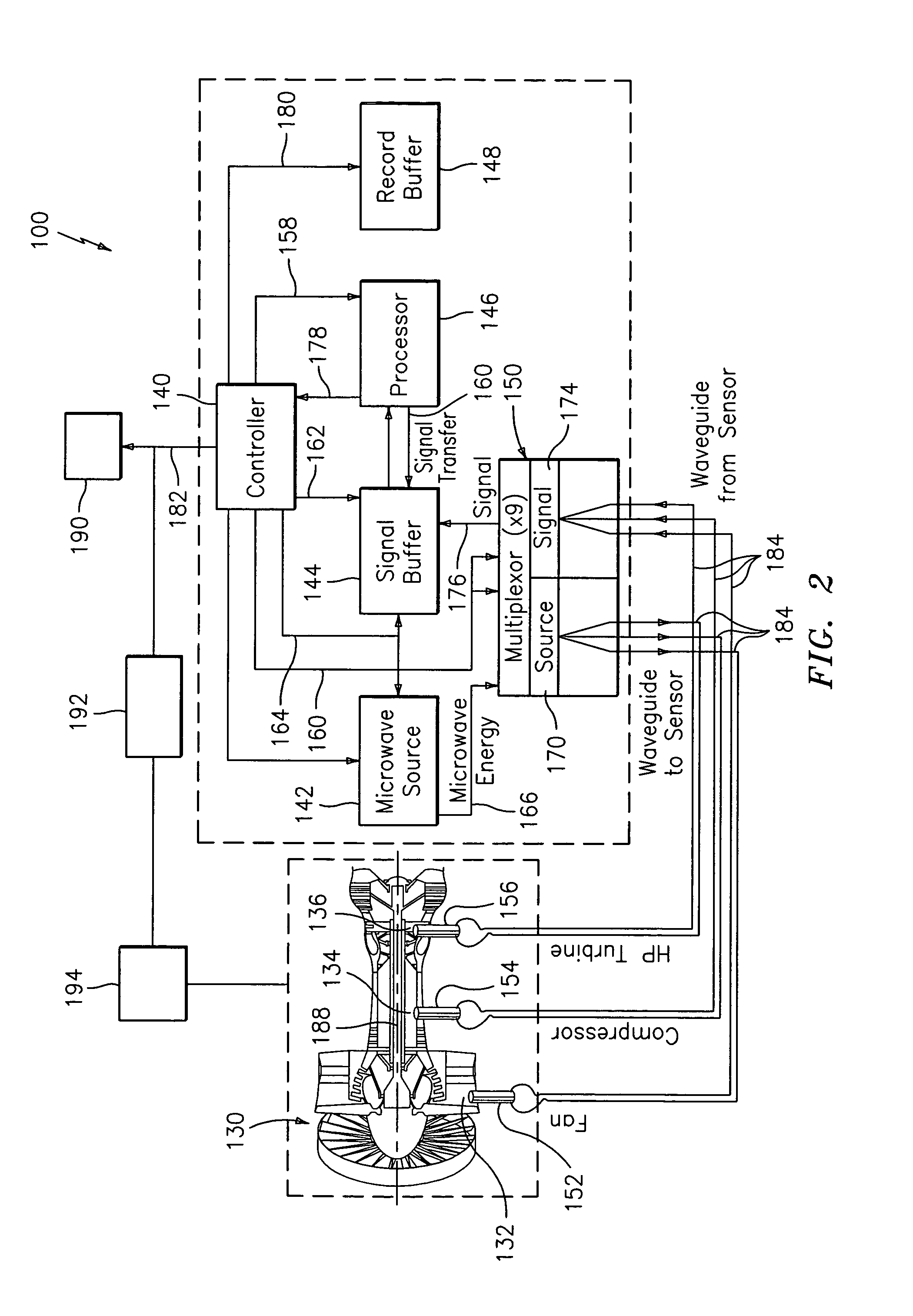

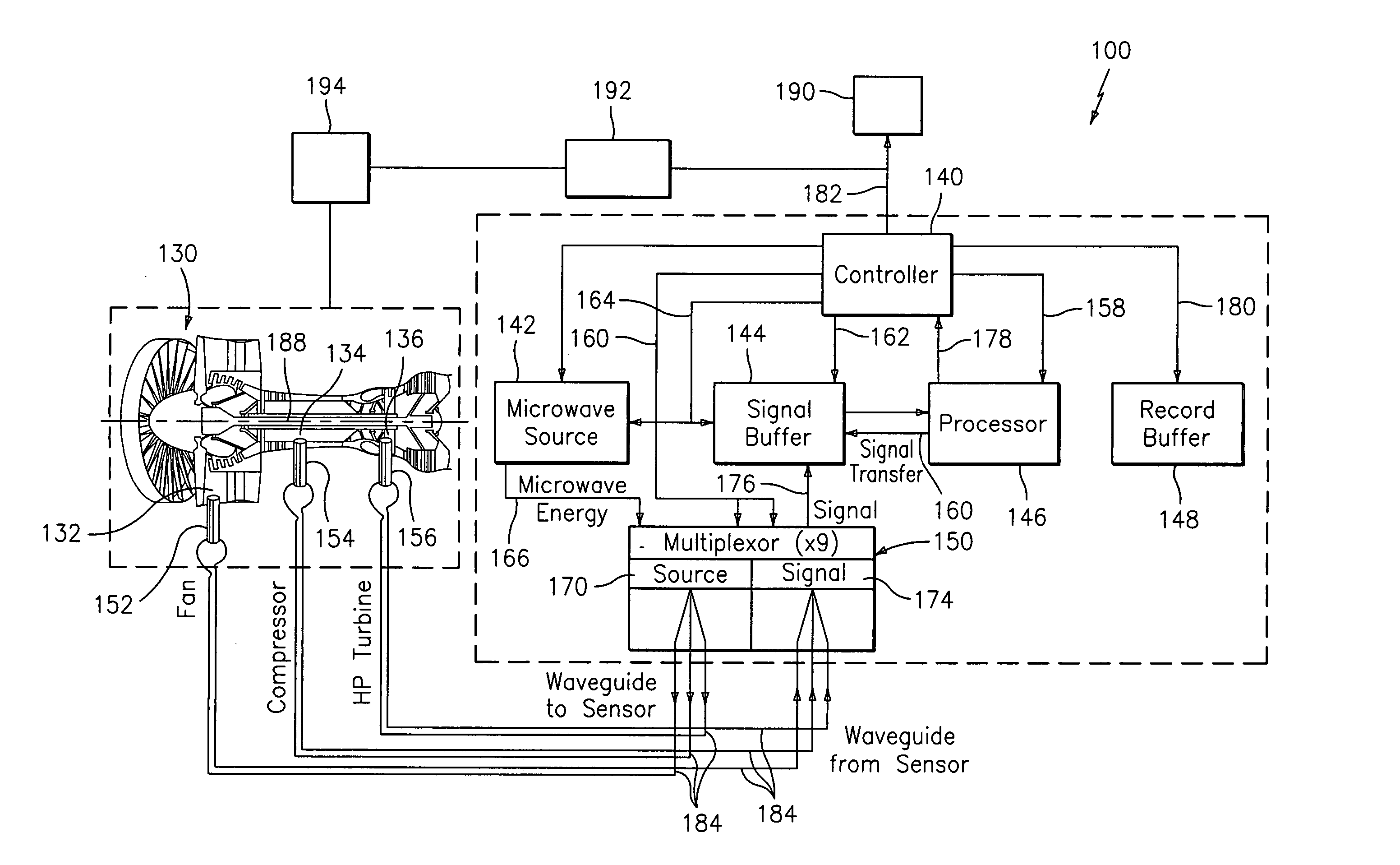

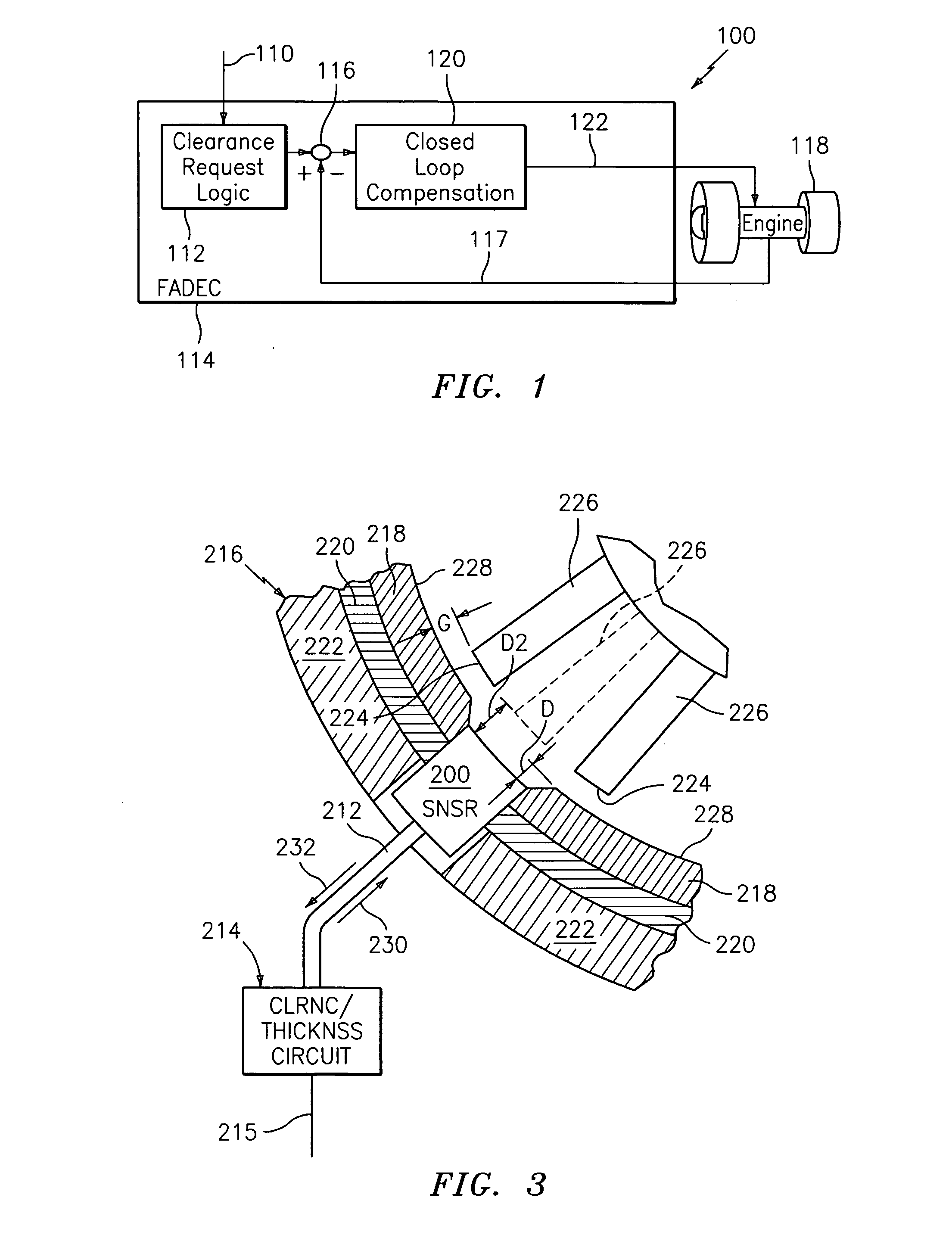

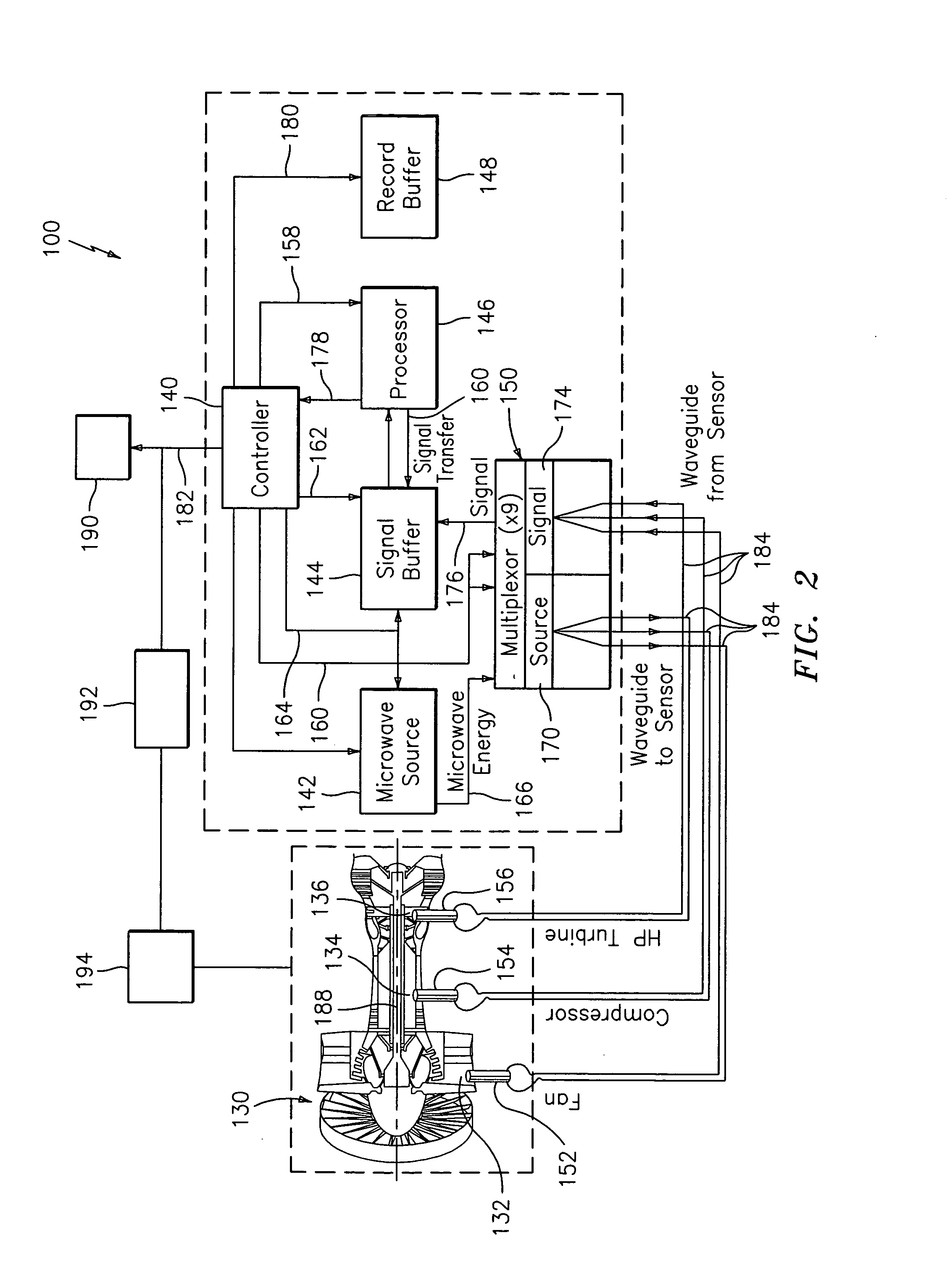

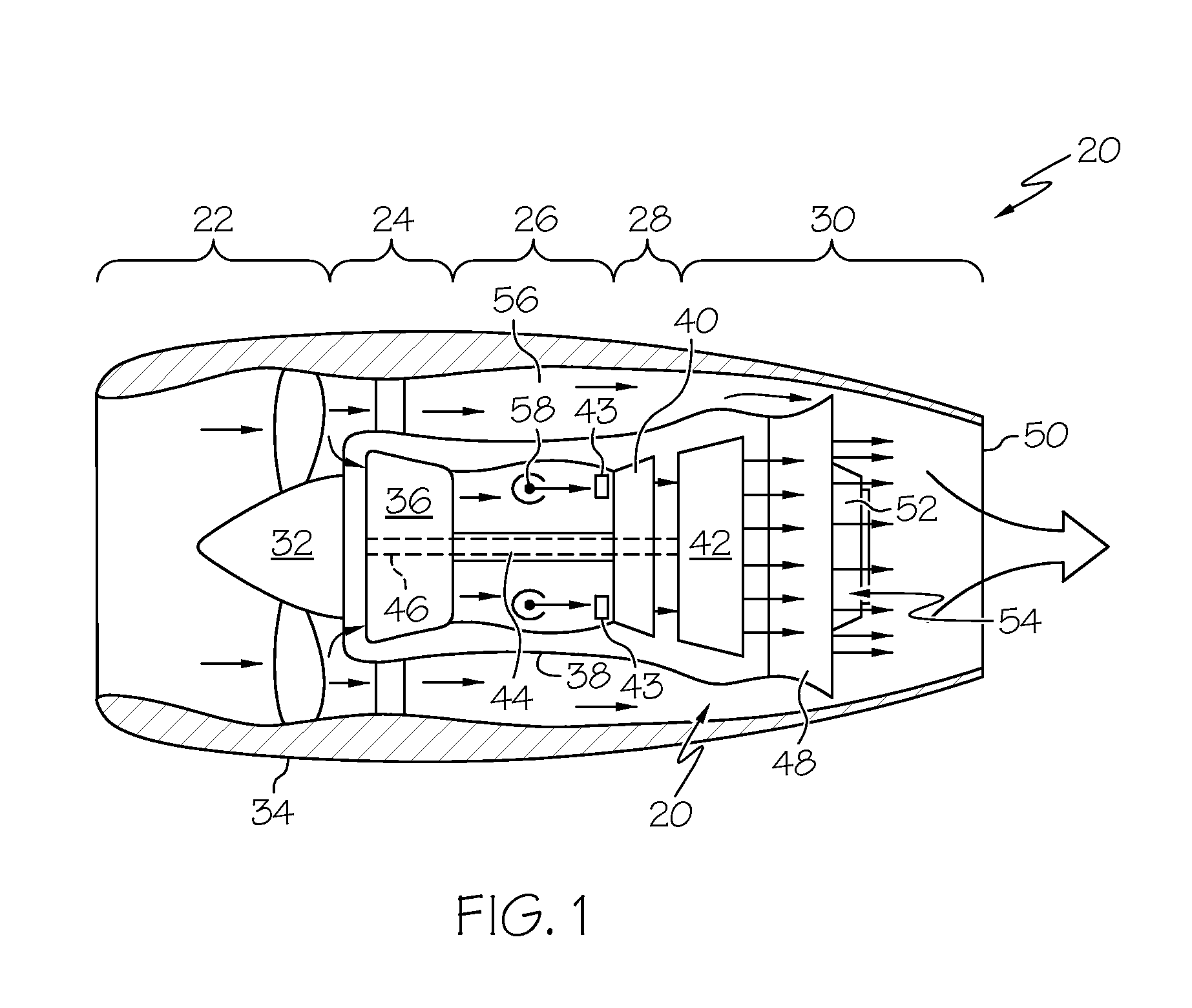

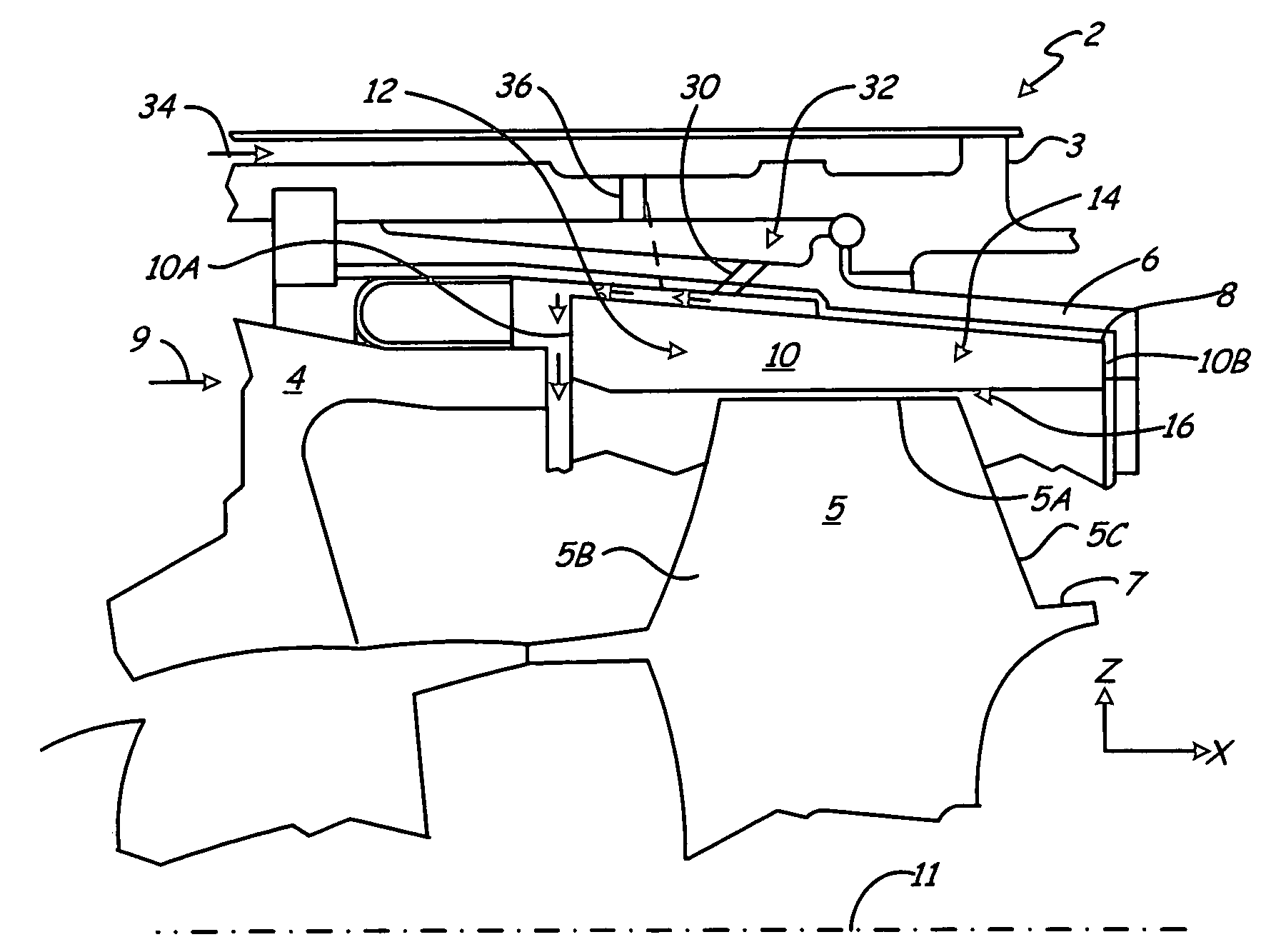

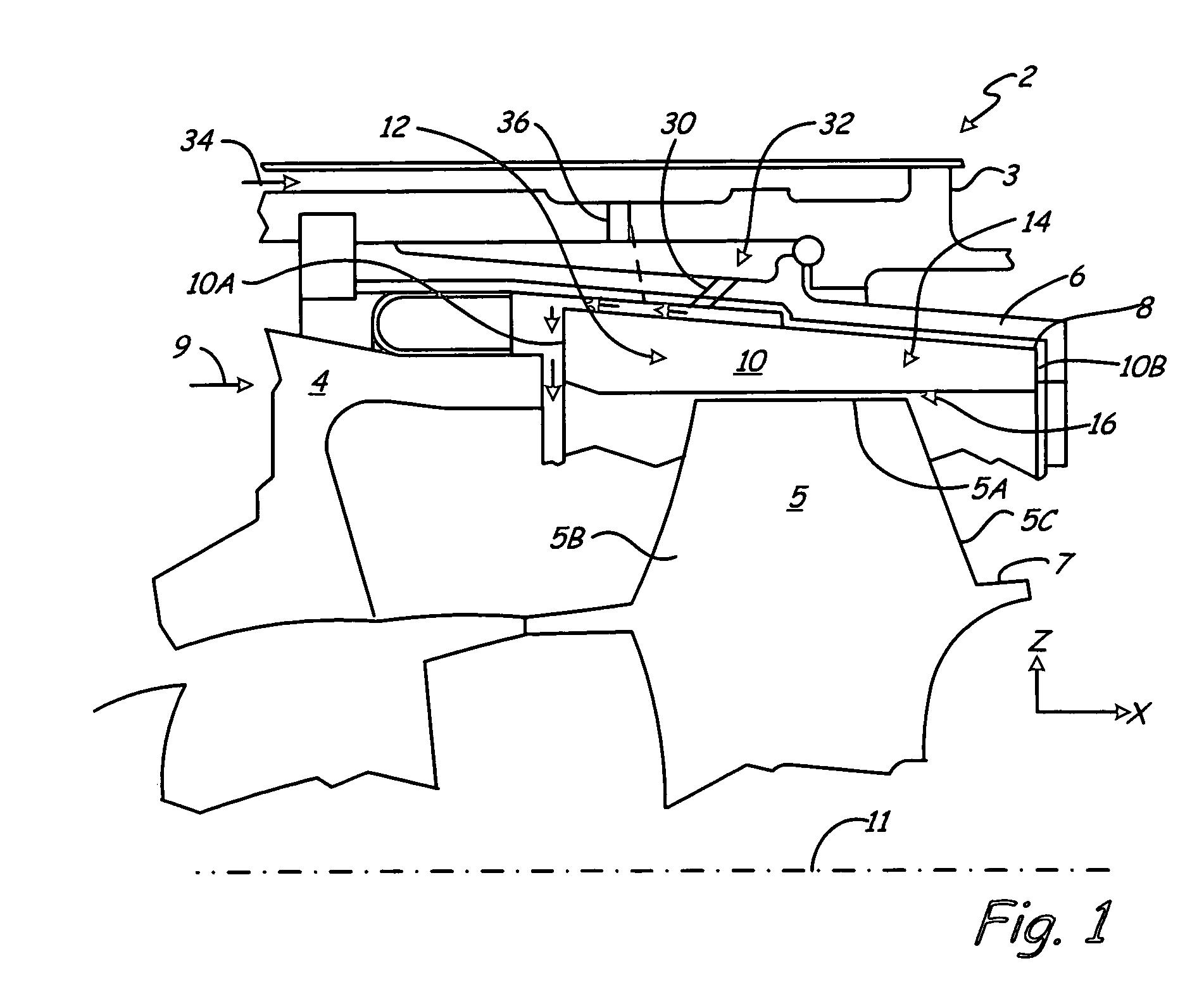

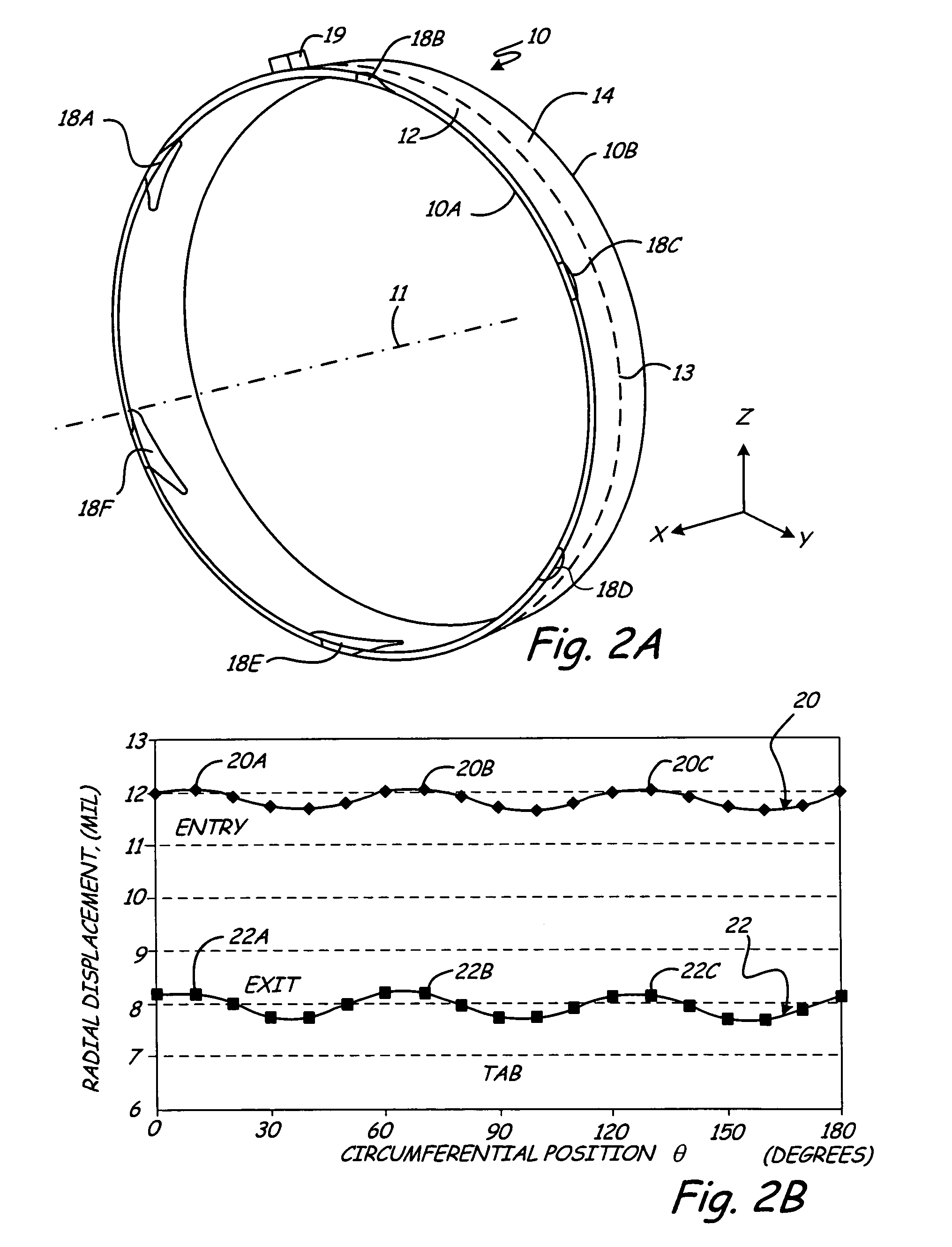

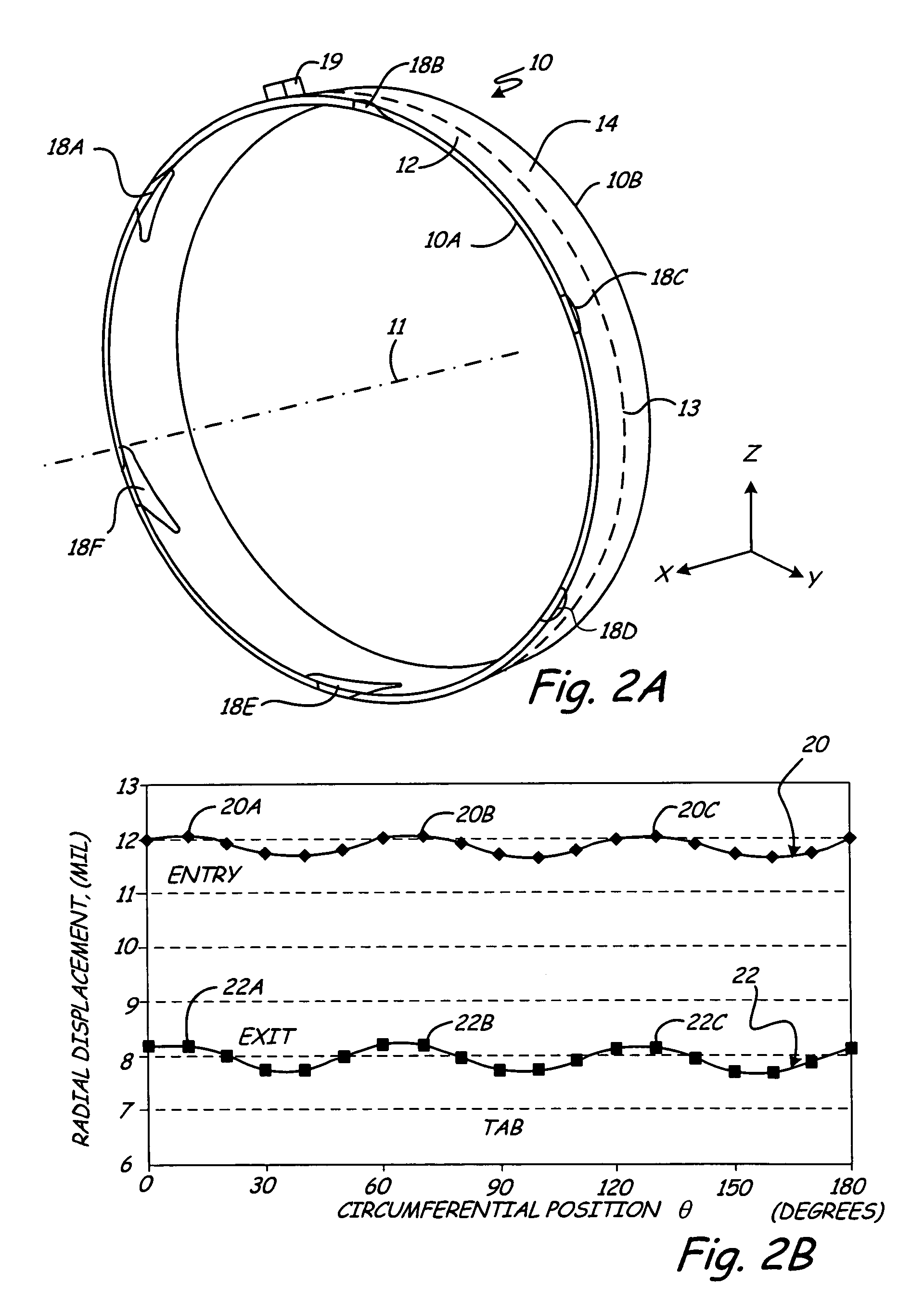

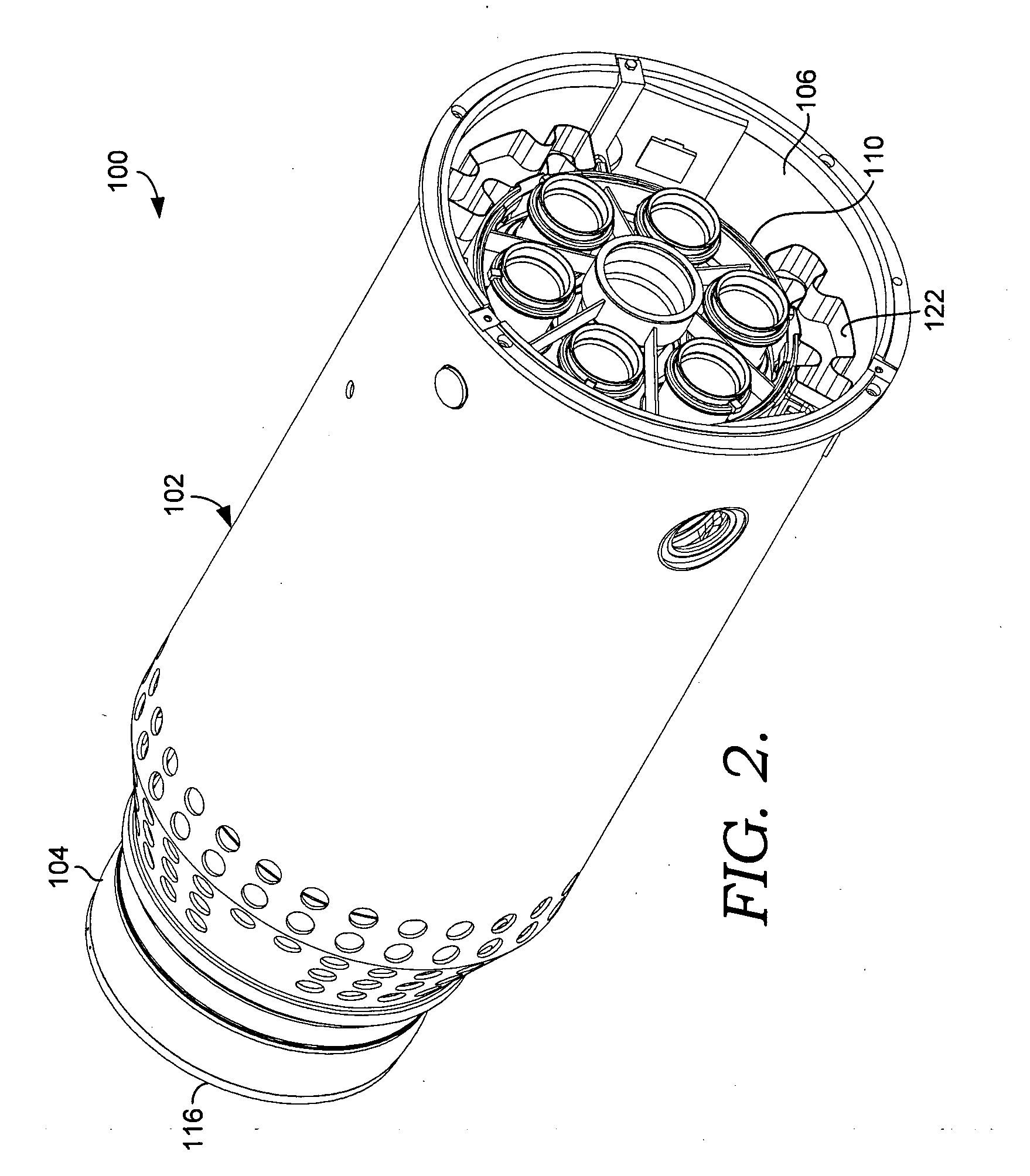

Systems and methods for monitoring thermal growth and controlling clearances, and maintaining health of turbo machinery applications

A system and method for determining thermal growth of motor or engine parts to thereupon control the clearance of motor or engine fan blades is disclosed herein. In addition, a system and method for monitoring the health of a turbine engine, its components and sub-components is also described herein. The system(s) and method(s) described herein permit continuous monitoring during the life of the engine for radial clearances and blade and rotor vibration problems, which will assist in correcting and retaining performance for a longer on-wing time in operation. In addition, inconsistent engine-to-engine performance variations due to component tolerances, engine operation characteristics, and operation during extremes in ambient temperatures can be eliminated or significantly minimized when employing the system(s) and method(s) described herein.

Owner:RAYTHEON TECH CORP

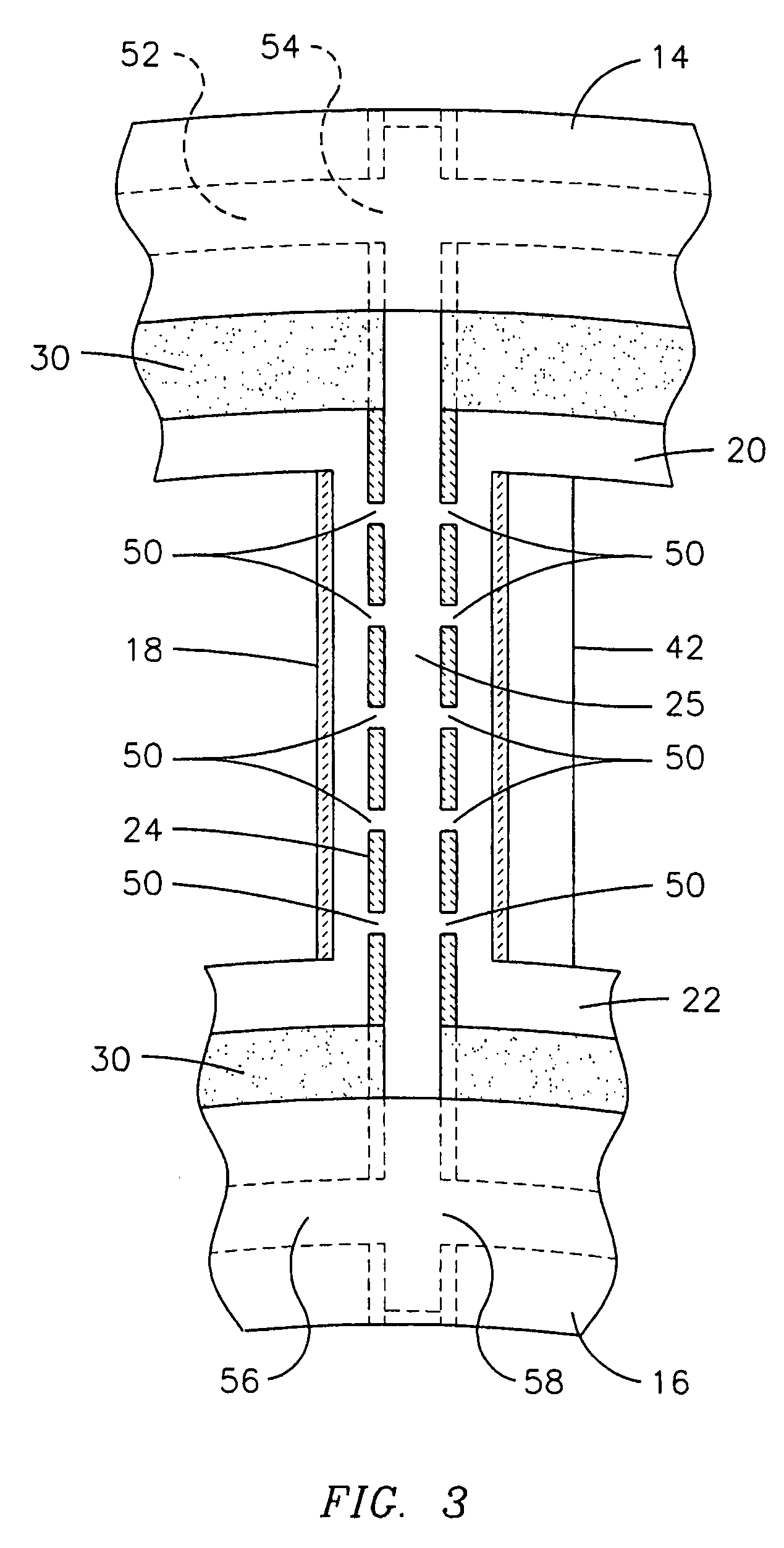

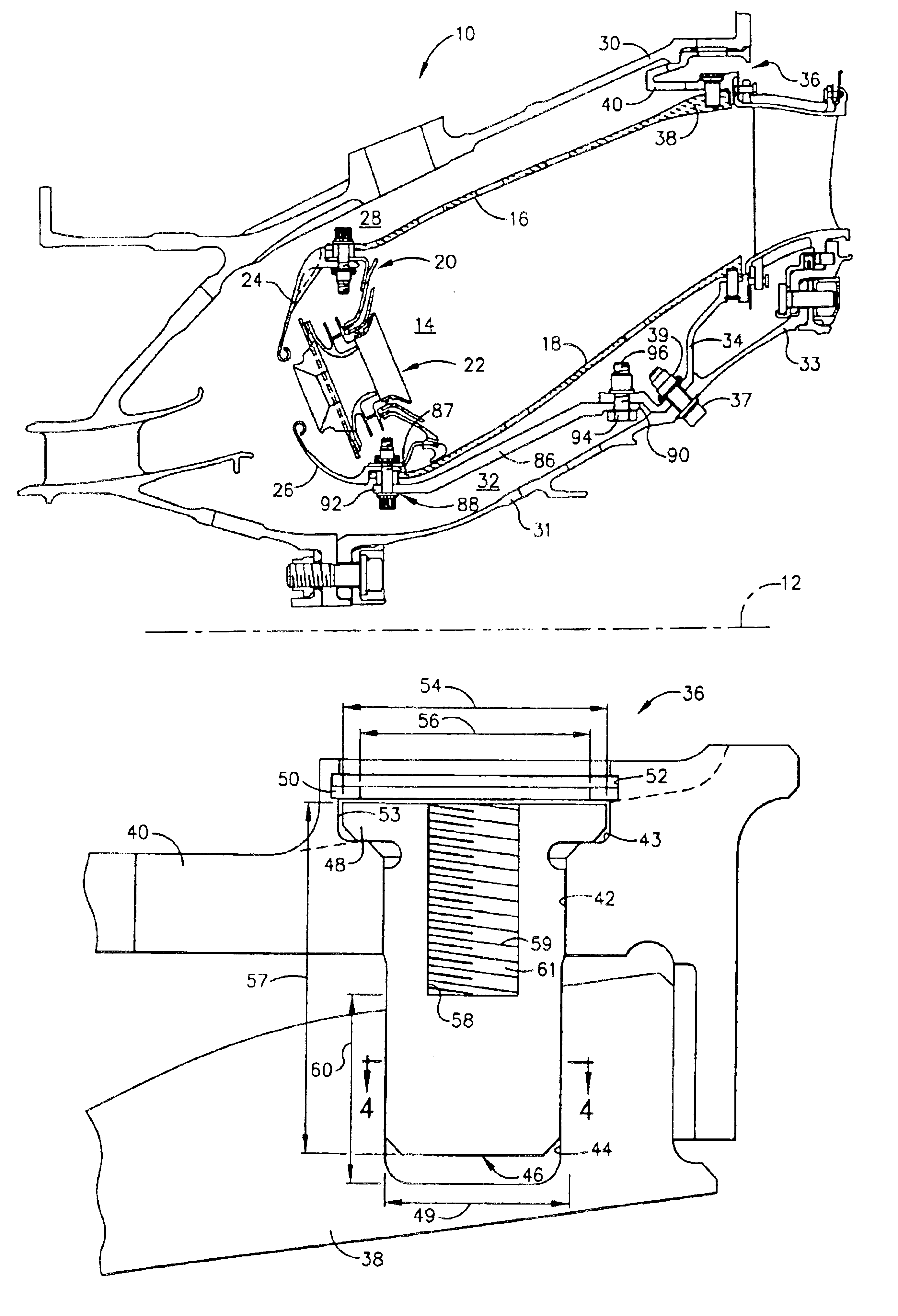

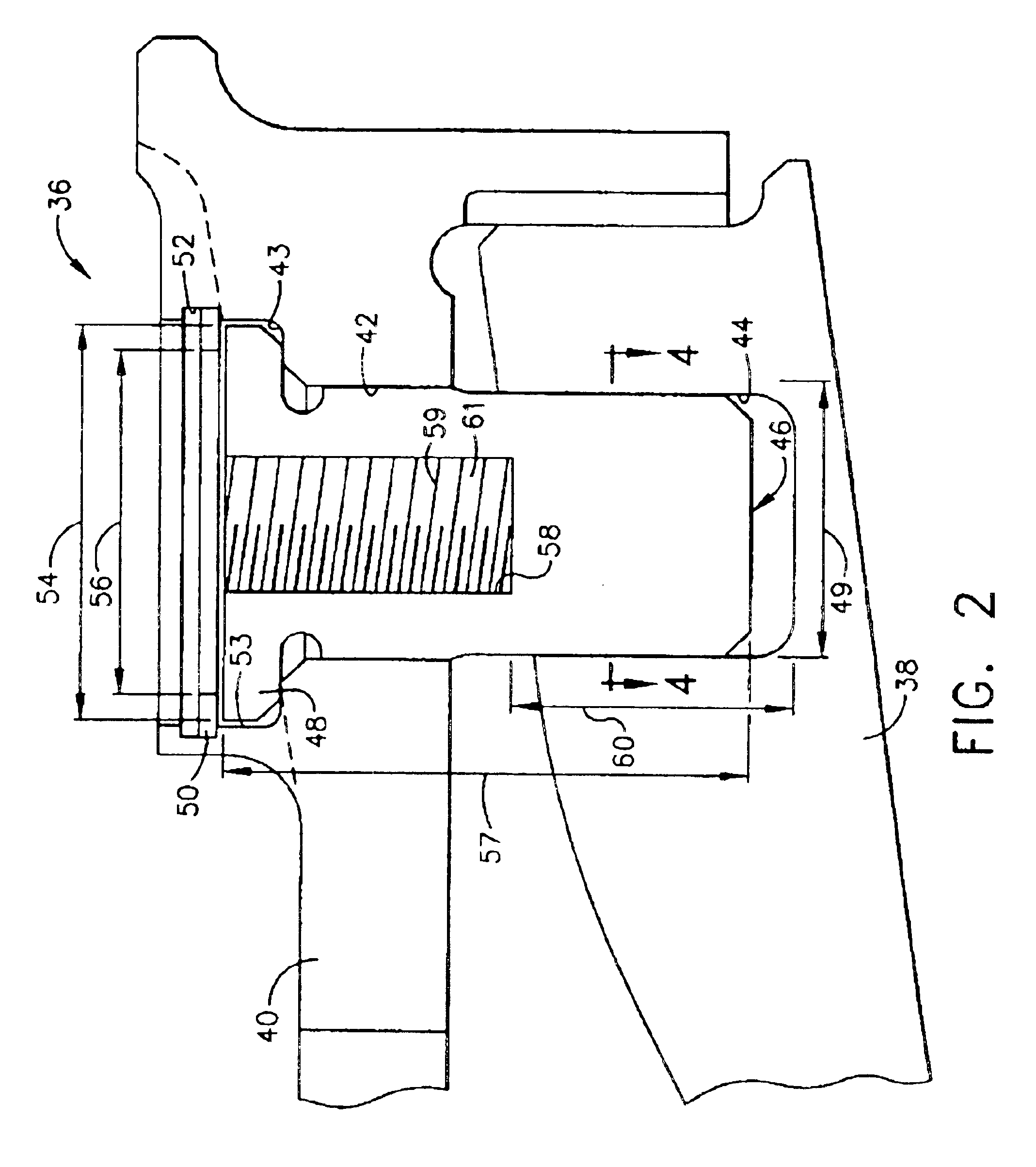

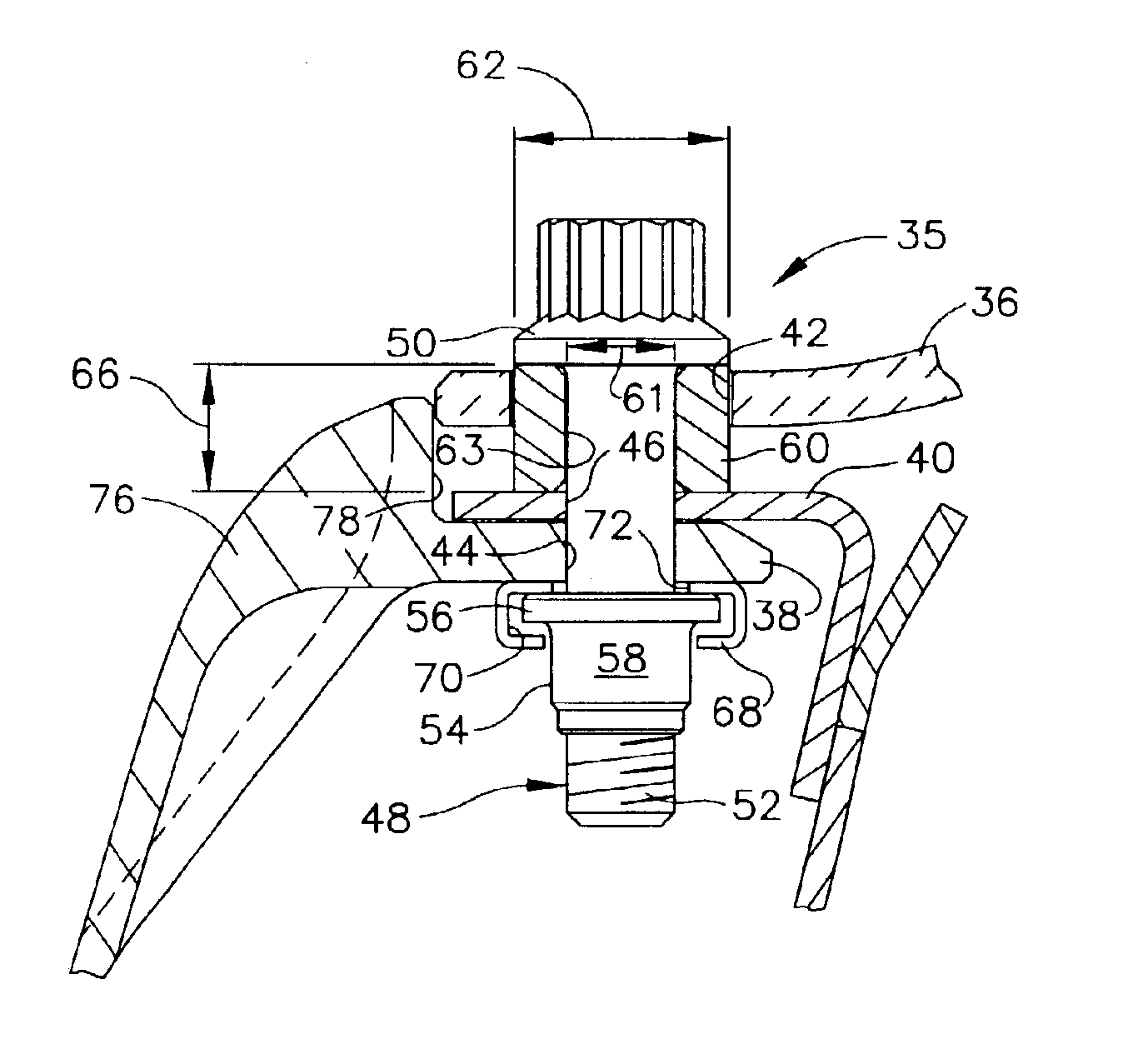

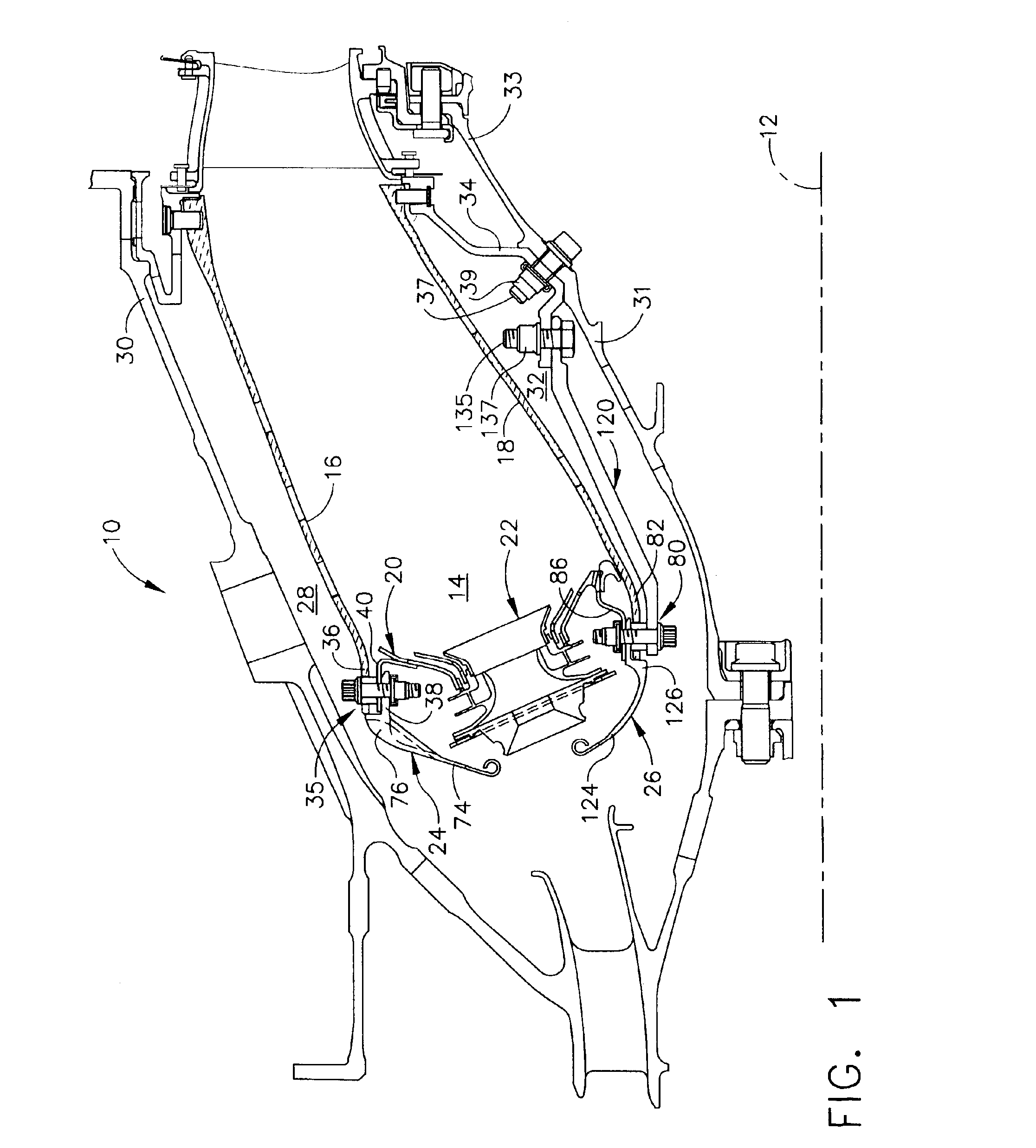

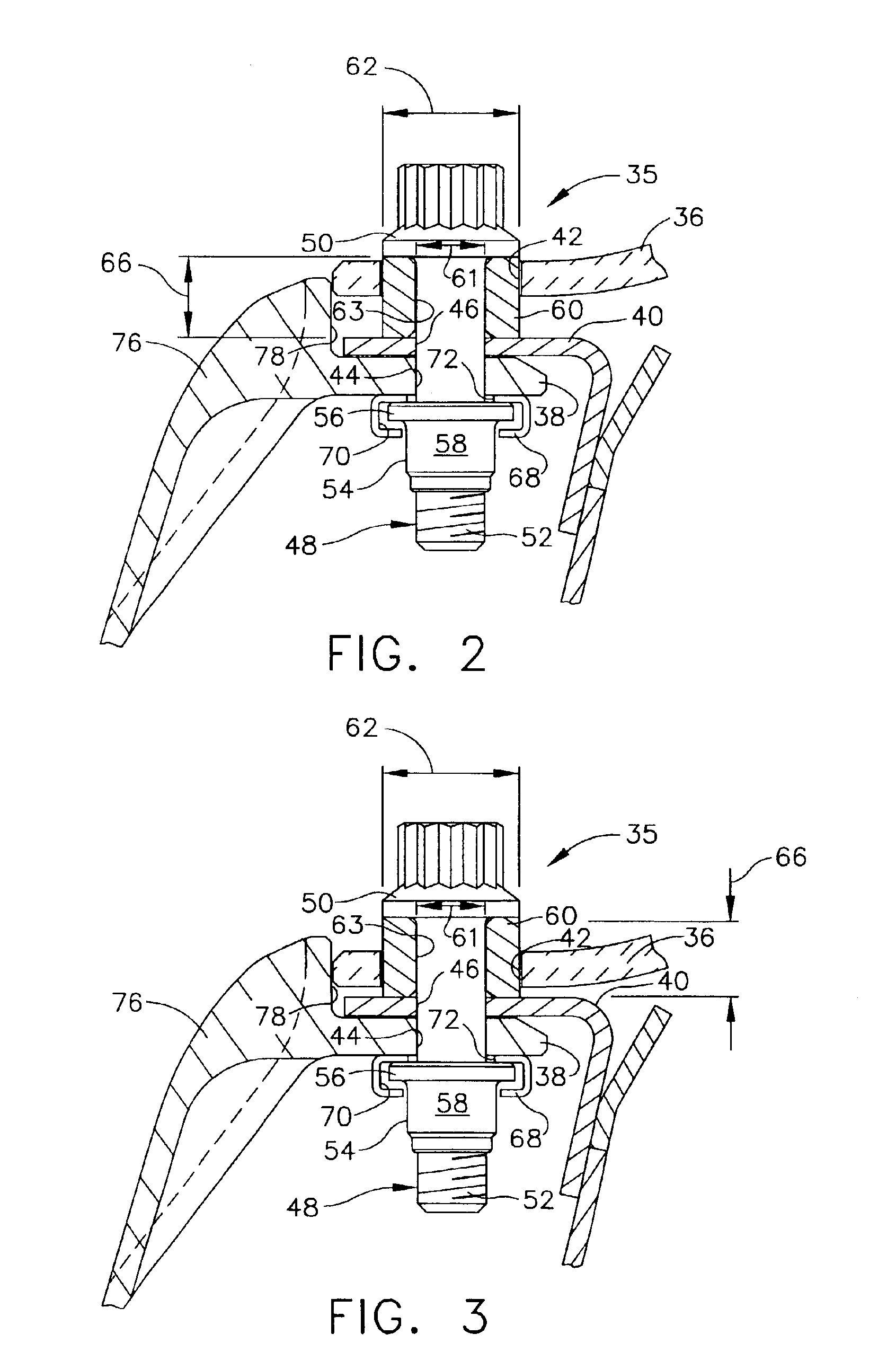

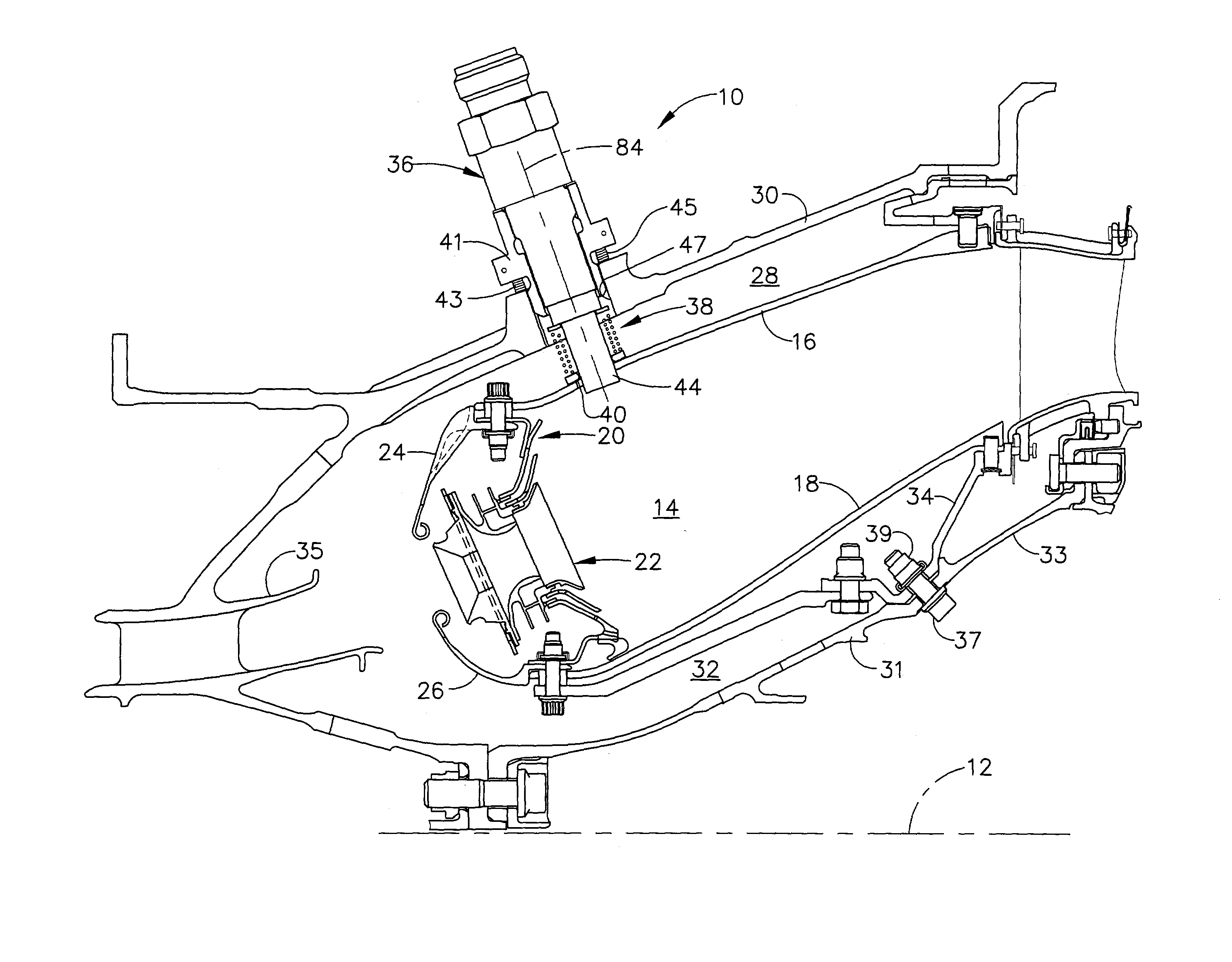

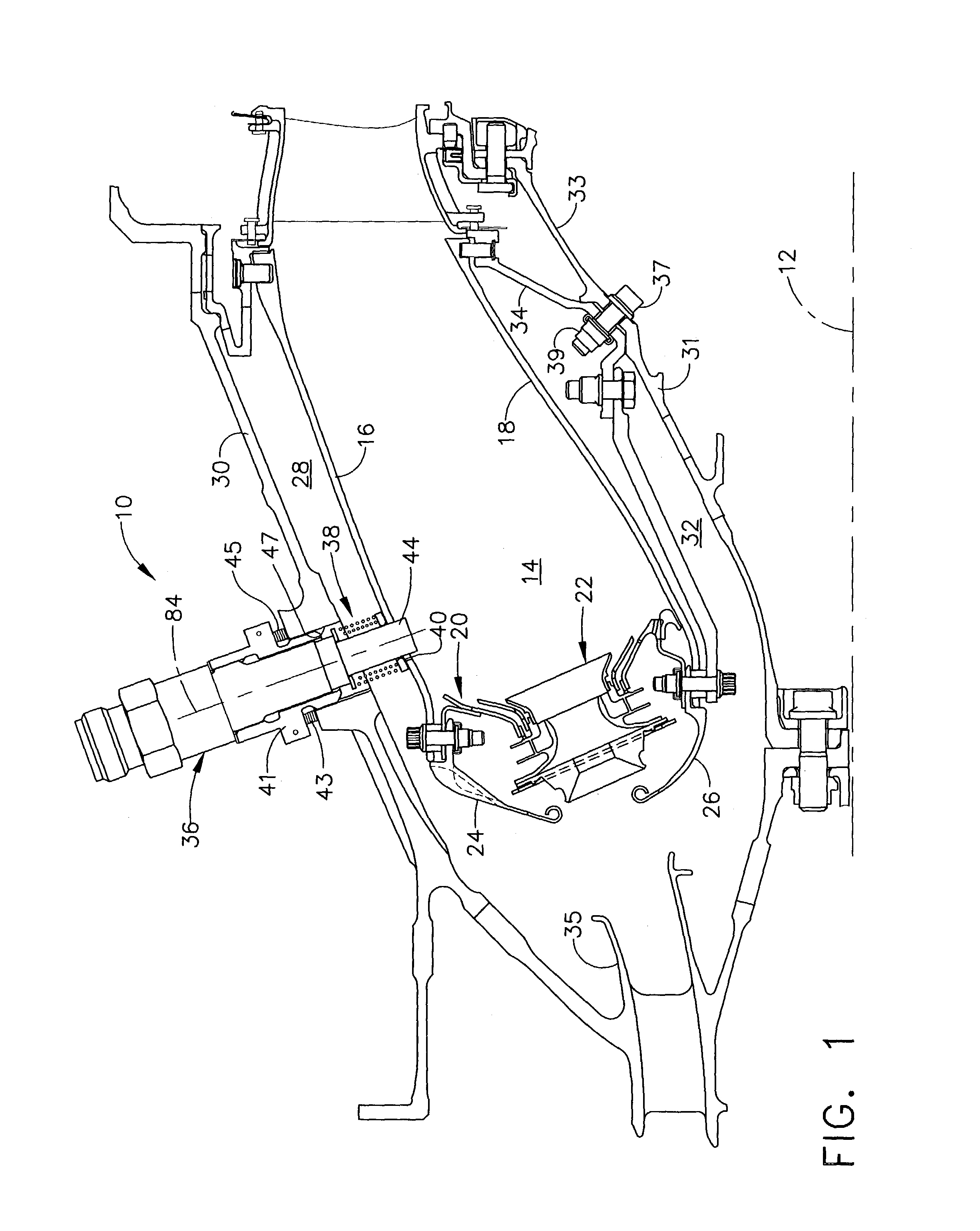

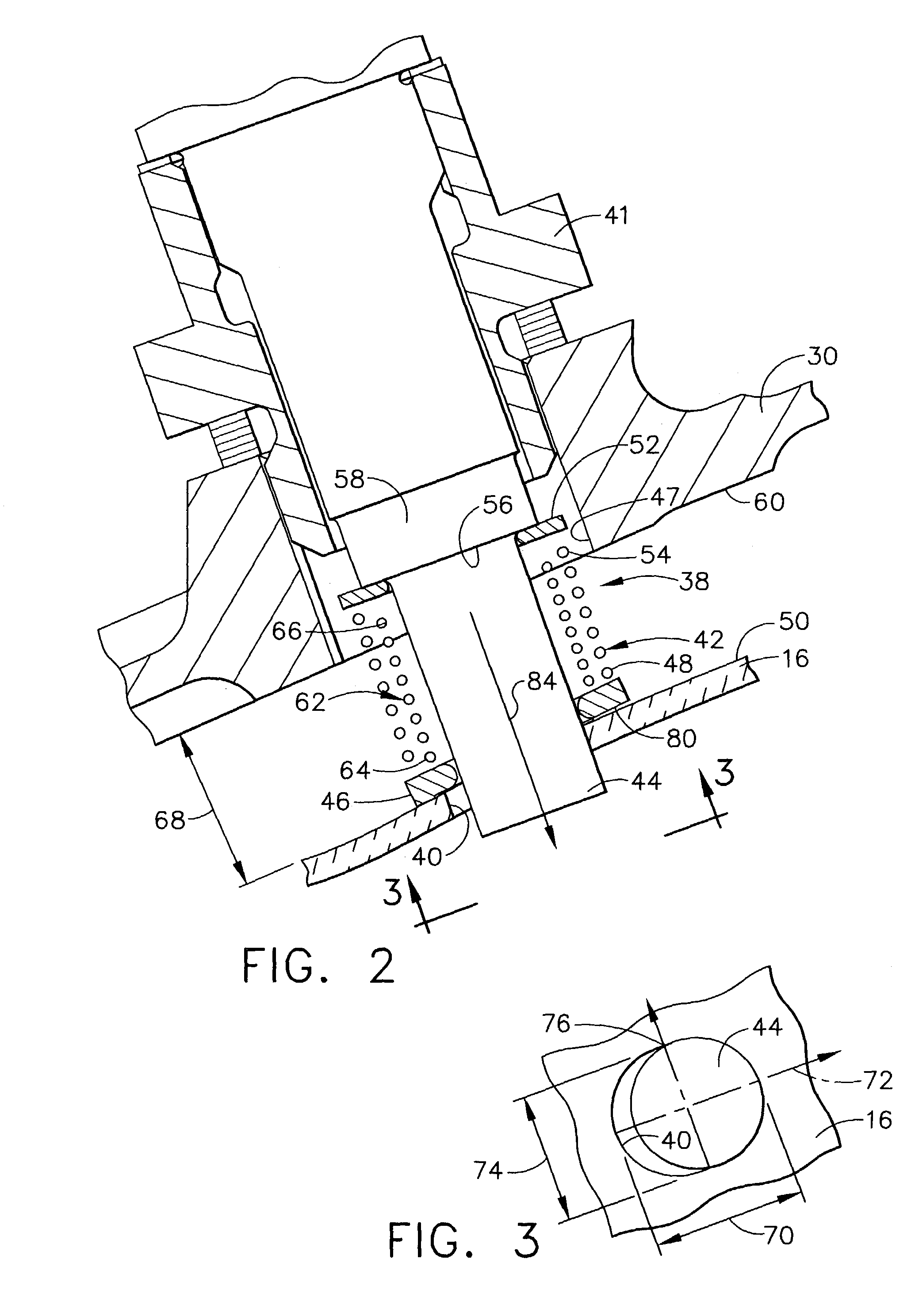

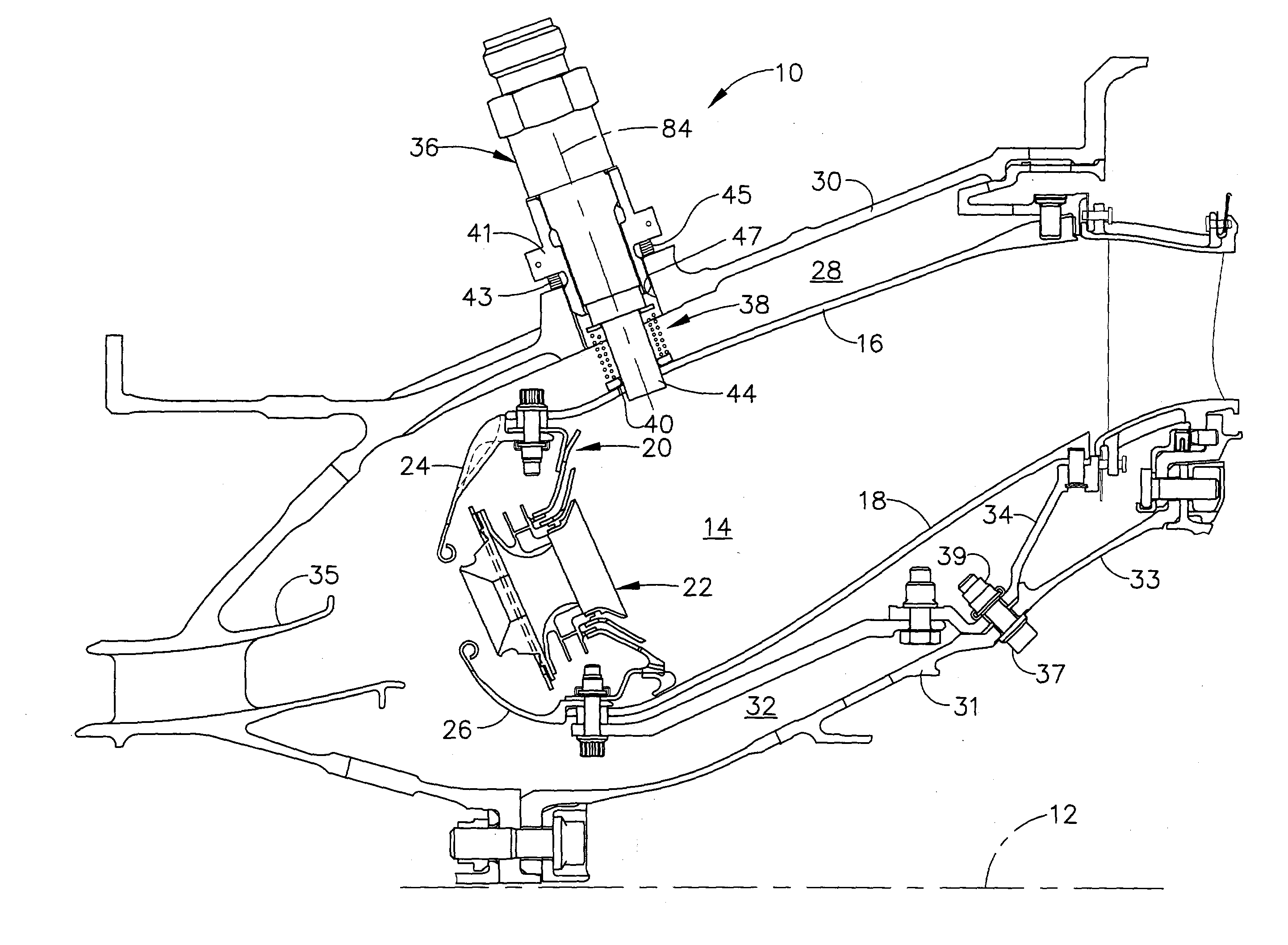

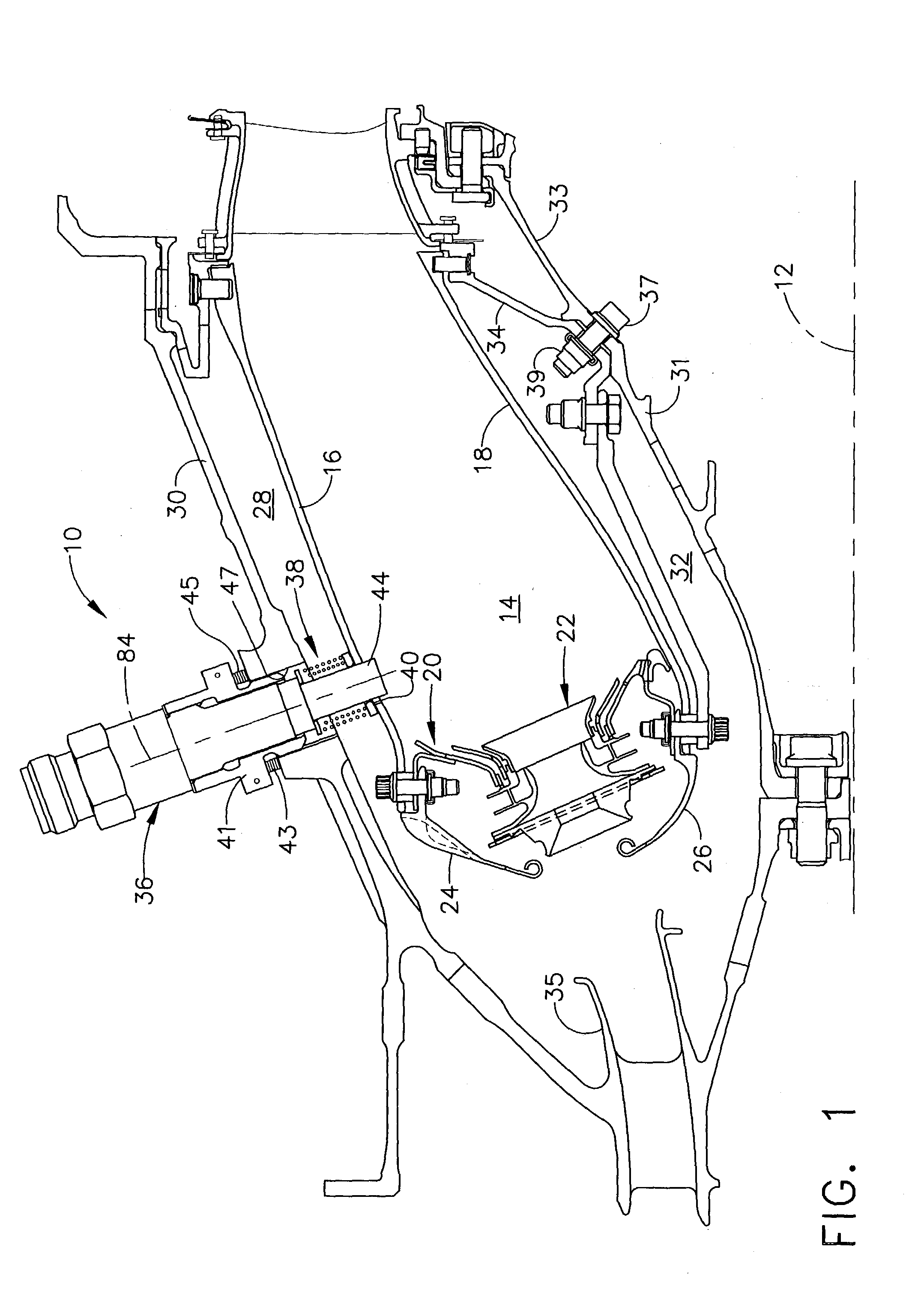

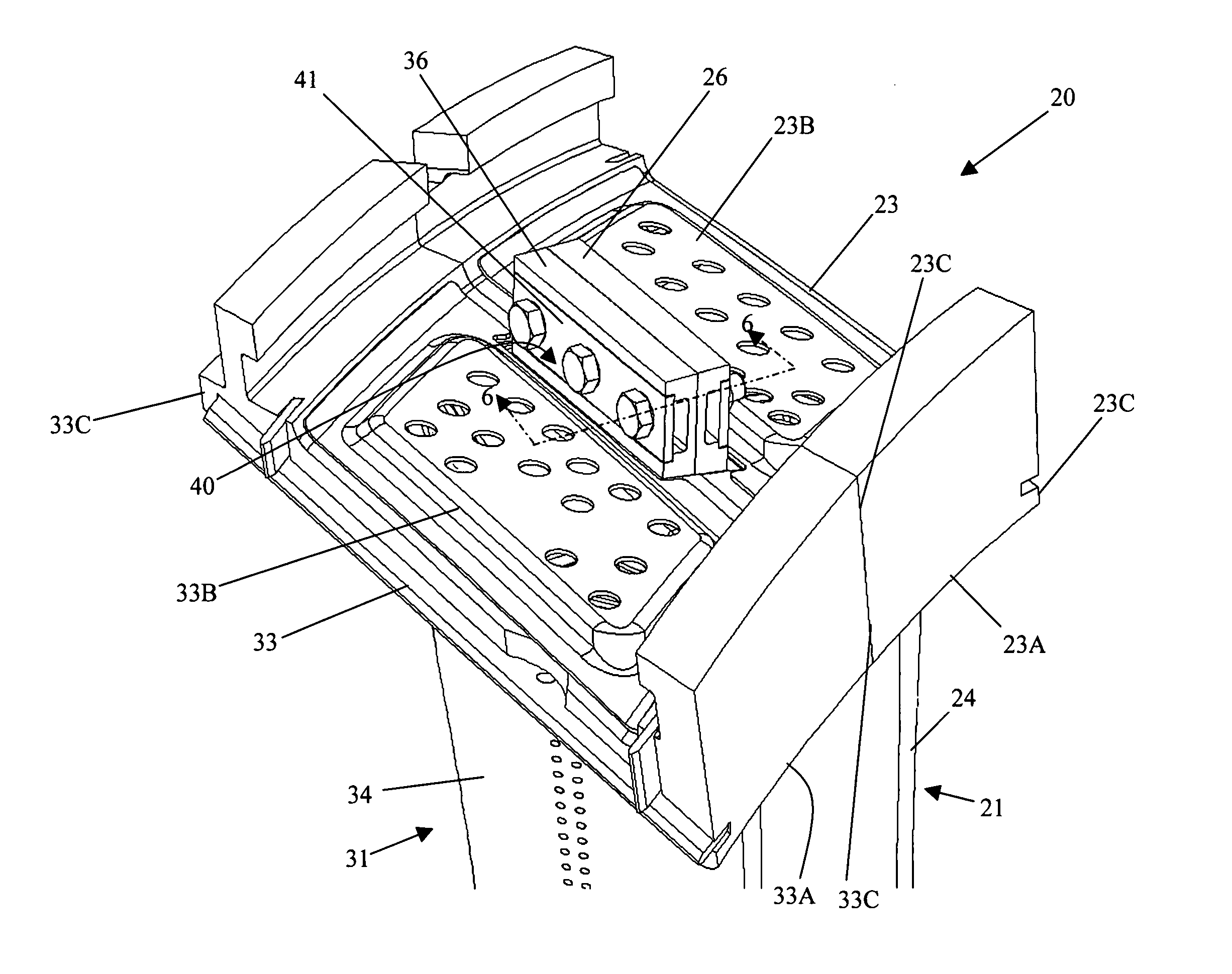

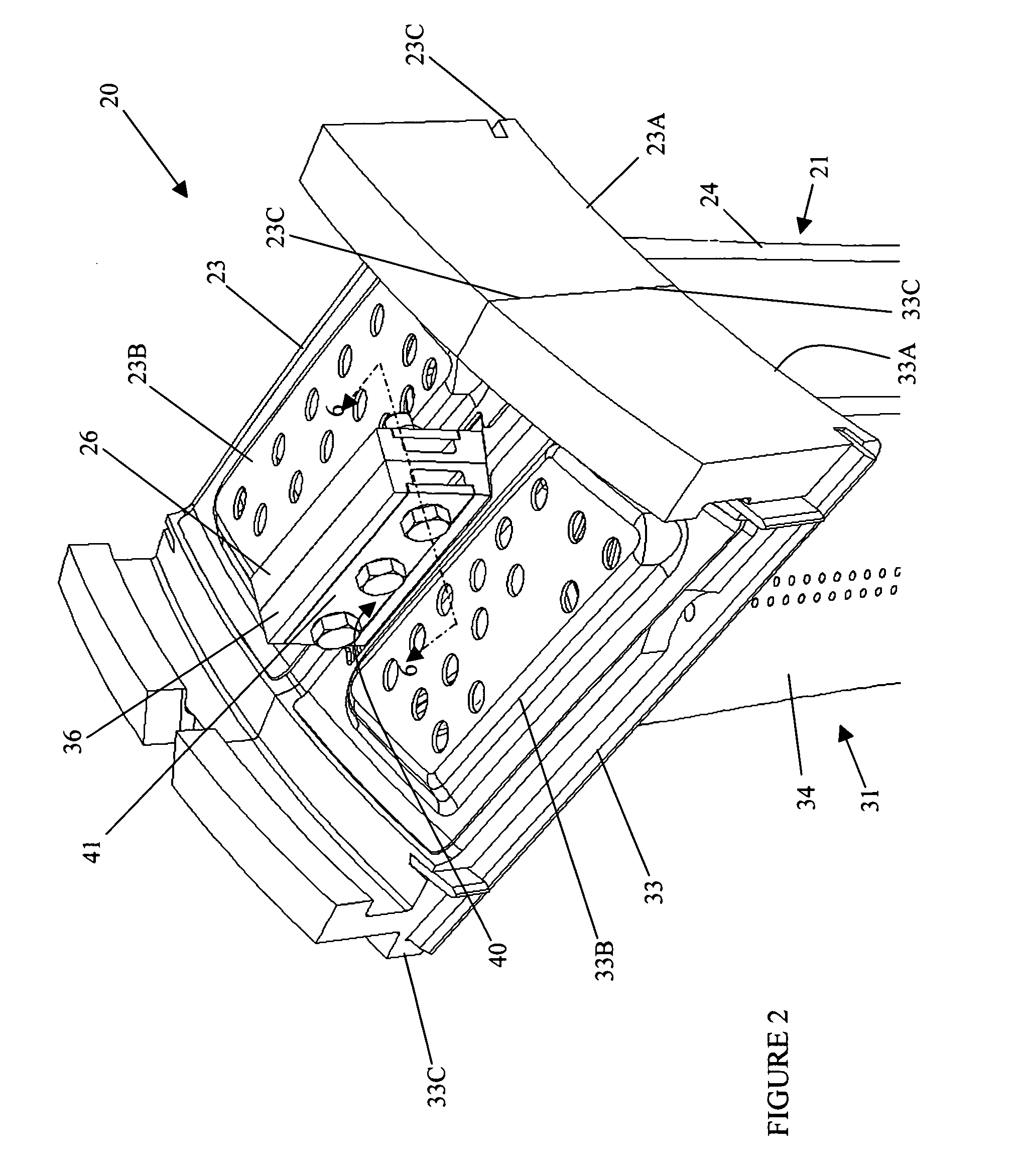

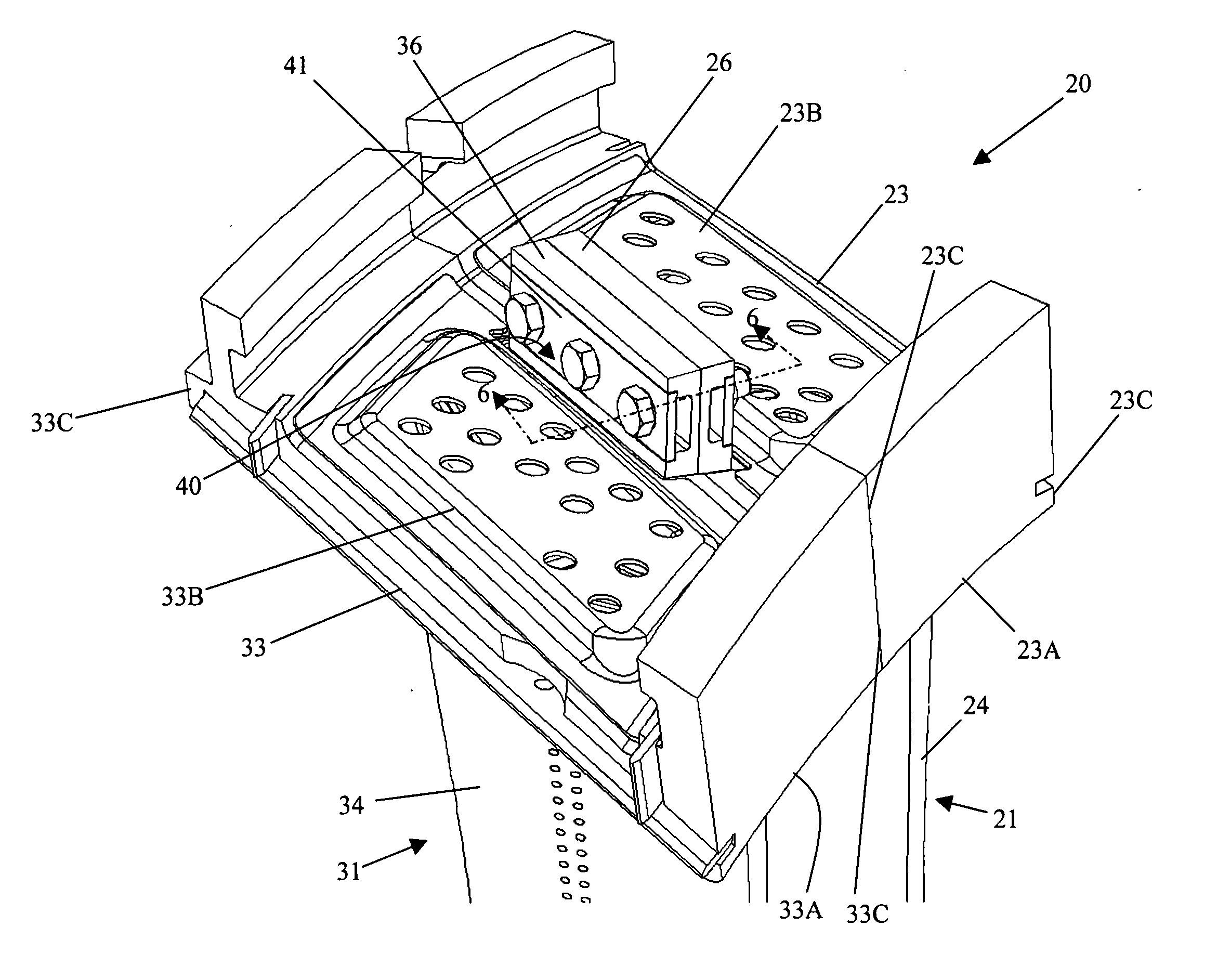

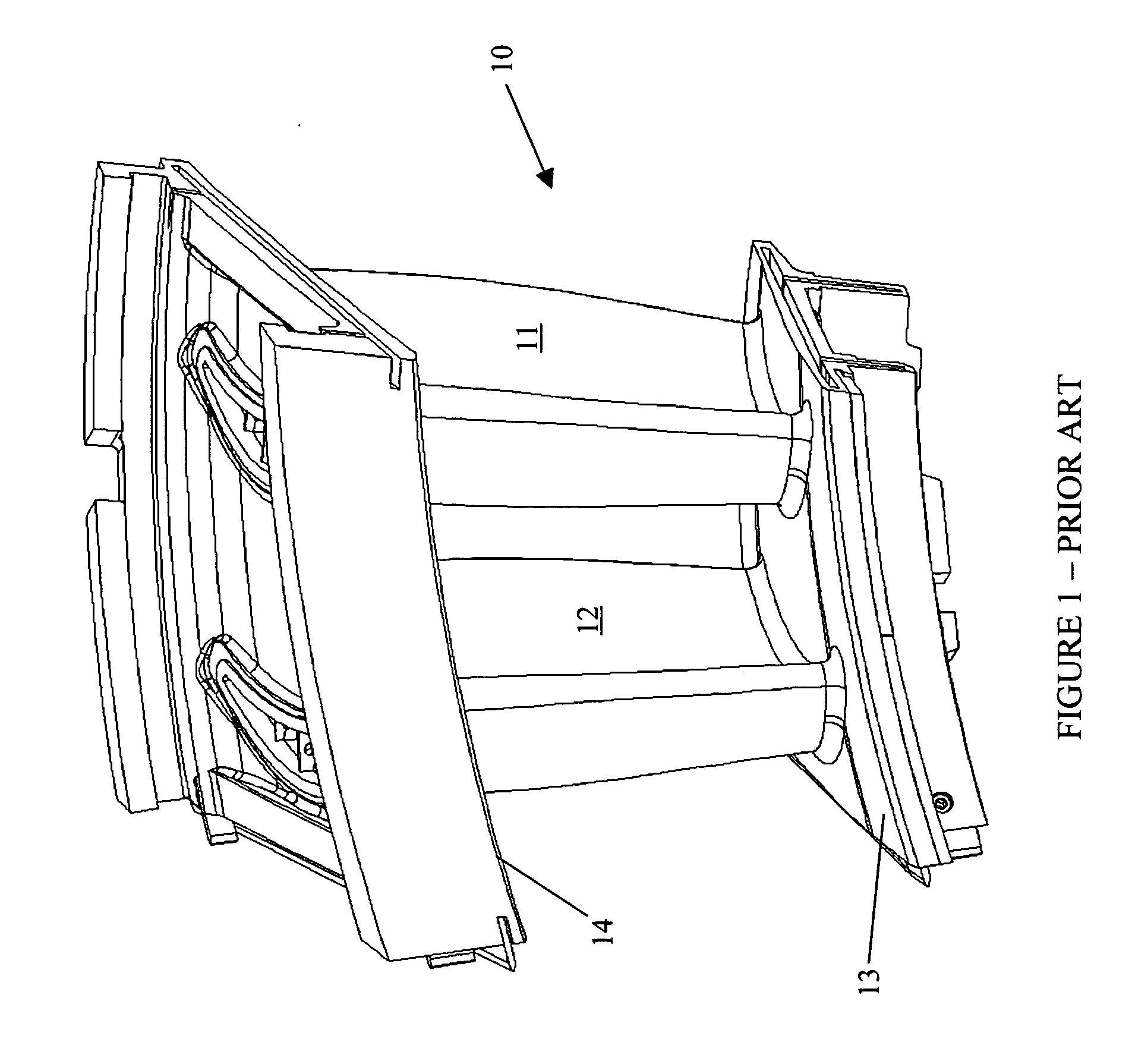

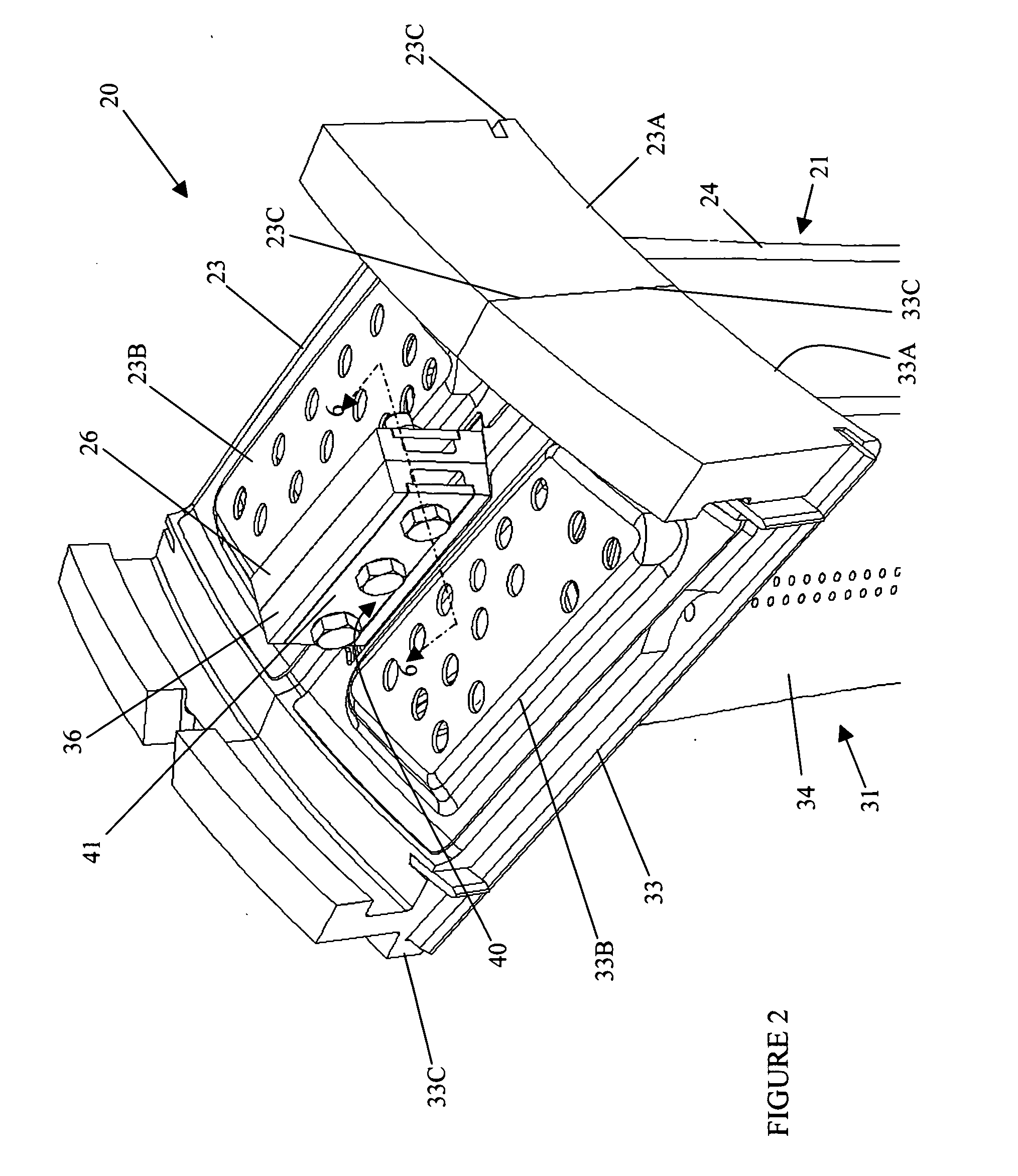

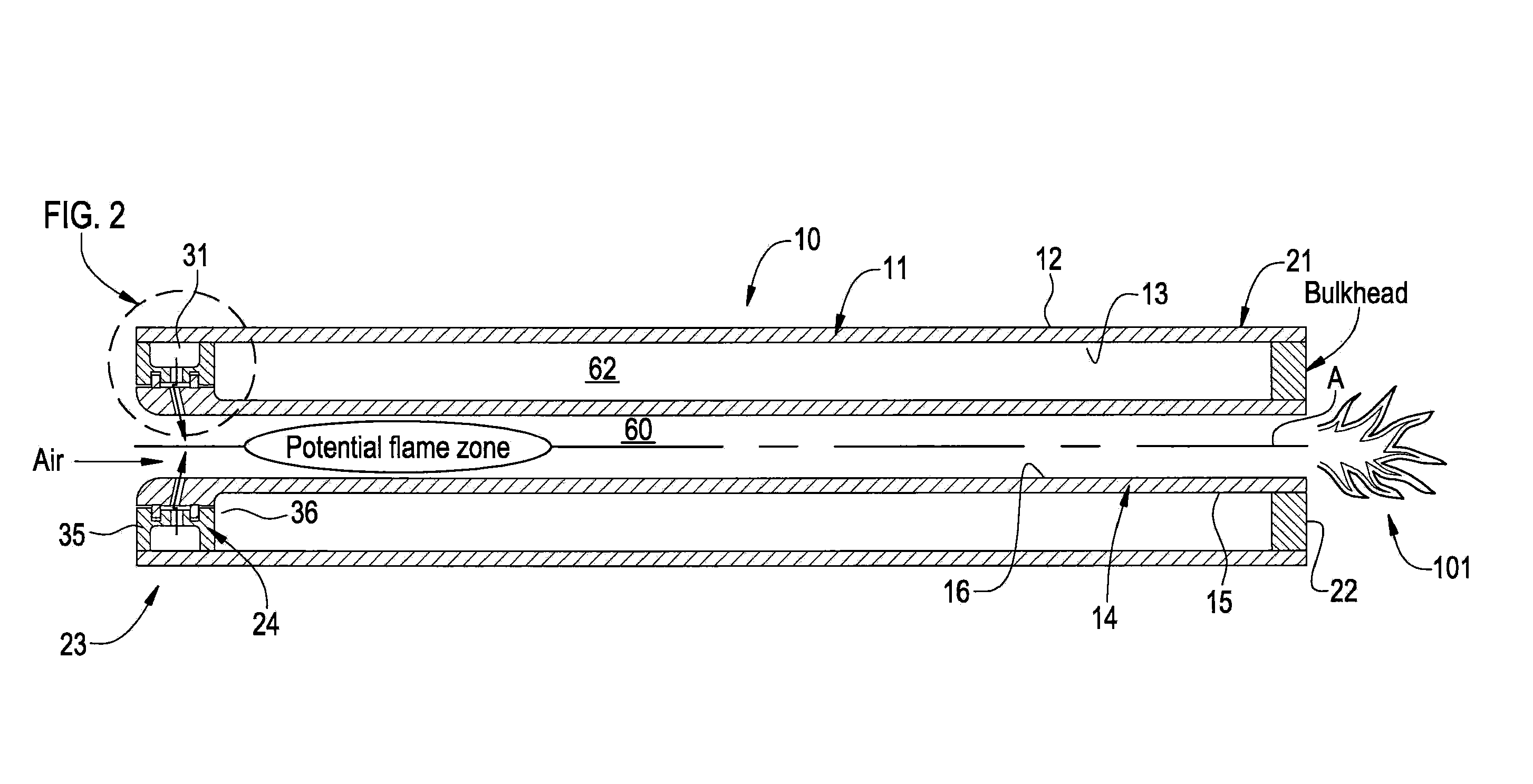

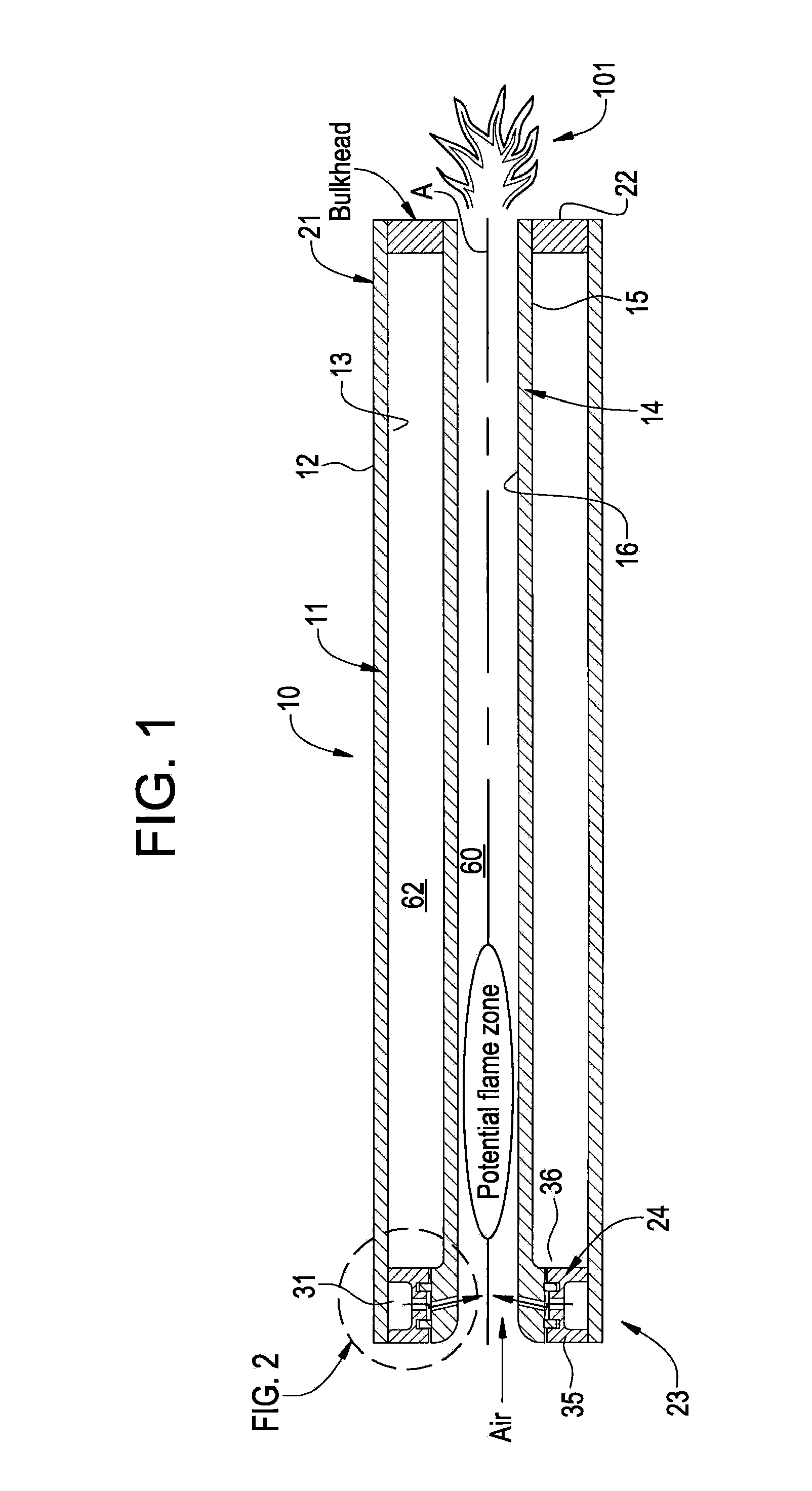

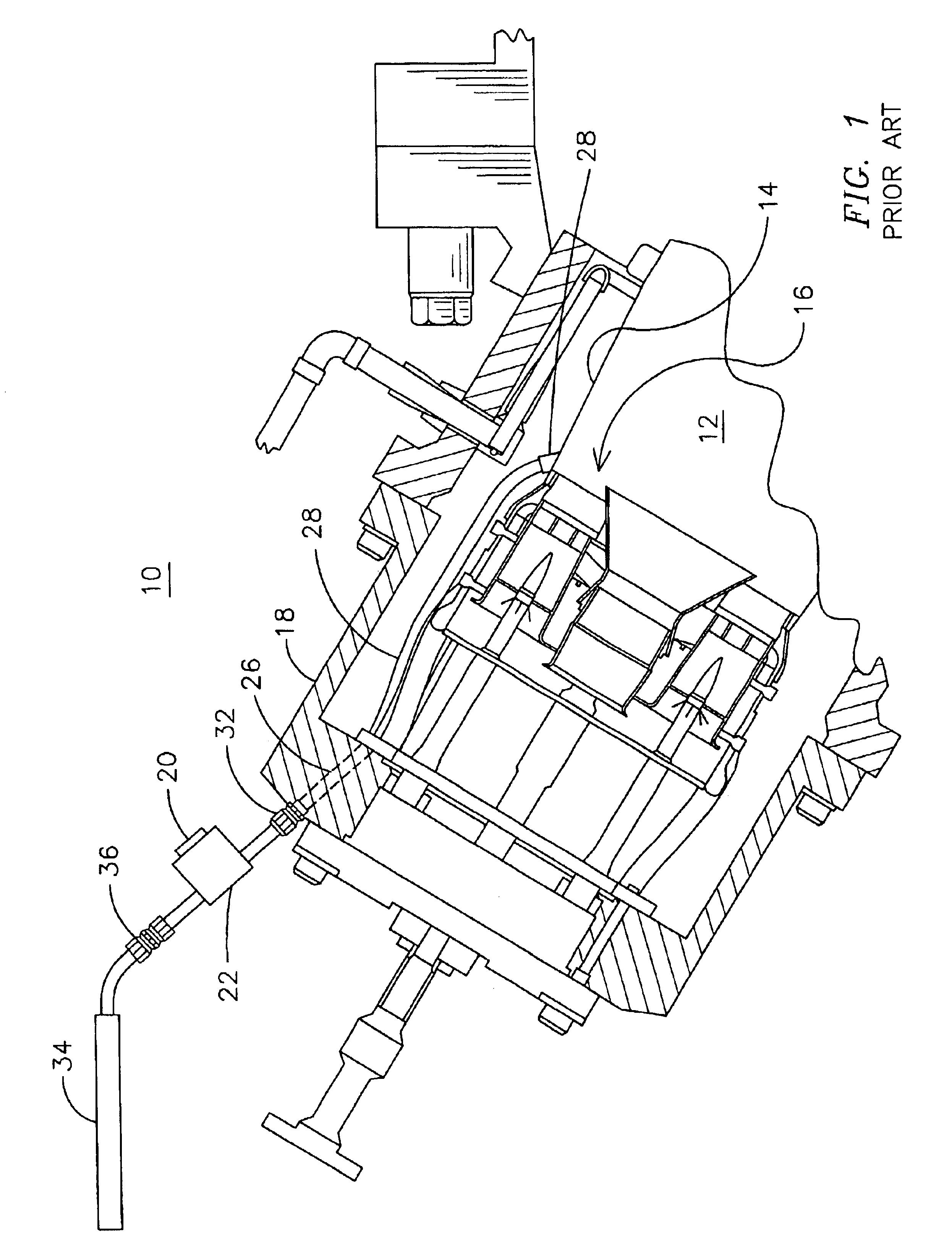

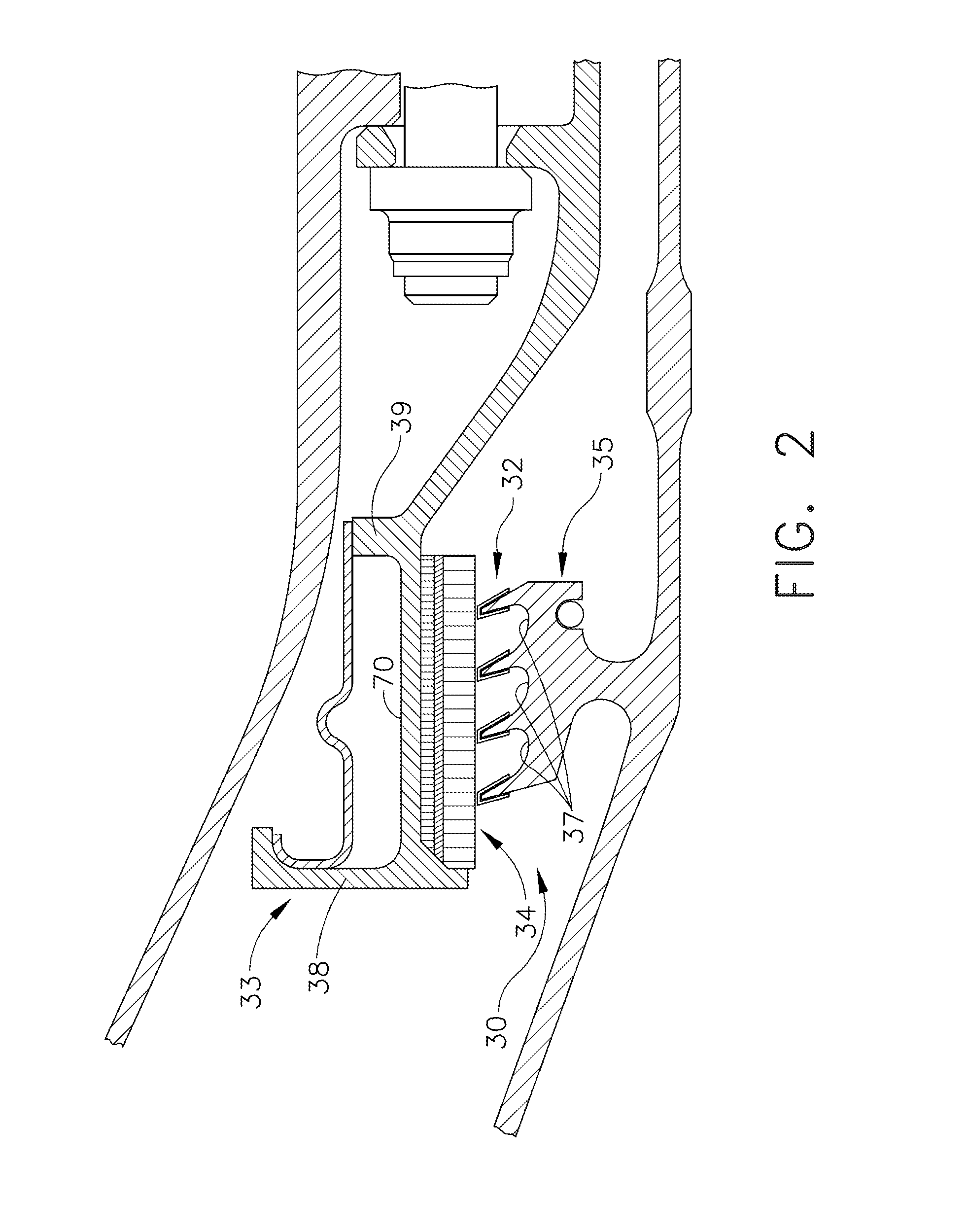

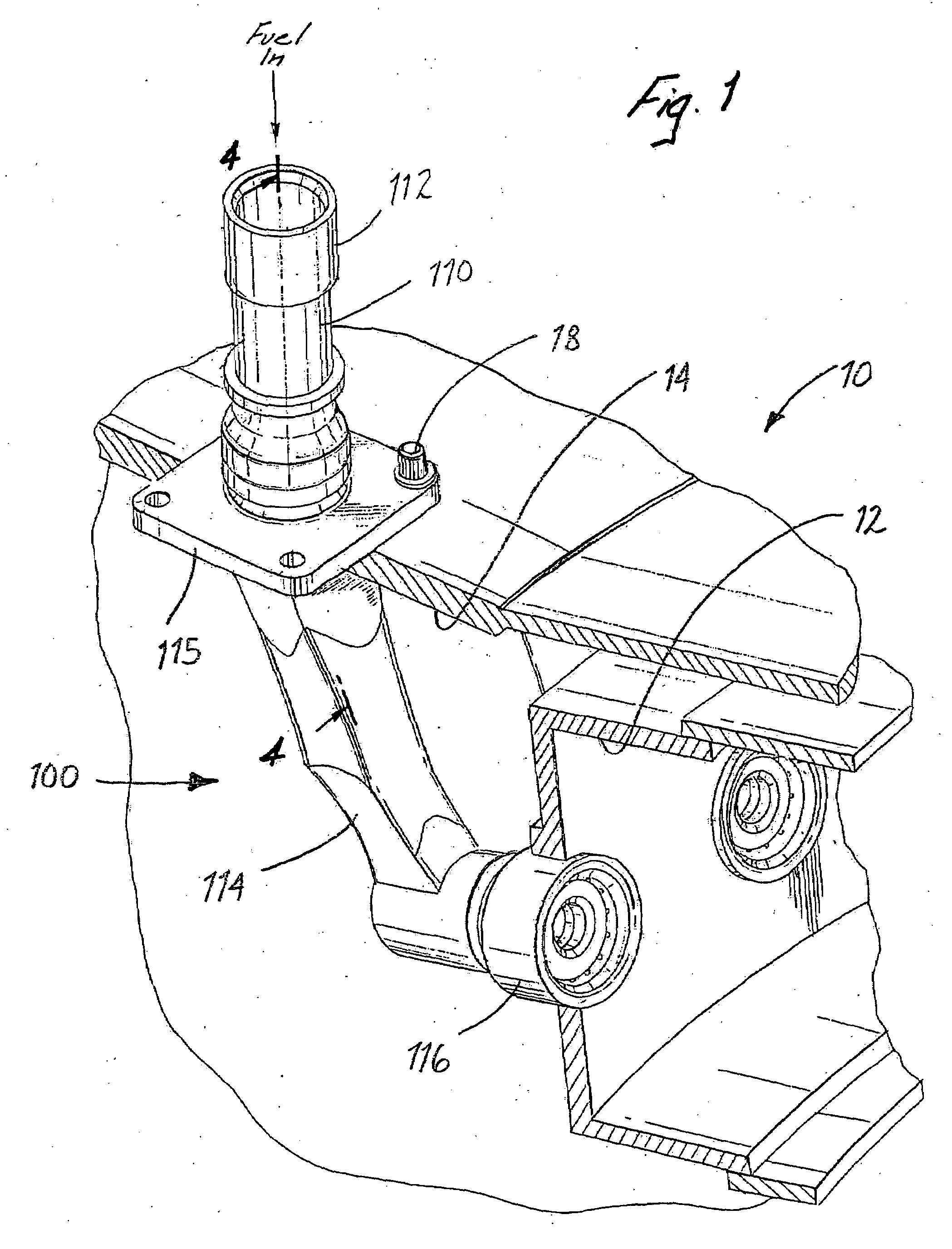

Mounting assembly for igniter in a gas turbine engine combustor having a ceramic matrix composite liner

An assembly for mounting an igniter in a gas turbine engine combustor between an outer casing and an outer liner, wherein a longitudinal centerline axis extends through the gas turbine engine. The igniter mounting assembly includes a first spring member encircling a portion of said igniter and being positioned between a surface adjacent the outer casing and an outer surface of the outer liner, a first ring member connected to a first end of the first spring member adjacent the outer surface of the outer liner, and a second ring member connected to a second end of the first spring member adjacent the surface adjacent the outer casing. Accordingly, the igniter is able to maintain substantial alignment with respect to an opening in the outer liner while moving radially and / or axially with respect to the outer liner as the outer casing experiences thermal growth greater than the outer liner.

Owner:GENERAL ELECTRIC CO

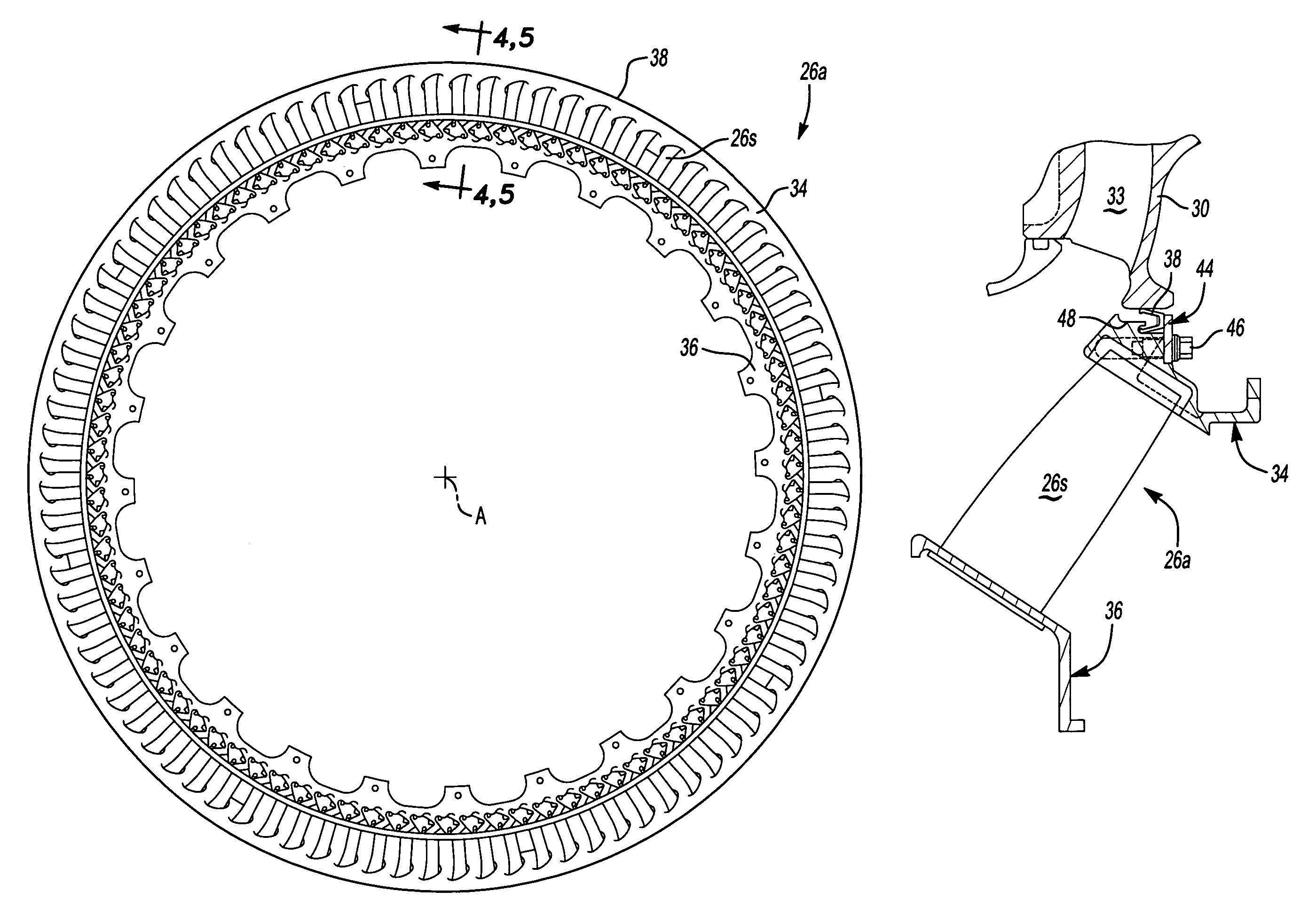

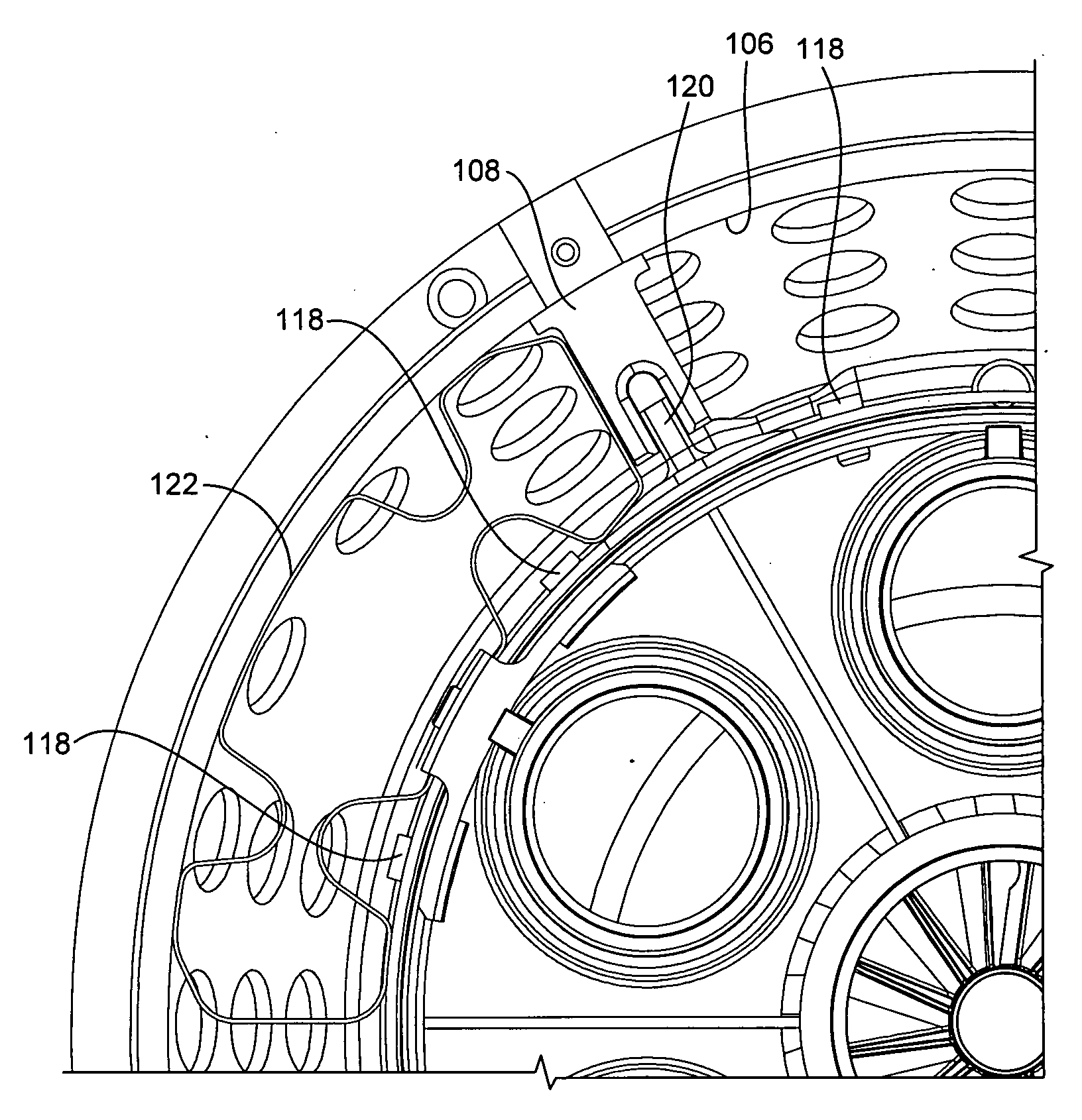

Compliant mounting system for turbine shrouds

The mounting of low expansion full ring shrouds in a turbine engine requires radial compliance to limit the stresses experienced by the shroud due to thermal growth differences between the shroud and its support. A method provides radial compliance with no looseness in a mounting system. The mounting system also allows for axial motion of the shroud, should such motion be needed or desired. The lack of looseness in the mounting system results in an ability to achieve smaller tip clearances and thus better engine performance.

Owner:HONEYWELL INT INC

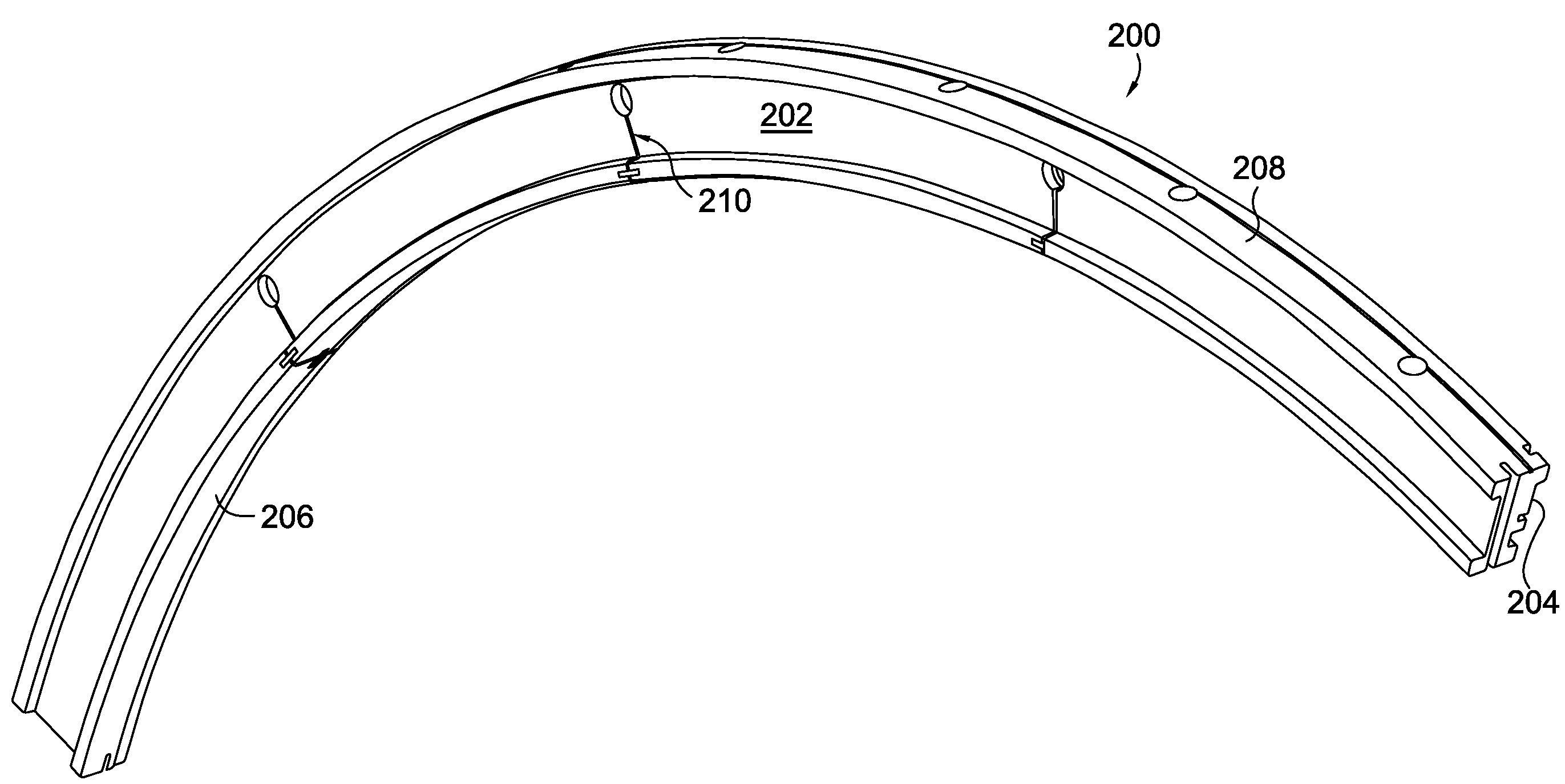

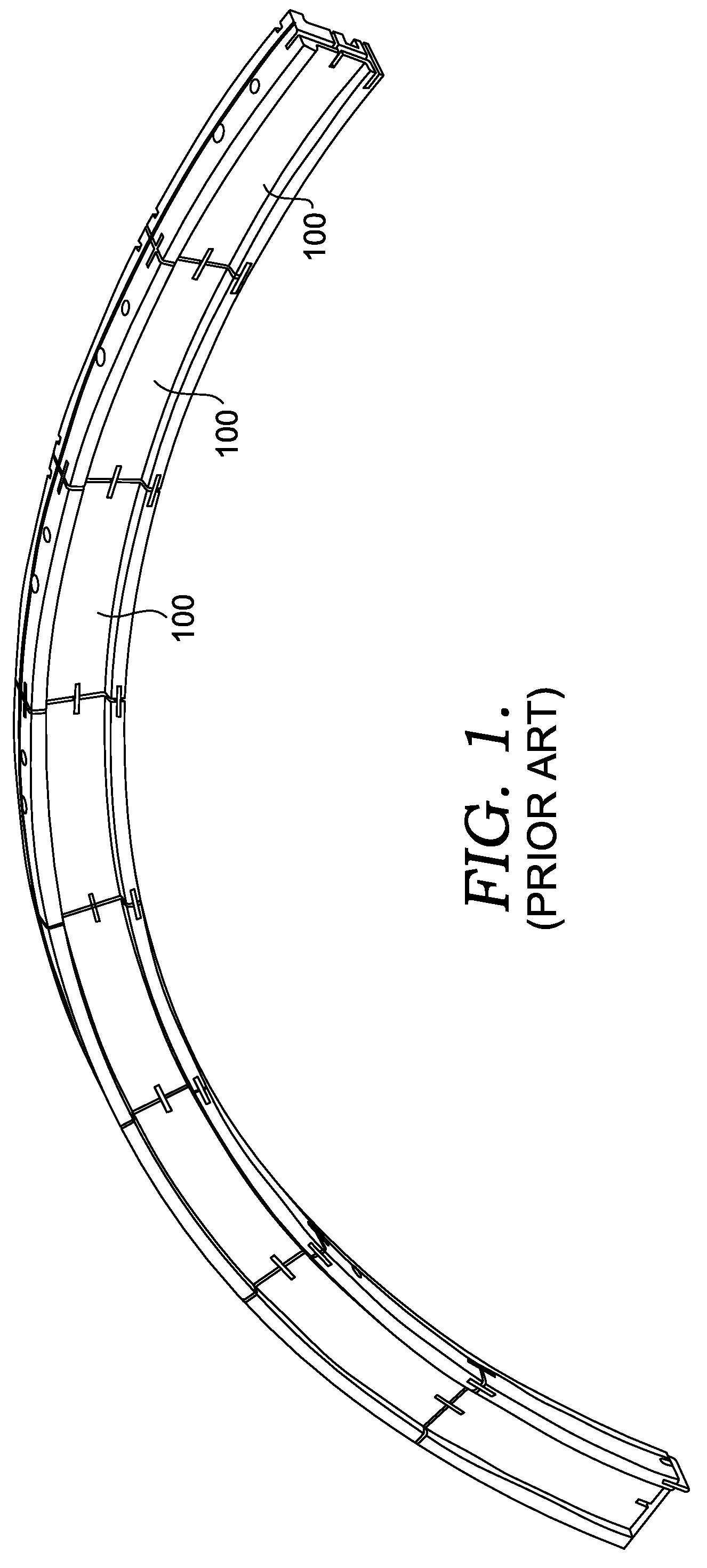

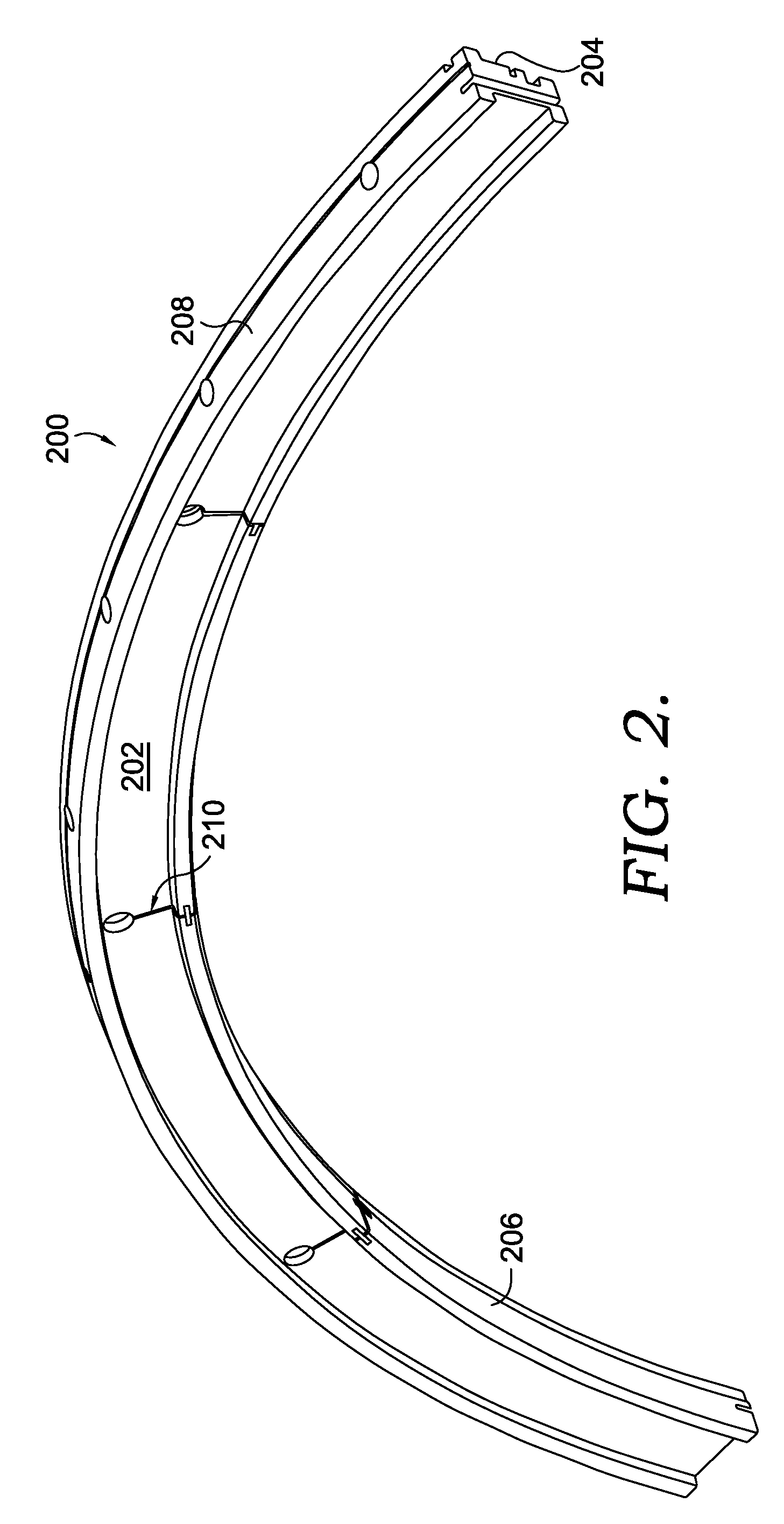

Methods and tooling assemblies for the manufacture of metallurgically-consolidated turbine engine components

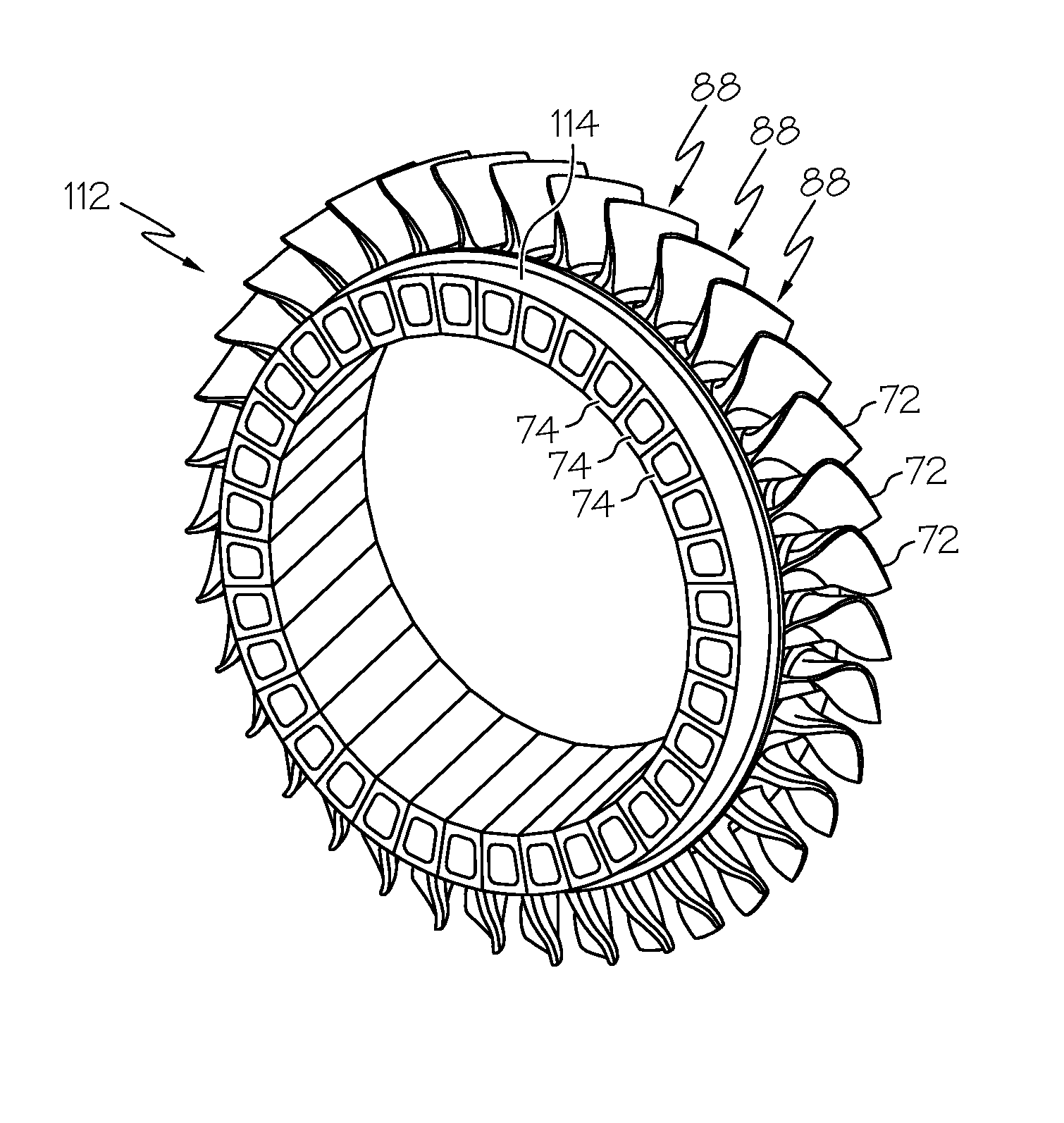

Embodiments of a method for manufacturing a turbine engine component are provided, as are embodiments of a thermal growth constraint tool for the manufacture of turbine engine components. In one embodiment, the method includes the steps of obtaining a plurality of arched pieces, arranging the plurality of arched pieces in a ring formation, and bonding the plurality of arched pieces together to produce a monolithic ring by heating the ring formation to a predetermined bonding temperature while constraining the outward radial growth thereof.

Owner:HONEYWELL INT INC

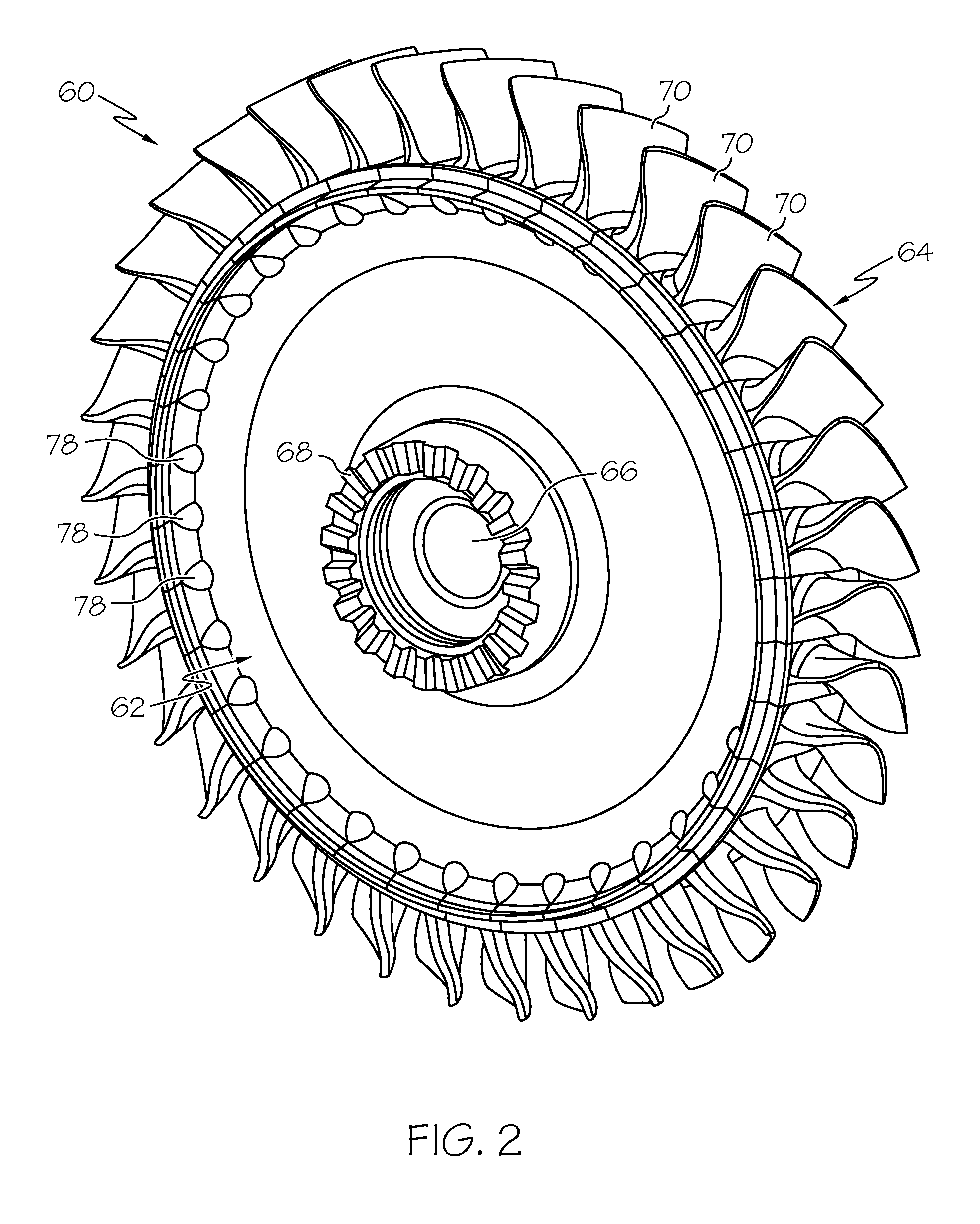

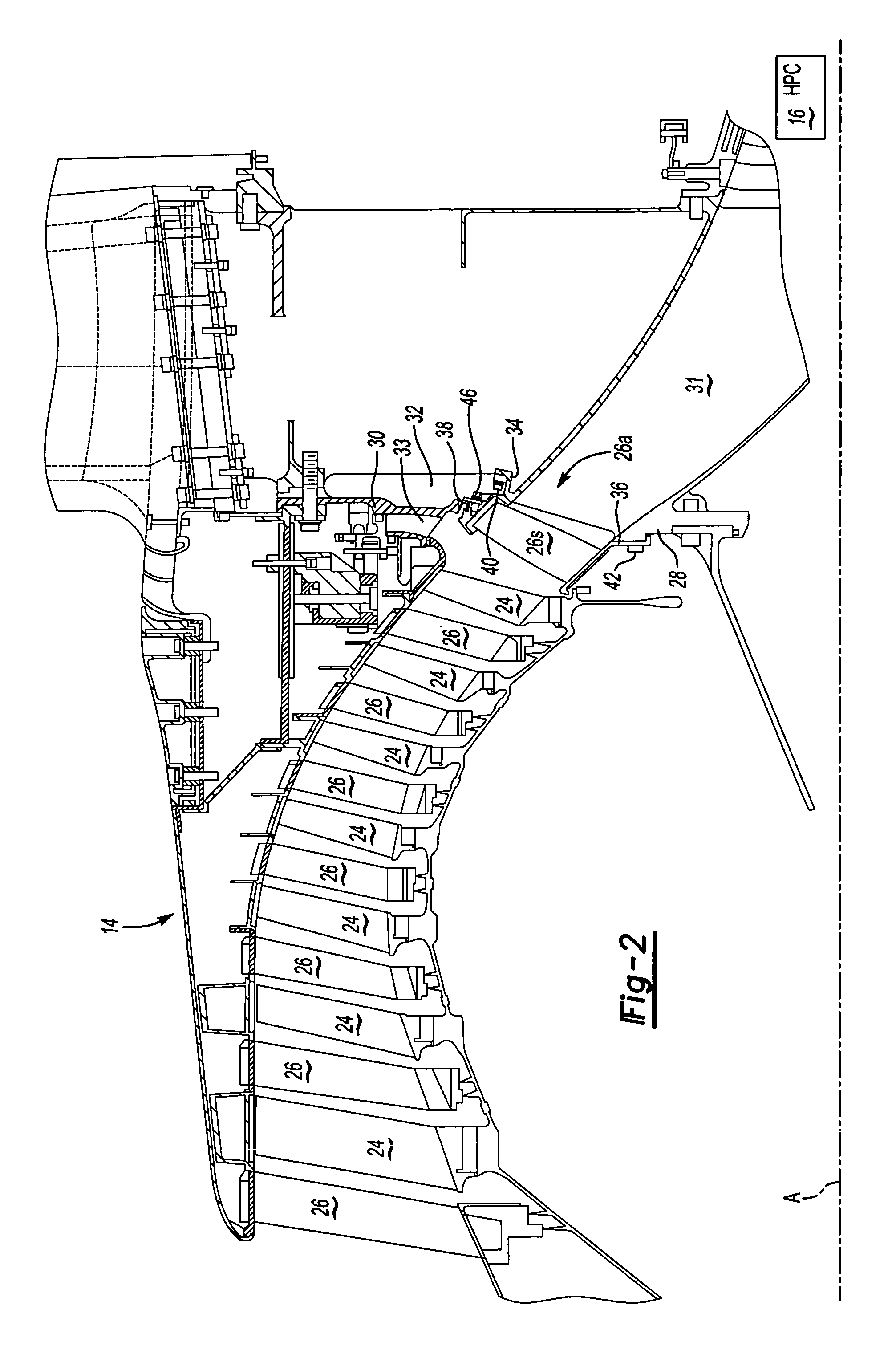

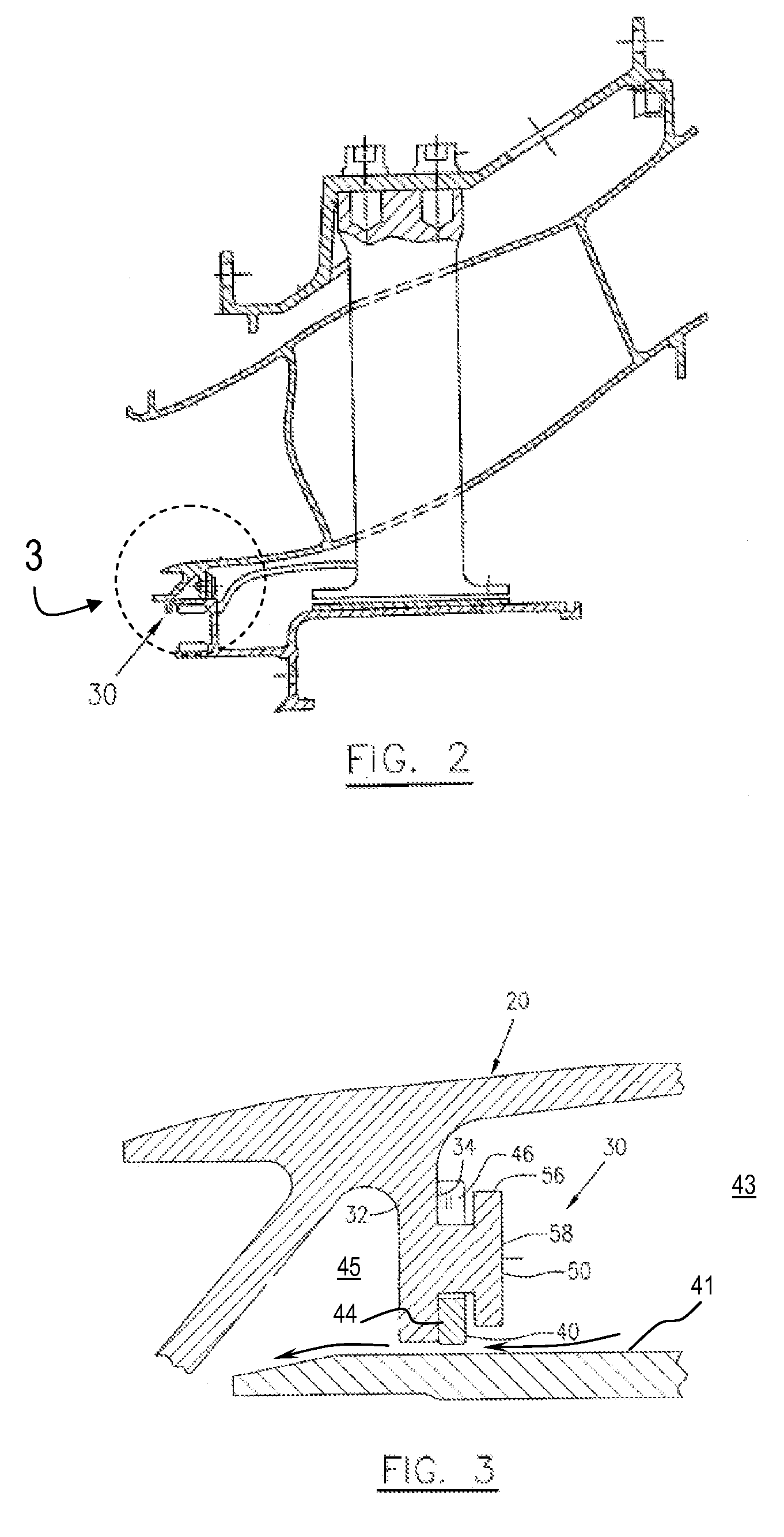

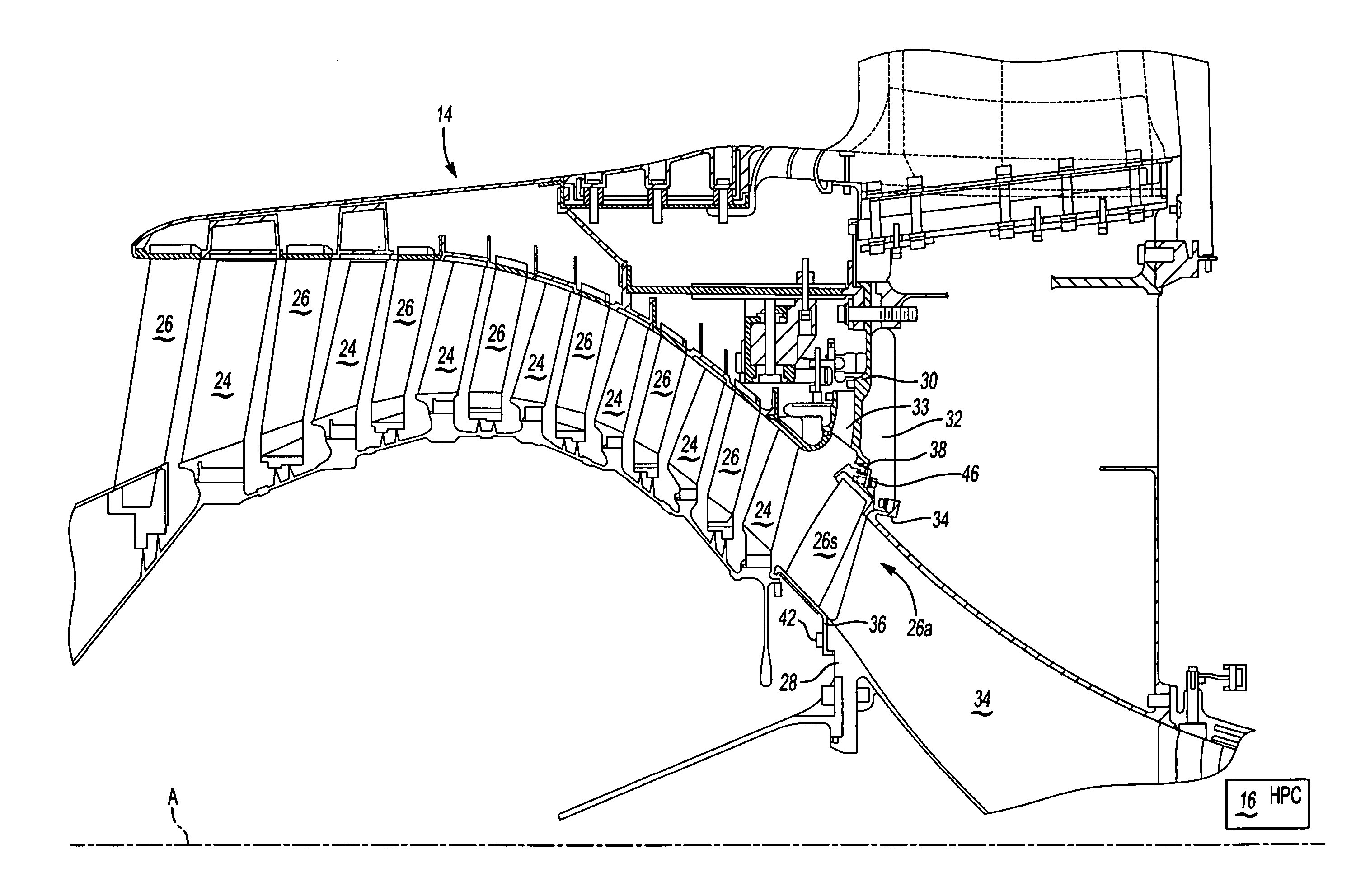

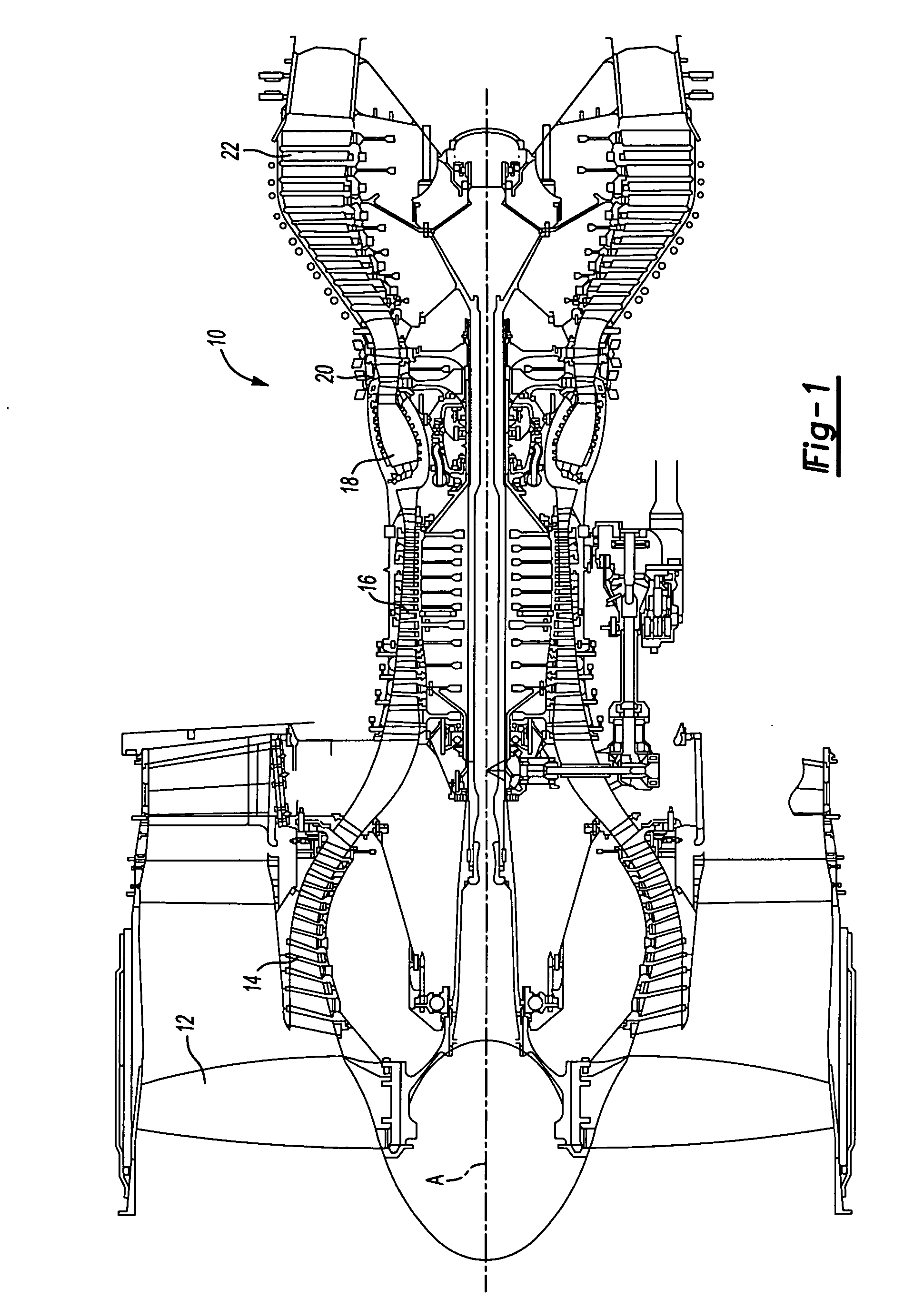

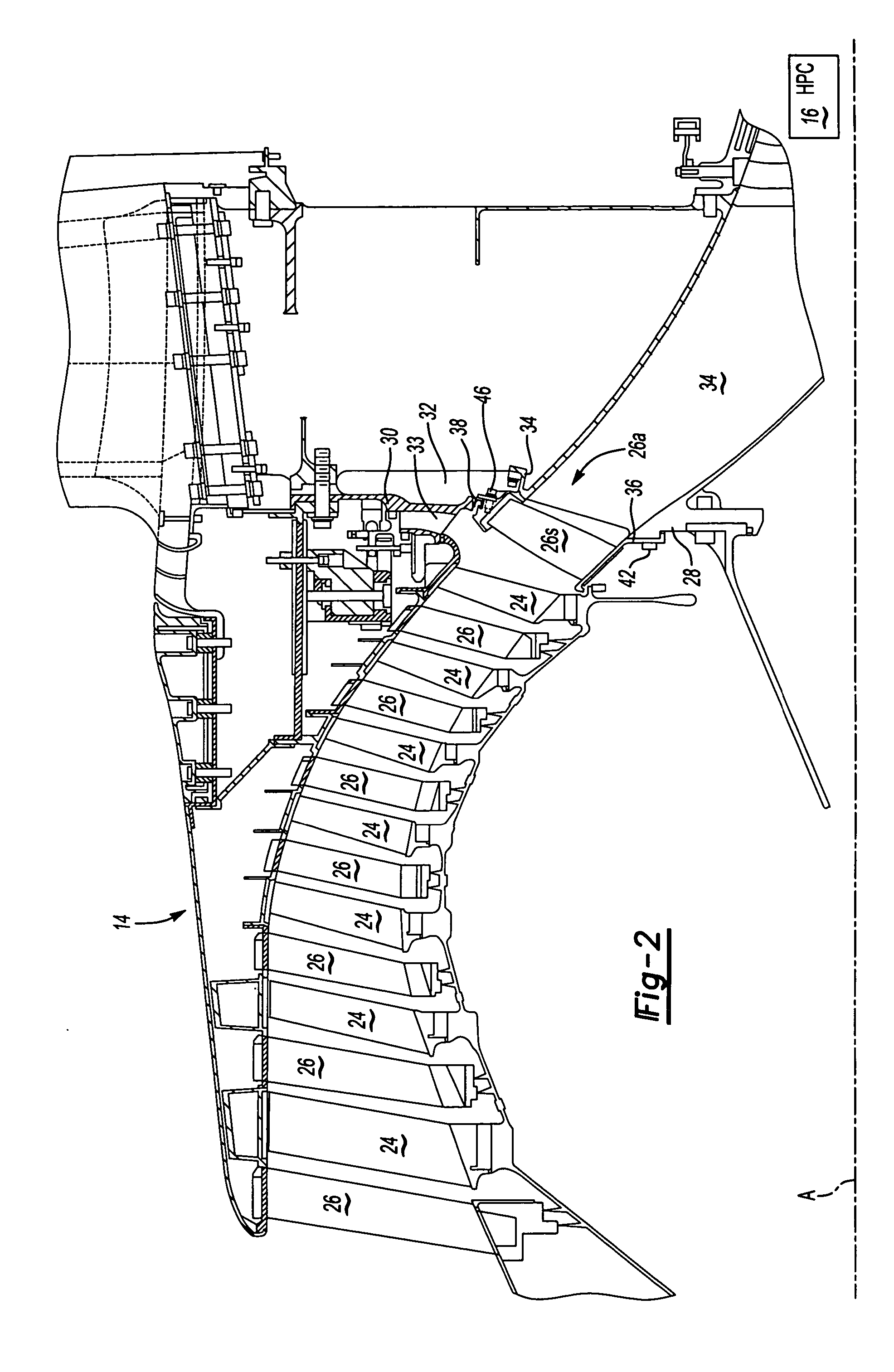

Stator vane assembly for a gas turbine engine

A low-pressure compressor exit stator assembly for a gas turbine includes a multiple of vanes mounted between a full hoop outer shroud and an inner shroud. The outer shroud and inner shroud are mounted to the intermediate case structure. A seal is located between the outer shroud and a bleed duct structure to accommodate thermal growth mismatch.

Owner:RTX CORP

Mounting assembly for igniter in a gas turbine engine combustor having a ceramic matrix composite liner

An assembly for mounting an igniter in a gas turbine engine combustor between an outer casing and an outer liner, wherein a longitudinal centerline axis extends through the gas turbine engine. The igniter mounting assembly includes a first spring member encircling a portion of said igniter and being positioned between a surface adjacent the outer casing and an outer surface of the outer liner, a first ring member connected to a first end of the first spring member adjacent the outer surface of the outer liner, and a second ring member connected to a second end of the first spring member adjacent the surface adjacent the outer casing. Accordingly, the igniter is able to maintain substantial alignment with respect to an opening in the outer liner while moving radially and / or axially with respect to the outer liner as the outer casing experiences thermal growth greater than the outer liner.

Owner:GENERAL ELECTRIC CO

Turbine shroud thermal distortion control

Owner:RAYTHEON TECH CORP

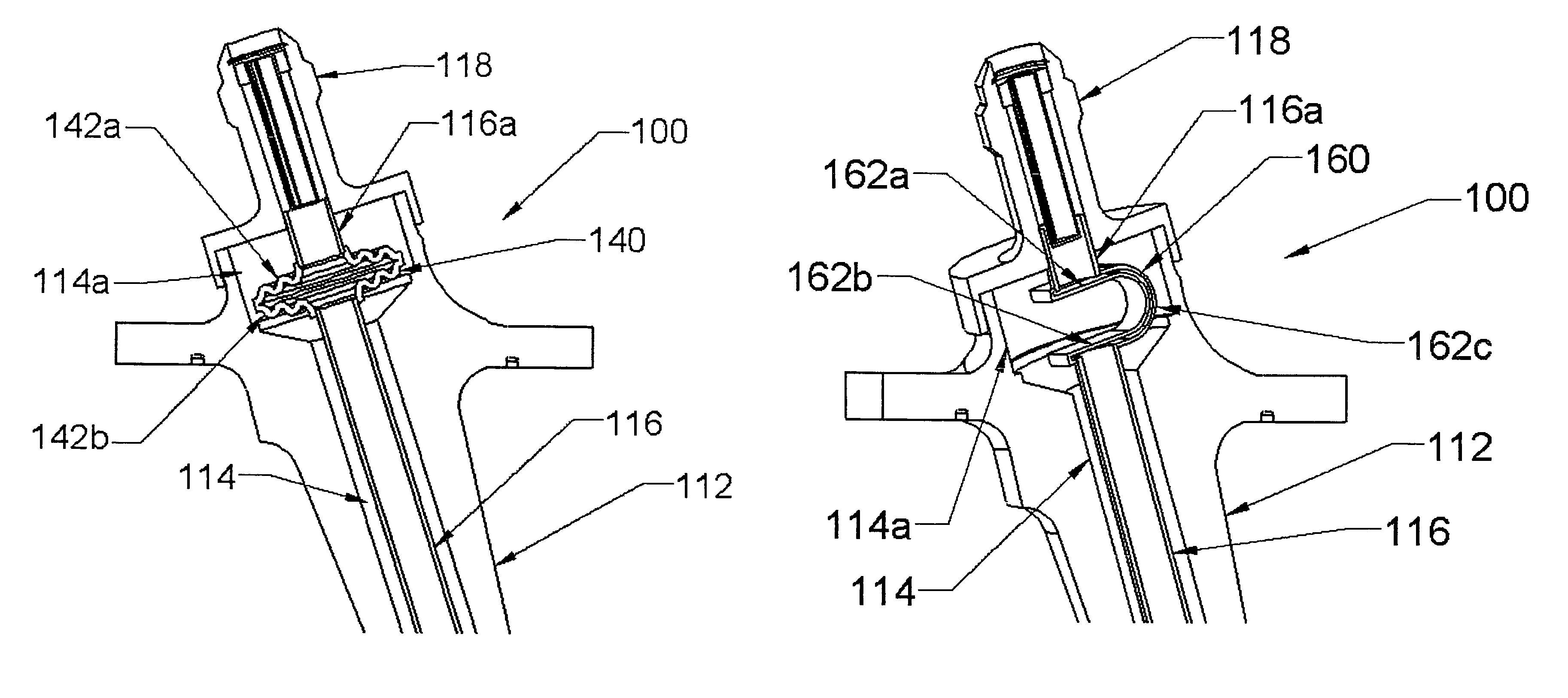

Fastened vane assembly

A vane assembly for a gas turbine is described wherein the vane assembly comprises a first vane and a second vane connected together by a plurality of flanges, at least one fastener, and at least one spring plate. The fastener and hole diameters in the respective flanges are sized such that the first vane and second vane are essentially pinned together along their inner flanges and allowed to adjust due to thermal growth along their outer flanges, while maintaining a constant seal along both inner and outer platform edges. The thermal growth along the outer flanges is made possible by oversized flange holes relative to the diameter of the fastener.

Owner:H2 IP UK LTD

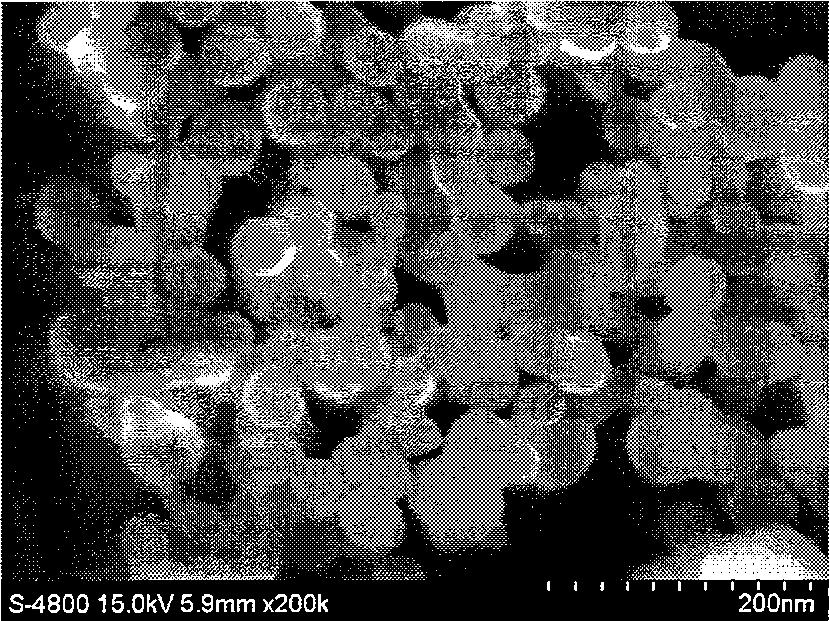

Ion thermal growth method of near infrared light upper conversion fluoride nano crystal

InactiveCN101476151ALow melting pointNon-volatilePolycrystalline material growthFrom normal temperature solutionsSolubilityLuminous intensity

The invention relates to an ion thermal growth method for converting fluoride nano crystal near infrared light which includes steps as follows: weighing some solid yttrium nitrate (lanthanum nitrate), ytterbium nitrate, erbium nitrate (thulium nitrate or holmium nitrate) pro rata. Mol ratio of the rare earth ion is that yttrium ion (lanthanum ion) : ytterbium ion : erbium ion (thulium ion, holmium ion) equal to 70-90 : 0 : 0.001-15; adding tetrafluoroborate type ion liquor into the mixing solid, selective adding some NaCl solid according with various basic, then placing the mixing solution into a high pressure reaction kettle with polyfluortetraethylene lining, placing into an oven for heating reacting, finally, washing, centrifugating, drying and obtaining the product. The prepared nano upper converting fluorescence material has small and uniform granule, strong lighting strength, better water-solubility and can satisfy need of biomolecule fluorescence mark material.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Air metering device for gas turbine engine

An air metering apparatus for a secondary air system of gas turbine engine includes a metering gap defined between surfaces comprised of one or more metals having one of similar coefficients of thermal expansion or similar thermal expansions at an operating temperature. Provided is an air metering gap which undergoes thermal growth in a way which provides a suitable air metering gap during engine running conditions.

Owner:PRATT & WHITNEY CANADA CORP

Stator vane assembly for a gas turbine engine

A low-pressure compressor exit stator assembly for a gas turbine includes a multiple of vanes mounted between a full hoop outer shroud and an inner shroud. The outer shroud and inner shroud are mounted to the intermediate case structure. A seal is located between the outer shroud and a bleed duct structure to accommodate thermal growth mismatch.

Owner:RAYTHEON TECH CORP

Fastened vane assembly

A vane assembly for a gas turbine is described wherein the vane assembly comprises a first vane and a second vane connected together by a plurality of flanges, at least one fastener, and at least one spring plate. The fastener and hole diameters in the respective flanges are sized such that the first vane and second vane are essentially pinned together along their inner flanges and allowed to adjust due to thermal growth along their outer flanges, while maintaining a constant seal along both inner and outer platform edges. The thermal growth along the outer flanges is made possible by oversized flange holes relative to the diameter of the fastener.

Owner:H2 IP UK LTD

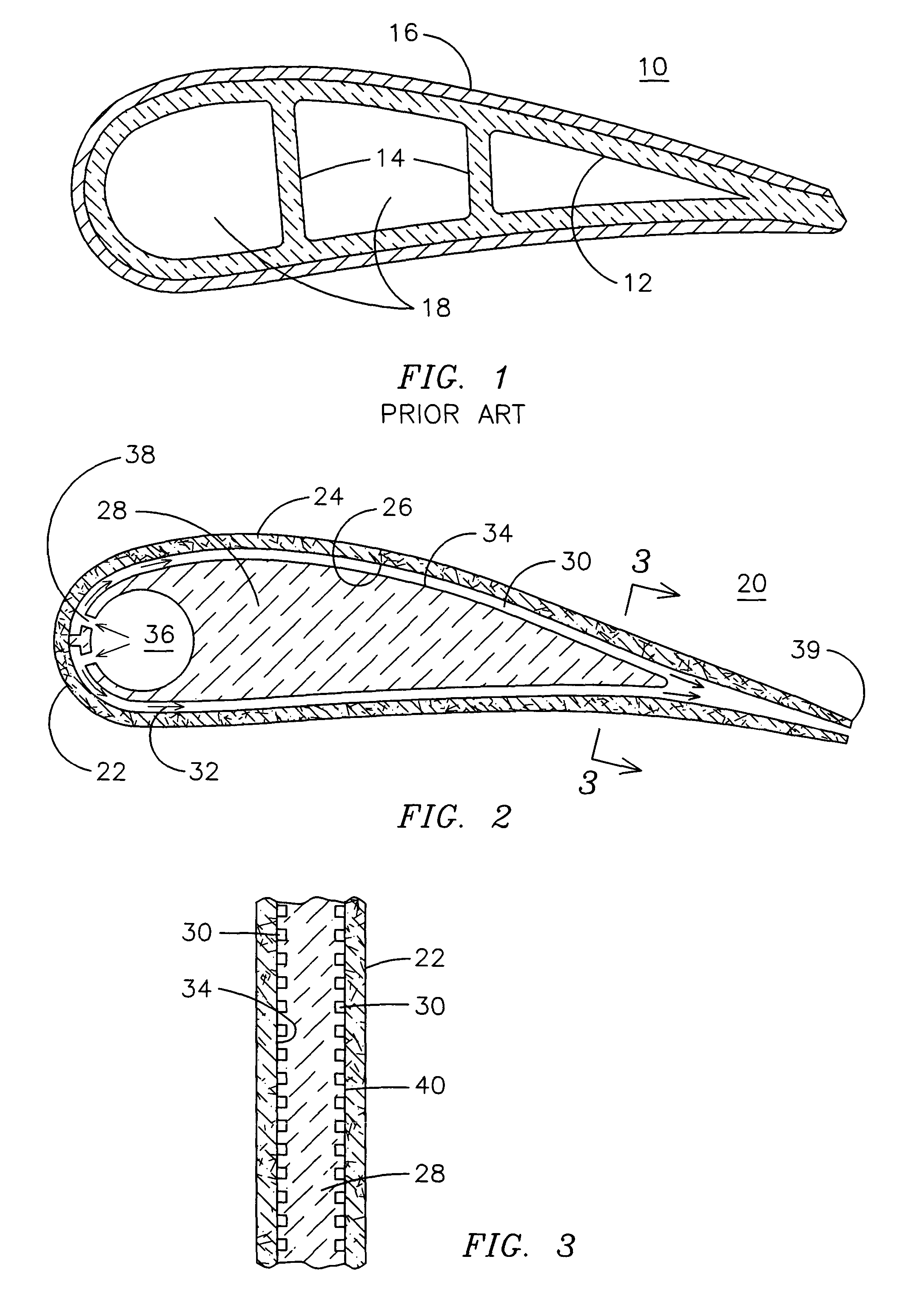

Fuel nozzle assembly

A fuel nozzle assembly is provided. The assembly includes an outer nozzle body having a first end and a second end and at least one inner nozzle tube having a first end and a second end. One of the nozzle body or nozzle tube includes a fuel plenum and a fuel passage extending therefrom, while the other of the nozzle body or nozzle tube includes a fuel injection hole slidably aligned with the fuel passage to form a fuel flow path therebetween at an interface between the body and the tube. The nozzle body and the nozzle tube are fixed against relative movement at the first ends of the nozzle body and nozzle tube, enabling the fuel flow path to close at the interface due to thermal growth after a flame enters the nozzle tube.

Owner:GENERAL ELECTRIC CO

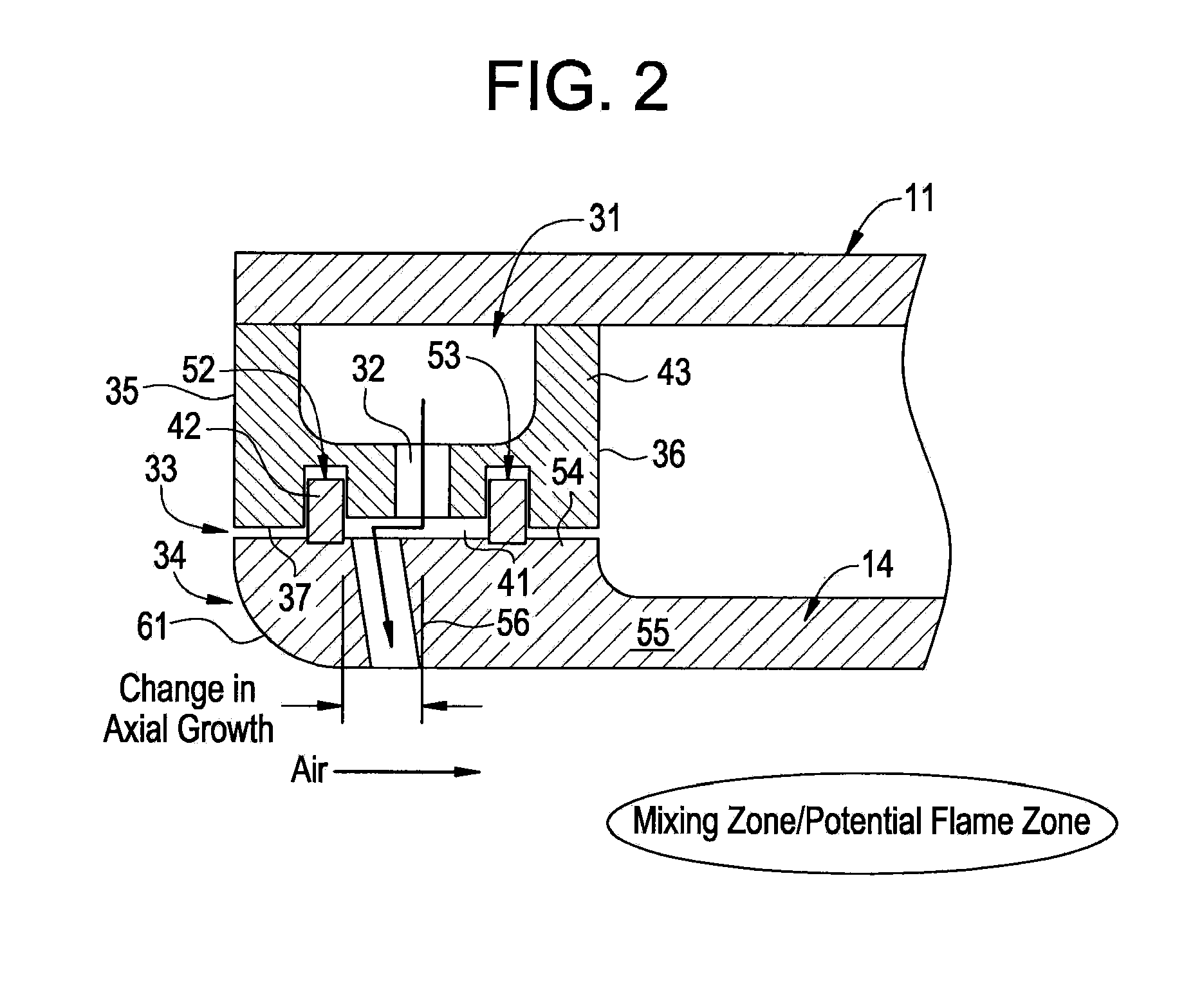

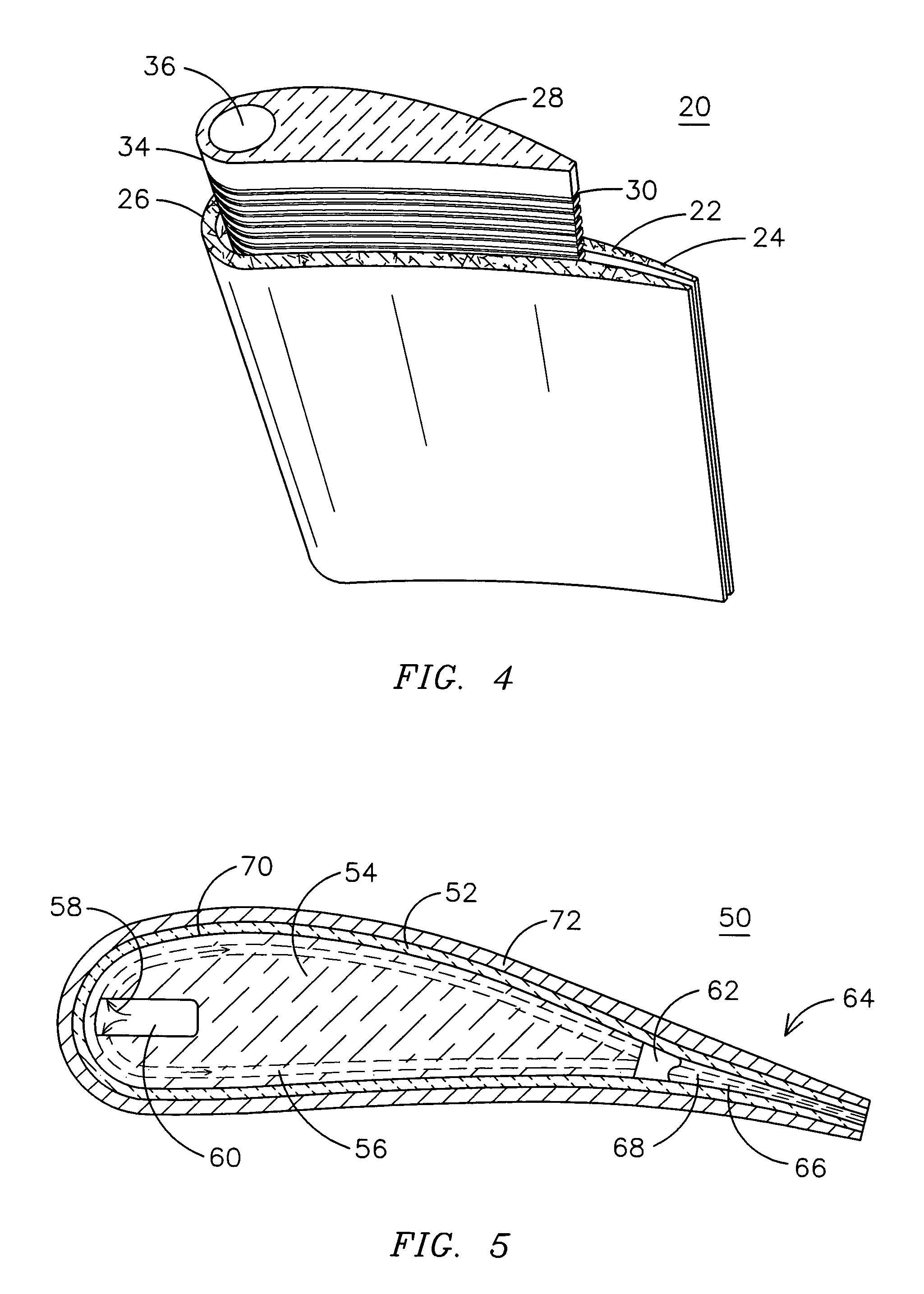

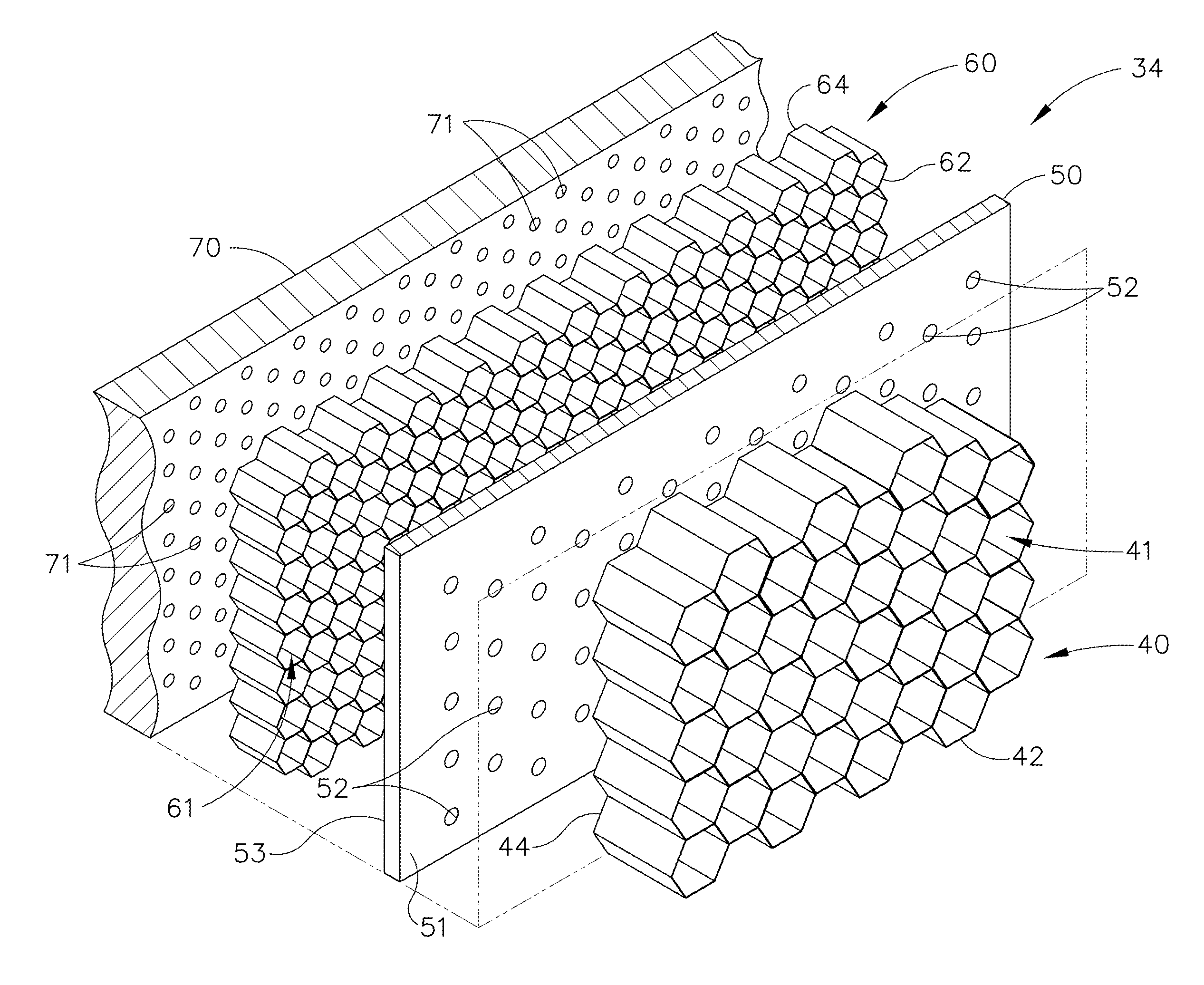

Strain tolerant aggregate material

A material (100) formed of a sintered aggregation of ceria particles (106), mullite particles (108) and an alumina matrix material (110). Differential thermal expansion of the ceria and mullite particles generates thermal stress sufficient to create micro-cracking of the ceria particles. The ratio of ceria to mullite may be selected to achieve a desired coefficient of thermal expansion for matching the thermal growth of a mating CMC material (102). The micro cracks provide the material with a desired degree of strain tolerance useful in high temperature applications such as a solid core gas turbine vane (20).

Owner:SIEMENS ENERGY INC

Reduced noise valve stack connection

ActiveUS6968923B2Minimize and eliminate excessive force and bending momentAvoid formingValve members for absorbing fluid energySpray nozzlesNoise levelEngineering

Disclosed is a silencer system configured to allow for thermal growth thereof while attenuating noise created by expansion of high-pressure fluid flowing therethrough. The silencer system comprises a tubular inner sleeve, a tubular flexible bellows, a tubular vent stack and a muffler disc. The inner sleeve has a sleeve inlet and a sleeve outlet. The inner sleeve is concentrically disposed in spaced relation within the bellows which is concentrically disposed in spaced relation within the vent stack. The bellows is configured to allow for axial and lateral movement of the inner sleeve relative to the vent stack when fluid passes through the silencer system to minimize excessive deflective forces and bending moments on the silencer system. The muffler disc is oriented relative to the sleeve outlet such that the high-pressure fluid impinges the muffler disc prior to creating shockwaves which may otherwise result in the production of high noise levels.

Owner:CONTROL COMPONENTS INC

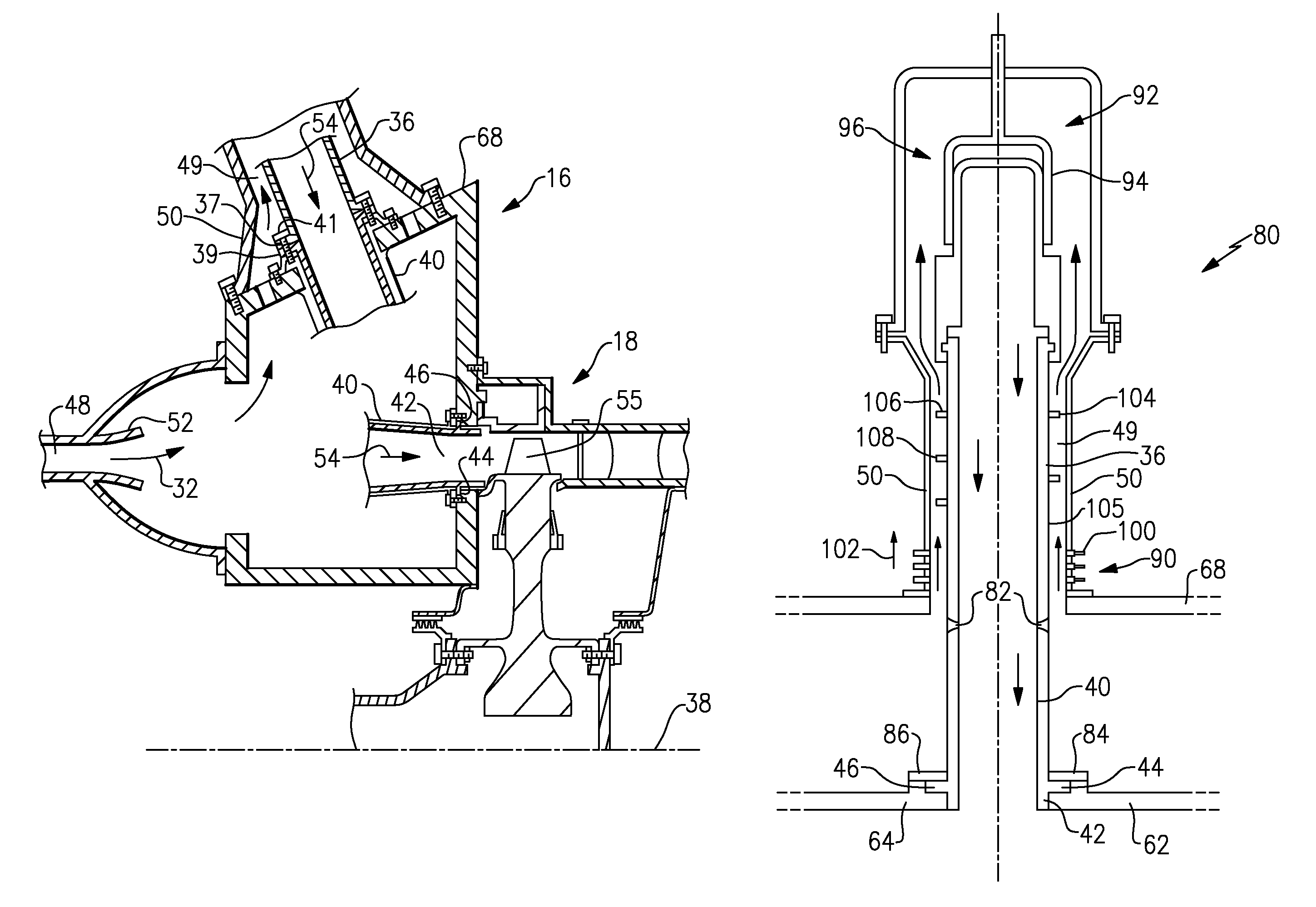

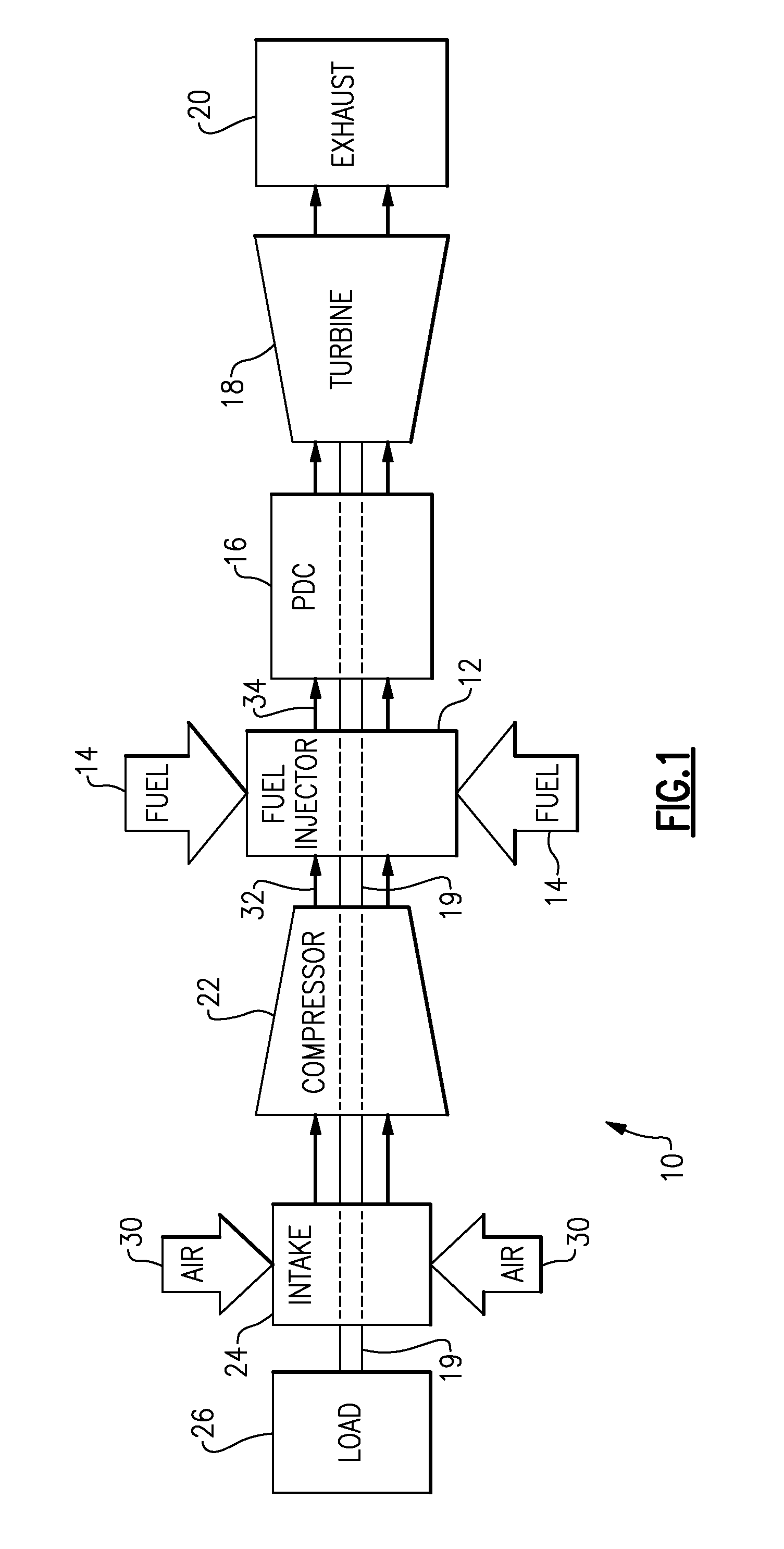

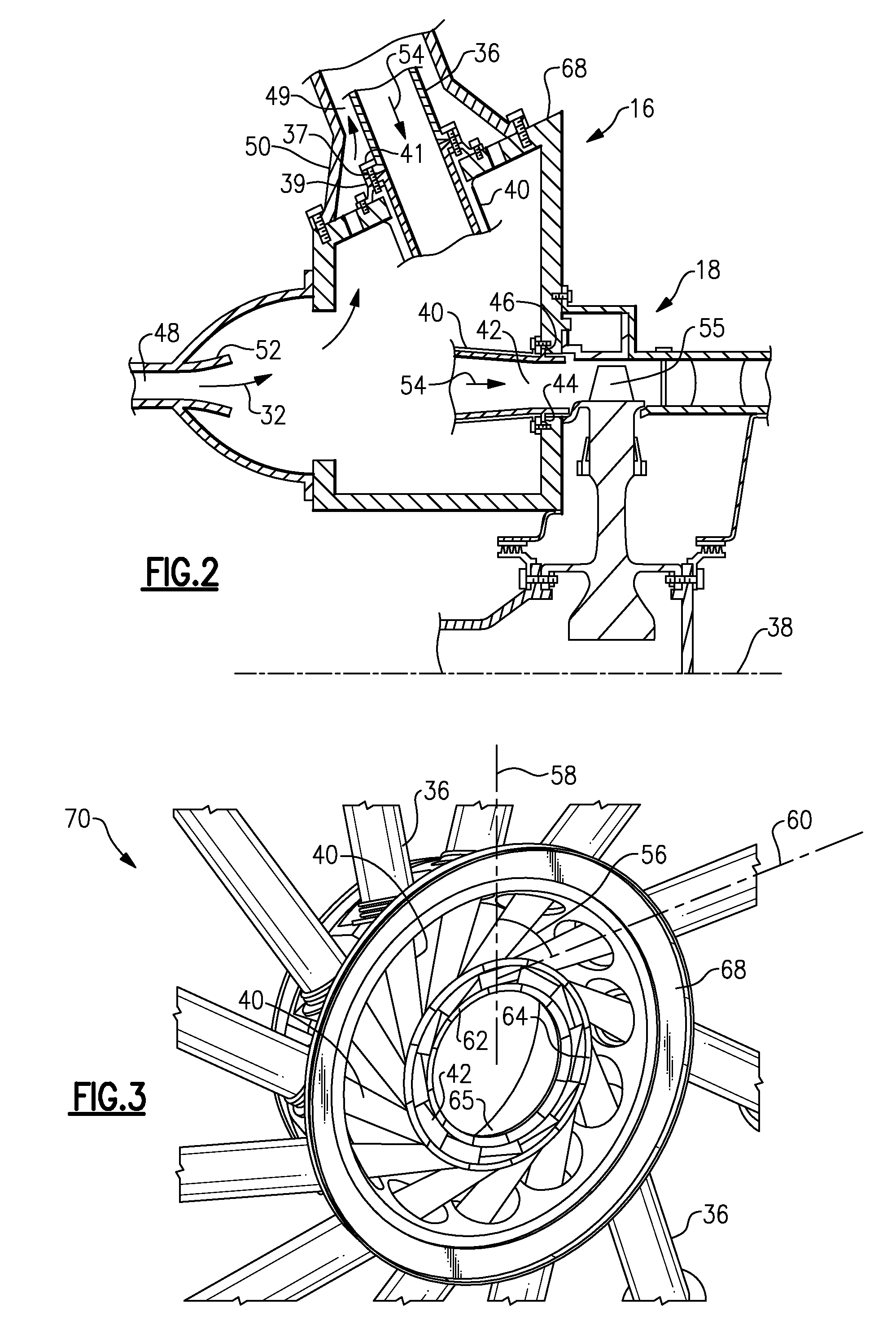

Pulse detonation combustor

A pulse detonation combustor including a plurality of nozzles engaged with one another via mating surfaces to support a gas discharge annulus in a circumferential direction. The pulse detonation combustor also including multiple pulse detonation tubes extending for the nozzles and a plurality of thermal expansion control joints coupled to the plurality of pulse detonation tubes. Each of the plurality of thermal expansion control joints is configured to facilitate independent thermal growth of each of the plurality of pulse detonation tubes. The thermal expansion control joints may be configured as a bellows expansion joint or a sliding expansion joint.

Owner:GENERAL ELECTRIC CO

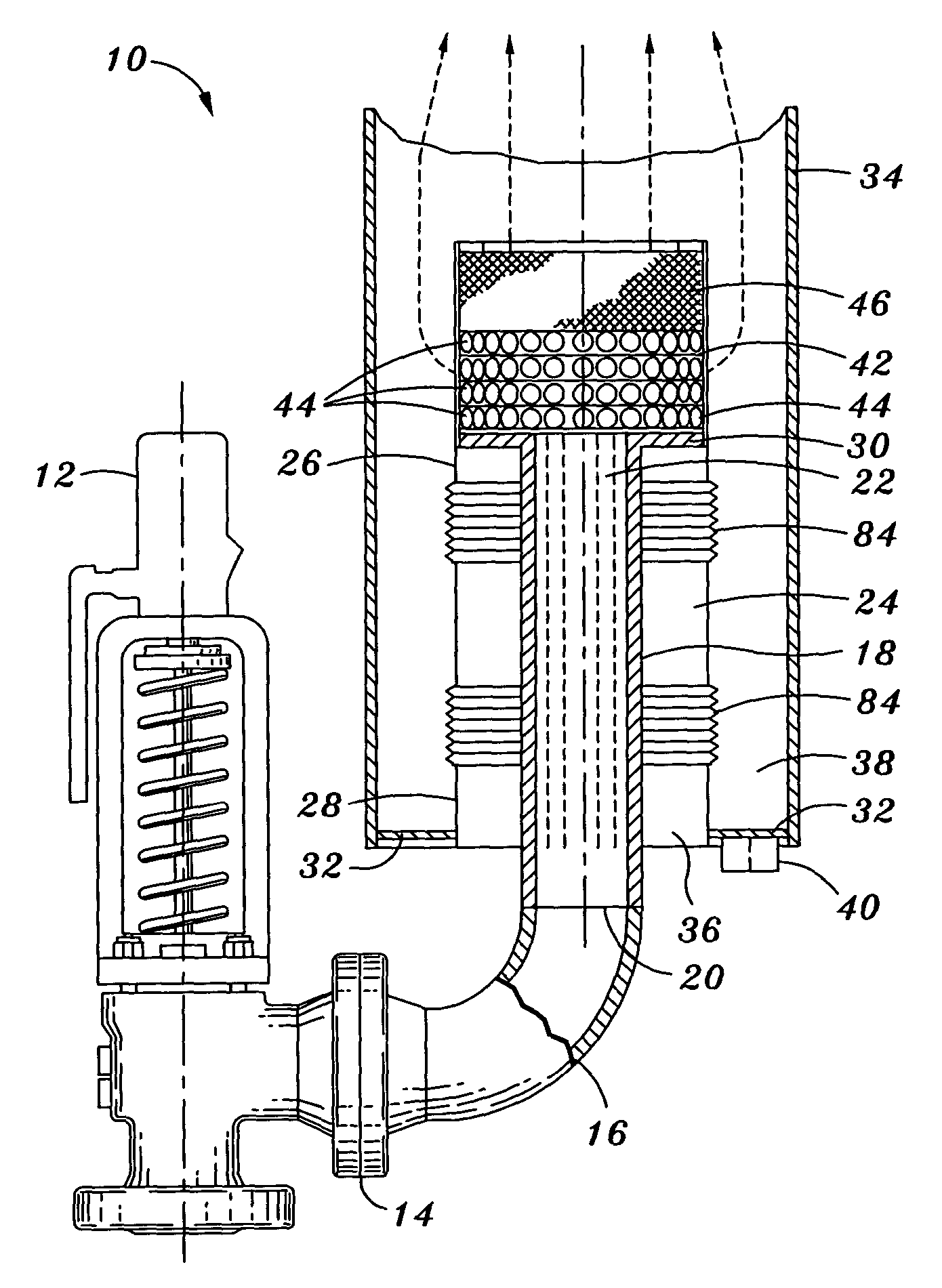

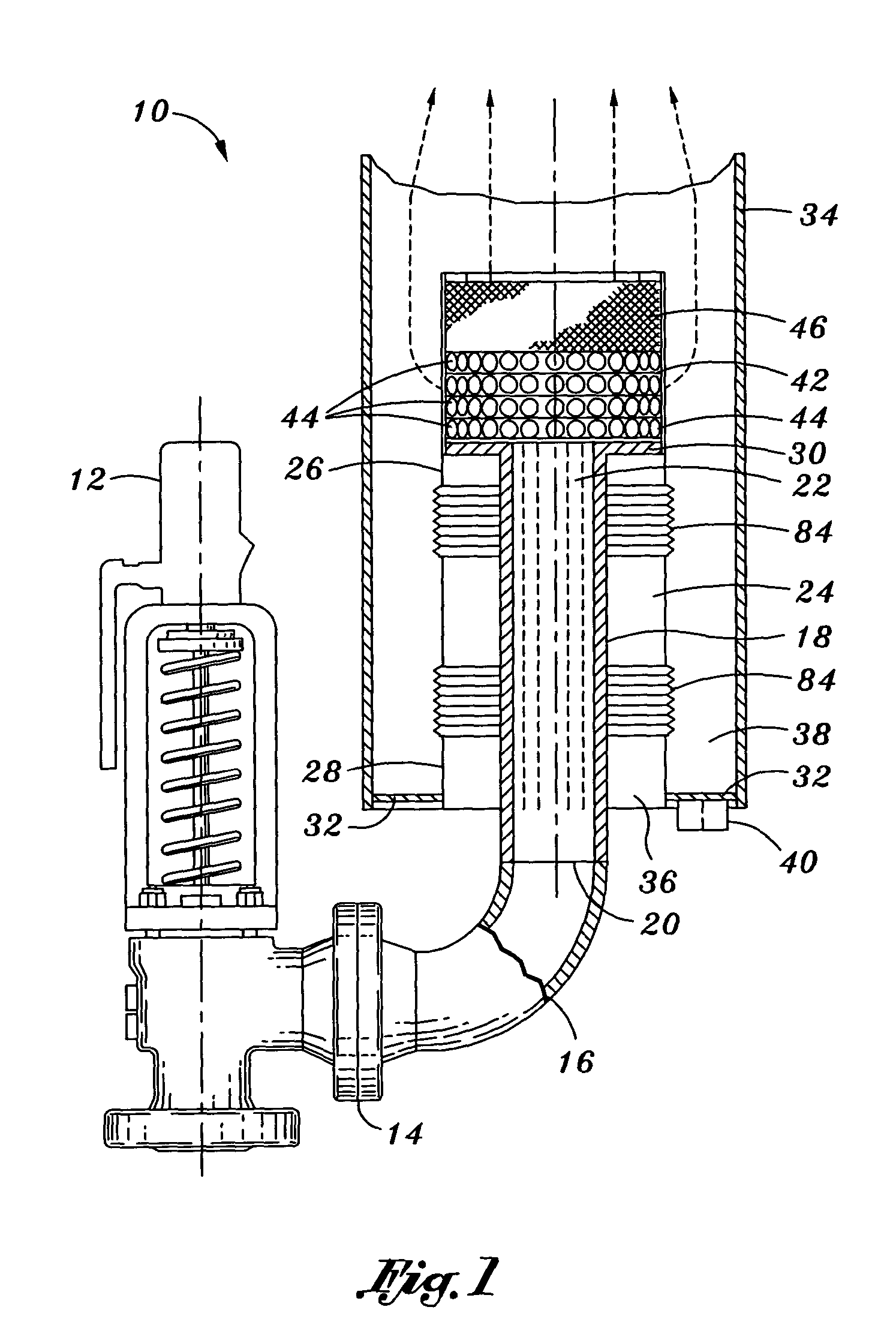

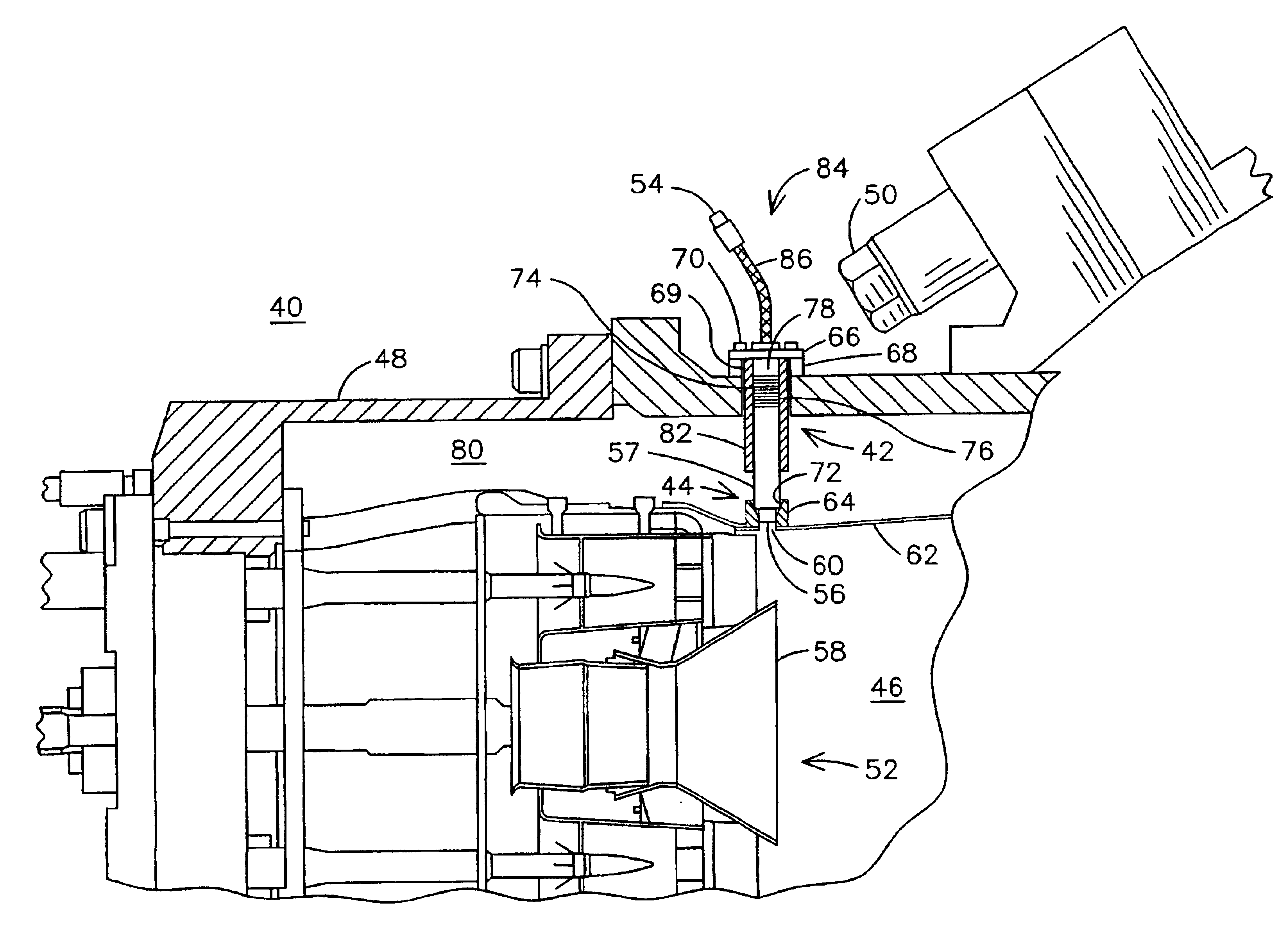

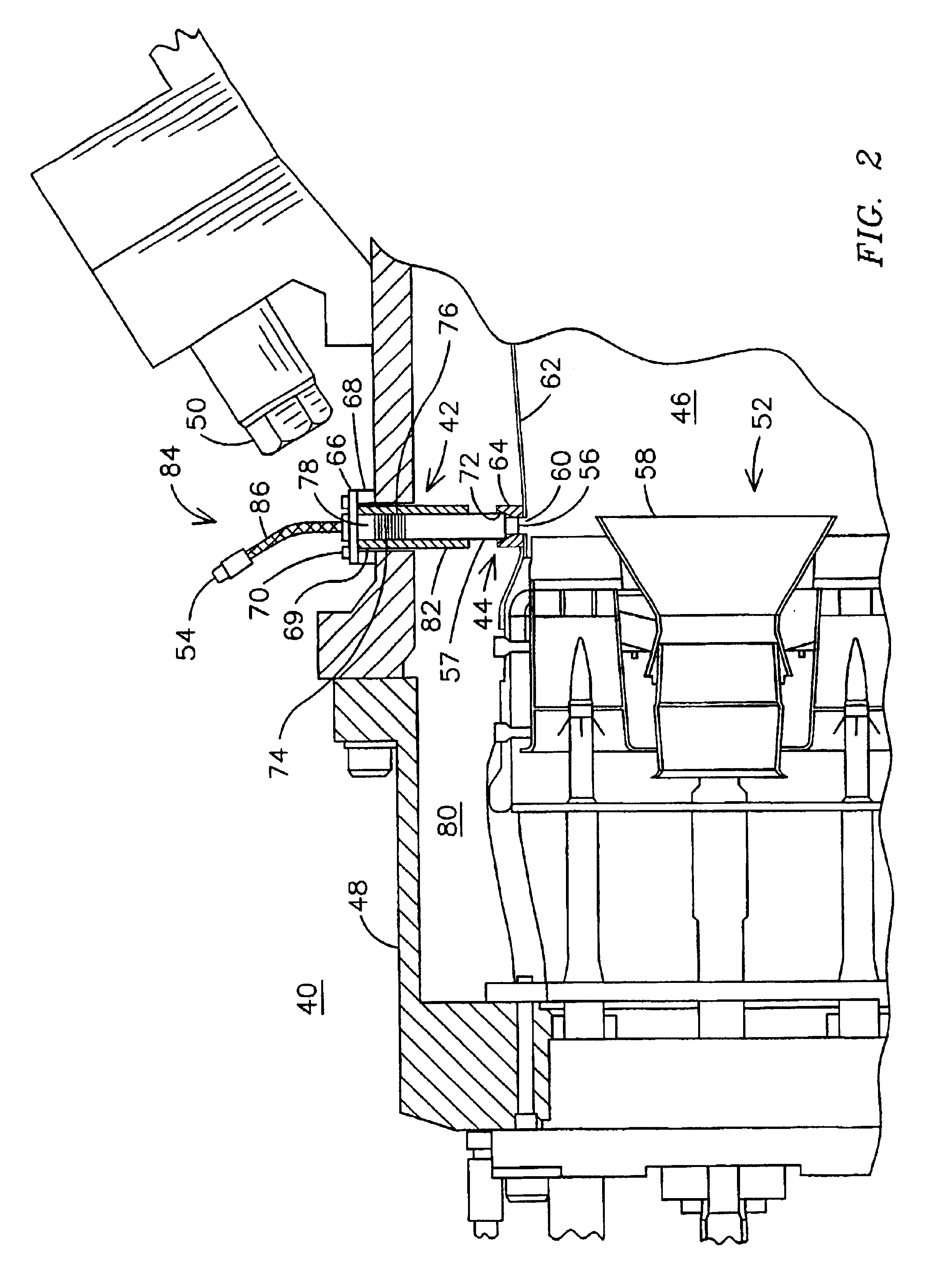

Gas turbine with flexible combustion sensor connection

InactiveUS6843061B2Easy maintenanceAvoid excessively strict mechanical alignment criterionGas turbine plantsTurbine/propulsion fuel controlCombustorCombustion chamber

A gas turbine engine (40) having an active combustion control system (54) including a sensor element (44) positioned proximate the combustion chamber (46) as part of a sensor assembly (84) including a spring-action bellows (74). The sensor assembly is installed through an opening (69) in the casing (48) of the engine to make contact with the combustor wall (62). The bellows is compressed from its resting position by tightening mounting bolts (70) against a mounting flange (66) of the sensor assembly. The spring action of the bellows ensures contact between the sensing assembly and the combustor wall in spite of differential thermal growth between the casing and the combustor. The sensor element may be replaced by simply removing the mounting bolts without further disassembly of the engine.

Owner:SIEMENS ENERGY INC

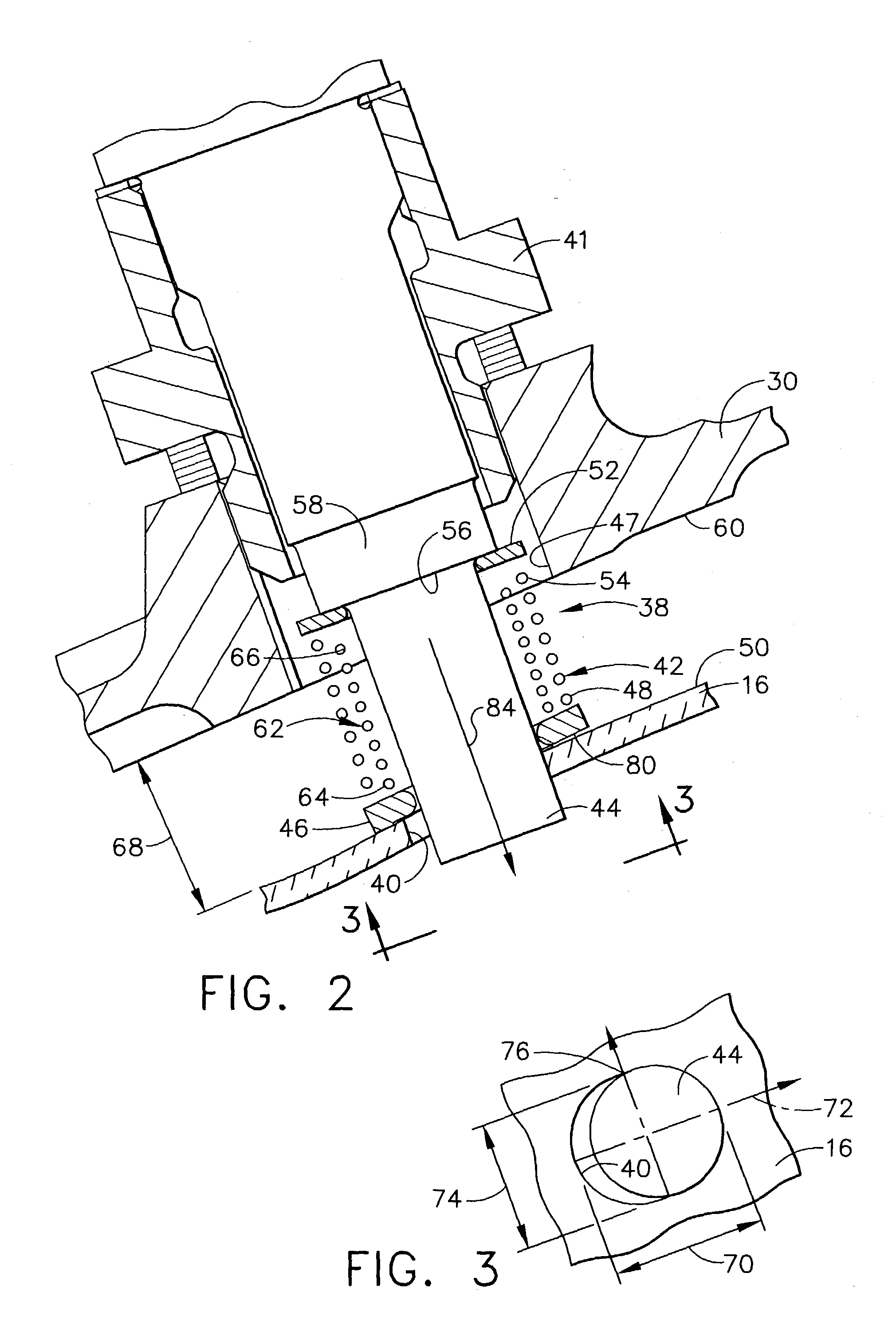

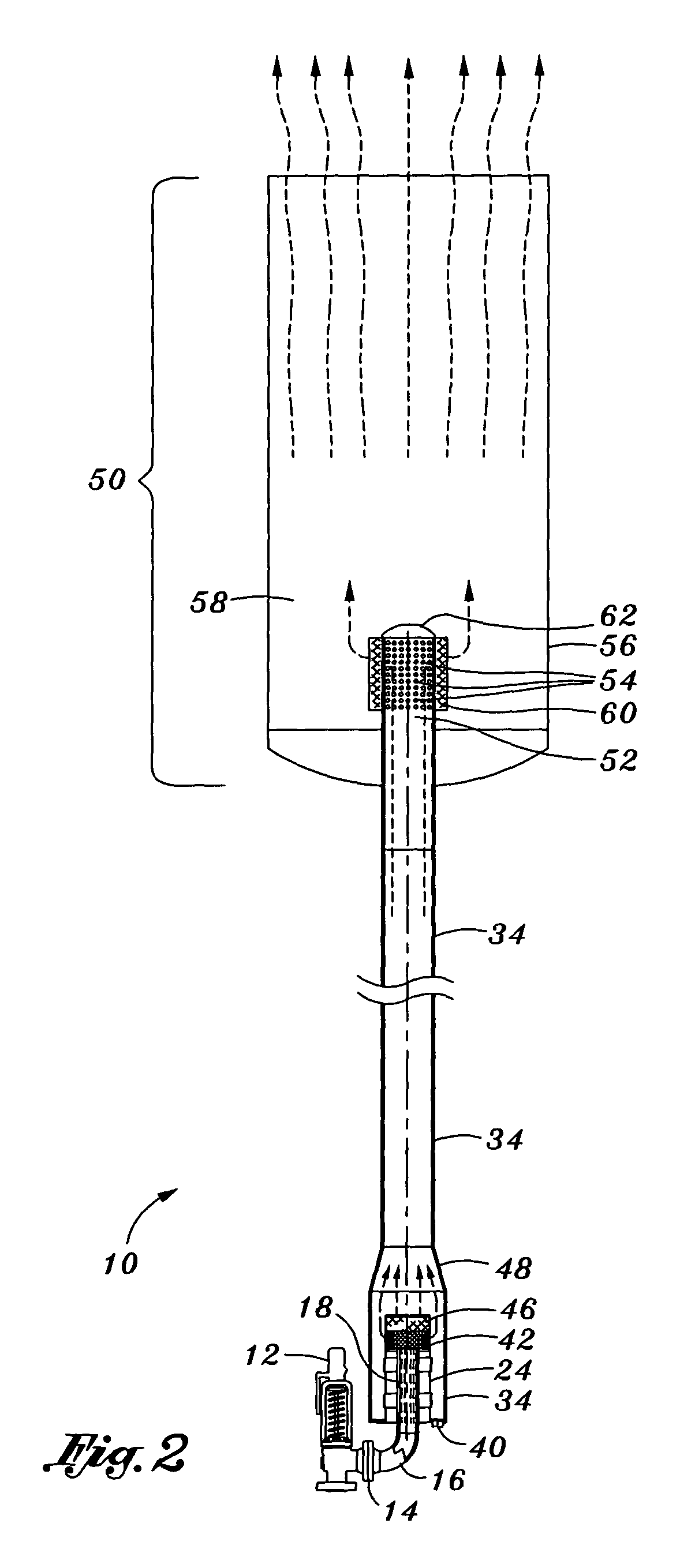

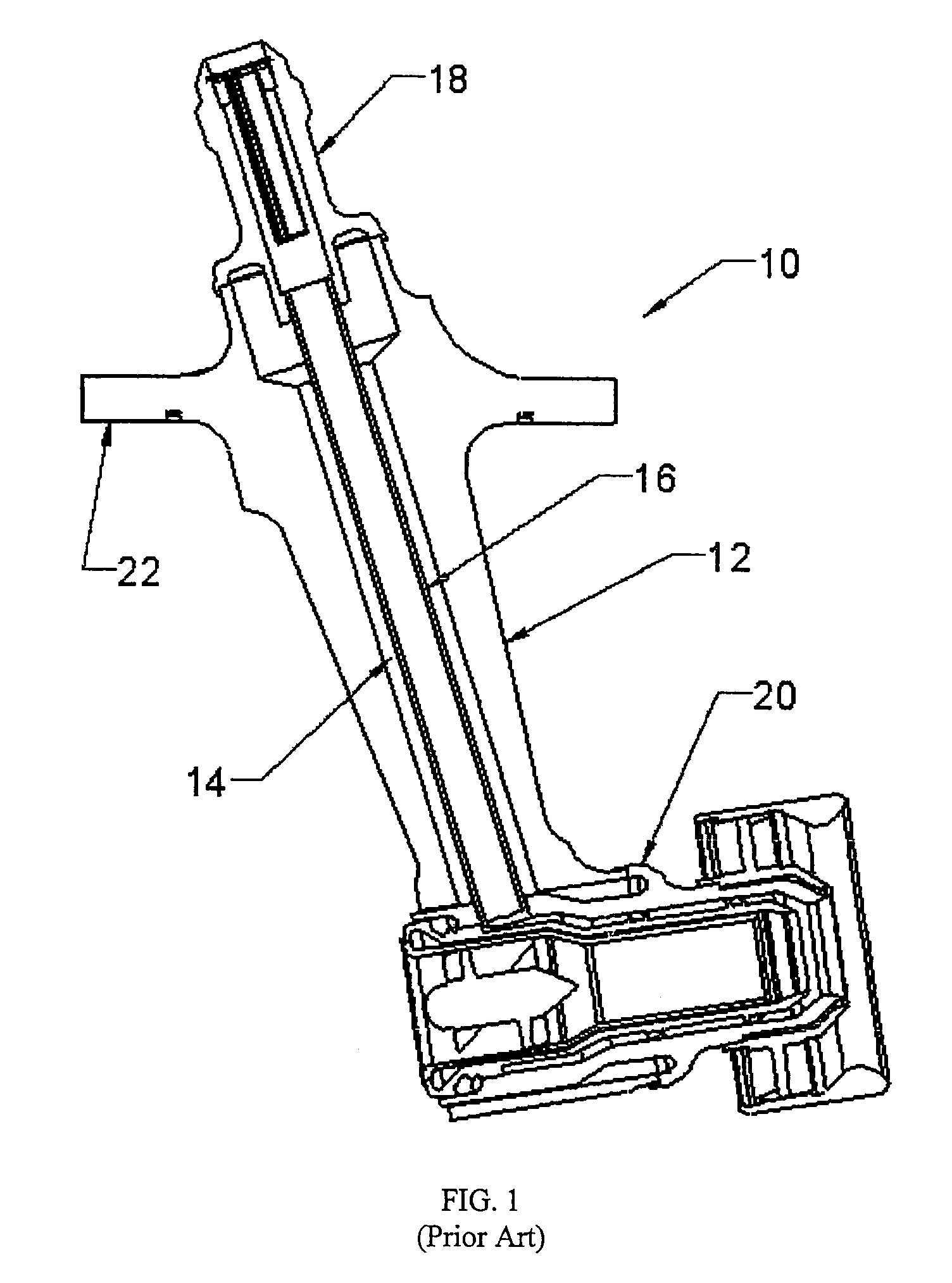

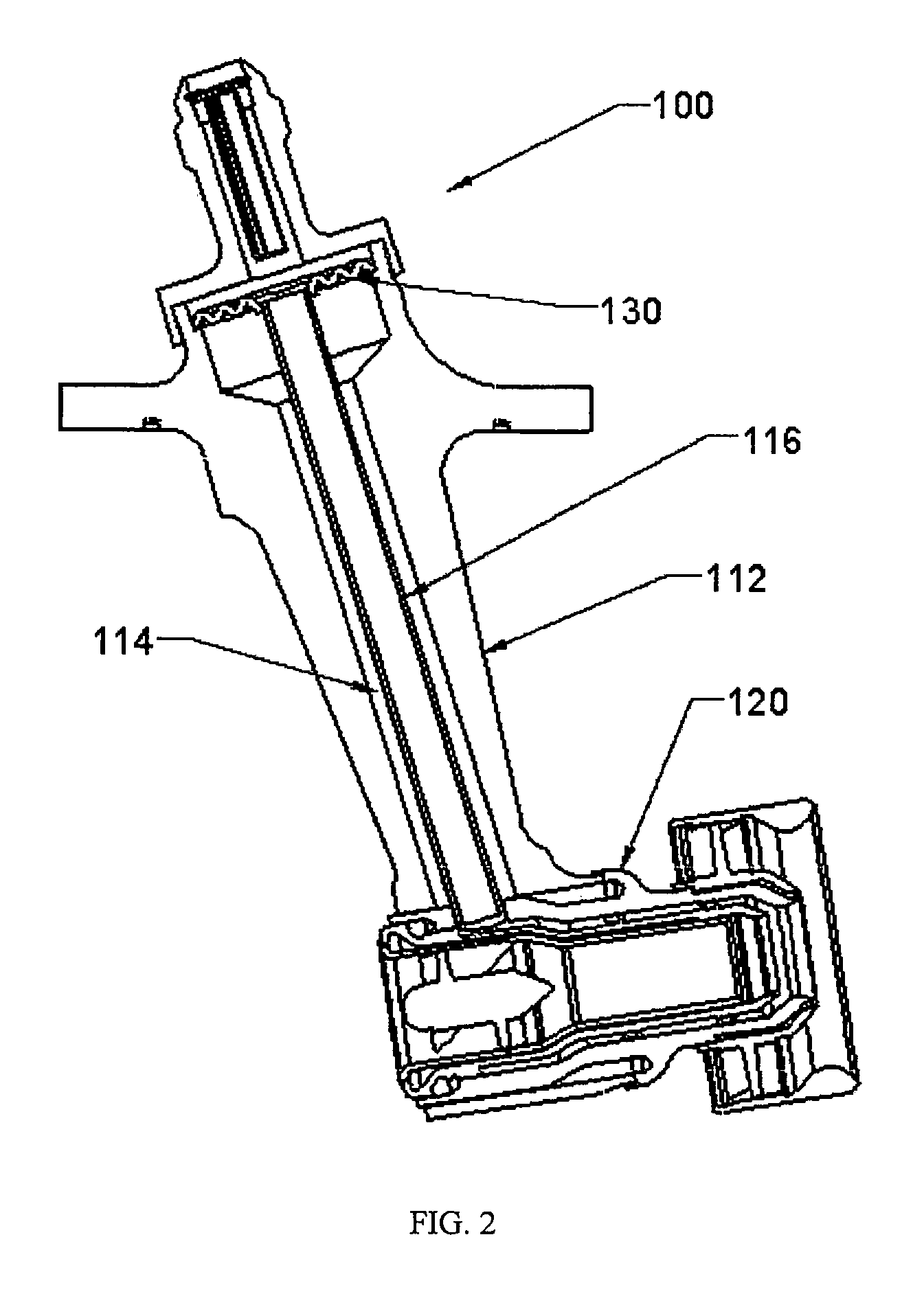

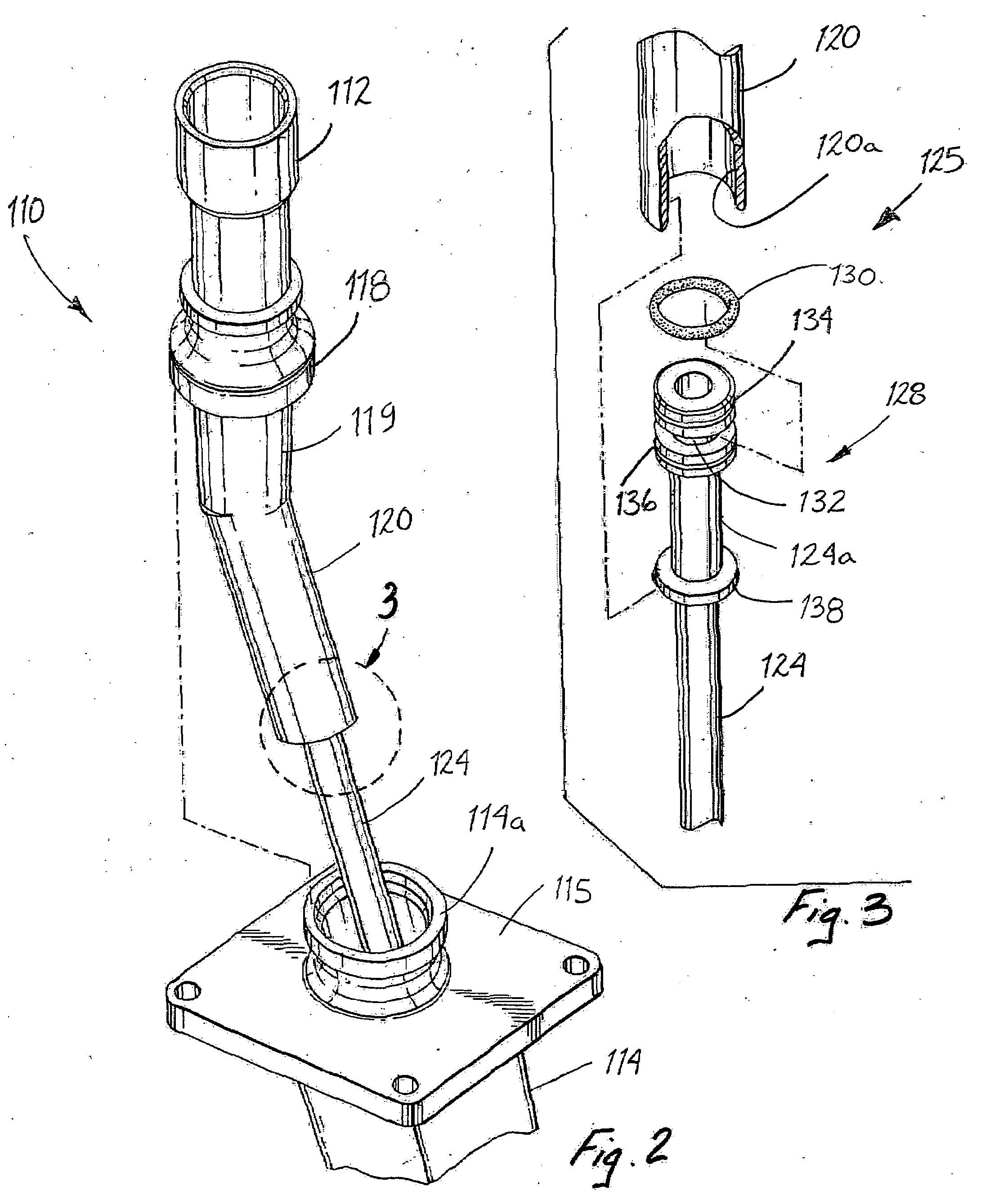

Apparatus and method to compensate for differential thermal growth of injector components

A fuel injector for a gas turbine engine is disclosed that includes an injector body having a bore, a fitting at an inlet end of the injector body for receiving fuel, an atomizer at an outlet end of the injector body for delivering atomized fuel to a combustor of the gas turbine engine, a fuel tube disposed within the bore of the injector body for delivering fuel from the fitting to the atomizer, the fuel tube having an inlet end portion adjacent the fitting and an outlet end portion joined to the atomizer, and structure joined to the inlet end portion of the fuel tube to compensate for thermal growth of the injector body relative to the fuel tube during engine operation.

Owner:DELAVAN

Gas turbine laminate seal assembly comprising first and second honeycomb layer and a perforated intermediate seal plate in-between

InactiveUS20160215646A1Reduce gapImproved differentialEngine manufactureEfficient propulsion technologiesHoneycombThermal growth

A laminate seal assembly, disposed on a stator seal portion and opposite a rotor seal portion of a gas turbine engine comprises a first honeycomb layer having a first edge which engages the rotor portion and a second edge distal from said rotor seal portion, a plurality of honeycomb cells extending between the first edge and the second edge, an intermediate seal plate having a first material surface and a second material surface, the first material surface disposed against the second edge of the first honeycomb layer, a low conductivity structure disposed on the second surface, and a backing plate disposed on against said low conductivity structure, wherein the stator portion may be tuned for thermal growth to match the thermal growth of the rotor portion.

Owner:GENERAL ELECTRIC CO

Turbine shroud thermal distortion control

InactiveUS20090272122A1Uniform growthImprove efficiencyPropellersPump componentsThermal growthTurbine

Owner:RAYTHEON TECH CORP

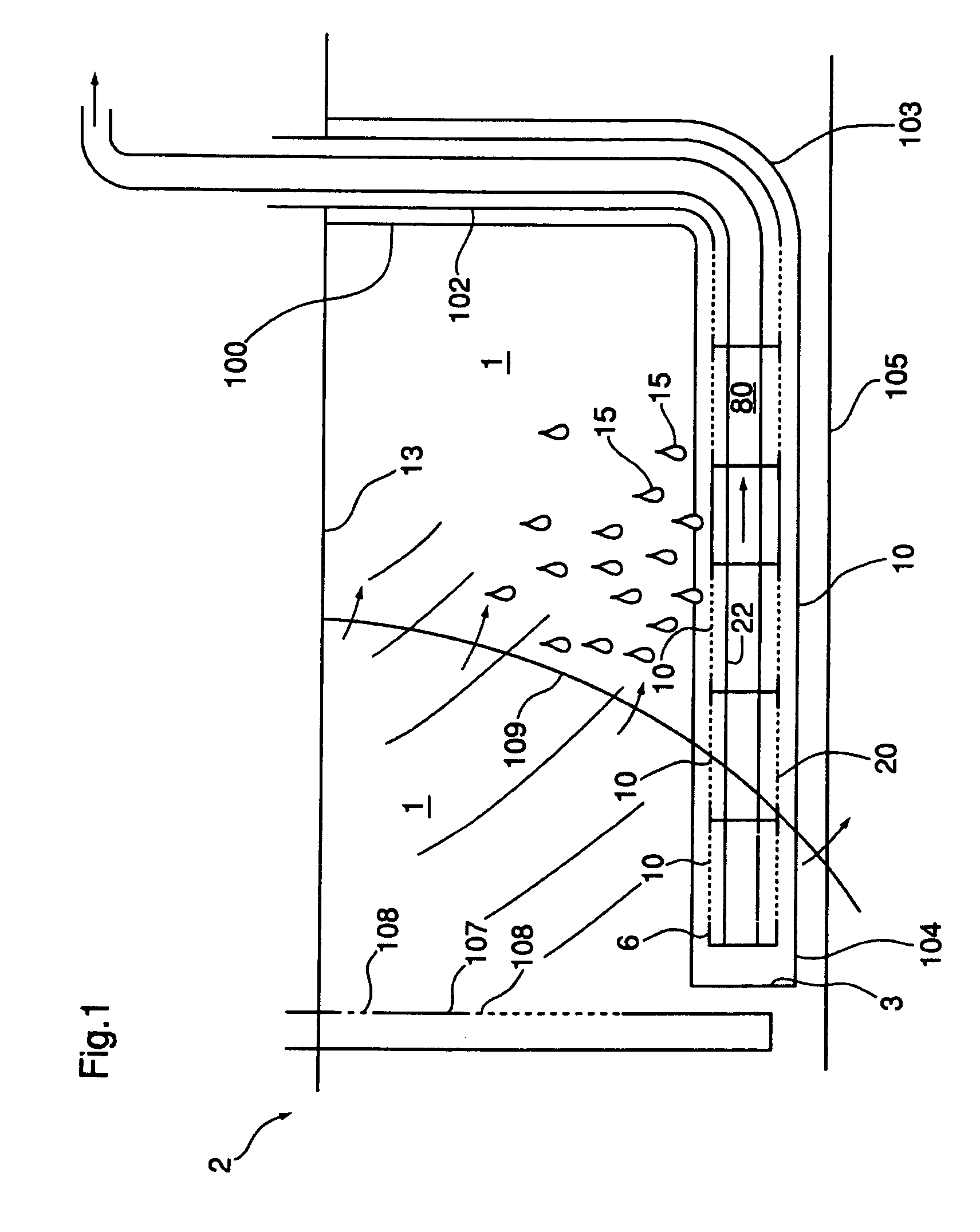

Combustion liner damper

ActiveUS20100089068A1Reduce vibrationReduce the overall heightPortable framesContinuous combustion chamberCombustorEngineering

The present invention are directed towards a system and method for providing a way of reducing the vibrations and wear between mating components of a gas turbine combustor. The gas turbine combustor includes a flow sleeve having a plurality of liner stops and a combustion liner located radially within the flow sleeve. Spring dampers are positioned between the combustion liner and the flow sleeve to restrict the relative movement between the flow sleeve and the combustion liner and dampen vibrations at their assembly location. The spring dampers are capable of compressing to permit thermal growth between the combustion liner and flow sleeve.

Owner:ANSALDO ENERGIA SWITZERLAND AG

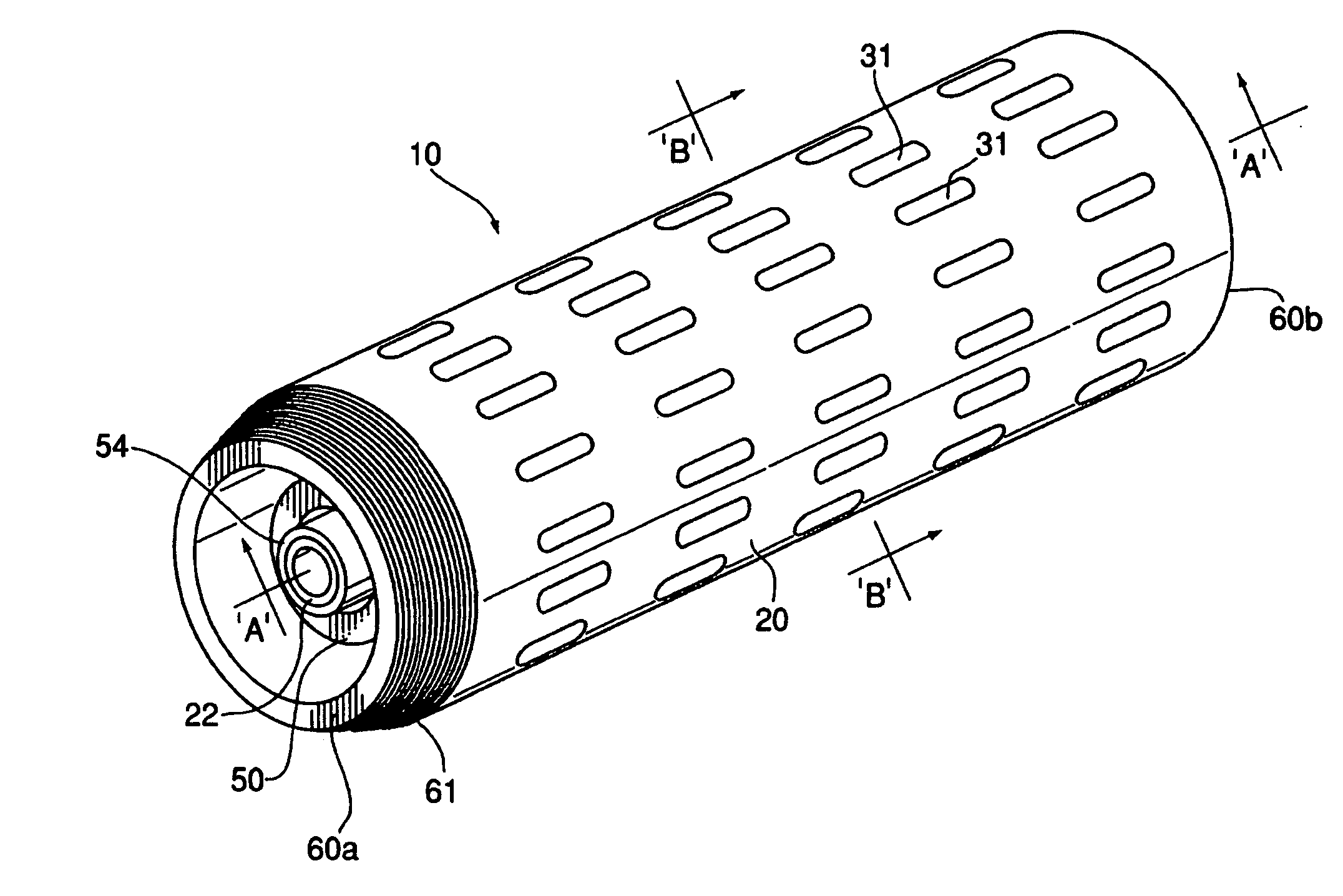

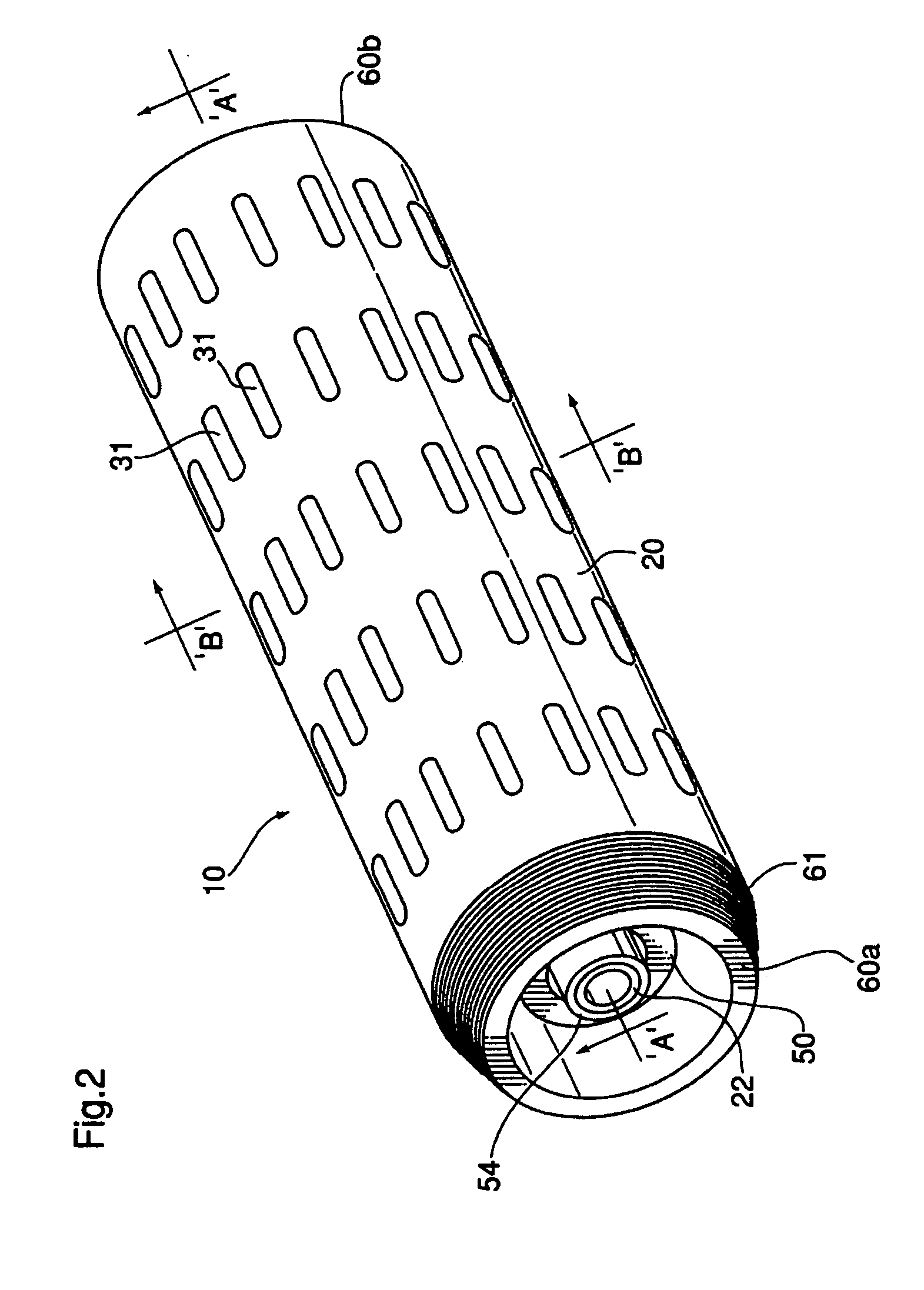

Well liner segments for in situ petroleum upgrading and recovery, and method of in situ upgrading and recovery

InactiveUS20100096120A1Extension of timeSimple methodDrilling rodsFluid removalRecovery methodEngineering

A well liner segment for use in hydrocarbon recovery processes. An elongate, typically cylindrical outer liner member, and an inner elongate liner member concentrically located therewithin is provided. Hydrocarbon upgrading catalyst is provided in the interstitial space between the two members. The outer liner members may be threadably coupled together. A slidable seal is provided between the outer liner and the inner liner to accommodated differential thermal growth between the two liners. A process for use of well liner segments having hydrocarbon upgrader catalyst pre-installed therein, is also provided, as is a method for manufacture of a well liner segment.

Owner:ARCHON TECH LTD

Turbine Static Structure for Reduced Leakage Air

ActiveUS20080148737A1Reduce leakageReduce stiffnessPump componentsGas turbine plantsThermal expansionThermal growth

A turbine static structure having reduced leakage air is disclosed. A static structure turbine support ring having few segments is disclosed in which the segments have improved thermal expansion capability with reduced air leakage. A plurality of radially extending slots are placed in the segments to reduce stiffness. In order to minimize air leakage through the support ring, generally circumferential slots are placed in the ring and connect with the generally radially extending slots. Positioned in each of the generally radially extending slots and generally circumferential slots, and in contact with each other, are two sheet metal plates. The plates are staked to the support ring structure so as to provide a seal member, yet compensate for thermal growth.

Owner:H2 IP UK LTD

Treatment method of improving oxidation resistance of thermal barrier coating

InactiveCN101994078APromote growthImprove high temperature service performanceMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionGas phase

The invention relates to a treatment method of improving oxidation resistance of a thermal barrier coating, belonging to the technical field of thermal barrier coating surface treatment and modification. High current pulse electron beam irradiation is utilized to realize electron beam physical vapor deposition to prepare a yttrium oxide stabilizing zirconium oxide thermal barrier coating to cap ceramic layer columnar crystals, thus the heat-shielding performance and the high temperature oxidation resistance of the coating are improved. The process conditions are shown as follows: the vacuum is 3.5*10<-2>Pa, the voltage is 15kV, the frequency is 1Hz, the pulse width is 120-150ms, the energy density is 10J / cm<2>-20J / cm<2>, the pulse time is 30-40 and the remelting layer thickness reaches at least 10 micrometers. The invention has the advantages that the electron beam physical vapor deposition layer columnar crystals are capped after the high current pulse electron beam irradiation is ended, and thus, the surface of the thermal barrier coating becomes smooth, no penetrable microcracks are generated, the oxygen element diffusion is effectively stopped, the growth of a thermal growth oxidation layer is relieved and the heat-shielding performance and the high temperature oxidation resistance of the thermal barrier coating are obviously improved.

Owner:DALIAN UNIV OF TECH

Dynamic sealing assembly to accommodate differential thermal growth of fuel injector components

ActiveUS20080098737A1Easy to store and protectBurnersTurbine/propulsion fuel supply systemsEngineeringThermal growth

A fuel injector for a gas turbine engine is disclosed which includes an inlet fitting for receiving fuel, a nozzle for issuing fuel into the gas turbine engine, an injector body extending between the inlet fitting and the nozzle and having and interior bore extending therethrough, and an elongated fuel tube disposed within the interior bore of the injector body for delivering fuel from the inlet fitting to the nozzle. The fuel tube has an inlet end portion dynamically associated with the inlet fitting and an outlet end portion rigidly connected to the nozzle. An adapter is operatively associated with either the inlet end section of the fuel tube or a reception bore formed with the inlet fitting of the injector for accommodating a seal member in a manner that permits thermal growth of the injector body relative to the fuel tube.

Owner:COLLINS ENGINE NOZZLES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com