Treatment method of improving oxidation resistance of thermal barrier coating

A technology of thermal barrier coating and treatment method, applied in coating, metal material coating process, ion implantation plating, etc. Improve the thermal conductivity of the coating and other issues, to achieve the effect of improving high temperature service performance, improving structure morphology and surface compactness, and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

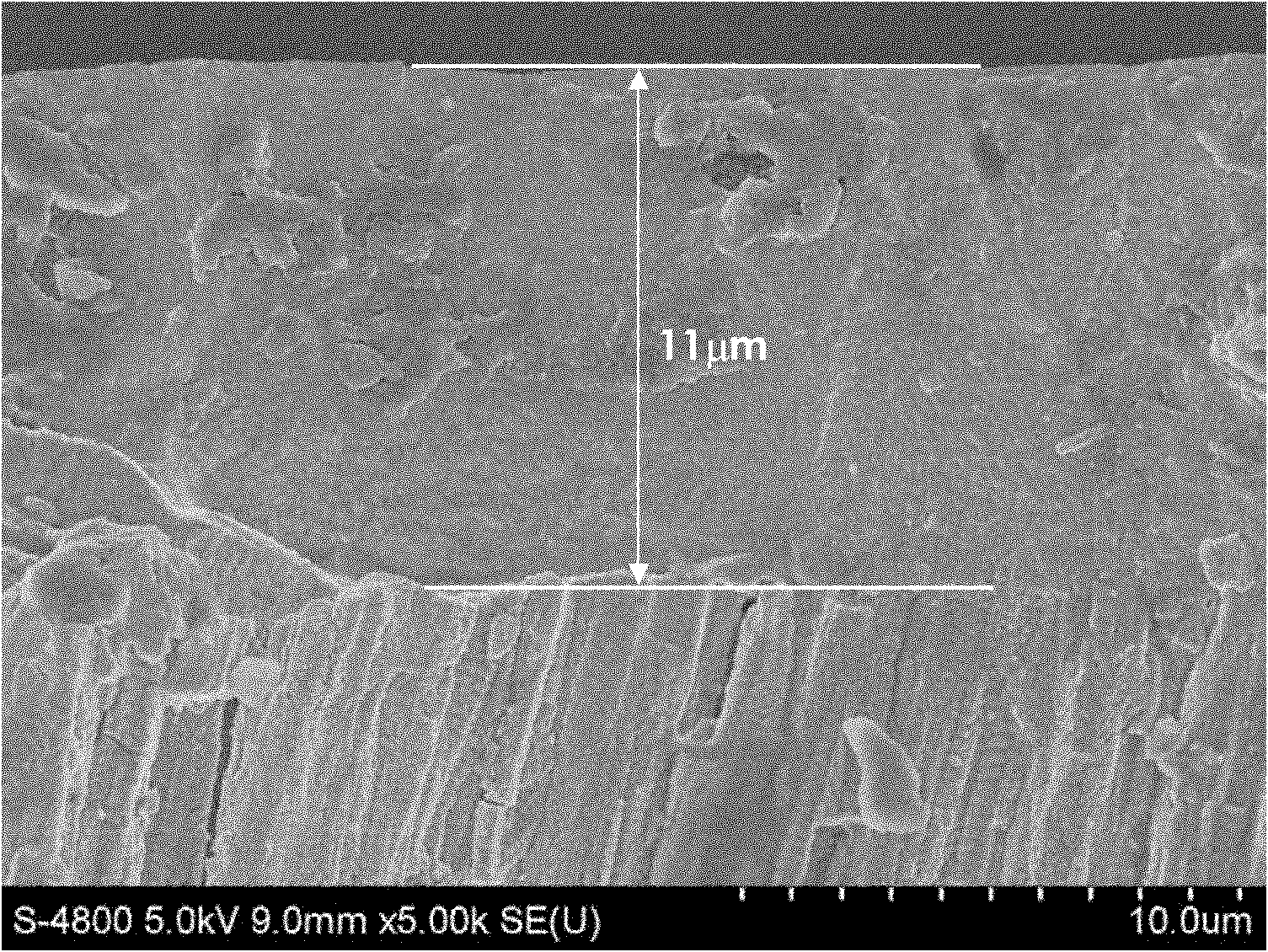

[0020] Combined with the specific experimental process, the implementation plan for improving the high-temperature oxidation resistance of thermal barrier coatings by high-current pulsed electron beam irradiation is described in detail. Taking the same pulse width and different energy densities as an example, the specific steps are as follows:

[0021] The first step is to fix the sample with deposited thermal barrier coating on the sample stage and vacuumize

[0022] Fix the prepared thermal barrier coating sample on the sample stage of the high-current pulsed electron beam device, close the vacuum chamber and evacuate to make the vacuum degree reach 3.5×10 -2 Pa.

[0023] In the second step, the high-current pulsed electron beam irradiation treatment realizes the capping of the columnar crystals of the ceramic layer

[0024] According to the technical requirements of the equipment, the voltage is 15kV and the frequency is 1Hz. At room temperature, the pulse width of the hi...

Embodiment 2

[0032] Combined with the specific experimental process, the implementation plan for improving the high-temperature oxidation resistance of thermal barrier coatings by high-current pulsed electron beam irradiation is described in detail. Taking the same energy density and different pulse widths as an example, the specific steps are as follows:

[0033] The first step is to fix the sample with deposited thermal barrier coating on the sample stage and vacuumize

[0034] Fix the prepared thermal barrier coating sample on the sample stage of the high-current pulsed electron beam device, close the vacuum chamber and evacuate to make the vacuum degree reach 3.5×10 -2 Pa.

[0035] In the second step, the high-current pulsed electron beam irradiation treatment realizes the capping of the columnar crystals of the ceramic layer

[0036] According to the technical requirements of the equipment, the voltage is 15kV and the frequency is 1Hz. At room temperature, the energy density of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com