Patents

Literature

172 results about "Electron beam physical vapor deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electron-beam physical vapor deposition, or EBPVD, is a form of physical vapor deposition in which a target anode is bombarded with an electron beam given off by a charged tungsten filament under high vacuum. The electron beam causes atoms from the target to transform into the gaseous phase. These atoms then precipitate into solid form, coating everything in the vacuum chamber (within line of sight) with a thin layer of the anode material.

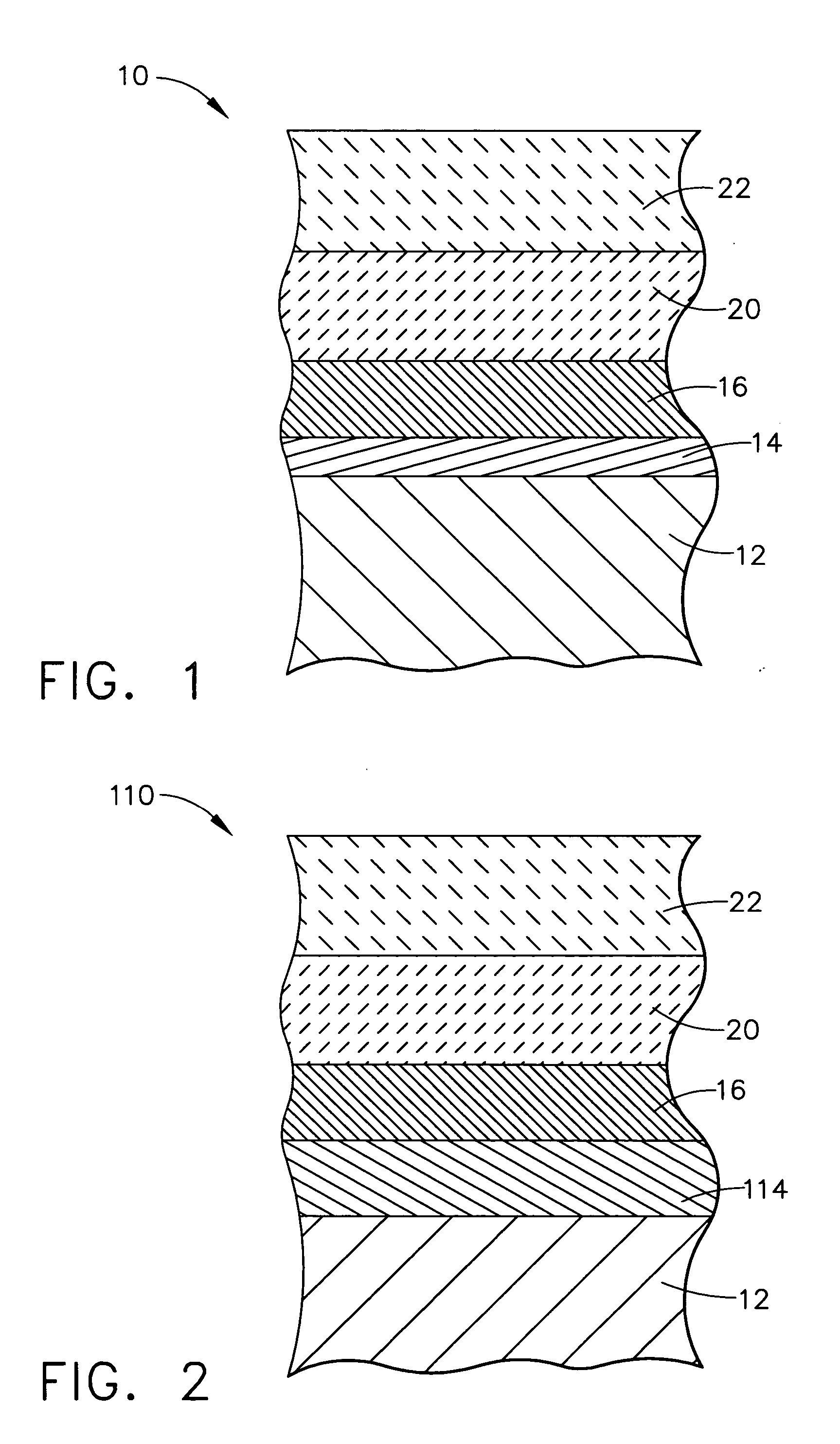

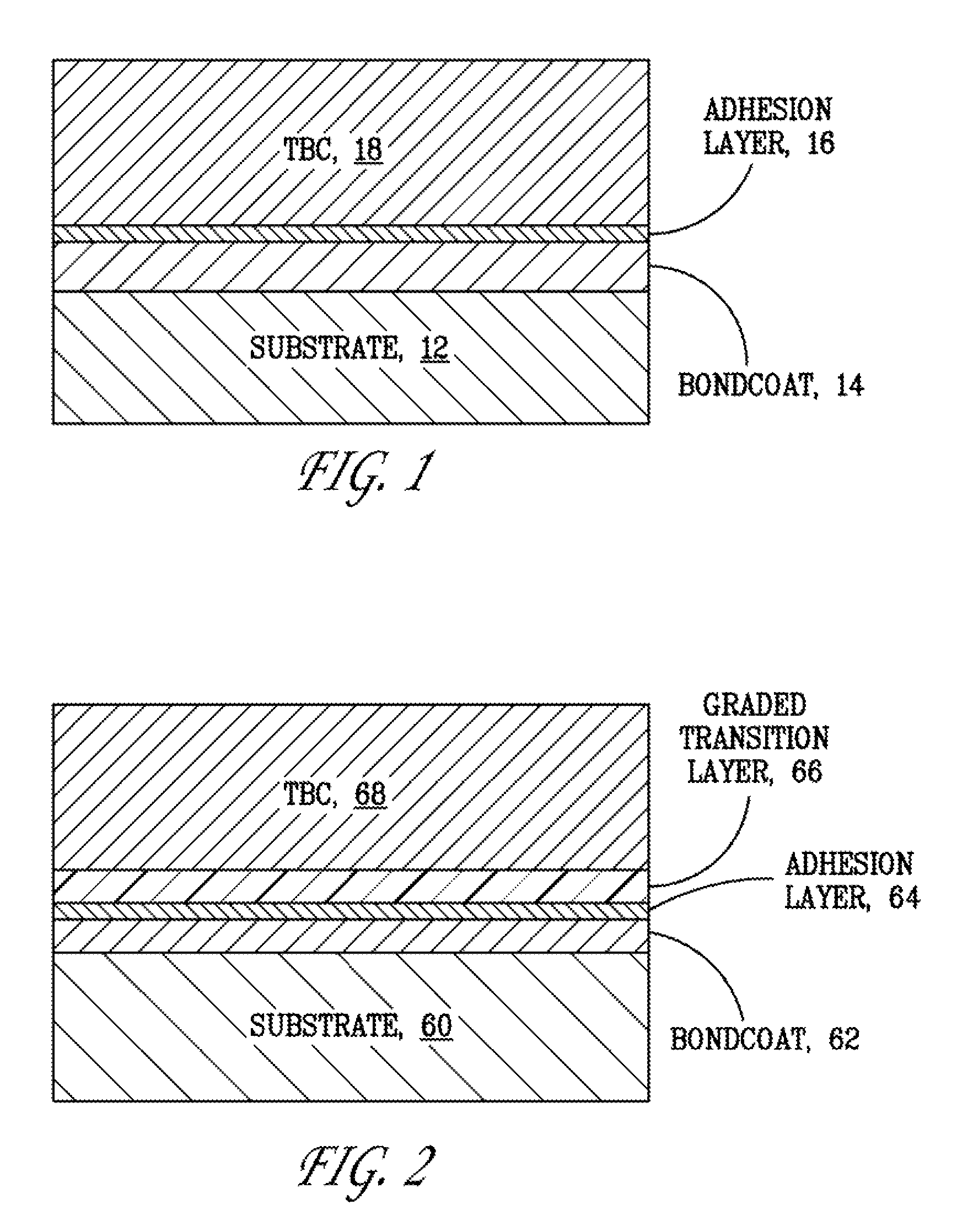

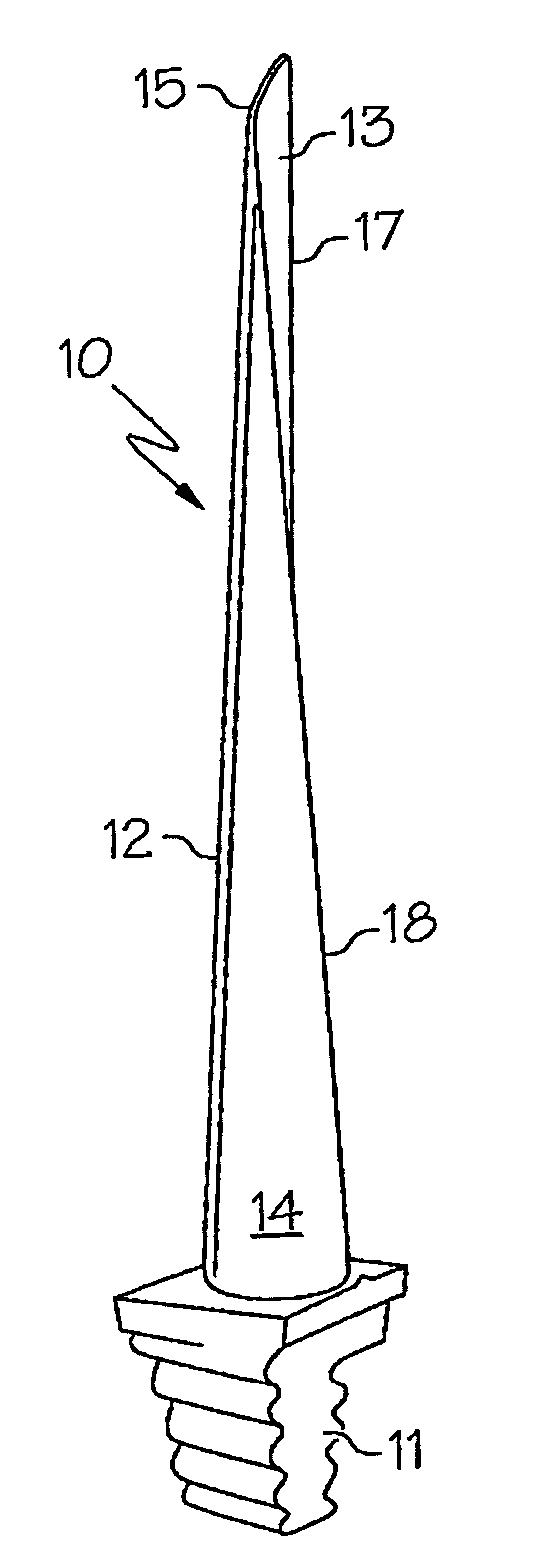

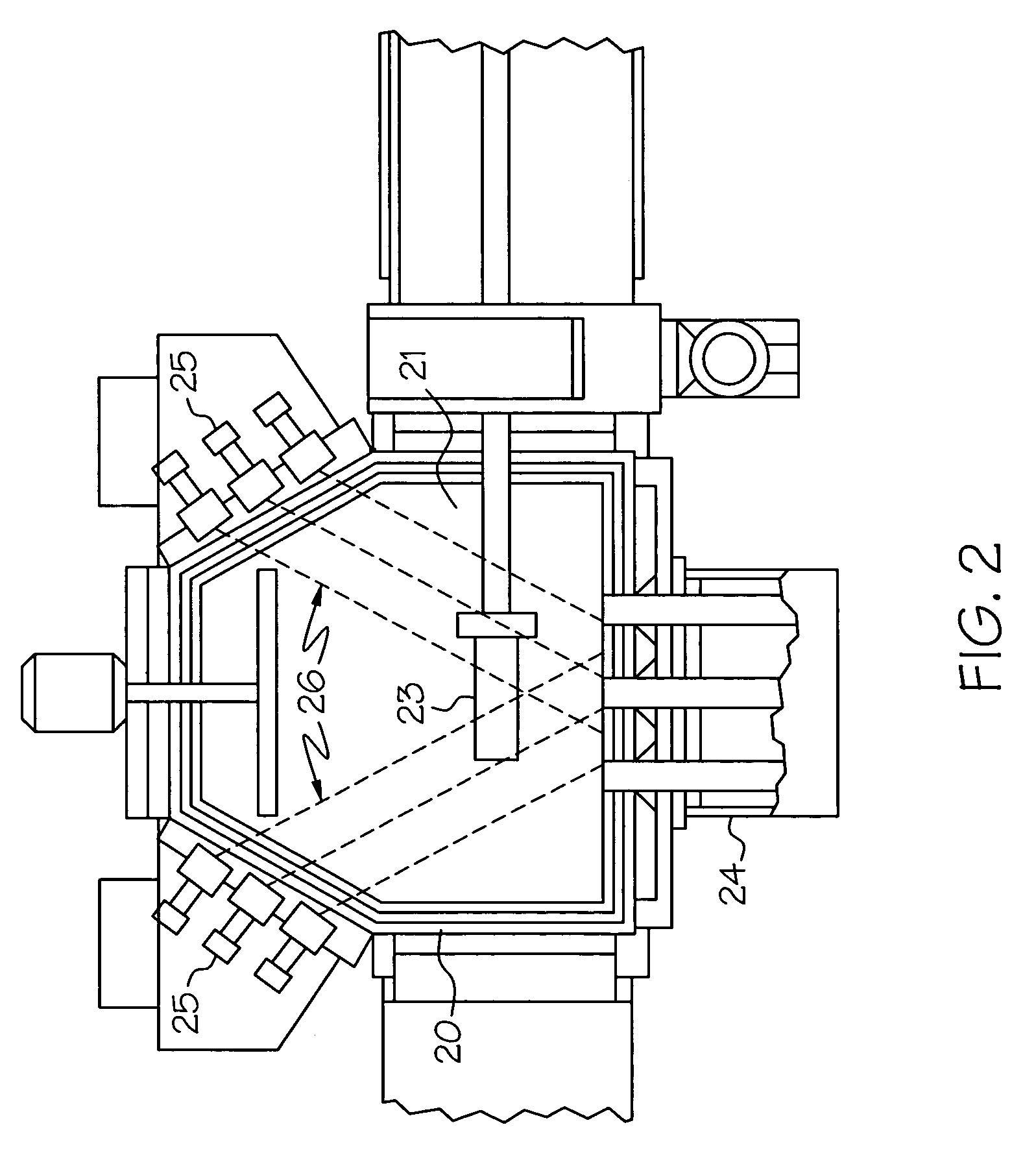

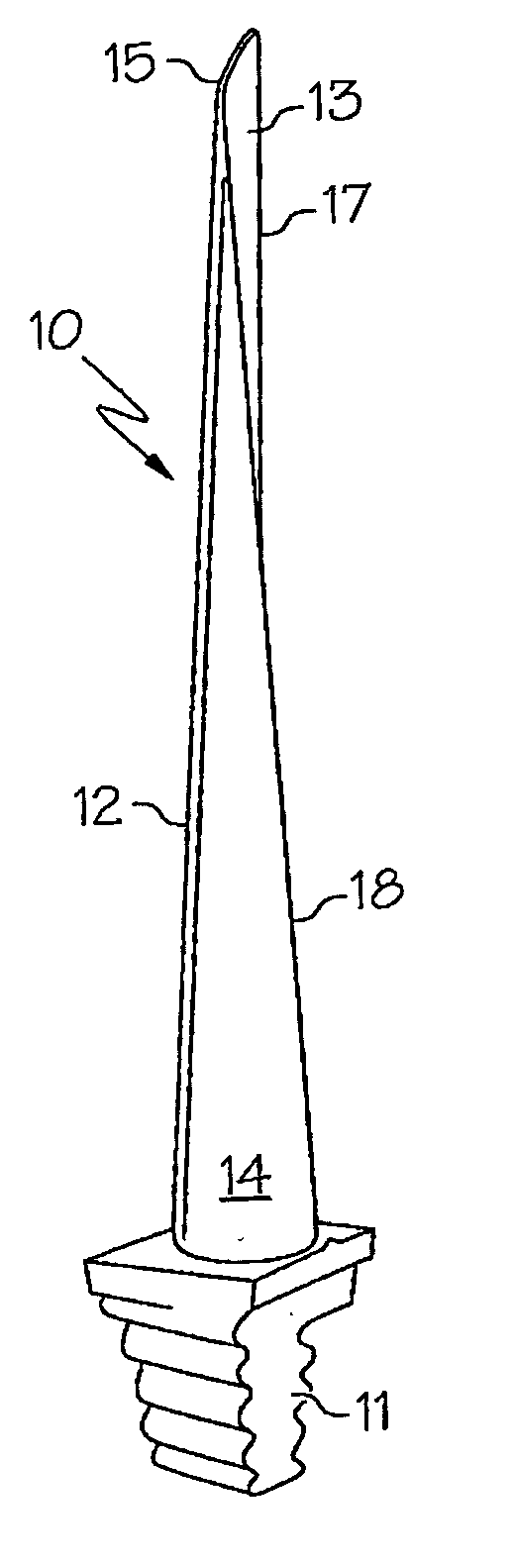

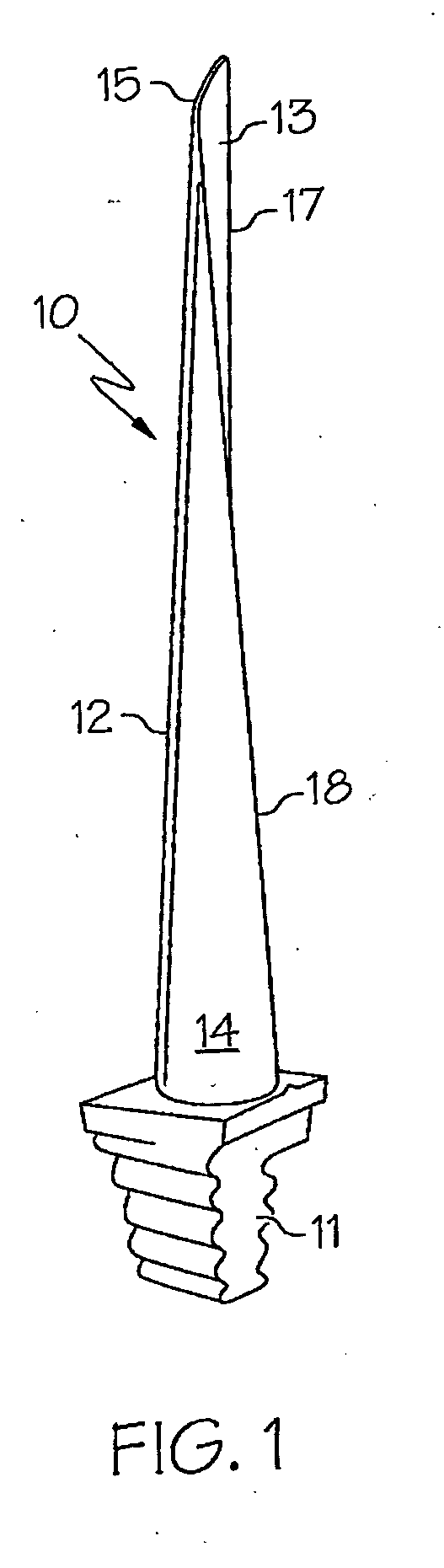

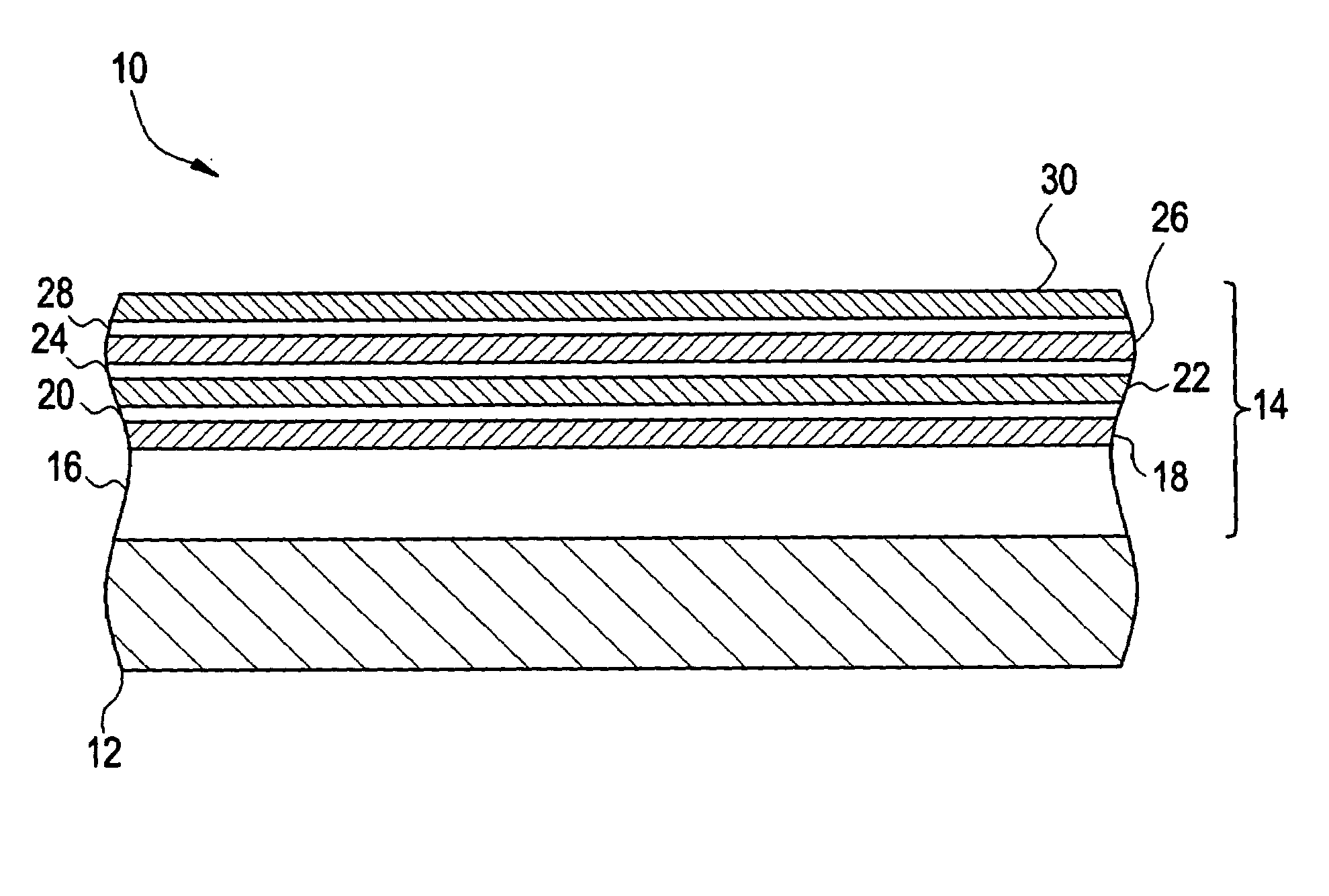

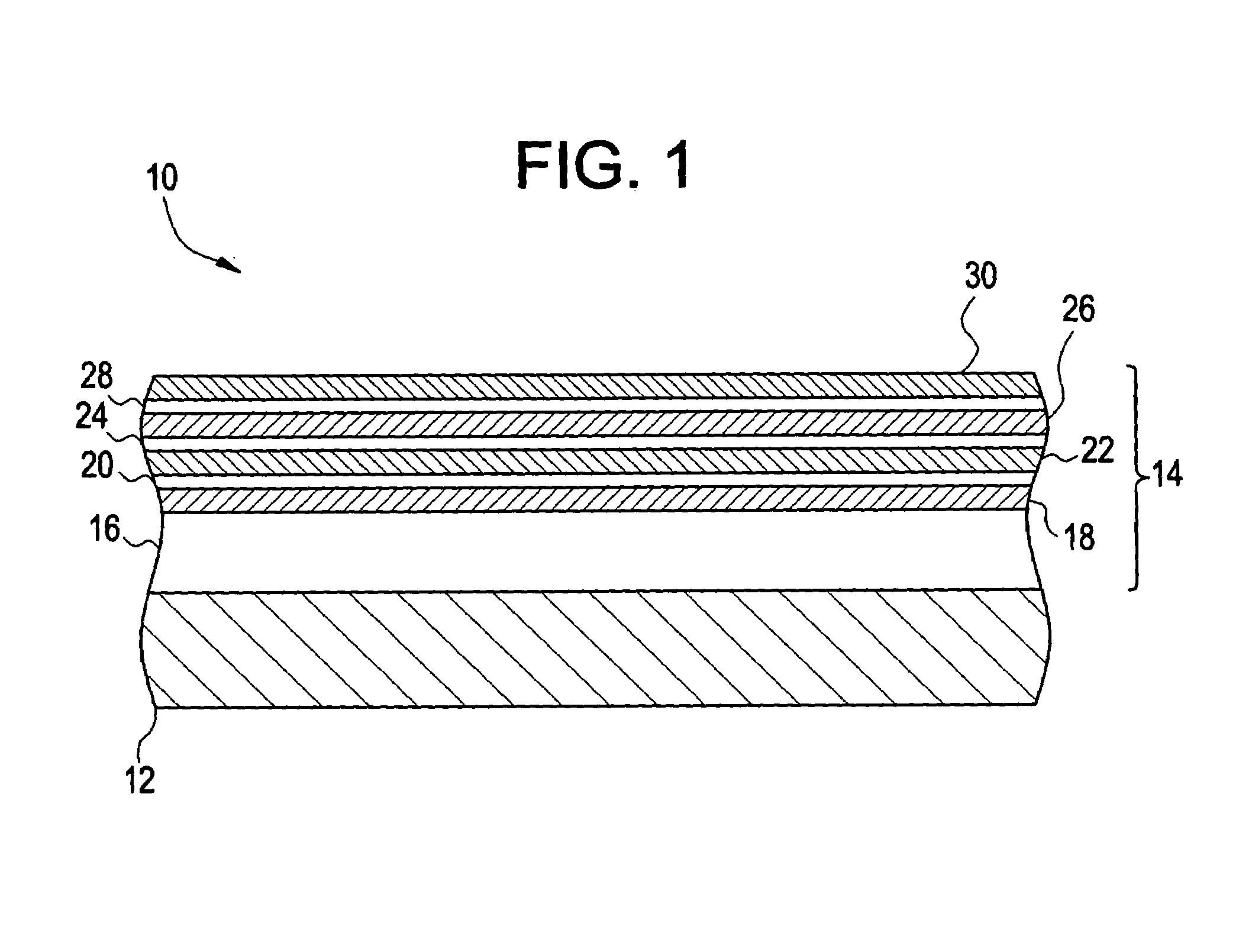

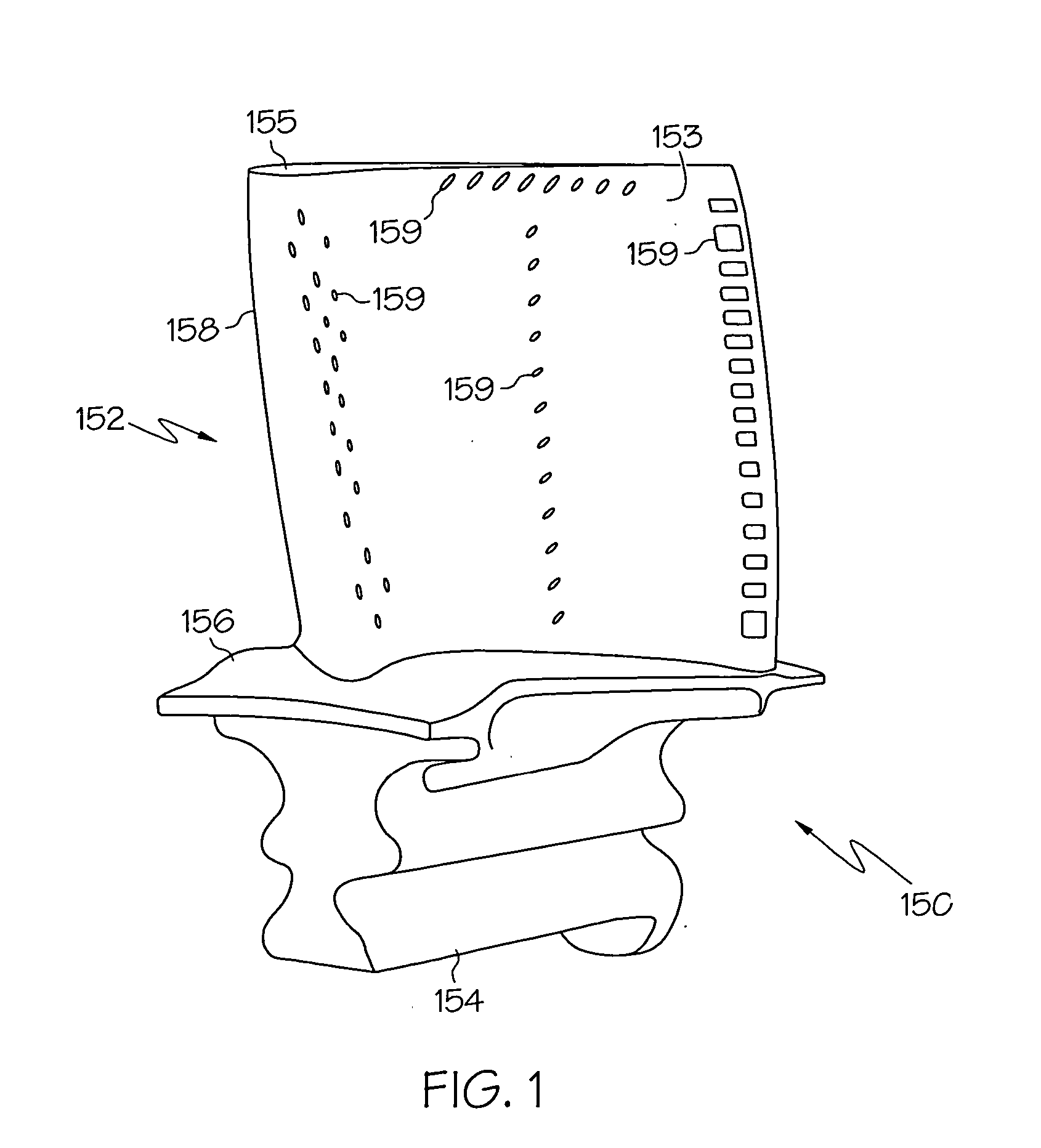

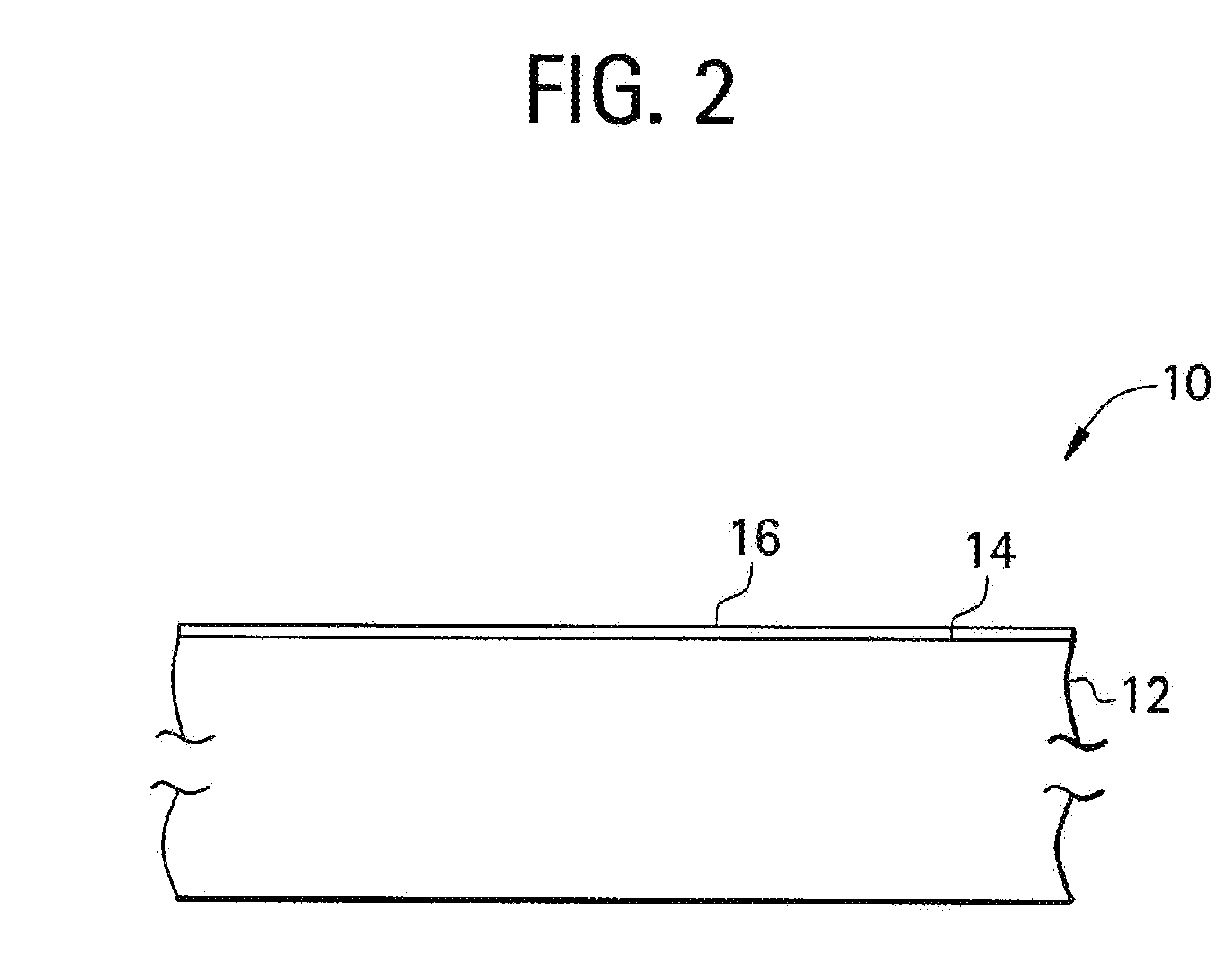

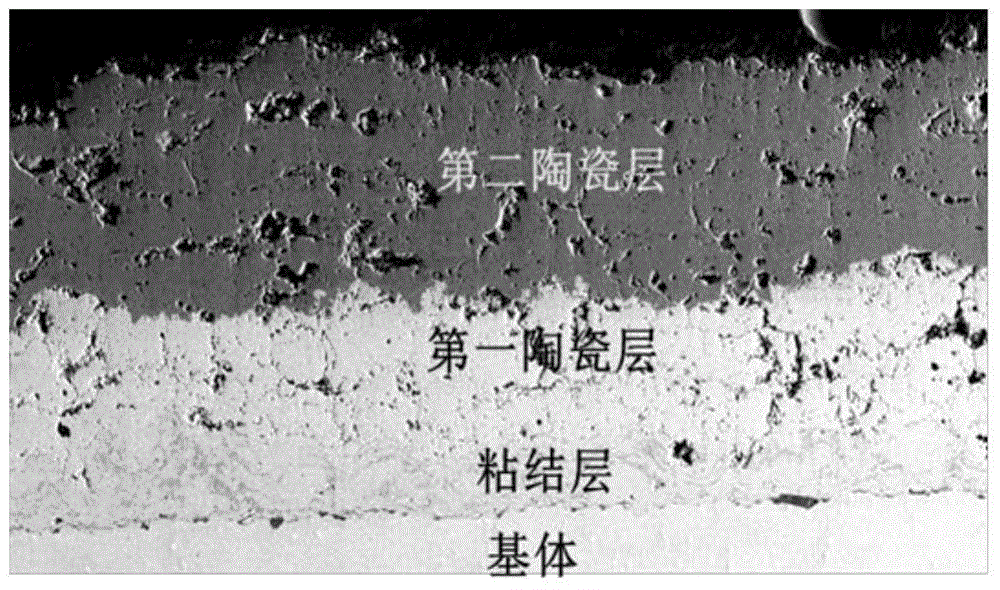

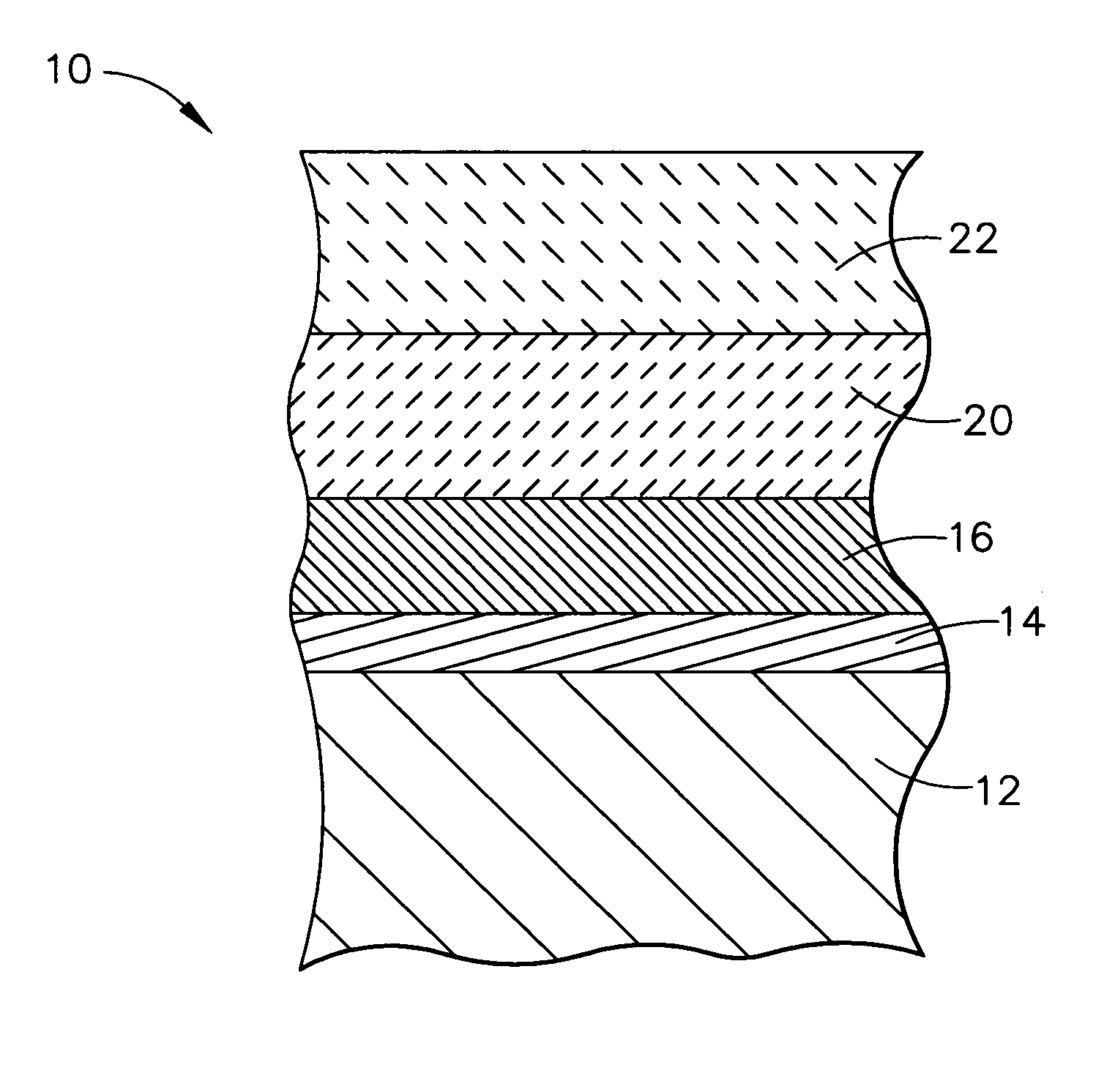

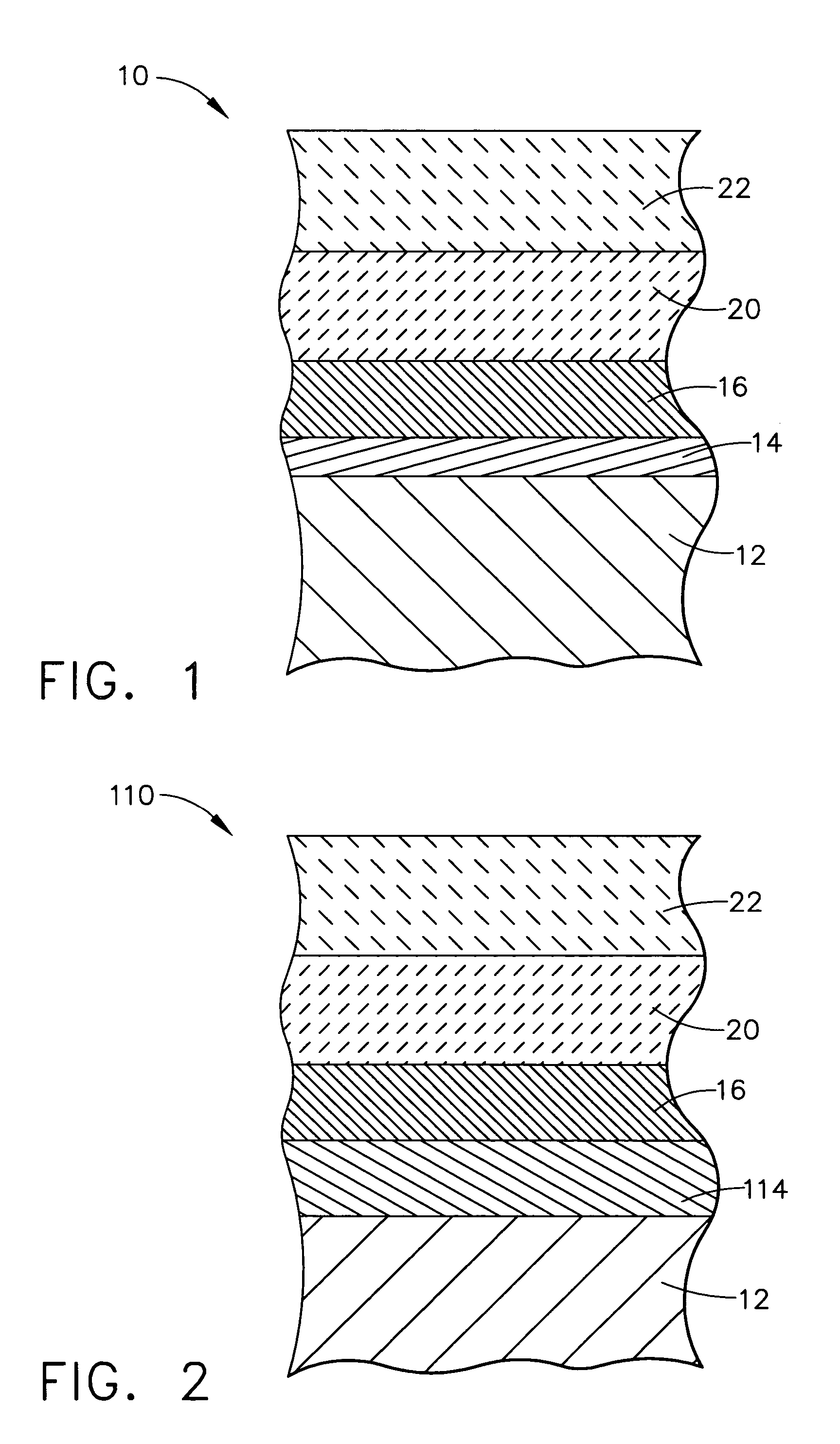

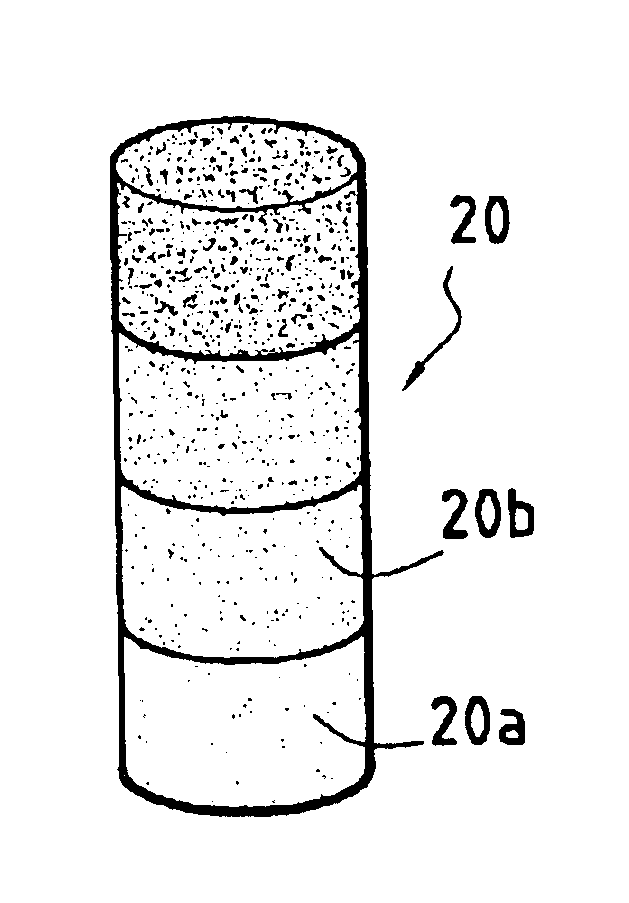

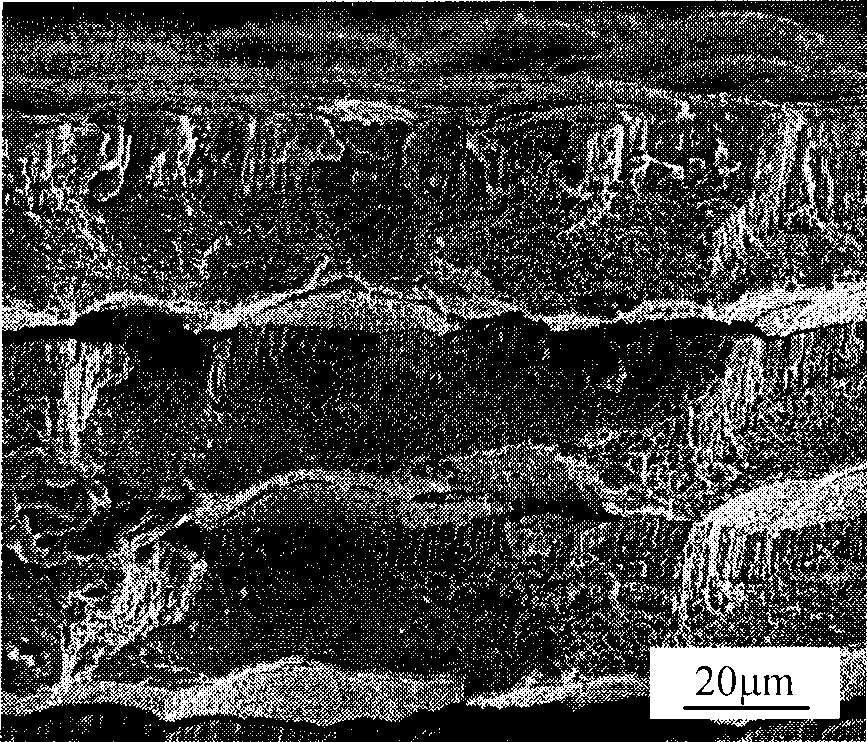

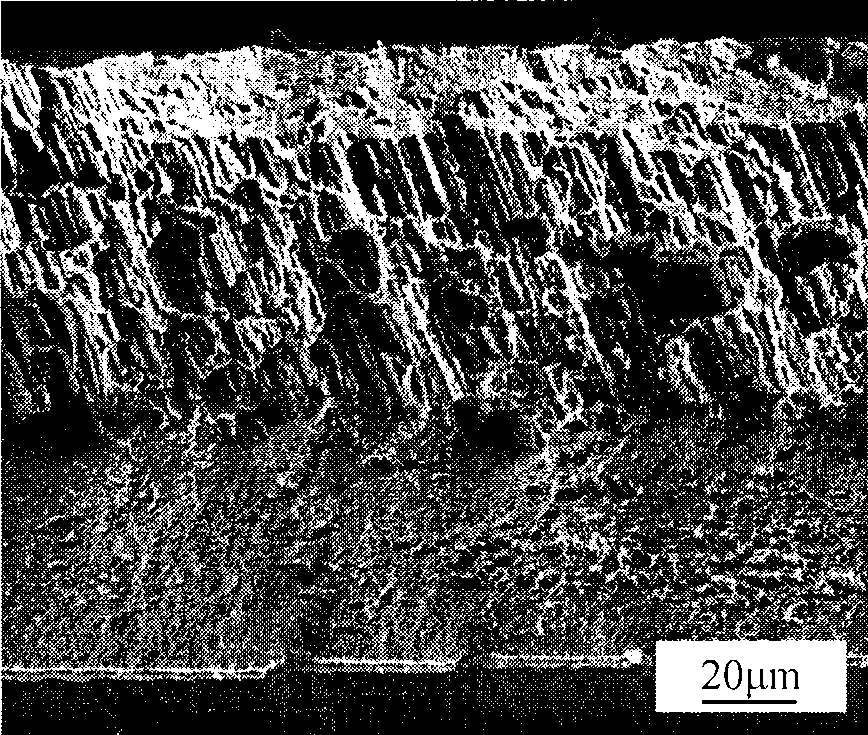

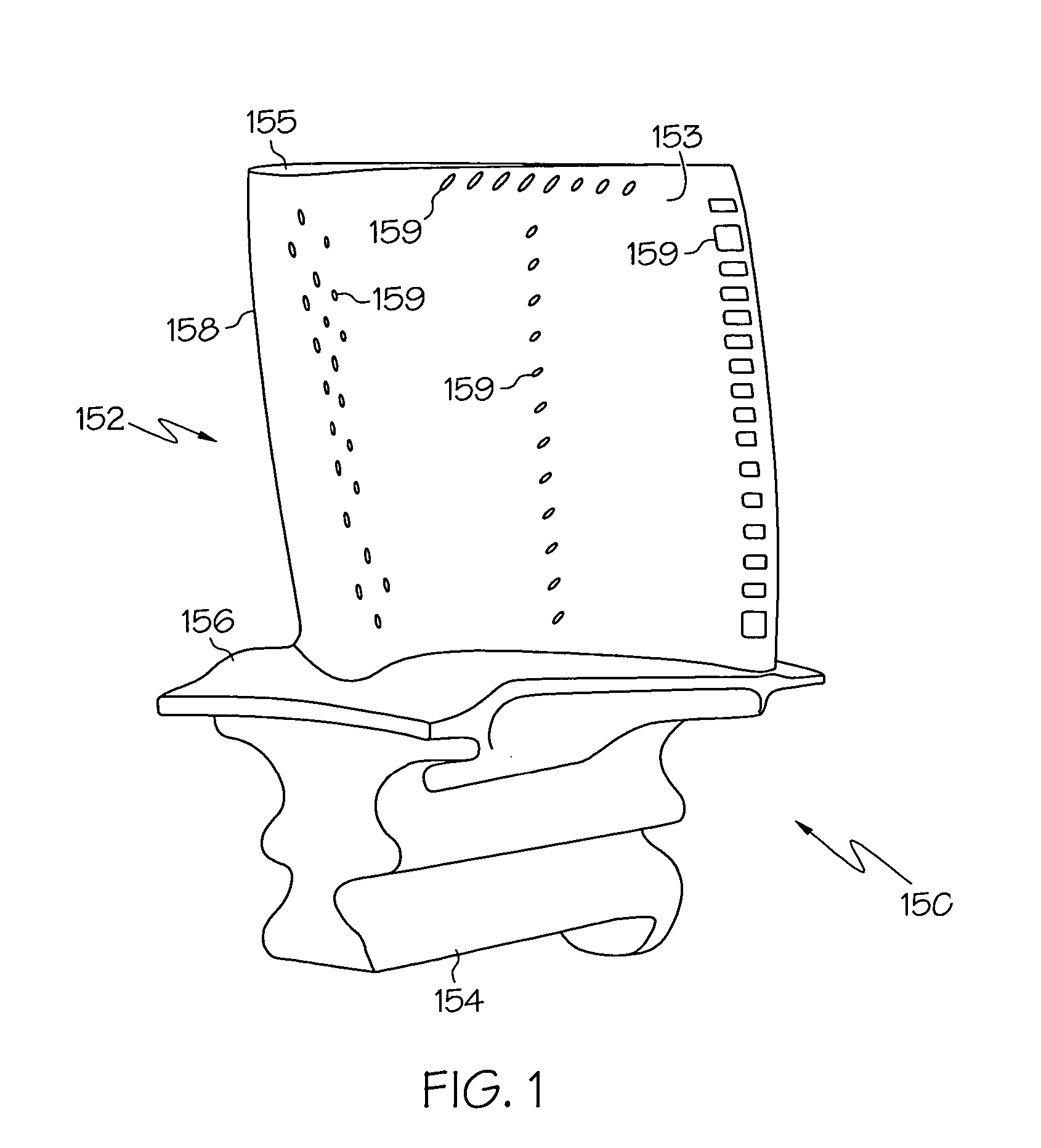

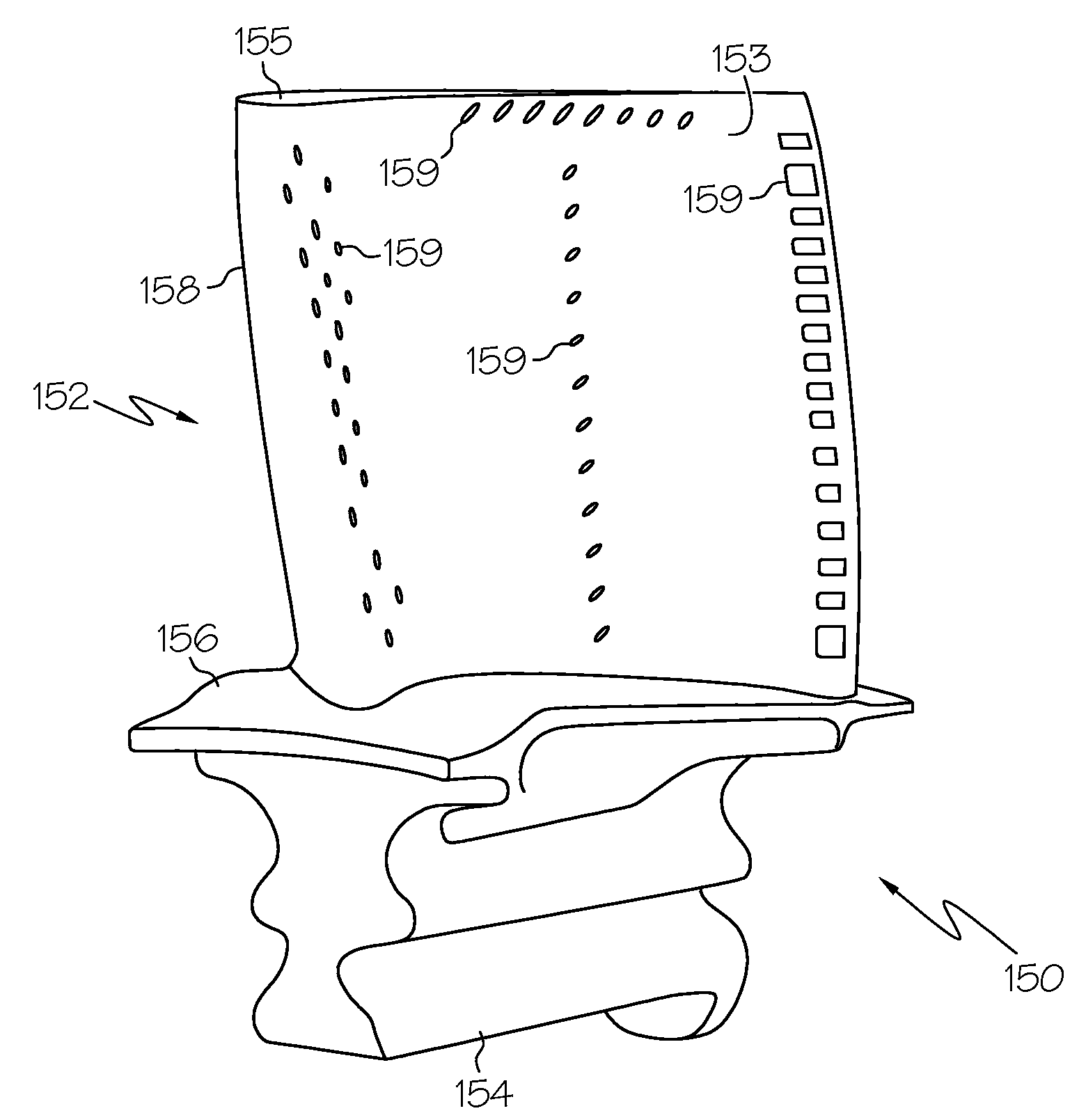

Thermal barrier coating ceramic structure

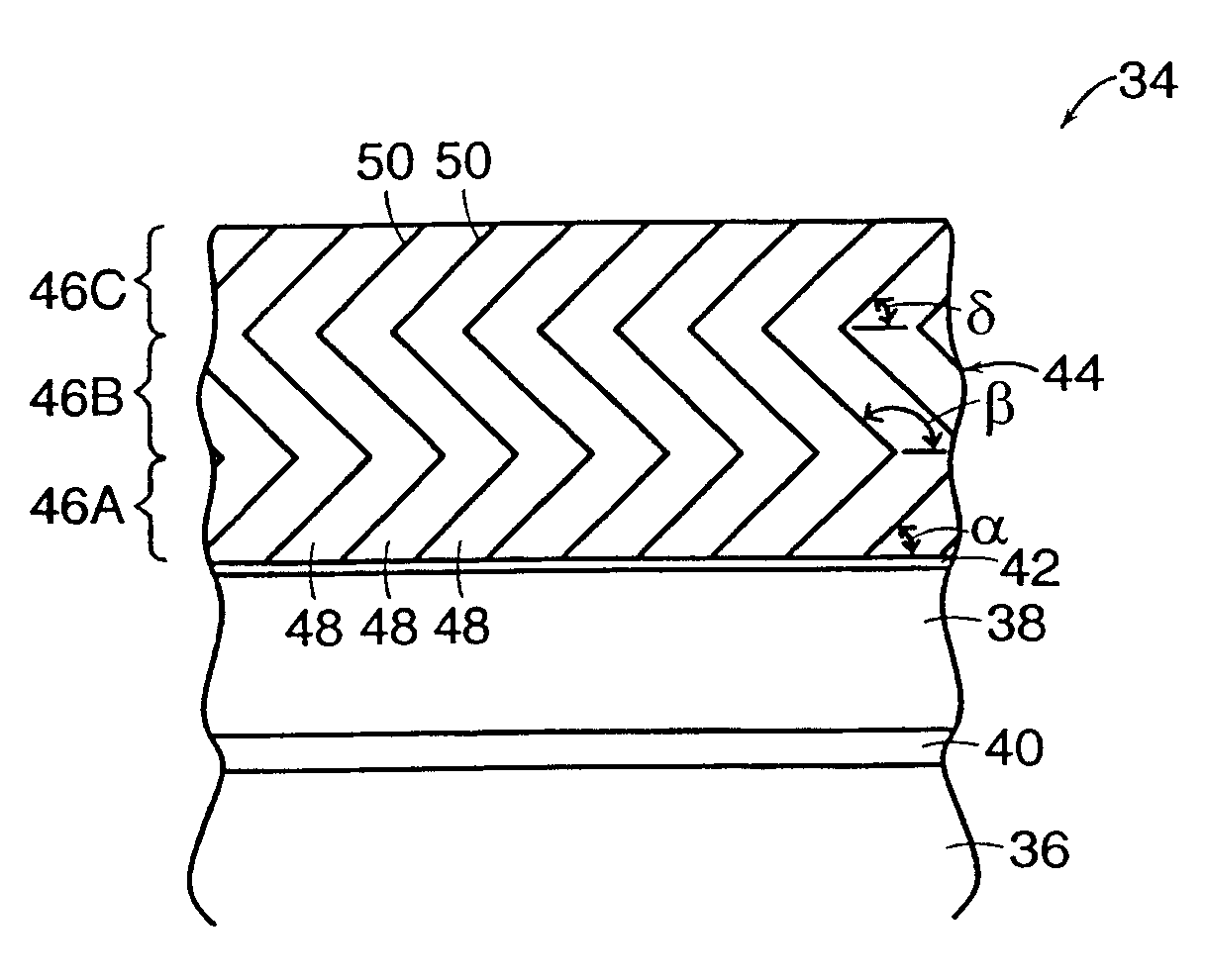

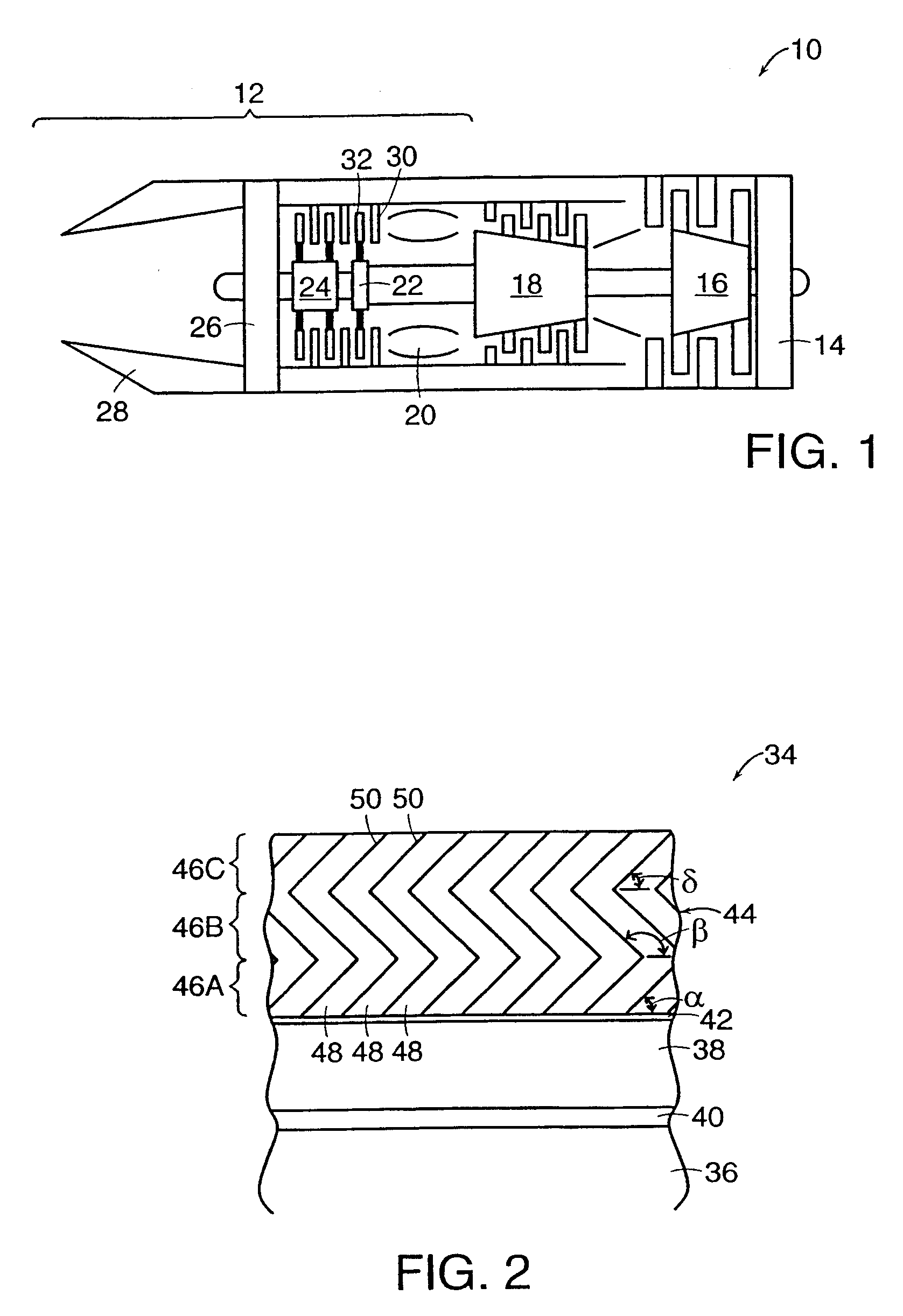

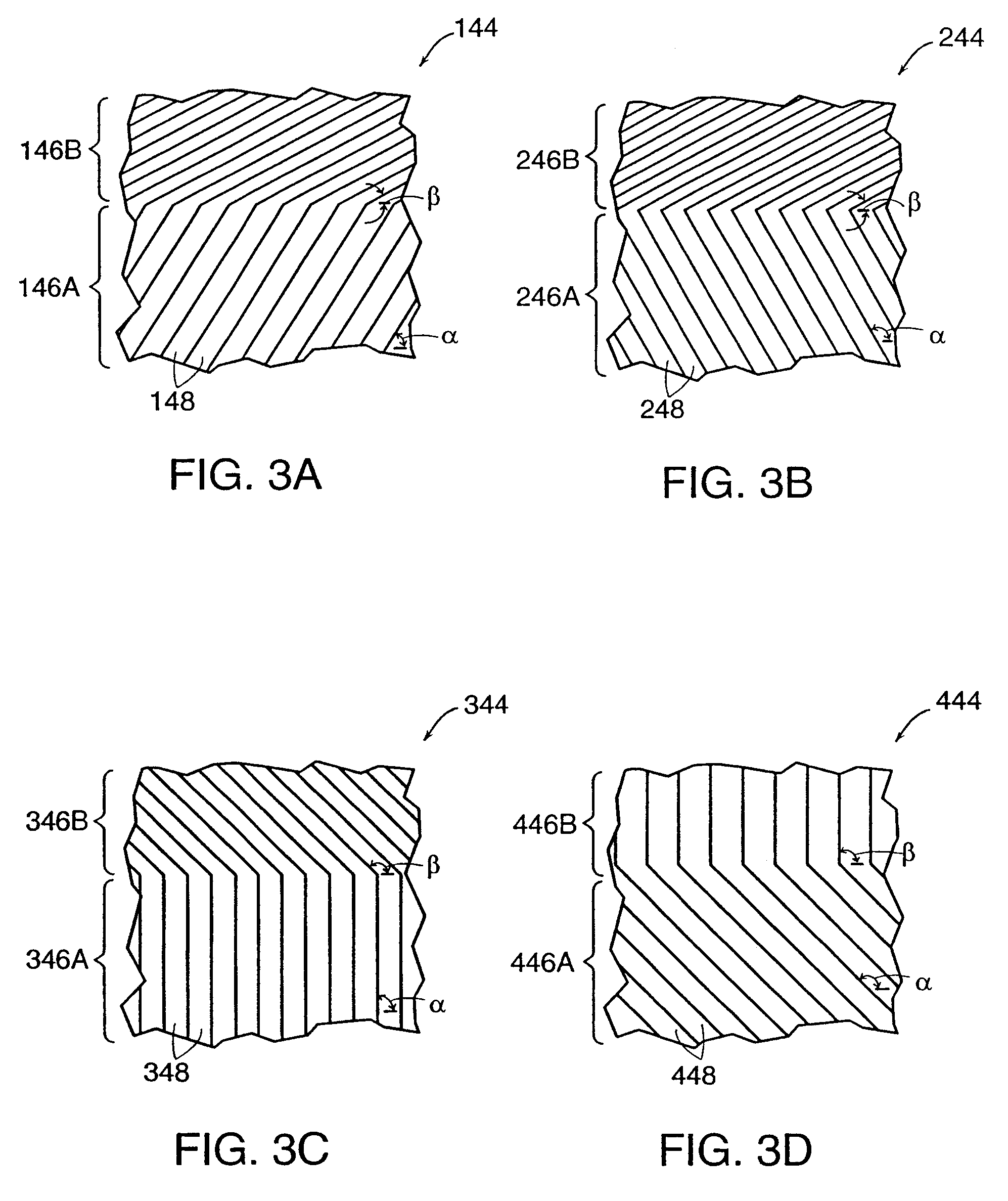

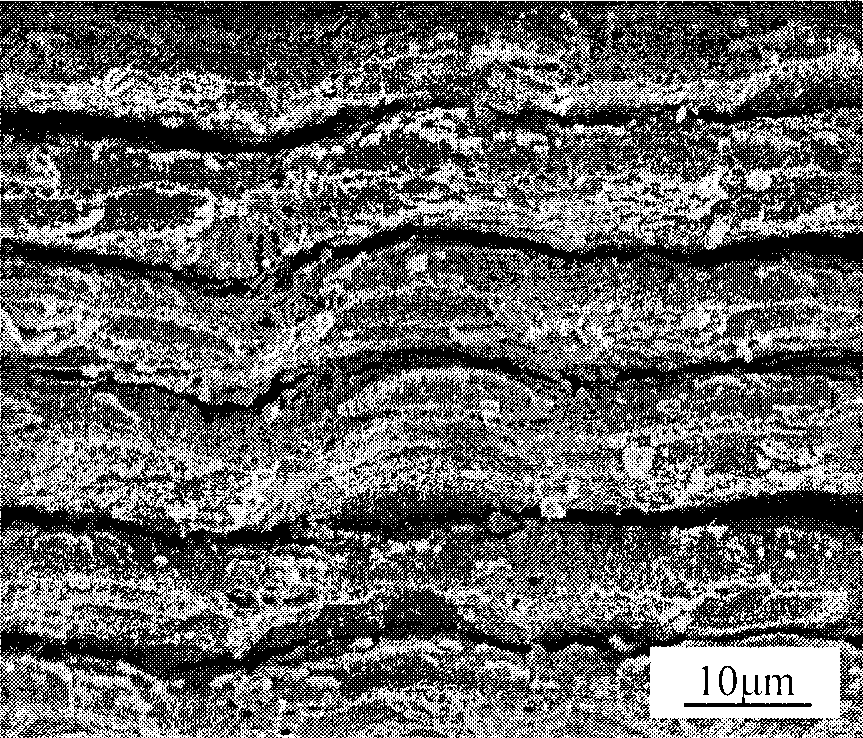

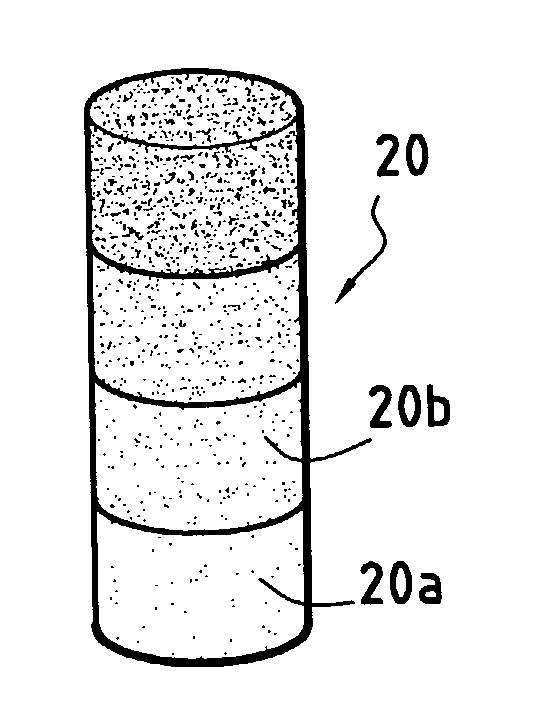

InactiveUS6455173B1PropellersSurface reaction electrolytic coatingElectron beam physical vapor depositionVapor cloud

A multilayered ceramic topcoat of a thermal barrier coating system is useful for high temperature corrosive applications such as hot section components in gas turbine engines. The ceramic topcoat includes at least two layers, each having generally columnar grain microstructures with different grain orientation directions. A preferred method of producing the multilayered ceramic topcoat includes positioning a superalloy substrate at a first angled orientation relative to a ceramic vapor cloud in an electron beam physical vapor deposition apparatus for a time sufficient to grow a first ceramic layer. The substrate is then reoriented to a second, different angled orientation for a time sufficient to grow a second ceramic layer. The ceramic layers exhibit columnar microstructures having respective grain orientation directions which are related to the first and second substrate orientations. For uniformly coating a complex contoured surface such as a turbine blade airfoil, the blade can be rotated during coating deposition at each angled orientation. Alternatively, the article may be continuously reoriented according to a predetermined speed cycle to produce generally arcuate, sinusoidal, helical, or other columnar grain microstructures.

Owner:MARIJNISSEN GILLION HERMAN +4

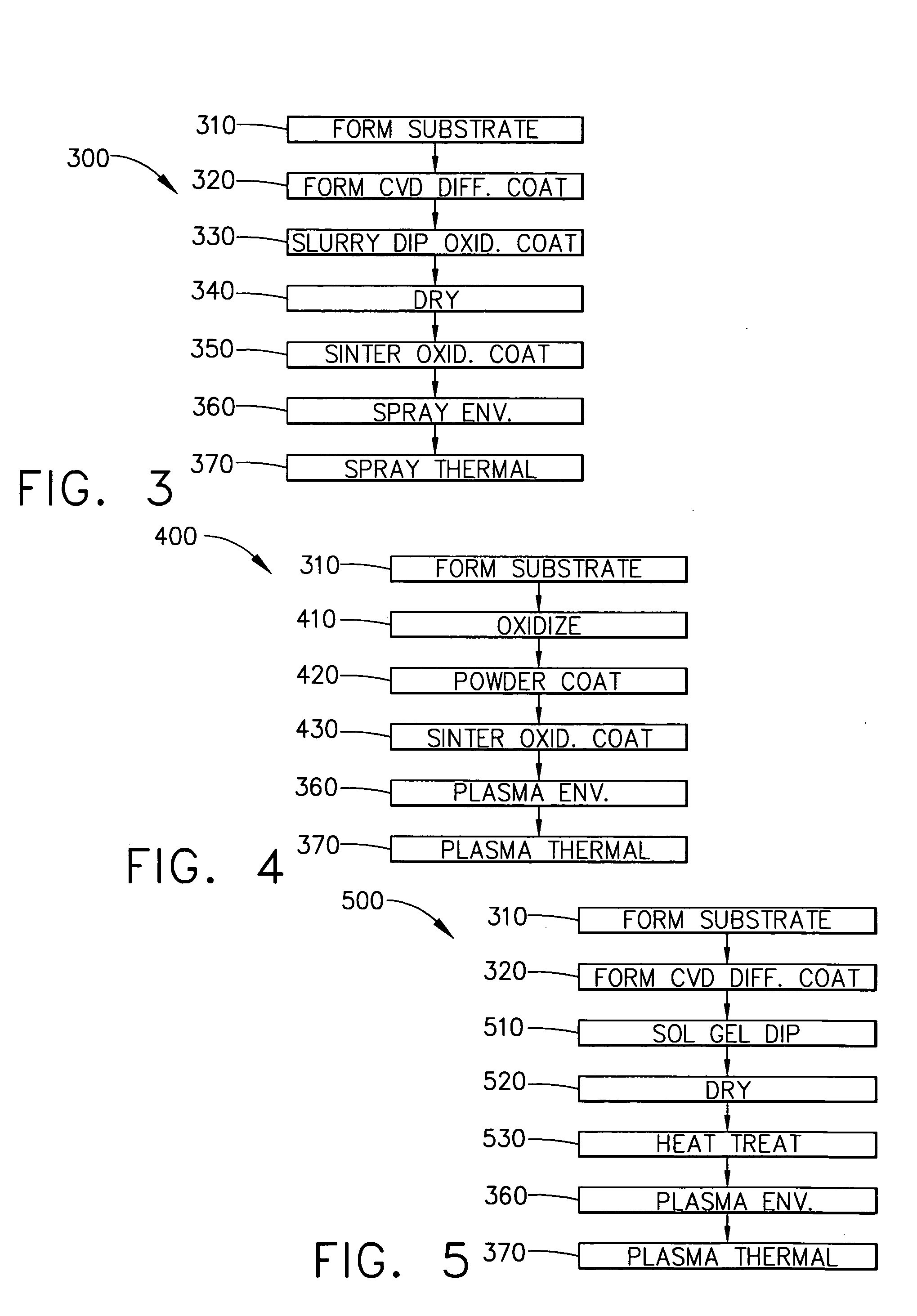

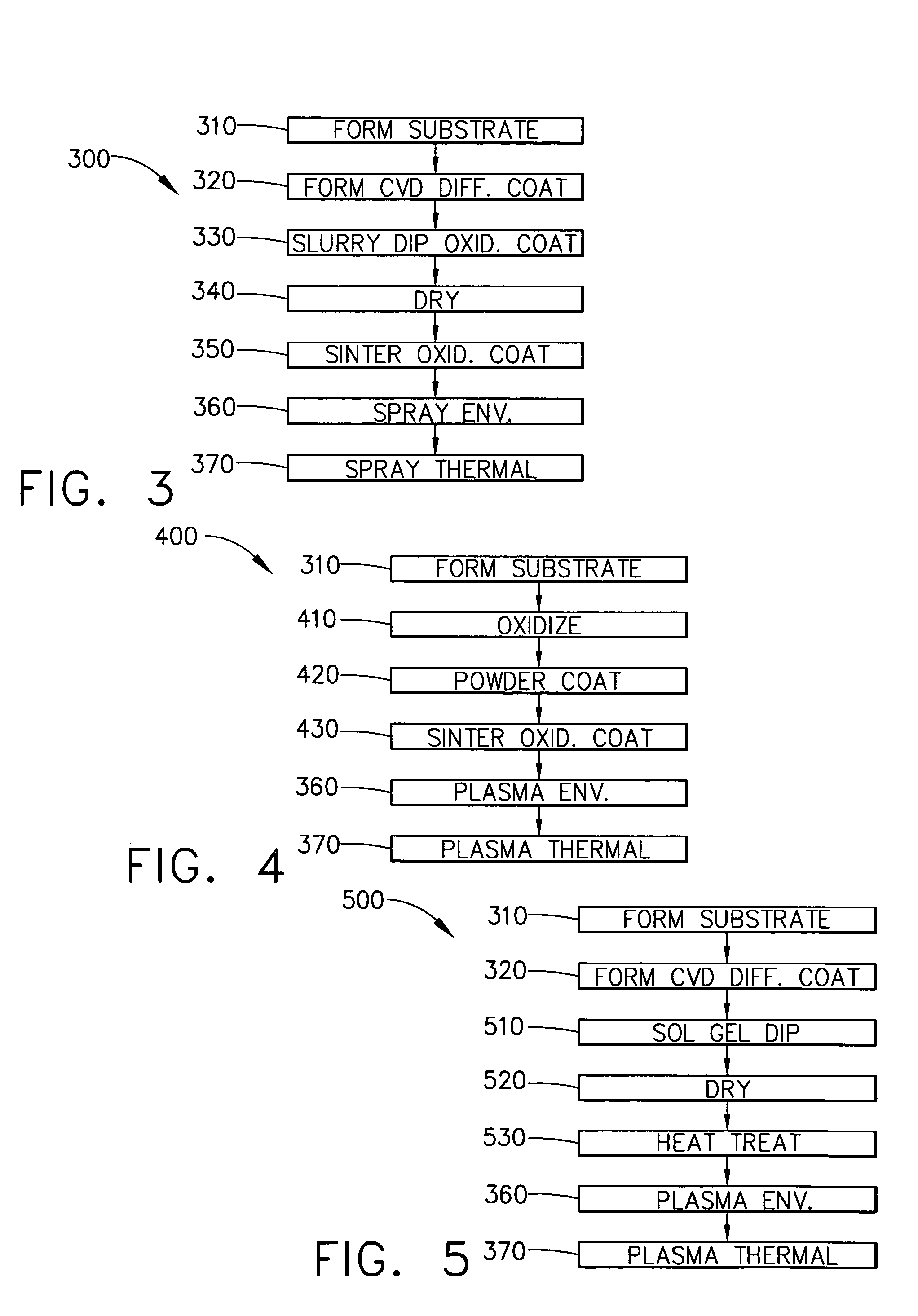

Oxidation barrier coatings for silicon based ceramics

ActiveUS20050112381A1Avoid Explosion HazardsContinuous combustion chamberBlade accessoriesElectron beam physical vapor depositionGas phase

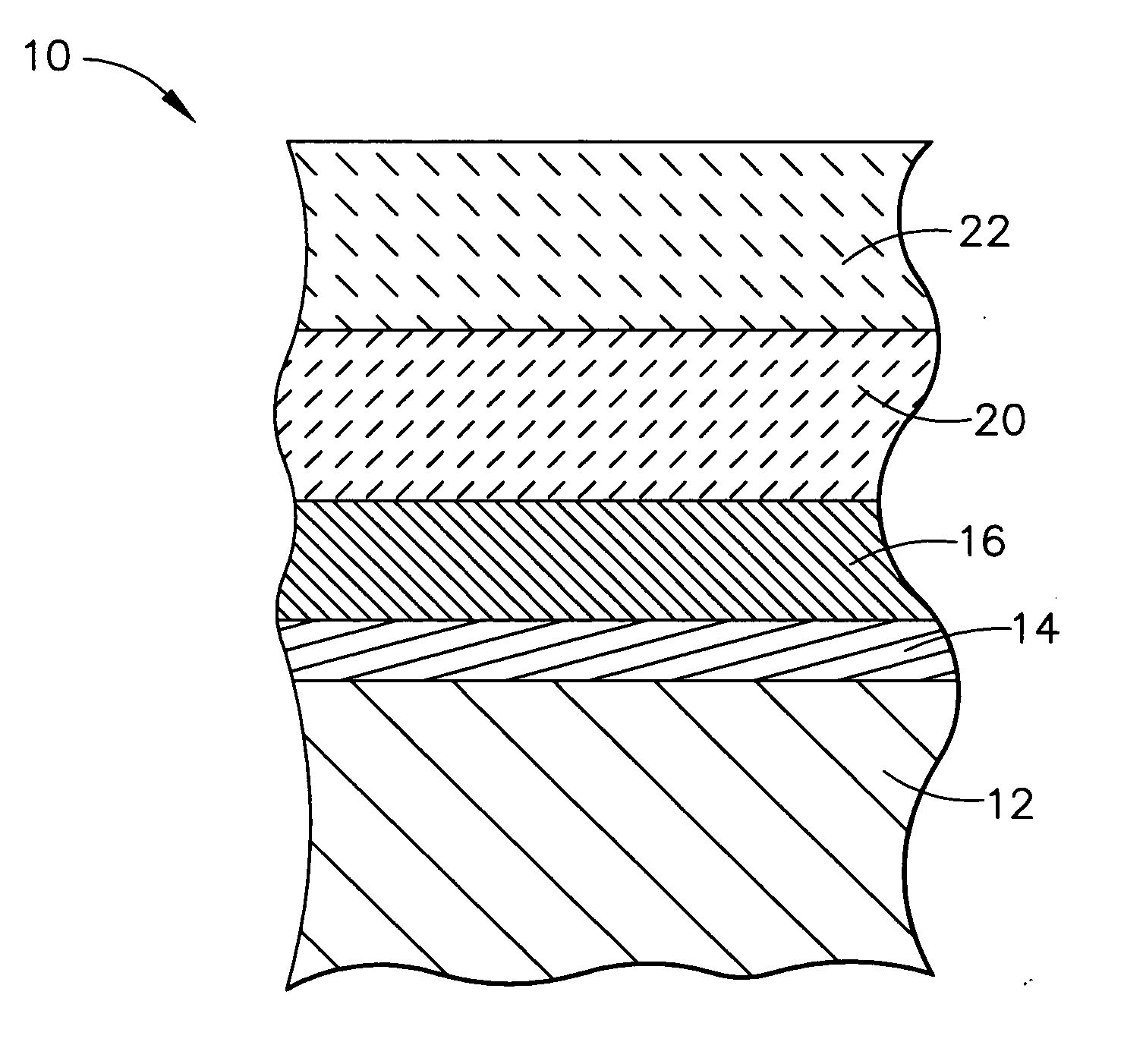

A protective barrier coating system including a diffusion barrier coating and an oxidation barrier coating and method for use in protecting silicon-based ceramic turbine engine components. A complete barrier coating system includes a thermal barrier coating of stabilized zirconia and an environmental barrier coating of an alloyed tantalum oxide. The oxidation barrier coating includes a layer of metallic silicates formed on a substrate of silicon nitride or silicon carbide to be protected. The oxidation barrier coating can include silicates of scandium, ytterbia or yttrium. The oxidation barrier coating may also include an inner layer of Si2ON2 between the diffusion barrier and the metallic silicate layer. The oxidation barrier coating can be applied to the substrate by spraying, slurry dipping and sintering, by a sol-gel process followed by sintering, by plasma spray, or by electron beam-physical vapor deposition. The diffusion layer of essentially pure Si3N4 can be applied to the substrate to prevent the migration of damaging cations from the protective layers to the substrate and is preferably formed by chemical vapor deposition. A method for protecting silicon based substrates can comprise a step of forming an oxidation barrier coating on a substrate, where a step of forming the oxidation barrier includes a step of sintering the oxidation barrier and substrate in a wet gas containing hydrogen.

Owner:HONEYWELL INT INC

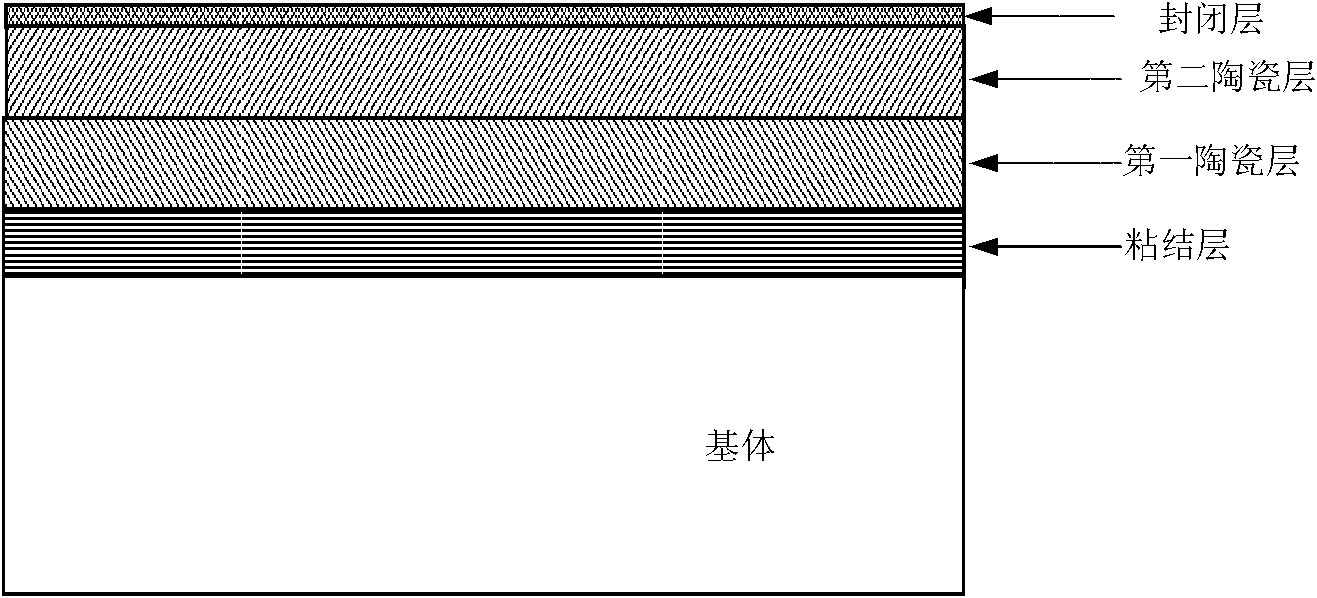

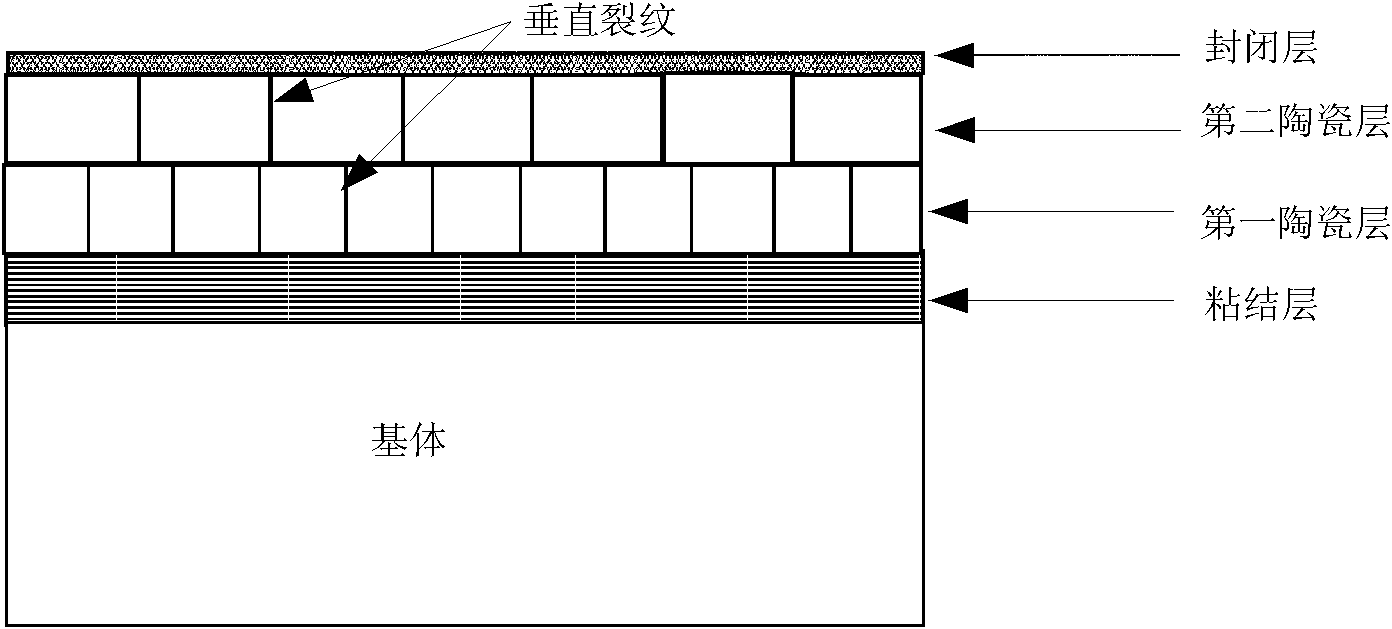

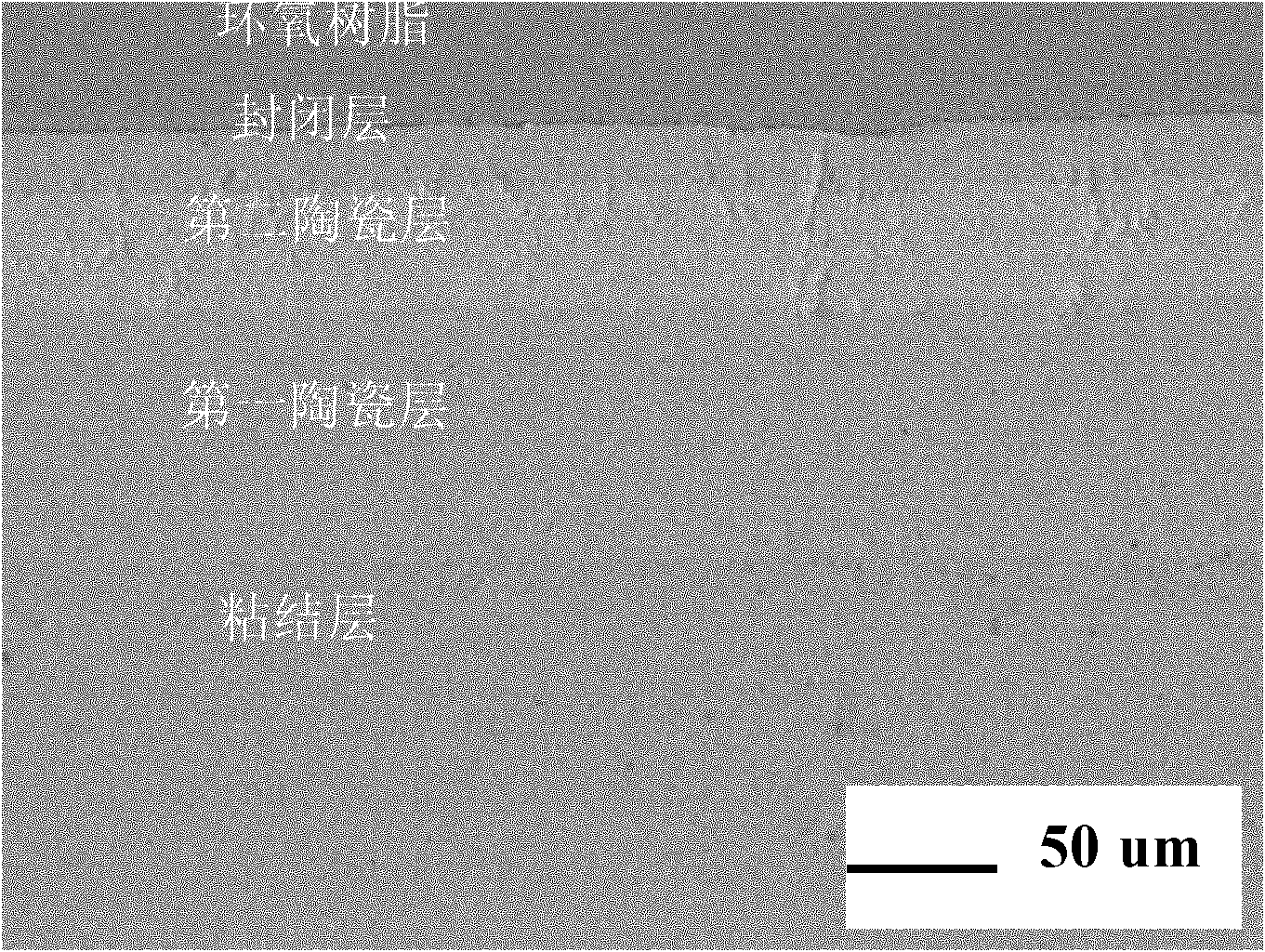

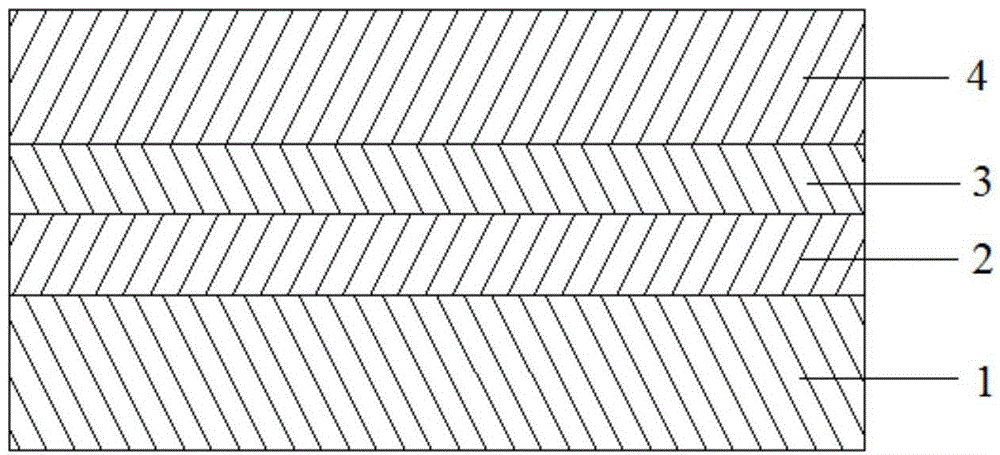

Multilayer thermal barrier coating and preparation method thereof

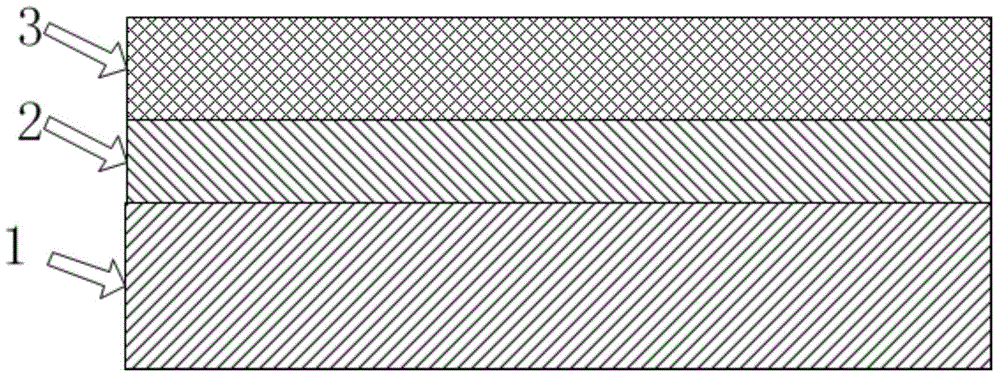

InactiveCN102127738ANo layer peeling phenomenon occursImprove hot corrosion resistanceMolten spray coatingVacuum evaporation coatingPorosityElectron beam physical vapor deposition

The invention provides a multilayer thermal barrier coating and a preparation method thereof. The multilayer thermal barrier coating sequentially comprises an adhesion layer, a first ceramic layer, a second ceramic layer and a closing layer from bottom to top, wherein the closing layer has the thickness of 10-30 micros and the porosity of 2-8 percent and is made from the Al2O3. The thermal barrier coating can be prepared by adopting an electron beam physical gas-phase deposition technology or a plasma spraying method. The multilayer thermal barrier coating provided by the invention can avoid the stripping of the ceramic layers in a thermal circulating process, the thermal erosion resistance of the thermal barrier coating is greatly improved than the dual ceramic layers; and vertical crackles are introduced in the ceramic layer through improving a conventional plasma spraying process so that the thermal shock life of the thermal barrier coating is greatly prolonged.

Owner:BEIHANG UNIV

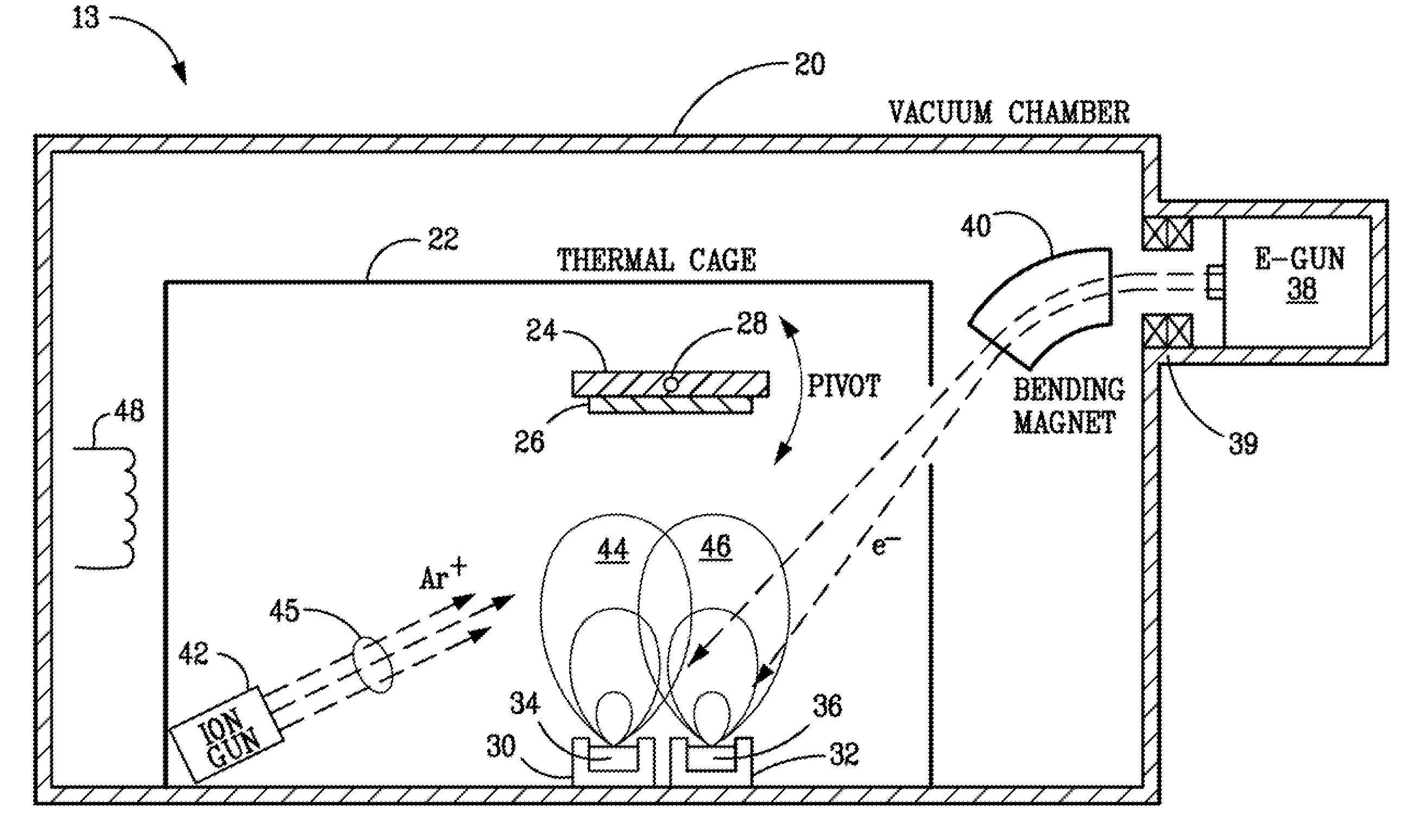

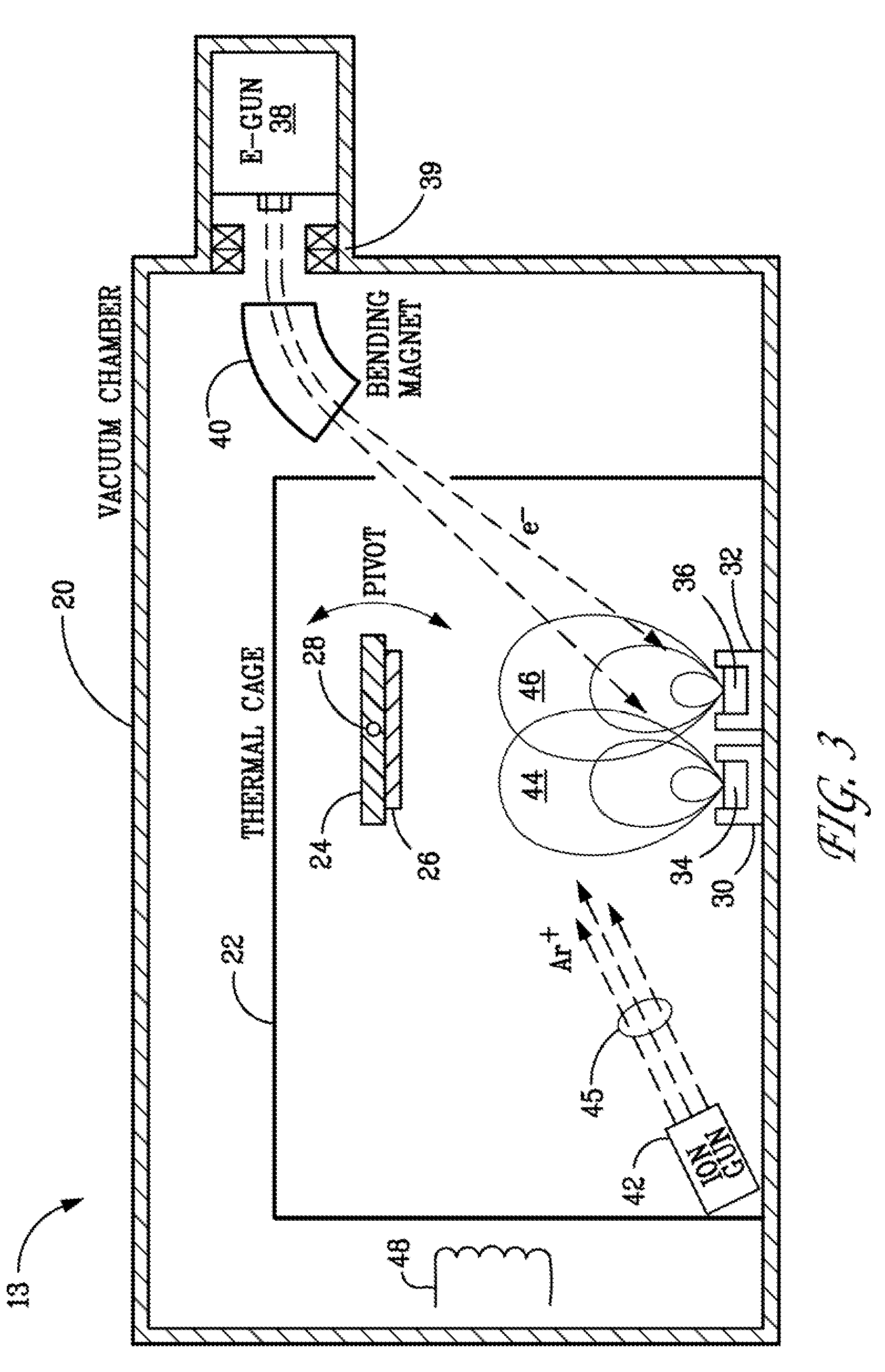

Ion beam assisted deposition of thermal barrier coatings

InactiveUS7838083B1Engine manufactureVacuum evaporation coatingElectron beam physical vapor depositionIon beam-assisted deposition

Methods and apparatus for depositing thermal barrier coatings on gas turbine blades and vanes using Electron Beam Physical Vapor Deposition (EBPVD) combined with Ion Beam Assisted Deposition (IBAD).

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Chromium and active elements modified platinum aluminide coatings

ActiveUS7229701B2Promote oxidationIncrease resistanceVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

The present invention provides a chromium and active elements modified platinum aluminide coating that may be used on a surface of a gas turbine engine component such as a turbine blade. The coating may be used as a protective coating that impedes the progress of corrosion, oxidation, and sulfidation in superalloy materials that comprise the substrate of the turbine blade. Additionally, the coating may be used as a bond coat onto which a thermal barrier coating is deposited. The presence of active elements as well as chromium and platinum provides improved corrosion, oxidation, and sulfidation resistance. The coating is applied using an electron beam physical vapor deposition. The coating is applied alternatively using selected sequential diffusion processing steps involving chromium, platinum and aluminum.

Owner:HONEYWELL INT INC

Chromium and active elements modified platinum aluminide coatings

ActiveUS20060046091A1Accelerated corrosionPromote oxidationBlade accessoriesVacuum evaporation coatingElectron beam physical vapor depositionOxidation resistant

The present invention provides a chromium and active elements modified platinum aluminide coating that may be used on a surface of a gas turbine engine component such as a turbine blade. The coating may be used as a protective coating that impedes the progress of corrosion, oxidation, and sulfidation in superalloy materials that comprise the substrate of the turbine blade. Additionally, the coating may be used as a bond coat onto which a thermal barrier coating is deposited. The presence of active elements as well as chromium and platinum provides improved corrosion, oxidation, and sulfidation resistance. The coating is applied using an electron beam physical vapor deposition. The coating is applied alternatively using selected sequential diffusion processing steps involving chromium, platinum and aluminum.

Owner:HONEYWELL INT INC

Erosion resistant coatings and methods of making

InactiveUS20080102296A1Engine manufactureEngine fuctionsElectron beam physical vapor depositionCathodic arc deposition

A coated turbine engine component includes a turbine engine component and an erosion resistant coating disposed on at least a portion of a surface of the turbine engine component using electron beam physical vapor deposition or ion plasma cathodic arc deposition.

Owner:GENERAL ELECTRIC CO

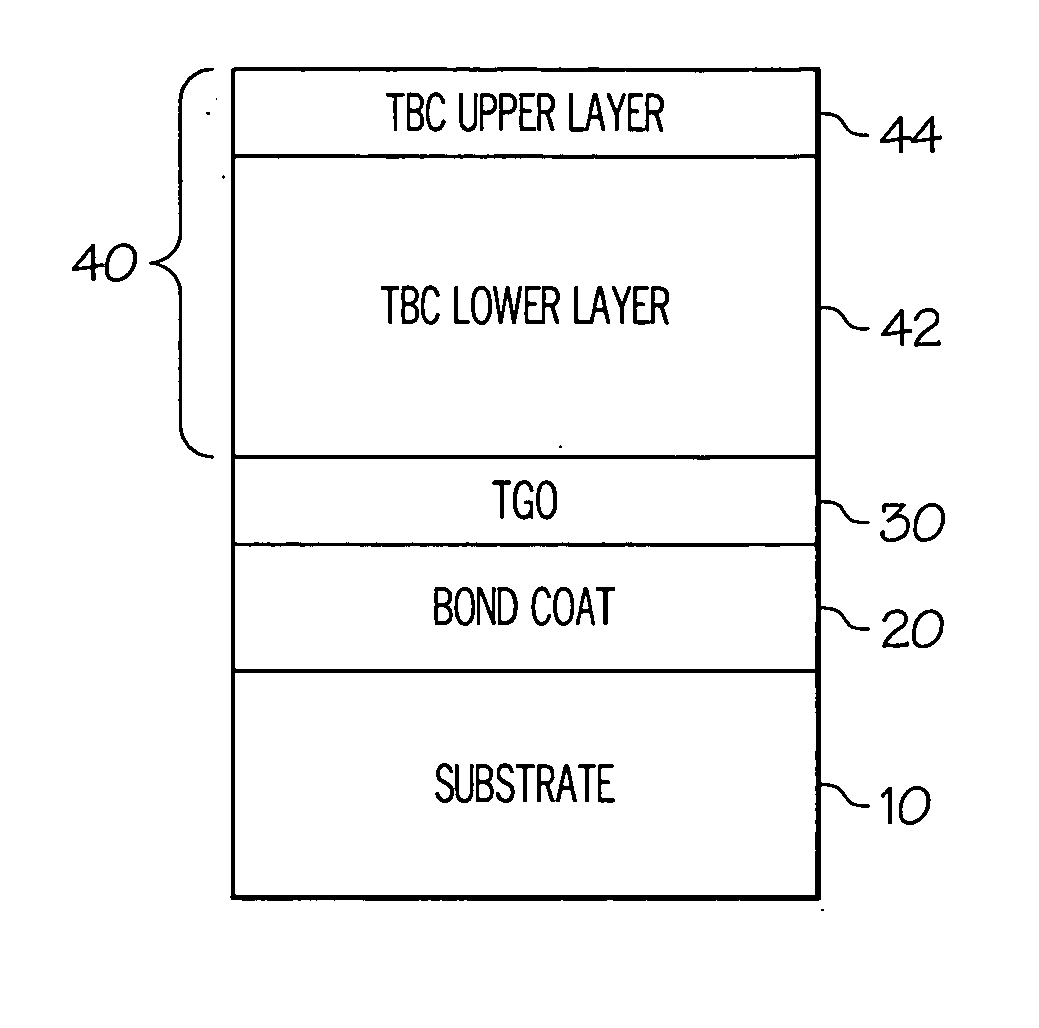

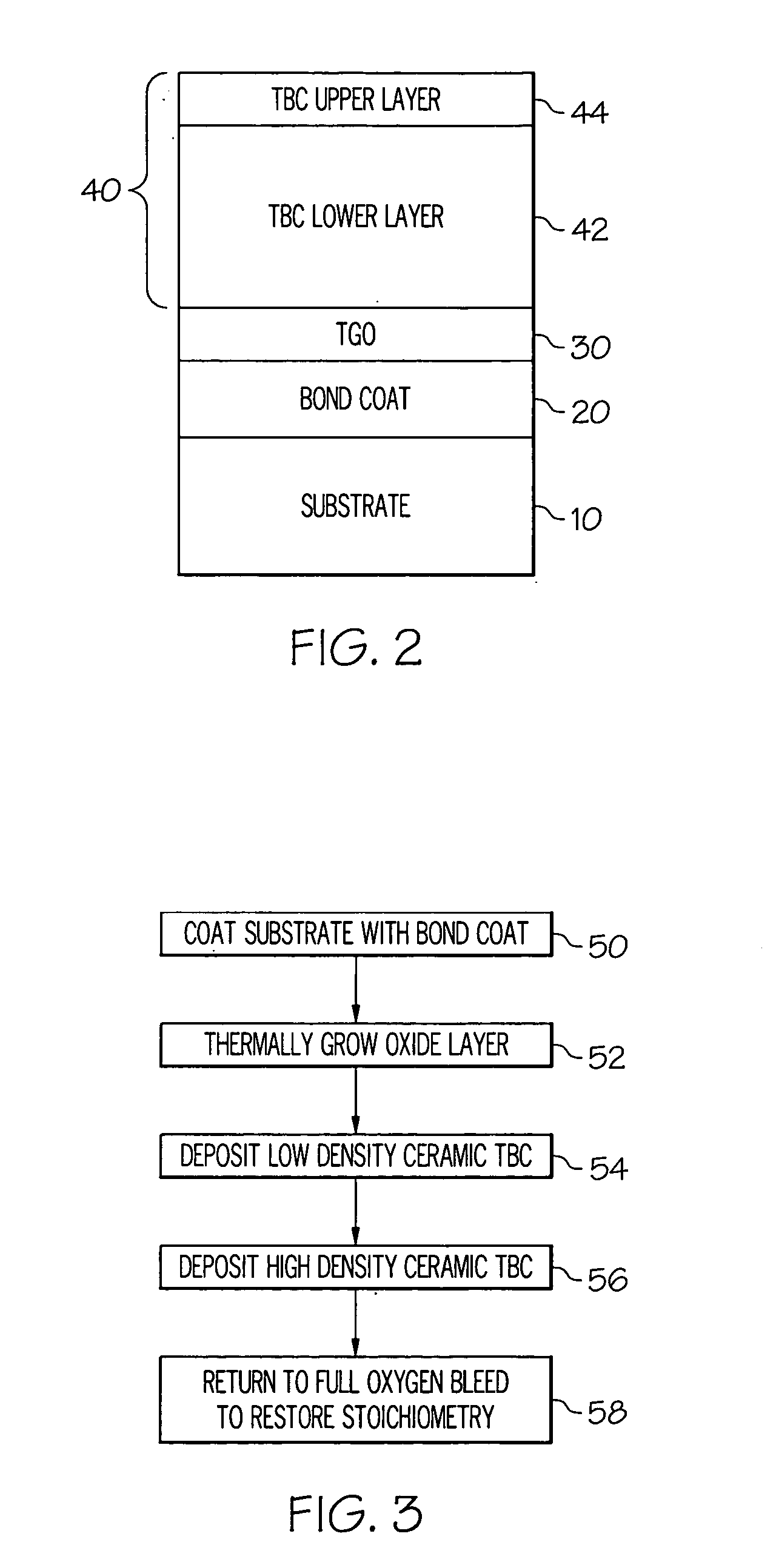

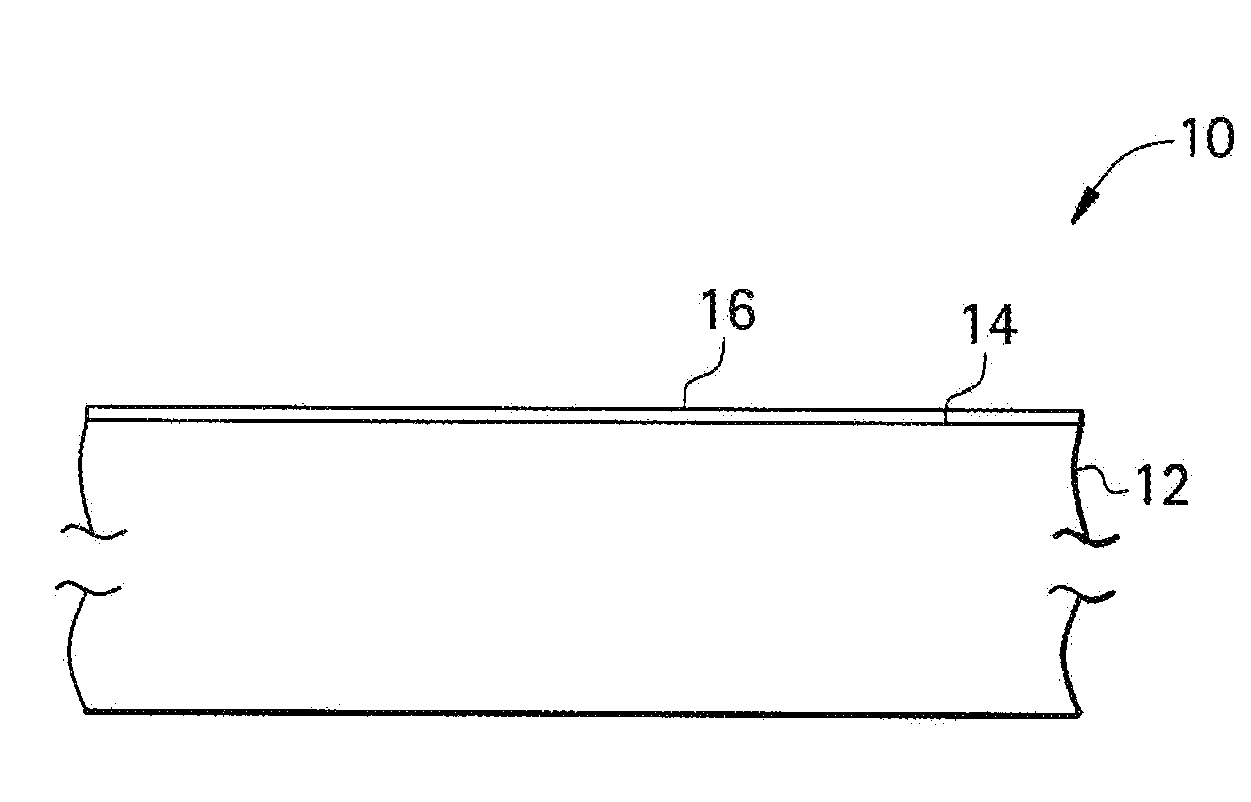

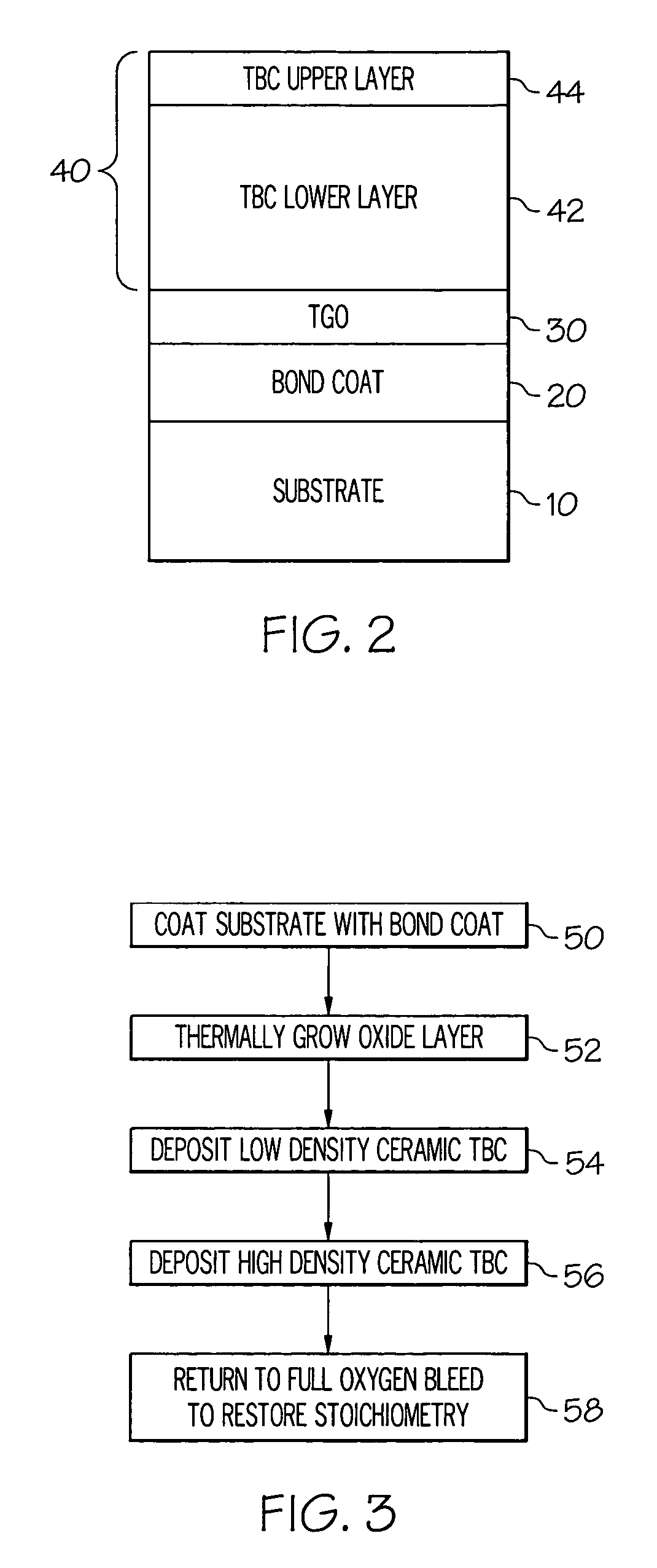

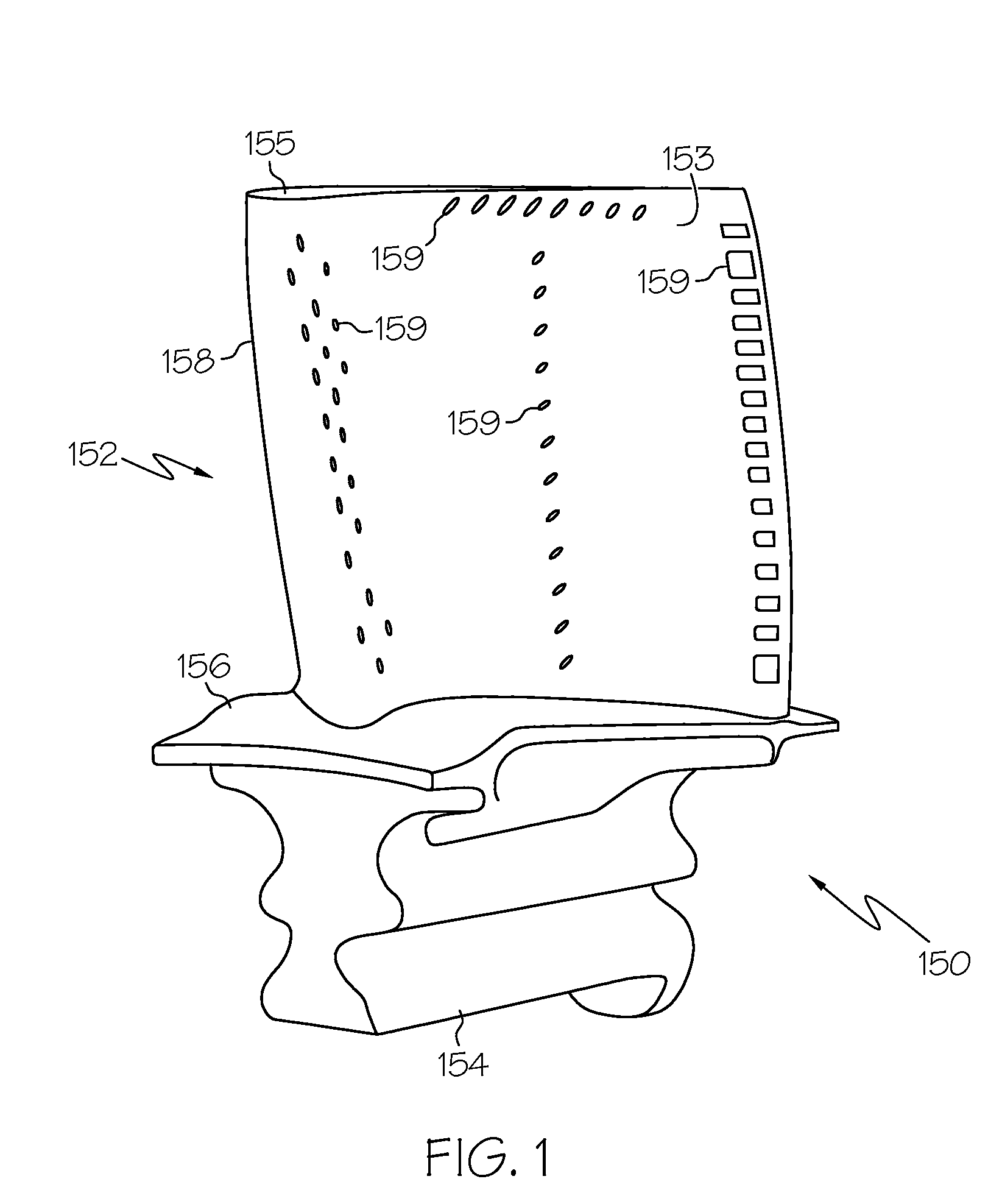

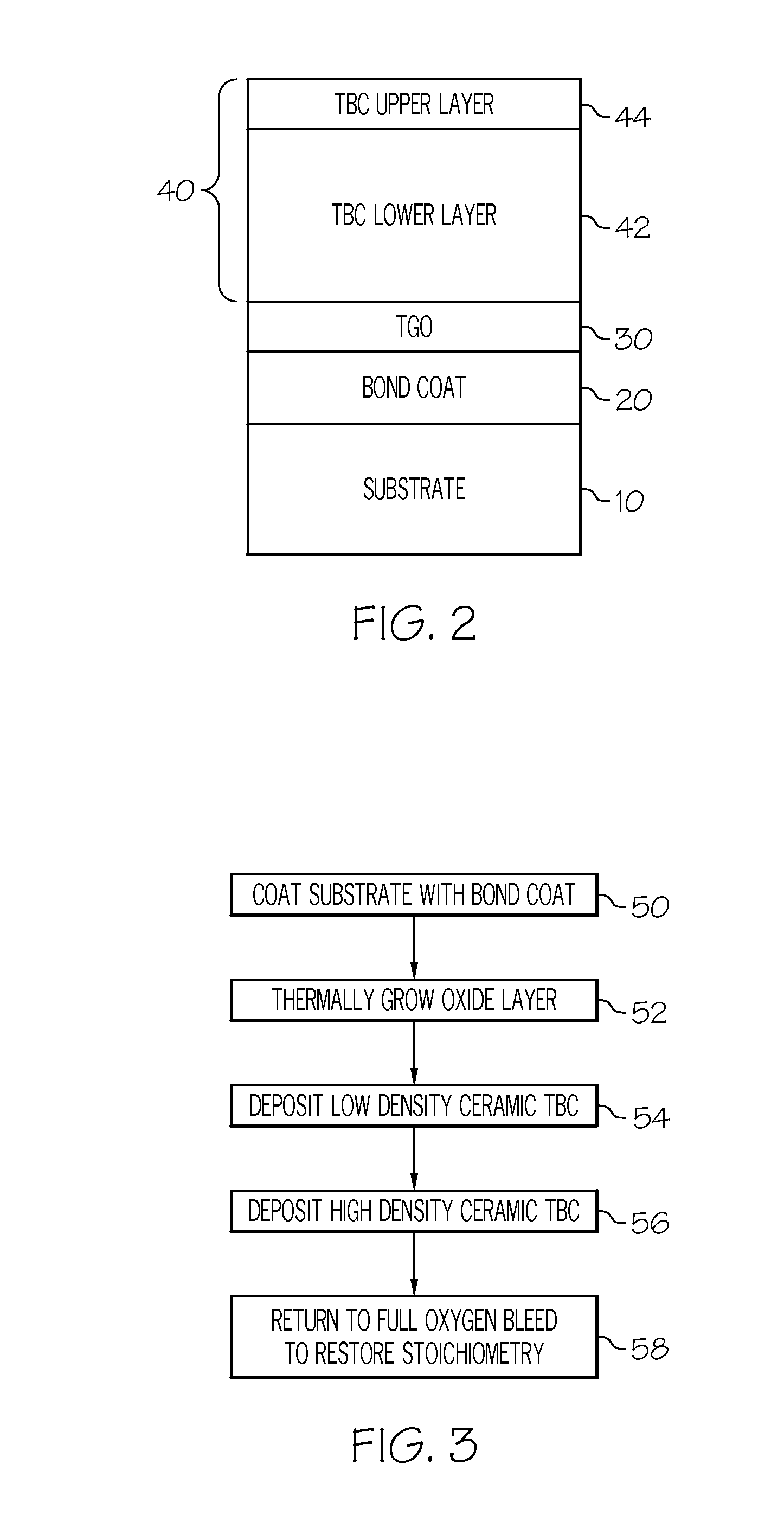

Thermal barrier coating resistant to penetration by environmental contaminants

ActiveUS20070036997A1Avoid heatBlade accessoriesEfficient propulsion technologiesPorosityElectron beam physical vapor deposition

A turbine engine component includes an electron beam-physical vapor deposition thermal barrier coating covering at least a portion of a substrate. The thermal barrier coating includes an inner layer having a columnar-grained microstructure with inter-columnar gap porosity. The inner layer includes a stabilized ceramic material. The thermal barrier coating also includes a substantially non-porous outer layer, covering the inner layer and including the stabilized ceramic material. The outer layer is deposited with continuous line-of-sight exposure to the vapor source under oxygen deficient conditions. The outer layer may further comprise a dopant oxide that is more readily reducible than the stabilized ceramic material. During deposition, the outer layer may also have an oxygen deficient stoichiometry with respect to the inner layer. Oxygen stoichiometry in the outer layer may be restored by exposure of the coated component to an oxidizing environment.

Owner:HONEYWELL INT INC

Preparation method for thermal-barrier coating

InactiveCN103668191AVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

A preparation method for a thermal-barrier coating comprises the following steps: performing ultrasonic cleaning on alloy or stainless steel successively by gasoline and alcohol, and then performing corundum sand-blast processing; employing ultrasonic flame spraying, low-pressure plasma spraying, atmosphere plasma spraying, cold spraying or electron beam-physical vapor deposition to prepare a NiCoCrAlYTa or NiAl bonding layer with a thickness of 50-200 mu m on the surface of alloy or stainless steel; employing low-pressure plasma spraying, atmosphere plasma spraying, plasma spraying-physical vapor deposition or electron beam-physical vapor deposition to prepare a ZrO2-7 wt% of Y2O3 ceramic layer with a thickness of 100-300 mu m on the above bonding layer; employing magnetron sputtering to prepare an aluminium film with a thickness of 5-30 mu m on the above ceramic layer; and performing heat treatment on the thermal-barrier coating with the aluminium film. The preparation method provided by the invention is capable of improving the anti-oxidation property and the corrosion resisting property of the thermal-barrier coating.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

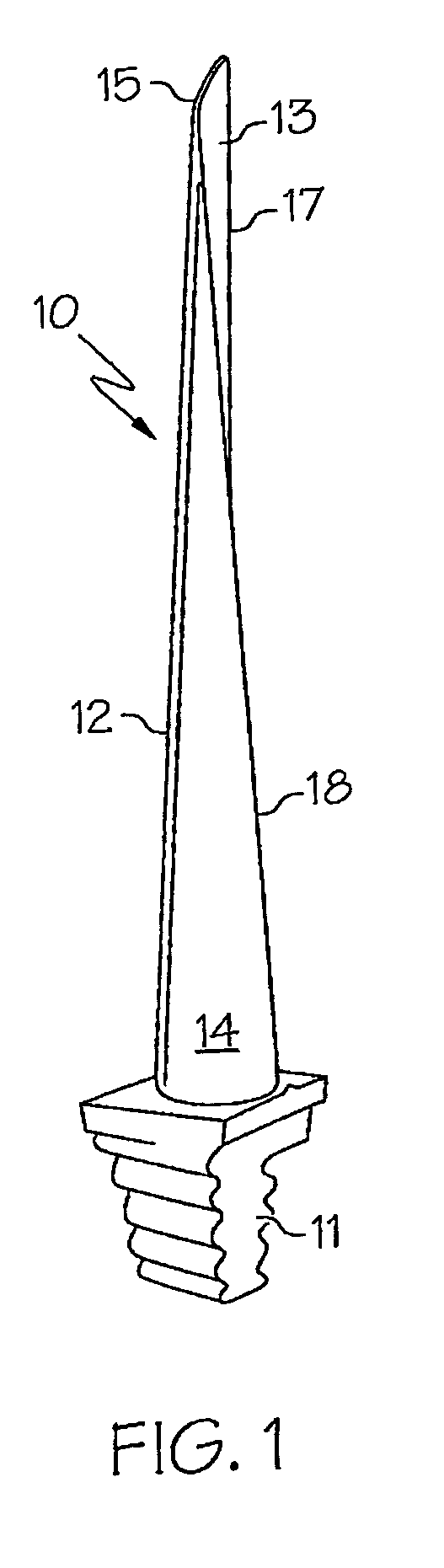

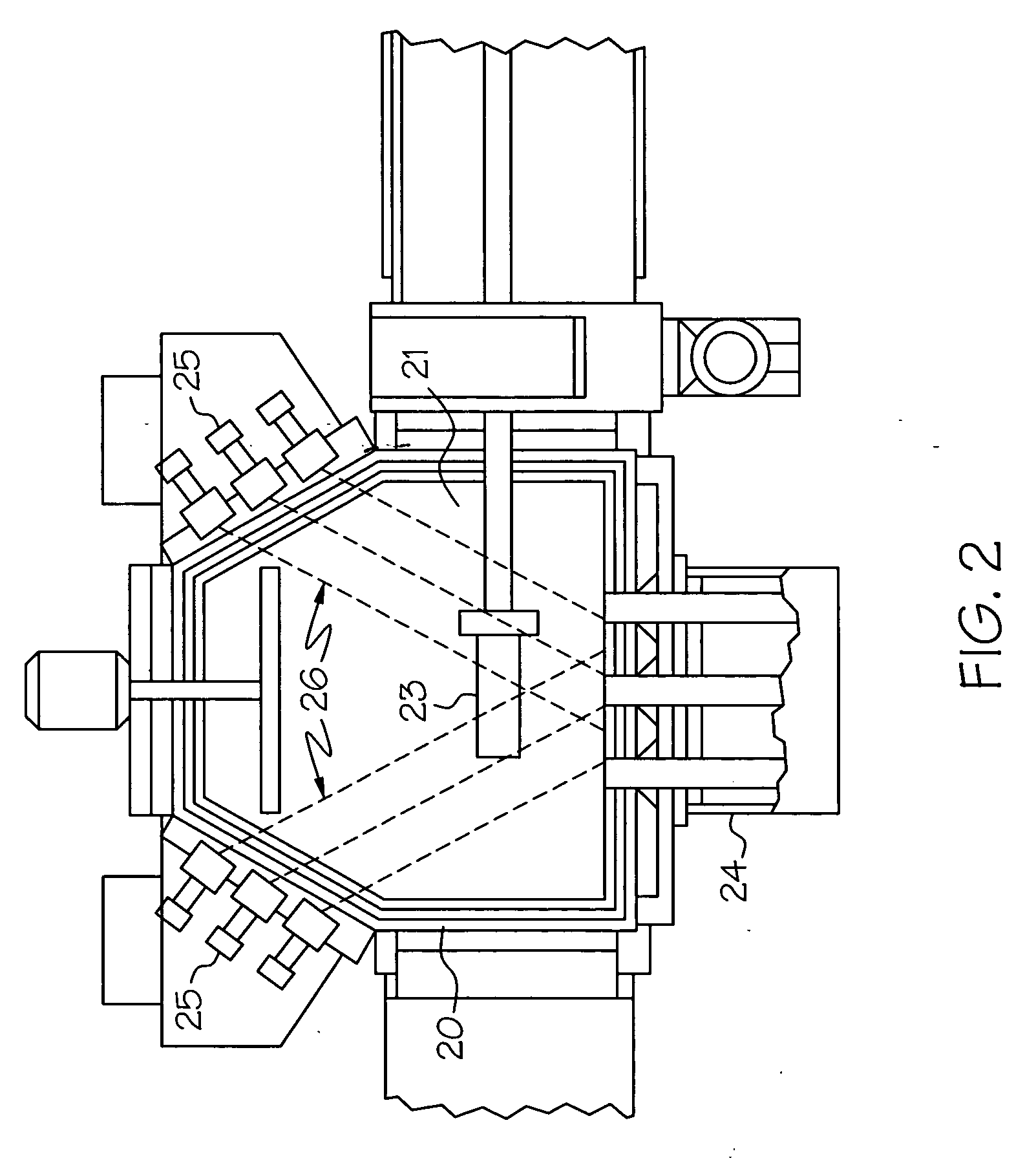

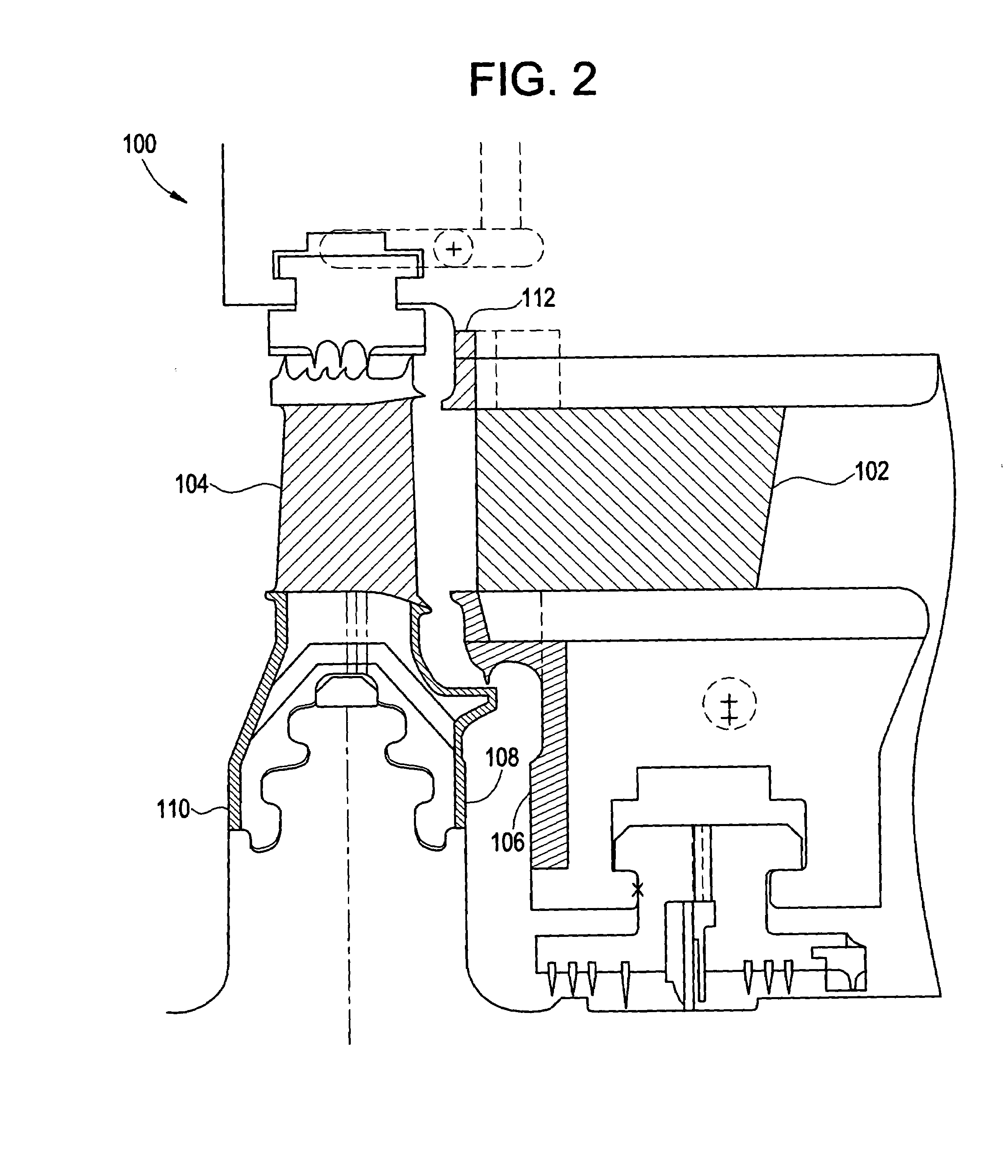

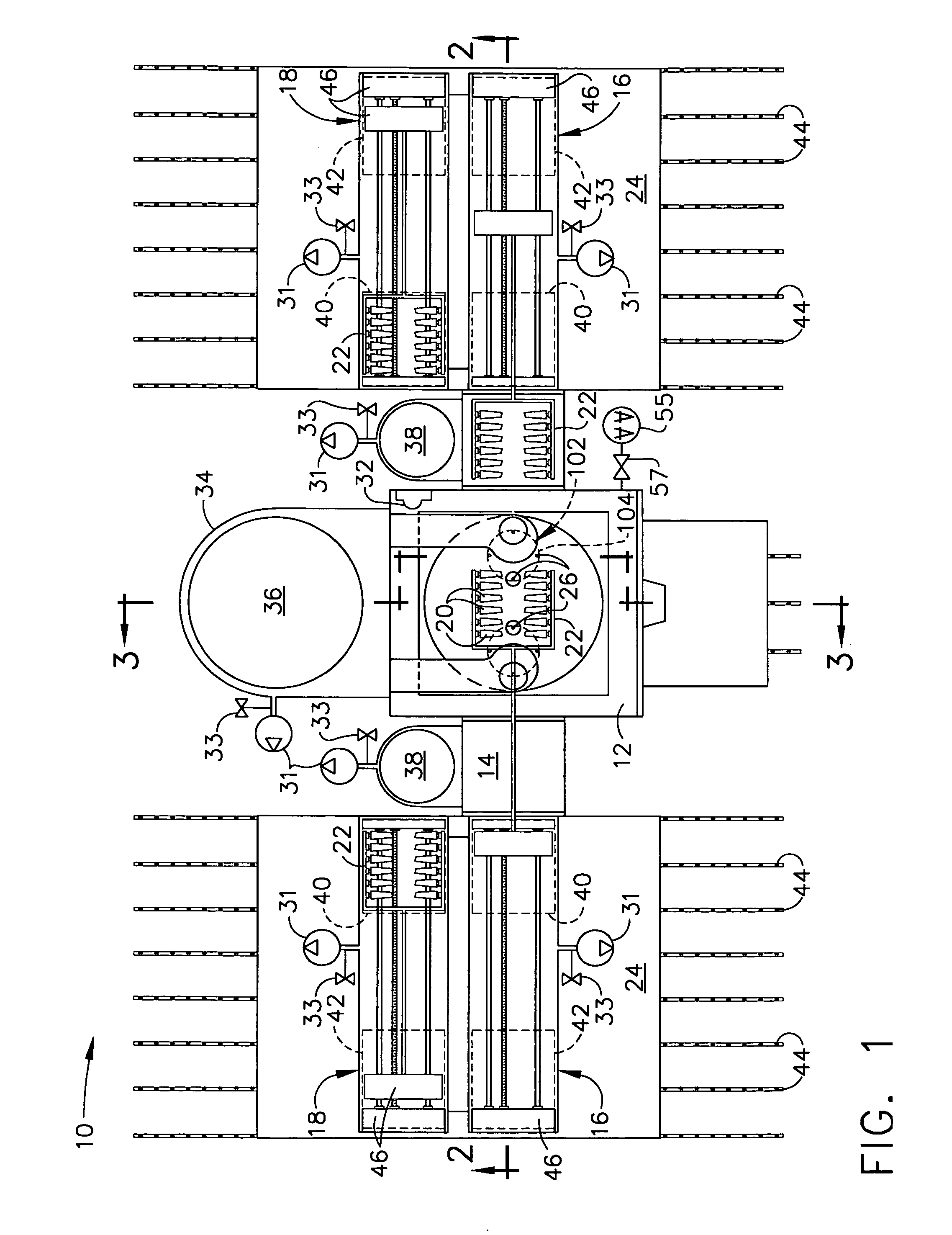

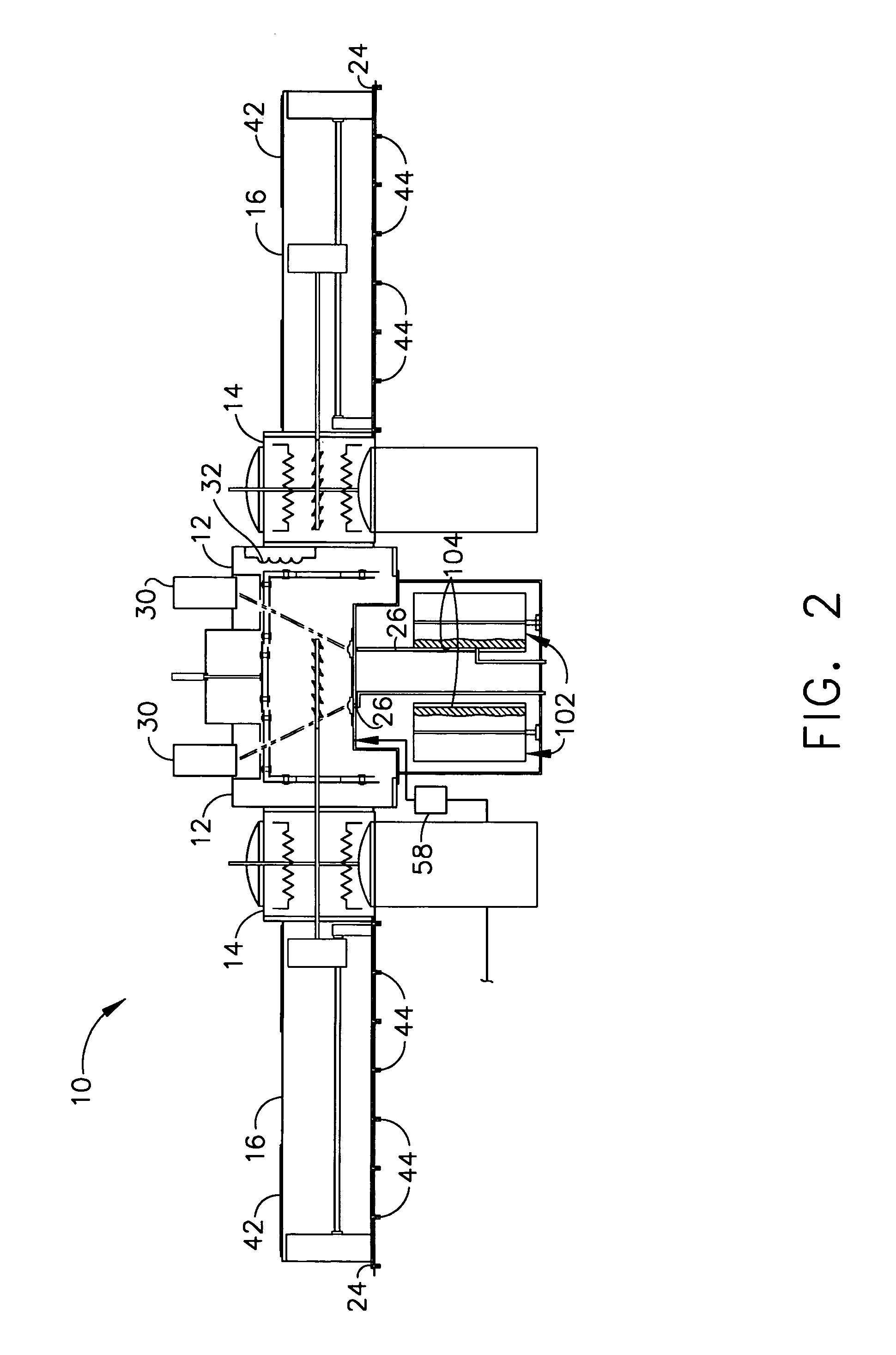

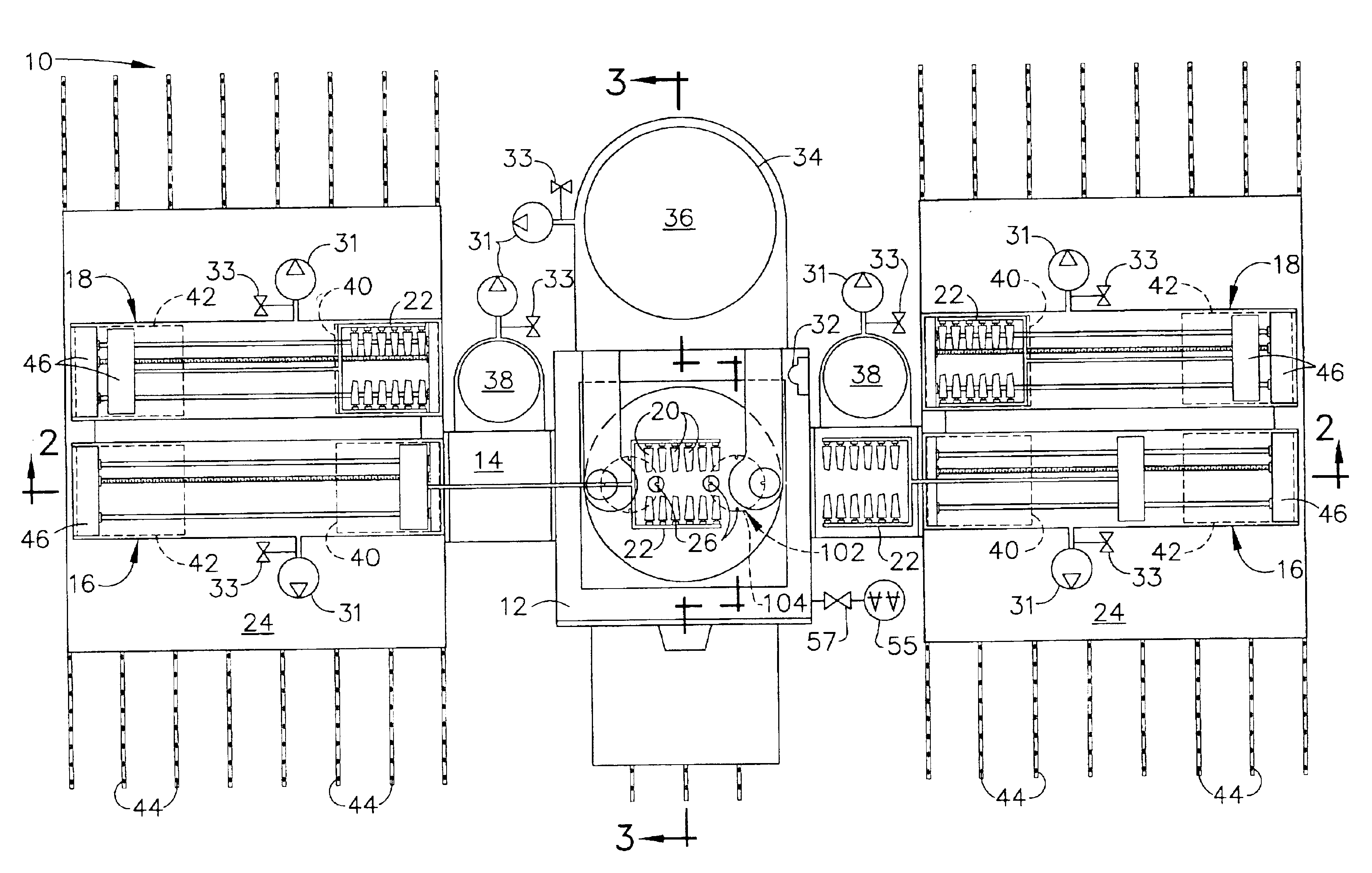

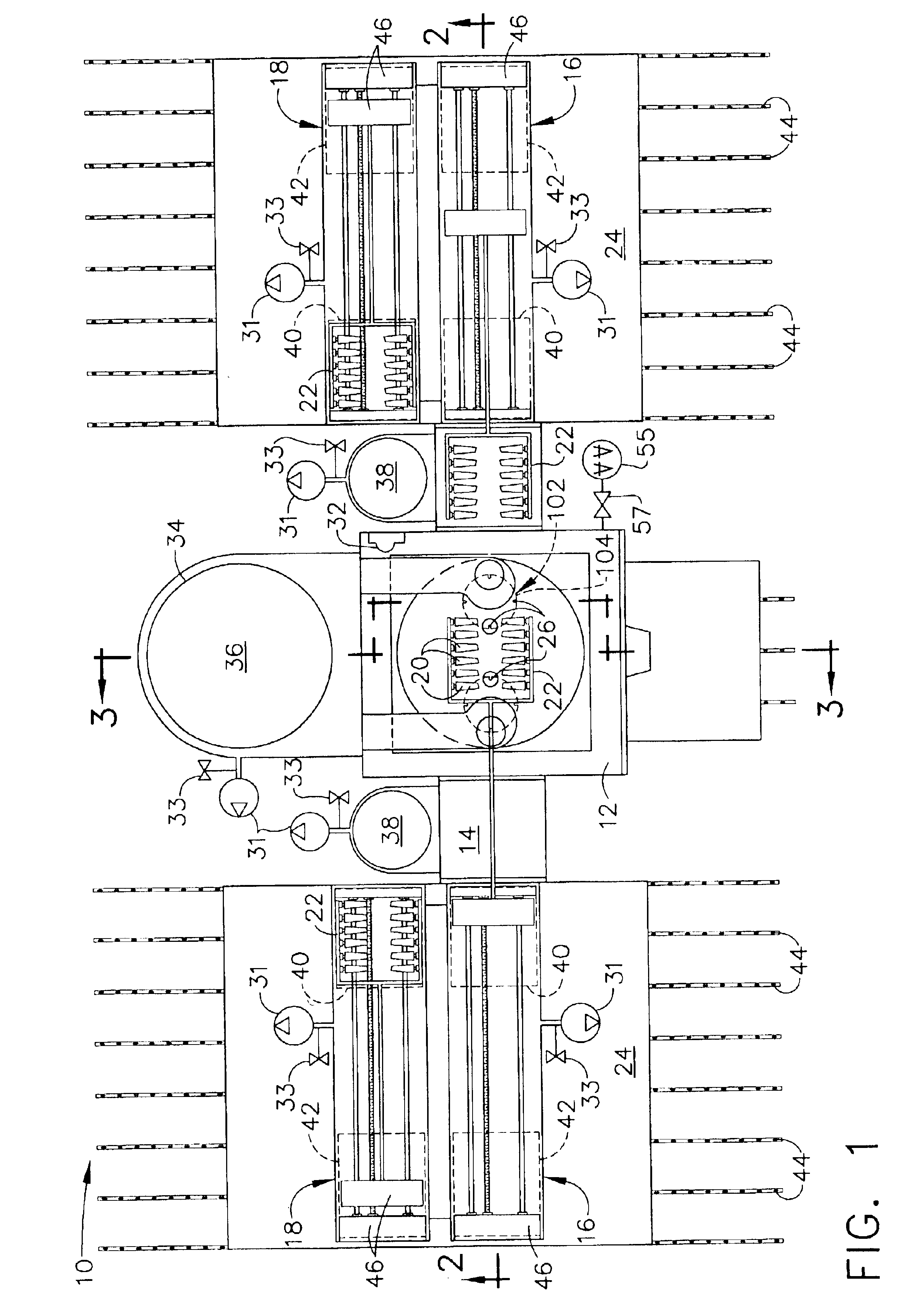

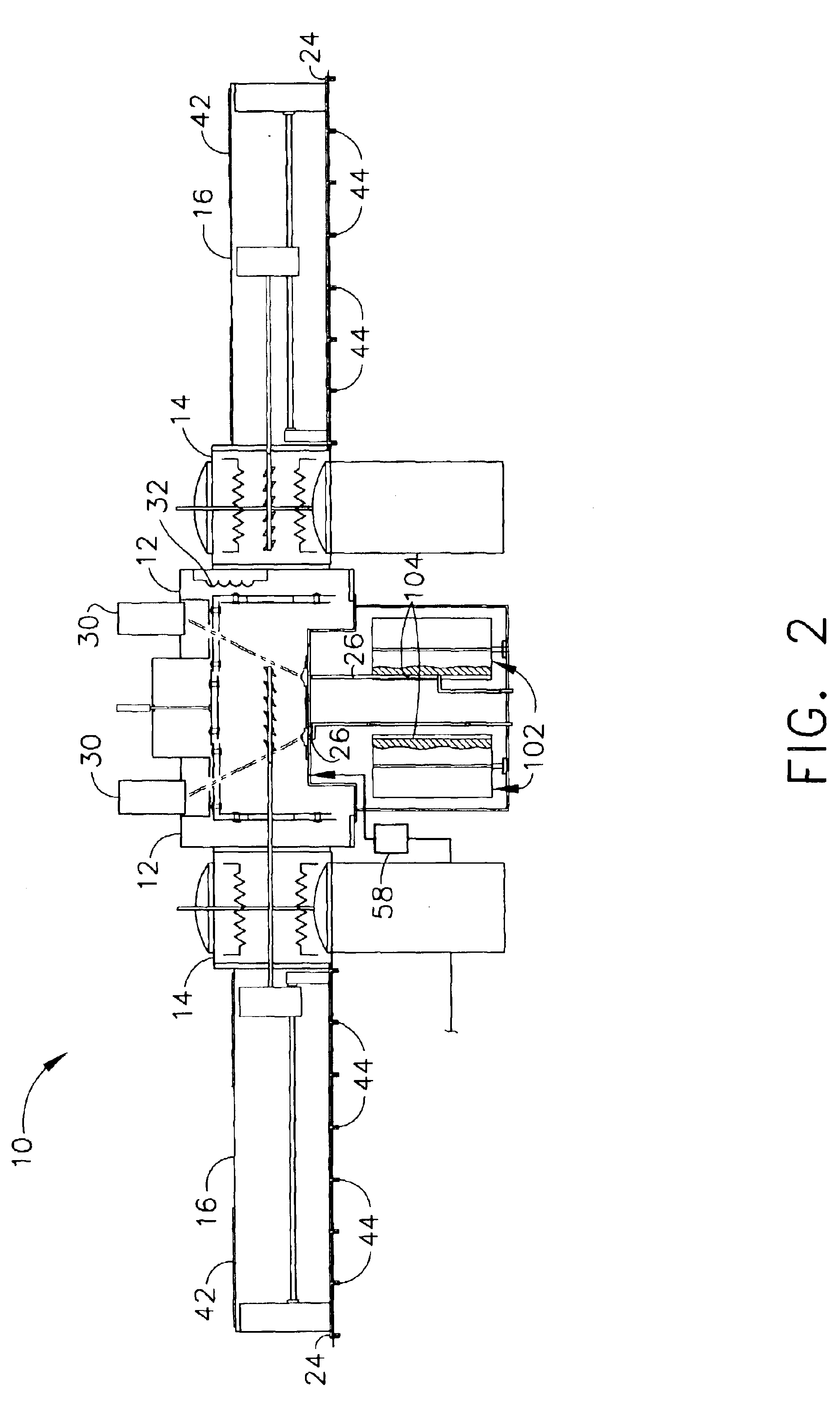

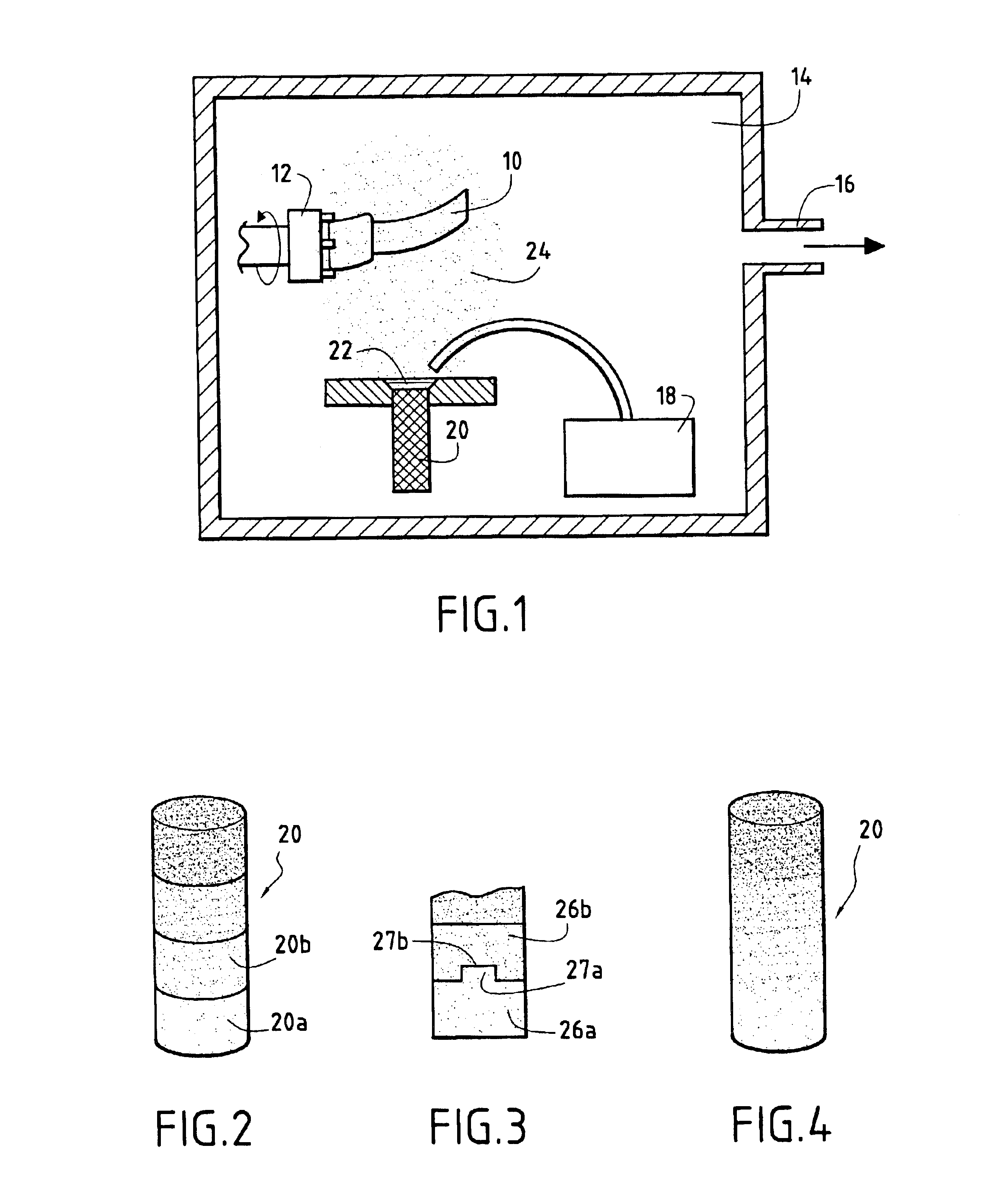

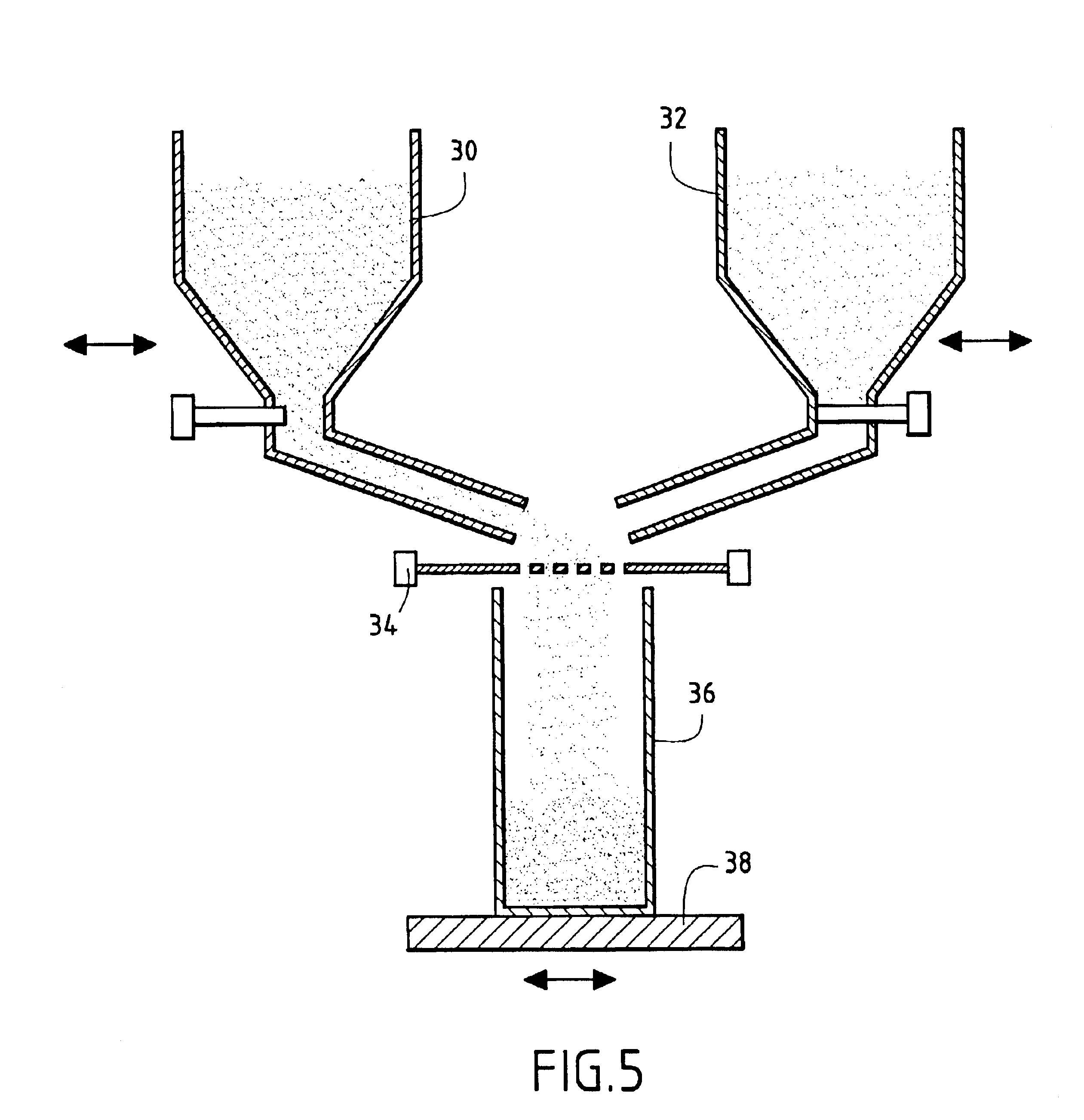

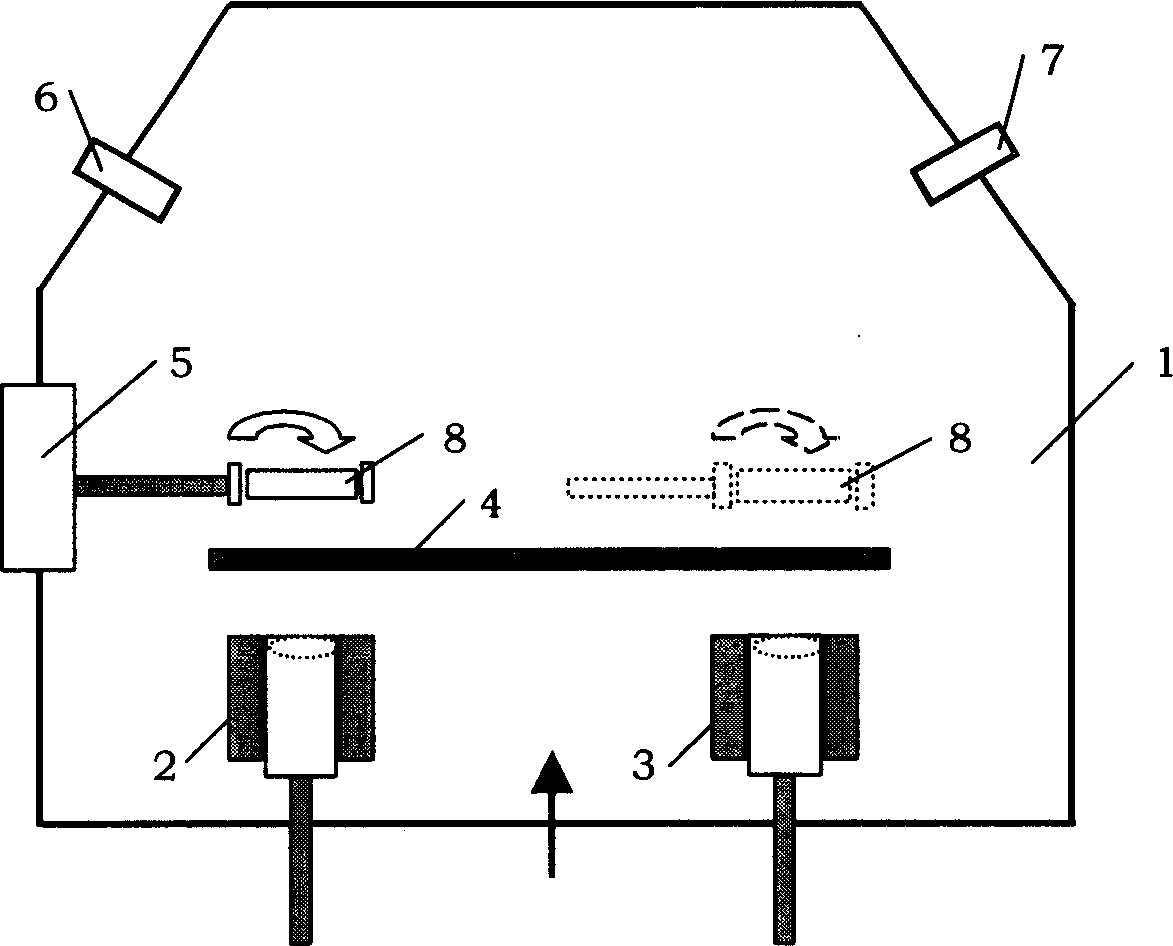

Electron beam physical vapor deposition apparatus

InactiveUS6946034B1Increase or decreaseEasy to operateElectric discharge tubesVacuum evaporation coatingElectron beam physical vapor depositionThermal barrier coating

An electron beam physical vapor deposition (EBPVD) apparatus for producing a coating material (e.g., a ceramic thermal barrier coating) on an article. The EBPVD apparatus generally includes a coating chamber that is operable at elevated temperatures and subatmospheric pressures. An electron beam gun projects an electron beam into the coating chamber through an aperture in a wall of the chamber and onto a coating material within a coating region defined within the chamber, causing the coating material to melt and evaporate. An article is supported within the coating chamber so that vapors of the coating material deposit on the article. The operation of the EBPVD apparatus is enhanced by the inclusion within the coating chamber of a second chamber that encloses the aperture so as to separate the aperture from the coating region. The second chamber is maintained at a pressure lower than the coating region.

Owner:GENERAL ELECTRIC CO

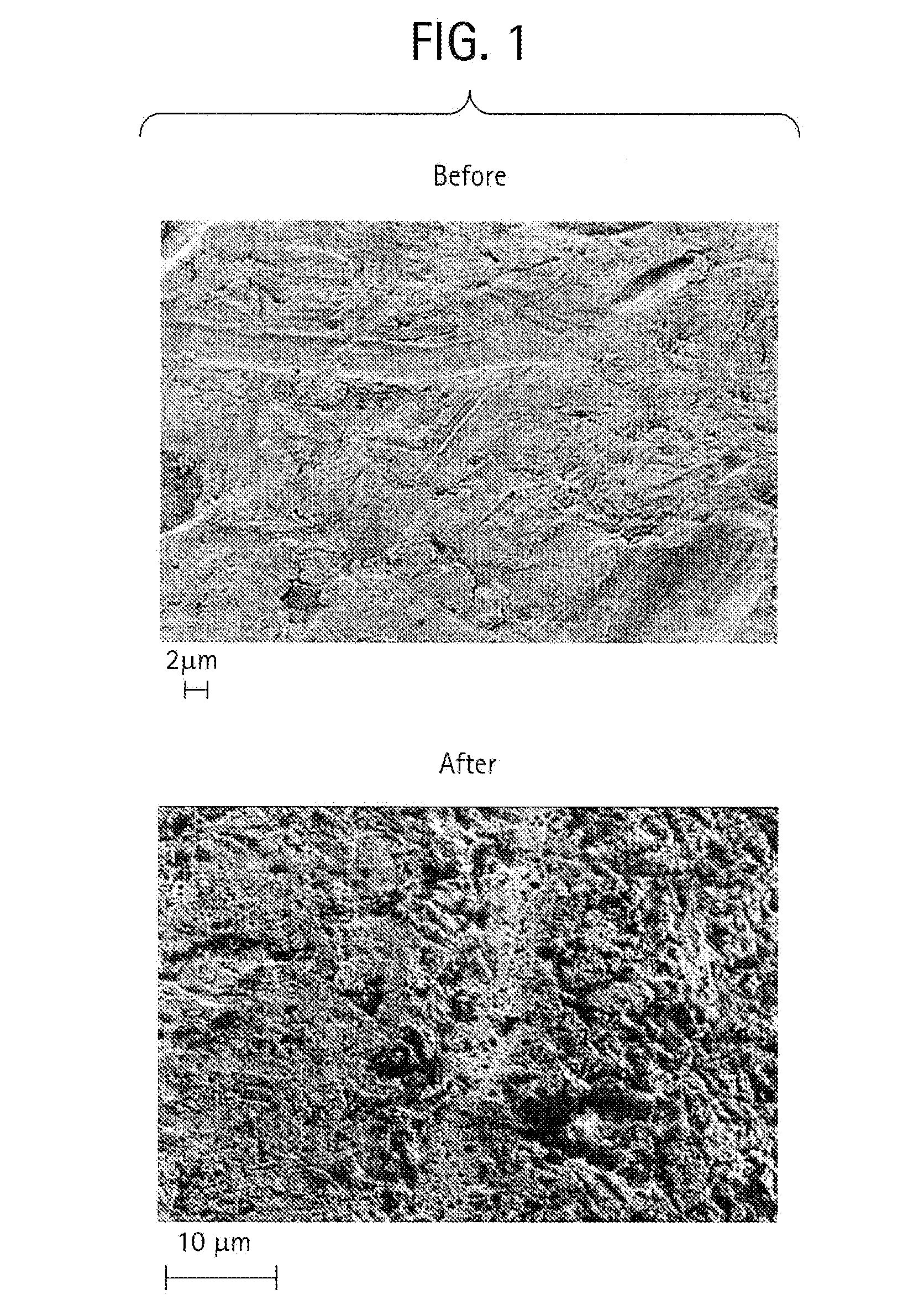

Surface Treatments for Turbine Components to Reduce Particle Accumulation During Use Thereof

InactiveUS20100086397A1Preventing micropittingEasy to understandPropellersVacuum evaporation coatingElectron beam physical vapor depositionSputtering

A turbine engine component includes at least one treated surface wherein the treated surface has a surface roughness (Ra) of less than 12 microinches; and a hard coating disposed on the superfinished surface, wherein the hard coating is a nitride and / or a carbide material at a thickness of less than 50 microns formed using electron beam physical vapor deposition, cathodic arc evaporation, or magnetron sputtering. disclosed are methods for substantially preventing micropitting on a surface of a turbine engine component.

Owner:GENERAL ELECTRIC CO

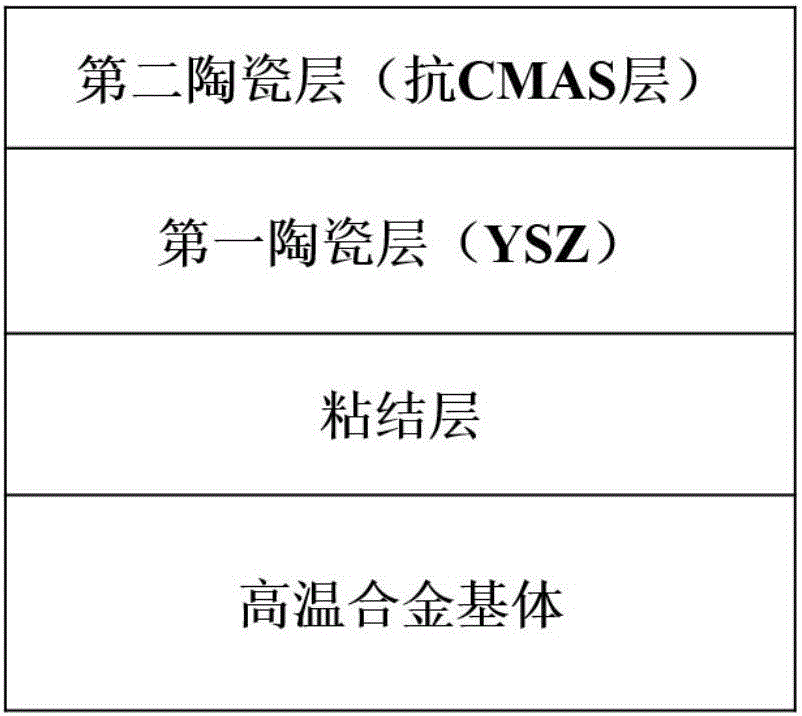

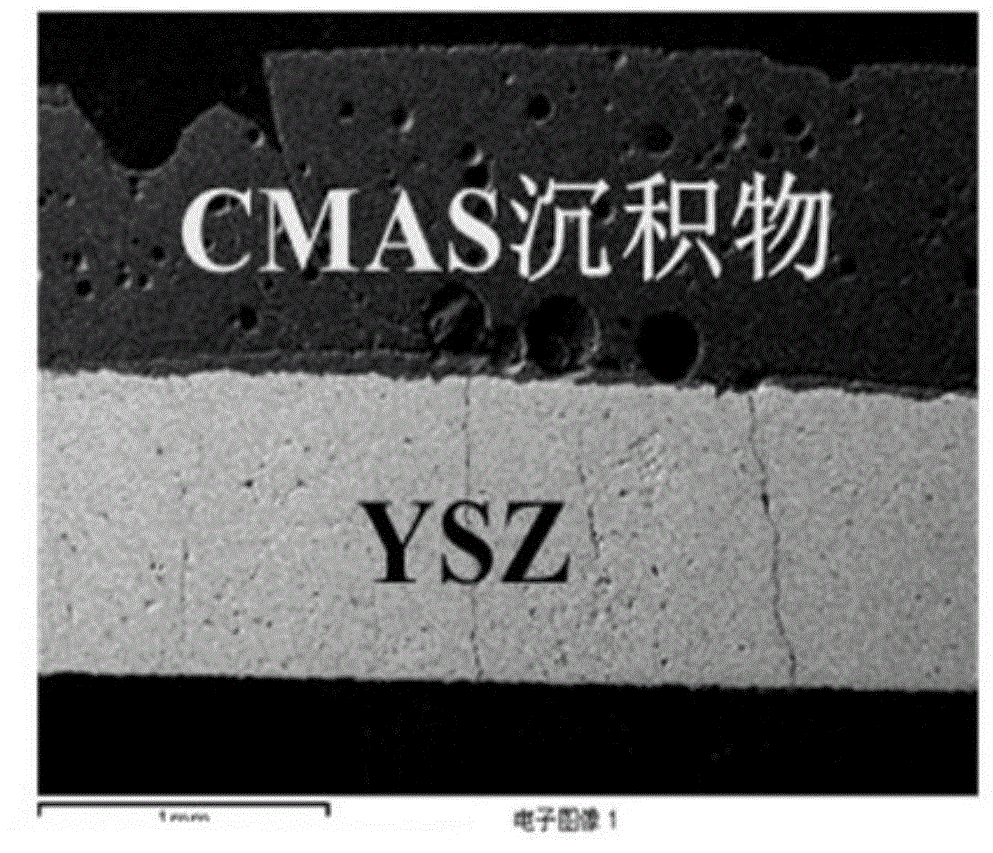

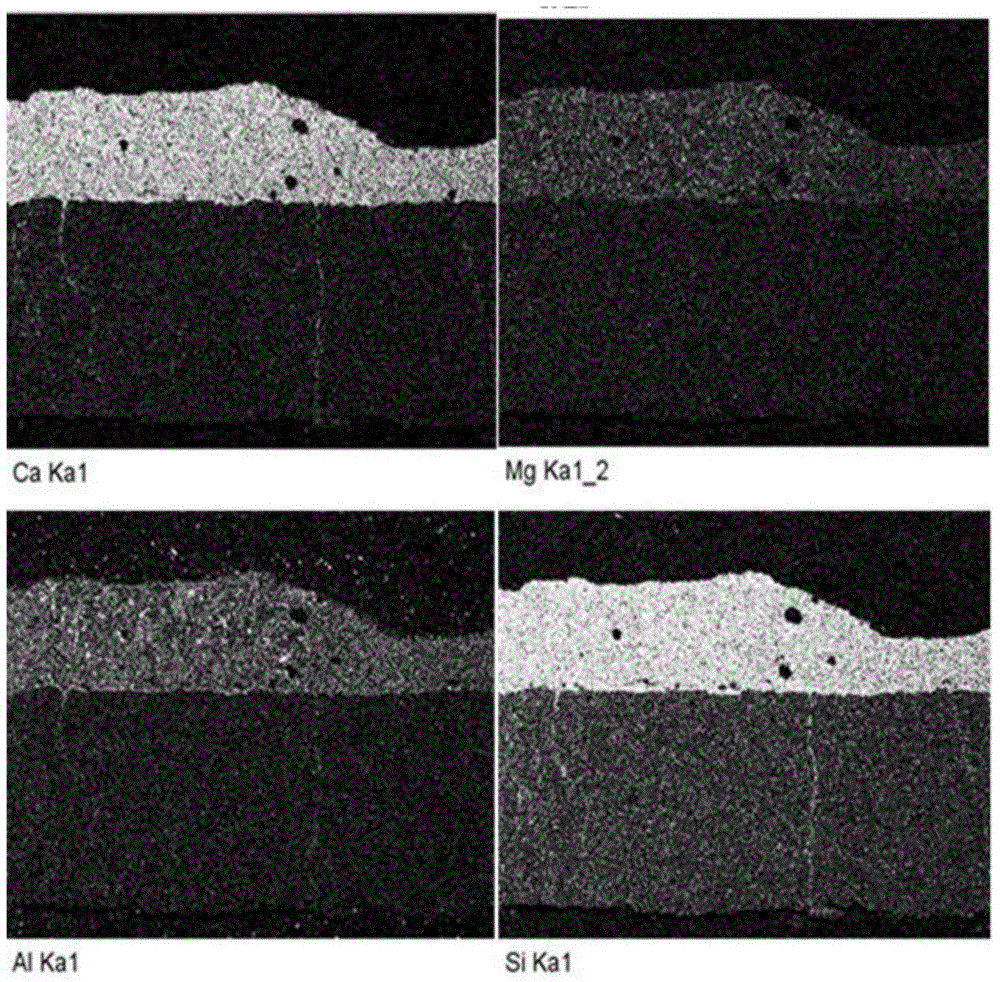

CMAS corrosion-resistance micronanometer composite thermal barrier coating layer and preparation method thereof

InactiveCN106086765ASuperhydrophobicCleanlinessMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionAlloy

The invention discloses a preparation method of a CMAS corrosion-resistance micronanometer composite thermal barrier coating layer. The thermal barrier coating layer includes a bonding layer prepared on an alloy basal body, a first ceramic layer and a second ceramic layer; the first ceramic layer is a yttrium oxide part stable zirconium oxide coating layer, can be prepared by atmosphere plasma spraying, an electronic beam physical vapor deposition method or a plasma evaporation deposition method, and has a thickness of 50-200 microns; and the second ceramic layer is a CMAS-resistance coating layer prepared by a plasma evaporation deposition system, and has a thickness of 1-100 microns. At high temperature, molten CMAS is not wet on the surface of the prepared second ceramic layer. The prepared multi-layer thermal barrier coating layer system including the bonding layer, the first ceramic layer and the CMAS-resistance second ceramic layer can effectively stop permeation of molten CMAS, and is excellent in molten CMAS corrosion resistance.

Owner:BEIHANG UNIV

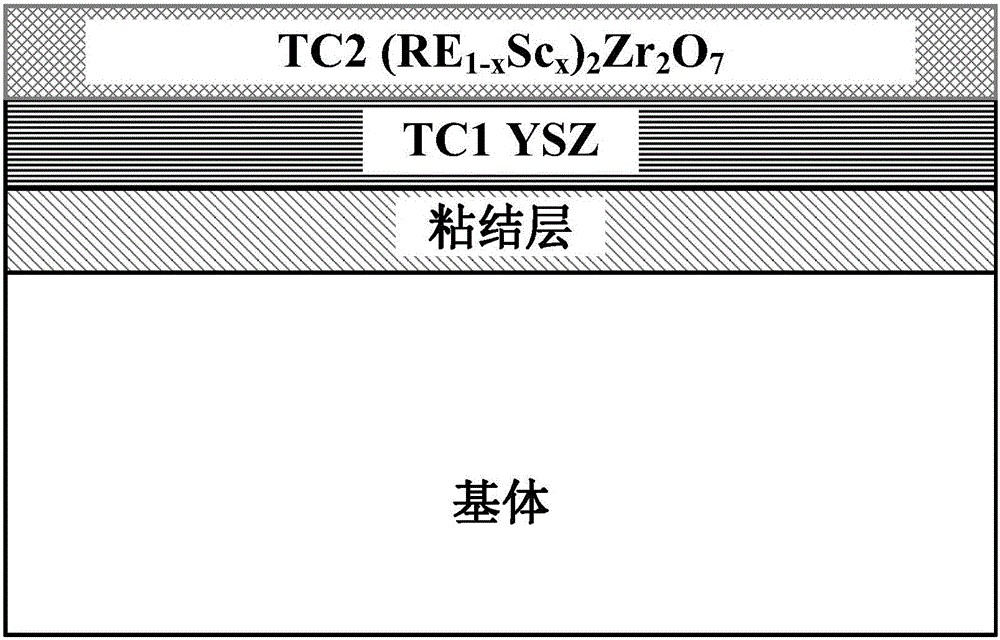

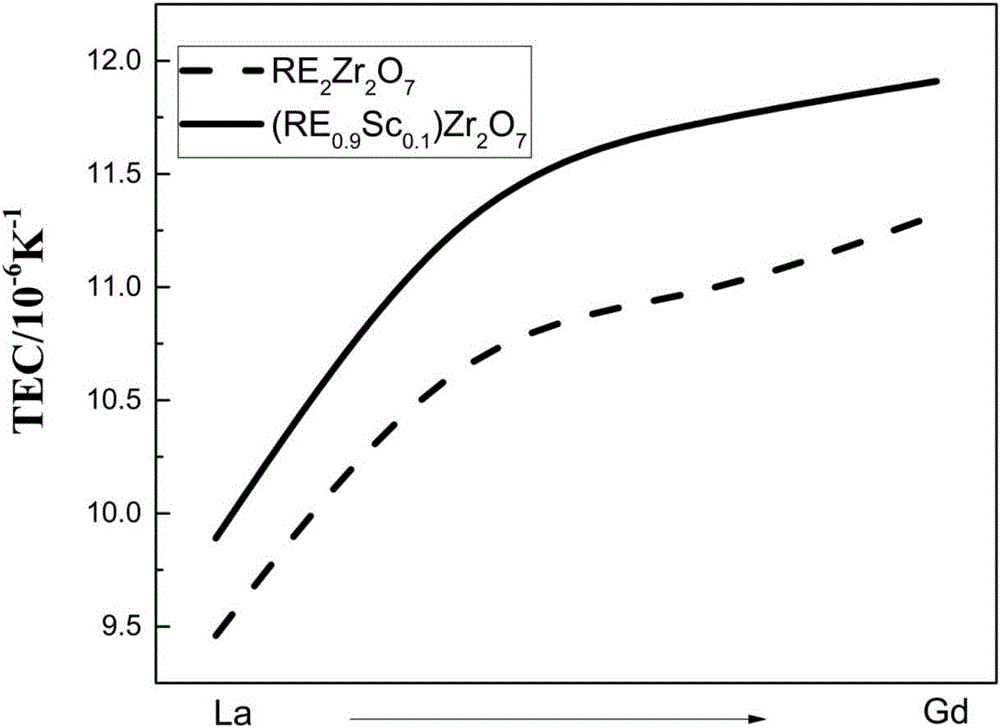

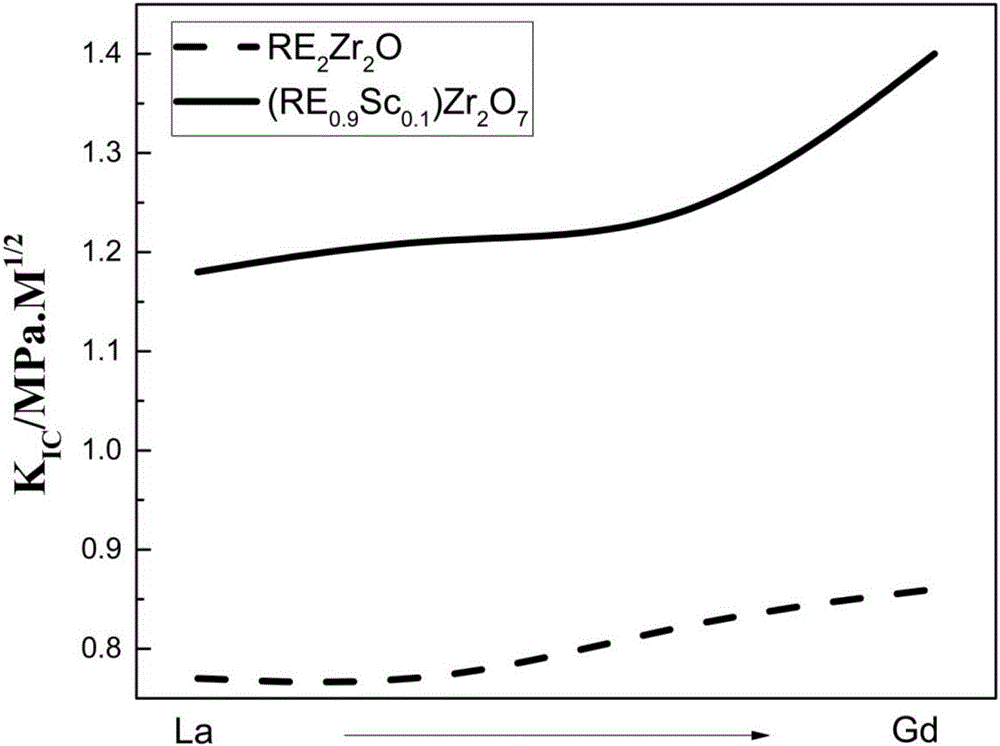

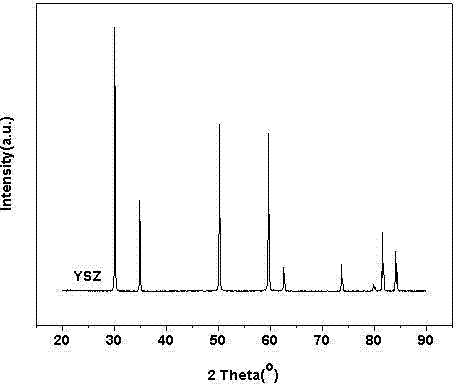

Anti-CMAS-corrosion ultrahigh-temperature-resistant long-service-life thermal barrier coating and preparation method thereof

ActiveCN105862038ALow thermal conductivityImprove toughnessMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionZirconate

The invention relates to an anti-CMAS-corrosion ultrahigh-temperature-resistant long-service-life thermal barrier coating and a preparation method thereof. The thermal barrier coating is sequentially provided with a binding layer, a first ceramic layer and a second ceramic layer on a matrix from bottom to top, the binding layer is made of an MCrAlX alloy, M refers to Ni, or Co or a composition of Ni and Co, X refers to one of or a composition of two of Y, Hf, Si and Pt, the first ceramic layer is made of YSZ, and the second ceramic layer is rare earth zirconate with Sc2O3. The preparation method includes that an electron beam physical vapor deposition method or an atmosphere plasma spraying method are adopted. Sc2O3 is doped in a rare earth zirconate coating, so that heat conductivity of the coating can be further lowered, toughness of the coating is improved, anti-CMAS-corrosion capability of the coating is improved, thermal cycling life of the coating can be prolonged, and high-temperature stability of the coating under CMAS coupling action can be improved.

Owner:TIANJIN UNIV

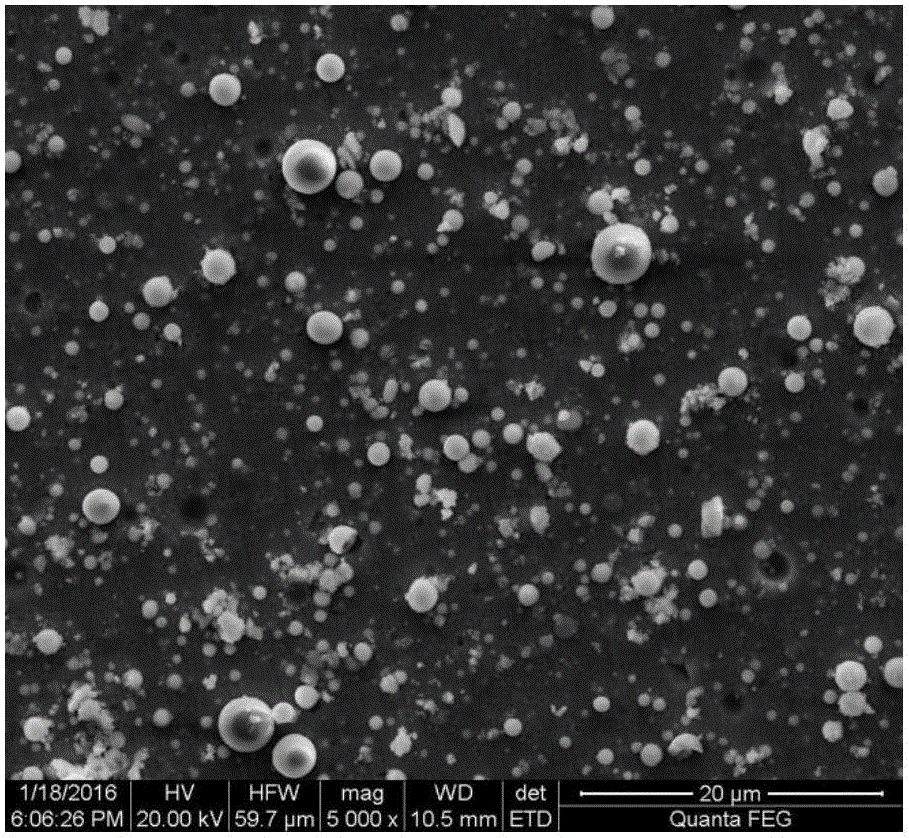

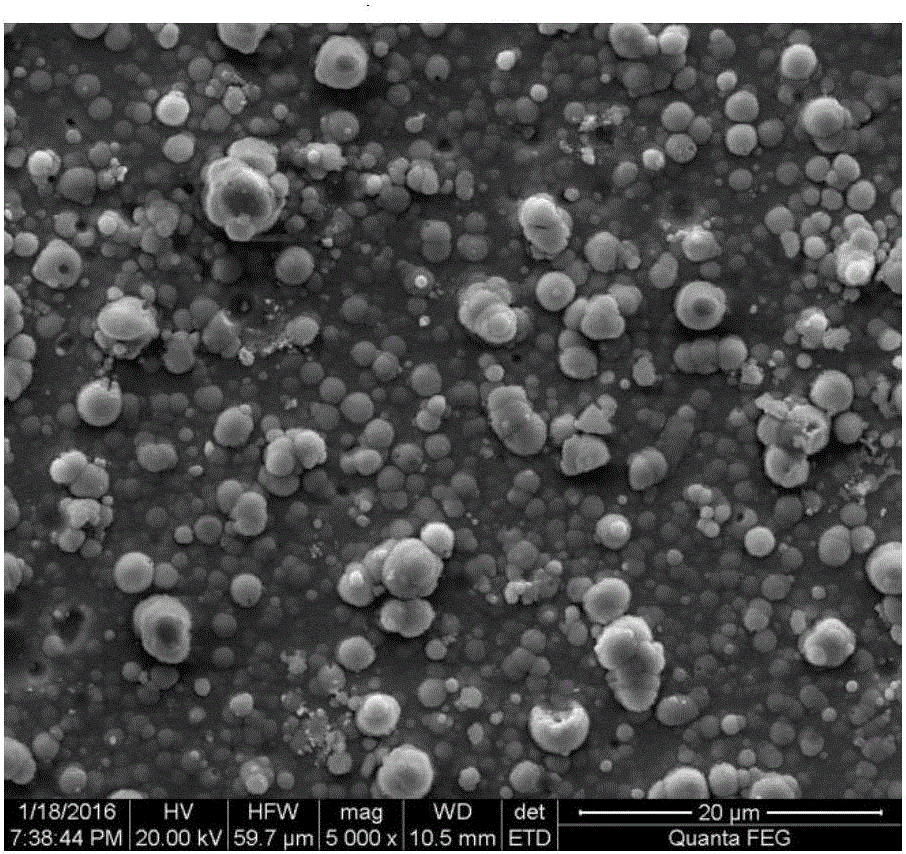

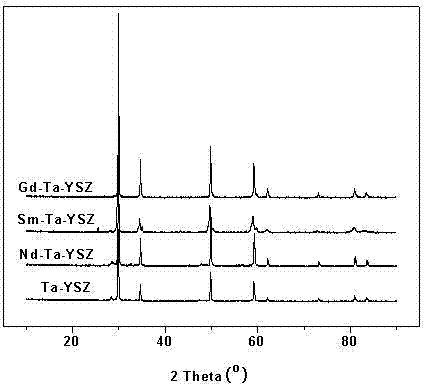

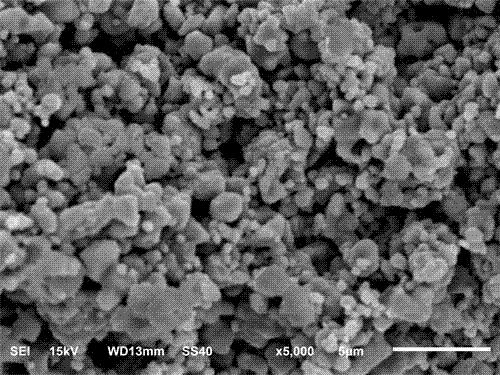

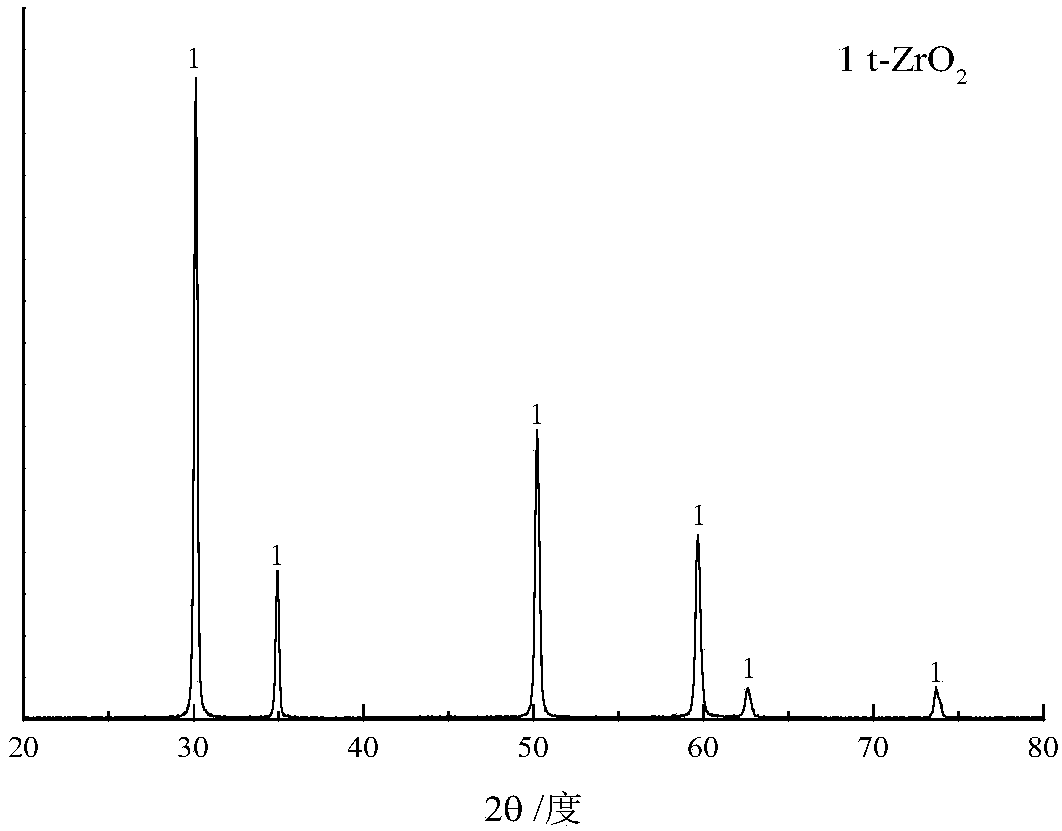

Stable zirconia ceramic target material for electron beam physic vapor deposition, and its preparation method

ActiveCN103936415AMeet the needs of engineering applicationsSpeed up the development processElectron beam physical vapor depositionGas phase

The invention relates to a stable zirconia ceramic target material for electron beam physic vapor deposition (EB-PVD), and its preparation method, and belongs to the ceramic material preparation field. The ceramic target material with a good deposition performance is obtained by adopting a two-step solid phase sintering process with highly pure zirconia and an oxide stabilizer as raw materials. The preparation method comprises the following steps: carrying out high temperature solid phase synthesis and ball milling to prepare ceramic powder raw materials with stable crystal phase and uniform granularity, carrying out high pressure molding through combining molding pre-pressing with isostatic pressing, carrying out dimensional fine finishing, and carrying out low temperature sintering to prepare the EB-PVD ceramic target material. The ceramic target material prepared in the invention has the advantages of accurate chemical components, stable crystal phase, and small high-temperature volume deformation, has a microscopic crystal grain size uniformity of below 5mum, and satisfies technologic requirements of no splashing of the EB-PVD technology, and stable composition and performances of the obtained coating. The two-step solid phase sintering process realizes a short high temperature sintering time, low temperature heat treatment of the target material reduces the energy consumption, and the preparation method has the advantages of simple technology and equipment, good batch performance stability, and realization of the popularization to the industrialized production.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Preparation method for porous zirconium oxide thermal barrier coating

InactiveCN107699840AHighlight substantive featuresImprove insulation performanceMolten spray coatingPorosityElectron beam physical vapor deposition

The invention discloses a preparation method for a porous zirconium oxide thermal barrier coating, and relates to coating of metal materials by oxides. The method for preparing the porous zirconium oxide thermal barrier coating by combining a thermal spraying technology with thermal treatment comprises the following steps of: uniformly mixing nano zirconium oxide powder stabilized by 8% (in percentage by mass) of yttrium oxide and high-molecular polymer pore-forming agent powder to obtain a mixture, uniformly mixing a binder to prepare zirconium oxide based composite powder used for thermal spraying; pre-treating a metal matrix material; preparing a porous zirconium oxide coating through a thermal spraying method; and thermally treating the porous zirconium oxide coating, thereby preparingthe porous zirconium oxide thermal barrier coating on the surface of the metal matrix material. According to the preparation method disclosed by the invention, effective control on porosity can be realized by regulating components and adding amount of the pore-forming agent, so that porosity is obviously improved, and therefore, heat insulation of the coating is also improved. The preparation method overcomes various defects of electron beam physical vapor deposition in the prior art for preparing the porous zirconium oxide thermal barrier coating.

Owner:HEBEI UNIV OF TECH

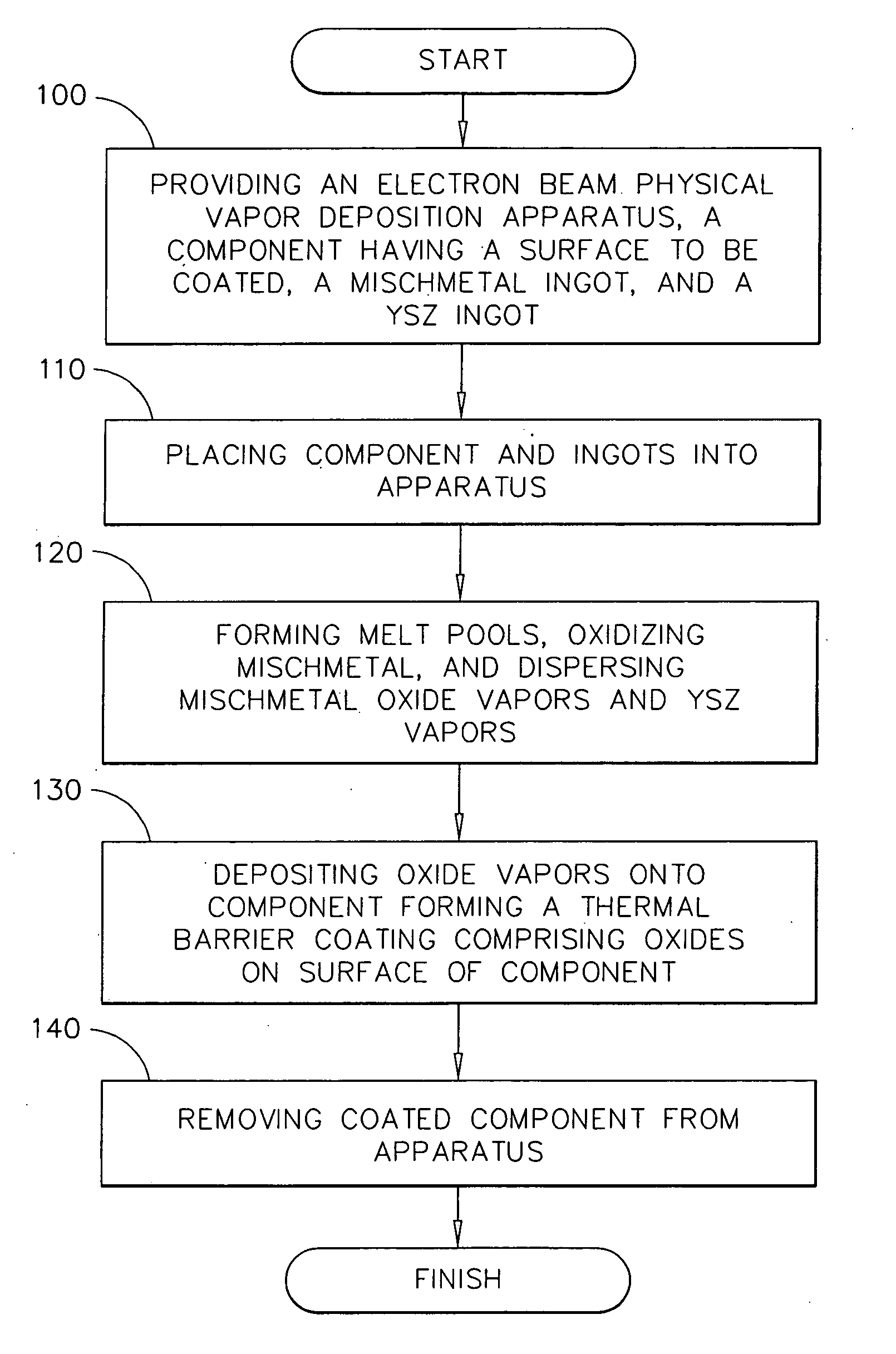

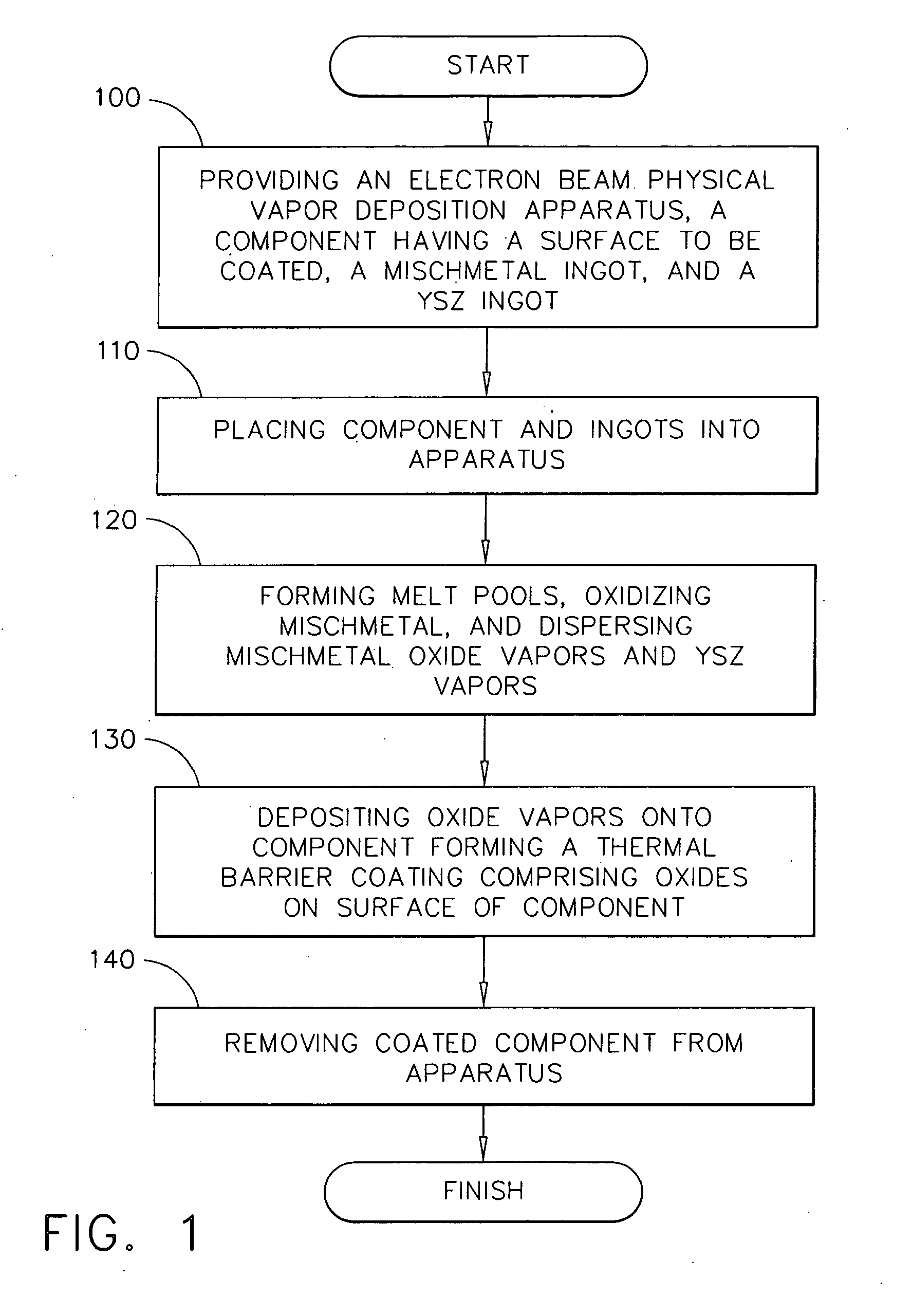

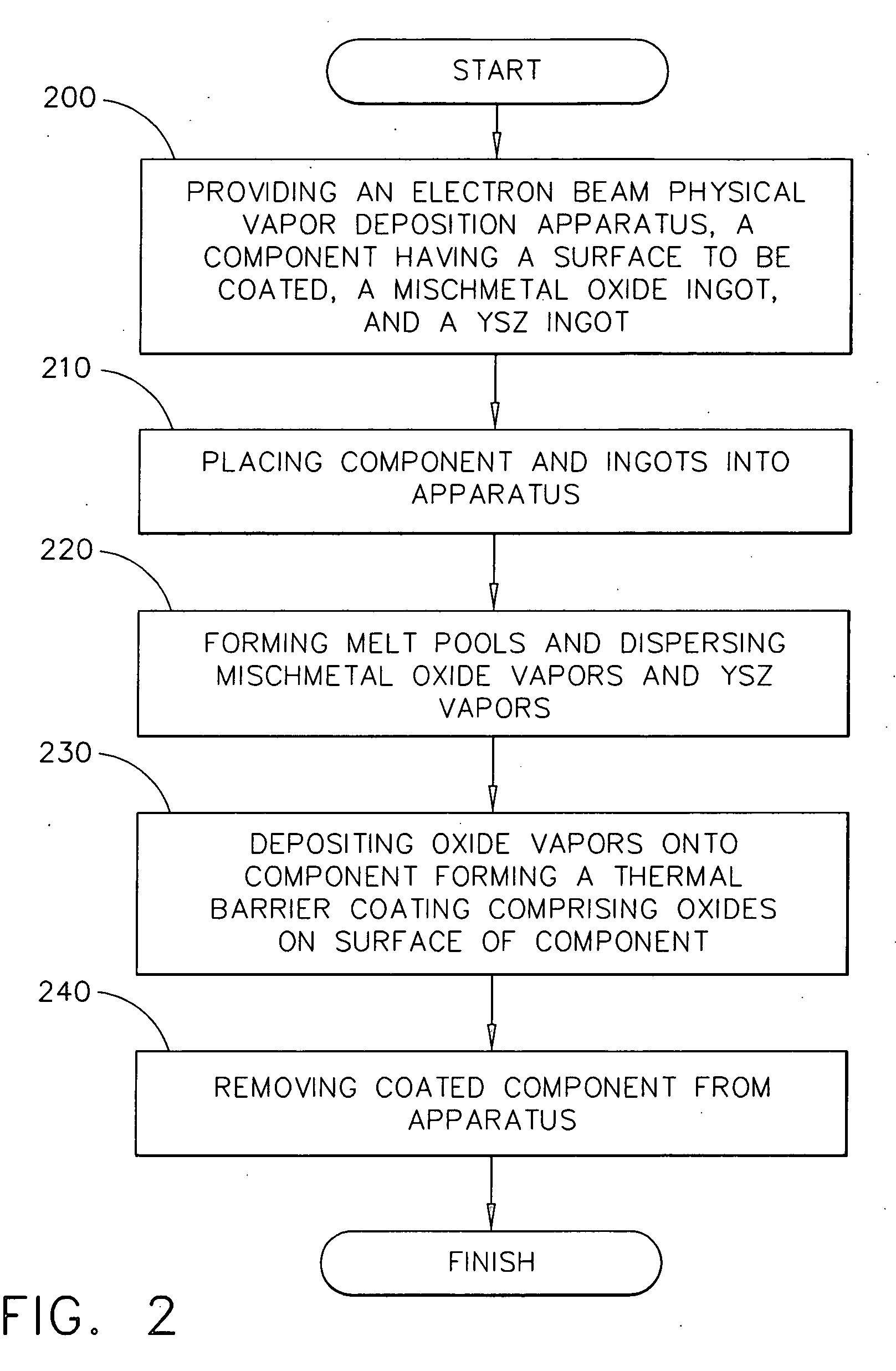

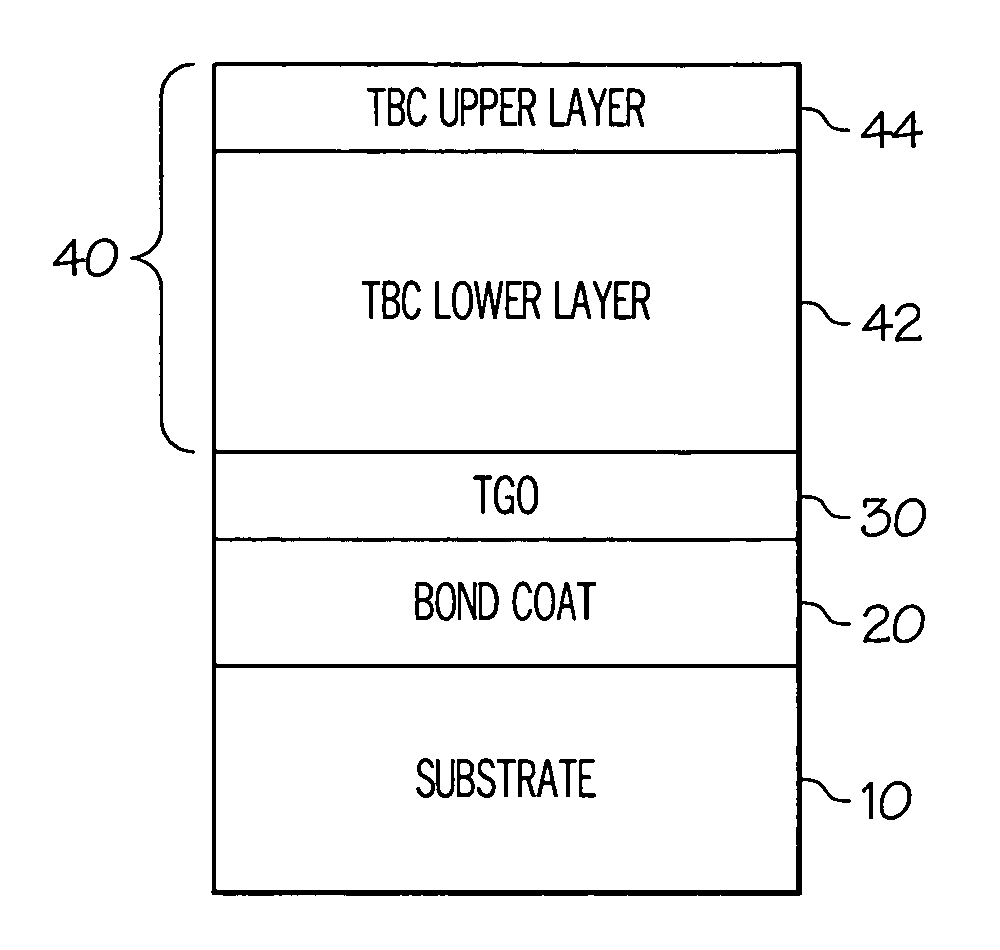

Mischmetal oxide TBC

InactiveUS20050196635A1Reduce conductivityLow thermal conductivityVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionRare earth

The present invention is a turbine engine component comprising a superalloy substrate, a bond coat overlying the substrate having a thickness in the range of about 0.0005 inch to about 0.005 inch, a thin alumina scale overlying the bond coat, and a thermal barrier coating (TBC) overlying the thin alumina scale, the TBC having a thickness in the range of about 0.0025 inch to about 0.010 inch, and comprising at least mischmetal oxide. The present invention is also a method for the application of a thermal barrier coating to a superalloy turbine engine component comprising the steps of: providing an electron beam physical vapor deposition apparatus, providing a turbine engine component comprising a surface to be coated, providing an oxide ingot comprising mischmetal oxide and another oxide material selected from the group consisting of yttria-stablized zirconia, zirconia, yttria, hafnia, at least one other rare earth oxide, and combinations thereof, placing the component and the ingot into the apparatus, drawing a vacuum within the apparatus, forming a melt pool on the ingot, dispersing mischmetal oxide vapors and yttria-stabilized zirconia vapors, depositing the mischmetal oxide vapors and the yttria-stabilized zirconia vapors onto the surface to be coated, said deposition forming a thermal barrier coating having a thickness in the range of about 0.0025 inch to about 0.010 inch.

Owner:GENERAL ELECTRIC CO

Method of operating an electron beam physical vapor deposition apparatus

InactiveUS6863937B2Increase or decreaseEasy to operateElectric discharge heatingElectric discharge tubesElectron beam physical vapor depositionThermal barrier coating

An electron beam physical vapor deposition (EBPVD) apparatus and a method for using the apparatus to produce a coating material (e.g., a ceramic thermal barrier coating) on an article. The EBPVD apparatus generally includes a coating chamber that is operable at elevated temperatures and subatmospheric pressures. An electron beam gun projects an electron beam into the coating chamber and onto a coating material within the chamber, causing the coating material to melt and evaporate. An article is supported within the coating chamber so that vapors of the coating material deposit on the article. The operation of the EBPVD apparatus is enhanced by the inclusion or adaptation of one or more mechanical and / or process modifications, including those necessary or beneficial when operating the apparatus at coating pressures above 0.010 mbar.

Owner:GENERAL ELECTRIC CO

Melted CMAS-corrosion resistant rare-earth aluminate thermal barrier coating and preparation method thereof

InactiveCN104988454AImprove deposition efficiencyLow oxygen transmission rateMolten spray coatingAluminateElectron beam physical vapor deposition

The invention discloses a melted CMAS-corrosion resistant rare-earth aluminate thermal barrier coating and a preparation method thereof and belongs to the field of thermal barrier coating materials and preparation thereof. The melted CMAS-corrosion resistant rare-earth aluminate thermal barrier coating comprises a bonding layer, a first ceramic layer and a second ceramic layer which are obtained by being prepared on a matrix, wherein the first ceramic layer is a YSZ coating; the second ceramic layer is composed of garnet structure compound rare-earth aluminate or perovskite compound rare-earth aluminate; the first ceramic layer and the second ceramic layer are prepared by the adoption of methods of atmosphere plasma spraying, plasma physical vapor deposition and electron beam physical vapor deposition. According to the melted CMAS-corrosion resistant rare-earth aluminate thermal barrier coating and the preparation method thereof, the prepared rare-earth aluminate thermal barrier coating can prevent melted CMAS from permeating, and the excellent melted CMAS-corrosion resistant performance is achieved.

Owner:BEIHANG UNIV

Oxidation barrier coatings for silicon based ceramics

ActiveUS7323247B2Continuous combustion chamberBlade accessoriesElectron beam physical vapor depositionCoating system

A protective barrier coating system including a diffusion barrier coating and an oxidation barrier coating and method for use in protecting silicon-based ceramic turbine engine components. A complete barrier coating system includes a thermal barrier coating of stabilized zirconia and an environmental barrier coating of an alloyed tantalum oxide. The oxidation barrier coating includes a layer of metallic silicates formed on a substrate of silicon nitride or silicon carbide to be protected. The oxidation barrier coating can include silicates of scandium, ytterbia or yttrium. The oxidation barrier coating may also include an inner layer of Si2ON2 between the diffusion barrier and the metallic silicate layer. The oxidation barrier coating can be applied to the substrate by spraying, slurry dipping and sintering, by a sol-gel process followed by sintering, by plasma spray, or by electron beam-physical vapor deposition. The diffusion layer of essentially pure Si3N4 can be applied to the substrate to prevent the migration of damaging cations from the protective layers to the substrate and is preferably formed by chemical vapor deposition. A method for protecting silicon based substrates can comprise a step of forming an oxidation barrier coating on a substrate, where a step of forming the oxidation barrier includes a step of sintering the oxidation barrier and substrate in a wet gas containing hydrogen.

Owner:HONEYWELL INT INC

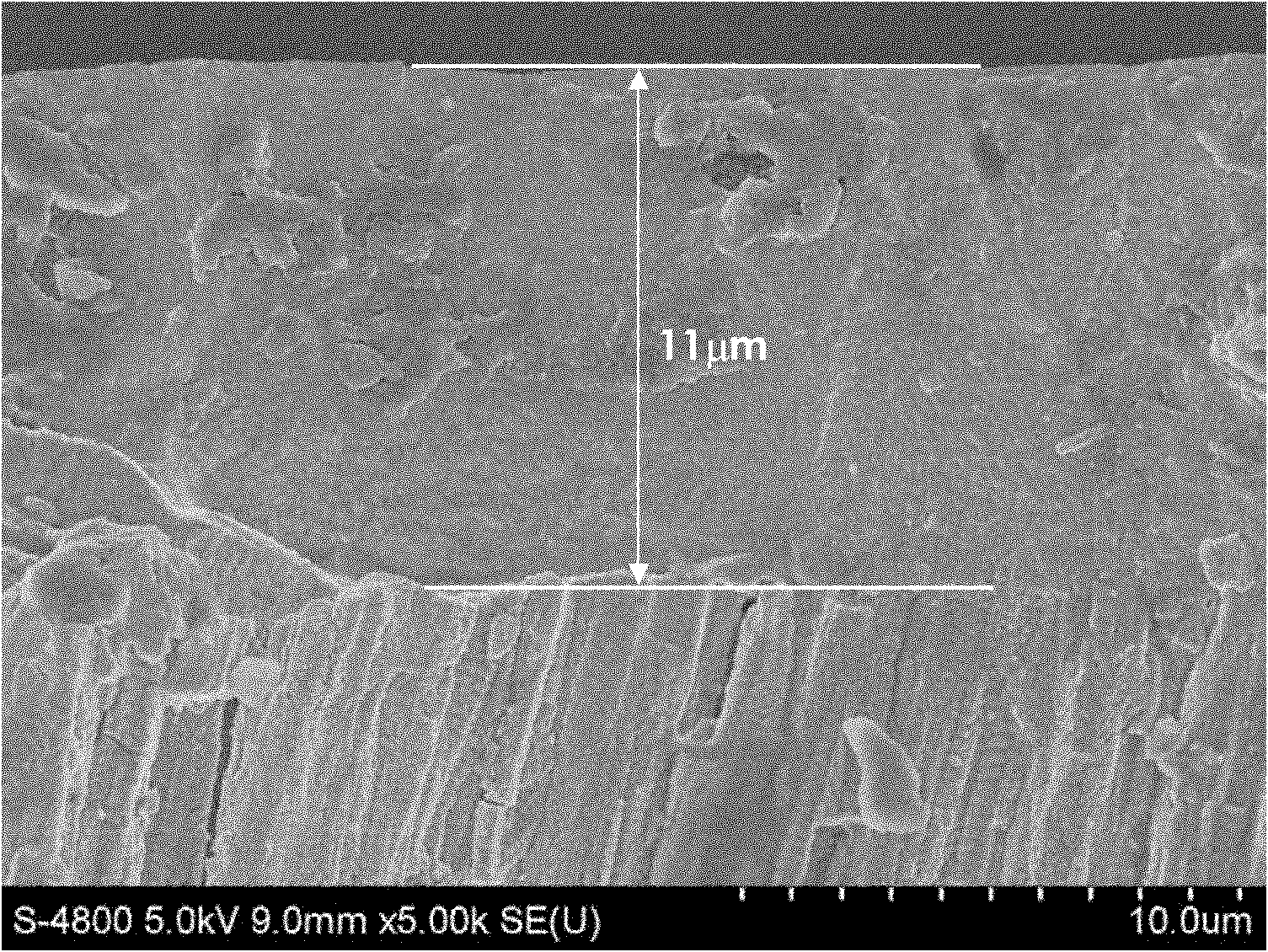

Treatment method of improving oxidation resistance of thermal barrier coating

InactiveCN101994078APromote growthImprove high temperature service performanceMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionGas phase

The invention relates to a treatment method of improving oxidation resistance of a thermal barrier coating, belonging to the technical field of thermal barrier coating surface treatment and modification. High current pulse electron beam irradiation is utilized to realize electron beam physical vapor deposition to prepare a yttrium oxide stabilizing zirconium oxide thermal barrier coating to cap ceramic layer columnar crystals, thus the heat-shielding performance and the high temperature oxidation resistance of the coating are improved. The process conditions are shown as follows: the vacuum is 3.5*10<-2>Pa, the voltage is 15kV, the frequency is 1Hz, the pulse width is 120-150ms, the energy density is 10J / cm<2>-20J / cm<2>, the pulse time is 30-40 and the remelting layer thickness reaches at least 10 micrometers. The invention has the advantages that the electron beam physical vapor deposition layer columnar crystals are capped after the high current pulse electron beam irradiation is ended, and thus, the surface of the thermal barrier coating becomes smooth, no penetrable microcracks are generated, the oxygen element diffusion is effectively stopped, the growth of a thermal growth oxidation layer is relieved and the heat-shielding performance and the high temperature oxidation resistance of the thermal barrier coating are obviously improved.

Owner:DALIAN UNIV OF TECH

Preparation method of thermal barrier coating containing long-service-life antioxidant bonding layer

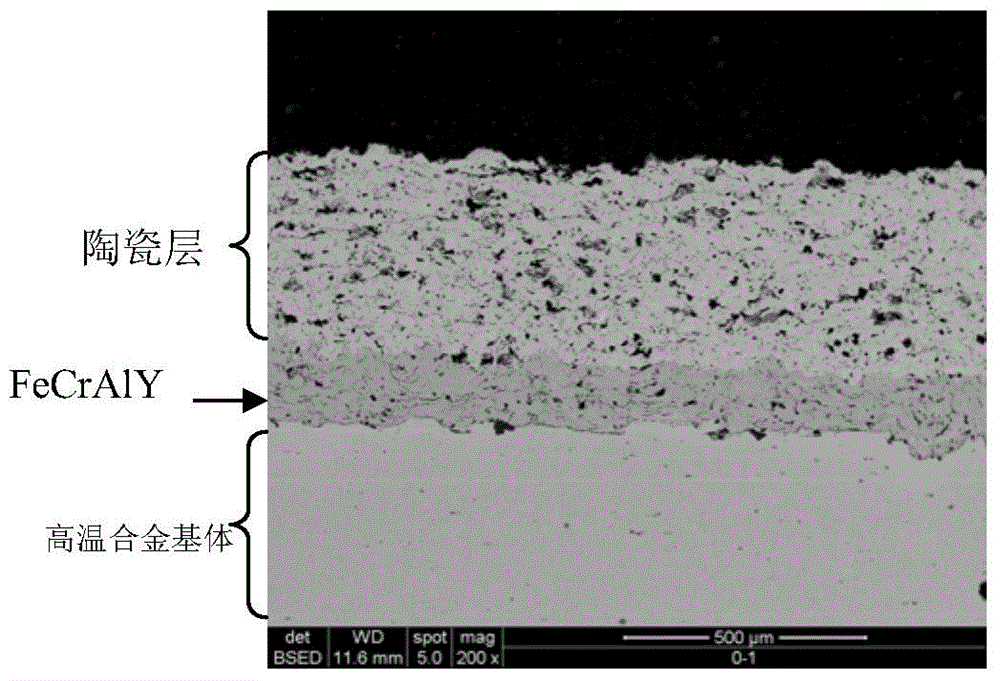

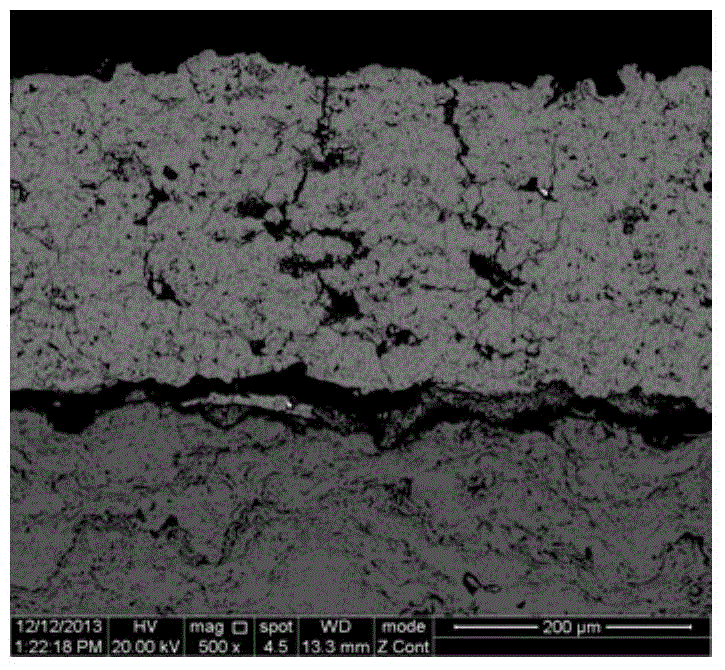

InactiveCN104630686APromote growthImprove antioxidant capacityMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionGas phase

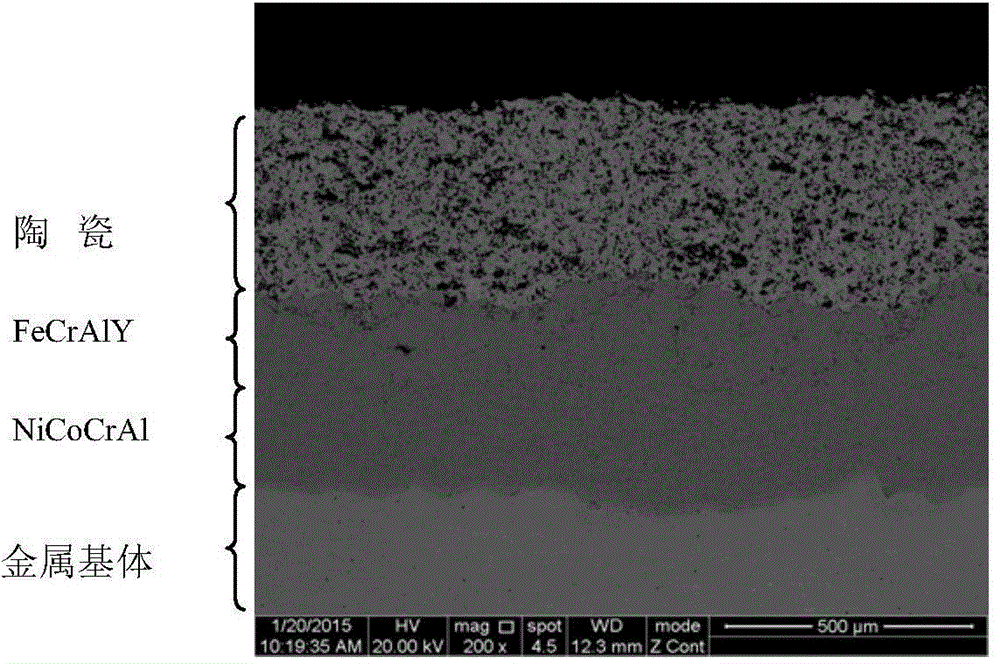

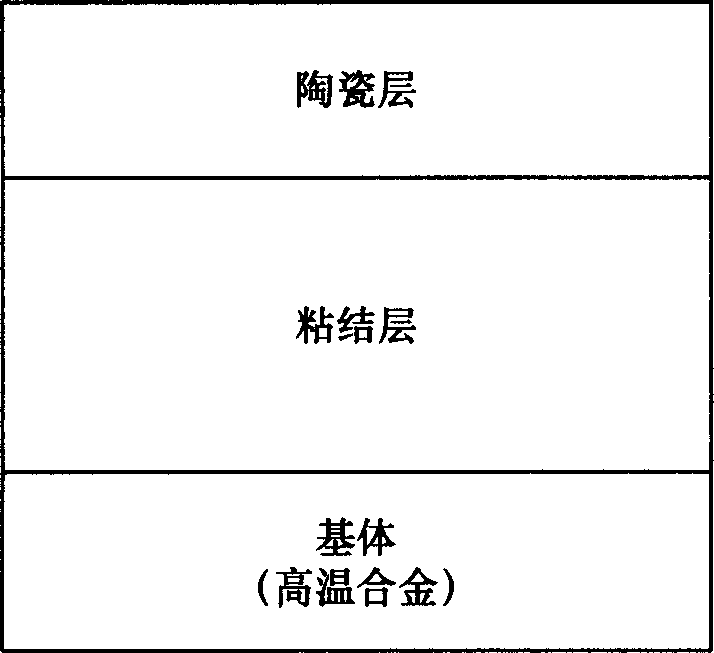

The invention relates to a preparation method of a thermal barrier coating containing a long-service-life antioxidant bonding layer. The preparation method comprises the following steps: (1) sequentially performing deoiling and sand blasting treatment on a high-temperature alloy matrix; (2) preparing a metal bonding layer on the high-temperature alloy matrix by virtue of atmosphere plasma spraying, low-pressure plasma spraying, high-speed oxygen flame spraying or high-speed compressed air flame spraying; and (3) then depositing a ceramic layer on the metal bonding layer by virtue of atmosphere plasma spraying, high-speed oxygen flame spraying, supersonic plasma spraying, solution plasma spraying or electron beam physical vapor deposition. Compared with the prior art, the thermal barrier coating prepared by using an FeCrAlY bonding layer, disclosed by the invention, has higher working temperature and slower oxidation layer growth rate compared with that of a conventional MCrAlY thermal barrier coating (M refers to Ni and Co) so as to avoid the interfacial properties of the bonding layer and the ceramic layer from forming a brittle Ni2Al2O4 phase; and the thermal barrier coating has excellent high-temperature oxidation resistance and longer service life.

Owner:HENAN PULAIMU COATING TECH +1

Method of forming a ceramic coating on a substrate by electron-beam physical vapor deposition

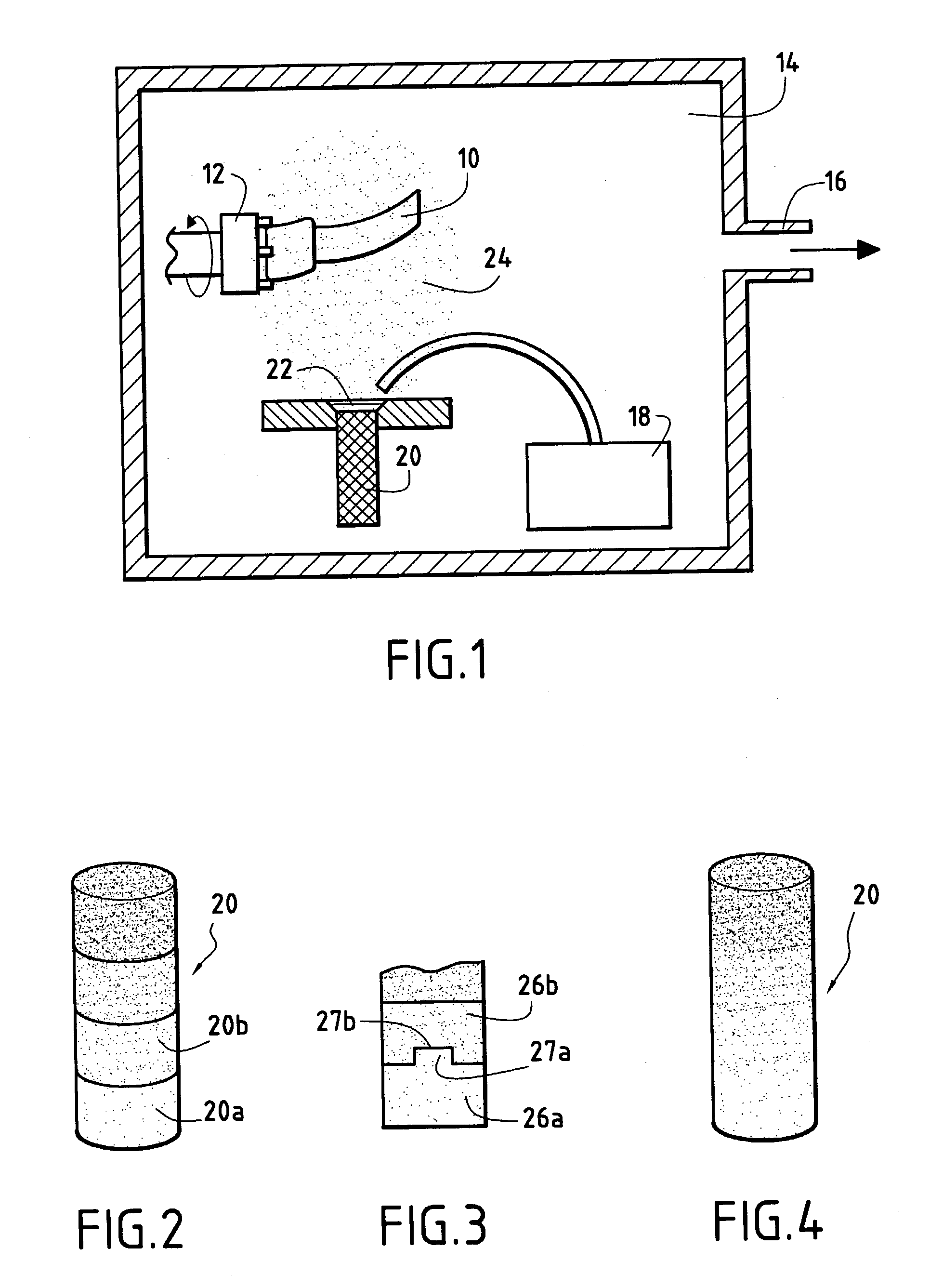

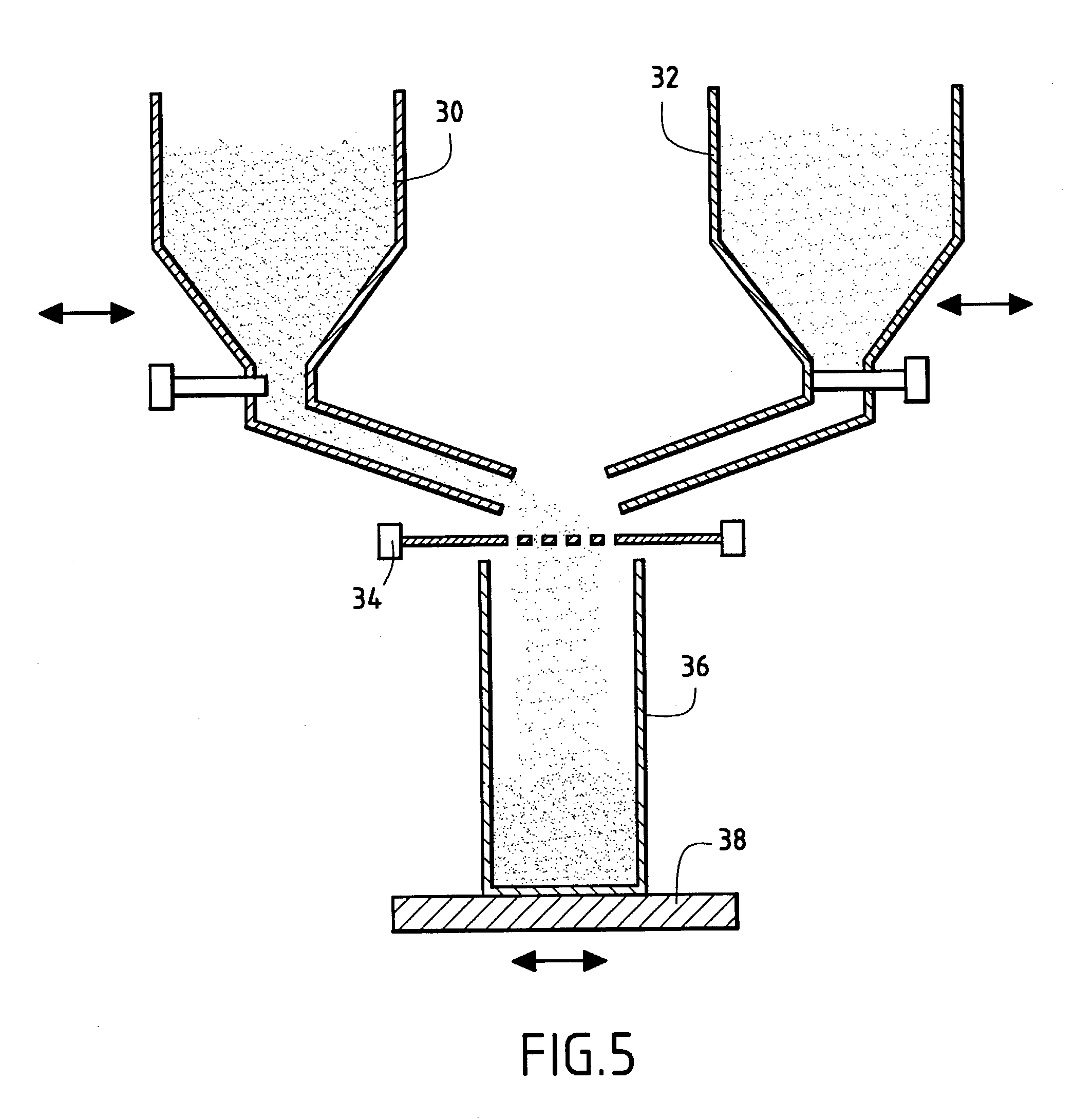

InactiveUS6808761B2Easy to controlFunction increaseElectric discharge heatingBlade accessoriesElectron beam physical vapor depositionGas phase

A composite target is placed in a chamber. The target is in the form of a bar made of ceramic powder and it presents composition that is not uniform in the longitudinal direction. At least one substrate is introduced into the chamber in order to have formed thereon a ceramic coating with a composition gradient. The top face of the bar is swept by an electron beam so as to melt the bar material at its top face and form a vapor cloud in the chamber under low pressure. A bar is used that presents a plurality of superposed layers of different compositions, with the composition within each layer being uniform over the entire cross-section of the bar. Each layer of the bar comprises zirconia and at least one oxide selected from the oxides of nickel, cobalt, iron, yttrium, hafnium, cerium, lanthanum, tantalum, niobium, scandium, samarium, gadolinium, dysprosium, ytterbium, and aluminum.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

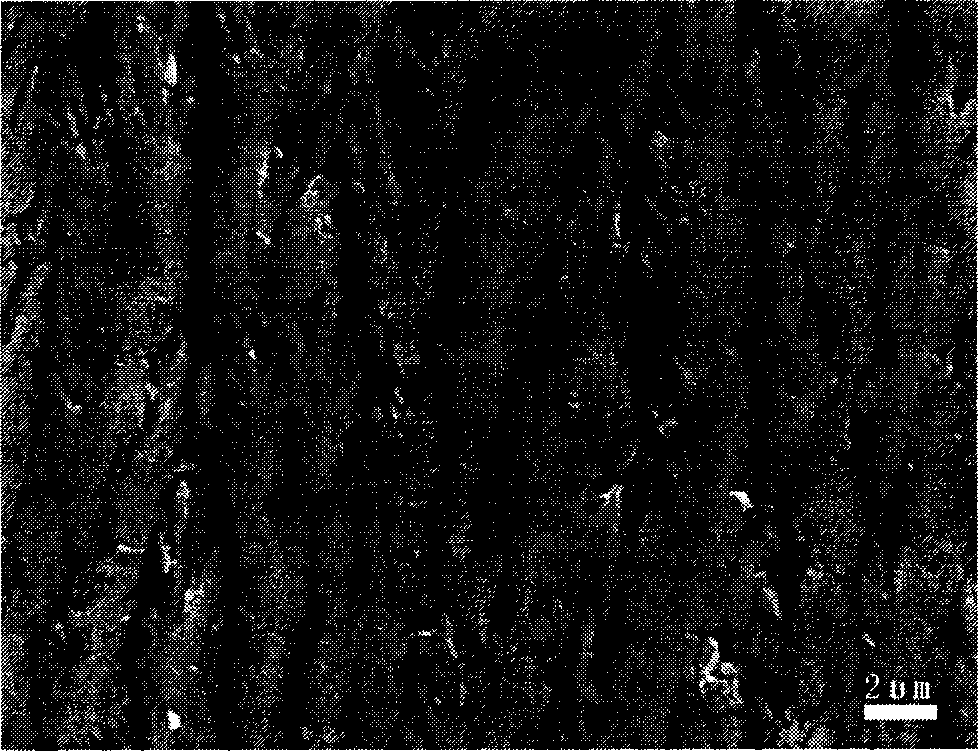

Metal / ceramic microlaminate material and preparation thereof

InactiveCN101413101AImprove toughnessReduce toughnessVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionMetal sheet

The invention provides a metal / ceramic micro-lamination material and a preparation method thereof. The method adopts an electron beam physical vapor deposition technology and alternately evaporates a metal target material and a ceramic material through an electron gun to prepare the metal / ceramic micro-lamination material. The thickness of a ceramic layer is 1 mu m; and the thickness of a metal layer is between 10 and 35 mu m, and the volume fraction ratio of the metal layer and the ceramic layer, namely the thickness ratio or the thickness ratio of layers is between 10 and 35. The metal target material is Ni-20Co-12Cr-4Al (weightt percent); and the ceramic target material is ZrO2(YSZ) containing 8 weight percent of Y2O3. The metal / ceramic micro-lamination material has large thickness ratio of layers; therefore, the material can keep the characteristic of good toughness of the metal material to a great extent. Simultaneously, the existence of a lamination structure limits the growth of columnar crystals in the metal layer and reduce the possibility that crack expands along the metal grain boundary. Compared with a monolayer EB-PVD metal sheet, the metal layer of the micro-lamination material has less probability of brittle intergranular fracture and higher strength.

Owner:HARBIN INST OF TECH

Method of forming a ceramic coating on a substrate by electron-beam physical vapor deposition

InactiveUS20040058200A1Easy to controlFunction increaseElectric discharge heatingBlade accessoriesElectron beam physical vapor depositionGas phase

A composite target is placed in a chamber. The target is in the form of a bar made of ceramic powder and it presents composition that is not uniform in the longitudinal direction. At least one substrate is introduced into the chamber in order to have formed thereon a ceramic coating with a composition gradient. The top face of the bar is swept by an electron beam so as to melt the bar material at its top face and form a vapor cloud in the chamber under low pressure. A bar is used that presents a plurality of superposed layers of different compositions, with the composition within each layer being uniform over the entire cross-section of the bar. Each layer of the bar comprises zirconia and at least one oxide selected from the oxides of nickel, cobalt, iron, yttrium, hafnium, cerium, lanthanum, tantalum, niobium, scandium, samarium, gadolinium, dysprosium, ytterbium, and aluminum.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Preparation method of composite ceramic powder material for high-temperature-resistant sintering thermal barrier coating

InactiveCN103304234AHigh phase structure stabilityStrong resistance to high temperature sinteringElectron beam physical vapor depositionChemical reaction

The invention discloses a preparation method of a composite ceramic powder material for a high-temperature-resistant sintering thermal barrier coating. The powder material is prepared by codoping ZrO2 in three rare earth oxides Y2O3, Yb2O3 and Gd2O3 in a chemical reaction method, and Y2O3, Yb2O3, Gd2O3 and ZrO2 are completely solidified and compounded. The composite ceramic power material subjected to ball milling, agglomeration and granulation and sintering can be used for preparing a thermal barrier coating through plasma spraying or can be compressed into a bar material to prepare a thermal barrier coating by electron beam physical vapor deposition. The thermal barrier coating is high-temperature sintering resistant, is stable in phase structure, is low in heat conductivity, can achieve the working temperature of 1450 DEG C, and can be used for high-temperature thermal-insulation protection of aircraft engines and hot end parts of ground surface combustion gas turbines.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

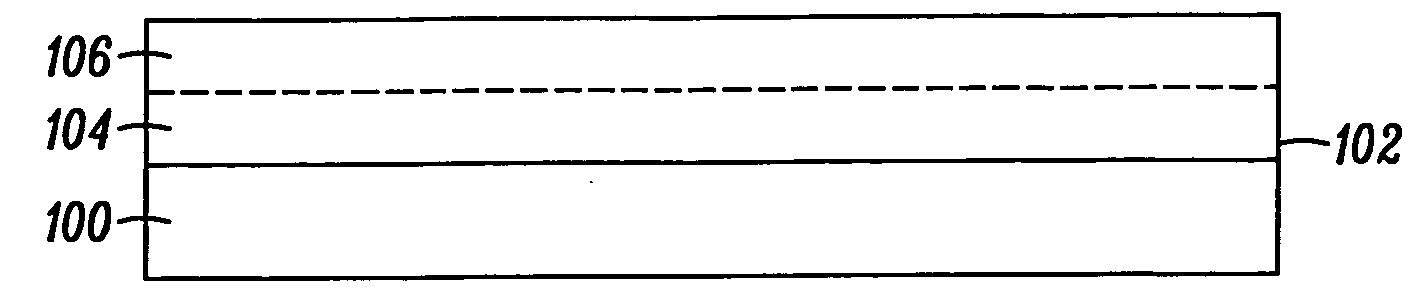

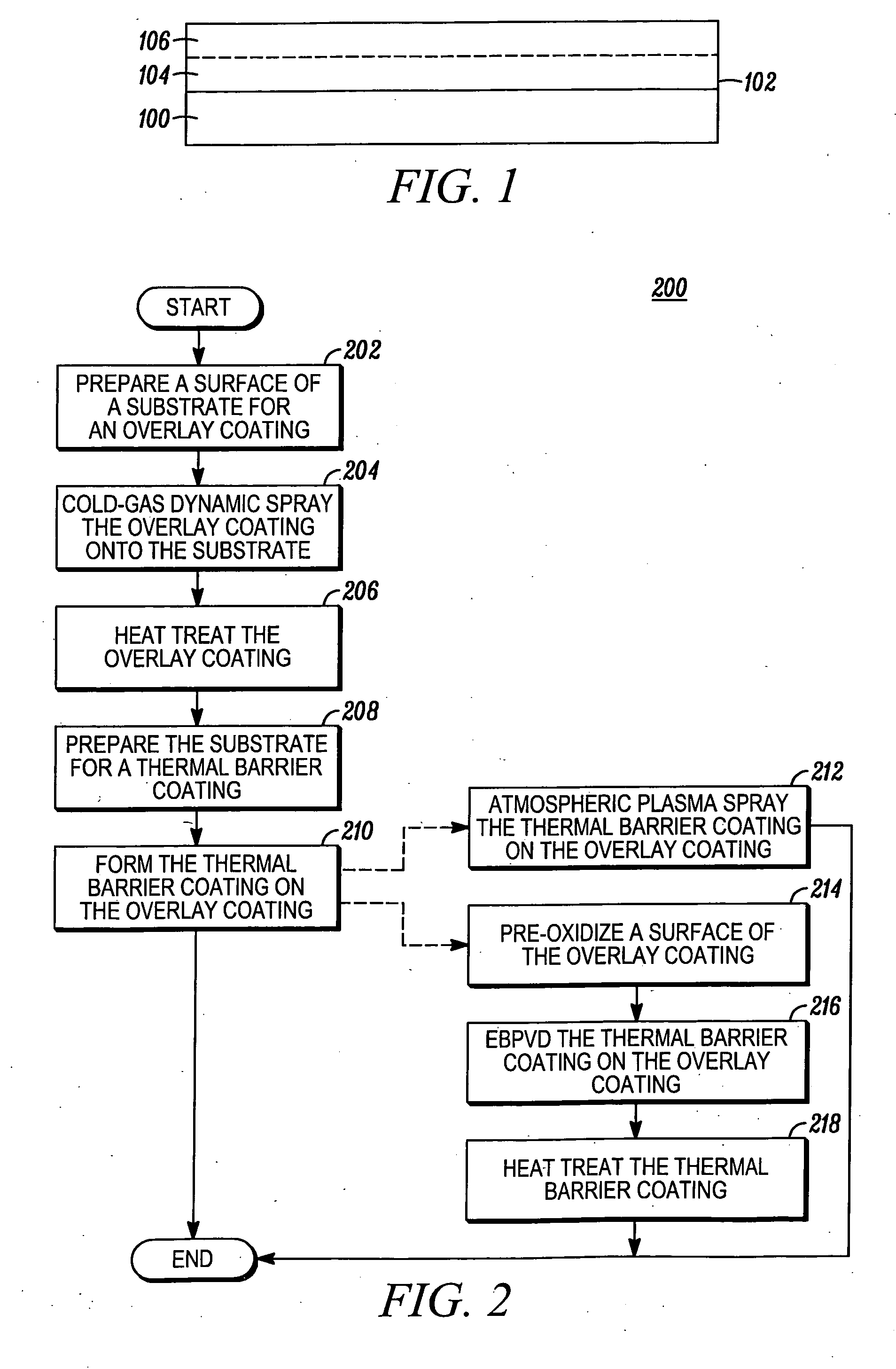

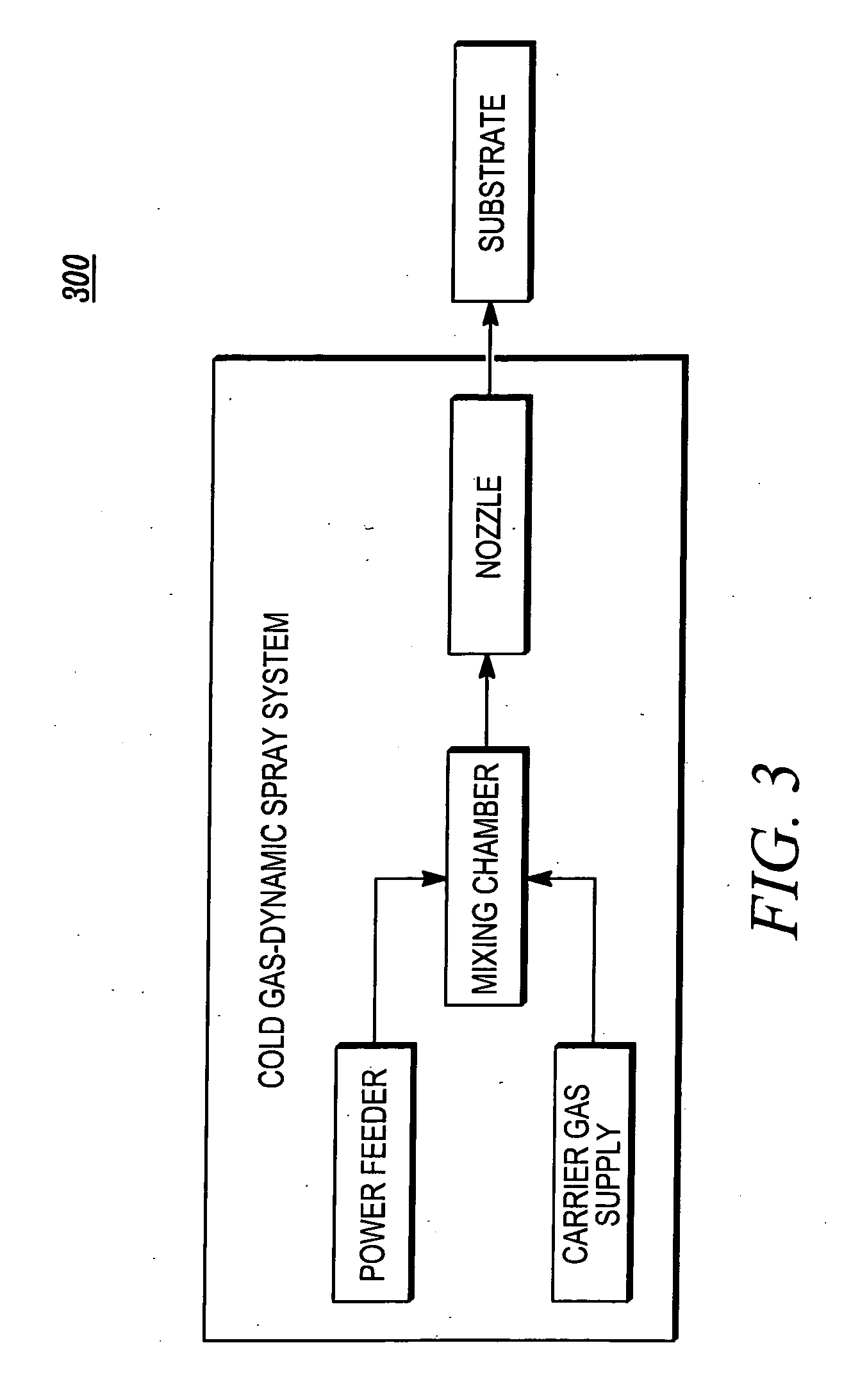

Method for making an environment-resistant and thermal barrier coating system on a component

InactiveUS20080131612A1Molten spray coatingElectric discharge heatingElectron beam physical vapor depositionCoating system

Methods are provided for forming a coating system on a gas turbine component. In one embodiment, and by way of example only, the method includes cold spraying a material onto the component surface to form an overlay coating, the material comprising MCrAlY, wherein M comprises a constituent selected from the group consisting of Ni, Co, or Fe, or combinations of Ni, Co, and Fe. Then, the overlay coating is heat treated. The overlay coating is then shot peened and vibro polished. A thermal barrier coating is then applied onto the overlay coating to form the coating system via air plasma spaying or electron beam physical vapor deposition technique.

Owner:HONEYWELL INT INC

Thermal barrier coating resistant to penetration by environmental contaminants

A turbine engine component includes an electron beam-physical vapor deposition thermal barrier coating covering at least a portion of a substrate. The thermal barrier coating includes an inner layer having a columnar-grained microstructure with inter-columnar gap porosity. The inner layer includes a stabilized ceramic material. The thermal barrier coating also includes a substantially non-porous outer layer, covering the inner layer and including the stabilized ceramic material. The outer layer is deposited with continuous line-of-sight exposure to the vapor source under oxygen deficient conditions. The outer layer may further comprise a dopant oxide that is more readily reducible than the stabilized ceramic material. During deposition, the outer layer may also have an oxygen deficient stoichiometry with respect to the inner layer. Oxygen stoichiometry in the outer layer may be restored by exposure of the coated component to an oxidizing environment.

Owner:HONEYWELL INT INC

Preparation method of thermal barrier coating containing bilayer structure of bonding layers

InactiveCN104674217AIncrease temperatureStop the spreadMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionFragility

The invention relates to a preparation method of a thermal barrier coating containing a bilayer structure of bonding layers. A metal substrate is subjected to deoiling and sand blasting treatment; a first bonding layer is deposited on the metal substrate through low-pressure plasma spraying, high-velocity oxygen flame spraying or high-velocity compressed air flame spraying; a second bonding layer is deposited through atmosphere plasma spraying, high-velocity oxygen flame spraying or high-velocity compressed air flame spraying; a ceramic thermal insulating layer is deposited on the second bonding layer through atmosphere plasma spraying, high-velocity oxygen flame spraying, solution plasma spraying or an electron beam physical vapor deposition technology. Compared with conventional MCrAlY thermal barrier coating adopting a single bonding layer, M is Ni, Cr and the like, the prepared thermal barrier coating adopting the double bonding layers has higher use temperature, Ni2Al2O4 fragility phase is avoided for the interfacial properties of the bonding layers and the ceramic layer, sufficient Al is supplied, roughness of an interface is kept, the coating has more excellent oxidation resistance and organization structure stability, and the service life of the coating is greatly prolonged.

Owner:HENAN PULAIMU COATING TECH +1

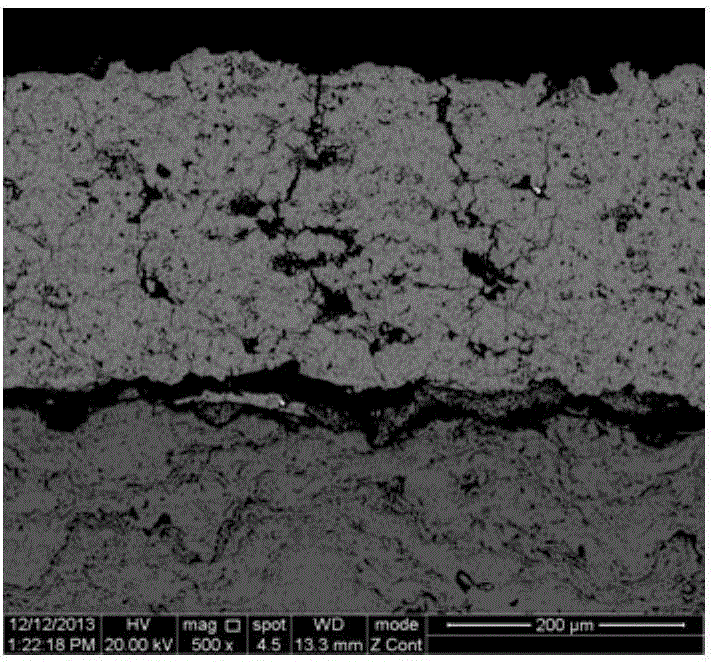

Method for depositing thermal barrier coating of porous dentrite ceramic layer by electron beam physical vapor deposition process

InactiveCN1844445AHigh densityImproves low density, thermal insulation effectVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

This invention discloses a heat barrier coating method which uses electric beam physics vapor to deposited multi-holes branch ceramic layer, and it deposits a layer of cemented material and ceramic material with multi-holes and branch structure in order on the nickel radical high temperature alloy base surface. The preparation method makes the ceramic layer have lower heat conductivity coefficient by controlling evaporation deposition technique parameter of two sticks A and B which have different components. This invention improves heat barrier coating serving life greatly under high temperature condition.

Owner:BEIHANG UNIV

Thermal barrier coating resistant to penetration by environmental contaminants

ActiveUS20090038935A1Electric discharge heatingBlade accessoriesPorosityElectron beam physical vapor deposition

A turbine engine component includes an electron beam-physical vapor deposition thermal barrier coating covering at least a portion of a substrate. The thermal barrier coating includes an inner layer having a columnar-grained microstructure with inter-columnar gap porosity. The inner layer includes a stabilized ceramic material. The thermal barrier coating also includes a substantially non-porous outer layer, covering the inner layer and including the stabilized ceramic material. The outer layer is deposited with continuous line-of-sight exposure to the vapor source under oxygen deficient conditions. The outer layer may further comprise a dopant oxide that is more readily reducible than the stabilized ceramic material. During deposition, the outer layer may also have an oxygen deficient stoichiometry with respect to the inner layer. Oxygen stoichiometry in the outer layer may be restored by exposure of the coated component to an oxidizing environment.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com