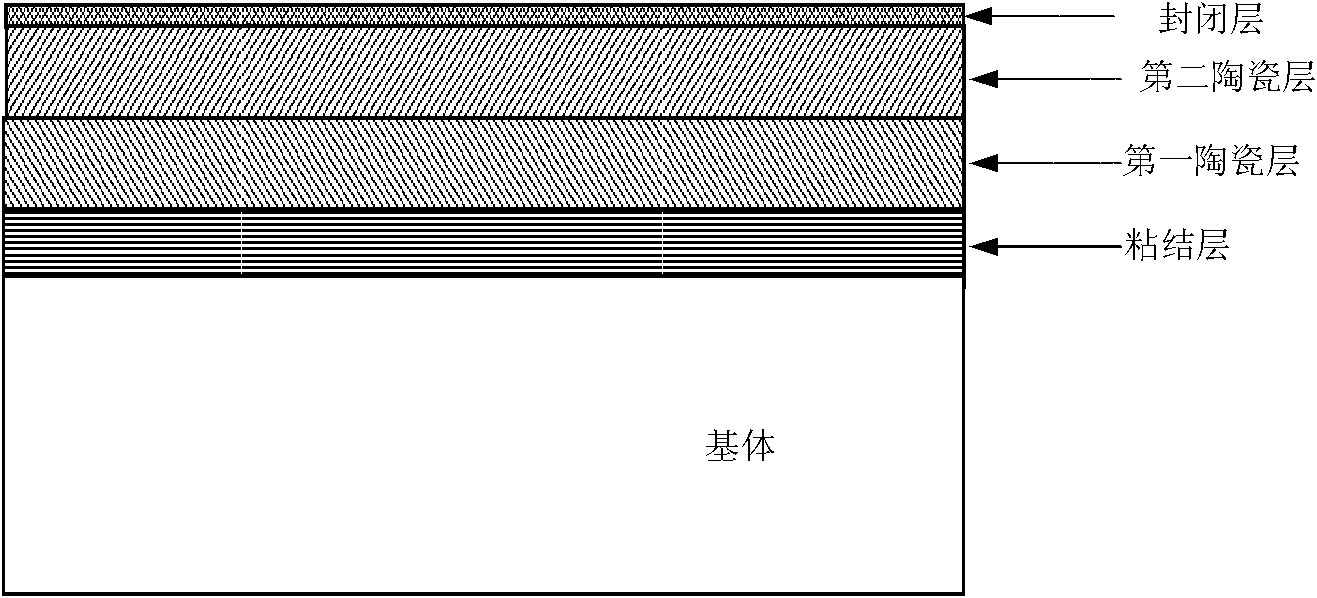

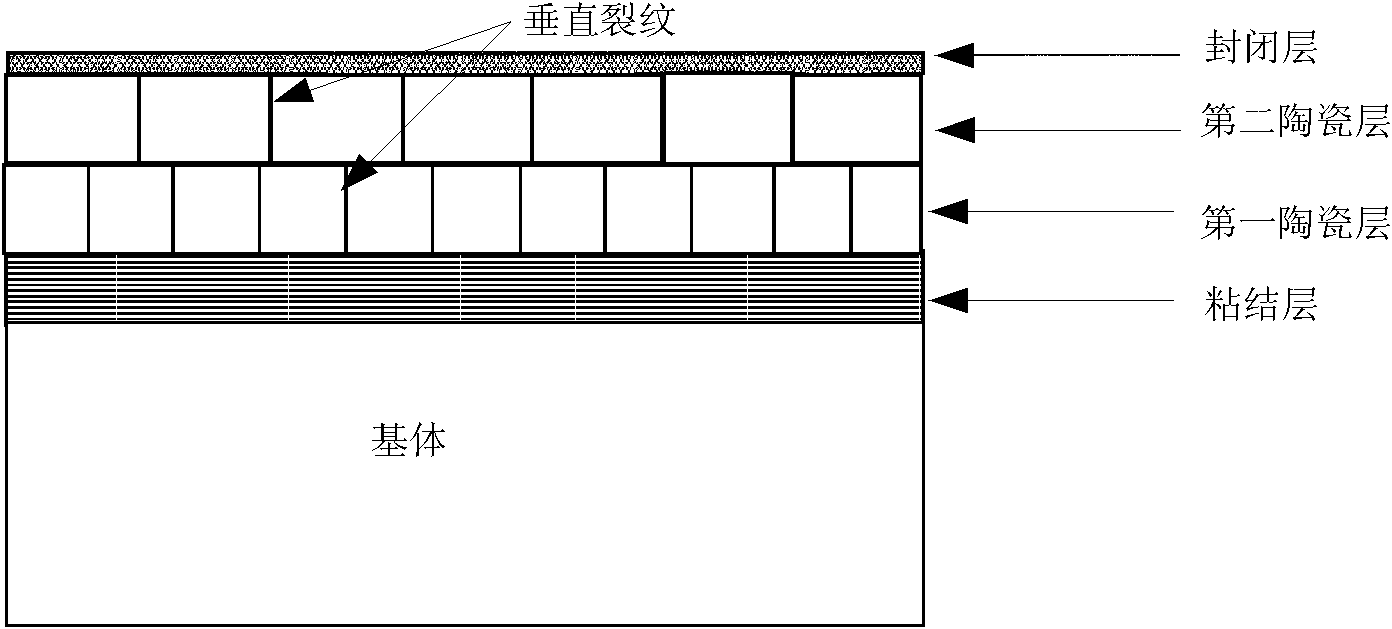

Multilayer thermal barrier coating and preparation method thereof

A technology of thermal barrier coatings and ceramic layers, applied in coatings, chemical instruments and methods, metal material coating processes, etc., can solve problems such as poor corrosion resistance, failure of thermal barrier coatings, low thermal shock resistance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

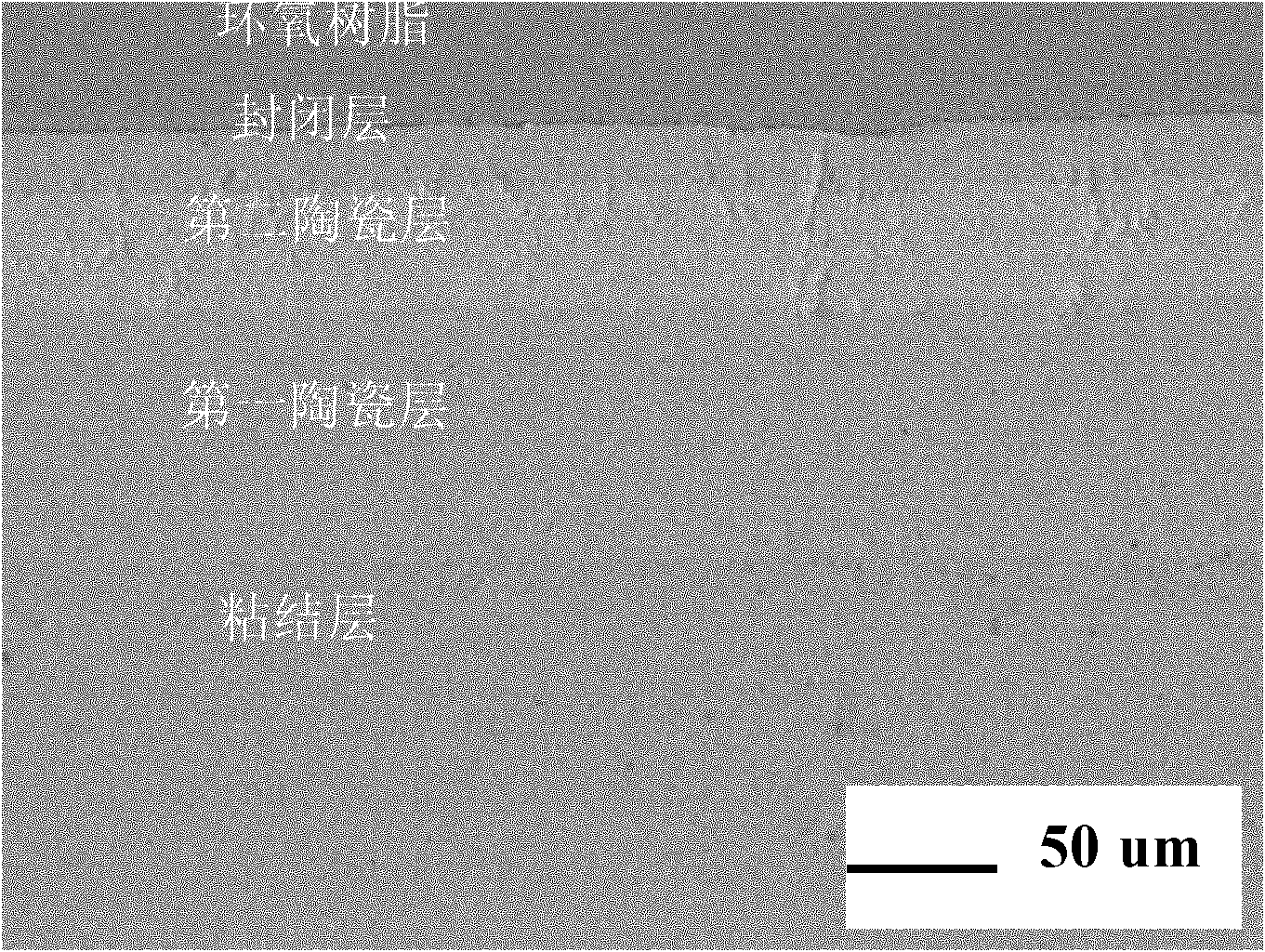

[0112] Example 1 : 8YSZ / La prepared by electron beam physical vapor deposition method 2 Ce 2 o 7 / Al 2 o 3 Multi-layer thermal barrier coating.

[0113] Step 1: Deposit the bonding layer, the first ceramic layer and the second ceramic layer on the surface of the substrate:

[0114] (1) Preparation of target material:

[0115] A: Preparation of bonding layer material target:

[0116] NiCrAlY alloy is selected as the material of the bonding layer, and the composition weight percentage is 73% Ni, 19% Cr, 7% Al, 1% Y, and is melted at 1400°C to obtain the bonding layer material target.

[0117] B: Prepare the first ceramic layer and the second ceramic layer material targets:

[0118] The first ceramic layer material powder 8YSZ and the second ceramic layer material powder La 2 Ce 2 o 7 Cold-press forming to obtain a cylindrical rod, and the cold-press-formed rod is kept in a high-temperature furnace at 1300°C for 24 hours to obtain a dense ceramic rod, as the first cer...

Embodiment 2

[0134] Example 2 : 8YSZ / La prepared by electron beam physical vapor deposition method 2 Ce 2 o 7 / Al 2 o 3 Multi-layer thermal barrier coating.

[0135] Step 1: Deposit the bonding layer, the first ceramic layer and the second ceramic layer on the surface of the substrate:

[0136] (1) Preparation of target material:

[0137] A: Preparation of bonding layer material target:

[0138] NiCrAlYHf alloy is selected as the material of the bonding layer, and the component weight percentage is 64% Ni, 24% Cr, 10% Al, 1.5% Y, 0.5% Hf, and is melted at 1600°C to obtain the bonding layer material target.

[0139] B: Prepare the first ceramic layer and the second ceramic layer material targets:

[0140] The first ceramic layer material powder 8YSZ and the second ceramic layer material powder La 2 Ce 2 o 7 Cold-press forming to obtain a cylindrical rod, and the cold-press-formed rod is kept in a high-temperature furnace at 1400°C for 12 hours to obtain a dense ceramic rod, whic...

Embodiment 3

[0156] Example 3 : 8YSZ / La prepared by electron beam physical vapor deposition method 2 Ce 2 o 7 / Al 2 o 3 Multi-layer thermal barrier coating.

[0157] The difference between this embodiment and embodiment 2 is only in step one (3), (4) and step two (2)

[0158] Step 1: (3) depositing the bonding layer:

[0159] A bonding layer is deposited on the surface of the substrate. Evacuate the vacuum chamber to the required vacuum degree of 5×10 -4 Pa, during the deposition process, the substrate temperature is 900° C., the substrate rotation speed is 15 rpm, the deposition rate is 1.5 μm / min, and the deposition time is 42 minutes. After the deposition is completed, take it out, put it into a vacuum heat treatment furnace for heat treatment for 3 hours, and the vacuum degree is 5×10 -4 Pa, the heat treatment temperature is 1050°C. Shot blasting is performed on the samples with adhesive layer deposited after heat treatment, and then ultrasonically cleaned with acetone;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com