A kind of nickel base superalloy and its manufacturing method

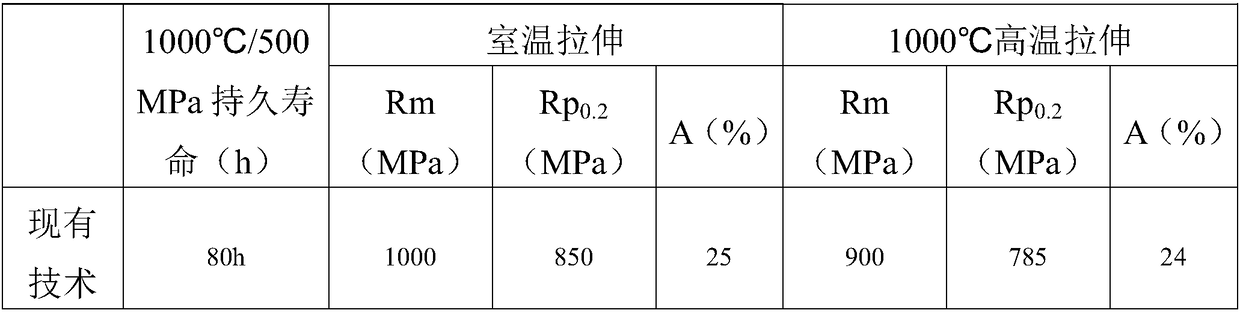

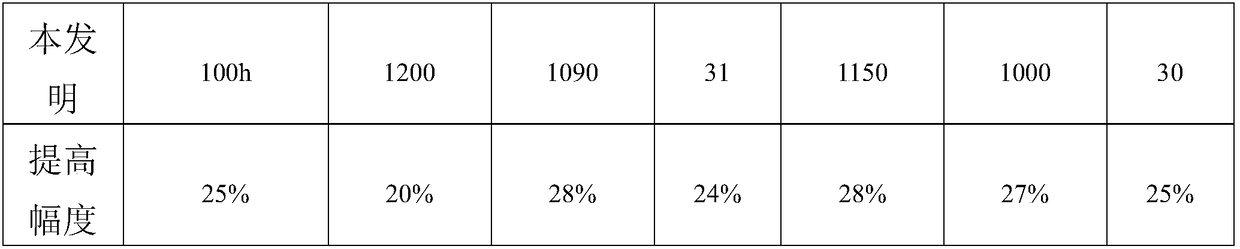

A technology of nickel-based superalloy and manufacturing method, which is applied in the field of superalloy, can solve the problems of non-deterioration of surface properties, inability to meet the needs of scientific and technological progress, etc., and achieve the effects of improving creep resistance and structure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a nickel-based superalloy. The alloy includes the following components in weight percentage: C0.10%, Si 0.35%, Mn 0.65%, Fe 0.22%, Co 1.8%, Al 0.25%, Ti 0.05%, Cr 22.4%, Nb 0.20%, Mo 1.5% , W 13%, Re 0.30%, B 0.005%, Ce 1.1%, Ru 1.2%, Hf 0.8%, Ta2.5%, V 0.15%, S 0.005%, P 0.007%, N 0.02%, the balance is nickel and unavoidable impurities;

[0027] The preparation method of above-mentioned alloy comprises the steps:

[0028] The first step is to select raw materials according to a certain ratio, and all raw materials should use low S and P raw materials as much as possible;

[0029] In the second step, alloy ingots conforming to the composition are formed by vacuum induction melting and casting.

[0030] In the third step, the alloy is subjected to three homogenization treatments, the temperature of the first homogenization is 1000°C, the time is 20 hours, the heating and cooling rates above 300°C are both 200°C / h, and the second homogenization...

Embodiment 2

[0036] The difference between this embodiment and Example 1 is that the content of each substance is not the same. Specifically, in this embodiment, the nickel-based superalloy includes the following components in weight percentage: C 0.15%, Si 0.55%, Mn 0.95%, Fe3.00%, Co5.0%, Al 0.50%, Ti0.09%, Cr 24.0%, Nb0.40%, Mo 3.0%, W15.0%, Re1.0%, B 0.009%, Ce 2.0%, Ru 1.8%, Hf 3.0%, Ta 5.0%, V 0.35%, the balance is nickel and unavoidable impurities.

[0037] Samples were taken from the test block and stretched at room temperature and 1000°C. At room temperature, its tensile strength Rm was 1200MPa, Rp0.2 was 1010MPa, and the elongation rate was 31%. At 1000°C, its tensile strength Rm1115MPa, Rp0. 2 The range is 988MPa, the elongation range is 29%, and the duration of the 1000°C, 500MPa endurance test is 98h.

Embodiment 3

[0039] The difference between this example and Example 1 is that the content of each substance is not the same. Specifically, in this example, the nickel-based superalloy includes the following components in weight percentage: C 0.08%, Si 0.30%, Mn 0.45%, Fe 0.10%, Co 1.5%, Al 0.10%, Ti 0.03%, Cr 20.5%, Nb 0.05%, Mo 1.0%, W 12.5%, Re 0.15%, B 0.003%, Ce 0.9% , Ru 0.9%, Hf 0.5%, Ta 2.2%, V 0.08%, the balance is nickel and unavoidable impurities.

[0040]Samples were taken from the test block and stretched at room temperature and 1000°C. At room temperature, its tensile strength Rm was 1189MPa, Rp0.2 was 1001MPa, and the elongation rate was 31%. At 1000°C, its tensile strength Rm1112MPa, Rp0. 2 The range is 987MPa, the range of elongation is 29%, and the endurance time of 1000℃, 500MPa endurance test is 99h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com