High low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and production method thereof

A technology of low temperature impact toughness and hydrogenation equipment, which is applied to 14Cr1MoR thick steel plate and its manufacturing field, can solve the problems of deterioration of low temperature impact toughness of steel plate, failure to meet user requirements, and large decrease of low temperature toughness of steel plate, and achieve excellent low temperature impact performance, Excellent mechanical properties, excellent low temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

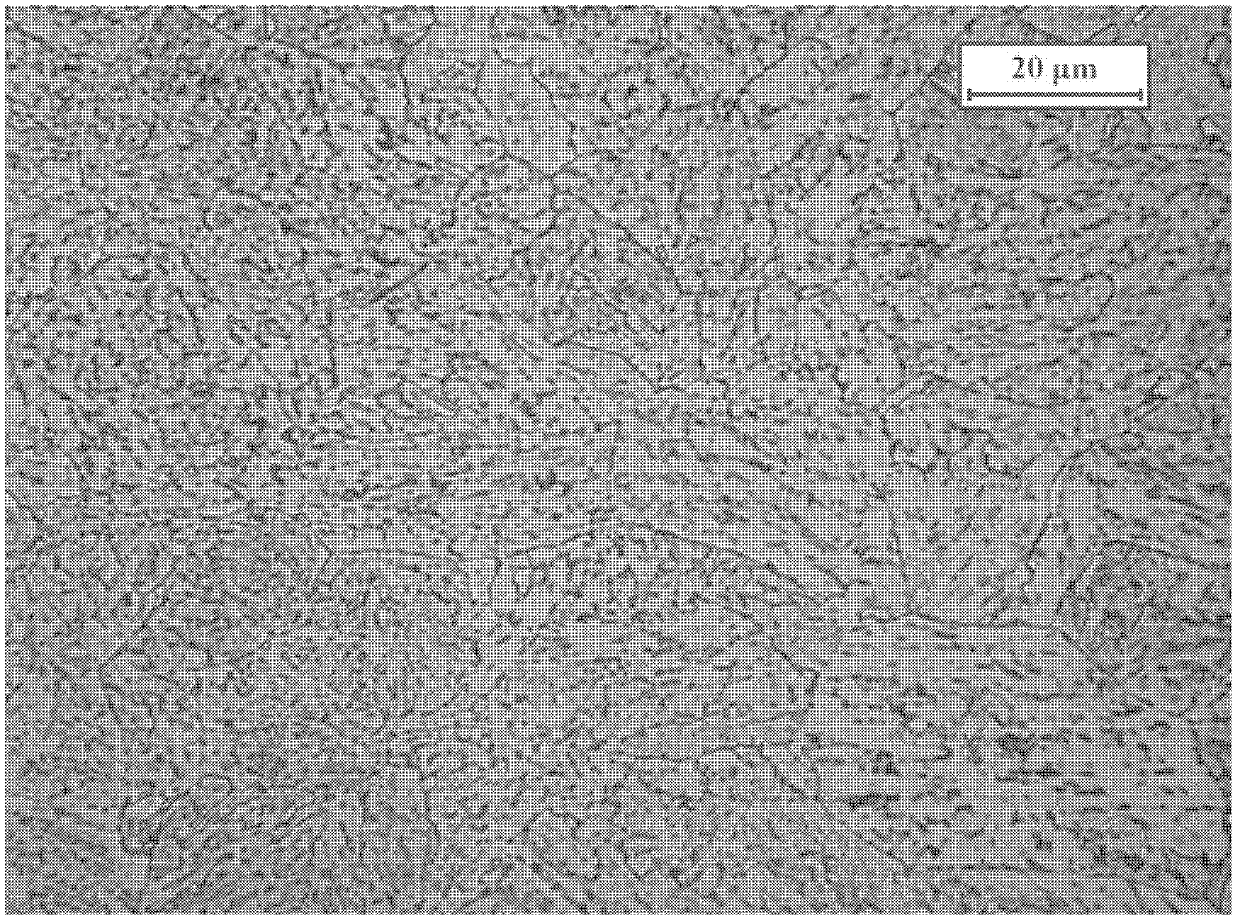

Image

Examples

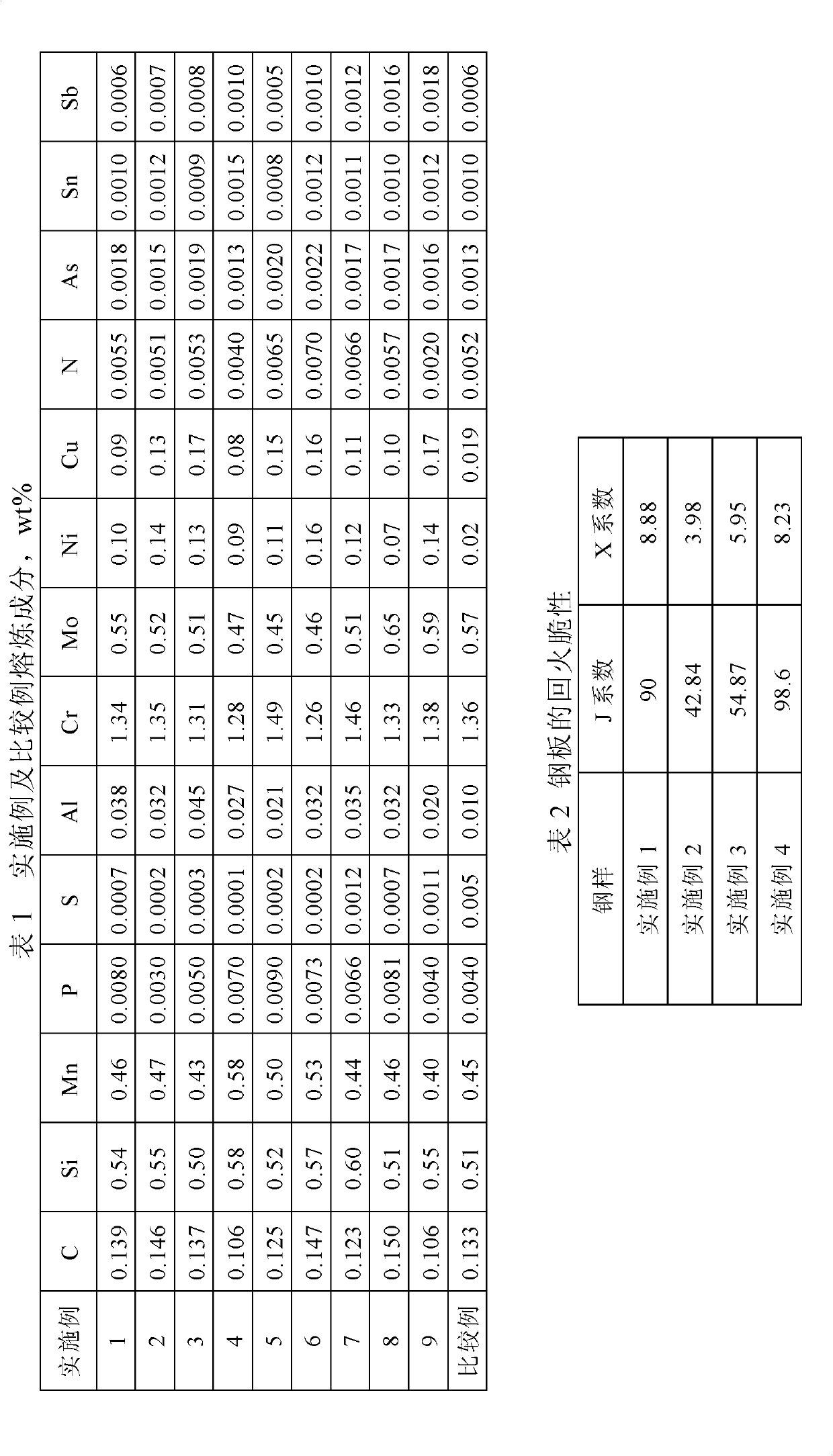

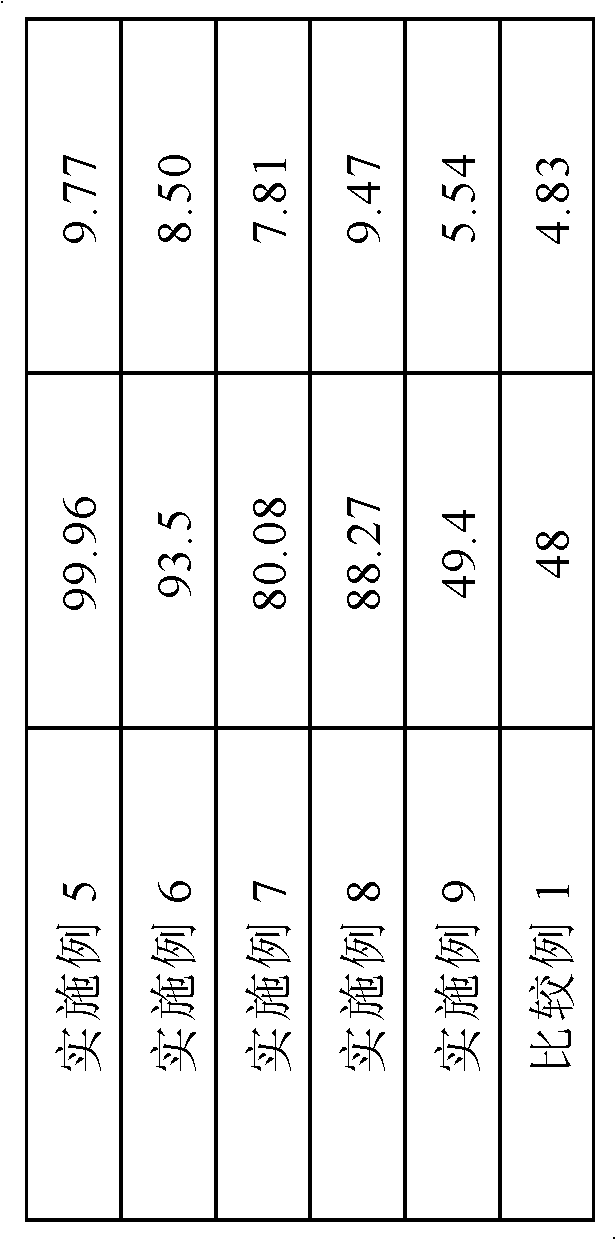

Embodiment 1

[0045] According to the design chemical composition, it is smelted in a 300t converter, alloyed with Cr and Mo, and a small amount of Al, Ni and Cu are added at the same time to control the inclusions in the steel and refine the grains to achieve a reasonable match between strength and toughness. Die-casting into ingots and opening billets, 350mm thick slabs are heated in a heating furnace at 1100°C, rough rolling and finish rolling are performed on the slabs, and rolled into 60mm thick steel plates, the normalizing temperature of the steel plates is 905°C, and the pressure is used after normalizing The quenching machine performs accelerated cooling, and the water flow rate of the low-pressure section of the pressure quenching machine is 25m 3 / min; the water cooling time is 6min, the surface temperature of the steel plate at the exit of the pressure quenching machine is not more than 120°C; the water volume ratio of the upper and lower sides of the steel plate of the pressure ...

Embodiment 2

[0047] According to the design chemical composition, it is smelted in a 300t converter, alloyed with Cr and Mo, and a small amount of Al, Ni and Cu are added at the same time to control the inclusions in the steel and refine the grains to achieve a reasonable match between strength and toughness. Die-casting into ingots and opening billets, 400mm thick slabs are heated in a heating furnace at 1150°C, rough rolling and finish rolling are performed on the slabs, and rolled into 84mm thick steel plates. The normalizing temperature of the steel plates is 920°C. The quenching machine is used for accelerated cooling, and the water flow in the low-pressure section of the pressure quenching machine is 30m 3 / min; water cooling time is 8 minutes, the surface temperature of the steel plate at the outlet of the pressure quenching machine is not more than 120°C; the water volume ratio of the upper and lower sides of the steel plate of the pressure quenching machine is 1:1.0~1.3; then tempe...

Embodiment 3

[0049] According to the design chemical composition, it is smelted in a 300t converter, alloyed with Cr and Mo, and a small amount of Al, Ni and Cu are added at the same time to control the inclusions in the steel and refine the grains to achieve a reasonable match between strength and toughness. Die-casting into ingots and opening billets, 400mm thick slabs are heated in a heating furnace at 1180°C, rough rolling and finish rolling are performed on the slabs, and rolled into 110mm thick steel plates. The normalizing temperature of the steel plates is 930°C. The quenching machine is used for accelerated cooling, and the water flow rate of the low-pressure section of the pressure quenching machine is 35m 3 / min; the water cooling time is 8min, the surface temperature of the steel plate at the exit of the pressure quenching machine is not more than 120°C; the ratio of water volume between the top and bottom of the steel plate of the pressure quenching machine rod is 1:1.0~1.3; s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com