Patents

Literature

39results about How to "Lower brittle transition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength steel plate for Q500GJE quenched and tempered building structure and manufacturing method of high-strength steel plate

ActiveCN110184525AGood brittle transition temperatureLower brittle transition temperatureImpact energyBainite

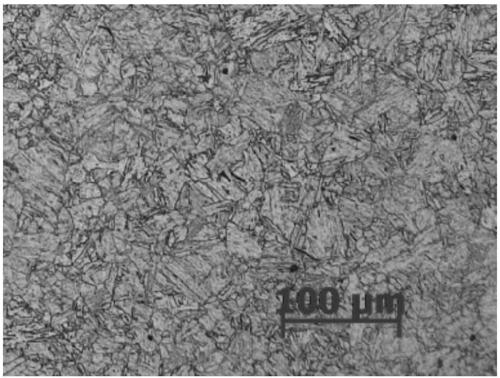

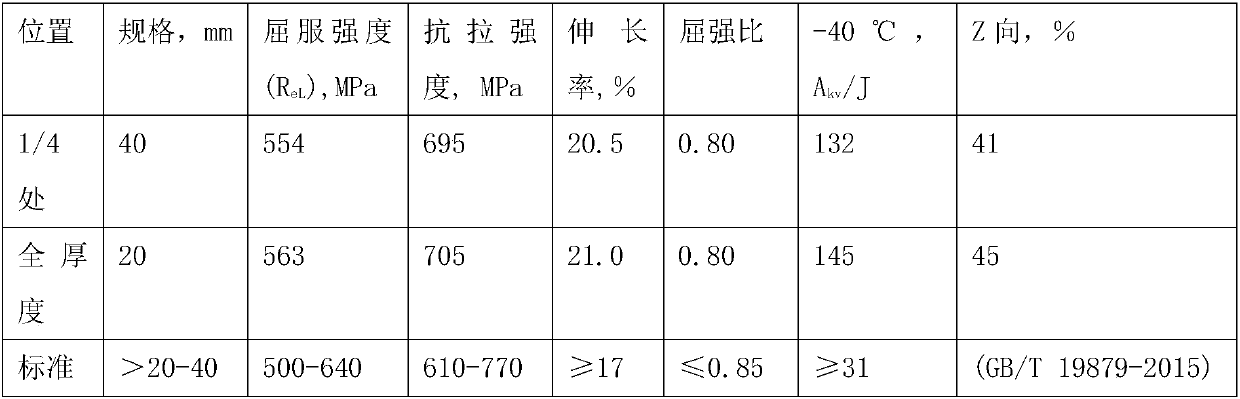

The invention relates to a high-strength steel plate for a Q500GJE quenched and tempered building structure. The high-strength steel plate comprises the following chemical components: less than or equal to 0.14% of C, 0.20%-0.50% of Si, 1.10%-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.20% of Cr, less than or equal to 0.30% of Mo, lessthan or equal to 0.90% of Ni+Mo, less than or equal to 0.30% of Cu, 0.02%-0.04% of Al, less than or equal to 0.20% of V+Nb+Ti, less than or equal to 0.006% of N, and the balance of Fe and inevitableimpurity elements, wherein the carbon equivalent is less than or equal to 0.52%. The yield strength is 545-585 MPa, the tensile strength is 670-715 MPa, and the elongation is larger than or equal to 18.5%. A high-strength steel product for a building, with the yielding-to-tensile ratio less than or equal to 0.84, and the V-type impact energy higher than or equal to 110 J at -40 DEG C, is of a ferrite+pearlite+bainite structure, and the grain size is 8.5 levels or above. The comprehensive performance can completely meet GB / T 19879-2015 and the clients' requirements of steel plates for high-risebuildings.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Double-phase stainless steel smelting technology

The invention belongs to the technical field of steel smelting, and relates to a double-phase stainless steel smelting technology. According to the technology, a carbon steel material head, a stainless steel material head, stainless steel cuttings and high carbon ferro-chrome are adopted to serve as raw materials, high-chromium high-carbon molten steel is smelted through an intermediate frequency furnace, and relatively-high-cost low-carbon or micro-carbon chromium iron is not required to be adopted for smelting; after the temperature is proper, the molten steel is transferred into an AOD furnace from a steel ladle; smelting devices like the AOD furnace is adopted for conducting oxygen blowing, decarbonization and molten steel refining, and nitrogen is blown to the steel for increasing nitrogen to the steel; the cost generated by adopting nitralloy for nitrogen adding is reduced, and after the components are qualified, the steel is cast into an electrode blank; when electric slag is remelted, argon or dry air is adopted for protection, and the suction amount of a furnace hearth is further reduced; and the voltage and the current are adjusted to control the melting rate. The double-phase stainless steel smelting technology is also suitable for other applicable fields.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Ferritic stainless steel for tubular heat exchangers and manufacturing method thereof

The invention relates to a ferritic stainless steel for tubular heat exchangers and a manufacturing method thereof. The ferritic stainless steel comprises the following chemical components in percentage by weight: at most 0.015% of C, at most 0.020% of N, at most 0.5% of Si, at most 0.5% of Mn, at most 0.035% of P, at most 0.01% of S, 22-24% of Cr, 1.5-3.0% of Mo, 0.0050-0.050% of Al, and the balance of Fe and inevitable impurities, wherein 10(C+N)<=(Nb+Ti)<=0.6%. The manufacturing method comprises the following steps: smelting by an arc furnace+AOD (argon oxygen decarburization)+VOD (vacuum oxygen decarburization) three-step process, carrying out continuous casting to obtain a continuous casting blank, and carrying out hot rolling, acid washing, cold rolling, annealing, acid washing and the like to obtain the high-weldability cold-rolled stainless steel sheet strip. The high-weldability cold-rolled stainless steel sheet strip is suitable for manufacturing welded tubes with higher requirements for corrosion resistance and flaring performance; and the flaring ratio is up to higher than 35%.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Ferrite stainless steel for buildings and preparation method thereof

ActiveCN102234738AImprove corrosion resistanceReduce glossTemperature control deviceFurnace typesSheet steelImpurity

The invention discloses ferrite stainless steel for buildings. The ferrite stainless steel comprises the following chemical elements in percentage by mass: less than or equal to 0.015 percent of C, less than or equal to 0.020 percent of N, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.010 percentof S, more than 21.5 percent and less than 23.5 percent of Cr, more than 1.0 percent and less than 3.0 percent of Mo, more than or equal to 0.35 percent and less than or equal to 0.6 percent of Nb, less than or equal to 0.2 percent of Ti and the balance of Fe and other inevitable impurities, wherein (Nb+Ti) is more than or equal to 16(C+N) and less than or equal to 0.6 percent. Correspondingly, the invention further provides a method for preparing the stainless steel for buildings. Compared with the conventional stainless steel for buildings, the ferrite stainless steel has the advantages of excellent corrosion-resistant effect, low surface gloss, good scattered reflection effect, difficulty in deformation of steel plates, low cost and very good application effect.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

P110 steel level high frequency straight welded pipe manufacturing method

InactiveCN102430901AImprove toughnessImprove resistance to delayed crackingFurnace typesHeat treatment furnacesMedium frequencyEngineering

A P110 steel level high frequency straight welded pipe manufacturing method comprises (1) taking hot-rolled coil as raw material; (2) shaping the coil into a straight seam pipe by continuous shaping techniques, welding the straight seam on the pipe by a high frequency inductive welding machine to produce a primary pipe, and after the welding, timely removing external and internal burrs of the primary pipe; (3) heating the primary pipe removed of burrs by a medium frequency induction furnace to 920-950 degrees centigrade and conveying it to a hot rolling and diameter reducing machine, rolling the primary pipe into pipe blanks with different apertures by hot mechanical rolling; (4) conducting whole-pipe quenching and tempering to the hot roller pipe blank to produce finished pipe; (5) conducting ultrasonic flaw detection and pipe end magnetic powder inspection to the finished pipe. The invention takes low steel level coil as raw material to produce primary pipe, produces pipe blanks with different diameter specifications by the primary pipe with the same specification, and produces oil casing product with high steel level and high performance by low steel level economical pipe blanks. The working efficiency is high. The production cost is low.

Owner:BAOJI PETROLEUM STEEL PIPE

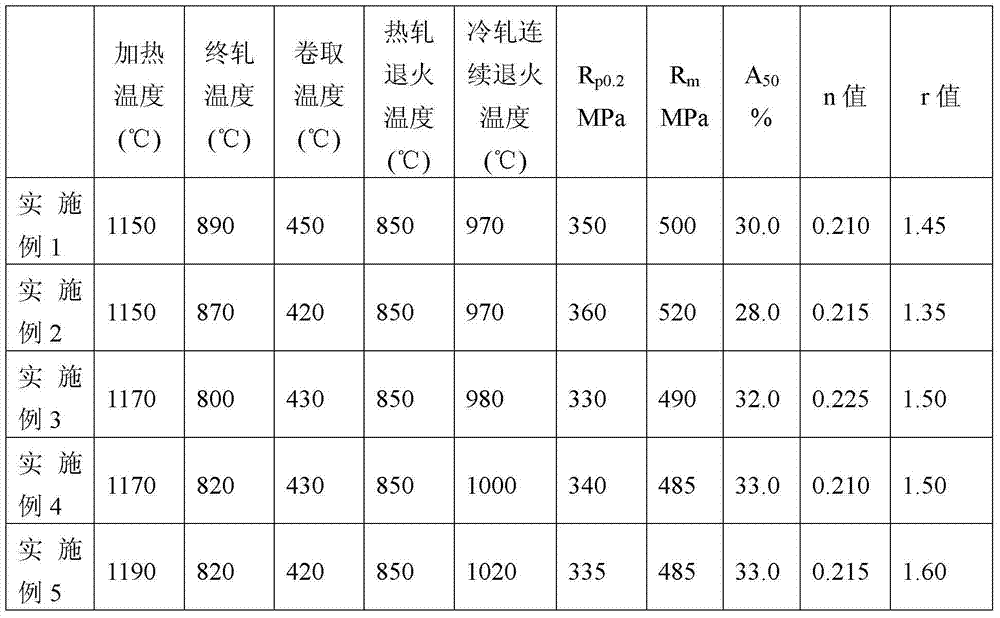

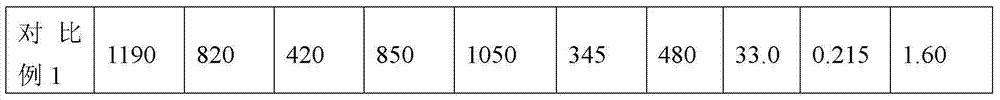

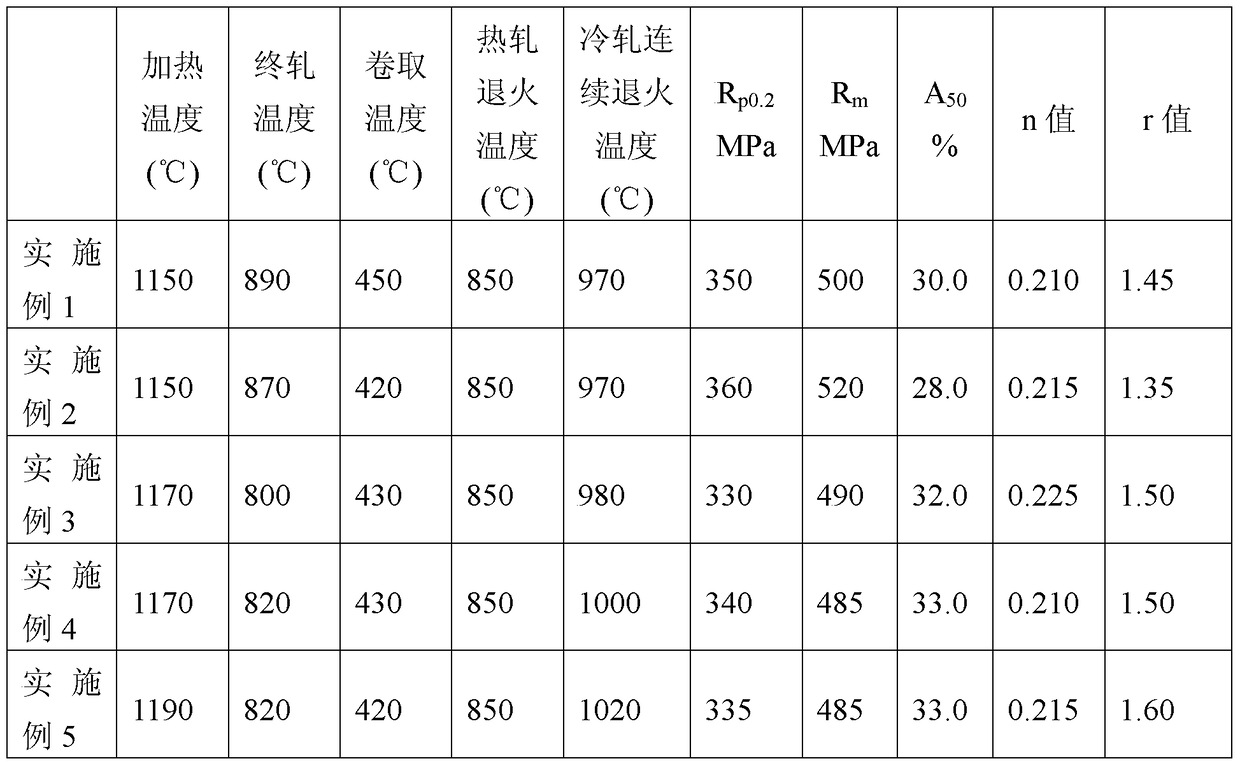

800MPa grade automobile box steel and production method thereof

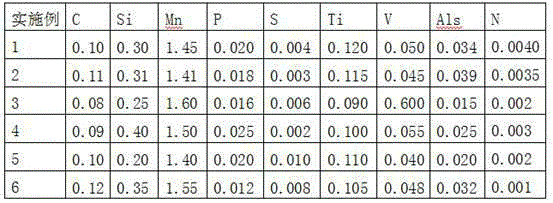

The invention discloses an 800MPa grade automobile box steel and a production method thereof. The production method comprises the steps of heating, rough rolling, finish rolling, cooling and coiling; the slab adopted contains the following components in percentage by mass: 0.08-0.12% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, less than or equal to 0.025% of P, less than or equal to 0.010% of S, 0.040-0.060% of V, 0.090-0.120% of Ti, greater than or equal to 0.015% of Als, less than or equal to 0.004% of N and the balance of Fe and inevitable impurities. The steel is strengthened by both vanadium and titanium and a precipitation strengthening effect can be developed more thoroughly, and the overall properties of the steel plate can be improved; besides, the load of rolling can be reduced thoroughly and the production difficulty can be reduced; the steel has the characteristics of low cost, high quality and easiness in machining. According to the method, the precipitation of carbon and carbonitrides, the recrystallization of the austenite and the deformation state of the austenite are controlled by controlling the tapping temperature of the rolled steel, the temperature of the intermediate slab, the finish rolling temperature and the coiling temperature; the strength index and the overall properties of the obtained product are guaranteed, and the product is low in production cost and easy to machine.

Owner:HEBEI IRON AND STEEL

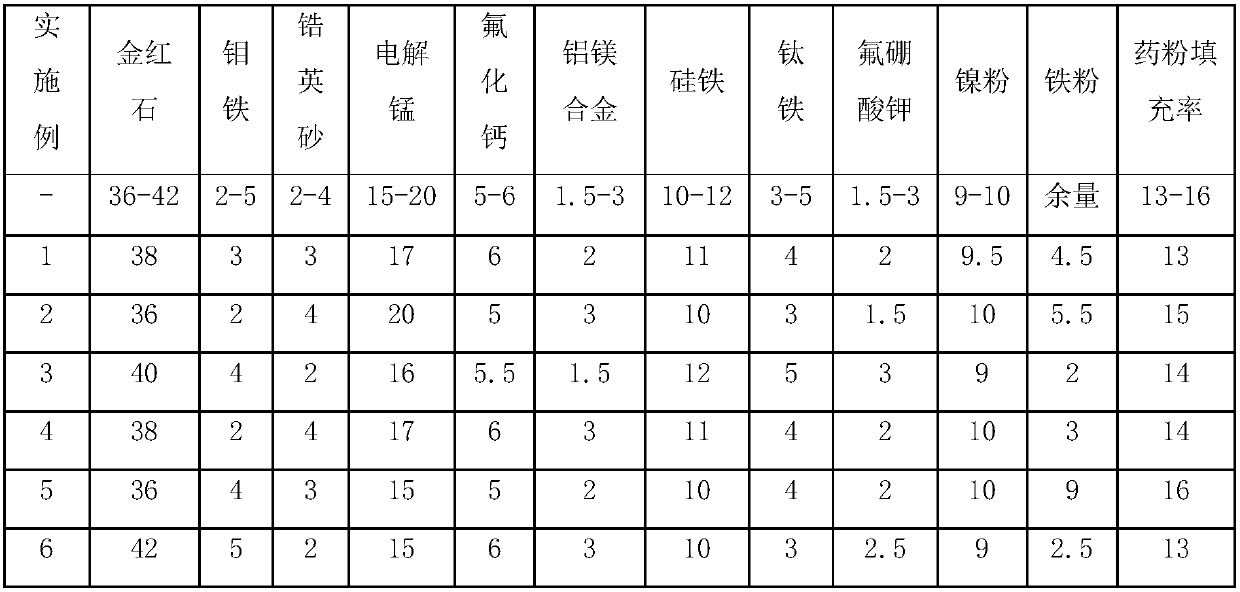

Flux-cored wire for 620 MPa-level low-temperature steel and welding method of flux-cored wire

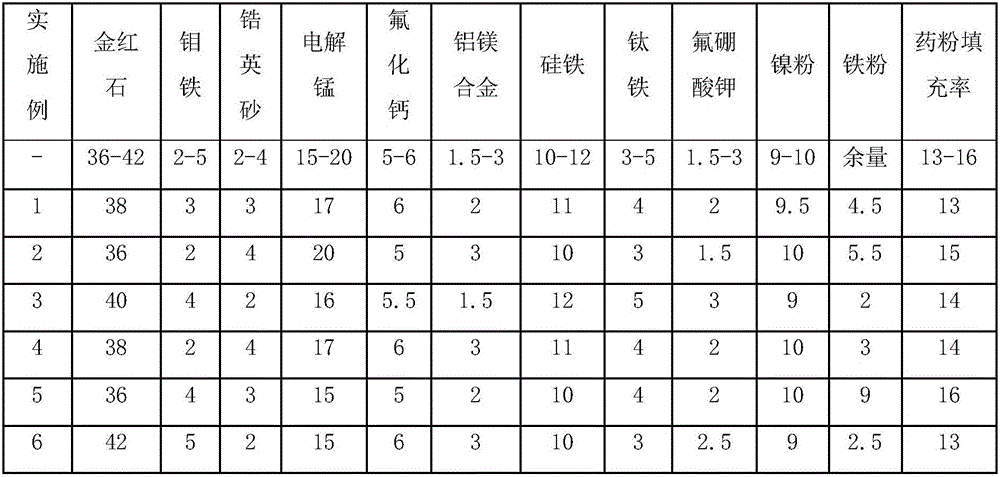

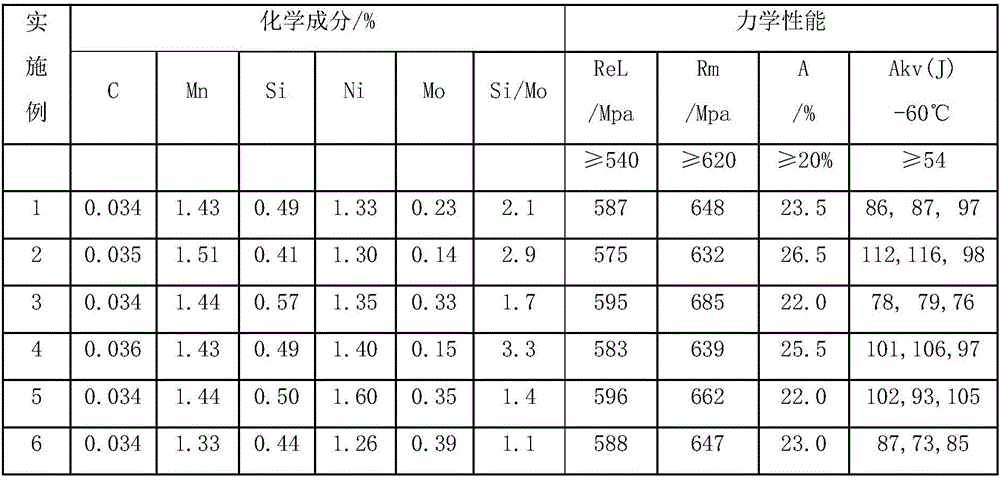

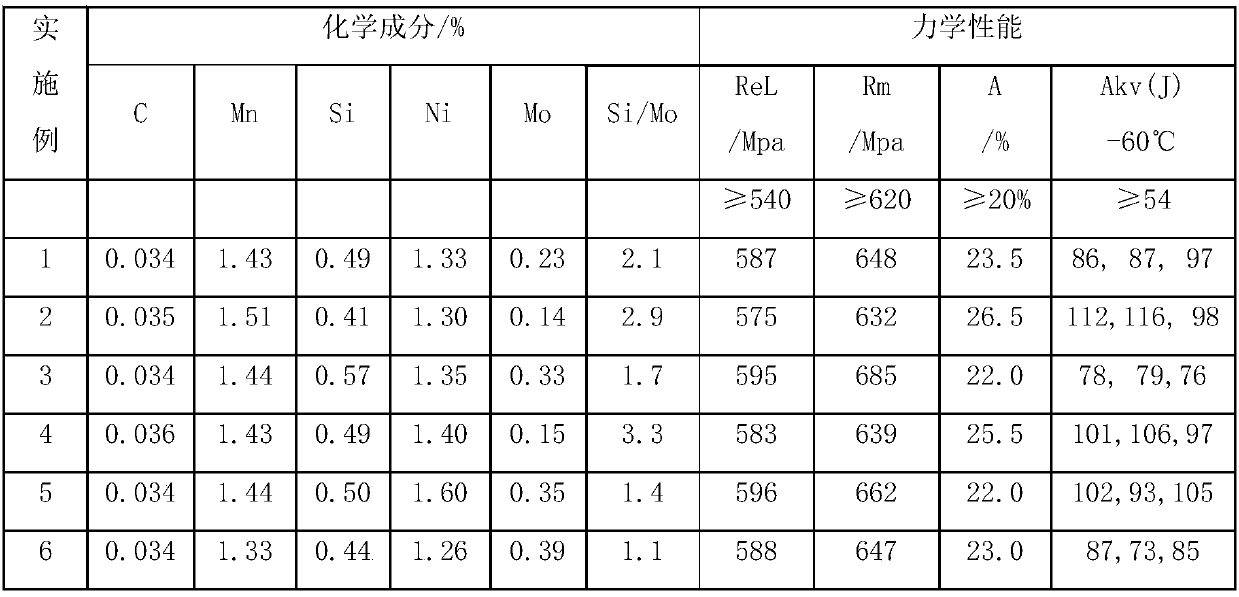

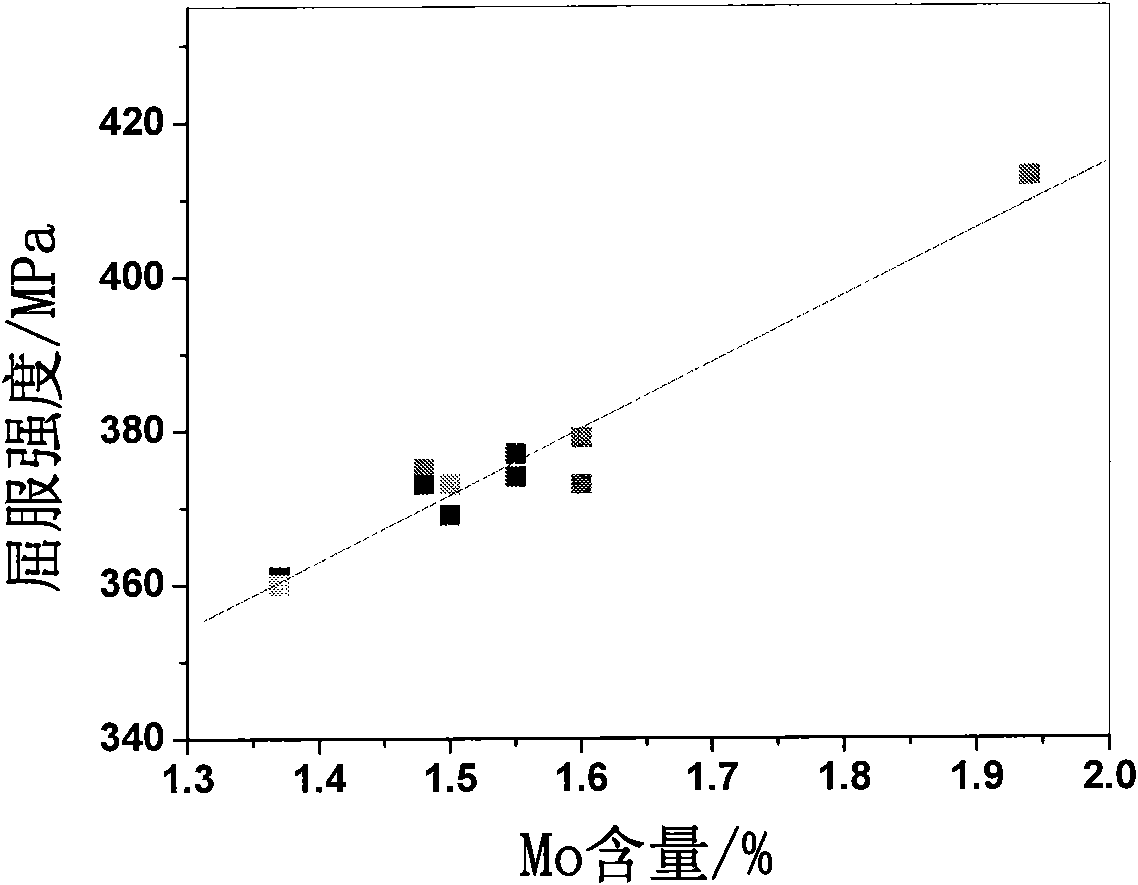

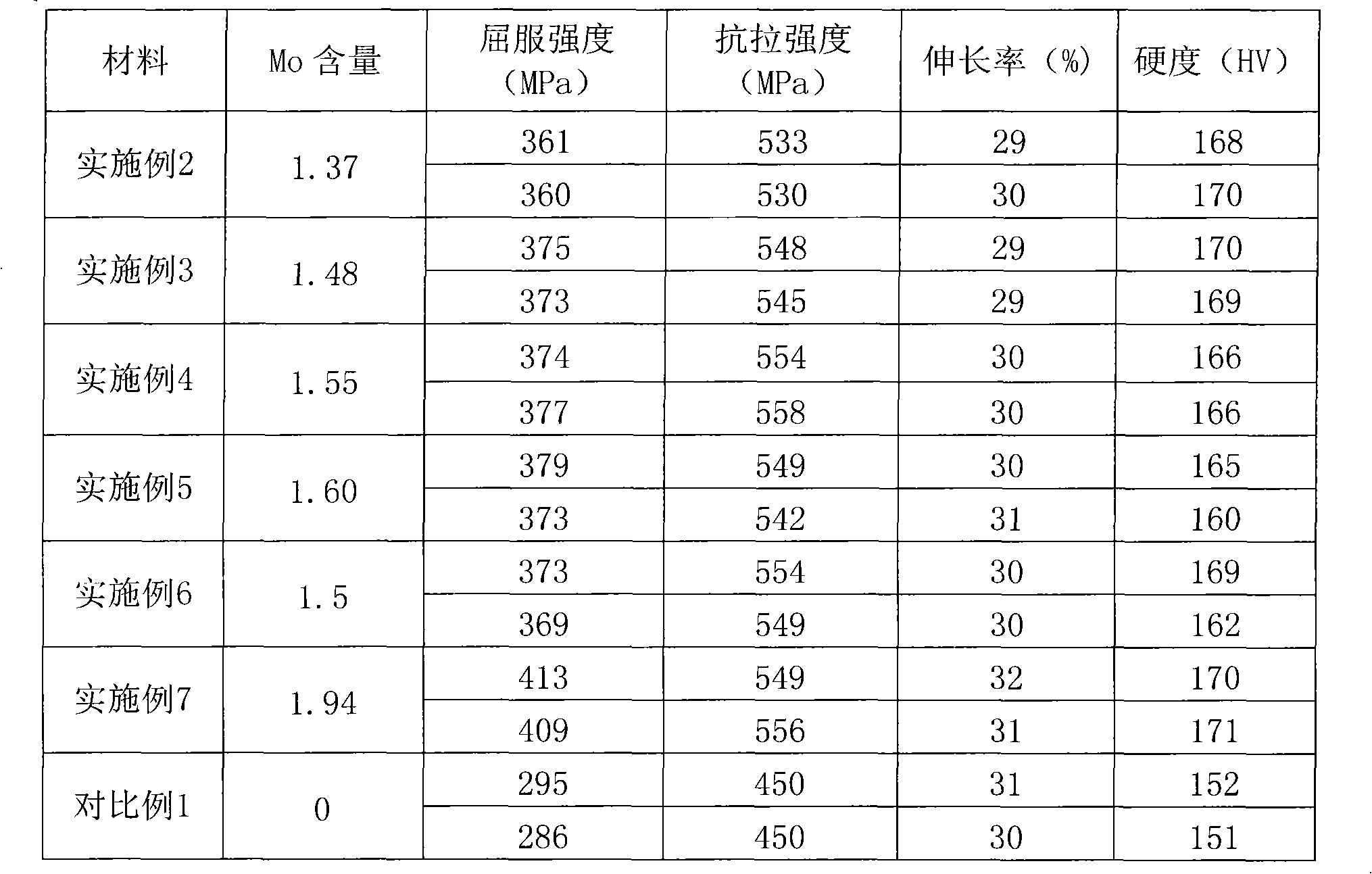

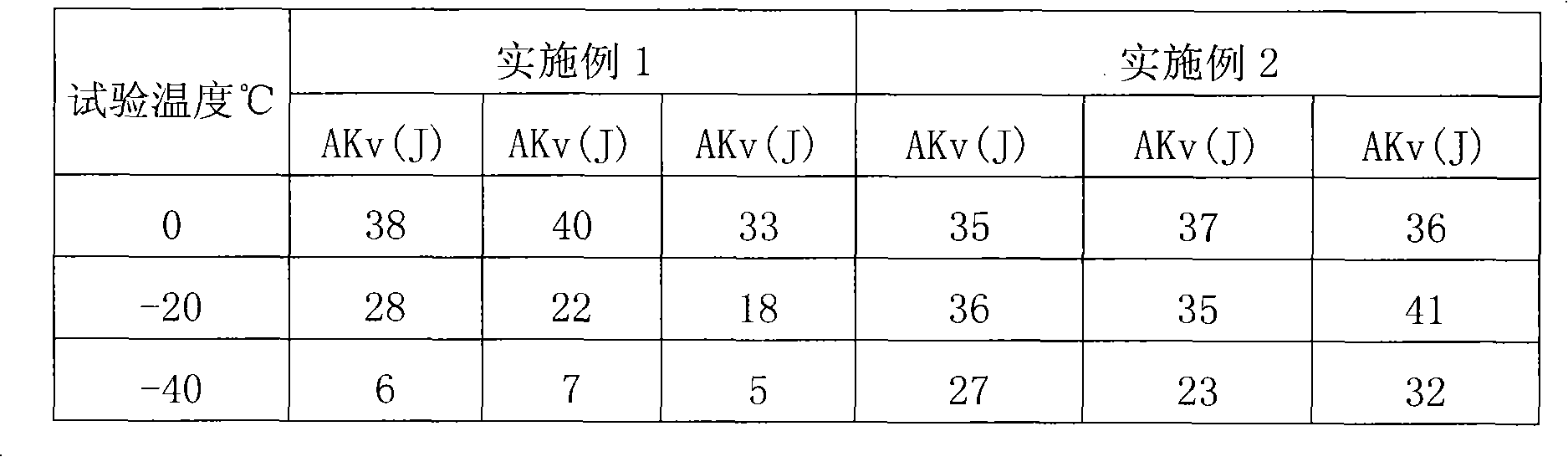

ActiveCN106825992ASimple welding processWeld impact toughness decreasedWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention provides a flux-cored wire for 620 MPa-level low-temperature steel. The flux-cored wire for 620 MPa-level low-temperature steel comprises carbon steel skin and a flux core arranged in the carbon steel skin. The flux core comprises the following raw material components, by mass percent, 36%-42% of rutile, 2%-5% of ferromolybdenum, 2%-4% of zircon sand, 15%-20% of electrolytic manganese, 5%-6% of calcium fluoride, 1.5%-3% of an aluminum magnesium alloy, 10%-12% of silicon iron, 3%-5% of ferrotitanium, 1.5%-3% of potassium fluoborate, 9%-10% of nickel powder and the balance ferrous powder and unavoidable impurities. The flux-cored wire for the 620 MPa-level low-temperature steel utilizes CO2 protective gas for welding and has excellent welding process performance and comprehensive performance of deposited metal and a welded joint. The yield strength is larger than or equal to 540 MPa, the extension strength is larger than or equal to 620 MPa, the elongation is larger than or equal to 20%, and under the condition of -60 DEG C, Akv is larger than or equal to 54 J.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

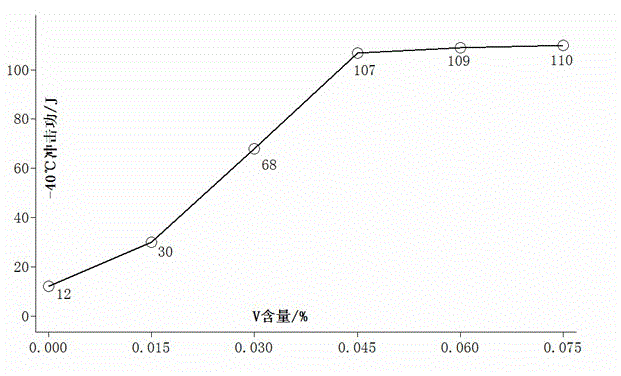

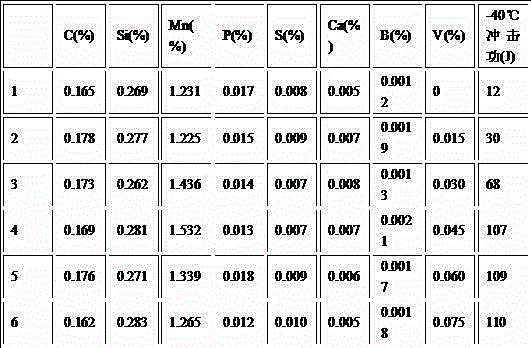

Hot-rolling H-shaped steel containing and vanadium boride and having excellent low-temperature impacttoughness and preparation method of hot-rolling H-shaped steel

InactiveCN103820706ALower brittle transition temperatureSolve the problem of low low temperature impact toughnessRoll mill control devicesMetal rolling arrangements50SSmelting process

The invention relates to hot-rolling H-shaped steel containing and vanadium boride and having excellent low-temperature impacttoughness and a preparation method of the hot-rolling H-shaped steel. The H-shaped steel comprises the following chemical components in percentage by weight(%): 0.10-0.20 percent of C, 0.20-0.35 percent of Si, 1.10-1.45 percent of Mn, not more than 0.020 percent of P, not more than 0.010 percent of S, not more than 0.010 percent of Ca, 0.0005-0.0040 percent of B, 0.02-0.08 percent of V and the balance of Fe and trace amount of impurities. In the smelting process, the mass percentage of gas in a beamblank is that [N] is controlled to be not more than 80ppm and [O] is controlled to be not more than 100ppm. In the rolling process, the heating temperature of the beam blank is 1,190-1,290DEG C, the cogging temperature is 1,120-1,230DEG C and the finish rolling temperature is not more than 850DEG C. In the universal rolling process, the stay time is 15-50s and the accumulative compression ratio is 55 percent or greater. According to the hot-rolling H-shaped steel disclosed by the invention, the low-temperature impacttoughness of Q345 H-shaped steel products can be greatly improved and the low-temperature impacttoughness is better stabilized, so that the quality of the products is ensured and the products are suitable for harsh environments more easily.

Owner:山西新泰钢铁有限公司

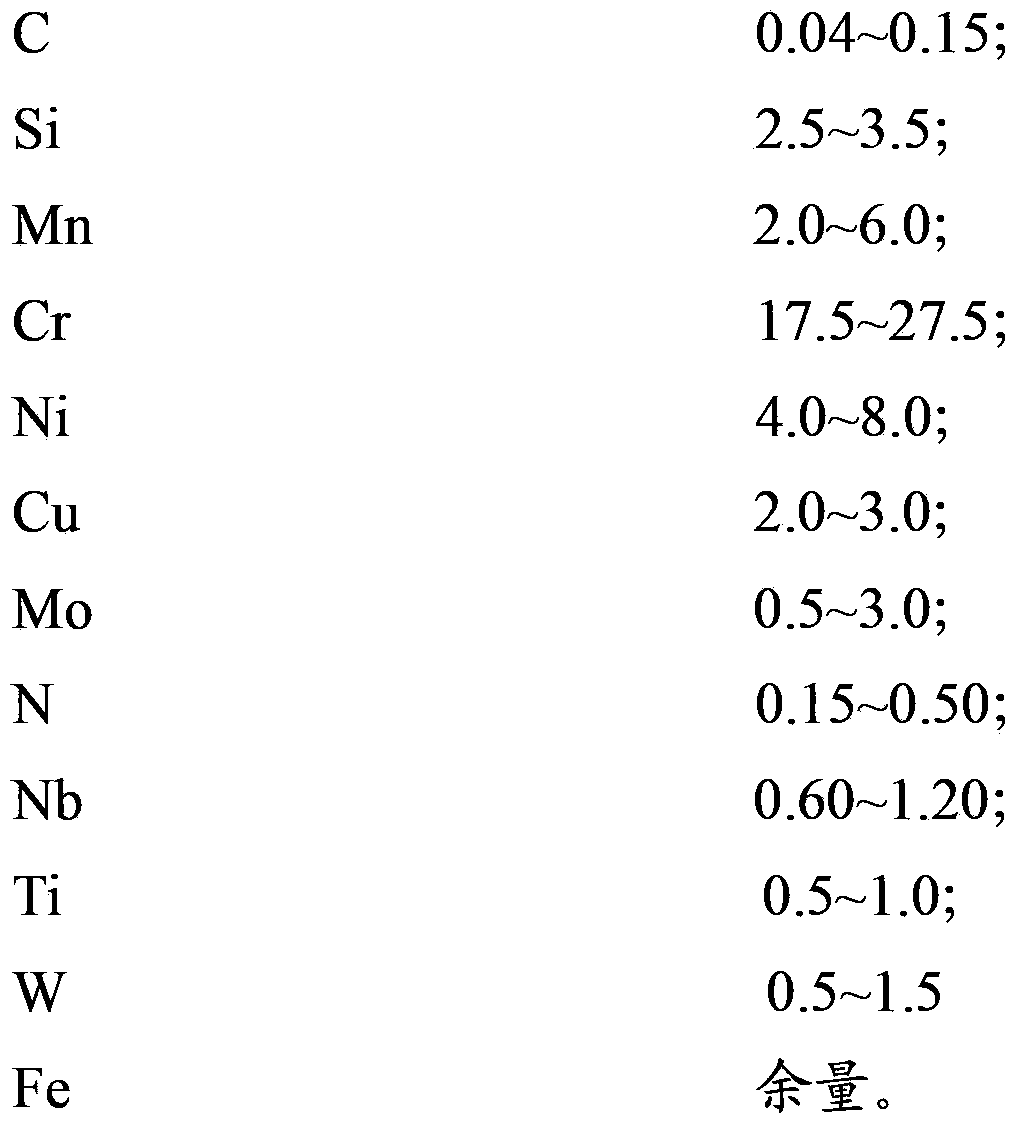

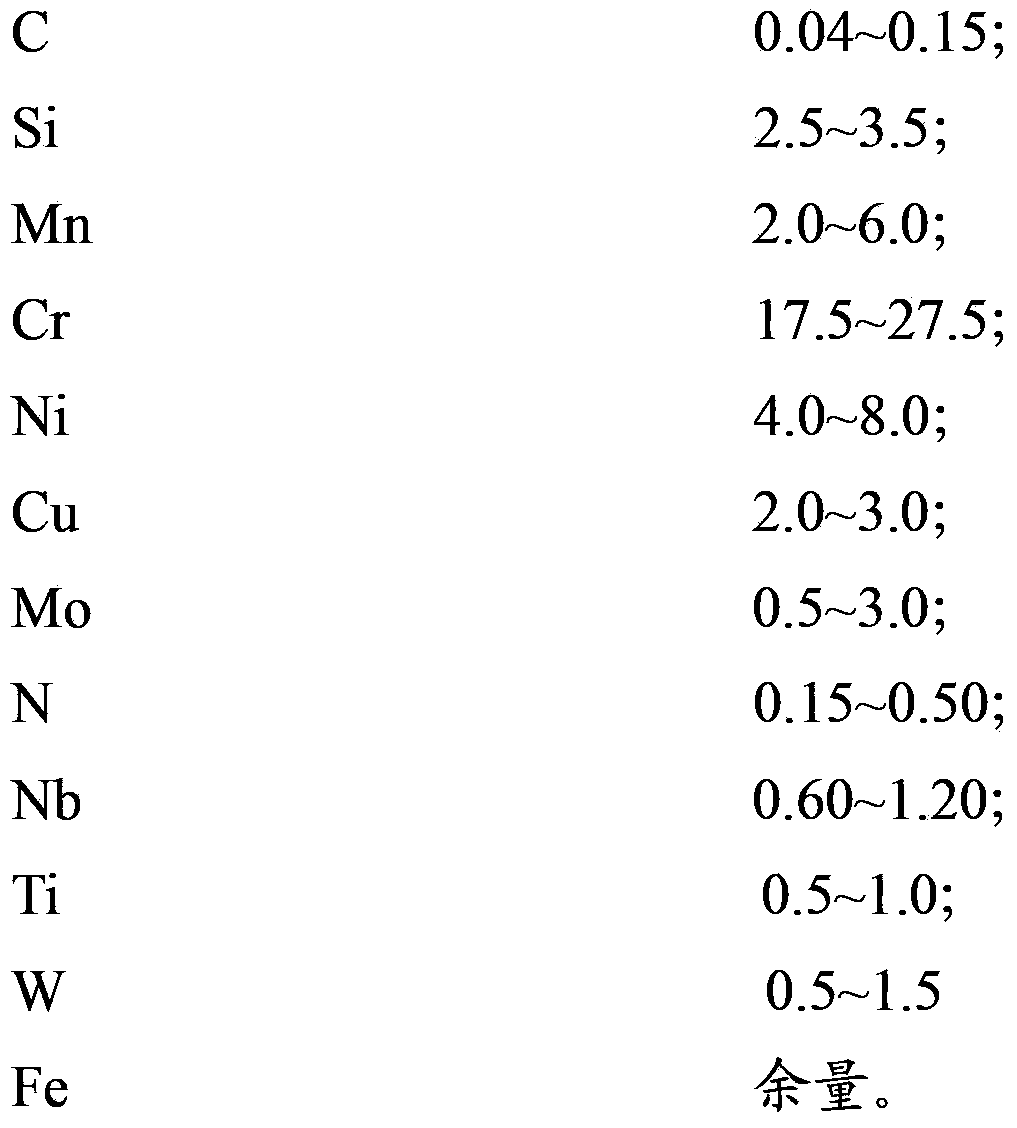

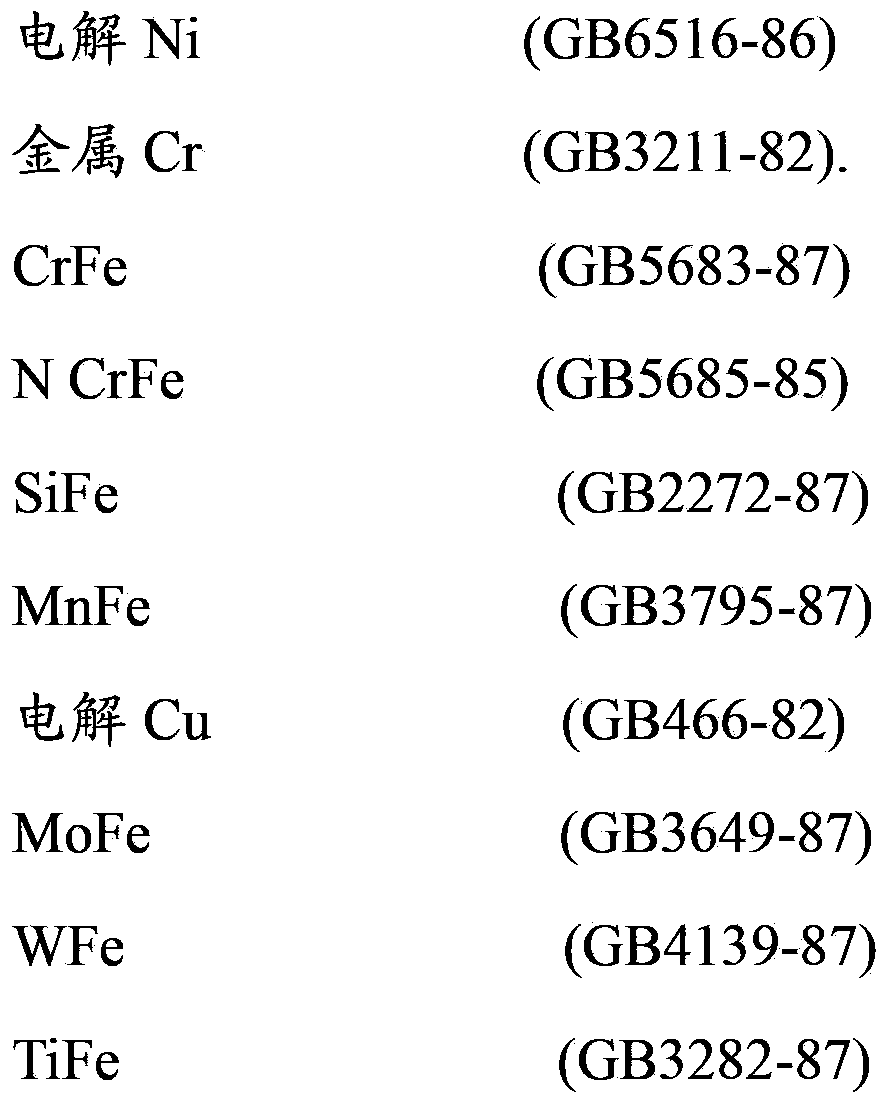

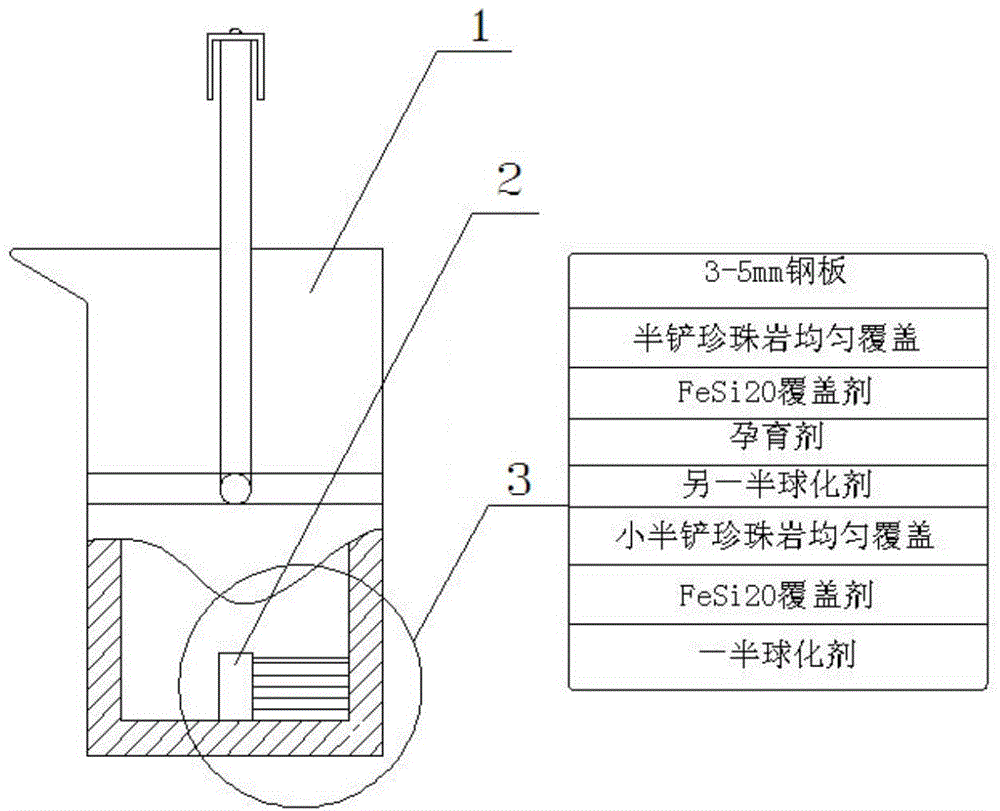

Duplex stainless steel master alloy and preparation method thereof

InactiveCN103469051AHigh mechanical resistance propertiesImprove mechanical propertiesThermal deformationSS - Stainless steel

The embodiment of the invention provides a duplex stainless steel master alloy and a preparation method thereof. The duplex stainless steel master alloy comprises the following components in weight percentage: 0.04-0.15% of C, 2.5-3.5% of Si, 2.0-6.0% of Mn, 17.5-27.5% of Cr, 4.0-8.0% of Ni, 2.0-3.0% of Cu, 0.5-3.0% of Mo, 0.15-0.50% of N, 0.60-1.20% of Nb, 0.5-1.0% of Ti, 0.5-1.5% of W, and the balance of Fe and unavoidable impurities. The duplex stainless steel master alloy disclosed by the invention is resistant to various forms of corrosion under different use conditions, has higher mechanical properties, is improved in mechanical properties such as tensile strength (sigma b) and elongation percentage (delta 5%) as compared with common commercial duplex stainless steel (such as WNr1.4462 of the Germany and S31803 of the USA), and can be cast directly or made into parts for use through thermal deformation.

Owner:广东华鳌合金新材料有限公司

Nodular cast iron gear box with high impact toughness at ultralow temperature, and making method thereof

ActiveCN104988382AHigh nodularityLower brittle transition temperatureChemical compositionIntermediate frequency

Owner:CRRC DALIAN CO LTD

Method for producing 380MPa-grade wheel steel

InactiveCN105088070ALower brittle transition temperatureGood welding performanceChemical compositionMaterial technology

The invention discloses a method for producing 380MPa-grade wheel steel and belongs to the technical field of materials. According to the technical scheme, the method for producing the 380MPa-grade wheel steel comprises the following technological steps that plate blank heating, high-pressure water dephosphorization, rough rolling, coiling through a hot coil box, finish rolling, laminar cooling and curling through a curling machine are conducted on a billet, and then the 380MPa-grade wheel steel is obtained. The billet comprises, by mass, 0.06%-0.10% of C, equal to or less than 0.10% of Si, 0.80%-1.10% of Mn, equal to or less than 0.020% of P, equal to or less than 0.010% of S, 0.010%-0.030% of Ti, 0.015%-0.050% of Als and the balance Fe and inevitable impurities. Ti is added into an original C-Mn strengthening system, and thus the strength and the weldability of the wheel steel are improved. Through the design of low-carbon and low-silicon components and reasonable adding of the Als, free N in the steel can be controlled, and the comprehensive performance of the wheel steel is improved.

Owner:HEBEI IRON AND STEEL

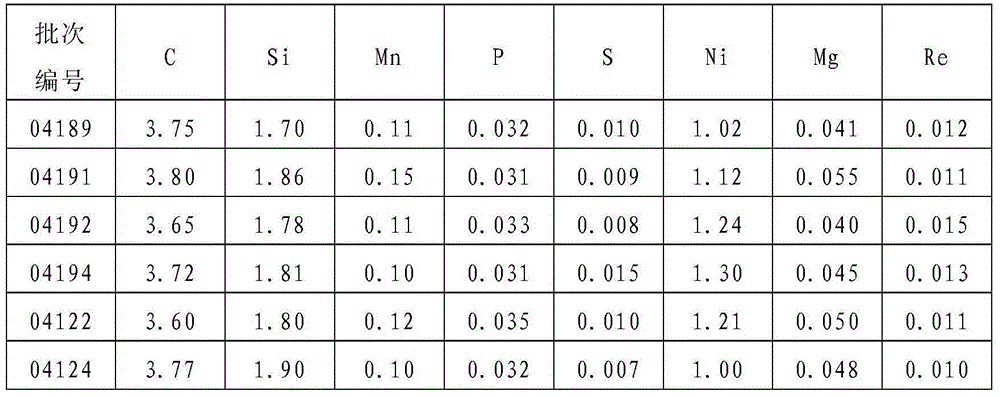

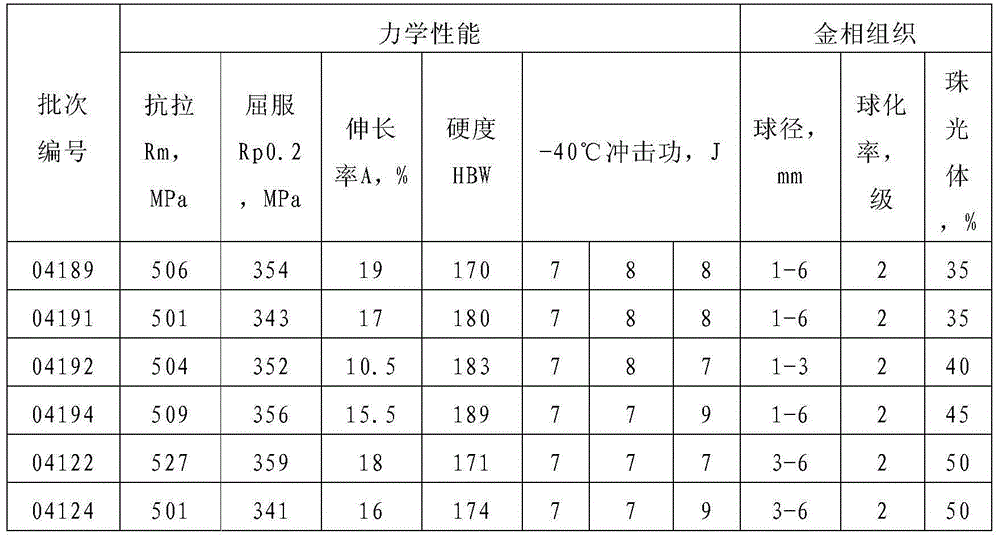

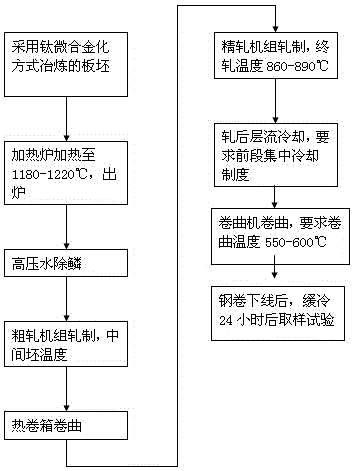

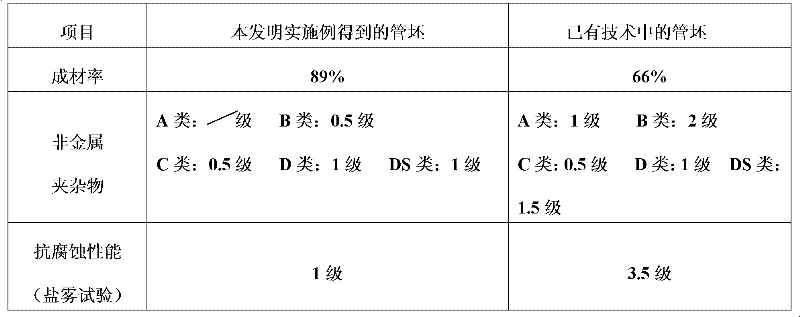

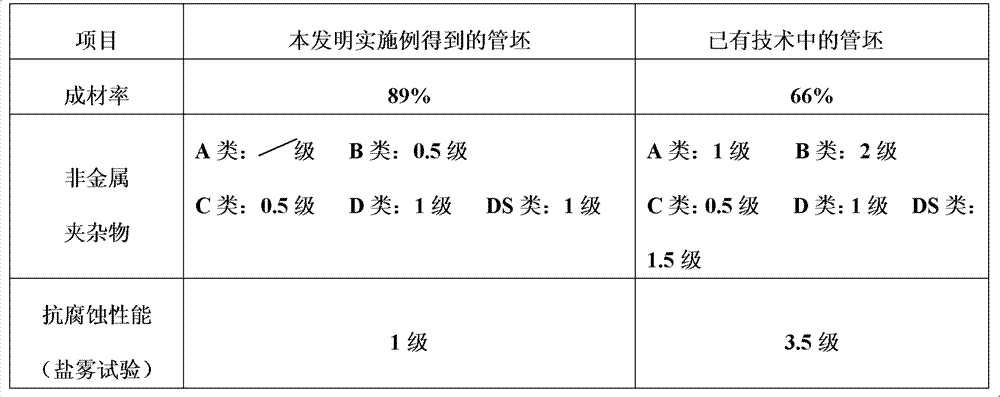

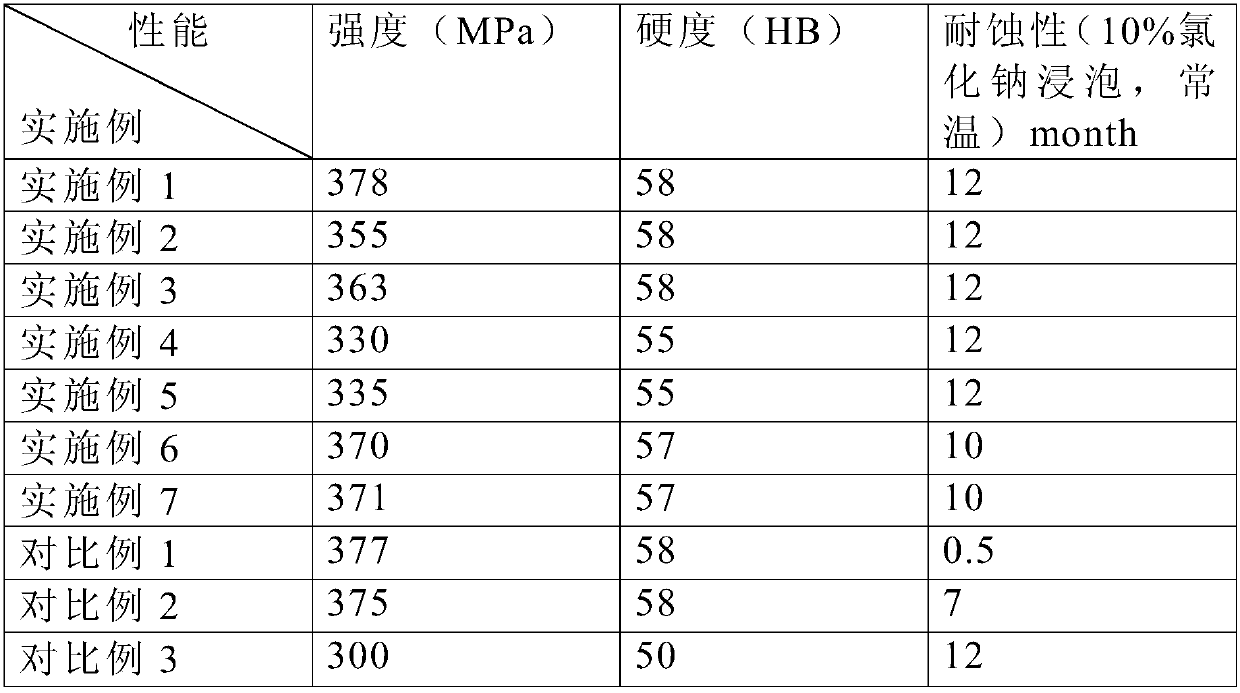

00Cr18Mo2 stainless steel pipe billet and manufacture method thereof

The invention discloses a 00Cr18Mo2 stainless steel pipe billet and a manufacture method thereof, which belong to the technical field of stainless steel materials. The 00Cr18Mo2 stainless steel pipe billet comprises the following components: 0.01-0.025wt% of C, 0.15-0.35wt% of Si, 0.22-0.45wt% of Mn, 0.023-0.030wt% of P, 0.002-0.015wt% of S, 18.00-19.50wt% of Cr, 1.70-2.50wt% of Mo and the balance of Fe. The 00Cr18Mo2 stainless steel pipe billet has the advantages of excellent corrosion resistance, low brittle transition temperature and good adaptability and can be applied to a generator set cooled by sea water, and resource is saved. Because the provided manufacture method has few technical steps, energy can be saved because the 00Cr18Mo2 stainless steel pipe billet does not need to be heated by electricity energy for multiple times. The manufacture method is favorable for the content of O2, N and C so as to control the content of harmful chemical elements. The non-metal inclusion in the obtained pipe billet can reach B-class 0.5 grade, C-class 0.5 grade, D-class 1 grade and DS class 1 grade. The yield rate is above 89%.

Owner:常熟市长江不锈钢材料有限公司

High-strength alloy steel plate for pressure vessel and preparation method thereof

InactiveCN104674112AReduce high temperature performance requirementsGuaranteed high strength at room temperatureManganeseMetallic materials

The invention belongs to the technical field of metal material manufacture and particularly relates to a high-strength alloy steel plate for a pressure vessel and a preparation method thereof. The high-strength alloy steel plate for the pressure vessel comprises the following components by weight percentage: 0.20-0.25% of carbon, 0.20-0.40% of silicon, 1.35-1.60% of manganese, less than or equal to 0.018% of phosphorus, less than or equal to 0.008% of sulphur, 0.14-0.18% of vanadium, 0.40-0.70% of nickel and the balance of iron and unavoidable impurities. The high-strength alloy steel plate for the pressure vessel is high in strength and tenacity, low in yield ratio and good in welding performance and can be widely used in the pressure vessel manufacture.

Owner:SHANDONG IRON & STEEL CO LTD

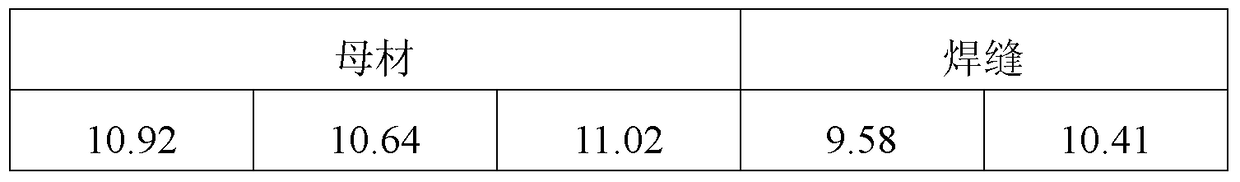

Seawater corrosion resistant austenitic stainless steel and application thereof

The invention relates to seawater corrosion resistant austenitic stainless steel and application thereof, belonging to field of the metallurgical alloy and the application thereof. The matrix materials of the seawater corrosion resistant austenitic stainless steel comprise the following components by weight percent in addition to allowed trace impurities: 0.08 percent of C or more, 0.10 percent of Si or more, 2.00 percent of Mn or more, 0.04 percent of P or more, 0.03 percent of S or more, 7-10 percent of Ni, 17-19 percent of Cr, 1-2 percent of Cu, 0.05 percent of Nb or more and the balance of Fe. The seawater corrosion resistant austenitic stainless steel is used for manufacturing the floating production storage and offloading (FPSO) system and the air valve matched with the oil tanker. The austenitic stainless steel can resist the long-time corrosion of the seawater and the seawater vapor so as to ensure that the air valve operates safely and is free from the accident.

Owner:盐城中油船舶海洋工程科技有限公司

Formula of welding rod coating

InactiveCN105397338ASolve the problem of easy corrosionHigh tensile strengthWelding/cutting media/materialsSoldering mediaFerrosiliconSodium silicate

The invention provides a formula of a welding rod coating. The formula consists of marbles, quartz, ferrosilicon, ferromanganese iron, calcium carbonate, potassium carbonate, sodium silicate, starch, aluminum oxide, cryolite and sodium silicate. The formula has the beneficial effects that: the problem that a welding seam is liable to corrode after a welding rod is used for welding is solved, tensile strength and impact toughness of a welding seam are strengthened, a brittle transition temperature of the welding seam is reduced, thermal hardness of the welding seam is improved, and surface hardness of the welding seam is strengthened. Moreover, the formula is low in production cost, simple in manufacturing process, wide in scope of application and easy to popularize.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

Air blower

InactiveCN107739905AImprove toughnessLower brittle transition temperatureAnodisationHigh resistanceMetallic materials

The invention discloses an air blower and a preparation technique thereof, and belongs to the technical field of metal materials. The air blower comprises 0.5-1.5% of Li, 0.1-0.3% of Pt, 0.1-0.3% of Ir, 2-4% of Ni, 0.5-1.5% of Mg, 1-5% of Cu, and the balance Al and impurities. The chemical activity of Li of the raw materials is high and can react with gas elements such as hydrogen, oxygen, sulfurand nitrogen in alloy to generate a chemical compound with a low density and a low melting point, and bubbles and other defects of metal are eliminated. Pt and Ir are likely to form a Pt-Ir binary alloy phase, the expansion coefficient is small, and thus the capacity to resist thermal expansion and cold contraction of aluminum alloy can be improved. Meanwhile, grains are refined through solid solution treatment and aging treatment, so that the alloy has a good mechanical property. A uniform and compact ceramic-like film is formed on the surface of a product through micro-arc oxidation, and thus the product has extremely high resistance in complex and changeable environments.

Owner:NINGBO SHENGHONG MACHINERY EQUIP

Ferritic stainless steel for tubular heat exchanger and manufacturing method thereof

The invention relates to a ferritic stainless steel for tubular heat exchangers and a manufacturing method thereof. The ferritic stainless steel comprises the following chemical components in percentage by weight: at most 0.015% of C, at most 0.020% of N, at most 0.5% of Si, at most 0.5% of Mn, at most 0.035% of P, at most 0.01% of S, 22-24% of Cr, 1.5-3.0% of Mo, 0.0050-0.050% of Al, and the balance of Fe and inevitable impurities, wherein 10(C+N)<=(Nb+Ti)<=0.6%. The manufacturing method comprises the following steps: smelting by an arc furnace+AOD (argon oxygen decarburization)+VOD (vacuum oxygen decarburization) three-step process, carrying out continuous casting to obtain a continuous casting blank, and carrying out hot rolling, acid washing, cold rolling, annealing, acid washing and the like to obtain the high-weldability cold-rolled stainless steel sheet strip. The high-weldability cold-rolled stainless steel sheet strip is suitable for manufacturing welded tubes with higher requirements for corrosion resistance and flaring performance; and the flaring ratio is up to higher than 35%.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

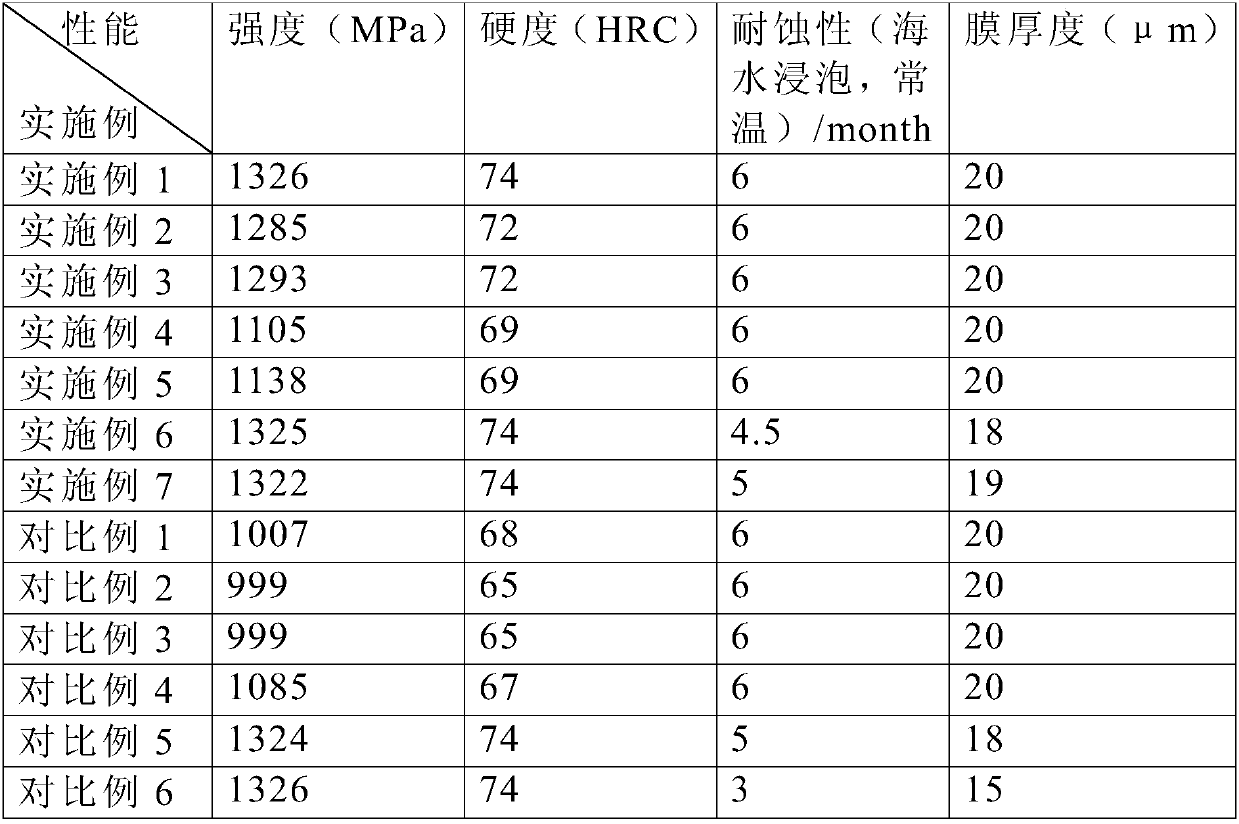

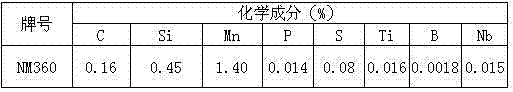

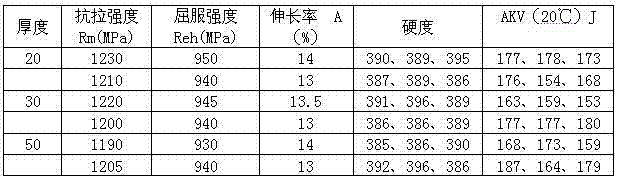

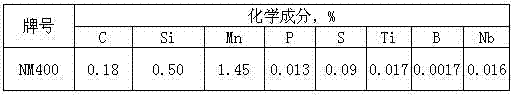

Method for producing wear-resisting steel plate

The invention relates to a method for producing a wear-resisting steel plate. Steel comprises the following chemical ingredients in percentage by mass: 0.15 to 0.20 percent of C, 0.4 to 0.7 percent of Si, 0.7 to 1.50 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.020 to 0.10 percent of Ti, 0.0005 to 0.0020 percent of B, 0.010 to 0.020 percent of Nb and the balance of Fe and inevitable impurities. A production process for the steel comprises the following steps of: desulfurizing by molten iron, smelting by a converter, refining, casting continuously, rolling and performing quenching-carbon partition (Q-P) treatment. In the ingredients of the wear-resisting steel, a C-Si-Mn-Nb-Ti ingredient system and the Nb and Ti micro alloy treatment are adopted, the hardenability of the steel is improved by adding B, an appropriate heat treatment process is adopted to ensure that the steel plate has high plasticity and toughness, and the impact energy of the steel plate is improved by over one time; and the heat treatment is performed by a Q-P process, lath martensite and lath retained austenite (between 5 and 10 percent) are formed and 50 to100 nanometers of carbide complex tissue is precipitated, so that the tissue is fine and uniform, and the tenacity of the steel plate is high.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

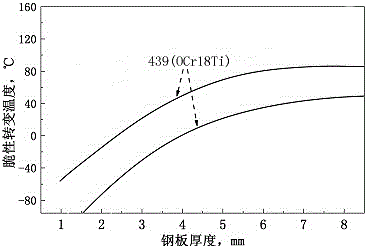

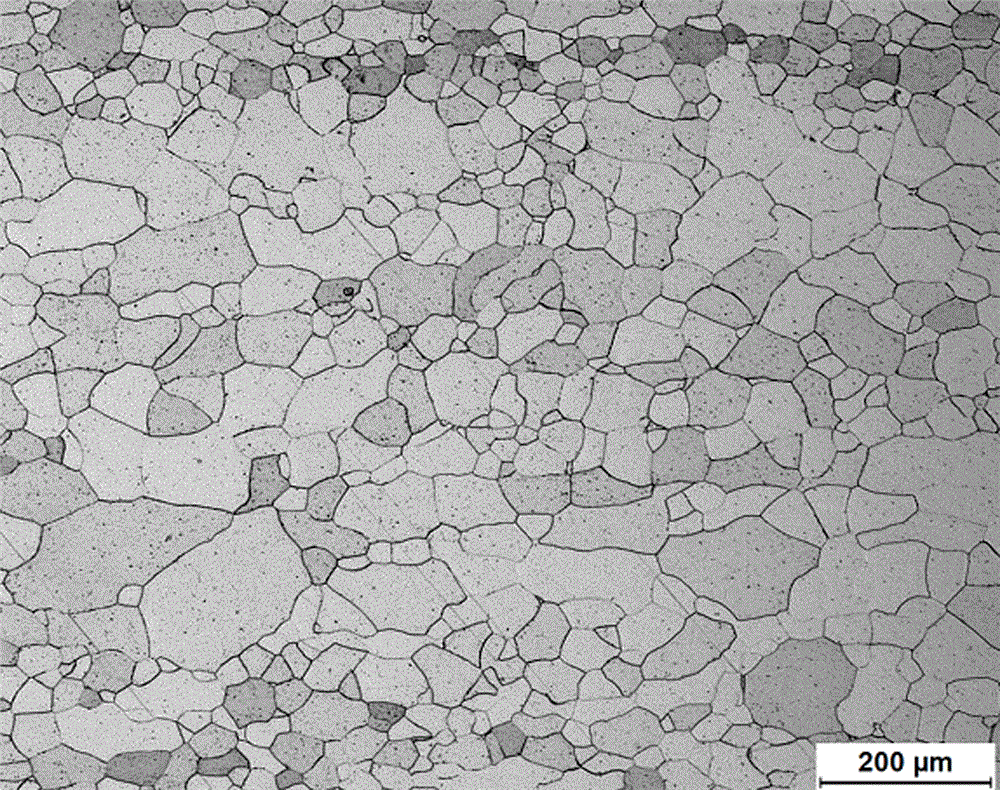

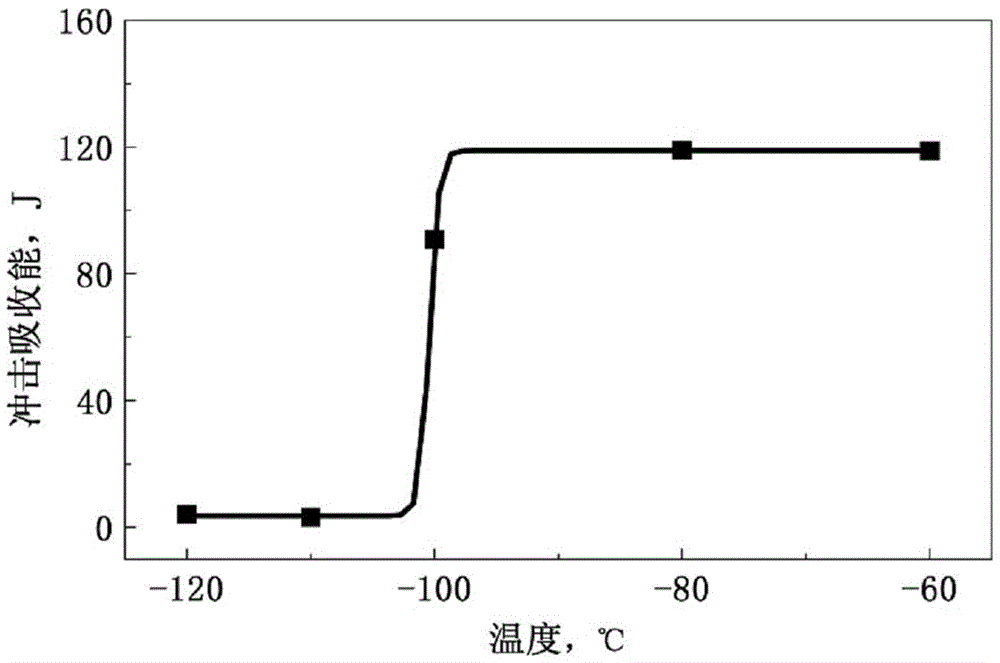

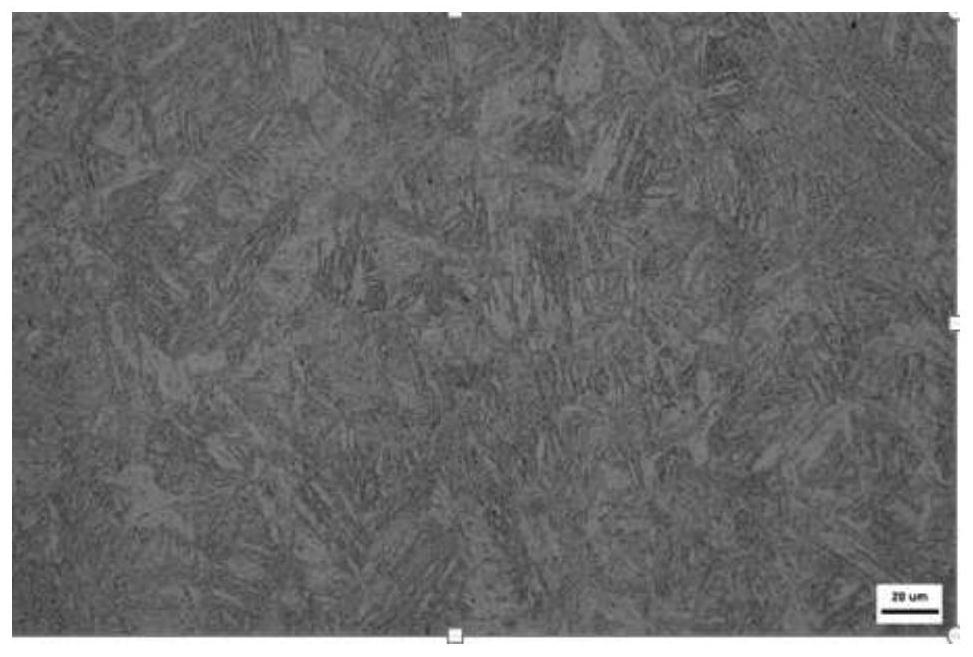

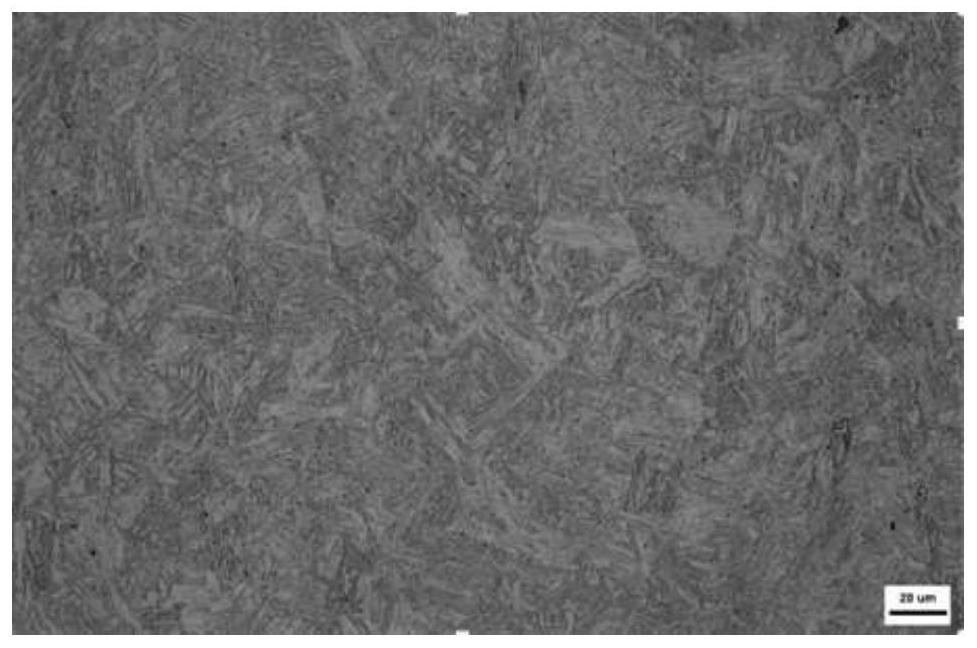

Medium-chromium molybdenum-free ferritic stainless steel extremely low in brittle transition temperature and preparation method thereof

ActiveCN106399833ALower brittle transition temperatureLower life cycle costsTransition temperatureImpurity

The invention discloses medium-chromium molybdenum-free ferritic stainless steel extremely low in brittle transition temperature and a preparation method thereof. The medium-chromium molybdenum-free ferritic stainless steel comprises, by mass percentage, 0.005-0.015% of C, 0.005-0.015% of N, less than or equal to 0.5% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, less than or equal to 0.01% of S, less than or equal to 0.005% of O, 18-22% of Cr, 0.08-0.18% of Nb, 0.05-0.1% of Ti, 0.2-0.4% of Ni, 0.1-0.2% of Al, 0.3-0.5% of Cu and the balance iron and inevitable impurities, wherein the brittle transition temperature ranges from minus 120 DEG C to minus 100 DEG C. The preparation method comprises the steps of 1, conducting smelting and pouring in a vacuum induction smelting furnace; 2, heating the materials to 1000-1200 DEG C, preserving the temperature for 60-150 minutes, and then conducting hot rolling, wherein the accumulative reduction amount is 96-98%; and 3, heating the materials to 850-950 DEG C, and preserving the temperature for 6-8 minutes. By means of the method, the service life of the medium-chromium molybdenum-free ferritic stainless steel in a severe service environment such as the low temperature environment is prolonged, and safety of the medium-chromium molybdenum-free ferritic stainless steel is improved; steel production cost is lowered; and the targets that in stainless steel production, resources are saved, energy is saved, emission is reduced, and environmental pollution is prevented are finally achieved.

Owner:NORTHEASTERN UNIV

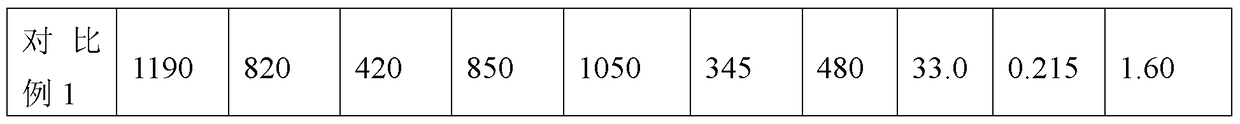

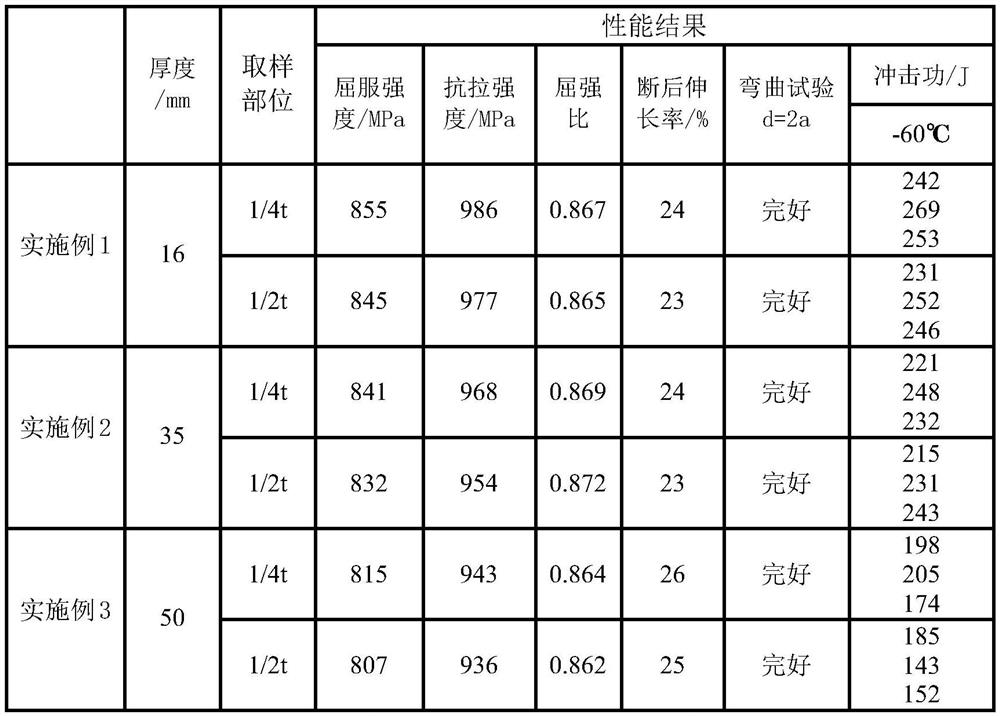

Medium carbon ferromanganese medium-thick steel for 800MPa engineering machinery and manufacturing method of medium carbon ferromanganese medium-thick steel

The invention discloses medium carbon ferromanganese medium-thick steel for 800MPa engineering machinery and a manufacturing method of the medium carbon ferromanganese medium-thick steel, and relatesto the technical field of iron and steel smelting. The medium carbon ferromanganese medium-thick steel comprises the chemical components in percentage by mass of 0.05%-0.08% of C, 4.8%-5.8% of Mn, 0.10%-0.35% of Si, P being smaller than or equal to 0.010%, S being smaller than or equal to 0.003%, 0.01%-0.05% of Ti, 0.7%-1.2% of Ni+Cr+Mo, and balance Fe and inevitable impurities. The medium carbonferromanganese medium-thick steel can have excellent core mechanical properties than common 800MPa high-intensity structural steel, and requirements for extra-high-intensity steel safety performance and low manufacturing cost in the engineering machinery trade under complete adverse environment, can be met.

Owner:NANJING IRON & STEEL CO LTD

Production method of super-thin diamond frame saw blade matrix

ActiveCN102211232ASolve rigid problemsIncrease contentMetal sawing tool makingResource consumptionSquare meter

The invention relates to a production method of super-thin diamond frame saw blade matrix which comprises the following steps of: selecting steel materials containing nickel to be the material of the matrix, preparing a matrix blank with a given size according to different scale requirements of saw blade; laminating the surface of the matrix blank to improve the intensity of the material; punching riveting holes at two ends of the matrix; riveting dovetail fixed plates at two ends of the matrix, so as to obtain a frame saw blade matrix 1.8 mm in thickness. In the invention, the problems that the rigidity and toughness are not enough are solved by changing material and using new tension processing method, so that the super-thin diamond frame saw blade matrix 1.8 mm in thickness is obtained, and the area of the plates produced in the grouping use process is more than 10 square meters than the plate area of the plates produced by cutting the same scale of rough stone blocks in conventional thickness diamond frame saw blade matrix; simultaneously, the weight of the matrix is reduced as the thickness of the matrix is reduced; the steel resource consumption of products and the energy consumption during the use process of the matrix are reduced, and the effect for saving energy and reducing consumption is achieved.

Owner:HEIXUANFENG SAW IND

Low-temperature additive manufacturing wire capable of controlling grain size as well as preparation and application thereof

ActiveCN113319429AGuaranteed tensile strengthGuaranteed SolderabilityAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyAdditive layer manufacturing

The invention discloses a low-temperature additive manufacturing wire capable of controlling the grain size as well as preparation and application of the low-temperature additive manufacturing wire. The low-temperature additive manufacturing wire comprises, by mass: 0.03%-0.10% of C, less than or equal to 0.4% of Si, 0.5%-1.5% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.07%-0.12% of Nb, 1.6%-4.0% of Ni, less than or equal to 0.4% of Mo, 0.01%-0.20% of Cr, less than or equal to 0.02% of V, less than or equal to 0.05% of Al, less than or equal to 0.03% of Cu, 0.006%-0.02% of Ti, less than or equal to 0.005% of B, and the balance Fe. The wire has good impact toughness under different additive manufacturing processes, the change of low-temperature toughness along with temperature is small, and the wire can be used for additive manufacturing of products in the field of oil and gas transportation in a low-temperature environment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

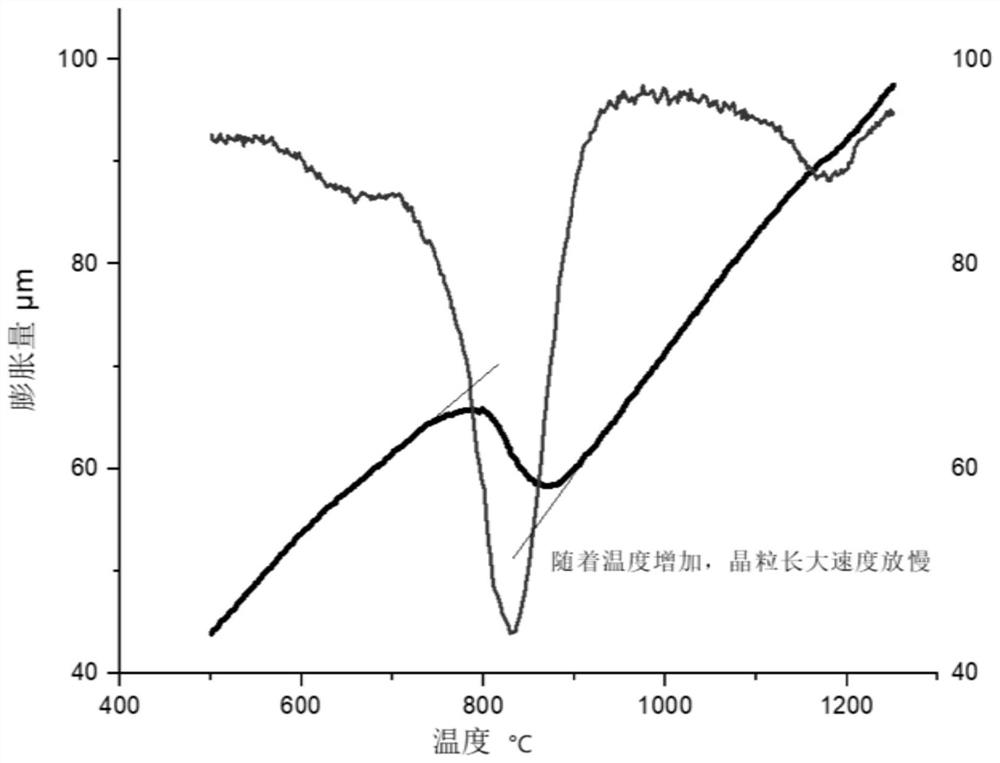

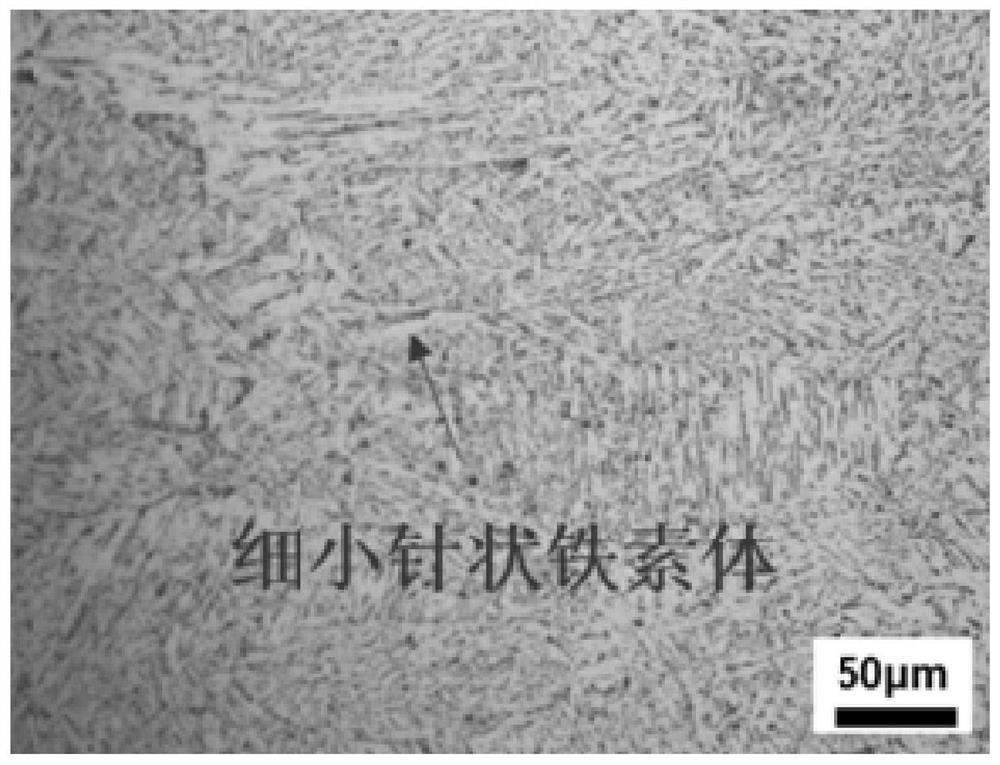

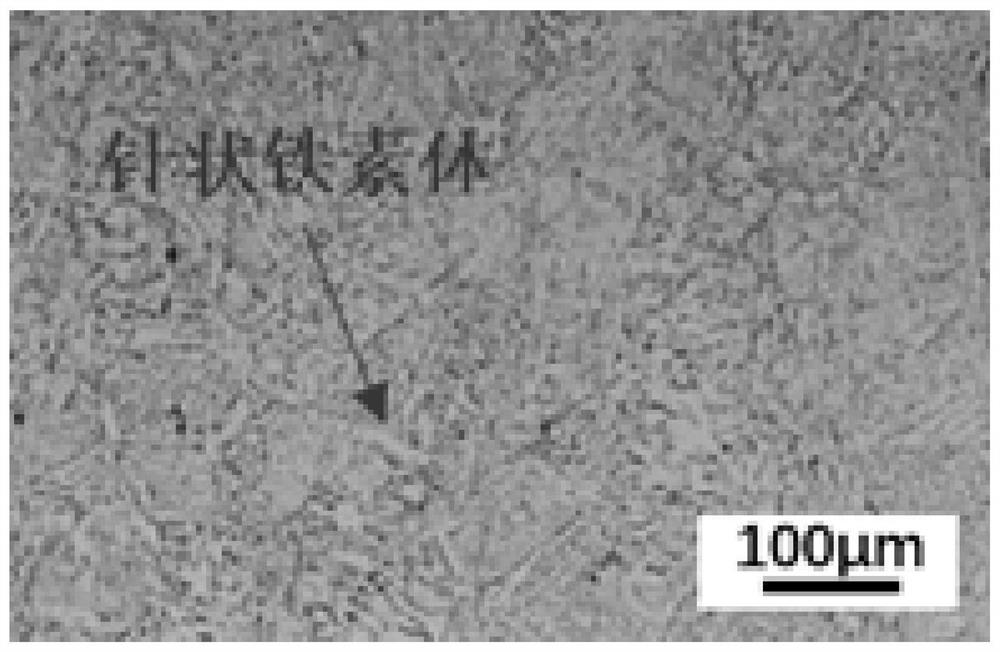

A flux-cored welding wire for 620mpa low-temperature steel and its welding method

ActiveCN106825992BWeld impact toughness decreasedLower brittle transition temperatureWelding/cutting media/materialsSoldering mediaPotassiumManganese

The invention provides a flux-cored wire for 620 MPa-level low-temperature steel. The flux-cored wire for 620 MPa-level low-temperature steel comprises carbon steel skin and a flux core arranged in the carbon steel skin. The flux core comprises the following raw material components, by mass percent, 36%-42% of rutile, 2%-5% of ferromolybdenum, 2%-4% of zircon sand, 15%-20% of electrolytic manganese, 5%-6% of calcium fluoride, 1.5%-3% of an aluminum magnesium alloy, 10%-12% of silicon iron, 3%-5% of ferrotitanium, 1.5%-3% of potassium fluoborate, 9%-10% of nickel powder and the balance ferrous powder and unavoidable impurities. The flux-cored wire for the 620 MPa-level low-temperature steel utilizes CO2 protective gas for welding and has excellent welding process performance and comprehensive performance of deposited metal and a welded joint. The yield strength is larger than or equal to 540 MPa, the extension strength is larger than or equal to 620 MPa, the elongation is larger than or equal to 20%, and under the condition of -60 DEG C, Akv is larger than or equal to 54 J.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Ferrite stainless steel for buildings and preparation method thereof

ActiveCN102234738BImprove corrosion resistanceReduce glossTemperature control deviceFurnace typesMetallurgyChemical element

The invention discloses ferrite stainless steel for buildings. The ferrite stainless steel comprises the following chemical elements in percentage by mass: less than or equal to 0.015 percent of C, less than or equal to 0.020 percent of N, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.010 percentof S, more than 21.5 percent and less than 23.5 percent of Cr, more than 1.0 percent and less than 3.0 percent of Mo, more than or equal to 0.35 percent and less than or equal to 0.6 percent of Nb, less than or equal to 0.2 percent of Ti and the balance of Fe and other inevitable impurities, wherein (Nb+Ti) is more than or equal to 16(C+N) and less than or equal to 0.6 percent. Correspondingly, the invention further provides a method for preparing the stainless steel for buildings. Compared with the conventional stainless steel for buildings, the ferrite stainless steel has the advantages of excellent corrosion-resistant effect, low surface gloss, good scattered reflection effect, difficulty in deformation of steel plates, low cost and very good application effect.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Stainless steel plate for fuel tank of automobile and manufacturing method thereof

InactiveCN102312165AImprove corrosion resistanceBrittle transition temperature improvementUnderstructuresChemical compositionFuel tank

The invention relates to a stainless steel plate for a fuel tank of an automobile and a manufacturing method thereof. The stainless steel plate comprises the following chemical components, by weight, more than zero and equal to or less than 0.02% of C, 0.10-0.60% of Si, 0.10-0.60% of Mn, 19.0-24.0% of Cr, equal to or less than 0.020%, equal to or less than 0.010%, more than zero and equal to or less than 0.020%, 0.3-0.4% of Ti, 0.9-1.0% of Nb, and the balance Fe and avoidless impurities. The manufacturing method sequentially comprises the following steps: I, smelting a billet: carrying out primary smelting on molten iron and a chromium alloy with a K-OBM-S converter, carrying out refine processing with a VOD furnace, and casting into a casting billet when the component of molten steel reaches requirements; II, hot rolling the casting billet: heating to 1050-1070DEG C, rolling into stainless steel coil, and naturally cooling after hot rolling; and III, cold rolling the steel coil: controlling the roughness Ra of the surface of a cooled plate at 0.03-0.05mum. The stainless steel plate for the fuel tank of the automobile manufactured in the present invention has the advantages of good corrosion resistance and good weldability.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Protective rubber sleeve for low-temperature container junction valves

The invention relates to the technical field of low-temperature materials, specifically to a protective rubber sleeve for low-temperature container junction valves. The material of the protective rubber sleeve comprises the following ingredients: butyl rubber, cold-resistant modified natural rubber, fluorinated silicone rubber, a chlorosulfonated polyethylene elastomer, hydroxypropyl methacrylate,carbon black, nano-zinc oxide, stearic acid, a vulcanizing agent, a promoter, a silane coupling agent and an anti-aging agent, wherein the vulcanizing agent used in the ingredients is sulphur; the promoter is one of a promoter TE, a promoter ZIP and a promoter NA-22; and the anti-aging agent is a mixture of an anti-aging agent AW and an anti-aging agent PPD mixed according to the mass ratio of 1:3. The protective rubber sleeve is prepared from a low temperature resistant rubber material. By a new formula for preparation of the low temperature resistant rubber, brittle transition temperature of the material is remarkably reduced.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

High-temperature-resistant seamless steel pipe and preparation method thereof

ActiveCN113106347AHigh mechanical strengthAntioxidant is goodChemical compositionOxidation resistant

The invention relates to the technical field of steel pipes, in particular to a high-temperature-resistant seamless steel pipe and a preparation method thereof. The high-temperature-resistant seamless steel pipe comprises the chemical components in percentage by mass: 0.12%-0.22% of C, 0.5%-0.8% of Mn, 0.5%-1.5% of Si, 8%-12% of Cr, 22%-30% of Ni, 0.05%-0.15% of Ti, 0.02%-0.05% of V, 0.05%-0.2% of Cu, 0.18%-0.25% of W, 0.005%-0.02% of Pt, 0.05%-0.1% of Mo, 0.002%-0.01% of Os, 0.005%-0.05% of Nb, 0.005%-0.02% of Re, 0.005%-0.02% of Zr, 0.015%-0.02% of Ta, smaller than or equal to 0.02% of P, smaller than or equal to 0.005% of S and the balance of Fe and inevitable impurities. The seamless steel pipe prepared by the method is excellent in high-temperature resistance and mechanical strength, also has better oxidation resistance and corrosion resistance, the method is simple in production and preparation process and suitable for large-scale production, and the problems of poor high-temperature resistance and mechanical strength and complex preparation process of seamless steel in the prior art are solved.

Owner:无锡恒丰祥钢管科技有限公司

Production method of super-thin diamond frame saw blade matrix

ActiveCN102211232BSolve rigid problemsIncrease contentMetal sawing tool makingResource consumptionSquare meter

The invention relates to a production method of super-thin diamond frame saw blade matrix which comprises the following steps of: selecting steel materials containing nickel to be the material of the matrix, preparing a matrix blank with a given size according to different scale requirements of saw blade; laminating the surface of the matrix blank to improve the intensity of the material; punching riveting holes at two ends of the matrix; riveting dovetail fixed plates at two ends of the matrix, so as to obtain a frame saw blade matrix 1.8 mm in thickness. In the invention, the problems that the rigidity and toughness are not enough are solved by changing material and using new tension processing method, so that the super-thin diamond frame saw blade matrix 1.8 mm in thickness is obtained, and the area of the plates produced in the grouping use process is more than 10 square meters than the plate area of the plates produced by cutting the same scale of rough stone blocks in conventional thickness diamond frame saw blade matrix; simultaneously, the weight of the matrix is reduced as the thickness of the matrix is reduced; the steel resource consumption of products and the energy consumption during the use process of the matrix are reduced, and the effect for saving energy and reducing consumption is achieved.

Owner:HEIXUANFENG SAW IND

00Cr18Mo2 stainless steel pipe billet and manufacture method thereof

Owner:常熟市长江不锈钢材料有限公司

Robot cover plate and preparation technology thereof

ActiveCN108034861AEliminate internal stressReduce residual stressAnodisationPolyamide coatingsManganeseMechanical property

The invention discloses a robot cover plate and a preparation technology thereof, and belongs to the technical field of metal materials. The raw materials of the cover plate comprise the following components, by weight percentage, 0.1-0.3% of Ba, 0.4-0.6% of Ge, 0.3-0.5% of Zn, 0.04-0.06% of Co, 0.3-0.5% of Fe, 0.6-0.8% of Mn, and the balance Al and impurities. According to the robot cover plate and the preparation technology thereof, the Ge in the raw materials is an important component for improving internal alloy phase flow of an aluminum alloy so that an alloy phase can obtain the best fluidity from hypereutectic to eutectic; in addition, the Ge can also improve the tensile strength, the hardness, the machinability and the high temperature strength of the aluminum alloy; the Mn can eliminate the brittleness-increasing damage of the Fe to the alloy, and the effect of enhancing the mechanical property of the Fe to the aluminum alloy can be maintained; and meanwhile, by means of a mode that a cover plate body and a high polymer layer outside the cover plate body are combined, a product can be endowed with excellent surface corrosion resistance and wear resistance.

Owner:泰安泰山科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com