00Cr18Mo2 stainless steel pipe billet and manufacture method thereof

A 00cr18mo2, stainless steel tube technology, applied in the field of stainless steel materials, can solve the problems of large power consumption, high content of non-metallic inclusions, large material consumption, etc., and achieve the effect of saving resources, saving energy and fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

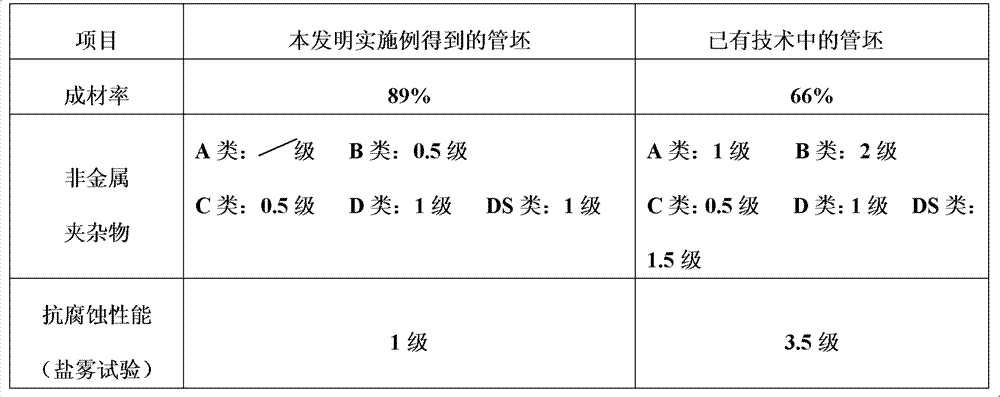

Examples

Embodiment 1

[0024] To manufacture a circular cross-sectional shape and a diameter (outer diameter) of 00Cr18Mo2 stainless steel tube blank as an example:

[0025] A) smelting, stainless steel scrap steel, carbon steel scrap steel and ferroalloy are put into the intermediate frequency furnace for primary refining to obtain the primary molten steel, and the initial molten steel is sampled and analyzed and the mass % content of the chemical elements of the primary molten steel is adjusted to be adjusted to : 1.70% by mass of carbon, 0.75% by mass of silicon, 0.43% by mass of manganese, 0.023% by mass of phosphorus and 0.016% by mass of sulfur, 18.50% by mass of chromium and 1.78% by mass of molybdenum, The balance is iron. After the above-mentioned sampling and adjustment of chemical elements, the primary molten steel is mixed into AOD refining. The refining temperature of AOD refining is controlled at 1630 ° C. The refining time of AOD refining is controlled at 45 minutes. In the process ...

Embodiment 2

[0030] Still manufactured with a circular cross-sectional shape and a diameter (outer diameter) of 00Cr18Mo2 stainless steel tube blank as an example:

[0031] A) smelting, stainless steel scrap steel, carbon steel scrap steel and ferroalloy are put into the intermediate frequency furnace for primary refining to obtain the primary molten steel, and the initial molten steel is sampled and analyzed and the mass % content of the chemical elements of the primary molten steel is adjusted to be adjusted to : 1.75% by mass of carbon, 0.78% by mass of silicon, 0.45% by mass of manganese, 0.022% by mass of phosphorus, 0.013% by mass of sulfur, 18.65% by mass of chromium and 1.75% by mass of molybdenum, The balance is iron. After the above-mentioned sampling and adjustment of chemical elements, the primary molten steel is mixed into AOD refining. The refining temperature of AOD refining is controlled at 1680 ° C. The refining time of AOD refining is controlled at 40 minutes. In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com