Duplex stainless steel master alloy and preparation method thereof

A duplex stainless steel and master alloy technology, which is applied in the field of high-performance stainless steel master alloy and its preparation, duplex stainless steel master alloy and its preparation, can solve the problems of unsatisfactory mechanical properties and characteristics, and achieve the improvement of toughness and strength. Effect of low mechanical properties and brittle transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

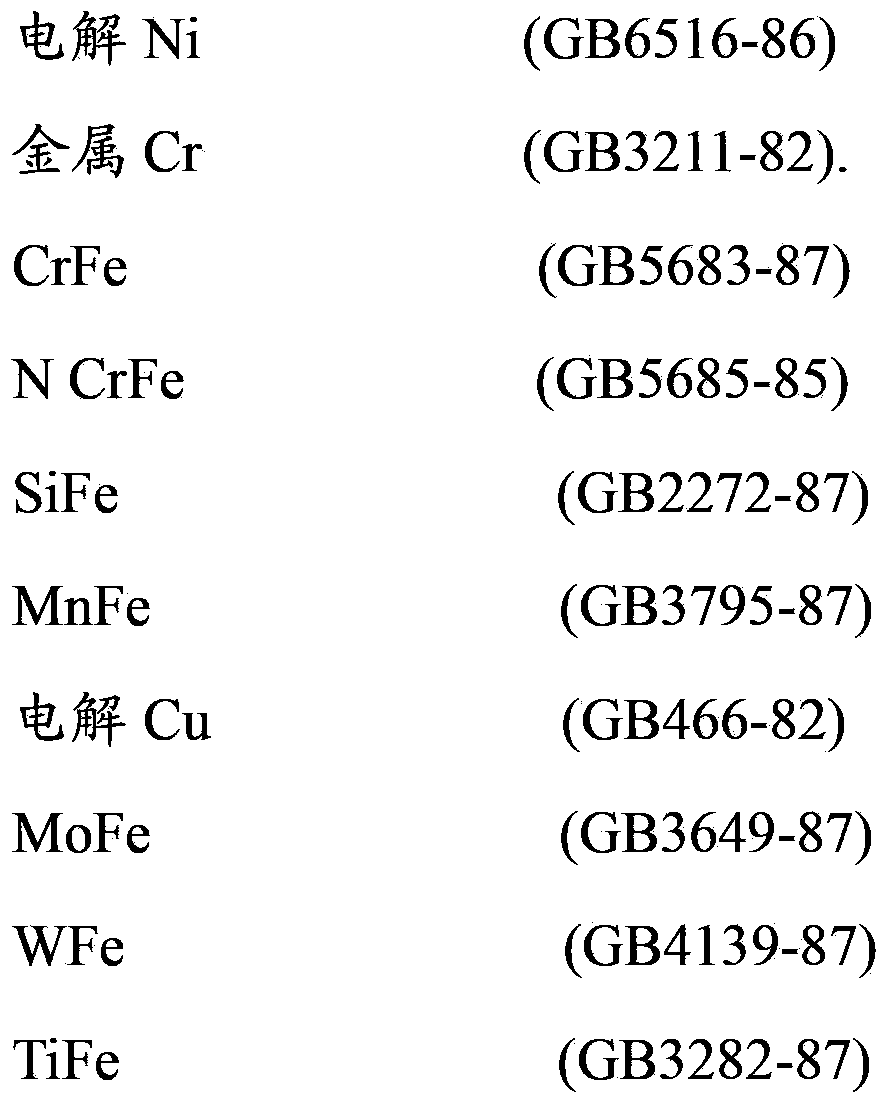

Method used

Image

Examples

Embodiment 1-4

[0024] Embodiment 1-4 (without adding trace elements)

[0025] In the vacuum induction furnace, each of Examples 1, 2, and 3 was completed, and each 25 kg steel ingot was smelted.

Embodiment 1

[0026] Example 1 and Example 2 are deformed by thermal processing at 1080°C, Example 3 is cast state, Example 4 is non-vacuum intermediate frequency melting, the chemical composition of the mother liquor is controlled by AOD, and then horizontal continuous casting is performed to form a round rod with a diameter of 100mm (as-cast structure).

[0027] According to GB / T20123-2006 analysis: carbon (C); according to GB / T20124-2006 analysis: nitrogen (N); according to GB / T11170-2008 analysis: Cr, Mn, Mo, Ni, S, P, Si. Mechanics and mechanical properties are tested according to GB / T2281-2010, and the mechanical properties of the four examples are tested after heating at 1050°C-1100°C, quenching, and solution heat treatment.

[0028] The test results are shown in Table 1

[0029] Table 1

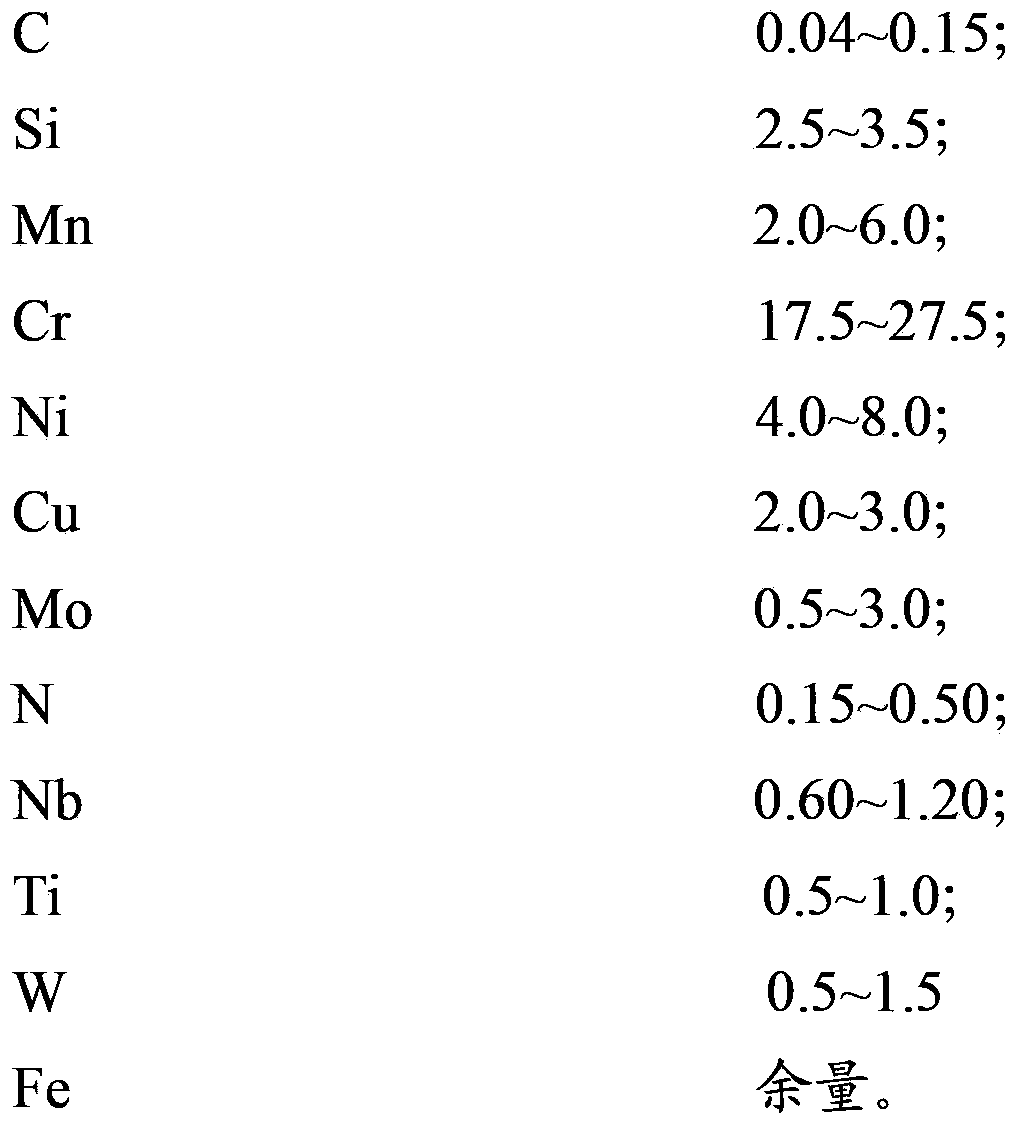

[0030] element Example 1 Example 2 Example 3 Example 4 C 0.04 0.05 0.07 0.08 Si 2.53 2.60 3.01 3.34 mn 2.73 3.09 3.78 4.01 Cr 23.56 24.89 25.53 ...

Embodiment 5-10

[0031] Embodiment 5-10 (addition of trace elements)

[0032] The chemical composition of Example 4 is selected, and its size is a round rod with a diameter of 100 mm. The process is a duplex stainless steel master alloy produced by a non-vacuum intermediate frequency furnace + AOD blowing + horizontal continuous casting. Add trace elements and remelt into Example 5, Example 6 (modified form) and Example 7, Example 8 (cast state)

[0033] Similarly, the chemical composition and mechanical properties of Example 5, Example 6, Example 7, and Example 8 were analyzed by testing the methods of Examples 1-4 and standard detection.

[0034] The test results are shown in Table 2

[0035] Table 2

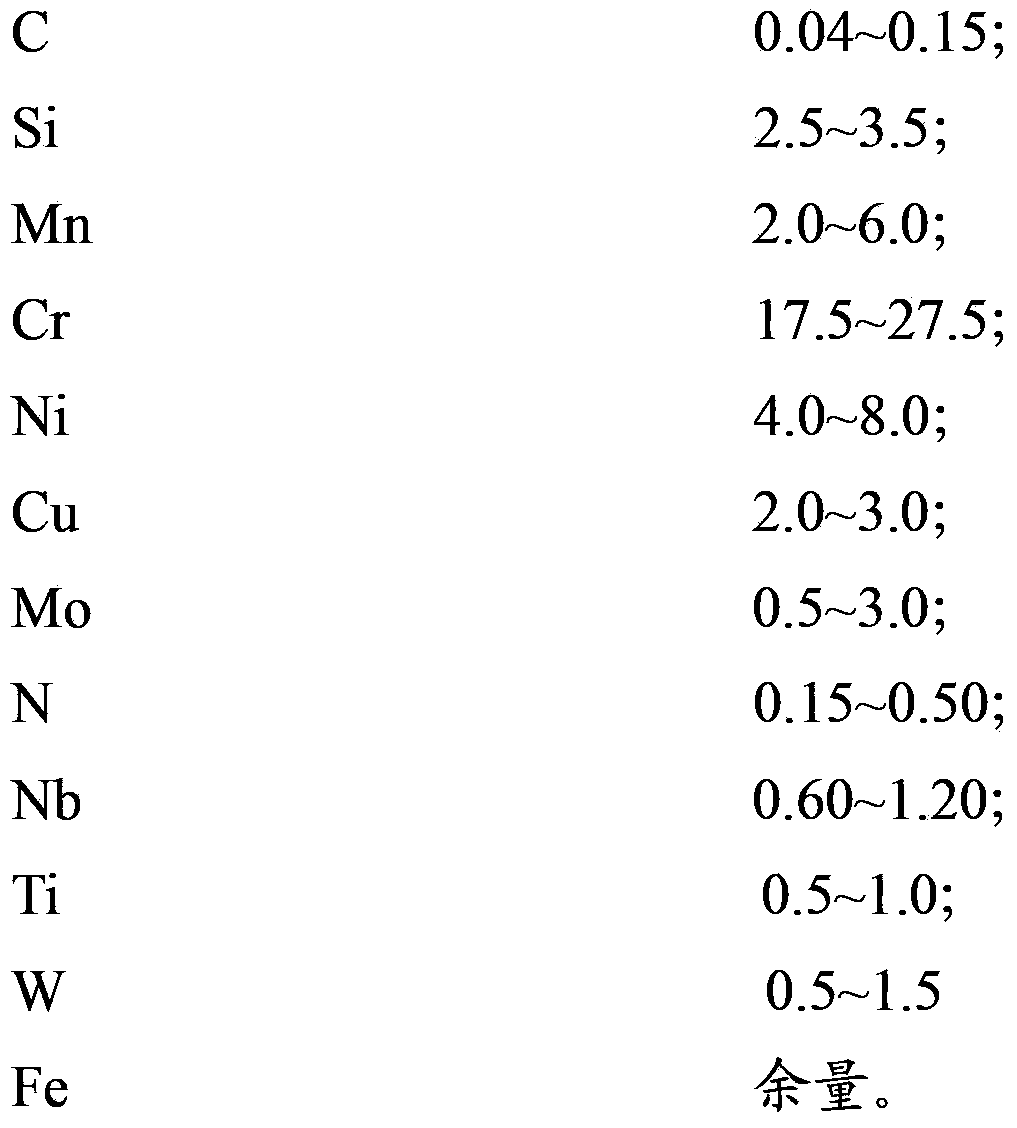

[0036] element Example 5 Example 6 Example 7 Example 8 C 0.08 0.08 0.09 0.10 Si 3.01 3.10 3.21 3.15 mn 4.01 4.12 4.08 4.30 Cr 25.01 25.24 25.50 25.07 Ni 5.78 5.49 5.86 5.64 Cu 2.10 2.22 2.31 2.19 N 0.21 0.25 0.22 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com