Flux-cored wire for 620 MPa-level low-temperature steel and welding method of flux-cored wire

A technology of flux-cored welding wire and low-temperature steel is applied in the field of welding material manufacturing, which can solve the problems of inability to solve the problem of low-temperature toughness, difficult to guarantee low-temperature toughness, poor stability of strengthening effect, etc., and achieve the effect of excellent welding process performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 620

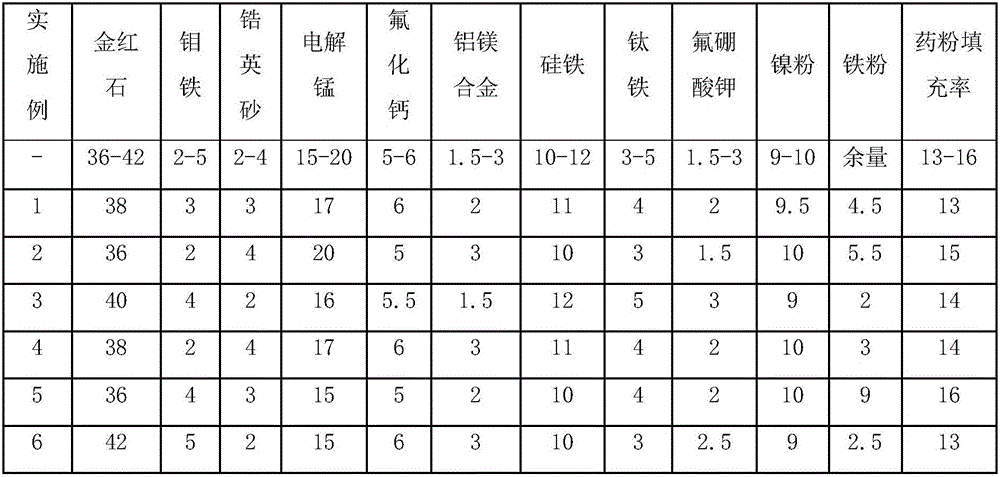

[0026] Example 620 MPa low-temperature steel flux-cored wire formula is shown in Table 1, and the carbon steel sheath is SPCC steel strip, which is produced by conventional flux-cored wire manufacturing process. Table 2 shows the chemical composition and mechanical properties of the deposited metal of the corresponding embodiment flux-cored wire; its welding conditions: shielding gas CO 2 The purity is 99.95%, the welding current is 230-250A, the welding voltage is 26-28V, and the welding speed is 20-40mm / min.

[0027] Table 1: Flux cored wire formula (mass percentage)

[0028]

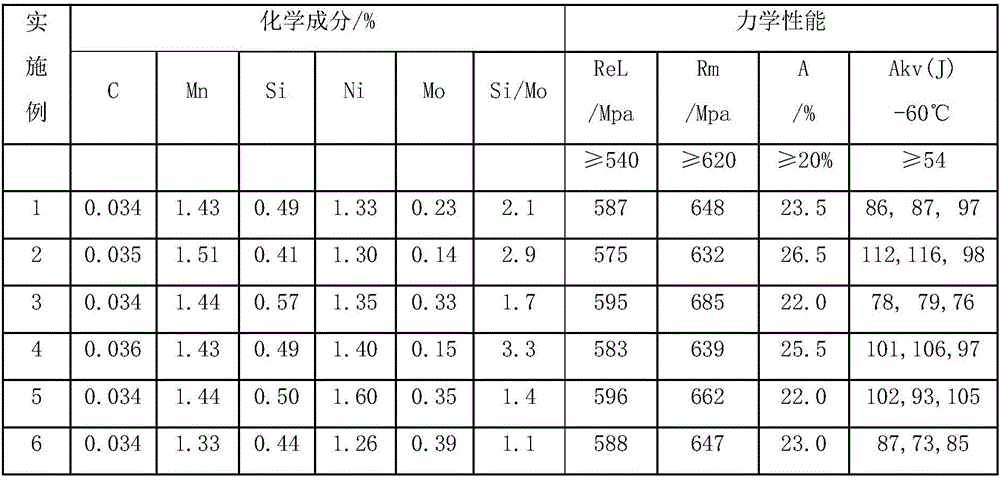

[0029] Table 2: Chemical composition and mechanical properties of deposited metal

[0030]

[0031] From the chemical composition and mechanical properties of the examples shown in Table 1 and Table 2, it can be concluded that the flux-cored welding wire of the present invention uses CO 2 Comprehensive properties of shielding gas welding, deposited metal and welded joints: yield strength ReL≥5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com