Ferritic stainless steel for tubular heat exchangers and manufacturing method thereof

A tubular heat exchanger and a manufacturing method technology are applied in the field of ferritic stainless steel for tubular heat exchangers and its manufacturing, which can solve the problem of not involving the welding performance of ferritic stainless steel and the flaring performance of welded pipes, and it is difficult to meet the requirements of heat exchangers. The requirements of pitting corrosion resistance and the low chromium content of ferritic stainless steel can achieve the effect of improving intergranular corrosion resistance, improving plasticity and excellent stress corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

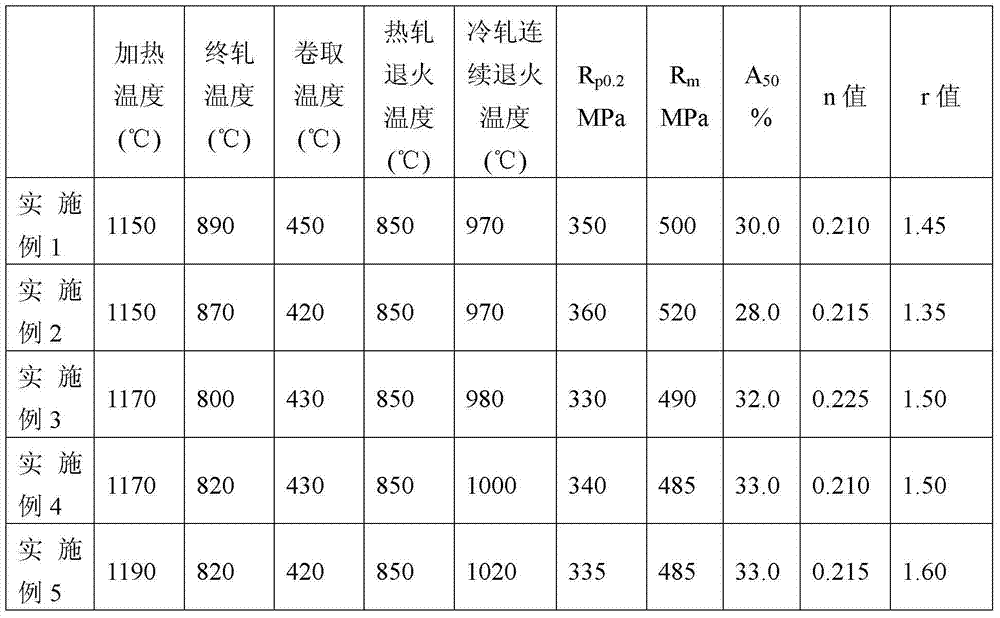

Examples

Embodiment 1

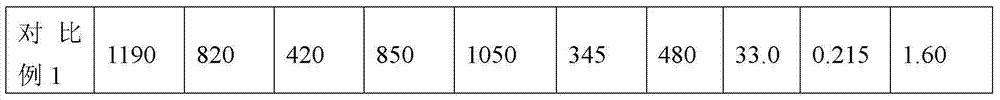

[0064] Table 3 shows the base metal and weld cup of Example 1. It can be seen that the cupping of the weld is slightly lower than that of the base metal, with a difference of 8%. The lower difference ensures that the weld does not crack during the flaring process, thereby increasing the flaring rate.

[0065] Table 3. Base metal and weld cupping values

[0066]

[0067] The obtained stainless steel plate is welded by argon tungsten arc welding in a welded pipe production line to form a welded pipe. The welding parameters are shown in Table 4. Bright annealing after welding. In Example 1, due to the double stabilization of Ti and Nb, TiN is used as nucleation particles to refine the structure of the weld seam, and the expansion rate of the welded pipe reaches more than 35%. In comparative example 1, Nb monostabilization was used, and the weld microstructure was developed columnar crystals. This is because during welding, the solidification process of the molten pool start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com