Ceramic composite material bullet-proof chest board and preparation method thereof

A ceramic composite material and composite material technology, applied in the field of ceramic composite material bulletproof chest plate and its manufacturing, can solve the problems of loss of mobility, flexibility, loss of original properties of lightweight composite materials, etc., to achieve enhanced bulletproof properties, bulletproof Stable properties and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

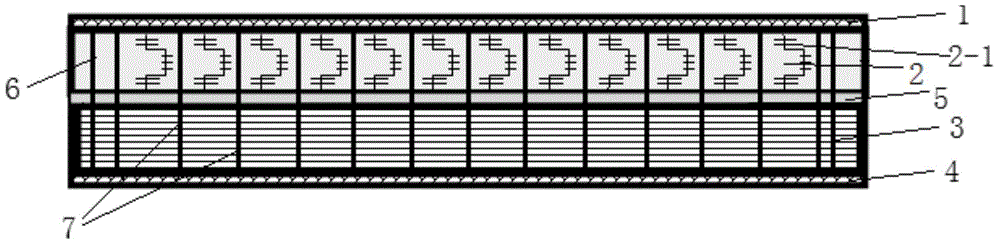

[0037] Such as Figure 1-3 As shown, the ultra-high molecular weight polyethylene fiber with a strength of 40g / d was selected, and the modified polyurethane resin was used to prepare the two-dimensional prepreg. The resin content was 15wt%, and the fiber arrangement was 0° and 90°. After that, a certain number of layers of two-dimensional fabric prepregs are laminated according to the protection level, and the number of layers is 170 layers, and the main layer 3 of the bulletproof fiber composite material is prepared through a molding process. The molding temperature is 140°C, and the pressing time is controlled at 20 minutes.

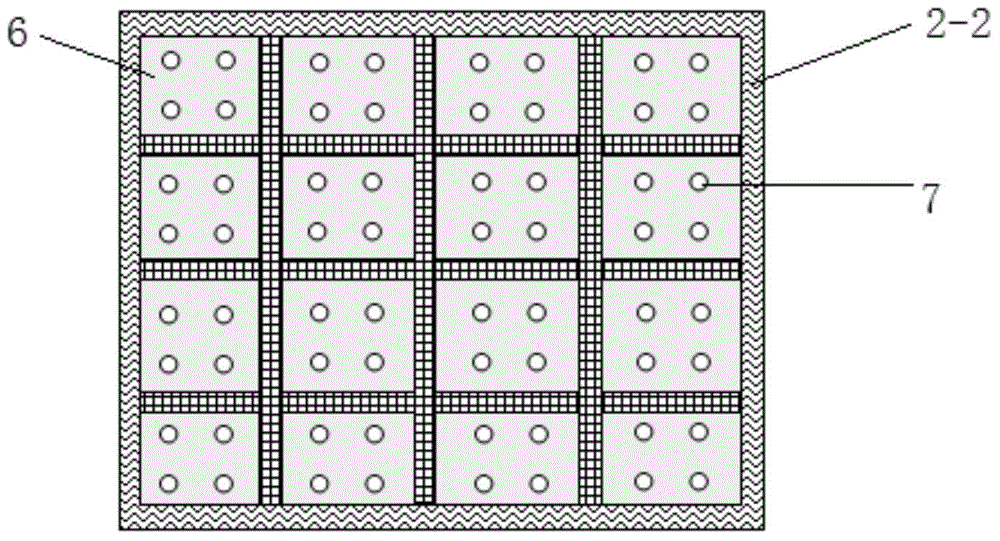

[0038] Carbon fiber and silicon carbide fiber are mixed to form a two-dimensional reinforced fabric, and a silicon carbide matrix is used to form a composite material to prepare a ceramic composite sheet 6, which is square in shape, with a side length of 3 cm, a quantity of 150 pieces, and a single sheet thickness of 6 mm. The edge of the material s...

Embodiment 2

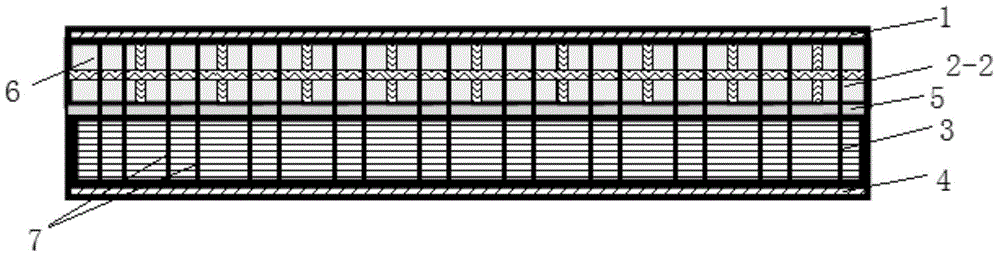

[0042] Aramid fibers with a strength of 35g / d were selected, and two-dimensional prepreg fabrics were prepared using modified polyethylene resins. The resin content was 20wt%, and the fiber arrangement adopted a unidirectional structure. The cloth is laminated in a certain number of layers according to the protection level, and the number of laminated layers is 180, and the main body layer 3 of the bulletproof fiber composite material is prepared through a molding process. The molding temperature is 130° C., and the pressing time is controlled at 50 minutes.

[0043] Carbon fiber and alumina fiber are mixed to form a two-dimensional reinforced fabric, and alumina matrix is used to form a composite material to prepare alumina ceramic composite sheet 6. The shape is hexagonal, the side length is 2cm, the quantity is 140 pieces, and the thickness of each piece is 5mm. The edge of the ceramic composite material sheet 6 is an acupuncture-inserted combined structure 2-1, the conve...

Embodiment 3

[0047] The ultra-high molecular weight polyethylene fiber with a strength of 45g / d was selected, and the modified polyethylene resin was used to prepare a two-dimensional prepreg. The resin content was 25wt%, and the fiber arrangement adopted a unidirectional structure. The fabric prepreg is laminated in a certain number of layers according to the protection level, and the number of laminated layers is 175 layers. The main layer 3 of the bulletproof fiber composite material is prepared by a molding process. The molding temperature is 135° C., and the pressing time is controlled at 40 minutes.

[0048] Carbon fiber and boron nitride fiber are mixed to form a two-dimensional reinforced fabric, and a boron nitride matrix is used to form a composite material to prepare a boron nitride composite ceramic composite sheet 6, which is hexagonal in shape, with a side length of 3 cm, and a quantity of 110 pieces. The thickness of the sheet is 4 mm, and the boron nitride fiber is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com