Packaging method for organic light-emitting diode display

An encapsulation method and electroluminescence technology, which can be applied to electric solid devices, circuits, electrical components, etc., can solve problems such as damage to organic functional layers, and achieve the effects of extending service life, strengthening mechanical strength, and fast packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment first introduces the structure of the OLED of the present invention.

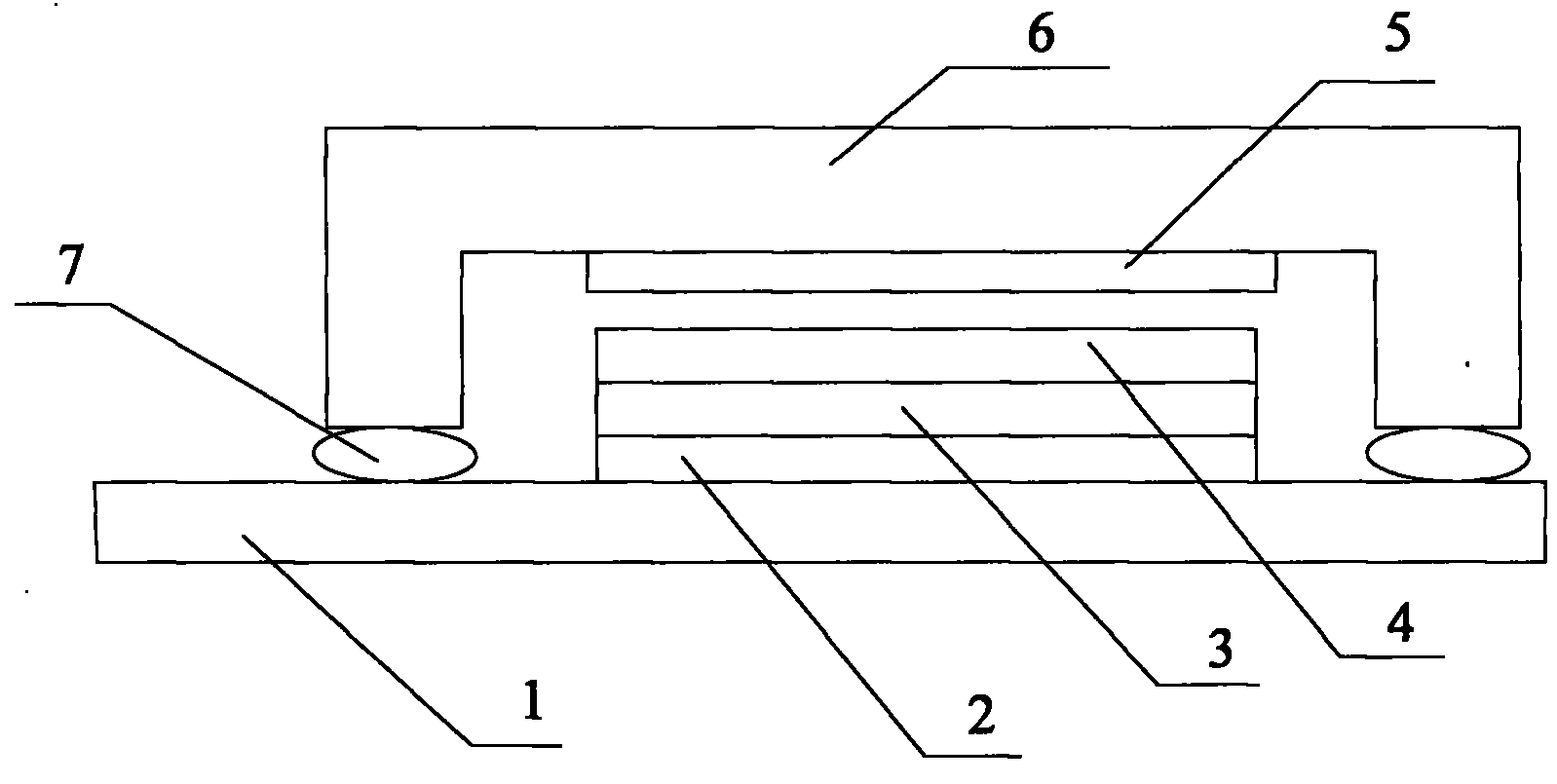

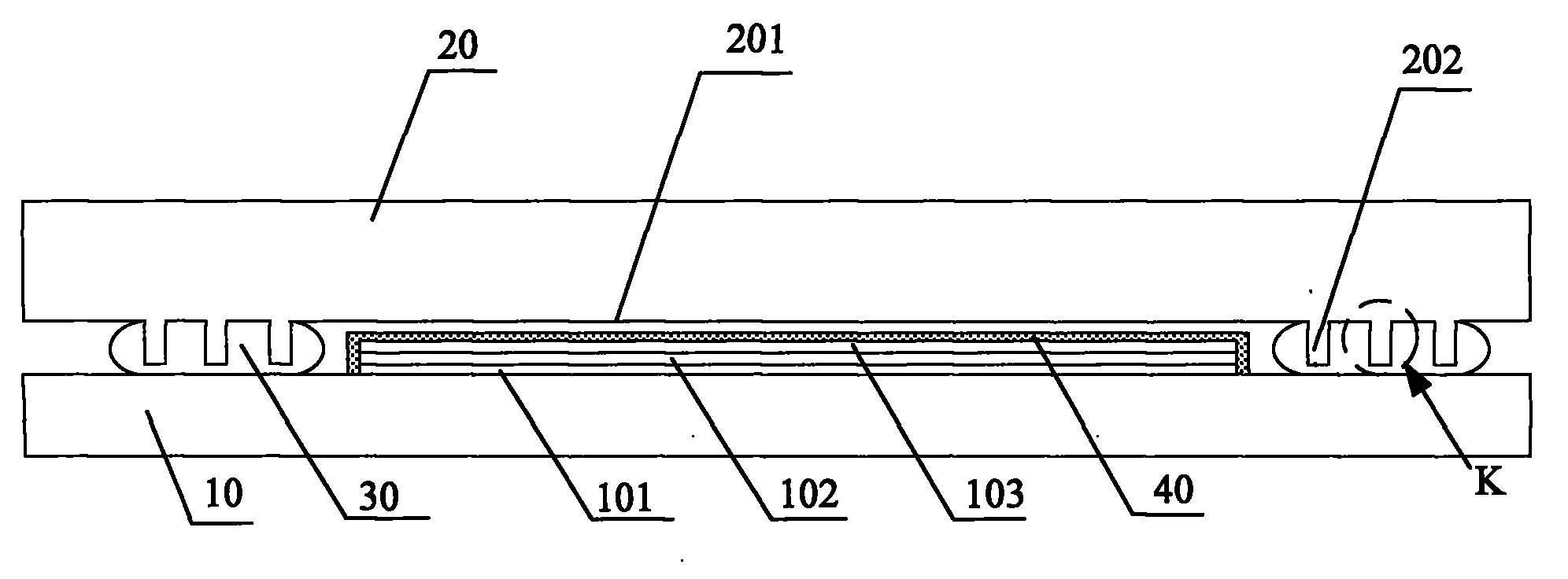

[0034] figure 2 is a schematic cross-sectional view of the OLED of the present invention. The invention provides an OLED, such as figure 2 As shown, the OLED includes: a substrate 10 , a back cover 20 , and an encapsulant 30 .

[0035] A pixel display area matrix is formed on the substrate 10; each pixel display area in the pixel display area matrix includes a transparent anode 101, an organic functional layer 102 and a cathode 103 deposited on the substrate 10 in sequence. The surface of each pixel display area is covered with a water-absorbing protective layer 40; if the special conductive glass is selected for use in the preparation of the substrate 10, the pre-deposited ITO (Indium Tin Oxide, indium tin oxide) coating on the conductive glass can be used as The anode of the OLED is used.

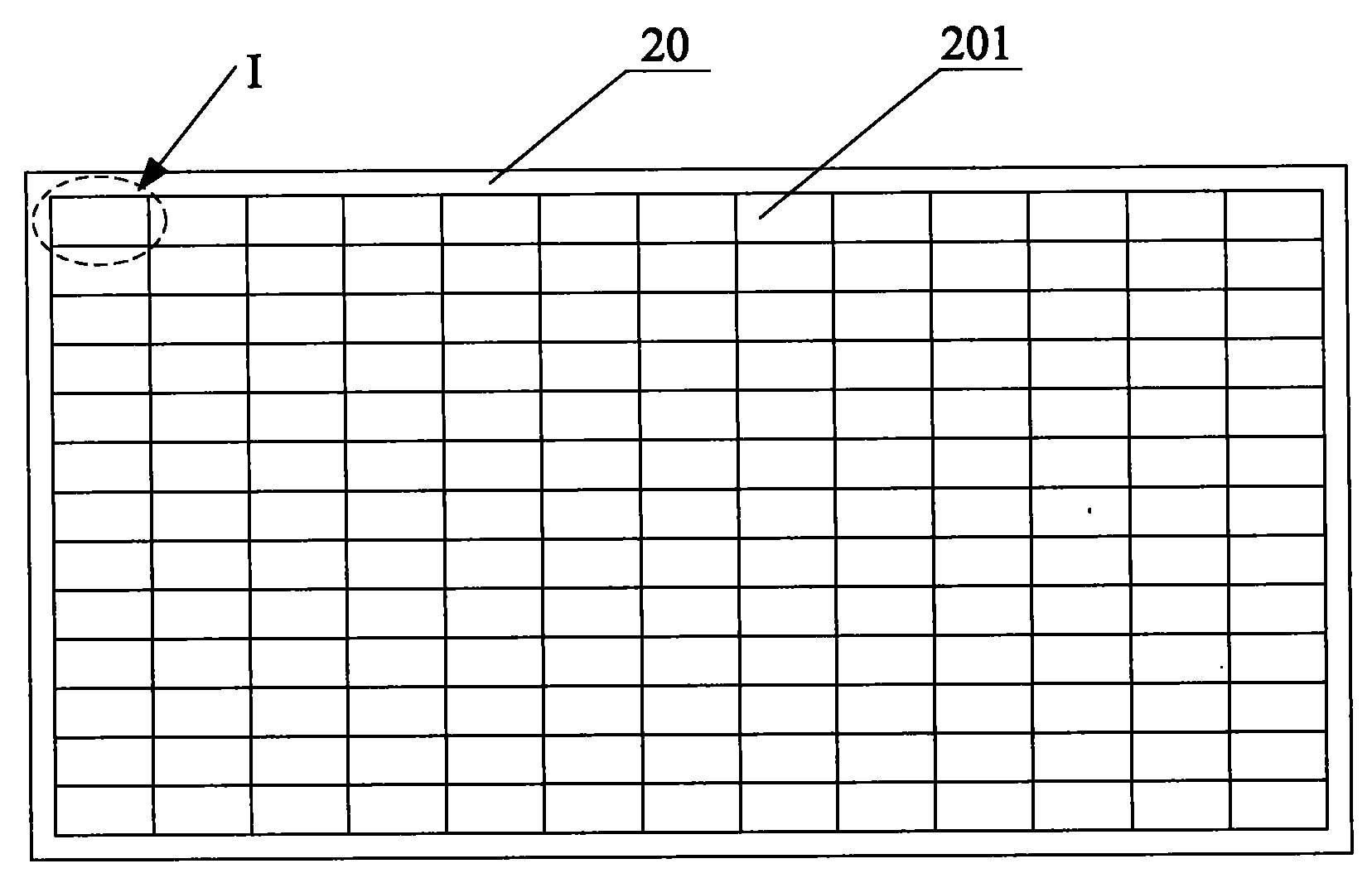

[0036] See also image 3 , Figure 4 ,in, image 3 It is a schematic bottom view o...

Embodiment 2

[0052] This embodiment introduces the encapsulation method of the above-mentioned OLED. The side of the rear cover of the OLED facing the substrate is formed with a light-emitting area corresponding to the pixel display area matrix on the substrate, and the back cover further includes at least one circle of continuous protrusions surrounding the light-emitting area on the periphery of the light-emitting area ; The surface of each pixel display area of the substrate is covered with a water-absorbing protective layer. Such as Figure 9 As shown, the packaging method includes:

[0053] S10, coating encapsulation glue on the periphery of the light-emitting area of the rear cover; the encapsulation glue surrounds the light-emitting area and completely covers at least one ring of protrusions surrounding the light-emitting area.

[0054] The height of the protrusions may be 5-100 μm, and the width may be 5-200 μm. The material of the water-absorbing protective layer may be an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com