Patents

Literature

2148 results about "Hybrid material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hybrid materials are composites consisting of two constituents at the nanometer or molecular level. Commonly one of these compounds is inorganic and the other one organic in nature. Thus, they differ from traditional composites where the constituents are at the macroscopic (micrometer to millimeter) level. Mixing at the microscopic scale leads to a more homogeneous material that either show characteristics in between the two original phases or even new properties.

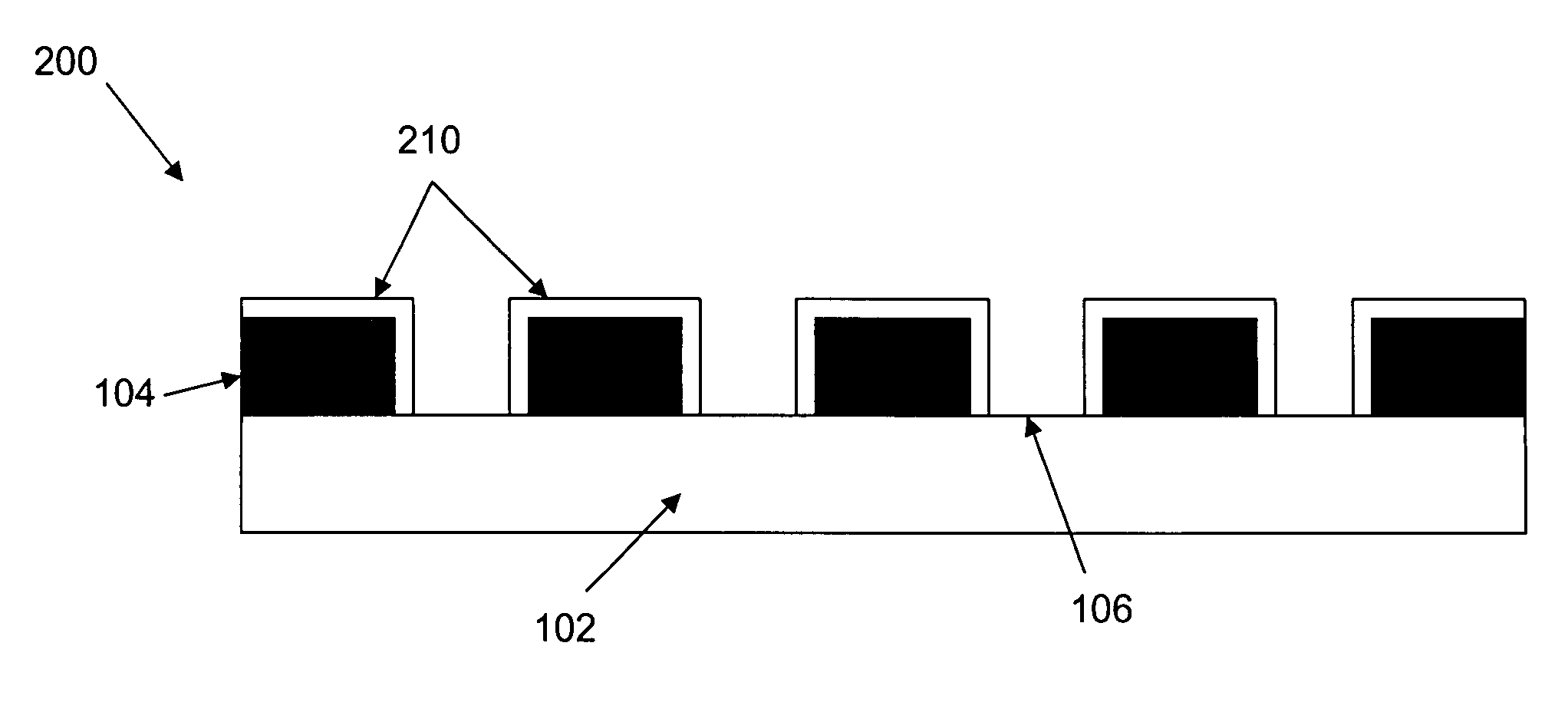

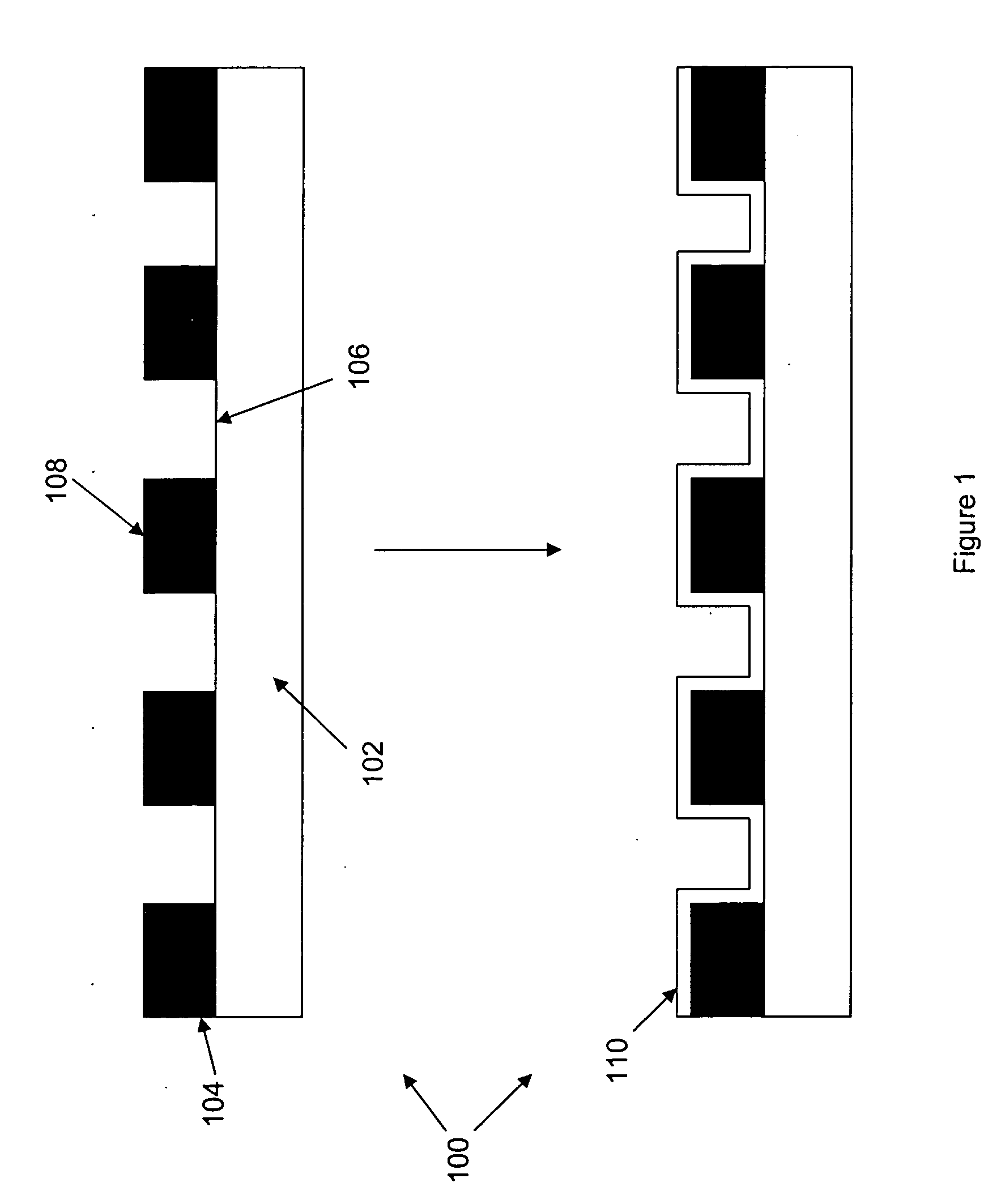

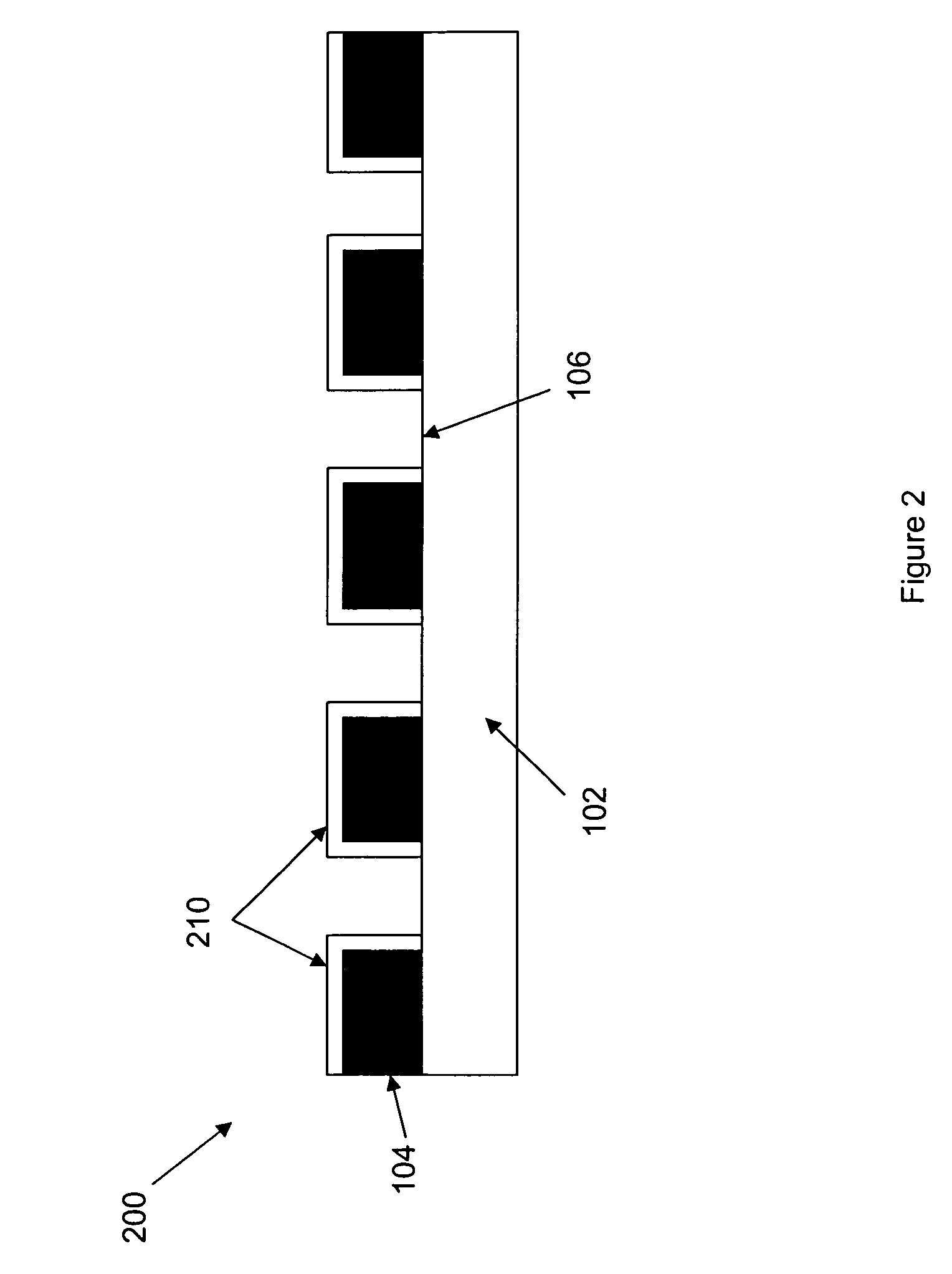

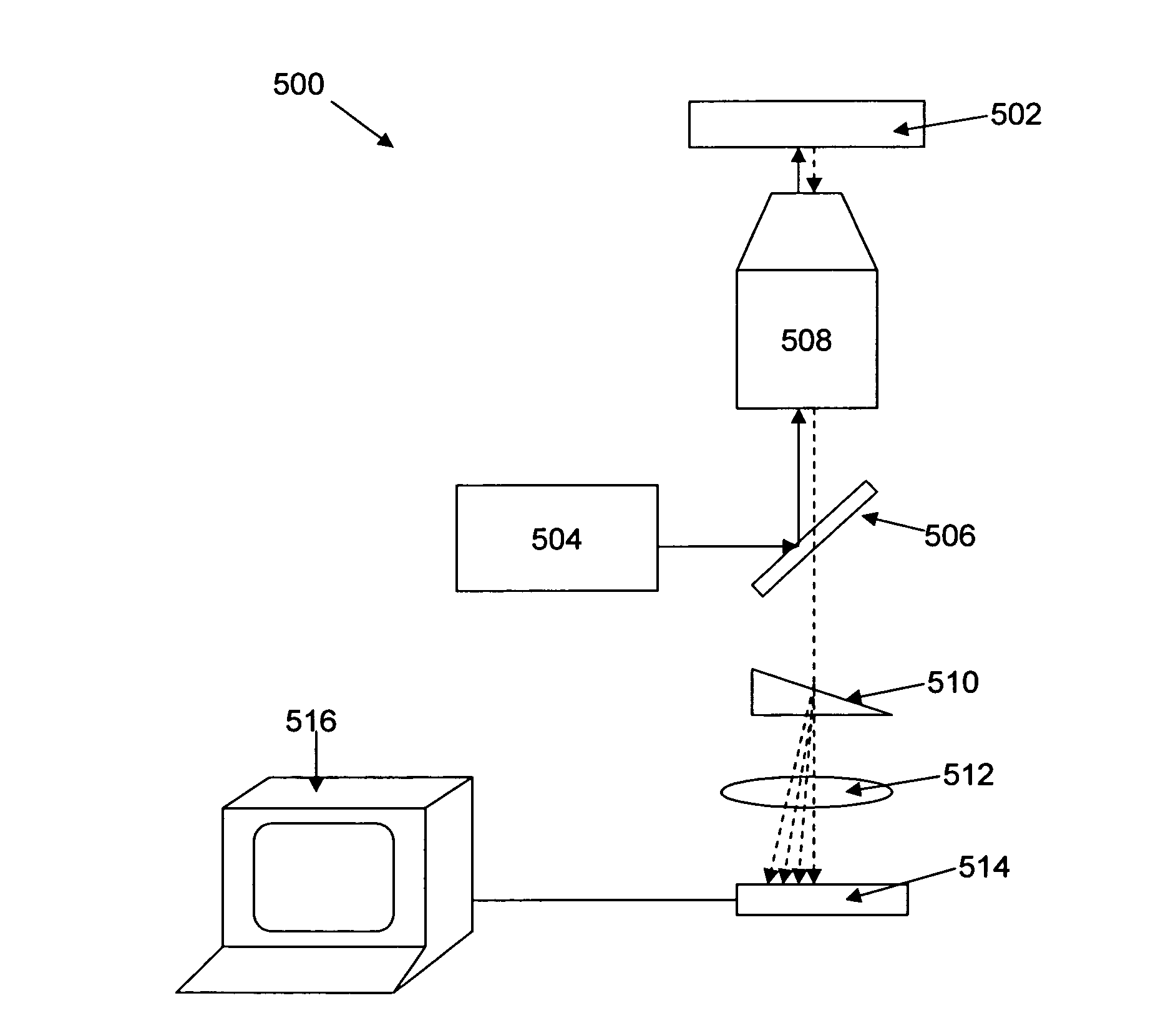

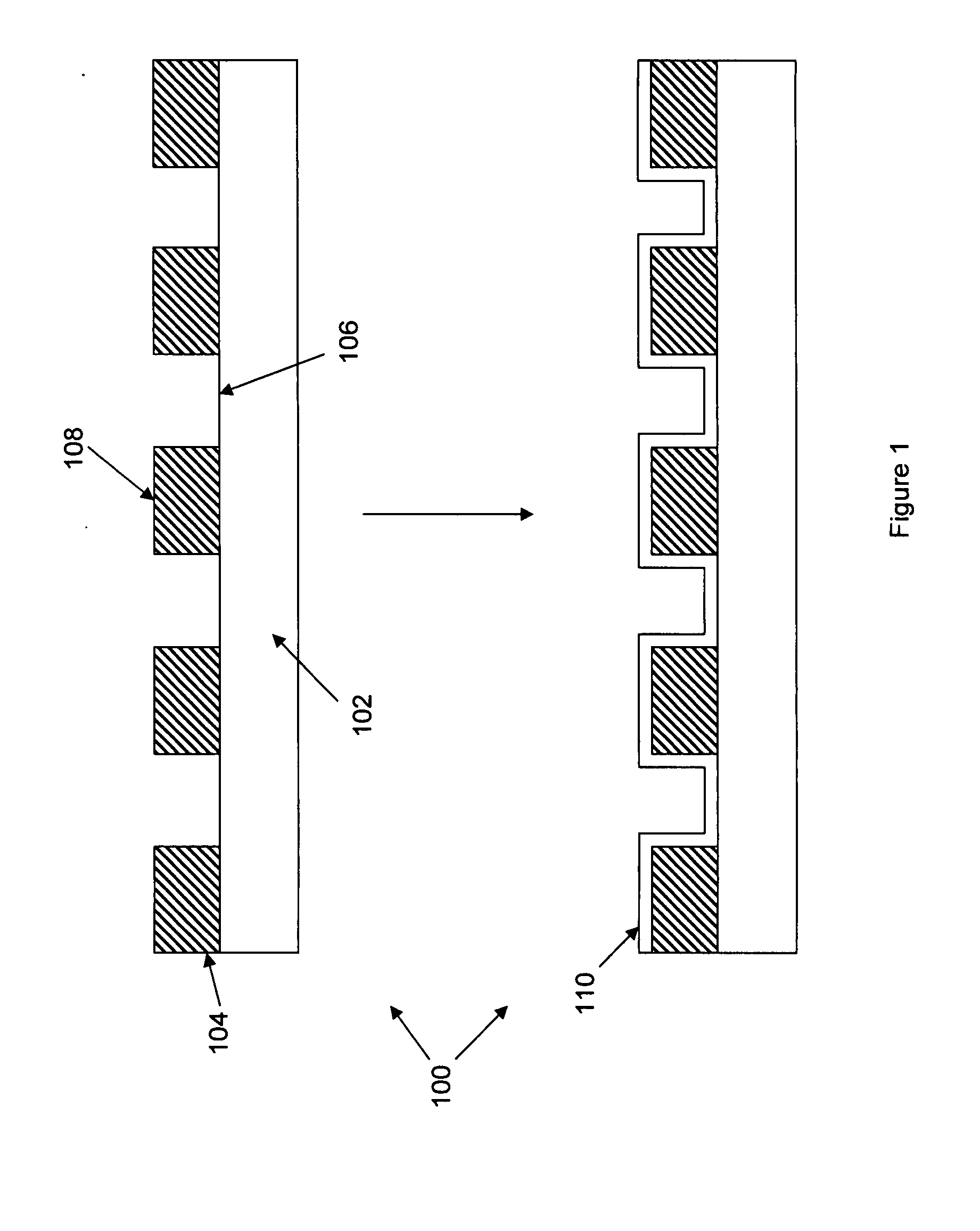

Uniform surfaces for hybrid material substrate and methods for making and using same

Devices, systems and methods of using same where hybrid substrate materials are provided with a substantially uniform surface to provide uniformity of properties, including interaction with their environments. Uniform surfaces are applied as coatings over, e.g., hybrid metal / silica, metal / polymer, metal / metal surfaces to mask different chemical properties of differing regions of the surface and to afford a protective surface for the hybrid structure.

Owner:PACIFIC BIOSCIENCES

Hybrid anode compositions for lithium ion batteries

ActiveUS20090117466A1Superior multiple-cycle behaviorSmall capacity fadeAlkaline accumulatorsConductive materialHybrid materialSodium-ion battery

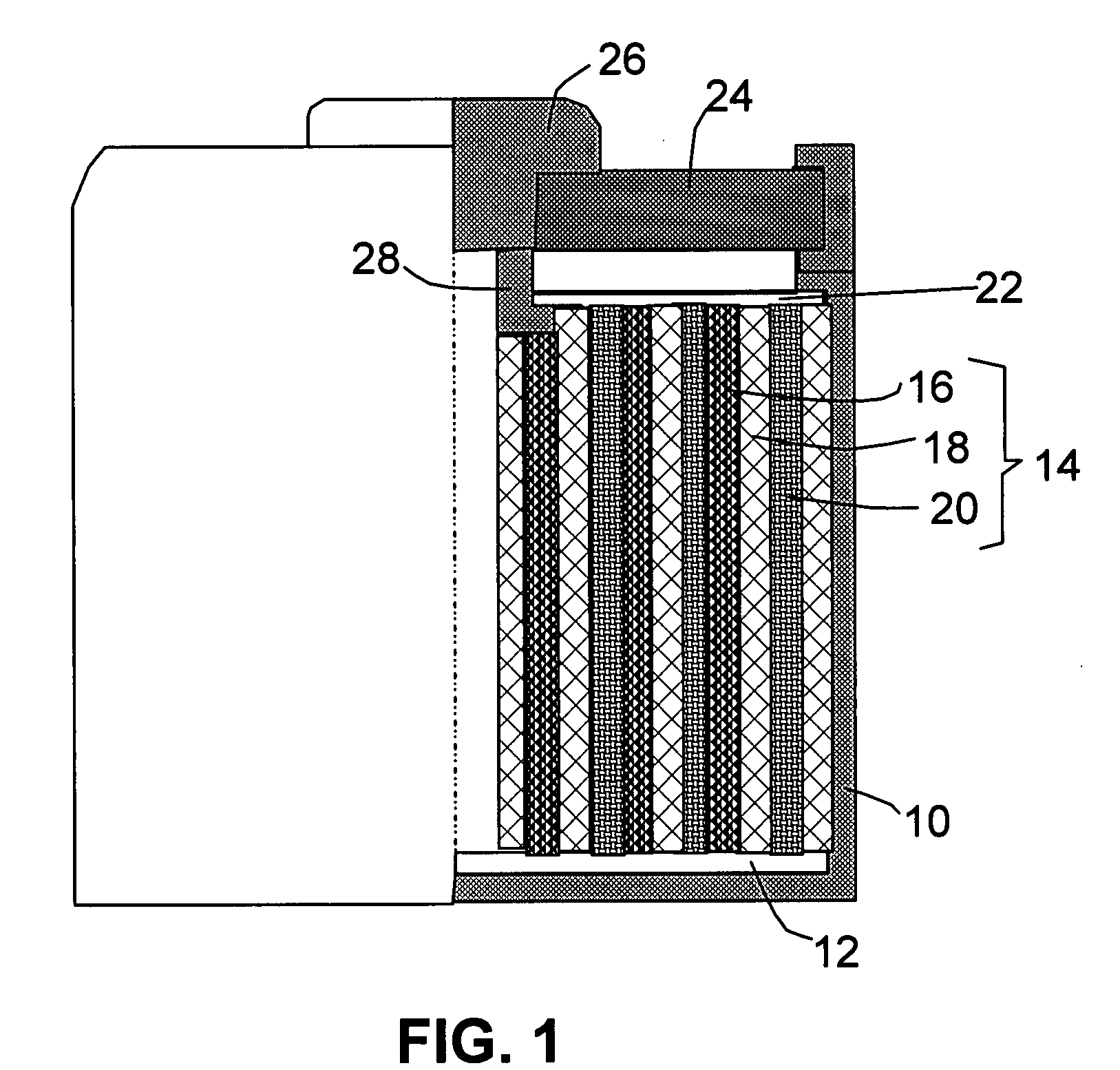

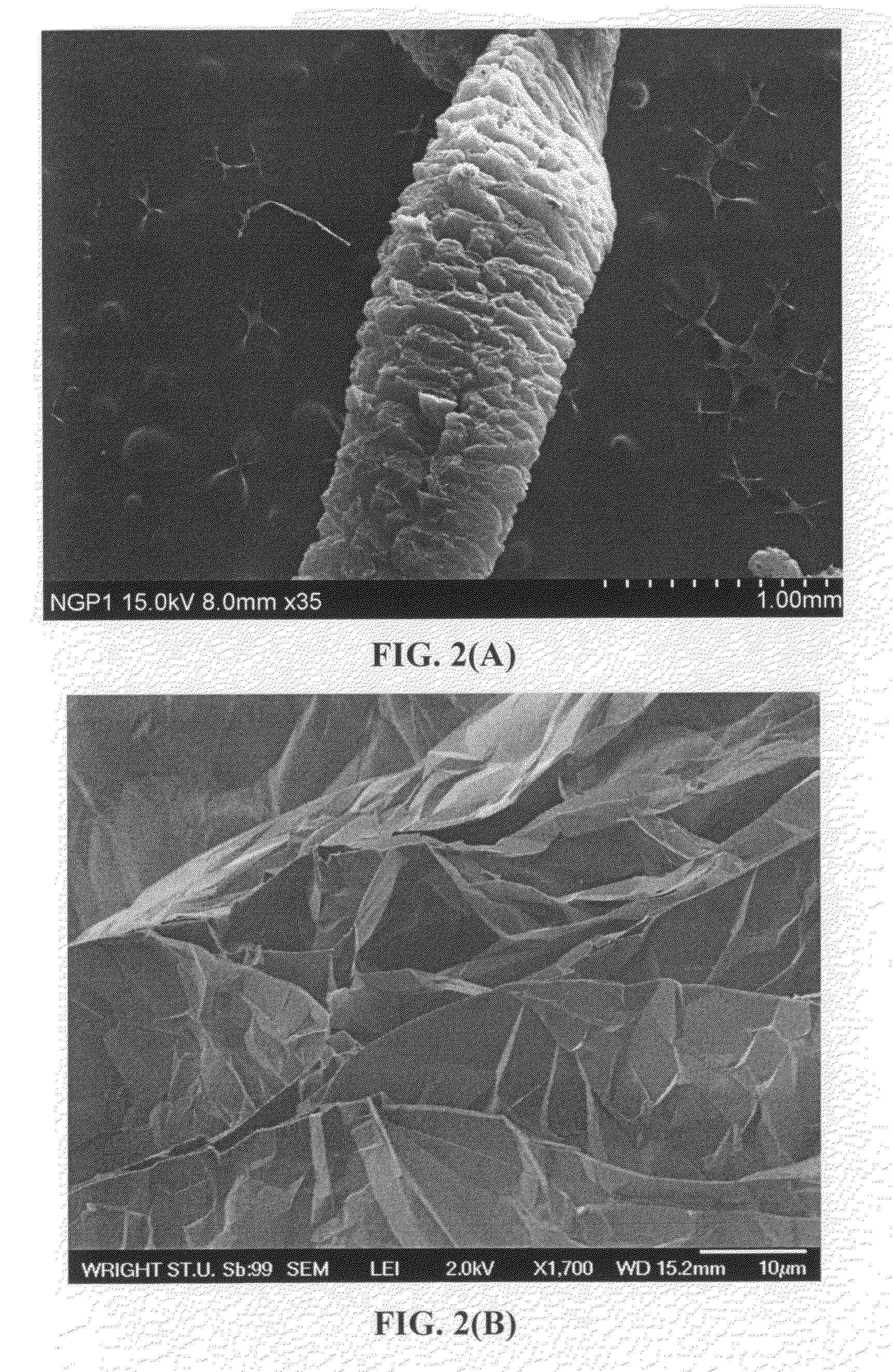

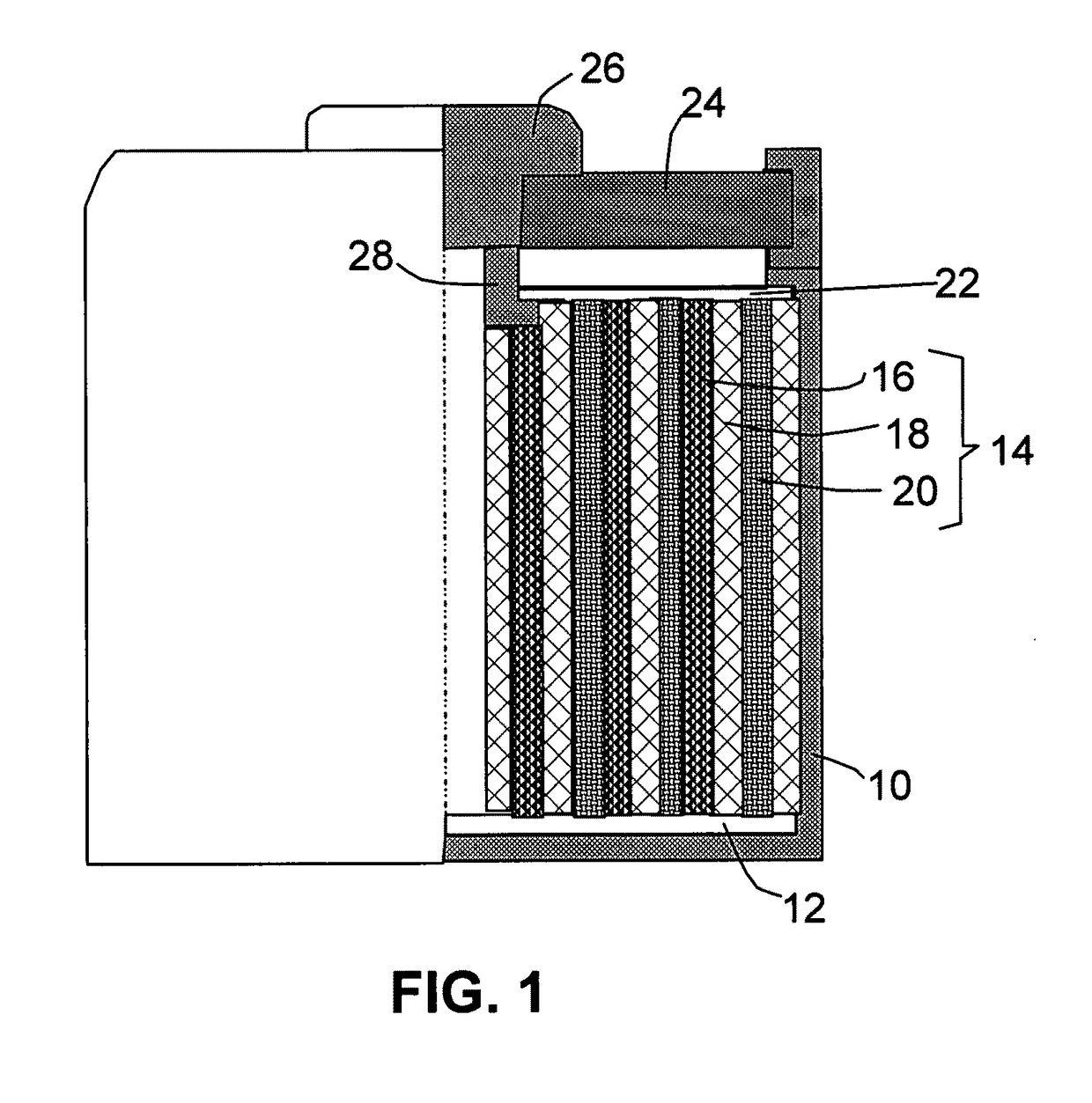

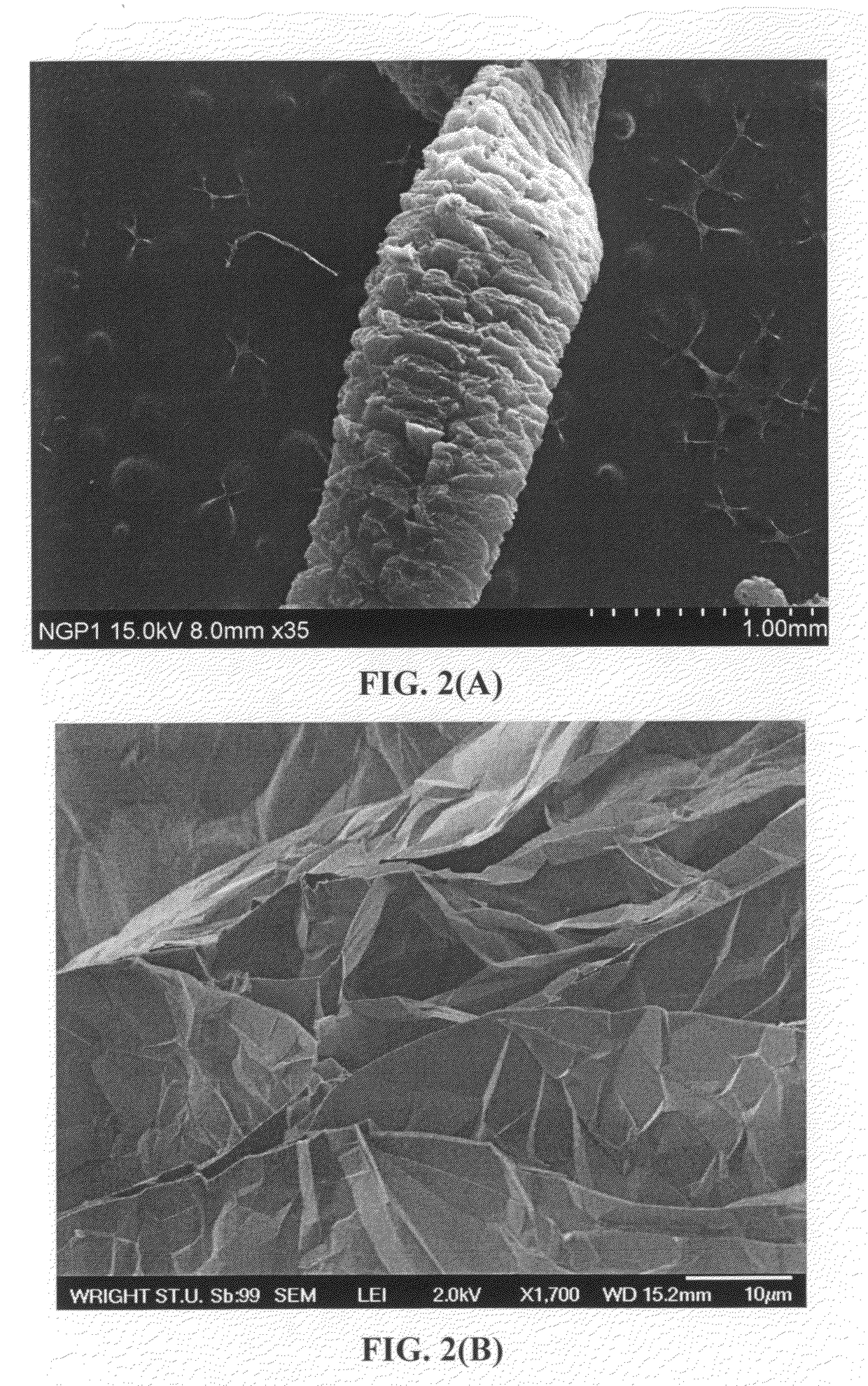

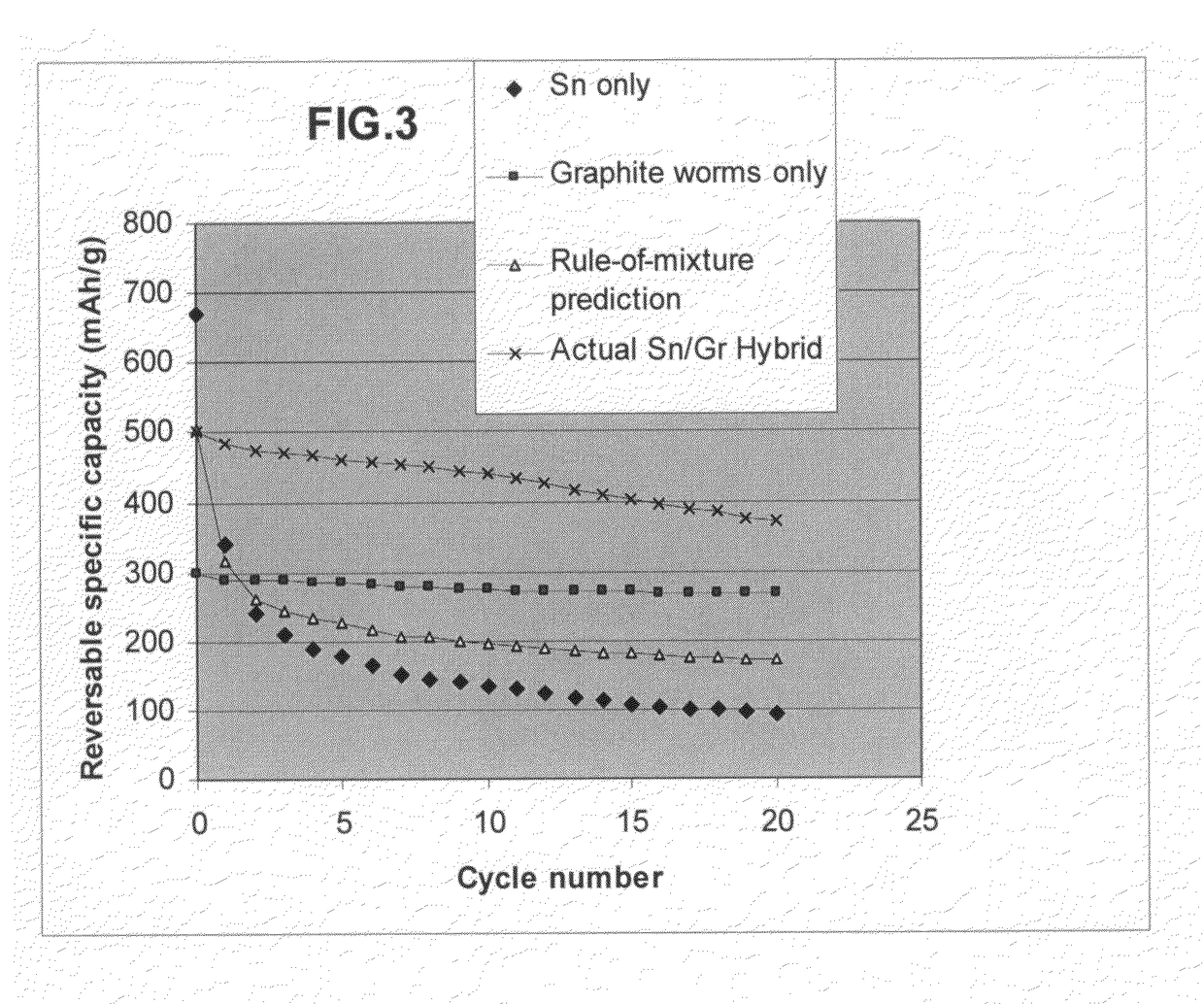

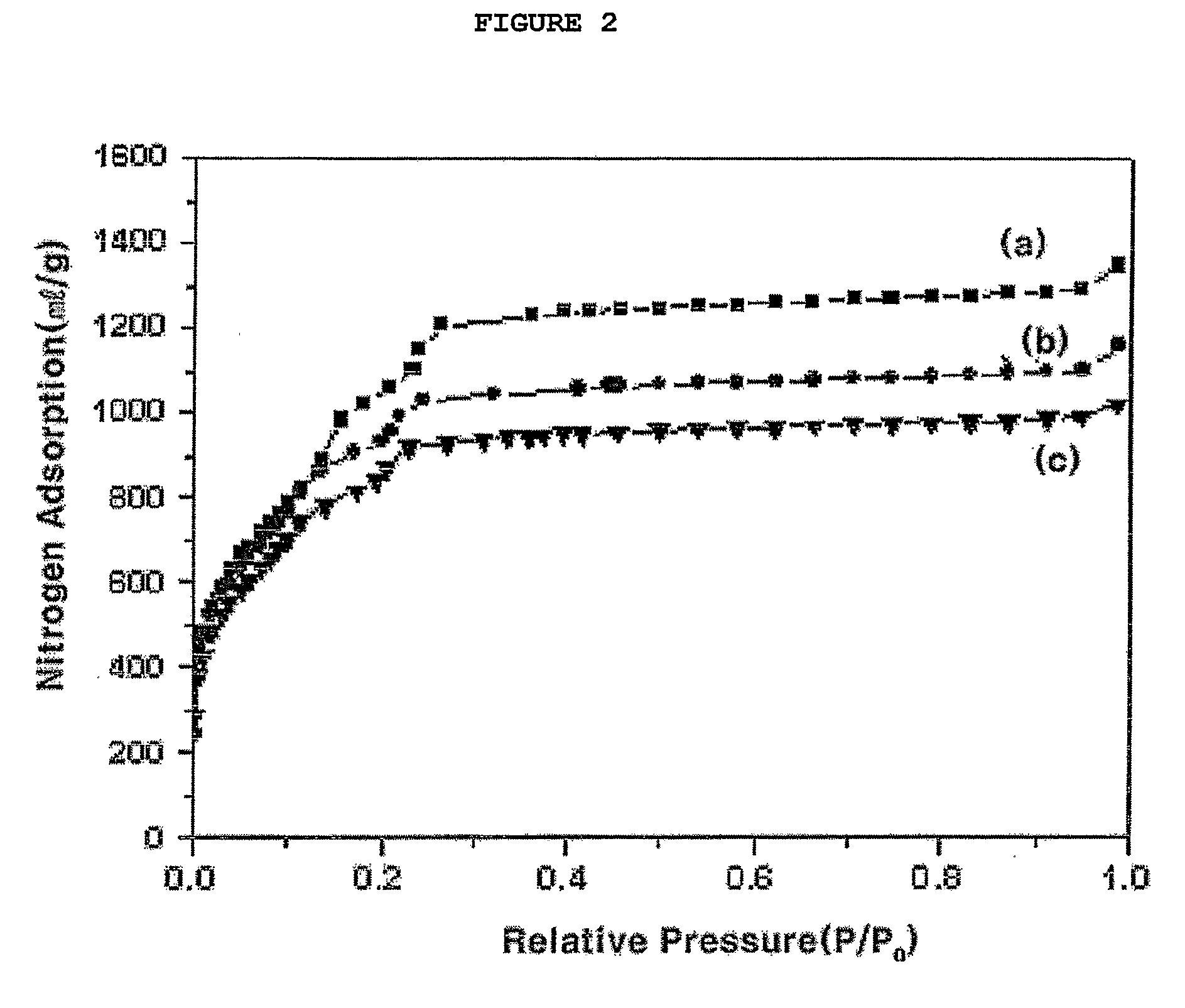

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

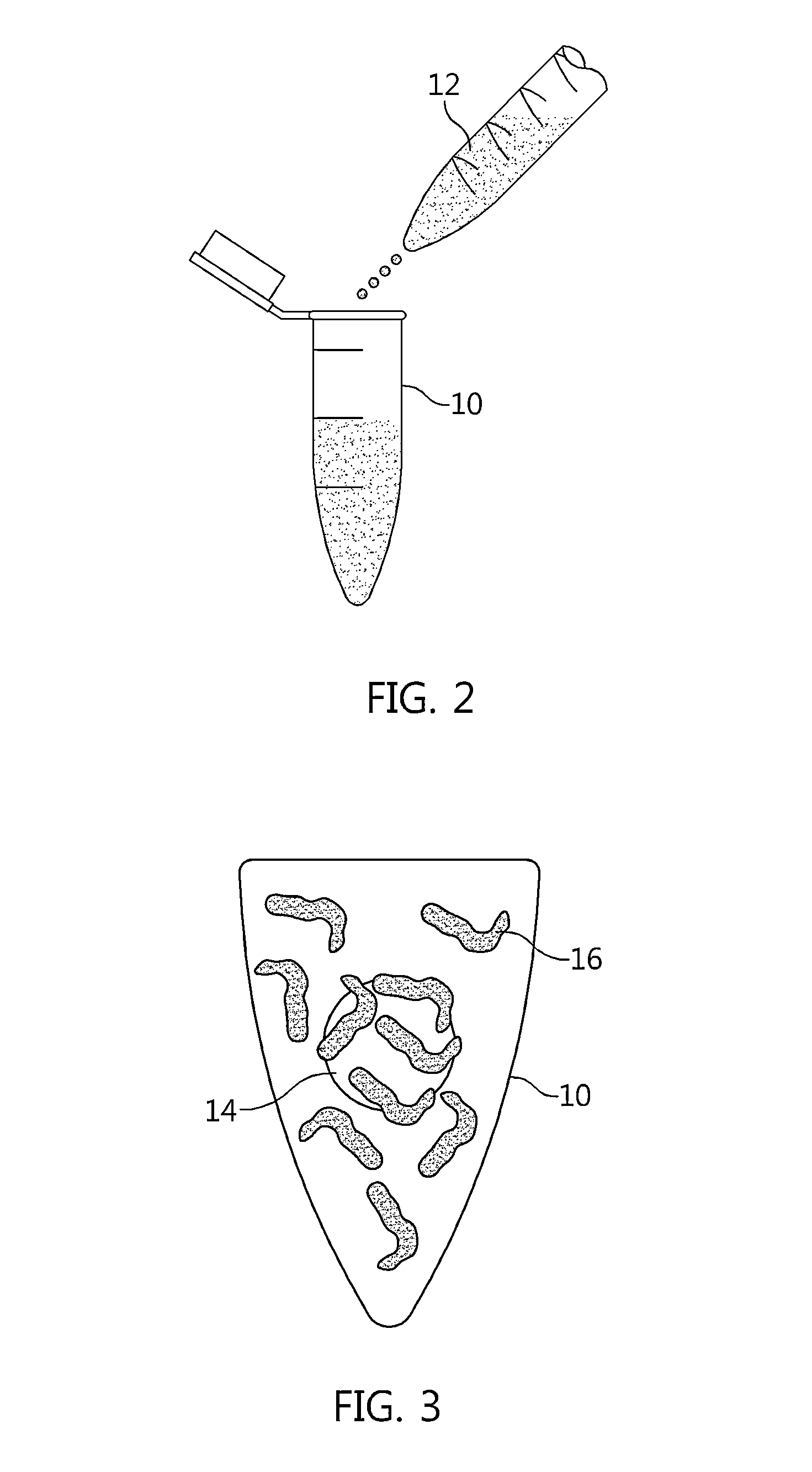

Compositions and methods for intervertebral disc reformation

Methods of reforming degenerated intervertebral discs. Hybrid materials useful in methods of reforming degenerated intervertebral discs.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

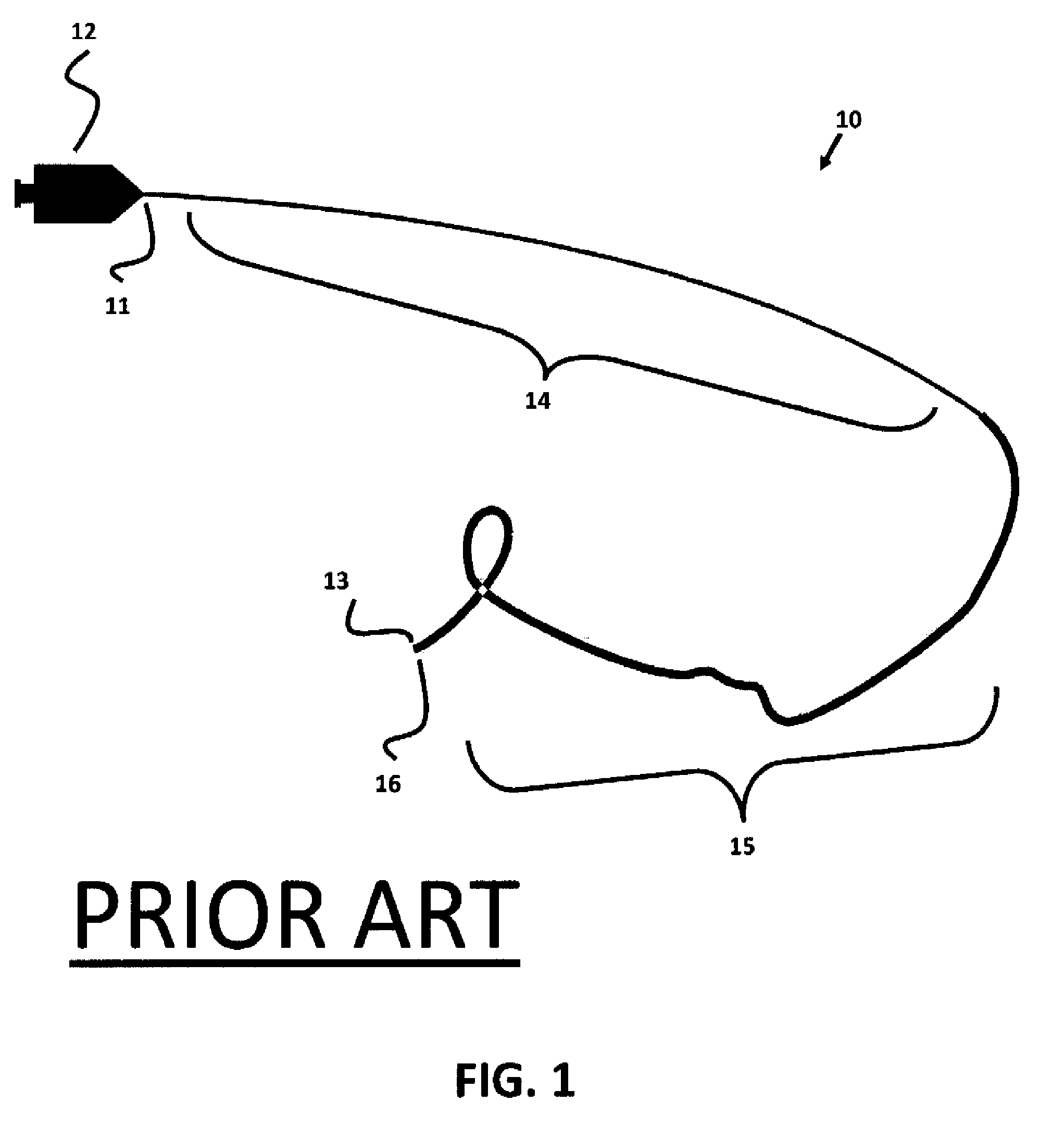

Hybrid organic-inorganic planar optical waveguide device

InactiveUS6144795AReduce stressAvoid deformationGlass shaping apparatusCoatingsHybrid materialOxygen

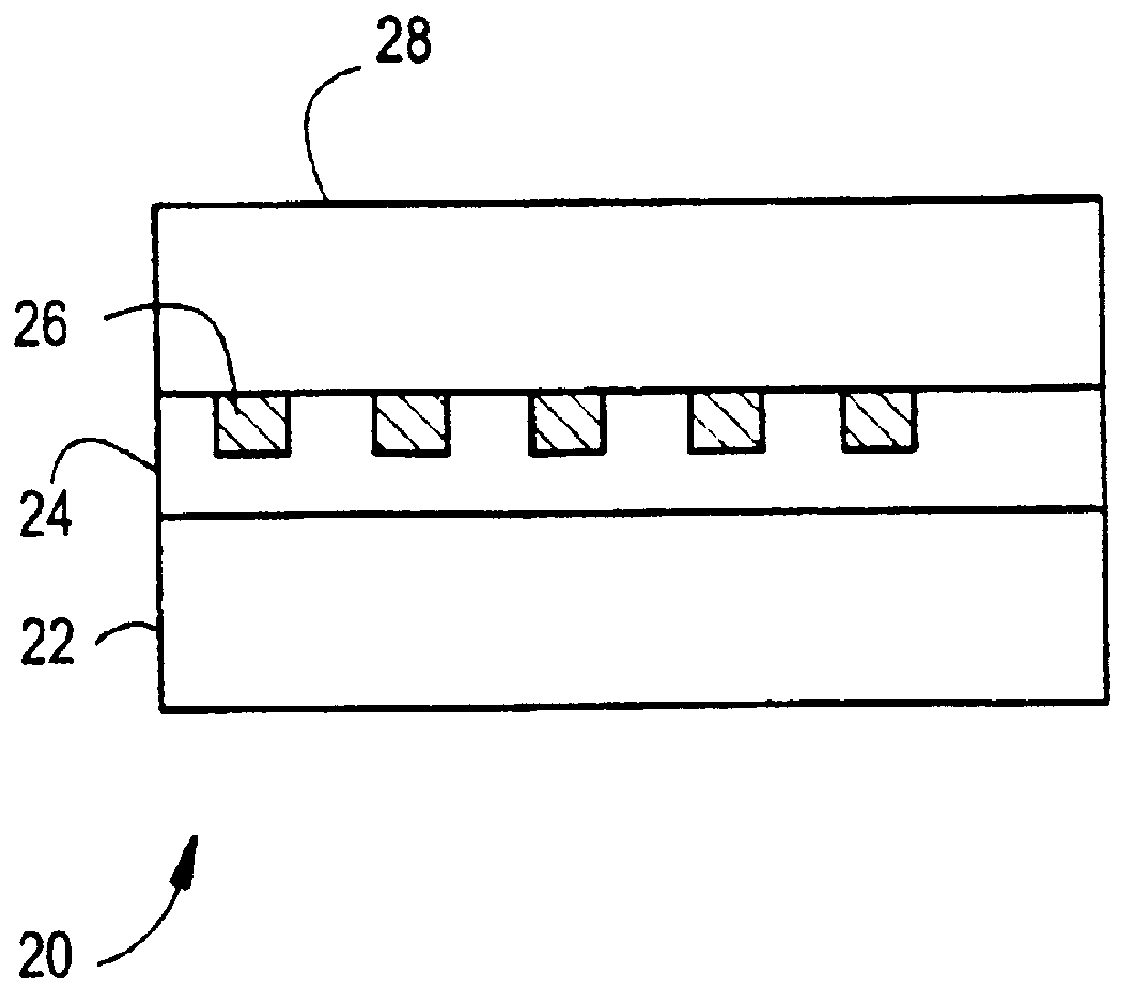

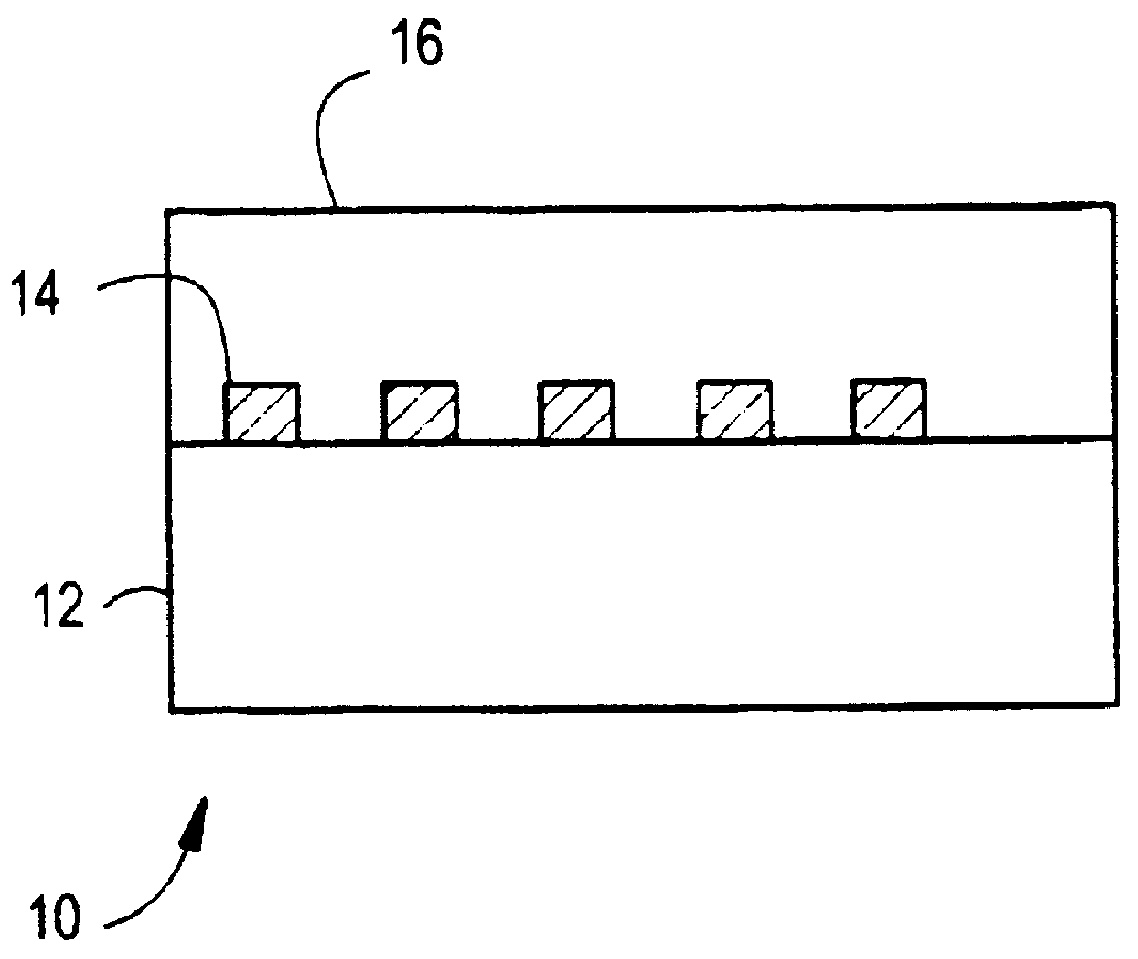

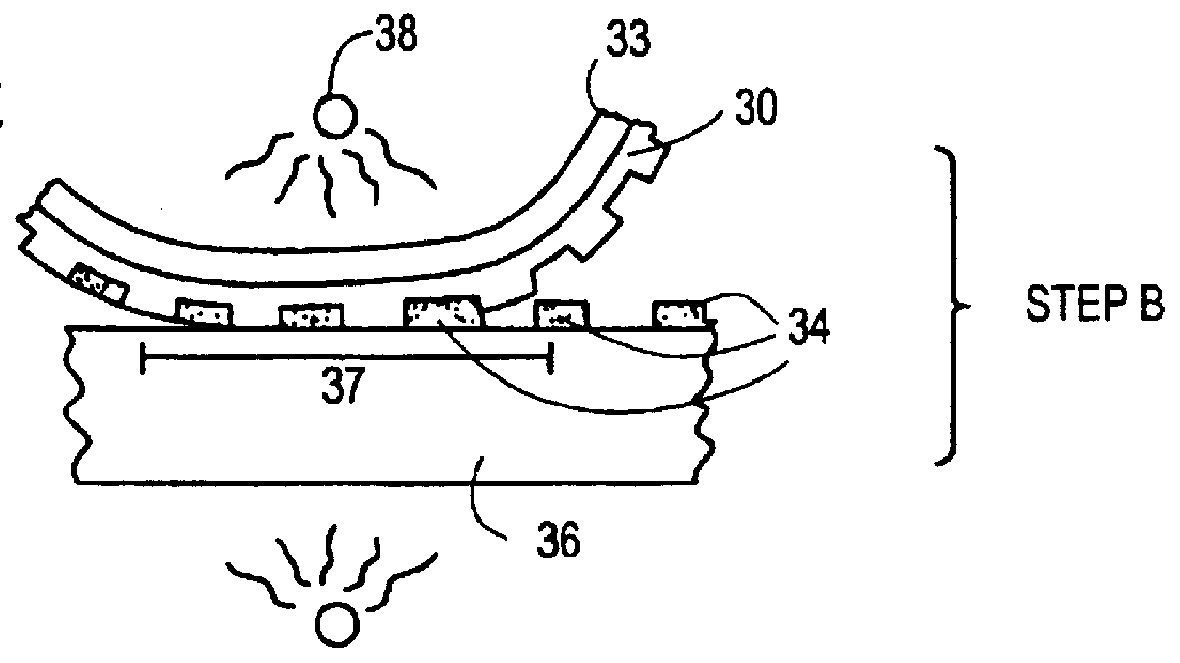

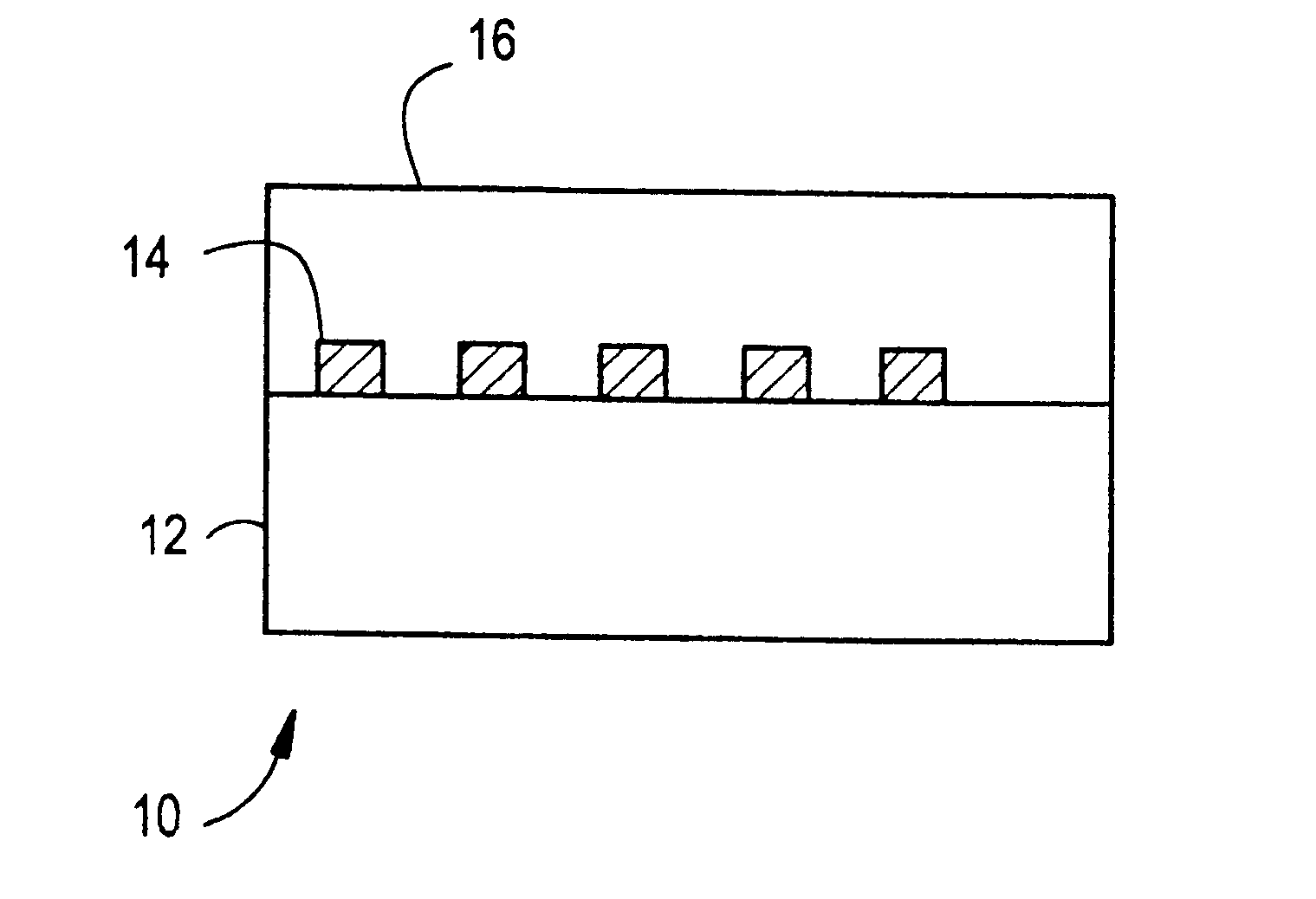

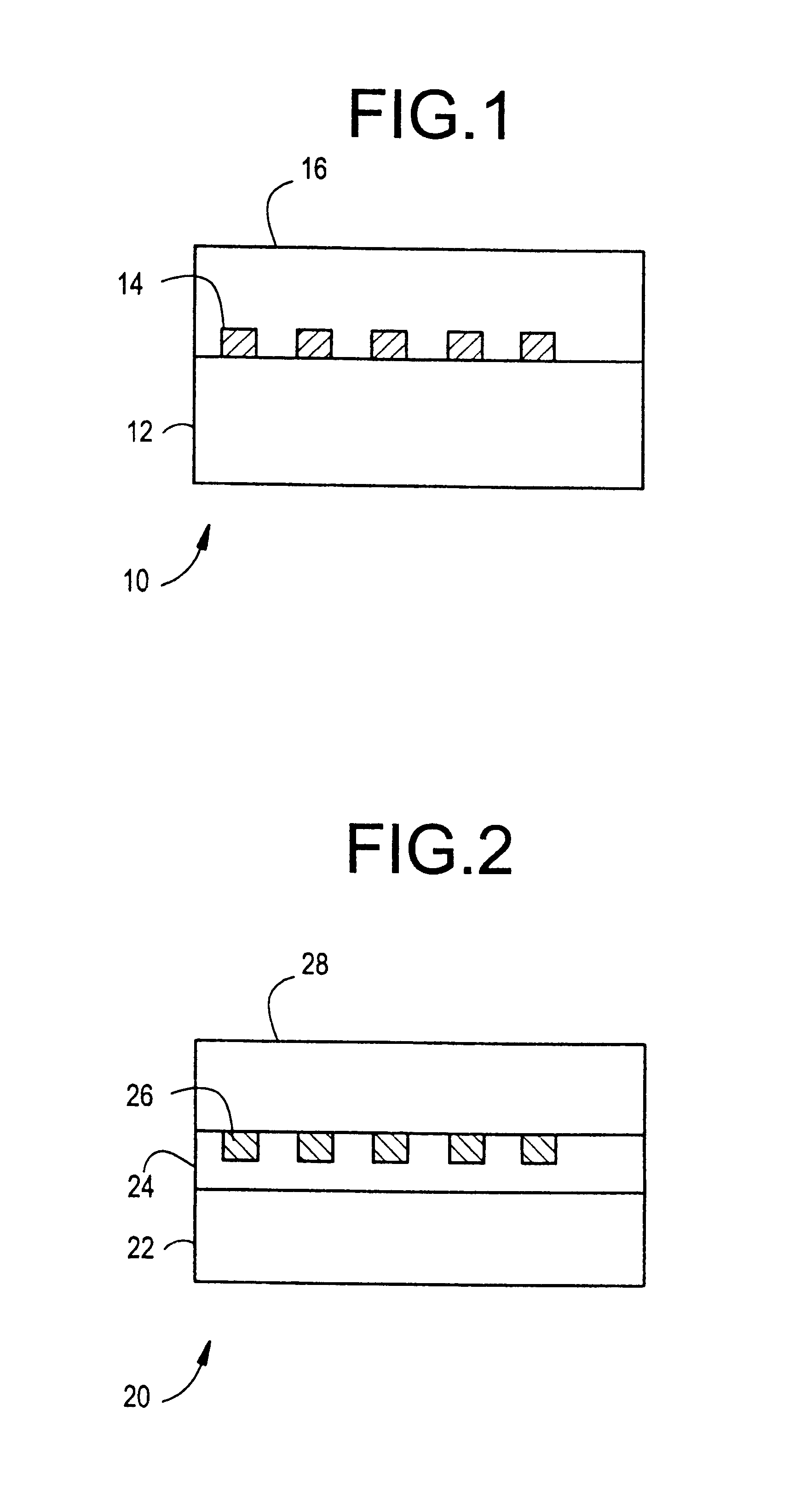

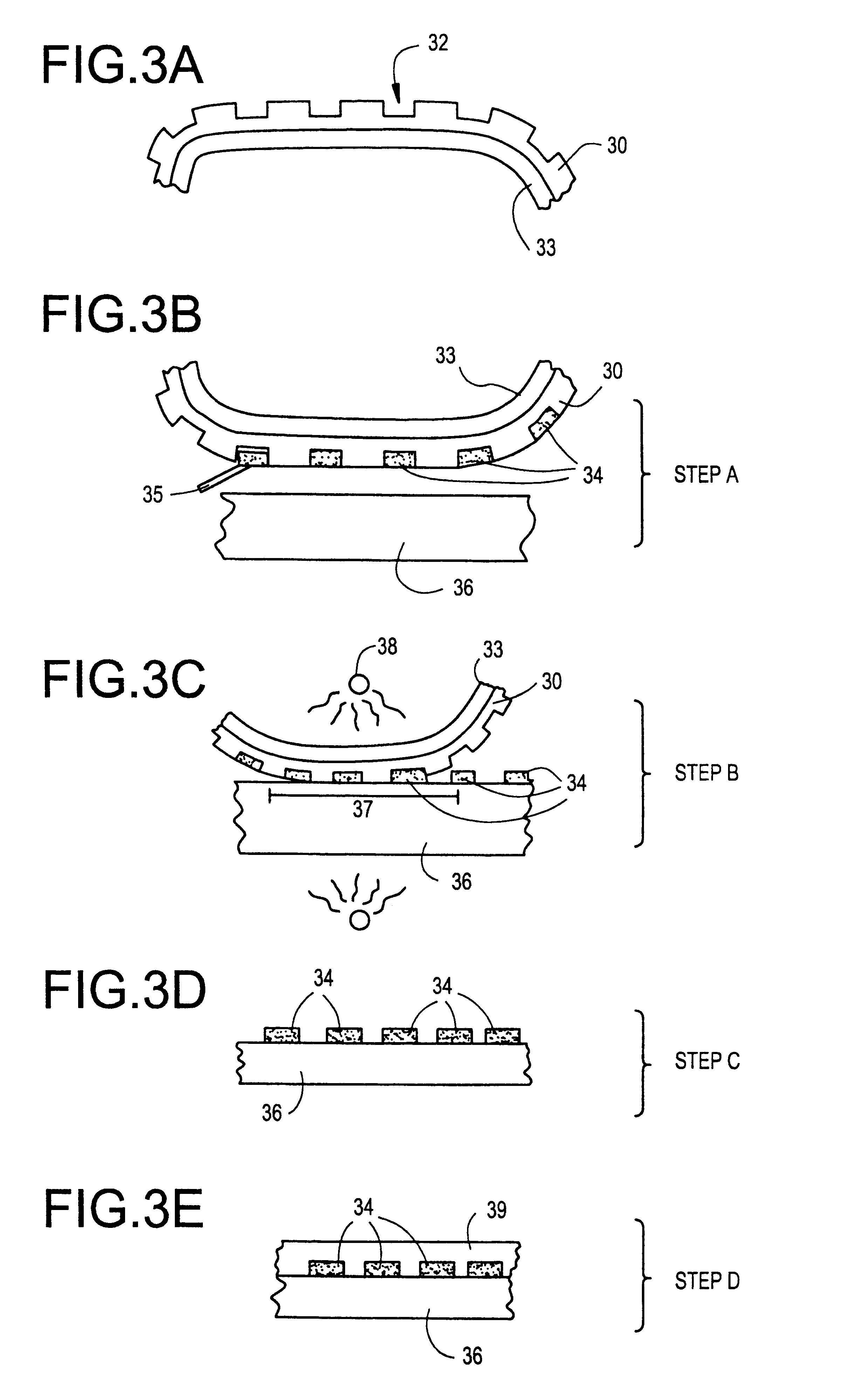

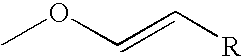

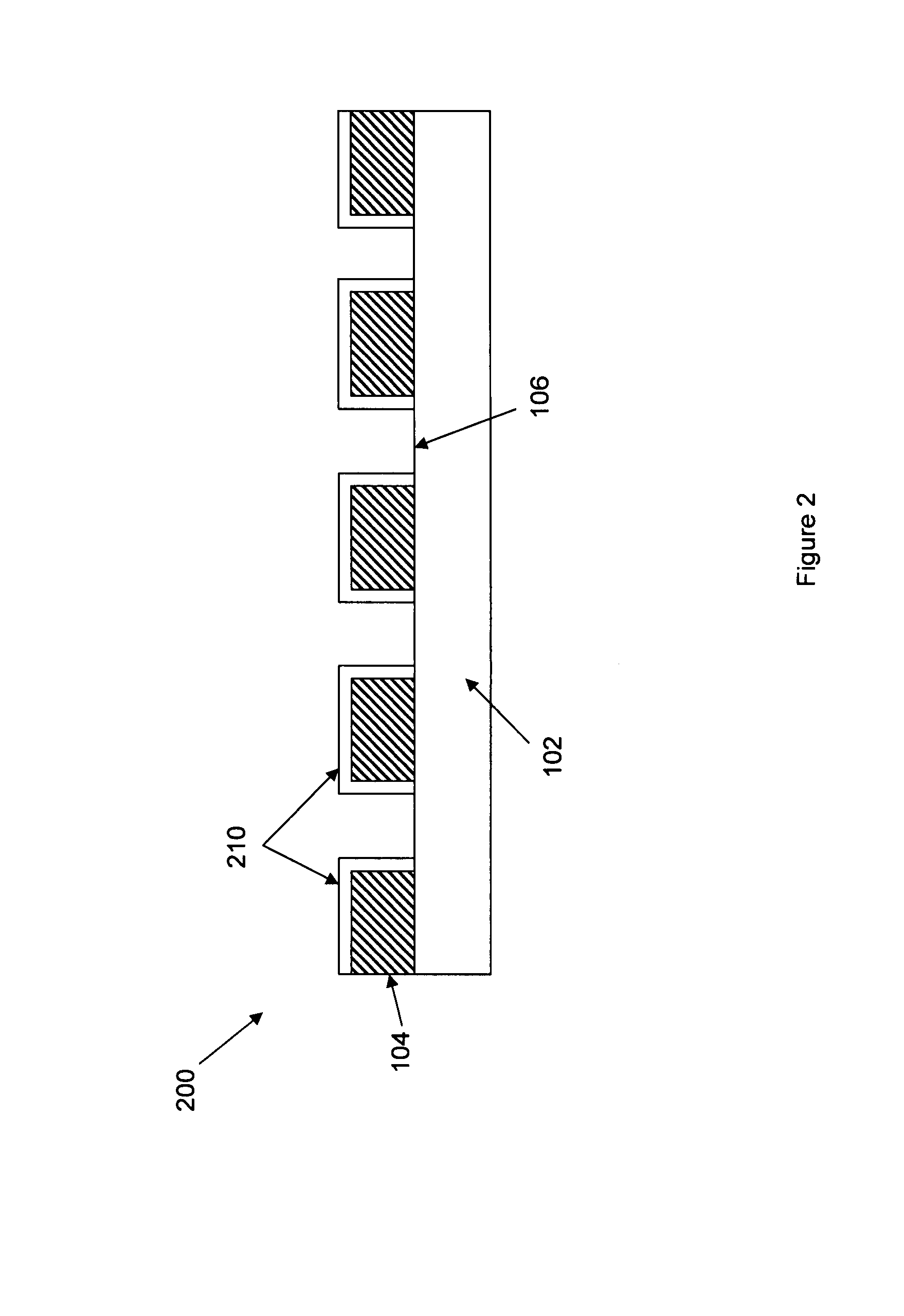

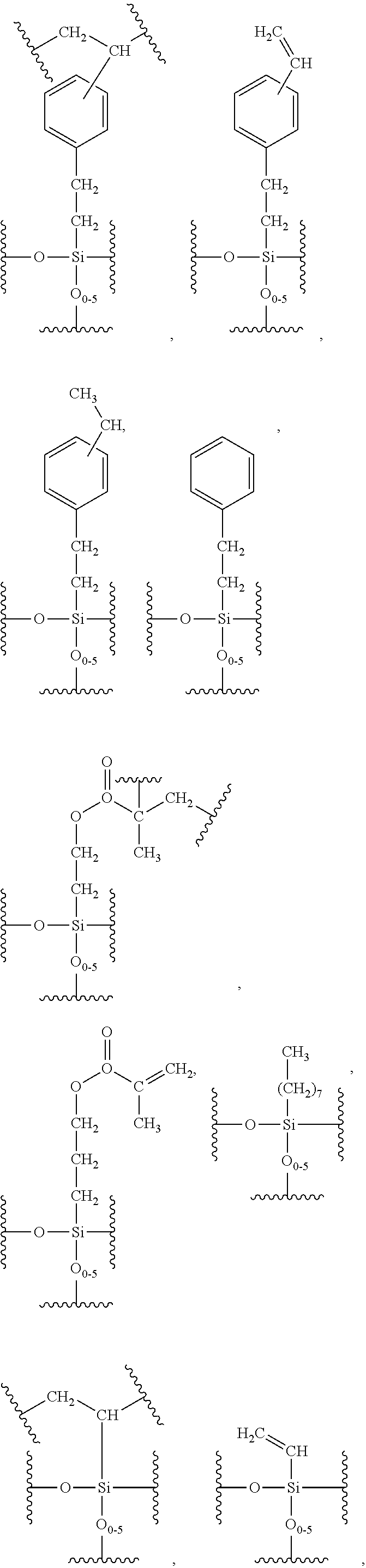

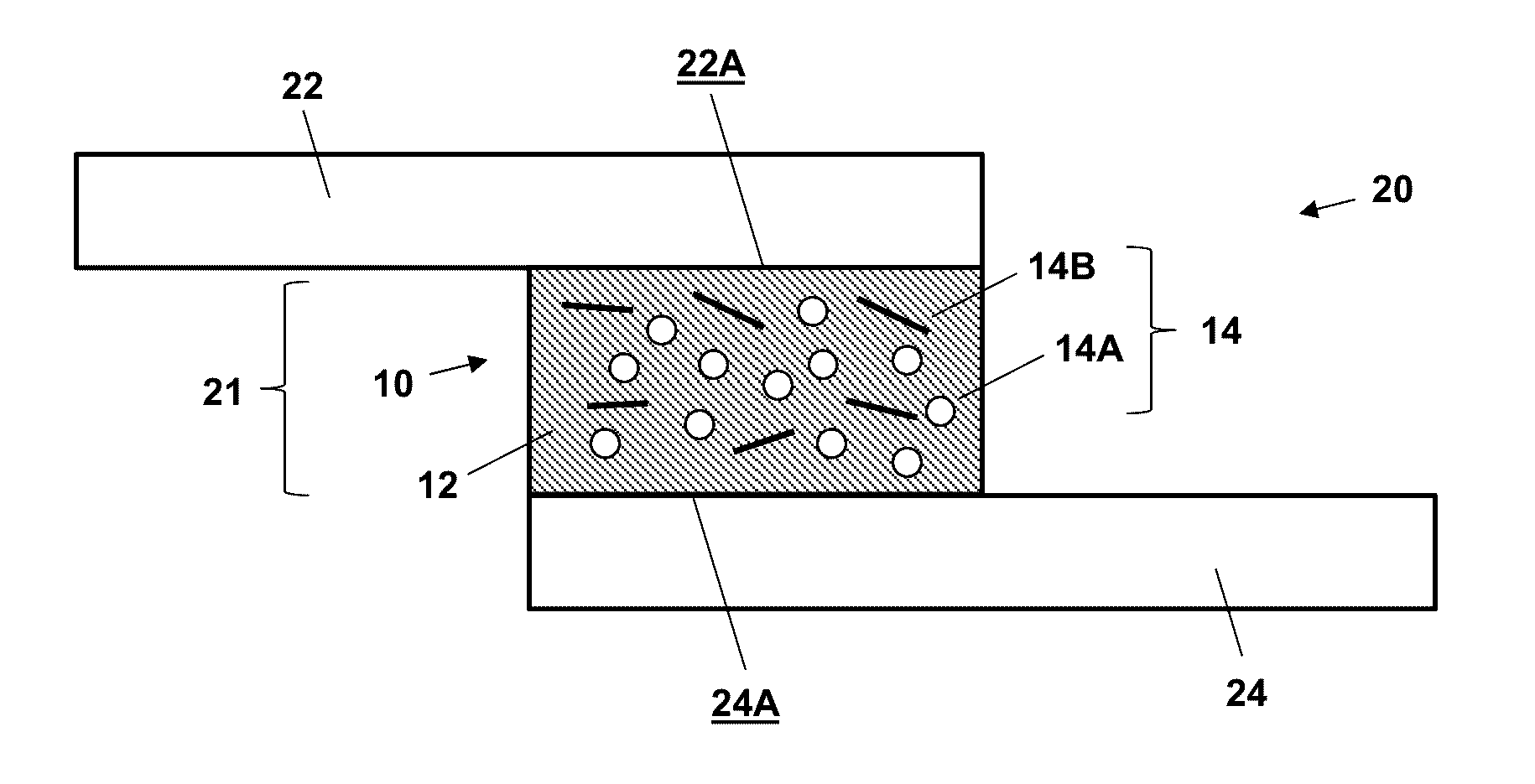

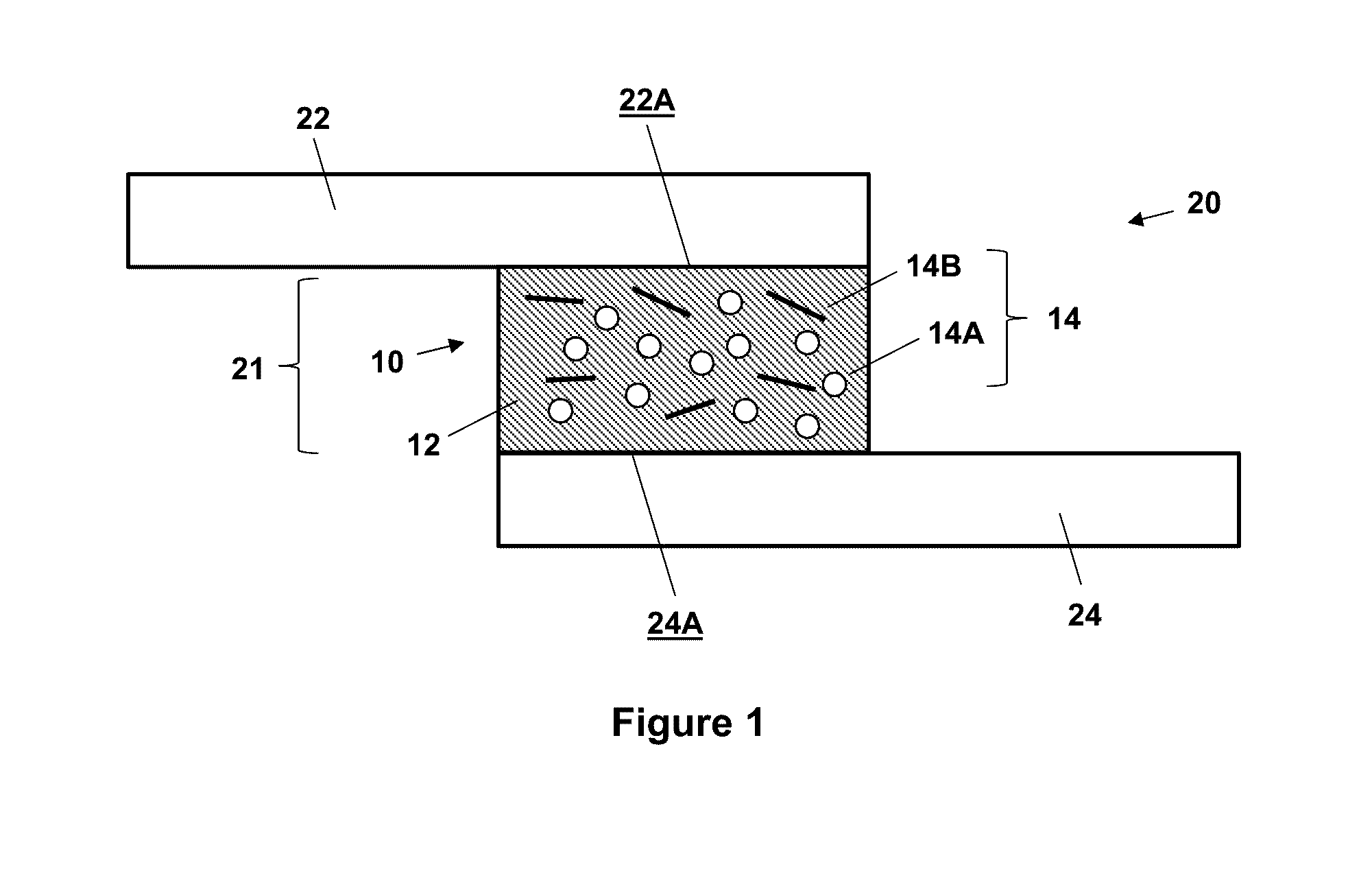

PCT No. PCT / US97 / 22760 Sec. 371 Date Jun. 10, 1999 Sec. 102(e) Date Jun. 10, 1999 PCT Filed Dec. 12, 1997 PCT Pub. No. WO98 / 26315 PCT Pub. Date Jun. 18, 1999A planar optical device is formed on a substrate (12) and comprising an array of waveguide cores (14) and a cladding layer (16) formed contiguously with the cores. At least one of the array of waveguide cores (14) and the cladding layer (16) is an inorganic-organic hybrid material that comprises an extended matrix containing silicon and oxygen atoms with at least a fraction of the silicon being directly bonded to substituted or unsubstituted hydrocarbon atoms. In accordance with other embodiments of the invention, a method of forming an array of cores comprises the steps of preparing a core composition precursor material; partially hydrolyzing and polymerizing the material; forming an array of waveguide cores under conditions effective to form an inorganic-organic hybrid material that comprises an extended matrix containing silicon and oxygen atoms with at least a fraction of the silicon being directly bonded to substituted or unsubstituted hydrocarbon atoms.

Owner:CORNING INC

Hybrid organic-inorganic planar optical waveguide device

InactiveUS6511615B1Reduce stressStress induced polarization effects can be minimizedOptical articlesGlass shaping apparatusOptical radiationSilanes

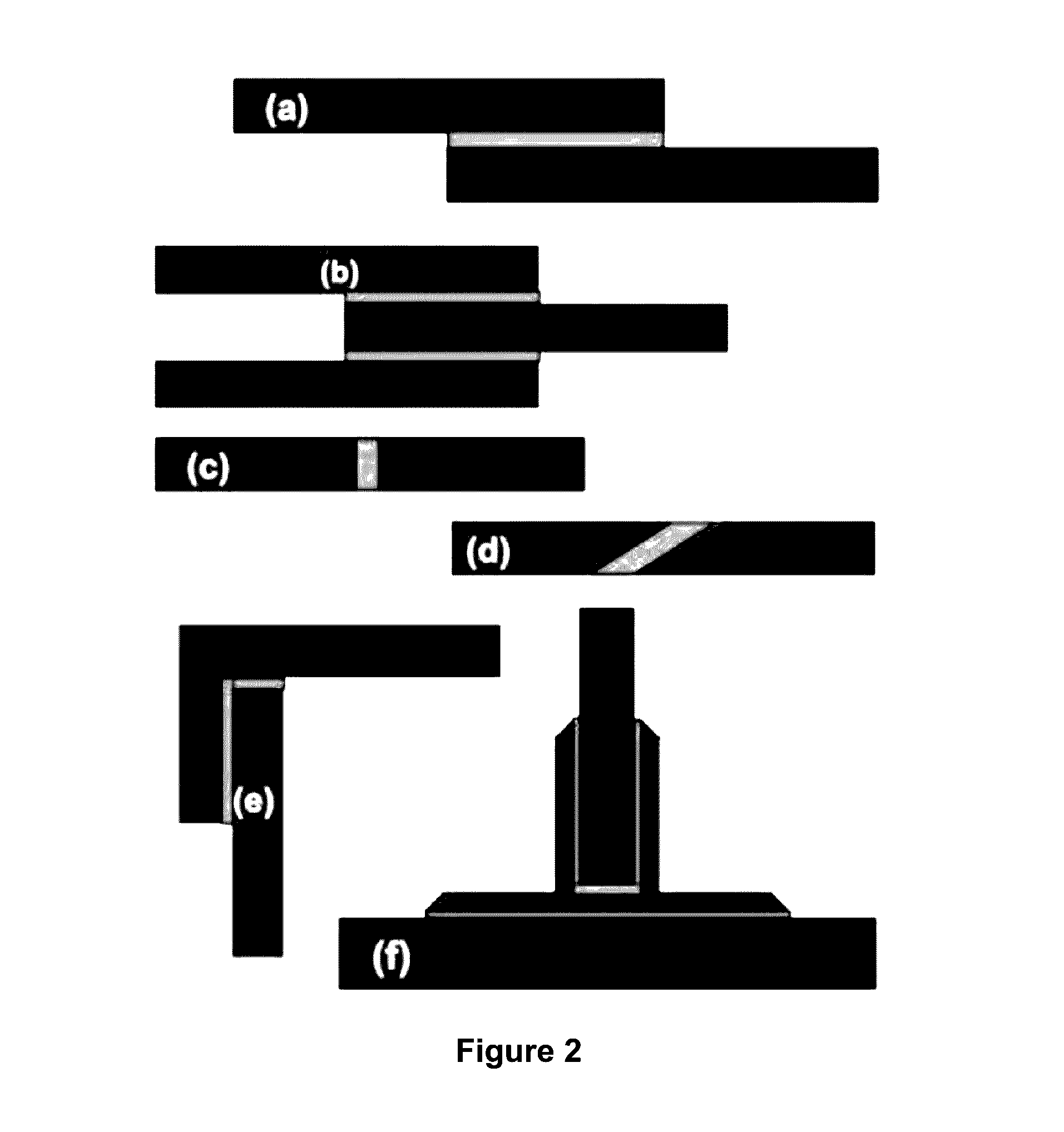

A planar optical device is formed on a substrate. The device comprises an array of waveguide cores which guide optical radiation. A cladding layer is formed contiguously with the array of waveguide cores to confine the optical radiation to the array of waveguide cores. At least one of the array of waveguide cores and cladding layer is an inorganic-organic hybrid material that comprises an extended matrix containing silicon and oxygen atoms with at least a fraction of the silicon atoms being directly bonded to substituted or unsubstituted hydrocarbon moieties. This material can be designed with an index of refraction between 1.4 and 1.55 and can be deposited rapidly to thicknesses of up to 40 microns. In accordance with another embodiment of the invention, a method for forming a planar optical device obviates the need for a lithographic process. Illustratively, a method for forming an array of cores comprises the steps of: (1) preparing a waveguide core composition precursor material comprising at least one silane and a source of hydrocarbon moiety, (2) partially hydrolyzing and polymerizing the waveguide core precursor material to form a waveguide core composition, (3) using a mold, forming an array of waveguide cores comprising the waveguide core composition, and (4) completing hydrolysis and polymerization of the waveguide core composition under conditions effective to form an inorganic-organic hybrid material that comprises an extended matrix containing silicon and oxygen atoms with at least a fraction of the silicon atoms being directly bonded to substituted or unsubstituted hydrocarbon moieties. A cladding layer is then deposited over the array of waveguide cores. The use of the mold to pattern the array of waveguide cores obviates the need for a lithographic process.

Owner:CORNING INC

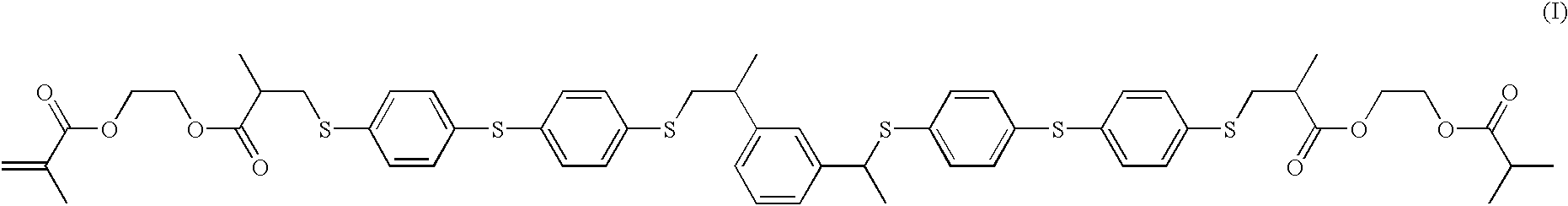

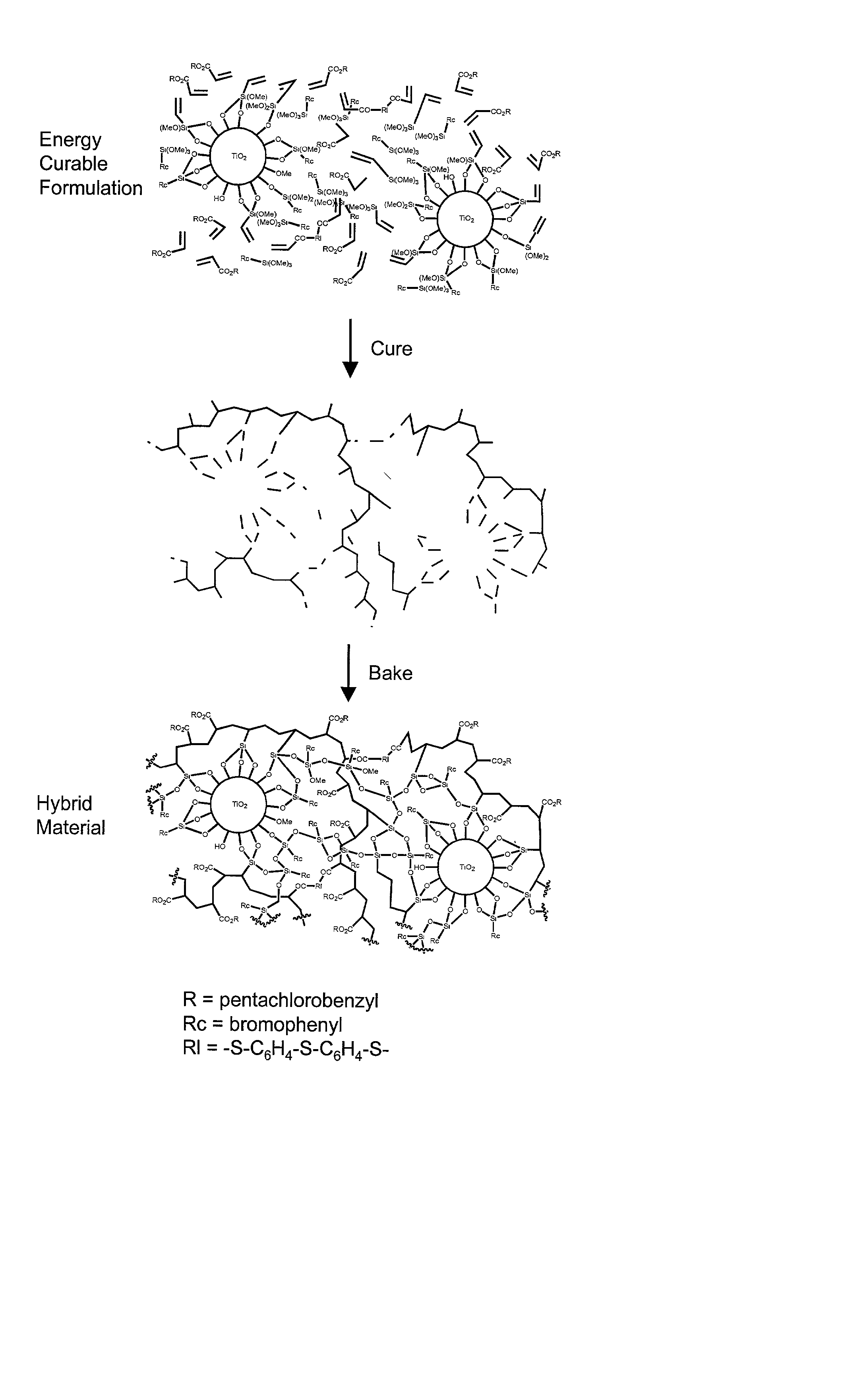

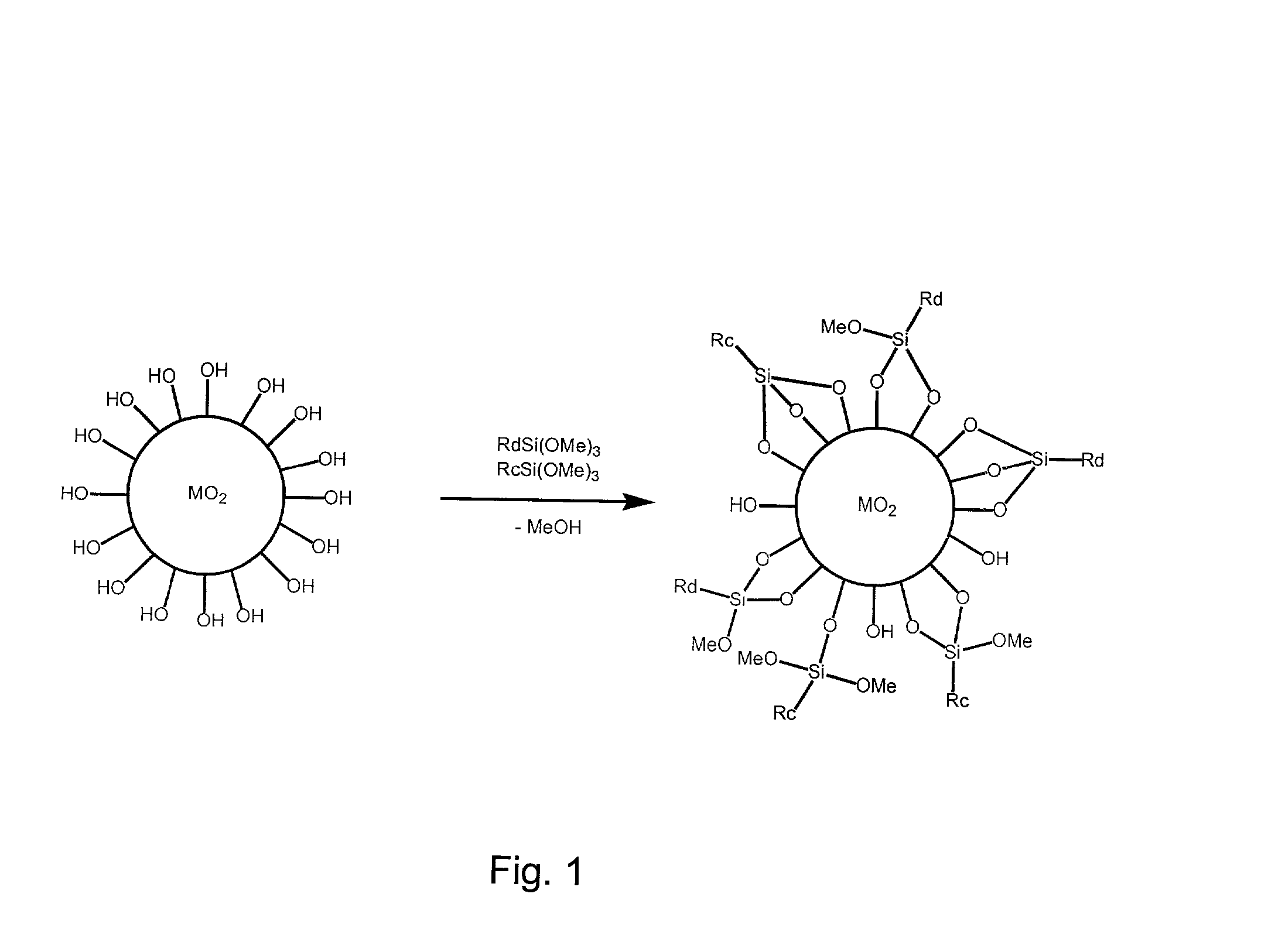

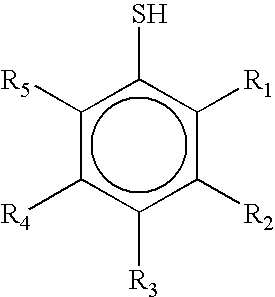

Curable high refractive index compositions

The invention provides an organic / inorganic hybrid material with a high refractive index at telecommunications wavelengths. Energy curable compositions of the present invention include condensed metal oxide nanoparticles, a high refractive index organometallic coupling agent, an energy curable organometallic coupling agent, and a high refractive index monomer or oligomer. Polymeric materials of the present invention include condensed metal oxide nanoparticles having a mixture of organometallic coupling agents covalently bound to the exterior surface of the nanoparticles and a high refractive index solid polymer matrix, wherein the mixture of organometallic coupling agents includes a high refractive index coupling agent, and a coupling agent covalently bound to the polymer matrix. The materials of the present invention are useful in making optical devices for telecommunications applications.

Owner:CORNING INC

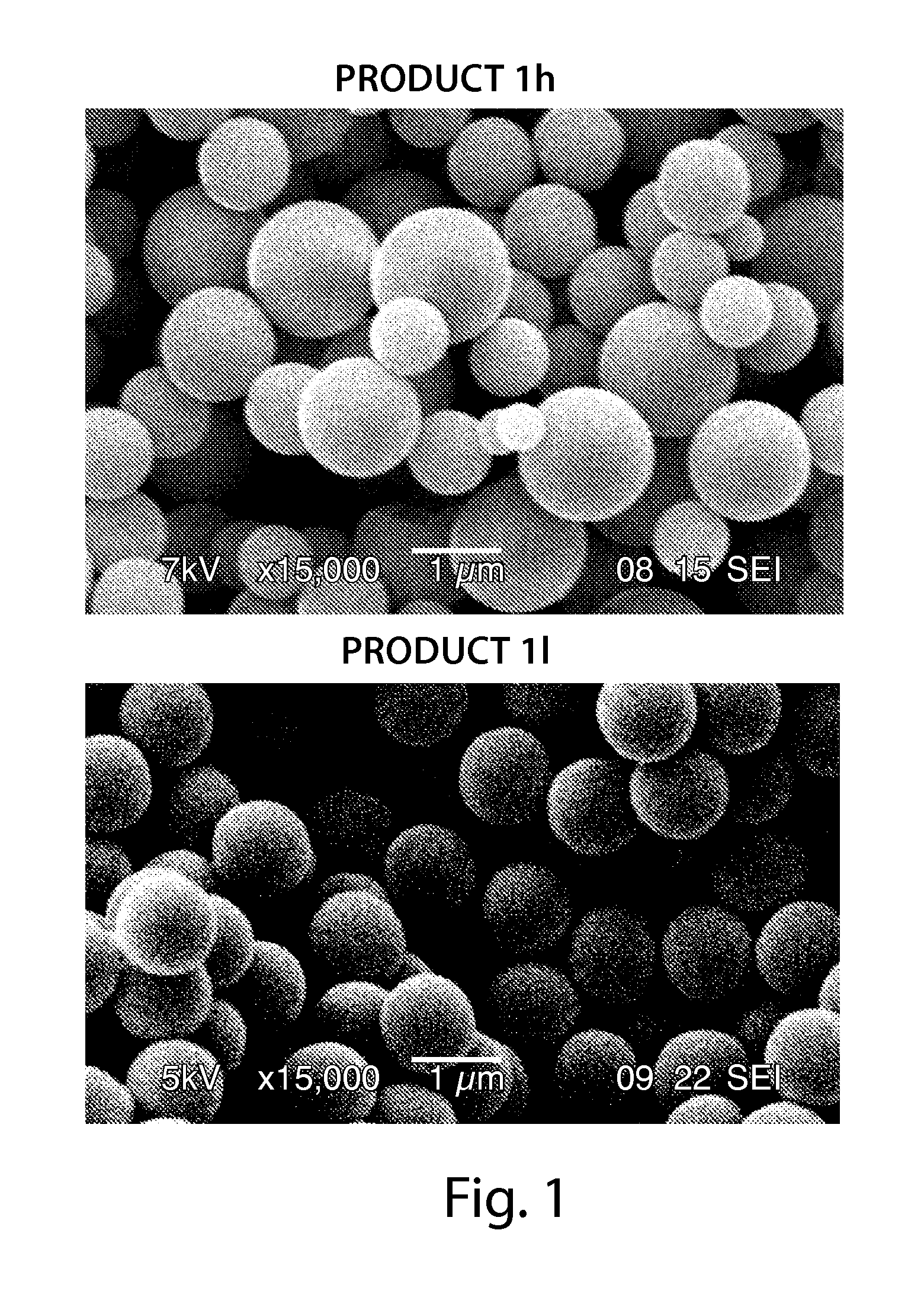

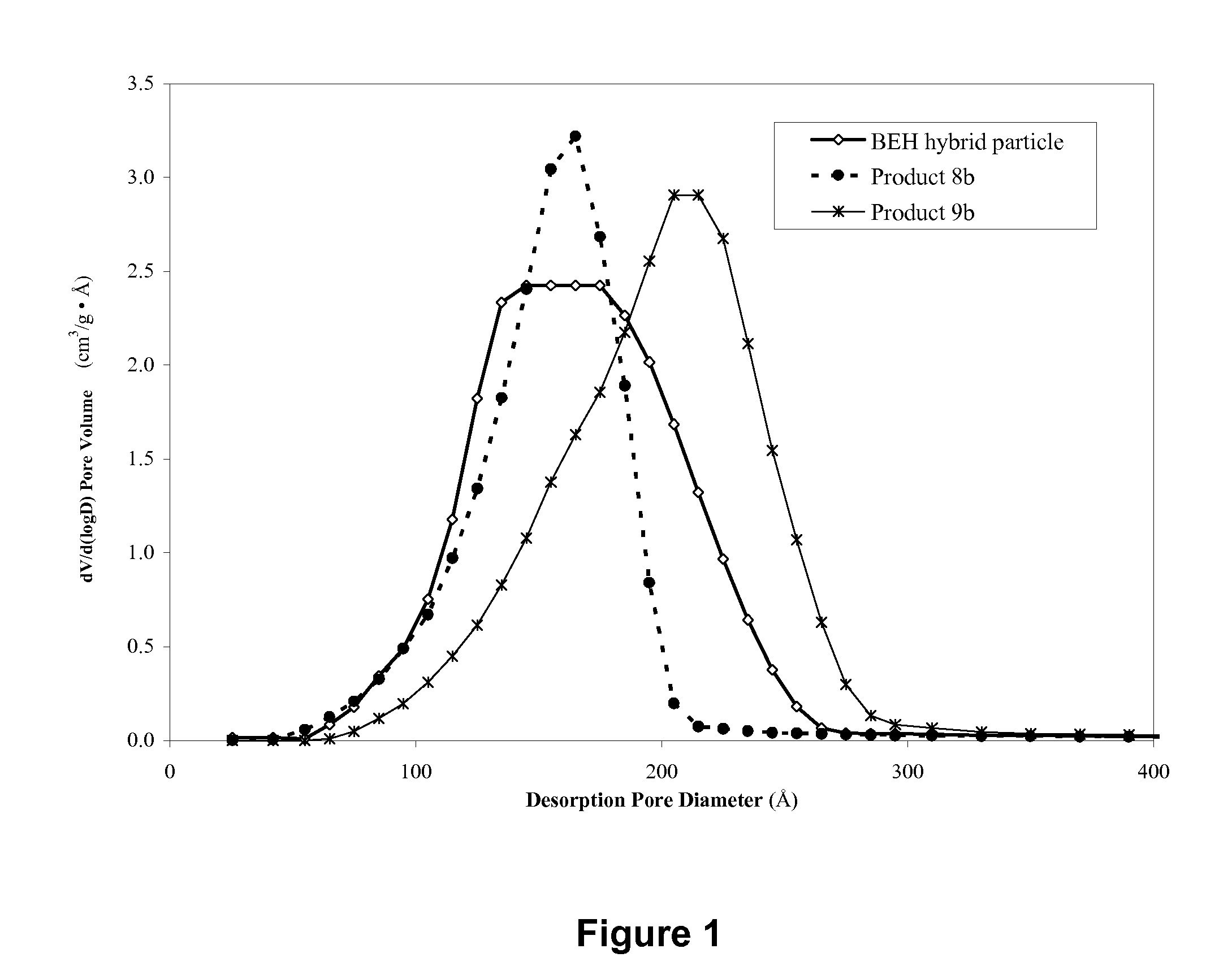

Porous hybrid particles with organic groups removed from the surface

InactiveUS7175913B2Reduced peak tailingEasy to separateComponent separationIon-exchanger regenerationChromatographic separationHybrid material

A material for chromatographic separations, processes for its preparation, and separation devices containing the chromatographic material. In particular, porous inorganic / organic hybrid materials are provided with a decreased concentration of surface organic groups. These particles may be surface modified and have enhanced stability at low pH.

Owner:WATERS TECH CORP

Compositions and methods for intervertebral disc reformation

Methods of reforming degenerated intervertebral discs are provided in accordance with methods of the invention. Hybrid materials useful in methods of the present invention are also provided.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

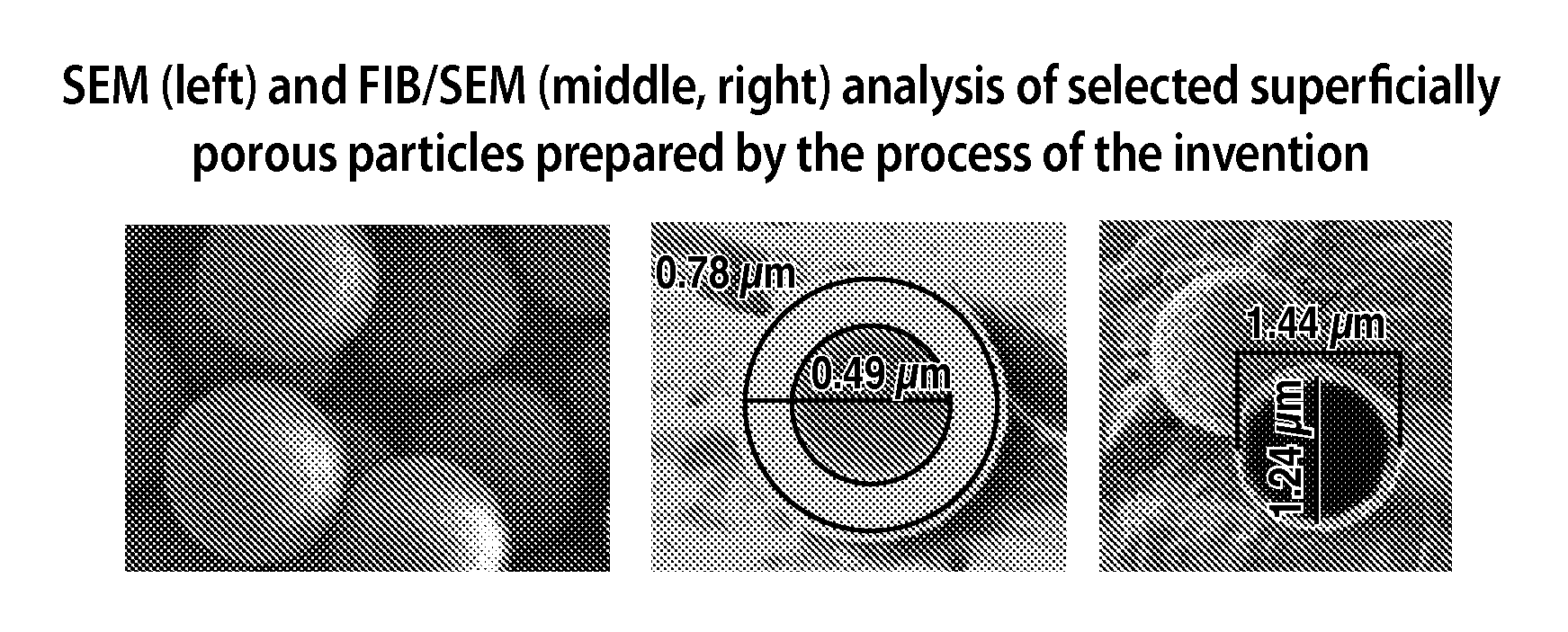

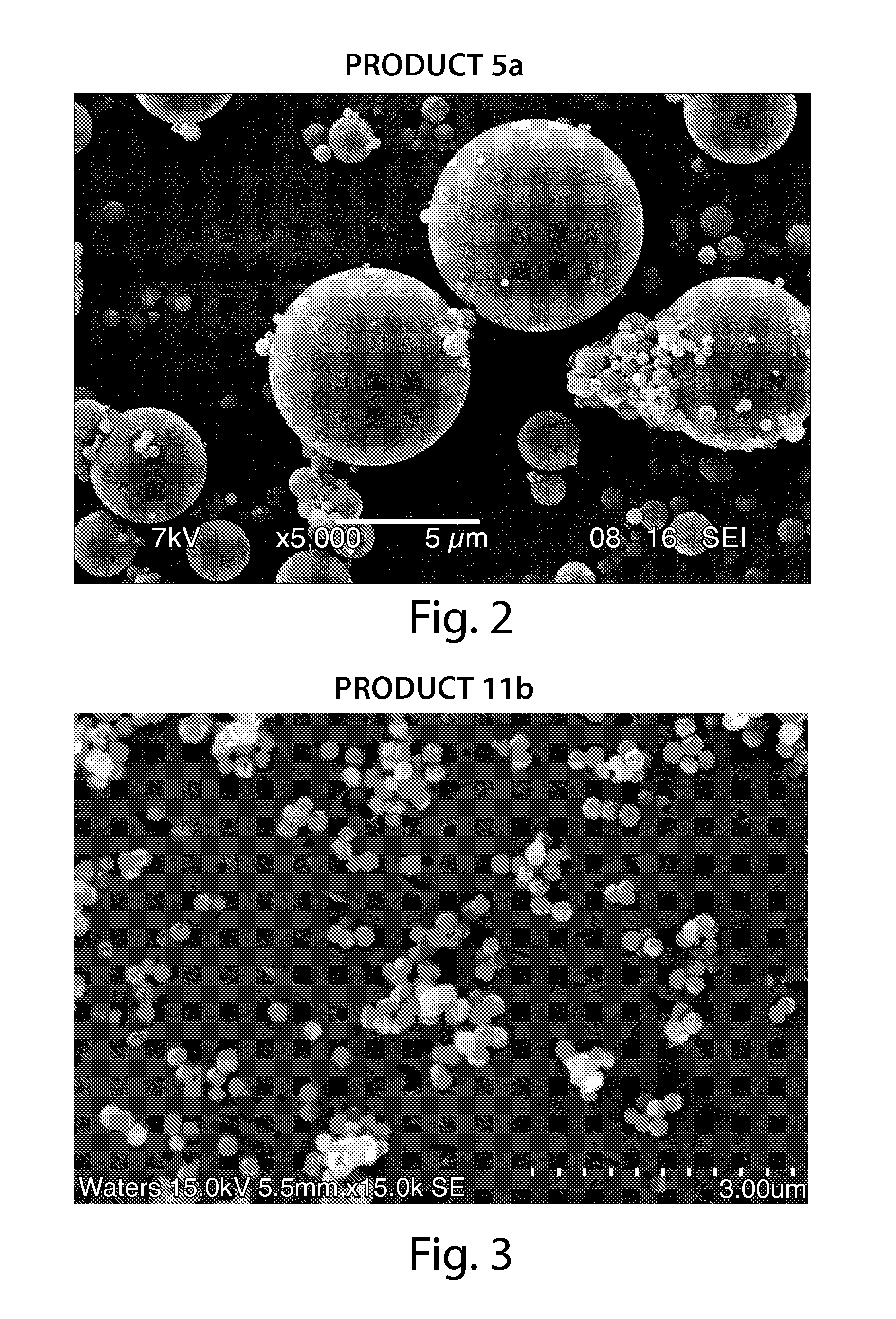

Superficially porous materials comprising a substantially nonporous core having narrow particle size distribution; process for the preparation thereof; and use thereof for chromatographic separations

InactiveUS20130112605A1Prevent fine generationInhibit aggregationIon-exchanger regenerationPretreated surfacesChromatographic separationHybrid material

Novel chromatographic materials for chromatographic separations, columns, kits, and methods for preparation and separations with a superficially porous material comprising a substantially nonporous core and one or more layers of a porous shell material surrounding the core. The material of the invention is comprised of superficially porous particles and a narrow particle size distrution. The material of the invention is comprised of a superficially porous monolith, the substantially nonporous core material is silica; silica coated with an inorganic / organic hybrid surrounding material; a magnetic core material; a magnetic core material coated with silica; a high thermal conductivity core material; a high thermal conductivity core material coated with silica; a composite material; an inorganic / organic hybrid surrounding material; a composite material coated with silica; a magnetic core material coated with an inorganic / organic hybrid surrounding material; or a high thermal conductivity core material coated with an inorganic / organic hybrid surrounding material.

Owner:WATERS TECH CORP

Golf balls comprising glass ionomers, ormocers, or other hybrid organic/inorganic compositions

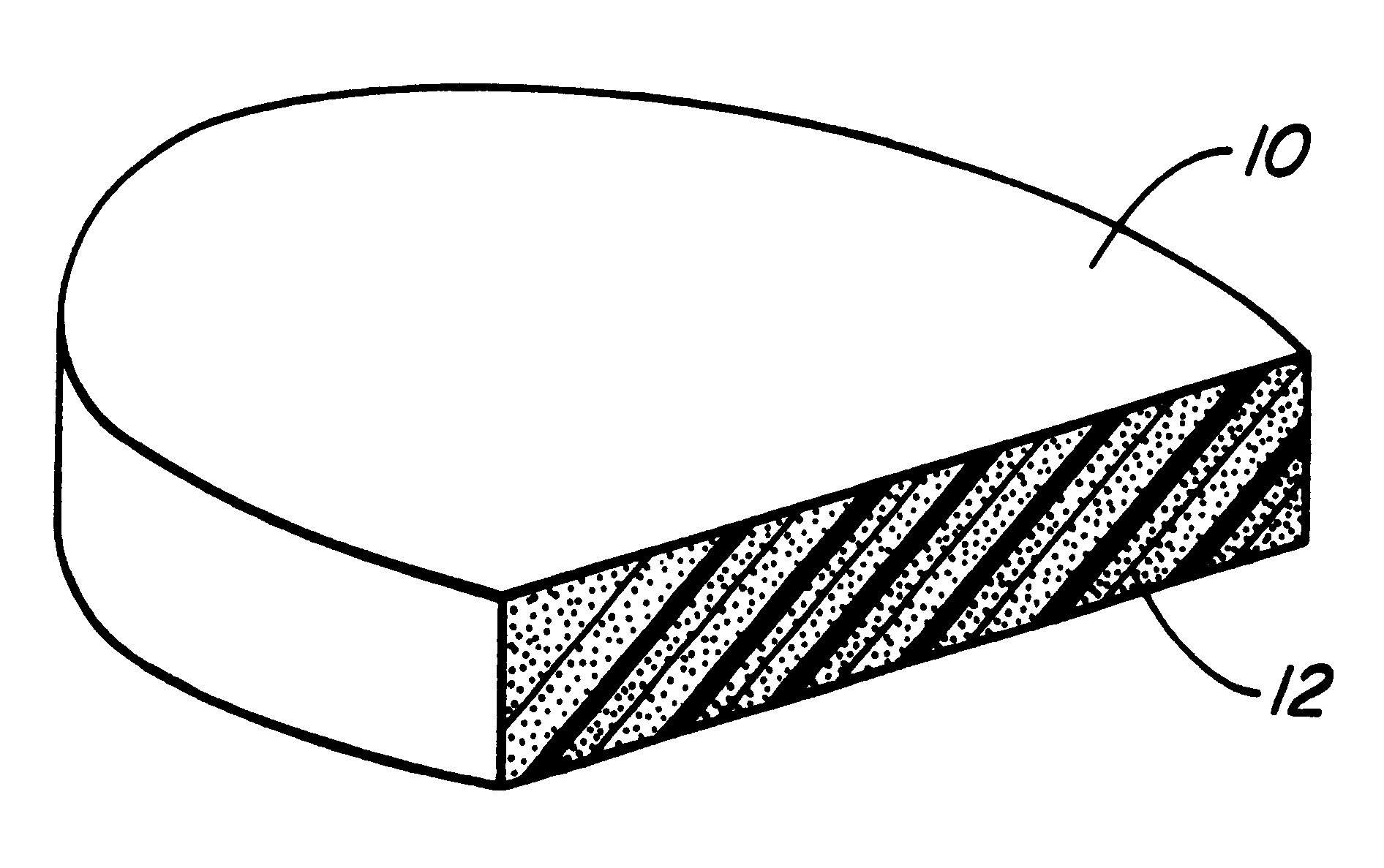

A golf ball comprising a core and a cover layer, wherein at least one of the core or cover layer comprises a hybrid material that contains fatty acid-modified glass ionomers, an ormocer or other inorganic-organic materials.

Owner:ACUSHNET CO

Uniform surfaces for hybrid material substrates and methods for making and using same

Devices, systems and methods of using same where hybrid substrate materials are provided with a substantially uniform surface to provide uniformity of properties, including interaction with their environments. Uniform surfaces are applied as coatings over, e.g., hybrid metal / silica, metal / polymer, metal / metal surfaces to mask different chemical properties of differing regions of the surface and to afford a protective surface for the hybrid structure.

Owner:PACIFIC BIOSCIENCES

Hybrid anode compositions for lithium ion batteries

ActiveUS8119288B2Improve conductivityLower internal resistanceAlkaline accumulatorsConductive materialPhysical chemistryHybrid material

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

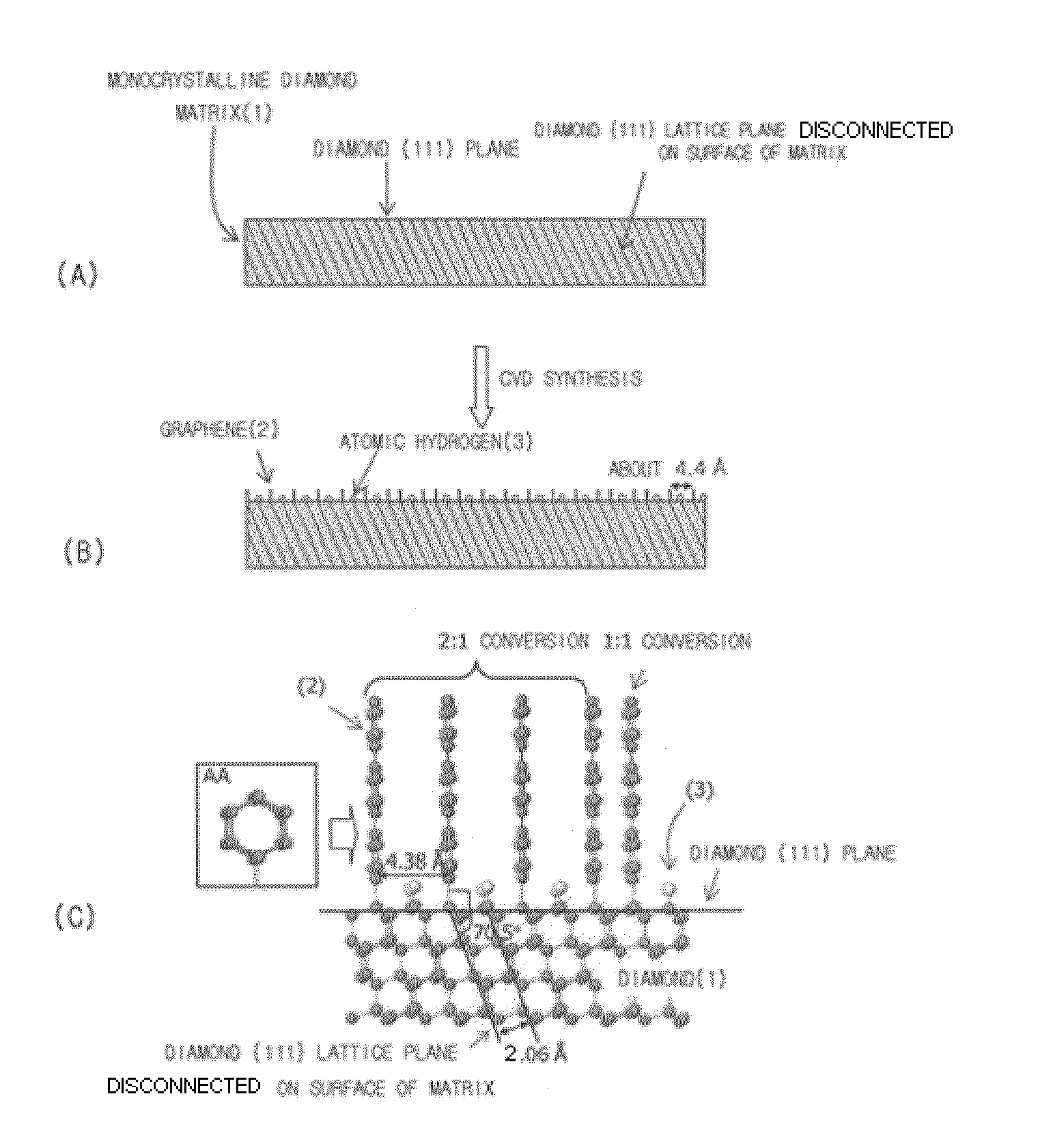

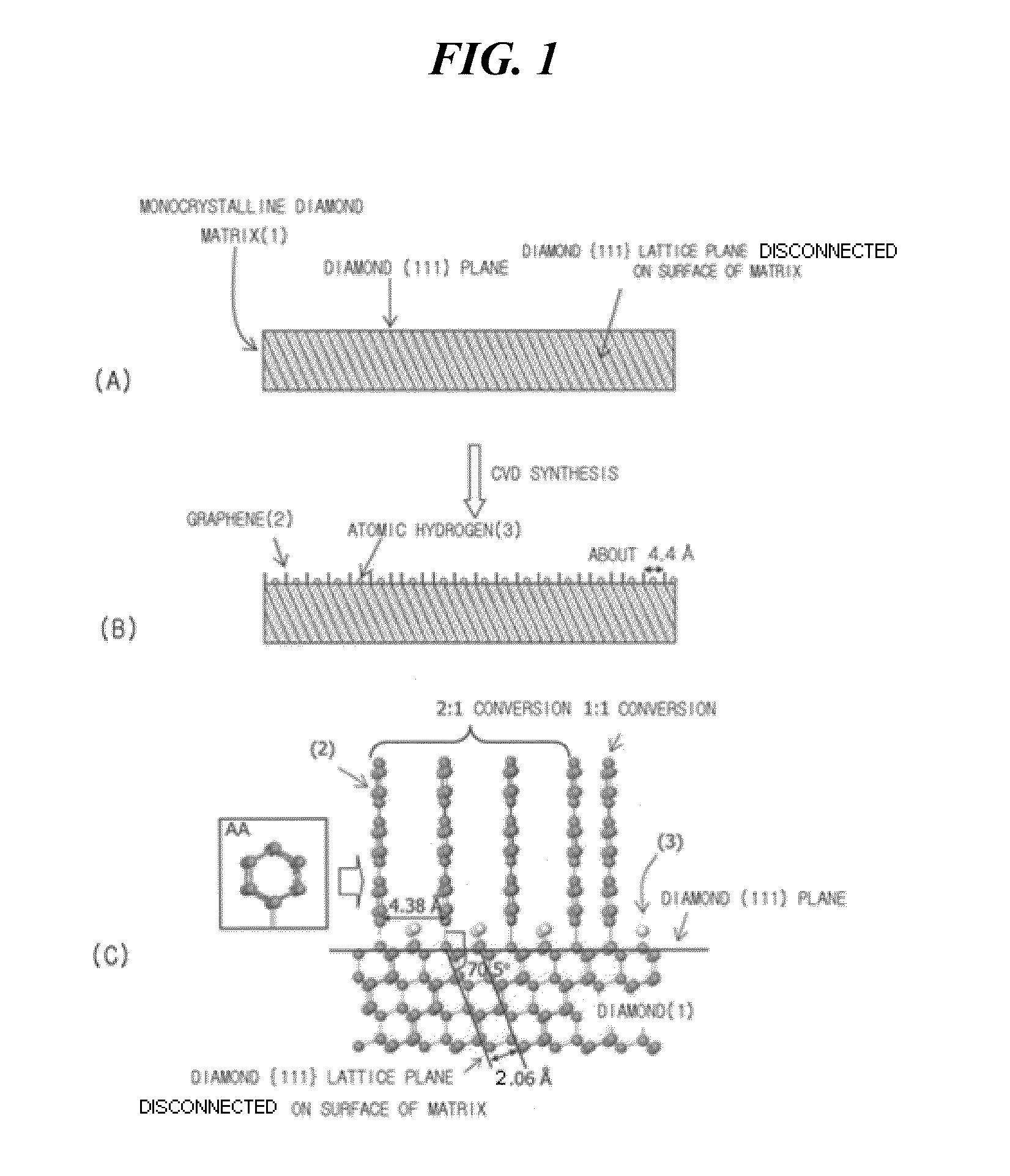

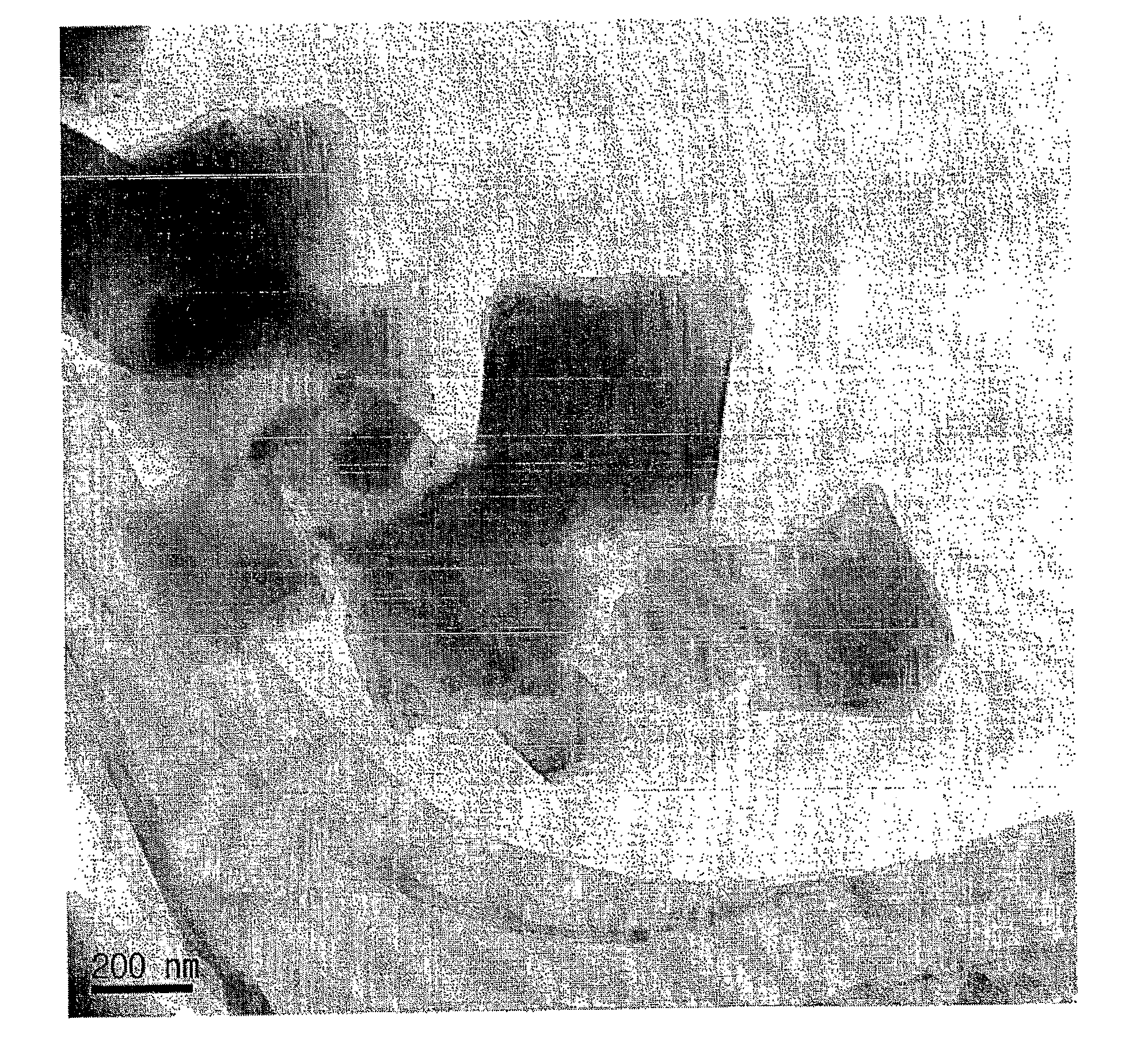

Graphene hybrid material and method for preparing same using chemical vapor deposition

Disclosed herein are a graphene hybrid material and a method for preparing the graphene hybrid material, the graphene hybrid material comprising: a matrix having lattice planes disconnected on a surface thereof; and layers of graphene which are epitaxially grown along the lattice planes disconnected on the surface of the matrix such that the layers of graphene are oriented perpendicularly to the matrix, and which are spaced apart from each other and layered on the matrix in the same shape. The graphene hybrid material can be usefully used in the fields of next-generation semiconductor devices, biosensors, electrochemical electrodes and the like.

Owner:KOREA INST OF SCI & TECH

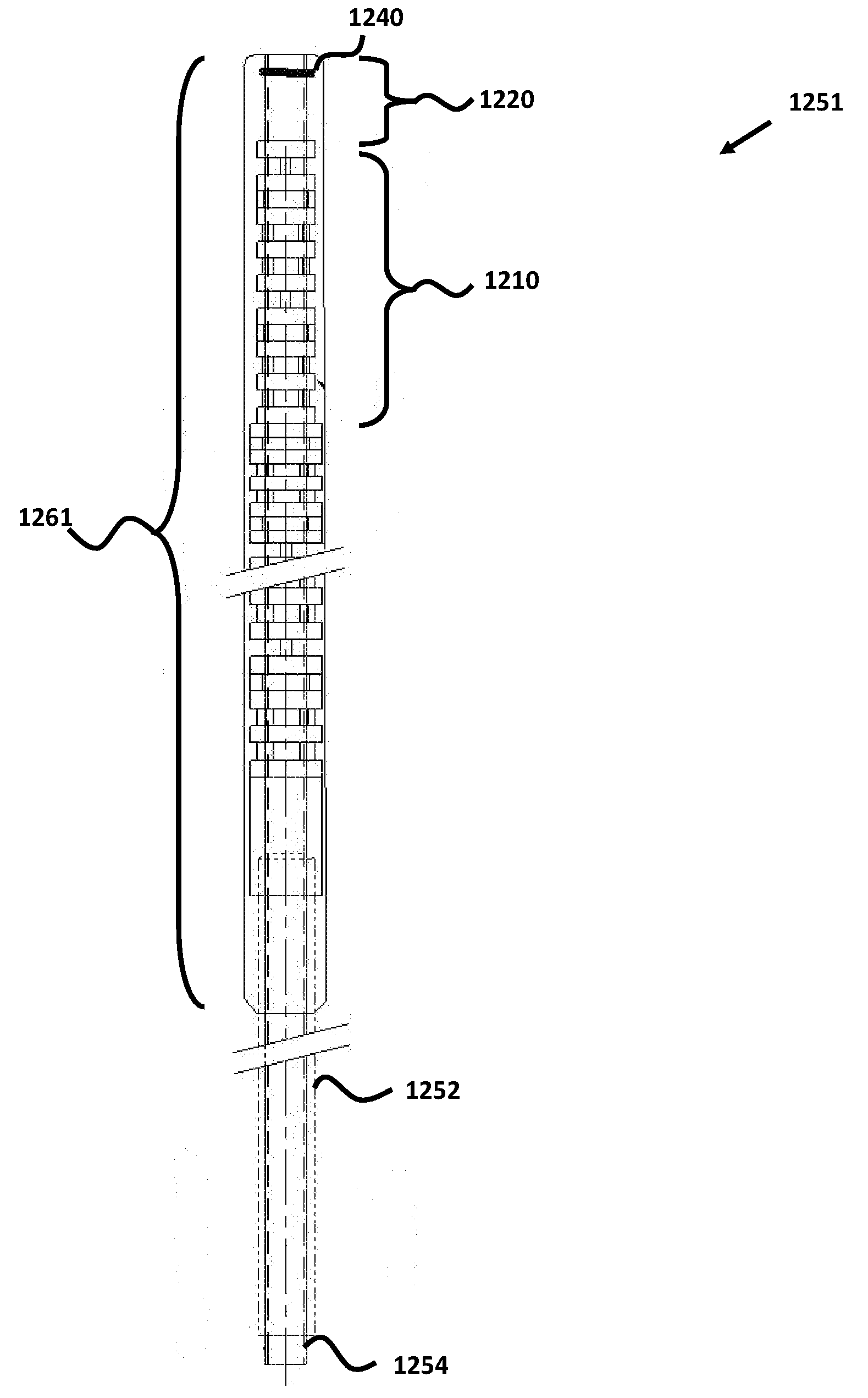

Micro-fabricated Guidewire Devices Formed With Hybrid Materials

Owner:SCIENTIA VASCULAR INC

Preparation of surface functionalized porous organic-inorganic hybrid materials or mesoporous materials with coordinatively unsaturated metal sites and catalytic applications thereof

ActiveUS20100273642A1Improve adhesionHigh catalytic activityMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsSorbentHybrid material

Disclosed herein is a method of surface-functionalizing a porous organic-inorganic hybrid material or a organic-inorganic mesoporous material, in which organic substances, inorganic substances, ionic liquids and organic-inorganic hybrid substances are selectively functionalized on the coordinatively unsaturated metal sites of a porous organic-inorganic hybrid material or organic-inorganic mesoporous material, and thus the porous organic-inorganic hybrid material can be used for adsorbents, gas storage devices, sensors, membranes, functional thin films, catalysts, catalytic supports, and the like, and the applications of the surface-functionalized porous organic-inorganic hybrid material prepared using the method to catalytic reactions.

Owner:KOREA RES INST OF CHEM TECH

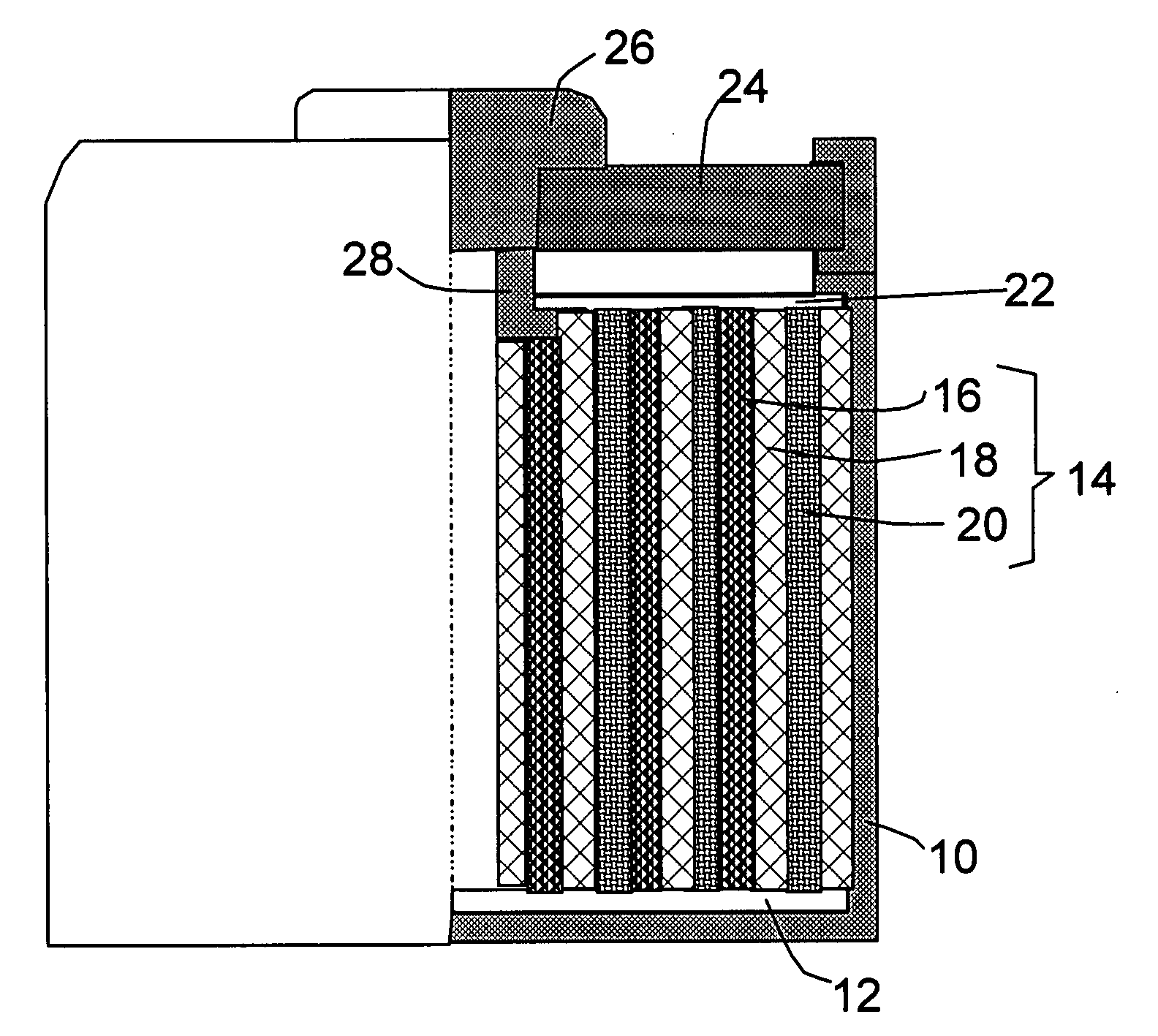

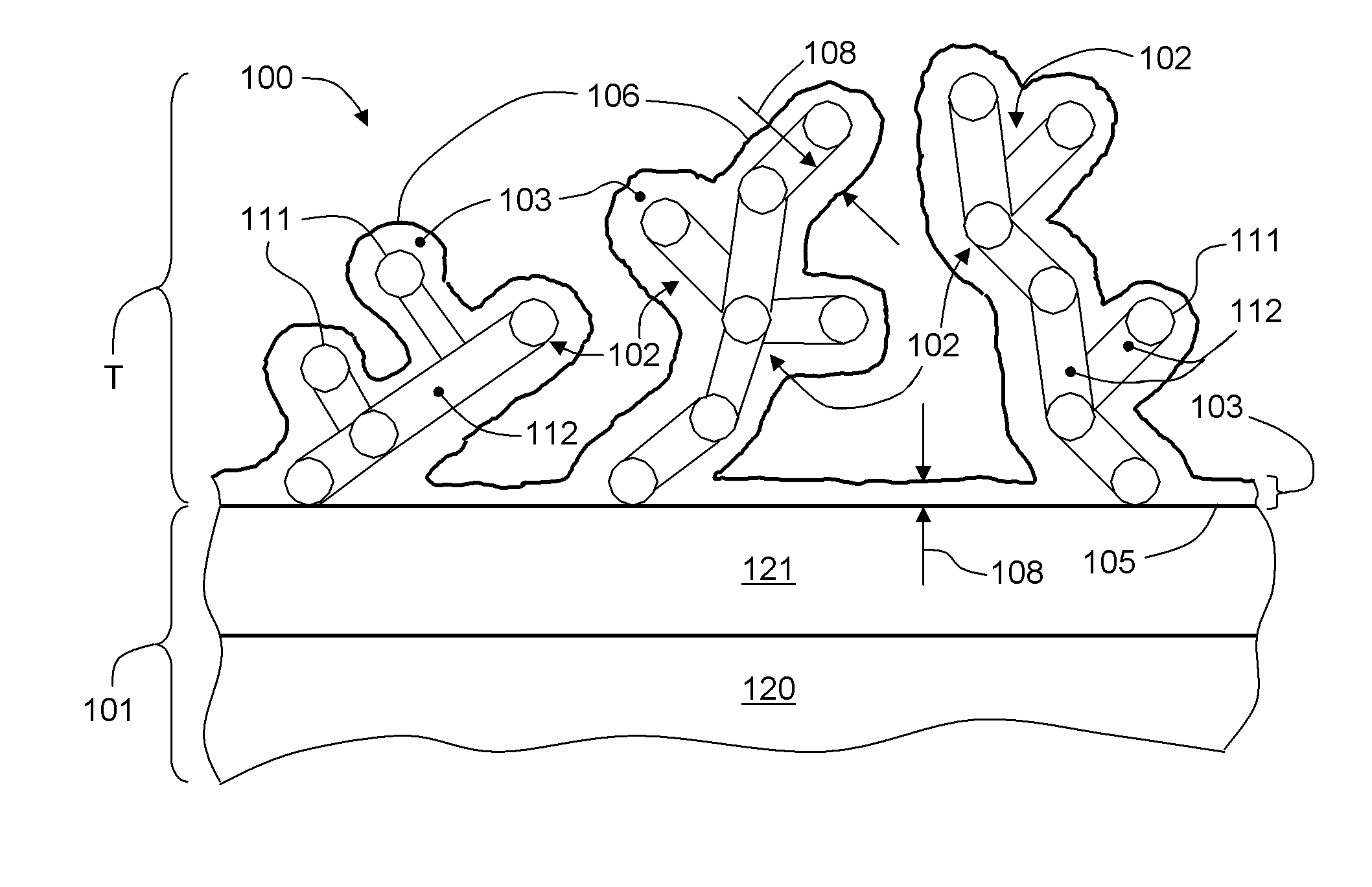

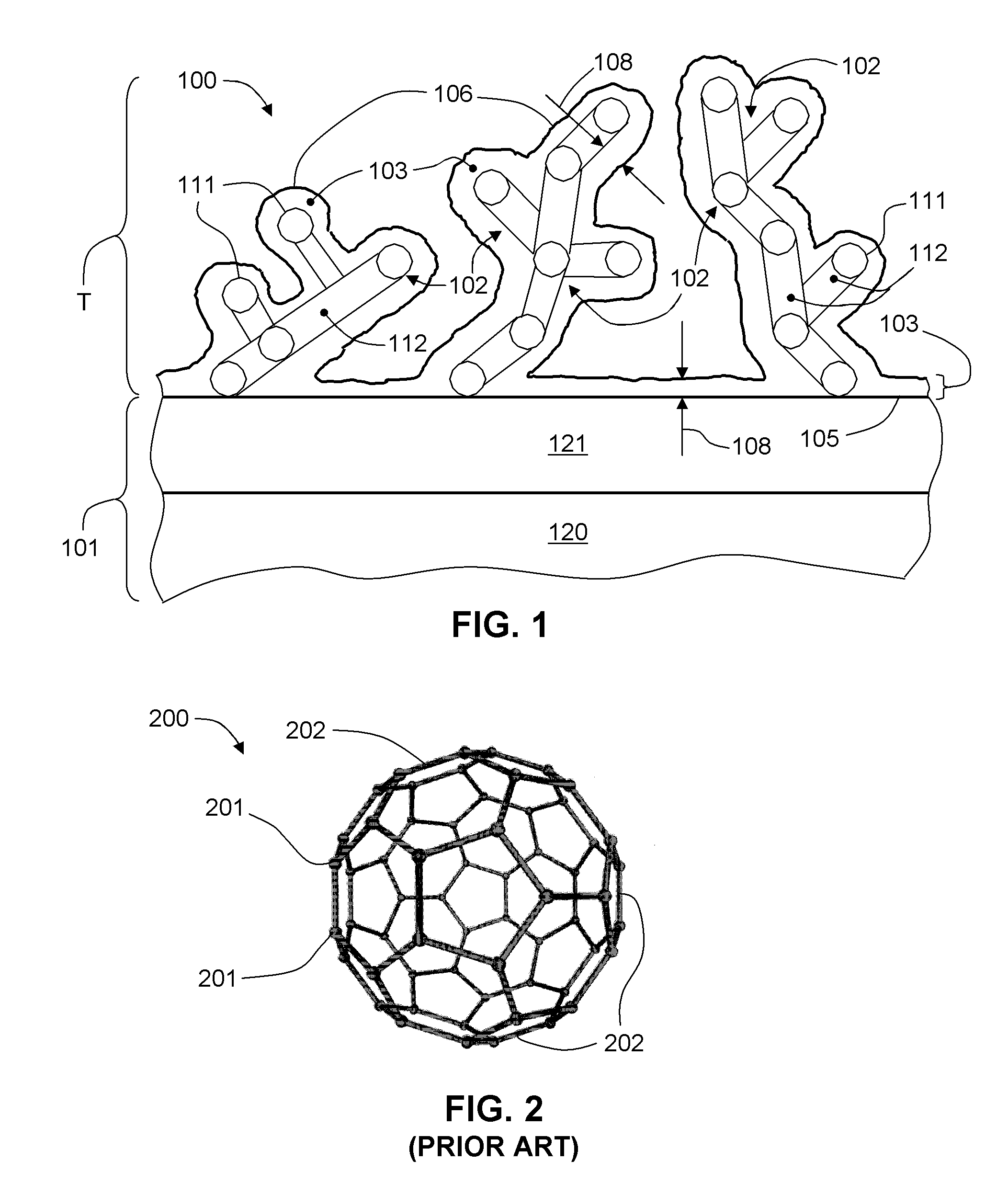

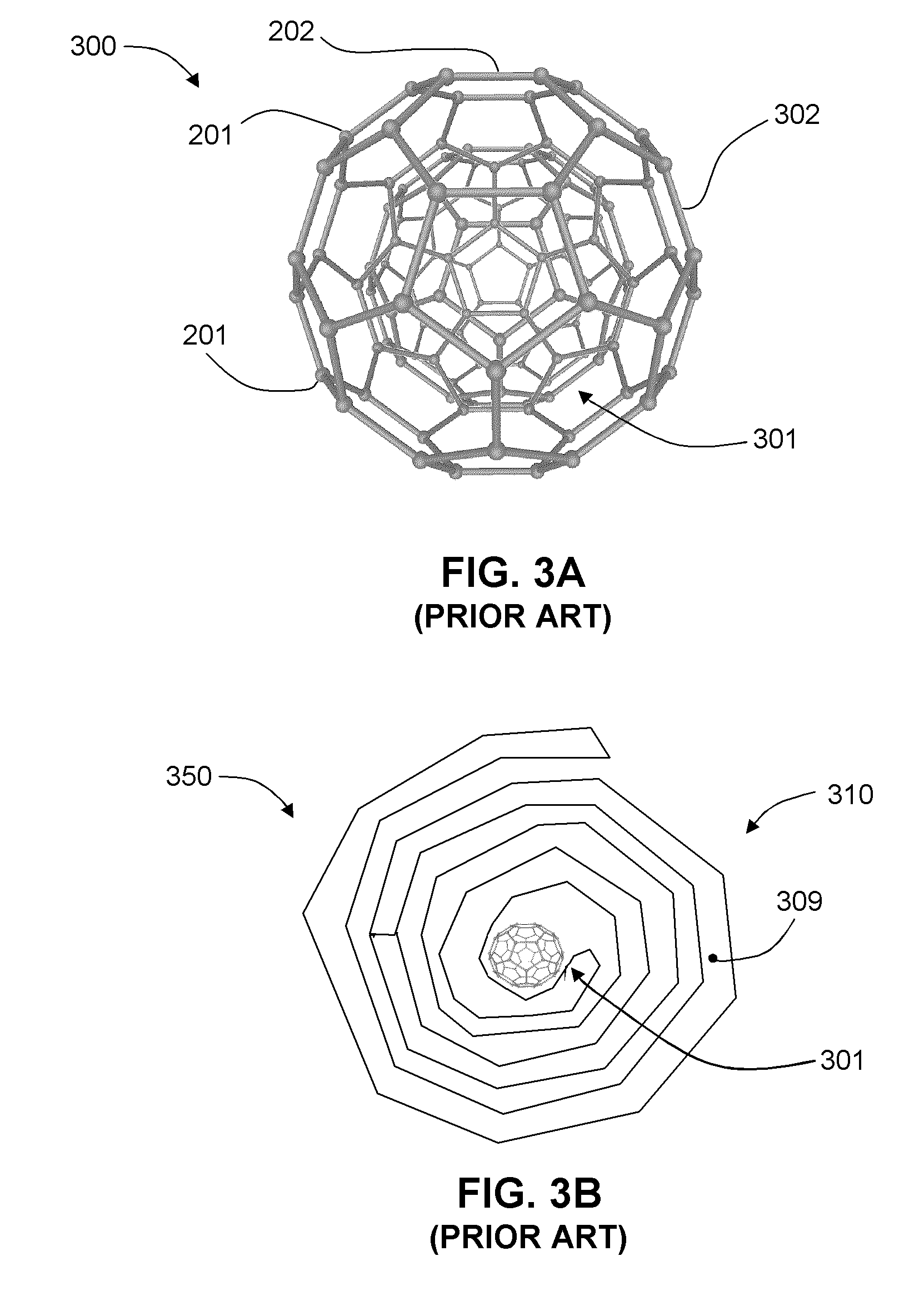

Three-dimensional battery with hybrid nano-carbon layer

InactiveUS20100151318A1Good electrical contactMaterial nanotechnologyNanostructure manufactureCarbon nanotubeHigh surface area

A Li-ion battery cell is formed from deposited thin-film layers and comprises a high-surface-area 3-D battery structure. The high-surface-area 3-D battery structure includes a fullerene-hybrid material deposited onto a surface of a conductive substrate and a conformal metallic layer deposited onto the fullerene-hybrid material. The fullerene-hybrid material is made up of chains of fullerene “onions” linked by carbon nanotubes to form a high-surface-area layer on the conductive substrate and has a “three-dimensional” surface. The conformal metallic layer acts as the active anode material in the Li-ion battery and also has a high surface area, thereby forming a high-surface-area anode. The Li-ion battery cell also includes an ionic electrolyte-separator layer, an active cathodic material layer, and a metal current collector for the cathode, each of which is deposited as a conformal thin film.

Owner:APPLIED MATERIALS INC

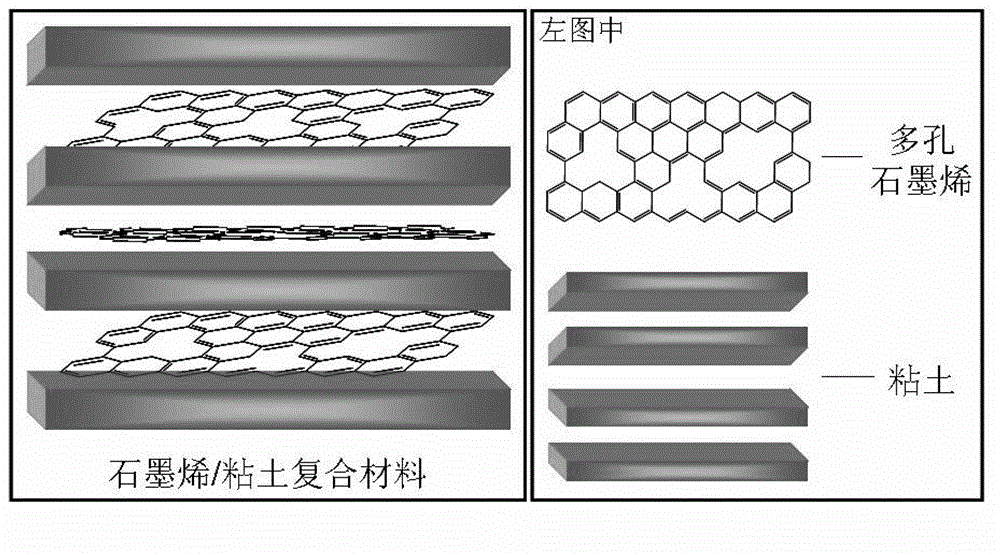

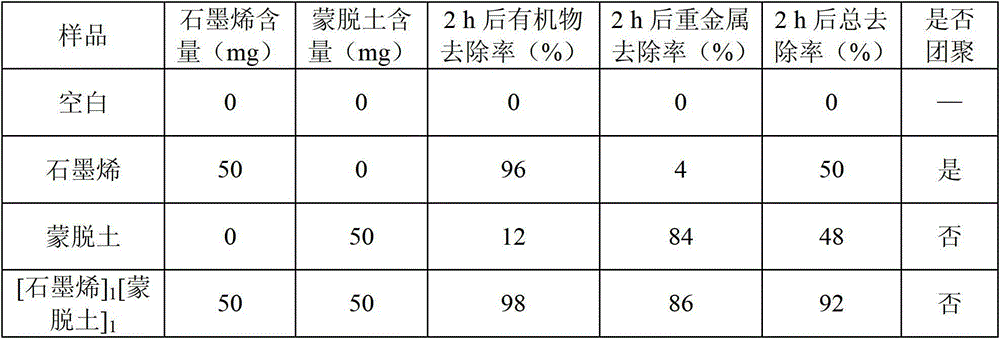

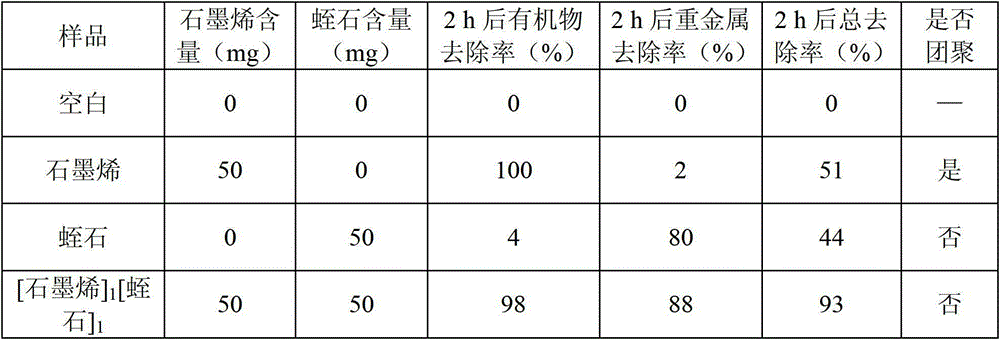

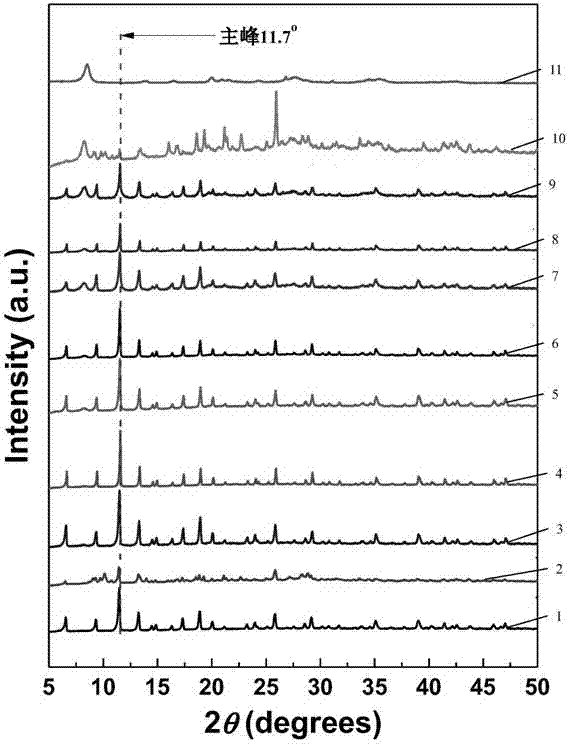

Graphene/clay composite material, and preparation method and application thereof

ActiveCN103143319AGood dispersionReduce reunionOther chemical processesWater/sewage treatment by sorptionIntercalation reactionDispersity

The invention belongs to the field of adsorbing materials, and relates to an inorganic-inorganic hybrid material, particularly a graphene / clay composite material. The composite material is powdery, is compounded from porous graphene and clay, and has a porous structure; the porous graphene is inserted among clay layers through intercalation reaction; the mass ratio of the porous graphene to the clay is 1:(0.1-10); the specific area of the graphene / clay composite material is 200-250 m<2> / g, and the weight loss within 900 DEG C is 3-6 wt%; and the clay is montmorillonite, vermiculite, illite, kaolin or rectorite. The graphene / clay composite material can be easily dispersed, can be used for comprehensively and efficiently adsorbing heavy metals and organic substances, and has the characteristics of high dispersity and efficient and selective adsorbability for heavy metals and organic substances; the maximum comprehensive removal rate can reach 99%; and thus, the invention has wide prospects in industrialized application.

Owner:JINAN UNIVERSITY

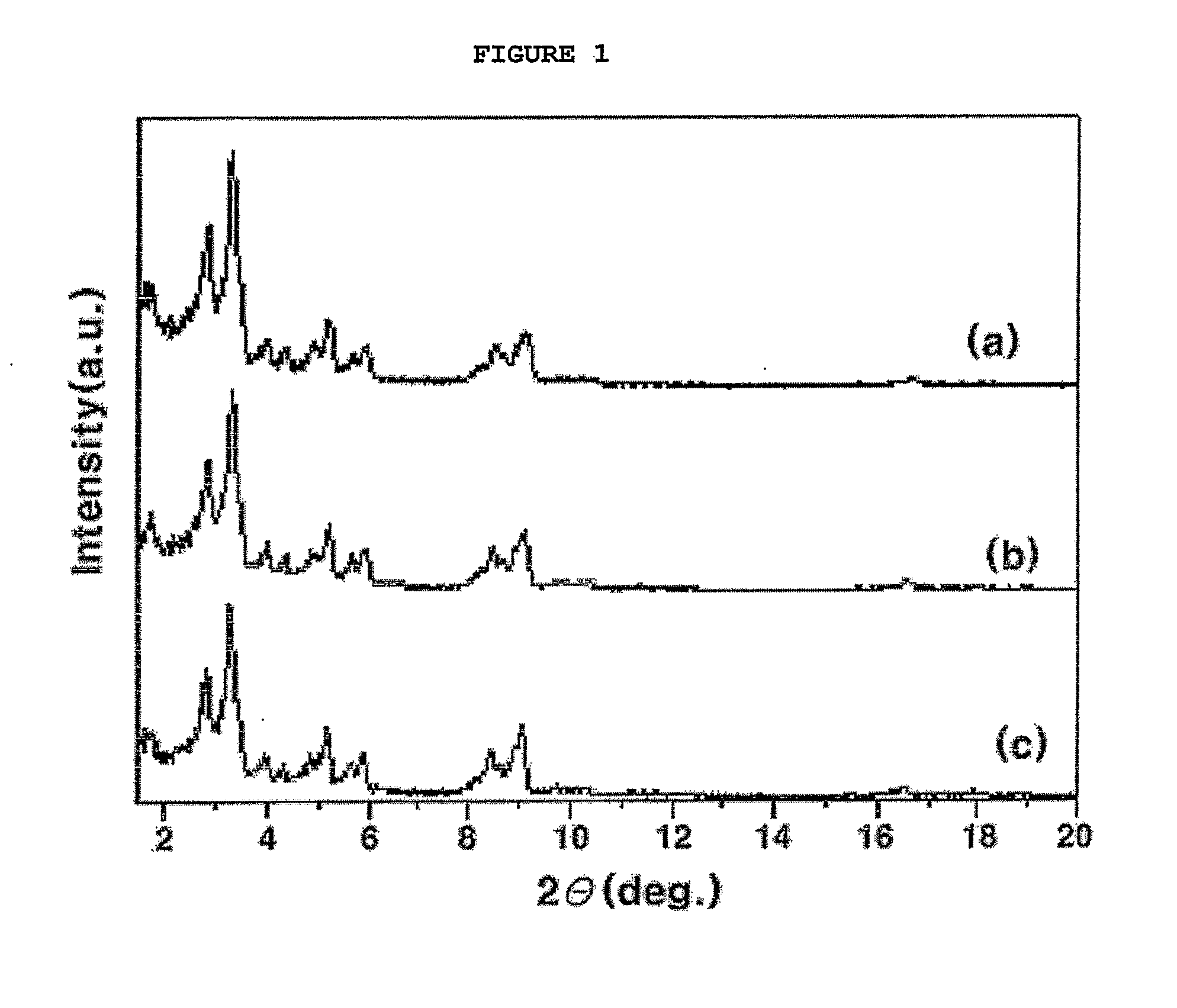

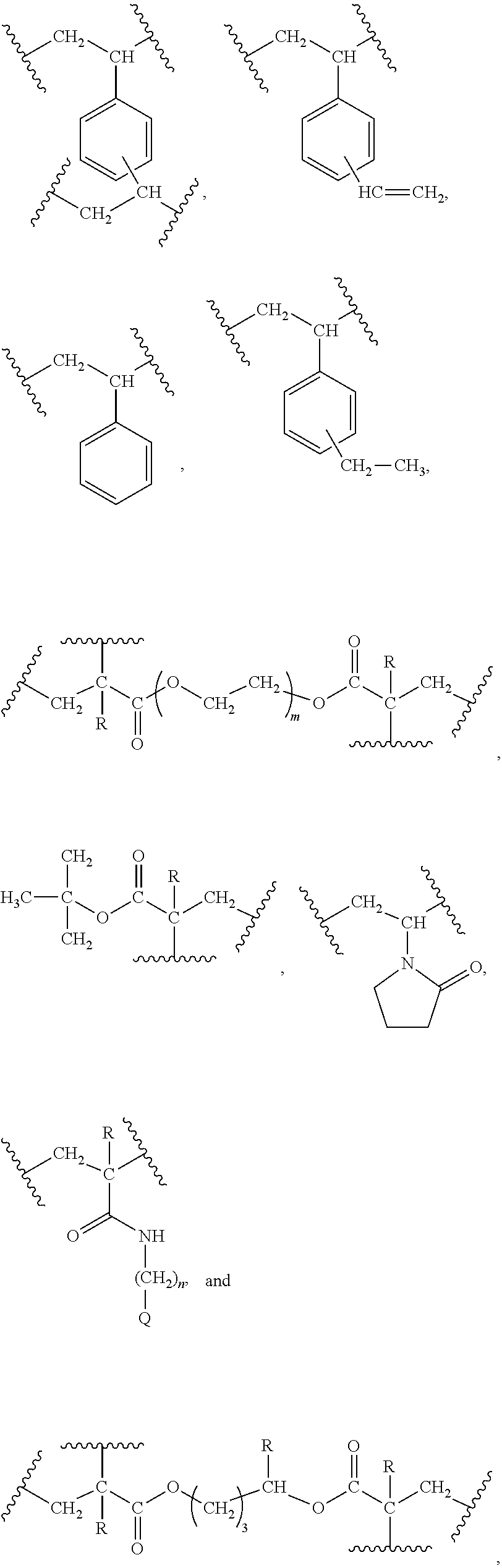

Porous inorganic/organic homogenous copolymeric hybrid materials for chromatographic separation and process for the preparation thereof

InactiveUS20050230298A1Ion-exchange process apparatusComponent separationChromatographic separationPolymer science

Owner:WATERS TECH CORP

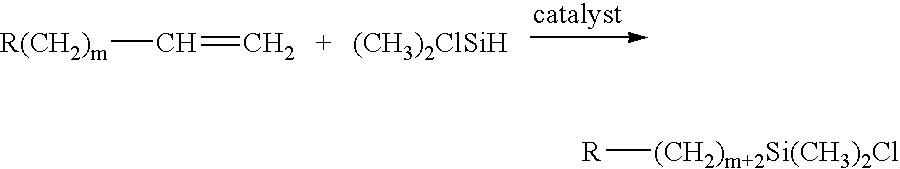

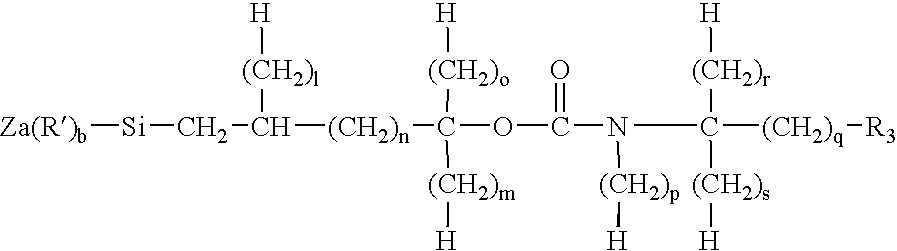

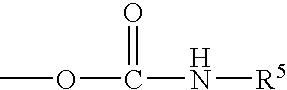

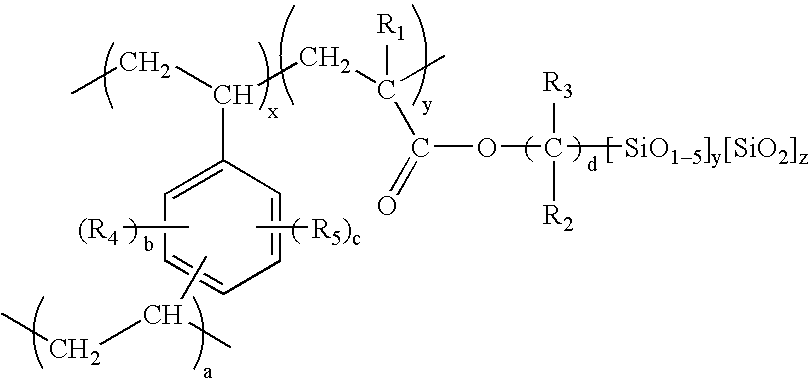

Hybrid inorganic/organic materials having novel surface modification; process for the preparation of inorganic/organic hybrid materials; and use of said particles for chromatographic separations

ActiveUS20120055860A1Enhancing oneMany of characteristicIon-exchange process apparatusSemi-permeable membranesChromatographic separationIon exchange

The present invention provides novel chromatographic materials, e.g., for chromatographic separations, processes for their preparation and separations devices containing the chromatographic materials. The preparation of the inorganic / organic hybrid materials of the invention wherein a surrounding material is condensed on a porous hybrid core material will allow for families of different hybrid packing materials to be prepared from a single core hybrid material. Differences in hydrophobicity, ion-exchange capacity, surface charge or silanol activity of the surrounding material may be used for unique chromatographic separations of small molecules, carbohydrates, antibodies, whole proteins, peptides, and / or DNA.

Owner:WATERS TECH CORP

Organic-inorganic hybrid super-hydrophilic coating as well as preparation method and application thereof

InactiveCN102241939AEasy to prepareMild reaction conditionsPretreated surfacesCoatingsHydrophilic monomerPtru catalyst

The invention discloses an organic-inorganic hybrid super-hydrophilic coating as well as a preparation method and an application thereof. The preparation method comprises: firstly carrying out hydrolysis condensation polymerization by a sol-gel method with ethyl orthosilicate used as a precursor, hydrochloric acid used as a catalyst, ethanol used as a solvent, a silane coupling agent used as a modifier and a proper amount of water to obtain a modified silica sol, then carrying out free radical polymerization on the modified silica sol and reactive hydrophilic monomers to obtain an organic-inorganic hybrid material, and carrying out solvent replacement to obtain an aqueous organic-inorganic hybrid super-hydrophilic coating. The coating is coated on plastics, glass or metal substrates through dipping or brushing to form a coating layer, the coating layer has a contact angle with water less than 5 degrees, the adhesion force with the substrates of level-0 and the hardness greater than 6H, and water drops can spread out quickly on the coating layer.

Owner:SOUTH CHINA UNIV OF TECH

Truss Cable Semi-submersible Floater for Offshore Wind Turbines and Construction Methods

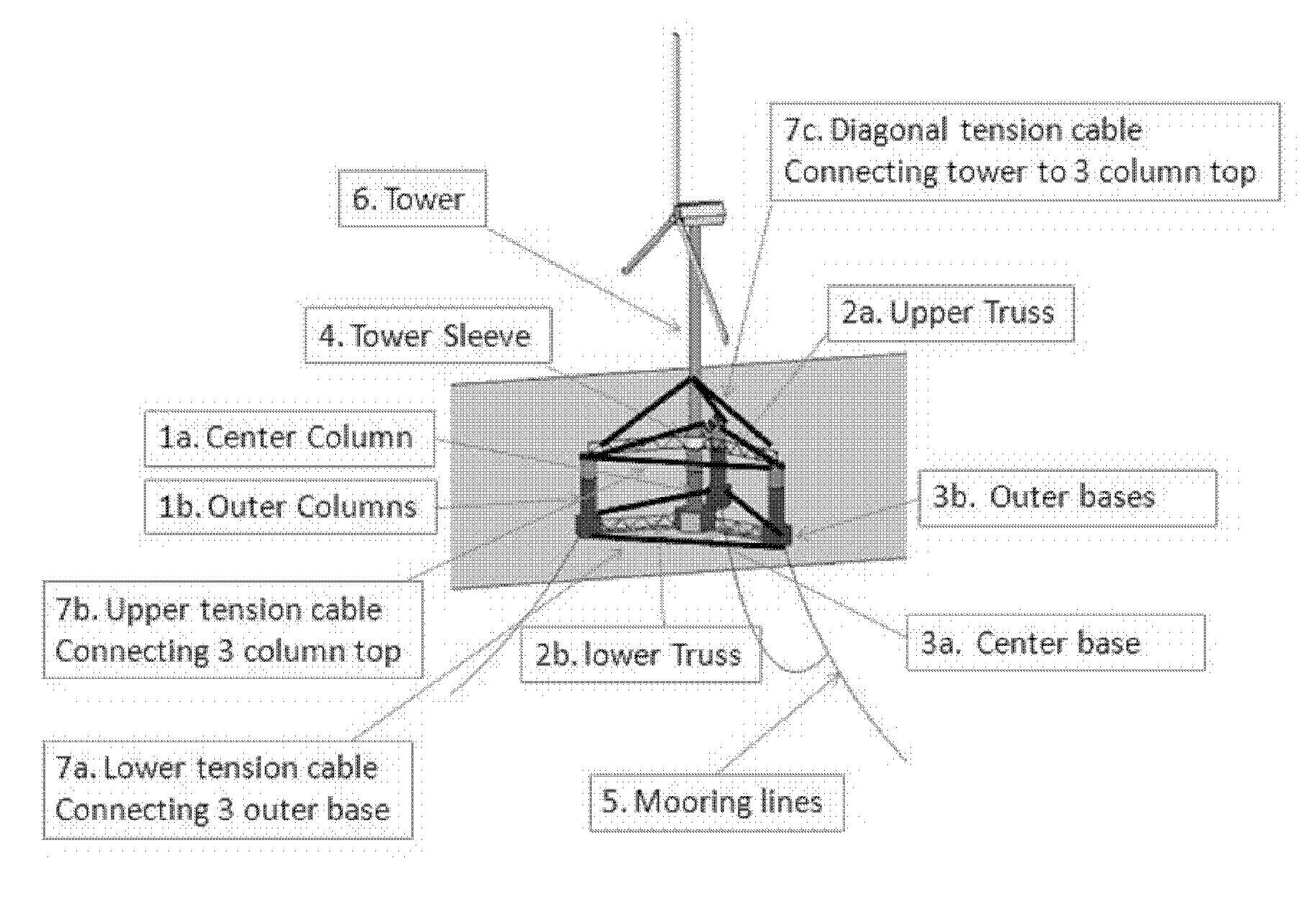

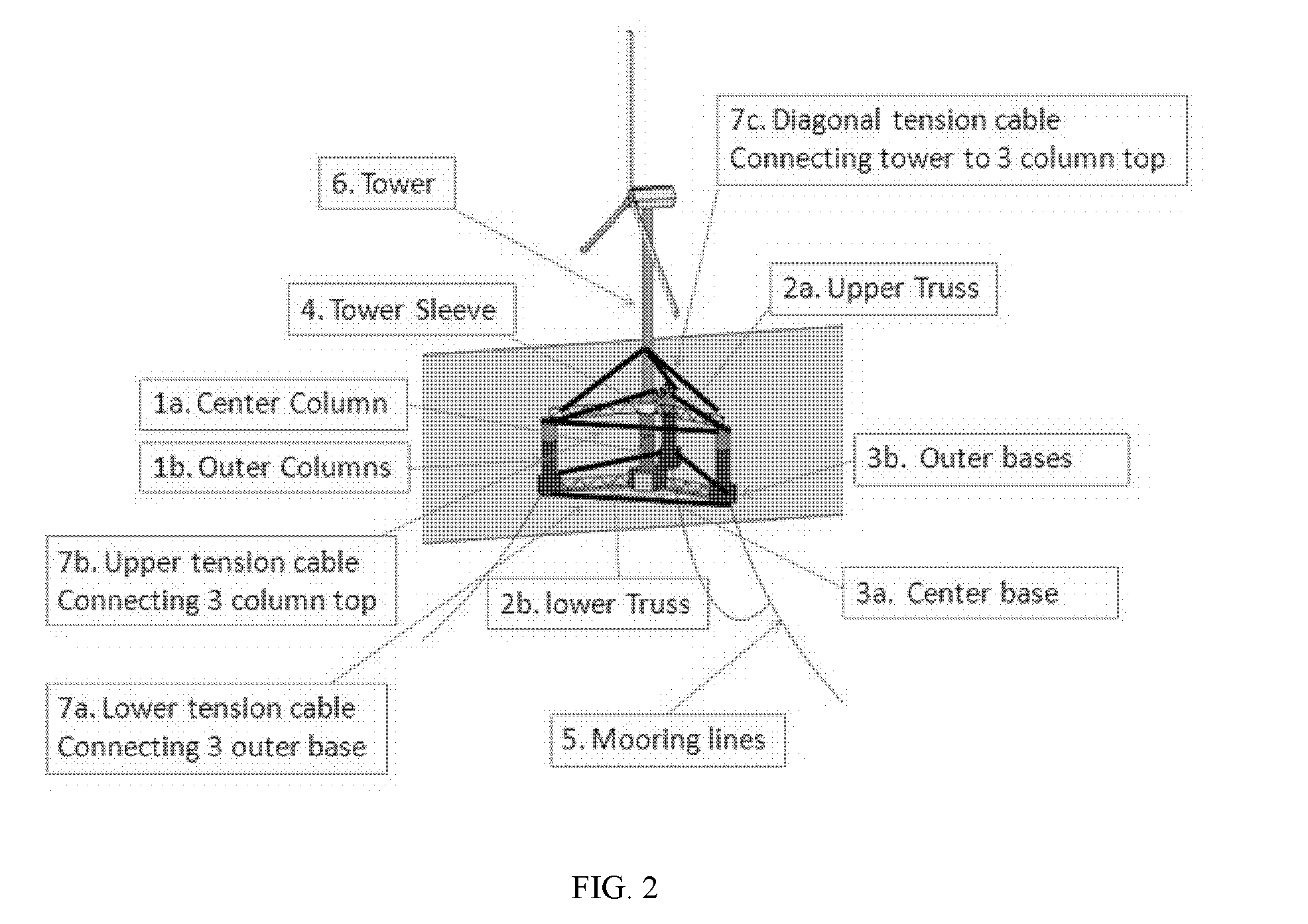

InactiveUS20120103244A1Improve dynamic performanceImprove stabilityWind energy generationFloating buildingsHull structureHybrid material

Truss cable semi-submersible floater for offshore wind turbines and construction methods are provided. A floating system includes a hull, a tensioned cable system, and a tower. The hull includes vertical buoyant columns with one column at the center of the pattern, larger size column base tanks, and a truss system, all of which are coupled to each other for supporting the tower and wind turbines. The column can be made of hybrid materials, including steel and composite-concrete. The steel section and the composite-concrete section of the column can be connected by grouting. The tensioned cable system including upper, lower, and diagonal tensioned cables to connect the column, the column base, and the tower to reduce the bending moments and improve stability, strength and dynamic performance of the hull structure.

Owner:WANG JIN +1

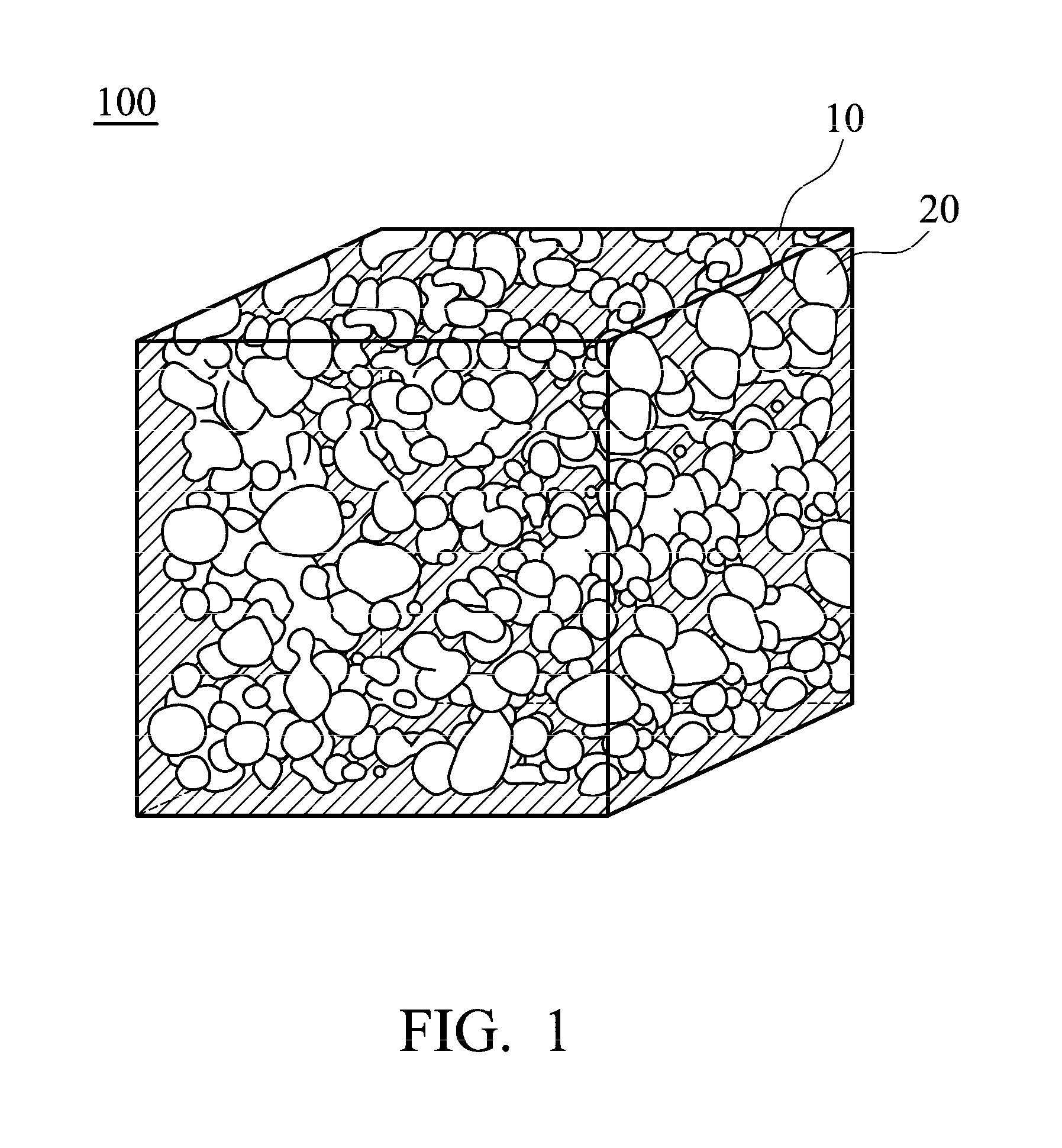

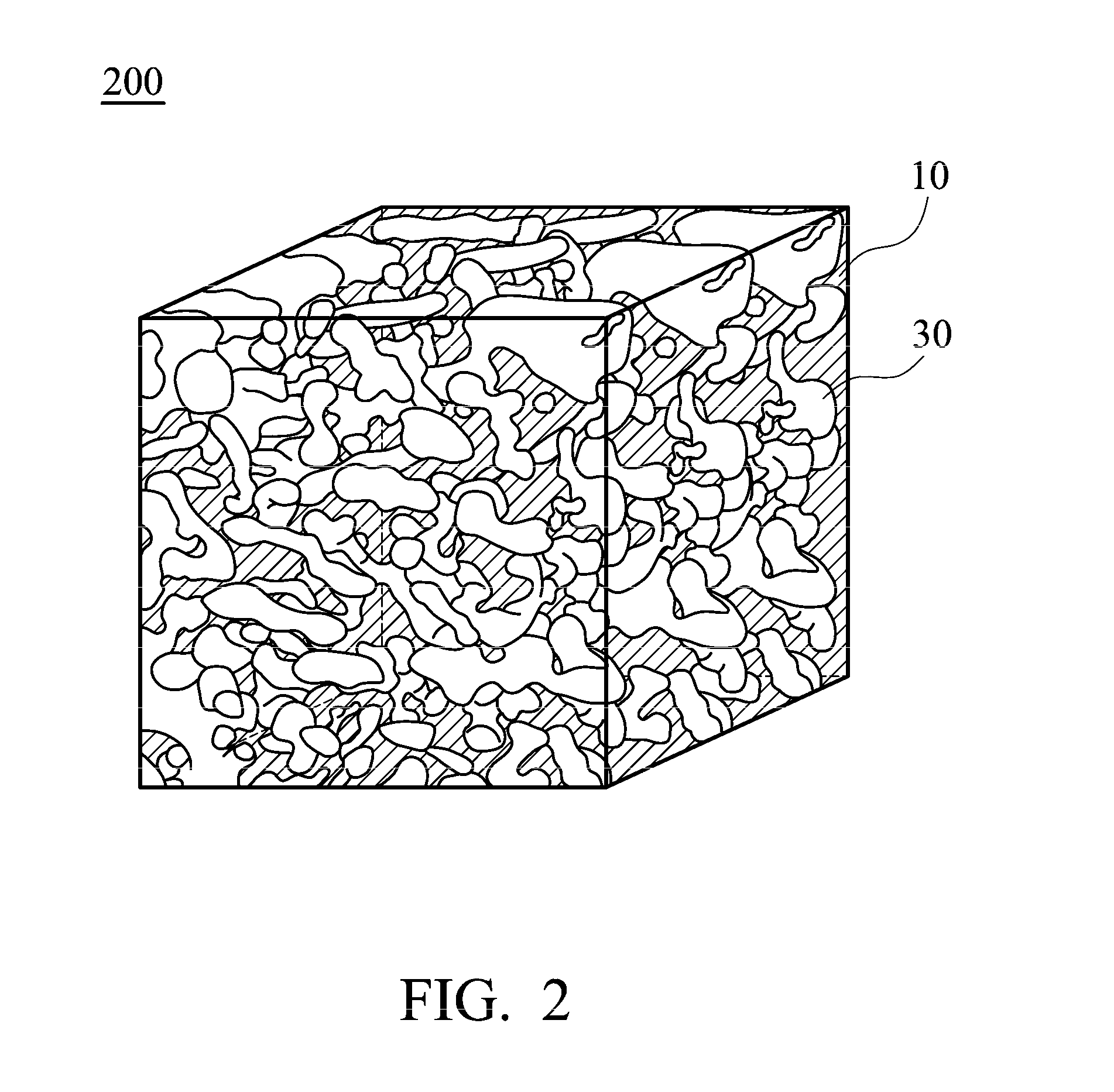

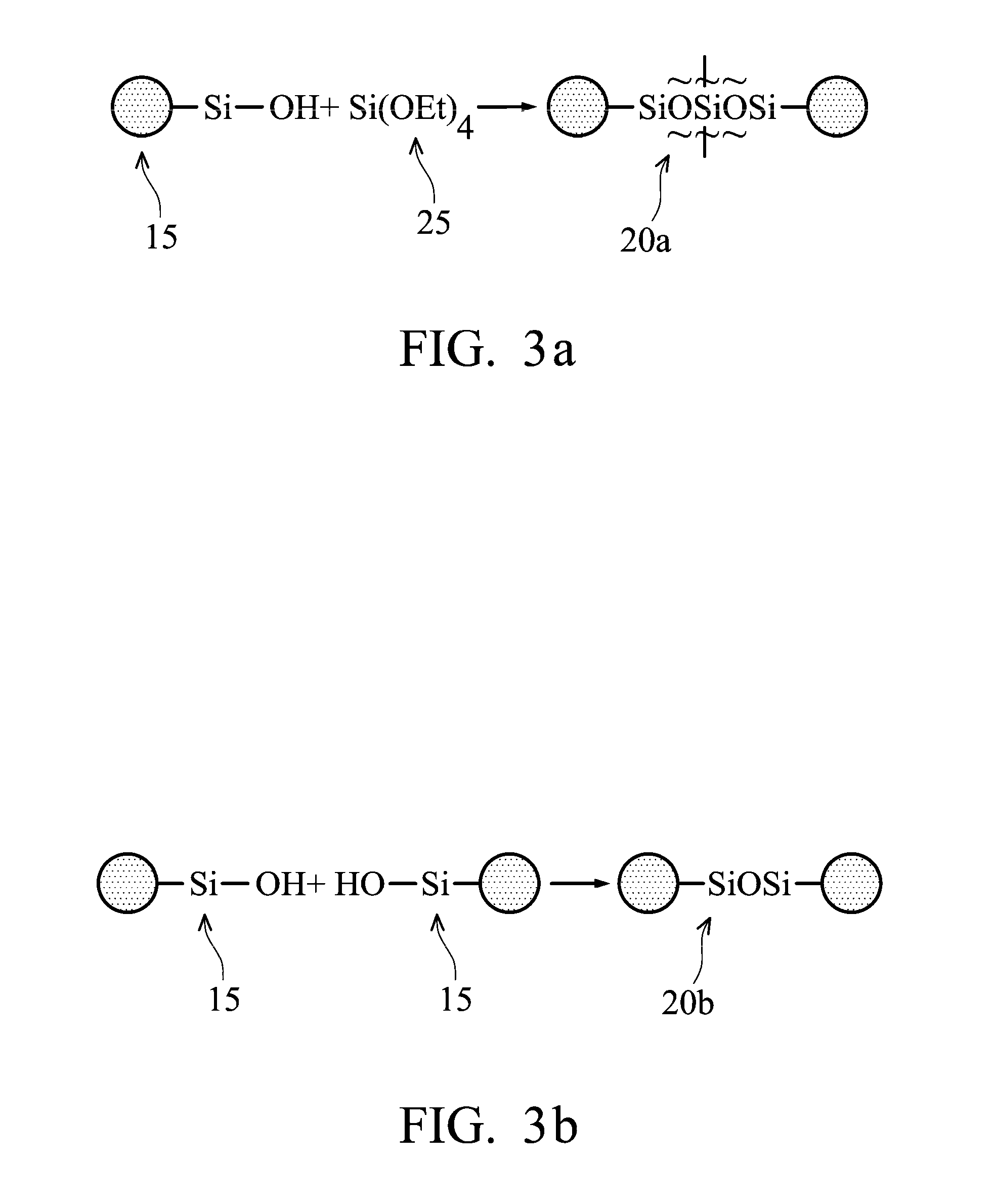

Organic/inorganic hybrid material and fabrication method thereof

An organic / inorganic hybrid material is provided, which includes an organic polymer and a plurality of inorganic nanoparticles, wherein the inorganic nanoparticles are self-connected or connected via a linker to constitute an inorganic network structure. By forming the inorganic network structure through interconnection of inorganic nanoparticles, the inorganic content in the hybrid materials can be drastically increased to improve the properties thereof. A method for fabricating the organic / inorganic hybrid material is also provided.

Owner:IND TECH RES INST

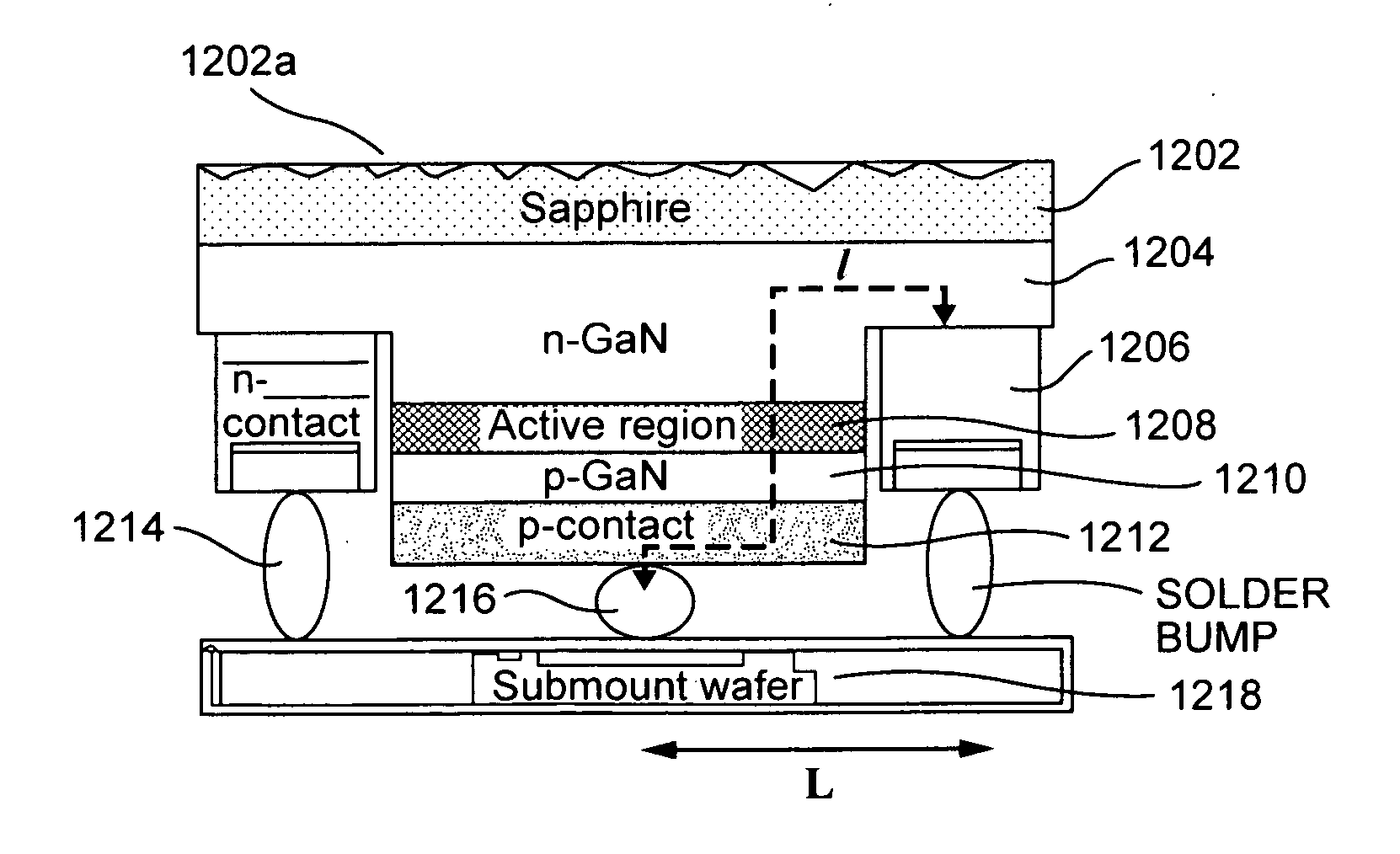

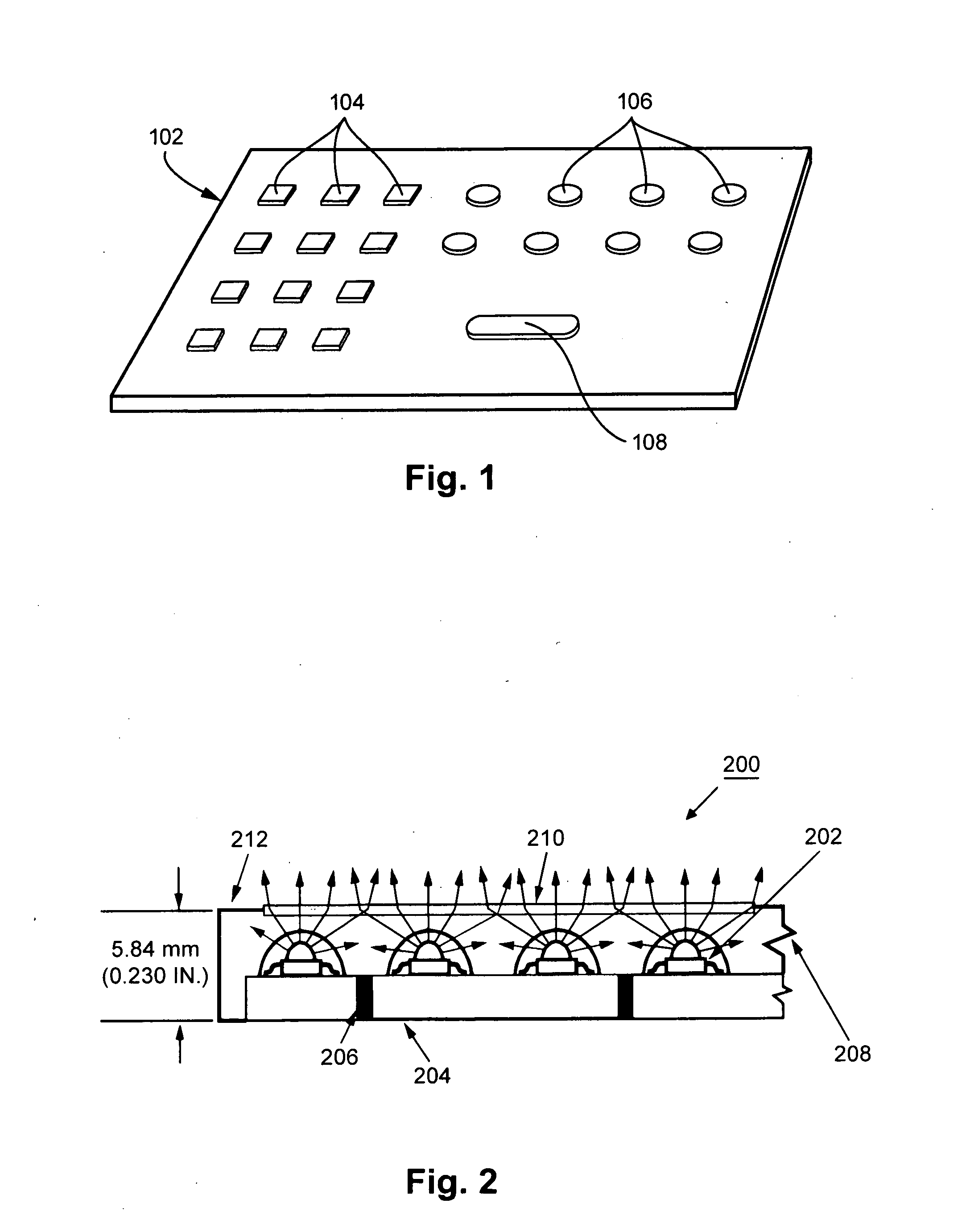

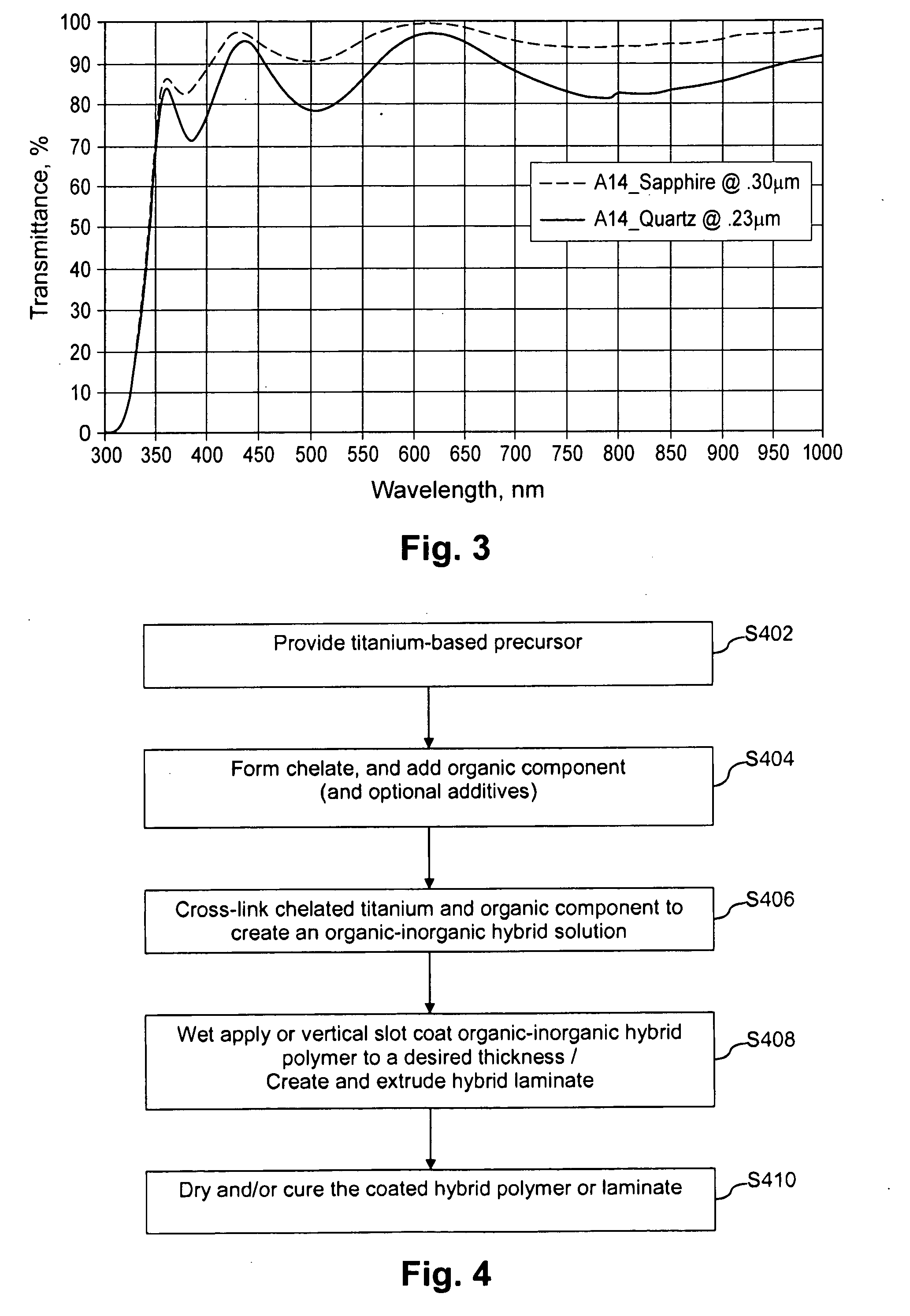

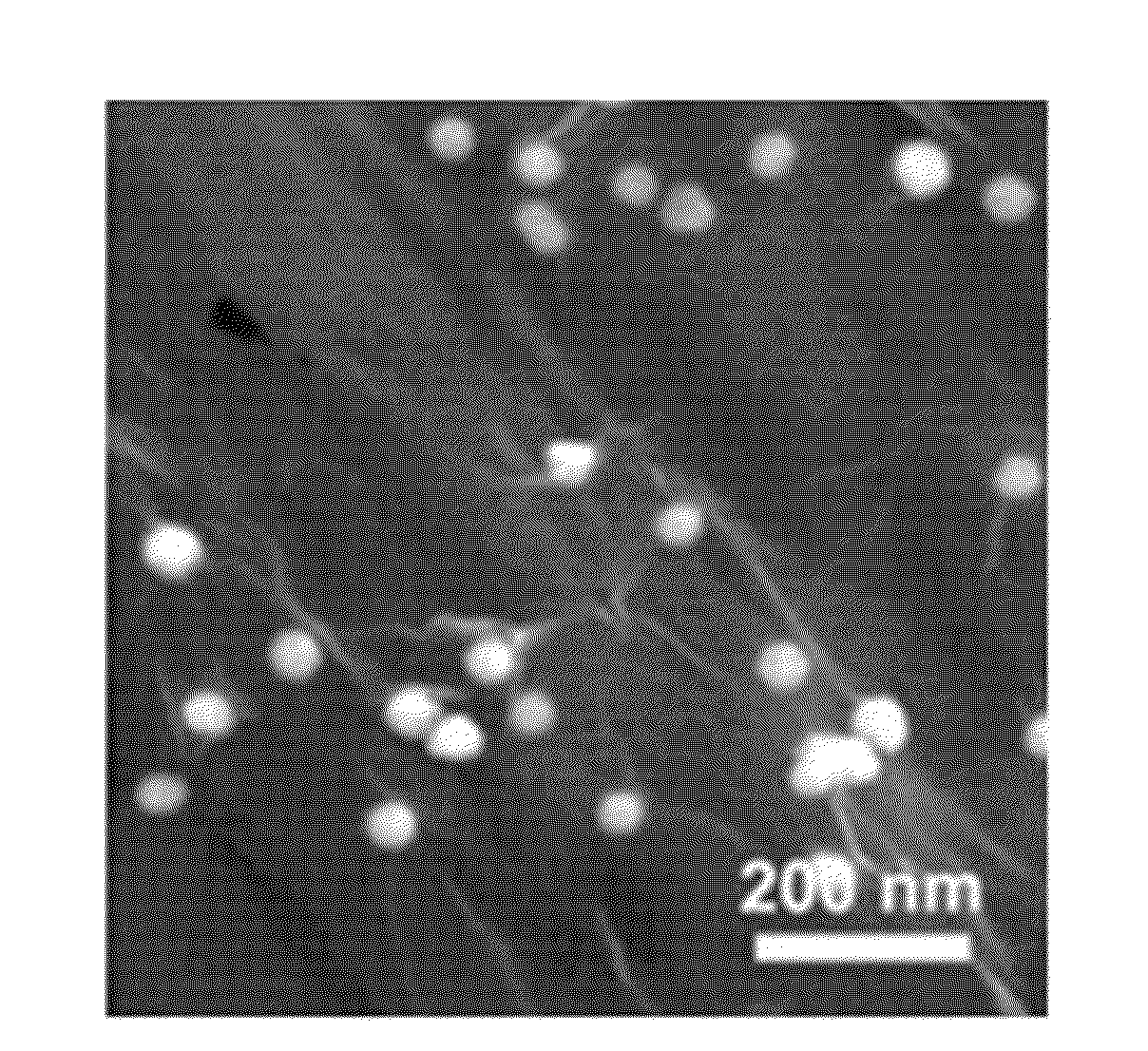

Insulating glass (IG) or vacuum insulating glass (VIG) unit including light source, and/or methods of making the same

InactiveUS20120086023A1Short lifeLong lastingLighting elementsSolid-state devicesPerformance enhancementHybrid material

Certain example embodiments of this invention relate to techniques for improving the performance of Lambertian and non-Lambertian light sources. In certain example embodiments, this is accomplished by (1) providing an organic-inorganic hybrid material on LEDs (which in certain example embodiments may be a high index of refraction material), (2) enhancing the light scattering ability of the LEDs (e.g., by fractal embossing, patterning, or the like, and / or by providing randomly dispersed elements thereon), and / or (3) improving performance through advanced cooling techniques. In certain example instances, performance enhancements may include, for example, better color production (e.g., in terms of a high CRI), better light production (e.g., in terms of lumens and non-Lambertian lighting), higher internal and / or external efficiency, etc.

Owner:GUARDIAN GLASS LLC

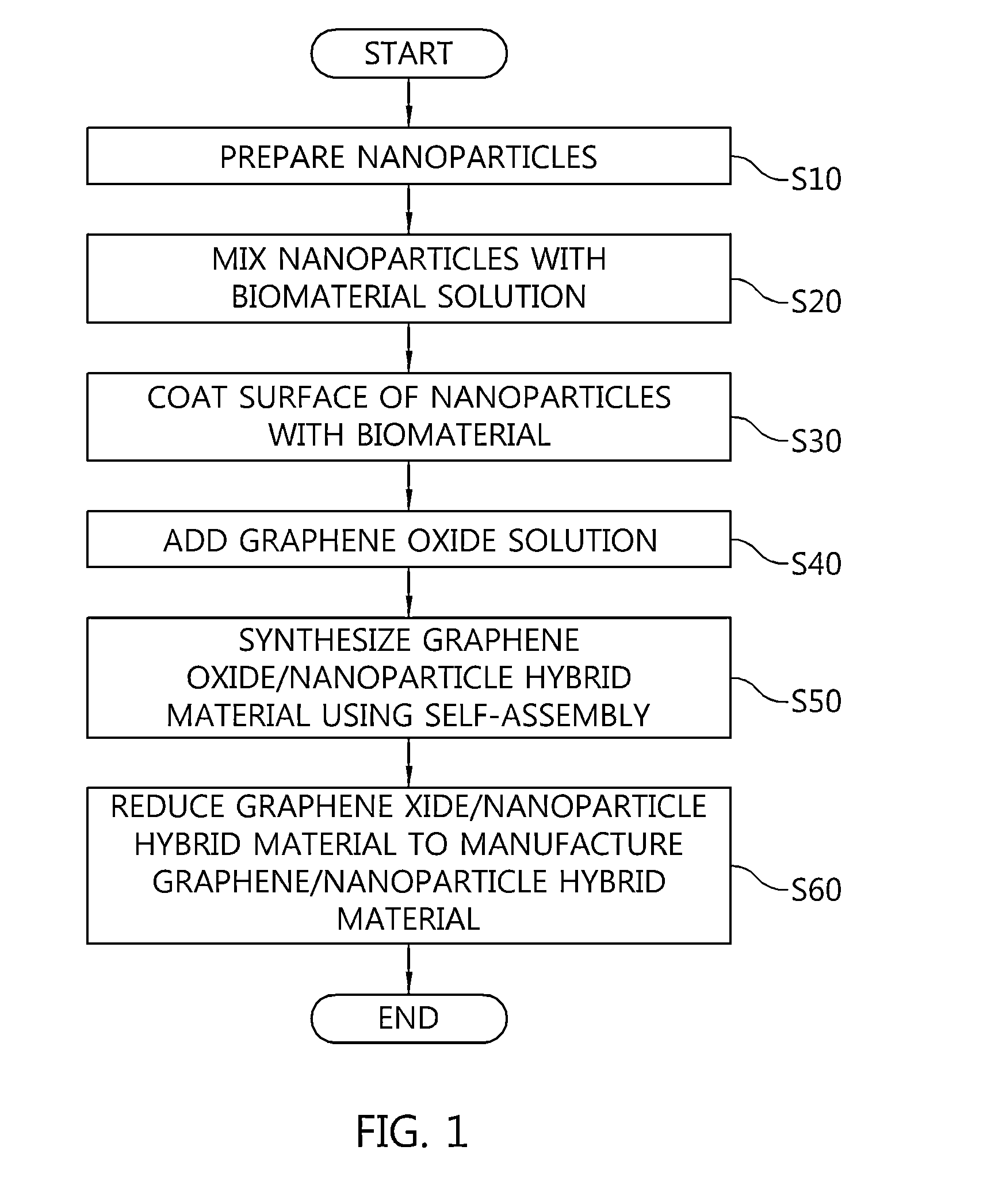

Method of manufacturing graphene hybrid material and graphene hybrid material manufactured by the method

InactiveUS20140346408A1Easily and rapidly and eco-friendly manufacturedUse minimizedNon-metal conductorsSpecific nanostructure formationNanoparticleHybrid material

This invention relates to a method of manufacturing a graphene or graphene oxide / nanoparticle hybrid material and a graphene / nanoparticle hybrid material manufactured thereby, wherein the hybrid material can be easily, rapidly and eco-friendly synthesized while minimizing the use of chemicals and thermal treatment because of electrostatic self-assembly properties of a biomaterial. This method includes preparing nanoparticles, a biomaterial solution and a graphene oxide solution, mixing the nanoparticles with the biomaterial solution to form biomaterial-coated nanoparticles, mixing the biomaterial-coated nanoparticles with the graphene oxide solution to obtain a graphene oxide / nanoparticle hybrid material, and reducing the graphene oxide / nanoparticle hybrid material to obtain a graphene / nanoparticle hybrid material.

Owner:ELECTRONICS & TELECOMM RES INST

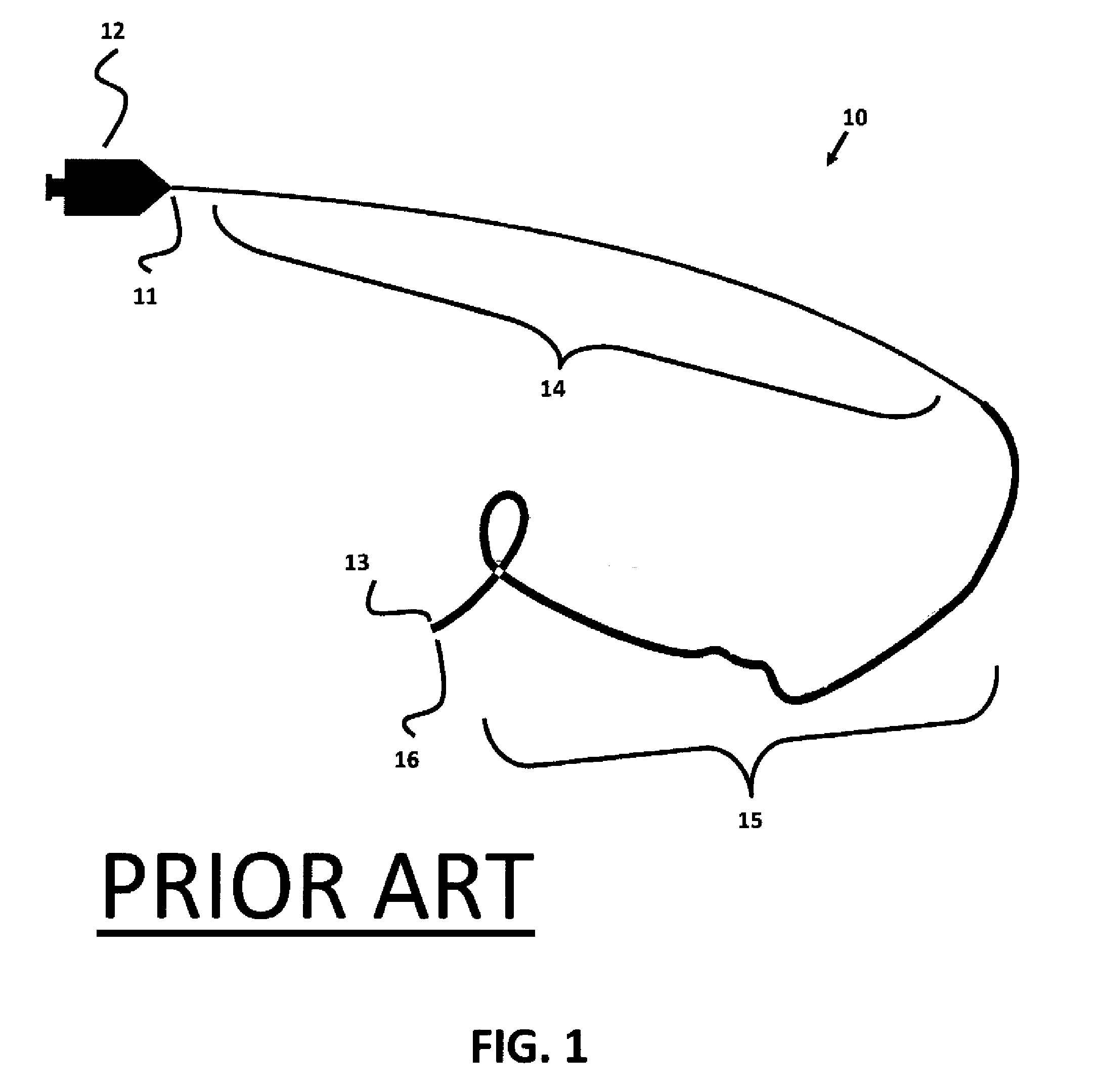

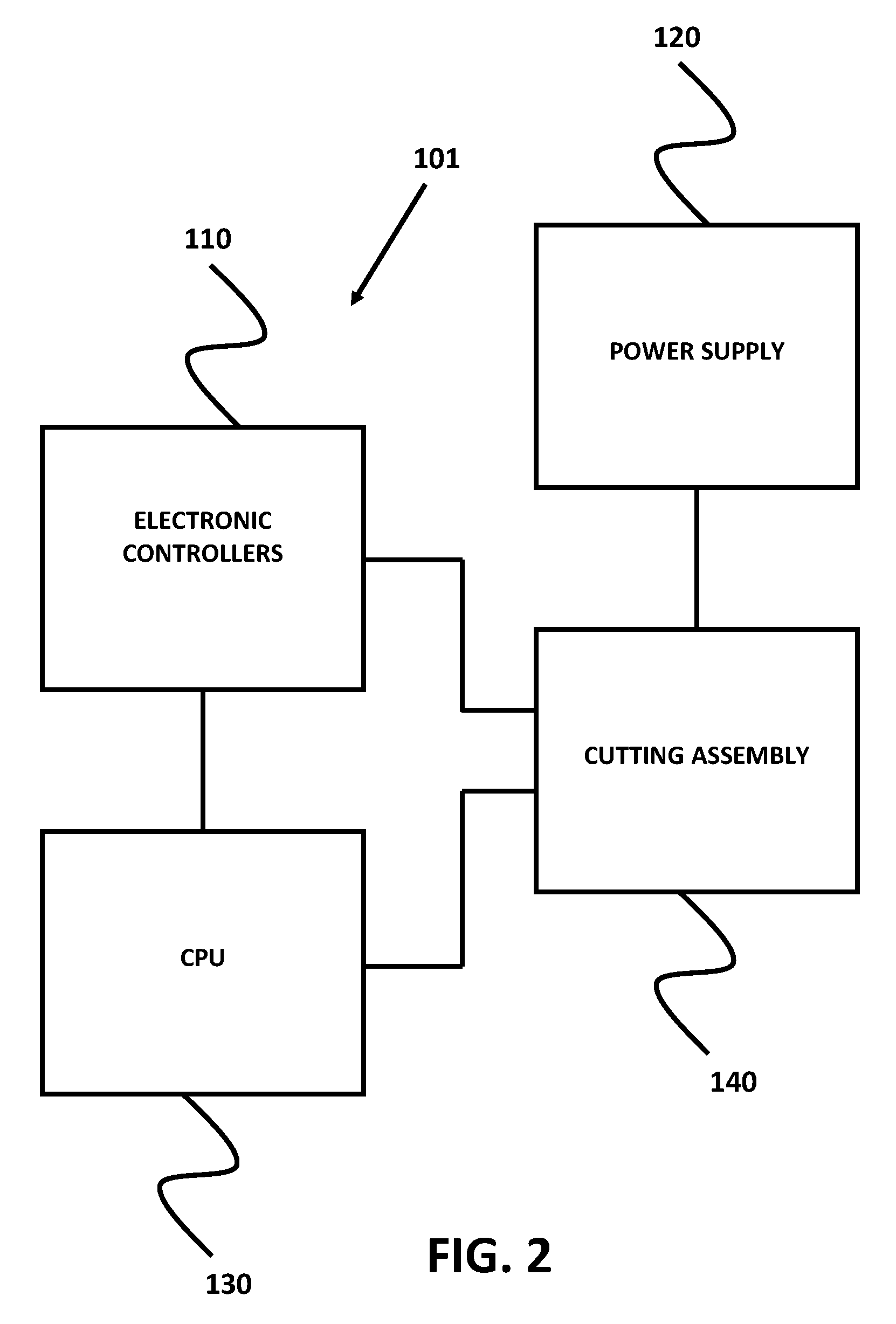

Micro-fabricated Catheter Devices Formed With Hybrid Materials

ActiveUS20100256605A1Sufficient torquabilityReliable transmissionGuide wiresCoatingsHybrid materialBiomedical engineering

A catheter device comprising: a micro-fabricated elongated outer member having an outer surface and an interior surface forming a lumen extending from a proximal end to a distal end, wherein said outer member is formed from two or more different stock materials, and embodiments thereof.

Owner:SCIENTIA VASCULAR INC

Low temperature curing high temperature resistant inorganic / organic hybridization epoxy adhesive and preparation thereof

InactiveCN101440268AImprove brittlenessImprove high temperature heat aging resistanceInorganic adhesivesEpoxy resin adhesivesCouplingLow temperature curing

The invention discloses a low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive and a preparation method thereof, which relate to an inorganic / organic hybrid epoxy adhesive and a preparation method thereof. The invention solves the problems that inorganic / organic hybrid epoxy adhesive prepared by the prior art has poor high-temperature thermal aging resistance and needs high curing temperature. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive is prepared by an epoxy resin, an epoxy resin low-temperature curing agent, a coupling agent, an inorganic active hybrid material and a dispersant. The preparation method comprises the following steps: the epoxy resin, the epoxy resin low-temperature curing agent and the coupling agent are mixed and stirred evenly, and then the inorganic active hybrid material and the dispersant are added into the mixture to be stirred evenly to obtain the low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive has high high-temperature bonding strength, good high-temperature thermal aging performance and low curing temperature. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive has the advantages of simple production technology, convenient operation and broad application.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

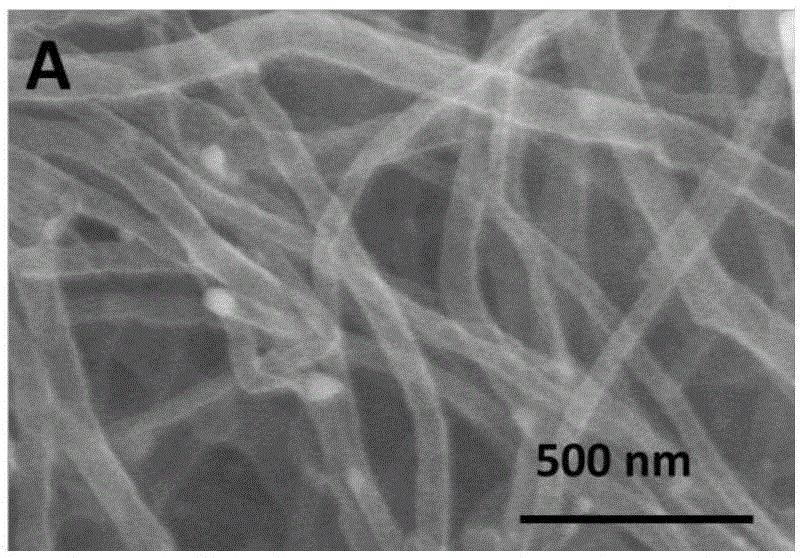

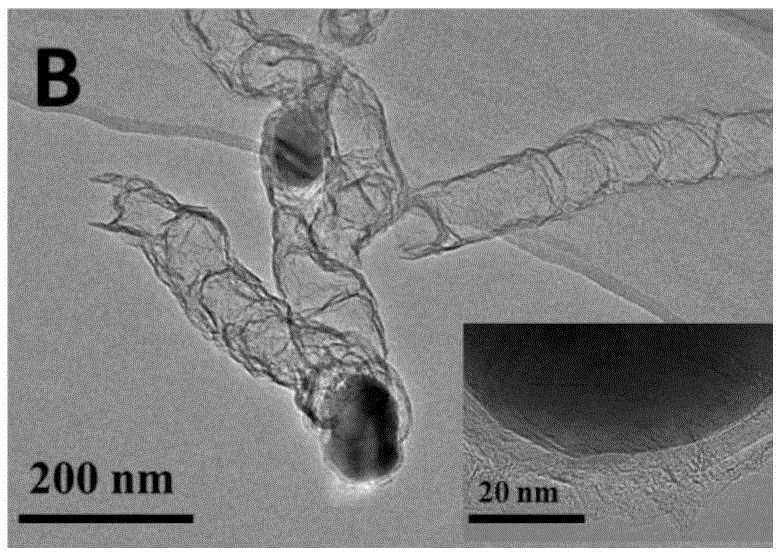

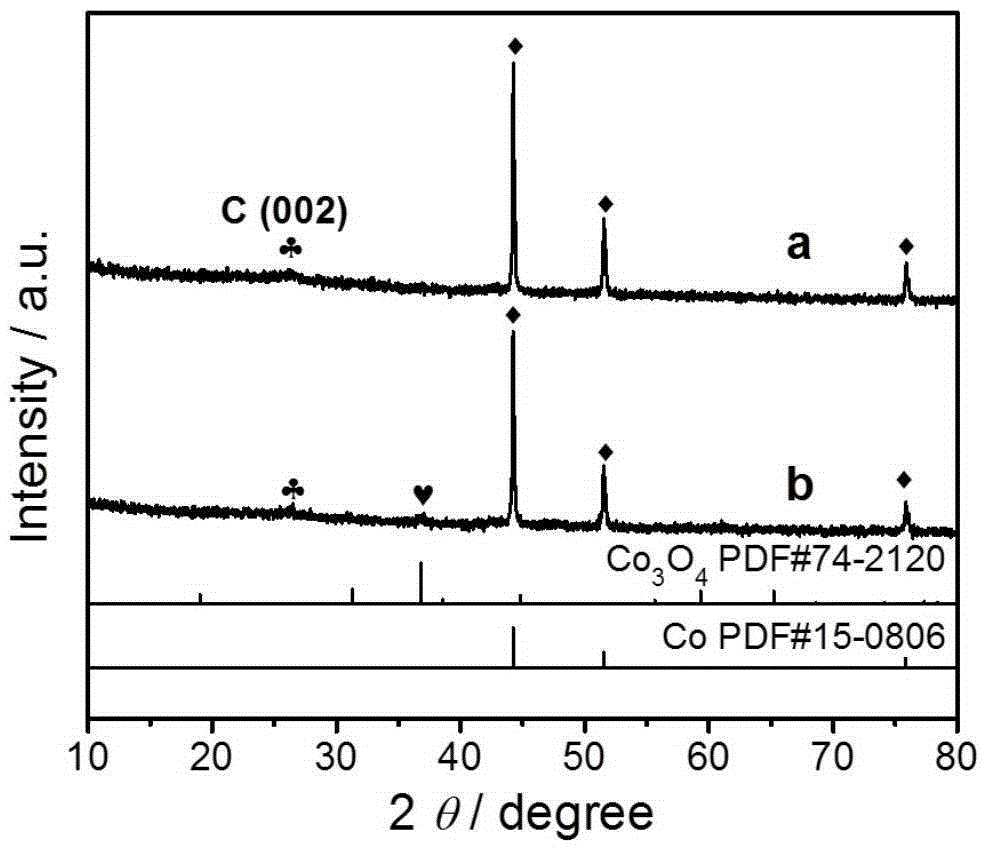

Preparation method of cobalt electro-catalysis oxygen reduction material wrapping nitrogen-doped carbon nanotube

ActiveCN105413730AOrderly arrangement and assemblyImprove performancePhysical/chemical process catalystsCell electrodesCooking & bakingOxygen

The invention discloses a preparation method of a cobalt electro-catalysis oxygen reduction material wrapping a nitrogen-doped carbon nanotube. The method includes the following steps of making melamine, cobalt nitrate hexahydrate and glucose react to obtain a self-assembled melamine precursor, and baking the self-assembled melamine precursor to obtain a cobalt nanoparticle hybrid material electro-catalysis oxygen reduction agent wrapping the nitrogen-doped carbon nanotube. In preparation of the precursor, a self-assembled body can be formed through the electrostatic interaction and the hydrogen-bond interaction by means of nitrate radicals and melamine under the acid condition, cobalt ions are adsorbed into the self-assembled body, ordered arrangement and assembly of materials in the high-temperature baking process are facilitated by the pre-assembled precursor, and therefore more catalysis active sites are exposed, and the improvement of the performance of a catalyst is facilitated.

Owner:QINGDAO UNIV

High-stability metal organic skeleton hybrid material, preparation method and application thereof

ActiveCN103694260AHigh hydrothermal stabilitySimple methodOrganic-compounds/hydrides/coordination-complexes catalystsCopper organic compoundsMass ratioHybrid material

The invention discloses a high-stability metal organic skeleton hybrid material. The metal organic skeleton hybrid material has high hydrothermal stability, and comprises metal organic skeleton and attapulgite, wherein the mass ratio of the attapulgite to the metal organic skeleton is (0.005-0.7):1.

Owner:NANJING TECH UNIV

Reversible Adhesive Compositions and Related Methods

ActiveUS20160284449A1Negligible changeMaterial gluingSynthetic resin layered productsHybrid materialMixed materials

The disclosure relates to reversible bonded structural joints using active adhesive compositions that can allow for dis-assembly, repair, and re-assembly. The disclosure is particularly directed to the adhesive composition material, irrespective of the type of the substrate(s) being joined. The adhesive composition can include any thermoplastic adhesive material that can be remotely activated for targeted heating of just the adhesive composition (e.g., and not the surrounding substrates being joined) via the inclusion of electromagnetically excitable particles in the adhesive composition. The substrates can be any metal material, any composite material, any hybrid material, or otherwise. The disclosed adhesive compositions allow for recyclability of parts at the end of their lifetime and repair / replacement of parts during their lifetime.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

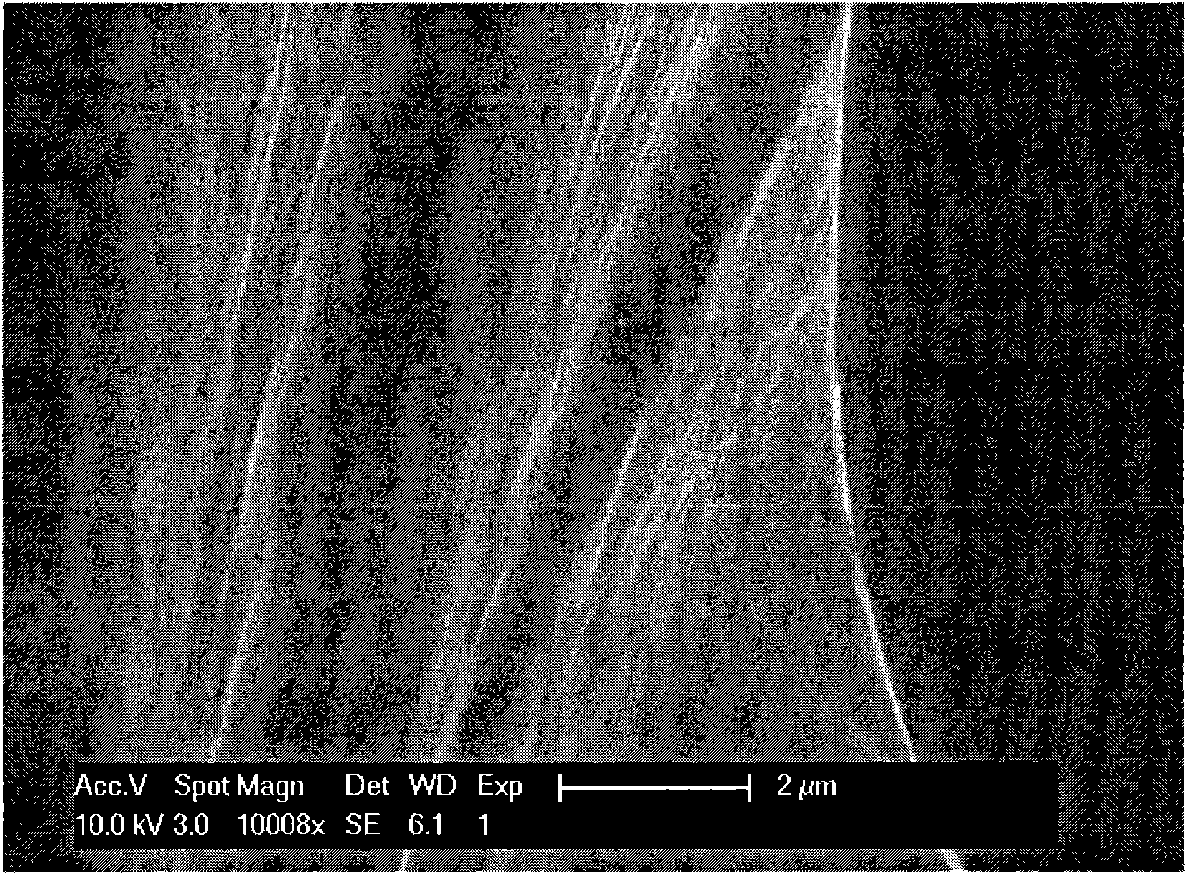

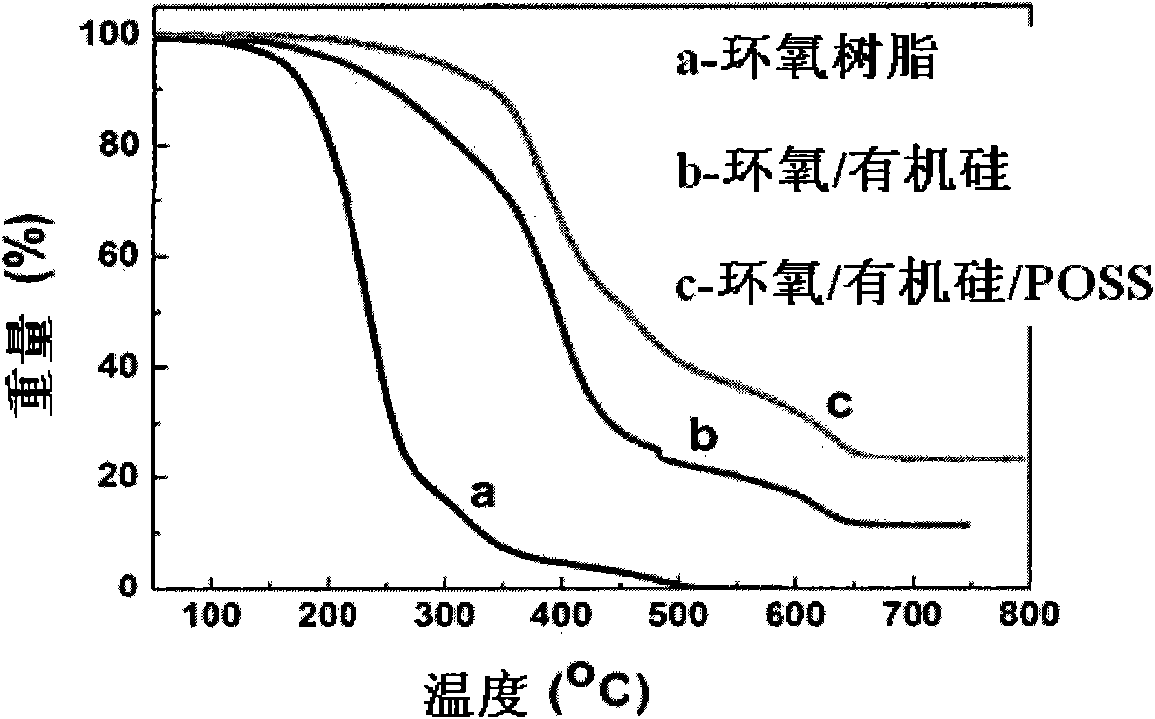

Low-stress epoxy/organic silicon/POSS nano hybrid material, and preparation method and application thereof

InactiveCN101974227AImprove thermal stabilityHigh light transmittanceEpoxy resin adhesivesEpoxy resin coatingsChemical industryEpoxy

The invention relates to the technical fields of photoelectricity and chemical industry, in particular to a low-stress epoxy / organic silicon / POSS nano hybrid material, and a preparation method and application thereof. The epoxy / organic silicon / POSS nano hybrid material comprises (a) an epoxy resin, (b) a polyorganosiloxane, (c) a cage-type polysilsesquioxane (POSS), (d) an epoxy hardener, (e) non-essential silane oxycompound and (f) non-essential assistants, wherein the polyorganosiloxane contains epoxy groups and silane oxygen groups. The cured nano hybrid system has excellent reticular cross-linked structure and does not have microphase separation. The epoxy / organic silicon / POSS nano hybrid material has the advantages of high mechanical strength, favorable heat resistance, favorable cohesive property, high chemical stability, favorable ultraviolet aging resistance, favorable optical transparency and other excellent properties, has the functions of low internal stress and pressure buffer, and can be used as an LED packaging material, optical protection material, circuit protection coating material, adhesive paint and the like.

Owner:FUDAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com